Preparation method of polyurethane hollow fiber filter membrane

A fiber filter membrane and polyurethane technology, which is applied in the field of hollow fiber filter membrane preparation, can solve the problems of high cost, low elasticity and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

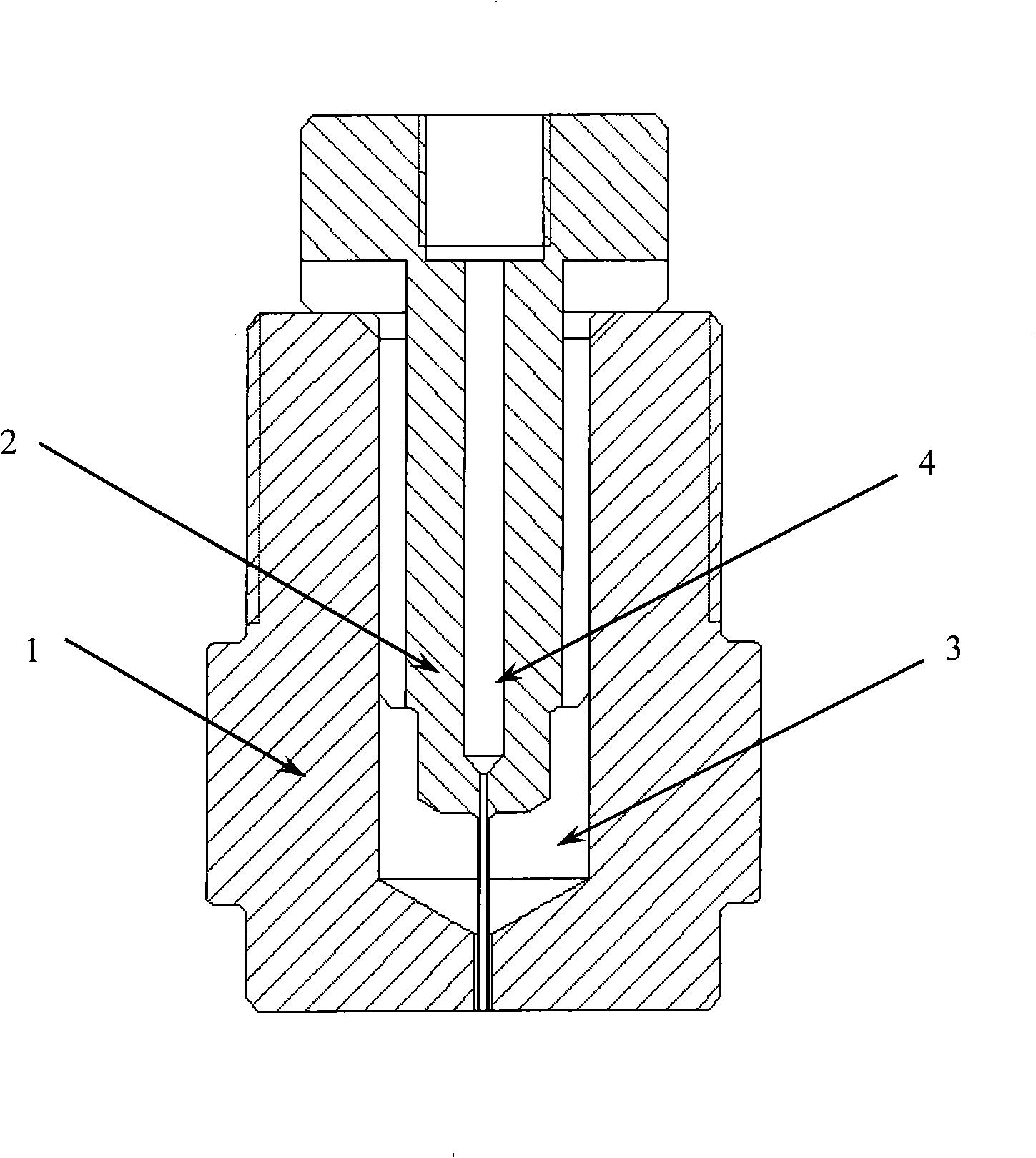

Image

Examples

preparation example Construction

[0014] (1) Preparation of polyurethane prepolymer

[0015] The mass percentage formula of polyol, isocyanate and prepolymer additive is:

[0016] Polyol: 64.5~85%;

[0017] Isocyanate: 15-34%;

[0018] Pre-polymerization additives: 0.1-1.5%.

[0019] Add specific polyols and isocyanates into the reactor according to the above ratio, and at the same time add metered pre-polymerization additives, stir gently until completely mixed, and react at 65-80°C for 120 minutes to form polyols as the center. Isocyanate-blocked polyurethane prepolymer. The addition of prepolymer additives can increase the molecular weight of the stock solution after the chain extension of the prepolymer, thereby increasing the elongation and elasticity of the fiber, which is extremely important for the preparation of PUHFFM. In order to ensure the stability of the prepolymer, after the prepolymer is generated, the temperature of the prepolymer is lowered to 40° C. to reach a stable state by using a coo...

Embodiment 1

[0049] Weigh the raw materials according to the following mass percentages, PEG with a molecular weight of 2000: 67.9%, MDI: 32%, 1,4-BDO: 0.1%, mix and gently stir until completely dissolved, react at 75°C for 120 minutes to prepare polyurethane Prepolymer, use a cooling water bath to lower the temperature of the polyurethane prepolymer to 40°C to reach a steady state. According to mass percentage, polyurethane prepolymer: 35%, NMP: 59.95%, phenylenediamine: 0.05%; PEG (molecular weight: 200,000): 5% Mix the materials, stir gently at 25°C until completely dissolved, React for 100 minutes to prepare polyurethane film-forming glue. The inner gel medium was prepared according to the mass ratio of NMP:PEG (molecular weight: 200,000)=7.4:2.6. Pour the prepared film-forming glue solution and inner gel medium into the storage tank respectively, and let stand for 12 hours for defoaming. Start the water heater and the hot water circulating pump to stabilize the temperature of the fi...

Embodiment 2

[0052] According to mass percentage PTMEG (molecular weight: 2600): 70%, TDI: 29.8%, mixture of 1,3-PDO and DABCO: 0.5% (mixing ratio 1:4) mix the raw materials and stir gently, at 65°C The polyurethane prepolymer was prepared by reacting for 120 minutes, and then the temperature of the polyurethane prepolymer was lowered to 40° C. to reach a stable state. According to mass percentage, polyurethane prepolymer: 30.9%, DMF: 65%, phenylenediamine: 0.1%; PVP K30: 4%, stirred gently at 20°C until completely dissolved, and reacted for 100 minutes to prepare polyurethane film-forming adhesive liquid. Other film-forming process conditions are the same as in Example 1, and the process of Example 1 is repeated to obtain PUHFFM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com