Patents

Literature

258 results about "Polyurethane membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

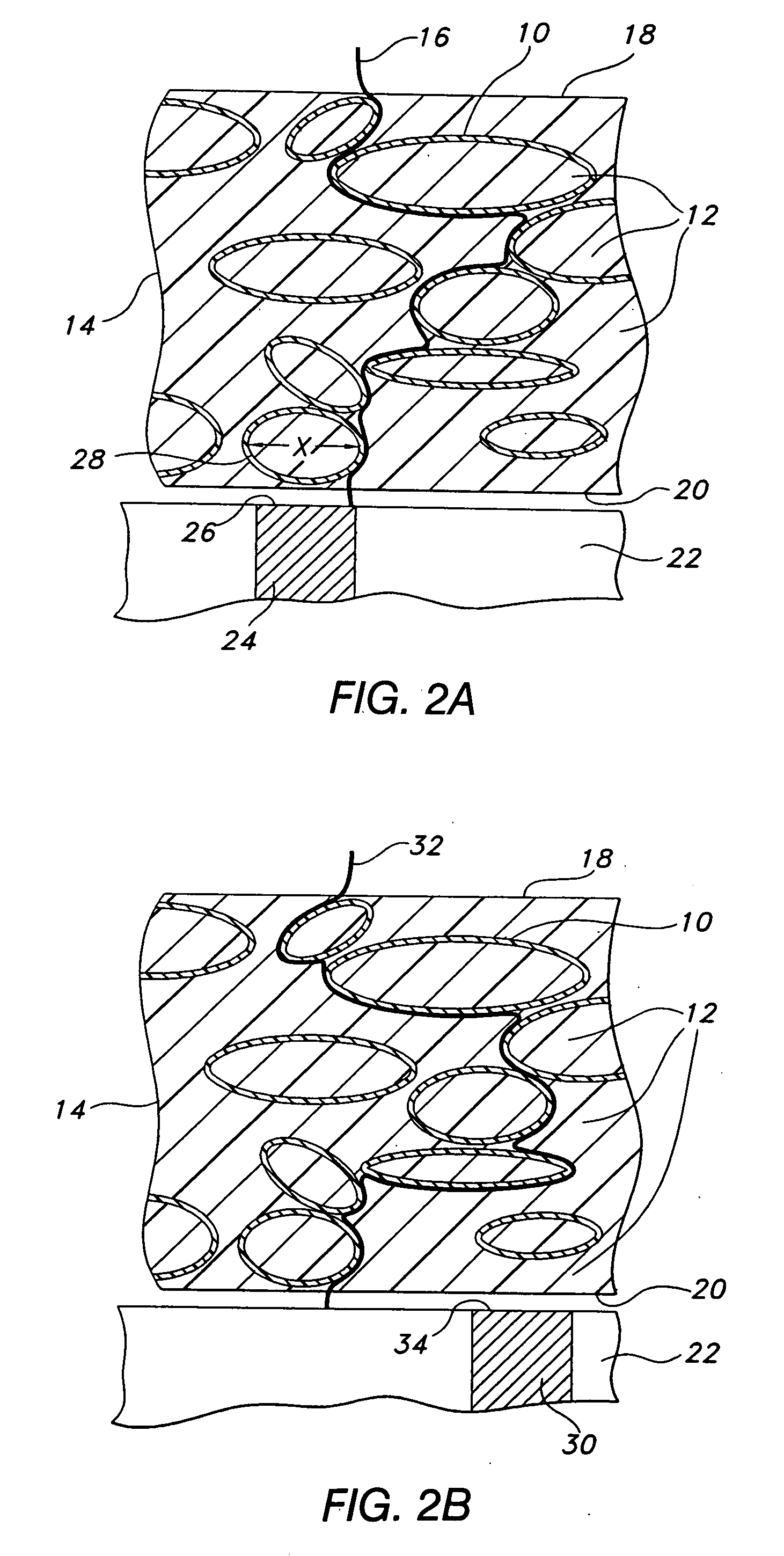

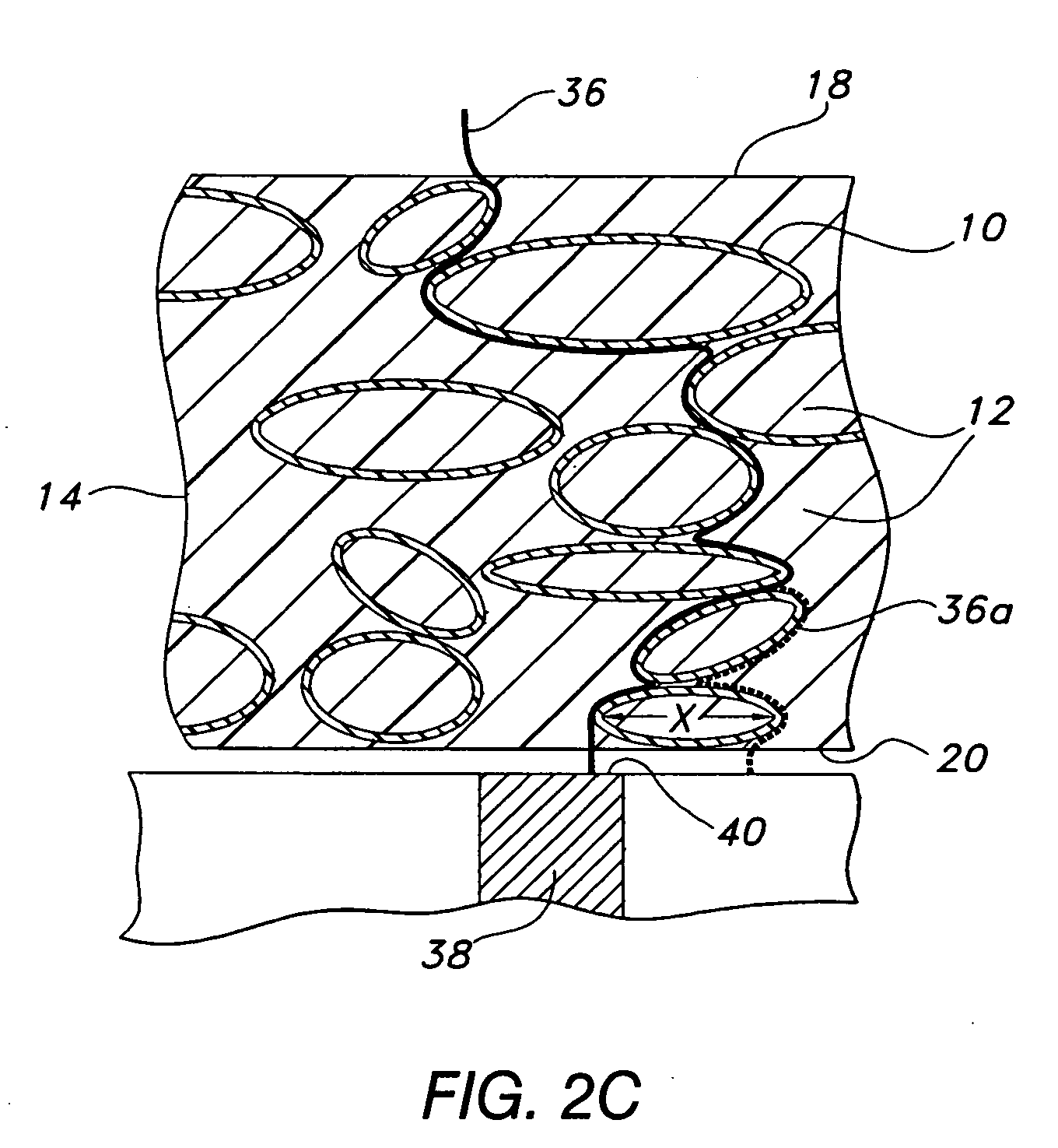

Techniques to improve polyurethane membranes for implantable glucose sensors

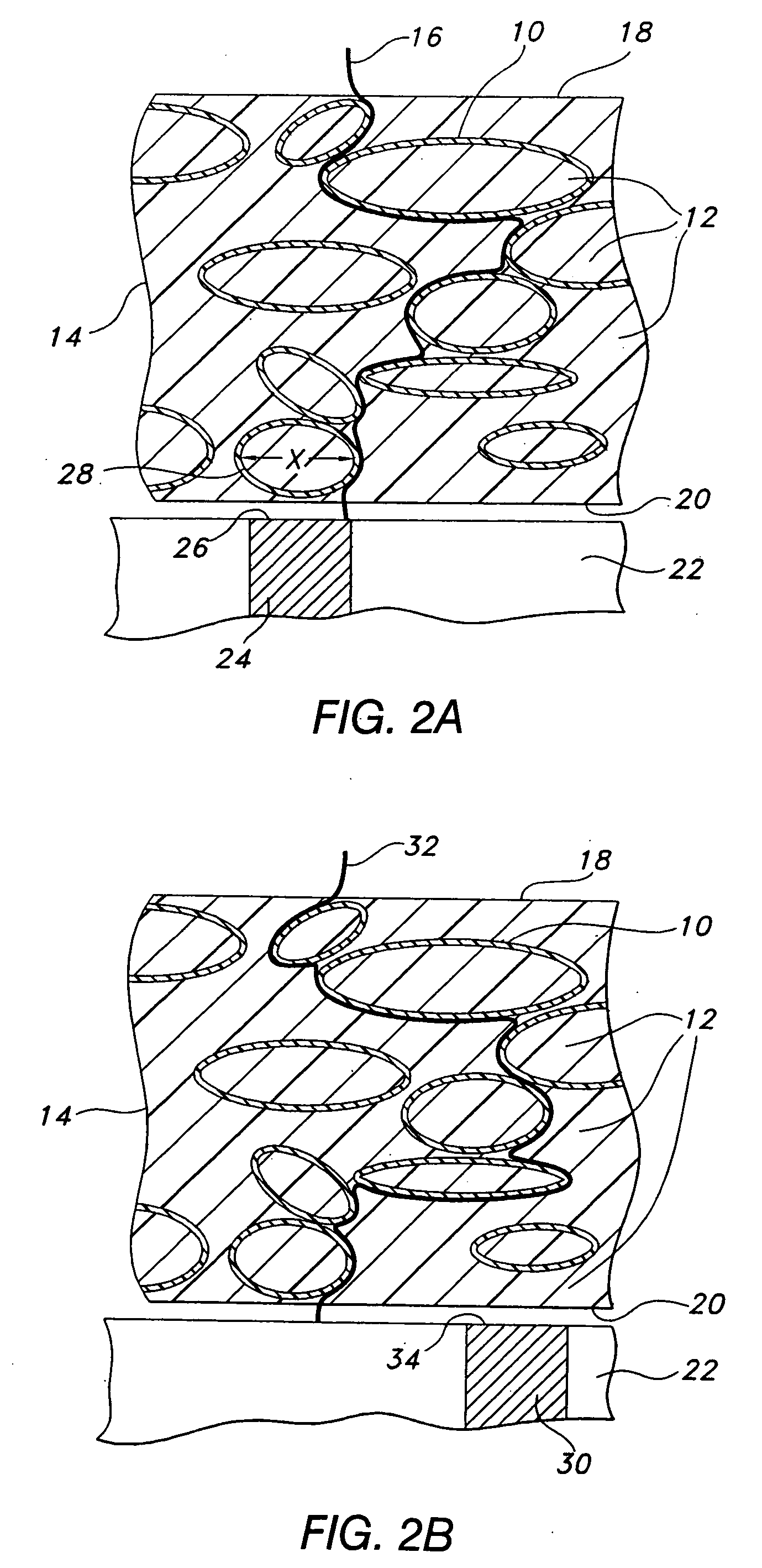

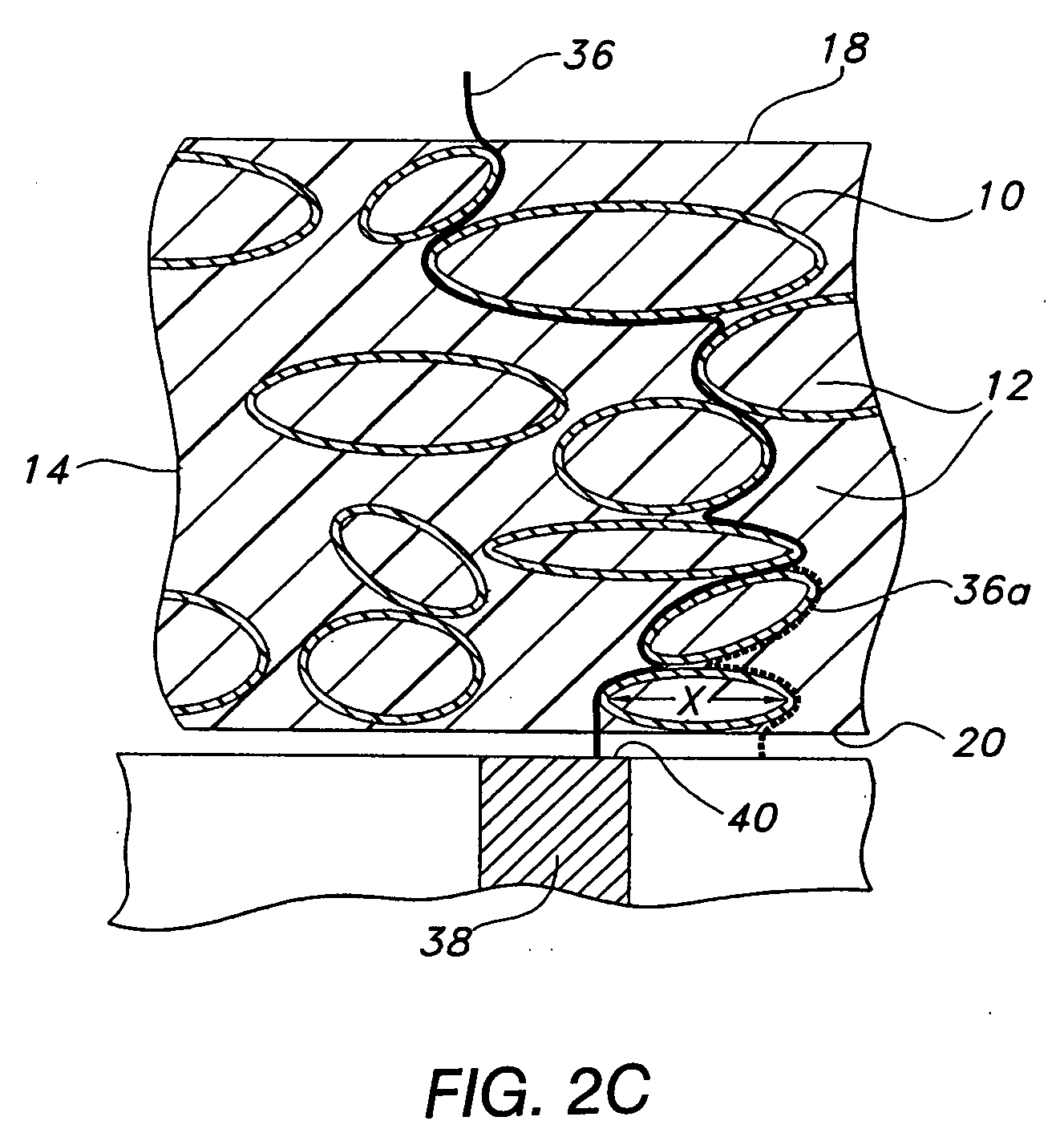

The invention provides an implantable membrane for regulating the transport of analytes therethrough that includes a matrix including a first polymer; and a second polymer dispersed throughout the matrix, wherein the second polymer forms a network of microdomains which when hydrated are not observable using photomicroscopy at 400× magnification or less. In one aspect, the homogeneous membrane of the present invention has hydrophilic domains dispersed substantially throughout a hydrophobic matrix to provide an optimum balance between oxygen and glucose transport to an electrochemical glucose sensor.

Owner:DEXCOM

Techniques to improve polyurethane membranes for implantable glucose sensors

ActiveUS20060086624A1Easy to makeImmobilised enzymesVolume/mass flow measurementAnalyteGlucose sensors

The invention provides an implantable membrane for regulating the transport of analytes therethrough that includes a matrix including a first polymer; and a second polymer dispersed throughout the matrix, wherein the second polymer forms a network of microdomains which when hydrated are not observable using photomicroscopy at 400× magnification or less. In one aspect, the homogeneous membrane of the present invention has hydrophilic domains dispersed substantially throughout a hydrophobic matrix to provide an optimum balance between oxygen and glucose transport to an electrochemical glucose sensor.

Owner:DEXCOM INC

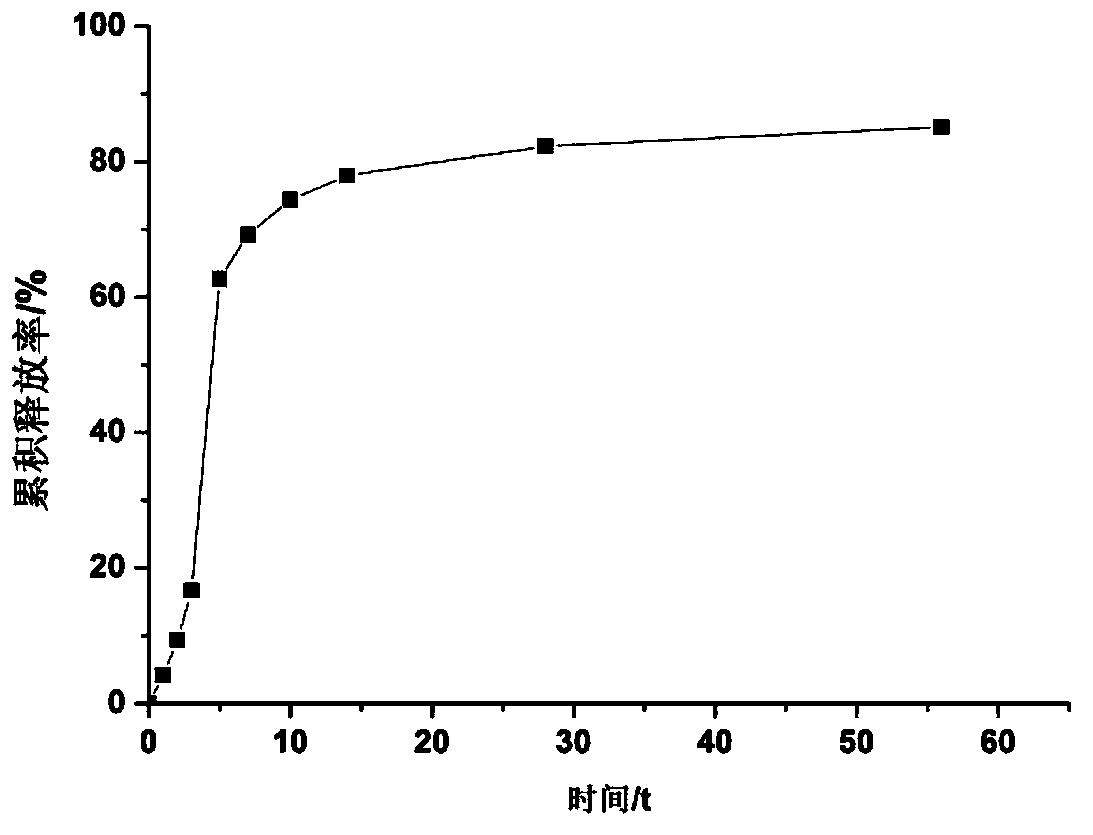

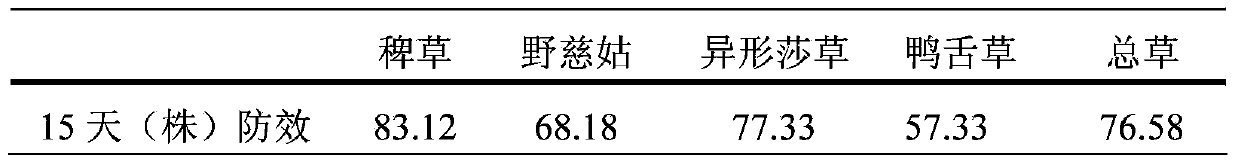

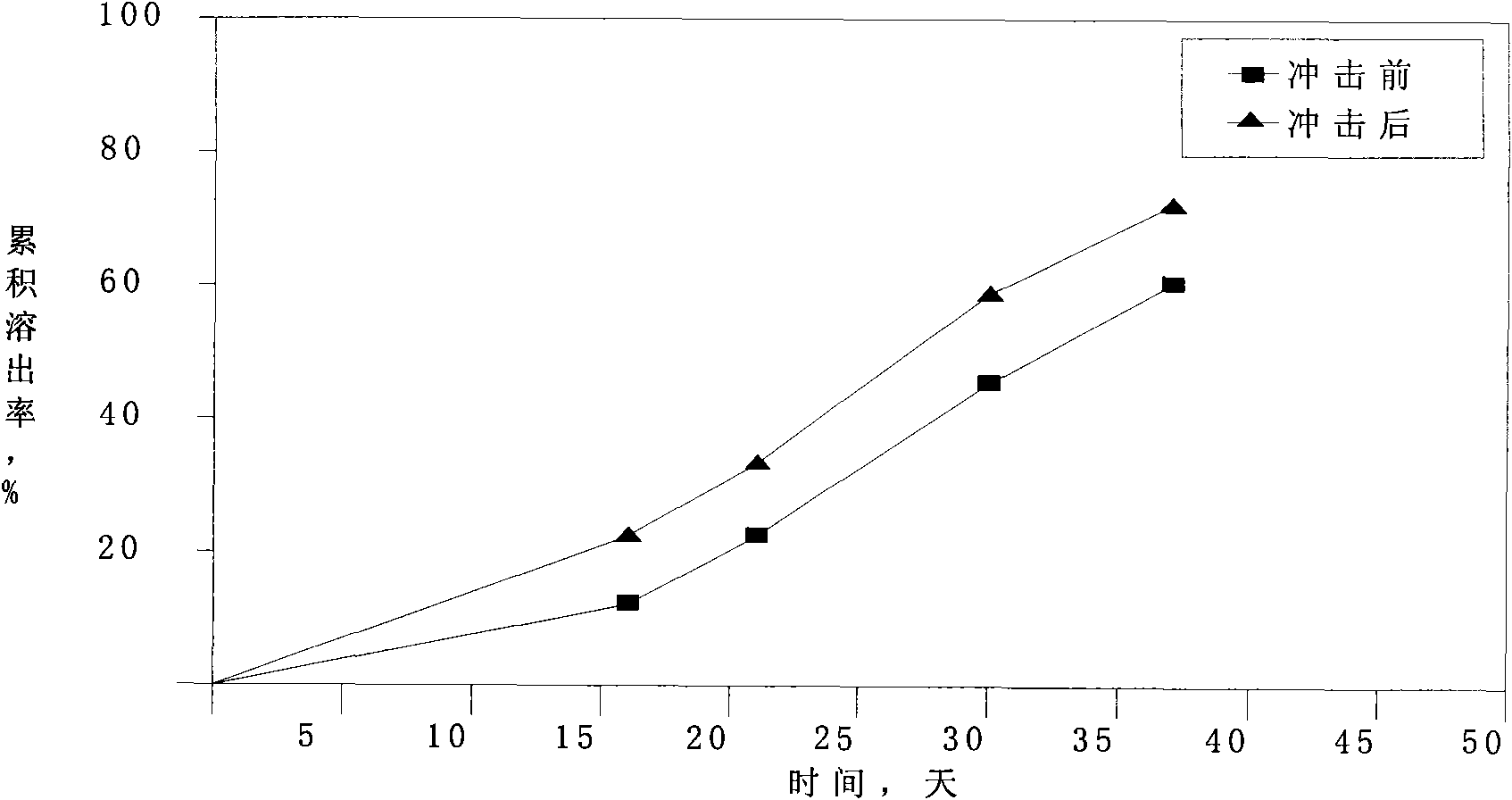

Polymer-coated controlled release pesticide granule and preparation method thereof

ActiveCN103387456AImprove water resistanceImprove targetingFertilizer mixturesWater basedPolyurethane membrane

The invention discloses a polymer-coated controlled release pesticide granule and a preparation method thereof. The polymer-coated controlled release pesticide granule comprises a pesticide granule and a polymer layer, wherein the pesticide granule is coated by the polymer layer; the pesticide granule contains one or more effective pesticide components; the polymer layer is a hydrophobic membrane layer and comprises a water-based polyacrylate membrane material or a polyurethane membrane material; the mass of the polymer layer accounts for 3%-15% of the weight of the polymer-coated controlled release pesticide granule. The effective pesticide components are acted on the peripheries of crop roots after the polymer-coated controlled release pesticide granule disclosed by the invention is applied along with a base fertilizer. The polymer-coated controlled release pesticide granule has good prevention and control effects on farmland weeds, soil insects and soil-borne diseases, and the coating material synthesis and preparation process is advanced and the polymer-coated controlled release pesticide granule has good controlled release property. The polymer-coated controlled release pesticide granule provided by the invention has the advantages of pesticide utilization ratio improvement, environment pollution reduction, sustainable development and wide application prospect.

Owner:BEIJING BOYICHENG SCI & TECH

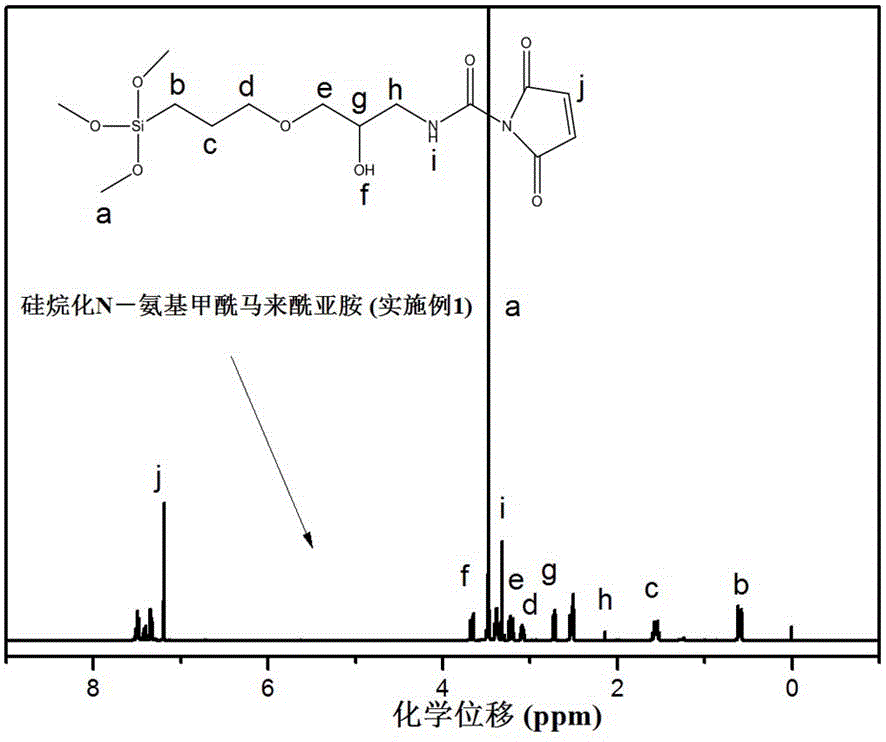

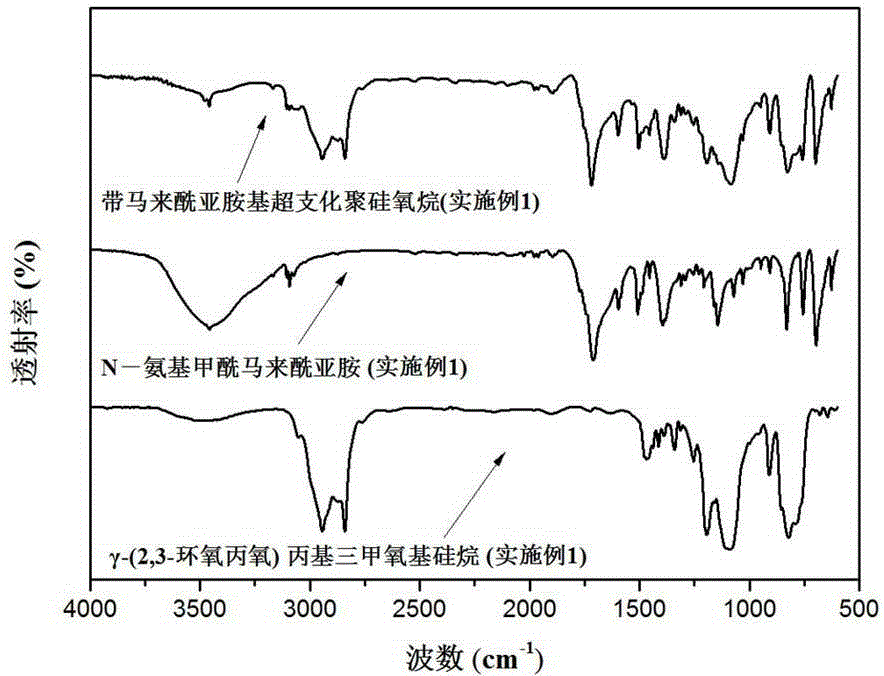

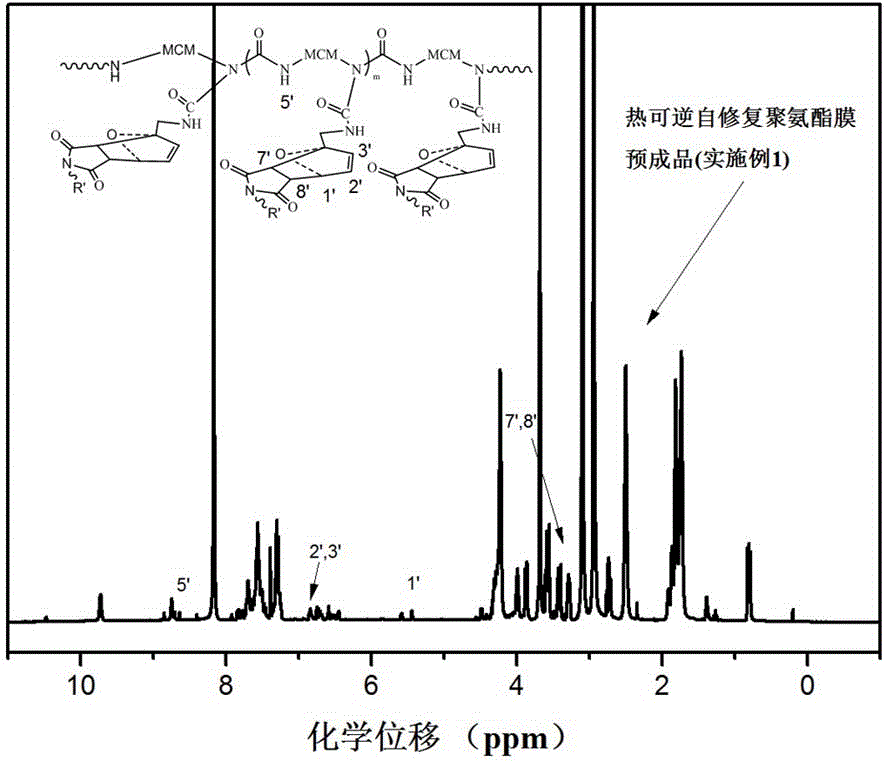

Thermal-reversible self-repair polyurethane membrane and preparation method therefor

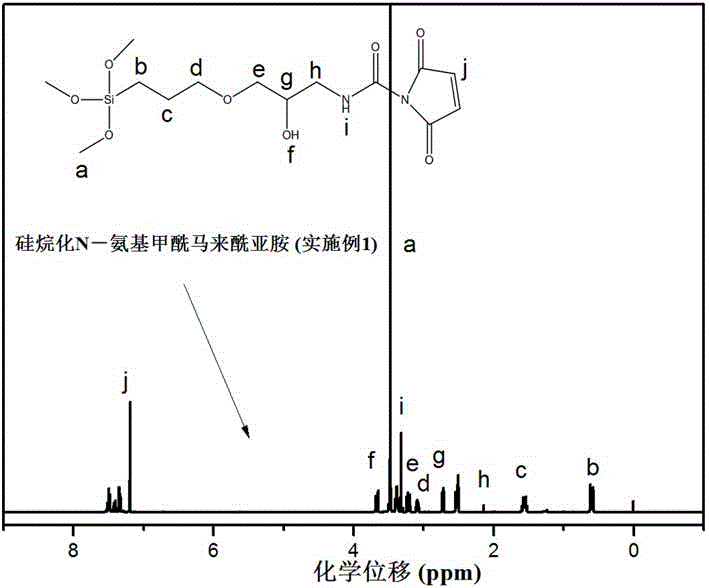

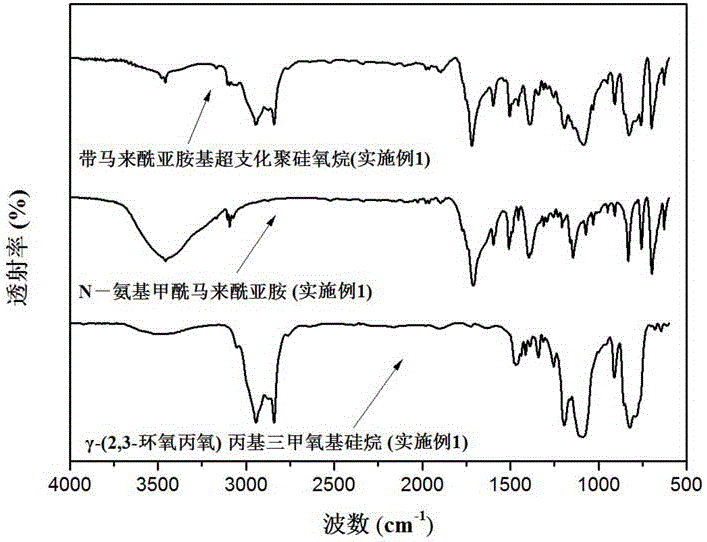

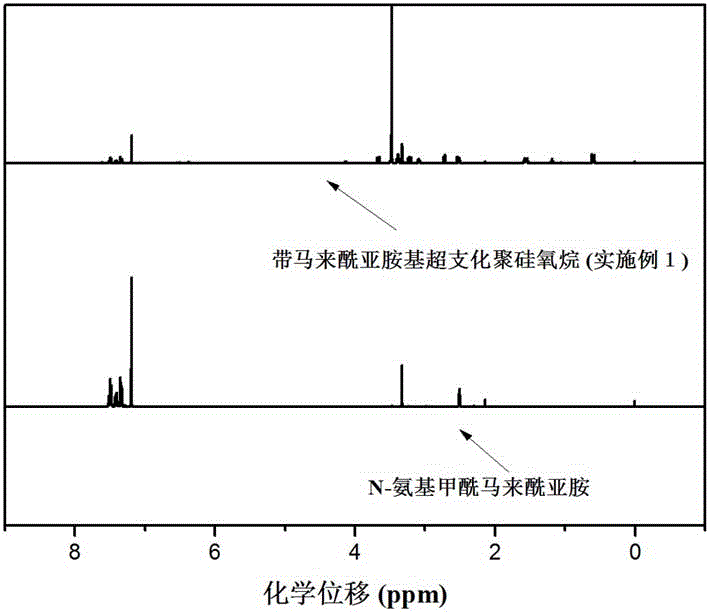

The invention discloses a thermal-reversible self-repair polyurethane membrane and a preparation method therefor. Under protection of inert gases, 4,4-diphenylmethane diisocyanate, polycaprolactone glycol and N,N-dimethyl formamide are mixed uniformly, a reaction is carried out at a temperature of 50-60 DEG C, then the solution is cooled to a temperature of less than 5DEG C, 2-furan methylamine is added in the solution, the temperature is risen to 95-105 DEG C, the reaction is carried out for 10-11h, then hyperbranched polysiloxane with maleimide groups is added, the pre-finishing product prepared after the reaction is finished is poured into a die and dried, and a thermal-reversible self-repair polyurethane membrane is obtained. By utilization of the Diels-Alder (DA) reaction, thermal-reversible self-repair of a polyurethane membrane is achieved, the prepared polyurethane membrane has advantages of excellent thermal stability and high hardness, and raw materials have wide sources. The preparation method has characteristics of simple technology, strong practicality, wide applicability and the like.

Owner:SUZHOU UNIV

Stable three enzyme creatinine biosensor

InactiveUS20090045056A1Controlled diffusionAvoid contactImmobilised enzymesBioreactor/fermenter combinationsCreatinine risePolyurethane membrane

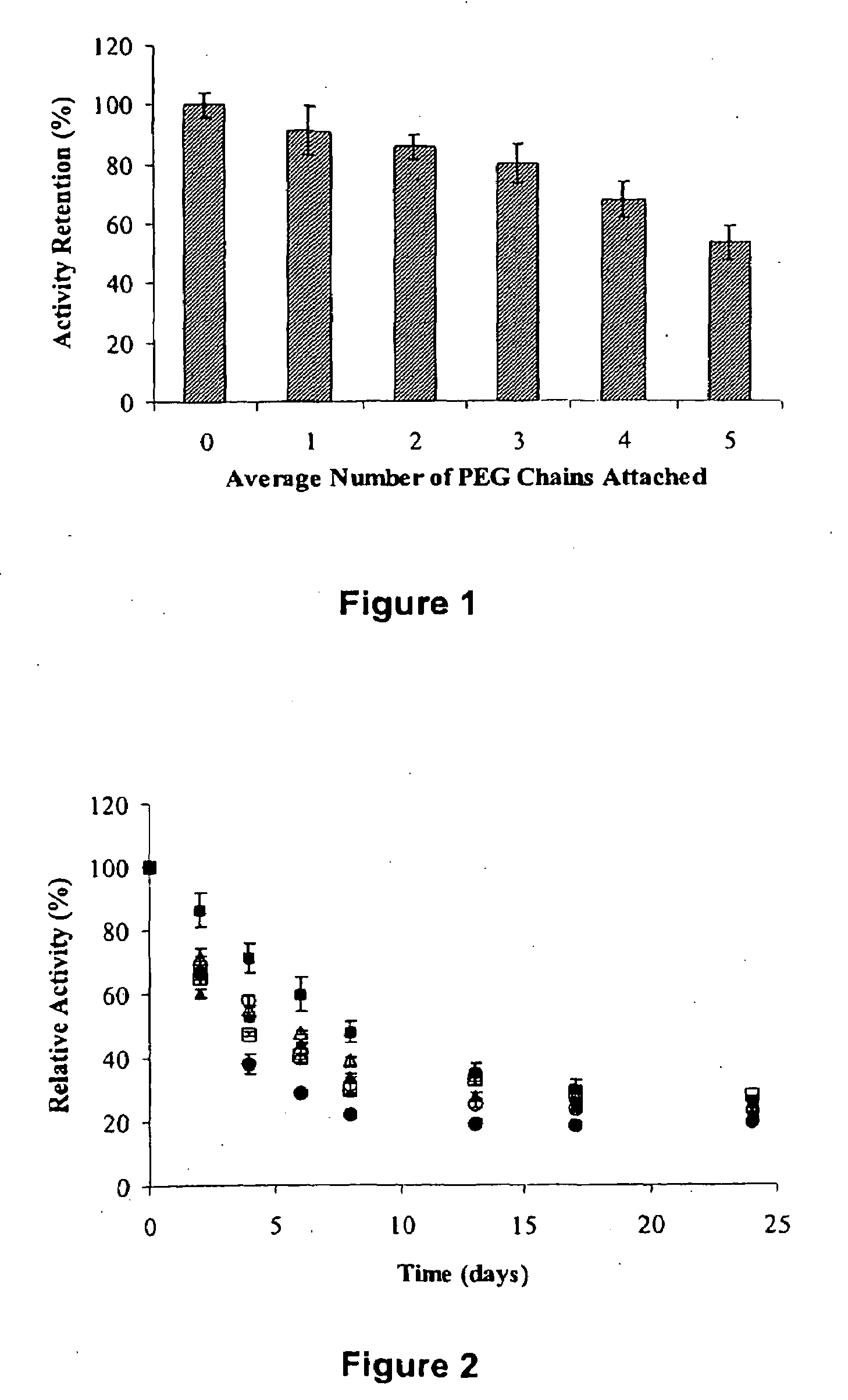

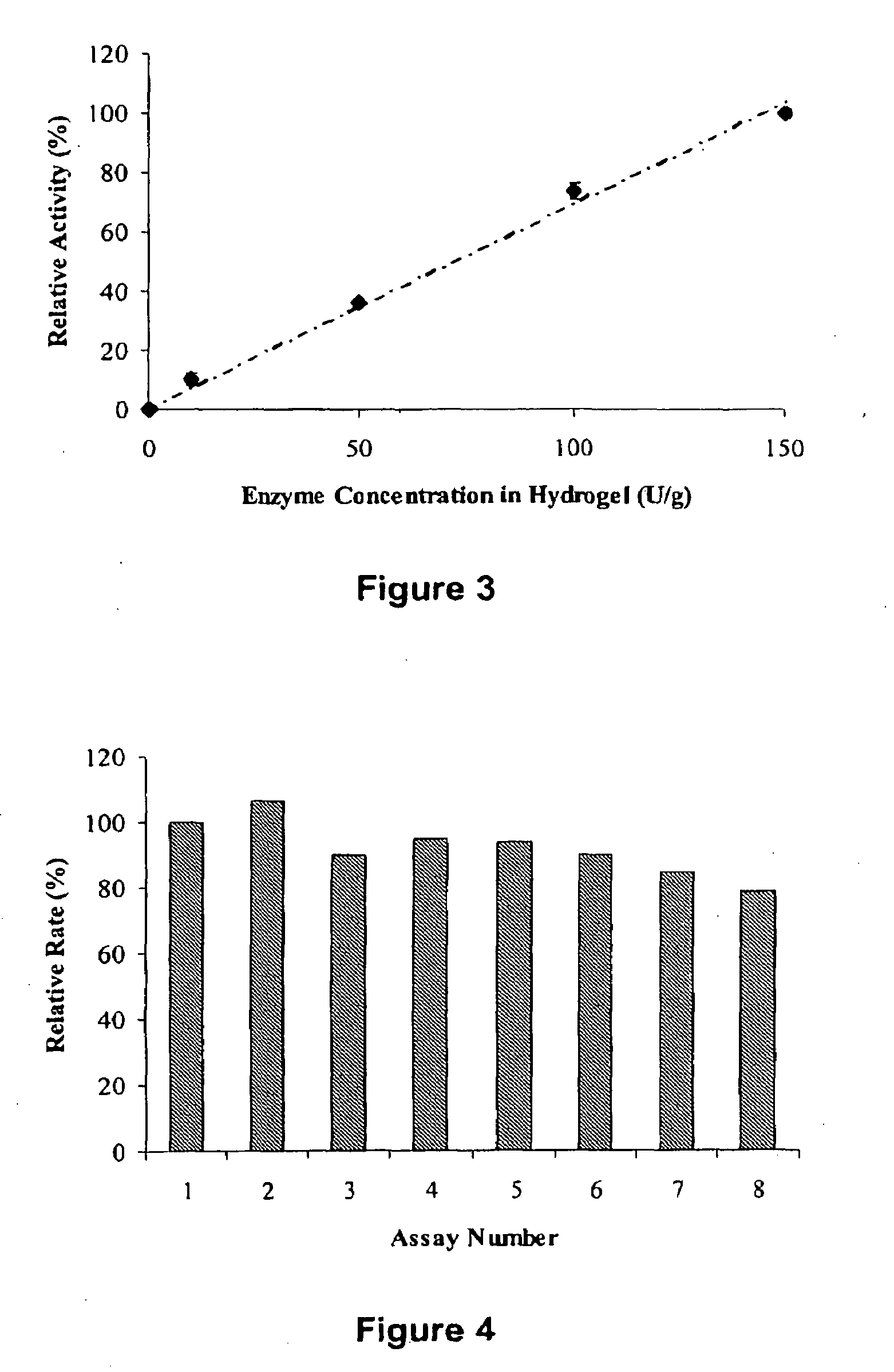

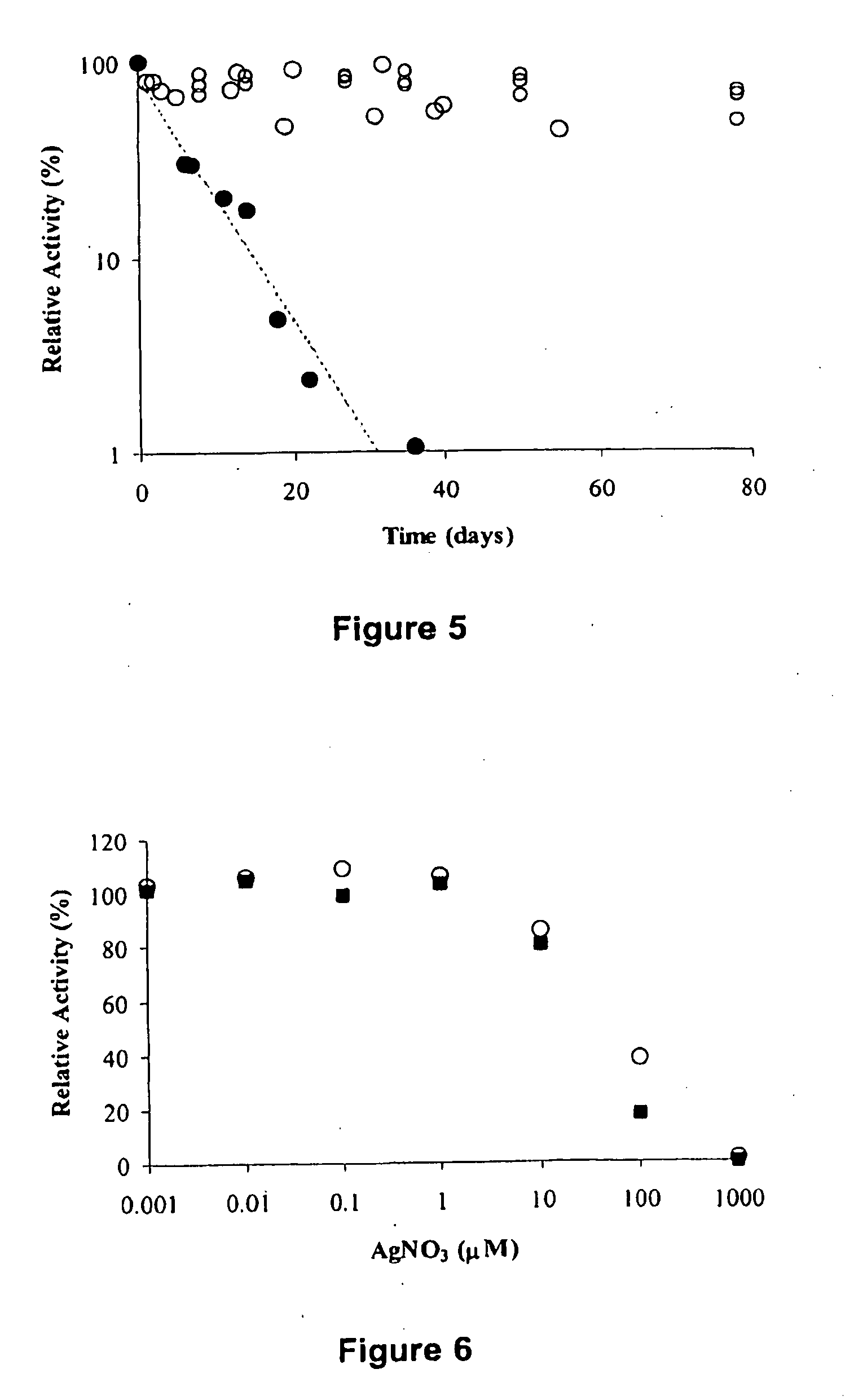

The invention provides methods for preparing a stable, multiple-use three enzyme biosensor for the amperometric determination of creatinine in biological liquids that has a useful lifetime that extends significantly beyond that of presently available amperometric biosensors. The biosensor prepared by the methods of the invention encompasses a plurality of immobilized enzymes that are applied to the biosensor as an enzyme-polymer composition. The enzymes, which can include creatinine amidohydrolase, creatine amidinohydrolase and sarcosine oxidase, are immobilized into the enzyme-polymer composition simultaneously as well as applied to the biosensor simultaneously. Prior to being immobilized, the enzymes can be chemically modified by attaching one or more polyethylene glycol (PEG) chains per enzyme monomer. The polymer component can be provided by a polyurethane membrane. The invention also provides a method of preparing a biosensor that limits the diffusion of silver ions emanating the reference electrode, thereby preventing, contact between the silver ions and the enzymes. Related methods of preparing an enzyme-polymer composition for incorporation into a multiple use three enzyme biosensor for the amperometric determination of creatinine in biological liquids also are provided. The invention also provides multiple-use biosensors and enzyme-polymer compositions prepared by the methods disclosed.

Owner:BERBERICH JASON +3

Method for preparing waterproof moisture-penetrating coated fabric

InactiveCN101956331AGood waterproof and breathableComfortable and soft touchFibre typesWoven fabricsPolyesterPorous coating

The invention relates to a method for preparing a waterproof moisture-penetrating coated fabric, which comprises the following steps of: preparing a base fabric with high density by adopting superfine high-elasticity polyester fibers, performing water-proof finish on the base fabric by using a micro molecular waterproofing agent and a softening agent, and coating a polyurethane membrane of numerous micropores with apertures of between diameters of water-drop molecules and water molecules on a shell fabric by a micro porous wet coating method. Therefore, the prepared shell fabric has the advantages of high-density fabrics and micro porous coating fabrics, has the advantages of soft texture, high tear resistance and tear fastness and good waterproof moisture-penetrating function, and can well meet the requirement of the market.

Owner:WUJIANG HENGRUN TEXTILE FACTORY

Thermally-reversible self-repairing electrostatic dissipation polyurethane membrane and production method thereof

ActiveCN105062040AReversible self-healingAlso has static dissipative propertiesPolyurea/polyurethane coatingsElectrically-conductive paintsPolyurethane membraneDimethyl formamide

The invention discloses a thermally-reversible self-repairing electrostatic dissipation polyurethane membrane and a production method thereof. The method comprises the following steps: uniformly mixing 4,4-diphenylmethane diisocyanate, polycaprolactone glycol and N,N-dimethyl formamide, reacting, cooling to a temperature being smaller than 5DEG C, adding 2-furanmethanamine, reacting, heating to 95-105DEG C, adding maleimido group-containing hyperbranched polysiloxane and functionalized carbon nanotubes, uniformly mixing, reacting the above obtained solution at 50-55DEG C to obtain a pre-finished product, pouring the pre-finished product into a die, and drying to obtain the thermally-reversible self-repairing electrostatic dissipation polyurethane membrane. A Diels-Alder (DA) reaction is used to realize thermal reversing and self repairing of the electrostatic dissipation polyurethane membrane; the electrostatic dissipation polyurethane membrane has the advantages of excellent thermal stability and electrostatic dissipation ability, and wide sources of raw materials; and the production method has the characteristics of simple process, strong practicality and extensive applicability.

Owner:SUZHOU UNIV

Waterborne polyurethane/dopamine modified graphene nano-composite emulsion preparation method

The invention discloses a waterborne polyurethane / dopamine modified graphene nano-composite emulsion preparation method and belongs to the field of organic-inorganic nano-composite materials. According to the preparation method, an improved Hummers method is utilized to prepare graphene oxide dispersion liquid at first, and then dopamine is utilized to surface modify the graphene oxide and compounded with waterborne polyurethane to prepare a waterborne polyurethane / dopamine modified graphene nano-composite emulsion. According to the preparation method disclosed by the invention, low polymer polyalcohol is utilized as a soft segment, isocyanate compound is utilized as a hard segment, and the dopamine modified graphene oxide dispersion liquid is guided into a waterborne polyurethane preparation process in site to prepare the waterborne polyurethane / dopamine modified graphene nano-composite emulsion. As the dopamine modified graphene is guided into, mechanical property, static resistance,conductivity, electromagnetic shielding, thermal conductivity, chemical resistance, corrosion resistance and the like of waterborne polyurethane membranes and coatings are effectively improved. The waterborne polyurethane / dopamine modified graphene nano-composite emulsion and rubber powder have a better application prospect in the fields of coatings, adhesives, printing ink, surface treating agents, elastomer, foam materials, functional films and the like.

Owner:JIANGNAN UNIV

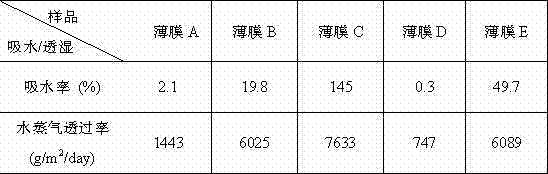

Waterproof moisture-permeable polyurethane membrane and composite material and preparation method and application thereof

ActiveCN101775203AHigh strengthExcellent waterproof and moisture-permeable functionRoof covering using flexible materialsSynthetic resin layered productsPolyesterProcedure Agents

The invention relates to a waterproof moisture-permeable polyurethane membrane and a four-layer composite material as well as a preparation method thereof and application thereof in the building field, wherein the four-layer composite material takes a polyurethane membrane as a water proof moisture-permeable functional layer, fiberglass gridding cloth as a reinforced layer and a polyester spunbonded non-woven fabric as a fabric layer and a bottom layer. By the invention, the four-layer composite material with a waterproof moisture-permeable function and high strength is prepared by taking the fiberglass gridding cloth as the reinforced layer and the polyester spunbonded non-woven fabric as the fabric layer and the bottom layer and carrying out hot press and compounding while a waterproof moisture-permeable membrane is prepared from polyurethane, inorganic filler and a processing aid by using a film coating method. The composite material can be used as a waterproof moisture-permeable layer of a slope type roofing cover or used as dry-hanging type decoration of a building outer wall and a waterproof moisture-permeable lining layer inside a heat-insulating material.

Owner:宁波曦昀高分子新材料有限公司

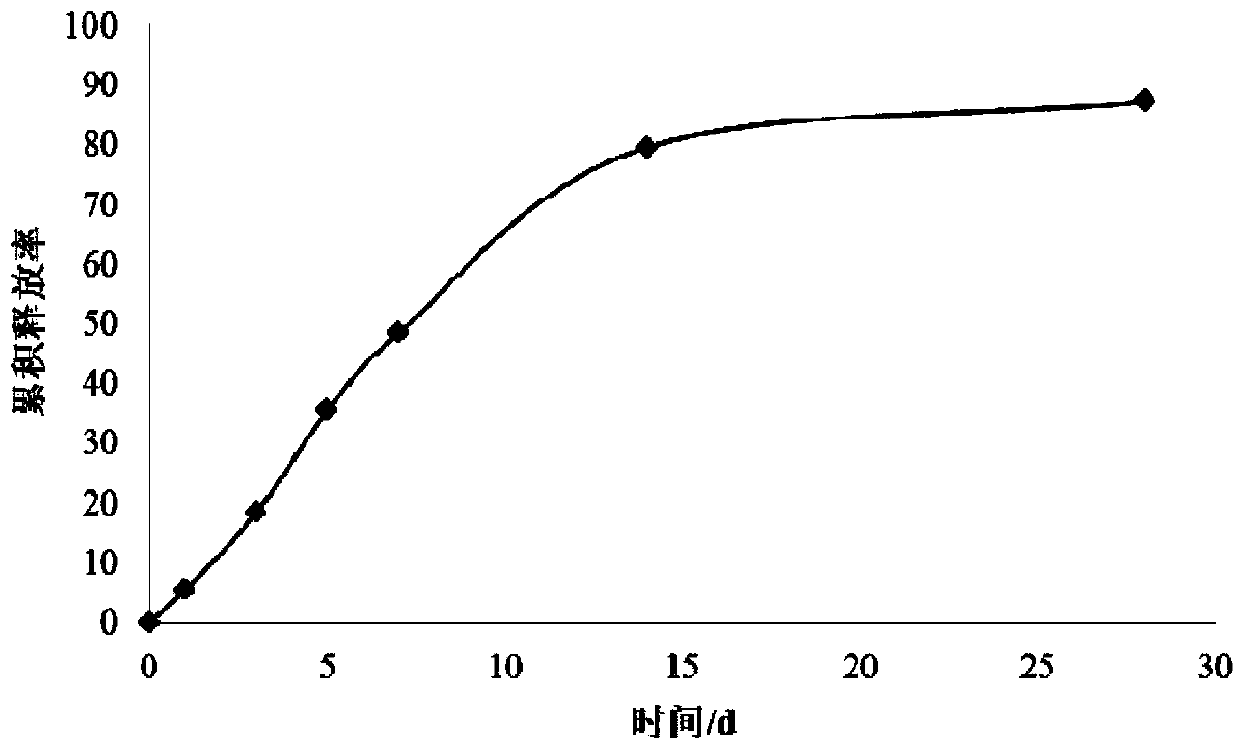

Polyurethane coated controlled-release fertilizer with improved mechanical property, preparation method thereof and special coating material

ActiveCN101671425AIncrease elasticityImprove toughnessPolyurea/polyurethane coatingsFertilizer mixturesMechanical propertyToughening

The invention discloses a polyurethane coated controlled-release fertilizer, a preparation method thereof and a special coating material. The coating material comprises modified isocyanate, polyalcohol and additive, wherein the mole ratio between hydroxyl (OH) in the polyalcohol and isocyanic acid radical (NCO) in the modified isocyanate is 1: 0.8-2.0; the polyalcohol is alcohol containing 2-6 hydroxies and has the molecular weight of 60-3000Da; and the additive is lubricating agent and / or toughening agent, and the adding quantity of the additive is 0.1%-20% of the mass of the modified isocyanate and the polyalcohol. The coated controlled-release fertilizer consists of a core and a core film, wherein the core is granular fertilizer, the core film is made of the coating material, and the mass of the core film is 1.0-10% of the mass of the core. The polyurethane coating prepared by the coating material can enhance the elasticity and the toughness of a polyurethane film layer and correspondingly improve the mechanical damage resistance performance of the coated fertilizer.

Owner:CHINA NAT OFFSHORE OIL CORP +2

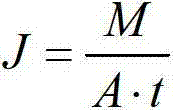

Process for preparing hygroscopic vapor transmission polyurethane membrane

The invention belongs to the filed of polyurethane material processing, in particular to a production method of a moisture-absorbing and breathable polyurethane film. The production process of the moisture-absorbing and breathable polyurethane film includes the following steps: the superfine powder of organic polymer material is modified and dispersed; polyurethane solution is prepared; the products are mixed to cast the film. The polyurethane film processed by the method not only includes polymer material superfine powder, but also includes micro-pores which are around the superfine powder particles, go through the interface of the polyurethane film and for water vapor to go through; in the polyurethane film, the superfine powder can absorb and release the moisture by the micro-pores around, so that the polyurethane film has excellent moisture absorbing and breathable effect; meanwhile, the process of the technical proposal has simple and convenient processing route, and is easy for industrialized promotion.

Owner:WUHAN TEXTILE UNIV

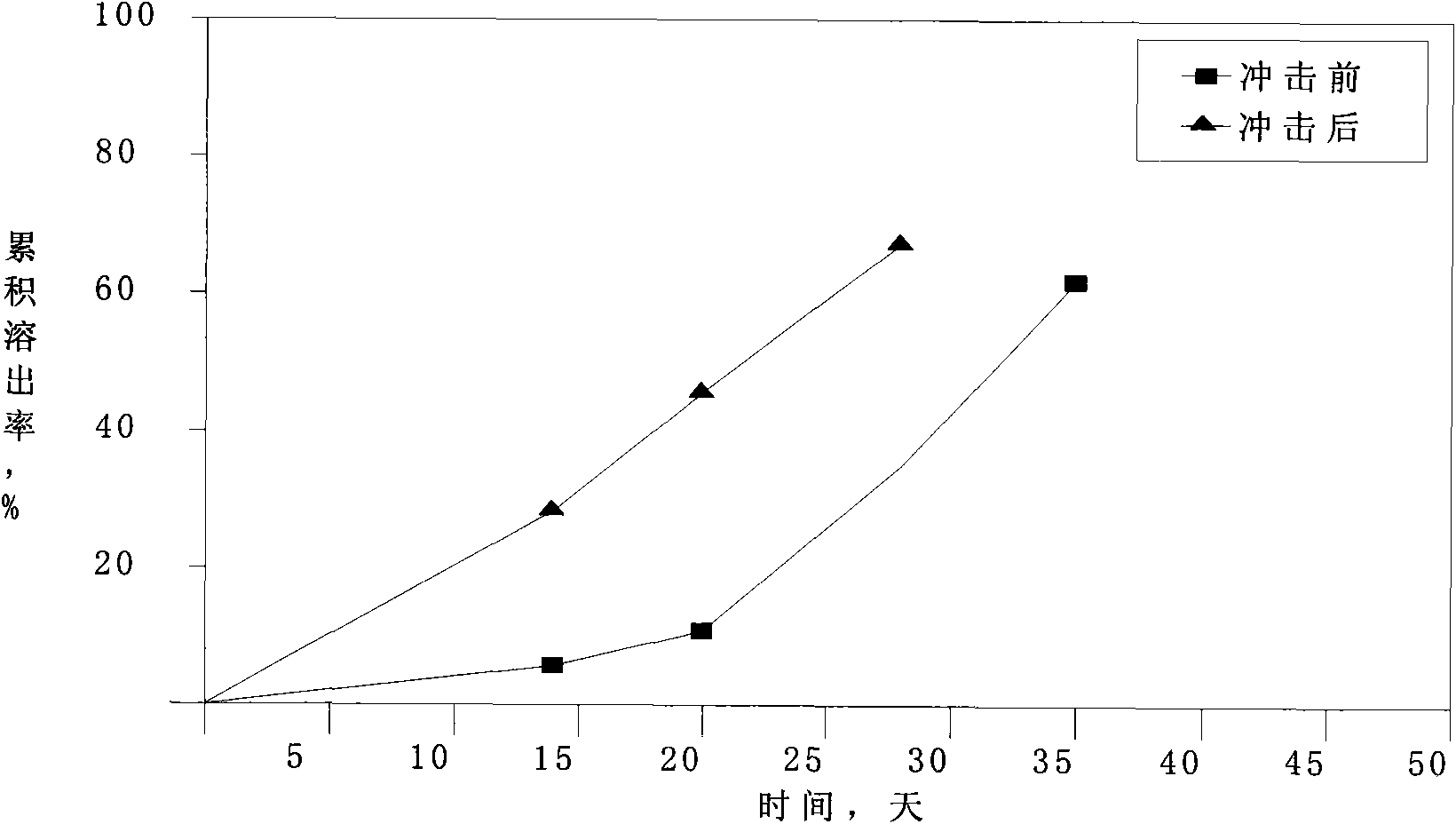

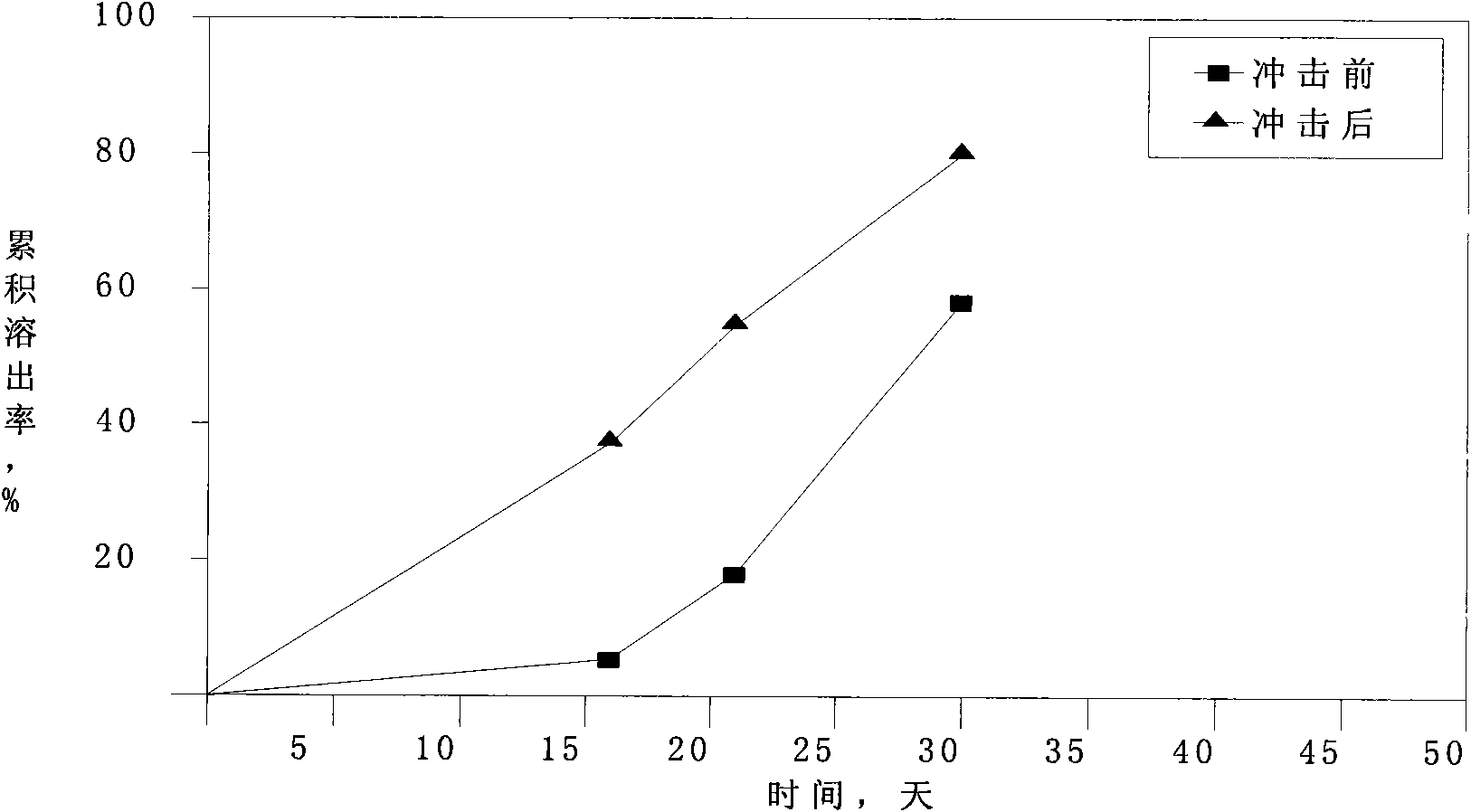

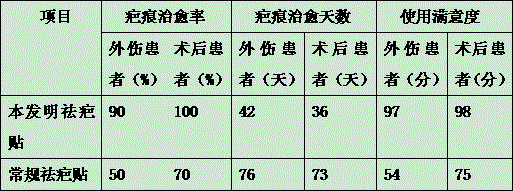

Scar treatment strip capable of lowering tissue tension and preparation method thereof

InactiveCN105536027AReduce tensionIncrease elasticityNon-adhesive dressingsAdhesive dressingsHuman bodyPolyurethane membrane

The invention discloses a scar treatment strip capable of lowering tissue tension and a preparation method thereof. The scar treatment strip comprises a polyurethane membrane of which two ends are provided with adhesive, wherein the middle of the polyurethane membrane is provided with medical dressing; the upper part of the medical dressing and the upper part of the adhesive are provided with isolation paper of which the shape and the size are matched with the shape and the size of the polyurethane membrane; the medical dressing not only can cure scars but also can form prestressing force on the scar, tension applied to the scar by the surrounding tissues of the scar can be lowered, the scar is under the dynamic balance of the tension, and the scar can be quickly recovered so as to lighten scar marks and aberration between the scar and the surrounding skin tissues of a human body.

Owner:HENAN HUIBO MEDICAL CO LTD

Preparation method for macromonomer modified nanometer silica aqueous silica sol and light-cured aqueous polyurethane nanometer composite emulsion of same

ActiveCN102336884ASimple processReaction is easy to controlPolyurea/polyurethane coatingsDispersion stabilityPolyurethane membrane

The invention relates to a preparation method for macromonomer modified nanometer silica aqueous silica sol and light-cured aqueous polyurethane nanometer composite emulsion. According to the invention, since there are a great amount of silanol groups on the surface of unmodified nanometer silica, water-soluble polyethylene glycol acrylate macromonomers are employed and enabled to adhere to the surface of aqueous nanometer silica through hydrogen bonding, and the macromonomer modified nanometer silica aqueous silica sol is formed; the macromonomer modified nanometer silica aqueous silica sol is introduced in situ during the preparation process for light-cured aqueous polyurethane emulsion so as to prepare the light-cured aqueous polyurethane nanometer composite emulsion. The nanometer composite emulsion prepared by the method has good dispersion stability; simultaneously, nanometer silica has very good dispersibility in a polyurethane membrane; introduction of inorganic nanometer silica enables mechanical properties of a light-cured coating to be obviously improved. Obtained dispersion in the invention can be extensively applied in the field of surface coatings for high damage resistant and wear resistant woodenwares, metals, plastics, etc.

Owner:HAIMEN MAOFA ART DESIGN CO LTD

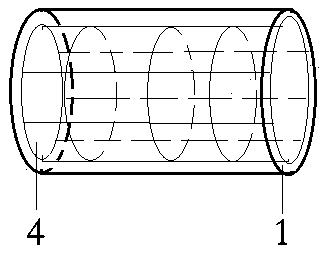

Preparation method of polyurethane hollow fiber filter membrane

The invention relates to a method for preparing a high permeation flux polyurethane hollow fiber filter membrane. The method comprises the following steps: a polyurethane prepolymer is obtained by stirring and mixing polyol, isocyanate and prepolymerization adding material; then polyurethane membrane forming gel fluid is generated by adding a solvent, a chain extender and an additive therein; the solvent and the additive are simultaneously used for preparing an inner gel medium; a spinning device is used for carrying out the dry-wet spinning membrane preparation; the treatment is carried out after that to remove the residual solvent and the additive, thereby obtaining the high permeation flux polyurethane hollow fiber filter membrane. The obtained hollow fiber filter membrane has excellent performances, the porosity achieves more than 92 percent, and the permeation flux of purified water can achieve 950 to 1000L / (h*m<2>*1 atmospheric pressure). The hollow fiber filter membrane produced by utilizing the membrane preparation formula, the process and the parameters of the invention has relatively lower cost and can obtain very high permeation flux, thereby having wide industrial application prospect in waste water treatment, separation of medical products from other biochemical products, concentration and other fields.

Owner:深圳龙澄高科技环保股份有限公司

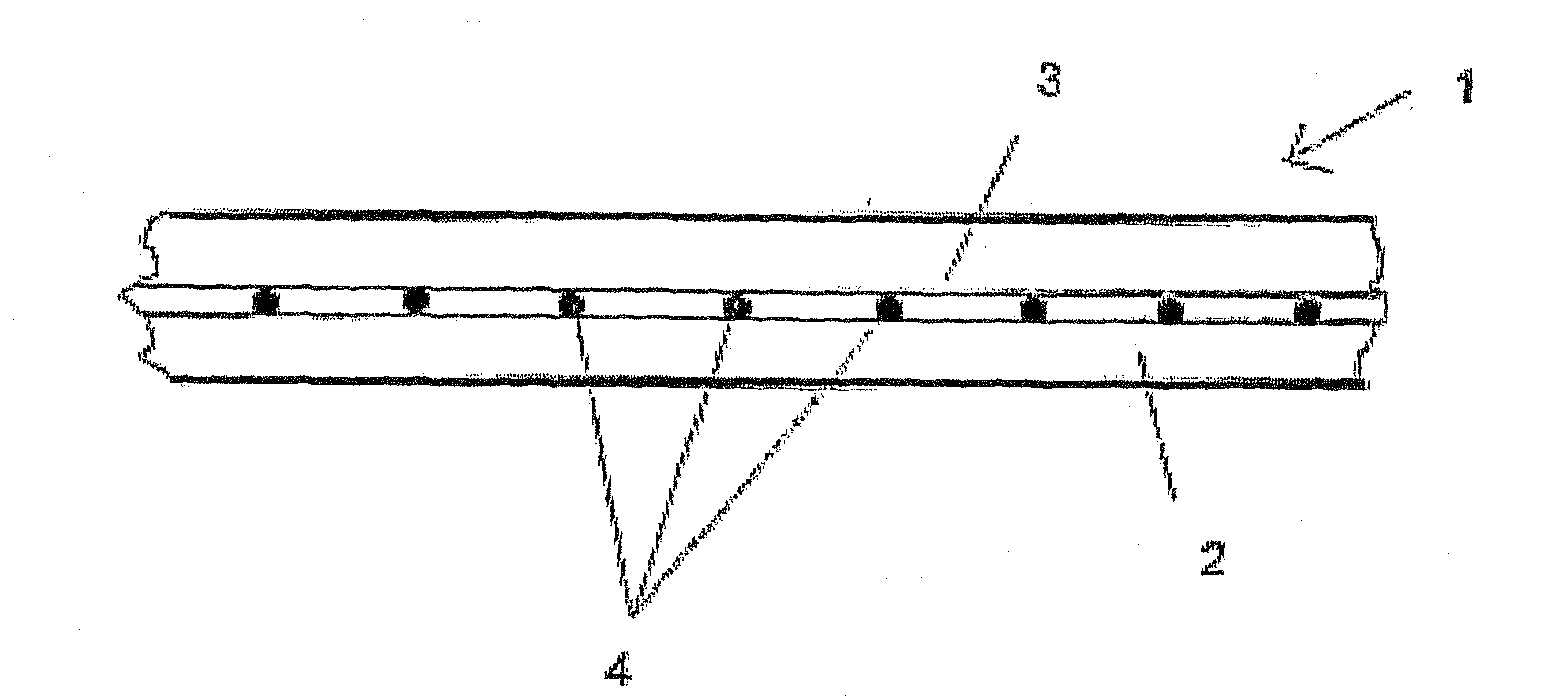

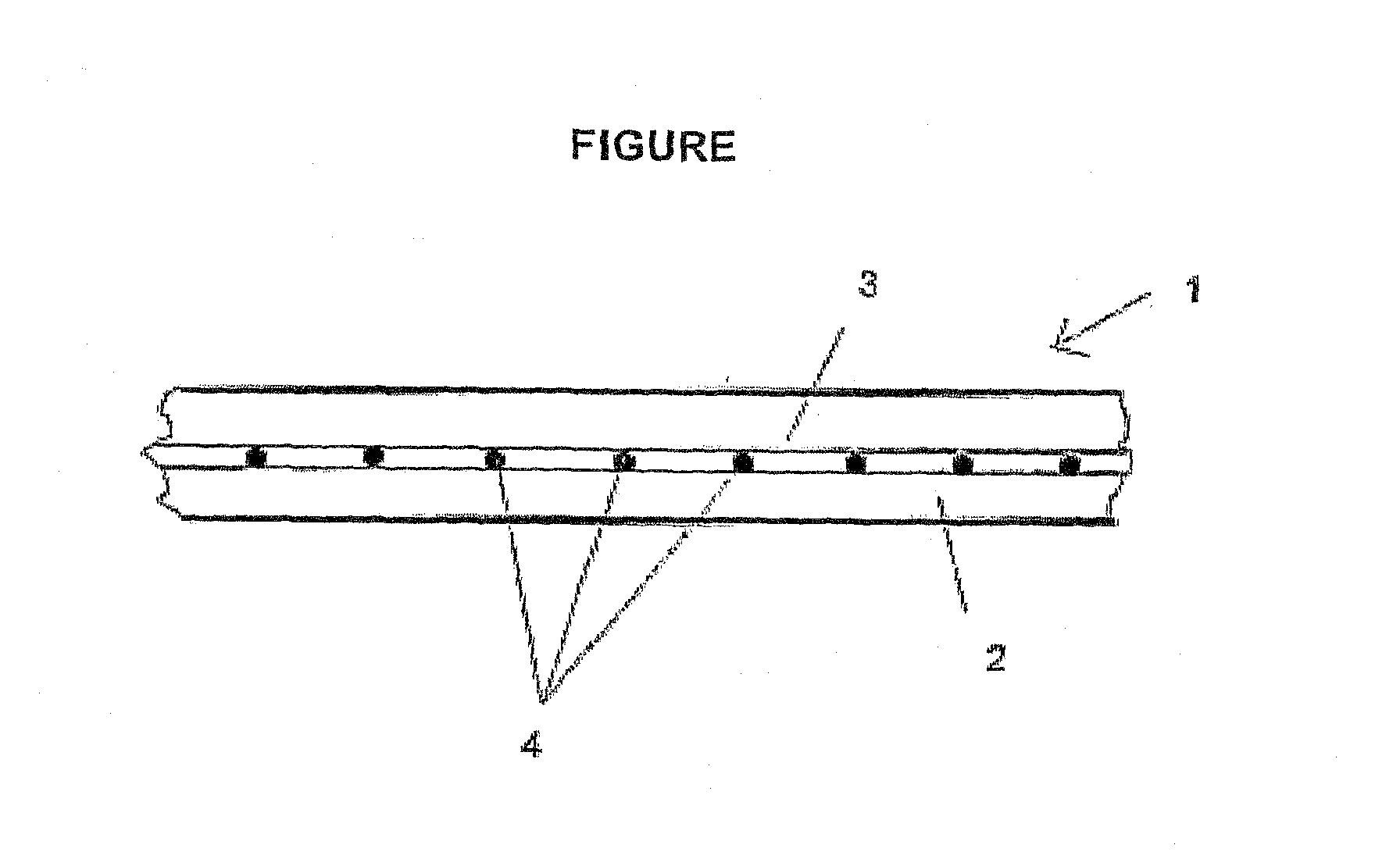

Multi-Ply Technical Composite Which Is Breathable And Moisturising, Releases Active Constituents And Promotes Their Absorption, And Can Be Uses As A Medical Aid Or To Make Clothing Or Structures That Come Into Direct Contact With Healthy Or Diseased Skin

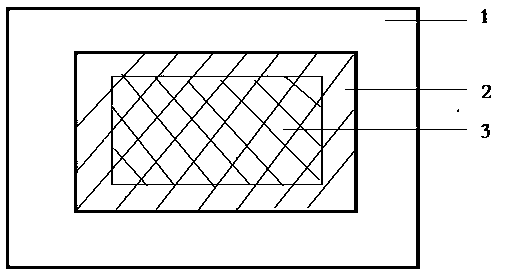

InactiveUS20080195016A1Garment special featuresSynthetic resin layered productsPolyurethane membraneSkin contact

A multi-ply technical composite, usable in particular for making medical aids, garments and medical articles, includes at least two layers (2, 3), the first of which (2), in contact with the skin, is a cotton fabric (elasticised to a greater or lesser extent) or silk, or fabrics to which chitosan, silver or another antibacterial substance or active constituent is added, and the second, outer layer (3) is constituted by a semipermeable membrane, such as polyurethane between 5 and 80 microns thick, with considerable elasticity in order to ensure the user's comfort. Receptors rechargeable with active constituents are inserted into fabric (2) and protected by the polyurethane membrane.

Owner:BOTTINI EMILIO

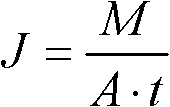

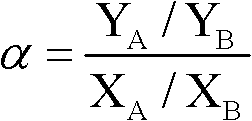

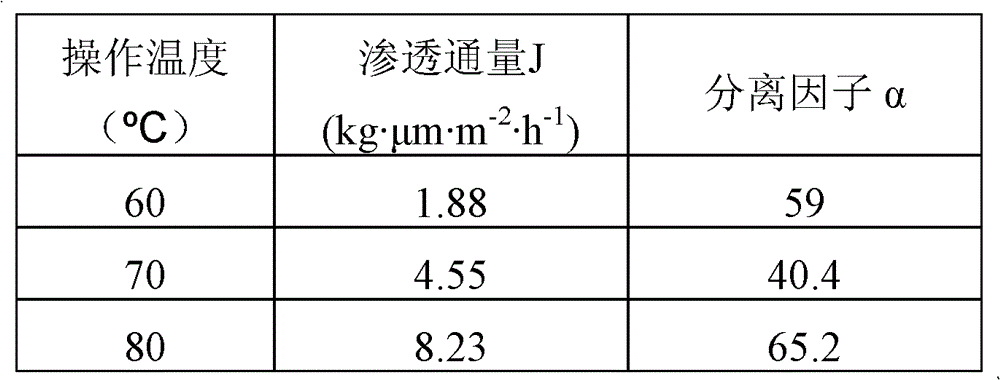

Preparation method of polyurethane pervaporation phenol/water separating membrane compounded by inorganic particles

InactiveCN103084077AHigh temperature resistantHigh temperature resistanceDistillationFiberDiphenylmethane

The invention discloses a preparation method of a polyurethane pervaporation phenol / water separating membrane compounded by inorganic particles, and belongs to the field of pervaporation membrane separation. The polyurethane membrane basic material is obtained by polymerizing and mixing monomer hydroxyl-terminated polybutadiene, toluene diisocynate, 4,4'-diamine diphenylmethane solution, cyclodextrin and silica or carbon fiber powder. The preparation method comprises the following steps: reacting hydroxyl-terminated polybutadiene with toluene diisocynate to obtain blocked prepolymer, then adding 4,4'-diamine diphenylmethane solution and cyclodextrin as chain extenders to perform the chain extension, and adding inorganic modified particle silica or carbon fiber powder (using N,N-dimethylacetamide as solvent) to obtain prepolymer solution of polyurethane; casting the solution on a polyfluortetraethylene plate to form a membrane, solidifying for 1-1.5 hours at room temperature, and moving the membrane to an oven at 80 DEG C to thermally treat to obtain the polyurethane membrane compounded by inorganic particles. The preparation method disclosed by the invention is simple in process, and the prepared membrane has good heat and chemical stability and mechanical property.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Preparation method of polyurethane and sericin medical composite film with water absorption and moisture permeability

InactiveCN102294048AImprove hydrophilicityGood water absorption and moisture permeabilityAbsorbent padsBandagesAnalgesics drugsComposite film

The invention discloses a preparation method of a polyurethane and sericin medical composite film with water absorption and moisture permeability. The steps are as follows: (1) preparation of polyurethane solution; (2) preparation of sericin suspension; (3) configuration of aliphatic polyurethane and sericin blend solution; (4) pouring membrane-forming liquid into glassine On the paper, the smear stick is evenly applied, and two methods of dry film formation and wet film formation are used to make a uniform film. Using sericin as the filling material, introducing sericin particles into the matrix not only forms micropores around the sericin particles, but also sericin contains a variety of amino acids with polar groups, and its good hydrophilicity provides a bridge for water transfer , so that the prepared film has good water absorption and moisture permeability. Bioactive ingredients can be loaded during the preparation process, and the bioactive ingredients can include various antibacterial, hemostatic, anti-inflammatory, analgesic drugs and / or growth factors and other active ingredients required for treatment to promote wound healing.

Owner:ZHEJIANG SCI-TECH UNIV

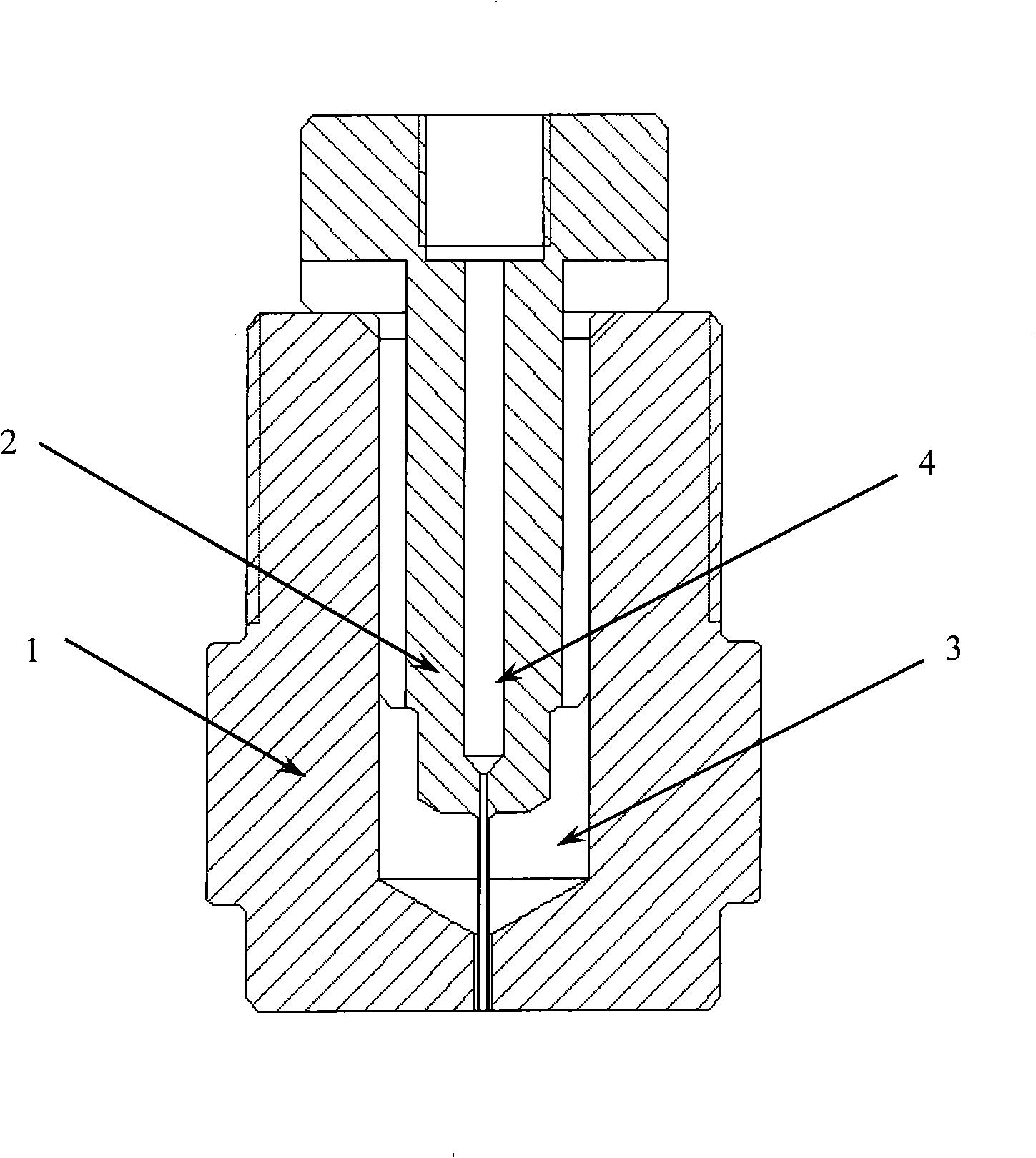

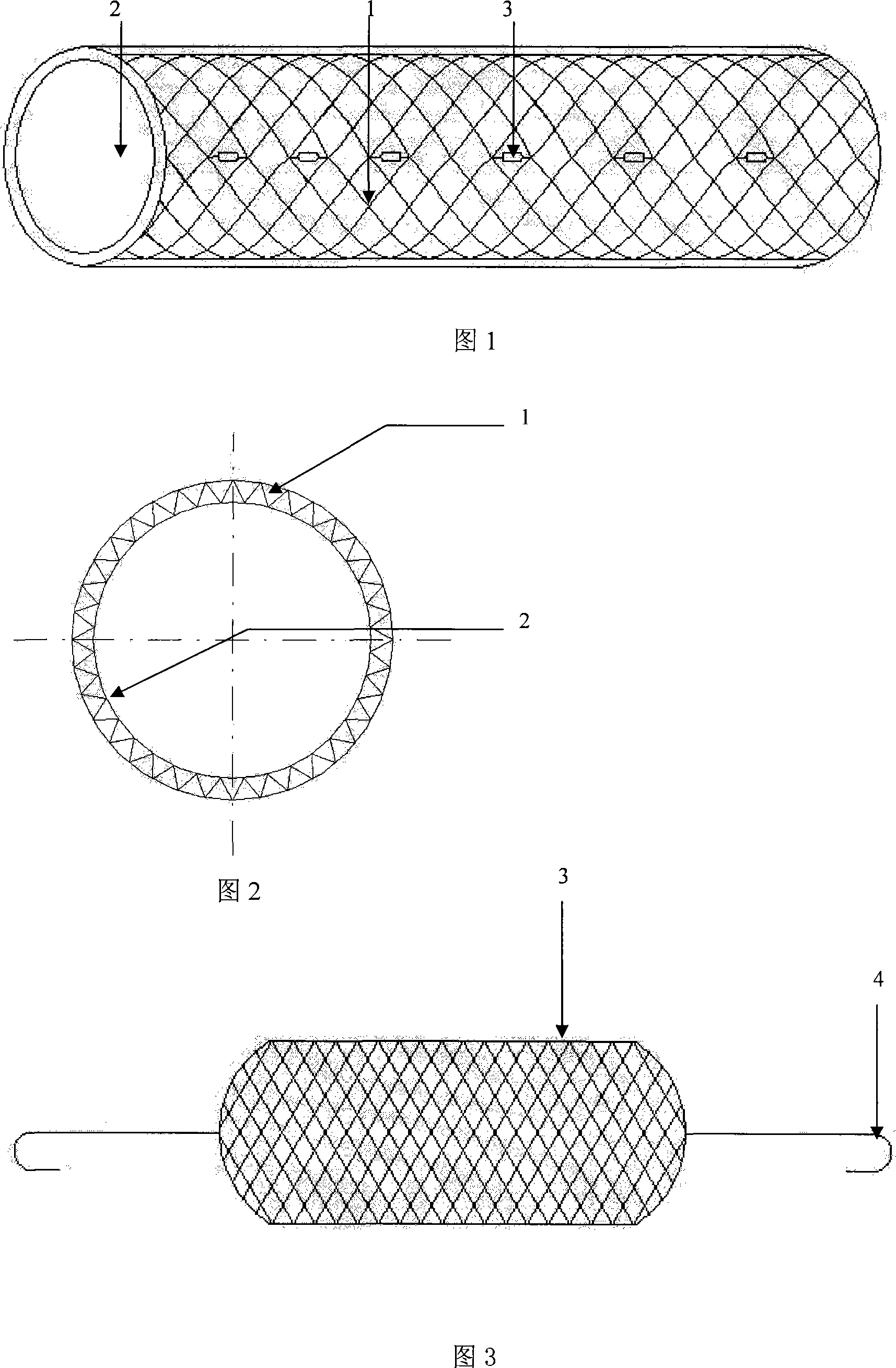

Medical tectorial membrane shaped radiation NiTi alloy endovascular stent

InactiveCN101161297AShort doubling timeRestore proliferative abilityStentsSurgeryTectorial membraneNiti alloy

The present invention belongs to the technique category of the medical instrument, relates to a tectorial conformal radiate NiTi alloy vascular inner rack which is implanted to the blood vessel of the human body. To settle the problems of that the existing vascular inner rack can not restrain the growth of the tumour and the thrombus is easy to form, etc., the bracket used by the invention is self-expanding NiTi alloy vascular inner rack, a layer of polycarbonate type polyurethane membrane is covered at the inner wall, the antineoplastic medicine is spraying-coated to the inner surface of the membrane, and the active particles which are used for the inner radiating of the tumour are inserted at the outer bracket of the membrane according to the conformal property. The NiTi alloy vascular inner rack applied by the invention can effectively expand and support the blood vessel; the novel film forming material polycarbonate type polyurethane has an excellent bioavailability; the active particles for the conformal radiotheraphy outside the membrane are inserted to the bracket with a simple and convenient double-buckle mode, the growth surround the blood vessel area is effectively restrained and the radioactive side injury of the normal tissue is reduced. The invention has the advantages of easy making, low cost, strong innovation and wide market prospect.

Owner:李楠

Preparation method of modified polyurethane pervaporation phenol/water separation membrane

InactiveCN102743982AHigh affinityHigh mechanical strengthSemi-permeable membranesPolyurethane membraneSeparation technology

Belonging to the technical field of pervaporation membrane separation, the invention relates to a preparation method of a modified polyurethane pervaporation phenol / water separation membrane. The preparation method of the membrane consists of: reacting hydroxyl-terminated polybutadiene with diisocyanate to obtain a terminated prepolymer, adding diamine and cyclodextrin as a chain extender for chain extension, and taking N, N-dimethyl acetamide as a solvent to obtain a modified polyurethane solution, carrying out membrane casting on the solution on a polyfluortetraethylene plate, and conducting curing at room temperature for 1 to 1.5 hours, then moving the obtained membrane into an oven at a temperature of 80DEG C for 10-15 hours of heat treatment, thus obtaining the modified polyurethane membrane. The material synthesis and membrane preparation process of the invention is simple, and the prepared membrane has good thermal and chemical stability as well as mechanical properties. Moreover, compared with traditional unmodified polyurethane separation membranes, the membrane prepared in the invention, due to the existence of the modifier cyclodextrin, has a better comprehensive separation effect on phenol in a phenol / water mixed solution, and has a great practical value.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Method for forming porous polyurethane membrane

ActiveCN102343224AUniform internal pore sizeHigh porositySemi-permeable membranesPorositySurface layer

The invention relates to a method for forming a porous polyurethane membrane, belonging to the technical field of membrane science and engineering. The method for forming the porous polyurethane membrane, provided by the invention, comprises the steps of: dissolving thermoplastic polyurethane in an organic solvent to prepare a membrane casting solution, immersing the membrane casting solution in an environment constituted by atomized microspheres which is prepared by an atomization device and used for solidification, and slowly performing a solidification forming process of the membrane casting liquor from outside to inside. According to the method, the forms of the microspheres on the surface and in the inner part can be effectively controlled in a forming process of the porous polyurethane membrane, and compact structures on the surface layer of the porous polyurethane membrane can be effectively reduced. The formed porous polyurethane membrane has the characteristics of uniformly distributed microspheres on the surface layer, no compact layer structure, uniform inner pore size, and large porosity. The method is simple to operate and has not pollution to the environment, and thedosage of an atomizing solution for solidification is lower. The prepared porous polyurethane membrane has a favorable waterproof breathability, and can be widely applied to the fields of clothes fabrics, leather, medical treatment and public health, and the like.

Owner:WUHAN YONGSEN BIOTECH

Ceramic tile mould preparation method

ActiveCN103085162ARealistic effectThe pattern is natural and beautifulCeramic shaping apparatusPolymer sciencePolyurethane membrane

The invention discloses a ceramic tile mould preparation method. The ceramic tile mould preparation method includes steps of fixing a material, spraying release agents or parting agents on the surface of the material, uniformly painting silica gel on the surface of the material, taking down the silica gel when the silica gel completely solidifies, and obtaining a silica gel membrane. The surface of the silica gel membrane copies stereoscopic layering textures of the surface of the material. The textures are copied on the surface of a fine carving greasy filth mold, then copied on the surface of a plaster mold, next copied on the surface of the silica gel membrane, and last copied on the surface of a polyurethane membrane, and the obtained polyurethane membrane is a ceramic tile mould. The ceramic tile mould prepared in the ceramic tile mould preparation method has the stereoscopic layering textures of the surface of the material, is vivid and natural in effects, and has the advantages of having clear, natural, concave-convex textures and natural and beautiful patterns like natural stones, wood or fabrics. The ceramic tile mould preparation method solves the problems that an existing ceramic tile mould has surface texture defects which can not be improved, causes resource waste and is time-consuming and labor-consuming in production.

Owner:广东道氏陶瓷材料有限公司

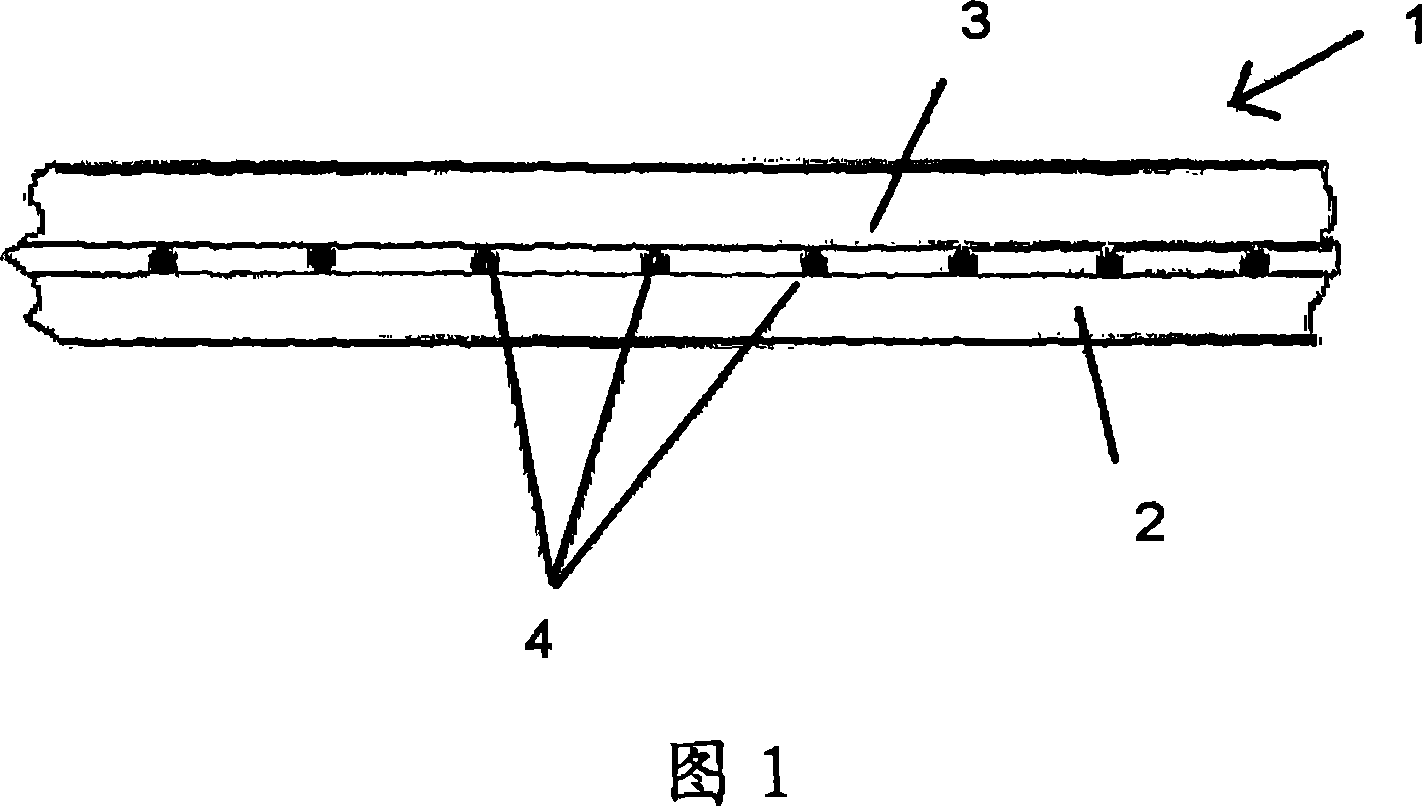

Flexible flooring system

A flooring system for floors exhibiting surface movement, and / or for cushioning hard floors, which includes an epoxy or polyurethane primer, a two-component ambient temperature cured polyurethane membrane substrate base atop the primer of a urethane grade castor oil, polyether based polyol, a tin catalyst and a thickening agent, along with a polymeric isocyanate activator, and a polyurethane or polyurea, aromatic or aliphatic coating atop the substrate base, in providing a very tough, but flexibly soft non-cracking overlay which moves with the floor.

Owner:MCGRATH JR WILLIAM H

Flexible and foldable biomembrane and preparation method thereof

PendingCN108888798AGuaranteed continued dosingGood treatment effectSurgeryPharmaceutical delivery mechanismPolyurethane membraneCervical diseases

The invention provides a flexible and foldable biomembrane and a preparation method thereof. The flexible and foldable biomembrane is composed of an inner layer and an outer layer, wherein the outer layer is a medical polyurethane membrane which can be fragmented after absorbing liquid, the inner layer is a wounded surface covering layer and is composed of, for example, chitosan and derivatives thereof or alginate or the mixture dressings of both the chitosan and the alginate, the inner layer can be separately applied to wounded surface repairing and can be used for bonding treatment medicinesto a medicine carrier absorbing layer before the inner layer is used to achieve a treating effect, wounded surfaces comprises skin, mucous membranes or in vivo tissues, and the biomembrane is particularly suitable for cervical repairing. The flexible and foldable biomembrane is produced to be a mushroom-shaped, a protrusion is arranged in the middle, before the flexible and foldable biomembrane is used, the treating medicines are bonded to the chitosan and the derivatives thereof or the alginate dressings, when the biomembrane is used, a special vaginal clamp or a special pushing tool is usedfor pushing the biomembrane and covering the surface of os uteri, the protrusion is fixed to orificium vaginae, sustained local application of a cervical part is achieved, and the treating effect onchronic cervical diseases of cervical erosion and HPV is improved.

Owner:YUANRONG BIOLOGICAL PHARMA WUXI CO LTD

Multi-ply technical composite which is breathable and moisturising, releases active constituents and promotes their absorption, and can be used as a medical aid or to make clothing or structures that

InactiveCN101163585AGarment special featuresCosmetic preparationsPolyurethane membraneSemipermeable membrane

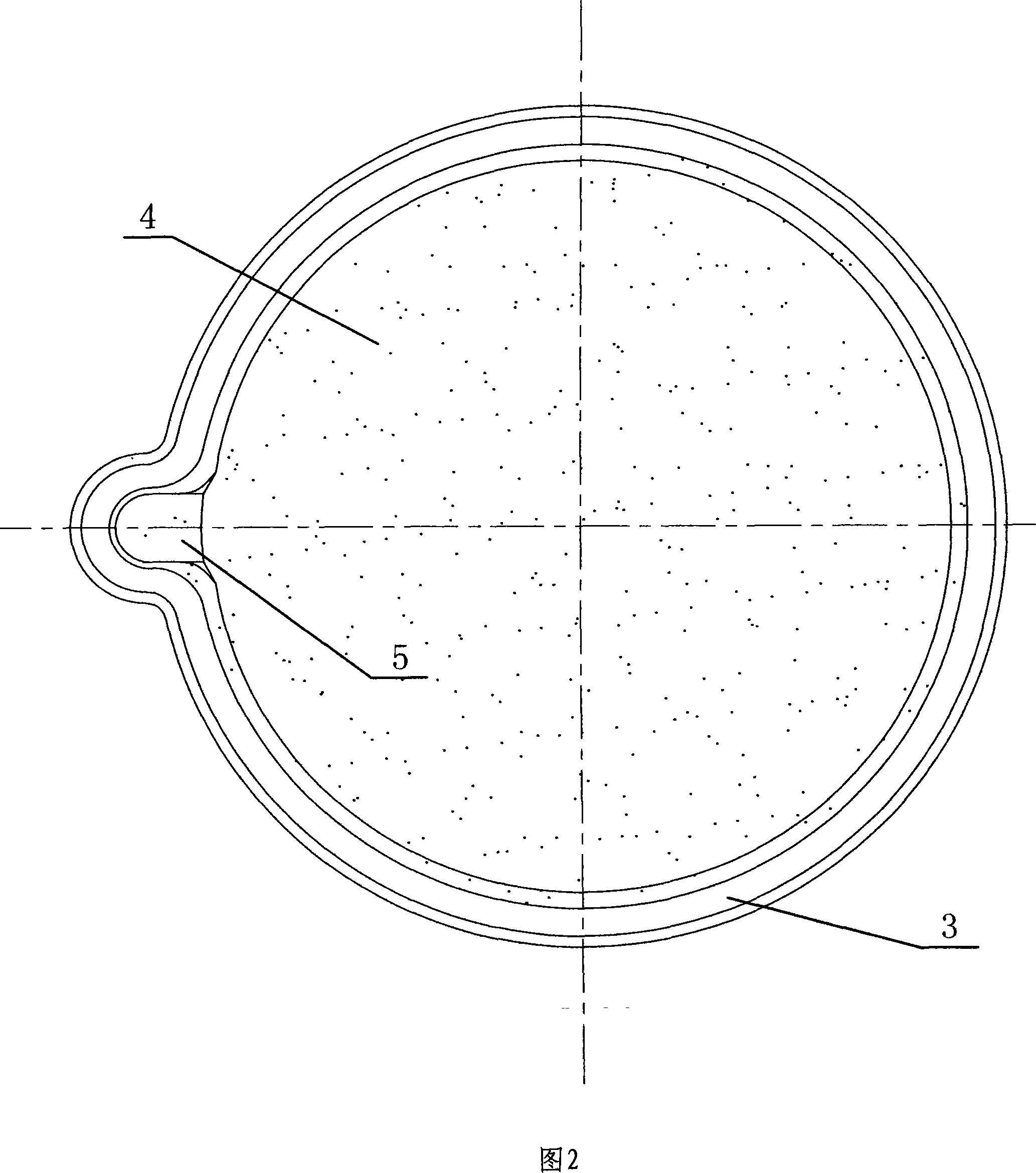

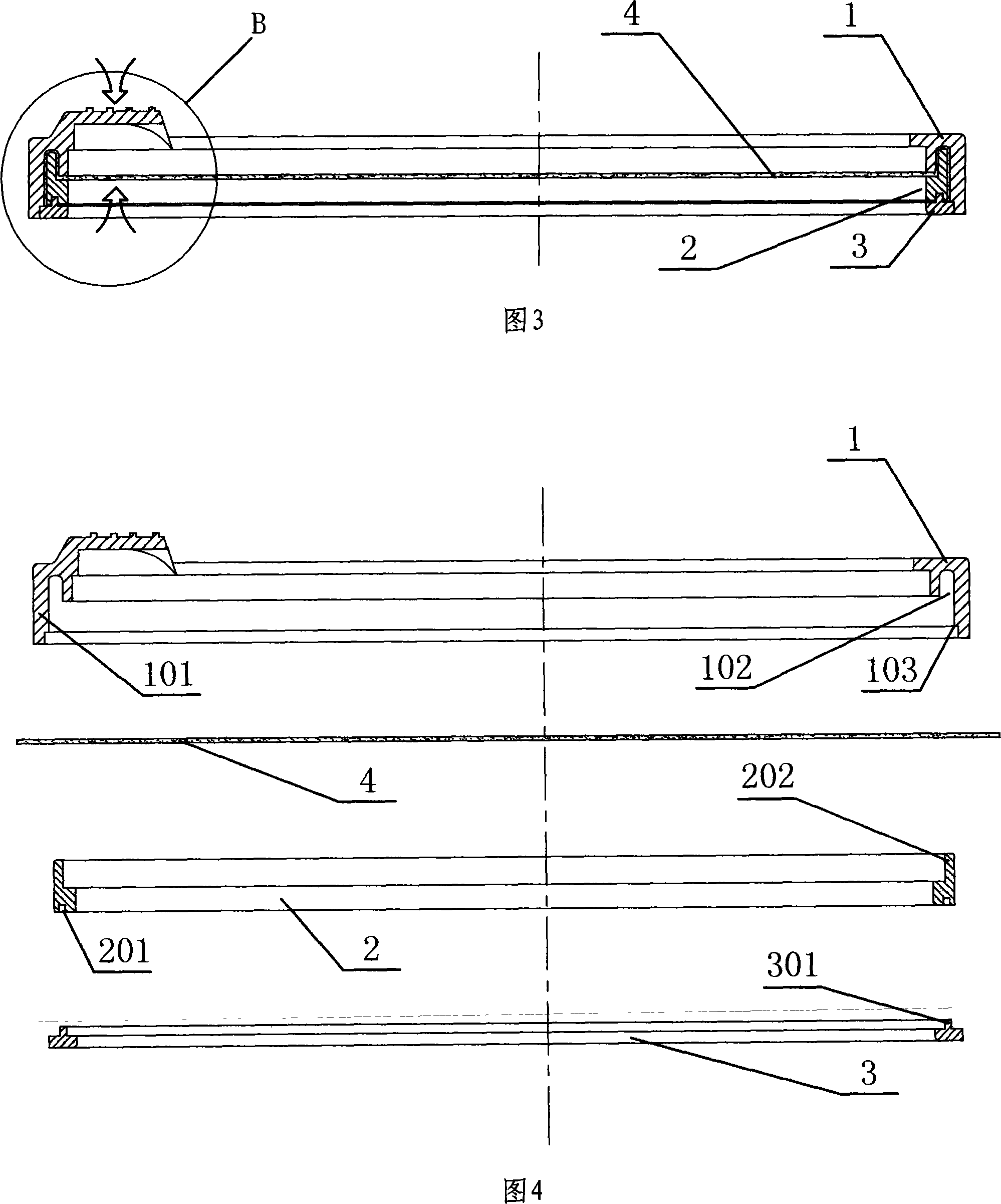

The invention relates to a multi-ply technical composite, usable in particular for making medical aids, garments and medical articles, comprising at least two layers (2,3), the first of which (2), in contact with the skin, is a cotton fabric (elasticised to a greater or lesser extent) or silk, or fabrics to which chitosan, silver or another antibacterial substance or active constituent is added, and the second, outer layer (3) is constituted by a semipermeable membrane, such as polyurethane between 5 and 80 microns thick, with considerable elasticity in order to ensure the user's comfort. Receptors rechargeable with active constituents are inserted into fabric (2) and protected by the polyurethane membrane.

Owner:埃米利奥·伯蒂尼

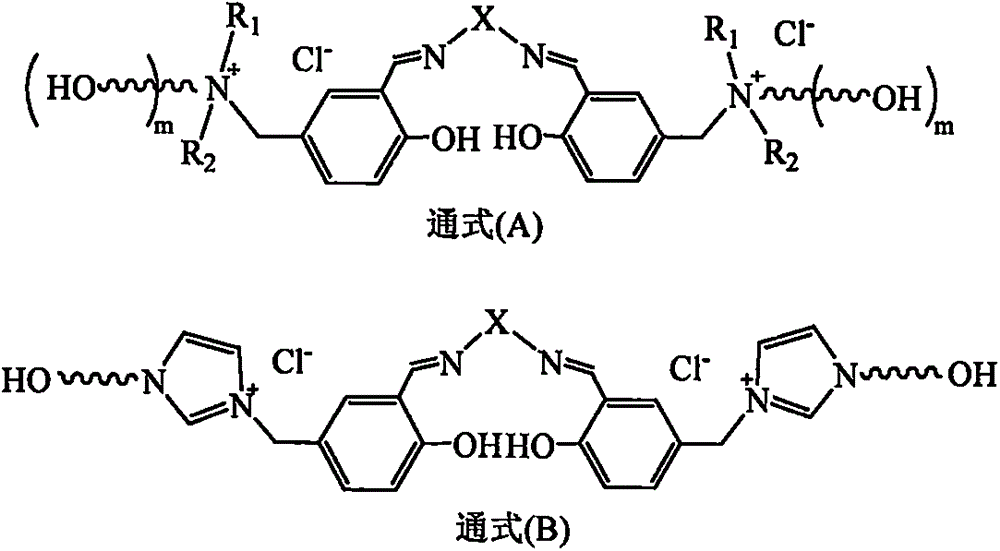

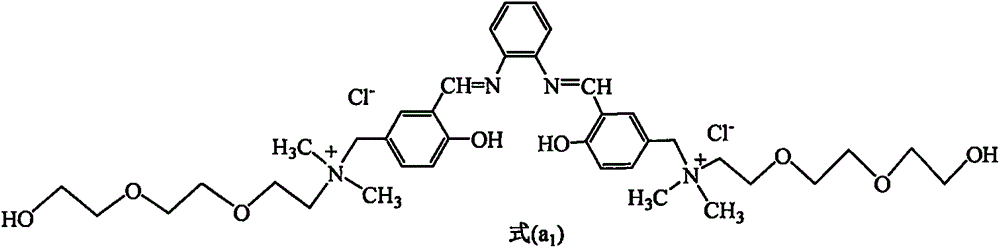

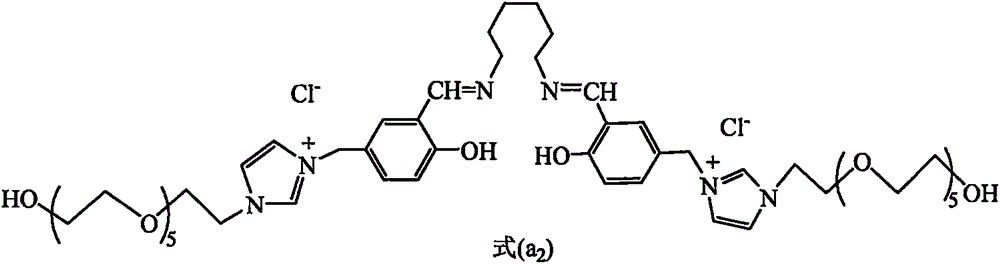

Application of function polyol to preparation of multifunctional polyurethane

The invention provides application of function polyol to preparation of multifunctional polyurethane. Advantages of the research achievement of the research group, namely the industrial scale of 5-chlorine methyl salicylic aldehyde are utilized, the 5-chlorine methyl salicylic aldehyde serves as the raw material and is subjected to a chemical reaction with quaternary ammonium salt of hydroxyl tertiary amine and then subjected to a condensation reaction with bis-primary amine, and the polyol with the molecular structure containing quaternary ammonium positive ions and Salen or Salophen functional groups is obtained and applied to preparation of the multifunctional polyurethane. The function polyol enables the multifunctional polyurethane to have high hydrophilia and water absorption performance, an antibacteria and sterilization function, a rapid cation and anion exchange function, a rapid heavy metal ion absorption function with the saturated absorption time within the level of several minutes and a remarkable color change property generated when the multifunctional polyurethane meets certain heavy metal ions. The multifunctional polyurethane can be used as polymer electrolyte, an ionic conductivity polyurethane membrane, cation and anion exchange resin, an online solid phase extraction material of heavy metal ions, a solid-loaded precious metal catalytic material, a multifunctional polyurethane based gas purification material and a disposable hygiene product.

Owner:HUAIHAI INST OF TECH

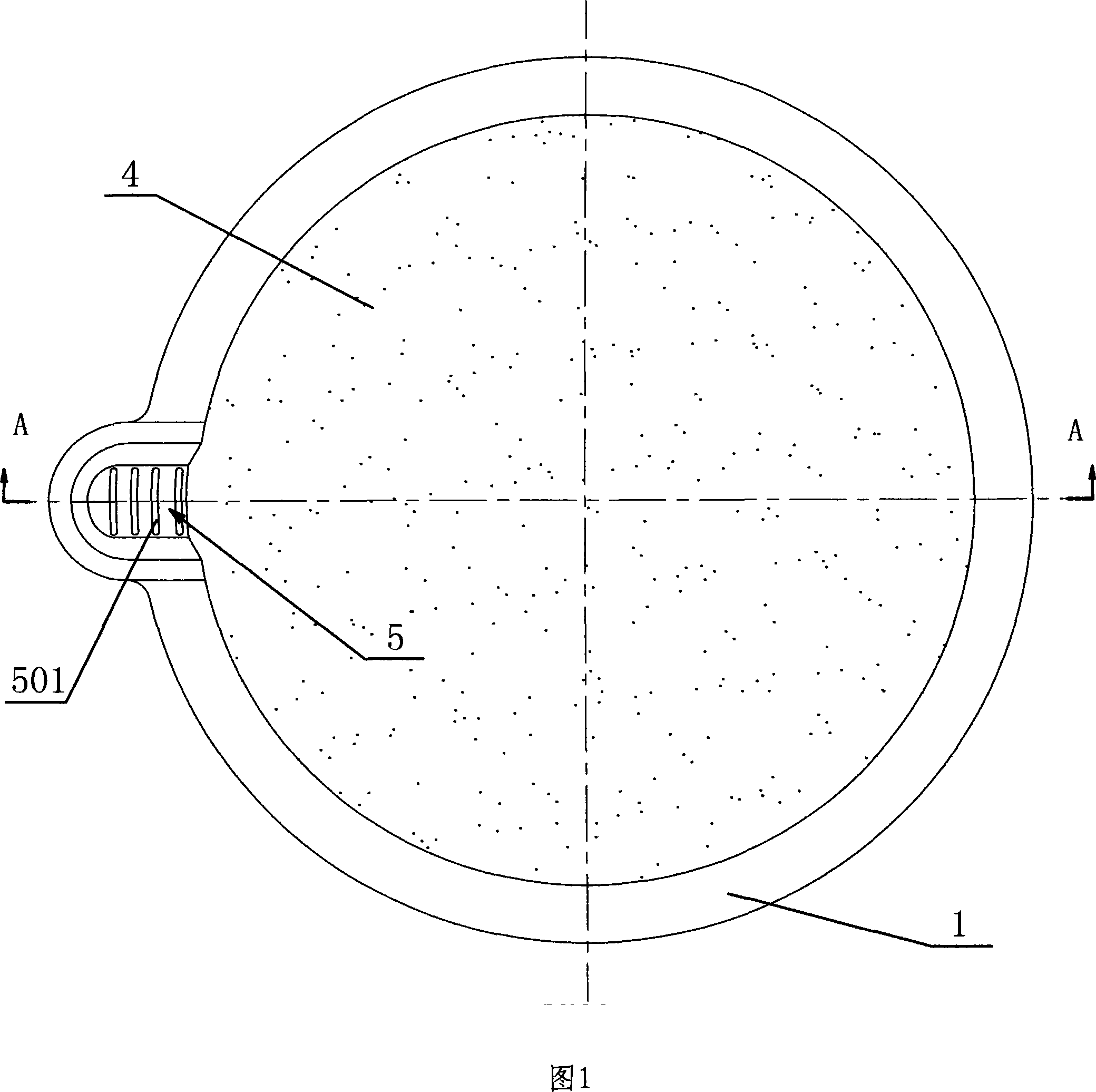

Vacuum 000 storage method and fresh-keeping cover thereby

InactiveCN101234681AEffective headroomSo as not to damageClosuresPackaging under vacuum/special atmosphereSocial benefitsPolyurethane membrane

The invention discloses a vacuum storage method and a refreshing cover thereof. The method includes the following steps: a polyurethane membrane fixed at a frame is covered on a container opening, pinched inward and then released; as the membrane recovers the plane state, the inside of the container generates relative vacuum to reach the effect of enclosed vacuum refreshing. At the same time, the invention also discloses the refreshing cover, consisting of a cover surface and a circular frame, wherein, the cover surface is the polyurethane membrane fixedly arranged on the frame which is provided with a handle for opening the cover protruding out from an outer circumference. The invention provides a device adopting a high-elasticity plastic membrane with a fixed frame and a locking mechanism and a vacuum refreshing method, which greatly prolong the time of corruption and degeneration of food; at the same time, compared with the conventional method and device, the invention is more convenient and effective and has the advantages of stable and reliable work, low manufacture cost, and high economic and social benefits. The invention is applied to the objects and the packaging methods requiring vacuum storage such as medical instruments, drugs, etc.

Owner:SHANGHAI MUYE TRADING

Method of making articles of protective clothing containing adsorptive membranes

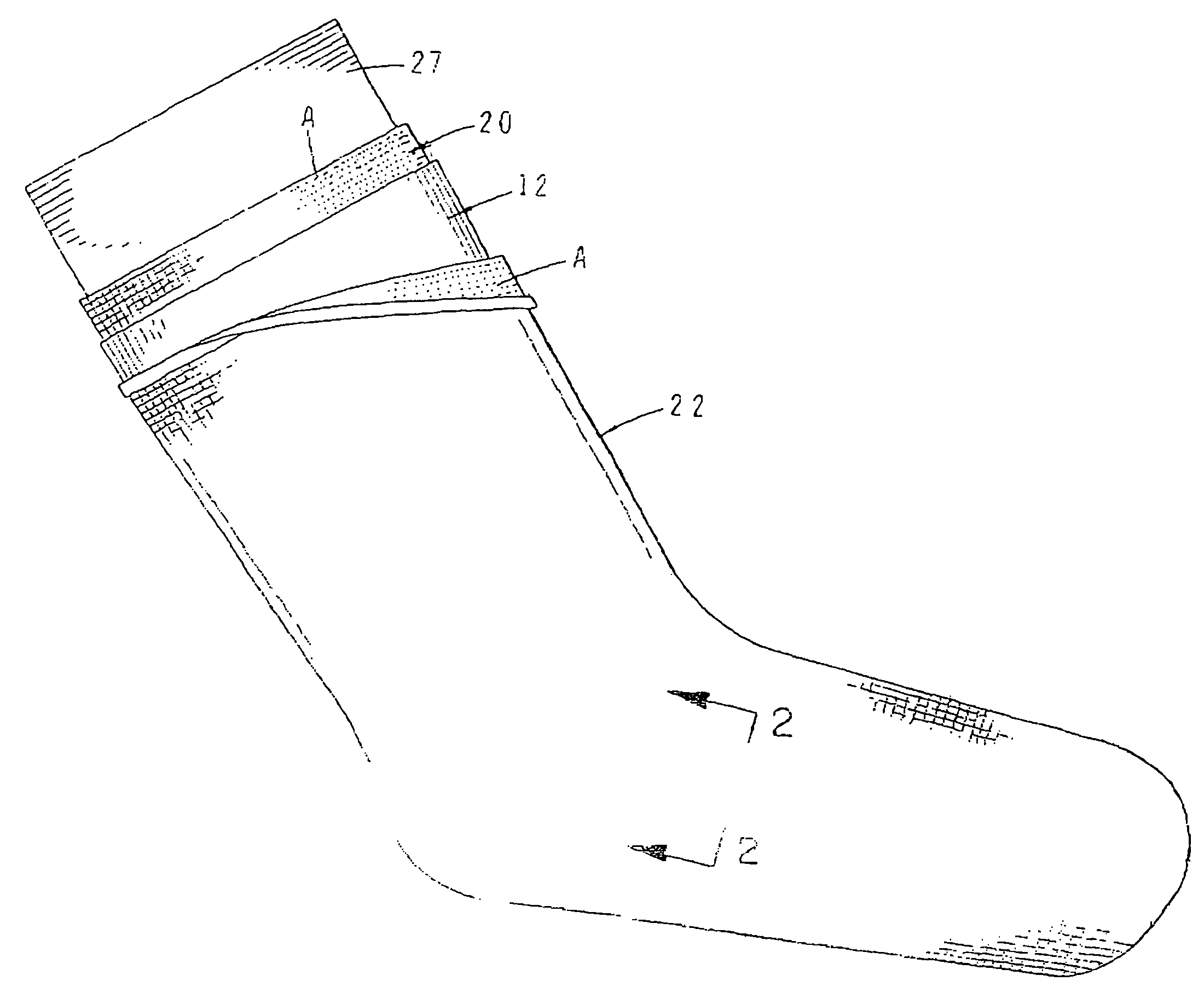

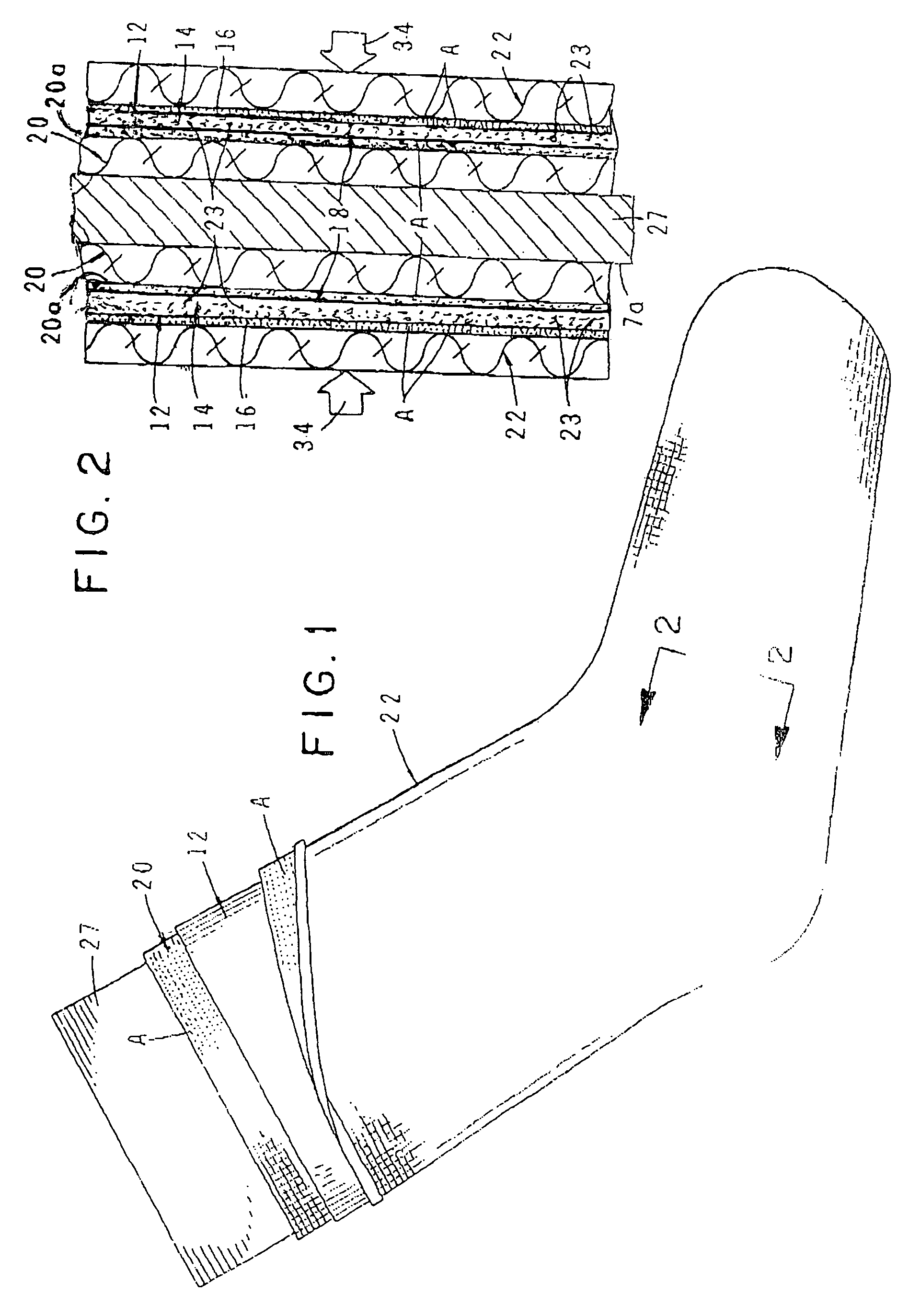

InactiveUS20060065353A1High protection levelComfortable to wearChemical protectionHeat protectionActivated carbonAdsorptive membrane

A protective article such as a glove, sock or vest and the method of making same that is easy to don, is comfortable to wear and, at the same time, due to the incorporation of a novel membrane within which the highly adsorptive super-activated carbon particles are embedded, provides substantial protection to the user against exposure from hazardous chemical vapors. A unique feature of the method of the invention for making the protective articles of the invention is the novel step of incorporating highly adsorptive super-activated carbon particles within a thin polyurethane membrane in a manner such that the adsorptive properties of the activated carbon particles remain substantially undiminished.

Owner:WILLIAMS COLE

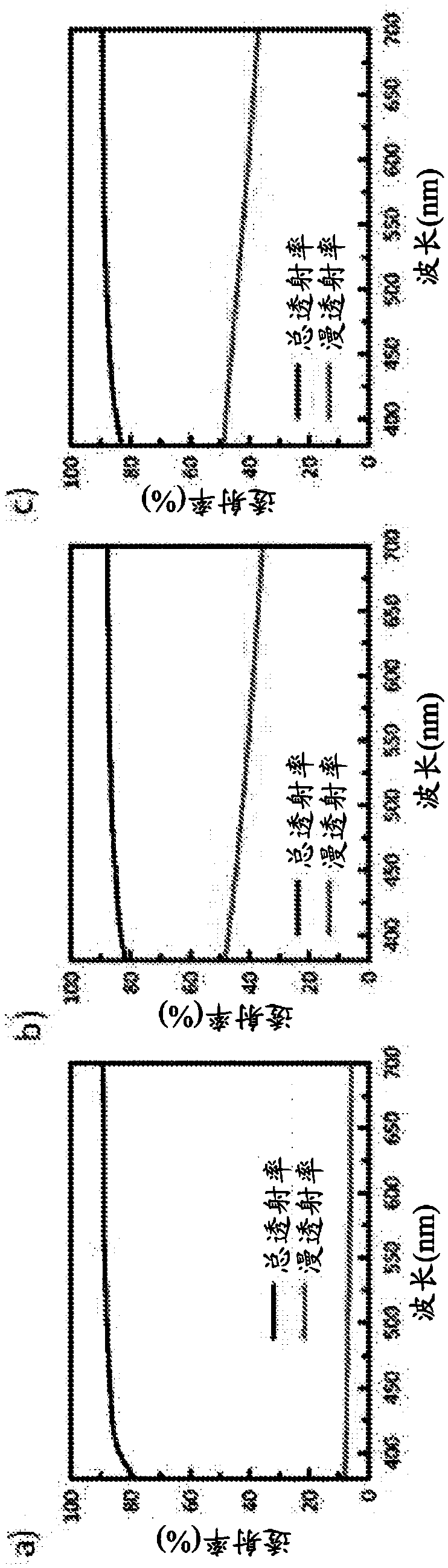

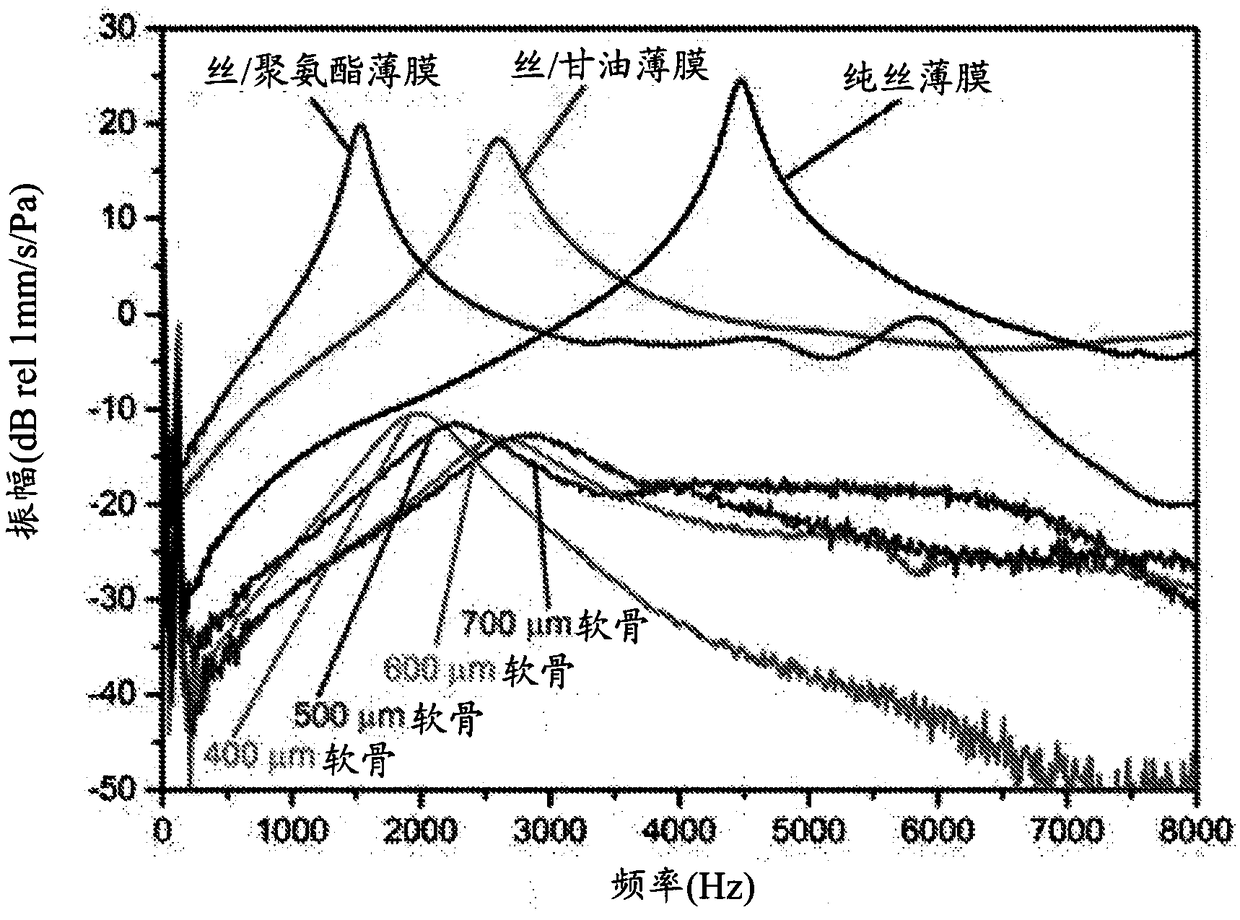

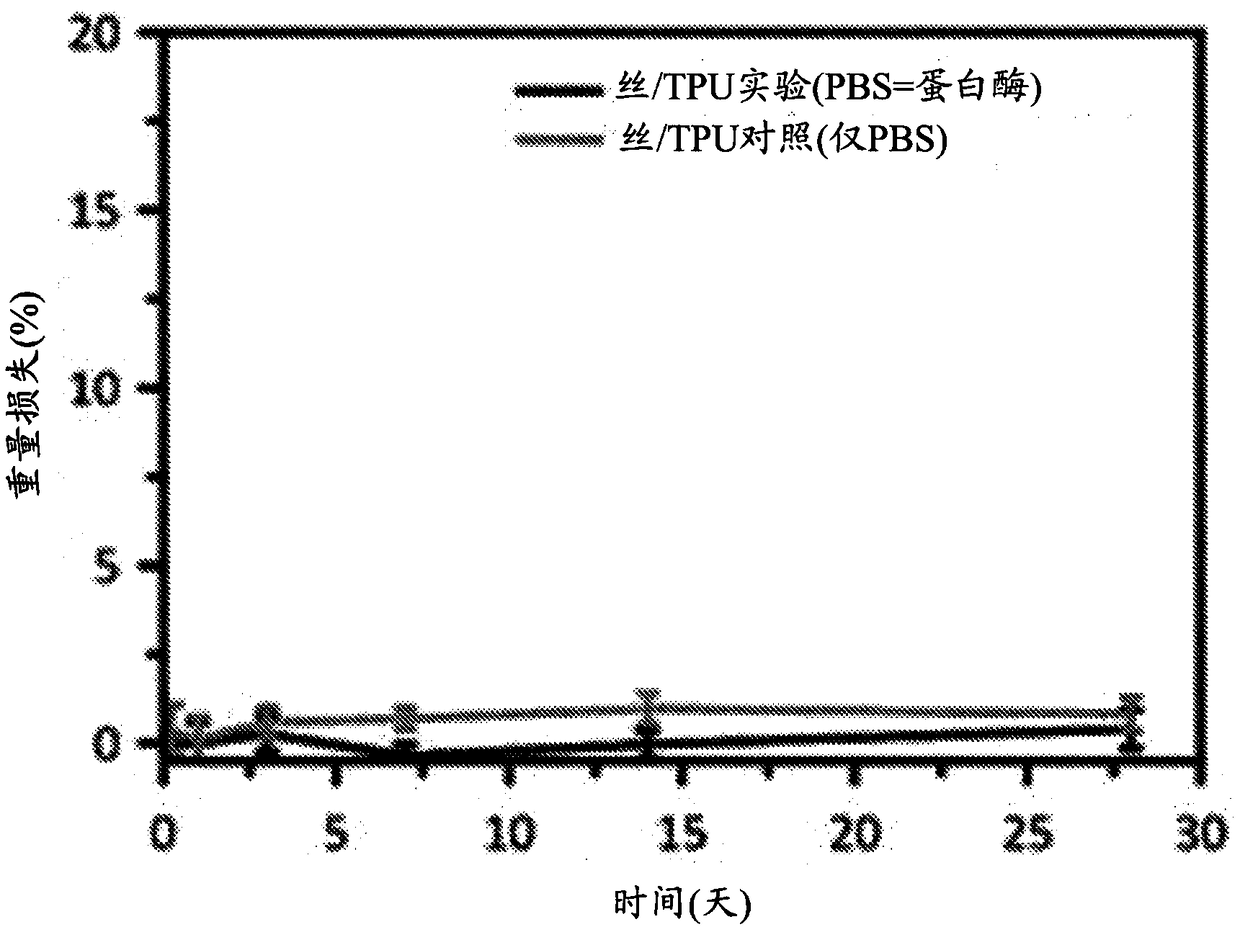

Improved silk fibroin biocompatible polyurethane membranes

ActiveCN109069699AExtended featuresFibre treatmentTissue regenerationPolyurethane membraneTympanic Membrane Perforation

The present invention relates to the preparation of a membrane for use in the repair of the middle ear including perforations and damage to the tympanic membrane. More particularly, the invention provides for compositions and methods for preparing silk fibroin biocompatible polyurethane membranes using a solvent, which have improved biodegradation, mechanical and vibroacoustic properties.

Owner:EAR SCI INST AUSTRALIA +1

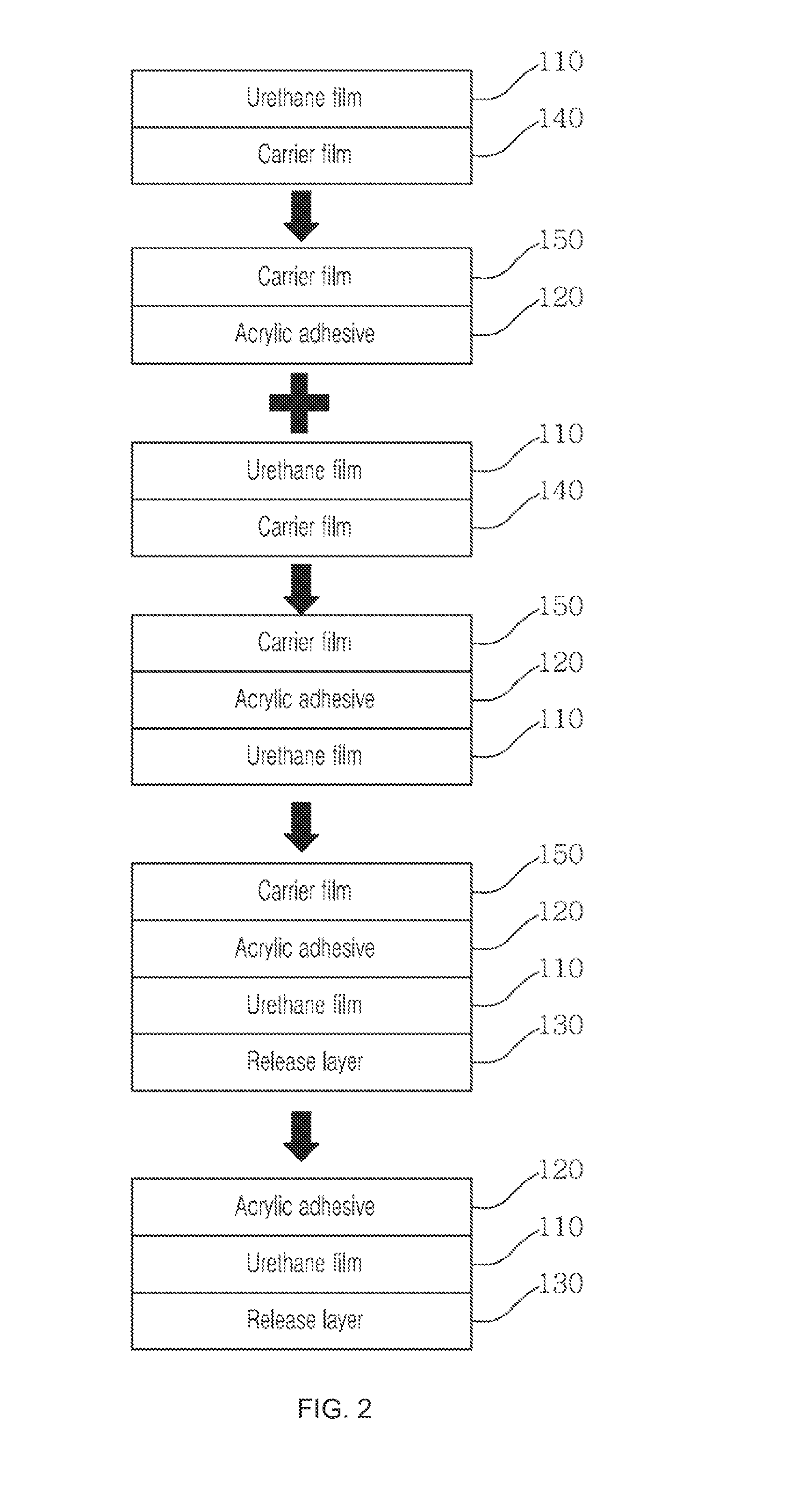

Swelling tape comprising polyurethane film and method for manufacturing same

ActiveUS20160376472A1Uniform thicknessLow costDomestic sealsLamination ancillary operationsPolymer scienceCarbamate

A swelling tape is disclosed comprising a polyurethane film and a method for manufacturing the same. The swelling tape comprises: a base layer including a polyurethane film that is composed of a chain of monomers joined by urethane links as a result of a reaction between a liquid polyol and a crosslinker; and an adhesive layer formed on a first surface of the base layer in a direction horizontal to a lengthwise direction of the base layer. When made with the liquid polyol and the crosslinker, a resulting polyurethane film exhibits appearance and performance similar to polyurethane film prepared through extrusion. The resulting polyurethane film has a uniform thickness and the advantage of being produced at a low cost.

Owner:SEIL HITEC CO LTD

Holographic anti counterfeit polyurethane membrane

InactiveCN1709692AHigh strengthGood optical performanceSynthetic resin layered productsCalcium biphosphatePolyester

The present invention relates to one kind of counterfeit-resistant polyester-base film which contains two intrinsic surfaces and two exterior ones, and everyone of the intrinsic surface has a definitive proportional crystallizing polyester and polyester-based film trimming materials. One of the extrinsic surfaces is a holographic counterfeit-resistant film, the other is a holographic counterfeit-resistant film or a generic polyester-based film. The holographic counterfeit-resistant film contains 10-100 percent amorphous polyester and 0-90 percent additive carrier according to mass percent. The generic polyester-base film contains 50-90 percent crystal polyester and 10-50 percent additive carrier according to mass percent. The additive carrier talked about upward contains silicon dioxide, kaolin, calcium phosphate or barium sulfate, besides crystallizing polyester, and the content of the additive carrier is 3000pp which is counted according to mass percent. The holographic counterfeit-resistant polyester-based film, so that the holographic counterfeit-resistant design can be die stamped at first hand. It will increase of efficiency, reduce the cost of production.

Owner:WEIFANG FUWEI PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com