Patents

Literature

33results about How to "Excellent discharge specific capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature type lithium manganate anode material for power lithium ion battery and preparation method of high-temperature type lithium manganate anode material

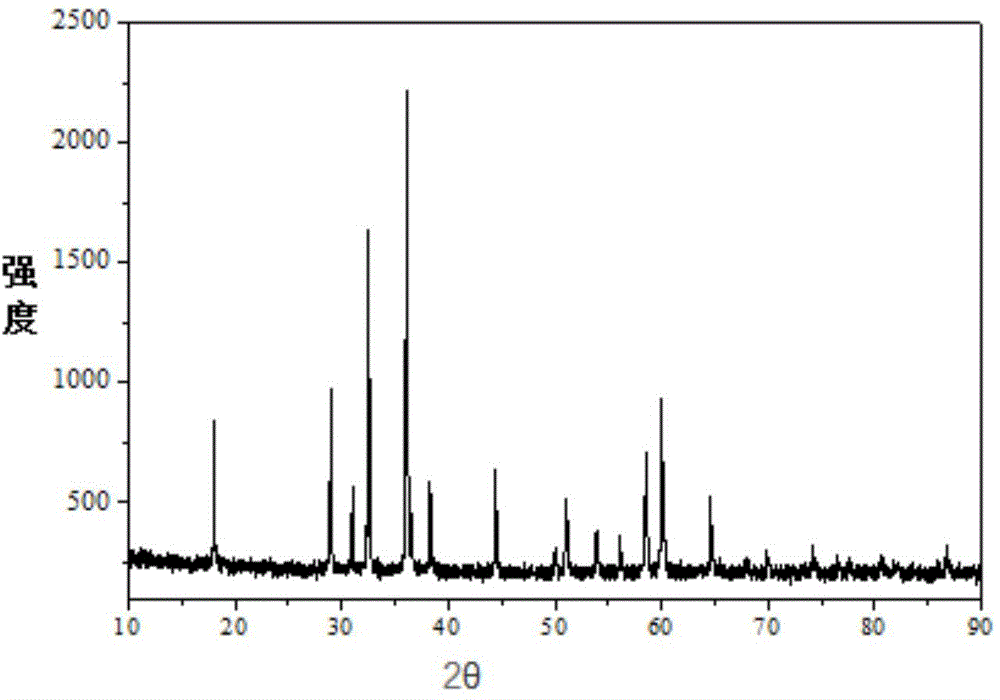

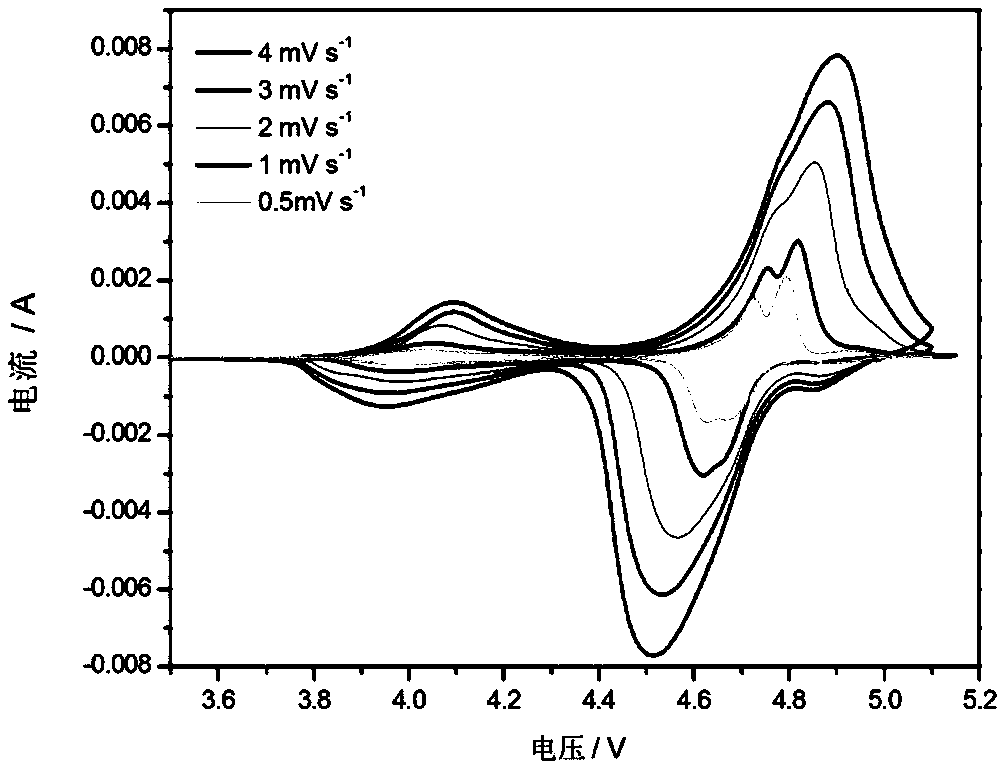

ActiveCN104485452AImprove high temperature resistanceExcellent discharge specific capacityCell electrodesCobalt(II,III) oxideManganate

The invention discloses a high-temperature type lithium manganate anode material for a power lithium ion battery. The high-temperature type lithium manganate anode material consists of a core material as shown in a formula Li1+xMn2-y-zAyQzO4, and a coating layer on the surface of the core material, wherein the coating layer is one or more of cobaltosic oxide, aluminum oxide and nickel protoxide. The anode material is excellent in high-temperature property, and is good in specific discharge capacity, capacity retention ratio and electrochemical circulation property at high temperature. In addition, the preparation method of the anode material disclosed by the invention is simple in production process, easy to achieve and low in cost, and can be applied to large-scale industrialization production.

Owner:北京盟固利新材料科技有限公司

LiAlO2 coated LiNi1-xCoxO2 lithium-ion battery positive electrode material and preparation method thereof

ActiveCN105185954AGood thermal stabilityExcellent discharge specific capacityCell electrodesSecondary cellsElectric vehicleCyclic stability

The present invention belongs to the field of lithium-ion batteries, and provide a modified lithium-ion battery positive electrode material LiNi1-xCoxO2@LiAlO2 with high thermal-stability LiAlO2 coated on the LiNi1-xCoxO2 surface, and a preparation method thereof. A purpose of the present invention is to overcome the disadvantages of overcharging intolerance and pool thermal-stability of the lithium-ion battery LiNi1-xCoxO2 (x is more than 0 and is less than or equal to 0.5) positive electrode material. According to the present invention, the positive electrode material of the present invention has characteristics of good thermal-stability, good discharge specific capacity and excellent cycle stability compared with the LiNi1-xCoxO2 positive electrode material, can meet the large rate charge and discharge requirements, and is especially suitable for the positive electrode material of the electric vehicle power battery; and the product prepared through the preparation method has characteristics of high purity, high chemical uniformity, good coating effect, high crystal quality, fine particle, uniform distribution, excellent electrochemical performance and low manufacturing cost.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

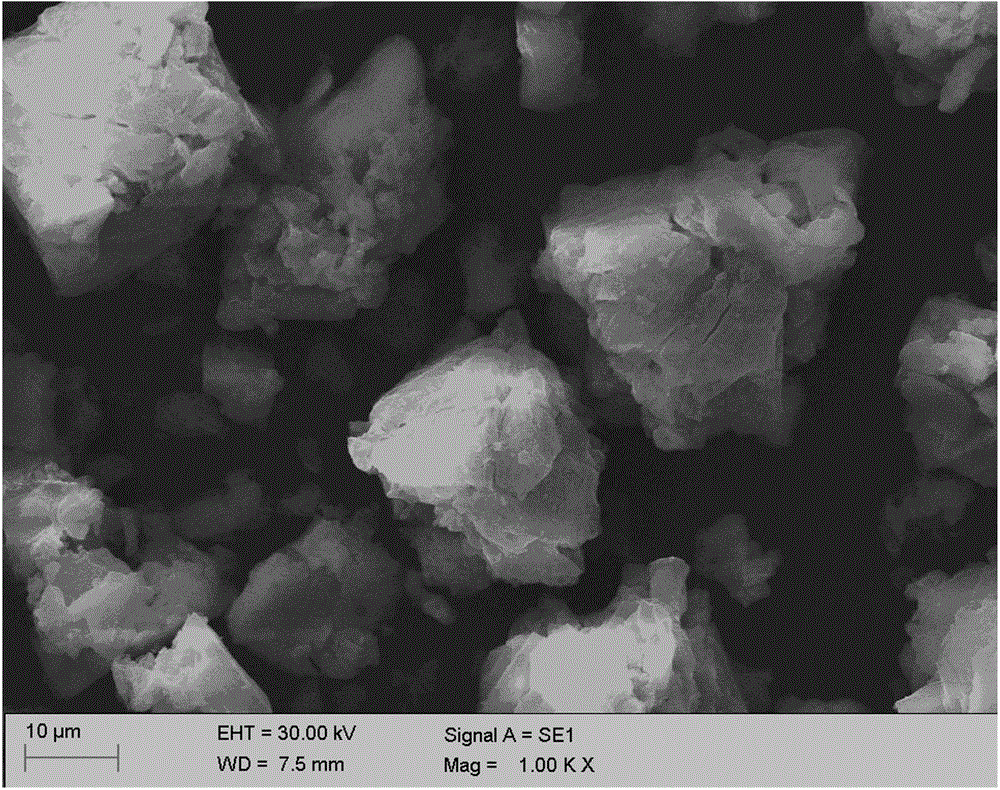

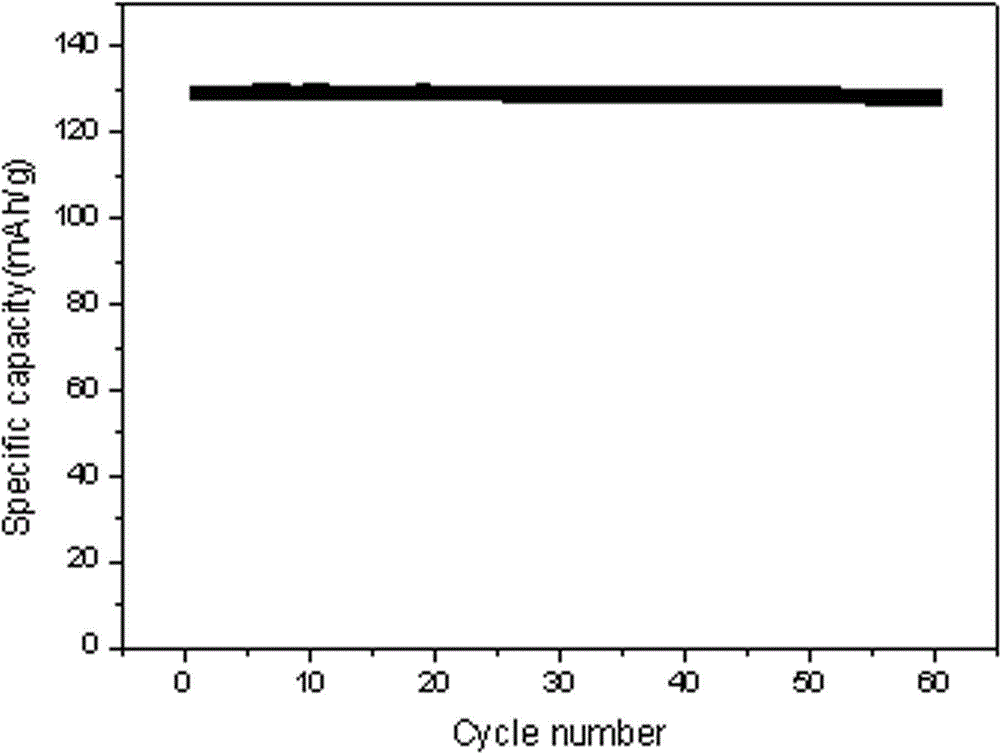

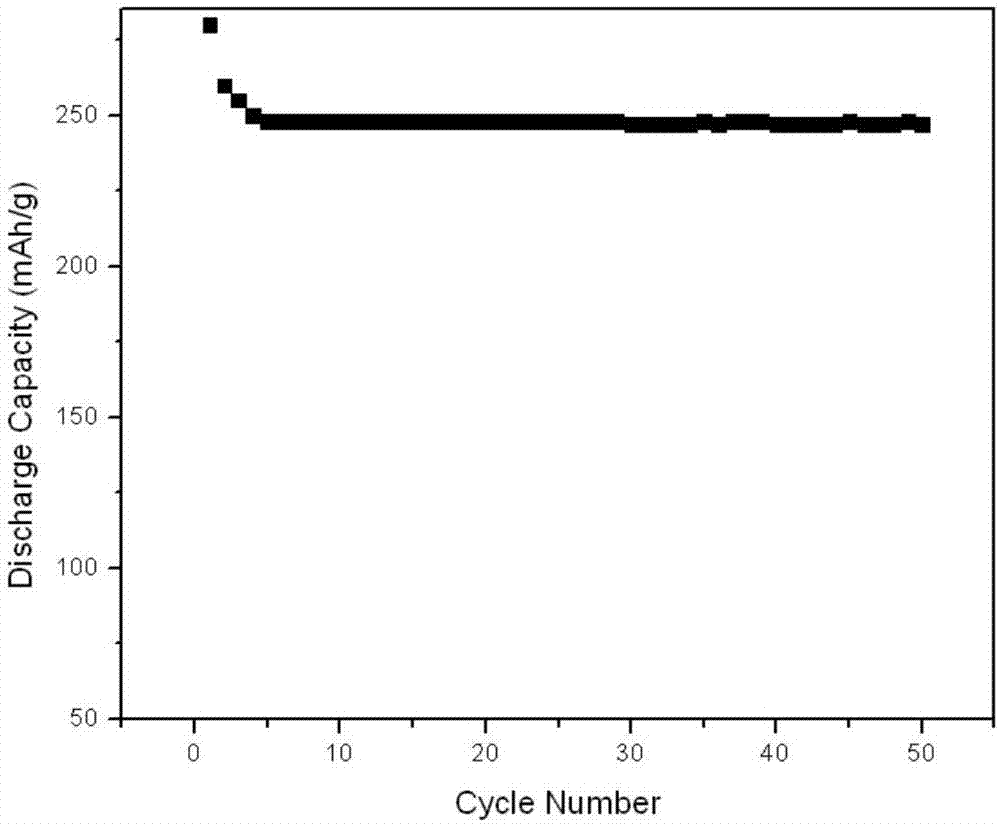

Lithium ion battery electrode material and its application in lithium ion batteries

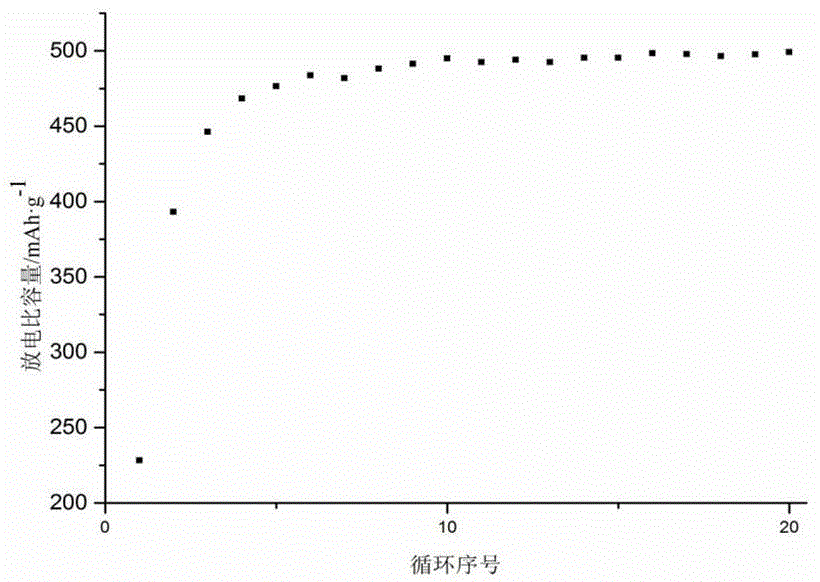

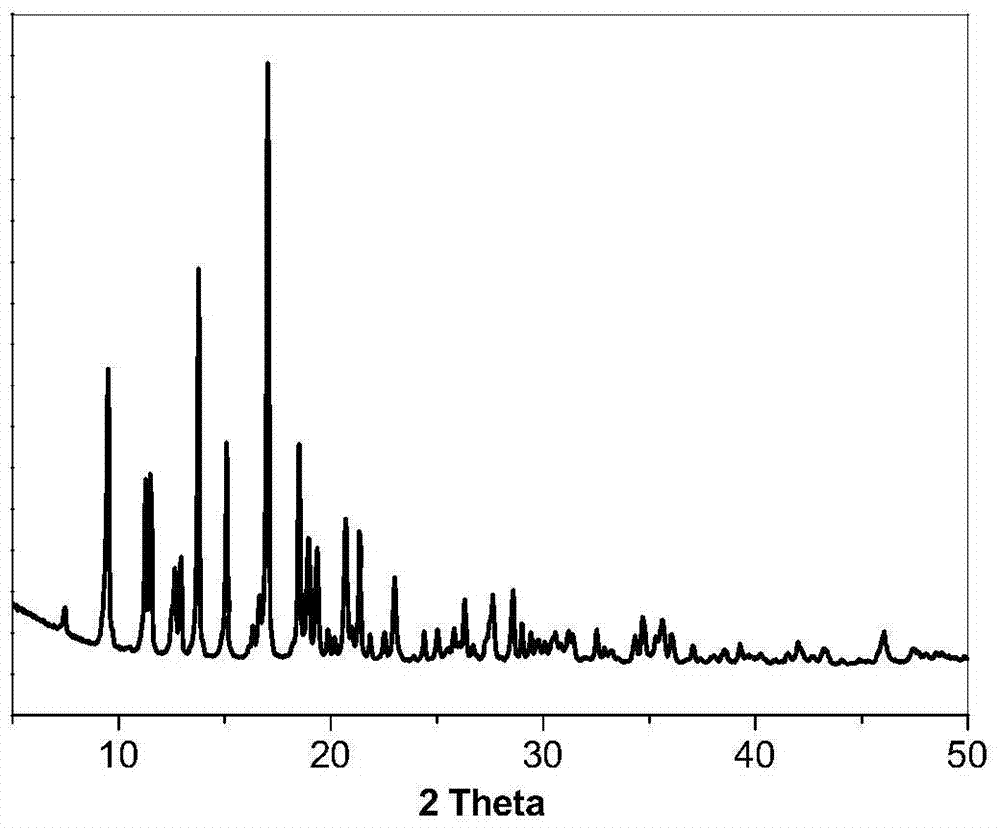

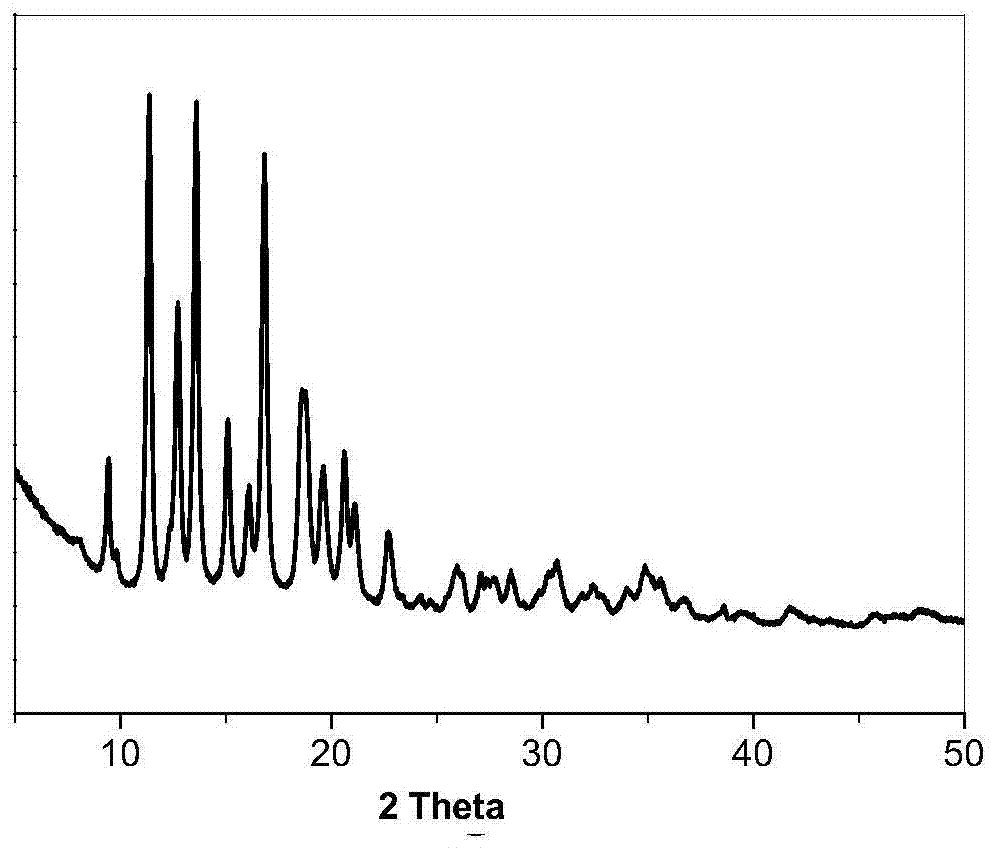

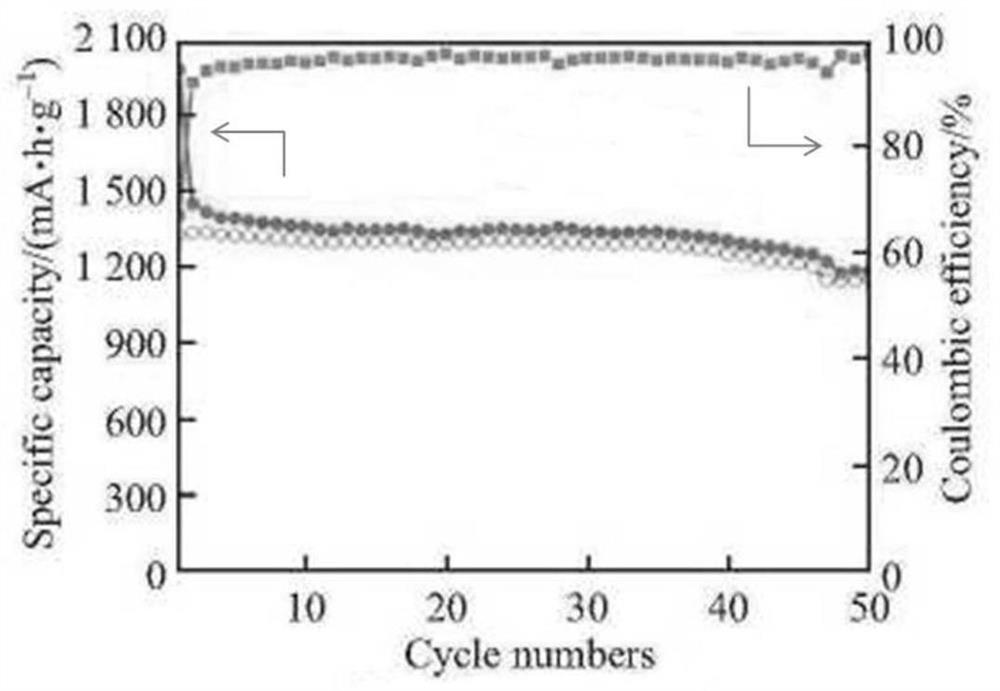

ActiveCN104393300AExcellent discharge specific capacityThe first discharge specific capacity is highSecondary cellsNon-aqueous electrolyte accumulator electrodesMetal-organic frameworkEngineering

The invention provides a lithium ion battery electrode material. The electrode material comprises a metal-organic framework, and the metal-organic framework includes at least one diazole and at least one metal ion. Experiments confirm that the above lithium ion battery electrode has good charge and discharge cycle stability, and after multi-time cycle, the metal-organic framework still has a good structure, and the discharge specific capacity of the battery tends to stability, maintains at a high valve and has a small change amplitude, so the lithium ion battery electrode material is an electrode material with a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Lithium ion battery positive electrode material lithium iron manganese phosphate and liquid phase preparation method thereof

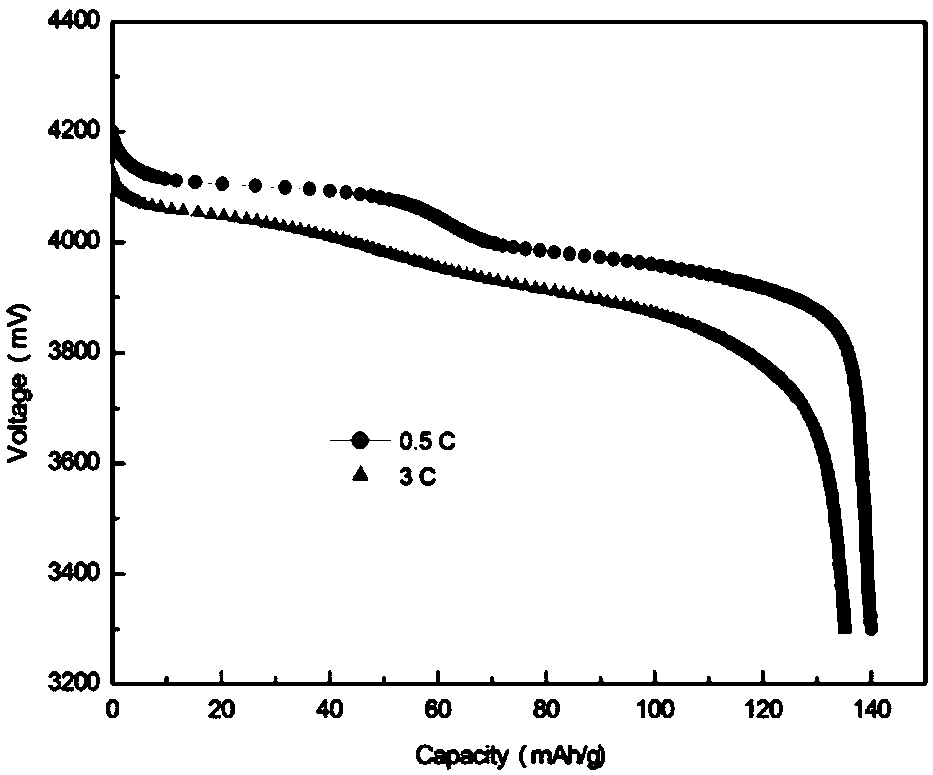

InactiveCN104577114AExcellent discharge voltage platformExcellent discharge specific capacityCell electrodesIron saltsAntioxidant

The invention discloses a lithium ion battery positive electrode material lithium iron manganese phosphate which has a general chemical formula of LiFe1-xMnxPO4, wherein x is equal to 0.2-0.8. The liquid phase preparation method of the lithium ion battery positive electrode material lithium iron manganese phosphate comprises the following steps: synthesizing a precursor, namely weighing an iron salt, a manganese salt and oxalate according to a molar ratio, preparing a solution A from the iron salt, the manganese salt and an antioxidant, preparing the oxalate into a solution B, and preparing ammonia water into a solution C; measuring the solution B to serve as a base solution; simultaneously dripping the solution A and the solution C, and dripping the solution B; filtering, washing and performing vacuum drying, thereby obtaining an iron manganese oxalate precipitate precursor; dosing, namely weighing a carbon source, adding a lithium source, the precursor and a phosphorus source, mixing and performing ball-milling; compounding, namely adding the mixed materials into a compounding furnace, and treating the materials for calcining; and sintering, namely controlling the temperature rise rate, and performing furnace cooling on the compounded precursor powder to room temperature under the protection of inert gas atmosphere, thereby obtaining the carbon-coated lithium iron manganese phosphate positive electrode material.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

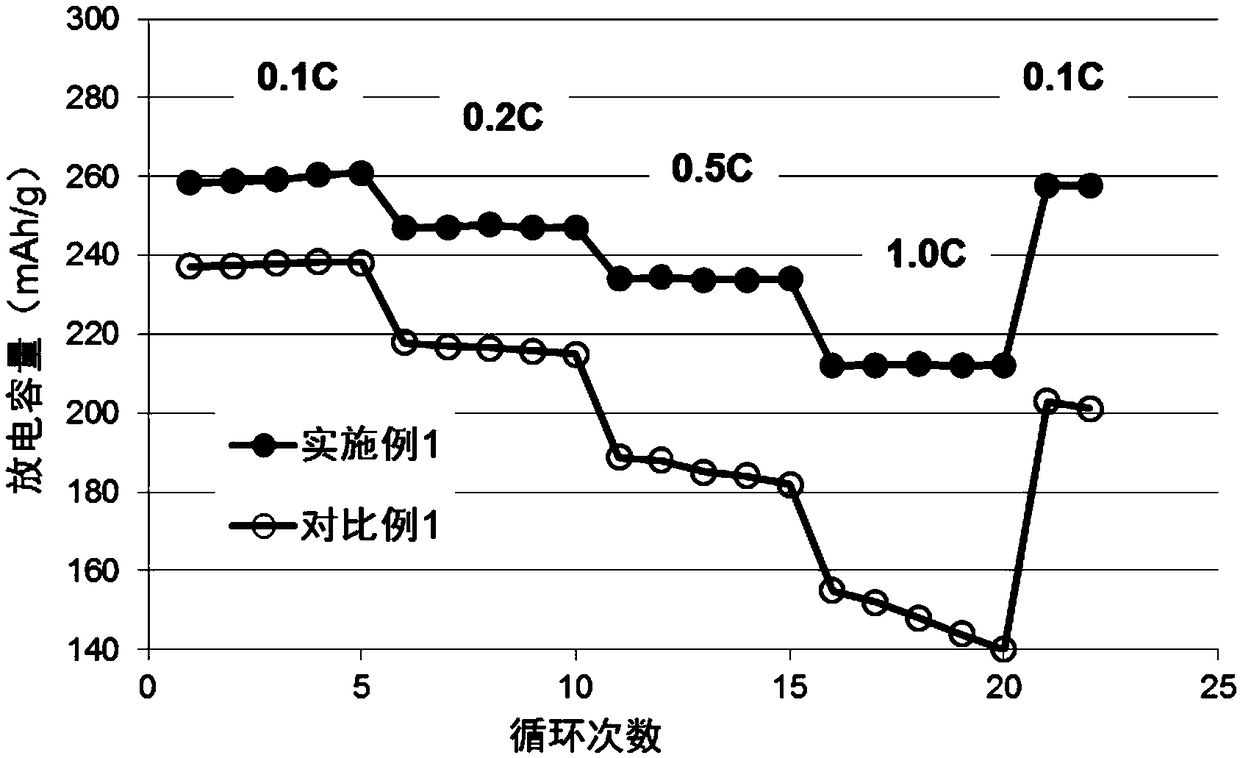

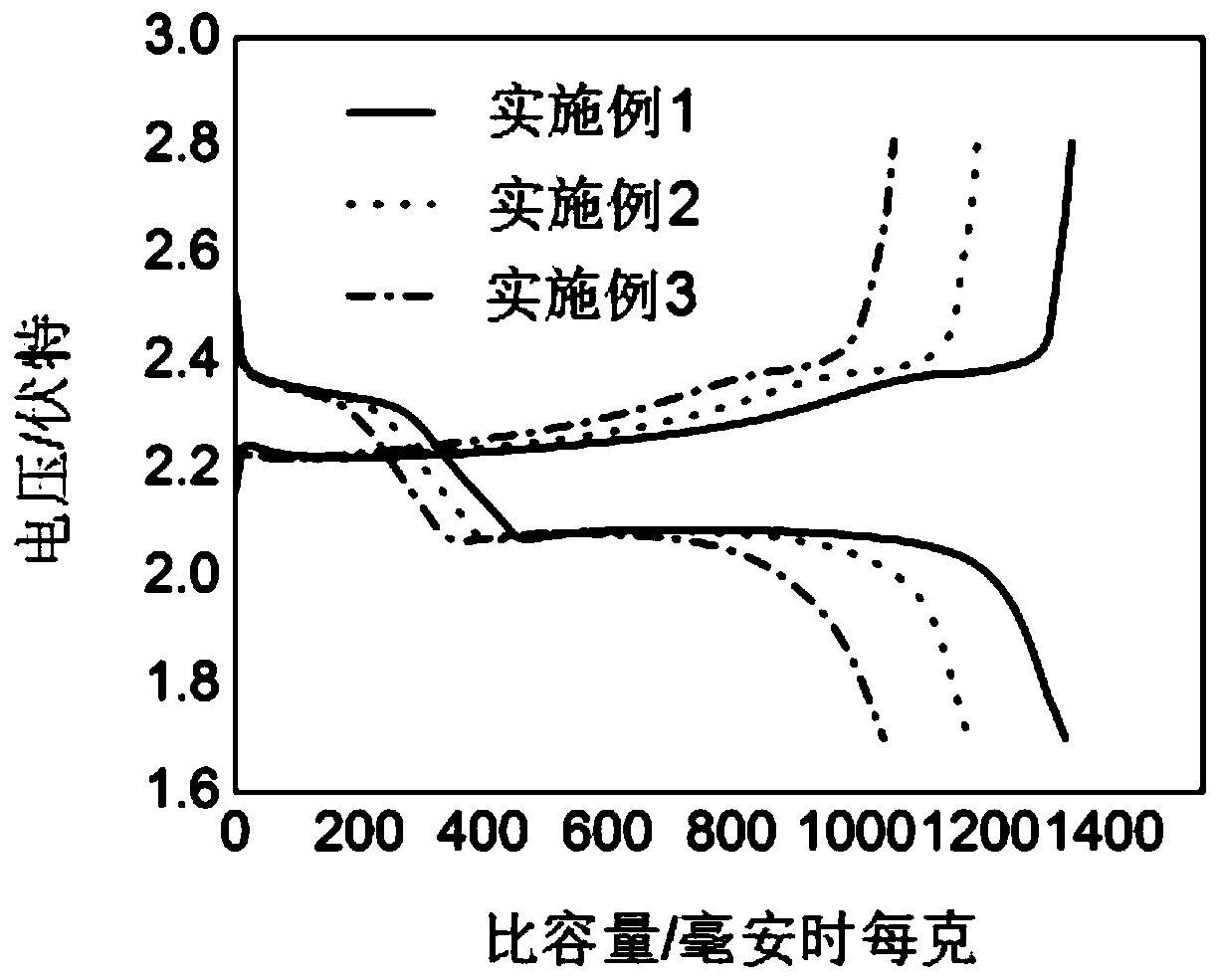

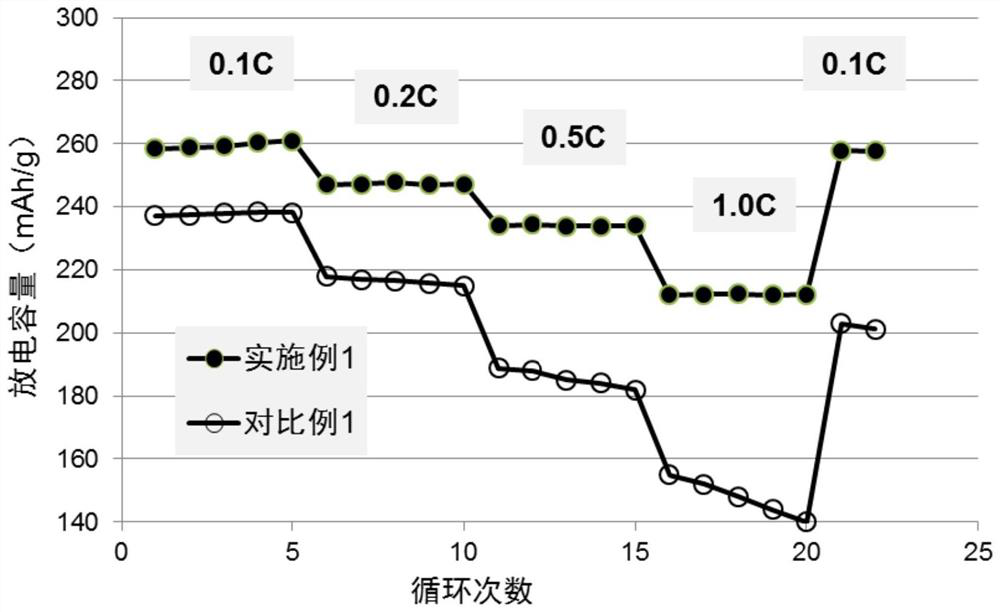

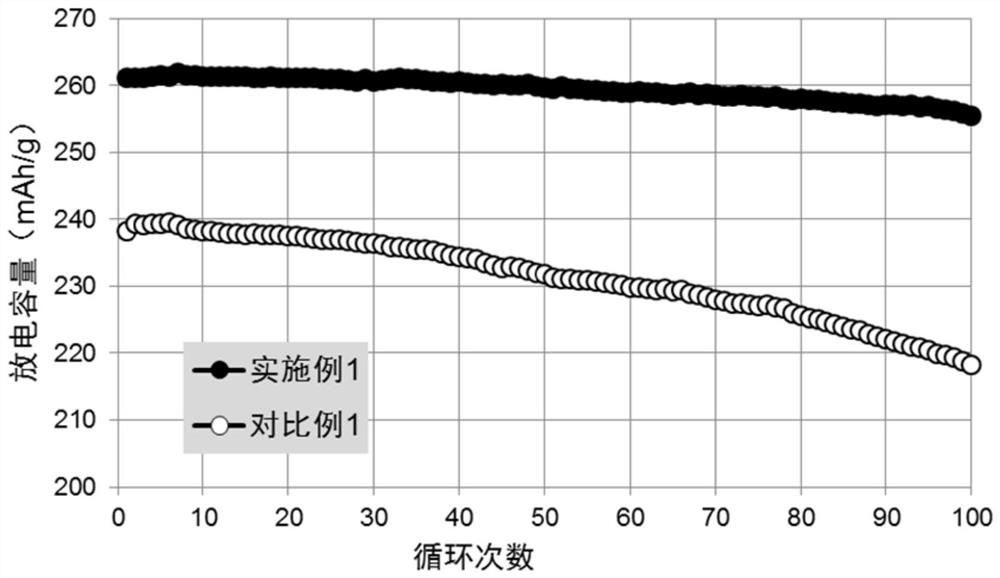

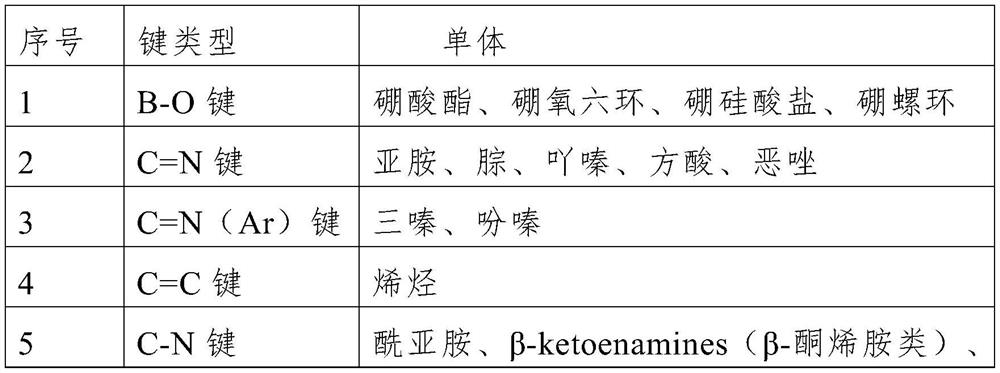

Lithium-rich manganese-based cathode material coated with composite carbon material and preparation method thereof, and lithium battery

ActiveCN109167042AImprove conductivityImproved magnification performanceCell electrodesSecondary cellsPorous carbonManganese

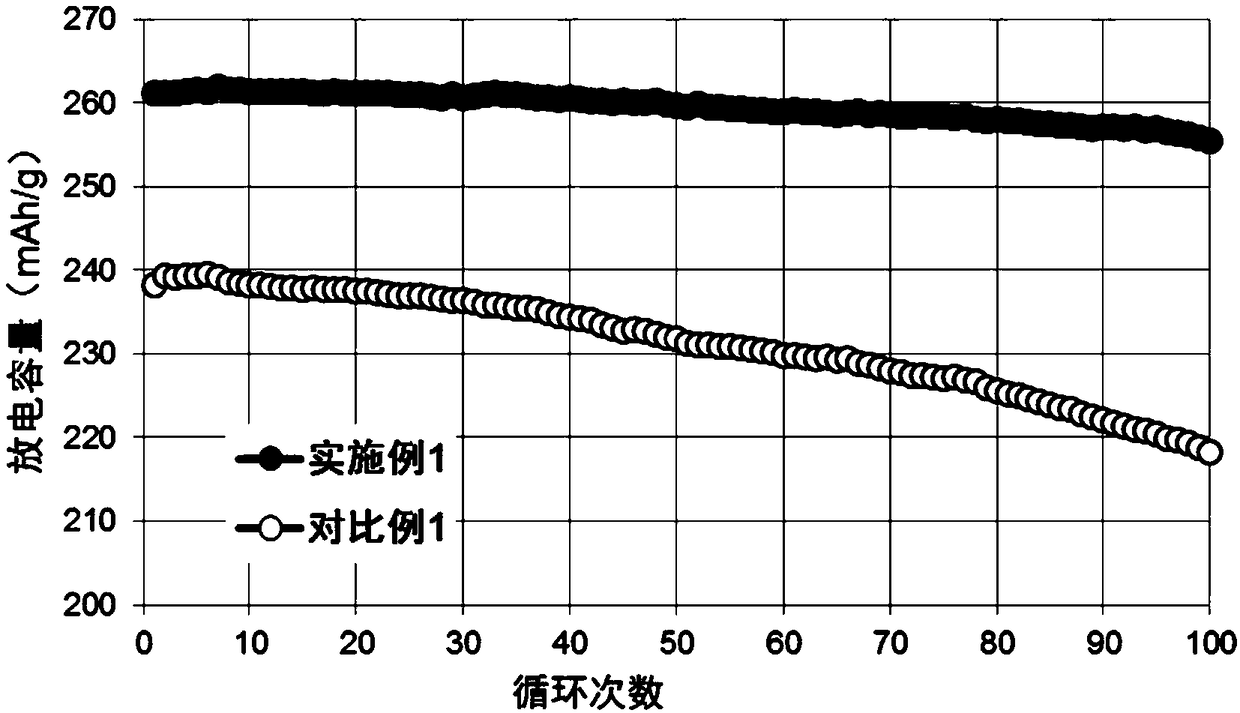

The invention relates to a lithium-rich manganese-based cathode material coated with a composite carbon material derived from a COFs material containing at least one element of N and B, and a preparation method thereof, and a lithium battery, wherein the surface of the lithium-rich manganese-based cathode material is coated with a composite carbon material. The lithium-rich manganese-based cathodematerial coated with the composite carbon material can obviously improve the conductivity of the material and the rate performance and cycle performance of the battery containing the composite carbonmaterial, and the composite carbon material is coated more uniformly. The invention adopts a simple one-step carbonization method to prepare a composite porous carbon material coated with a lithium-rich manganese-based cathode material, the prepared porous carbon has controllable specific surface area and pore size, and the preparation method is simple and efficient, and is suitable for large-scale preparation and synthesis.

Owner:桑德新能源技术开发有限公司 +1

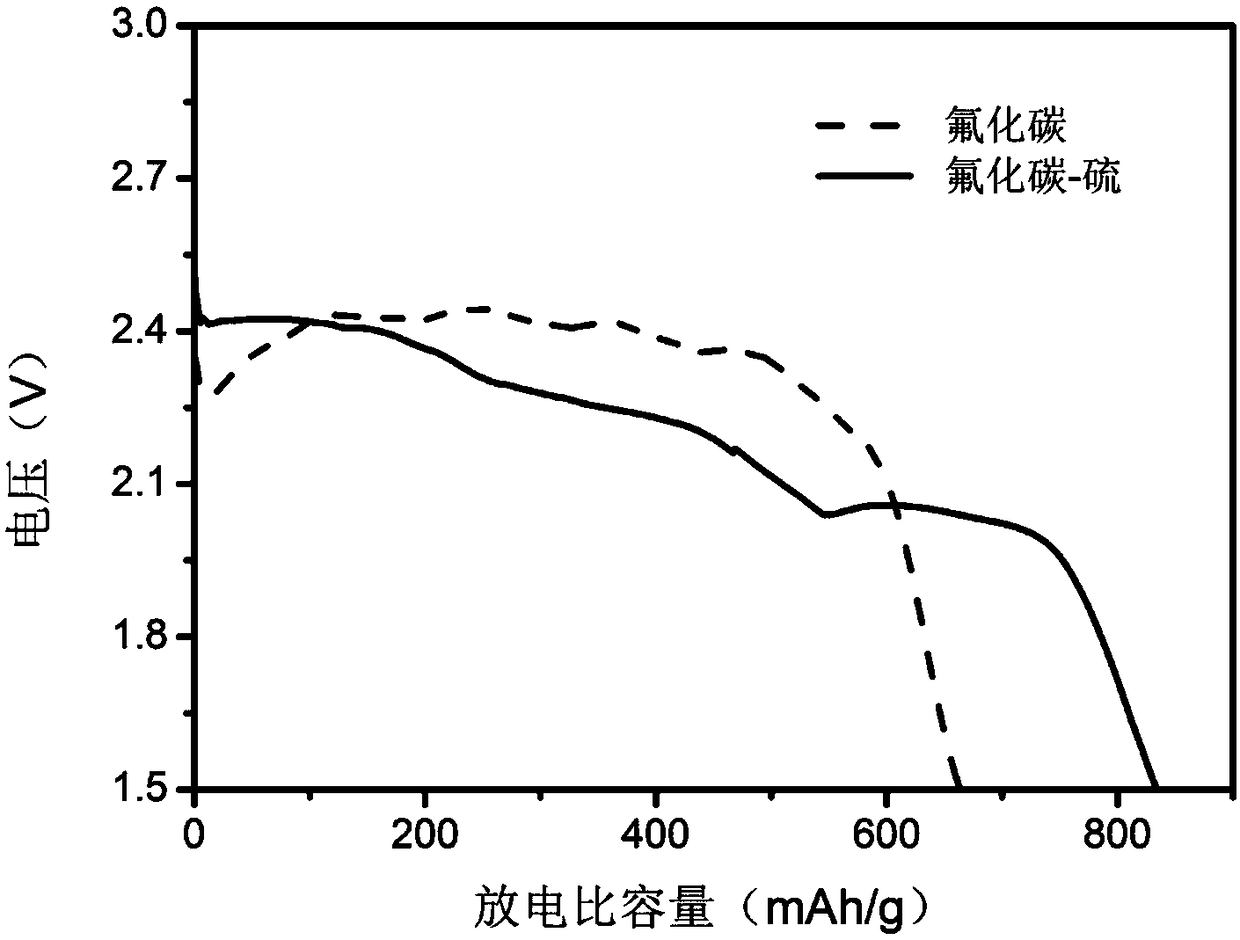

Method for preparing high-energy density disposable battery anode material

InactiveCN108565430AControl percentageIncrease energy densityNon-aqueous electrolyte cellsPrimary cell electrodesElectrical batteryHigh energy

The invention discloses a method for preparing a high-energy density disposable battery anode material. The method comprises the following steps: grinding a fluorinated carbon powder and a single nanosulfur powder for 20-40 minutes in an agate mortar; dropping a sovlvent CS2 into the agate mortar under a ventilation condition, grinding, and terminating the grinding when no yellow-white single sulfur powder is separated from materials any longer; putting the materials into the inner container of a polytetrafluoroethylene reaction kettle in the presence of an argon atmosphere, and enabling thecomponents to react for 8-14 hours at 150-160 DEG C; finally cooling to a room temperature, so as to obtain the high-energy density disposable battery anode material. By adopting the method, a fluorinated carbon-sulfur binary anode activated material can be prepared, the characteristic of a relatively high specific capacity of sulfur is taken into play, and the fluorinated carbon self plays a roleof a carrier for immobilizing sulfur and improving conductivity. The method is simple and convenient in process, low in cost and high in industrial feasibility.

Owner:HEBEI UNIV OF TECH +1

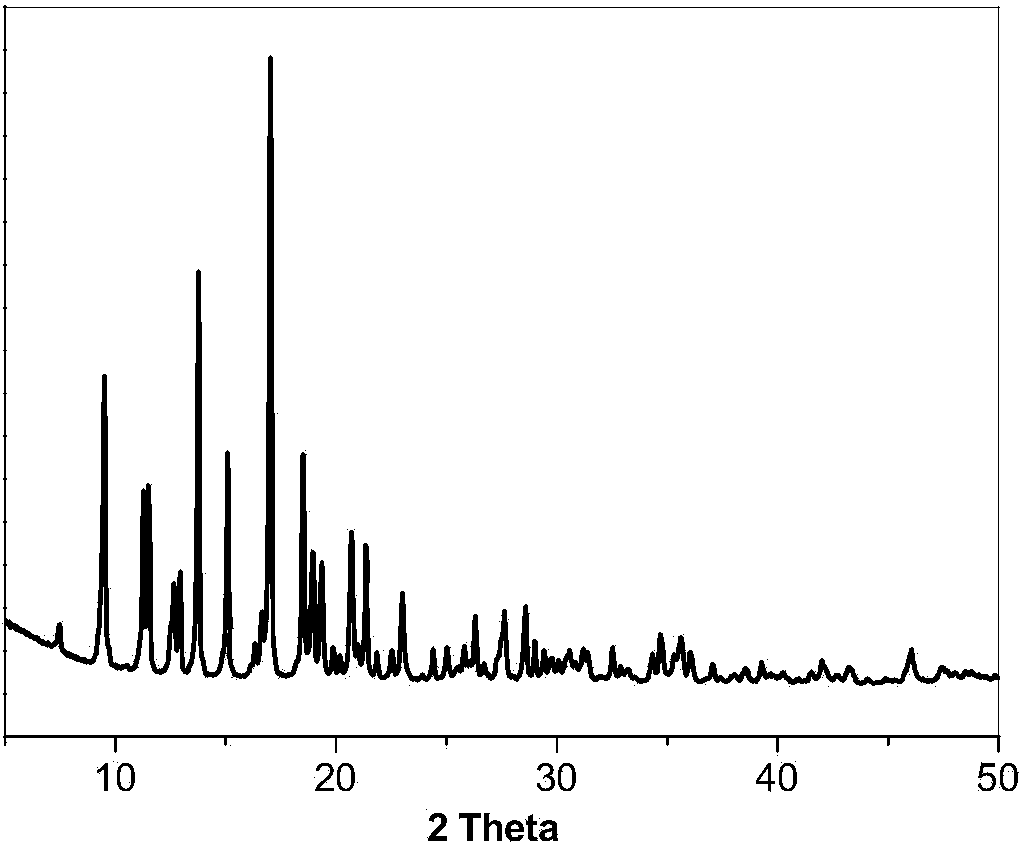

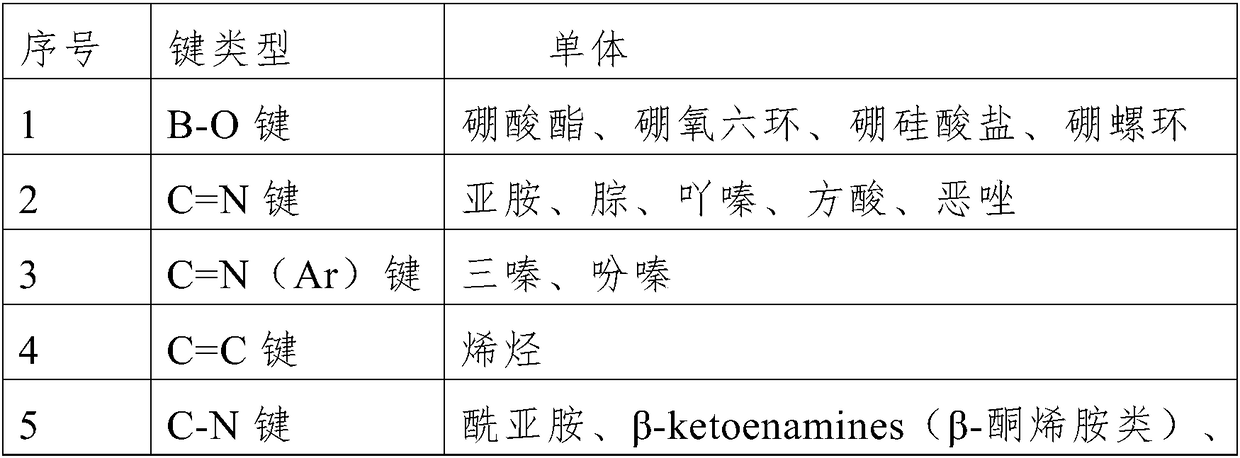

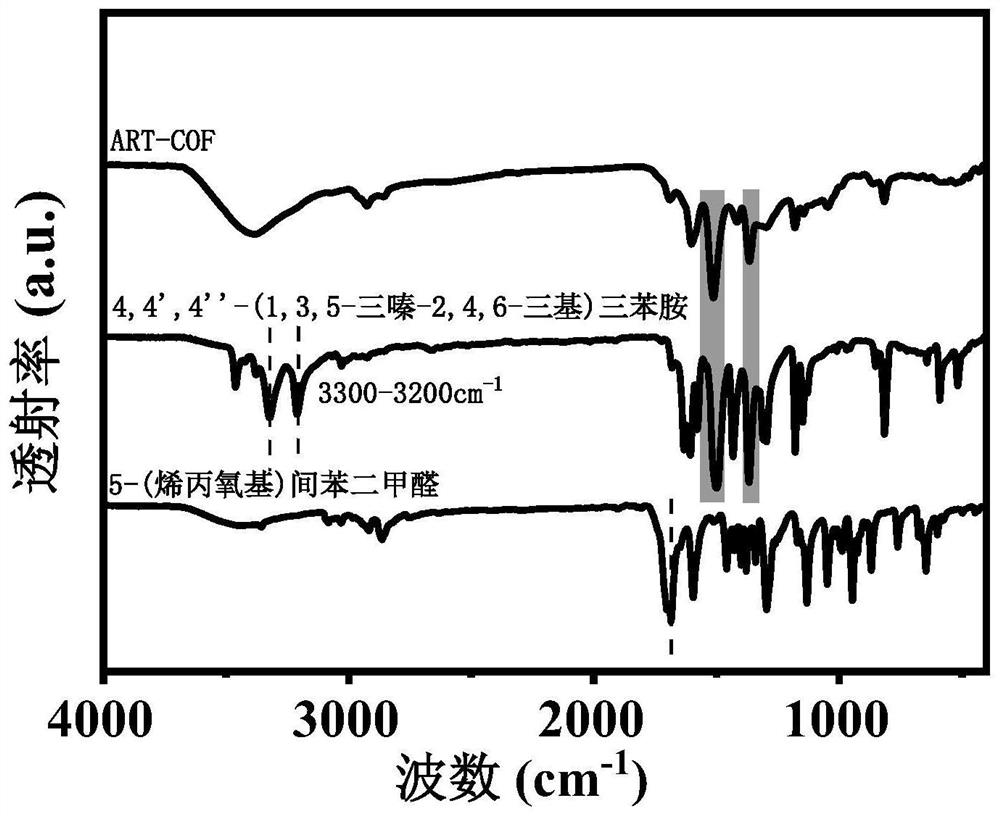

Triazine covalent organic framework material rich in allyloxy as well as preparation method and application of triazine covalent organic framework material

ActiveCN113388082AAvoid lostStrong lithium affinityPositive electrodesNon-aqueous electrolyte accumulator electrodesLithium sulfurStructural formula

The invention relates to a triazine covalent organic framework material rich in allyloxy as well as a preparation method and application of the triazine covalent organic framework material. The material is formed by continuously splicing 5-allyloxy isophthalaldehyde and 4,4',4''-(1,3,5-triazin-2,4,6-triyl)triphenylamine through a condensation reaction, and the unit structural formula of the material is shown in the specification. According to the preparation method, aldehyde with an allyloxy group and amine with a triazine group are subjected to a traditional Schiff base reaction, and synthesis of the covalent organic framework material arranged in order is achieved. The material obtained by the invention has an allyloxy group and a triazine group, can significantly improve the cycle performance of the lithium-sulfur battery, and has a good application prospect.

Owner:HEBEI UNIV OF TECH

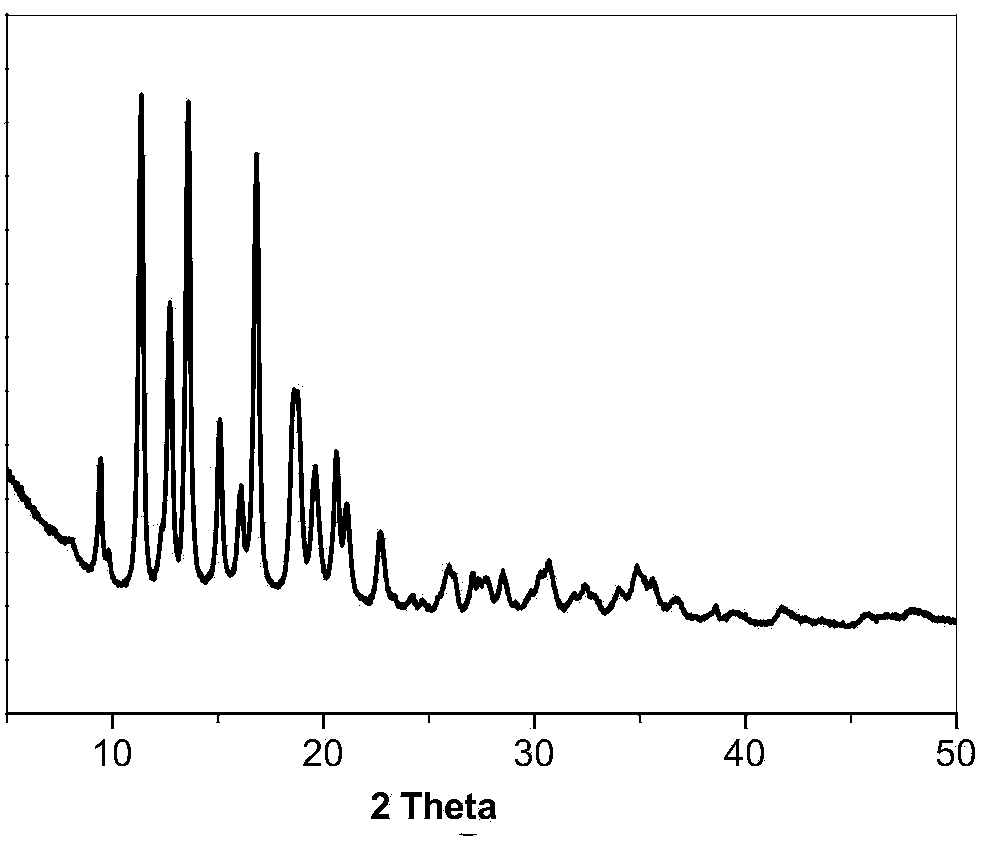

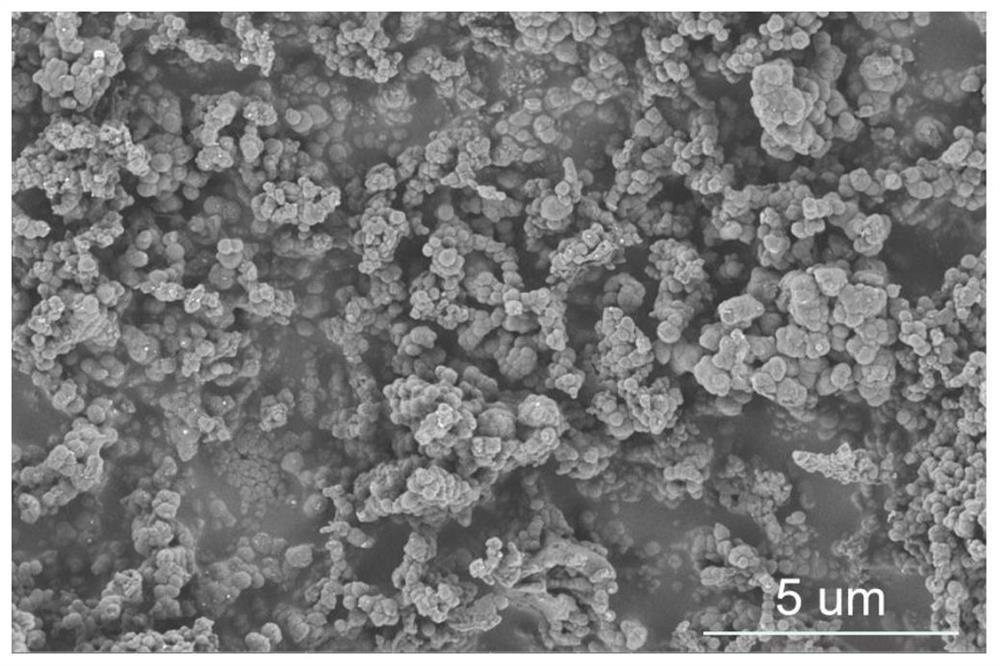

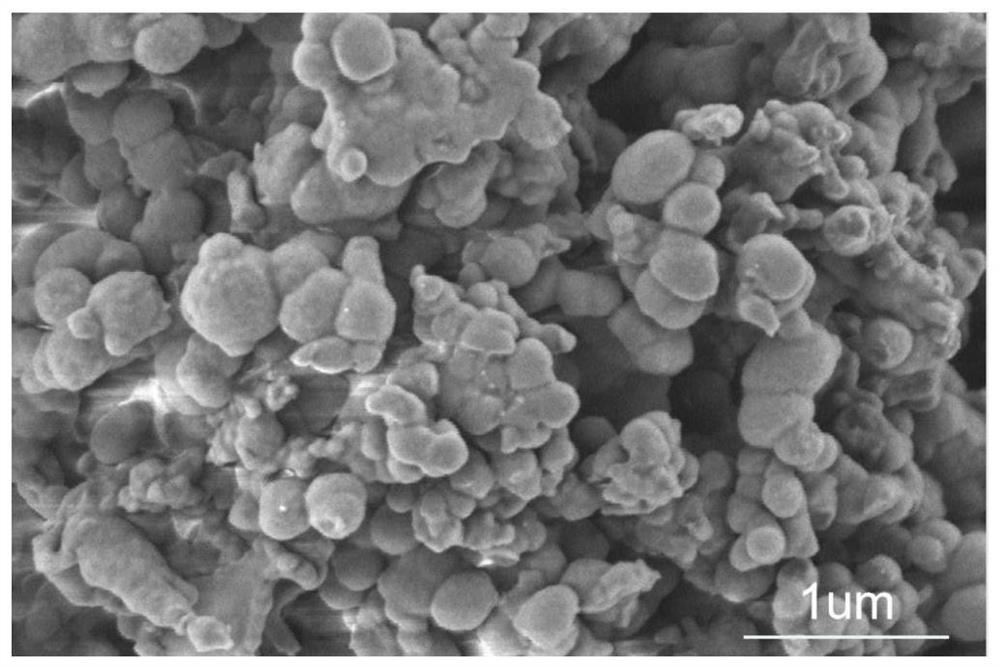

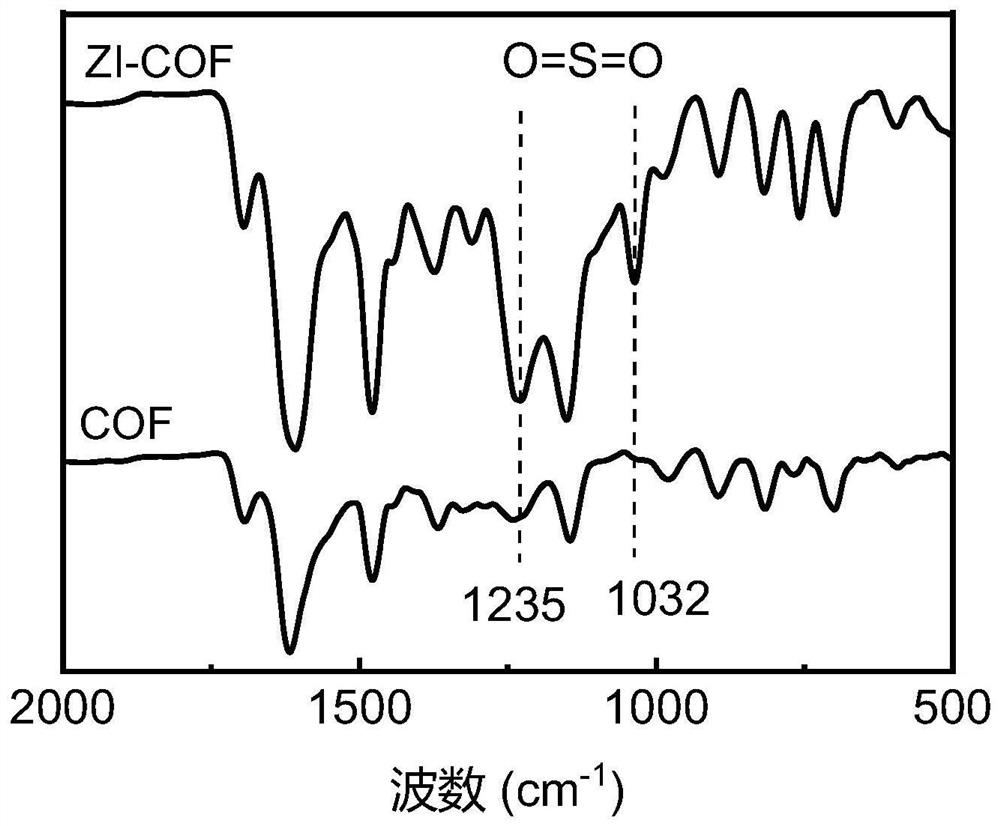

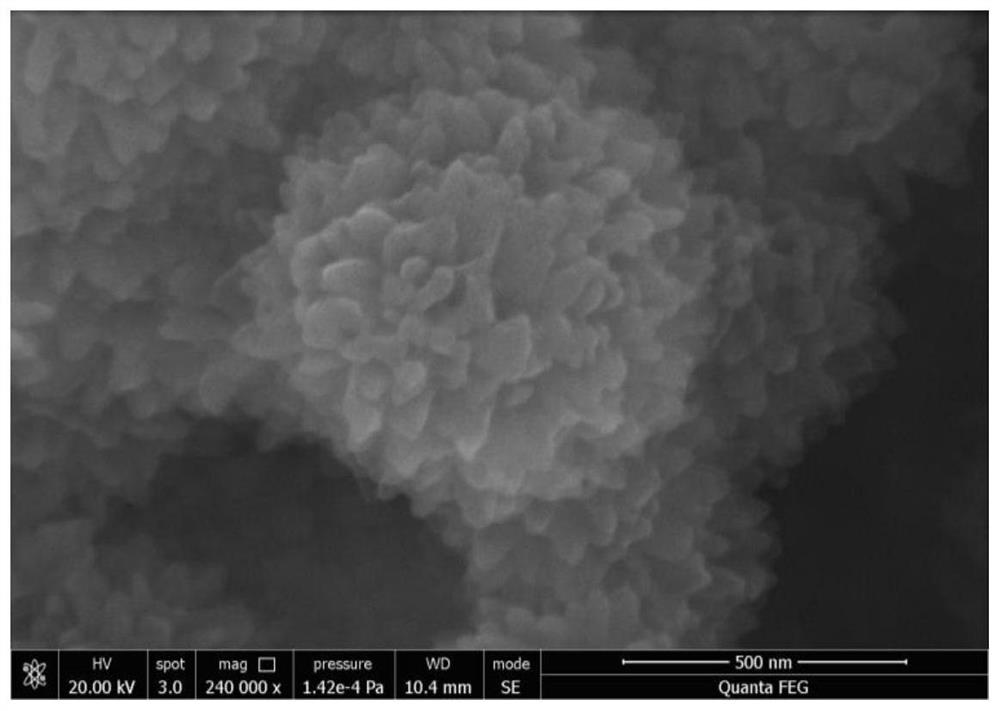

Covalent organic framework material rich in zwitterions as well as preparation method and application of covalent organic framework material

PendingCN114349921AInhibition of the shuttle effectFacilitate catalytic conversionElectrode thermal treatmentElectrode collector coatingLithium sulfurPhenyl group

The invention relates to a zwitter-ion-rich covalent organic framework material as well as a preparation method and application thereof. The covalent organic framework material is prepared by taking 3, 8-diamino-6-phenyl phenanthridine and benzenetricarboxaldehyde as raw materials and introducing sulfo groups through a post-modification method. According to the invention, sulfo groups are introduced to a COF skeleton, so that the COF skeleton has positive and negative charges; wherein positively charged nitrogen atoms and negatively charged sulfo groups not only can inhibit the loss of an active substance sulfur in the lithium-sulfur battery, but also can promote the catalytic conversion of polysulfide, so that the cycle performance of the lithium-sulfur battery can be remarkably improved.

Owner:HEBEI UNIV OF TECH

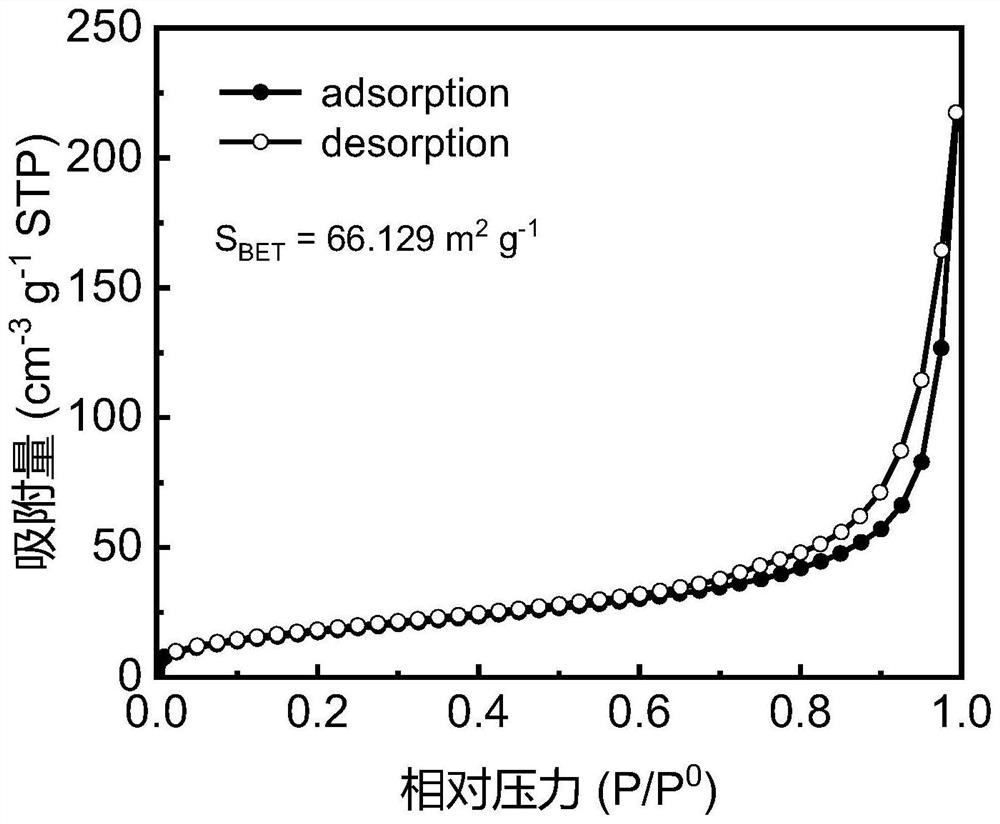

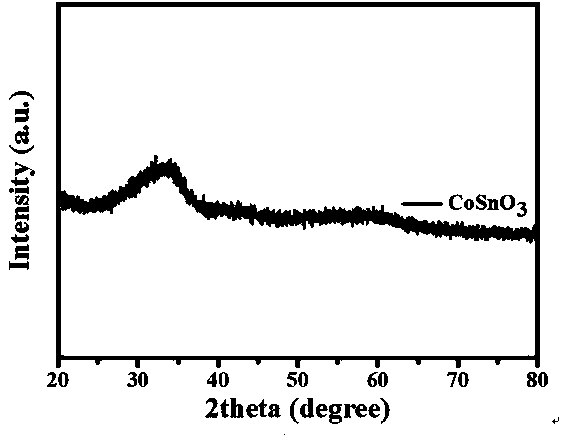

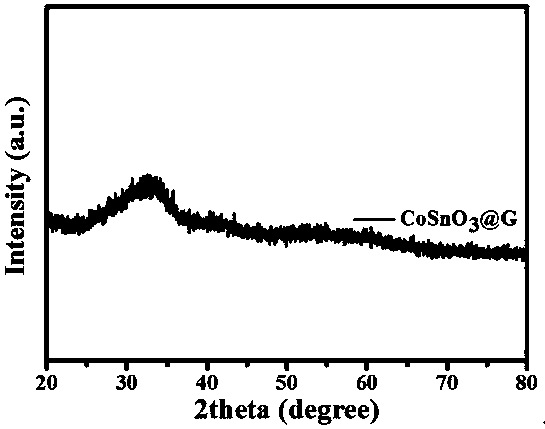

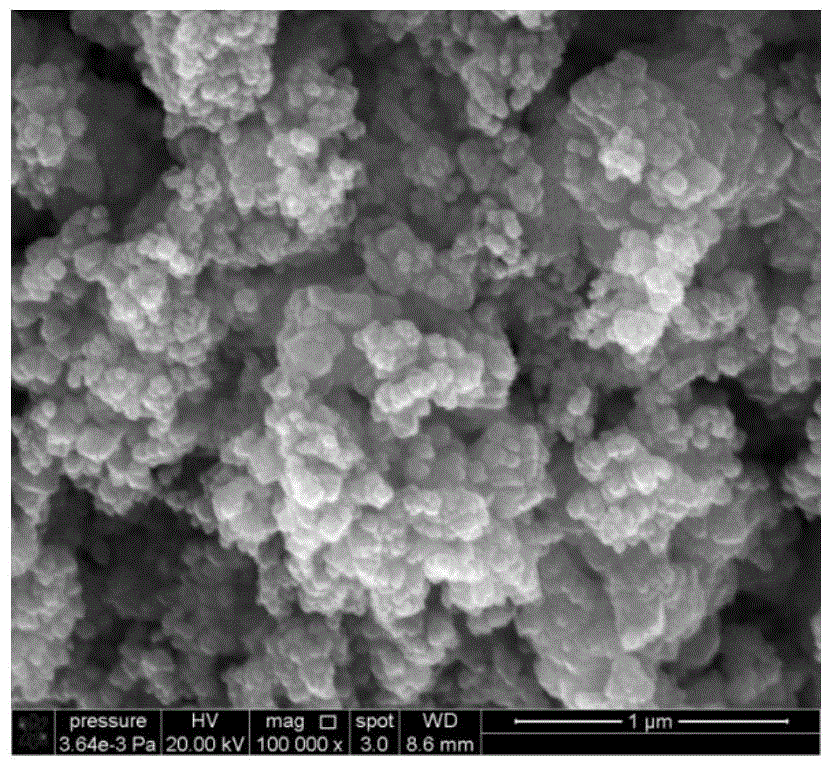

Nano-scale cube cobalt stannate and graphene composite material and preparation method and application thereof

InactiveCN107799748AThe process is simple and controllableReduce manufacturing costMaterial nanotechnologyCell electrodesGraphene coatingSodium-ion battery

The invention discloses a nano-scale cube CoSnO<3> and graphene composite material. The composite material is characterized in that nano-scale cube CoSnO<3> and gauzy graphene form a coating structure. The nano-scale cube CoSnO<3> and graphene composite material is prepared by a simple and easy method, wherein the nano-scale cube CoSnO<3> is uniformly coated with graphene, and by virtue of graphene coating, the conductivity of the CoSnO<3> material is greatly improved; meanwhile, volume expansion of the CoSnO<3> material is also relieved, and pulverization and falling off of the electrode material are also suppressed effectively; and therefore, when the nano-scale cube CoSnO<3> and graphene composite material prepared in the invention is used as the negative electrode material of a sodiumion battery, excellent discharge specific capacity and stable cycle performance are represented.

Owner:TIANJIN NORMAL UNIVERSITY

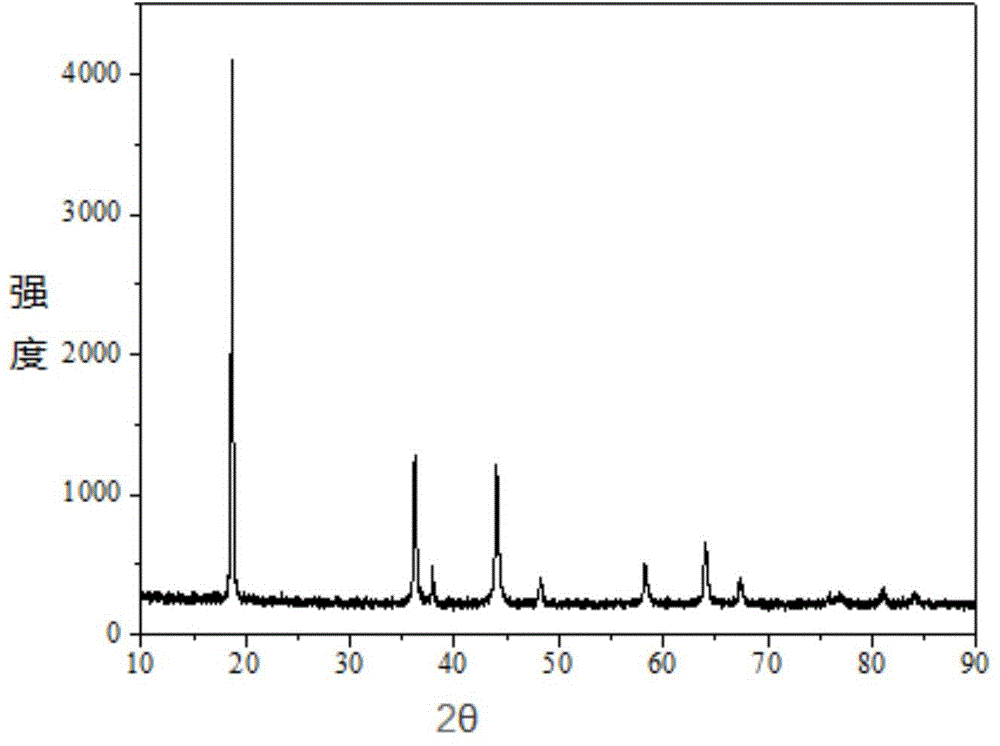

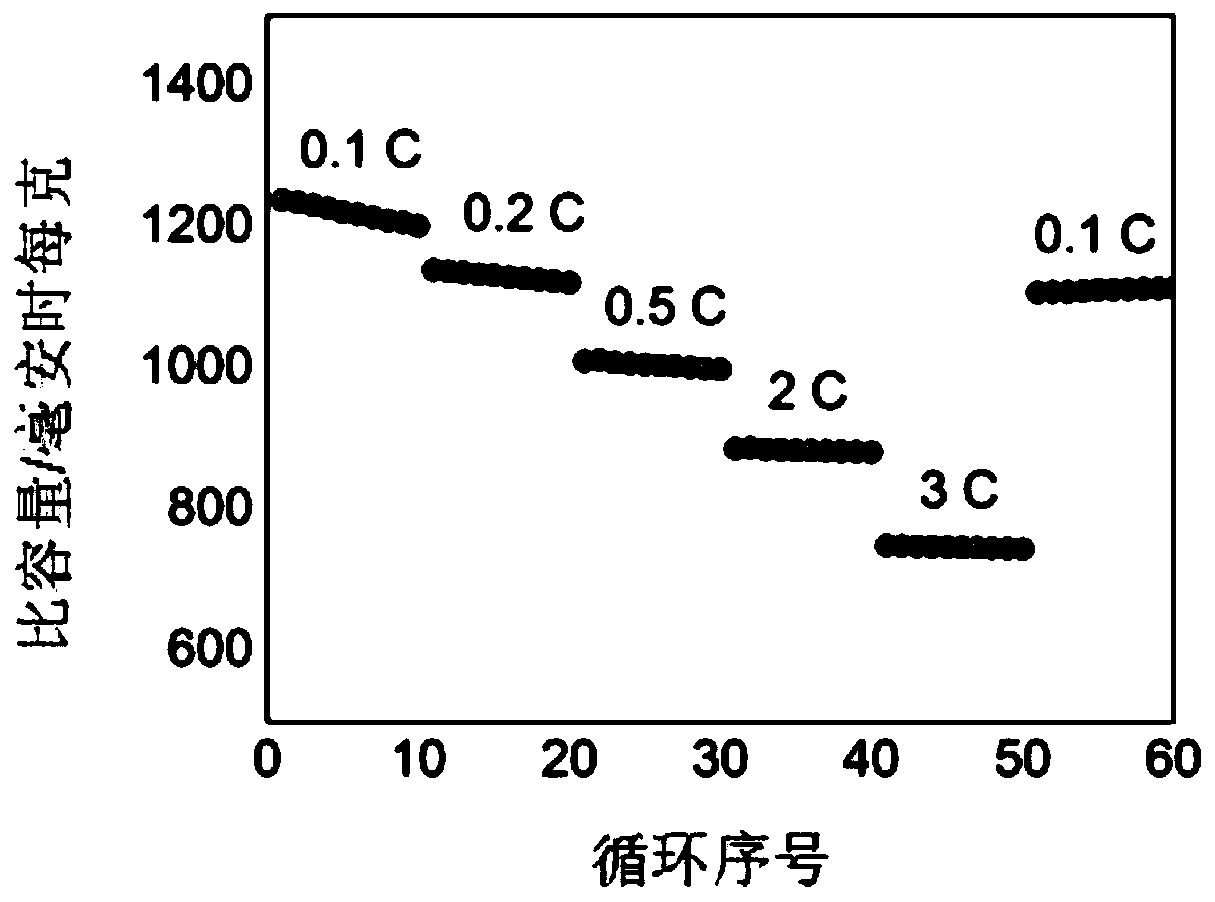

Porous metallic cathode material doped with lithium manganate/carbon for composite lithium batteries, and preparation method of porous metallic cathode material

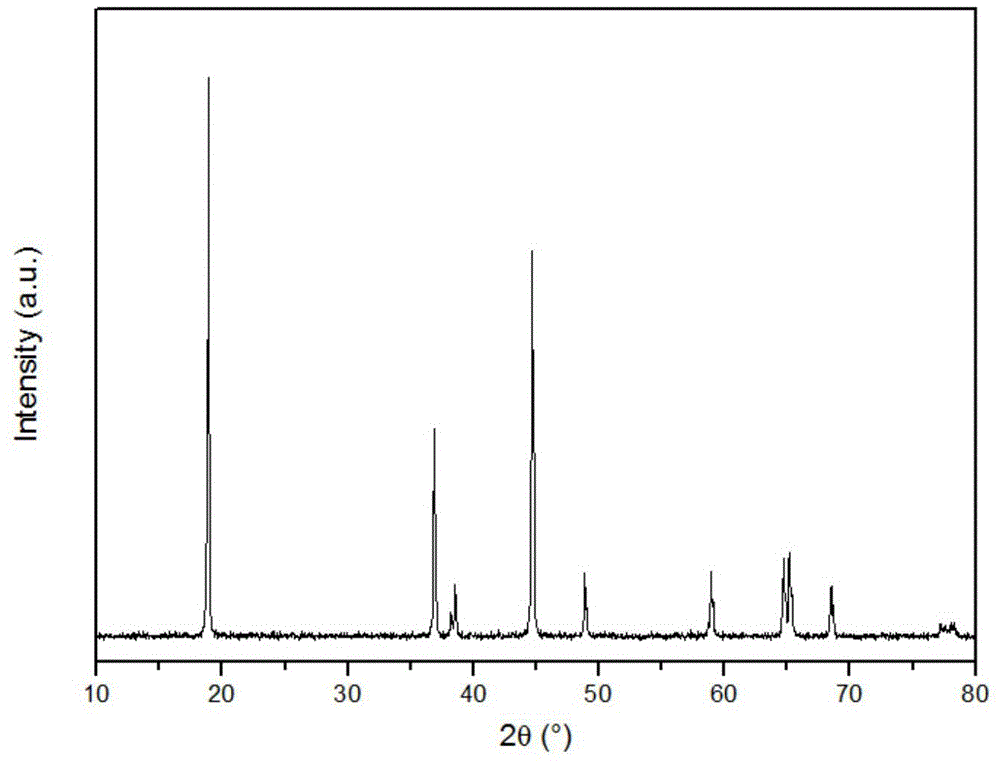

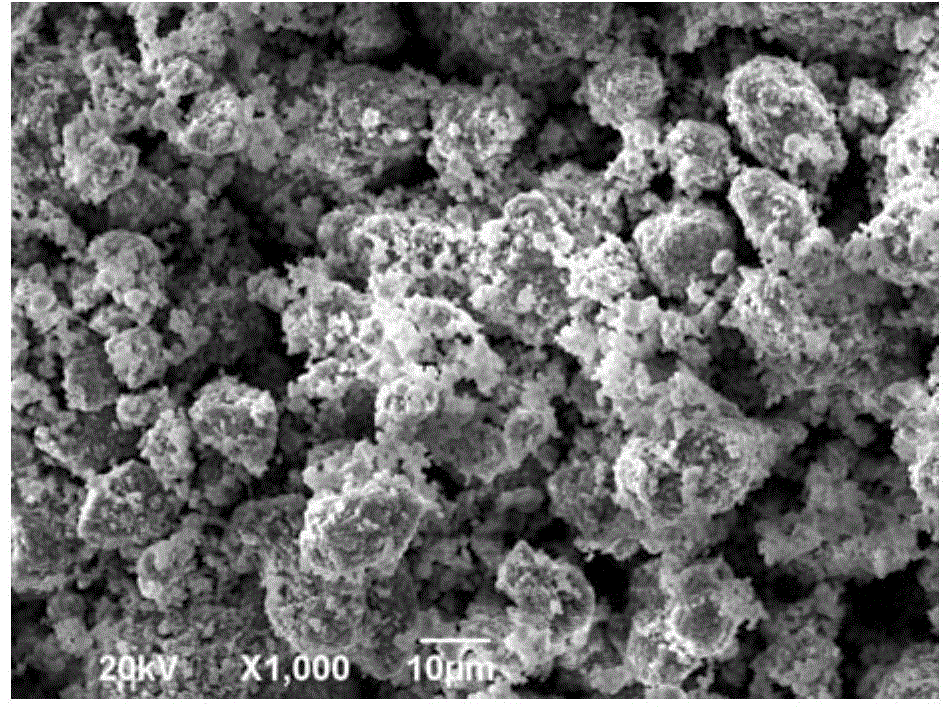

InactiveCN104795557AHigh crystallinityUniform particlesCell electrodesSecondary cellsManganeseManganate

The invention relates to a porous metallic cathode material doped with lithium manganate / carbon for composite lithium batteries, and a preparation method of the porous metallic cathodmaterial. The preparation method comprises the following steps: dissolving a surfactant in absolute ethyl alcohol, and stirring the surfactant and the absolute ethyl alcohol so as to obtain gel; adding lithium nitrate, and nitrate mixed with metal nitrate and manganese in the obtained gel, and performing uniform stir; after uniformly mixing, drying the mixture in a blast drying box, and further calcining the dried mixture in a muffle furnace so as to obtain the porous material doped with lithium manganate LiM0.2Mn1.8O4; dissolving the LiM0.2Mn1.8O4 in glucose solution, enabling the LiM0.2Mn1.8O4 to uniformly disperse, and after performing air blast drying, calcining the dried product in nitrogen atmosphere so as to obtain the metallic composite material LiM0.2Mn1.8O4 / C doped with lithium manganate / carbon, wherein M refers to the doped metal. Compared with the prior art, the porous metallic cathode material prepared through the preparation method disclosed by the invention has the advantages that the crystallizing property is good, the particle size is about 20nm, and the material has good specific discharge capacity, rate capability and cycling properties as the cathode material for lithium batteries. The preparation idea of the preparation method disclosed by the invention can be applied to the preparation of other cathode materials of composite materials of porous metallic oxides.

Owner:SHANGHAI JIAO TONG UNIV

Sulfur-doped carbon material and preparation method thereof

The invention aims to provide a sulfur-doped carbon material with relatively high discharge specific capacity. The thickness of a carbon layer of the sulfur-doped carbon material is 20-300 nanometers, and the sulfur content accounts for 3-20wt%. Meanwhile, the invention also discloses a preparation method of the sulfur-doped carbon material. The sulfur-doped carbon material provided by the invention has relatively high discharge specific capacity.

Owner:SHENZHEN CAPCHEM TECH

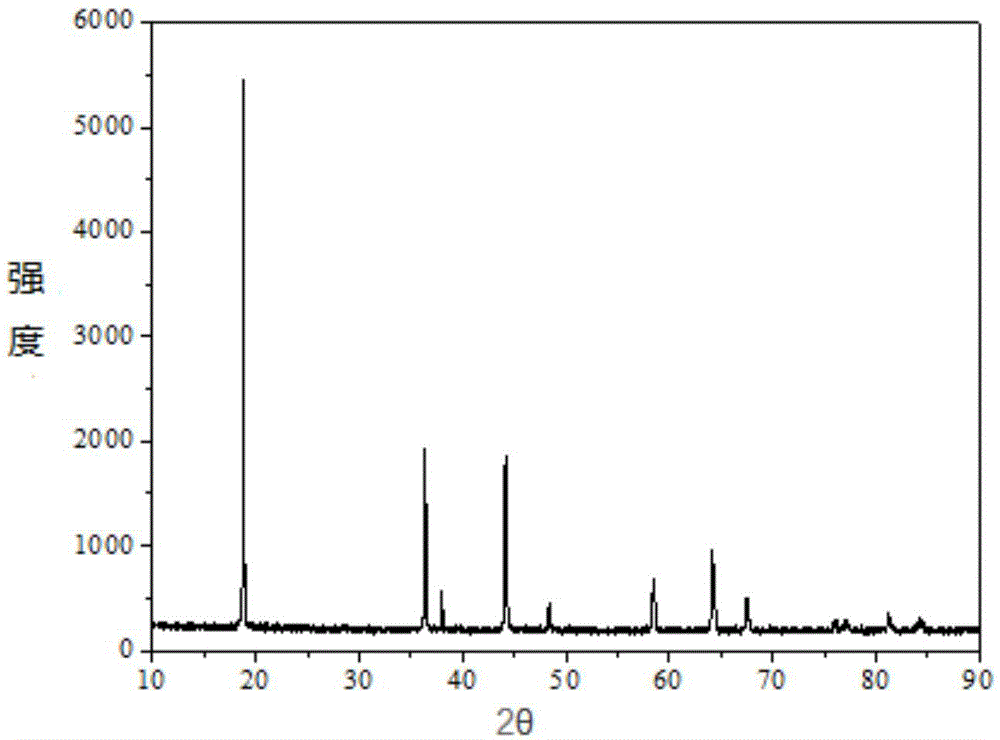

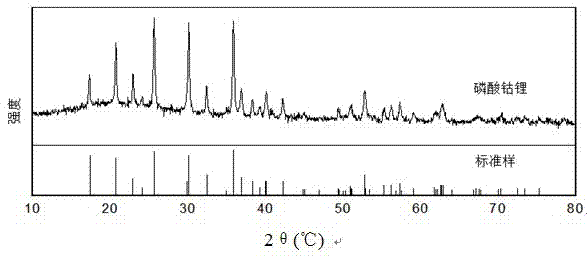

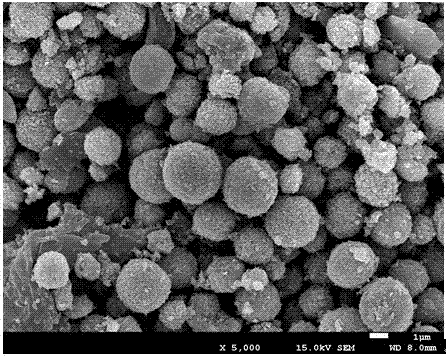

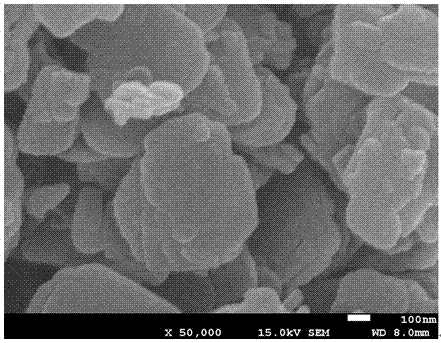

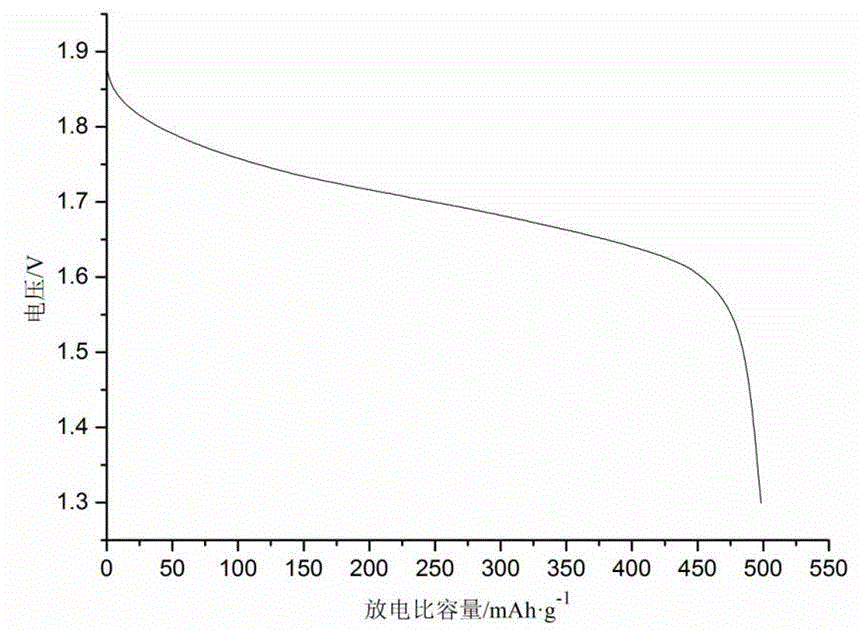

Lithium ion battery positive electrode material and preparation method thereof

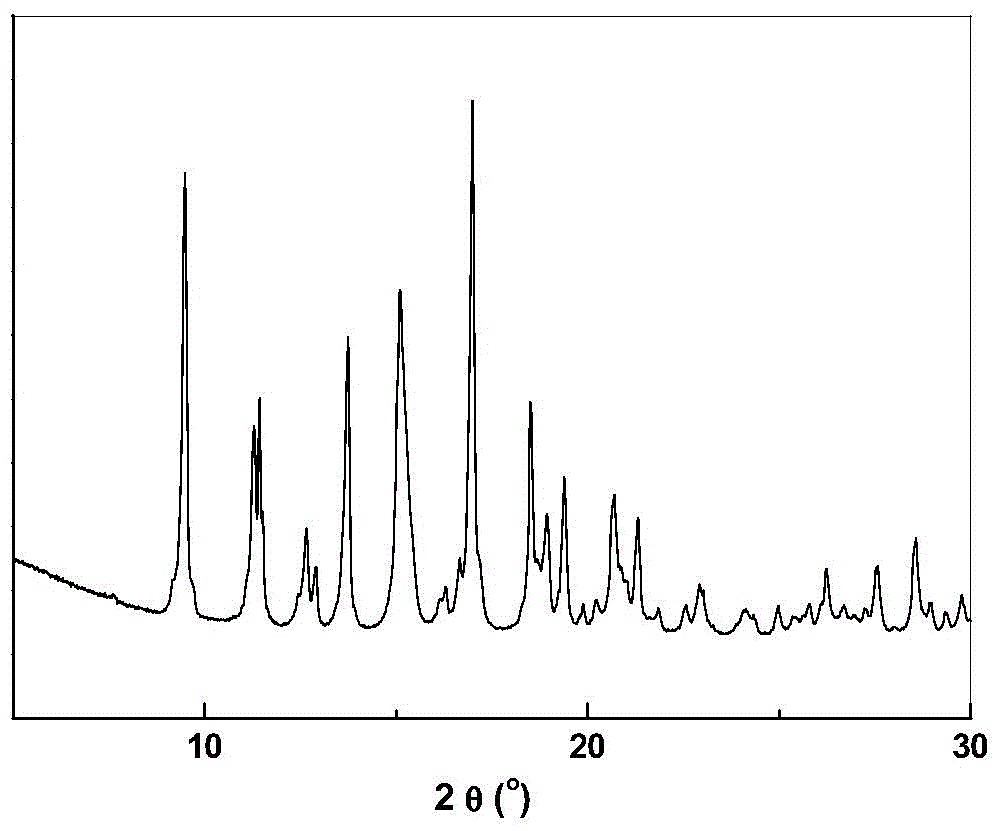

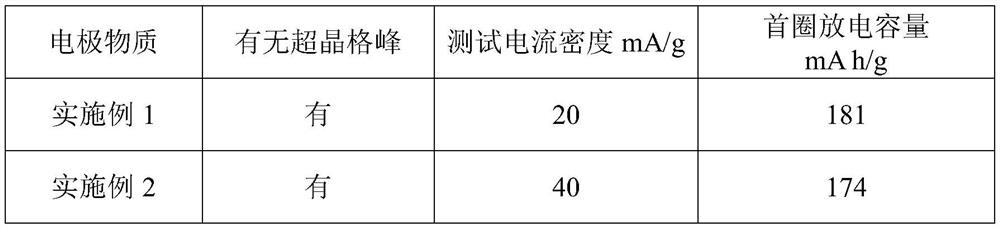

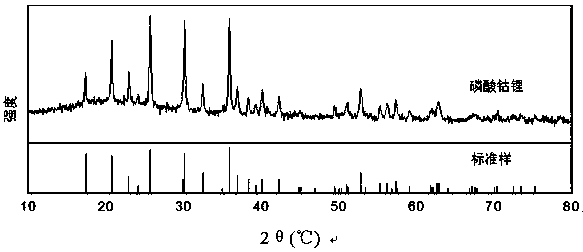

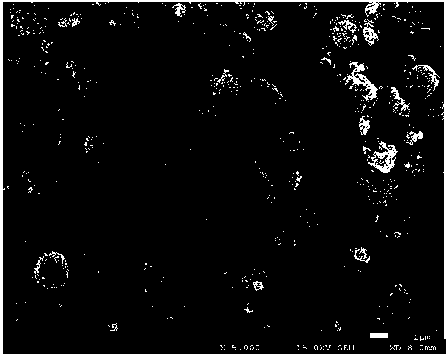

ActiveCN106935849AUniform particle sizeExcellent discharge specific capacityCell electrodesSecondary cellsPorous carbonMicrometer

The invention relates to a lithium ion battery positive electrode material and a preparation method thereof. The positive electrode material comprises a porous carbon sphere and a lithium cobalt phosphate material, wherein the lithium cobalt phosphate material is arranged in the porous carbon sphere, the peak intensity of X-ray diffraction peak of the lithium cobalt phosphate material conforms to the following: I<200> / I<131> is less than 1.5 but more than 0.8, the average grain size of the porous carbon sphere is 0.8-10 micrometers, the pore volume of the porous carbon sphere is (0.01-0.1) cm<3> / g and the carbon content of the positive electrode material is 2-10%. The lithium cobalt phosphate material obtained by employing the preparation method is uniform in particle size and excellent in electrochemical characteristics such as discharge specific capacity and cycle capacity retention ratio.

Owner:BYD CO LTD

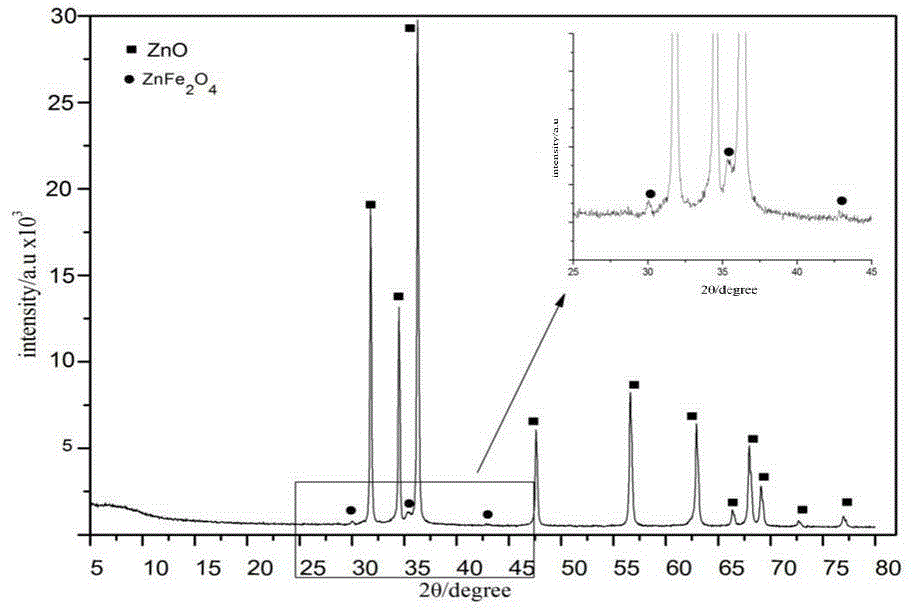

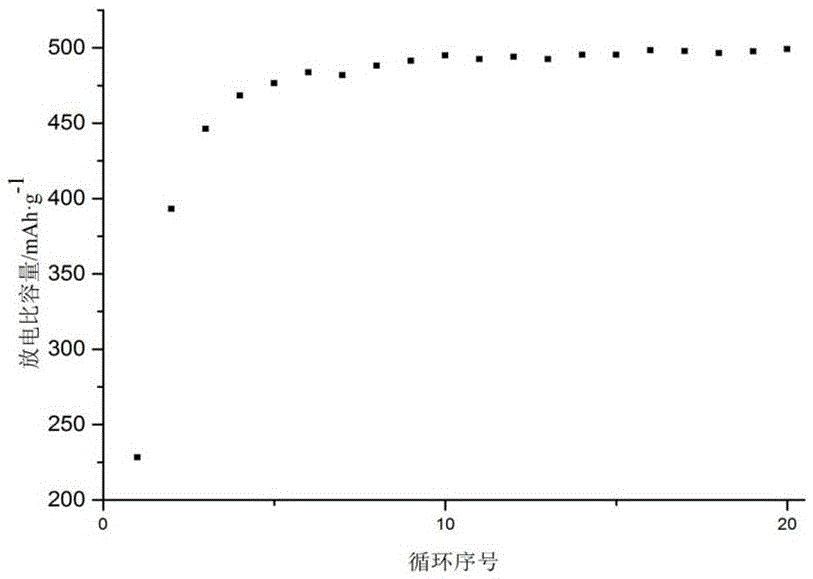

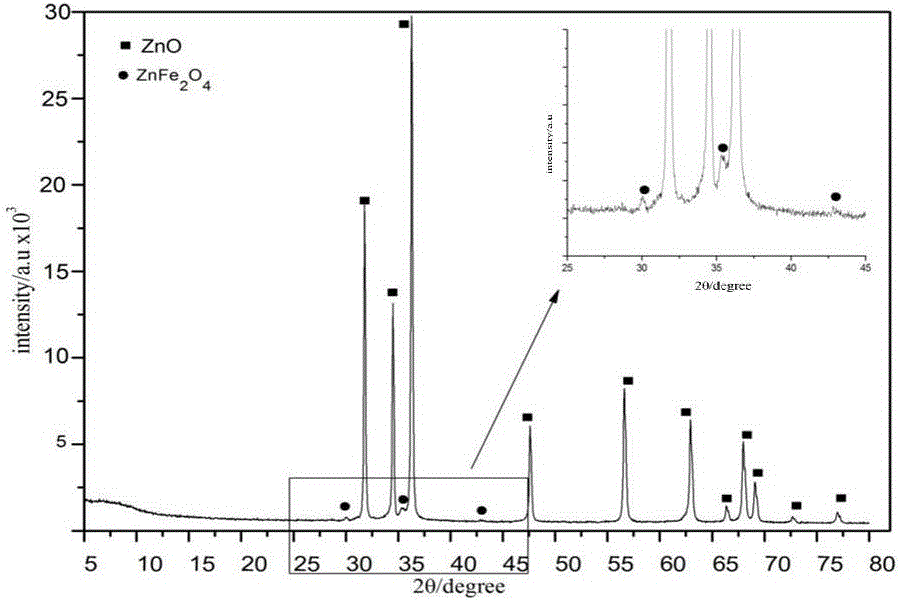

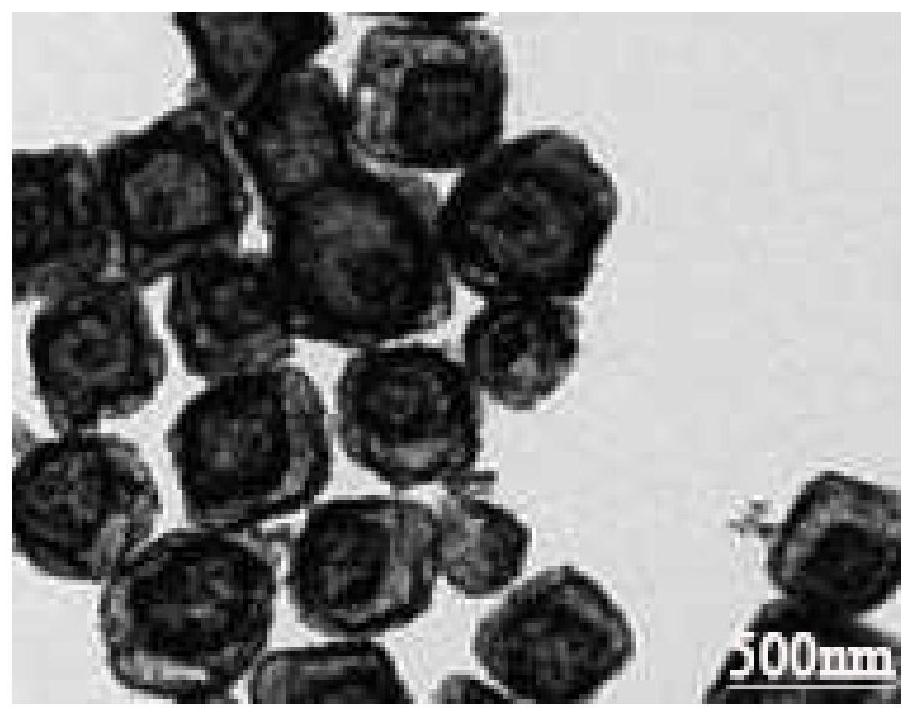

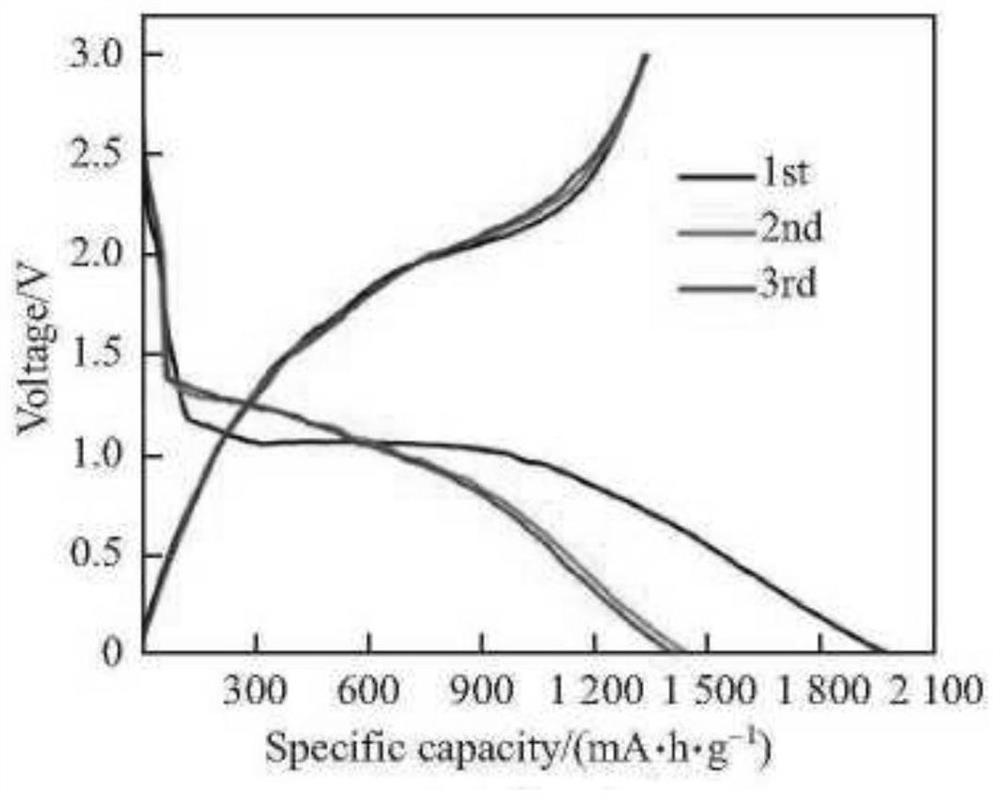

Zinc cathode material of nickel-zinc battery as well as preparation method and application of zinc cathode material

ActiveCN104617268AImprove poor cycle performanceHigh charge and discharge capacityCell electrodesNickel accumulatorsWater bathsFiltration

The invention provides a zinc cathode material of a nickel-zinc battery as well as a preparation method and application of the zinc cathode material. The zinc cathode material of the nickel-zinc battery comprises ZnXnO4 and ZnO, wherein ZnXnO4 accounts for 0.5-5% of the amount of total substances of the zinc cathode material; X is Fe and / or Co; n is equal to 1 or 2. The preparation method comprises the following steps: preparing a salt solution from one or two of ferric salts and cobalt salts together with one of zinc salts, preparing a precipitant from one or two or more of sodium hydroxide, sodium carbonate, urea and ammonia water, stirring the salt solution and the precipitant, dripping into a water bath environment, performing hydrothermal reaction on the titrated mixed liquid for 8-12 hours at 100-150 DEG C, and finally performing suction filtration, washing and drying to obtain the zinc cathode material. The zinc cathode material provided by the invention can be mixed with carbon powder, polytetrafluoroethylene and carboxymethyl cellulose sodium so as to prepare the zinc negative electrode of the nickel-zinc battery. The zinc cathode material of the nickel-zinc battery is relatively high in specific capacity, and the circulation stability of the nickel-zinc battery is improved.

Owner:CHONGQING UNIV

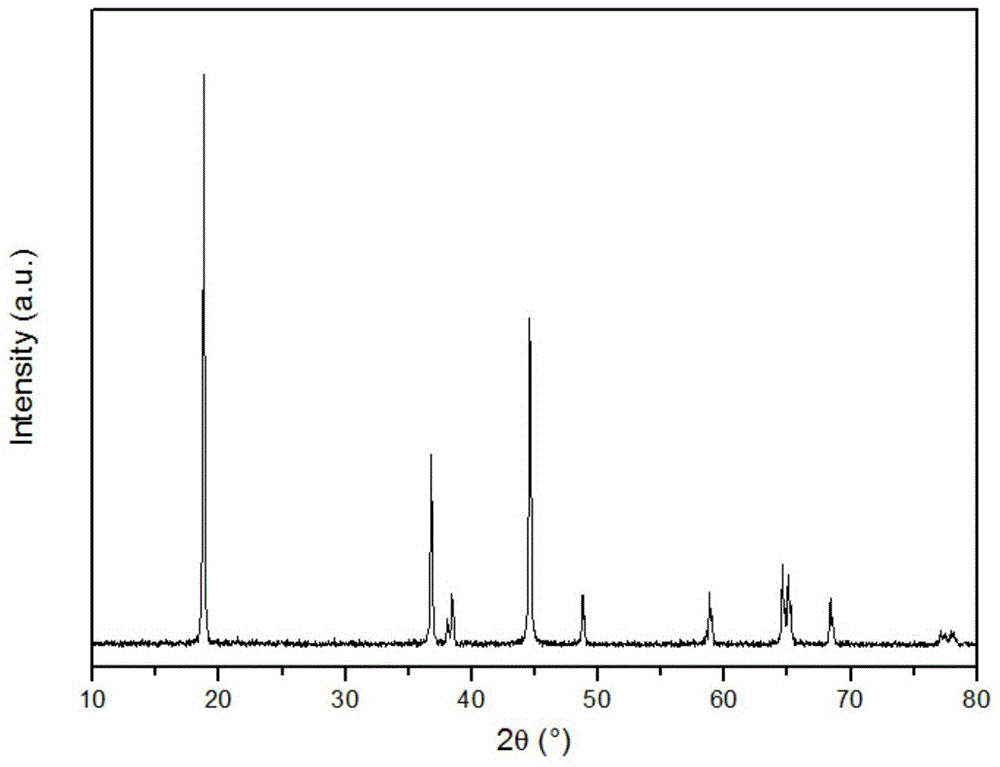

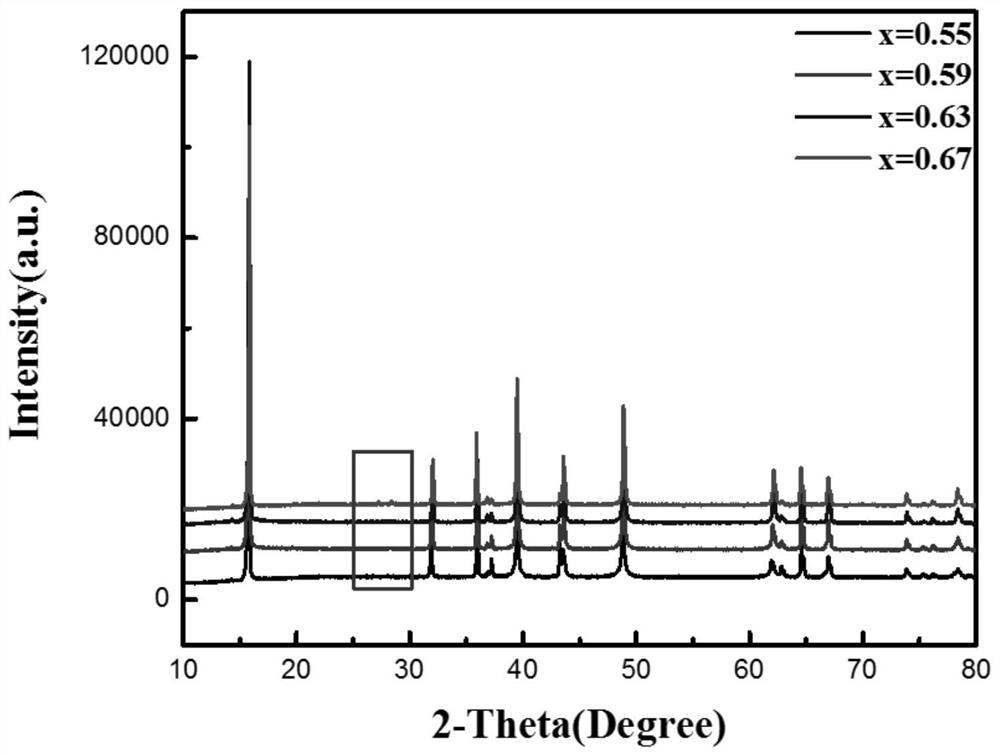

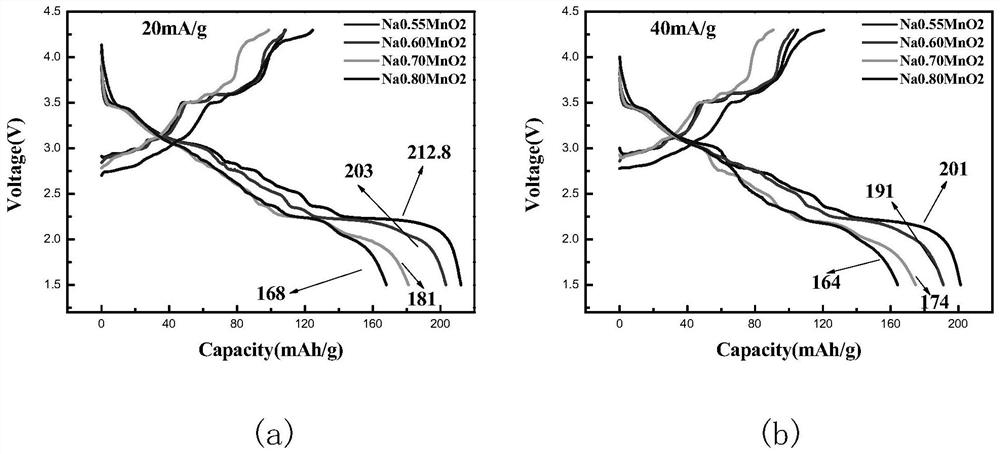

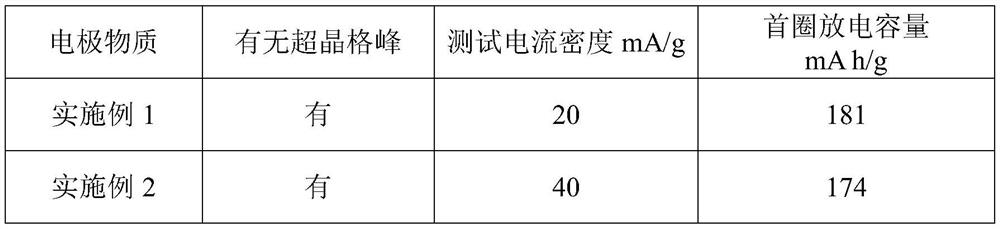

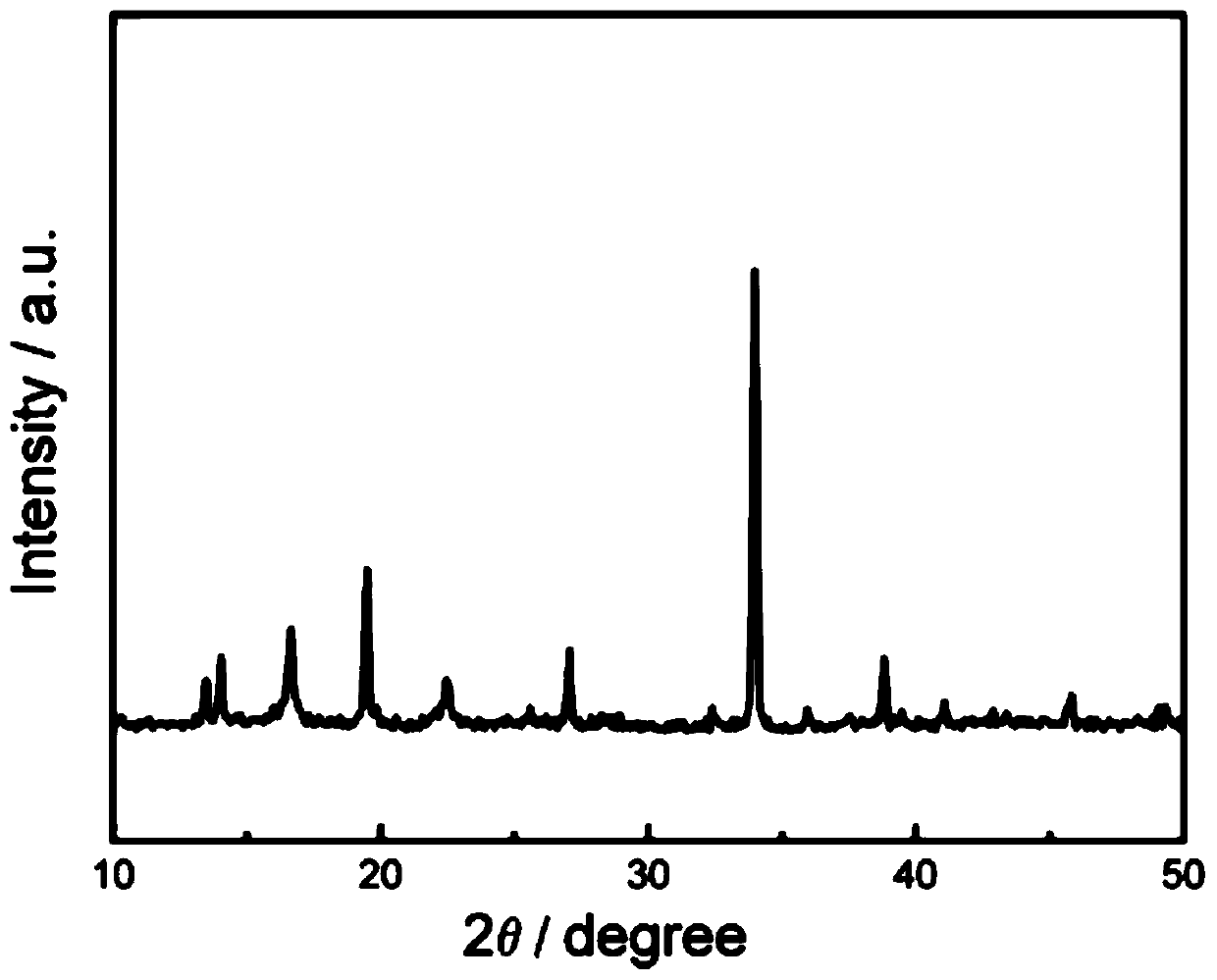

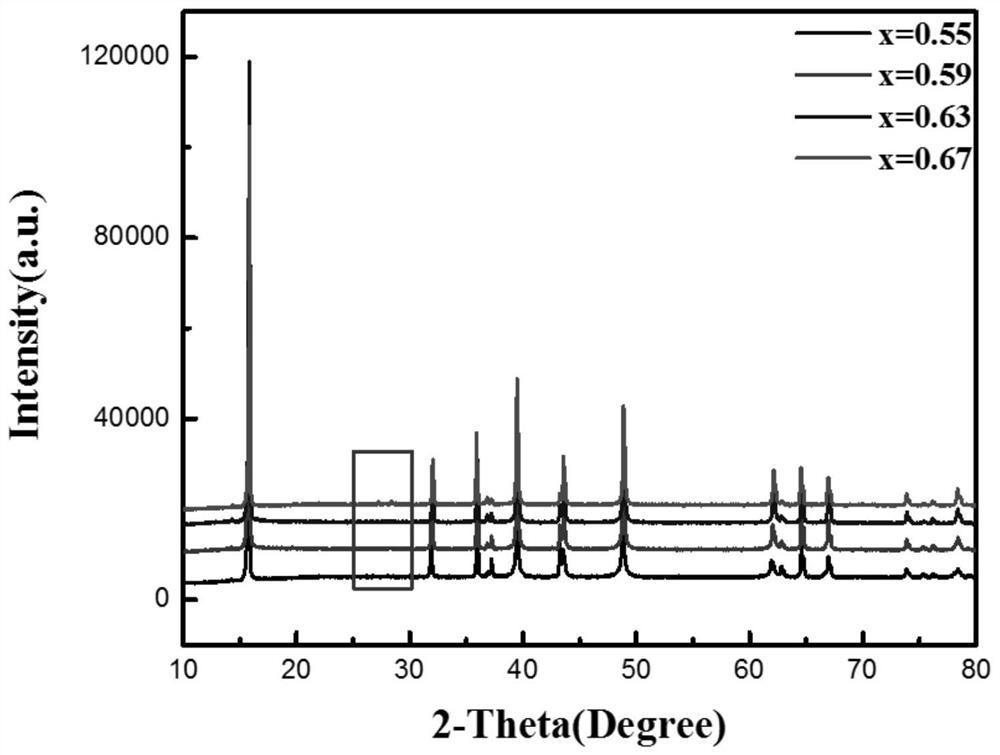

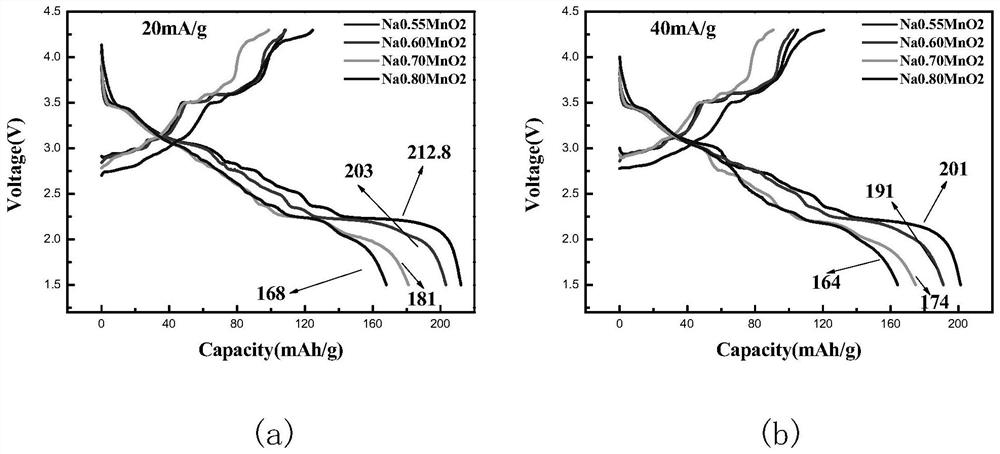

High-capacity P2-type positive electrode material of sodium-ion battery, and method for orderly improving specific capacity by inhibiting sodium/vacancy

ActiveCN112290013AReduce contentExtensive sourcesSecondary cellsPositive electrodesPhysical chemistrySodium-ion battery

The invention discloses a high-capacity P2-type positive electrode material of a sodium-ion battery, and a method for orderly improving specific capacity by inhibiting sodium / vacancy. The positive electrode material is a sodium-based layered metal oxide NaxTmO2, Tm is a transition metal, Tm comprises one or more of Mn, Fe, Ni, Co and other elements, and x is a stoichiometric number of sodium and ranges from 0.55 to 0.65. By regulating the content of sodium ions in the P2-type layered positive electrode material of the sodium ion battery, the charge order of the transition metal layer and the sodium / vacancy order in the charging and discharging process are effectively inhibited, the diffusion rate of the sodium ions in the P2-type layered positive electrode material is improved, and then the electrode material with higher specific capacity is obtained. The method disclosed by the invention is simple and easy to operate, rich in raw materials, low in price and high in practical application degree, can provide a new insight for structure and performance optimization of the layered positive electrode material of the sodium-ion battery, and has a wide application prospect.

Owner:FUJIAN NORMAL UNIV

Three-dimensional current collector/Zn/Zn-E composite negative electrode, preparation thereof and application of composite negative electrode in aqueous zinc ion battery

PendingCN114883560AIncrease profitHigh densityElectrode manufacturing processesElectrode carriers/collectorsBattery cellAnalytical chemistry

The invention belongs to the technical field of aqueous zinc ion batteries, and particularly discloses a three-dimensional current collector / Zn / Zn-E composite negative electrode which comprises a three-dimensional current collector substrate, a zinc body layer deposited on the surface of the three-dimensional current collector substrate and a Zn-E alloy layer deposited on the zinc surface. In addition, the invention also discloses a preparation method of the negative electrode and an application method of the negative electrode in an aqueous zinc ion battery. The composite zinc negative electrode has high utilization rate, the energy density of the battery is greatly improved, and the assembled aqueous zinc ion total battery has excellent cycle and rate performance. In addition, the preparation method is simple, efficient and low in cost, and further application of the water-based zinc ion battery is promoted.

Owner:CENT SOUTH UNIV +1

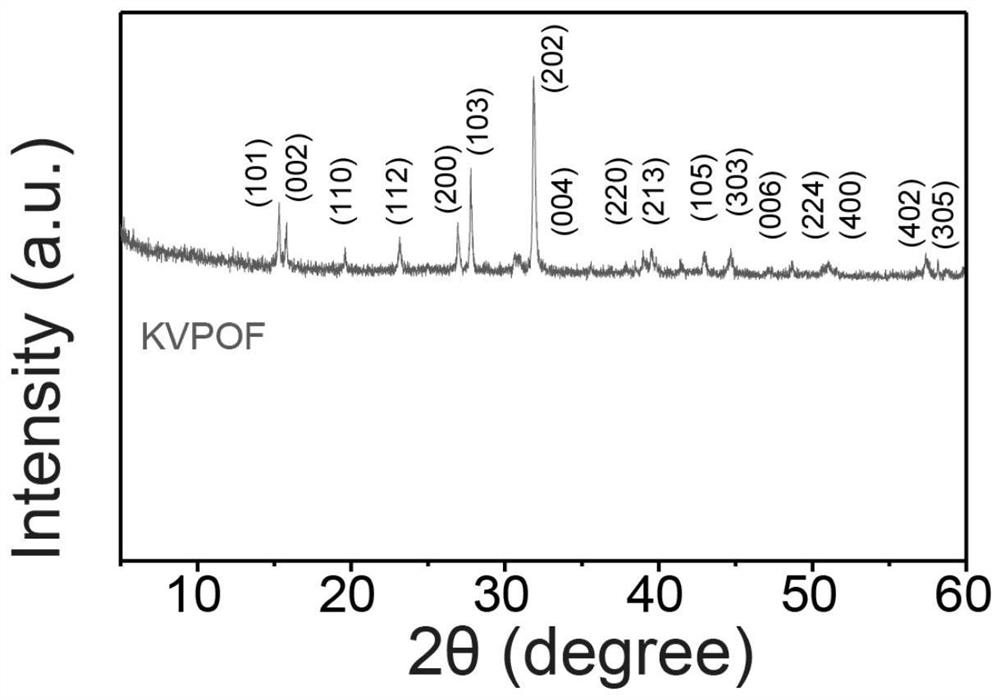

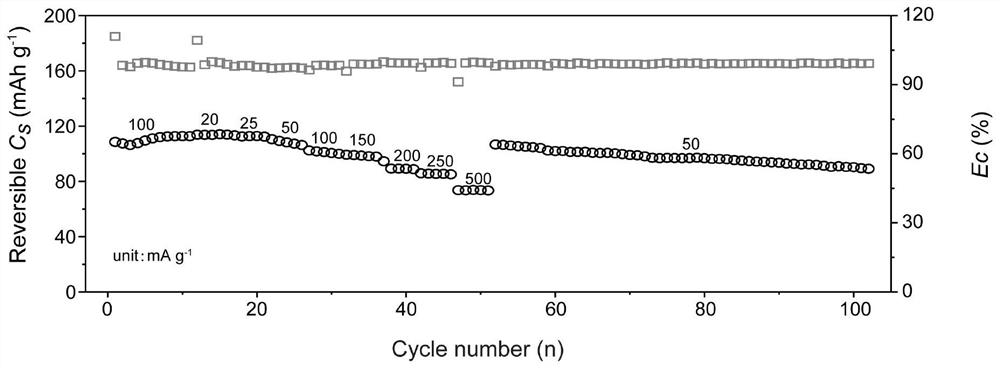

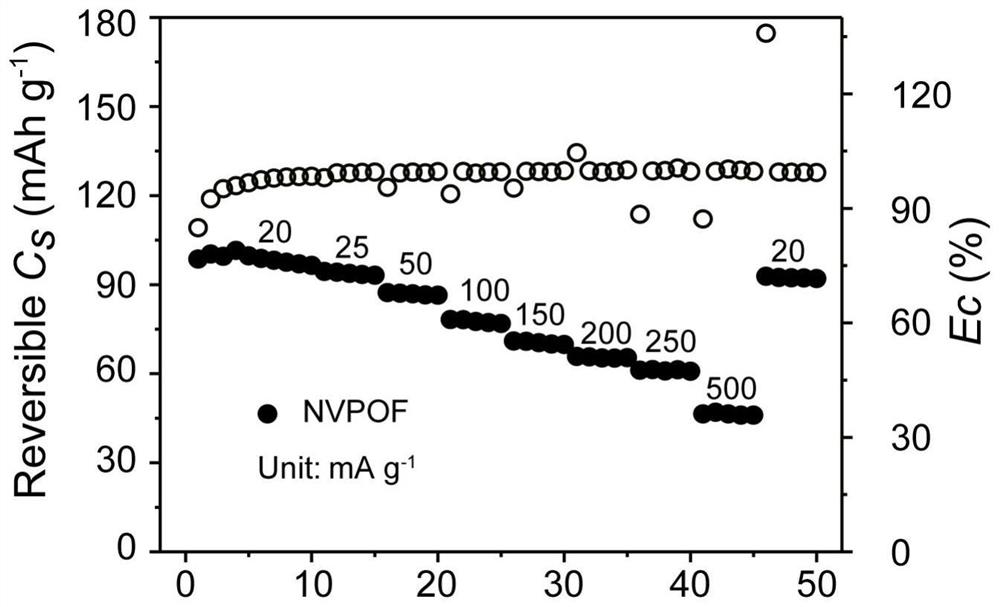

Vanadium oxygen potassium fluorophosphate, preparation method and application thereof, and potassium ion battery

ActiveCN113046768AStable crystal structureIncrease working voltageElectrolysis componentsSecondary cellsPotassium ionsVanadium atom

The invention provides vanadium oxygen potassium fluorophosphate, a preparation method and application thereof, and a potassium ion battery, and belongs to the technical field of lithium ion batteries. According to the invention, Na3(VO)2(PO4)2F is used as a raw material, the Na3(VO)2(PO4)2F has a relatively large polyanion group, ion exchange is carried out in a constant-current electrochemical charging and discharging mode, and the obtained vanadium oxygen potassium fluorophosphate has a stable crystal structure and can inhibit a volume effect of deintercalation of potassium ions in a charging and discharging process when being used as a lithium ion positive electrode active material, so that the cycle performance of the lithium ion battery is improved; fluorine ions have strong electronegativity and induction effect, and can induce the redox potential of V, so that the vanadium oxygen potassium fluorophosphate has higher working voltage. Meanwhile, the obtained vanadium oxygen potassium fluorophosphate has good low-temperature performance and has good specific capacity at the temperature of -25 DEG C to 25 DEG C.

Owner:NORTHEAST NORMAL UNIVERSITY

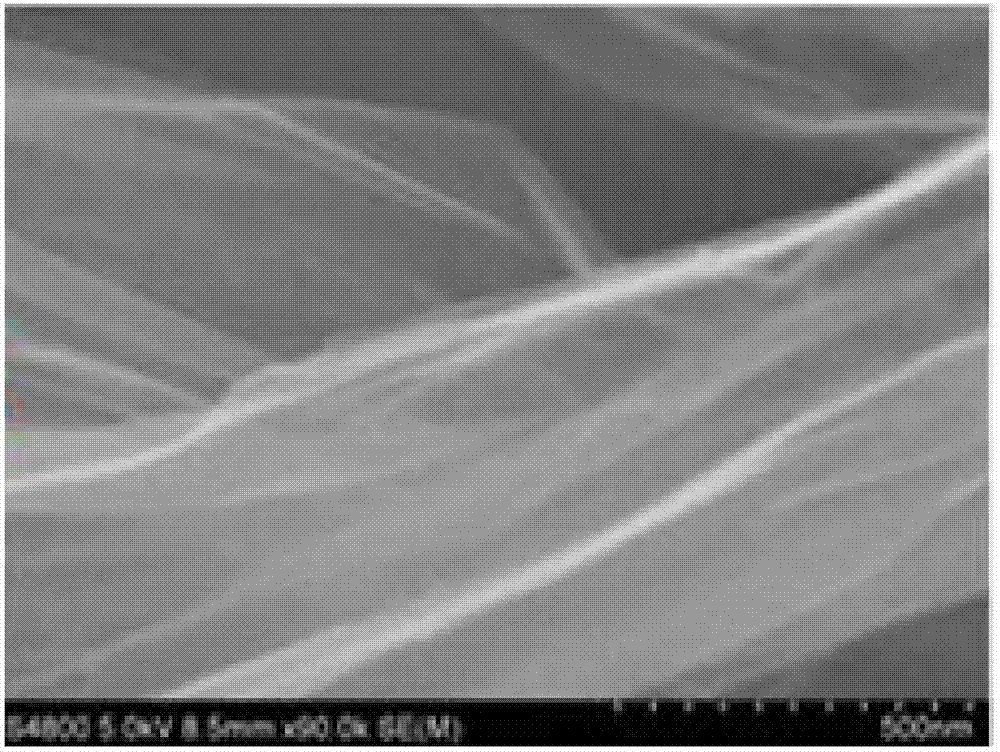

A lithium ion battery cathode material, preparation method and application thereof

InactiveCN109167016AImprove electrochemical performanceImprove rate charge and discharge performanceElectrode carriers/collectorsSecondary cellsHigh rateCharge discharge

The invention relates to a lithium ion battery cathode material and a preparation method and application thereof. The preparation method comprises the following steps: ball milling the cathode raw material and dispersing it in a solvent to obtain a suspension; A graphene electrode and a metal electrode are placed in a suspension and an electric field is applied between the two electrodes, whereinthe graphene electrode is used as an anode and the metal electrode is used as a cathode; Taking out the graphene electrode and drying to obtain the cathode material of the lithium ion battery; The preparation method has simple process and is easy to be produced on a large scale. Moreover, the cathode material prepared by the preparation method has excellent electrochemical performance and high rate charge-discharge performance.

Owner:盐城市新能源化学储能与动力电源研究中心

Carrier material for positive electrode of lithium-sulfur battery and preparation method thereof

PendingCN111490248AExcellent discharge specific capacityHigh discharge specific capacityPositive electrodesLi-accumulatorsCyclic stabilityLithium–sulfur battery

The invention belongs to the technical field of lithium-sulfur batteries, and particularly relates to a carrier material for a positive electrode of a lithium-sulfur battery and a preparation method of the carrier material. The carrier material is an Nb-Nb4N5 composite material with a one-dimensional mesoporous nanobelt array, and the specific discharge capacity, the cycling stability, the rate capability and the cycle life of the lithium-sulfur battery can be remarkably improved when the carrier material is used for the positive electrode of the lithium-sulfur battery.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Electrode materials for lithium-ion batteries and their applications in lithium-ion batteries

ActiveCN104393300BExcellent discharge specific capacityThe first discharge specific capacity is highSecondary cellsNon-aqueous electrolyte accumulator electrodesMetal-organic frameworkEngineering

The invention provides a lithium ion battery electrode material. The electrode material comprises a metal-organic framework, and the metal-organic framework includes at least one diazole and at least one metal ion. Experiments confirm that the above lithium ion battery electrode has good charge and discharge cycle stability, and after multi-time cycle, the metal-organic framework still has a good structure, and the discharge specific capacity of the battery tends to stability, maintains at a high valve and has a small change amplitude, so the lithium ion battery electrode material is an electrode material with a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

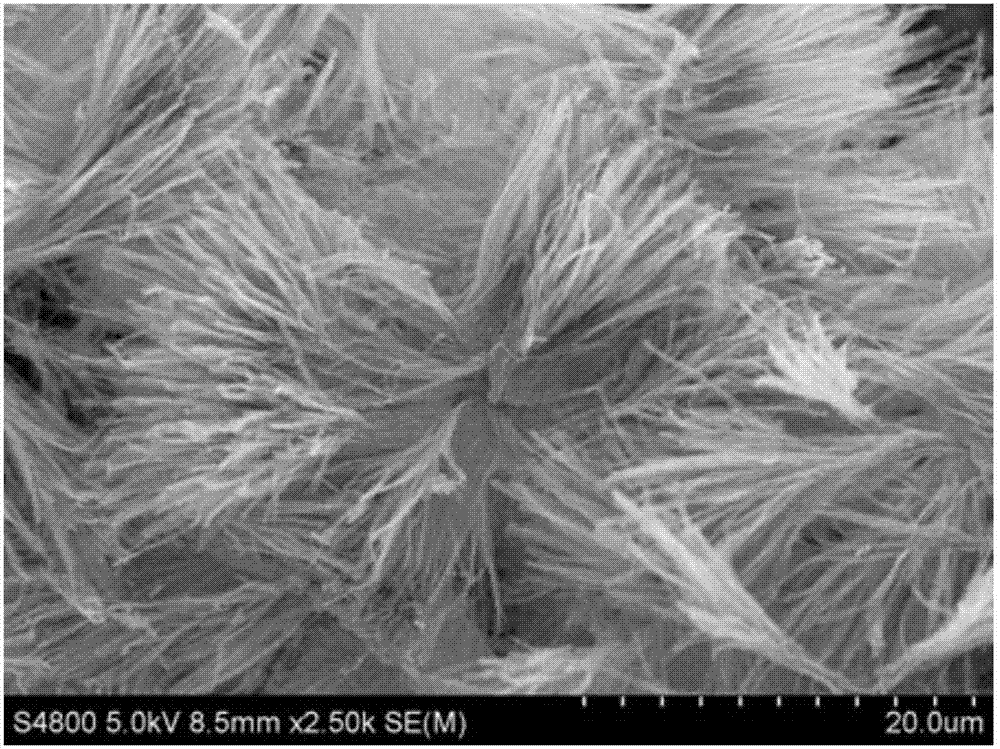

Nanofiber framework-based sodium-ion battery positive electrode material and preparation method and application thereof

InactiveCN111584874AImprove cycle stabilityImprove cycle lifeMaterial nanotechnologyElectrode manufacturing processesElectrical batteryManganese

The invention discloses a nanofiber framework-based sodium-ion battery positive electrode material as well as a preparation method and application thereof. The method comprises the following steps: ball-milling and mixing a sodium salt, a manganese salt and alcohol, and drying and grinding to obtain a powder precursor; calcining and then cooling to room temperature to obtain a Na0.44MnO2 single crystal; preparing an electrostatic spinning solution from the Na0.44MnO2 single crystal, PVP and distilled water and preparing a Na0.44MnO2 nanofiber material by adopting an electrostatic spinning method; and forming the carbon material-coated Na0.44MnO2 sodium-ion battery positive electrode material through carbonization treatment by adopting a grinding process. The electrostatic spinning technology is adopted; experimental conditions such as temperature, atmosphere and time are regulated and controlled; the preparation process flow of a novel Na0.44MnO2@CNTs / C nanofiber composite material electrode material is explored by selecting electrostatic spinning process parameters, and the Na0.44MnO2 material prepared by the method has good specific discharge capacity and reliable cycle performance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

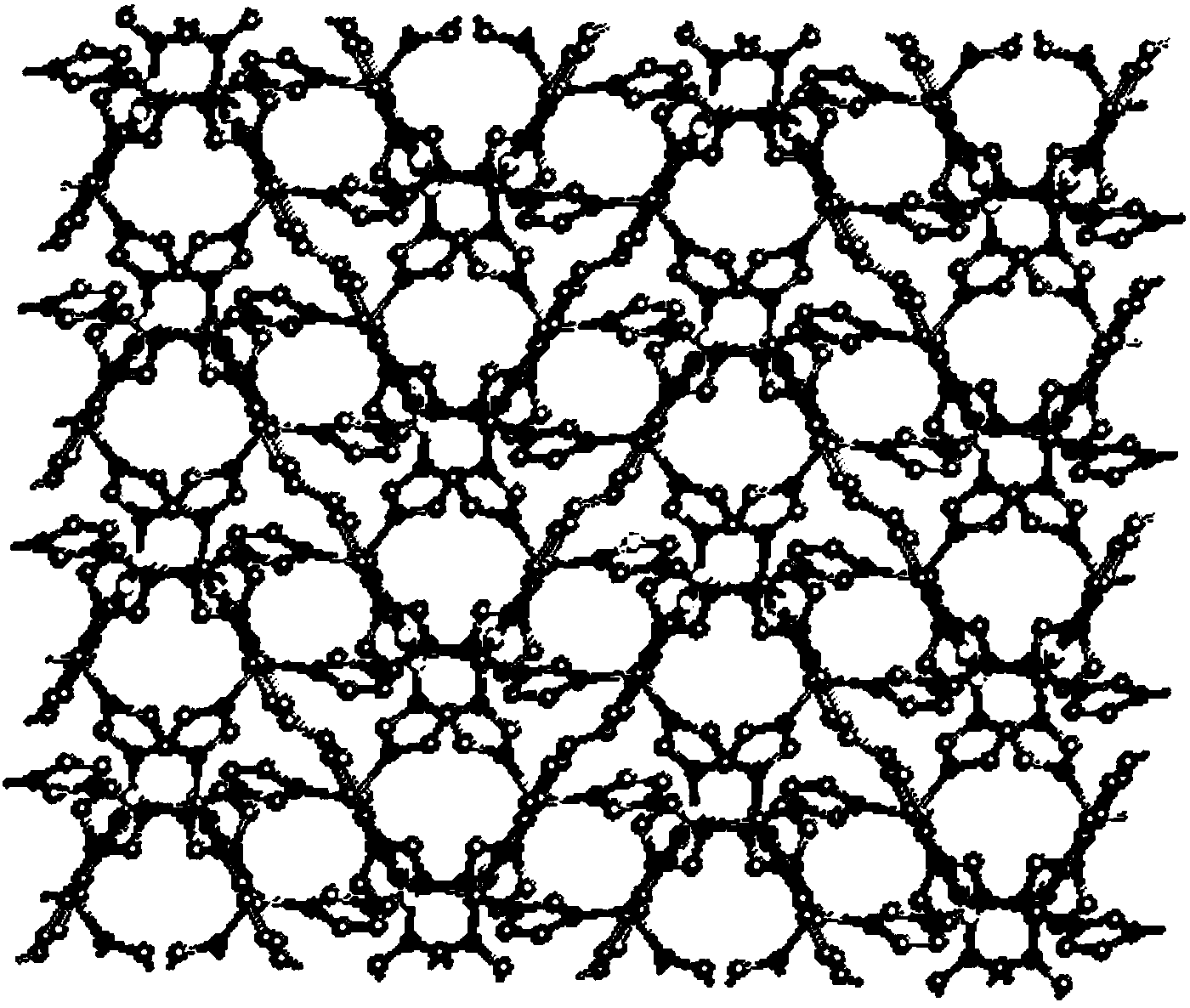

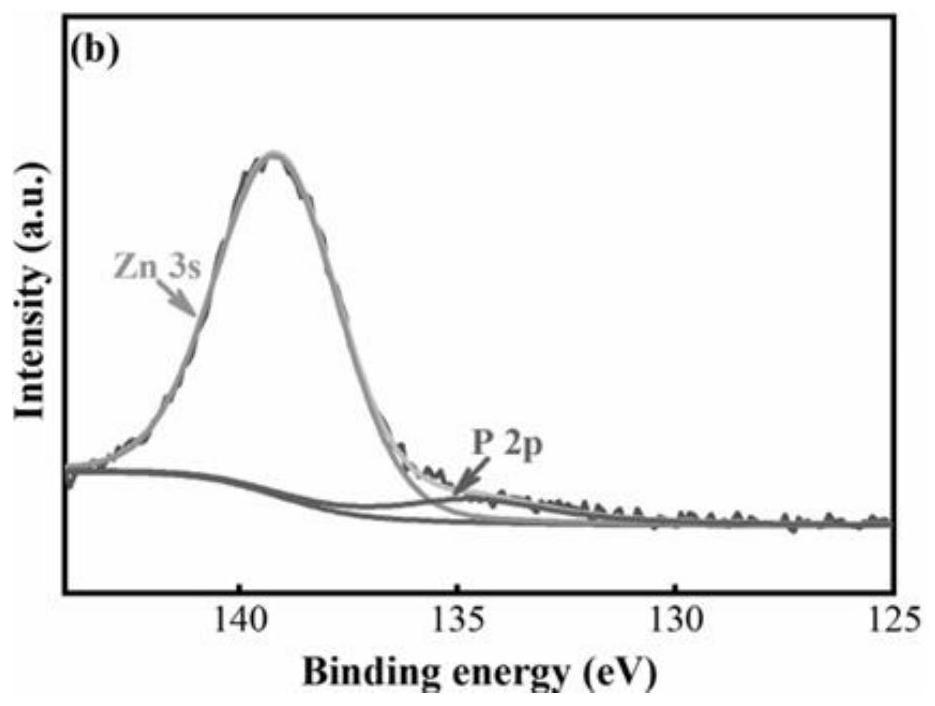

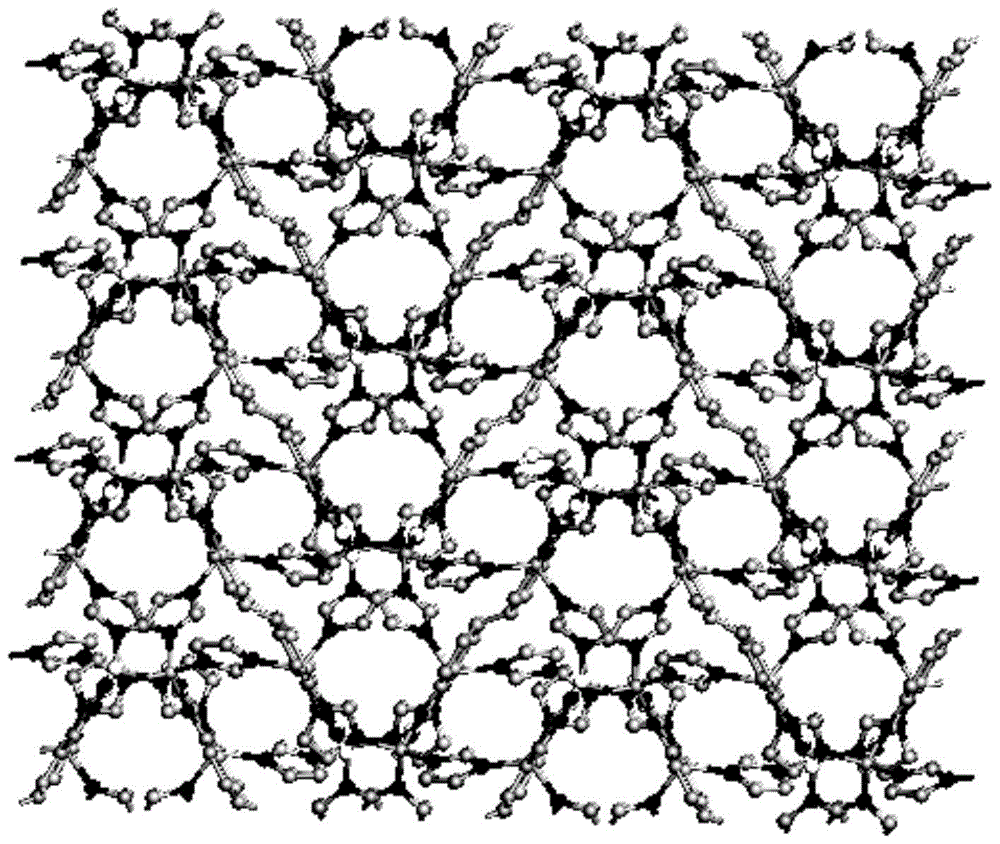

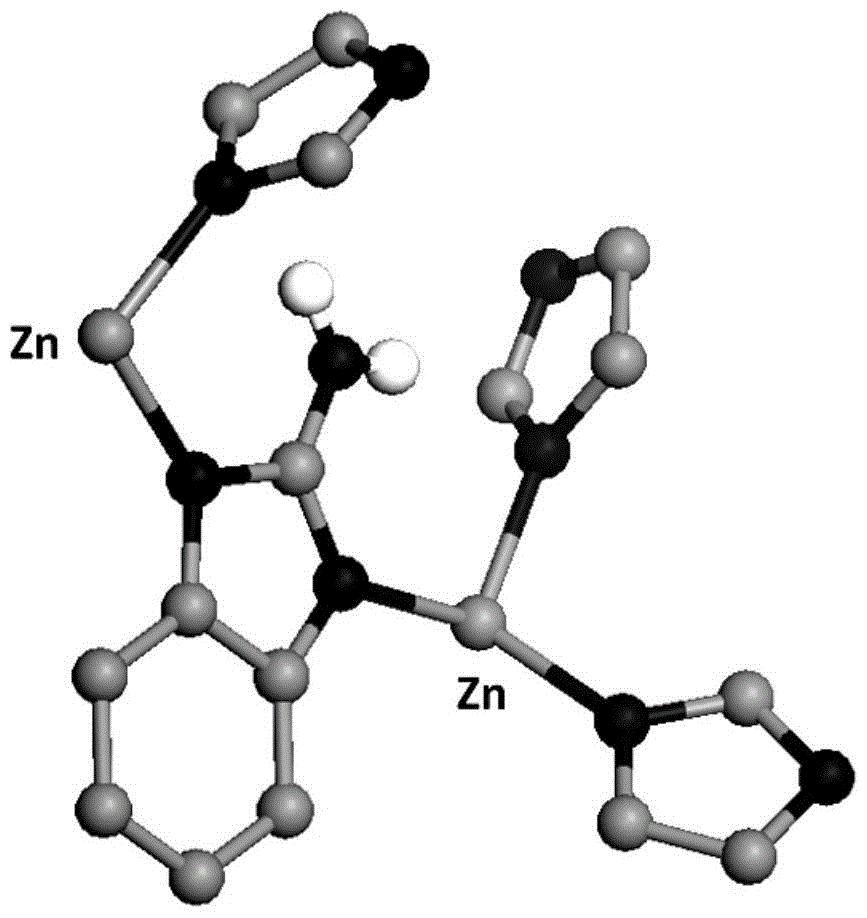

Functional zif type metal organic framework porous material, its preparation method and application

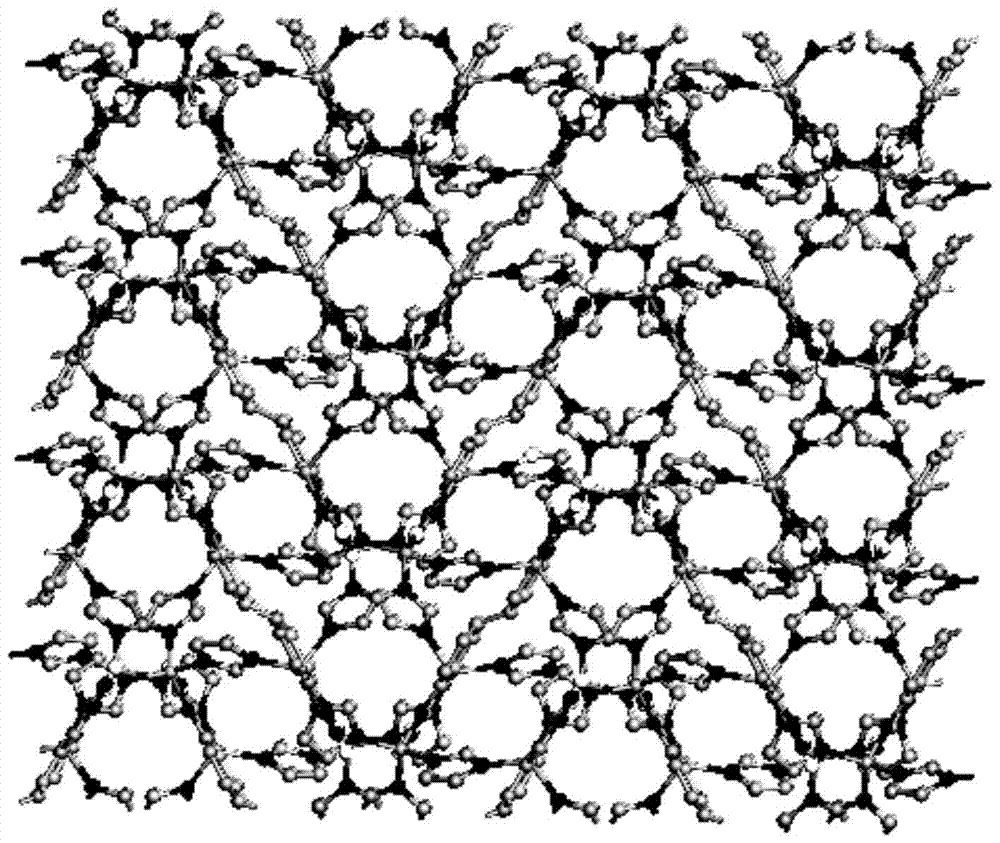

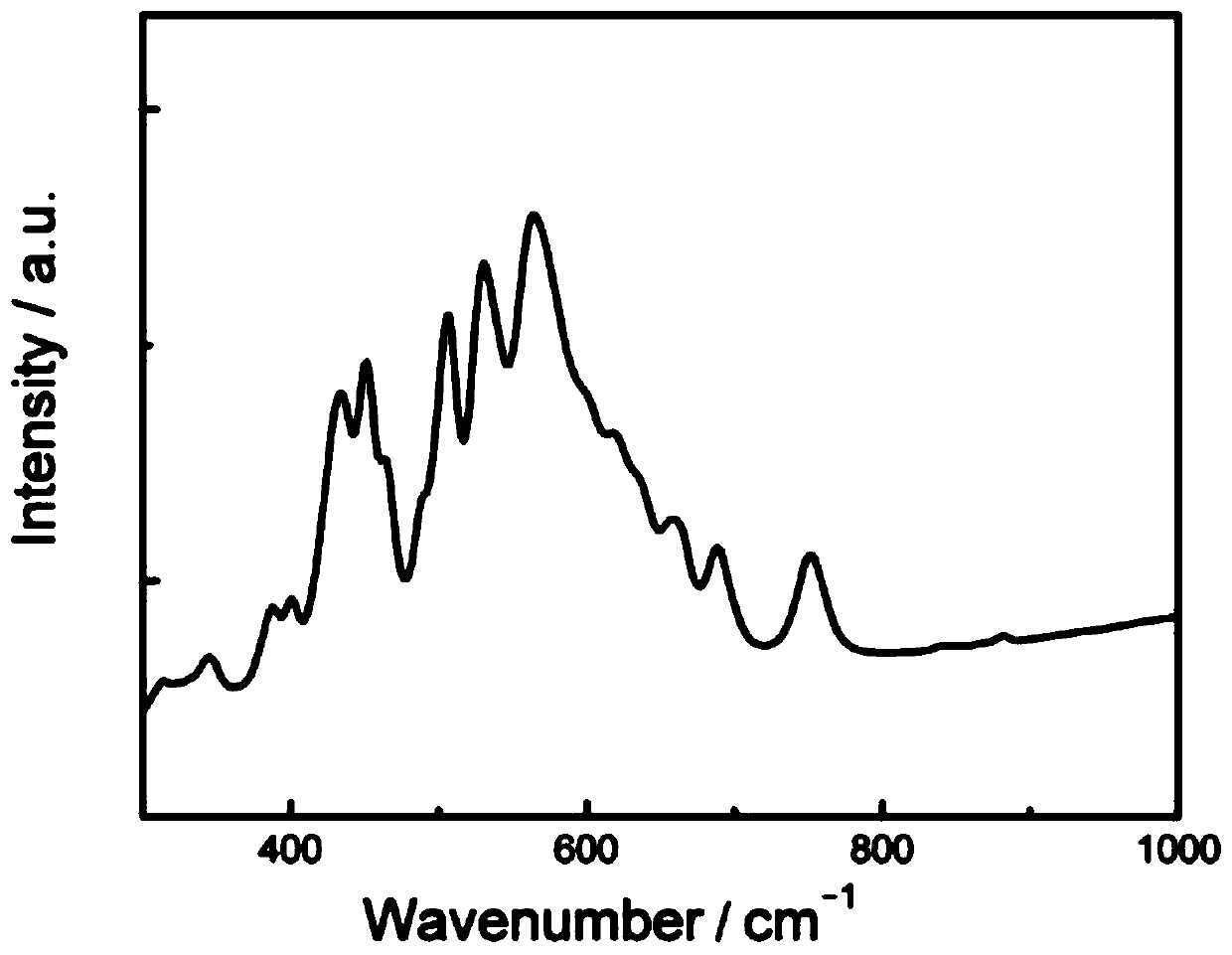

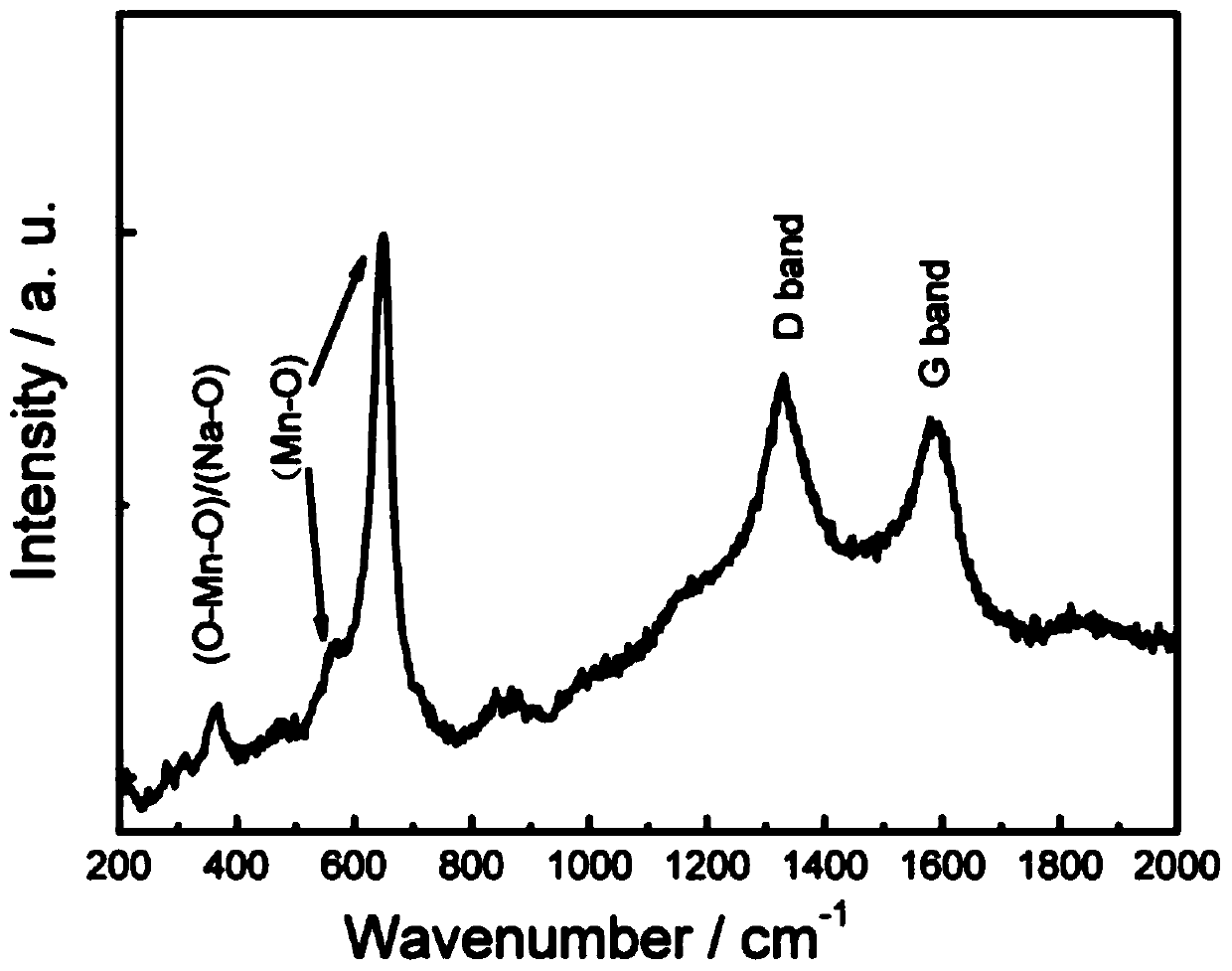

ActiveCN104307482BImprove electrochemical performanceExcellent discharge specific capacityOther chemical processesCell electrodesMetal-organic frameworkLithium-ion battery

The invention provides a functionalized ZIF type metal organic framework (MOF) porous material. A framework of the material comprises metal ions Zn<2+> or Co<2+> as well as imidazole and aminobenzimidazole. The material is excellent in physical and chemical stability and overcomes the defect that a traditional MOF porous material is sensitive to water; the material has a good CO2 adsorption property; besides, a lithium ion battery manufactured with the material as an electrode material has good electrochemical properties, and furthermore, after N cycles, the specific discharge capacity of the lithium ion battery tends to be stable, wherein N is greater than or equal to 10; as a result, the functionalized ZIF type MOF porous material has bright application prospect in the field of lithium ion batteries.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Lithium-rich manganese-based cathode material coated with composite carbon material and preparation method thereof, and lithium battery

The invention relates to a lithium-rich manganese-based cathode material coated with a composite carbon material derived from a COFs material containing at least one element of N and B, and a preparation method thereof, and a lithium battery, wherein the surface of the lithium-rich manganese-based cathode material is coated with a composite carbon material. The lithium-rich manganese-based cathodematerial coated with the composite carbon material can obviously improve the conductivity of the material and the rate performance and cycle performance of the battery containing the composite carbonmaterial, and the composite carbon material is coated more uniformly. The invention adopts a simple one-step carbonization method to prepare a composite porous carbon material coated with a lithium-rich manganese-based cathode material, the prepared porous carbon has controllable specific surface area and pore size, and the preparation method is simple and efficient, and is suitable for large-scale preparation and synthesis.

Owner:桑德新能源技术开发有限公司 +1

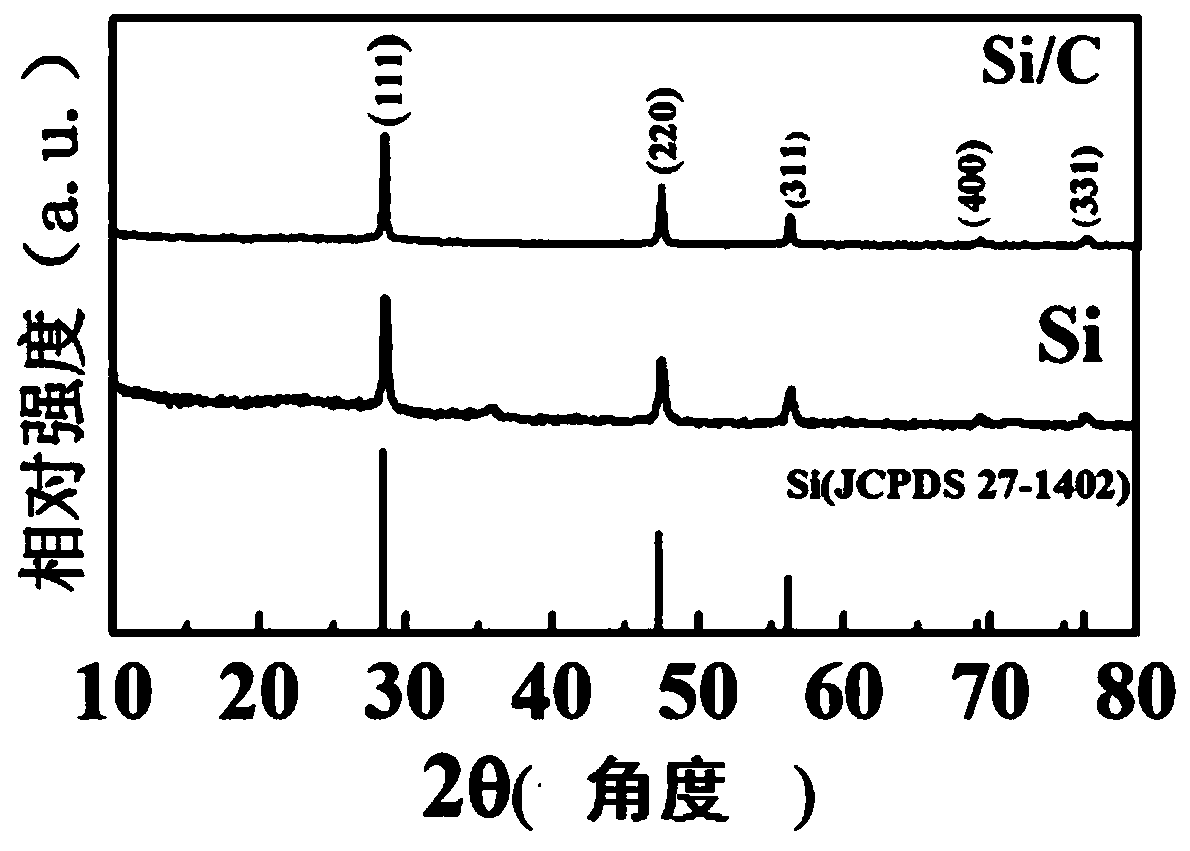

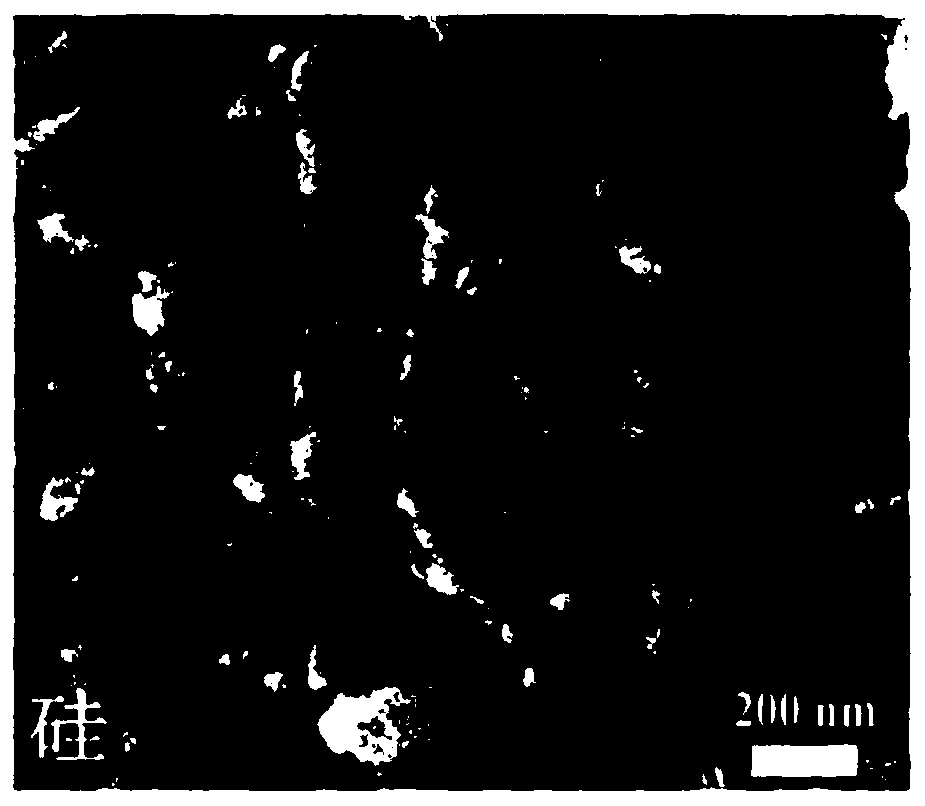

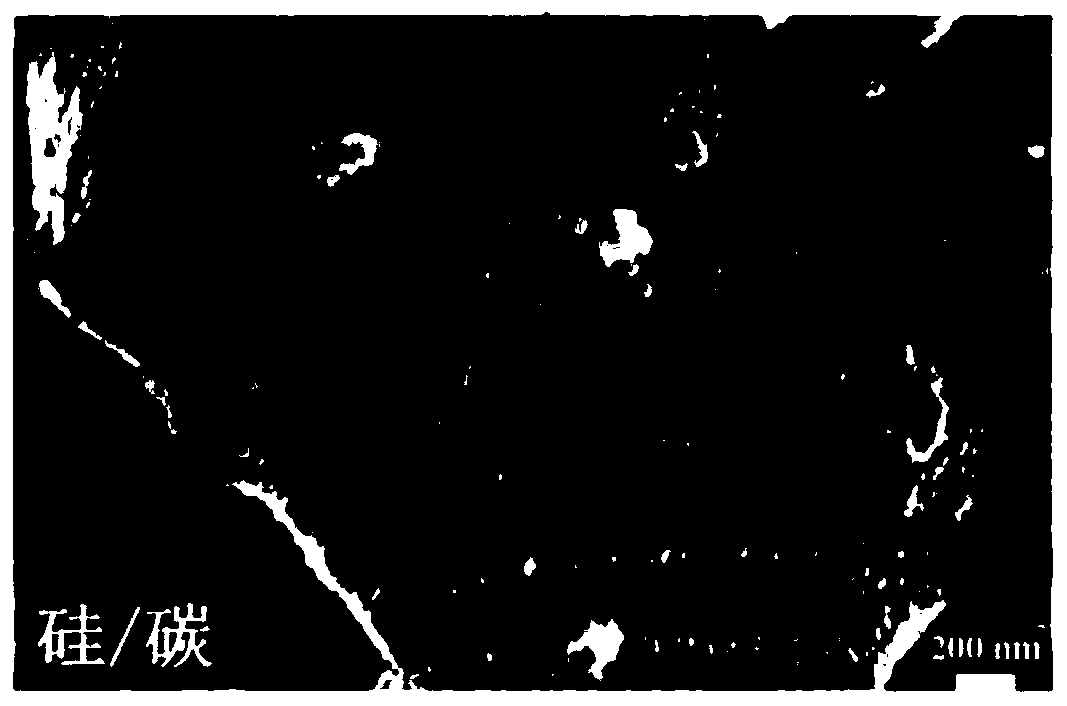

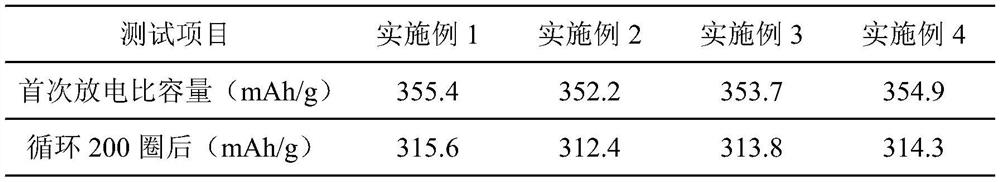

A kind of high-performance lithium-ion secondary battery negative electrode material Si/C composite material and preparation method thereof

ActiveCN107317012BAlleviate volume expansionExcellent discharge specific capacityMaterial nanotechnologyNegative electrodesAir atmosphereAscorbic acid

The invention provides a high-performance negative electrode material Si / C composite material for lithium ion secondary batteries and a preparation method thereof. The preparation method comprises the following steps: soaking bagasse into an acid solution, washing, drying and calcining in an air atmosphere to obtain SiO2 powder; after grinding and uniformly mixing the SiO2 powder and magnesium powder, calcining in a reducing protective gas atmosphere, soaking in the acid solution and a hydrofluoric acid water solution, then washing and drying to obtain Si nanometer particles; adding the obtained Si nanometer particles into an ascorbic acid water solution, stirring at room temperature, and then stirring at the temperature of 80 to 100 DEG C for 0.5 to 1 h; and calcining in the protective gas atmosphere to obtain the Si / C composite material. The raw materials used in the invention are simple and easily obtained, and the high-performance negative electrode material is green and environmentally-friendly and low in cost and can be produced in large scale; the experimental method is simple and easy to operate, and low in requirement for equipment; and the prepared material is uniform in pore diameter distribution and has excellent electrochemical performance.

Owner:山东大学深圳研究院

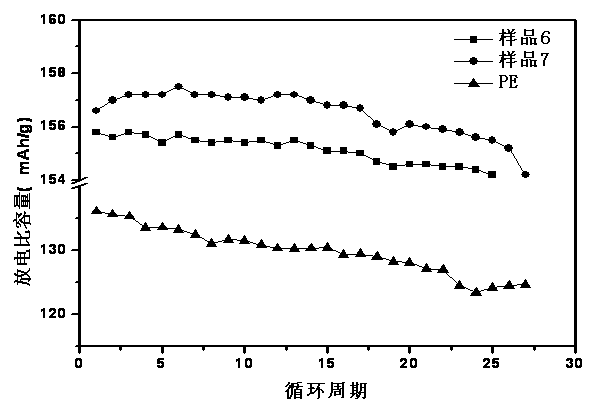

Composite polymer separator and preparation method thereof

ActiveCN103066229AImprove breathabilityImprove mechanical propertiesSynthetic resin layered productsCell component detailsPolymer sciencePolyolefin

The present invention discloses a composite polymer separator which is composed of a polyolefin-based separator and coating film on the polyolefin-based separator. The coating film is composed of the following raw materials, by mass: 5-10 parts of PVDF, 90-120 parts of NMP, and 0.1-3 parts of SiO2. A preparation method for the composite polymer separator comprises the following steps: 1) uniformly mixing the various raw materials to give a film-forming solution; 2) coating the film-forming solution on the surface of the polyolefin-based separator to obtain a wet separator; 3) performing soaking treatment in water to the wet separator; and 4) removing the wet separator and drying. The separator prepared in the invention had good permeability, good mechanical properties, and strong resistance to high temperature. After battery tests, the battery made by using the separator of the present invention has a voltage platform, a specific discharge capacity and cycle performance better than those of a battery made by using a commercial separator; and the preparation method of the separator is simple, thereby saving manufacturing cost.

Owner:ADVANCED ELECTRONICS ENERGY LIMITED GUANGDONG

High-capacity p2-type cathode material for sodium-ion batteries and a method for increasing specific capacity by suppressing sodium/vacancy order

ActiveCN112290013BReduce contentExtensive sourcesSecondary cellsPositive electrodesElectrical batterySodium-ion battery

The invention discloses a high-capacity sodium-ion battery P2 positive electrode material and a method for orderly increasing the specific capacity by suppressing sodium / vacancies. The positive electrode material is a sodium-based layered metal oxide Na x TmO 2 , Tm is a transition metal, Tm includes one or more of Mn, Fe, Ni, Co and other elements, x is the stoichiometric number of sodium, and the range is 0.55⩽x⩽0.65. The present invention regulates the content of sodium ions in the P2-type layered positive electrode material of the sodium ion battery, effectively inhibits the charge order of the transition metal layer and the order of sodium / vacancy during the charging and discharging process, improves the diffusion rate of sodium ions in it, and then obtains Electrode materials with higher specific capacity. The method of the invention is simple and easy to operate, rich in raw materials and low in price, and has a high degree of practical application, can provide new insights into the structure and performance optimization of layered cathode materials for sodium ion batteries, and has broad application prospects.

Owner:FUJIAN NORMAL UNIV

A kind of positive electrode material of lithium ion battery and preparation method thereof

ActiveCN106935849BUniform particle sizeExcellent discharge specific capacityCell electrodesSecondary cellsAluminium-ion batteryPorous carbon

The invention relates to a lithium ion battery positive electrode material and a preparation method thereof. The positive electrode material comprises a porous carbon sphere and a lithium cobalt phosphate material, wherein the lithium cobalt phosphate material is arranged in the porous carbon sphere, the peak intensity of X-ray diffraction peak of the lithium cobalt phosphate material conforms to the following: I<200> / I<131> is less than 1.5 but more than 0.8, the average grain size of the porous carbon sphere is 0.8-10 micrometers, the pore volume of the porous carbon sphere is (0.01-0.1) cm<3> / g and the carbon content of the positive electrode material is 2-10%. The lithium cobalt phosphate material obtained by employing the preparation method is uniform in particle size and excellent in electrochemical characteristics such as discharge specific capacity and cycle capacity retention ratio.

Owner:BYD CO LTD

Lithium ion battery anode material and preparation method thereof

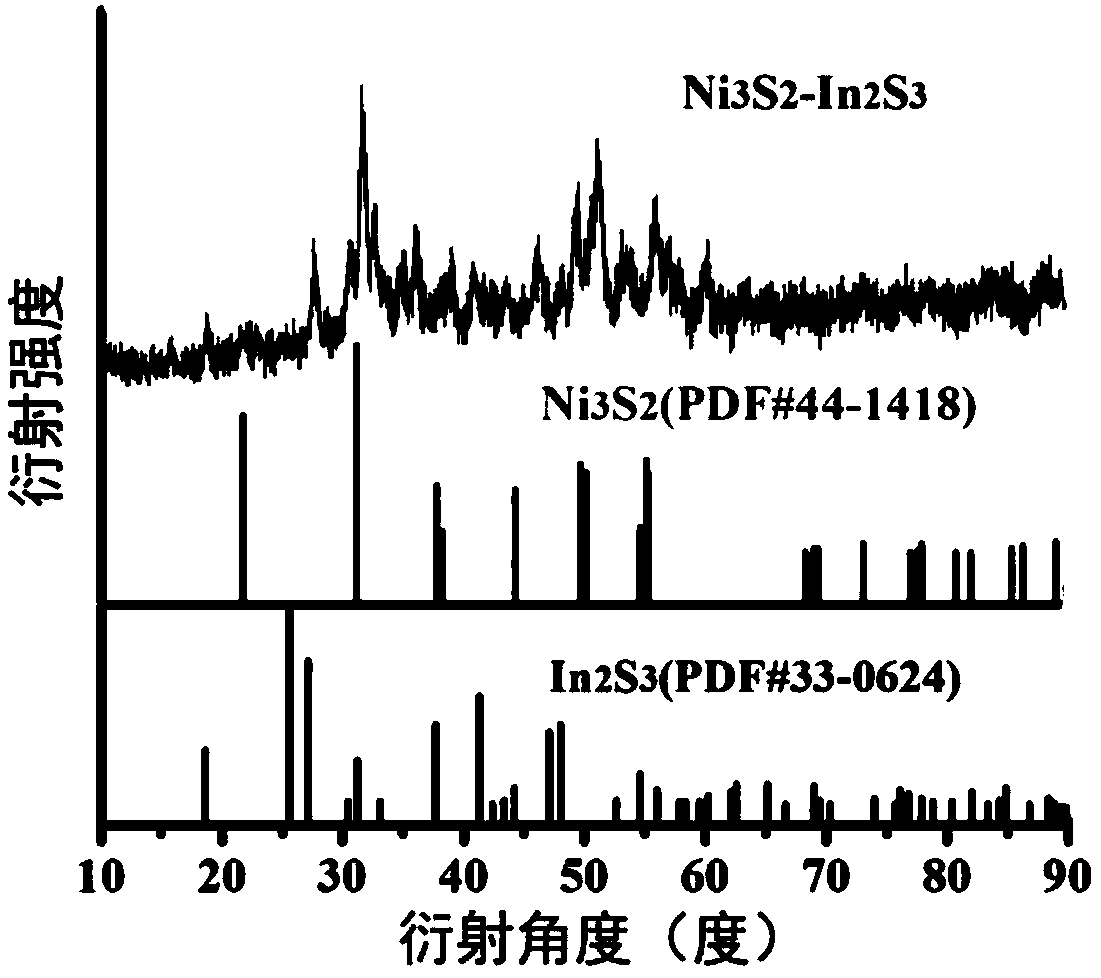

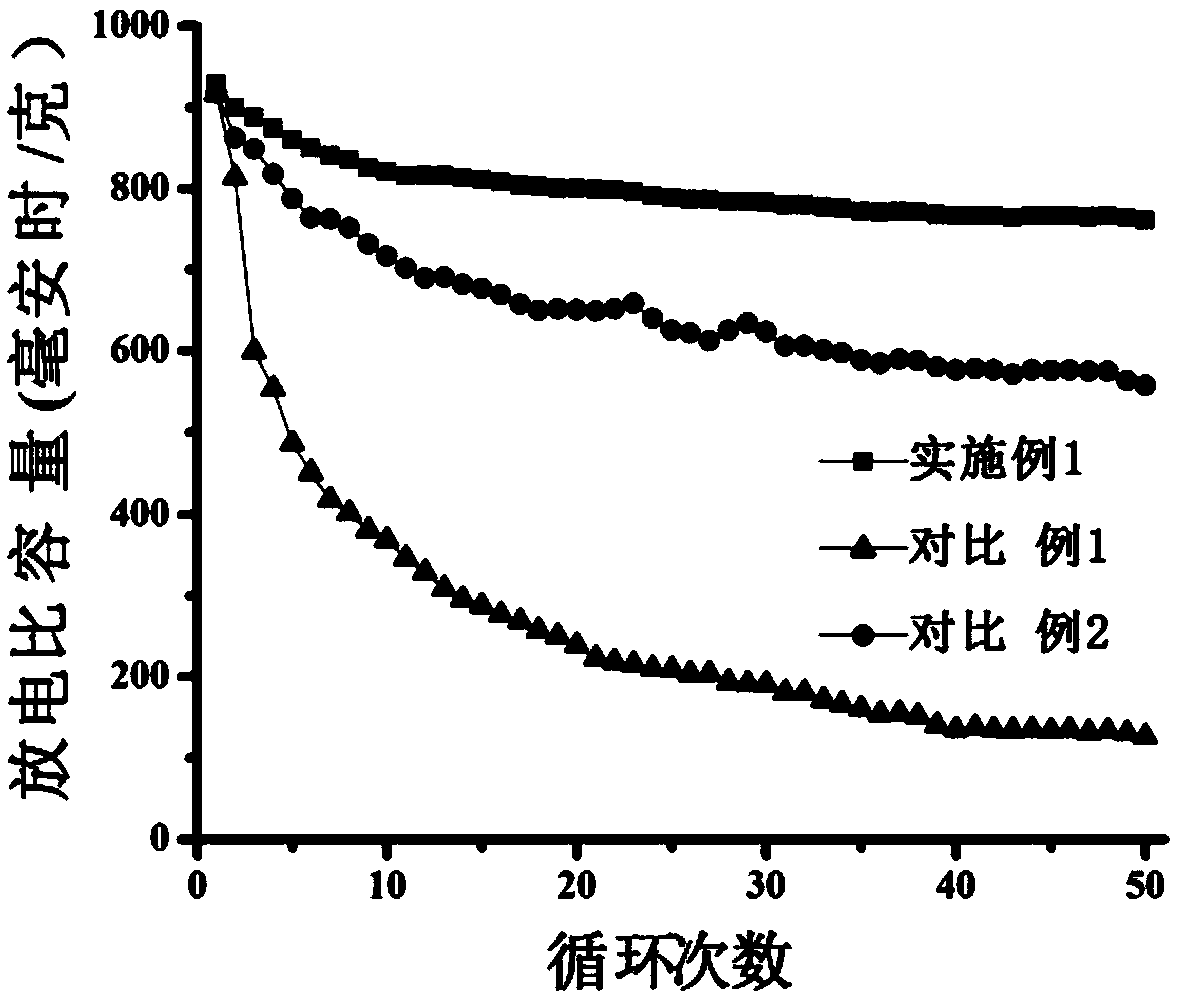

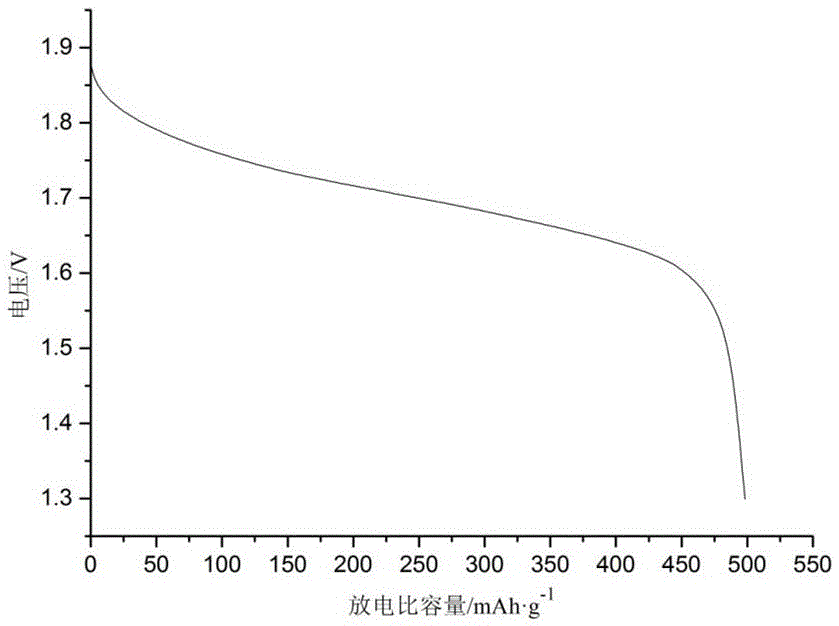

InactiveCN109411720AExcellent discharge specific capacityImprove cycle stabilityCell electrodesGrapheneIndiumCharge discharge

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery anode material and a preparation method thereof. Nickel sulfide, indium sulfideand graphene are compounded as a negative active substance, and an anode material with high charge-discharge specific capacity and good cycling performance is obtained.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

A kind of nickel-zinc battery zinc negative electrode material and its preparation method and application

ActiveCN104617268BImprove poor cycle performanceHigh charge and discharge capacityCell electrodesNickel accumulatorsWater bathsFiltration

The invention provides a zinc cathode material of a nickel-zinc battery as well as a preparation method and application of the zinc cathode material. The zinc cathode material of the nickel-zinc battery comprises ZnXnO4 and ZnO, wherein ZnXnO4 accounts for 0.5-5% of the amount of total substances of the zinc cathode material; X is Fe and / or Co; n is equal to 1 or 2. The preparation method comprises the following steps: preparing a salt solution from one or two of ferric salts and cobalt salts together with one of zinc salts, preparing a precipitant from one or two or more of sodium hydroxide, sodium carbonate, urea and ammonia water, stirring the salt solution and the precipitant, dripping into a water bath environment, performing hydrothermal reaction on the titrated mixed liquid for 8-12 hours at 100-150 DEG C, and finally performing suction filtration, washing and drying to obtain the zinc cathode material. The zinc cathode material provided by the invention can be mixed with carbon powder, polytetrafluoroethylene and carboxymethyl cellulose sodium so as to prepare the zinc negative electrode of the nickel-zinc battery. The zinc cathode material of the nickel-zinc battery is relatively high in specific capacity, and the circulation stability of the nickel-zinc battery is improved.

Owner:CHONGQING UNIV

A kind of preparation method of lithium ion battery composite material with double shell structure

ActiveCN113097467BExcellent discharge specific capacityImprove cycle stabilityCell electrodesSecondary cellsAir atmosphereCopper nitrate

The invention discloses a preparation method of a lithium ion battery composite material with a double-shell structure, which comprises adding cobalt nitrate hexahydrate into N,N-dimethylformamide, and then dissolving by ultrasonic to obtain a solution I, and then adding 2,5-dihydroxyterephthalic acid was added to the absolute ethanol solution, and ultrasonically dissolved to obtain solution II. After the solutions I and II were mixed and stirred, distilled water was added and then moved to a polytetrafluoroethylene reaction kettle. React at ℃ for 24-30 h, and cool to obtain metal-organic framework Co-MOF-74, adding copper nitrate trihydrate to methanol solution, ultrasonically dissolving, adding metal-organic framework Co-MOF-74 in step S1, magnetically at room temperature Stir for 3 to 6 hours, then add citric acid to sonicate, move to a polytetrafluoroethylene reactor, react at 60 to 80 °C for 3 to 5 hours, cool, filter, and dry; place the dried product in a tube furnace, In an air atmosphere, the temperature is raised to 580-520°C at a heating rate of 5-8°C / min, maintained at this temperature for 4-7 hours, and then brought to room temperature at a rate of 0.5-1.2°C / min to obtain the composite material.

Owner:深圳中芯能科技有限公司

Preparation method of high-capacity and high-stability lithium ion battery negative electrode material

ActiveCN113135565AIncrease spacingExcellent discharge specific capacityGraphiteCell electrodesPotassium peroxidePhysical chemistry

The invention discloses a preparation method of a high-capacity and high-stability lithium ion battery negative electrode material, which comprises the following steps: carrying out heat treatment on petroleum coke at 300-350 DEG C for 3-6 hours, then carrying out grinding treatment, and keeping the particle size of the ground powder at 5-10 microns to obtain a product for later use; s2, mixing the product in the step S1 with sodium peroxide or potassium peroxide, stirring for 0.5-2 hours at room temperature, adding distilled water, reacting for 2-4 hours, drying the solid, adding into a tubular furnace, and performing secondary heat treatment for 10-15 hours at the temperature of 700-800 DEG C under the air condition for later use; and graphitizing the product obtained in the step S2, graphitizing and calcining the product for 15-20 hours under the atmospheric condition of 2500-3000 DEG C, cooling, grinding, controlling the particle size of the product to be 3-6 microns, mixing the product meeting the particle size requirement with sodium peroxide or potassium peroxide according to the mass ratio of 1: (0.02-0.03), dropwise adding distilled water until the product is viscous, stirring, standing for 0.5-2 hours, and drying to obtain the negative electrode material.

Owner:青岛龙迪碳材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com