Patents

Literature

126results about How to "Prevent bad connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

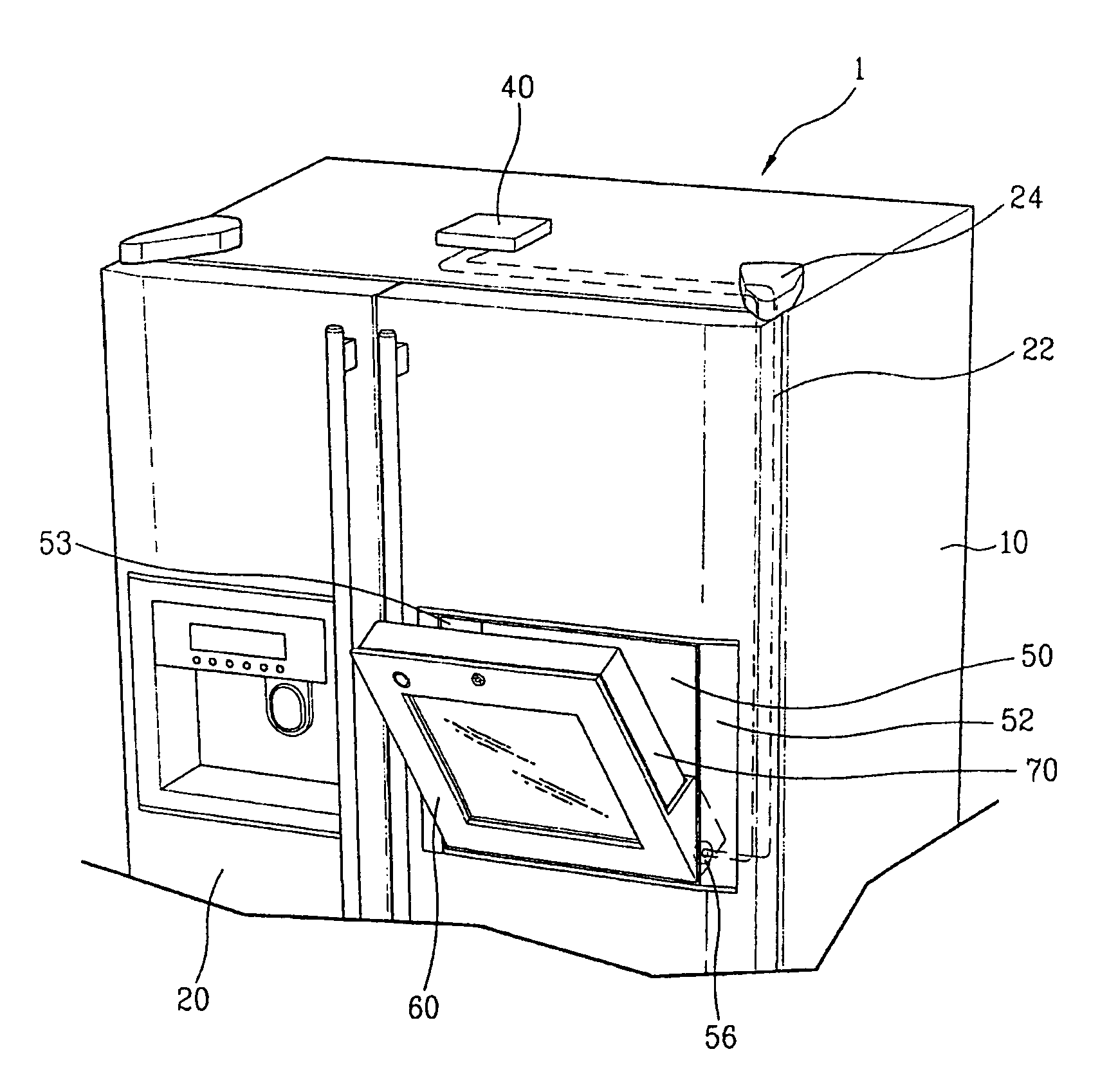

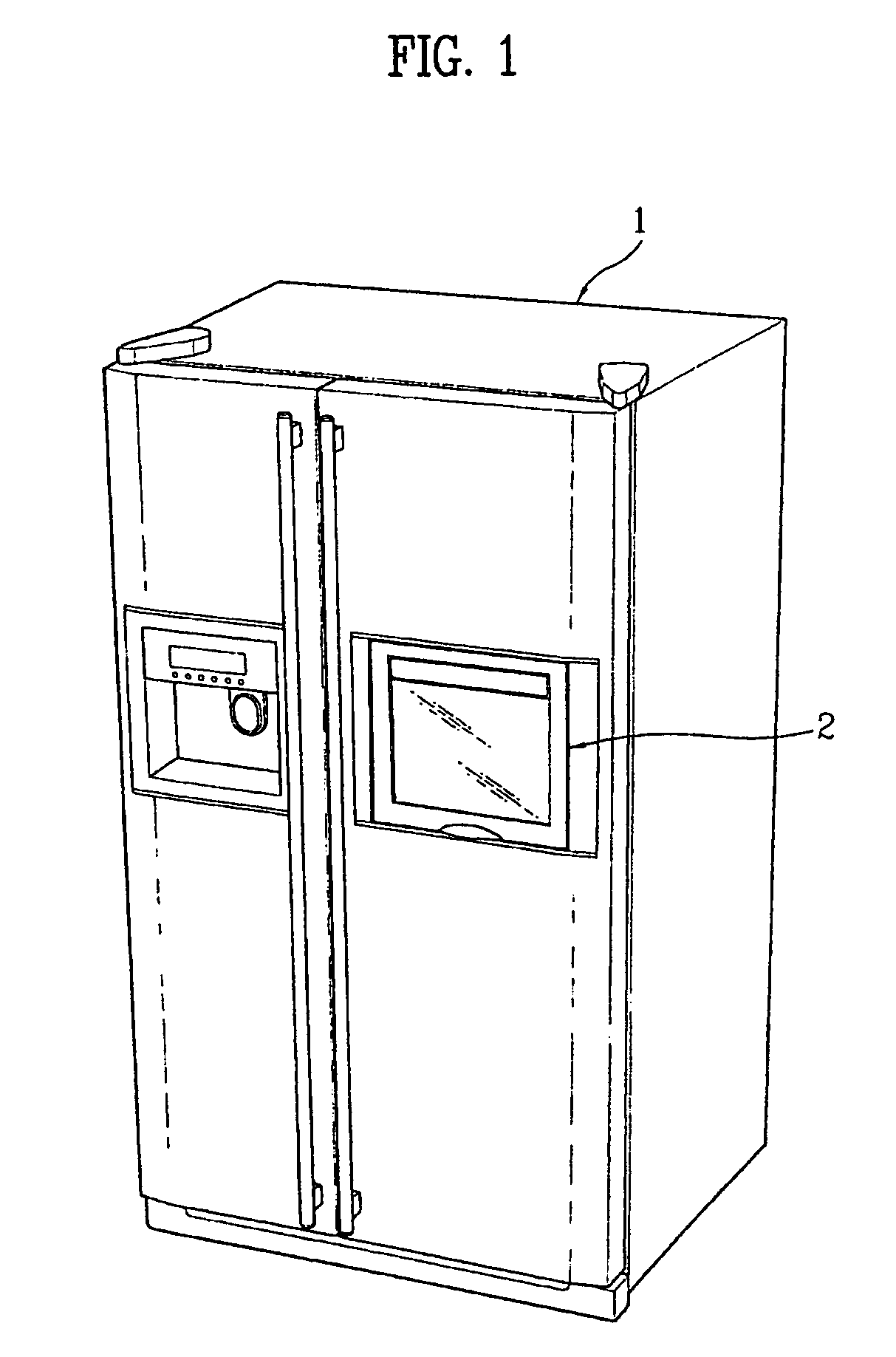

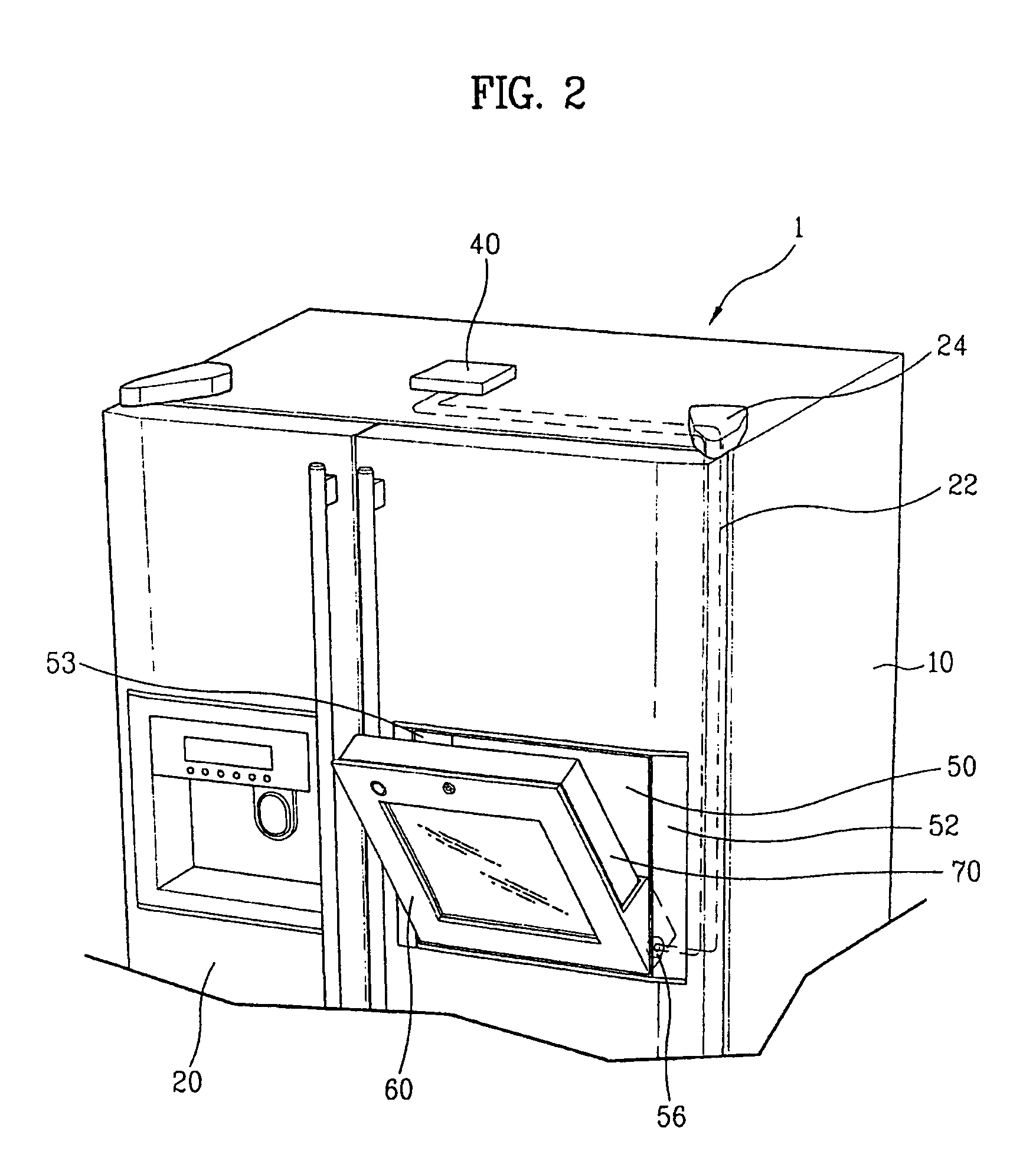

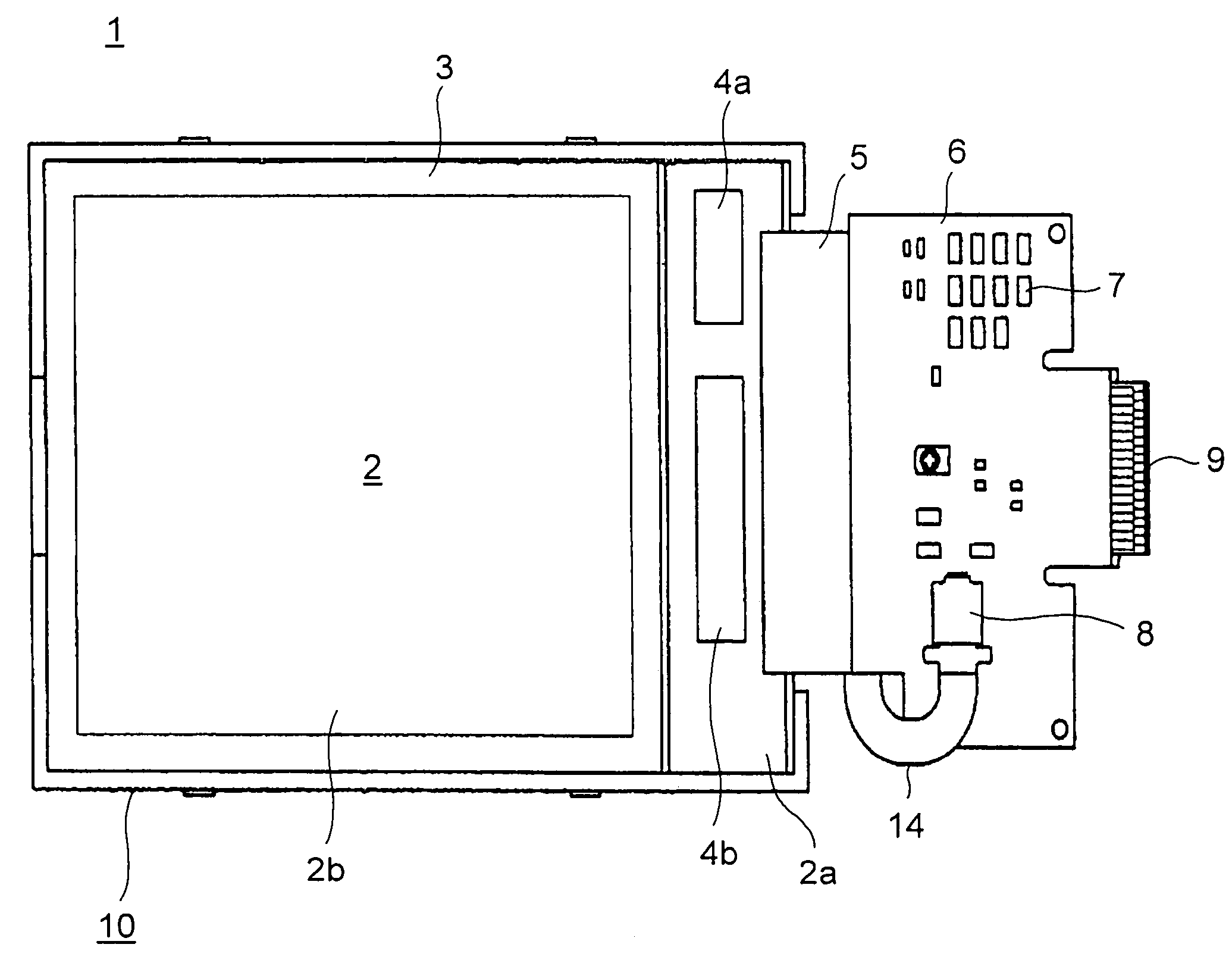

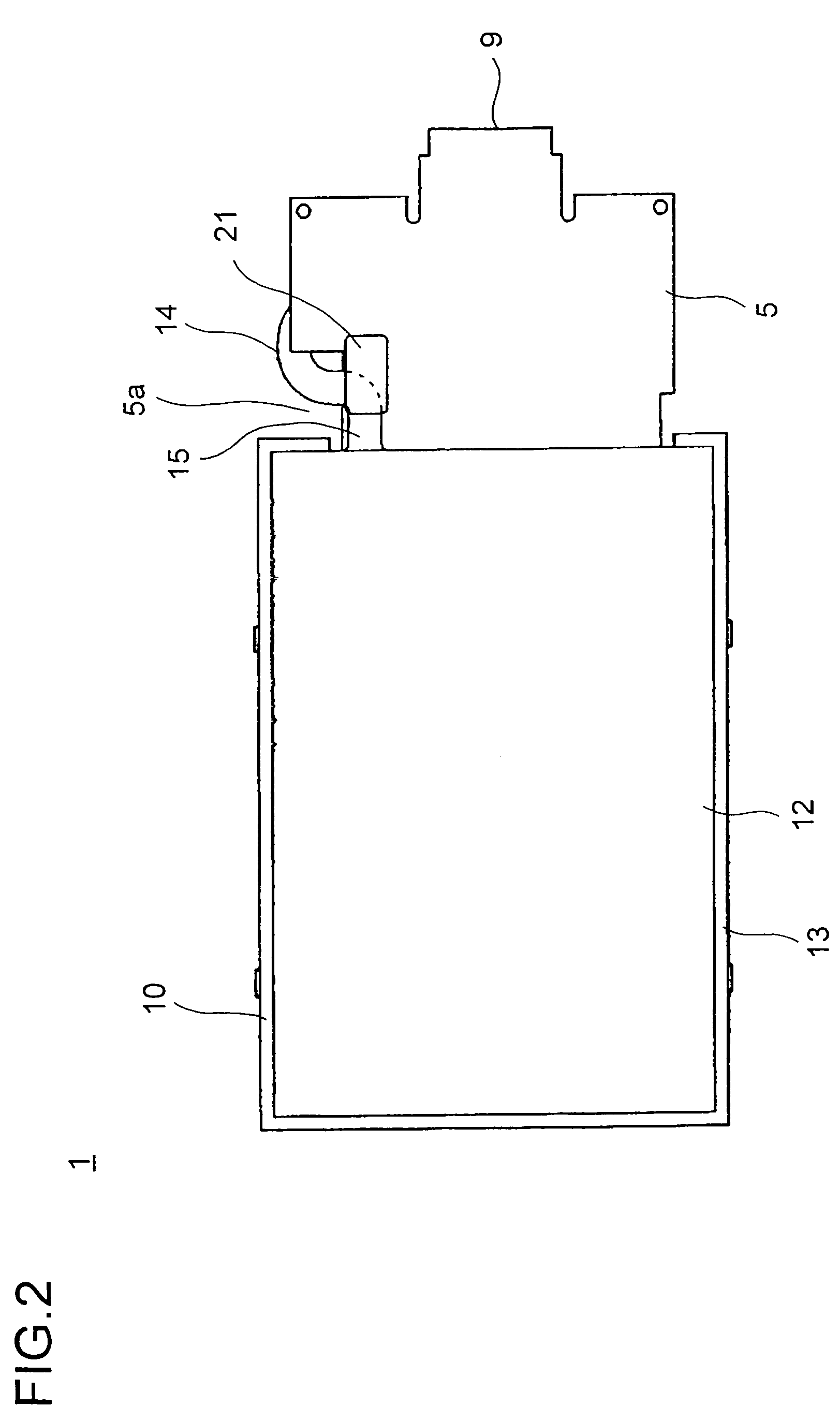

Refrigerator

InactiveUS7404298B2Easy to insertPrevent bad connectionShow cabinetsSubstation/switching arrangement cooling/ventilationElectricityEngineering

Owner:LG ELECTRONICS INC

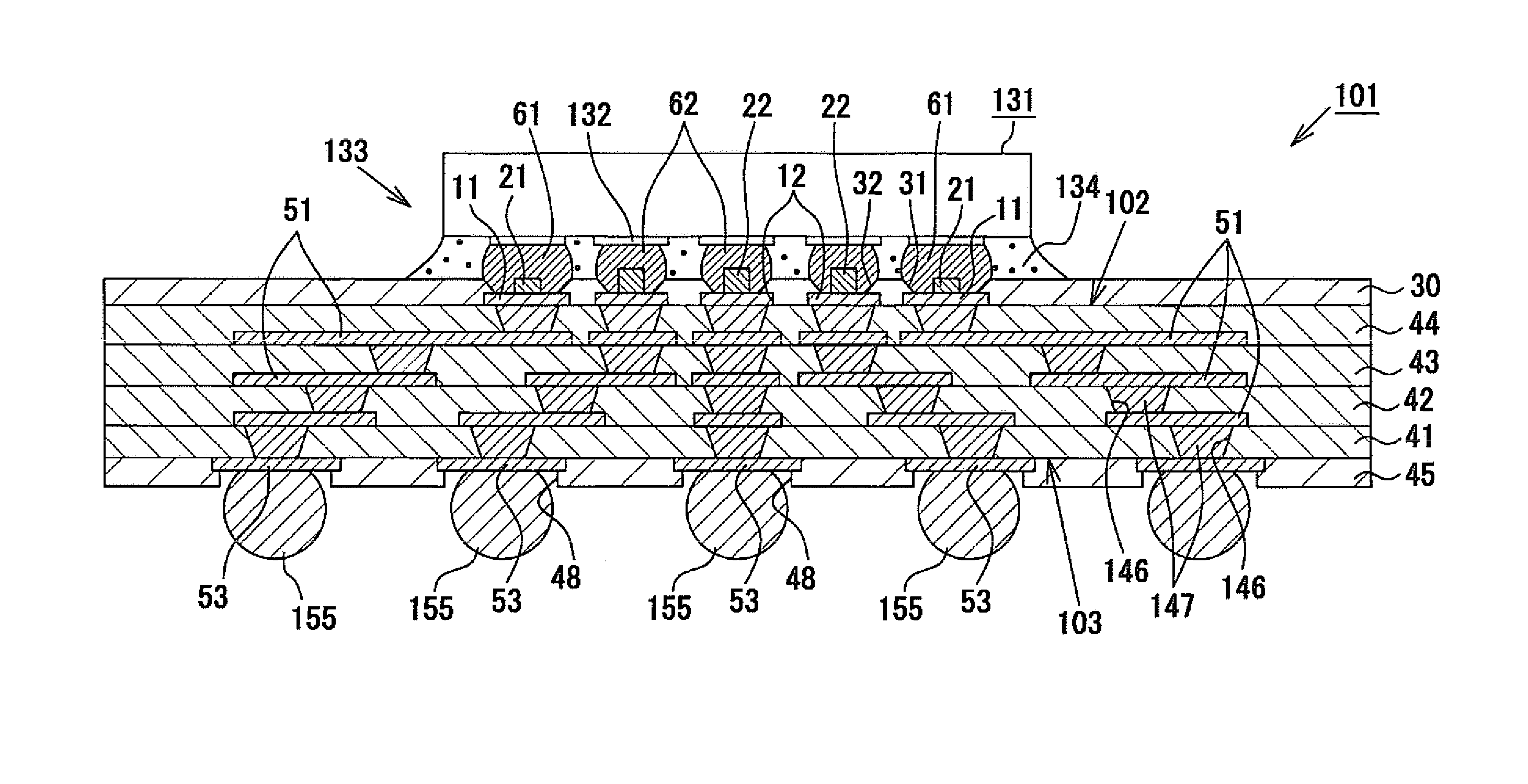

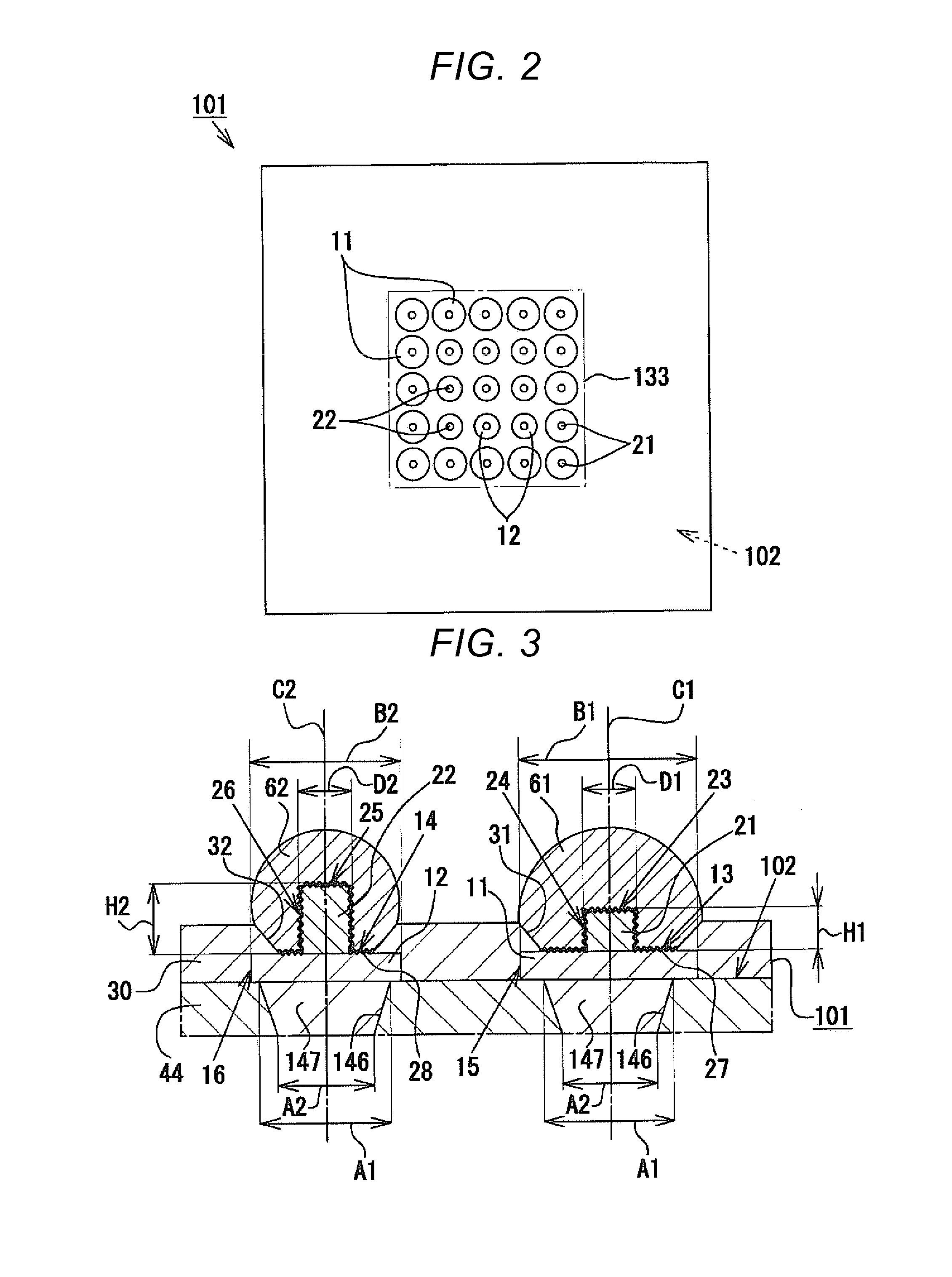

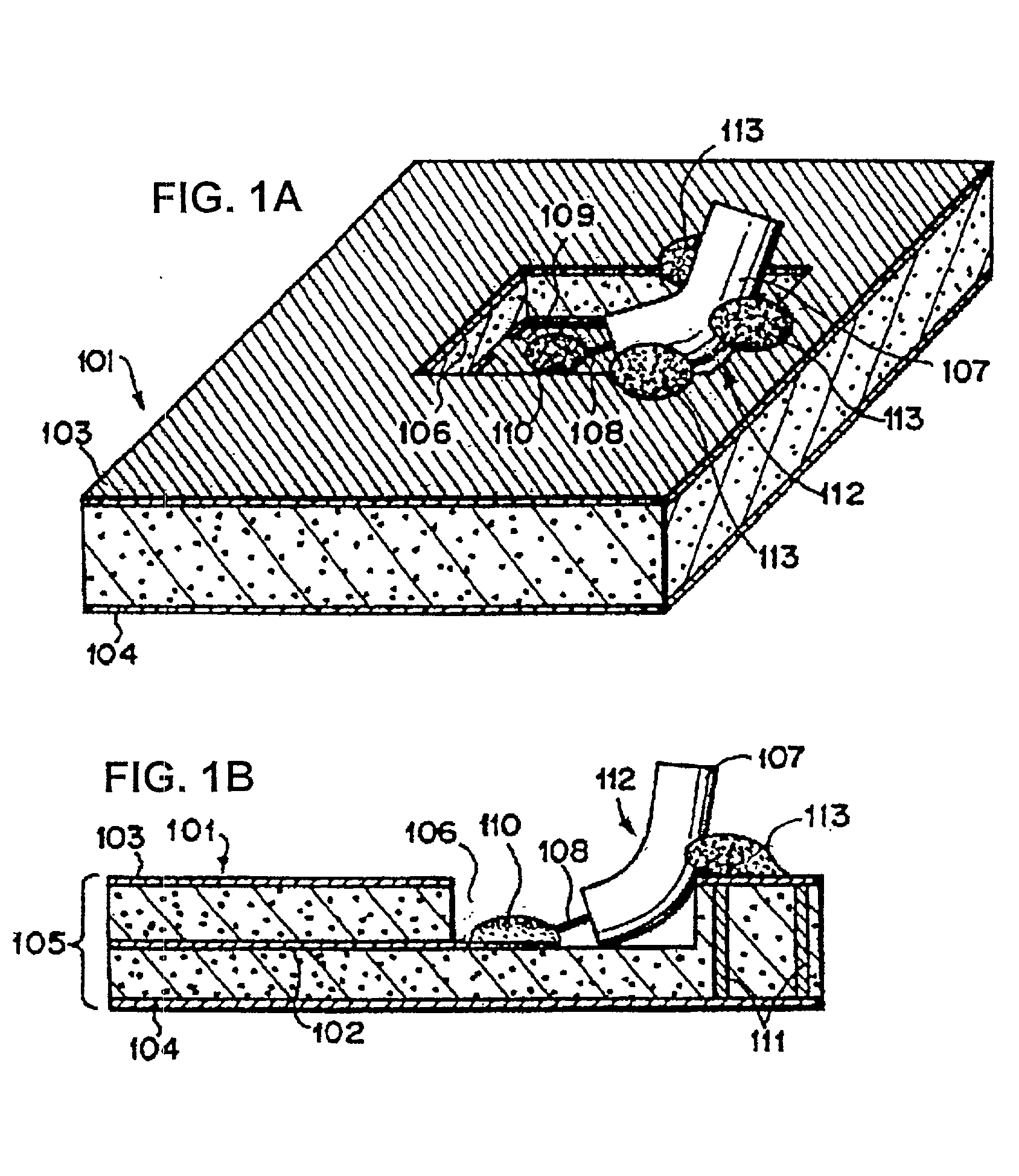

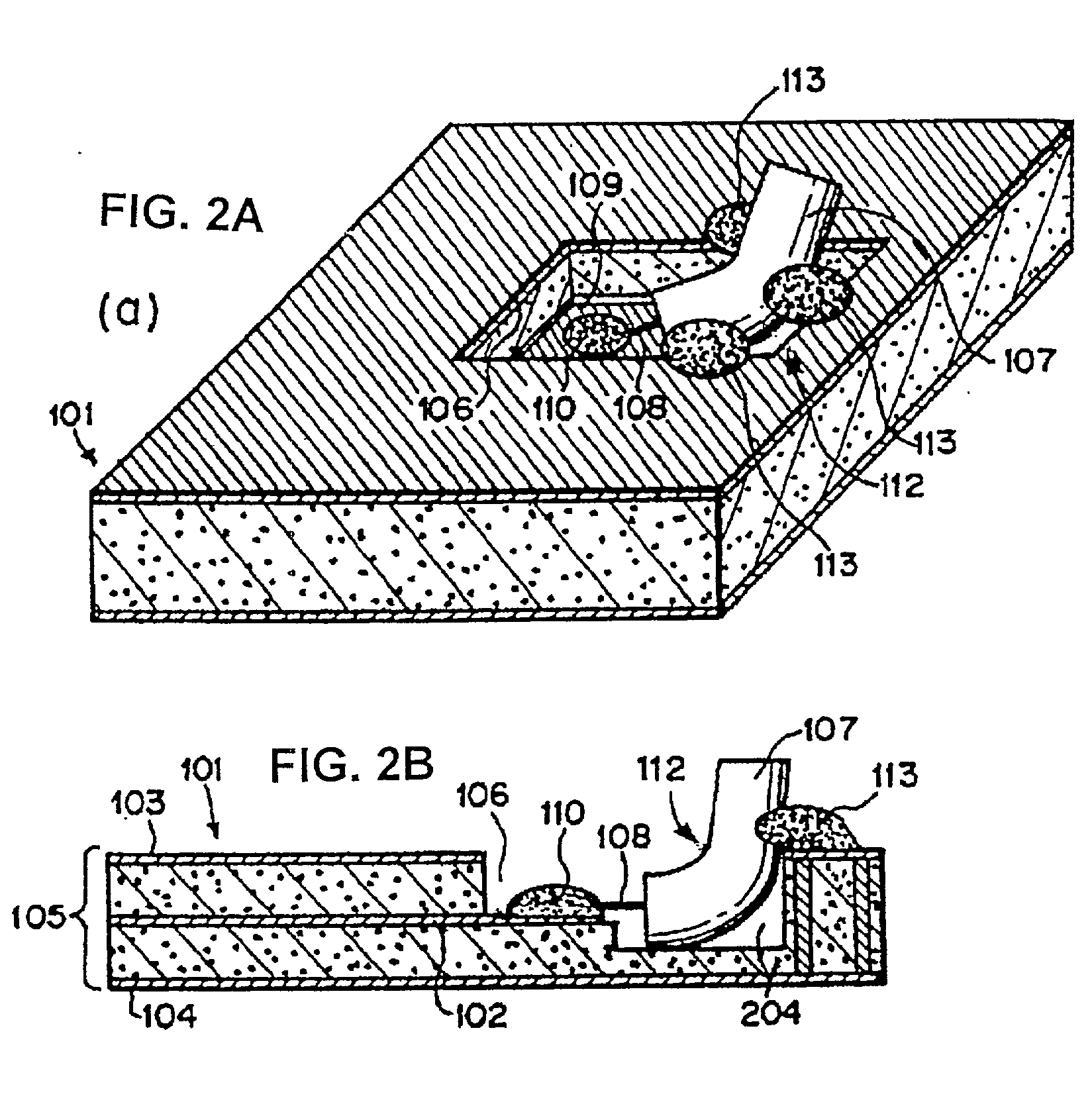

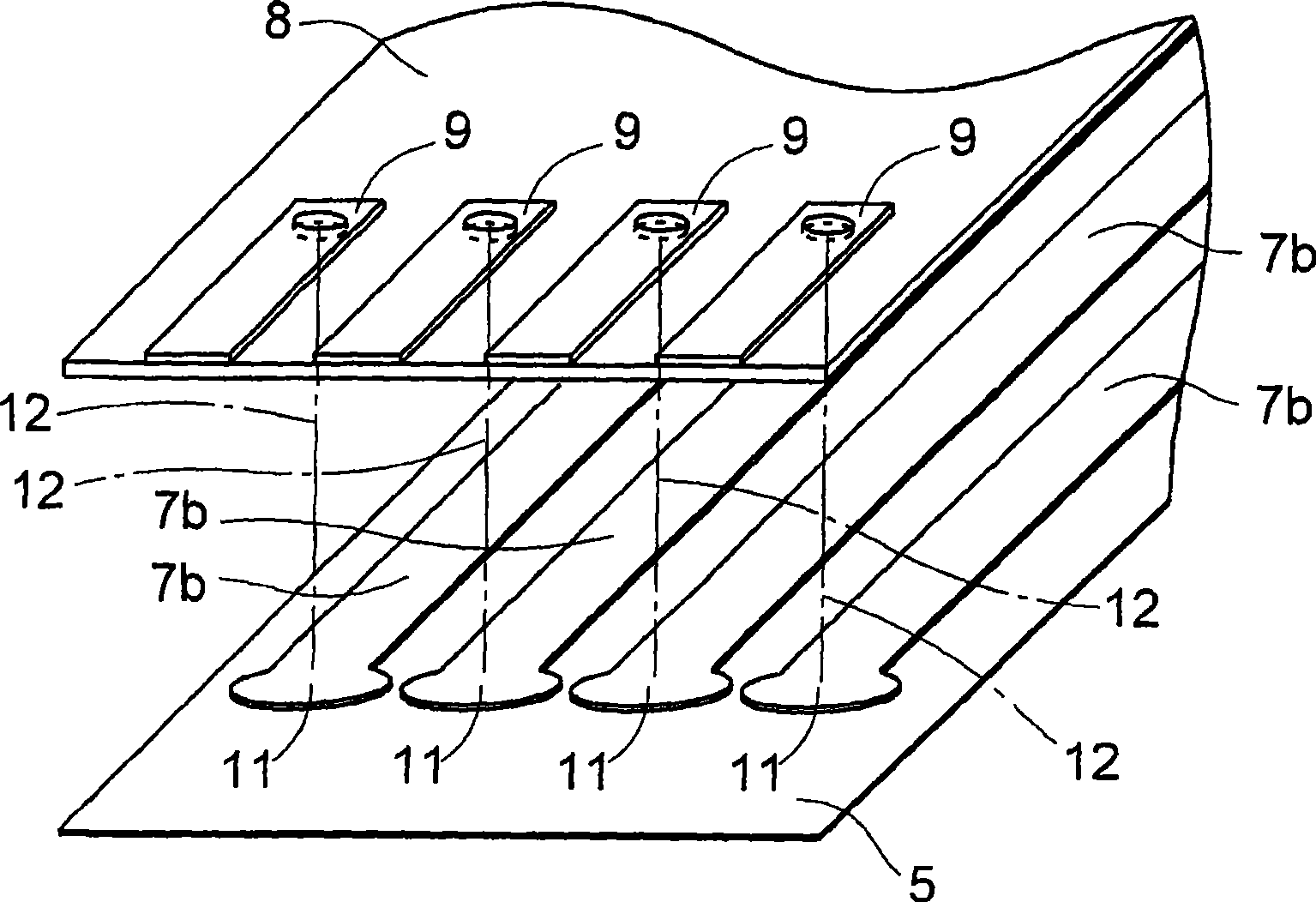

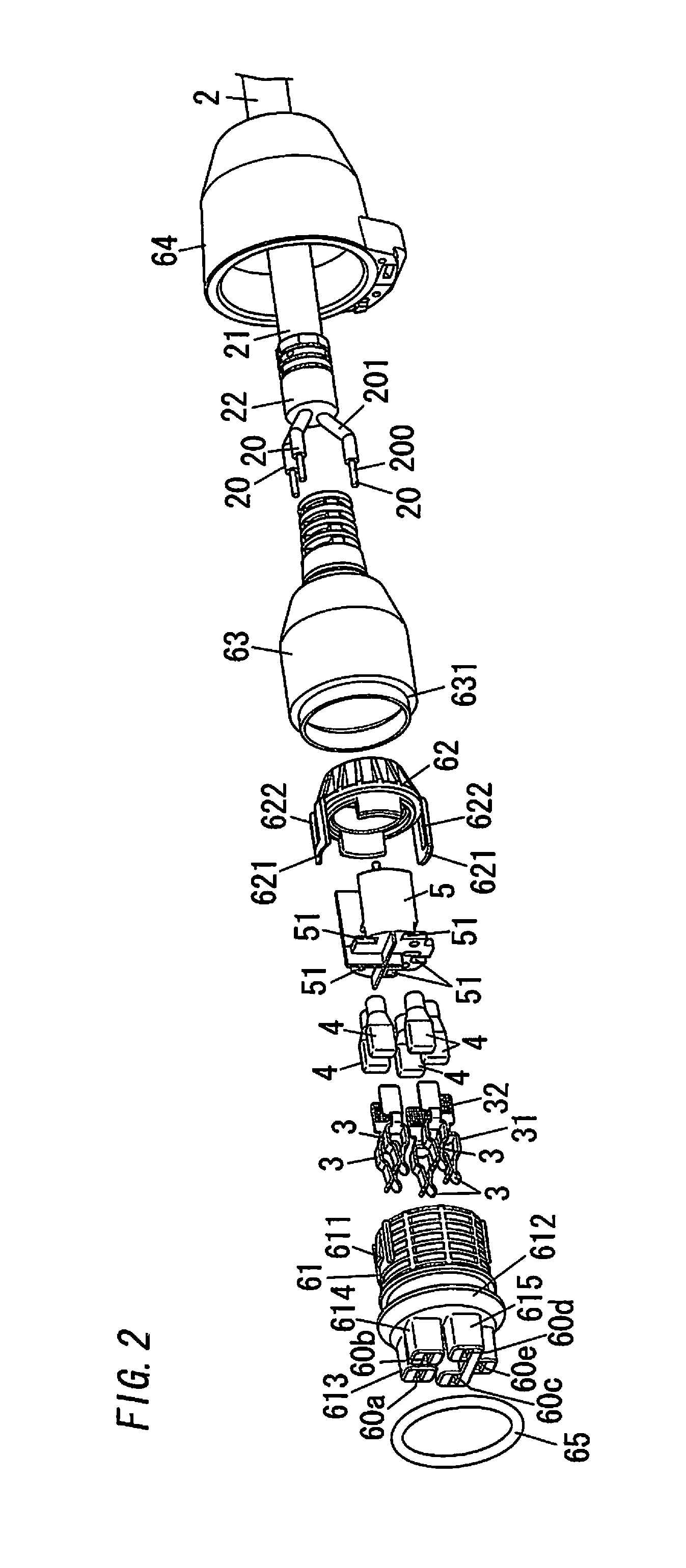

Wiring board and method of manufacturing the same

InactiveUS20130180772A1Avoid poor connectionImprove reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsResistElectrical and Electronics engineering

Embodiments provide a wiring board which is structured to be suitable for connection with components, whereby its reliability can be improved. An embodied wiring board of the invention has pads and a solder resist in which opening portions which expose the pads are formed. Protrusion-shaped members are fixed to some of the surfaces of the pads. The surfaces of the pads and the surfaces of the protrusion-shaped members are covered with solder bumps. The height of the solder bumps is larger than the height H1 and H2 of the protrusion-shaped members. The opening portions have different inner diameters, and the volume of the protrusion-shaped members increases as the diameter of the opening portion decreases.

Owner:NGK SPARK PLUG CO LTD

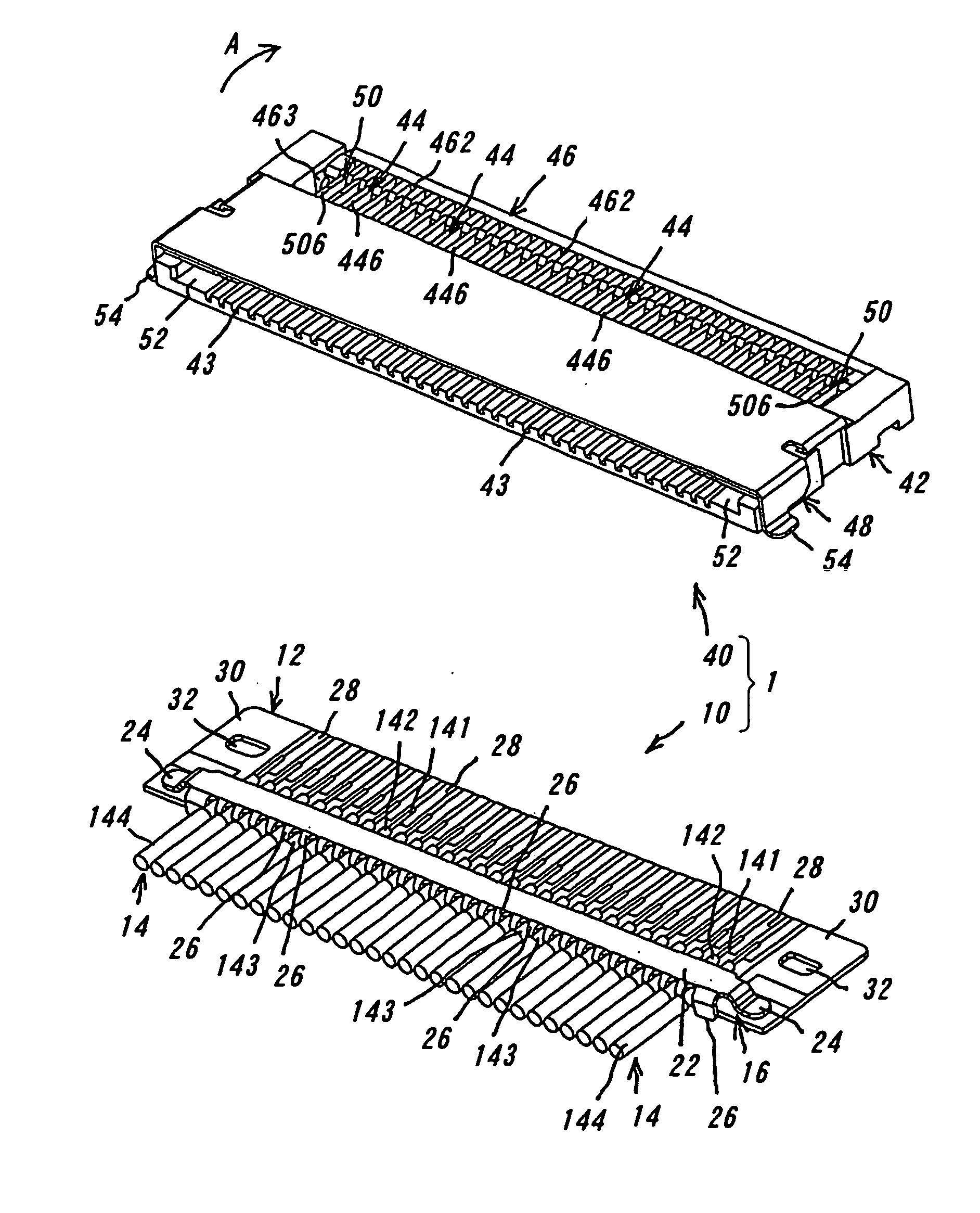

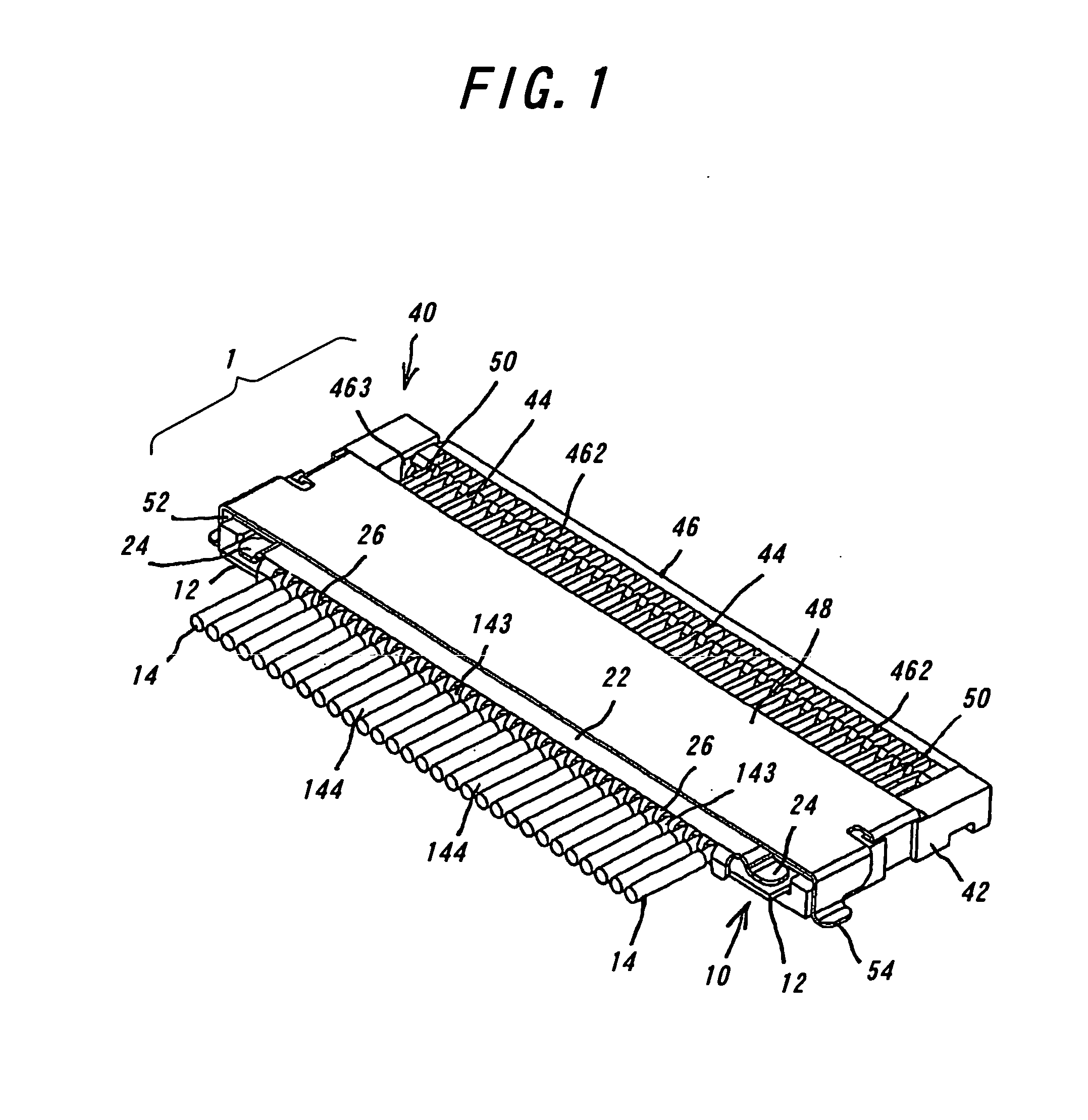

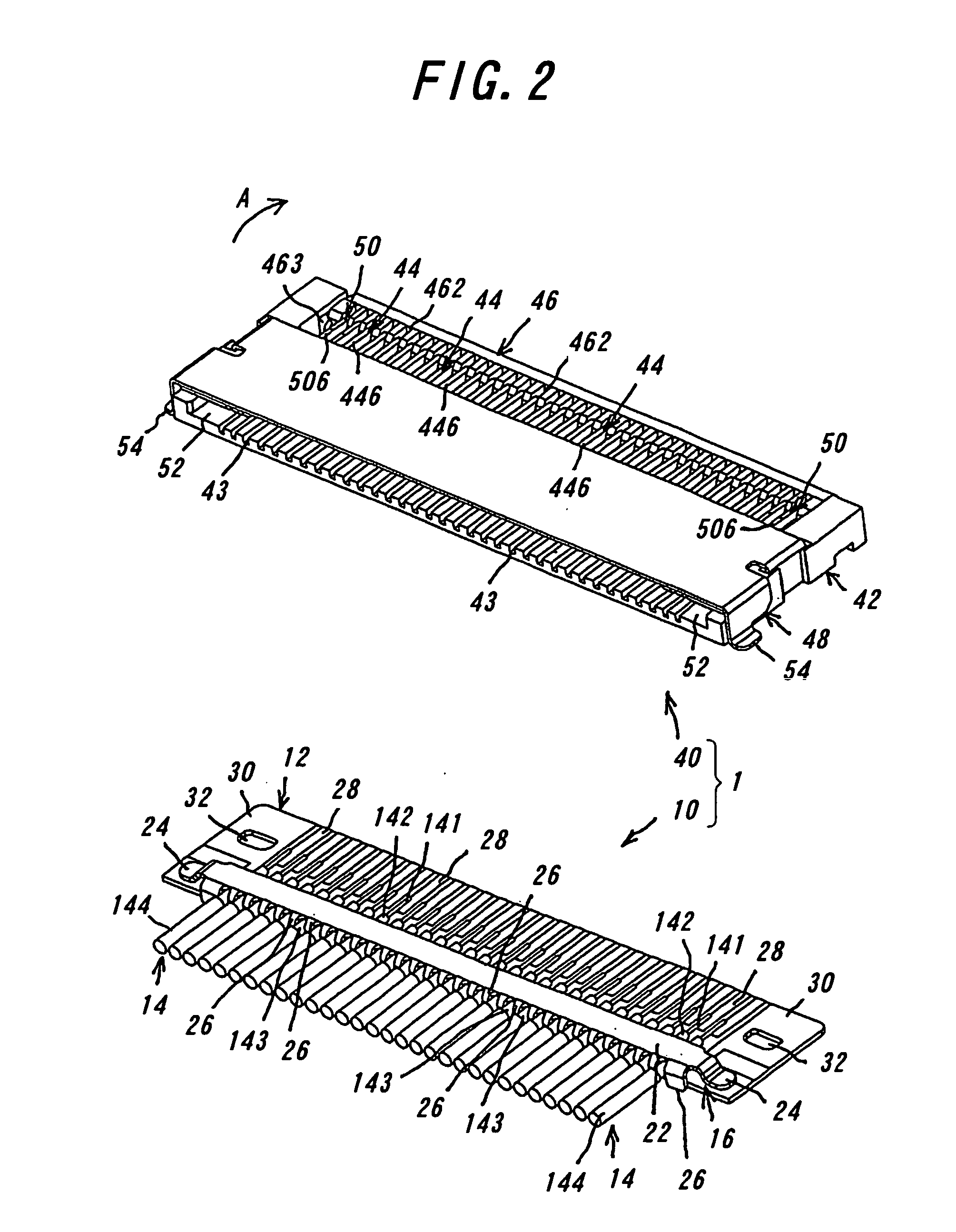

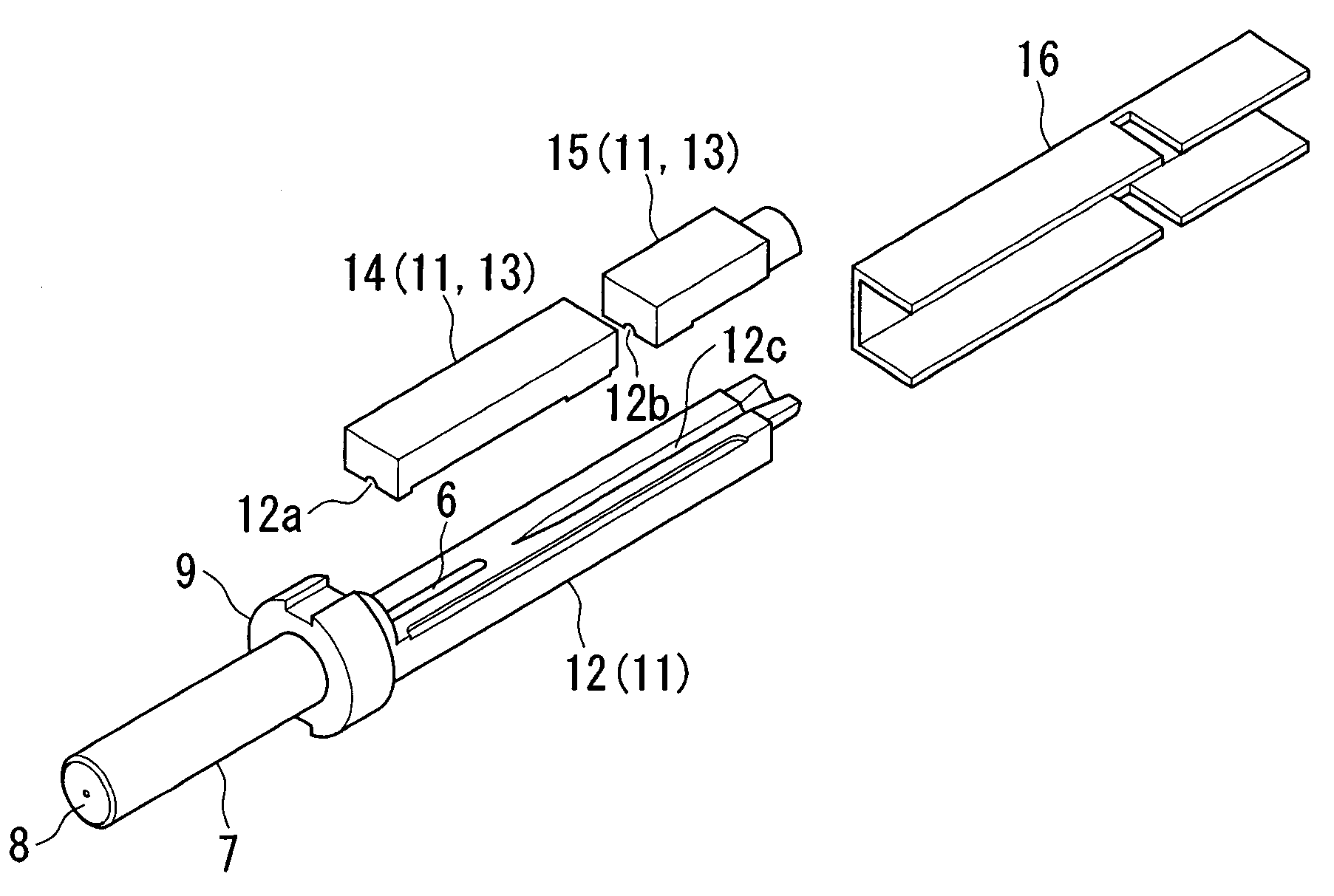

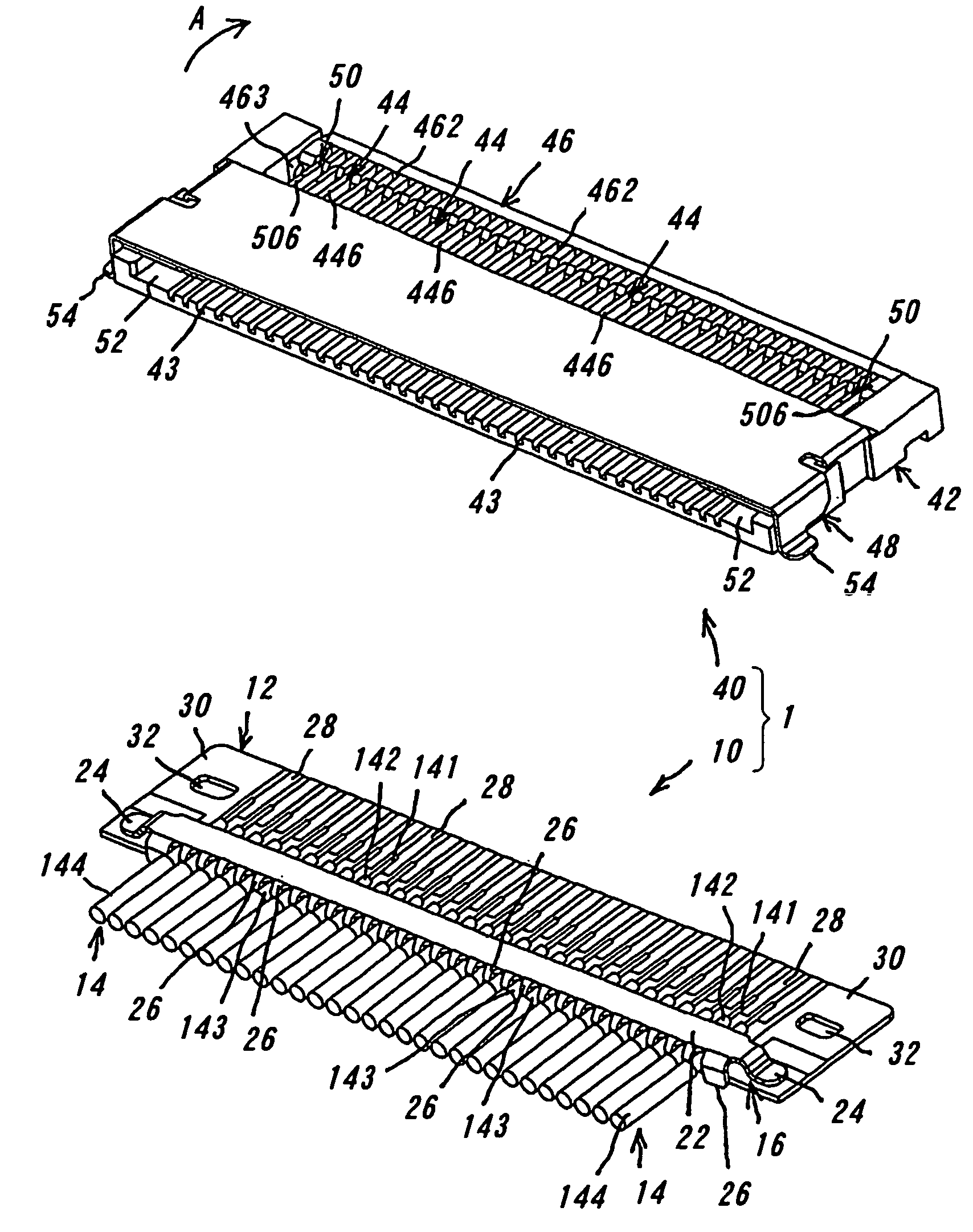

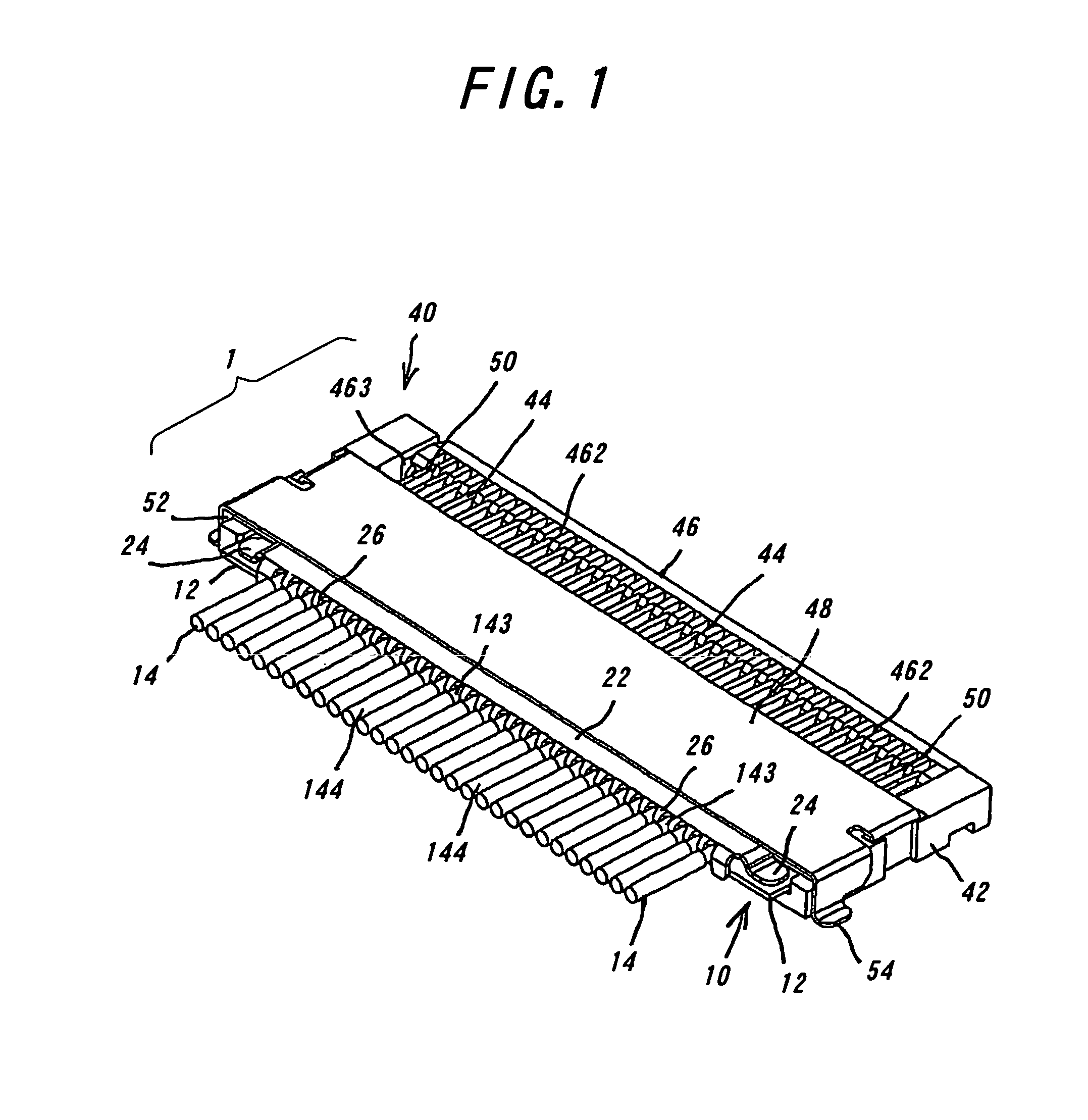

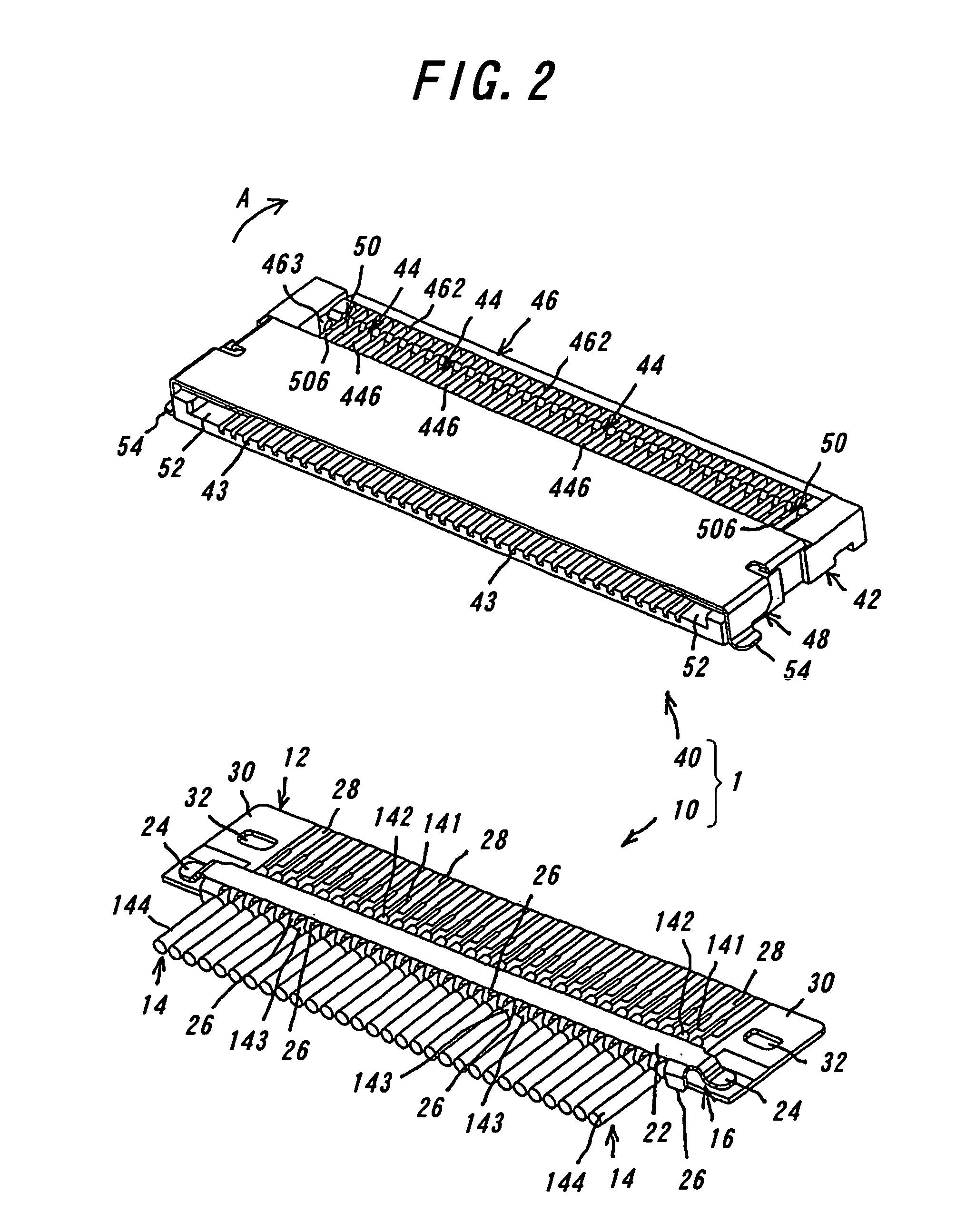

Electrical connector

InactiveUS20060252310A1Preclude any defective connectionPrevent bad connectionPrinted circuit assemblingElectrically conductive connectionsFlexible electronicsPrinted circuit board

An electrical connector includes a plug connector and a receptacle connector detachably fitted with each other. The plug connector comprises a plurality of coaxial cables, a flexible printed circuit board and a ground bar. Each of the coaxial cable has a center conductor, an insulator covering the center conductor, a braid as an external conductor covering the insulator, and a sheath covering the braid. The flexible printed circuit board has lands each connected to the center conductor of the coaxial cable and land portions to which the ground bar is connected. The grand bar has a main portion adapted to contact the braids of the coaxial cables, and fixed portions each positioned contiguously with the main portion and connected to the land portion. The electrical connector achieves the low height geometry of the plug connector and hence that of the receptacle connector and precludes any failed connection between the ground bar and the coaxial cables.

Owner:DDK LTD

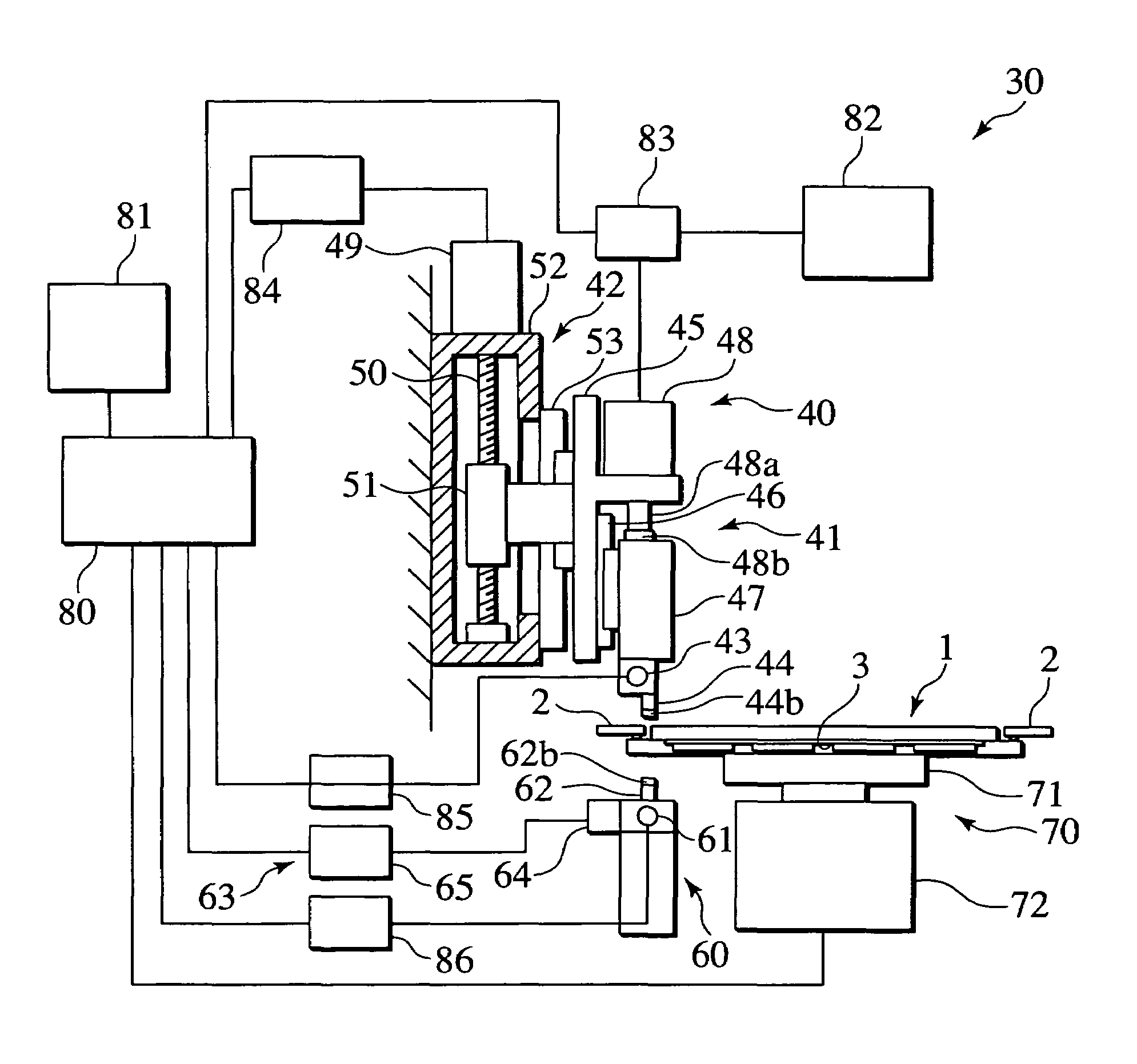

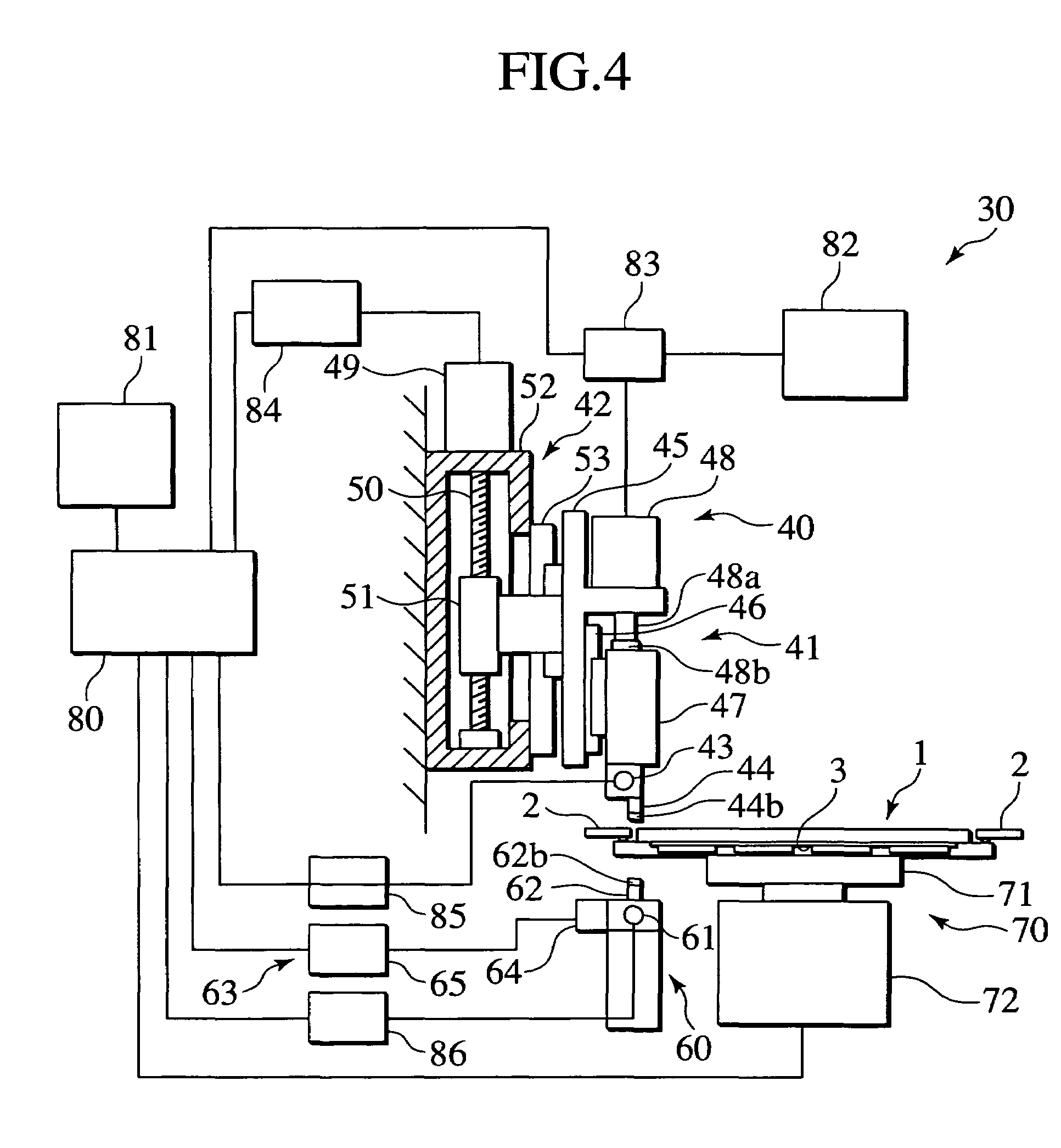

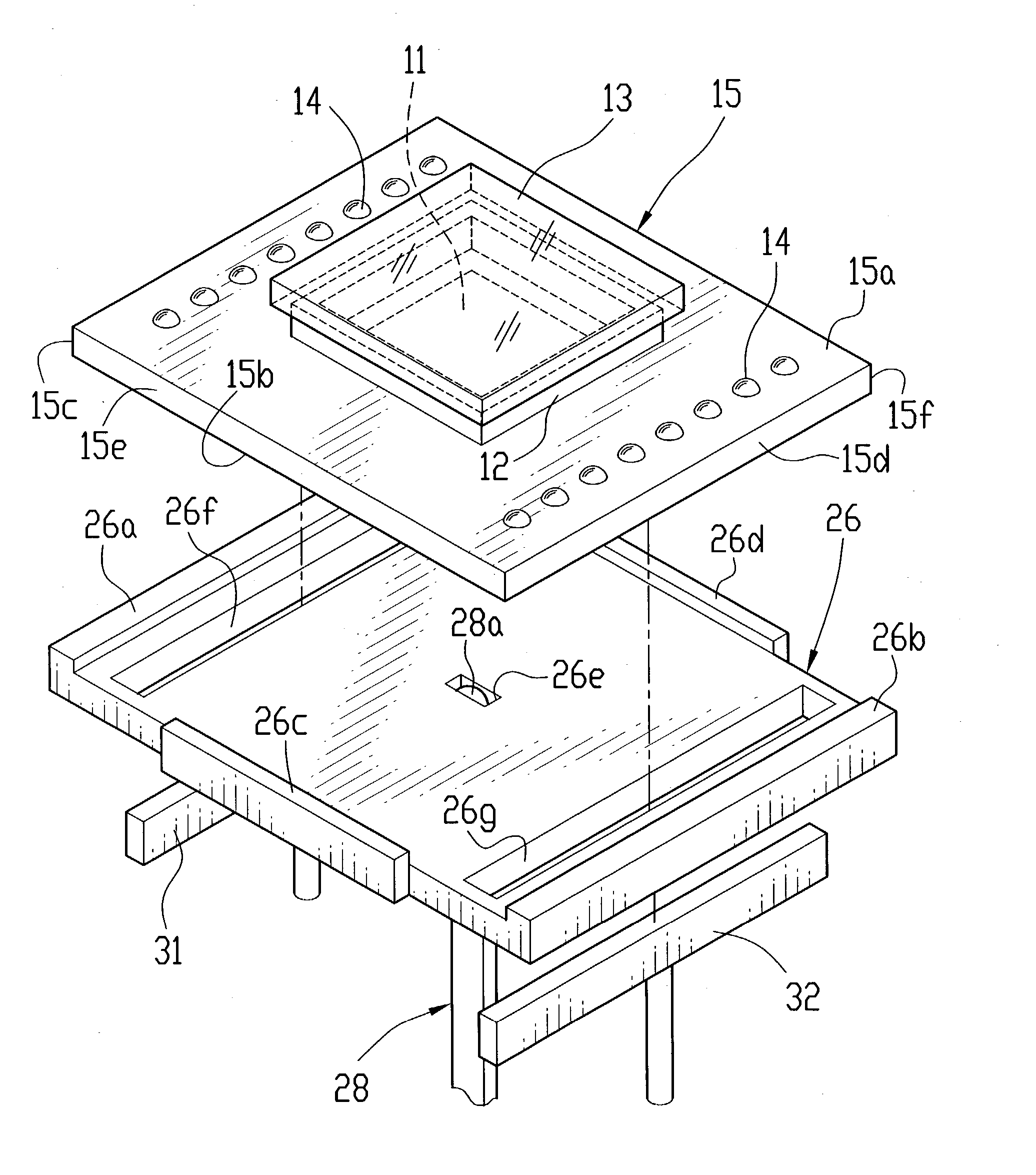

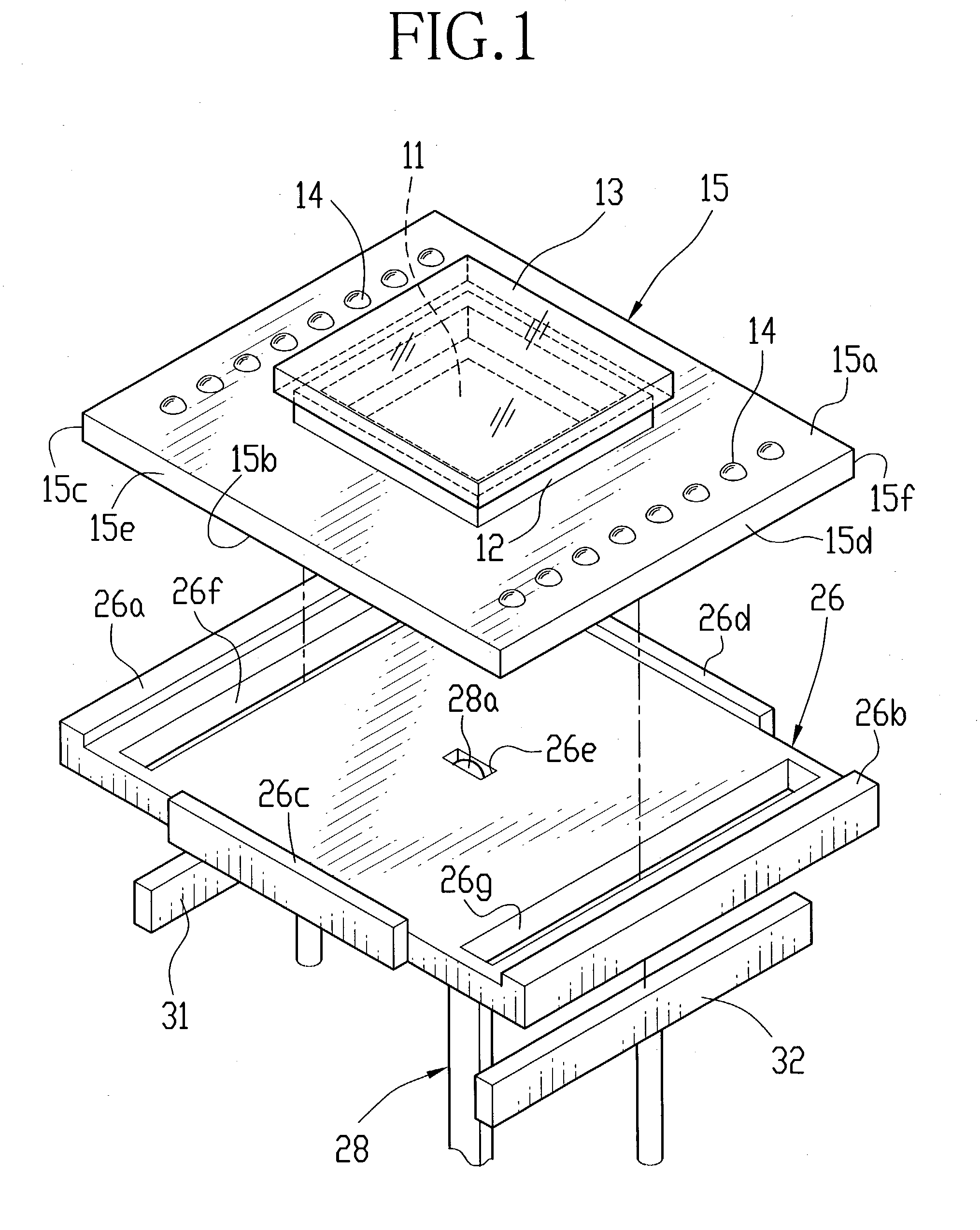

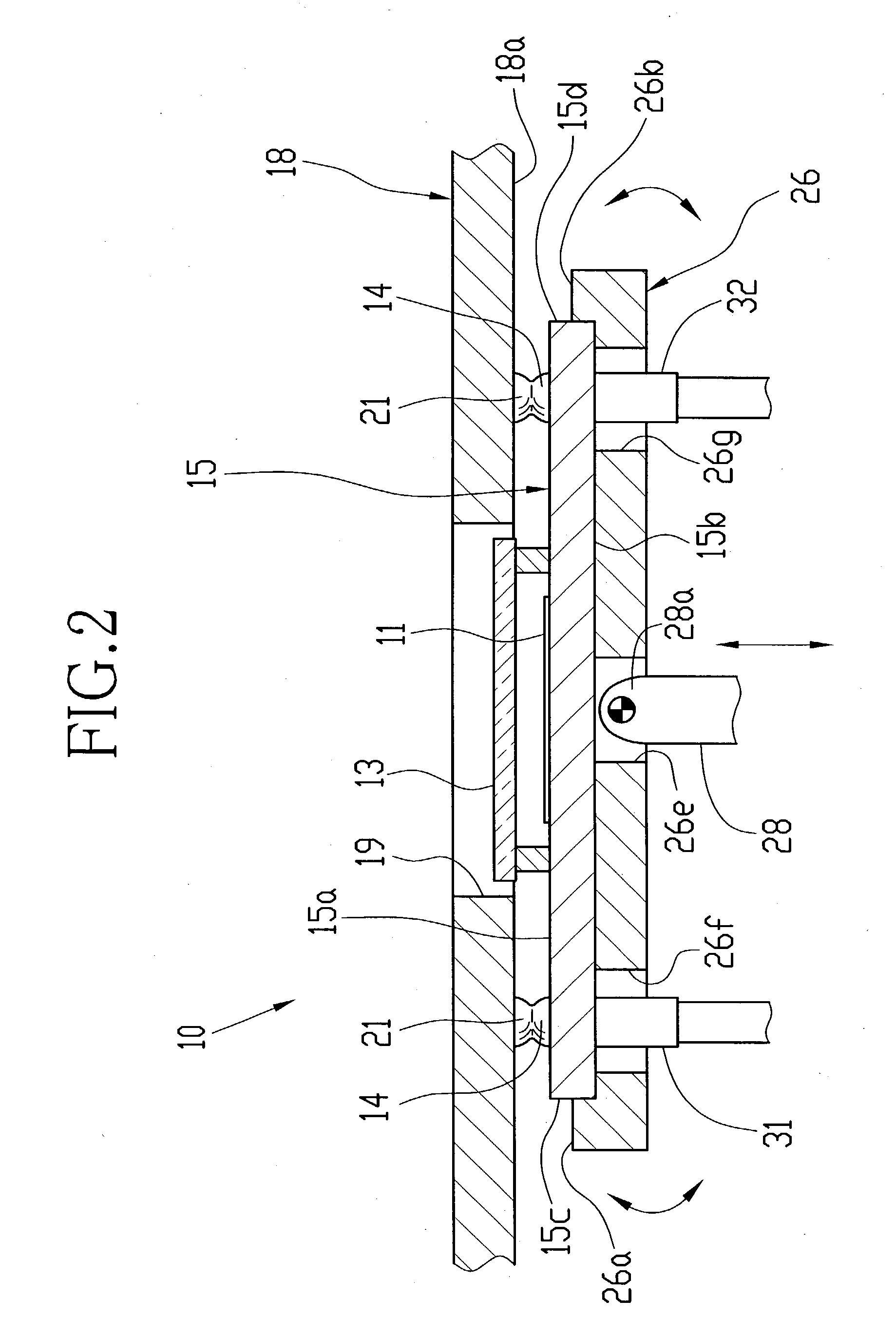

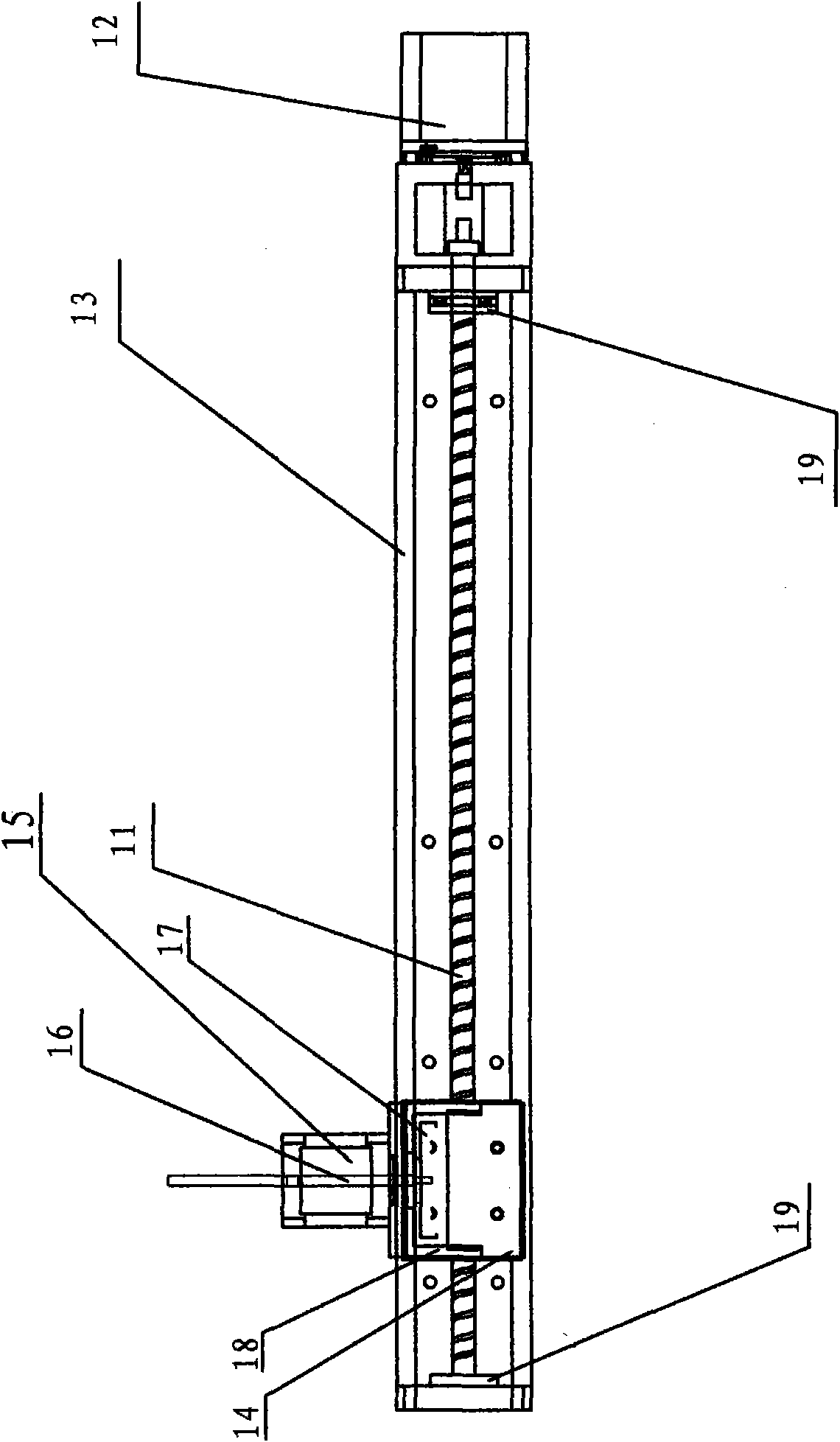

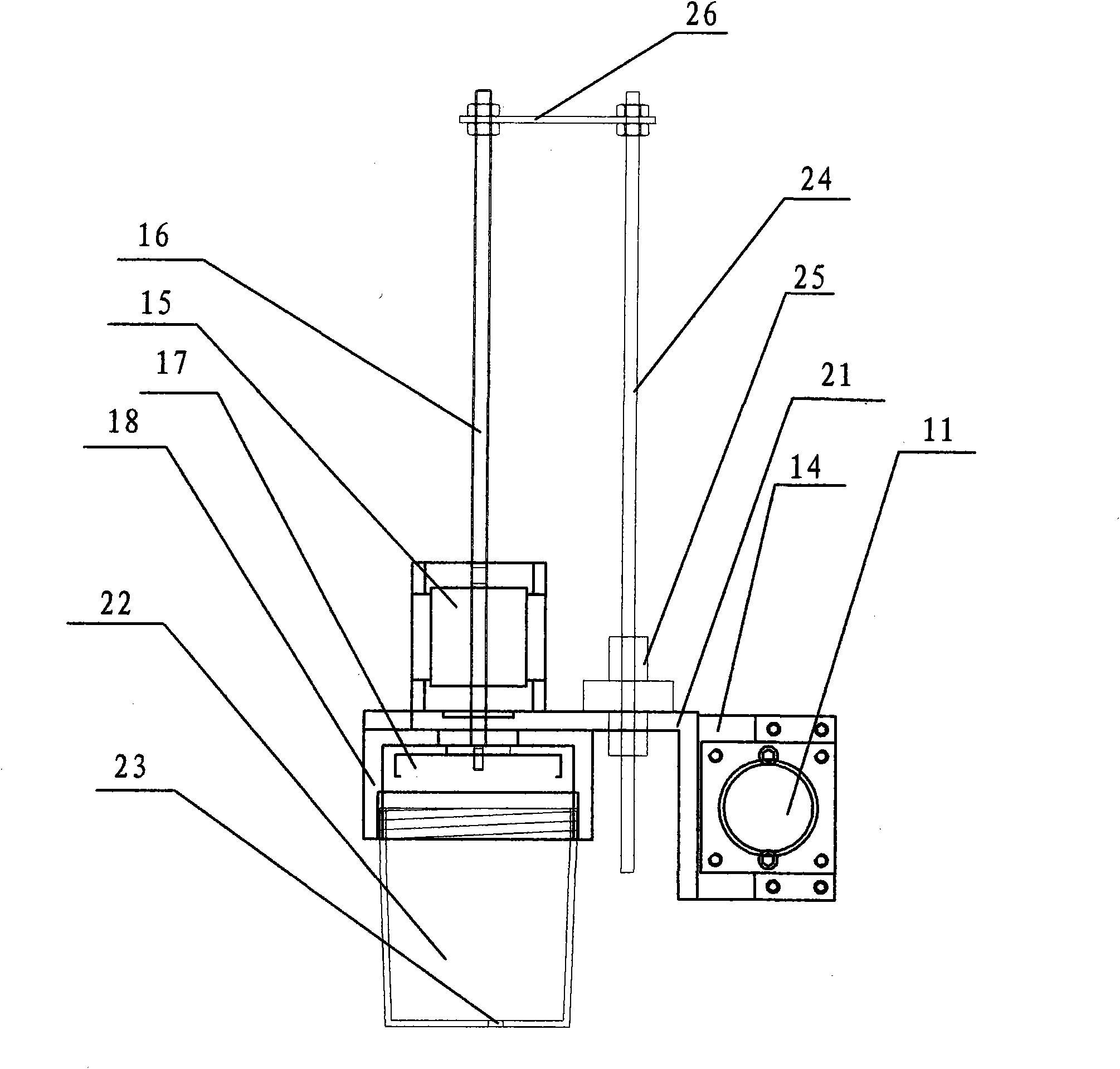

Electronic part compression bonding apparatus and method

InactiveUS7075036B2Easy to controlPrevent bad connectionSemiconductor/solid-state device manufacturingOhmic-resistance heating detailsTemperature controlEngineering

An electronic part compression bonding apparatus includes a compression bonding unit which bonds the electronic parts onto the substrate by thermocompression, a pressure supply unit, a pressure control unit which controls pressure, a heating unit which heats the compression bonding unit, a temperature control unit, and a thermocompression bonding control unit which controls the pressure control unit and the heating unit based on thermocompression bonding condition data in which at least one of pressure and heating temperature is variably set during a process from start until completion of a thermocompression bonding operation of the electronic parts. In the thermocompression bonding condition data, the pressure is set to a first pressure in a first stage in a process of the thermocompression bonding operation and a second pressure, which is lower than the first pressure, in a second stage that follows the first stage.

Owner:SHIBAURA MECHATRONICS CORP

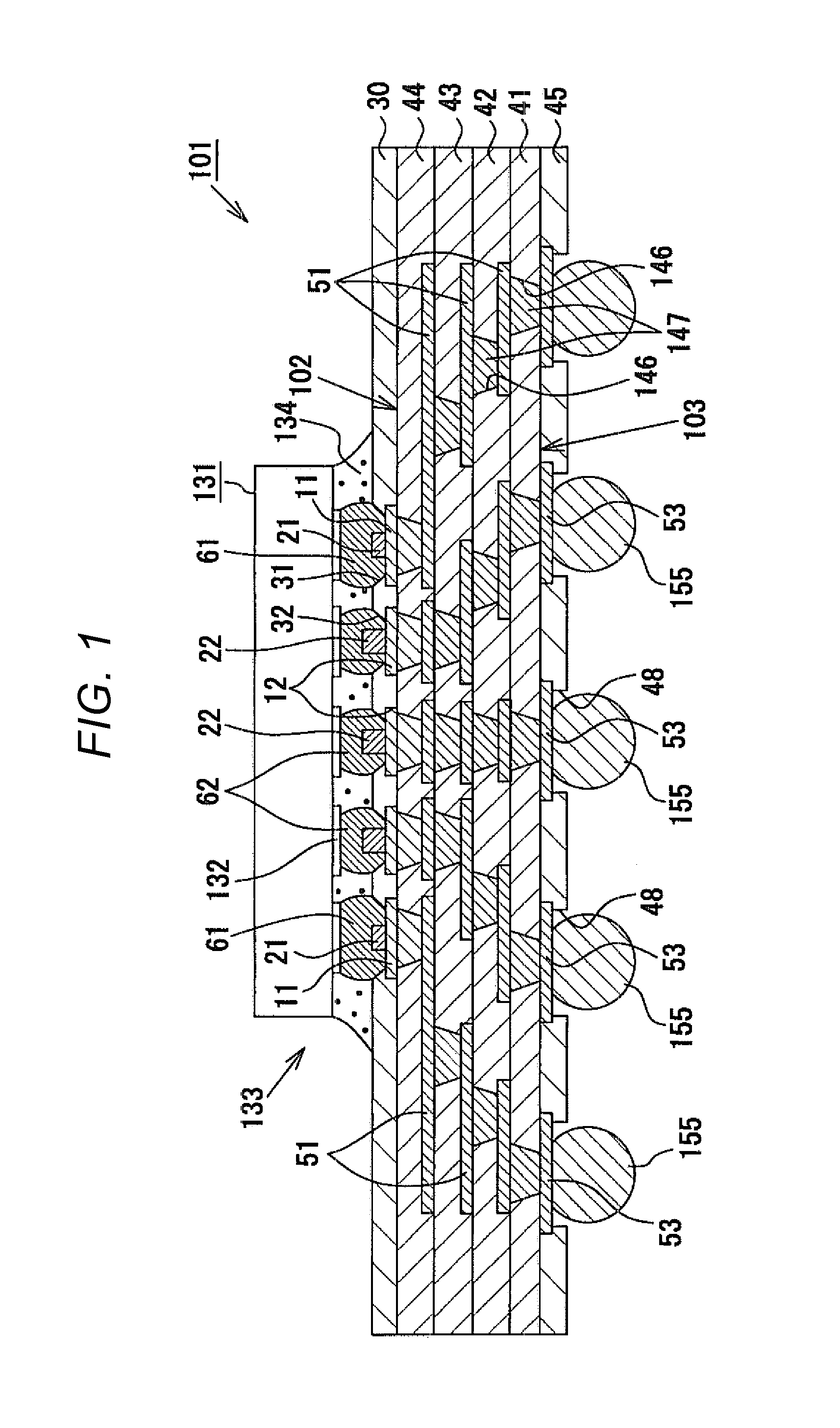

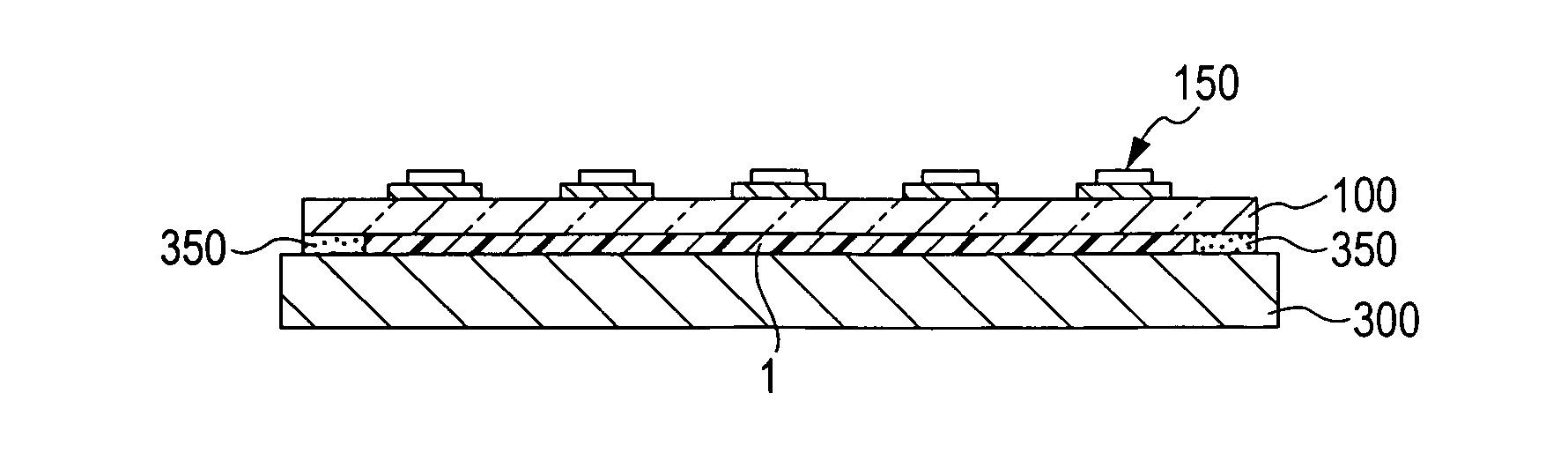

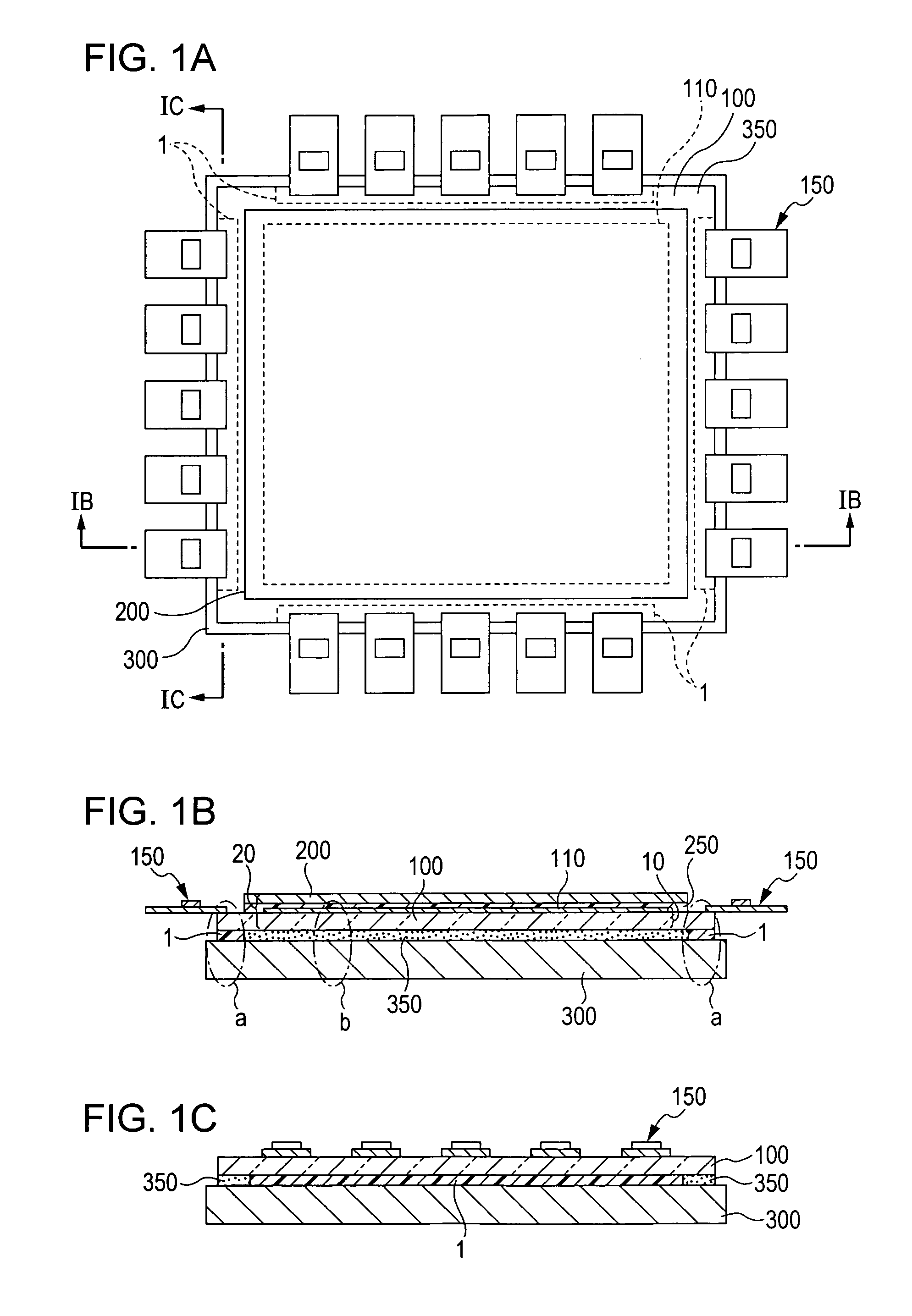

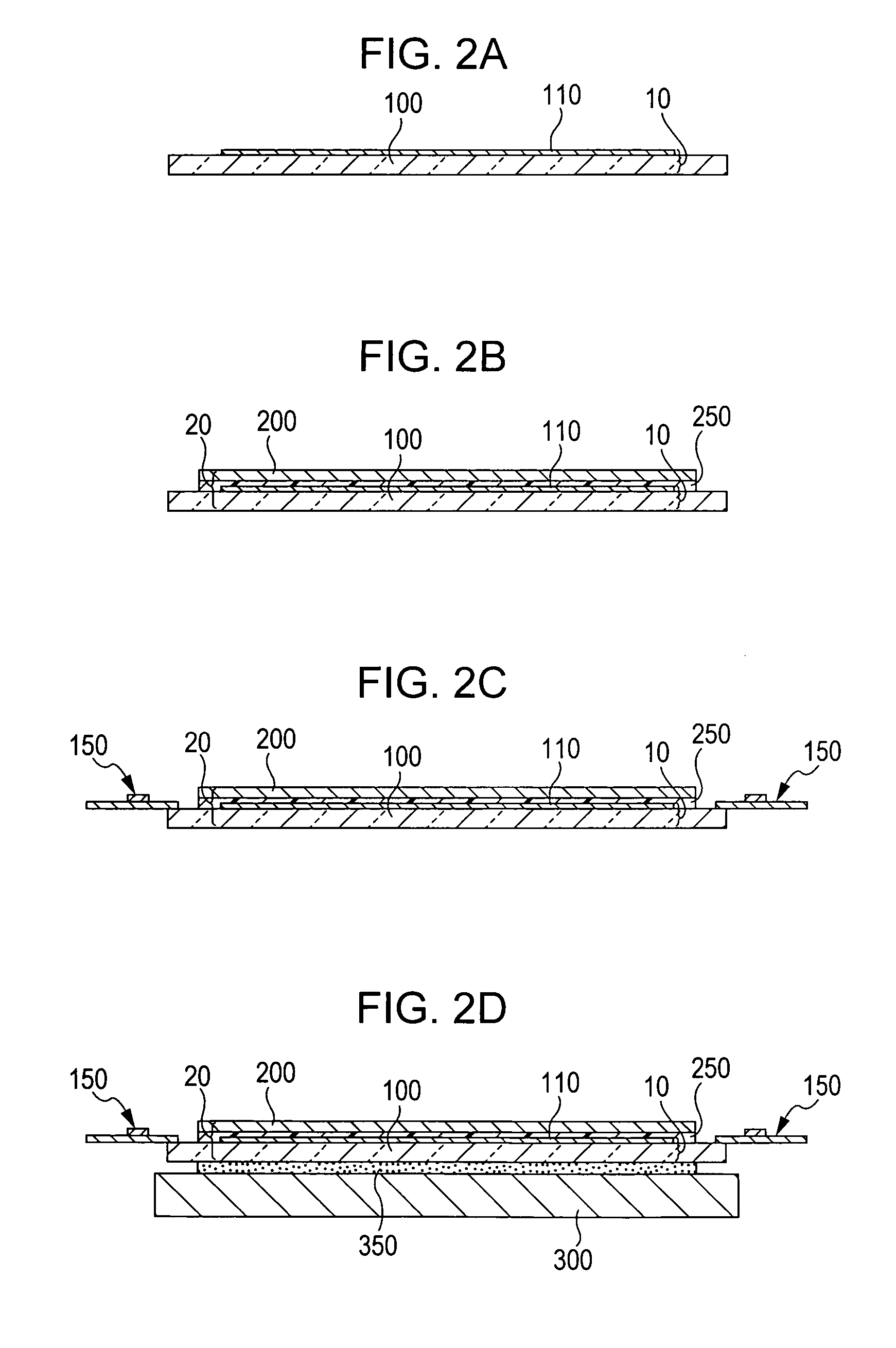

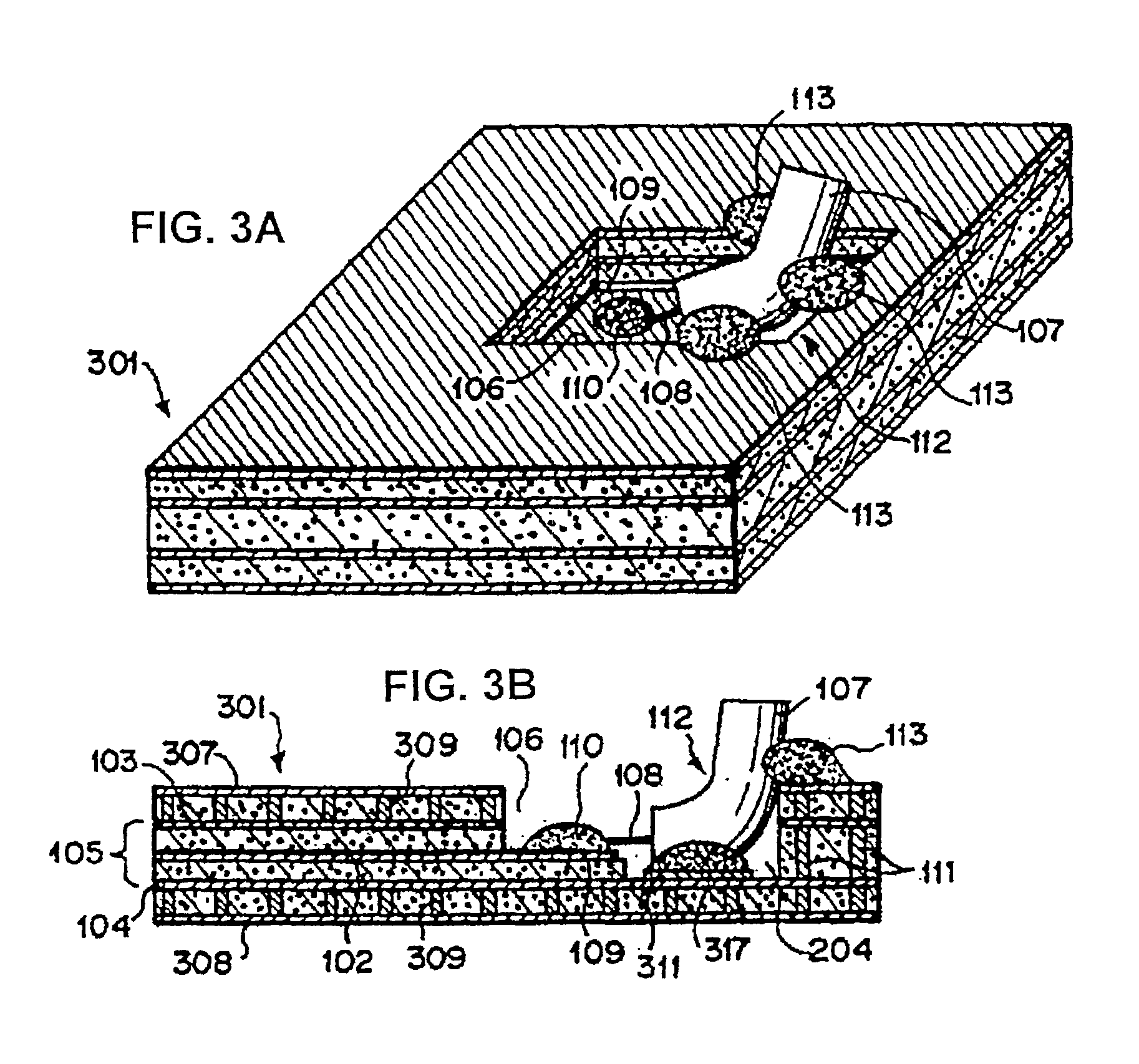

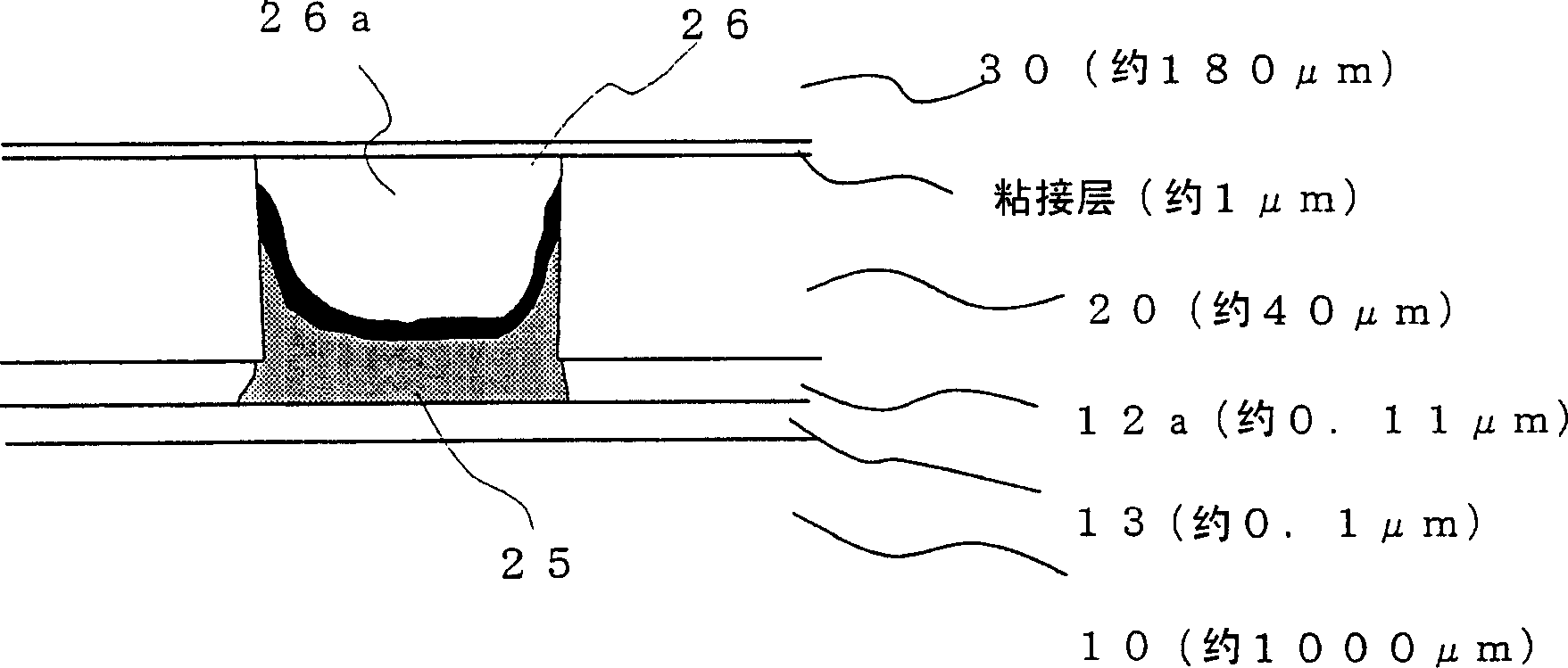

Semiconductor device, radiographic imaging apparatus, and method for manufacturing the same

InactiveUS20060108683A1Improve impact resistanceImprove adhesionSemiconductor/solid-state device detailsLaminating printed circuit boardsDevice materialElectrical connection

A semiconductor device or a radiographic imaging apparatus includes a substrate and a supporting member, the substrate having a semiconductor element or a conversion element and being bonded to the supporting member with a laminating member. The semiconductor device or the radiographic imaging apparatus further includes at least one cushioning member in at least one space between the substrate and the supporting member at least in a region including an electrical connection portion connected to at least one electrical component. Thus, when a malfunction or a defect is found in the at least one electrical component, such as TCP, on the periphery of the substrate, the defective electrical component can easily be replaced.

Owner:CANON KK

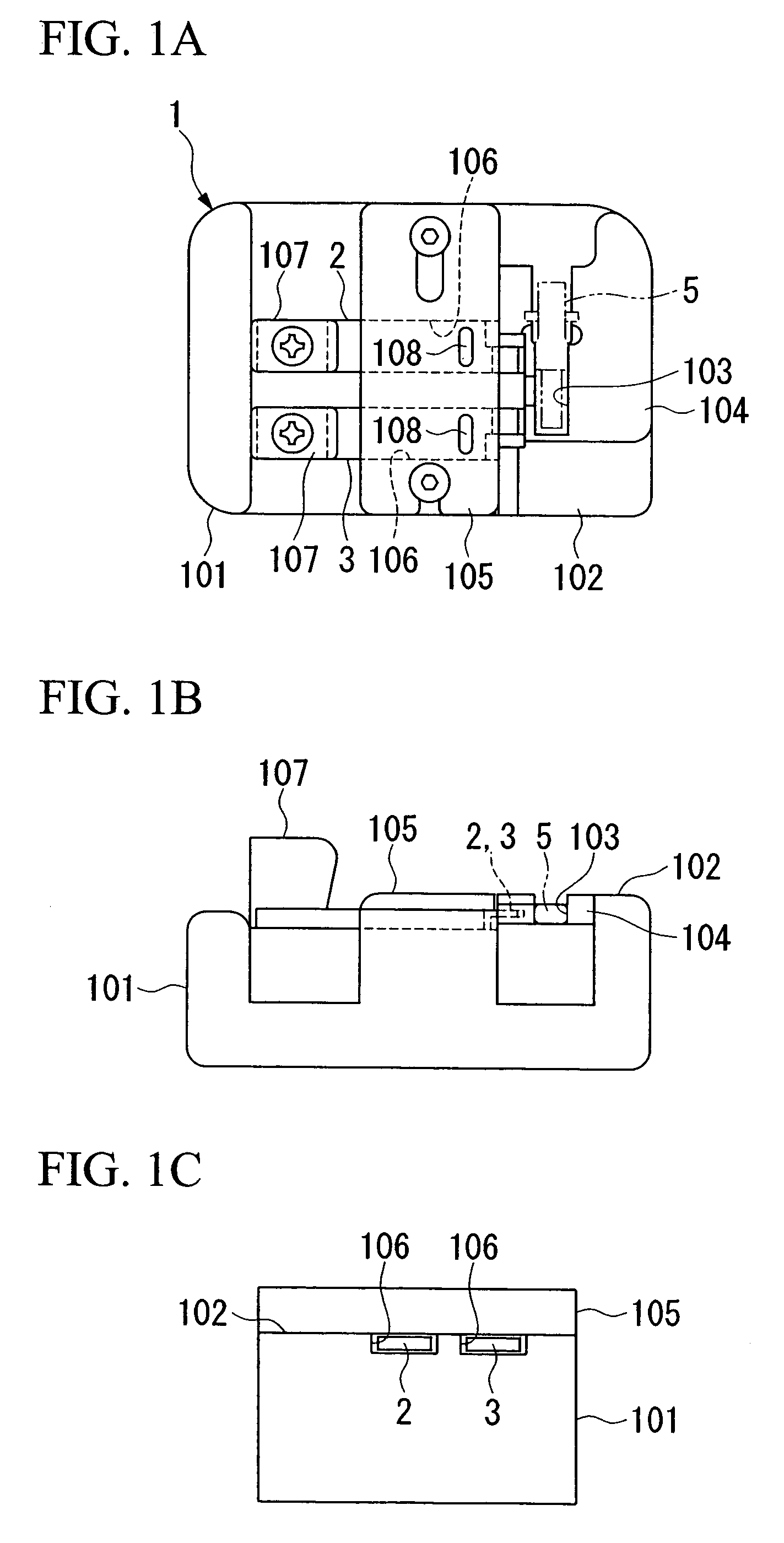

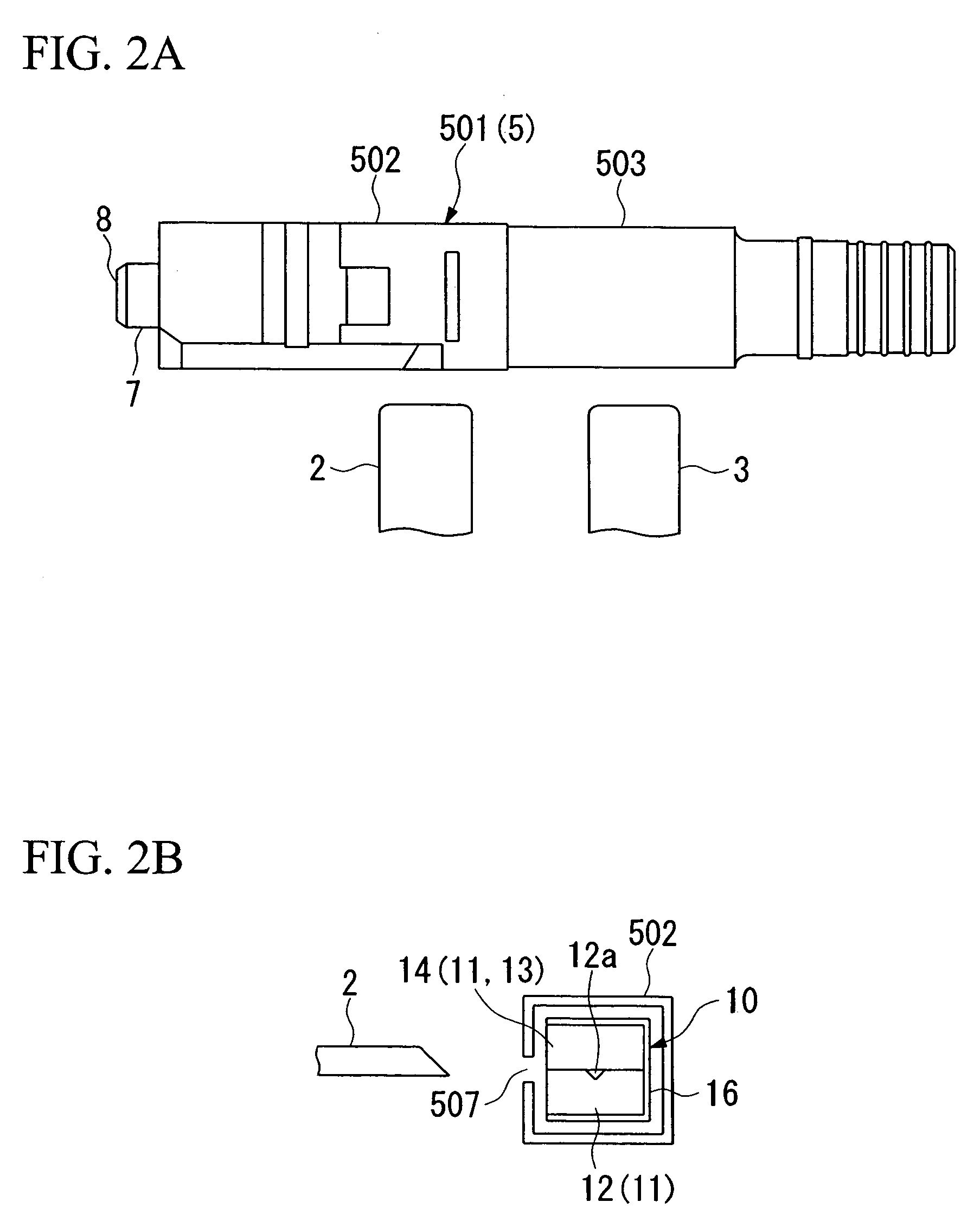

Optical fiber connection tool and optical fiber connection method

InactiveUS7258496B2Avoiding the increase in a lossPrevent bad connectionCoupling light guidesEngineeringOptical fiber cable

Owner:FUJIKURA LTD

Radio frequency circuit module on multi-layer substrate

InactiveUS20010042907A1Suppress interferenceHighly reliable signal transmissionPrinted circuit assemblingMultiple-port networksElectricityRadio frequency signal

An object of the present invention is to provide a radio frequency integrated circuit module that is less susceptible to the electromagnetic influence and that is not degraded in electric connection. The radio frequency circuit module of the present invention including circuit elements mounted on a multi-layer circuit substrate having dielectric layers is characterized in that an exposed connection portion is provided by removing a part of the dielectric, and a strip line connected to said circuit elements and a co-axial line for transmitting a radio frequency signal from / to said strip line are connected together in a bottom portion of said exposed connection portion so as to be rectilinear in a three dimensional way.

Owner:NEC CORP

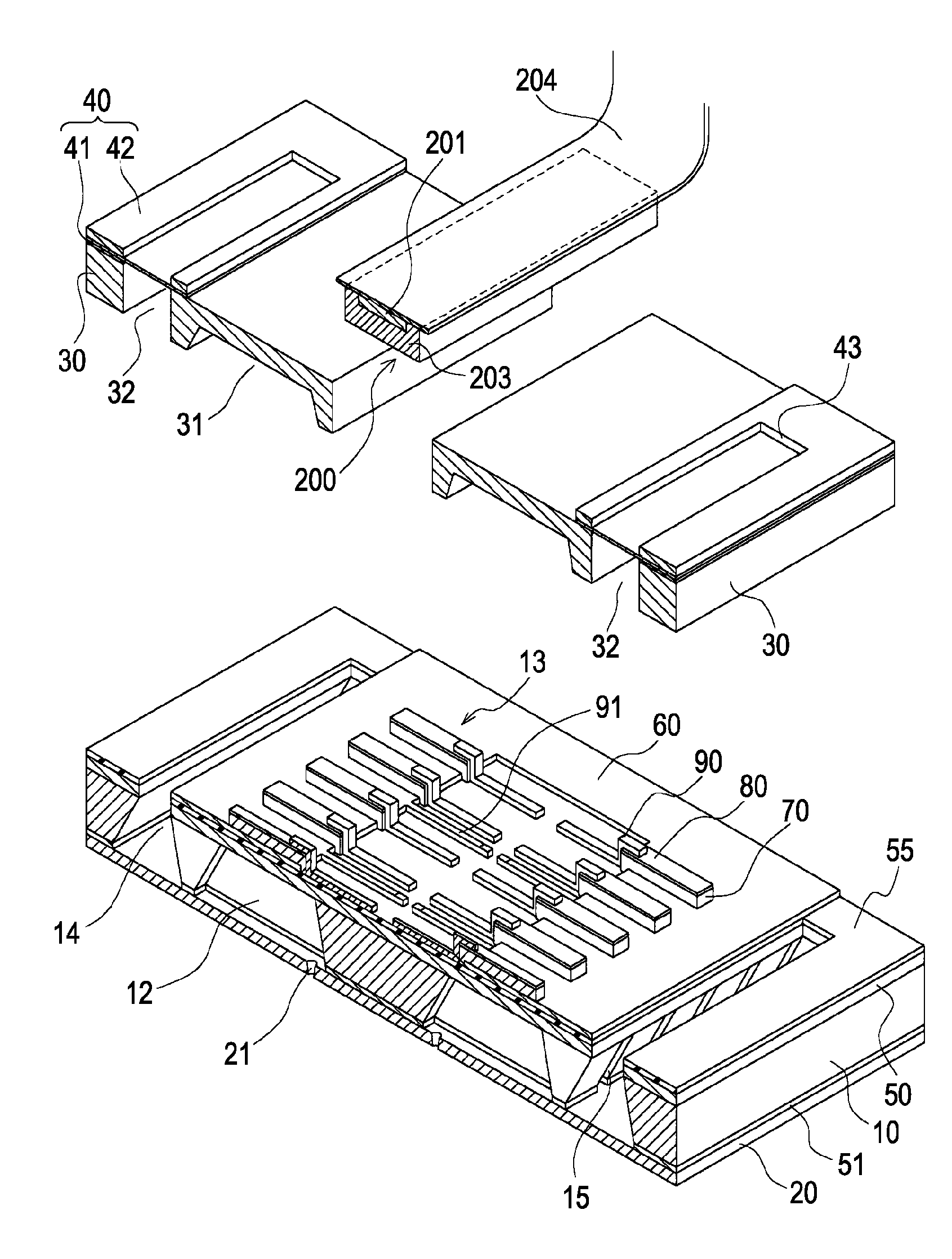

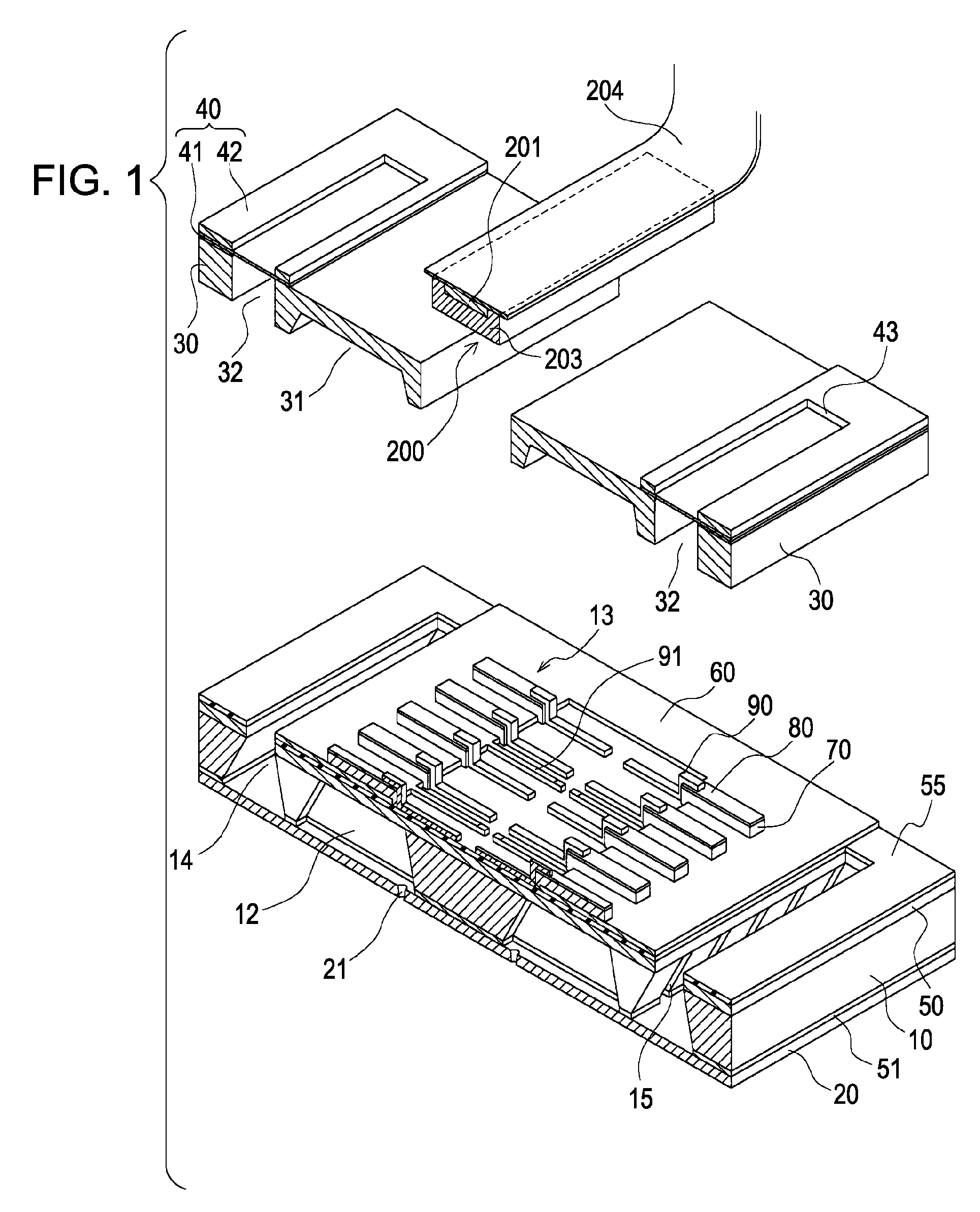

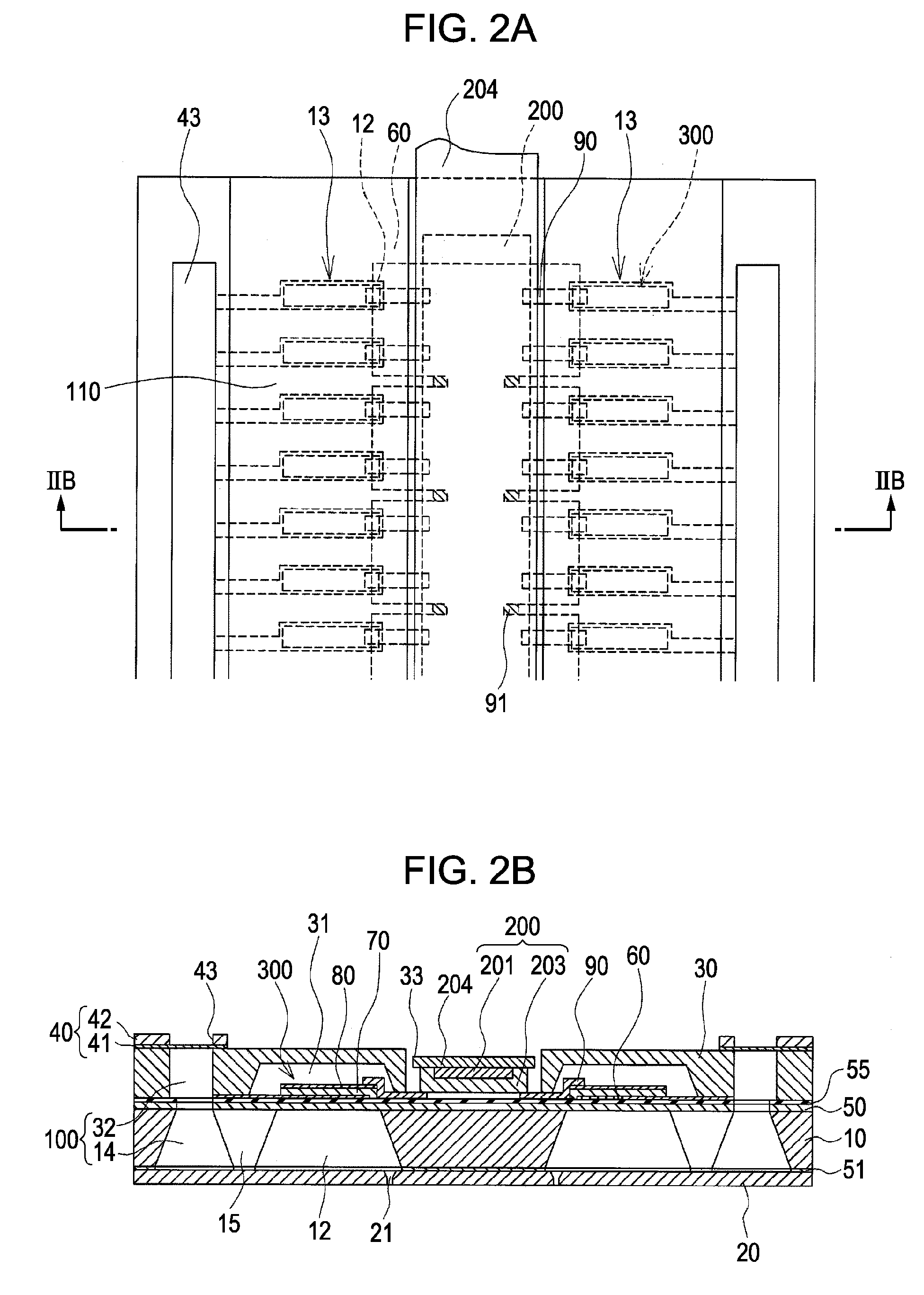

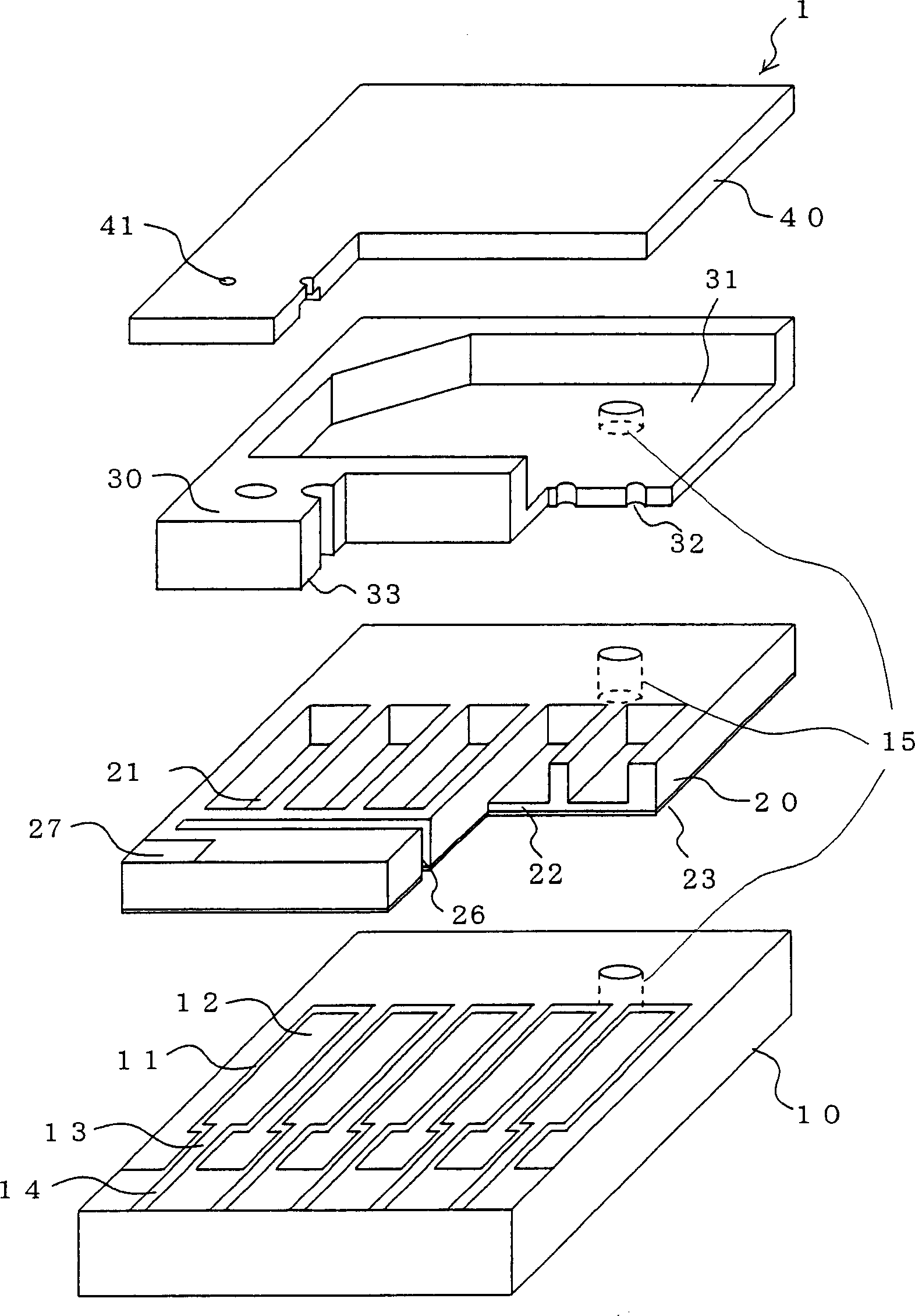

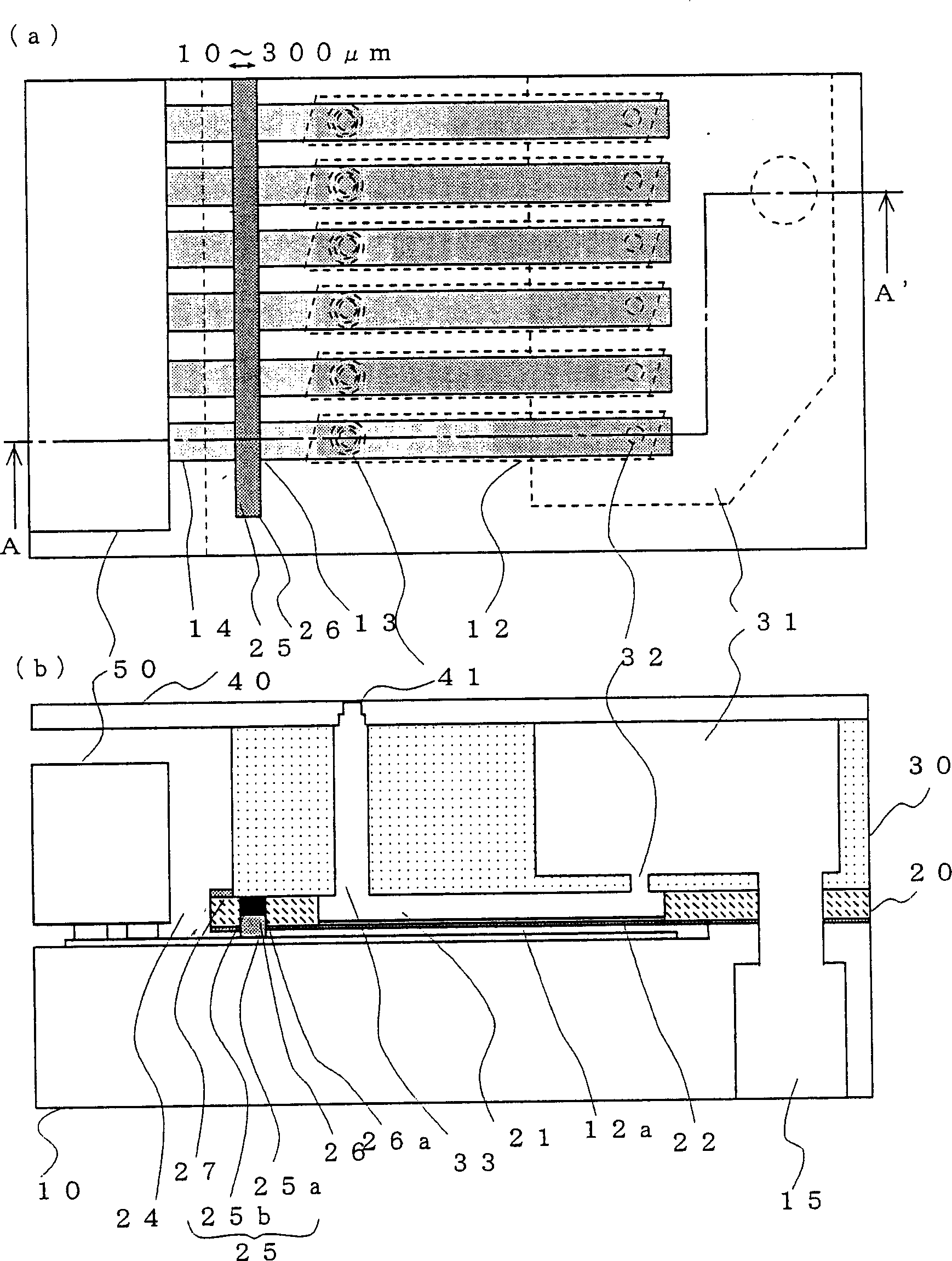

Liquid ejecting head and liquid ejecting apparatus

A liquid ejecting head includes a passage-forming substrate, a plurality of pressure-generating elements, and an IC chip. The passage-forming substrate has a nozzle opening, and a pressure-generating chamber communicating with the nozzle opening. The plurality of pressure-generating elements are provided on a surface of the passage-forming substrate with a diaphragm interposed therebetween. The pressure-generating elements have electrodes and cause pressure change in the pressure-generating chamber. The IC chip is mounted on the surface of the passage-forming substrate with the pressure-generating elements. In this liquid ejecting head, the electrodes of the pressure-generating elements include individual electrodes, and at least the individual electrodes are electrically connected to the driver circuit via the through electrode.

Owner:SEIKO EPSON CORP

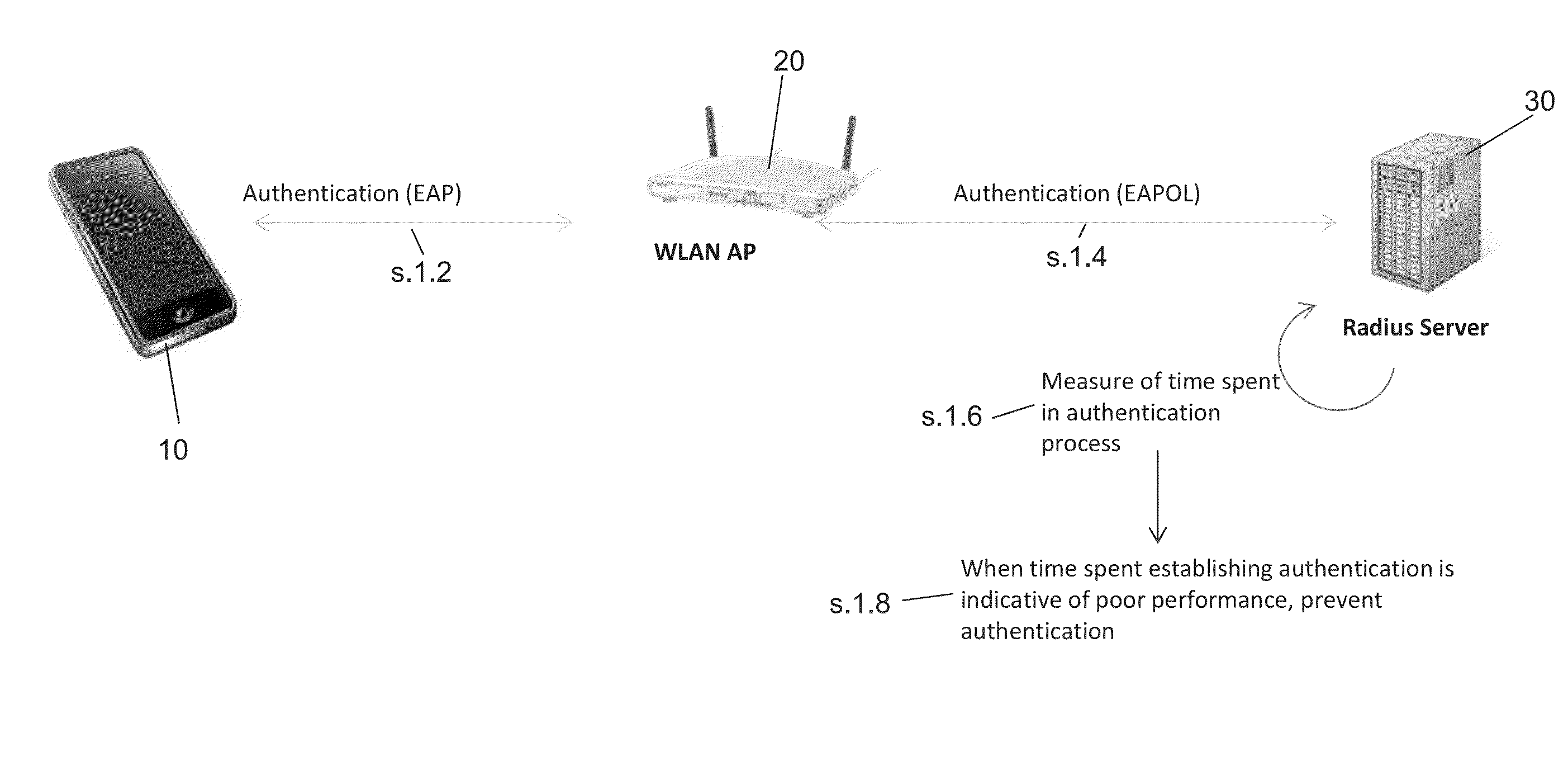

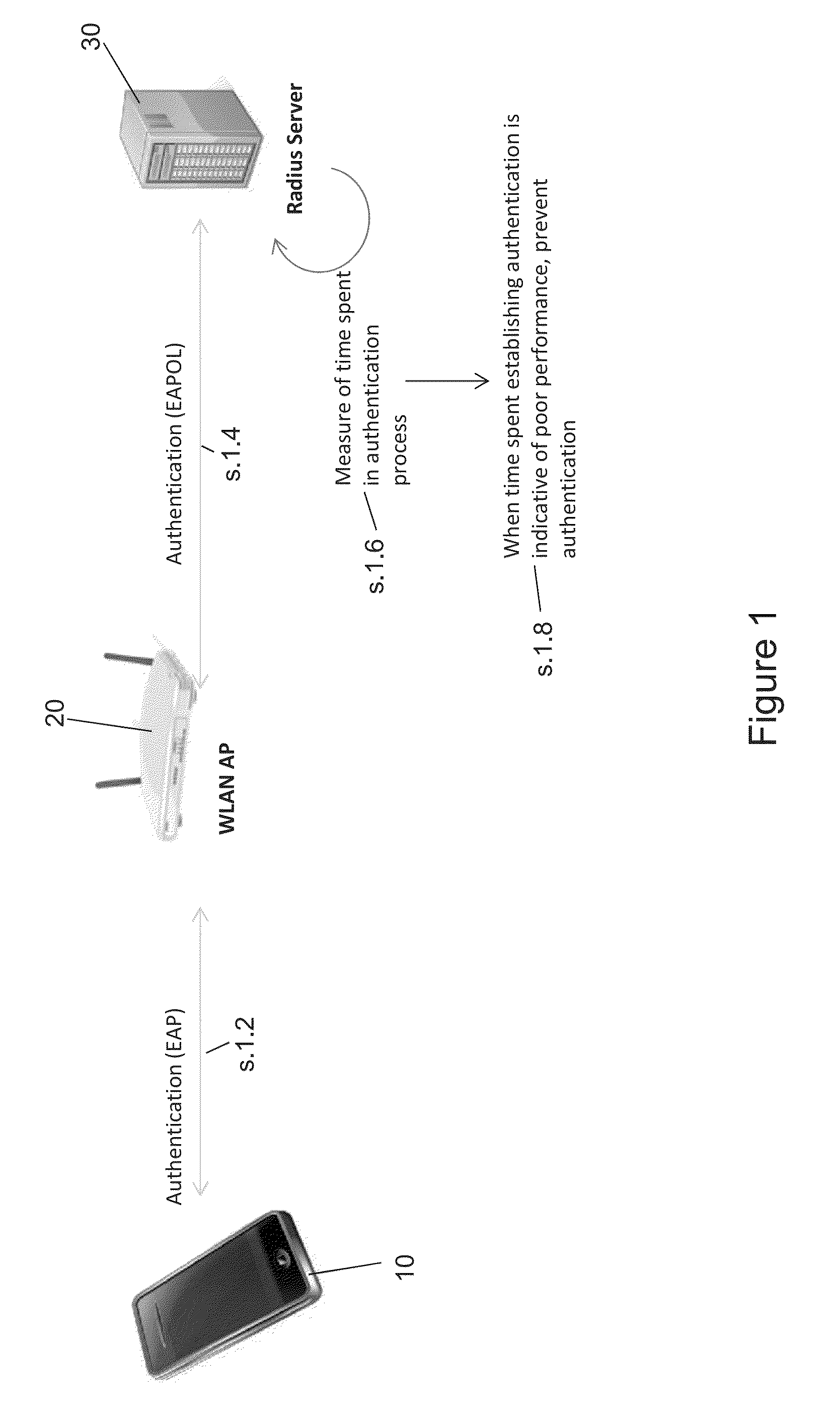

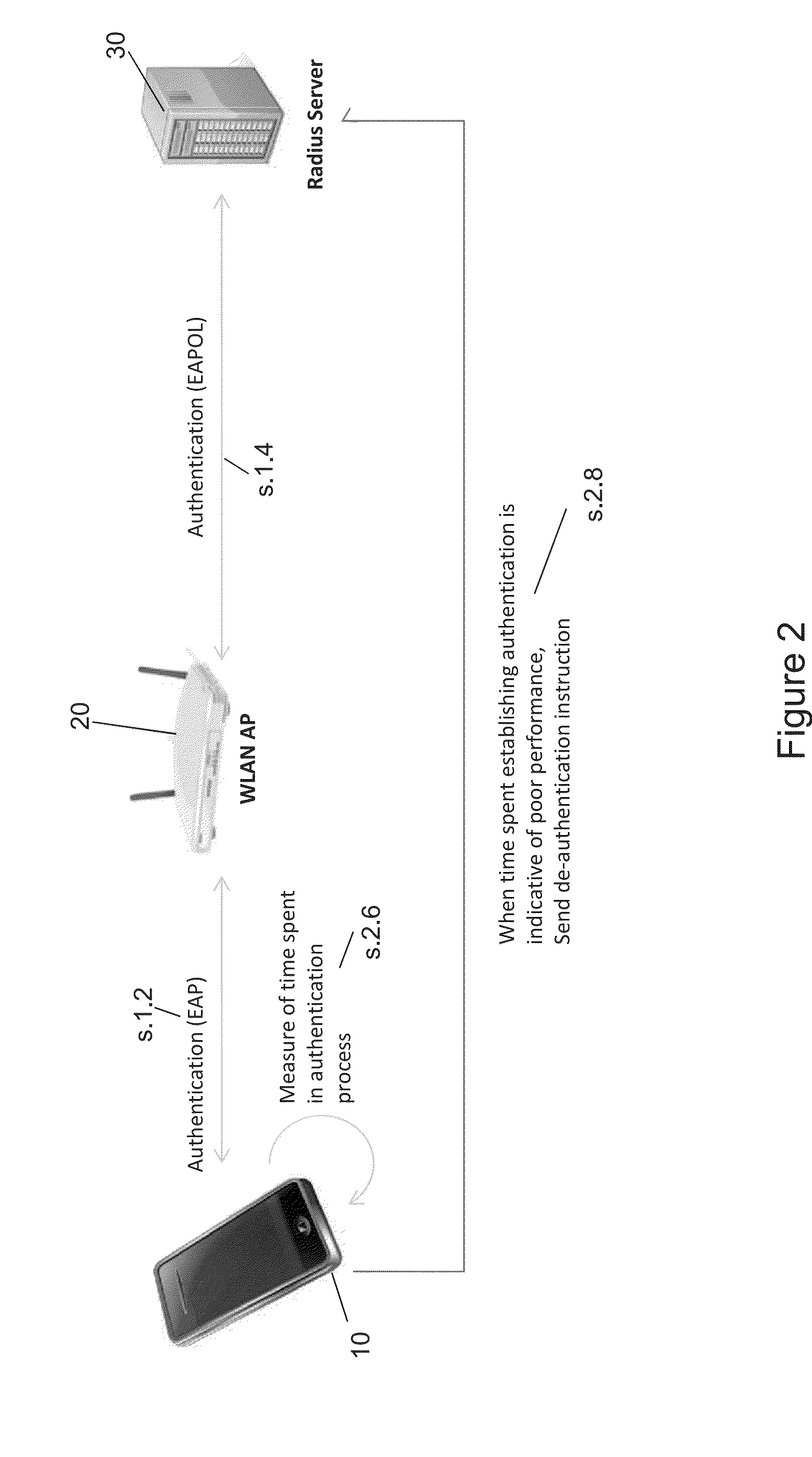

Method and System for WLAN Connection Control

ActiveUS20140105051A1Improve securityPrevent bad connectionError preventionTransmission systemsQuality of serviceConnection control

Embodiments of the invention proxy control the establishment or continued existence of a WLAN connection by using the back end authentication mechanism to authenticate / de-authenticate a WLAN session in dependence on the experienced quality of the connection during the set-up phase or session itself. This has the effect of preventing a bad quality connection from being established or from continuing, and hence should improve the user experience, and help a WLAN network operator maintain a service with high Quality of Service (QoS).

Owner:CARNEGIE TECH UK

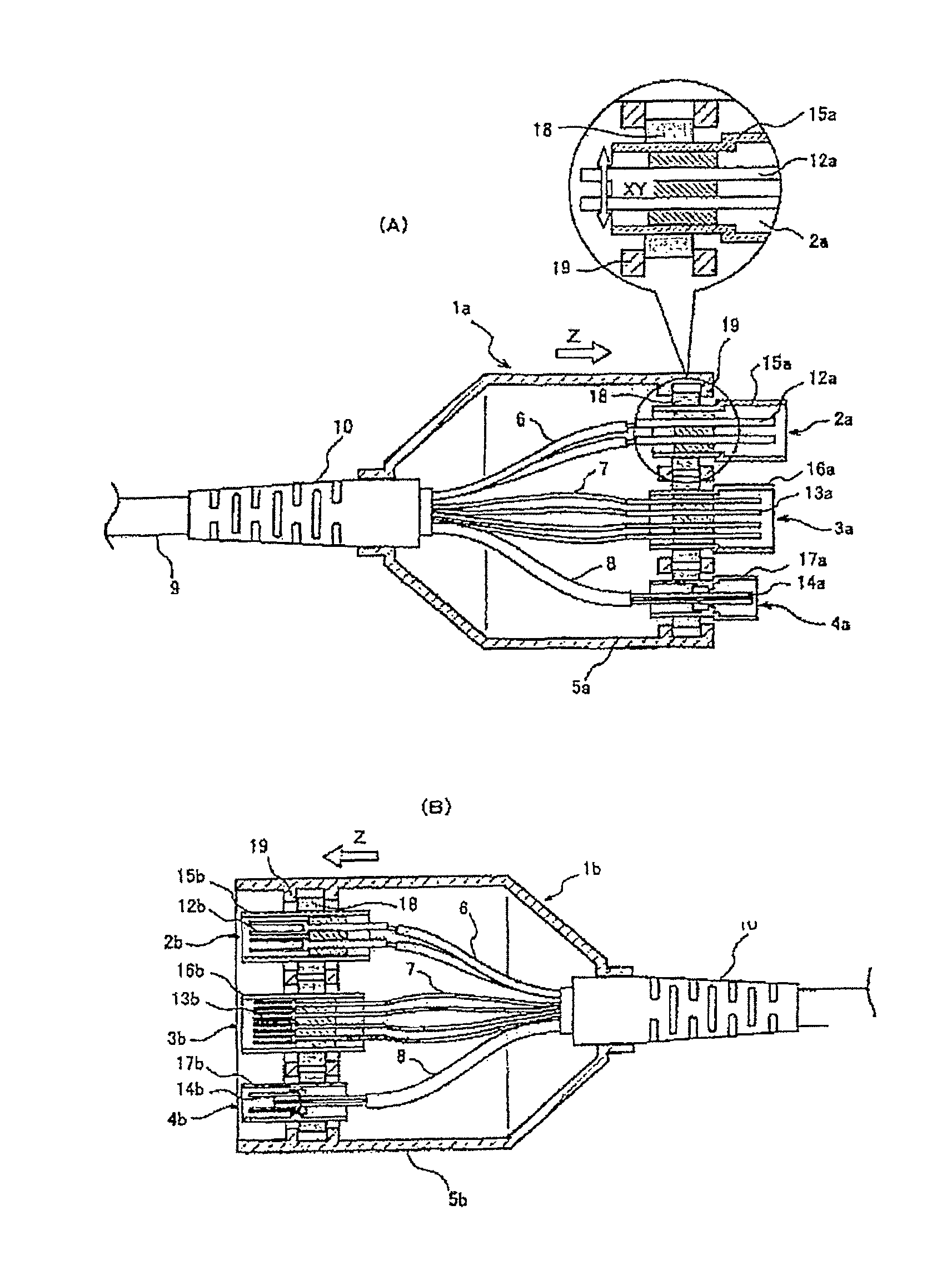

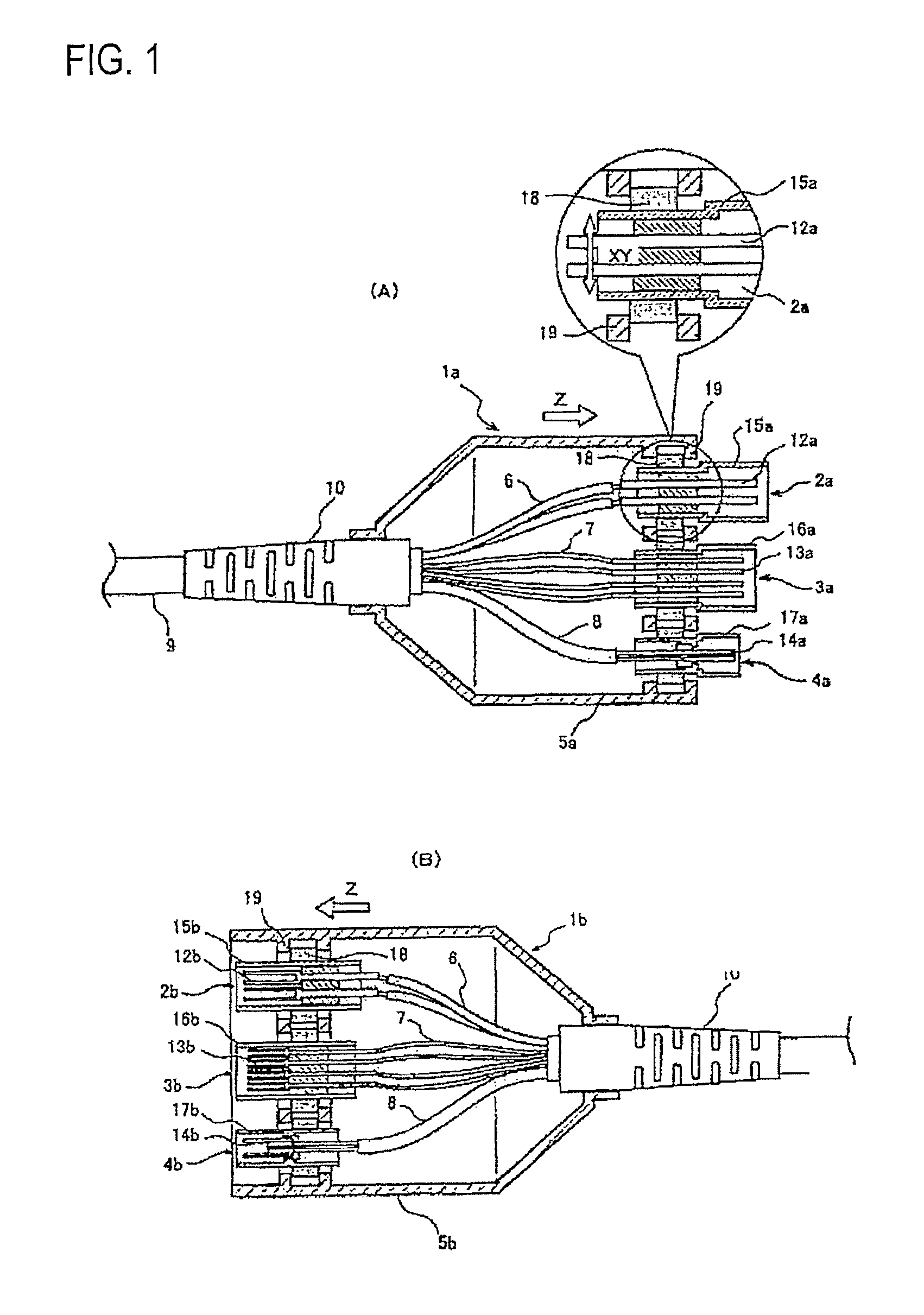

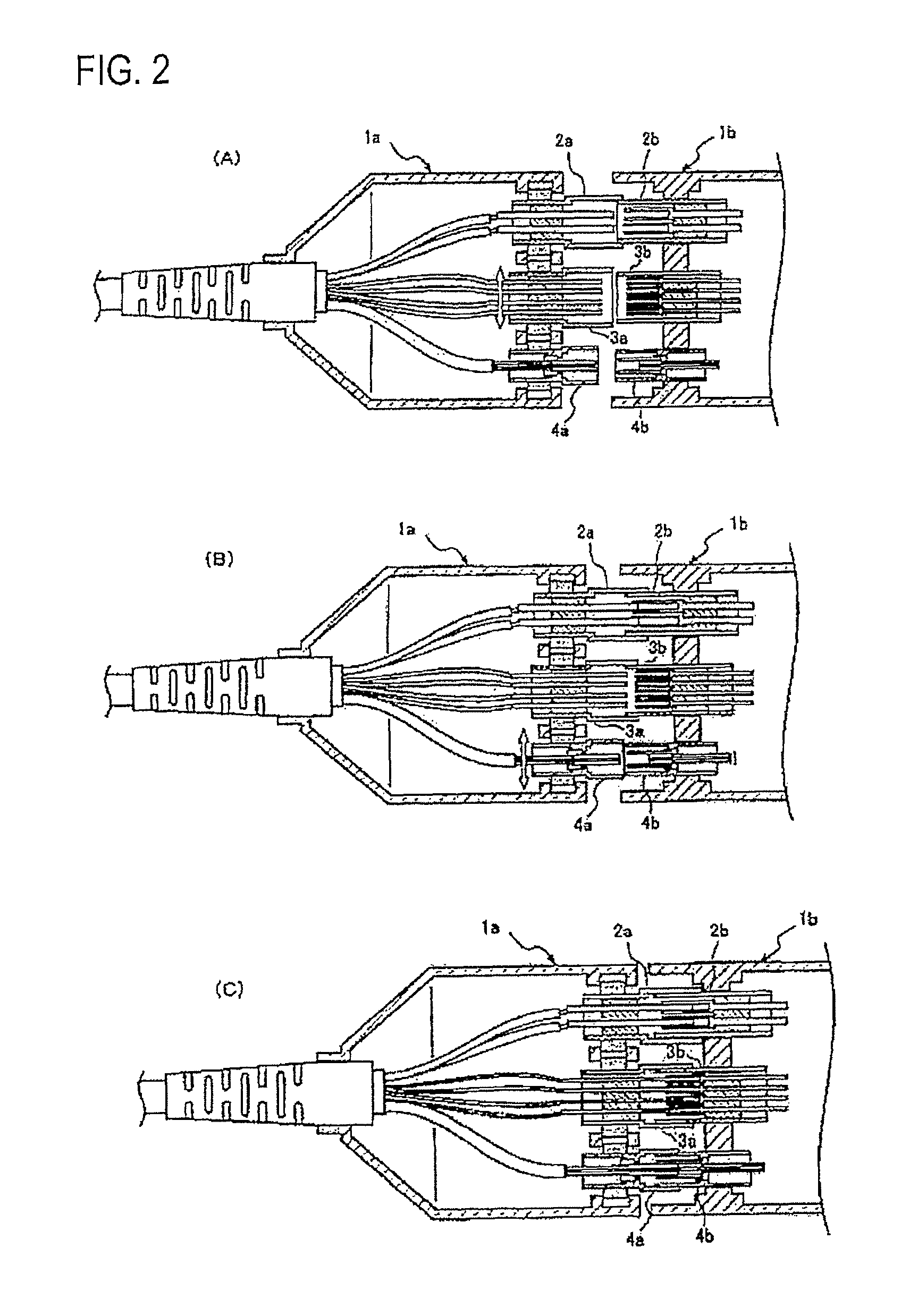

Hybrid connector and cable with said connector

InactiveUS8672696B2Avoid poor connectionPrecise positioningElectrically conductive connectionsElectric discharge tubesEngineeringFront edge

[Problem] To provide a hybrid connector and a cable with the connector which correct a positional error of connector units and enable to connect connectors when they are connected and even if there is a small positional error of the connection unit.[Solving Means] A hybrid connector holds plural connector units 2a to 4b in a common connector housing 5a, 5b. Each of the plural connector units is held individually movably in a direction (XY) orthogonal to an axial direction (Z) of connection. The connector unit is preferably movably held through a holding member 18 formed by an elastic matter. Front edges at the fitting start of the plural connector units 2a to 4b are tapered, and the connector units move along tapered portions in the connection fitting time. The plural connector units may be different in front-edge fitting start position along a connecting direction.

Owner:SUMITOMO ELECTRIC IND LTD

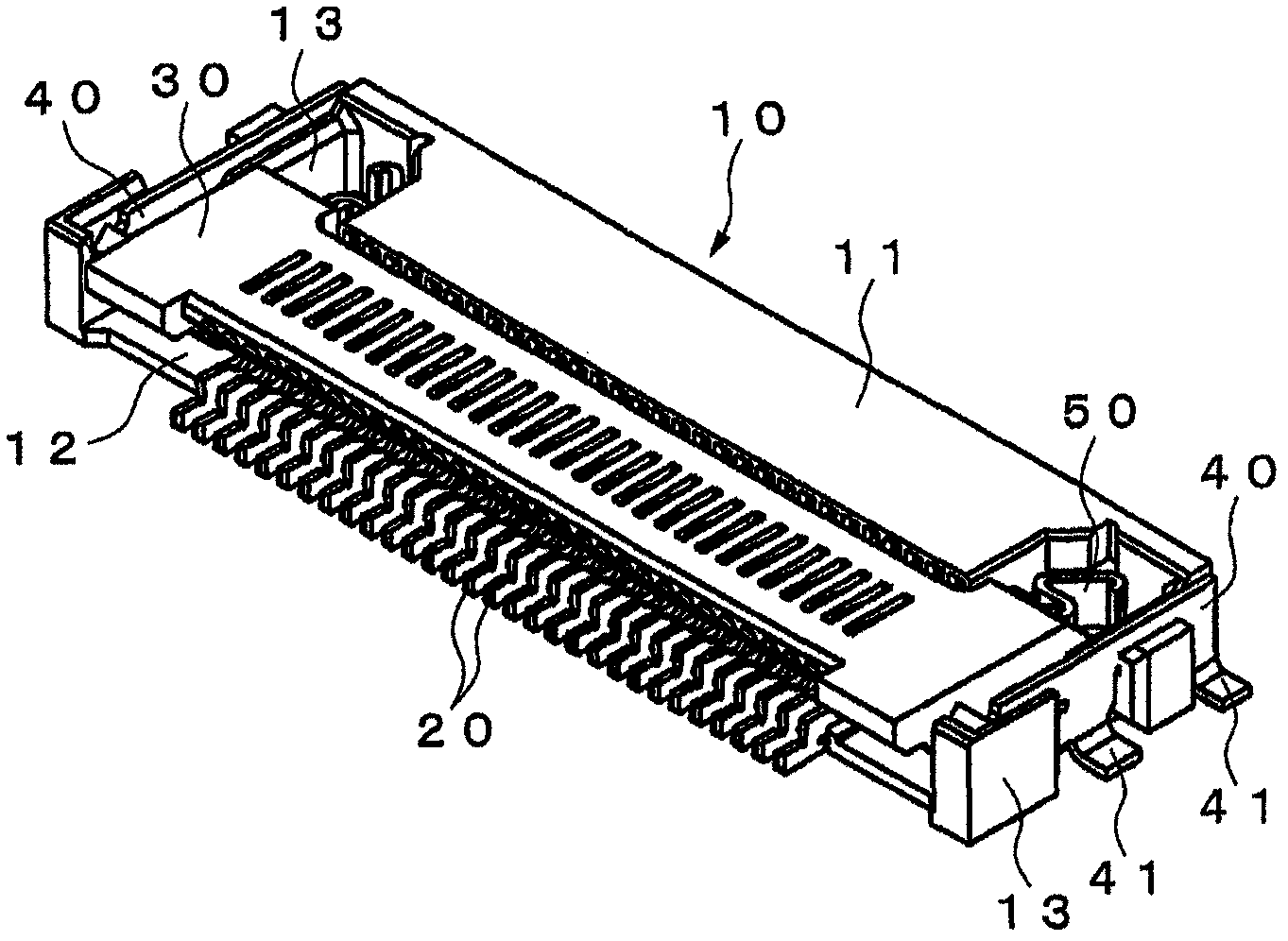

Electrical connector

InactiveUS7354299B2Prevent bad connectionEliminate disadvantagesPrinted circuit assemblingElectrically conductive connectionsElectrical conductorCoaxial cable

An electrical connector includes a plug connector and a receptacle connector detachably fitted with each other. The plug connector comprises a plurality of coaxial cables, a flexible printed circuit board and a ground bar. Each of the coaxial cable has a center conductor, an insulator covering the center conductor, a braid as an external conductor covering the insulator, and a sheath covering the braid. The flexible printed circuit board has lands each connected to the center conductor of the coaxial cable and land portions to which the ground bar is connected. The grand bar has a main portion adapted to contact the braids of the coaxial cables, and fixed portions each positioned contiguously with the main portion and connected to the land portion. The electrical connector achieves the low height geometry of the plug connector and hence that of the receptacle connector and precludes any failed connection between the ground bar and the coaxial cables.

Owner:DDK LTD

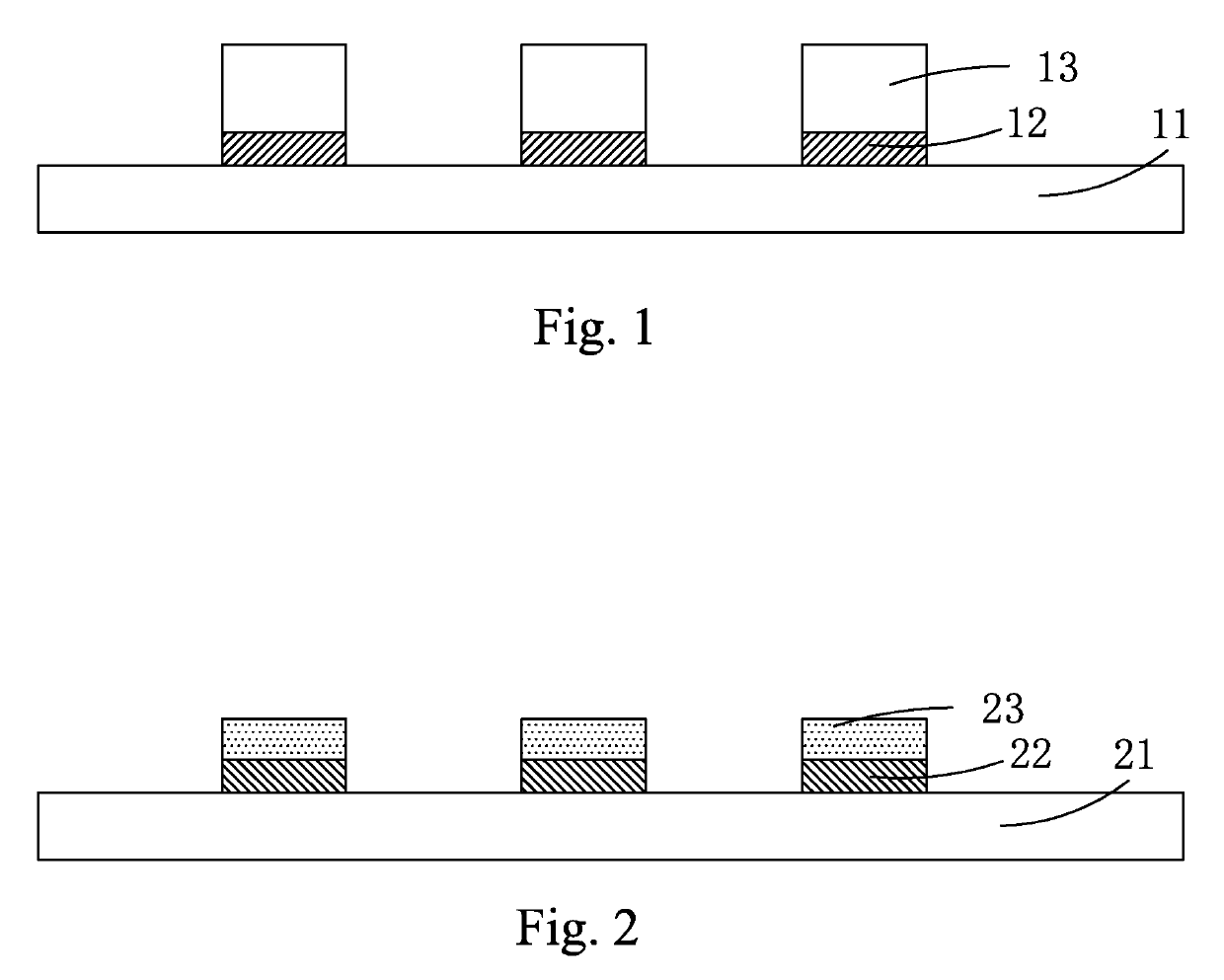

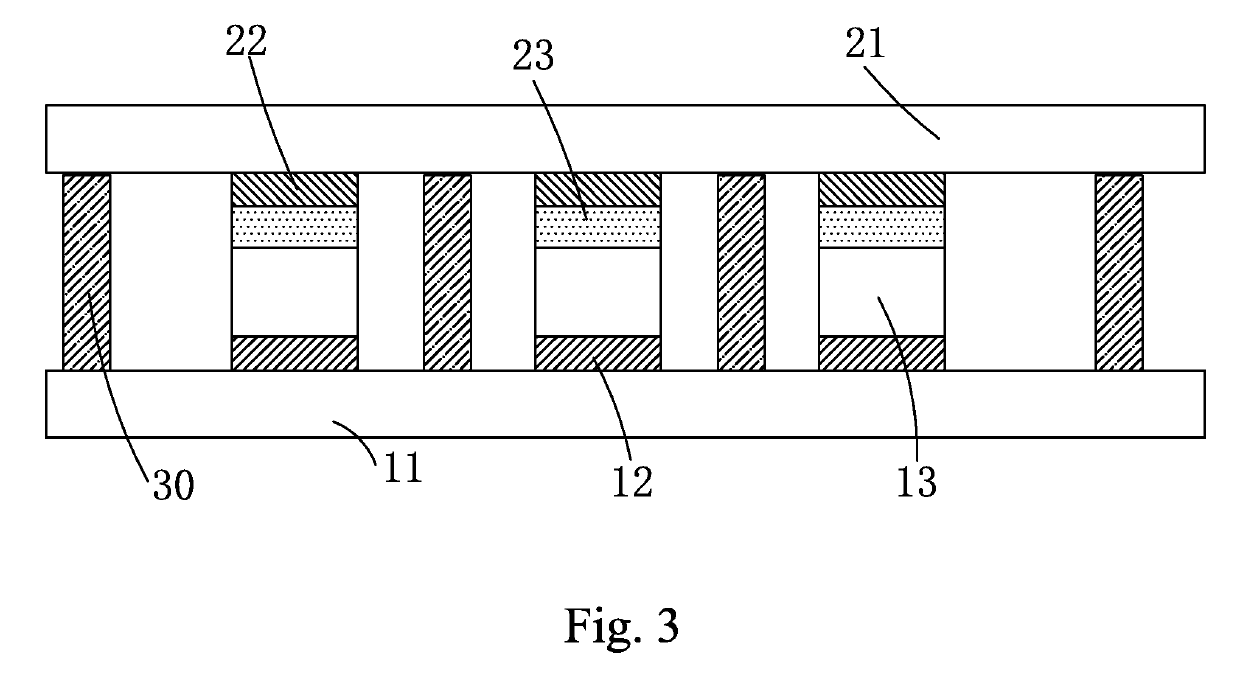

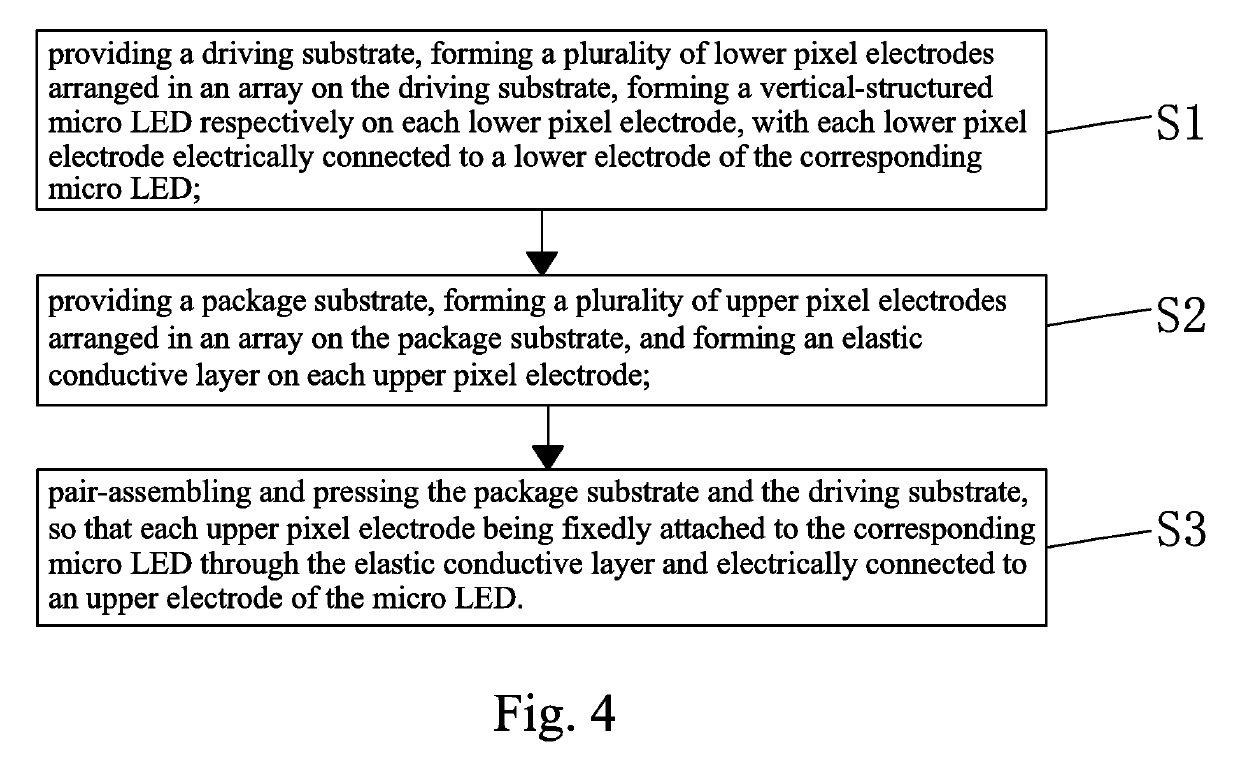

Manufacturing method of micro light-emitting diode display panel and micro light-emitting diode display panel

ActiveUS20190333897A1Improve pairing performancePrevent bad connectionSolid-state devicesSemiconductor devicesLED displayEngineering

The invention provides a manufacturing method of micro LED display panel and micro LED display panel. In the manufacturing method, an elastic conductive layer is formed on the upper pixel electrode on the package substrate. When the package substrate and the driving substrate are assembled, the upper pixel electrode and the upper electrode of the micro LED are electrically connected through the elastic conductive layer, and the elasticity of the elastic conductive layer is utilized to fill the height difference between the individual micro LEDs, avoid poor connection between the upper pixel electrode and the upper electrode of the micro LED, and improve the assembling effect of the micro LED display panel and the process yield of the micro LED display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Imaging device and manufacturing method for imaging device

InactiveUS20030203532A1Simple structureReduce thicknessTelevision system detailsSolid-state devicesEngineeringMaterials science

An imaging device unit comprises a CCD chip and a substrate on which the CCD chip is soldered. A light receiving surface is provided in the front surface of the CCD chip. A dustproof member for protect the light receiving surface from dust is attached around the light receiving surface. Chip terminals are arranged between the light receiving surface and the dustproof member. When the CCD chip is pressed against the rear surface of the substrate, the dustproof member is elastically deformed and tightly makes contact with the substrate. Since ultrasound is applied to the chip terminals and the substrate terminals in this state to melt them, the CCD chip is positioned in parallel with the substrate. Upon stopping ultrasound horns, both of the terminals are immediately soldered to each other, so that the CCD chip is securely fixed on the substrate with ease.

Owner:FUJIFILM CORP +1

Laser processing bearing device of flexible circuit board

InactiveCN101296581AFixedHigh precisionMultilayer circuit manufactureElectrical componentsLaser processingFlexible circuits

The invention relates to a bearing device for the laser processing of a flexible printed circuit, which comprises a first surface and a second surface. The first surface is provided with at least one first groove and at least one vacuum-absorbing positioning hole; the at least one vacuum-absorbing positioning hole passes through the first surface and the second surface. The second surface is provided with at least one second groove; the sum of the depth of the second groove and the depth of the first groove which is corresponding to the second groove is less than the thickness from the first surface to the second surface of the bearing device for the laser processing of the flexible printed circuit. The bearing device for the laser processing of the flexible circuit board ensures that the double-sided flexible circuit board can be levelly fixed on a laser processing device, and can effectively improve the precision of the laser cutting of the double-sided flexible circuit board and effectively prevent bad connection and breaking off between or damage to electronic components and the flexible circuit board.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

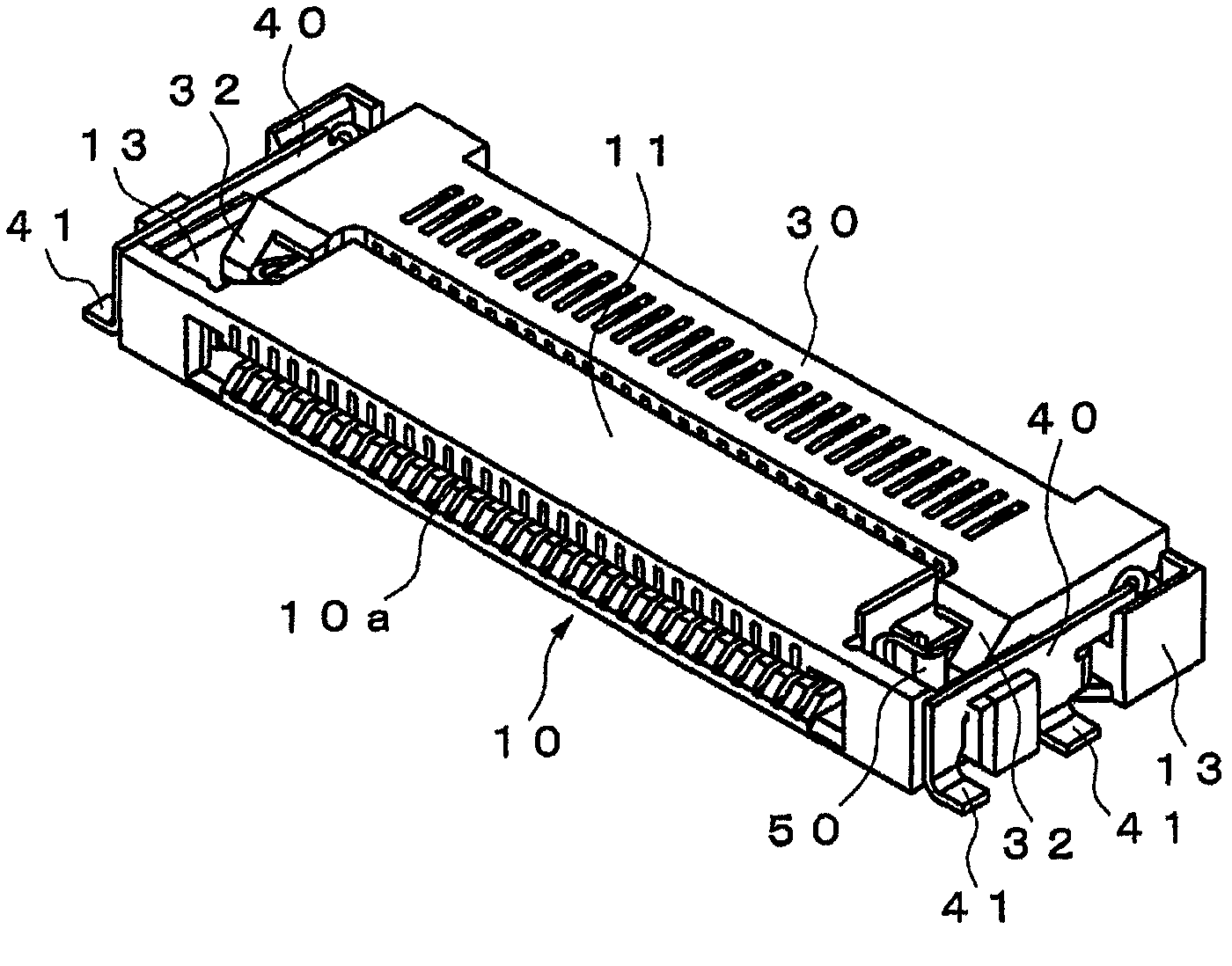

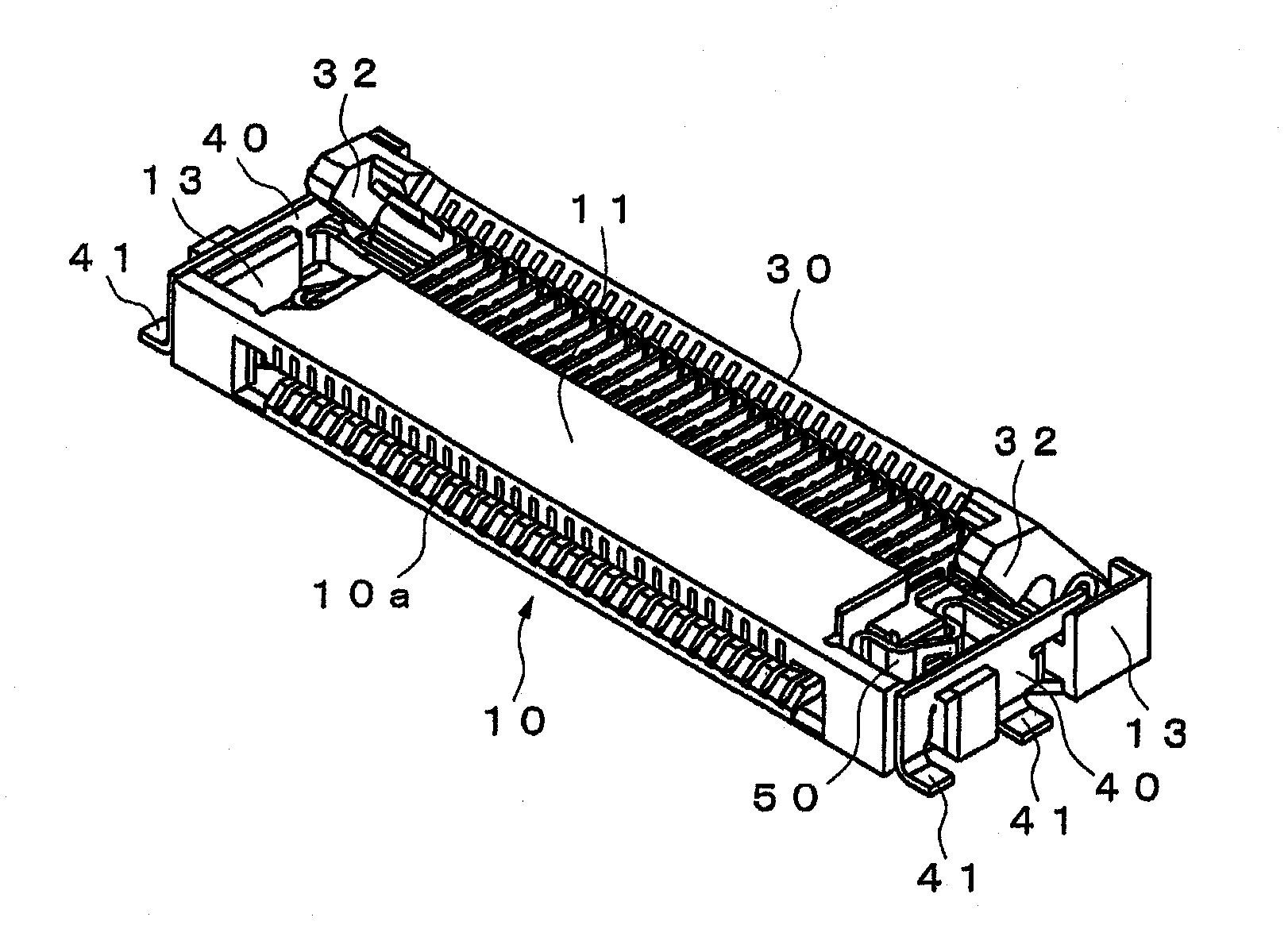

Connector

InactiveCN102057539AFacilitate thinningPrevent bad connectionIncorrect coupling preventionFlexible circuitsEngineering

A connector capable of effectively preventing a connection failure due to incomplete insertion of an object which is connected to the connector. When the front end of a flexible circuit (1), which is inserted in the connector body (10), makes contact with a lock member (50) and when a pressing member (30) is then pivoted in one direction with the lock member (50) deformed to the outside in the width direction of the connector body (10), a protrusion (32) of the pressing member (30) makes contact with the lock member (50) to restrict the rotation of the pressing member (30), and when the pressing member (30) is pivoted in said direction with the lock member (50) returned to the inside in the width direction of the connector body (10), the pressing member (30) is permitted to rotate. The configuration prevents the pressing member (30) from pivoting to a closed position with the flexible circuit (1) incompletely inserted, and this effectively prevents a connection failure due to the incomplete insertion of the flexible circuit (1).

Owner:IRISO ELECTRONICS CO LTD

Multilayer printed wiring board and method for fabrication thereof

InactiveCN101400219AAvoid pollutionPrevent bad connectionPrinted circuit detailsPrinted circuit aspectsElectrical and Electronics engineering

Owner:SHARP KK

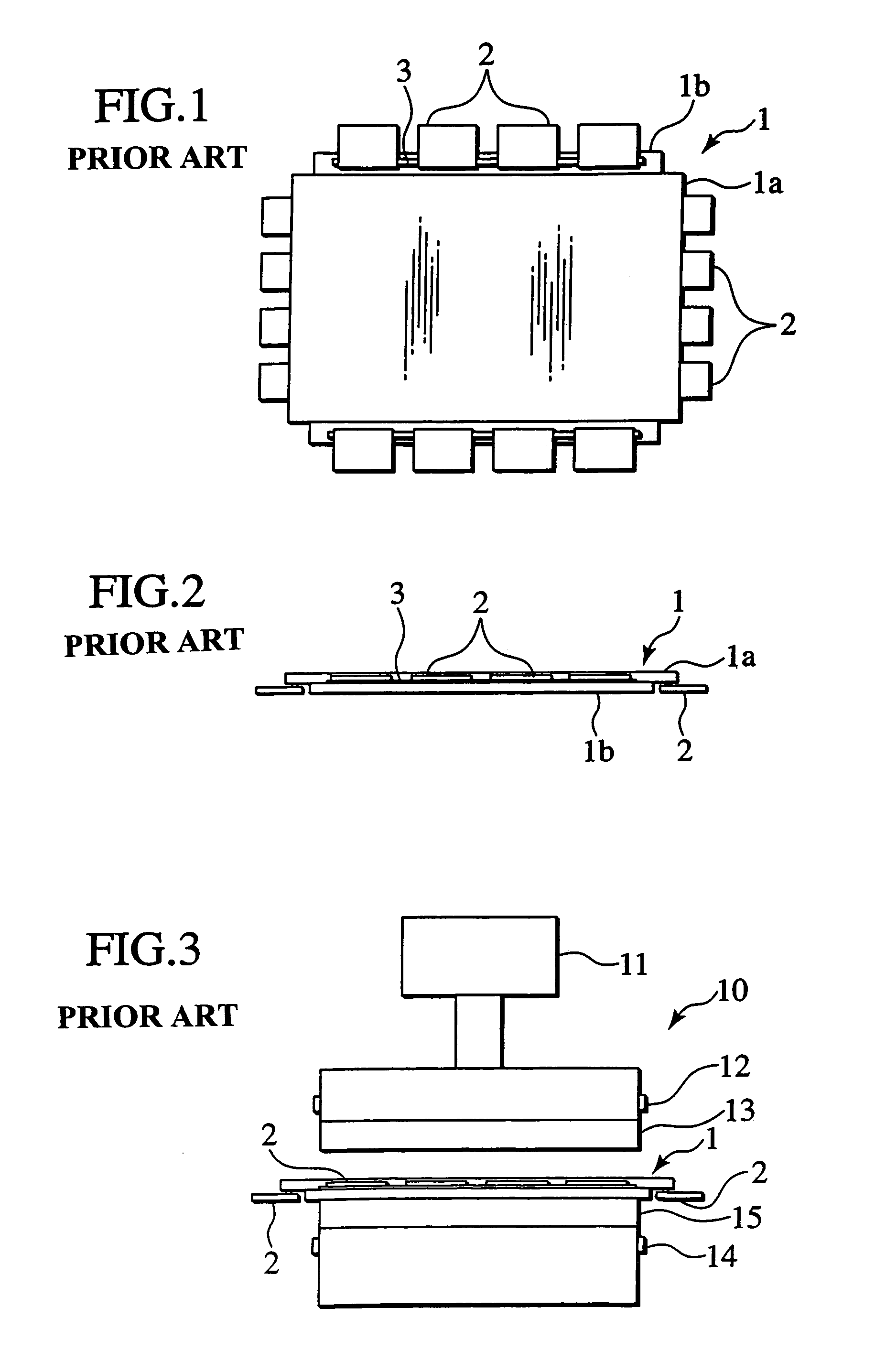

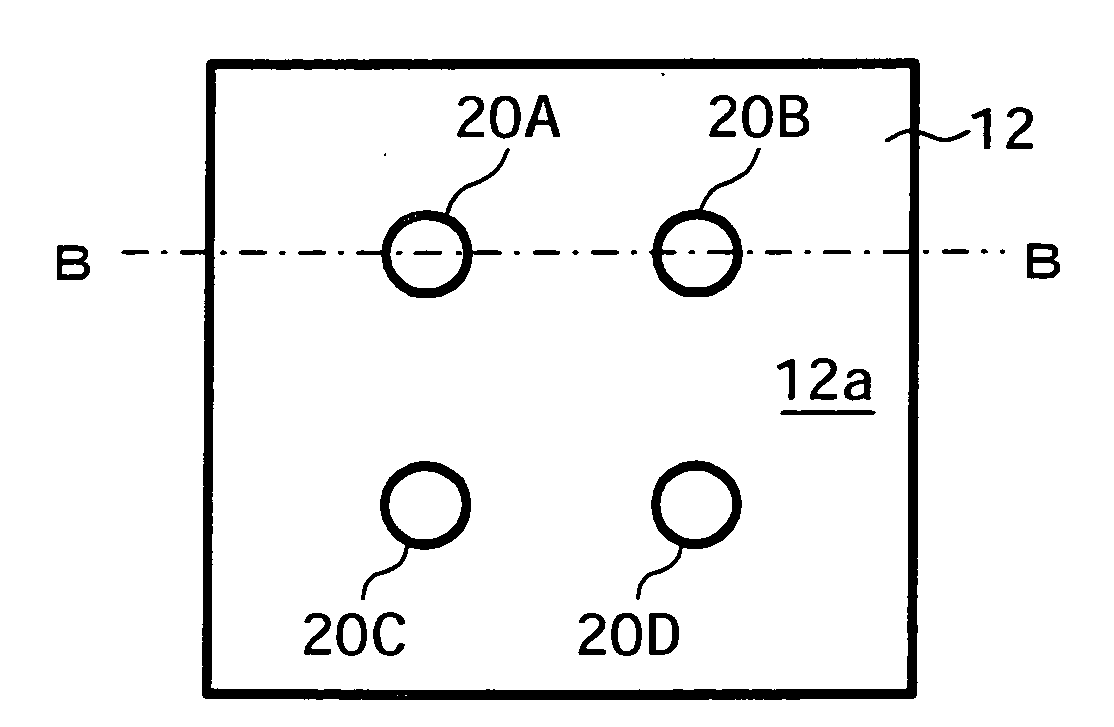

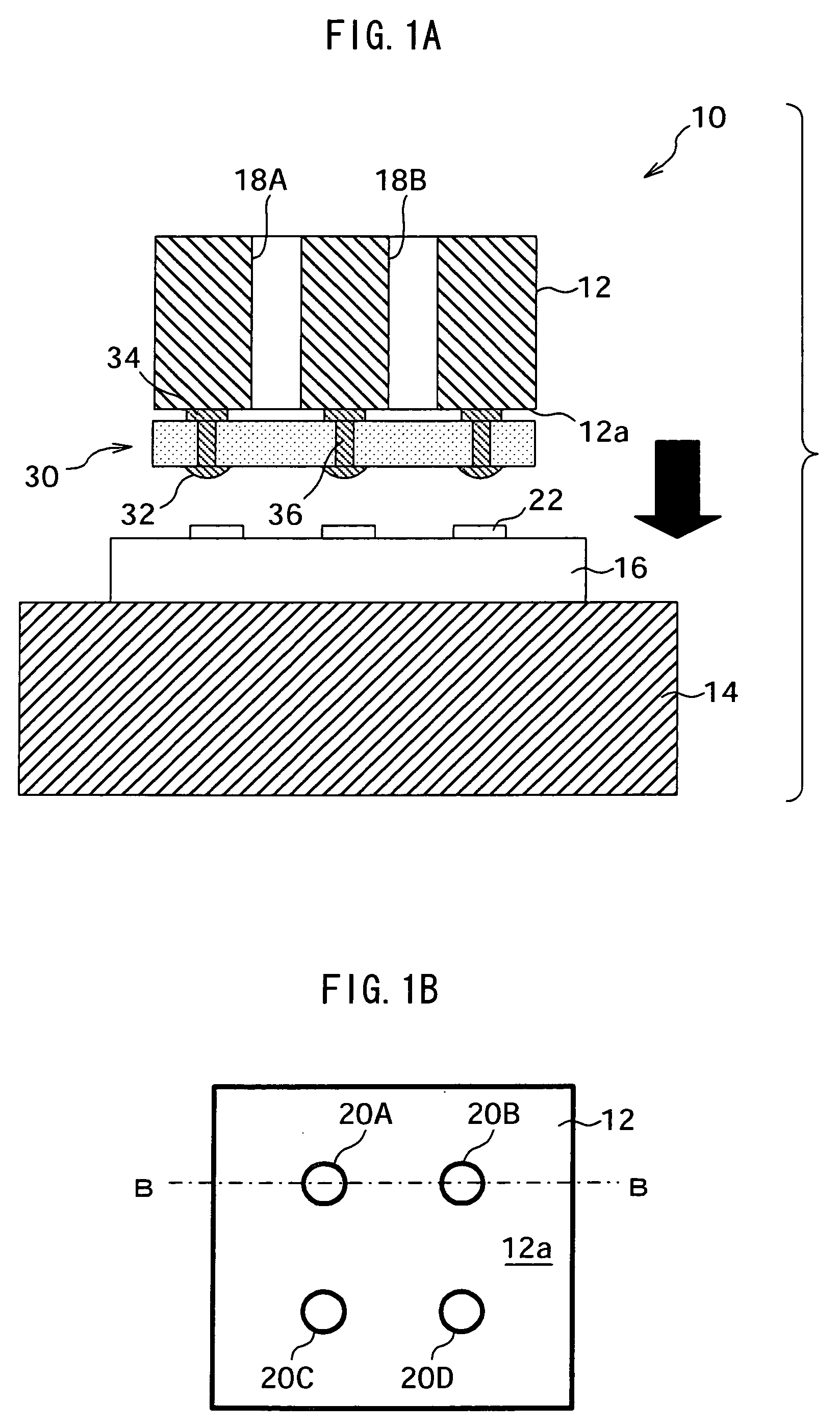

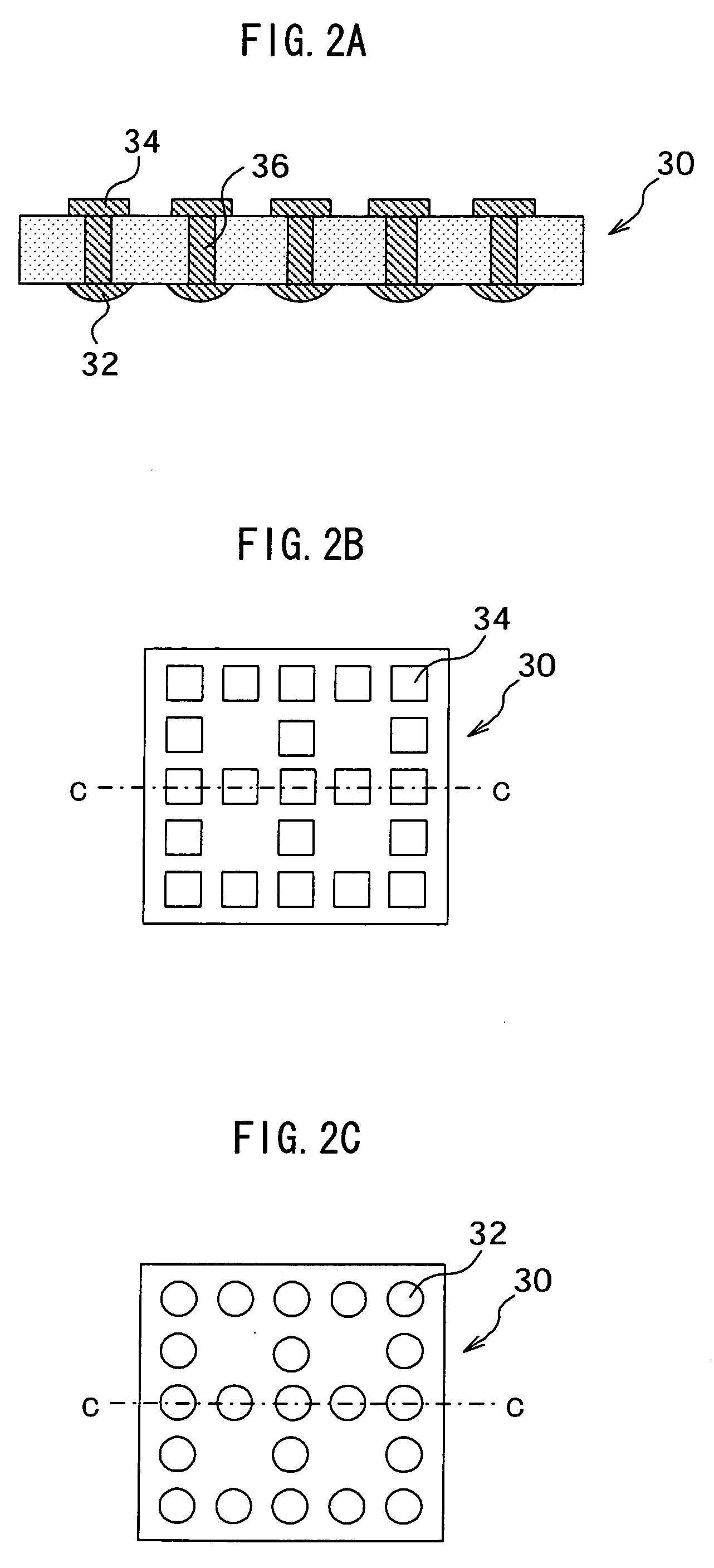

Semiconductor device fabricating method and fabricating apparatus

ActiveUS20090155953A1Prevent bad connectionPoor joining of bump electrodes can be preventedSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor device fabrication

Respective attracting openings of a bonding head are disposed so as to avoid joining regions at which bump electrodes (obverse electrodes) of a semiconductor chip are joined with bump electrodes of a package substrate. Bump electrodes (reverse electrodes) that are connected to the bump electrodes are provided at a reverse side of the semiconductor chip at positions opposing the bump electrodes. Because the attracting openings do not overlap the joining regions, the bump electrodes (reverse electrodes) are not suctioned at the joining regions.

Owner:TAIWAN SEMICON MFG CO LTD

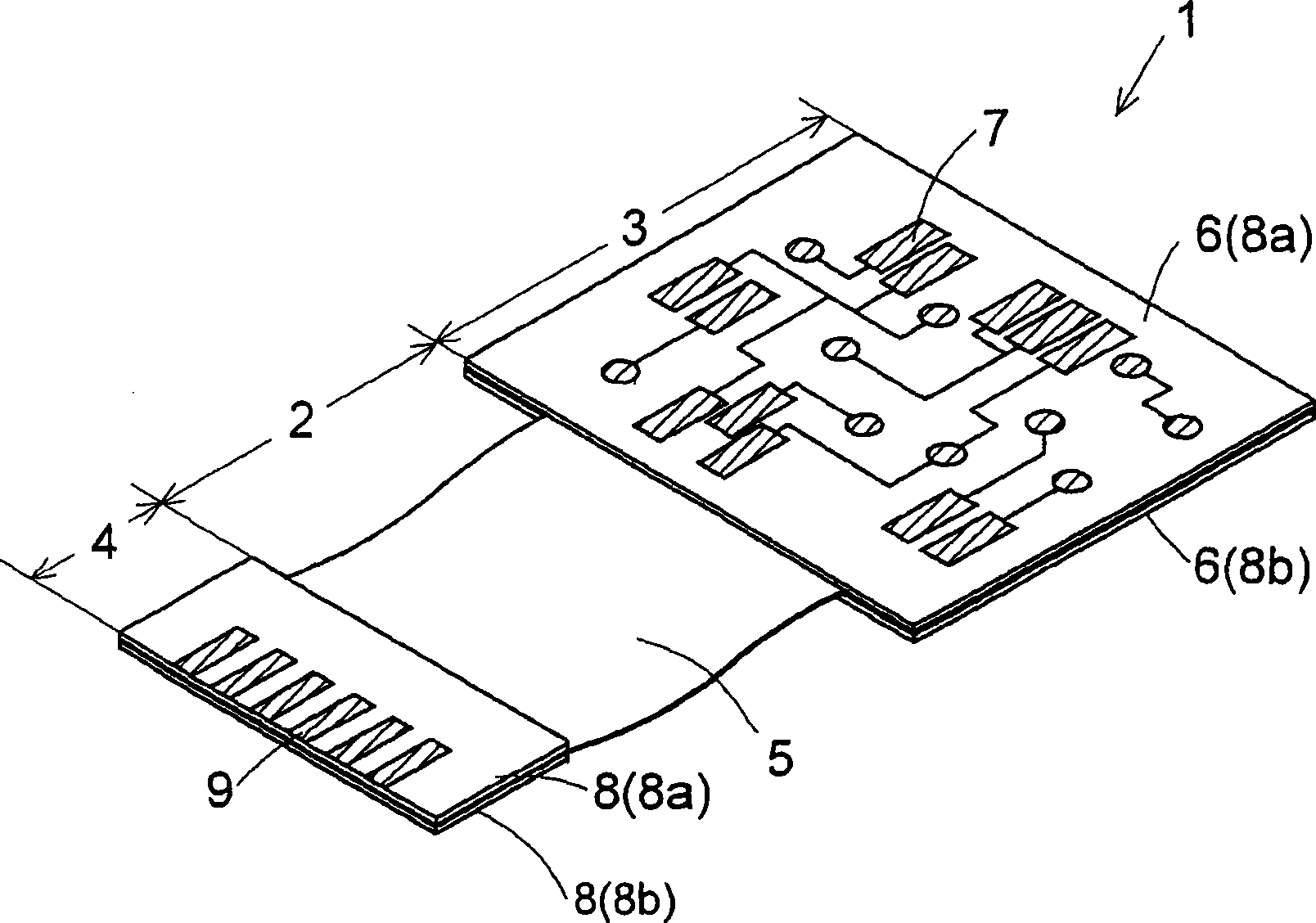

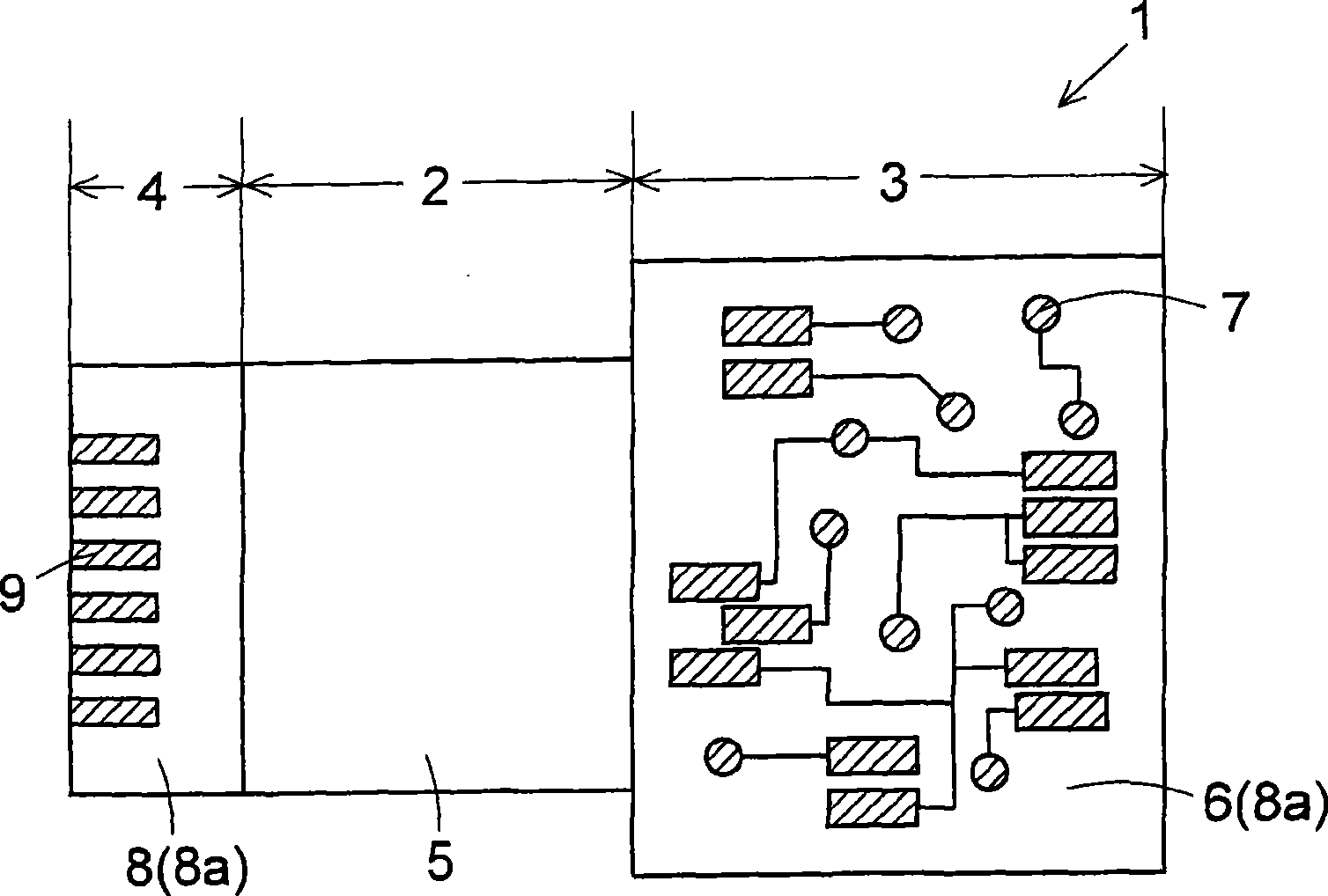

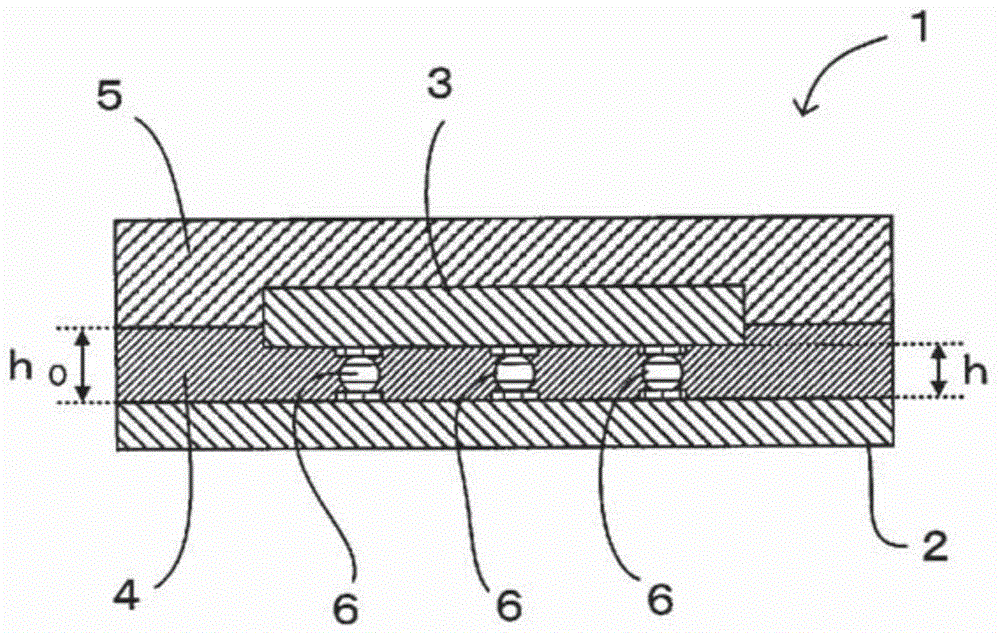

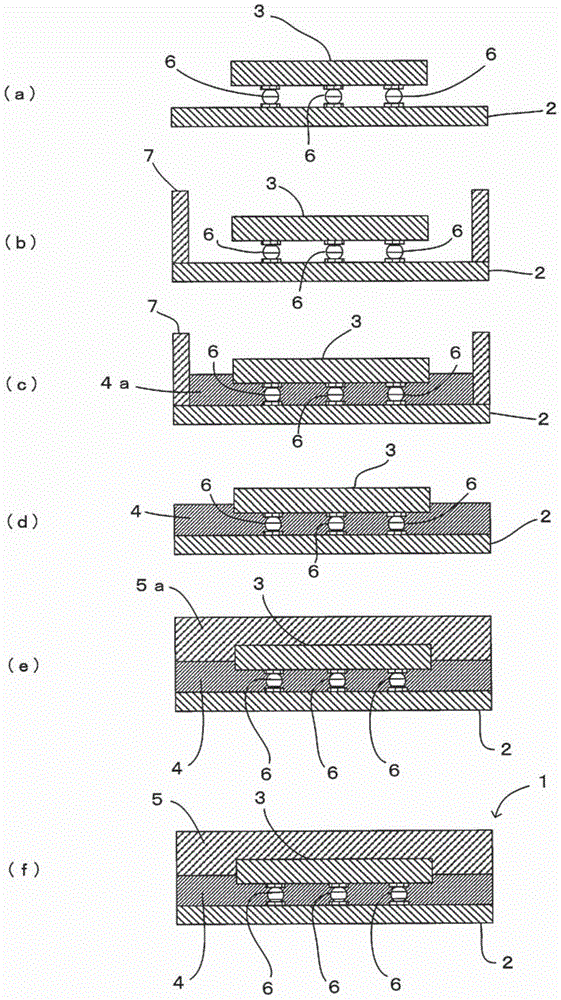

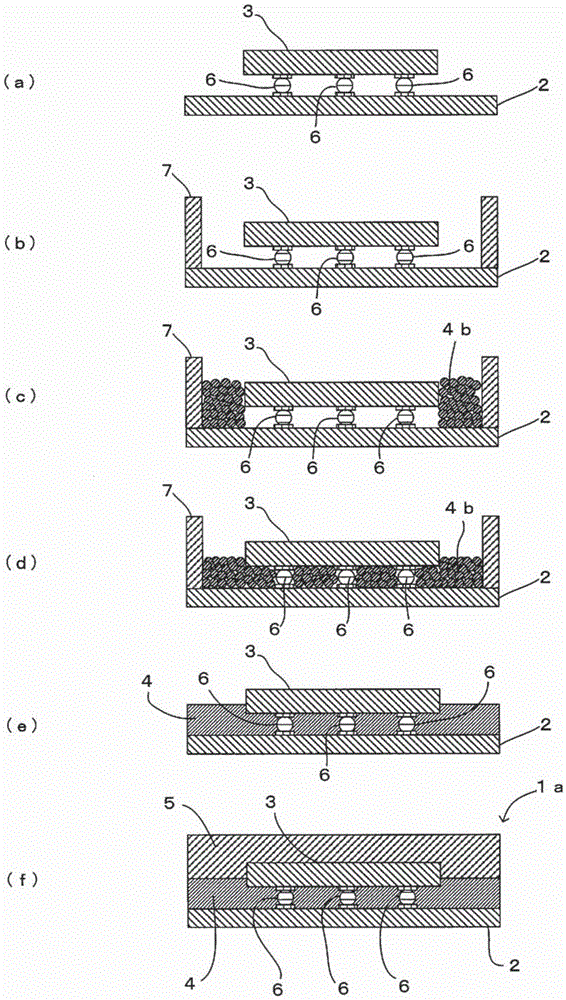

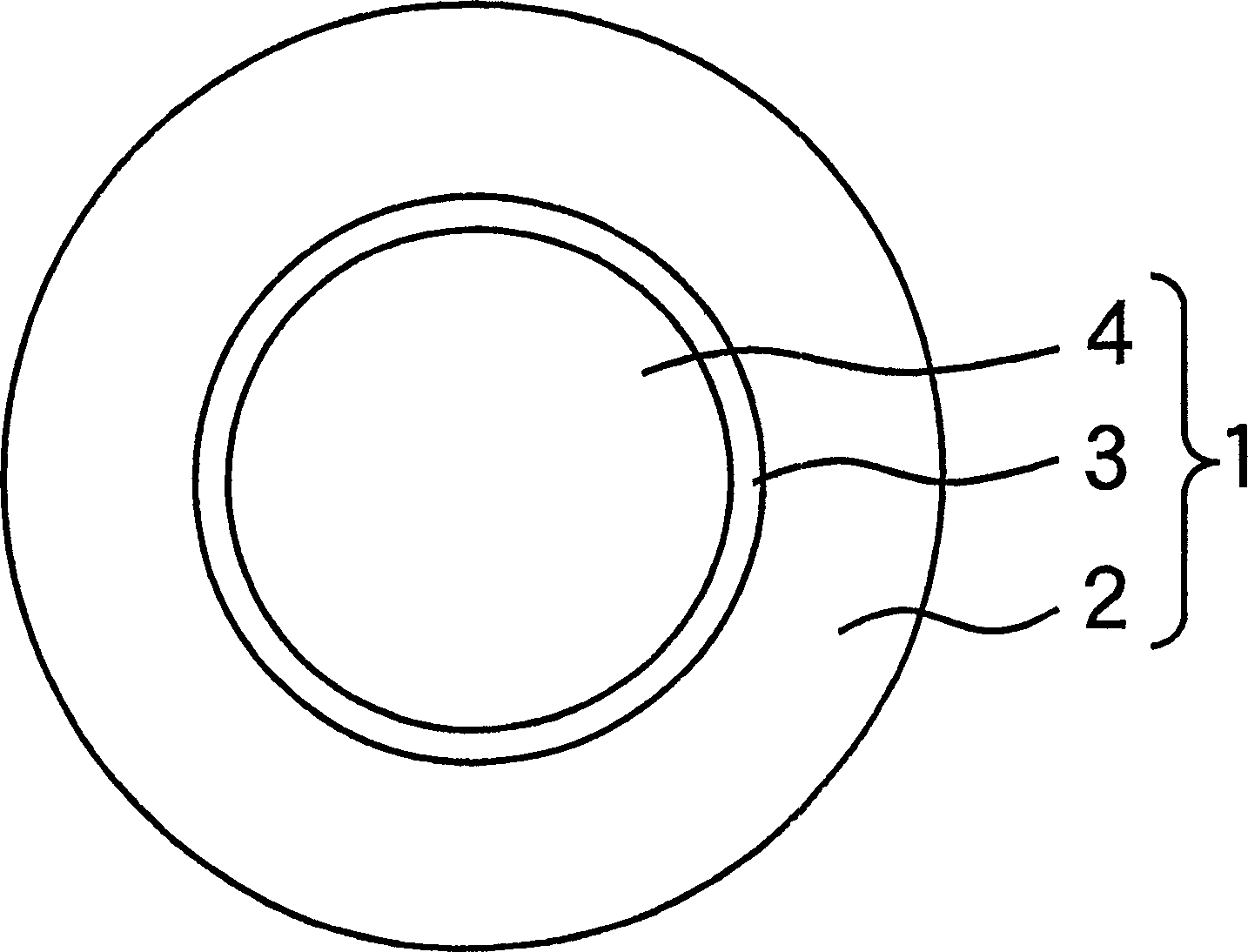

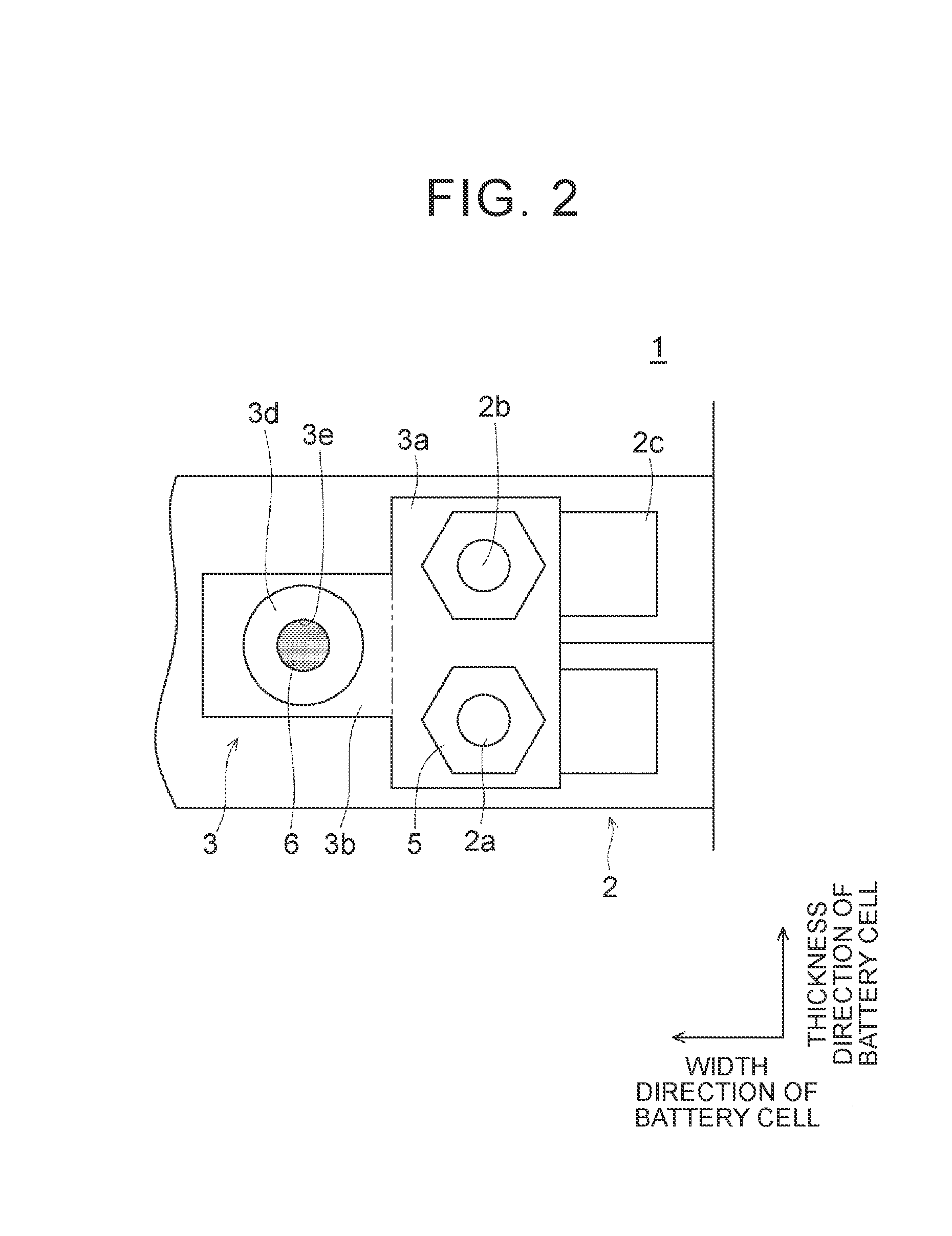

Module and method for producing same

InactiveCN104919586APrevent bad connectionImprove connection reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

The purpose of the present invention is to provide a module which is capable of improving the connection reliability between a wiring board and an electronic component that is mounted on the wiring board. A module (1) is provided with: a wiring board (2); an electronic component (3) that is mounted on one main surface of the wiring board (2); an underfill resin layer (4) that is formed on all over the surface of the one main surface of the wiring board (2) so as to fill up the gap between the one main surface of the wiring board (2) and the electronic component (3); and a mold resin layer (5) that is formed so as to cover the underfill resin layer (4) and the electronic component (3). The underfill resin layer (4) is formed of a resin which contains a filler having a particle diameter that is smaller than the distance between the one main surface of the wiring board (2) and the electronic component (3).

Owner:MURATA MFG CO LTD

Conductive ball, method of forming electrode of electronic part, electronic part and electronic equipment

ActiveCN1826664AAvoid crackingAvoid disconnectionPrinted circuit assemblingNon-insulated conductorsMetallic materialsAlloy

Owner:SEKISUI CHEM CO LTD

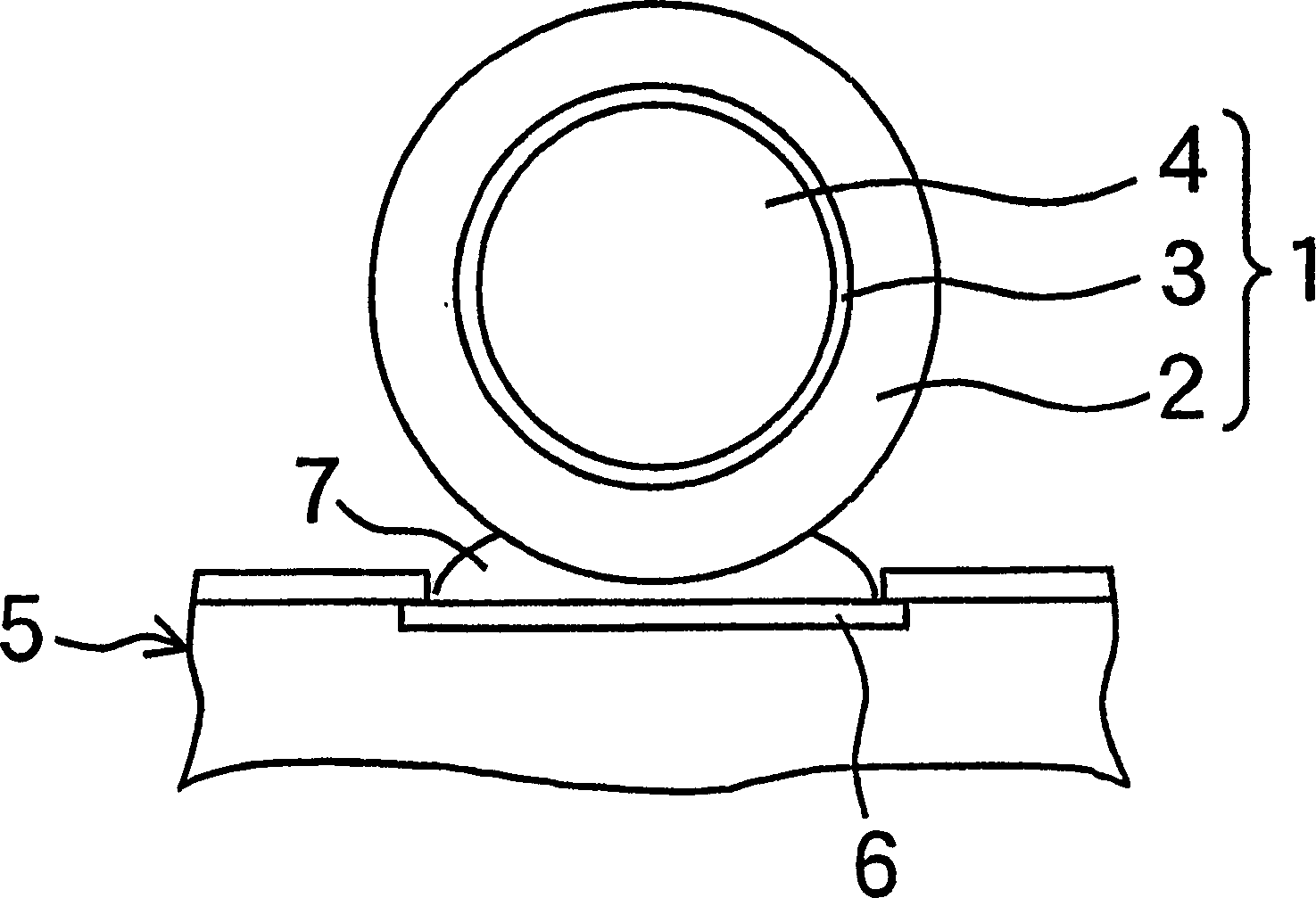

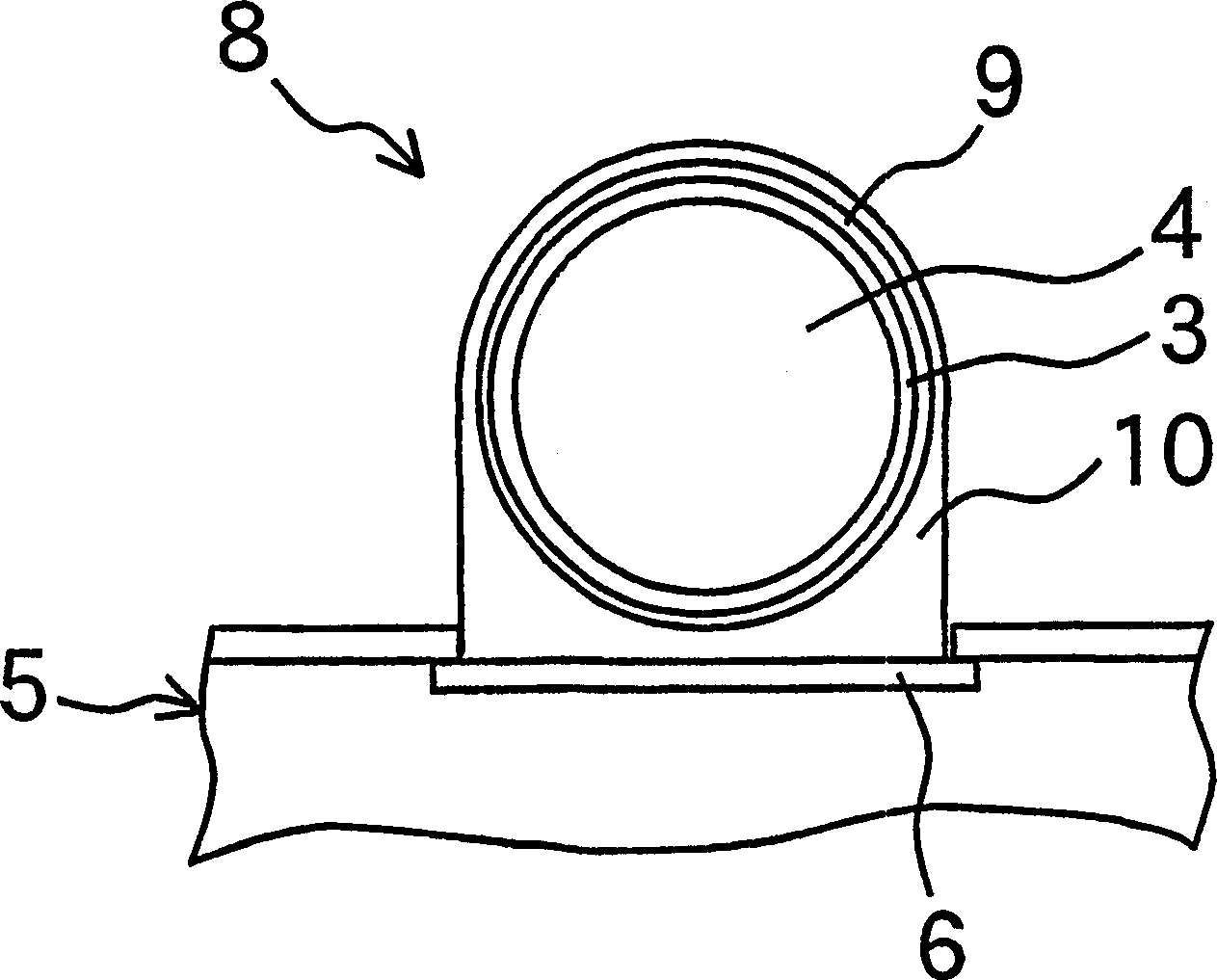

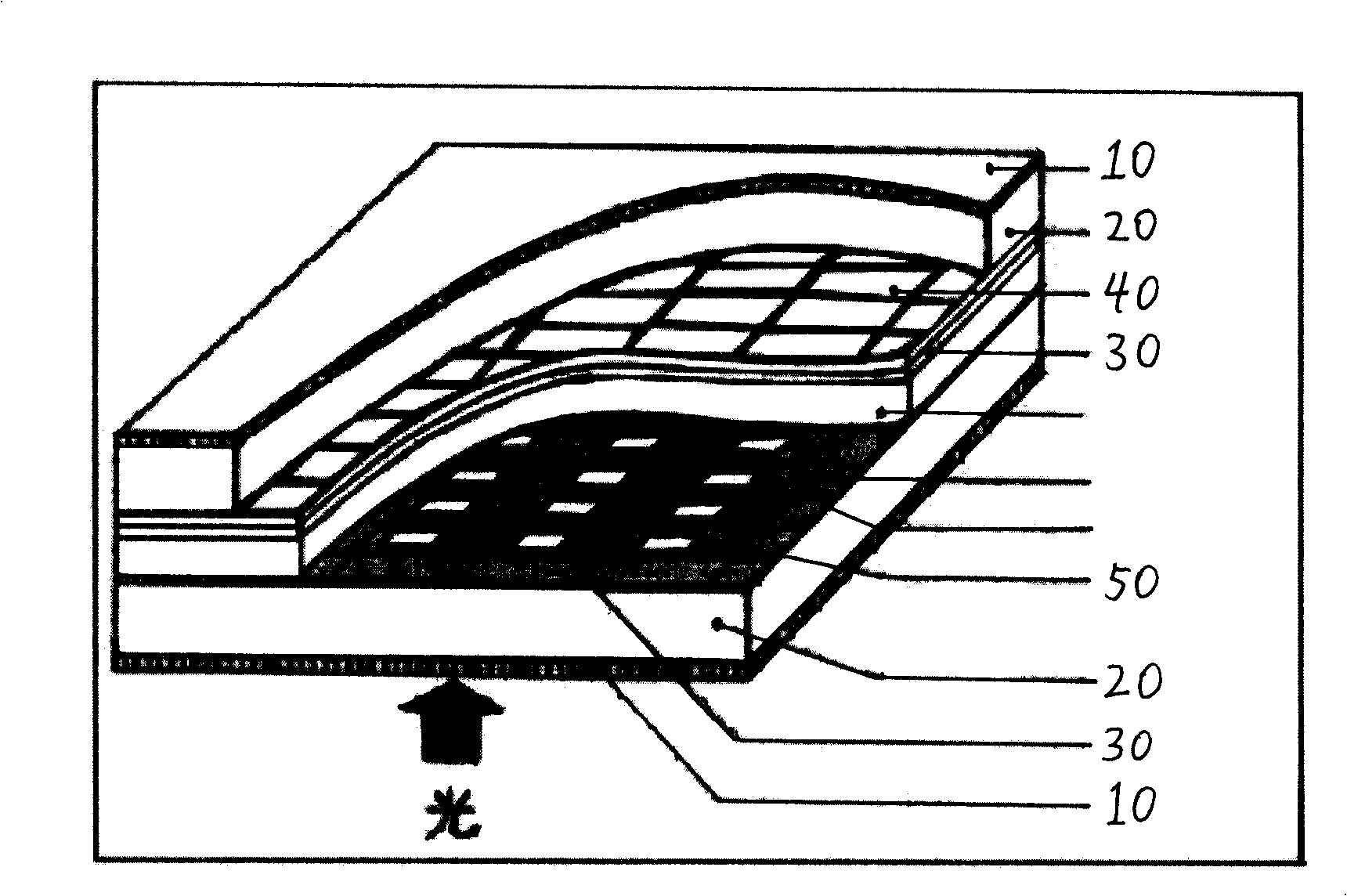

Electrostatic actuator, droplet discharging head, droplet discharging apparatus, electrostatic device

InactiveCN1803453AReduce thicknessAvoid enteringDecorative surface effectsElectrostatic generators/motorsMiniaturizationMoisture permeation

The invention provides an electrostatic actuator, etc. which is capable of miniaturizing the size, and preventing moisture, etc. from entering a gap in an effective manner. An electrostatic actuator includes an electrode substrate 10 having individual electrodes 12 as fixed electrodes, and a cavity substrate 20 having diaphragms 22 as movable electrodes which are disposed so as to be opposed to the fixed electrodes 12 with a predetermined distance, and operated due to an electrostatic force occurring between the cavity substrate 20 and the individual electrodes 12. Sealing portions 26 a are formed on one of the electrode substrate 10 and the cavity substrate 20, each of the sealing portions 26 a has a plurality of sealing layers (a TEOS layer 25 a, a moisture permeation preventing layer 25 b) laminated one another, and each of the sealing layers is made of a sealing material 25 for isolating a space formed between the individual electrode 12 and the diaphragm 22.

Owner:SEIKO EPSON CORP

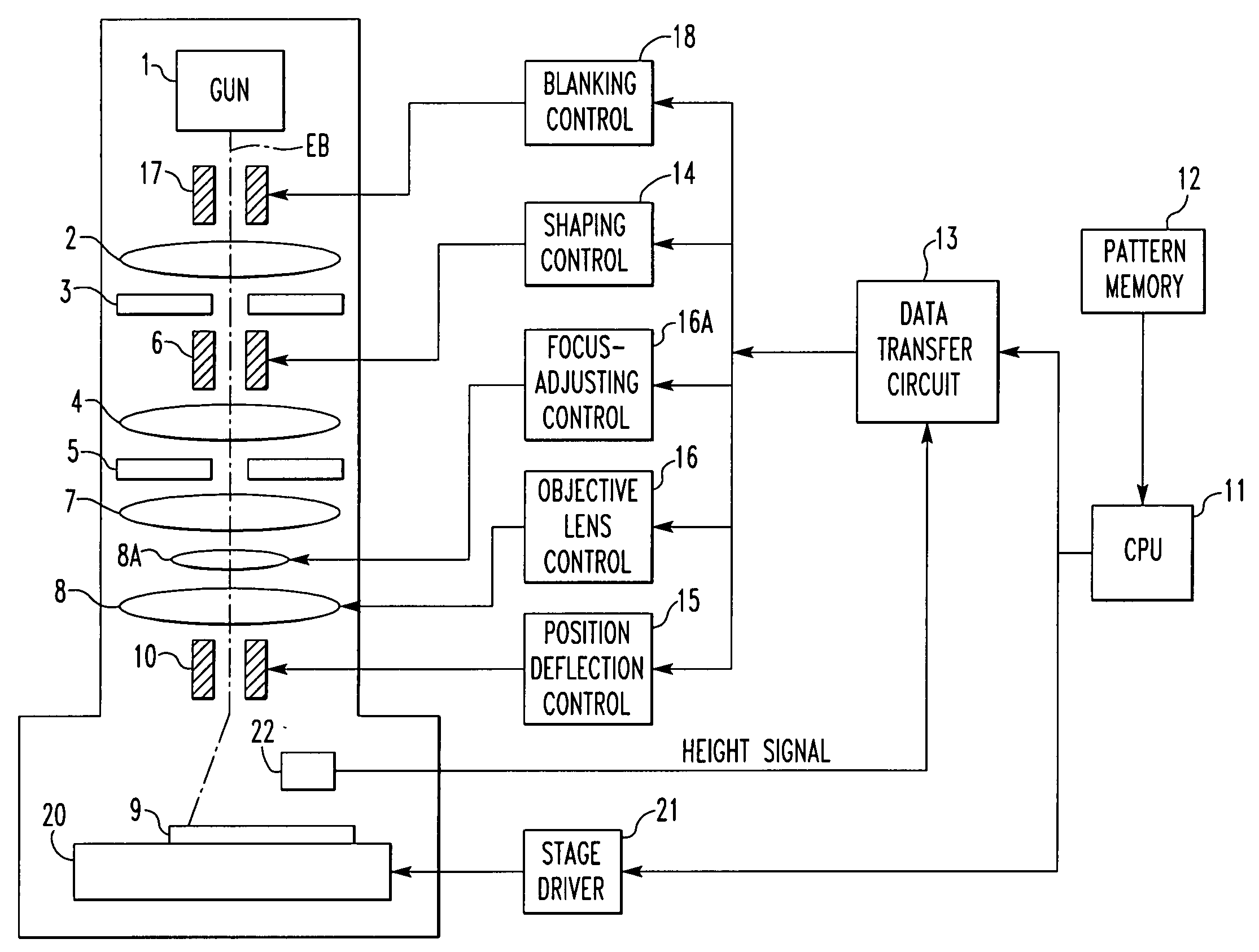

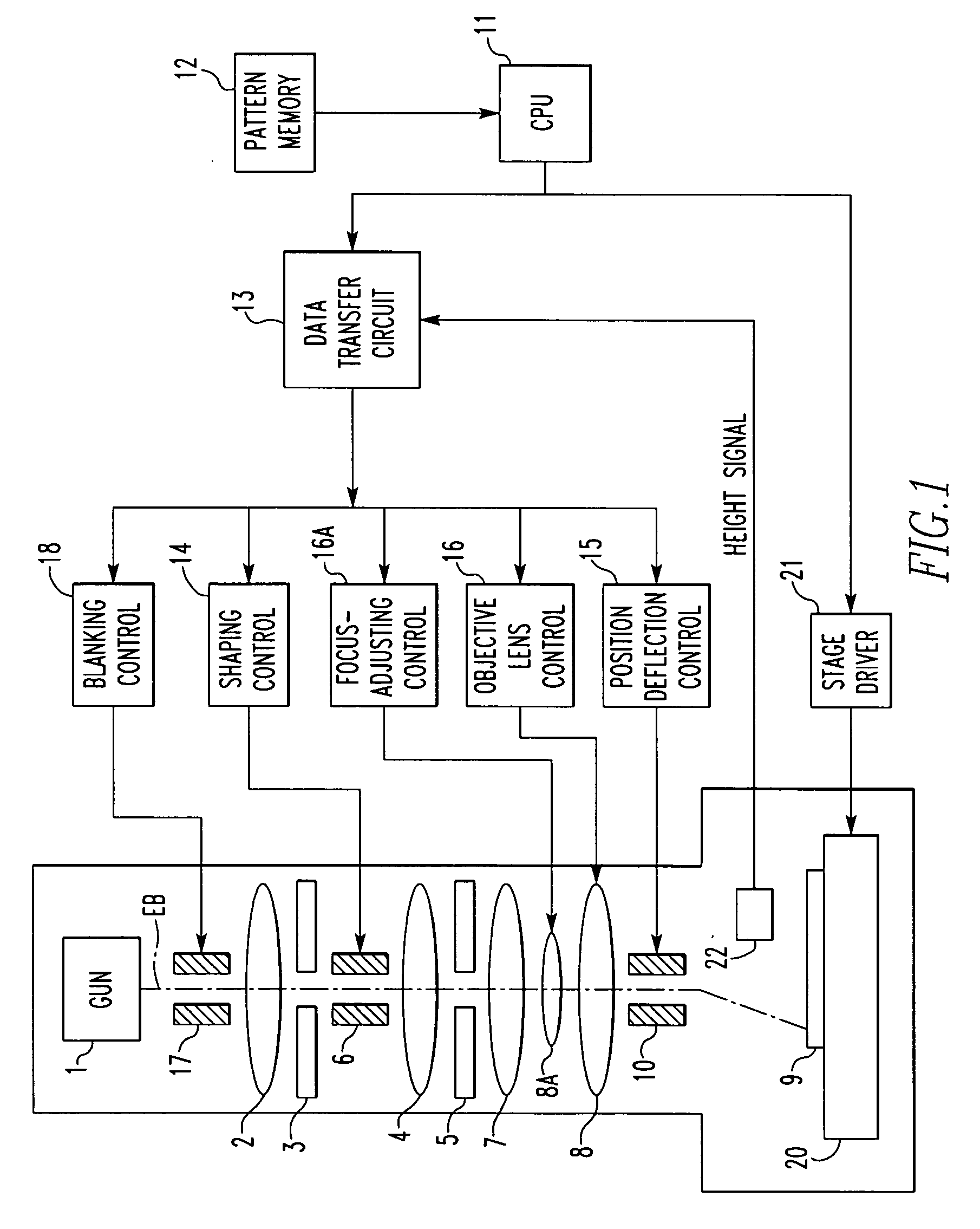

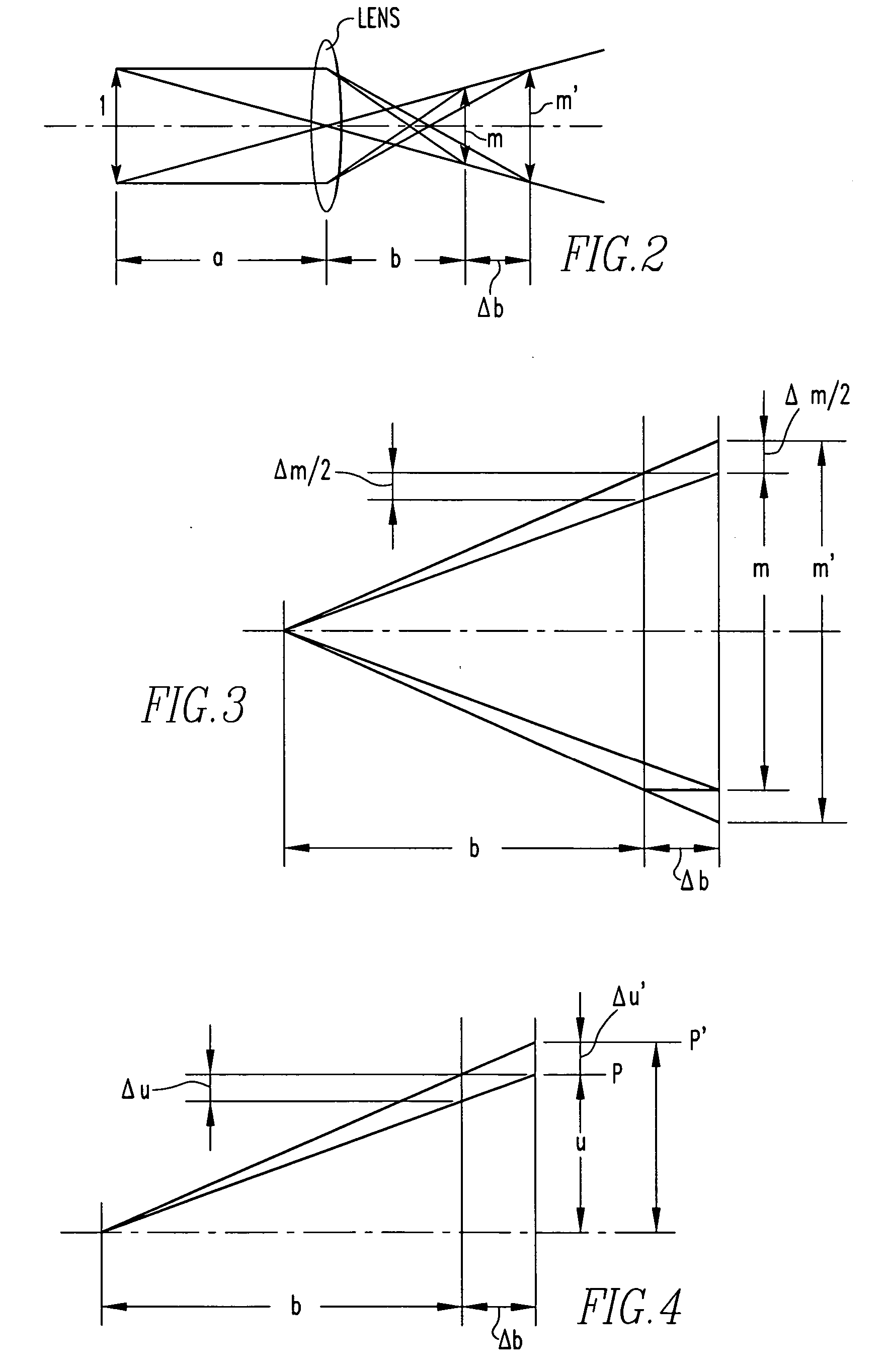

Charged-particle beam lithographic system

InactiveUS20050116180A1Improve accuracyDefective connection in to differenceOptical radiation measurementNanoinformaticsMagnificationCharged particle beam

When the focal point of the objective lens of a charged-particle beam lithographic system is shifted according to the deflection position within a writing field, the image magnification of the objective lens will vary. In the present invention, the focal point of the objective lens is shifted in a corresponding manner to deflection positions in X- and Y-directions, respectively. Amounts of variations in the image magnification are previously measured, as well as the amounts of shifts. The results are stored in a memory. During lithographic writing, the focus of the objective lens is varied by referring to the memory according to the deflection positions. The size and position of a pattern to be written are corrected by controlling a shaping deflector and a positioning deflector.

Owner:JEOL LTD

Connecting device of a flexible printed circuit board

InactiveUS7374435B2Firmly connectedPrevent bad connectionRelieving strain on wire connectionLaminating printed circuit boardsElectrical conductorEngineering

A connecting device of a flexible printed circuit board has a reinforced backlight FPC board, is free from bad contact resulting from insufficient insertion of a terminal portion of a flexible printed circuit board into a connector, and ensures good connection without leaving contaminants, scratches, or the like on contacts of the terminal portion. The connecting device of a flexible printed circuit board has a terminal portion having a contact formed as a printed conductor in a tip end portion of a film-form flexible printed circuit board, and a connector having an insertion slot into which the terminal portion is inserted and a contact fitted inside the insertion slot and connected to the contact of the terminal portion. Moreover, a reinforcing plate is bonded on the face of the terminal portion opposite to the face thereof on which the contact is formed, and an ear-like piece that makes contact with the opening rim of the insertion slot in the connector is formed in a position a predetermined distance inward from the tip end of the terminal portion in the length direction of the flexible printed circuit board.

Owner:JAPAN DISPLAY WEST

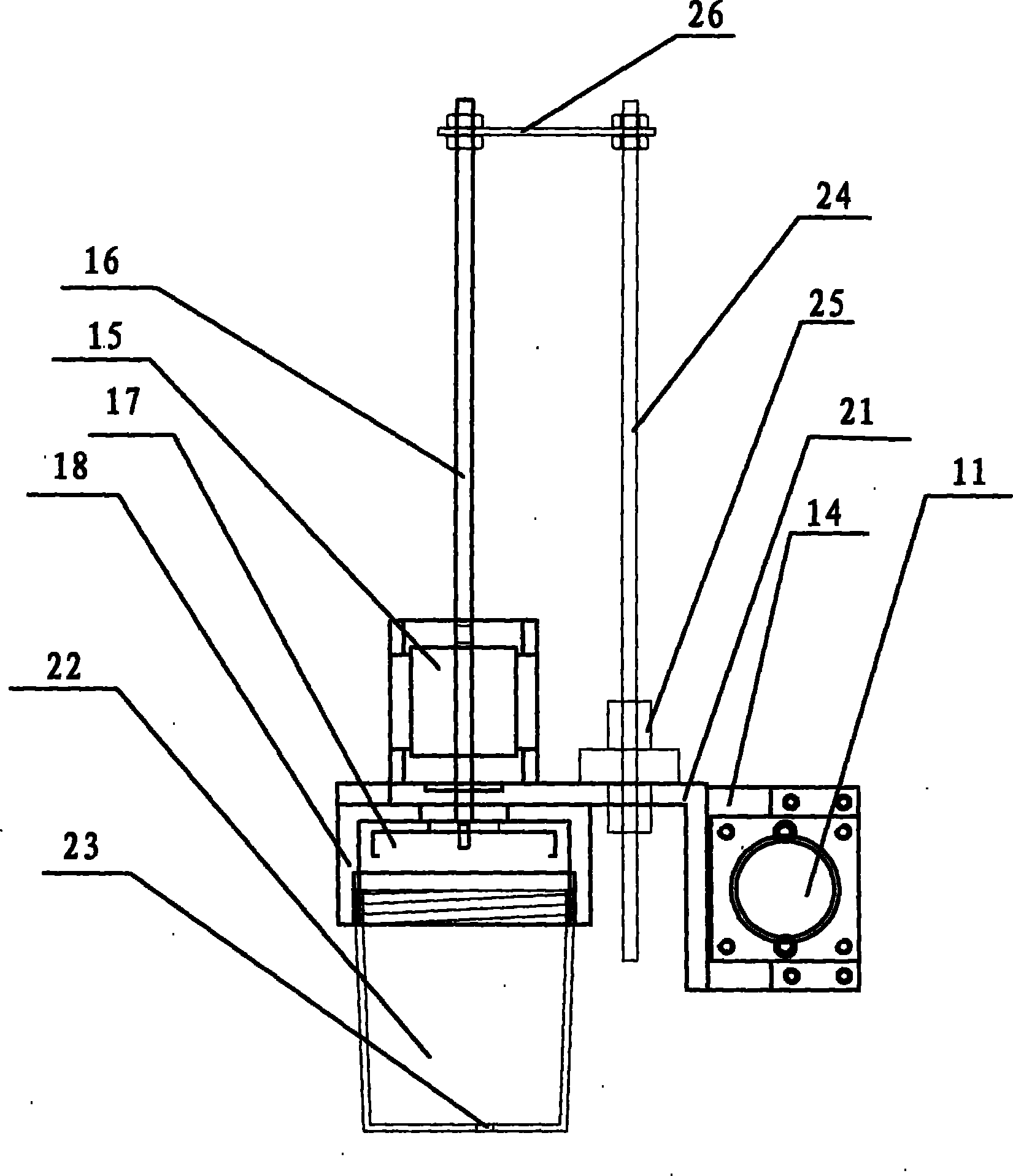

Automatic tin adding machine

InactiveCN102582230AControl flowControl movement speedScreen printersPrinting press partsEngineeringFlange

The invention discloses an automatic tin adding machine, which comprises a controller, a horizontal transmission mechanism and an automatic tin adding mechanism. The automatic tin adding mechanism is connected with the horizontal transmission mechanism via a connecting support and comprises a vertical transmission mechanism, a squeezing flange and a fixing flange, the vertical transmission mechanism is connected with the connecting support, the squeezing flange is connected with the vertical transmission mechanism and used for downwards squeezing a tin cream box, the fixing flange is connected with the connecting support and used for fixing the tin cream box, and the horizontal transmission mechanism and the vertical transmission mechanism are electrically connected with the controller. The automatic tin adding machine can achieve purposes of uniformly squeezing out tin cream, increasing the quality of products and saves resources.

Owner:SUZHOU HUILONG AUTOMATION EQUIP

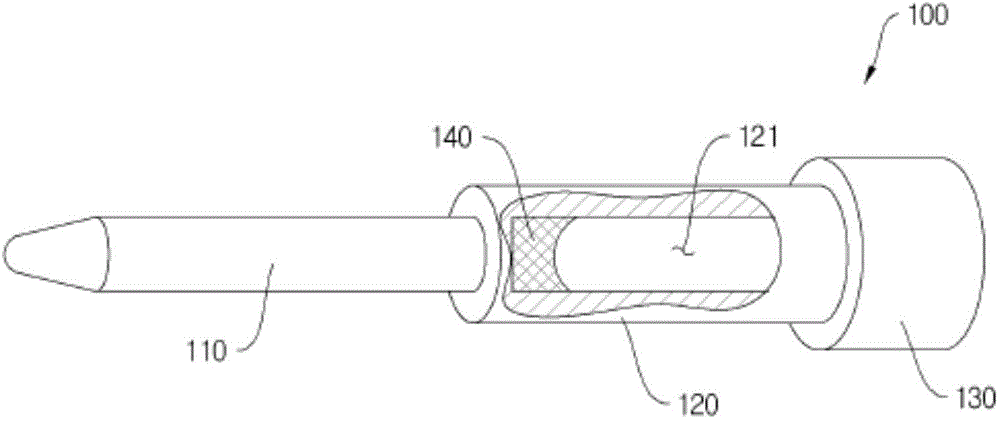

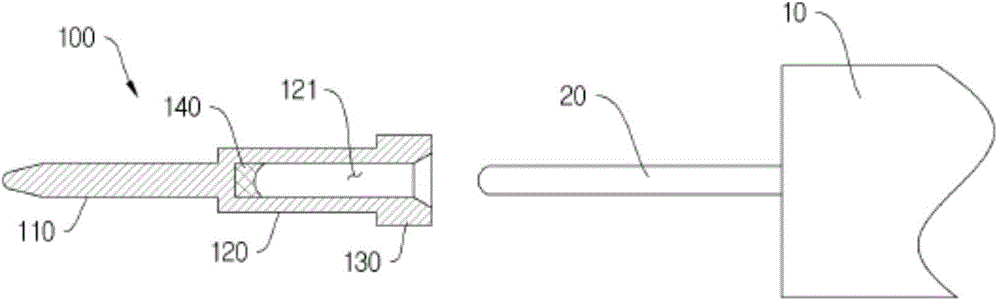

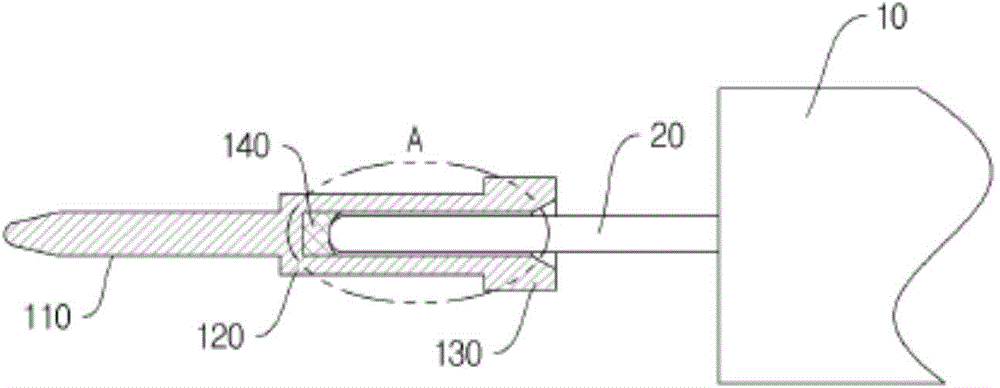

Connection terminal core for cable connector and method for connecting said connection terminal core for cable connector and said cable with each other

InactiveCN104685720AImprove securityPrevent bad connectionLine/current collector detailsCoupling contact membersElectrical and Electronics engineering

The present invention relates to a connection terminal core for a cable connector and a method for connecting the connection terminal core for the cable connector and a cable with each other. The connection terminal core for a cable connector according to the present invention includes: a connection terminal portion; a terminal core body; and a lead member. When heat is applied from the outside to the terminal core body in a state in which a cable side connection line is inserted into a cable side connection line insertion hole, the heat conducted through the terminal core body melts the lead member introduced into the cable side connection line insertion hole, and the terminal core body and the cable side connection line can be coupled with each other as the lead member is melted and then hardens again. According to the above, a faulty connection can be prevented, and a neat external appearance can be obtained after connection.

Owner:崔钟一

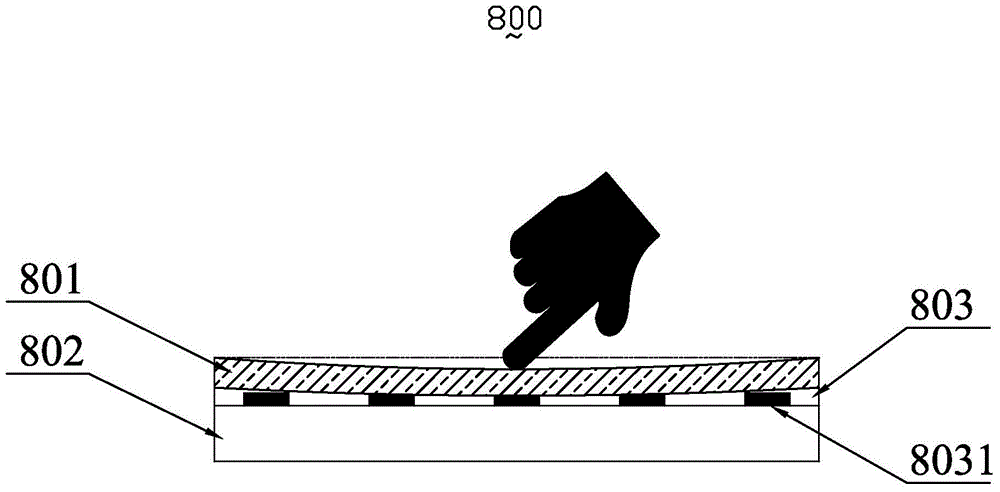

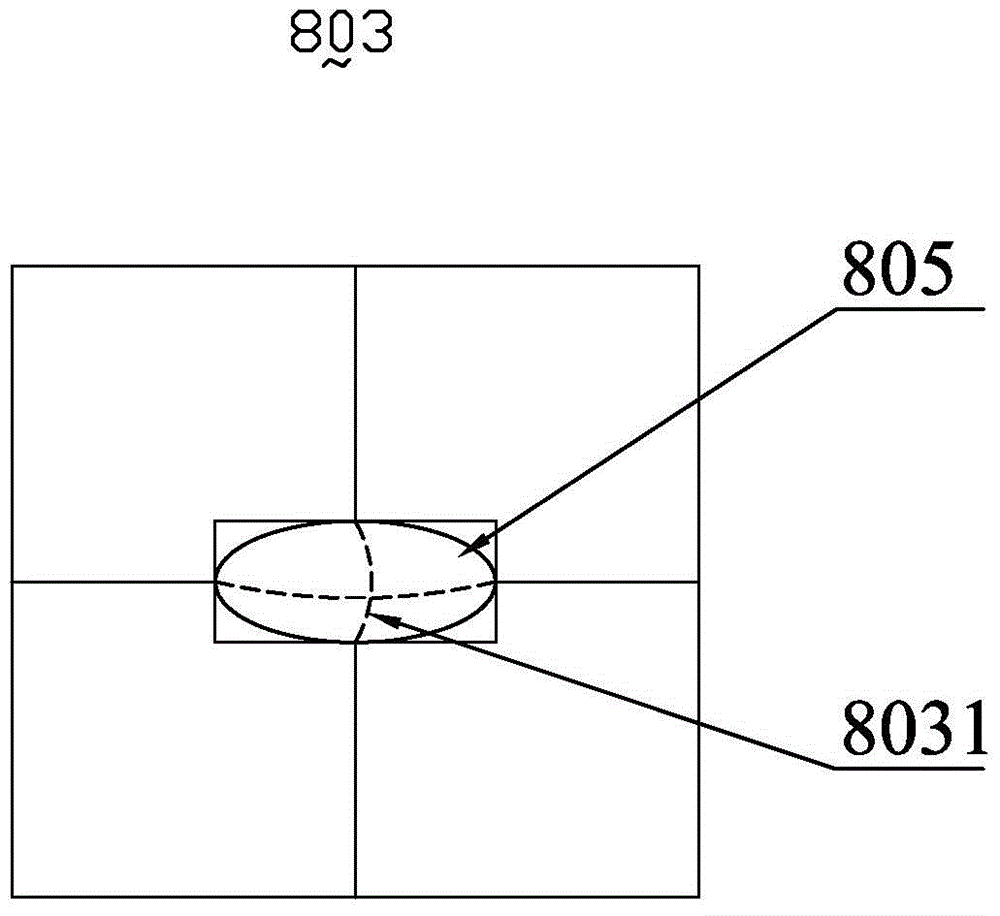

Pressure sensing device

PendingCN106325580AReduce thicknessFix visibility issuesInput/output processes for data processingPressure sensePressure sensing

The invention relates to the technical field of pressure sensing, and in particular to a pressure sensing device which can be used for detecting the pressure intensity. The pressure sensing device comprises a substrate, a conductive pattern layer and a pressure sensing signal wire, wherein the substrate comprises a first surface and a second surface; the first surface and the second surface are oppositely arranged; the conductive pattern layer is arranged on the first surface, comprises a plurality of pressure sensing electrodes and is used for sensing the touch pressure intensity; the pressure sensing signal wire is used for connecting the pressure sensing electrodes to a detection chip in a conducting manner and is of a hollow-out structure.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

Repairing line structure and method for manufacturing same

The invention provides a new repairing line structure, which comprises the original repairing lines, intermittent repairing lines and auxiliary repairing lines; the repairing lines are not directly overlapped with signal scan lines. The intermittent repairing lines are partially overlapped with two signal scan lines, or more than two signal scan lines are outspread as a unit. The intermittent repairing lines and the signal scan lines are overlapped into two or more rows. The manufacturing method of the repairing line structure is as follows: a metal film is arranged on a substrate through sputtering; a mask template forms intermittent repairing lines and auxiliary repairing lines outside a pixel area of the substrate through the exposure process and the chemical etching process; an electrode insulating layer film is arranged on the substrate; a metal film is deposited on the substrate; the mask template forms array substrate signal scanning electrodes through the exposure process and the chemical etching process, and forms the repairing lines outside the pixel area of the substrate at the same time. The repairing points are completely positioned in liquid crystal so as to avoid bad connections caused by oxidation corrosion; in addition, various repairing routes are provided to avoid incapable repairing due to the breaking of certain repairing line. The repairing points are completely positioned in liquid crystal so as to avoid bad connections caused by oxidation corrosion; in addition, various repairing routes are provided to avoid incapable repairing caused by the breaking of certain repairing line.

Owner:SHANGHAI SVA LIQUID CRYSTAL DISPLAY

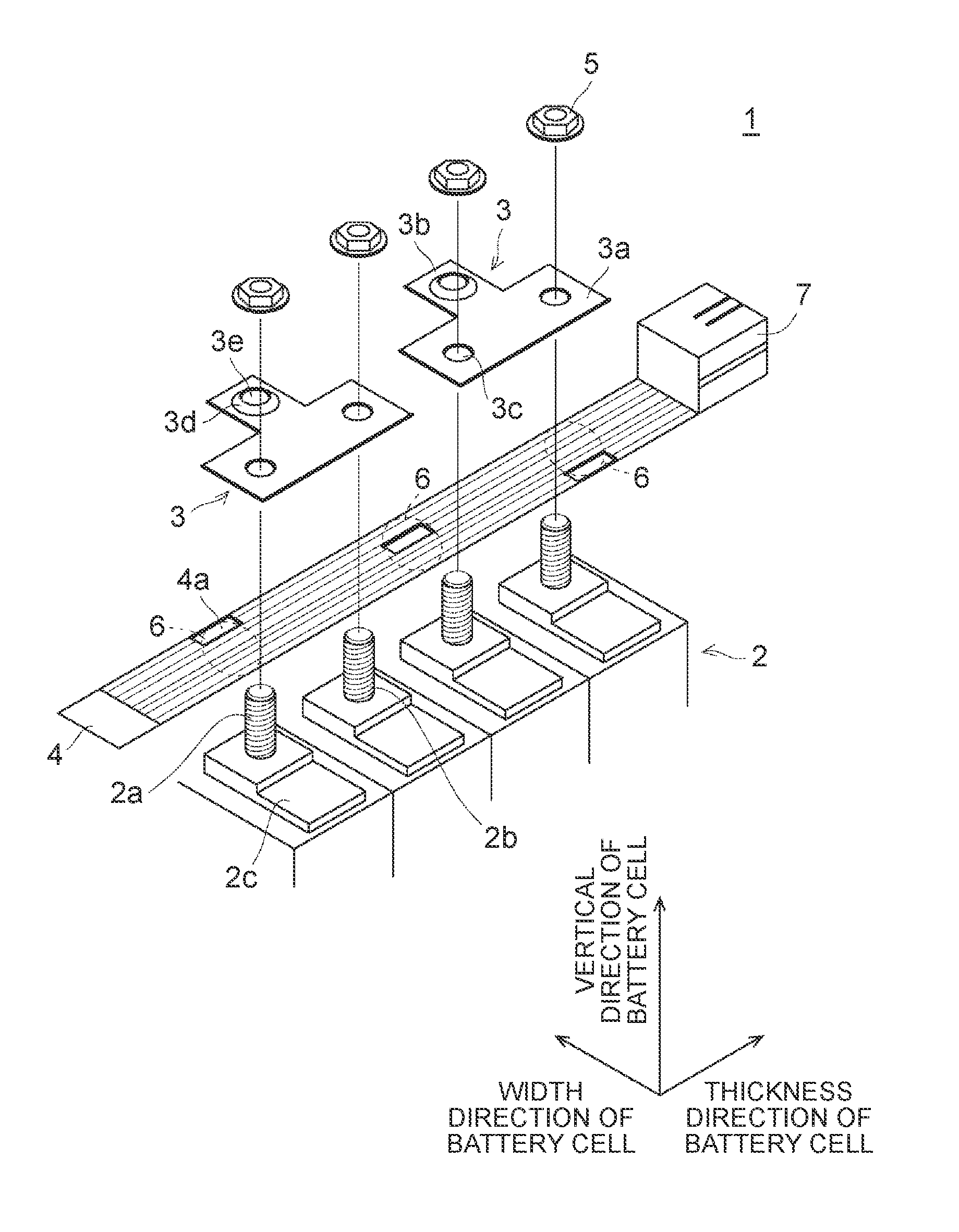

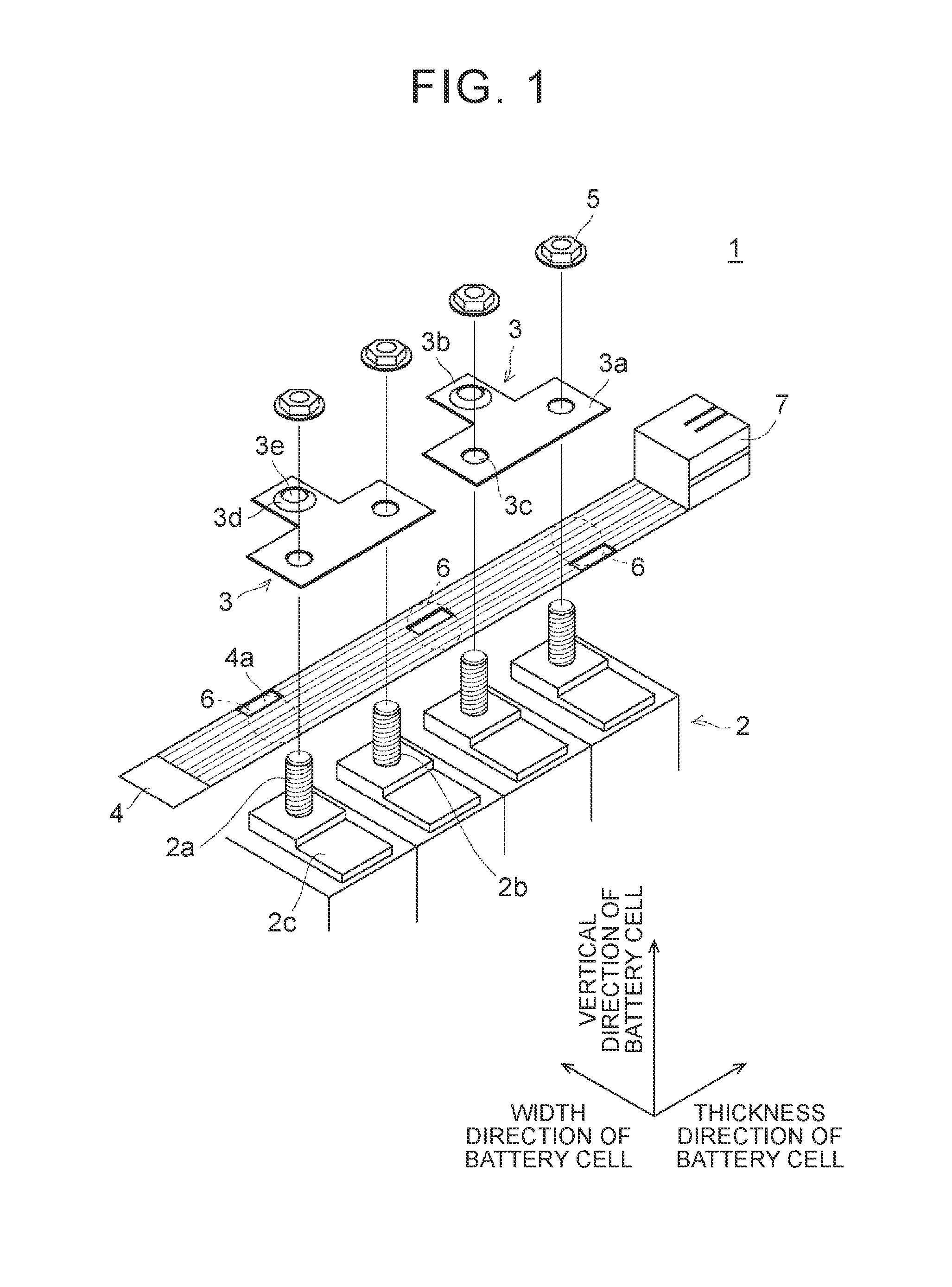

Assembled battery

ActiveUS20160172647A1Avoid poor connectionReduce intensityCells structural combinationCell component detailsElectricityAdhesive

An assembled battery includes a plurality of battery cells, a bus bar that electrically connects the battery cells with each other, and a circuit board that is electrically connected with the battery cells. The bus bar has a first connection part that is electrically connected with the battery cells, and a second connection part that is electrically connected with a connection part of the circuit board via a conductive adhesive. The second connection part has a concave portion that contains the conductive adhesive.

Owner:TOYOTA JIDOSHA KK

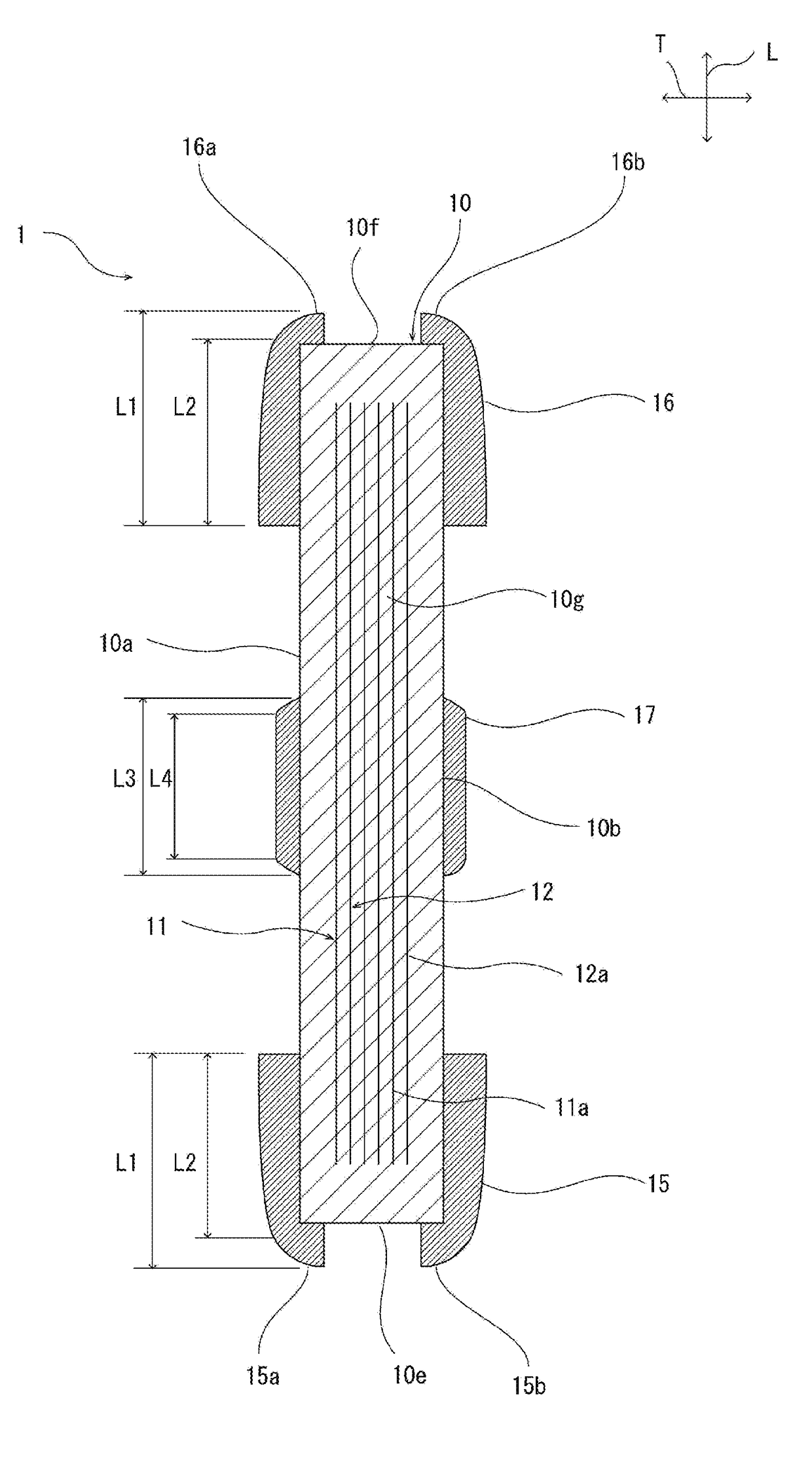

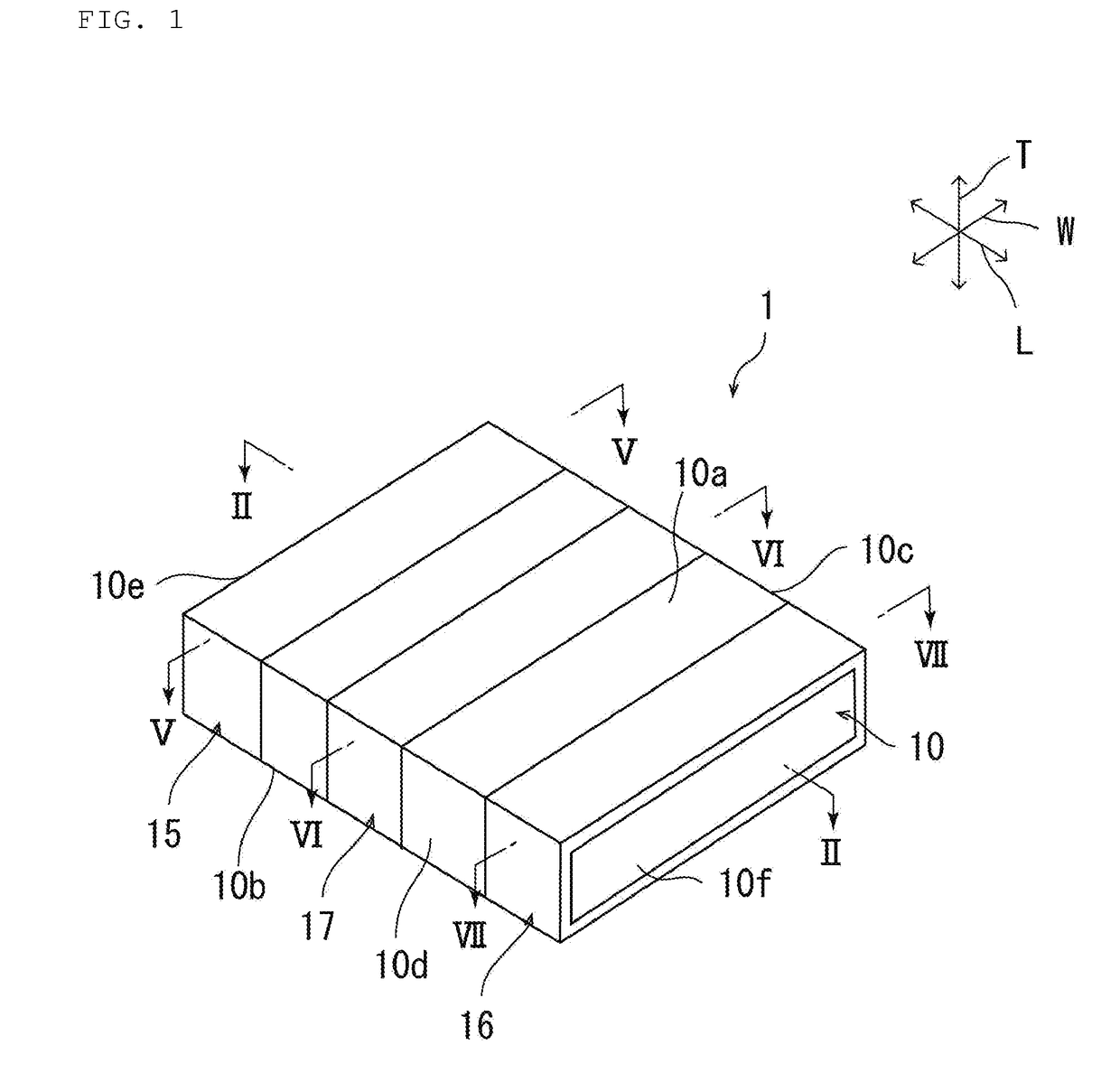

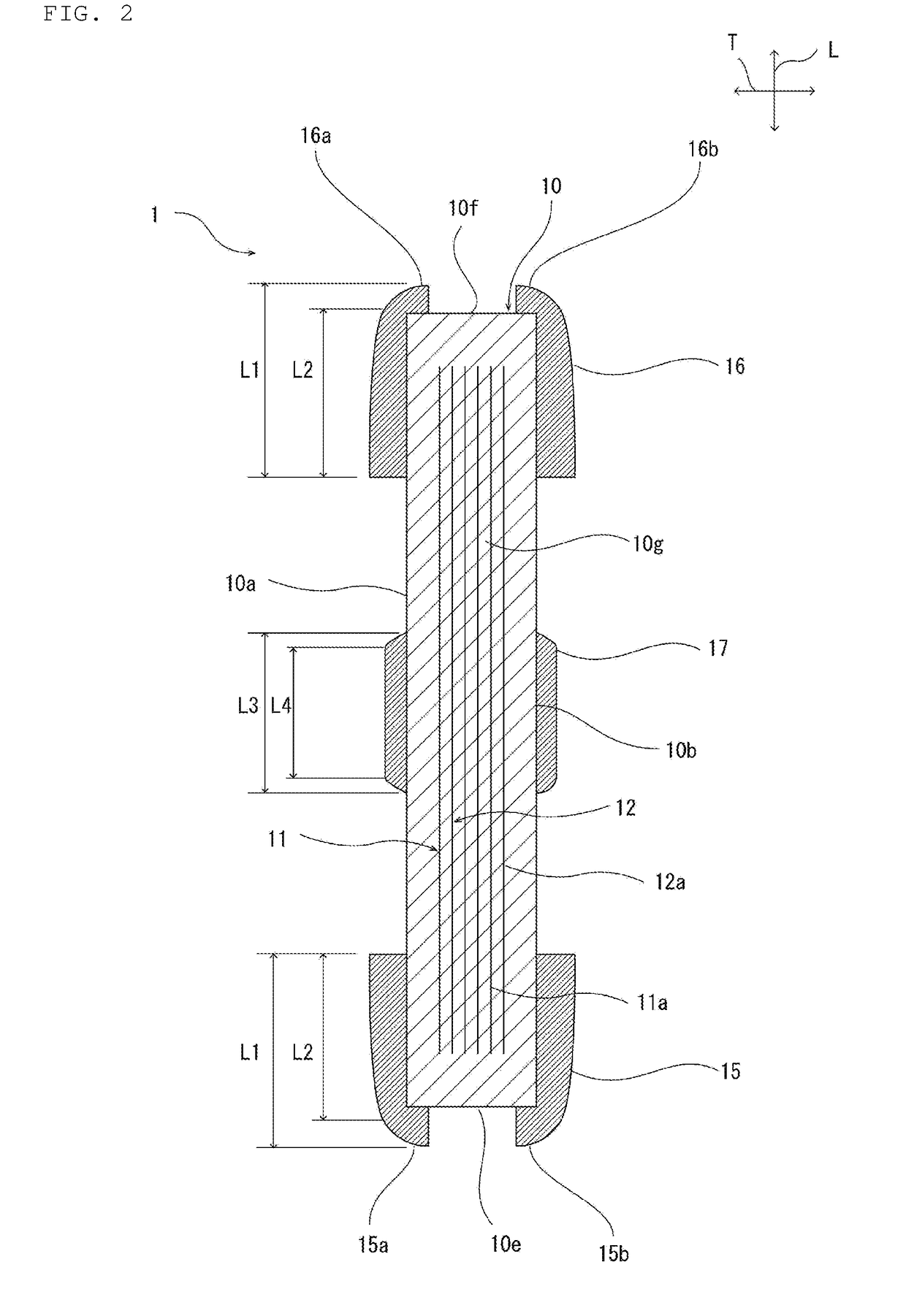

Ceramic capacitor

ActiveUS20170345565A1Increase the areaIncrease freedomFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorMaterials science

In a planar view of a ceramic capacitor that has low ESL and is embeddable into a substrate, lengths of first and second external electrodes are L1, lengths from portions of the first and second external electrodes farthest from a capacitor main body to portions closer to the capacitor main body by about 40% of a thickness of the first or second external electrode in a laminating direction are L2, a ratio L2 / L1 is about 80% or more and about 90% or less. In the planar view, a length of a third external electrode is L3, a length from a portion of the third external electrode farthest from the capacitor main body to a portion closer to the capacitor main body by about 40% of a thickness of the third external electrode in the laminating direction is L4, a ratio L4 / L3 is about 80% or more.

Owner:MURATA MFG CO LTD

Female connector

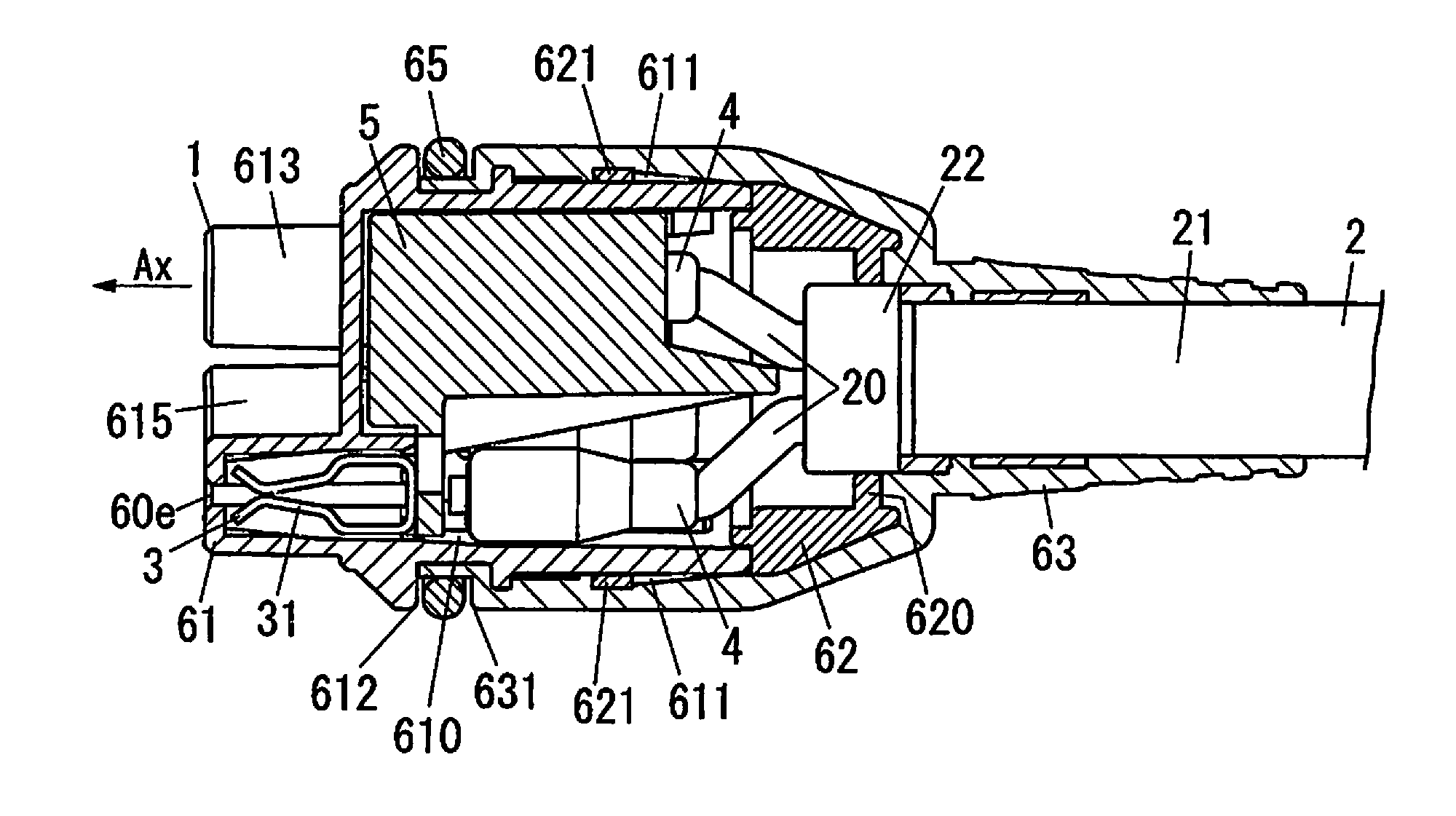

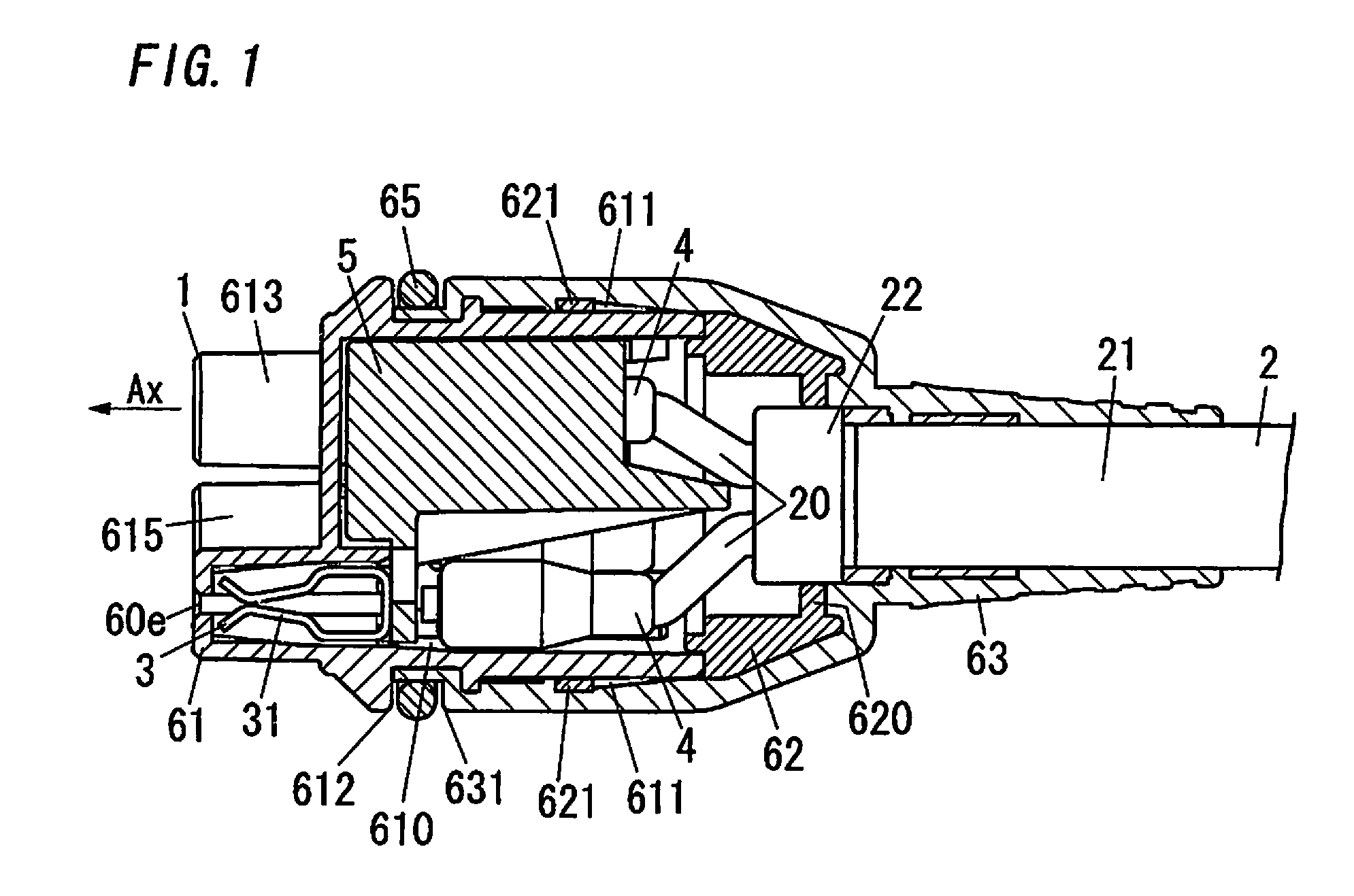

ActiveUS20140295710A1Prevent bad connectionPrevent fallingElectric discharge tubesDustproof/splashproof/drip-proof/waterproof/flameproof connectionEngineeringClose contact

A female connector 1 includes a plurality of contactors 3, a holding body 5, a body 61, and a holder 62. Plurality of contactors 3 are connected to a plurality of electric wires 20 of a cable 2, respectively. Holding body 5 is designed to hold the plurality of contactors 3. Body 61 has a housing recess 610 designed to house the plurality of contactors 3 and holding body 5. Holder 62 is designed to prevent holding body 5 from falling from housing recess 610 by coupling to body 61. Female connector 1 includes a cover 63 formed by double molding so as to cover holder 62 in a state where cable 2 is inserted into holder 62 and where holder 62 and body 61 are coupled to each other. Holder 62 is designed to be in close contact with cable 2 along a whole circumference thereof.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

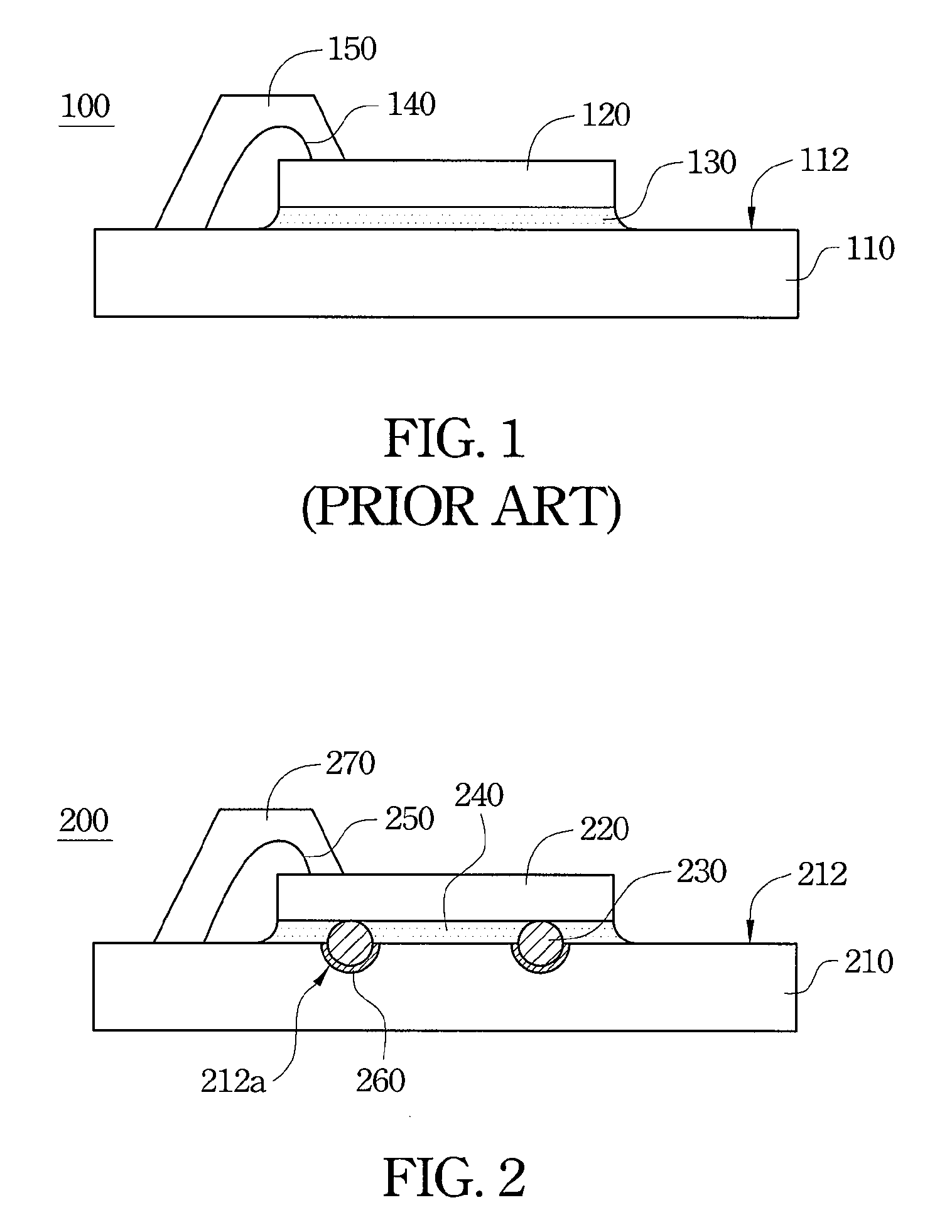

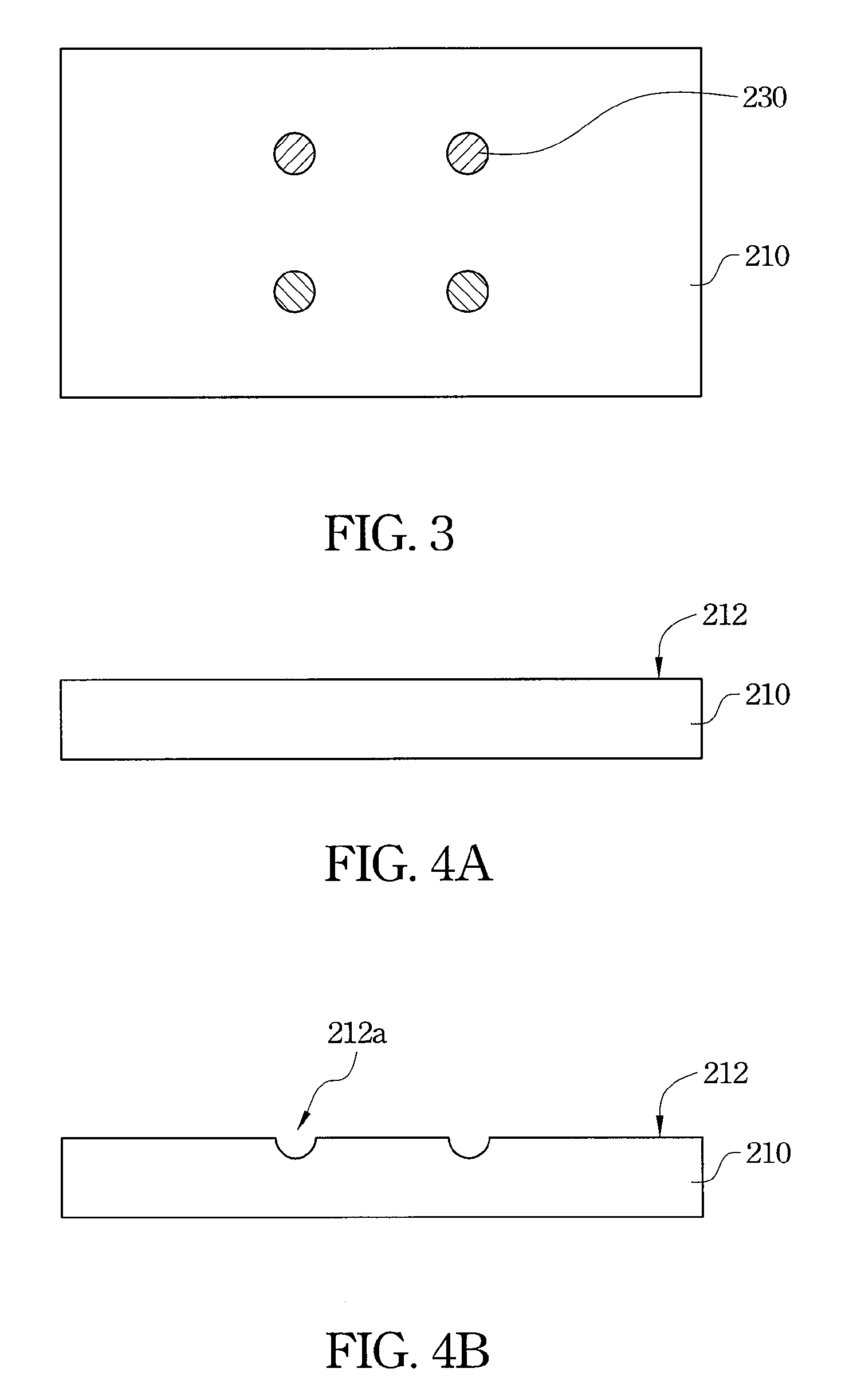

Chip Package and Package Process Thereof

ActiveUS20070042534A1Enhance connection intensityImprove connection efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

A chip package and a package process thereof are provided. The chip package comprises a package substrate, a chip, a plurality of spacers, an adhesive layer, and a plurality of wires. The package substrate has a carrying surface. The chip is disposed on the carrying surface. The spacers are formed between the chip and the carrying surface to maintain an interval between the chip and the package substrate. The adhesive layer is disposed between the chip and carrying surface to encapsulate the spacers. The chip is electrically connected to the package substrate via the wires.

Owner:ADVANCED SEMICON ENG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com