Repairing line structure and method for manufacturing same

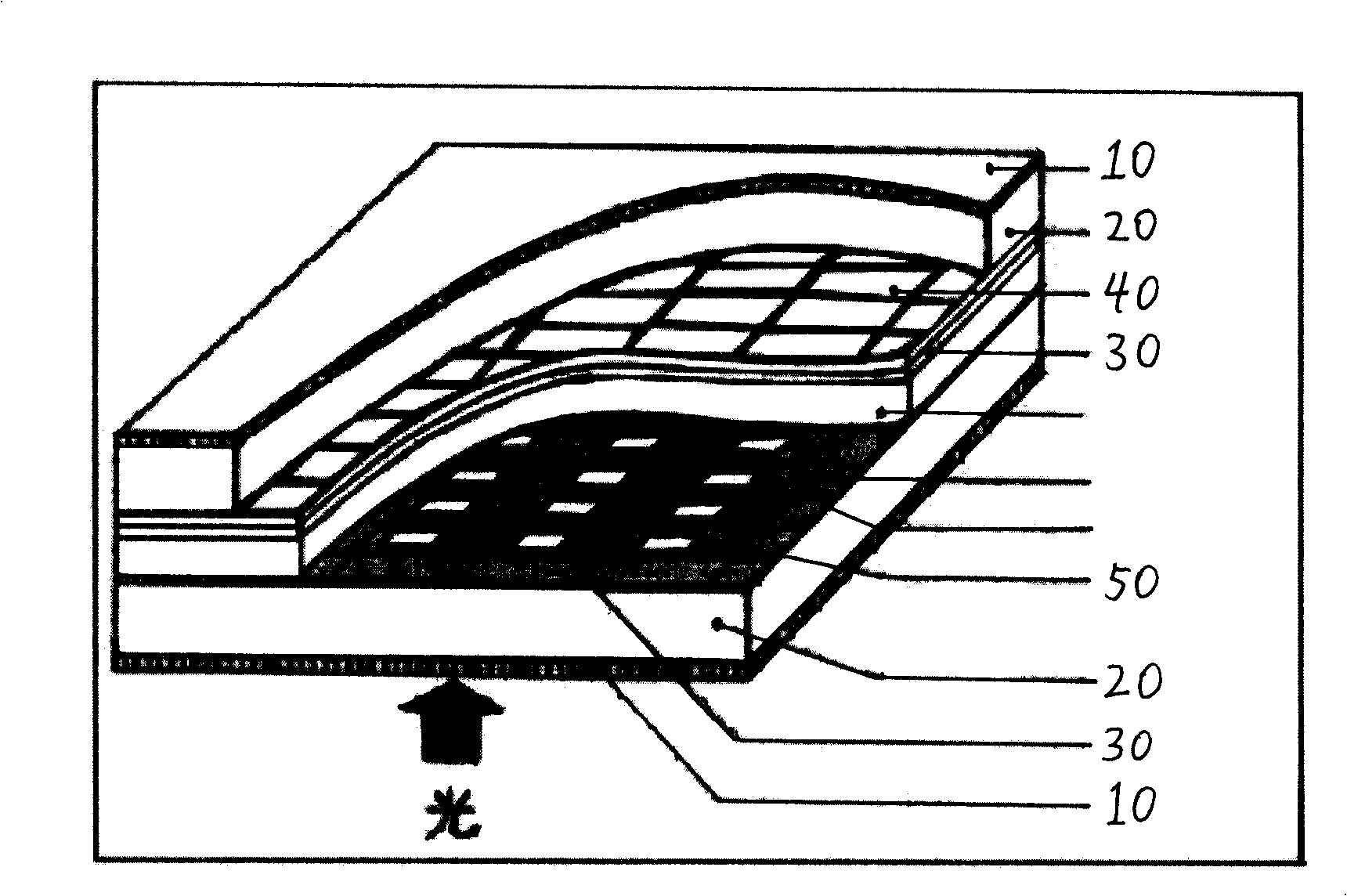

A technology for repairing lines and scanning lines, which is applied in nonlinear optics, instruments, optics, etc., and can solve problems such as existence, increasing coupling capacitance, and affecting the normal repair of repair lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

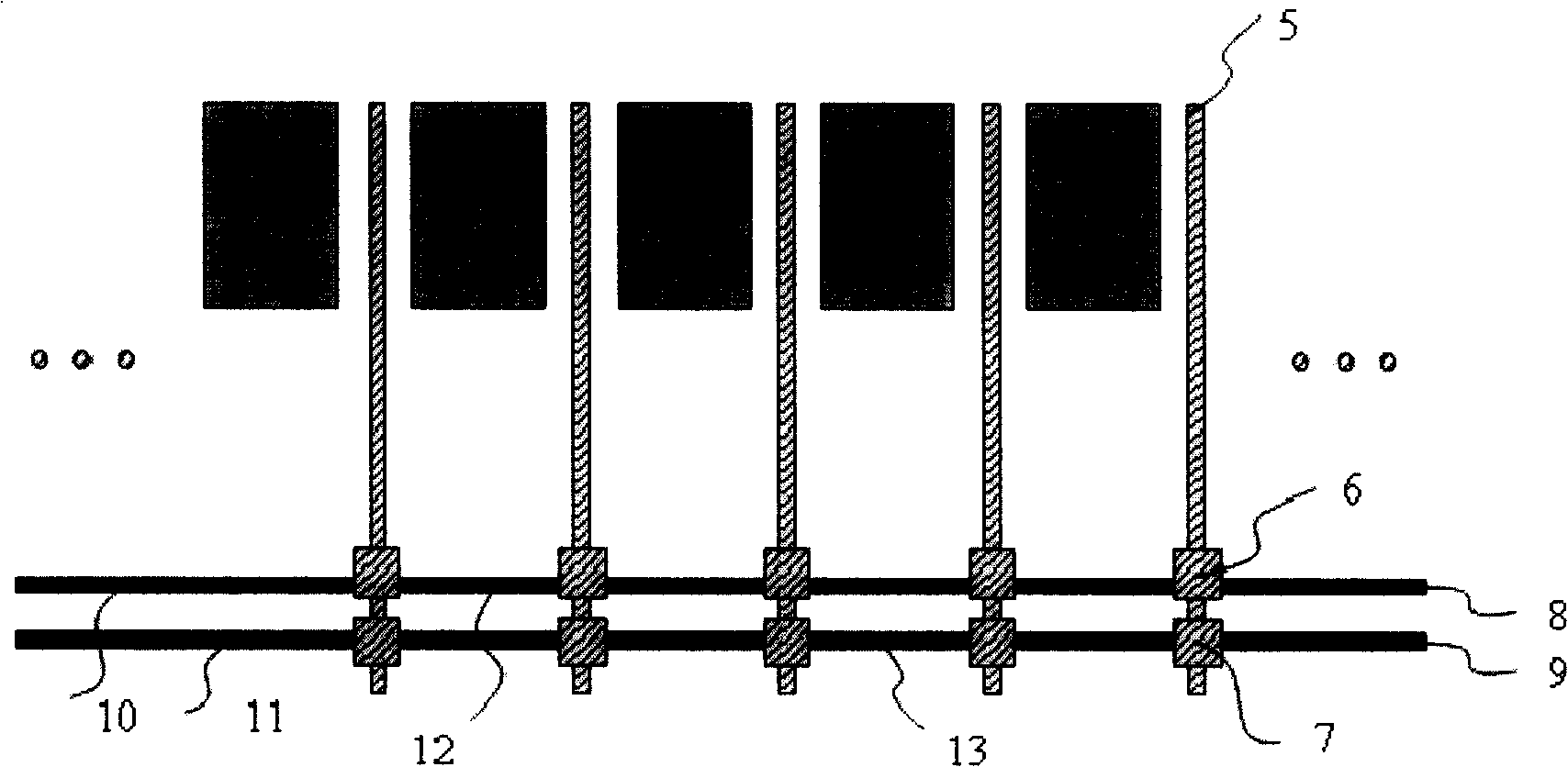

Embodiment 1

[0030] like Figure 5 , intermittent repair line 3, auxiliary repair line 4 is the same layer process, the same layer of metal sputtering manufacturing; repair line, signal scanning line is the same layer process, the same layer of metal sputtering manufacturing; repair lines L1, L2 and intermittent repair Line 3 is made by non-same-layer process and non-same-layer metal sputtering.

[0031] When repairing one point, the repairing signal can be input from any point of 14 and 15; when repairing two points, the repairing signal can be input from two points of 14 and 15. When repairing more than two points, the number of 12, 13 repair lines and repair signal input lines can be increased accordingly, and the number of intermittent repair lines can be two or more rows.

[0032] When the scanning signal line 5 needs to be repaired, you can connect the repair points 2 and 6 by laser dotting, or do the following points by laser marking: 1, 6 methods; 2, 7 methods; 1, 7 methods; 2, 17...

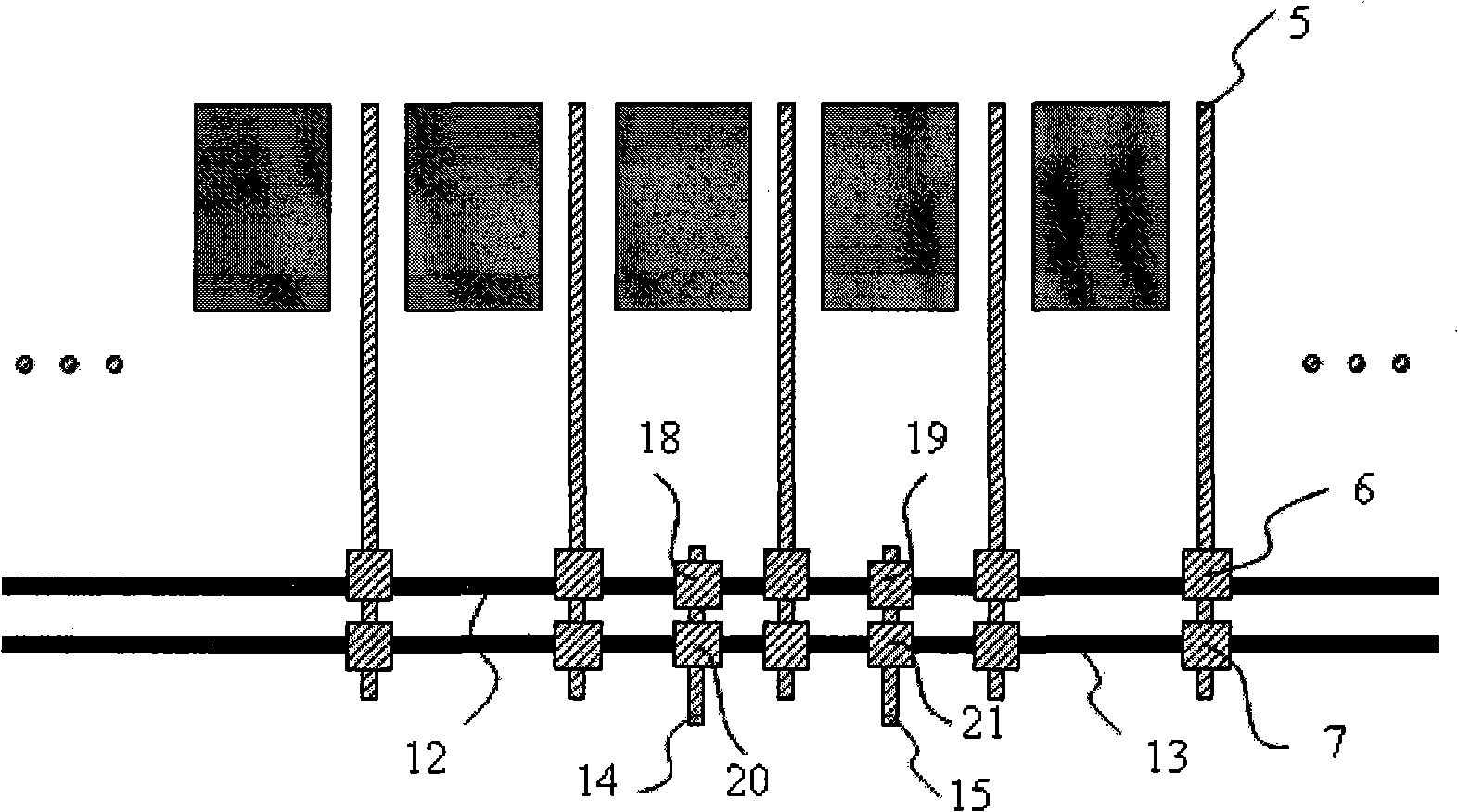

Embodiment 2

[0039] like Image 6 , intermittent repair line 3, auxiliary repair line 4 is the same layer process, the same layer of metal sputtering manufacturing; repairing lines L1, L2 and scanning signal line 5 are the same layer process, the same layer of metal sputtering manufacturing; repairing lines L1, L2 , The intermittent repair line is made by non-same-layer technology and non-same-layer metal sputtering.

[0040] When repairing one point, the repair signal can be input from any point among 8, 9, 10, 11; when repairing two points, the repair signal can be input from any two points among 8, 9, 10, 11; when repairing more than two points, The number of 12, 13 repair lines and repair signal input lines can be increased accordingly, and the number of intermittent repair lines can be two or more rows.

[0041] When the scanning signal line 5 needs to be repaired, the repair points 2 and 6 can be connected by laser dotting, or the following laser dotting methods can be used: 1, 6, 2...

Embodiment 3

[0044] like Figure 7 , the intermittent repair line 3, the auxiliary repair line 4 is manufactured by a different layer process, and the metal sputtering is not the same layer; the repair lines L1, L2 and the signal scanning line 5 are not made by the same layer process, and the metal sputtering is not made by the same layer; Lines L1, L2, and discontinuous repair lines are manufactured by the same layer process and metal sputtering on the same layer.

[0045] When repairing one point, the repair signal can be input from any point of 14 and 15; when repairing two points, the repair signal can be input from two points 14 and 15; when repairing more than two points, the repair line of 12 and 13 and the repair signal can be added accordingly Enter the number of lines, and the number of intermittent repair lines can be two rows or more.

[0046]When the scanning signal line 5 needs to be repaired, you can connect the repair points 2 and 6 through laser dots, or you can use 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com