Flexible metal-clad laminate and process for preparing the same

a metalclad laminate and flexible technology, applied in the direction of coatings, transportation and packaging, metal adhesion improvement of insulation substrates, etc., can solve the problems of limited application to chip-on-flex and blisters, peeling, peeling, etc., and achieve the effect of reducing the difficulty of punching afterward, curling and twisting of flexible printed boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

Synthesis of Resin A

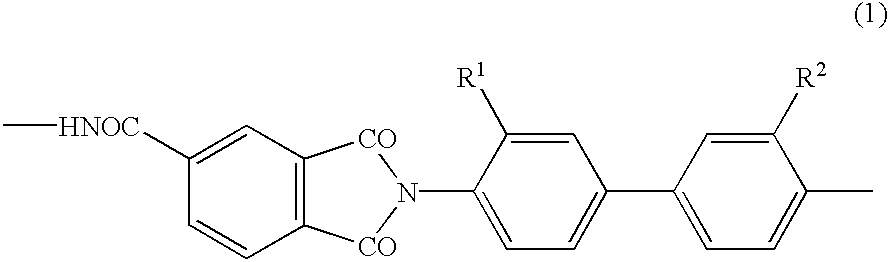

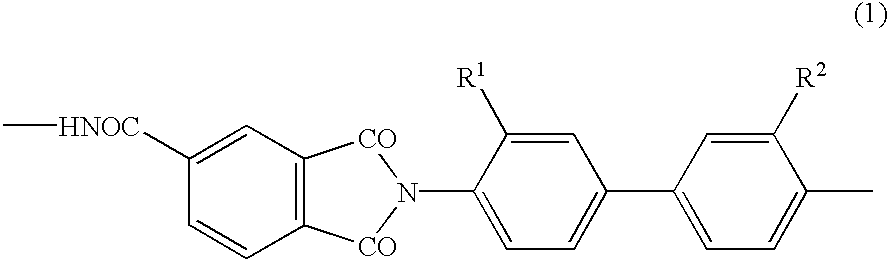

[0150] Into a reaction vessel were placed 192 g of trimellitic acid anhydride (manufactured by MITSUBISHI GAS CHEMICAL COMPANY, INC.), 211 g (80 mol %) of 3,3'-dimethyl- 4,4'-biphenyldiisocyanate (manufactured by NIPPON SODA CO., LTD., "O-tolidinediisocyanate"), 35 g (20 mol %) of 2,4-tolylene diisocyanate (manufactured by NIPPON POLYURETHANE INDUSTRY CO., LTD., "Coronate T-100"), 0.5 g of sodium methylate (manufactured by WAKO PURE CHEMICALS INDUSTRIES, LTD.) and 2.5 kg of N-methyl-2-pyrrolidone (manufactured by MITSUBISHI CHEMICAL CORPORATION). The mixture was heated to 150.degree. C. over 1 hour and was further reacted at 150.degree. C. for 5 hours. The resulting polymer had an inherent viscosity of 1.6 dl / g and a glass transition temperature of 320.degree. C.

synthesis example 2

Synthesis of Resin B

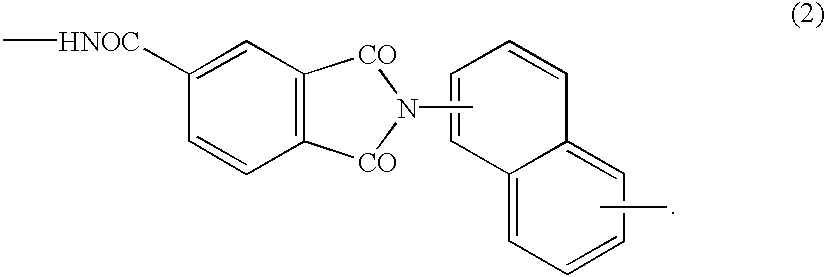

[0151] Into a reaction vessel were placed 192 g of trimellitic acid anhydride, 157 g (75 mol %) of 1,5-naphthalenediisocyanate (manufactured by SUMITOMO BAYER URETHANE CO., LTD., "Desmodur 15"), 63 g (25 mol %) of 4,4'-diphenylmethanediisocyanate (manufactured by SUMITOMO BAYER URETHANE CO., LTD.), 1 g of diazabicycloundecene (manufactured by SAN-APRO LIMITED) and 2 kg of N-methyl-2-pyrrolidone. The mixture was heated to 170.degree. C. over 1 hour and further reacted at 170.degree. C. for 5 hours. The resulting polymer had an inherent viscosity of 1.4 dl / g and a glass transition temperature of 356.degree. C.

synthesis example 3

Synthesis of Resin B-1

[0152] Into a reaction vessel were placed 384 g of trimellitic acid anhydride, 378 g (90 mol %) of 1,5-naphthalenediisocyanate, 50 g (10 mol %) of 4,4'-diphenylmethanediisocyanate, 2.5 g of potassium fluoride (manufactured by TOKYO KASEI KOGYO CO., LTD.) and 2 kg of N-methyl-2-pyrrolidone. The mixture was heated to 130.degree. C. over 1 hour, and further reacted at 130.degree. C. for 5 hours. The resulting polymer had an inherent viscosity of 1.7 dl / g and a glass transition temperature of 381.degree. C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| heat resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com