Doped carbon aerogel material as well as preparation method and application thereof

A carbon aerogel, doped technology, applied in the field of porous materials, to achieve the effects of large pore volume, wide pore size, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Dissolve 3 g of zinc chloride in 5 mL of ultrapure water to obtain a high-salt zinc chloride solution, add 0.01 mol of pyrrole and 0.03 mol of formaldehyde monomer, and stir in an ice-water bath for 2 min to make it fully mixed. Polymerize the obtained mixed solution in an oil bath at 105°C and react for 24 hours to obtain a pyrrole-formaldehyde gel material containing zinc chloride; place the obtained pyrrole-formaldehyde gel material containing zinc chloride in an oven at 80°C After drying, the pyrrole-formaldehyde block material containing zinc chloride can be obtained.

[0046] Put the pyrrole-formaldehyde block material containing zinc chloride in a high-temperature tube furnace protected by nitrogen, and raise the temperature to 900°C at a rate of 10°C / min; activate the reaction at 900°C for 2 hours; The temperature is lowered to room temperature at a certain rate, and nitrogen-doped carbon aerogels are obtained.

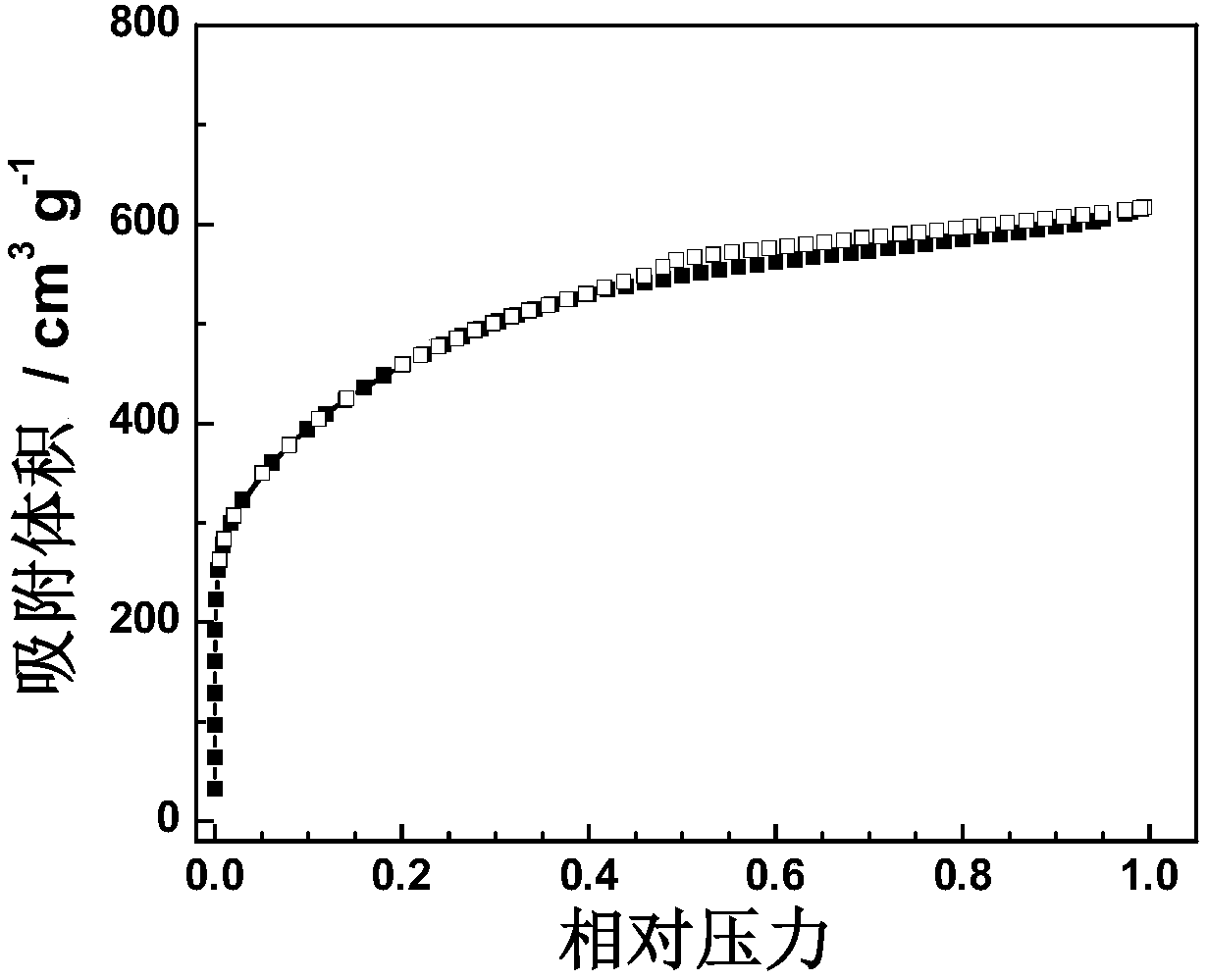

[0047] The specific surface area of the materi...

Embodiment 2

[0049] Dissolve 5g of zinc chloride in 5mL of ultrapure water to obtain a high-salt zinc chloride solution, add 0.01mol of pyrrole and 0.03mol of formaldehyde monomer, stir in an ice-water bath for 2min, and make it fully mixed. Polymerize the resulting mixture in an oil bath at 105°C and react for 12 hours to obtain a pyrrole-formaldehyde gel material containing zinc chloride; place the obtained pyrrole-formaldehyde gel material containing zinc chloride in an oven at 80°C After drying, the pyrrole-formaldehyde block material containing zinc chloride can be obtained.

[0050] Put the pyrrole-formaldehyde block material containing zinc chloride in a high-temperature tube furnace protected by nitrogen, and raise the temperature to 800°C at a rate of 5°C / min; activate the reaction at 800°C for 3 hours; The temperature is lowered to room temperature at a certain rate, and nitrogen-doped carbon aerogels are obtained.

[0051] The specific surface area of the material measured by...

Embodiment 3

[0053] Dissolve 5g of zinc chloride in 5mL of ultrapure water to obtain a high-salt zinc chloride solution, add 0.01mol of pyrrole and 0.03mol of formaldehyde monomer, stir in an ice-water bath for 2min, and make it fully mixed. Polymerize the resulting mixture in an oil bath at 105°C and react for 12 hours to obtain a pyrrole-formaldehyde gel material containing zinc chloride; place the obtained pyrrole-formaldehyde gel material containing zinc chloride in an oven at 80°C After drying, the pyrrole-formaldehyde block material containing zinc chloride can be obtained.

[0054] Place the pyrrole-formaldehyde block material containing zinc chloride in nitrogen, and raise the temperature to 900°C at a rate of 5°C / min; activate the reaction at 900°C for 2 hours; cool down to room temperature at a rate of 5°C / min, That is, nitrogen-doped carbon aerogels are obtained.

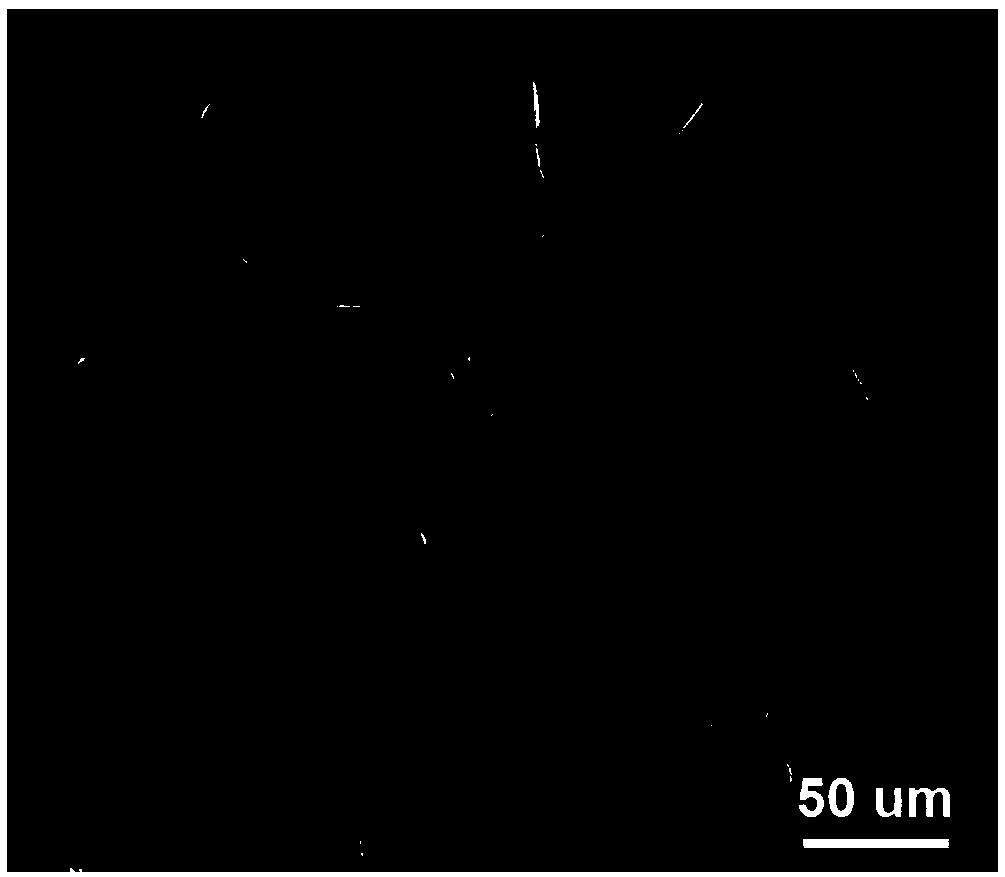

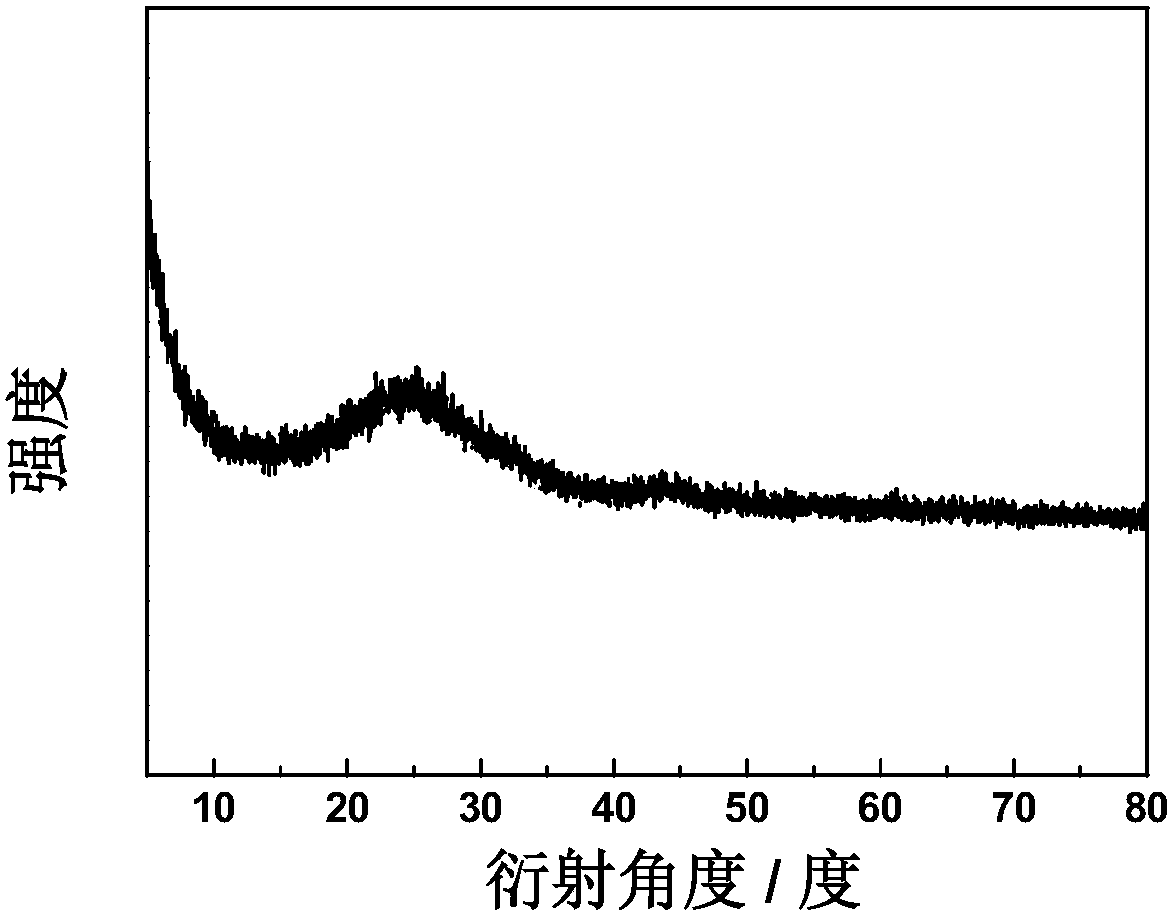

[0055] Relevant experiments were carried out on the nitrogen-doped carbon airgel material prepared in Example 3, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com