Patents

Literature

669 results about "Retention ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

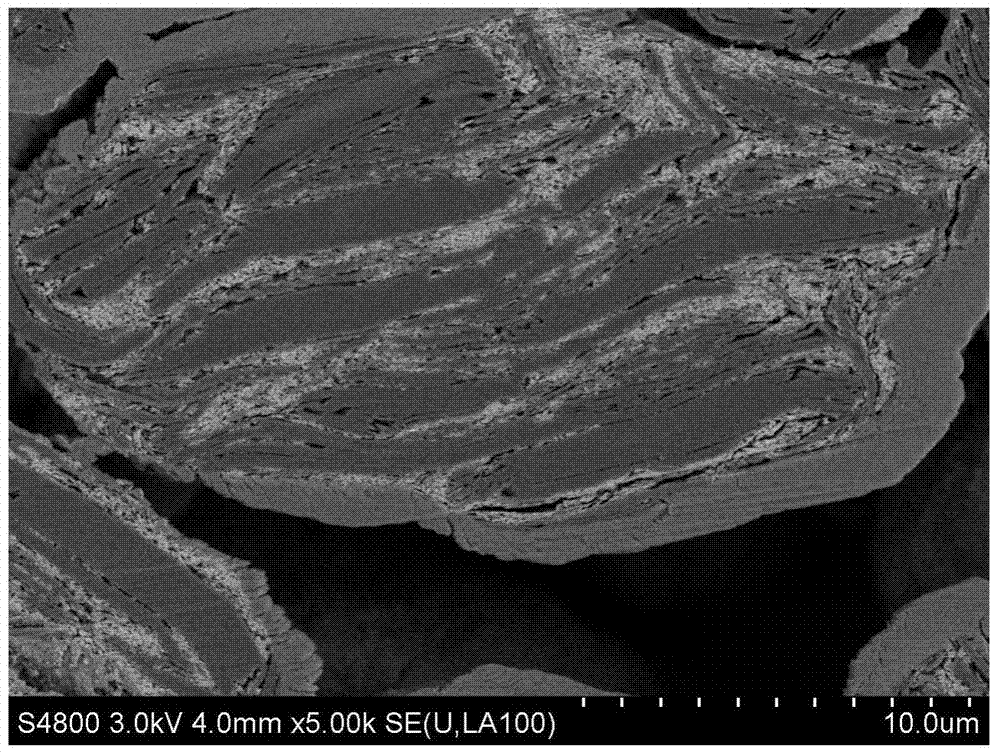

Lithium ion battery silicon-carbon anode material and preparation method thereof

ActiveCN103367727APromote circulationHigh specific capacityCell electrodesSecondary cellsLithium-ion batteryRetention ratio

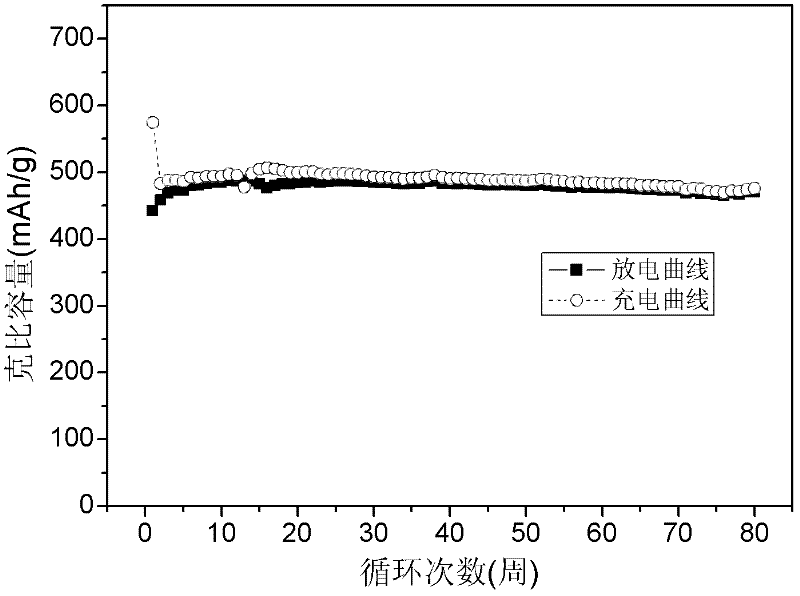

The invention relates to a lithium ion battery silicon-carbon anode material which comprises nanometer silicon, graphite polymer and organic matter pyrolysis carbon, wherein the graphite polymer is formed by granular graphite; the nanometer silicon is embedded and clamped among gaps of the granular graphite or attached on the surface of the granular graphite; nanometer silicon / graphite polymer is covered by the organic matter pyrolysis carbon. A preparation method of the lithium ion battery silicon-carbon anode material comprises the steps of: mixing the nanometer silicon, a dispersing agent, a bonding agent and the granular graphite in an organic solvent, and drying to obtain composite nanometer silicon / graphite polymer; adding the obtained composite nanometer silicon / graphite polymer into the dispersion liquid of a carbon source precursor, mixing and drying; and carrying out heat treatment on material to obtain the lithium ion battery silicon-carbon anode material. The prepared silicon-carbon material has high specific capacity, high first time efficiency and excellent cycle performance, the capacity is larger than 450mAh / g, the first time efficiency is more than 85%, and the capacity retention ratio is more than 97% after circulation is carried out for 60 times.

Owner:BTR NEW MATERIAL GRP CO LTD

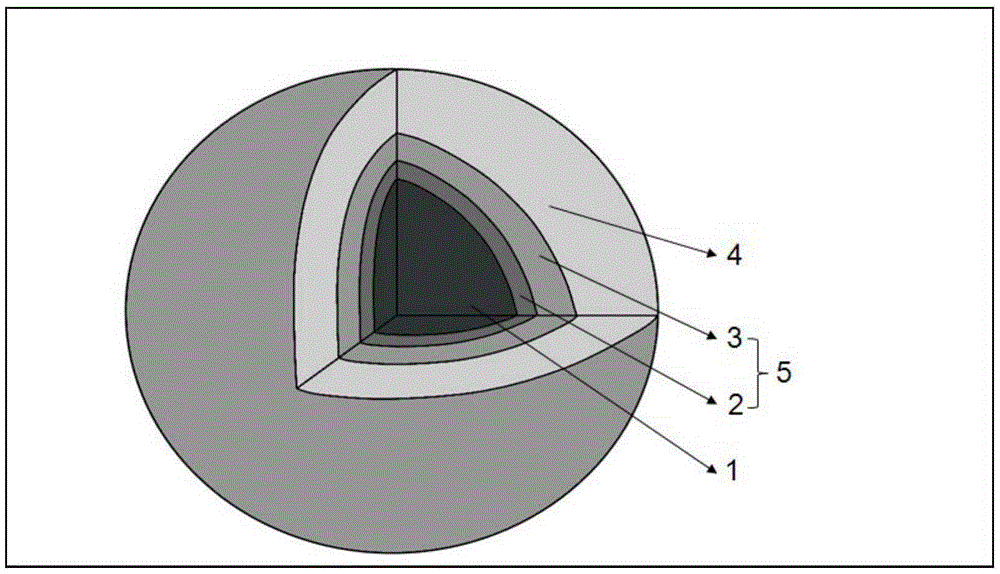

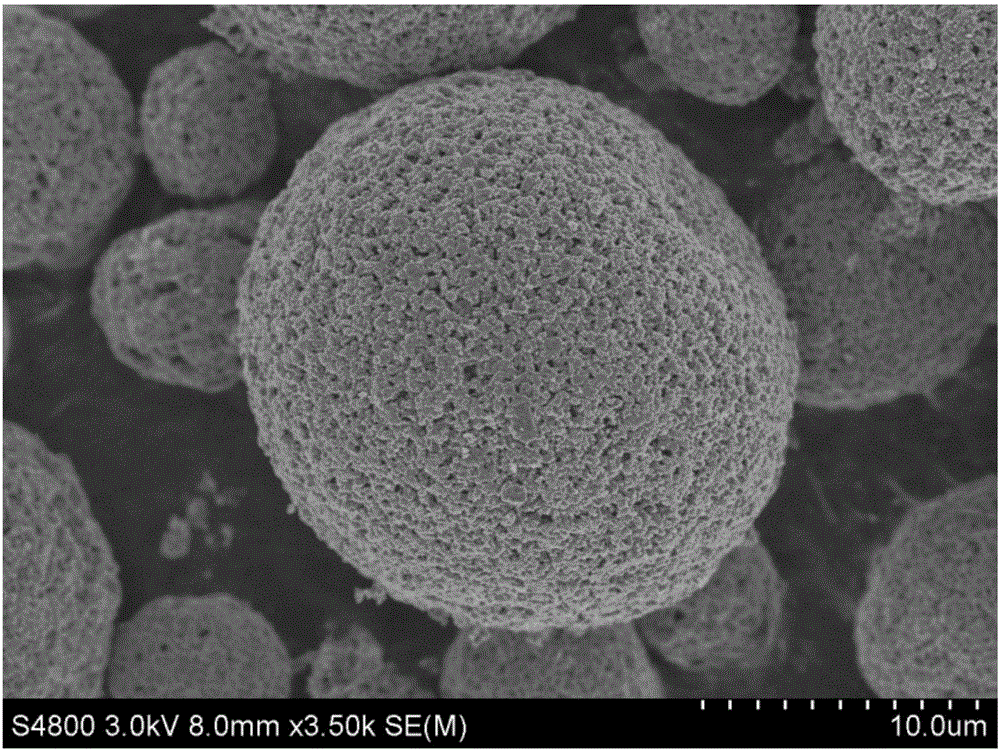

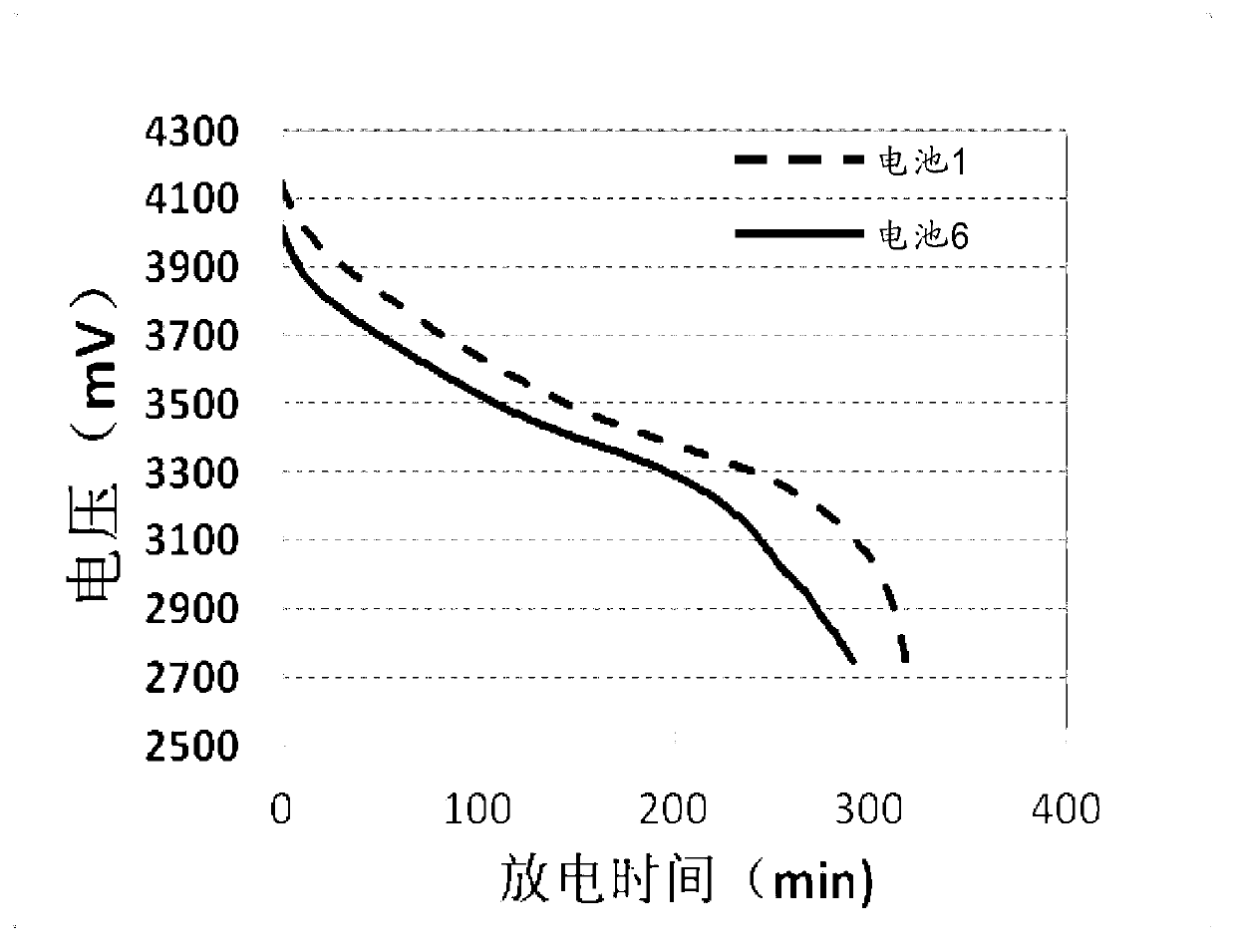

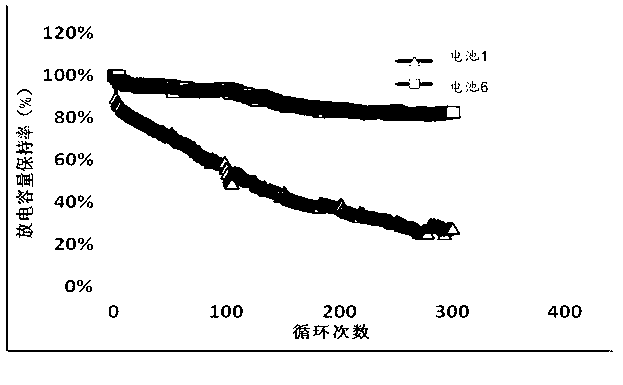

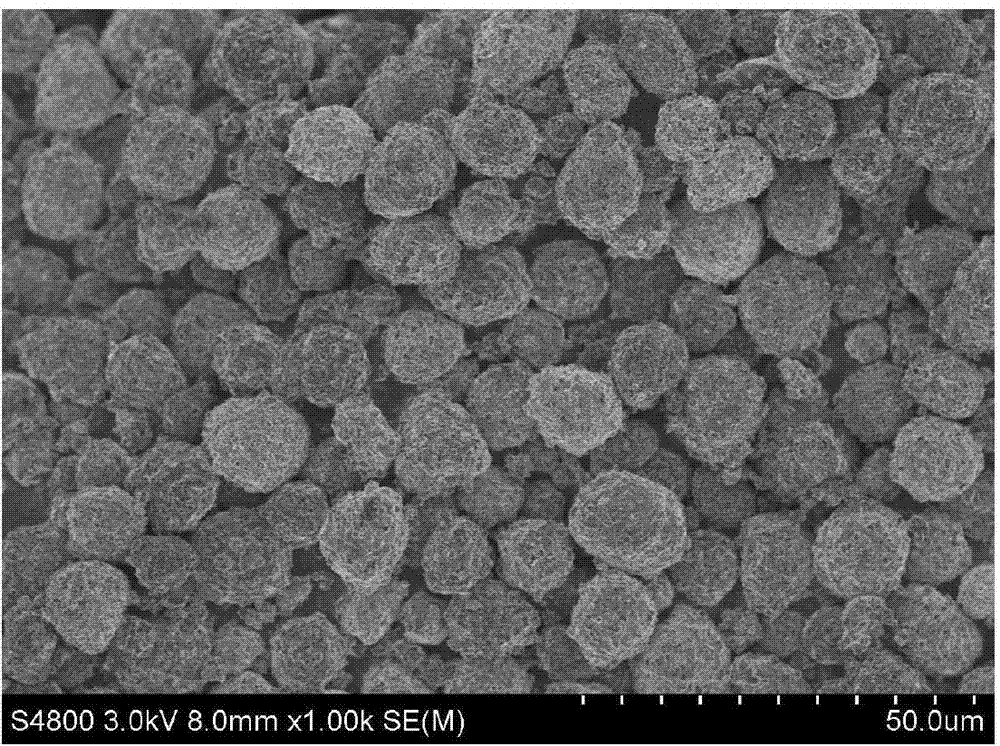

Lithium ion battery silicon-based composite anode material, preparation method thereof and battery

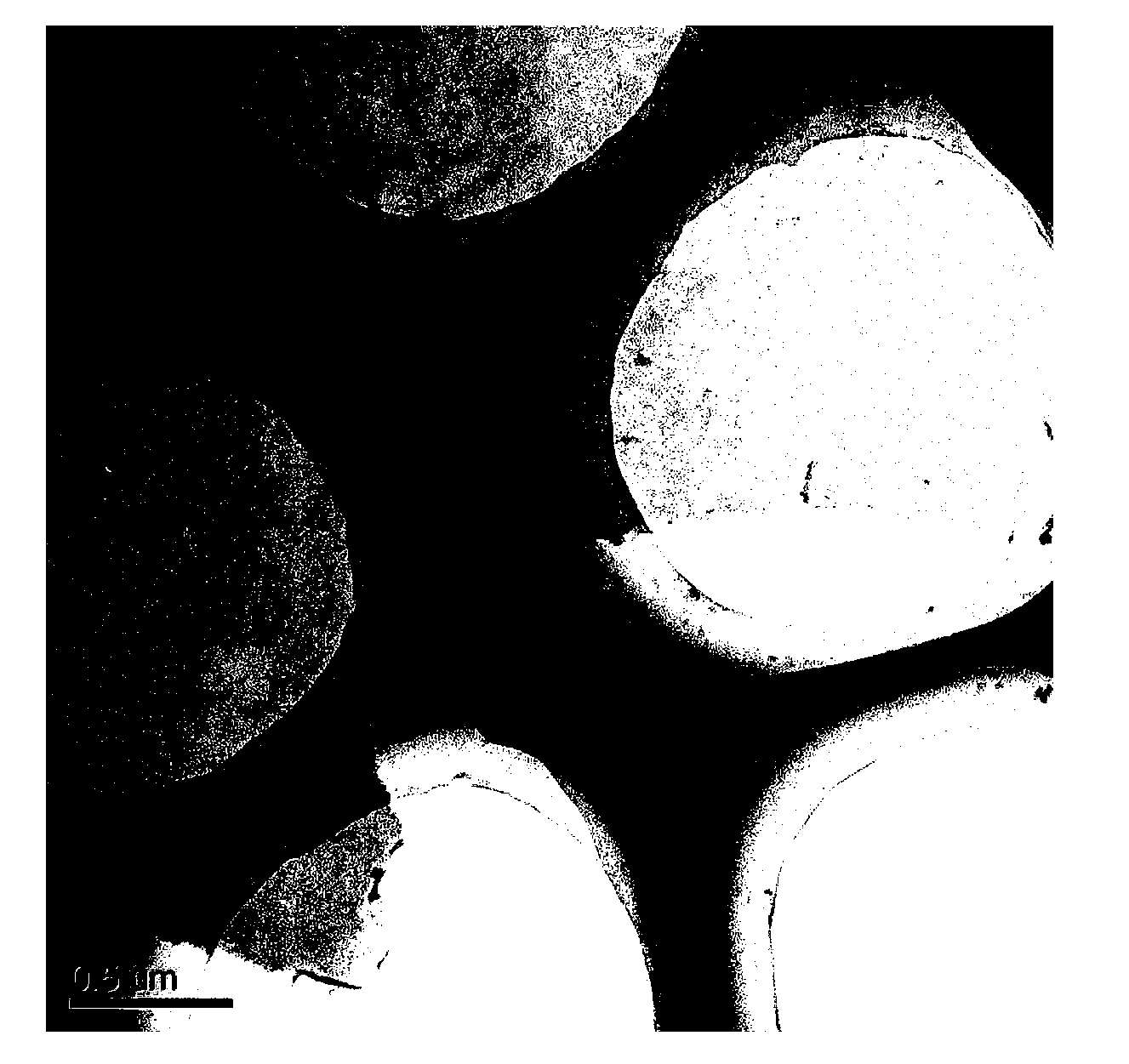

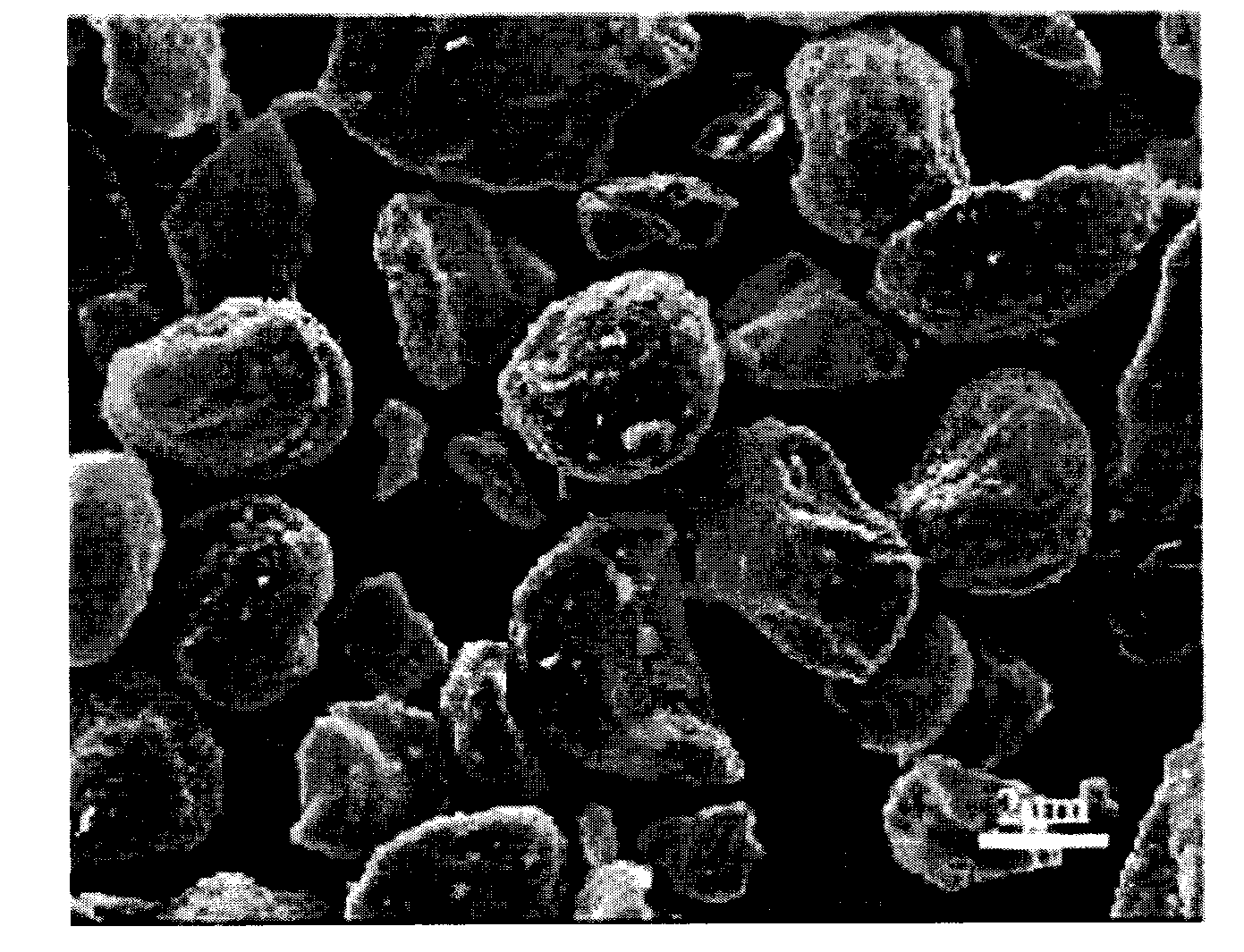

ActiveCN103682287AGood dispersionInhibit swellingCell electrodesSecondary cellsCarbon coatingRetention ratio

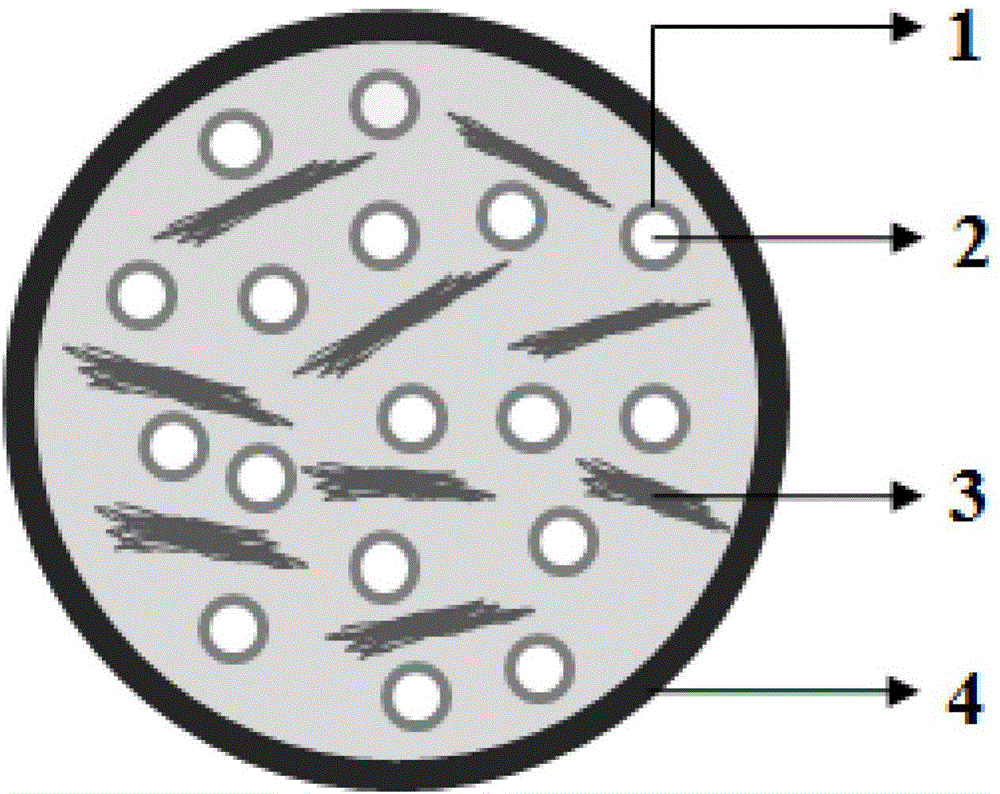

The invention relates to a lithium ion battery silicon-based composite anode material, a preparation method of the lithium ion battery silicon-based composite anode material, and a battery. The lithium ion battery silicon-based composite anode material adopts an embedded composite core-shell structure, a core has a structure formed by embedding nano silicon particles into a gap of an inner layer of hollowed graphite, and a shell is made from a non-graphite carbon material. According to the silicon-based composite anode material, mechanical grinding, mechanical fusing, isotropic compression processing and carbon coating technologies are combined, so that the nano silicon particles can be successfully embedded into the inner layer of the graphite and the surfaces of graphite particles are uniformly coated; the high-performance silicon-based composite anode material is obtained and is excellent in cycle performance (the 300-times cycle capacity retention ratio is more than 90%) and high in first efficiency (more than 90%); in addition, the silicon-based composite anode material is high in specific energy and compaction density, and can meet the requirements of a high-power density lithium ion battery; the preparation process is simple, the raw material cost is low, and the environment is protected.

Owner:BTR NEW MATERIAL GRP CO LTD

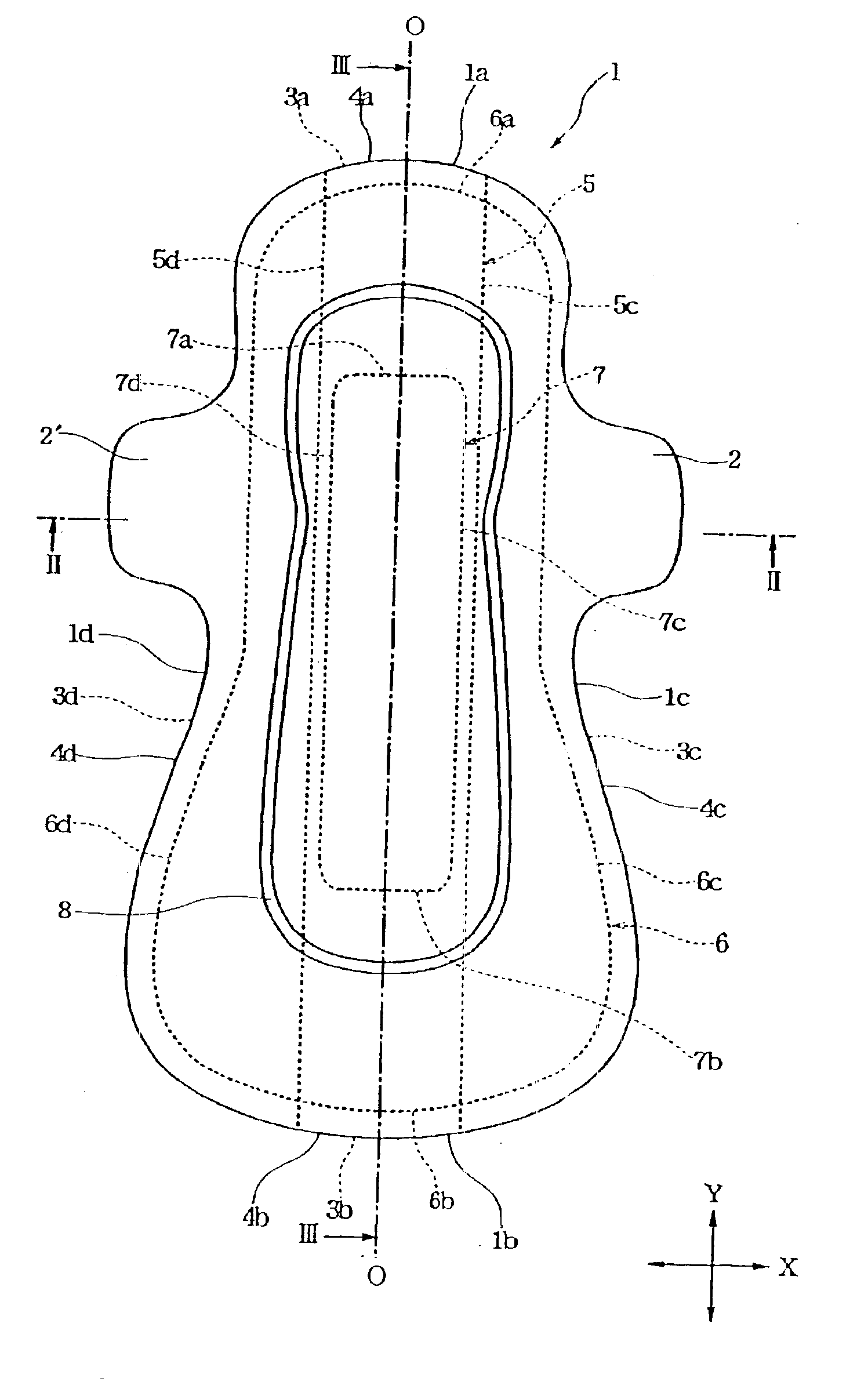

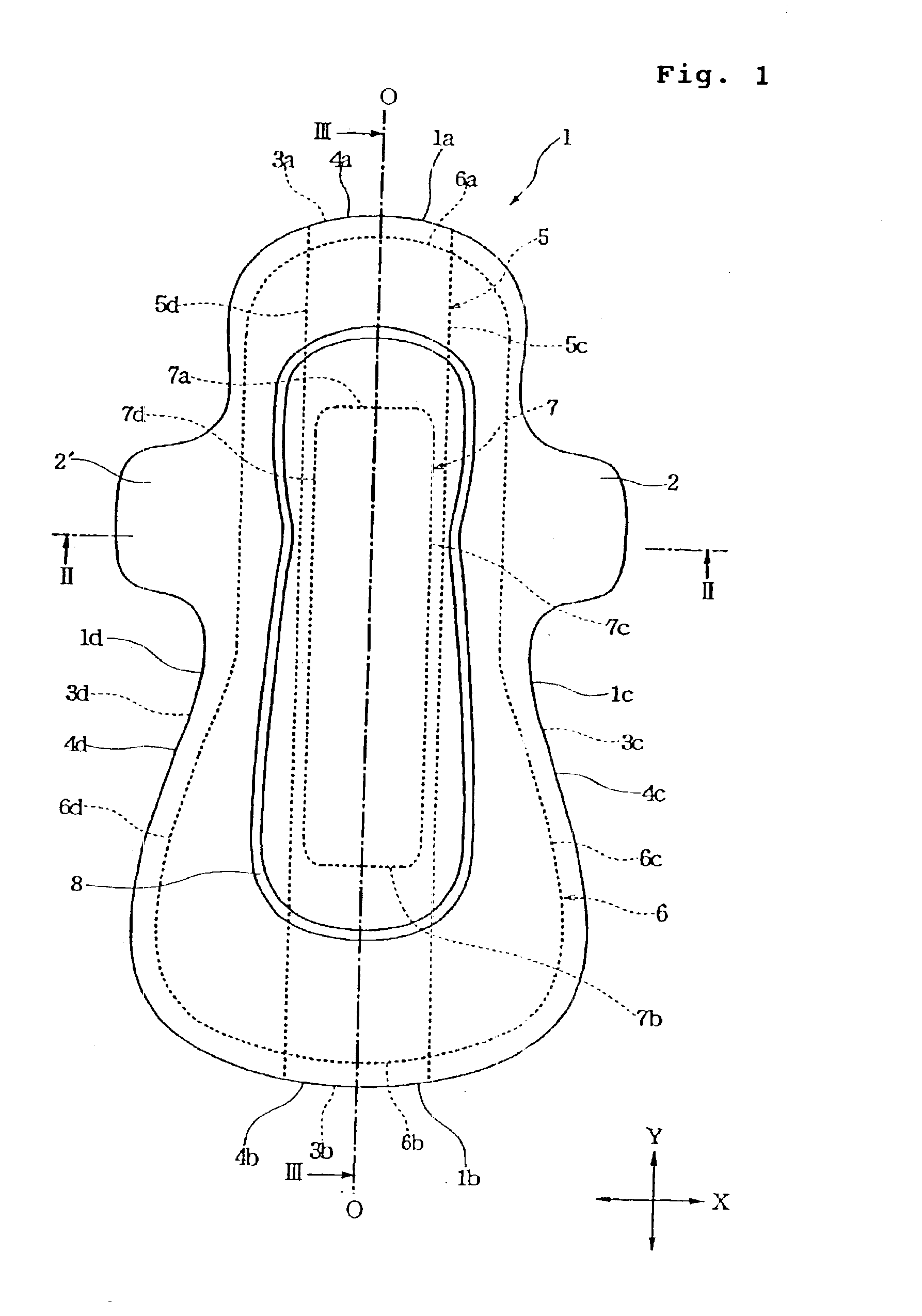

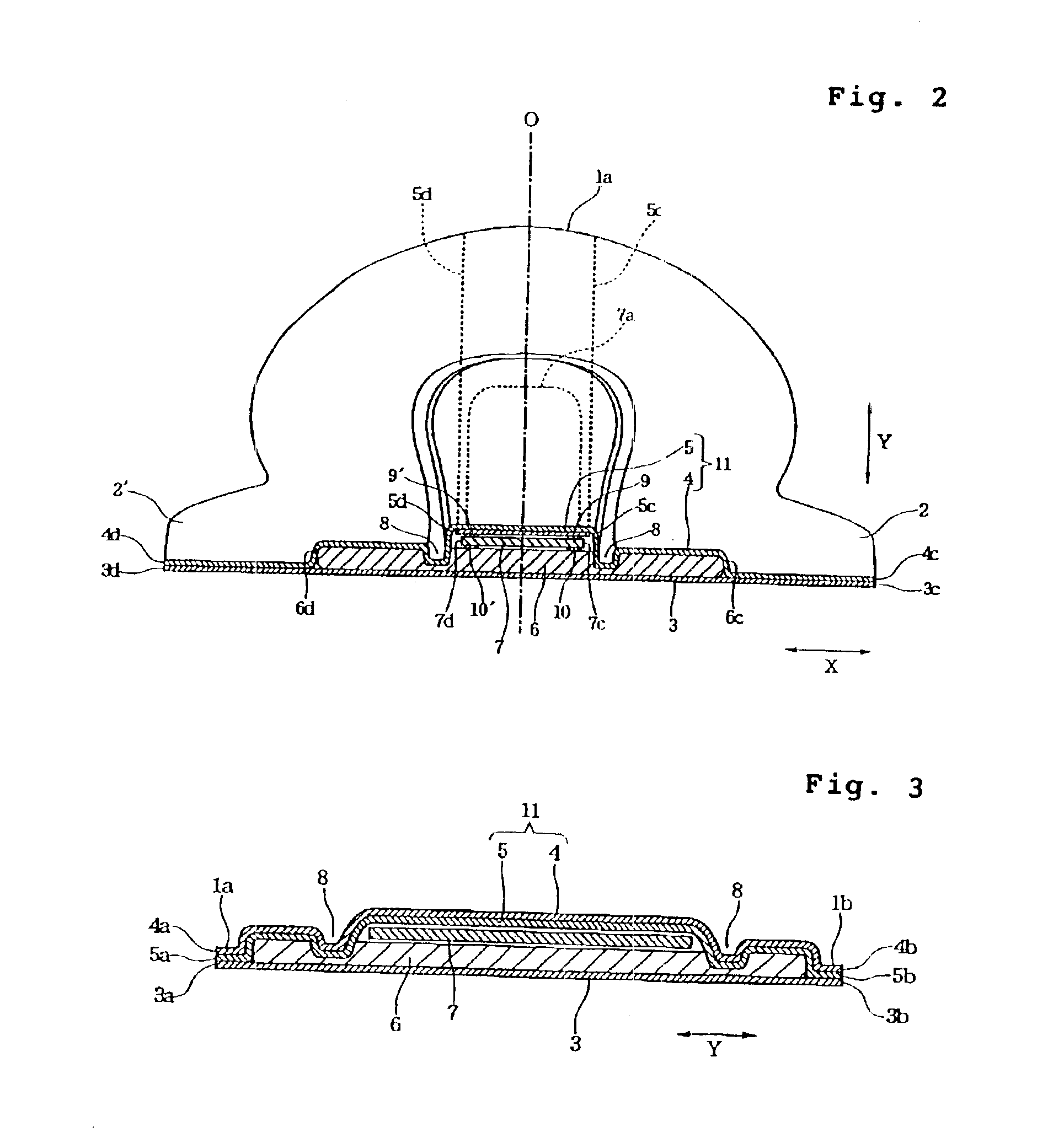

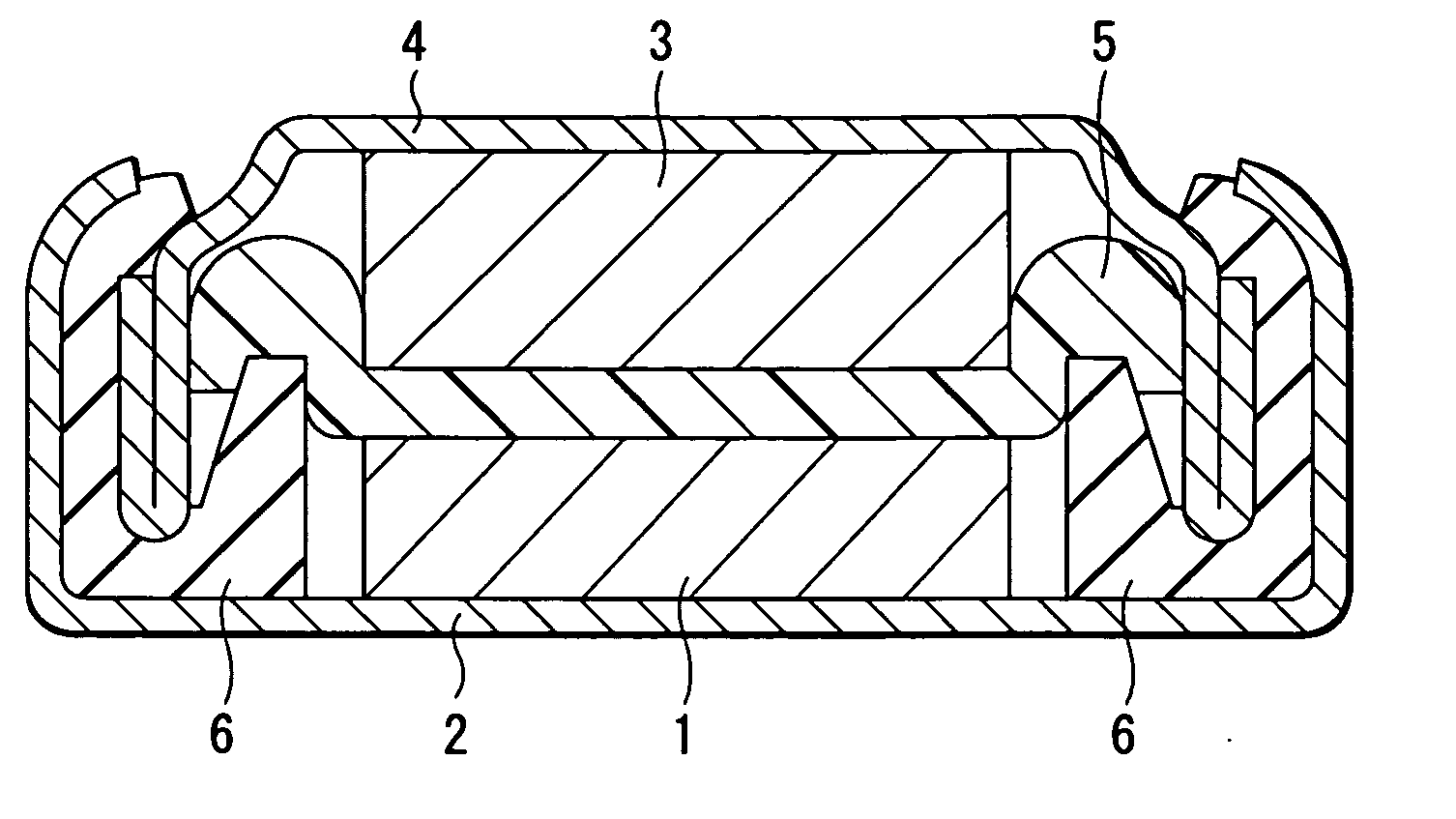

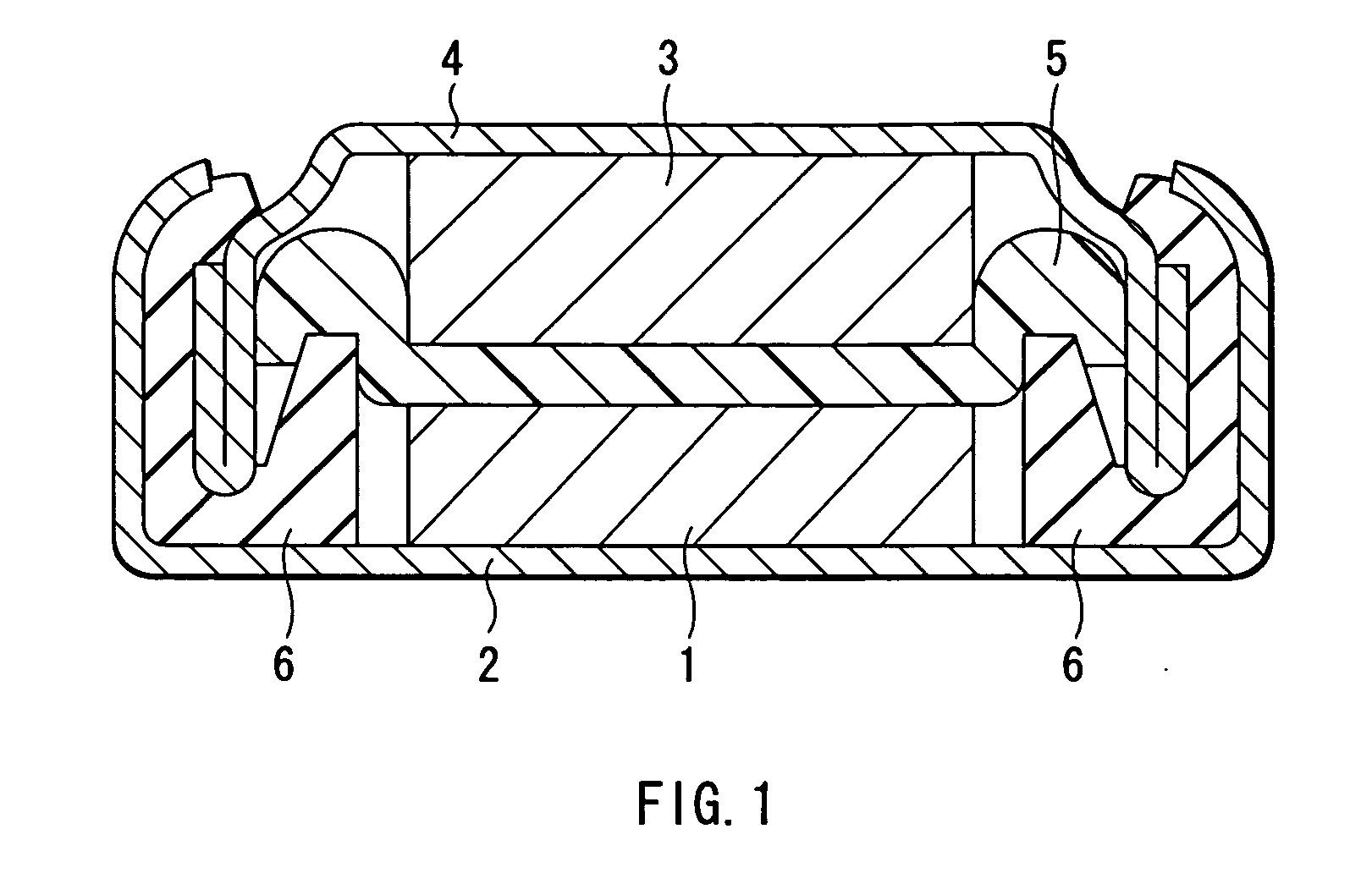

Absorbent article with compressed grooves

InactiveUS6858771B2Avoid lateral spreadConvenient guidanceSanitary towelsBaby linensEngineeringRetention ratio

Disclosed is an absorbent article including a backsheet, an absorbent storage layer, a liquid guide layer, and a top layer. The absorbent storage layer, the liquid guide layer and the top layer satisfy the following relationships: the liquid guide layer>the absorbent storage layer>the top layer with respect to a water absorbency due to capillary phenomenon; the liquid guide layer>the absorbent storage layer>the top layer with respect to a retention ratio of a liquid dropped onto the top layer in an amount less than a maximum water absorption amount of the liquid guide layer; and the absorbent storage layer>the liquid guide layer>the top layer with respect to a retention ratio of a liquid dropped onto the top layer in an amount more than the maximum water absorption amount of the liquid guide layer.

Owner:UNI CHARM CORP

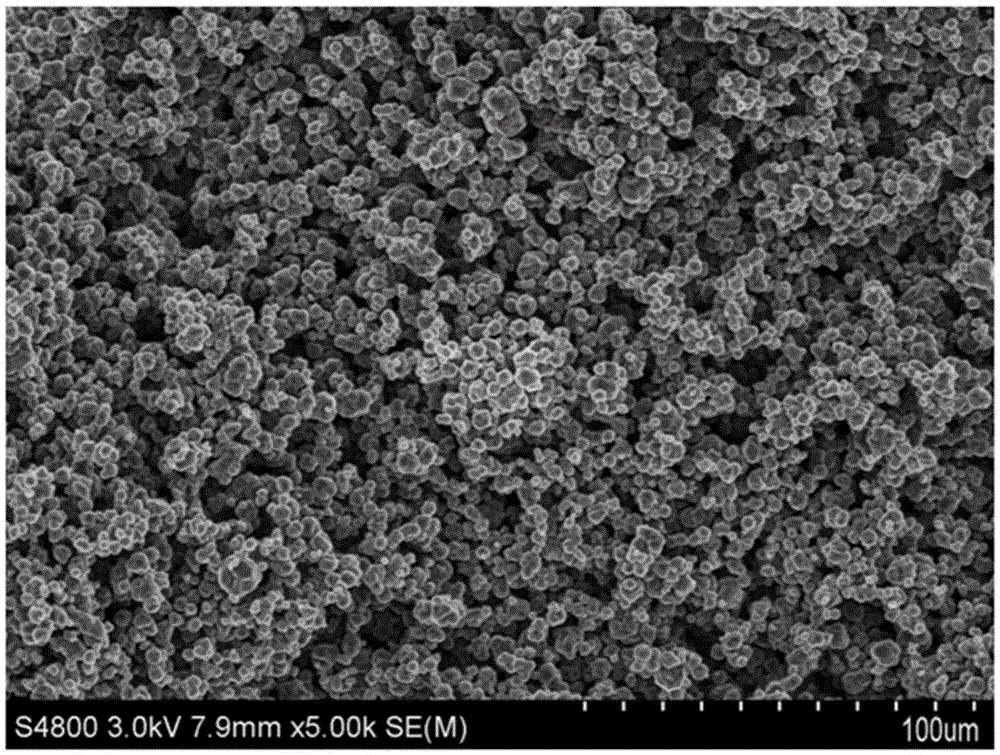

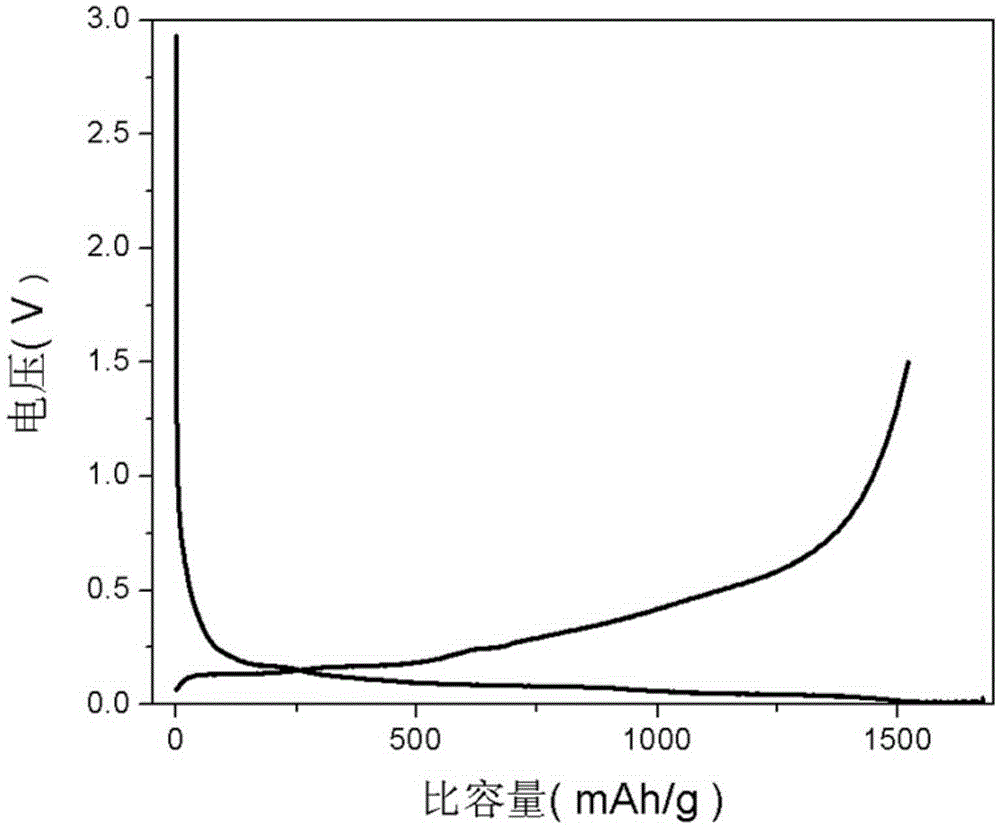

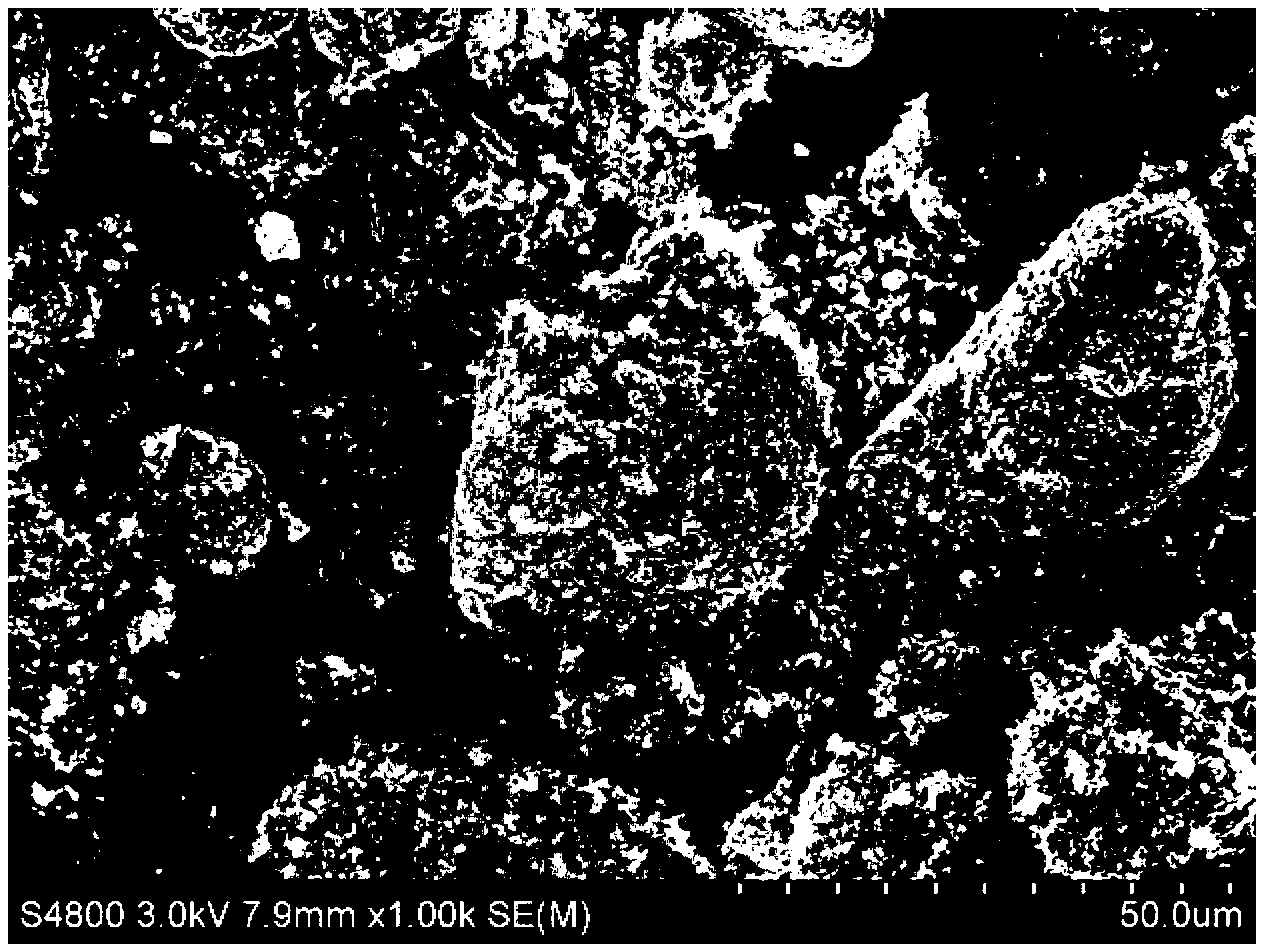

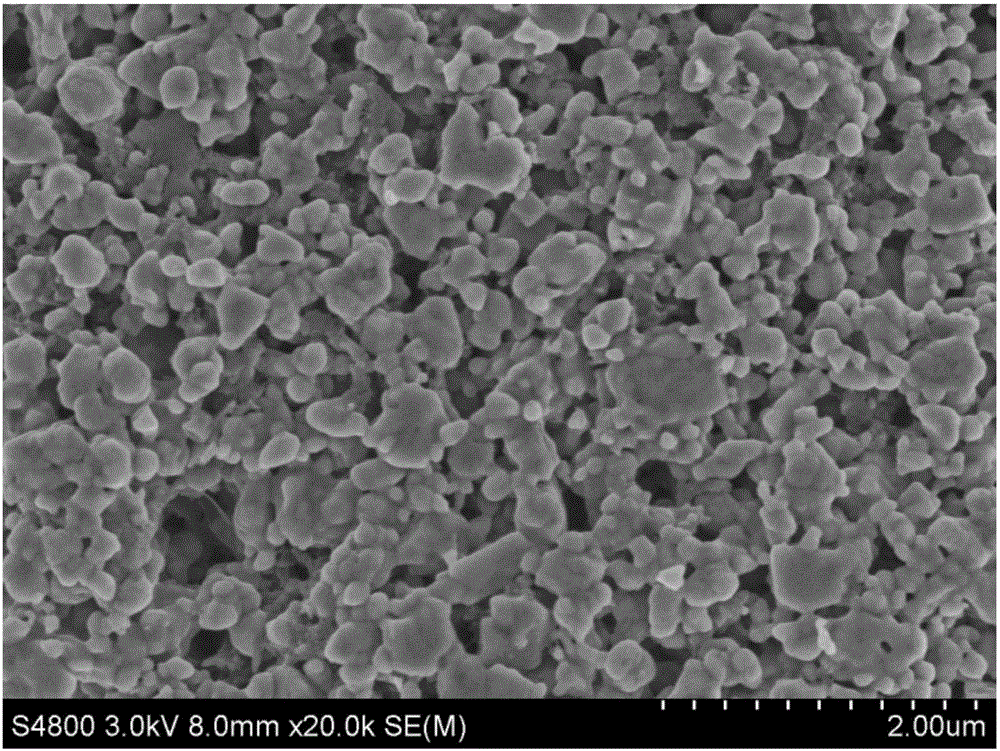

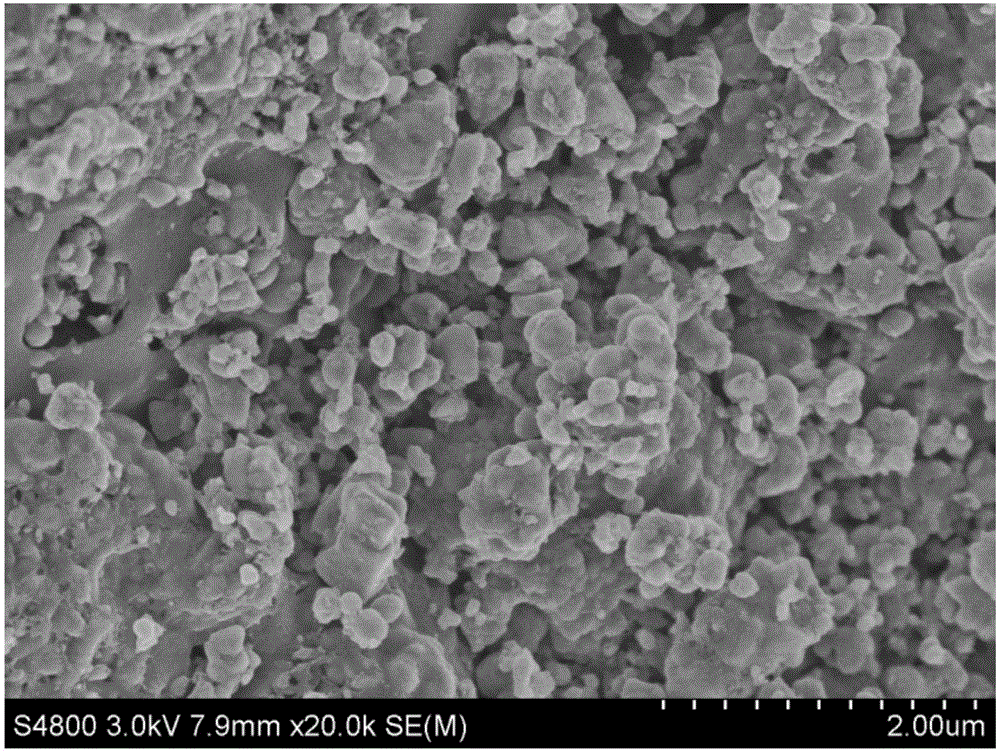

Composite silicon negative electrode material, and preparation method and application thereof

ActiveCN105406050AGood electrical conductivityIncrease capacitySiliconElectrode thermal treatmentCarbon layerLithium

The invention relates to a composite silicon negative electrode material. The composite silicon negative electrode material comprises nanometer silicon, a nanometer composite layer coating the surface of nanometer silicon and a conductive carbon layer uniformly coating the nanometer composite layer, wherein the nanometer composite layer is silicon oxide and metal alloy. According to the composite silicon negative electrode material with a three-layer structure, the nanometer composite layer composed of the silicon oxide and the metal alloy coating the surface of the silicon oxide effectively reduces volume expansion of the nanometer silicon, maintains the characteristic of high conductivity of the silicon material, improves mobility of lithium ions, prevents direct contact between a silicon negative electrode and an electrolyte, and can form a hard SEI film on the surface of the composite silicon negative electrode material, thereby allowing the cycle performance of the material to be substantially enhanced. The composite silicon negative electrode material has the characteristics of high capacity (greater than 1500 mAh / g), long cycle life (with a capacity retention ratio of more than 90% after 300 cycles) and high conductivity. The preparation method for the composite silicon negative electrode material is simple, easily controllable, and applicable to industrial production.

Owner:DINGYUAN NEW ENERGY TECH CO LTD

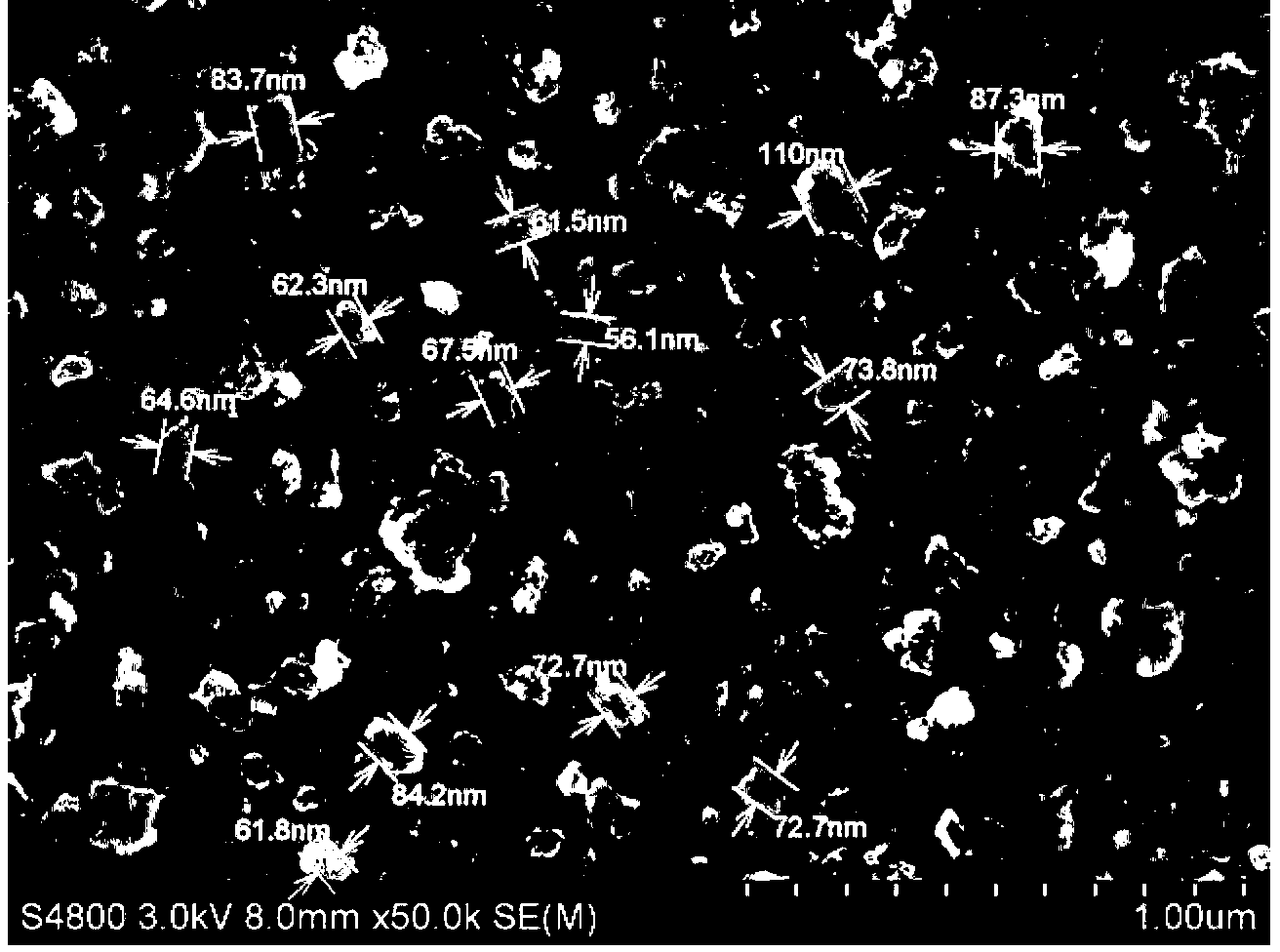

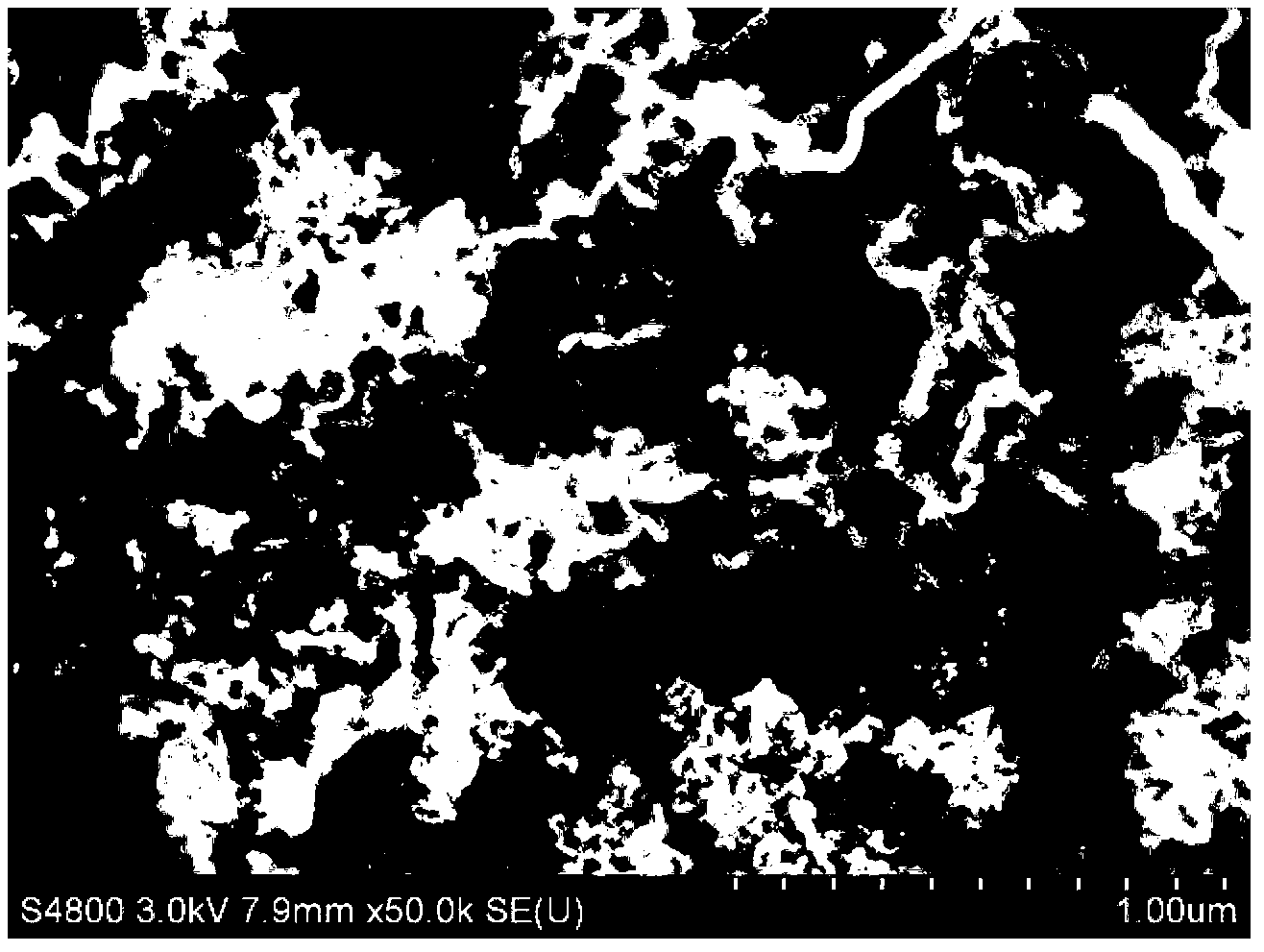

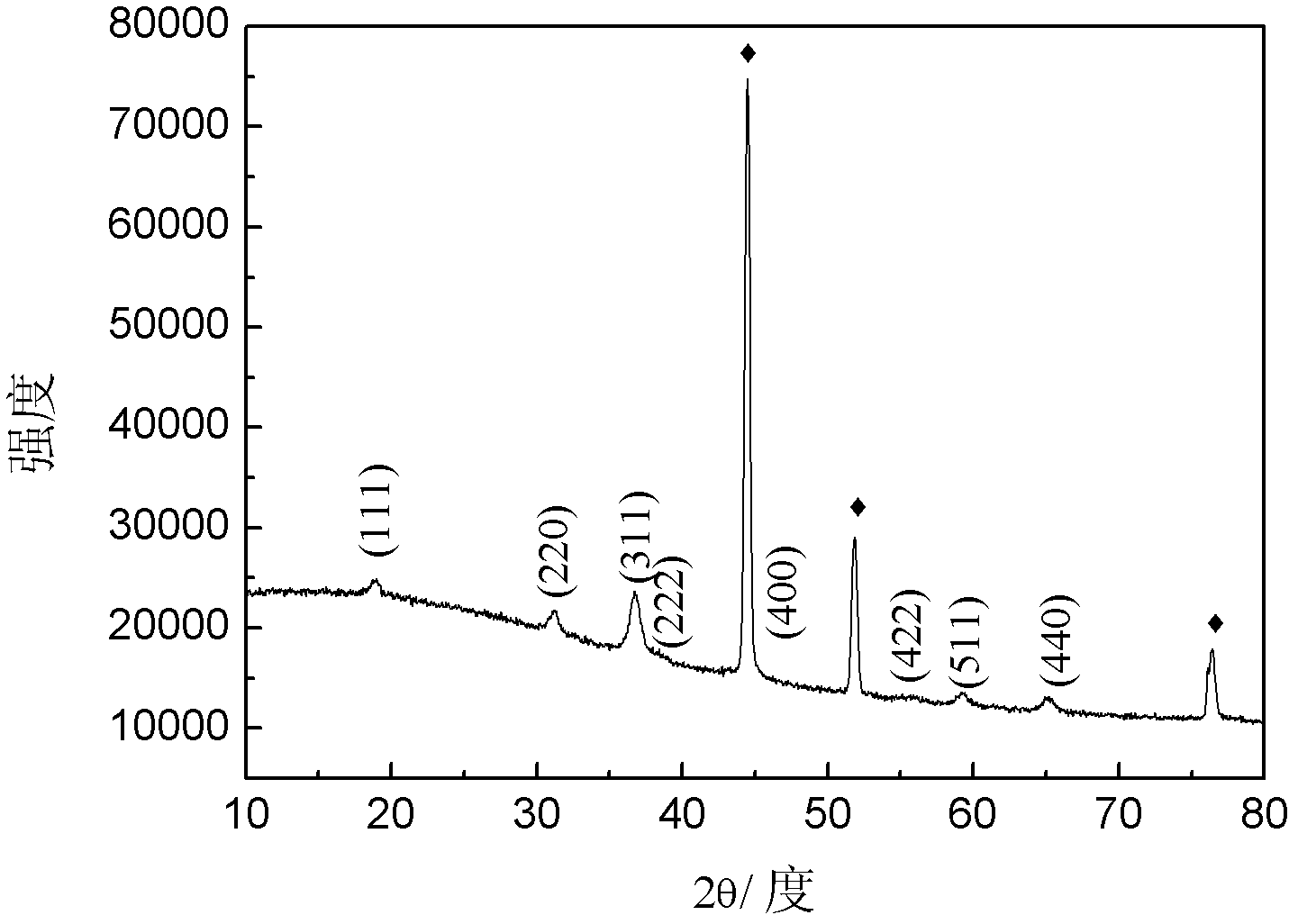

Carbon-coated nano silicon/graphene/cracked carbon layer composition material, preparation method, and lithium ion battery including the composition material

InactiveCN106067547AAchieve perfect compoundSimple processMaterial nanotechnologyCell electrodesNano siliconCarbon layer

The invention relates to a carbon-coated nano silicon / graphene / cracked carbon layer composition material, a preparation method thereof, and a lithium ion battery including the composition material. The composite material comprises spherical particles formed by uniformly dispersing carbon-coated nano silicon in graphene sheets, and a cracked carbon layer which coats the surfaces of the spherical particles. The carbon-coated nano silicon comprises nano silicon and carbon coating layer which coats the surface of the nano silicon. The method is simple, has excellent process performance and is environment-friendly. The carbon-coated nano silicon / graphene / cracked carbon layer composition material has stable structure and high compact density, has excellent performance when being used as an anode material of the lithium ion battery, has high anode capacity, excellent rate capability and cyclic performance, is more than 1500 mAh / g in first-time reversible capacity, is more than 90% in first-time coulomb efficiency and is more than 90% in 500-time cyclic capacity retention ratio and has low expansion.

Owner:BTR NEW MATERIAL GRP CO LTD

Negative Electrode Material For Lithium Secondary Battery, Method For Producing Same, Negative Electrode For Lithium Secondary Battery Using Same And Lithium Secondary Battery

InactiveUS20080032192A1High electrode-mechanical strengthImprove immersion effectNegative electrodesNon-aqueous electrolyte accumulator electrodesHigh current densityMetal particle

A negative-electrode material for a lithium secondary battery is provided that can be produced through a simple procedure and can yield a lithium secondary battery having a high electrode-mechanical strength, being excellent in immersibility, involving a small initial irreversible capacity, being excellent in charge-discharge characteristic under high current densities, and having a high cycle retention ratio, i.e. having an excellent balance of various battery characteristics. The material includes particles (A), which are selected from the group consisting of carbon-material particles, metal particles, and metal-oxide particles, and two or more different polymeric materials each attached to different sites of the particles.

Owner:MITSUBISHI CHEM CORP

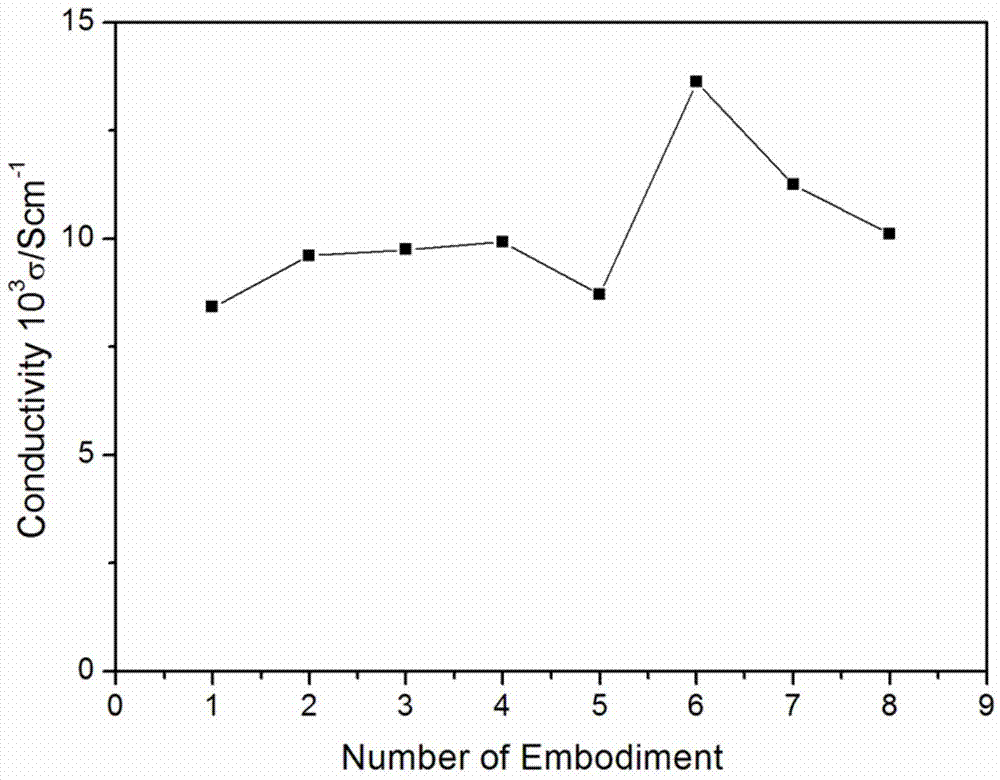

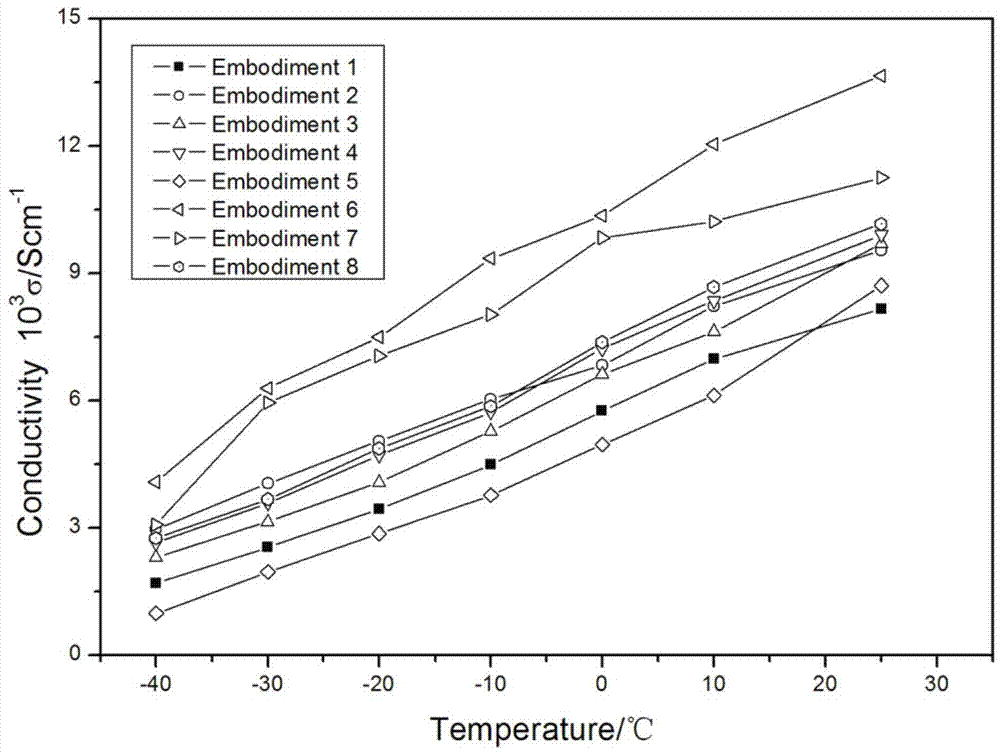

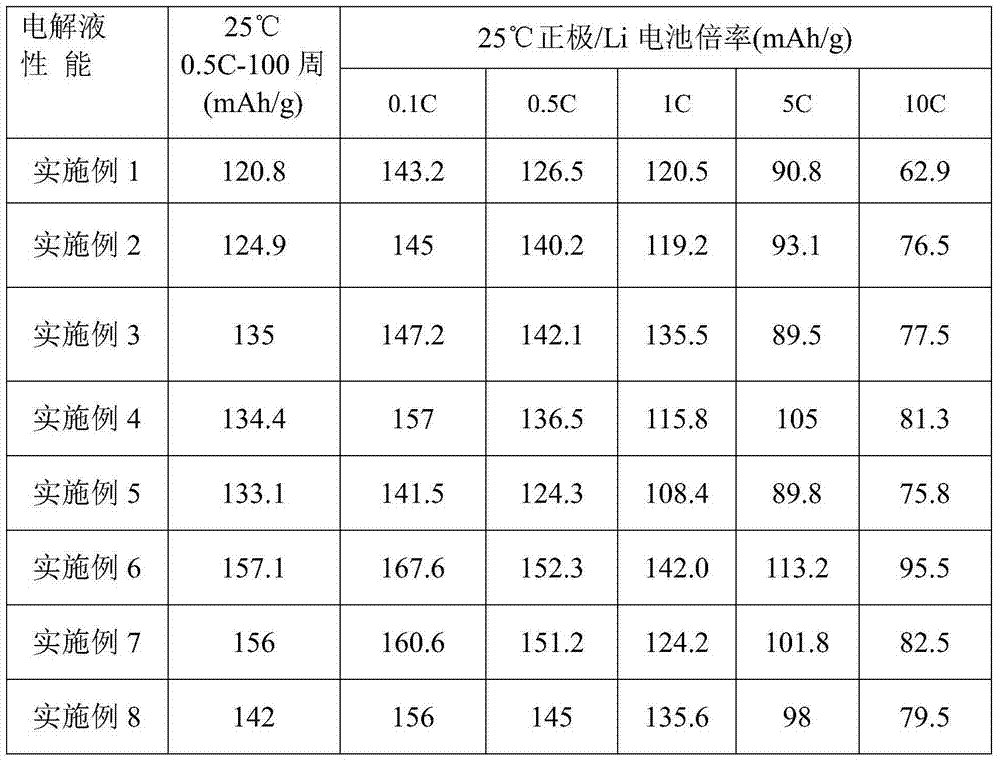

Electrolyte and lithium ion battery comprising same

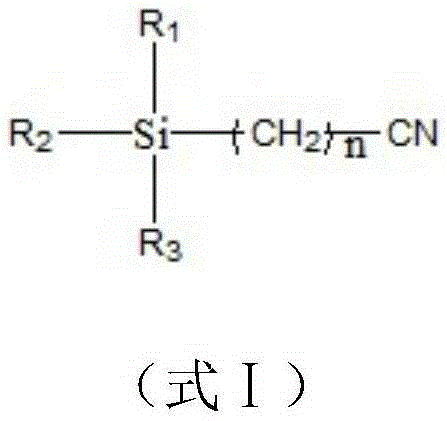

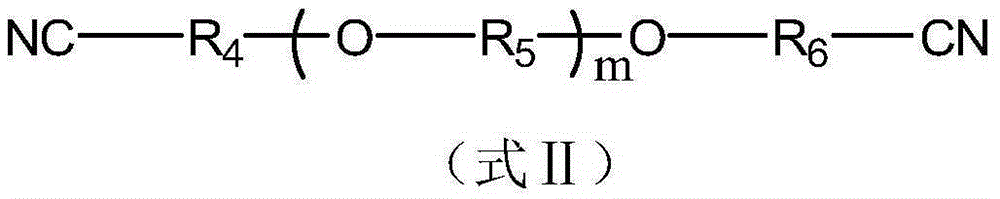

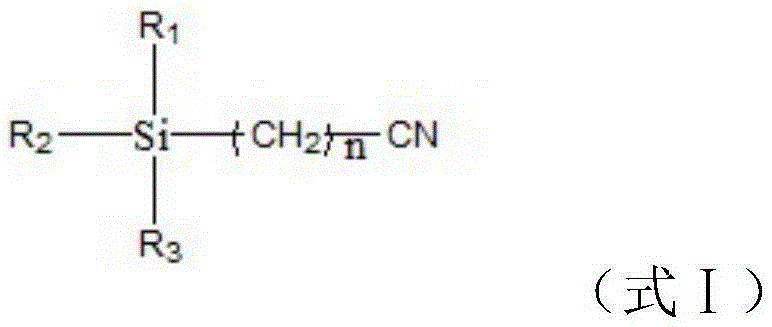

ActiveCN105428701AExcellent rate performanceImprove low temperature discharge performanceSecondary cellsElectrolysisDouble bond

The invention relates to the technical field of lithium ion batteries, particularly relates to electrolyte and a lithium ion battery comprising the same. The electrolyte disclosed by the invention comprises lithium salt, an organic solvent and an additive A, wherein the additive A comprises silane compounds containing cyano groups and dinitrile compounds containing ether bonds; the additive A can be used for improving the rate capability and low-temperature discharge performance of the battery under a high voltage, thereby improving the service life of the lithium ion battery. The electrolyte disclosed by the invention further comprises an additive B which is one or more of ether compounds, nitrile compounds, cyclic ester compounds containing S=O double bonds, cyclic carbonate compounds containing C-C unsaturated bonds and compounds containing imido groups. The lithium ion battery comprising the electrolyte can achieve the objective of high voltage and the highest normal working voltage can be improved to 4.4V-5.0V; in addition, the cycle performance of the lithium ion battery is excellent and the capacity retention ratios during charging and discharging can be both high.

Owner:DONGGUAN AMPEREX TECH

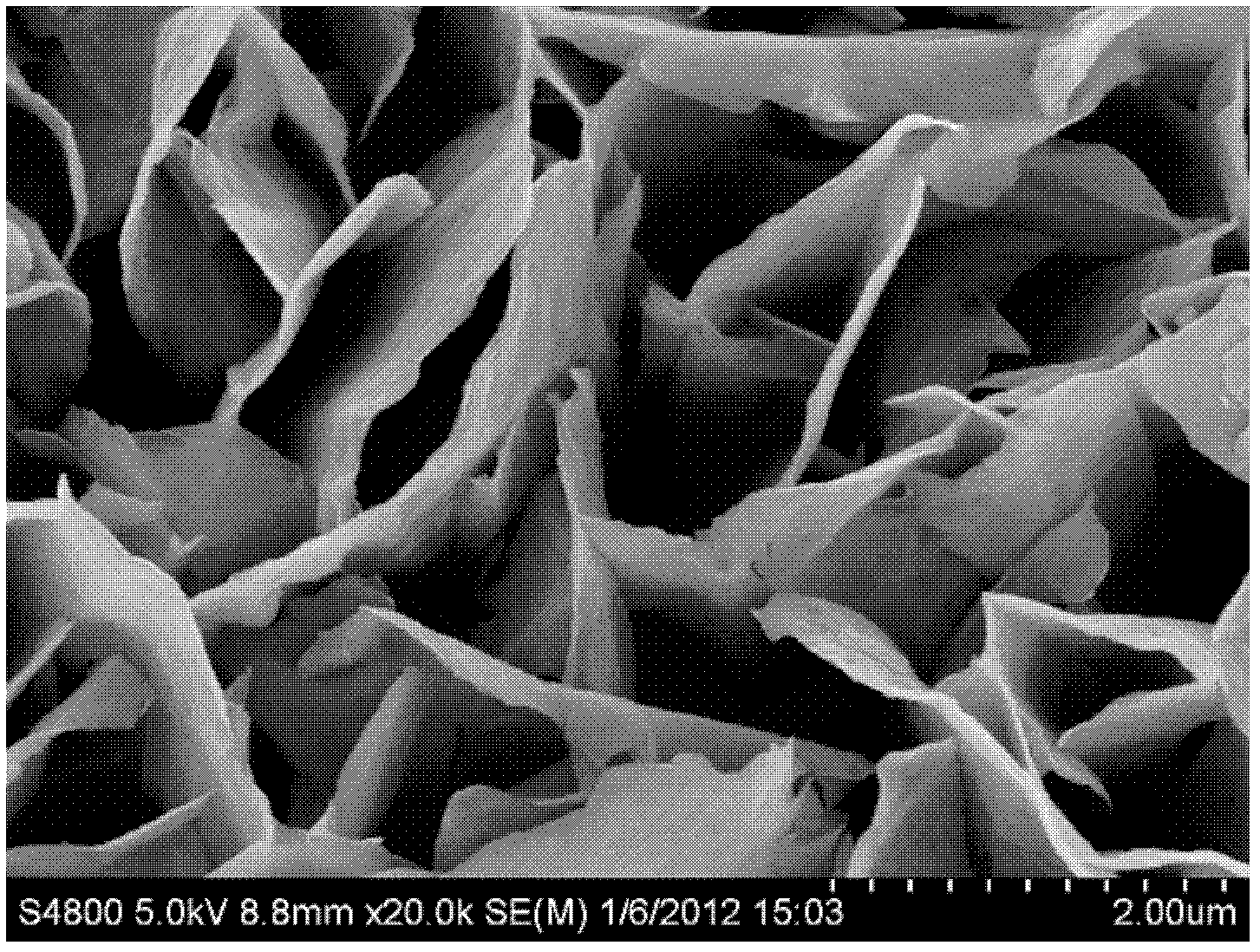

Preparation method of electrode material graphene nanometer sheet and electrode sheet prepared therefrom

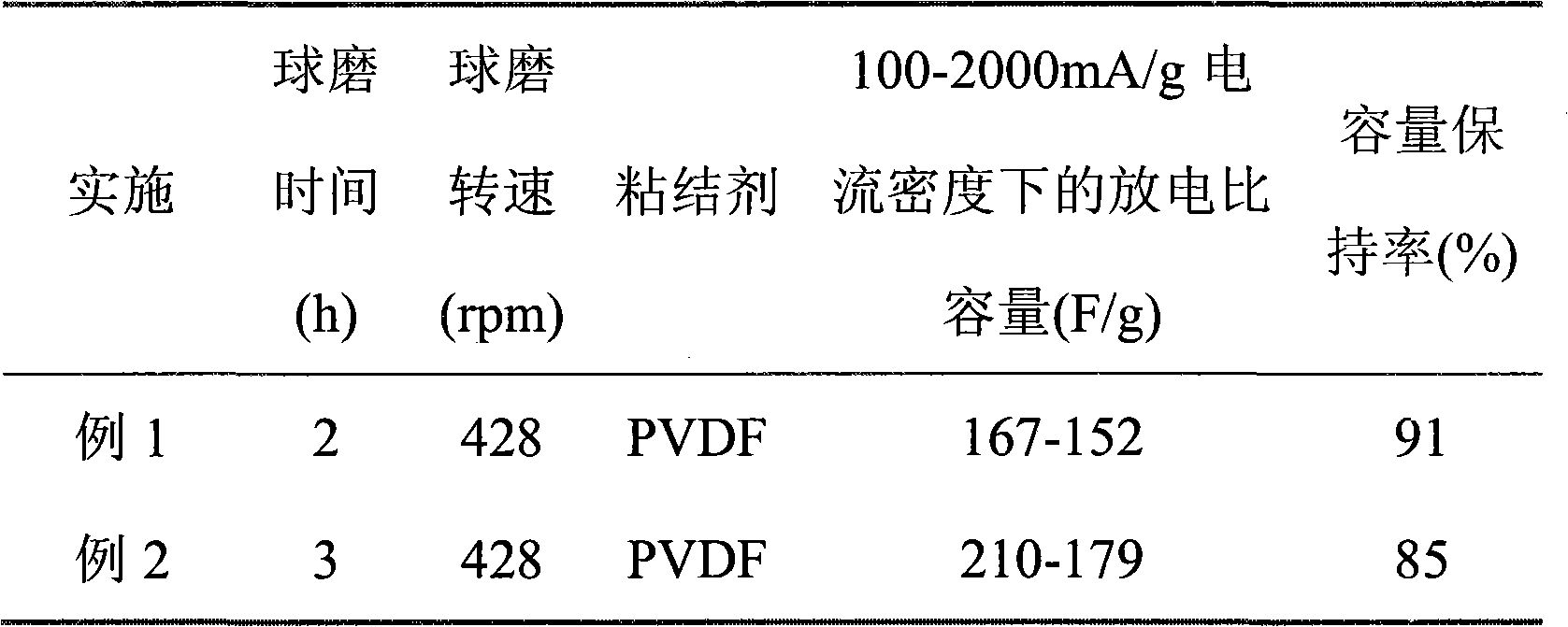

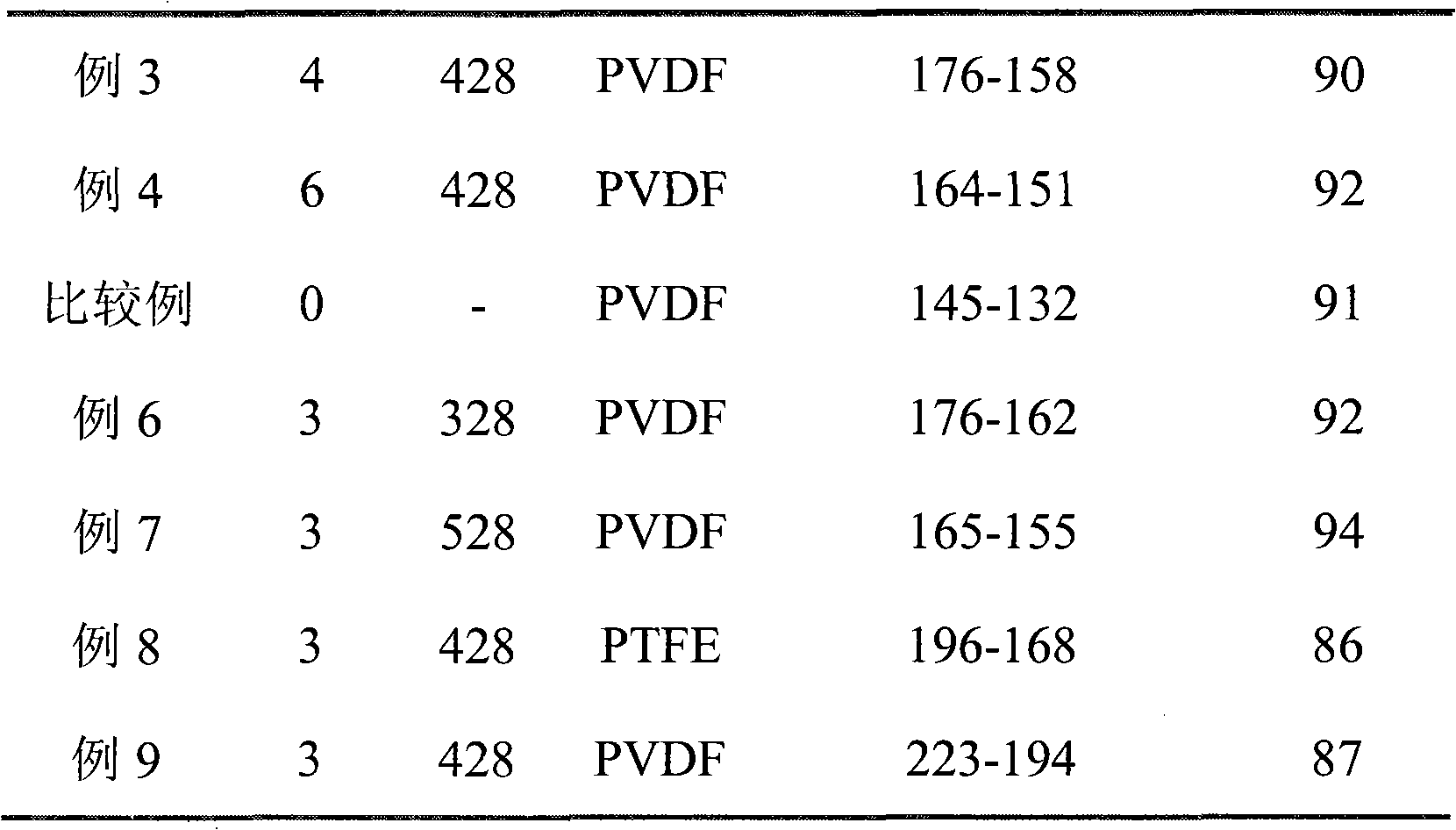

ActiveCN101870466AImprove electrochemical performanceEasy to operateElectrolytic capacitorsHybrid capacitor electrodesSupercapacitorGraphene

The invention provides a preparation method of an electrode material graphene nanometer sheet and an electrode sheet of a super capacitor prepared from the material. An electrode of the super capacitor assembled by using the material has a stable specific capacity up to 164-210 F / g under the current density of 100 mA / g; and a capacity retention ratio is more than 85% when the current density is gradually increased to 2000 mA / g from 1000 mA / g. The preparation of the graphene nano sheet by using a ball milling method has the advantages of simple method, easy operation, high specific capacity, good cycle performance and the like.

Owner:北京华科讯能石墨烯新技术研究院有限公司

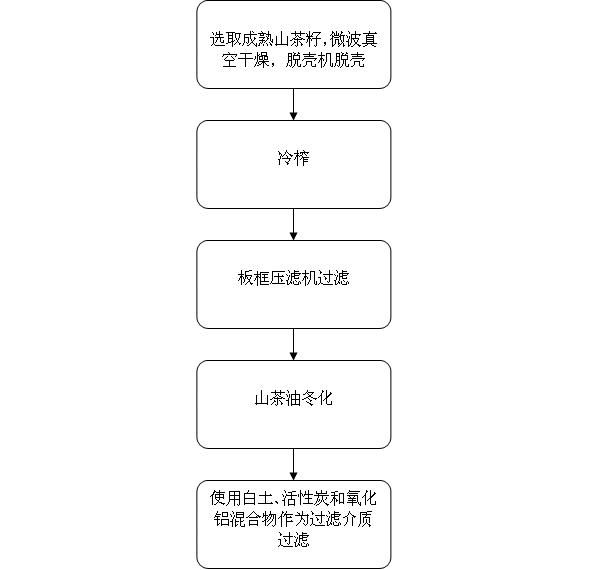

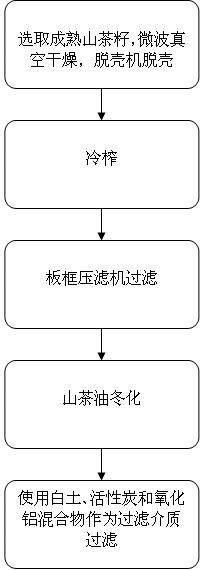

Cold pressing and physical refining process of camellia oil

ActiveCN102504938ASolve perishableImprove stabilityFatty-oils/fats refiningFatty-oils/fats productionOil and greaseDistillation

The invention relates to a cold pressing and physical refining process of camellia oil. The cold pressing and physical refining process of the camellia oil is characterized by comprising the following steps of: (1) selecting ripe camellia seeds and drying the ripe camellia seeds by microwave vacuum until the water content is 3-6%; and conveying the dried camellia seeds into a huller to be hulled;(2) carrying out cold pressing on the hulled camellia seeds to squeeze the camellia oil, wherein the temperature of a barrel is in a range of 100-150 DEG C and an oil output temperature is in a rangeof 80-120 DEG C; (3) removing solid impurities in the squeezed camellia oil through a plate and frame filter press; (4) winterizing the camellia oil filtered by the plate and frame filter press at a temperature in a range from below 5 DEG C to 5 DEG C; (5) carrying out molecular distillation on the winterized camellia oil to remove free fatty acid, oil peroxide products, moisture and other low-boiling-point substances from the camellia oil; and (6) taking a mixture of carclazyte, active carbon and aluminum oxide as a filtering medium to filter; and removing impurities and pigments of the camellia oil treated by the molecular distillation to obtain the finished product. The cold pressing and physical refining process of the camellia oil has the advantages of environmental friendliness, high oil yield, and high retention ratio of micronutrients in finished oil.

Owner:温州瑞雪农业开发有限公司

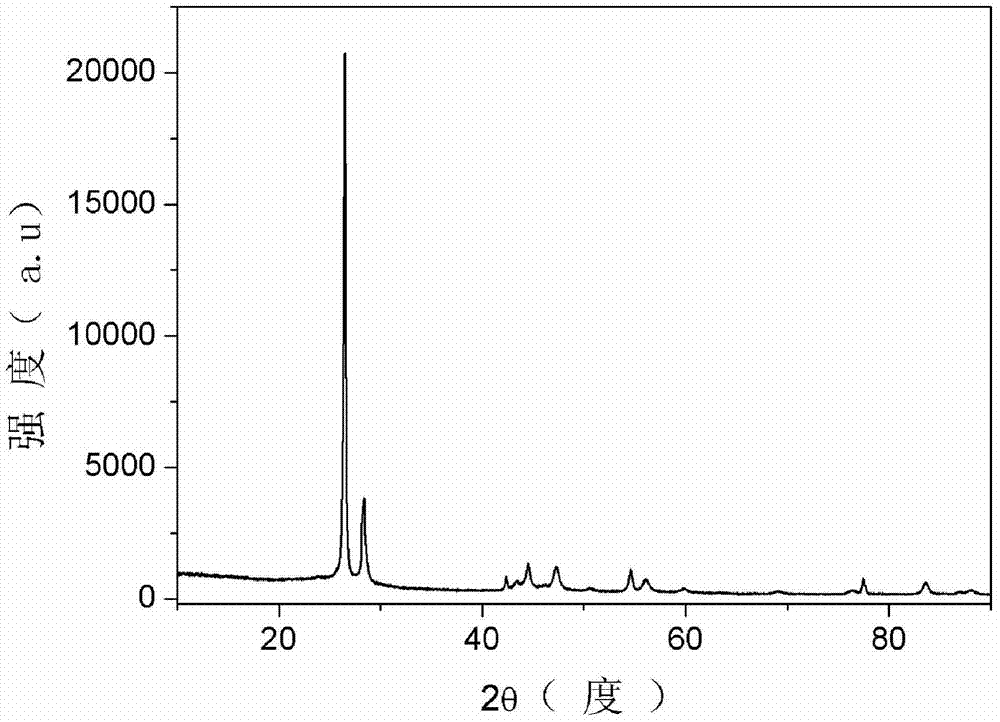

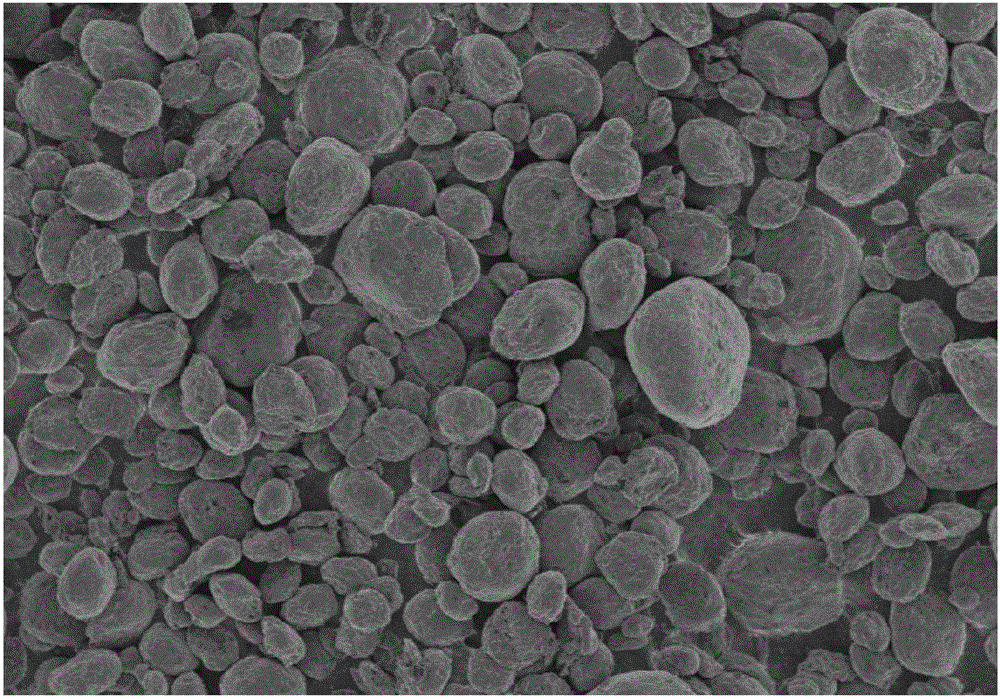

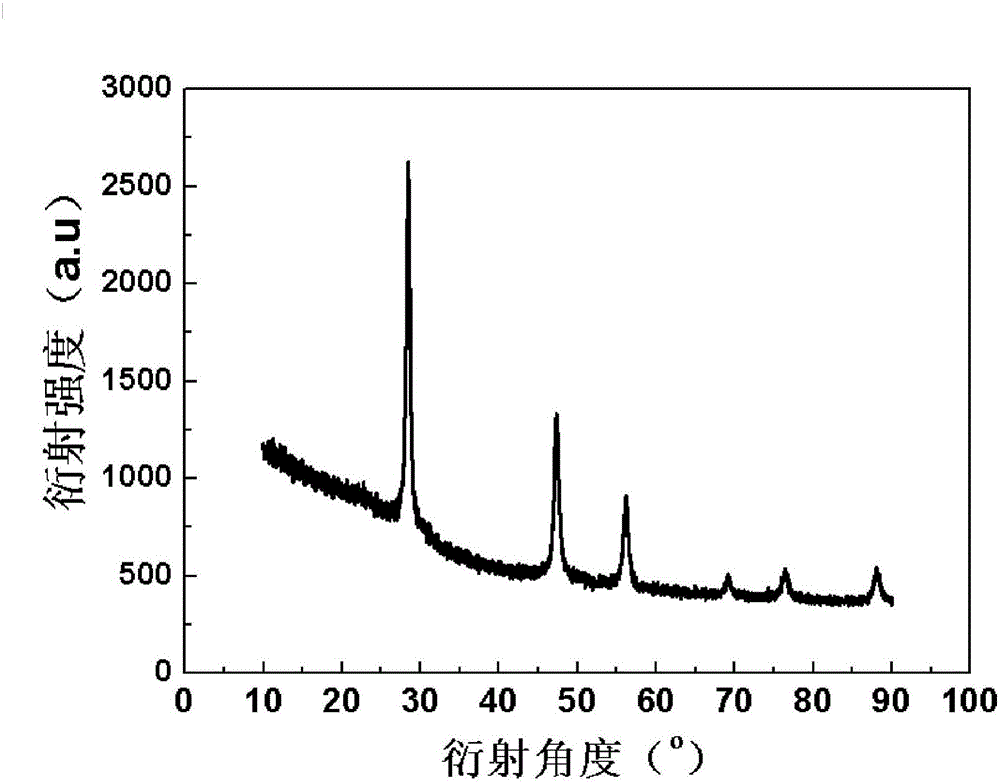

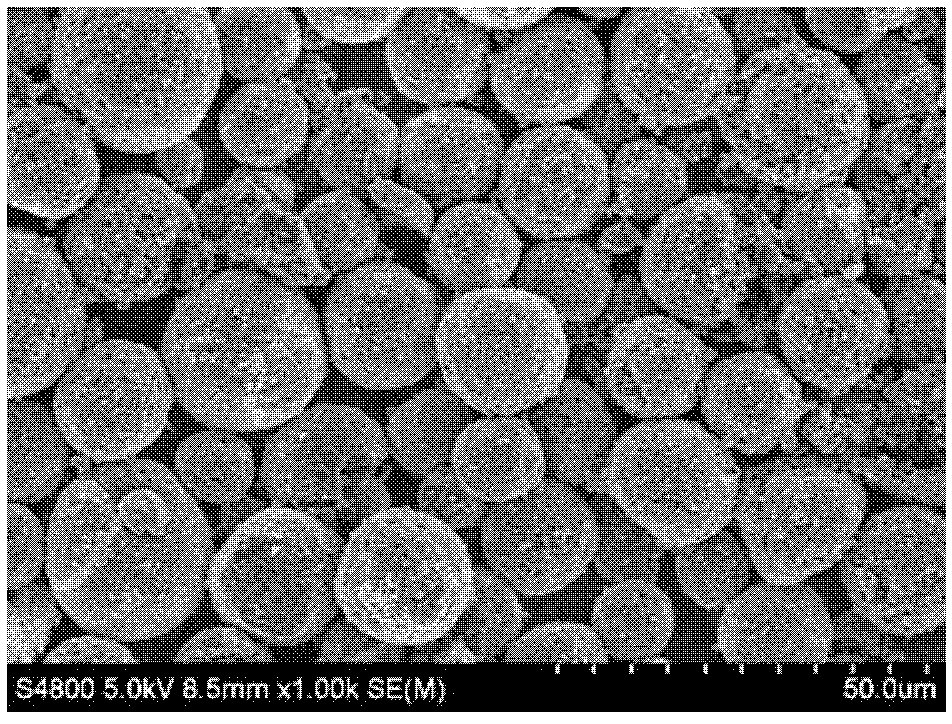

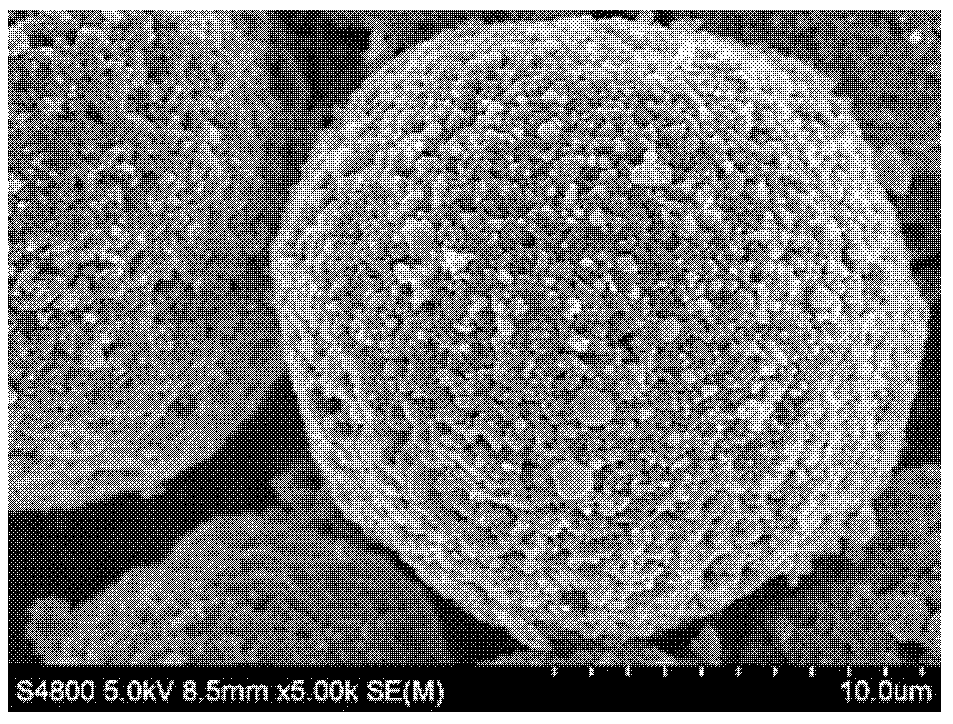

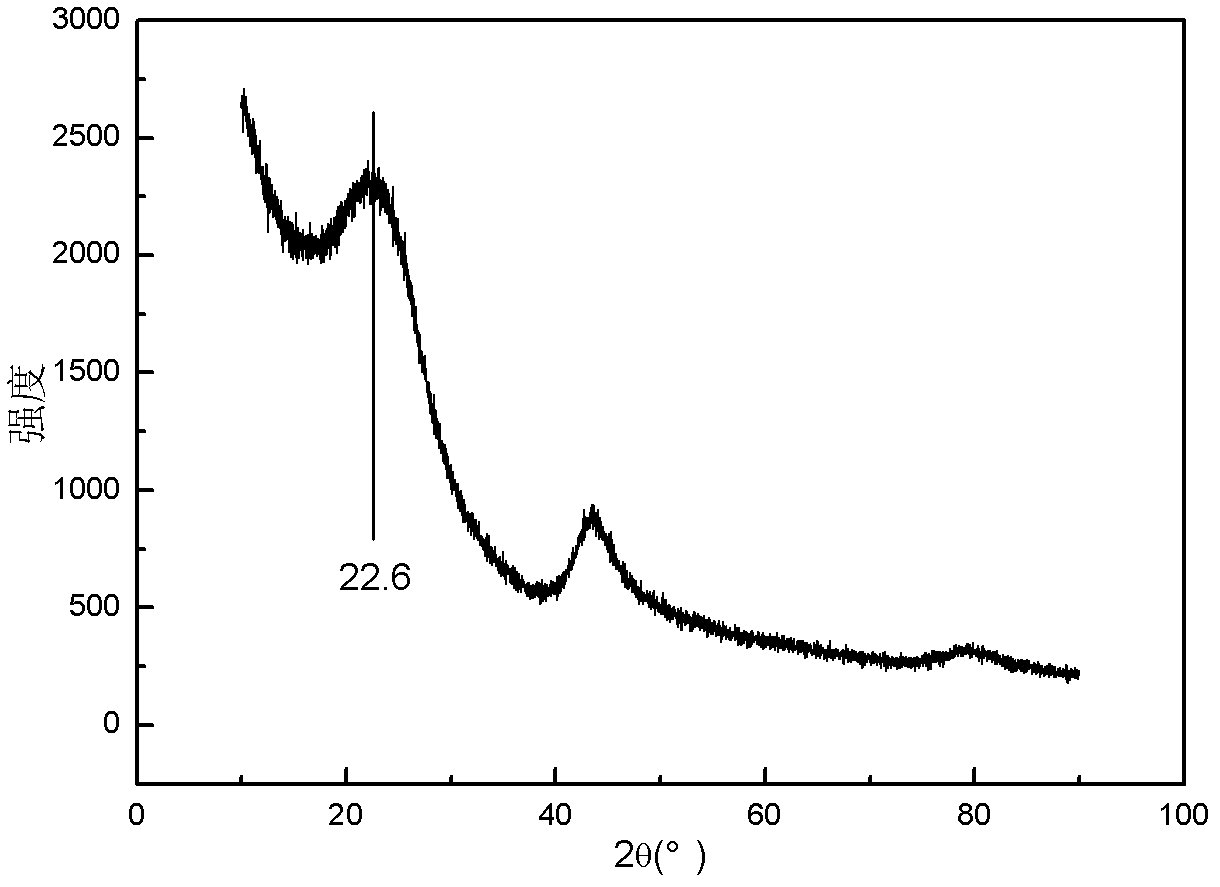

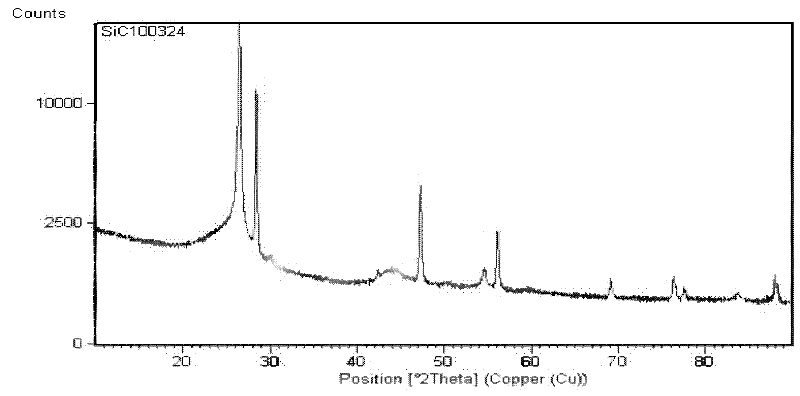

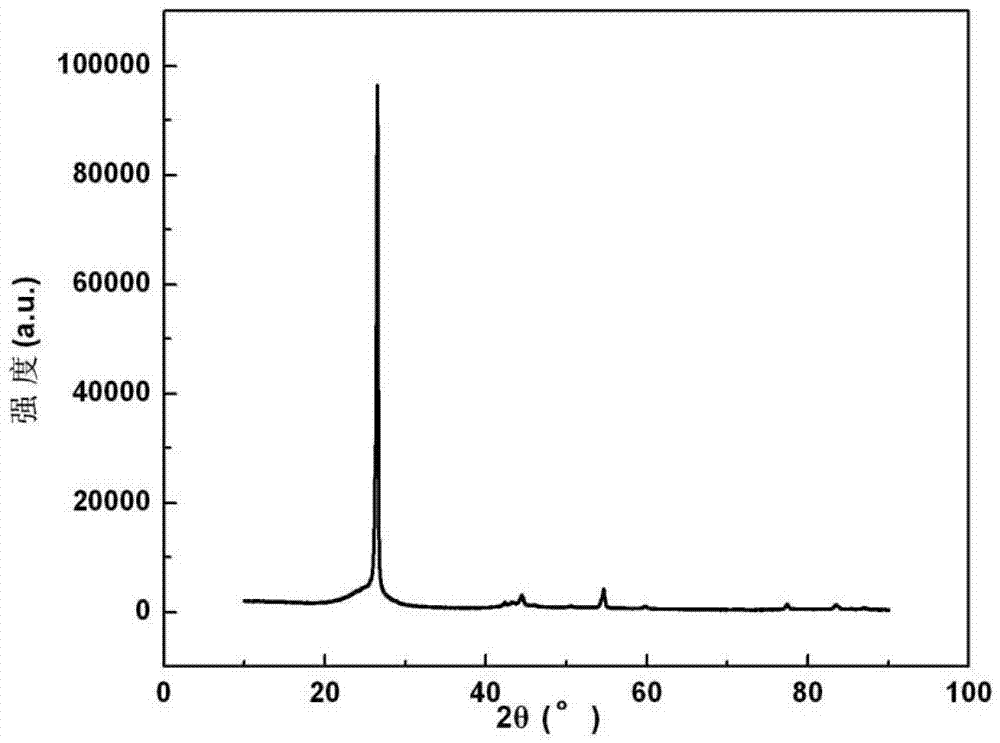

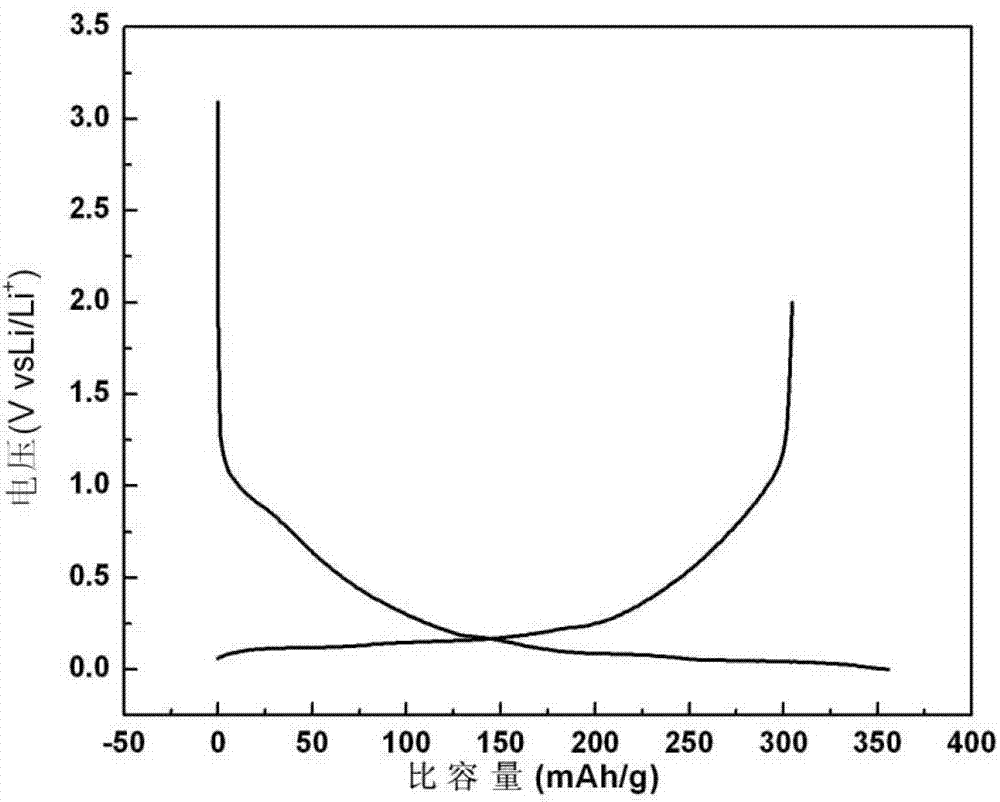

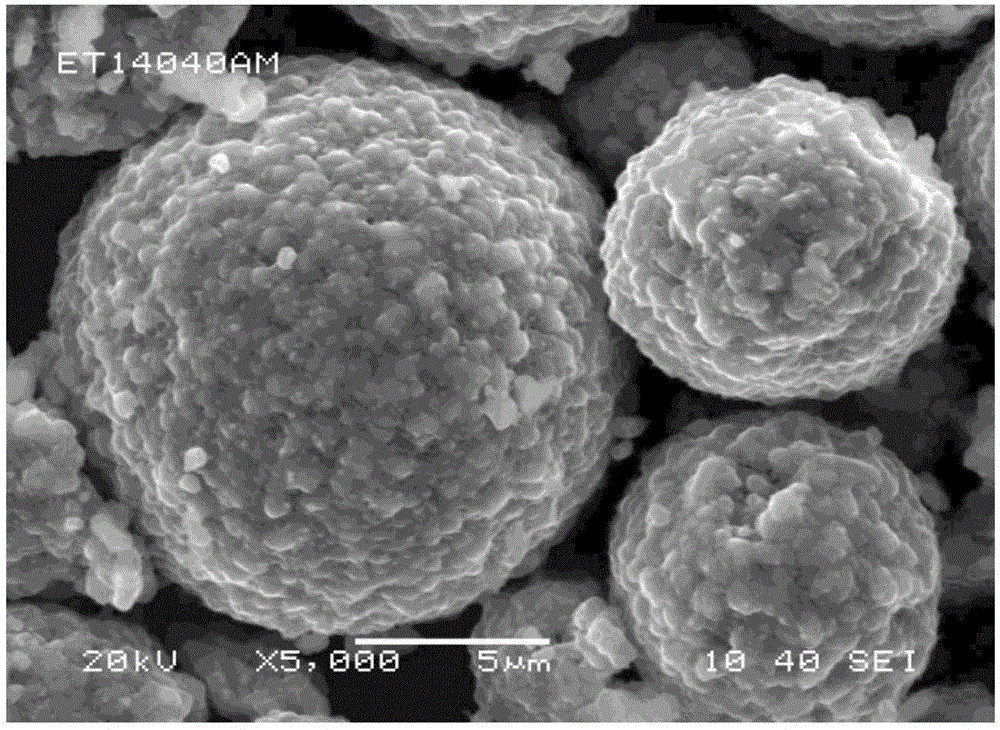

Spherical hard carbon lithium ion battery cathode material and preparation method thereof

The invention discloses a spherical hard carbon lithium ion battery cathode material and a preparation method thereof, aiming to solve the technical problem of improving the capacity retention ratio and rapid charging / discharging capacity of the material. The spherical hard carbon lithium ion battery cathode material adopts hard carbon as a basal body, carbon material is coated outside the basal body, and the 002 peak is at 22.6-23.8 degrees. The preparation method comprises ball milling a hard carbon precursor to granules, placing the granules into a water solution containing surfactant, ball milling to obtain a dispersion of the hard carbon precursor, drying, coating, and carrying out pyrolytic decomposition treatment. Compared with the prior art, the prepared spherical hard carbon material has a compacted density greater than 1.1 g / cm<3>, an initial coulombic efficiency greater than 80%, capacity retention ratio after 500 cycles greater than 85%, and 30C / 1C capacity retention ratiogreater than 98%, and has excellent rapid lithium ion intercalation and deintercalation capacity, and simple preparation method.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +3

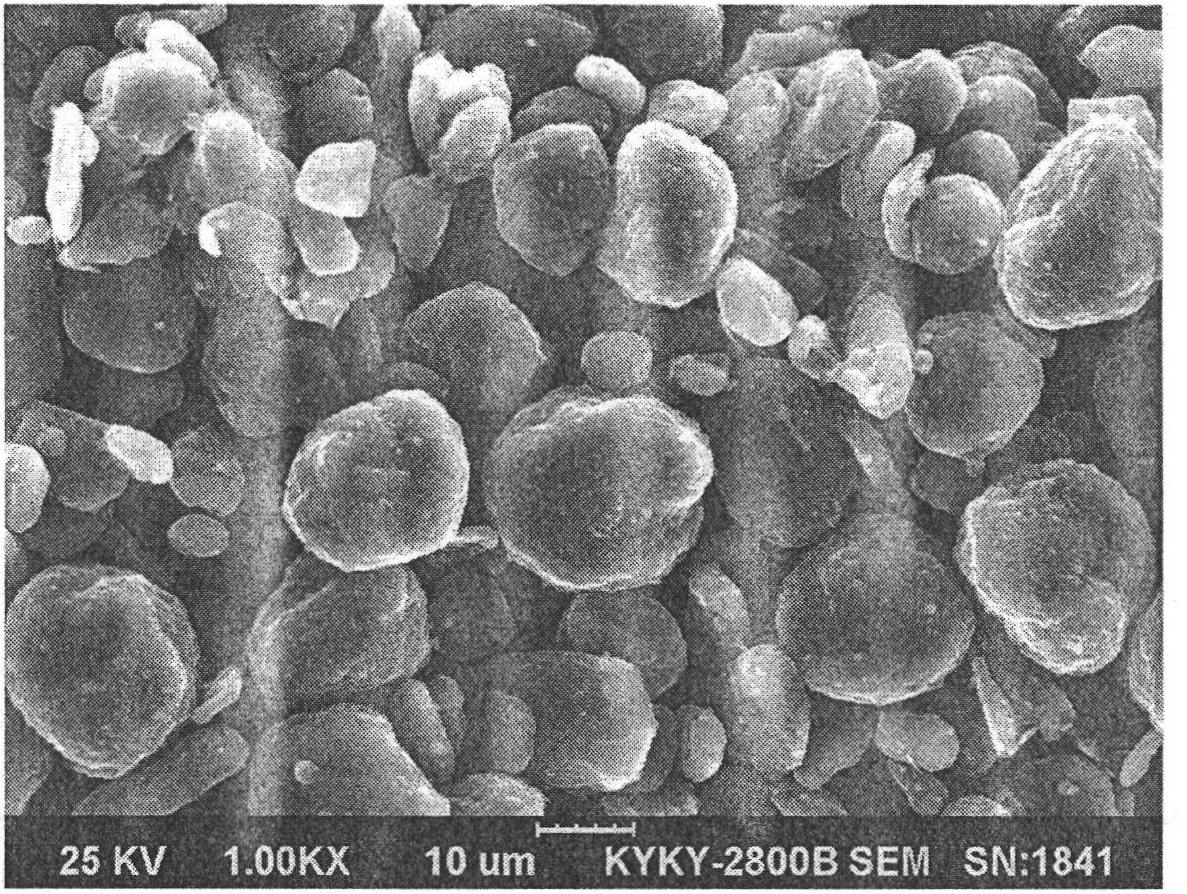

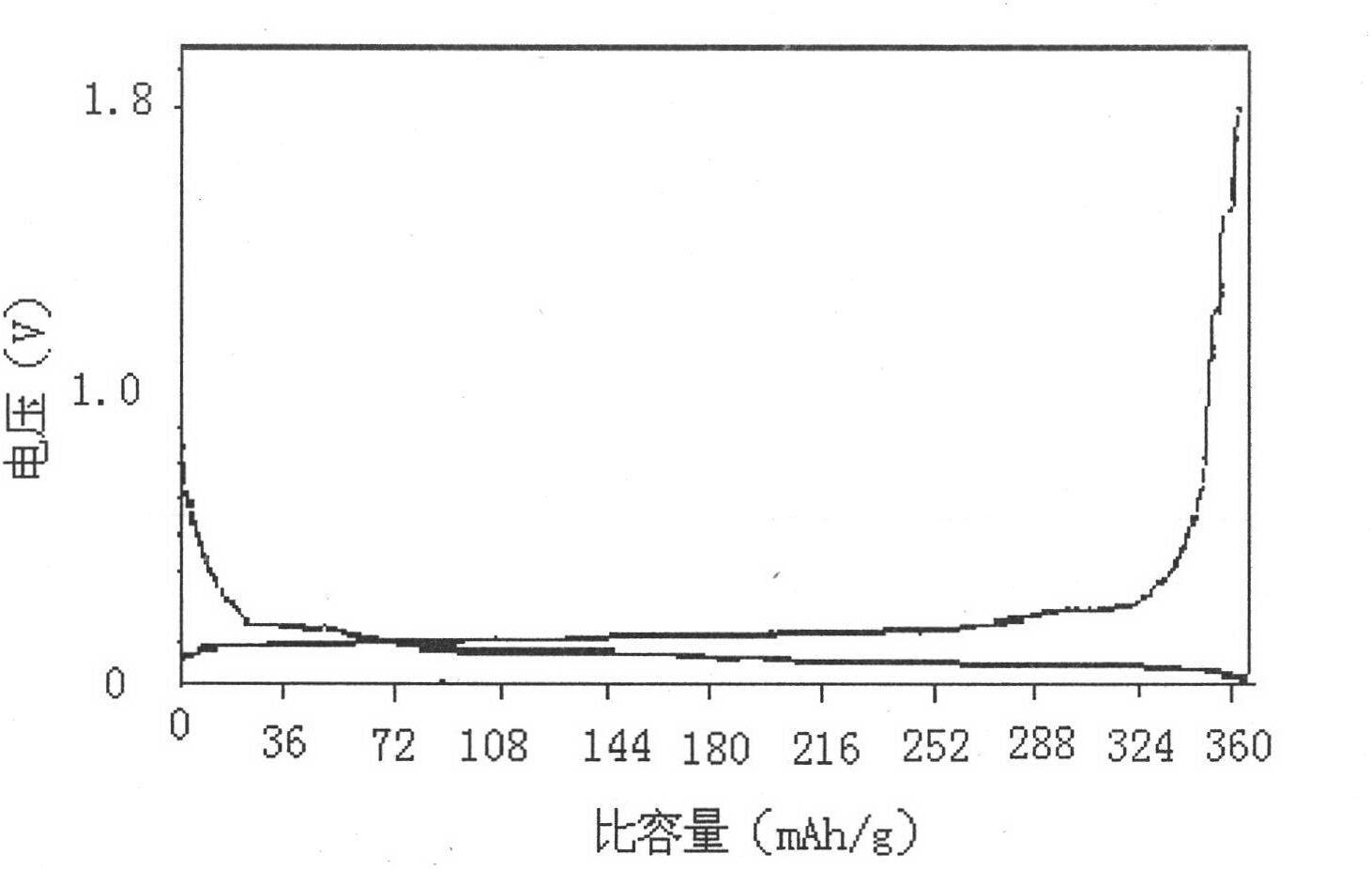

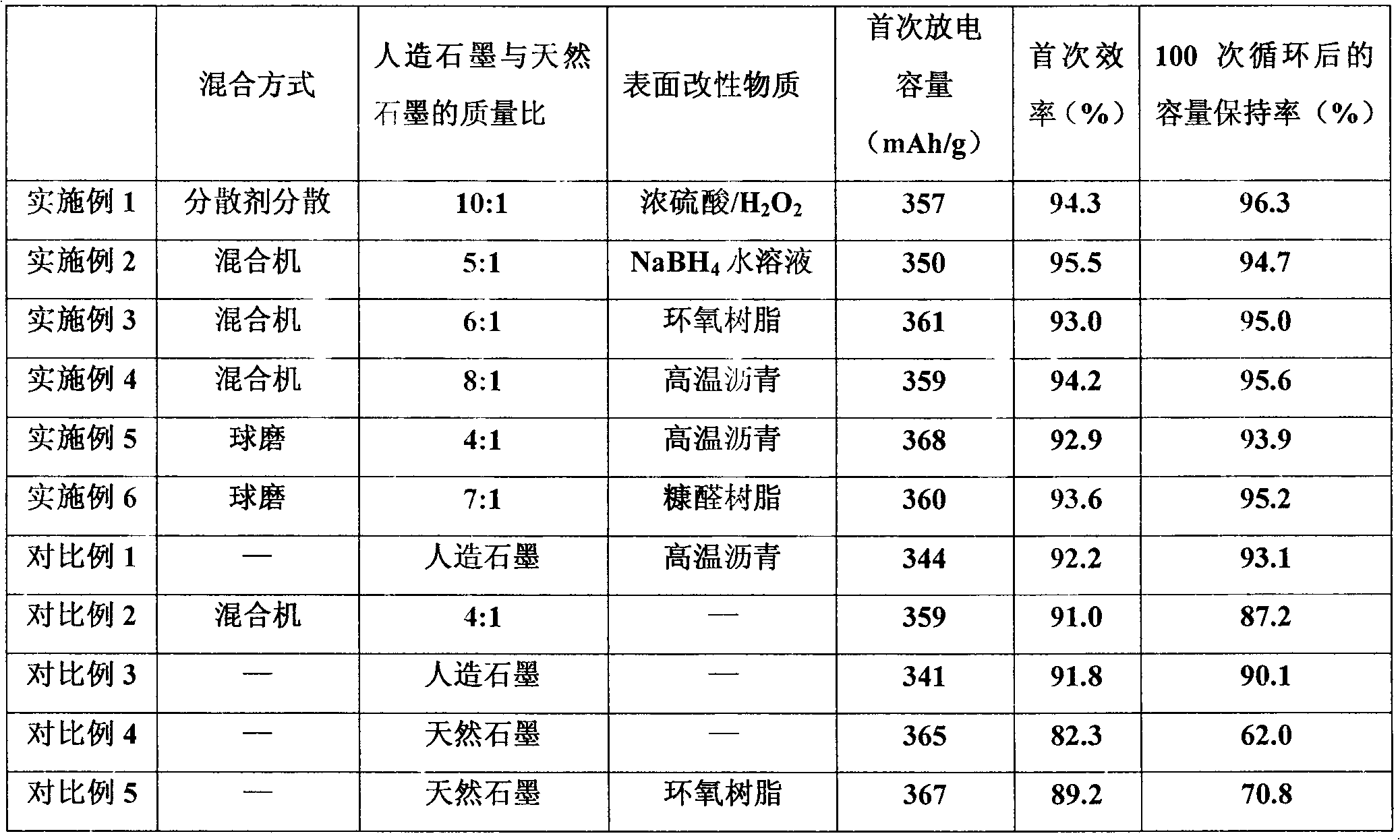

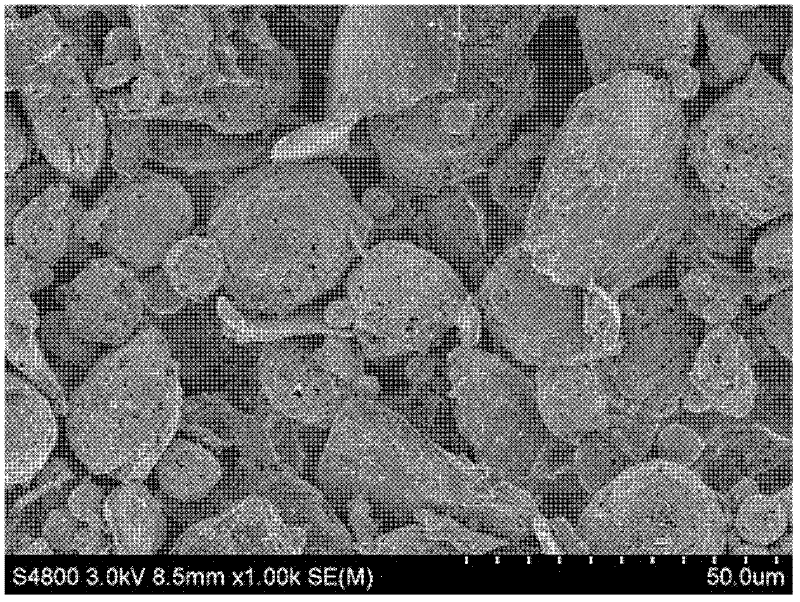

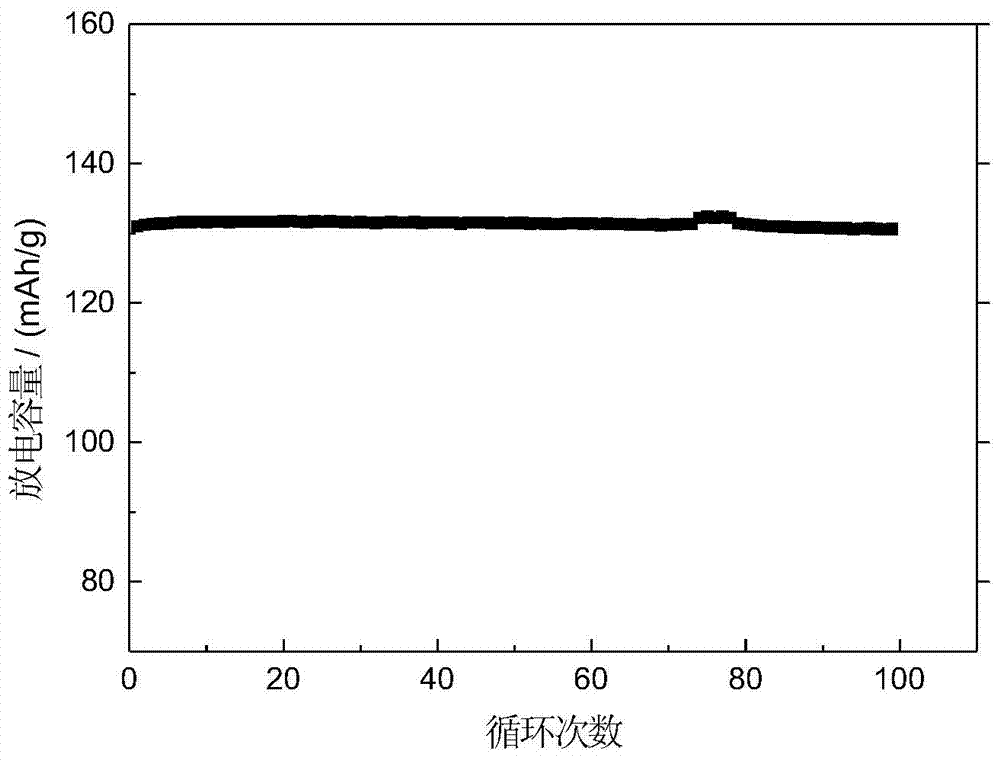

High-capacity graphite material and preparation method as well as application thereof

InactiveCN102659091AImprove discharge capacityImprove first-time efficiencyGraphiteCell electrodesMass ratioMetallurgy

The invention relates to a high-capacity graphite material and a preparation method as well as application thereof. The high-capacity graphite material comprises artificial graphite and natural graphite, wherein the mass ratio of artificial graphite to natural graphite is 20:1 to 1:1. According to the preparation method, the artificial graphite and the natural graphite are uniformly mixed according to a certain mass ratio, and then surface modification is carried out on the mixture. The prepared graphite material has the advantages of high discharge capacity, high first efficiency, long cycle life, low cost and the like; the discharge capacity of the high-capacity graphite material can reach up to more than 350mAh / g (even reach up to more than 368mAh / g); a half-cell of the high-capacity graphite material charges and discharges at the 1C multiple power; after the high-capacity graphite material cycles for 100 times, the capacity retention ratio of the high-capacity graphite material is still more than 90% (even reaches up to more than 96.3%); the first efficiency reaches up to more than 95.5%; and the manufacturing cost is reduced by about 1-10%. The high-capacity graphite material provided by the invention not only can meet the requirement of a lithium ion power battery for the high multiplying power charge-discharge of the material, but also reduces the manufacturing cost of the cathode material of the lithium ion battery.

Owner:天津市贝特瑞新能源科技有限公司

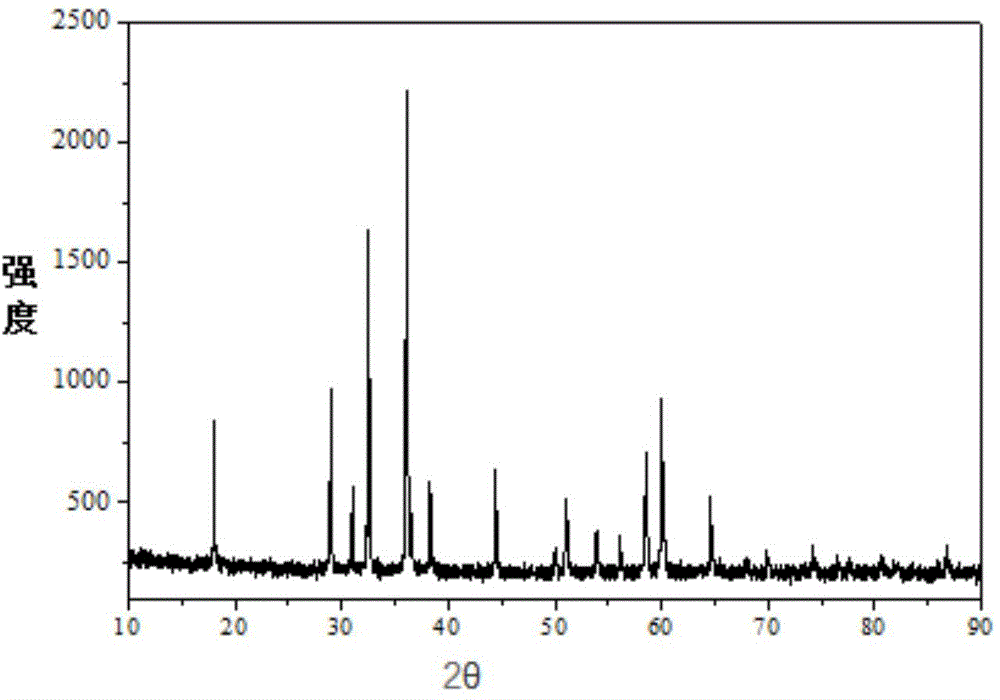

Method for coating conductive polymer on Ni-Co-Mn acid lithium positive electrode material

ActiveCN104466135AHigh specific capacityImprove cycle lifeCell electrodesSecondary cellsConductive polymerDissolution

The invention discloses a method for coating a conductive polymer on a Ni-Co-Mn acid lithium positive electrode material, and relates to the technical field of electrode materials of lithium ion batteries and preparation. The method comprises the following steps: (1) preparing LiNi1 / 3Co1 / 3Mn1 / 3 precursor mixed liquid by means of mechanical activation; (2) adding aqueous solution or organic solution of the conductive polymer into the LiNi1 / 3Co1 / 3Mn1 / 3 precursor mixed liquid; (3) performing spray drying on the mixture prepared in the step (2) to obtain precursor powder which is uniformly mixed; and (4) calcining the precursor powder which is subjected to jolt ramming or compaction, and cooling to a room temperature to obtain a conductive polymer coated Ni-Co-Mn acid lithium positive electrode material. According to the method, the conductive polymer is coated on the surface of the Ni-Co-Mn acid lithium positive electrode material, the dissolution of transition metals in the positive electrode material in electrolytes during charging / discharging circulation is inhibited, and the battery cycle performance and capacity retention ratio of the positive electrode material are improved.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

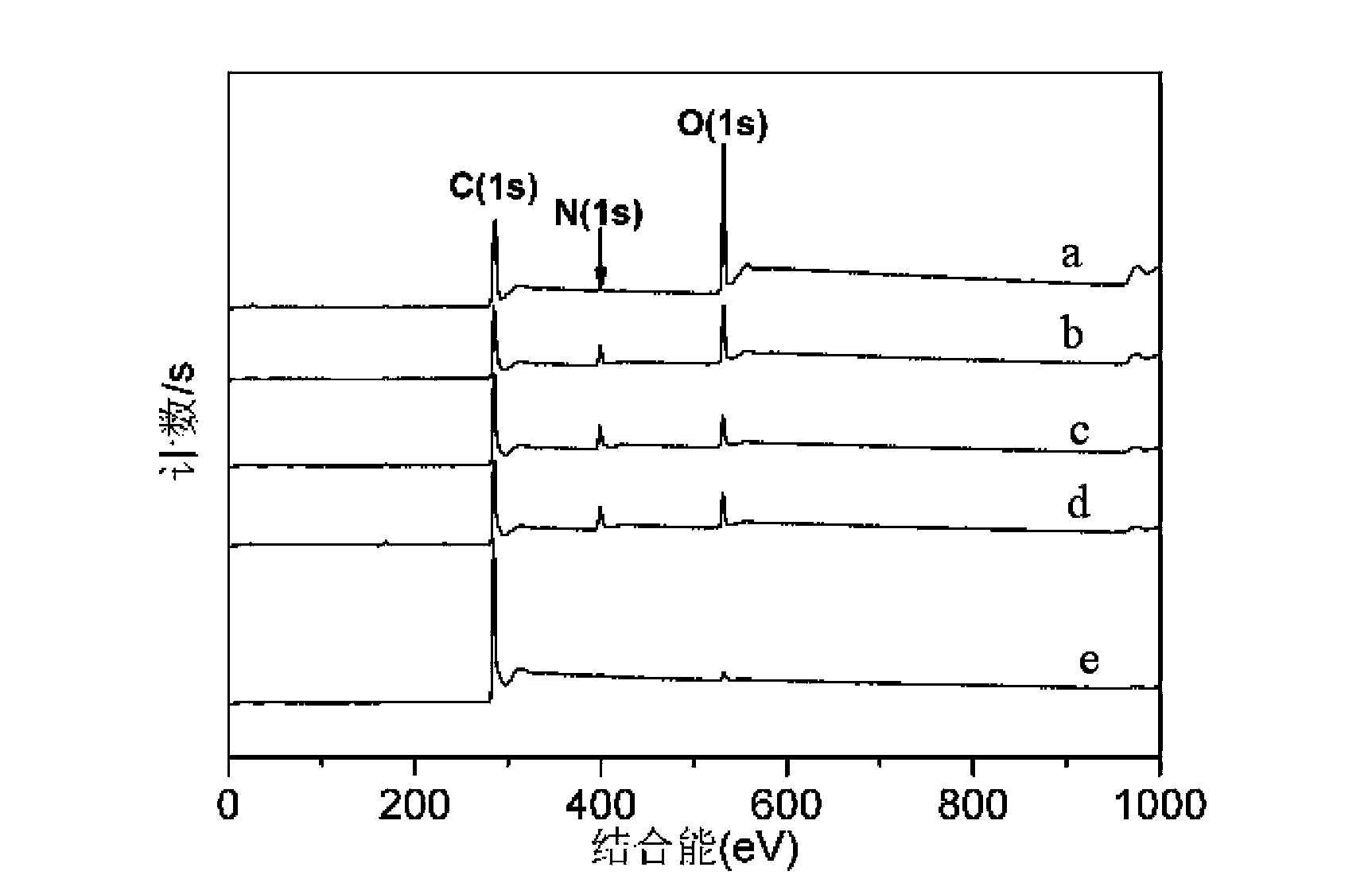

Preparation method of nitrogen doped graphene and application of nitrogen doped graphene

ActiveCN103626158AHighly dopedIncrease pressureHybrid capacitor electrodesGrapheneReaction temperatureSupercapacitor

The invention provides a preparation method of nitrogen doped graphene and an application of the nitrogen doped graphene in super capacitors. The preparation method of the nitrogen doped graphene specifically comprises the following steps: putting a carbon material and a compound containing active nitrogen elements in an enclosed container, and heating to a temperature of 100 to 300 DEG C so as to obtain the nitrogen doped graphene. In the preparation process of the nitrogen doped graphene, under a heating condition, nitrogen elements in the compound containing active nitrogen elements are mixed into the carbon material so as to obtain the nitrogen doped graphene. The nitrogen doped graphene preparation method mentioned above avoids adopting a high reaction temperature, and has the advantages of mild preparation conditions and low production cost. The prepared nitrogen doped graphene is used as an electrode material of a super capacitor, and the specific capacity of the super capacitor can reach 190 F / g, when the electric current density is 5 A / g. The capacity retention ratio is 96.3% after 10000 times of circulation.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

Silicon monoxide composite cathode material for lithium ion battery, and preparation method thereof

The invention discloses a silicon monoxide composite cathode material for a lithium ion battery, and a preparation method of the silicon monoxide composite cathode material, aiming at improving the cycle performance. The composite cathode material comprises the components by mass percent: 10-30% of composite particle material and 70-90% of natural graphite or artificial graphite, wherein the composite particle material is silicon monoxide covered by a carbon nano tube and an amorphous carbon coating layer. The method comprises the following steps of: forming the carbon nano tube and the amorphous carbon coating layer on the surface of silicon monoxide to obtain composite particles, and mixing the composite particles with the graphite. Compared with the prior art, the preparation method enables cracking carbon to be covered on the surfaces of silicon monoxide particles, so that the volume effect of the silicon monoxide particles can be effectively inhibited in the charge-discharge process of a battery, the cycle performance is good, the specific capacity is more than 500mAh / g, and the capacity retention ratio is more than 85% after the circulation is carried out for 100 times; and the preparation method is simple in preparation technology, low in raw material cost and suitable for the cathode material for the high-capacity lithium ion battery.

Owner:BTR NEW MATERIAL GRP CO LTD

Silicon-carbon cathode material for lithium ion battery and manufacturing method thereof

ActiveCN102394288ALow costHigh specific gram capacityMaterial nanotechnologyCell electrodesCarbon compositesMass ratio

The invention discloses a silicon-carbon cathode material for a lithium ion battery and a manufacturing method thereof, aiming at solving the technical problem of improving the circulating performance of the silicon-carbon cathode material. The silicon-carbon cathode material comprises a silicon-carbon composite material and graphite powder, and comprises the components by mass ratio as follows: 1-20% of nano-silicon powder, 1-40% of carbon material presoma and the balance of graphite powder. The preparing method of the invention comprises the following steps: mixing, thermal processing, smashing, removing silicon powder with defects at the wrapping layer, mixing, thermal processing and smashing the silicon powder, and mixing the silicon powder with the graphite powder. Compared with the prior art, the material has higher specific capacity, and has a better circulating performance than that of a common alloy cathode material; the specific capacity of the material is 400-1000mAh / g according to different technological parameters, and the capacity retention ratio of the material is maintained to be above 95% with 50 times of circulation; and the preparing process is simple, and the material cost is low, so that the method is applicable to mass production of high-capacity lithium ion battery cathode materials.

Owner:BTR NEW MATERIAL GRP CO LTD

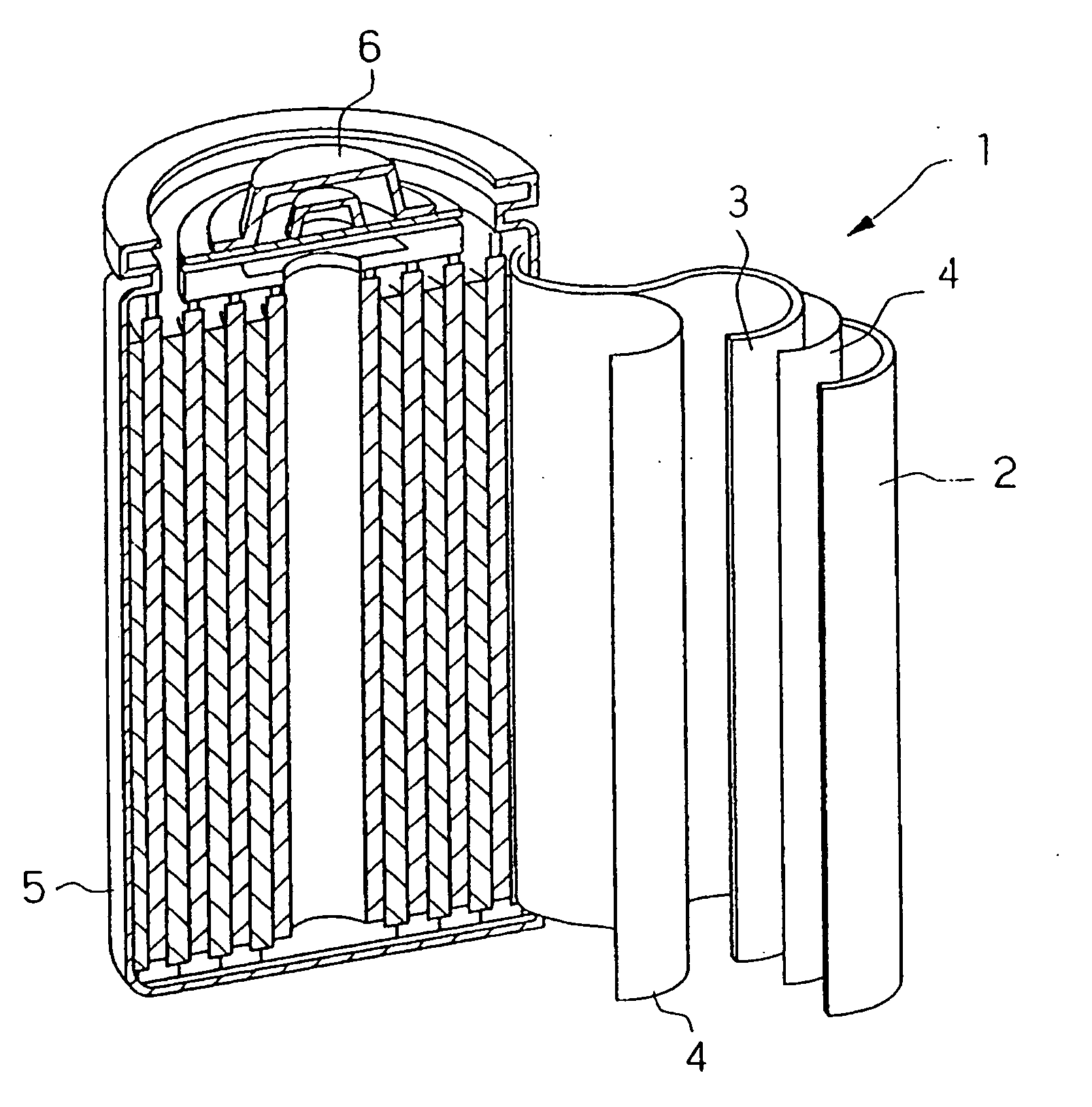

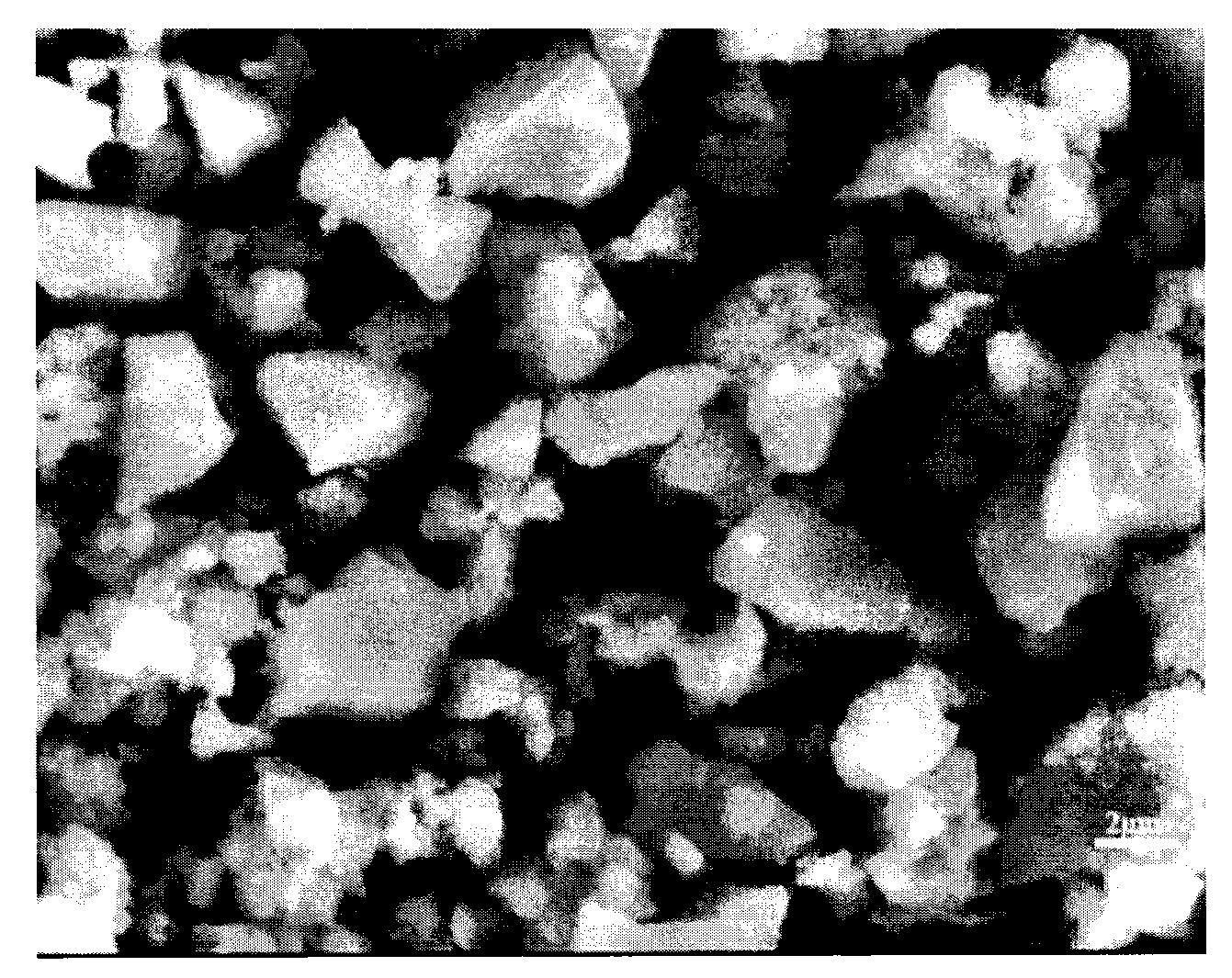

Negative active material and method for production thereof, non-aqueous electrolyte secondary cell using the same

An anode active material having a high discharge capacity and a superior capacity retention ratio during a charge-discharge cycle is provided. The anode active material includes an alloy material including an element M capable of being alloyed with Li and at least one kind of element R selected from elements with an atomic number of 20 or less, except for H, Li and a noble gas. As the element M, for example, Sn and at least one kind, such as, of Ni, Cu, Fe, Co, Mn, Zn, In and Ag are included. As the element R, B, C, Al, Si, P, S or the like is included. The anode active material can have a low-crystalline or amorphous structure by the element R, thereby Li can be smoothly inserted and extracted. The content of the element R is preferably within a range from about 10 wt % to about 50 wt %.

Owner:MURATA MFG CO LTD

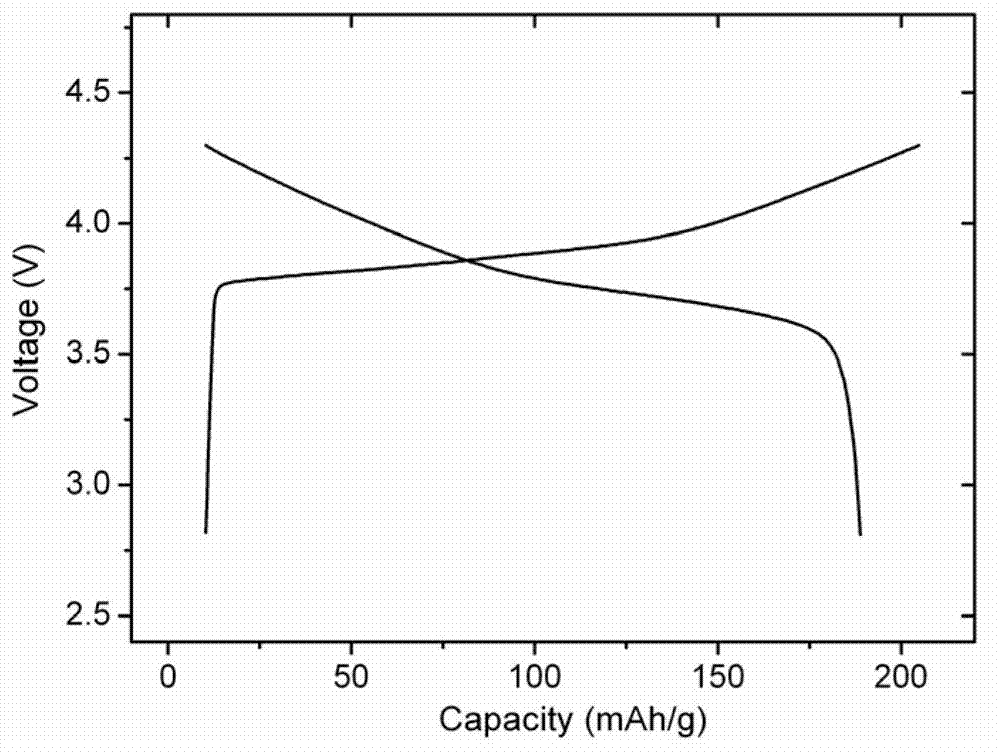

Sodium-titanium phosphate/carbon composite material and preparation method and use thereof

InactiveCN106784696AUneven solutionImprove uniformityCell electrodesSecondary cellsCarbon layerCarbon coating

The invention belongs to the field of electrode material synthesis, and relates to a sodium-titanium phosphate / carbon composite material and a preparation method and use thereof. The sodium-titanium phosphate / carbon composite material comprises secondary particles formed by clustering primary particles, the primary particles comprise sodium-titanium phosphate particles and carbon layers coated on the surfaces of the sodium-titanium phosphate particles, and the carbon layers are prepared through two times of carbon coating. According to the sodium-titanium phosphate / carbon composite material and the preparation method and use thereof, by means of preparing a precursor of the sodium-titanium phosphate and then adopting a spray drying method to carry out primary carbon coating and secondary carbon coating, the sodium-titanium phosphate / carbon composite material having a uniform and compact coating carbon layer is prepared, and the problem that the coating carbon layer obtained by the primary carbon coating is not uniform is solved. The composite material is good in stability, electrodes prepared from the sodium-titanium phosphate / carbon composite material and assembled batteries have excellent electrochemical properties, the discharge capacity is above 115mAh / g, and the capacity retention ratio is above 95% after 500 weeks of circulation.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Cobalt oxide anode material, amorphous carbon coated cobalt oxide anode material and preparation method and application of cobalt oxide anode material and amorphous carbon coated cobalt oxide anode material

InactiveCN102659192ASimple preparation processPromote circulationCell electrodesCobalt oxides/hydroxidesHigh rateRetention ratio

The invention discloses a preparation method of a cobalt oxide anode material or an amorphous carbon coated cobalt oxide anode material, which comprises the following steps of: placing a conductive metal substrate in aqueous solution containing soluble cobalt salt and hexamethylene tetramine and carrying out heat preservation for 3h to 12h at a temperature of 80 DEG C to 150 DEG C to obtain the conductive metal substrate on which a cobalt hydroxide thin film is deposited; calcining the conductive metal substrate for 1h to 3h at a temperature of 200 DEG C to 400 DEG C to obtain the cobalt oxide anode material; and soaking the cobalt oxide anode material into aqueous solution of glucose, drying and calcining for 1h to 8h at a temperature of 300 DEG C to 500 DEG C to obtain the amorphous carbon coated cobalt oxide anode material. The preparation method has a simple preparation process and good reproducibility, is easy to implement, has an environmental-friendly production process and low cost and is beneficial to industrial production. The invention also provides the cobalt oxide anode material and the amorphous carbon coated cobalt oxide anode material. The cobalt oxide anode material and the amorphous carbon coated cobalt oxide anode material have high capacity retention ratios and good high-rate capabilities and are particularly suitable to use as a cathode electrode of a lithium ion battery.

Owner:ZHEJIANG UNIV

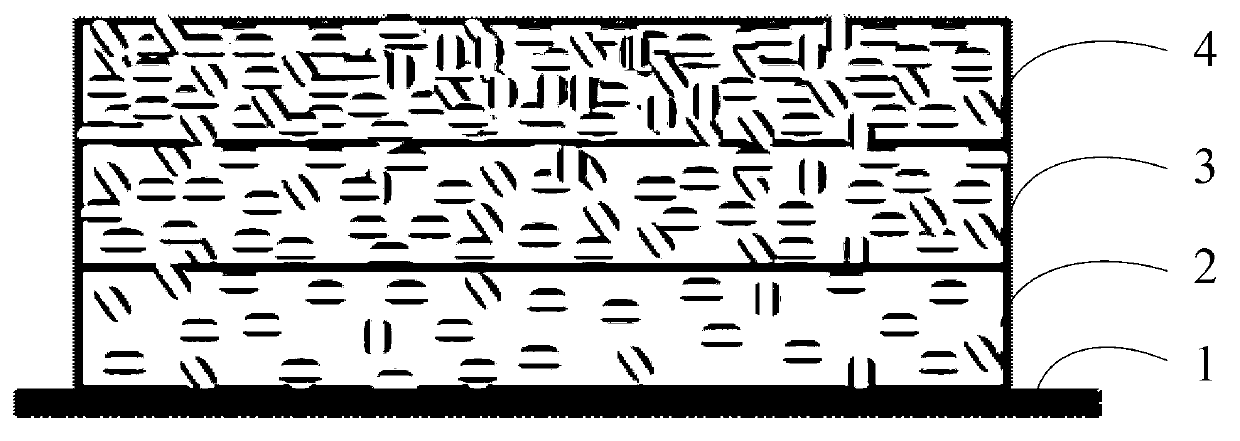

Gradient cathode piece and lithium ion battery preparation method with same

The invention provides a gradient cathode piece and a lithium ion battery preparation method with the same. The gradient cathode piece is prepared by sequentially coating a first size layer, a second size layer and a third size layer on a copper foil, wherein active components in the first size layer, the second size layer and the third size layer increase gradually. A lithium ion battery is prepared with the gradient cathode piece. The gradient cathode piece is easy to industrialize. Inner stress, generated during lithium insertion and lithium removing, of alloy materials of the gradient cathode piece in the lithium ion battery can be controlled effectively, damage, caused by expansion stress, of the gradient cathode piece is lowered greatly, and accordingly wrinkle and breakage of the gradient cathode piece are avoided, and performances such as multiplying power and capacity retention ratio of the lithium ion battery are increased effectively.

Owner:韩志娟

Soft-carbon composite cathode material of lithium ion battery and preparation method thereof

ActiveCN103500815AExcellent fast embeddingExcellent delithiation abilityCell electrodesSecondary cellsCarbon compositesMass ratio

The invention discloses a soft-carbon composite cathode material of a lithium ion battery and a preparation method of the soft-carbon composite cathode material, aiming to increase the first charge and discharge efficiency and energy density of the soft-carbon cathode material. The composite material is prepared from a soft-carbon material and graphite and simultaneously has an irregular-layer structure and a layer structure, and the mass ratio of the precursor of the soft-carbon material to the graphite is (90-40):(10-60). The preparation method comprises the following steps: adding the graphite into pitch, catalyzing, gathering, and carbonizing; or catalyzing and gathering the pitch to be compounded with the graphite, and carbonizing; or catalyzing and gathering the pitch, and compounding the treated pitch with the graphite after carbonizing. Compared with the prior art, the compaction density of the soft-carbon composite cathode material of the lithium ion battery is larger than 1.5g / cm<3>, the first charge and discharge coulombic-efficiency achieves more than 90 percent, and the capacity retention ratio of circulating for 800 times is larger than 95 percent; the soft-carbon composite cathode material of the lithium ion battery has good capacity of rapid deinsertion and insertion of lithium, and the 30C / 1C capacity retention ratio is larger than 95 percent.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

Cathode material for lithium ion batteries and preparation method thereof

ActiveCN105185974AImprove electrochemical performanceImprove securityMaterial nanotechnologyCell electrodesCarbon layerFiltration

The invention discloses a cathode material for lithium ion batteries. The cathode material is a core-shell structure. The ''core'' of the core-shell structure is a cathode active material, and the ''shell'' of the core-shell structure is a carbon layer containing discontinuous nano-LixMOy. The carbon layer uniformly coats the cathode active material. The LixMOy is one or more of LiAlO2, Li2TiO3 or Li2ZrO3. The cathode active material is one or more of lithium cobalt oxide, LiNixCoyMn1-x-yO2, lithium manganate, lithium nickel manganese oxide and LiNi_(0.7)Co_(0.3-x)Al_xO_2. A preparation method of the cathode material comprises the following steps: adding the cathode active material, nano-LixMOy, phenol, aldehyde and a catalyst into a surfactant and uniformly dispersing, carrying out vacuum filtration, washing and drying, calcining in the inert atmosphere and cooling to prepare the cathode material. The cathode material for lithium ion batteries has good electrochemical stability. A battery prepared from the cathode material has excellent cycle and rate performance, and capacity retention ratio of the battery is high.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

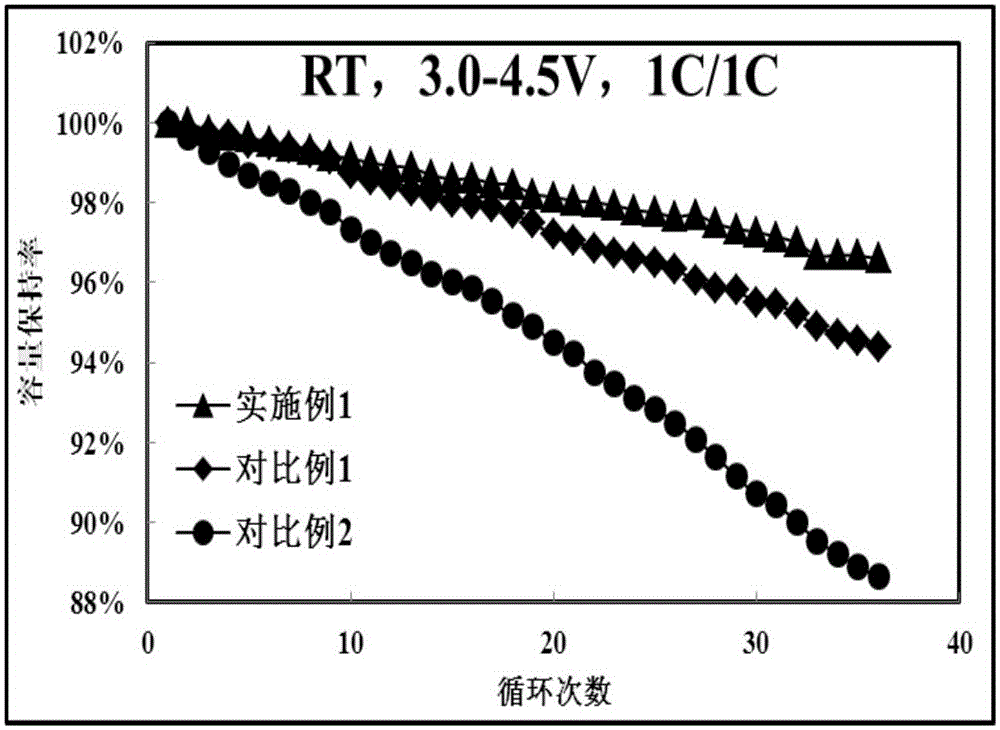

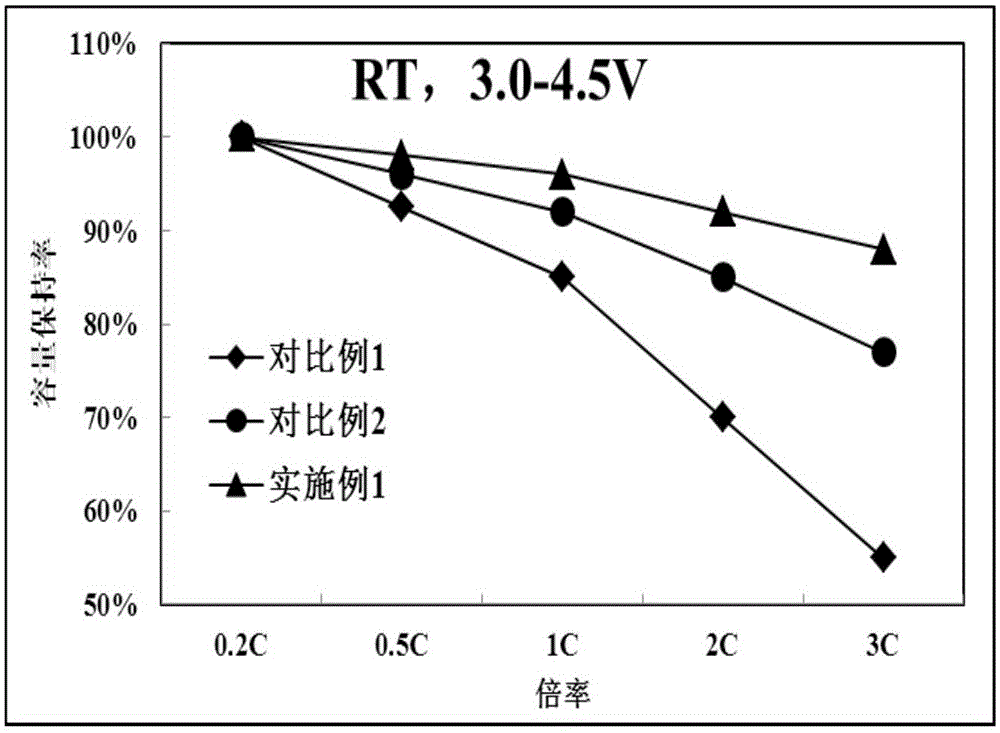

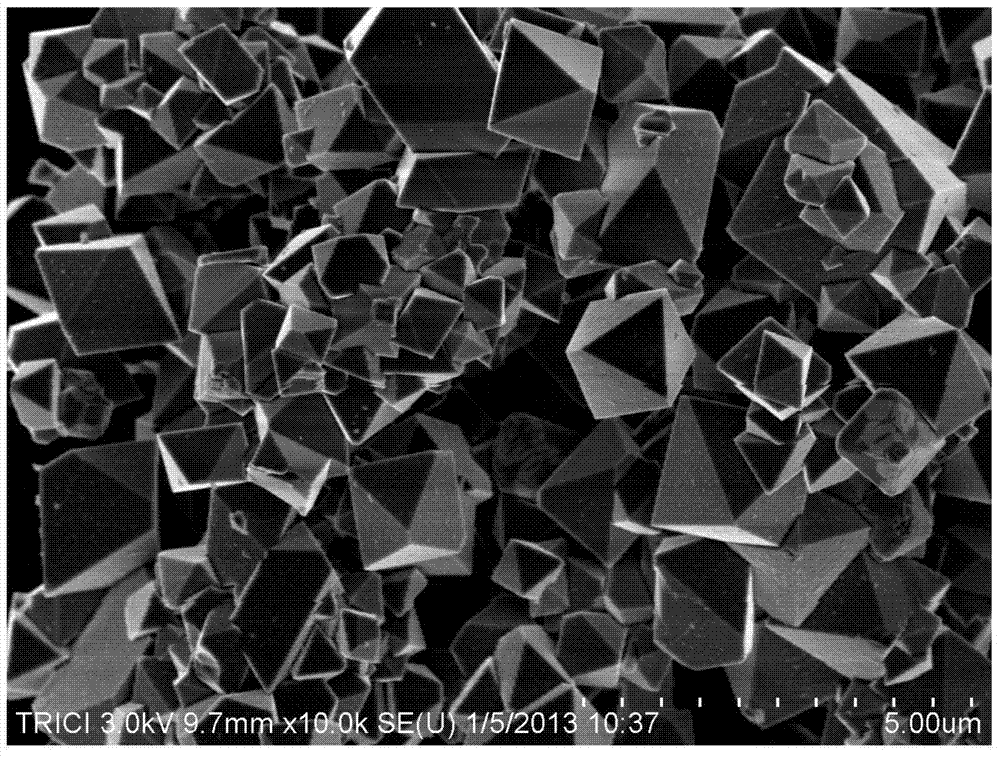

Method for modifying lithium nickel manganese oxide positive electrode material for lithium ion battery

ActiveCN104766960AImprove adsorption capacityCoated evenlyCell electrodesSecondary cellsManganese oxideRetention ratio

The invention discloses a method for modifying a lithium nickel manganese oxide positive electrode material for a lithium ion battery. The method comprises the following steps: adding lithium nickel manganese oxide into water, and adding a surfactant into the turbid liquid; adding 5-15 percent of the prepared sodium metaaluminate solution, and introducing carbon dioxide gas into the mixed solution while stirring until the pH value of the solution is 8.0-10.0; dripping the residual sodium metaaluminate solution, introducing the carbon dioxide gas, controlling the pH value of the solution to be 8.0-10.0, and carrying out a concurrent flow reaction; stirring, aging, filtering, washing, drying, thereby obtaining an aluminum hydroxide coated lithium nickel manganese oxide material; and performing heat treatment on the material in a muffle furnace for 300-450 DEG C, thereby obtaining the alumina coated and modified lithium nickel manganese oxide positive electrode material. According to the coated and modified lithium nickel manganese oxide positive electrode material disclosed by the invention, the capacity retention ratio is 99.8 percent under the 1C rate after cycling for 100 times, and compared with that of an uncoated material, the capacity retention ratio is improved by about 10 percent.

Owner:天津寻木科技有限责任公司

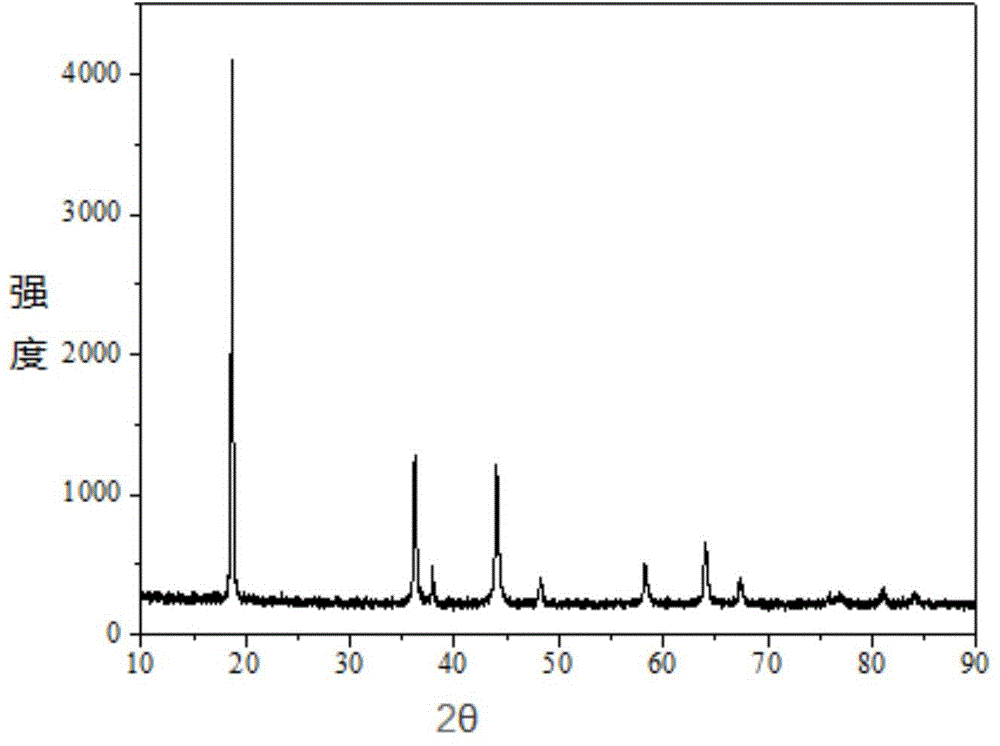

High-temperature type lithium manganate anode material for power lithium ion battery and preparation method of high-temperature type lithium manganate anode material

ActiveCN104485452AImprove high temperature resistanceExcellent discharge specific capacityCell electrodesCobalt(II,III) oxideManganate

The invention discloses a high-temperature type lithium manganate anode material for a power lithium ion battery. The high-temperature type lithium manganate anode material consists of a core material as shown in a formula Li1+xMn2-y-zAyQzO4, and a coating layer on the surface of the core material, wherein the coating layer is one or more of cobaltosic oxide, aluminum oxide and nickel protoxide. The anode material is excellent in high-temperature property, and is good in specific discharge capacity, capacity retention ratio and electrochemical circulation property at high temperature. In addition, the preparation method of the anode material disclosed by the invention is simple in production process, easy to achieve and low in cost, and can be applied to large-scale industrialization production.

Owner:北京盟固利新材料科技有限公司

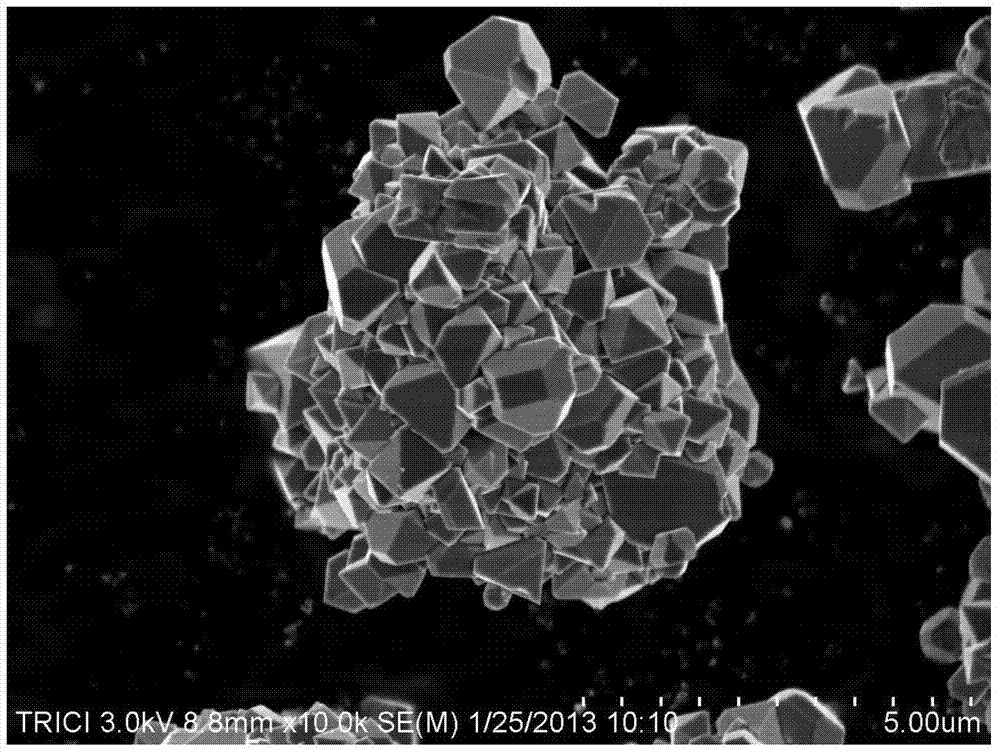

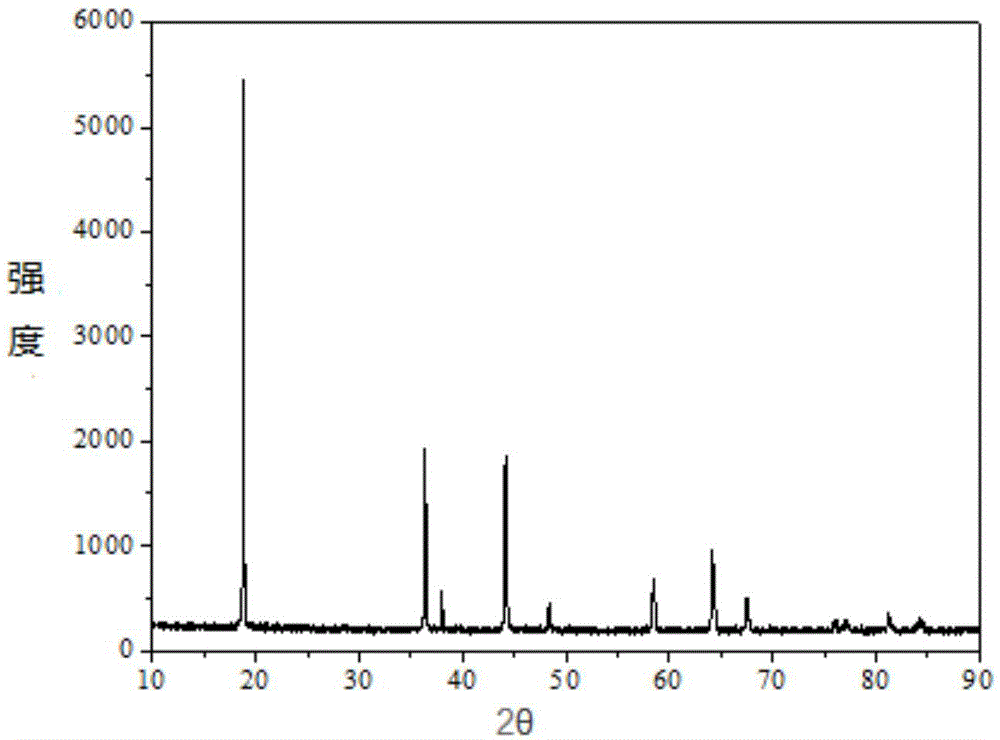

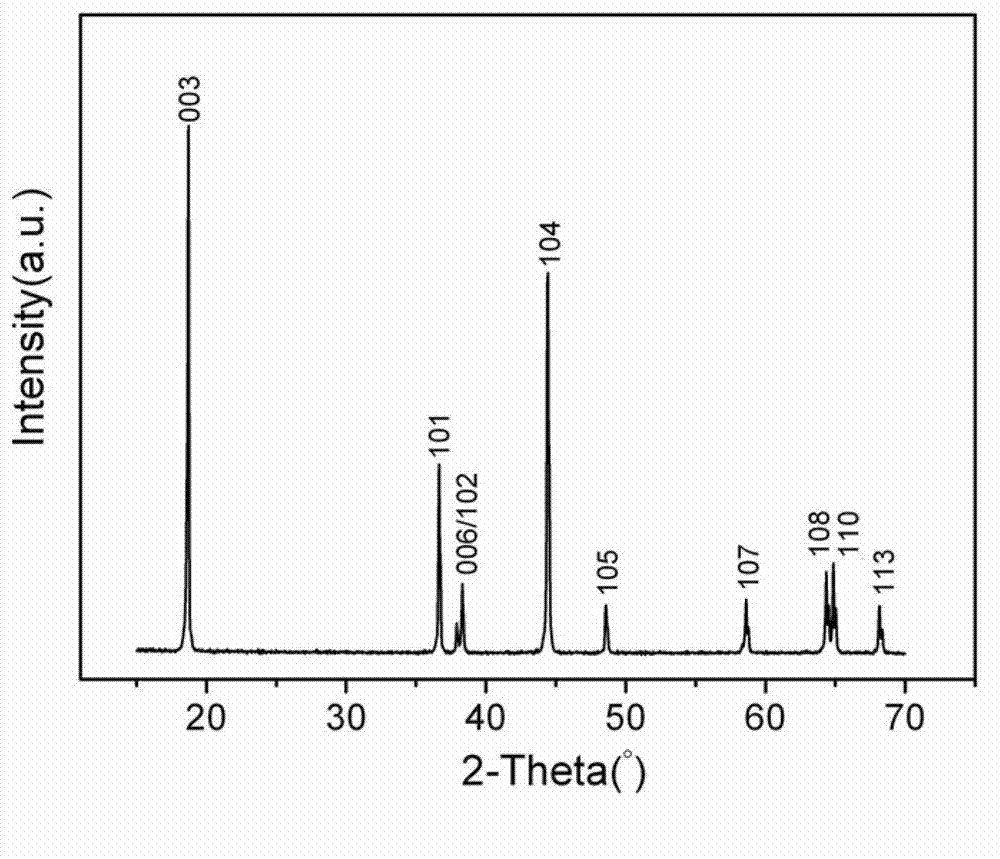

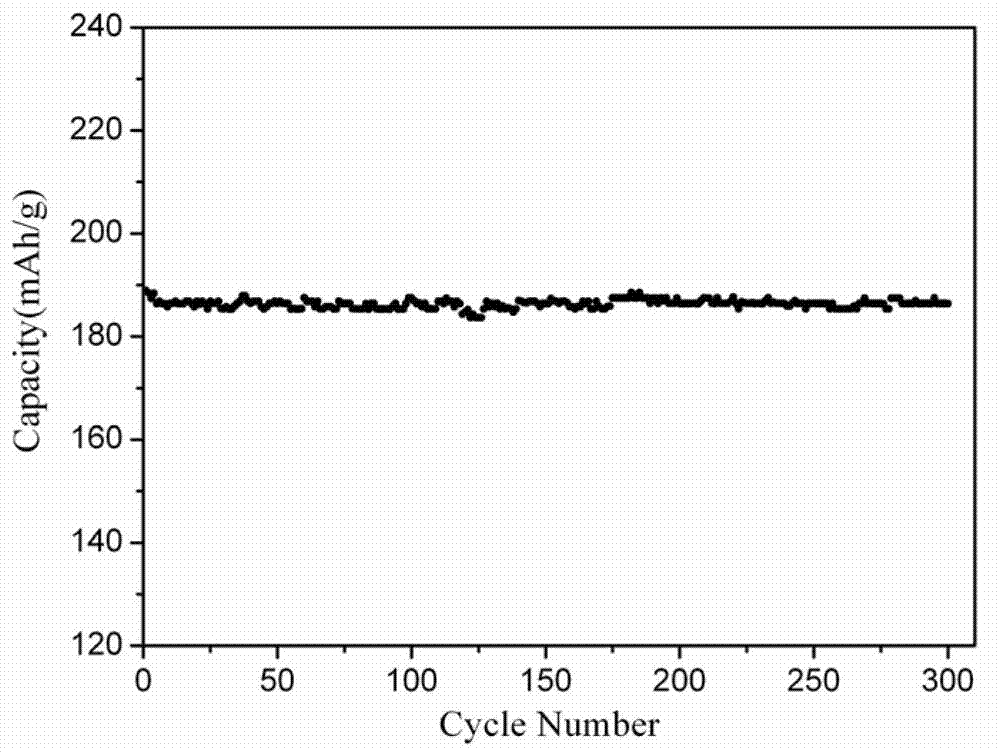

Method for preparing coated lithium ion battery cathode material of lithium nickel manganese oxide

The invention discloses a method for preparing a coated lithium ion battery cathode material of lithium nickel manganese oxide, comprising: firstly preparing a spherical precursor Ni1-xMnx(OH)2 (x=0.25-0.50) by a wet-process coprecipitation crystallization process; then mixing the prepared precursor and a mixed lithium source, and by preparing a spherical nickel and manganese binary composite oxide cathode material LiNi-xMnxO2 (x=0.25-0.50) by high temperature solid phase sintering; coating MnCO3 on the surface of the nickel and manganese binary composite oxide by a solution coating method; and finally sintering to obtain the lithium nickel manganese oxide cathode material Ni1-xMnx(OH)2 (x=0.25-0.50) coated with MnO2. The prepared material is spherical particles with smooth and compact surface and perfect layered crystallization, raises discharge specific capacity thereof, and simultaneously greatly raises cycling stability of the material, wherein the initial discharge specific capacity reaches 188.9mAh / g, and a capacity retention ratio after 1C 300 cyclictimes is more than 98.7%.

Owner:HENAN KELONG NEW ENERGY CO LTD

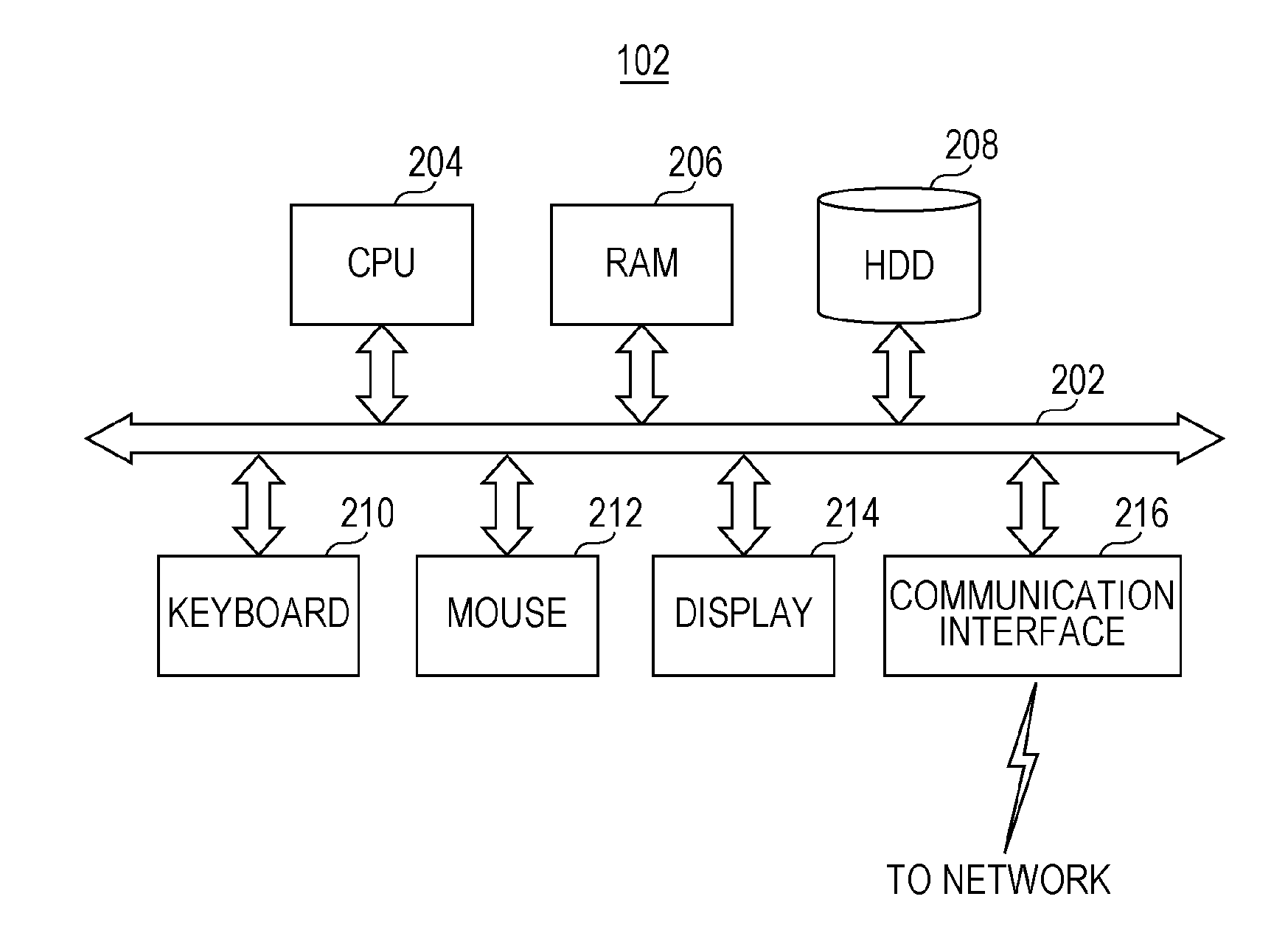

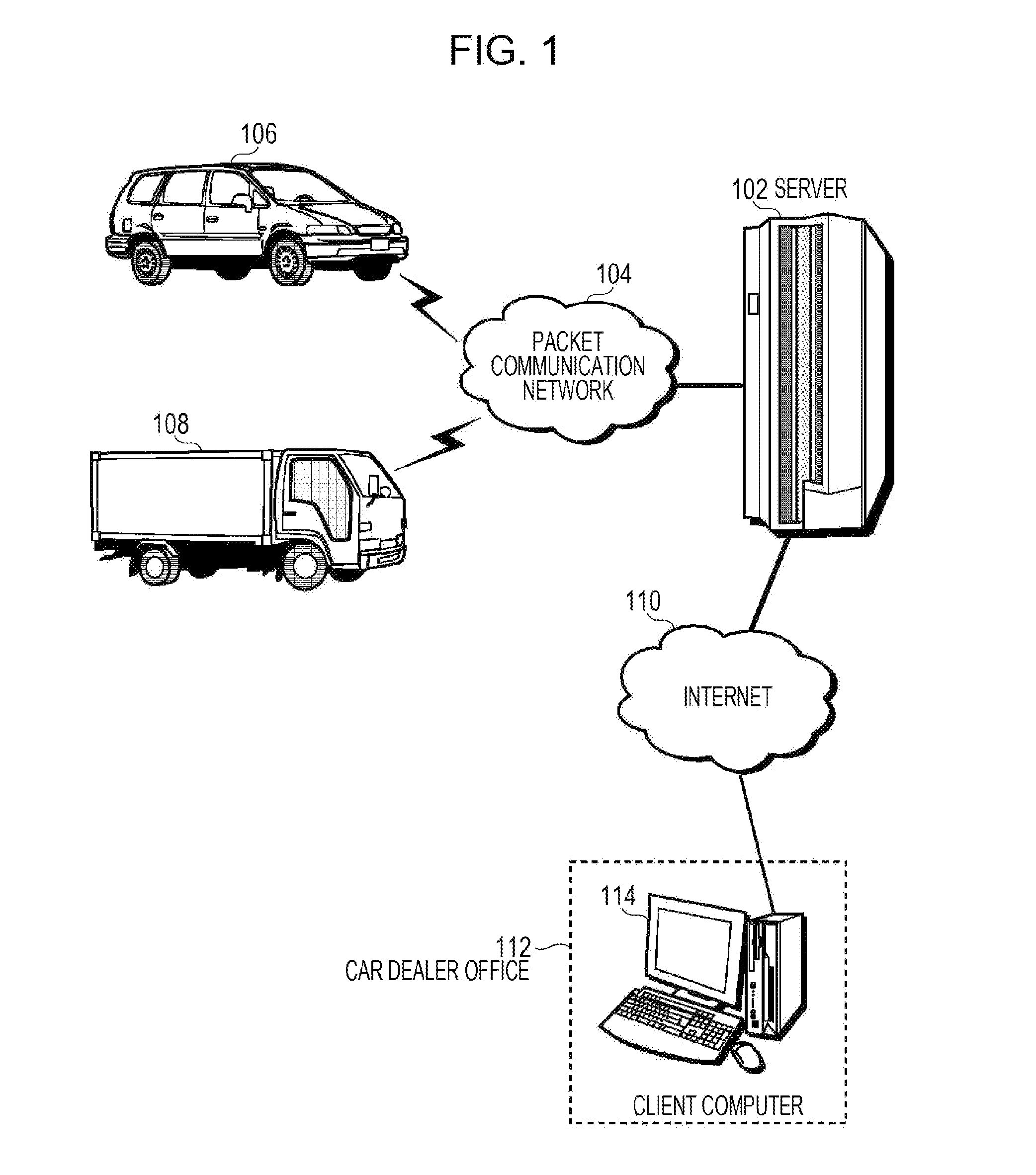

System, method, and program for predicting state of battery

InactiveUS20130096858A1Reduce the differenceElectrical testingComplex mathematical operationsComputational modelEngineering

A method and system for predicting degradation of a battery. Modeling of a battery is made to be separated into an aging section and a current-carrying section. The modeling is established such that the amount of degradation of a capacity retention ratio is determined by the linear sum of stay at each temperature and each SOC. The separation into degradation components at each temperature and each SOC enables predicting degradation under various degradation environments. A model for a battery separated into an aging section and a current-carrying section and a calculation model of a root law are combined into an objective function, and a table of discharge coefficients ah(T,S) and a table of current-carrying coefficients ac(T,S) are generated using a solver, where T indicates the temperature and S indicates SOC. Once tables are generated, degradation of the battery can be predicted by calculation using the tables.

Owner:IBM CORP

Method for preparing positively charged nanofiltration membranes

InactiveCN101766962ASeparation performance is differentHigh retention rateSemi-permeable membranesCross-linkAqueous solution

The invention discloses a method for preparing positively charged nanofiltration membranes. The positively charged nanofiltration membranes are formed by porous support layers and functional layers which are formed by copolymers containing cations and hydroxy. The preparation process is as follows: firstly, obtaining functional copolymers through free radical copolymerization, preparing the copolymers into water solution with certain concentration, coating the prepared water solution on the support layers and drying the support layers; and secondly, immerging the support layers into solution containing cross-linking agents, and finally carrying out heating and curing to obtain the positively charged nanofiltration membranes. Under the operation pressure of 0.6MPa, the positively charged nanofiltration membranes have water flux of 12-18L / m<2>.h, show very high retention ratio which is generally 75-95% to bivalent cations and show retention ratio which is generally lower than 65% to monovalent cations. The prepared positively charged nanofiltration membranes have excellent separation property, and the method is simple and feasible, low in cost and easy for industrial production.

Owner:ZHEJIANG UNIV

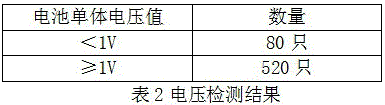

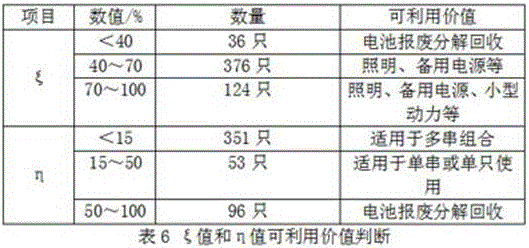

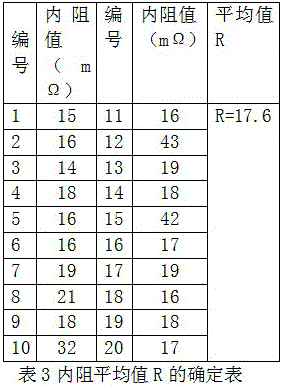

Recycling method for waste power lithium ion batteries

ActiveCN105489962AImprove consistencyGuaranteed service lifeWaste accumulators reclaimingSecondary cells servicing/maintenancePower batteryInternal resistance

The invention provides a recycling method for waste power lithium ion batteries. The method solves the problem that the complementary energy of the waste power lithium ion batteries can be effectively utilized and exerts the use value of the power batteries to the maximum extent. In order to realize the purpose, the technical scheme adopted by the recycling method is that the recycling method for the waste power lithium ion batteries comprises the following steps: firstly, information collection: examining nameplate and label information on a battery pack; secondly, performance detection: A, battery monomer voltage detection, B, battery monomer internal resistance detection, C, capacity detection, and D, self-discharge detection; and thirdly, utilizability judgment. The recycling method has the beneficial technical effects that the waste batteries are recycled to fully exert the use value of the complementary energy of the waste power lithium ion batteries; the consistency effect of the combination of the waste batteries once again is effectively improved through the system testing of battery voltage, internal resistance, capacity, capacity retention ratio and self-discharge rate, and then the service life of the recycled batteries is guaranteed.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

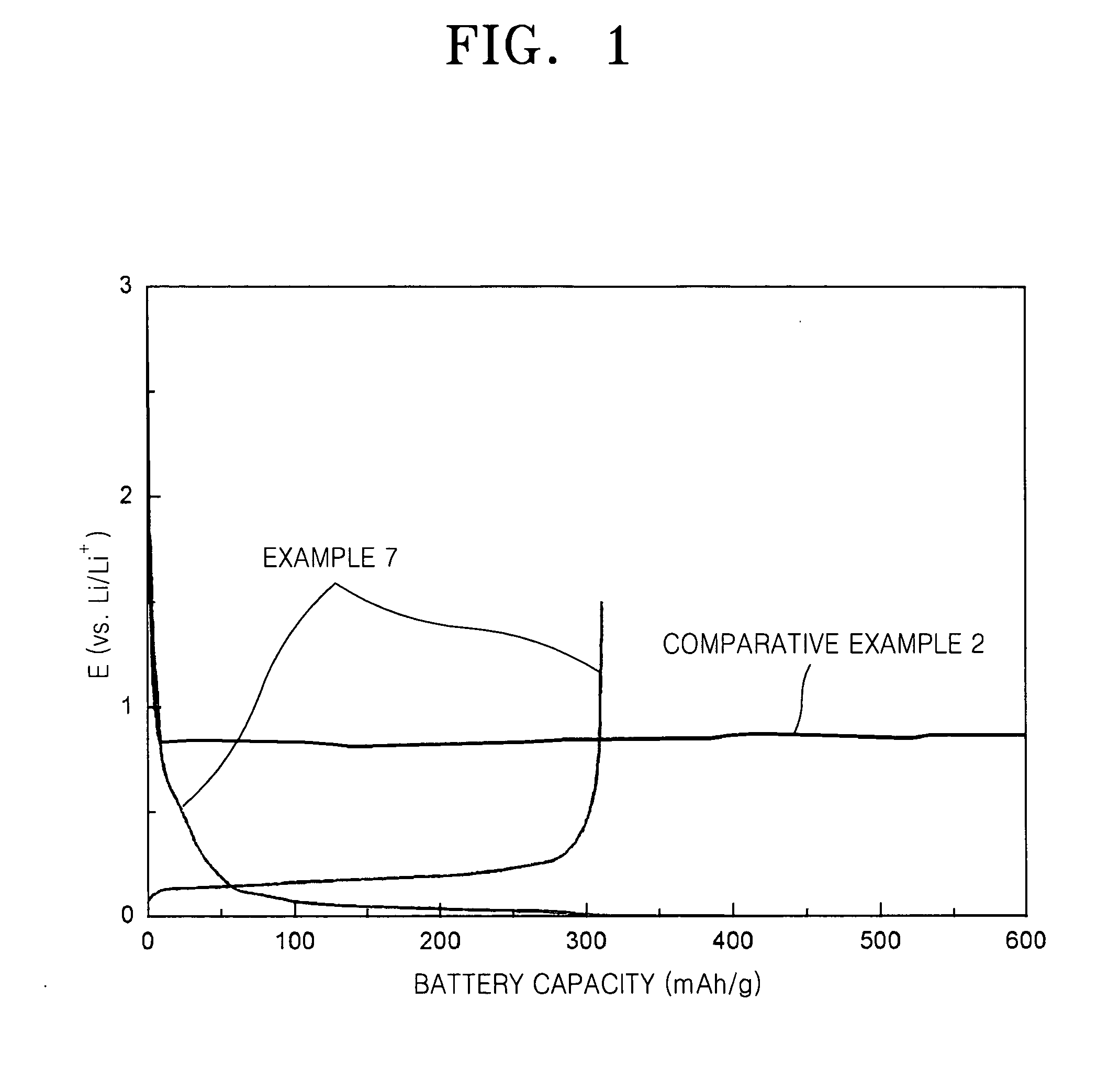

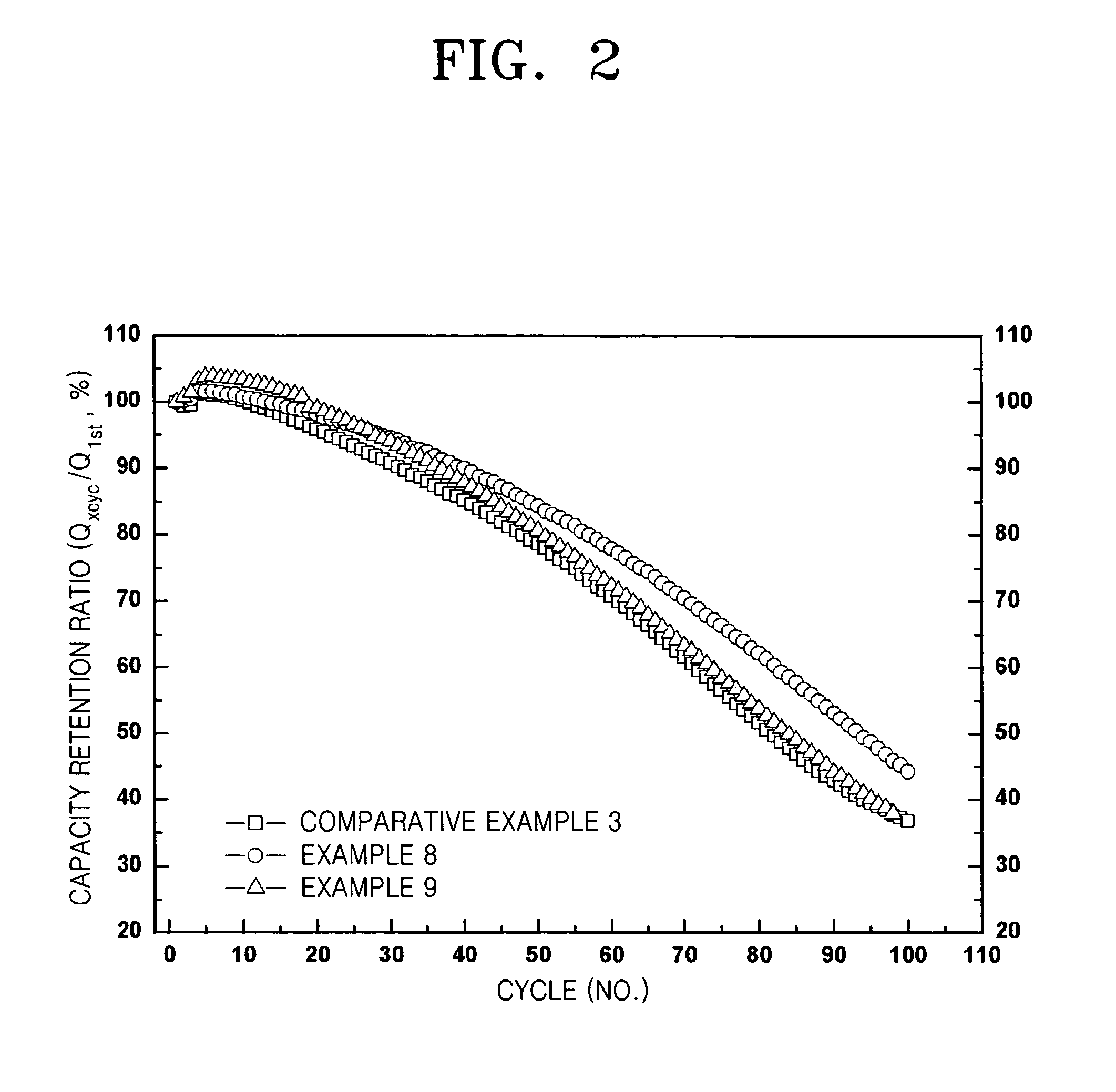

Organic electrolytic solution and lithium battery employing the same

ActiveUS20060292451A1High capacity retentionEnsuring reliability of a batteryOrganic electrolyte cellsLi-accumulatorsDischarge efficiencyOrganic solvent

An organic electrolytic solution includes a lithium salt; an organic solvent including a high dielectric constant solvent and a low boiling point solvent; and an additive of a hetero ring compound including a cyano group and an alkenyl group as substituents. The organic electrolytic solution and the lithium battery employing the organic electrolytic solution suppress the reduction decomposition of a polar solvent to improve the capacity retention ratio of the battery. Thus, the charge / discharge efficiency and lifespan of the battery can be improved.

Owner:SAMSUNG SDI CO LTD

SiO/C composite cathode material of lithium ion battery and preparation method of SiO/C composite cathode material

The invention discloses a preparation method of a SiO / C composite cathode material of a lithium ion battery. The preparation method comprises the following steps of: mixing graphite with an average particle diameter D50 being 300-500nm, ethyl orthosilicate, polyvinylpyrrolidone, ethanol and water, and stirring to enable the materials to be dispersed uniformly; regulating pH to 8-9 by using a pH regulator, removing the solvent after stirring, and carrying out pyrolysis in inert atmosphere at 500-600 DEG C to obtain black powder; and mixing ethanol solution of citric acid with the black powder, volatilizing the solvent after ball-milling for 1-3 hours, and carrying out pyrolysis, classification or screening in inert atmosphere at 450-550 DEG C. The invention also provides the SiO / C composite cathode material prepared by the preparation method. By improving a formula and the preparation method of the SiO / C composite cathode material, the SiO / C composite cathode material of the lithium ion battery with high specific capacity and good cycling performance is obtained, the reversible capacity of the SiO / C composite cathode material exceeds 500 mAh / g, and the capacity retention ratio of the SiO / C composite cathode material is above 90% after 100 cycles of 0.2 C charge and discharge. Moreover, the preparation method provided by the invention is low in operating temperature, thus being more conducive to industrial production.

Owner:宁波杉杉硅基材料有限公司

Low-temperature electrolyte of lithium iron phosphate battery

InactiveCN103500850AEasy to buyFair priceSecondary cellsOrganic electrolytesLithium vanadium phosphate batteryLithium iron phosphate

The invention relates to a low-temperature electrolyte of a lithium iron phosphate battery. The low-temperature electrolyte includes the following solvents of, by volume, 30%-45% of carbonic ester solvent, 50%-65% of carboxylic ester solvent and 4%-10% of additive. The solvents contain solute lithium, the lithium is LiPF6 or a combination of the LiPF6 and LiBF4, and the concentration of the lithium is 0.8-1.4mol / L. The low-temperature electrolyte is a nonaqueous electrolyte, through optimization of kinds and proportioning combination of the solvents of the electrolyte, low-viscosity carbonic ester and low-melting-point carboxylic ester are selected and used, the freezing point at low temperature is lowered, and low-temperature conductivity is increased. According to the low-temperature electrolyte, the lithium of the electrolyte is optimized, the low-temperature additive is selected preferably, normal-temperature circulation ratio performance of the electrolyte is maintained, and meanwhile, the low-temperature capacity retention ratio of the lithium iron phosphate battery and the ratio performance of the lithium iron phosphate battery are improved. The commercial application requirements of the electrolyte can be met, the low-temperature performance of the electrolyte is improved particularly, and therefore the electrolyte is suitable for aerospace and plateau alpine environment.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com