High-temperature type lithium manganate anode material for power lithium ion battery and preparation method of high-temperature type lithium manganate anode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as restricted applications, fast capacity decay, and poor high-temperature storage performance, and achieve good discharge specific capacity, low cost, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] According to another aspect of the present invention, there is provided a method for preparing a high-temperature type lithium manganate positive electrode material for a power lithium ion battery, the method comprising the following steps:

[0070] Step 1, the preparation of the precursor of positive electrode material,

[0071] Step 2, preparation of the core material shown in formula I,

[0072] Step 3, preparation of positive electrode material.

[0073] In the above step 1, the preparation method of the precursor of the high-temperature lithium manganate cathode material is not particularly limited, and methods such as high-temperature solid-state reaction method, sol-gel method, and co-precipitation method are all available.

[0074] In a preferred implementation method, the preparation method of the precursor of the positive electrode material comprises the following steps:

[0075] 1) The soluble salt of manganese and the soluble salt containing element A are ...

Embodiment 1

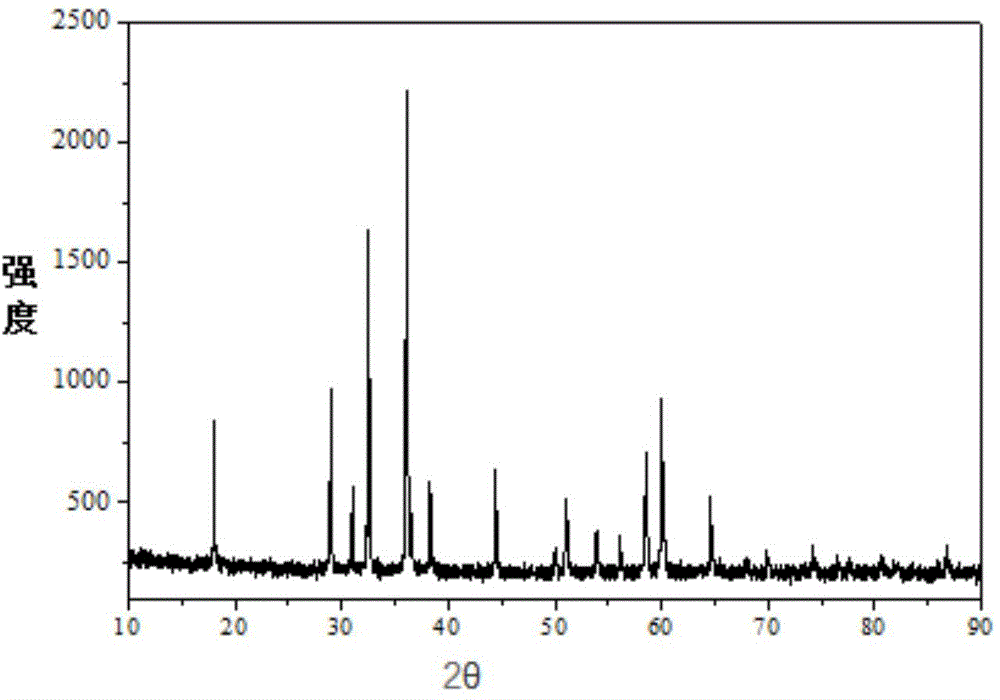

[0123] Prepare the core material as: Li 1.08 mn 1.9 Al 0.06+0.04 O 4 , the cladding layer is: 0.01Al 2 O 3 positive electrode material

[0124] Step 1, the preparation of the precursor:

[0125] 1) Weigh 984g MnSO respectively 4 ·H 2 O, 120g Al 2 (SO 4 ) 3 18H 2 O was added to deionized water to prepare 2L of mixed aqueous solution, and was added to the CSTR reactor at a rate of 1ml / min.

[0126] 2) Prepare 4mol / l aqueous sodium hydroxide solution and 3mol / l ammonia solution, add ammonia solution and sodium hydroxide solution to the CSTR reactor filled with deionized water with a peristaltic pump,

[0127] Among them, the adding rate of the ammonia solution is controlled to be 0.5ml / min, the adding rate of the sodium hydroxide aqueous solution is controlled to stabilize the pH value of the system at 9.0±0.5, the reaction temperature is controlled to be 60±2°C, the stirring speed is 1200r / min, continuous Reaction for 20h, followed by aging f...

Embodiment 2

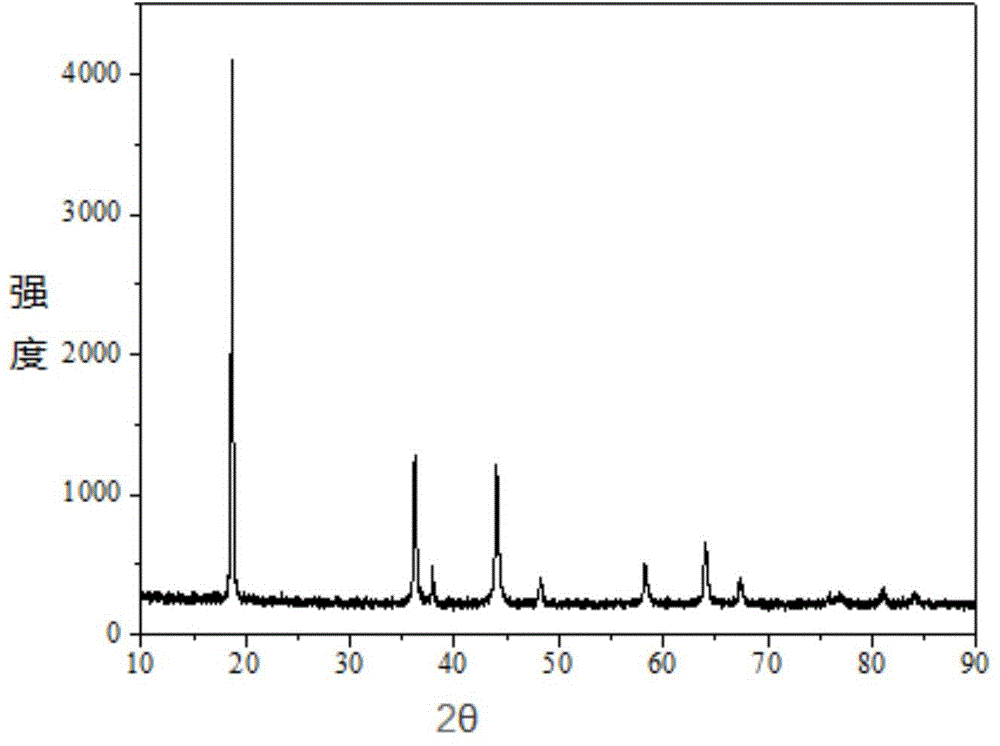

[0138] Prepare the core material as: Li 1.102 mn 1.9 co 0.05 Cr 0.05 O 4 , the cladding layer is: 0.005NiO cathode material

[0139] Step 1, the preparation of the precursor:

[0140] 1) take by weighing 2097g mass percent respectively and be 50% Mn (NO 3 ) 2 Aqueous solution, 59g Co(NO 3 ) 2 ·6H 2 O was added to deionized water to prepare 2L of mixed aqueous solution, and was added to the CSTR reactor at a rate of 1ml / min.

[0141] 2) Prepare 2mol / L aqueous sodium carbonate solution and 3mol / L ammonia solution, add ammonia solution and sodium carbonate solution to the CSTR reactor filled with deionized water with a peristaltic pump,

[0142] Among them, control the adding rate of ammonia solution to 0.5ml / min, control the adding rate of sodium carbonate aqueous solution to stabilize the pH value at 7.0±0.05, control the reaction temperature to 60±2°C, stir at 1200r / min, react continuously for 20h, and then Then aging for 5h,

[0143] 3) The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com