Textile finishing agent preparation method

A technology of fabric finishing agent and auxiliary agent, applied in the field of fabric finishing agent preparation, can solve the problems of poor fabric bonding performance, poor effect of fabric finishing agent, easy loss of titanium dioxide, etc. The effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

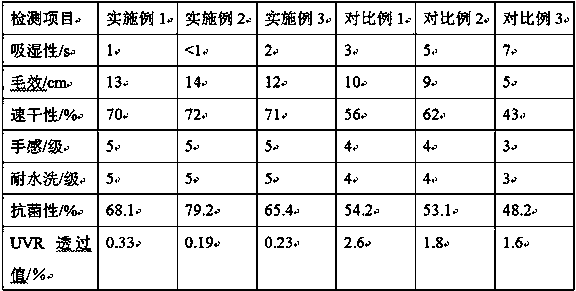

Examples

preparation example Construction

[0025] The preparation method of the conditioning liquid is to mix silk fibroin, maleic anhydride and glacial acetic acid in a mass ratio of 3:1:9-12 to obtain the conditioning liquid.

[0026] The auxiliary agent is aminopropyltriethoxysilane.

[0027] The additives are mixed with thiosemicarbazide and hydroxyethyl methacrylate in a mass ratio of 9:1 to 2.

[0028] The preparation method of the additive liquid is as follows: the surface active agent, the metal salt, and the mixed solvent are mixed in a mass ratio of 1:6 to 8:16 to obtain the additive liquid.

[0029] The surfactant is any one of isotridecyl alcohol polyoxyethylene ether and sodium dodecylbenzene sulfonate.

[0030] The metal salt is a mixture of platinum nitrate and zinc nitrate in a mass ratio of 4:1 to 6.

[0031] The mixed solvent is a mixture of salicylic acid solution and ethanol solution in a volume ratio of 3:6-8.

[0032] The auxiliary solvent is a mixture of tetrahydrofuran and petroleum ether in a volume ratio ...

Embodiment 1

[0041] The preparation method of the conditioning liquid is to mix silk fibroin, maleic anhydride and glacial acetic acid in a mass ratio of 3:1:12 to obtain the conditioning liquid.

[0042] The auxiliary agent is aminopropyltriethoxysilane.

[0043] The additives are thiosemicarbazide and hydroxyethyl methacrylate mixed in a mass ratio of 9:2.

[0044] The preparation method of the additive liquid is as follows: the surfactant, the metal salt, and the mixed solvent are mixed in a mass ratio of 1:8:16 to obtain the additive liquid.

[0045] The surfactant is sodium dodecylbenzene sulfonate.

[0046] The metal salt is a mixture of platinum nitrate and zinc nitrate in a mass ratio of 4:6.

[0047] The mixed solvent is a mixture of salicylic acid solution and ethanol solution in a volume ratio of 3:8.

[0048] The auxiliary solvent is a mixture of tetrahydrofuran and petroleum ether in a volume ratio of 6:3.

[0049] The auxiliary agent is a mixture of ammonium citrate and acrylic acid in a ...

Embodiment 2

[0057] The preparation method of the conditioning liquid is to mix silk fibroin, maleic anhydride and glacial acetic acid in a mass ratio of 3:1:11 to obtain the conditioning liquid.

[0058] The auxiliary agent is aminopropyltriethoxysilane.

[0059] The additives are mixed with thiosemicarbazide and hydroxyethyl methacrylate in a mass ratio of 9:1.5.

[0060] The preparation method of the additive liquid is as follows: the surfactant, the metal salt, and the mixed solvent are mixed in a mass ratio of 1:7:16 to obtain the additive liquid.

[0061] The surfactant is isomerized tridecanol polyoxyethylene ether.

[0062] The metal salt is a mixture of platinum nitrate and zinc nitrate in a mass ratio of 4:5.

[0063] The mixed solvent is a mixture of salicylic acid solution and ethanol solution in a volume ratio of 3:7.

[0064] The auxiliary solvent is a mixture of tetrahydrofuran and petroleum ether in a volume ratio of 6:2.

[0065] The auxiliary agent is a mixture of ammonium citrate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com