Patents

Literature

37results about How to "Inhibition of disproportionation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

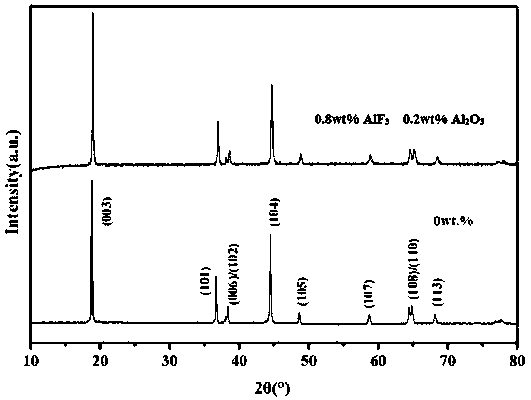

Preparation method of NCM811-type high-nickel ternary positive electrode material

InactiveCN107910534ALow costIncrease energy densityCell electrodesSecondary cellsOxygenLithium-ion battery

The invention discloses a solid-phase preparation method of an NCM811-type high-nickel ternary positive electrode material. The preparation method comprises the process steps of raw material mixing, primary sintering performed in three segments, composite coating agent coating, secondary sintering and processing after sintering. According to relevant performance test, the composite coating methodof doping nanometer Al2O3 and AlF3 or Al2O3 and LiF into a lithium ion battery positive electrode is employed, primary sintering is performed in three segments, sintering and oxygen introduction are performed, the capacity attenuation of the material can be effectively reduced under the condition that favorable reversible capacity of the material is maintained, the cycle lifetime is prolonged, andthe comprehensive performance of the lithium ion battery positive electrode material is improved.

Owner:淮安新能源材料技术研究院

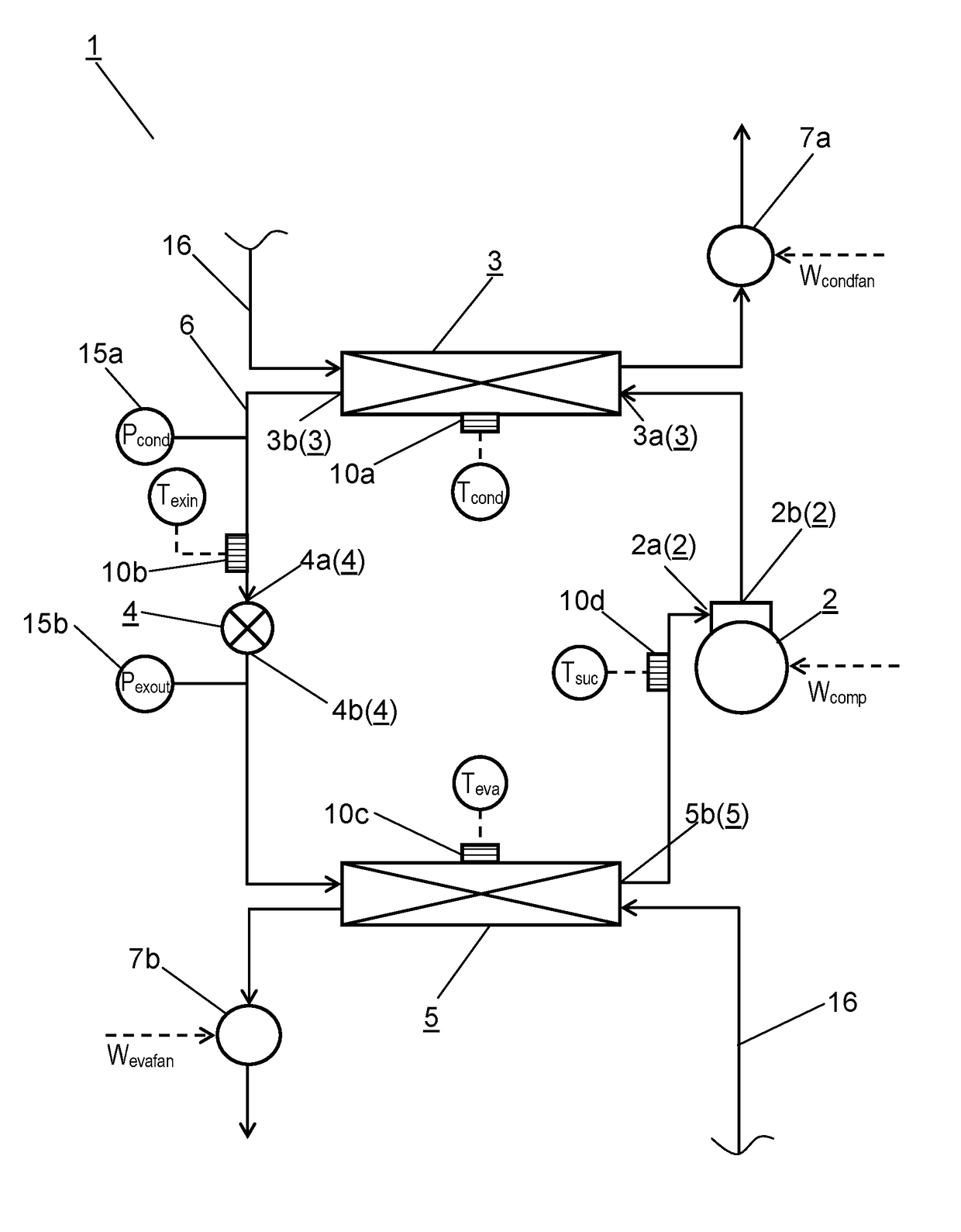

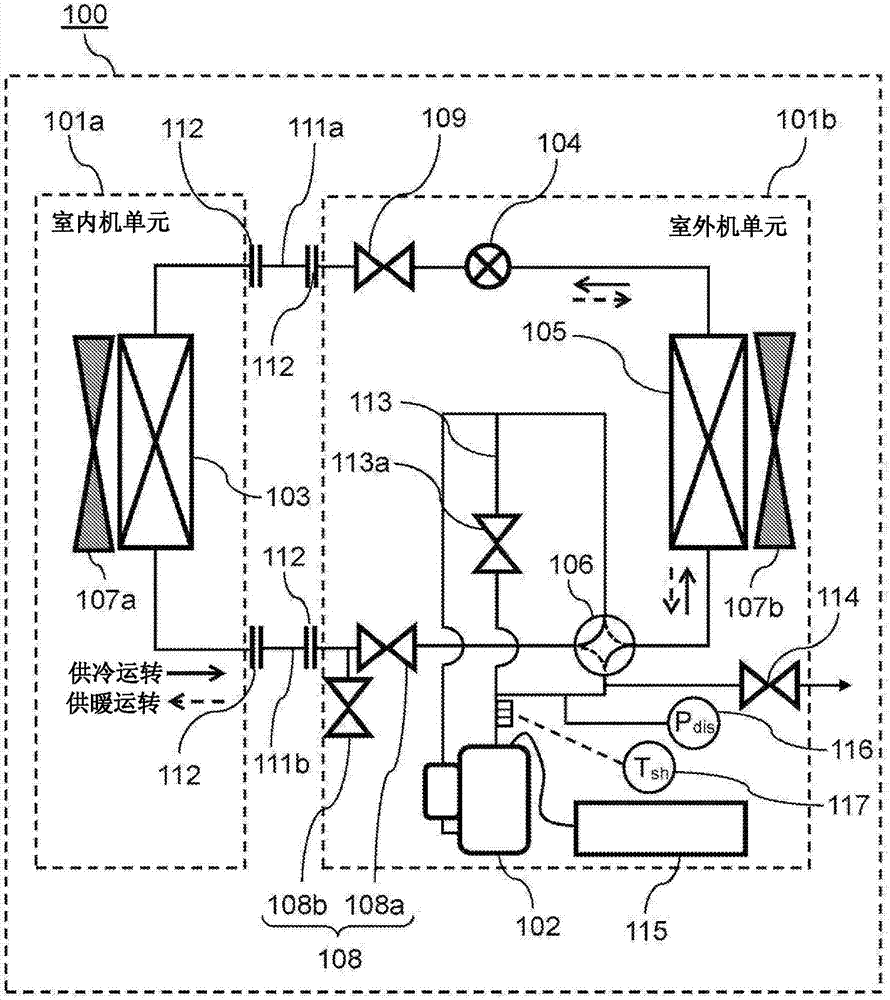

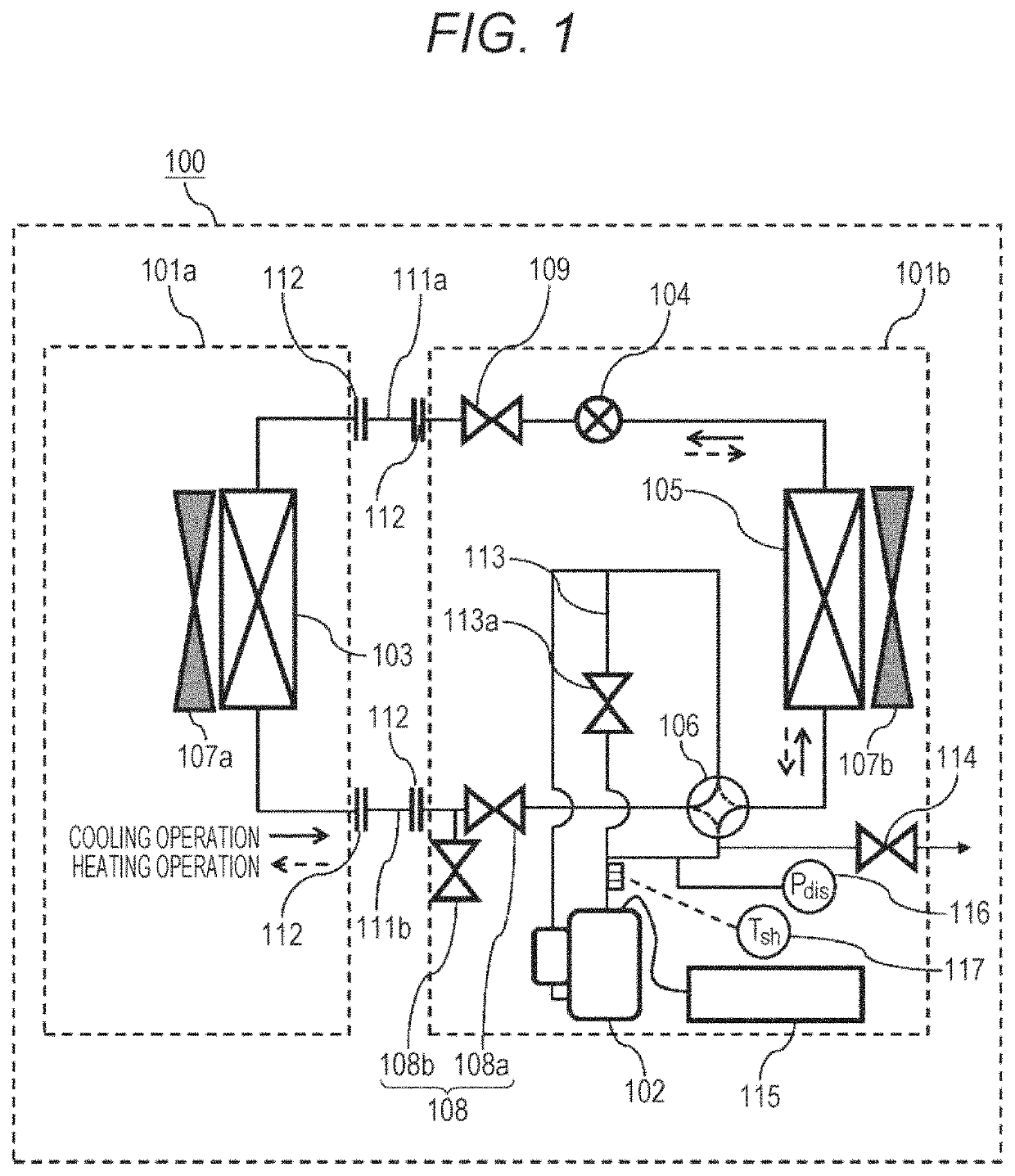

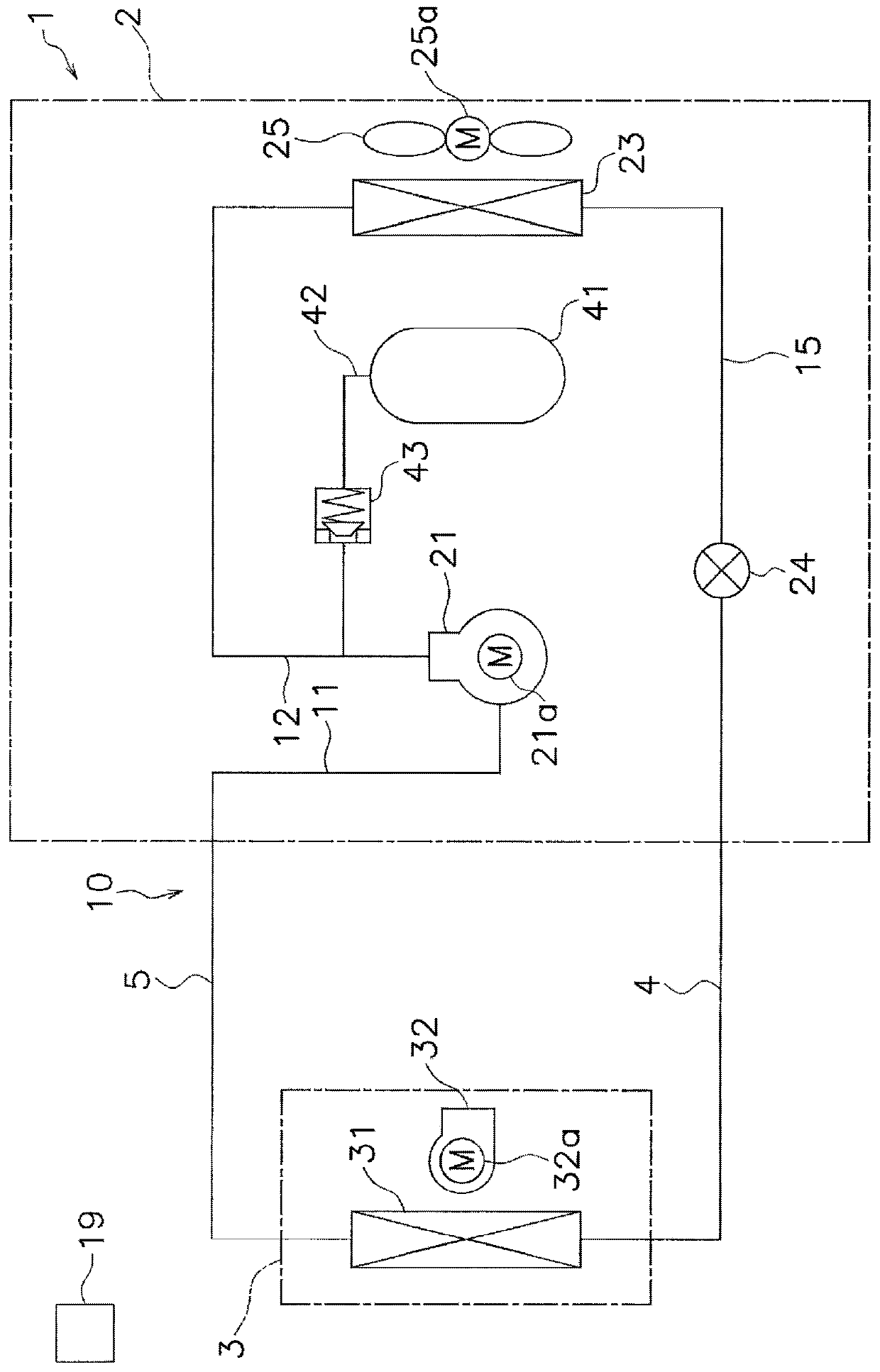

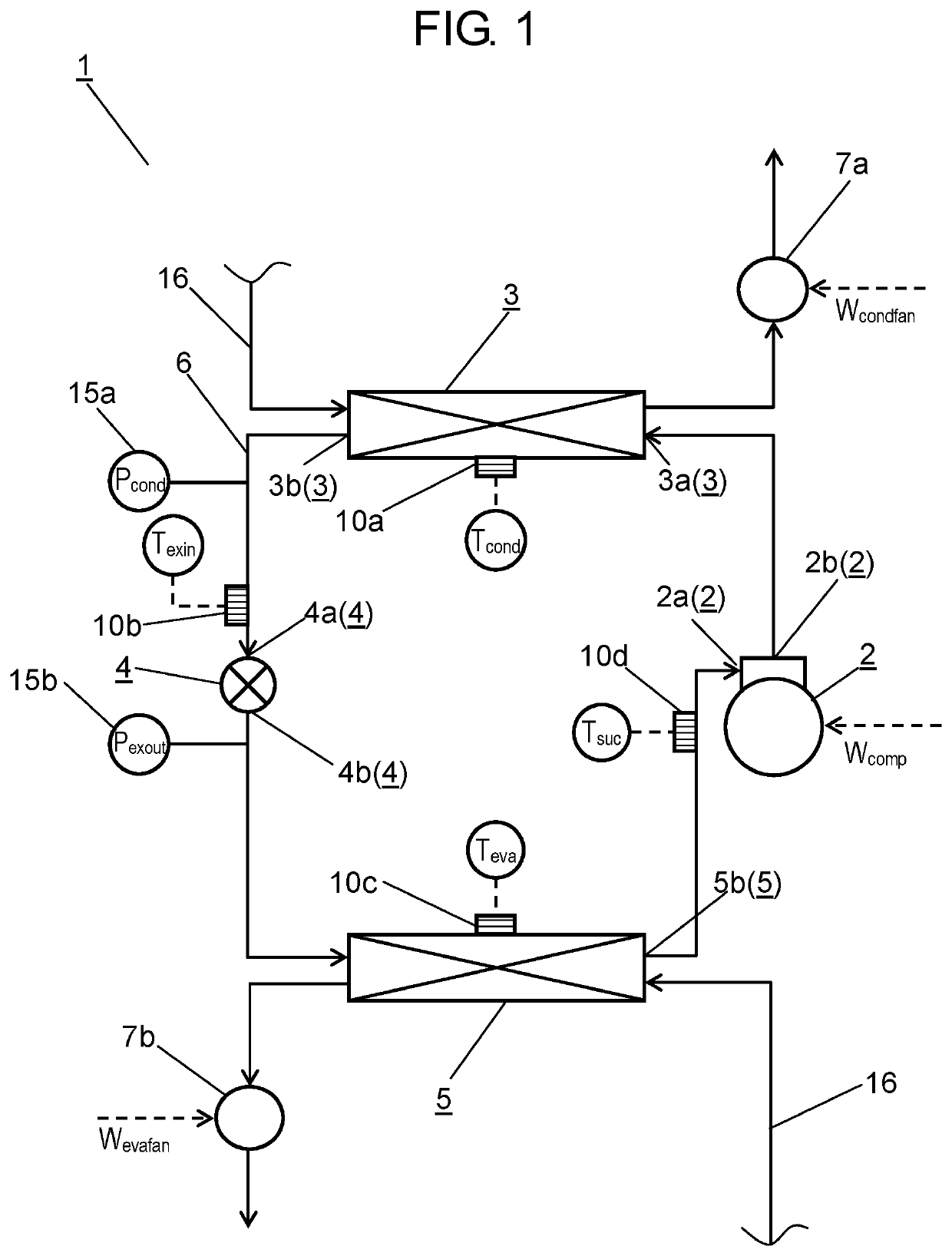

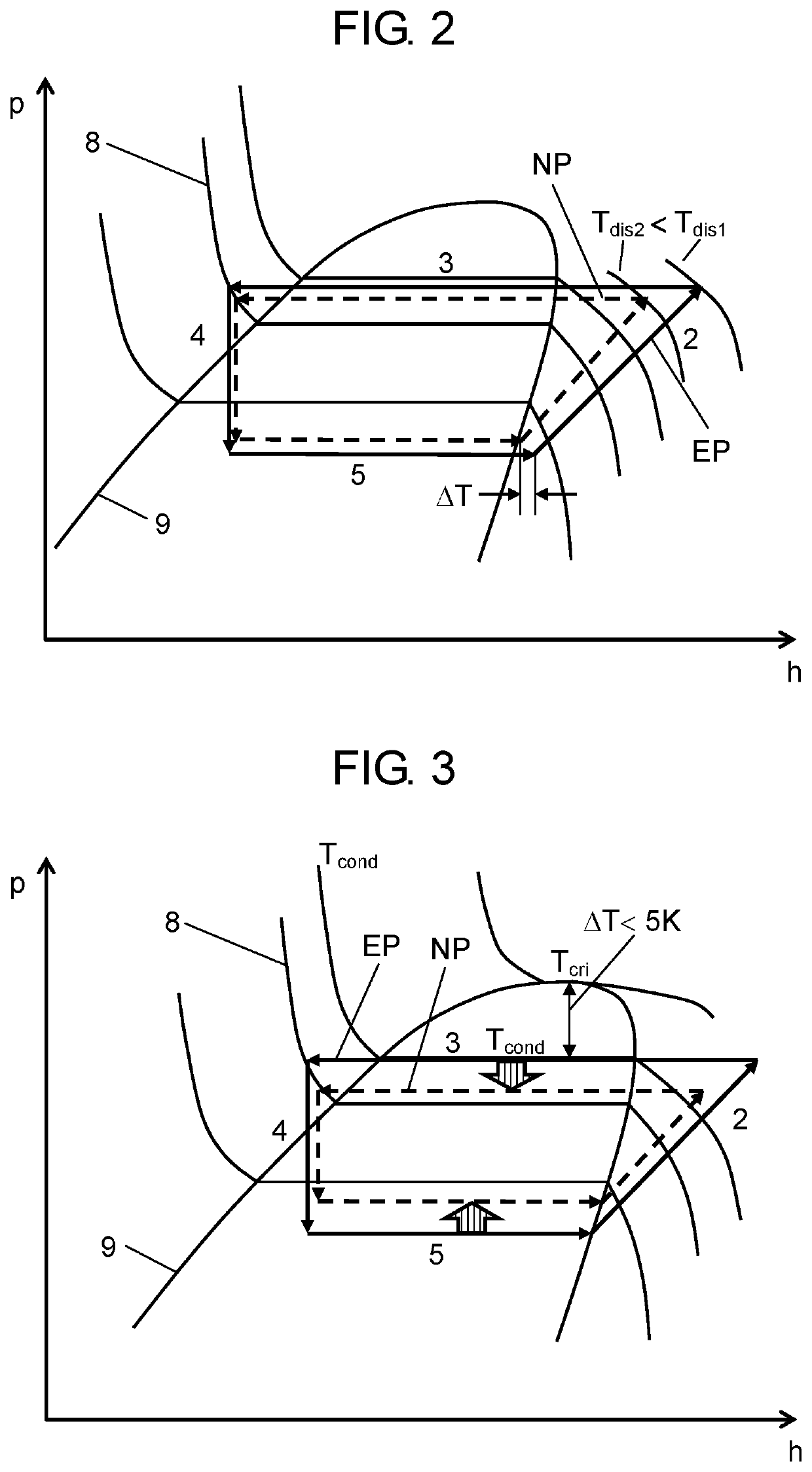

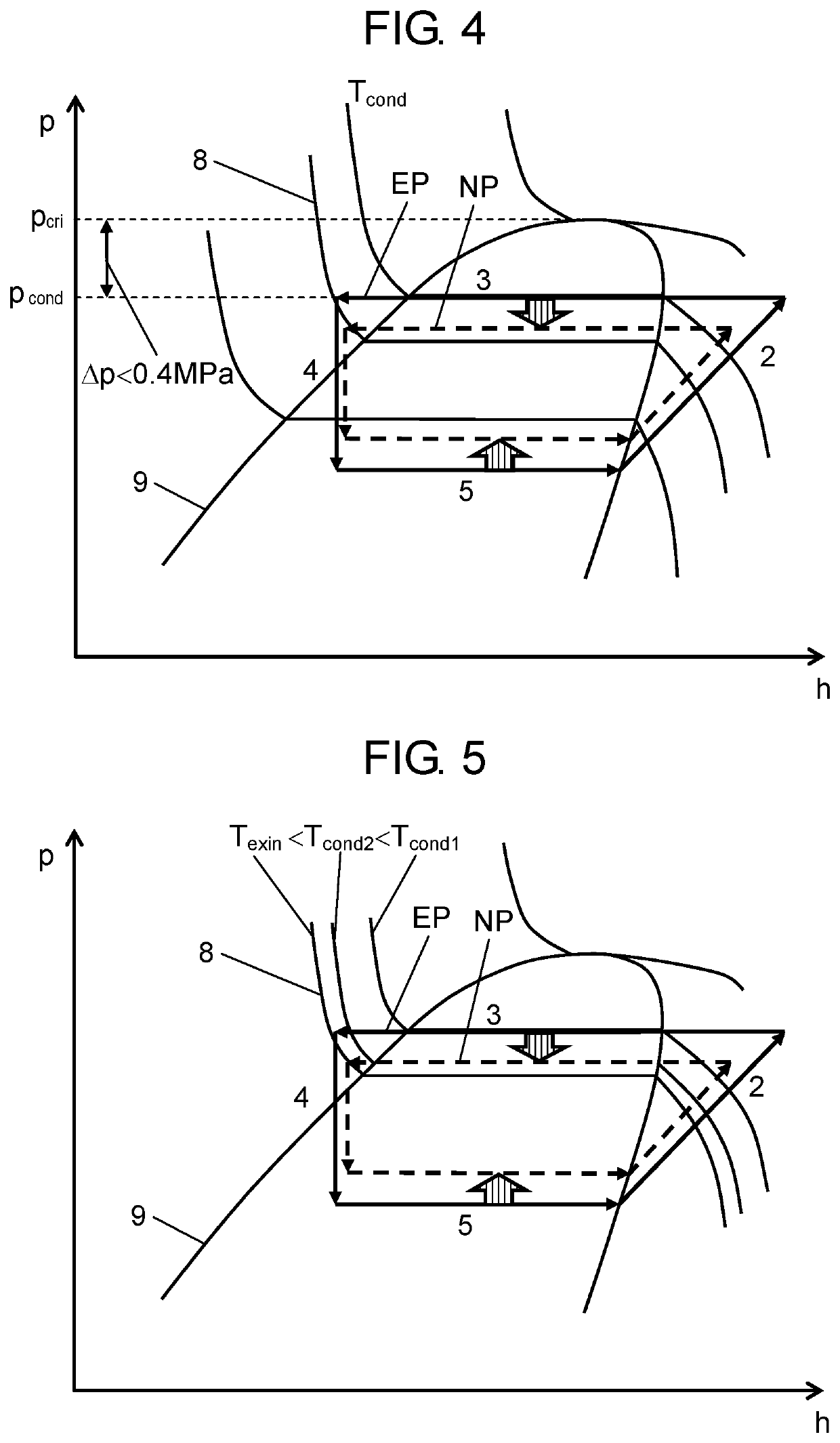

Refrigeration cycle device

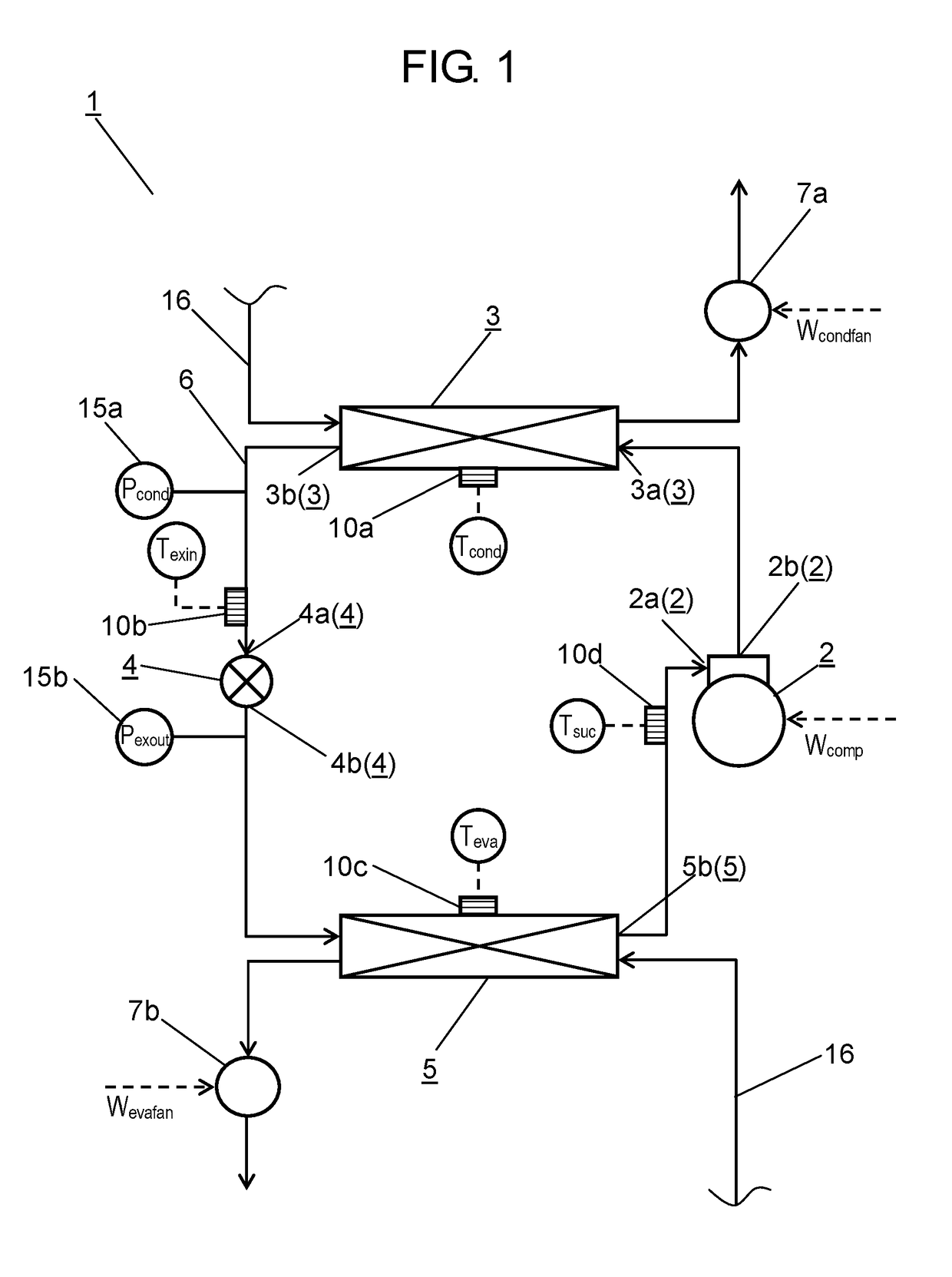

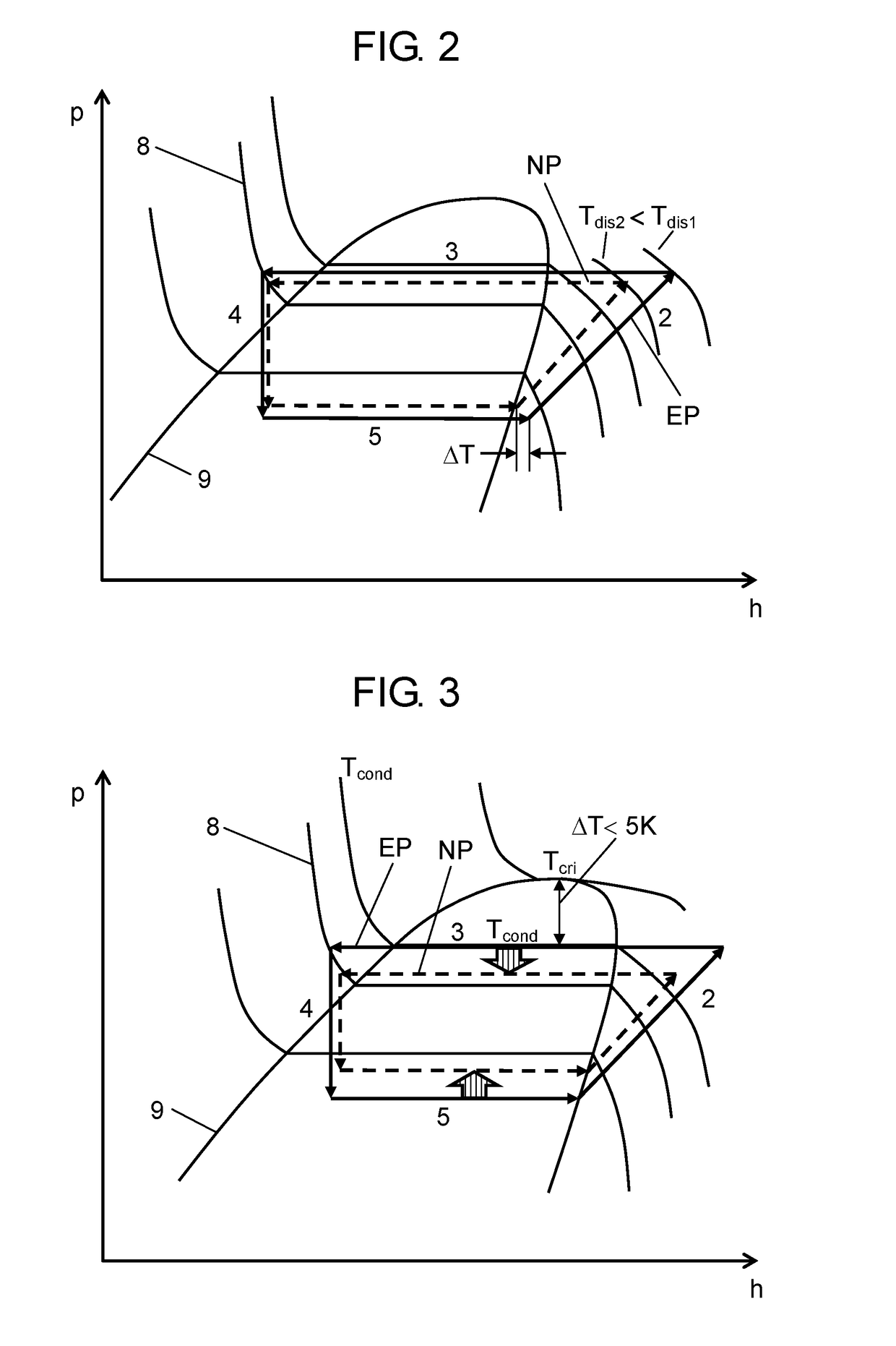

ActiveUS20170138645A1Improve reliabilityInhibition of disproportionationMechanical apparatusCompression machines with non-reversible cycleWorking fluidEngineering

A refrigeration cycle device includes a refrigeration cycle formed by connecting a compressor, a condenser, an expansion valve and an evaporator to each other. As a refrigerant in the refrigeration cycle, a working fluid containing 1,1,2-trifluoroethylene (R1123) and difluoromethane (R32) is used. A degree of opening of the expansion valve is controlled such that the refrigerant has two phases at a suction portion of the compressor. With such a configuration, it is possible to provide highly reliable refrigeration cycle device by suppressing occurrence of a disproportionation reaction of R1123.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Refrigeration cycle apparatus

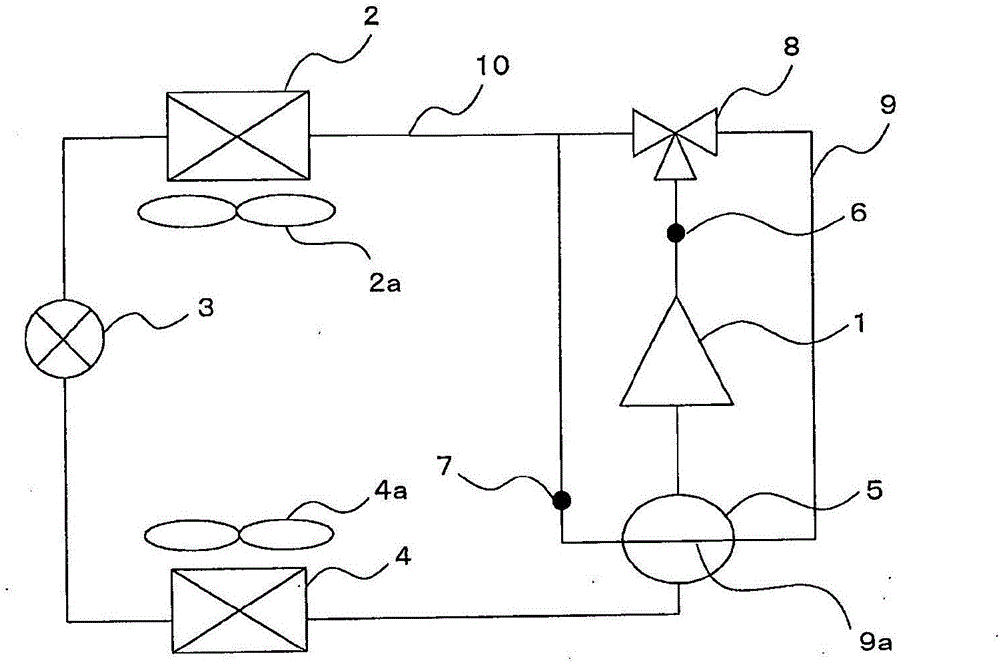

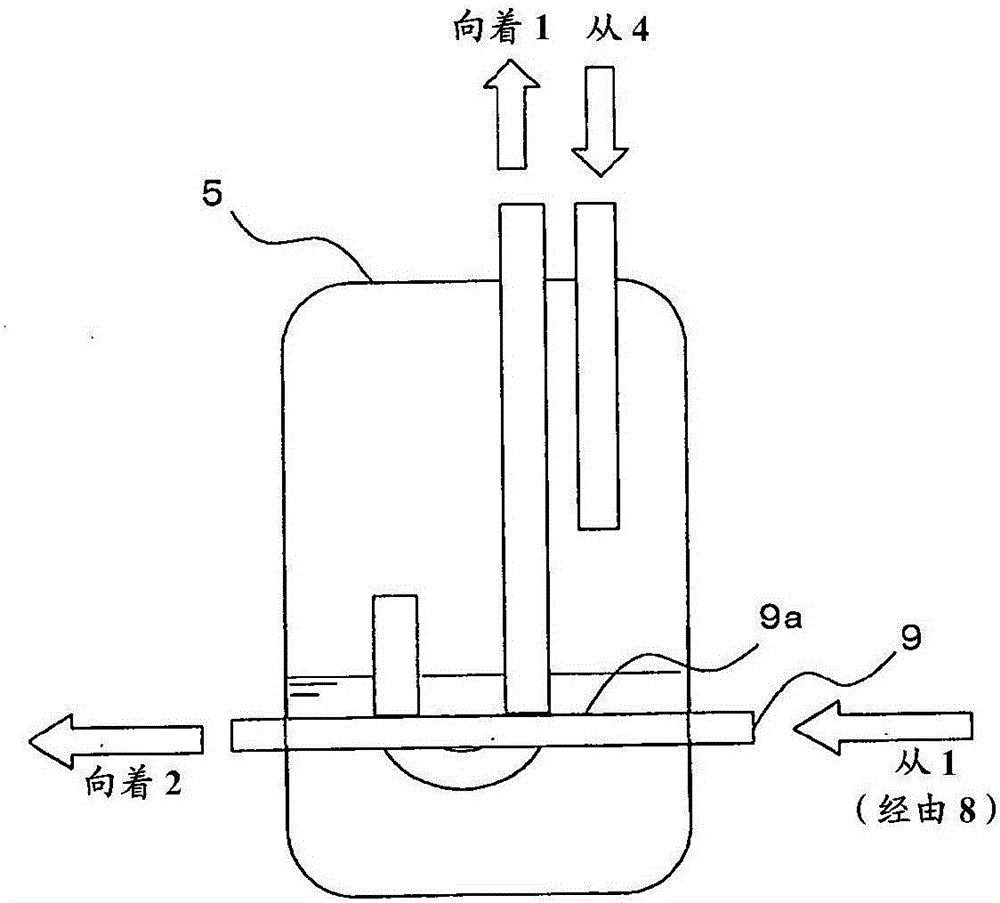

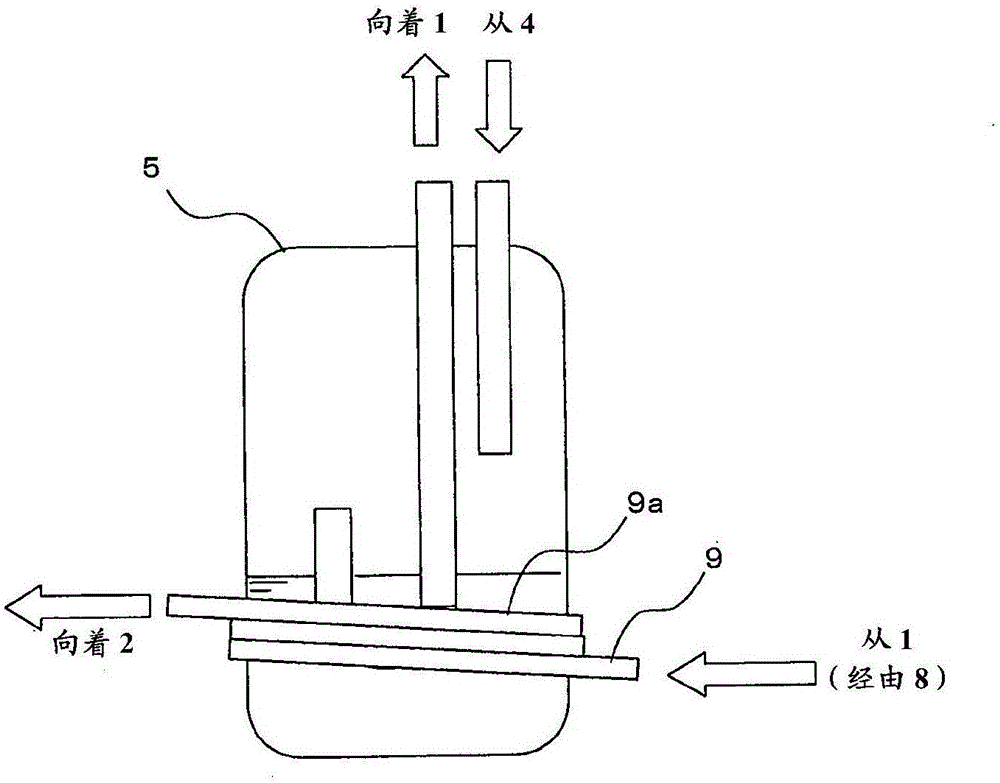

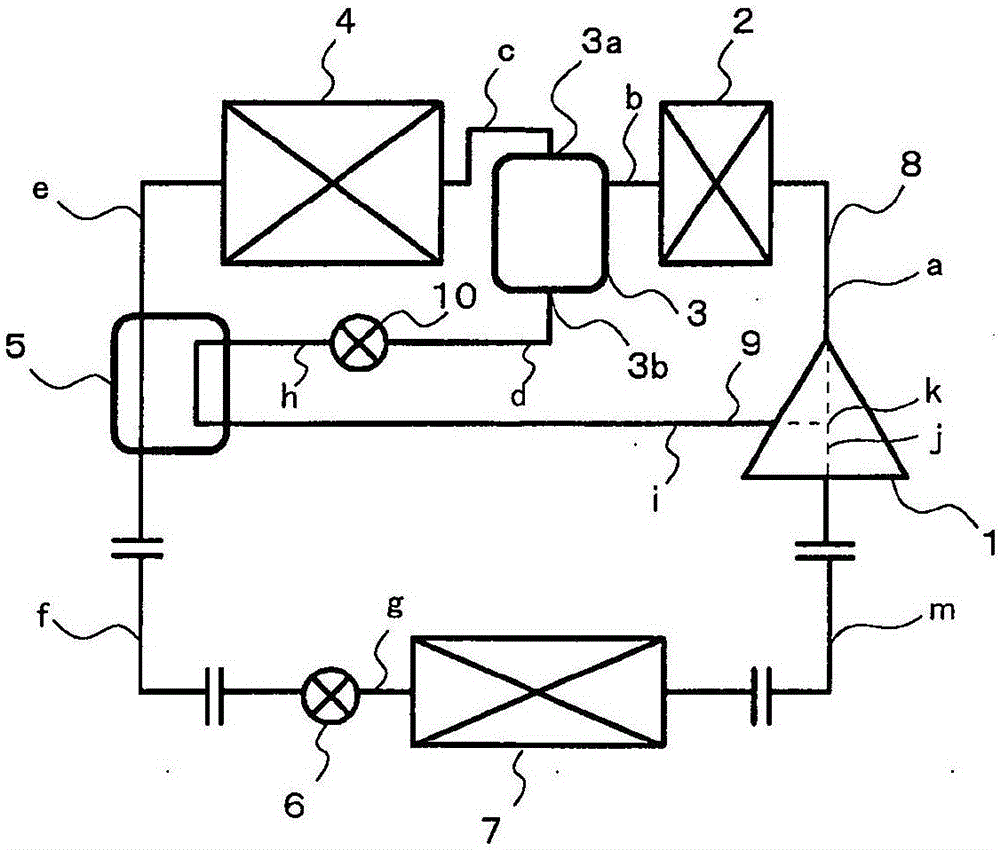

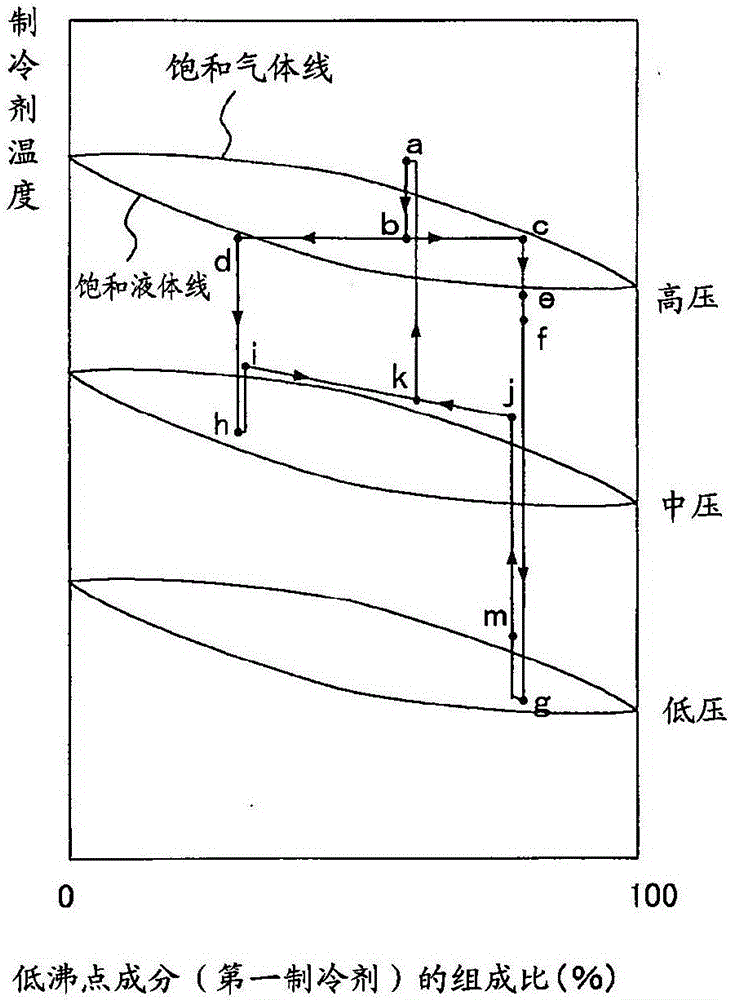

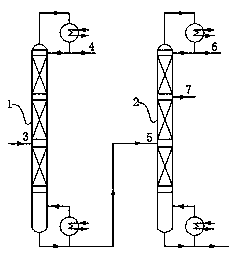

ActiveCN106104173AImprove composition ratioReduce partial pressureMechanical apparatusCompression machines with non-reversible cycleVapor–liquid separatorBoiling point

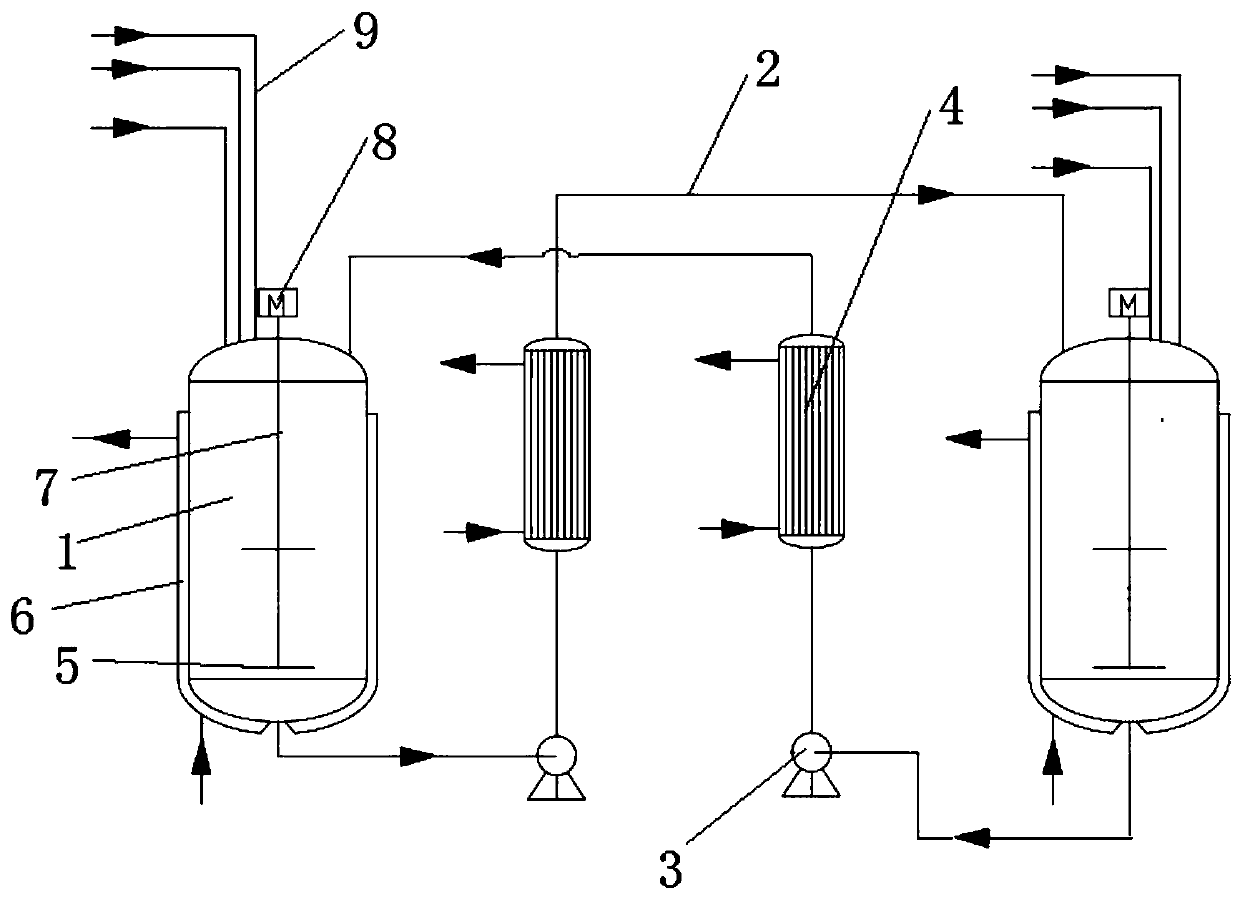

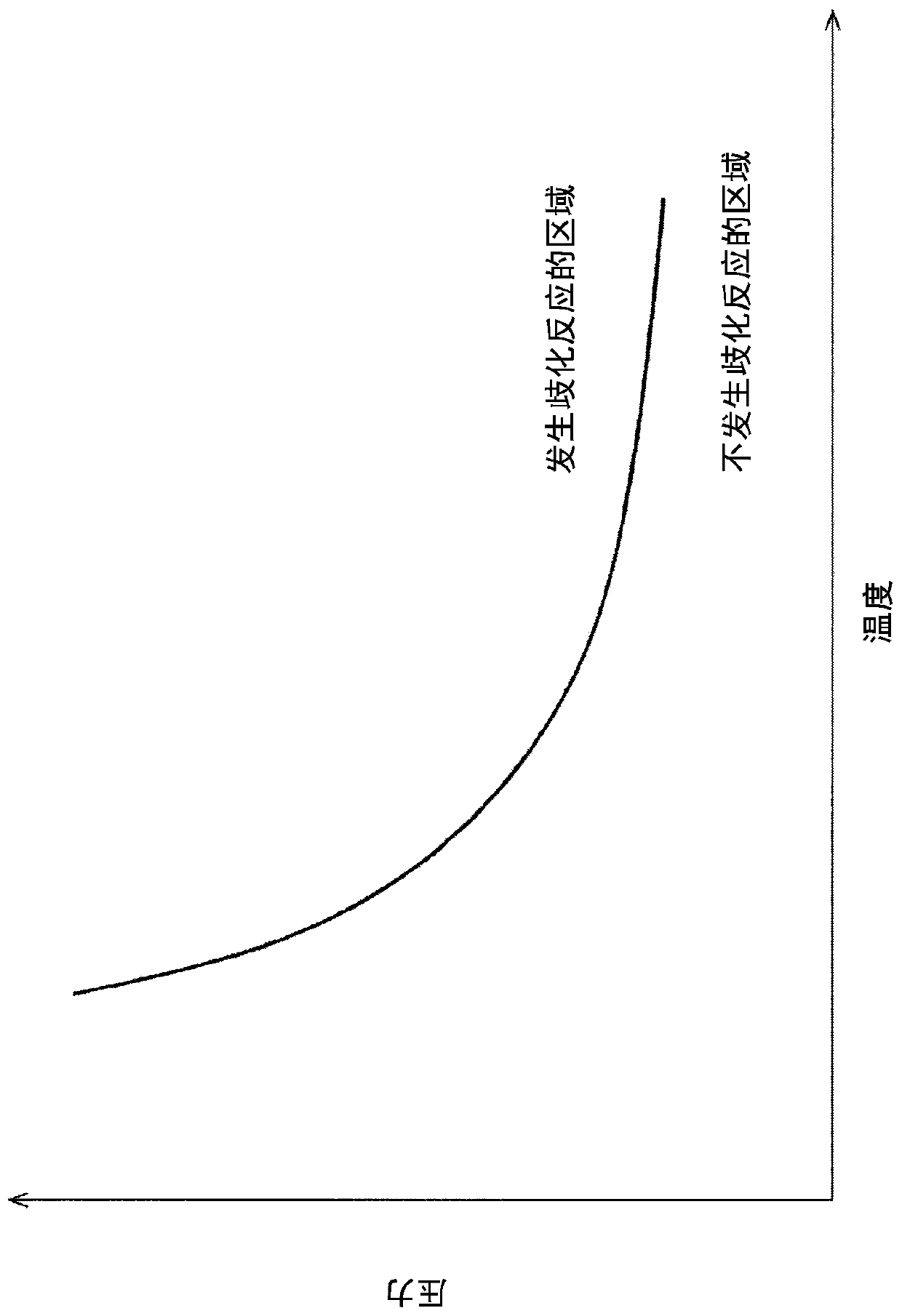

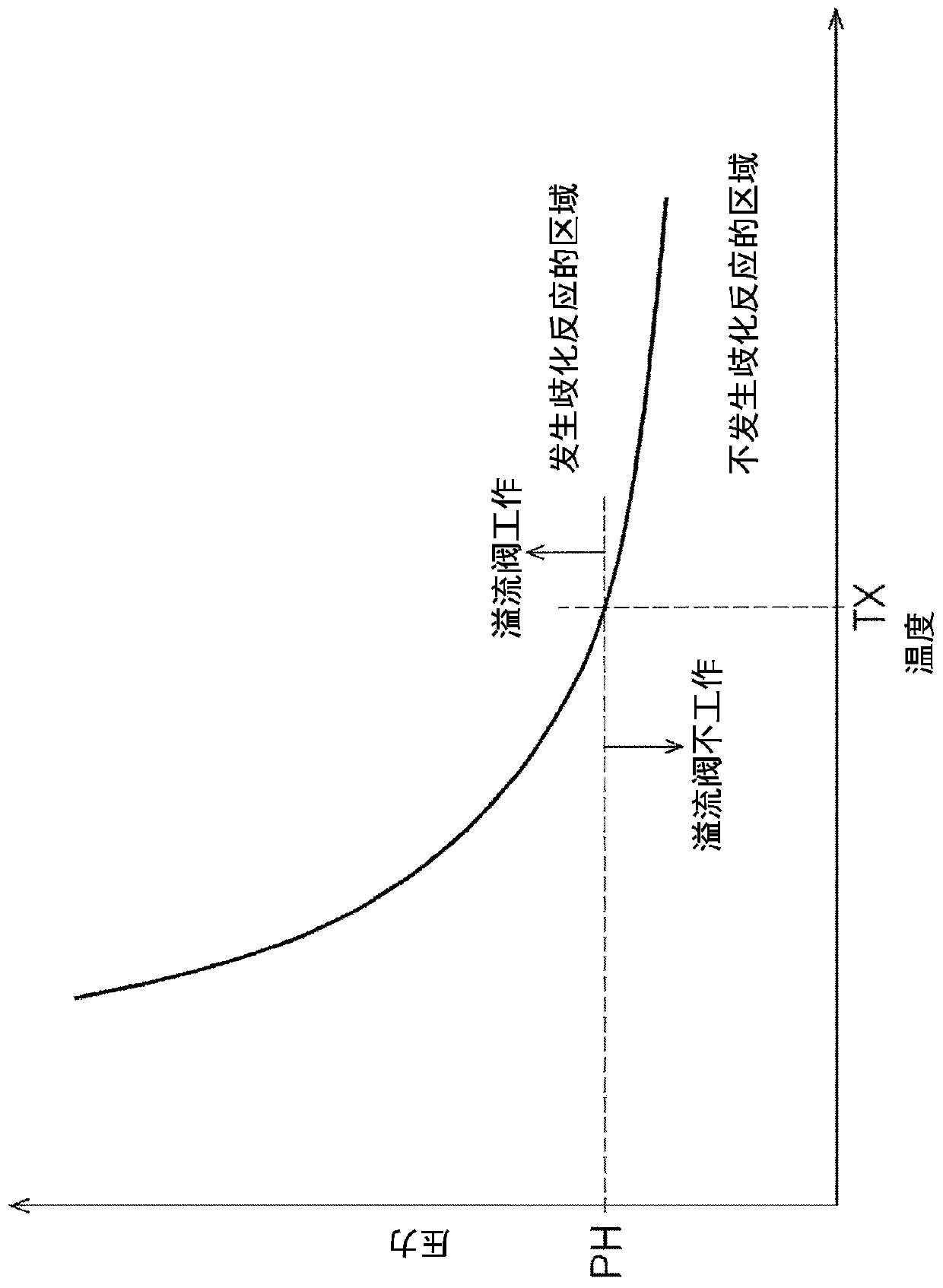

The purpose of the present invention is to provide a safe and high-performance refrigeration cycle apparatus whereby, even when a refrigerant that can cause a disproportionation reaction is used as one component of a non-azeotropic refrigerant mixture in the refrigeration cycle apparatus, it becomes possible to avoid the refrigerant being exposed to a condition in which the disproportionation reaction can occur. A refrigeration cycle apparatus, in which a non-azeotropic refrigerant mixture is used as a working refrigerant, wherein the non-azeotropic refrigerant mixture comprises a first refrigerant and a second refrigerant having such a property that the boiling point of the second refrigerant can become higher than that of the first refrigerant under the same pressure. The refrigeration cycle apparatus is equipped with at least a main passage, wherein the main passage is composed of a compressor, a first heat exchanger, an expansion valve, a gas / liquid separator and a second heat exchanger which are connected in this order. In the refrigeration cycle apparatus, the first refrigerant has a property of causing a disproportionation reaction, and an initial operation for reducing the temperature or pressure of the refrigerant ejected from the compressor compared with that employed in an ordinary operation on the basis of the amount of the liquid refrigerant in the gas / liquid separator is carried out in an initial stage that is to be carried out subsequently to the starting up of the compressor.

Owner:MITSUBISHI ELECTRIC CORP +1

Refrigeration cycle device

ActiveCN106104172AInhibition of disproportionationCompressorMechanical apparatusBoiling pointEngineering

The objective is to provide a safe, high-performance refrigeration cycle device with which it is possible to avoid a condition wherein the refrigerant causes a chain reaction, even when a refrigerant that generates a disproportionation reaction is used in the refrigeration cycle device. This refrigeration cycle device is equipped with: a main circuit wherein a compressor, a first heat exchanger, an expansion valve, and a second heat exchanger are sequentially connected, and in which a non-azeotropic mixed refrigerant (which includes at least a first refrigerant and a second refrigerant characterized by having a higher boiling point than the first refrigerant under the same pressure) operates as a standard composition refrigerant; and a composition separation circuit connected to the main circuit. The first refrigerant has the property of producing a disproportionation reaction, and the composition separation circuit is configured such that when operating in a separation / storage mode wherein the composition of the standard composition refrigerant is separated, a mixed refrigerant for which the composition ratio of the first refrigerant is higher than the standard composition refrigerant is separated from the main circuit, and is stored.

Owner:MITSUBISHI ELECTRIC CORP +1

Compound anode material for lithium ion battery and preparation method thereof

InactiveCN106784701AStable structureImprove cycle stabilityCell electrodesPower batterySodium-ion battery

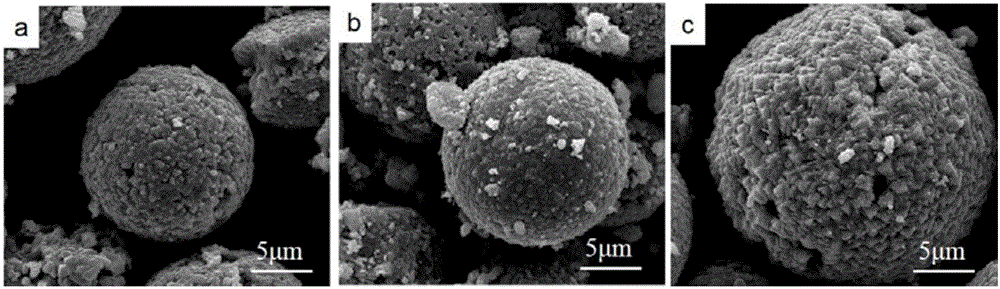

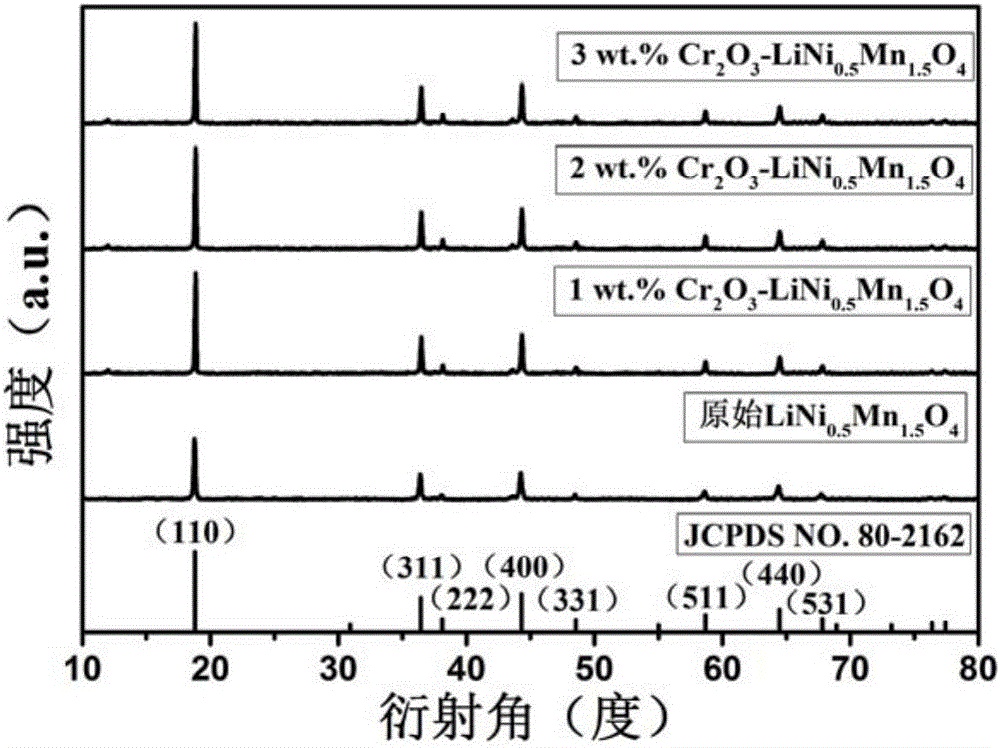

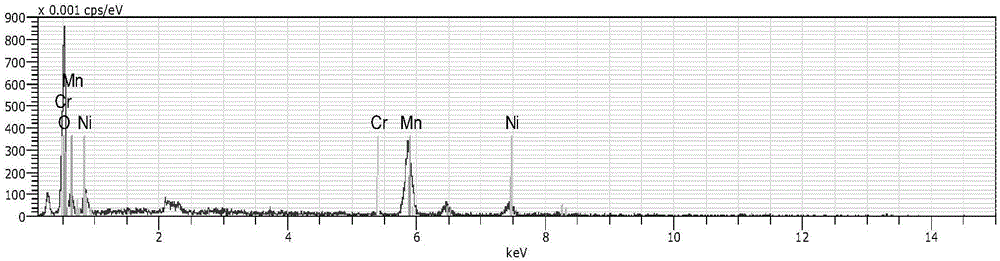

The invention belongs to the field of a lithium ion battery and specifically relates to a compound anode material for the lithium ion battery and a preparation method thereof. The material provided by the invention is prepared by a hydrothermal reaction method; Cr2O3 is coated on the outer layer of a LiNi0.5Mn1.5O4 anode material; the material has a shape of sphere with grain diameter of 15-20mu m; the morphology is uniform; the structure is stable; the component is controllable; the specific discharge capacity is high; the cycling stability and the capacity retention ratio are increased; the synthesizing method is simple and easy to operate; and the compound anode material can be used as a high-performance standby anode material of the power battery.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for improving stability of catalyst during resource utilization of HFC-23

ActiveCN112979410AImprove stabilityExtend your lifePreparation by halogen replacementCatalyst regeneration/reactivationHalohydrocarbonPtru catalyst

The invention discloses a method for improving the stability of a catalyst during resource utilization of HFC-23. The resource utilization is realized by a fluorine-chlorine exchange reaction of HFC-23 and halogenated hydrocarbon; the catalyst for the fluorine-chlorine exchange reaction comprises a main catalyst and a metal oxide; and the metal oxide is at least one selected from K, Na, Fe, Co, Cu, Ni, Zn and Ti, and the addition amount of the metal oxide is 0.1-5 wt%. The catalyst has the advantages of good stability, long service life, low content of the by-product CFC-12 and the like.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +2

Method for preparing manganese sulfate solution through direct reduction leaching of manganese oxide ores

PendingCN110373541AReduce consumptionSolve the problem of high residueProcess efficiency improvementPregnant leach solutionSulfate

The invention discloses a method for preparing manganese sulfate solution through direct reduction leaching of manganese oxide ores. The method comprises the steps of (1) pre-reduction: adding manganese oxide ore powder in water or dilute sulfuric acid for pulping so as to obtain pulp liquid, gradually adding concentrated sulfuric acid in the pulp liquid, maintaining the temperature of the reaction system, carrying out stirring reaction, and adding manganese sulfate for continuous stirring so as to prepare pre-reduced ore pulp; (2) reduction and acid leaching: preparing dilute sulfuric acid solution, adding the pre-reduced ore pulp and a reducing agent in the dilute sulfuric acid solution, maintaining the temperature of the reaction system, and carrying out stirring reaction to prepared manganese sulfate leaching liquid; and (3) solution purification: adding a neutralizer and an oxidant in the manganese sulfate leaching liquid, carrying out filter to prepare primary purified liquid, and adding a vulcanizing agent and polyacrylamide in the primary purified liquid for filter so as to obtain the manganese sulfate solution. The method has the beneficial effects of overcoming the defects in the prior art, simplifying the production process, reducing the material consumption in the reduction process, improving the manganese reducing and leaching rate, decreasing the waste residue yield and reducing the leaching cost.

Owner:GUIZHOU UNIV

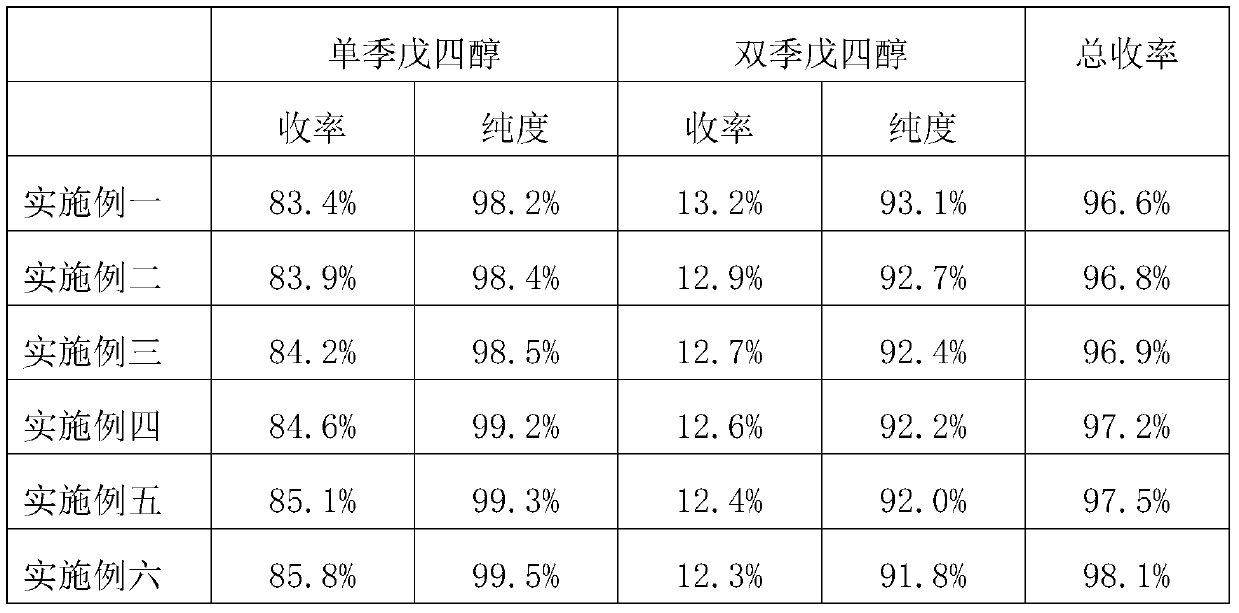

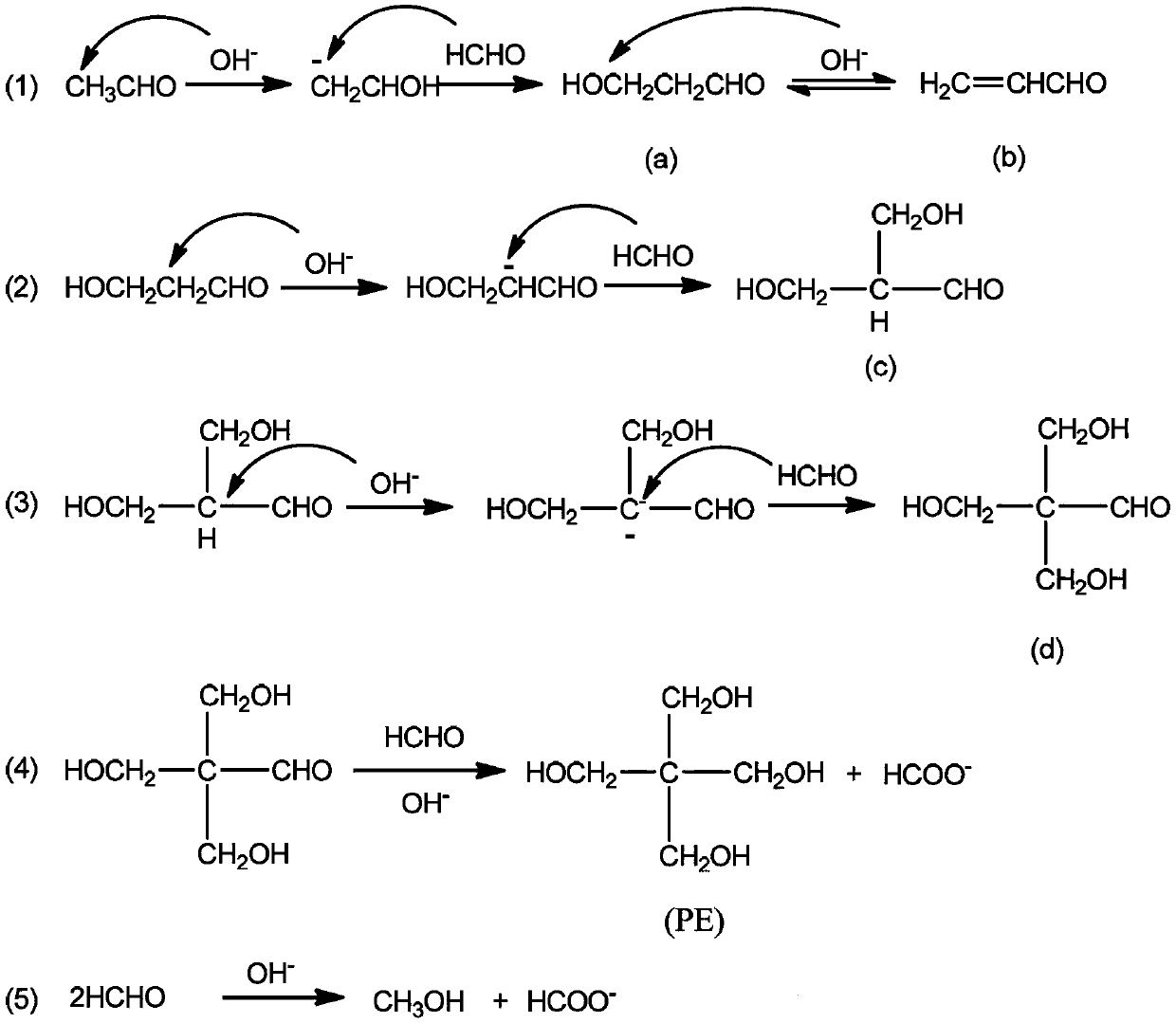

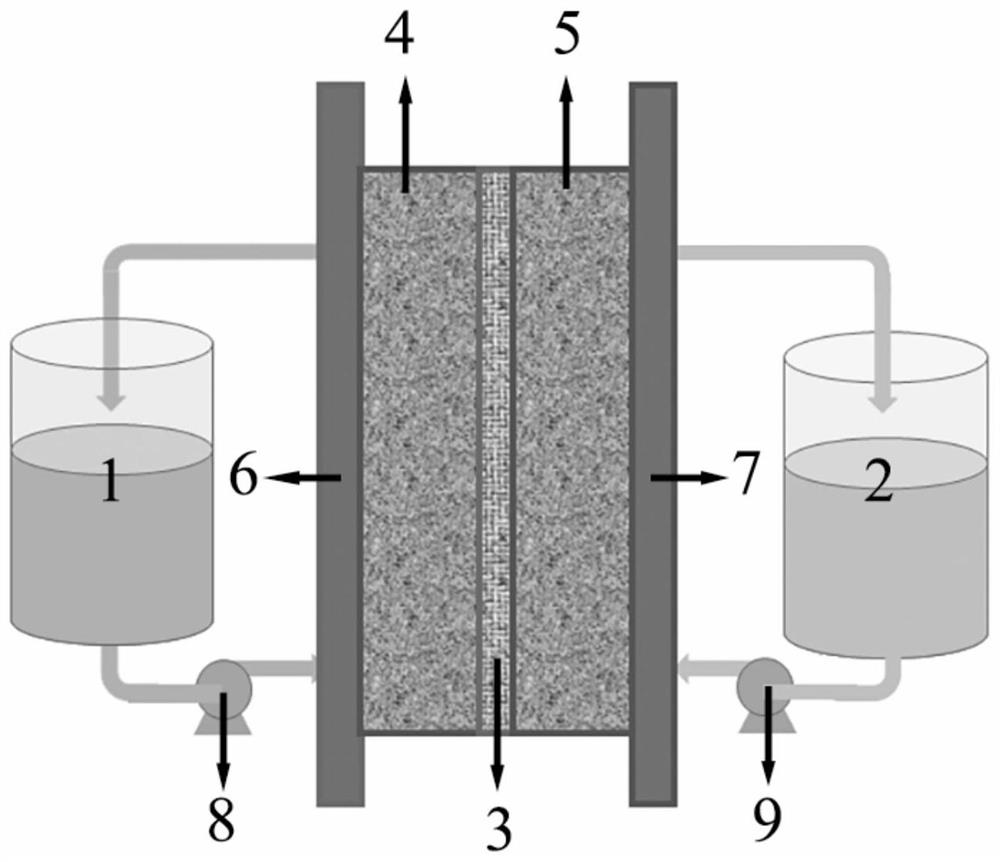

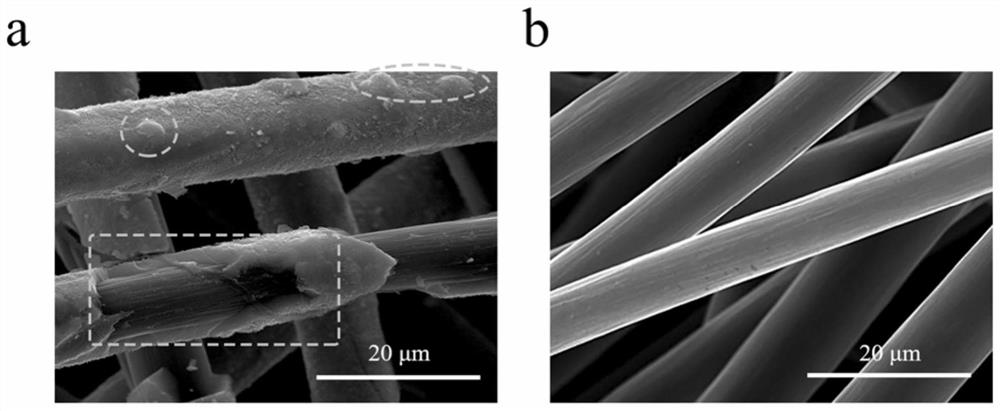

Preparation method of pentaerythritol and dipentaerythritol

InactiveCN109942373AInhibit productionShort reaction timeOrganic compound preparationHydroxy compound preparationPentaerythritolEvaporation

The invention discloses a preparation method of pentaerythritol and dipentaerythritol, which comprises the following steps of: S1, heating formaldehyde to a set temperature by taking a formaldehyde aqueous solution as bottom water, adding an alkali solution and an acetaldehyde aqueous solution into the bottom water, and carrying out condensation reaction at a constant temperature; S2, adding a formic acid aqueous solution into the bottom water to stop the reaction to obtain a condensation solution containing pentaerythritol, dipentaerythritol and formate; S3, carrying out multistage evaporation and crystallization, and respectively collecting excessive formaldehyde, pentaerythritol, dipentaerythritol and formate from the condensation solution to obtain the pentaerythritol and the dipentaerythritol, wherein the molar ratio of the formaldehyde to the acetaldehyde is (4-10):1, the molar ratio of the alkali to the acetaldehyde is (1-2):1. According to the invention, the condensation reaction is carried out under the condition of constant temperature, the raw materials are easy to obtain, the control is simple, the product yield is high, and the product purity is high.

Owner:江苏汉凯工程技术有限公司

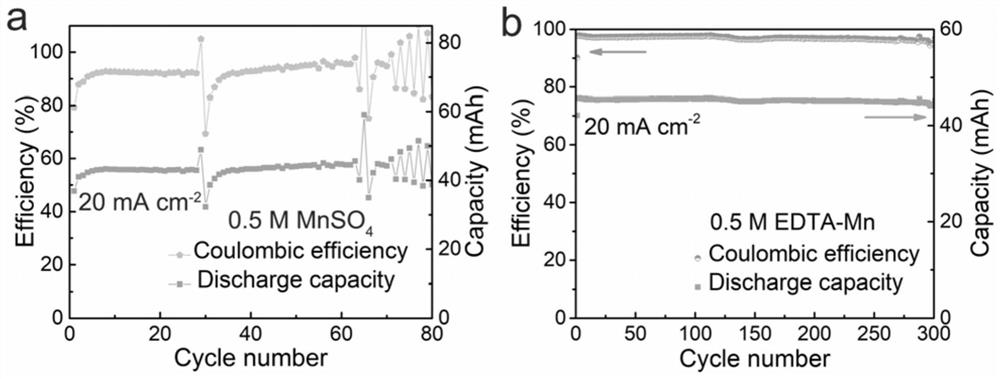

Positive electrode electrolyte for zinc-manganese flow battery

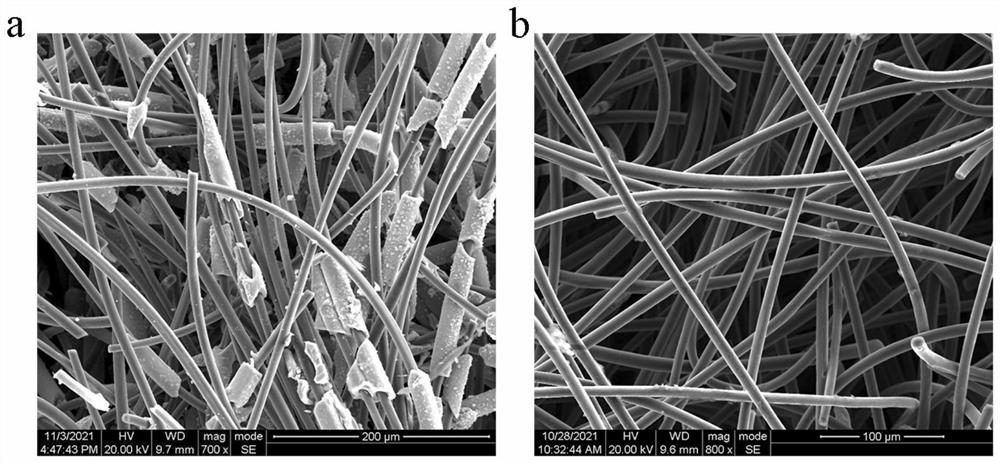

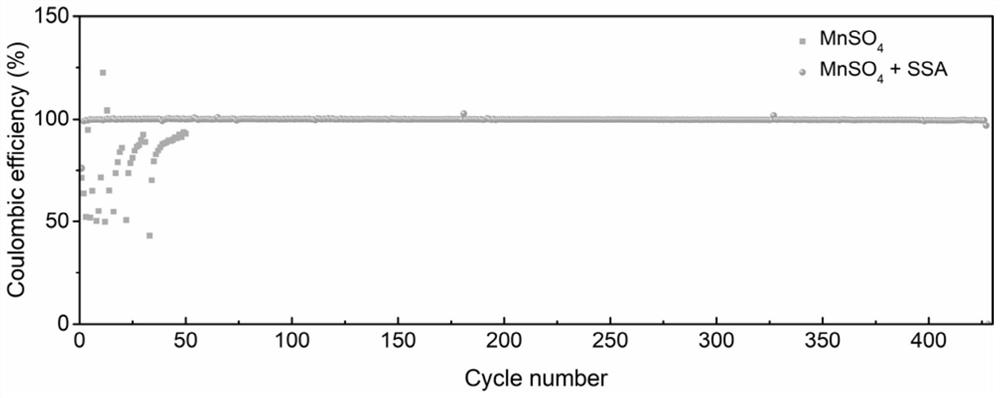

ActiveCN113437340AInhibition of disproportionationImprove cycle stabilityRegenerative fuel cellsAqueous electrolytesSupporting electrolyteElectrolytic agent

The invention is applied to the field of flow batteries, and particularly relates to a positive electrode electrolyte for a zinc-manganese flow battery. The positive electrode electrolyte of the zinc-manganese flow battery comprises a manganese ion reaction active substance, a supporting electrolyte and solvent water, the manganese ion reaction active substance is a divalent manganese ion complex, and the supporting electrolyte is used for improving the solution conductivity. According to the invention, the manganese ion complex is selected as a positive active material, and the coordination structure of manganese ions is changed by utilizing the complexation reaction of divalent manganese ions and the complexing agent, so that the problem of disproportionation of trivalent manganese ions is solved, and the coulombic efficiency and the energy efficiency of the battery are improved, and long-term stable circulation is realized. The novel zinc-manganese flow battery provided by the invention is pollution-free, safe and reliable, and has price and resource advantages.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

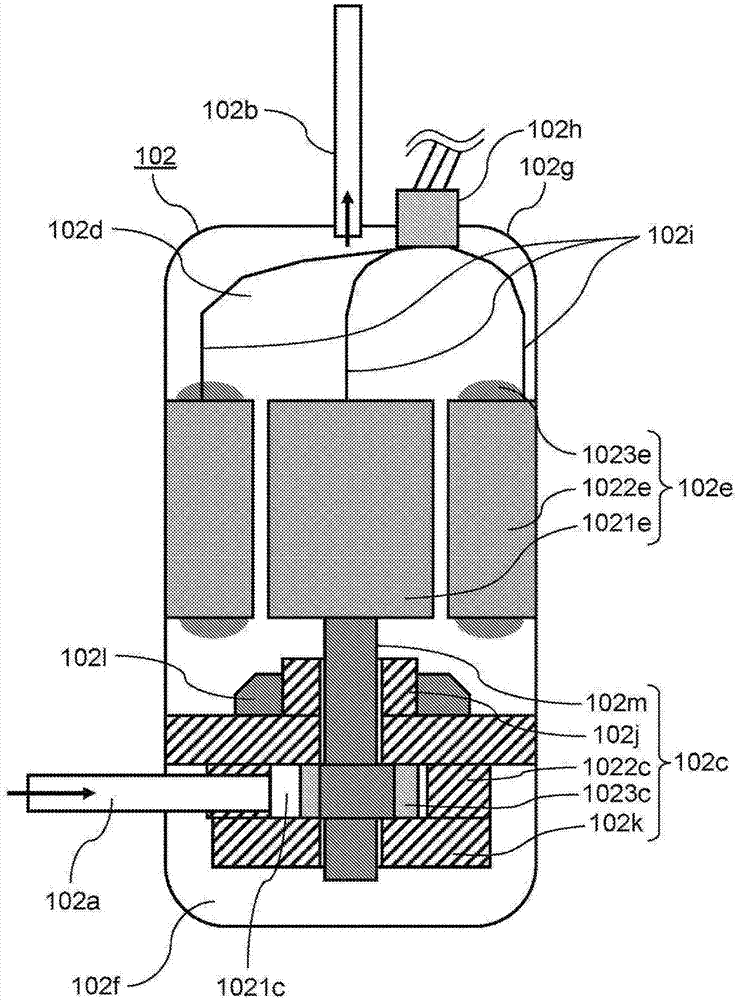

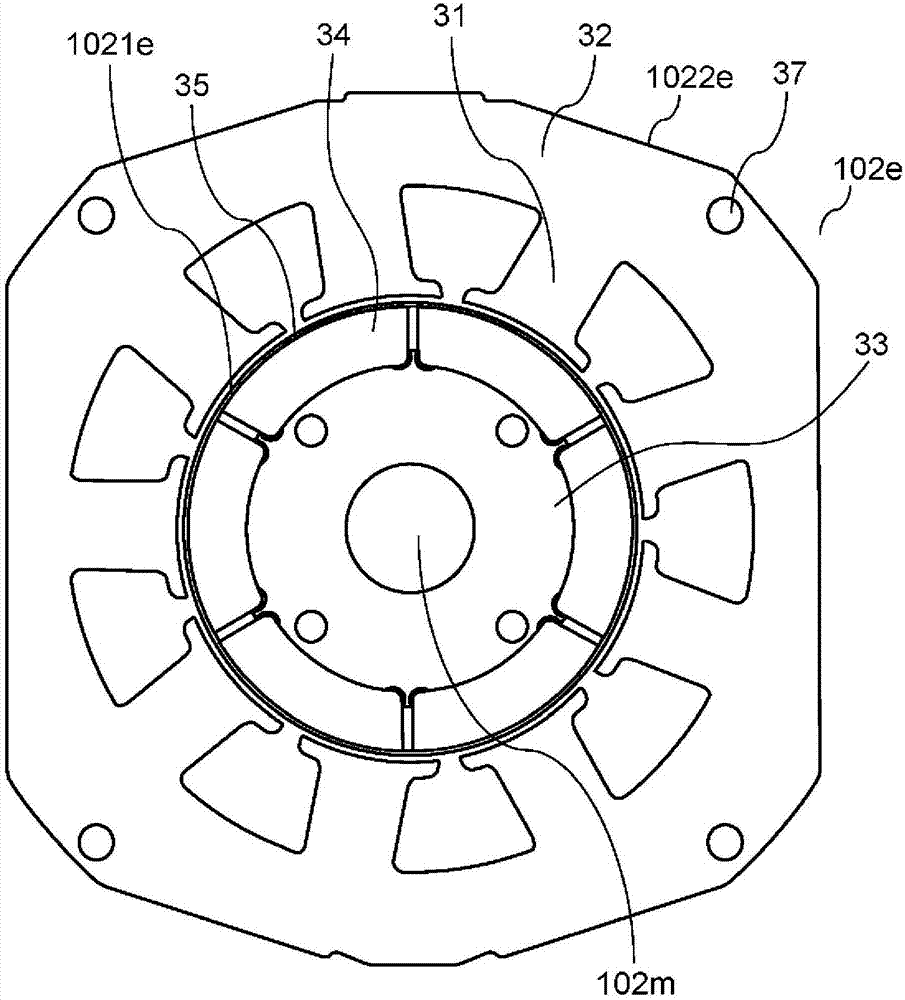

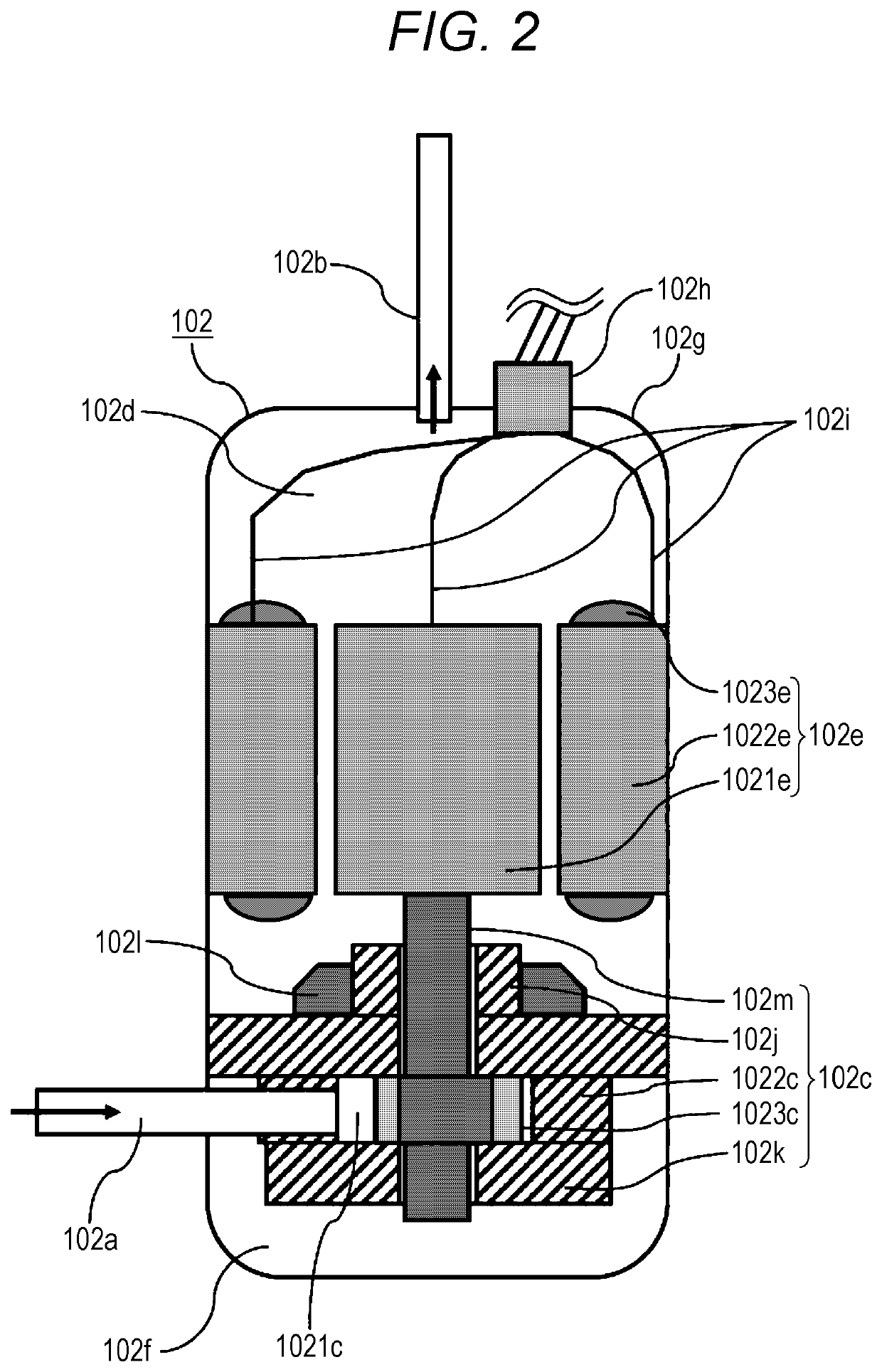

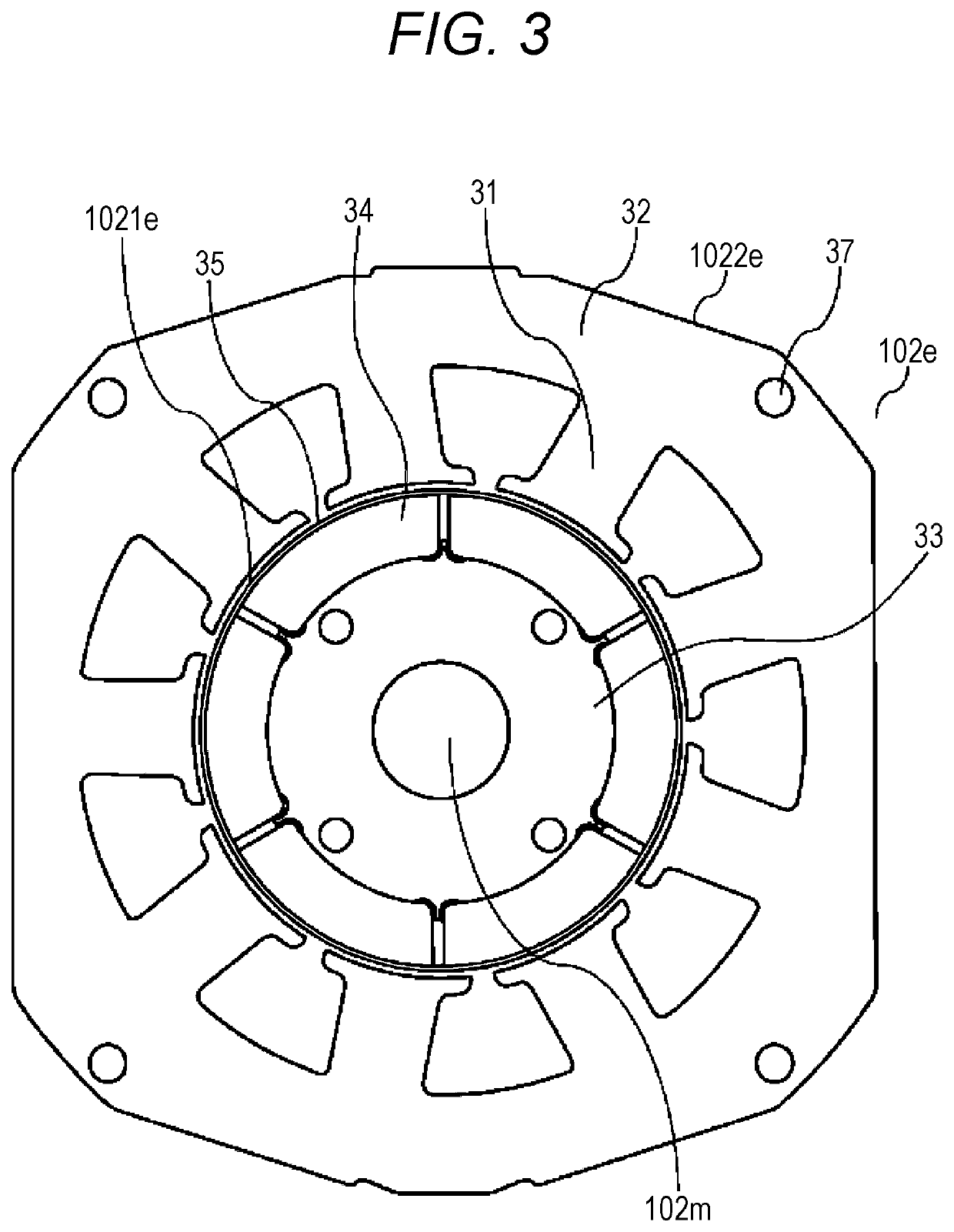

Refrigeration cycle device

ActiveCN107532825AInhibition of disproportionationImprove reliabilityRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsWorking fluidMagnetic poles

Owner:PANASONIC INTPROP MANAGEMENT CO LTD

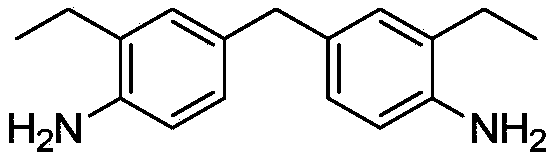

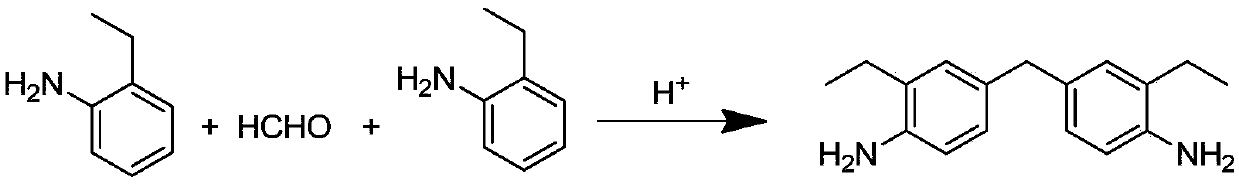

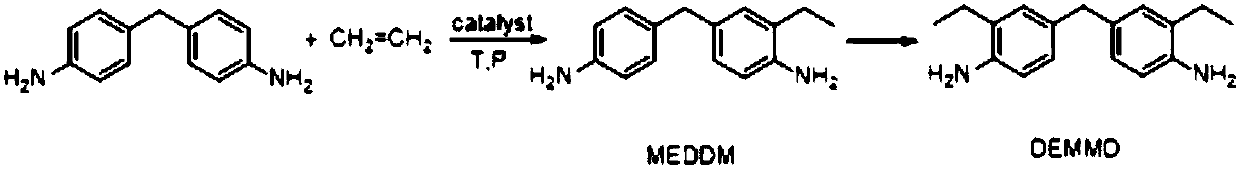

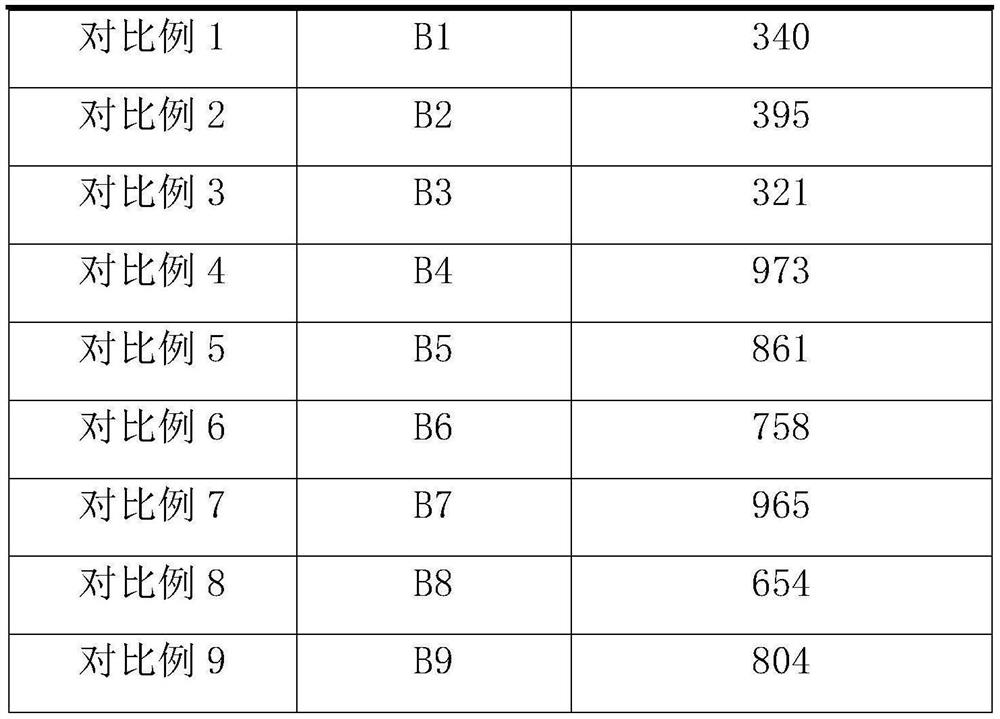

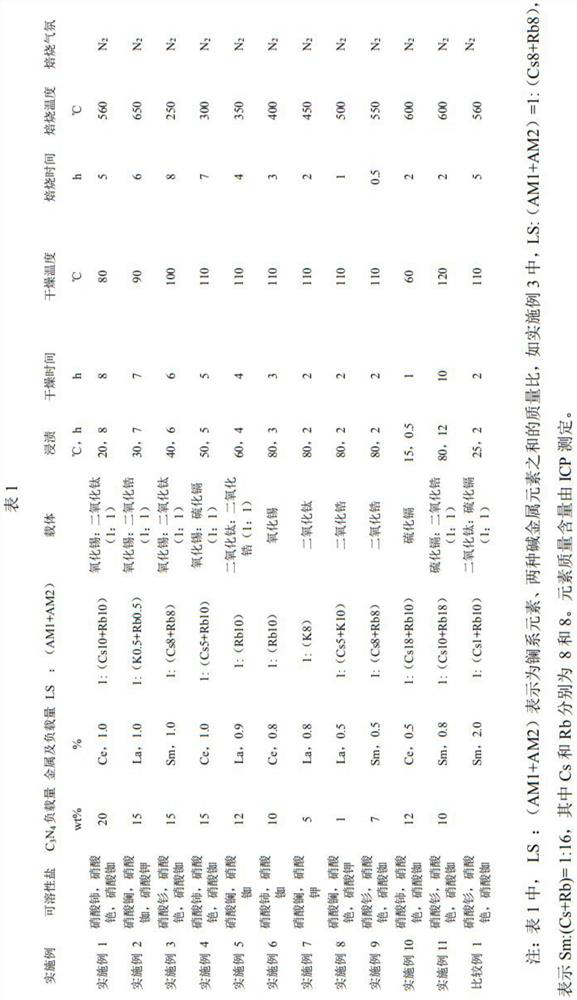

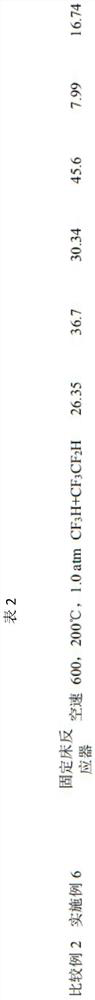

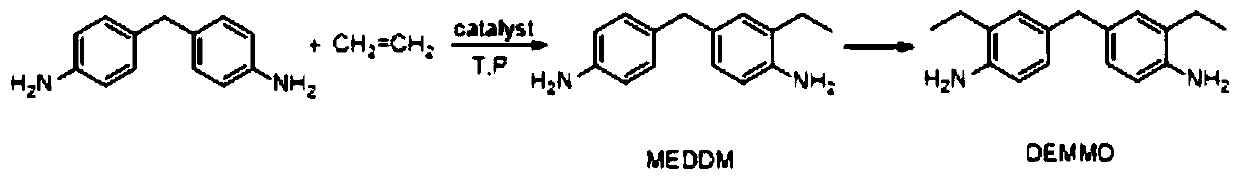

Catalyst for synthesizing DEMMA as well as preparation method and application thereof

ActiveCN107866264AReduce contentInhibition of disproportionationMolecular sieve catalystsAmino preparation from aminesMolecular sievePtru catalyst

The invention discloses a supported modified zeolite molecular sieve catalyst. The catalyst comprises a modified zeolite molecular sieve carrier and a loaded active component, wherein the modified zeolite molecular sieve carrier is prepared through modification of a zeolite molecular sieve through the following steps: mixing the molecular sieve with an alkaline solution of alkali metal elements, and carrying out washing, drying and roasting to obtain a preliminary modified carrier; impregnating the preliminary modified carrier with a soluble compound solution containing lanthanide and boron, and carrying out drying and roasting to obtain the modified zeolite molecular sieve carrier containing lanthanide oxide and boron trioxide. The invention also discloses a preparation method of the catalyst and the application of the catalyst in synthesis of DEMMA. By using the catalyst provided by the invention, the advantages of high raw material conversion rate, good product selectivity and few byproducts are achieved; moreover, the preparation process of the catalyst is simple, the economical efficiency is good, and the catalyst has a good application prospect.

Owner:WANHUA CHEM GRP CO LTD

Method for reducing carbon deposition of catalyst in resource utilization of HFC-23

ActiveCN112973685AEliminate carbon depositsImprove stabilityPreparation by halogen replacementCatalyst regeneration/reactivationHalohydrocarbonPtru catalyst

The invention discloses a method for reducing carbon deposition of a catalyst in resource utilization of HFC-23. The resource utilization is realized by performing a fluorine-chlorine exchange reaction on HFC-23 and halogenated hydrocarbon; the catalyst for the fluorine-chlorine exchange reaction comprises a main catalyst and a noble metal; the noble metal is at least one selected from Pt, Pd, Ru, Au and Rh, and the addition amount of the noble metal is 0.01-2 wt%; and hydrogen is introduced in the process of the fluorine-chlorine exchange reaction. The catalyst used in the invention has the advantages of good stability, long service life and the like.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +2

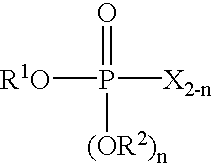

Process for producing phosphorohalidate

InactiveUS6462216B1High purityInhibition of disproportionationPhysical/chemical process catalystsOrganic chemistry methodsDistillationLewis acid catalysis

The present invention provides a process for producing phosphorohalidate characterized in that a crude reaction product obtained by reacting a phosphorus oxyhalide with an aromatic hydroxy compound in the presence of a Lewis acid catalyst is purified by distillation in the presence of an alkali metal salt. The process of the invention produces a high-purity phosphorohalidate in high yield which contains no impurities such as the phosphorus oxihalidate and aromatic hydroxy compound used as starting materials and the catalyst.

Owner:DIAHACHI CHEMICAL INDUSTRY CO LTD

Method for rapidly dissolving copper in electrolytic copper foil manufacturing process

PendingCN113441066AIncrease dissolved oxygen concentrationHelp productionTransportation and packagingMixersElectrolytic agentCu2 ions

The invention belongs to the technical field of electrolytic copper foil manufacturing, relates to a rapid copper dissolving technology which is used for preparing an electrolyte for electrolytic copper foils, and in particular, relates to a method for rapidly dissolving copper in an electrolytic copper foil manufacturing process, wherein the method comprises the following steps: putting a copper material to be dissolved into a copper dissolving tank filled with a sulfuric acid aqueous solution in advance; then introducing oxygen into the copper dissolving tank through a nano bubble generating device, and controlling the concentration of the sulfuric acid aqueous solution in the copper dissolving tank to be larger than that of electrolyte sulfuric acid in the dissolving process. Based on the method, copper can be dissolved rapidly, generation of cuprous ions can be avoided and effectively reduced, and the rapid copper dissolving technology can completely meet the production requirement of electrolytic copper foils.

Owner:CHANGZHOU UNIV

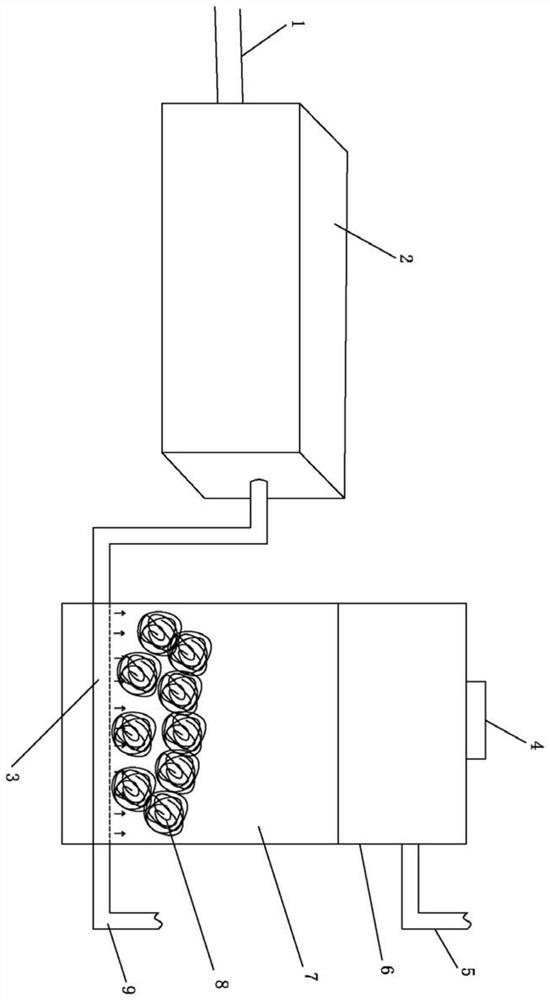

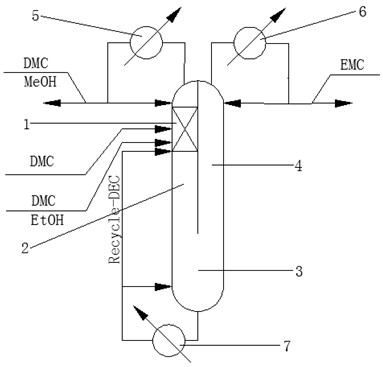

A method for preparing high-purity ethyl methyl carbonate in a partitioning reactive distillation column

ActiveCN109776322BRealize industrial productionHigh yieldChemical industryPreparation from organic carbonatesPtru catalystMethyl carbonate

Owner:FUZHOU UNIV

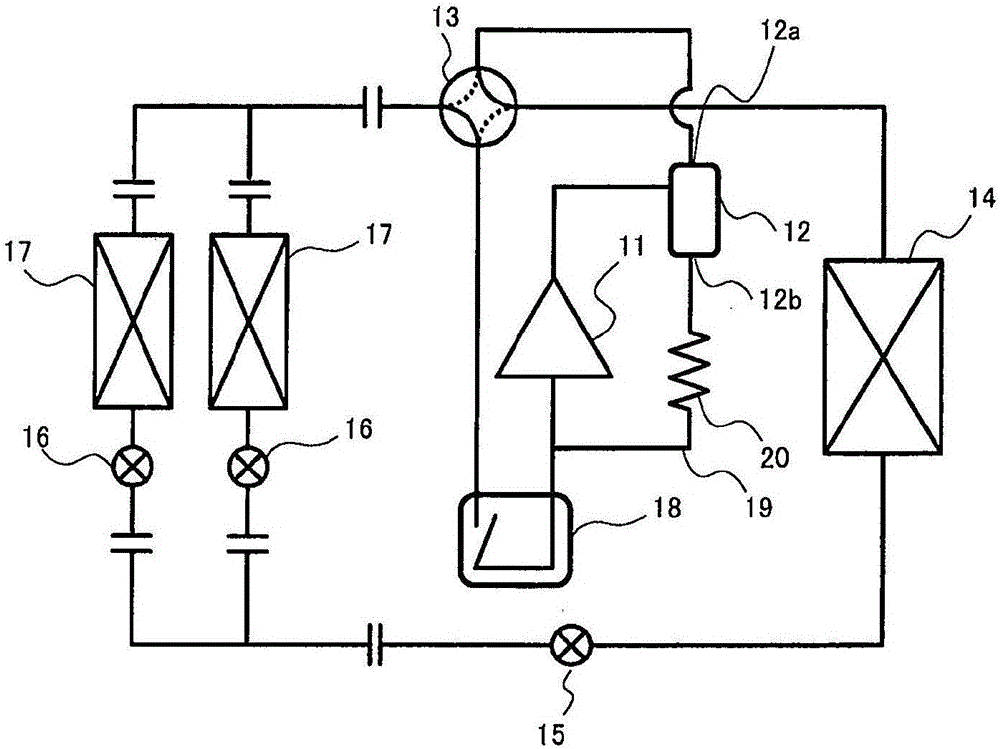

Refrigeration cycle device with motor speed estimator

ActiveUS10590934B2Inhibition of disproportionationImprove reliabilityRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsMotor speedWorking fluid

The present invention includes a refrigeration cycle circuit that includes compressor, indoor heat exchanger, expansion valve, and outdoor heat exchanger that are connected to each other. A working fluid containing R1123 (1,1,2-trifluoroethylene) and R32 (difluoromethane) is used as a refrigerant sealed in the refrigeration cycle circuit, and an electric motor driving device that drives an electric motor of compressor includes a rotational speed estimator. The rotational speed estimator estimates rotational speed based on information on a detection value of an electric current input to the electric motor or a magnetic pole position of a rotor that constitutes the electric motor.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

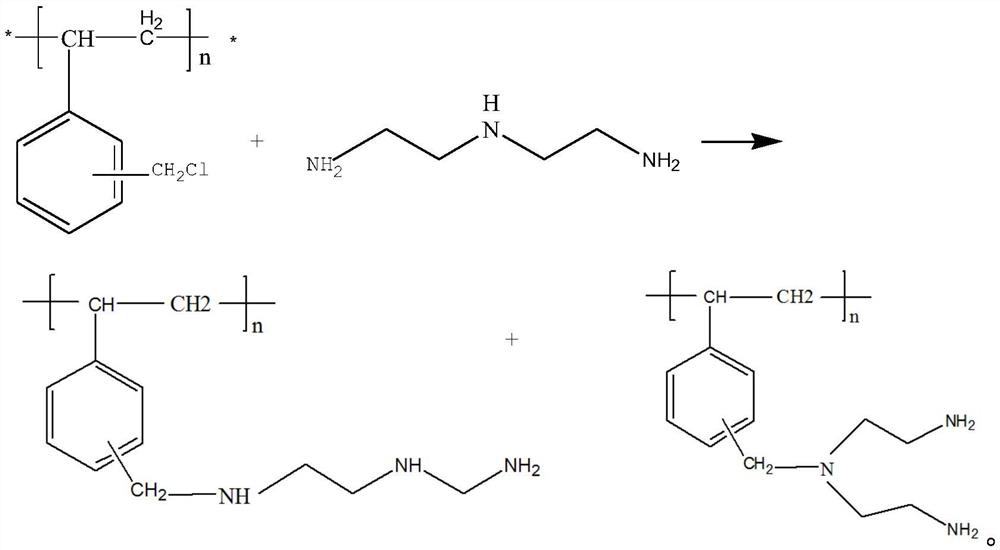

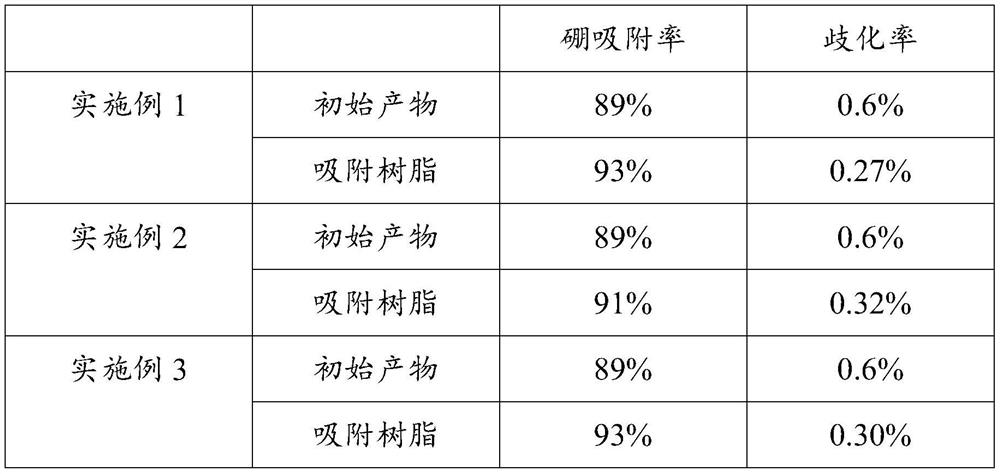

Adsorbing resin for removing impurities from chlorosilane and preparation method of adsorbing resin

InactiveCN113402640AImprove adsorption capacityInhibition of disproportionationOther chemical processesOrganic solventPolyamine

The invention provides an adsorbing resin for removing impurities from chlorosilane and a preparation method thereof, and relates to the technical field of high polymer materials. The preparation method of the adsorbing resin for impurity removal of chlorosilane comprises the following steps: swelling chlorine balls in an organic solvent, and reacting with a reactant to obtain an initial product; wherein the reactant contains polyamine, and the initial product contains tertiary amine; and reacting the initial product with an optimization reagent to convert the tertiary amine into secondary amine, thereby obtaining the adsorbing resin. In the adsorbing resin prepared by the preparation method, tertiary amine is converted into secondary amine, so that the disproportionation effect of chlorosilane can be inhibited.

Owner:青海亚洲硅业半导体有限公司 +2

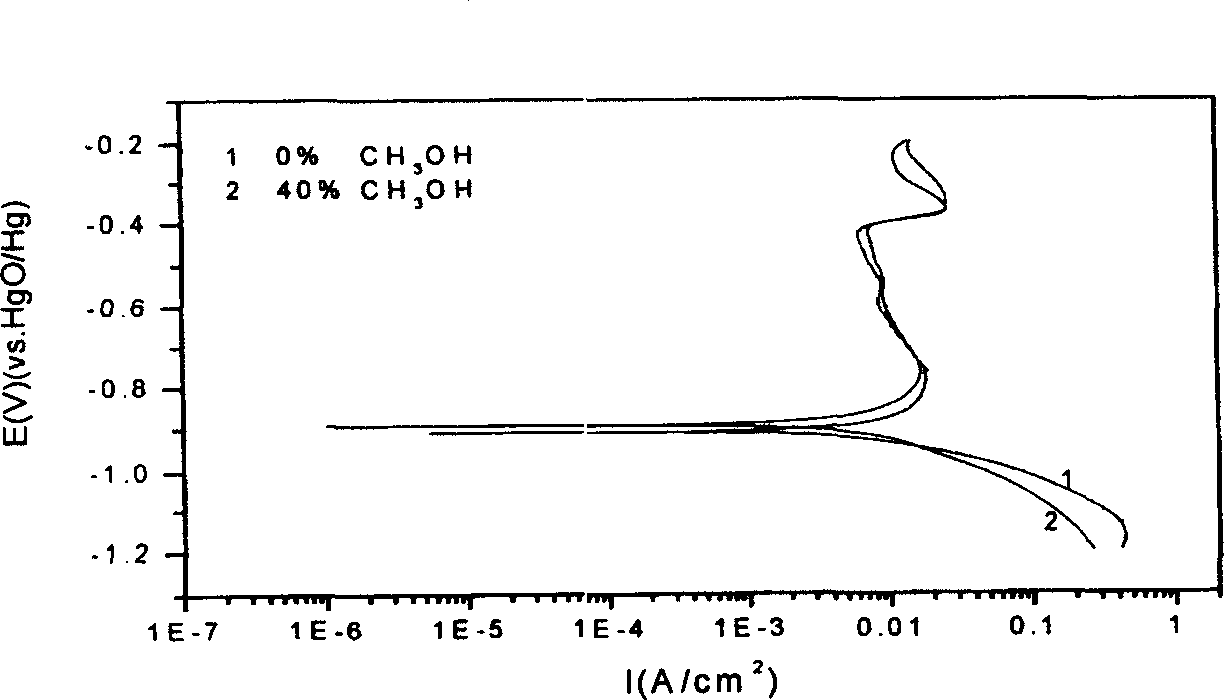

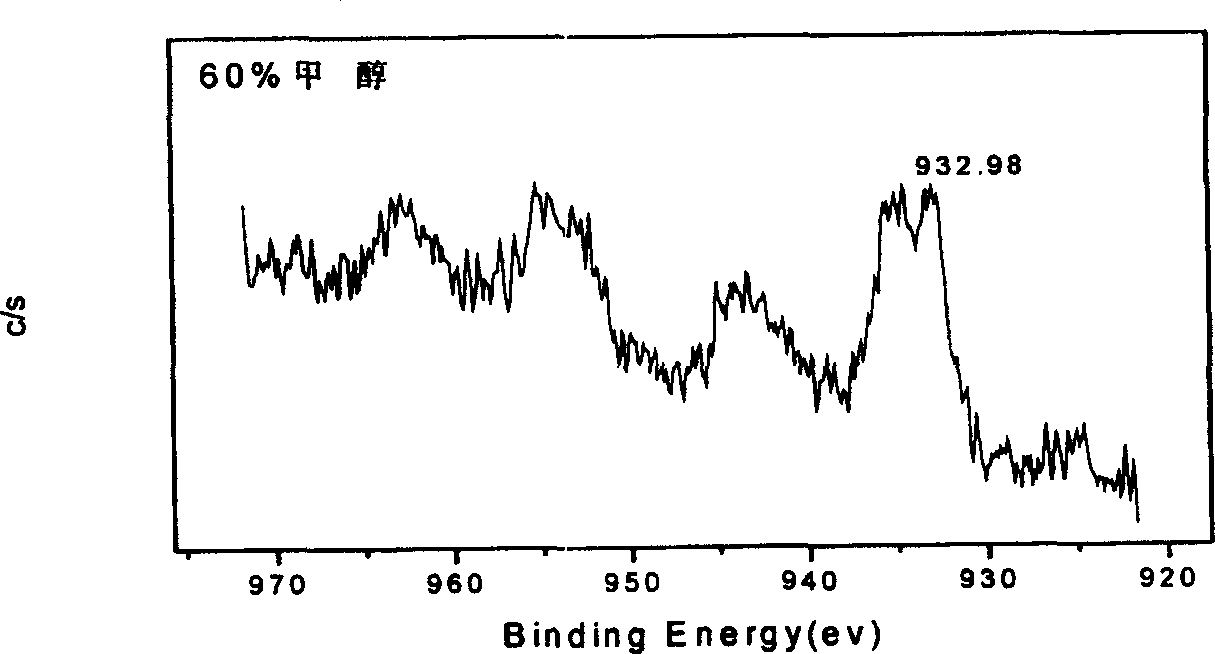

Chemical copper plating process for non-aqueous system magnesium base hydrogen storage alloy powder

InactiveCN1223706CInhibition of disproportionationReduce generationLiquid/solution decomposition chemical coatingCopper platingCorrosion

A chemical copper plating process for hydrogen bearing alloy powder by non-water system features that in the plating procedure, part of water is replaced by organic polar substance (5-80 vol%), which is the mass with hydrophilic polar radicals such as hydroxy, carboxy, or amino radical. Its advantages are high effect on preventing the corrosion and dismutation reaction of copper and plating copper, and high uniformity.

Owner:NANKAI UNIV

A method for reducing catalyst carbon deposition in hfc-23 resource utilization

ActiveCN112973685BEliminate carbon depositsImprove stabilityPreparation by halogen replacementCatalyst regeneration/reactivationHalohydrocarbonPtru catalyst

The invention discloses a method for reducing catalyst carbon deposition in resource utilization of HFC-23. The resource utilization adopts HFC-23 and halogenated hydrocarbon to carry out fluorine-chlorine exchange reaction, and the catalyst of the fluorine-chlorine exchange reaction includes a main body Catalyst and noble metal, the noble metal is selected from at least one of Pt, Pd, Ru, Au or Rh, and the addition amount is 0.01-2wt%. During the process of the fluorine-chlorine exchange reaction, hydrogen gas is introduced. The invention has the advantages of good catalyst stability, long service life and the like.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +2

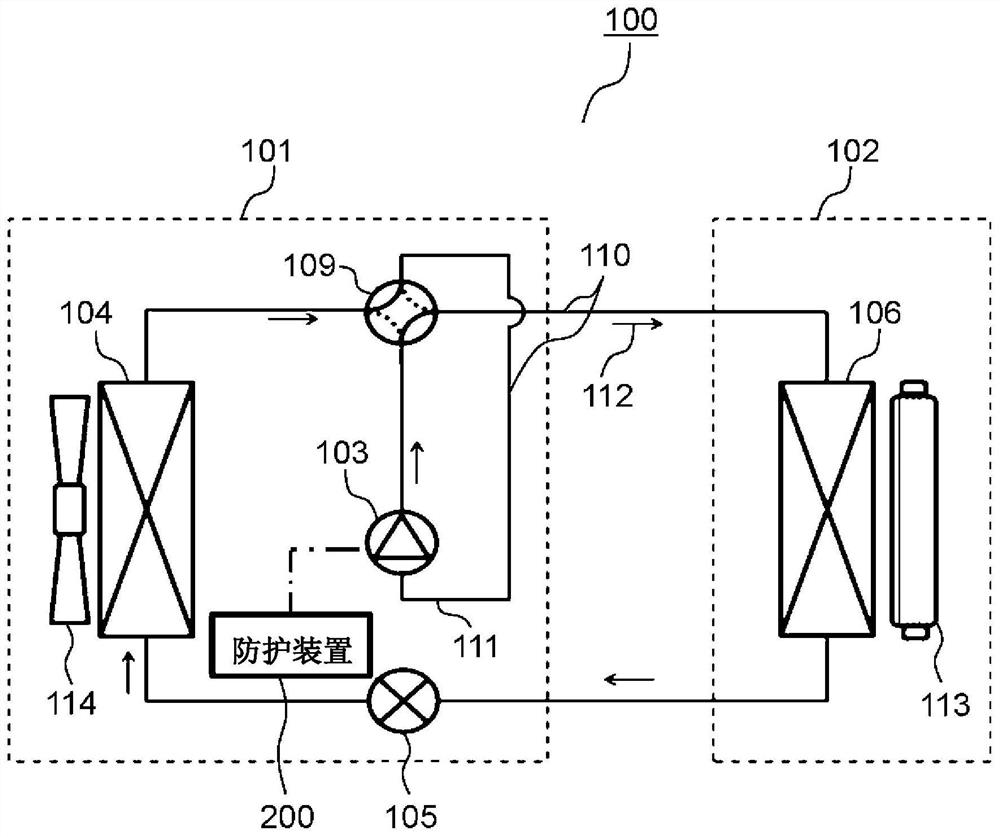

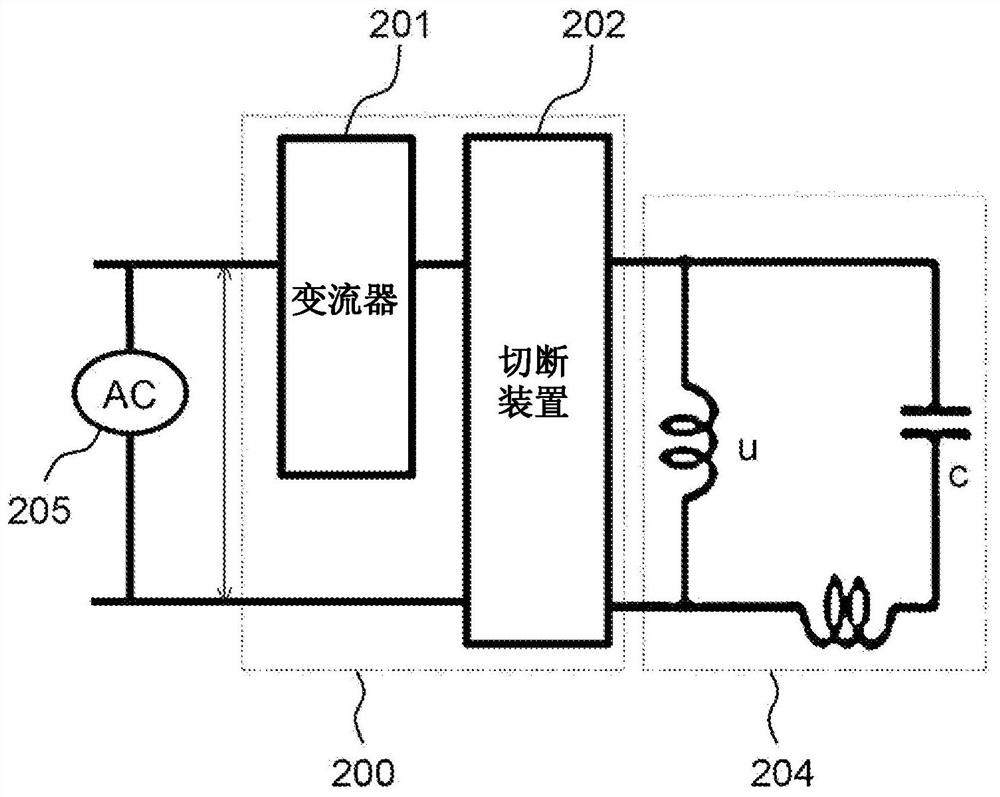

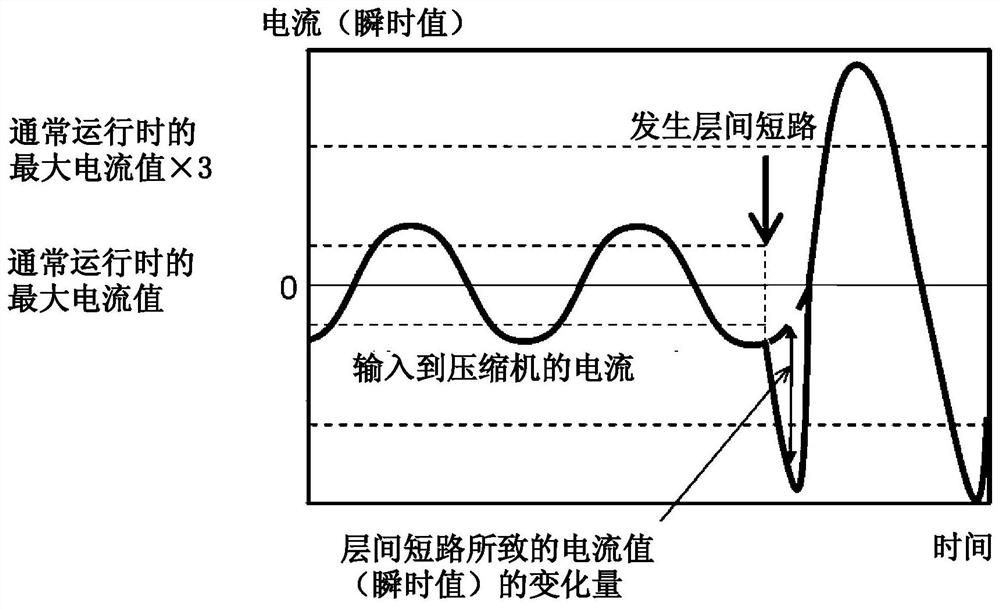

Refrigeration cycle device

ActiveCN111771091BIncrease concentrationInhibition of disproportionationCompression machines with non-reversible cycleHeat-exchange elementsStart timeAir conditioning

The air conditioner (100) as a refrigerating cycle device of the present invention includes: a protective device (200), which is set when the current value of the input current of the motor of the compressor (103) exceeds the start time of the compressor (103) When the first predetermined value is three times or more the maximum current value during normal operation, the current value of the input current to the motor of the compressor (103) exceeds 2 times the current value set at the start of the compressor (103) When the second predetermined value is more than twice, the number of discharged electrons in the discharge space calculated based on the change in the current value of the input current of the motor of the compressor (103) is set to 1.0×10 19 In the case of at least one of the third predetermined value of units / second or more, at least one of stopping power supply to the compressor (103) and reducing the rotation speed of the compressor (103) is performed.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Refrigeration device

PendingCN110268208AInhibition of disproportionationAvoid damageCompression machines with non-reversible cycleRefrigeration safety arrangementRefrigerant reclamationEngineering

Provided is a refrigeration device in which a refrigerant circuit (10) comprises a discharged refrigerant recovery receiver (41) and a discharged refrigerant relief mechanism (43, 44, 45). The discharged refrigerant recovery receiver (41) branches and is connected between the discharge side of a compressor (21) and the gas side of radiators (23, 31) via a discharged refrigerant branch pipe (42). The discharged refrigerant relief mechanism (43, 44, 45) is provided to the discharged refrigerant branch pipe (42) and connects the discharge side of the compressor (21) with the discharged refrigerant recovery receiver (41) when the refrigerant on the discharge side of the compressor (21) causes a disproportionation reaction or when said refrigerant satisfies a predetermined condition before causing a disproportionation reaction.

Owner:DAIKIN IND LTD

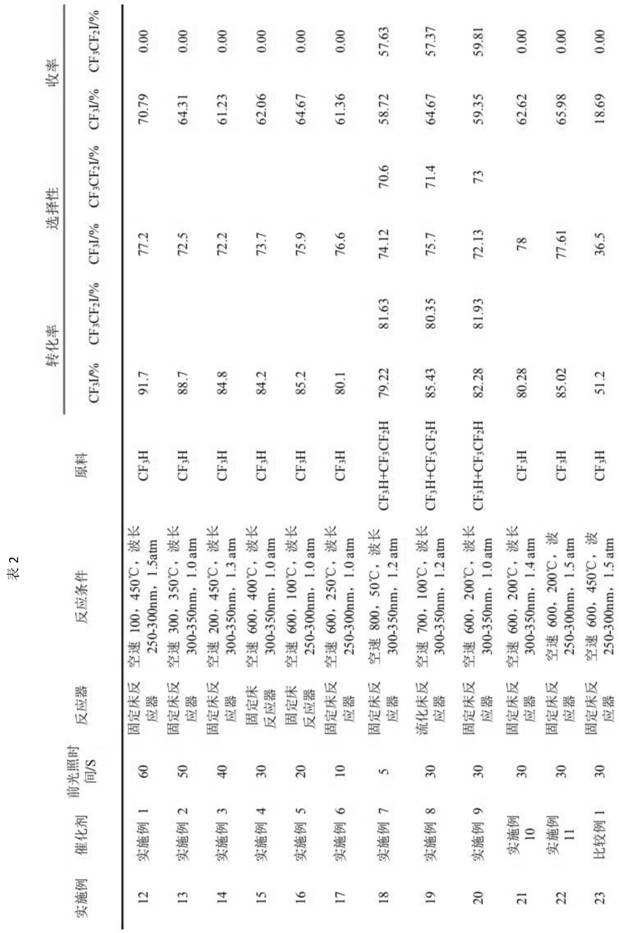

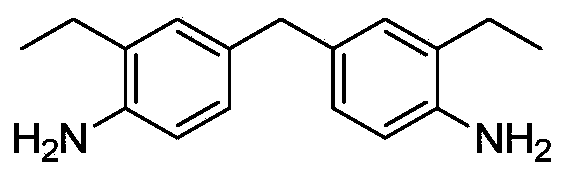

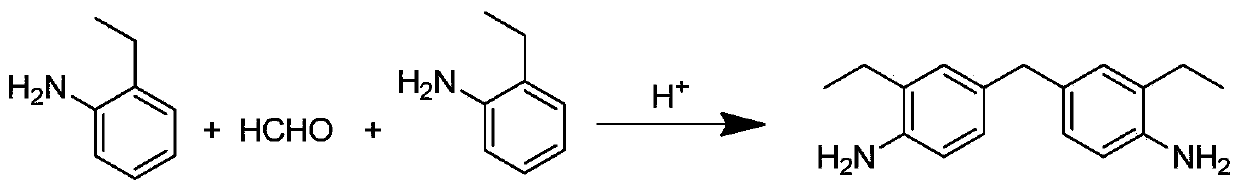

Catalyst for gas-phase catalytic synthesis of perfluoroiodocarbons and its preparation and application

ActiveCN109289885BImprove photocatalytic efficiencyModulation of photocatalytic performancePhysical/chemical process catalystsHalogenated hydrocarbon preparationPtru catalystLanthanide

The invention discloses a gas-phase photothermal catalysis catalyst for synthesizing perfluoroiodomethane as well as its preparation and application. The catalyst is composed of a carrier and an active component. The carrier is one or a combination of tin oxide, titanium dioxide, zirconium dioxide or cadmium sulfide. The active component includes C coated on the surface of the carrier. 3 N 4 And the metal element loaded on the surface of the carrier, the metal element is composed of a lanthanide element and at least one alkali metal element, wherein the mass ratio of a lanthanide element and at least one alkali metal element is 1.0:( 0.1‑30), in the catalyst, based on the carrier quality, C 3 N 4 The loading is 0.5‑30%, and the lanthanide loading is 0.1‑8.0%. The invention provides the application of the catalyst in gas-phase photothermal catalytic synthesis of perfluoroiodocarbon compounds. The catalyst of the invention has good photocatalytic performance, can reduce the reaction temperature, improve the selectivity, and suppress the generation of carbon deposition to increase the service life of the catalyst.

Owner:ZHEJIANG UNIV OF TECH

A kind of catalyst for synthesizing demma and its preparation method, application

ActiveCN107866264BReduce contentInhibition of disproportionationAmino preparation from aminesMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a supported modified zeolite molecular sieve catalyst, which comprises a modified zeolite molecular sieve carrier and a loaded active component, wherein, the modified zeolite molecular sieve carrier is prepared by modifying the zeolite molecular sieve, including: combining the molecular sieve with an alkali metal The alkaline solution of the elements is mixed, washed, dried, and roasted to obtain a preliminary modified carrier; the preliminary modified carrier is impregnated with a soluble compound solution containing lanthanides and boron, dried, and roasted to obtain oxides containing lanthanides and three The modified zeolite molecular sieve carrier of diboron oxide. The invention also discloses the preparation method of the catalyst and the application in synthesizing DEMMA. The catalyst of the invention has high raw material conversion rate, good product selectivity and few by-products, and meanwhile, the catalyst preparation process is simple and economical, and has good application prospect.

Owner:WANHUA CHEM GRP CO LTD

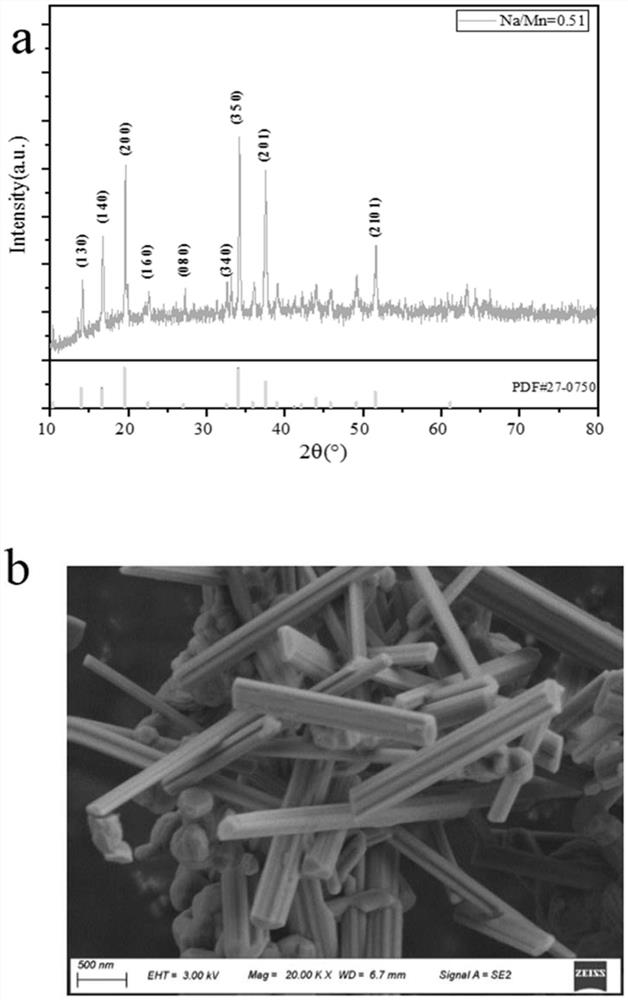

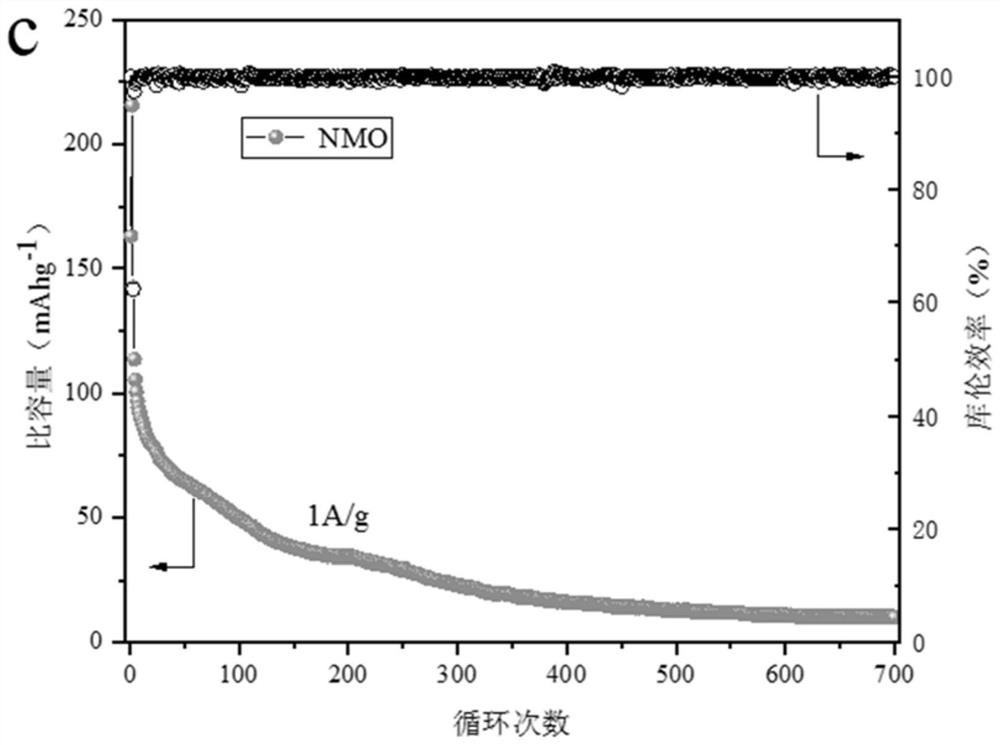

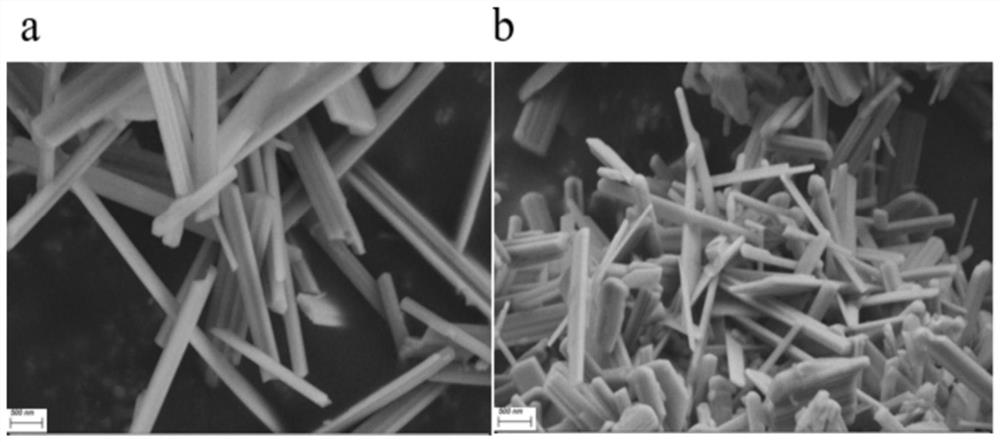

Modified sodium manganate material as well as preparation method and application thereof

PendingCN114655991AImprove electrochemical performanceInhibition of dissolutionCell electrodesManganates/permanganatesElectrical batteryPhysical chemistry

The invention discloses a modified sodium manganate material as well as a preparation method and application thereof, belongs to the technical field of aqueous ion battery preparation, and solves the technical problem of poor cycling stability of an aqueous battery due to a dissolution phenomenon existing when manganese oxide is used as a positive electrode material in the prior art. According to the preparation method of the modified sodium manganate material disclosed by the invention, pure-phase sodium manganate is prepared by using a coupling agent assisted sol-gel method, and doping treatment is performed at the Mn site through different transition metals on the basis of preparing the pure-phase sodium manganate, so that the crystal stability and the electrochemical performance are improved. The modified sodium manganate prepared by the method is used as a positive electrode material of an aqueous ion battery, and has good cycle stability.

Owner:RES & DEV INST OF NORTHWESTERN POLYTECHNICAL UNIV IN SHENZHEN

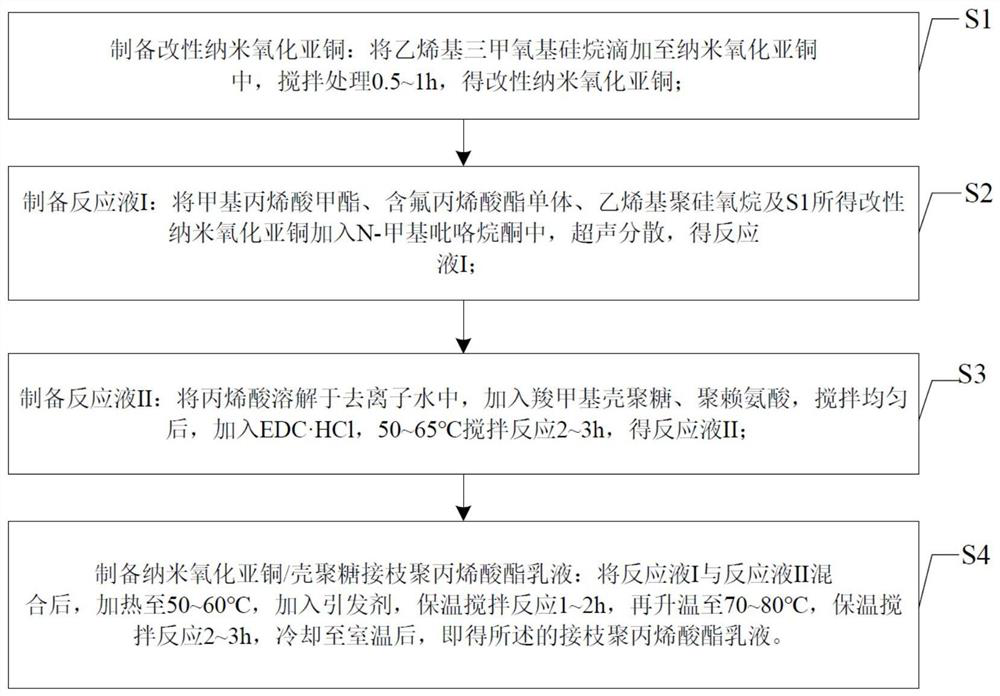

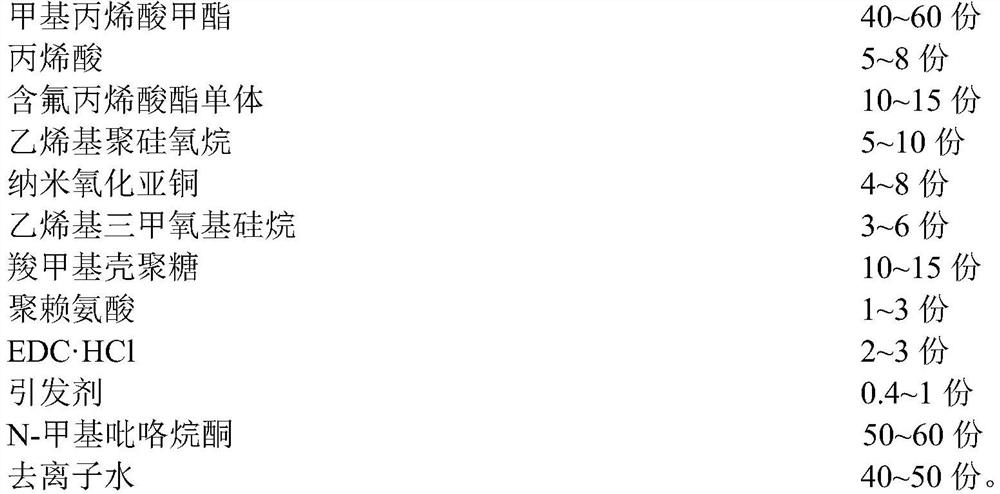

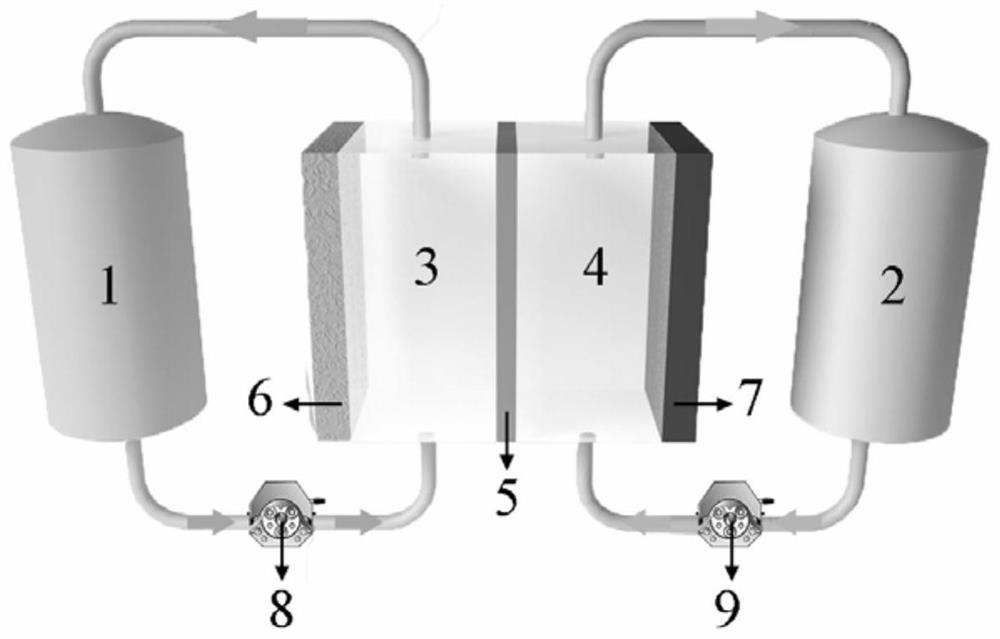

Antibacterial nano cuprous oxide/chitosan grafted polyacrylate emulsion as well as preparation method and application thereof

InactiveCN112724342AImprove hydrophobicityExcellent oleophobicAntifouling/underwater paintsPaints with biocidesEmulsionMeth-

The invention discloses an antibacterial nano cuprous oxide / chitosan grafted polyacrylate emulsion as well as a preparation method and application thereof. The polyacrylate emulsion is prepared from the following raw materials in parts by mass: 40 to 60 parts of methyl methacrylate, 5 to 8 parts of acrylic acid, 10 to 15 parts of a fluorine-containing acrylate monomer, 5 to 10 parts of vinyl polysiloxane, 4 to 8 parts of nano cuprous oxide, 3 to 6 parts of vinyl trimethoxy silane, 10 to 15 parts of carboxymethyl chitosan, 1 to 3 parts of polylysine, 2 to 3 parts of EDC.HCl, 0.4 to 1 part of an initiator, 50 to 60 parts of N-methyl pyrrolidone and 40 to 50 parts of deionized water. The preparation method comprises the following steps: S1, preparing modified nano cuprous oxide; s2, preparing a reaction solution I; s3, preparing a reaction solution II; and S4, preparing the nano cuprous oxide / chitosan grafted polyacrylate emulsion. According to the invention, vinyl trimethoxy silane is used for modifying nano cuprous oxide for the first time, acrylic acid reacts with carboxymethyl chitosan and polylysine to introduce C = C, and then the product is further copolymerized with other monomers, so that polyacrylate is endowed with excellent hydrophobic, oleophobic, antibacterial and self-cleaning properties.

Owner:蚌埠泰鑫材料技术有限公司

Positive electrode electrolyte for zinc-manganese flow battery

PendingCN114400357AInhibition of disproportionationImprove performanceRegenerative fuel cellsAqueous electrolytesSupporting electrolyteElectrolytic agent

The invention is applied to the field of zinc-manganese flow batteries, and particularly relates to a positive electrode electrolyte for a zinc-manganese flow battery. An electrolyte in a positive electrode electrolyte of the zinc-manganese flow battery comprises a manganese salt, an additive and a supporting electrolyte, the manganese salt is one or two of manganese sulfate, manganese chloride and manganese nitrate, the additive is sulfosalicylic acid, and the supporting electrolyte is potassium ions or sodium ions. By selecting the additive and utilizing the complexing structure of the divalent manganese ions and the additive, the disproportionation reaction of the trivalent manganese ions is changed and inhibited, the generation of manganese dioxide is avoided, the performance of the battery is improved, and the cycle life of the battery is prolonged. The invention has the advantages of outstanding performance, safety, environmental protection and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

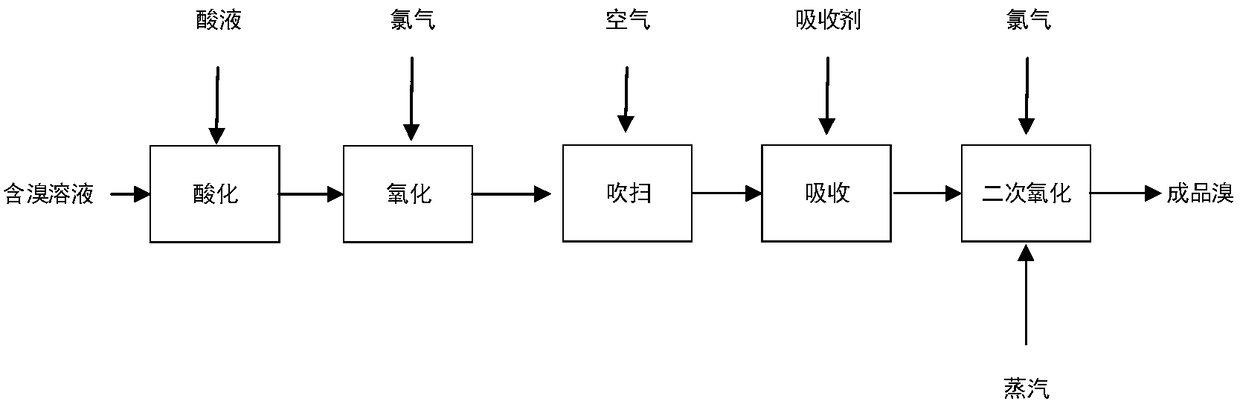

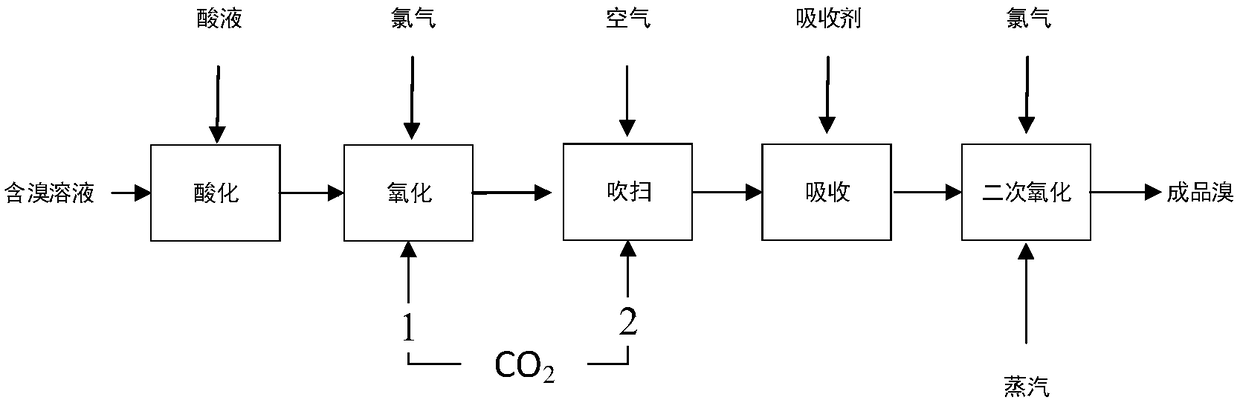

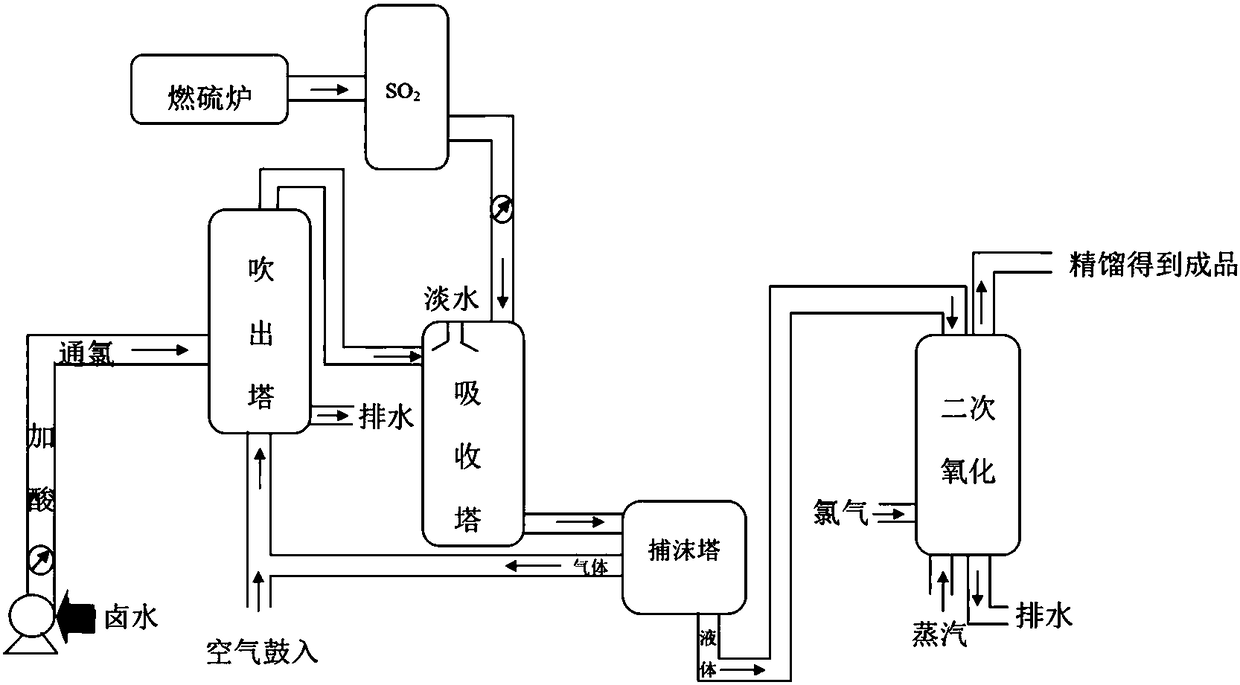

Method and device for increasing bromine stripping rate and extraction rate in air blowing-out process

The invention discloses a method and a device for increasing bromine stripping rate and extraction rate in an air blowing-out process and belongs to the field of bromine extraction. The method specifically includes: feeding CO2 gas into a bromine-containing solution during or before air blowing-out of oxidation completing liquid. Compared with the prior art, the method has the advantages that by feeding CO2 into brine before sweeping, disproportionation reaction can be inhibited, and dissolution of bromine can be reduced, so that sweeping recovery rate of bromine is increased, and final bromine integral extraction rate is increased.

Owner:山东特检科技有限公司

Refrigeration cycle device using working fluid containing 1,1,2-trifluoroethylene (R1123) and difluoromethane (R32)

ActiveUS10591188B2Inhibition of disproportionationHighly reliable refrigeration cycle deviceMechanical apparatusCompression machines with non-reversible cycleWorking fluidEngineering

A refrigeration cycle device includes a refrigeration cycle formed by connecting a compressor, a condenser, an expansion valve and an evaporator to each other. As a refrigerant in the refrigeration cycle, a working fluid containing 1,1,2-trifluoroethylene (R1123) and difluoromethane (R32) is used. A degree of opening of the expansion valve is controlled such that the refrigerant has two phases at a suction portion of the compressor.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

A kind of method for improving catalyst stability in hfc-23 resource utilization

ActiveCN112979410BImprove stabilityExtend your lifePreparation by halogen replacementCatalyst regeneration/reactivationHalohydrocarbonPtru catalyst

The invention discloses a method for improving the stability of a catalyst in resource utilization of HFC-23. The resource utilization adopts HFC-23 and halogenated hydrocarbons to carry out fluorine-chlorine exchange reaction, and the catalyst of the fluorine-chlorine exchange reaction includes a main body A catalyst and a metal oxide, the metal oxide is at least one metal oxide selected from K, Na, Fe, Co, Cu, Ni, Zn or Ti, and the added amount is 0.1-5 wt%. The invention has the advantages of good catalyst stability, long service life, low content of by-product CFC-12, and the like.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +2

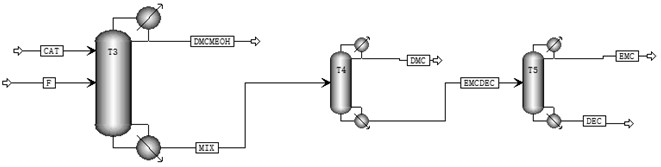

Method for preparing ultrahigh-purity ethyl methyl carbonate through continuous rectification device

InactiveCN110903195AComponent content is stableStable contentCarbonic/haloformic acid esters purification/separationMethyl carbonateEthyl ester

The invention discloses a method for preparing ultrahigh-purity ethyl methyl carbonate through a continuous rectification device. The device comprises a rectifying tower I and a rectifying tower II, ethyl methyl carbonate is added into the rectifying tower I through a feeding hole I; a discharge hole I formed in the tower top of the rectifying tower I is used for removing gas-phase light components; tower kettle materials at the bottom in the rectifying tower I are conveyed to a feeding hole II through a conveying pump and enter the rectifying tower II; a discharging opening II formed in the tower top of the rectifying tower II is used for removing gas-phase light components, a discharging opening III formed in the rectifying tower II is used for extracting a high-purity ethyl methyl carbonate product, and tower kettle material heavy components at the bottom in the rectifying tower II are extracted through the conveying pump. By adopting the technical scheme, the defects of batch-typerectification are overcome, the production efficiency is high, and more than 99.99% of high-purity ethyl methyl carbonate product can be conveniently extracted from the tower of the rectifying tower II.

Owner:TONGLING JINTAI CHEM INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com