A method for preparing high-purity ethyl methyl carbonate in a partitioning reactive distillation column

A technology of reactive distillation column and ethyl methyl carbonate, which is applied in the field of preparation of high-purity ethyl methyl carbonate, can solve the problems of low selective yield, equipment cost and high process energy consumption, achieve simple operation mode and alleviate overcapacity , the effect of increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

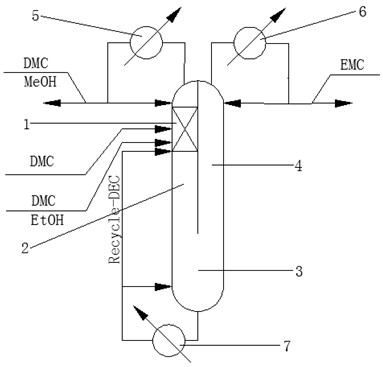

[0023] process such as figure 1 As shown, the mixed feed DMC and ethanol are mixed at a ratio of 1.35:1, preheated to 50°C, specifically, the DMC flow rate is 2500kg / h, the ethanol flow rate is 950kg / h, and the feed is fed from the ninth plate of the main tower T1. The single-strand DMC is also preheated to 50°C, and the feed is fed from the 8th plate at a flow rate of 1200kg / h. The position of the DEC cycle feed is the 7th plate. The number of plates in the reaction section is 9, and the number of plates in the stripping section is 37. The number of plates in the common stripping section is 10, and the reflux ratio is 3.71; the total number of plates in the sub-column T2 is 30, and the reflux ratio is 4.03; after the raw materials are fully reacted in the reaction section, the methanol and a small amount of unreacted DMC generated from T1 Extracted from the top of the tower, the output is 979.7kg / h; the vapor phase at the bottom of the stripping section of T1 is extracted to...

Embodiment 2

[0026] process such as figure 1 As shown, the mixed feed DMC and ethanol are mixed at a ratio of 1.35:1, preheated to 50°C, specifically, the DMC flow rate is 2500kg / h, the ethanol flow rate is 950kg / h, and the feed is fed from the ninth plate of the main tower T1. The single-strand DMC is also preheated to 50°C, and the feed is fed from the 8th plate at a flow rate of 1200kg / h. The position of the DEC cycle feed is the 7th plate. The number of plates in the reaction section is 9, and the number of plates in the stripping section is 33. The number of plates in the common stripping section is 10, and the reflux ratio is 3.71; the total number of plates in the sub-column T2 is 30, and the reflux ratio is 4.03; after the raw materials are fully reacted in the reaction section, the methanol and a small amount of unreacted DMC generated from T1 Extracted from the top of the tower, the output is 979.7kg / h; the vapor phase at the bottom of the stripping section of T1 is extracted to...

Embodiment 3

[0029] process such as figure 1 As shown, the mixed feed DMC and ethanol are mixed at a ratio of 1.35:1, preheated to 50°C, specifically, the DMC flow rate is 2500kg / h, the ethanol flow rate is 950kg / h, and the feed is fed from the ninth plate of the main tower T1. The single-strand DMC is also preheated to 50°C, and the feed is fed from the 8th plate at a flow rate of 1200kg / h. The position of the DEC cycle feed is the 7th plate. The number of plates in the reaction section is 9, and the number of plates in the stripping section is 30. The number of plates in the common stripping section is 10, and the reflux ratio is 3.71; the total number of plates in the sub-column T2 is 30, and the reflux ratio is 4.03; after the raw materials are fully reacted in the reaction section, the methanol and a small amount of unreacted DMC generated from T1 Extracted from the top of the tower, the output is 979.7kg / h; the vapor phase at the bottom of the stripping section of T1 is extracted to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com