Cellular sandwich structure and production method thereof

A technology of honeycomb sandwich structure and honeycomb core, which is applied in the direction of chemical instruments and methods, lamination, layered products, etc., which can solve the problem of difficulty in ensuring the necessary bonding between the skin and the honeycomb core, unsatisfactory mechanical properties of the honeycomb sandwich structure, and the impact of Problems such as product performance and service life, to achieve the effect of not easy degumming and delamination, high bonding stability, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

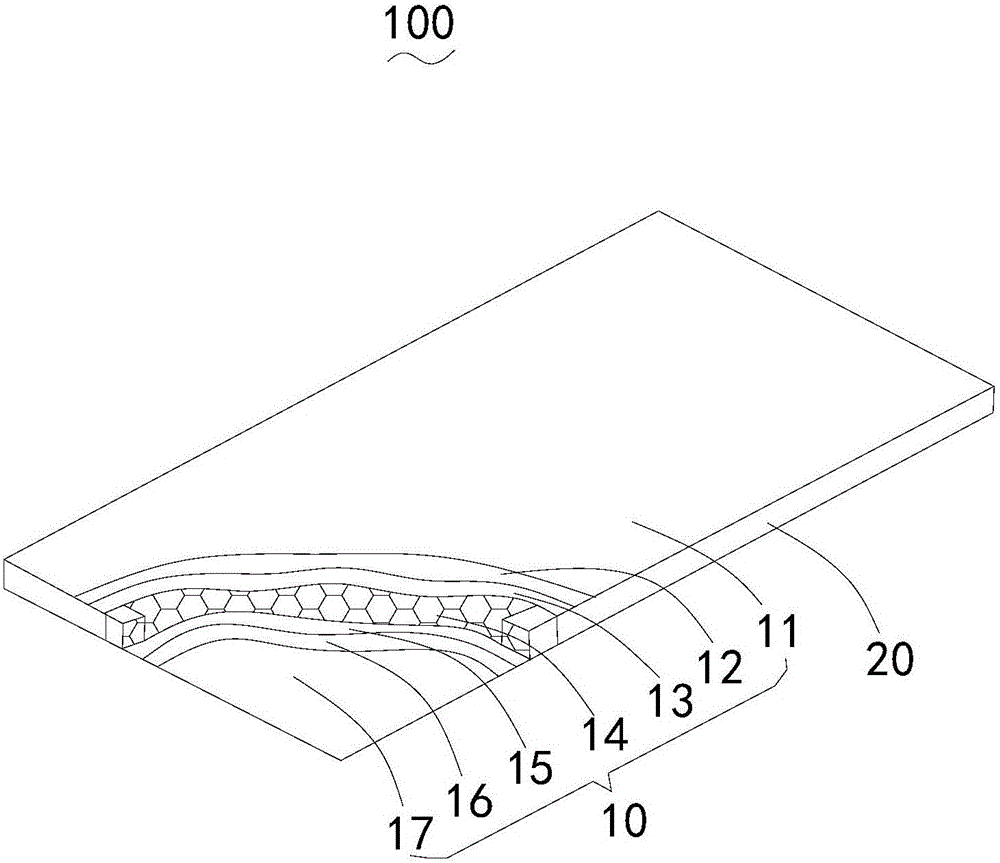

[0027] The preparation method of honeycomb sandwich structure of the present invention, it comprises the steps:

[0028] S1. A honeycomb core is selected. The honeycomb core has a plurality of holes, and the pores of the honeycomb core are filled with foam to form a foam honeycomb core. In this embodiment, the thickness of the honeycomb core is 3mm-30mm, and the thickness is determined according to the required thickness of the overall structural member. The material of the honeycomb core is one of PE honeycomb core, PP honeycomb core, PVC honeycomb core, PC honeycomb core, PET honeycomb core, paper honeycomb core, Nomex honeycomb core and aluminum honeycomb core. The foam is one or a combination of PVC foam, PS foam, PU foam, PUR foam, PEI foam, PI foam, PMI foam, PPSU foam and SAN foam, and the density of the foam is 40-200kg / m 3 . When several materials are selected for the foam, different types of foam can be filled in one hole, or one kind of foam can be filled in the s...

Embodiment

[0036] In this embodiment, the preparation method of the honeycomb sandwich structure comprises the following steps:

[0037] S1. A honeycomb core is selected. The honeycomb core has a plurality of holes, and the pores of the honeycomb core are filled with foam to form a foam honeycomb core. In this embodiment, the thickness of the honeycomb core is 6mm. The material of the honeycomb core is a PC honeycomb core, which is filled with PVC foam to obtain a foam honeycomb core.

[0038] S2, select the first non-woven fabric layer, the second non-woven fabric layer, the first hot-melt adhesive film layer, and the second hot-melt adhesive film layer, and provide the first mold, the first non-woven fabric layer, the second non-woven fabric layer The woven fabric layer and the first hot-melt adhesive film layer, the second hot-melt adhesive film layer and the foam honeycomb core are cut to the same size to ensure that the circumference of the manufactured structural parts is neat, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com