Preparation method of anti-ultraviolet modified silane polyether adhesive

An anti-ultraviolet, silane polyether technology, applied in the field of sealants, can solve the problems of low tear strength, easy to contaminate building materials, application restrictions, etc., and achieve the effects of rapid surface drying and debonding, high activity, and excellent bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the modified silane polyether glue of anti-ultraviolet of the present invention, described preparation method comprises the steps:

[0049] 1) In parts by weight, put 10-20 parts of plasticizer, 60-70 parts of powder, and 1-2 parts of silane coupling agent in a reaction kettle, stir and mix, and dry in vacuum;

[0050] 2) In parts by weight, add 5 to 10 parts of anti-ultraviolet absorber, 0.1 to 0.5 parts of antioxidant, 0.1 to 0.5 parts of light stabilizer, 1 to 3 parts of Silane coupling agent, normal pressure heating, cooling treatment;

[0051] 3) In parts by weight, add 10 to 30 parts of modified silane polyether resin 30000T and 1 to 5 parts of fumed white carbon black to the mixture obtained in step 2), and stir under vacuum conditions;

[0052] 4) In parts by weight, add the remaining amount of silane coupling agent and 0.1 to 0.3 parts of catalyst to the mixture obtained in step 3), stir and hold pressure under vacuum conditions to ob...

Embodiment 1

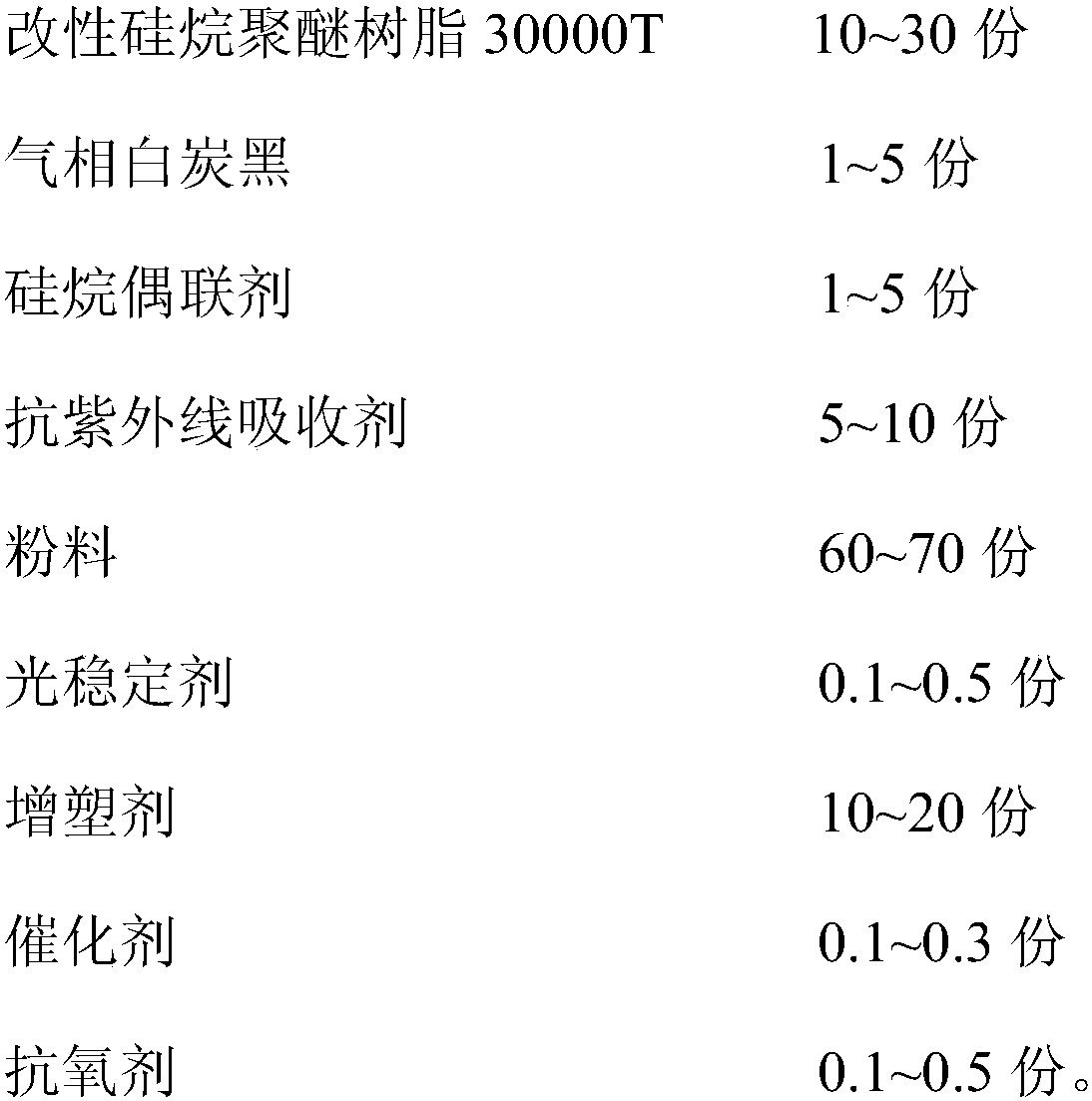

[0055] The anti-ultraviolet modified silane polyether glue of the present embodiment comprises the following preparation raw materials in parts by weight:

[0056]

Embodiment 2

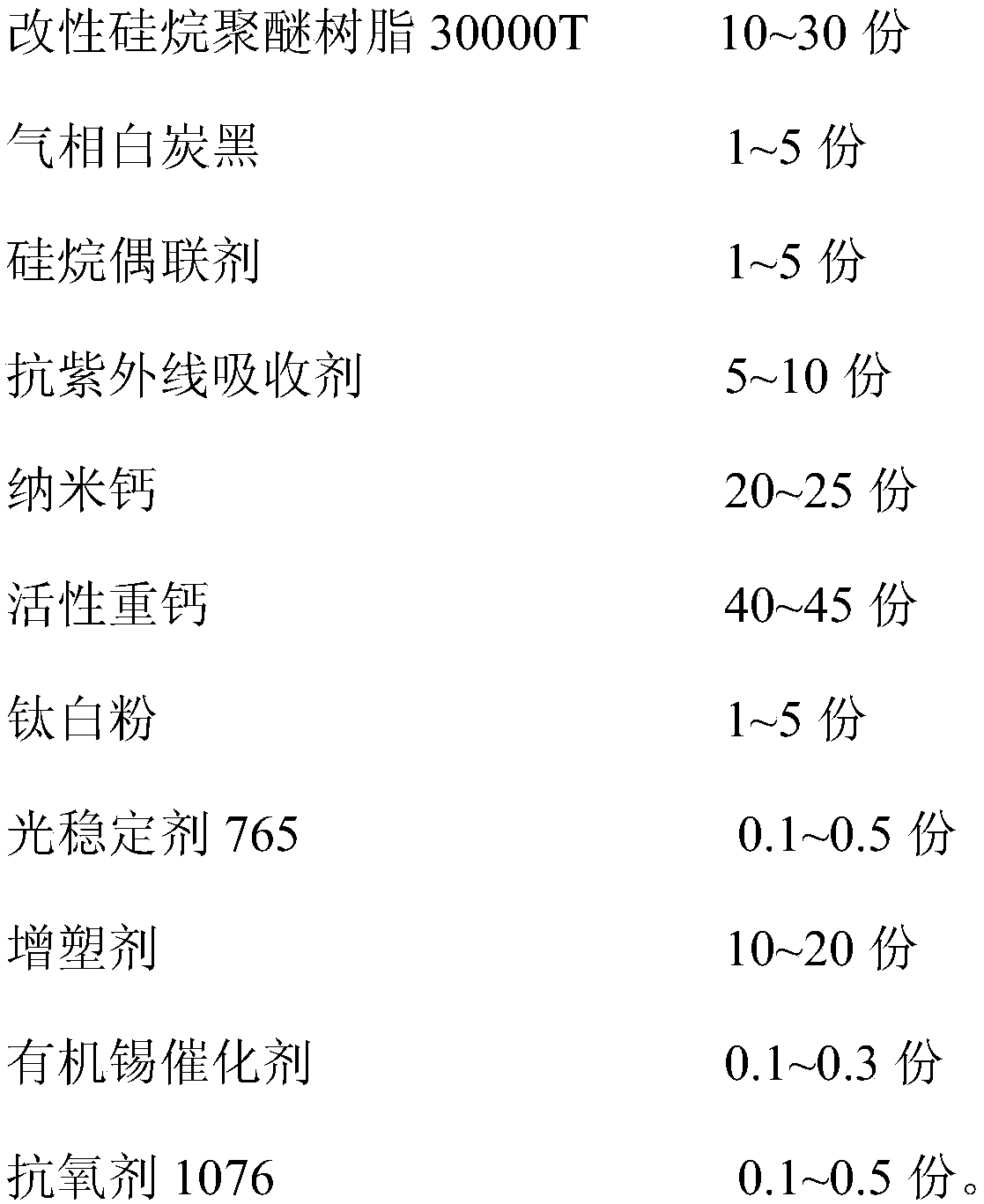

[0058] The anti-ultraviolet modified silane polyether glue of the present embodiment comprises the following preparation raw materials in parts by weight:

[0059]

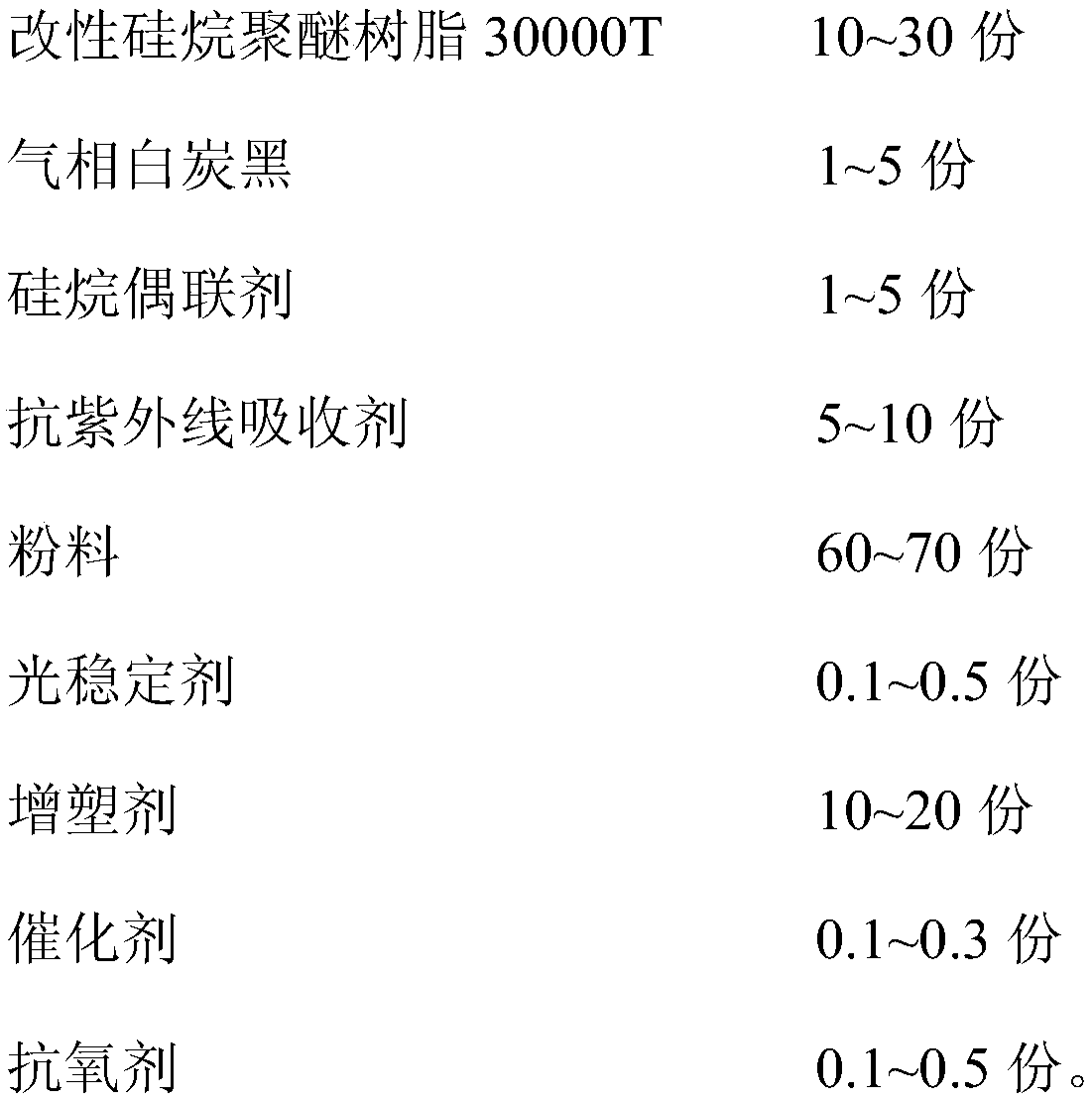

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com