Patents

Literature

79 results about "Octadecyltrimethylammonium bromide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trimethyloctadecylammonium bromide 98% Synonym: C 18 TAB, Octadecyltrimethylammonium bromide, TMODAB CAS Number 1120-02-1. Linear Formula CH 3 (CH 2) 17 N(Br)(CH 3) 3. Molecular Weight 392.50 . Beilstein Registry Number 3574090 . EC Number 214-294-5. MDL number MFCD00043171. PubChem Substance ID 24862061

Nanoparticle enhanced low-interfacial-tension foam system and preparation method thereof

InactiveCN107556997AImprove performanceInhibit aggregationDrilling compositionOctadecyltrimethylammonium bromideSurface-active agents

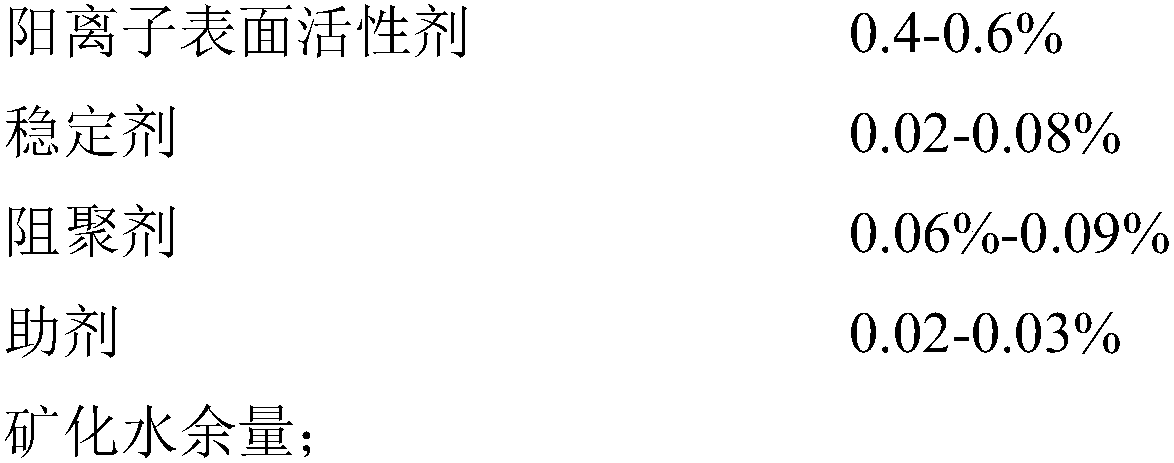

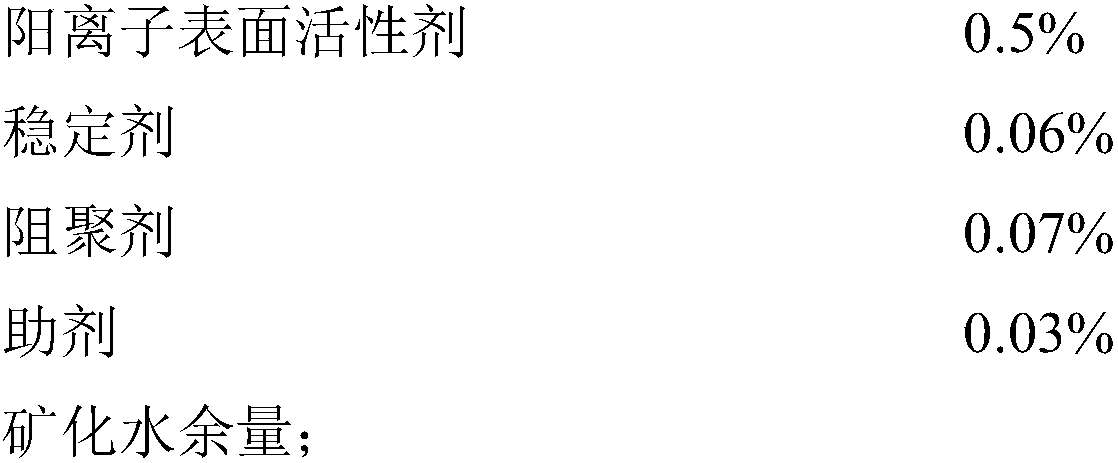

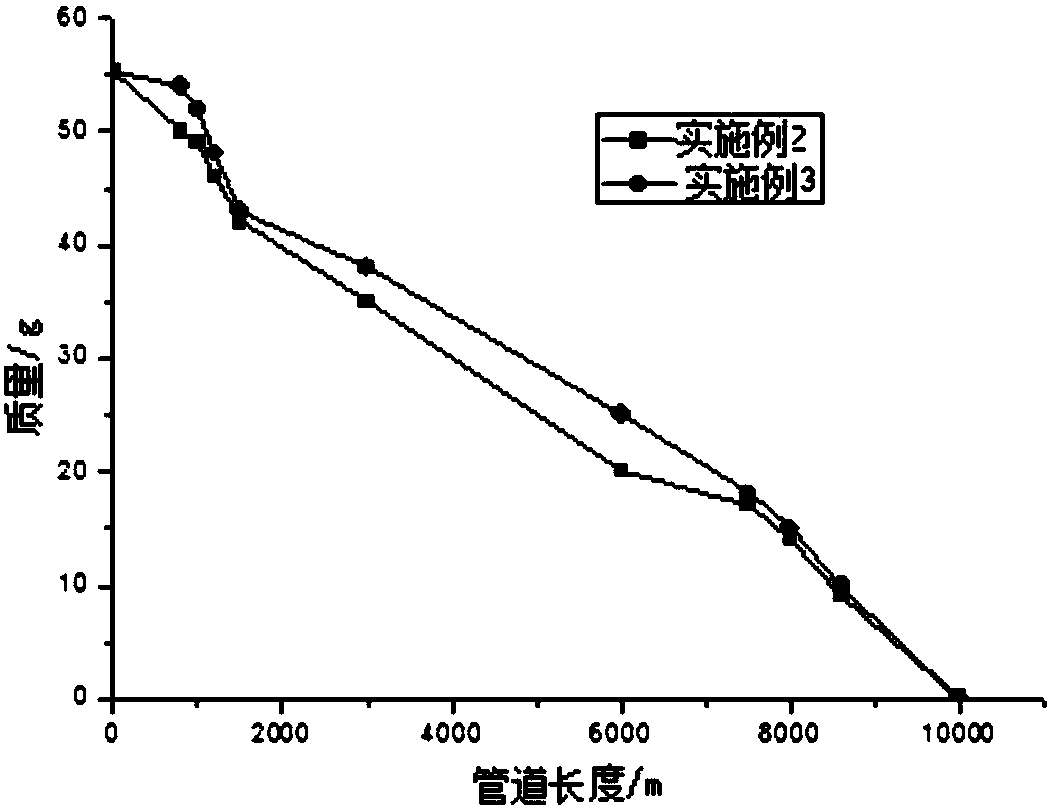

The invention discloses a nanoparticle enhanced low-interfacial-tension foam system and a preparation method thereof. The foam system comprises the following components by weight percent: 0.2-0.8% ofa cationic surface active agent, 0.01-0.1% of a stabilizer, 0.5-1.0% of a polymerization inhibitor, 0.3-1.0% of an additive and the balance of mineralized water, wherein the cationic surface active agent is selected from dodecyl trimethyl ammonium bromide, tetradecyl trimethyl ammonium bromide, hexadecyl trimethyl ammonium bromide and stearyl trimethyl ammonium bromide; the stabilizer is selectedfrom modified nano-SiO2, modified nano-MgO and modified nano-TiO2; the polymerization inhibitor is sodium citrate; the additive is selected from ethylene glycol and dodecanol; the mineralized water isa mixed water solution of sodium chloride, anhydrous calcium chloride and anhydrous magnesium sulfate. The nanoparticle enhanced low-interfacial-tension foam system is good in foaming performance andfoam stabilizing performance, high in interfacial activity, cheap and easily accessible in raw material, simple in preparation method and excellent in foam combination performance.

Owner:YANGTZE UNIVERSITY

Soluble chemical paraffin removal ball and preparation method and use method of soluble chemical paraffin removal ball

ActiveCN108559675APrevent redepositionPlay the role of physical wax removalCationic surface-active compoundsDetergent mixture composition preparationSodium stearateOctadecyltrimethylammonium bromide

The invention provides a soluble chemical paraffin removal ball and a preparation method and a use method of the soluble chemical paraffin removal ball. The soluble chemical paraffin removal ball comprises the following raw materials: 60-104 parts of a surfactant and 7-27 parts of a thickener; the surfactant is one or more of sodium stearate, hexadecyl trimethyl ammonium chloride, hexadecyl trimethyl ammonium bromide, sodium laurate, octadecyl trimethyl ammonium chloride, and octadecy trimethyl ammonium bromide; the thickener comprises 2-10 parts of sodium carboxymethylcellulose, 2-10 parts ofpolyacrylamide and 2-7 parts of sodium polyphosphate. The raw materials are proportionally added into absolute ethyl alcohol, stirred evenly, formed through a mould, and dried to obtain the soluble chemical paraffin removal ball. The paraffin removal ball is added according to the conditions of the pipeline length and the paraffin precipitation. The chemical paraffin removal ball has double effects of physically removing paraffin and chemically preventing paraffin, and the problem of paraffin precipitation in a transportation pipeline of the crude oil is solved.

Owner:XI'AN PETROLEUM UNIVERSITY

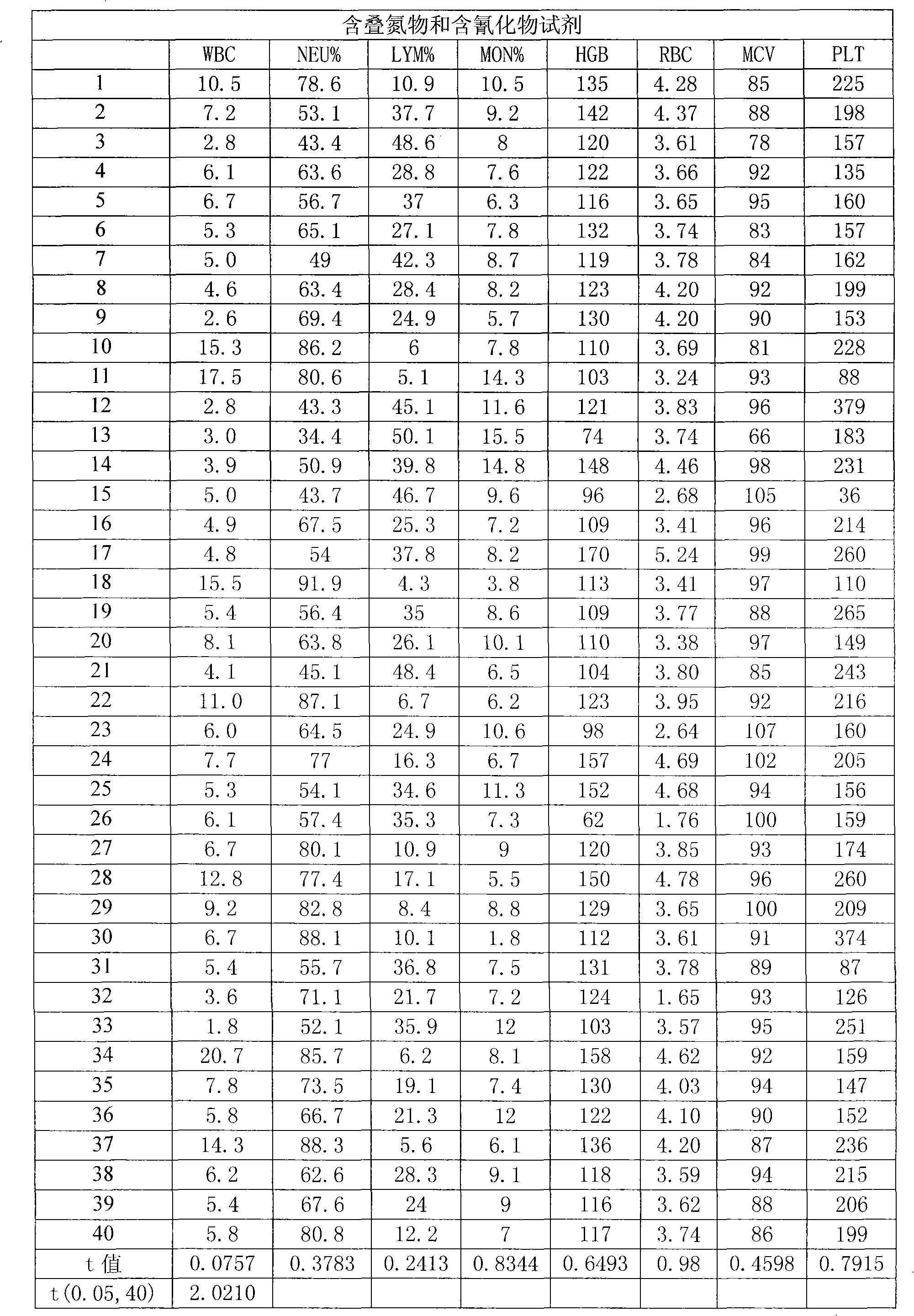

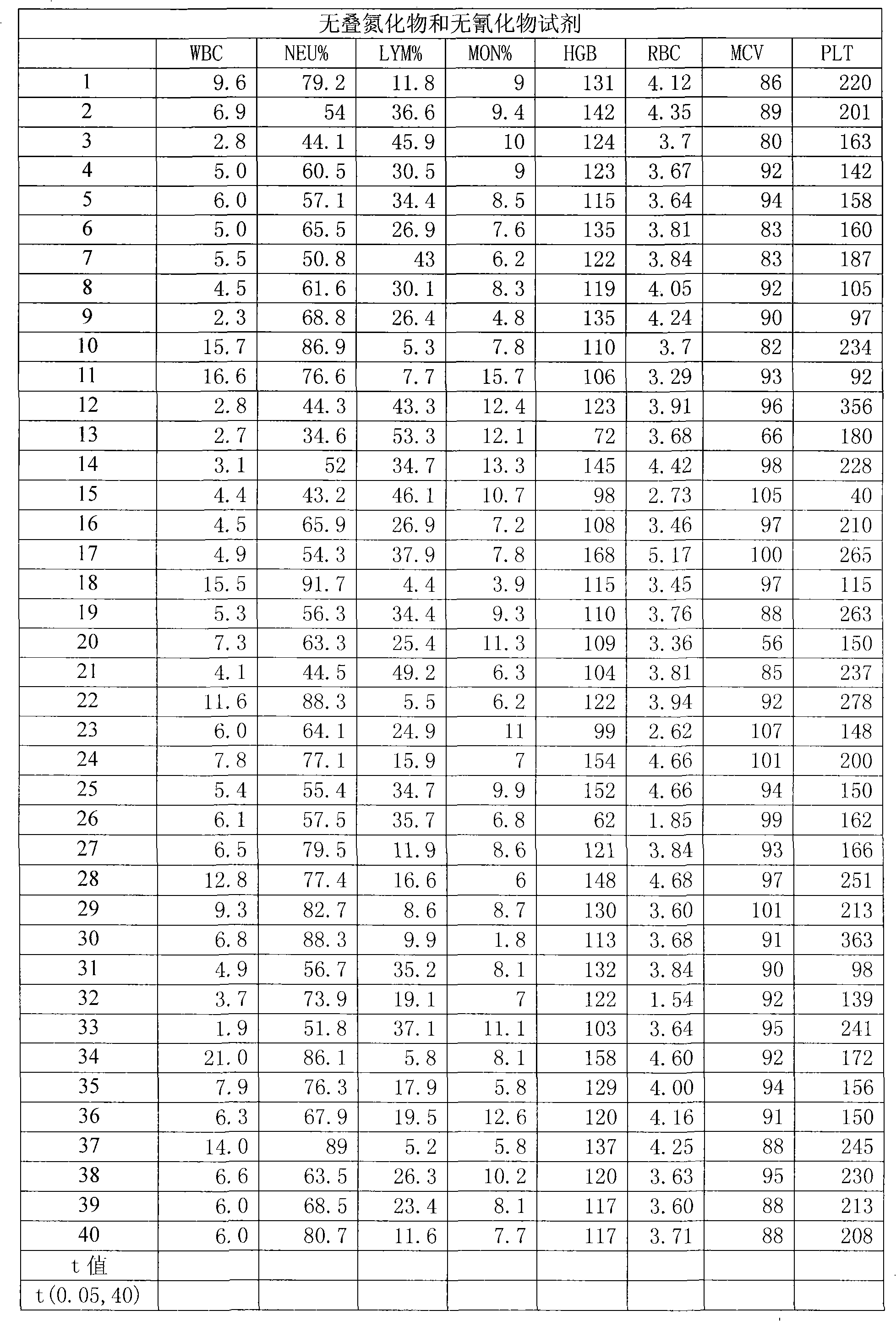

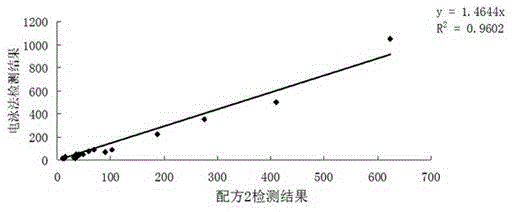

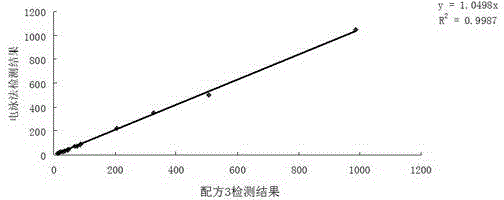

Blood cell analyzer dilution as well as hemolytic agent

InactiveCN101281193AImprove working environmentReduce harmIndividual particle analysisBiological testingNon toxicityToxicant

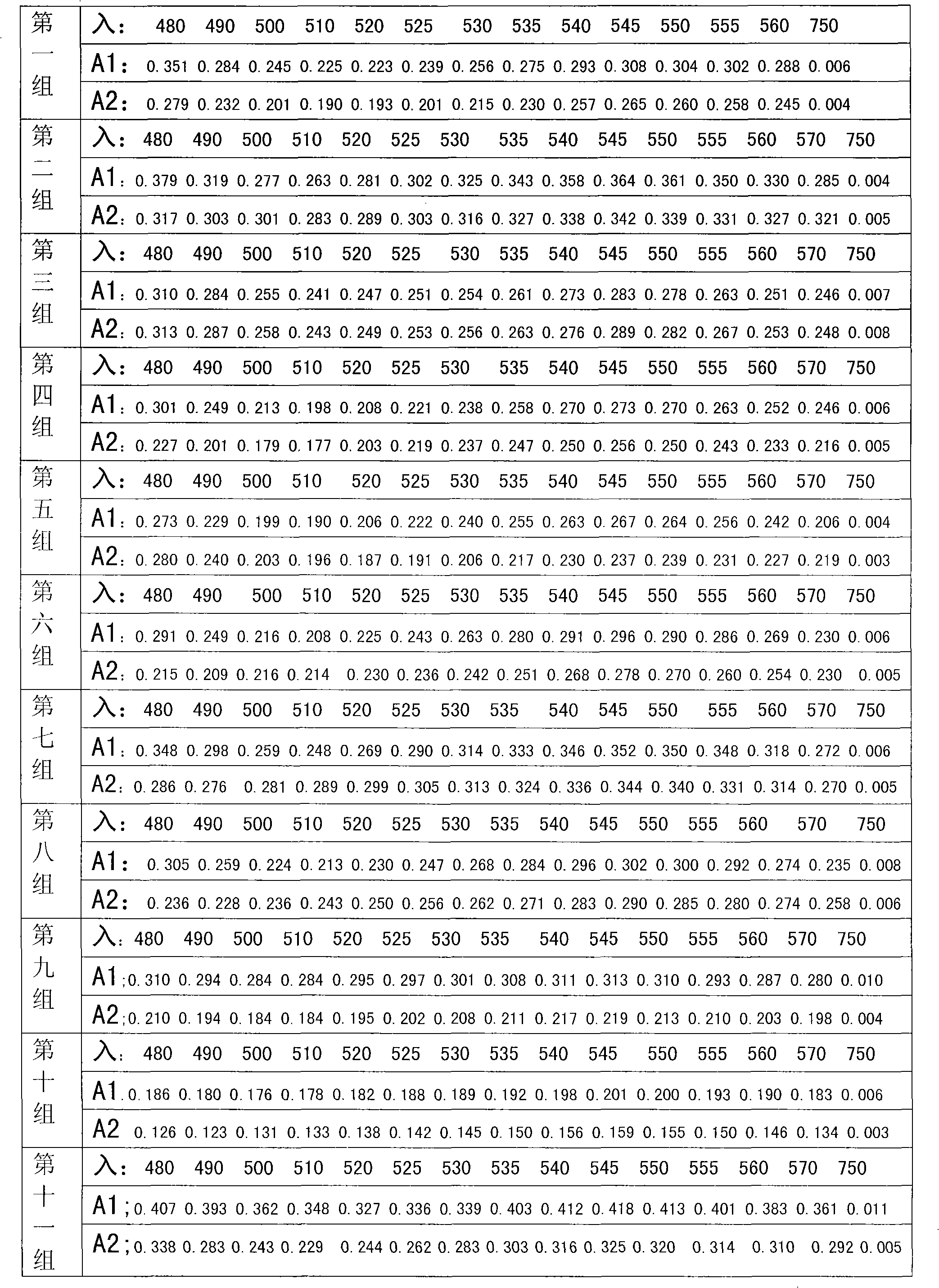

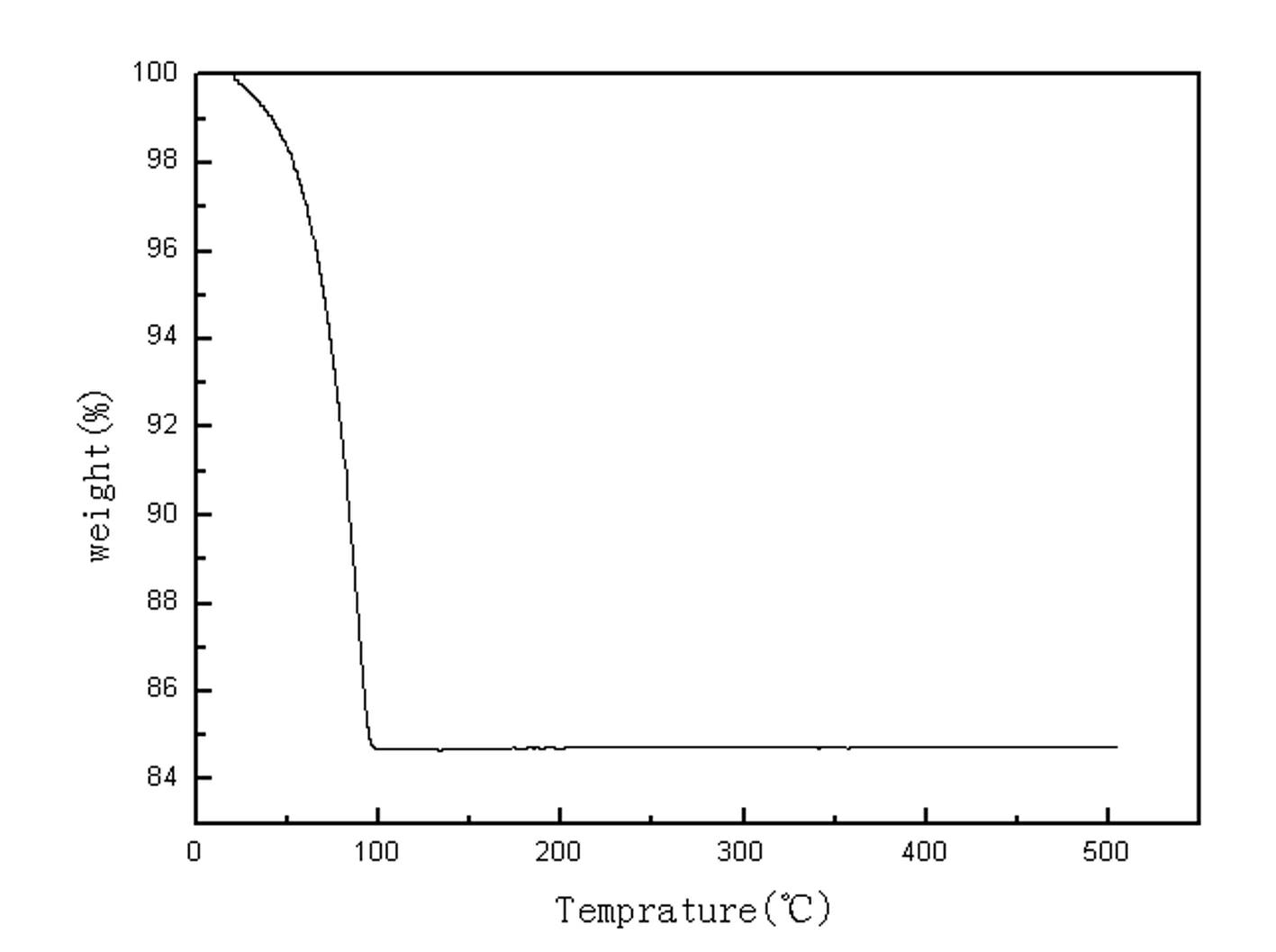

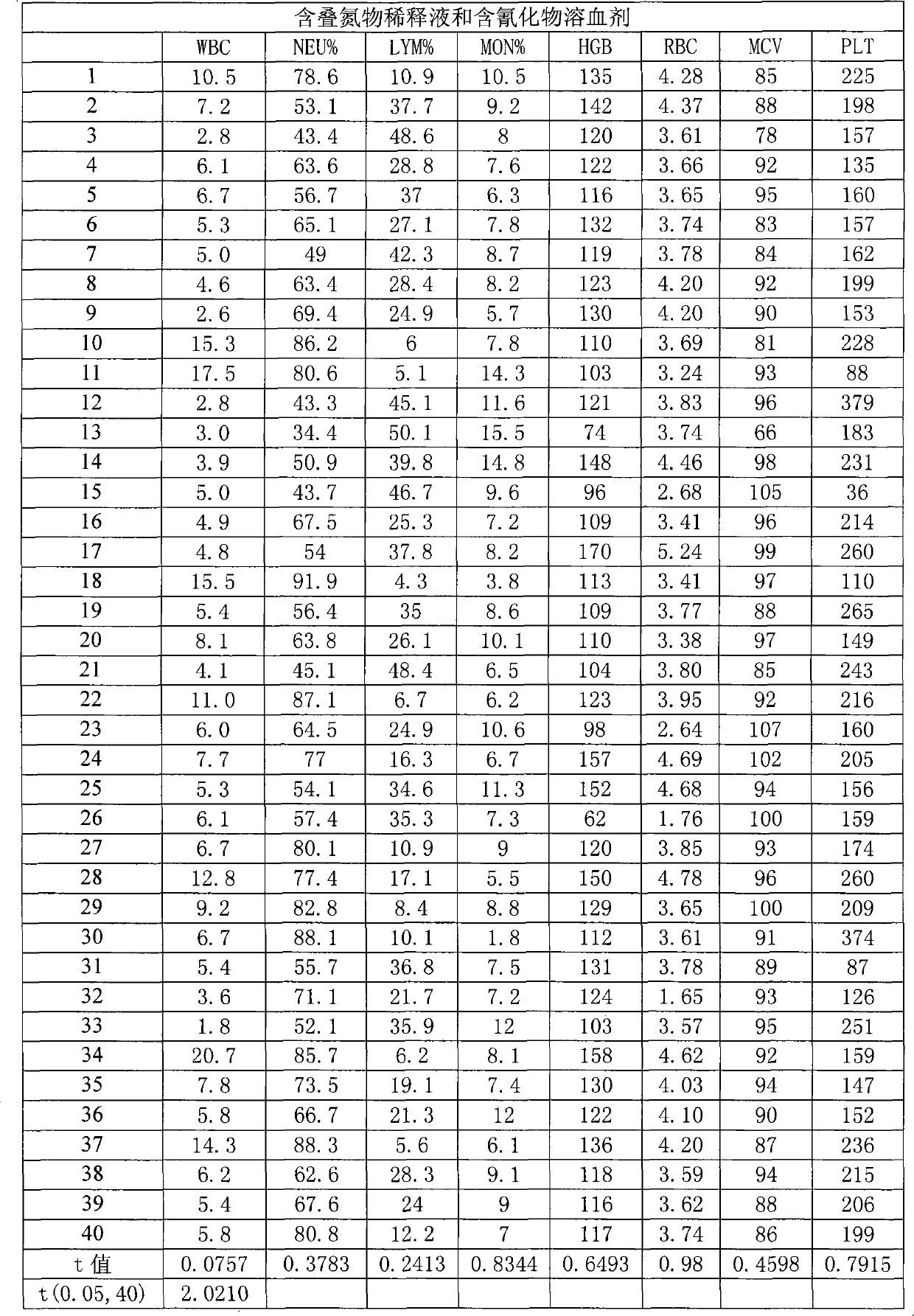

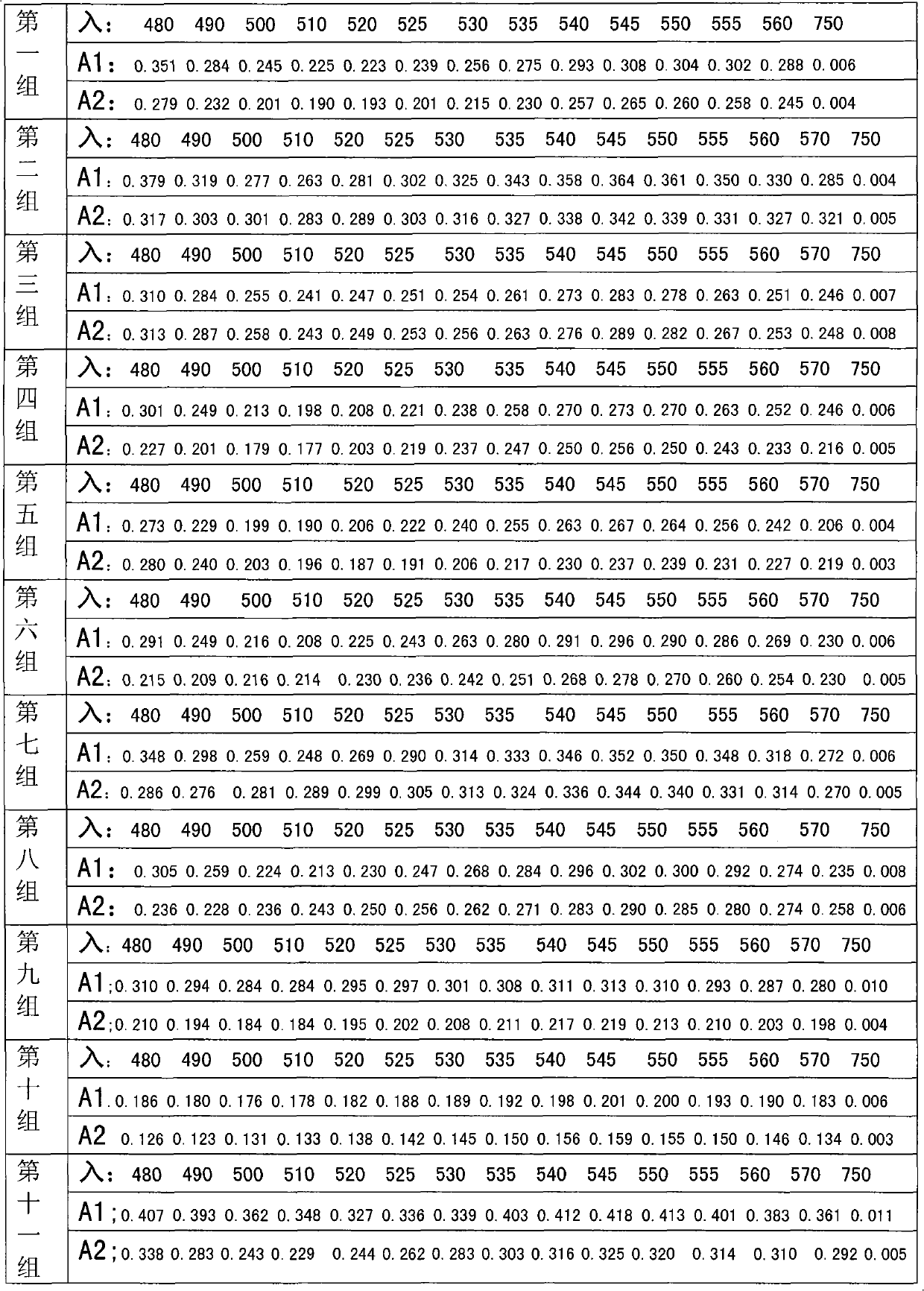

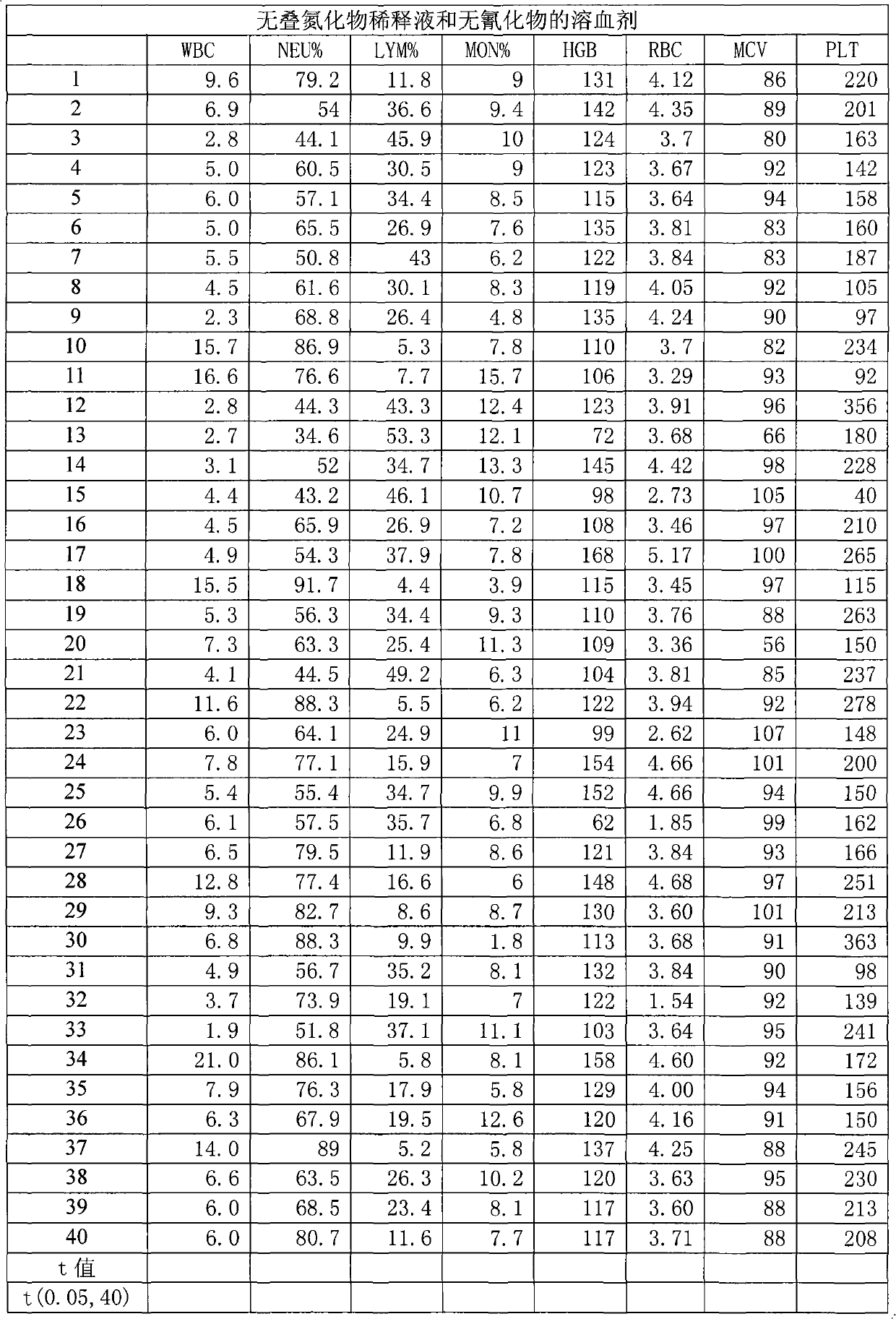

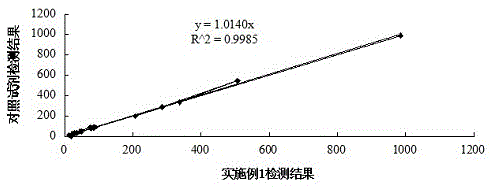

A blood cell analyzer diluent and a hemolytic agent, are characterized in that one litre diluent is provided with 12.0-4.0g of sodium chloride, 2.0-10.0g of sodium sulfate, 0.8-0.5g of 1,3,2-methylol urea, 0.2-0.5g of copper sulfite, 3.0-8.0g of EDTA-2Na, 0.2-0.7g of Piperacillin Sodium, a borate buffering liquid toning the ph value to 7.2-7.8, and the balance is water; one litre hemolytic agent is provided with 0.8-5.0g of potassium chloride, 0-60.0g of dodecyl trimethyl ammonium chloride, 14.0-0g of octadecyl trimethyl ammonium bromide, 6.0-10.0ml of isopropanol, carbonate or alcaine buffering liquid toning the ph value to 7.2-7.8, and the balance is water. The inventive reagent can form stable hemoglobin derivatives, and the absorption spectrum curves are similar when lambada is 540nm, lambada is 504nm, which can satisfy the clinical inspection requirement; the reagent does not contain cyanide, azide, and has non-toxicity, which can effective improve working atmosphere of operating staff, and can reduce harm of toxicant to personal health.

Owner:南昌百特生物高新技术股份有限公司

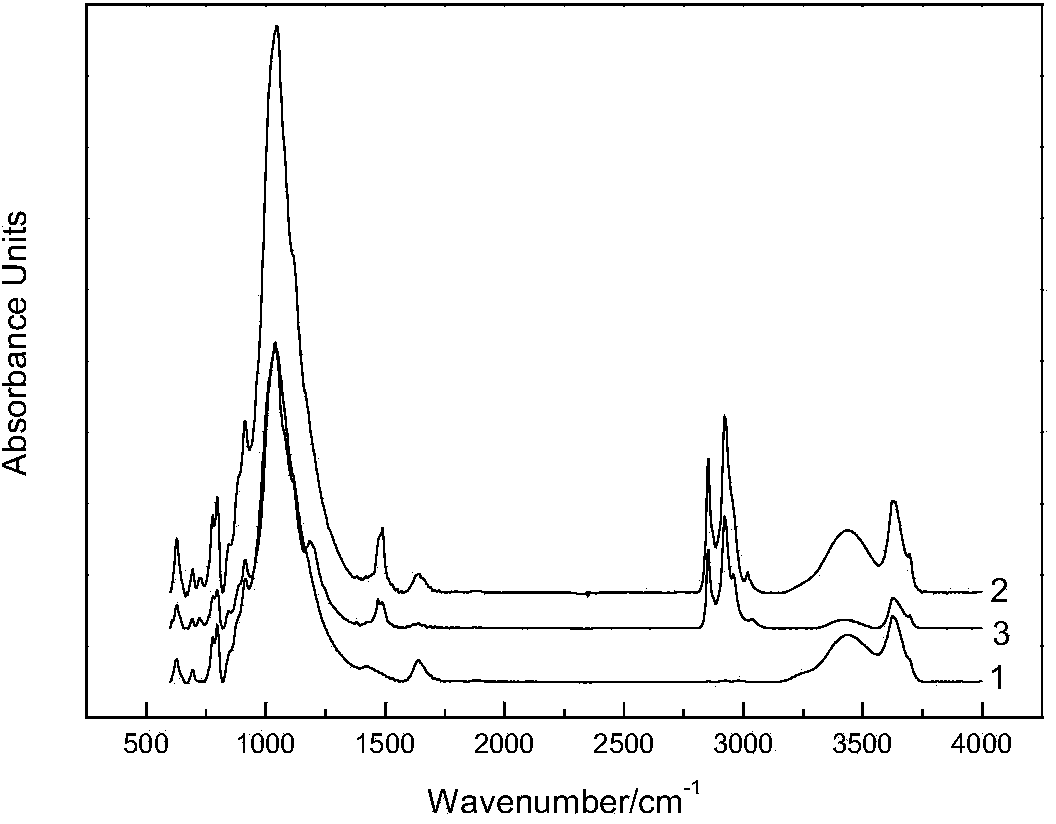

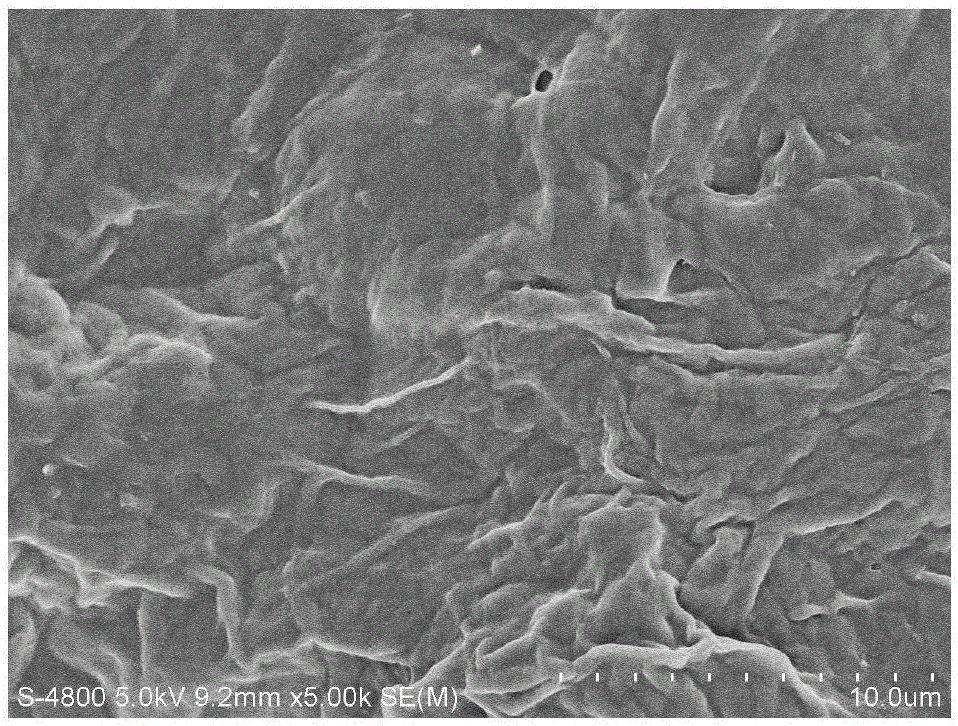

Novel preparation method of rubber-clay nanocomposite

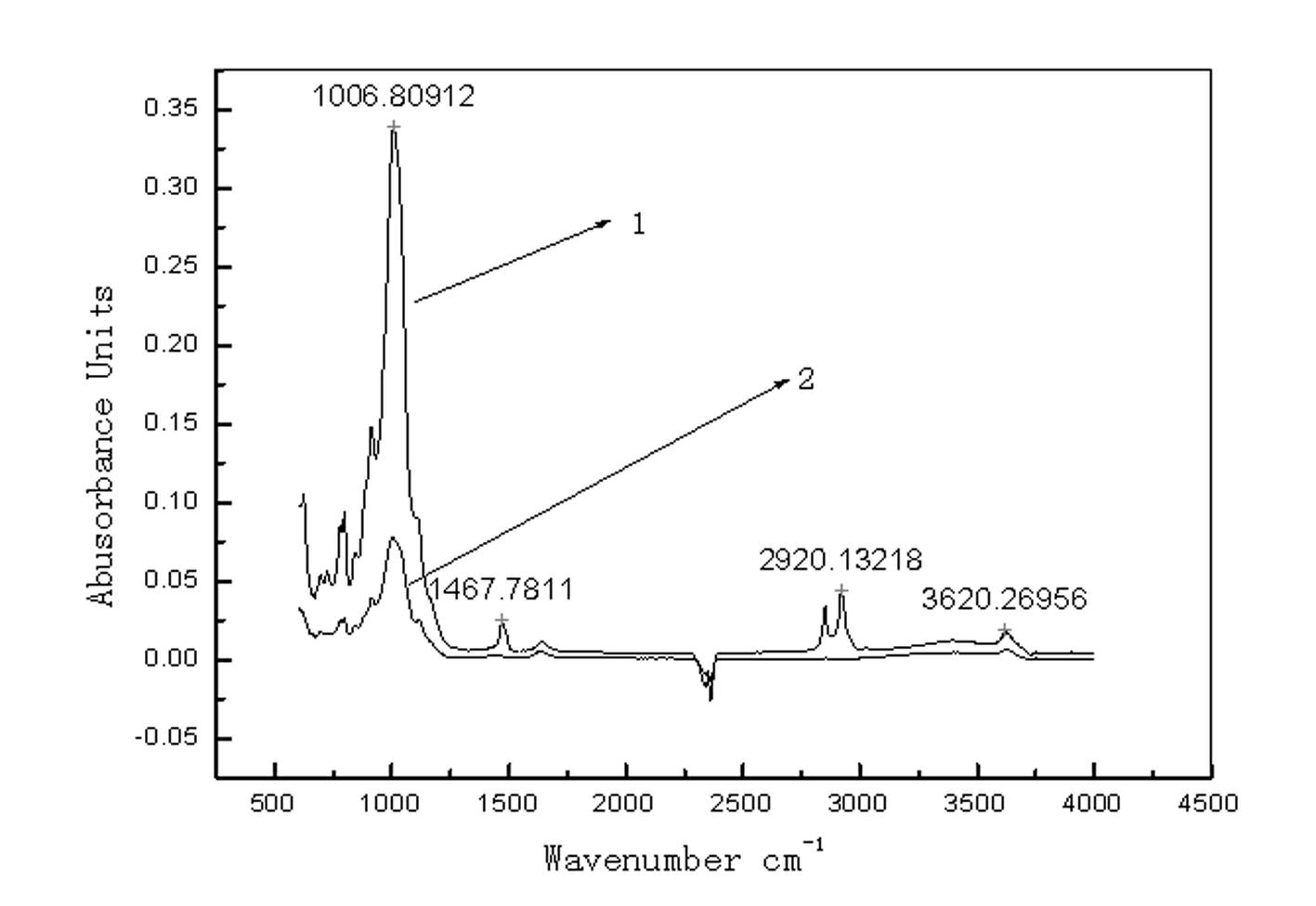

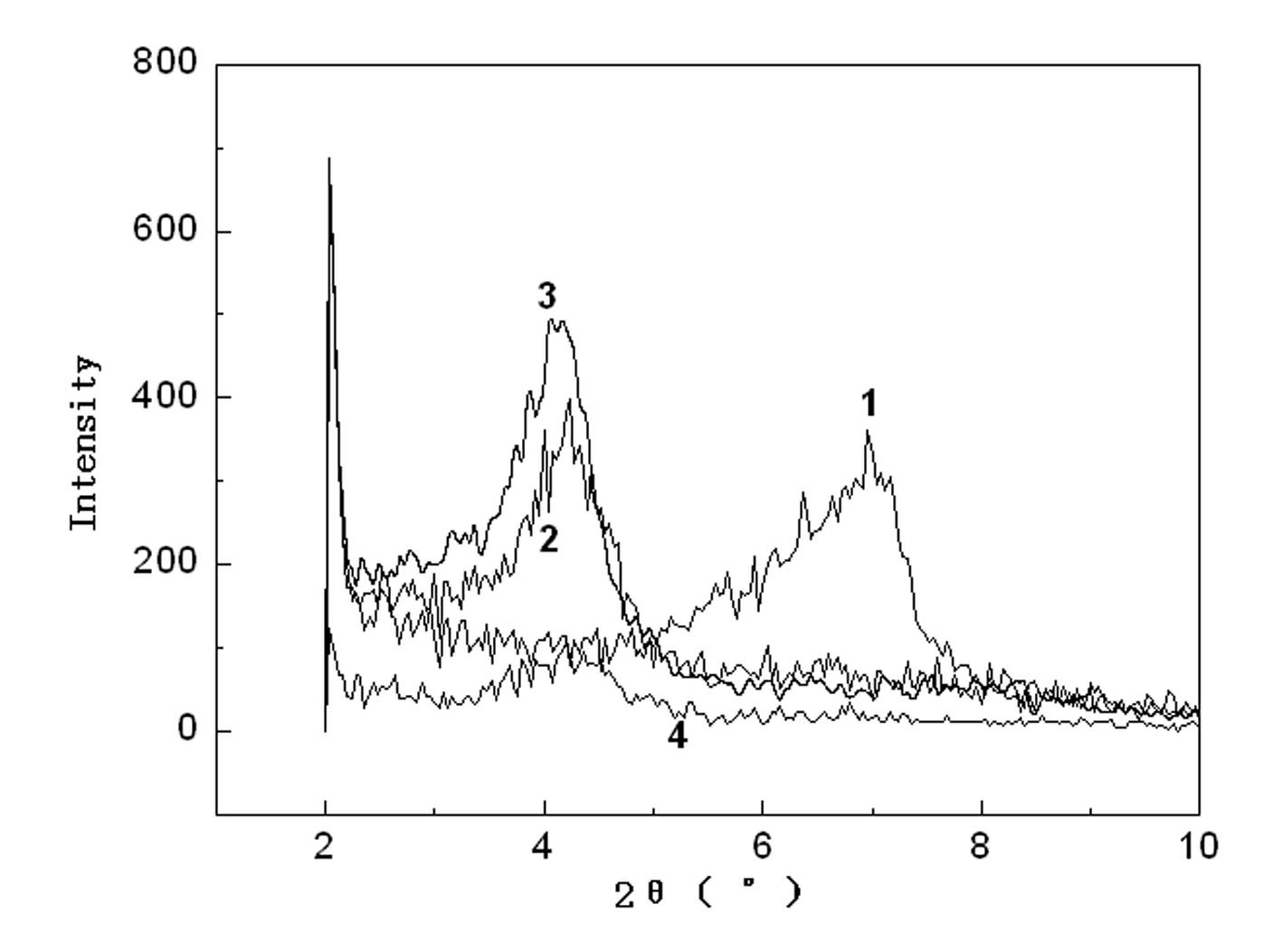

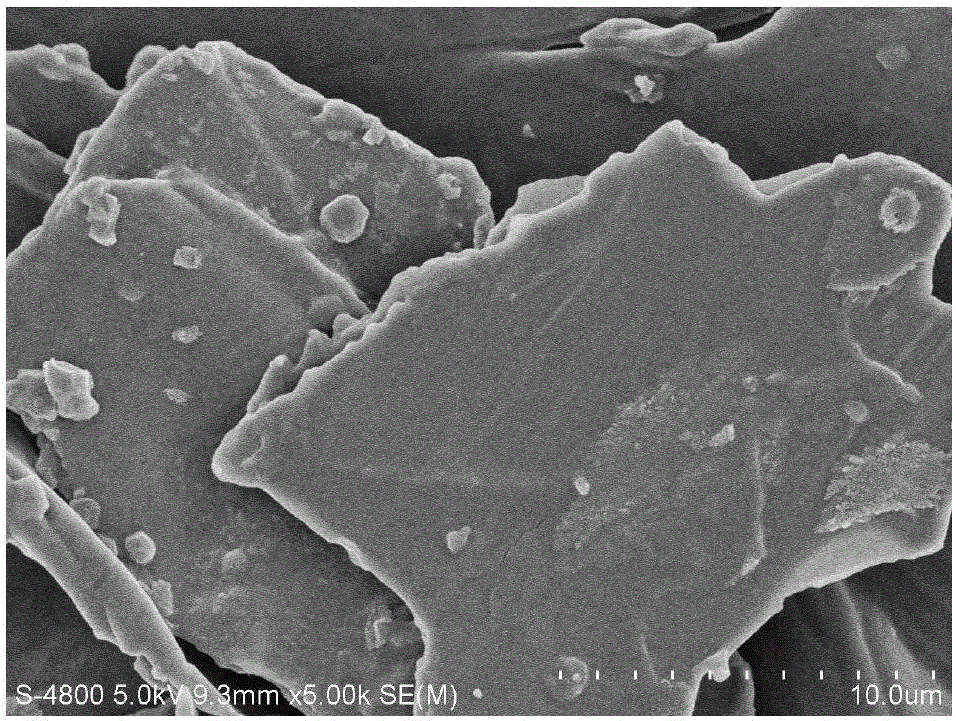

The invention discloses a novel preparation method of a rubber-clay nanocomposite. The preparation method comprises the following steps of: adding an organic modifier into inorganic clay to modify the inorganic clay into organic clay; simultaneously adding an organic solvent for pre-expanding to obtain pre-expanded organic clay; and mixing the pre-expanded organic clay with rubber and an accessory ingredient to obtain the rubber-clay nanocomposite, wherein the organic modifier is hexadecyl trimethyl ammonium bromide, hexadecyl trimethyl ammonium chloride or octadecyl trimethyl ammonium bromide; the organic solvent is acroleic acid, castor oil, Vaseline or n-butyl alcohol; and 5 parts by mass of pre-expanded organic clay is added into 100 parts by mass of rubber. Due to the adoption of themethod, stepwise treatment of organic modification and pre-expanding of clay is avoided, and the production process is simplified; and meanwhile, the microcosmic phase state structure and mechanical property of the prepared nanocomposite is remarkably superior to corresponding structure and performance of a composite material prepared from pre-expanded organic clay by adopting a mechanical blending method. The method is easy for industrial production, and has a wider application prospect.

Owner:TAIYUAN INST OF TECH

Coating composition of nano cellulose, its uses and a method for its manufacture

InactiveCN104781081ADuplicating/marking methodsCellulose coatingsActive agentOctadecyltrimethylammonium bromide

The invention relates to an aqueous coating composition of nano cellulose (e.g. microfibrillated cellulose), characterized in that has a dry matter concentration of 2%-12% of nano celluloseand comprises at least one cationic surfactant, which may be chosen among Hexadecyltrimethyl-ammonium bromide,Octadecyltrimethyl- ammonium bromide,Hexadecylpyridinium chloride andTetradecyltrimethyl- ammonium bromide, Dodecylpyridinium chloride. The invention also pertains to use of the composition as a coating layer and as an oxygen barrier layer. Further it relates to substrates, e.g. board, cardboard or paper coated with the composition. Moreover, the invention pertains to a process for preparing the coating composition.

Owner:PAPER & FIBER RES INST

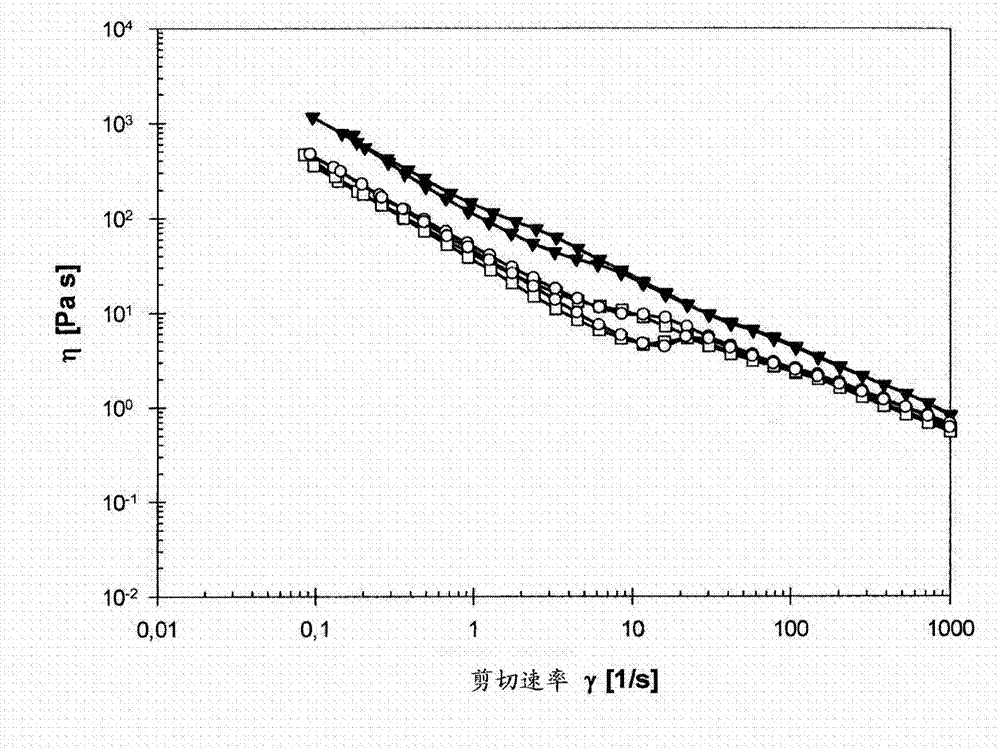

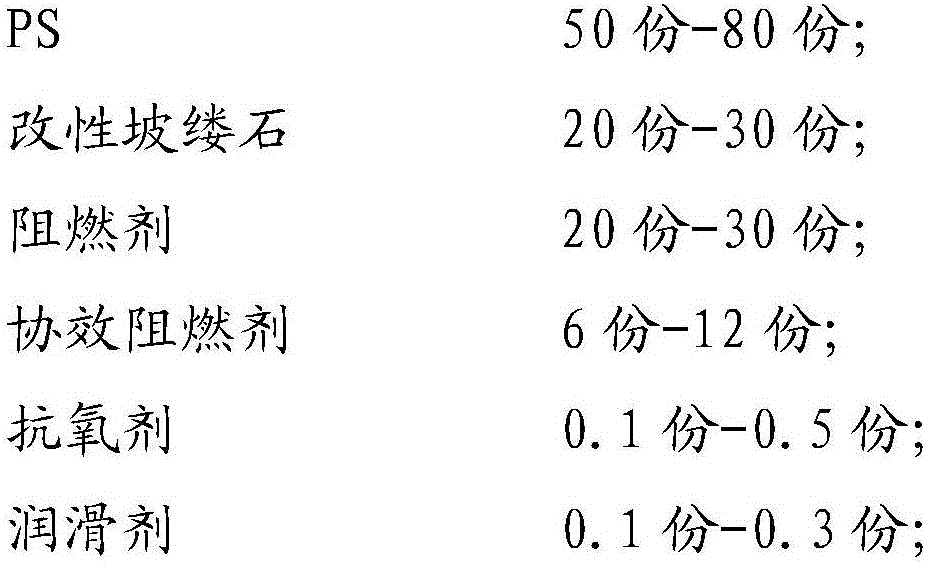

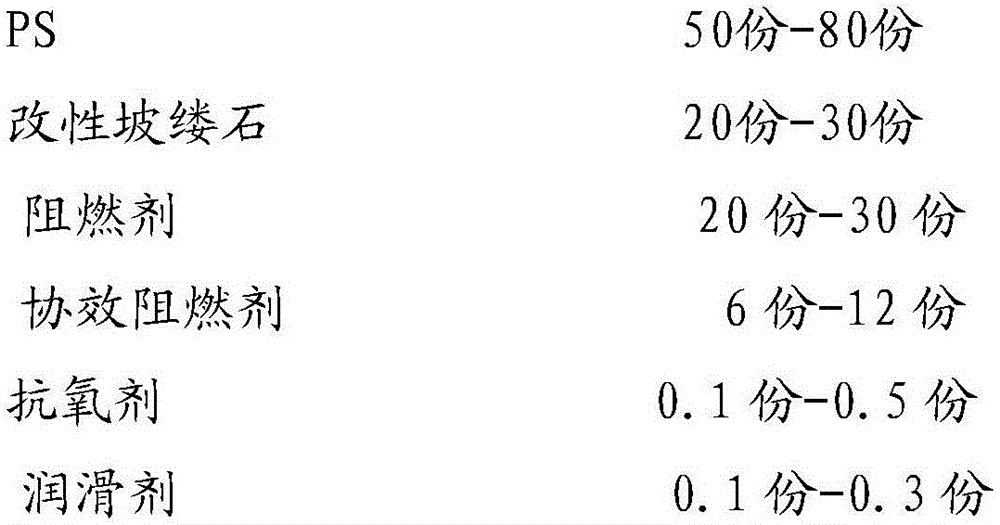

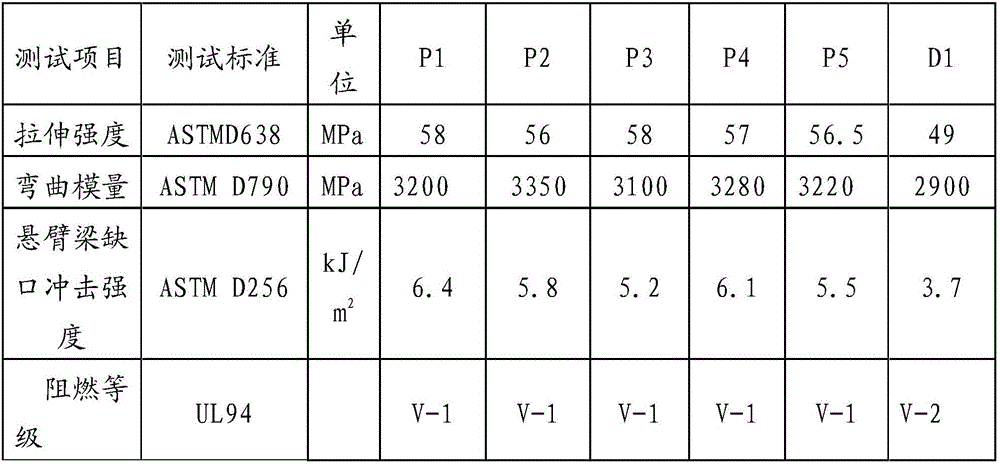

Flame retardant PS composite and method of processing flame retardant PS composite

ActiveCN106479071AGood dispersionImprove physical performanceOctadecyltrimethylammonium bromidePalygorskite

The invention discloses a flame retardant PS composite and a method of processing the flame retardant PS composite. The flame retardant PS composite is made by following weight compositions: PS accounts for 50 to 80 portions; modified palygorskite accounts for 20 to 30 portions; fire retardant accounts for 20 to 30 portions; synegistic flame retardant accounts for 6 to 12 portions; antioxygen accounts for 0.1 to 0.5 portions and lubricant accounts for 0.1 to 0.3 portions. Natural palygorskite is smaller than superficial area. The method of processing the flame retardant PS composite improves the natural palygorskite by HCL, by replacing Mg+ with H+ and by changing SI-O-Mg-O-Si into twoSI-O-Mg-O-Si bonds. Thus, inner passages are connected with each other and the superficial area is enlarged. After being improved, palygorskite can scatter much better in matrix of the PS. At the same time, octadecyl trimethyl ammonium bromide can react with hydroxyl on the palygoskite. Organics can be grafted to surface of the palygoskite. Compatible problem between the palygoskiteand the PS can be improved, which also indirectly improves physical properties of the PS composite.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Clay/rubber nano composite material prepared from compound modified clay

The invention discloses a clay / rubber nano composite material prepared from compound modified clay. A preparation method comprises the following steps: adding a cationic modifying agent into inorganic clay, adding an anionic modifying agent after a period of time to prepare compound modified organic clay, and then mixing the compound modified organic clay with rubber and a compounding agent to obtain a rubber and clay nano composite material, wherein the cationic modifying agent is dodecyltrimethylammonium bromide, octadecy trimethyl ammonium bromide or cetyl trimethyl ammonium bromide; the anionic modifying agent is sodium dodecyl sulfonate or sodium dodecyl benzene sulfonate; and 10 parts by mass of organic clay is added into 100 parts by mass of the rubber. Results show that compared with a nano composite material which is prepared from the clay modified by a single cationic modifying agent, the clay / rubber nano composite material prepared from the compound modified clay, disclosed by the invention, has a better micro phase structure and comprehensive mechanical performance.

Owner:TAIYUAN INST OF TECH

Eichhornia crassipes adsorbing material and preparation method thereof

ActiveCN102631889AIncrease polarityOther chemical processesSorbentOctadecyltrimethylammonium bromide

The invention discloses an eichhornia crassipes adsorbing material and a preparation method thereof. The preparation method comprises the following steps: firstly placing the fresh root-removal eichhornia crassipes into water containing sodium thiosulfate for soaking; continuously adding methyl alcohol and acetic acid in the above solution; preserving for 15-30 days; baking the eichhornia crassipes when the eichhornia crassipes is approximate to paste, placing the eichhornia crassipes into a chromatographic column; washing the eichhornia crassipes by acetic acid, fumaric acid and oxoglutarate, placing into an octadecyl trimethyl ammonium bromide solution for soaking; carbonizing under the protection of nitrogen and at the condition of high temperature; cooling to a room temperature; and finally grinding to obtain the adsorbing material. The adsorbent surface property is improved through a microbial action, so that the adsorbing material is rich in polyhydroxy and carboxyl compound; and the preparation method is novel and independent.

Owner:奚金明

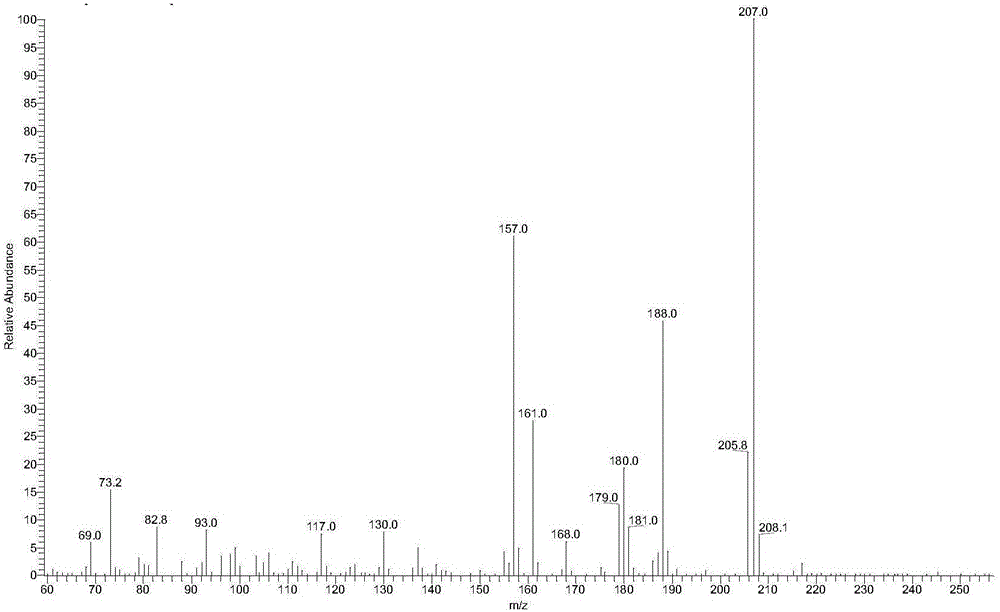

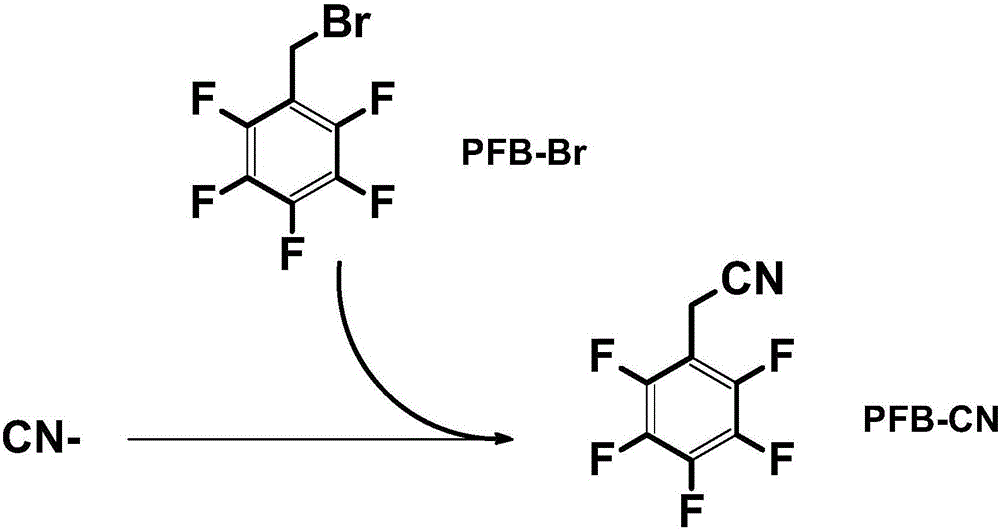

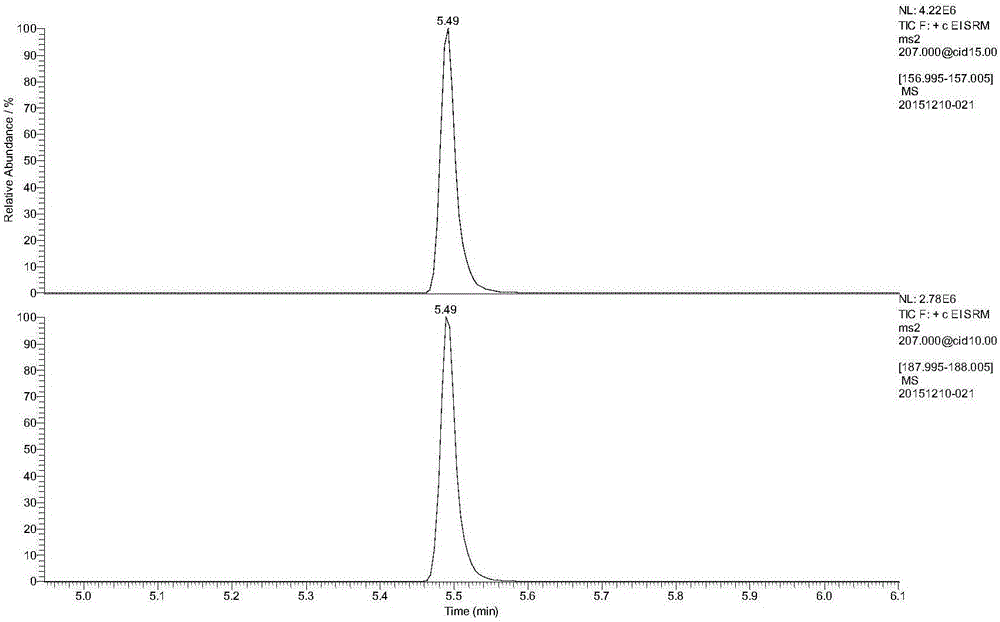

Method for detecting content of cyanide in milk and milk powder

ActiveCN105699574AAvoid interferenceDetermination is accurate and reliableComponent separationGas phaseOctadecyltrimethylammonium bromide

The invention relates to a gas chromatography-serial four-rod mass spectrometric detection method for detecting the content of cyanide in milk and milk powder. A sample is placed under an alkaline condition; octadecyl trimethyl ammonium bromide is taken as a phase transfer catalyst; Pentafluorobenzyl Bromide (PFB-Br) is taken as a derivation reagent; the cyanide ion (CN-) is derived into a volatile derivative product Pentafluorobenzyl Bromide (PFB-Br); and gas chromatography-serial four-rod mass spectrometric (GC-MS / MS) detection is adopted and a standard curve method is adopted for quantifying, thereby acquiring the content of cyanide in the sample. The method provided by the invention is adopted for detecting the content of cyanide in milk and milk powder and has the advantages of simple and convenient operation and high sensitivity.

Owner:INSPECTION & QUARANTINE TECH CENT OF QINHUANGDAO ENTRY EXIT INSPECTION & QUARANTINE BUREAU

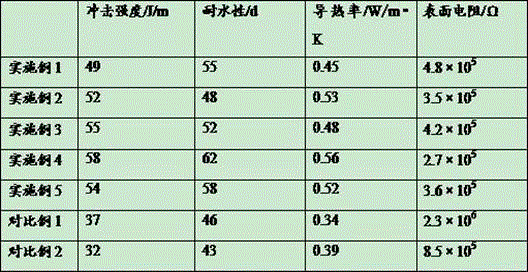

Graphene-based polyurethane composite preparation method

InactiveCN105885008AHigh impact strengthLow water resistanceOctadecyltrimethylammonium bromideDissolution

The invention discloses a graphene-based polyurethane composite preparation method. The method includes: dispersing graphene oxide, regulating pH, adding polyvinyl alcohol, molybdenum disulfide, vinyltributoxysilane, octadecyl trimethyl ammonium bromide and N-methyl-2-pyrrolidone, well stirring, adding isocyanate and vitamin C, and performing heating reaction to obtain modified graphene; adding diphenyl methane diisocyanate, naphthalene-1,5-diisocyanate, polycaprolactone polyalcohol, polypropylene oxide polyalcohol and polyoxalic acid-1,4-butanediol ester into dichloromethane and n-butyl acetate, heating for dissolution, adding 3,3'-dichloro-4,4'-diaminodiphenyl methane, 4-acetaminosalicylic acid, tetraglycidyl diaminodiphenylmethane and glycerin, well stirring, adding modified graphene and octyltin mercaptide, and reacting to obtain products; putting the products on a flat plate, drying, and performing film stripping to obtain a graphene-based polyurethane composite. The graphene-based polyurethane composite prepared according to the method has excellent comprehensive performances and promising application prospect.

Owner:SUZHOU FAST INFORMATION TECH CO LTD

PP (polypropylene) nano plastic and preparation method thereof

InactiveCN105602117AHigh strengthExcellent friction and wear resistanceOctadecyltrimethylammonium bromideMelt flow index

The invention discloses a PP (polypropylene) nano plastic and a preparation method thereof. The PP nano plastic is prepared from nano organic montmorillonite, octadecyltrimethyl ammonium bromide, dimethyl polysiloxane PP grafted maleic anhydride, nano silicon dioxide, nano calcium carbonate, maleic anhydride grafted polyethylene, nano mullite, a silane coupling agent KH-570, nano aluminum oxide and nano calcium oxide. The product has high strength, the tensile strength is 45-65 MPa, and the Rockwell hardness is 120-140. The impact strength is 80-100 KJ / m<2>, and the Vicat softening point is 165-185 DEG C. The shrinkage is 0.3-0.7%, the bending strength is 55-75 MPa, and the bending modulus is 2500-4500 MPa. The melt flow index is 11.3-11.7 g / 10 minutes, and the elongation at break is 45-85%. The PP nano plastic has the advantages of excellent frictional wear and low cost, is simple to operate, and can be widely produced and continuously substituted for the existing materials.

Owner:张哲夫

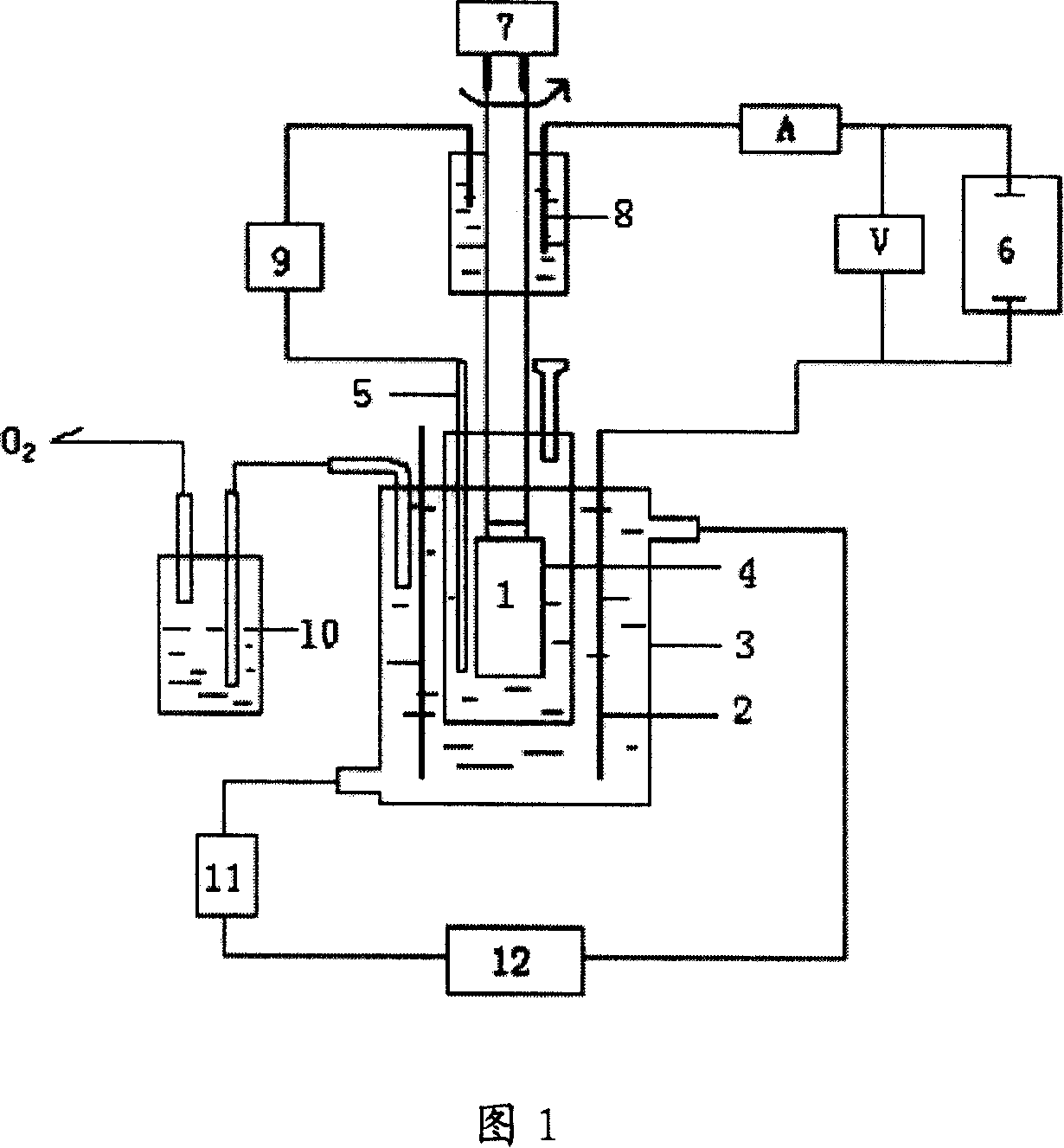

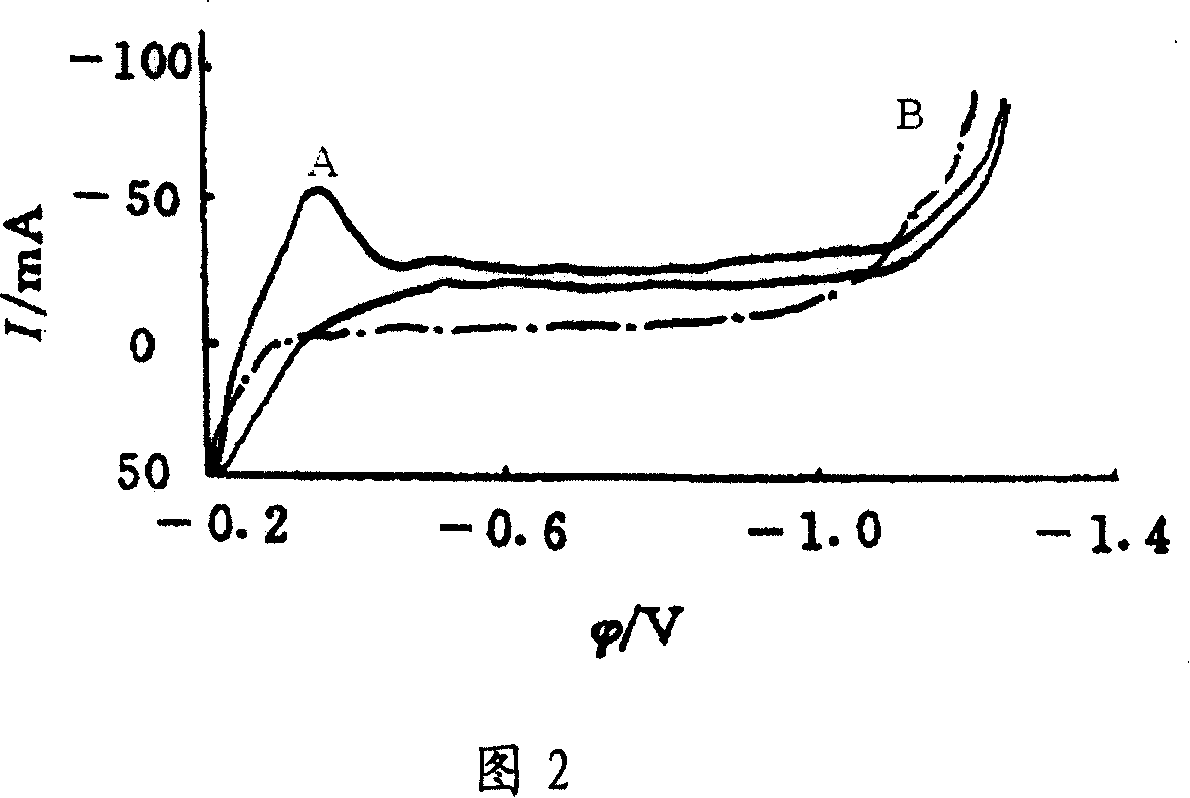

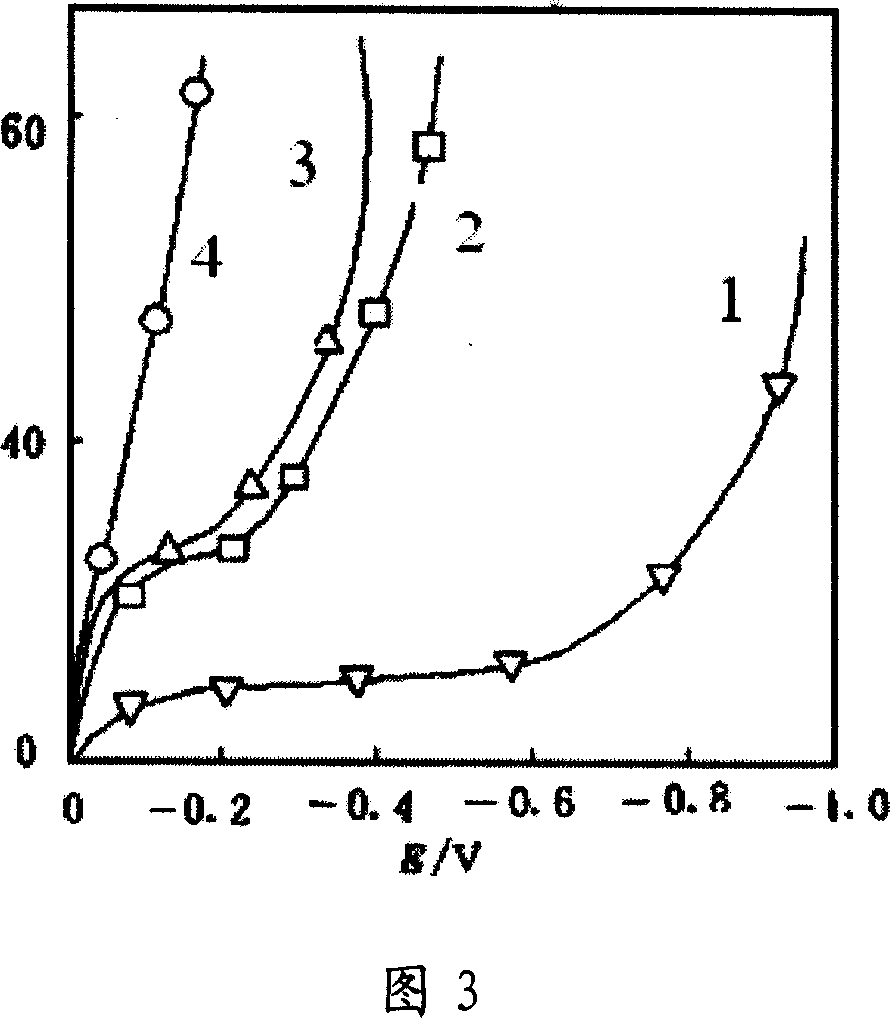

Electrolytic synthesis method for 1,5-diamino-4,8-dihydroxyanthraquinone by one-step method

InactiveCN101054681AShort process routeHigh selectivityElectrolysis componentsElectrolytic organic productionElectrolysisSynthesis methods

The present invention relates to a one-step method for electrolytic synthesis of 1,5-diamino-4,8-dihydroxyanthraquinone. Principally, according to the method, by adopting a cathode rotation cellular-type electrolytic tank, adopting sulfuric acid of 7.5-14.2 mol / L as electrolysing solution, adopting 1,5-dinitroanthraquinone as raw material, adopting a phase transfer catalyst, controlling the temperature at 100-160 DEG C, controlling the cathode electric potential of -0.1--0.4 V, controlling the electric current density at 200-2000A, an electroanalysis is performed to prepare said 1,5-diamino-4,8-dihydroxyanthraquinone final product, with one one step. Said phase transfer catalyst is SnCl2, BiCl3, cetyl trimethyl ammonium bromide or octadecyl trimethyl ammonium bromide. Said electrolytic synthesis method in accordance with the present invention is characterized by its short process route, high selectivity, low cost of manufacture, few environment pollution, high total outcome yield, and the like. Especially, the method is capable of one-step preparing 1,5-diamino-4,8-dihydroxyanthraquinone product. At the same time, said method can be extensively used for electrolytic synthesis of other aromatics aminophenol compounds.

Owner:ZHEJIANG UNIV OF TECH

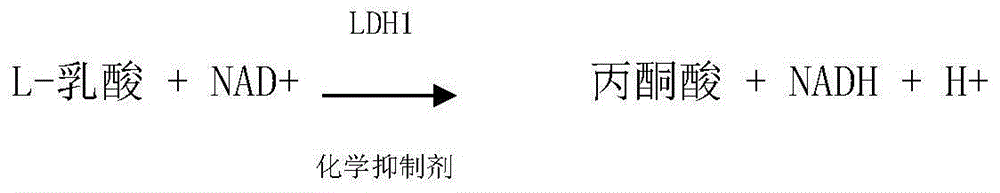

Lactic dehydrogenase isozyme 1 detection reagent and method

ActiveCN104931448AGood emulsifying effectImprove accuracyColor/spectral properties measurementsLithiumIsozyme

The invention relates to a detection reagent for detecting lactic dehydrogenase isozyme 1 through a chemical inhibition method. The detection reagent comprises a reagent R1 and a reagent R2. The detection reagent is characterized in that the reagent R1 comprises a biological buffer solution in which a solute in the reagent R1 ranges from 50 mmol / L to 150 mmol / L in concentration, 1.0 mmol / L to 1.5 mmol / L of L-lithium lactate, 1.5 mmol / L to 2.5 mmol / L of sodium perchlorate, 1ml / L to 5ml / L of hydroxy ethidene diphosphonic acid, 0.1 g / L to 1g / L of octadecyl trimethyl ammonium bromide, 0.1 ml / L to 1 ml / L of polyoxyethylene alkyl ether, and 0.5 ml / L to 5 ml / L of preservative. The reagent R2 comprises a buffer solution in which a solute in the reagent R2 ranges from 50 mmol / L to 150 mmol / L in concentration, 8-12 mmol / L NAD+ and 0.5-5 ml / L of preservative. The lactic dehydrogenase isozyme 1 detection reagent has the advantages of being high in accuracy and cheap in price.

Owner:山东中安生物安全检测有限公司

Water-treating agent for desizing sewage

InactiveCN1390792AImprove adsorption capacityGood removal effectSedimentation separationWater/sewage treatment by flocculation/precipitationAcetic acidAluminium chlorohydrate

A water treating agent for the desizing sewage containing PVA is prepared from aluminium polychloride (20-40 Wt portions), SiO2 (15-25), sodium silicate (20-30), Al2O3 (5-10), bitter salt (0.5-2), boric acid (0.5-1), ammonium octadecyltrimethyl bromide (0.1-0.3) and deacetic chitin (0.1-0.3). Its advantage is high effect on removing PVA.

Owner:翁林兴

Preparation method for cement based composite material taking steel slag as admixture

InactiveCN106977150AImprove gelling activityImprove wear resistanceSlagOctadecyltrimethylammonium bromide

The invention discloses a preparation method for a cement based composite material taking steel slag as an admixture. The method comprises the following steps: firstly, preparing a mixed preparation, mixing the mixed preparation with the steel slag and ball-milling, thereby acquiring pretreated steel slag micro-powder; mixing imvite with octadecy trimethyl ammonium bromide and cyclohexane and then adding carboxylated carbon nano-tube, thereby acquiring a carbon nano-tube intercalated imvite material; mixing cement, pretreated steel slag micro-powder, carbon nano-tube intercalated imvite material, coal ash, wollastonite powder, gypsum and natural river sand, uniformly stirring, adding a mixture of water reducer, de-foaming agent, expanding agent, dispersing agent and deionized water, uniformly mixing and then acquiring cement based mixed slurry; and adding the cement based mixed slurry into a mold, compacting and forming, de-molding and maintaining, thereby acquiring the cement based composite material. According to the invention, the steel slag is taken as the raw material, the cost is low, the gelling activity of the pretreated steel slag is high, the composite material strength is high and the mechanical property is excellent.

Owner:佛山慧创正元新材料科技有限公司

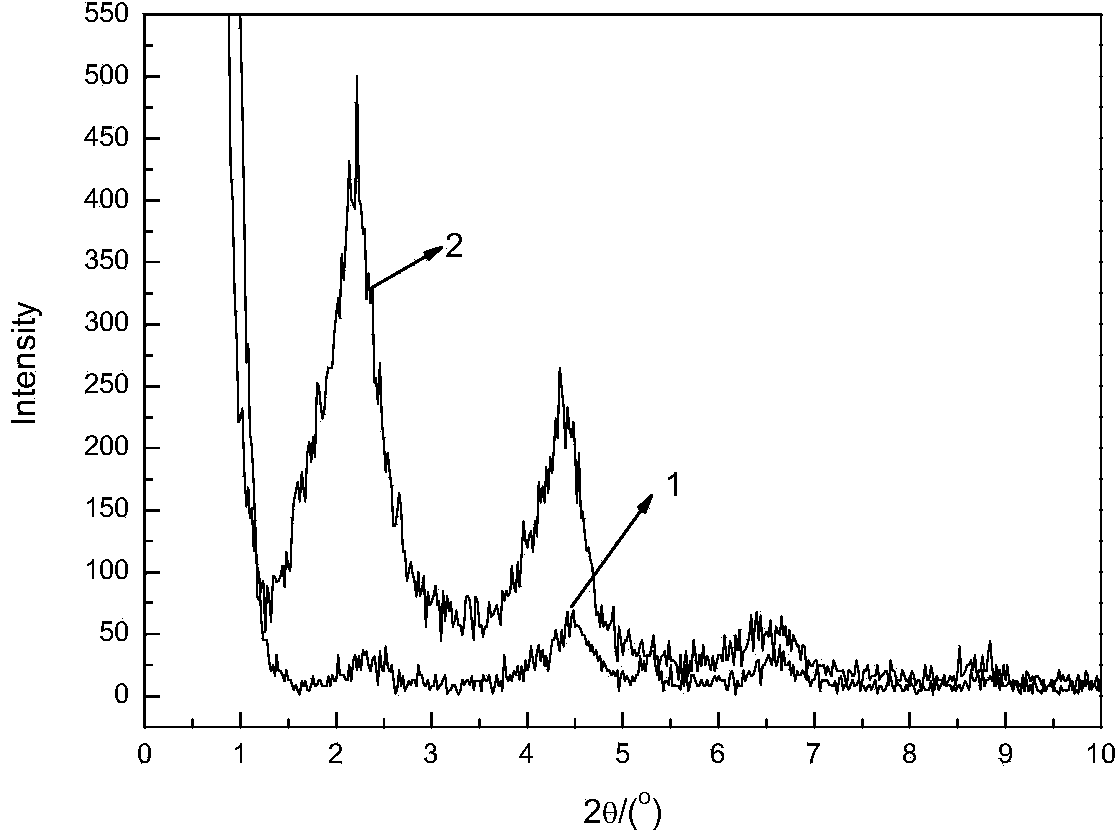

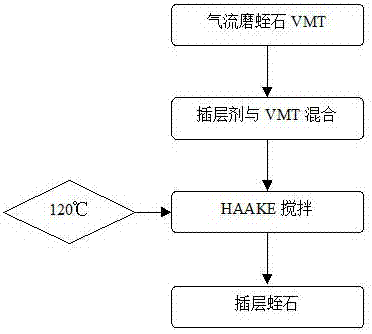

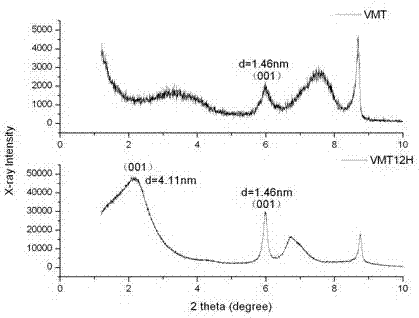

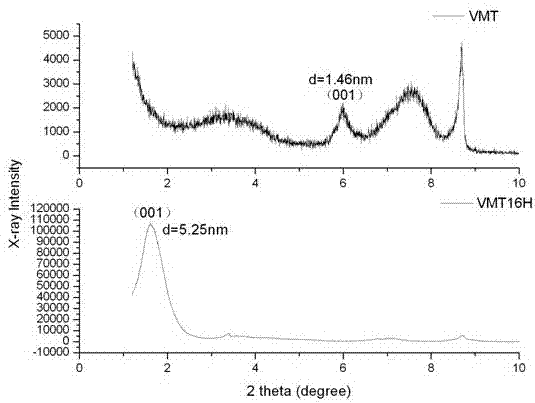

Method for rapidly preparing intercalation-type vermiculite by dry method

InactiveCN107021502AImprove reaction efficiencyFast intercalation reactionSilicon compoundsIntercalation reactionClay minerals

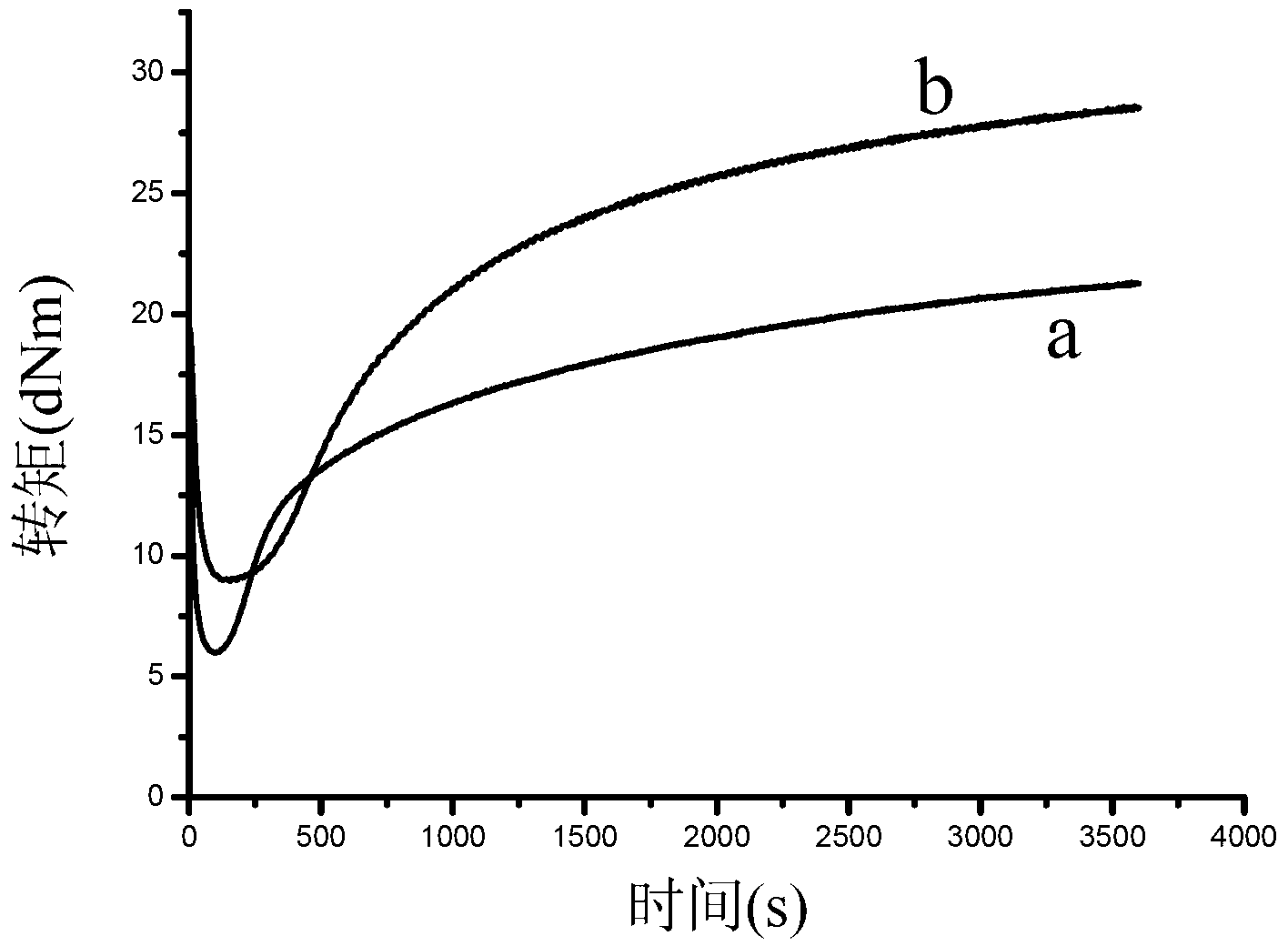

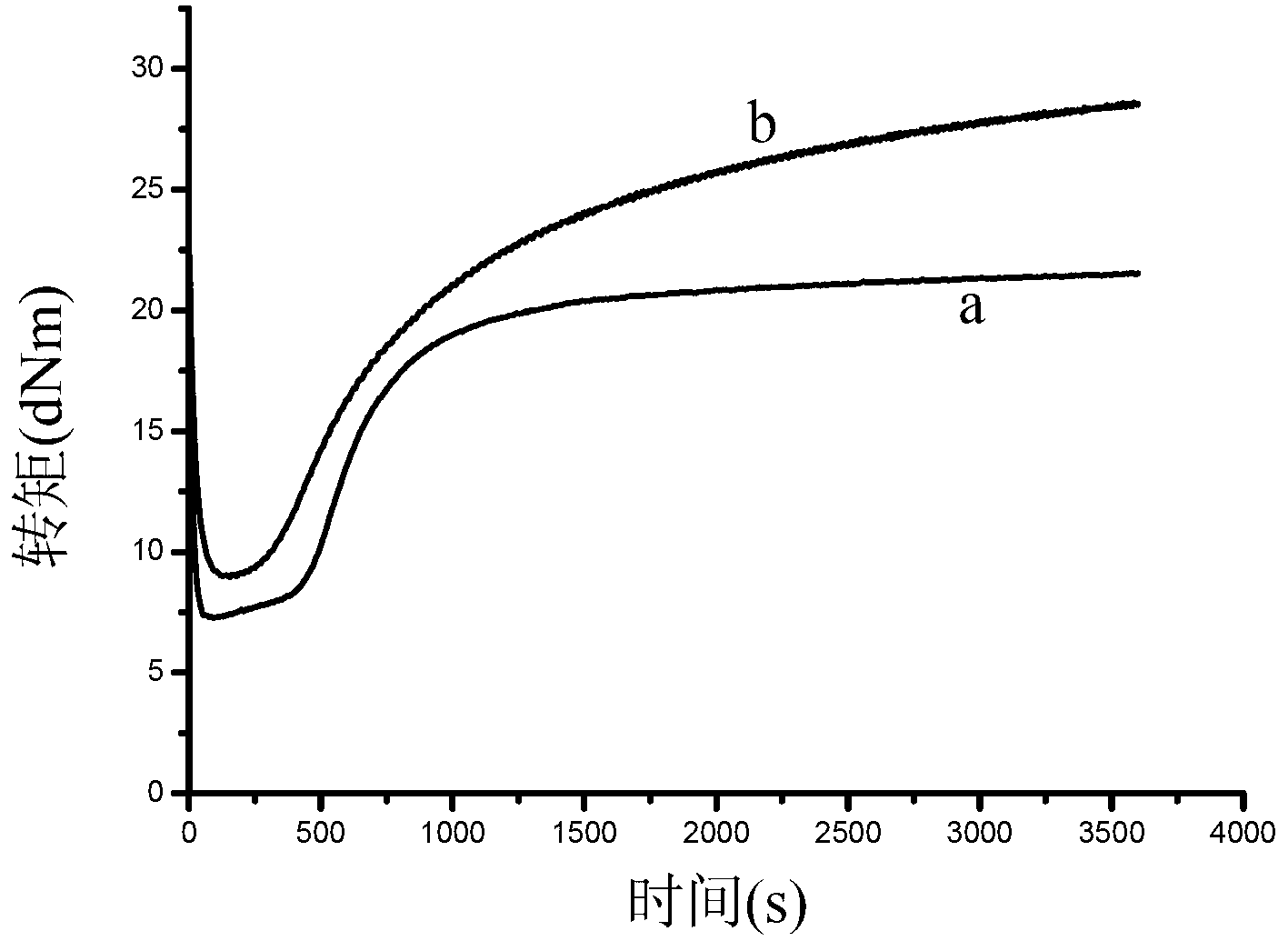

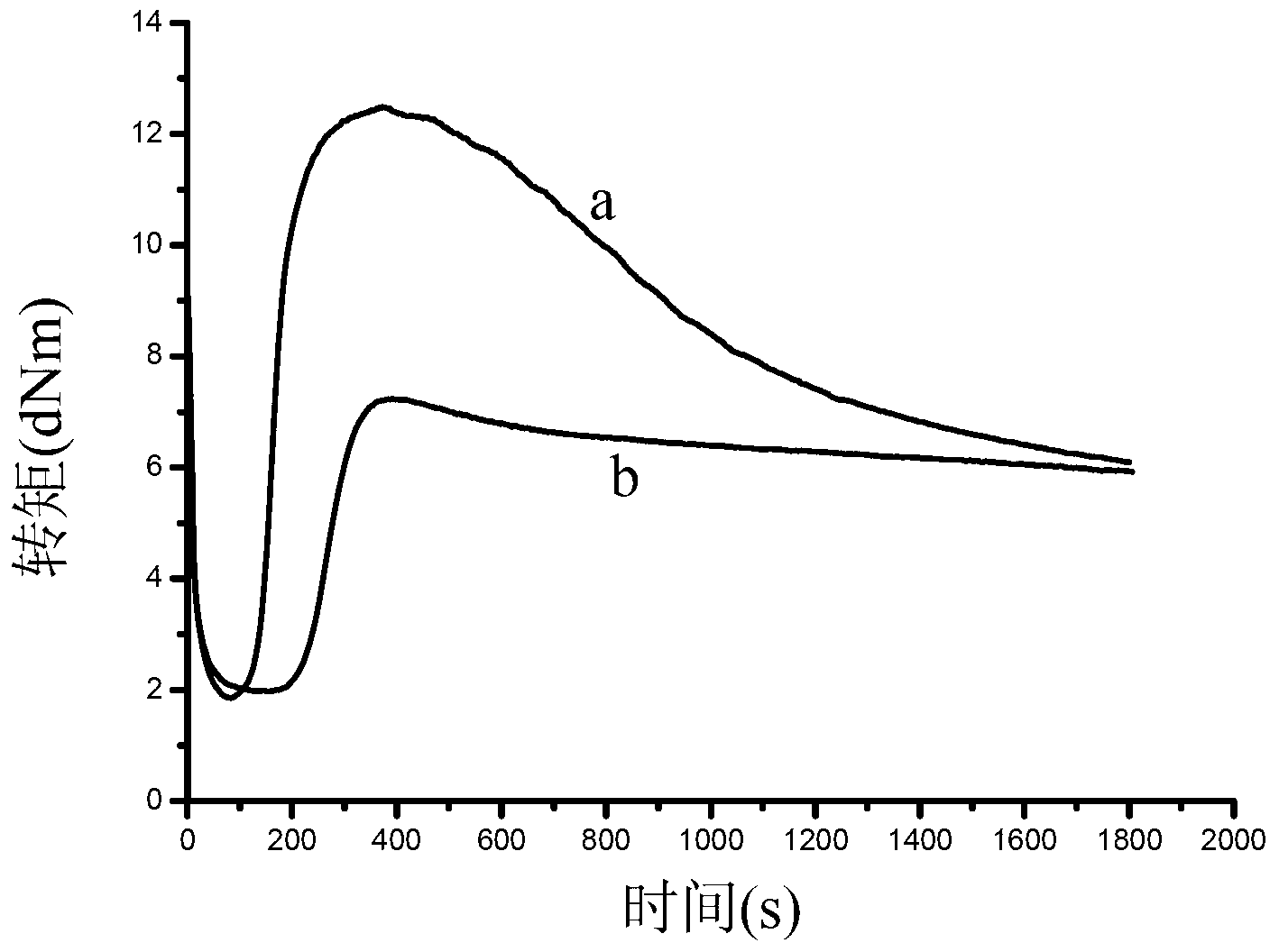

The invention relates to a preparation method for organic intercalation modification of vermiculite. Disclosed is a method for quickly preparing intercalated vermiculite by dry method, which is characterized in that raw material of vermiculite is used as raw material, pulverized by jet mill, and then mixed with a certain proportion (2 times of CEC) of intercalation agent (dodecyl Trimethylammonium bromide, hexadecyltrimethylammonium bromide, octadecyltrimethylammonium bromide) were mixed and stirred for a certain period of time (30min) at a certain temperature (120°C) in the HAAKE torque rheometer ), the intercalation type vermiculite can be obtained, and the interlayer spacing of the vermiculite (001) crystal plane is enlarged to 4.03-5.25nm. Different from the traditional heating and stirring method to prepare intercalated clay minerals, the advantages of this method are (1) it can produce fast and efficient intercalation reaction, reduce the time of intercalation reaction and improve the efficiency of intercalation reaction; (2) There is no introduction of a liquid phase, and the final product does not need to be dried, which greatly simplifies the intercalation process.

Owner:无锡永高新材料科技有限公司

Tire tread rubber without zinc oxide

ActiveCN103304860AAvoid pollutionImprove performancePolymer scienceOctadecyltrimethylammonium bromide

The invention relates to tire tread rubber without zinc oxide. The zinc oxide is added in the existing tread rubber. Zinc is released to the environment during the production, using and recovery processes of a tire, and the zinc release causes adverse effects to the health of a human body, in particular to aquatic organisms and pollutes groundwater. In the formula of the tire tread rubber without the zinc oxide, disclosed by the invention, calculated by mass fraction, 2-4 parts of quaternary ammonium salt, as well as carbon black, stearic acid, an accelerator CZ, sulfur and an anti-aging agent 4010NA are simultaneously added into each 100 parts of the rubber. The matrix rubber used by the tire tread rubber takes styrene-butadiene rubber, natural rubber, polybutadiene rubber and blends thereof as main bodies; and the adopted quaternary ammonium salt is hexadecyl trimethyl ammonium bromide, hexadecyl trimethyl ammonium chloride or stearyl trimethyl ammonium bromide and stearyl trimethyl ammonium chloride. According to the tire tread rubber disclosed by the invention, the quaternary ammonium salt is used for replacing the zinc oxide to activate the accelerator, so that ash pollution is reduced and the tire tread rubber is more environment-friendly.

Owner:BEIJING UNIV OF CHEM TECH

Method for removing cobalt in sewage

InactiveCN102964007ASimple processLow running costMultistage water/sewage treatmentOctadecyltrimethylammonium bromideCobalt

The invention discloses a method for removing cobalt in sewage, belonging to the field of sewage treatment in environmental protection. The method comprises the following steps: adding polyaluminum chloride, ion dispersant and surfactant into cobalt-containing sewage, flocculating, stirring, and aerating to achieve the purpose of removing cobalt, wherein the ion dispersant is one of sodium carboxymethyl cellulose and ethylene bis stearamide wax; and the surfactant is one of sodium dodecyl benzene sulfonate, sodium dodecyl sulfate, octadecyl trimethyl ammonium chloride and octadecyl trimethyl ammonium bromide. The method disclosed by the invention has the characteristics of wide raw material sources, low price, relatively low pharmaceutical dosage, low operating cost, no secondary pollution in the treatment process, high cobalt removal efficiency and high cobalt removal rate (up to 99.9% or above) the like.

Owner:CHANGZHOU UNIV

Cable material of heat resistance ageing resistance butadiene styrene rubber

InactiveCN106349528AGood vulcanizationIncrease crosslink densityRubber insulatorsInsulated cablesCalcium silicateRare earth

The invention discloses a cable material of heat resistance ageing resistance butadiene styrene rubber, a comprises, by weight: 50 - 80 parts of butadiene styrene rubber, 5 -15 parts of epoxidized natural rubber, 10 - 20 parts of silicone rubber, 2 - 10 parts of polybutylene terephthalate, 2 - 5 parts of zinc oxide, 1 -3 parts of stearic acid, 1 - 2 parts of sulfur, 0.5 - 2 parts of coumarone resin, 3 - 12 parts of silane coupling agent KH550 modified carbon nanotubes, 2 - 10 parts of octadecyl trimethyl ammonium bromide modified montmorillonite, 1 -5 parts of kaolin, 3 - 15 parts of active calcium silicate, 2 - 4 parts of stabilizer, 1 - 2 parts of promoter, 1 - 2 parts of rare earth compound, 2 - 5 parts of dioctyl phthalate. The cable material of heat resistance ageing resistance butadiene styrene rubber has the advantages of being high in strength, excellent in heat resistant performance and good in ageing resistance performance.

Owner:ANHUI LAND GRP

Preparation method of modified watermelon peel adsorbent

ActiveCN106268677ALarge specific surface areaGood chemical stabilityOther chemical processesWater contaminantsWater bathsSorbent

The invention discloses a preparation method of a modified watermelon peel adsorbent. The preparation method includes the steps that watermelon peel powder is prepared first; the obtained watermelon peel powder is put into a phosphoric acid solution to be soaked for 10-15 h and then cleaned with deionized water till the pH of effluent after cleaning is neutral; deionized water and an alkali solution are added into the cleaned watermelon peel powder; octadecy trimethyl ammonium bromide is added into the alkalized watermelon peel powder, and water bath heating is carried out for 3-5 h at 50-70 DEG C; the product after the water bath heating reaction is cleaned till the pH of effluent after cleaning is neutral, then drying and smashing are carried out, and the modified watermelon peel adsorbent is obtained. The preparation method is simple in process and low in preparation cost, and raw materials are easy to obtain; the obtained adsorption material has the advantages of being large in specific surface area, good in chemical stability, good in adsorption effect and easy to regenerate; compared with an adsorbent of the same kind, the adsorption material obtained through the preparation method is better in adsorption effect, and the adsorption capacity of the adsorption material on orange yellow can reach 225 mg / g.

Owner:HOHAI UNIV

Method for removing cobalt in sewage

InactiveCN103011476ASimple processLow running costWater contaminantsWater aerationOctadecyltrimethylammonium bromideCobalt

The invention discloses a method for removing cobalt in sewage, and belongs to the field of sewage treatment in environmental protection. The purpose of removing the cobalt is achieved by adding polymeric aluminium, an ion dispersant and a surfactant to the sewage containing cobalt, flocculating mixing and aerating, wherein the ion dispersant is one of sodium carboxymethylcellulose, and ethylene bis stearamide wax; and the surfactant is one of sodium dodecyl benzene sulfonate, lauryl sodium sulfate, octadecyl trimethyl ammonium chloride, and trimethylstearylammonium bromide. The method has the characteristics that the method is wide in material source, low in price, small in pharmaceutical dosage, low in operating expense, free of secondary pollution in treatment process, high in cobalt removal rate and the like, and the removal rate can be up to over 99.9%.

Owner:CHANGZHOU UNIV

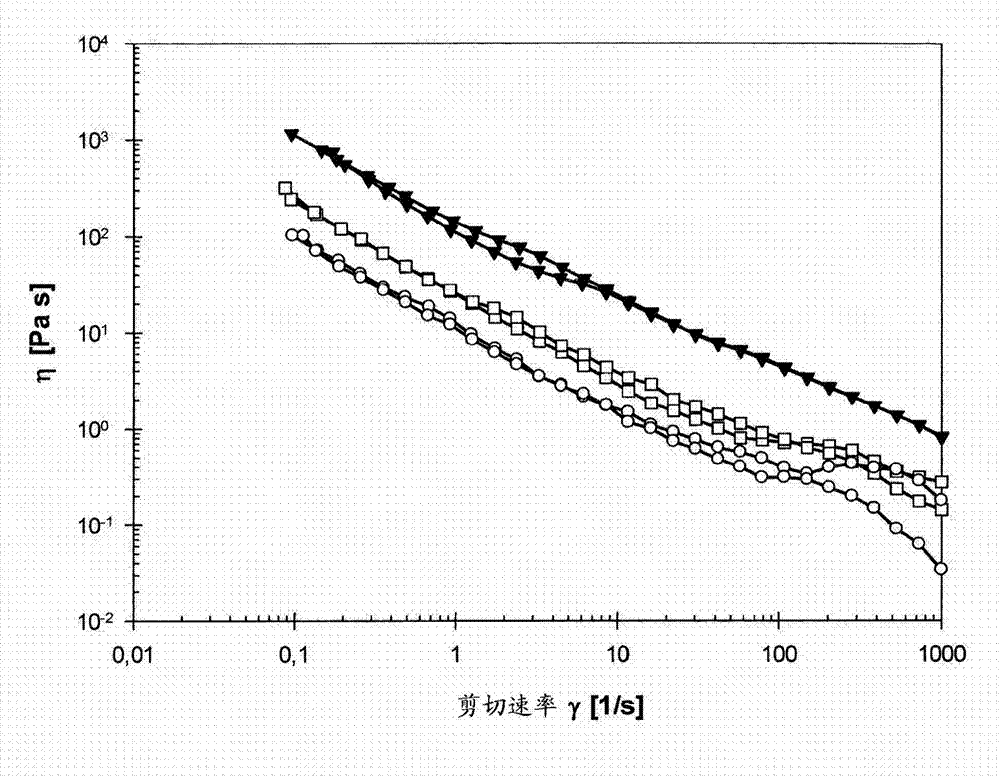

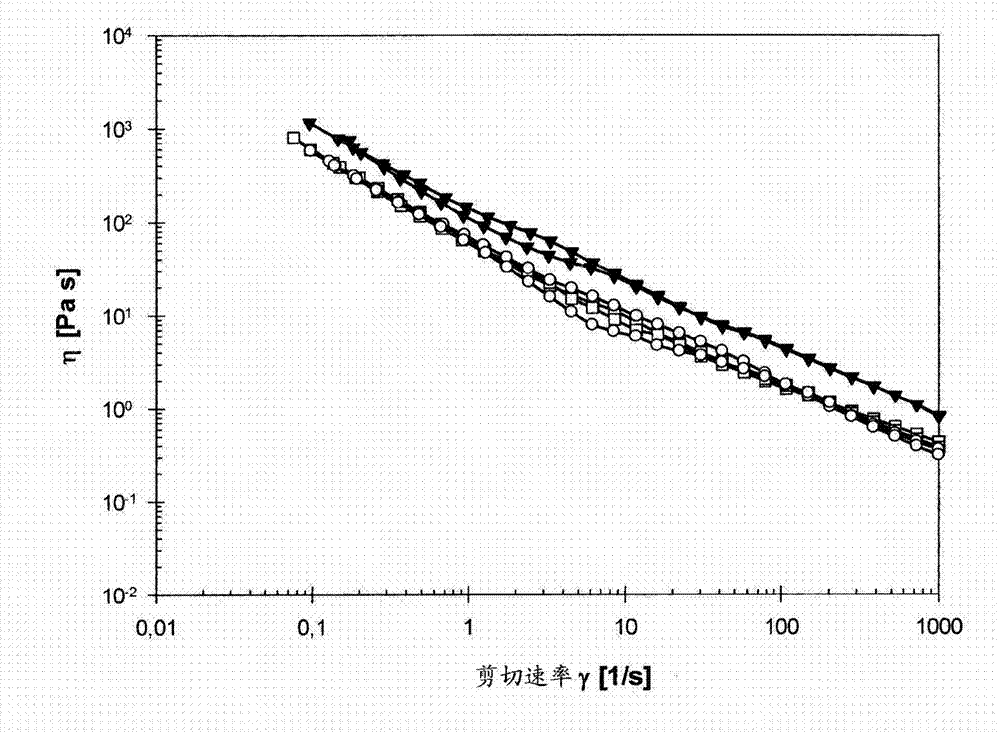

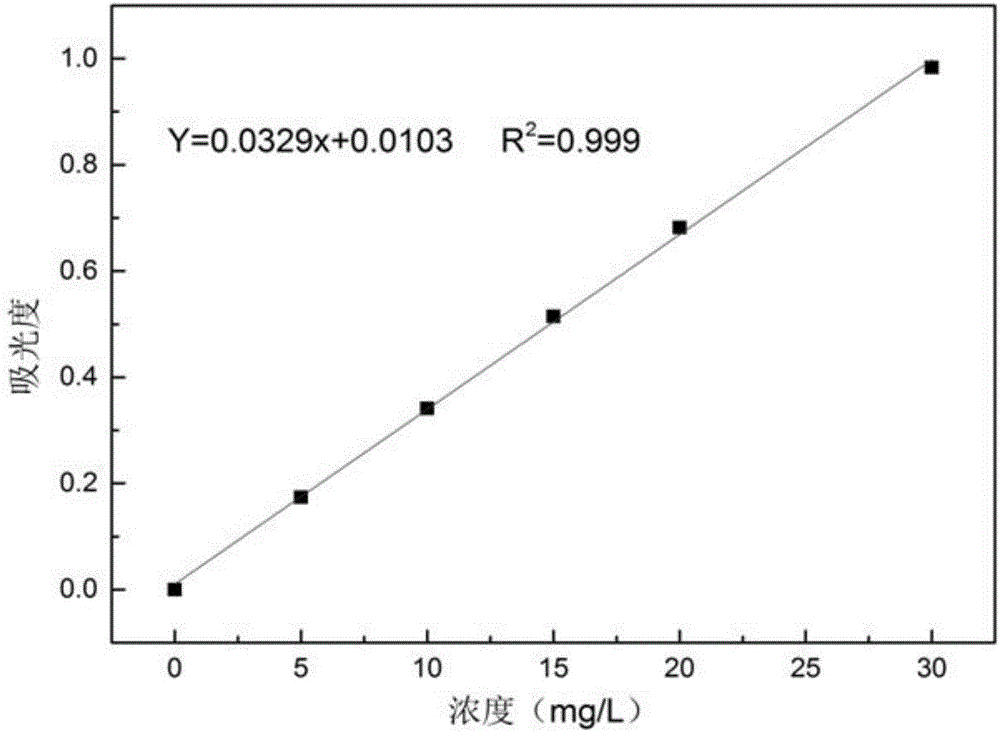

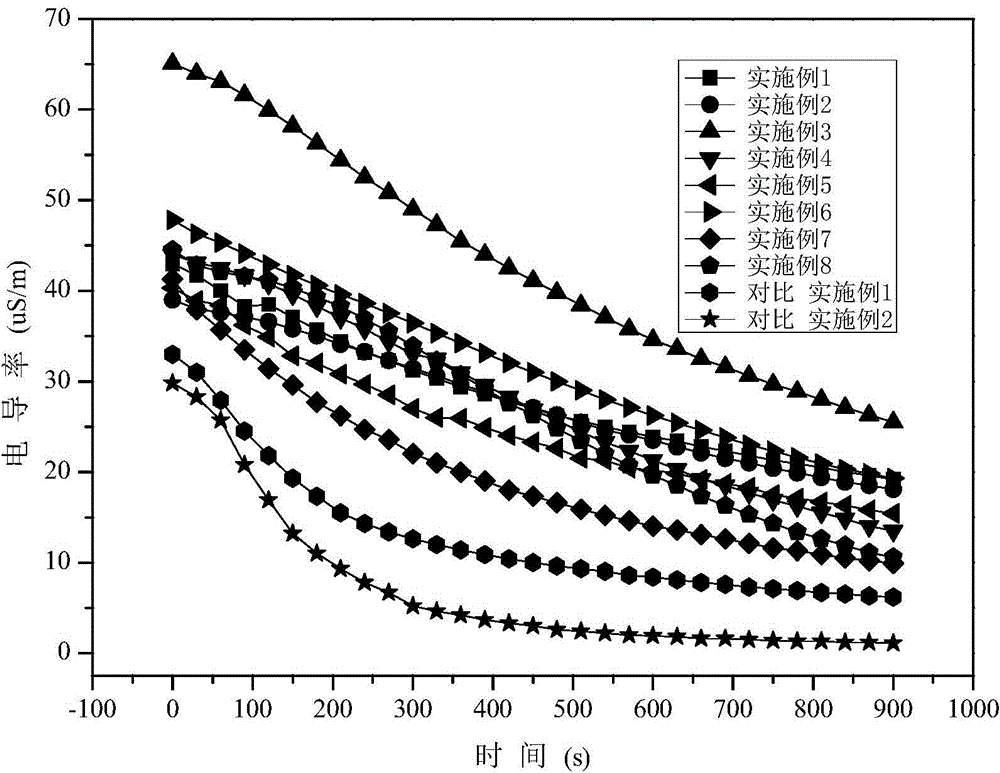

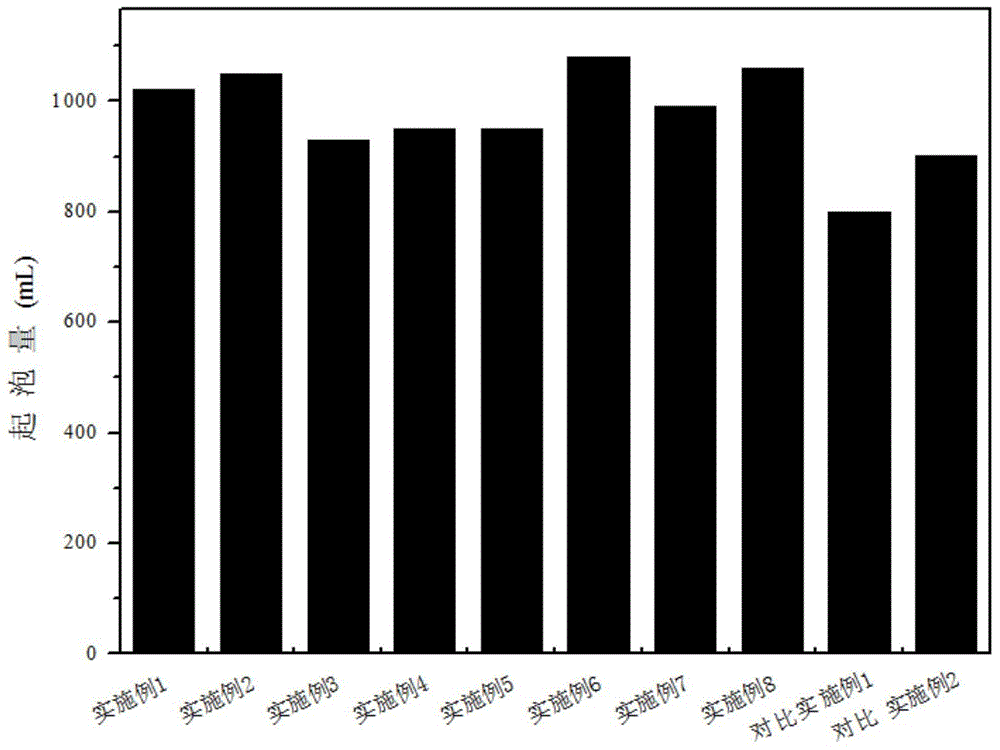

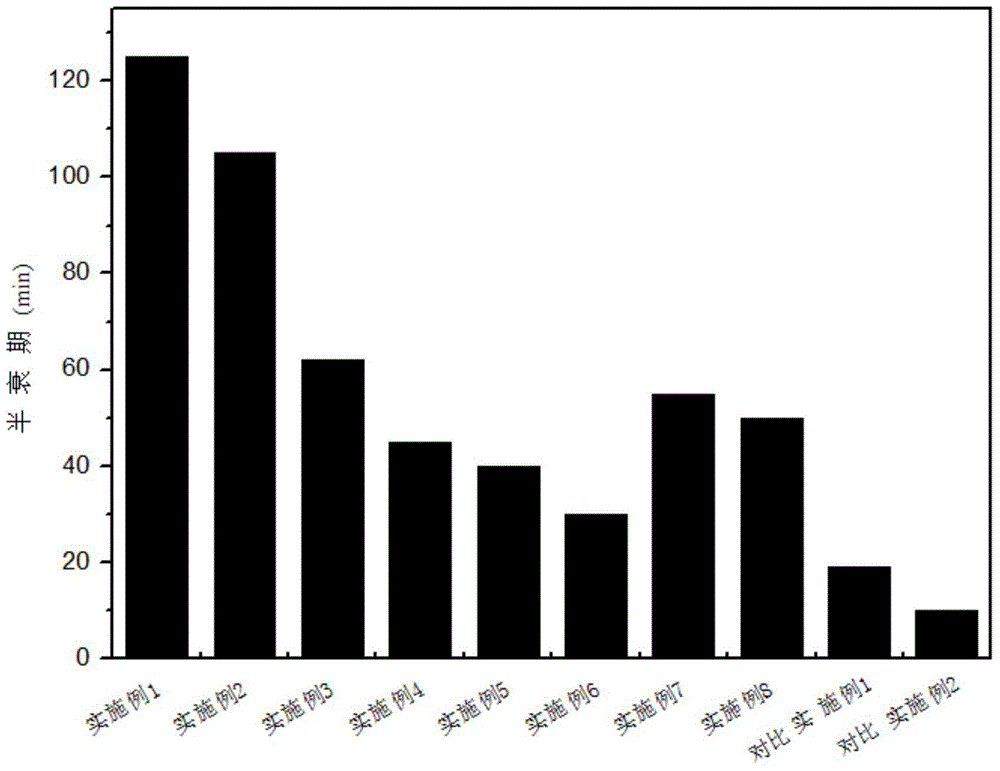

Amino acid anionic-cationic surfactant based composite foaming agent

The invention discloses an amino acid anionic-cationic surfactant based composite foaming agent. The composite foaming agent is prepared by mixing an amino acid anionic surfactant with an amino acid cationic surfactant at a mass ratio of 1:(1-4), wherein the amino acid anionic surfactant is sodium lauroyl glycine, sodium palmitoyl glycine or sodium octadecanoyl glycine, and the amino acid cationic surfactant is dodecyl trimethyl ammonium bromide, hexadecyl trimethyl ammonium bromide or octadecyl trimethyl ammonium bromide. Because the two different types of surfactants act synergistically, the surface tension of the amino acid anionic-cationic surfactant based composite solution can be reduced, the thickness of the foam film can be increased effectively, and further the strength of the foam can be enhanced. The composite foaming agent disclosed by the invention contains a few components, does not contain any additive, can foam quickly in quantity and has good stability.

Owner:SHAANXI NORMAL UNIV

Monstera deliciosa adsorbing material and preparation method thereof

ActiveCN102641723AIncrease polarityOther chemical processesOctadecyltrimethylammonium bromideNitrogen gas

The invention discloses a monstera deliciosa adsorbing material and a preparation method thereof. The preparation steps are as follows: fresh monstera deliciosa without roots is first soaked in water containing sodium thiosulfate, methanol and acetic acid are then constantly added into the solution, and after the monstera deliciosa is kept for 15 to 30 days, the nearly silt-like monstera deliciosa is then dried and loaded into a chromatographic column, washed with acetic acid, fumaric acid and ketoglutaric acid, soaked in trimethylstearylammonium bromide solution, then carbonized under the conditions of nitrogen protection and high temperature, cooled to the room temperature and finally ground. Different from modification by way of soaking, acidification, activation and the like, the invention utilizes the function of microorganisms to change the surface properties of the adsorbent, and attaches polycarboxyl compound and polyhydroxy compound on the surface of the adsorbent, so that the properties of the adsorbent are further enhanced and the adsorbing capability of the adsorbent is better.

Owner:奚金明

Preparation method of antibacterial polyvinyl chloride pipe material

The invention discloses a preparation method of an antibacterial polyvinyl chloride pipe material. The preparation method comprises the following steps: mixing polyvinyl chloride and chloroprene rubber, heating and stirring, so that a first premixture is obtained; heating solid paraffin, adding octadecyl trimethyl ammonium bromide and cotton linters, stirring, carrying out microwave expansion, regulating temperature and stirring, adding a copper chloride aqueous solution, regulating temperature and stirring, cooling, drying, smashing, adding the first premixture, bentonite and calcined kaolin, uniformly stirring, adding an antioxidant, microcrystalline wax and magnesium hydroxide, uniformly stirring, cooling to room temperature, and standing, so that a second premix is obtained; and putting the second premix into an extruding machine, and extruding, so that the antibacterial polyvinyl chloride pipe material is obtained. The preparation method of the antibacterial polyvinyl chloride pipe material is simple in operation, raw materials are available, cost is low, the obtained polyvinyl chloride pipe material has excellent antibacterial property and good mechanical properties, toughness and hardness reach the equilibrium, and the antibacterial polyvinyl chloride pipe material is difficult to break.

Owner:ANHUI LANTONG TECH CO LTD

The producing method of the rubber softener with good compatibility

ActiveCN106279843AHigh tensile strengthGood compatibilityPolymer scienceOctadecyltrimethylammonium bromide

The invention involves the producing method of a kind of rubber softener with good compatibility. it belongs to the producing technology field of rubber assistant. in this invention, it needs to process the fruit powder of Swida wilsoniana with potassium hydroxide and normal butanol into liquid and the liquefied solution is achieved. Then heat the compound matters of octadecyl trimethyl ammonium bromide, tetrabutyl titanate, xylene and other matters and the reacted solution is achieved. After the still standing, it separates in layers. Take the upper layer liquid and react by hydrothermal method. Dry the generated reactions and grind them. Then heat and mix them together with the liquefied solution and linoleic acid palm oil and we can achieve the rubber softener with good compatibility. The rubber softener with good compatibility producing in this way and the rubber raw materials are of good compatibility. The tensile strength of the rubber is also improved and it can reach 19.56 - 20.12 MPa. The raw materials are easy to get and the processing is quite simple. Therefore, the products are quite popular in the market and have good industrialization future.

Owner:鑫泓裕重庆复合材料有限公司

Feed mycotoxin adsorbent, application thereof, and feed

InactiveCN109287935AFood safetyReasonable formulaAccessory food factorsFood ingredientsMycotoxinSodium Bentonite

The invention relates to a feed mycotoxin adsorbent, an application thereof, and a feed, and belongs to the technical field of feeds. Raw materials of the adsorbent comprise 20-25 parts by weight of first modified bentonite, 15-30 parts by weight of second modified bentonite, 5-8 parts by weight of third modified bentonite, 5-8 parts by weight of fourth modified bentonite, 2-5 parts by weight of nanometer zinc oxide and 8-10 parts by weight of pinctada martensii glycoprotein, wherein four kinds of modified bentonite is obtained through modifying refined Liaoning bentonite through di-octadecyldimethyl ammonium chloride, lauramidopropyl betaine, octadecy trimethyl ammonium bromide and Tween-80. The adsorbent is reasonable in formula, low in cost and high in adsorption capacity, can effectively adsorb various mycotoxin except flavacin, and can be used for adsorbing the flavacin, deoxynivalenol and the like; and a feed containing the adsorbent is safe to eat, and increase of breeding benefits is facilitated.

Owner:博智农贸易(深圳)有限公司

Cyanogens-free hemolytic agent for hemocyte analyzer

The invention relates to a cyanogens-free hemolytic agent for hemocyte analyzer. One litre of the cyanogens-free hemolytic agent comprises the following components: 0.8-5.0 g of potassium chloride, 0-60.0 g of dodecyl trimethyl ammonium chloride, 0-14.0 g of octadecyl trimethyl ammonium bromide, 6.0-10.0 ml of isopropanol, a carbonate or hydrochloric acid buffer solution, and the balance of water, wherein the carbonate or hydrochloric acid buffer solution is used for regulating pH to 3.2-5.8; the addition quantities of the dodecyl trimethyl ammonium chloride and the octadecyl trimethyl ammonium bromide are complementary, but the sum of the addition quantities of the dodecyl trimethyl ammonium chloride and the octadecyl trimethyl ammonium bromide is less than or equal to 60 g. The invention can form stable hemoglobin derivatives and meet the requirements of clinical examination because absorption spectrum curves are similar when lambda is equal to 540 nanometers and lambda is equal to 504 nanometers; and in addition, the invention can effectively improve the work environments of operators and reduce the injury of poisons on human body health because reagents do not contain cyanides and trinitrides or have no toxicity.

Owner:南昌百特生物高新技术股份有限公司

Method for removing germanium in sewage

InactiveCN103011371ANothing producedSimple processWater/sewage treatmentSludgeOctadecyltrimethylammonium bromide

The invention discloses a method for removing germanium in sewage and belongs to the field of sewage treatment in environmental protection. The method comprises the following steps of: placing aluminum trioxide into a triangular round-bottom flask; adding aluminum potassium sulfate dodecahydrate, magnesium sulfate and water into the flask; heating and continuously agitating; when the temperature is raised, adding calcium aluminate powder; adding ferric trichloride and octadecy trimethyl ammonium bromide into reactants and agitating and mixing uniformly; adding the substances into wastewater containing the germanium; and agitating, standing, precipitating and discharging effluent into a clean water pool. The method disclosed by the invention is simple in process flow, simple in operation, lower operation cost, no sludge, high germanium removing effect and the like; and no sediment is generated and secondary pollution is not caused, and metal oxides in the effluent and the wastewater can be recycled.

Owner:CHANGZHOU UNIV

Fuel oil emulsifier and preparation method thereof

InactiveCN104629825AExtended storage timeNo separationLiquid carbonaceous fuelsActive agentOctadecyltrimethylammonium bromide

The invention relates to a fuel oil emulsifier and a preparation method thereof, and belongs to the technical field of fuel additives. In the provided fuel oil emulsifier, sodium aliphatic alcohol sulfate, sodium hydroxyethyl sulfonate, and polysodium amino acid are taken as the anionic surfactants; lauryl trimethyl ammonium bromide and octadecyl trimethyl ammonium bromide are taken as the cationic surfactants; n-butanol and isopropanol are taken as the co-surfactants, and isopropyl ketone is taken as the cosolvent. Compared with the conventional anion / non-ion compounded surfactants and cation / non-ion compounded surfactants, the provided fuel oil emulsifier is more efficient, the micro-emulsification effect is better, the system is more stable, the micro-emulsified fuel oil processed by the fuel oil emulsifier can be store for a longer time, the fuel oil will not layer after being stored for six months or more, the phenomenon of oil-water separation will not happen, no precipitation is generated, and the processed fuel oil is convenient for storage and transportation.

Owner:高硕

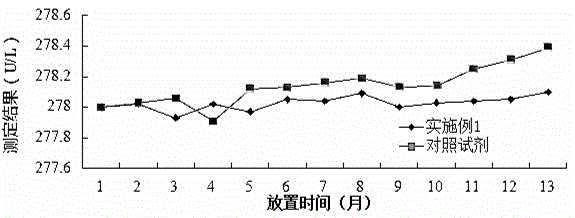

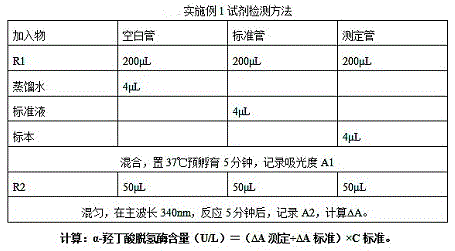

Alpha-hydroxybutyrate dehydrogenase detection reagent with good stability and high accuracy

InactiveCN105651763AImprove stabilityImprove anti-interference abilityMaterial analysis by observing effect on chemical indicatorSucroseEtidronic acid

Owner:BIOBASE BIODUSTRY (SHANDONG) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com