Nanoparticle enhanced low-interfacial-tension foam system and preparation method thereof

A technology of interfacial tension and nanoparticles, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of poor salt resistance and shear resistance of polymers, adverse effects of foam foamability, and reduce foam foaming Volume and other issues, to achieve the effect of long foam stability time, conducive to sustainable mining, and reduce interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

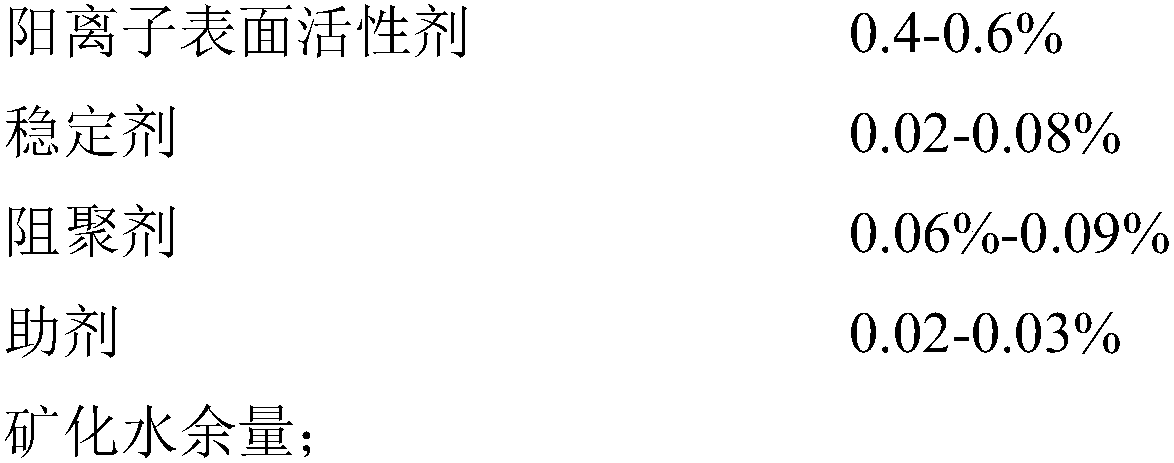

[0057] A nanoparticle-enhanced low interfacial tension foam system consists of the following components by weight percentage:

[0058]

[0059] Described cationic surfactant is made of dodecyl trimethyl ammonium bromide, tetradecyl trimethyl ammonium bromide, hexadecyl trimethyl ammonium bromide, octadecyl trimethyl ammonium bromide Ammonium is mixed according to the mass ratio of 1:2:1:2;

[0060] Described stabilizer is made of modified nano-SiO 2 , modified nano-MgO, modified nano-TiO 2 Mixed according to the mass ratio of 1:1:1;

[0061] Described polymerization inhibitor is sodium citrate;

[0062] Described auxiliary agent is that ethylene glycol and lauryl alcohol are formed by mixing in a mass ratio of 1:1;

[0063] The mineralized water is prepared by mixing 10000g of water, 85g of sodium chloride, 8.5g of anhydrous calcium chloride and 11.6g of anhydrous magnesium sulfate in parts by mass.

[0064] The preparation method of the nanoparticle-enhanced low inter...

Embodiment 2

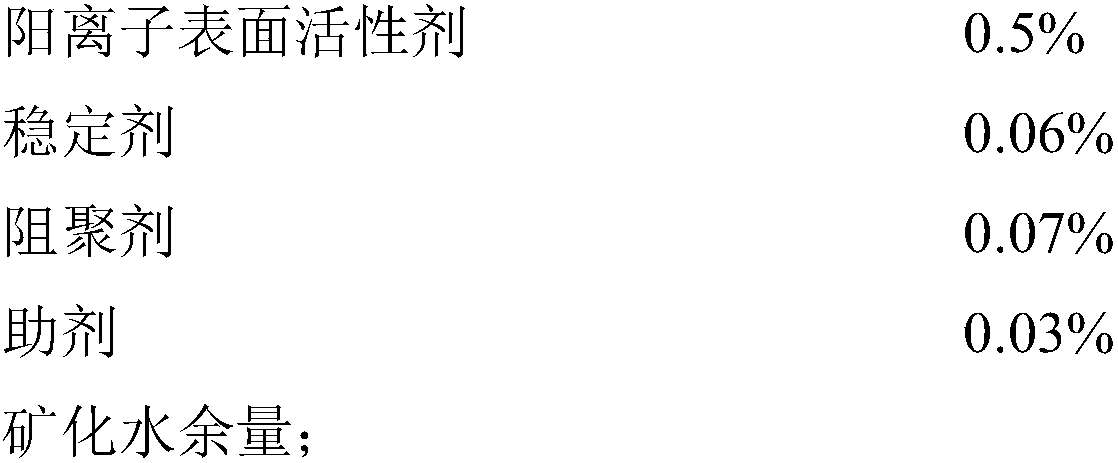

[0070] A nanoparticle-enhanced low interfacial tension foam system consists of the following components by weight percentage:

[0071]

[0072] Described cationic surfactant is made of dodecyl trimethyl ammonium bromide, tetradecyl trimethyl ammonium bromide, hexadecyl trimethyl ammonium bromide, octadecyl trimethyl ammonium bromide Ammonium is mixed according to the mass ratio of 1:1:1:1;

[0073] Described stabilizer is made of modified nano-SiO 2 , modified nano-MgO, modified nano-TiO 2 Mixed according to the mass ratio of 1:1:1;

[0074] Described polymerization inhibitor is sodium citrate;

[0075] Described auxiliary agent is that ethylene glycol and lauryl alcohol are formed by mixing in a mass ratio of 1:1;

[0076] The mineralized water is prepared by mixing 10000g of water, 95g of sodium chloride, 12.5g of anhydrous calcium chloride and 15.6g of anhydrous magnesium sulfate in parts by mass.

[0077] The preparation method of the nanoparticle-enhanced low inte...

Embodiment 3

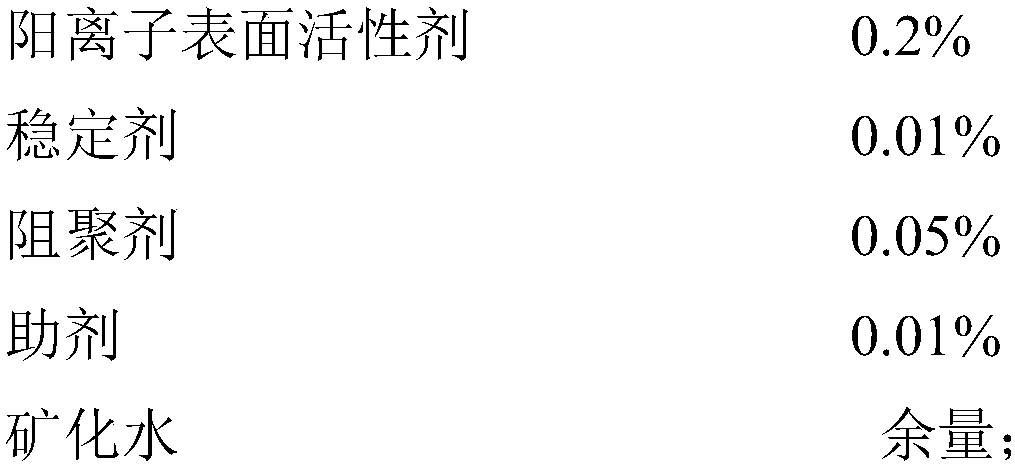

[0083] A nanoparticle-enhanced low interfacial tension foam system consists of the following components by weight percentage:

[0084]

[0085] The cationic surfactant is mixed with dodecyltrimethylammonium bromide, tetradecyltrimethylammonium bromide and octadecyltrimethylammonium bromide in a mass ratio of 1:2:3 made;

[0086] Described stabilizer is made of modified nano-SiO 2 , modified nano-TiO 2 Mixed according to the mass ratio of 1:1;

[0087] Described polymerization inhibitor is sodium citrate;

[0088] Described auxiliary agent is that ethylene glycol and lauryl alcohol are formed by mixing in a mass ratio of 1:1;

[0089] The mineralized water is prepared by mixing 10000g of water, 90g of sodium chloride, 10.5g of anhydrous calcium chloride and 13.6g of anhydrous magnesium sulfate in parts by mass.

[0090] The preparation method of the nanoparticle-enhanced low interfacial tension foam system of the present invention comprises the following steps:

[0091...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum interfacial tension | aaaaa | aaaaa |

| Minimum interfacial tension | aaaaa | aaaaa |

| Minimum interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com