Preparation method of pentaerythritol and dipentaerythritol

A technology of dipentaerythritol and monopentaerythritol, which is applied in chemical instruments and methods, preparation of organic compounds, ether preparation, etc., can solve the problem of low yield of monopentaerythritol, complicated operation, unsatisfactory high quality and quantity of monopentaerythritol and dipentaerythritol, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

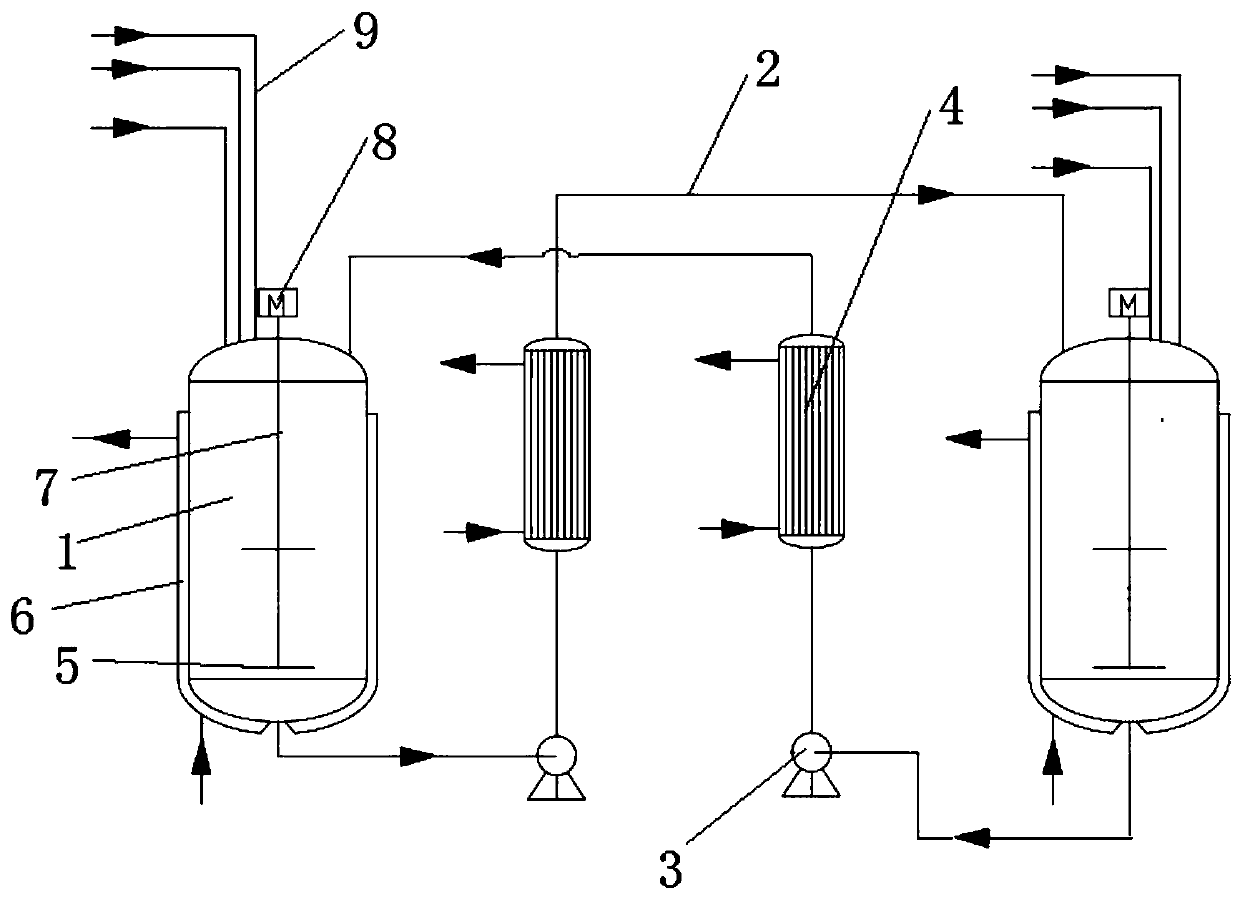

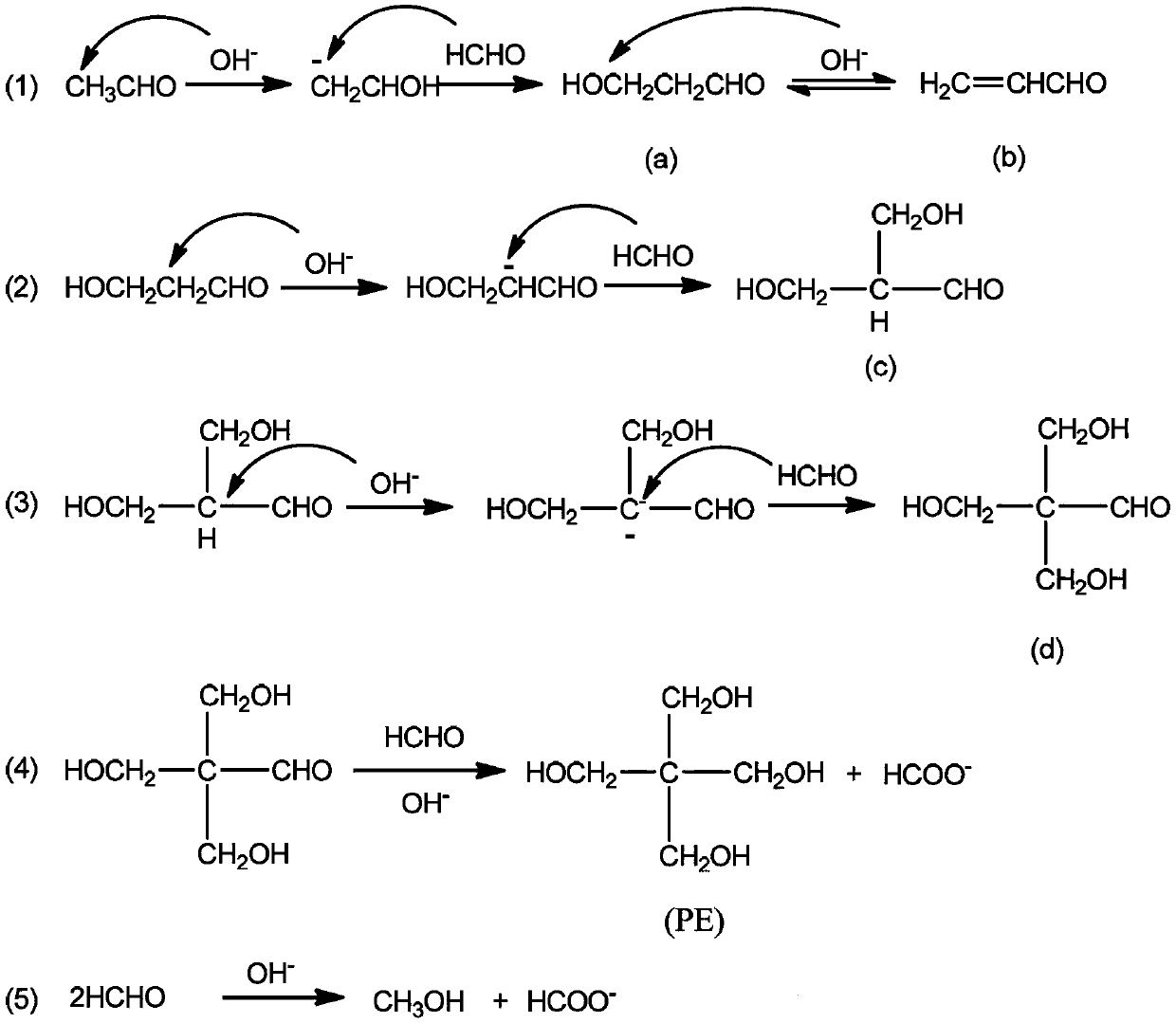

Method used

Image

Examples

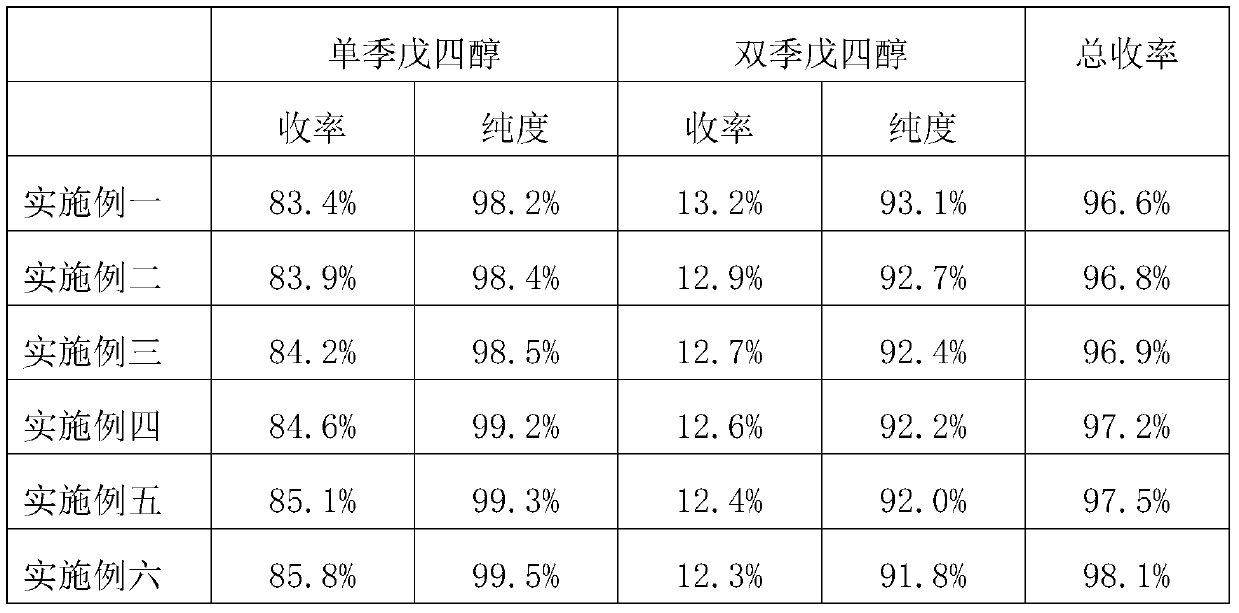

Embodiment 1

[0027] Prepare 60kmol of pure formaldehyde into a formaldehyde solution with a mass concentration of 25% and put it into a constant temperature reactor. Set the reaction temperature to 50°C. When the temperature reaches 50°C, add 10.2kmol of pure hydrogen with a weight percentage of 25%. Sodium oxide solution, after 2 minutes, add the acetaldehyde aqueous solution that is prepared as 55% by weight and convert to pure 10kmol, and add formic acid aqueous solution to adjust the pH value to 6.5 after the constant temperature reaction at 50 ° C for 15 minutes, and then stop the reaction to obtain a mixture containing pentaerythritol and dipentaerythritol. Condensation solution with formate, the condensation solution is processed through conventional rectification tower dealdehyde, multi-effect continuous vacuum evaporation, crystallization, centrifugation, drying and packaging, etc., to obtain finished pentaerythritol, dipentaerythritol and sodium formate. In this embodiment, ethyl ...

Embodiment 2

[0029] Put 60kmol of pure formaldehyde into 25% formaldehyde aqueous solution and put it into a constant temperature reactor. Set the reaction temperature to 70°C. When the temperature reaches 70°C, add 10.2kmol of pure sodium hydroxide solution with a weight percentage of 25%. After 2 minutes, add the acetaldehyde aqueous solution that is prepared as 55% by weight and convert to pure 10kmol. After 15 minutes of constant temperature reaction at 70°C, add formic acid aqueous solution to adjust the pH value to 6.5 and stop the reaction to obtain a mixture containing pentaerythritol, dipentaerythritol and formic acid. Condensation of salt. The condensed liquid is processed by conventional rectification tower for dealdehyde, multi-effect continuous vacuum evaporation, crystallization, centrifugation, drying and packaging to obtain finished pentaerythritol, dipentaerythritol and sodium formate. In this embodiment, the yield of each product is calculated by acetaldehyde The results ...

Embodiment 3

[0031]Put 60kmol of pure formaldehyde into 25% formaldehyde aqueous solution and put it into a constant temperature reactor, set the reaction temperature to 90°C, when the temperature reaches 90°C, add 10.2kmol of pure 10.2kmol of sodium hydroxide prepared into 25% by weight Solution, after 2 minutes, add the acetaldehyde aqueous solution that is formulated into 55% by weight and convert to pure 10kmol, and add formic acid aqueous solution to adjust the pH value to 6.5 after the constant temperature reaction at 90° C. for 15 minutes, and then stop the reaction, and obtain a mixture containing pentaerythritol, dipentaerythritol and formaldehyde. acid condensation solution. The condensate is processed by conventional rectification tower for dealdehyde, multi-effect continuous vacuum evaporation, crystallization, centrifugation, drying and packaging to obtain finished pentaerythritol, dipentaerythritol and sodium formate. In this embodiment, the yield of each product is calculated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com