Damp-proof water-proof paint for air compressors and preparation method thereof

An air compressor and paint technology, applied in the field of paint, to achieve the effects of scientific preparation method, fast drying and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

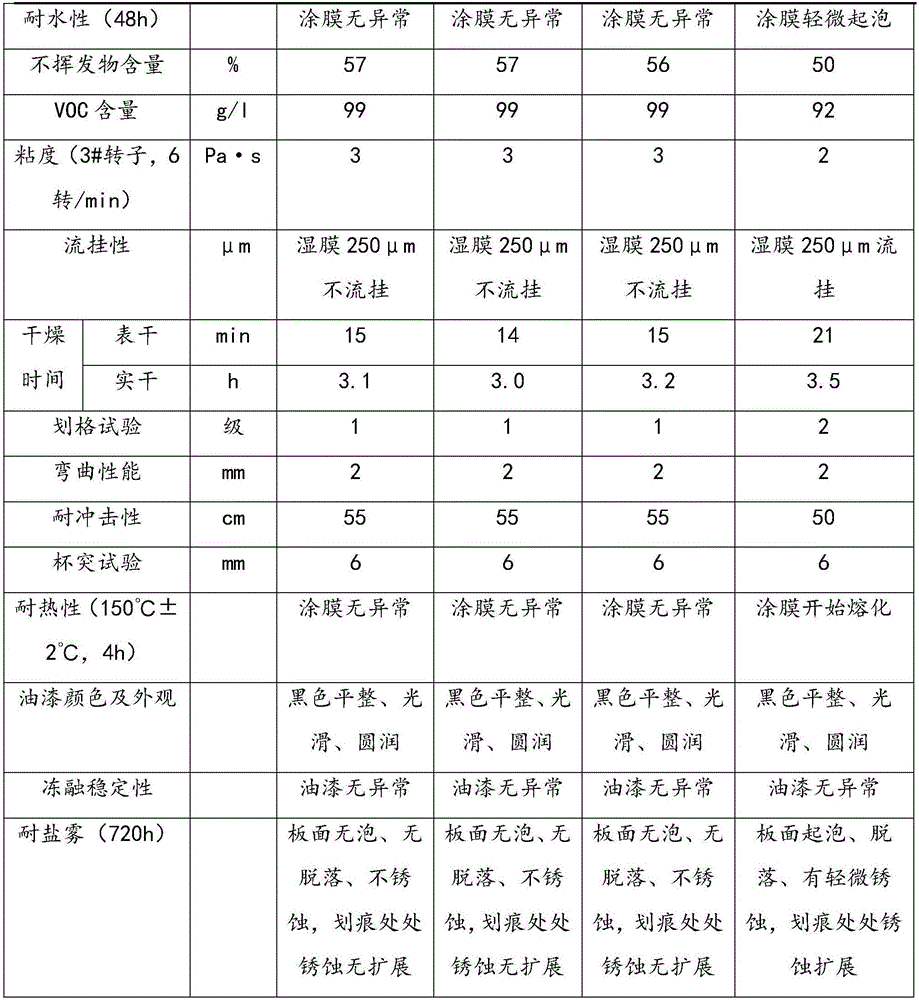

Embodiment 1

[0016] Embodiment 1 A kind of moisture-proof and waterproof paint for air compressor and preparation method thereof

[0017] A moisture-proof and waterproof paint for air compressors, consisting of the following raw materials in parts by weight: 36 parts of acrylate emulsion, 12 parts of tetrabutyl titanate, 6 parts of expanded vitrified microbeads, 5 parts of PAN-based carbon fiber, erucamide 2 parts, 2 parts of nano-copper powder colloidal solution, 1 part of pigment, 4 parts of magnesium oxide nanoparticles, 6 parts of polyaluminum sulfate, 3 parts of lauryl alcohol ester, 8 parts of chlorinated polyethylene, and 2 parts of polyacrylamide.

[0018] The present invention also provides a preparation method of moisture-proof and waterproof paint for air compressors, which consists of the following steps:

[0019] (1) Mix tetrabutyl titanate, expanded vitrified microbeads, and PAN-based carbon fibers, then crush them, pass through a 10-mesh sieve, mix them together, add nano-co...

Embodiment 2

[0022] Embodiment 2 A kind of moisture-proof and waterproof paint for air compressor and preparation method thereof

[0023] A moisture-proof and waterproof paint for air compressors, consisting of the following raw materials in parts by weight: 39 parts of acrylate emulsion, 14 parts of tetrabutyl titanate, 7 parts of expanded vitrified microbeads, 6 parts of PAN-based carbon fiber, erucamide 5 parts, 14 parts of nano-copper powder colloidal solution, 3 parts of pigment, 4 parts of magnesium oxide nanoparticles, 6 parts of polyaluminum sulfate, 3 parts of lauryl alcohol ester, 8 parts of chlorinated polyethylene, and 2 parts of polyacrylamide.

[0024] The present invention also provides a preparation method of moisture-proof and waterproof paint for air compressors, which consists of the following steps:

[0025] (1) Mix tetrabutyl titanate, expanded vitrified microbeads, and PAN-based carbon fiber, then pulverize them, pass through a 120-mesh sieve, mix them together, add n...

Embodiment 3

[0028] Embodiment 3 A kind of moisture-proof and waterproof paint for air compressor and preparation method thereof

[0029] A moisture-proof and waterproof paint for air compressors, which consists of the following raw materials in parts by weight: 42 parts of acrylate emulsion, 16 parts of tetrabutyl titanate, 8 parts of expanded vitrified microspheres, 7 parts of PAN-based carbon fiber, erucamide 8 parts, 6 parts of nano-copper powder colloidal solution, 5 parts of pigment, 4 parts of magnesium oxide nanoparticles, 6 parts of polyaluminum sulfate, 3 parts of lauryl alcohol ester, 8 parts of chlorinated polyethylene, and 2 parts of polyacrylamide.

[0030] The present invention also provides a preparation method of moisture-proof and waterproof paint for air compressors, which consists of the following steps:

[0031] (1) Mix tetrabutyl titanate, expanded vitrified microbeads, and PAN-based carbon fiber, then pulverize them, pass through a 200-mesh sieve, mix them together, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com