Multipoint dynamic measuring device with total temperature and total pressure measuring points arranged back to back

A dynamic measurement and multi-point technology, which is applied in the field of total pressure test and dynamic total temperature of flow field, can solve the problems of small airflow insensitivity angle, inability to measure dynamic total temperature and total pressure, and high experimental cost, so as to improve the spatial resolution of measurement rate and measurement accuracy, increased lifetime and airflow insensitive angular range, and improved spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

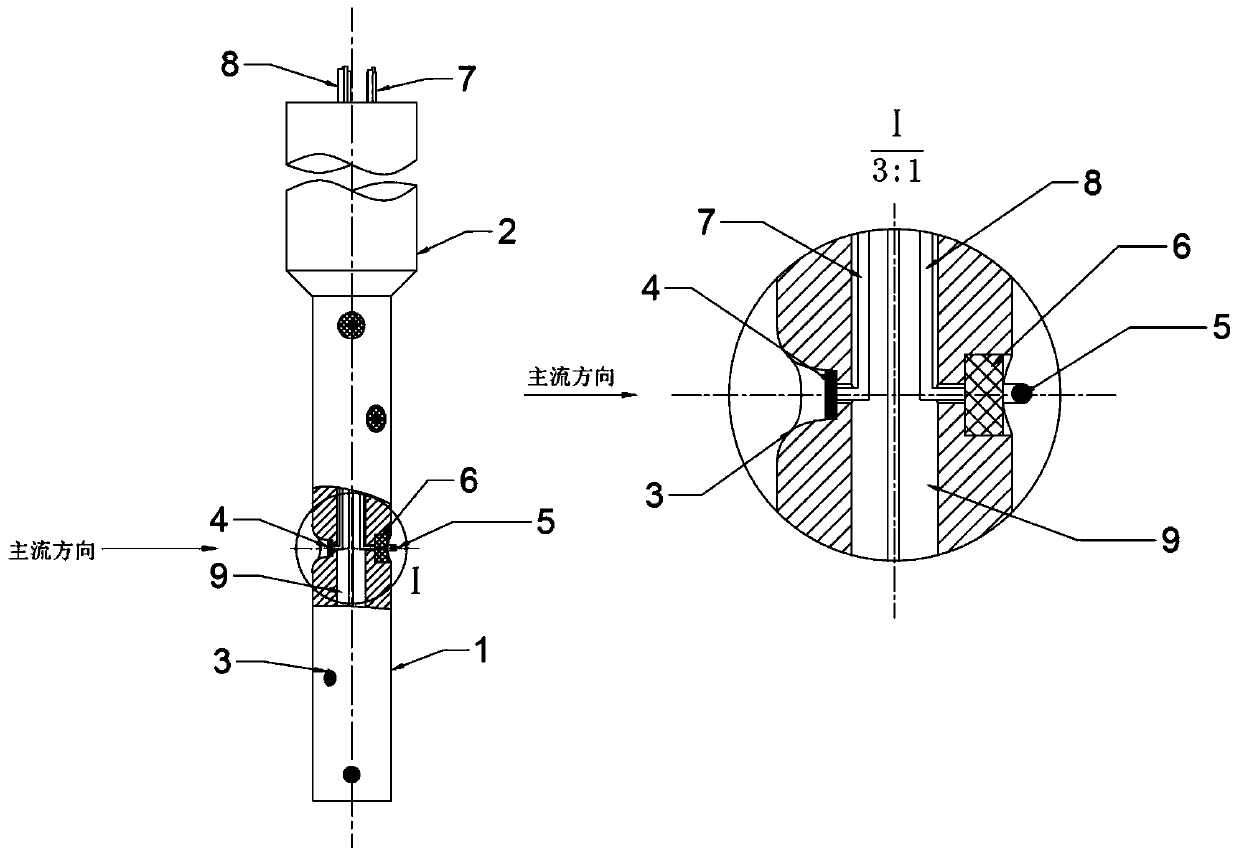

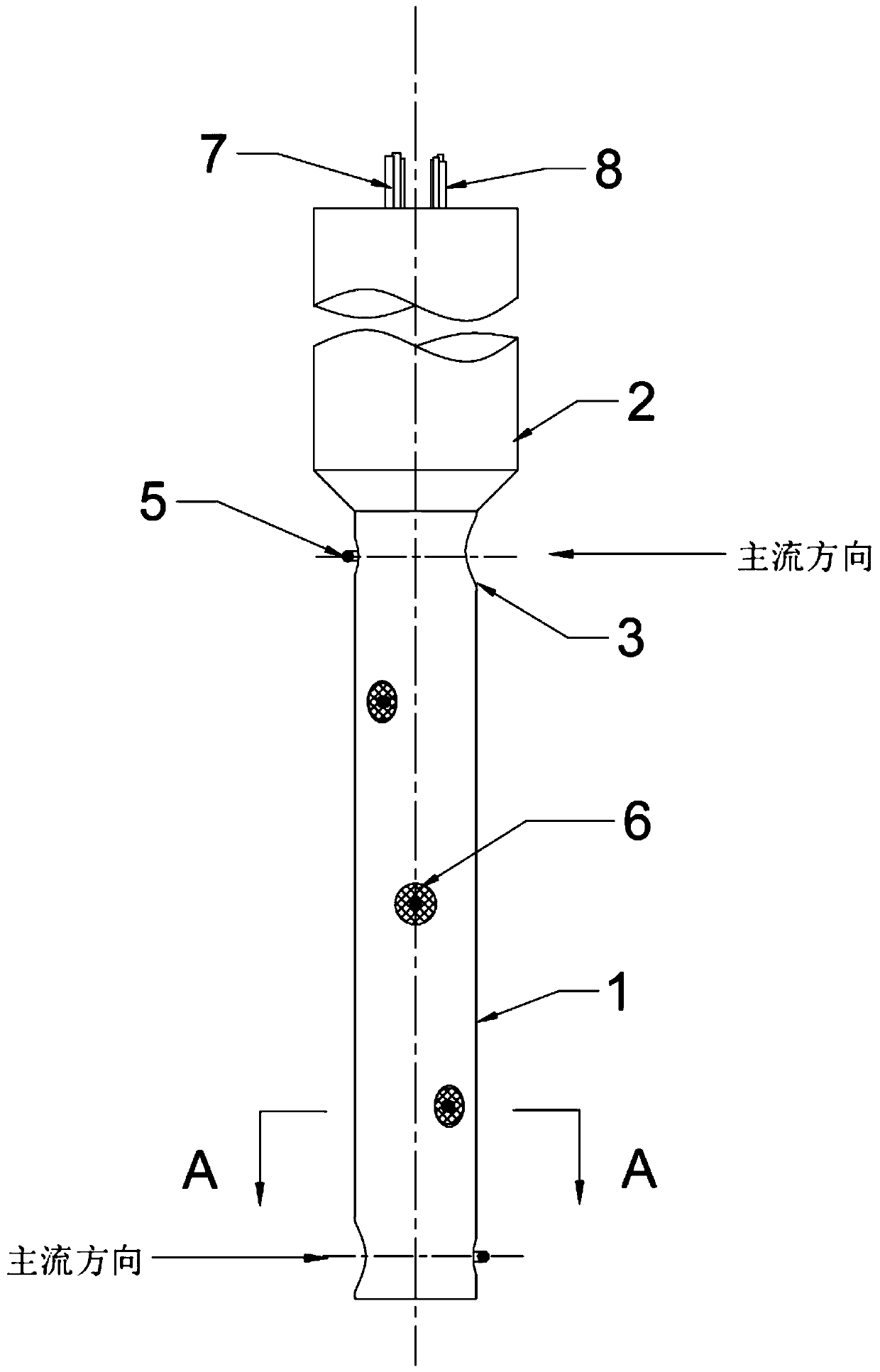

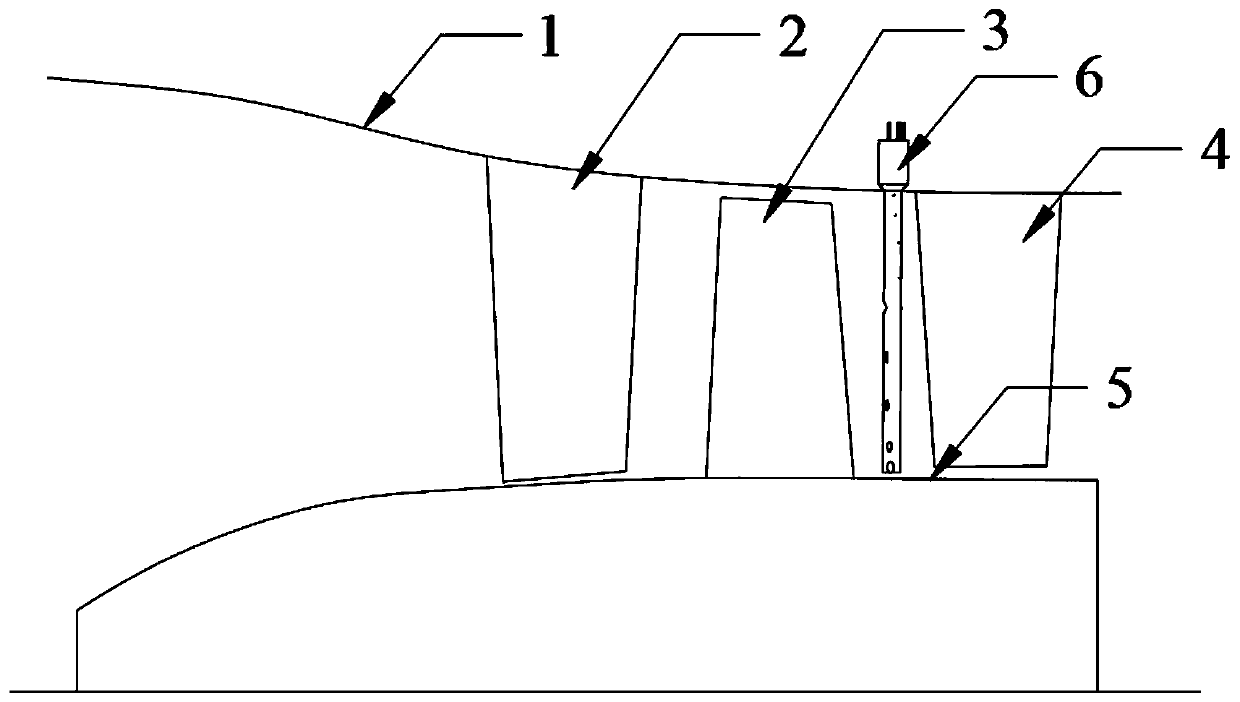

[0037] Such as Figure 1~2 As shown, it is a schematic diagram of a multi-point dynamic measuring device in which the total temperature and total pressure measuring points are arranged in the opposite direction created by the present invention. image 3 is a schematic diagram of the device of the present invention used to measure the flow field between compressor stages, Figure 4 It is a schematic diagram of measuring the boundary layer between compressor stages. This implementation example introduces a multi-point dynamic measuring device with the total temperature and total pressure measuring points facing away from each other. It consists of a head (1), a support rod (2), a pressure sensing hole (3), a dynamic pressure sensor (4), Composed of thermocouple (5), thermal insulation seal (6), dynamic pressure sensor cable (7), dynamic temperature sensor cable (8), lead wire channel (9), characterized in that: the head (1) is a cylinder There are 5 pressure sensing holes (3) ...

Embodiment 2

[0048] For the measurement of total temperature and total pressure distribution along the same blade between turbine stages, the mainstream velocity is relatively high. In order to ensure the strength of the measuring device, a larger lateral dimension of the head of the device and the diameter of the pressure measuring hole should be selected. The temperature sensor can use armored thermal resistance to ensure fine measurement and improve strength. Therefore, the following implementation methods can be adopted:

[0049] Figure 5 It is a structural schematic diagram of the second embodiment of the present invention, Image 6 It is a schematic diagram of the device of the present invention used to measure the flow field between turbine stages. This implementation example introduces a multi-point dynamic measuring device with the total temperature and total pressure measuring points facing away from each other. It consists of a head (1), a support rod (2), a pressure sensing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com