Liquid state electrolyte for zinc-nickel secondary batteries and preparing method thereof

A liquid electrolyte, nickel secondary battery technology, applied in the direction of alkaline storage batteries, etc., can solve the problems of poor solubility, etc., and achieve the effects of easy mass production, prolonging cycle life, and improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

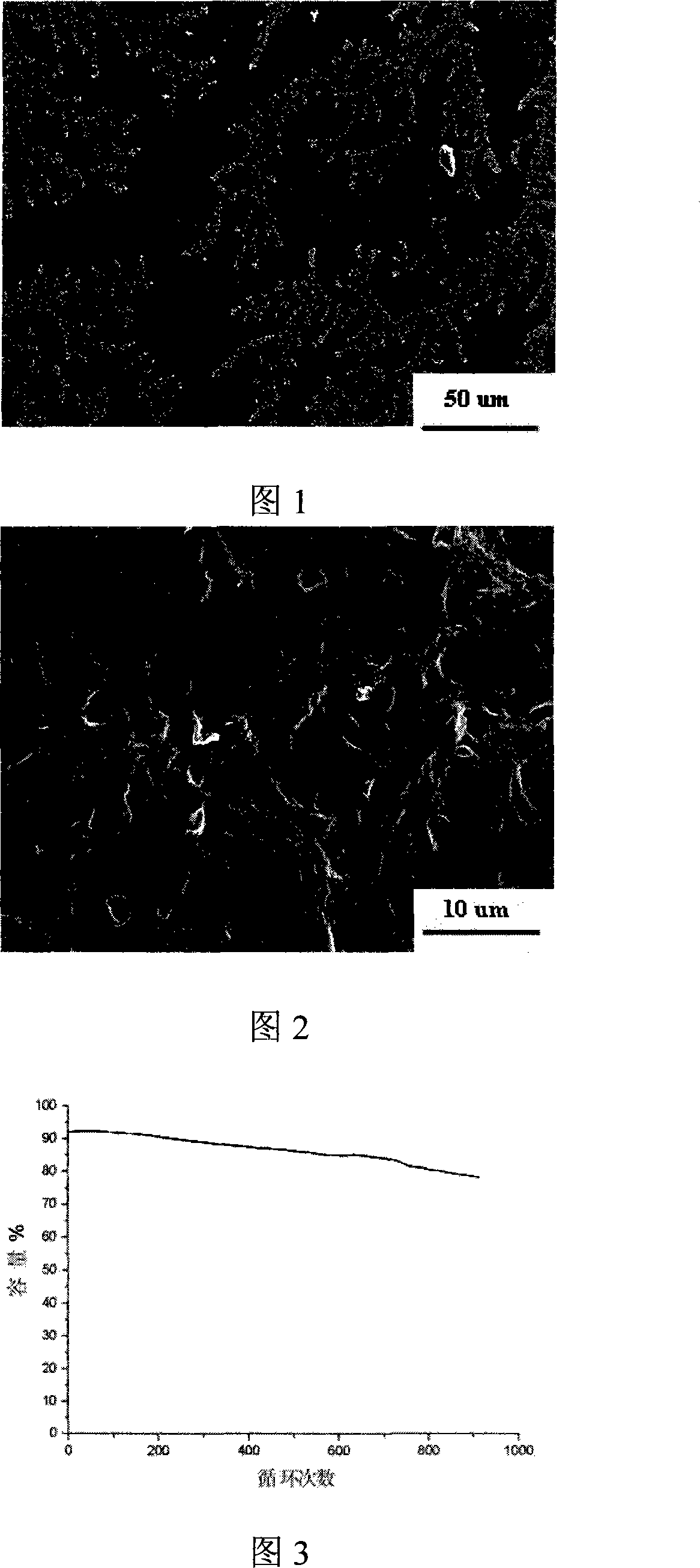

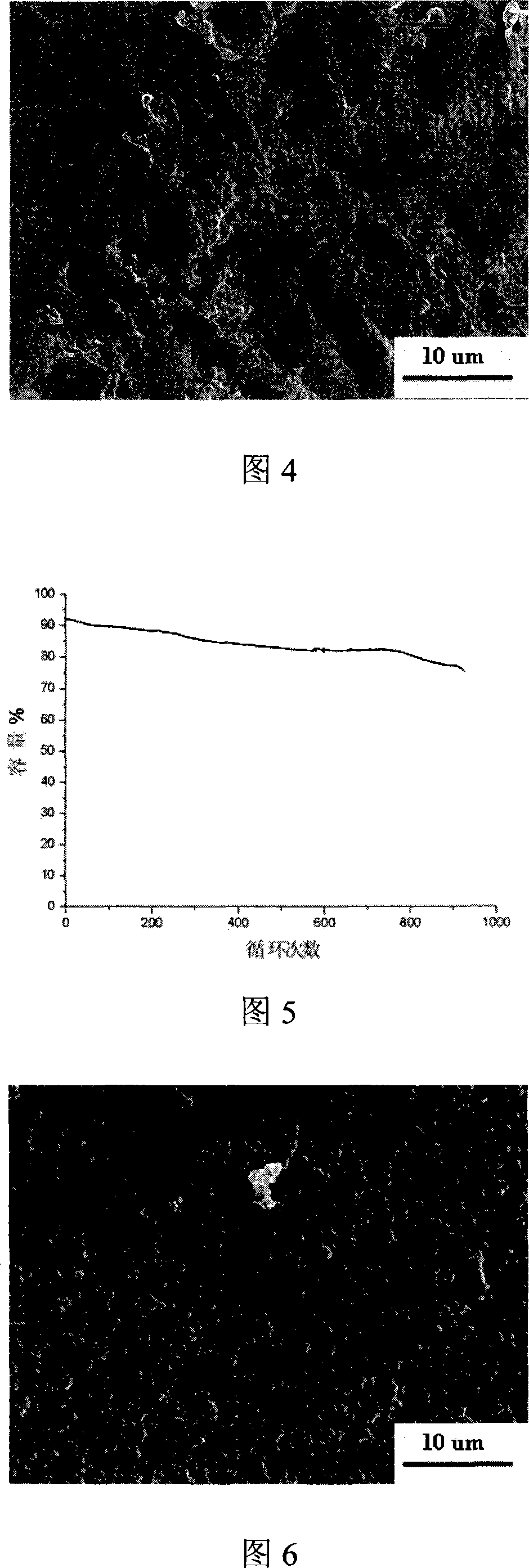

Embodiment 1

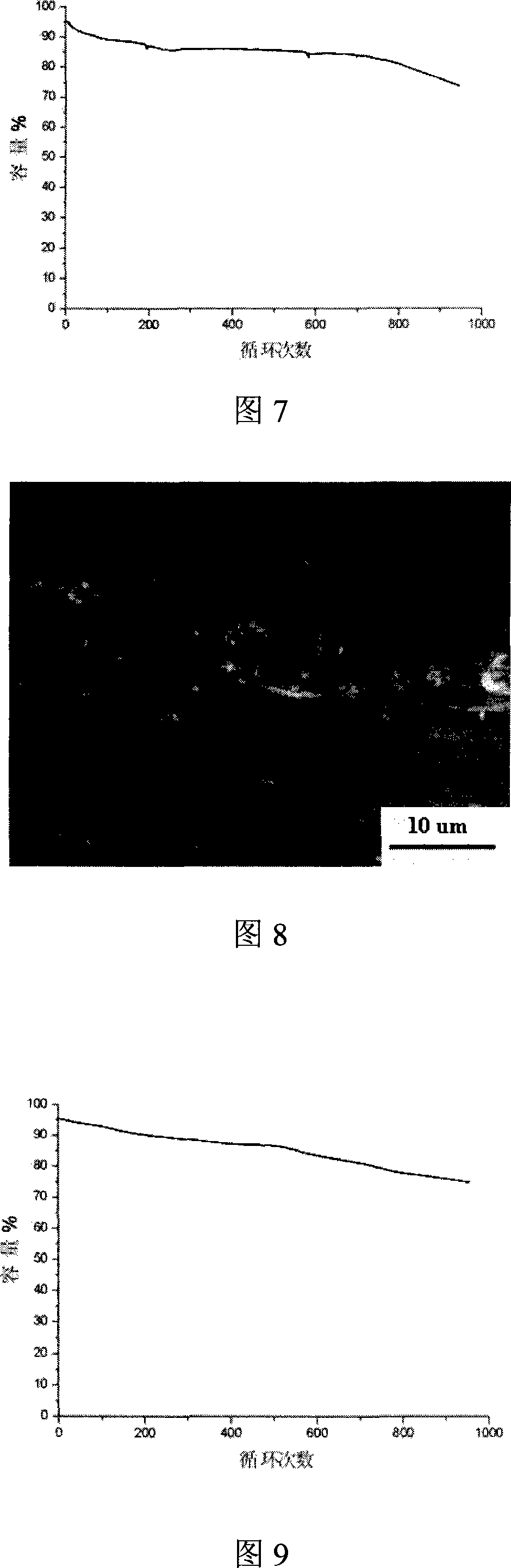

[0050] 28g Na 2 HPO 4 , a mixture of 23g KF, 5g LiF and 112g KOH was added to 1L deionized water, stirred to dissolve, and an alkaline electrolyte solution was prepared. Then 8g of polyacrylic acid (polymerization degree: 80) additive was added thereto, stirred to dissolve it, and a liquid electrolyte was prepared. This liquid electrolyte is used in zinc-nickel secondary battery. The scanning electron microscope results of the zinc electrode surface after 100 charge and discharge cycles are shown in Figure 2, and the results of the battery capacity changing with the number of discharge / charge cycles are shown in Figure 3.

Embodiment 2

[0052] 12g NaH 2 PO 4 , A mixture of 29g KF, 112g KOH and 80g NaOH was added to 1L deionized water, stirred to dissolve it, and an alkaline electrolyte solution was obtained. Then 15 g of sodium polymethacrylate (polymerization degree: 600) additive was added thereto, stirred to dissolve, and a liquid electrolyte was prepared. This liquid electrolyte is used in zinc-nickel secondary battery. The scanning electron microscope results of the zinc electrode surface after 100 charge and discharge cycles are shown in Figure 4, and the results of the battery capacity changing with the number of discharge / charge cycles are shown in Figure 5.

Embodiment 3

[0054] 12g NaH 2 PO 4 , A mixture of 29g KF and 168g KOH was added to 1L of ionized water and stirred to dissolve it to obtain an alkaline electrolyte solution. Then 10 g of polyhydroxyethyl methacrylate (polymerization degree: 2000) additive was added thereto, stirred to dissolve, and a liquid electrolyte was prepared. This liquid electrolyte is used in zinc-nickel secondary battery, the scanning electron microscope results of the surface of the zinc electrode after 100 charge and discharge cycles are shown in Figure 6, and the results of battery capacity changing with the number of discharge / charge cycles are shown in Figure 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| aggregation | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com