Polyphenylene oxide composition used for photovoltaic junction box

The technology of polyphenylene ether and junction box is applied in the field of polyphenylene ether composition, which can solve the problems of poor fluidity, difficult processing and molding, and can not meet the field of solar photovoltaic, and achieves the effect of improving long-term thermal oxygen aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

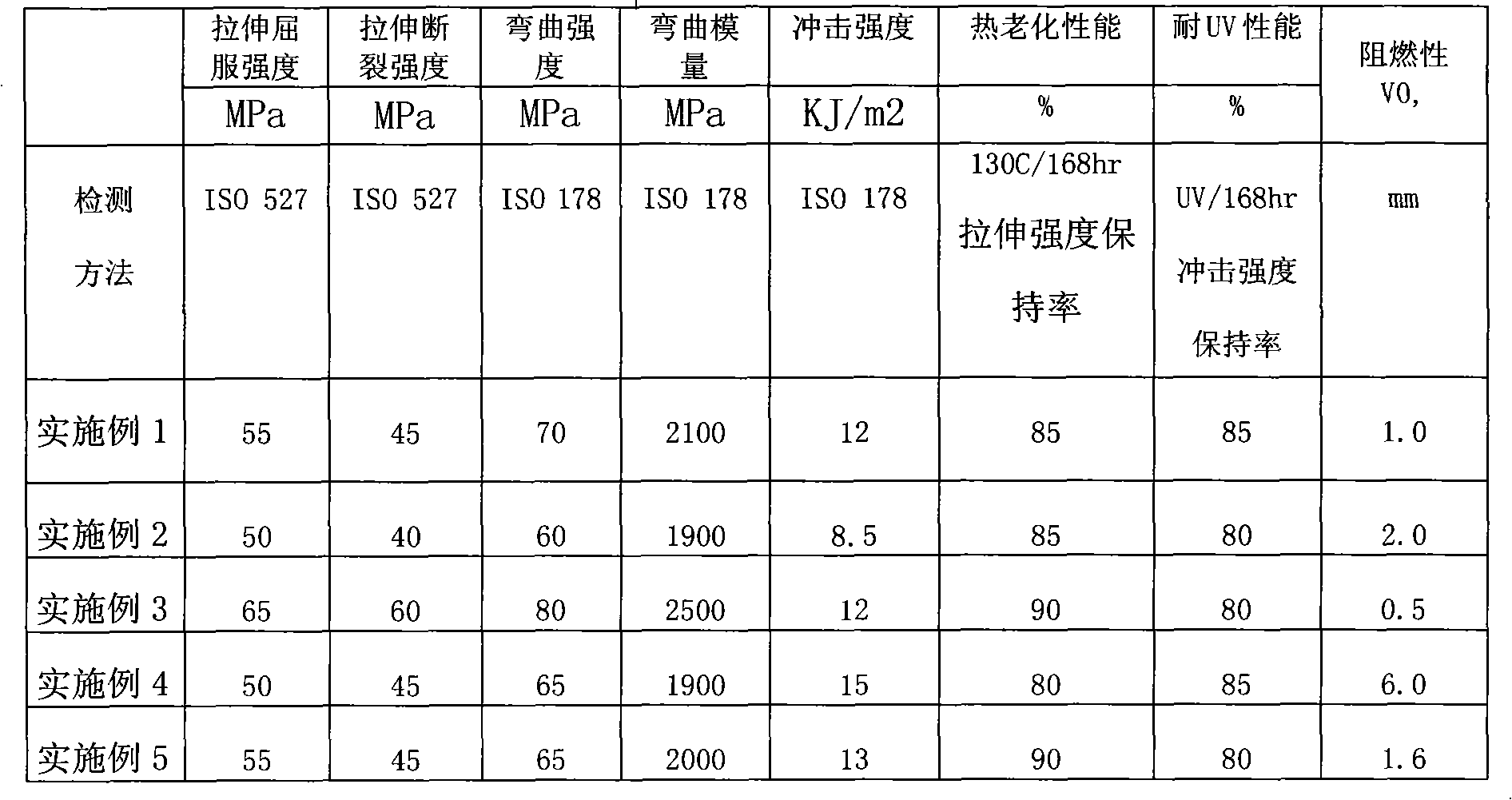

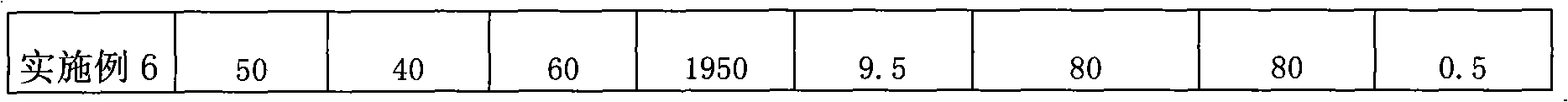

Examples

Embodiment 1

[0026] The components of the composition of this embodiment are: 75 kg of polyphenylene ether, 25 kg of polystyrene resin, 3 kg of SEBS, 10 kg of TPP, 1 kg of hydrotalcite, 10760.2 kg of antioxidants, and 1680.2 kg of phosphite auxiliary antioxidants. Kg, UV absorber UVA-10.5 kg, light stabilizer HALS-10.5 kg, PE wax 0.3 kg, carbon black 0.5 kg.

[0027] Among them, the viscosity of polyphenylene ether resin is IV0.52dl / g, produced by Asahi Kasei Corporation; the MFR of polystyrene resin (HIPS) is 3g / 10min, produced by BASF; the hydrotalcite is produced by Kyowa Chemical, and the antioxidant is 1076. Produced by Great Lakes Company, phosphite auxiliary antioxidant 168 is produced by Ciba Company, UV absorber UVA-1 is produced by BASF Company, light stabilizer HALS-1 is produced by Ciba Company, PE wax is produced by BASF Company, carbon black Produced for Cabot Corporation.

[0028] The above components are mixed uniformly, and then extruded and pelletized with a twin-screw extrud...

Embodiment 2

[0030] The components of the composition in this embodiment are: 55 kg of polyphenylene ether, 45 kg of polystyrene resin, 2 kg of SEPS, 8 kg of TPP, 1.5 kg of hydrotalcite, 10760.2 kg of antioxidants, and phosphite auxiliary antioxidant 6260.2 Kg, ultraviolet absorber UVA-10.5 kg, light stabilizer HALS-10.3 kg, PP wax 0.2 kg, carbon black 0.3 kg.

[0031] Among them, the viscosity of the polyphenylene ether resin is IV0.40dl / g, produced by Asahi Kasei, Japan; the MFR of polystyrene resin is 5g / 10min, produced by BASF.

[0032] The above components are mixed uniformly, and then extruded and granulated with a twin-screw extruder, and the processing temperature is: 260°C (plasticizing section).

Embodiment 3

[0034] The components of the composition of this embodiment are: 95 kg of polyphenylene ether, 5 kg of polystyrene resin, 5 kg of SEBS-MAH (grafting rate 3%), 12 kg of BDP, 0.5 kg of MgO, and 3300.4 kg of antioxidants. Phosphite auxiliary antioxidant 1680.5 kg, ultraviolet absorber UVA-40.3 kg, light stabilizer HALS-10.5 kg, PE wax 0.3 kg, carbon black 0.6 kg.

[0035] Among them, the viscosity of polyphenylene ether resin is IV0.42, produced by Sabic Company of Saudi Arabia; the MFR of polystyrene resin is 8g / 10min, produced by Chi Mei Company.

[0036] The above components are mixed uniformly, and then extruded and pelletized with a twin-screw extruder, and the processing temperature is: 280°C (plasticizing section).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com