Industrial microwave ultrasonic reaction kettle

一种微波超声、工业用的技术,应用在工业用微波超声反应釜领域,能够解决处理量小、作用范围有限、均匀性差等问题,达到节约能源、作用范围大、提高浸出效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

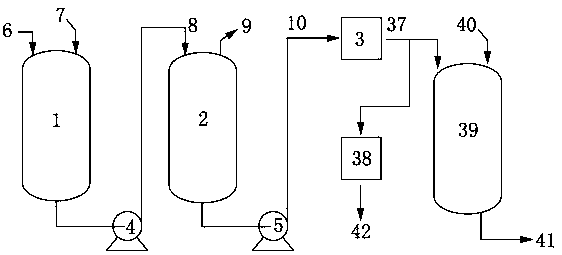

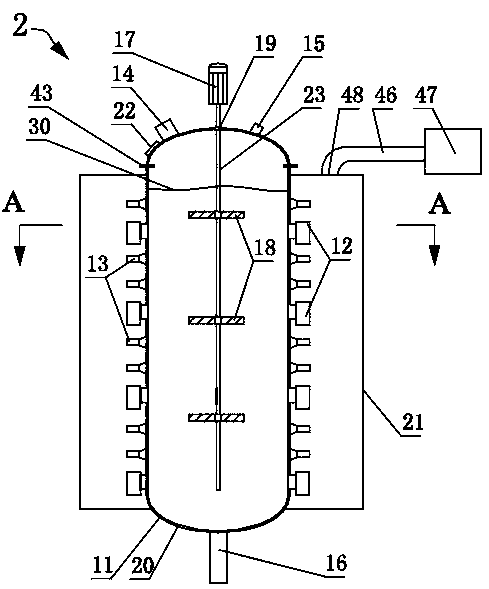

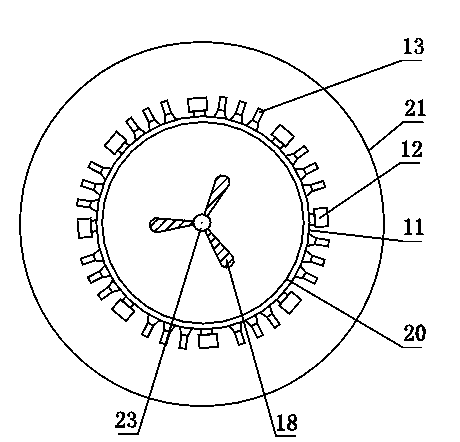

[0054] Such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, a microwave ultrasonic reaction kettle 2 includes a kettle body 11, a microwave generating device, an ultrasonic generating device, a stirring device and a heat removal device. The top of the kettle body 11 is provided with a feed port 14, an exhaust port 15, and a viewing window 22 , a pressure relief valve and a pressure gauge (not shown in the figure), and a discharge port 16 is provided at the bottom of the kettle body 11 .

[0055] The kettle body 11 is a cylindrical reaction kettle, and the lining of the kettle body 11 is made of anti-corrosion wave-transmitting material, preferably a PTFE coating 20 with a thickness of 0.05-1 mm; Direct contact with leachate such as salt will cause equipment corrosion.

[0056] The microwave generating device includes 4 groups of horizontal arrangements, each group of 8 microwave units 12 arranged at intervals along the outer wall of the kettle body 11. The micr...

Embodiment 2

[0061] Such as Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, a microwave ultrasonic reaction kettle 2 of the present invention comprises a kettle body 11, a microwave generating device, an ultrasonic generating device, a stirring device, a heat removal device and a circulation pipe 26, and the top of the kettle body is provided with a feed port 14, an exhaust gas Port 15 and viewing window 22, and the bottom of kettle body 11 is provided with discharge port 16.

[0062] Still body 11 is a cylindrical reactor, as Figure 9 As shown, the lining of the kettle body is an anti-sticking and anti-corrosion barrel 24 with a shape matching the inner wall of the kettle body 11 and a thickness of 3 to 30 mm in diameter, such as a PP (polypropylene) barrel. The wave-transparent glass wool 25 is arranged between the body 11, so that the anti-sticking and anti-corrosion barrel 24, the glass wool 25 and the kettle body 11 are closely attached to each other from the inside to ...

Embodiment 3

[0069] Such as Figure 10 , Figure 11 , Figure 12 and Figure 13As shown, a microwave ultrasonic reactor 2 of the present invention includes a kettle body 11, a microwave generating device, an ultrasonic generating device, a stirring device, a heat exhaust device, a baffle plate 29 and a return pipe I34, and the top of the kettle body is provided with a feed inlet 14. An exhaust port 15, a viewing window 22, and a discharge port 16 is provided at the bottom of the kettle body 11.

[0070] Such as Figure 11 As shown, the kettle body 11 is a cylindrical reaction kettle, and the inner lining of the kettle body 11 is a layer of PTFE coating 20 with a thickness of 0.05-3mm closely attached to the inner wall of the kettle body 11 .

[0071] The microwave generating device includes 4 groups of horizontal arrangements, each group of 8 microwave units 12 arranged at intervals along the outer wall of the kettle body 11. The microwave unit 12 is provided with a magnetron, a second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com