Patents

Literature

638 results about "Thermocompression bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermocompression bonding describes a wafer bonding technique and is also referred to as diffusion bonding, pressure joining, thermocompression welding or solid-state welding. Two metals, e.g. gold (Au)-gold (Au), are brought into atomic contact applying force and heat simultaneously. The diffusion requires atomic contact between the surfaces due to the atomic motion. The atoms migrate from one crystal lattice to the other one based on crystal lattice vibration. This atomic interaction sticks the interface together. The diffusion process is described by the following three processes...

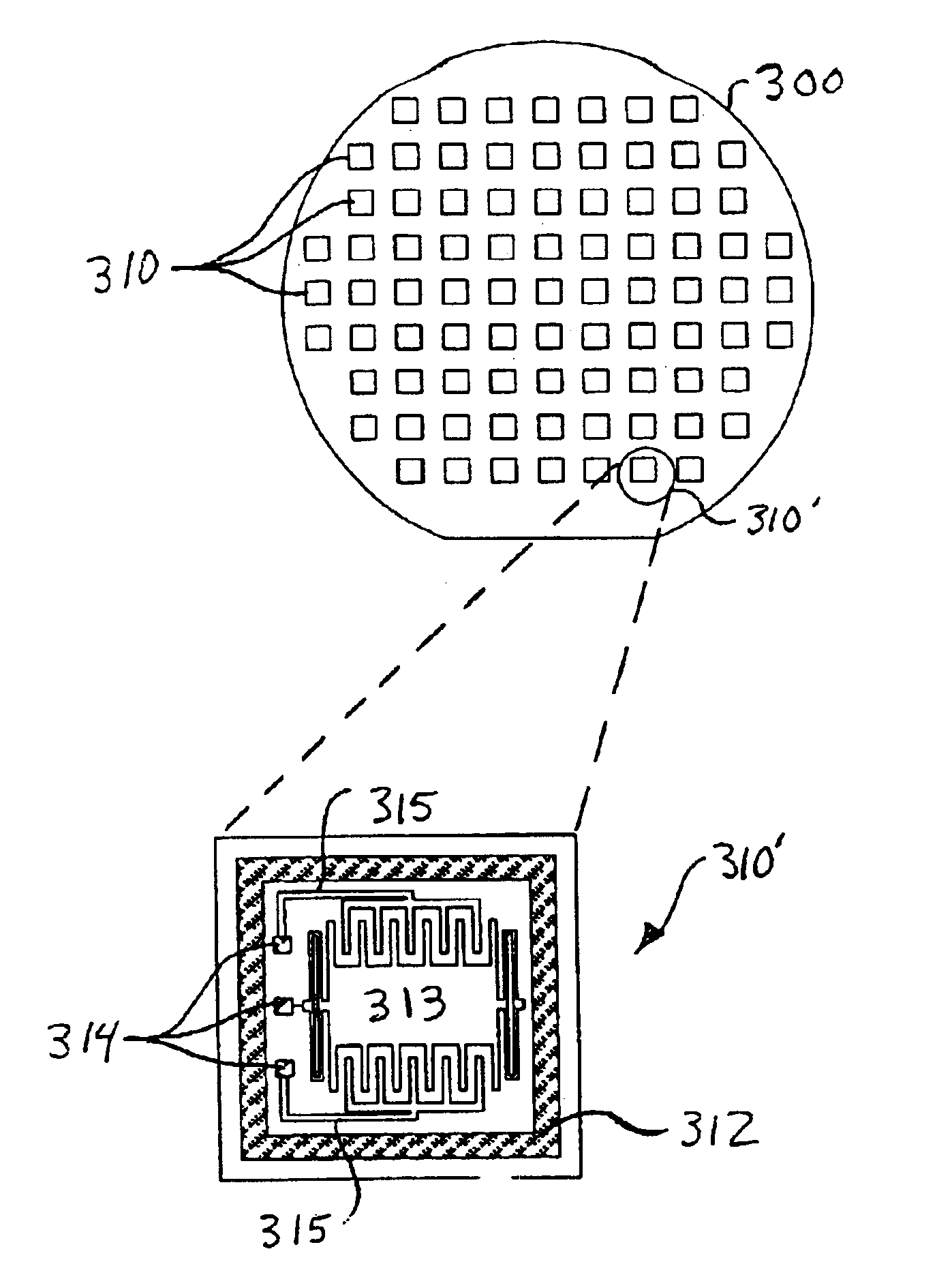

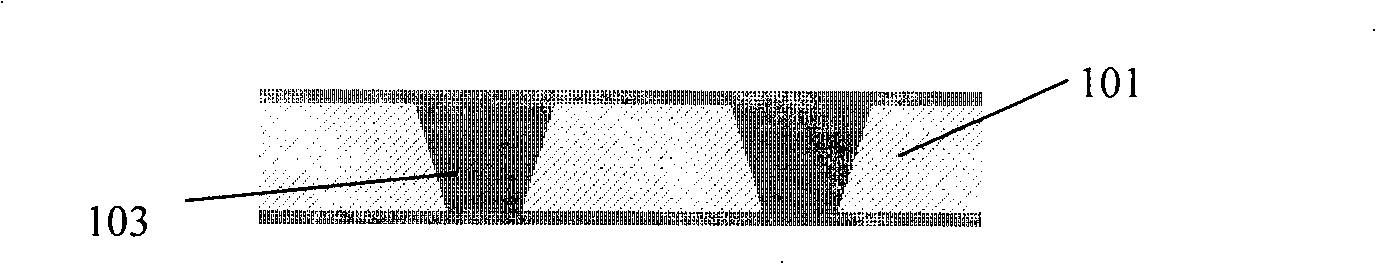

Method of Fabricating High Aspect Ratio Transducer Using Metal Compression Bonding

InactiveUS20100193884A1Television system detailsAcceleration measurement using interia forcesTransducerCapacitive sensing

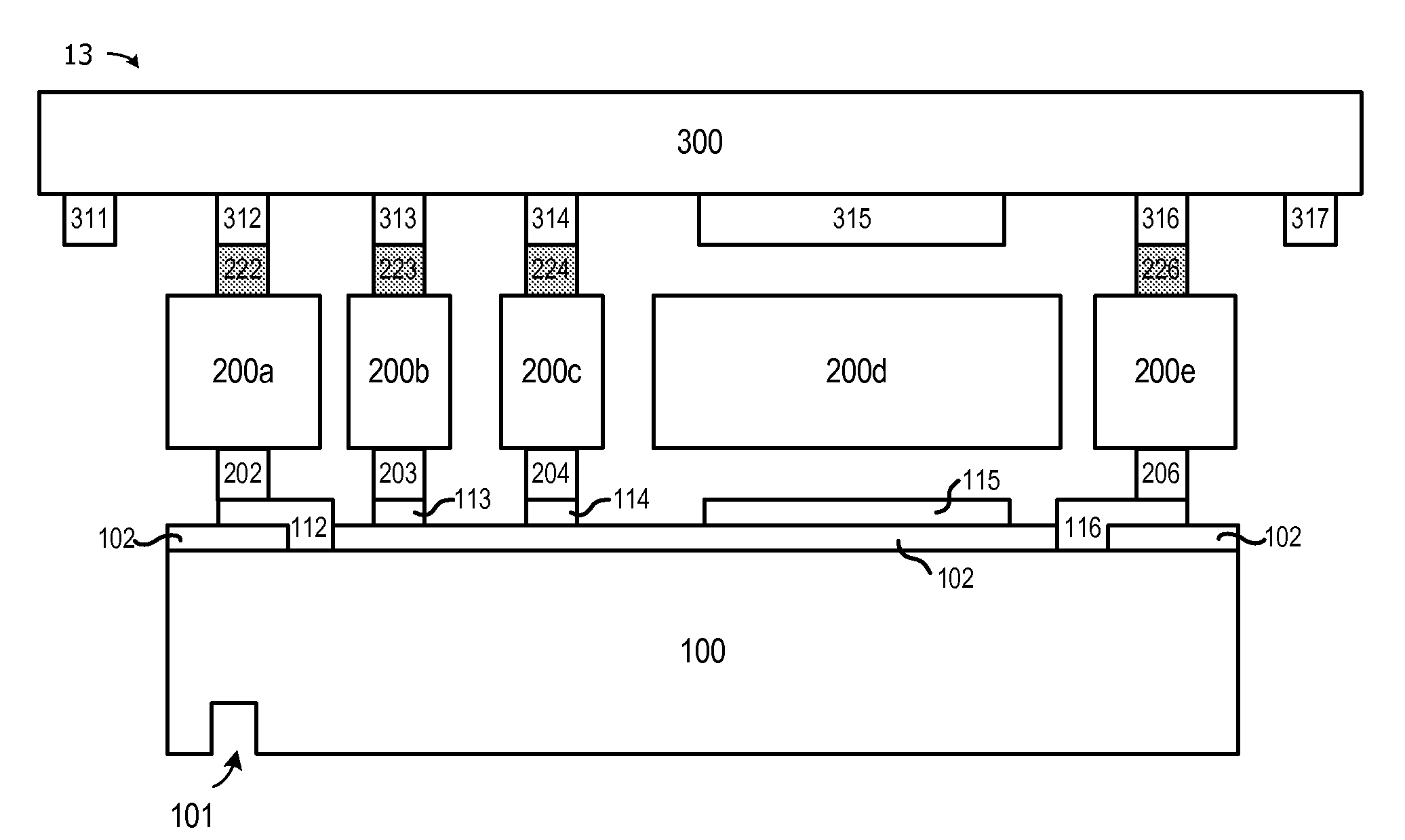

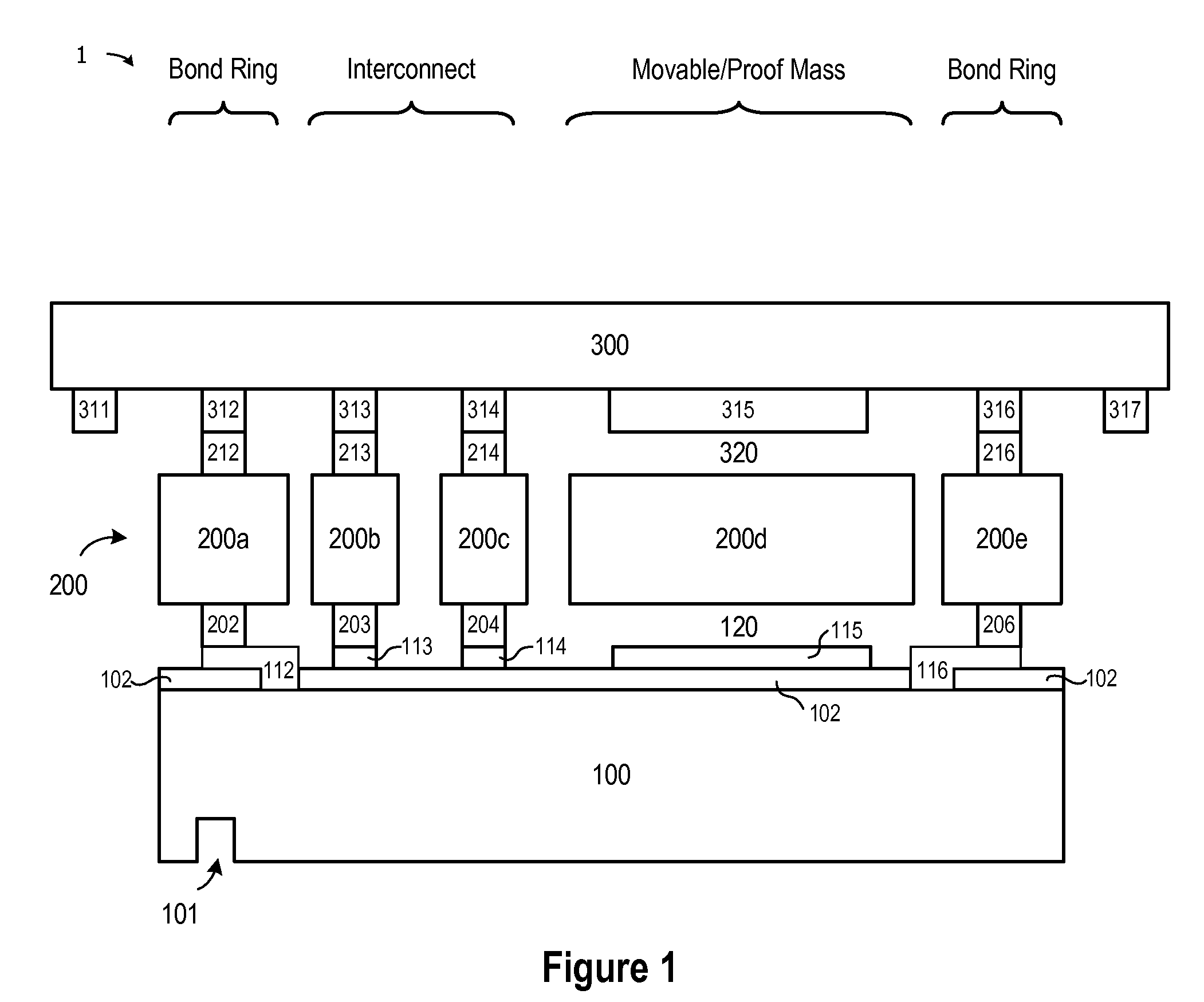

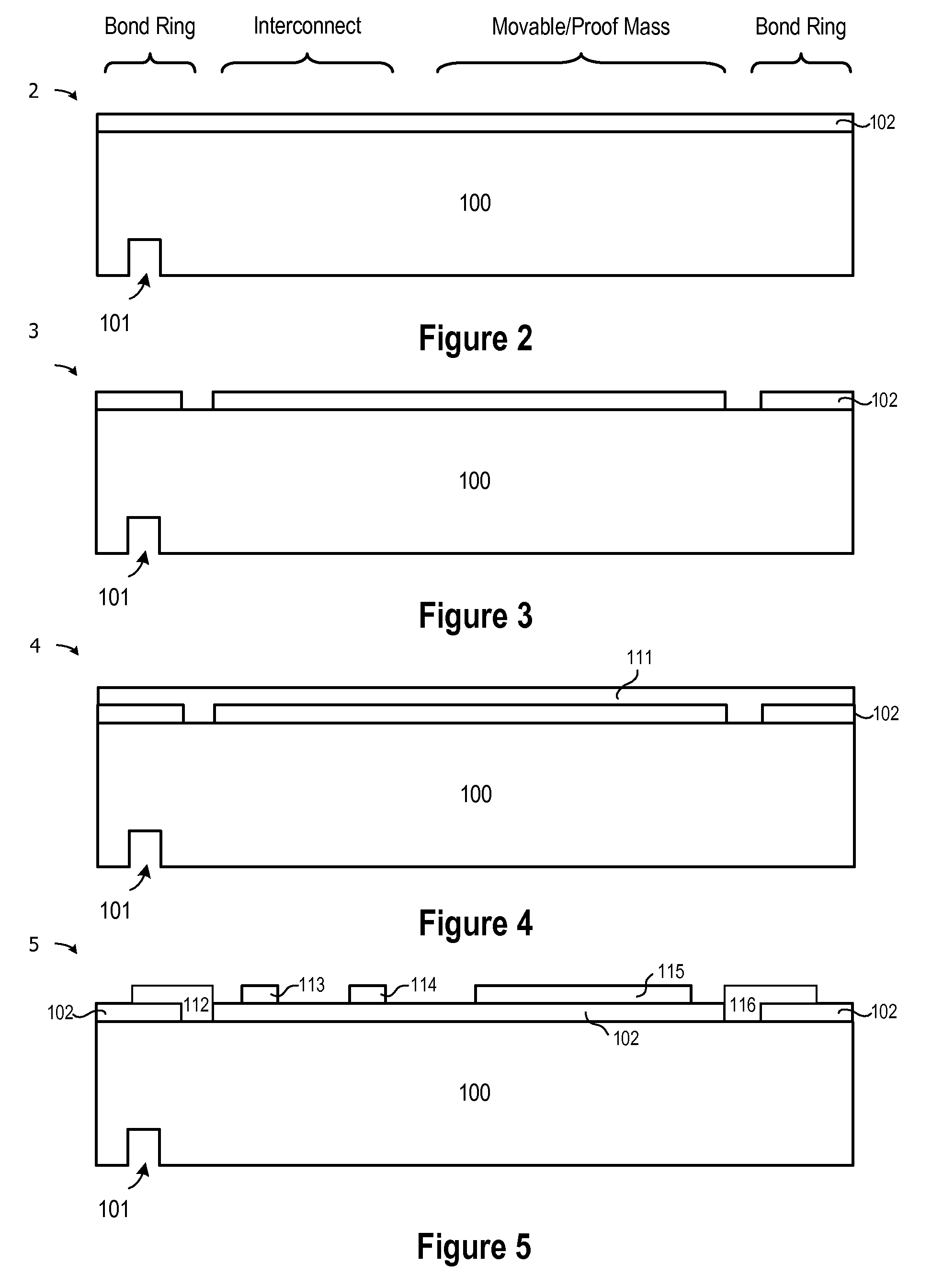

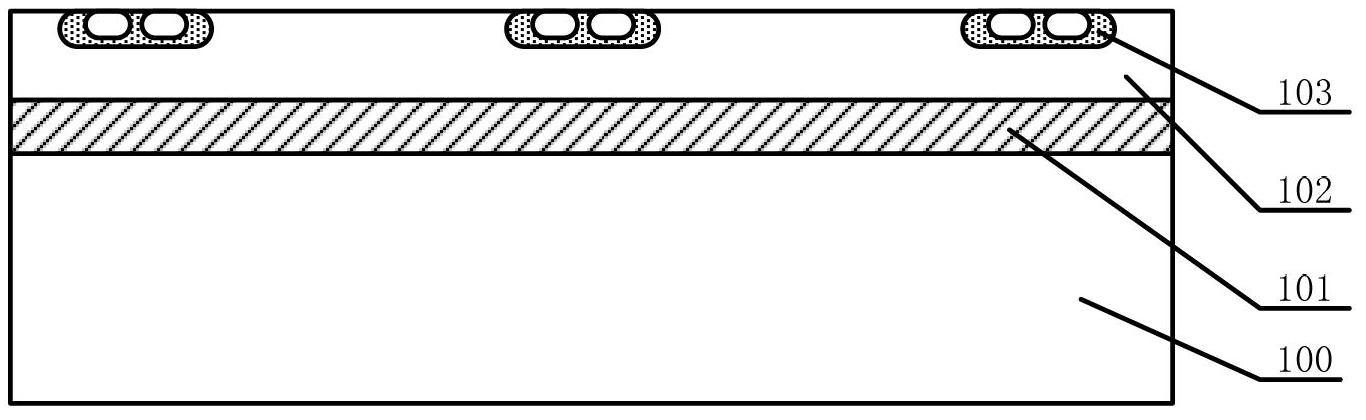

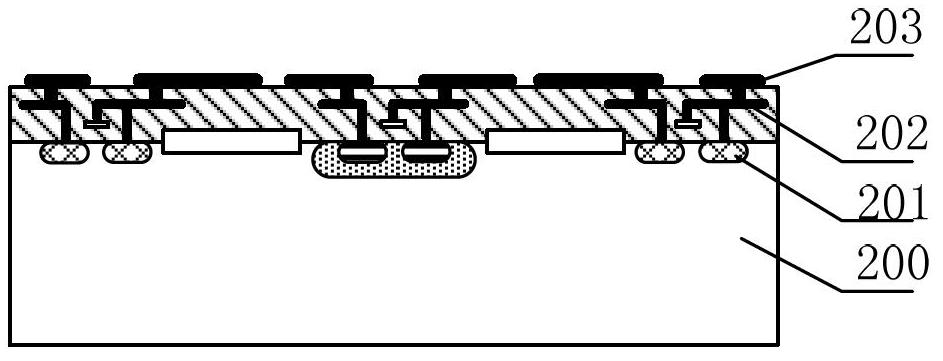

A method and apparatus are described for fabricating a high aspect ratio MEMS device by using metal thermocompression bonding to assemble a reference wafer (100), a bulk MEMS active wafer (200), and a cap wafer (300) to provide a proof mass (200d) formed from the active wafer with bottom and top capacitive sensing electrodes (115, 315) which are hermetically sealed from the ambient environment by sealing ring structures (112 / 202 / 200a / 212 / 312 and 116 / 206 / 200e / 216 / 316).

Owner:FREESCALE SEMICON INC

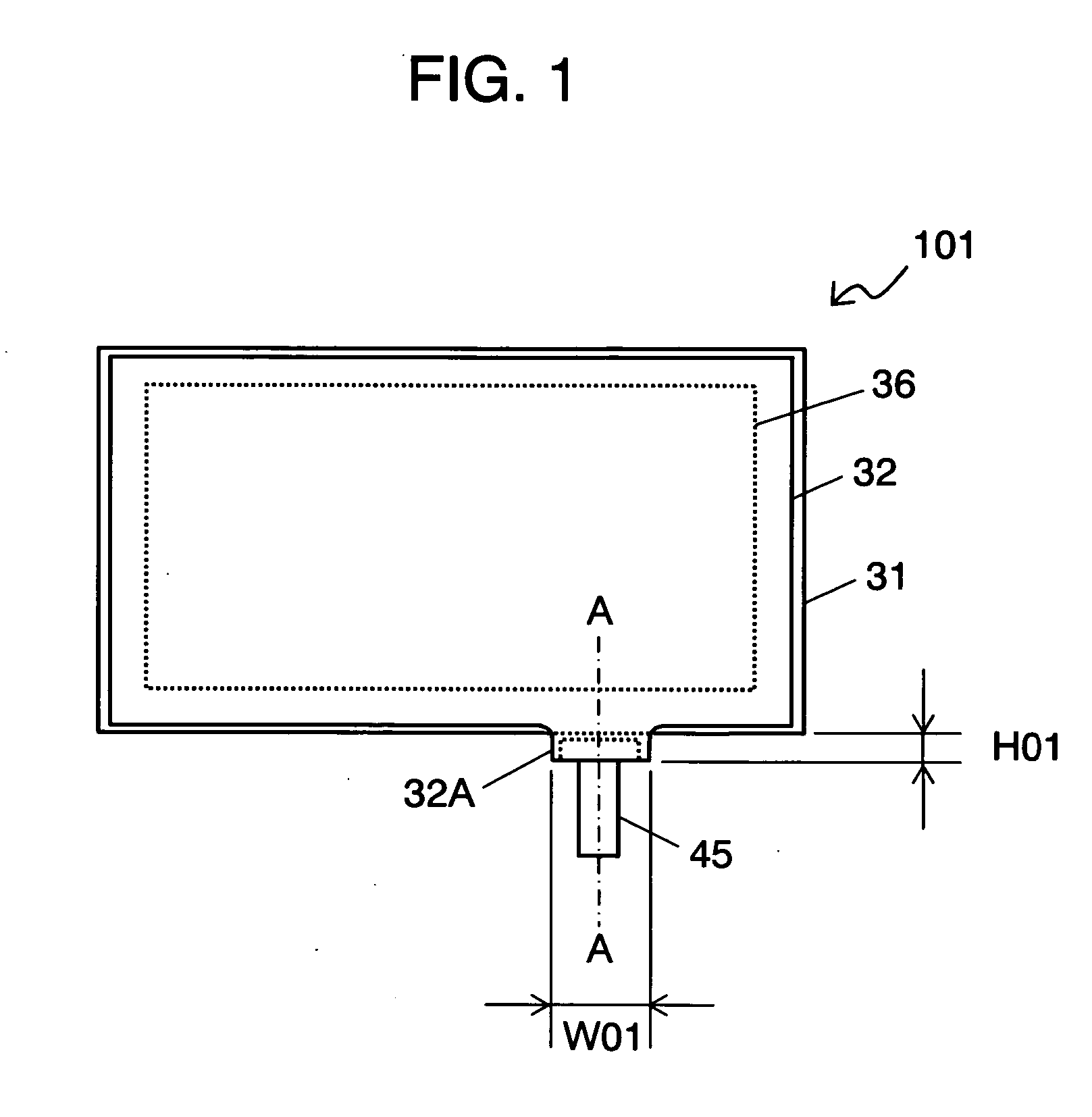

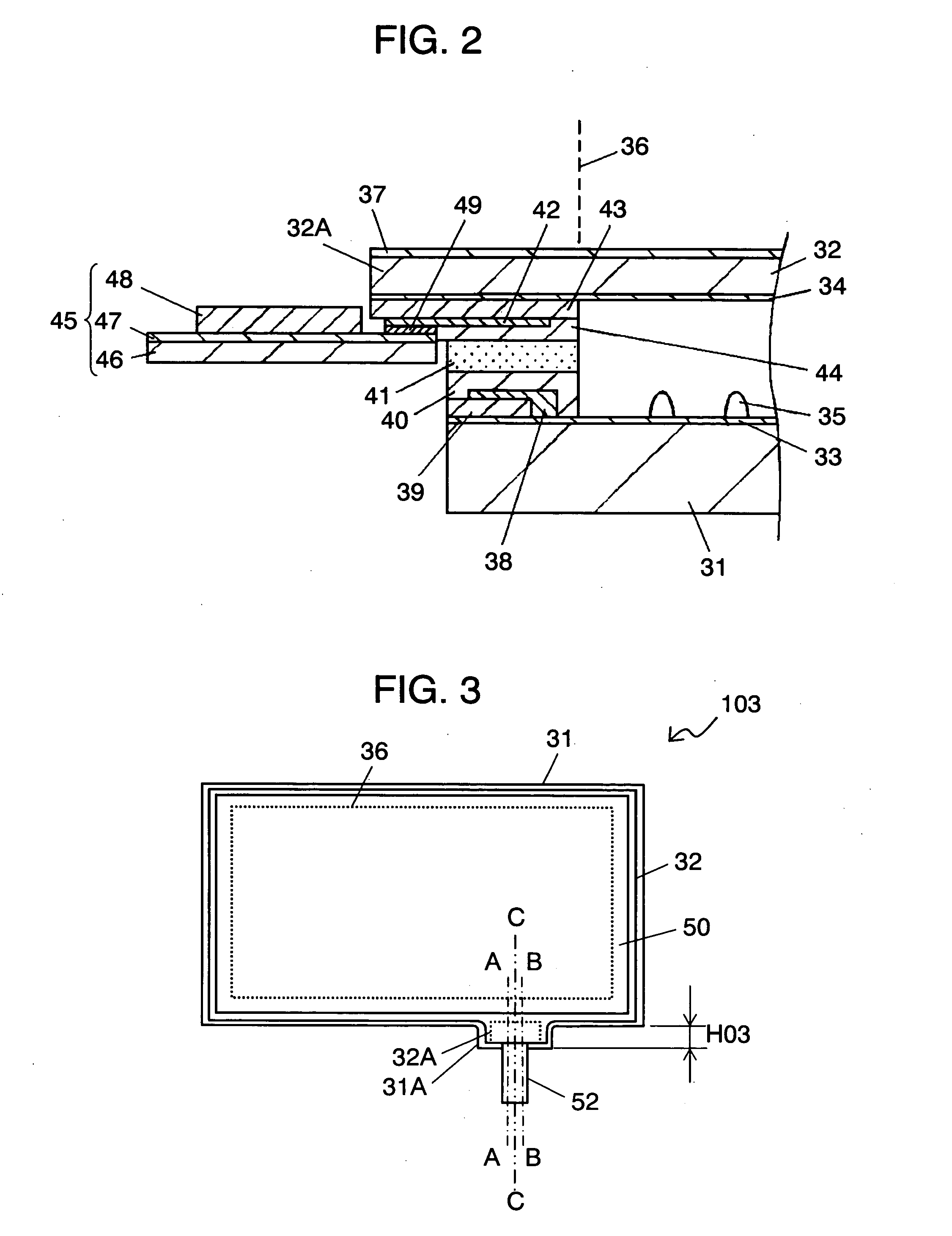

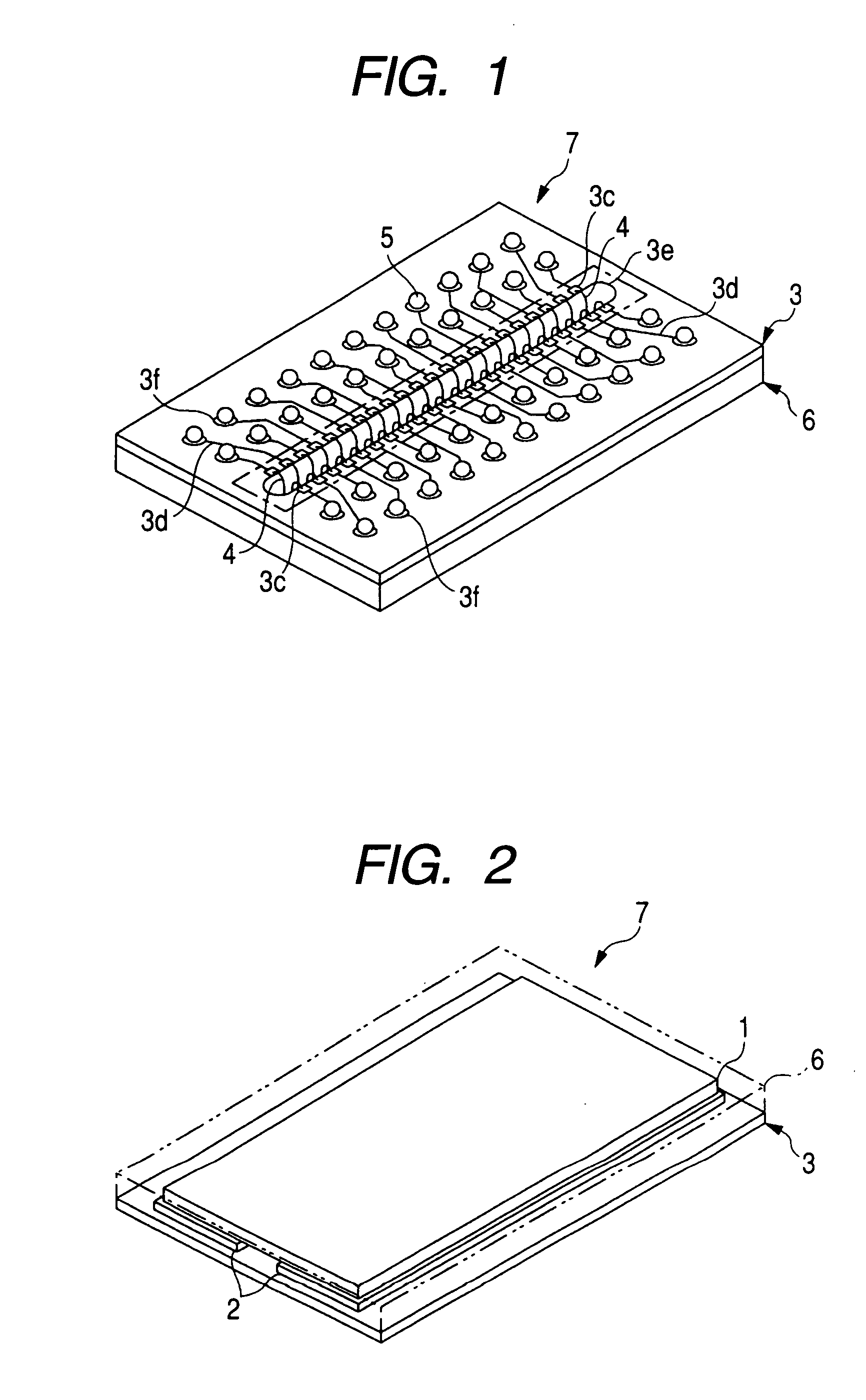

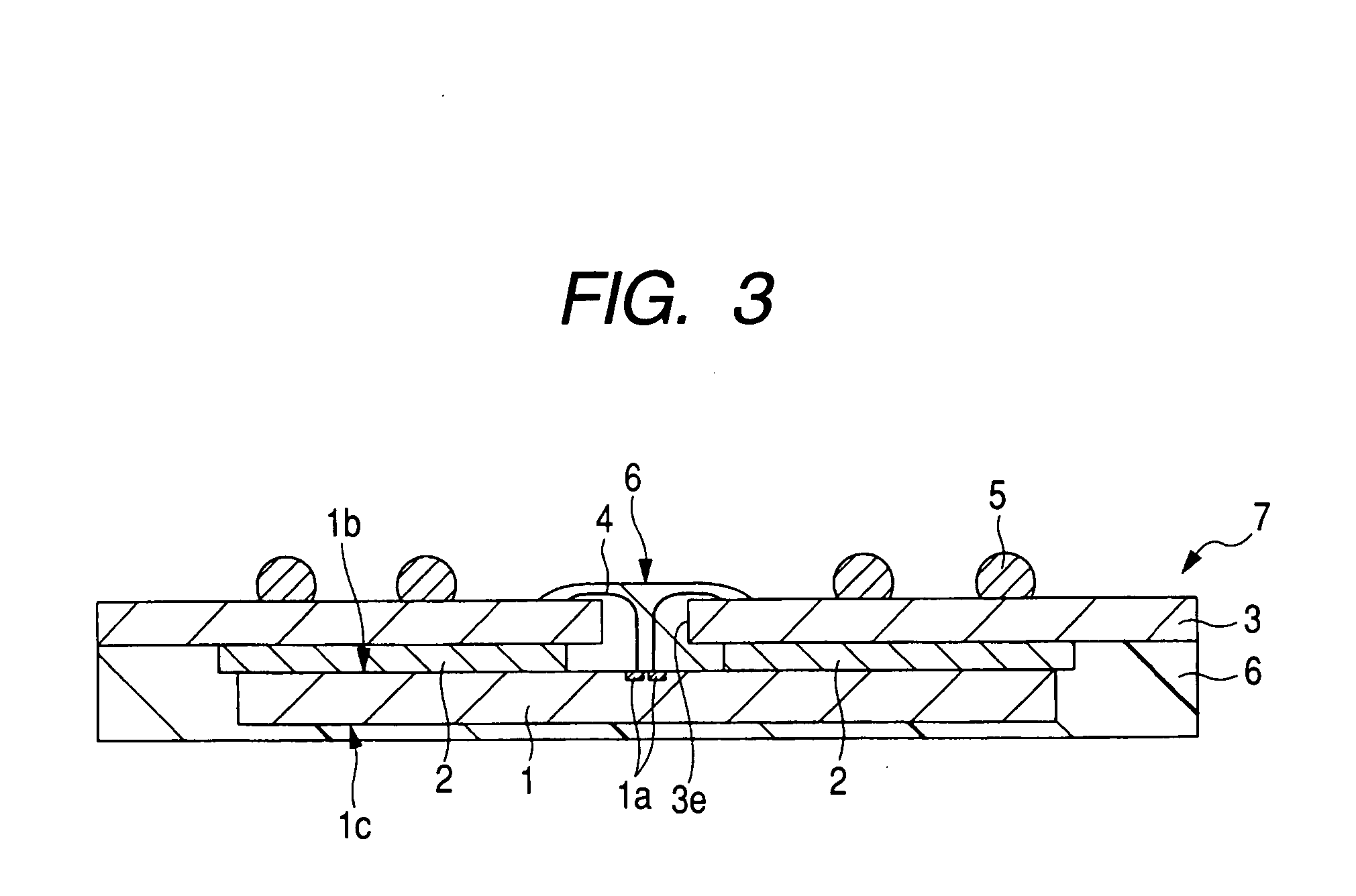

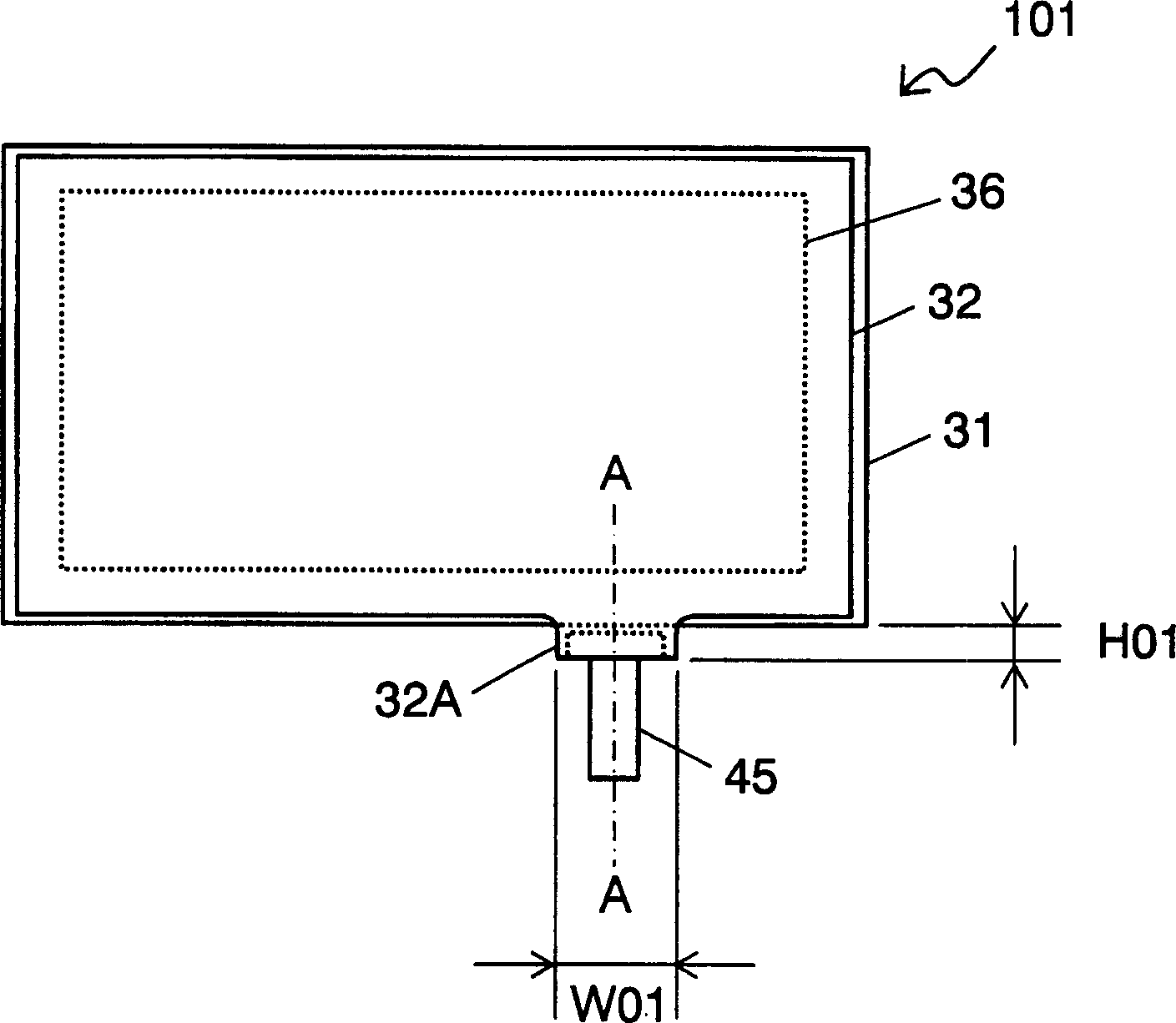

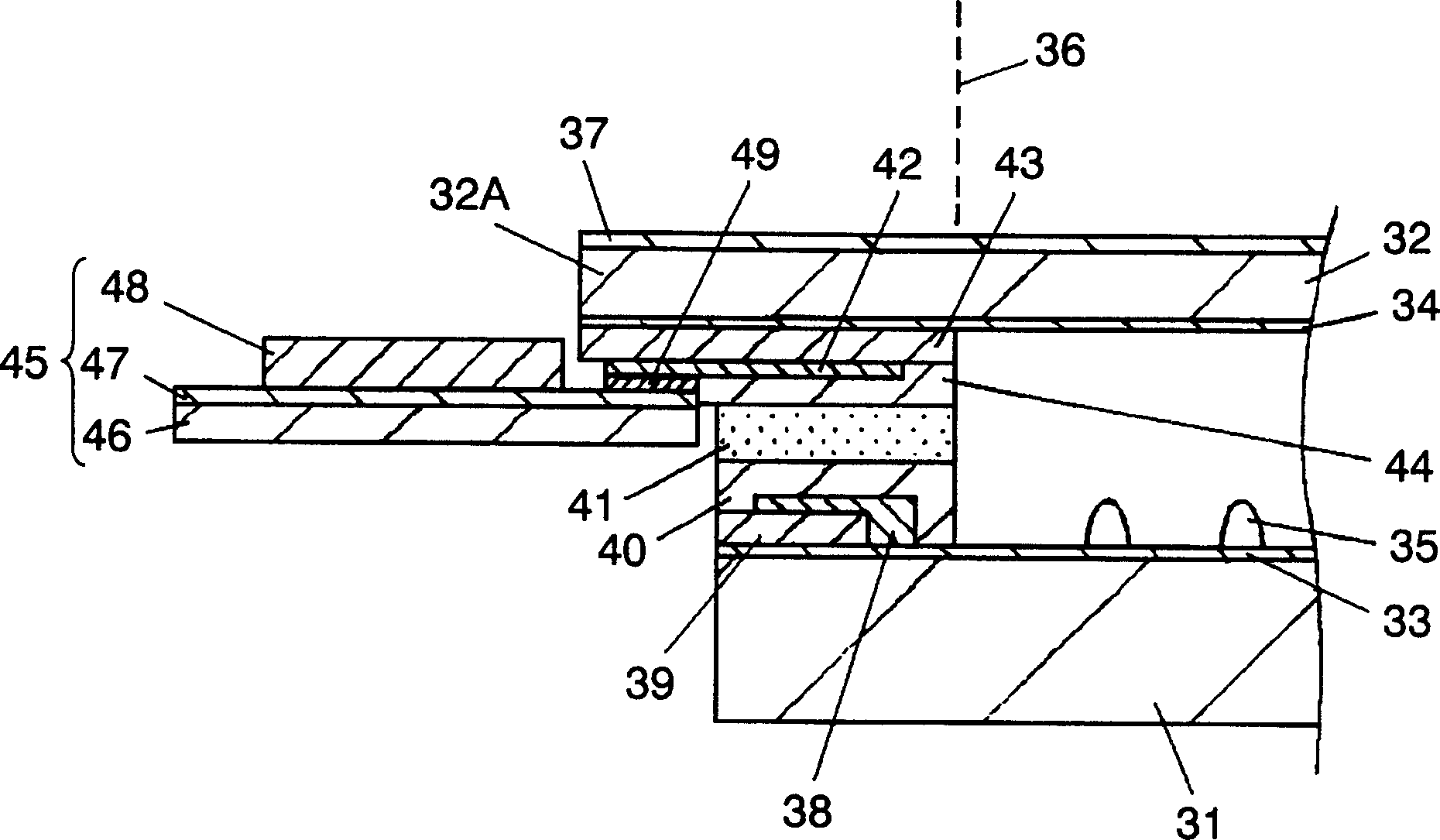

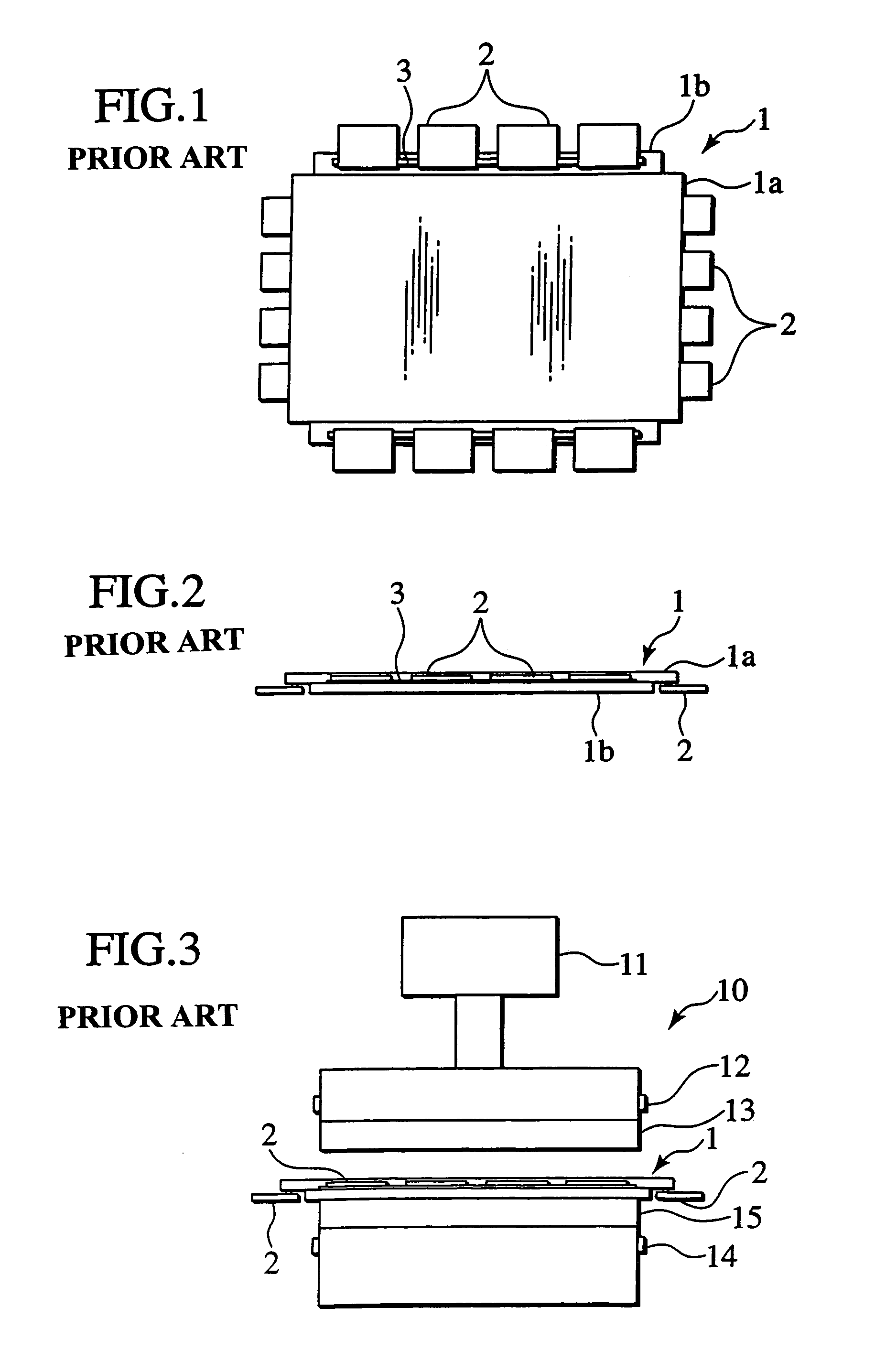

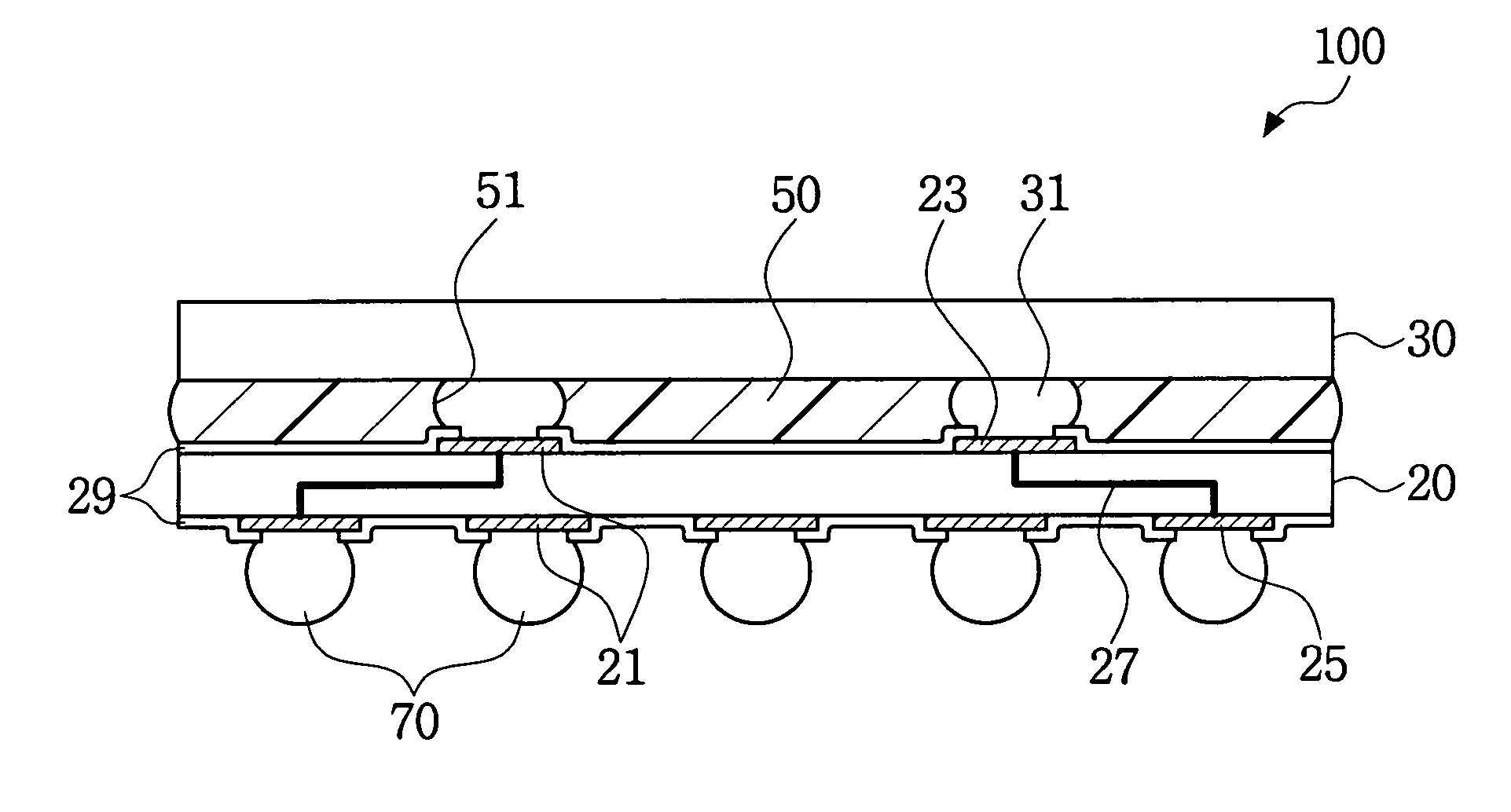

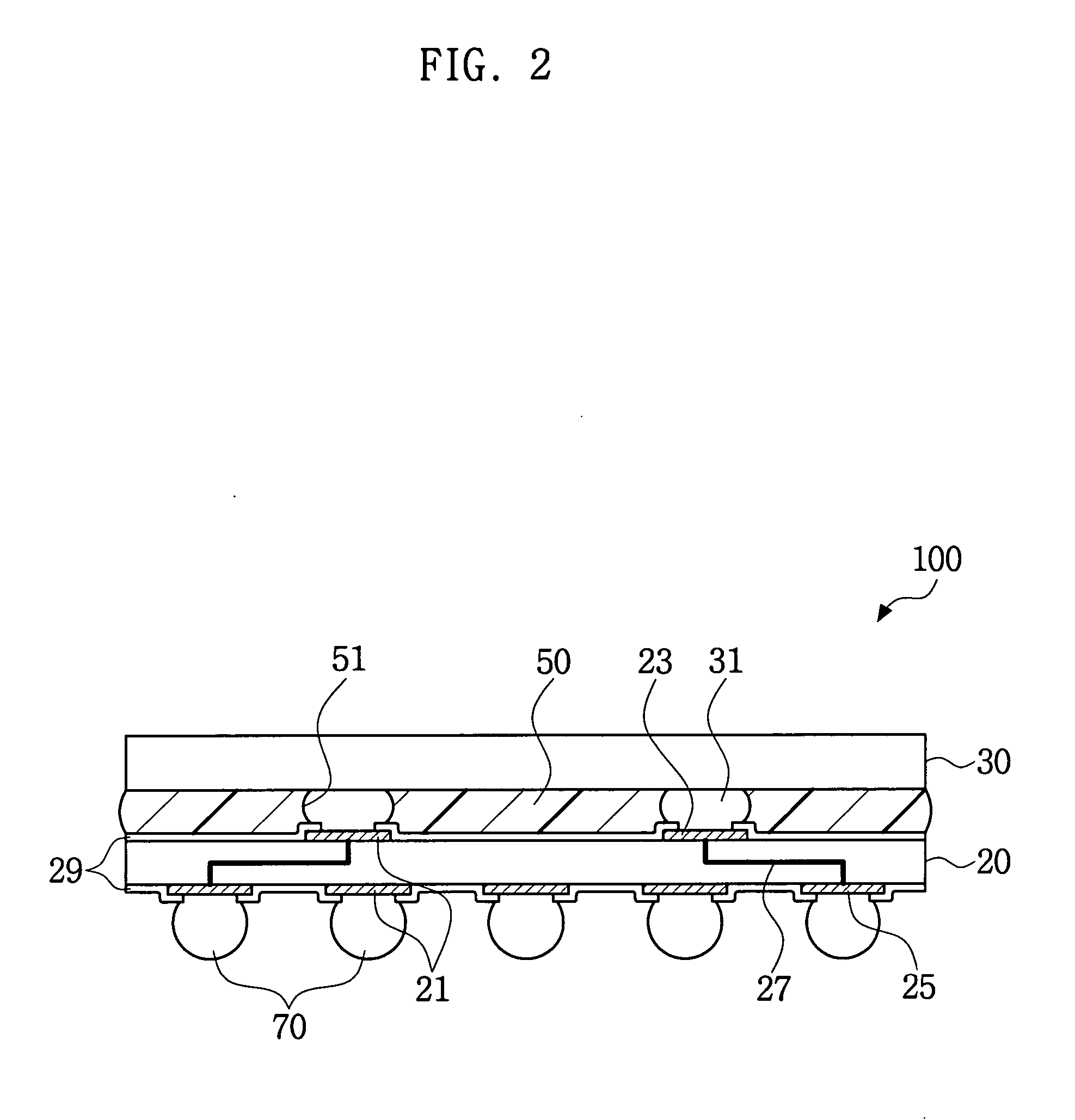

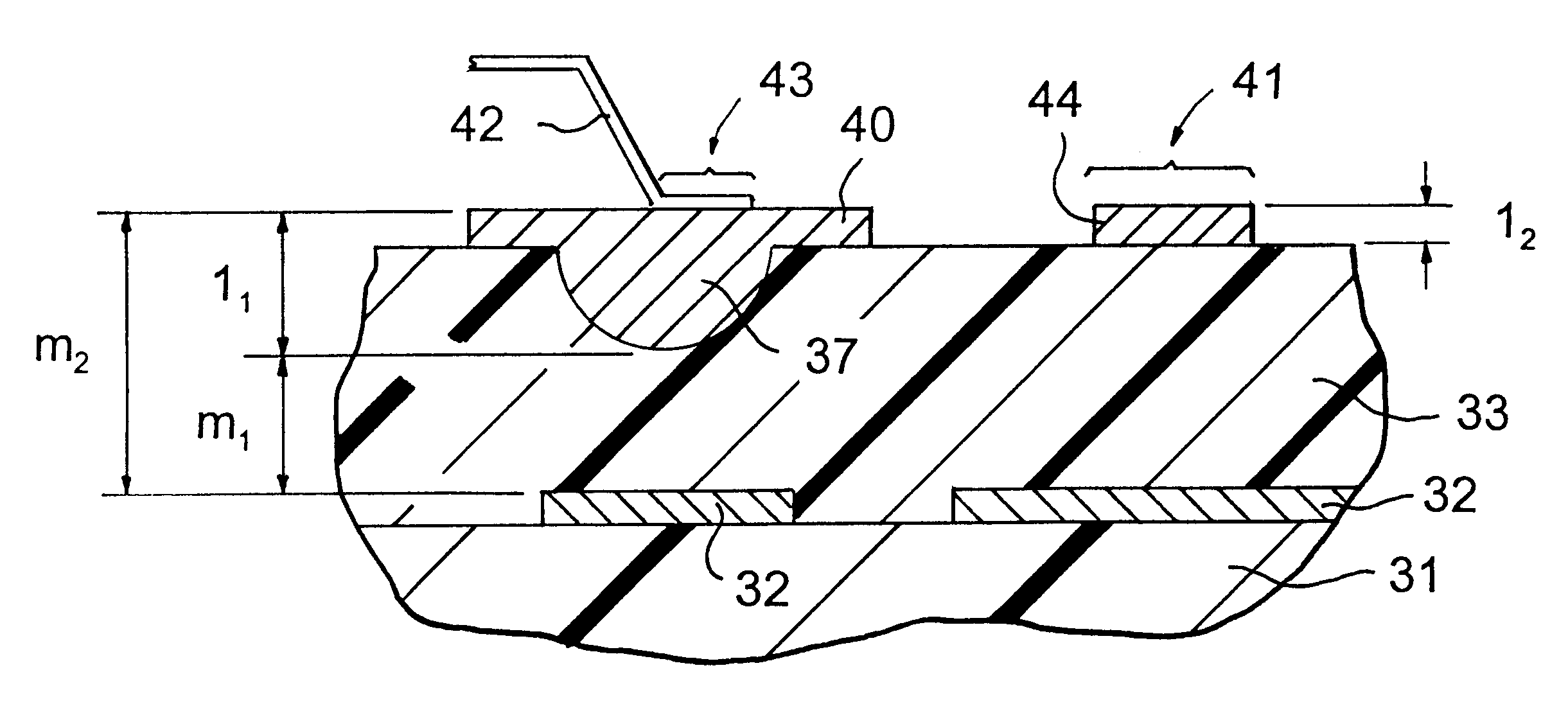

Touch panel and liquid crystal display apparatus using the same

InactiveUS20050099402A1Low costSmall sizeInput/output for user-computer interactionPrinted circuit assemblingElectricityLiquid-crystal display

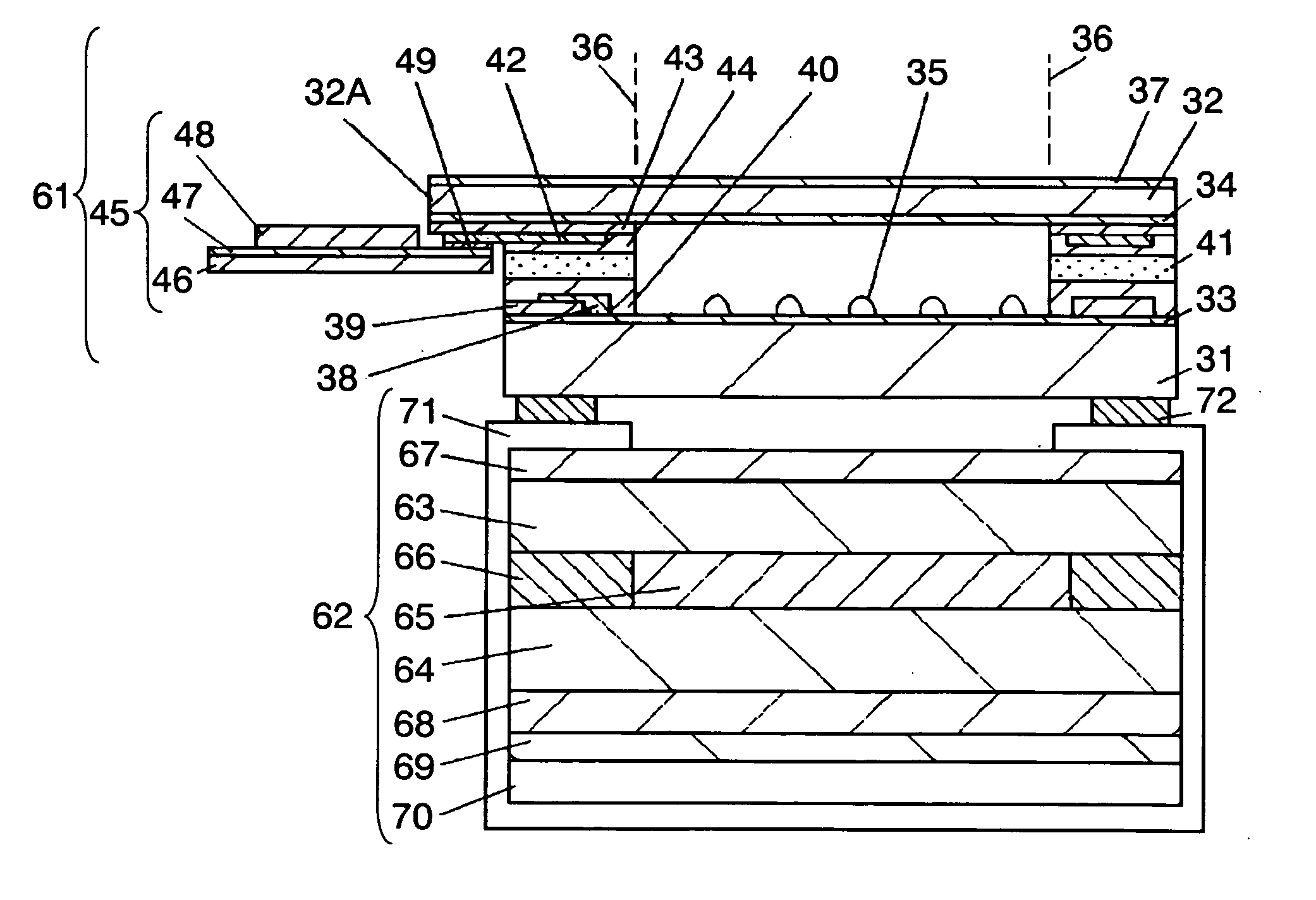

The touch panel has a structure such that a projection portion is provided on a second transparent substrate and a flexible printed-circuit board is bonded by thermocompression to the projection portion. By allowing width of a picture frame to be smaller in other portions than the projection portion, downsizing and a lighter weight of a touch panel-carrying apparatus can be attained. By bonding a sheet member such as a polarizing plate to a top face of the second transparent substrate excluding an area of the projection portion, stress to be applied from the sheet member to the thermocompression-bonding portion of the FPC is reduced and, therefore, electric connection stability of the FPC can be enhanced.

Owner:PANASONIC CORP

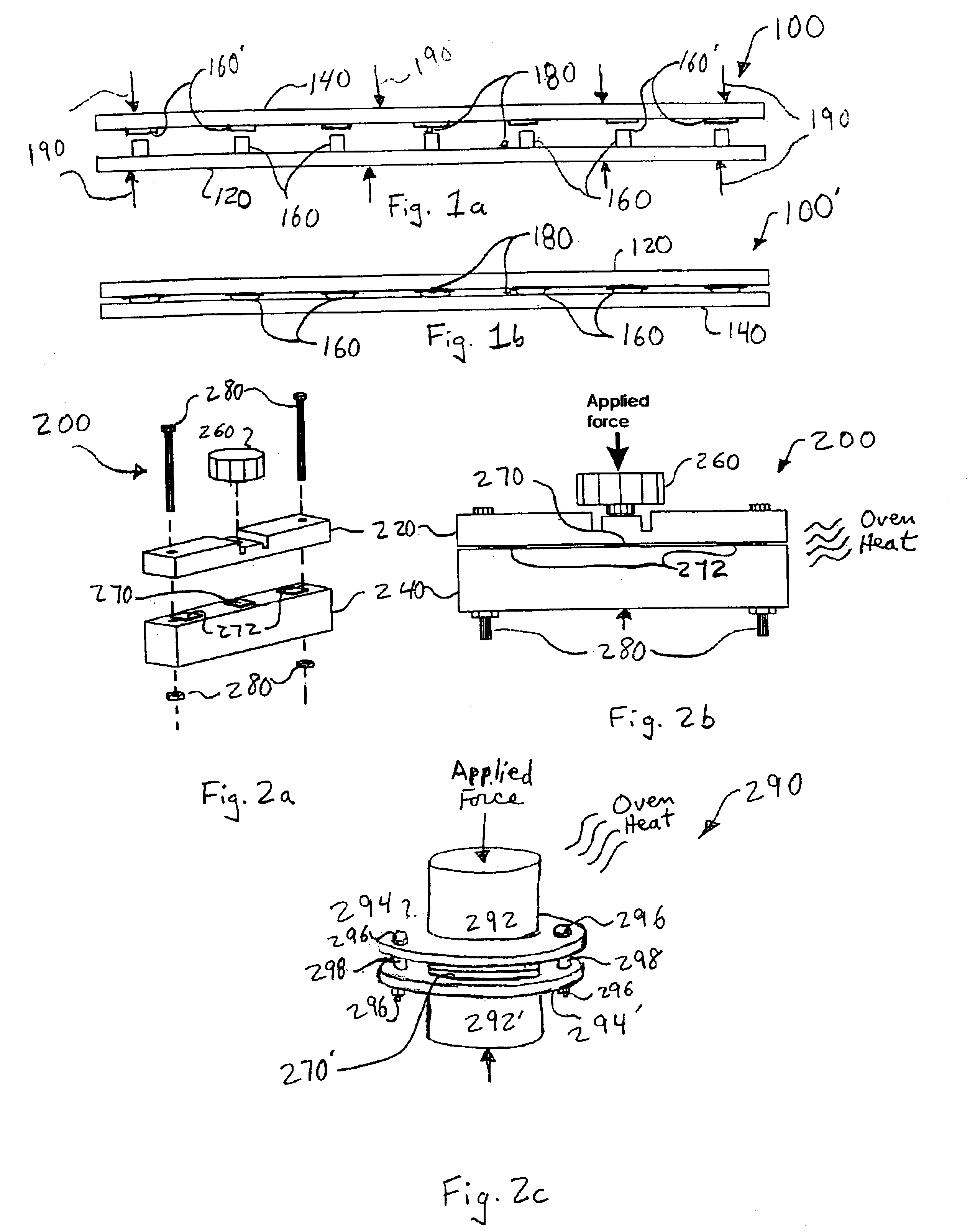

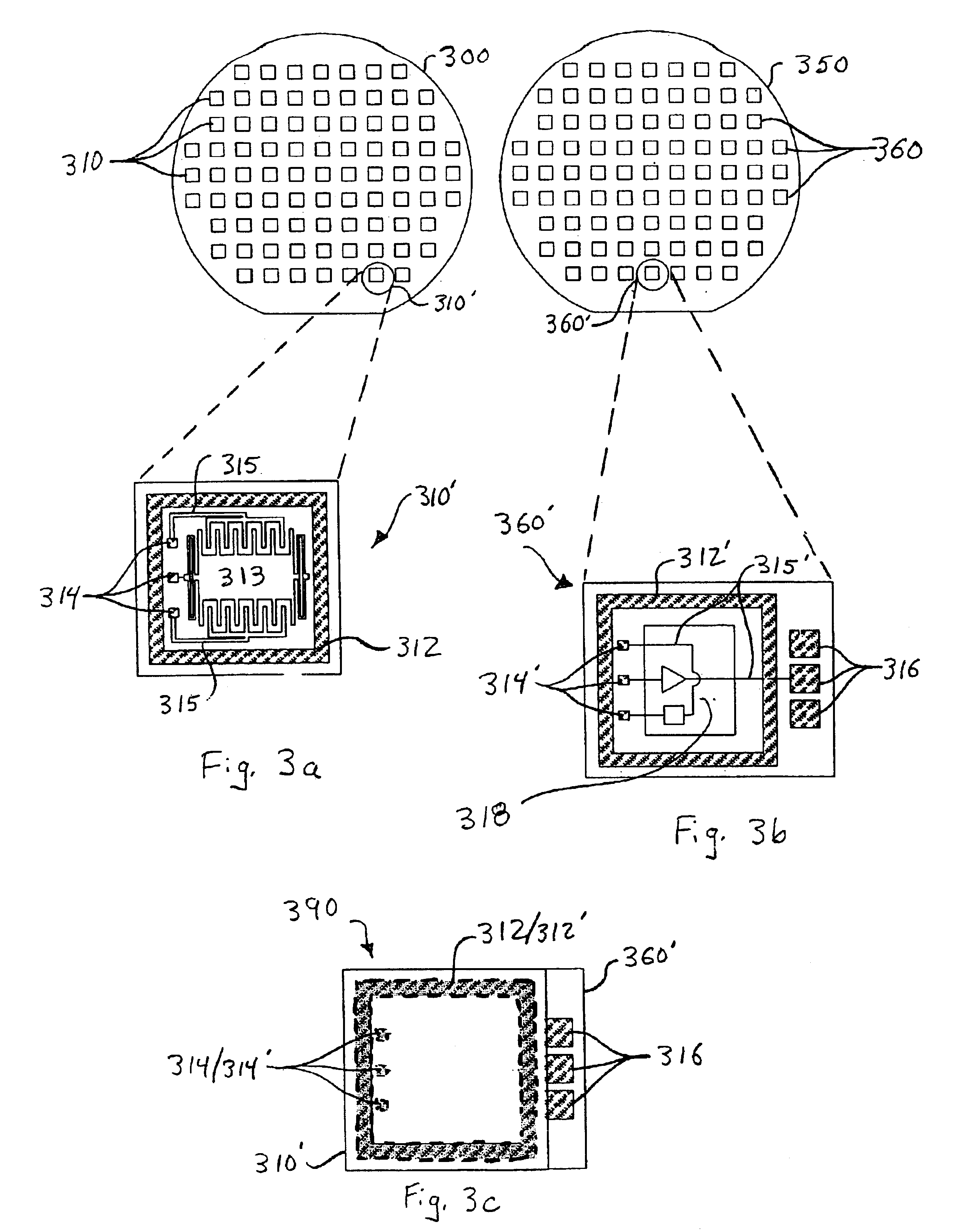

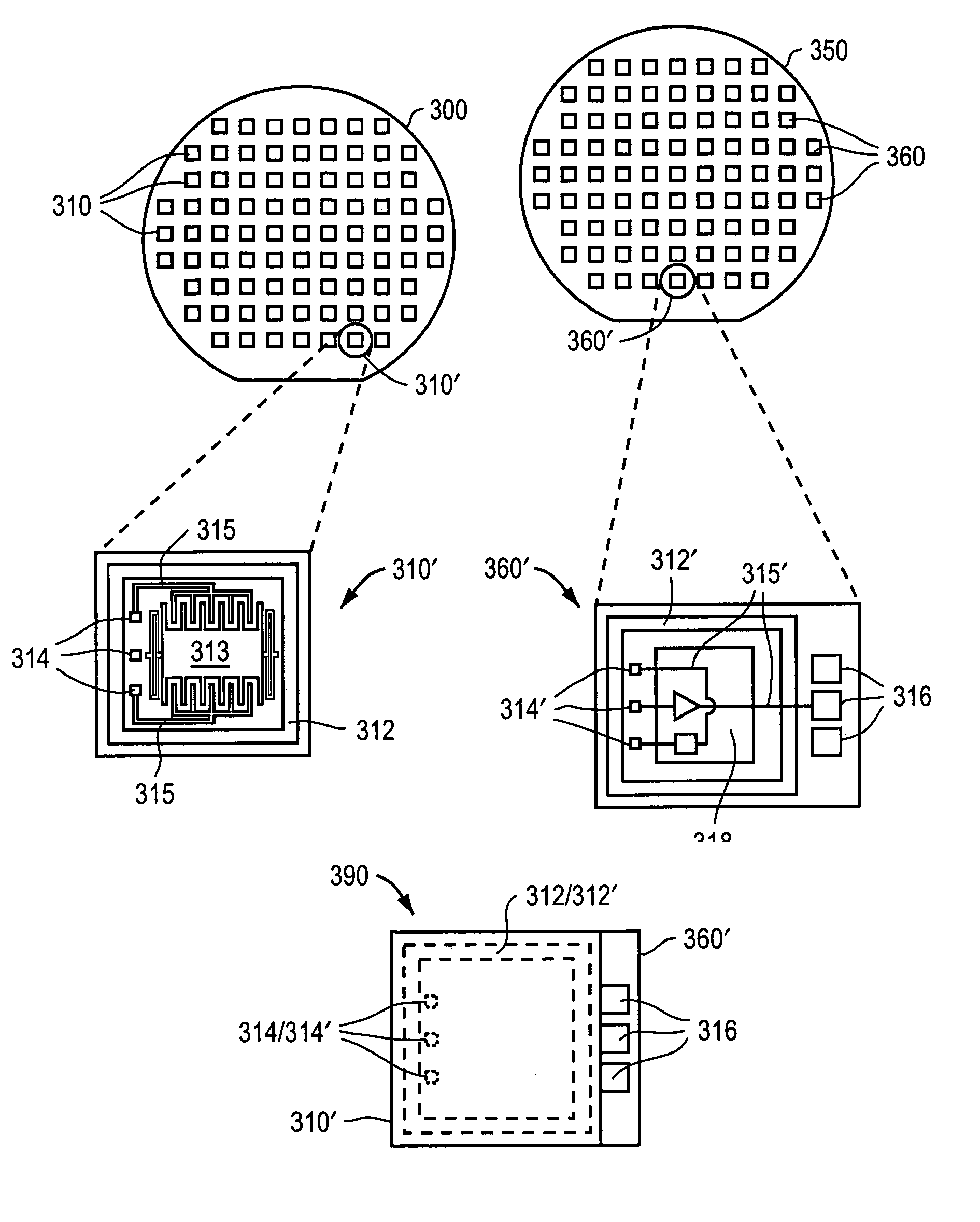

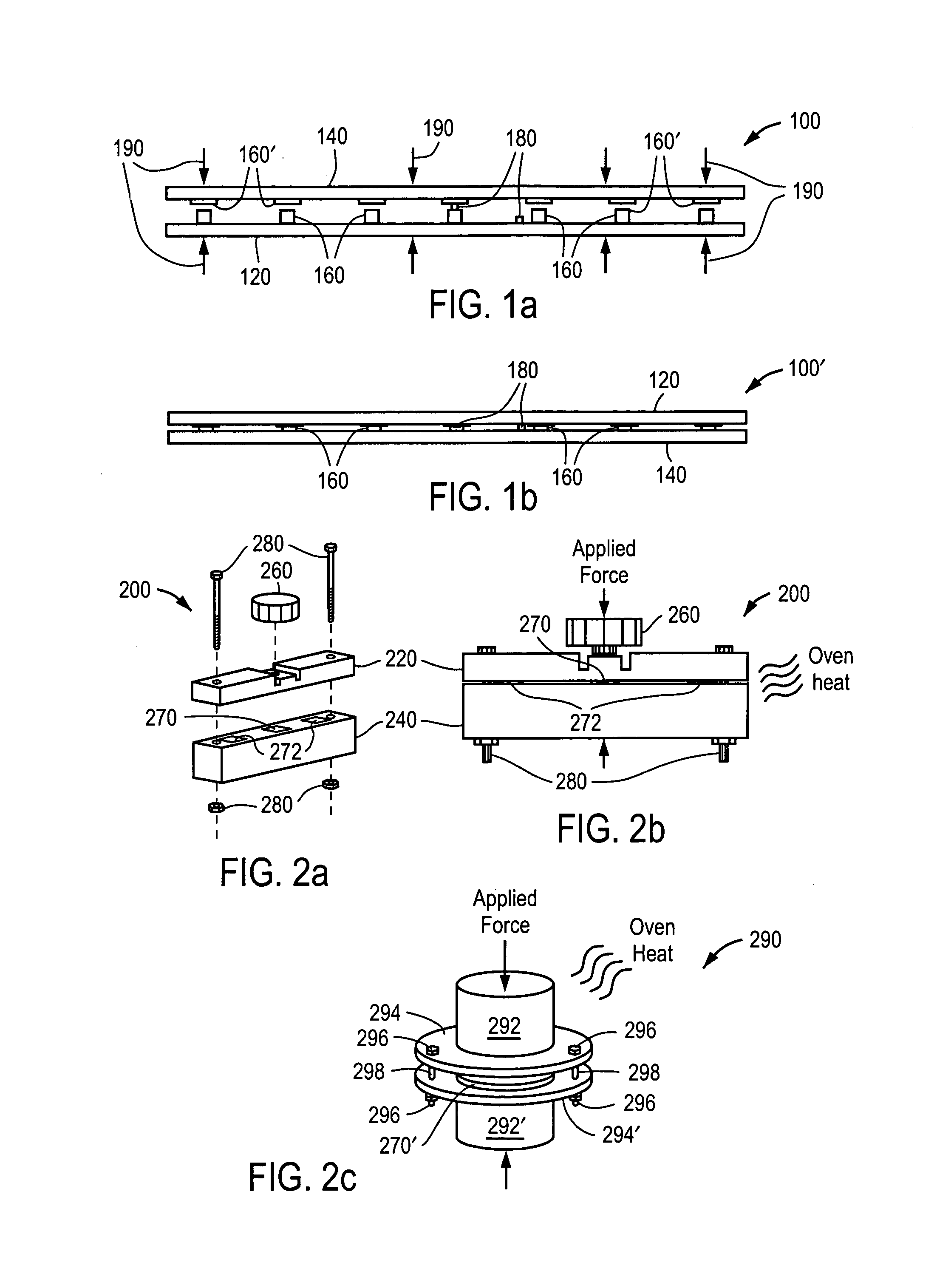

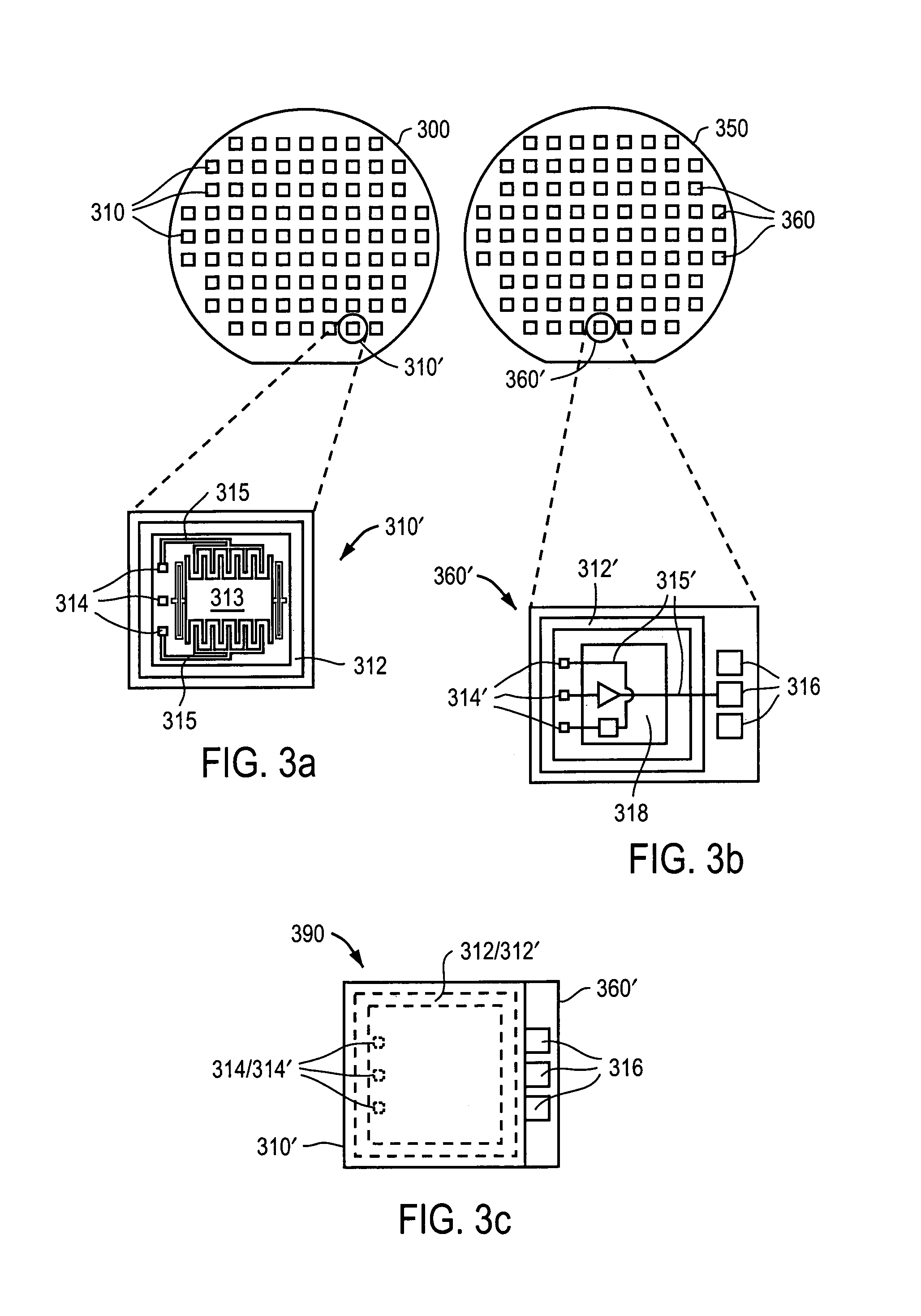

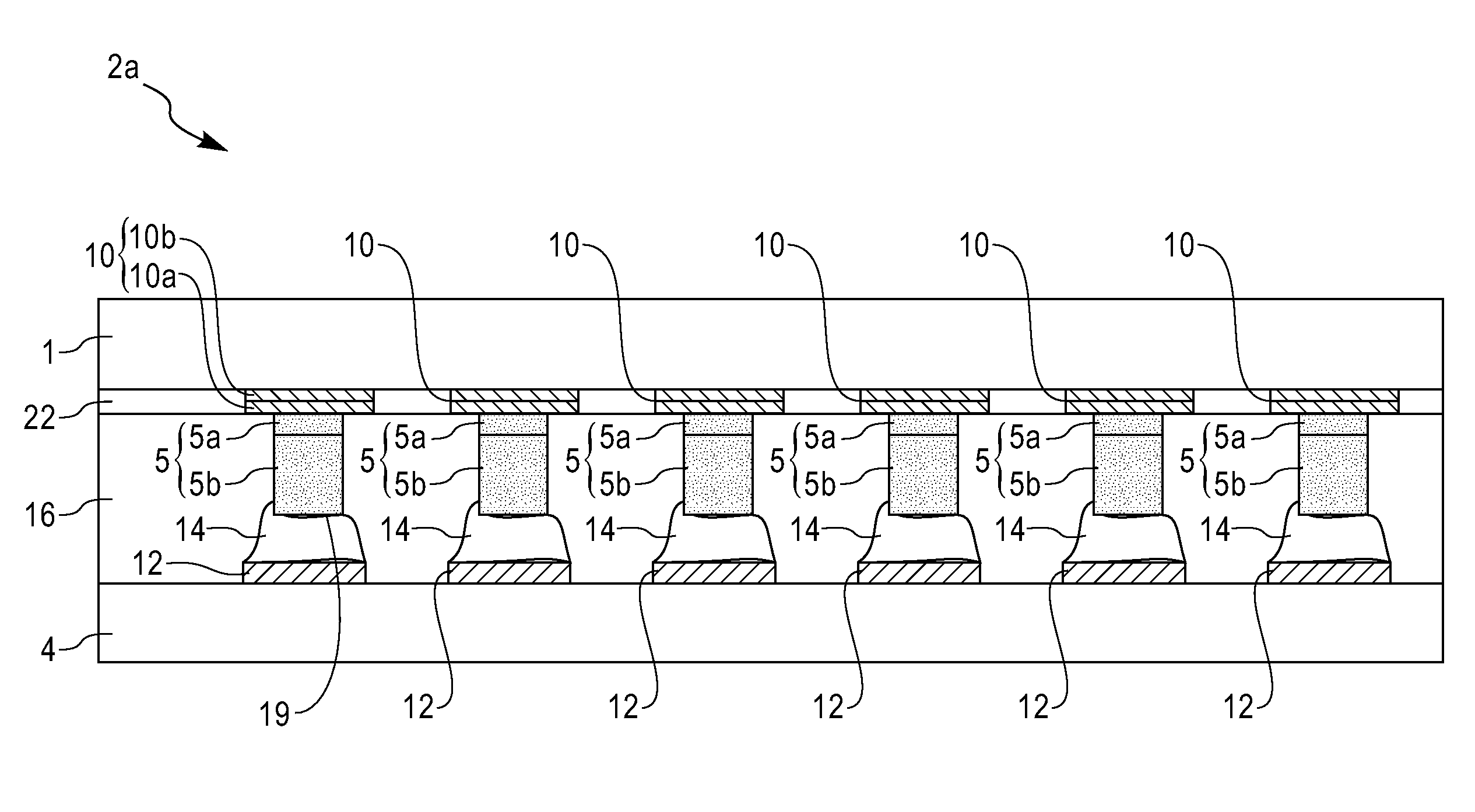

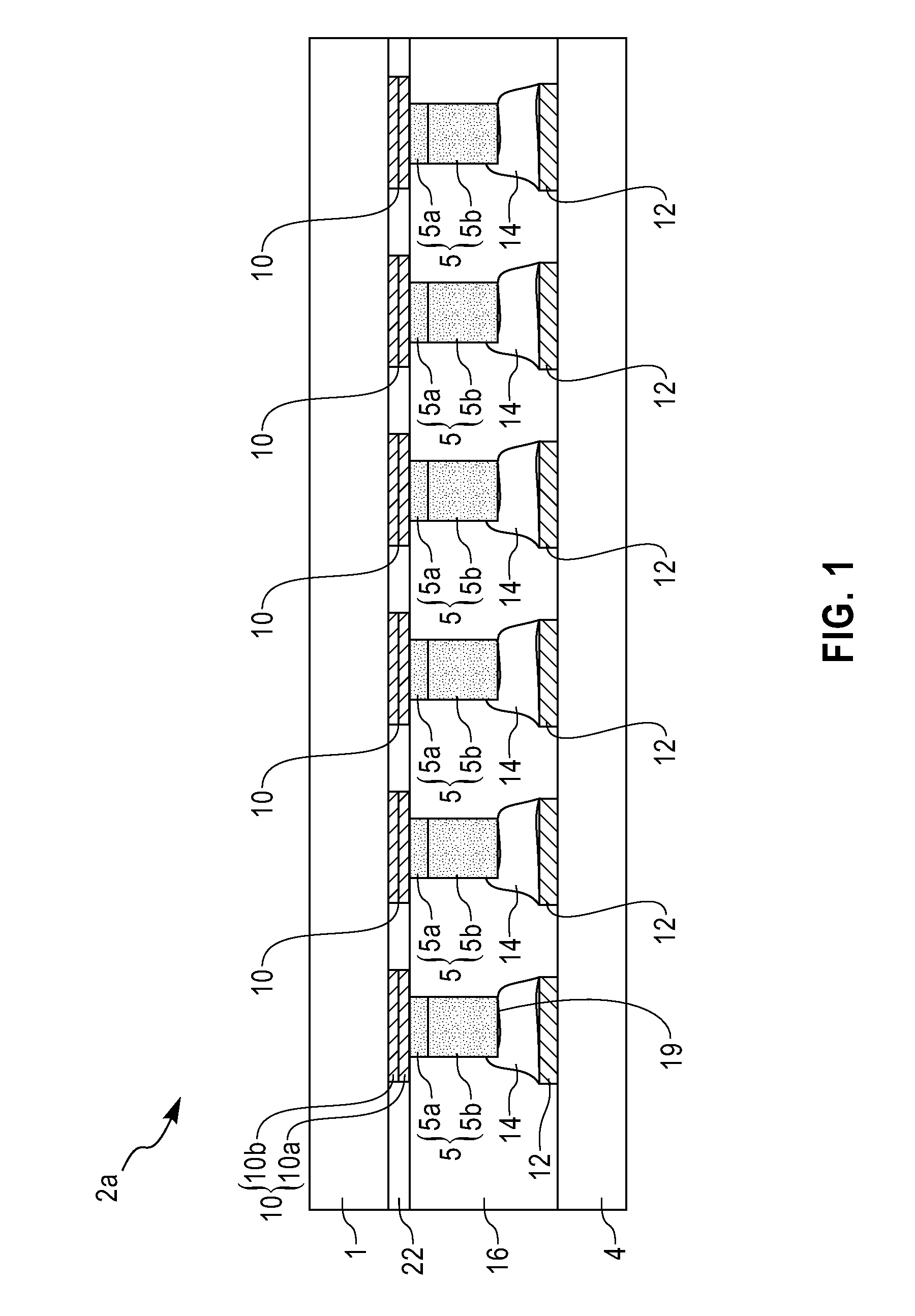

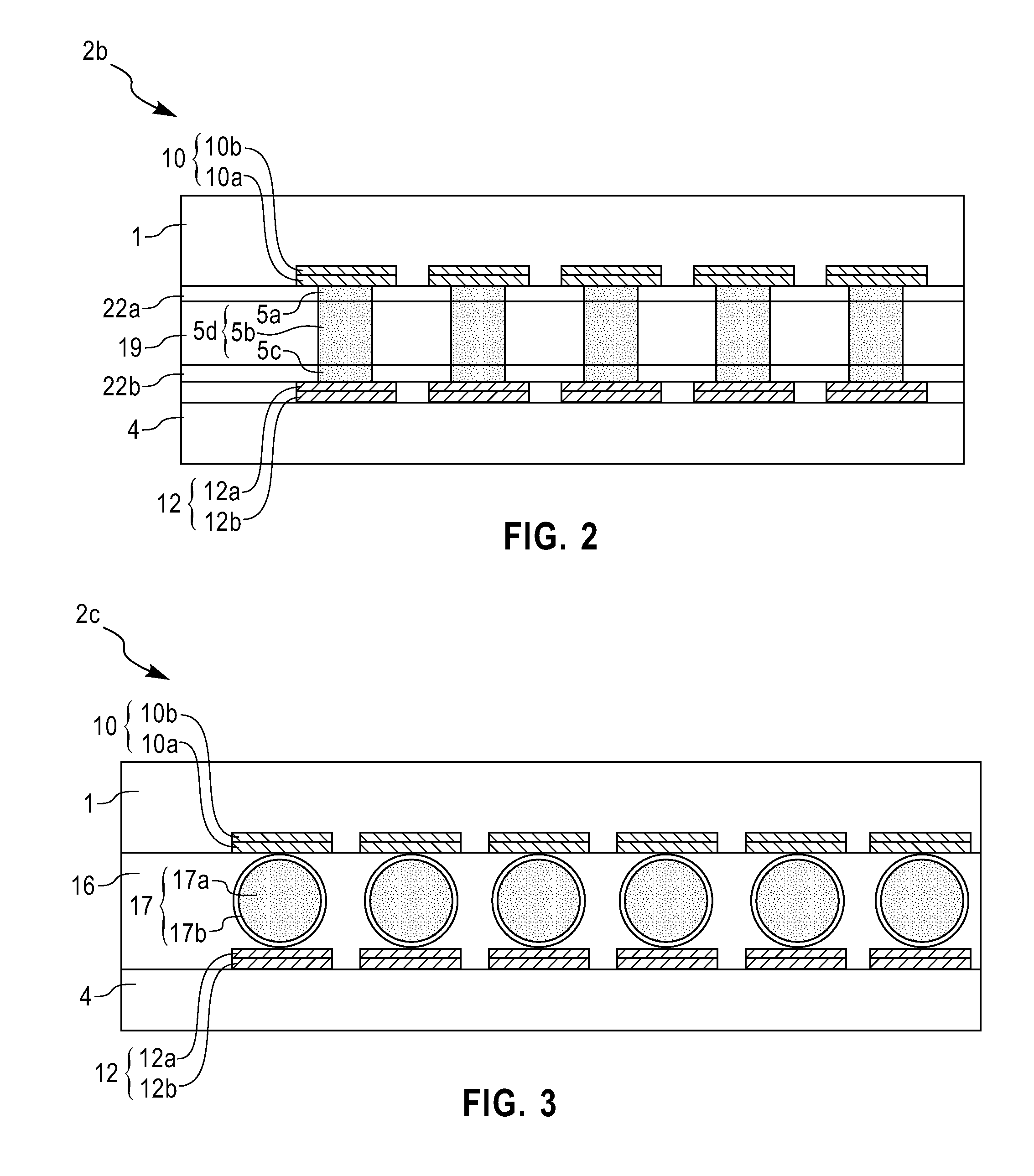

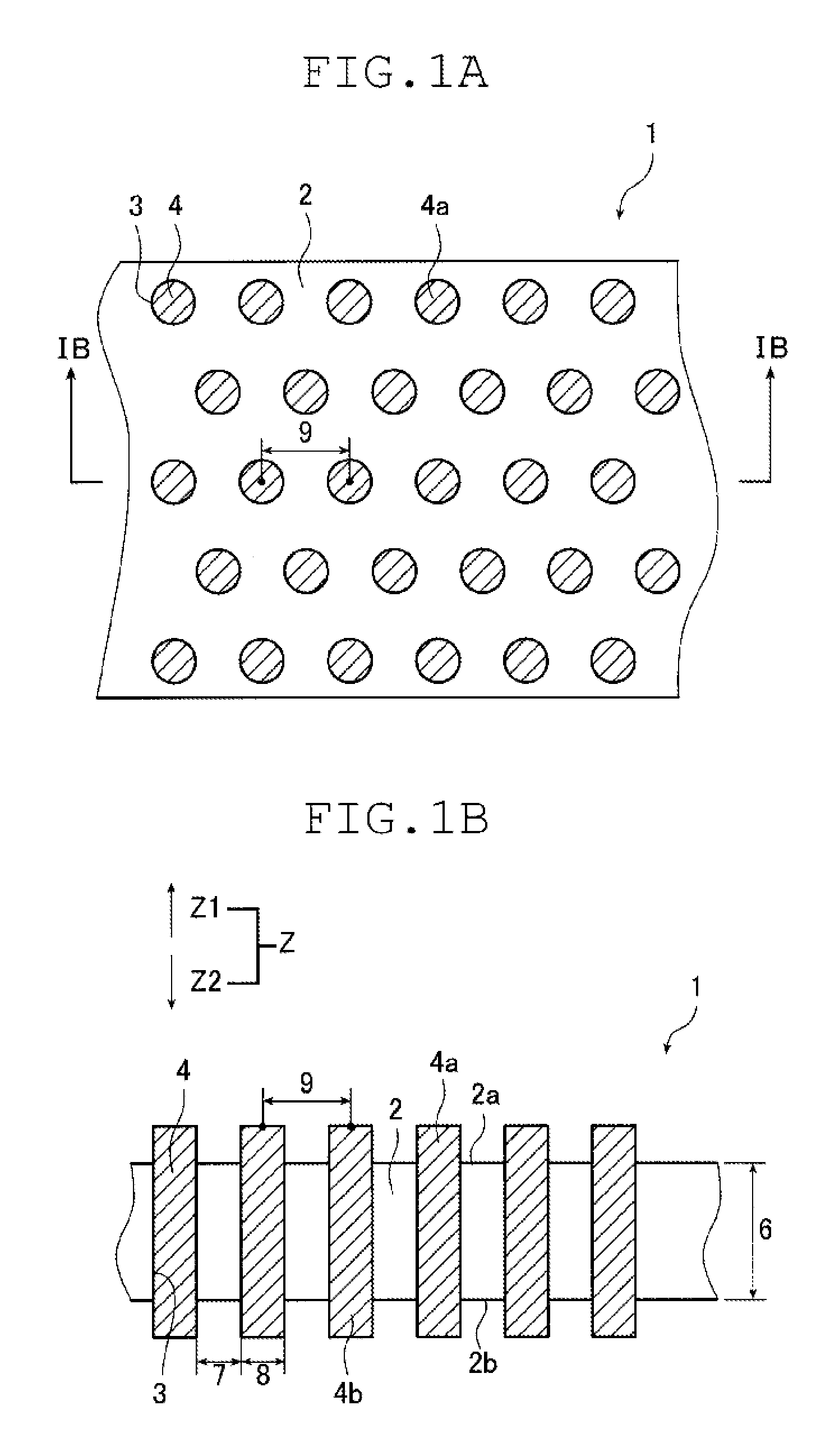

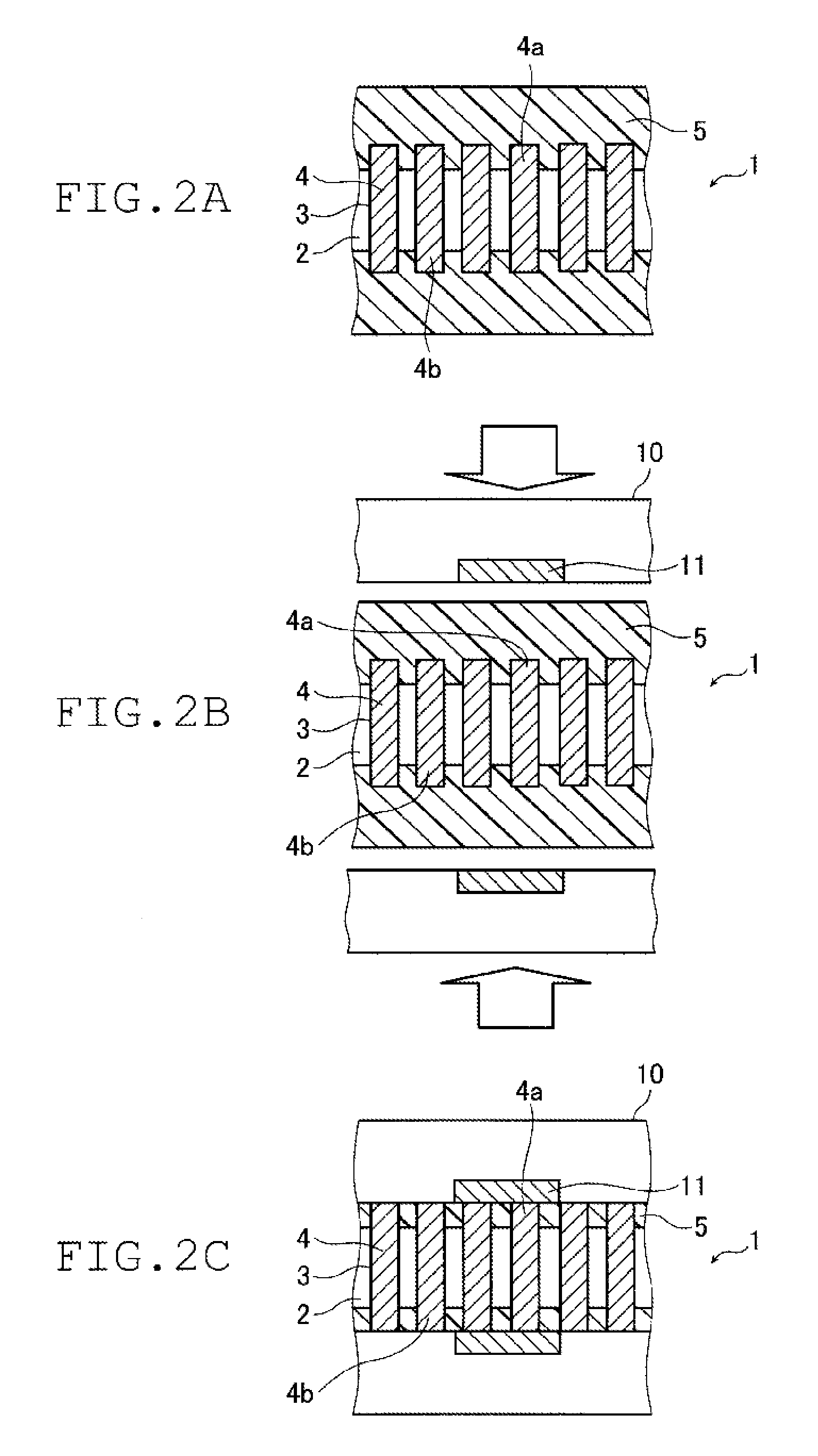

Microelectromechanical systems using thermocompression bonding

InactiveUS6853067B1Reduce parasitic capacitanceReduce parasitismDecorative surface effectsSemiconductor/solid-state device detailsReduced sizeEngineering

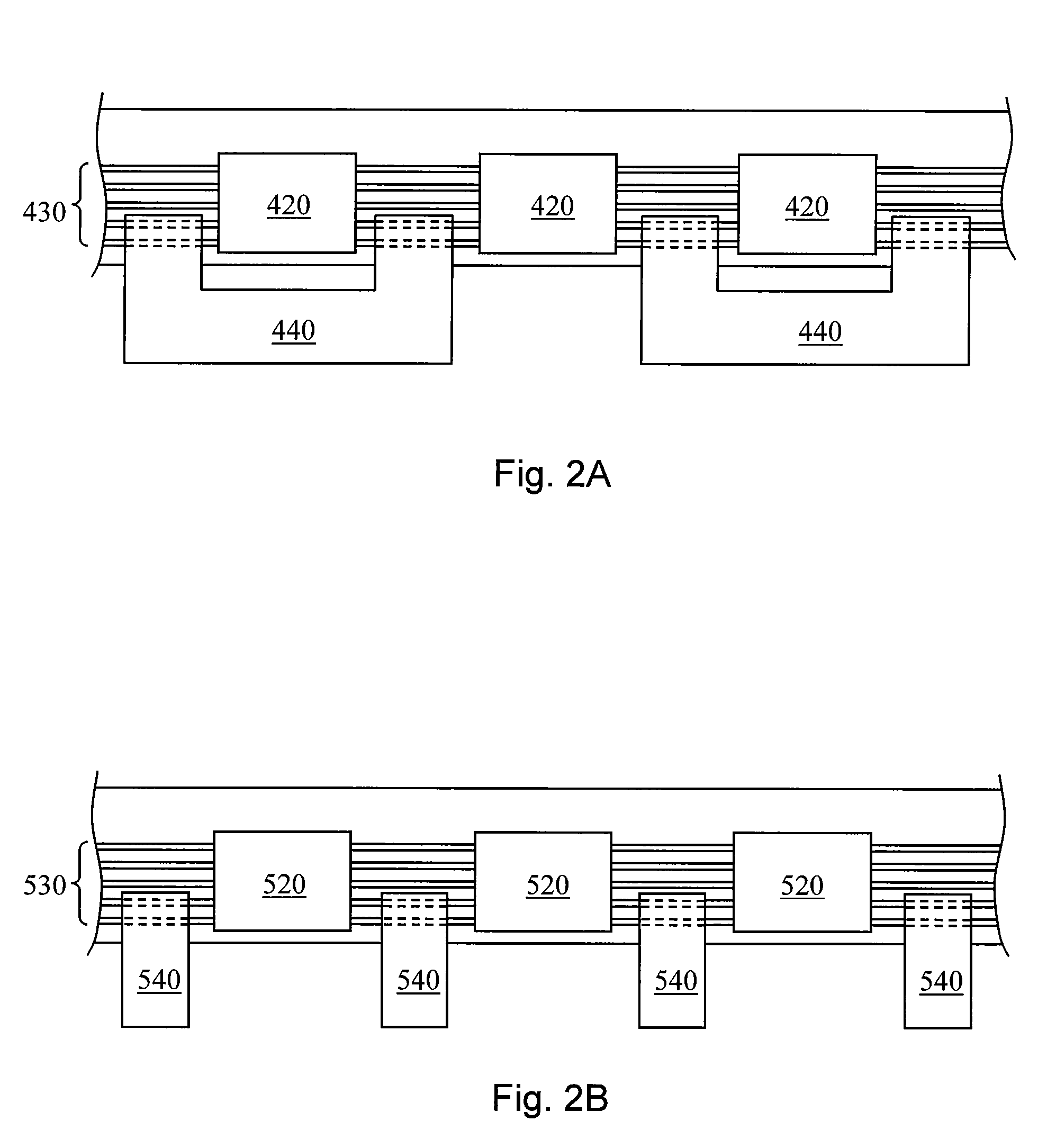

Improved microelectromechanical systems (MEMS), processes and apparatus using thermocompression bonding are disclosed. For example, process embodiments are disclosed in which wafer-scale as well as die-scale thermocompression bonding is utilized to encapsulate MEMS and / or to provide electrical interconnections with MEMS. Apparatus embodiments include apparatus for performing thermocompression bonding and bonded hybrid structures manufactured in accordance with the process embodiments. Devices having various substrate bonding and / or sealing configurations variously offer the advantage of reduced size, higher manufacturing yields, reduced costs, improved reliability, improved compatibility with existing semiconductor manufacturing process and / or greater versatility of applications.

Owner:MICROASSEMBLY TECH

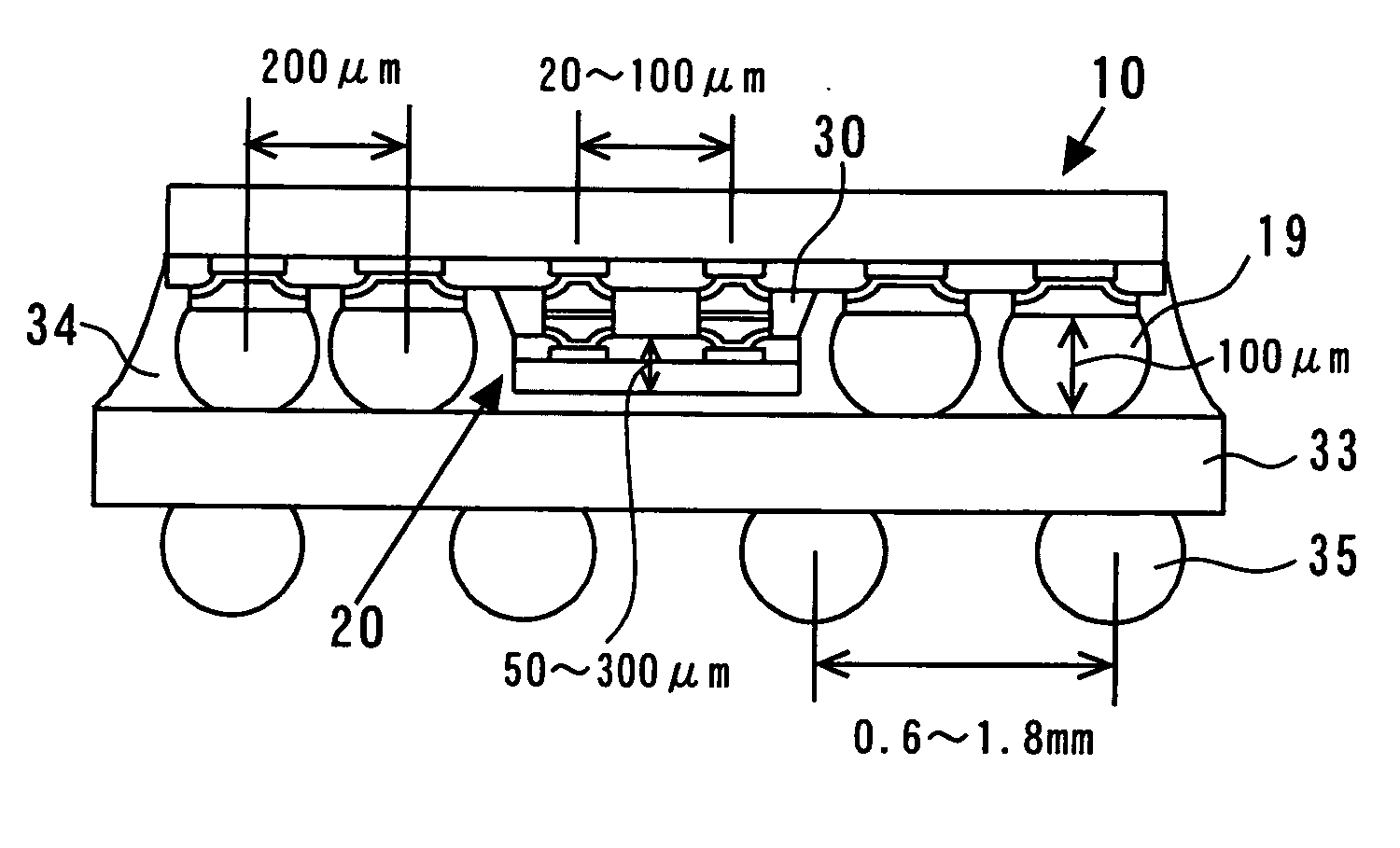

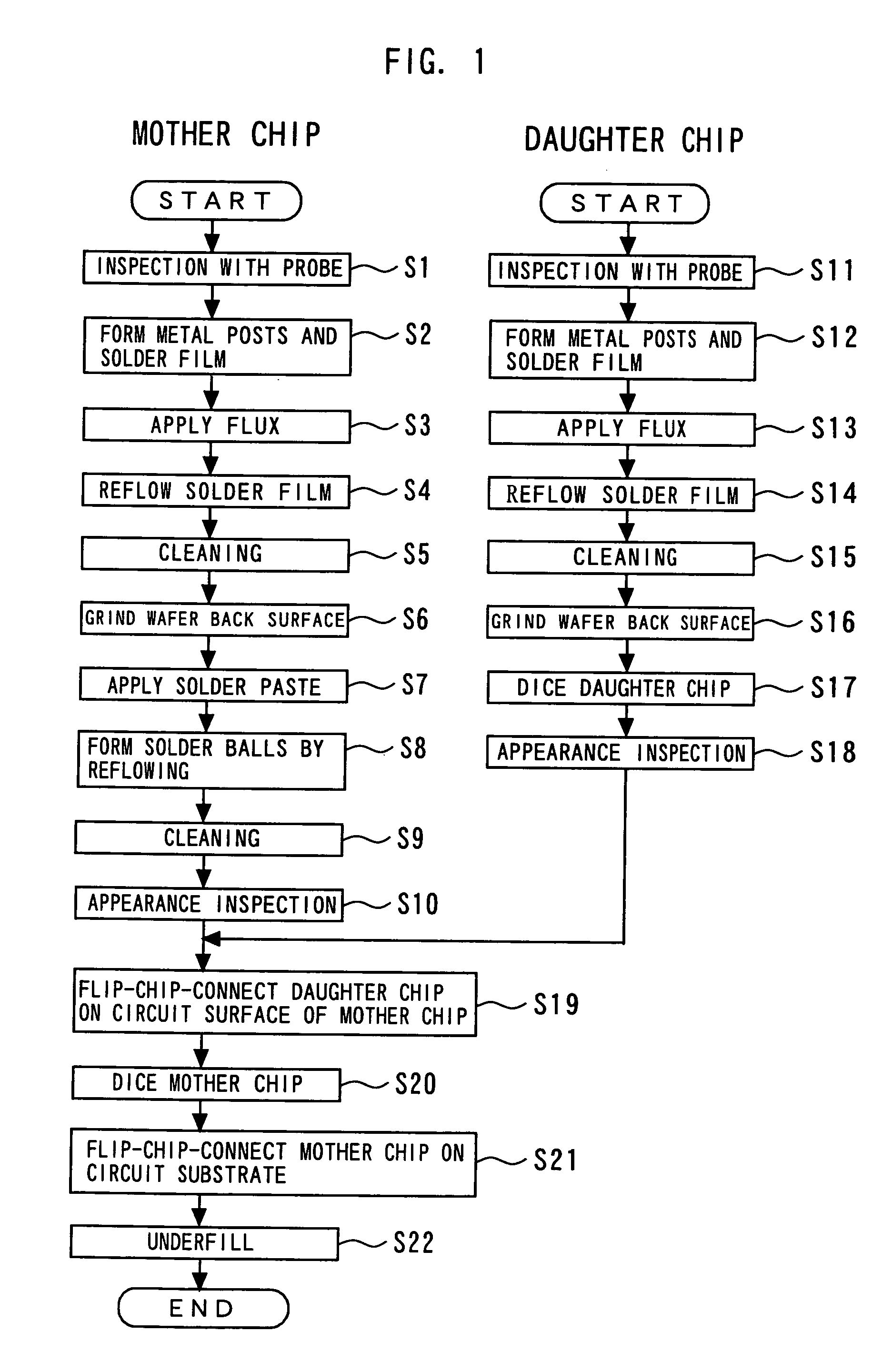

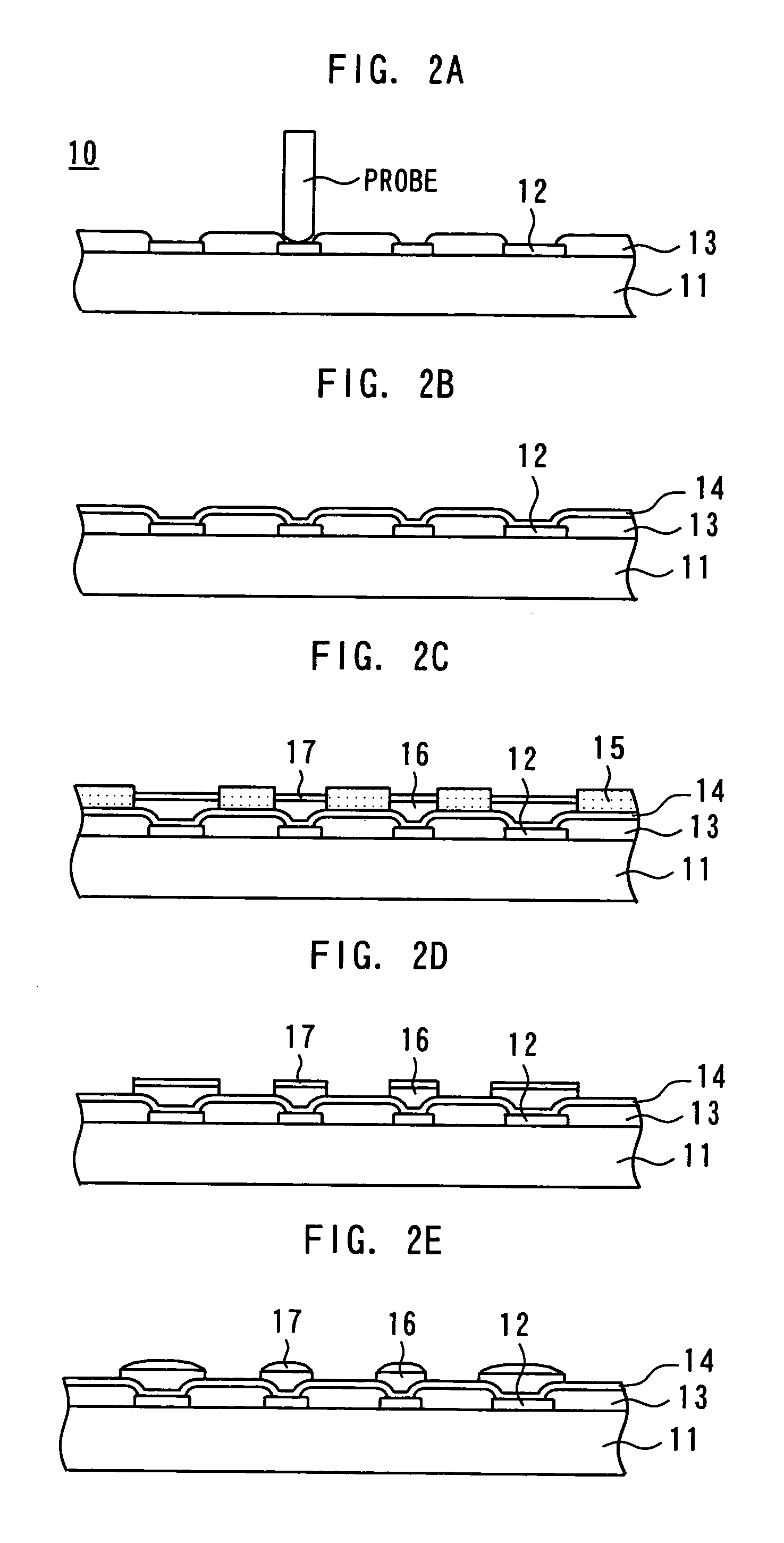

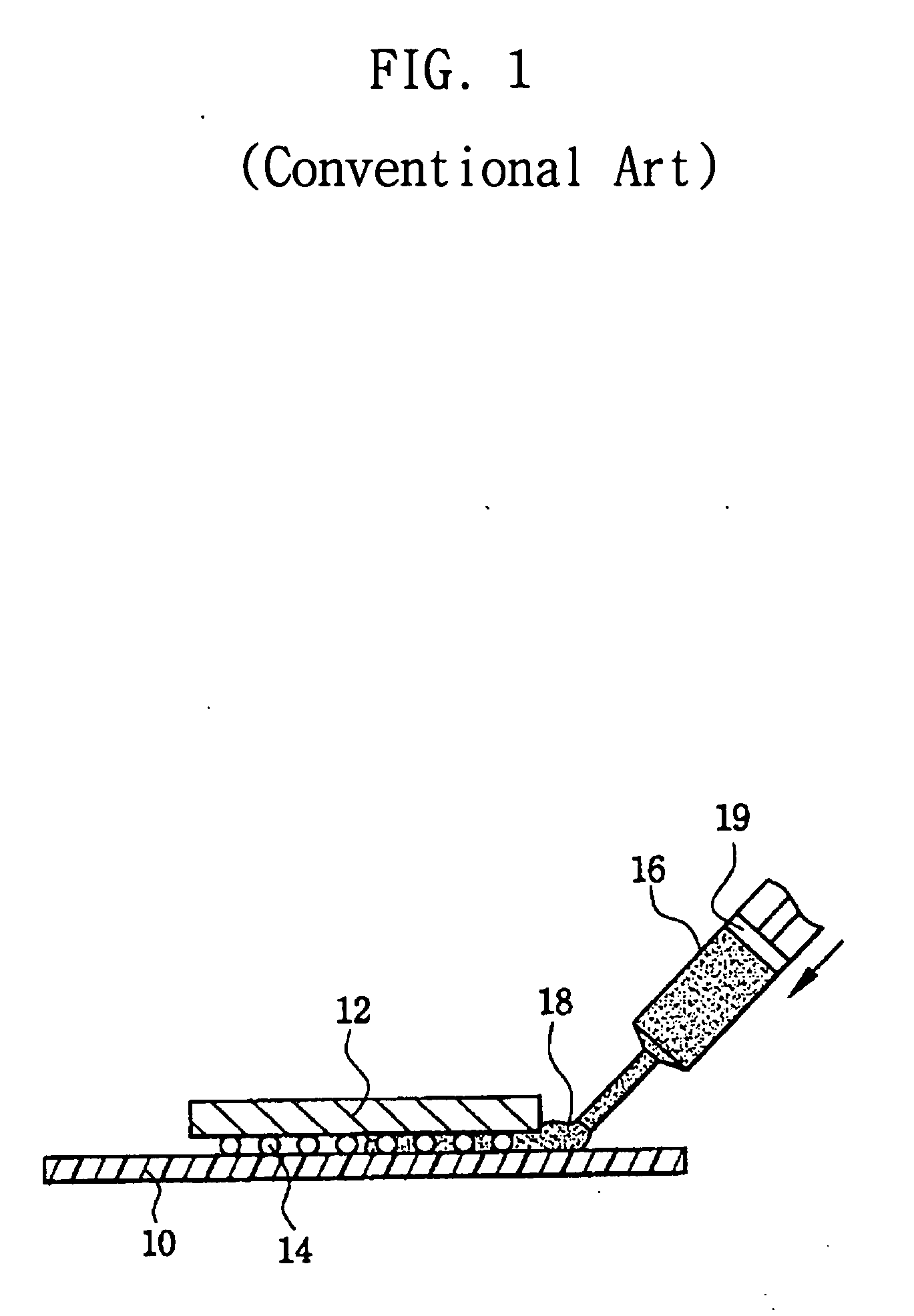

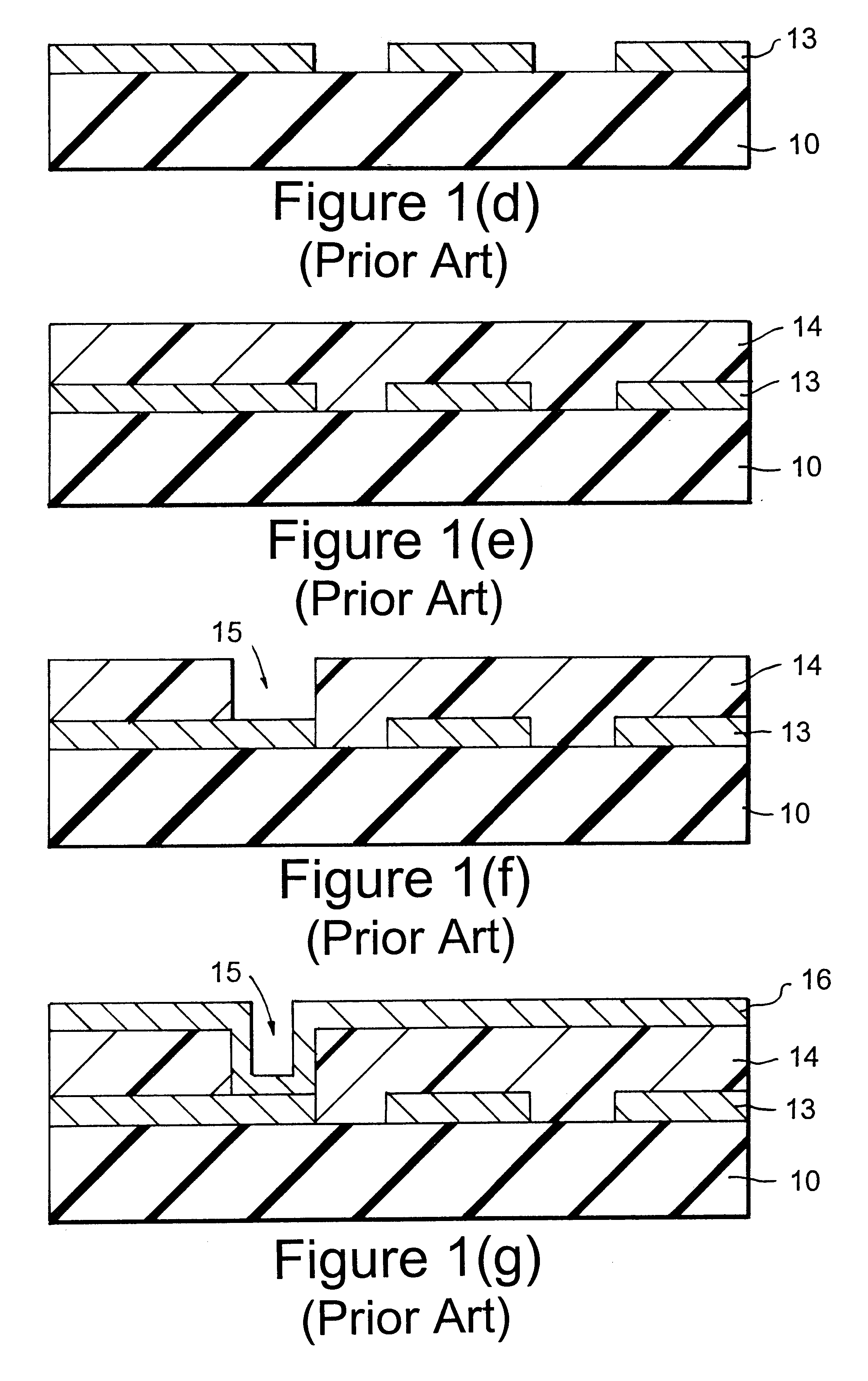

Method of manufacturing semiconductor device

InactiveUS20070141750A1Avoid connection failureSolid-state devicesSemiconductor/solid-state device manufacturingNitrogen atmosphereSolder ball

A method of manufacturing a semiconductor device includes a first step of forming solder film on metal posts of a mother chip, a second step of forming solder balls after the first step by printing a solder paste on the mother chip and heating the mother chip so that the solder paste is ref lowed, a third step of bonding the metal posts of the mother chip and metal posts of a daughter chip to each other in a thermocompression bonding manner by means of the solder film after the second step, and a fourth step of flip-chip-connecting the mother chip on a circuit substrate by using the solder balls. In the second step, the mother chip is heated in a nitrogen atmosphere in which the oxygen concentration is 500 ppm or less.

Owner:RENESAS ELECTRONICS CORP

Nonwoven fabric for cylindrical bag filter, process for producing the same, and cylindrical bag filter therefrom

InactiveUS20100180558A1Excellent characteristicsImprove rigidityElectric discharge heatingDispersed particle filtrationEngineeringNonwoven fabric

The present invention provides a nonwoven fabric for cylindrical bag filter, wherein a long-fiber nonwoven fabric made of a synthetic fiber is used and the long-fiber nonwoven fabric is a long-fiber nonwoven fabric which is made of a thermoplastic continuous filament and is partially thermocompression-bonded. It is preferable that the circular arc flexural rigidity per basis weight is 0.050 to 1.000 ((cN / 2 cm) / (g / m2)) and the air permeation rate per basis weight is 0.010 to 0.500 ((cc / cm2 / sec) / (g / m2)). Further, there is provided a method for producing a nonwoven fabric for cylindrical bag filter including the steps of: melt-extruding a thermoplastic polymer through a spinneret; sucking and drawing the extrudate with an air sucker to form a thermoplastic continuous filament; allowing the filament to be subjected to electrification opening and to be piled on a moving collection surface to form a fiber web; and allowing the fiber web to be subjected to pressure welding treatment with a flat roll and partially thermocompression-bonding the fiber web with hot embossing rolls to form a long-fiber nonwoven fabric.

Owner:TORAY IND INC

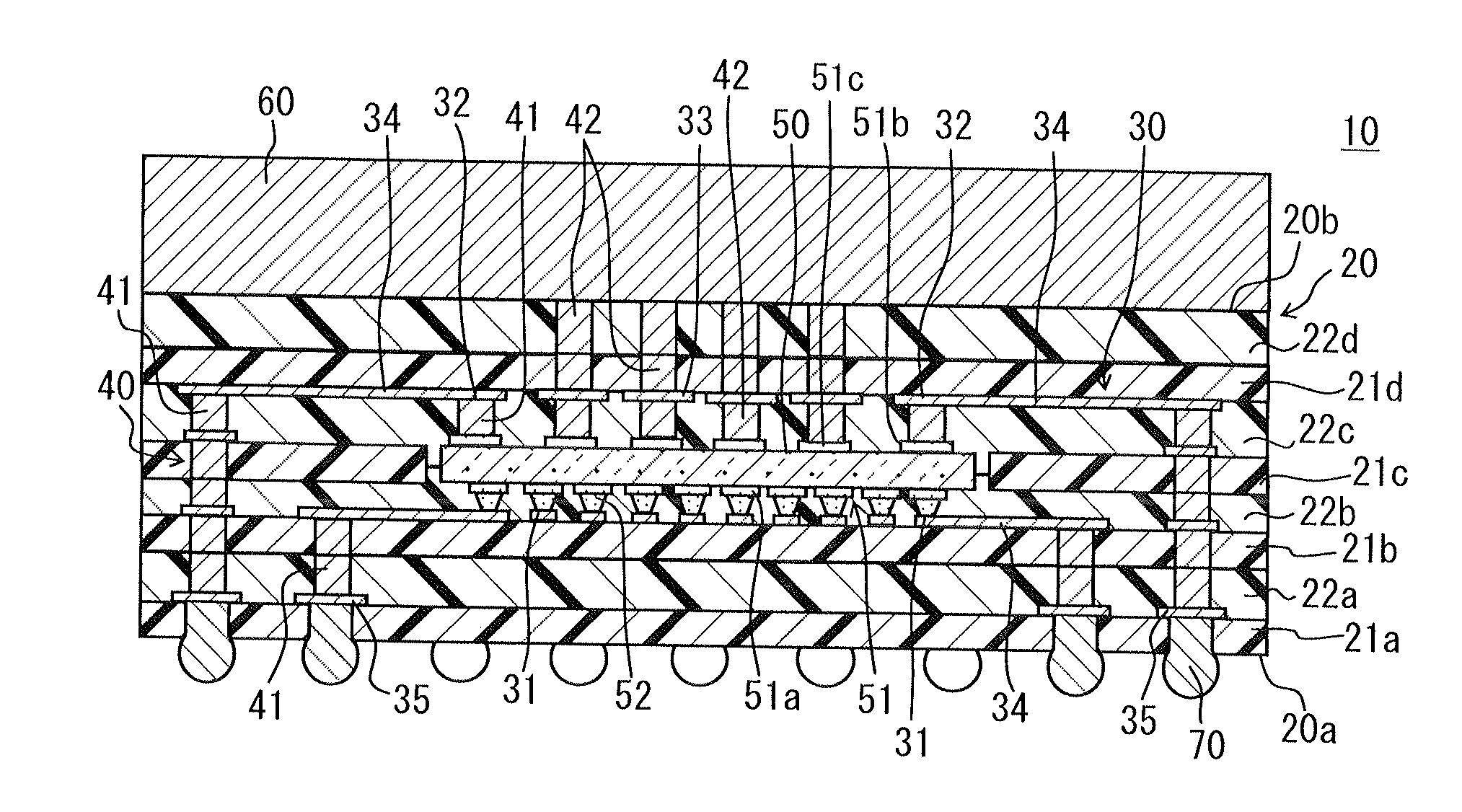

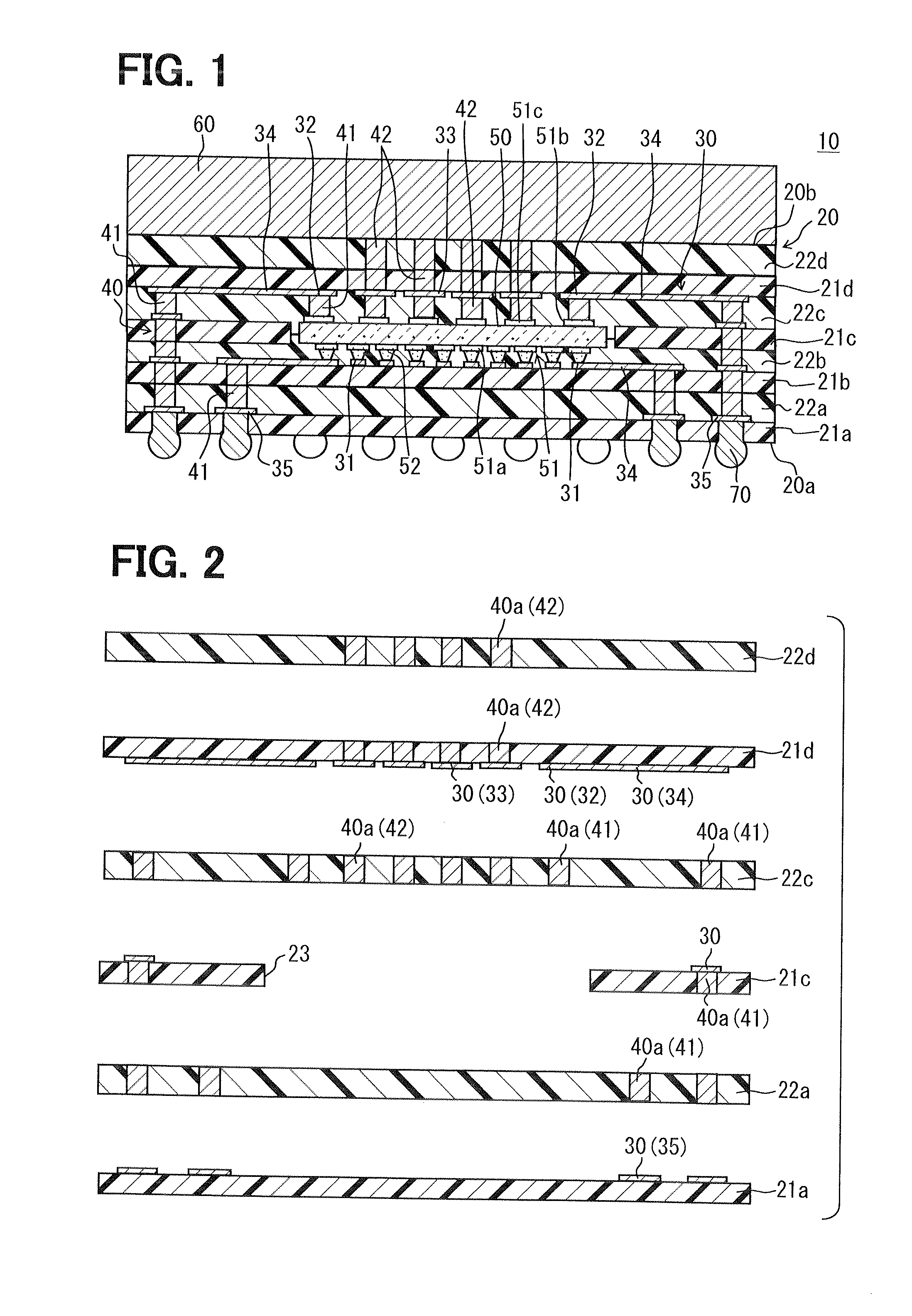

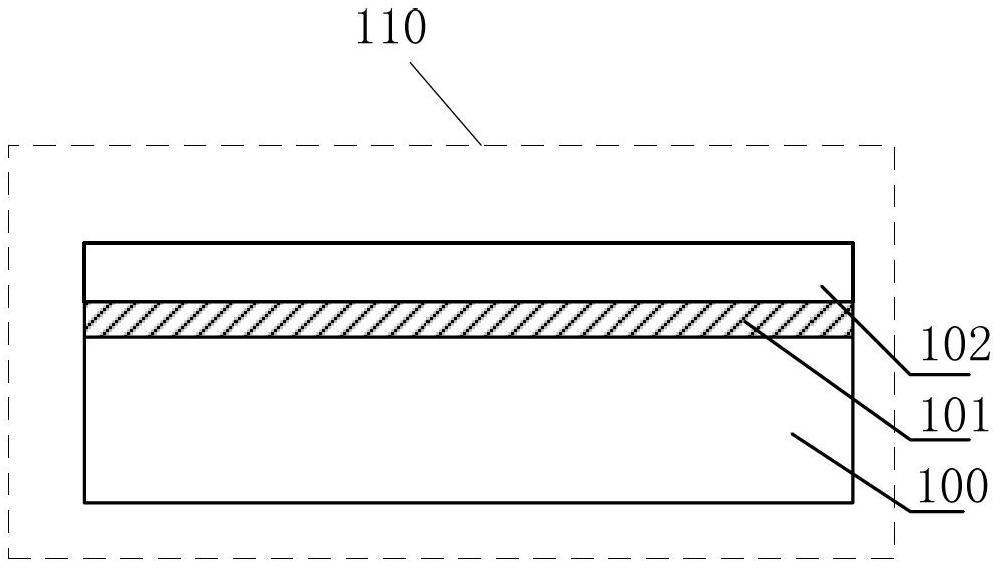

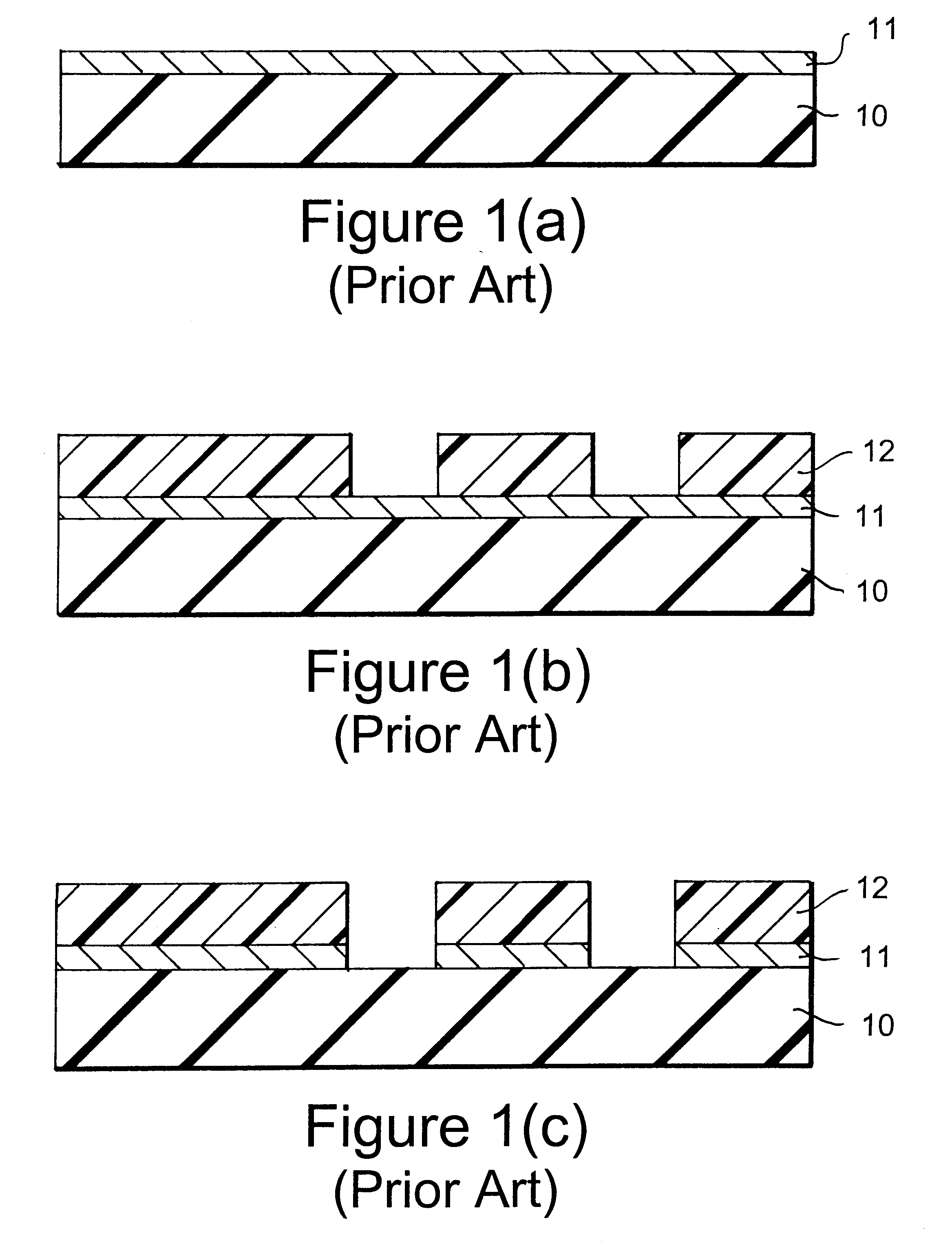

Manufacturing method of semiconductor chip-embedded wiring substrate

InactiveUS20110244636A1Simple manufacturing processShorten production timeSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor chipThermal compression

With respect to a substrate including a first film, on a surface of which a pad is formed, a second film made of thermoplastic resin is a thermal compression bonded to a pad formation surface of the substrate. A stud bump formed on a semiconductor chip is stuffed into the second film while melting the second film and is pressure welded to the pad by application of pressure and heat. The melted second film seals between the semiconductor chip and the substrate. Then, multiple resin films are stacked with the substrate and the second film to form a stacked body. In a pressurizing and heating process, the multiple resin films, the substrate and the second film are integrated at one time so that the stud bump is bonded to the pad.

Owner:DENSO CORP

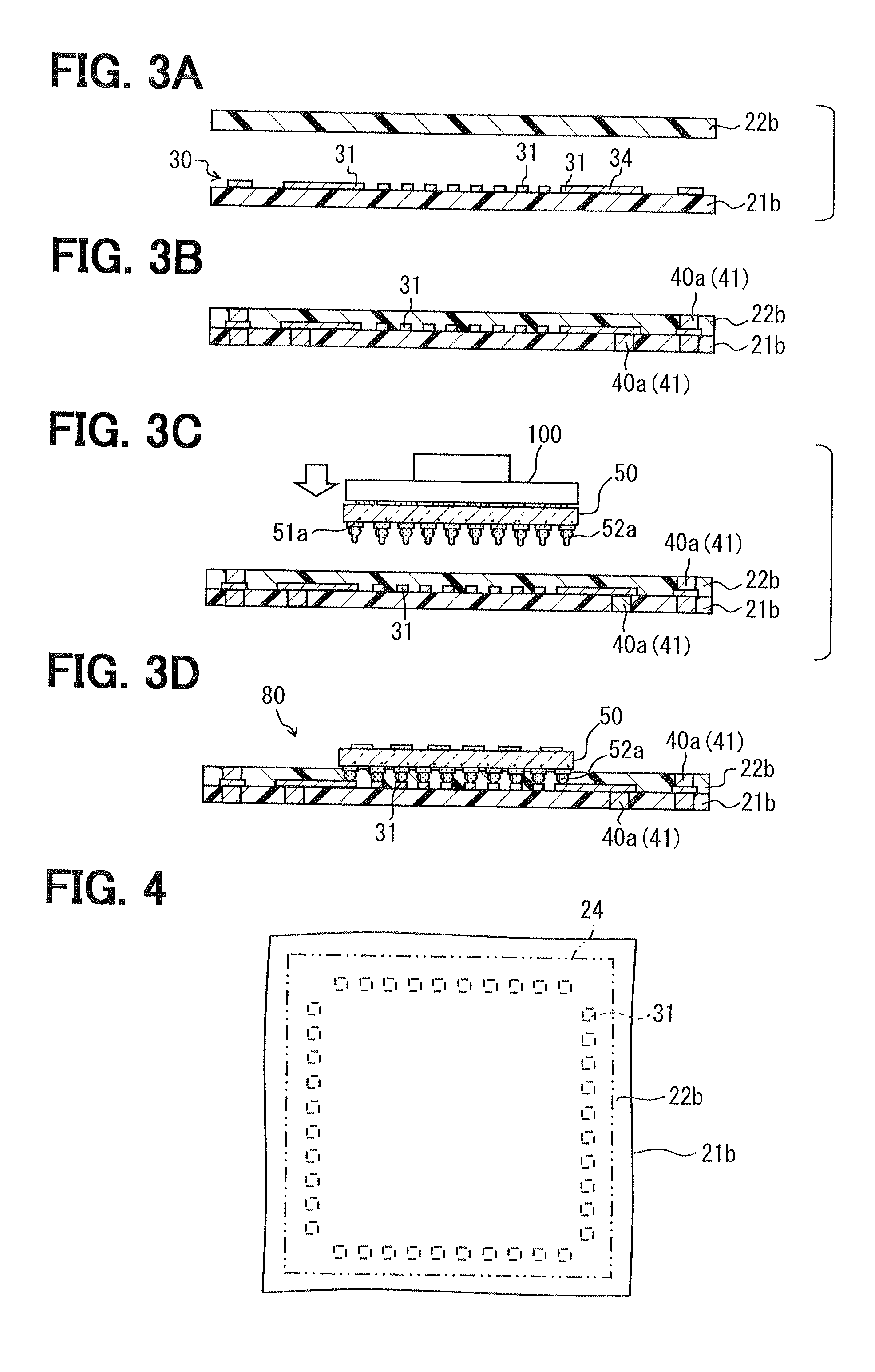

Fabrication method of semiconductor integrated circuit device

InactiveUS20050061856A1Improve productivityImprove bonding qualitySemiconductor/solid-state device detailsSolid-state devicesProduction rateSemiconductor chip

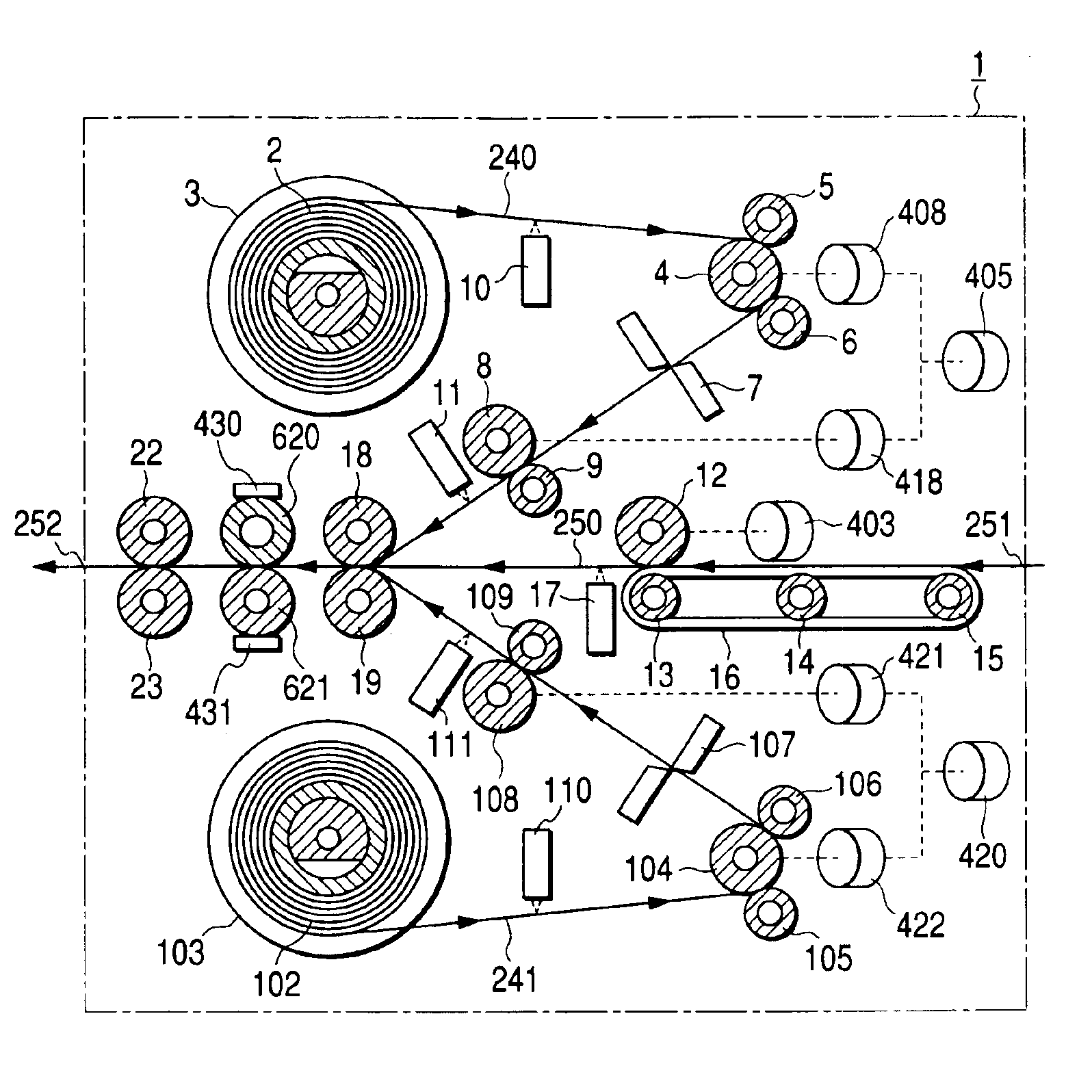

Productivity is to be improved in assembling a semiconductor integrated circuit device. A matrix substrate is provided and semiconductor chips are disposed on a first heating stage, and then the matrix substrate is disposed above the semiconductor chips on the first heating stage. Subsequently, the semiconductor chips and the matrix substrate are bonded to each other temporarily by thermocompression bonding, while heating the chips directly by the first heating stage. Thereafter, the temporarily bonded matrix substrate is disposed on a second heating stage adjacent to the first heating stage, and then, on the second heating stages, the semiconductor chips are thermocompression-bonded to the matrix substrate, while being heated directly by the second heating stage.

Owner:RENESAS ELECTRONICS CORP +1

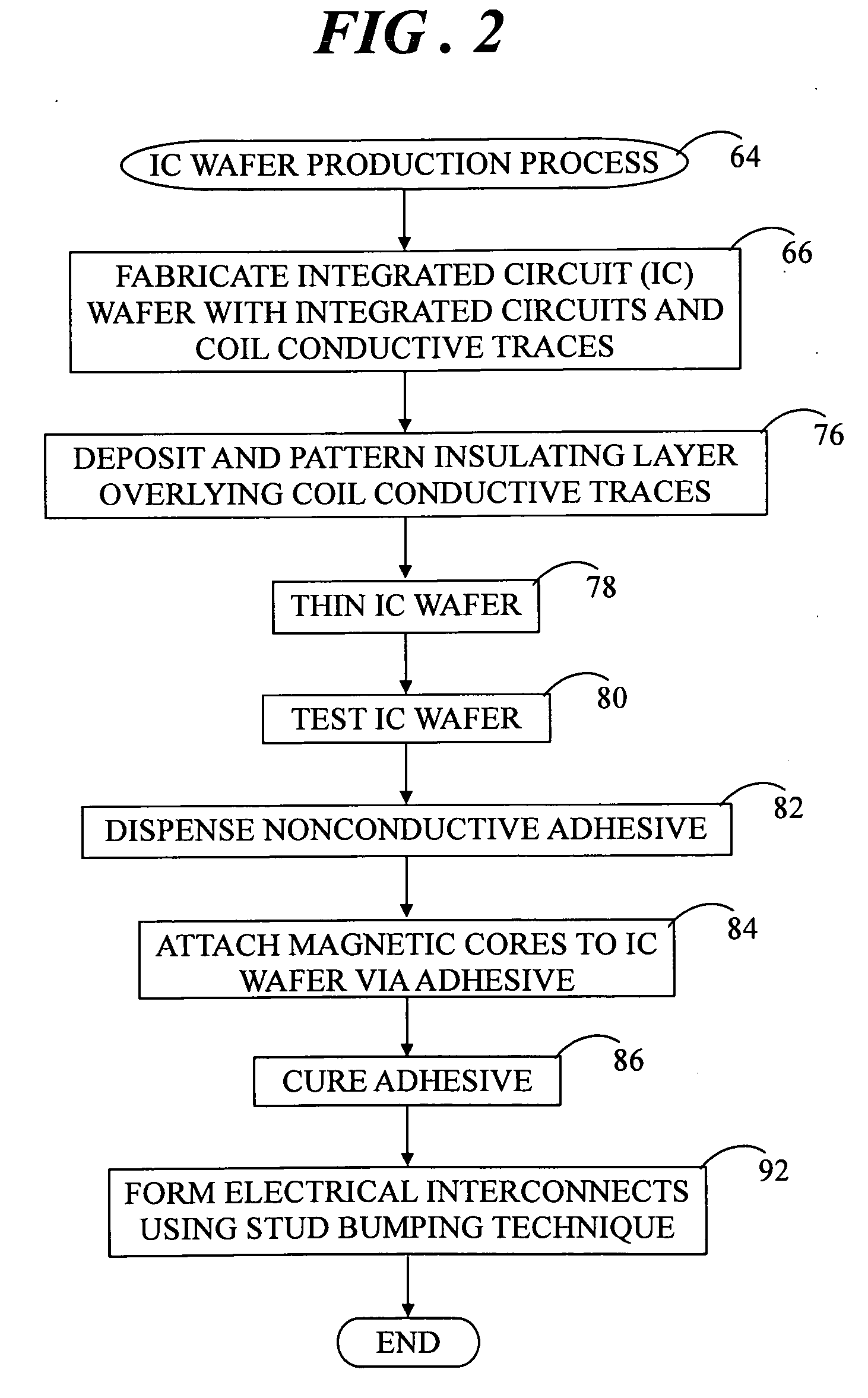

Microelectromechanical systems using thermocompression bonding

InactiveUS7276789B1Electrical interconnections formedReduce parasitic capacitanceDecorative surface effectsSemiconductor/solid-state device detailsReduced sizeEngineering

Improved microelectromechanical systems (MEMS), processes and apparatus using thermocompression bonding are disclosed. For example, process embodiments are disclosed in which wafer-scale as well as die-scale thermocompression bonding is utilized to encapsulate MEMS and / or to provide electrical interconnections with MEMS. Apparatus embodiments include apparatus for performing thermocompression bonding and bonded hybrid structures manufactured in accordance with the process embodiments. Devices having various substrate bonding and / or sealing configurations variously offer the advantage of reduced size, higher manufacturing yields, reduced costs, improved reliability, improved compatibility with existing semiconductor manufacturing process and / or greater versatility of applications.

Owner:MICROASSEMBLY TECH

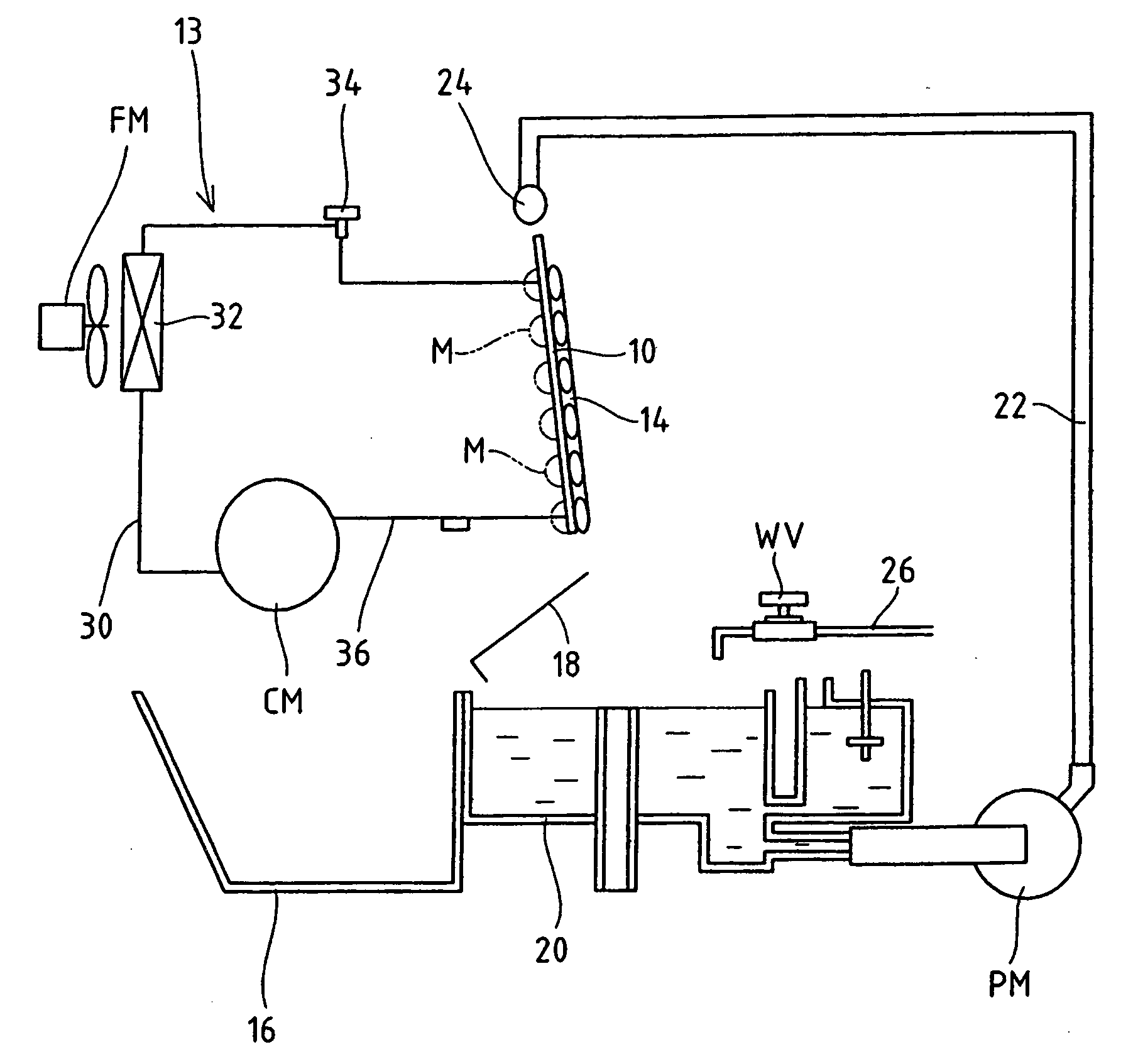

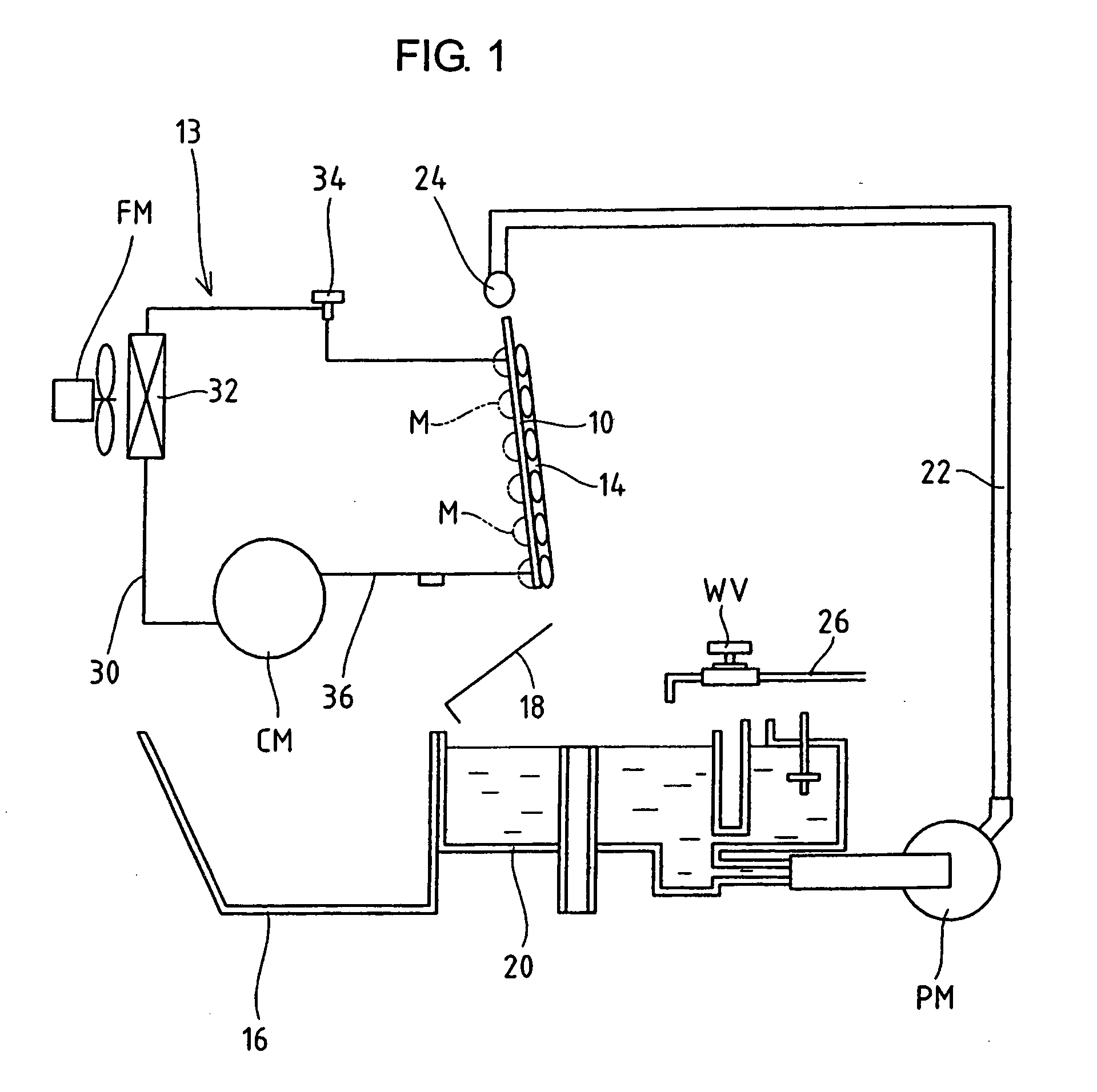

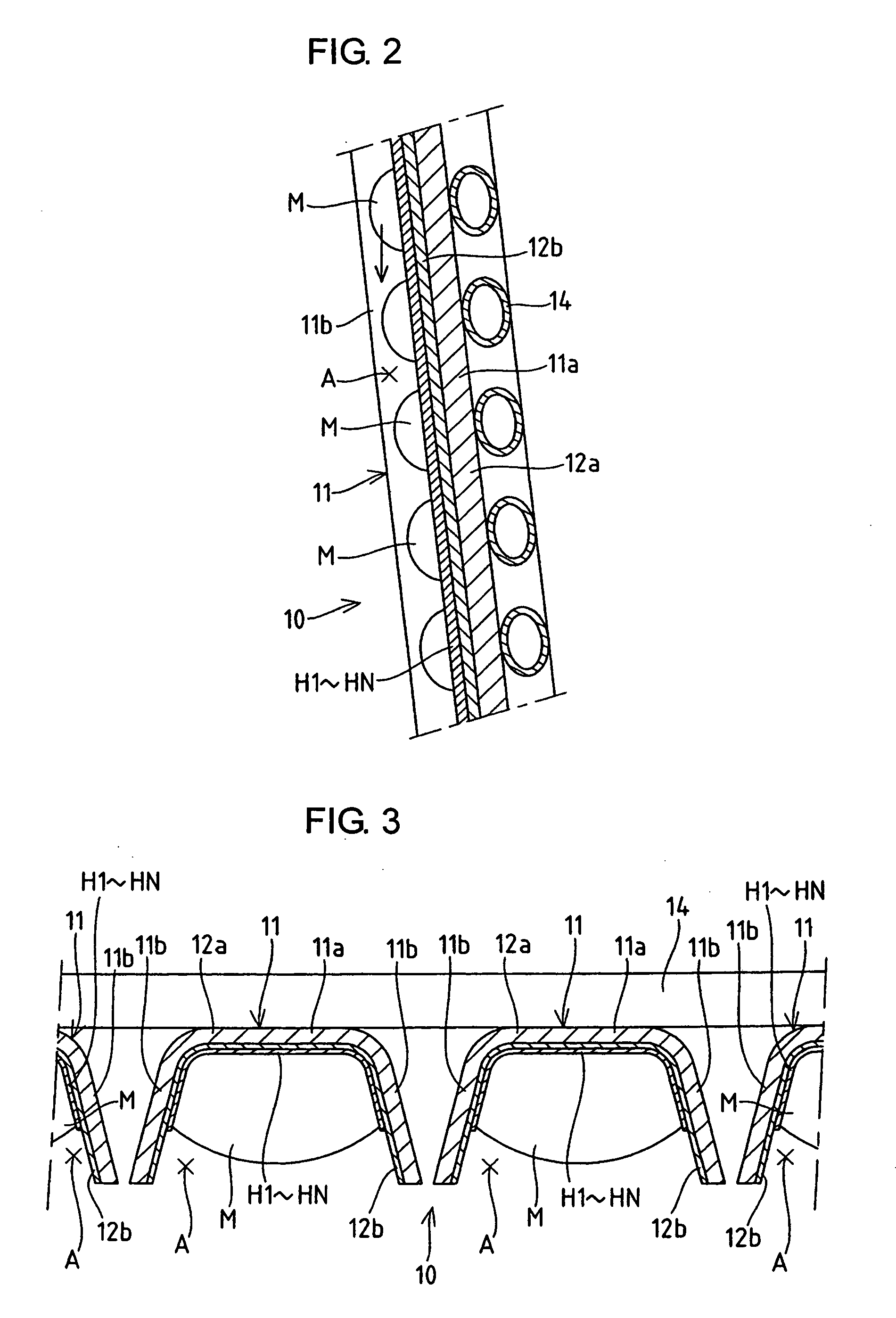

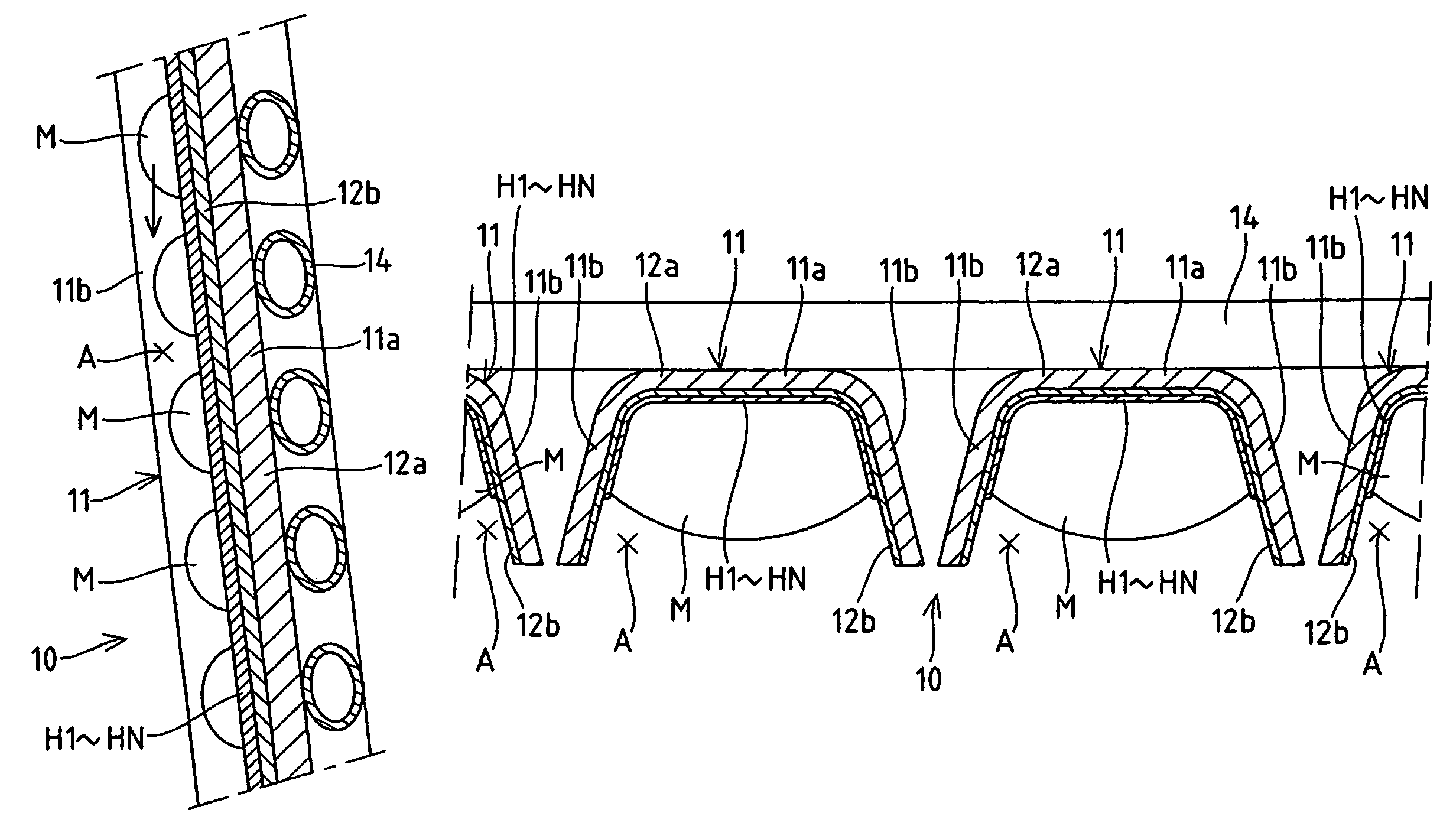

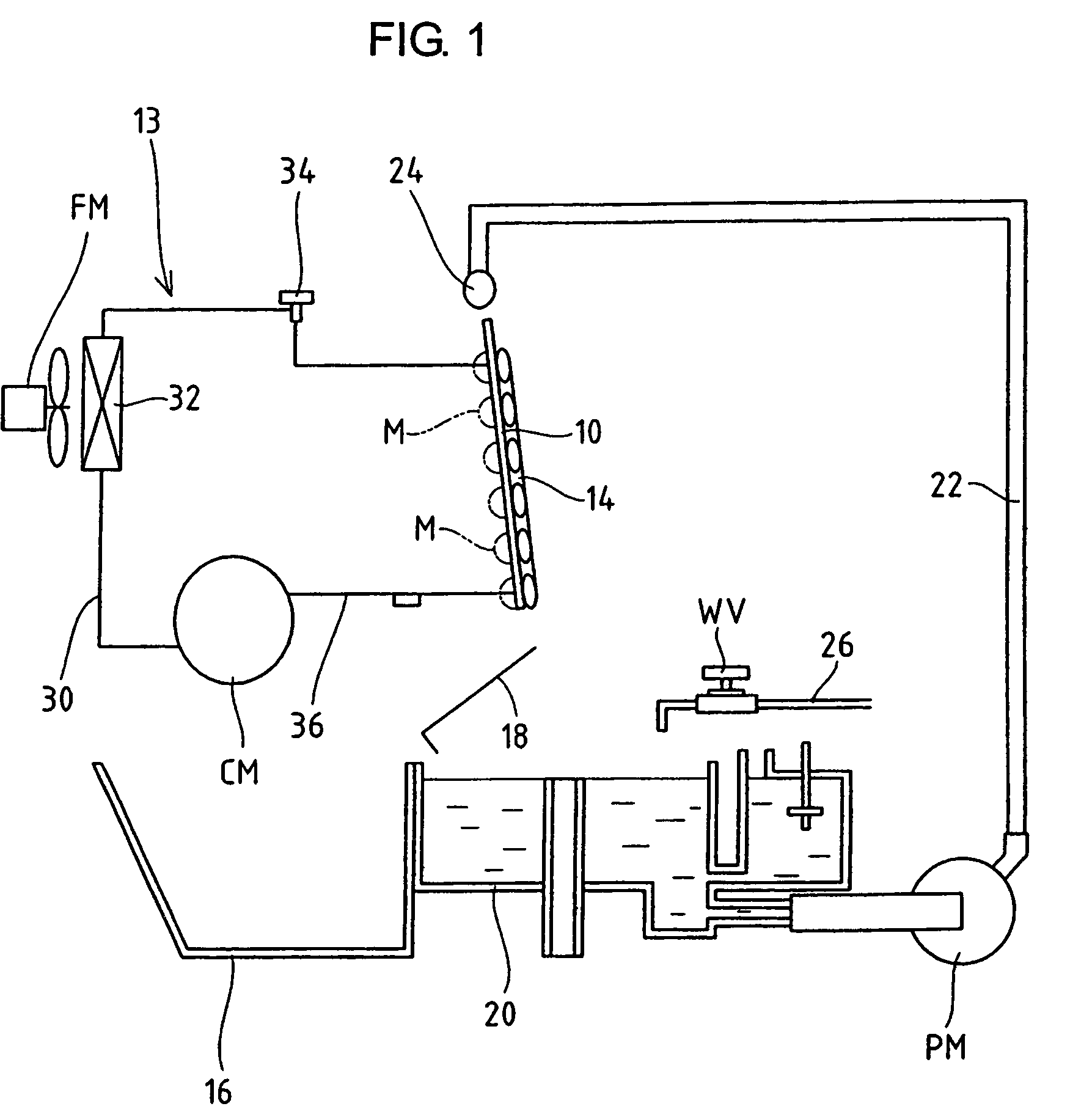

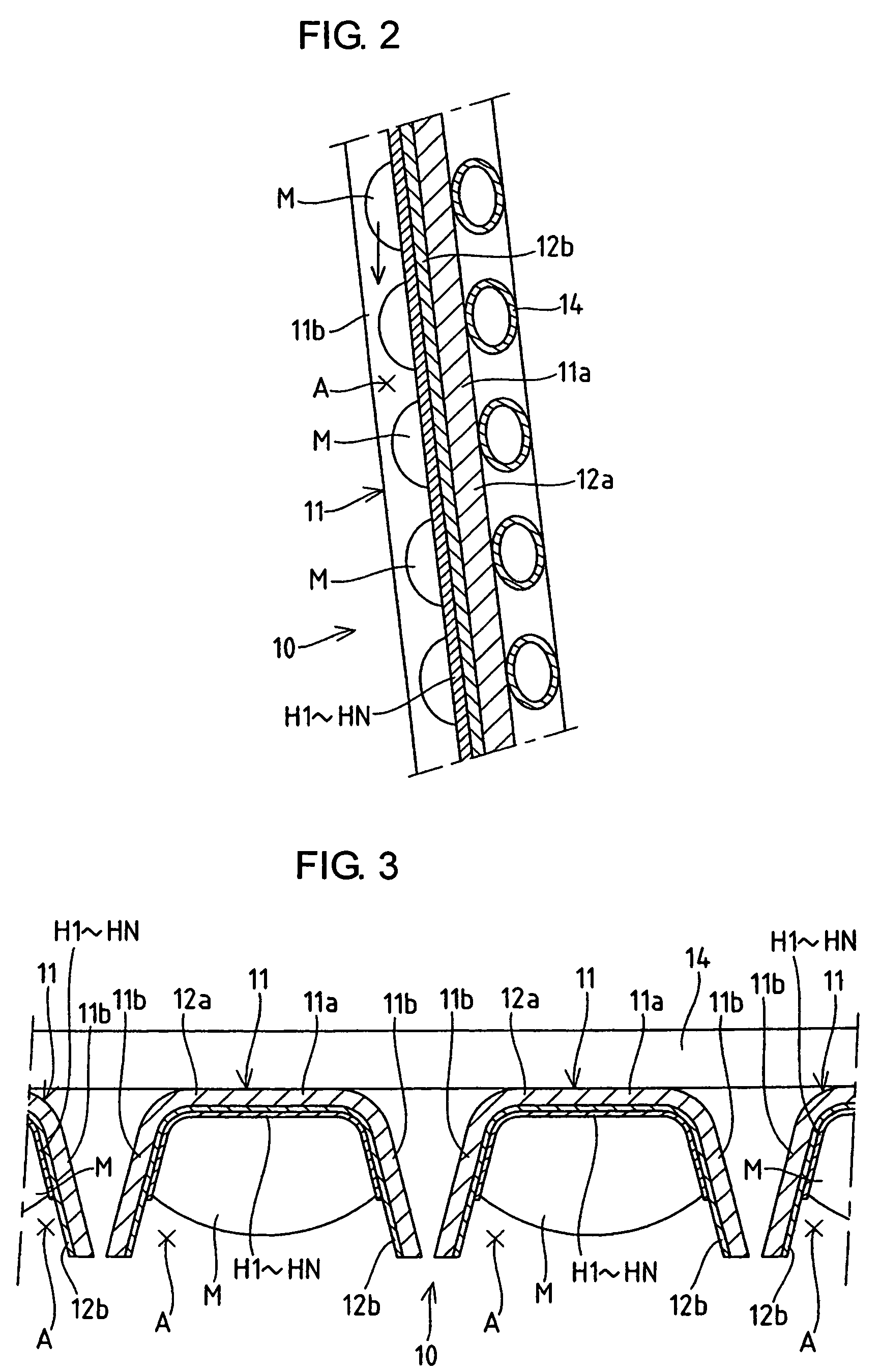

Automatic ice maker

ActiveUS20060288726A1No decrease in ice making efficiencyGuaranteed uptimeLighting and heating apparatusIce productionEvaporationEngineering

The peel off between an ice making plate and an insulating layer or between the insulating layer and heating means is prevented so that an ice making operation can be performed efficiently. Also, a metal plate is insulated from the heating means reliably. An evaporation pipe 14 and electric heaters H1 to HN are provided in an ice making member 11. A coolant is circulatingly supplied through the evaporation pipe 14 so as to cool the ice making member 11 and ice making water is supplied to the ice making member 11 so as to form an ice block M during the ice making operation. During the deicing operation, heat is generated in the heaters H1 to HN by applying current so that the ice block M is removed from the ice making member 11 by melting. The ice making member 11, in a state that an insulating layer 12b lies between a metal plate 12a to which the evaporation pipe 14 is fixed and the heaters H1 to HN, is formed by bonding the metal plate 12a with the insulating layer 12b, and the insulating layer 12b with each of the heaters H1 to HN by thermocompression. Also, in addition to thermocompression bonding, the external outline of the heating means (H1 to HN) may be located inside the insulating layer 12b.

Owner:HOSHIZAKI ELECTRIC CO LTD

Thermo-compression bonded electrical interconnect structure and method

InactiveUS20090075469A1Simple structureSimple methodFinal product manufactureSemiconductor/solid-state device detailsMetalElectrical interconnect

An electrical structure and method for forming electrical interconnects. The method includes positioning a sacrificial carrier substrate such that a first surface of a non-solder metallic core structure within the sacrificial carrier substrate is in contact with a first electrically conductive pad. The first surface is thermo-compression bonded to the first electrically conductive pad. The sacrificial carrier substrate is removed from the non-solder metallic core structure. A solder structure is formed on a second electrically conductive pad. The first substrate comprising the non-solder metallic core structure is positioned such that a second surface of the non-solder metallic core structure is in contact with the solder structure. The solder structure is heated to a temperature sufficient to cause the solder structure to melt and form an electrical and mechanical connection between the second surface of the non-solder metallic core structure and the second electrically conductive pad.

Owner:ULTRATECH INT INC

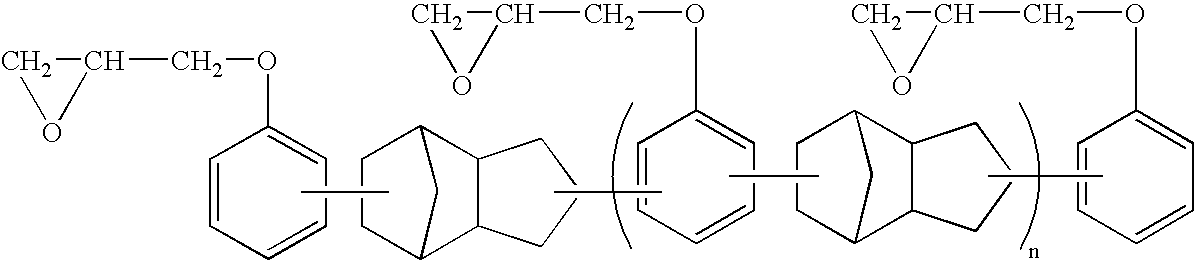

Adhesive tape

InactiveUS20040232563A1Improve abilitiesAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesEpoxyElastic modulus

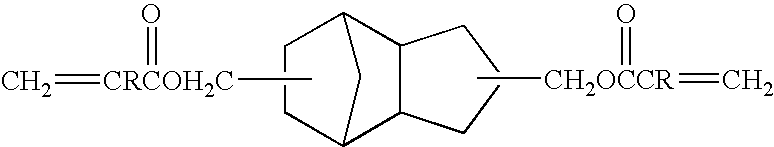

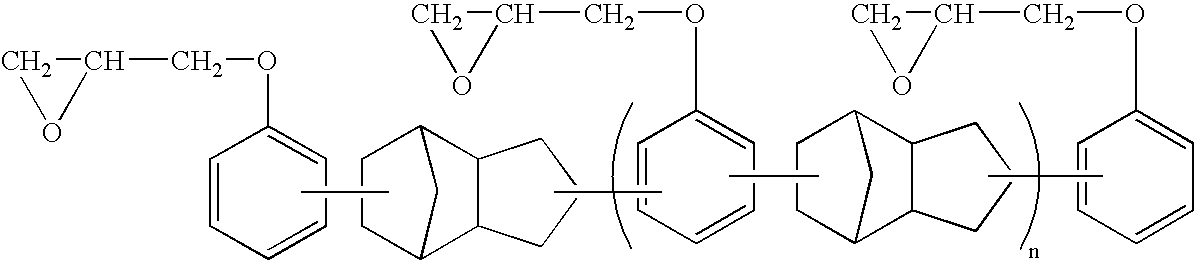

An adhesive tape comprising a base and, superimposed thereon, an adhesive layer, this adhesive layer comprising an adherent component (A), an epoxy resin (B), a thermally active latent epoxy resin curing agent (C), an energy radiation polymerizable compound (D) and a photopolymerization initiator (E), wherein either or both of the epoxy resin (B) and energy radiation polymerizable compound (D) have a dicyclopentadiene skeleton in its molecule or molecules thereof. The resultant adhesive tape has an adhesive layer which provides reduced water absorption of an adhesive curing product and which enables a lowering of the elastic modulus thereof during thermocompression bonding.

Owner:LINTEC CORP

Wafer-to-wafer oxide fusion bonding

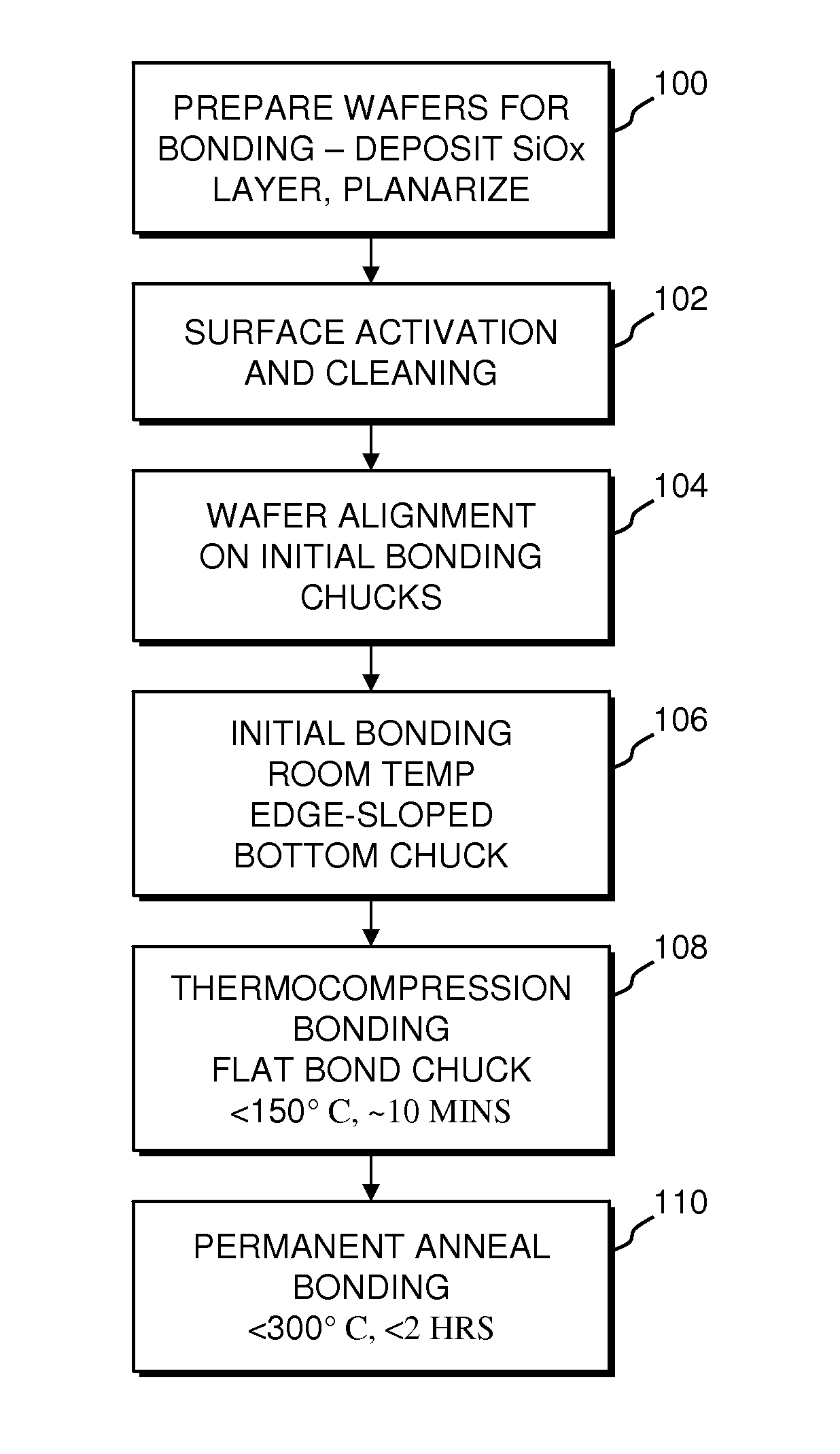

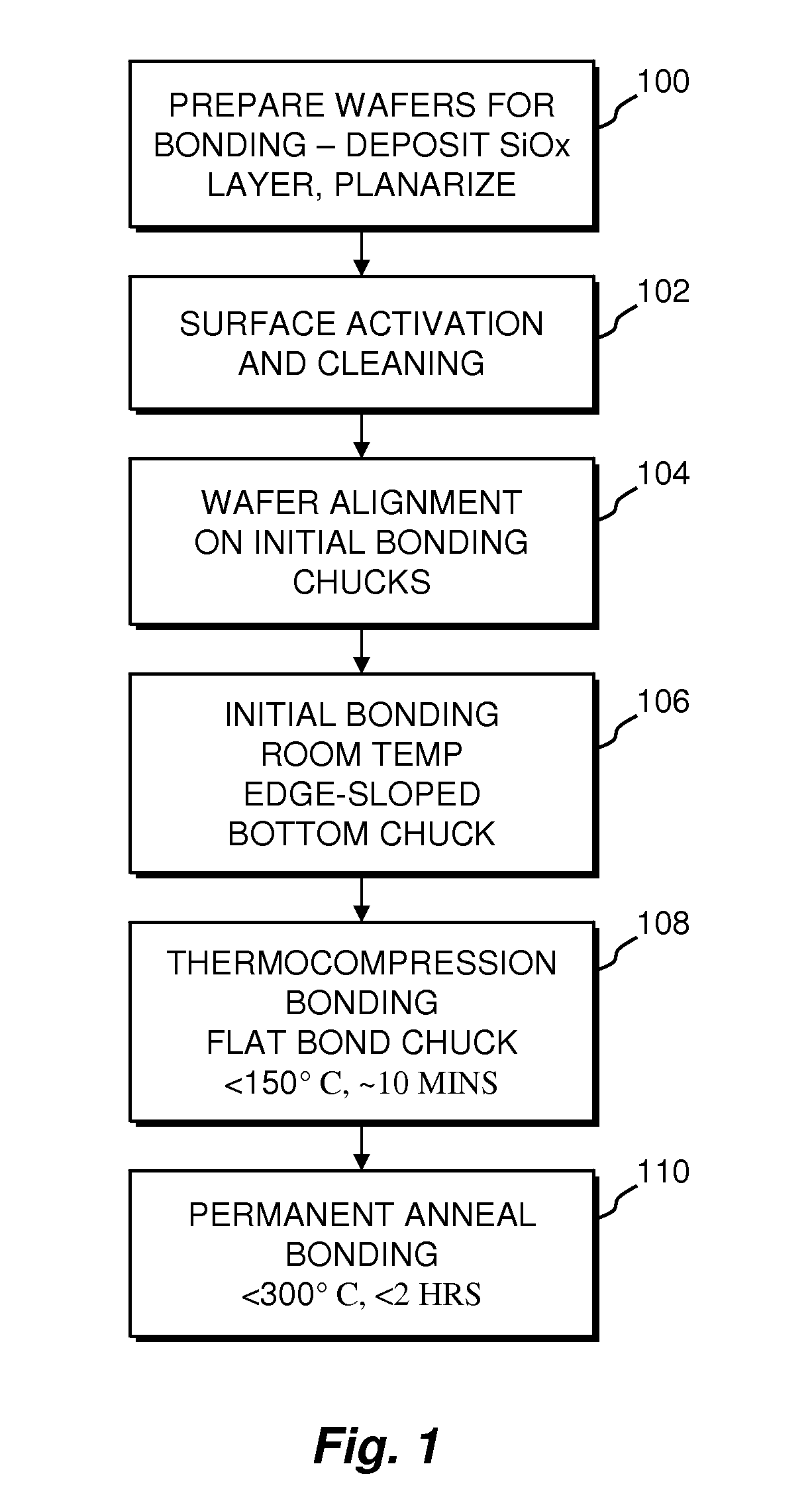

InactiveUS20140261960A1Reduce pressureEliminate gapsLamination ancillary operationsLaminationAtmospheric airThermal compression

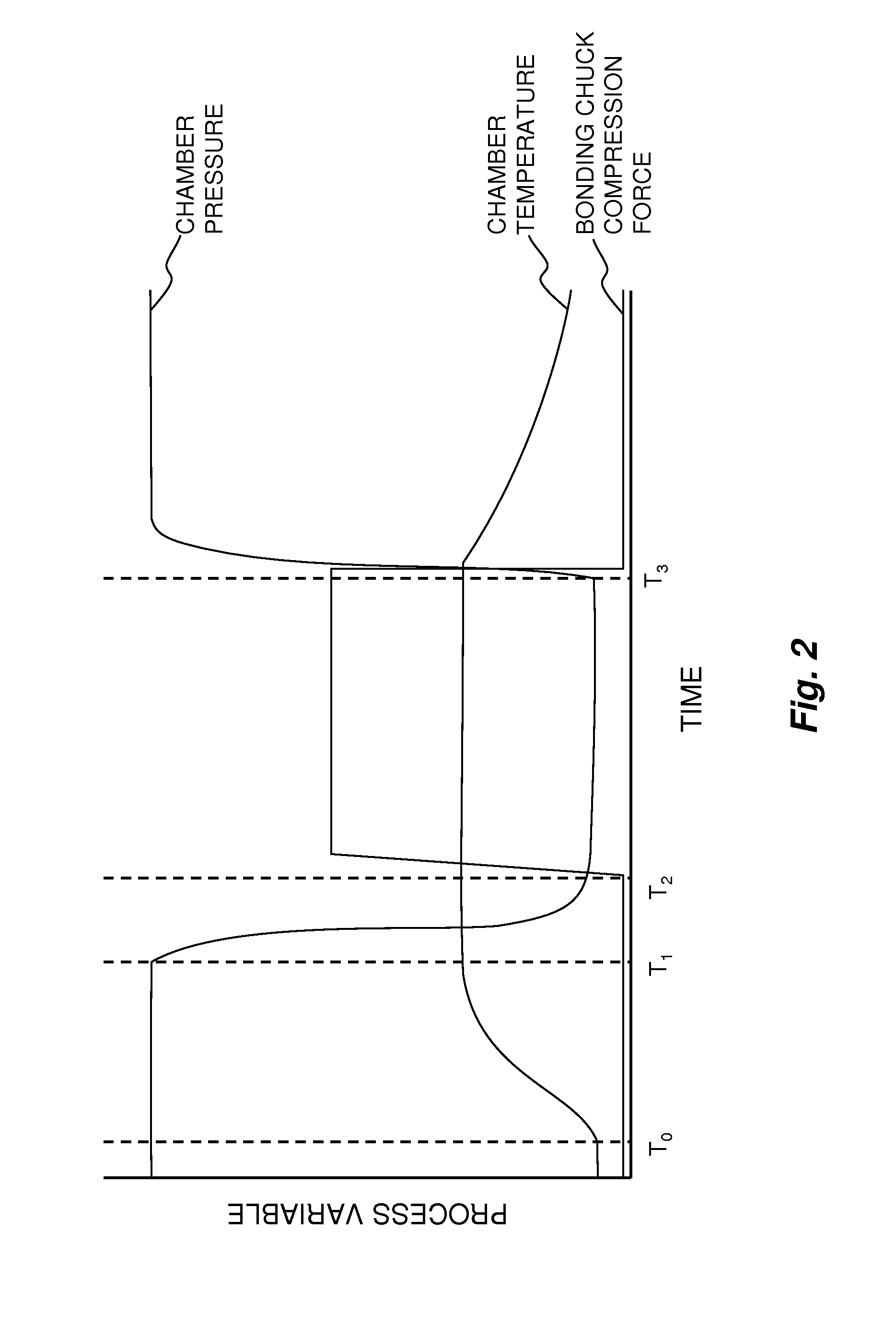

Oxide-oxide fusion bonding of wafers that includes performing a van der Waals force bonding process with a chuck having at least a flat central zone and an outer annular zone lower than the central zone, an edge portion of a mounted wafer is biased towards the outer annular zone. The van der Waals bonding wave is disrupted at the outer annular zone, causing an edge gap. A thermocompression bonding process is performed that includes heating the bonded wafers to a temperature sufficient to initiate condensation of silanol groups between the bonding surfaces, reducing the atmospheric pressure to cause degassing from between the wafers, applying a compression force to the wafers with flat chucks so as to substantially eliminate the edge gap, and performing a permanent anneal bonding process.

Owner:IBM CORP

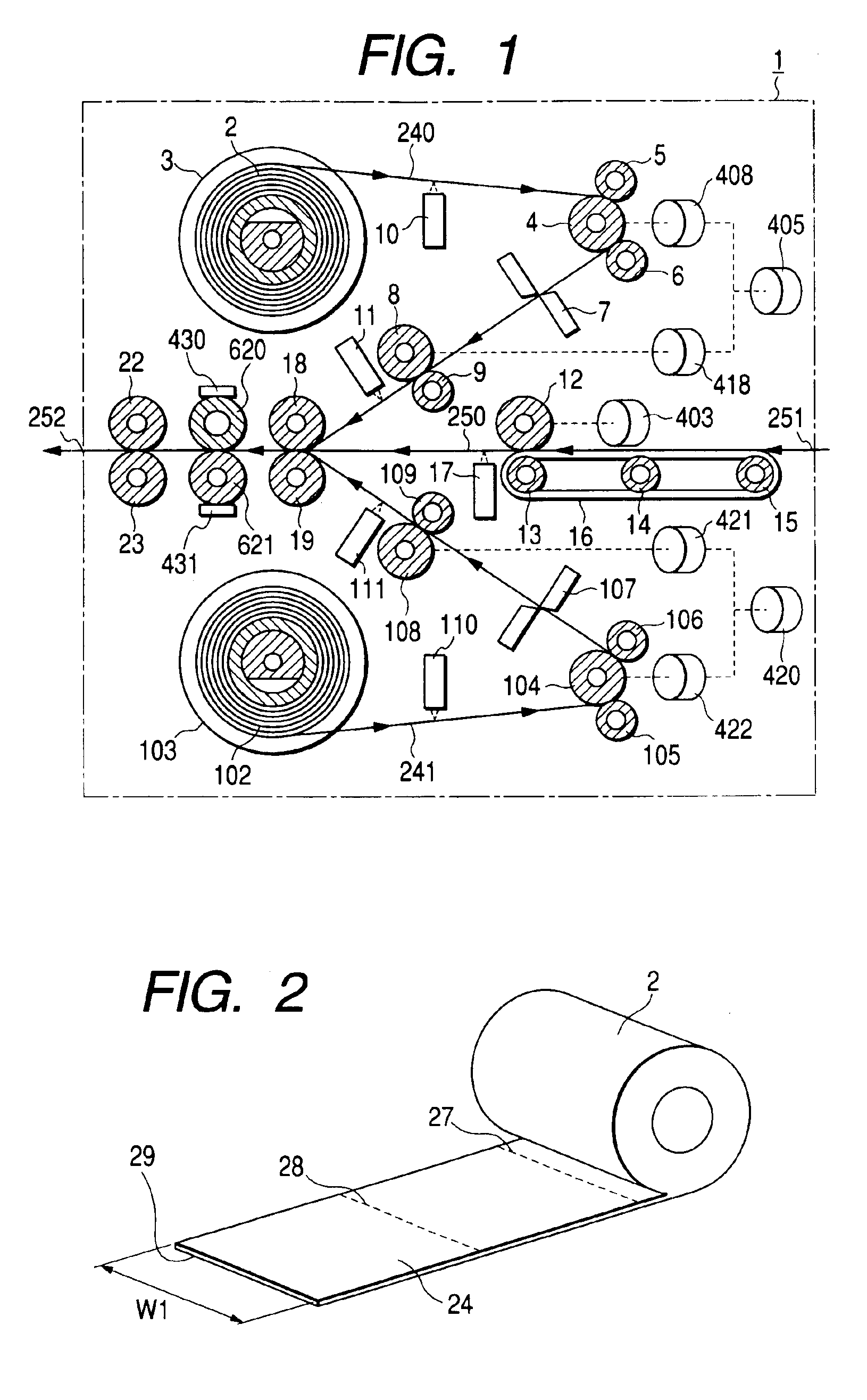

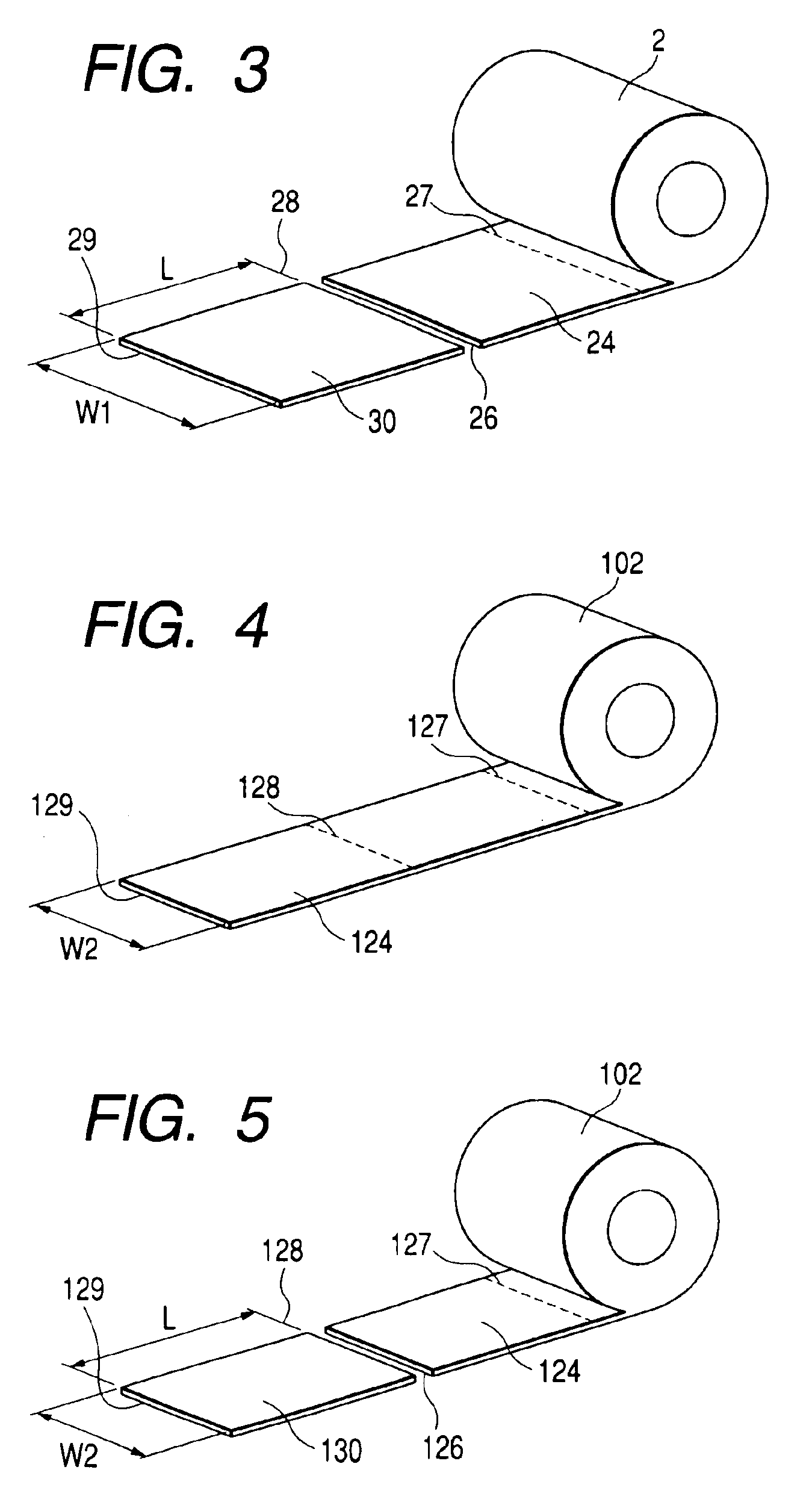

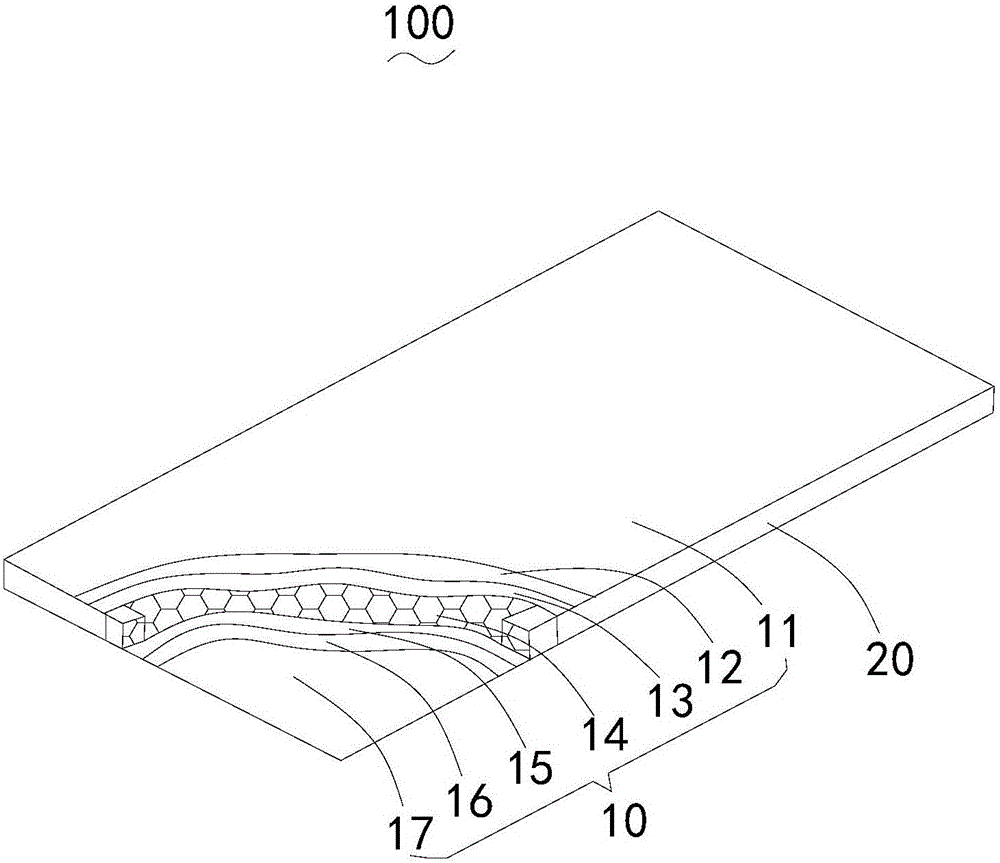

Solar cell module and method for manufacturing the same

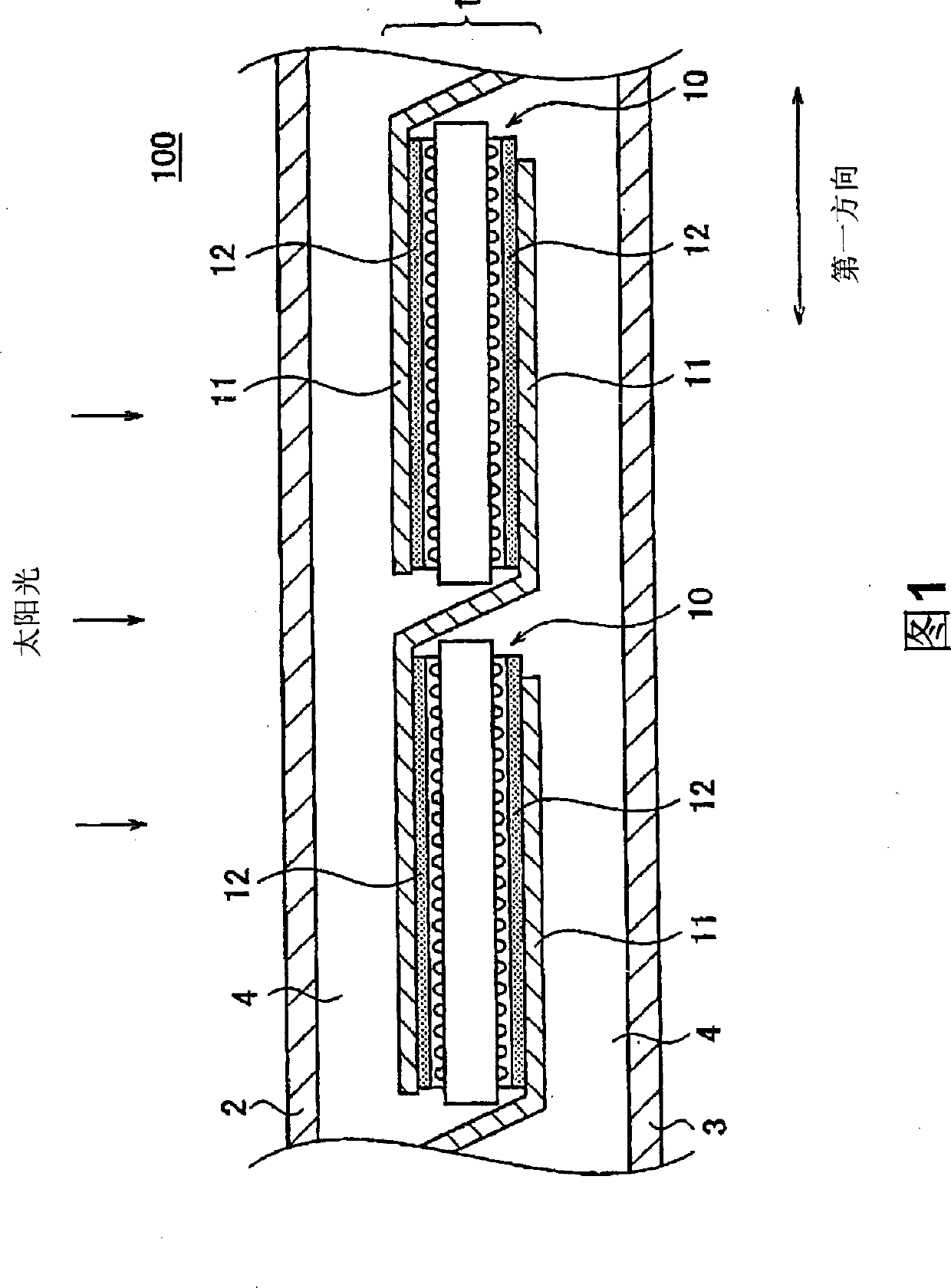

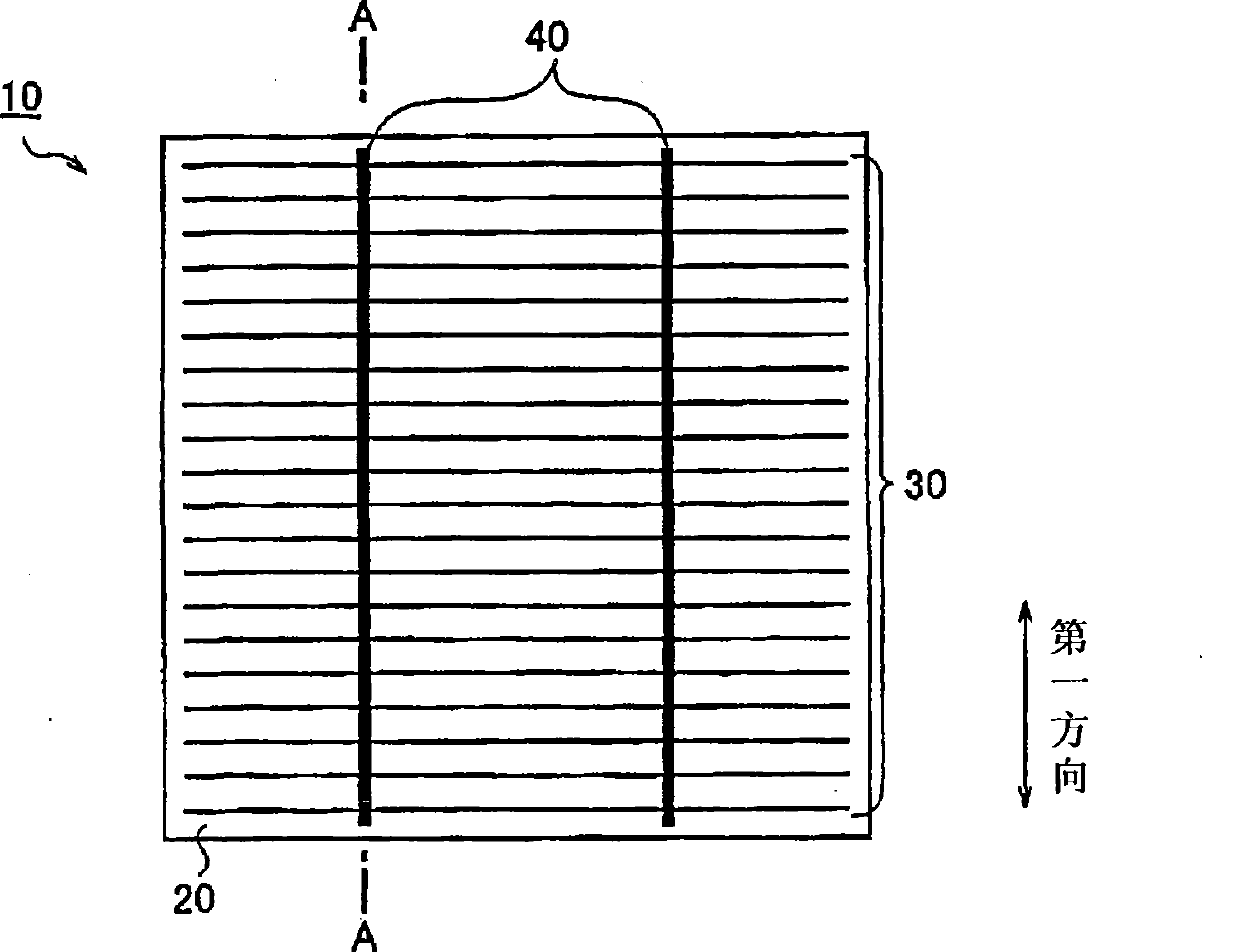

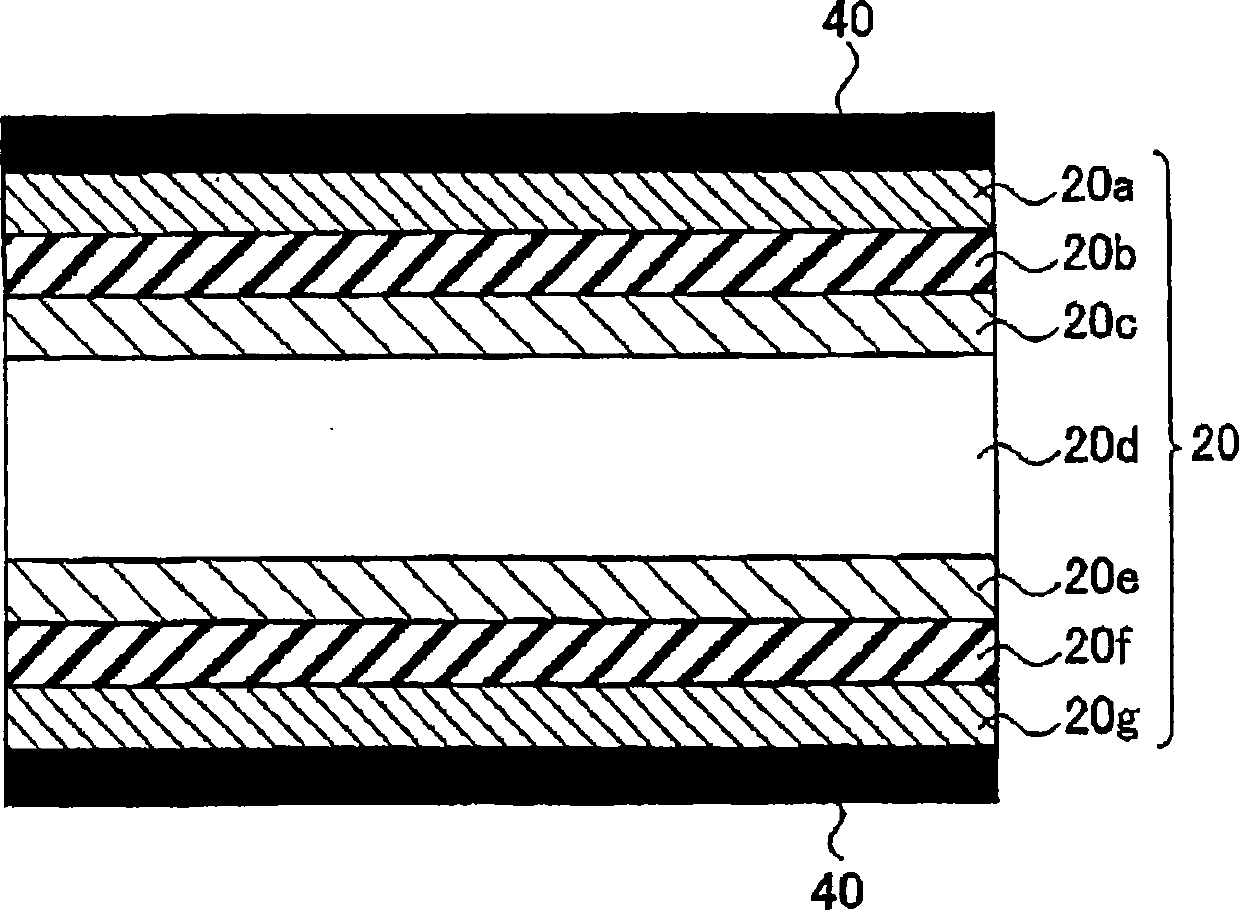

ActiveCN101373796AImprove collection efficiencyGood adhesionFinal product manufacturePhotovoltaic energy generationBonding processResin adhesive

The invention provides a cell solar module and method for manufacturing the same. On the cross-section surface approximately orthogonal to the first direction, the peripheral of the wiring member 11 faces to the connecting electrode 40 to form as a convex. With the method for manufacturing the solar cell module 100 according to the present embodiment, the width W1 of the connection region C in which the wiring member 11 and the connecting electrode 40 are electrically connected is set to be larger than the substantially half of the width W2 of the wiring member 11 in the thermocompression bonding process of the wiring member 11 using the resin adhesive 12 including the particles 13 onto the principal surface of the solar cell 10.

Owner:SANYO ELECTRIC CO LTD

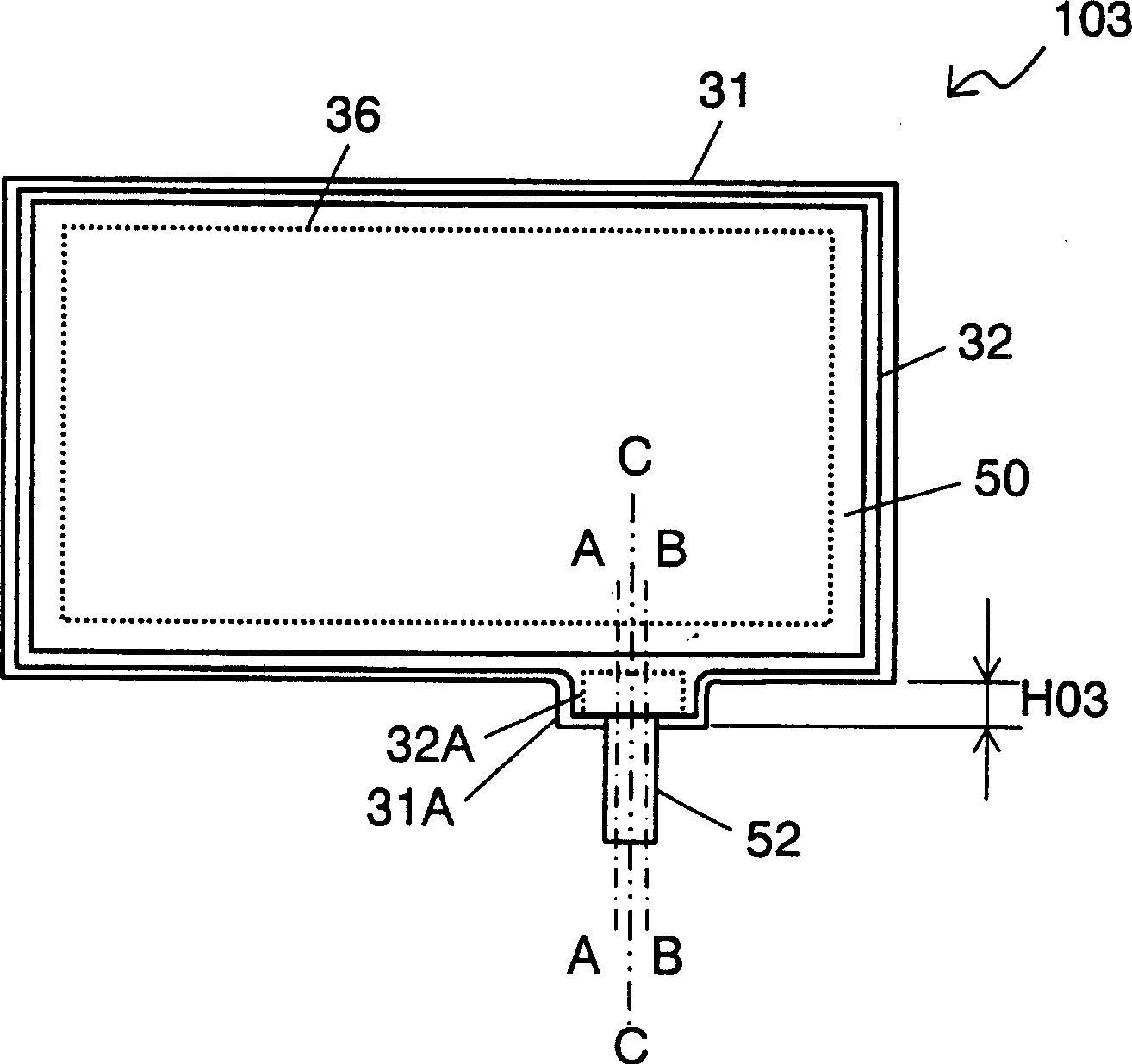

Touch panel and liquid crystal display apparatus using the same

InactiveCN1614624AInput/output for user-computer interactionPrinted circuit assemblingLiquid-crystal displayElectrical connection

The present invention provides a touch panel, which is constituted by providing a protruding part (32A) on a second transparent substrate (32), bonding a flexible wiring board (45) to the protruding part (32A) by thermocompression, and In the parts other than the part (32A), the size and weight of the equipment to be mounted are realized by narrowing the width of the frame edge. In addition, by sticking a sheet-like member such as a polarizing plate (50) to the upper surface portion of the second transparent substrate (32) except the area of the protruding portion (32A), the action from the sheet-like member to the FPC (52) is alleviated. Stress on the bonded portion is applied to improve the electrical connection stability of the FPC (52).

Owner:PANASONIC CORP

Three-dimensional integrated method of sensor array and signal processing circuits

InactiveCN102689874ARealize floatingSimplify the manufacturing processDecorative surface effectsChemical vapor deposition coatingSensor arraySignal processing circuits

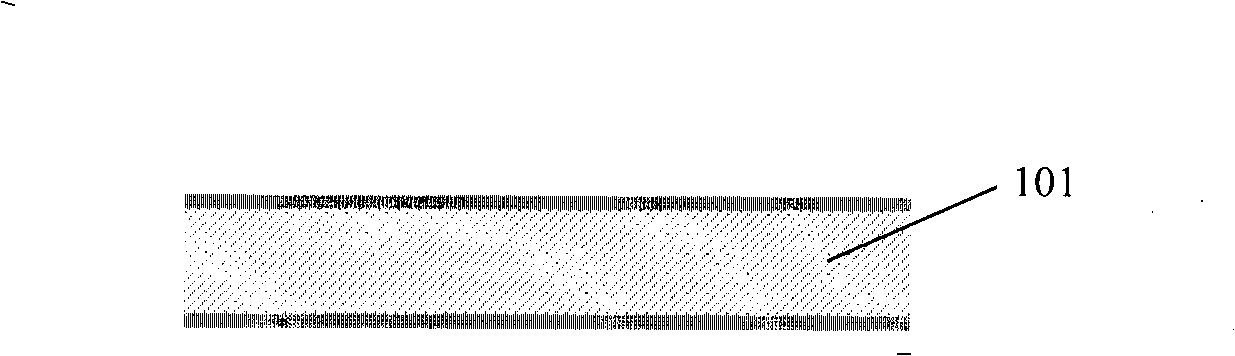

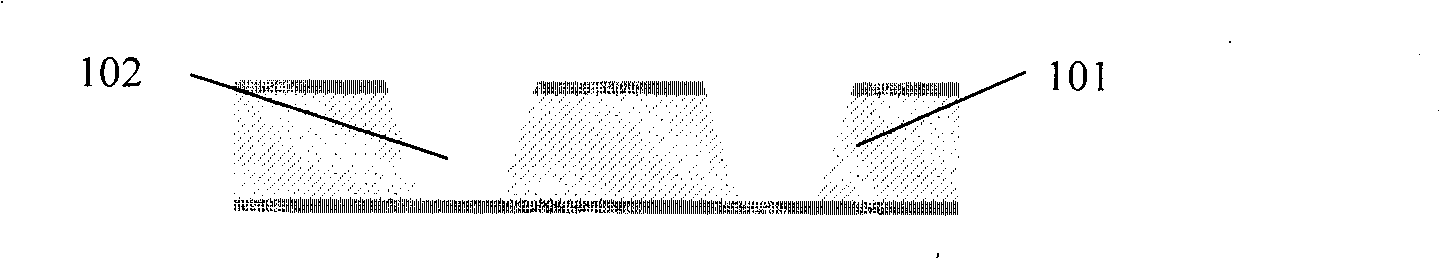

The invention discloses a three-dimensional integrated method of a sensor array and signal processing circuits in the technical field of semiconductor three-dimensional integration. The three-dimensional integrated method comprises the following steps of: (1) manufacturing sensors on a top layer single crystal material of an insulating substrate device; (2) manufacturing the signal processing circuits and metal interconnection lines on the surface of a signal processing circuit substrate and manufacturing metal salient points on the metal interconnection lines; (3) carrying out a bonding process or a three-dimensional interconnection process; (4) carrying out metal thermocompression bonding on bonding metal salient points and the salient points; (5) removing a temporary bonding polymer layer and auxiliary wafers; and (6) manufacturing plane interconnection lines. By utilizing the three-dimensional integrated method, integration of the sensors and the signal processing circuits is realized, hovering of the sensors is realized, electric signal connection of the sensors and the signal processing circuits is realized by utilizing three-dimensional interconnection lines, the manufacture process is simple, the sensors can be suspended, and excellent consistency of the sensors and large-scale array structure can be obtained.

Owner:TSINGHUA UNIV

Processing method of ultra-thin core board in manufacturing of printed circuit board or integrated circuit package substrate

ActiveCN101541145ALow costIncrease productivitySemiconductor/solid-state device manufacturingMultilayer circuit manufactureElectrical conductorEngineering

A processing method of thin core board in manufacturing of printed circuit board or integrated circuit package substrate comprises the followings: copper foil and bonding sheet, two core boards are used for laminating and thermocompression bonding to obtain a processing board with periphery being bonded, and the thickness and strength thereof can satisfy the processing requirements of conventional devices; pattern conversion processing is carried out on the bonded processing board; laminating method is carried out on newly formed conductor line pattern surface, insulating medium and conductor line are formed through laminating, laser beam drilling, plating and pattern conversion technology; the previous processes are repeated to form multilayer processing boards; when two sides of multilayer processing boards reaches certain thickness and strength, the multilayer processing boards are incised at the bonding joint to form two processing boards; conventional laminating, drilling, plating and pattern conversion technologies are adopted to process the two processing boards respectively until the manufacturing of the needed circuit board and package substrate is finished. The invention needs no special device or processing tool to process thin core board, thus greatly reducing cost and improving productivity and yield of the product.

Owner:SHANGHAI MEADVILLE SCI & TECH

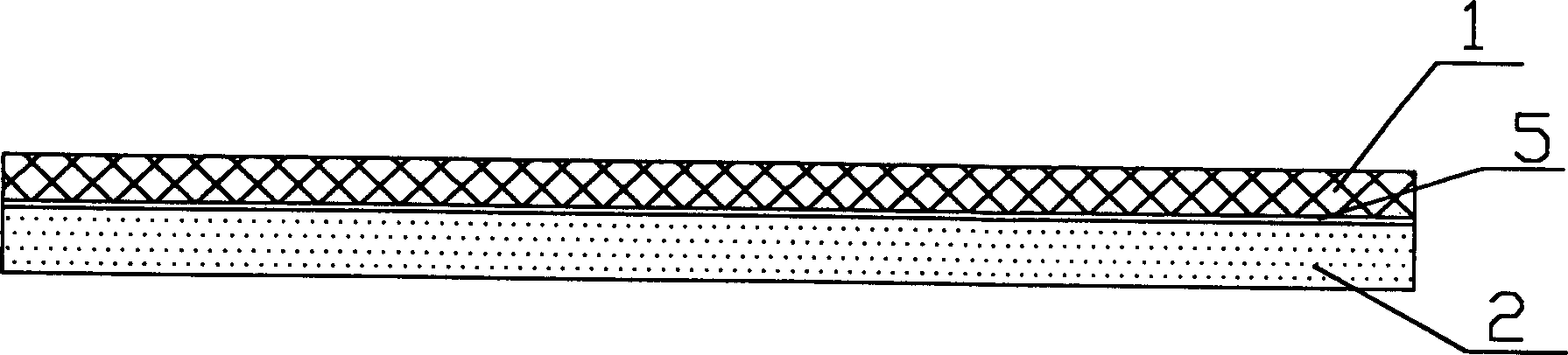

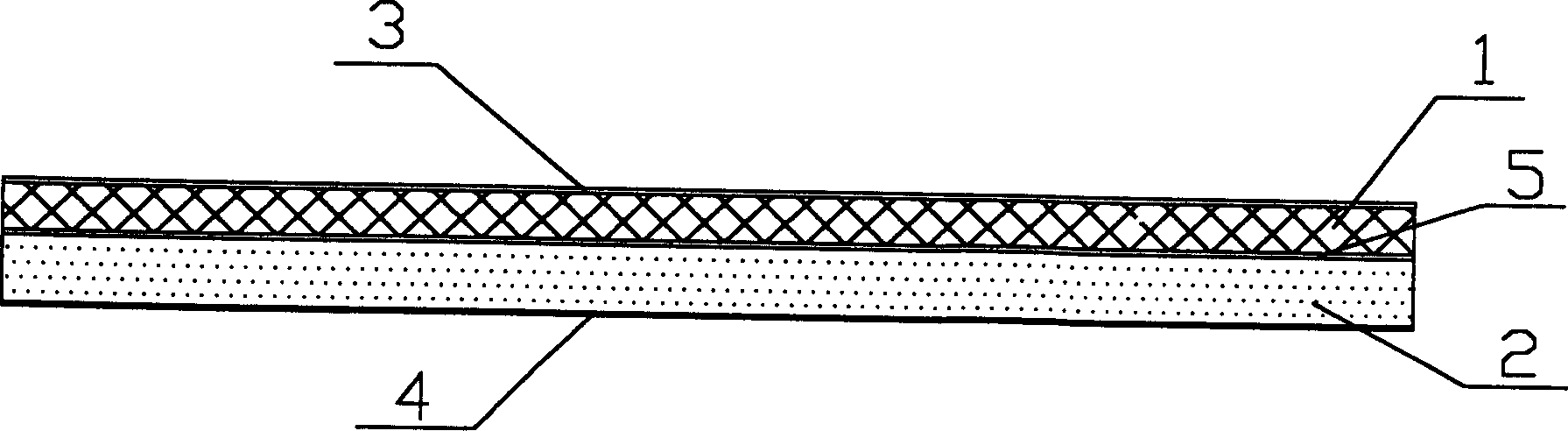

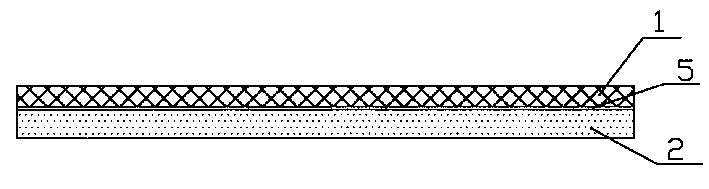

Plastic composite sheet and its producing method

InactiveCN1457981AGood adhesionGood matting effectSynthetic resin layered productsInter layerEngineering

The composite plastic sheet includes facing layer, middle layer and base layer, the facing layer is made of PVC, modified PP or modified PE; the middle layer is made of PVA film or polyurethane thermosol film; and the base layer is made of foamed PVC, modified PP or modified PE. Over the facing layer, there is one layer of coated dulling agent with pressed pattern. The composite plastic sheet has good comprehensive performance and its adhering middle layer combines the facing layer and the base layer well. The composite plastic sheet has the advantages of excellent heat insulating and sound isolating performance, high shock resistance, high anticorrosive performance, high electric insulating performance, high strength, beautiful appearance and easy cleaning.

Owner:长春一塑汽车内饰材料有限公司

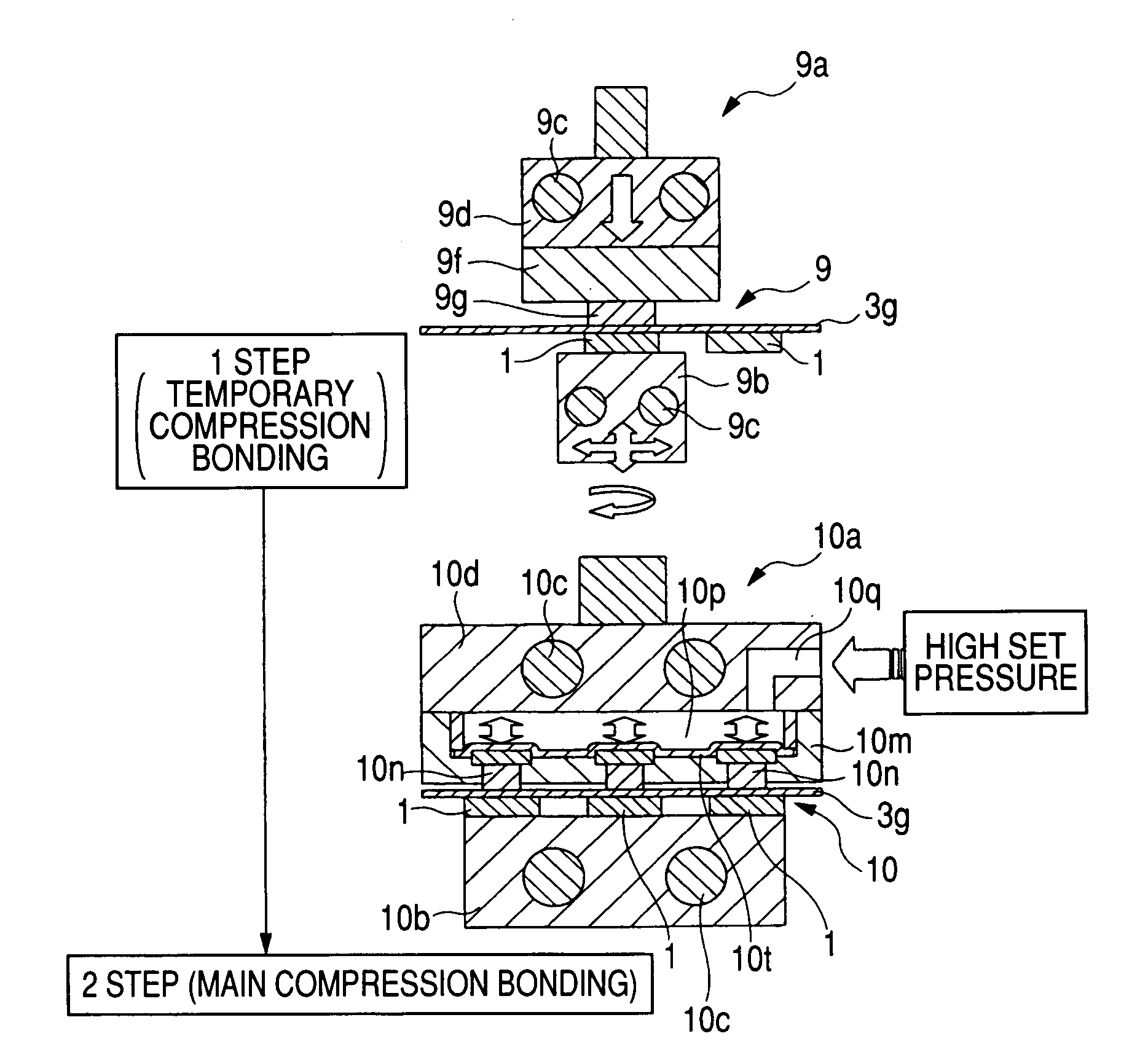

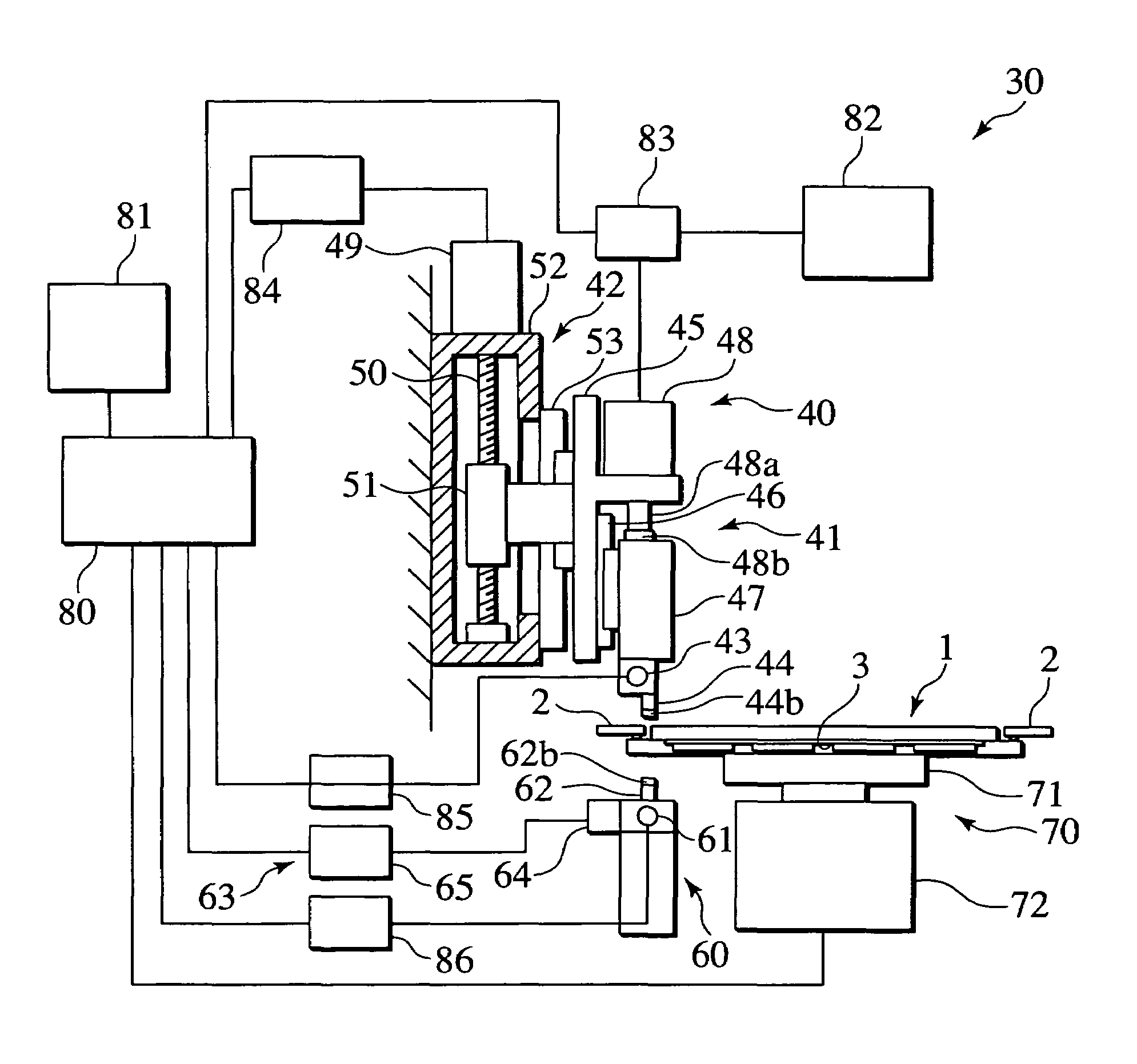

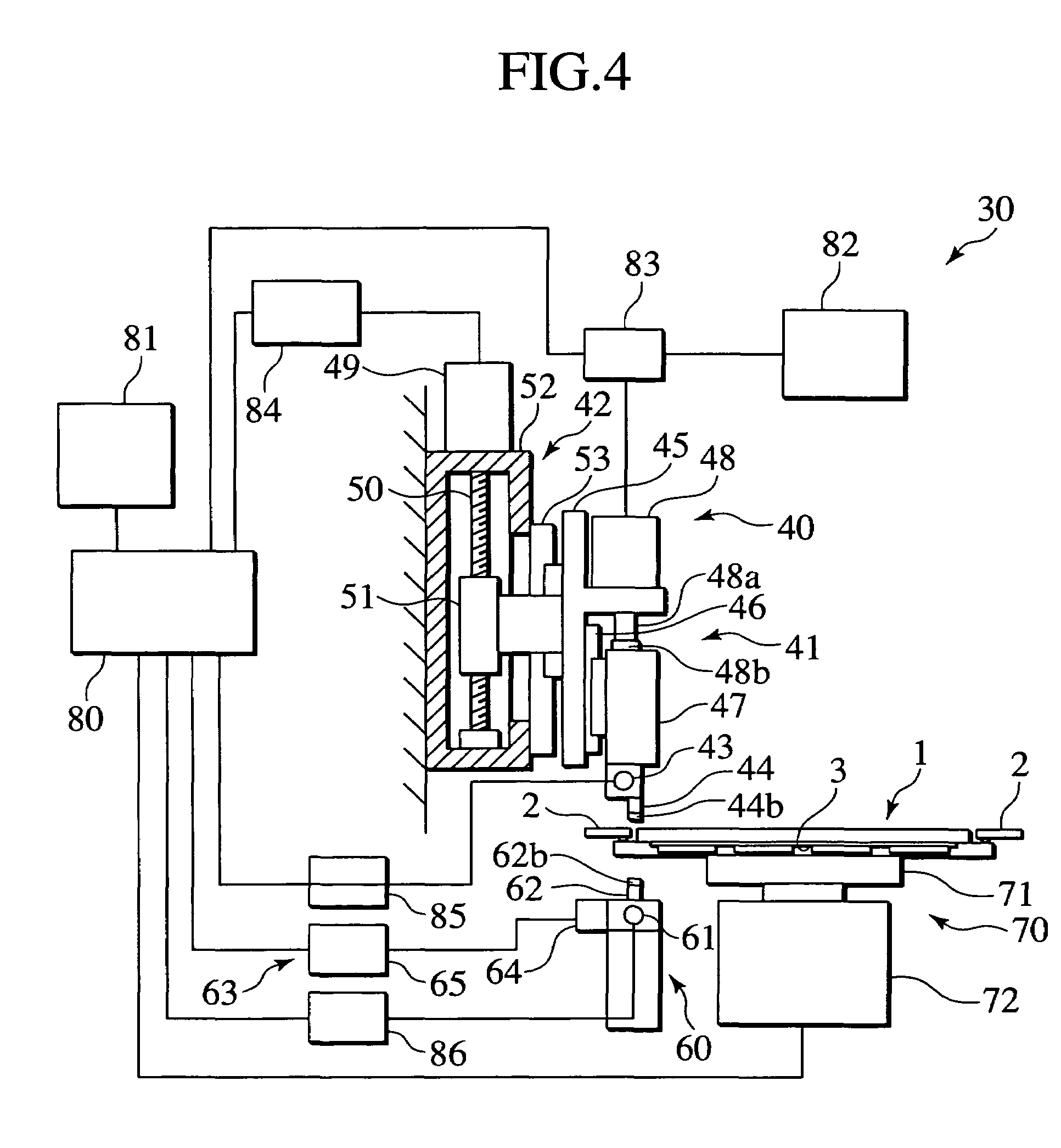

Electronic part compression bonding apparatus and method

InactiveUS7075036B2Easy to controlPrevent bad connectionSemiconductor/solid-state device manufacturingOhmic-resistance heating detailsTemperature controlEngineering

An electronic part compression bonding apparatus includes a compression bonding unit which bonds the electronic parts onto the substrate by thermocompression, a pressure supply unit, a pressure control unit which controls pressure, a heating unit which heats the compression bonding unit, a temperature control unit, and a thermocompression bonding control unit which controls the pressure control unit and the heating unit based on thermocompression bonding condition data in which at least one of pressure and heating temperature is variably set during a process from start until completion of a thermocompression bonding operation of the electronic parts. In the thermocompression bonding condition data, the pressure is set to a first pressure in a first stage in a process of the thermocompression bonding operation and a second pressure, which is lower than the first pressure, in a second stage that follows the first stage.

Owner:SHIBAURA MECHATRONICS CORP

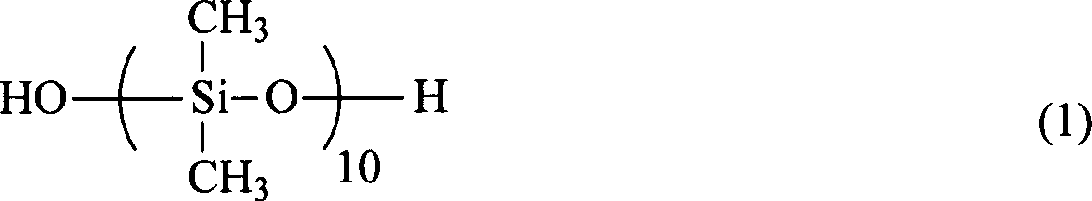

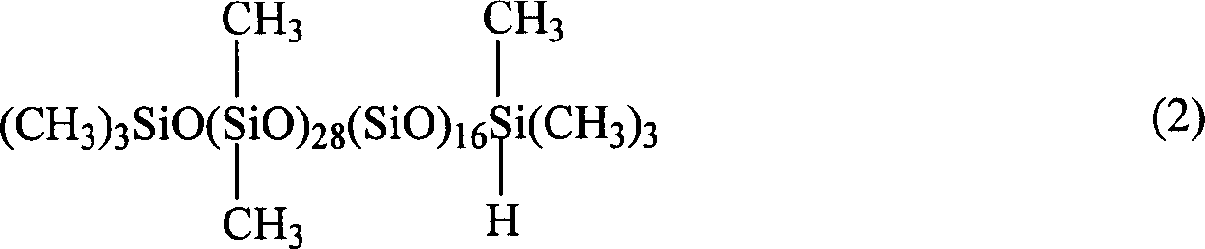

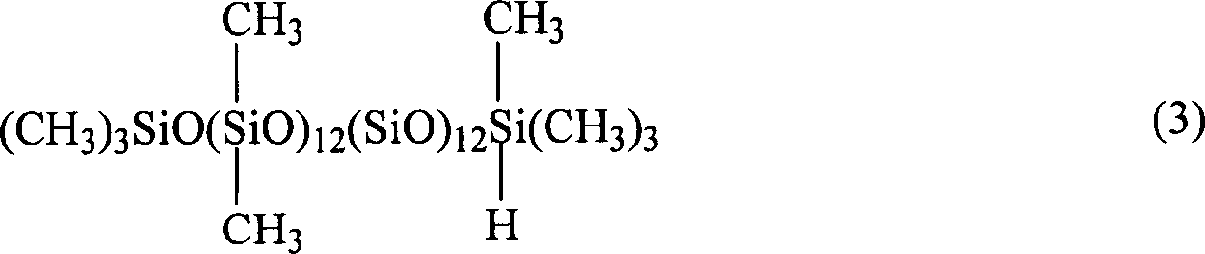

Thermal pressed silicon rubber sheets and manufacture thereof

InactiveCN1680506AAvoid bondingLow costFilm/foil adhesivesSynthetic resin layered productsDusting powdersSilicon dioxide

The invention provides a silicone rubber sheet for thermocompression bonding which does not stick the periphery without dusting powder, does not adhere to an anisotropic electrically conductive adhesive, is excellent in surface releasing properties and durability, is provided with flexibility, and is inexpensive, and to provide a method for manufacturing the same. The silicone rubber sheet for thermocompression bonding is manufactured by providing the second silicone rubber layer prepared by molding and curing a composition comprising (F) an organopolysiloxane, (G) a silicone powder, preferably, (H) a carbon black with a volatile content of <=0.5 mass% or (I) a fine powder silica with a specific surface area of >=50 m2 / g, and (J) a curing agent, on one face or both faces of the first silicone rubber layer prepared by molding and curing a composition comprising (A) an organopolysiloxane with an average degree of polymerization of >=200, (B) a carbon black with a volatile content of <=0.5 mass%, (C) a fine powder silica with a specific surface area of >=50 m2 / g, (D) one or more selected from metals, metal oxides, metal nitrides, or metal carbides, and (E) a curing agent.

Owner:SHIN ETSU CHEM IND CO LTD

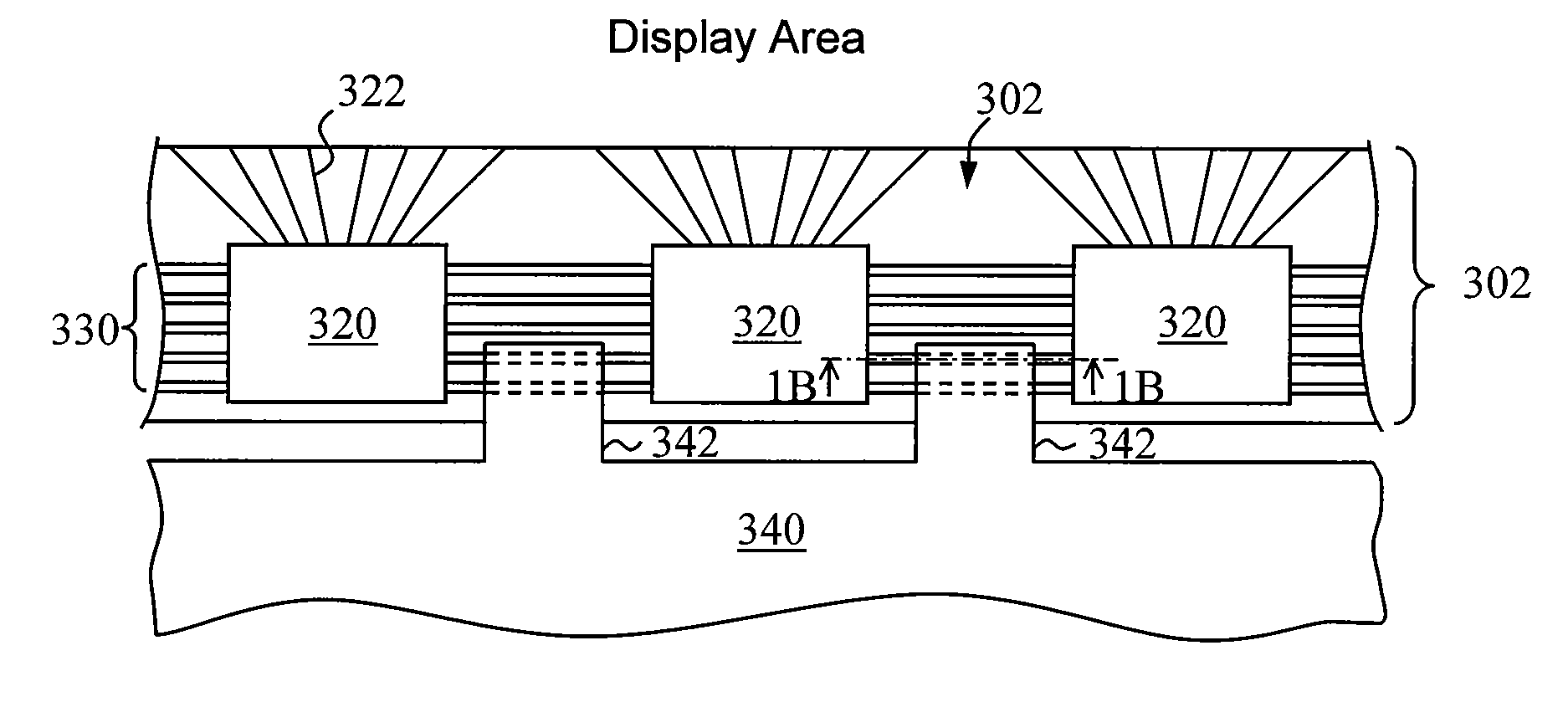

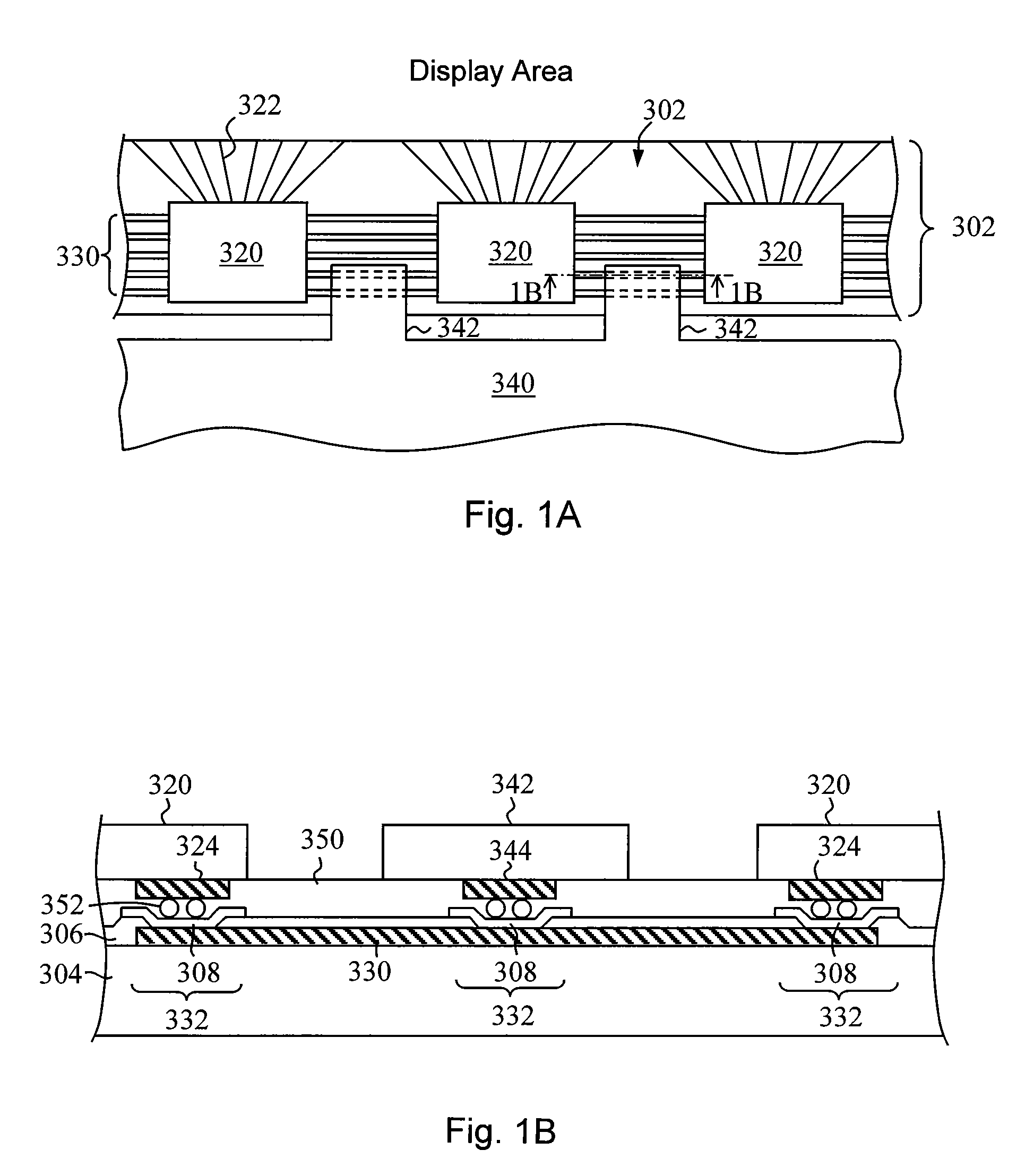

Flat display panel and assembly process or driver components in flat display panel

ActiveUS7515240B2Low costShorten the timePrinted circuit assemblingStatic indicating devicesAnisotropic conductive filmElectricity

A flat display panel comprises a plurality of driver ICs and one or more flexible printed circuit, a plurality of common wires formed on the substrate to electrically connect the ICs to the one or more flexible printed circuit, and at least one anisotropic conductive film that connects respective connecting terminals of the driver ICs and flexible printed circuit to terminals pads of the common wires. The anisotropic conductive film is laminated over the substrate to cover the terminal pads. The driver ICs and flexible printed circuit are aligned and attached on the anisotropic conductive layer by thermocompression bonding.

Owner:AU OPTRONICS CORP

Highly-oil-repellenting highly-waterproof seamless polytef expansion sheet materials and preparation method thereof

ActiveCN103158310AReduce weightCorrosion resistantSynthetic resin layered productsFlat articlesLubricationChemical stability

The invention belongs to the technical field of aerospace sealing materials, and particularly discloses highly-oil-repellenting highly-waterproof seamless polytef expansion sheet materials and a preparation method thereof. The preparation method comprises the following steps: mixing materials, performing, pushing and pressing, calendaring, drying, puffing, sizing, thermocompression bonding, surface chemical processing, and the like. The highly-oil-repellenting highly-waterproof seamless polytef expansion sheet materials which are prepared and obtained by the method have good chemical stability, electrical insulating property, and self-lubrication performance, overcome the cold flow property (creepage) of pure polytef sealing materials, cannot become hard or crisp ( good elasticity) with the time, can bear the temperature range of -65 DEG C - +177 DEG C, are applicable to flat seal of various shapes, and are indispensable and important materials in frontier science and modern industries.

Owner:HUZHOU SENNUO FLUORINE MATERIAL TECH

LCD device sensing structure

ActiveCN101236311AReduce the use effectReduce the number of thermocompression bondingStatic indicating devicesNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a sensing structure of a liquid crystal display, which comprises a first baseplate, a second baseplate, a sensing unit and a flexible printed circuit board. The sensing unit is arranged above the first baseplate and is suitable for producing a touch signal when the sensing unit is touched. The flexible printed circuit board is provided with a first end and a second end; the first end is provided with a first copulae and a second copulae, wherein, the first copulae is positioned above the first baseplate and is in electric connection with the sensing unit; the second copulae is connected to the second baseplate. The invention uses the same flexible printed circuit board to be in electric connection with the sensing unit, a chip and a signal processing system, thereby reducing the material use and the times for thermocompression bonding; if the invention is matched with a contact control unit integrated with the display for use, the whole thickness of the liquid crystal display can also be reduced further in order that the final product meets the development trend of the thin and light type of a flat panel display device.

Owner:AU OPTRONICS CORP

Double-side lamination system

InactiveUS6893521B2Reduce operating costsMinimize wasted materialMechanical working/deformationRecord carriersEngineeringElectrical and Electronics engineering

In a double-side lamination system having a thermocompression bonding device for laminating laminate films on both surfaces of a card by applying heat and pressure using a pair of heat rollers, a temperature measurement device for measuring temperatures of the heat rollers are provided, and whether the lamination system is in a double-side lamination mode in which laminations are carried out on both surfaces of the card, or in a single-side lamination mode in which lamination is carried out on one of the surfaces of the card, is automatically distinguished by comparing measured temperatures of the heat rollers at a predetermined time after turn-on of the power of the system with a predetermined reference temperature.

Owner:JAPAN SERVO CO LTD

Method for producing fiberboards by lignocelluloses as raw materials

InactiveCN102650108AEnvironmentally friendlyFunctionalWood working apparatusDomestic articlesCelluloseAdhesive

The invention provides a method for producing fiberboards by lignocelluloses as raw materials. The method comprises the steps as follows: degrading and transforming the lignocelluloses through the biological modification effect of special basidiomycetes; enabling the modified lignocelluloses to have a physical structure with stronger adhesion effect, and chemical properties; and carrying out compression of various density fiberboards on the modified lignocelluloses through a hot press process so as to prepare the density fiberboards free of chemical adhesives. An effective solution is provided for new material preparation, environmental protection and low-carbon economy. According to the method, the chemical adhesives are not added, the fiberboards do not need to be produced by the biological modification-thermocompression bonding process for the basidiomycetes of the added expensive laccases, and the problems of environmental pollution due to formaldehyde released by the chemical adhesives used in the conventional fiberboards, high cost due to treatment of the directly added laccases on the lignocelluloses, or the like is effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

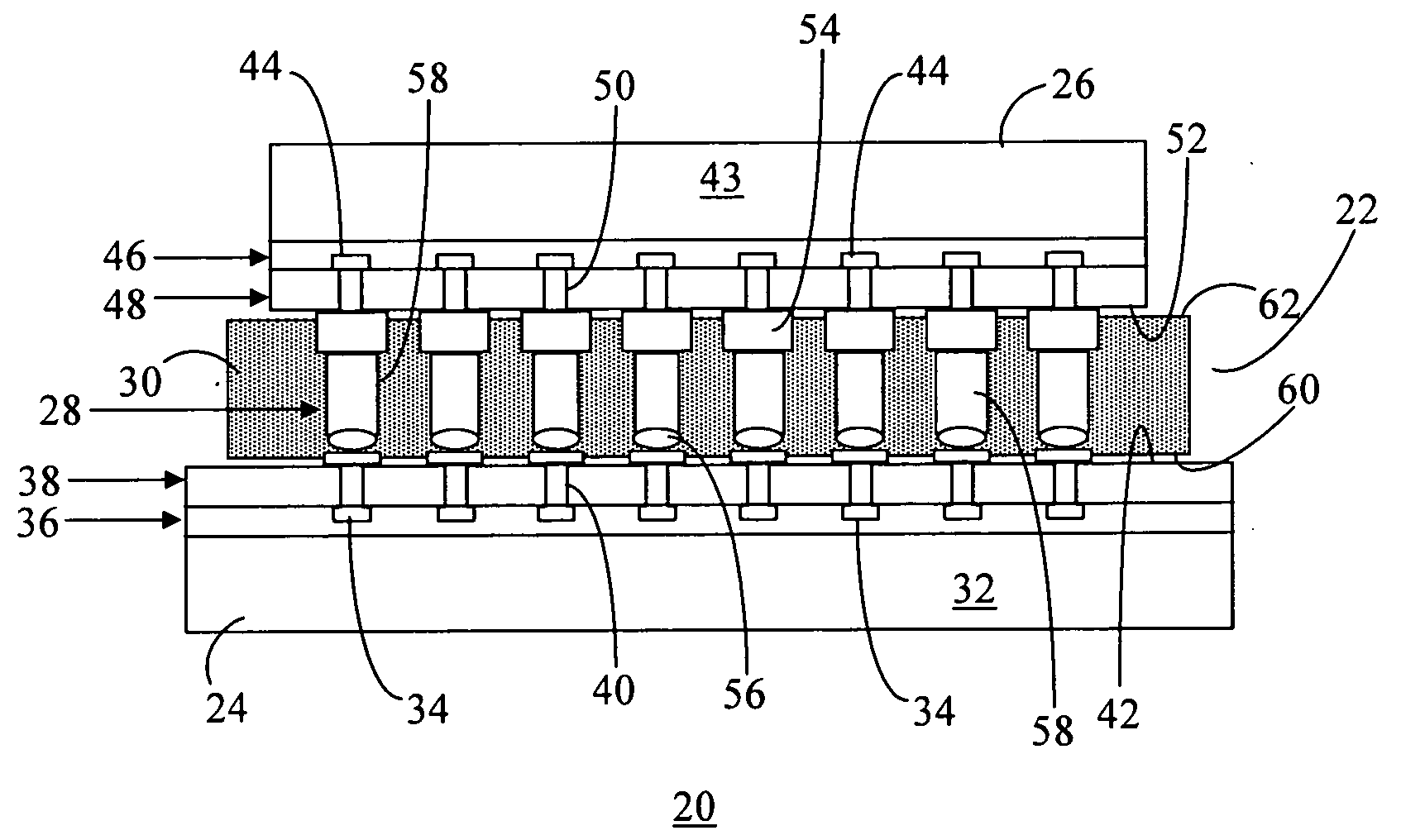

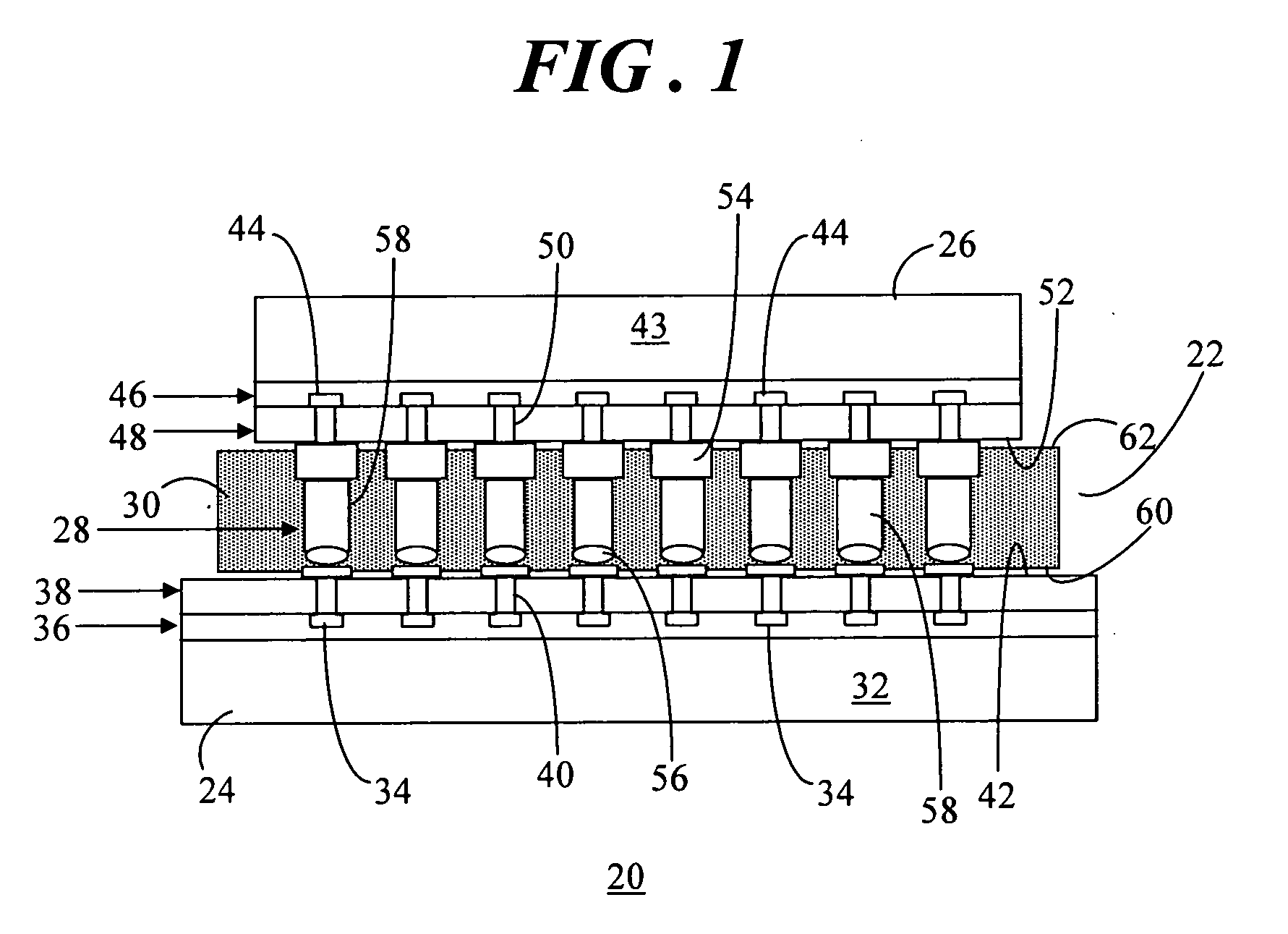

Stacked device assembly with integrated coil and method of forming same

InactiveUS20100225434A1Line/current collector detailsSemiconductor/solid-state device detailsElectrical connectionEngineering

A stacked semiconductor device assembly (20) includes a device (24) having conductive traces (34) formed therein, and conductive interconnects (28) electrically connected to the conductive traces (34). Another device (26) has conductive traces (44) formed therein and device pads (54) formed on an outer surface (52) of the device (26). A method (120) entails attaching (84) a magnetic core (30) to an outer surface (42) of the device (24) and forming (92) the conductive interconnects (28) on the outer surface (42) using a stud bumping technique such that the interconnects (28) surround the magnetic core (30). The conductive interconnects (28) are coupled (126) with the device pads (54) using thermocompression bonding to couple the device (26) with the device (24) to form a continuous device coil (22) wrapped around the magnetic core (30) from an alternating electrical connection of the traces (34), the conductive interconnects (28), and the traces (44).

Owner:TAIWAN SEMICON MFG CO LTD

Automatic ice making machine

ActiveUS7444829B2No decrease in ice making efficiencyGuaranteed uptimeLighting and heating apparatusIce productionEvaporationEngineering

The peel off between an ice making plate and an insulating layer or between the insulating layer and heating means is prevented so that an ice making operation can be performed efficiently. Also, a metal plate is insulated from the heating means reliably.An evaporation pipe 14 and electric heaters H1 to HN are provided in an ice making member 11. A coolant is circulatingly supplied through the evaporation pipe 14 so as to cool the ice making member 11 and ice making water is supplied to the ice making member 11 so as to form an ice block M during the ice making operation. During the deicing operation, heat is generated in the heaters H1 to HN by applying current so that the ice block M is removed from the ice making member 11 by melting. The ice making member 11, in a state that an insulating layer 12b lies between a metal plate 12a to which the evaporation pipe 14 is fixed and the heaters H1 to HN, is formed by bonding the metal plate 12a with the insulating layer 12b, and the insulating layer 12b with each of the heaters H1 to HN by thermocompression. Also, in addition to thermocompression bonding, the external outline of the heating means (H1 to HN) may be located inside the insulating layer 12b.

Owner:HOSHIZAKI ELECTRIC CO LTD

Cellular sandwich structure and production method thereof

ActiveCN106003850AImprove mechanical propertiesNot prone to degumming and delaminationSynthetic resin layered productsLaminationOne-hotHot melt

The invention discloses a cellular sandwich structure and a production method thereof. The method comprises the following steps: S1, selecting a cellular core and filling with foam to form a foam cellular core; S2, selecting two nonwoven layers and two hot-melt film layers, placing one nonwoven layer, one hot-melt film layers, the foam cellular core, the other hot-melt film layer and the other nonwoven layer sequentially in a first mold, and adjusting temperature and pressure for hot-pressing combination to obtain a middle core; S3, placing the middle core between two fiber-reinforced thermoplastic panels, placing in a second mold, adjusting temperature and pressure for hot-pressing combination, cooling quickly after hot pressing to obtain a cellular sandwich intermediate plate; S4, performing injection molding and binding on the periphery of the cellular sandwich intermediate plate to obtain the cellular sandwich structure. The cellular sandwich structure produced by the production method described herein has high mechanical properties, is resistant to peeling and layering and is long in service life.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

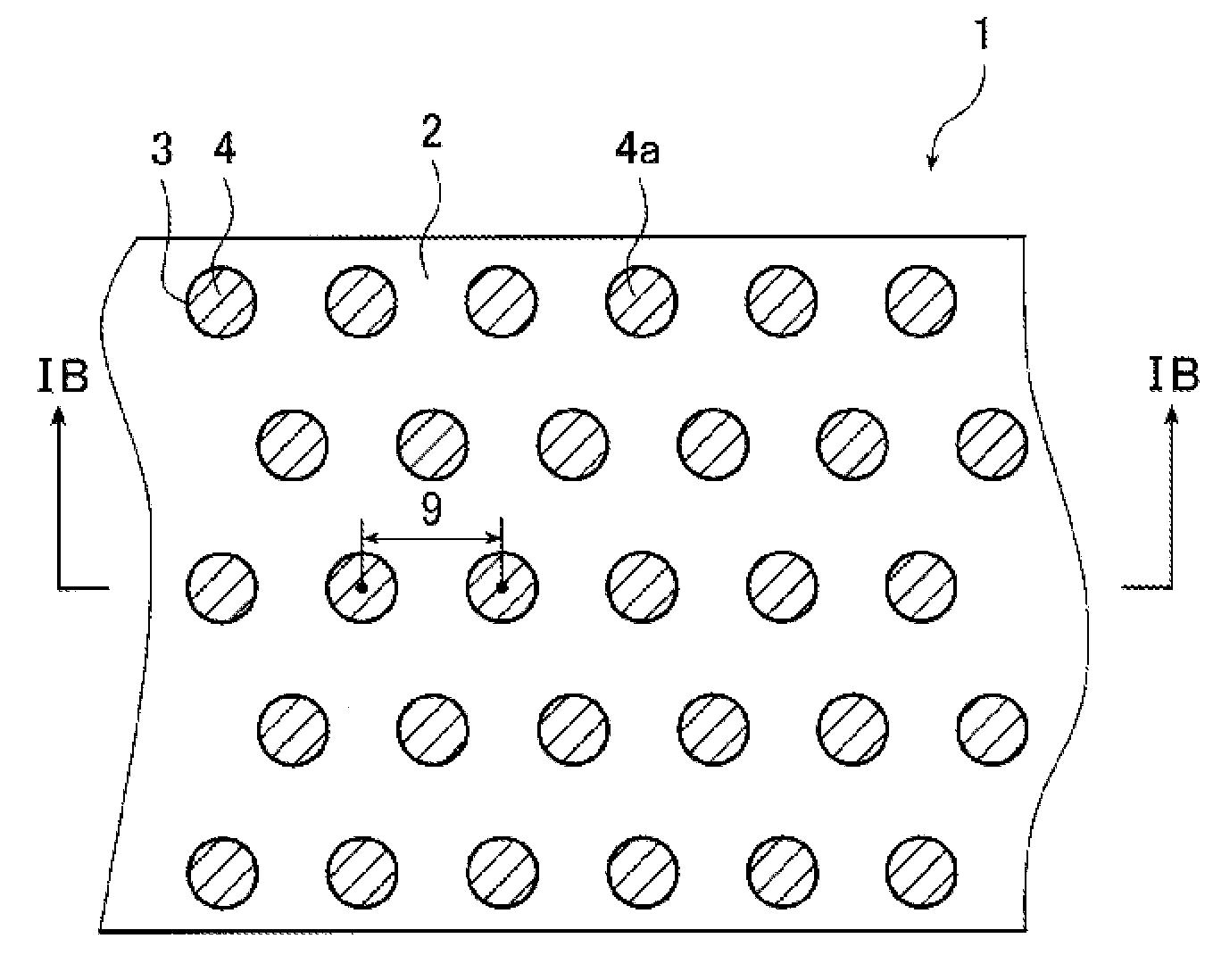

Microstructure, and method for production thereof

InactiveUS20110117357A1Improve long-term stabilityFirmly connectedPorous dielectricsNon-insulated conductorsVolumetric Mass DensityUltimate tensile strength

A microstructure which has excellent long-term stability and is capable of simple joining by thermocompression bonding at a high joint strength is provided. The microstructure includes an insulating base in which through micropores with a pore size of 10 to 500 nm are disposed at a density of 1×106 to 1×1010 micropores / mm2. The through micropores are filled with a metal at a filling ratio of at least 30% and a polymer layer is formed on at least one surface of the insulating base.

Owner:FUJIFILM CORP

Stack circuit member and method

InactiveUS20060278991A1Semiconductor/solid-state device detailsSolid-state devicesPhotosensitive polymerElectrical connection

A stack circuit member may include a first circuit member and a second circuit member. The first and the second circuit members may be electrically and mechanically connected together using a thermocompression bonding method. A photosensitive polymer layer may be interposed between the first circuit member and the second circuit member. A gap fill process and an electrical connection process may be performed at the same time.

Owner:SAMSUNG ELECTRONICS CO LTD

Multilayer printed circuit board having a concave metal portion

InactiveUS6184479B1Printed circuit assemblingElectrically conductive connectionsPrinted circuit boardDielectric layer

The multilayer printed circuit board includes a substrate, a first conductive circuit layer, a photosensitive dielectric layer and a second conductive circuit layer which is electrically connected to the first conductive circuit layer through photo-via holes formed in the photosensitive dielectric layer. The second conductive circuit layer includes a wiring area where a plurality of wires are arranged and a pad area to which an external wire is to be connected using thermocompression bonding. Significantly, to avoid depressing the photosensitive dielectric layer underneath the pad area during the thermocompression bonding, the thickness of the second conductive circuit layer at least in the pad area, is made greater than that in the wiring area by extending this thickness into the photosensitive dielectric layer.

Owner:GLOBALFOUNDRIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com