Patents

Literature

70results about How to "Improve UV resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyphenylene oxide composition used for photovoltaic junction box

ActiveCN102399433AImprove liquidityGuaranteed toughnessHazardous substanceComparative Tracking Index

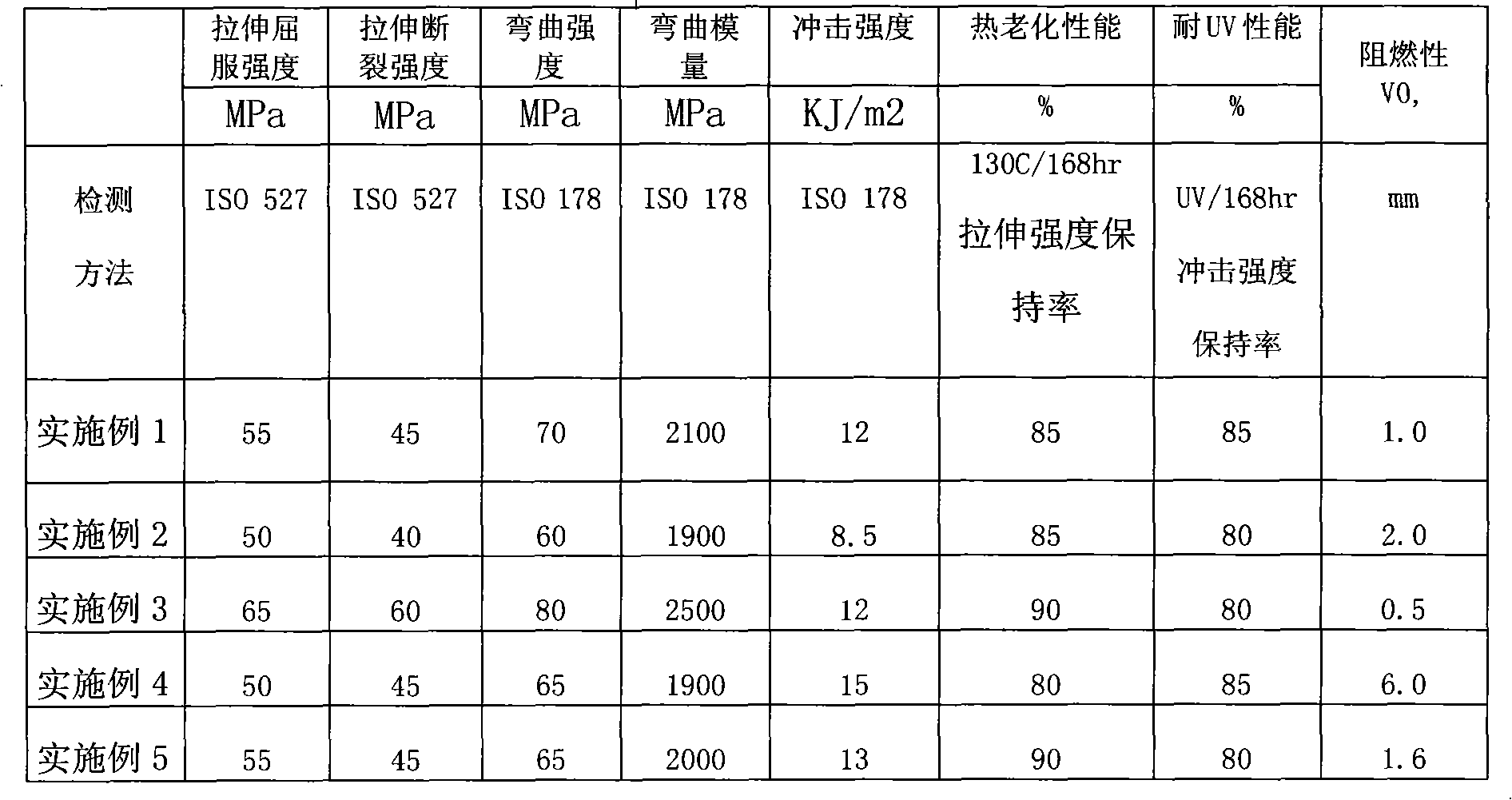

The invention provides a polyphenylene oxide composition used for a photovoltaic junction box. The composition comprises the following components by weight: 55-95 parts of polyphenylene oxide, 45-5 parts of styrene resin, 2-10 parts of a flexibilizer, 5-20 parts of a phosphate fire retardant, 0.5-2.5 parts of an acid absorbent, 0.2-0.6 part of a hindered phenol main antioxidant, 0.2-0.6 part of a phosphite auxiliary antioxidant, 0.3-1.5 parts of an ultraviolet absorbent, 0.3-1.5 parts of a hindered amine light stabilizer, 0.1-0.5 part of a lubricating agent, and 0.1-1.0 part of toner. With the characteristics of good flame resistance, thermo-oxidative aging resistance, UV (ultraviolet) resistance, excellent electrical performances, the composition of the invention has flame retardancy up to grade UL945VA, RTI (relative temperature index)=110DEG C, CTI (comparative tracking index) PLC ( programmable logic controller)=2, and GWIT (glow wire ignition temperature)=750DEG C, thus satisfying the requirements in ROHS (restriction of hazardous substances) standard. Thus, the composition provided in the invention can be used for electronic and electrical component production of solar photovoltaic junction boxes, etc.

Owner:广东瑞能新材料有限公司

Ice-cold fiber knitted fabric and manufacturing method thereof

InactiveCN101613907AWith cooling functionReduce unit weightWeft knittingWarp knittingUltraviolet protectionPulp and paper industry

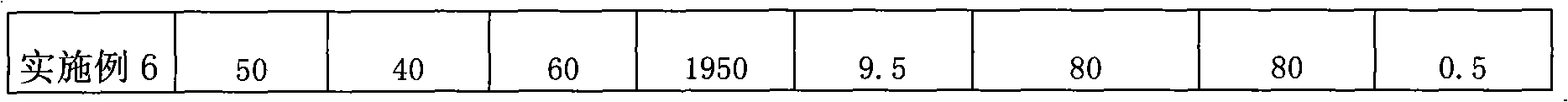

The invention relates to a fabric with a double-sided composite structure interweaved by cooling ice-cold fibers and cotton yarns. The inner layer of the fabric is formed by the ice-cold fibers and has a mesh-like tissue structure; and the outer layer of the fabric has a plain weave tissue structure. Australia AS / NZS 4399:1996 Evaluation and Classification of Ultraviolet Protective Fabric' standard tests show that the ultraviolet protection factor UPF level of the fabric reaches 50 +. A method for manufacturing the fabric comprises the following steps of: weaving, preprocessing, dyeing and scotching forming. The dyeing step comprises cotton dyeing, water washing, dewatering, polyamide fiber dyeing, water washing, color fixing and water washing in sequence. A coolfresh auxiliary agent and an uvioresistant auxiliary agent are added in one bath during dyeing, and the coolfresh auxiliary agent is added again by squeezing when scotching forming. The fabric combines the multiple functions of ice cooling, temperature reduction, coolfresh and uvioresistance into the whole fabric and is an ideal outdoor sportswear fabric.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Efficient long-lasting graphene anti-ultraviolet fabric and preparation method thereof

InactiveCN107119372AIncreased ability to absorb UV raysImprove UV resistanceHeating/cooling textile fabricsWoven fabricsLong lastingDyeing

The invention relates to an efficient long-lasting graphene anti-ultraviolet fabric and a preparation method thereof. The fabric is obtained by spinning warp yarns and weft yarns; at least one of the warp yarns and weft yarns is a graphene yarn; the graphene yarn is prepared from, by mass, 40-50% of graphene fibers and 50-60% of other fibers. The invention also provides the preparation method of the fabric which breaks through a traditional anti-ultraviolet performance fabric manufacturing method; novel graphite fiber materials are adopted to further strengthen anti-ultraviolet absorbing performance, thus the fabric does not use anti-ultraviolet shielding agent in the dyeing process, is not affected by the number of washing, and the layer processing is not performed on the fabric, which achieves the permanent anti-ultraviolet performance. Therefore, the efficient long-lasting graphene anti-ultraviolet fabric has the advantages of having the permanent anti-ultraviolet effect; being novel in materials, strong in practicability; being capable of being widely used in sports, swimwear, sanitation, tents, military projects, civil and the like.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

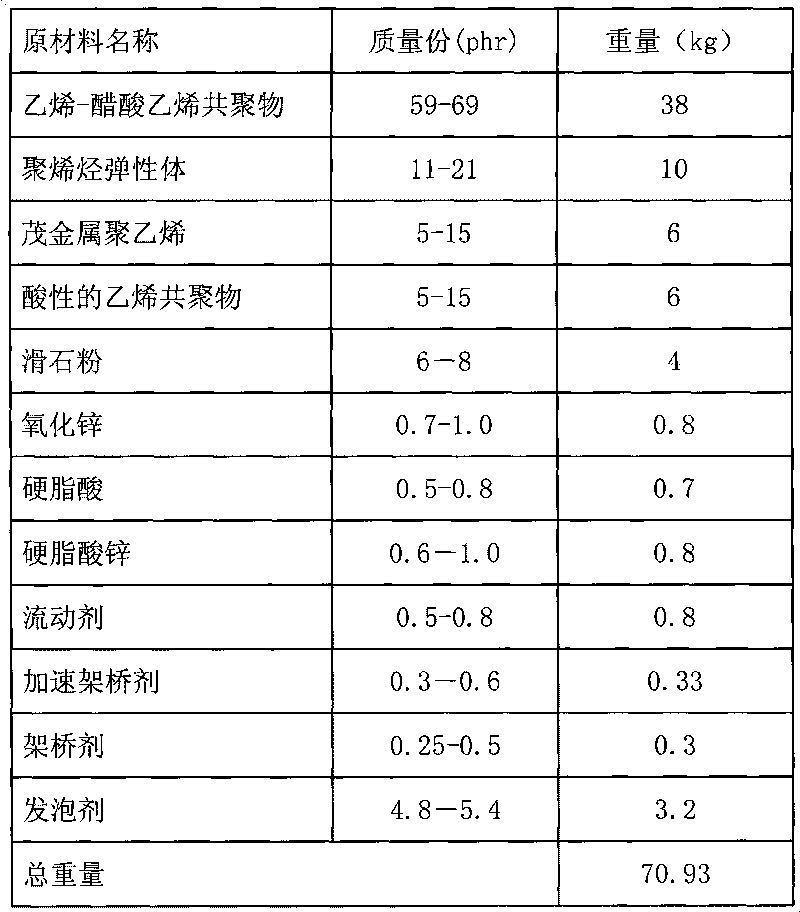

Super-light plastic formula for sports shoe soles

The invention discloses a super-light plastic formula for sports shoe soles, and the formula comprises the following components in parts by weight: 59-69 parts by weight of ethylene-vinyl acetate copolymer, 11-21 parts by weight of polyolefin elastomer, 5-15 parts by weight of metallocene polyethylene, 5-15 parts by weight of acidic ethylene copolymer, 6-8 parts by weight of talc powder, 0.7-1.0 part by weight of zinc oxide, 0.5-0.8 part by weight of stearic acid, 0.6-1.0 part by weight of zinc stearate, 0.5-0.8 part by weight of flowable agent A, 0.3-0.6 part by weight of accelerated bridging agent, 0.25-0.5 part by weight of bridging agent and 4.8-5.4 parts by weight of foaming agent. Plastic soles of sports shoes produced by the technical scheme have super-light performance and the comfort which are unmatched by the ordinary plastic formula, have durable comfort, durable damping performance and other performances and can greatly reduce the consumption of physical strength of athletes.

Owner:ANTA CHINA

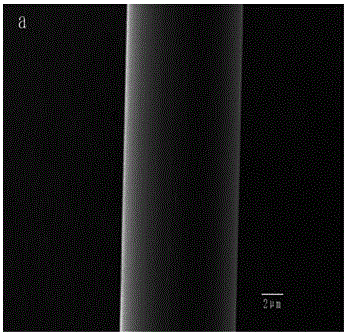

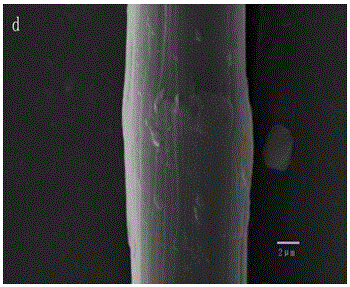

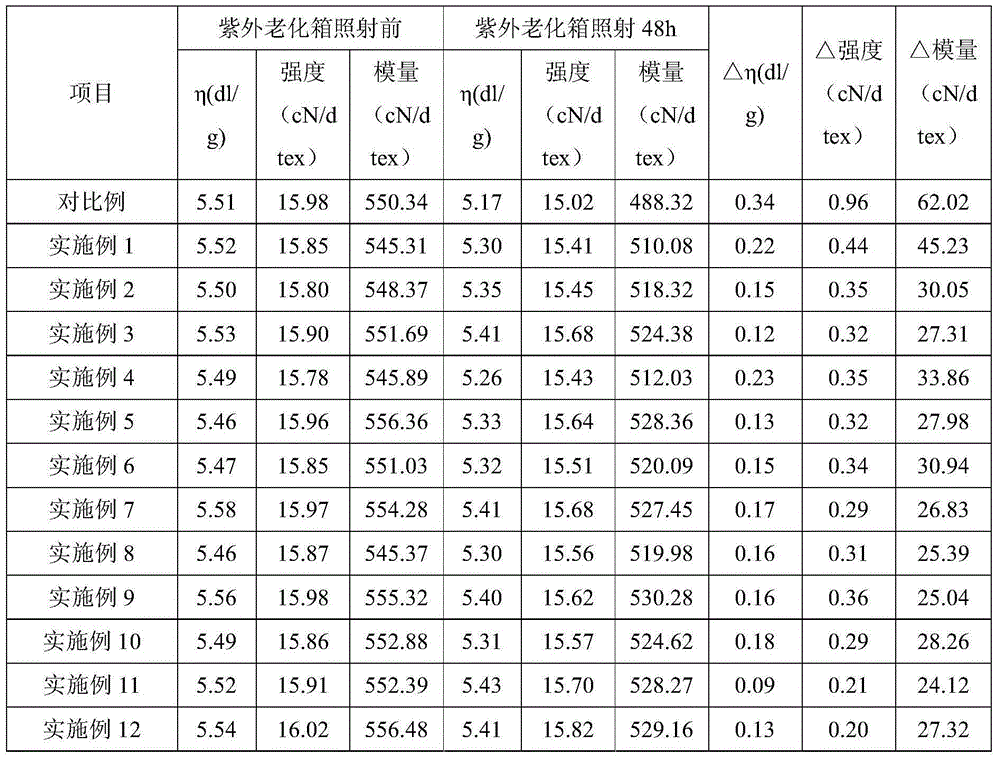

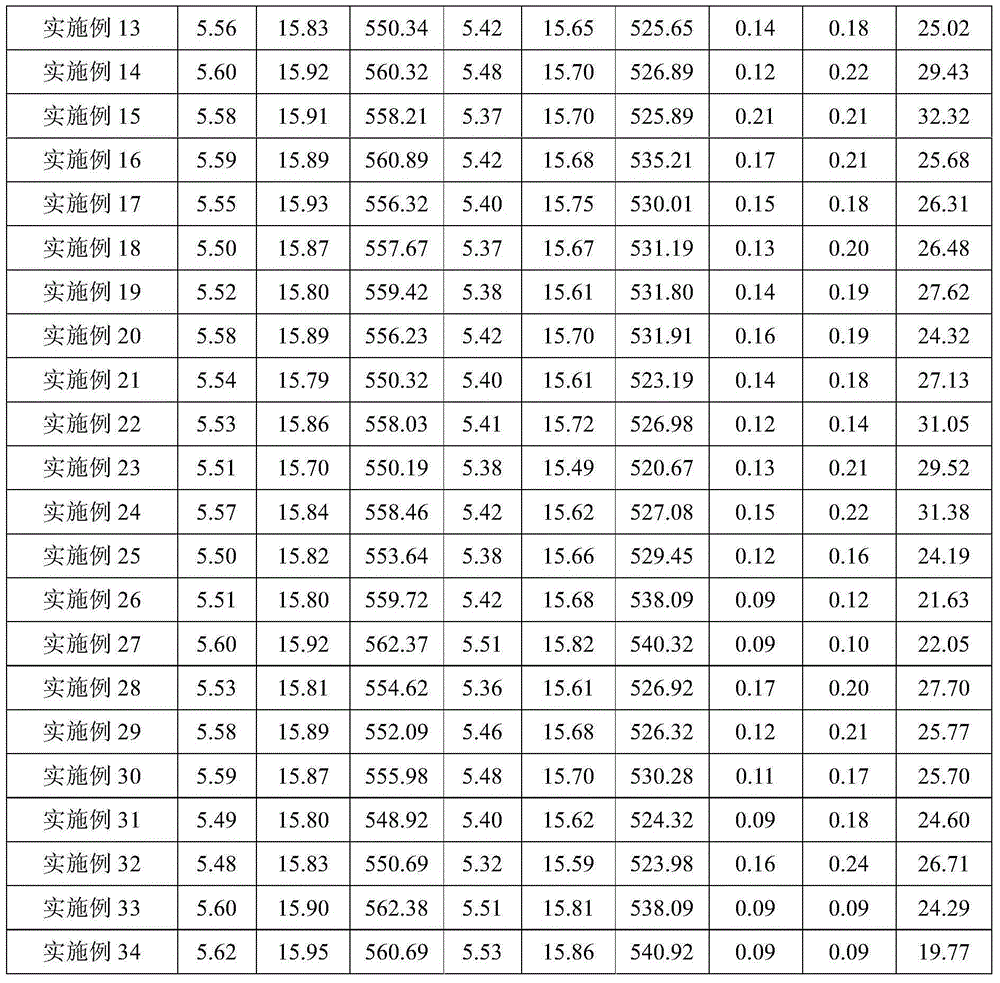

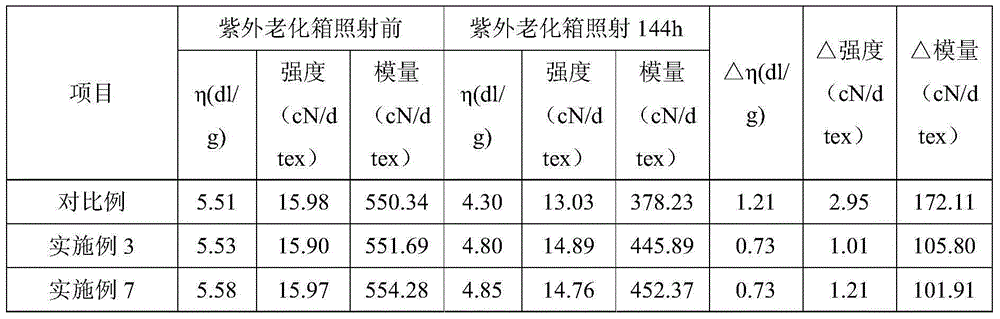

Method for improving ultraviolet resistance of POB fibers by using bifunctional hyperbranched siloxane

ActiveCN106012492ALow priceImprove UV resistancePhysical treatmentLight resistant fibresSolventSiloxane

The invention discloses a method for improving the ultraviolet resistance of POB fibers by using bifunctional hyperbranched siloxane. The method comprises the following steps: (1) putting Epoxy chloropropane grafted PBO (poly(p-phenylenebenzobisoxazole)) fibers in a 3-mouth bottle; (2) adding distilled water and a methanol solvent to the 3-mouth bottle to immerse the fibers, and adding a certain amount of NaOH to adjust the pH to 8-10; (3) putting bifunctional hyperbranched siloxane in the 3-mouth bottle at 30-40DEG C; (4) heating the bottle to 60-80DEG C from 30-40DEG C, and continuously stirring above materials for 4-5 h to obtain bifunctional hyperbranched siloxane grafted PBO fibers; and (5) taking out the fibers, cleaning the fibers with a large amount of deionized water and anhydrous ethanol, and carrying out vacuum drying. Grafting combination of the hyperbranched siloxane to the PBO fibers obviously enhances the ultraviolet resistance of the PBO fibers; and a hyperbranched siloxane system has a large amount of active groups, so the PBO can get a good coating layer, and the cohesiveness between the surface and resin is improved.

Owner:HARBIN INST OF TECH

Polyamide yarn with anti-ultraviolet and anti-radiation functions

InactiveCN105177749AImprove wear resistanceGood radiation protectionArtifical filament manufactureMonocomponent polyamides artificial filamentEpoxyFiber

The invention discloses a polyamide yarn with anti-ultraviolet and anti-radiation functions, and relates to the technical field of polyamide yarn spinning and manufacturing. The polyamide yarn is prepared from the following components: a PA6 slice, a carbon fiber, unsaturated polyester resin, polystyrene, epoxy resin, silicone powder, a silver fiber, a mulberry silk, nanosilicon dioxide, an alkali-free glass fiber, zinc oxide, a silica gel vulcanizing agent, titanium dioxide and an assistant; and the assistant is prepared from the following components: polyvinyl chloride, polystyrene, unsaturated polyester resin, polycarbonate, a coupling agent and a lubricating agent. According to the polyamide yarn, the radiation resistance of the polyamide yarn can be effectively improved; the anti-ultraviolet function of the polyamide yarn is improved; the wear-resisting property of the polyamide yarn can also be improved when the radiation protection capability and the anti-ultraviolet radiation ability are ensured; use by people is facilitated; and the safety performance is effectively improved.

Owner:LANGXI HEXIN CHEM FIBER WEAVING

Large-area perovskite solar cell composite photoelectric conversion layer and preparation method therefor

InactiveCN106784323AWide absorption wavelength rangeWell formedSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellCyanuric acid

The invention relates to a perovskite solar cell composite photoelectric conversion layer and a preparation method therefor. The perovskite solar cell composite photoelectric conversion layer comprises a three-dimensional perovskite type photoelectric conversion material thin film and a polymerizable two-dimensional layered perovskite type photoelectric conversion material thin film; the composition of the polymerizable two-dimensional layered perovskite type photoelectric conversion material thin film is NMX<4>, wherein N is cyanuric acid, melamine, trithiocyanuric acid, ammonium triphosphate, amino cyclotriphosphazene or a mixture thereof; M is Pb<2+>, Sn<2+>, Ge<2+>, Cu<2+>, Ni<2+>, Mn<2+>, Zn<2+>, Fe<2+> or a mixture thereof; and X is Cl<->, Br<->, I<-> or a mixture thereof. The polymerizable two-dimensional layered perovskite type photoelectric conversion material is used as the material of a perovskite solar cell composite photoelectric conversion layer and a hole transport layer at the same time, so that the large-area perovskite solar cell preparation process is simplified, and the photoelectric conversion efficiency can be stabilized and improved.

Owner:TIANJIN VOCATIONAL INST

Preparation method of uvioresistant aramid fiber

InactiveCN106592216AImprove UV resistanceGood UV resistanceFibre typesHindered amine light stabilizersChemistry

The invention relates to a preparation method of uvioresistant aramid fiber. The method comprises the steps that in the para-aramid spinning production process, an appropriate amount of benzinidazole, an appropriate amount of substituted acrylonitrile, an appropriate amount of triazine and an appropriate amount of hindered amine uvioresistant absorbent are added into spinning oil, the mixture is uniformly sprayed on the surface of the aramid fiber through nozzle oil equipment, and the aramid fiber with the surface uniformly attached with the uvioresistant absorbent is produced through spinning equipment. The problems that para-aramid ultraviolet-resistant property is poor, oxidative degradation is likely to occur under ultraviolet light are better solved, and the preparation method can be used for spinning industrial production for preparing the uvioresistant aramid fiber.

Owner:SINOPEC YIZHENG CHEM FIBER +1

Method for generating functionalized nano zinc oxide-graphene on surfaces of aramid fibers

InactiveCN109537264AExcellent adhesionImprove flame retardant performanceLight resistant fibresHeat resistant fibresZno nanoparticlesHigh pressure

The invention discloses a method for generating functionalized nano zinc oxide-graphene on surfaces of aramid fibers. The method comprises the following steps: placing flame-retardant modified aramidfibers in a ZnCl2 ethanol solution; taking out after ultrasonic treatment; washing with deionized water multiple times; drying in a drying box to obtain pretreated aramid fibers; adding zinc gluconate, sodium hydroxide and absolute ethanol into deionized water; stirring uniformly; placing the pretreated aramid fibers therein; placing in a high-pressure hydrothermal reactor; taking out after reacting in an oven; washing with deionized water multiple times; drying in vacuum to obtain nano zinc oxide surface in-situ generation-functionalized aramid fibers; immersing the obtained nano zinc oxide surface in-situ generation-functionalized aramid fibers in an immersion tank filled with a functional coating additive blend solution; and making the aramid fibers slowly pass under a compression roller in the immersion tank and slowly pass a drying region after leading out the aramid fibers from the immersion tank so as to obtain the aramid fibers.

Owner:合肥巧织纺织科技有限公司

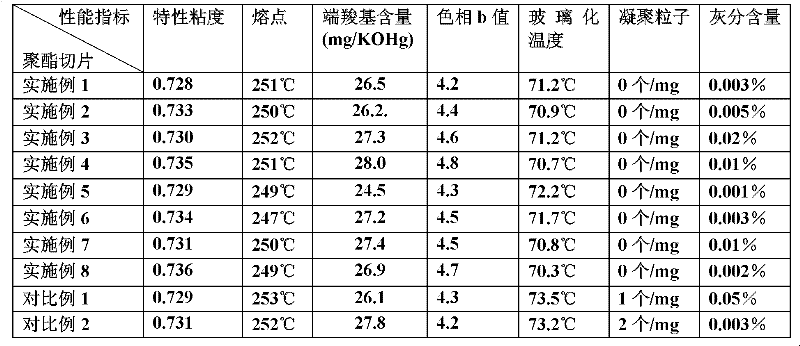

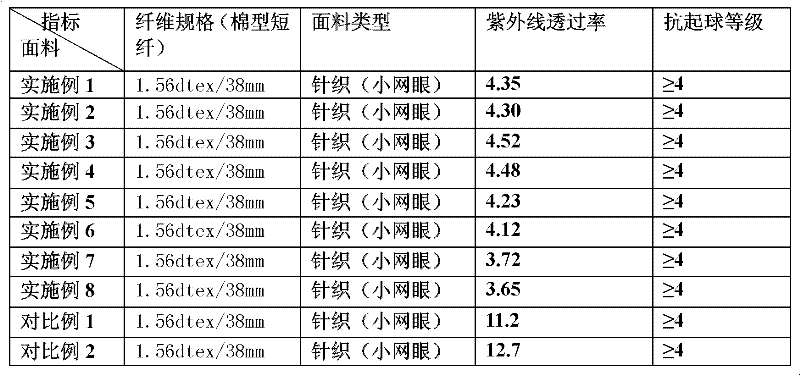

Preparation method of anti-ultraviolet anti-pilling polyester slices

ActiveCN102443153AImprove the diffusion effectReduce transmittanceMonocomponent polyesters artificial filamentPolyesterUltraviolet lights

The invention relates to a preparation method of anti-ultraviolet anti-pilling polyester slices. The preparation method comprises an esterification reaction working procedure and a polymerization reaction working procedure, wherein the esterification reaction working procedure comprises a primary esterification reaction section and a secondary esterification reaction section; in the primary esterification reaction section, aliphatic dicarboxylic acid and / or non-para-aryl dicarboxylic acid are / is introduced to serve as a third monomer; in the secondary esterification reaction section, flexiblepolyethylene glycol is introduced to serve as a fourth monomer; after esterification is completed, a hindered amine light stabilizer and a hindered phenol antioxidant which are respectively prepared from acetic acid and ethylene glycol as a solvent and hydroxy silicone oil are added; and after prepolymerization and before final polymerization in the polymerization reaction working procedure, an ultraviolet absorbent is added. The polyester fibers spun from the polyester slices prepared by the method provided by the invention have excellent anti-ultraviolet and anti-pilling performances; and after the polyester fibers are knitted / woven into knitted / woven fabric, test shows that the fabric has the following correlated technical indexes: the ultraviolet light transmittance is not more than 5.0%, and the anti-pilling performance is not less than 4-level.

Owner:JIANGSU ZHONGLU TECH DEV +1

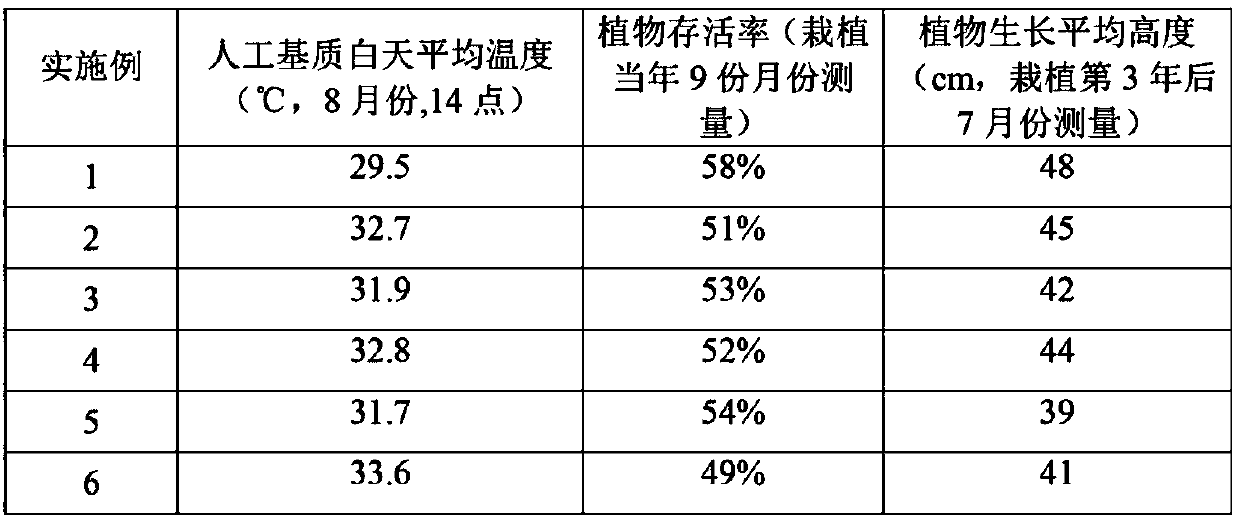

Artificial soil suitable for slope vegetation restoration of high-altitude areas and preparation method thereof

InactiveCN110612886AAvoid churnEasy maintenanceGrowth substratesCulture mediaMonopotassium phosphateBiology

The invention discloses artificial soil suitable for slope vegetation restoration of high-altitude areas and a preparation method thereof. The artificial soil comprises, by weight, 20-30 parts of calcium based bentonite, 10-15 parts of diatomite, 10-15 parts of citric acid, 10-20 parts of ceramic powder, 5-8 parts of potassium dihydrogen phosphate, 15-30 parts of peat soil, 10-15 parts of sodium humate, 5-10 parts of zinc oxide, 10-15 parts of bamboo fiber, 5-8 parts of compound fertilizer, 5-10 parts of polyacrylamide, 5-15 parts of super absorbent resin and 15-30 parts of microbial residue.The artificial soil prepared by the method has excellent buffering ability to temperature change and can enhance plant survival rate.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

Anti-UV cotton-imitated polyester-polyamide composite superfine fiber and production method thereof

ActiveCN105369392AImprove flexibilityImprove UV resistanceFilament/thread formingConjugated synthetic polymer artificial filamentsChemistryCerium oxide

The invention discloses an anti-UV cotton-imitated polyester-polyamide composite superfine fiber. The fiber includes superfine cotton-imitated polyester fiber and modified polyamide fiber. The superfine cotton-imitated polyester fiber is used as a core wire, and modified polyamide fiber coats on the outer side of the superfine cotton imitated polyester fiber. The superfine cotton- imitated polyester fiber consists of polyester fiber and a modifier; and the modified polyamide fiber is obtained by adding a graphene nano powder material into polyamide fiber under the active catalysis of a cerium oxide nano powder. Through experimental tests, the anti-UV cotton-imitated polyester-polyamide composite superfine fiber obtained by the invention has infrared emission rate of more than 90% in room temperature wavelength of 2-16; zinc oxide and diphenyl ketone are used to enhance the anti-ultraviolet ability of the polyester fibers; the zinc oxide coverage in the fiber surface layer reduces the absorption surface; and the addition of graphene in modified polyamide fiber increases the flexibility and tensile property of polyamide fiber.

Owner:NINGBO SANBANG MICROFIBER

Manufacturing method of environmentally-friendly waterproof fabric for automobile interior decoration

ActiveCN109703126AImprove stabilityLow priceSynthetic resin layered productsChitin formationUltraviolet

The invention discloses a manufacturing method of an environmentally-friendly waterproof fabric for automobile interior decoration. The environmentally-friendly waterproof fabric comprises a base layer, and a waterproof layer is arranged on the upper and lower sides of the base layer respectively, wherein the waterproof fabric is prepared by the following steps: firstly cotton fiber, chitin fiber,polypropylene fiber, bamboo fiber and PET fiber are added into an extruder and mixed to prepare a spinning melt. The base layer prepared by the cotton fiber, the chitin fiber, the polypropylene fiber, the bamboo fiber and the PET fiber has natural antibacterial, deodorant and anti-ultraviolet, and the waterproof layer prepared by a PE fiber, a PA fiber, a flame retardant, an antibacterial agent,a modified ageing agent and a coupling agent has good environmental protection flame retardancy and waterproofness. By adding the antibacterial agent and the modified ageing agent, the antibacterial and anti-ultraviolet function of the whole fabric is further improved, and the fabric is more environmentally friendly and pollution-free in the whole preparation process.

Owner:吴江海角工业用布有限公司

Carbon fiber pipeline composite material

ActiveCN103937123AImprove mechanical performance indexImprove UV resistanceCoatingsCorrosionWood fibre

The invention discloses a carbon fiber pipeline composite material. The carbon fiber pipeline composite material is prepared by adopting the following steps: firstly putting and mixing 20-55 parts of wood fibers, 10-30 parts of straw fibers, 30-66 parts of plastic material and 1 part of additive, heating to 170 DEG C and blending by using a heating blender, melting, extruding by using an extruder to form a basic material, then manufacturing a pipeline by using the basic material, gluing carbon fibers at the outer side of the pipeline, and finally curing by using resin so as to obtain the composite material. By the manner, the carbon fiber pipeline composite material has the advantages of high reliability, corrosion resistance, ageing resistance, good specificity, high strength, good abrasive resistance, wide source of the materials, low cost and the like and meanwhile has wide market prospect in composite material markets.

Owner:寰易(广东)应急安全科技集团有限公司

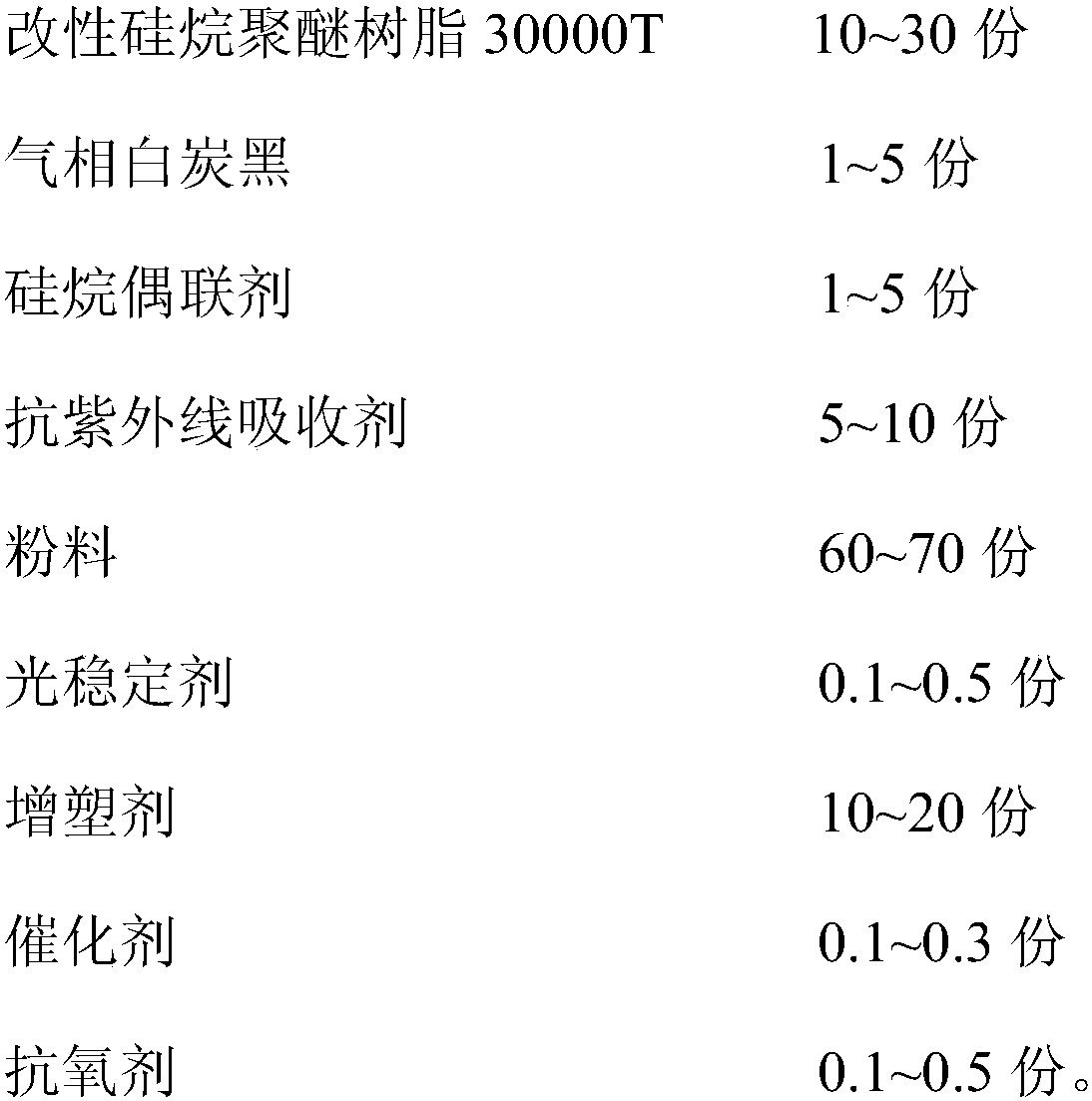

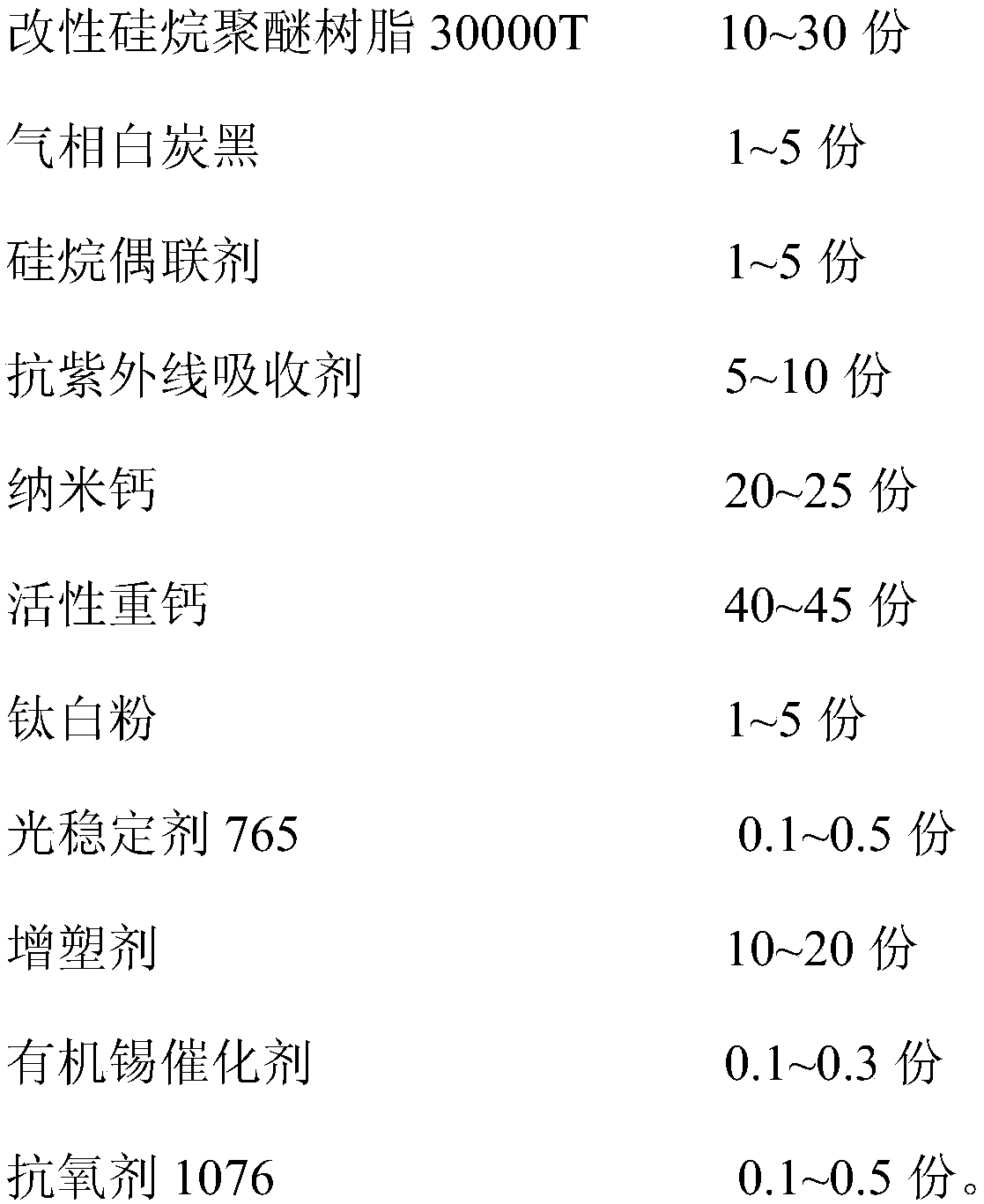

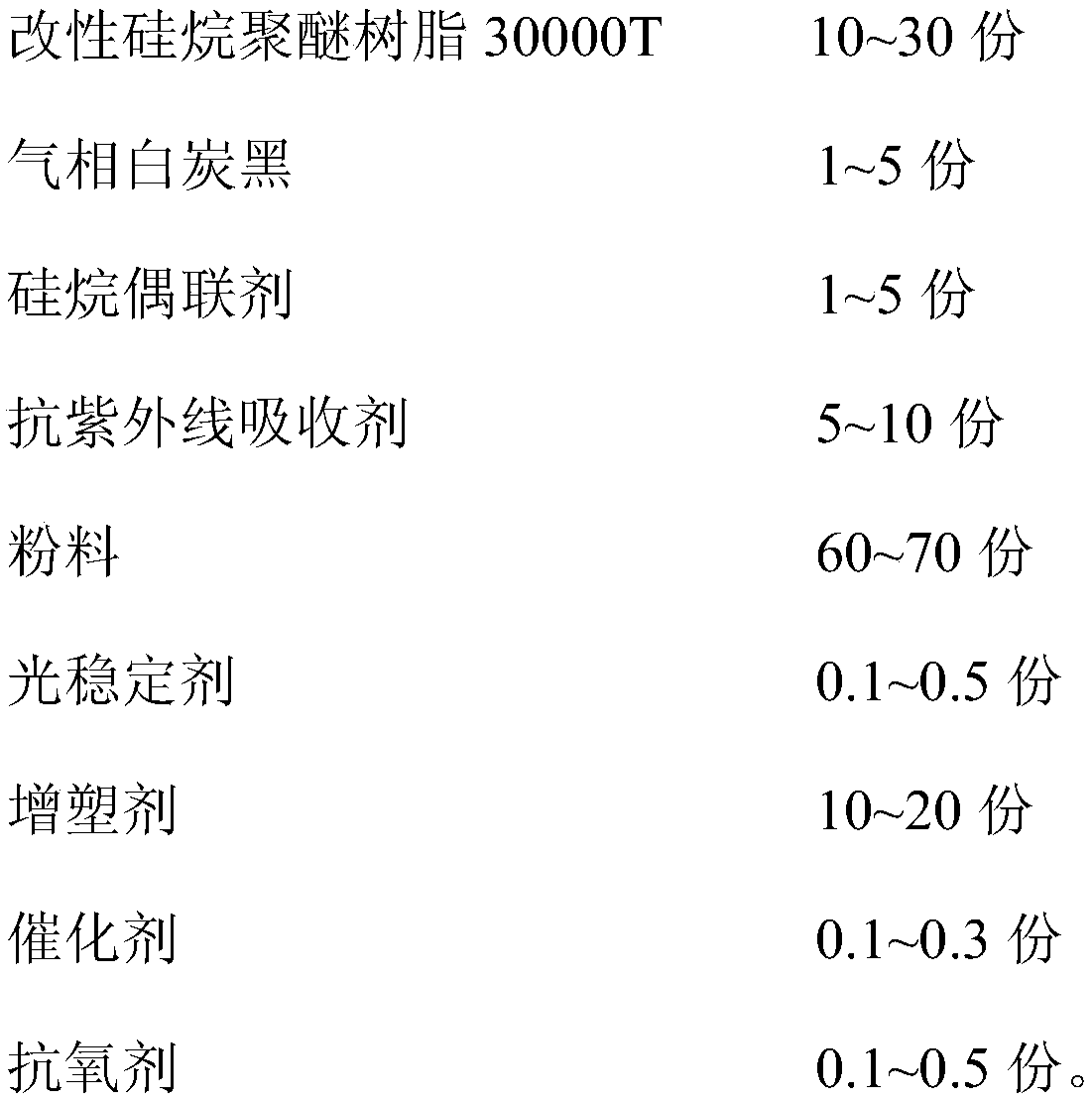

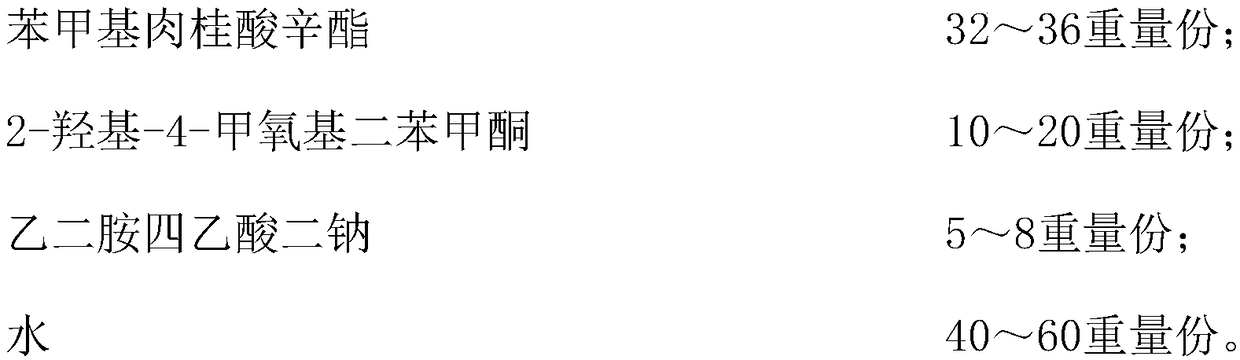

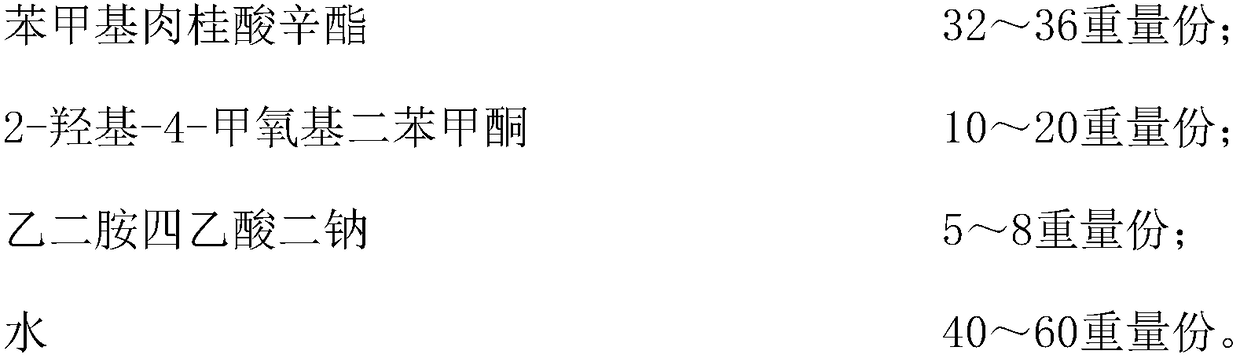

Preparation method of anti-ultraviolet modified silane polyether adhesive

InactiveCN108034396AHigh activitySurface dry and debond quicklyNon-macromolecular adhesive additivesPolyether adhesivesAntioxidantPlasticizer

The invention provides a preparation method of anti-ultraviolet modified silane polyether adhesive. The preparation method comprises the following steps: (1) stirring and mixing the following materials in parts by mass: 10 to 20 parts of a plasticizer, 60 to 70 parts of powder, and 1 to 2 parts of a silane coupling agent in a reaction kettle, and performing vacuum drying; (2) adding 5 to 10 partsof an anti-ultraviolet absorbent, 0.1 to 0.5 part of an antioxidant, 0.1 to 0.5 part of a light stabilizer, and 1 to 3 parts of a silane coupling agent, performing normal pressure heating, and cooling; (3) adding 10 to 30 parts of modified silane polyether resin 30000T, and 1 to 5 parts of fumed silica, and performing vacuum stirring; (4) adding the surplus of the silane coupling agent, and 0.1 to0.3 part of a catalyst, and performing vacuum stirring and pressure maintaining, so as to obtain the anti-ultraviolet modified silane polyether adhesive. The anti-ultraviolet modified silane polyether adhesive formed through the method has excellent bonding strength and a durable anti-ultraviolet function.

Owner:苏州启跃新材料科技有限公司

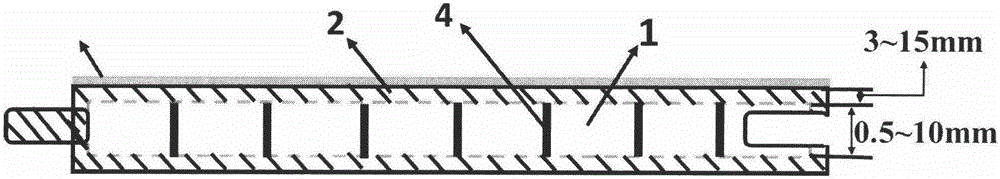

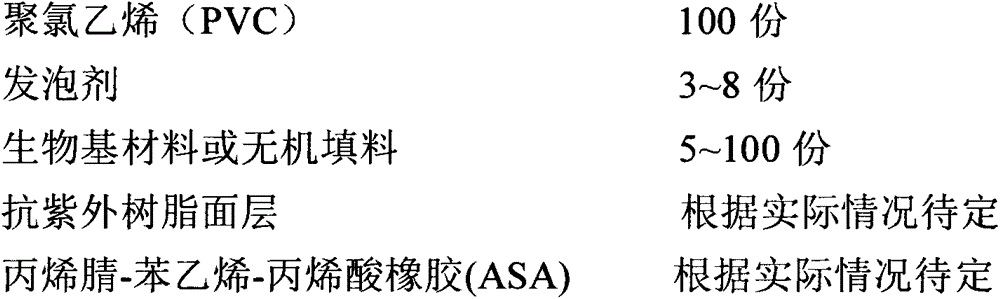

Novel energy saving hollow exterior wall decorative plate and manufacture method thereof

The invention discloses a novel energy saving hollow exterior wall decorative plate and a manufacture method thereof; the manufacture method comprises the following steps: using a hollow sheet material extruder to extrude, co-extruding an anti ultraviolet resin surface layer on the top surface of the hollow sheet material, and adding a support in the hollow portion; the decorative plate comprises the following components: polyvinyl chloride PVC, foaming agent, Biobased Material or inorganic filling material, and anti ultraviolet resin. The hollow external wall decorative plate can ensure energy saving and insulation effects, can improve lightweighting, sound insulation, anti-aging and insulation performances, can reduce cost, and complies with the sustainable development environmental protection demands; the manufacture method is simple, and industrialization can be easily realized, thus widely applying to the building exterior wall decorative plates.

Owner:无锡市天聚科技有限公司

Emulsified double-efficient reflecting luminescent paint and production

InactiveCN1817977APlay a reflective warning effectPrecipitation will notLuminescent paintsReflecting/signal paintsUltravioletPrecipitation

An emulsified anti-precipitation and luminescent reflecting double-efficient paint and its production are disclosed. When paint face is reflected and gives alert under light radiation, it will stop giving out night-light; on the contrary, it will give out night-light. It can be used in traffic, military, marine and industrial fields. It has excellent functions of anti-corrosive, acid and alkali-resistant, heat-resistant, waterproofing and abrasive-resistant.

Owner:万金林

Lignin raw lacquer compound coating

InactiveCN107955532AHigh hardnessGood flexibilityNatural resin coatingsLignin material coatingsVegetable oilAcrylic resin

The invention belongs to the technical field of coatings, and particularly discloses a lignin raw lacquer compound coating. The lignin raw lacquer compound coating is prepared from 15-20 parts of lignin, 8-12 parts of phennolic compound, 0.8-1 part of chlorine salt, 1-3 parts of graphite powder, 6-8 parts of dried vegetable oil, 4-6 parts of polyhydroxy acrylic resin, 50-60 parts of raw lacquer and 3-15 parts of auxiliaries. The lignin raw lacquer compound coating can greatly improve the adhesive force of the raw lacquer, the raw lacquer can become an antistatic coating, the application rangeof the raw lacquer compound coating is expanded, and the mechanical performance of the raw lacquer compound coating like the rigidity, flexibility and the shock resistance is improved; meanwhile, thedrying time is shortened, the function of resisting ultraviolet light is improved, the cost is low, and manufacturing is facilitated.

Owner:ZHONGSHAN DEGAOXING INTPROP CENT LLP

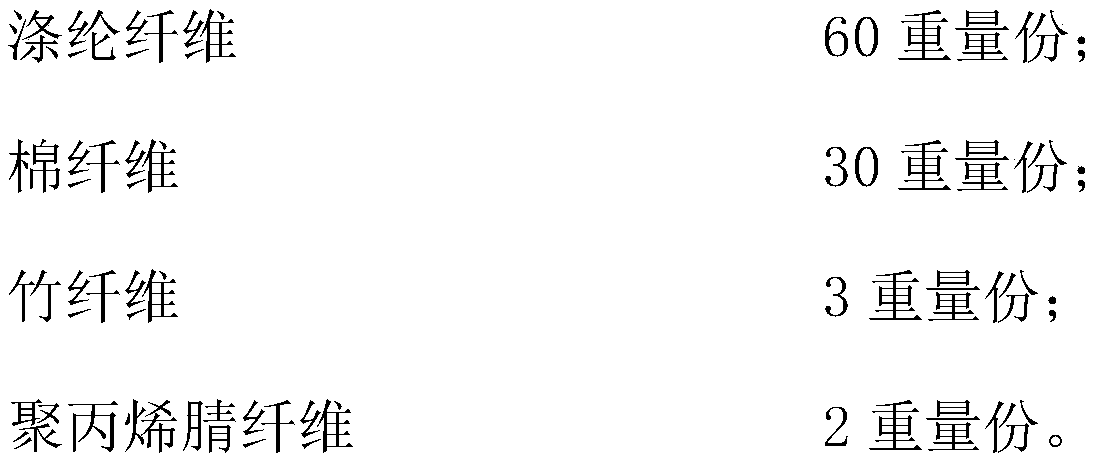

Anti-ultraviolet polyester-cotton fabric and preparation method thereof

InactiveCN109056156AImprove wearing comfortImprove breathabilityLight resistant fibresWoven fabricsFiberPolyester

The invention discloses a preparation method of anti-ultraviolet polyester-cotton fabric. The method comprises the following steps that gray fabric is subjected to oil removal treatment, dyed and pad-rolled in an anti-ultraviolet finishing agent to obtain the anti-ultraviolet polyester-cotton fabric; the gray fabric is prepared from, by weight, 60-70 parts of polyester fibers, 30-34 parts of cotton fibers, 3-5 parts of bamboo fibers and 2-4 parts of polyacrylonitrile fibers. According to the preparation method, the bamboo fibers are added to polyester-cotton fibers, so that the oil stain adsorption defect of the fabric is overcome, and the air permeability, moisture absorption and sweat releasing performance and dyeing performance and the anti-bacterium, mite-removal and anti-ultraviolet functions of the polyester-cotton fabric are improved; by adding the polyacrylonitrile fibers, the softness, chromophilous performance, anti-ultraviolet performance and anti-bacterium and mothproof performance of the fabric are improved; through compatibility with the anti-ultraviolet finishing agent, all components of the anti-ultraviolet finishing agent cooperate for promotion, the prepared anti-ultraviolet polyester-cotton fabric has the moisture absorption and sweat releasing performance, anti-bacterium performance and anti-ultraviolet performance, and the wearing comfort is improved.

Owner:NANTONG WEIXING TEXTILE TECH CO LTD

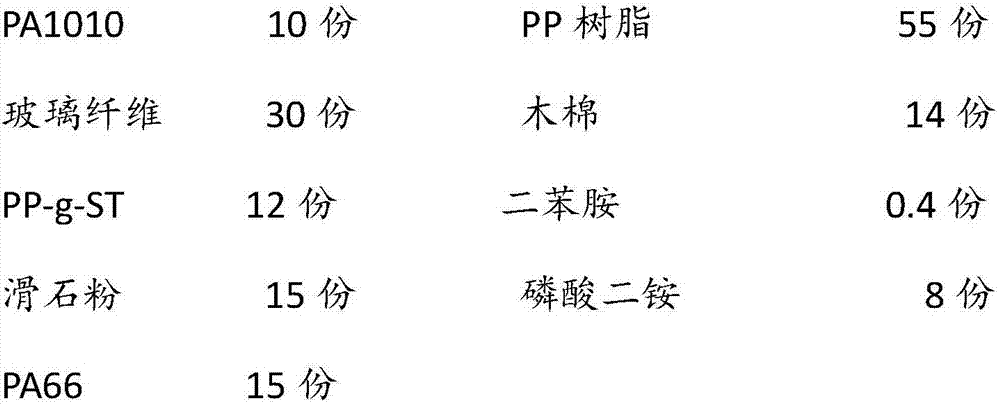

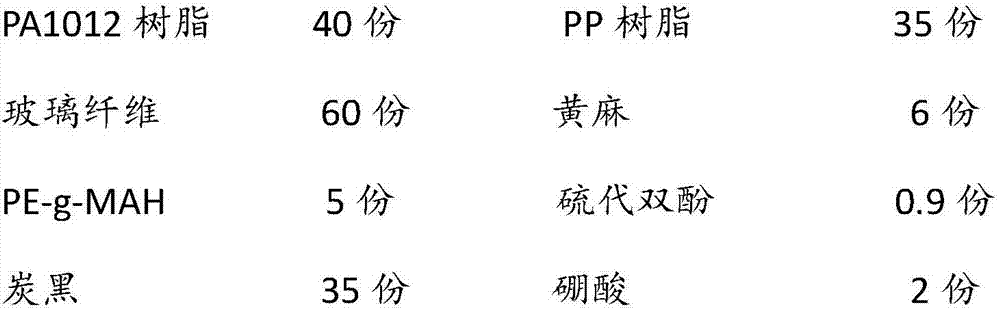

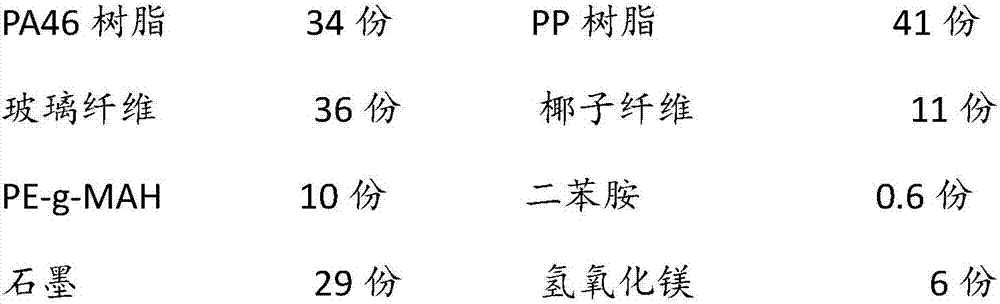

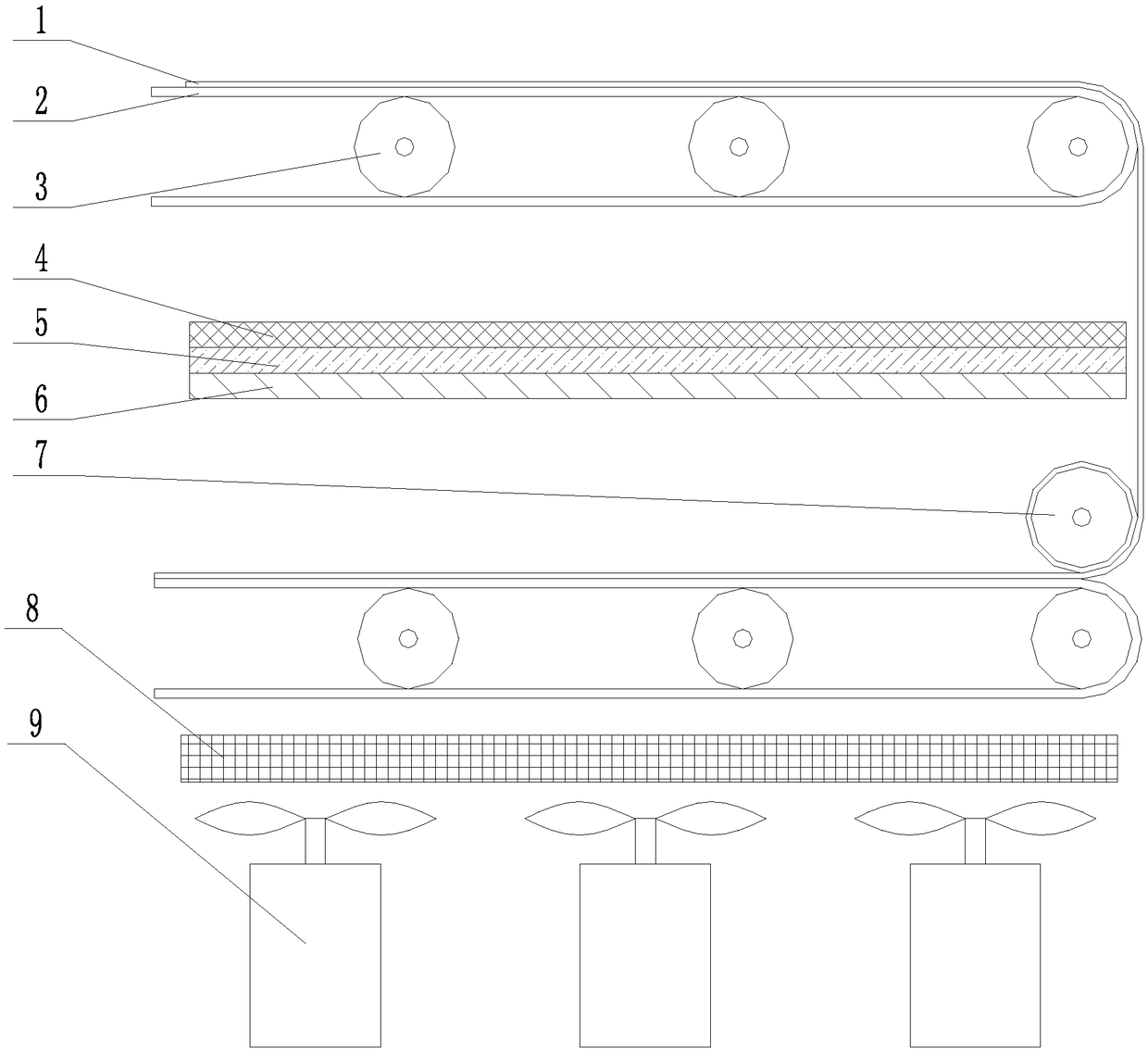

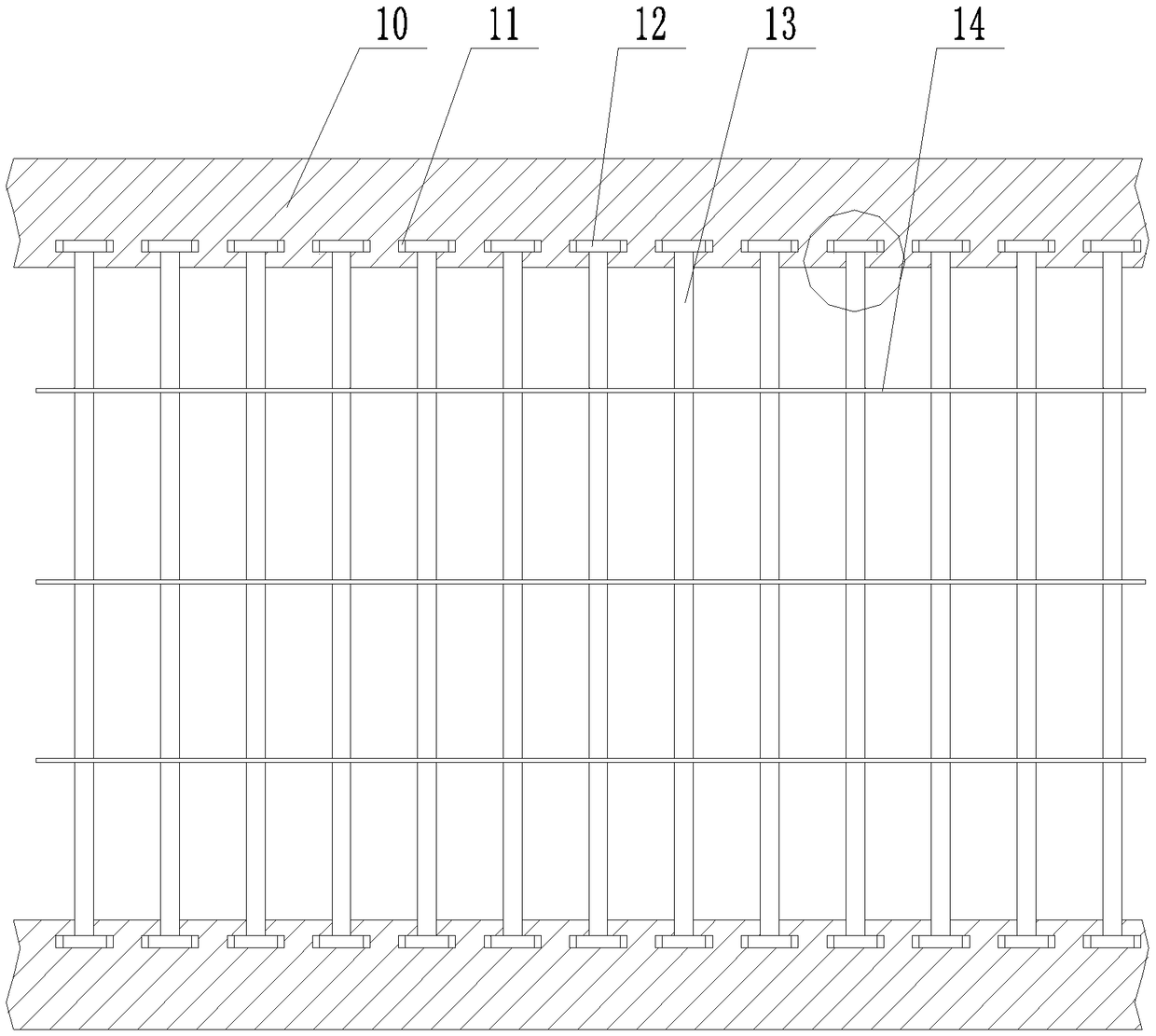

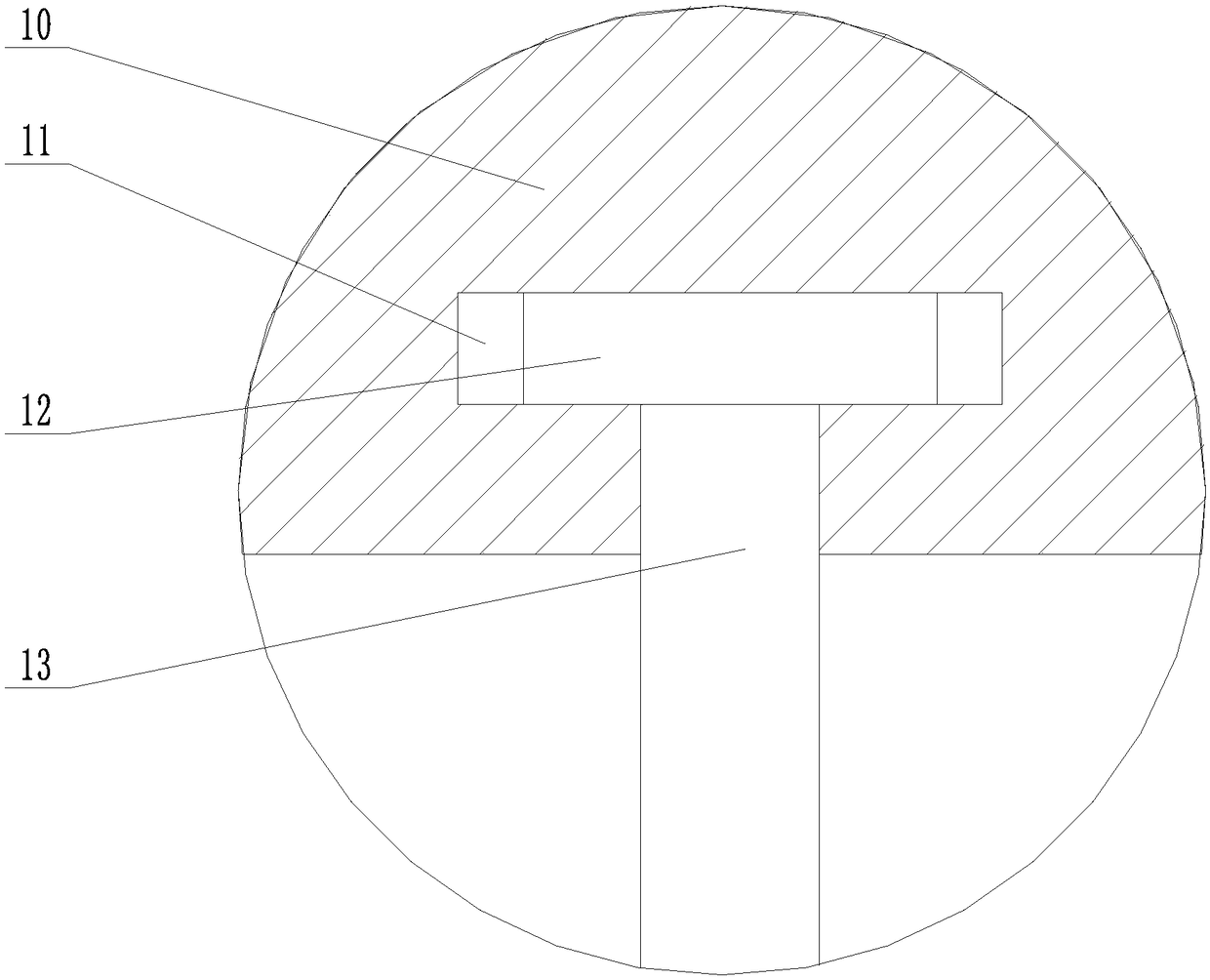

Preparing method for uvioresistant high-strength composite material

The invention discloses a preparing method for an uvioresistant high-strength composite material. The method comprises the steps that weighed PA resin, PP resin, glass fiber and plant fiber are arranged in a drying machine to be dried, the dried glass fiber and the dried plant fiber are arranged in a mixer, and a mixture a is obtained and used later; the dried PA resin, the dried PP resin, a compatilizer, an antioxidant, a filling agent and fire retardant are arranged in the mixer to be mixed, and a mixture b is obtained; and the mixture b is slowly poured into a double-screw extruder hopper, the speed of screws is controlled to range from 300 r / min to 400 r / min, the temperature of areas of the extruder is controlled to range from 190 DEG C to 215 DEG C, the temperature of a machine head ranges from 210 DEG C to 218 DEG C, the mixture a is added from the sixth area, melt is extruded out from the machine head, and the composite material is obtained. According to the preparing method, the PA resin and the PP resin are modified through the glass fiber and the plant fiber, the uvioresistant performance of the composite material can be greatly improved, and meanwhile the strength of the composite material can be improved.

Owner:FOSHAN HEHONG TAIYE TECH CO LTD

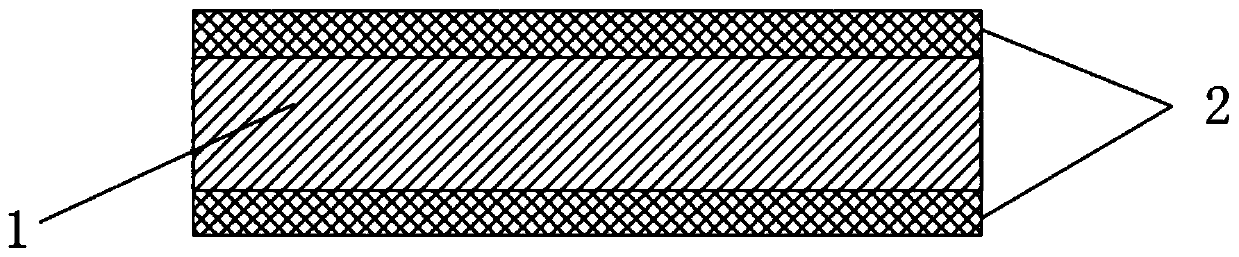

Solution-dyed skin-core anti-ultraviolet flame-retardant water-repellent polyester fiber and preparation method thereof

PendingCN111041608AImprove compatibilityAdd anti-ultraviolet functionArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsPolyesterPolymer chemistry

The invention relates to solution-dyed skin-core anti-ultraviolet flame-retardant water-repellent polyester fiber and a preparation method thereof. A skin layer component is prepared by blending phosphorus-based flame-retardant polyester slices and color master batches, and the skin layer component and a core layer component are extruded and melted into a melt in respective screw extruders to prepare a solution-dyed skin-core flame-retardant fiber precursor; in a precursor drafting process, an oiling agent M obtained by compounding a waterproof agent, a flame retardant, an anti-ultraviolet agent, an anti-static agent and a cross-linking agent is used for performing friction oiling on the front and back surfaces of a yarn sheet subjected to tension heat setting through double oil rollers ata yarn stacking machine; and then a crimped tow is sprayed with a compounded oiling agent N again to supplement oiling, and the tow is subjected to oven drying, setting cross-linking and cooling cutting to prepare the solution-dyed skin-core flame-retardant water-repellent polyester fiber. The fiber has the skin-core, color, flame-retardant and water-repellent functions and the anti-ultraviolet performance. Core layer raw materials can adopt the phosphorus-based flame-retardant polyester slices prepared from recycled materials, and the requirements of environmental protection industry policies and cyclic economic utilization are met.

Owner:SHANGHAI DEFULUN CHEM FIBER

Production technology of ultraviolet resistant fabric

InactiveCN109532190AImprove UV resistanceComfortable to wearGarment special featuresLamination ancillary operationsYarnUltraviolet

Relating to the technical field of fabric production, the invention specifically provides a production technology of an ultraviolet resistant fabric. The specific steps include: S1, treatment of an outer fabric: subjecting the outer fabric to padding treatment in an impregnation solution containing an anti-ultraviolet finishing agent, and then conducting drying and shaping to obtain the outer fabric containing an ultraviolet coating; S2, preparation of an inner fabric: weaving yarns that are not treated by the anti-ultraviolet agent into the inner fabric; and S3, lamination treatment of the outer fabric and the inner fabric by an ultrasonic laminating machine, thus obtaining the needed product. The product obtained by the invention has strong ultraviolet resistance, and is relatively comfortable for wearing at the same time.

Owner:江苏亨威实业集团有限公司

Antibacterial and deodorizing textile fabric and preparation method thereof

ActiveCN109295538AIncrease radiation rateImprove UV resistanceBiochemical fibre treatmentLiquid/gas/vapor removal by gas jetsFiberPolyvinyl alcohol

The invention relates to the technical field of textile materials, and concretely to an antibacterial and deodorizing textile fabric and a preparation method thereof. The antibacterial and deodorizingtextile fabric is prepared from the following raw materials, by weight, 30-35 parts of polyvinyl alcohol, 15-17 parts of chitosan, 14-16 parts of bamboo fibers, 8-10 parts of Tai Chi stones, 5-8 parts of honeysuckle flowers, 1-2 parts of garlic essential oil and 2-4 parts of single-layer graphene. The antibacterial and deodorizing textile fabric has the advantages of excellent bactericidal and antibacterial effects, soft texture, good moisture absorption and air permeation property and high tear strength. The preparation method adopting the raw materials to prepare the antibacterial and deodorizing textile fabric has a simple process, and the obtained antibacterial and deodorizing textile fabric has good breathable, antibacterial and antifungal effects.

Owner:HEYE HEALTH TECH CO LTD

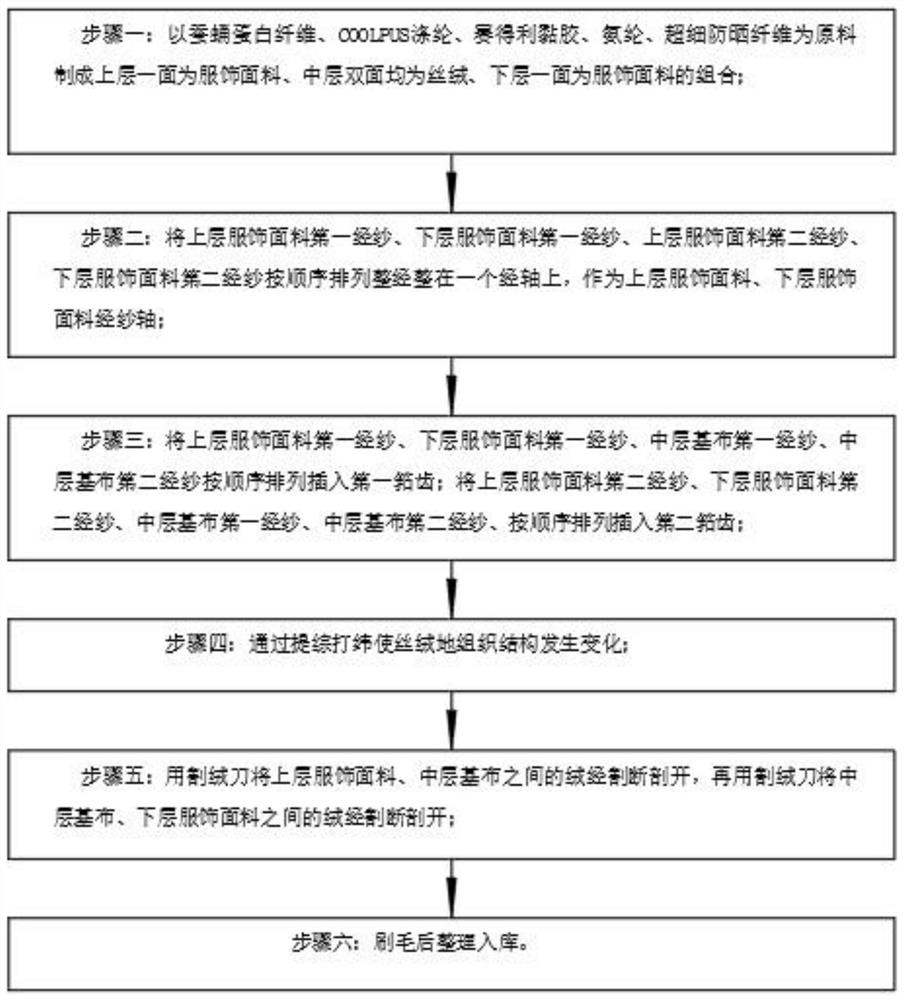

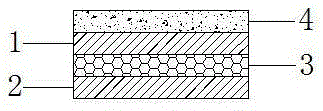

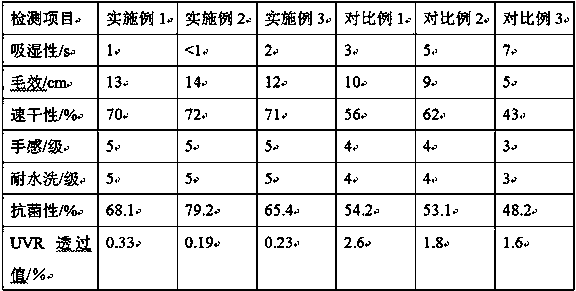

Processing technology of silkworm pupa protein lycra plain cloth

InactiveCN112981660AHelps moisture absorption and quick dryingImprove UV resistanceMulti-ply fabricsPolyesterYarn

The invention discloses a processing technology of silkworm pupa protein lycra plain cloth. The processing technology comprises the following steps: step 1, silkworm pupa protein fibers, COOLPUS polyester, Sateri viscose, spandex and superfine sun-proof fibers serve as raw materials to be made into a combination, wherein one face of an upper layer is a clothes fabric, two faces of a middle layer are velvet, and one face of a lower layer is a clothes fabric; and step 2, the first warp yarn of the upper-layer clothes fabric, the first warp yarn of the lower-layer clothes fabric, the second warp yarn of the upper-layer clothes fabric and the second warp yarn of the lower-layer clothes fabric are arranged and warped on a warp beam in sequence to serve as warp beams of the upper-layer clothes fabric and the lower-layer clothes fabric. The processing technology has the beneficial effects that the silkworm pupa protein fibers, the COOLPUS polyester, the Sateri viscose and the spandex are adopted, so that the prepared plain cloth is soft, skin-friendly, antibacterial, skin-care, and beneficial to moisture absorption and quick drying; and superfine sunscreen fibers are adopted, so that sunscreen particles with an intelligent sunscreen effect are attached to the surface of the prepared plain cloth, and the anti-ultraviolet function is increased.

Owner:浙江宁玥科技有限公司

A kind of protective coating for outdoor power equipment and preparation method thereof

ActiveCN109836917BExcellent weather resistance and corrosion resistanceImproved anti-corrosion and weather resistanceAntifouling/underwater paintsPaints with biocidesPtru catalystElectric power equipment

The invention provides a protective paint for outdoor power equipment, which belongs to the technical field of paint compositions. A protective coating for outdoor power equipment, made of the following raw materials in parts by weight: 30-45 parts of FEVE fluorocarbon resin, 12-20 parts of bisphenol A epoxy resin, 5-10 parts of modified nano-silica, solvent 25‑35 parts, catalyst 0.02~0.1 part, ultraviolet absorber 0.8~1.5 part. The protective coating for outdoor electric equipment of the present invention can enhance the weather resistance and anticorrosion performance of outdoor electric equipment.

Owner:国网河南省电力公司西峡县供电公司

Bacteriostatic and uvioresistant composite fabric

InactiveCN105383137ASoft touchStrong antibacterial functionSynthetic resin layered productsYarnUltraviolet

The invention relates to the technical field of a textile fabric, in particular to a bacteriostatic and uvioresistant composite fabric. The bacteriostatic and uvioresistant composite fabric comprises an upper layer fabric and a lower layer fabric, wherein the upper layer fabric is formed by weaving warp threads and weft threads; the warp threads are formed by blending uvioresistant fiber and bamboo charcoal fiber yarns; the weft threads are formed by blending soybean fiber and Shengma fiber; a moisture absorption and sweat releasing layer is arranged between the upper layer fabric and the lower layer fabric; a layer of uvioresistant auxiliary agent is also arranged on the upper layer fabric. The soybean fiber has good performance such as soft handfeel like cashmere, tender luster like silk, and heat insulation performance and good skin-friendly performance like cotton, and also has an obvious bacteriostatic function and better moisture absorbing performance and ventilation performance; when the fabric is worn by people, the moisture absorption and sweat releasing effects are achieved, and people feel very cool; by adopting the structural design, the uvioresistant performance and the bacteriostatic performance of the composite fabric are greatly improved; meanwhile, the moisture discharge and ventilation performance is also realized; in addition, the raw materials are natural, and green effects, environment protection and no pollution are achieved.

Owner:YANGZHOU JINHUI CHEM FIBER CO LTD

Textile finishing agent preparation method

InactiveCN109989264AHigh reactivityImprove UV resistanceBiochemical fibre treatmentLight resistant fibresMaleic anhydrideTitanate

The invention relates to a textile finishing agent preparation method, and belongs to the technical field of textile additives. Silk fibroin, maleic anhydride and tetrabutyl titanate serve as raw materials for preparing titanium dioxide, electrostatic attraction between the titanium dioxide and the silk fibroin is easily formed, imido combined hydrogen ions have positive charge, the surface of thesilk fibroin further contains rich hydroxy groups, the hydroxy groups and amino generated by auxiliary hydrolysis can form hydrogen bonds, and reaction activity is improved. The hydrogen bonds are inhybrid reaction with thiosemicarbazide, hydroxyethyl methylacrylate and the like, and the ultraviolet resistance and the antibacterial performance of a finishing agent are improved. The titanium dioxide is deposited on the surface of the silk fibroin and can be effectively combined with a fabric by the aid of rich active groups in the silk fibroin, the titanium dioxide and the fabric have good fusion properties by the aid of properties of the silk fibroin, the combination degree of the titanium dioxide and the fabric is further increased by an organic ligand formed on the surface of the titanium dioxide, and water resistance is enhanced under the action of aminopropyltriethoxysilane.

Owner:常州琨瑶纺织品有限公司

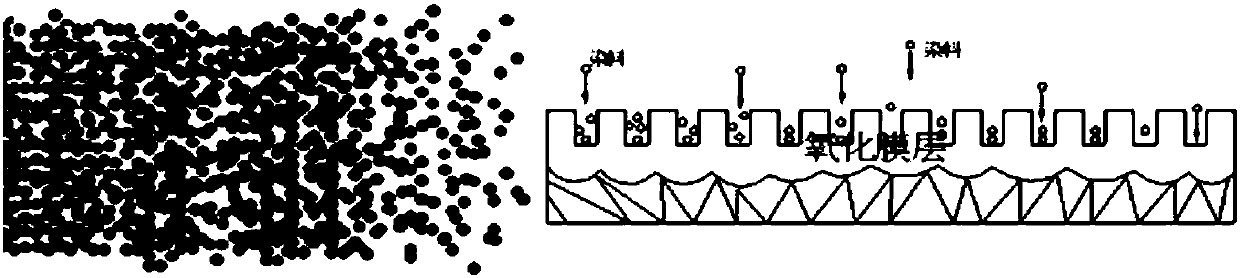

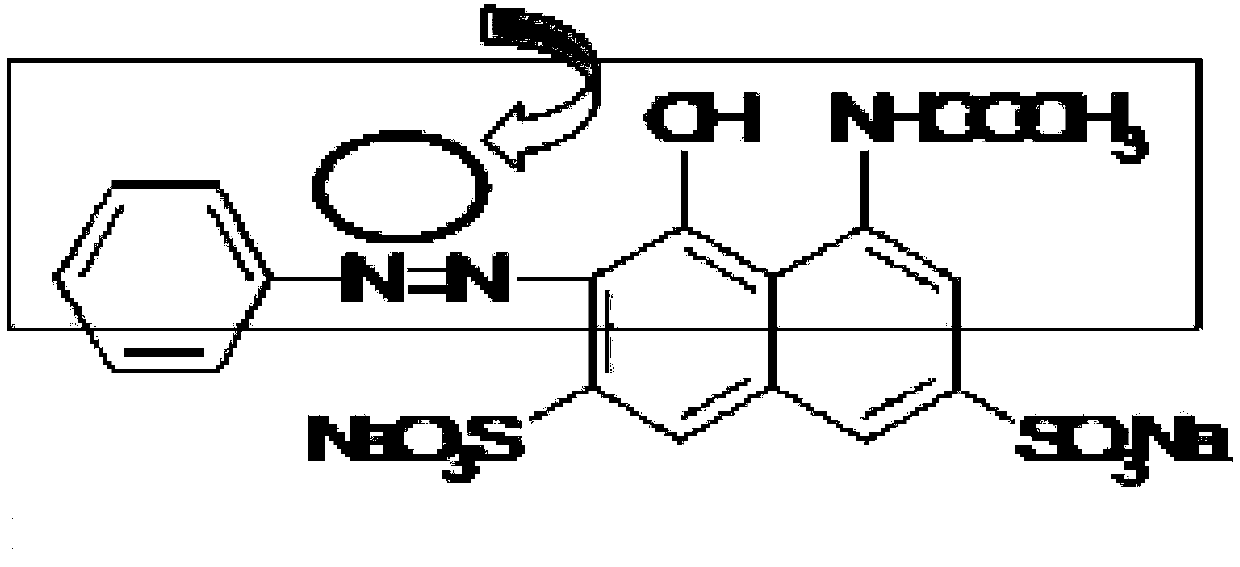

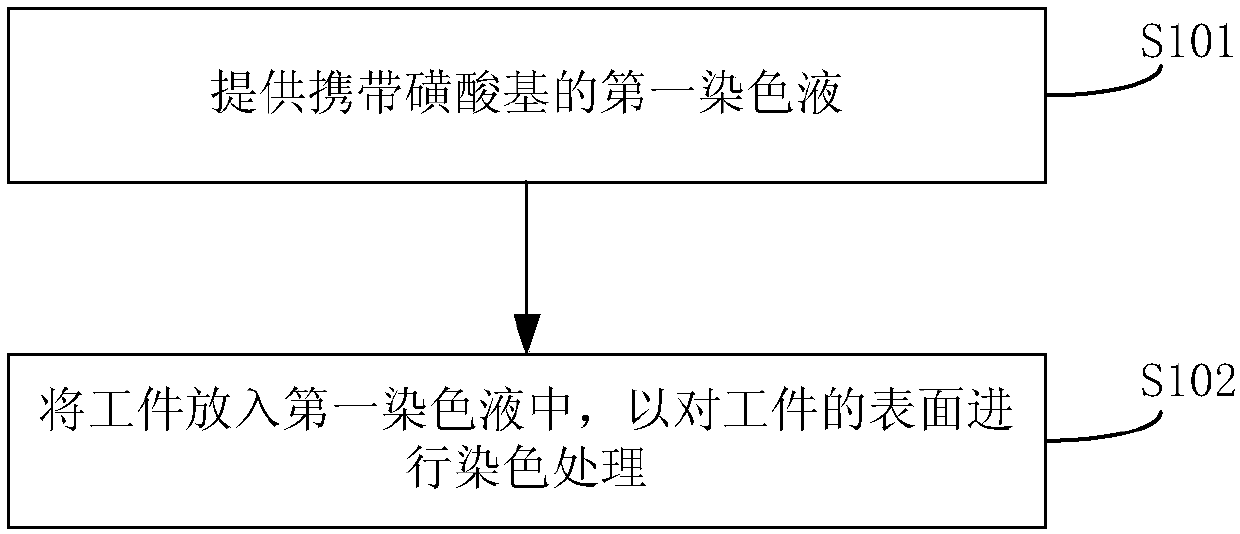

Method for treating surface of workpiece

ActiveCN107815716AGood light fastnessImprove color uniformitySurface reaction electrolytic coatingEngineeringDyeing

The invention discloses a method for treating the surface of a workpiece. The method includes the steps that first dyeing liquid carrying sulfonic groups is provided; and the workpiece is put into thefirst dyeing liquid, and dyeing treatment is conducted on the surface of the workpiece. By means of the above manner, the technical support can be provided for improving of sun-proof performance andcolor uniformity of the workpiece.

Owner:GUANGDONG EVERWIN PRECISION TECH

UV (ultraviolet) heat damage resistant cable

InactiveCN106398046AAvoid corrosionPrevent oxidationPlastic/resin/waxes insulatorsEpoxyElectrical conductor

The invention discloses an UV (ultraviolet) heat damage resistant cable. The cable consists of a conductor and an insulating sheath covering the conductor, wherein the outer insulating sheath is prepared from components in parts by weight as follows: 15-25 parts of epoxy resin, 10-15 parts of rubber resin, 25-35 parts of polyvinyl chloride resin, 20-35 parts of crosslinked polyethylene, 3-5 parts of a stabilizer, 1-3 parts of a lubricant, 3-7 parts of an UV light absorber and 2-5 parts of a light screening agent. The ultraviolet light absorber and the light screening agent are added to materials of the UV heat damage resistant cable to improve the UV-resistant performance, the aging resistance of the cable is further enhanced, and the service life is prolonged. The cable is simple in structure and easy to produce, and the cost is saved; the high-intensity UV heat damage corrosion and oxidation of the outer sheath of the cable due to long-term UV exposure can be effectively avoided, and the cable is particularly applicable to harsh altitude environments.

Owner:武汉广宏利机电设备有限公司

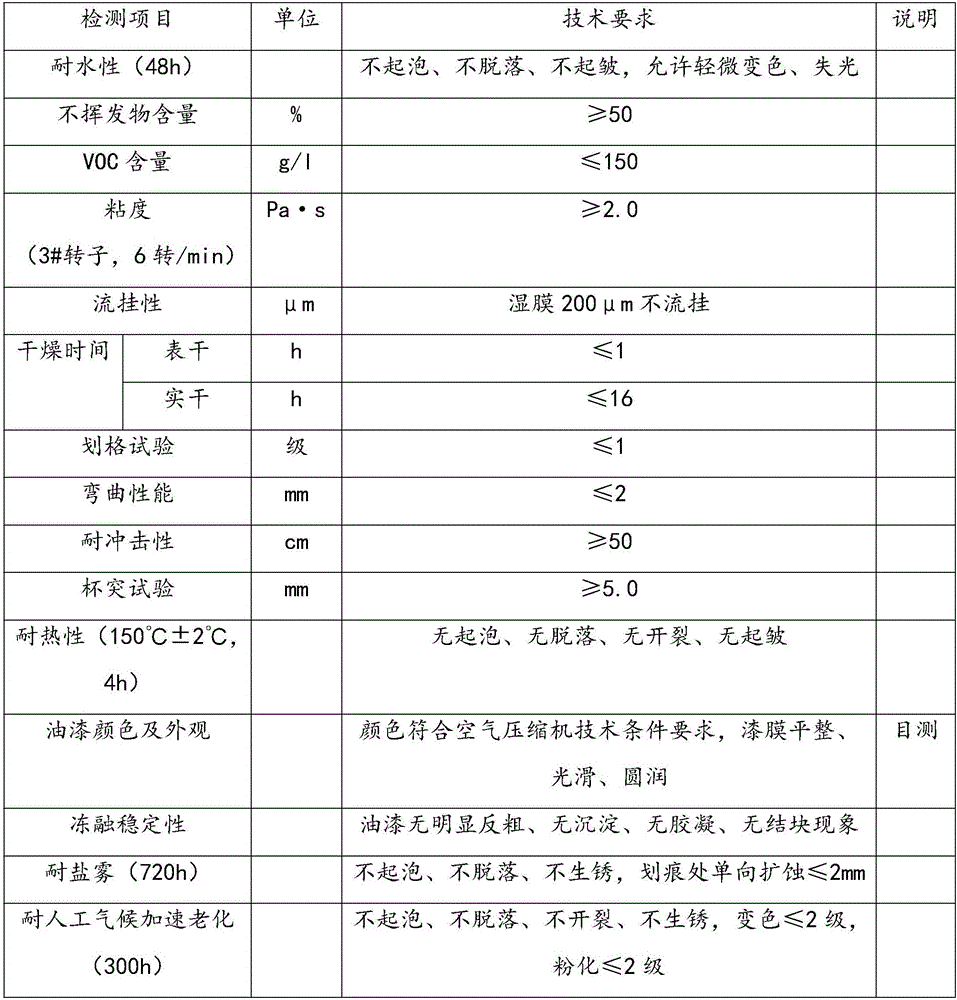

Damp-proof water-proof paint for air compressors and preparation method thereof

InactiveCN106634319APreparation method scienceImprove waterproof and moisture-proof performanceAnti-corrosive paintsFiberCarbon fibers

The invention discloses a damp-proof water-proof paint for air compressors and a preparation method thereof. The paint is composed of the following raw materials in parts by weight: 36-42 parts of acrylate emulsion, 12-16 parts of tetrabutyl titanate, 6-8 parts of expanded glass beads, 5-7 parts of PAN-based carbon fibers, 2-8 parts of erucyl amide, 2-6 parts of nano copper powder colloidal solution, 1-5 parts of pigment, 4 parts of magnesium oxide nano particles, 6 parts of polyaluminium sulfate, 3 parts of dodecanol ester, 8 parts of chlorinated polyethylene and 2 parts of polyacrylamide. The paint is reasonable in component configuration, low in cost and scientific in preparation method, and the prepared paint has excellent water-proof and damp-proof performance, the corrosion resistance, the weather resistance, the storage stability, the salt fog resistance, the acid and alkali resistance, the rust resistance and the like of the paint are improved, the method is rapid in drying, good in adhesive force, convenient to construct, safe and environment-friendly. The paint is suitable for the air compressor, in particular for the air compressor in a humid environment for a long time.

Owner:ANHUI RUITIAN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com