Water acrylic resin and preparing method thereof

A water-based acrylic and acrylic technology, applied in the coating and other directions, to achieve the effects of long storage time, small particle size and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

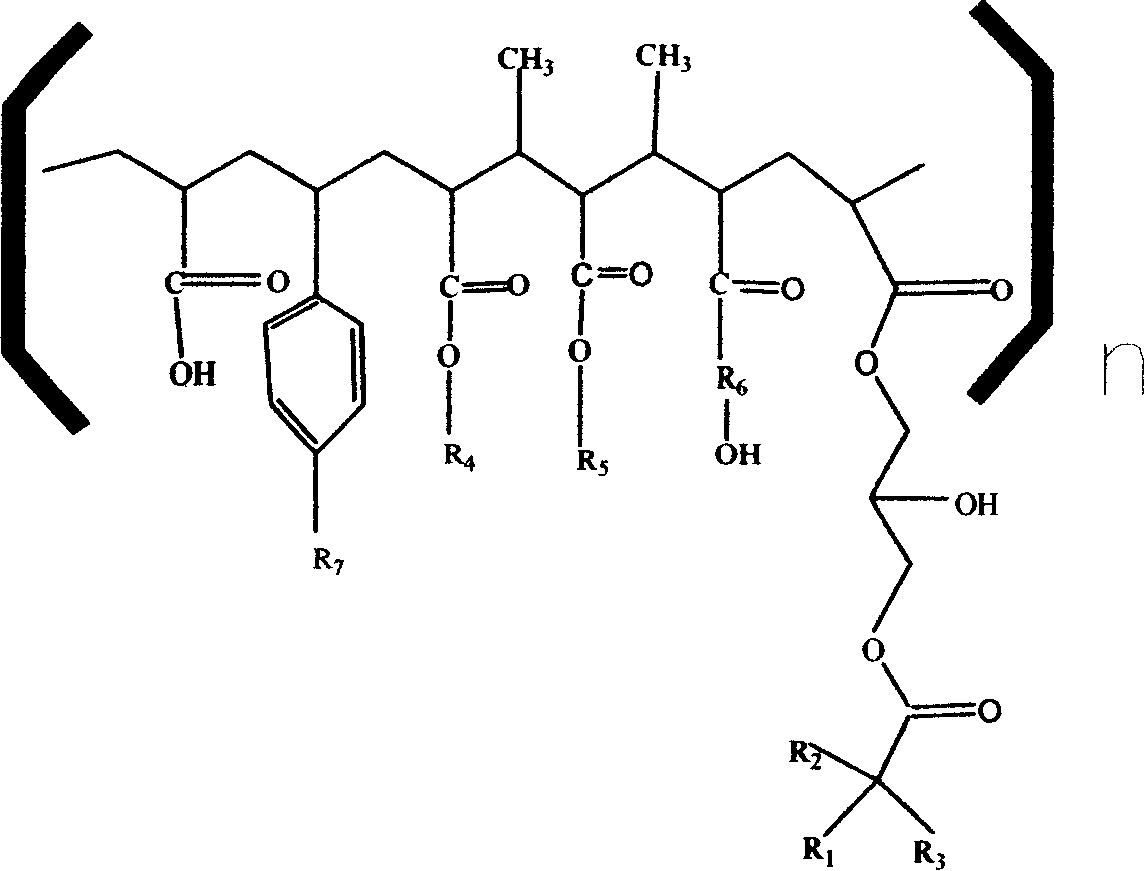

AI Technical Summary

Problems solved by technology

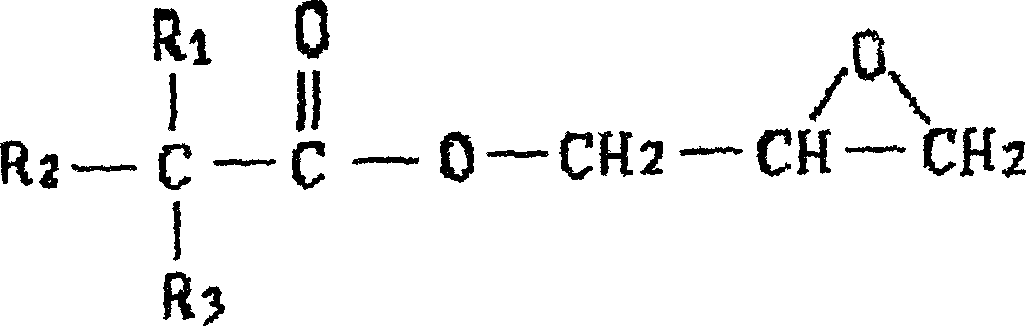

Method used

Image

Examples

Embodiment 1

[0041] The composition of raw materials for preparing waterborne acrylic resin is shown in Table 3.

[0042] Table 3 Preparation of water-based acrylic resin (embodiment 1) with raw material composition

[0043] Component

mass (g)

Propylene glycol butyl ether

8.3

24.7

acrylic

10.7

3.2

19.8

7.5

14.6

tert-butyl peroxybenzoate

2.8

8.4

Deionized water

160.0

[0044] The specific preparation method is as follows: add propylene glycol butyl ether and glycidyl tertiary carbonate to a 500mL four-necked flask equipped with a thermometer, a stirring device and a condenser, pass through dry nitrogen protection, start stirring and raise the temperature to 150-155°C; then start Add dropwise the mixture of acrylic acid, hydr...

Embodiment 2

[0051] The composition of raw materials for preparing water-based acrylic resin in this example is shown in Table 5. Different from Example 1, in this example, the amount of methyl methacrylate in the raw material components was increased, the amount of butyl acrylate was reduced, and methyl styrene was used instead of styrene.

[0052] Table 5 prepares waterborne acrylic resin (embodiment 2) with raw material composition

[0053] Component

[0054] The specific preparation method is as follows: Add propylene glycol butyl ether and glycidyl tert-carbonate into a 500mL four-necked flask equipped with a thermometer, a stirring device and a condenser, pass through dry nitrogen protection, start stirring and raise the temperature to 150-155°C; then start Add dropwise the mixture of acrylic acid, hydroxyethyl methacrylate, methyl methacrylate, butyl acrylate, methylstyrene and tert-butyl peroxybenzoate, wherein 7g of acrylic acid, 2.4g of tert-butyl peroxybenzoate, Add ...

Embodiment 3

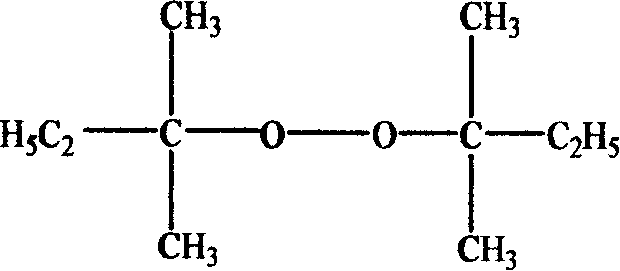

[0061] In this example, di-tert-amyl peroxide was used as the initiator, and the composition of the raw materials used to prepare the resin is shown in Table 7.

[0062] Table 7 prepares waterborne acrylic resin (embodiment 3) with raw material composition

[0063] Component

mass (g)

Propylene glycol butyl ether

8.2

Glycidyl tertiary carbonate

24.7

acrylic

10.7

3.2

19.8

7.5

14.6

Di-tert-amyl peroxide

3.3

8.0

[0064] Deionized water

160.0

[0065] The specific preparation method is as follows: Add propylene glycol butyl ether and glycidyl tert-carbonate into a 500mL four-necked flask equipped with a thermometer, a stirring device and a condenser, pass through dry nitrogen protection, start stirring and raise the temperature to 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com