Method for surface modification of polyurethane material by graft copolymerization

A polyurethane material, graft modification technology, applied in the field of polymer materials and polymer chemistry, to achieve the effects of easier control of process parameters, simple operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Put 0.98g of potassium thiocyanate and 40mL of anhydrous acetonitrile in a 100mL reaction flask and stir to dissolve. 0.82 mL of acryloyl chloride was slowly dropped into the reaction bottle, and stirred at room temperature for 12 hours. The precipitate was removed by filtration. The filtrate was directly used in the next reaction. Put 60 polyurethane diaphragms (thickness 0.5 mm) with a diameter of about 5 mm in a reaction flask containing 30 mL of the above-mentioned filtrate, add 0.75 g of triethylamine to the reaction flask, stir and react at 65 ° C for 2 hours, and place the polyurethane diaphragm Take it out, wash with acetonitrile, and dry to obtain a polyurethane membrane with carbon-carbon double bonds on the surface. Place 0.028g of azobisisobutyronitrile, 2.26g of N-isopropylacrylamide, 15mL of methanol and 30 pieces of polyurethane diaphragms with carbon-carbon double bonds on the surface in a 50mL reaction bottle. Under nitrogen protection, the reaction m...

Embodiment 2

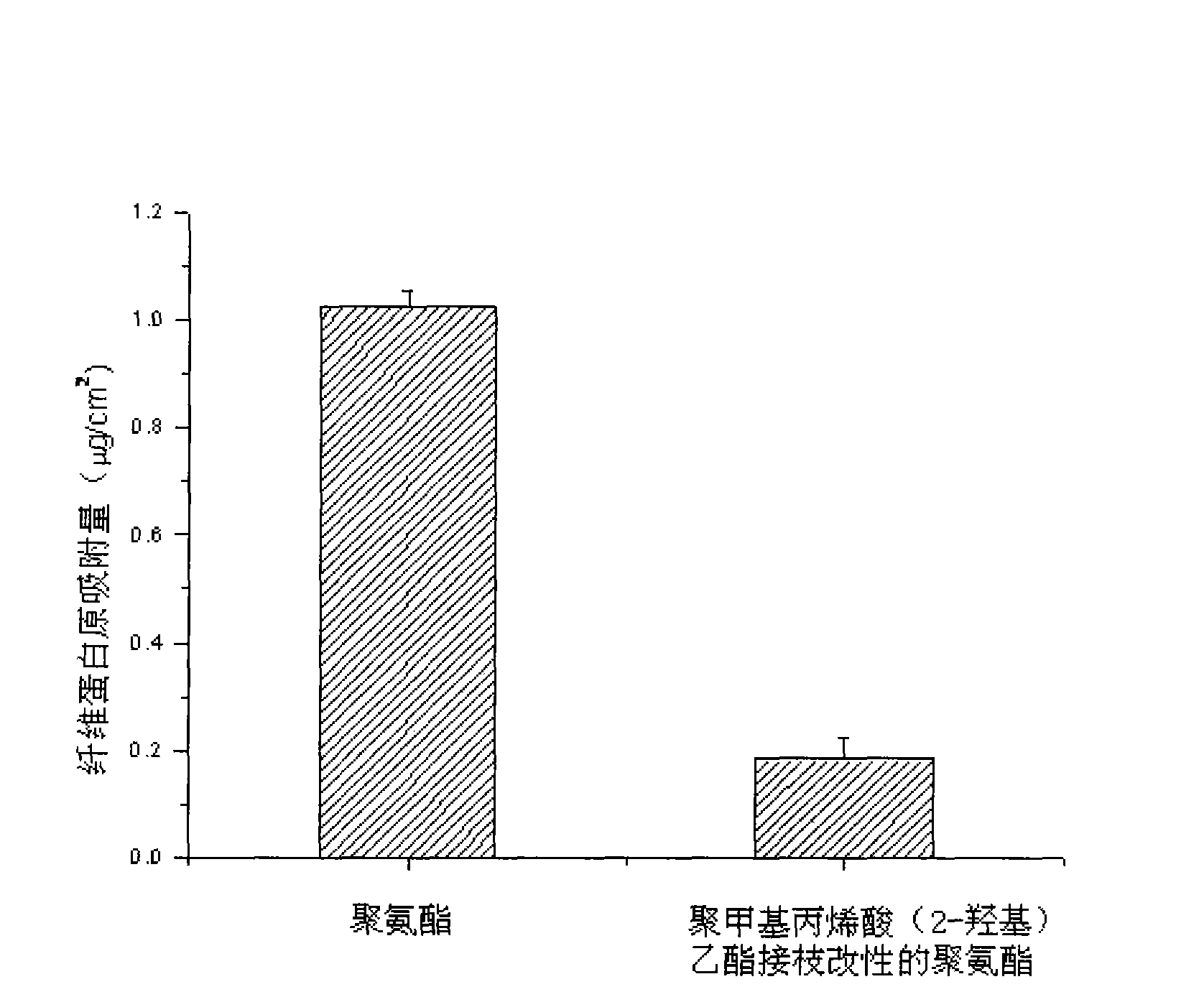

[0031] Put 0.98g of potassium thiocyanate and 40mL of anhydrous acetonitrile in a 100mL reaction flask and stir to dissolve. 0.82 mL of acryloyl chloride was slowly dropped into the reaction bottle, and stirred at room temperature for 12 hours. The precipitate was removed by filtration. The filtrate was directly used in the next reaction. Put 60 pieces of polyurethane diaphragms (thickness 0.5 mm) with a diameter of about 5 mm in a reaction flask containing 30 mL of the above filtrate, add 0.3 g of triethylamine to the reaction flask, stir and react at 65 ° C for 3 hours, and place the polyurethane diaphragms Take it out, wash with acetonitrile, and dry to obtain a polyurethane membrane with carbon-carbon double bonds on the surface. Place 0.028g of azobisisobutyronitrile, 2.6mL of (2-hydroxy) ethyl methacrylate, 15mL of methanol and 30 polyurethane diaphragms with carbon-carbon double bonds on the surface in a 50mL reaction bottle, under nitrogen protection , the reaction ...

Embodiment 3

[0033] Put 1.96g of potassium thiocyanate and 60mL of anhydrous acetonitrile in a 100mL reaction flask and stir to dissolve. Slowly drop 1.64 mL of acryloyl chloride into the reaction flask, and stir for 12 hours at room temperature. The precipitate was removed by filtration. The filtrate was directly used in the next reaction. Put 10g of polyurethane particles with a diameter of about 2mm in a reaction flask containing 40mL of the above filtrate, add 0.8g of triethylamine to the reaction flask, stir and react at 65°C for 4 hours, take out the polyurethane particles, wash with acetonitrile, and dry to obtain Polyurethane particles with carbon-carbon double bonds on the surface. Put 0.040g of dibenzoyl peroxide, 1.4mL of acrylic acid, 15mL of acetone and 8g of polyurethane particles with carbon-carbon double bonds on the surface into a 50mL reaction bottle, and under the protection of nitrogen, the reaction mixture was heated to 70°C with stirring And keep it warm for 3 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com