Compound anode material for lithium ion battery and preparation method thereof

A composite cathode material, lithium ion battery technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problems of non-stoichiometric ratio defects, unfavorable battery cycle properties, small improvement, etc. Cyclic discharge capacity retention rate, the effect of avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

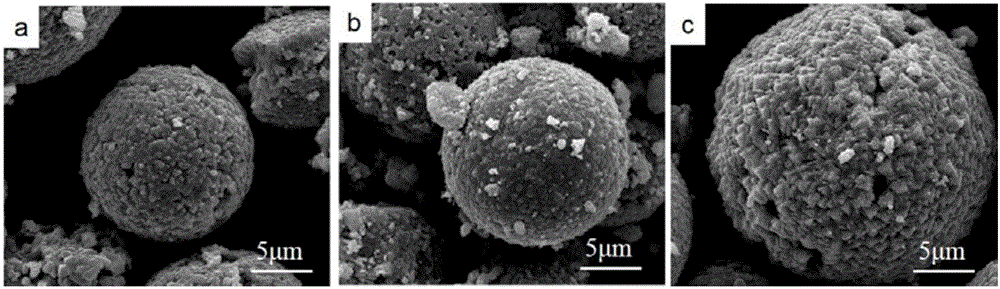

[0028] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

[0029] (1) Dissolve nickel sulfate hexahydrate and manganese sulfate hexahydrate in 250ml deionized water according to the ratio of 1:3, stir to obtain the mixture;

[0030] (2) According to the molar ratio of urea to the total amount of nickel and manganese in the mixture, which is 2:1, add it to the mixture obtained in step (1). Heated for 12 hours, washed 3 times with deionized water and ethanol, and dried to obtain a precursor;

[0031] (3) Place the precursor obtained in step (2) in a muffle furnace, sinter at 500°C for 3 hours, and heat up at a rate of 5°C / min, and then naturally cool down to room temperature to obtain a precursor oxide;

[0032] (4) According to the molar ratio of excess lithium source of 5%, lithium hydroxide monohydrate is mixed with the precursor oxide obtained in step (3), placed in a muffle furnace, sintered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com