Preparation method of a controllable porous ceramic/polymer matrix composite bone scaffold

A bone scaffold and polymer technology, applied in the field of bionic manufacturing science, can solve the problem that the bone scaffold cannot meet the requirements of tissue engineering, and achieve the effect of overcoming the uncontrollable and random channel structure, wide application range, and improving biological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is set forth below by an example:

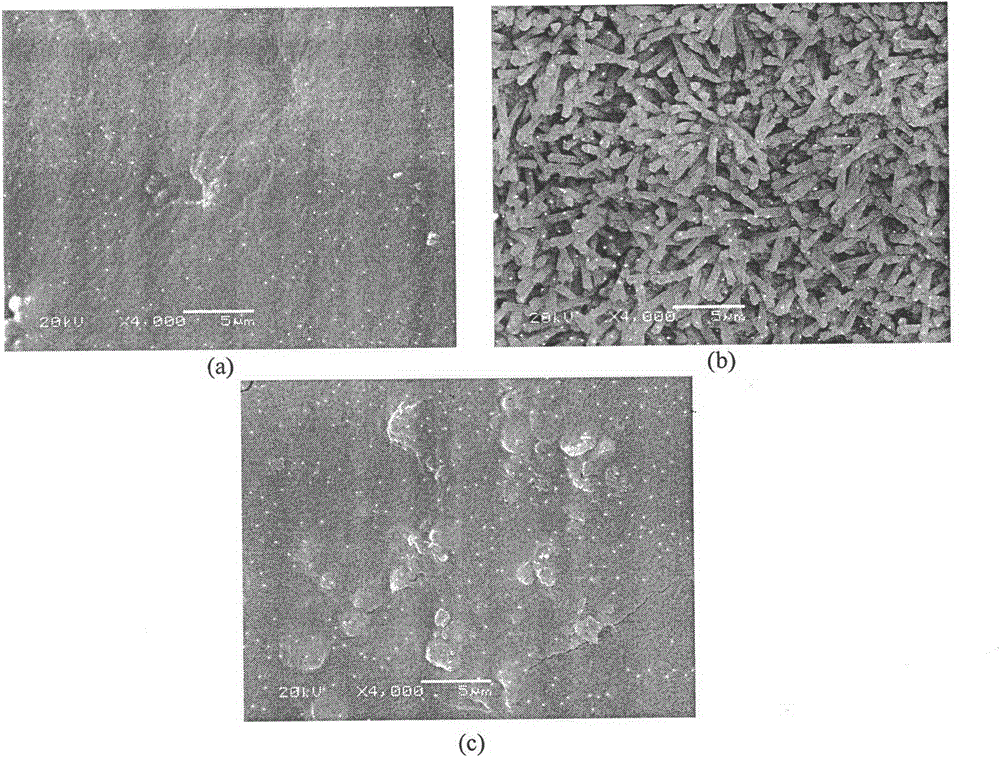

[0020] Polyvinyl alcohol powder and calcium silicate ceramic powder are used as raw materials, among which polyvinyl alcohol is purchased from Japan Synthetic Chemical Company, the average molecular modulus is 89000-98000g / mol, the degree of polymerization is 1700, and the particle size is 20-200μm; silicic acid Calcium was purchased from Kunshan Huaqiao Technology New Material Co., Ltd., with an average particle size of 1 μm and a purity of 98%. It was prepared by chemical precipitation.

[0021] A homogeneously mixed polyvinyl alcohol / calcium silicate composite powder was obtained after grinding for 1 h by mechanical mixing, wherein the mass fraction of calcium silicate was 10 wt%.

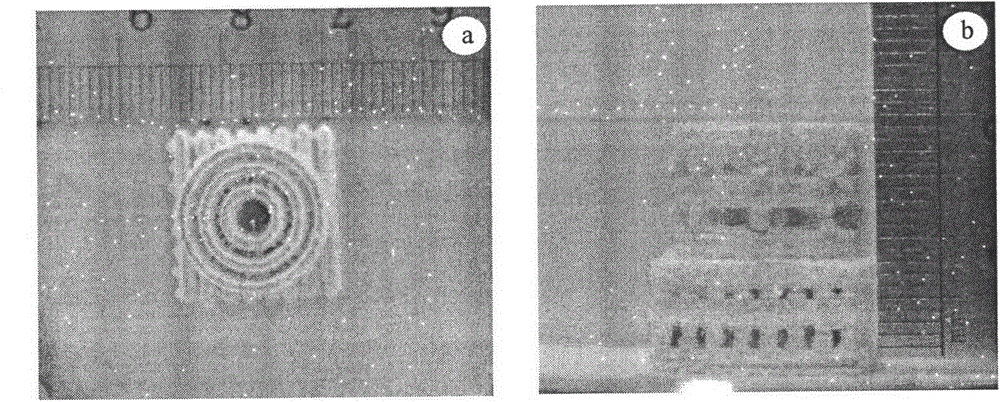

[0022] Using the self-developed selective laser sintering system, the selective laser sintering of polyvinyl alcohol / calcium silicate mixed powder is carried out under the process conditions of laser powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com