Method for preparing high-energy density disposable battery anode material

A technology with high energy density and positive electrode of battery, applied in the direction of primary battery electrode, battery electrode, non-aqueous electrolyte battery, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The first step is to prepare carbon fluoride-sulfur composite cathode material:

[0026] Weigh the carbon fluoride powder and the elemental nano-sulfur powder according to the mass ratio of 1:1, put the two into an agate mortar, and fully grind them for 30 minutes, so that the two are evenly mixed. Then move the agate mortar to the fume hood, add CS dropwise in proportion 2 solvent, then milled, after 3 drop-grinding processes, CS 2 After volatilization, until no yellow-white elemental sulfur powder is precipitated in the material (add 1mL CS for every 0.2g sulfur powder in total) 2 solution), and then put it into the polytetrafluoroethylene reactor liner (this process is carried out in an argon atmosphere glove box to ensure that the reactor liner is filled with rare gas argon), and then the reactor is transferred to a constant temperature oven, Sulfur is added by hot melting method, that is, heated at 155°C for 12 hours. After cooling to room temperature, the carbo...

Embodiment 2

[0033] Others are the same as in Example 1, except that the mass ratio of carbon fluoride powder and elemental nano-sulfur powder in the first step is 1:1.5.

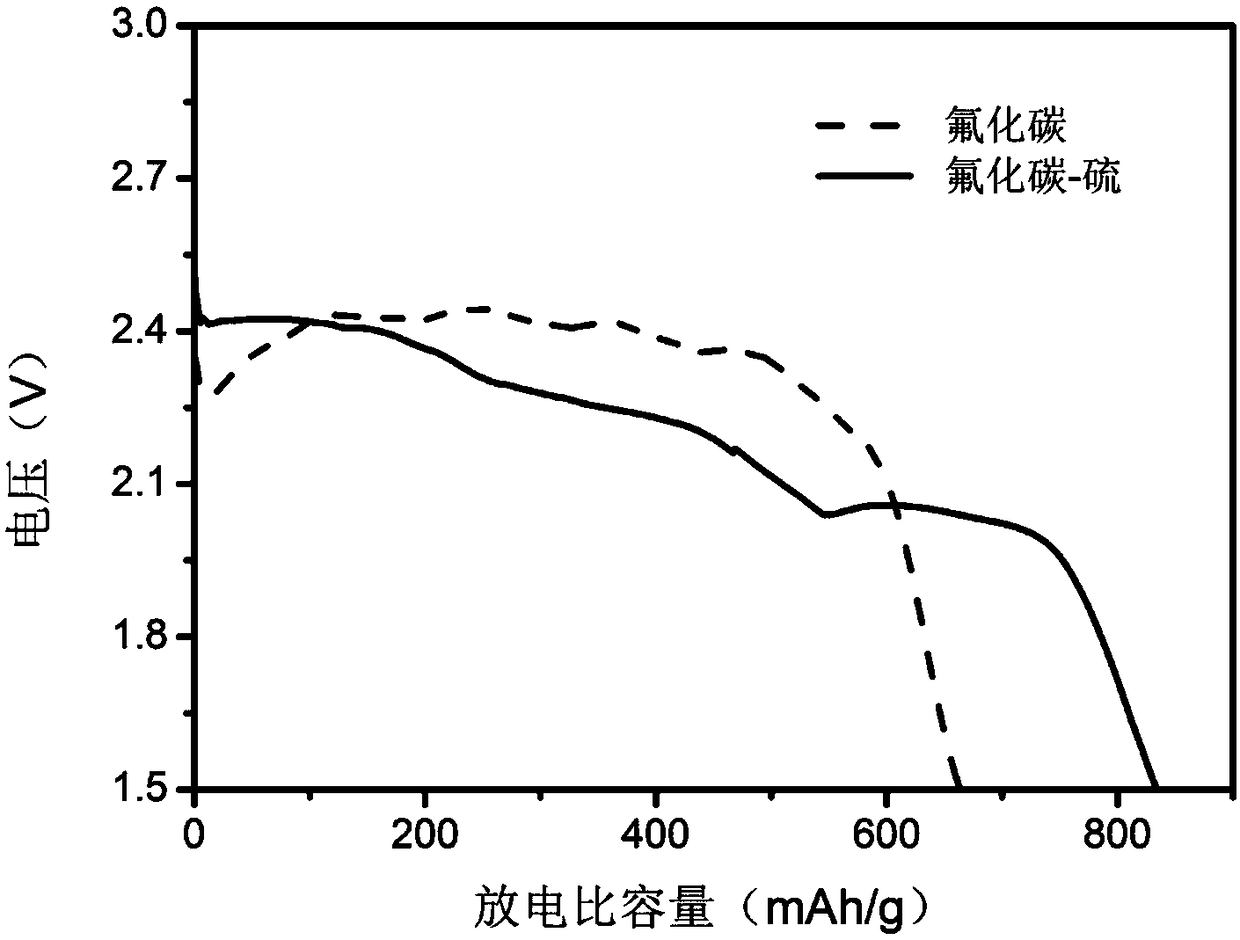

[0034] Electrical performance test: Xinwei BTS-2000 is used as the test equipment, and the test is carried out at a constant room temperature (25°C). Set the constant current discharge cut-off voltage to 1.5V, and the current density to 100mA / g. It can be seen from the figure that the discharge specific capacity of the primary lithium battery prepared in the present invention can reach 833.9mAh / g, and its comparative data is a lithium-carbon fluoride primary battery that adopts the same electrolyte and battery assembly process, and its discharge specific capacity Only 663.3mAh / g. It can be seen that the carbon fluoride-sulfur primary battery prepared by the present invention has a higher discharge specific capacity within the same discharge voltage range.

Embodiment 3

[0036] Others are the same as in Example 1, except that the mass ratio of carbon fluoride powder and elemental nano-sulfur powder in the first step is 1:2. The discharge specific capacity of the obtained primary battery can reach 779.3mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com