Patents

Literature

49results about How to "Reduce head size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

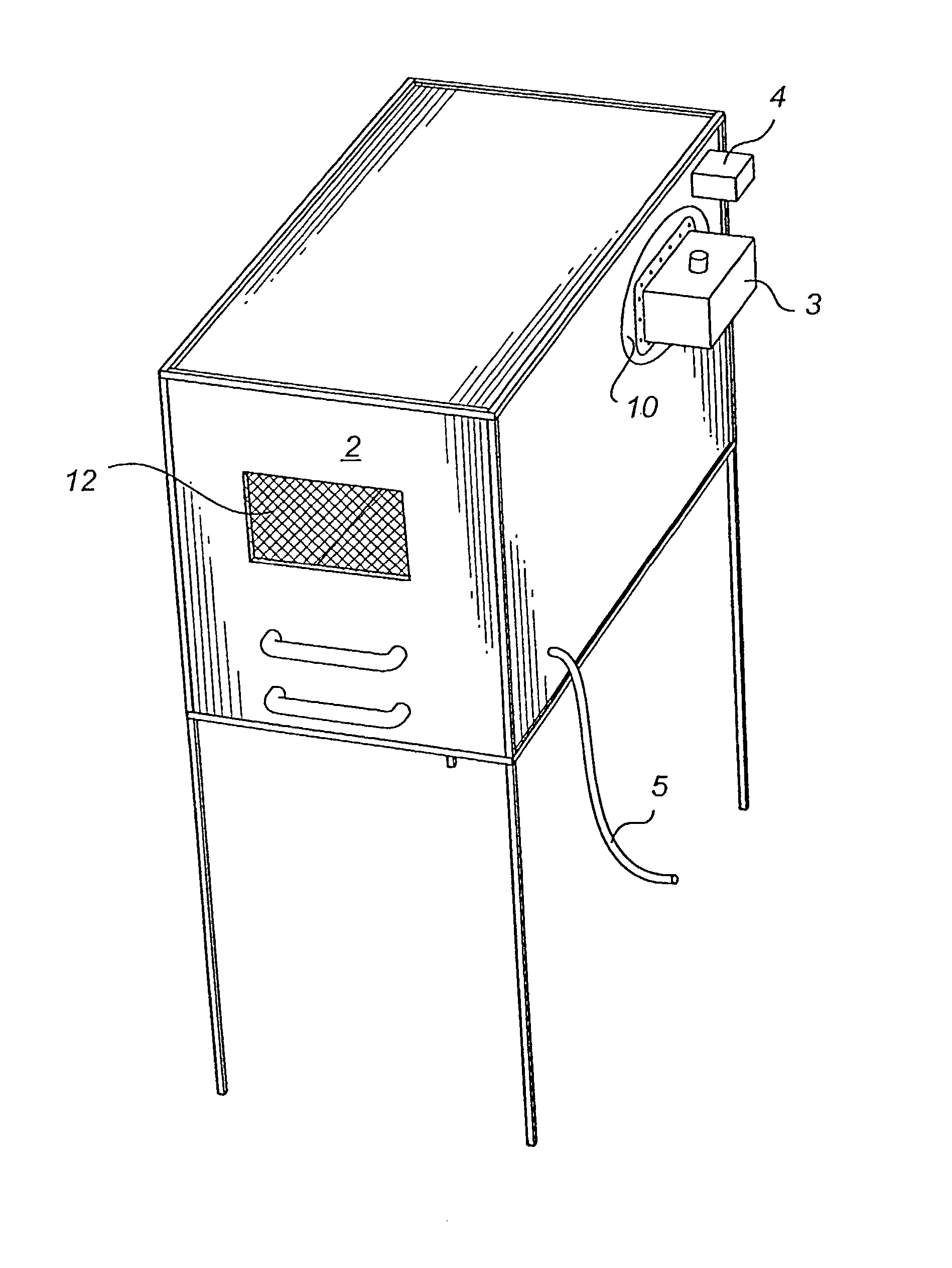

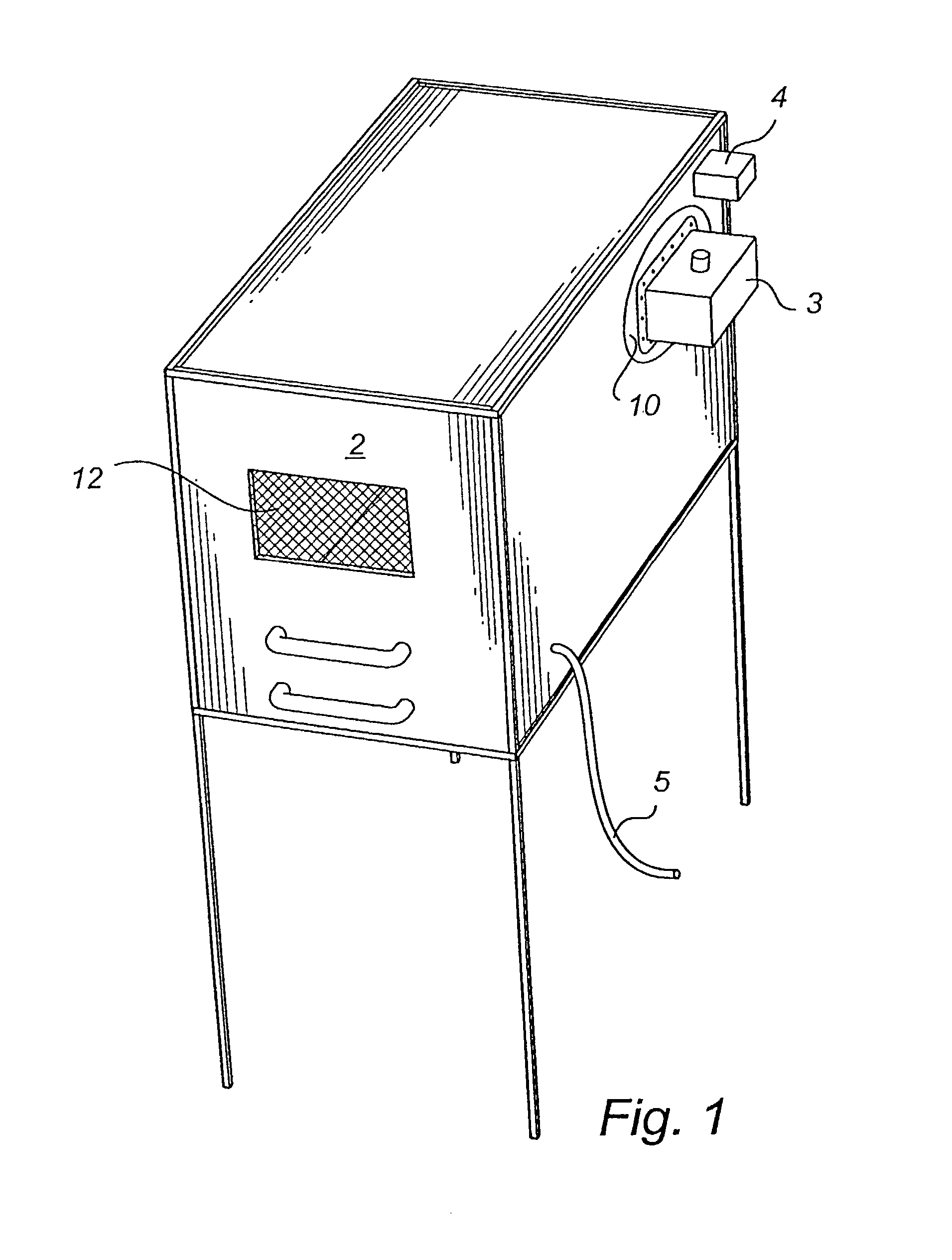

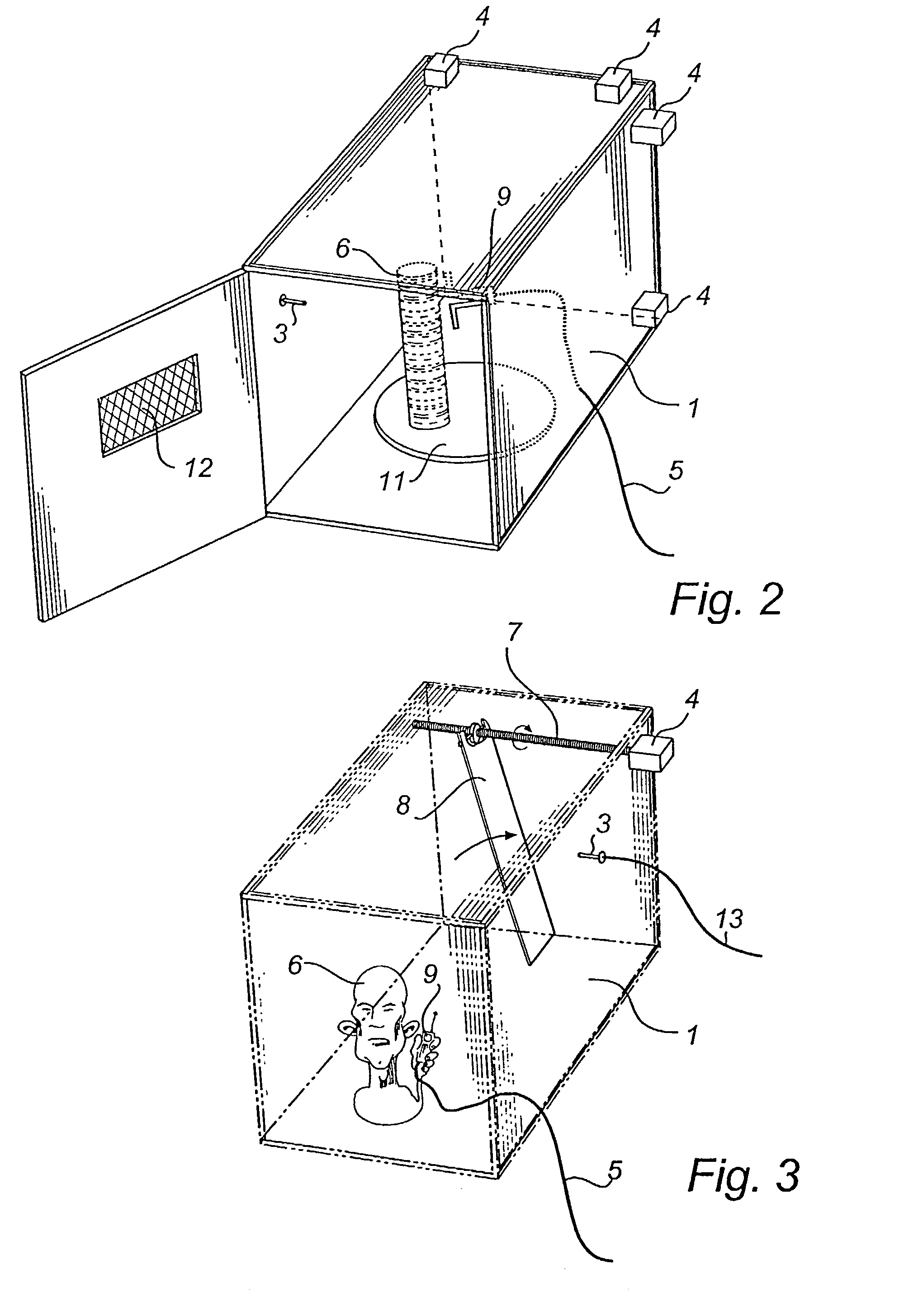

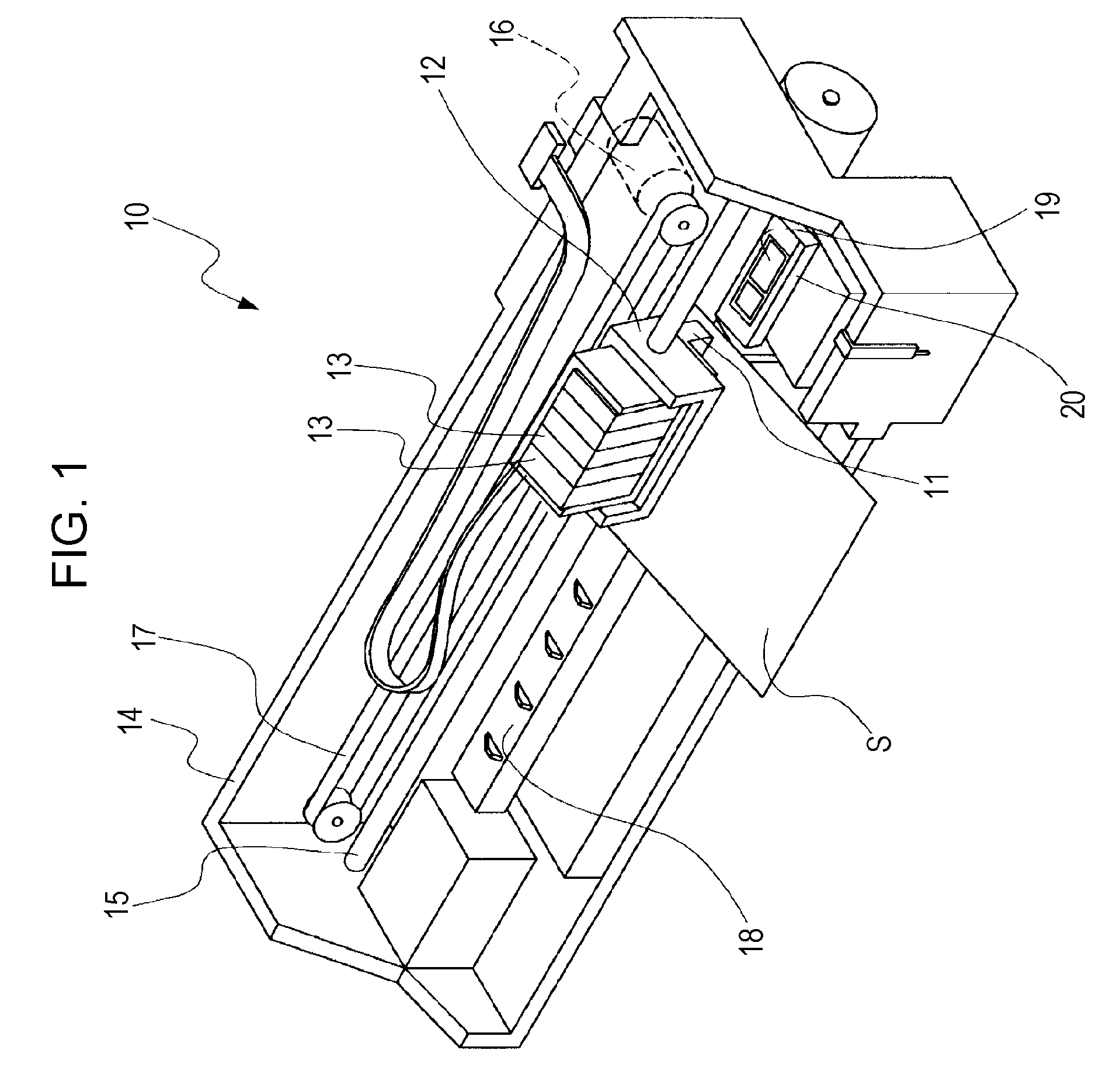

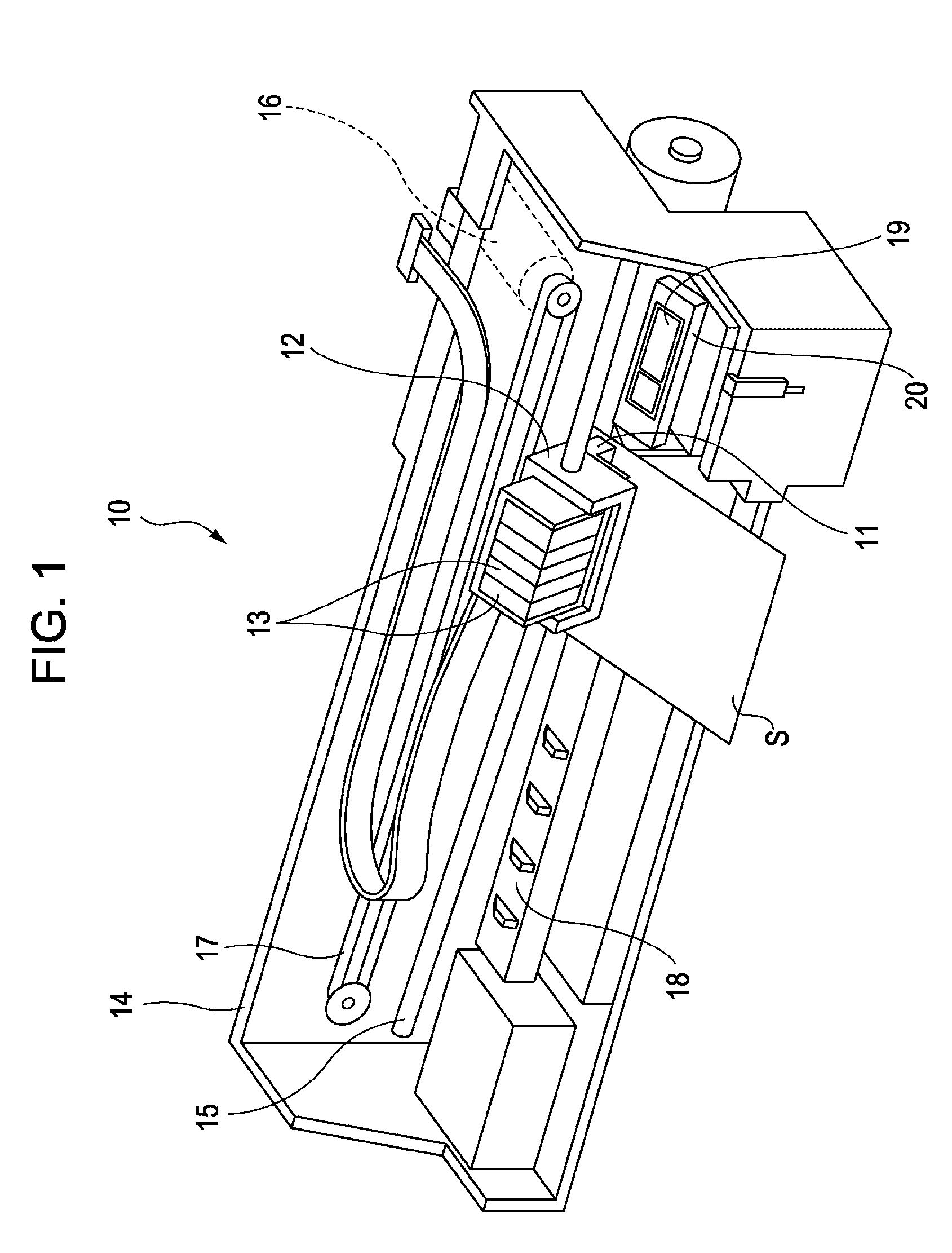

Method and an apparatus for measuring the performance of antennas, mobile phones and other wireless terminals

InactiveUS7444264B2Less effortLess spaceDigital circuit testingResistance/reactance/impedenceMobile objectRadiation

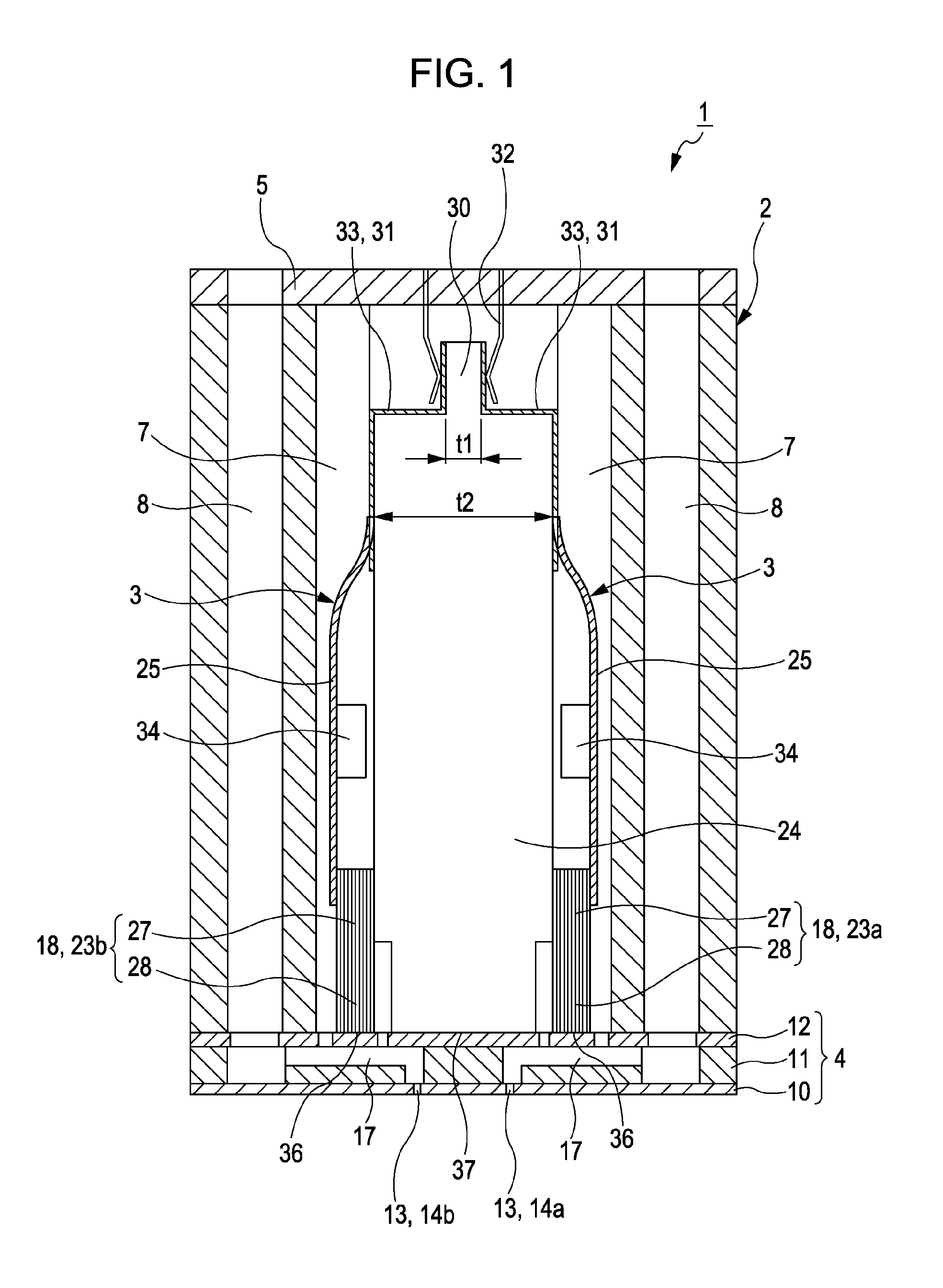

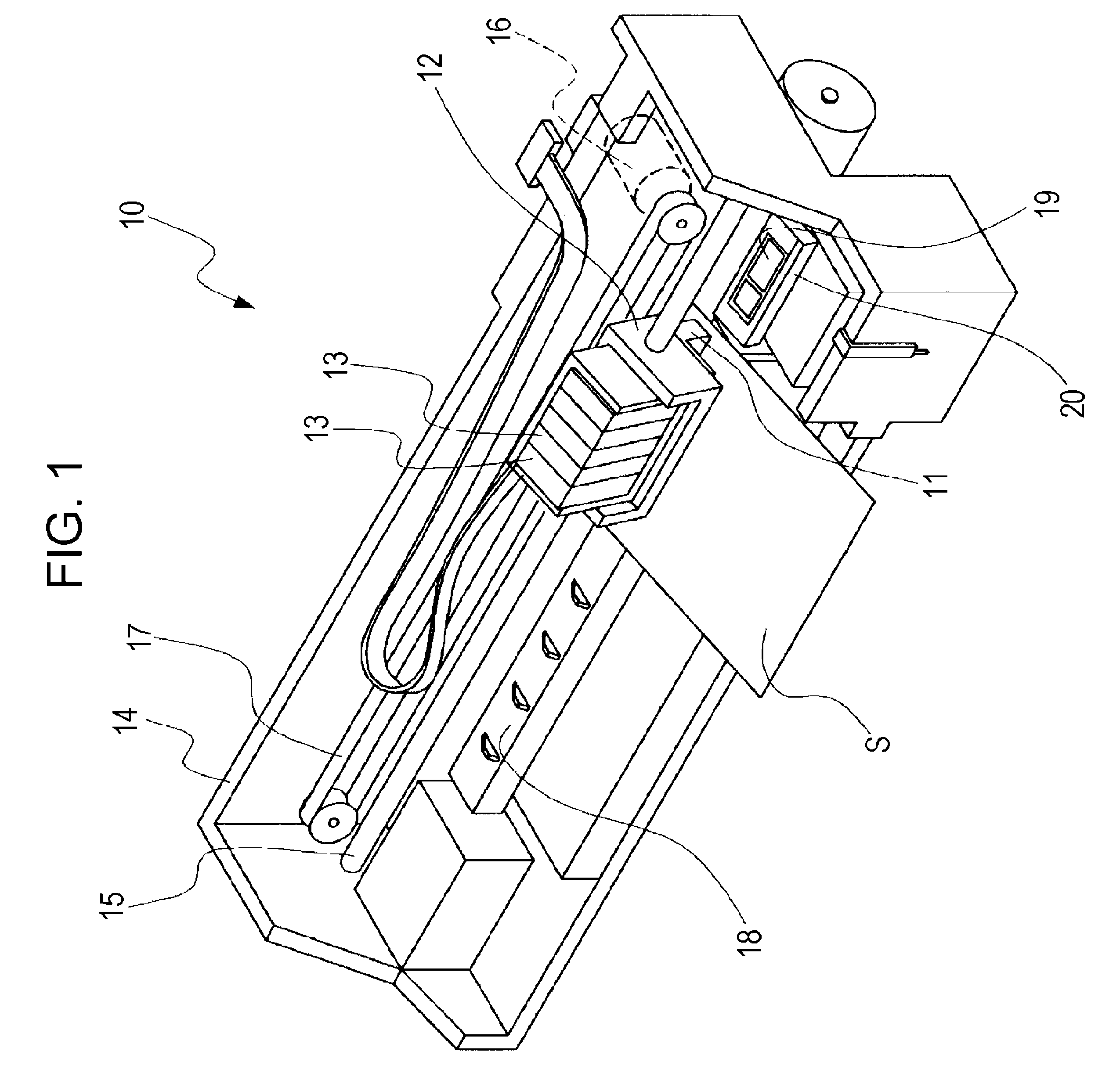

An apparatus and a method are for measuring the radiation efficiency of antennas and the communication power of mobile and wireless terminals. The apparatus includes a chamber to enclose the antenna or terminal to be tested. The chamber includes walls of an inwardly reflective material, rendering the walls reflective to electromagnetic waves. The quality of the antenna or terminal is obtained by averaging the power transmitted between the antenna under test and a fixed antenna, or the power received at the fixed antenna when the terminal under test is used as a transmitter. The averaging is done over the measured power for several different positions of moving objects in the chamber and of a moving platform on which the antenna or terminal under test is located. The radiation efficiency or communication power is obtained by relating the measured average levels to those of a reference antenna or a reference terminal of known radiation efficiency or communication power.

Owner:BLUETEST

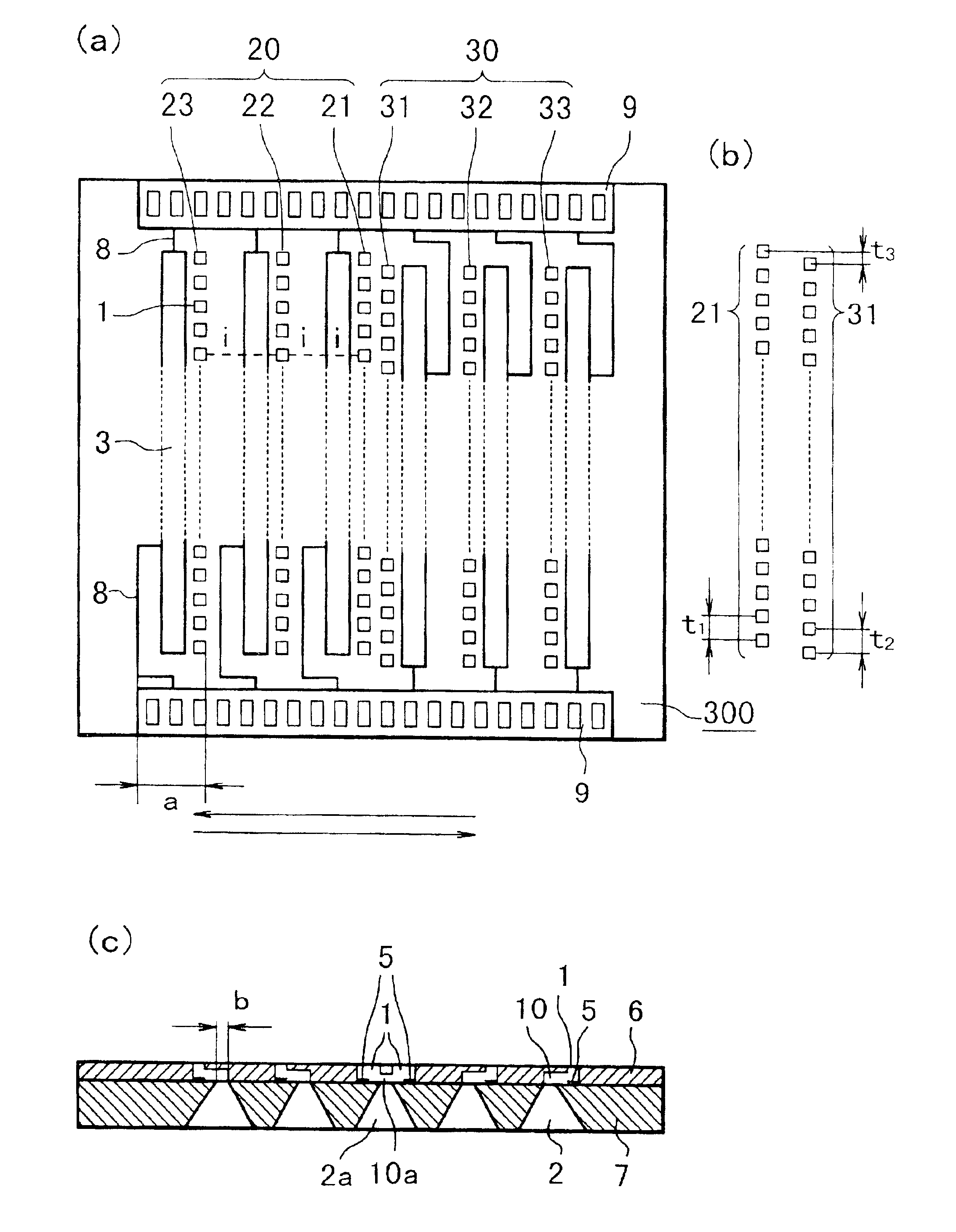

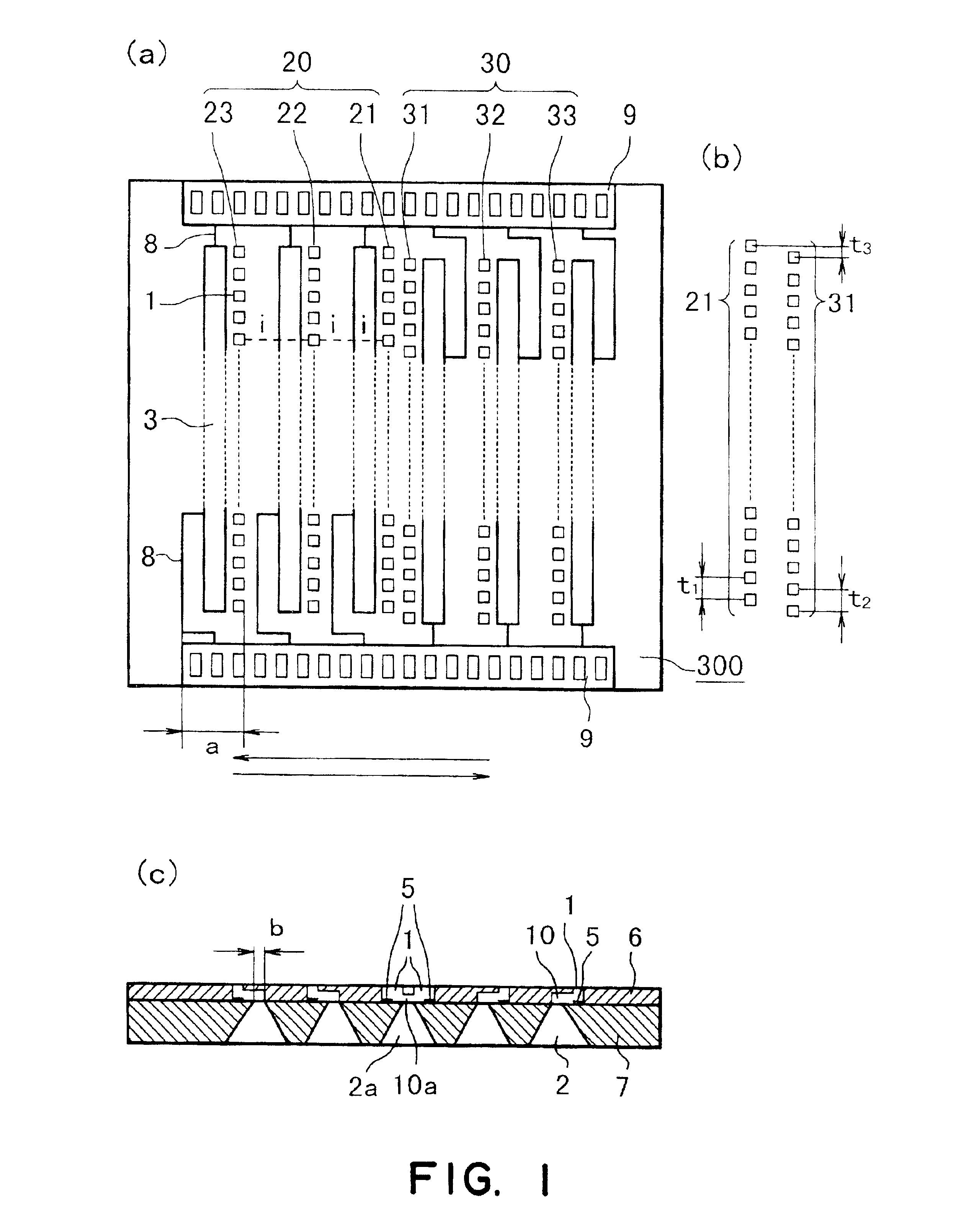

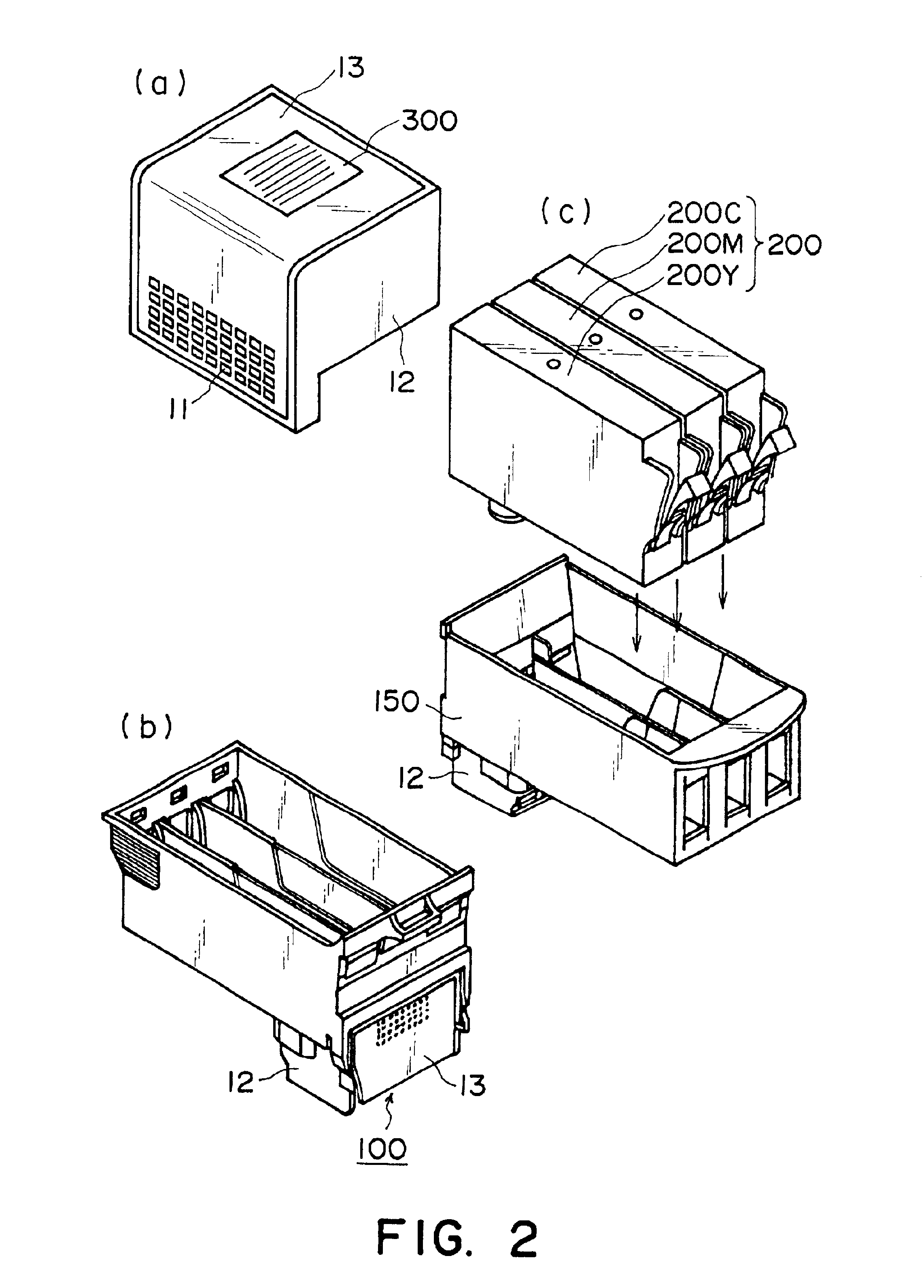

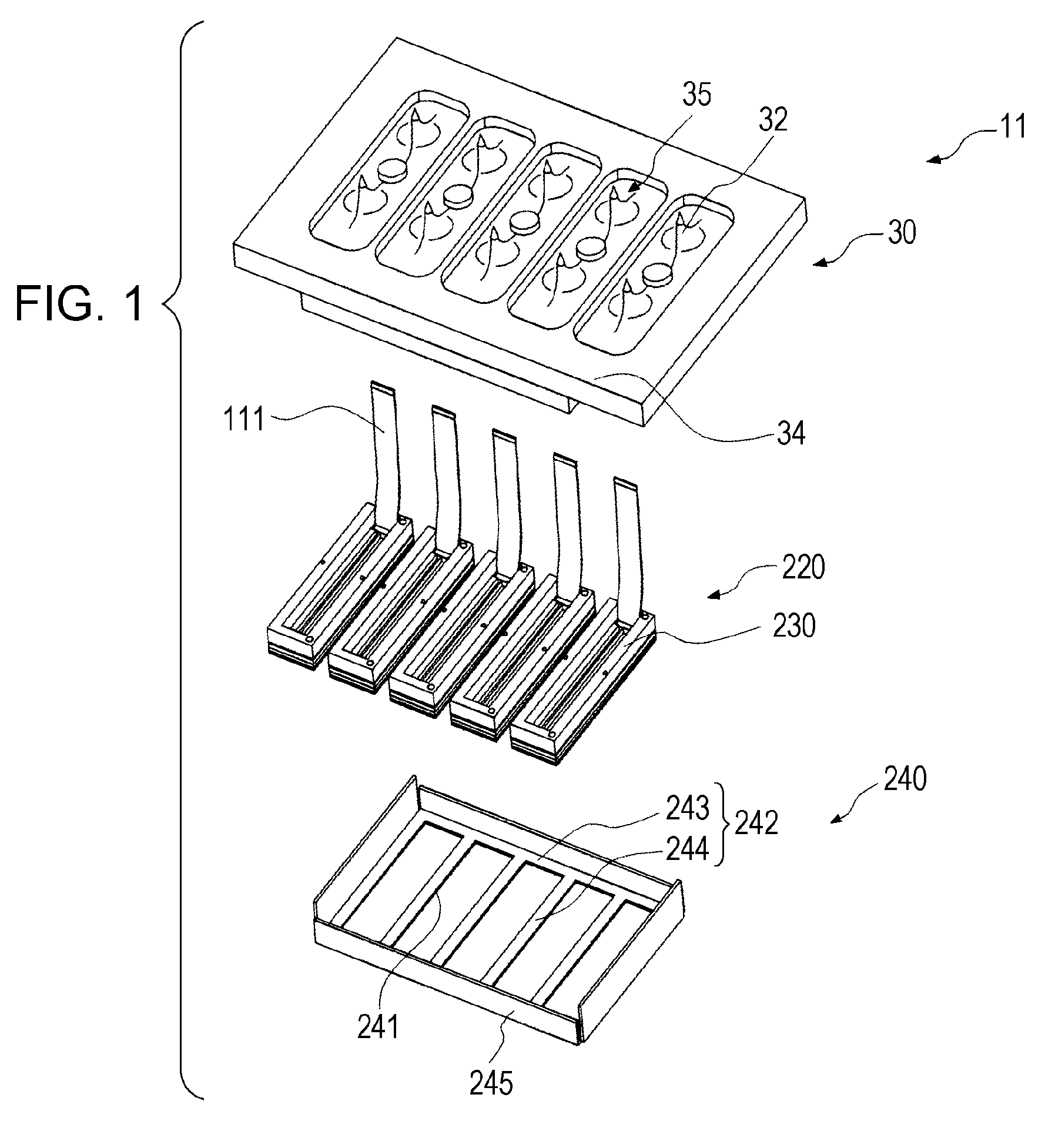

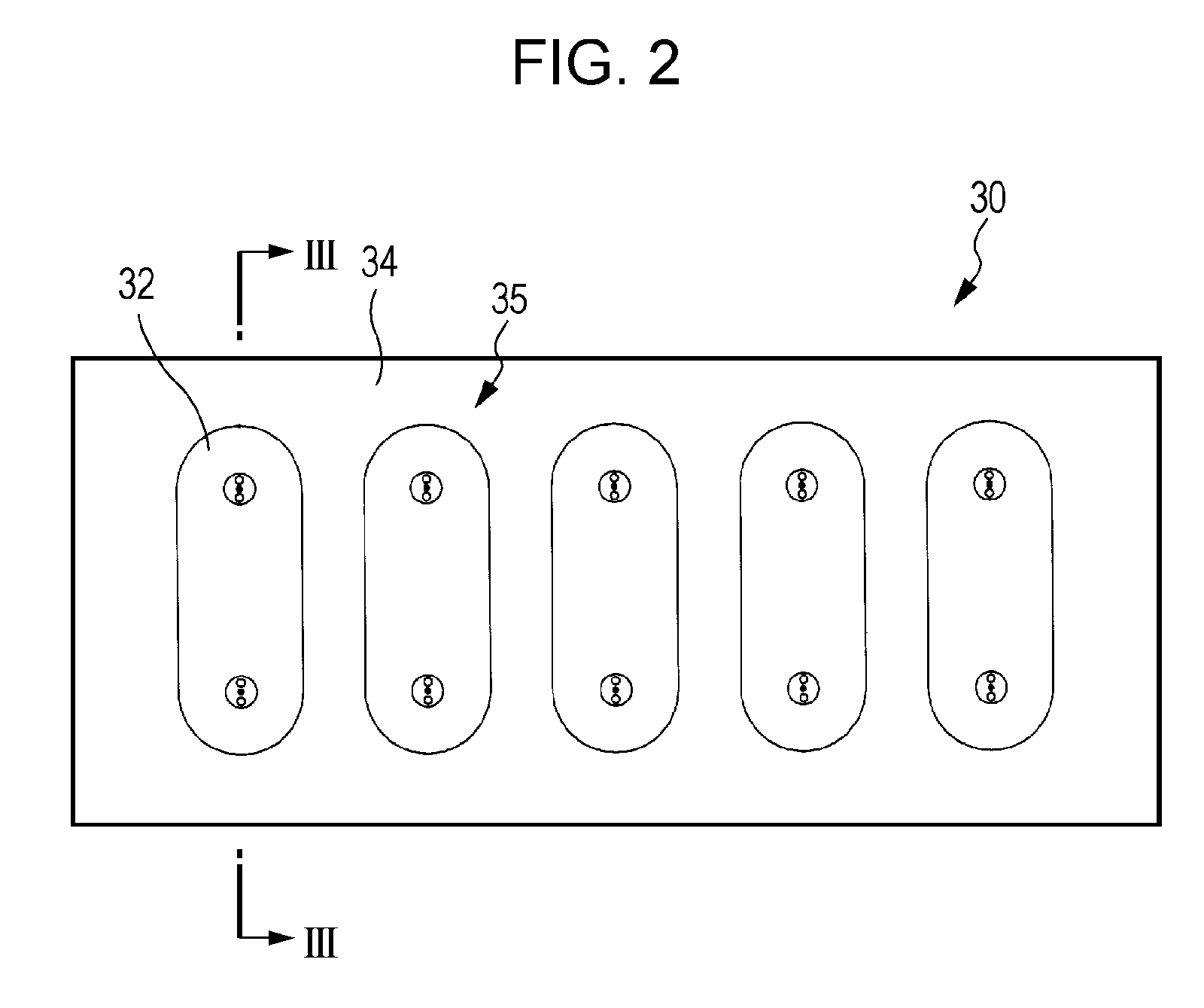

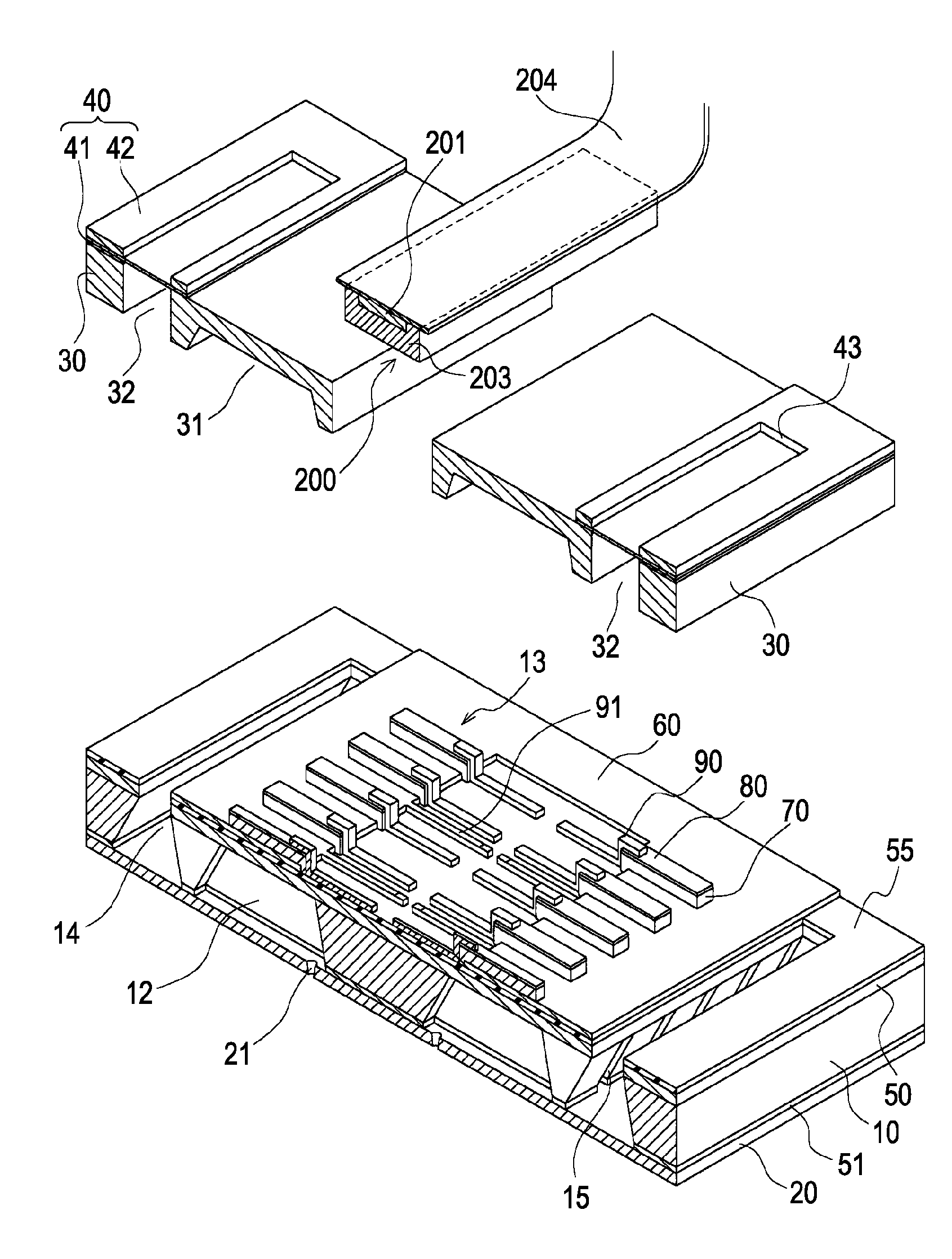

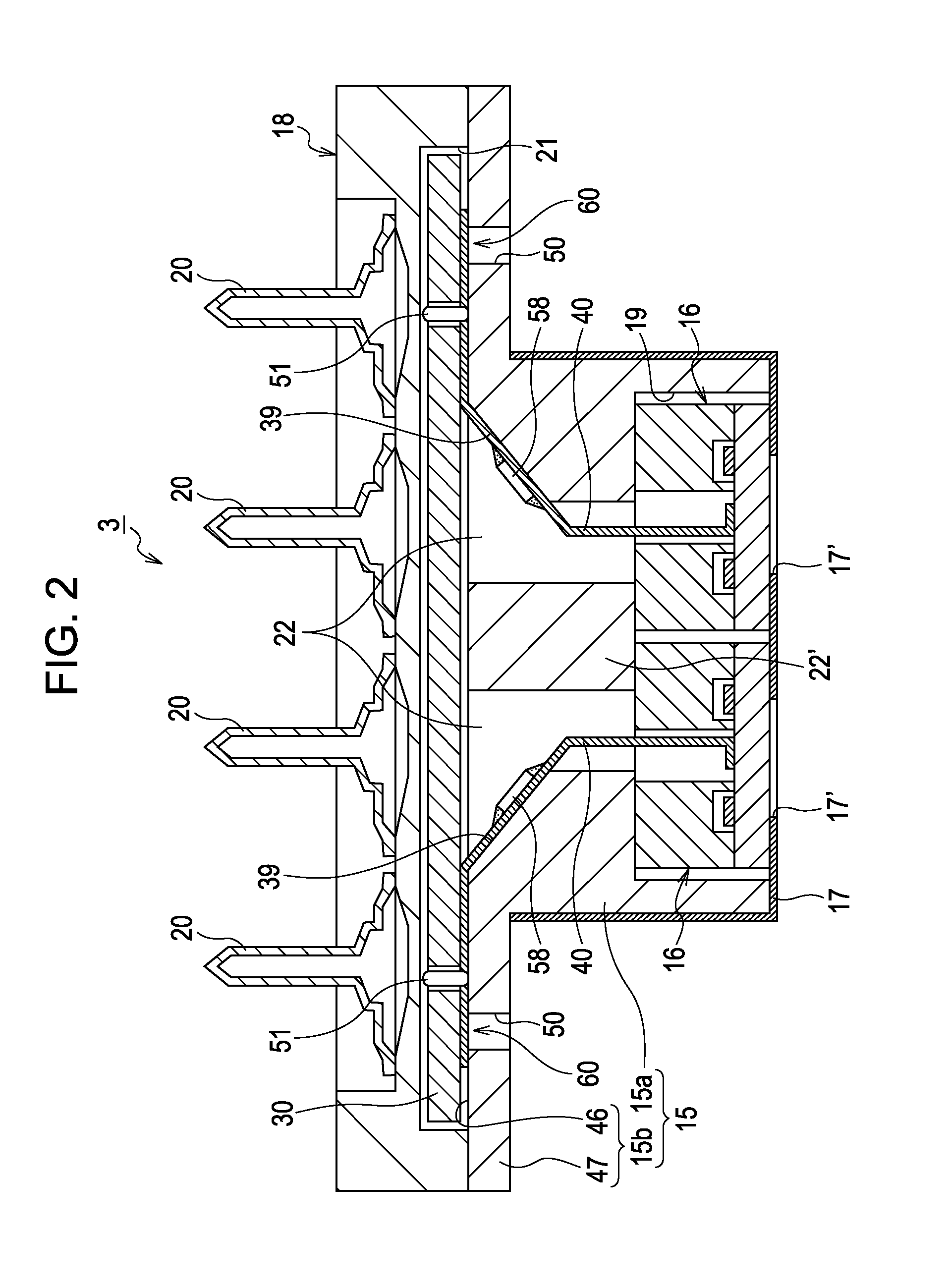

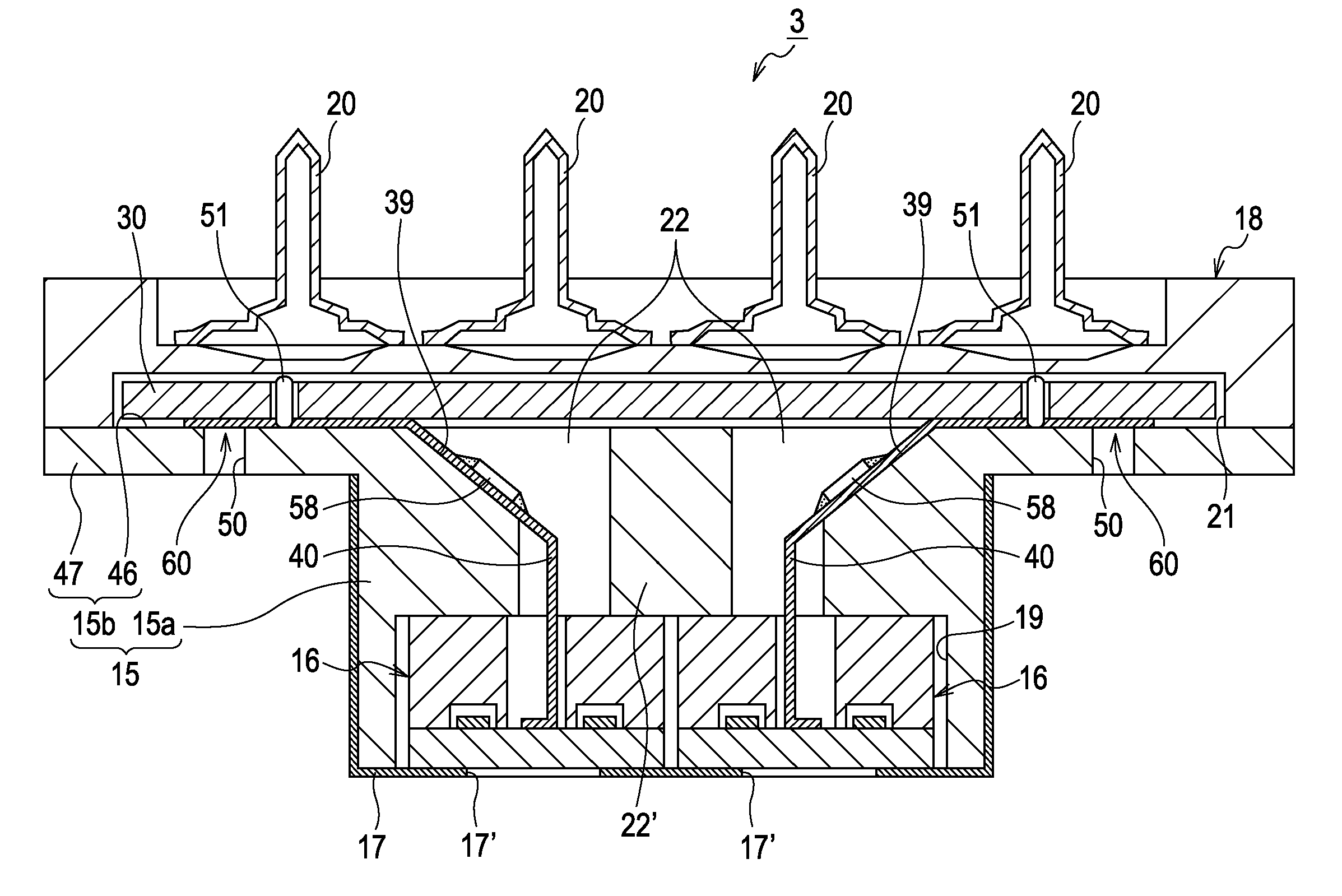

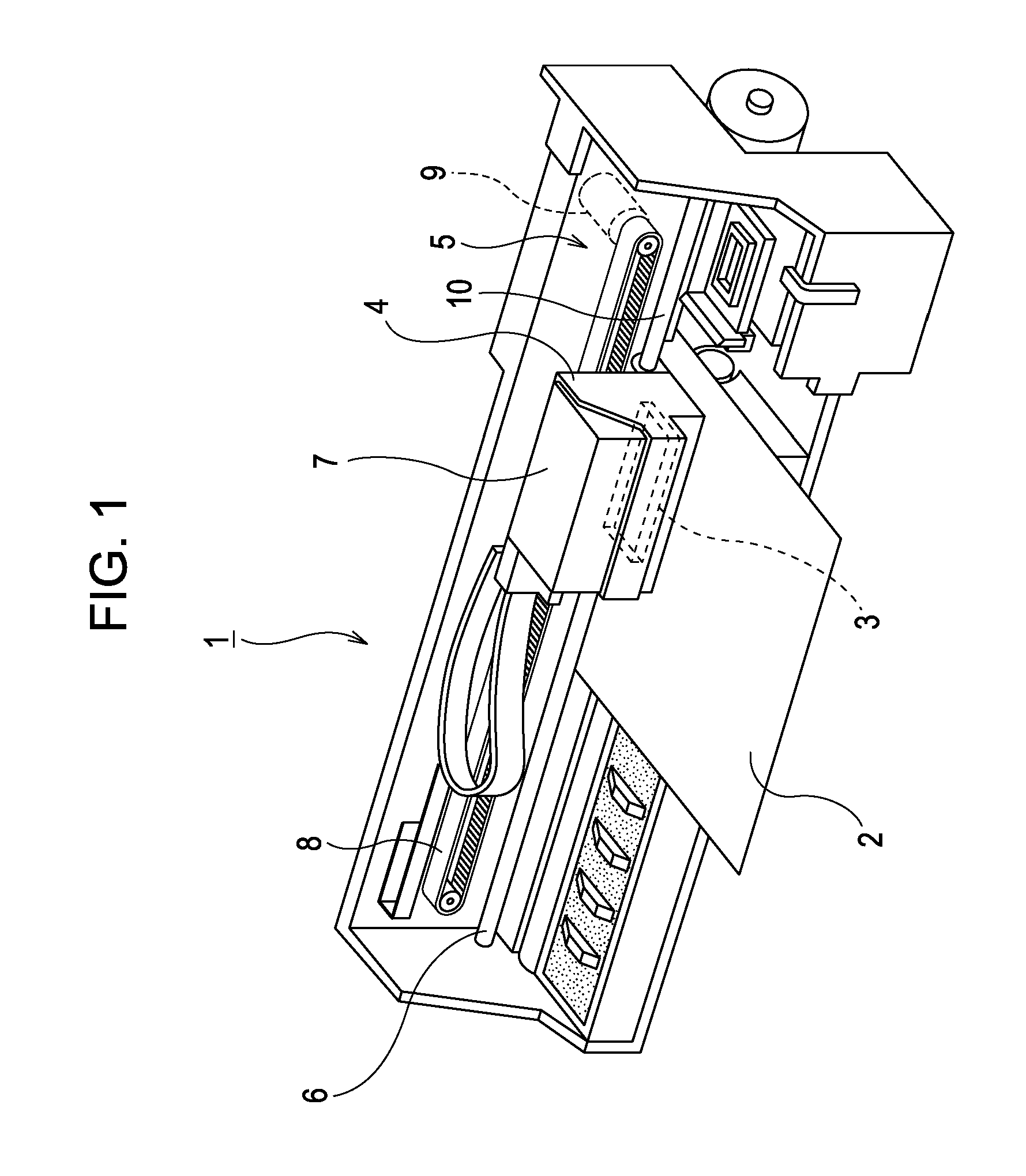

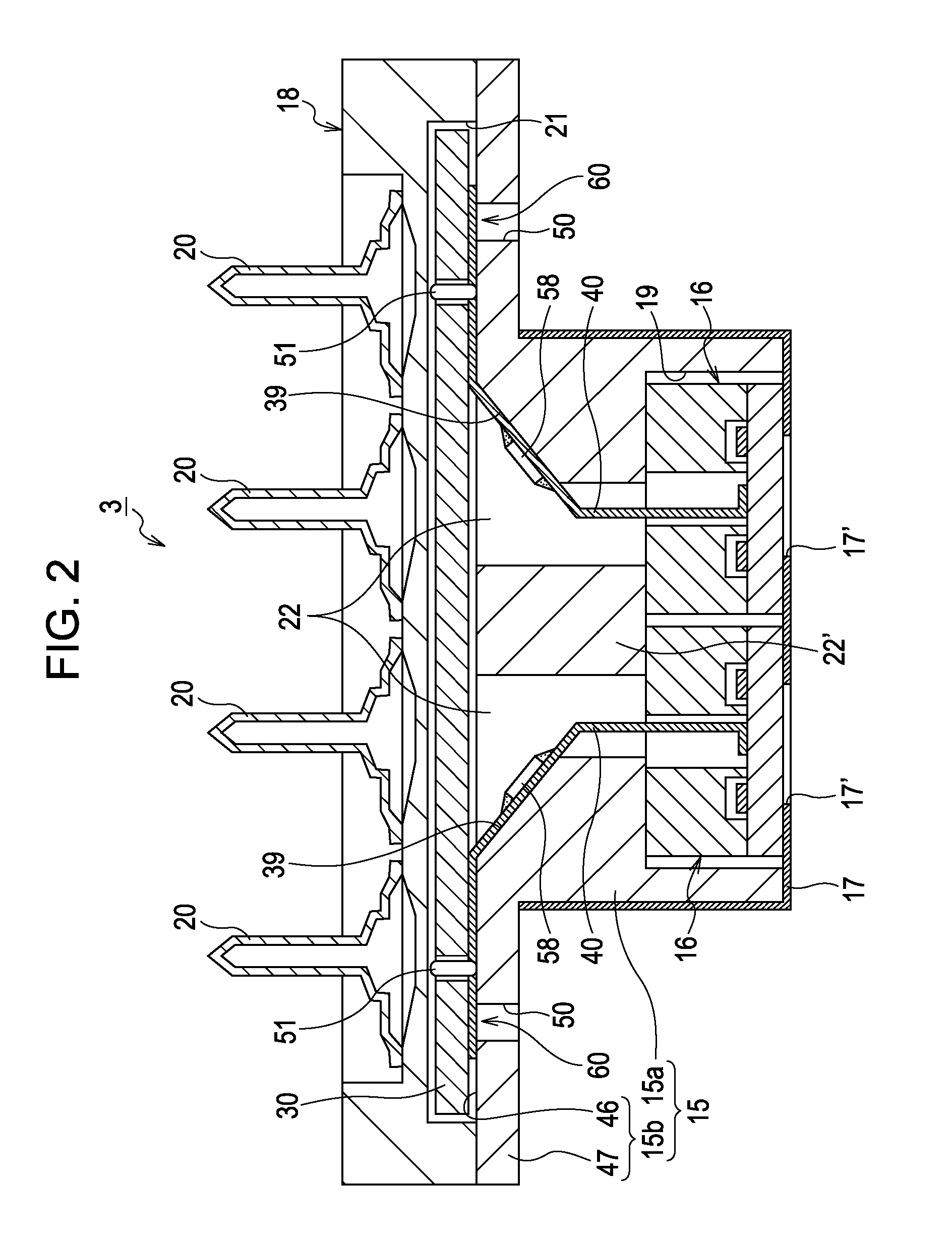

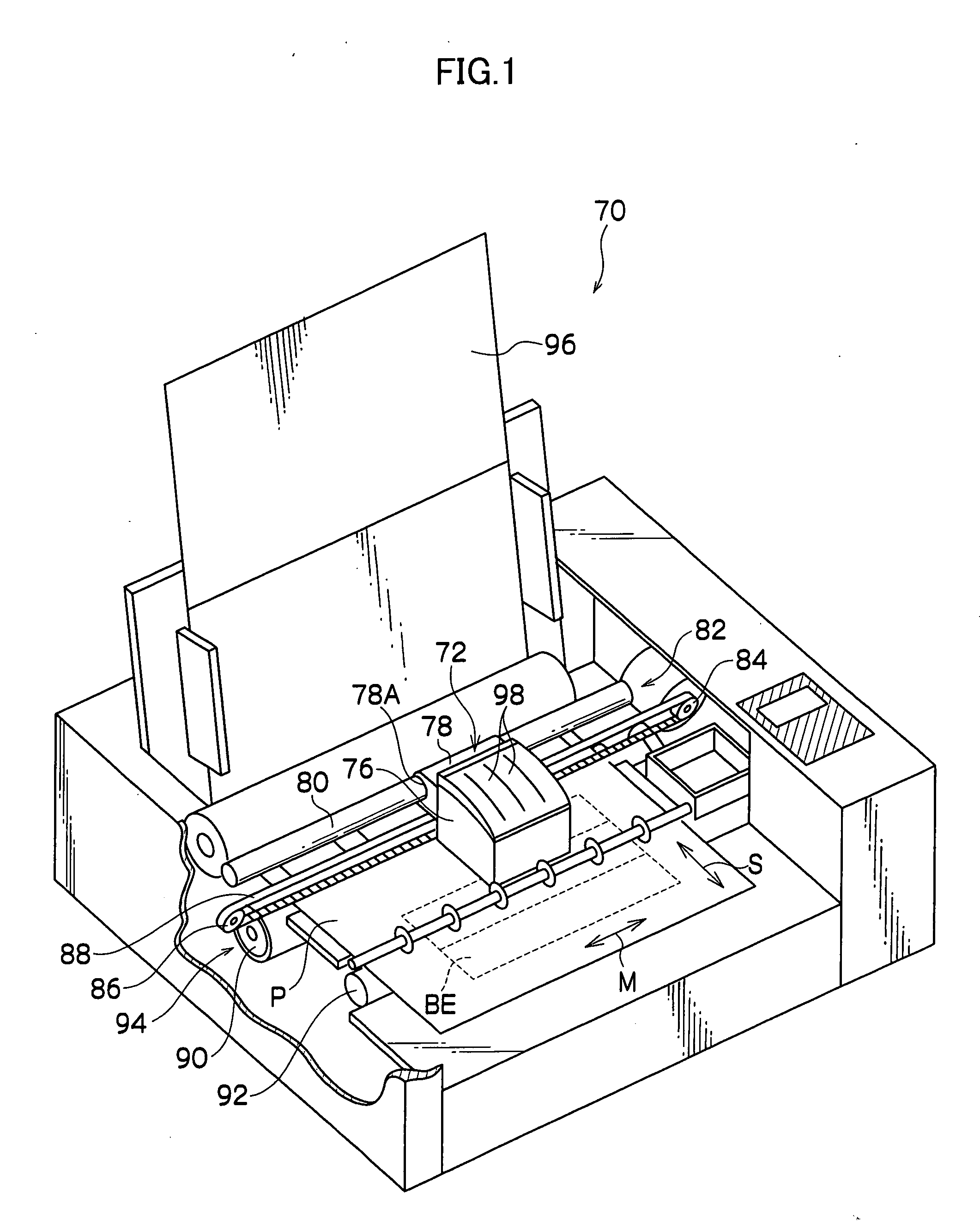

Liquid ejecting recording head and liquid ejecting recording apparatus

InactiveUS6964467B2High resolutionEasy to printInking apparatusSpacing mechanismsEngineeringMechanical engineering

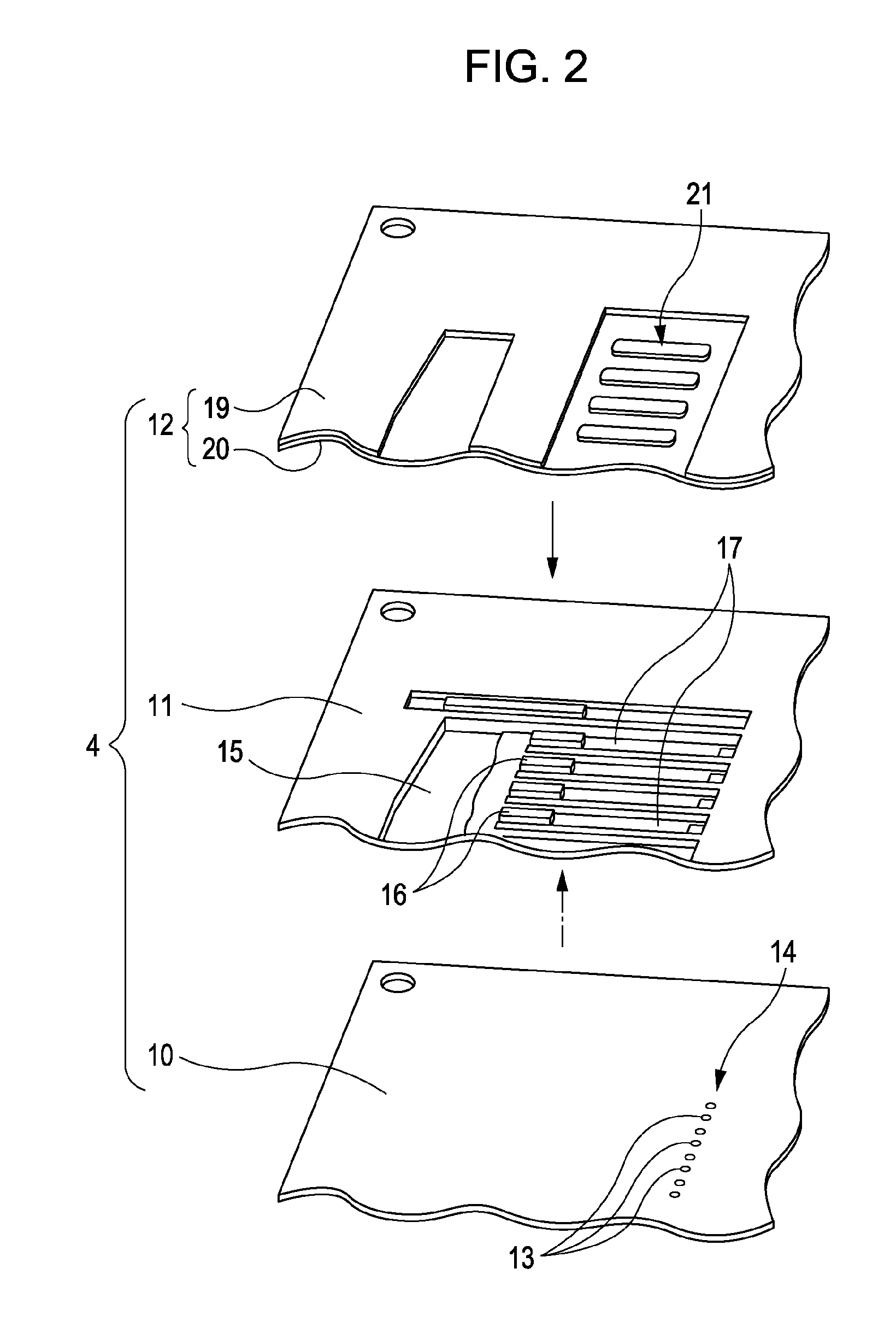

A liquid ejection recording head for effecting recording by ejecting first liquid and second liquid which is a different kind of liquid through different ejection outlets, while bi-directionally scanning a recording material in a scanning direction includes a group of first ejection outlet arrays each of which has a plurality of ejection outlets at predetermined intervals arranged in a direction different from the scanning direction, wherein corresponding ejection outlets in the respective ejection arrays are aligned in the scanning direction; a group, disposed adjacent the group of the first ejection outlet arrays, of second ejection outlet arrays arranged in a manner similar to the first ejection outlet array group; wherein the first ejection outlet arrays include a first ejection outlet array for ejecting the first liquid and a second ejection outlet array for ejecting the second liquid; wherein the second ejection outlet arrays include a third ejection outlet array for ejecting the first liquid and a fourth ejection outlet array for ejecting the second liquid; wherein the first ejection outlet array group and the second ejection outlet array group are disposed such that first ejection outlet array and third ejection outlet array are adjacent to each other and that ejection outlets of the first ejection outlet array and the ejection outlets of the third ejection outlet array are disposed with deviation in a direction of arrangement of the ejection outlets so as to be complementary to each other in the scanning direction.

Owner:CANON KK

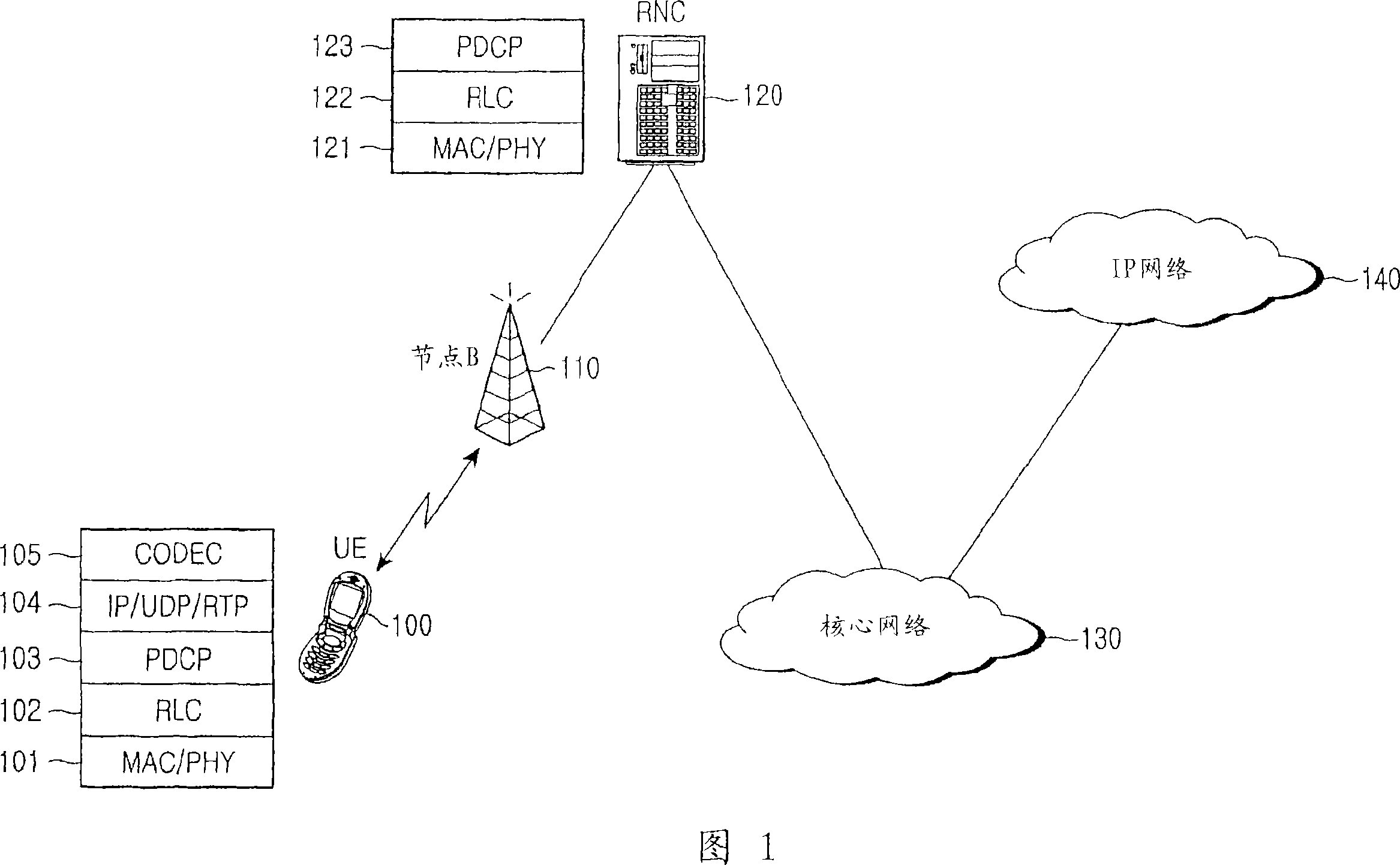

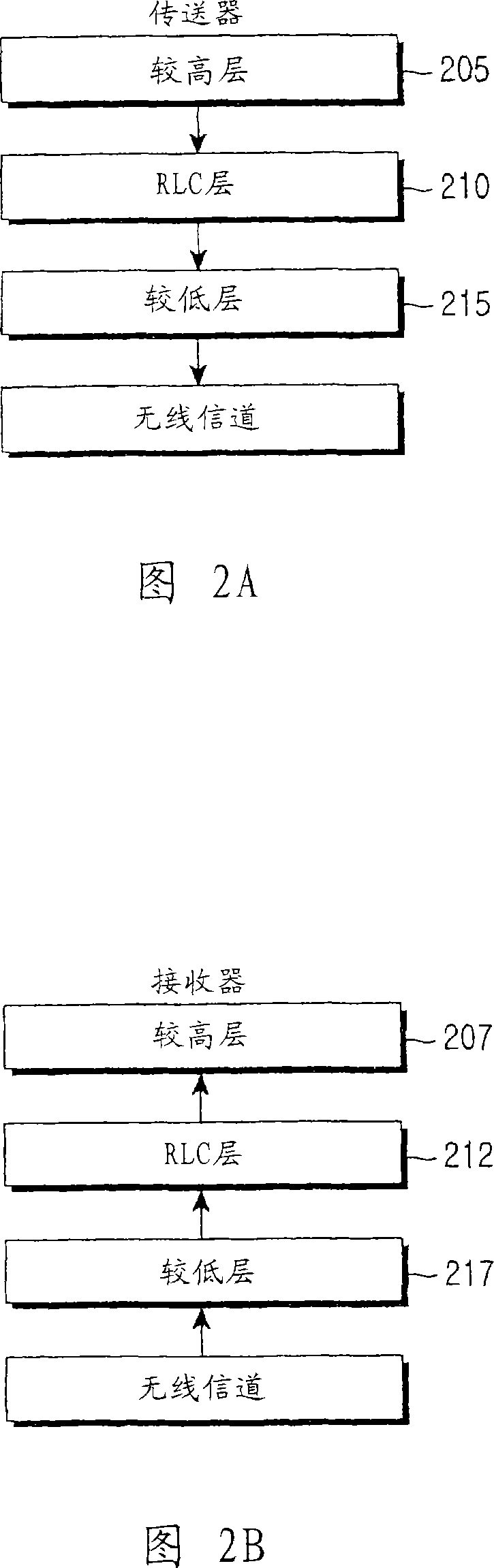

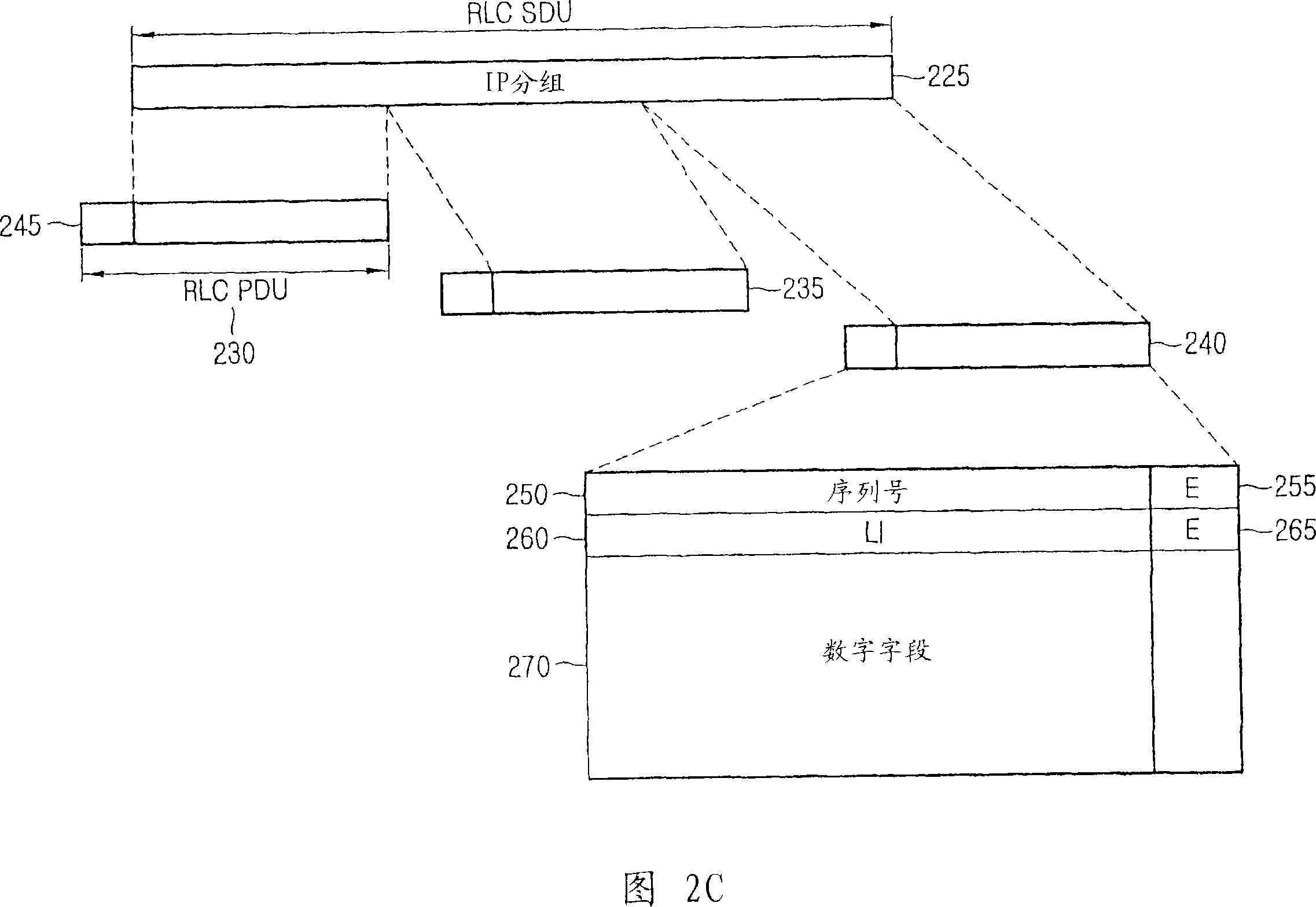

Method and apparatus for transmitting and receiving packet data using predefined length indicant in mobile communication system

ActiveCN101171806AReduce head sizeEasy to useError preventionNetwork traffic/resource managementComputer networkData field

A method and apparatus for enabling efficient use of radio resources by reducing an RLC PDU size in a mobile communication system supporting voice service over a packet network are provided. An RLC layer constructs an RLC PDU without inserting information indicating the start and end of an SDU or indicating the use or non-use of padding. The RLC layer sets an LI in a header to indicate inclusion of an intermediate SDU segment in the data field of the RLC PDU. Therefore, the resulting decrease of overhead arising from packet transmission facilitates the efficient use of limited radio resources.

Owner:SAMSUNG ELECTRONICS CO LTD

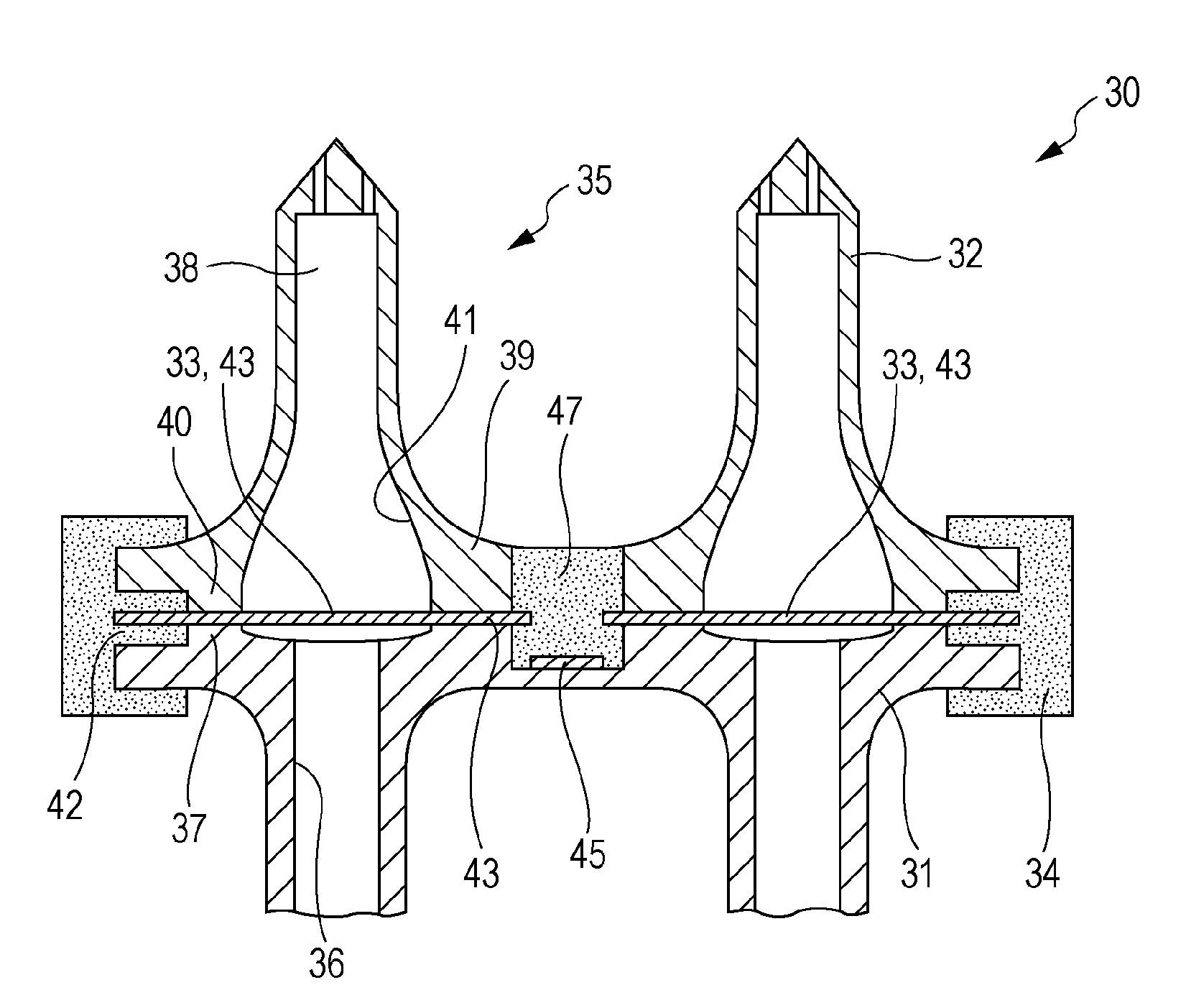

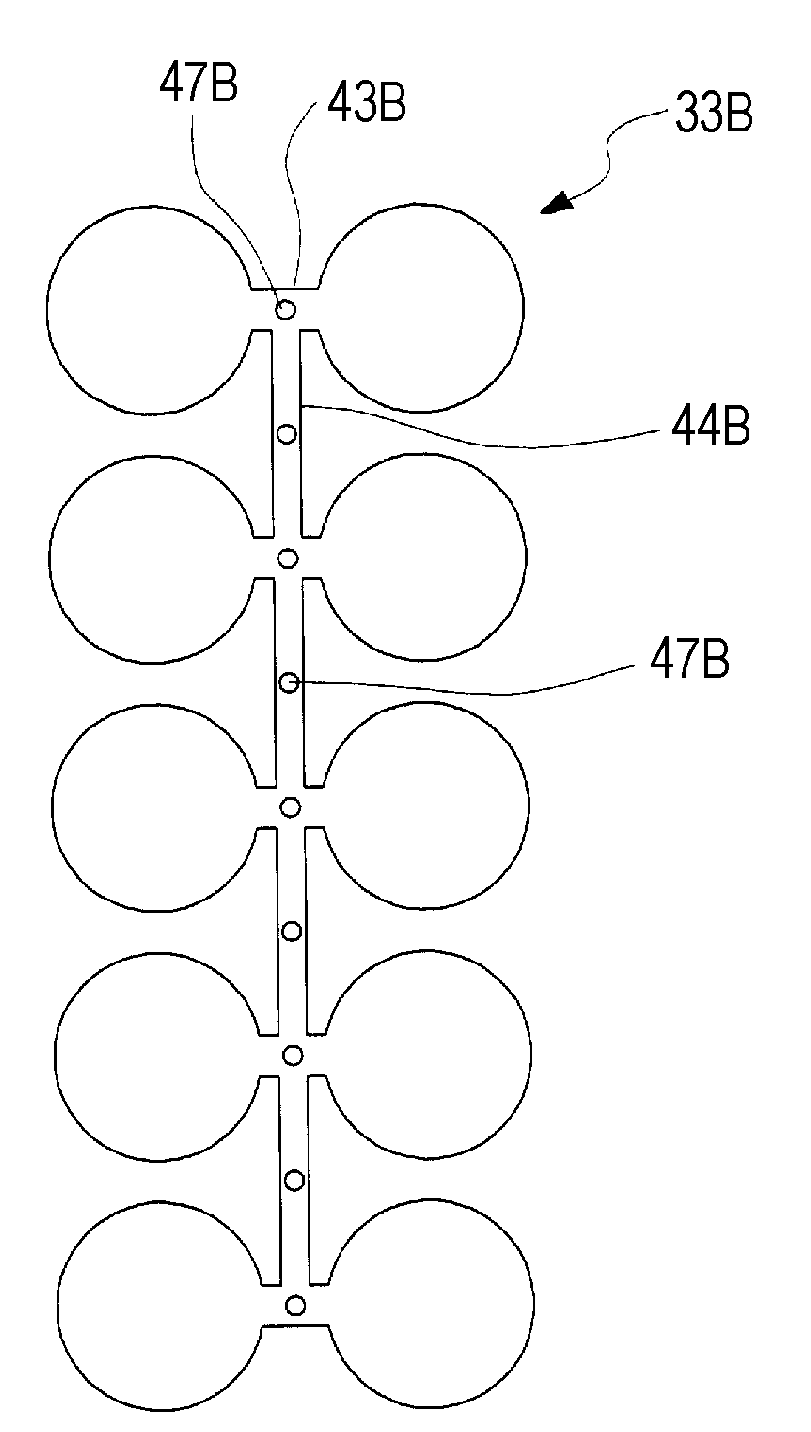

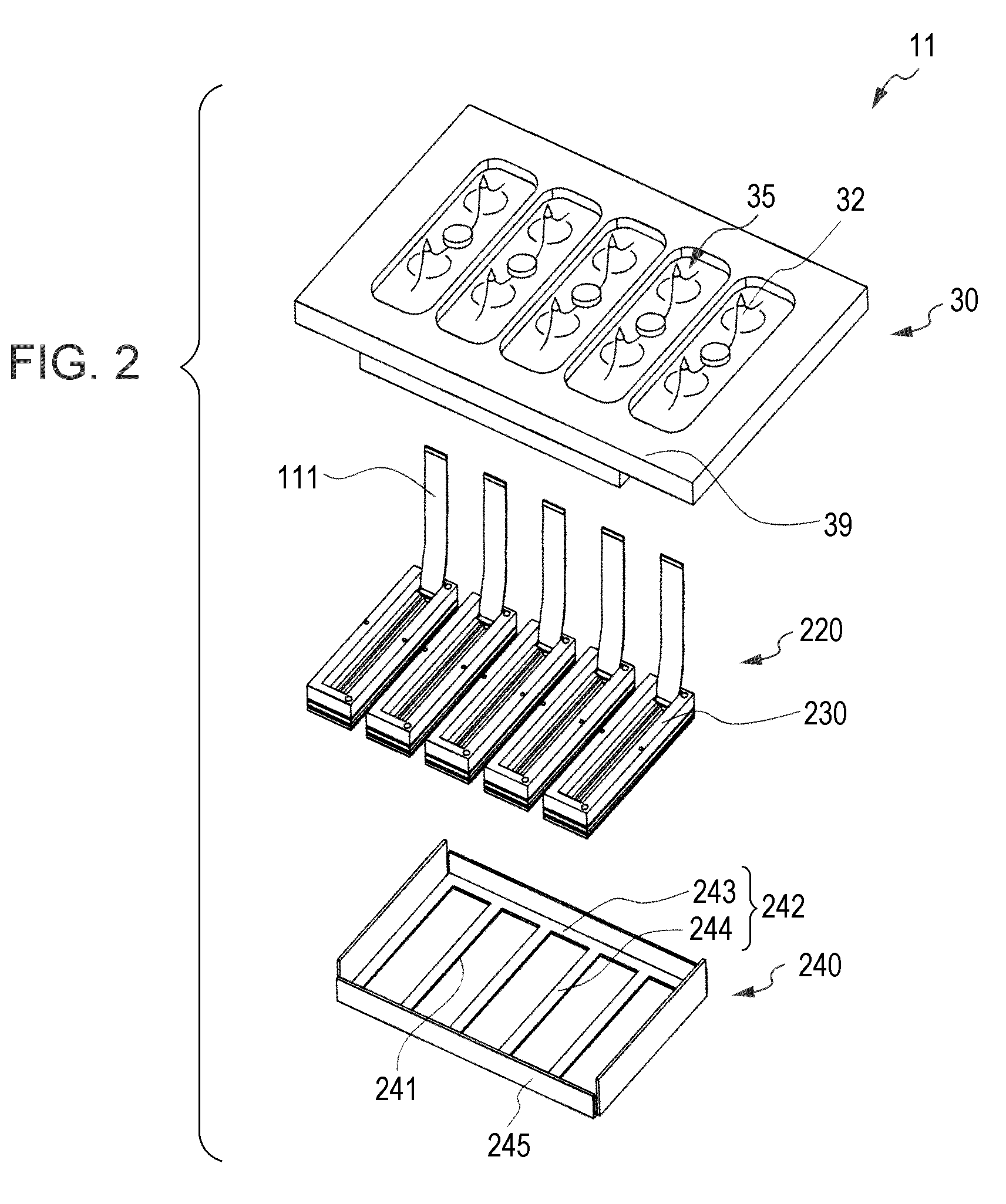

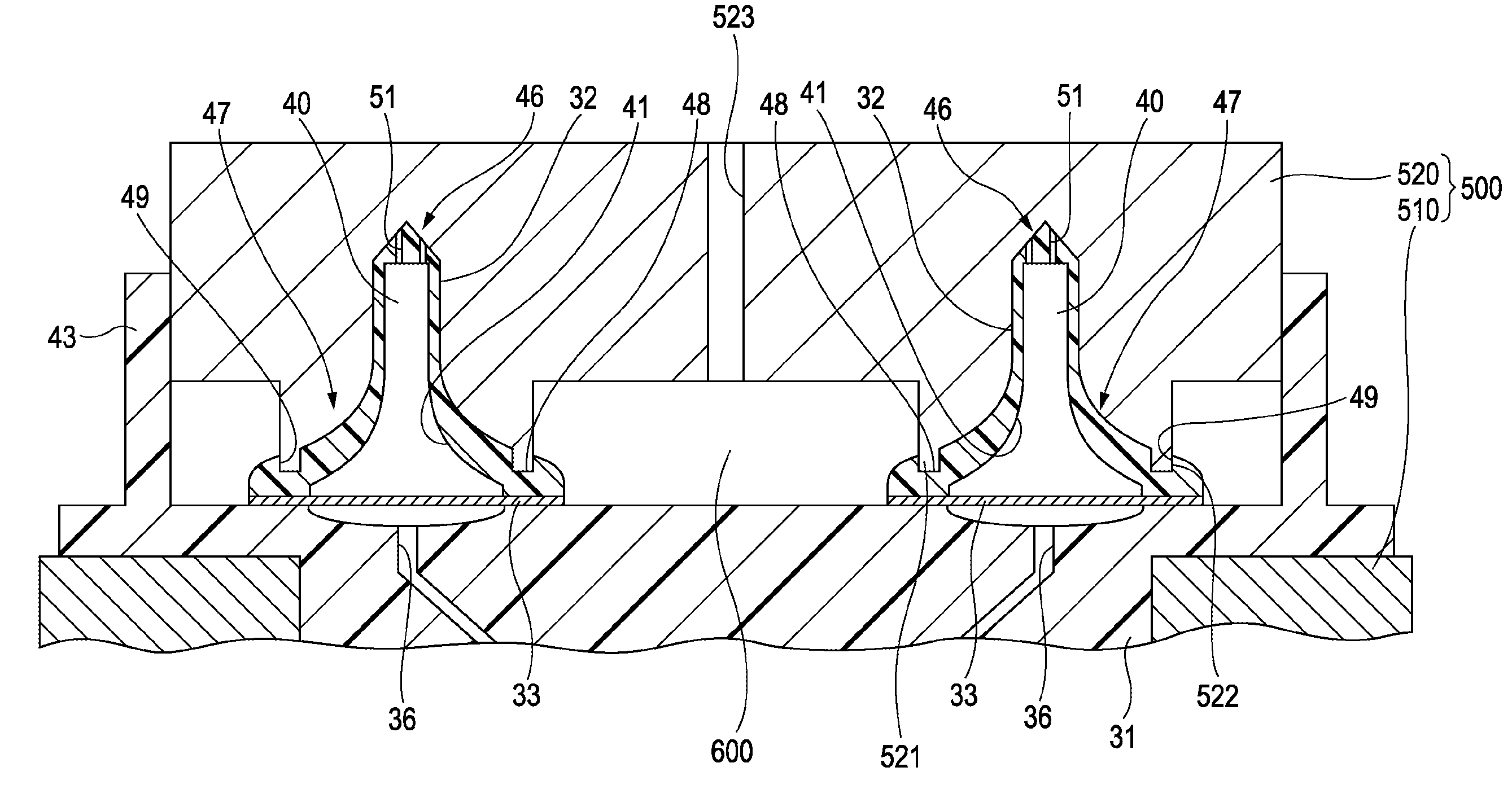

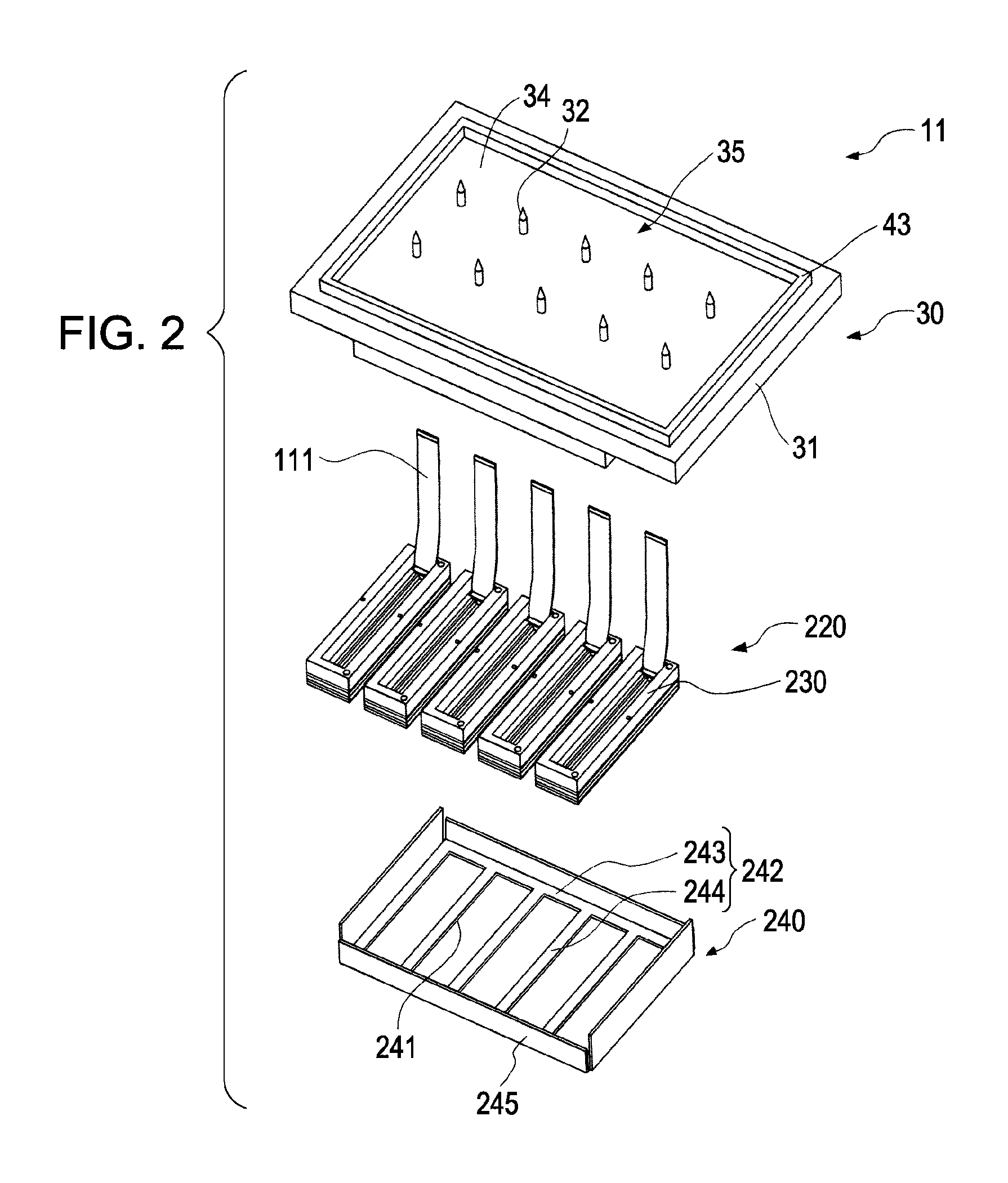

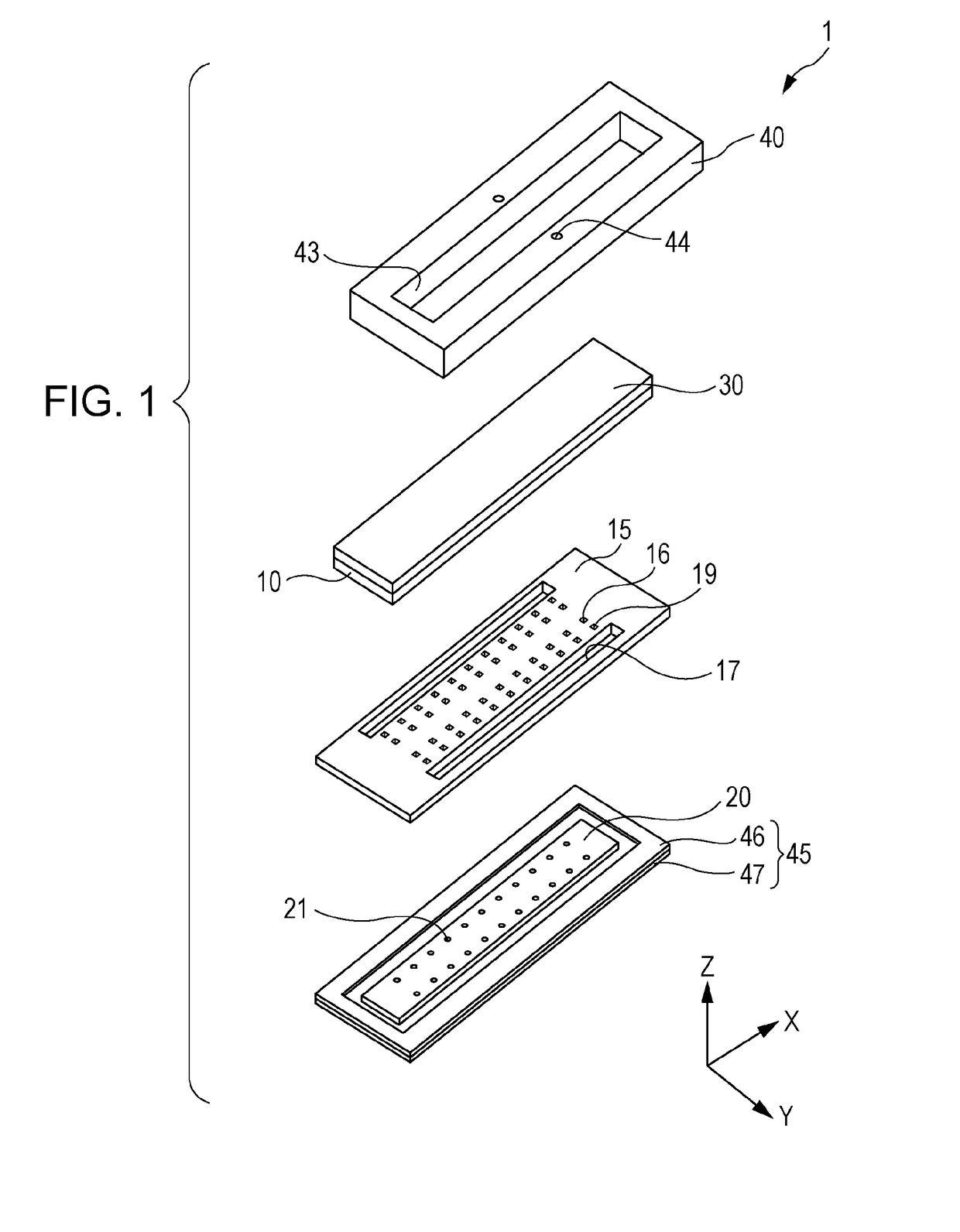

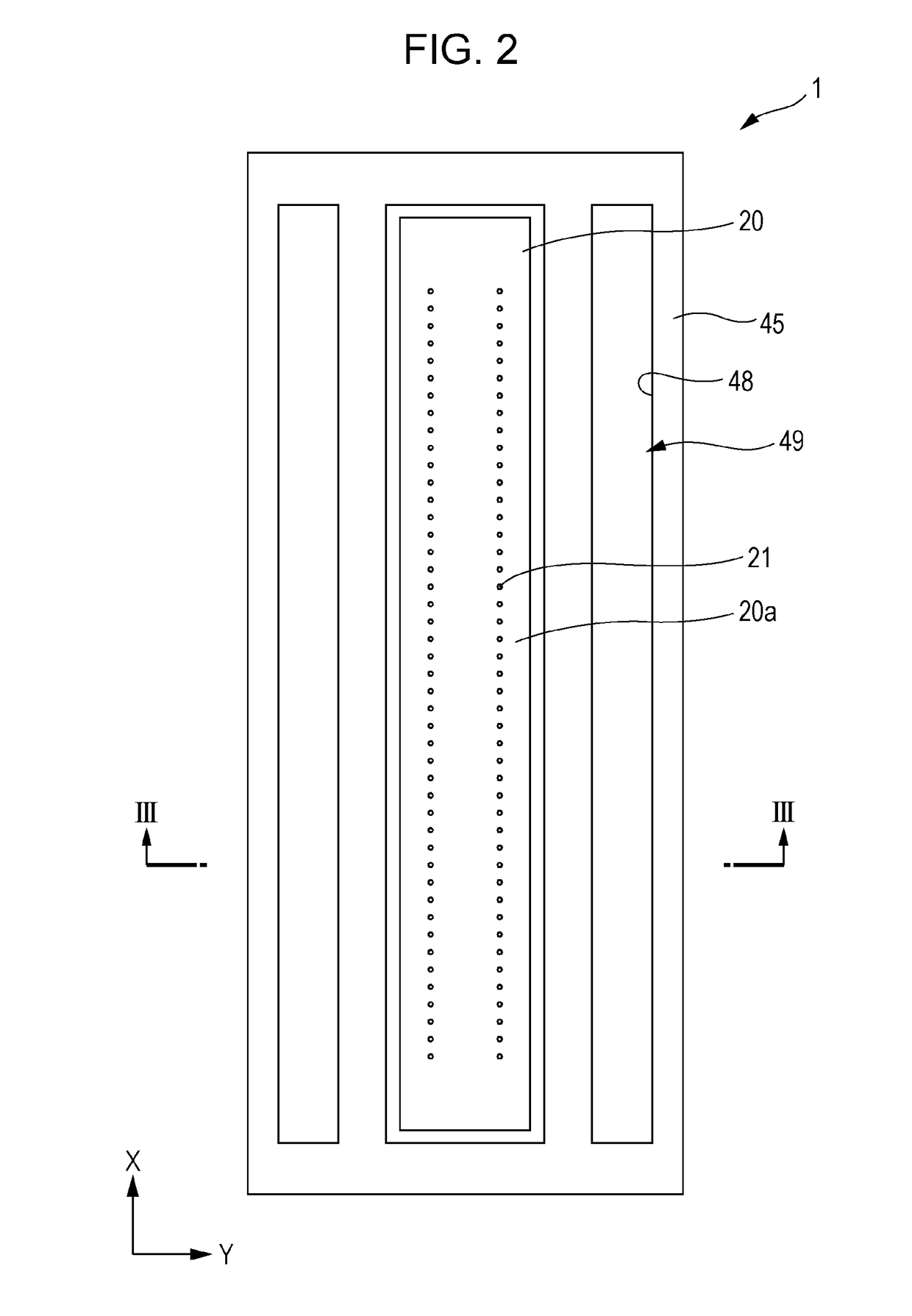

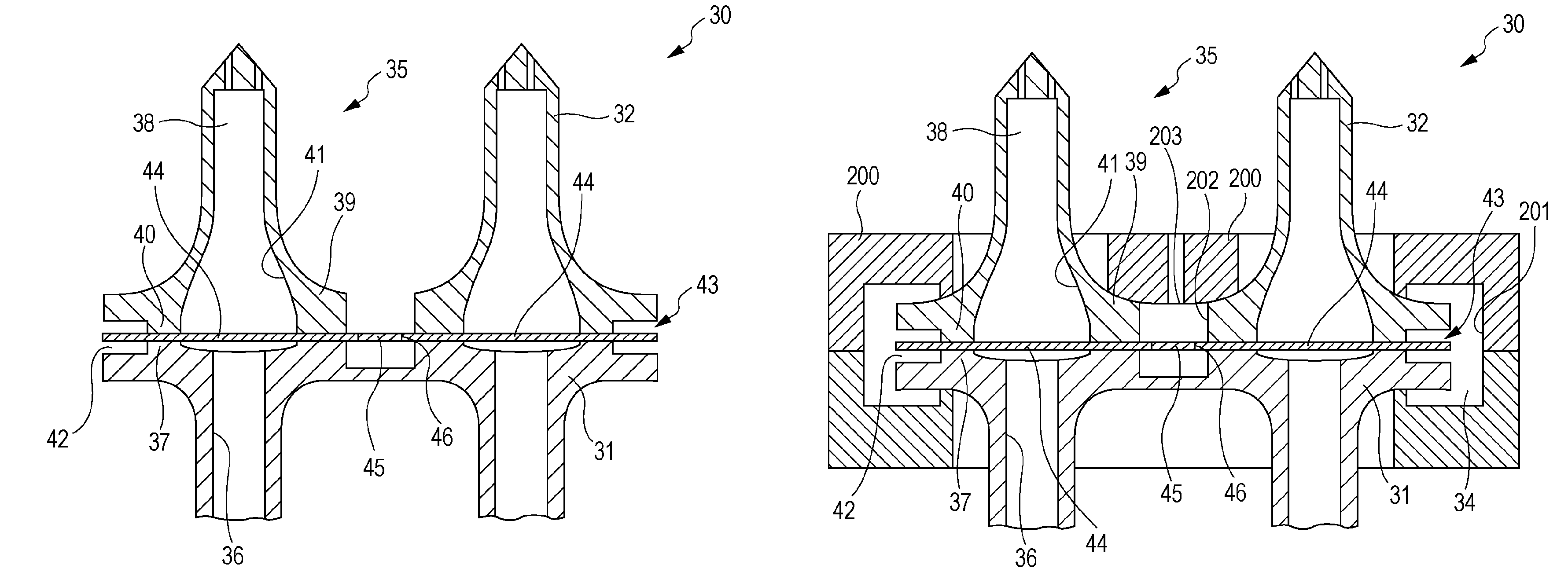

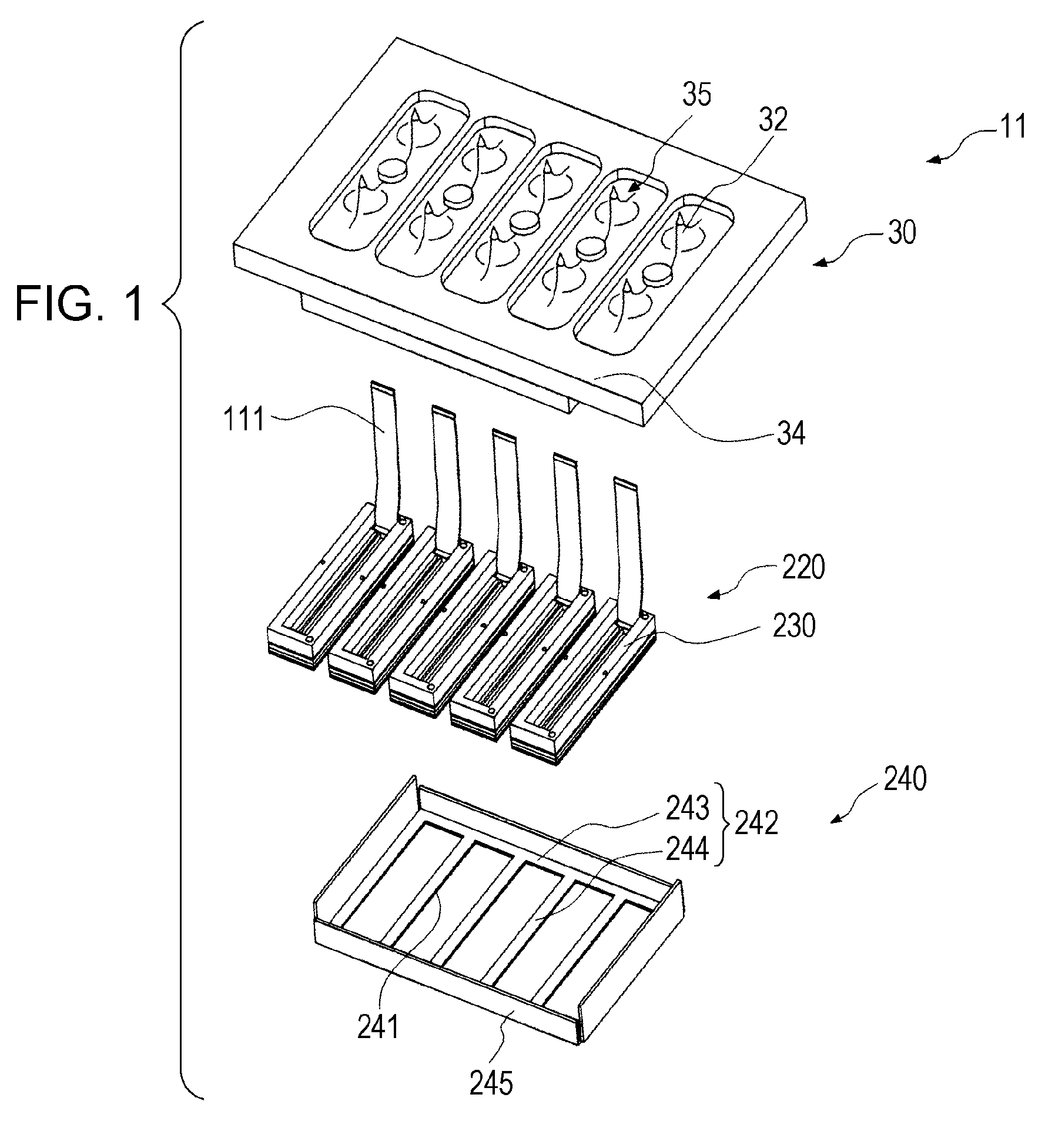

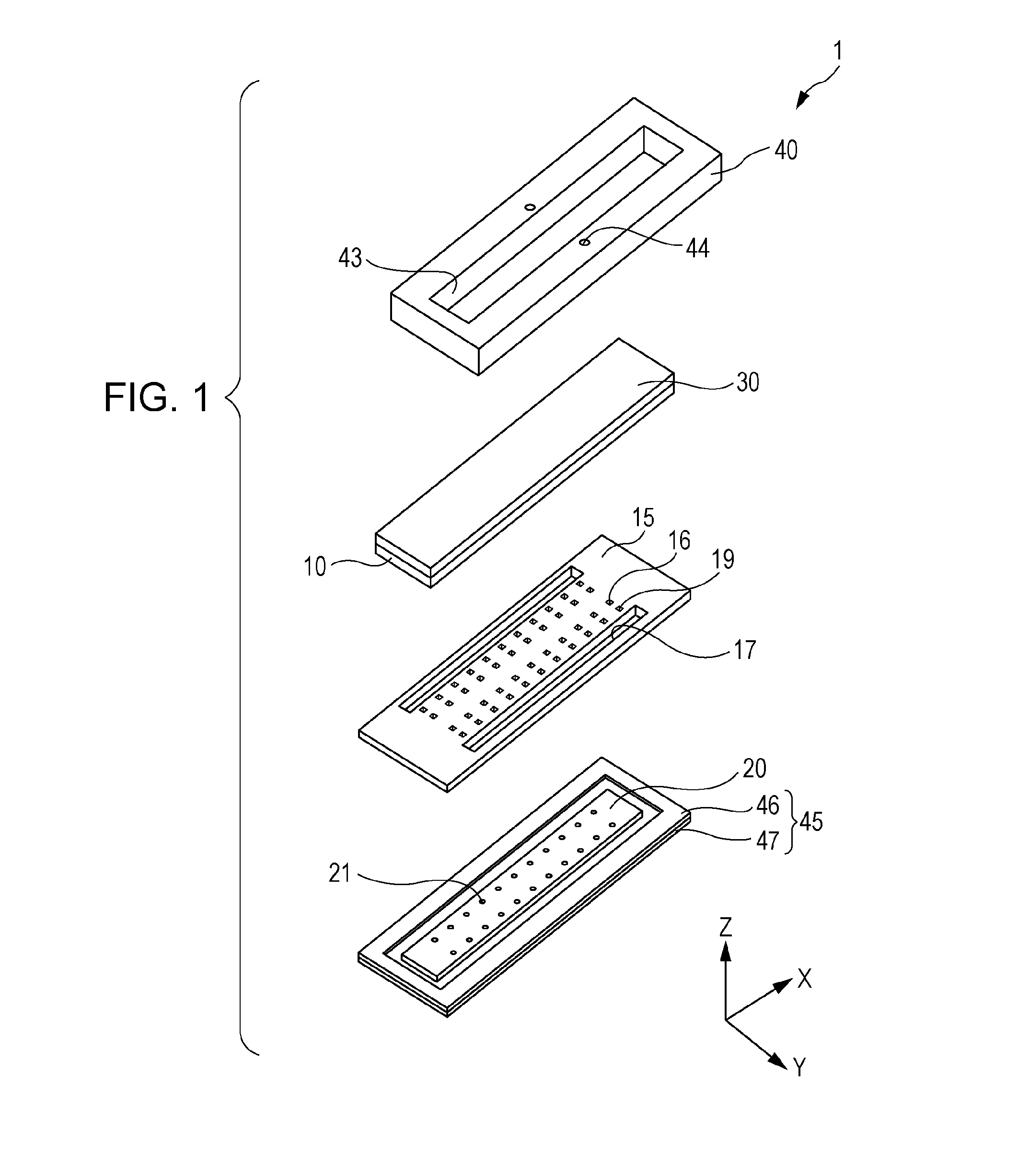

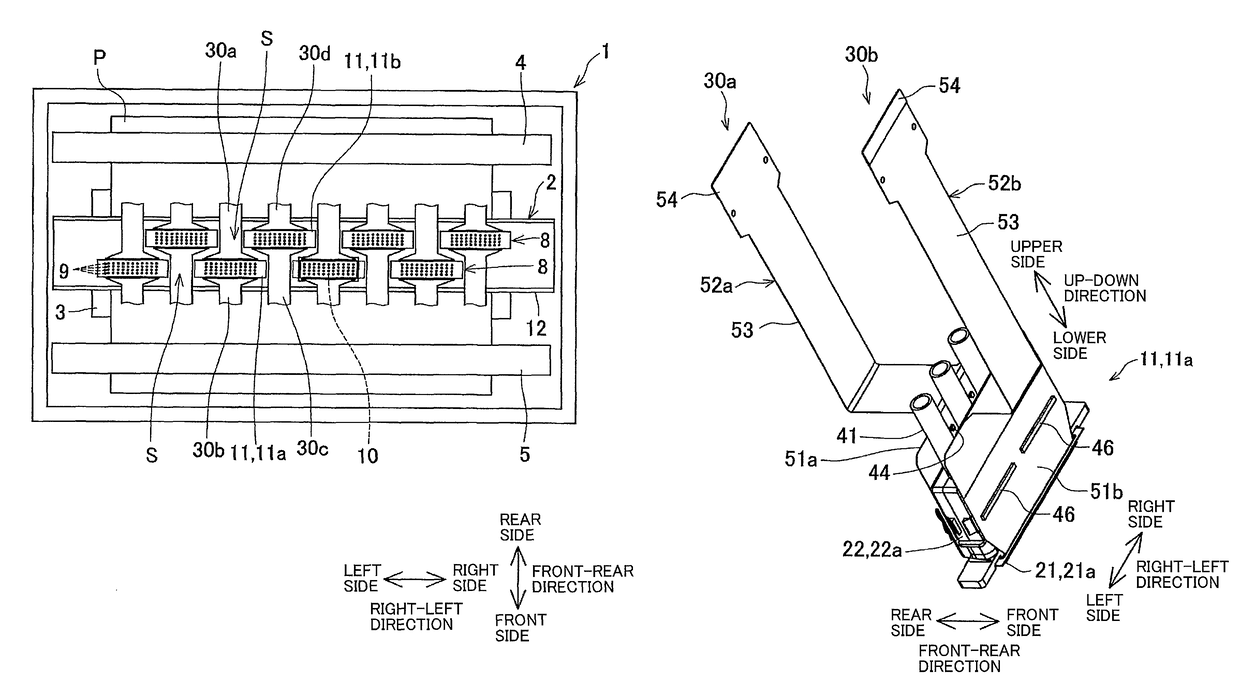

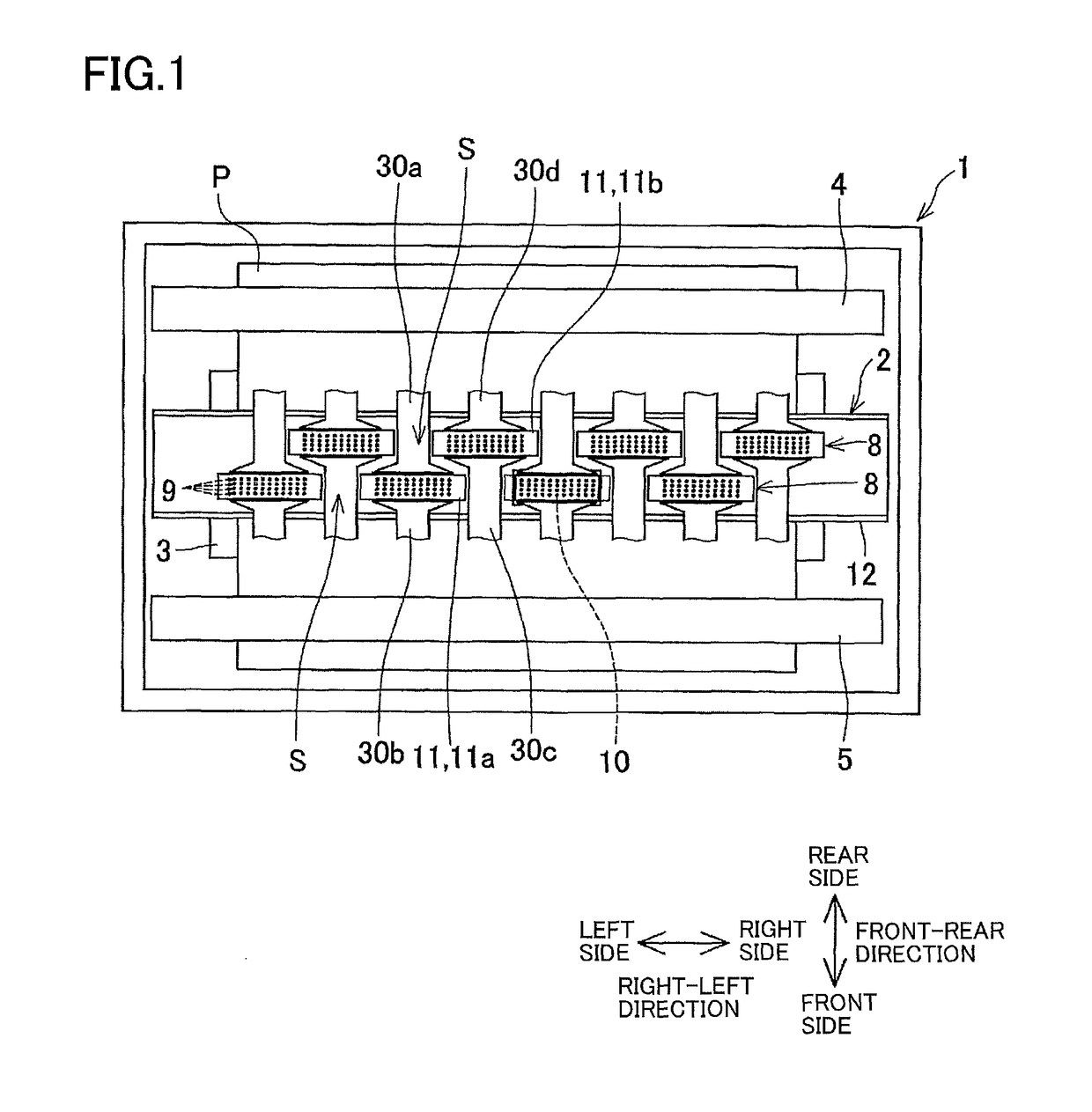

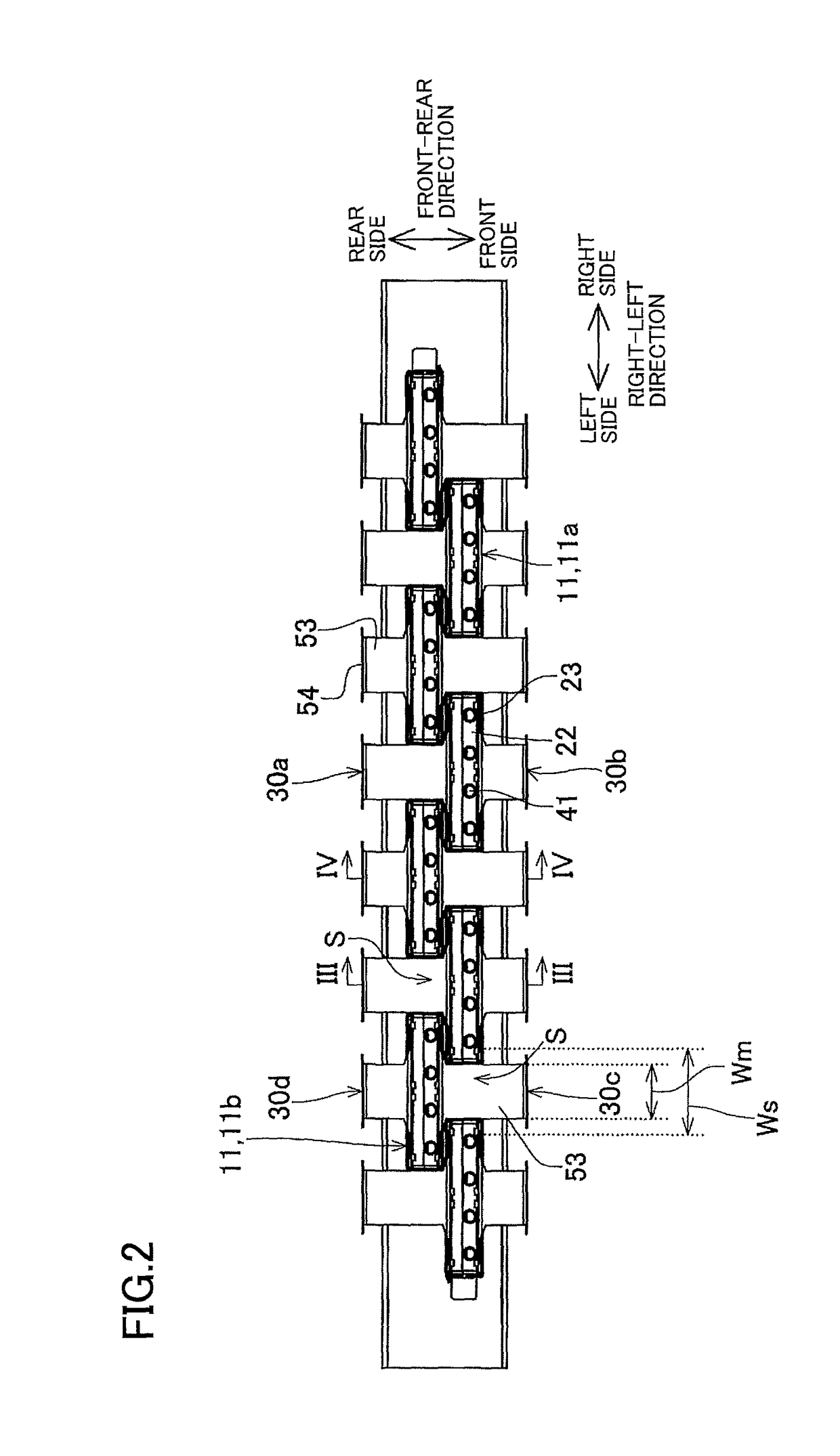

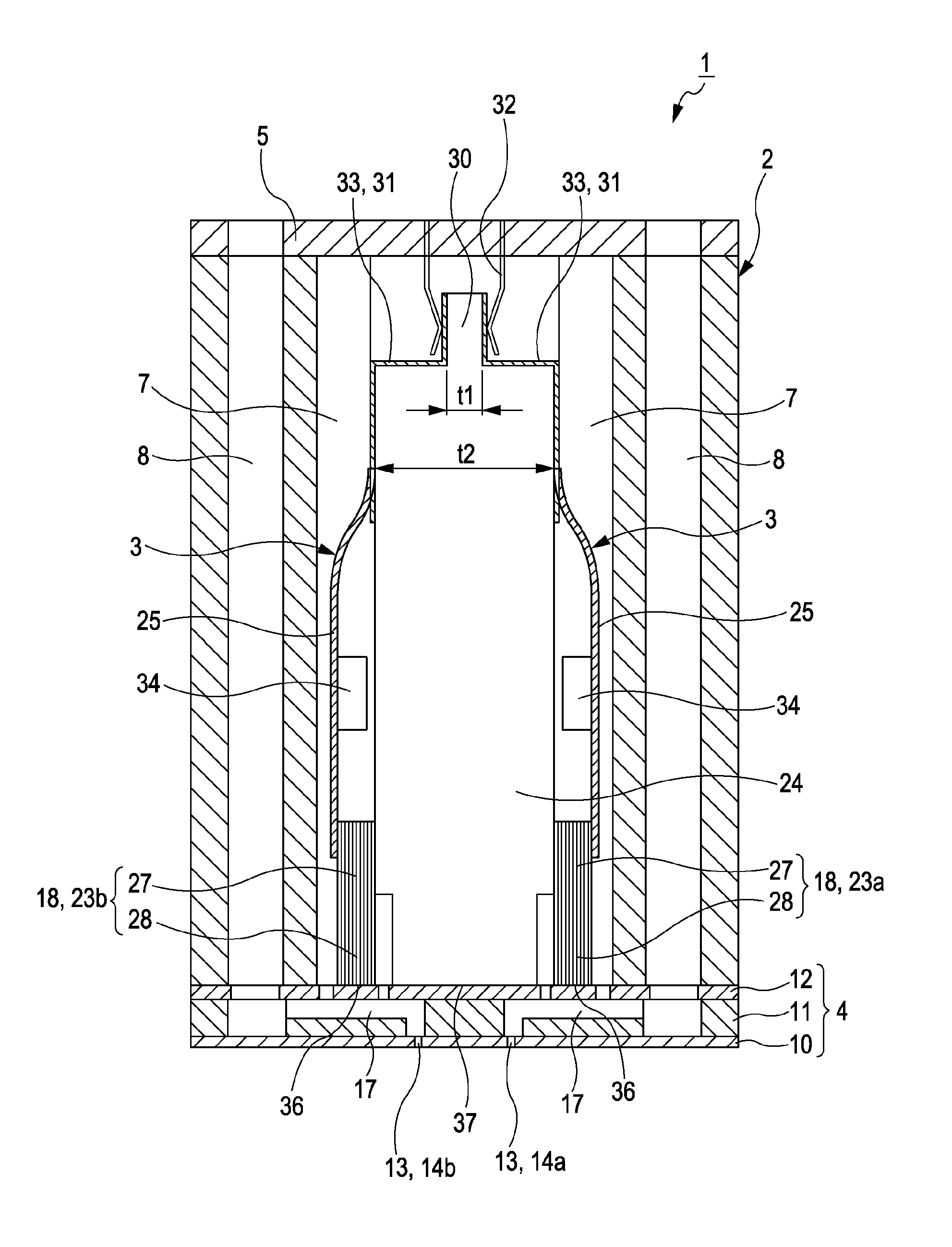

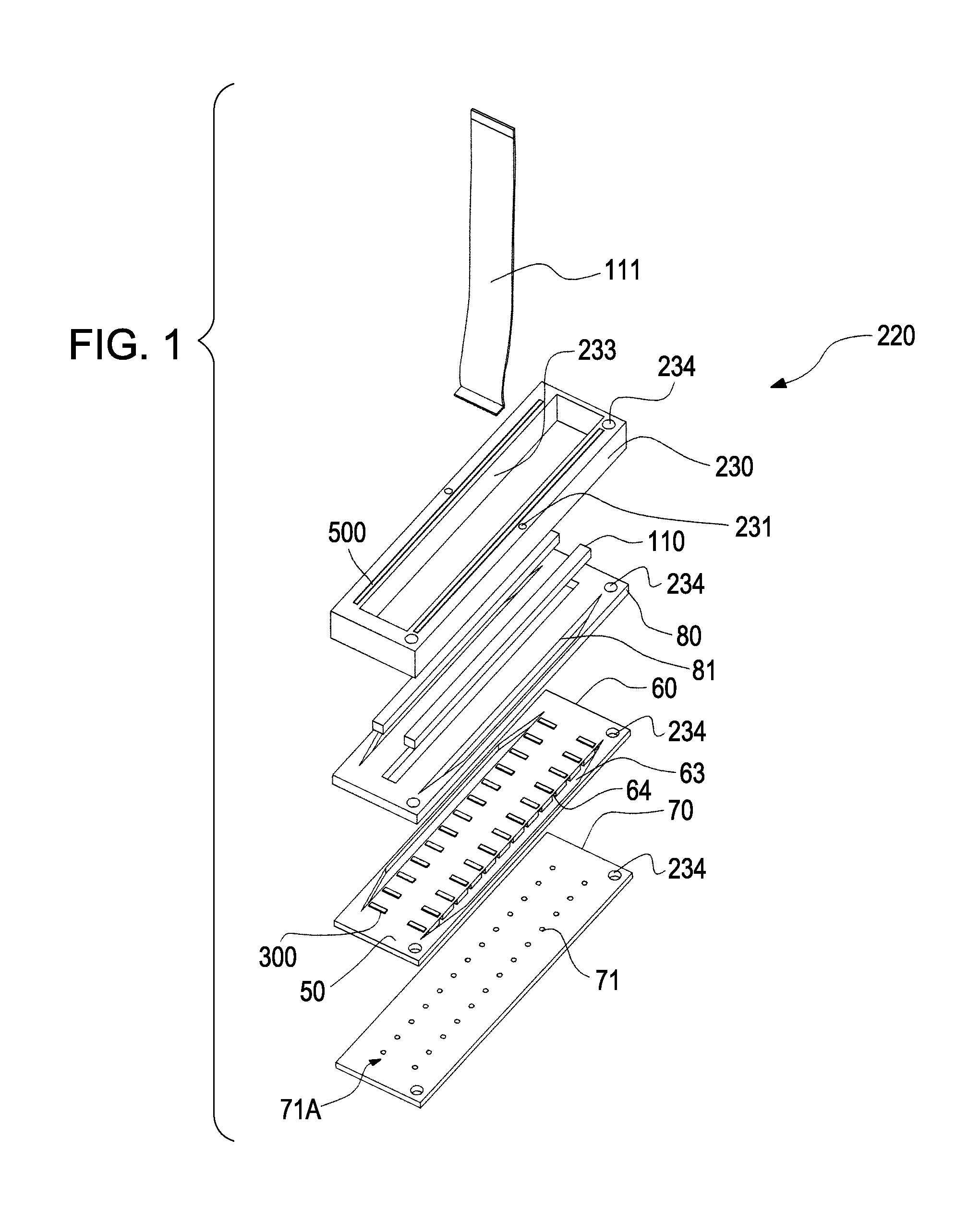

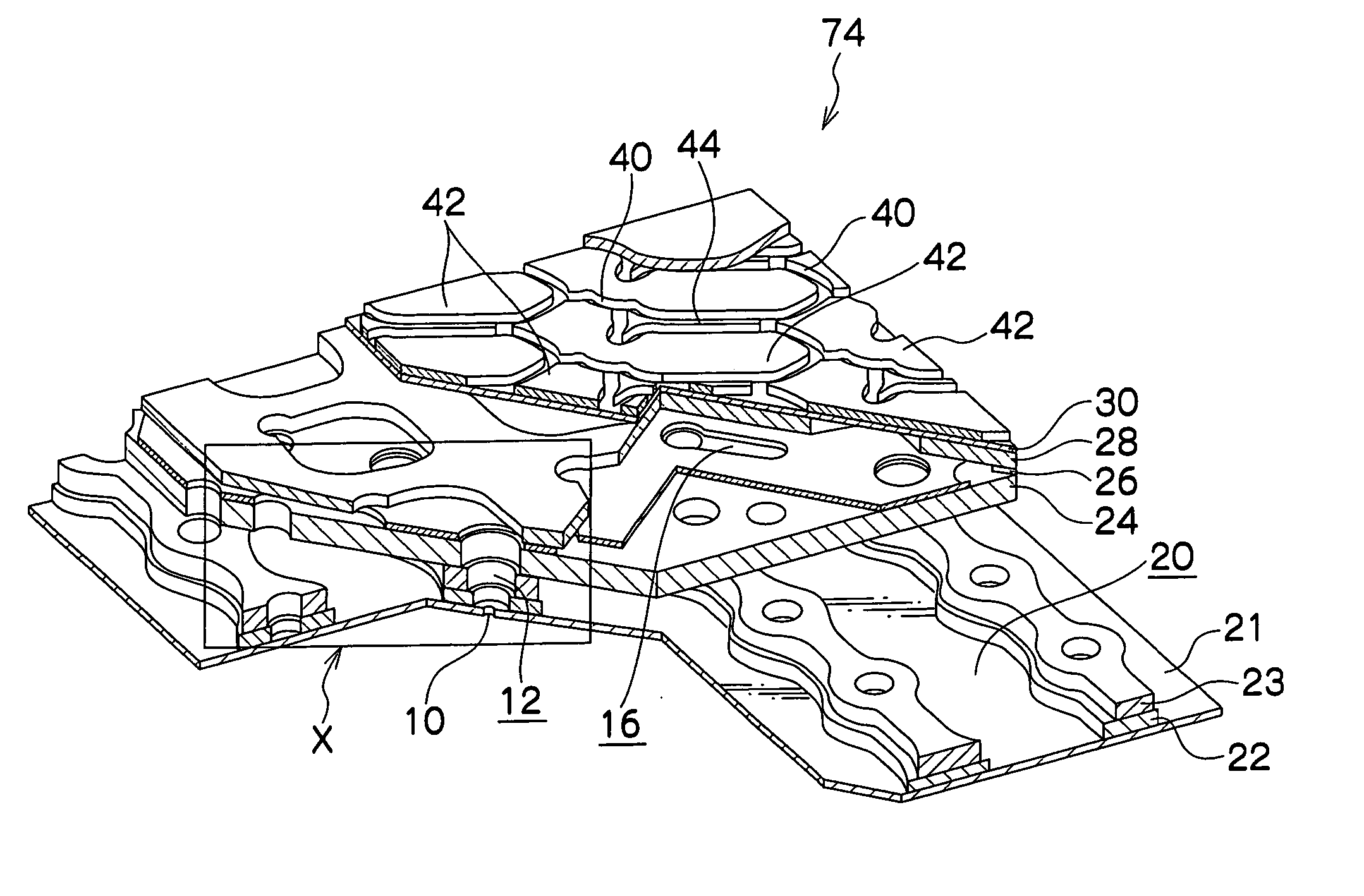

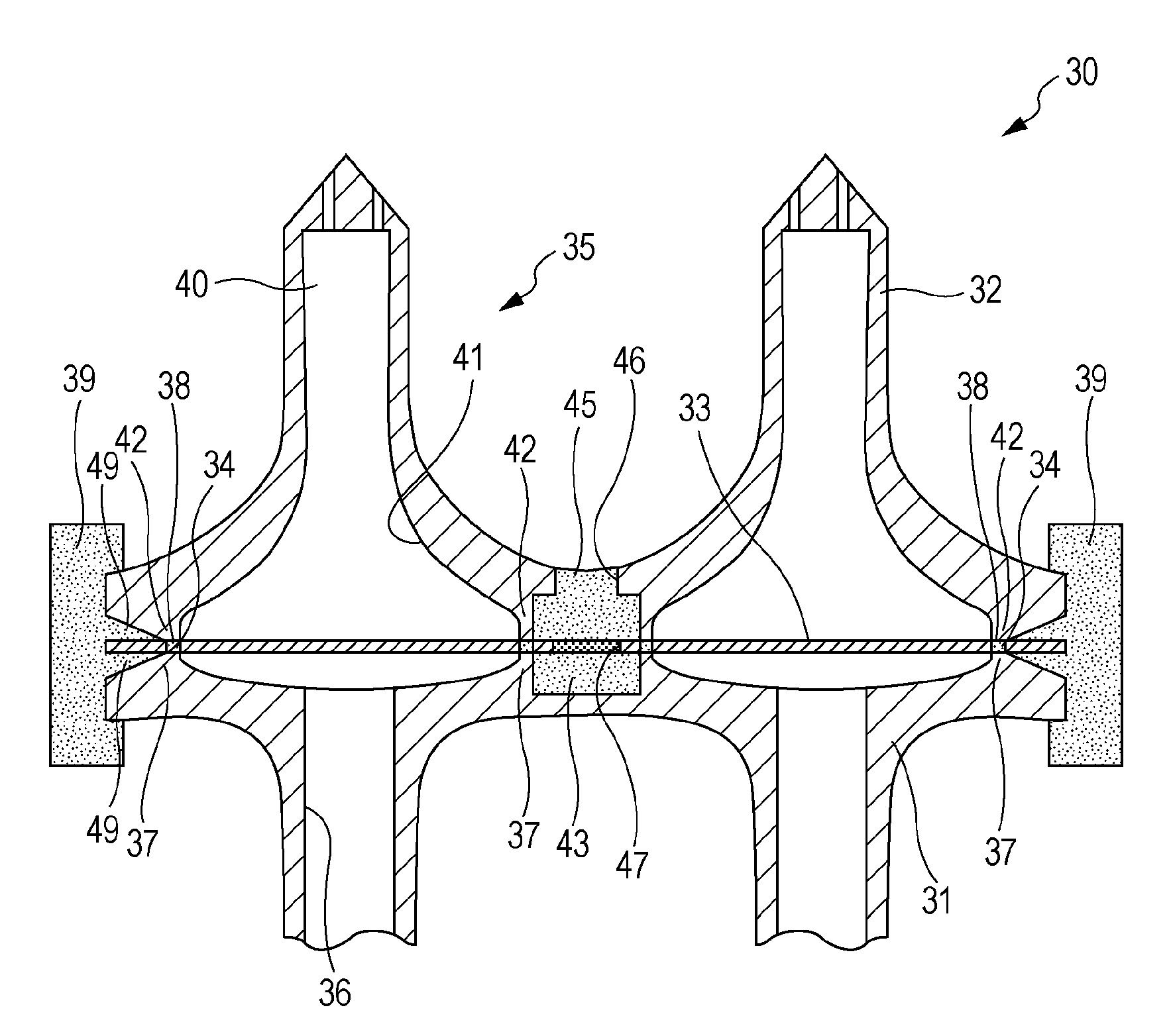

Method of manufacturing liquid ejecting head

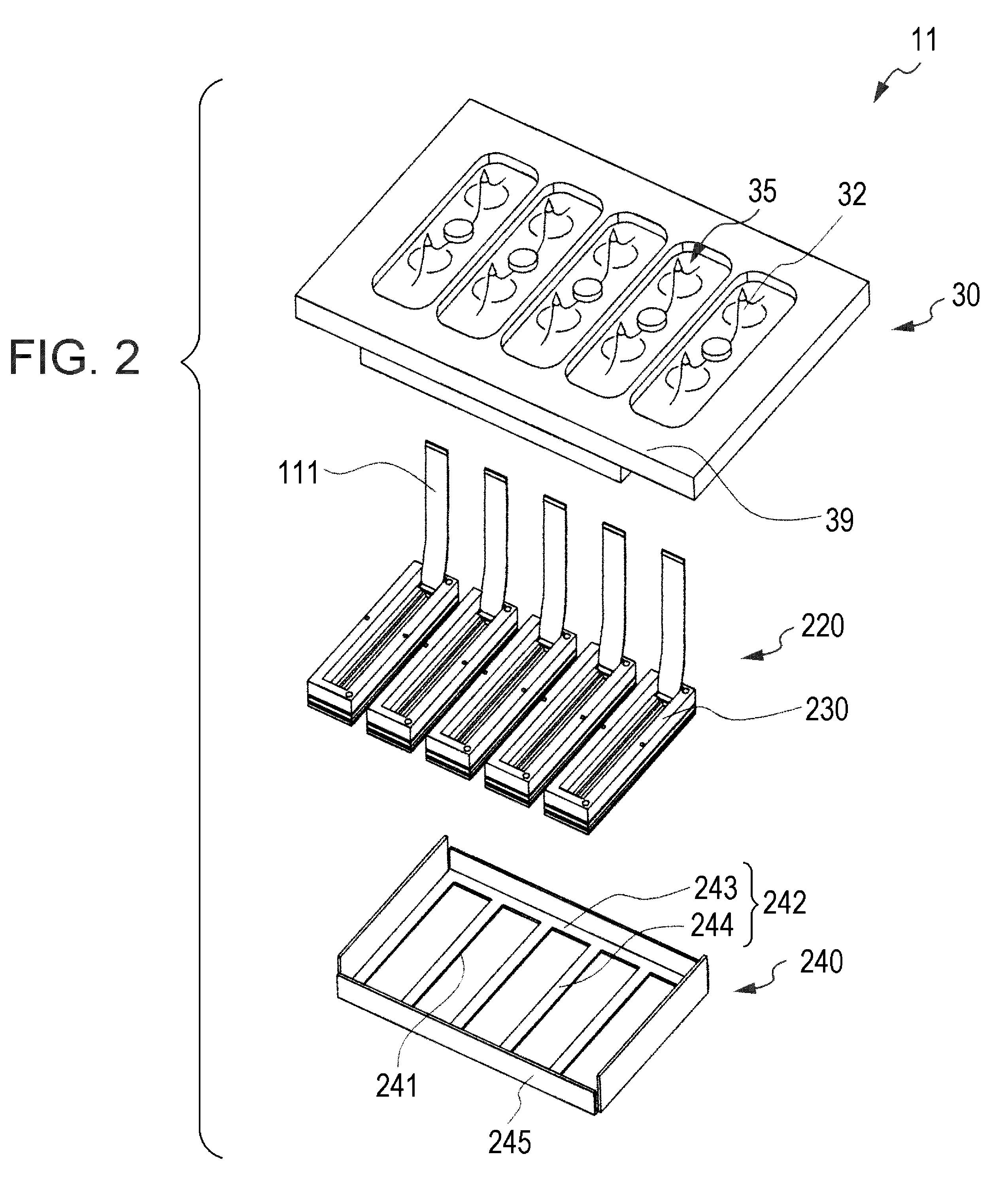

InactiveUS20090212460A1Prevent liquid leakageReduce intervalTailstocks/centresConfectioneryMechanical engineeringFilter element

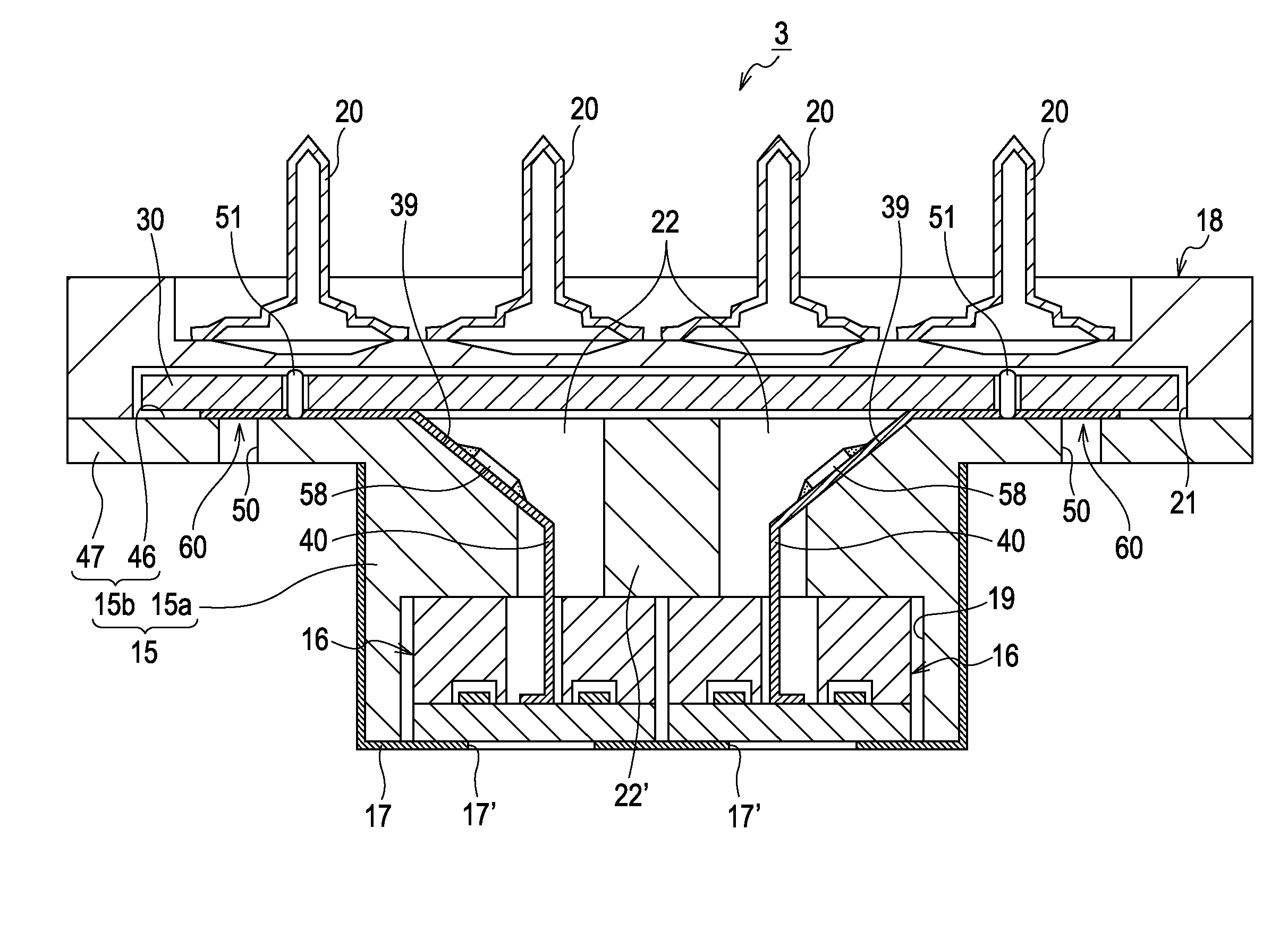

A method of manufacturing a liquid ejecting head and a supply member having a plurality of liquid supply passages is provided. The supply member includes first and second supply members in which liquid supply passages are provided and filters provided between the first supply member and the second supply member. The method includes: preparing a connected filter formed of a plurality of filter element portions corresponding to the plurality of liquid supply passages and a connecting portion that connects the plurality of filter element portions; in a state where the filter element portions of the connected filter are held between the first supply member and the second supply member, charging molten resin from a position corresponding to the connecting portion of the connected filter to separate the connecting portion; and, during the charging, molding.

Owner:SEIKO EPSON CORP

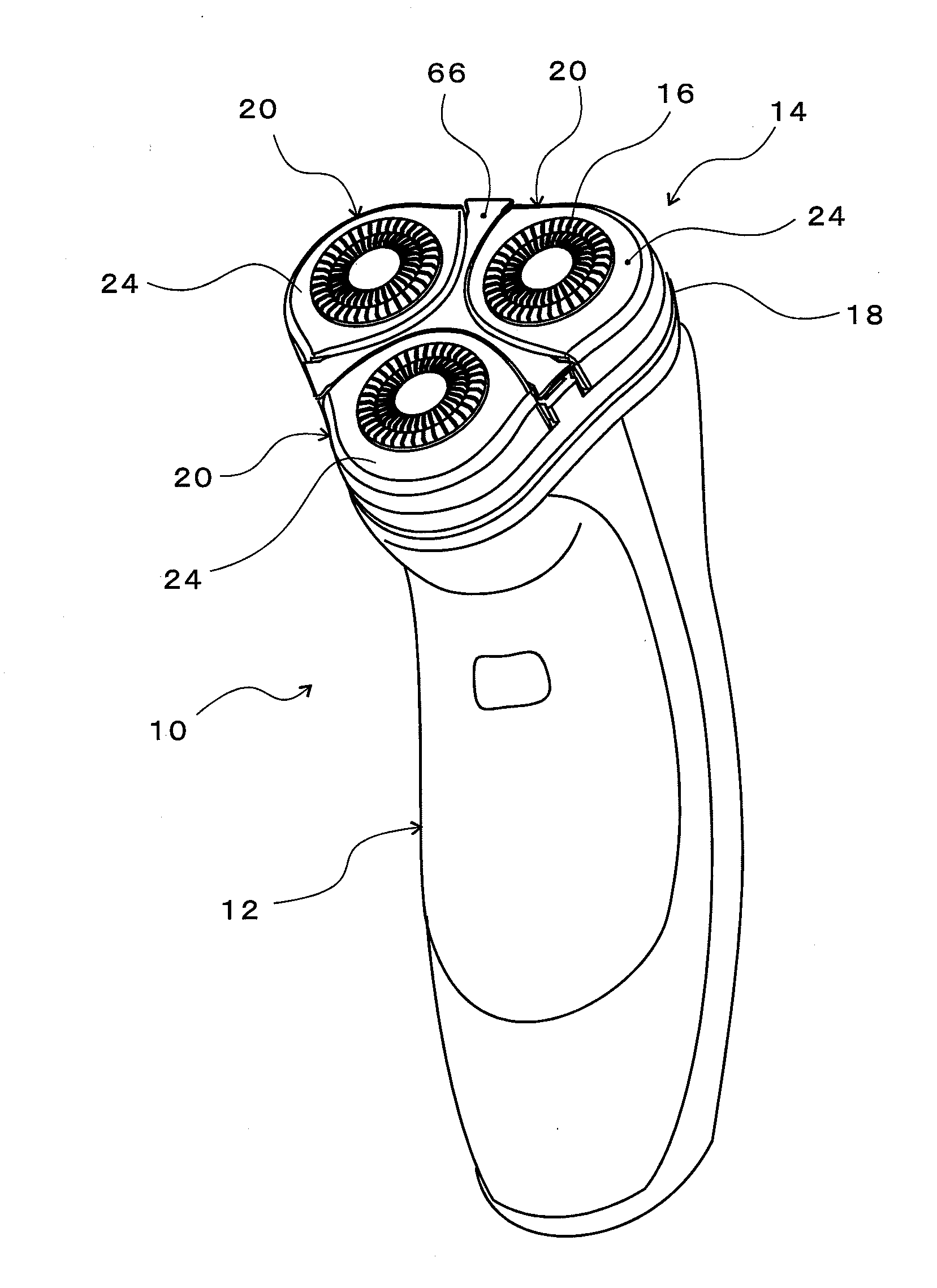

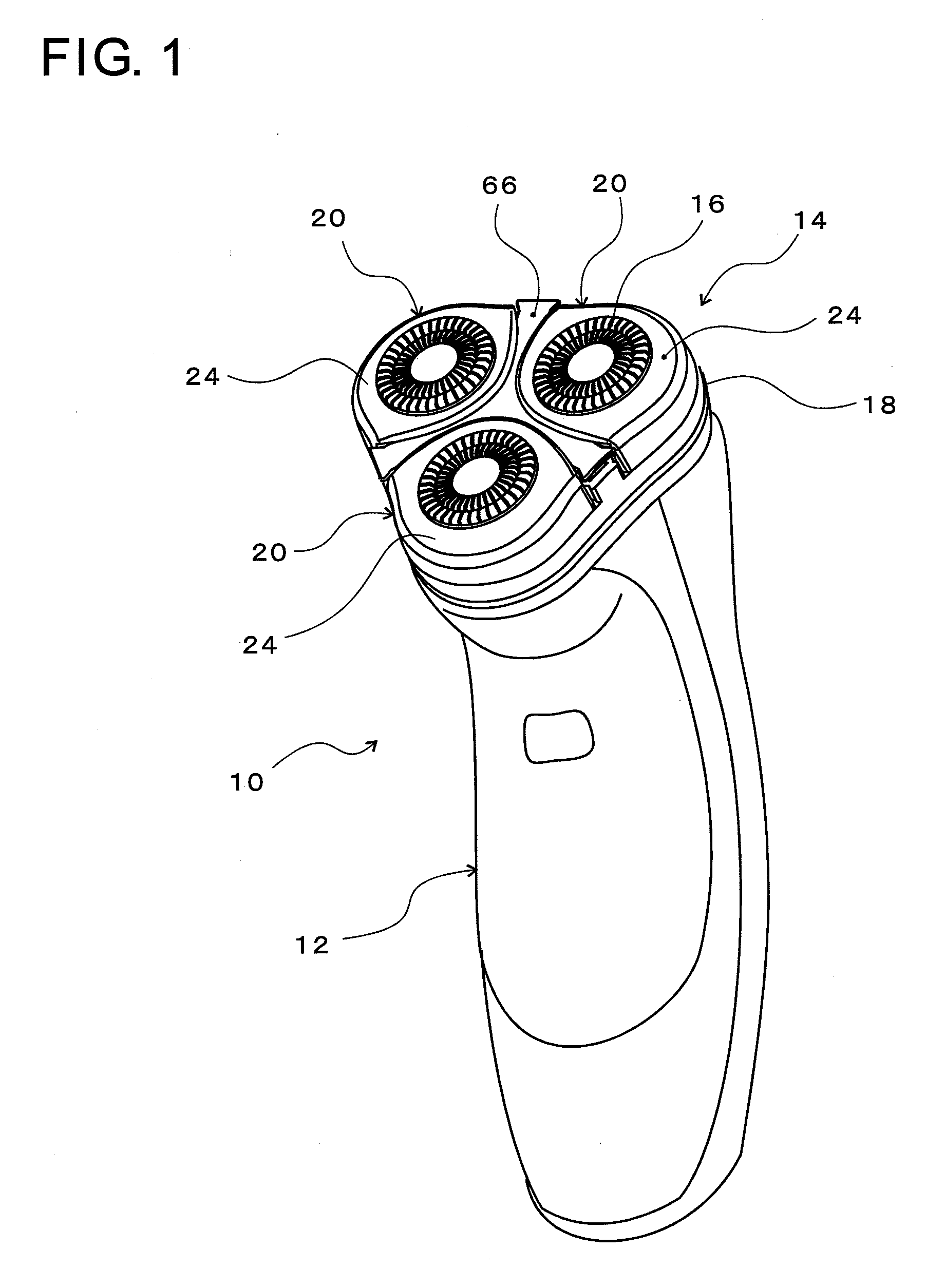

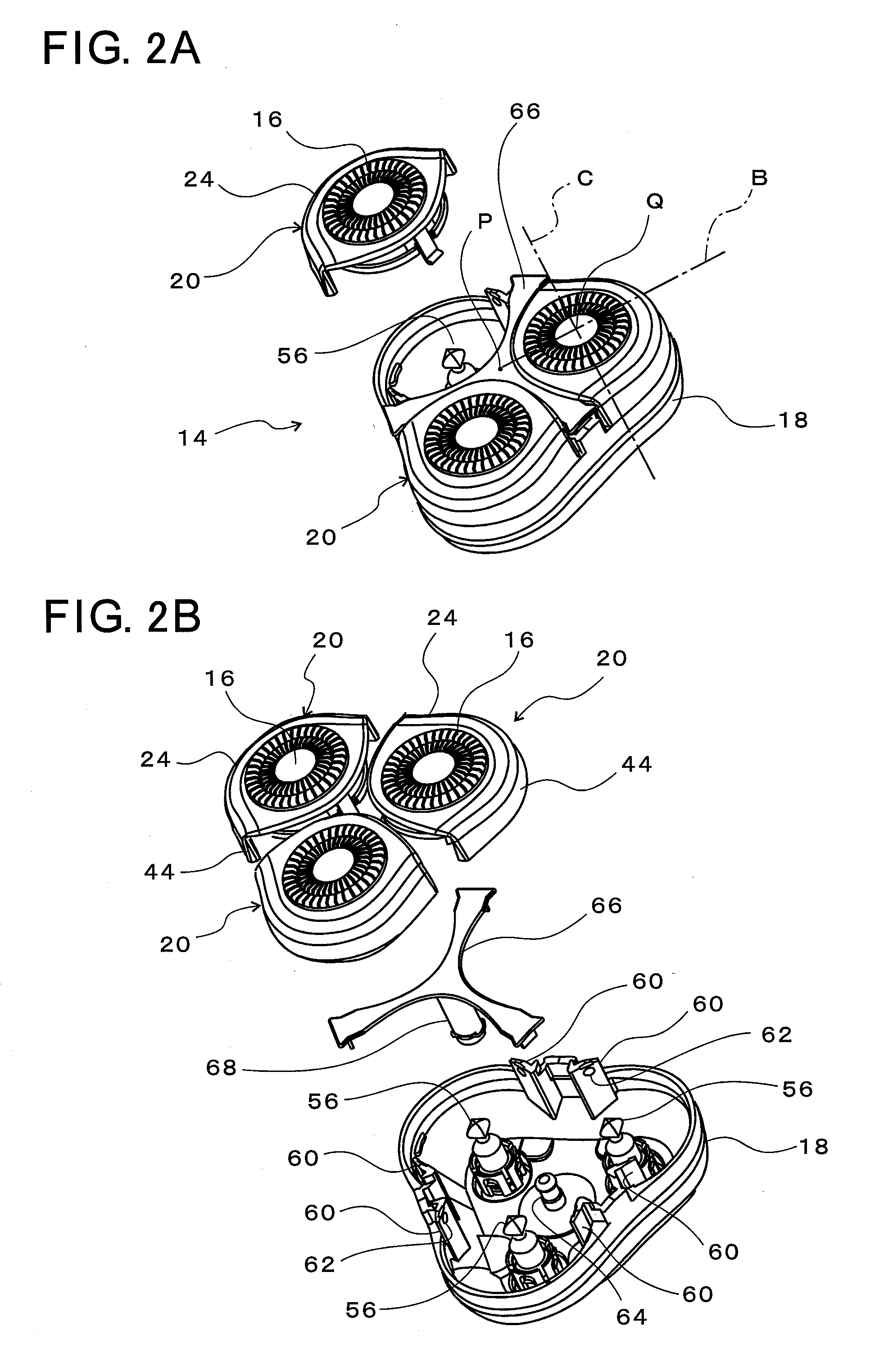

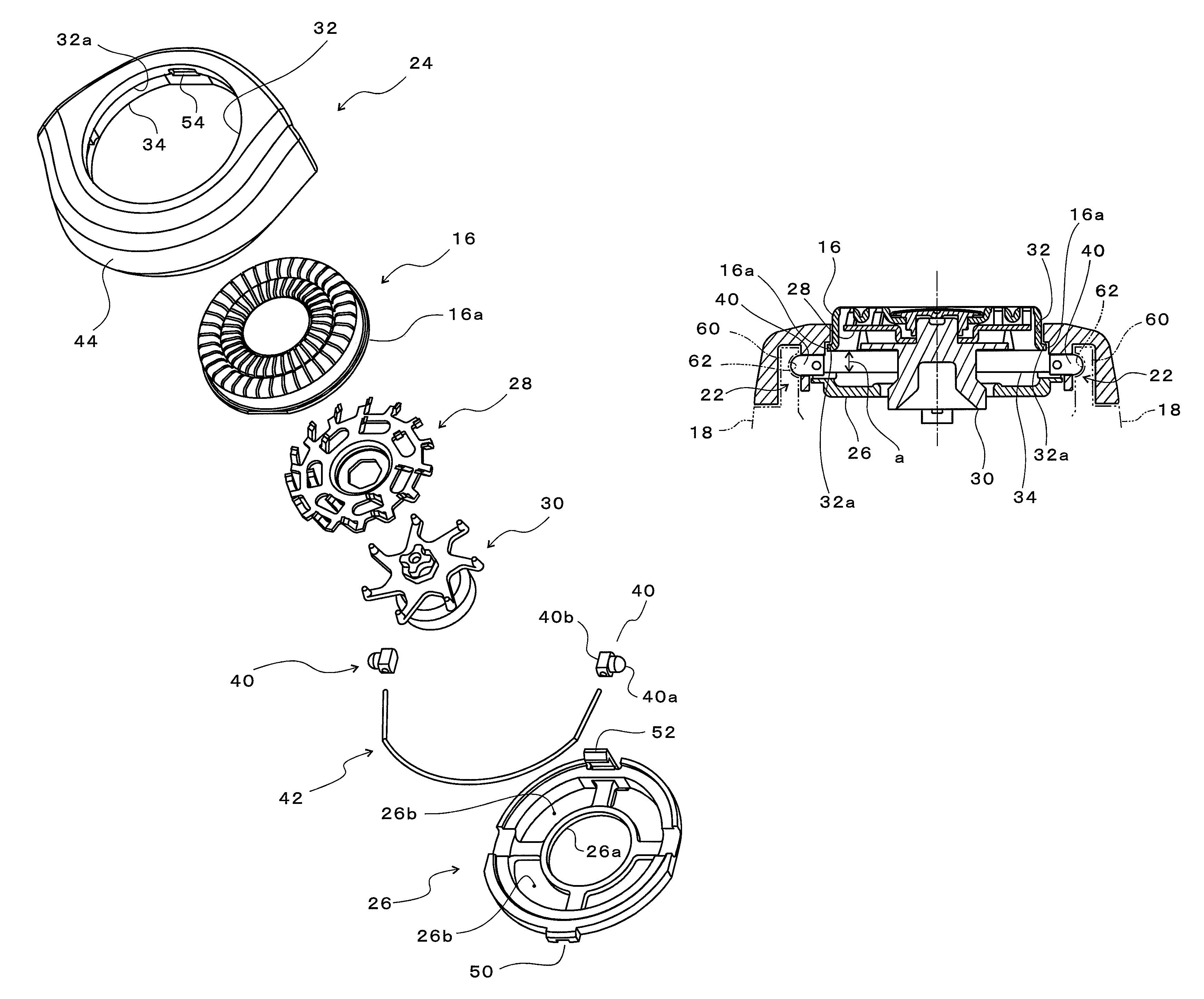

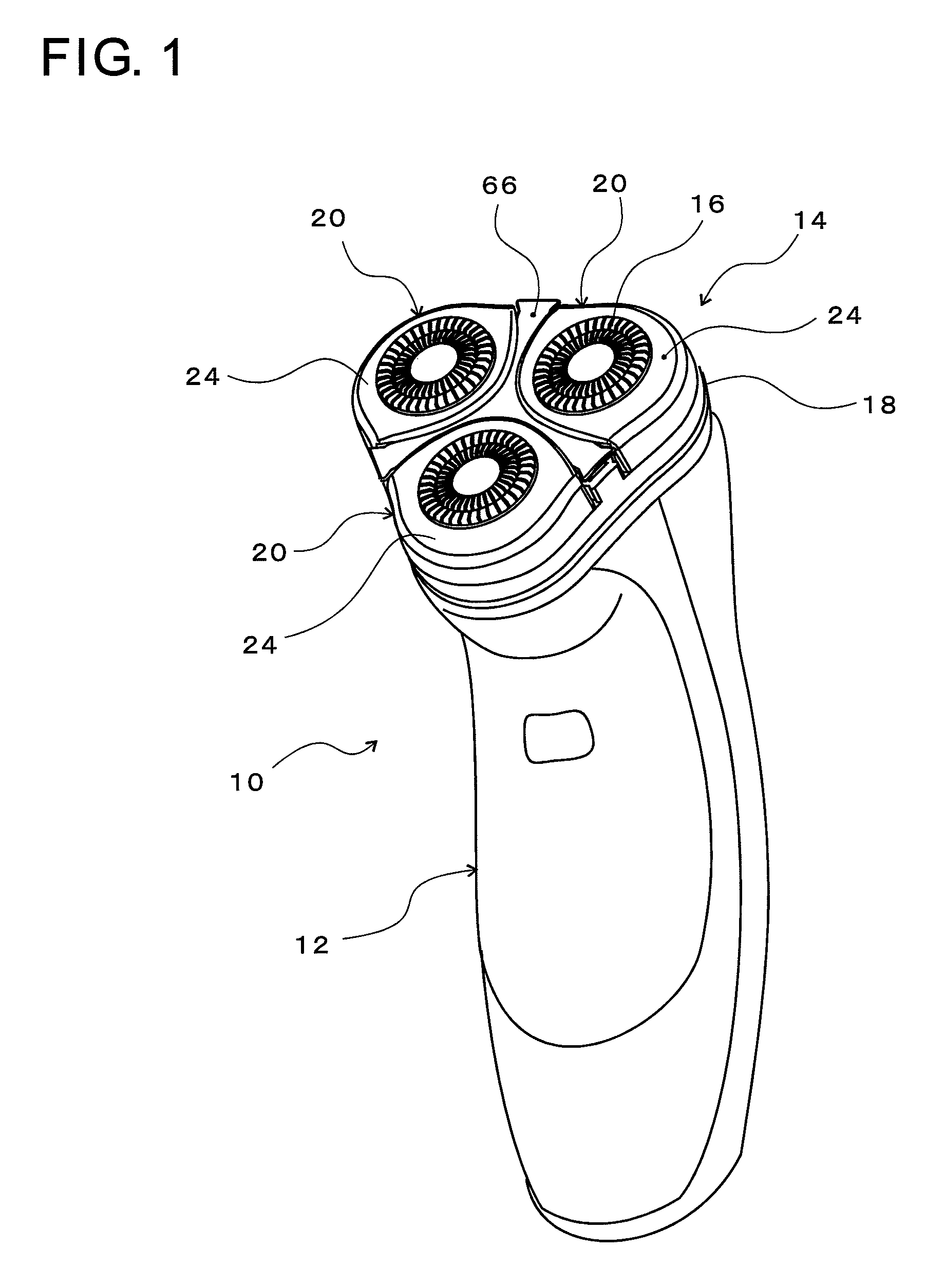

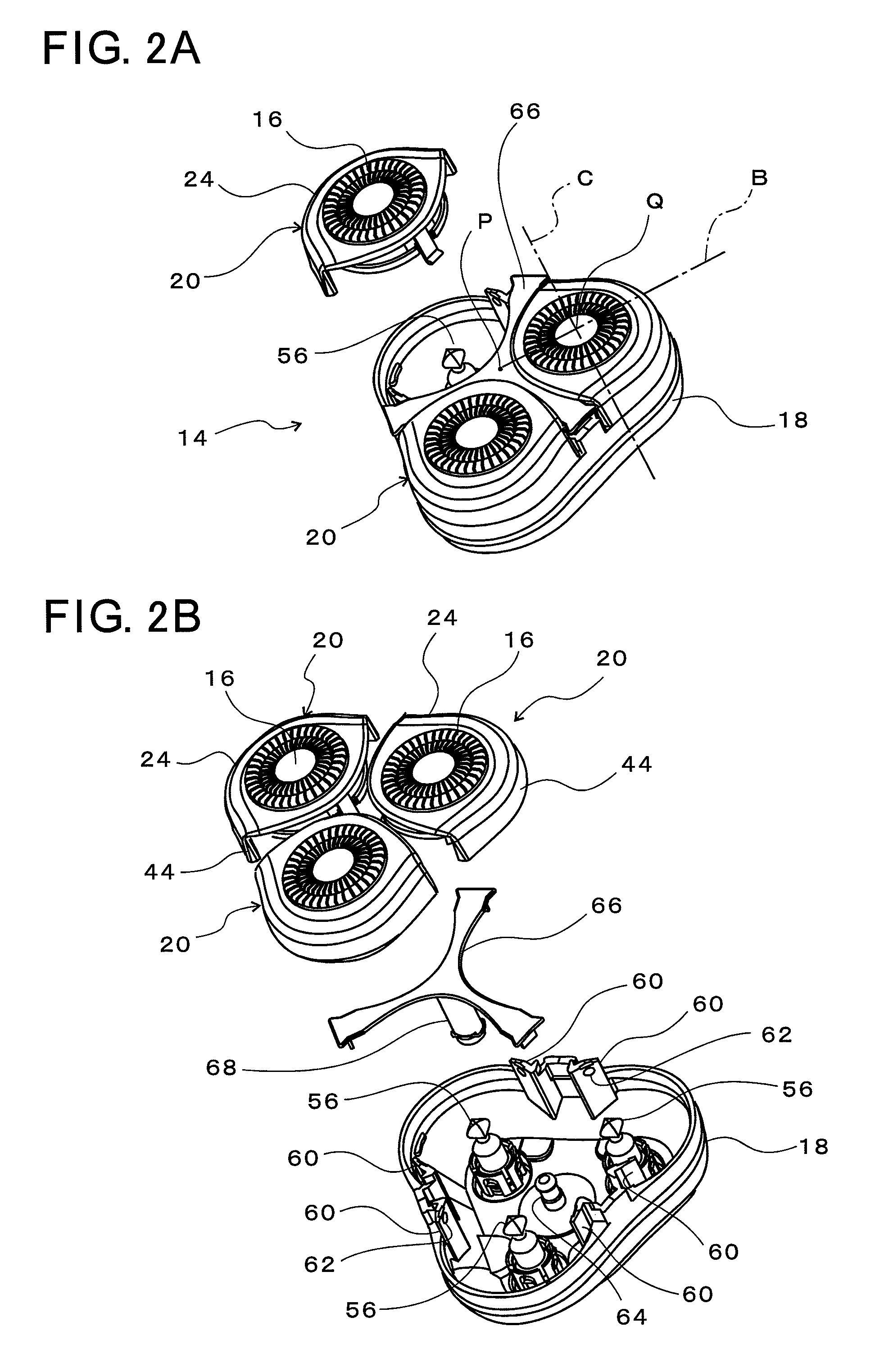

Rotary electric shaver

InactiveUS20090320295A1Reduce contact pressureIncrease widthMetal working apparatusEngineeringElectric razors

Owner:IZUMI PROD CO

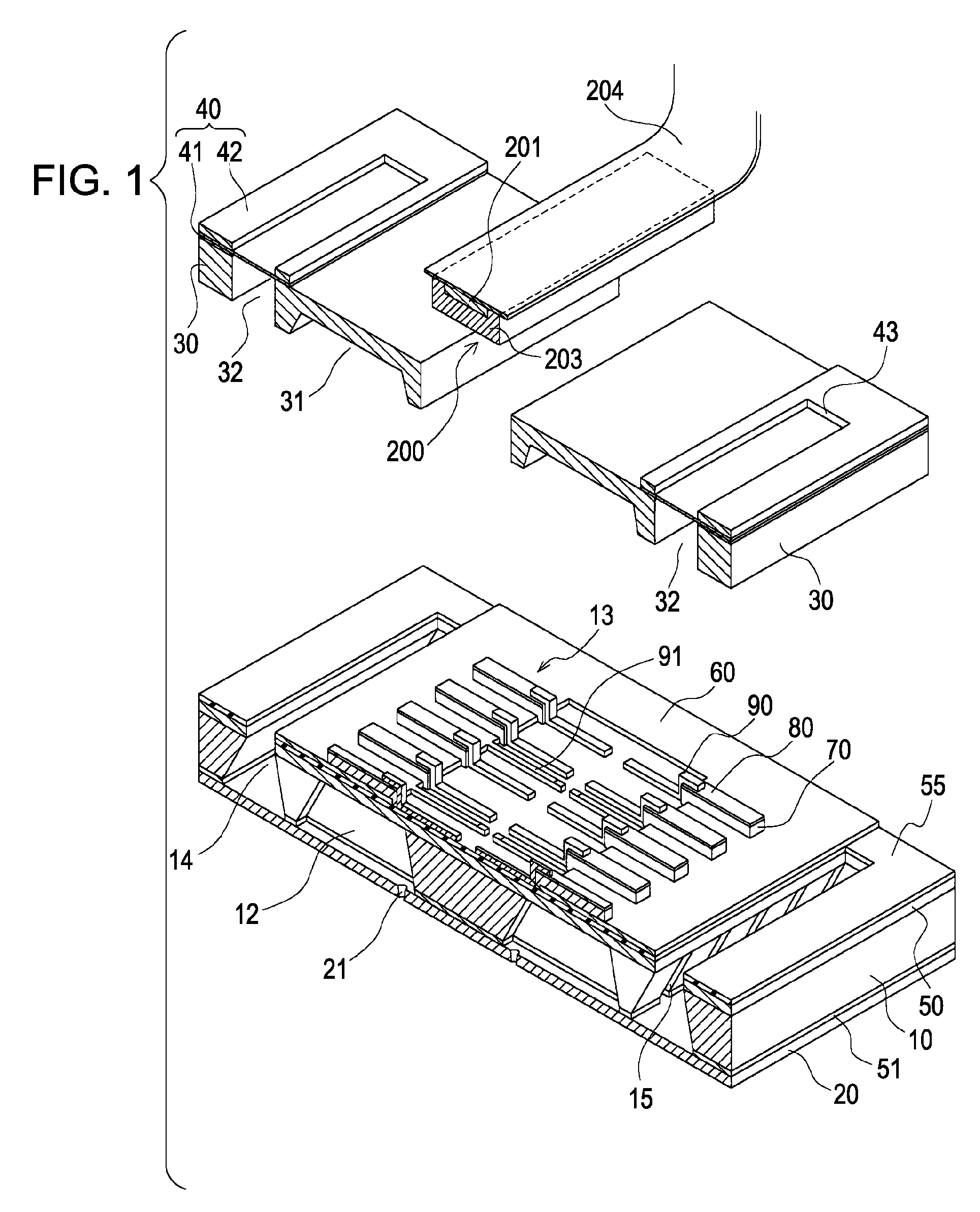

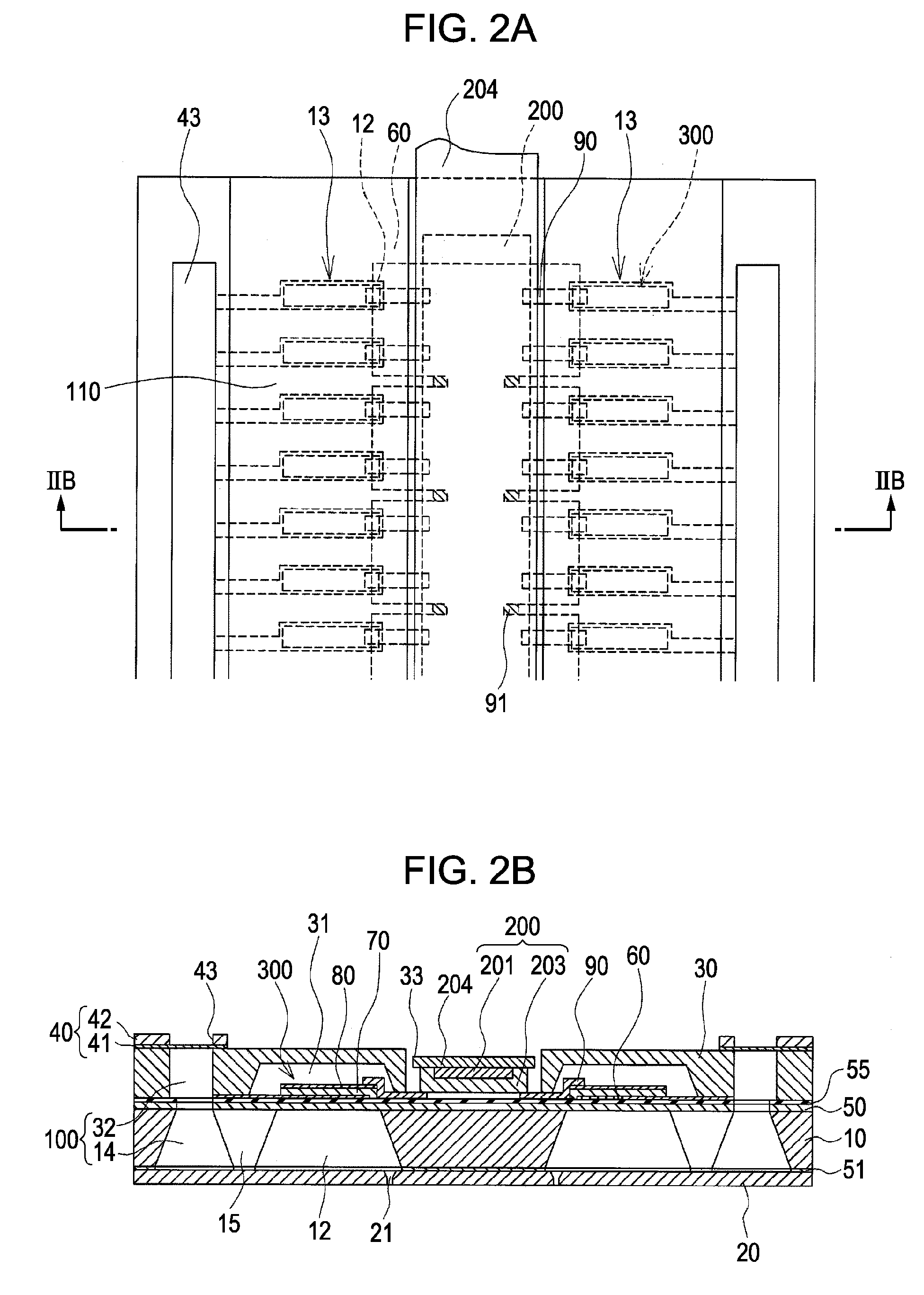

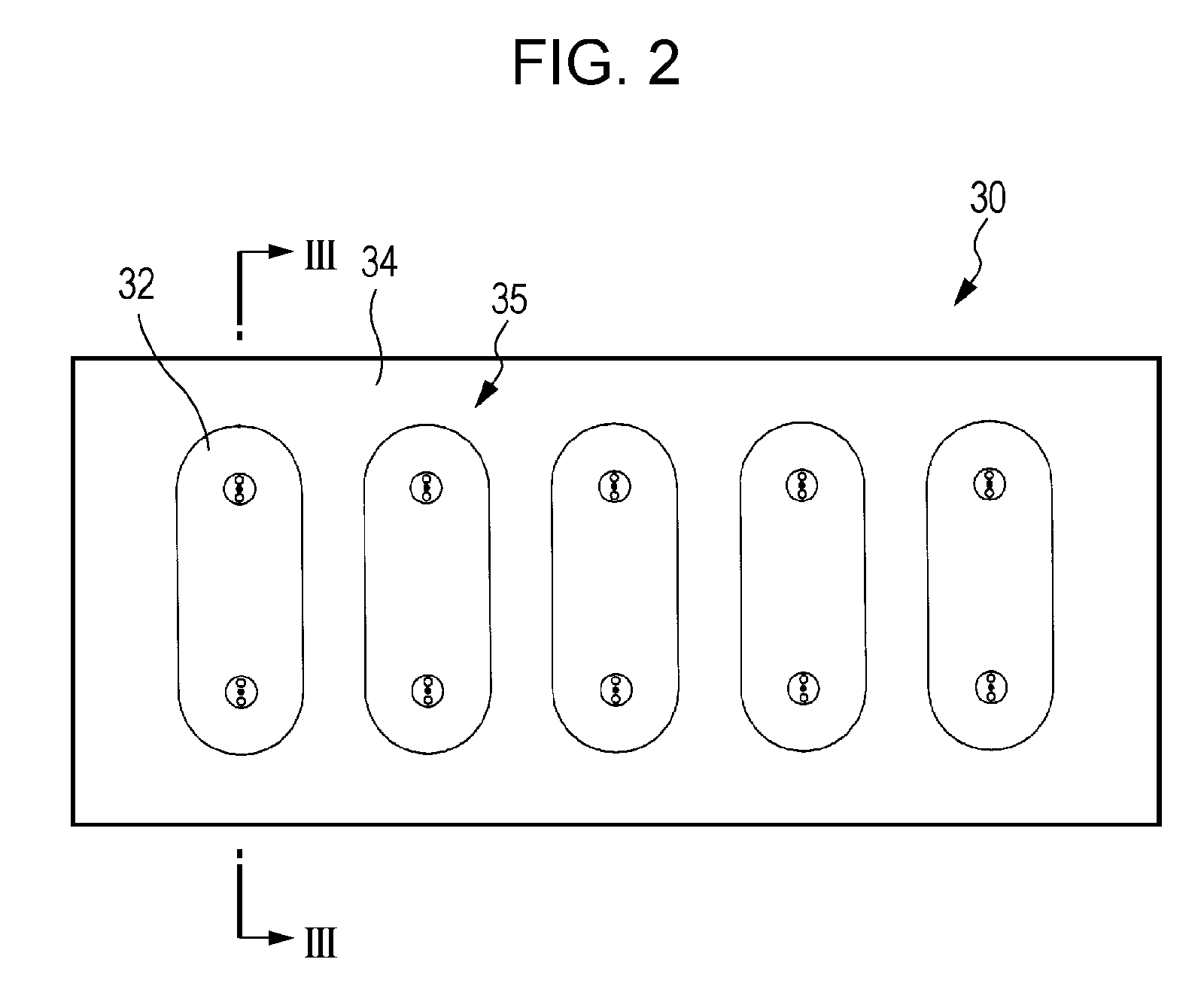

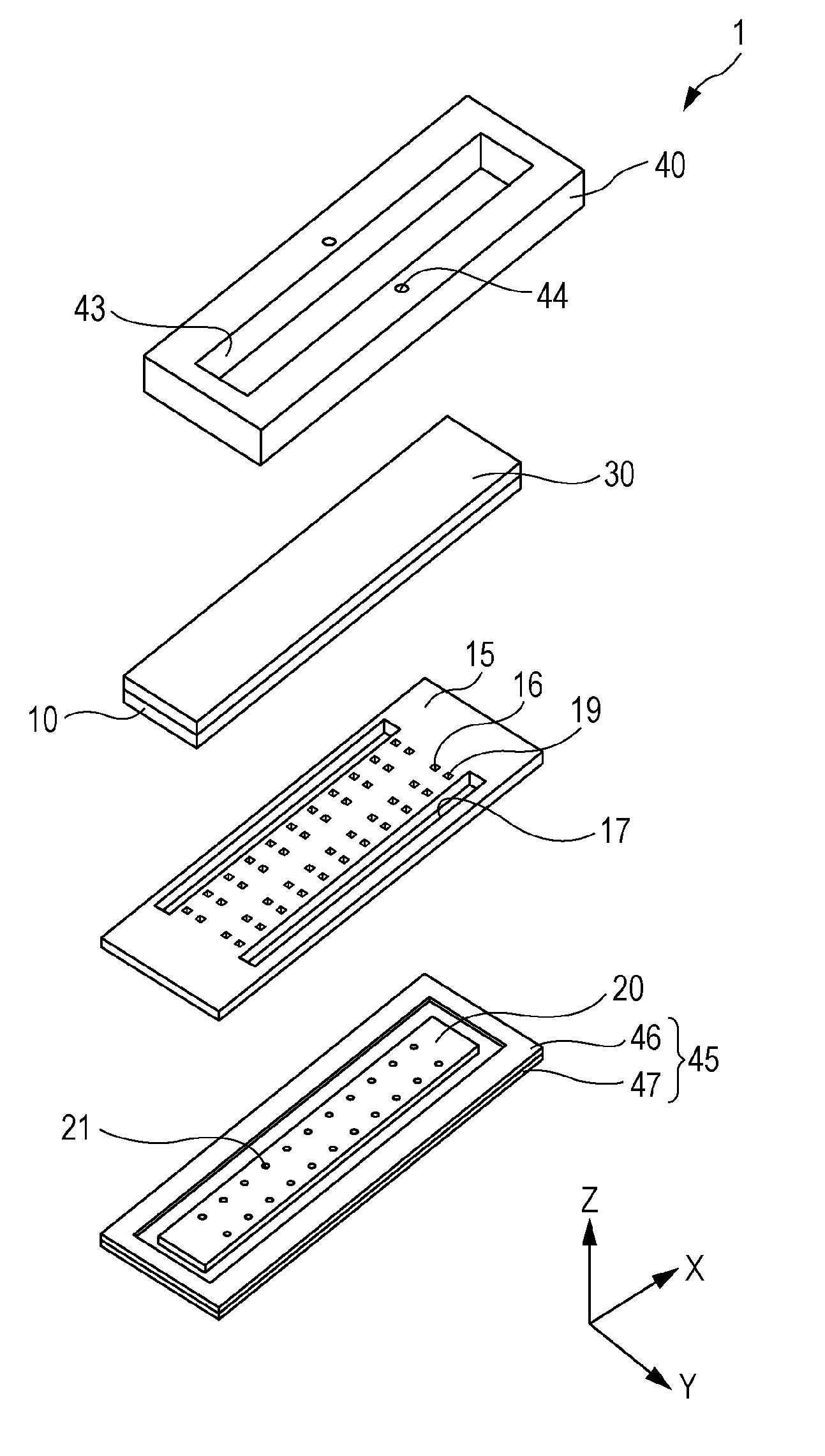

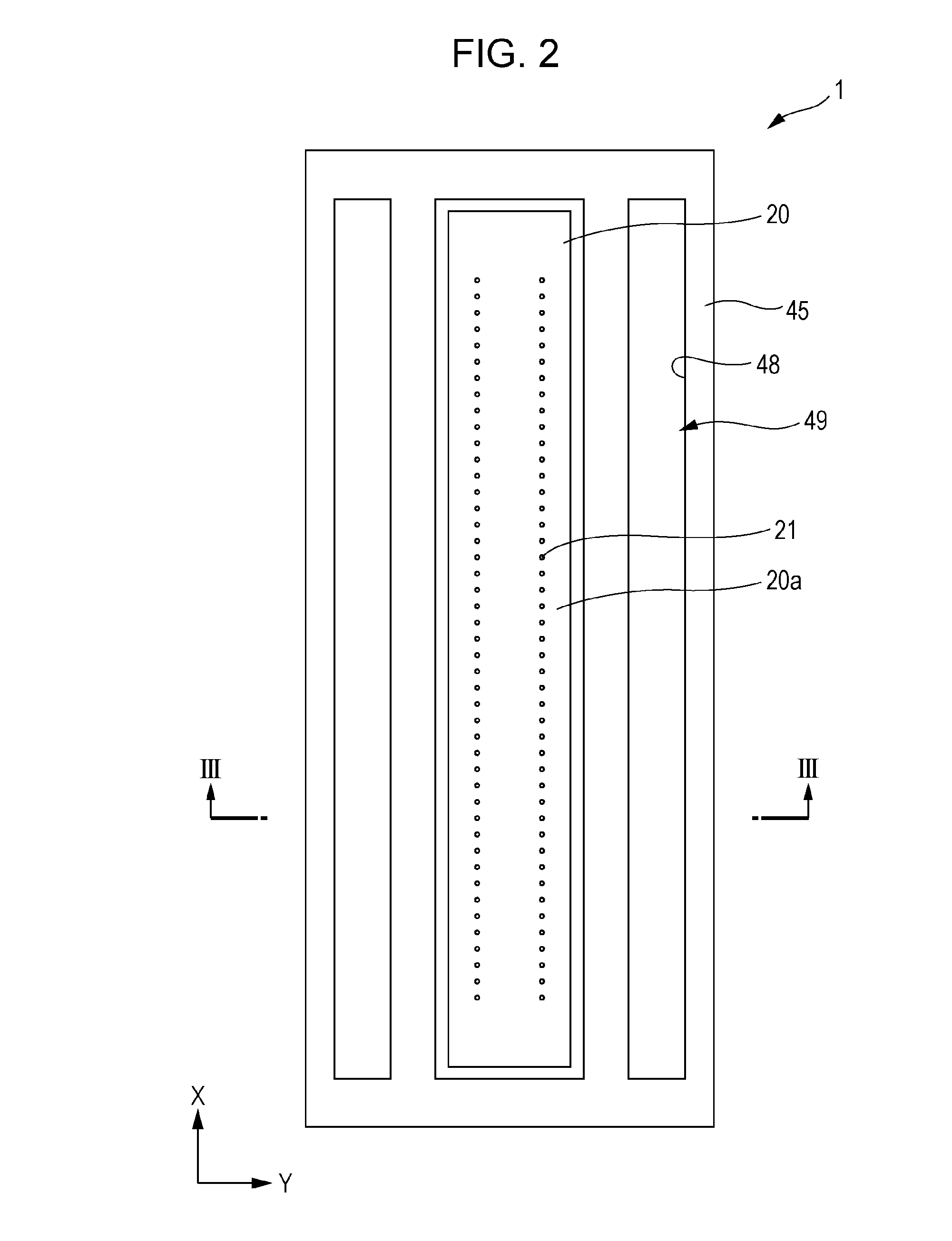

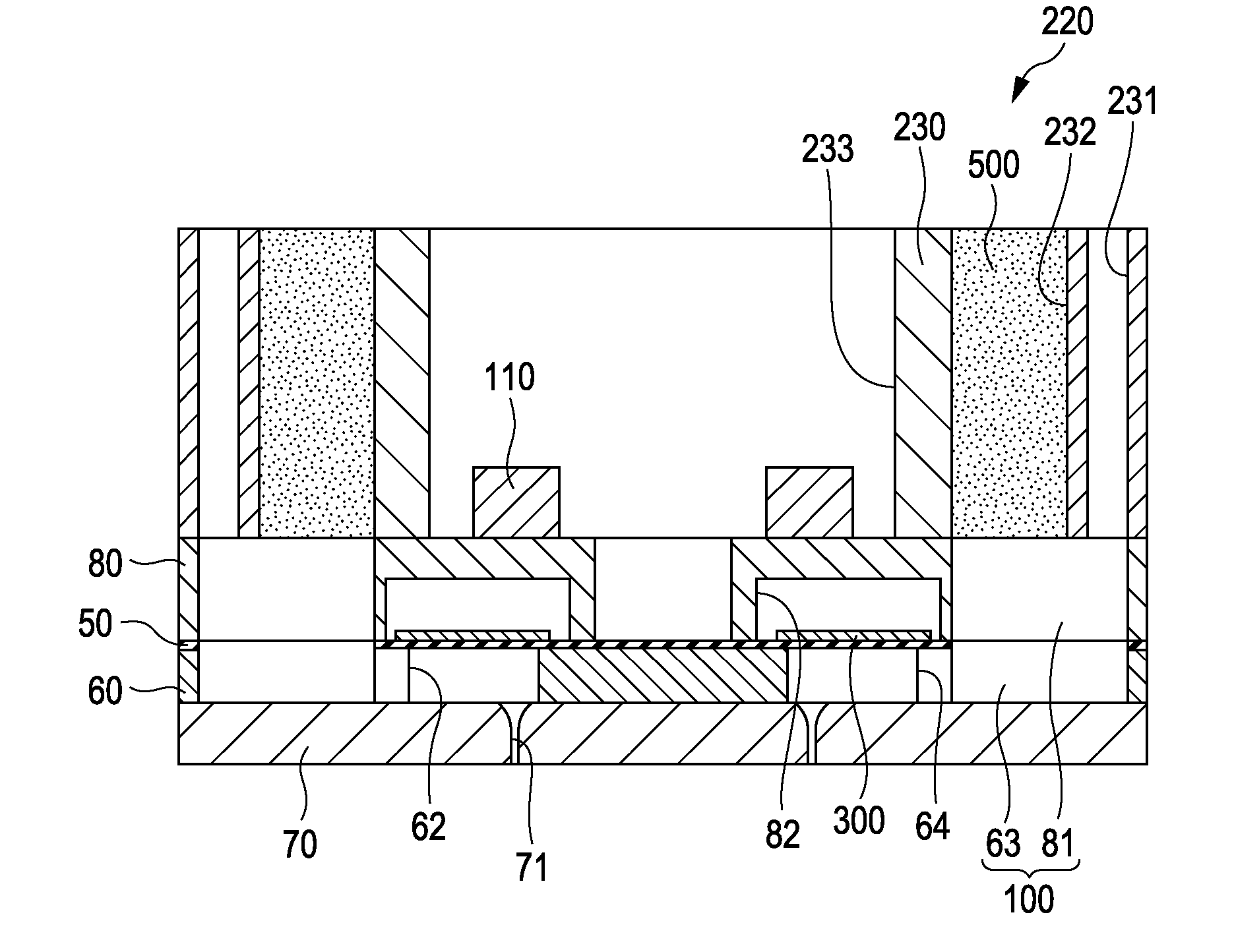

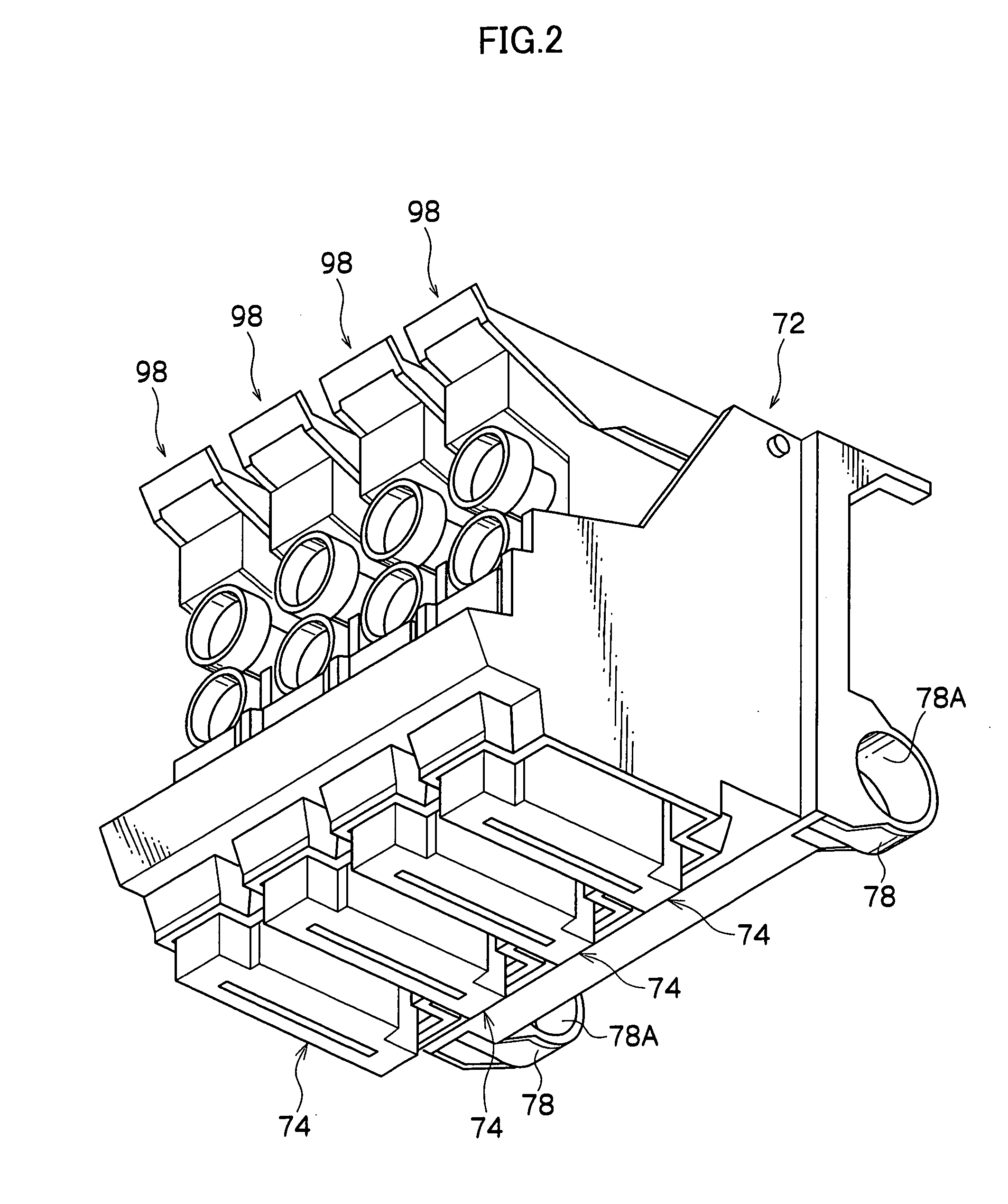

Liquid ejecting head and liquid ejecting apparatus

A liquid ejecting head includes a passage-forming substrate, a plurality of pressure-generating elements, and an IC chip. The passage-forming substrate has a nozzle opening, and a pressure-generating chamber communicating with the nozzle opening. The plurality of pressure-generating elements are provided on a surface of the passage-forming substrate with a diaphragm interposed therebetween. The pressure-generating elements have electrodes and cause pressure change in the pressure-generating chamber. The IC chip is mounted on the surface of the passage-forming substrate with the pressure-generating elements. In this liquid ejecting head, the electrodes of the pressure-generating elements include individual electrodes, and at least the individual electrodes are electrically connected to the driver circuit via the through electrode.

Owner:SEIKO EPSON CORP

Liquid ejecting head, method of manufacturing the same, and liquid ejecting apparatus

ActiveUS20090213199A1Prevent leakageReduce areaWriting implementsMetal-working apparatusEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

Manufacturing method of liquid ejecting head, liquid ejecting head, and liquid ejecting apparatus

ActiveUS20100214379A1Improve printing qualityReduce head sizeCeramic shaping apparatusDomestic articlesLiquid jetEngineering

Owner:SEIKO EPSON CORP

Rotary electric shaver

InactiveUS8220157B2Reduce contact pressureReduce head sizeMetal working apparatusEngineeringElectric razors

Owner:IZUMI PROD CO

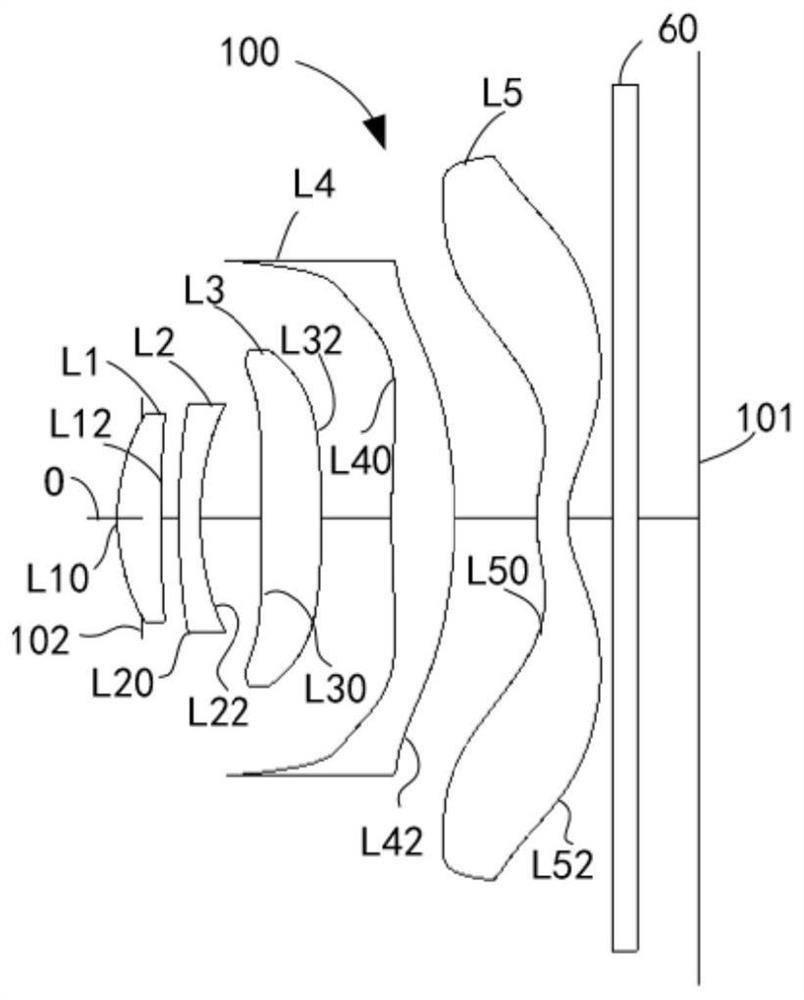

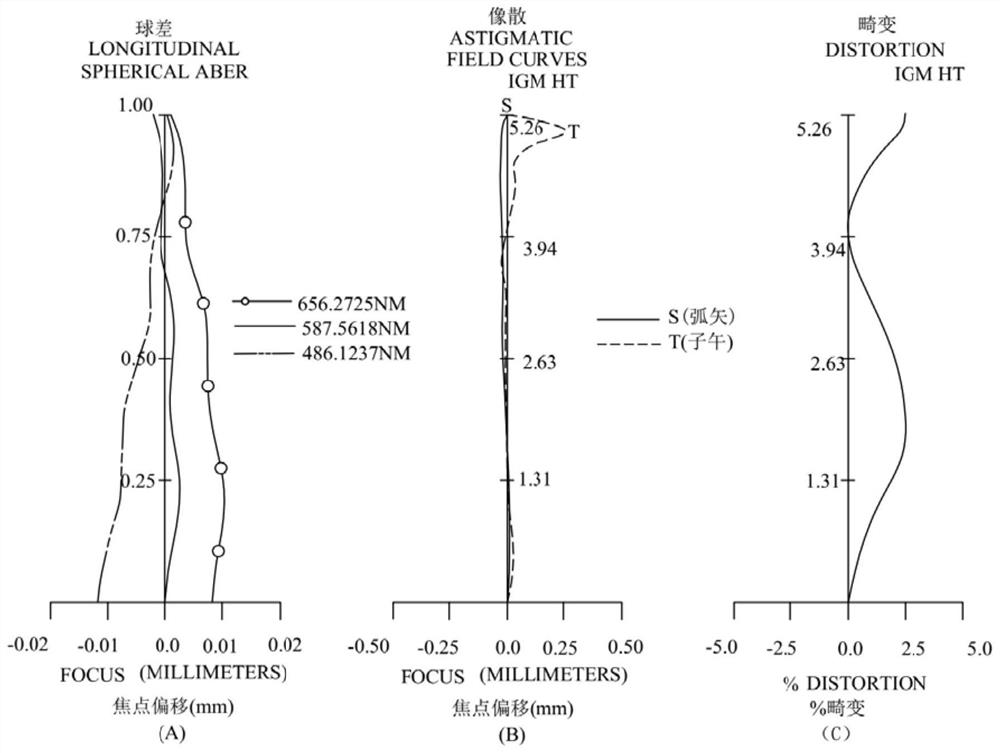

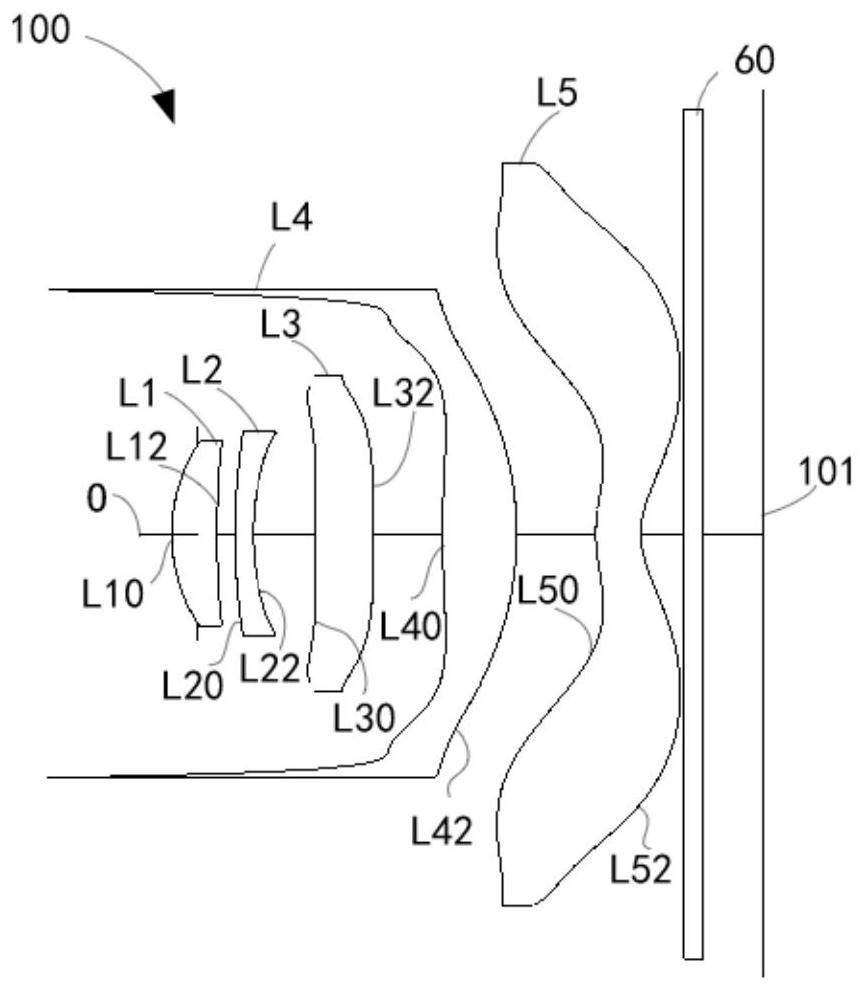

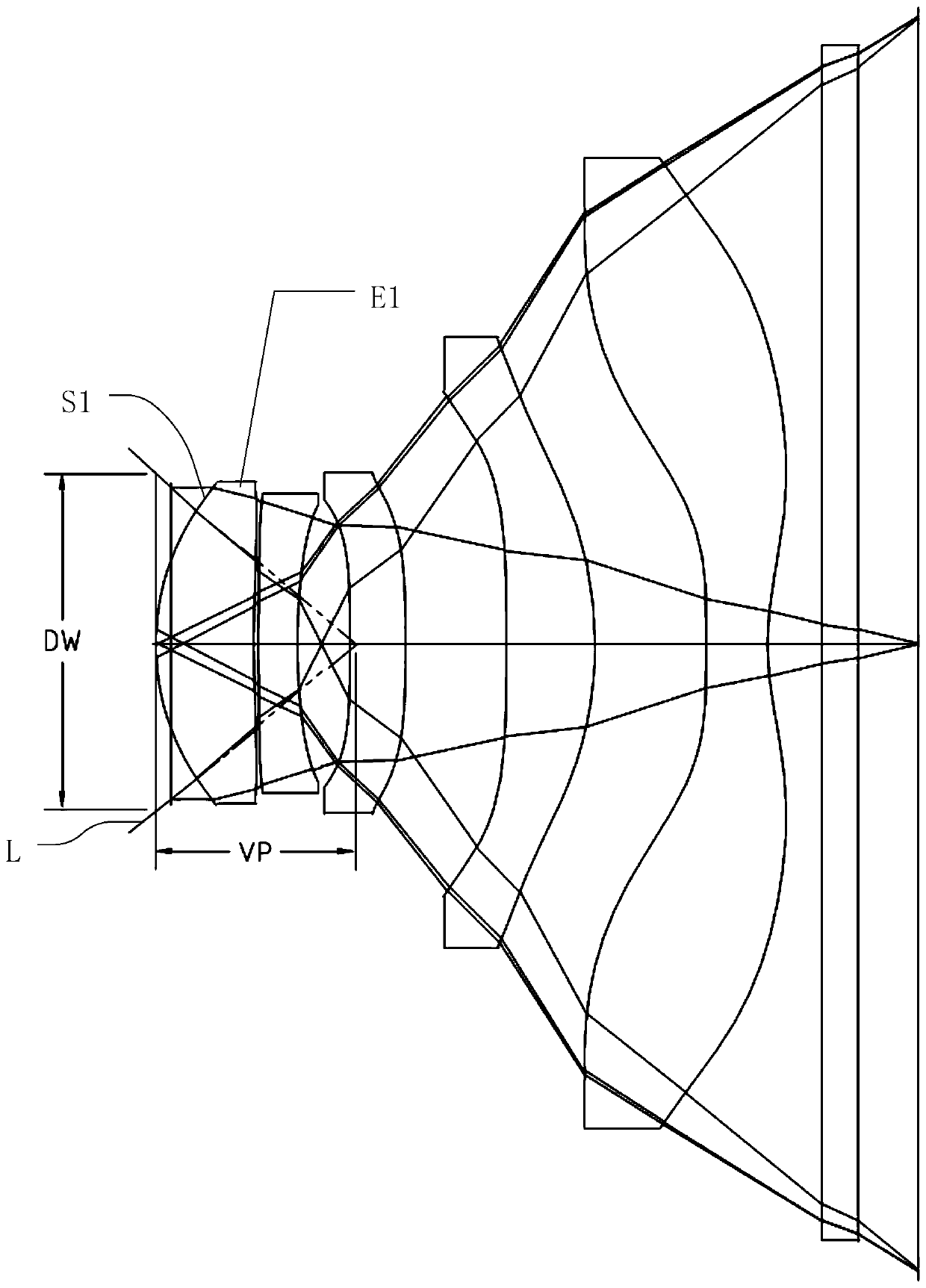

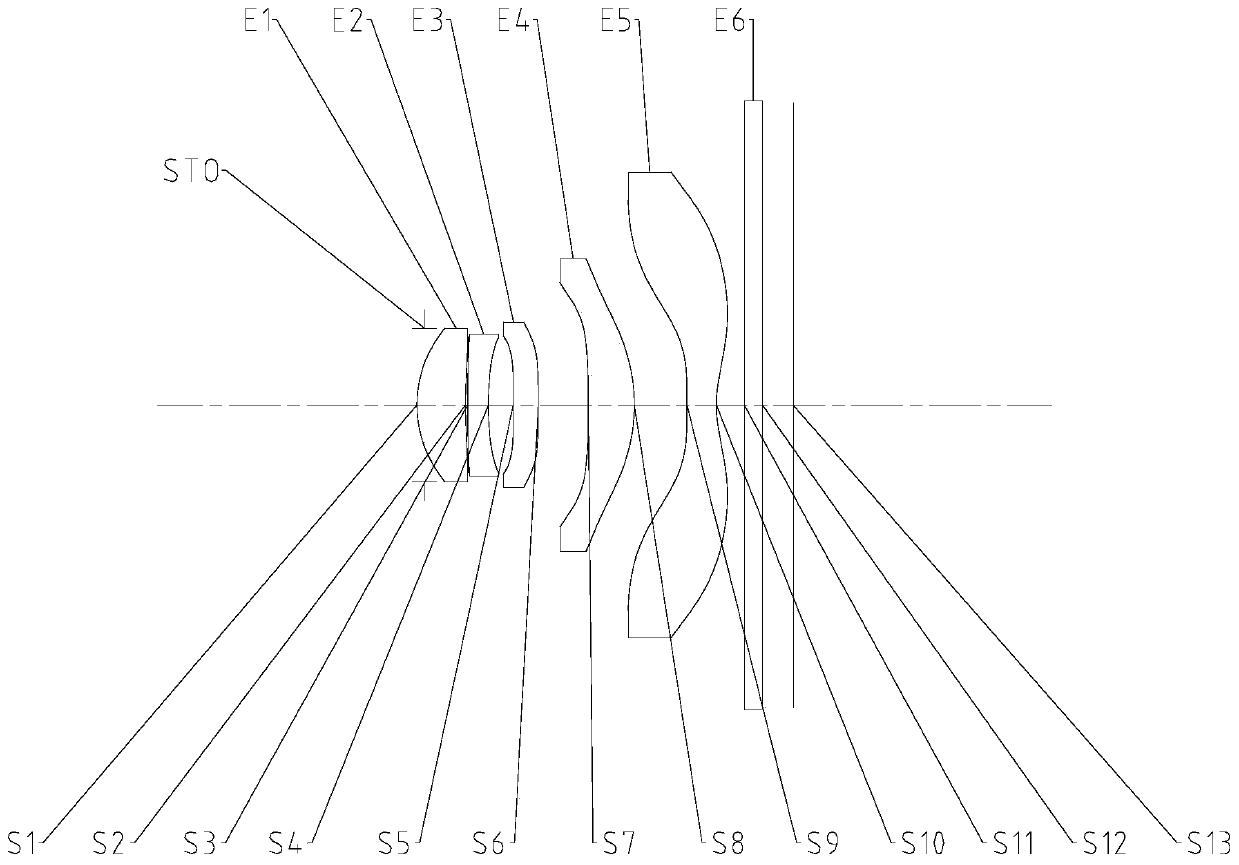

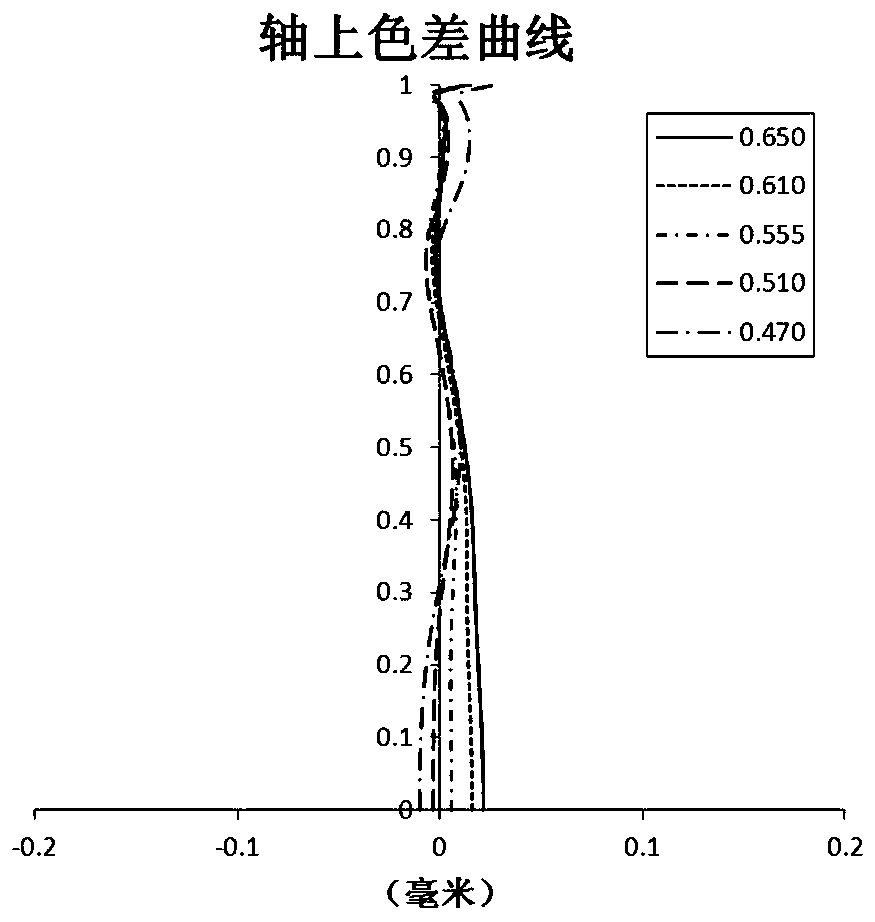

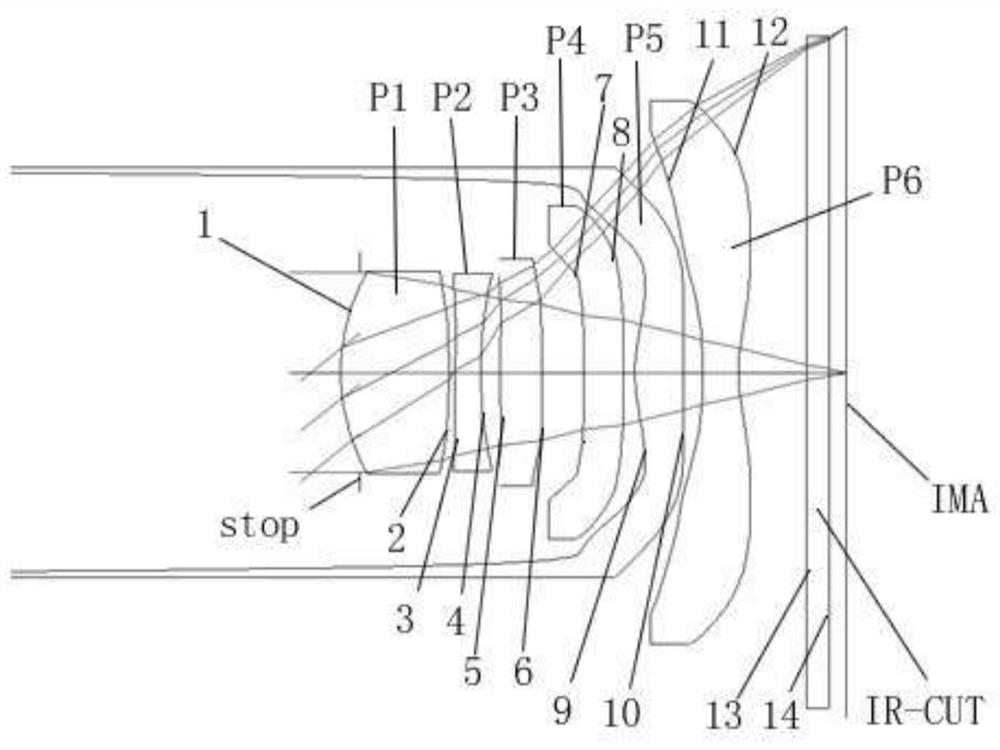

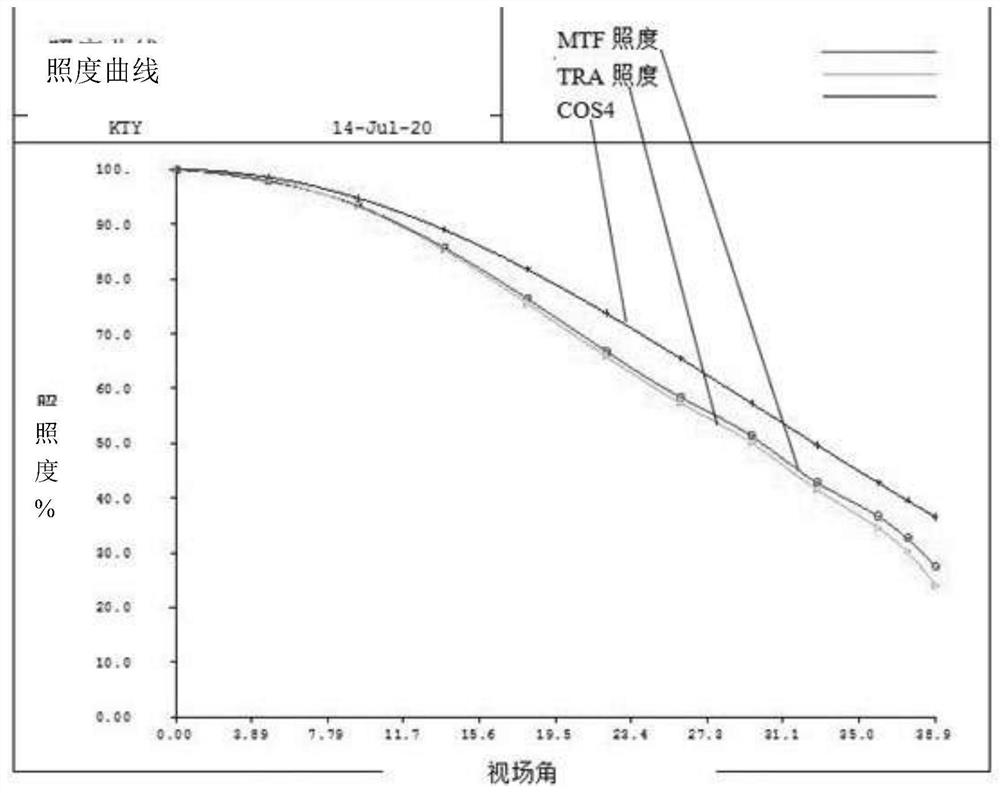

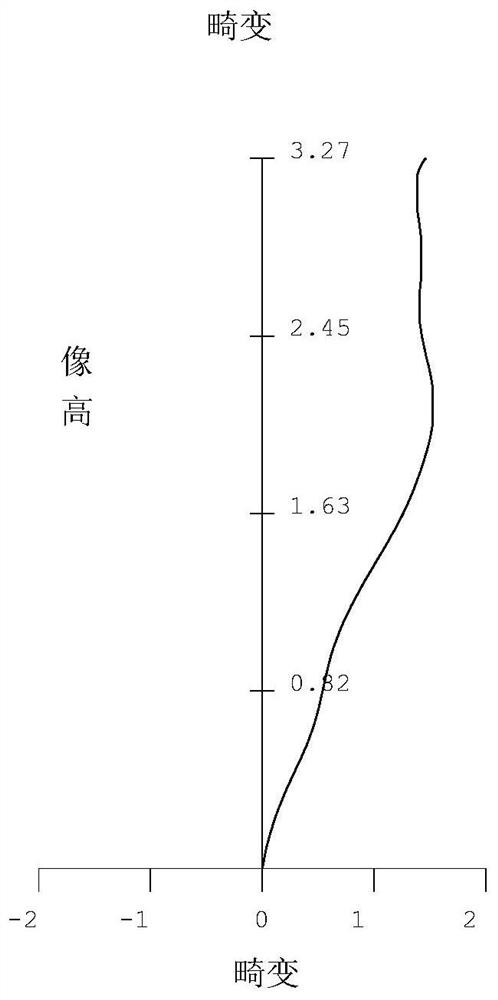

Optical lens, camera device and terminal

The invention discloses an optical lens, a camera device and a terminal. The optical lens comprises a first lens, a second lens, a third lens, a fourth lens and a fifth lens which are sequentially arranged from the object side to the image side along the optical axis. The first lens has positive focal power, and the object side surface of the first lens is a convex surface near the optical axis; the second lens has focal power; the third lens has focal power; the fourth lens has positive focal power, and the image side surface of the fourth lens is a convex surface near the optical axis; the fifth lens has negative focal power, and the image side surface of the fifth lens is a concave surface near the optical axis; and the optical lens satisfies the following relationship: 2<SD1 / CT12<12. According to the optical lens, through the focal power of the five-piece lens and the convex-concave design of the object side surface and the image side surface, and the met relationship: 2<SD1 / CT12<12, the size of the head of the optical lens can be effectively reduced, so that the width of the optical lens in the direction perpendicular to the optical axis is reduced, the overall size of the optical lens is compressed, the compactness of the optical lens is improved, the ghost image risk can be reduced, and the image shooting quality is ensured.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

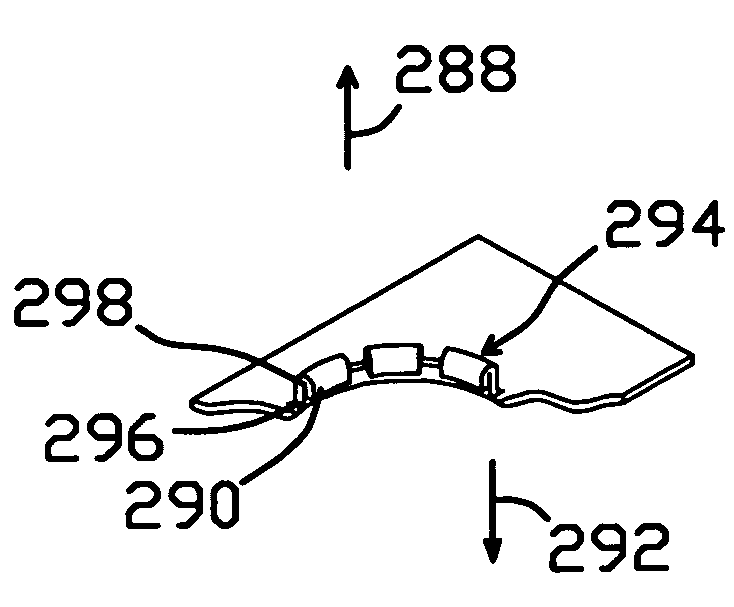

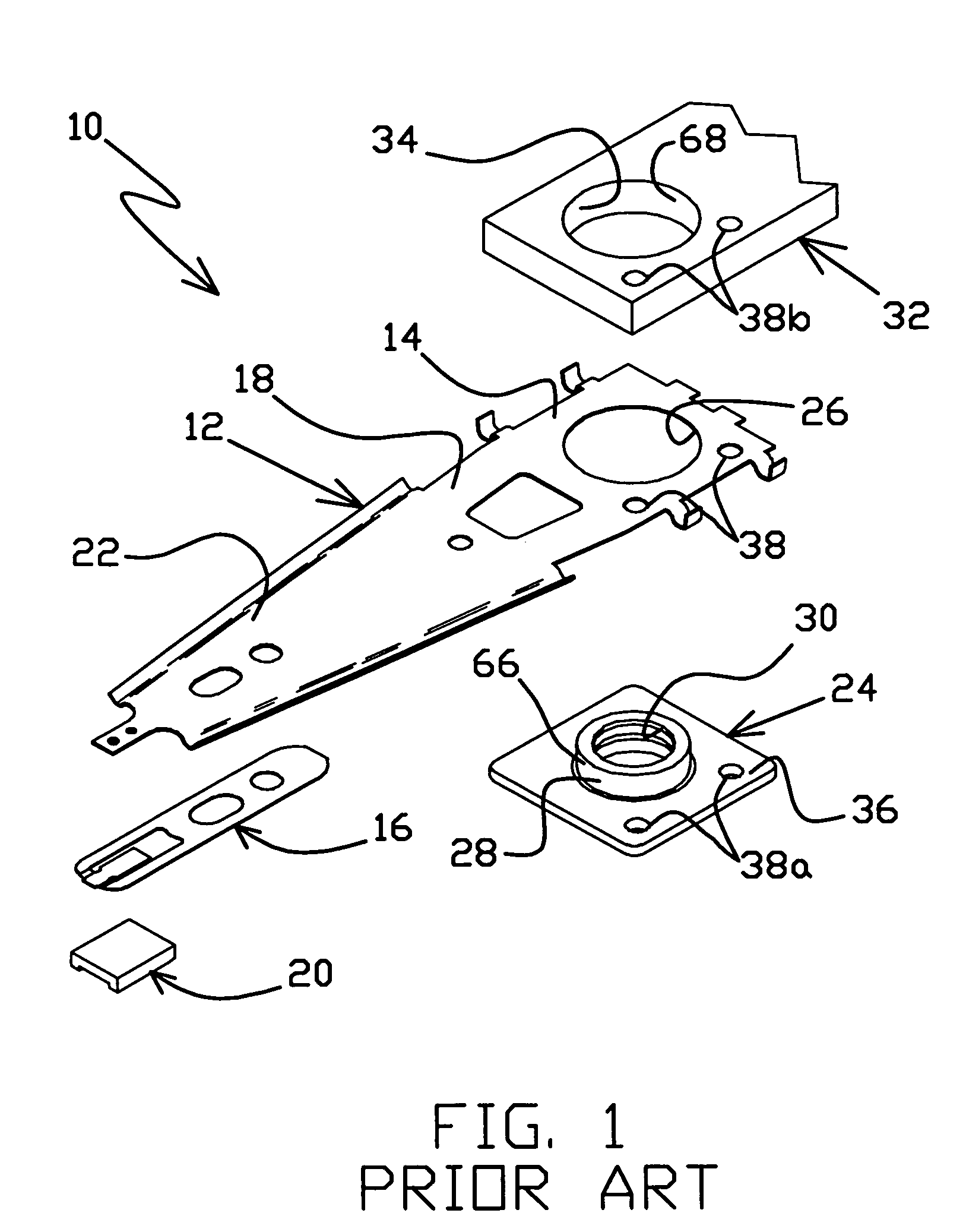

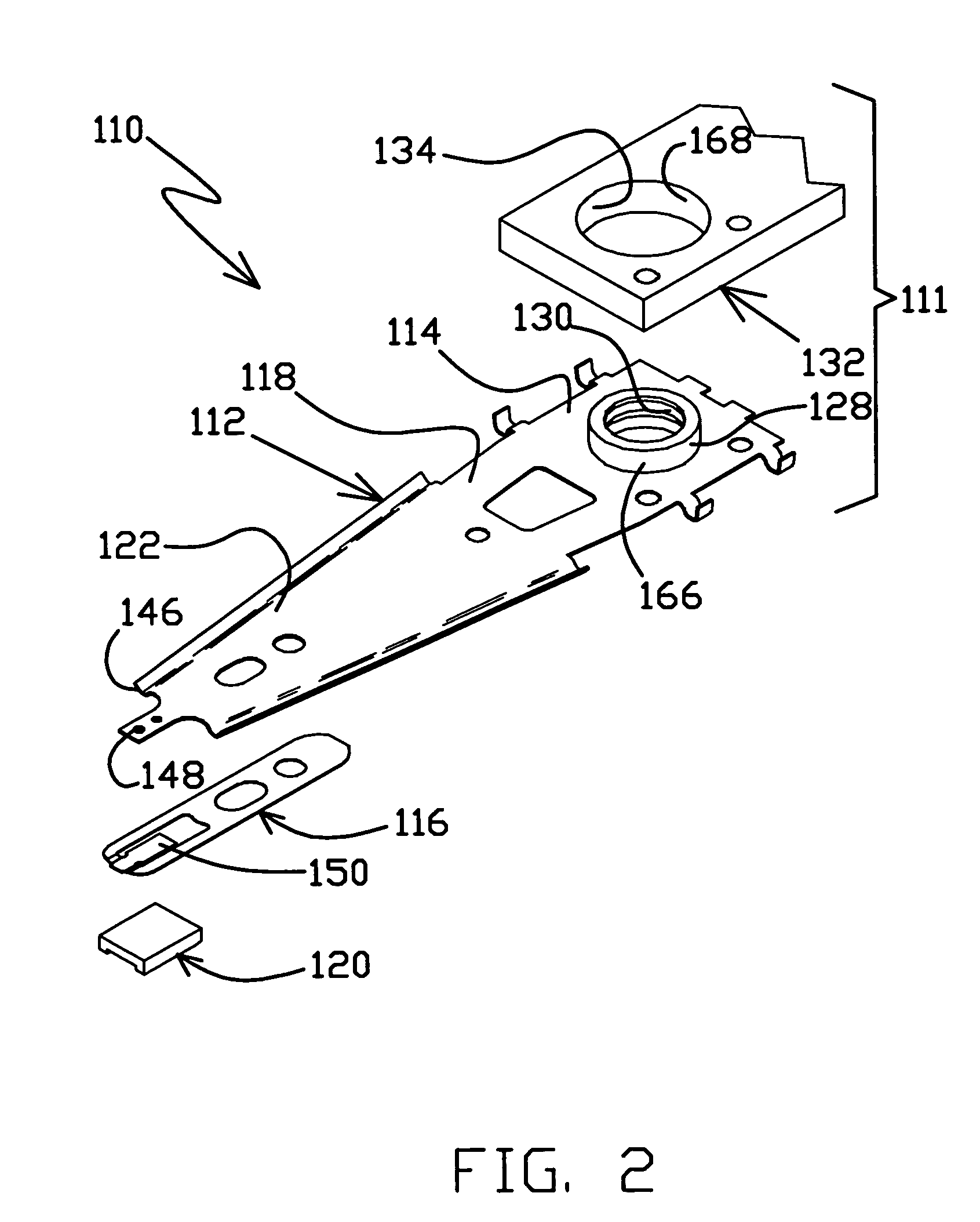

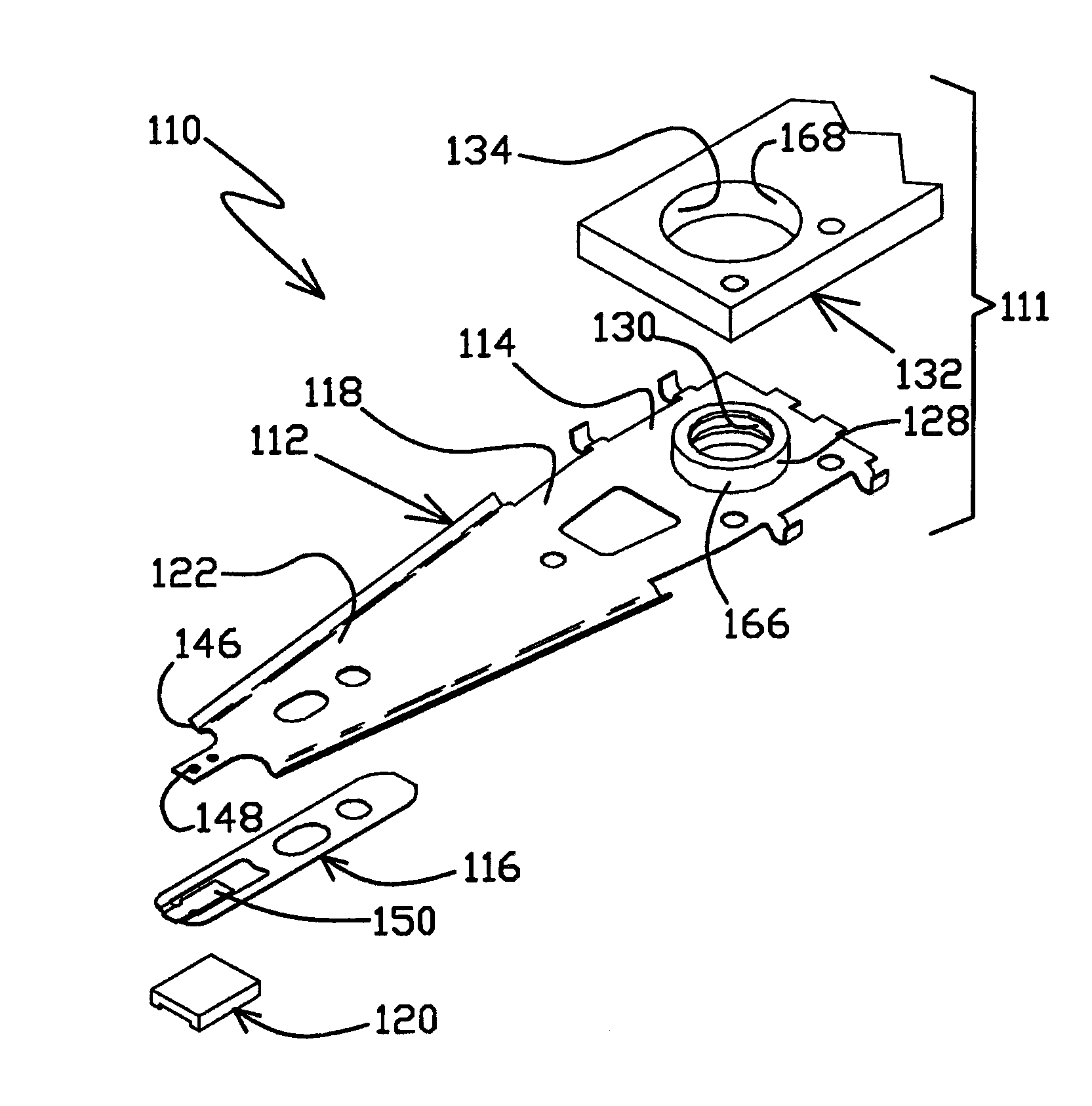

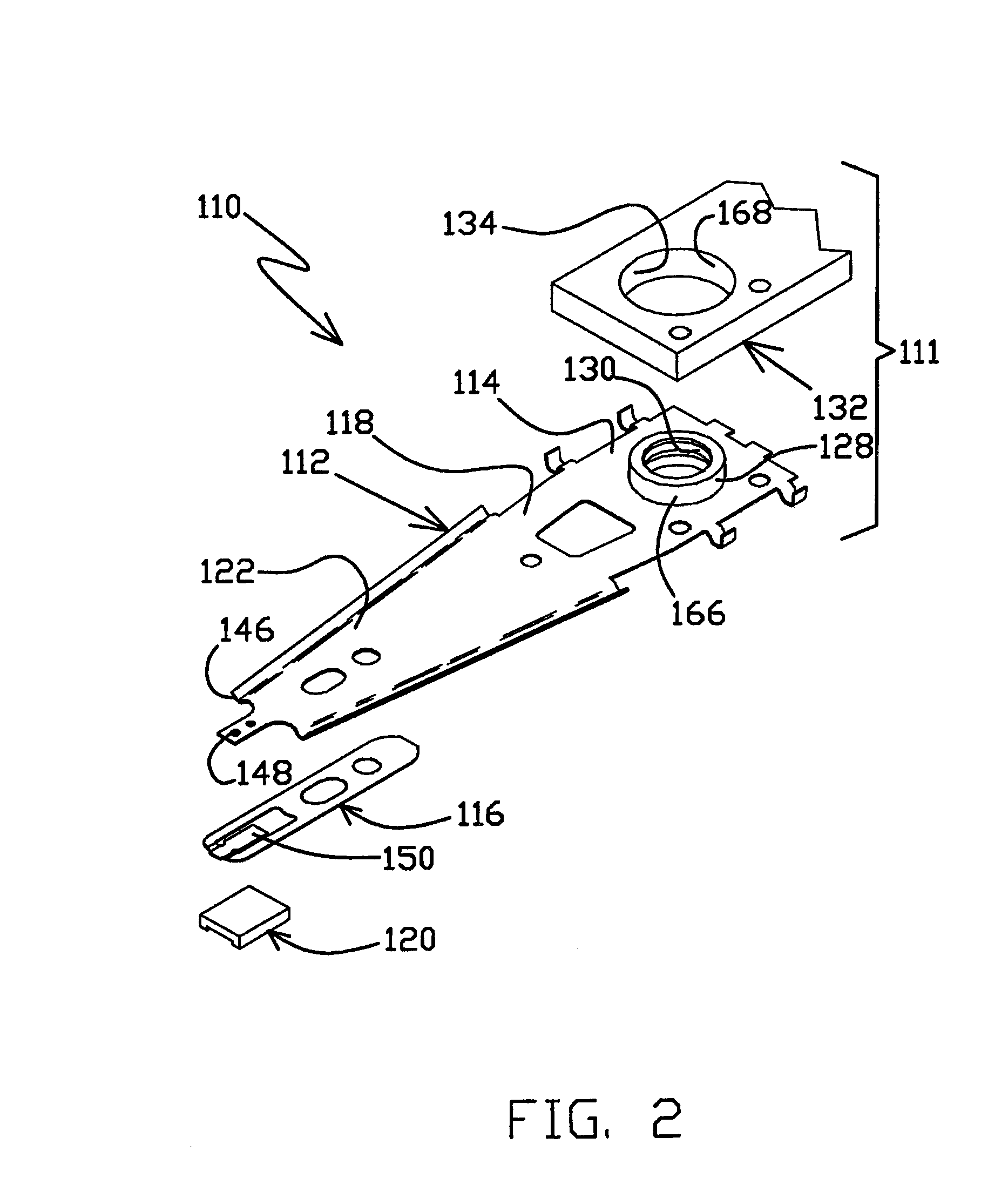

Method of forming a head suspension with an integral boss tower

InactiveUS7170716B2Reduce head sizeReduces disk spacingElectrical transducersRecord information storageMechanical engineeringTower

A method of making a multi-piece head suspension for a rigid disk drive. The method includes providing a first layer including a mounting region with an integral boss tower attached to a stiffener by one or more positioning tabs; attaching a second layer including a spring region to an interface between the mounting region and the stiffener; attaching a flexure to the stiffener; and removing the positioning tabs. The flexure can optionally be a portion of the second layer.

Owner:HUTCHINSON TECH

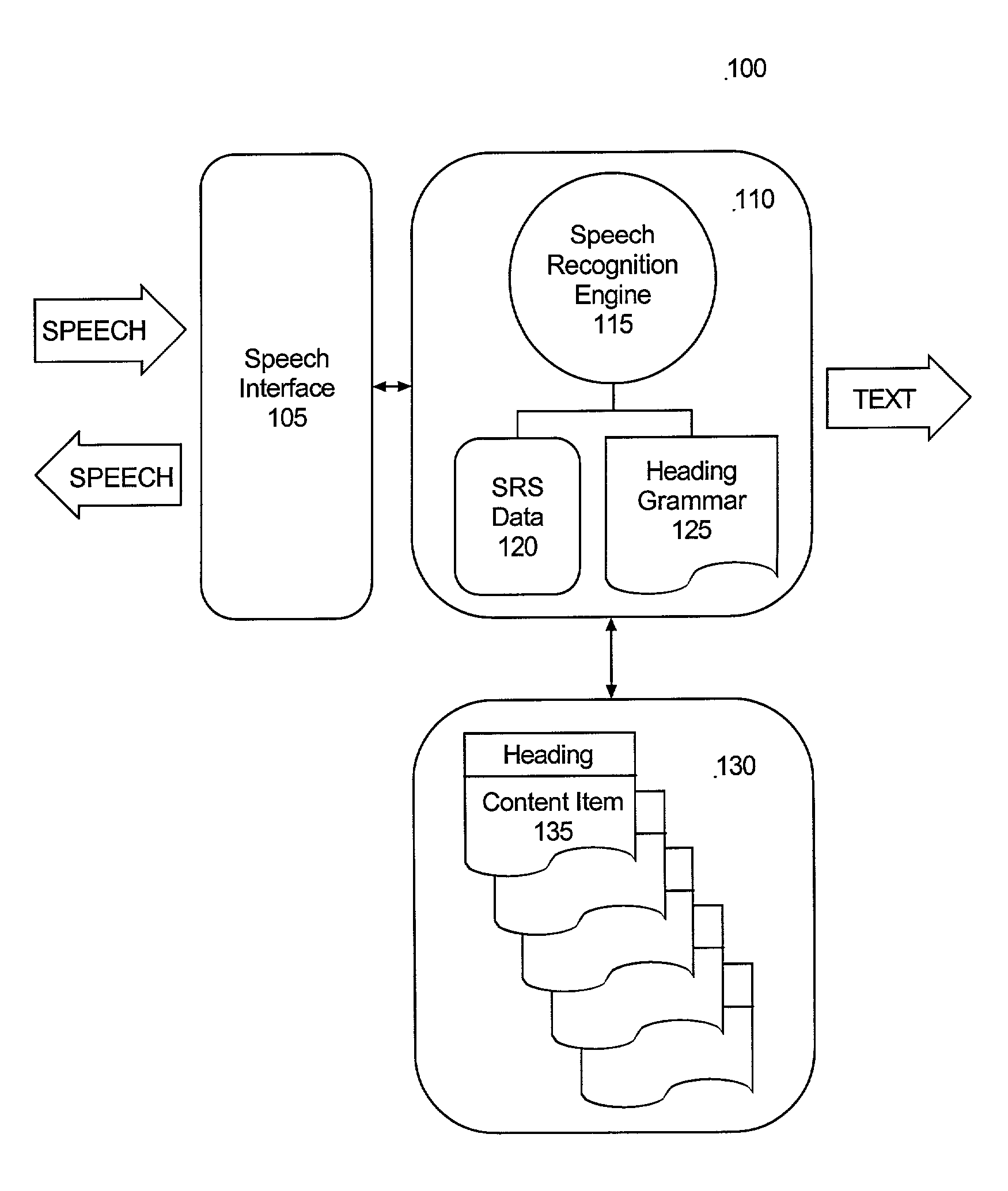

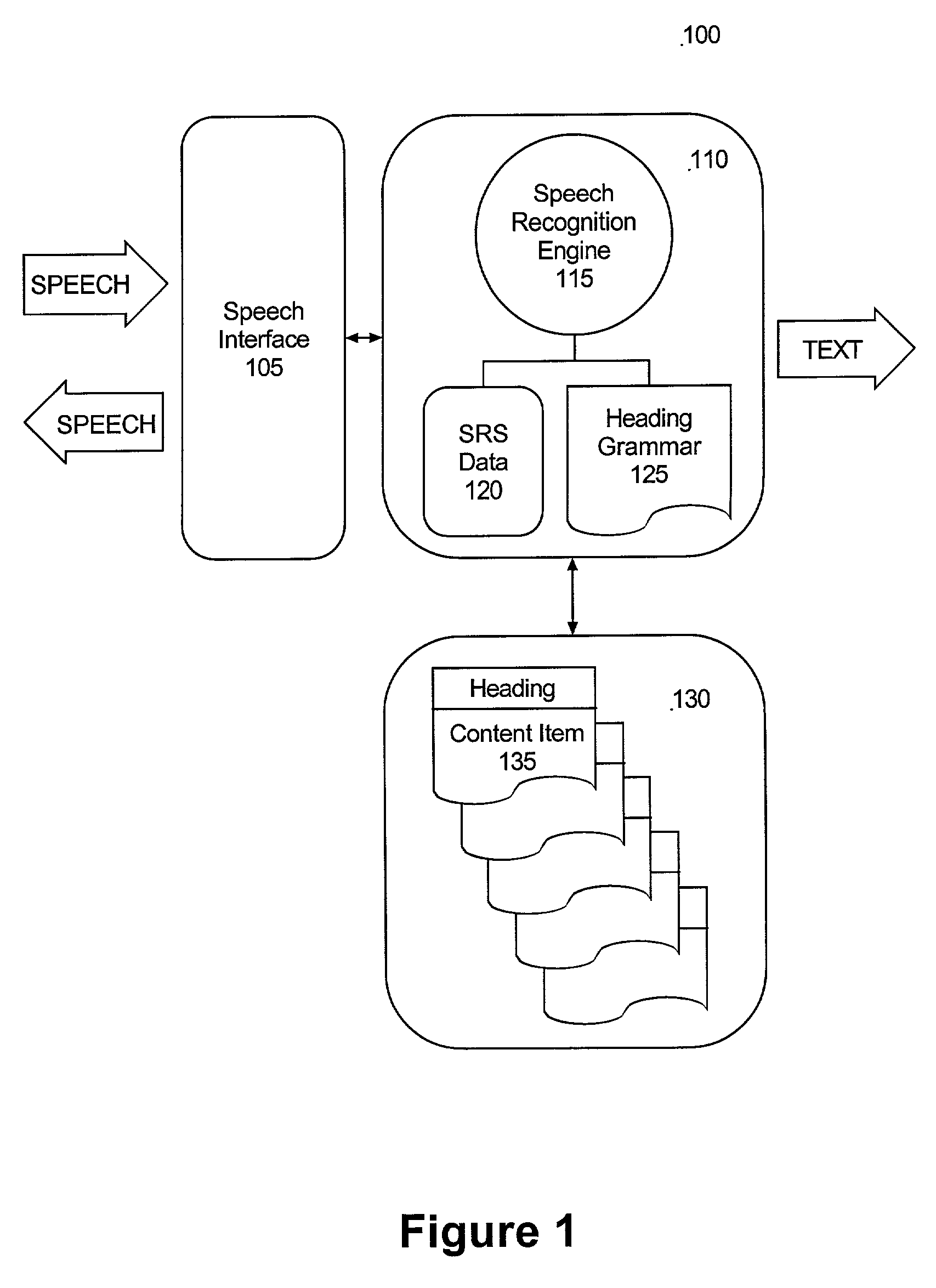

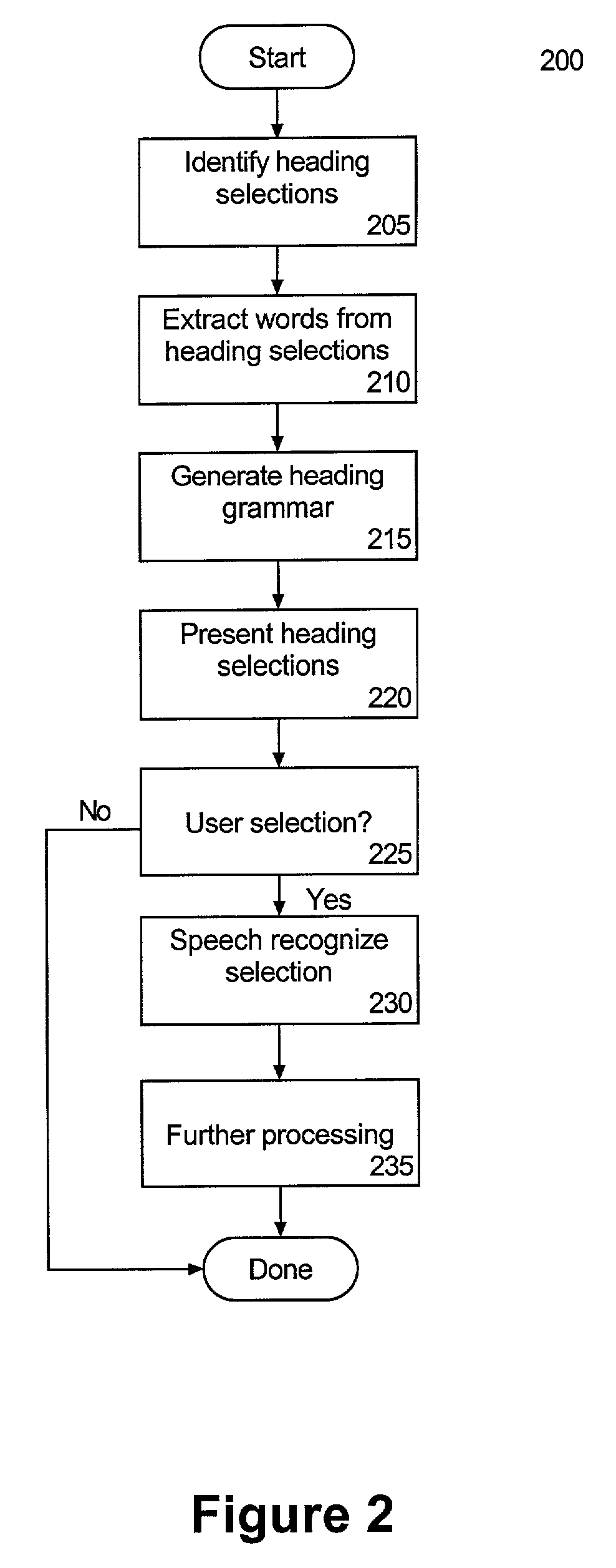

Automatic generation of efficient grammar for heading selection

ActiveUS7054813B2Improve speech recognition accuracyShorten the timeSpeech recognitionNatural language processingSpeech identification

A method of generating a grammar for recognizing headings in a speech recognition system can include identifying, within a data store, at least one heading selection associated with a content item. At least a first word from the identified heading selections can be extracted and a heading grammar automatically can be generated by including each extracted word of the identified heading selections within the heading grammar.

Owner:NUANCE COMM INC

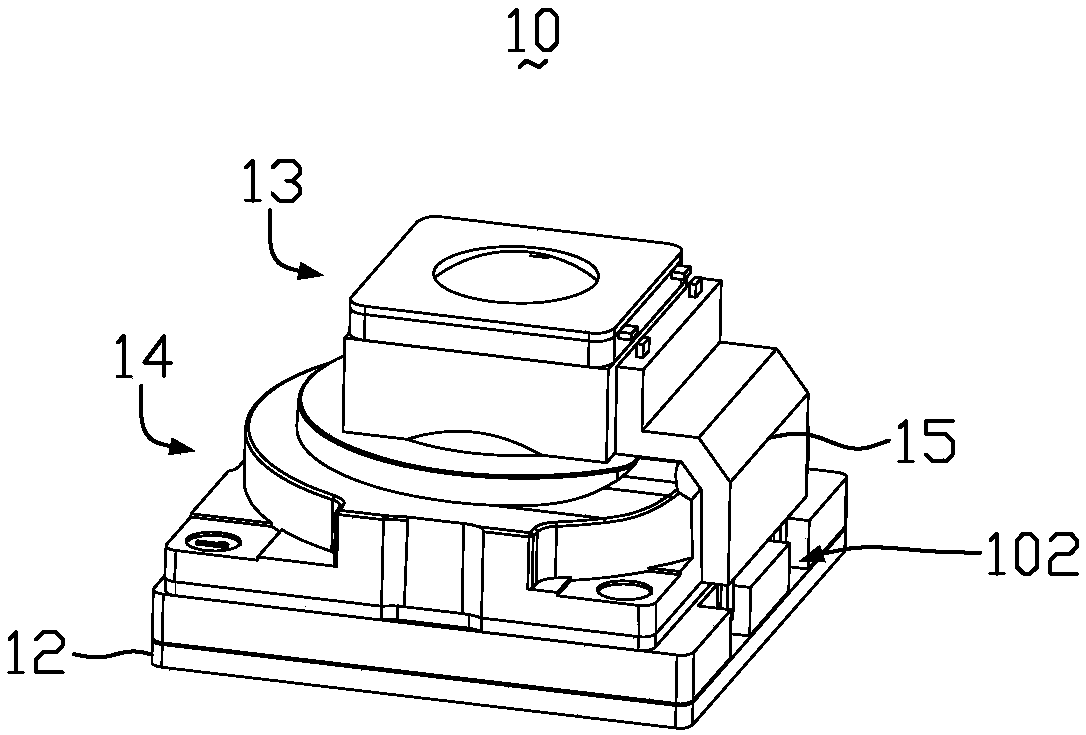

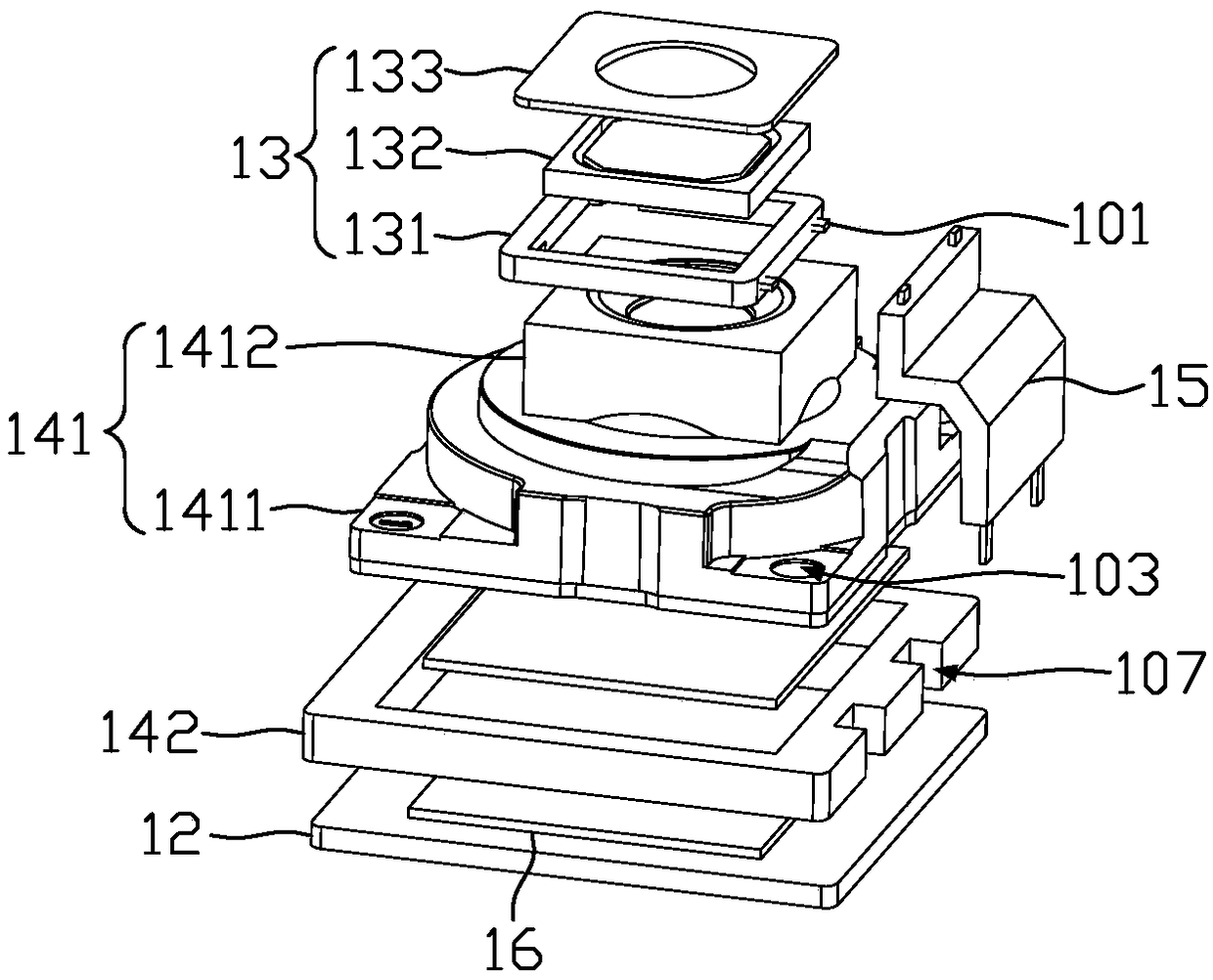

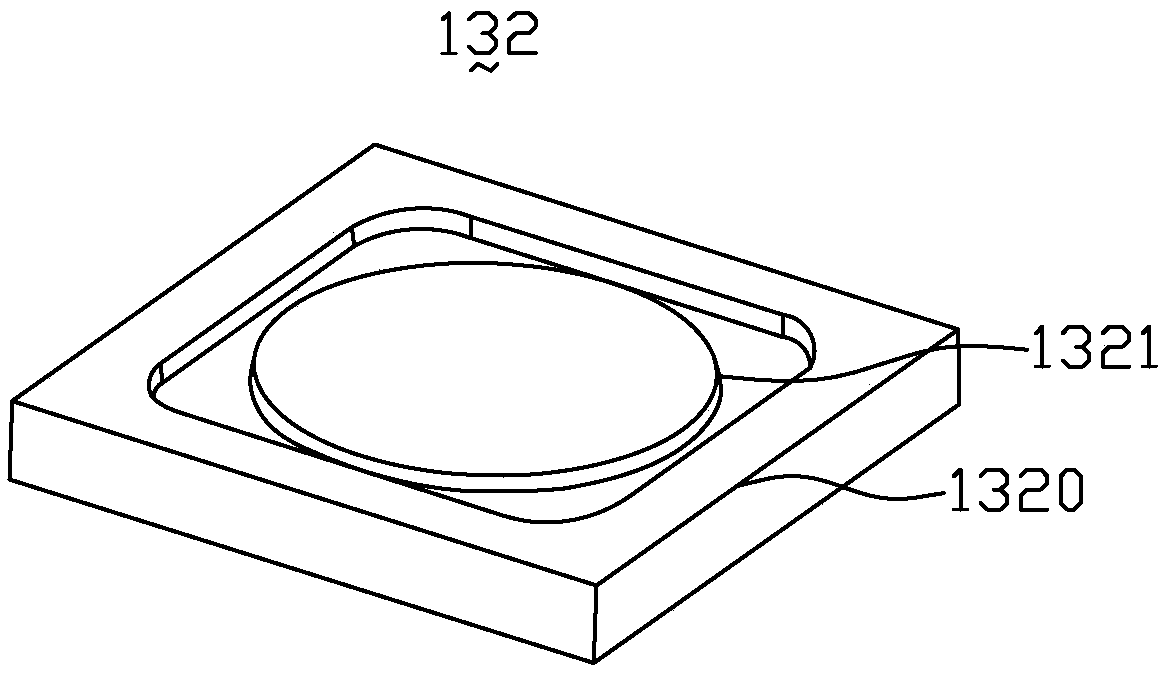

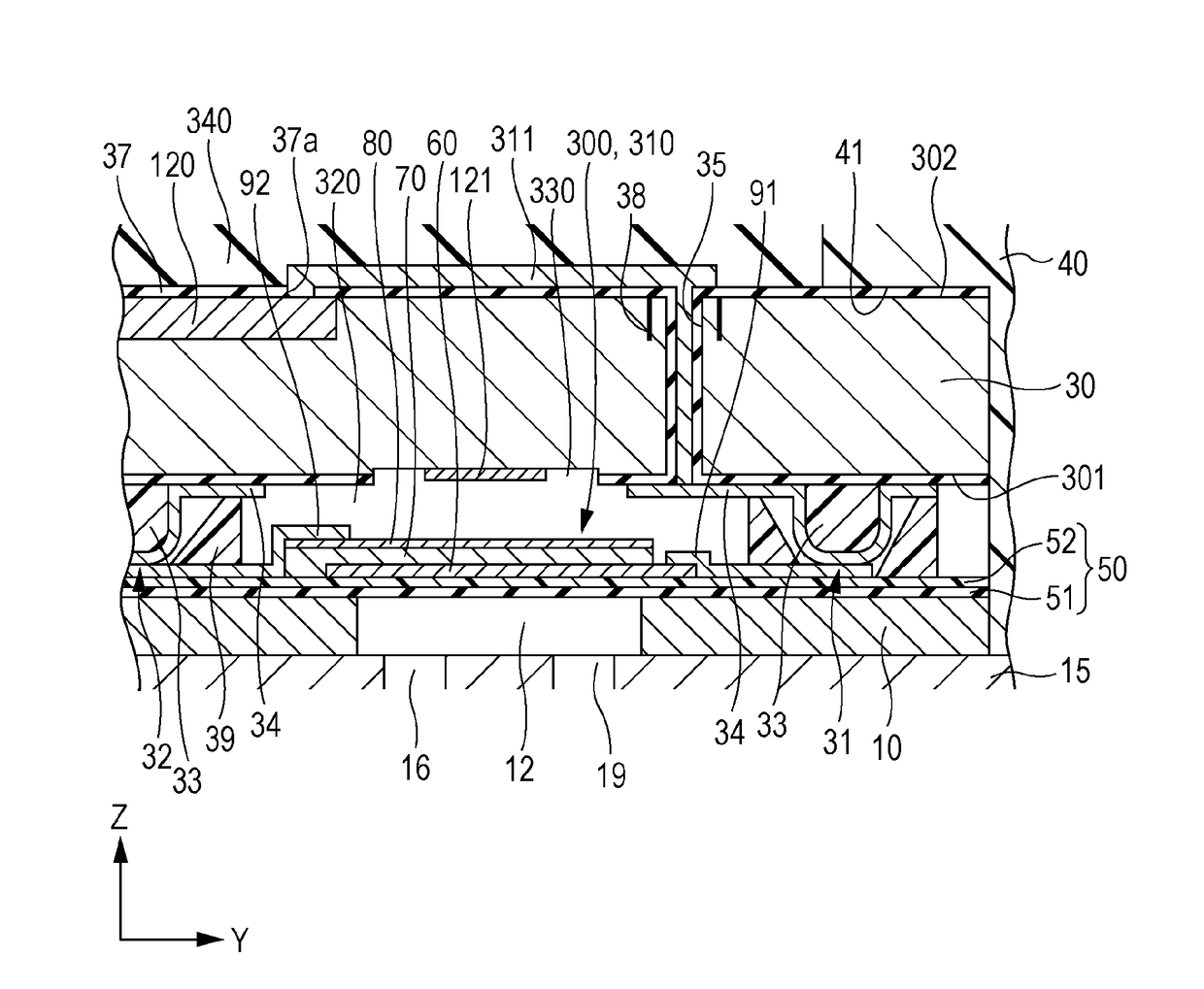

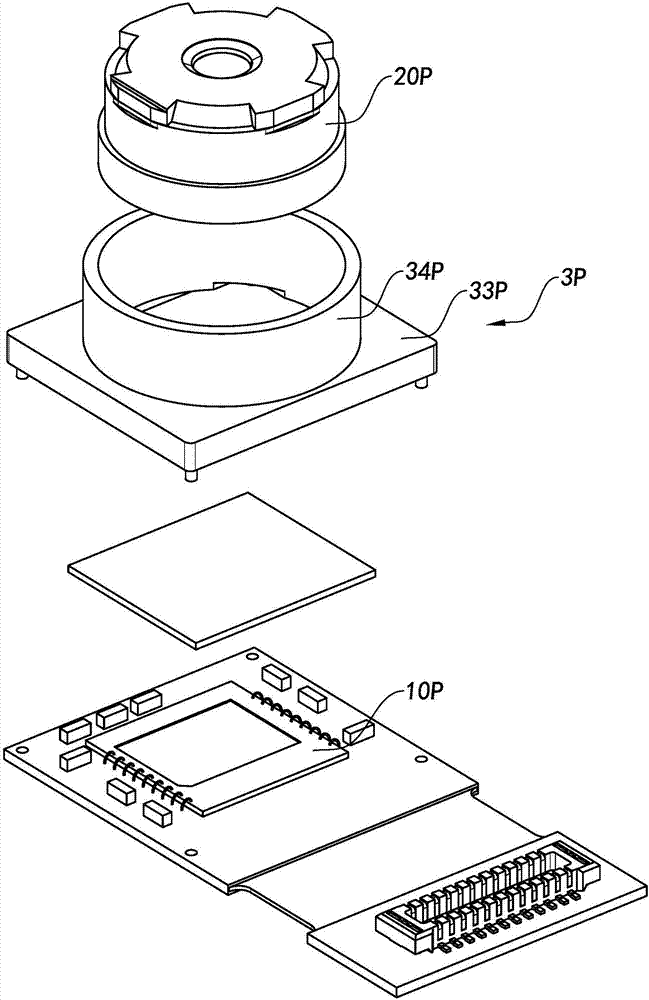

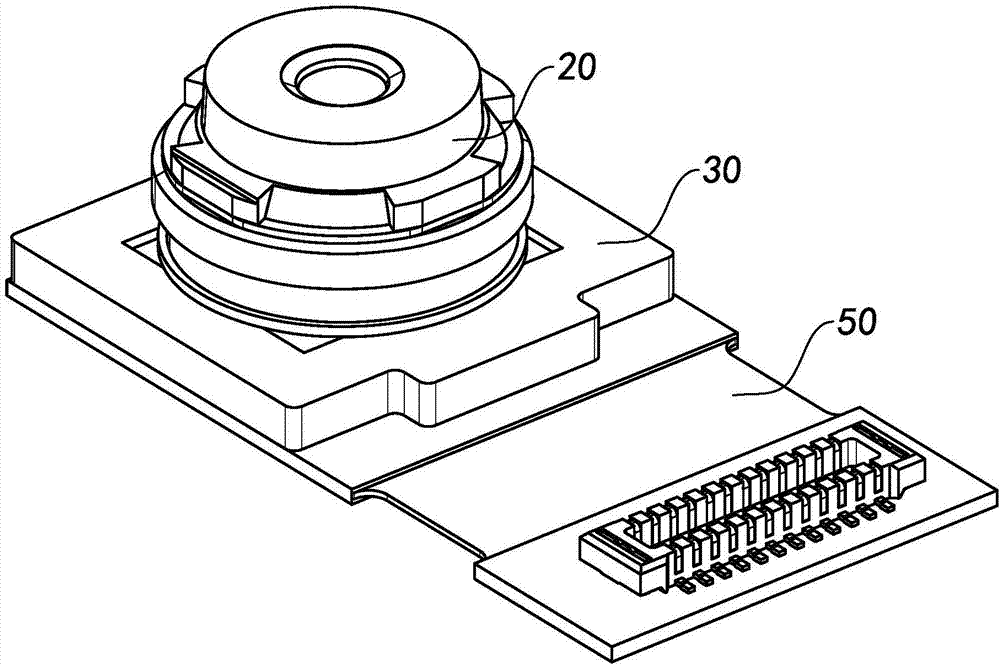

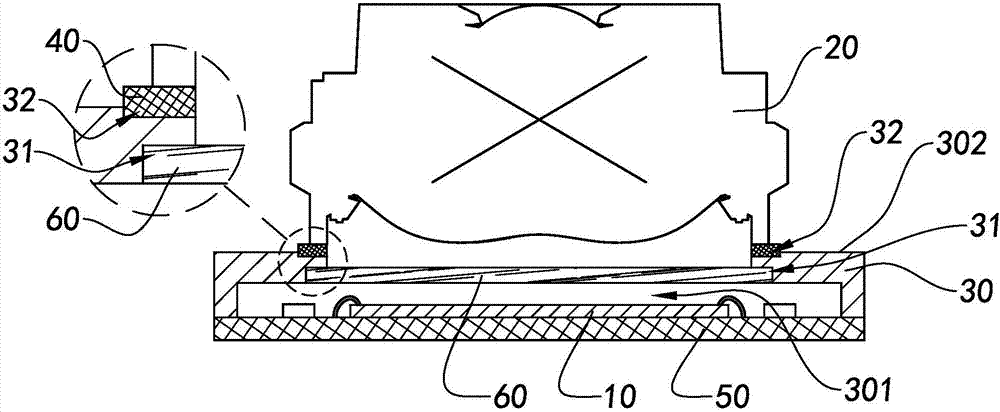

Camera module and terminal

PendingCN109451225ALess componentsReduce head sizeTelevision system detailsColor television detailsComputer terminalCamera module

The invention relates to a camera module, which comprises a circuit board. The camera module also comprises an adjustable lens module, a lens and an auxiliary block. The lens is arranged on the circuit board; the adjustable lens module comprises a lens outer frame and a lens body; the lens outer frame is fixed to the lens; the lens body is arranged in the lens outer frame; one side of the lens outer frame is provided with a first conductive position; one side of the circuit board is provided with a second conductive position; the auxiliary block comprises a conductive body; one end of the conductive body is electrically connected with the first conductive position and the other end is electrically connected with the second conductive position so as to connect the lens outer frame and the circuit board electrically. The lens outer frame of the camera module in the invention is fixed on the lens; the lens body is electrically connected with the circuit board through the auxiliary block;the lens is arranged on the circuit board, thereby reducing elements of the camera module and further reducing the size of the head of the camera module; the structure is simpler; and the reliabilityis improved. The camera module in the invention relates to a terminal as well.

Owner:KUNSHAN Q TECH CO LTD

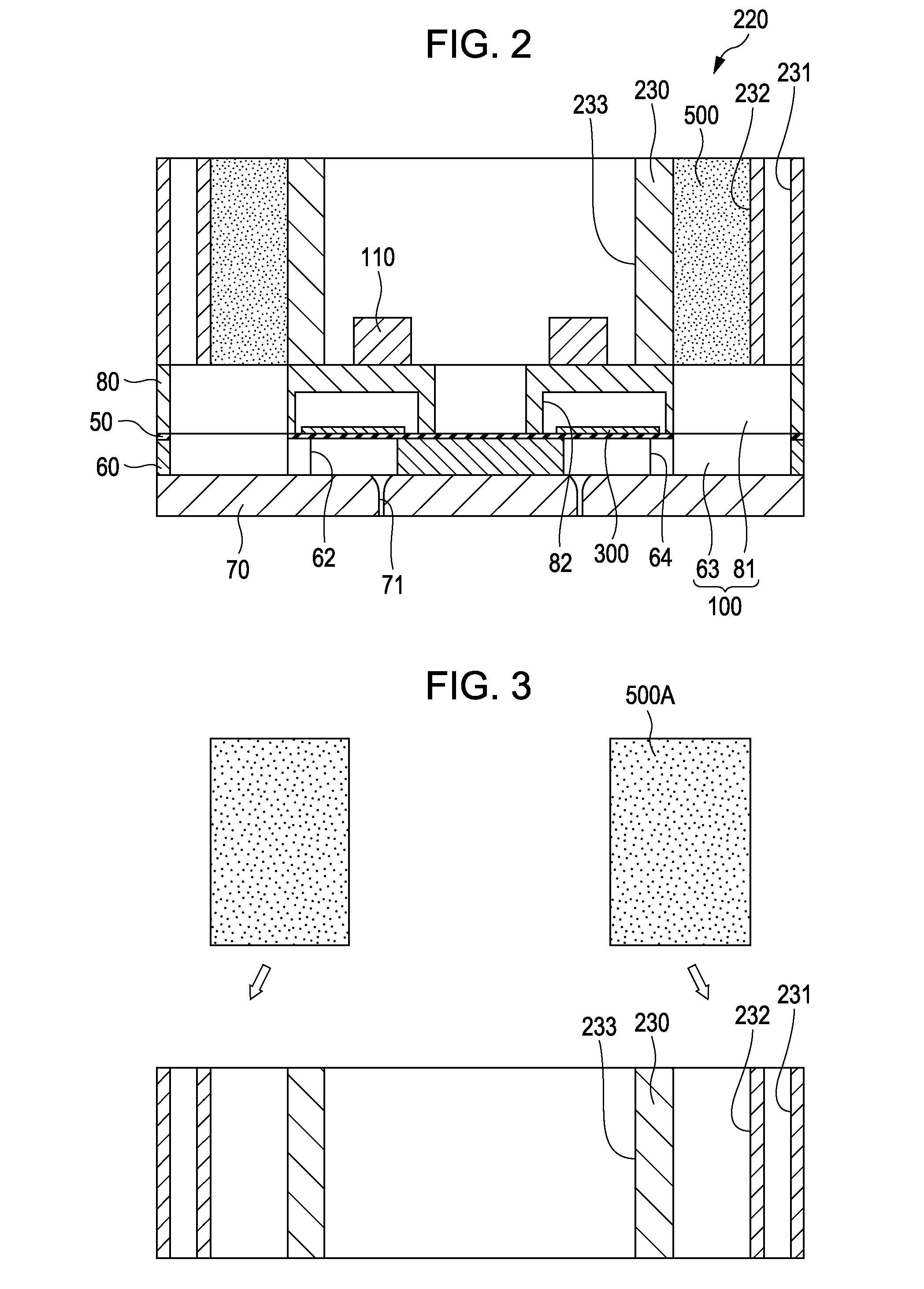

Head and liquid ejecting apparatus

ActiveUS9705066B2Reduce widthSmall sizeInking apparatusPiezoelectric/electrostrictive device detailsLiquid jetPiezoelectric actuators

A head includes a channel formation substrate having two piezoelectric actuator rows formed thereon, a driving circuit, and a driving circuit board which is provided with a first bump and a second bump, in which the first bump is provided on the outside of the piezoelectric actuator row, an adhesive layer is provided on both sides of the first bump and the second bump, a first through hole and a second through hole are provided on the driving circuit board, a first connection wiring and a second connection wiring are provided in the first through hole and the second through hole, and a first electrode of the piezoelectric actuator is electrically connected to a first connection wiring via the first bump and a second electrode is electrically connected to a second connection wiring via the second bump.

Owner:SEIKO EPSON CORP

Optical imaging lens

The invention discloses an optical imaging lens. The optical imaging lens sequentially comprises a first lens, a second lens, a third lens, a fourth lens and a fifth lens along an optical axis from anobject side to an image side, wherein the first lens has a positive focal power, an object side surface of the first lens is a convex surface, an image side surface of the first lens is a concave surface, the second lens has a negative focal power, the third lens has a focal power, the fourth lens has a positive focal power, the fifth lens has a negative focal power, and the distance VP from an intersection point of a straight line where an edge light ray of the optical imaging lens is located and the optical axis to an axis of the object side surface of the first lens conforms to a conditionthat VP is more than 0 millimeter but less than 1.5 millimeters.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

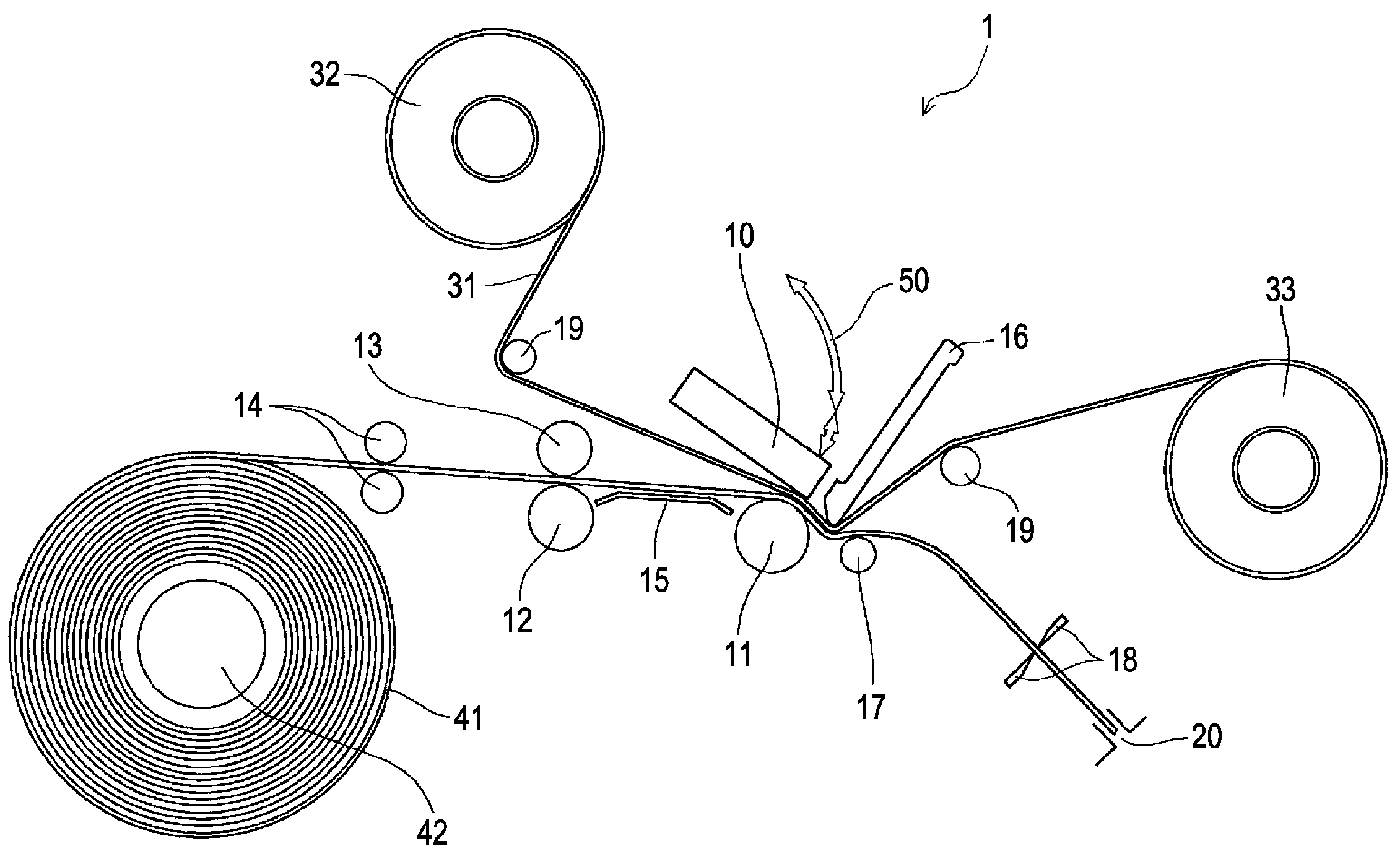

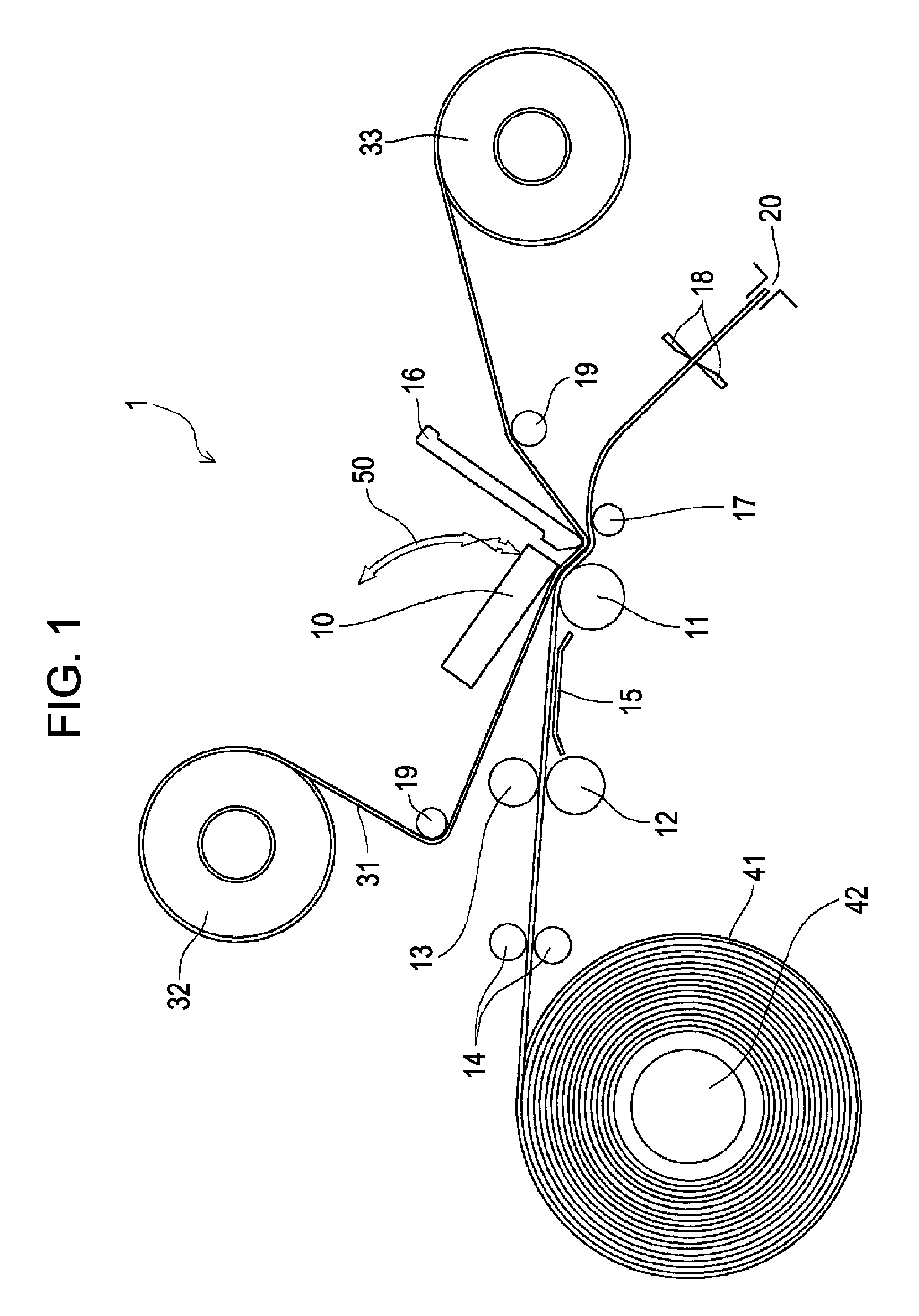

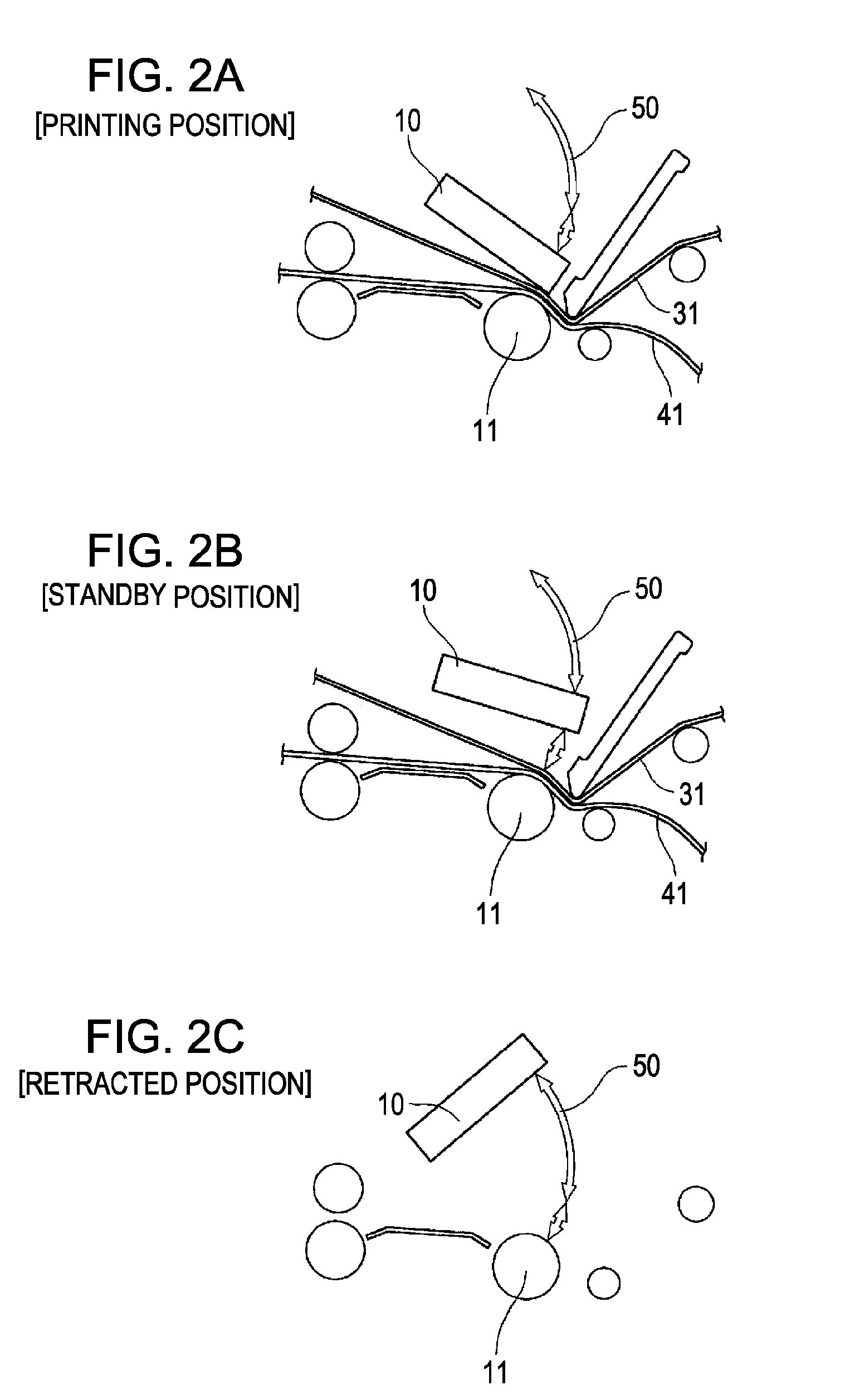

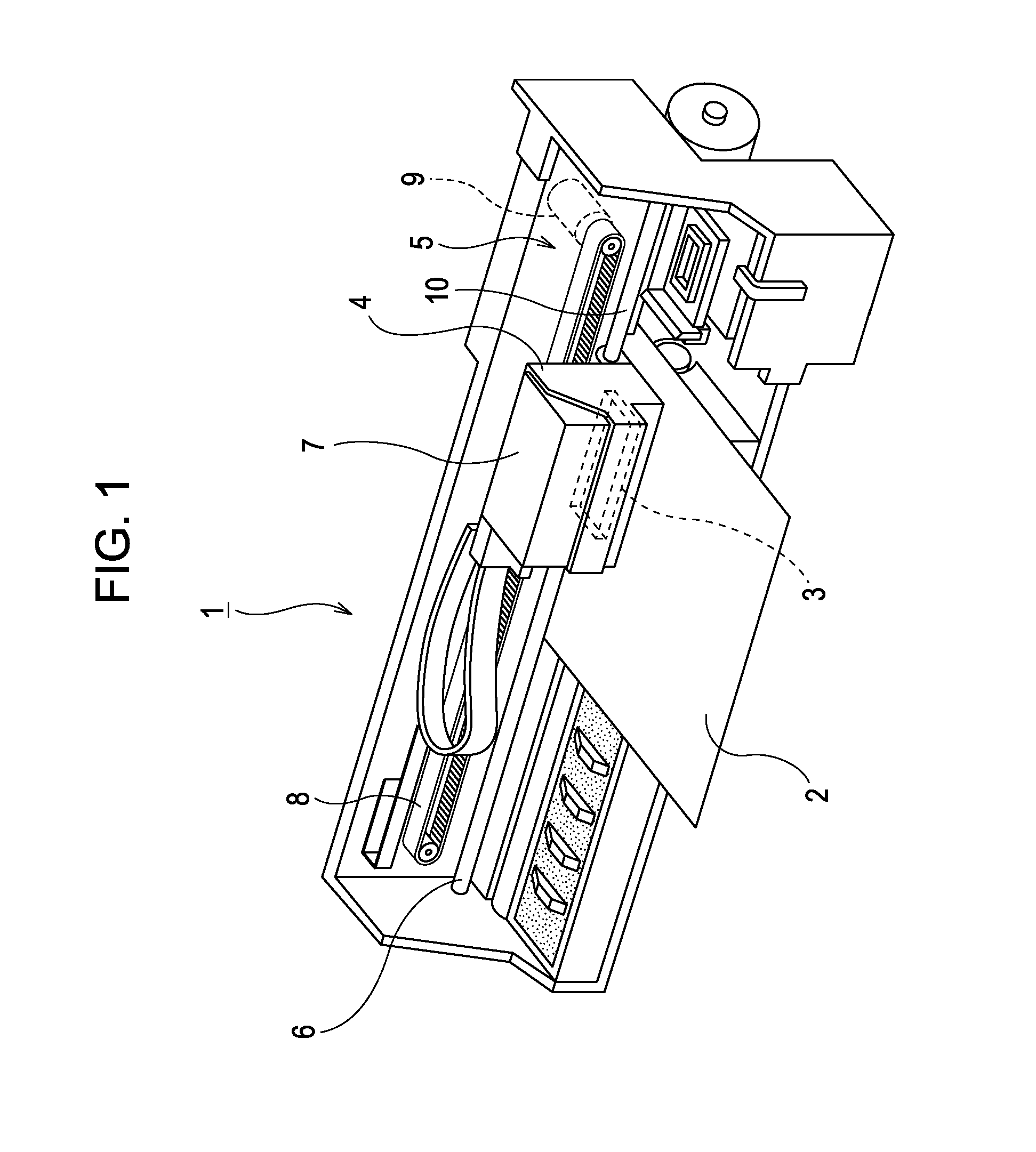

Head moving mechanism and image forming apparatus

A head moving mechanism includes a printhead configured to form an image and movable between a printing position where an image is formed, a standby position away from the printing position, and a retracted position across from the printing position relative to the standby position; a cam mechanism configured to move the printhead between the printing position and the standby position; and a rack-and-pinion mechanism configured to move the printhead between the standby position and the retracted position.

Owner:SONY CORP

Method of manufacturing liquid ejecting head

InactiveUS7862759B2Prevent liquid leakageReduce intervalTailstocks/centresConfectioneryEngineeringMechanical engineering

A method of manufacturing a liquid ejecting head and a supply member having a plurality of liquid supply passages is provided. The supply member includes first and second supply members in which liquid supply passages are provided and filters provided between the first supply member and the second supply member. The method includes: preparing a connected filter formed of a plurality of filter element portions corresponding to the plurality of liquid supply passages and a connecting portion that connects the plurality of filter element portions; in a state where the filter element portions of the connected filter are held between the first supply member and the second supply member, charging molten resin from a position corresponding to the connecting portion of the connected filter to separate the connecting portion; and, during the charging, molding.

Owner:SEIKO EPSON CORP

Head and liquid ejecting apparatus

ActiveUS20160263890A1Reduce widthSmall sizeInking apparatusPiezoelectric/electrostrictive device detailsPiezoelectric actuatorsEngineering

A head includes a channel formation substrate having two piezoelectric actuator rows formed thereon, a driving circuit, and a driving circuit board which is provided with a first bump and a second bump, in which the first bump is provided on the outside of the piezoelectric actuator row, an adhesive layer is provided on both sides of the first bump and the second bump, a first through hole and a second through hole are provided on the driving circuit board, a first connection wiring and a second connection wiring are provided in the first through hole and the second through hole, and a first electrode of the piezoelectric actuator is electrically connected to a first connection wiring via the first bump and a second electrode is electrically connected to a second connection wiring via the second bump.

Owner:SEIKO EPSON CORP

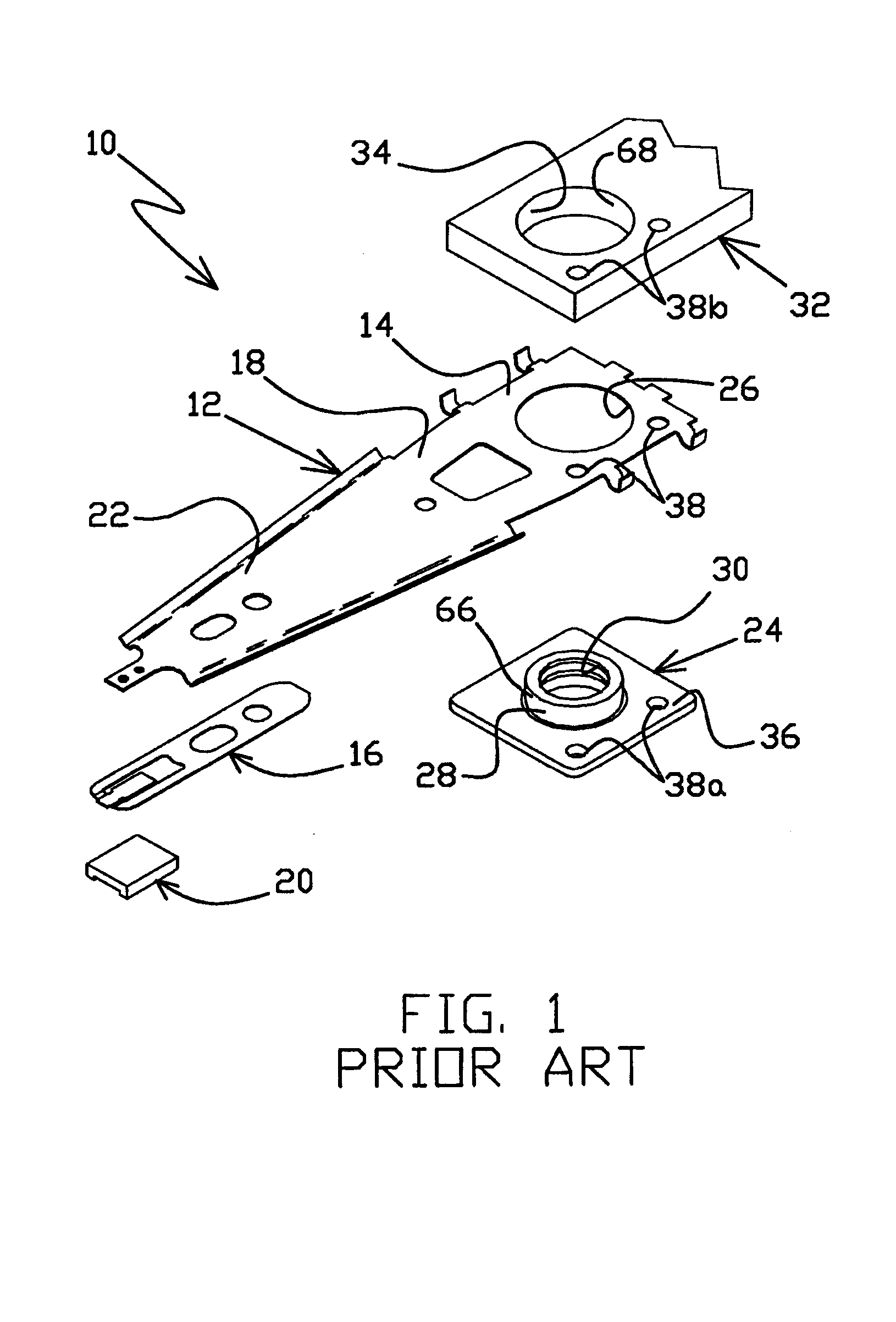

Method of forming a head suspension with an integral boss tower

InactiveUS20070086114A1Reduces mass and inertiaReduce head sizeElectrical transducersRecord information storageEngineeringTower

A method of making a multi-piece head suspension for a rigid disk drive. The method includes providing a first layer including a mounting region with an integral boss tower attached to a stiffener by one or more positioning tabs; attaching a second layer including a spring region to an interface between the mounting region and the stiffener; attaching a flexure to the stiffener; and removing the positioning tabs. The flexure can optionally be a portion of the second layer.

Owner:INTRI PLEX (THAILAND) LTD

Fixed focus camera module and manufacturing method thereof

ActiveCN107547777AReduce head sizeSmall sizeTelevision system detailsColor television detailsCamera lensEngineering

The invention provides a fixed focus camera module and a manufacturing method thereof. The fixed focus camera module comprises a photosensitive chip, an optical lens and a lens seat, wherein the optical lens is directly packaged on the lens seat, the optical lens is kept on a photosensitive path of the photosensitive chip, the size and the manufacturing cost of the fixed focus camera module can beeffectively reduced by this way, and the product competitiveness of the fixed focus camera module is improved.

Owner:NINGBO SUNNY OPOTECH CO LTD

Liquid ejection head

Owner:BROTHER KOGYO KK

Liquid ejecting head and liquid ejecting apparatus

A liquid ejecting head includes pressure generation elements that apply pressure change to liquid retained in corresponding pressure generation chambers to discharge the liquid from corresponding nozzle openings. Each of the pressure generation elements is fixed to a fixation plate. Nozzle lines include nozzle openings arrayed in a line. An electrical signal is sent through a flexible substrate from the outside to the pressure generation chambers. Pressure generation elements associated with the pressure generation chambers are fixed to the fixation plate, with the fixation plate being positioned between the pressure generation elements of each of two parallel nozzle lines. A wiring portion is formed at one end part of the fixation plate opposite to the other end that is closer to the pressure generation chambers. The flexible substrate is connected to the wiring portion.

Owner:SEIKO EPSON CORP

Liquid Ejecting Head and Liquid Ejecting Apparatus

A head unit fixed to a case in a position in which a nozzle forming surface thereof faces a first surface side of a head fixing portion, and a wiring substrate is arranged on a second surface side opposite from the first surface on a portion. A supply flow channel in the case communicate with a common liquid chamber at an end portion of the communicating flow channel in a first direction, and a flexible cable is disposed inside the supply flow channel in the case in the first direction.

Owner:SEIKO EPSON CORP

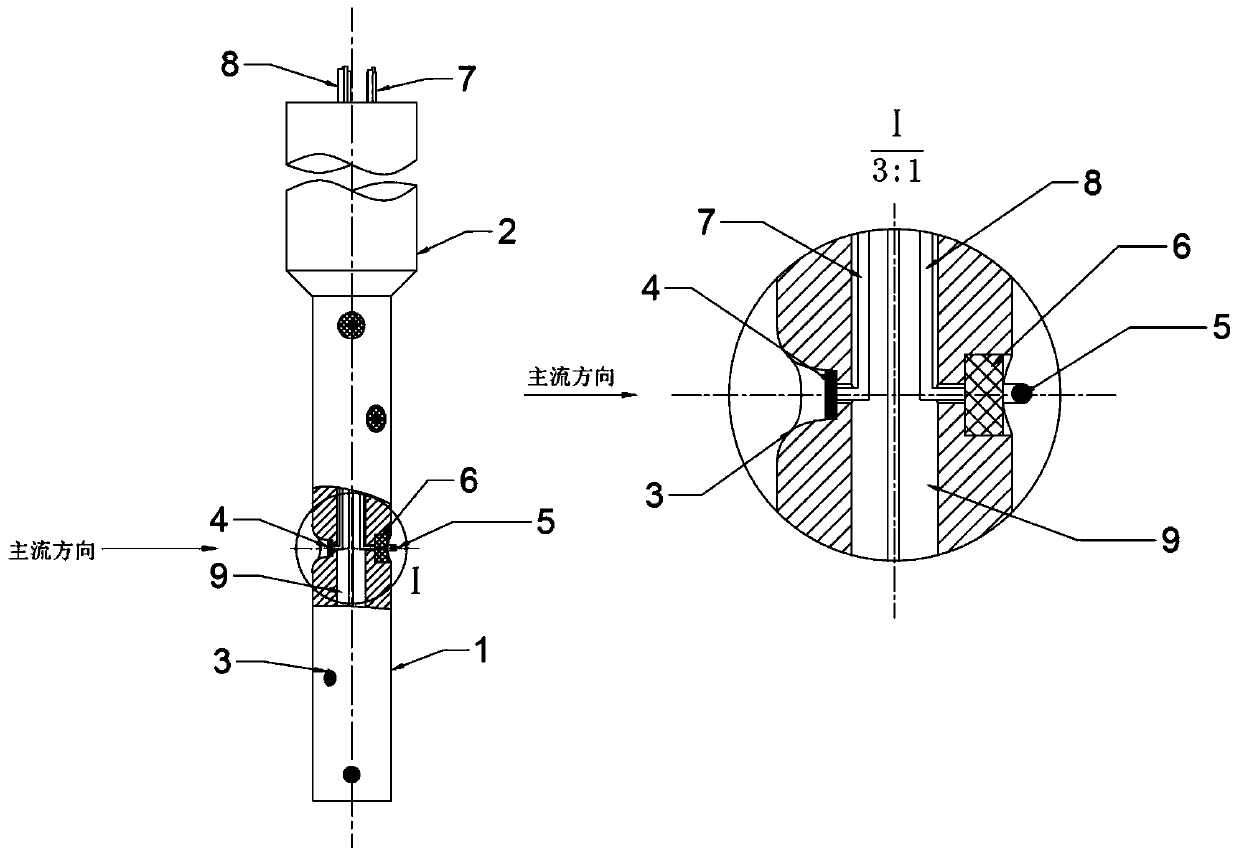

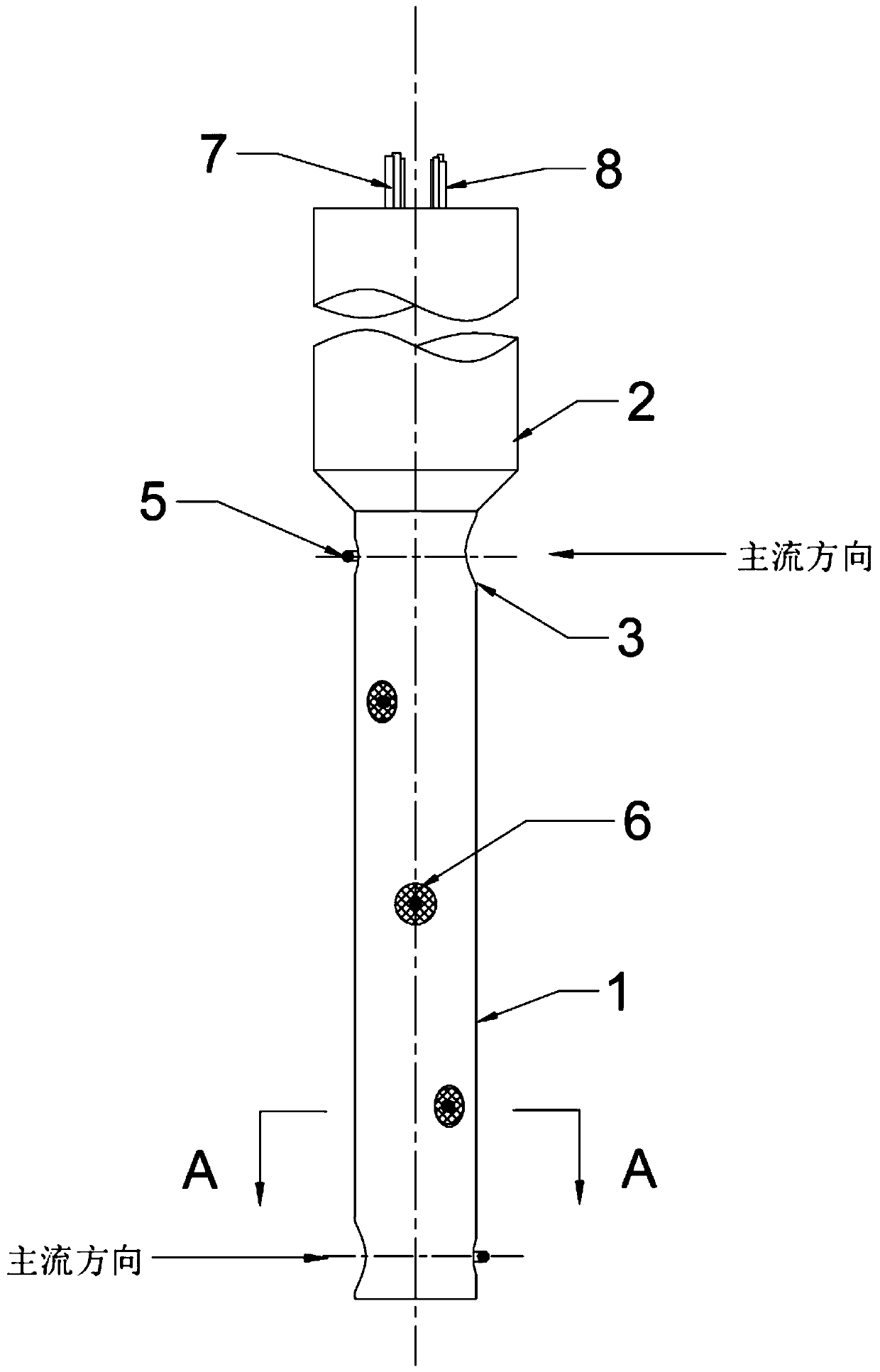

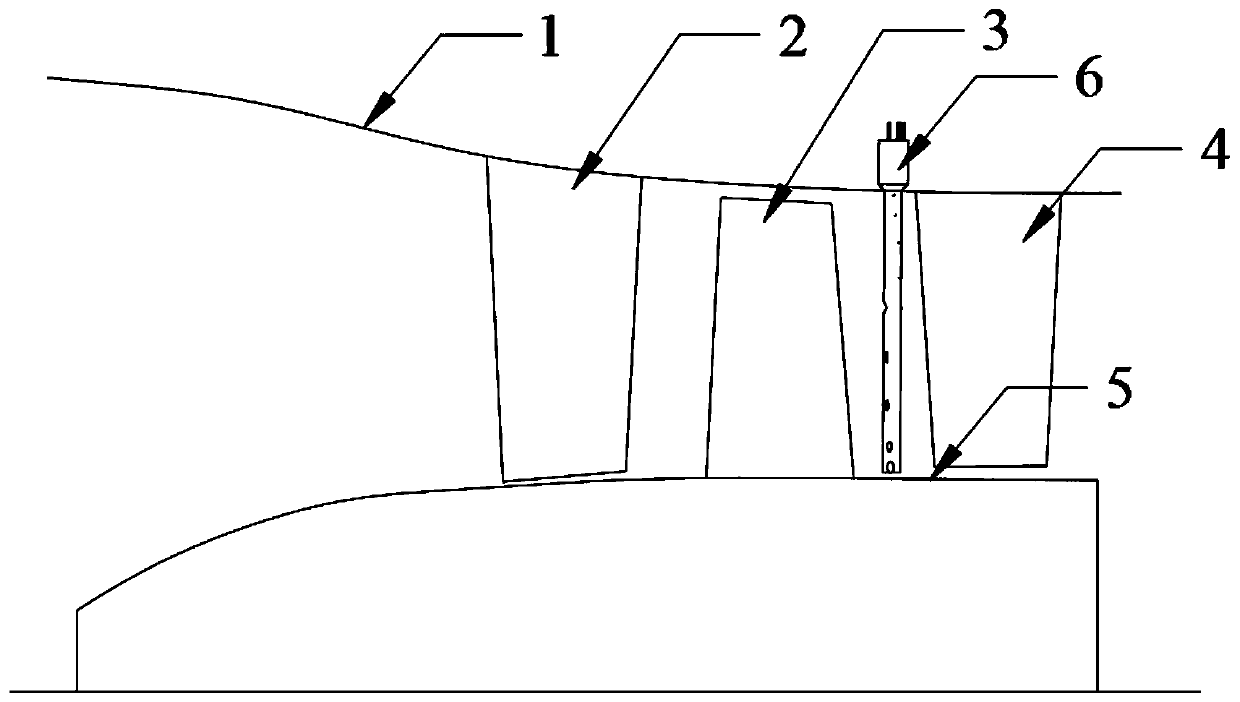

Multipoint dynamic measuring device with total temperature and total pressure measuring points arranged back to back

PendingCN111256940AAccurate measurementTotal temperature measurement guaranteeAerodynamic testingMeasurement deviceHigh spatial resolution

The invention belongs to the technical field of flow field testing, and particularly relates to a multipoint dynamic measuring device with total temperature and total pressure measuring points arranged back to back. The multipoint dynamic measuring device consists of a head part, a support rod, pressure sensing holes, dynamic pressure sensors, a dynamic temperature sensor, a heat insulation sealing element, a dynamic pressure sensor cable, a dynamic temperature sensor cable and a lead channel. The device head part is cylindrical, the pressure sensing holes with a sparse middle part and two dense ends are formed in the surface along the axial direction; the dynamic pressure sensors are packaged in the pressure sensing holes, the pressure sensing holes are designed to be of a micro-loss smooth structure, the center lines of the pressure sensing holes face the predicted incoming flow direction, the dynamic temperature sensors and the pressure sensing holes are distributed back to back, the center lines are collinear, and the dynamic temperature sensors slightly extend out of the head cylindrical surface. Simultaneous measurement of multi-point dynamic total temperature and total pressure of a blade row inlet, a blade row outlet and an interstage flow field in a turbomachinery flow channel can be realized, and the device has the characteristics of large measured airflow insensitiveangle, high measurement precision, high reliability and high spatial resolution.

Owner:BEIHANG UNIV

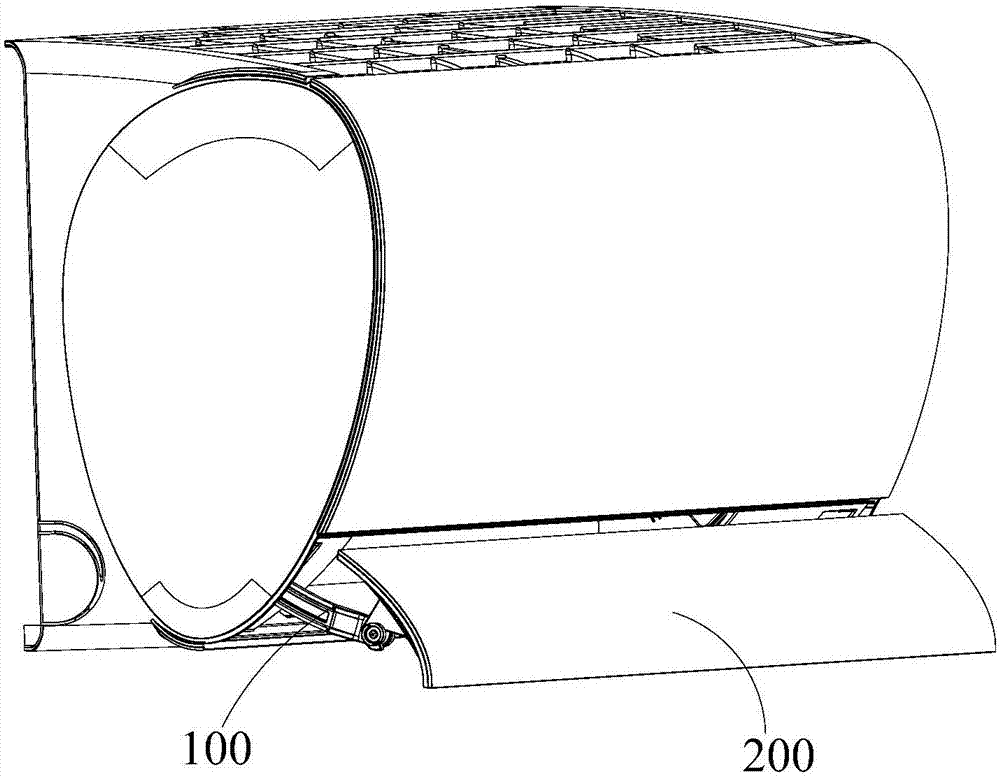

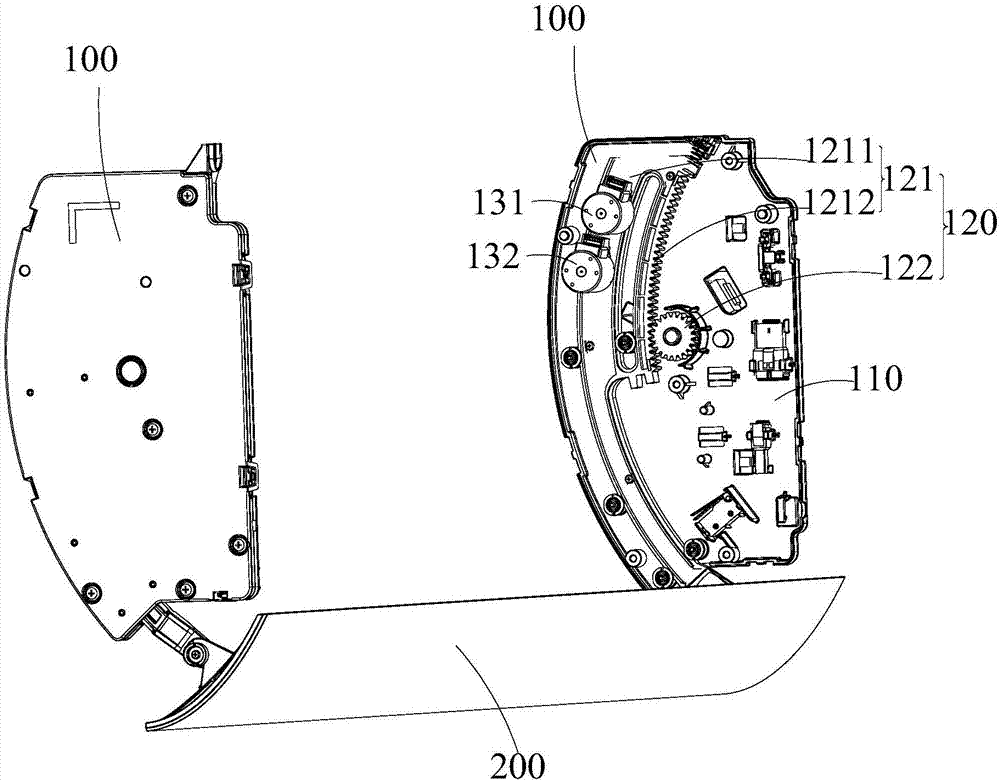

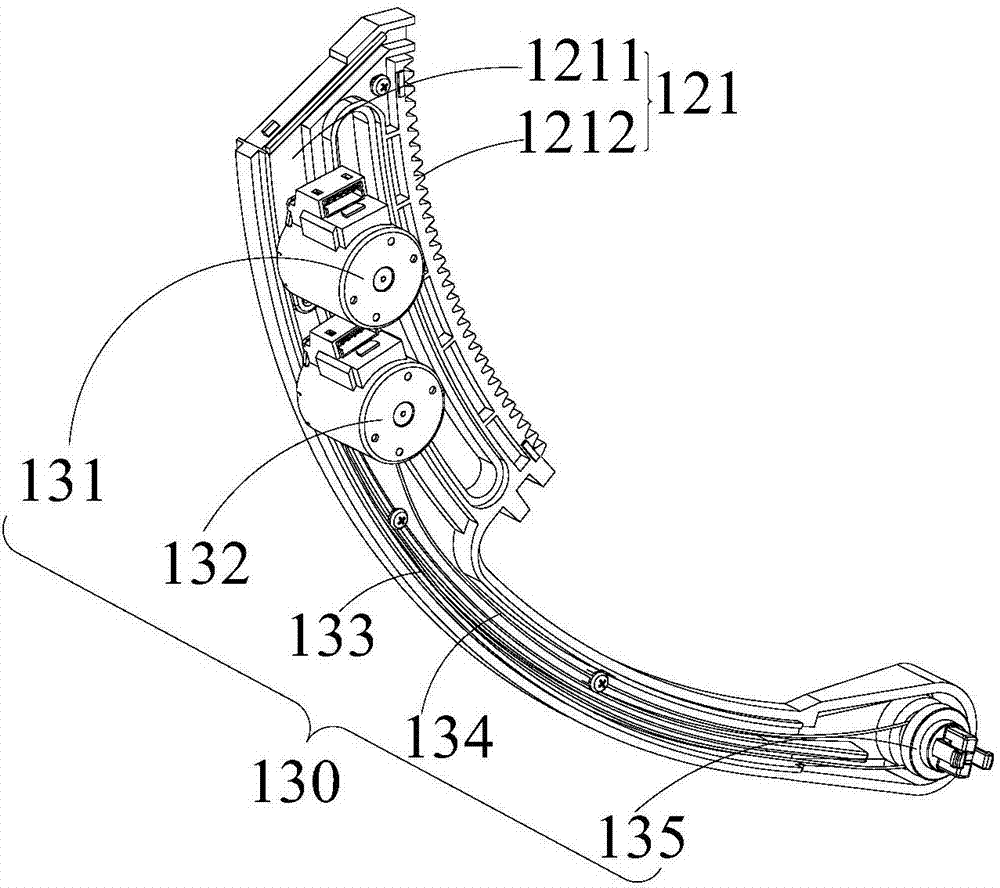

Air conditioner internal unit, air guiding plate drive device and control method of air guiding plate drive device

ActiveCN106918075ASmall sizeReduce volumeMechanical apparatusSpace heating and ventilation safety systemsHead sizeReliable transmission

The invention provides an air guiding plate drive device which comprises a drive box, a push-out mechanism and a air guiding mechanism; the push-out mechanism comprises a connection rod assembly; the air guiding mechanism comprises a first air guiding drive assembly, a second air guiding drive assembly, a first transmission component, a second transmission component and an output component, and the output component is arranged at the head of the connection rod assembly; the first air guiding drive assembly is connected with the output component through the first transmission component and can drive the output component to rotate in one direction; the second drive assembly is connected with the output component through the second transmission component and can drive the output component to rotate in one direction. By means of the air guiding plate drive device, the problem that a compact structure and a reliable transmission portion of an existing air guiding plate push-out structure cannot be compatible is solved, the head size of the connection rod assembly is reduced, it is guaranteed that an air guiding plate drive structure is compact, and inefficient transmission is avoided. The invention furthermore provides a control method of the air guiding plate drive device and an air conditioner internal unit.

Owner:GREE ELECTRIC APPLIANCES INC

Small-head large-aperture pick-up lens

PendingCN111751963AReduce head sizeIncrease the screen ratioOptical elementsOphthalmologyNegative refraction

The invention relates to a small-head large-aperture pick-up lens. The lens is technically characterized by sequentially comprising a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens and a diaphragm from an object side to an image side along an optical axis, wherein the first lens has positive refraction power, and the object-side surface of the first lens is a convex surface; the second lens, the third lens and the fourth lens all have refractive power; the fifth lens has positive refractive power, the paraxial position of the image-side surface of the fifthlens is a plane, and at least one convex surface exists at an off-axis position of the fifth lens; the sixth lens has negative refractive power, and the image-side surface of the sixth lens is concavesurface; the object-side surface and the image-side surface of each lens are aspheric surfaces; and the diaphragm is disposed on the object side of the first lens. According to the lens, the head size of the lens is small, the screen-to-body ratio of a mobile phone is improved, the performance of the lens is not reduced, resolution is high, and the lens has a large aperture and can meet the requirement of a user for shooting clearer images.

Owner:辽宁中蓝光电科技有限公司

Liquid ejecting head and liquid ejecting apparatus

A head unit fixed to a case in a position in which a nozzle forming surface thereof faces a first surface side of a head fixing portion, and a wiring substrate is arranged on a second surface side opposite from the first surface on a portion. A supply flow channel in the case communicate with a common liquid chamber at an end portion of the communicating flow channel in a first direction, and a flexible cable is disposed inside the supply flow channel in the case in the first direction.

Owner:SEIKO EPSON CORP

Liquid ejecting head, liquid ejecting head unit and liquid ejecting apparatus

ActiveUS20110187796A1Reduce manufacturing costSmall sizeInking apparatusPressure generationSpray nozzle

There is provided a liquid ejecting head including pressure generation chambers that communicate with nozzle openings from which liquid droplets are discharged, liquid flow paths that communicate with the pressure generation chambers, and pressure generation units that generate pressure for discharging liquid droplets in the pressure generation chambers. In the liquid ejecting head, foam members formed with closed cells are provided in the liquid flow paths.

Owner:SEIKO EPSON CORP

Liquid droplet discharge head and method of manufacturing the liquid droplet discharge head

A method of manufacturing a liquid droplet discharge head including nozzles that discharge liquid droplets, pressure chambers that are communicated with the nozzles and filled with liquid droplets, a diaphragm that configures part of the pressure chambers, and piezoelectric member groups that are configured by joining, to the surface of the diaphragm, piezoelectric plates that form groove portions and are processed in a matrix, with the piezoelectric member groups including piezoelectric elements that cause the diaphragm to be displaced as a result of a voltage being applied to the piezoelectric elements, the method comprising: processing the piezoelectric plates in a matrix to prepare the piezoelectric member groups; and joining the piezoelectric member groups to the diaphragm in a state where mutual boundaries of the piezoelectric member groups have been fitted together and with a predetermined clearance being disposed.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com