Camera module and terminal

A camera module and terminal technology, applied in image communication, TV, color TV, etc., can solve the problem of large head size of the lens module, and achieve the effect of compact structure, convenient assembly, and reduced components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

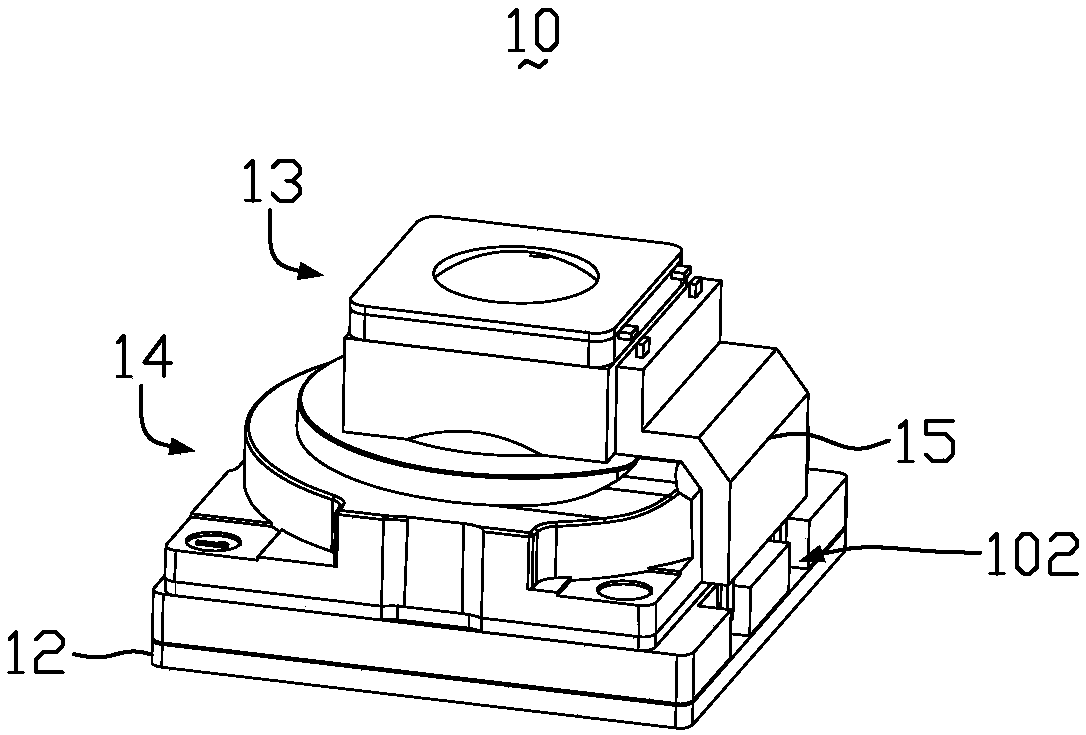

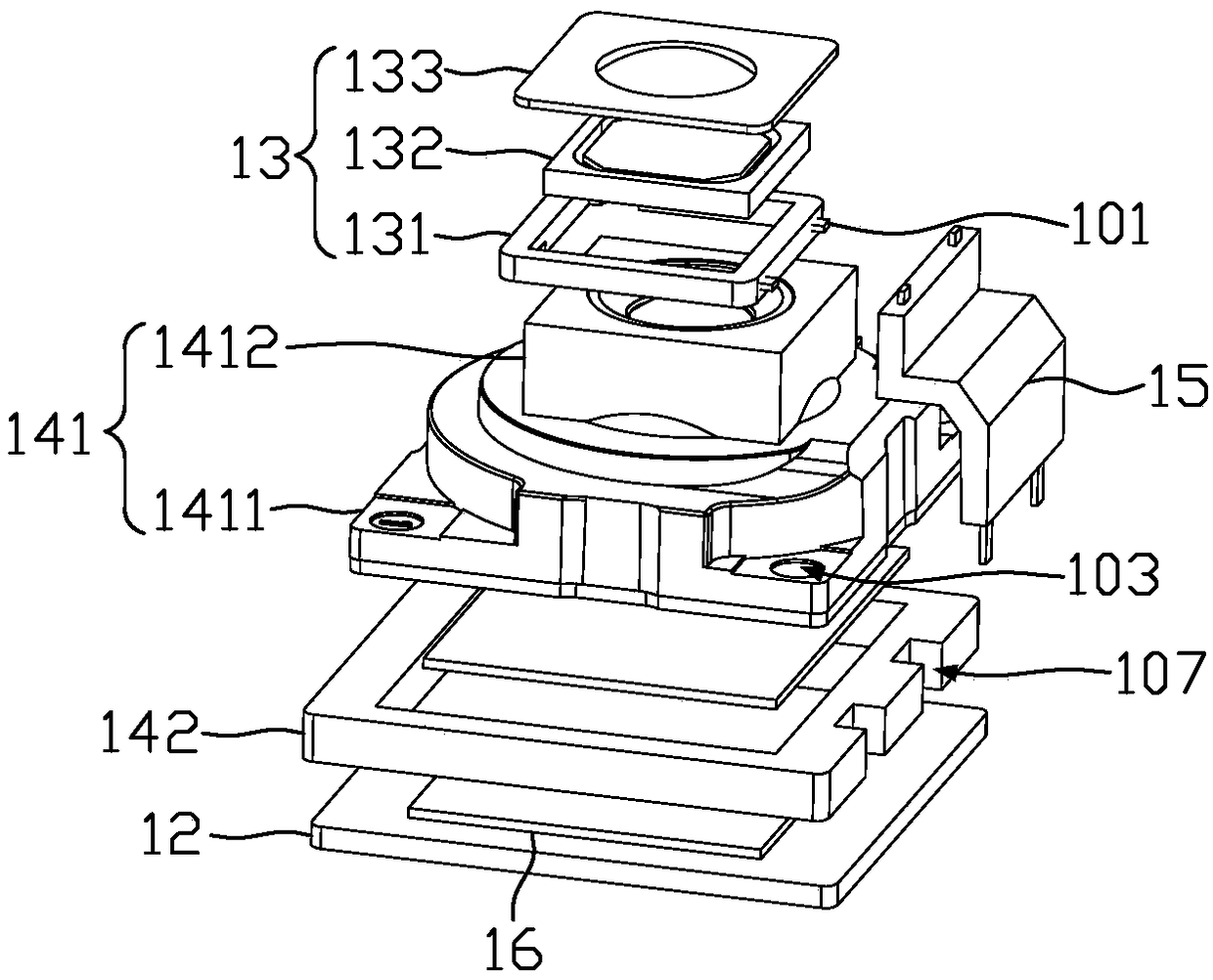

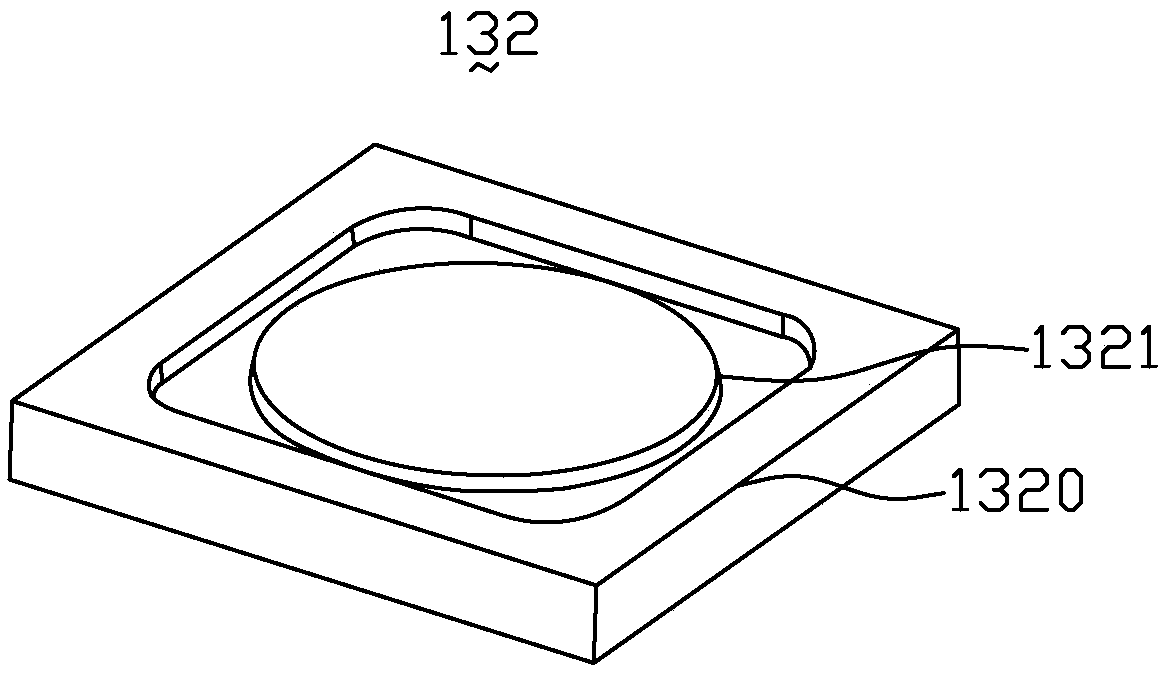

[0024] figure 1 It is a schematic structural diagram of the camera module according to the first embodiment of the present invention. figure 2 for figure 1 An exploded view of the camera module in the middle. Such as figure 1 and figure 2 As shown, the camera module 10 includes a circuit substrate 12 , an adjustable lens module 13 , a lens 14 , an auxiliary block 15 and a sensor 16 . The lens 14 is arranged on the circuit substrate 12, the auxiliary block 15 includes a body 151 and a conductor 152 wrapped in the body 151, the conductor 152 is electrically connected between the adjustable lens module 13 and the circuit substrate 12, and the auxiliary block 15 Locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com