Patents

Literature

162results about How to "Change chemical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

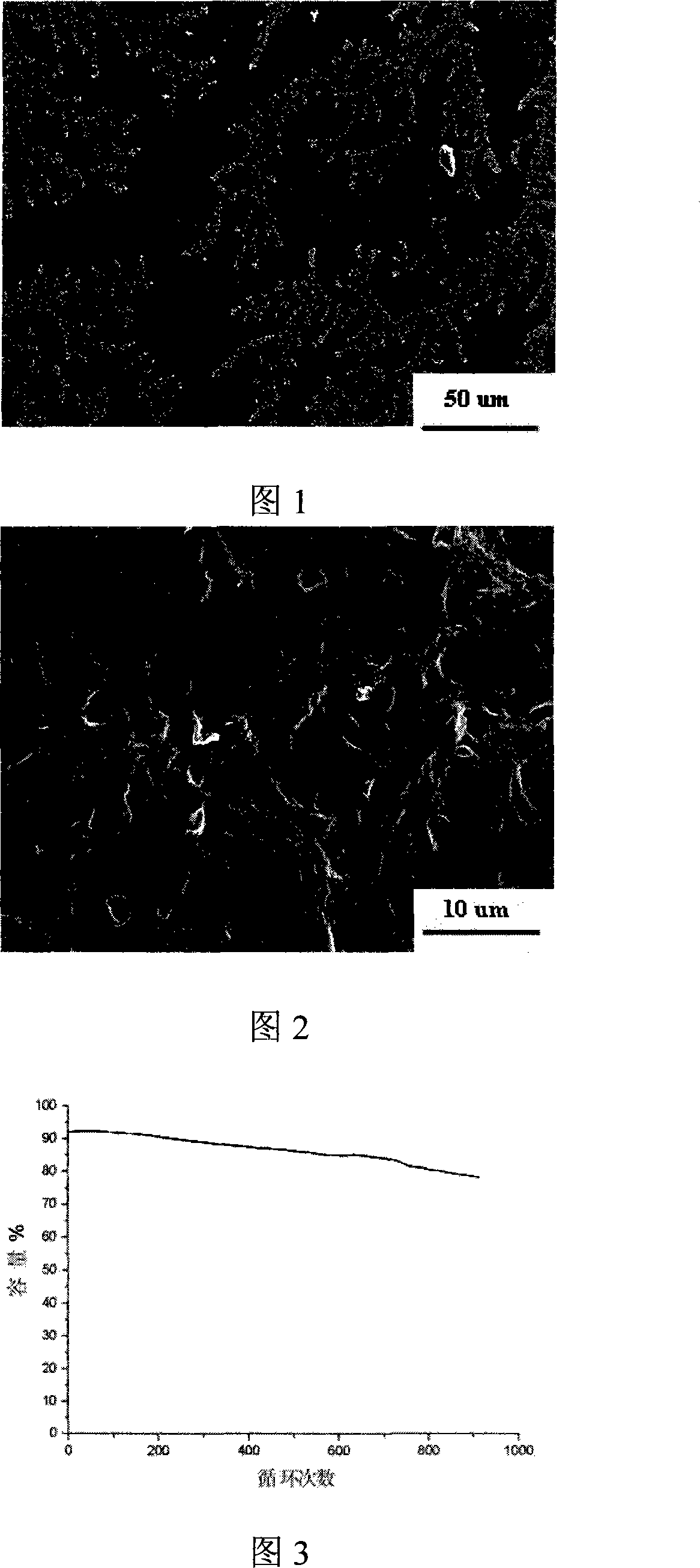

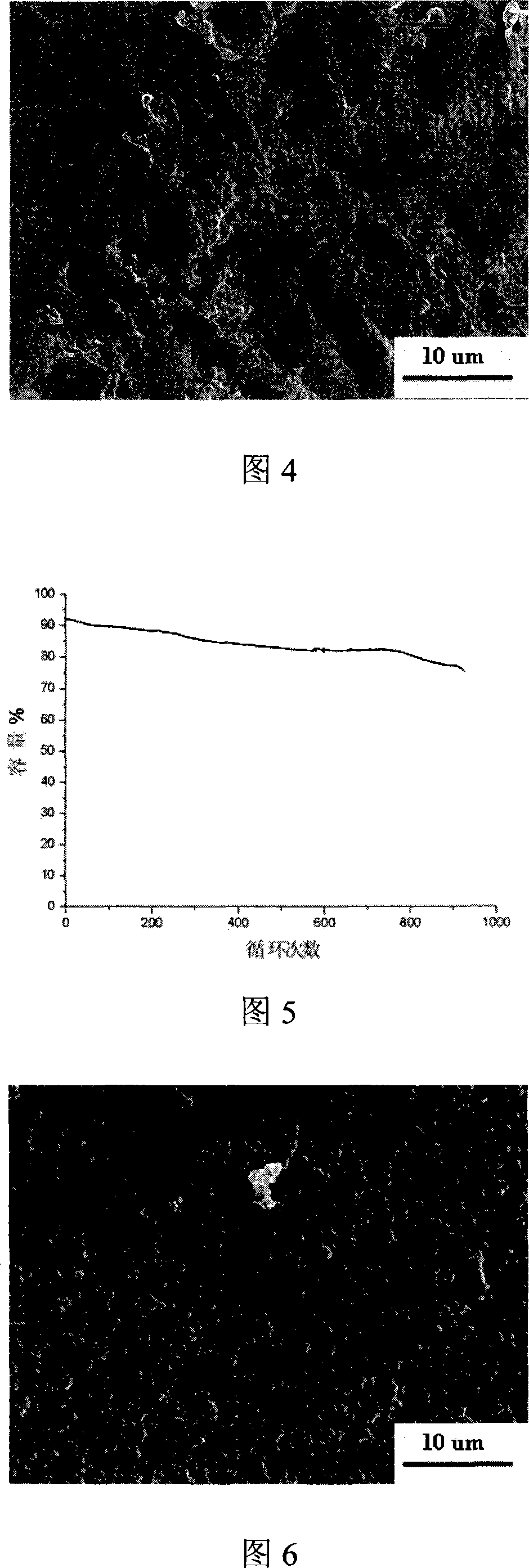

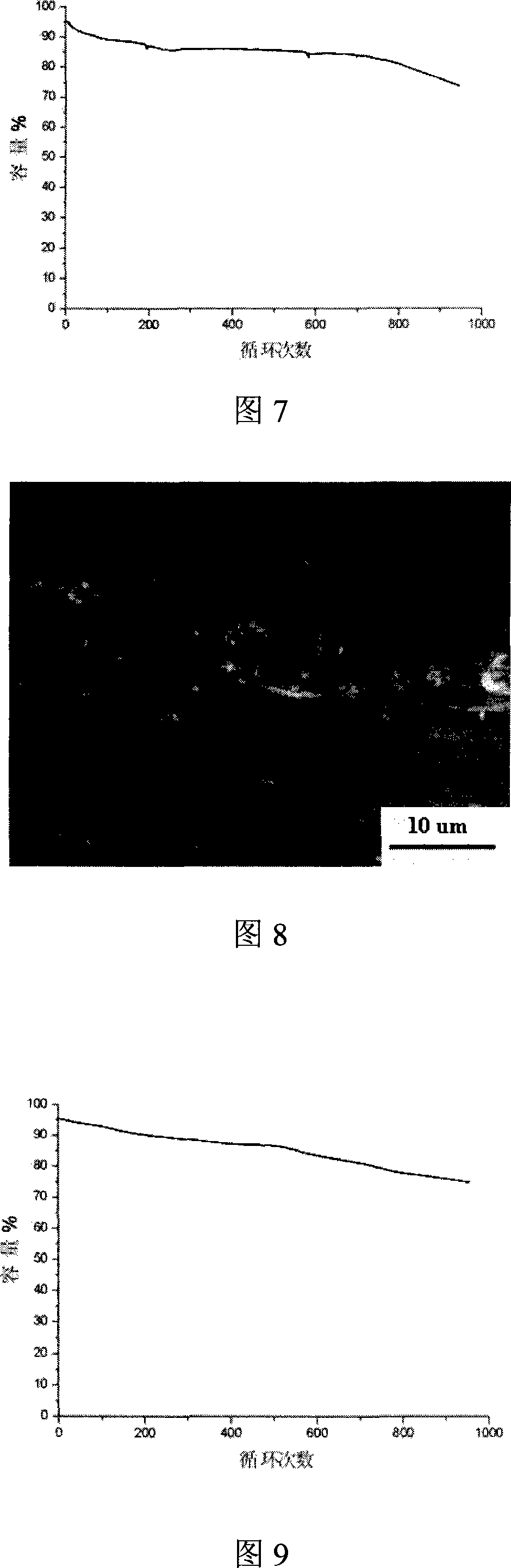

Lithium titanate composite electrode material with surface coating layer

InactiveCN101764209AChange physical propertiesChange chemical propertiesCell electrodesMagnesium phosphateMagnesium orthophosphate

The invention relates to a battery electrode material, in particular to a lithium titanate composite electrode material with surface coating layer; in the lithium titanate composite electrode material with surface coating layer, the electrode material is composed of lithium titanate particles and a coating layer coated with the surface of the lithium titanate particles; the particle size of the lithium titanate particles is 100nm-95mum, the average thickness of the surface coating layer is 0.2nm-5m, and the particle diameter of the composite electrode material is 0.1-100mum; the material of the surface coating layer is one or mixture of more than one kind of insulation oxide, insulation composite oxide, aluminium phosphate, magnesium phosphate, lithium fluoride, lithium phosphate or LiMPO4, wherein M is magnesium, ferrum, cobalt, nickel, chromium, titanium or vanadium; in the invention, by carrying out surface coating treatment to the surfaces of the existing lithium titanate particles, a layer of protective film is formed on the surface, so as to change the physical and chemical characteristics of the surface of the lithium titanate active material, the surface can not be reacted with electrolyte even if under overpotential condition, so as to avoid ballooning and ensure the capacity and the circularity of the battery not to be reduced.

Owner:SUZHOU PHYLION BATTERY

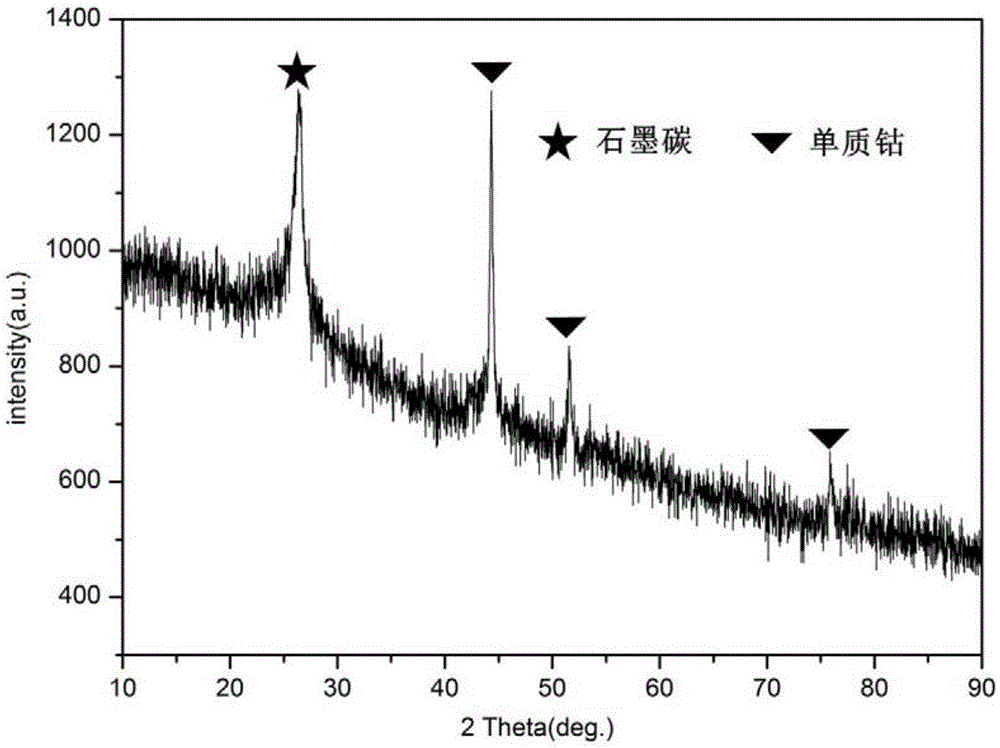

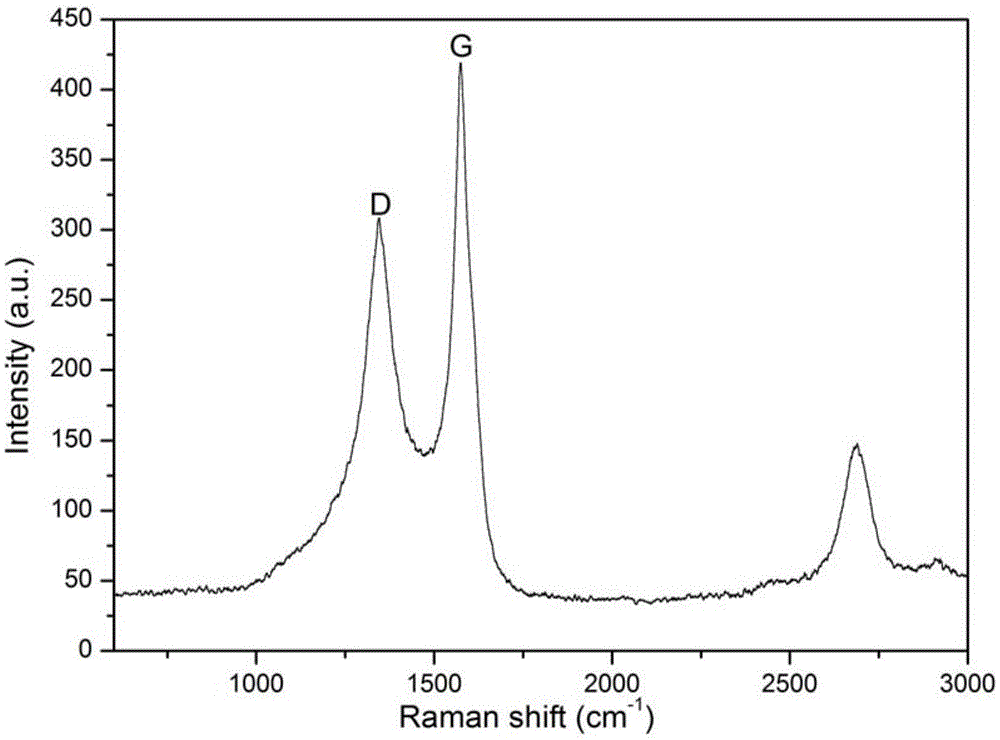

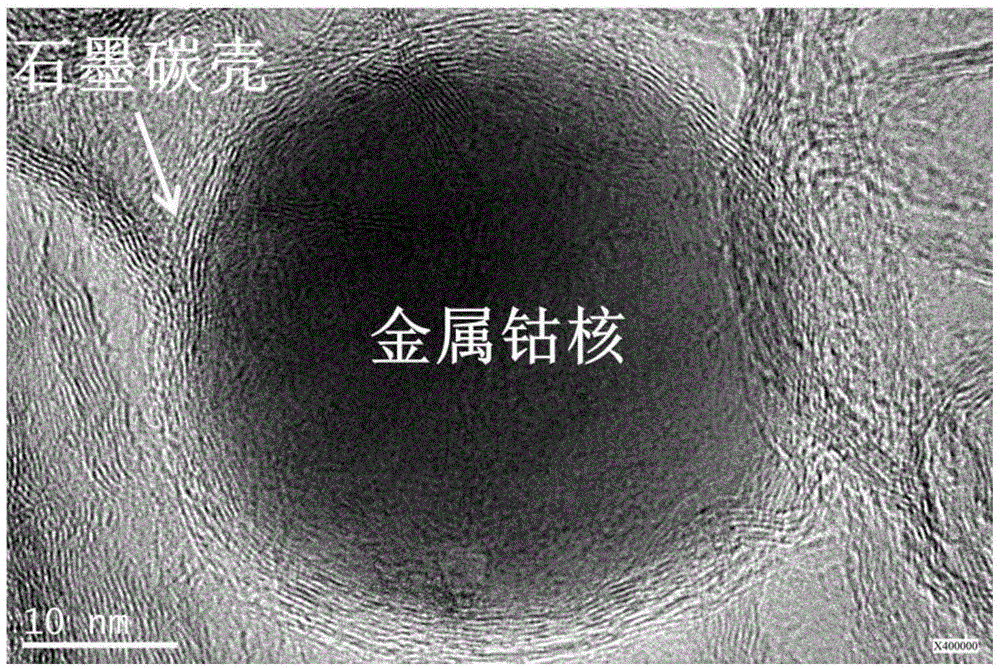

Method for preparing non-metallic element doped carbon coated metal nanoparticle magnetic composite

ActiveCN105478755AGood dispersionHigh purityTransportation and packagingMetal-working apparatusDispersityCyanamide compound

The invention discloses a method for preparing a non-metallic element doped carbon coated metal nanoparticle magnetic composite. The method comprises the steps that water-soluble metal divalent salt, a cyanamide compound and a nitrogen or boron or sulfur containing non-metallic compound are added into a methanol solution to be mixed, dissolved, dried and ground, and obtained homogeneous-phase powder is subjected to roasting pyrolysis under the protection of inert gas; and a pyrolysis product is subjected to acid pickling, washing, drying and grinding, and a target product is obtained. According to the whole preparing process of the method, metal ion reduction, metal nanoparticle coating and doping of nitrogen / boron / sulfur and other non-metallic elements are achieved in one step. The composite prepared through the method is high in degree of graphitization, good in dispersity between particles and high in purity, and the preparing method has the advantages that the cost is low, the process is simple, and large-quantity synthesis can be easily achieved.

Owner:合肥庐阳科技创新集团有限公司

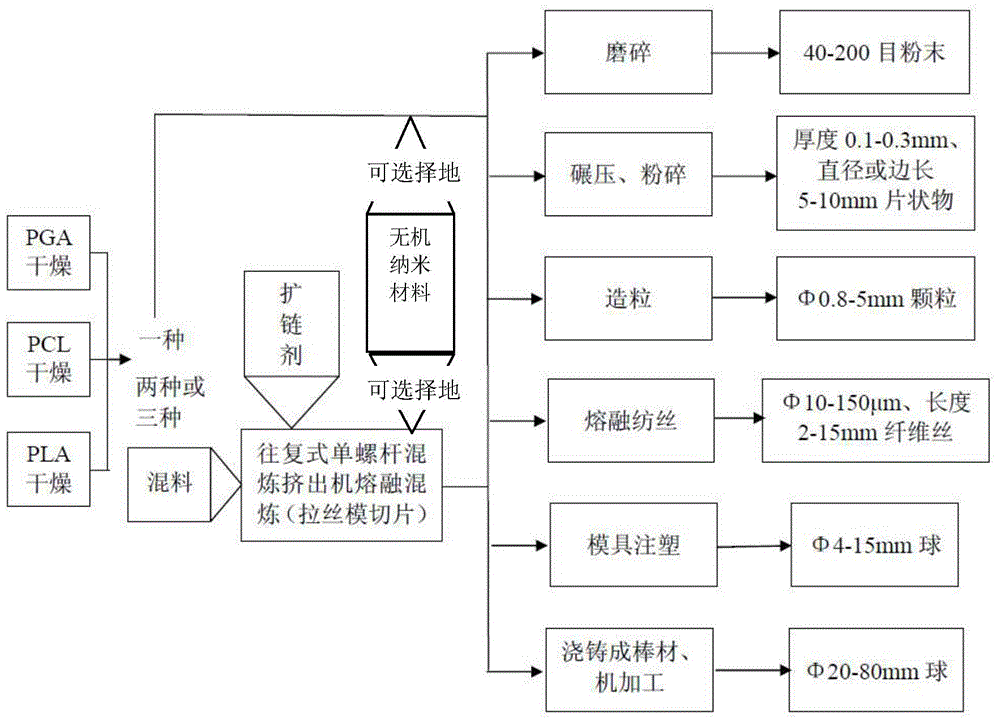

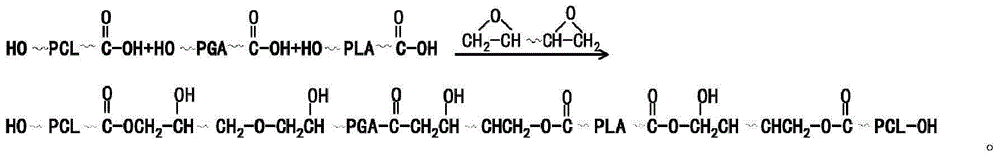

Biodegradable resin material applied to oil and gas fields and preparation method for biodegradable resin material

InactiveCN104987682ANew mechanical propertiesChange mechanical propertiesDrilling compositionWell drillingAlloy

The invention provides a biodegradable resin material applied to oil and gas fields and a preparation method for the biodegradable resin material. According to the preparation method for the biodegradable resin material applied to the oil and gas fields, two or three polymers of polyglycolic-colactic acid, polycaprolactone and polylactic acid and a chain extender are subject to melt mixing reaction to obtain a resin alloy, namely the biodegradable resin material applied to the oil and gas fields. The biodegradable resin material applied to the oil and gas fields is prepared from the method, can be prepared into the shapes of sheets, powder, granules, spheres and the like, or can be prepared into the shapes of the sheets, the powder, the granules, the spheres and the like by one of the polyglycolic-colactic acid, the polycaprolactone and the polylactic acid, is used for temporarily blocking filtrate to protect a reservoir, temporarily blocking a blast hole, a constructed layer section and the like in various construction (well drilling, well completing, well repairing, and acidizing and fracturing) operations of the oil and gas fields, and has the advantages of complete degradation and zero damage to stratum.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Anionic abrasive particles treated with positively charged polyelectrolytes for cmp

InactiveCN1630697AIncrease speedIdeal planarization efficiencyOther chemical processesSemiconductor/solid-state device manufacturingPolyelectrolytePolymer science

The invention provides chemical-mechanical polishing systems, and methods of polishing a substrate using the polishing systems, comprising (a) an abrasive, (b) a liquid carrier, and (c) a positively charged polyelectrolyte with a molecular weight of about 15,000 or more, wherein the abrasive comprises particles that are electrostatically associated with the positively charged polyelectrolyte.

Owner:CMC MATERIALS INC

Organic-inorganic improvement fertilizer for saline-alkali soil and preparation method thereof

InactiveCN105906442AStrong cation exchange capacityImprove soil physical and chemical propertiesCalcareous fertilisersExcrement fertilisersIon exchangeHumic acid

The invention discloses an organic-inorganic improvement fertilizer for saline-alkali soil and a preparation method thereof. The organic-inorganic improvement fertilizer is prepared from, 20-30 parts of bentonite, 20-30 parts of zeolite, 20-30 parts of flue gas desulfurization gypsum, 10-20 parts of dehydrated sludge, 20-30 parts of humic acid, 10-20 parts of coal ash, 20-30 parts of ardealite, 10-20 parts of peat, 10-20 parts of straw meal, 10-20 parts of animal waste, 2-8 parts of microbial inoculation bacteria and 2-5 parts of emulsified asphalt. The invention further provides a preparation method of the organic-inorganic improvement fertilizer for saline-alkali soil. According to the organic-inorganic improvement fertilizer, the physicochemical character of soil can be improved, soil permeability and moisture and fertilizer preservation can be improved, the soil ion exchange rate can be improved, the PH value can be buffered, the chemical fertilizer consumption can be reduced, the crop yield can be improved, the product quality can be improved, the soil improvement effect can be improved, and the soil improvement cycle can be shortened.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Method for treating container washing wastewater

InactiveCN101708935AReduce suspended solidsSave waterFatty/oily/floating substances removal devicesTreatment with anaerobic digestion processesOil separationReclaimed water

The invention relates to a method for treating container washing wastewater, comprising the pretreatment, physical and chemical treatment, biochemical treatment and advanced treatment, wherein the pretreatment comprises the step of filtering suspended matter and oil slick out by an oil separation tank and a collected water regulating reservoir so as to homogenize water quality and water quantity; the physical and chemical treatment comprises the step of removing oil substances and COD by an air flotation device; the biochemical treatment comprises the step of removing hazardous and noxious substances by an AF anaerobic filter chamber and an SBR reaction tank; and the advanced treatment comprises the steps of degrading organic matters and sterilizing by a moving bed biomembrane reactor and an ozone catalyzing oxidation pond, wherein the treated wastewater serves as washing water after reaching normal water reuse standards. The invention not only treats the container washing wastewater containing oil, poisonous substances and organic hazardous chemicals into clear water meeting the national discharging standards and discharging standards in Tianjin, but also reduces the content of the suspended matters and oils, and saves water resources because the clear water after being treated can serve as the reuse clear water.

Owner:TIANJIN TANGGU XINYU ENVIRONMENTAL PROTECTION TECH

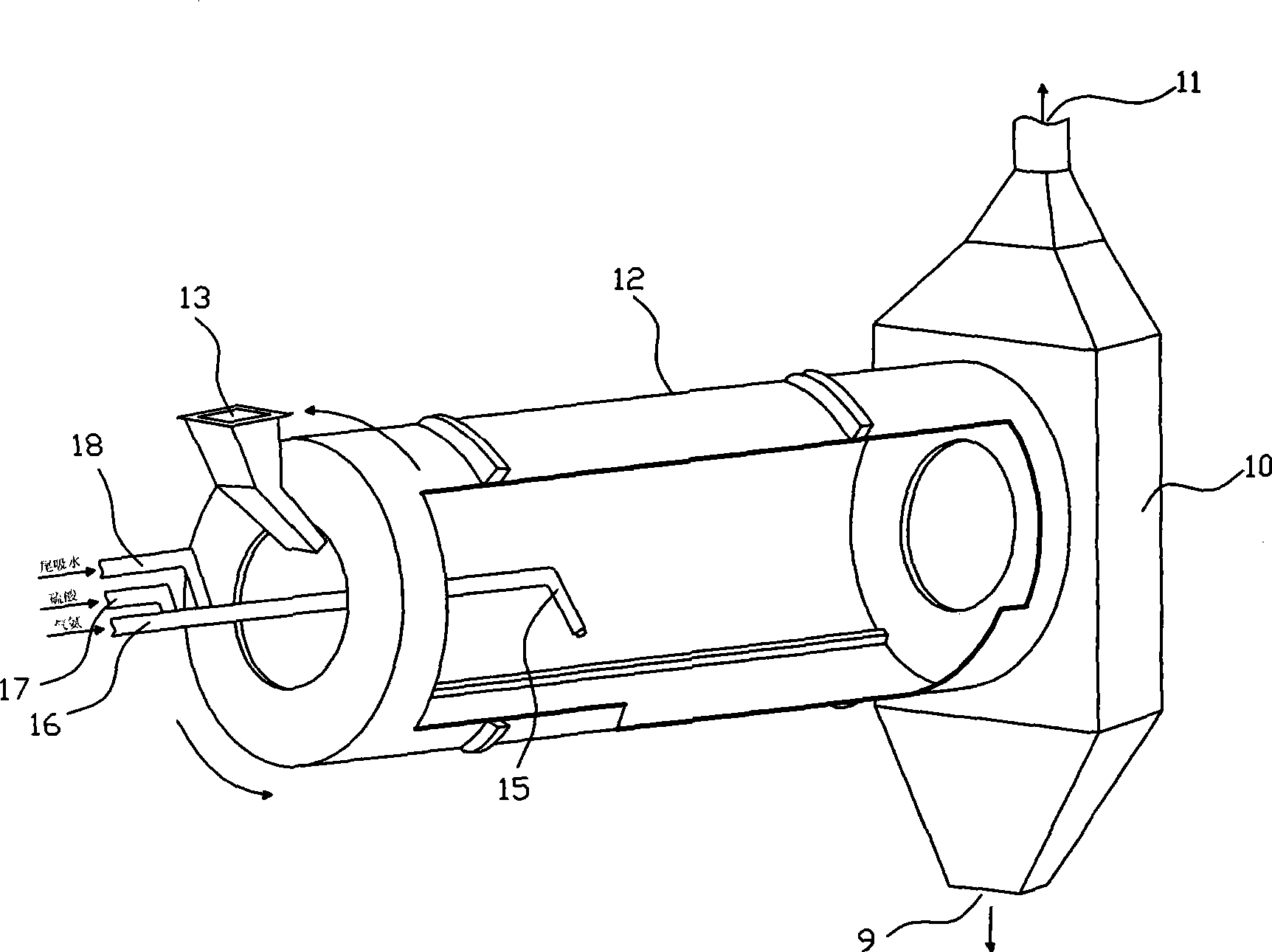

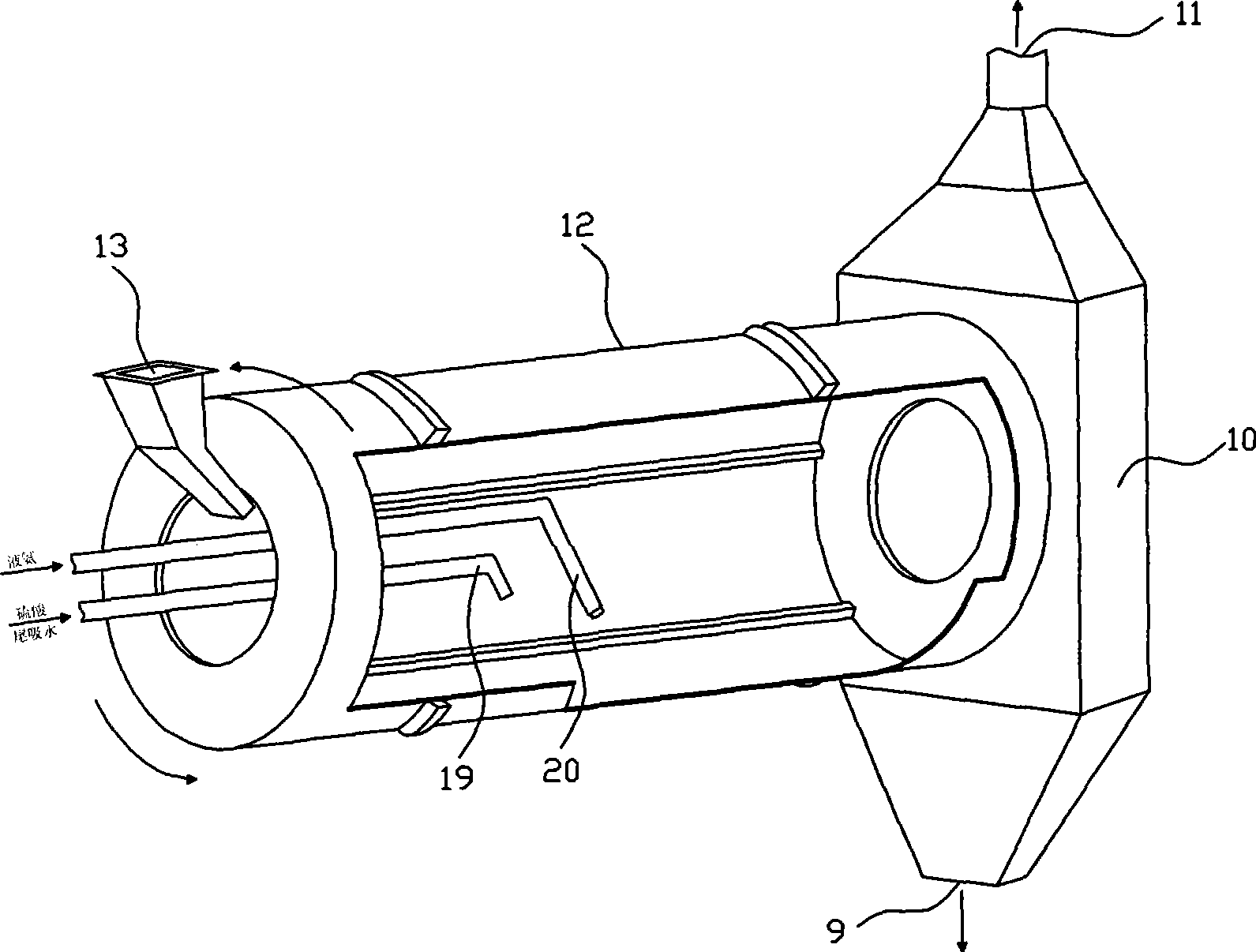

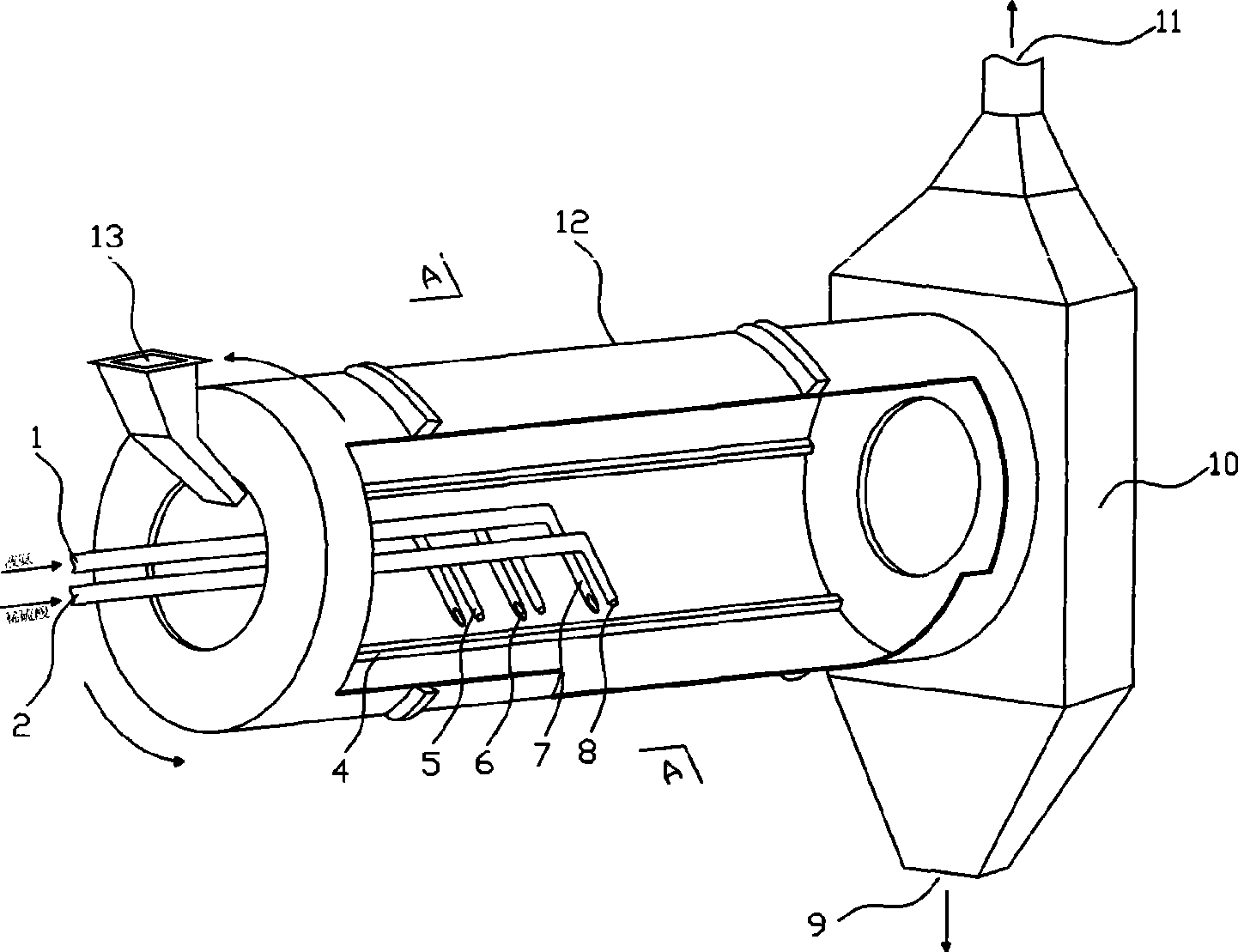

Ammoniation granulator and composite fertilizer production novel technique

InactiveCN101391934AEasy to adjustIncrease elasticityFertiliser formsFertilizer mixturesSolid particleWater resistant

The invention relates to an ammoniation granulator and a compound fertilizer production technology by an amino acid method, aiming at solving the technical problems in the compound fertilizer production process that: biuret is easy to generate, the granulating effect is not good, the production efficiency is low and the energy consumption is high. An amino acid distributor of the ammoniation granulator is respectively and independently arranged, an amino spraying branch pipe provided with an inclined plane spout has an angle of 30 to 60 degrees with a vertical line on the cross section of a cylinder, the rotating directions of the inclined plane spout and the cylinder are consistent; the spout of an acid spraying branch pipe is correspondingly arranged in the opening direction of the inclined spout of the amino spraying branch pipe; and when ammoniation granulating, the granulator sprays liquid ammonia in a material layer with the pressure of 0.5 to 1.0MPa through the amino distributor, an acid distributor sprays sulphuric acid of 50 to 70 percent in the material layer with the pressure of 0.2 to 0.5Mpa, and each ton of solid material is injected with 15 to 25kg of liquid ammonia and 16.8 to 39.2kg of dilute sulphuric acid. The invention is applied in various raw materials and suitable for the scale production of various compound fertilizers; and the finished products have perfectly round and solid particles, are water resistant and movement resistant and not easy to be crushed and agglomerated.

Owner:JIANGSU ABOLUO COMPOUND FERTILIZER

Nano coating of negative electrode materials and preparation method of secondary aluminium cell using negative electrode materials

InactiveCN101662022AIncrease energy densityRich in aluminum resourcesElectrode manufacturing processesSecondary cellsSemimetalHigh energy

The invention discloses a novel high-energy secondary aluminium cell and a preparation method. The aim is to provide a method for preparing nano material-coated negative electrode active materials, by coating the negative electrode active materials with the nano materials, it is possible to subject the negative electrode active materials to nano treatment; therefore, the high-energy secondary aluminium cell features obviously improved properties, simple material composition, low cost, simple technology, environmentally friendly synthesis path, relatively high charge-discharge capacity and relatively good cycle property and market prospect. The aluminium cell comprises the positive and negative electrodes in the modified positive and negative electrode active materials coated by the nano material surfaces or any one electrode in the singly coated positive or negative electrode active materials, polyelectrolyte (ionic liquid) and a diaphragm. The coating materials are semimetals, oxides, salts or conductive polymers. The invention uses the nano materials in the secondary aluminium cell for the first time; therefore, the cell has higher open circuit voltage and reversible capacity and better cycle property, can be applied to such fields as portable power sources like mobile telephones, notebooks and portable electronic components, and as electric vehicles, hybrid electric vehicles and the like, and has broad application and development prospects.

Owner:无锡欧力达新能源电力科技有限公司

Immobilized biological additive and its preparation method and uses

ActiveCN1593268AImprove qualityReduce spreadTobacco treatmentSurface-active agentsProcess conditions

Disclosed is a cigarette use biological addition agent and use thereof, wherein the biological enzyme comprises degraded proteinase, amylase, pectic enzyme, polysaccharide degraded enzyme, cellulose, surface active agent, enzyme activating agent, wall material, emulsifying agent, and cushioning liquid. The preparing process comprises the steps of agitating, immobilizing, and utilizing addition agent.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

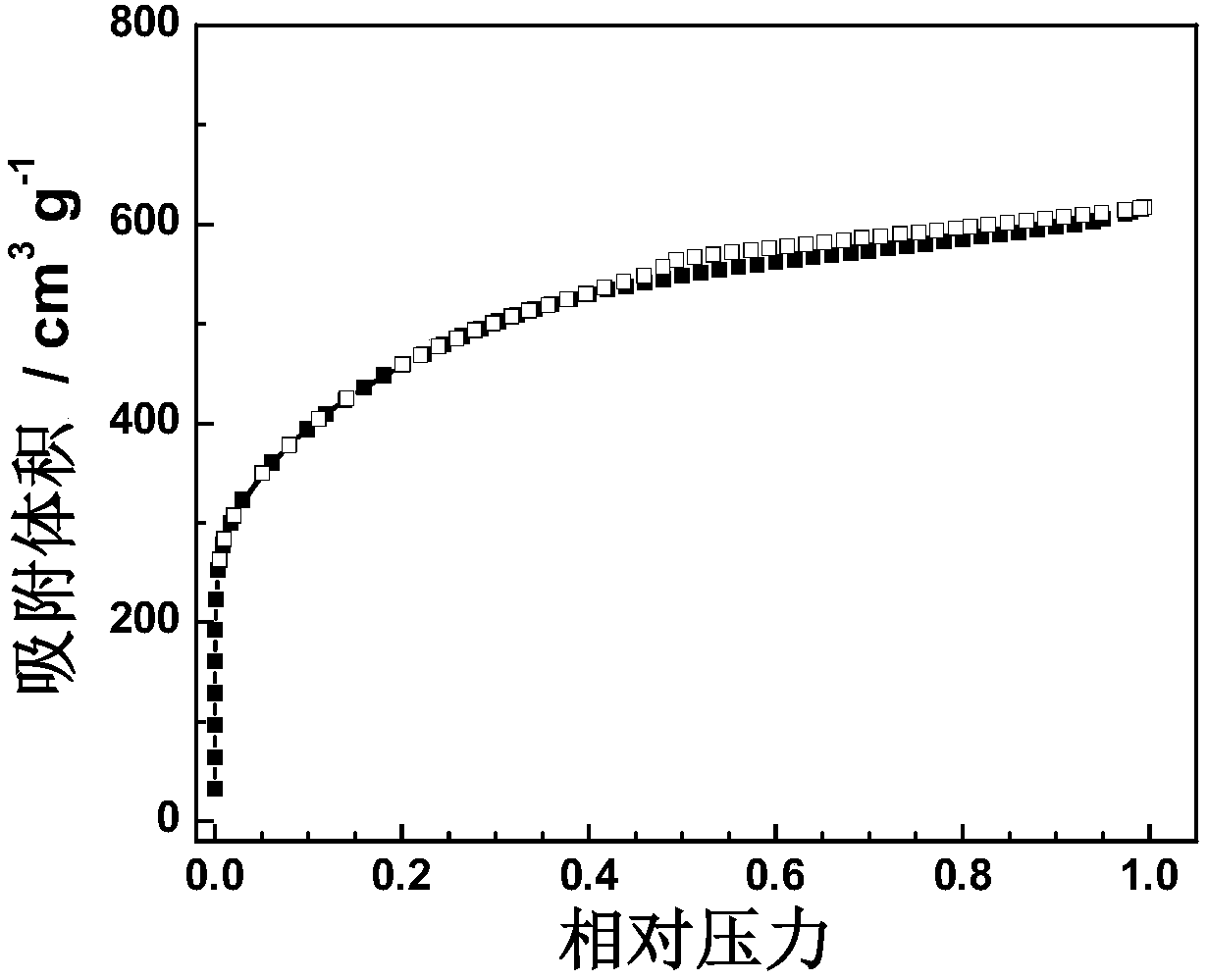

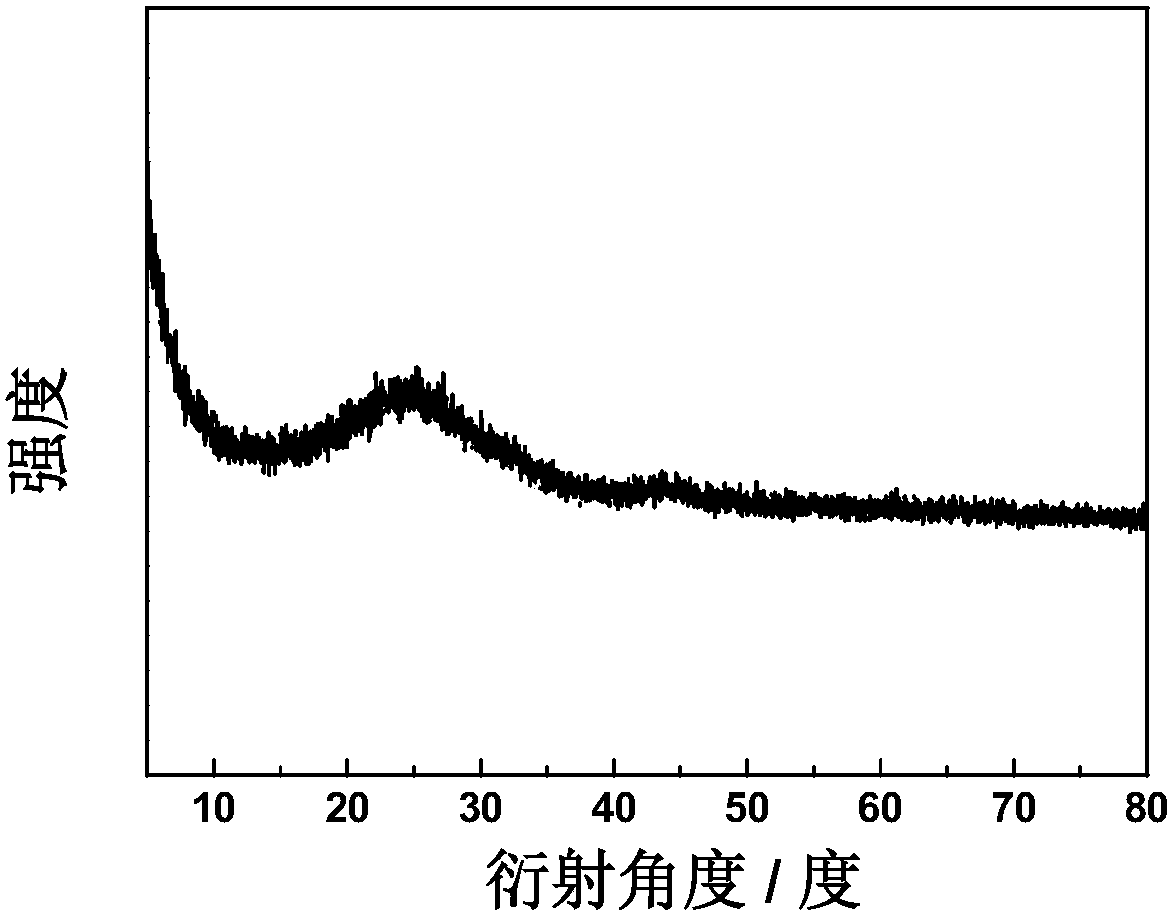

Doped carbon aerogel material as well as preparation method and application thereof

ActiveCN108238596ALarge specific surface areaLarge apertureGas treatmentMethane captureSulfurHeteroatom

The present invention provides a doped carbon aerogel material. The doped carbon aerogel material has a porous structure, a heteroatom is doped in the doped carbon aerogel material, the heteroatom isone or more of a nitrogen heteroatom, a sulfur heteroatom, and a phosphorus heteroatom, and the doped carbon aerogel material has a specific surface area of 1000-3000m<2> / g. The present invention alsoprovides a preparation method and application of the doped carbon aerogel material. The doped carbon aerogel material provided by the present invention has the characteristics of a large specific surface area, a wide pore size and the like, and the doped carbon aerogel material has the high specific surface area, a large pore volume, a three-dimensional porous structure, and excellent gas-adsorbing performance and electrochemical properties. Tests show that the material provided by the present invention has an adsorption capacity of 50-300mg / g at the condition of 273K and 1.0 bar; and a capacitor prepared from the material has an electrochemical capacitance of 50-250F / g at a current density of 0.1-10A / g.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

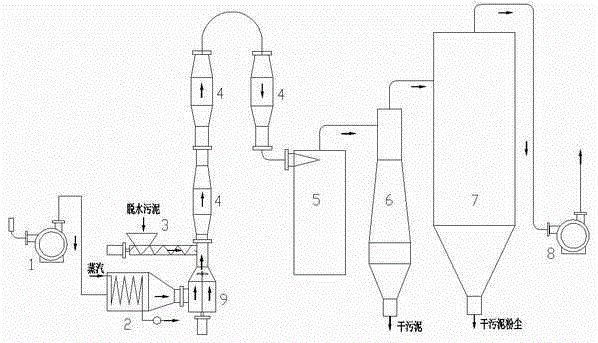

Novel sludge drying processing device

InactiveCN105399301AWith heat treatment effectLevel of inhibition of microbial activitySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFertilizerBuilding material

The invention discloses a novel sludge drying processing device, and belongs to the technical field of environmental protection equipment. The novel sludge drying processing device comprises a feeding machine, an air blower, an air heater, a diffuser, air flow dryers, a cyclone dryer, a cyclone separator, a dust remover, and an induced draft fan; air is heated by the air heater to a temperature higher than 100 DEG C, is delivered into the diffuser, and is mixed with dewatered sludge so as to obtain a hot air sludge flow, wherein water content of the dewatered sludge is controlled to be 80%, and the dewatered sludge is delivered into the diffuser via the feeding machine, and is smashed using the diffuser; sludge in the hot air sludge flow is dried using the air flow dryers and the cyclone dryer, dried air sludge flow is delivered into the cyclone separator so as to obtain dried sludge with a water content less than 5% via separation; hot air and dried sludge dust are delivered into the dust remover; and dried sludge dust is discharged via the bottom of the dust remover. The novel sludge drying processing device is used for processing sludge using a man-made heat source, deep dewatering is realized, thermal treatment effect is achieved, the activity of microorganisms in sludge are inhibited, and the obtained dried sludge can be taken as fertilizers, building materials, and the like.

Owner:大连大孤山污水处理有限公司

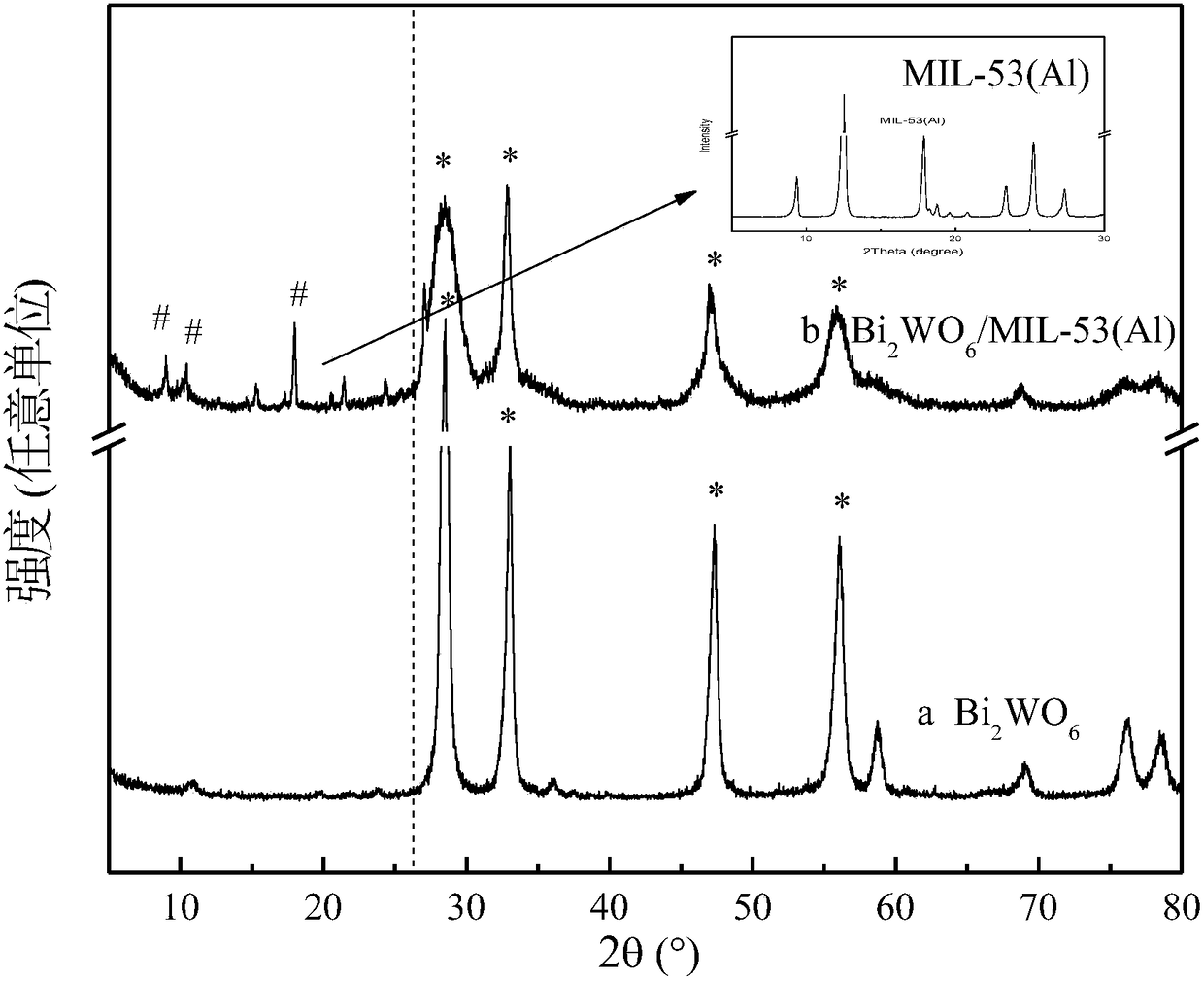

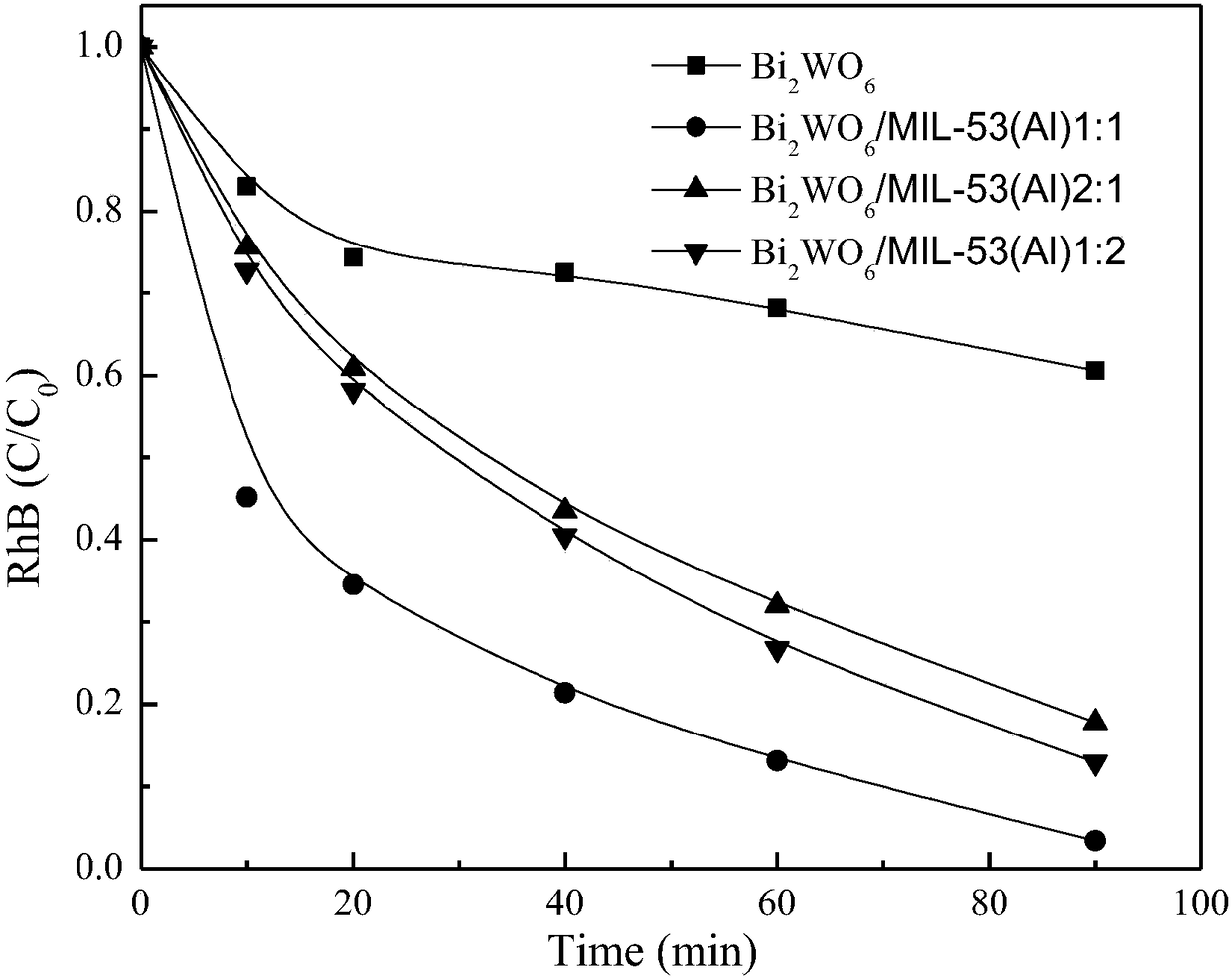

Bismuth tungstate-MIL-53 (Al) composite material and preparation method and application thereof

ActiveCN108126756AImprove stabilityEasy to useWater/sewage treatment by irradiationWater treatment compoundsTungstateMetal-organic framework

The invention discloses a bismuth tungstate-MIL-53 (Al) composite material and a preparation method and application thereof. The preparation method comprises adding a metal-organic framework materialMIL-53 (Al) into a metal salt solution for Bi2WO6 synthesis, carrying out full stirring, adjusting pH through a NaOH solution and preparing a loaded visible photocatalyst Bi2WO6 / MIL-53(Al) composite material through a solvothermal method. Through control of reaction conditions of the solvothermal method, the microstructure and morphology of the composite material are adjusted. The loaded Bi2WO6 / MIL-53(Al) composite material has bulk morphology. Bi2WO6 is uniformly distributed on the carrier MIL-53(Al). The loaded composite material photocatalyst has high catalytic activity, has a rhodamine B degradation rate of 97% and has a certain stability and reusability. The preparation method has simple processes and low energy consumption and is easy to industrialize.

Owner:SHANGHAI UNIV

Method for preparing microbial organic bacterial manure

InactiveCN103396175AChange physical propertiesChange chemical propertiesBio-organic fraction processingWaste based fuelFecesFermentation

The invention provides a method for preparing a microbial organic bacterial manure. The method comprises the following steps: S10. carrying out primary composting: after bone shell raw materials in an organic raw material are crushed into powder, adding activated carbon and BEST bacterial mixtures to compost; step 20. carrying out secondary composting: adding non-bone-shell materials in the organic raw material, biogas residues of animal dung subjected to biogas fermentation and the BEST bacterial mixtures into the product subjected to the primary composting to conduct the secondary composting, wherein the organic raw material is one or multiple of dry branches and fallen leaves, food and feeds, barks, kitchen garbage, animal dung, crop straws and household garbage. The organic bacterial manure prepared by the method for preparing the microbial organic bacterial manure can change the physical, chemical and biological properties of soil, can keep the soil loose, can promote formation of soil aggregate structures so as to improve the permeability of the soil, and can provide crops with the good soil environment so as to cause plants to strongly grow.

Owner:深圳市同昌和科技开发有限公司

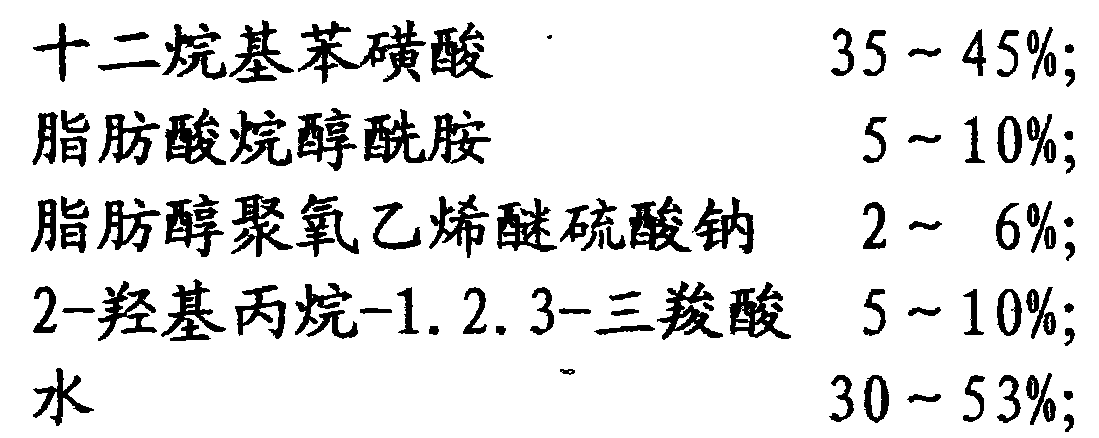

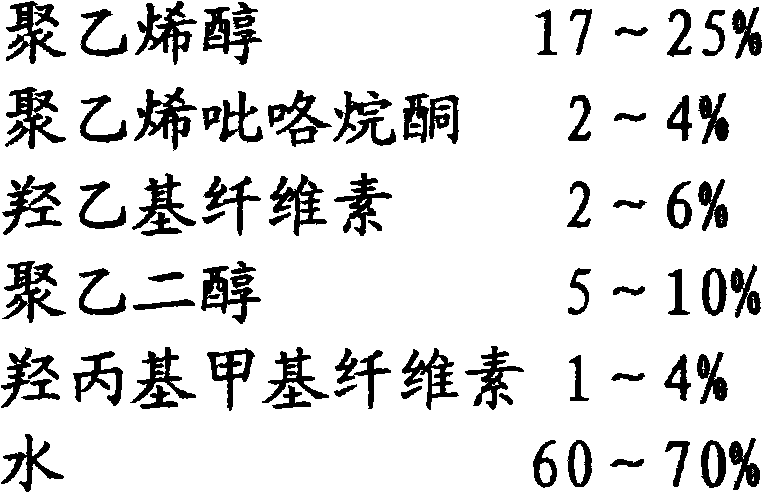

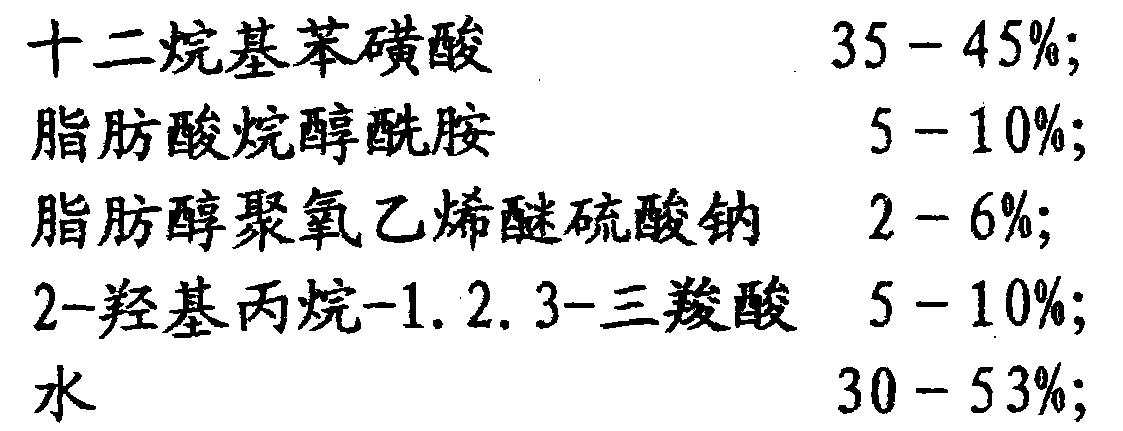

Swelling soil modifier

InactiveCN102079980AUse foreverHigh densityBuilding constructionsOrganic fertilisersRational useSwelling ratio

The invention relates to a material for regulating and improving the soil structure, soil compactness, and soil chemical properties and physical properties of a swelling soil roadbed. The technical scheme is that: a swelling soil stabilizer comprising a main component of dodecylbenzene sulfonic acid and a swelling soil firming agent comprising a main component of polyvinyl alcohol are combined to improve the chemical and physical properties of swelling soil. The swelling soil stabilizer regulates the components and molecular structure of the swelling soil so as to improve the structure, compactness and expansion and shrinkage performance of the swelling soil, and recombine the structure of the swelling soil; the firming agent is used to firm swelling-shrinking soil, reduce the swelling ratio, improve bearing capacity and reduce construction cost so as to reasonably use human, financial and material resources, and the aim that civil engineering including road engineering is durable is fulfilled; and after being rolled, the soil can be compressed to achieve high compactness, reduce an osmotic coefficient and improve soil consolidation capacity, so that the damage of water to the roadbed is reduced and the frost boiling phenomenon of the roadbed is effectively prevented.

Owner:钟维安 +2

Preparation method of nano sulfur slurry

ActiveCN101733030AGood dispersionChange stabilityCosmetic preparationsMixing methodsSulfurMass ratio

The invention discloses a preparation method of nano sulfur slurry. The preparation method comprises the following steps of: (1) respectively weighing sulfur powder with the grain diameter of 20-100Mum and water according to the mass ratio of 1: (1.225 to 8.6), pouring the sulfur powder and the water into a vessel, and dispersing for 20-30 minutes by using an emulsifying machine with the rotation speed of 10000-28000rpm; (2) pouring the slurry prepared in the step (1) into a ball milling can, adding a ball milling medium, a dispersing agent and a heat stabilizer with the addition amount of respectively 5-8 times, 2 to 6 percent and 2-5 percent of the sulfur powder by mass, and well sealing the ball milling can; (3) putting the ball milling can into a ball mill with the rotation speed of 300 to 500rpm, dispersedly milling with the ball milling time of 5 to 10h; and (4) removing granular impurities which can not disperse after the ball milling from the sulfur slurry through a vacuum suction filter with the filtering mesh number of 600 meshes, recovering the impurities and preparing the nano sulfur slurry with the grain size of 10nm to 80nm. The prepared sulfur grains are easy to disperse and have good stability and wide application prospect.

Owner:上海沪正实业有限公司

Preparation method of hetero-atom-doped graphyne

The invention discloses a preparation method of hetero-atom-doped graphyne, and belongs to the field of preparation of a doped nanometer material. The defect of single structure and performance of a graphyne material in the prior art can be overcome. The method comprises the following steps: drying a graphyne sample, putting the graphyne sample in a temperature programmed tubular furnace, beginning temperature programming, adding a simple substance or compound containing a doped element, and performing a reaction in a temperature range of 500-1500 DEG C to obtain the doped graphyne with the doped element substituted or added. The preparation method is simple in process and convenient to operate, and the doped graphyne can be obtained with no need of complex equipment. The preparation method is suitable for industrial production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

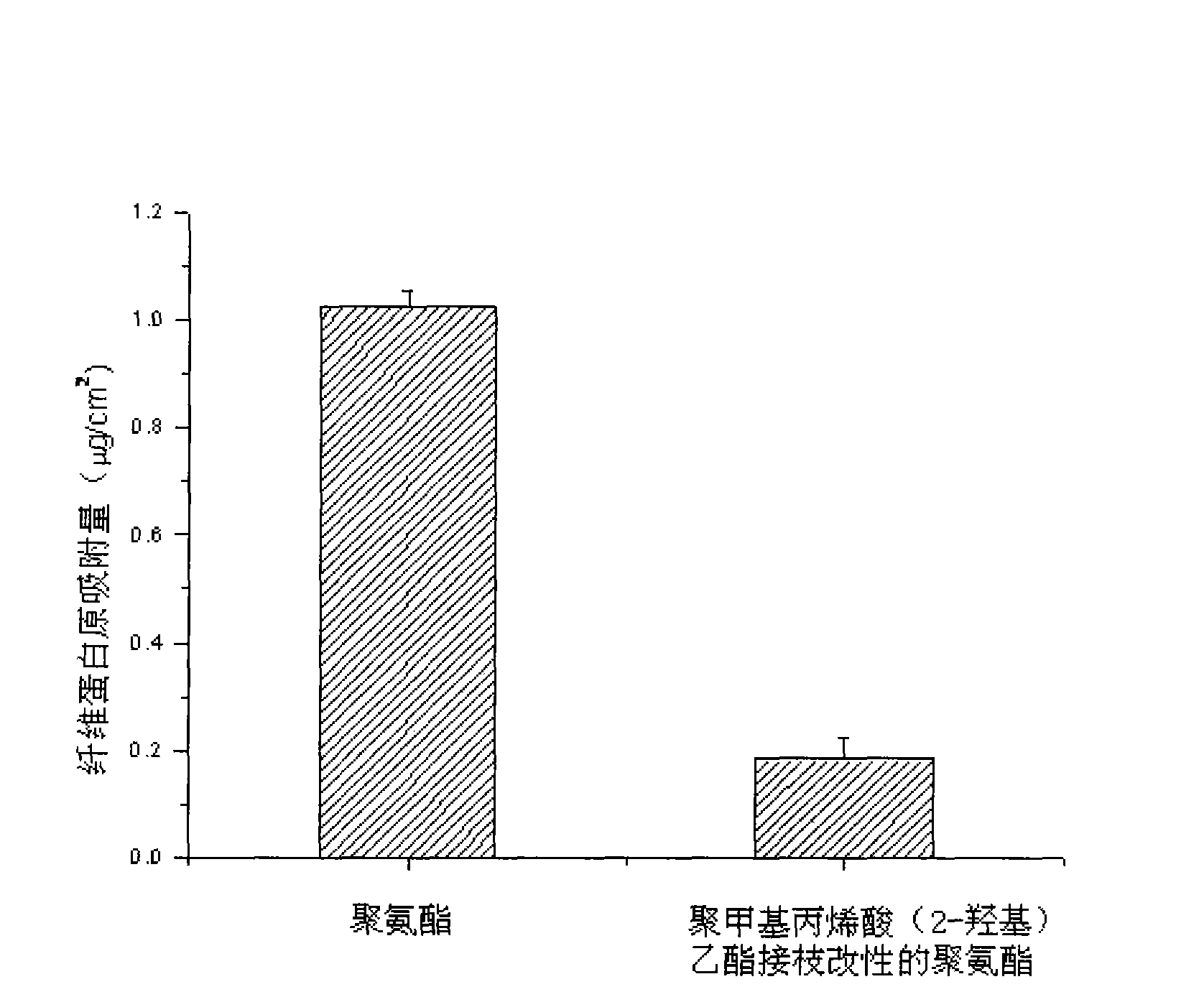

Method for surface modification of polyurethane material by graft copolymerization

The invention relates to the fields of high molecular materials and polymer chemistry and discloses a method for surface modification of a polyurethane material by graft copolymerization. The method comprises the following steps: chemically grafting polymerizable carbon-caron double bonds on the surface of the polyurethane material; and performing graft modification on the surface of the polyurethane material by graft copolymerization of free radicals in the presence of an initiator and vinyl monomers. The method is particularly characterized in that: the modification method has no severe requirements for appearance of the polyurethane material which can be solid polyurethane material taking a shape of granule, film, tube or rod or others; the modification method is a pure chemical method without needing expensive special equipment such as a plasma, an ozone generator and the like; the method has simple process and easily controlled process parameters; and the method has simple and practical operation and can conveniently modify physical and chemical properties of the surface of the polyurethane material.

Owner:WUHAN UNIV OF TECH

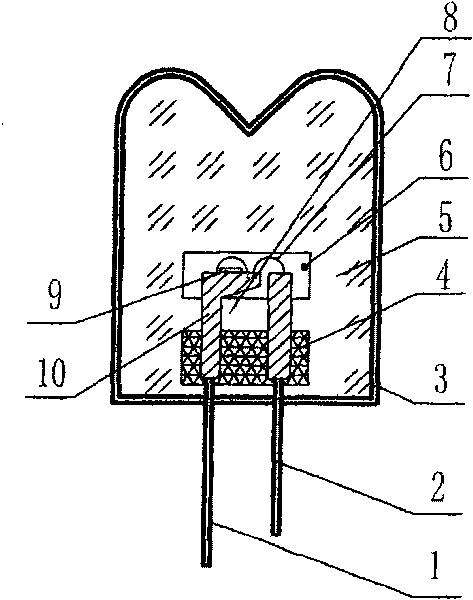

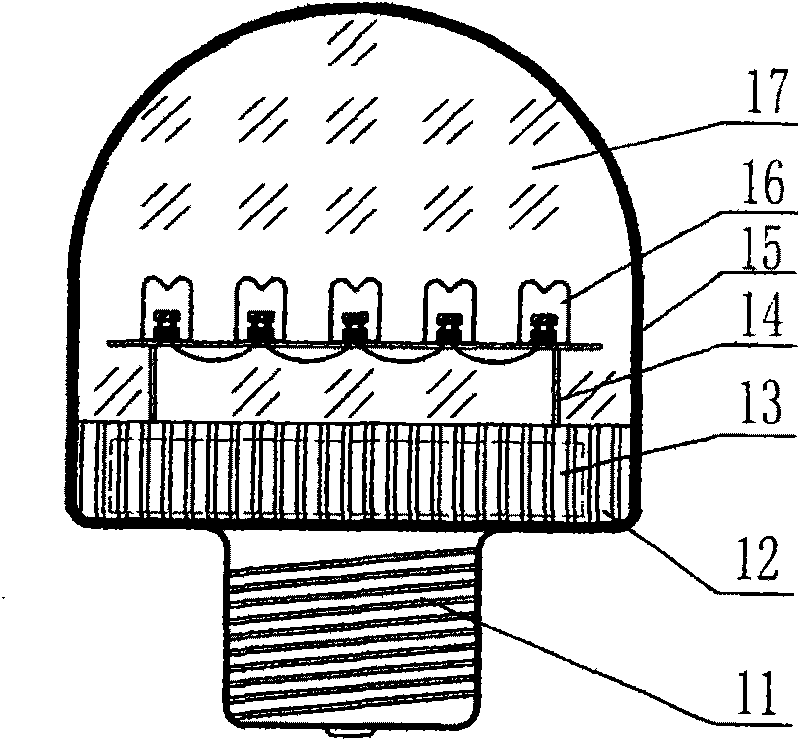

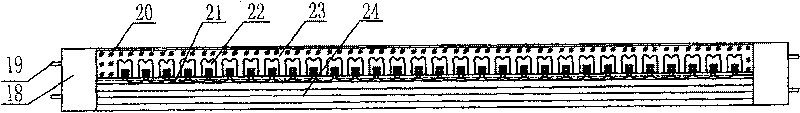

LED lamp radiating with optically coupled cooling liquid

InactiveCN101725858AFacilitate conductionImprove featuresPoint-like light sourceLighting heating/cooling arrangementsOptical propertyHeat conducting

The invention provides an LED lamp radiating with optically coupled cooling liquid. An excellent heat-conducting optically coupled cooling liquid is filled between the luminous body of the outgoing end of the LED lamp and an enclosed shell so as to complete leakage-free encapsulation. Excellent heat-conducting properties and excellent optical characters of the optically coupled cooling liquid are used for realizing the improvement of the excellent heat conduction and optical characters between the luminous body of the LED lamp and the shell. When the radiating effect is needed to further improve, the optically coupled cooling liquid is forced to complete adequate heat exchange in a cold pool in the manner of pumping in the cold optically coupled cooling liquid and overflowing the hot optically coupled cooling liquid so that the junction temperature of the luminous body is maintained below 125 DEG C, so as to completely improve the radiating conditions of the luminous body in the LED lamp, prolong the service life of the LED lamp radiating with optically coupled cooling liquid with power LED integrated light source and the outgoing effect of the outgoing end.

Owner:陈炜旻

High-bulk density low-heavy metal content chitosan and preparation method thereof

The invention provides a high-bulk density low-heavy metal content chitosan and a preparation method thereof, which belongs to the technical field of alkaline polysaccharide compounds containing amino groups. The invention solves the problems that the traditional chitosan products have a high heavy metal content and can not meet the requirement for applying to the fields of medicine, food, cosmetics, skin care products, and the like. The bulk density of the high-bulk density low-heavy metal content chitosan is 0.30-1.0T / M<3> at 25 DEG C. The contents of heavy metals are: lead content is less than or equal to 0.5ppm, arsenic content is less than or equal to 0.3ppm, and mercury content is less than or equal to 0.05ppm. The preparation method comprises the steps of A, blending; B, acidification, alkalization or salting out; C, desalting and drying; and D, pulverization. The preparation method of the high-bulk density low-heavy metal content chitosan has the advantages of simple adopted equipment, simple production process and low cost; and the prepared product has good liquidity, low heavy metal content, good quality and wide application field.

Owner:浙江澳兴生物科技有限公司

Nano bog muck series compositions, and their produsts and uses

InactiveCN1470600AChange physical propertiesChange chemical propertiesOrganic fertilisersSoil conditioning compositionsPeatMaterial physics

The present ivnention provides a method for combining nano material technology with peat and adopts different formulae and additives to form natural environment-protecting series products with several functions, several varieties and several purposes. Said nano material comprises compounds and oxides of nano metal and nonmetal, and the peat is the screened impurities (including sand and stone)-removed low-grade or high-grade peat whose organic substance content is above 50%, fibre content is above 35% and water content is 15-35%. Its concrete application includes (1). nano peat plant culture nutrient mechanism; (2) nano peat high-effective water and soil improvement environment-protecting nutrients mechanism; (3) nano peat pollution prevention and control mechanism; and (4) nano peat refuse degradation natural activity mechanism.

Owner:吴笑天

Soil improvement agent, and preparation method thereof

InactiveCN105254401AGood antibacterial effectImprove absorption rateFertilizer mixturesLivestock manurePhosphate

The invention belongs to the technical field of oil improvement, and especially relates to a soil improvement agent. The soil improvement agent is prepared from, by weight, 20 to 25 parts of dolomite powder, 19 to 22 parts of flyash, 13 to 16 parts of powdered rock phosphate, 12 to 15 parts of peat, 8 to 10 parts of food residue, 7 to 9 parts of polypropylene glycol, 6 to 10 parts of humic acid, 5 to 8 parts of livestock manure, 4 to 8 parts of leguminous green manure, and 0.5 to 1 part of dendrobium. The soil improvement agent is reasonable in formula, is capable of improving soil physical structure effectively, reducing soil volume weight, improving soil water content, changing soil chemical properties, adjusting all conditions or a part of conditions including soil water, fertilizer, gas, and heat, and improving soil fertility.

Owner:北京世纪阿姆斯生物工程有限公司

Method for enhancing degradability of antibiotics and hormones in livestock cultivating waste water

InactiveCN102491573AImprove biodegradabilityChange structureWater/sewage treatment by irradiationWaste water treatment from animal husbandryToxicityEnvironmental chemistry

The invention provides a method for enhancing the degradability of antibiotics and hormones in livestock cultivating waste water, belonging to the technical field of water pollution treatment. In the method, waste water is treated under the action of microwaves for a short time interval (2-5 minutes), so that the structural and chemical properties of the antibiotics and hormones are changed quickly, the bio-toxicity of the antibiotics and hormones is reduced, and degradability of the antibiotics and hormones is enhanced; and equipment is simple and readily-available, a key technology is easy to grasp, an equipment running method is easy, investment is small, and energy is saved.

Owner:SOUTHWEST UNIVERSITY

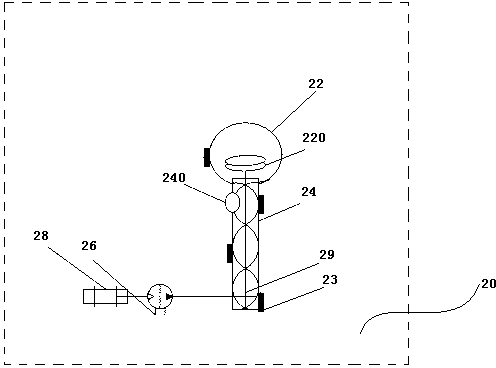

Device for promoting reaction by direct contact between blast furnace slag particles and biomass particles

InactiveCN103265964APromote pyrolysis gas productionSimple structureDirect heating destructive distillationBiofuelsSlagPhysical chemistry

The invention relates to a device for promoting reaction by direct contact between blast furnace slag particles and biomass particles. The device comprises a feeding device, a reaction device, a separation device and a gas purification and collection device, wherein the feeding device is provided with a discharge pipe of the feeding device; the bottom of the reaction device is provided with a discharge hole of the reaction device, and the top of the reaction device is provided with an air outlet and a feeding hole of the reaction device; the separation device is provided with a slag outlet, and the top of the separation device is also provided with a feeding hole of the separation device; the discharge pipe of the feeding device is communicated with the feeding hole on the top of the reaction device; the discharge hole at the bottom of the reaction device is communicated with the feeding hole on the top of the separation device; and the air outlet on the top of the reaction device is communicated with the gas purification and collection device. The device can be used for promoting gas production of biomass pyrolysis by the high temperature provided by the collision between the blast furnace slag particles and the biomass particles in the reaction device; and finally, the mixed particles are separated, the separated blast furnace slag particles can be taken as building materials, and the separated biomass particles can be taken as carbon fuel, so that the device is energy-saving and environment-friendly.

Owner:CHONGQING UNIV

Method for producing plasticizing bamboo or wood single-sided laminated sheet material and application

InactiveCN101376252AChange structural propertiesChange chemical propertiesWood compressionWood impregnation detailsMicrostructureHot pressing

The invention relates to a method for manufacturing plasticized surfacing linings of bamboo and wood veneers and the application thereof. The method comprises the following steps: (1) moistening with alkali at the low temperature; (2) treating with phenmethyl; and (3) hot-pressing and shaping treatment: plasticized surfacing linings of bamboo and wood veneers are applied to the surface linings of structural veneers of various artificial slabs, such as container bottom plates, carriage bottom plates, cement templates and the like, so as to improve the surface wear resistance and static bending strength, and reduce the cost of surface materials. The invention has the advantages that the crystal structure of wooden fabric is locally or completely damaged through the moistening of the alkali at the low temperature, so as to fully expose the hydroxide radical of the crystallization region, enable a phenmethyl agent to be bonded with the hydroxide radical to the maximum extent, and introduce new radical, thereby changing the original microstructure and chemical properties of the wooden fabric; and in the hot-pressing and shaping period, the novel material which can preserve the advantages of wooden material is formed and is provided with the certain characteristics of plastics, such as hot melt processability, stable dimension with moist heat, high wear resistance, and the like.

Owner:NANJING FORESTRY UNIV

Preparation process for novel red-rooted salvia root ultrafine powder particle traditional Chinese medicine decoction piece

ActiveCN103070920AReduce volatile lossKeep drug ingredientsGranular deliveryPlant ingredientsMedicinal herbsOfficinal

The invention discloses a preparation process for a novel red-rooted salvia root ultrafine powder particle traditional Chinese medicine decoction piece. The process includes the following steps: washing of red-rooted salvia roots, rough processing of red-rooted salvia roots, drying, material inspection, low-temperature ultrafine grinding, pelletization, semifinished product inspection, packaging and the like. The process is strictly controlled in order to guarantee the safety and acceptability of the finished product, and the red-rooted salvia root ultrafine powder particle traditional Chinese medicine decoction piece prepared by the process can be blended into suspension, soak or decoction and taken. Since ultralow-temperature grinding is used by the preparation process, the natural medicinal ingredients of the red-rooted salvia root are kept, the prepared traditional Chinese medicine decoction piece can be rapidly dissolved out, the dissolution amount is large, the extract content of the traditional Chinese medicine decoction piece is more than 20 percent higher than the extract content of the conventional decoction piece when the extract determination method of Chinese pharmacopoeia (2011 edition) is used for measurement, and thereby medicinal material resources are greatly saved; the time of decocting the traditional Chinese medicine decoction piece is shortened by more than five times in comparison with the time of decocting the conventionally formulated decoction piece; excipients are not added, and the physical and chemical properties of the red-rooted salvia root are not changed; and because the traditional Chinese medicine decoction piece is packaged in a porous soak bag and an aluminium foil bag, the decoction piece cannot be damped.

Owner:四川国强中药饮片有限公司

Liquid state electrolyte for zinc-nickel secondary batteries and preparing method thereof

The invention belongs to the chemical technical field, relating to electrolyte used on a zinc-nickel secondary cell, in particular to a liquid electrolyte to be used on the zinc-nickel secondary cell and a preparation method for the same. In the method, the corrosion on a zinc electrode by an electrolyte solvent during charging is reduced greatly by adding a polymeric additive into an alkaline electrolyte solution, which restrains the generation of dendrite arms, improves the utilization rate of the electrolyte and prolongs the cycle life of cells.

Owner:INST OF CHEM CHINESE ACAD OF SCI

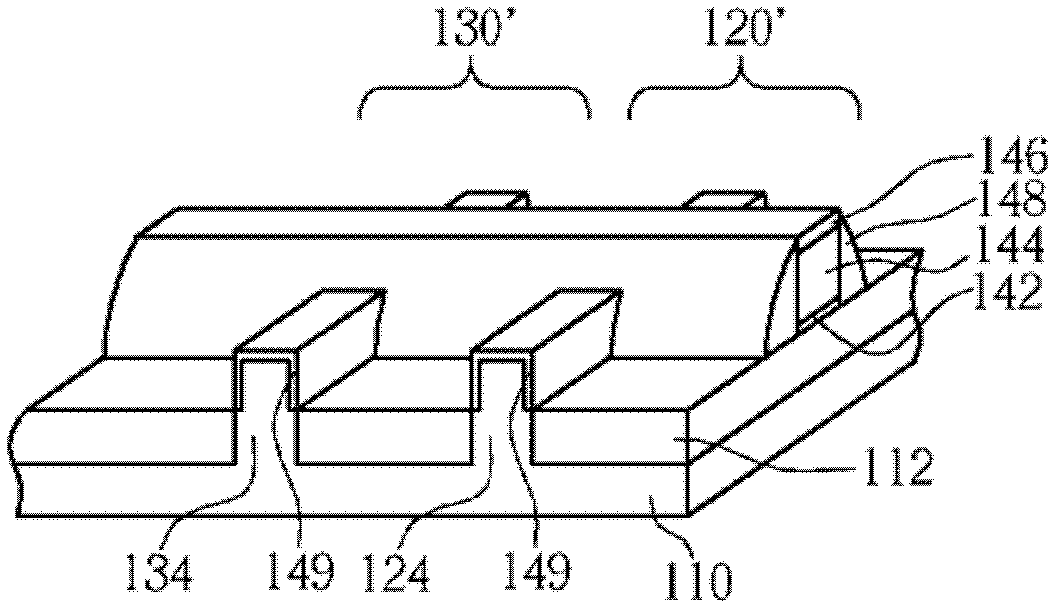

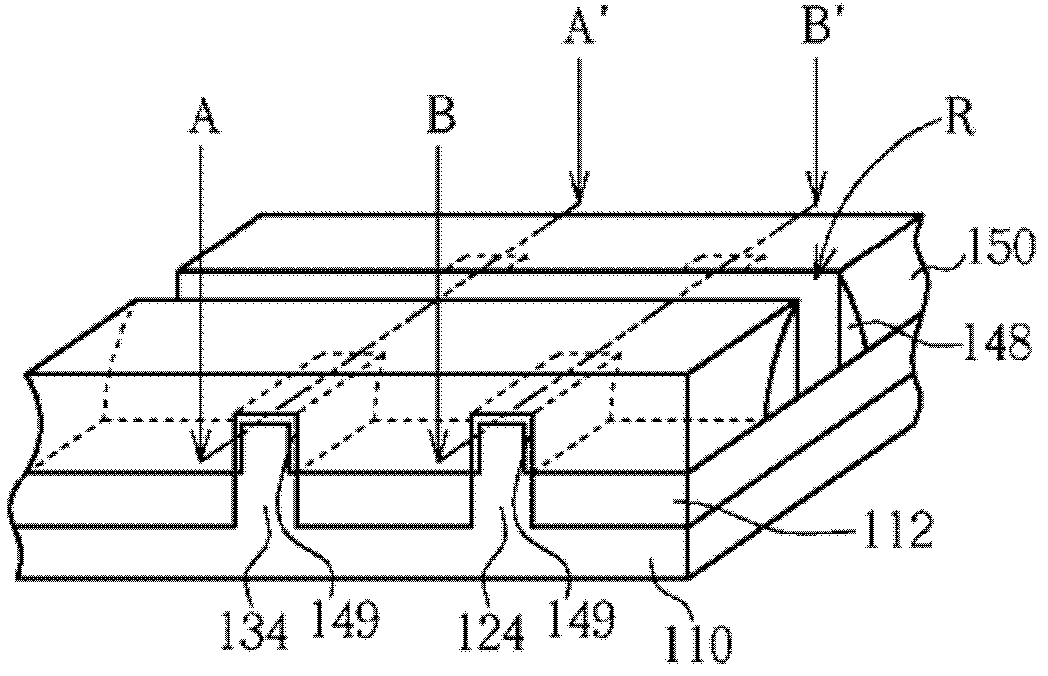

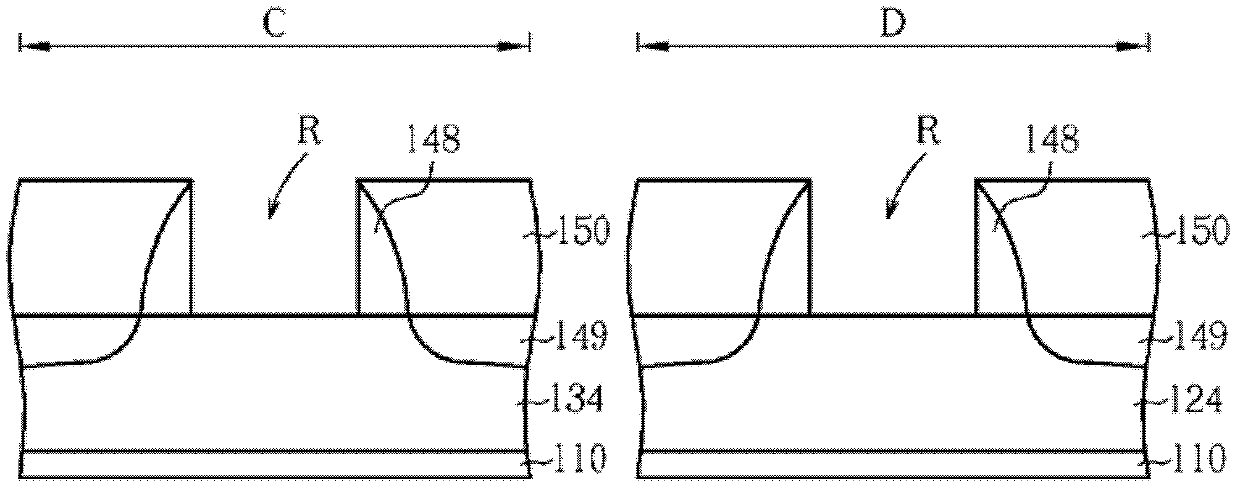

Fin field effect transistor and technology thereof

InactiveCN103325683AChange threshold voltageChange physical propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesField-effect transistorThreshold voltage

The invention discloses a fin field effect transistor and the technology of the fin field effect transistor. The technology of the fin field effect transistor comprises the following steps that a substrate is provided; a first fin field effect transistor and a second field effect transistor are formed on the substrate, wherein the first fin field effect transistor comprises a first metal layer, and the second fin field effect transistor comprises a second metal layer; the processing technology is conducted on the first metal layer to change the threshold voltage of the first fin field effect transistor.

Owner:UNITED MICROELECTRONICS CORP

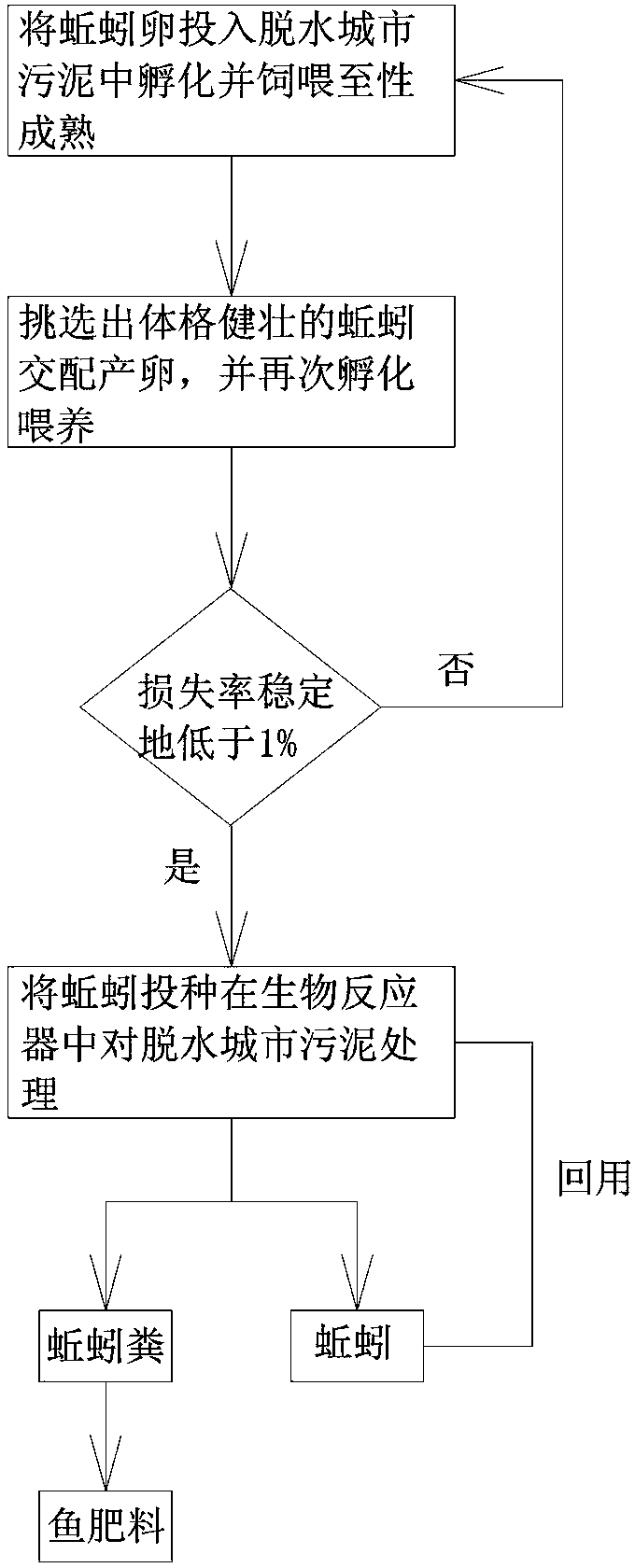

Method for disposing urban sludge by using earthworms

InactiveCN103803771AAvoid harmReduce disposal costsEnergy based wastewater treatmentBiological sludge treatmentLoss rateSludge

The invention discloses a method for disposing urban sludge by using earthworms. The method comprises the steps: incubating and feeding earthworm eggs in dehydrated urban sludge till sexual maturity; continuously feeding the robust sexual-mature earthworms in the dehydrated urban sludge; and laying eggs, continuously incubating and feeding in the sludge, domesticating circularly till the loss rate of the earthworms fed with the naturally oxidized dehydrated urban sludge is stably lower than 1%, treating the dehydrated urban sludge by using the domesticated earthworms, and converting into earthworm cast. According to the method for disposing the urban sludge by using the earthworms, the dehydrated urban sludge can gradually form microbes, enzymes and fish manure with high fused inorganic matters by using the earthworms, strong stench of the urban sludge is eliminated, the content of heavy metals is reduced, and harmlessness and recycle of the urban sludge are furthest realized. The environment-friendly requirement of human beings for sustainable utilization of the urban sludge is met.

Owner:BEIJING DEHUAI BIOLOGICAL SCI & TECH

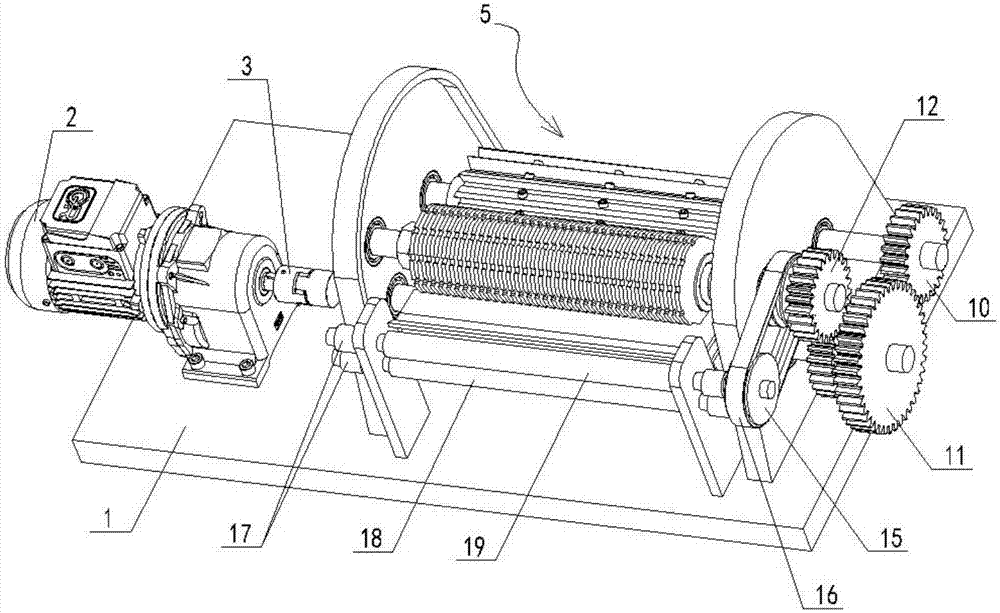

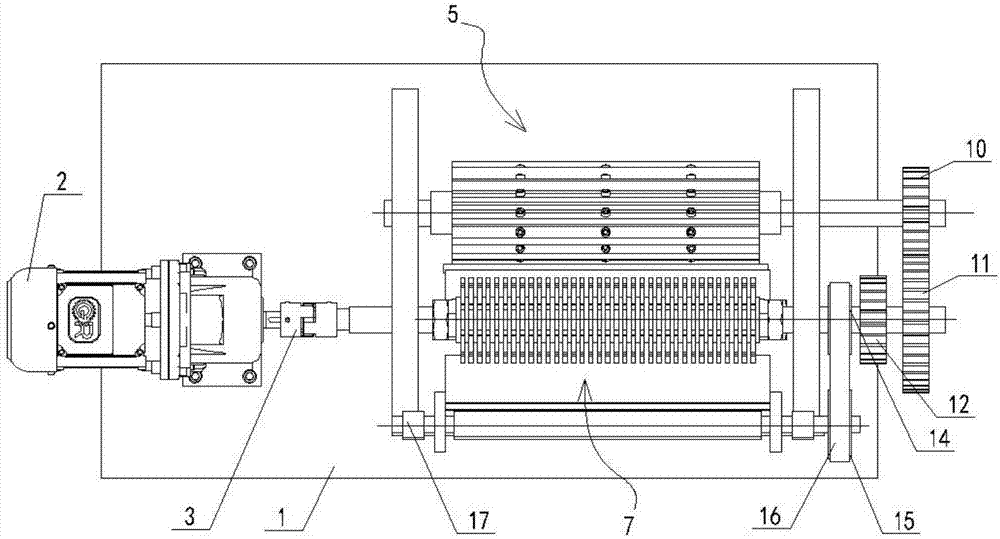

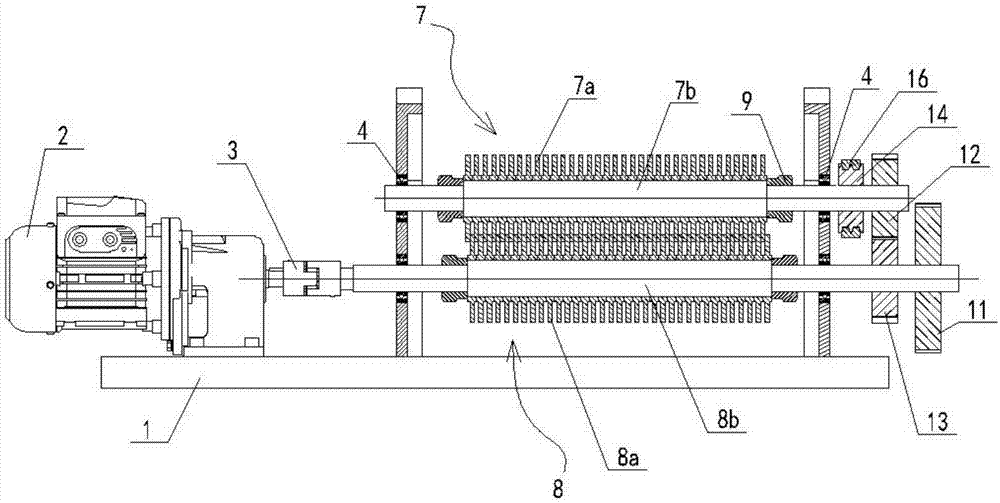

Abandoned liquid crystal display panel shear crusher

The invention discloses an abandoned liquid crystal display panel shear crusher, which comprises a double-shaft shearing mechanism, a rotary cutting mechanism and a feeding mechanism. The double-shaft shearing mechanism is provided with a lower cutter shaft and an upper cutter shaft arranged in parallel; a lower cutter disc is arranged on the lower cutter shaft; an upper cutter disc is arranged on the upper cutter shaft; the upper cutter disc and the lower cutter disc rotate face to face so as to realize shearing; the rotary cutting mechanism is a rear cutter shaft parallel to one side of the lower cutter shaft; the rear cutter shaft is a gear shaft; moving blades rotating along with the rear cutter shaft are arranged on teeth of an outer cylindrical surface of the rear cutter shaft; and the rotated moving blades are tangent to fixedly arranged fixed blades so as to realize cutting. According to the abandoned liquid crystal display panel shear crusher provided by the invention, liquid crystal display panels are sheared through the upper cutter disc and the lower cutter disc so as to be in strip shapes, and are then cut through the rotated moving blades so as to obtain granular materials, the process is simple, the efficiency is high, the friction heating amount is small, and fast heat radiation is realized; and through reasonably setting the transmission ratio of each transmission mechanism and appropriately adjusting the rotary speed of a gear motor, the liquid crystal display panels are sheared and crushed at a low rotary speed state, and the temperature rise of the liquid crystal display panels is effectively inhibited.

Owner:HEFEI UNIV OF TECH

Modifying and dyeing process of cotton fabric

InactiveCN103485203AChange physical propertiesChange chemical propertiesDyeing processAcid washingRoom temperature

The invention relates to a modifying and dyeing process of a cotton fabric. The process comprises the following steps: (1) modifying the cotton fabric, namely placing the cotton fabric in a modifying liquid containing a modifier and sodium hydroxide with the bath ratio of 1:20; dipping at a certain temperature for a certain time; taking out the fabric; flushing the fabric by running water for 5-6 minutes; carrying out acid washing on the fabric; then, washing the fabric till the fabric is neutral; naturally airing the fabric; (2) dyeing, namely preparing dye liquor by a certain amount of dyes; heating the dye liquor to 50 DEG C and placing the cotton fabric in the dye liquor; adjusting the pH; heating at a speed at 2 DEG C / minute to a certain dyeing temperature; maintaining the constant temperature; dyeing for a certain time, then cooling to the room temperature; washing by water and airing. The process provided by the invention has the beneficial effects that the cationic modification is carried out on the cotton fabric, so that the physical property and the chemical property of the cotton fiber are changed, thereby further changing the dyeing property of the cotton fabric; finally, the cotton fabric blended with wool fibers is dyed by using one bath process, so that the dyeing process flow is shortened, and the production efficiency is improved.

Owner:KUNSHAN WANFENG GARMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com