Patents

Literature

1370 results about "Residual solvent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Residual Solvent. Definition - What does Residual Solvent mean? In cannabis processing, residual solvent, as the name suggests, is the remaining solvent that is present in cannabis extracts. Residual solvents usually occur when the required processing and solvent-purging methods or steps are not properly utilized.

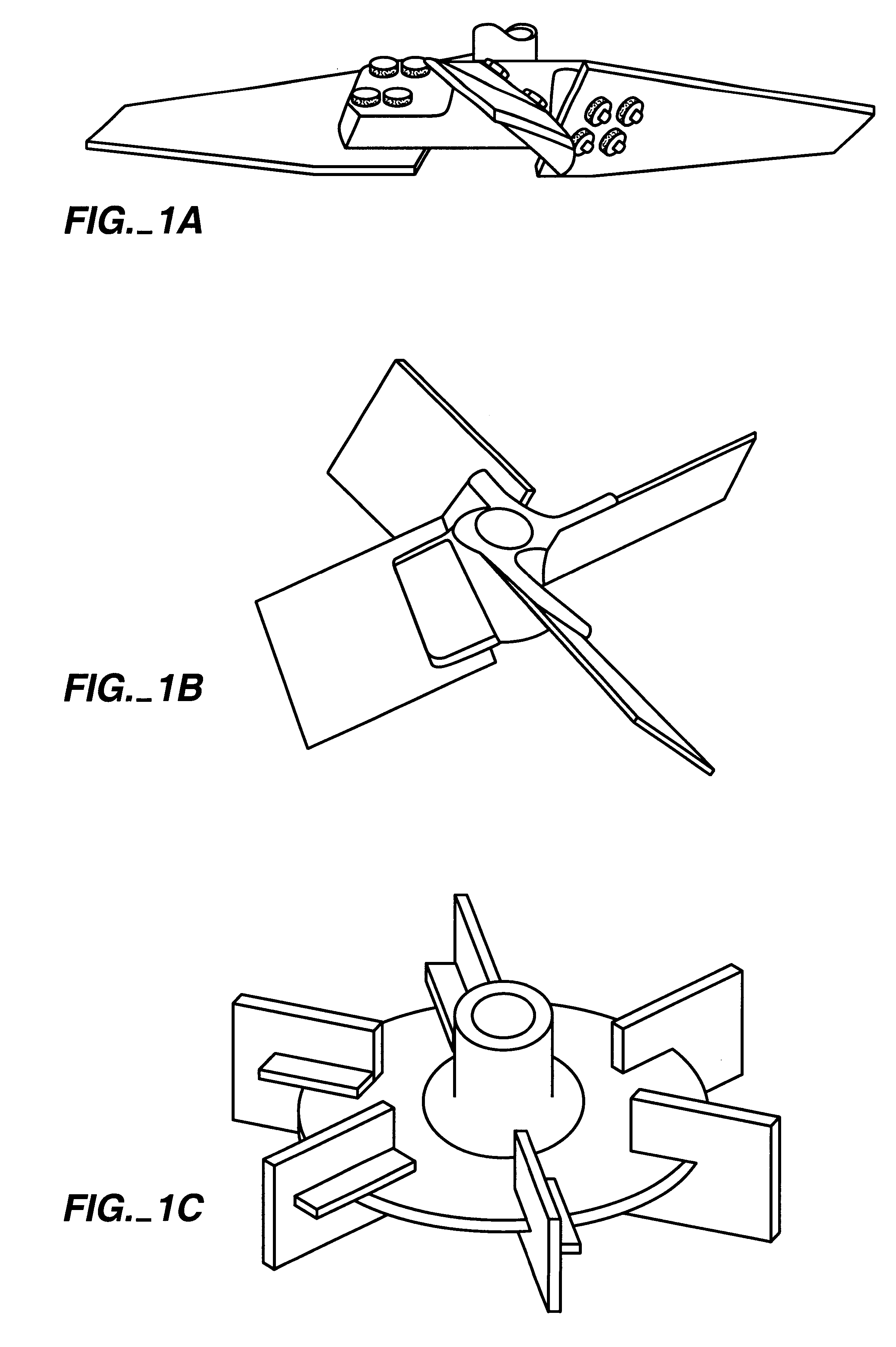

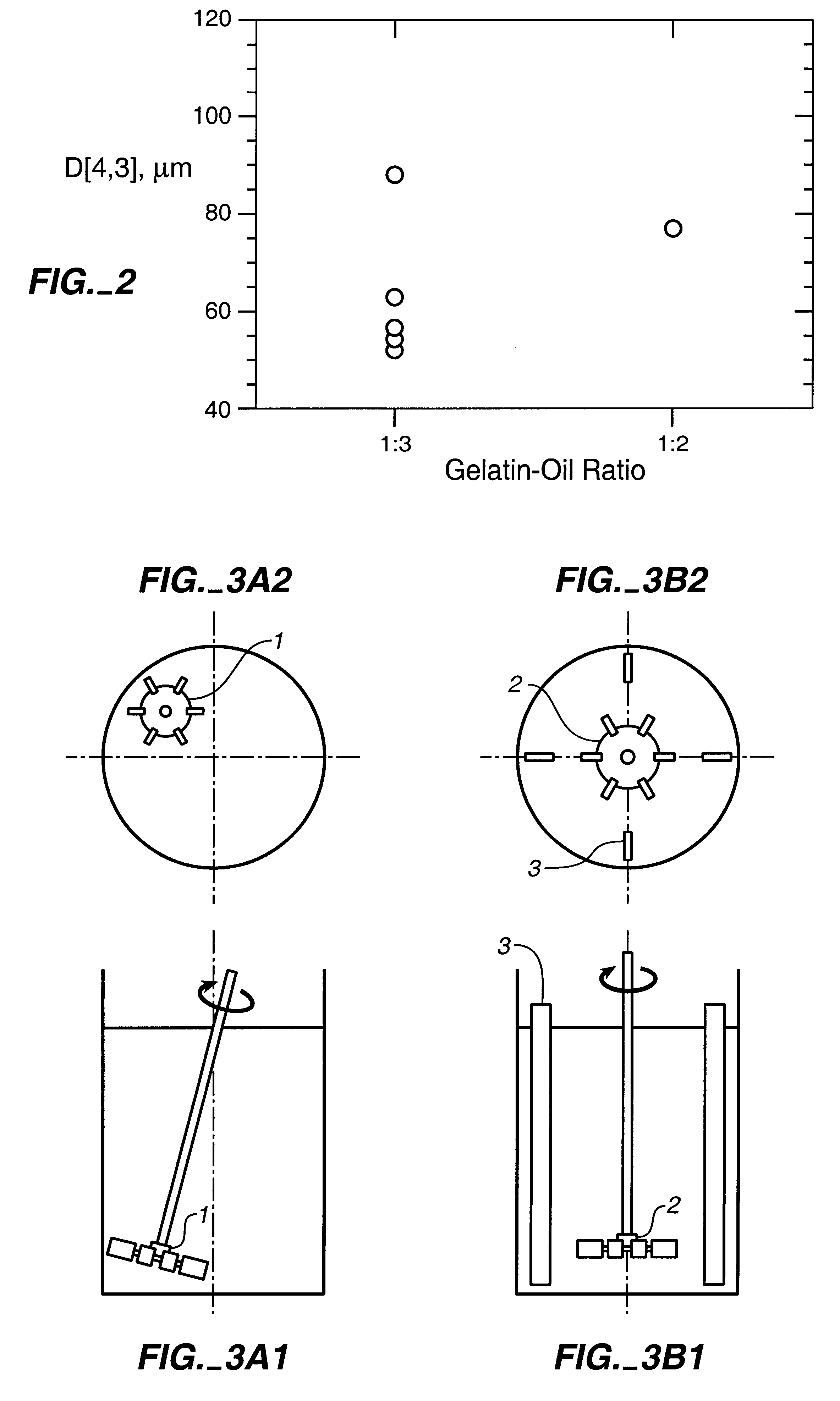

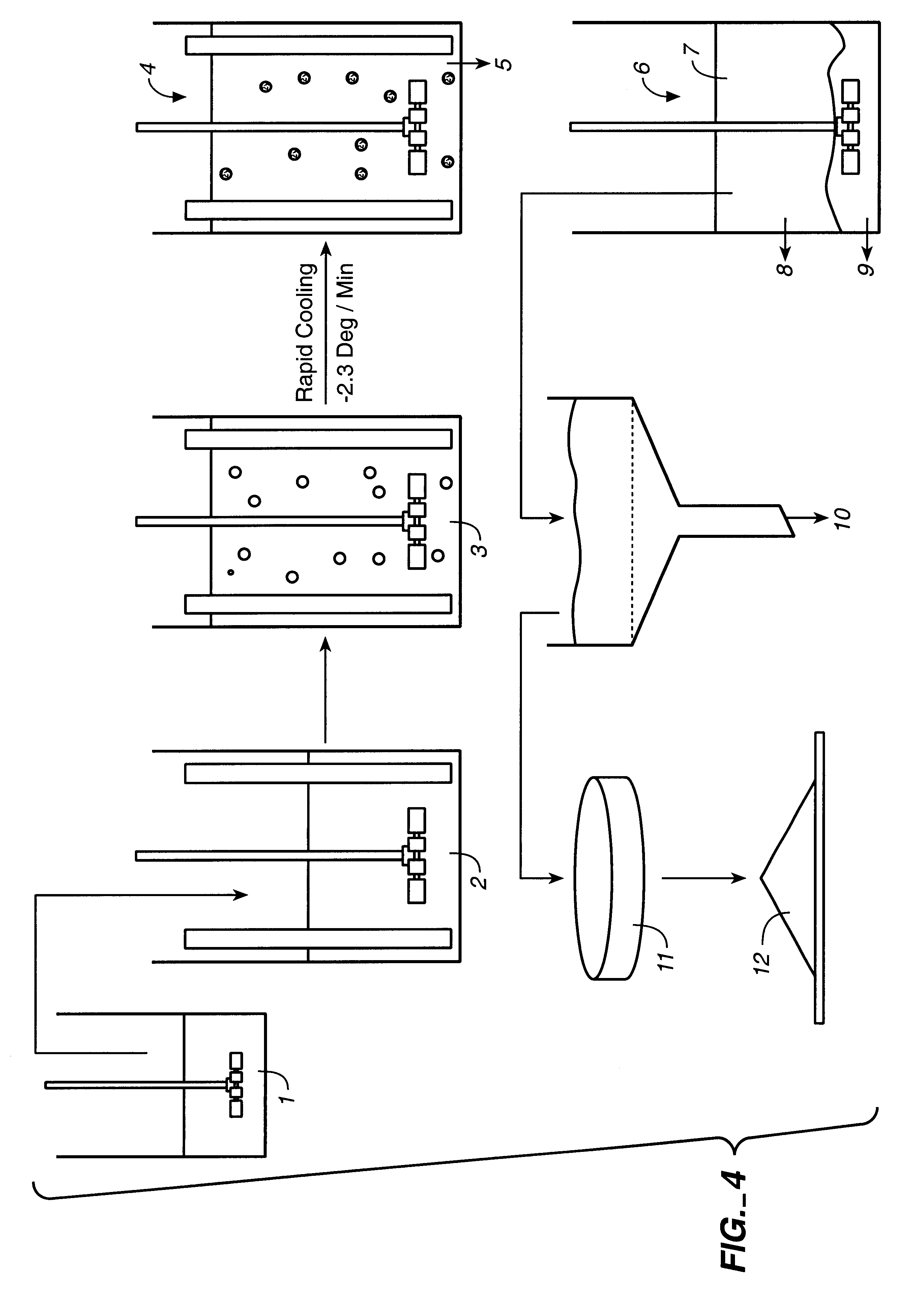

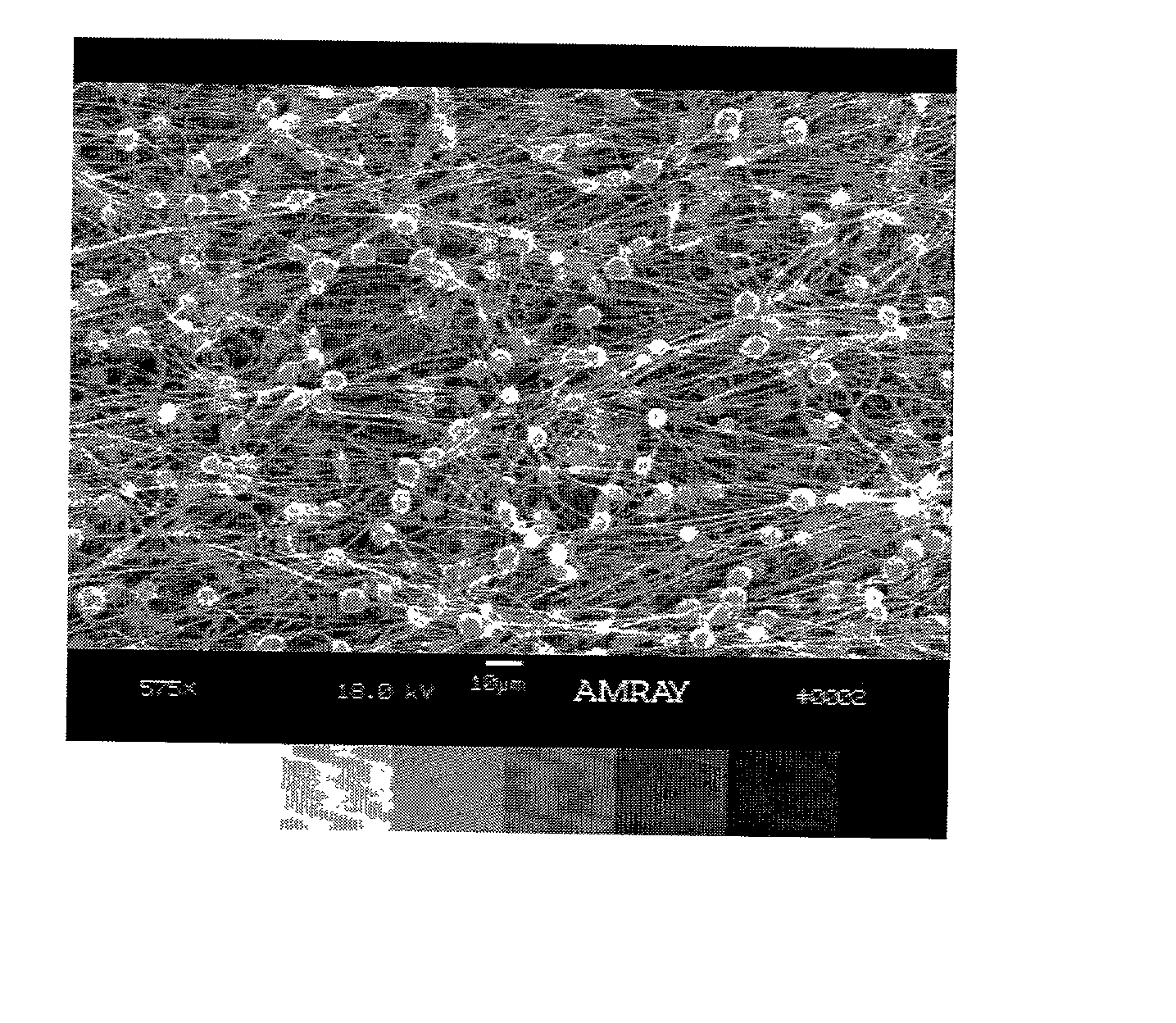

Compositions for nasal drug delivery, methods of making same, and methods of removing residual solvent from pharmaceutical preparations

InactiveUS6391452B1Taller in heightSlow down the mixing speedLiquid surface applicatorsPeptide/protein ingredientsNasal cavityNose

The present invention relates to pharmaceutical compositions for delivery of drugs intended to reside in the nose, compositions for nasal administration of drugs, e.g., antiviral agents, and particularly antiviral agents comprising the human major rhinovirus receptor, also known as intercellular adhesion molecule-1 (ICAM-1); to methods of making said nasal drug compositions, and to an improved process for the removal of residual solvent from pharmaceutical matrices.

Owner:BAYER PHARMA CORP

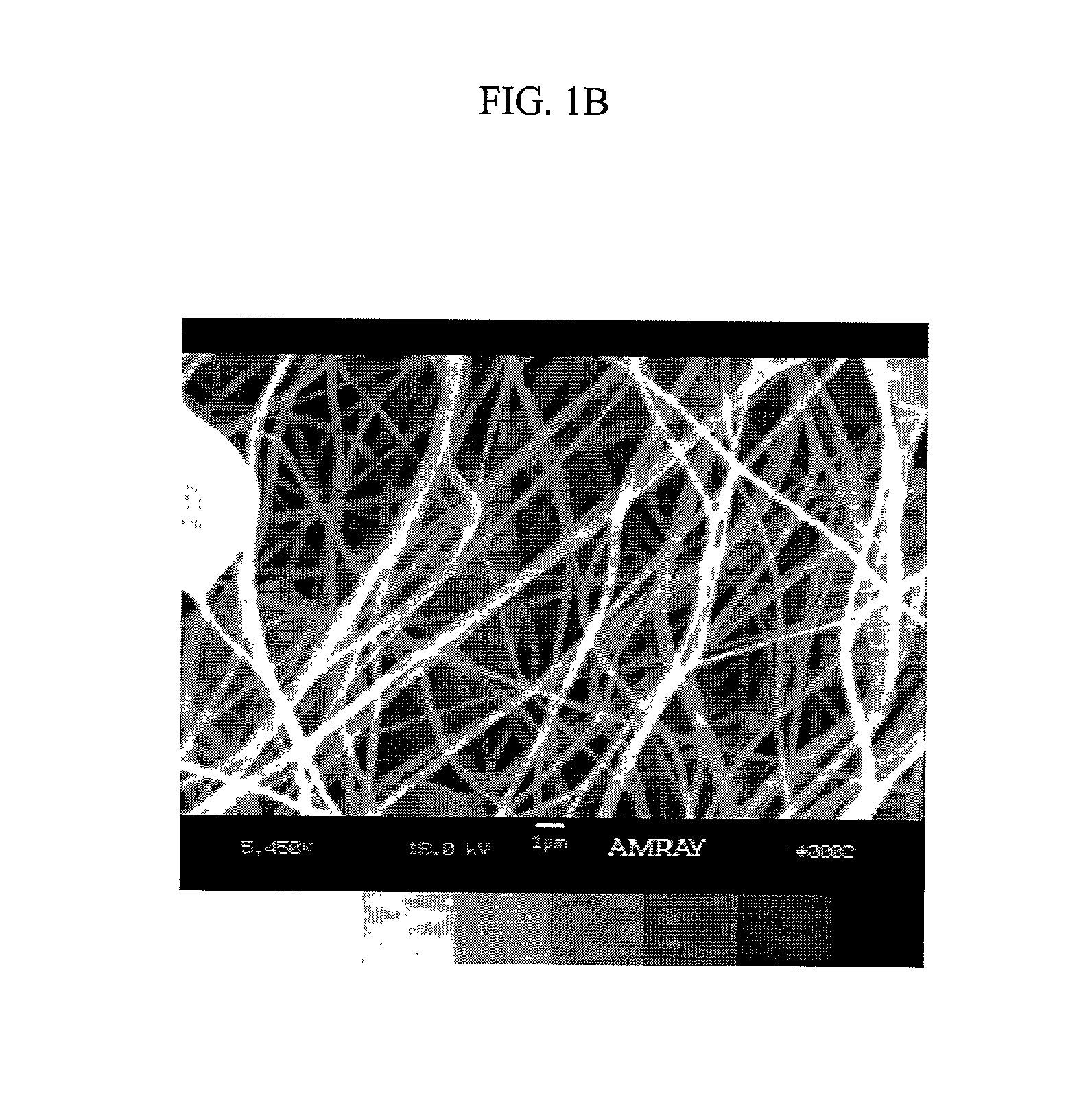

Vascular graft having a chemicaly bonded electrospun fibrous layer and method for making same

InactiveUS20030100944A1Improve surface morphologyGood tissue responseNon-woven fabricsCoatingsChemical LinkageElectrospinning

A vascular graft comprising a traditional graft material and an electrospun fibrous layer. The solvent used to reduce the material for the electrospun layer is also capable of reducing the graft material to a liquid solution. The electrospun layer is chemically bonded to the graft material, without adhesives, by either spraying the graft with the solvent prior to electrospinning or by assuring that a sufficient amount of residual solvent reaches the graft while electrospinning.

Owner:DATASCOPE INVESTMENT

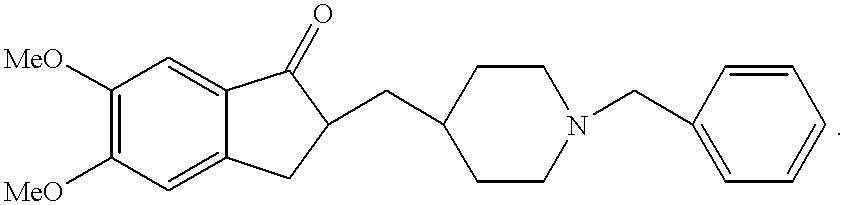

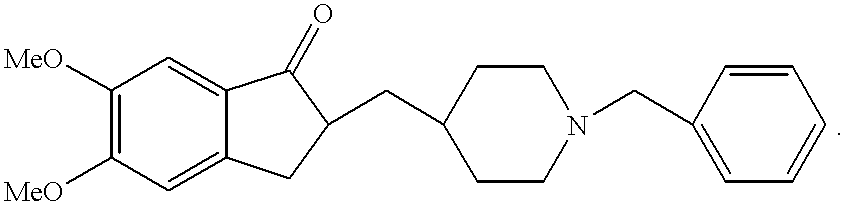

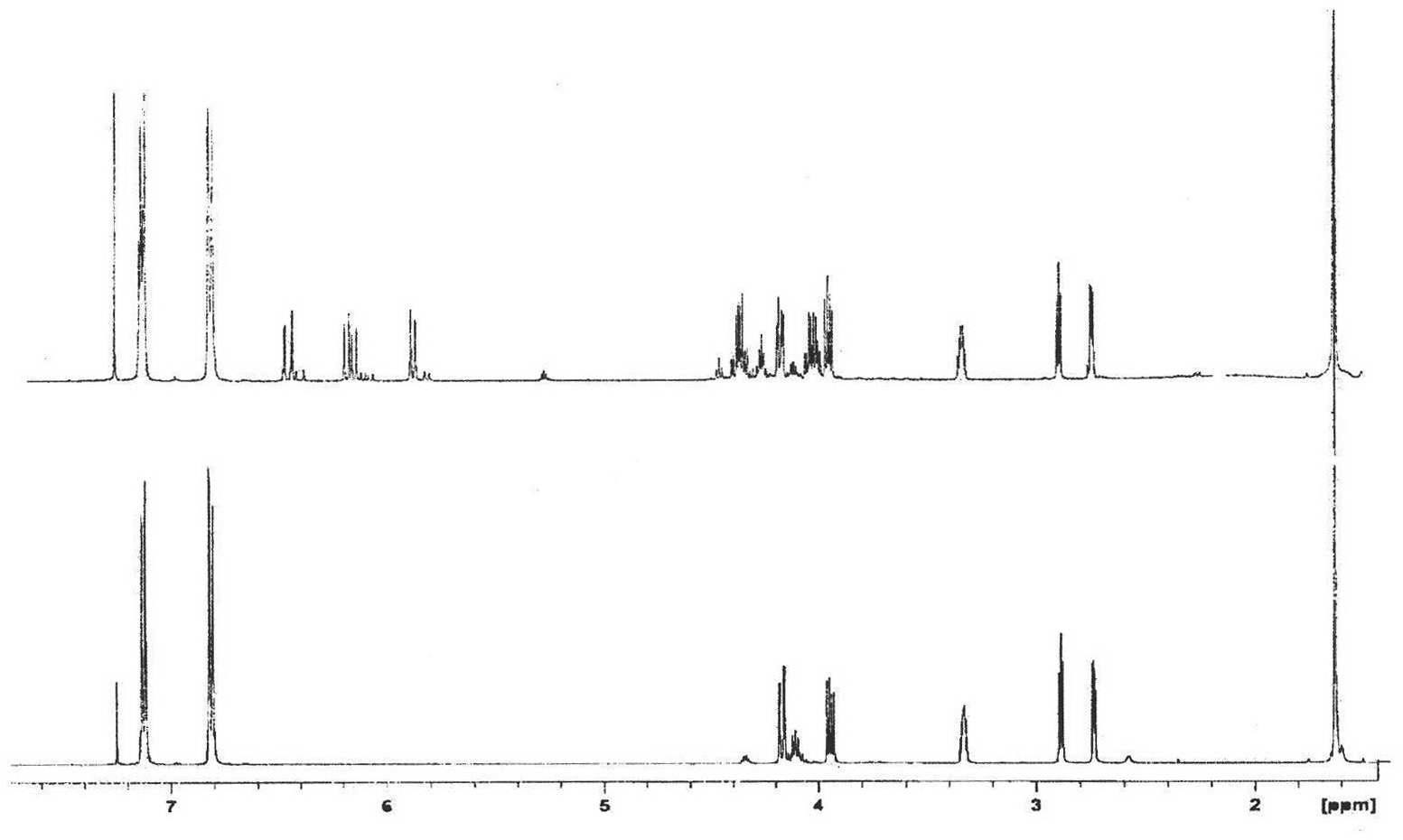

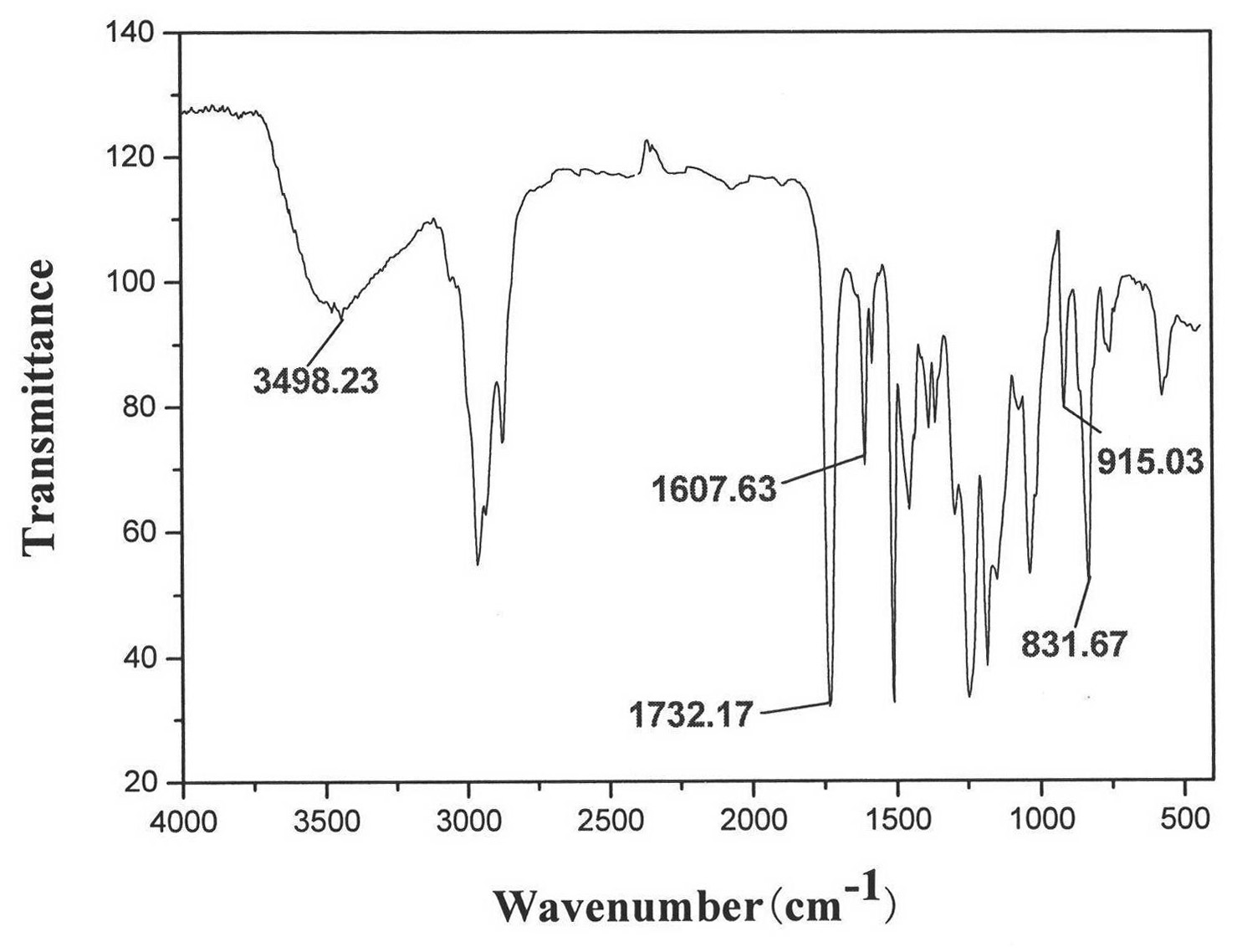

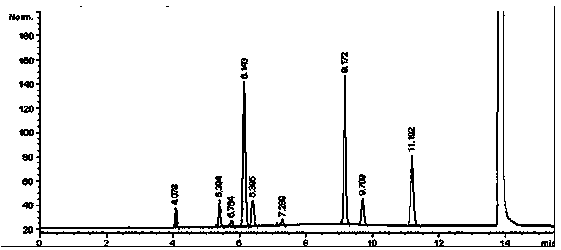

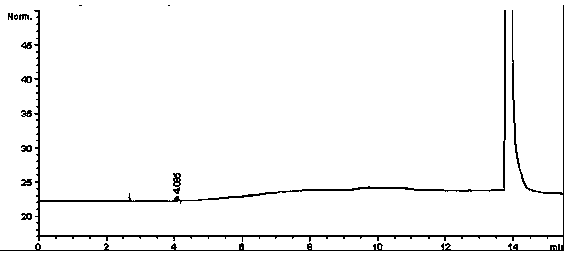

Donepezil polycrystals and process for producing the same

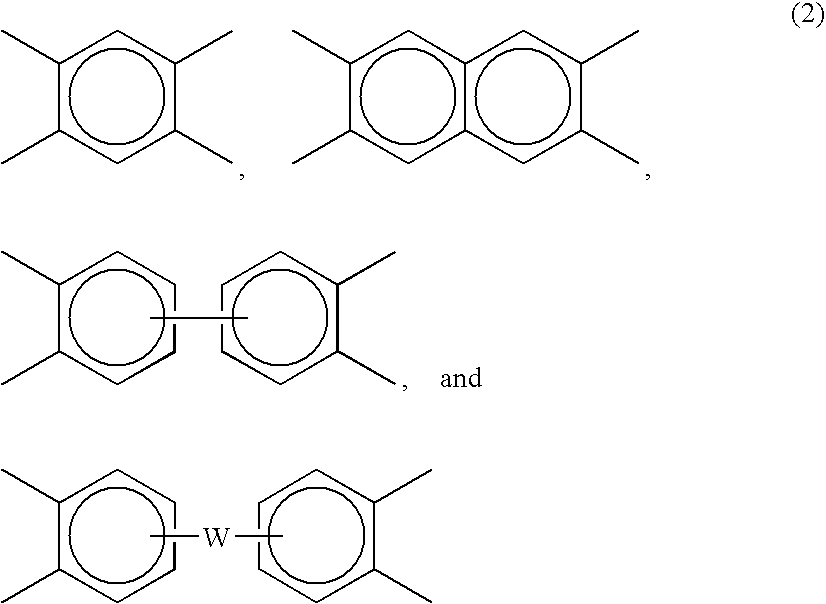

The present invention provides novel polymorphic crystals (A) to (C) having excellent handling properties and an extremely low content of residual solvent of donepezil used as a precursor for production of donepezil hydrochloride having an excellent action as a medicament, and an industrial process for producing the same. Further, the novel polymorphic crystals (A) to (C) according to the present invention are characterized by the powder X-ray diffraction pattern and / or IR absorption peaks of donepezil represented by the following formula:

Owner:EISAI CO LTD

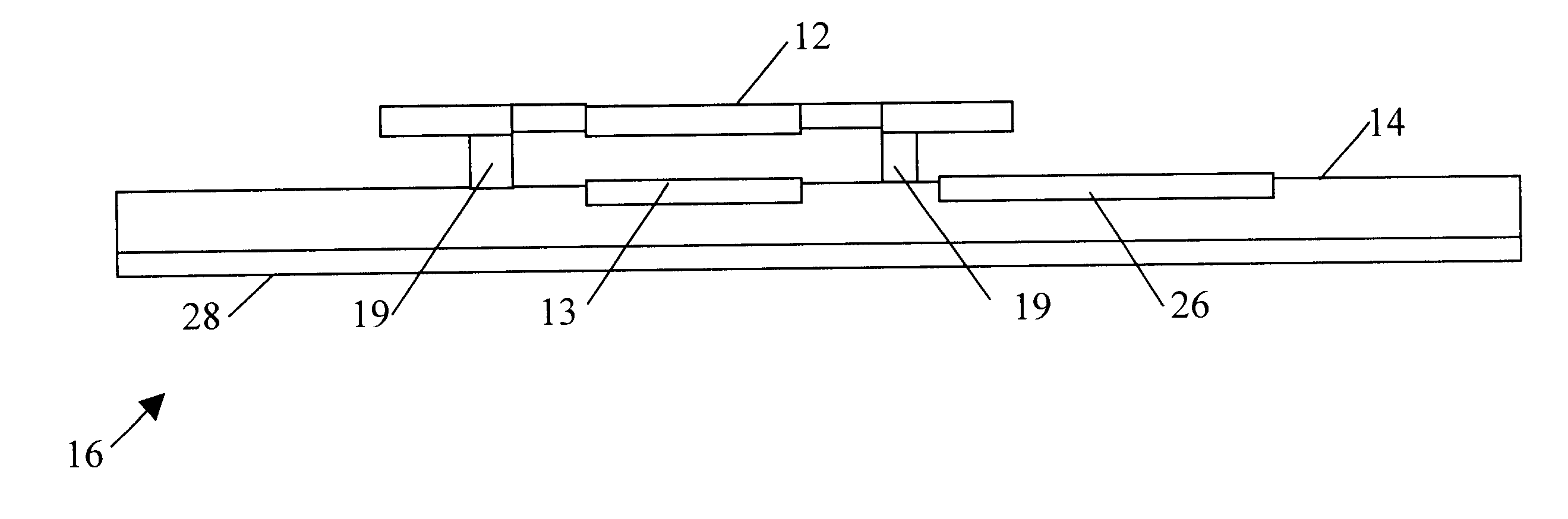

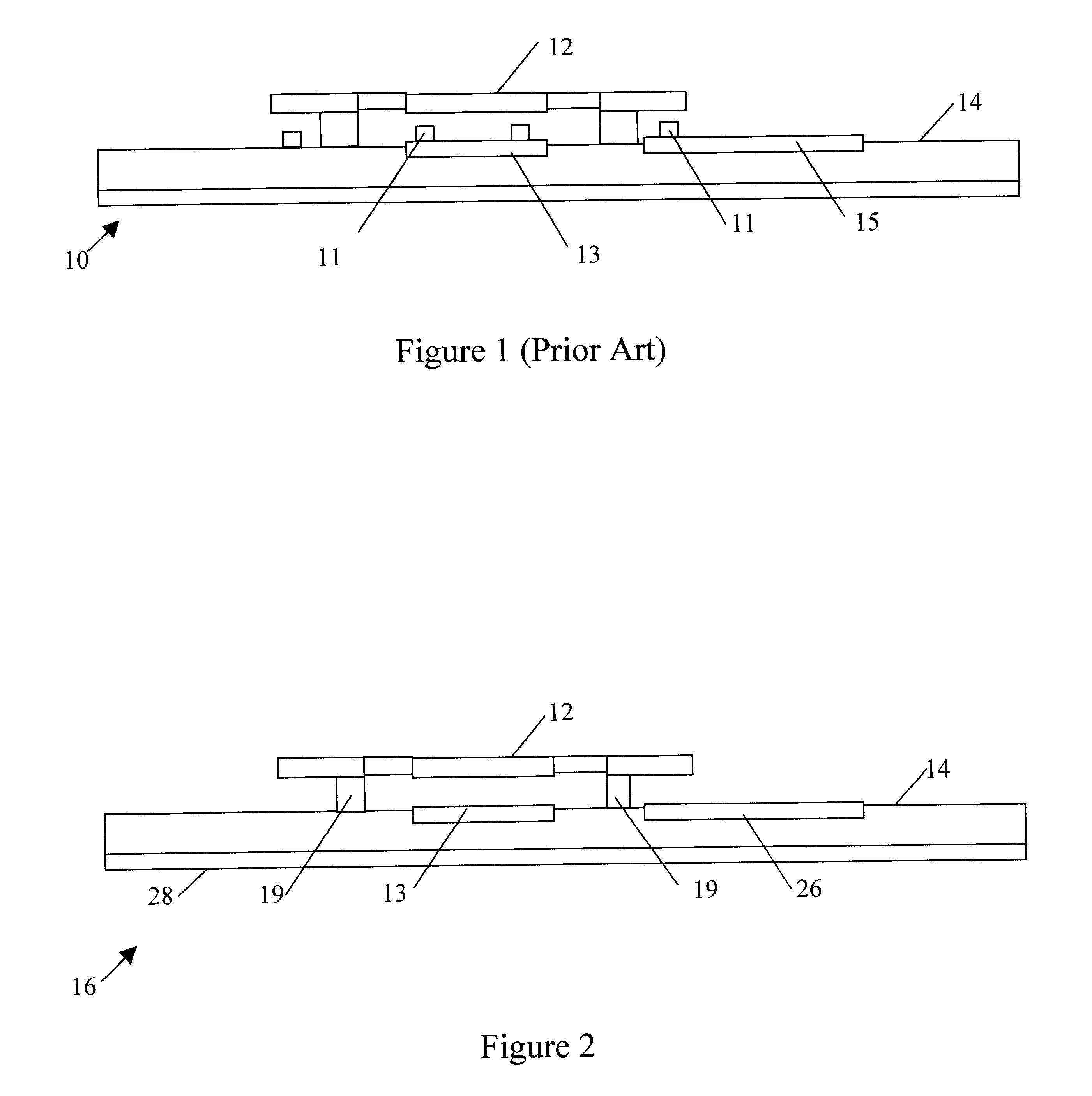

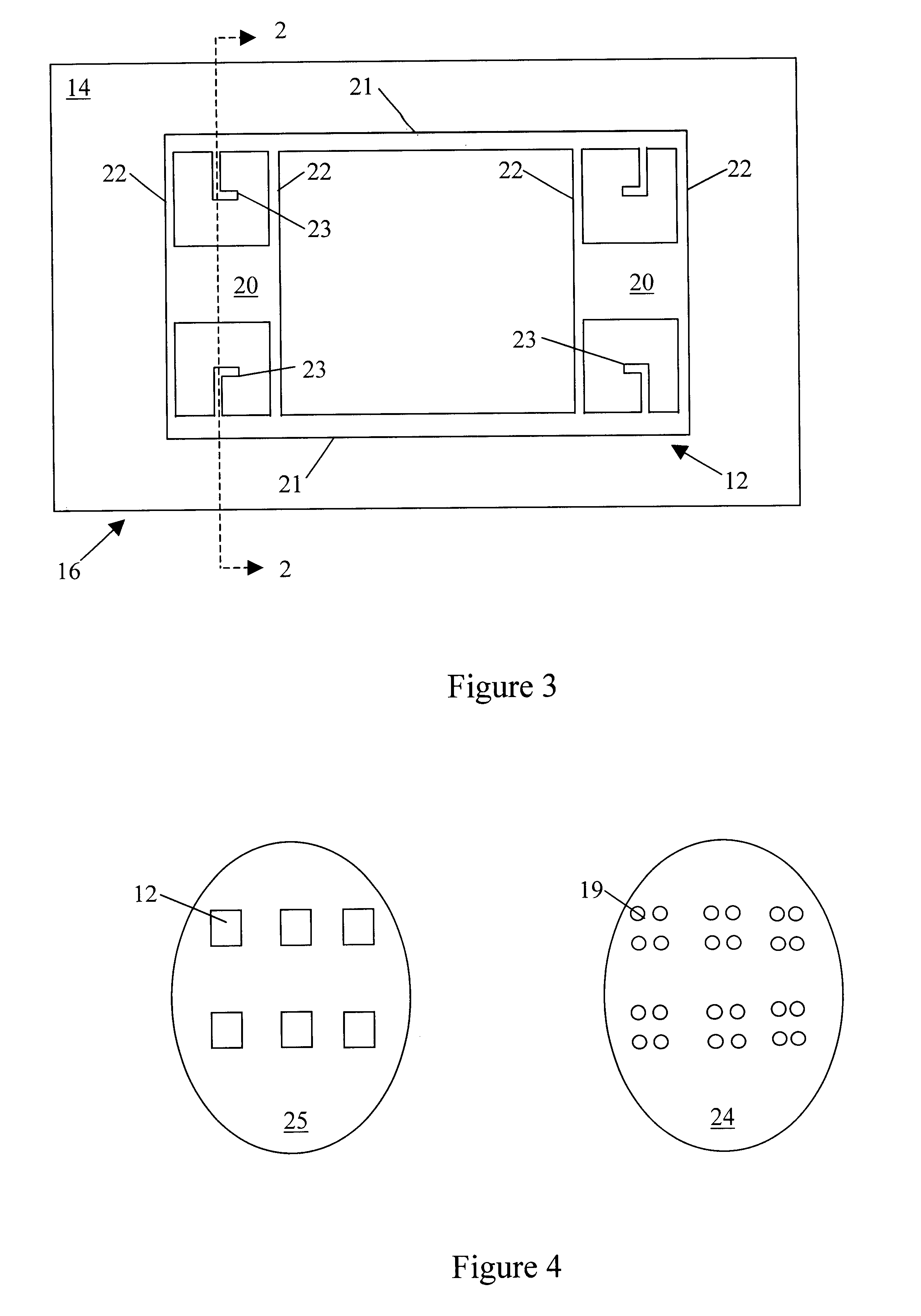

Microelectromechanical device manufacturing process

InactiveUS6337027B1Quantity minimizationEasily terminatedDecorative surface effectsSemiconductor/solid-state device manufacturingDissolutionEngineering

The present invention relates to micro electromechanical systems (MEMS) devices and more specifically to a process for manufacturing MEMS devices having at least one suspended structural element. The present invention seeks to provide an improved method for manufacture of MEMS devices having improved safety and increased yield and throughput compared to conventional EDP immersion process techniques. MEMS devices are made using a modified dissolution process that removes, in a selective etch step, inactive silicon to release an active silicon device from a sacrificial substrate. The present invention uses a selective etchant in conjunction with a commercial spray acid processing tool to provide a dissolution process with improved throughput, improved repeatable and uniform etch rates and reduction in the number of processing steps and chemical containment for improved safety. When the etch process is complete, the solvent spray is turned off and a spray of de-ionized water is directed onto composite structure to remove residual solvent without causing suspended elements to adhere to the support substrate.

Owner:TELEDYNE SCI & IMAGING

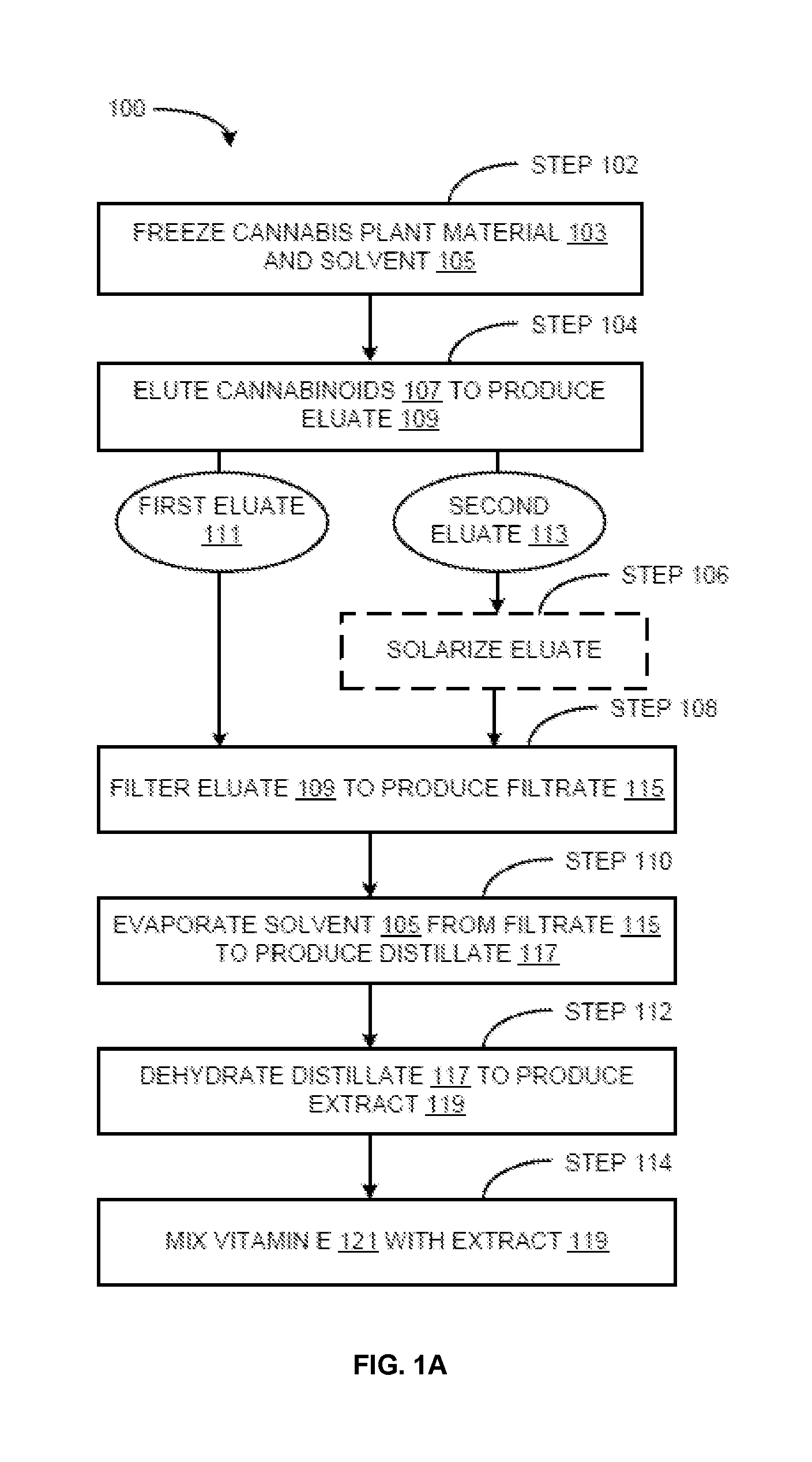

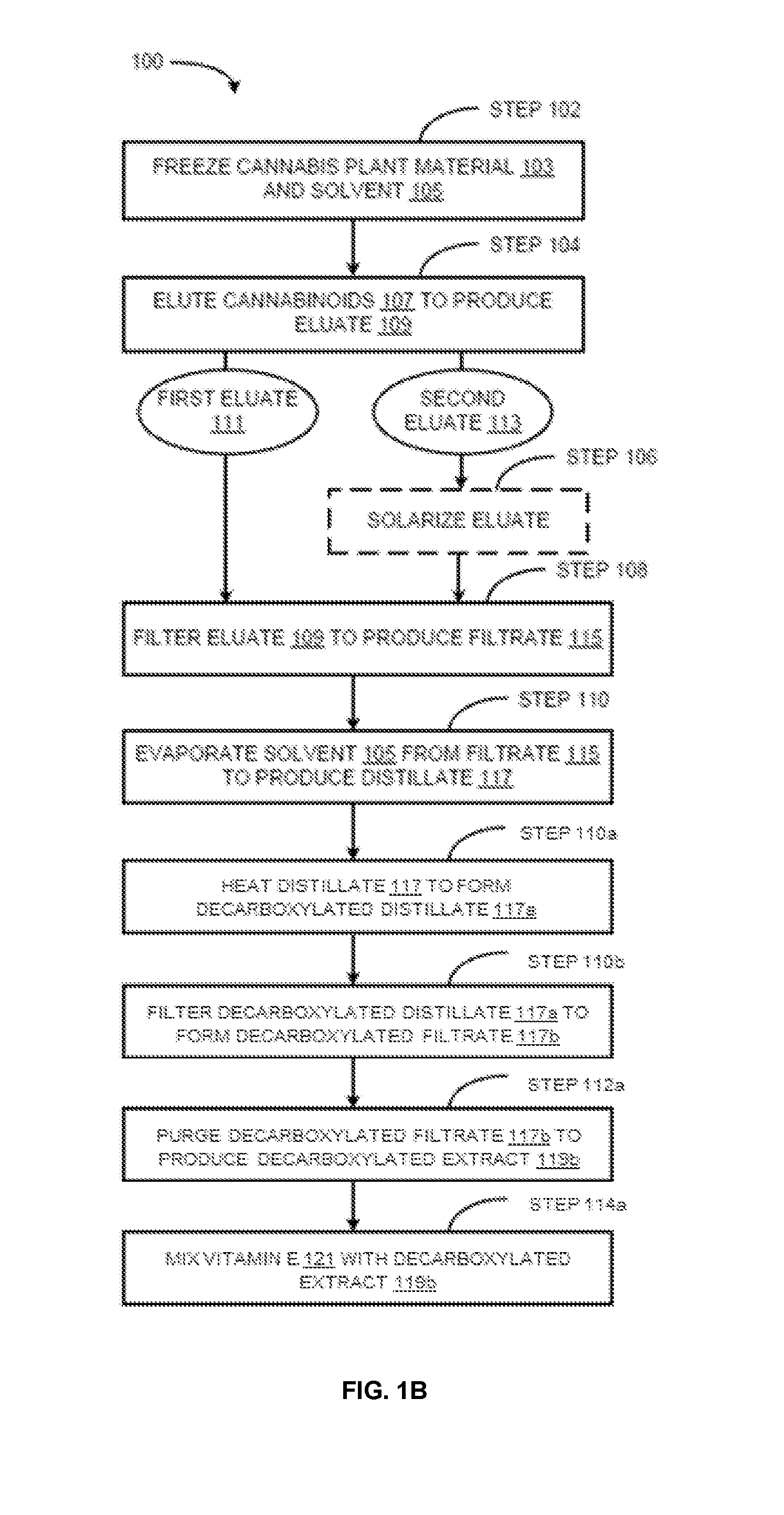

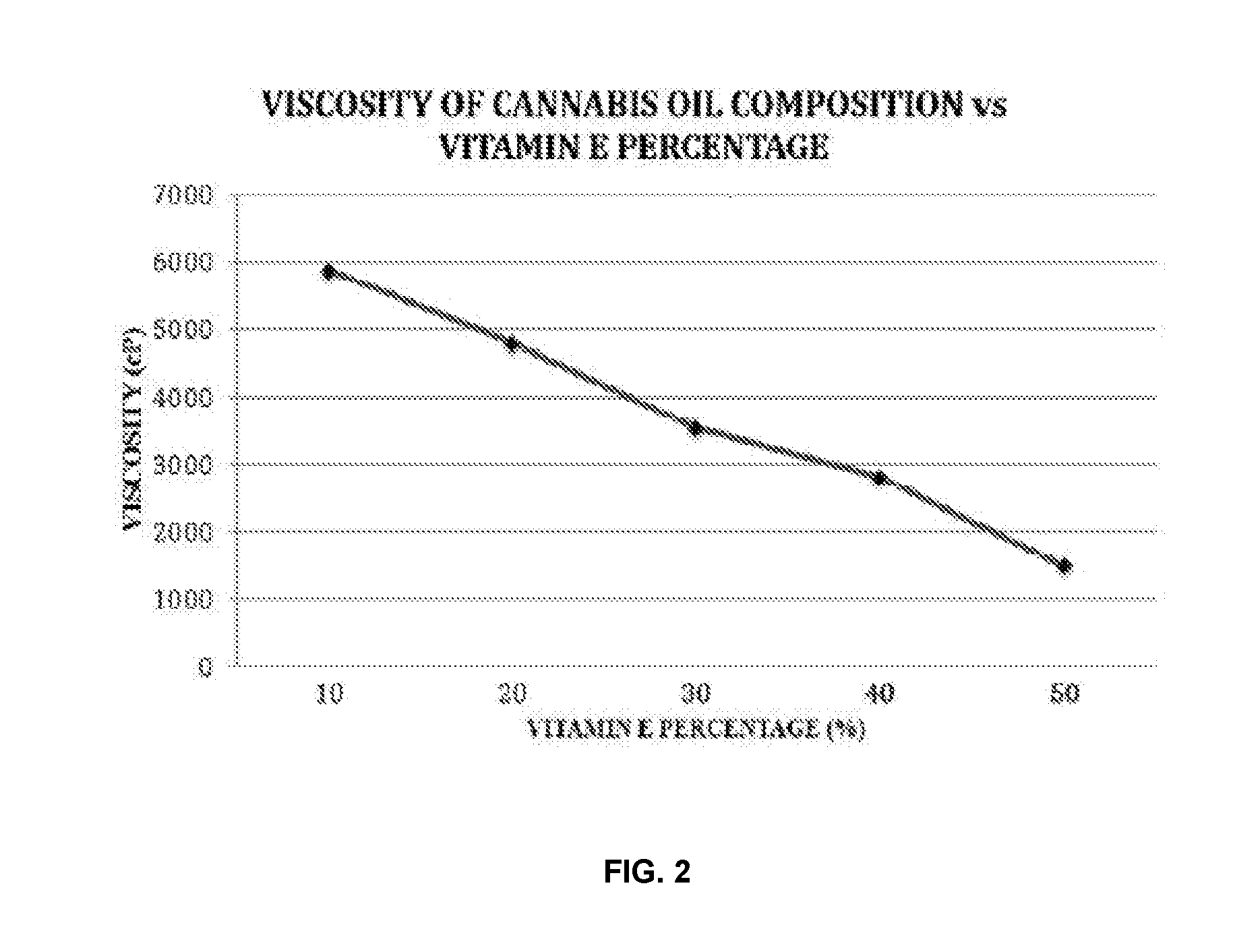

Methods for preparation of cannabis oil extracts and compositions

The present invention provides cannabis oil extracts and compositions thereof, including cannabis oil compositions containing vitamin E, and methods for preparing the extracts and compositions. In some embodiments, the present invention provides a method for preparing a cannabis oil extract comprising eluting cannabinoids from cannabis plant material with a solvent to produce an eluate, filtering the eluate with a filter to produce a filtrate, evaporating the solvent from the filtrate with a distiller to produce a distillate, and purging the distillate under conditions sufficient to remove residual solvent, thereby preparing the extract. In some embodiments, the method further includes mixing a quantity of vitamin E with the extract to produce a cannabis oil composition.

Owner:CONSTANCE THERAPEUTICS INC

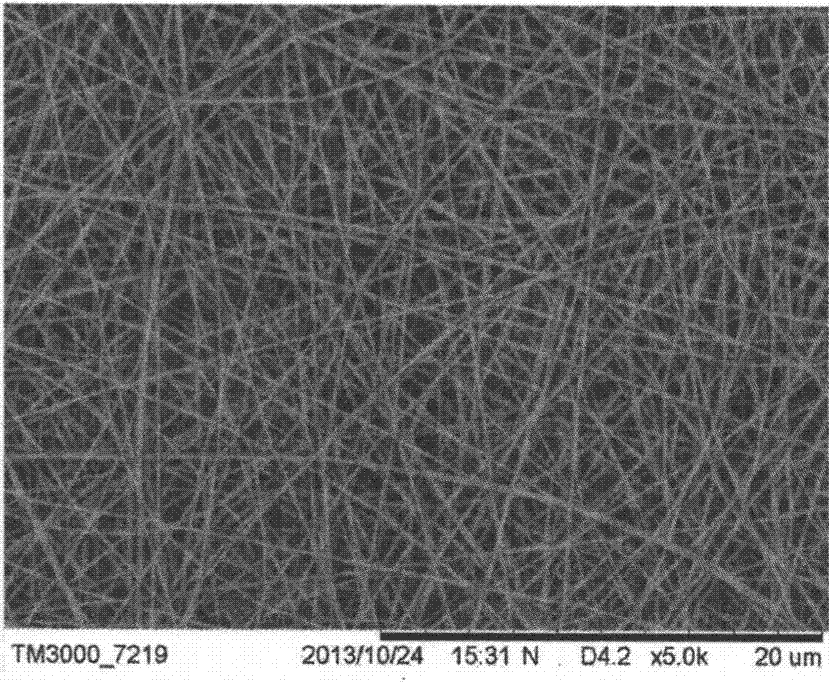

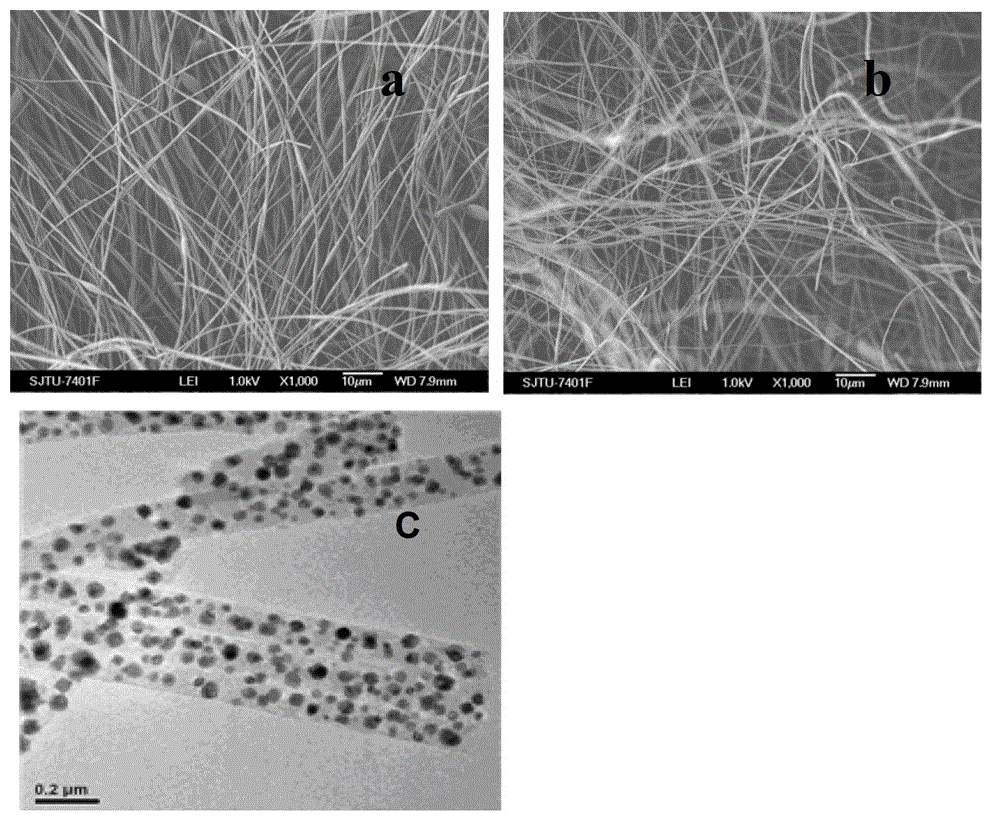

Preparation method of core-shell structure superfine fiber carrier material for medical dressing

ActiveCN103611182AEasy to operateOptimizing Control ParametersFilament/thread formingAbsorbent padsFiberWound healing

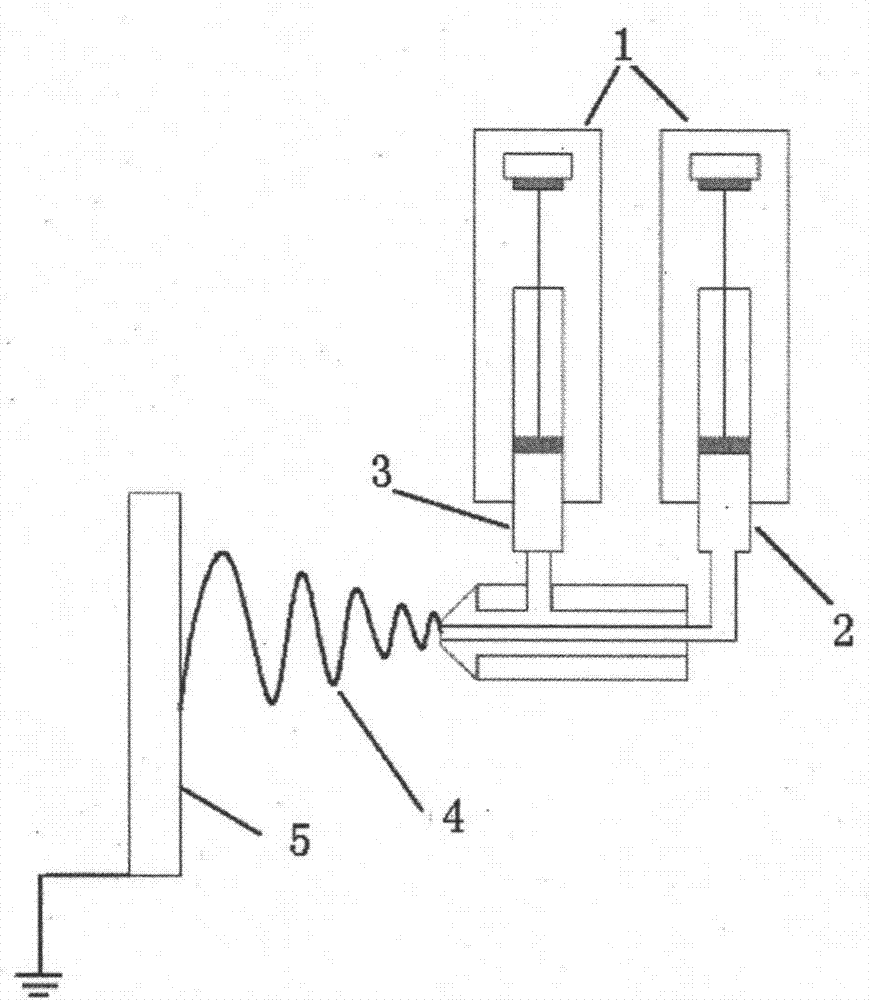

The invention provides a preparation method of a core-shell structure superfine fiber carrier material for medical dressing. The preparation method is basically characterized by specifically comprising the following steps: mixing and dissolving macromolecular polymers into a solvent to obtain a shell layer solution; selecting at least one of a functional high polymer and a medicine and dissolving the functional high polymer or the medicine into a solvent under the aseptic condition to obtain a core layer solution; and performing coaxial electrostatic spinning, placing into a vacuum drying box, and vacuum-drying to remove the residual solvent to obtain the core-shell structure superfine fiber carrier material for the medical dressing. The core-shell structure superfine fiber carrier material for the medical dressing has excellent water-absorbing property, moisturizing property and air permeability, can provide a wet microenvironment for wound healing, is uniform in pore size distribution, and achieves a bacterium blocking effect. The core layer high polymer or medicine can achieve zero-order release through corrosion or diffusion mechanism, so the influence of the environment on the medicine effect is reduced and unnecessary damage to a human body by the medicine is reduced.

Owner:上海必趣医疗科技有限公司

Method for producing aqueous dispersion of thermoplastic resin microparticles and toner for electrophotography

The present invention provides a method for producing an aqueous dispersion of thermoplastic resin microparticles containing considerably less residual solvent remaining in resin particles, and a toner for electrophotography containing considerably less residual solvent. A self-water-dispersible thermoplastic resin is swollen using an organic solvent having a boiling point lower than 100° C., which does not dissolve but can swell the self-water-dispersible thermoplastic resin, to produce a swollen material and the resulting swollen material is dispersed into an aqueous medium in the form of microparticles to produce an initial aqueous dispersion, and then the organic solvent is removed from the initial aqueous dispersion to prepare a dispersion. A toner for electrophotography contains microparticles obtained by separating microparticles of the self-water-dispersible thermoplastic resin from the aqueous dispersion of thermoplastic resin microparticles and drying the microparticles.

Owner:DAINIPPON INK & CHEM INC

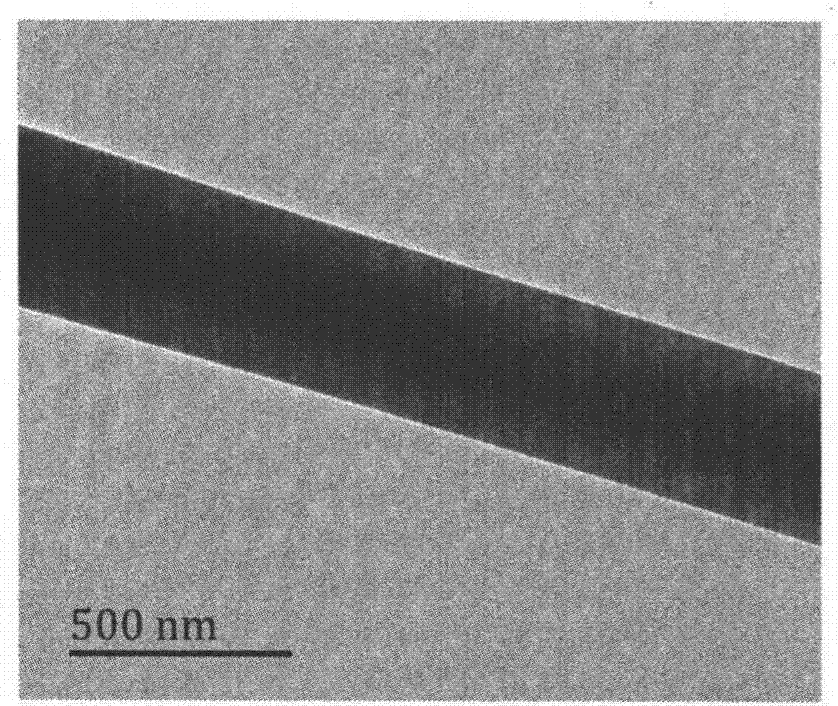

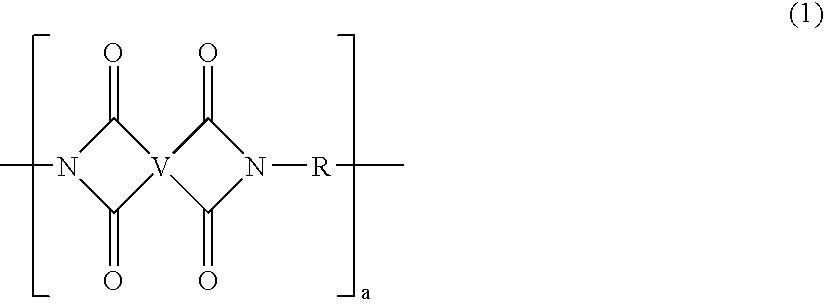

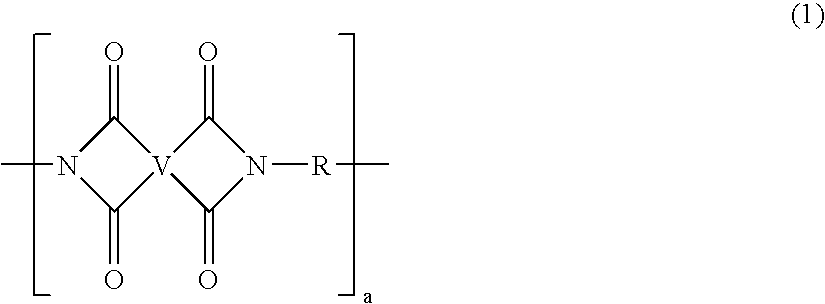

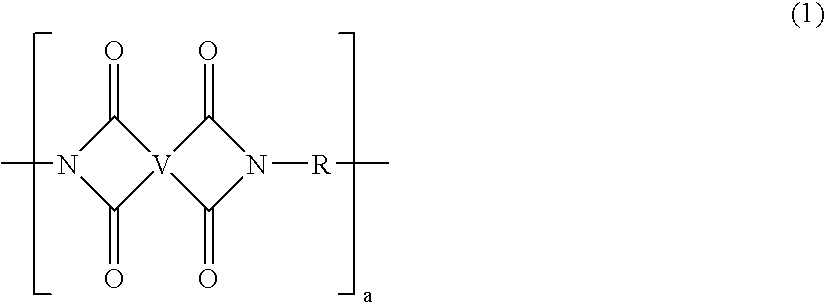

Polyimide solvent cast films having a low coefficient of thermal expansion and method of manufacture thereof

InactiveUS20080044639A1Material nanotechnologySynthetic resin layered productsPolymer scienceMicrometer

A solvent cast film comprises a polyimide comprising structural units derived from polymerization of a dianhydride component comprising a dianhydride selected from the group consisting of 3,4′-oxydiphthalic dianhydride, 3,3′-oxydiphthalic dianhydride, 4,4′-oxydiphthalic dianhydride, and combinations thereof, with a diamine component wherein the polyimide has a glass transition temperature of at least 190° C.; wherein the film has a coefficient of thermal expansion of less than 60 ppm / ° C., a thickness from 0.1 to 250 micrometers, and less than 5% residual solvent by weight; wherein the polyimide has less than 15 molar % of structural units derived from a member selected from the group consisting of biphenyltetracarboxylic acid, a dianhydride of biphenyltetracarboxylic acid, an ester of biphenyltetracarboxylic acid, and a combination thereof.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Method for preparing chitosan-based silver-loaded composite antimicrobial superfine fiber membrane

InactiveCN103705969ABroad-spectrum antibacterialImprove antibacterial propertiesAbsorbent padsNon-woven fabricsFiberPolyvinyl alcohol

The invention provides a method for preparing a chitosan-based silver-loaded composite antimicrobial superfine fiber membrane. The method is characterized by particularly comprising the following steps: 1, adding silver nitrate powder into an acetic acid aqueous solution with the mass fraction of 50-90%, stirring to dissolve to obtain a solution, weighing and adding chitosan and polyoxyethylene or polyvinyl alcohol powder into the solution, and stirring to obtain a spinning solution; and 2, adding the spinning solution into an electrostatic spinning device, carrying out electrostatic spinning under the conditions that the voltage is 10-20kv, the spinning solution injecting speed is 0.1-1.0mL / h, the receive distance is 8-30cm, the spinning temperature is 20-50 DEG C and the relative humidity is 10-55%, carrying out vacuum drying on the obtained white nanofiber membrane for 12-36 hours, and removing the residual solvent to obtain the chitosan-based silver-loaded composite antimicrobial superfine fiber membrane. The electrospun fiber membrane has the advantages of a certain mechanical property, good antimicrobial property and water absorbing ability and can be used for the fields of wound surface nursing and medical dressings with different anti-infection requirements through designing the compositing ratio of the chitosan and the nanometer silver.

Owner:DONGHUA UNIV

Method for extracting and refining paeonia rockii seed oil

InactiveCN101649246AImprove oil yieldNo solvent residueCosmetic preparationsToilet preparationsAdditive ingredientAntioxidant

The invention relates to a method for extracting and refining paeonia rockii seed oil. The method comprises the following steps: collecting seeds, unshelling, baking and frying, carrying out screw press, filtering, deacidifying, degumming, drying, decoloring, deodorizing in vacuum, adding an antioxidant and filling. After solid impurities and residues obtained by the screw press are broken up, ethylacetate is added, then refluxing extraction is carried out, and a solvent is recovered so as to obtain the paeonia rockii seed oil for cosmetics. A two-step method is used for extracting the paeonia rockii seed oil, wherein in the first step: primary pressed oil used for eating is obtained by physical pressing, and the produced paeonia rockii seed oil has higher oil recovery rate and no residual solvents and can be securely eaten; in the second step, the ethyl acetate is adopted for extraction, and ingredients for antioxidation, inflammation resistance, sun block, and the like in the paeonia rockii seed oil can be extracted and used for producing the cosmetics. The invention not only improves the oil recovery rate of paeonia rockii seeds, but also ensures that the effective ingredients in the paeonia rockii seeds are sufficiently utilized.

Owner:兰州牡丹园艺开发公司

Method for preparing cold water dispersing type carotenoid micro-capsule powder without using organic solvent

ActiveCN103406079ANo residueProcess environmental protectionMicroballoon preparationMicrocapsule preparationSuspended particlesVegetable oil

The invention provides a method for preparing cold water dispersing type carotenoid micro-capsule powder without using an organic solvent. The method concretely comprises the following steps: (a) enabling carotenoid crystal to suspend in a water solution containing antioxidant, protective colloid and at least one non-ionic emulsifier; (b) grinding and homogenizing the solution obtained in the step (a) under the nitrogen protection to enable crystal particles to be ground and stably suspend; (c) carrying out micronization on the suspended particles of the obtained solution by a heating device to form an emulsion; (d) dissolving the protective colloid into the emulsion obtained in the step (c), carrying out secondary embedding, dewatering and drying to obtain powder particles. The method can solubilize carotenoid without using the organic solvent or vegetable oil, thus solving the problems of residual solvent, low carrying capacity and the like caused by the existing solvent method and a high temperature melting method. In all the steps of the method, the organic solvent is not used, so that the method is environment-friendly in technology; the process of high-temperature treatment is not needed, so that trans isomer is not produced, and the method is high in carrying capacity and small in loss of active ingredients.

Owner:INNOBIO CORP LTD

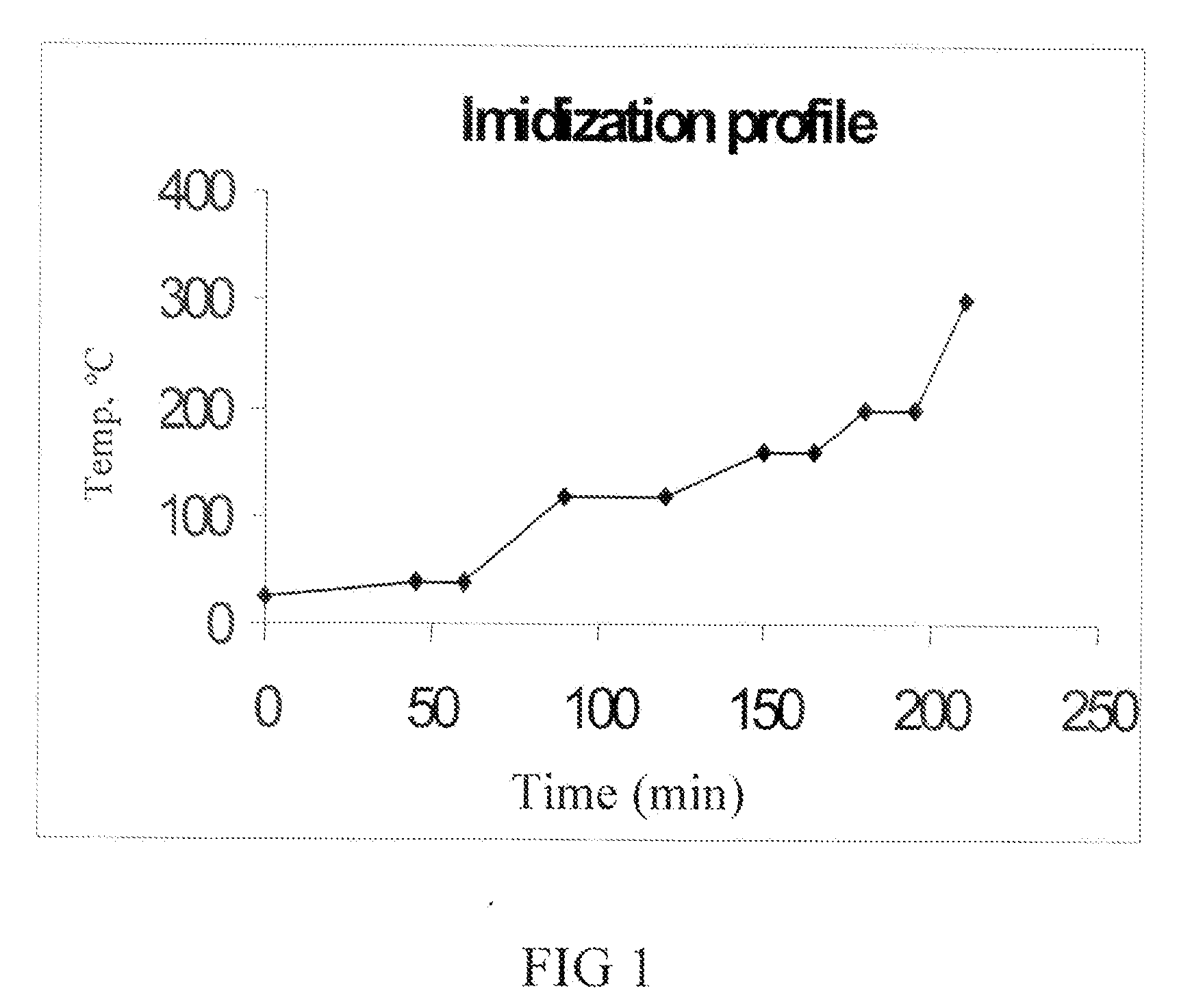

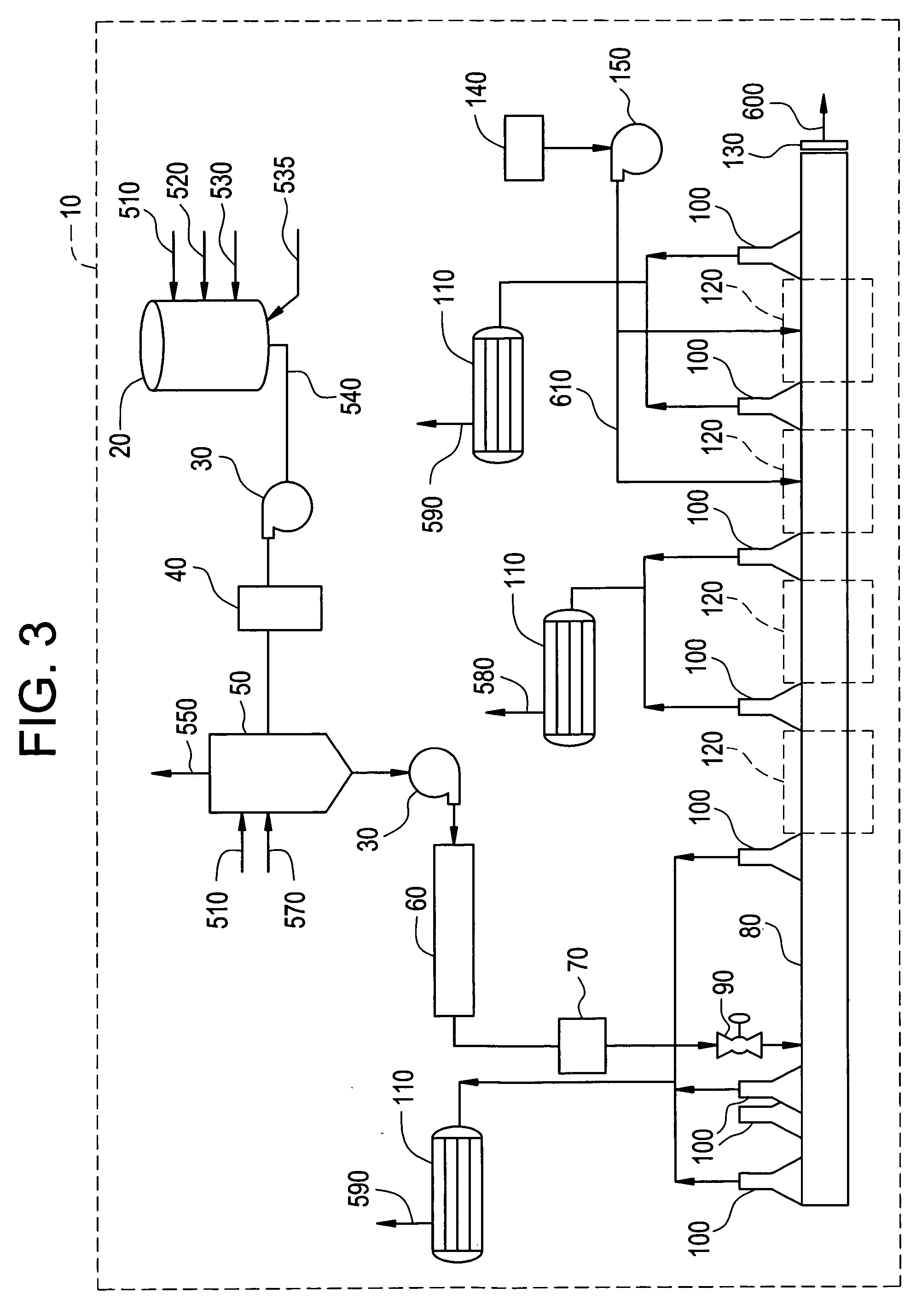

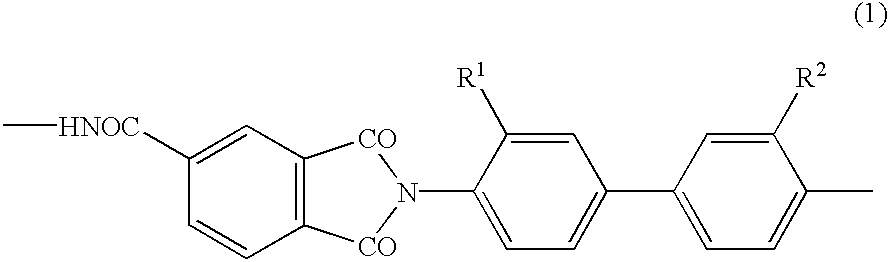

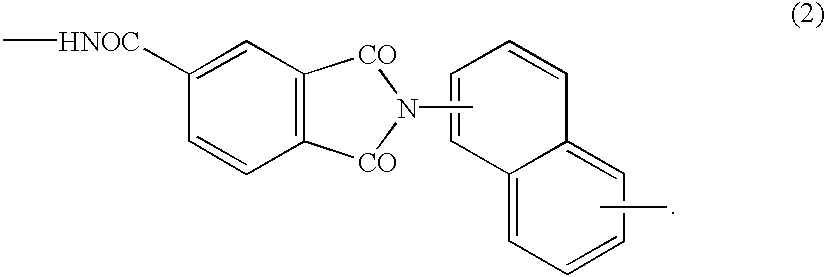

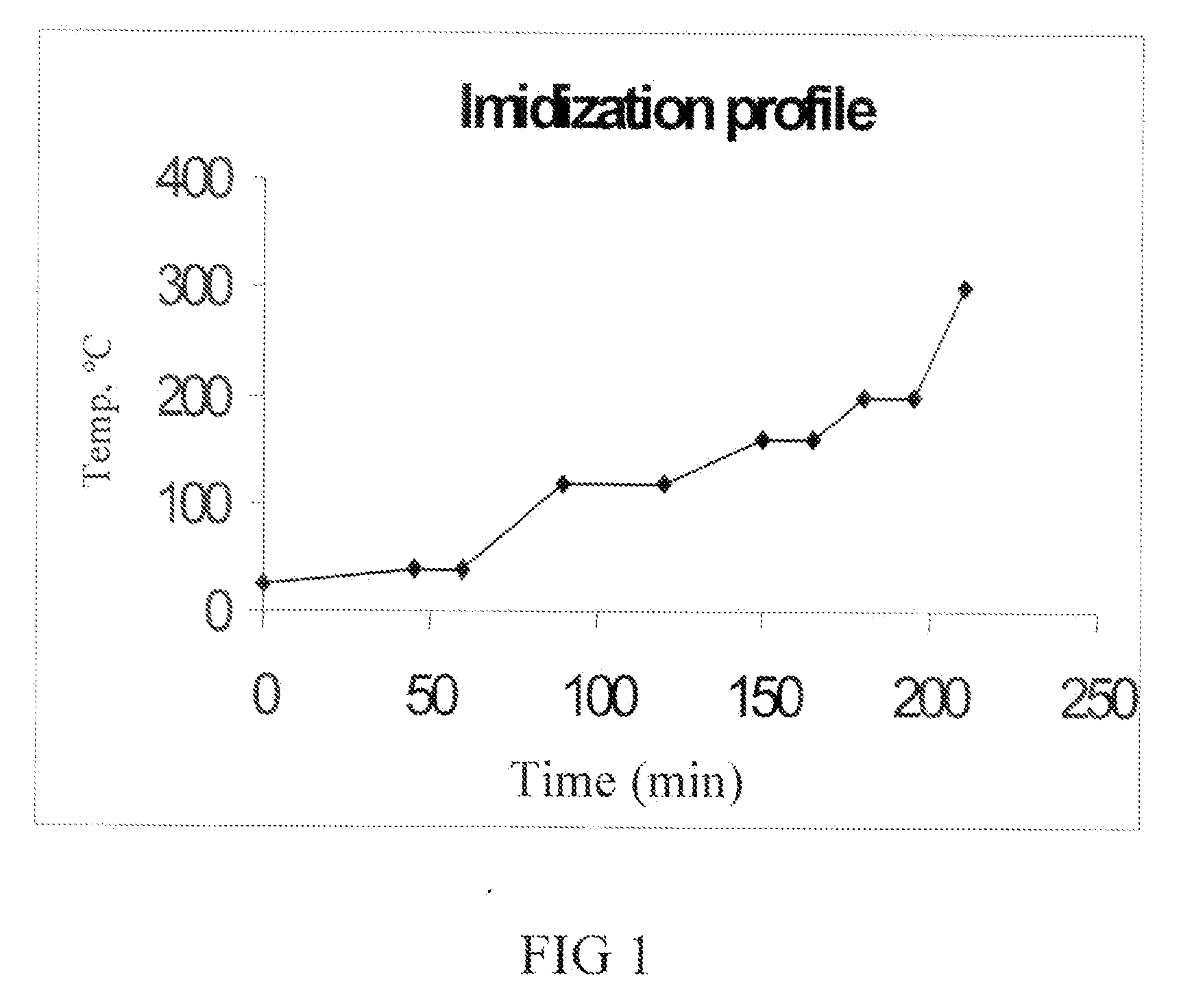

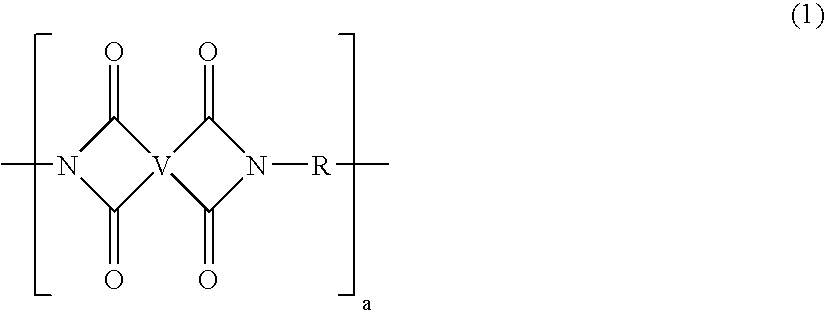

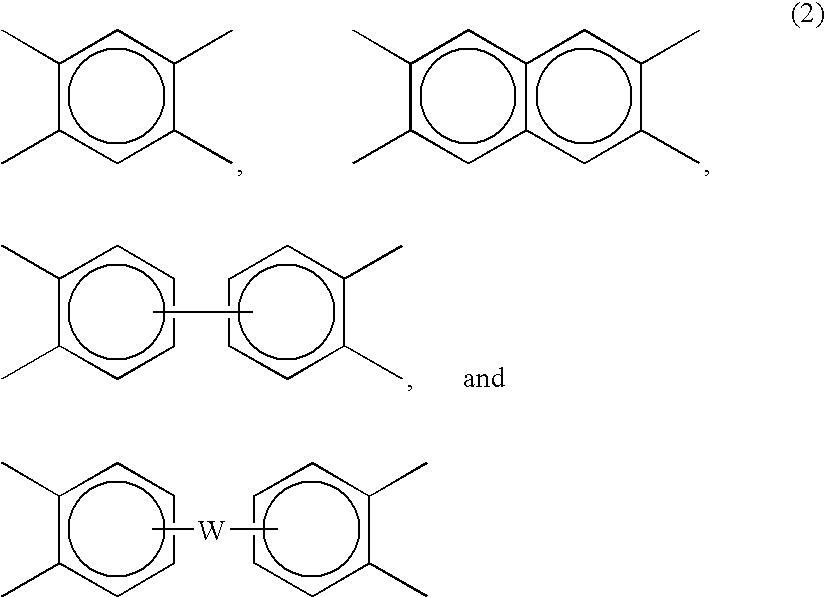

Method for preparing polyimide and polyimide prepared thereby

A method for preparing a polyimide includes introducing a mixture of an oligomer and a solvent to an extruder, removing solvent via at least one extruder vent, and melt kneading the oligomer to form a polyimide. The polyimide has a low residual solvent content. The method is faster than solution polymerization of polyimides, and it avoids the stoichiometric inaccuracies associated with reactive extrusion processes that use monomers as starting materials.

Owner:SHPP GLOBAL TECH BV

Articles comprising a polyimide solvent cast film having a low coefficient of thermal expansion and method of manufacture thereof

ActiveUS20080044682A1Printed circuit aspectsSynthetic resin layered productsPolymer sciencePolyetherimide

An article comprises a solvent cast film comprising a polyetherimide comprising structural units derived from a dianhydride component selected from the group consisting of 3,4′-oxydiphthalic anhydride, 3,3′-oxydiphthalic anhydride, 4,4′-oxydiphthalic anhydride, and combinations thereof, and a diamine component. The polyetherimide has a glass transition temperature that is at least 190° C. The film has a coefficient of thermal expansion of less than 60 ppm / ° C., a thickness from 0.1 to 250 micrometers, and less than 5% residual solvent by weight. The film has less than 15 molar % of a member selected from the group consisting of biphenyltetracarboxylic acid, dianhydrides of biphenyltetracarboxylic acid, esters of biphenyltetracarboxylic acid, and combinations thereof.

Owner:SHPP GLOBAL TECH BV

Method of separating a polymer from a solvent

InactiveUS6949622B2Material nanotechnologyChemical/physical/physico-chemical stationary reactorsPolymerFlash evaporation

A method of separating a polymer-solvent mixture is described wherein a polymer-solvent mixture is heated prior to its introduction into an extruder comprising an upstream vent and / or a side feeder vent to allow flash evaporation of the solvent, and downstream vents for removal of remaining solvent. The one-step method is highly efficient having very high throughput rates while at the same time providing a polymer product containing low levels of residual solvent.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Drying of drug-containing particles

A secondary drying process is disclosed for removing residual solvent from drug-containing particles that have been formed by solvent-based processes, the secondary drying process utilizing a combination of vacuum, agitation, and a stripping gas.

Owner:LONZA BEND INC

Articles comprising a polyimide solvent cast film having a low coefficient of thermal expansion and method of manufacture thereof

A solvent cast film comprises a polyimide comprising structural units derived from polymerization of a dianhydride component comprising a dianhydride selected from the group consisting of 3,4′-oxydiphthalic dianhydride, 3,3′-oxydiphthalic dianhydride, 4,4′-oxydiphthalic dianhydride, and combinations thereof, with a diamine component comprising 4,4′-diaminodiphenylsulfone; wherein the polyimide has a glass transition temperature from 190° C. to 400° C.; and wherein the film has a coefficient of thermal expansion of less than 60 ppm / ° C., a thickness from 0.1 to 250 micrometers, endless than 5% residual solvent by weight.

Owner:SHPP GLOBAL TECH BV

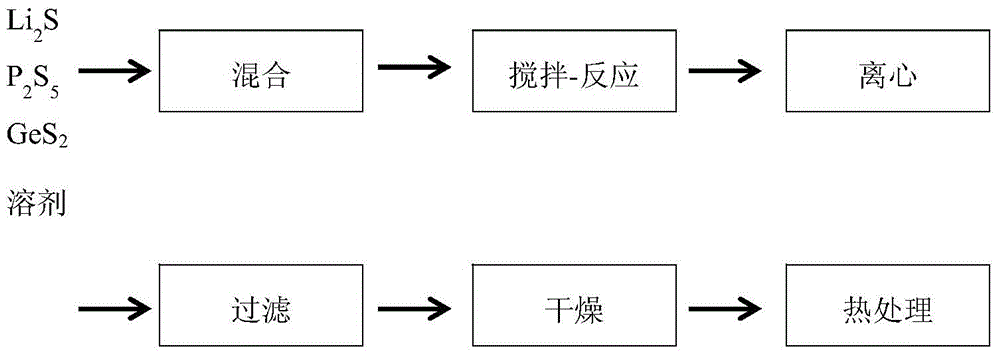

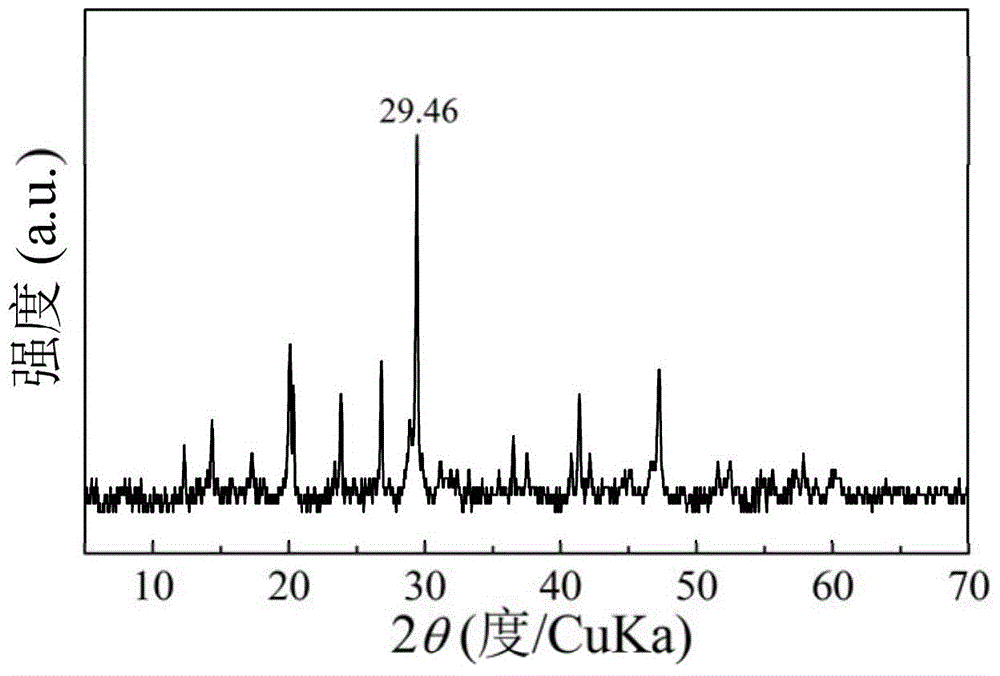

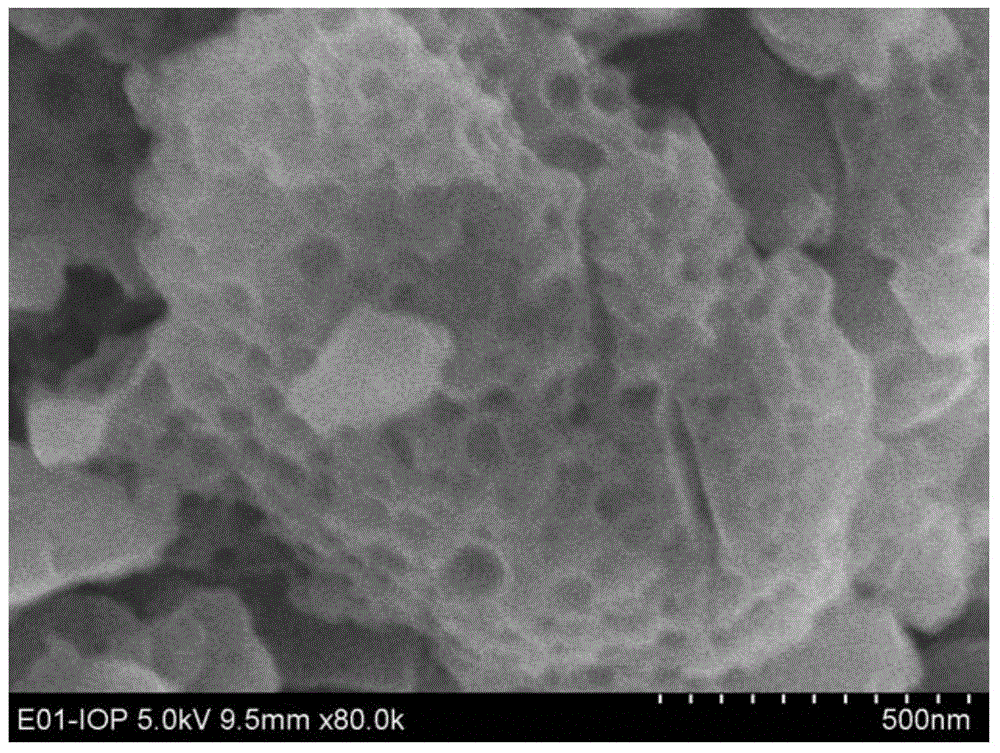

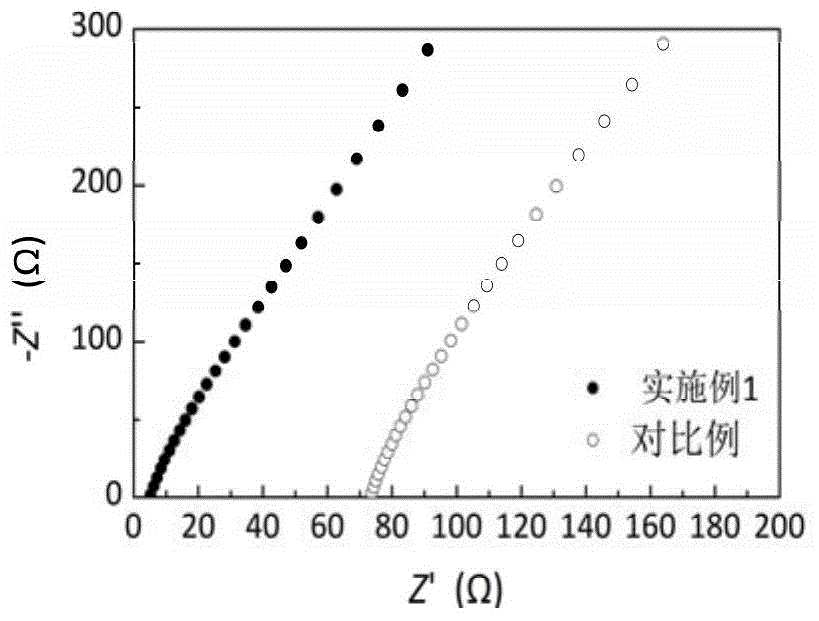

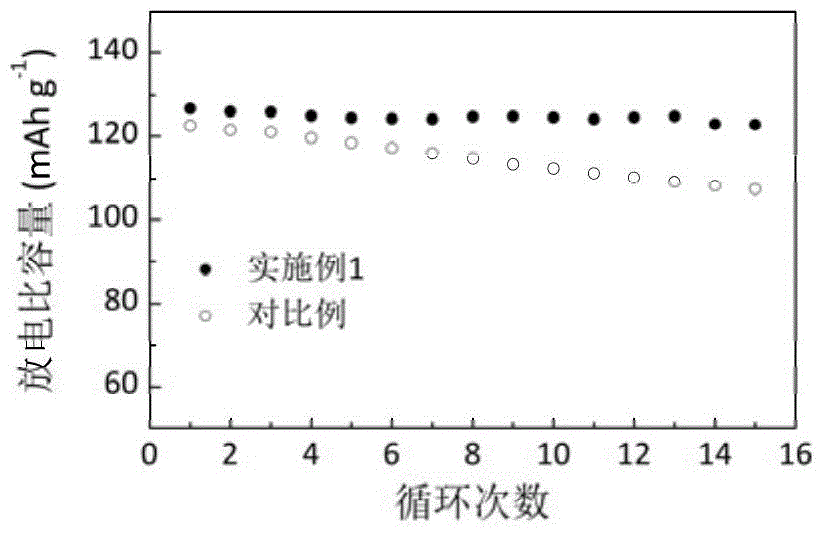

Sulfide solid electrolyte material and preparation method thereof

InactiveCN105098228AEasy to prepareImprove ionic conductivityNon-metal conductorsSecondary cellsState of artOrganic solvent

The invention provides a sulfide solid electrolyte material and a preparation method thereof. The preparation method comprises the following steps: mixing Li2S, P2S5 and M2Sn with an organic solvent to obtain a suspension liquid; sequentially stirring, dissolving, crystallizing, centrifuging, filtering and drying the suspension liquid; and then carrying out thermal treatment, so as to obtain the sulfide solid electrolyte material. Compared with the prior art, a compound containing Li, P, M and S is formed in an organic solution; the compound and a little of organic solvent form a crystalline state; the residual organic solvent in the suspension liquid is separated and volatilized in the centrifuging, separating and drying processes; meanwhile, most of crystalline-state solvent is also separated and volatilized; and nanopores are left by the residual solvent and the crystalline-state solvent in solid electrolyte in the volatilizing process. Due to the presence of the nanopores, the specific surface area of the sulfide solid electrolyte material is increased; and meanwhile, the material particles are relatively small, and easy to compact, therefore, the ionic conductivity of the sulfide solid electrolyte material is increased.

Owner:JIANGXI GANFENG BATTERY TECH

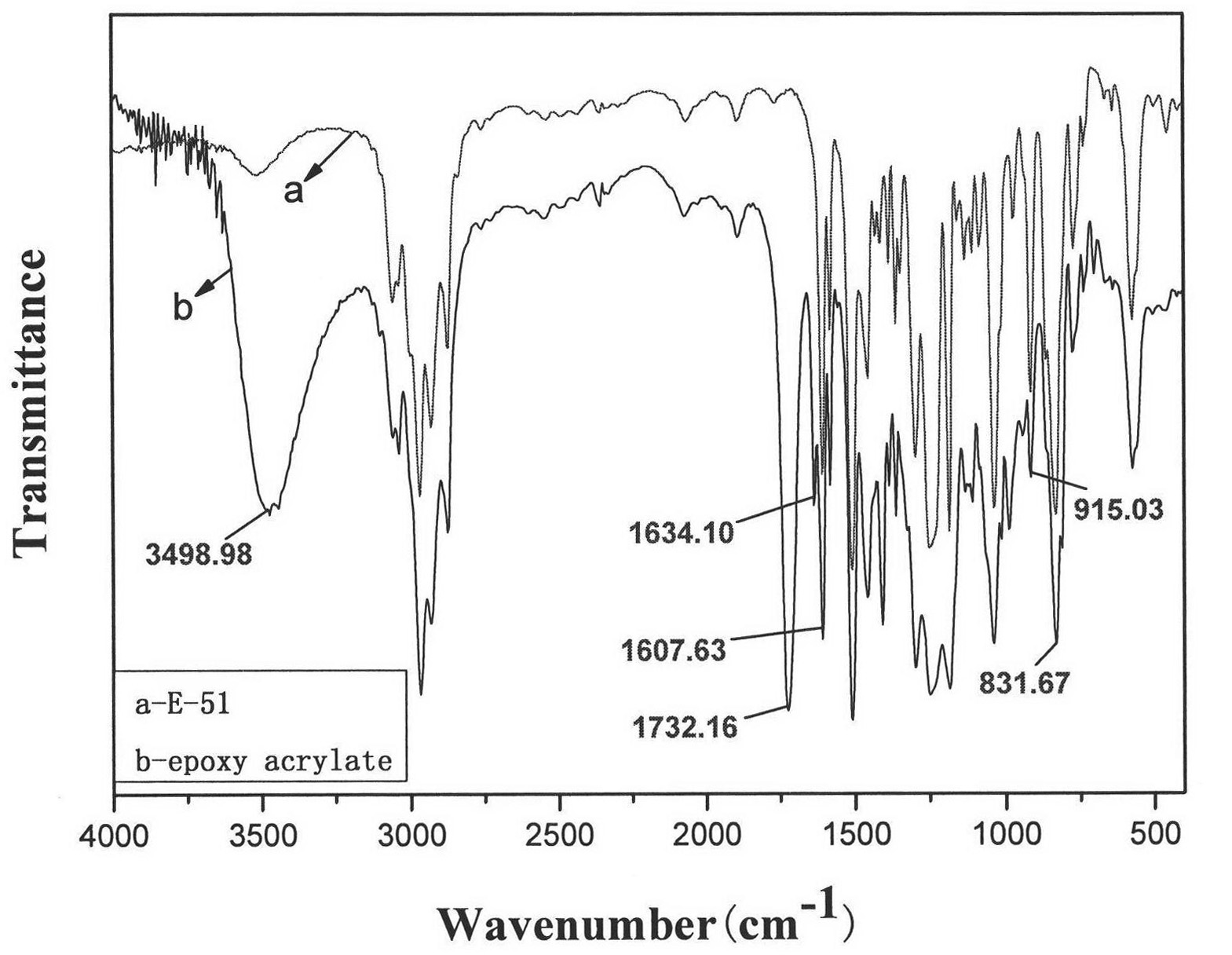

Waterborne epoxy acrylate-grafted composite emulsion and preparation method thereof

The invention relates to the field of manufacture of epoxy acrylate composite resin materials, in particular to a waterborne epoxy acrylate-grafted composite emulsion and a preparation method thereof. The process mainly comprises the following steps of: firstly, by taking a polymerizing monomer as a dispersing medium, enabling epoxide resin and acrylic acid to react under the action of tetrabutylammonium bromide to generate an epoxy acrylate monomer; and secondly, pre-emulsifying the epoxy acrylate monomer and other monomers and then enabling the epoxy acrylate monomer and other monomers to generate a copolymerization reaction to prepare the waterborne epoxy acrylate-grafted composite emulsion by adopting a semi-continuous seeded emulsion polymerization method. According to the process, the copolymerization monomer is used as a solvent dispersing medium for the esterification reaction of the epoxide resin and the acrylic acid in the first step and is also a monomer of the copolymerization reaction in the second step; an organic solvent in the reaction of the first step is prevented from being removed by adopting reduced pressure distillation, so that the influence of residual solvent on the performance of the product is avoided; the waterborne epoxy acrylate-grafted composite emulsion has high grafting rate and can be used for improving the compatibility of the epoxide resin and acrylic acid resin and enhancing the performances of the water resistance, the adhesive force, the salt resistance and the like of a coating and can be widely applied to the fields of metal coatings, building coating materials and the like.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

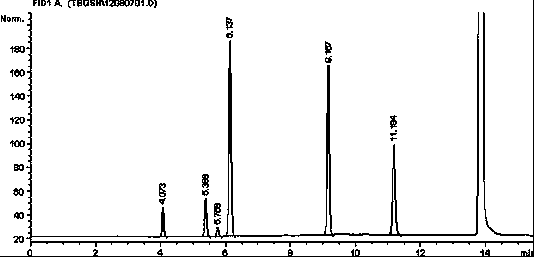

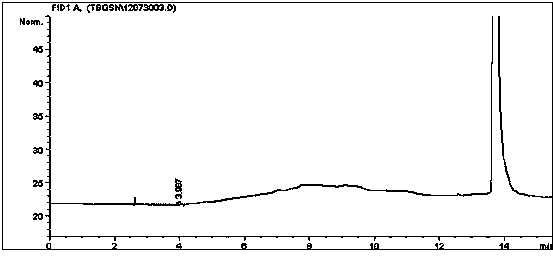

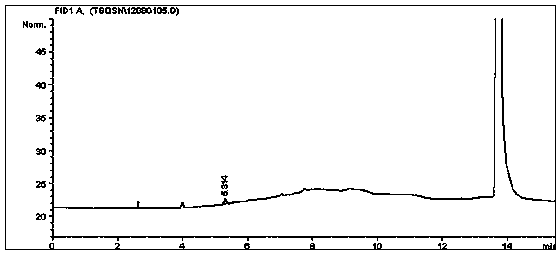

Method for detecting multiple residual solvents in medicament

ActiveCN103487519AHigh sensitivityHigh precisionComponent separationMethylene DichlorideVapor phase chromatography

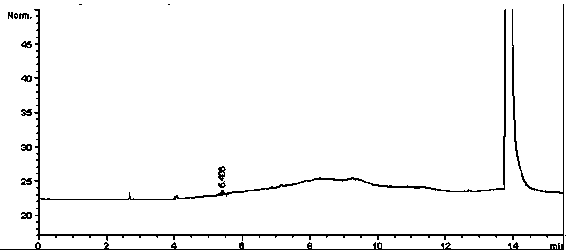

The invention relates to a method for detecting multiple residual solvents in a medicament. According to the method, by utilizing a gas chromatographic method, nine organic solvents including methanol, ethanol, acetonitrile, acetone, isopropanol, methylene dichloride, ethyl acetate, tetrahydrofuran and triethylamine in the medicament are simultaneously detected, the sensitivity and the precision are high, and the repeatability is good; by utilizing a standard addition method, other standard substances do not need to serve as internal standard substances, only pure substances of to-be-measured components are needed, the accuracy requirement on the sampling volume is low, and the operation is simple; by utilizing a headspace sampling method, a direct solution sample is prevented from interfering the detection and polluting a chromatographic column; by utilizing a temperature programming method, low-boiling-point organic solvents and high-boiling-point organic solvents can be effectively separated.

Owner:SHANGHAI NEW ASIA PHARMA

Synthesis of purified, partially esterified polyol polyester fatty acid compositions

InactiveUS6887947B1Adverse impactReduce riskEsterified saccharide compoundsCosmetic preparationsPolyesterPolyol

This invention relates to processes for the production of purified, partially esterified polyol fatty acid polyesters and the compositions derived from those processes. The purified, partially esterified polyol fatty acid polyesters of the present invention are particularly well suited for use in a variety of food, beverage, pharmaceutical, and cosmetic applications and comprise less than about 5% polyol; less than about 5 ppm of residual solvent; less than about 700 ppm of lower alky esters; less than about 5% of a soap and free fatty acid mixture; less than about 3% of ash; and have an acid value of less than about 6.

Owner:THE PROCTER & GAMBLE COMPANY

Preparing method of high content full cis-beta-carotene preparation

ActiveCN101016259ALess quantityInhibition of isomerizationOrganic active ingredientsOrganic chemistryBeta-CaroteneAlcohol

The invention discloses a making method of high-full trans-beta-carotene agent, which comprises the following steps: setting the weight rate of beta-carontene, combined antioxidant and solvent with emulsifier at 1:0.01-0.1:50-500; dissolving the mass into water to form solution under 30-60 deg.c; adding into high-speed stirring alcohol or isopropanol at spraying pattern; making beta-carontene to evolve at amorphous starch powder with size less than 2um; filtering; adding filtering pie into auxiliary water protected by gel in advance; emulsifying; removing residual solvent; spraying; drying; obtaining the product with antioxidant A and B.

Owner:ZHEJIANG UNIV +4

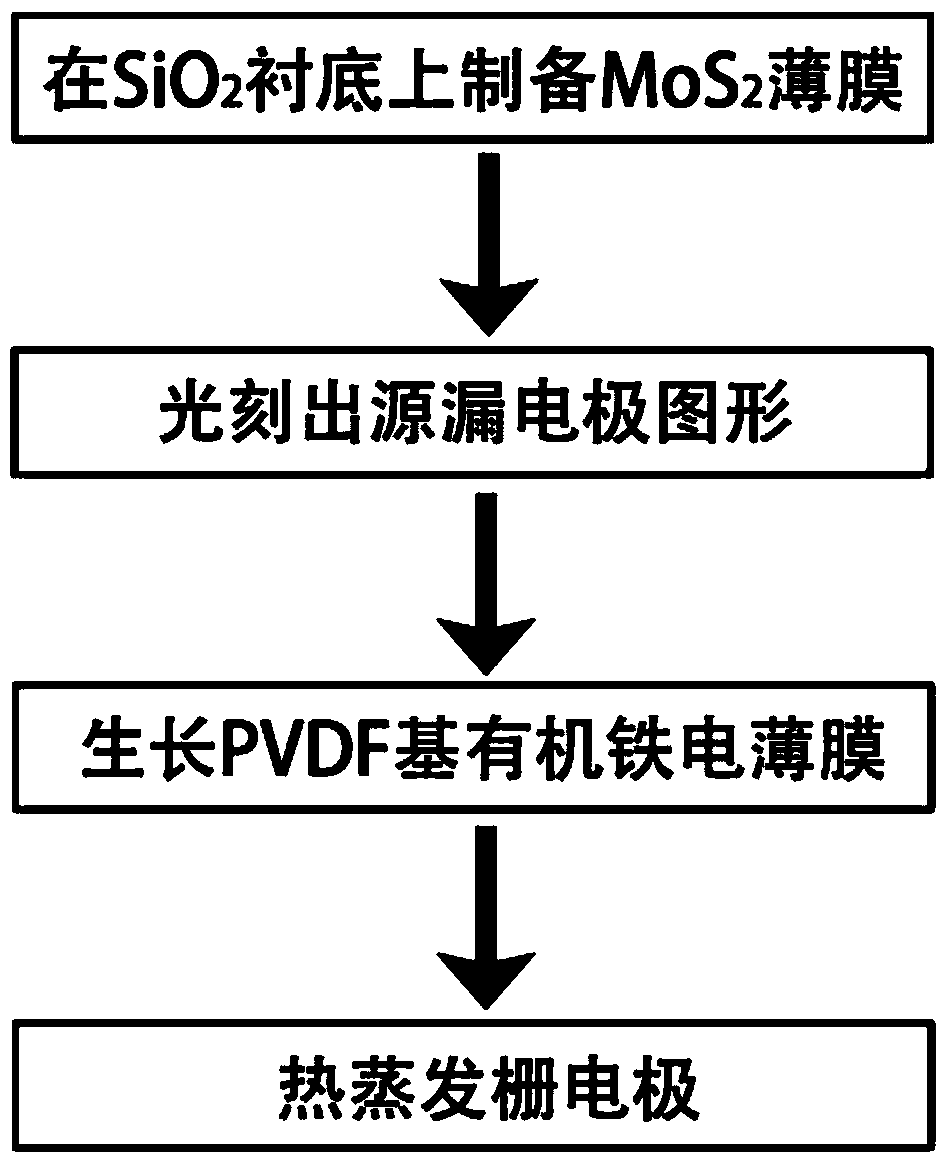

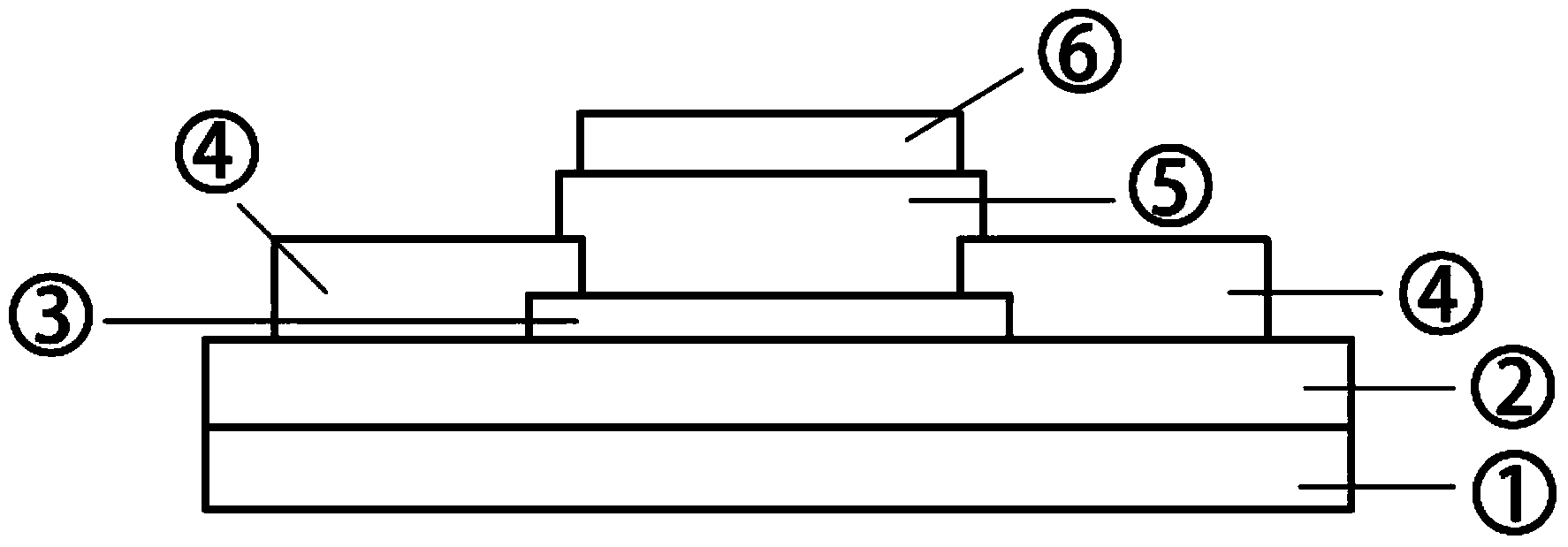

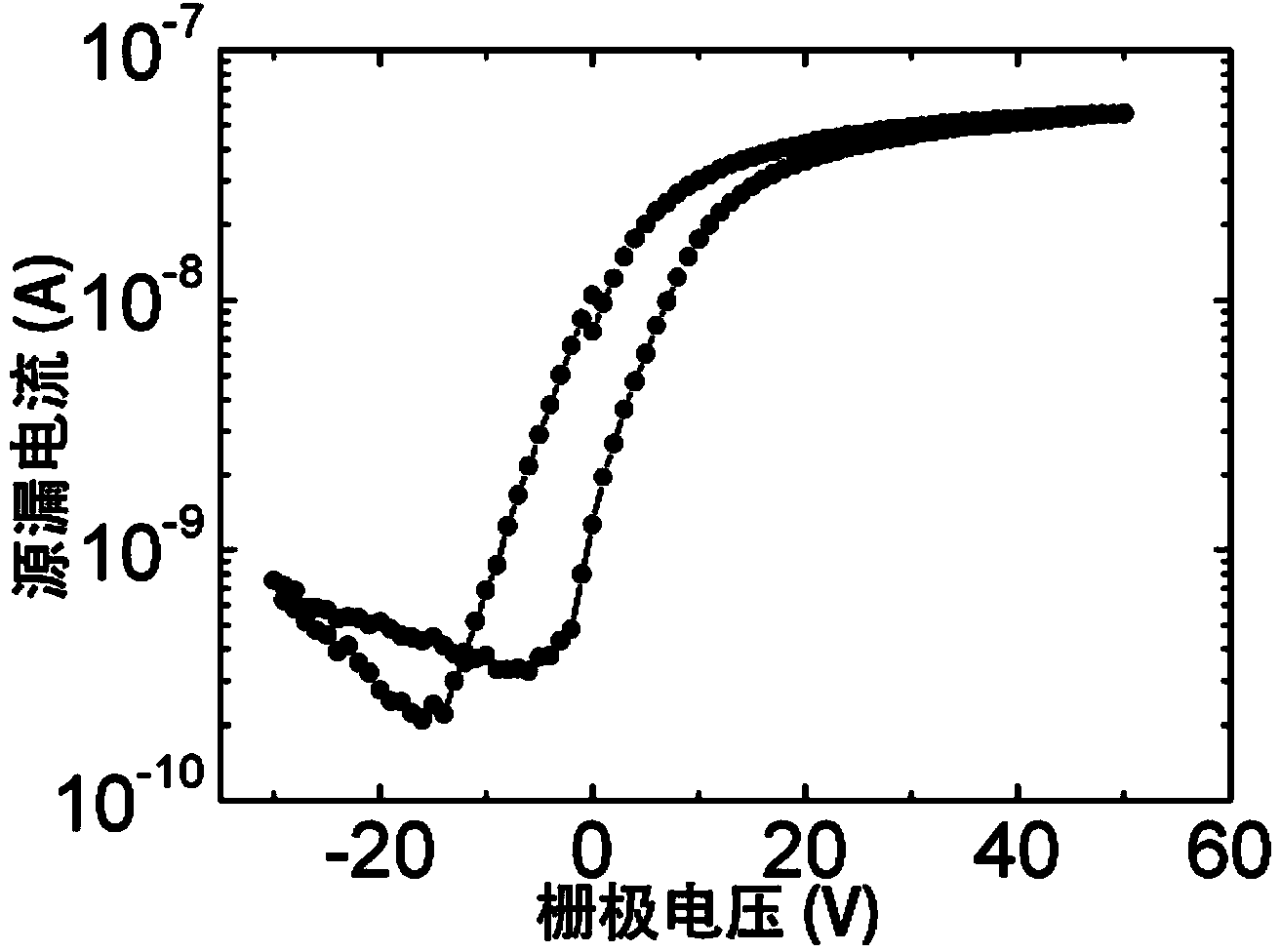

Production method of PVDF (polyvinylidene fluoride) ferroelectric field effect transistor based on molybdenum disulfide film

InactiveCN104362252AEasy to manufactureSimple processSolid-state devicesSemiconductor/solid-state device manufacturingOrganic field-effect transistorSilicon dioxide

The invention discloses a production method of a PVDF (polyvinylidene fluoride) ferroelectric field effect transistor based on a molybdenum disulfide film. The production method is characterized by including producing the MoS2 (molybdenum disulfide) film on a Si (silicon) substrate of thermal oxide growth SiO2 (silicon dioxide), etching source and drain electrodes of a field effect transistor structure by photoetching and lift off methods, transfers a PVDF organic ferroelectric polymer film onto the MoS2 film with the source and drain electrodes, removing residual solvent on an interface and guaranteeing good crystallization characteristic of the film after annealing treatment, and finally, producing a metal gate electrode by photoetching and etching methods to produce a MoS2 ferroelectric field effect transistor device. The production method has the advantages that the production method for producing the organic ferroelectric field effect transistor structure is simple in technology and guarantees research on ferroelectric polarization control of electronic transport features, related photoelectric devices and related memory devices of MoS2.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

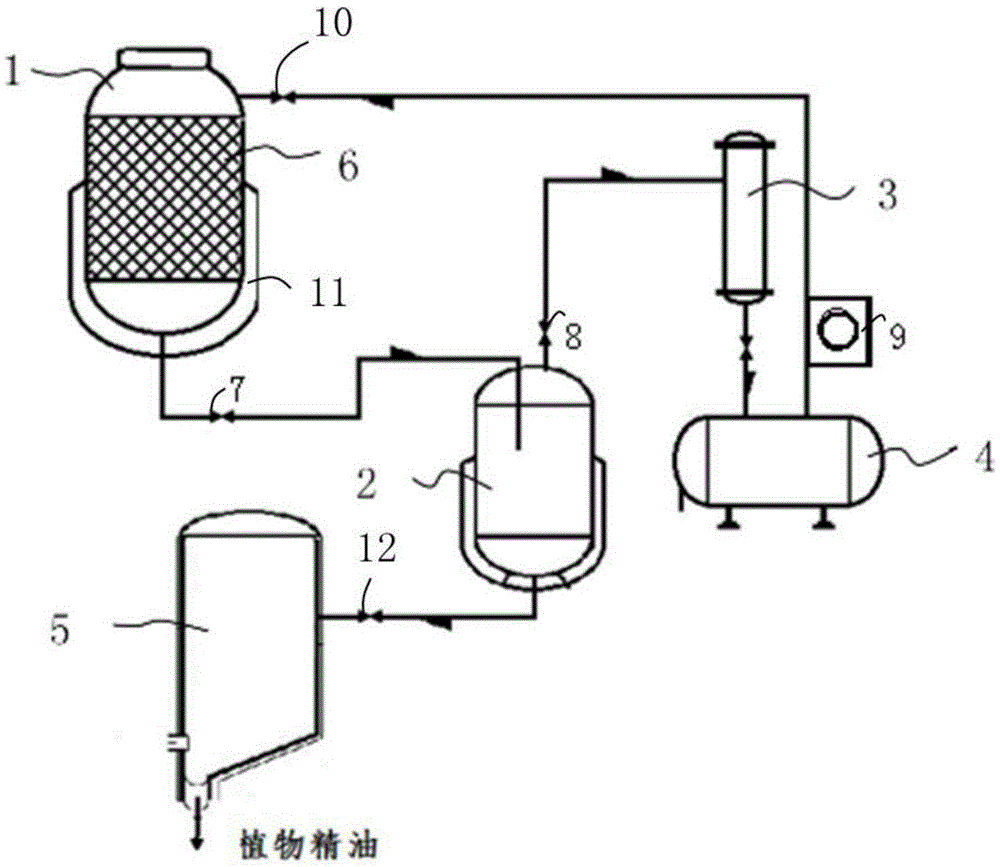

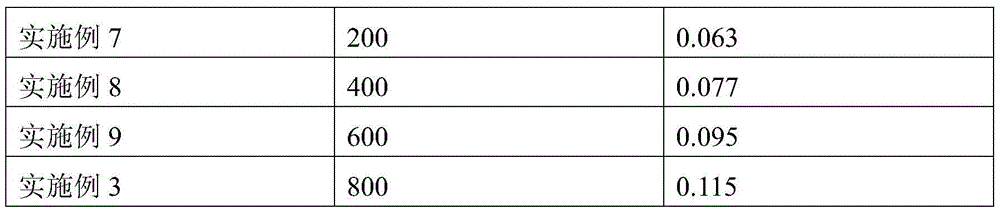

Microwave-assisted subcritical essential oil extracting method

InactiveCN105482897AUndamagedFast extraction rateEssential-oils/perfumesDistillation1,1,1,2-Tetrafluoroethane

The invention discloses a microwave-assisted subcritical essential oil extracting method. The microwave-assisted subcritical essential oil extracting method includes the steps that fresh plant tissues are frozen and then are smashed; 1,1,1,2-tetrafluoroethane is used as an extraction solvent and is led into the smashed plant tissues to perform microwave extraction; during microwave extraction, the extraction temperature is controlled to be 8-12 DEG C, the extraction pressure is controlled to be 0.8-6 Mpa, the microwave frequency is controlled to be 300-2400 MHZ, and the power is controlled to be 200-1200w; after a liquid phase in the system is separated out and microwave extraction is completed, the 1,1,1,2-tetrafluoroethane is recovered from the liquid phase, and the rest of the liquid phase is an essential oil stock solution; the essential oil stock solution is subjected to molecular distillation to obtain essential oil. By the adoption of the microwave-assisted subcritical essential oil extracting method, the essential oil free of any residual solvent can be obtained at lower temperature, the effective ingredients of the essential oil are not destroyed, and the natural quality of the essential oil can be kept to the most degree.

Owner:JIANGSU NAIQUE BIOLOGICAL ENG

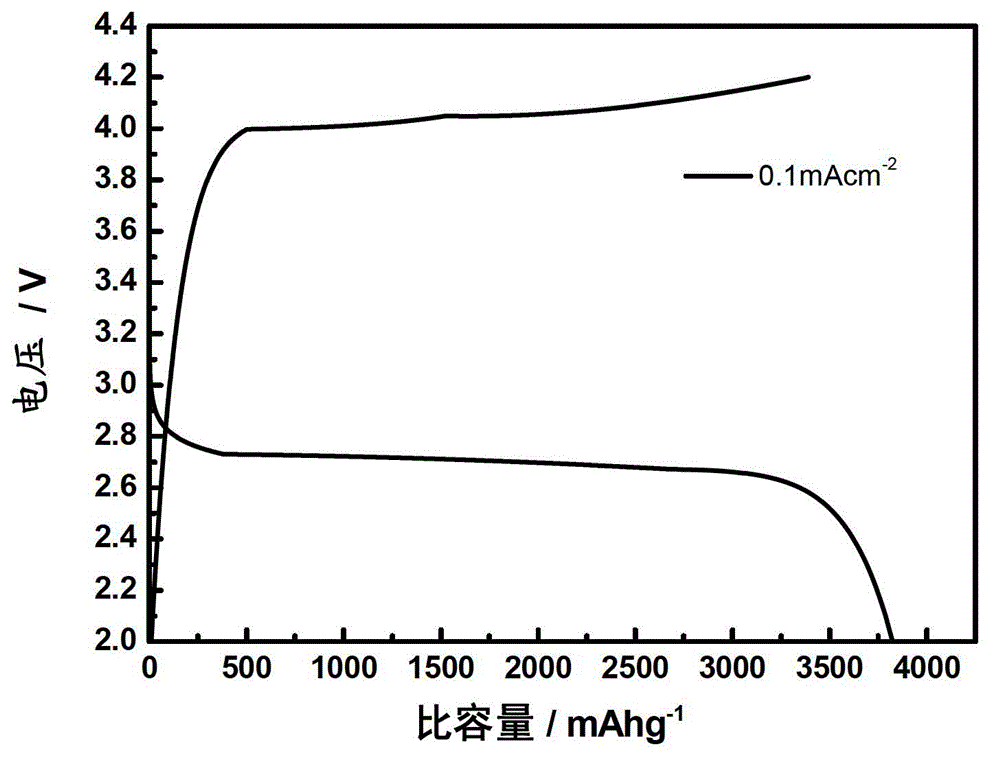

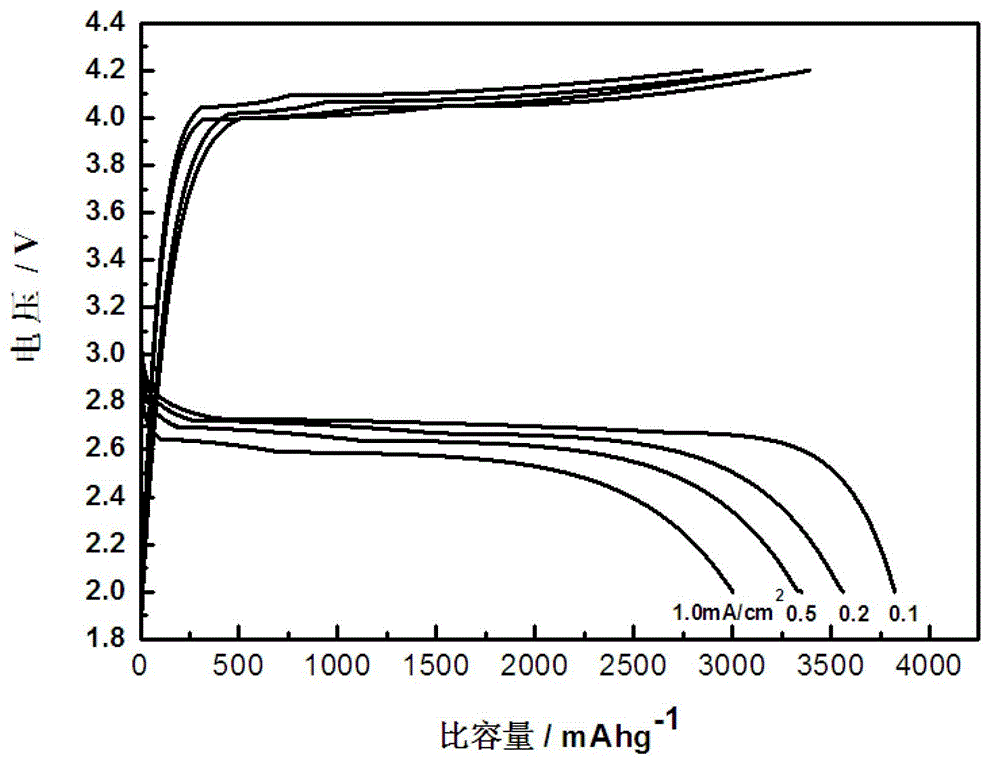

Oxygen electrode composite catalyst used for lithium-air batteries and preparation method of the oxygen electrode composite catalyst

InactiveCN103337641ALarge specific surface areaHigh charge and discharge capacityCell electrodesFiberPorous carbon

The invention discloses an oxygen electrode composite catalyst used for lithium-air batteries and a preparation method of the oxygen electrode composite catalyst. The composite catalyst is in a structure of nano-fiber meshes on the whole. The composite catalyst comprises a porous carbon nanometer fiber main body skeleton, and metal particles and / or metal oxide particles, wherein the metal particles and / or the metal oxide particles are uniformly grew on the carbon nanometer fiber main body skeleton in convex and embedded manners. The preparation method comprises a step of dissolving a polymer and a metal salt into a solvent, stirring until the mixture is completely dissolved, and forming an electrostatic spinning solution having a certain viscosity; a step of subjecting the electrostatic spinning solution to electrostatic spinning to prepare nanoscale polymer fibers having a diameter range of 300-800 nm; and a step of subjecting the nanoscale polymer fibers to drying under vacuum to remove residual solvent, performing low-temperature preheating treatment and high-temperature carbonization treatment to prepare the nano-fiber composite catalyst. The composite catalyst provided by the invention improves rate capacity and cyclic performance of lithium-air batteries.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH +1

Method for simultaneously detecting multiple residual solvents in ceftriaxone sodium

ActiveCN103487541AHigh sensitivityHigh precisionComponent separationCeftriaxonumGas liquid chromatographic

The invention relates to a method for simultaneously detecting multiple residual solvents in ceftriaxone sodium, which adopts a gas chromatographic analysis process to simultaneously detect six organic solvents in medicines, including methanol, ethanol, acetonitrile, acetone, ethyl acetate and triethylamine. The gas chromatographic process is adopted to simultaneously detect the contents of the six organic solvents, and has the advantages of high sensitivity, favorable repetitiveness and high precision; by using a standard addition process, the method does not need any additional standard substance as an internal standard, only needs a pure substance for predicting components, can counteract the matrix effect, and is simple to operate; by using a headspace sampling process, the method prevents the direct solution sample from interfering with detection and from polluting the chromatographic column; and a programmed heating process is adopted to effectively separate low-boiling-point organic solvents from high-boiling-point organic solvents.

Owner:SHANGHAI NEW ASIA PHARMA

Method for preparing chitosan-based superfine fiber carrier material for medical dressing

ActiveCN103394114APlay a barrier roleReduce generationAbsorbent padsNon-woven fabricsPorosityVacuum drying

The invention provides a method for preparing a chitosan-based superfine fiber carrier material for medical dressing, which is characterized in that the method comprises the following steps of: mixing chitosan powder and polyoxyethylene powder, dissolving the mixture into an acetate solution to preparing a spinning solution; adding the spinning solution into a static spinning device for static spinning, and receiving fiber on a cylindrical roller receiver to obtain a fiber film; and carrying out crosslinking treatment on the fiber film, and then placing the fiber film in a vacuum drying box to removing a residual solvent, to obtain the chitosan-based superfine fiber carrier material for medical dressing. The chitosan-based superfine fiber carrier material for medical dressing has advantages of ultrafine fiber structure, high porosity, and excellent hygroscopic property, moisture retention property and permeability, has certain bacterinertness, is conducive to healing of wound, and can reduce nursing intensity.

Owner:上海必趣医疗科技有限公司

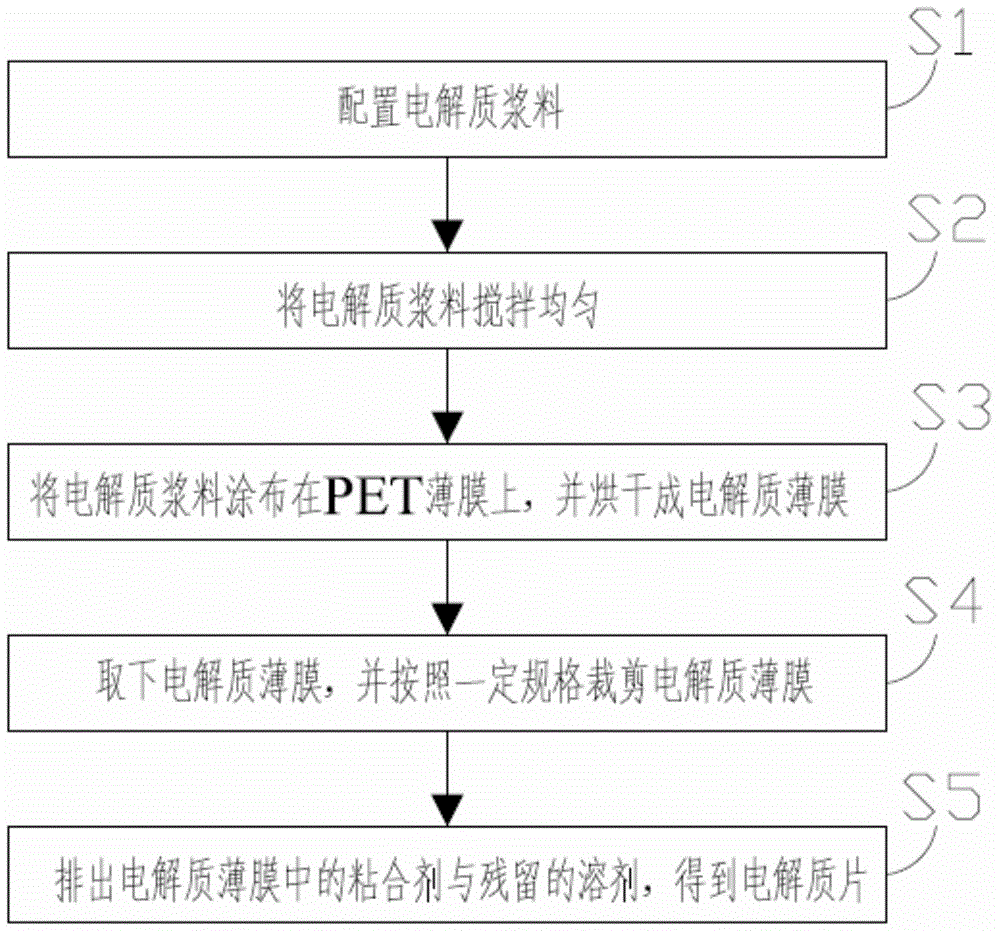

Preparation method of sulfide solid electrolyte material

InactiveCN105870497AUniform thicknessThin and uniformNon-metal conductorsSecondary cellsAll solid stateElectrolysis

The invention provides a preparation method of a sulfide solid electrolyte material. The preparation method comprises the following steps: sulfide lithium ion conductor electrolyte powder, an adhesive and a solvent are mixed, and electrolyte slurry is obtained; the electrolyte slurry is uniformly stirred and dispersed, and uniform electrolyte slurry is obtained; the uniform electrolyte slurry is uniformly coated on a PET film, the electrolyte slurry which is coated on the PET film is dried at a set drying temperature, in order to evaporate the solvent part, and an electrolyte film is obtained; the electrolyte film is taken from the PET film, and the electrolyte film is cut according to a certain specification; the adhesive and the residual solvent in the cut electrolyte film are discharged, and a compact sulfide lithium ion conductor electrolyte sheet is obtained. The preparation method of the sulfide solid electrolyte material can effectively solve the problem that when an electrolyte sheet is prepared according to the prior preparation method of the all solid state electrolyte sheet, the electrolyte sheet which is thicker influences electrical performance of an all solid state battery.

Owner:新余赣锋新能源产业投资合伙企业(有限合伙)

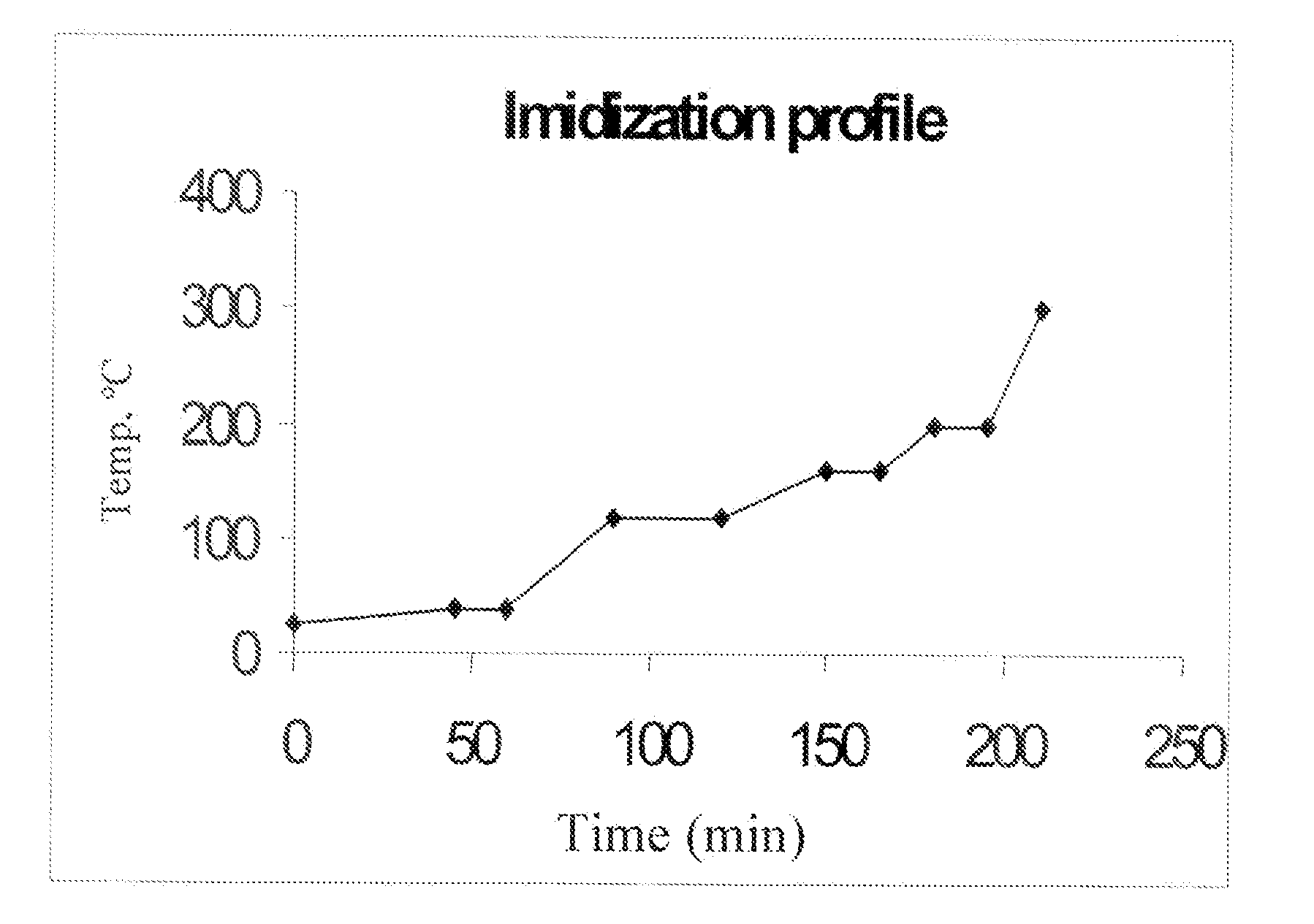

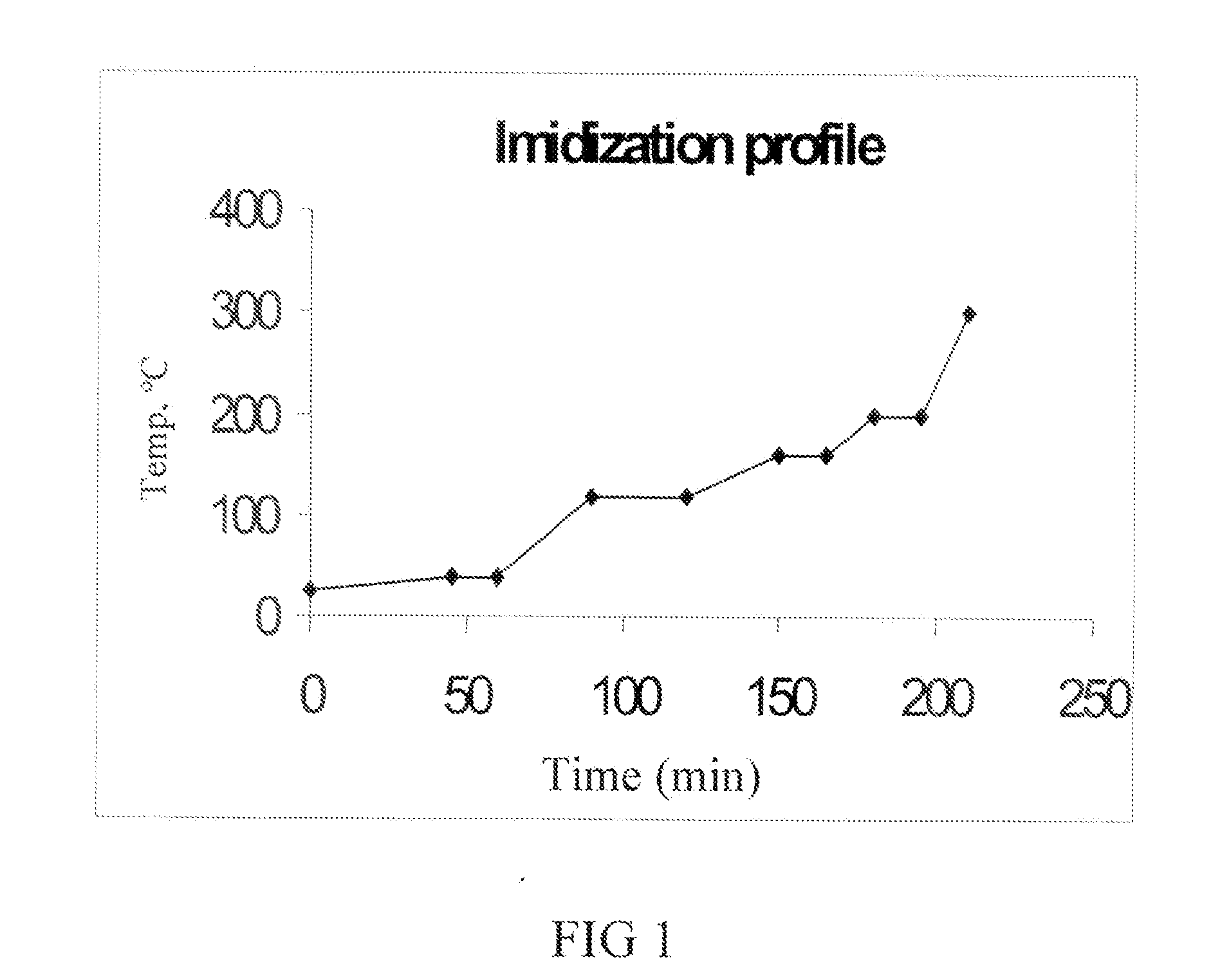

Flexible metal-clad laminate and process for preparing the same

InactiveUS20020160211A1Improve featuresSolve low adhesionInsulating substrate metal adhesion improvementPretreated surfacesPolymer scienceMetal foil

Disclosed are a flexible metal-clad laminate comprising a metal foil and a heat-resistant resin film layer formed on one side of the metal foil, the heat-resistant resin film layer comprising a crosslinked condensation polymer and having an N-methyl-2-pyrrolidone-insolule content of at least 1%, and a method for producing the flexible metal-clad laminate comprising the steps of applying a heat-resistant resin solution to a metal foil; predrying the metal foil until the heat-resistant resin layer has an residual solvent content of 10 to 40% by weight; and carrying out solvent removal and heat-treatment while controlling the crosslinking reaction of the resin.

Owner:TOYOBO CO LTD

Method for preparing ultra-thin porous lamination gradient composite support of tissue engineering

InactiveCN101628131AGood mechanical propertiesGood biocompatibilityProsthesisOsteoblastBiocompatibility Testing

The invention discloses a method for preparing an ultra-thin porous lamination gradient composite support of tissue engineering, belonging to the field of biomedicine material. The preparation method comprises the following steps: (1) determining materials and structures of a support to be prepared according to the condition of repair and defection; (2) preparing each layer of the support, waiting for the volatilization of a solvent, and gradually drying slurry for forming; (3) placing a formed object to a ventilation place, and demoulding the formed object after the residual solvent is completely volatilized; and (4) taking out the formed object and dry to obtain the ultra-thin porous lamination gradient composite support of the tissue engineering. The ultra-thin porous lamination composite support, the thickness of which is suitable for articular cartilage repair, can be prepared by using the method. The prepared support has favorable mechanical property, favorable biocompatibility and controllable degradation rate, is suitable for co-culture of osteoblast and chondrocyte and compound of specific growth factors, and can repair the synthetic defection of the joint cartilage tissue and the cartilage / bone tissue.

Owner:HUAZHONG UNIV OF SCI & TECH

Polyimide solvent cast films having a low coefficient of thermal expansion and method of manufacture thereof

InactiveUS20080044683A1Low thermal expansionSynthetic resin layered productsPrinted circuit aspectsVitrificationMicrometer

A solvent cast film comprises a polyimide comprising structural units derived from polymerization of a dianhydride component comprising a dianhydride selected from the group consisting of 3,4′-oxydiphthalic dianhydride, 3,3′-oxydiphthalic dianhydride, 4,4′-oxydiphthalic dianhydride, and combinations thereof, with a diamine component comprising 4,4′-diaminodiphenylsulfone; wherein the polyimide has a glass transition temperature from 190° C. to 400° C.; and wherein the film has a coefficient of thermal expansion of less than 60 ppm / ° C., a thickness from 0.1 to 250 micrometers, endless than 5% residual solvent by weight.

Owner:SHPP GLOBAL TECH BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com