Patents

Literature

1504 results about "Lauryl Alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

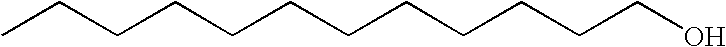

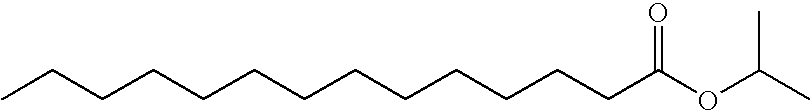

Dodecanol /ˈdoʊˈdɛkɑːnɒl/, or lauryl alcohol, is an organic compound produced industrially from palm kernel oil or coconut oil. It is a fatty alcohol. Sulfate esters of lauryl alcohol, especially sodium lauryl sulfate, are very widely used as surfactants.

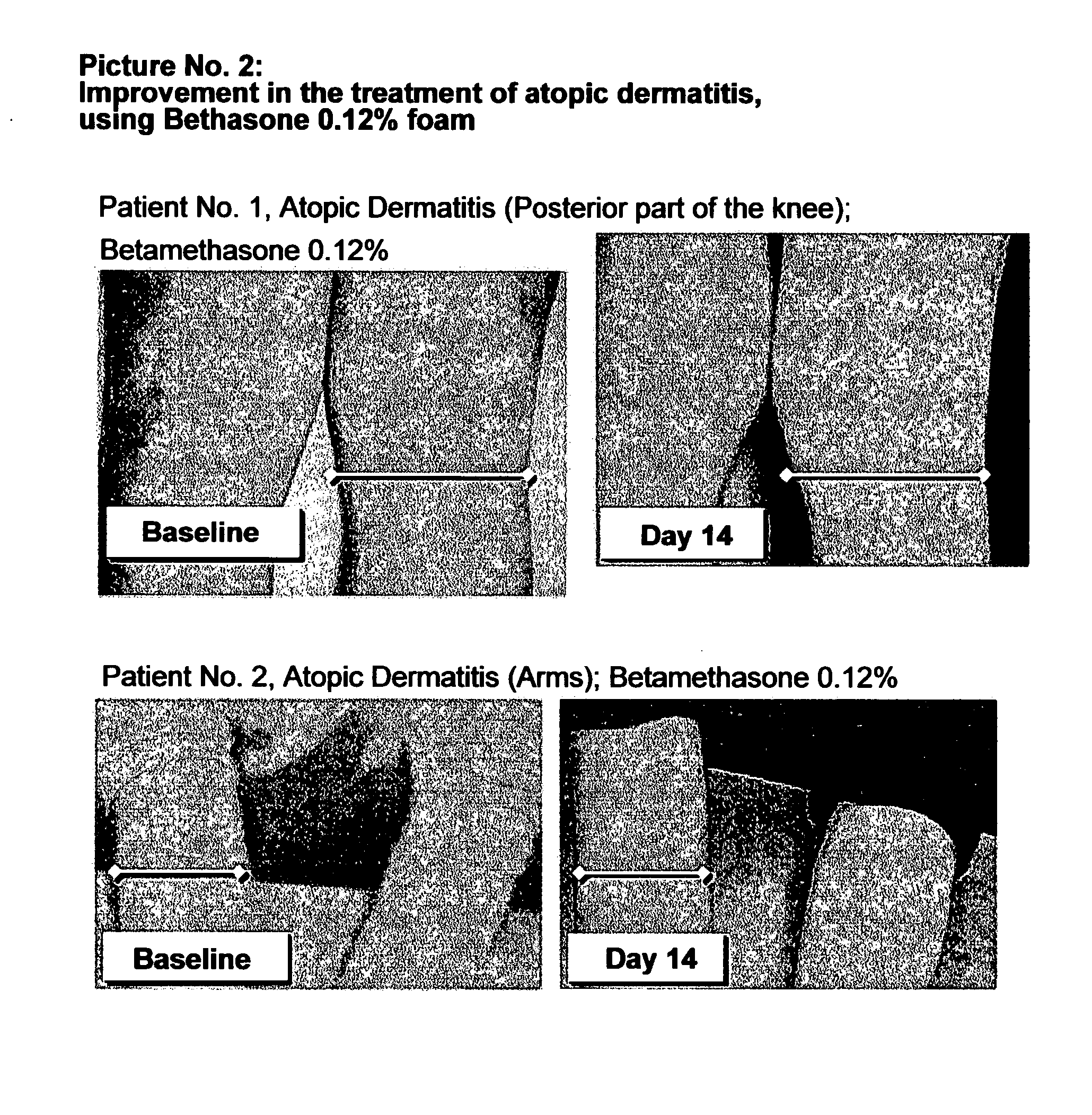

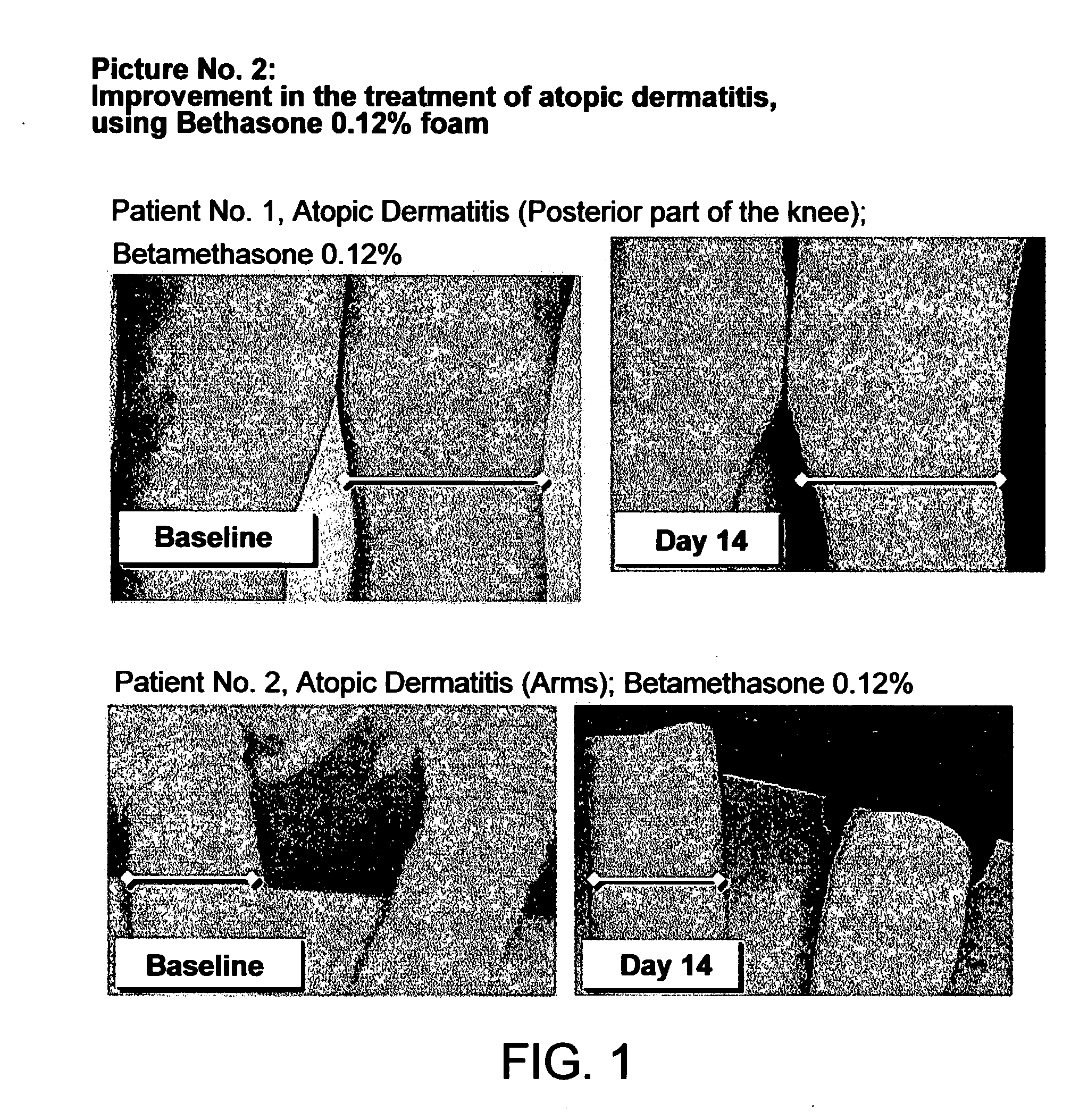

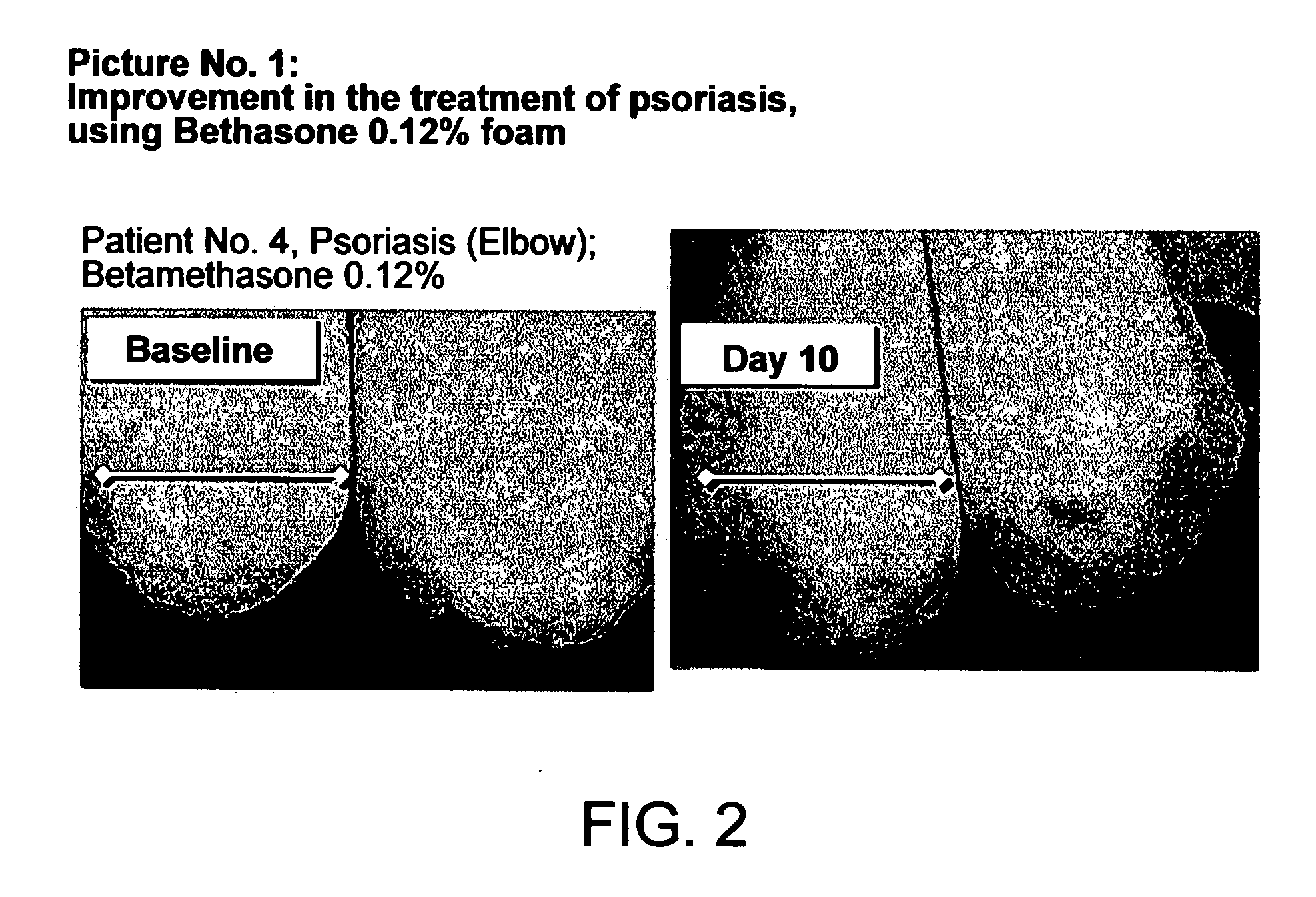

Cosmetic and pharmaceutical foam

InactiveUS20080031907A1Efficient ConcentrationReduce sensitivityAntibacterial agentsBiocideAlcohol freeVegetable oil

The invention relates to uses of an alcohol-free cosmetic or pharmaceutical foam carrier comprising water, a hydrophobic solvent, a foam adjuvant agent, a surface-active agent and a water gelling agent as a flame retardant or flame resistant foam. The hydrophobic solvent is preferably mineral oil; medium chain triglycerides; isopropyl myristearate or octyl dodecanol, silicone oil or vegetable oil or mixtures thereof. The cosmetic or pharmaceutical foam carrier does not contain aliphatic alcohols, also making it non-irritating and non-drying. The alcohol-free foam carrier is suitable for inclusion of both water-soluble and oil-soluble pharmaceutical and cosmetic agents.

Owner:FOAMIX PHARMACEUTICALS LIMITED

Flavor blend for masking unpleasant taste of zinc compounds

A synergistic flavoring combination of at least two flavoring oils and lauryl alcohol for use in an orally administered formulation which contains an ionizable zinc compound having an undesirable taste, the flavoring combination is unexpectedly effective in masking the unpleasant taste or aftertaste of zinc.

Owner:BLOCK DRUG CO INC

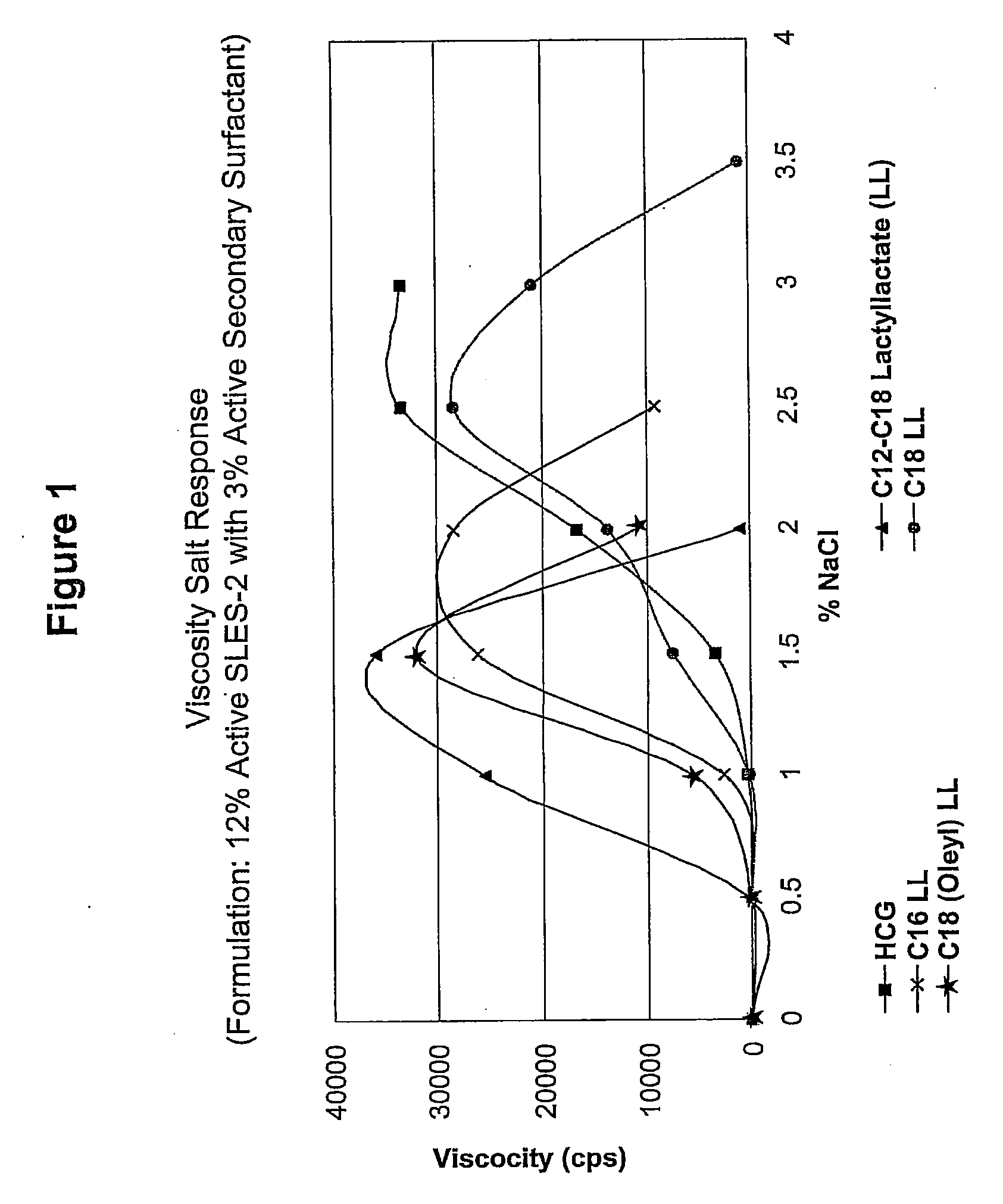

Alkyl Lactyllactates and Processes of Making the Same

Provided are alkyl lactyllactate compositions that can be prepared from (1) lactide or alternatively lactic acid, and (2) a hydroxyl containing compound such as an alcohol, preferably a fatty alcohol or an alkoxylated alcohol, with (3) an acid catalyst. Preferably, the fatty alcohol contains from about 6 to 18 carbon atoms, such as lauryl alcohol. The alkyl lactyllactates can be used as surfactants, emulsifiers, skin feel agents, film formers, thickeners, rheological modifiers, etc., for personal care and other application areas. Compositions containing at least one alkyl lactyllactate are also provided. The compositions can further contain at least one surfactant.

Owner:STEPAN COMPANY

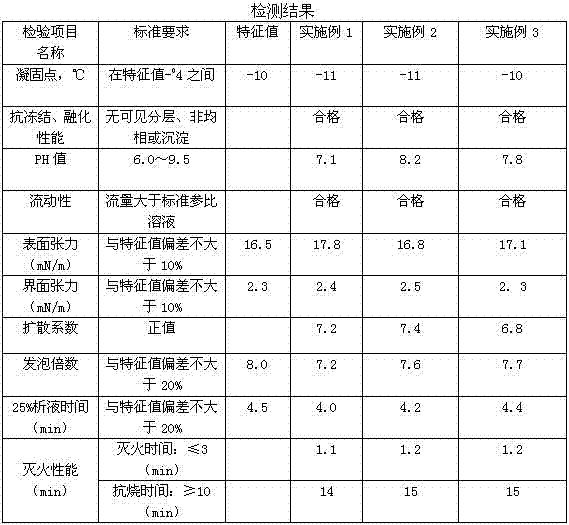

Aqueous film-forming foam extinguishing agent special for fire extinguishing bullet and throwing type fire extinguisher

InactiveCN104117176AImprove fire extinguishing effectPrevent re-ignitionFire extinguisherDiethylene glycol diethyl etherAmmonium dodecyl sulfate

The invention provides an aqueous film-forming foam extinguishing agent special for a fire extinguishing bullet and a throwing type fire extinguisher. The aqueous film-forming foam extinguishing agent has the advantages of being small in additive amount, rapid in fire extinguishing, good in recrudescence resisting effect, environmentally friendly, efficient and the like. The aqueous film-forming foam extinguishing agent comprises, by weight, 8 percent to 12 percent of main foaming agents, 8 percent to 20 percent of auxiliary foaming agents, two percent to 10 percent of antifreeze agents, 12 percent to 22 percent of cosolvents, 0.1 percent to one percent of stabilizers, 8 percent to 20 percent of fire retardants, two percent to five percent of burning-resistance agents and the balance water. The main foaming agents are selected from F1157N, F1203 and F1460, the auxiliary foaming agents are selected from lauryl sodium sulfate, ammonium lauryl sulfate, alkyl glycoside, dodecyl dimethyl betaine and cocamidopropyl betaine. The antifreeze agents are selected from ethylene glycol, glycerol and the like. The cosolvents are selected from dodecanol, n-butyl alcohol and diethylene glycol diethyl ether. The stabilizing agents are selected from xanthan gum, Arabic gum, guar gum and sodium alginate tech grade. The fire retardants are selected from ammonium polyphosphate and ammonium dihydrogen phosphate.

Owner:ANHUI TIANYUAN FIRE PROTECTION TECH

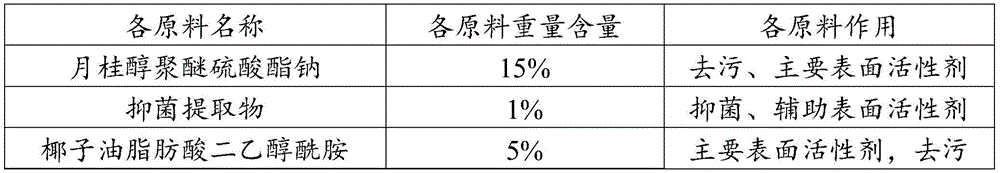

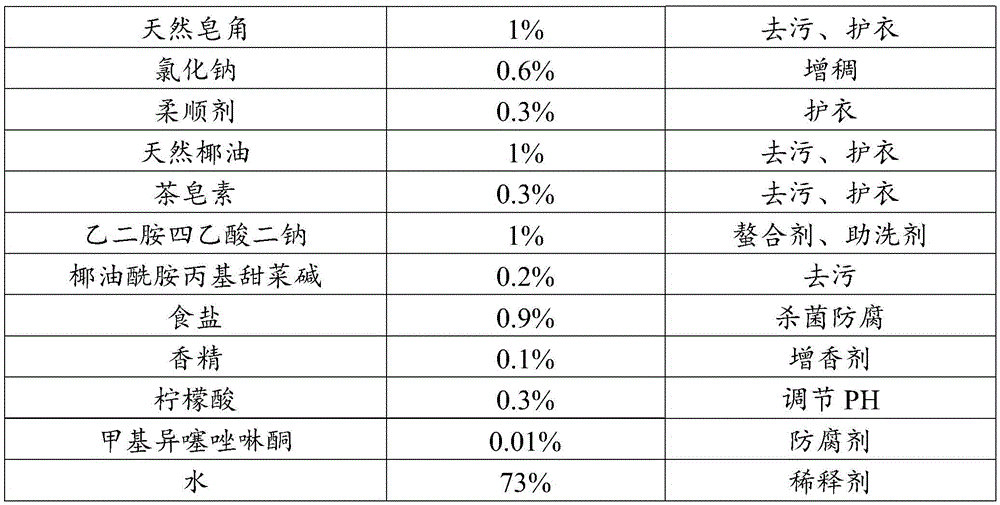

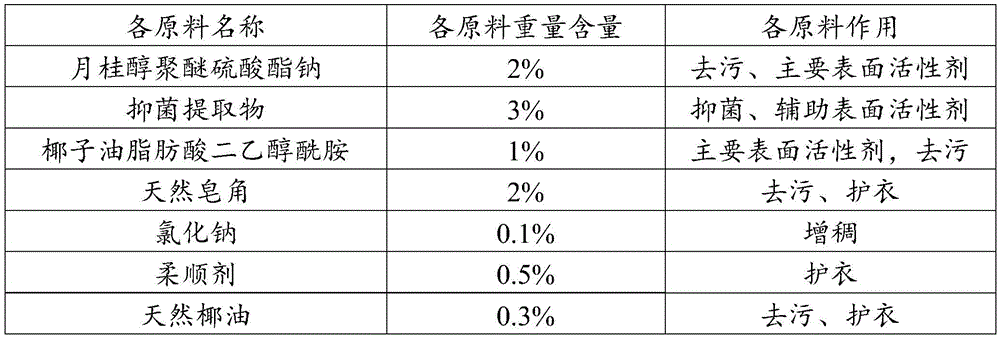

High-dirt-removing-power antibacterial protective laundry detergent and preparation method thereof

InactiveCN105623903ATo achieve the purpose of combining washing and nursingEfficient removalInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCocamidopropyl betaineLaundry detergent

The invention relates to the technical field of laundry detergents, and particularly discloses a high-dirt-removing-power antibacterial protective laundry detergent and a preparation method thereof. The laundry detergent comprises 1-15% of sodium lauryl alcohol polyether sulfate, 1-10% of antibacterial extract, 1-5% of coconut diethanol amide, 1-5% of natural saponin, 0.1-0.6% of sodium chloride, 0.3-1% of softening agent, 0.3-1% of natural coconut oil, 0.3-1% of tea saponin, 0.2-1% of disodium edetate, 0.1-0.9% of cocamidopropyl betaine, 0.1-0.9% of table salt, 0.1-0.6% of essence, 0.01-0.3% of citric acid, 0.01% of methyl isothiazolinone and the balance of water. The laundry detergent has the effects of high dirt-removing power, bacterial resistance and clothes protection, has the dual functions of cleaning and protection, is green and environment-friendly, has the advantages of mild properties, no phosphorus and no irritation, and achieves the goals of dirt removal, bacterial resistance and clothes protection in deed.

Owner:HUIZHOU MINGQUAN COSMETICS CO LTD

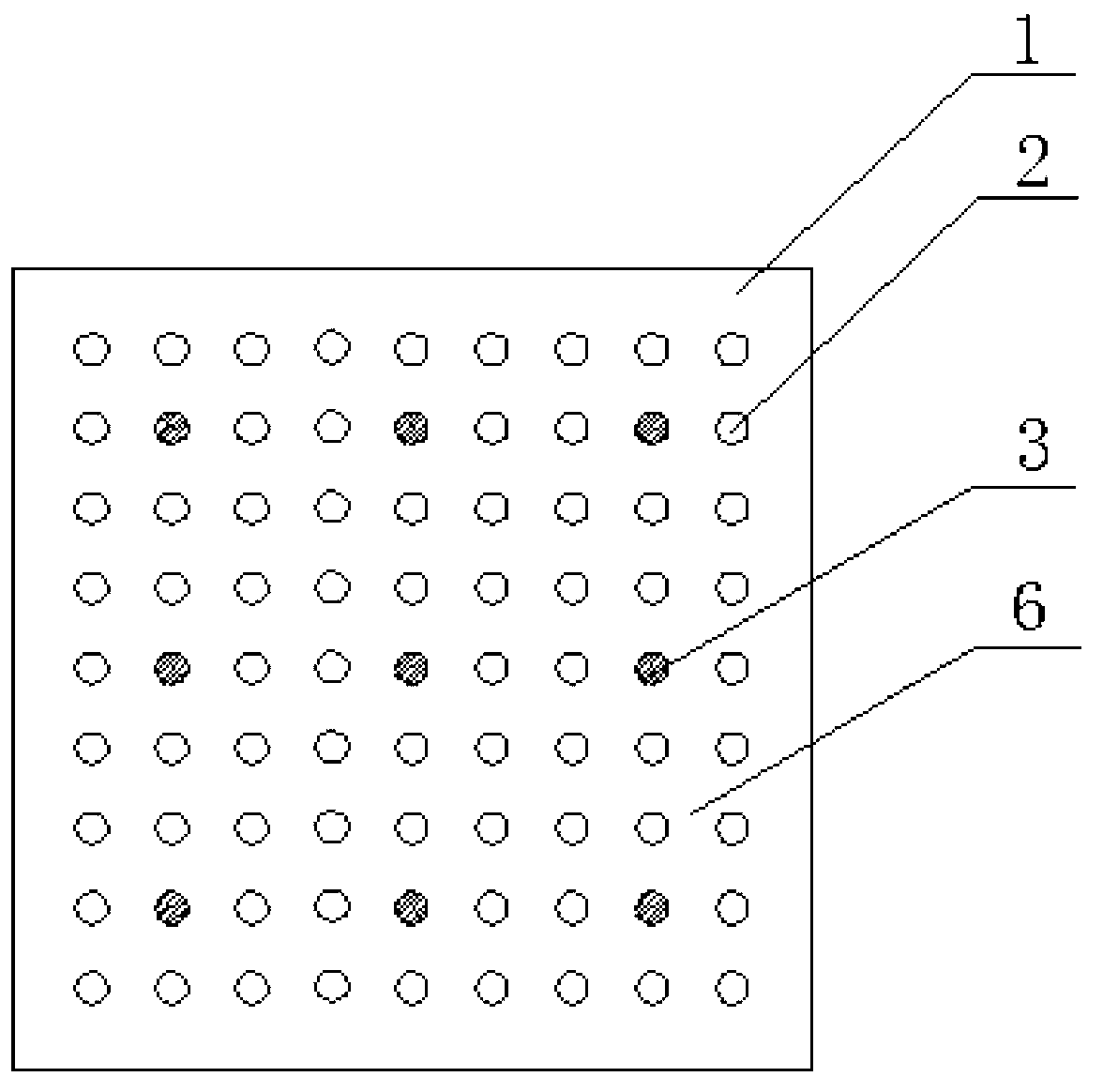

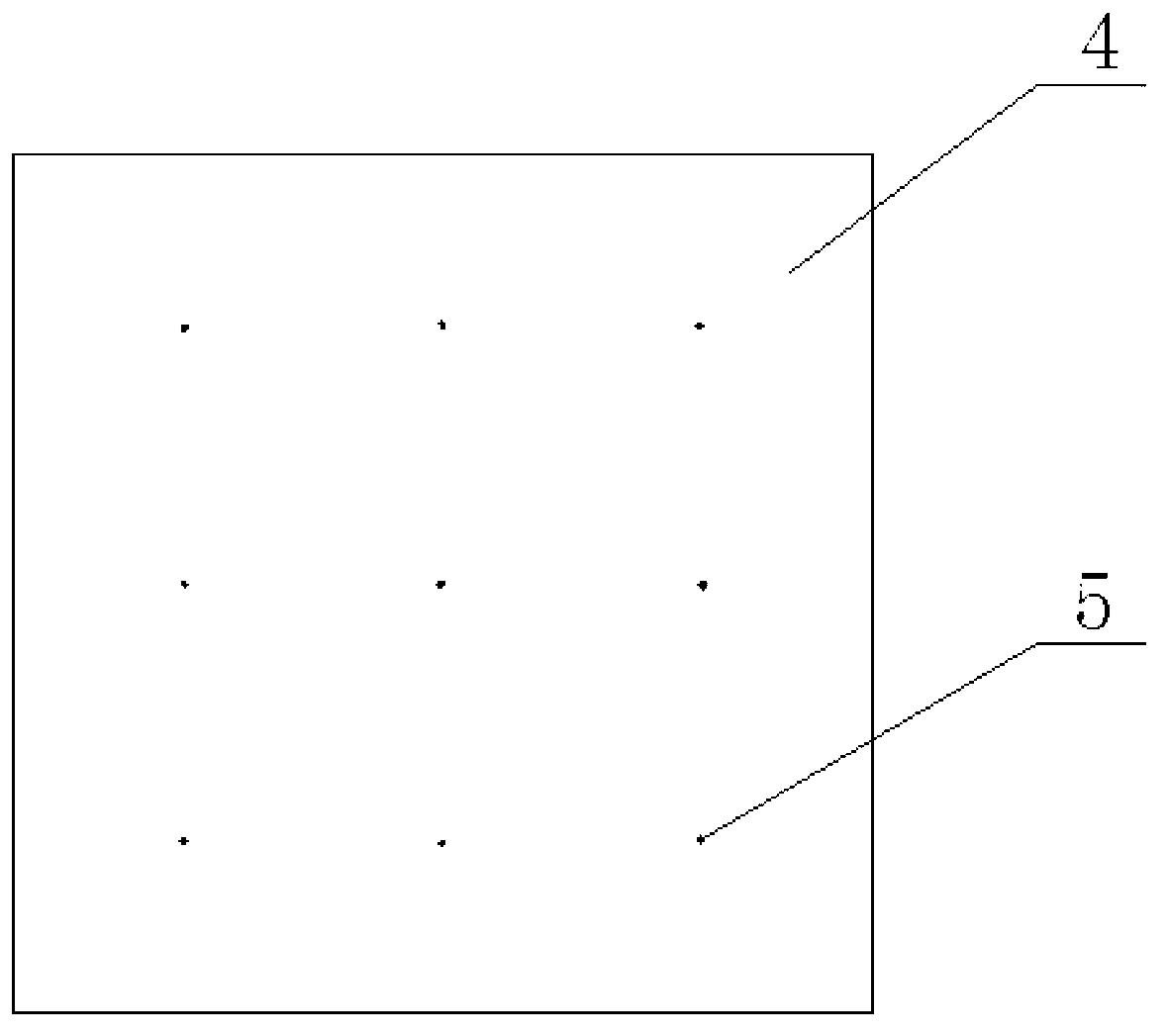

Constructional phase change energy storage plate and manufacturing method thereof

InactiveCN103015540APrevent leakageNo overflowLaminationLamination apparatusEnvironmental resistanceAlcohol

The invention discloses a constructional phase change energy storage plate, consisting of an upper cover plate, a lower bottom plate and a phase change material, wherein the phase change material is a mixture of fatty acid and high carbon alcohols; the fatty acid is n-decylic acid, lauric acid, myristic acid, palmitic acid and stearic acid; the alcohols are dodecanol, tetradecanol, hexadecanol and octadecanol; and the mass percent of the fatty acid to the mass percent of the high carbon alcohols is 46.4%: 53.6% to 97.5%: 2.5%. With the adoption of the constructional phase change energy storage plate and a manufacturing method thereof, the problems such as damages to mechanical performances, environmental protection, safety and the like are fundamentally solved, and meanwhile, the risks existing in actual application are prevented; the constructional phase change energy storage plate is stable in structure; the phase change material is not easy to leak; no irritant gas overflows; the appearance is attractive; and therefore, besides application onto constructed walls, the constructional phase change energy storage plate also can be used as an interior decoration, a suspended ceiling and a laid floor board.

Owner:TIANJIN UNIV

Amination catalyst and preparation method thereof

ActiveCN101406845AHigh catalytic activityImprove catalytic selectivityMolecular sieve catalystsOrganic compound preparationDodecaneMordenite

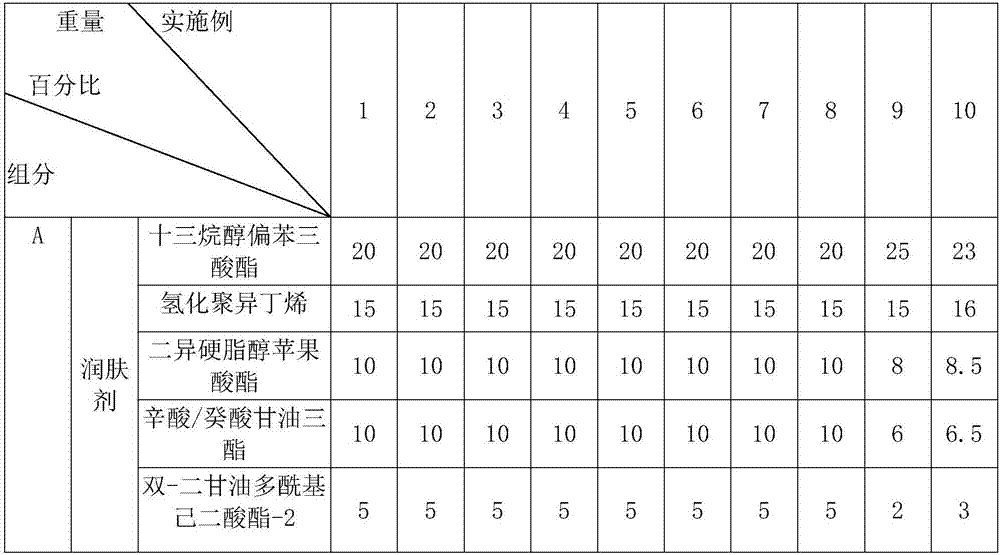

The invention discloses an amination catalyst and a preparation method thereof, which aims to solve the problem that the amination catalyst is not high in activity and selectivity. The compositions in weight percentage of the amination catalyst are: 15 to 25 percent of A, 5 to 10 percent of B, 1 to 3 percent of C, 0.1 to 1.5 percent of D, and the balance being h-type mordenite, wherein the A is alumina; the B is titanium oxide; the C is metallic ion W<6+>, Re<7+> or Bi<3+>; the D is metallic ion Cs<+>; and the metals exist in the form of elements or oxides. The preparation method comprises the following steps of loading the components C and D on the h-type mordenite, well mixing the components C and D with the alumina and ethanolamine titanate dodecane alcohol ester, molding, roasting and activating the mixture. The catalyst is used for synthesizing ethylene dimine under the conditions of ethanolamine and ammonia phase.

Owner:XIAN MODERN CHEM RES INST

Special high-property coating for chemical equipment

InactiveCN104946082AIncrease viscosityIncrease crosslink densityFireproof paintsEpoxy resin coatingsPyrophylliteMelamine phosphate

The invention discloses a special high-property coating for chemical equipment. The special high-property coating comprises the following raw materials: novolac epoxy resin, phosphorus-containing acrylic resin, boric acid modified organic silicon resin, polytetrafluoroethylene resin, polyvinylidene fluoride, a carbon nano tube, ammonium polyphosphate, pentaerythritol, alumina powder, pyrophyllite powder, graphite, expanded perlite, modified attapulgite, cerium oxide, n-butyl alcohol, n-amyl alcohol, ethanediol, water, amine resin, melamine polyphosphate, N-phenyl-N'-cyclohexyl p-phenylene diamine, dodecanol, dipropylene glycol mono butyl ether, dimethyl phthalate, a coupling agent and an auxiliary agent. The special high-property coating for the chemical equipment, which is disclosed by the invention, has the advantages of good corrosion resistance and high-temperature resistance, high adhesive power and excellent flame-retardant property, can be used for the chemical equipment, is difficult to desquamate, good in protection effect and capable of prolonging the service life of the chemical equipment.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

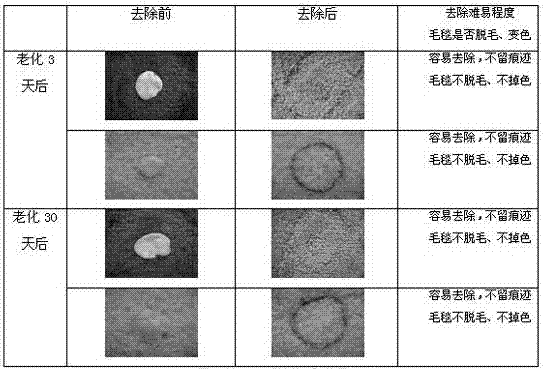

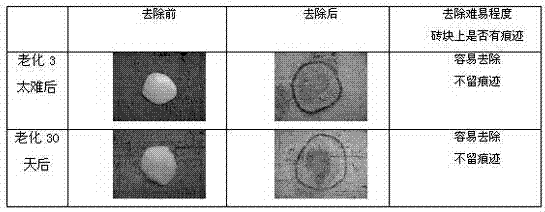

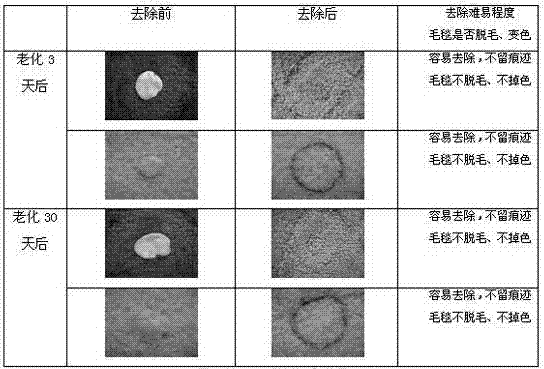

Environmentally friendly adhesive remover

ActiveCN102260599AGood value for moneyQuick removalOrganic detergent compounding agentsSurface-active detergent compositionsShoe polishEngineering

The invention relates to an environment-friendly degumming agent. The product can clear away residual chewing gums on clothes and waste chewing gums on the ground, also has good effects on label illegal advertisements, oil pen illegal advertisements, lipsticks, shoe polish, adhesive tape remaining trace and complex mixed oil blackspots, has a neutral formula, is safe and poisonless to the environment and human bodies, and is easy to use; and through experiments of comparing effects with those of the traditional degumming products which are prepared from tetrachloroethylene, acetic ether, dichloromethane, methylbenzene, dimethylbenzene and the like, the using amount is small under the condition that the same removal effect is achieved, and the environment-friendly degumming agent also has no pungent peculiar smell. The environment-friendly degumming agent comprises the following raw materials in part by weight: 20 to 60 parts of solvent, 5 to 20 parts of mixture containing cocamide, 1 to 10 parts of lauryl alcohol alkoxylate, 0.1 to 1.0 part of alkyl amine oxide, 10 to 30 parts of cosolvent, and the balance of water.

Owner:于文 +1

Foaming agent type shampoo

ActiveCN102697670AReduce contact timeReduce chance of baldnessCosmetic preparationsHair cosmeticsSodium lactateCopolymer

The invention relates to foaming agent type shampoo which comprises (30 percent) 20 percent to 40 percent of lauryl alcohol polyoxyethylene ether sulpho succinate monoester disodium salt, (30 percent) 20 percent to 40 percent of lauroyl sodium sarcosinate, 0.1 to 0.5 percent of disodium EDTA, 1 to 5 percent of sodium lactate, (40 percent) 1 to 5 percent of polyquat-7, (30 percent) 2 to 5 percent of acrylate copolymer, 1 to 6 percent of PEG-12 dimethyl silicone, 0.1 to 1 percent of aromatic oil or essence, 0.01 to 0.3 percent of citric acid, and 0.04 to 1 percent of preservative agents, and the rest is deionized water. the foaming agent type shampoo is characterized in that foam is squeezed out through a mousse pump head, and the shampoo is not centralized at the top of the head but applied and diffused to other parts, so that the contact of chemical substances and the scalp can be reduced, the probability of furfur, calvities and balding can be reduced, and the effects of economy, environmental friendliness and no side effect can be achieved.

Owner:GUANGZHOU YOUNGRACE COSMETIC LTD

Super-concentrated clothes washing sheet

InactiveCN105238584AEasy to filmEasy to carryInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBetaineFatty alcohol

The invention provides a super-concentrated clothes washing sheet. The super-concentrated clothes washing sheet comprises the following components in percentages by weight: 10-30% of a film forming agent, 1-10% of kaolin, 1-10% of silicon dioxide, 3-40% of sodium lauryl sulfate, 0.5-10% of fatty acid diethanol amide, 0.1-10% of dodecanol polyoxyethylene ether sodium sulphate, 0-10% of lauric acid betaine, 0-10% of fatty alcohol polyoxyethylene ether, 0-10% of polyalcohol, 0.1-5% of a chelate agent, and 1-50% of deionized water. Active components, the film forming agent and the like are scientifically collocated, so that the super-concentrated clothes washing sheet is easy to form a film.

Owner:GUANGZHOU LANJIEBAO BIOTECH CO LTD

Calendaring copper foil rolled oil and preparation method thereof

ActiveCN102660357AHigh surface finishLong anti-corrosion periodAdditivesPolyethylene glycolCopper foil

The invention relates to the technical field of lubricating agents, in particular to calendaring copper foil rolled oil and a preparation method thereof. The calendaring copper foil rolled oil is used for lubricating in the cold-rolled process of calendaring copper foil. The preparation method is characterized by comprising the following steps of: adding N5 engine oil, butyl stearate, dodecanol, nitrogen-containing borate, fatty alcohol polyethylene glycol phosphate, petroleum sodium sulfonate and benzotriazole into a reaction kettle of which the rotation speed is 80 to 120 revolutions / minute sequentially, heating and stirring; and when the temperature is 80 DEG C, keeping the temperature, stirring continuously for 30 minutes, stopping heating, and stirring continuously to room temperature to obtain uniform and transparent oil, namely the required rolled oil. The minimum rolling thickness of the calendaring copper foil lubricated by the rolled oil is 25 micrometers, so that the calendaring copper foil is high in surface smoothness, long in anti-corrosion period and high in annealing detergency.

Owner:UNIV OF SCI & TECH BEIJING

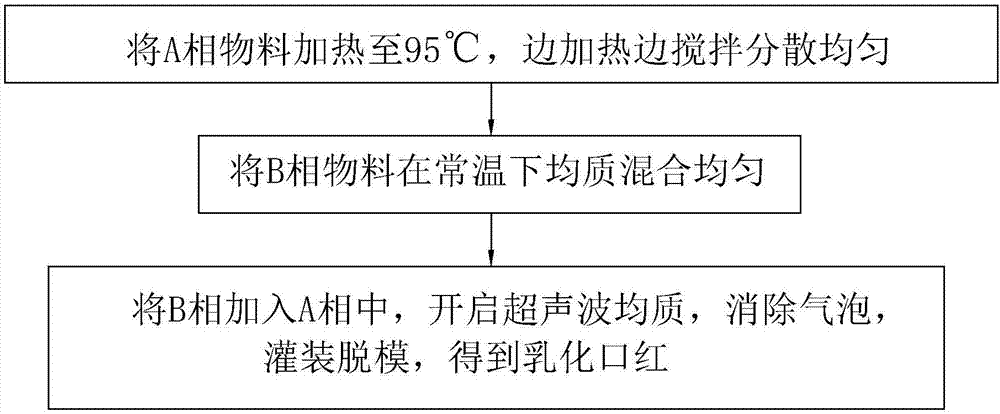

Emulsified lipstick and preparation method thereof

InactiveCN107496201AAvoid air bubblesImprove yieldCosmetic preparationsMake-upChemistryWater soluble

The invention discloses an emulsified lipstick and a preparation method thereof, and belongs to the technical field of cosmetics. The emulsified lipstick is prepared from the following components in percentage by weight: 51 to 71% of skin moisturizer, 13 to 17% of hardener, 4 to 10% of brightener, 2 to 3% of polyglycerol-2 triisostearate, 0.5 to 1% of dipoly-pentaerythritol tri-polyhydroxyl stearate, 2 to 5% of phytosterol / octyl dodecyl lauryl glutamate, 2 to 5% of water, 2.01 to 4.02% of water-soluble moisturizer, and 0.5 to 2.5% of water-soluble plant extract. The emulsified lipstick has the advantages that by adopting two types of emulsifiers, and matching with the ultrasonic demulsifying technology, the production of air bubbles due to evaporation of water phase is avoided, and the finished rate is improved; the moisturizer, cornflower flower extract, ginko leaf extract and golden chamomile flower extract can be added into the lipstick, so that the lip wrinkles can be lightened, the skin elasticity is improved, the toxicity is effectively removed, the circulation of micro-blood vessels is stimulated, the skins are nourished, and the functions of the lipstick are widened; under the synergistic function of glycerin, hyaluronic acid and polyquaternium-51, the natural skin bionic moisturizing film is formed, and the lip skin is moisturized and smooth.

Owner:上海禾雅化妆品有限公司

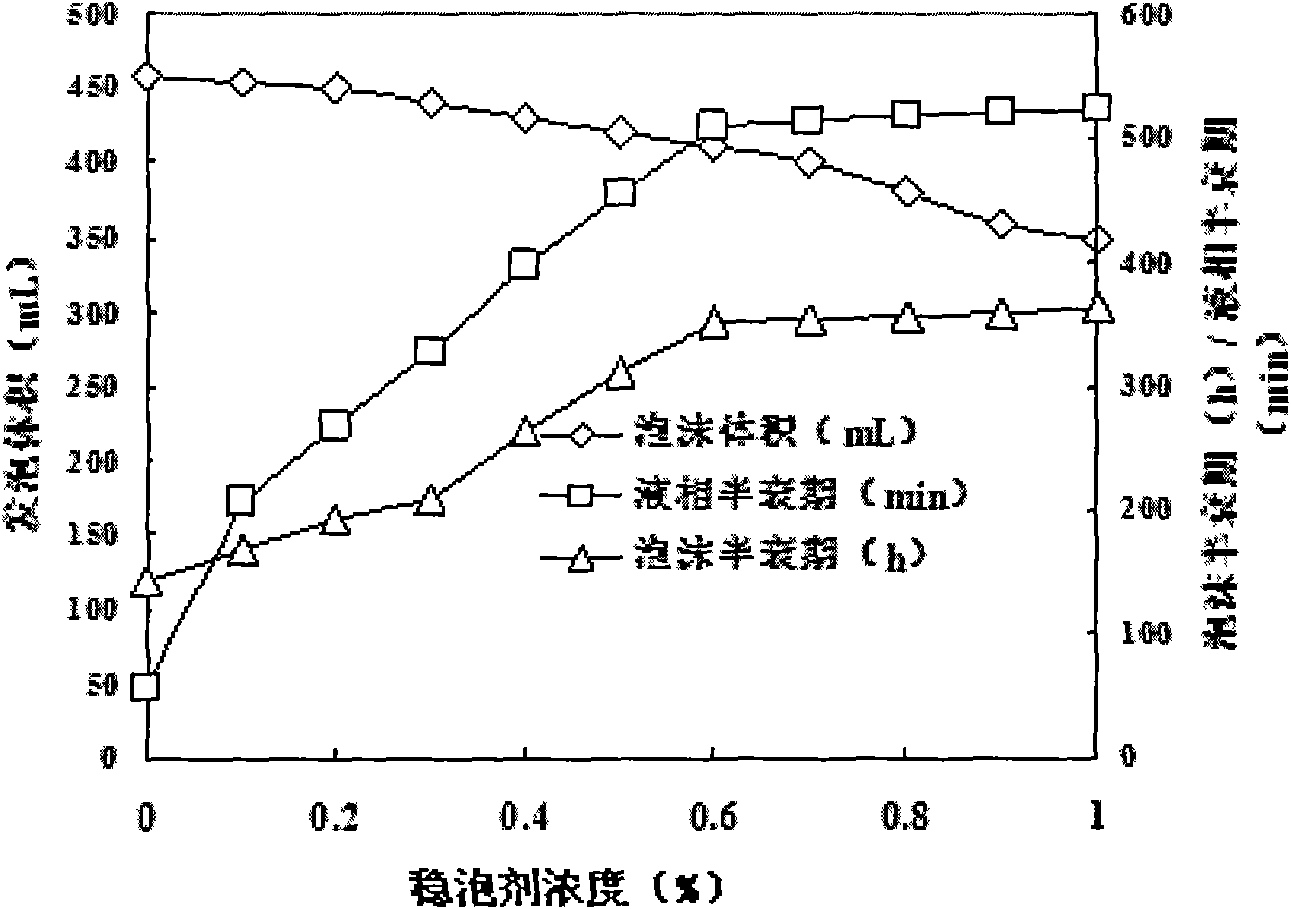

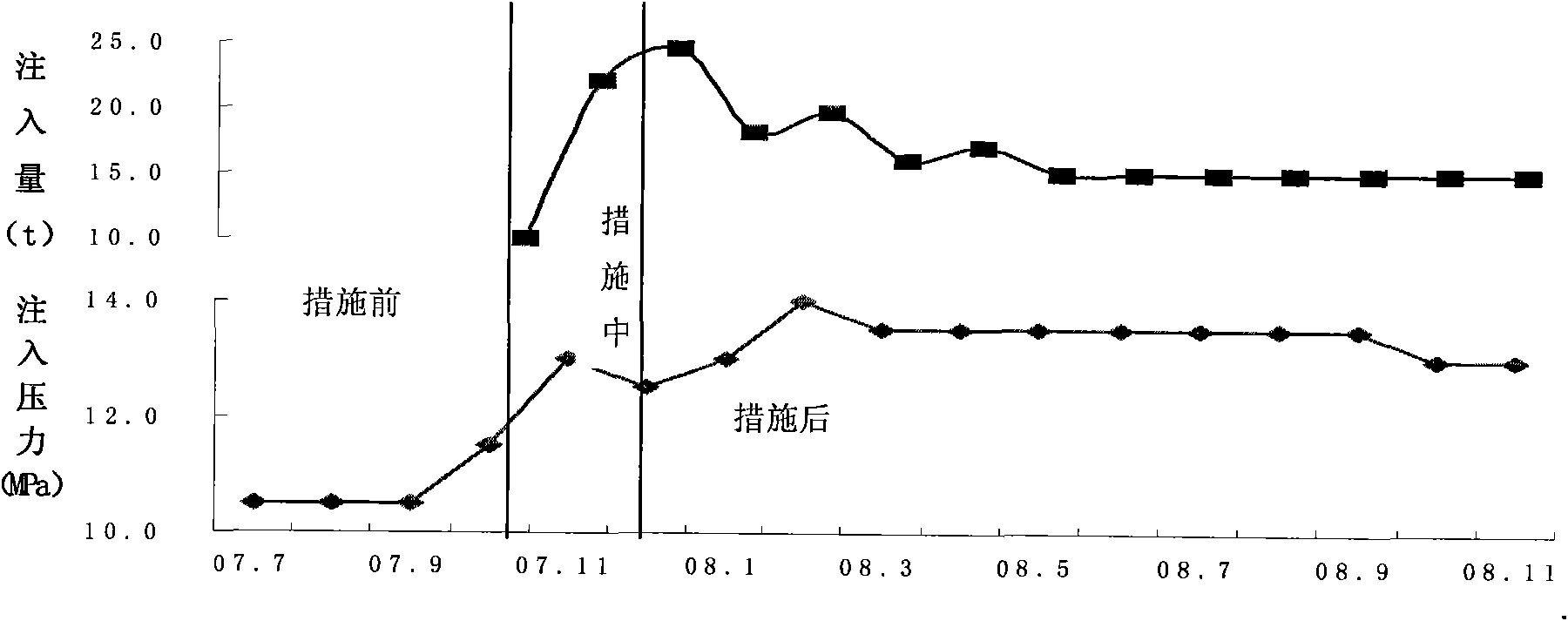

Carbon dioxide foam stabilizer suitable for low-permeability oil deposit

The invention discloses a carbon dioxide foam stabilizer suitable for low-permeability oil deposit, which is prepared from modified guargum, hydroxyethyl cellulose and lauryl alcohol, wherein the mass ratio of the modified guargum to the hydroxyethyl cellulose to the lauryl alcohol is 4 to 1 to 1. The invention is used for enhancing the stability of carbon dioxide foams, thereby the carbon dioxide foam stabilizer can plug a test well gas channeling passage, improve gas suction and a liquid generating section plane, reduce the gas-oil ratio, solve the problem of gas channeling emerged from low-permeability oil deposit gas injection development and provide technical support for the low permeable oil deposit gas injection development.

Owner:PETROCHINA CO LTD +1

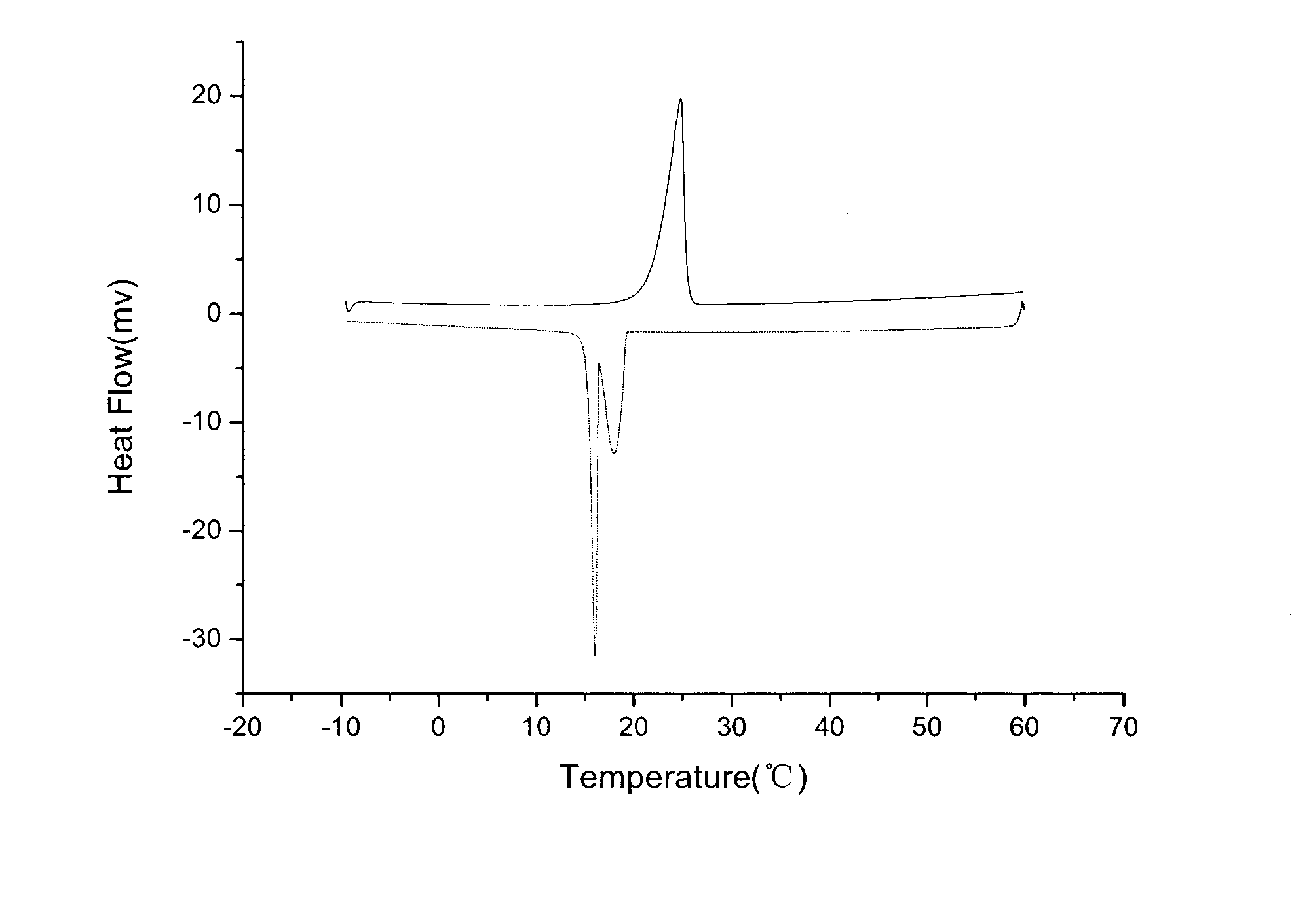

Phase change energy storage microcapsule material and its preparation method

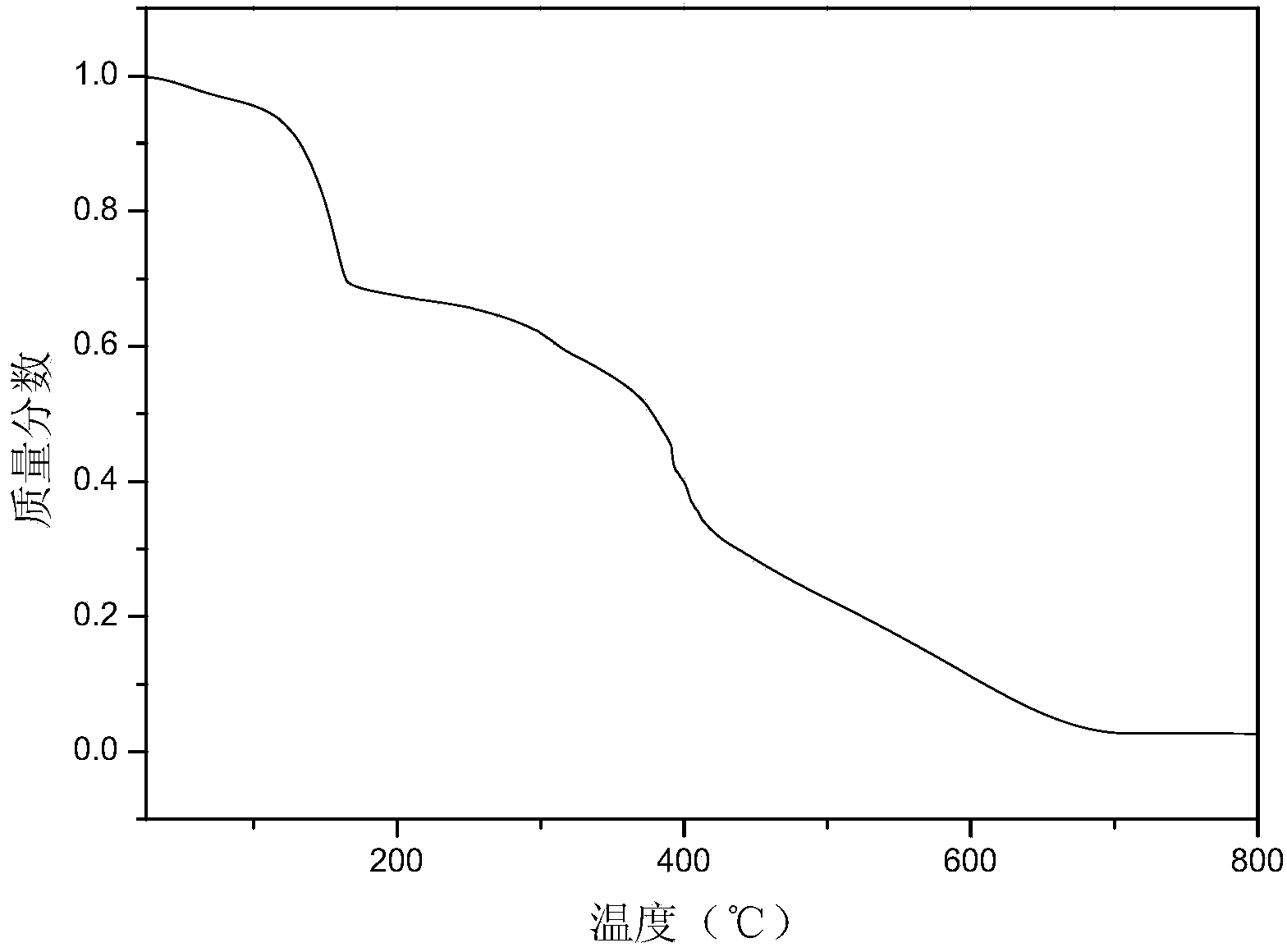

InactiveCN103509527AUniform particle sizeImprove stabilityHeat-exchange elementsMicroballoon preparationWater bathsUltrasonic emulsification

The invention relates to a phase change energy storage microcapsule, which takes n-dodecanol as a phase change material and adopts methyl methacrylate-acrylic acid copolymer as a capsule wall material. Ultrasonic-assisted emulsification is adopted, and interfacial polymerization is employed to perform microcapsule packaging. The preparation method of the phase change energy storage material includes: firstly mixing n-dodecanol with an emulsifier, performing ultrasonic emulsification, then conducting mechanical stirring, adding methyl methacrylate and an initiator under 80DEG C water bath to react for certain time, then adding acrylic acid to react, and completing polymerization; and carrying out cooling, filtering, and drying so as to obtain a sample. According to the invention, n-dodecanol is adopted as the phase change material, the phase change temperature can be controlled in the vicinity of room temperature. The methyl methacrylate-acrylic acid copolymer is taken as the capsule wall, which has very good chemical stability and strong adaptability to the environment. Ultrasonic assisted emulsification is employed to form a miniemulsion, and the reaction undergoes more easily. The phase change energy storage microcapsule material provided by invention has the advantages of simple process, low cost, and good stability, and can effectively improve the energy storage effect of a phase change material.

Owner:NANJING UNIV OF TECH

Super-concentration fabric cleaning agent formula and preparing method thereof

InactiveCN104479899AStrong decontaminationImprove decontamination abilityOrganic detergent compounding agentsNon-ionic surface-active compoundsLinear alkylbenzeneSurface-active agents

The invention relates to a super-concentration fabric cleaning agent which is composed of, by weight, 25-99 parts of surface active agents, 0-21 parts of addition agents and 1-75 parts of water. The surface active agent is at least one of ethoxylated lauryl alcohol sulfates (AES), fat polyoxyethylene ether (AEO), fat alcohol sodium sulfate (K12), fatty acid methyl ester ethoxylate (MEE), lauramidopropyl betaine (CAB), fatty alcohol diethanolamide (6501), linear alkylbenzene sulphonic acid (LAS) and alky glycoside (APG). The super-concentration fabric cleaning agent is free of organic solvents, no solubilization is needed, and the active matter content can reach 99%. Through the characteristic that the surface active agent fatty acid methyl ester ethoxylate (MEE) is free of cloud points, the complex formulation is conducted on the fatty acid methyl ester ethoxylate (MEE) and other surface active agents, and the functions of solubilization, complex formulation and surface activation are achieved.

Owner:WALCH GUANGZHOU COMMODITY

Nano insulating coating

The invention discloses a nano insulating coating which is prepared from the following raw materials in parts by weight: 100 parts of an organosiloxane modified acrylic emulsion, 5-12 parts of a silicon dioxide aerogel, 1-2.6 parts of ceramic fibers, 1-2.5 parts of a carbon nano tube, 0.2-1 part of calcium silicate, 2-5 parts of nano zirconium oxide, 3-7 parts of nano zinc oxide, 5-9 parts of calcium carbonate whiskers, 15-20 parts of sepiolite, 5-20 parts of expanded perlite, 8-15 parts of nano titanium dioxide, 0.8-2.0 parts of a segmented copolymer, 1.5-3.8 parts of dodecanol ester, 0.2-5.0 parts of benzotriazole, 2-3.5 parts of a defoaming agent, 0.5-2 parts of glycerol, 0-1.5 parts of a thickener, 3-10 parts of a coupling agent and 30-60 parts of water. The nano insulating coating disclosed by the invention is good in insulation, high-temperature resistant, high in strength and pollution resistant and is strong in adhesive force and long in service life of building wall spaces and base bodies.

Owner:南京红枫环保材料有限公司

Foaming agent type shampoo

ActiveCN102697670BReduce contact timeReduce chance of baldnessCosmetic preparationsHair cosmeticsSodium lactateCopolymer

The invention relates to foaming agent type shampoo which comprises (30 percent) 20 percent to 40 percent of lauryl alcohol polyoxyethylene ether sulpho succinate monoester disodium salt, (30 percent) 20 percent to 40 percent of lauroyl sodium sarcosinate, 0.1 to 0.5 percent of disodium EDTA, 1 to 5 percent of sodium lactate, (40 percent) 1 to 5 percent of polyquat-7, (30 percent) 2 to 5 percent of acrylate copolymer, 1 to 6 percent of PEG-12 dimethyl silicone, 0.1 to 1 percent of aromatic oil or essence, 0.01 to 0.3 percent of citric acid, and 0.04 to 1 percent of preservative agents, and the rest is deionized water. the foaming agent type shampoo is characterized in that foam is squeezed out through a mousse pump head, and the shampoo is not centralized at the top of the head but applied and diffused to other parts, so that the contact of chemical substances and the scalp can be reduced, the probability of furfur, calvities and balding can be reduced, and the effects of economy, environmental friendliness and no side effect can be achieved.

Owner:GUANGZHOU YOUNGRACE COSMETIC LTD

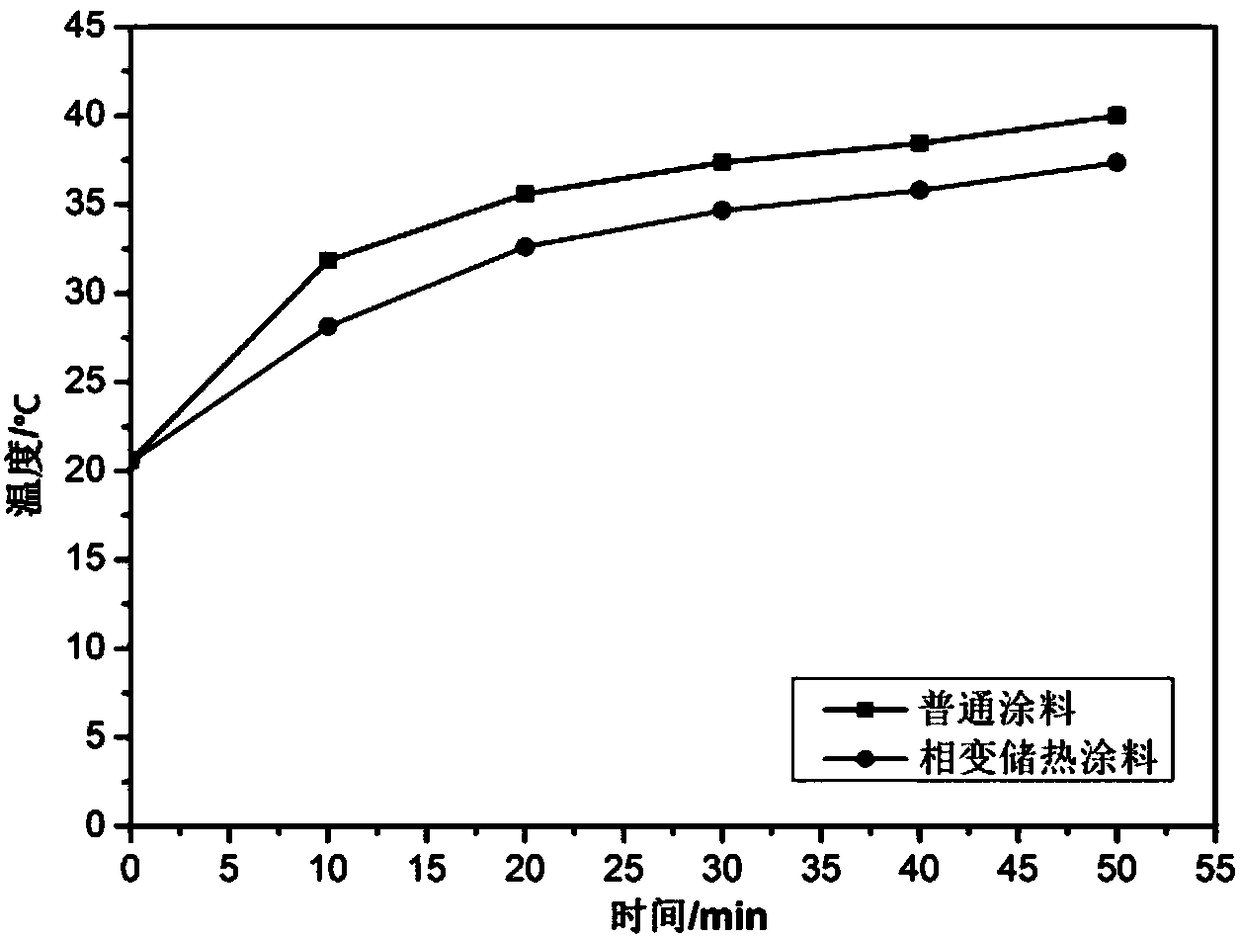

Phase change heat storage coating, and preparation method and application thereof

InactiveCN108192467AGood capacity storage performanceHigh heat storage efficiencyHeat-exchange elementsEpoxy resin coatingsWater basedPolymer science

The invention belongs to the field of new energy materials, and particularly relates to a phase change heat storage coating, and a preparation method and application thereof. The preparation method ofthe phase change heat storage coating comprises the following steps: (1) taking graphene oxide-modified melamine resin as a wall material, taking dodecanol as a core material, taking styrene maleic anhydride sodium salt as an emulsifying agent, and preparing phase change micro-capsules through an in-situ polymerization method; (2) taking water-based emulsion as a film forming matter, taking the phase change micro-capsules as filler, adding a suitable amount of water, a dispersing agent, a defoaming agent, a thickening agent and a coalescing agent in sequence, mixing uniformly, and finally, adding the thickening agent to adjust viscosity to prepare the phase change heat storage coating. The phase change heat storage coating prepared by the preparation method is used for an inner wall of abuilding, can show excellent temperature regulating performance, is low in cost, easy to prepare, can effectively improve the thermal comfort of the building and reduce the energy consumption of the building.

Owner:邹元月

Essential oil condensation beads for washing clothes and preparing method thereof

InactiveCN105039014AEasy to useGood effectAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsBiotechnologyTriclosan

The invention provides essential oil condensation beads for washing clothes. The essential oil condensation beads comprise, by weight, 20-25% of sodium C14-16 olefin sulfonate, 15-20% of fatty alcohol polyoxyethylene ether (9EO), 10-12% of sodium alcohol ether sulphate, 8-10% of lauryl alcohol sulphate triethanolamine, 2-4% of polyethylene glycol, 1-3% of cationic alkyl polysaccharide, 1-2% of D-panthenol, 0.3-0.7% of phenoxyethanol, 0.05-0.01% of disodium ethylenediamine tetraacetate, 0.5-1% of jasminum essential oil, 0.05-0.1% of triclosan, 0.1-0.2% of protease, 0.002-0.005% of red-33 pigment and the balance deionized water. The invention further provides a preparing method for the essential oil condensation beads. The essential oil condensation beads have the multiple effects of washing, caring, sterilizing, deodorizing and physical and mental delighting, and are convenient to use.

Owner:GUANGZHOU BAILICHEN COSMETICS CO LTD

Building material containing foaming material and preparation method thereof

The invention provides a building material containing a foaming material and a preparation method thereof. The building material comprises the following components in parts by weight: 200-400 parts of perlite, 100 parts of cement, 15-30 parts of pulverized fuel ash, 30-80 parts of water, 0.1-0.3 part of concrete foaming agent, 2-4 parts of reinforcing fiber and 0.5-2 parts of water reducing agent, wherein the concrete foaming agent consists of starch, a surfactant, lauryl alcohol and an alkali metal salt of carboxymethyl cellulose in the weight ratio (40-60):(32-47):(3-8):(2-5). Cells in the material have small diameters and are uniform, so that the material has the advantages of light weight, heat preservation, heat insulation, fire proofing and leakage prevention. Moreover, the materialfurther has the advantages of difficulty in molding and difficulty in denaturing due to the influences of external environments such as temperature, pH and the like.

Owner:BEIJING TIANJI NEW MATERIALS

Formulations and Methods for Enhancing the Transdermal Penetration of a Drug

InactiveUS20070065494A1Improve permeabilityIncrease the areaBiocidePharmaceutical non-active ingredientsPenetration enhancerLauryl Alcohol

Methods and formulations of enhancing the permeability the skin of a subject to a drug are disclosed. The method may include administering a combination of lauryl alcohol and isopropyl myristate as a penetration enhancer to the area of skin to provide synergistically enhanced penetration of the drug.

Owner:WATSON LAB INC

Washing agent for dishes

InactiveCN103820235AEasy to cleanLow toxicityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPreservativeSodium sulfate

The invention discloses a washing agent for dishes. The washing agent for the dishes is composed of, by mass, 15-21 parts of sodium dodecyl benzene sulfonate, 2-4 parts of dimethyltetradecylamine oxide, 2-5 parts of lauryl alcohol polyoxyethylene, 7-12 parts of sodium sulfate, 3-5 parts of lauroyl diethanolamide, 3-5 parts of glucose decanoate, 0.4-0.7 part of a preservative, 0.2-0.4 part of a condiment and 100 parts of water. The washing agent for the dishes is obtained by weighing the above components according to the mass parts and mixing uniformly. With the above way, the washing agent for the dishes has a good cleaning effect, can achieve a good effect by using a small amount, saves water, and has little residue on tableware. The washing agent has small toxicity and small stimulation to hands contacted with the washing agent directly, and can effectively reduce harm to human bodies.

Owner:SUZHOU LOTTE CHEM TECH

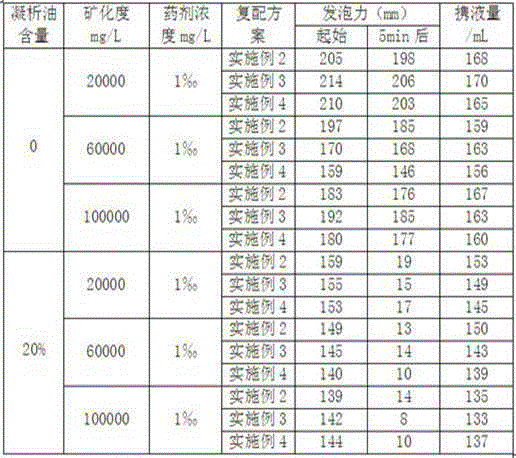

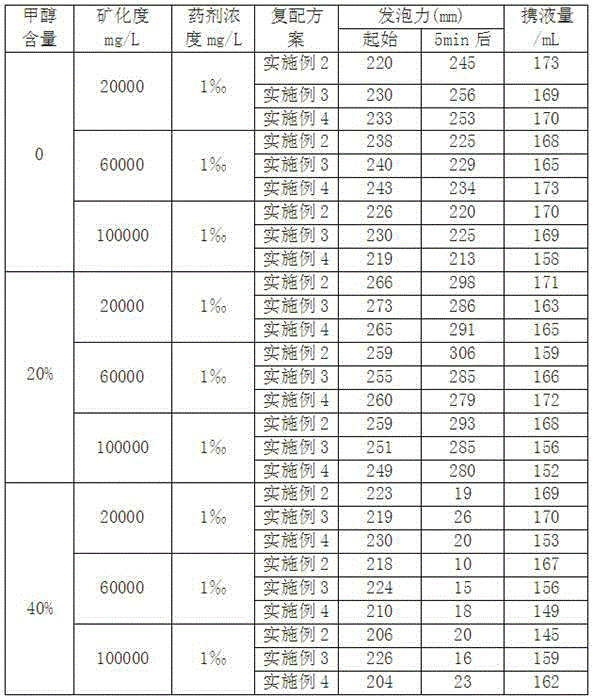

Foaming drainage agent resisting methanol, condensate oil and high salinity

ActiveCN104531121APromote degradationGood compatibilityDrilling compositionBetainePolyethylene glycol

The invention belongs to the technical field of oil-gas field chemical accessories, and in particular relates to a foaming drainage agent resisting methanol, condensate oil and high salinity. The foaming drainage agent is compounded from various nonionic surfactants, an anionic surfactant, an amphoteric surfactant, a drag reducer and pure water, wherein the various nonionic surfactants comprise polyether type surfactants including fatty alcohol-polyoxyethylene ether and alkyl alcohol ether carboxylate, the anionic surfactant comprises sodium lauryl alcohol sulfate and a Gemini cationic surfactant, the amphoteric surfactant is dodecyl dimethyl betaine, and the drag reducer is polyethylene glycol. The foaming drainage agent has relatively good biodegradability, and cannot be deposited and layered when in use. The foaming drainage agent provided by the invention is strong in foaming power, has rich and stable foams, is moderate in salt resistance, can be used in an oil-water-gas three-phase coproduction well containing condensate oil, has excellent foaming performance, is good in compatibility with various corrosion inhibitors, and also has good corrosion inhibiting ability.

Owner:PETROCHINA CO LTD

Paraffin emulsifier and its making method

InactiveCN1570038AGood water solubilityImprove stabilityWax physical treatmentTransportation and packagingParaffin waxEthylene oxide

Owner:杨建军

Oil well dispersive wax-proofing agent and preparation method thereof

The invention relates to an oil well dispersive wax-proofing agent which is applicable to wax proofing of a petroleum well. The invention is characterized in that the oil well dispersive wax-proofing agent comprises the following ingredients according to weight percentage: 5-7% of polyoxyethylenealkylphenol ether, 6.5-9.5% of sorbitan mono lauryl alcohol polyoxyethylene ether, 0.5-1.0% of potassium chloride, 0.05-0.1% of fluorocarbon surfactant FN-3, 0.5-1.0% of Vitamin C, 10-15.5% of polyoxyethylene alkylphenol ether carboxylic sodium, 0.005-0.01% of 6-chlorobenzotriazole-1,1,3,3-tetramethylcarbamidehexafluoroosphate, and the allowance of water. The invention has the effects that for an oil well with water content of high than 30%, the oil well dispersive wax-proofing agent can prolong the thermal cleaning cycle of the oil well by 2-4.5 times when the adding amount is 0.05-0.1% in daily oil well maintenance.

Owner:PETROCHINA CO LTD

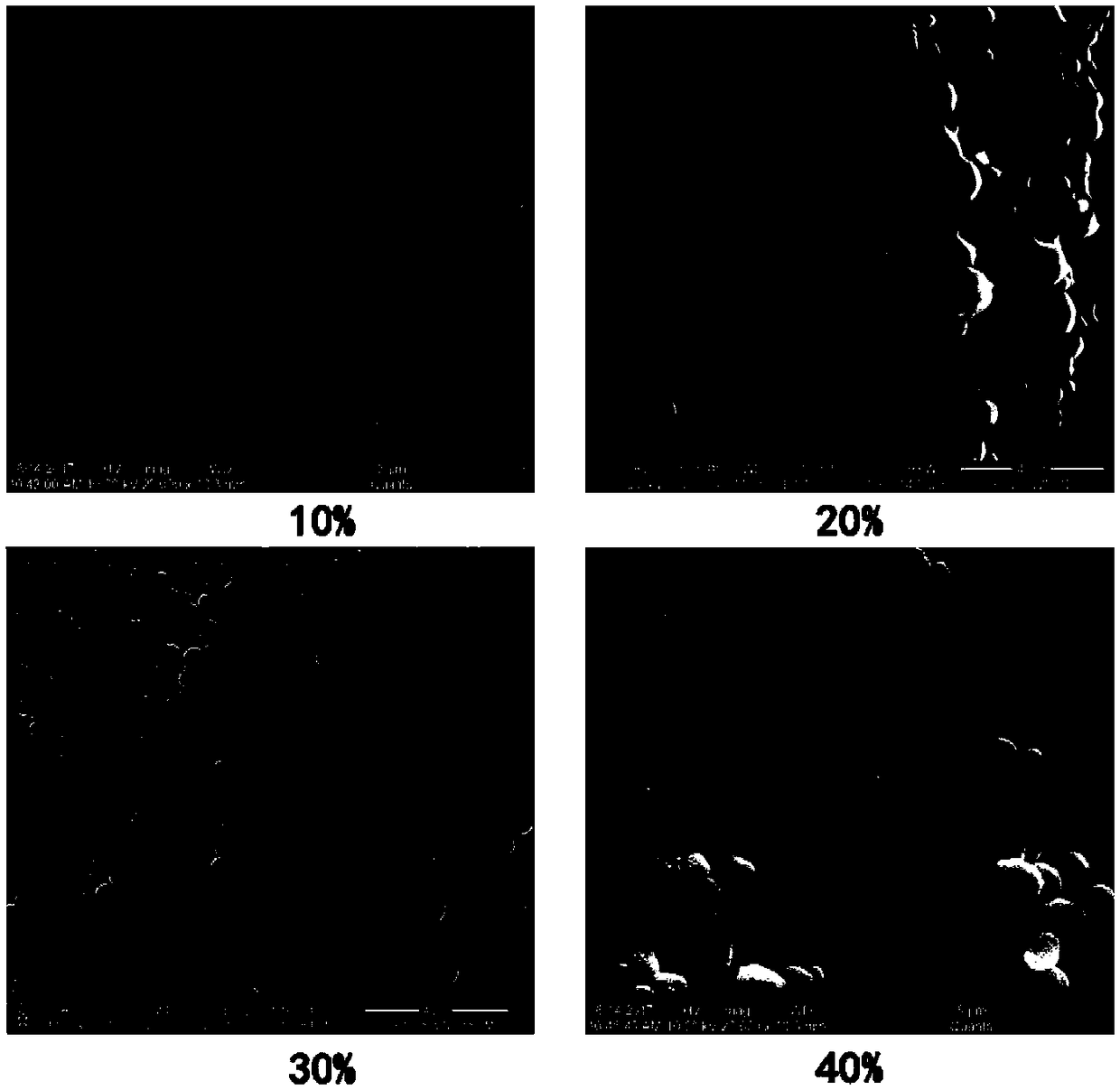

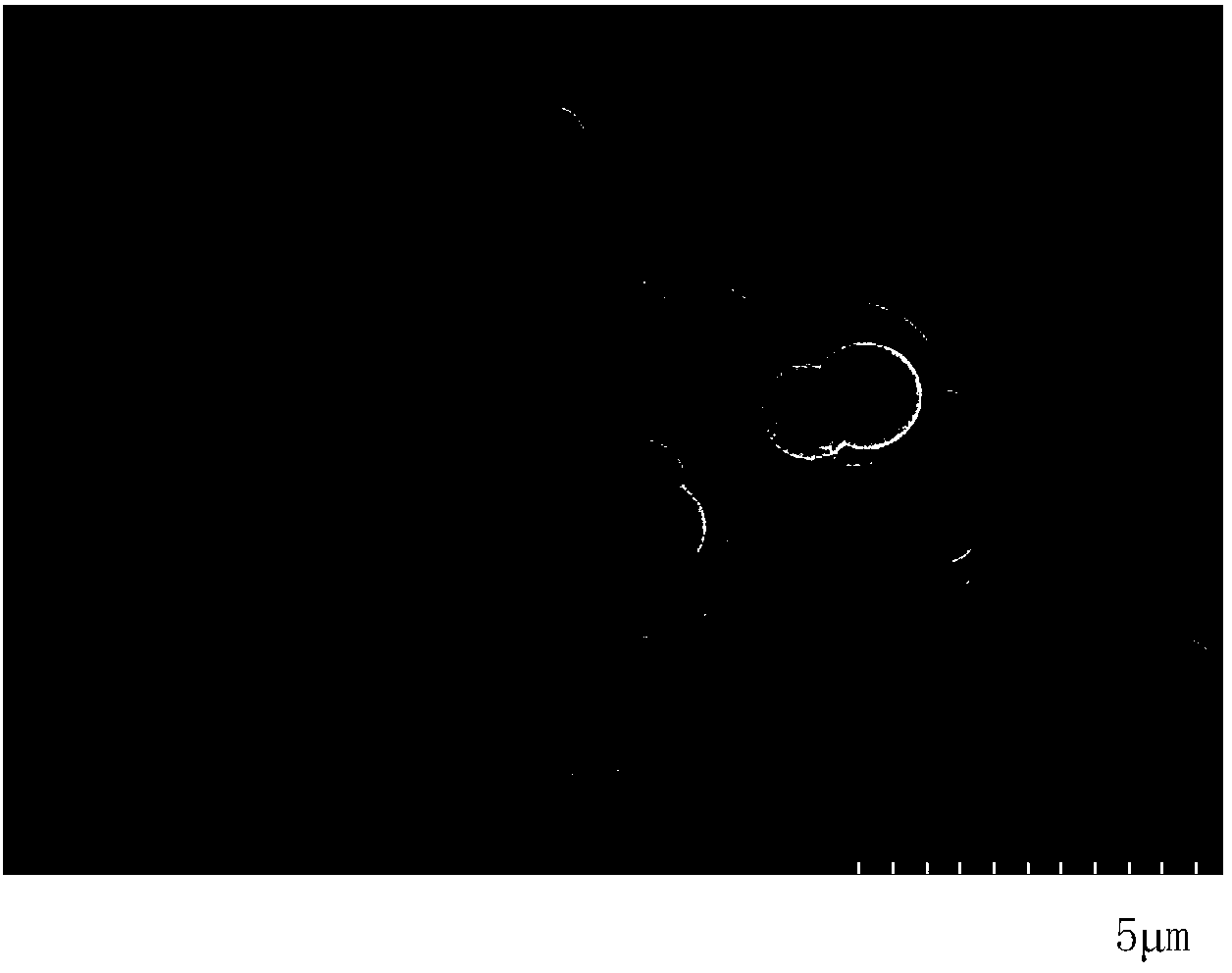

Preparation method of lauryl alcohol/melamine-formaldehyde resin microcapsule phase-change material

The invention discloses a preparation method of a lauryl alcohol / melamine-formaldehyde resin microcapsule phase-change material, and relates to preparation of a microcapsule phase-change material with an in-situ polymerization method. The method comprises the following steps: adding formaldehyde and a solvent to melamine, adjusting the pH to 8-9 by triethanolamine, and stirring until the solution is transparent, thereby obtaining a melamine-formaldehyde resin prepolymer; mixing an emulsifier, a cross-linking agent, a solvent and lauryl alcohol, and stirring for emulsifying, thereby obtaining a core material lauryl alcohol solution; adding the melamine-formaldehyde resin prepolymer to the core material lauryl alcohol solution, then adjusting the pH to 3-4 by formic acid, and stirring, thereby obtaining a lauryl alcohol / melamine-formaldehyde resin microcapsule phase-change material suspension; washing, suction-filtering, and baking to obtain the dried lauryl alcohol / melamine-formaldehyde resin microcapsule phase-change material powder. The prepared microcapsule has the small particle size of 1-2 microns, is even in particle size distribution, smooth in surface, round in shape and good in leakproofness, and has broad application prospect.

Owner:XIAMEN UNIV

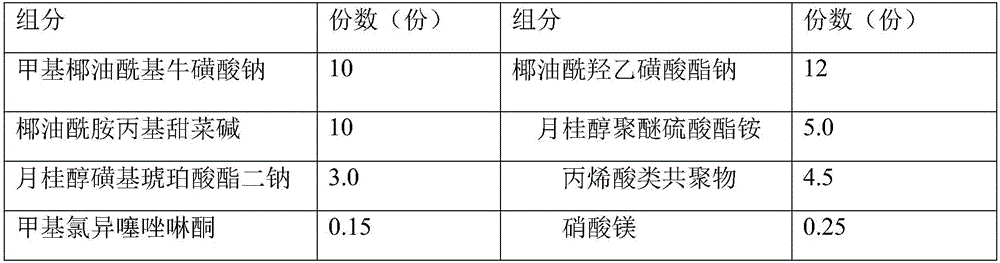

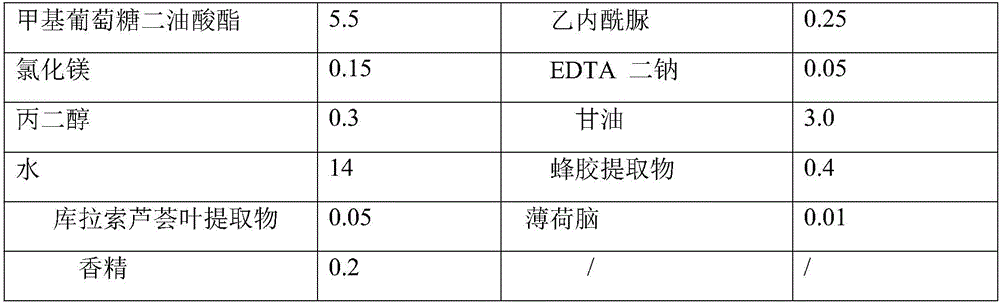

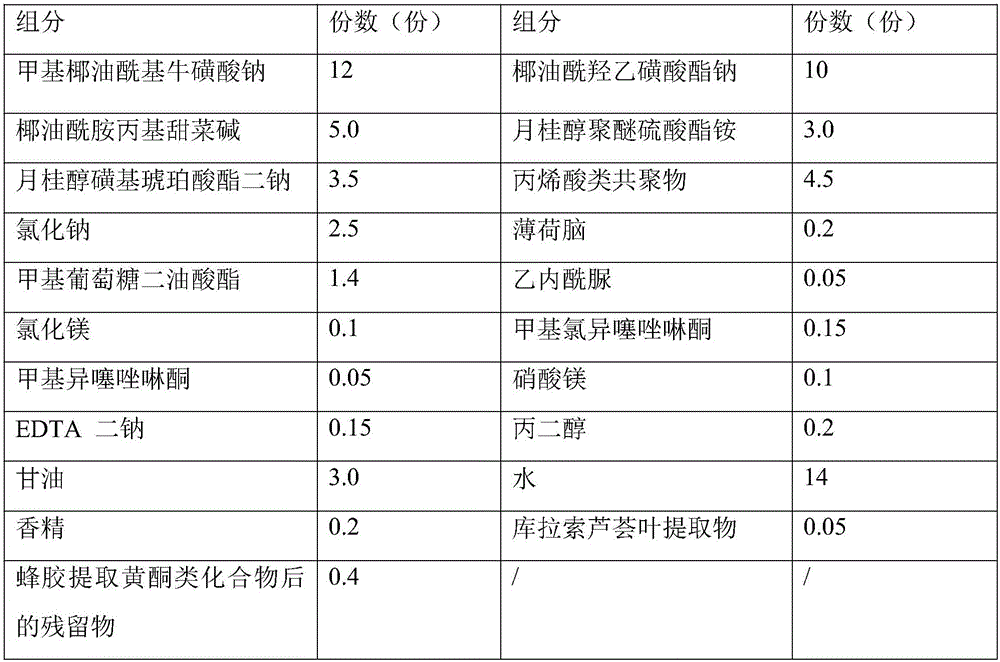

Facial cleanser and preparation method thereof

ActiveCN106038330APromote absorptionCosmetic preparationsToilet preparationsSODIUM METHYL COCOYL TAURATECocamidopropyl betaine

The invention discloses a facial cleanser and a preparation method thereof. The problem of skin tension caused by using the present facial cleanser for cleaning skin is solved. According to the technical scheme, the facial cleanser comprises the following components in parts by weight: 8-22 parts of sodium methyl cocoyl taurate, 3-12 parts of sodium cocoyl isethionate, 2-5 parts of lauryl sulfo succinate disodium, 2-10 parts of cocamidopropyl betaine, 1-5 parts of lauryl alcohol polyether ammonium sulfate, 3-10 parts of a thickening agent, 0.1-0.5 part of a preservative, 0.05-0.2 part of EDTA disodium, 0.2-0.6 part of propylene glycol, 2-12 parts of glycerinum, 0.1-0.5 part of essence and 10-18 parts of water. The prepared facial cleanser belongs to an amino acid facial cleanser, has the characteristics of safety, no stimulation, skin-relieving effect and deep skin-cleaning effect, and can be used by a user for a long term.

Owner:浙江高妍科技有限公司

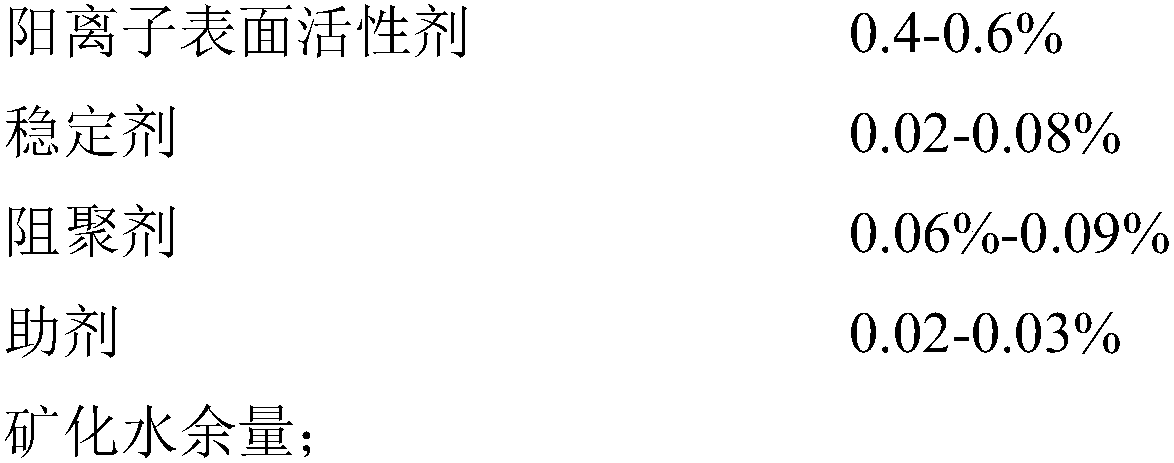

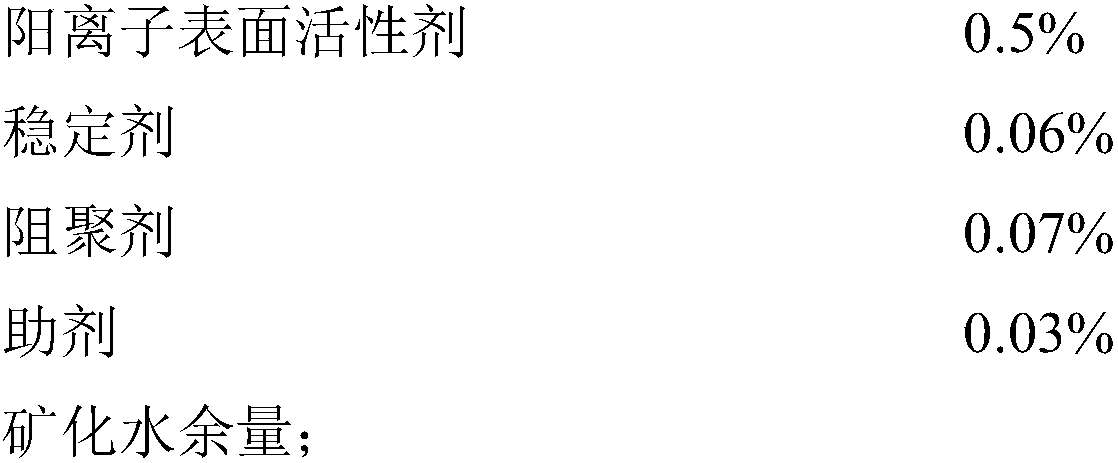

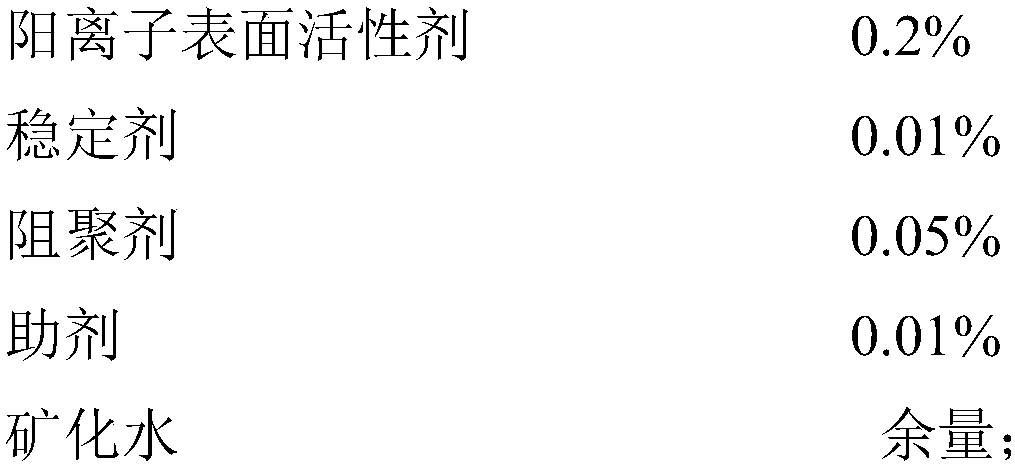

Nanoparticle enhanced low-interfacial-tension foam system and preparation method thereof

InactiveCN107556997AImprove performanceInhibit aggregationDrilling compositionOctadecyltrimethylammonium bromideSurface-active agents

The invention discloses a nanoparticle enhanced low-interfacial-tension foam system and a preparation method thereof. The foam system comprises the following components by weight percent: 0.2-0.8% ofa cationic surface active agent, 0.01-0.1% of a stabilizer, 0.5-1.0% of a polymerization inhibitor, 0.3-1.0% of an additive and the balance of mineralized water, wherein the cationic surface active agent is selected from dodecyl trimethyl ammonium bromide, tetradecyl trimethyl ammonium bromide, hexadecyl trimethyl ammonium bromide and stearyl trimethyl ammonium bromide; the stabilizer is selectedfrom modified nano-SiO2, modified nano-MgO and modified nano-TiO2; the polymerization inhibitor is sodium citrate; the additive is selected from ethylene glycol and dodecanol; the mineralized water isa mixed water solution of sodium chloride, anhydrous calcium chloride and anhydrous magnesium sulfate. The nanoparticle enhanced low-interfacial-tension foam system is good in foaming performance andfoam stabilizing performance, high in interfacial activity, cheap and easily accessible in raw material, simple in preparation method and excellent in foam combination performance.

Owner:YANGTZE UNIVERSITY

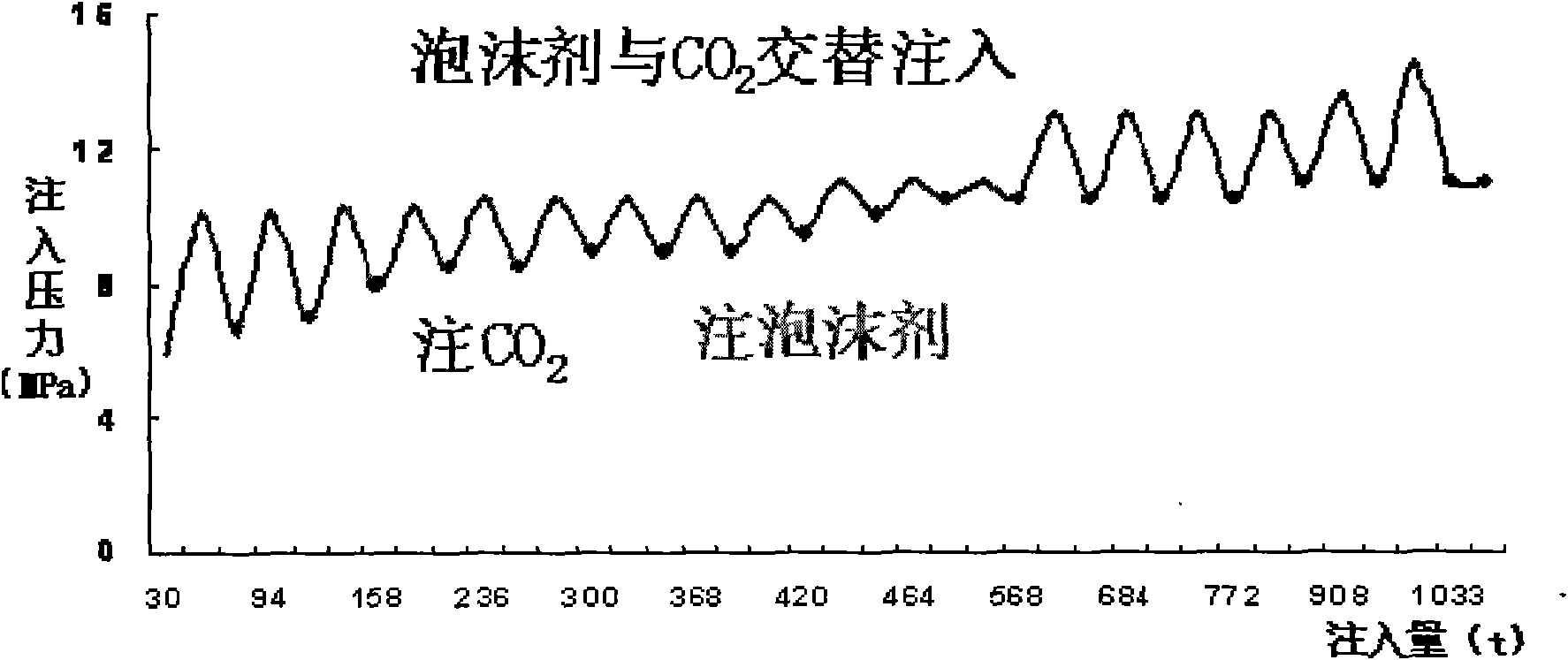

Foaming agent used in composite-foam oil flooding

ActiveCN102399548AFunctionalOvercome the shortcoming of gas drive "gas channeling"Drilling compositionSalt resistanceFoaming agent

The invention relates to a foaming agent used in composite-foam oil flooding. The foaming agent comprises materials of, by concentration: 0.2 to 0.4% of hydroxyl-sulfobetaine, 0.1% of 1227, 0.04 to 0.1% of dodecanol, and balance of formation water. The molecular formula of 1227 is C21H38NCl. The molecular formula of dodecanol is C12H26O. The foaming agent provided by the invention has a temperature resistance stabilized at 50 DEG C, and a good salt resistance of 80*10<3>mg / L. Foaming performance and foam stabilizing performance of the foaming agent are detected by using a Ross-mils method (a decanting method). The foaming height of the foaming agent is 14.4cm; the half-life period reaches 16 hours; and the oil-water interfacial tension is 0.192mN / m. According to the invention, advantages of chemical flooding and gas flooding are combined; viscose foam and gas are adopted as oil-flooding agents, such that double functions of profile modifying and oil flooding are achieved, and a defectof gas flooding of gas channeling is avoided. The foaming agent is suitable for oil reservoir with high water content, severe anisotropic, and cracks or large porous channels.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com