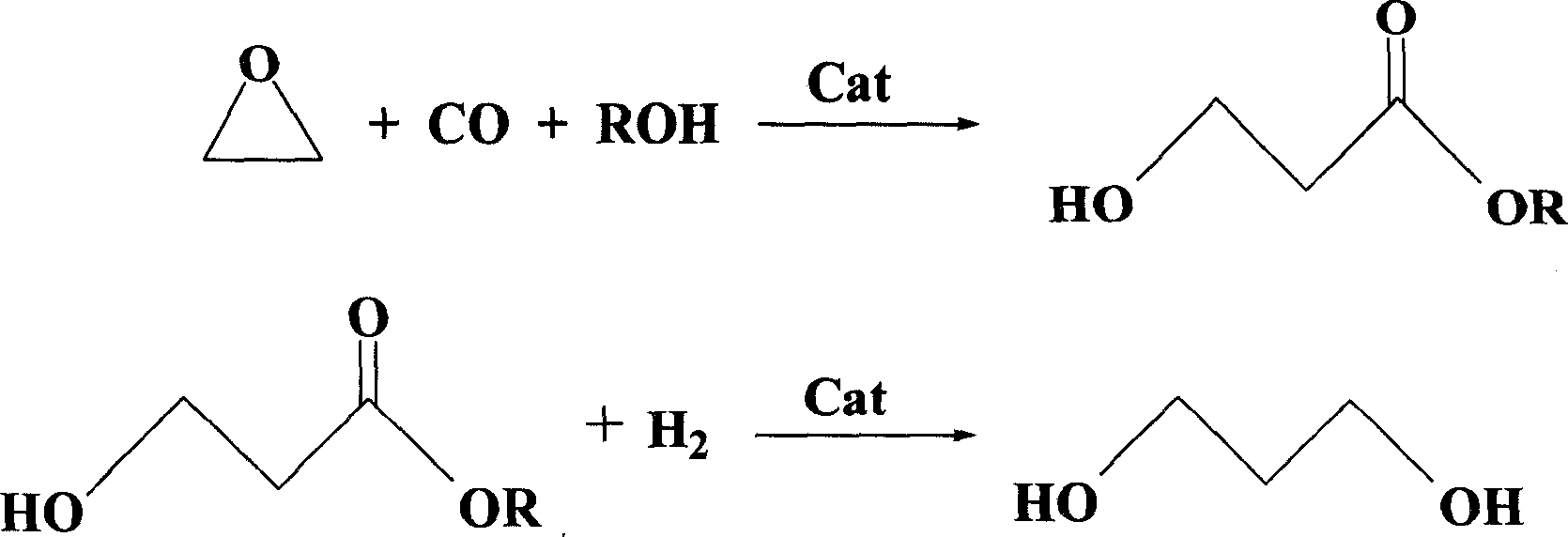

Prepn process of 3-hydroxy propionate and propylene glycol

A technology of hydroxypropionate and propylene glycol, which is applied in the field of preparing 3-hydroxypropionate and 1, can solve the problems of low hydrogenation product yield and no prospect of enlargement, and achieve the improvement of reaction activity and selectivity, selectivity and Strong stability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a 1-liter high-pressure stainless steel reactor, add 450 mL of methanol, Co 2 (CO) 8 5.0g, quinoline 3.5mL, water 6mL, H 2 0.5MPa. At room temperature, fill CO gas with a pressure of 4.0 MPa, 120 g of ethylene oxide, keep the reaction temperature at 65°C-75°C, and the reaction pressure at 5.5MPa, and react for 6 hours. The solution contains 16% by weight of methyl 3-hydroxypropionate, and the selectivity is 89.5%.

Embodiment 2

[0038] Add 450 mL of methanol, Co 2 (CO) 8 5.0g, isoquinoline 3.5mL, water 7.0mL, H 2 0.5MPa. At room temperature, fill CO gas with a pressure of 4.0 MPa, 120 g of ethylene oxide, keep the reaction temperature at 65-75° C., and the reaction pressure at 5.5 MPa, and react for 6 hours. The selectivity of methyl 3-hydroxypropionate is 88%, methyl acrylate is 7.2%, ethylene glycol monomethyl ether is 0.5%, and others are 2.0%.

Embodiment 3

[0040] Add 450 mL of methanol, Co 2 (CO) 8 5.0g, 8-hydroxyquinoline 4.2g, H 2 0.5MPa. At room temperature, fill CO gas with a pressure of 4.0 MPa, 120 g of ethylene oxide, keep the reaction temperature at 65°C-75°C, and the reaction pressure at 5.5MPa, and react for 6 hours. There was a small amount of precipitation in the reaction mixture, about 1.9 g, the selectivity of methyl 3-hydroxypropionate was 60.7%, methyl acrylate was 16.6%, ethylene glycol monomethyl ether was 5.9%, and others were 16.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com