Patents

Literature

337results about How to "Control movement speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

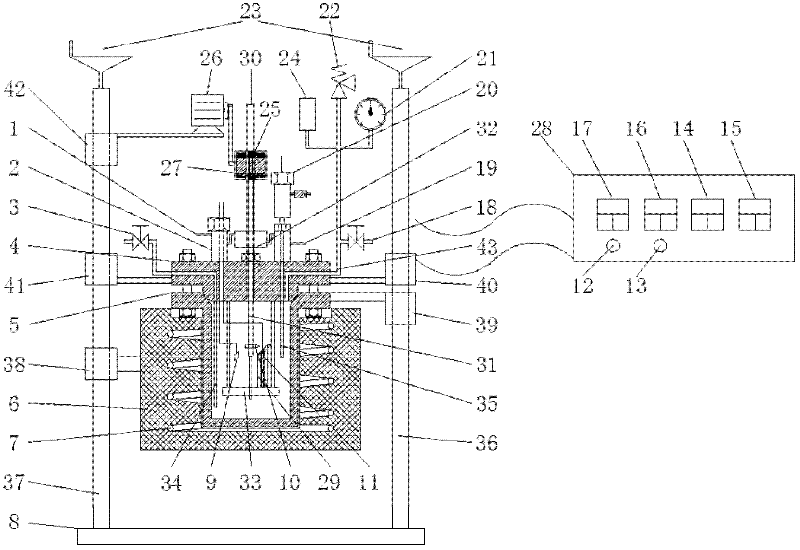

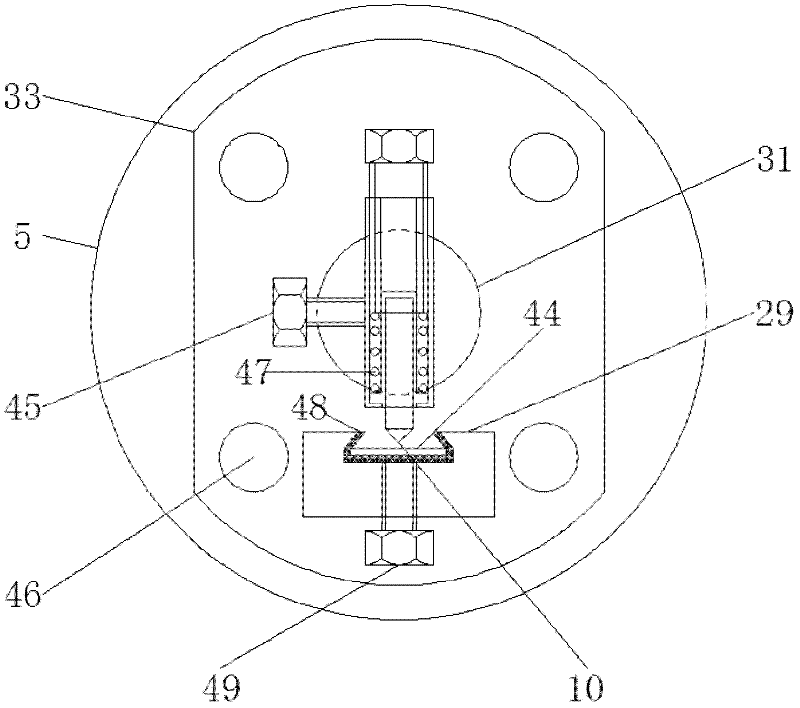

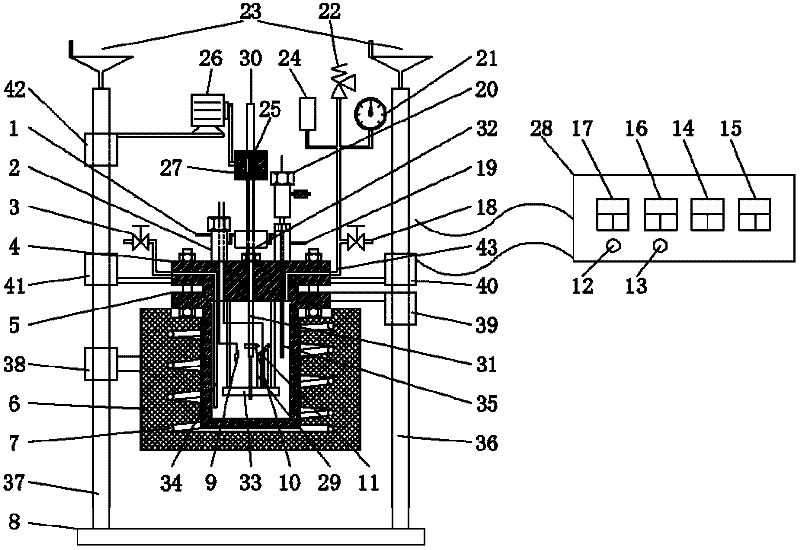

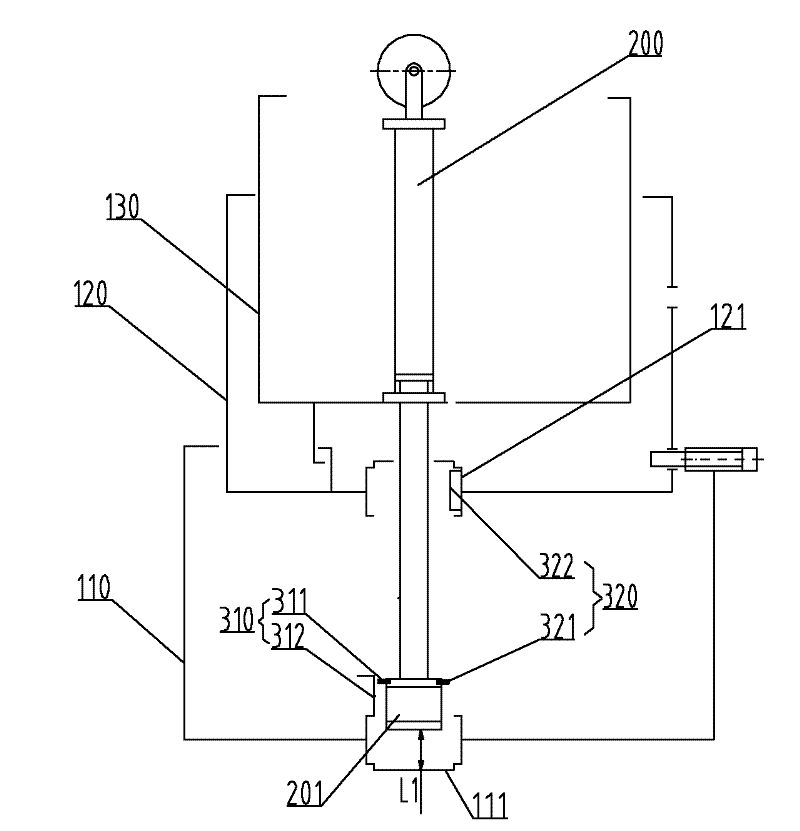

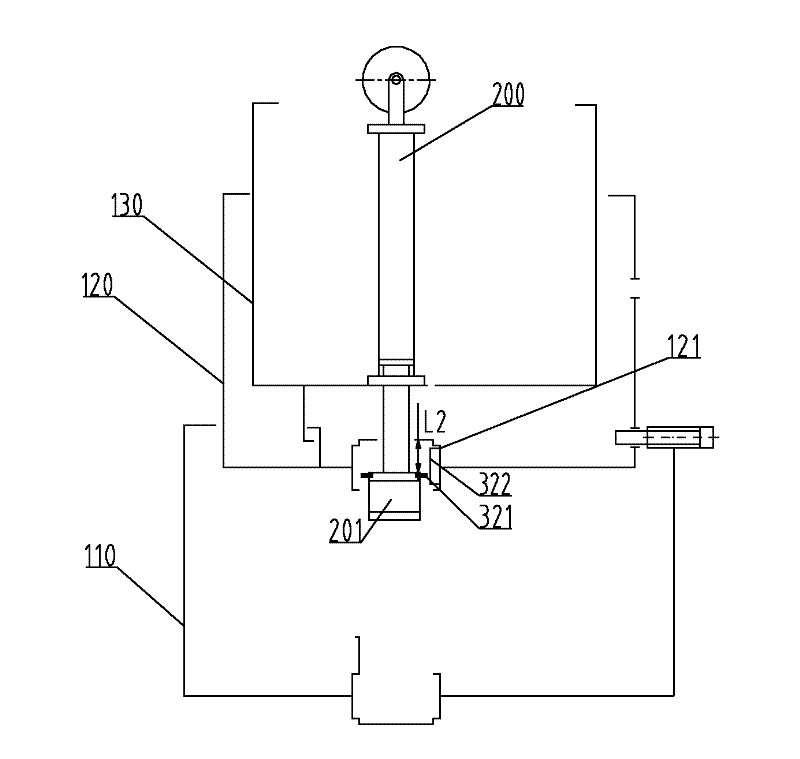

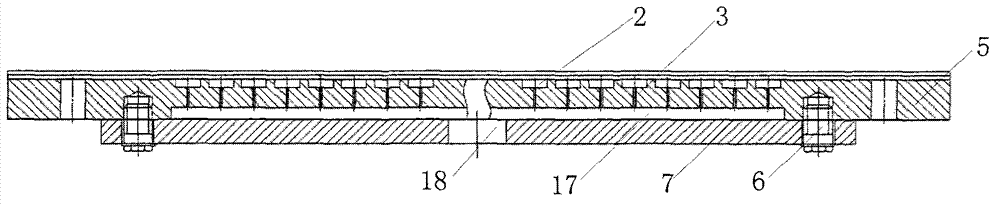

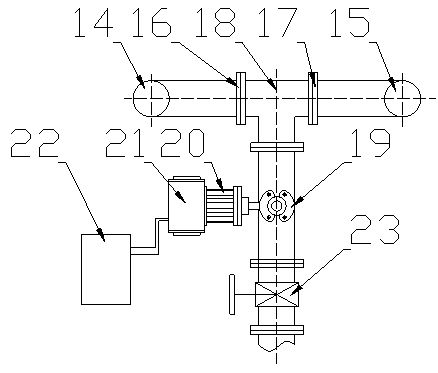

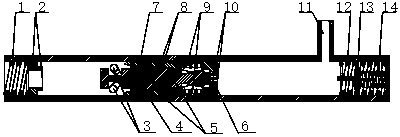

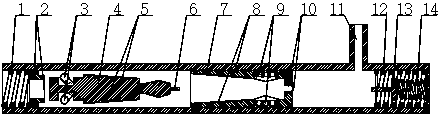

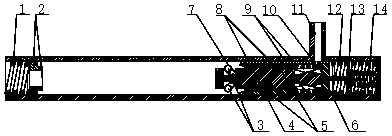

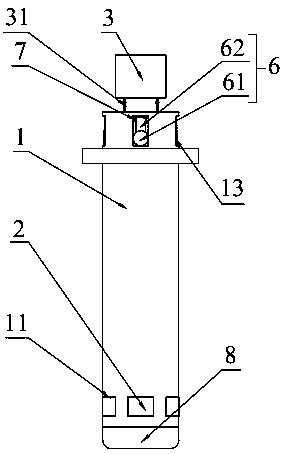

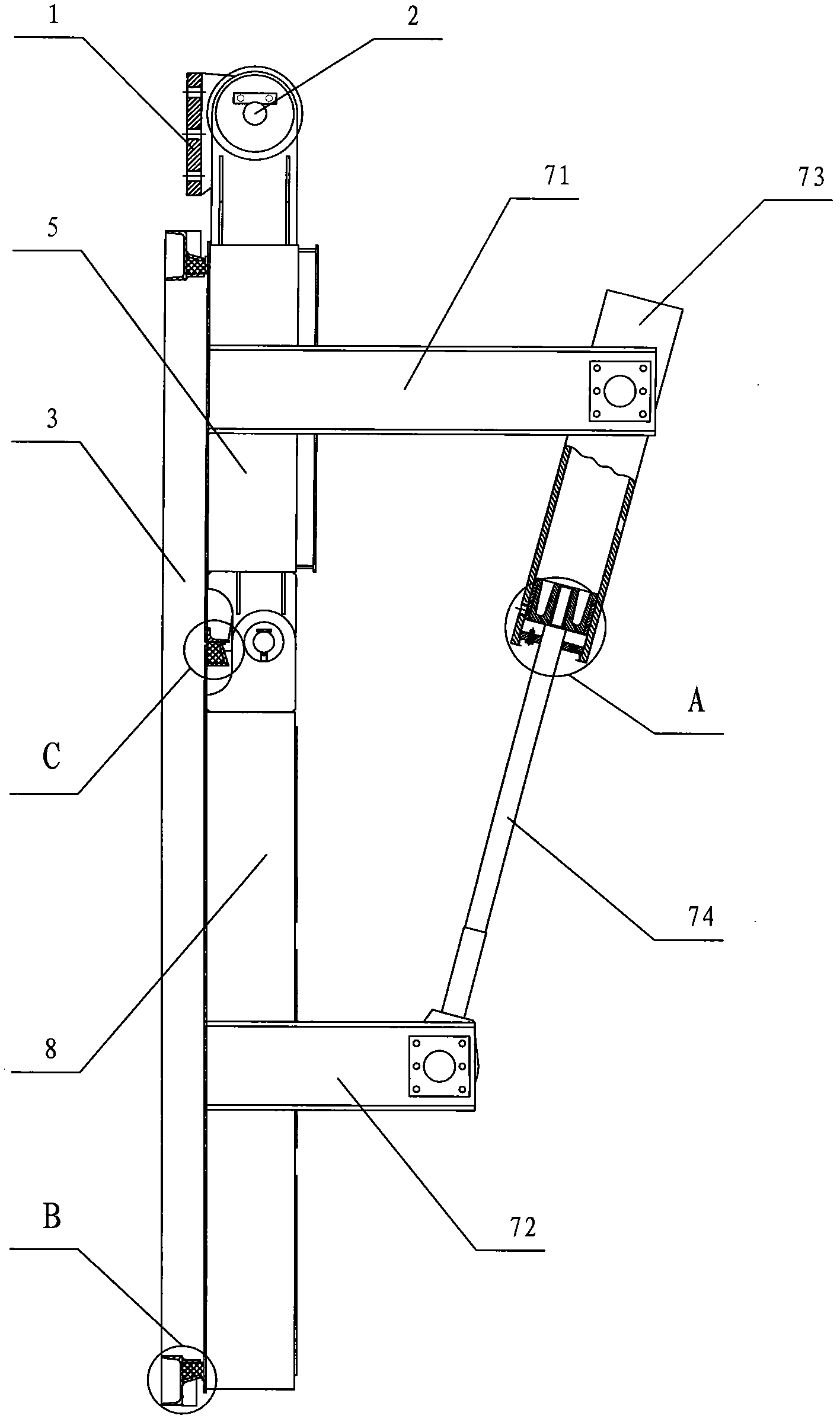

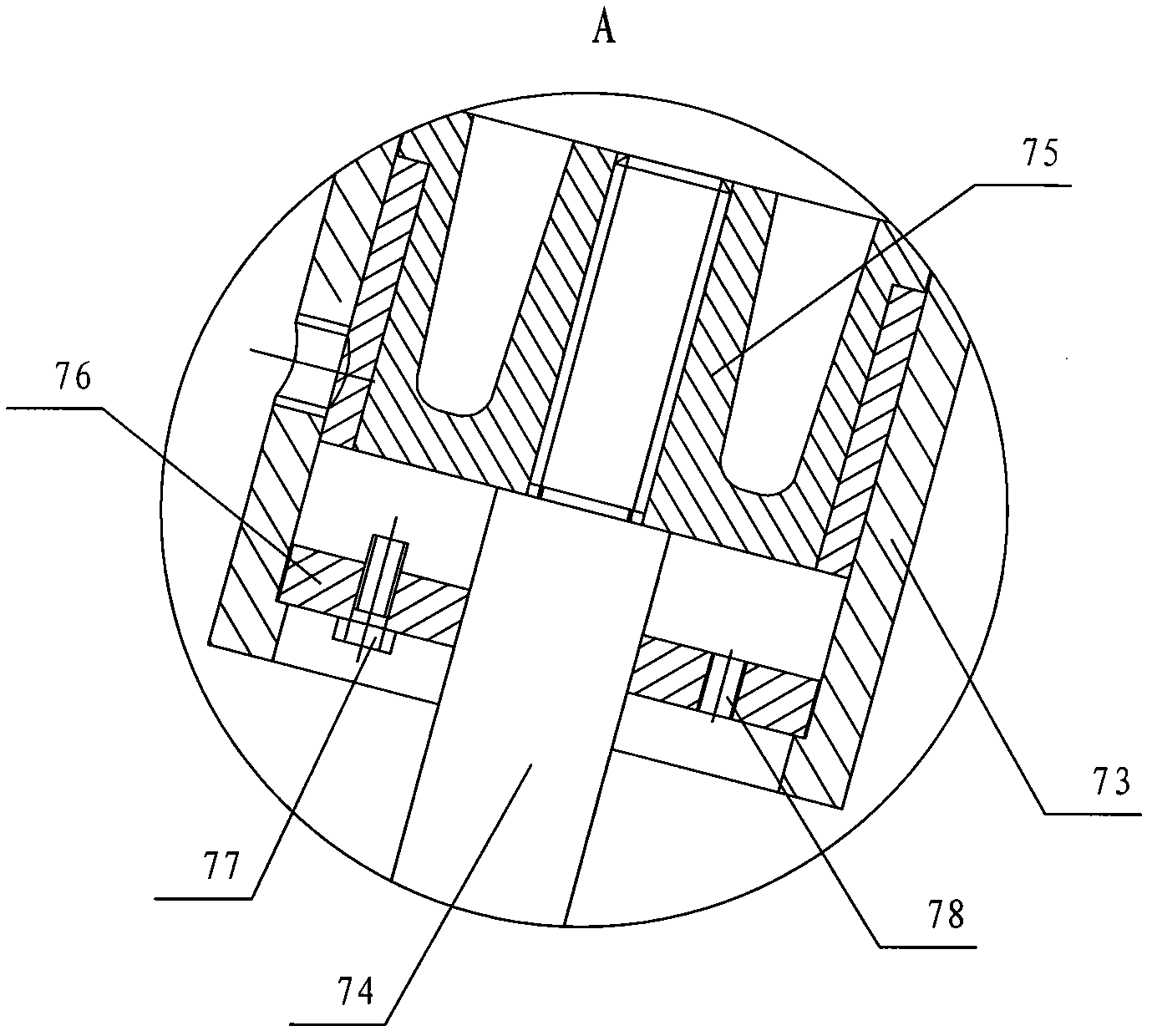

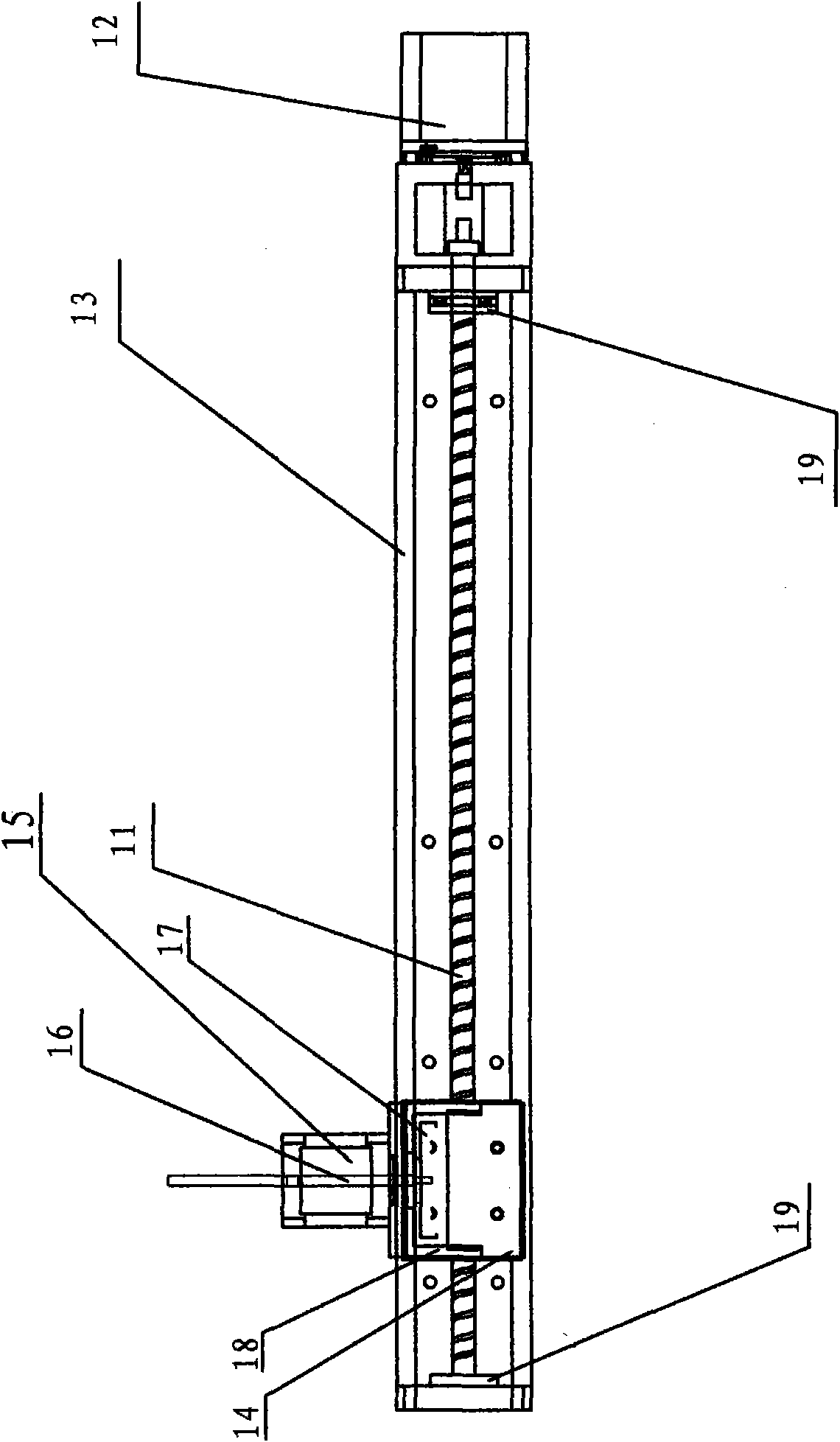

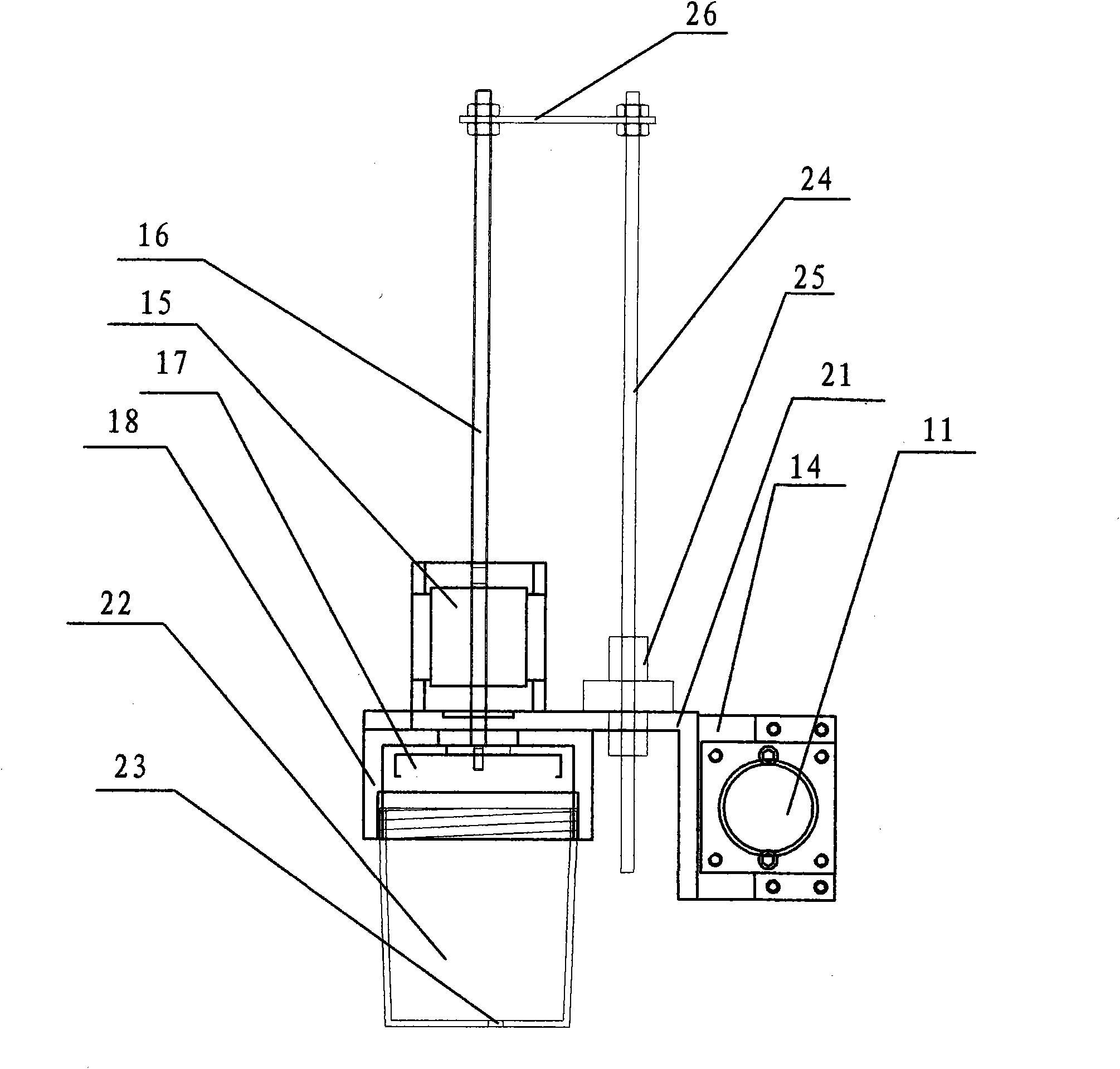

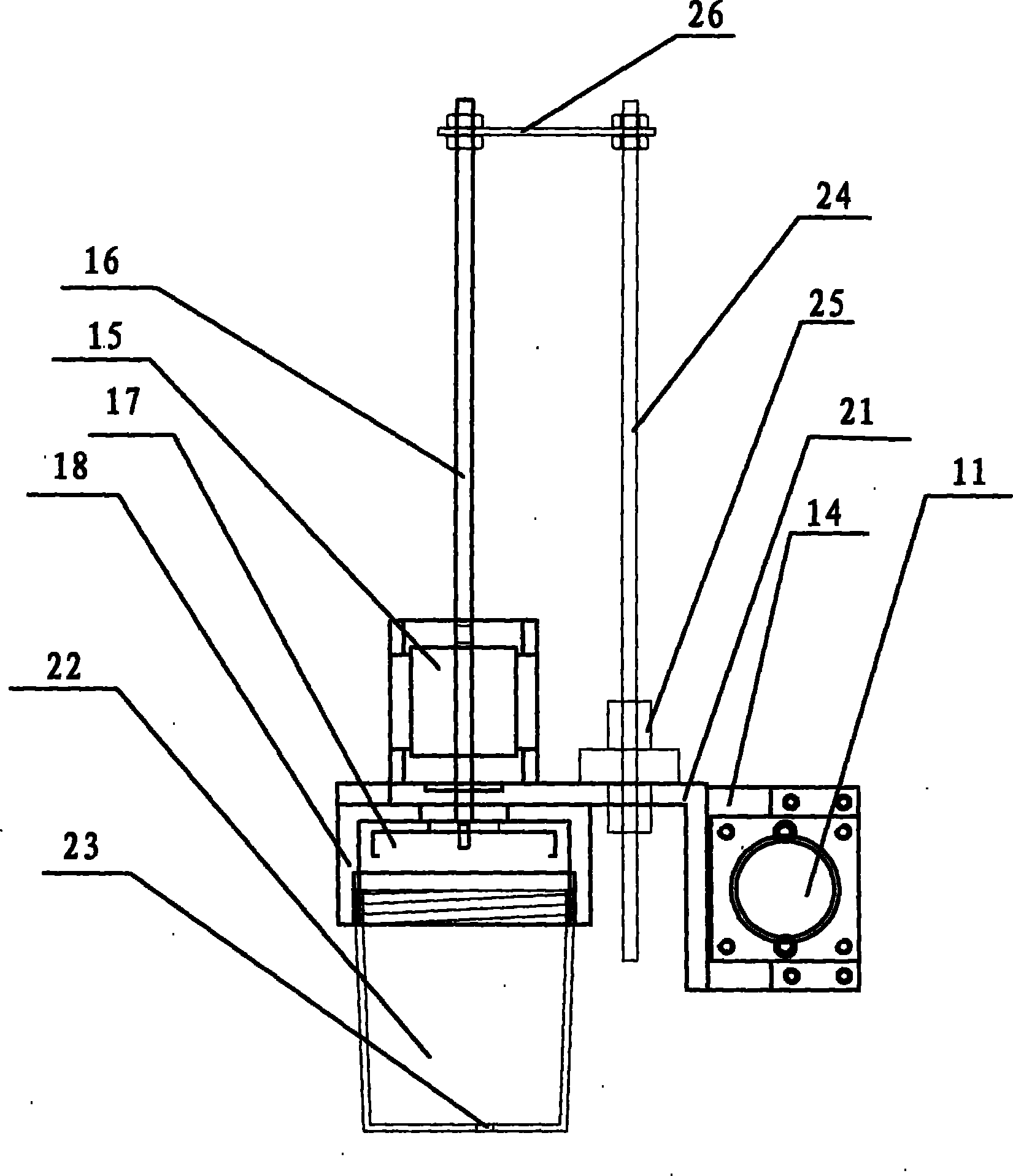

A high temperature and high pressure in-situ scratch and corrosion wear test device

ActiveCN102288504AHigh control precisionEasy to disassemble and maintainInvestigating abrasion/wear resistanceAuxiliary electrodeCorrosion

The invention relates to a scratching and corrosive wear test device, in particular to a high-temperature high-pressure in-situ scratching and corrosive wear test device. The device solves the problems that in-situ single-time scratching, reciprocating multiple-time corrosive wear and the like are difficult to realize under the high-temperature and high-pressure environment in the prior art. The device is provided with a frequency converter, a motor, a high-pressure kettle, a control cabinet, a double-upright-post fixed bracket, a moving shaft, a scratching head and the like, can perform in-situ single-time scratching, reciprocating multiple-time corrosive wear research on the surface of a test sample at high temperature and high pressure, and can detect a signal, which represents the process of a test sample surface membrane changed from damage to passivation in the scratching or corrosive wear process, by cooperating a high-temperature high-pressure reference electrode and a high-temperature high-pressure working auxiliary electrode which are arranged on the high-pressure kettle, with an electrochemical working station.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

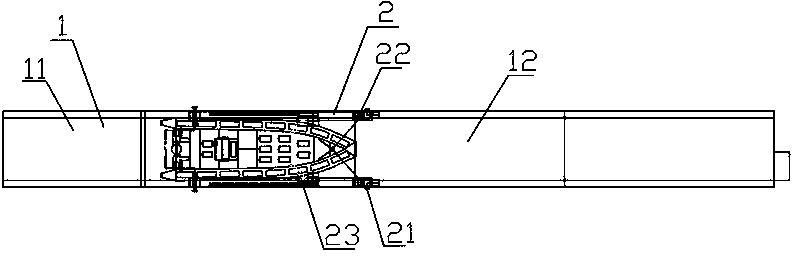

Telescopic arm and engineering machinery including the telescopic arm

The invention discloses an engineering machine and a telescopic arm. The telescopic arm comprises a telescopic cylinder, a multi-section arm, a hydraulic system, at least one mechanical limit mechanism, a controller and a position sensor, wherein the movable end of the telescopic cylinder is telescopic in the extending direction of the telescopic arm; the hydraulic system is connected with the telescopic cylinder through a hydraulic oil circuit; the mechanical limit mechanism is matched with the movable end of the telescopic cylinder; the position sensor corresponds to the mechanical limit mechanism and is used for detecting the position of the movable end of the telescopic cylinder; and the controller outputs a control signal to a proportional control valve according to a predetermined strategy, so that the speed of the movable end of the telescopic cylinder is reduced. Through the technical scheme, the telescopic speed of the telescopic cylinder can be reduced according to the control signal, and the speed of the movable end is reduced to a low value or the movable end just stops at a position corresponding to the mechanical limit mechanism when the movable end arrives at the corresponding mechanical limit mechanism, so that collision impact between the movable end and the mechanical limit mechanism can be reduced or avoided.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

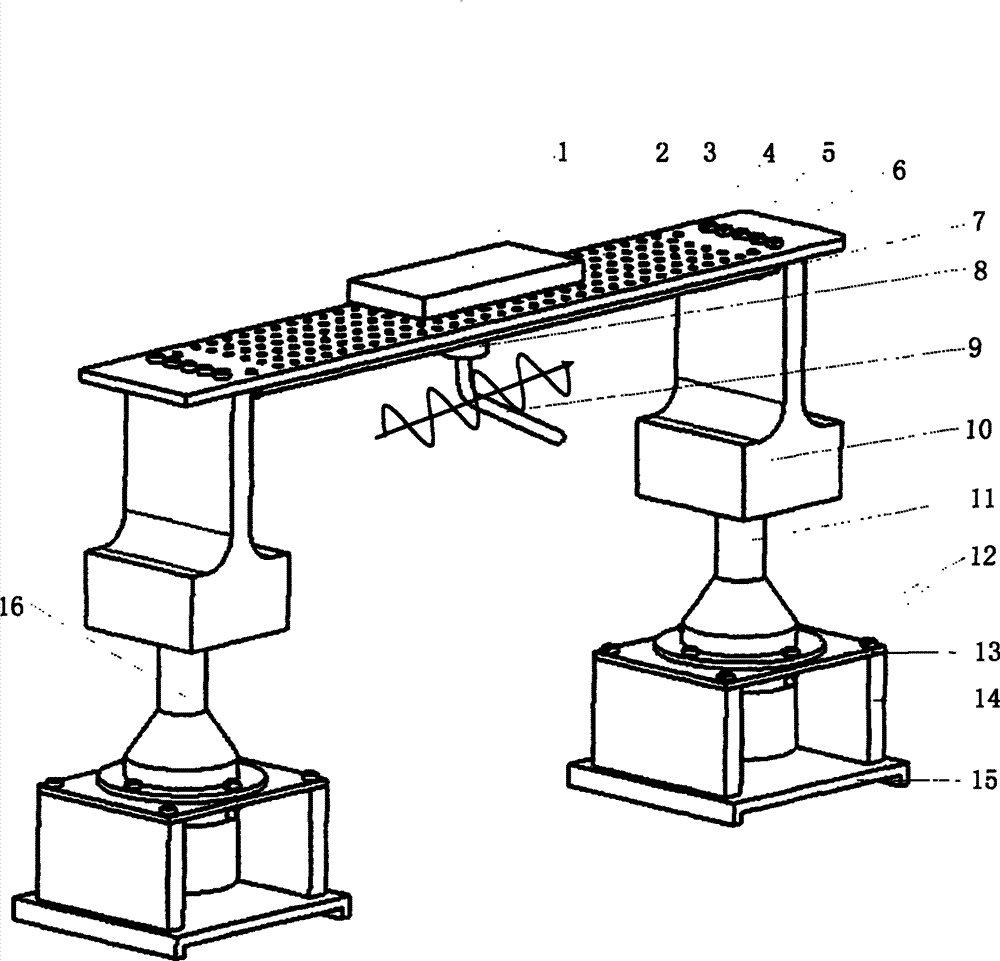

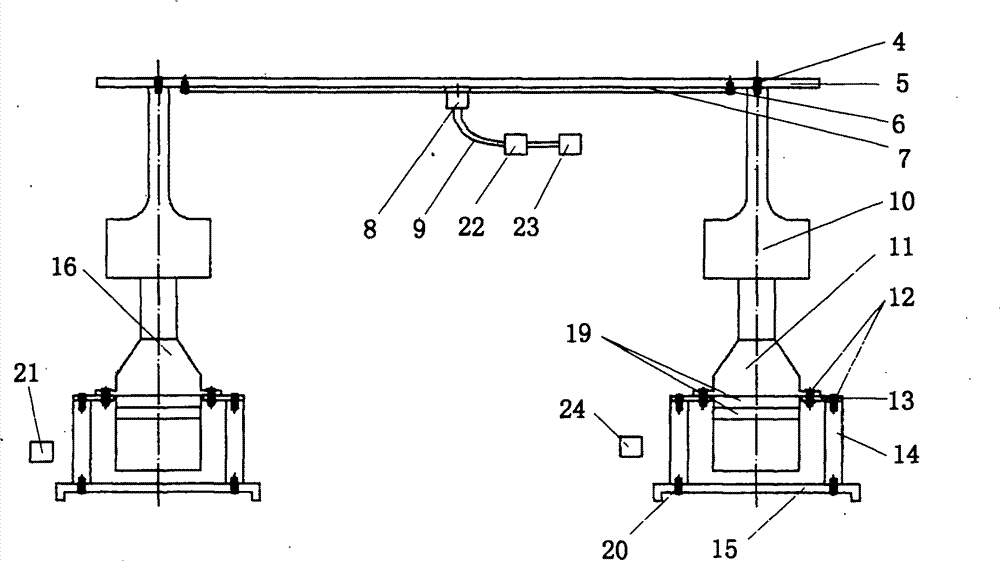

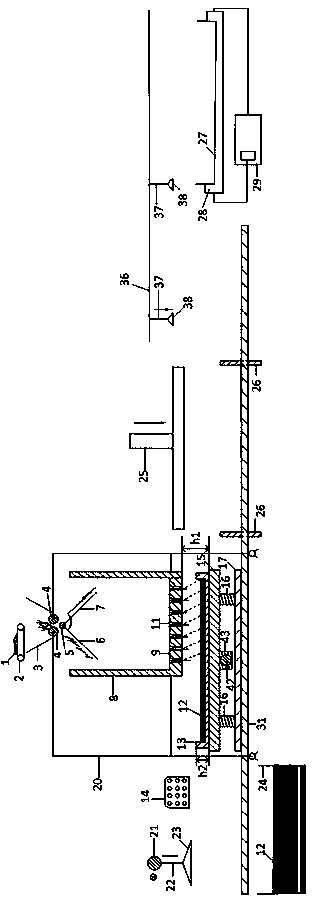

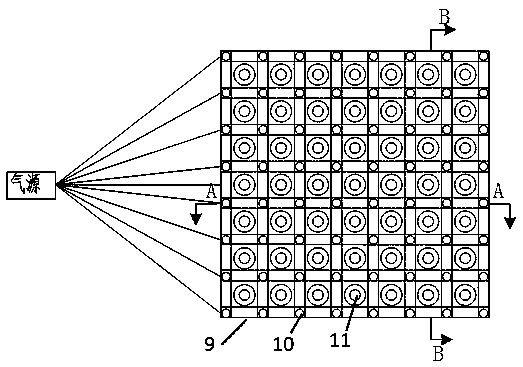

Ultrasonic/air flotation hybrid noncontact automatic transporter

InactiveCN102785940ASimple structureEasy to operateNon-mechanical conveyorsUltrasonic generatorEngineering

The invention relates to an ultrasonic / air flotation hybrid noncontact automatic transporter and belongs to the field of precise driving. The transporter comprises a vibration plate, a square sheet, an ultrasonic generator, ultrasonic transducers, an air compressor, horn-type amplitude transformers, an air inlet pipeline and a fixing device, wherein the vibration plate and the square sheet can form a pneumatic suspension structure, and heavy-load suspended matters can be suspended by means of pneumatic suspension. Two transducers are adopted to generate traveling waves, and the heavy-load suspended matters suspended by means of the pneumatic suspension can be conveyed from a starting point to a destination endpoint under the effect of the traveling waves, so that the noncontact automatic transporter capable of conveying heavy load is realized. The ultrasonic / air flotation hybrid noncontact automatic transporter has the advantages of easiness in operation, simplicity in structure and capability of realizing noncontact automatic transport and overcoming the defect that ultrasonic waves can only transport light-load suspended matters, and ultrasonic suspension force of the transporter can realize stable automatic transport of suspended matters.

Owner:JILIN UNIV

Arc source of dynamic controlled arc ion plating

InactiveCN101358328AImprove discharge formImprove job stabilityVacuum evaporation coatingSputtering coatingTarget surfaceIon plating

The invention relates to the field of film preparation, in particular to an arc ion plating arc source which controls the movement of arc pit with dynamic magnetic field. The dynamic controlled arc ion plating arc source is provided with a dynamic control magnetic field generator, a target and a target base; the target is arranged on the target base; the dynamic control magnetic field generator consists of a main control magnetic field generator and an auxiliary magnetic field generator; the main control magnetic field generator is arranged behind the target and is coaxial with the target; the auxiliary magnetic field generator is arranged around the main control magnetic field generator. In the invention, arc-shaped magnetic fields which are dynamically distributed are formed on the target surface with the help of the cooperation of the two magnetic field generators, so as to improve the discharge form and work stability of the arc pit, control the movement track of the arc pit, improve the erosion evenness and target utility rate of the target, reduce the emission of large target particles and prepare high-quality film.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

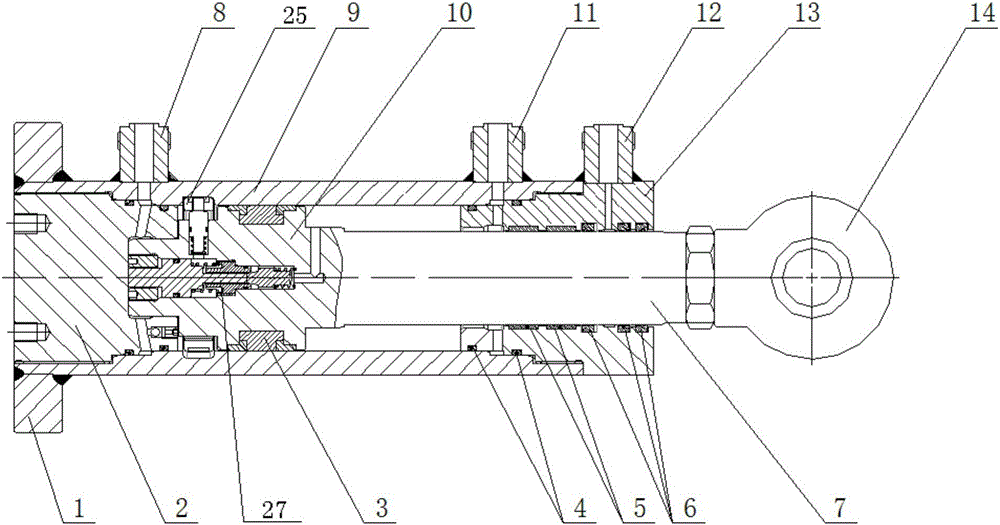

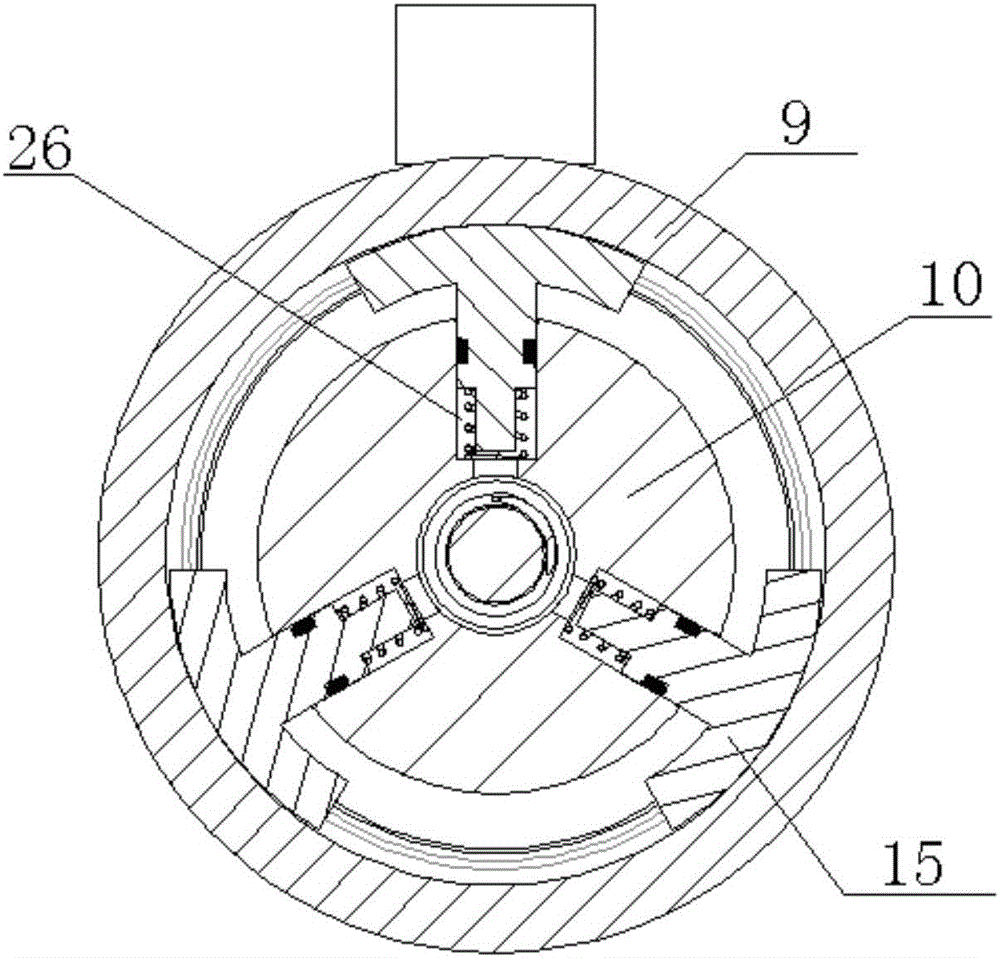

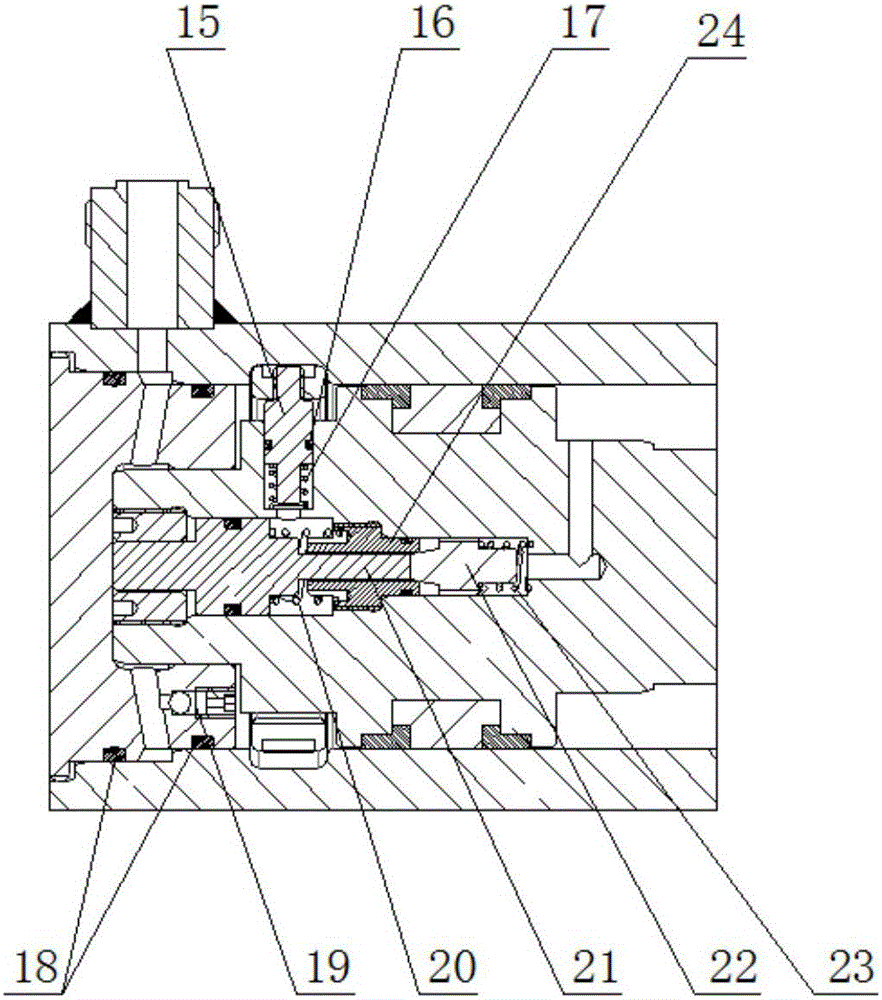

End mechanical self-locking hydraulic cylinder with buffering function

ActiveCN106286464AImplement bufferingRealize self-locking functionFluid-pressure actuatorsPistonSelf locking

The invention provides an end mechanical self-locking hydraulic cylinder with a buffering function. A groove is formed in the inner wall of a cylinder barrel, a cylindrical hole is formed in a piston, a locking block is installed in the cylindrical hole, and the locking block and the groove are matched and used for self-locking and unlocking of the hydraulic cylinder. A sealing ring is arranged between the locking block and the inner wall of the cylindrical hole, the piston is provided with a hydraulic oil channel, hydraulic oil reaches a one-way valve in the middle of the piston through the channel, and the cylindrical hole is communicated with the one-way valve. The cylinder bottom is provided with a one-way throttling valve, and when the hydraulic cylinder retracts and gets close to the cylinder bottom, the buffering function of the hydraulic cylinder is achieved. By means of the hydraulic cylinder, reciprocating of a common hydraulic cylinder can be achieved, and the retraction stroke tail end self-locking and retraction stroke tail end buffering functions can also be achieved.

Owner:武汉市天毅达测控科技有限公司 +1

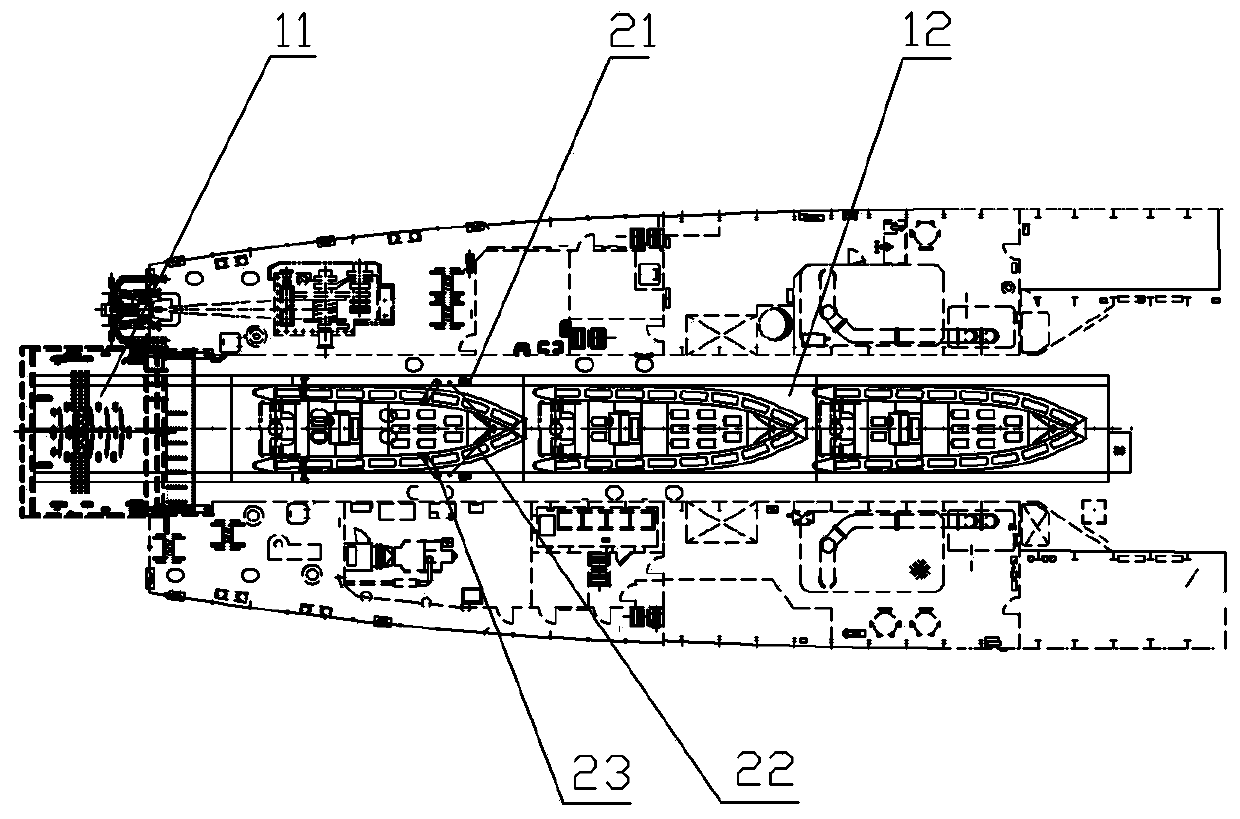

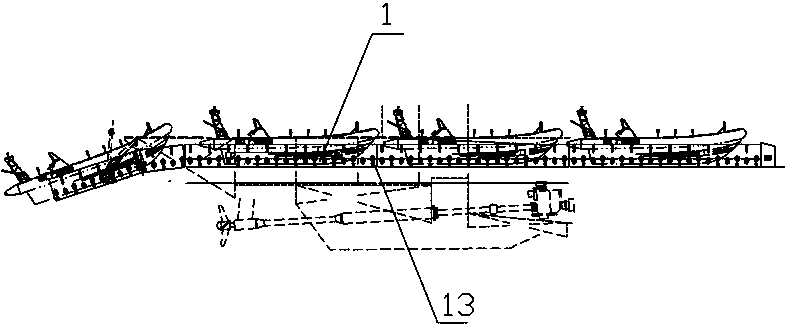

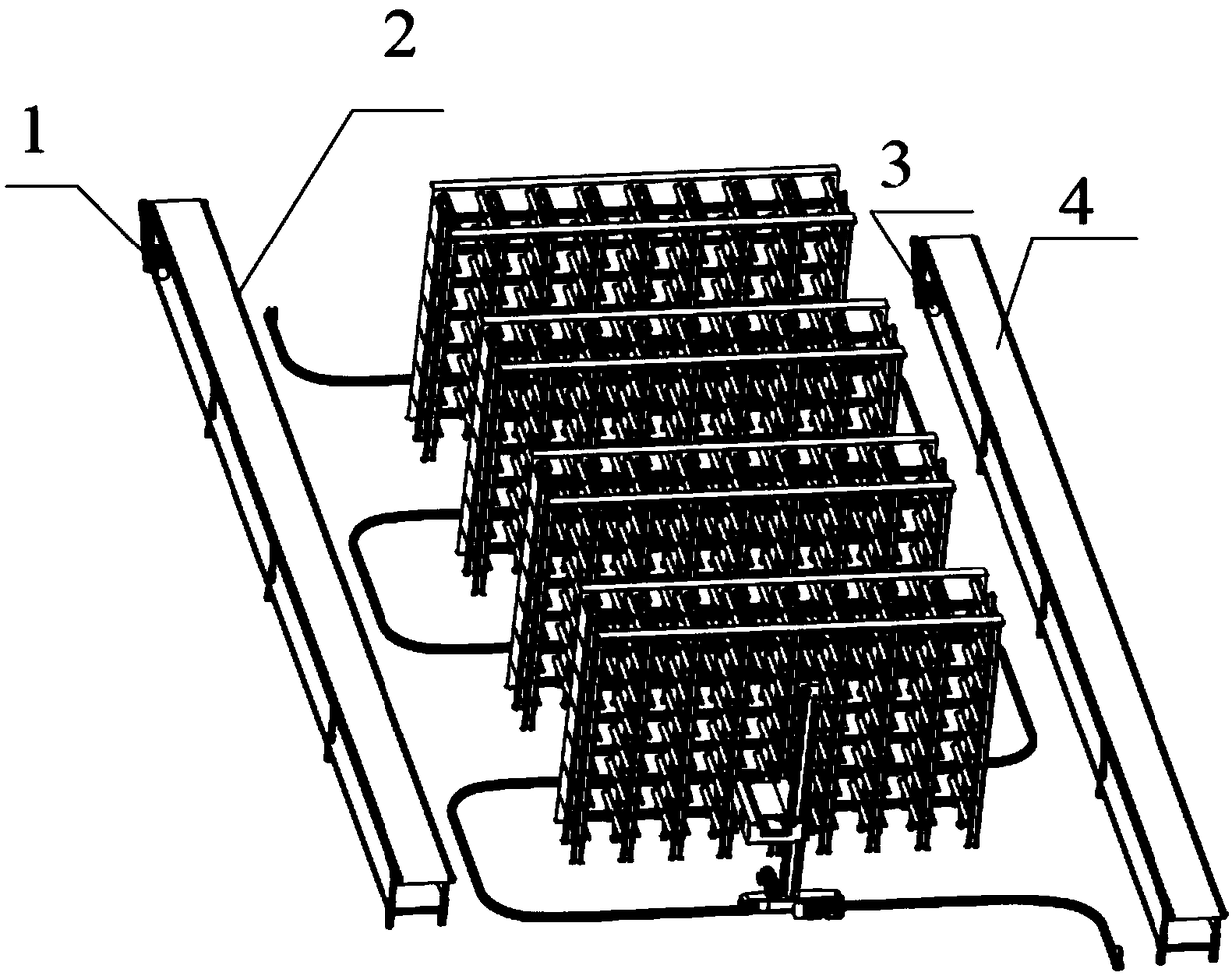

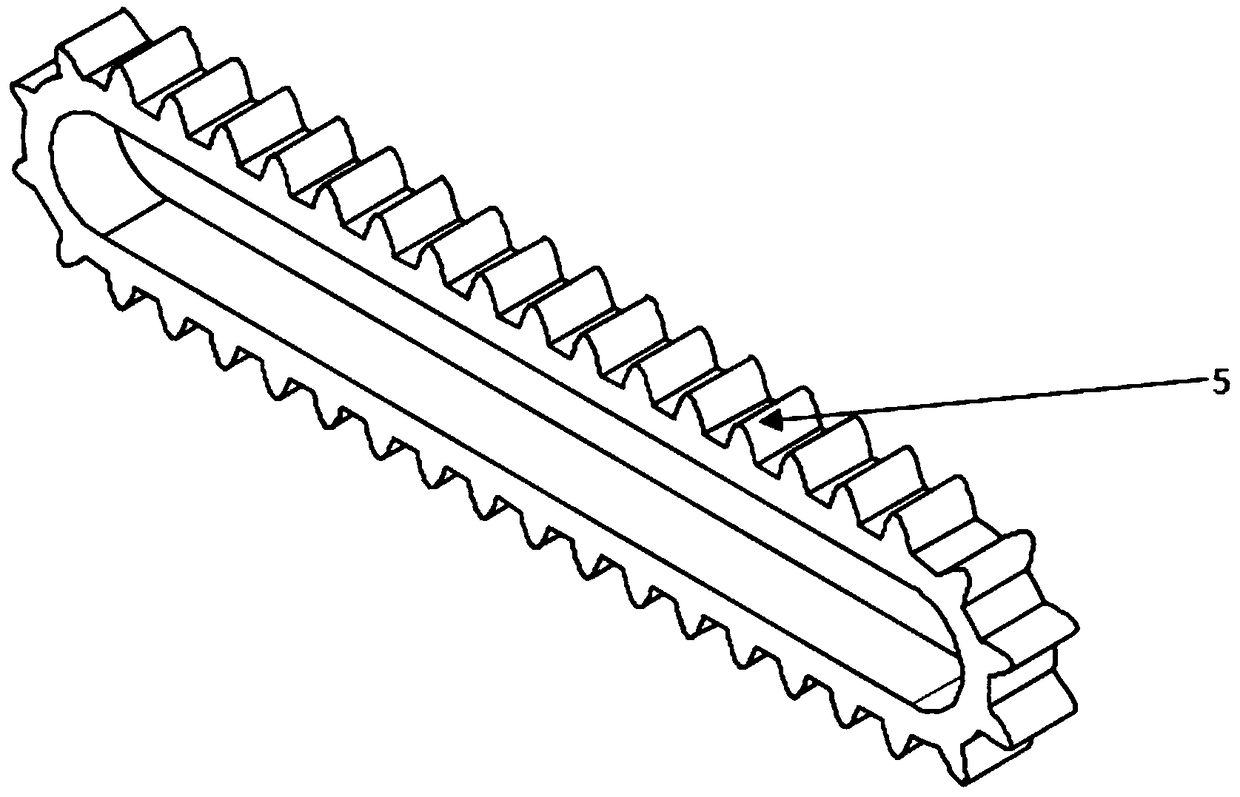

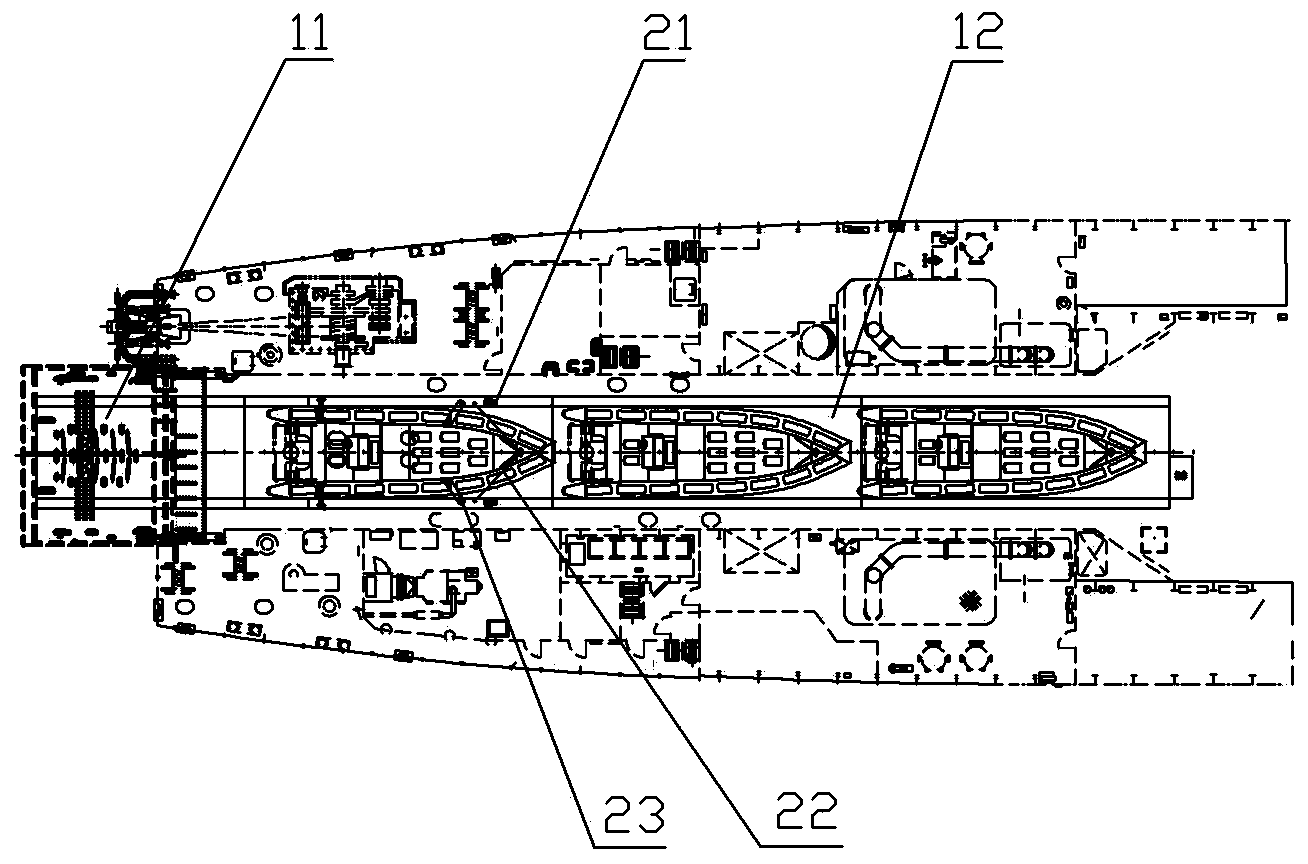

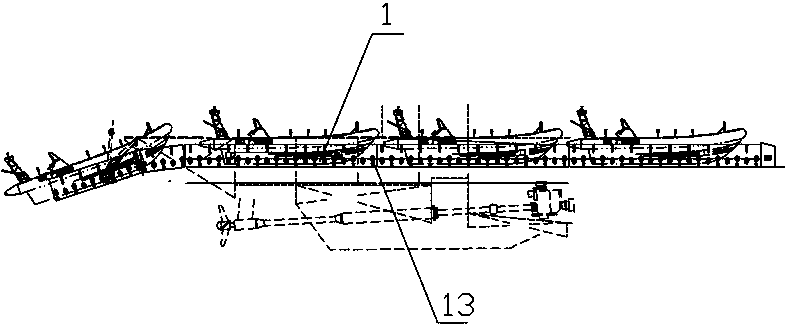

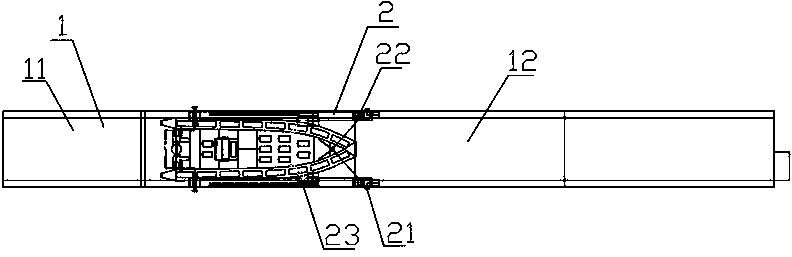

Device and method for storing small boats

ActiveCN104002929AAvoid offsetControl movement speedBoat guiding devicesBoat releasing/projecting devicesMechanical engineering

The invention discloses a device and method for storing small boats. Cabins for storing the small boats are arranged on a boat body of the device, a channel which tilts downwards is formed in the stern portion of the boat body, one end of the channel is connected with the cabins, and a stern door which can rotate downwards is hinged to the other end of the channel. The stern door, the channel and the cabins are respectively provided with an idler roller set which is composed of a plurality of pairs of idler rollers supporting the bottoms of the small boats from the two sides. The two sides of the idler roller set on the cabins are respectively provided with a mobile guide rail, the mobile guide rail on each side is provided with a trolley, and each trolley is provided with a traction device and a boat pushing device. According to the device and method for storing the small boats, the stern door can be rotated downwards, the small boats can slide to the boat body from the idler roller set on the stern door through the channel, then the trolleys are used for pushing the small boats to the corresponding positions of the small boats to be fixed, operation is convenient, the purpose that the storing device in one mother boat can be used for storing a plurality of small boats, operation is convenient, and the safety is high.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

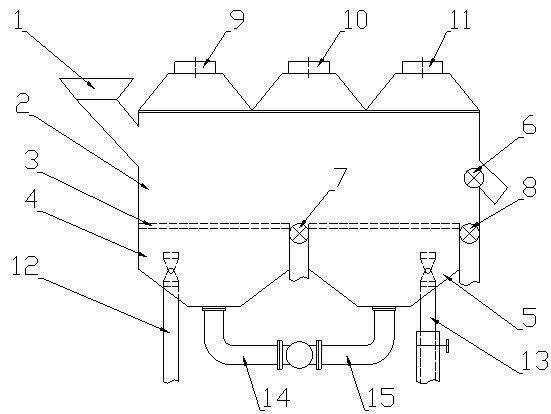

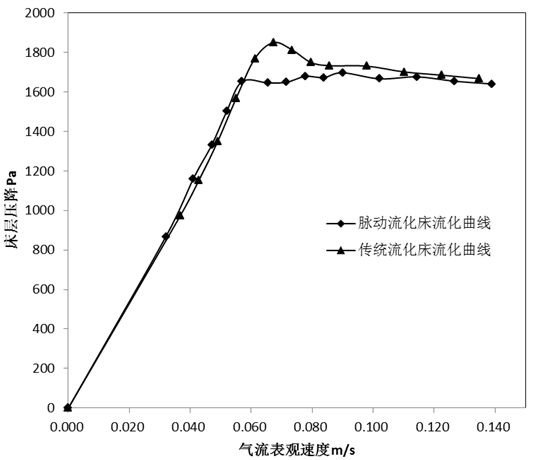

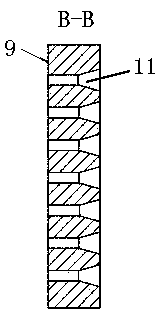

Gas-solid fluidized bed sorting machine based on pulse airflow

InactiveCN102652940AImprove uniformity and stabilitySimple structureGas current separationFluidized bedEngineering

The invention discloses a gas-solid fluidized bed sorting machine based on pulse airflow. The gas-solid fluidized bed sorting machine mainly comprises a sorting groove, an air distributing plate, a dedusting cover and a support, wherein the tail end of the sorting groove is provided with a light product material discharge wheel; the tail end of a rear air distributing chamber is provided with a rear heavy product material discharge wheel; the tail end of a front air distributing chamber is provided with a front heavy product material discharge wheel; the bottom parts of the rear air distributing chamber and the front air distributing chamber are respectively provided with a rear air tube and a front air tube; the rear air tube and the front air tube are connected with an air inlet tube through a three-way connector; and the air inlet tube is provided with a pulse airflow generator and an airflow quantity regulating valve in sequence. According to the invention, the pulse airflow is introduced into a gas-liquid fluidized bed, materials are conveyed forward relying on the oblique angle of the sorting groove and the effect of the pulse airflow; floating materials and sediment materials are respectively discharged through the light product material discharge wheel and the heavy product material discharge wheels, and the medium circulating quantity is reduced effectively; and the height of a front support leg can be adjusted, the front support leg can be used for regulating the oblique angle of the sorting groove, the regulation of coal conveying speed and sorting time can be realized.

Owner:CHINA UNIV OF MINING & TECH

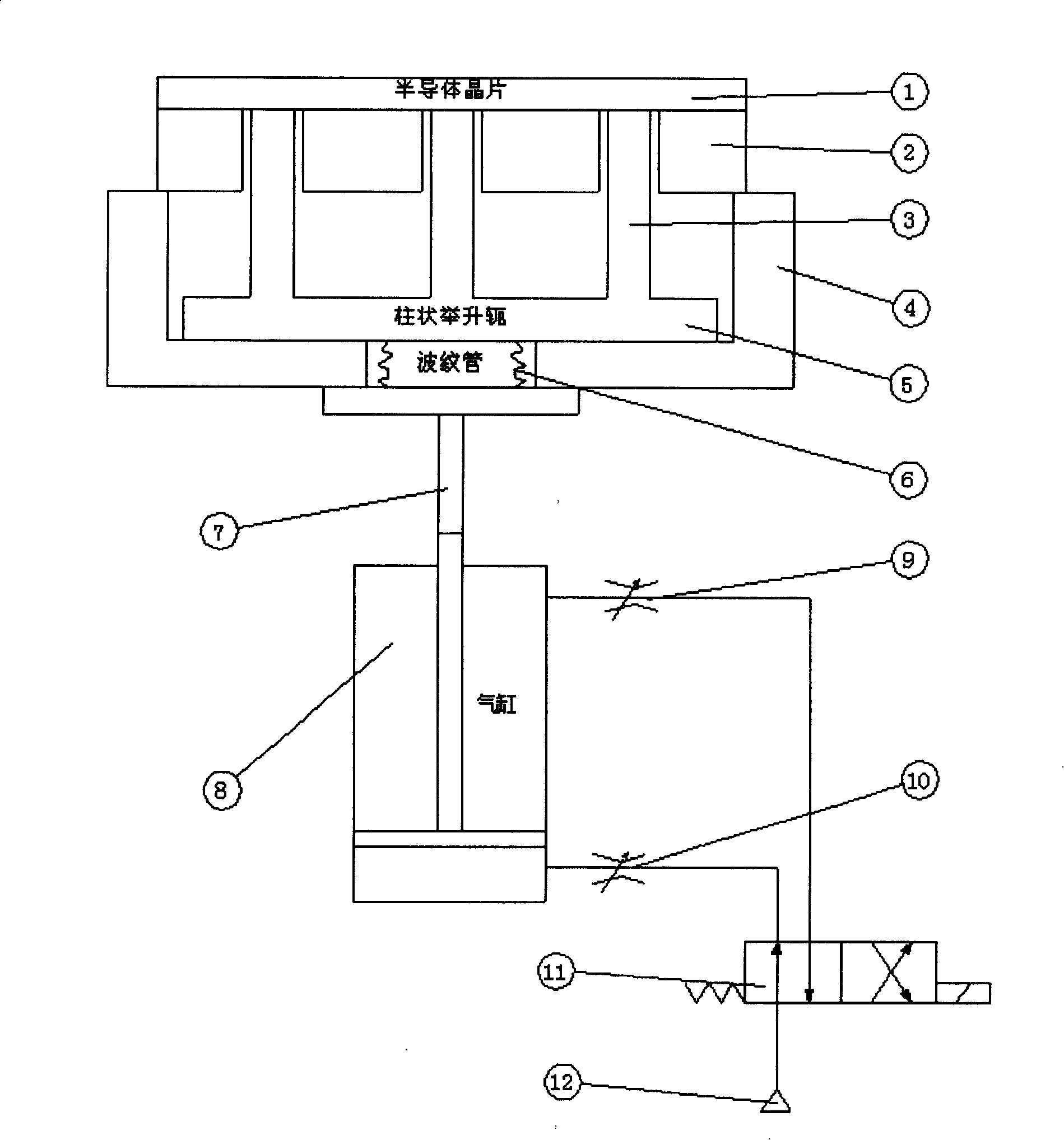

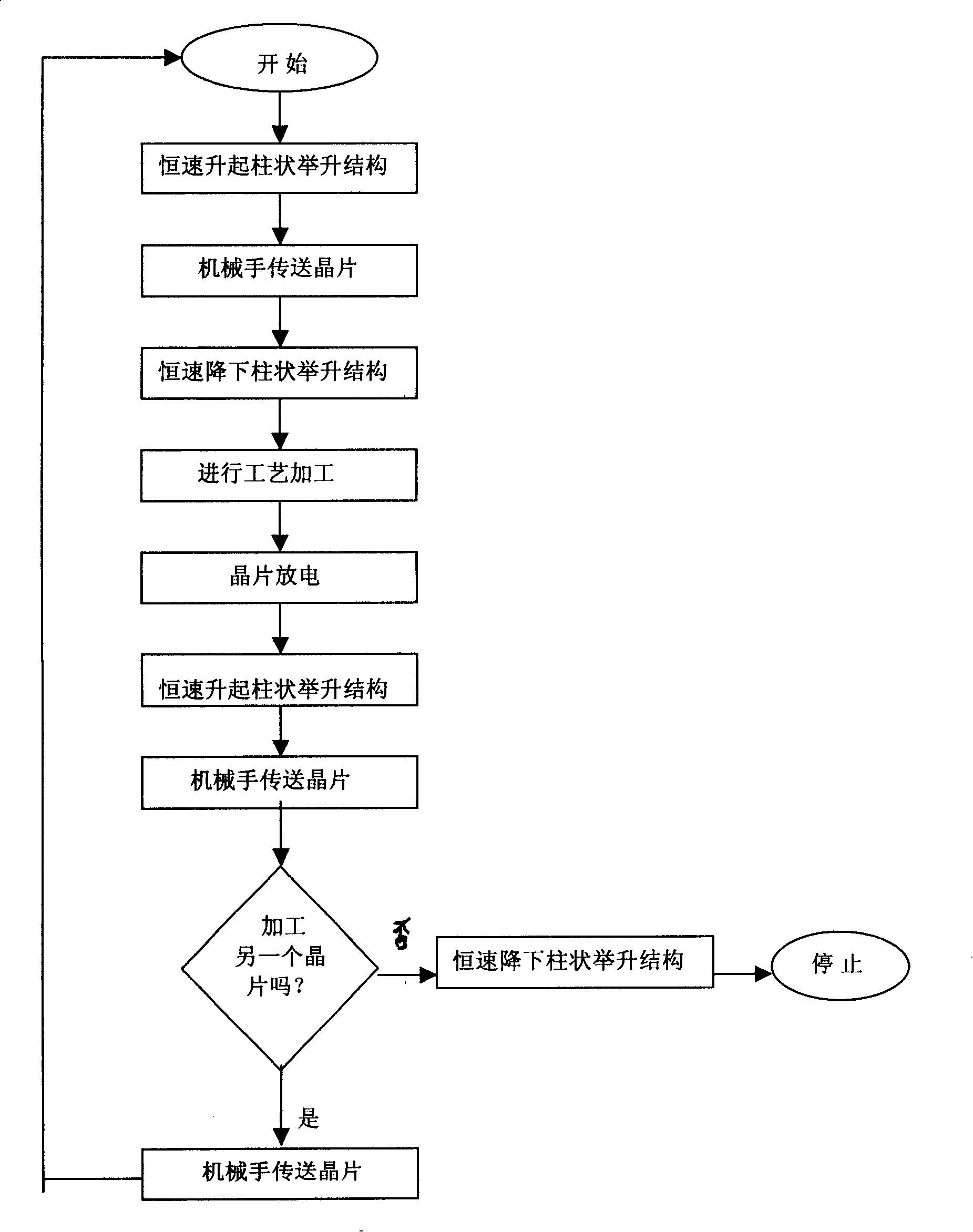

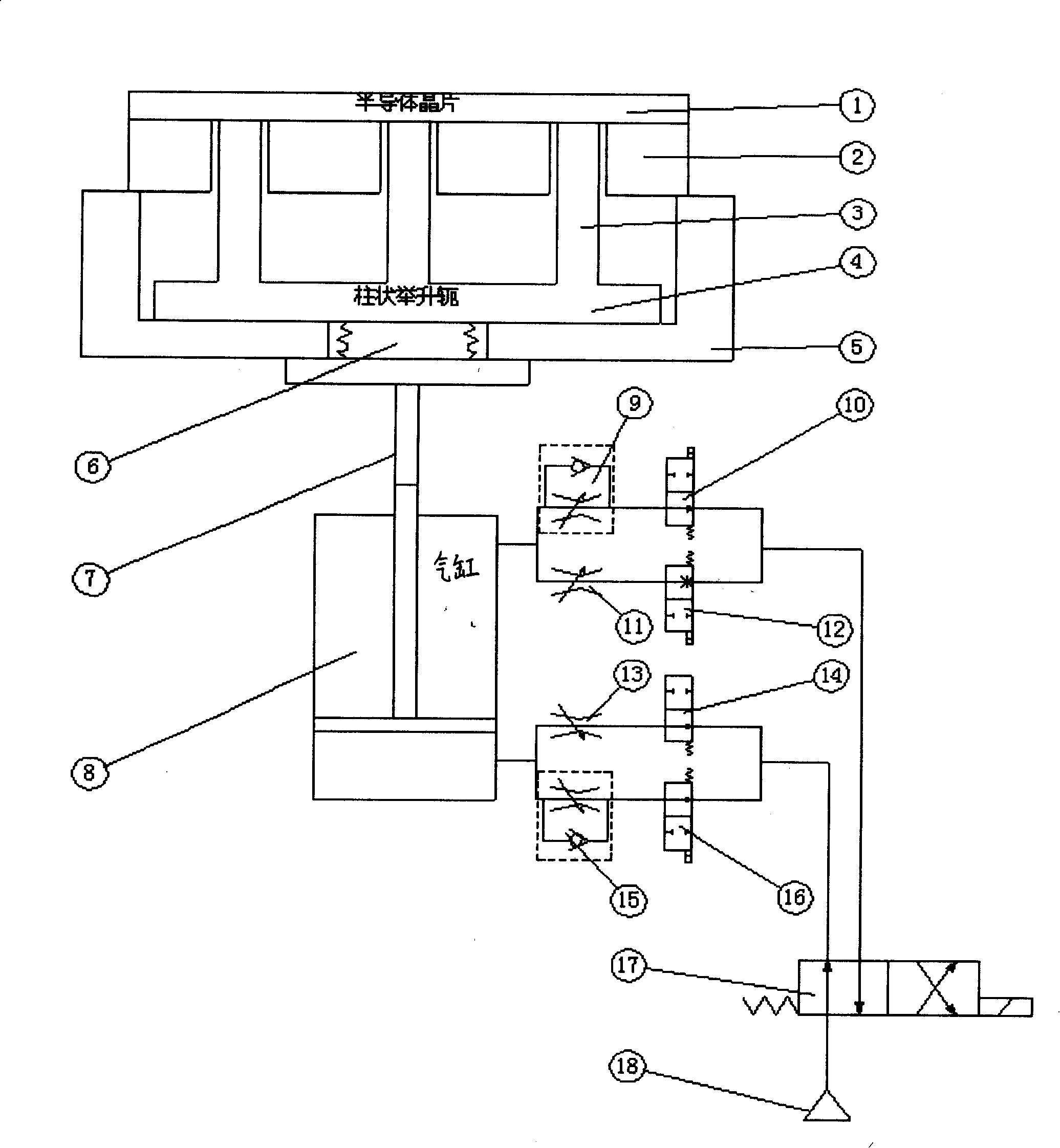

Device for controlling double-acting air cylinder piston traveling speed

ActiveCN101216058AControl movement speedAvoid damageServomotor componentsSemiconductor/solid-state device manufacturingElectromagnetic valveThrottle

The invention provides a device to control the translational speed of the plunger of a double-acting cylinder during wafer process. The device is connected with two inlet ends of the double-acting cylinder to control the motion of the double-acting cylinder. The control device comprises two sets of variable speed gears and a two-position five-way electromagnetic valve. The air intake of the two-position five-way electromagnetic valve of the control device is connected with an air supply; one air outlet of the two-position five-way electromagnetic valve is connected with one inlet end of the double-acting cylinder through a set of variable speed gear; the other air outlet of the two-position five-way electromagnetic valve is connected with the other inlet end of the double-acting cylinder through the other set of variable speed gear. The variable speed gear comprises two throttles and two two-position two-way electromagnetic valves. By adopting the control device, a wafer can move firstly quickly and then slowly in the processes of getting into the seat and out of the seat, thus preventing the wafer from being damaged because of impact.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

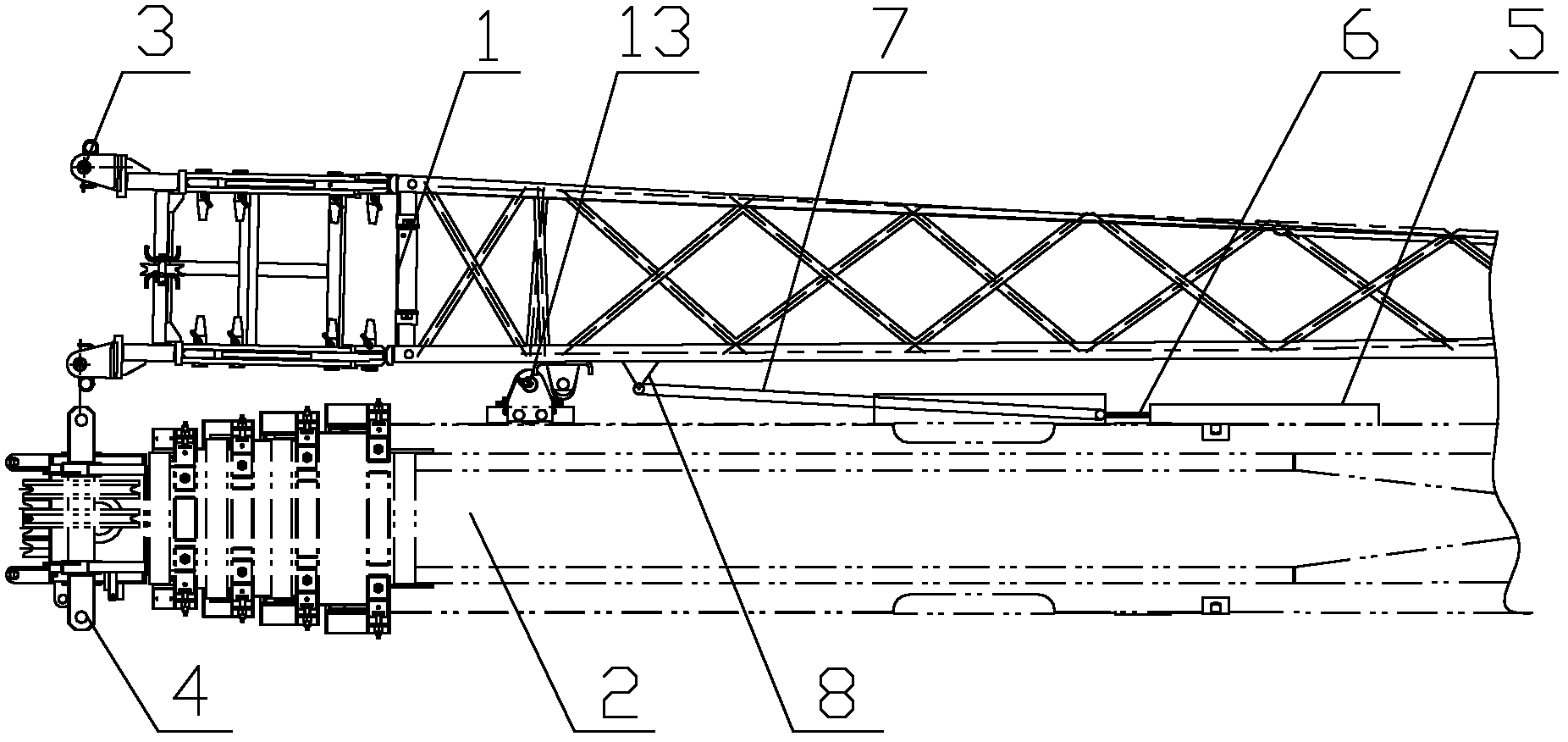

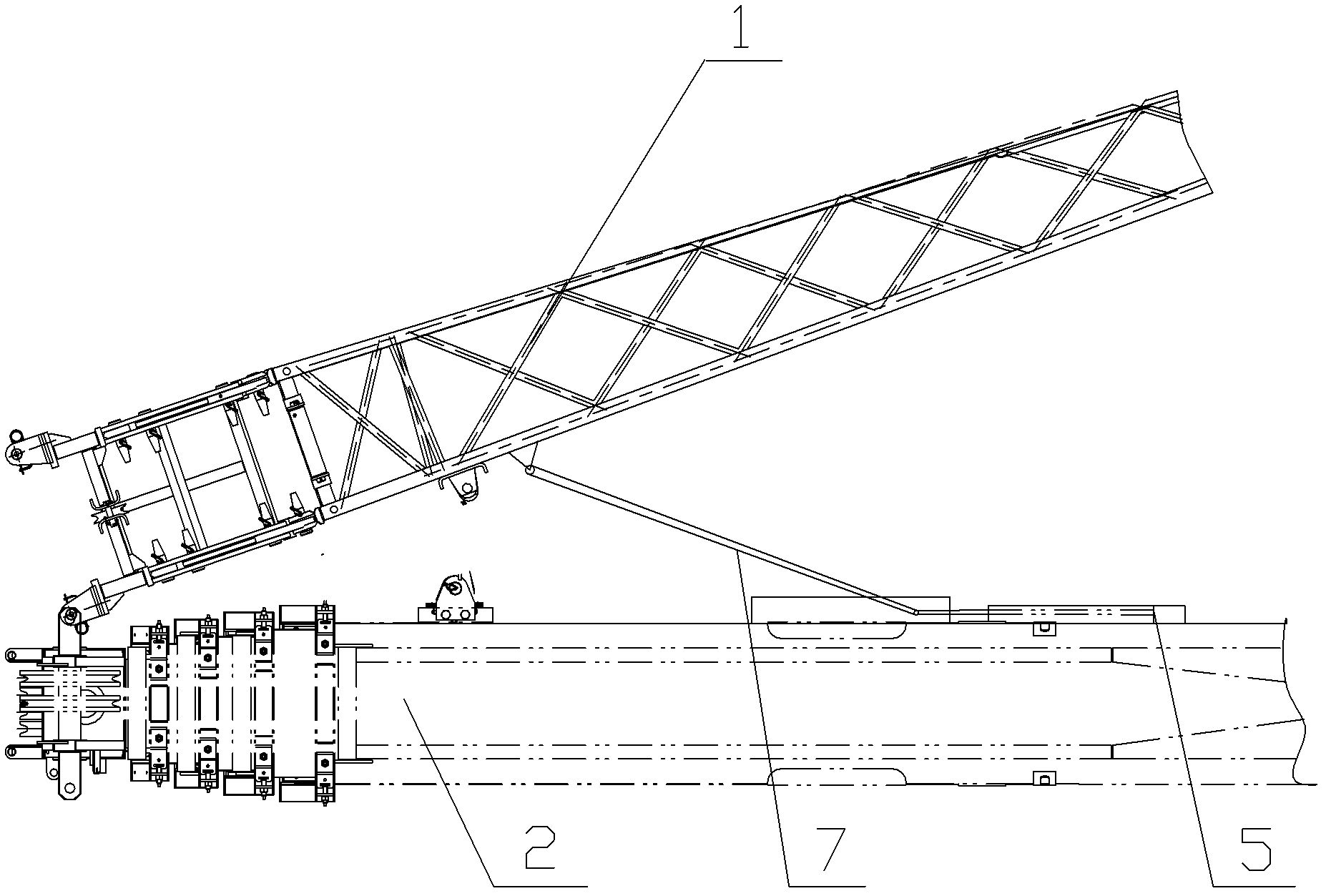

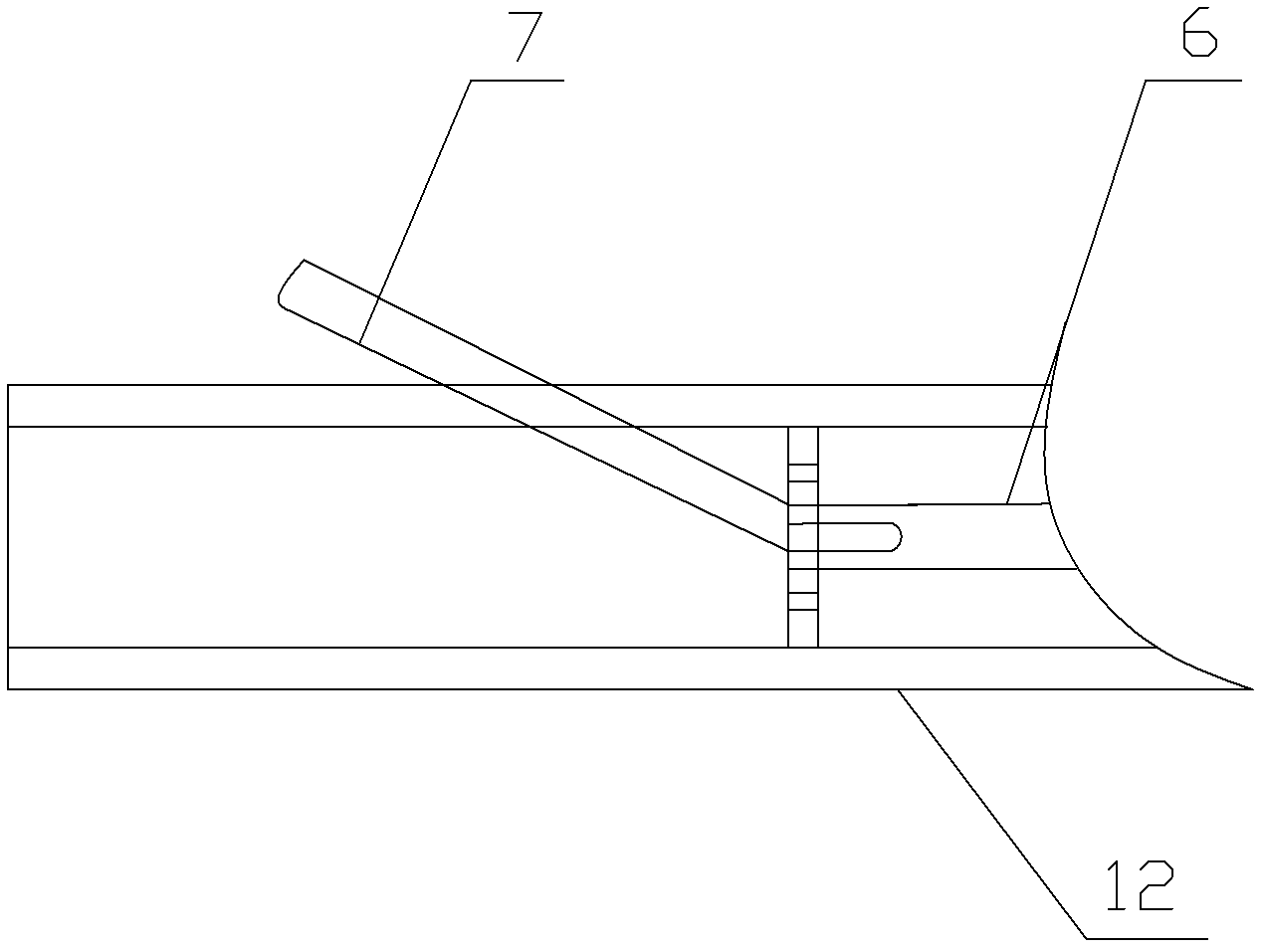

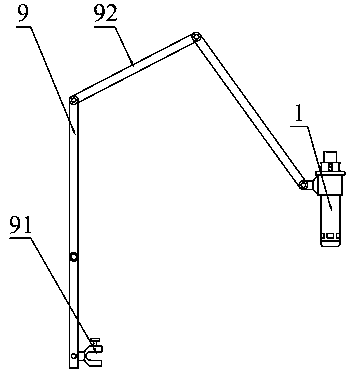

Crane and sub arm installing device thereof

ActiveCN102424329ATroubleshooting Alignment DifficultiesControl movement speedCranesPush and pullReciprocating motion

The invention provides a crane and a sub arm installing device thereof. The device comprises a linear driving mechanism and a connecting rod, wherein the linear driving mechanism comprises a fixed component and a movable component, the movable component is fixedly arranged on the side surface of a main arm and does linear reciprocating movement relative to the fixed component, the reciprocating movement direction is parallel to the side surface of the main arm, the first end of the connecting rod is hinged onto a hinging seat of a sub arm, the movable component pushes and pulls the second end of the connecting rod, and further, the first end of the connecting rod drives the sub arm to swing around the main arm. The crane and the sub arm installing device can realize the high-automation installation and folding of the sub arm and have the advantages that the operation efficiency is high, the alignment is precise, the applicability is high, the swinging speed is controllable, and the like.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

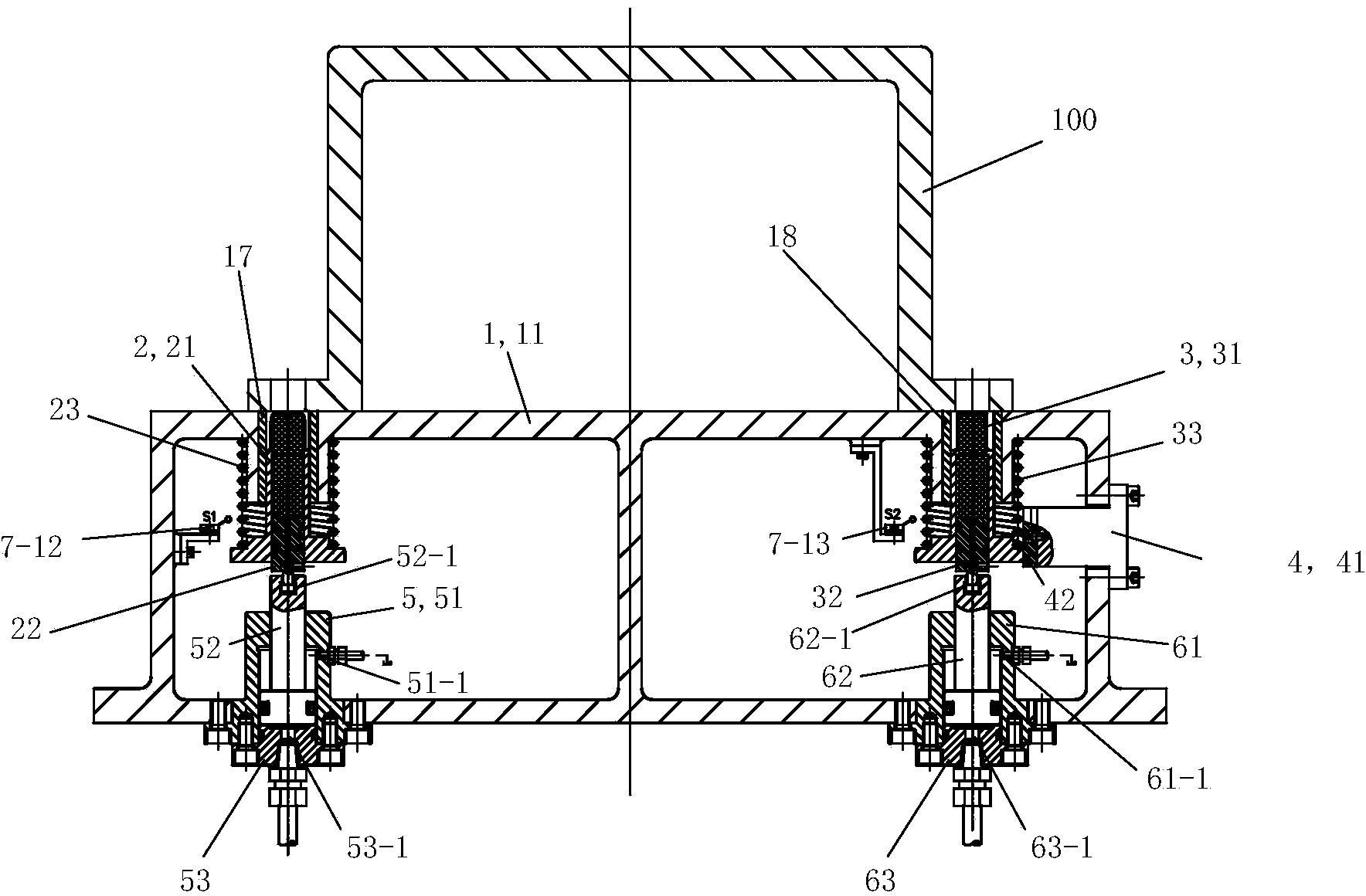

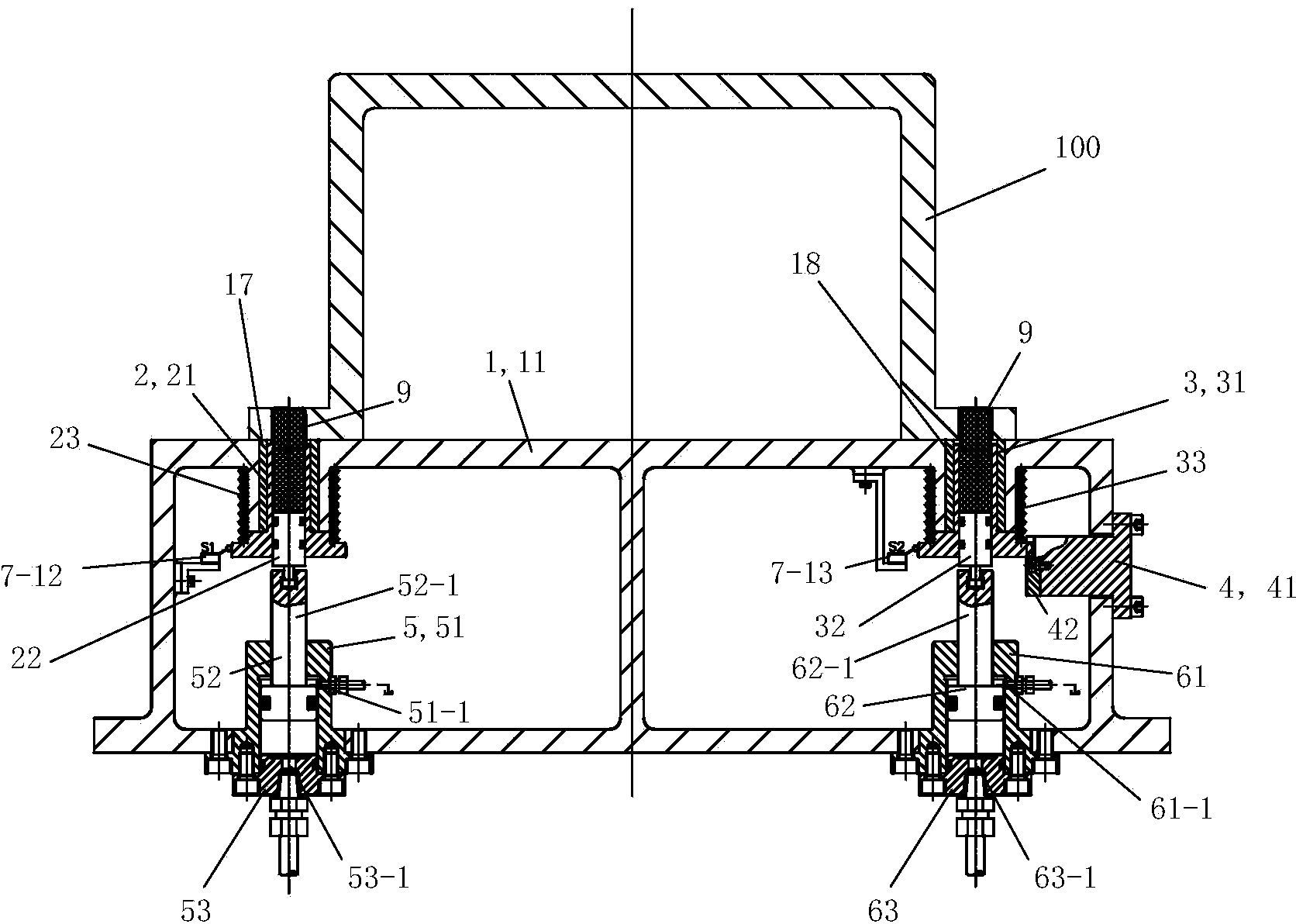

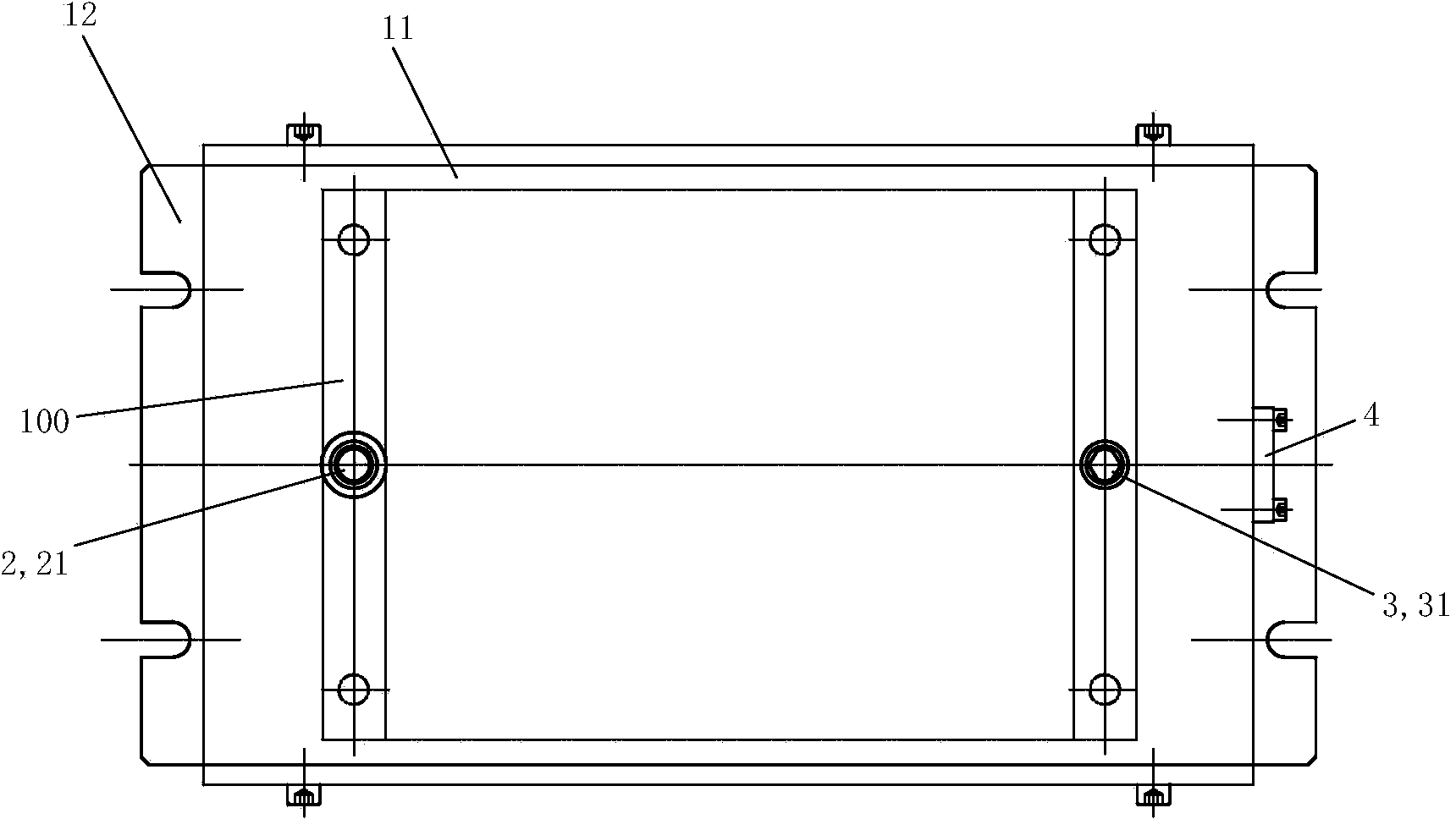

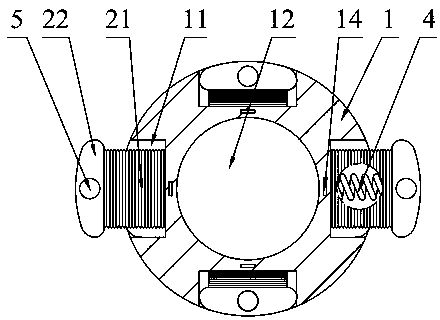

One-face two-pin precise positioning system and control method thereof

InactiveCN103962868AHigh positioning accuracySimple structureWork clamping meansPositioning apparatusControl systemEngineering

The invention discloses a one-face two-pin precise positioning system. The one-face two-pin precise positioning system is characterized by comprising a worktable, a round pin positioning device, a diamond pin positioning device and a control system; the control system comprises a first power device and a second power device, the first power drive drives a first plunger to move in a plunger hole of a round pin, the round pin is driven to move upwards by upwards extruding hydraulic plastics, the positioning portion of the round pin is inserted into a corresponding positioning hole of a workpiece, the positioning portion of the round pin generates corresponding plastic deformation and expands, and the gap between the round pin and the corresponding positioning hole in the workpiece is reduced. The second power device drives a second plunger to move in a plunger hole of a diamond pin, the diamond pin is driven to move upwards by upwards extruding the hydraulic plastics, the positioning portion of the diamond pin is inserted into a corresponding positioning hole of the workpiece, the positioning portion of the diamond pin generates corresponding plastic deformation and expands, and the gap between the diamond pin and the corresponding positioning hole in the workpiece is reduced.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

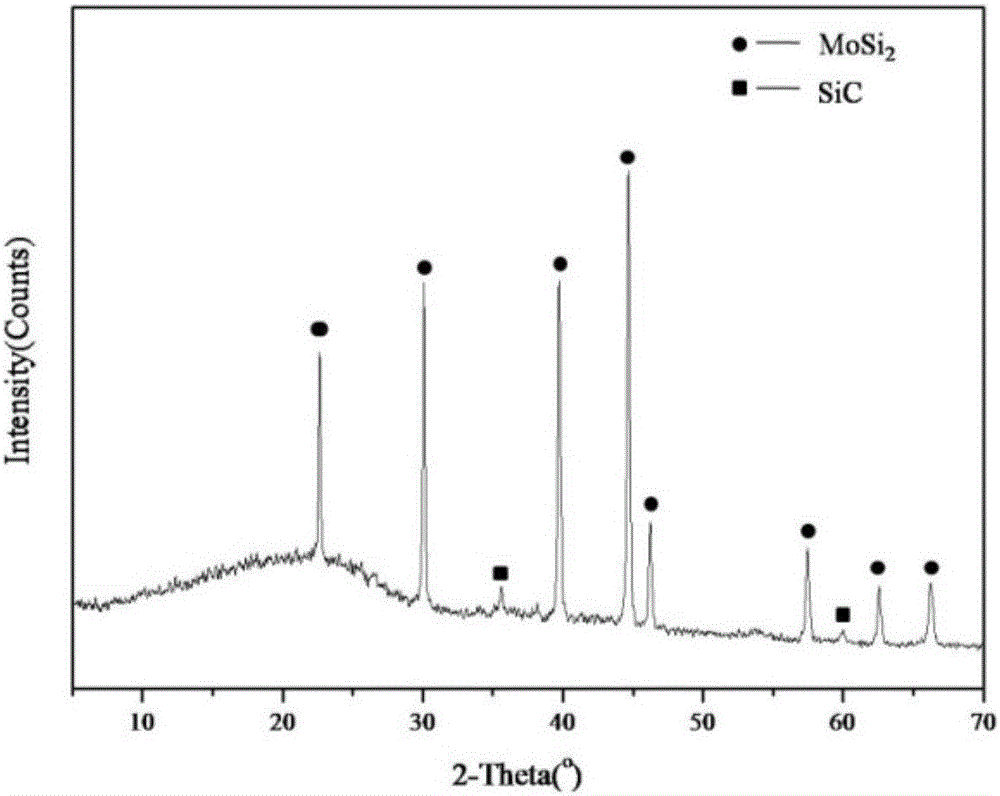

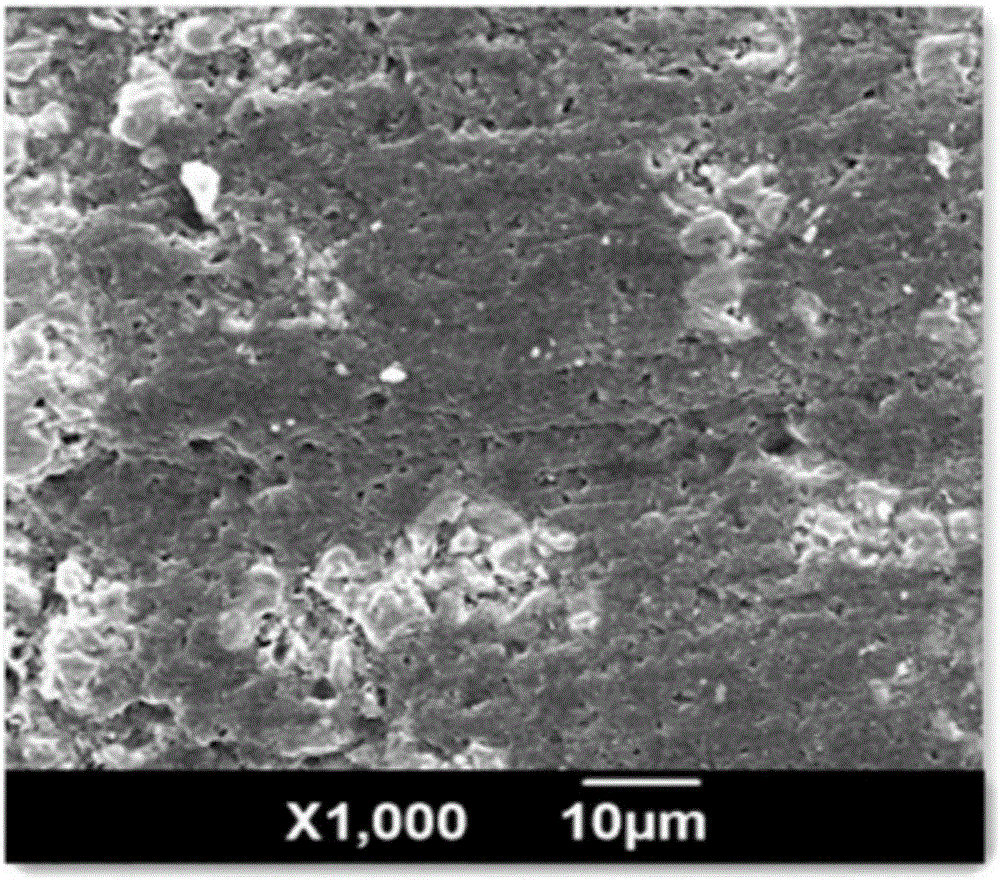

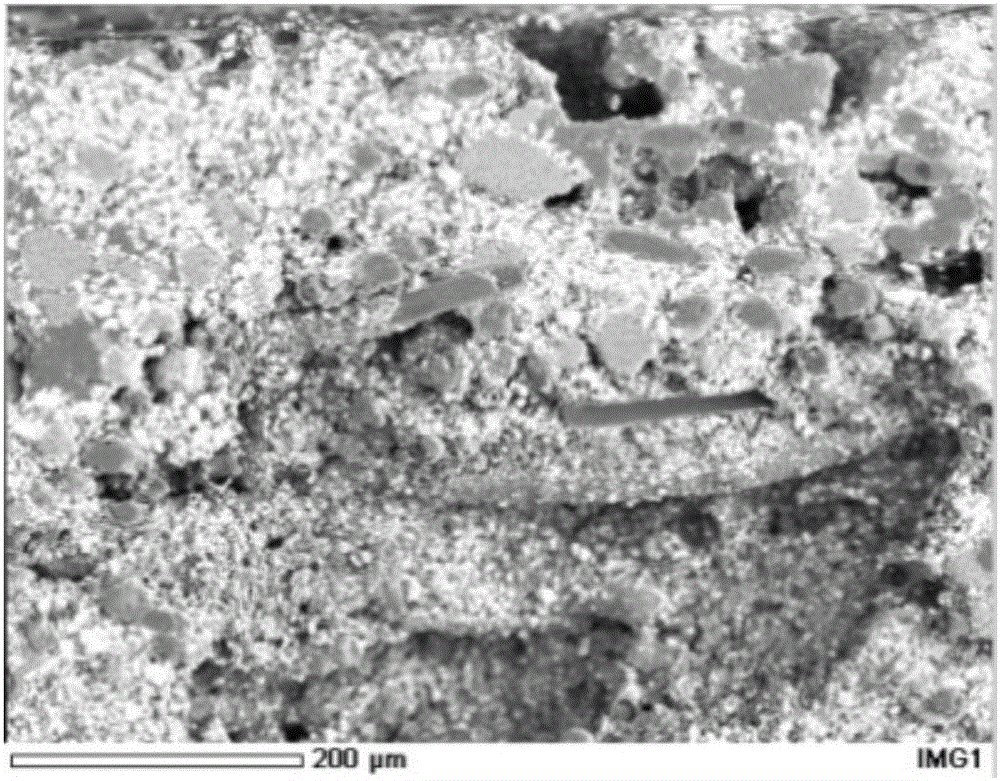

Preparation method for lamellar C/C-SiC-MoSi2 ceramic matrix composite

The invention provides a preparation method for a lamellar C / C-SiC-MoSi2 ceramic matrix composite. The method comprises the steps that silicon carbide powder and molybdenum disilicide powder are dispersed in isopropyl alcohol and then stirred evenly after iodine is added, and first suspension liquid and second suspension liquid is obtained; the density of a carbon-fiber three-dimensional fabric is increased by adopting the mode of hydrothermal glucose permeation, the carbon-fiber three-dimensional fabric is clamped in a specially-made hydrothermal kettle with a positive electrode and a negative electrode, then the specially-made hydrothermal kettle is placed in a drying oven for heat preservation, and then hydrothermal electrophoretic deposition is performed; homogeneous-phase hydrothermal treatment is repeatedly performed in an aqueous glucose solution until the density reaches 1.3-1.5 g / cm<3>, and then heat treatment is performed after the fabric is dried. According to the preparation method for the lamellar C / C-SiC-MoSi2 ceramic matrix composite, the prepared composite is moderate in density and compact in structure, and binding between a C / C interface and a SiC interface, binding between the SiC interface and a MoSi2 interface and binding between the C / C interface and the MoSi2 interface are good; the composite with the high strength and the good high-temperature oxidation resistance can be obtained at low temperature, and the preparation method has the advantages that the raw materials are easy to obtain, the preparation technology is simple, operation is easy and convenient, and the cost is low.

Owner:广西自贸区见炬科技有限公司 +1

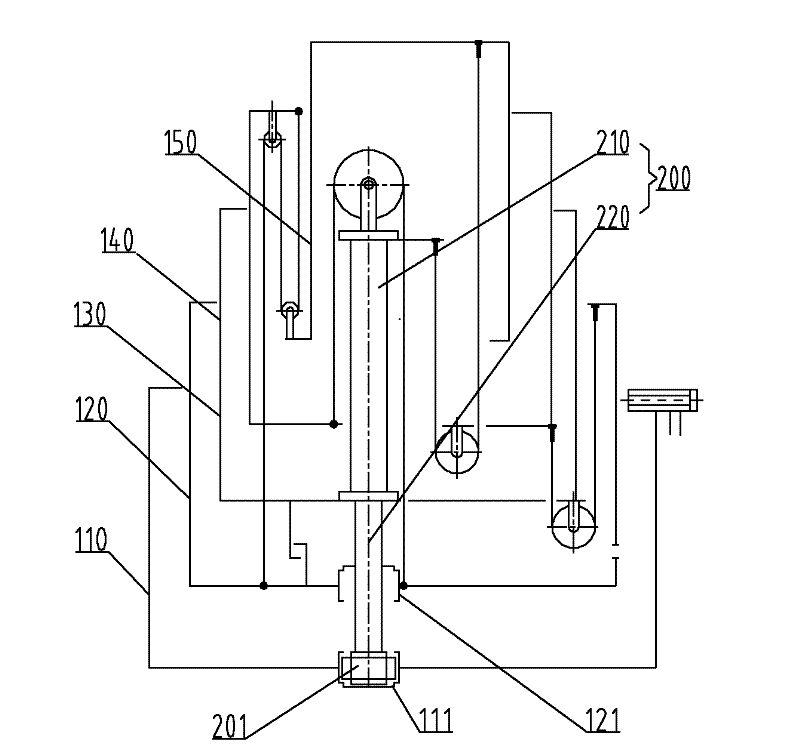

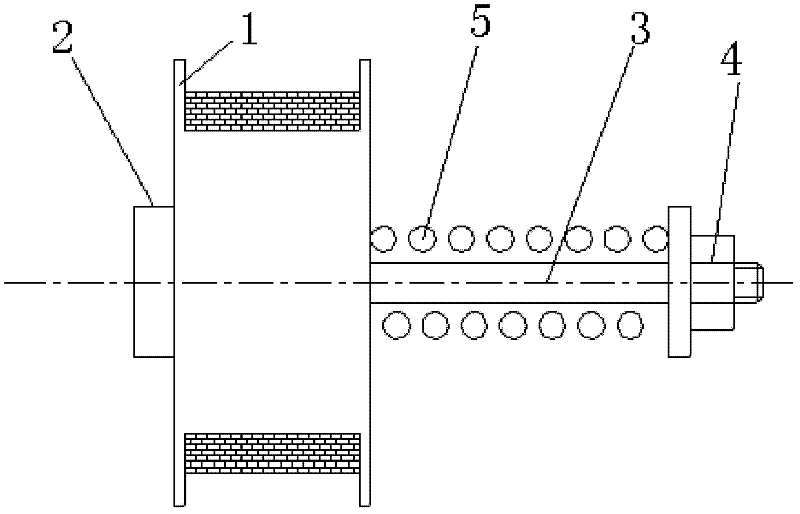

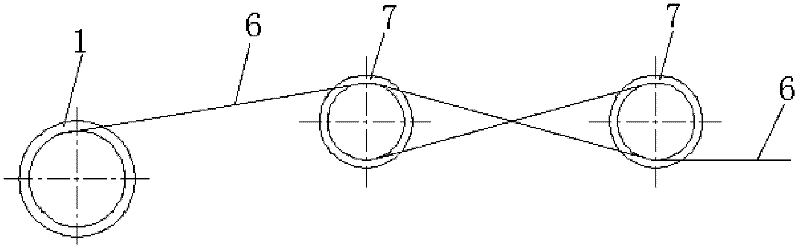

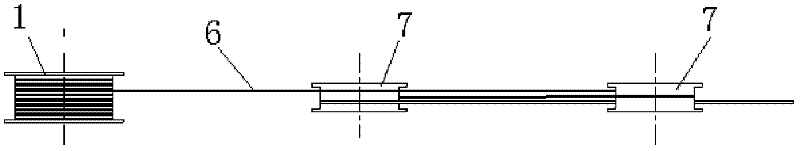

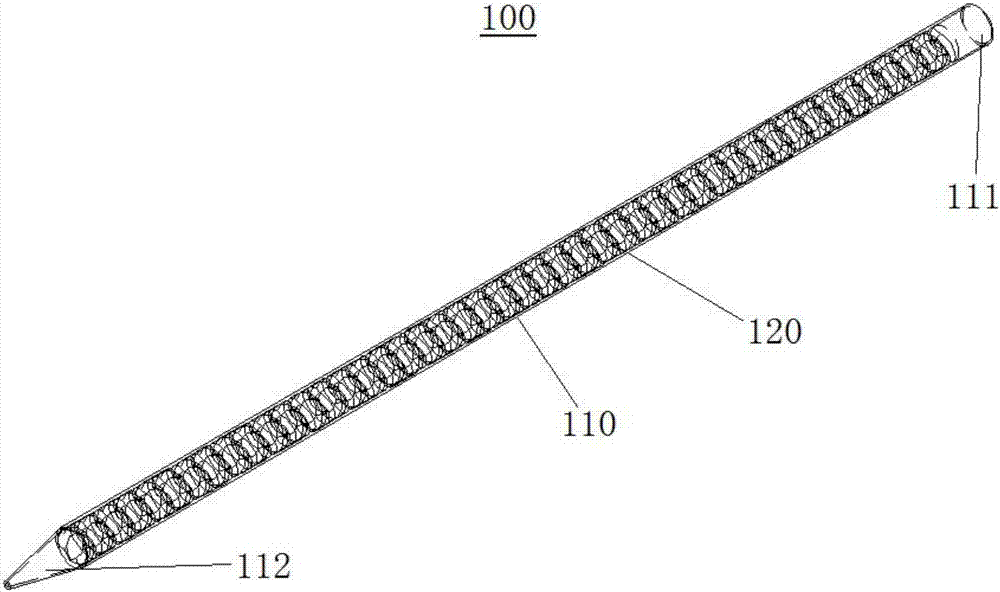

Winding device and method of spiral wires for traveling wave tubes and winding method

ActiveCN102243966AGuaranteed production efficiencyGuaranteed production workCold cathode manufactureEngineeringConductor Coil

The invention discloses a winding device and method of spiral wires for traveling wave tubes. The winding device of the spiral wires for the traveling wave tubes comprises a lathe, wherein an installing fixture, which is used for installing a whole disc of belt material, is connected on a tool rest of the lathe; a core bar is arranged on the fixture of the lathe; a tensioning fixture is arranged between the installing fixture and the core bar; and one end drawn out from the whole disc of belt material bypasses the tensioning fixture to reach the position of the core rod and is fixed on the core rod. The winding method of the spiral wires for the traveling wave tubes comprises the following steps of: with the winding device of the spiral wires for the traveling wave tubes, enabling a certain tensile force to exist between one end drawn out from the belt material and the whole disc of belt material by the tensioning fixture; manually rotating the core rod to ensure that few loops of thebelt material are wound on the core rod; tensioning and straightening the tail end of the core rod by the fixture at the tail end of the lathe; starting the lathe, rotating the core rod rotates, enabling the installing fixture to move axially along the lathe, wounding the belt material on the core rod along with the rotation of the core rod; controlling the rotating speed of the core rod and themoving speed of the installing fixture, and ensuing the accuracy requirements on pitches of the spiral wires.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

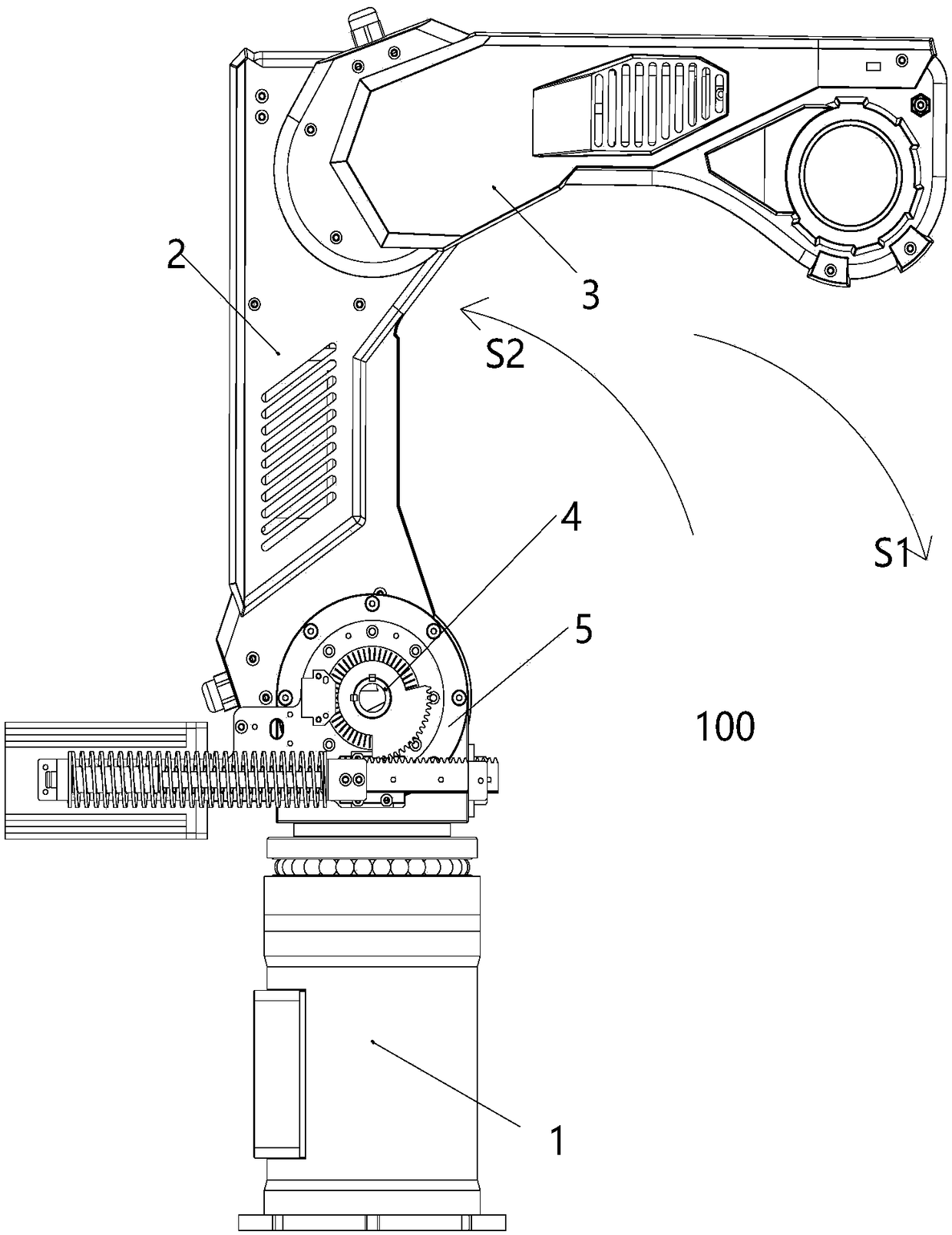

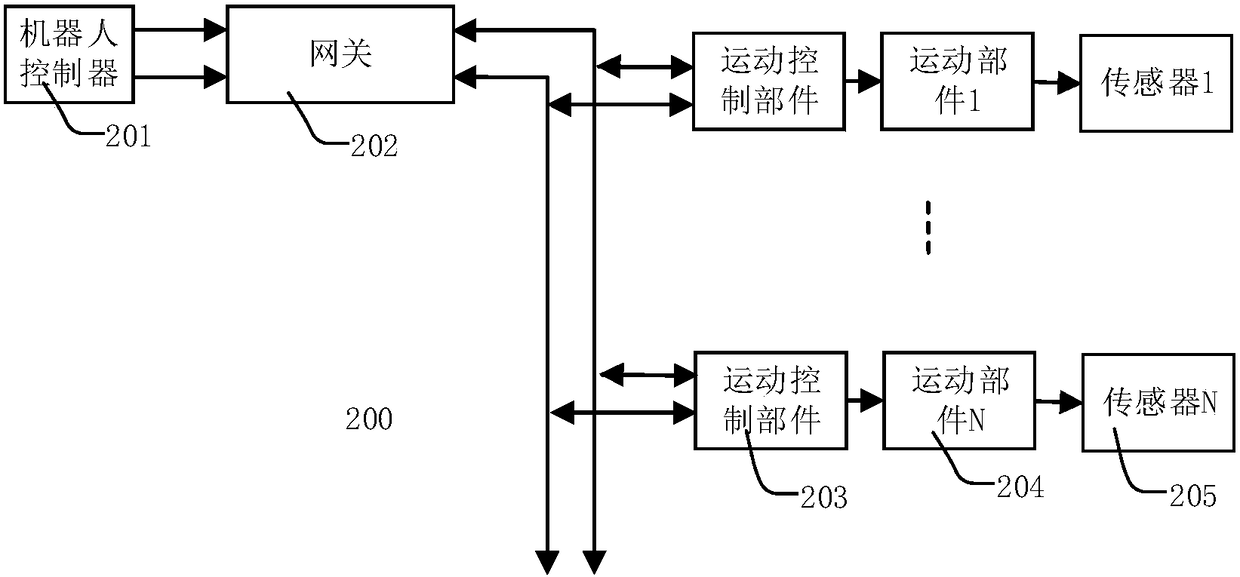

Robot with precise zeroing function, zeroing method, system and medium

InactiveCN108582082AReduce homing errorImprove positioning accuracyProgramme-controlled manipulatorMotion parameterMovement control

The invention discloses a robot with a precise zeroing function. The robot comprises a motion control part, a motion part and a position detecting sensor; the motion control part prestores first preset parameters and second preset parameters; the first preset parameters and the second preset parameters enable motion directions of motion bodies to be opposite; the motion control part receives a zeroing command, and reads the first preset parameters as motion parameters; when the position detecting sensor detects the motion positions of the motion bodies to reach a preset position and to generate a first trigger signal, the motion control part sensitizes the first trigger signal, and reads the second preset parameter as new motion parameters; and when the position detecting sensor detects the motion positions of the motion bodies to reach the preset position again and to generate a second trigger signal, the motion control part sensitizes the second trigger signal, and controls the motion bodies to stop moving. The robot is more accurate in zeroing.

Owner:深圳镁伽科技有限公司

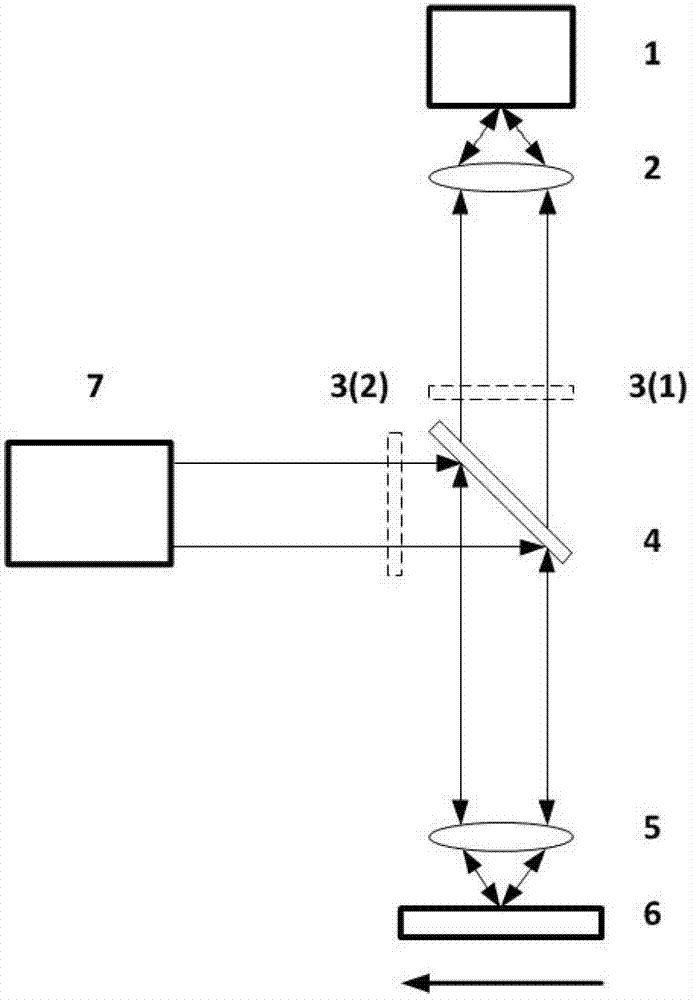

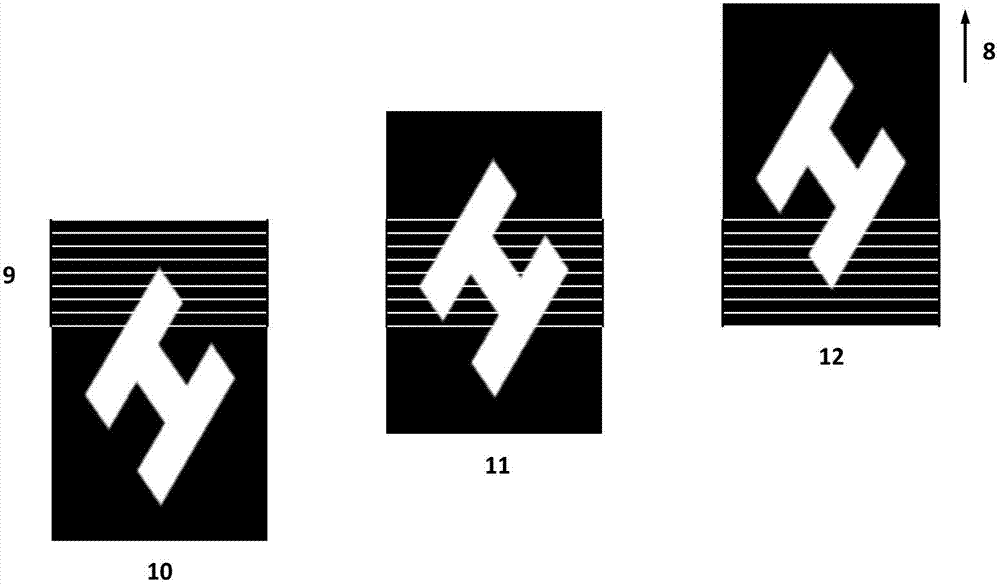

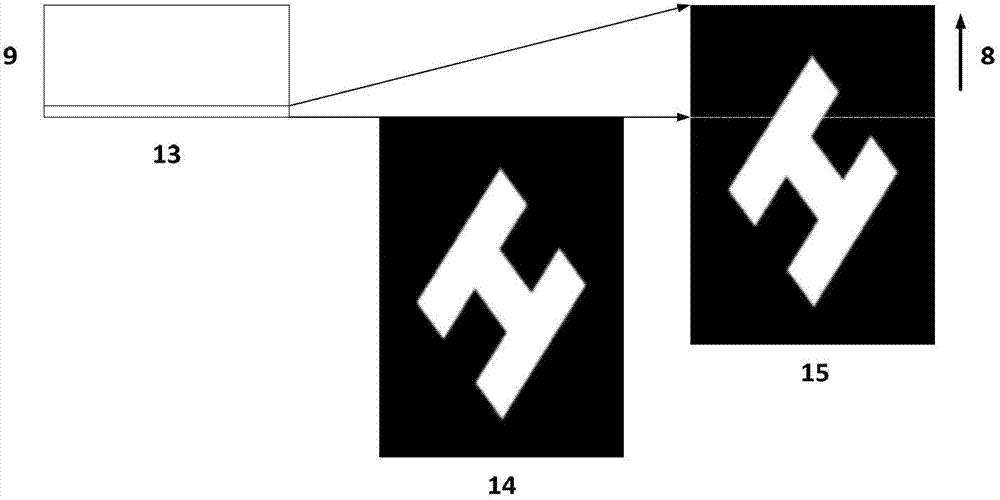

Scanning sampling and image processing method of fast imaging

InactiveCN103179331AHigh resolutionImprove signal-to-noise ratioTelevision system detailsColor television detailsRapid imagingImaging processing

The invention discloses a scanning sampling and image processing method of fast imaging. A sCMOS (Complementary Metal-Oxide-Semiconductor) camera is adopted as an imaging tool, and is worked in a subarray (or ROI) mode, the method comprises the following steps: enabling an imaging object to continuously translate vertical to a sampling direction of the sCMOS camera with a set speed by using a moving plateform, performing scanning imaging on the object by using the sCMOS camera, and outputting sampling frames, shifting and overlying the obtained images to obtain an image. By adopting of the high-speed sampling feature of the sCMOS camera under the subarray (or ROI) mode, and shifting and overlying the sampling frames of the sCMOS camera, the generated image is high in resolution, high in signal to noise ratio and low in distortion, and the method is especially suitable for the fast imaging of the large-size object.

Owner:HUAZHONG UNIV OF SCI & TECH

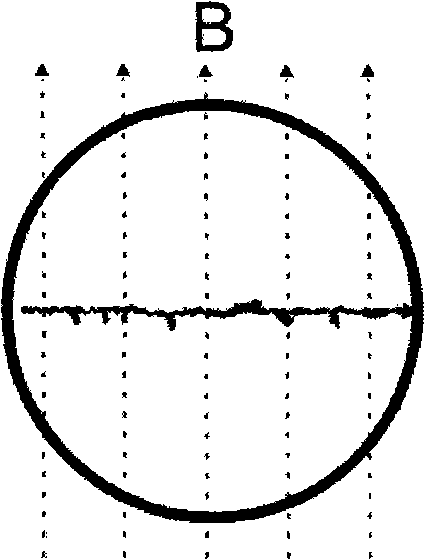

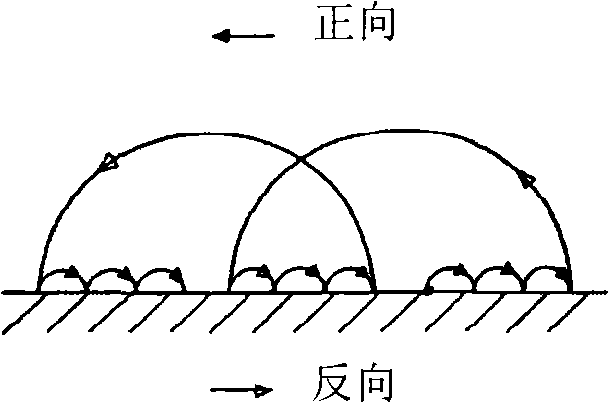

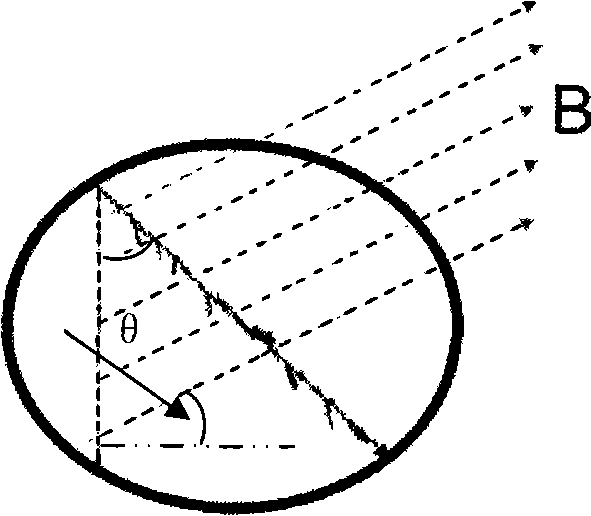

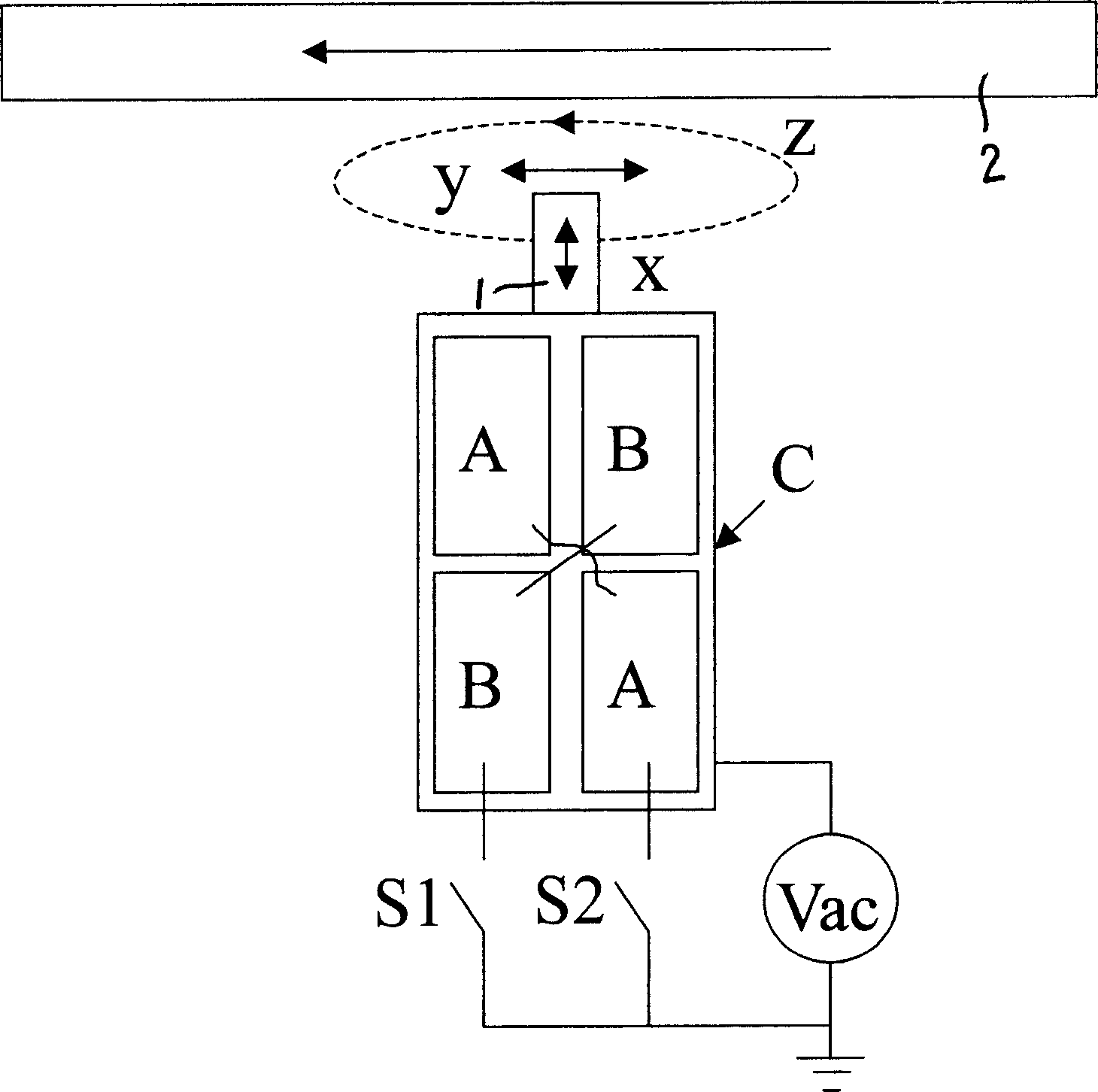

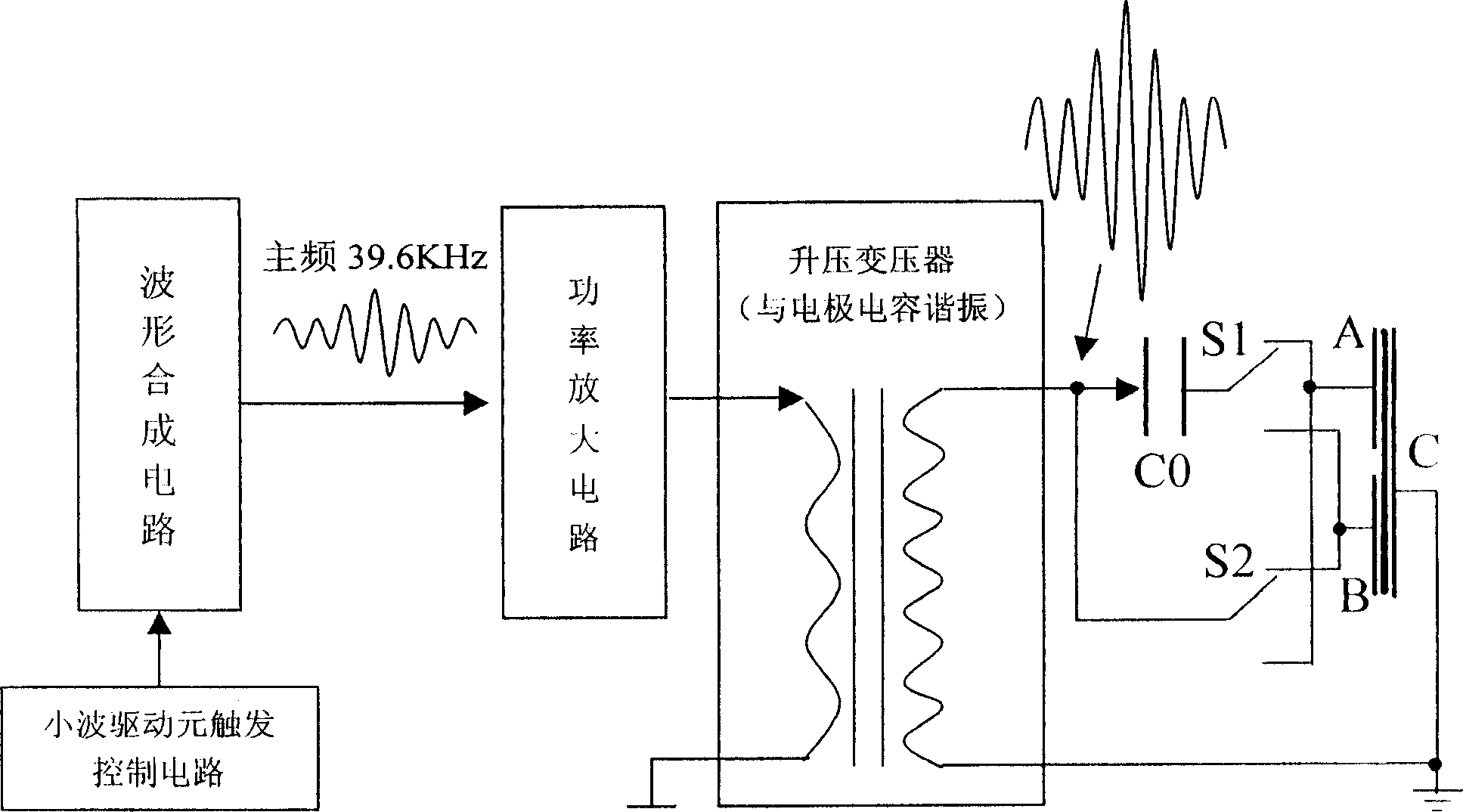

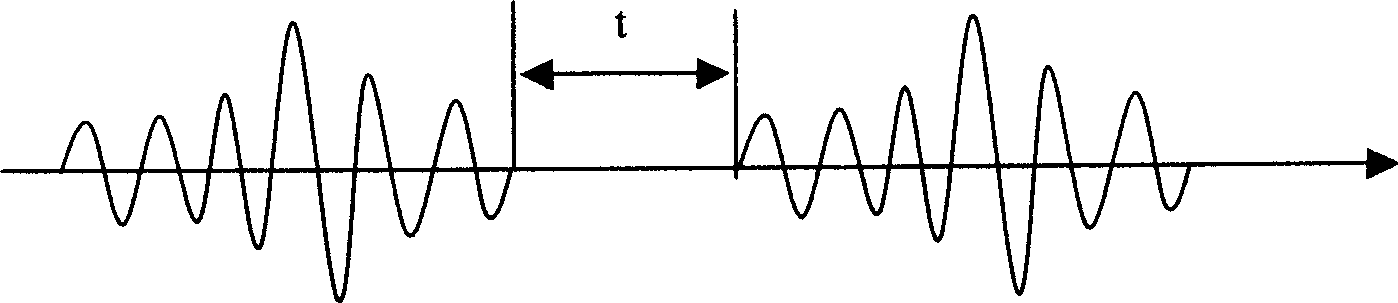

Double-vibrating mode driving piezoelectric ceramic ultrasound wave electric machine small wave differential controlling method

InactiveCN1848654AControl movement speedAchieve "controllablePiezoelectric/electrostriction/magnetostriction machinesDriven elementWave shape

A method for controlling wavelet differential motion of piezoelectric ceramic ultrasonic motor driven by double vibration mode includes providing wavelet voltage with frequency of 39.6 KH2 in N number of periods, making peak value of at least one period be greater then dead zone, using said voltage as a driving element and controlling sliding block speed by changing its output rate, dividing said voltage to be two paths and adding them on two sets of electrodes on said motor in differential way, controlling voltage D-value of said electrodes so as to control amplitude of vibration mode for changing oval motion trail of driving head.

Owner:HEFEI UNIV OF TECH

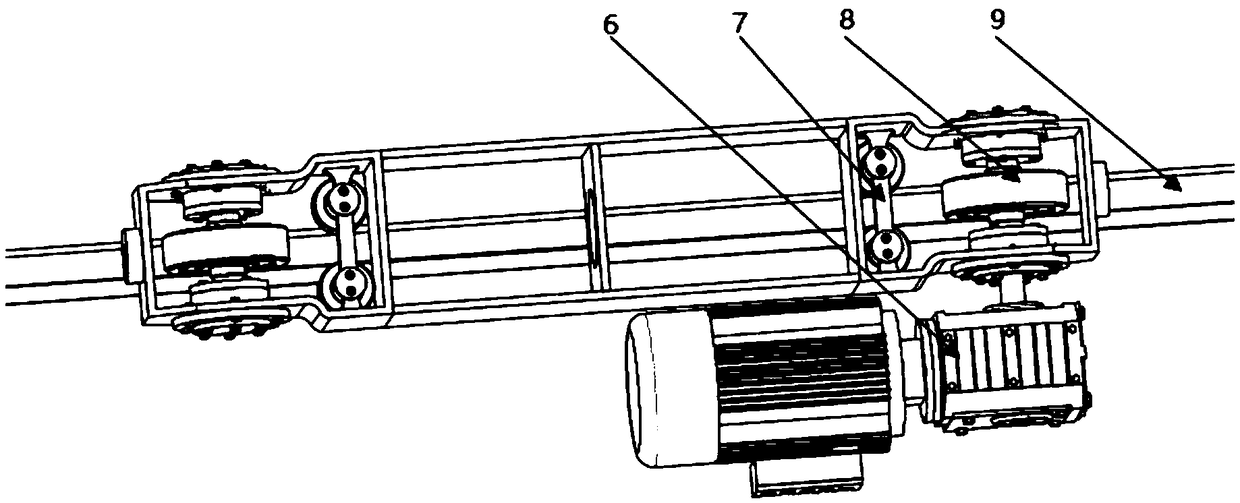

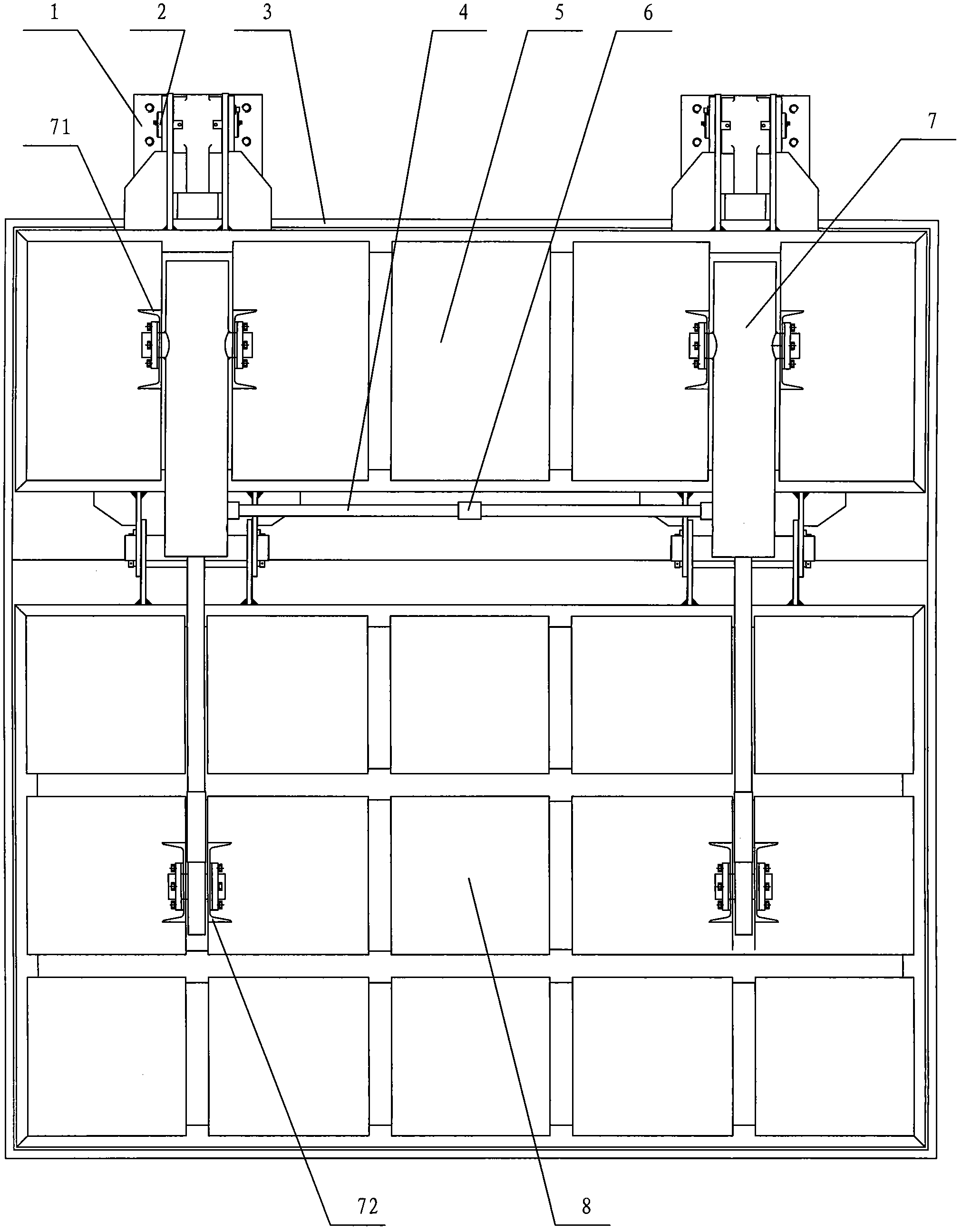

Novel efficient stacker used for warehousing logistics

InactiveCN108706264AAchieve accessRealize the secondary scaling functionStorage devicesLogistics managementGear wheel

The invention discloses a novel efficient stacker used for warehousing logistics. The novel efficient stacker comprises a conveyor belt unit, a stacking moving unit and a stacking travelling unit, wherein the stacking travelling unit consists of a horizontal moving mechanism, a lifting mechanism and an S-shaped guide rail; a systeml controls the horizontal moving mechanism and the lifting mechanism to separately regulate in the vertical direction and the horizontal direction along the S-shaped guide rail until the stacking travelling unit is positioned in front of a storage rack storage position; the stacking moving unit is of a double-rack gear mechanism, and comprises a third motor, a supporting flat plate, a middle plate and a goods carrying plate; and the system controls the third motor to drive the supporting flat plate, the middle plate and the goods carrying plate to move relatively. The novel efficient stacker realizes intelligent precise operation, greatly improves productionefficiency, saves cost, and is high in practicability.

Owner:SHANGHAI DIANJI UNIV

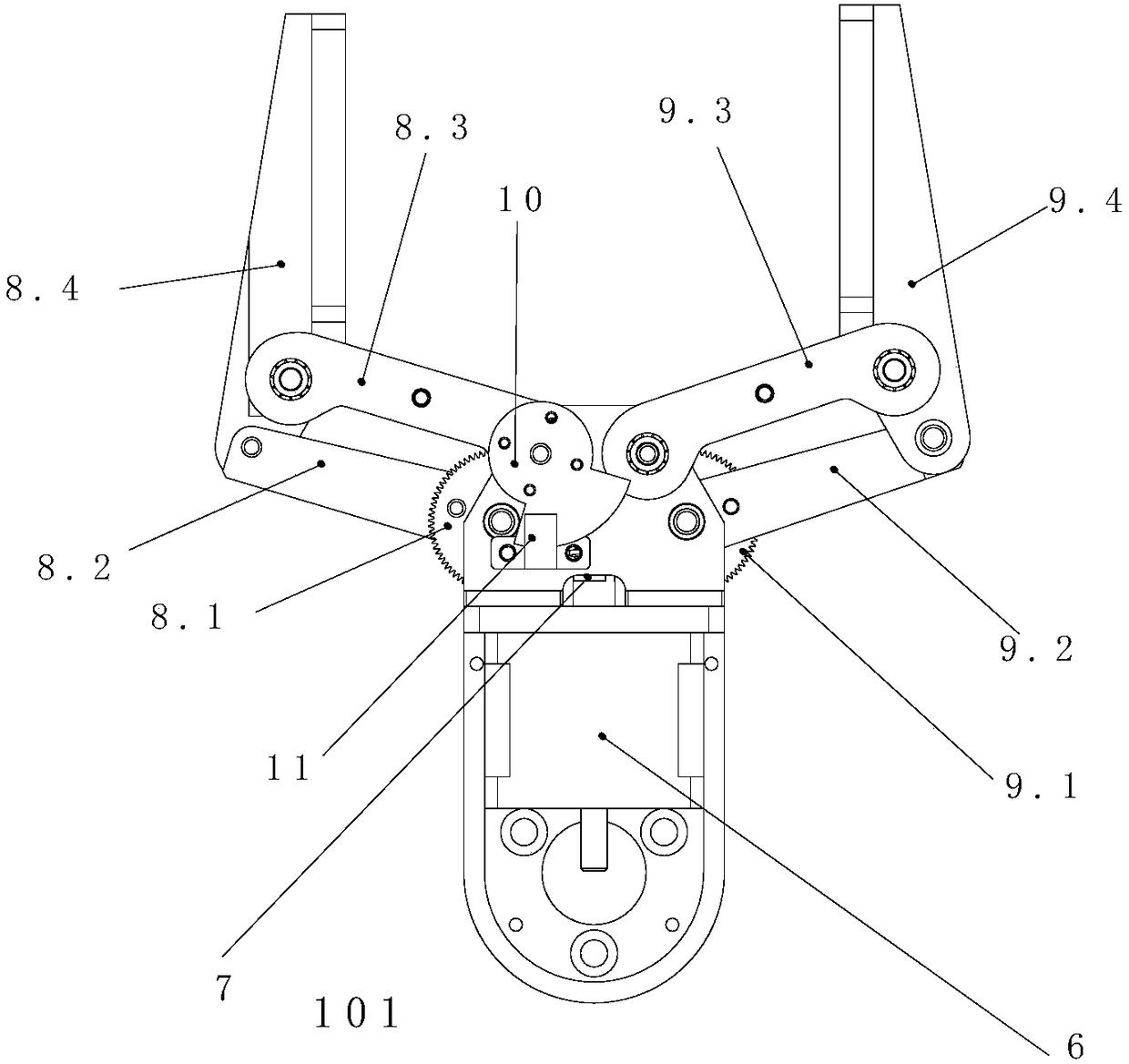

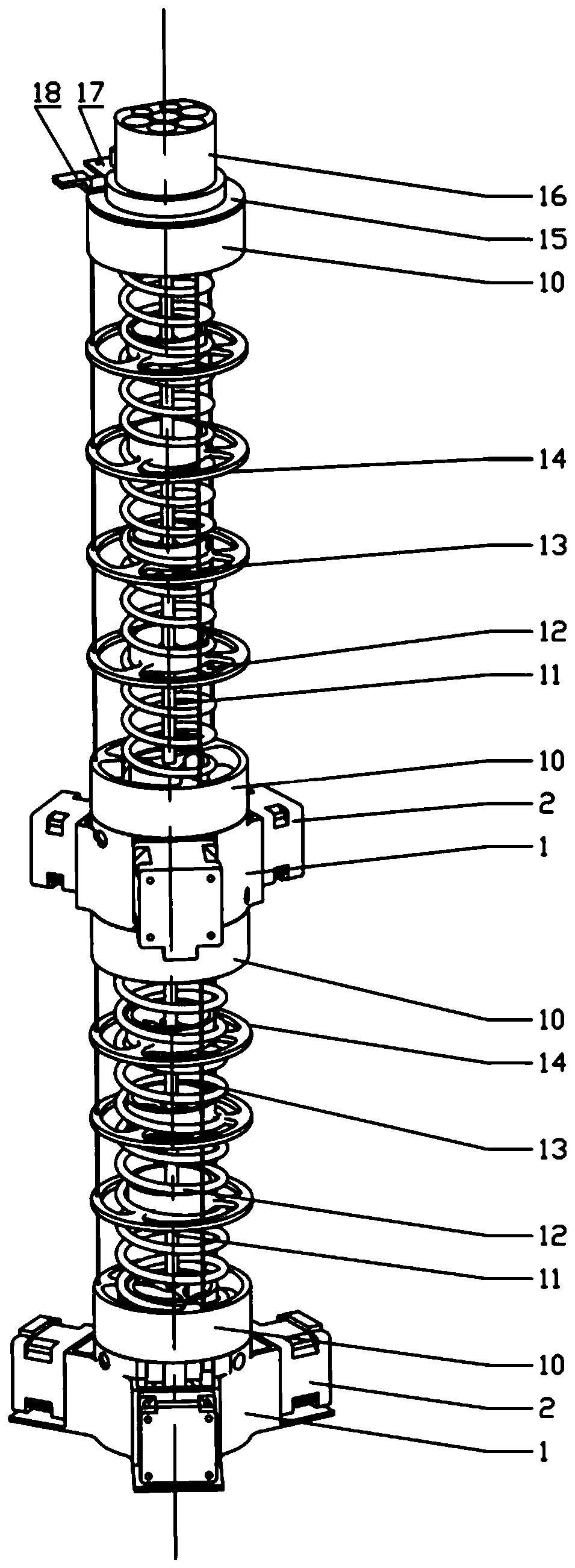

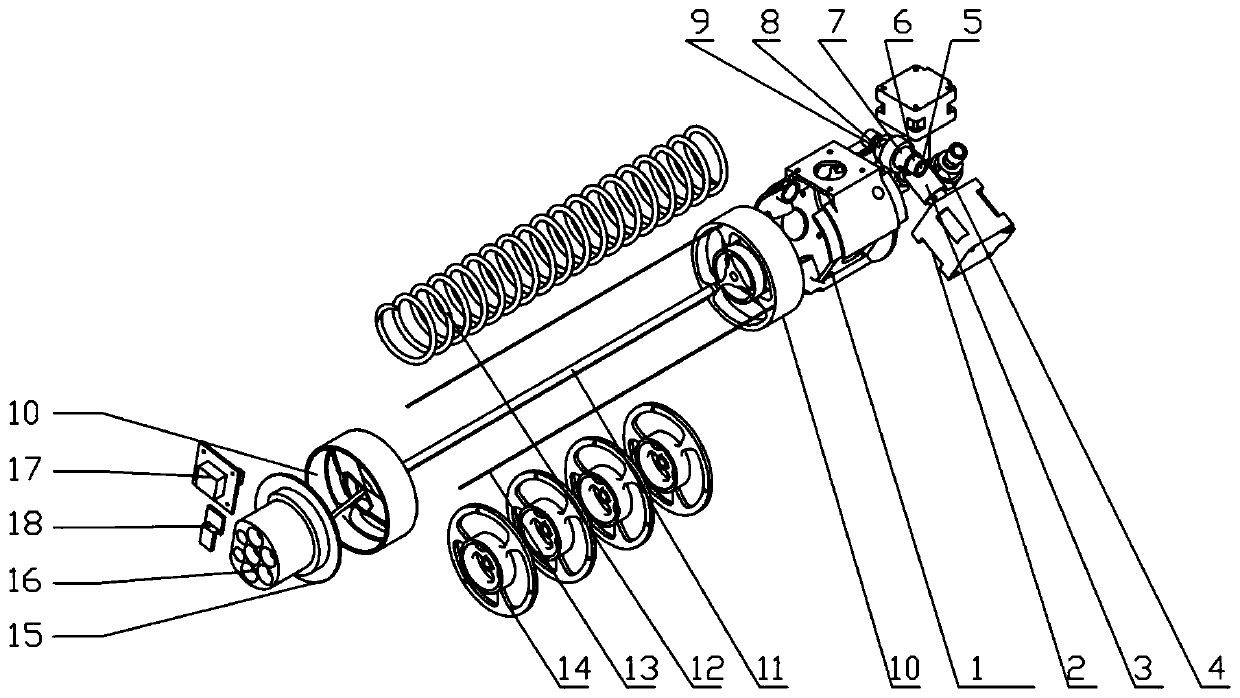

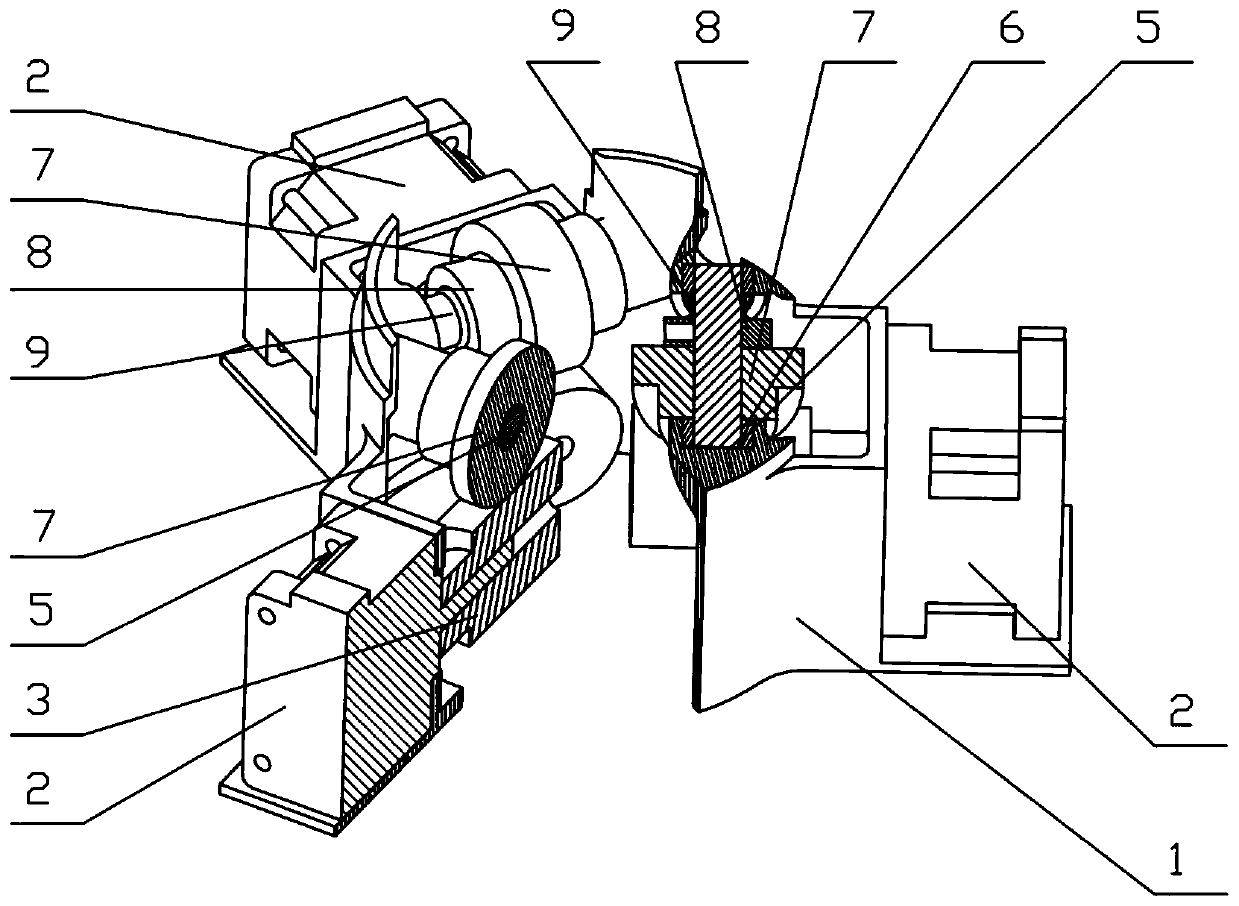

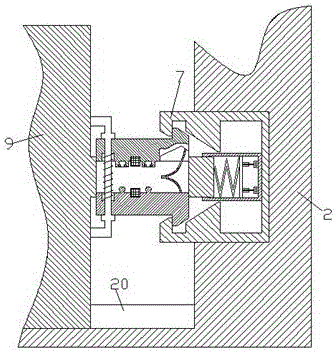

Elephant trunk-like flexible mechanical arm

ActiveCN110065058AControl movement speedImprove flexibilityProgramme-controlled manipulatorModularityHigh load

The invention discloses an elephant trunk-like flexible mechanical arm. The mechanical arm comprises a plurality of elephant trunk-like mechanical arm units and an end execution assembly, wherein eachelephant trunk-like mechanical arm unit comprises a drive mechanism and an elephant trunk-like mechanism; and the stretching and retreating of steel wire ropes in the elephant trunk-like mechanisms are driven through motors in the drive mechanisms, so that the movement speed of the mechanical arm can be conveniently controlled by controlling the rotational speeds of the motors. According to the elephant trunk-like flexible mechanical arm, sensitive control over a movement process is realized through the driving for the steel wire ropes and the combined bearing of a pressure spring and a flexible rod, the stability problem under a high load is avoided, and accurate location is achieved; and meanwhile, a mechanical arm structure is simplified, and the advantages of being flexible in movement, high in load capacity, simple in structure, and the like are achieved. Meanwhile, a modularized design is adopted, hand-eye control is introduced, and the elephant trunk-like flexible mechanical arm is especially applicable to a service robot for life service, and also applicable to other intelligent application occasions.

Owner:ZHEJIANG UNIV

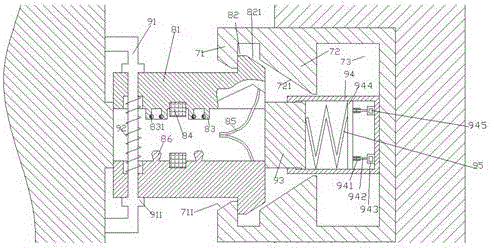

Electric device locking component with high security performance

InactiveCN105914587AAchieve lockingControl movement speedSubstation/switching arrangement boards/panels/desksEngineeringMechanical engineering

The invention provides an electric device locking component with a high security performance. The component comprises an electric cabinet body (2) with a horizontal track (20) and a sliding electric component (9) able to slide along the horizontal track (20). The upright back wall of the electric cabinet body (2) is fixedly provided with a locking and unlocking embedded piece (7). The electric component (9) is fixedly provided with a protruding part (93) which extends into the inner cavity of the locking and unlocking embedded piece (7). The protruding part (93) is provided with a sliding cavity, allowing two symmetrically arranged locking and sliding wedges to be mounted therein in a sliding manner.

Owner:QINGDAO HAITENGDA MACHINERY TECH CO LTD

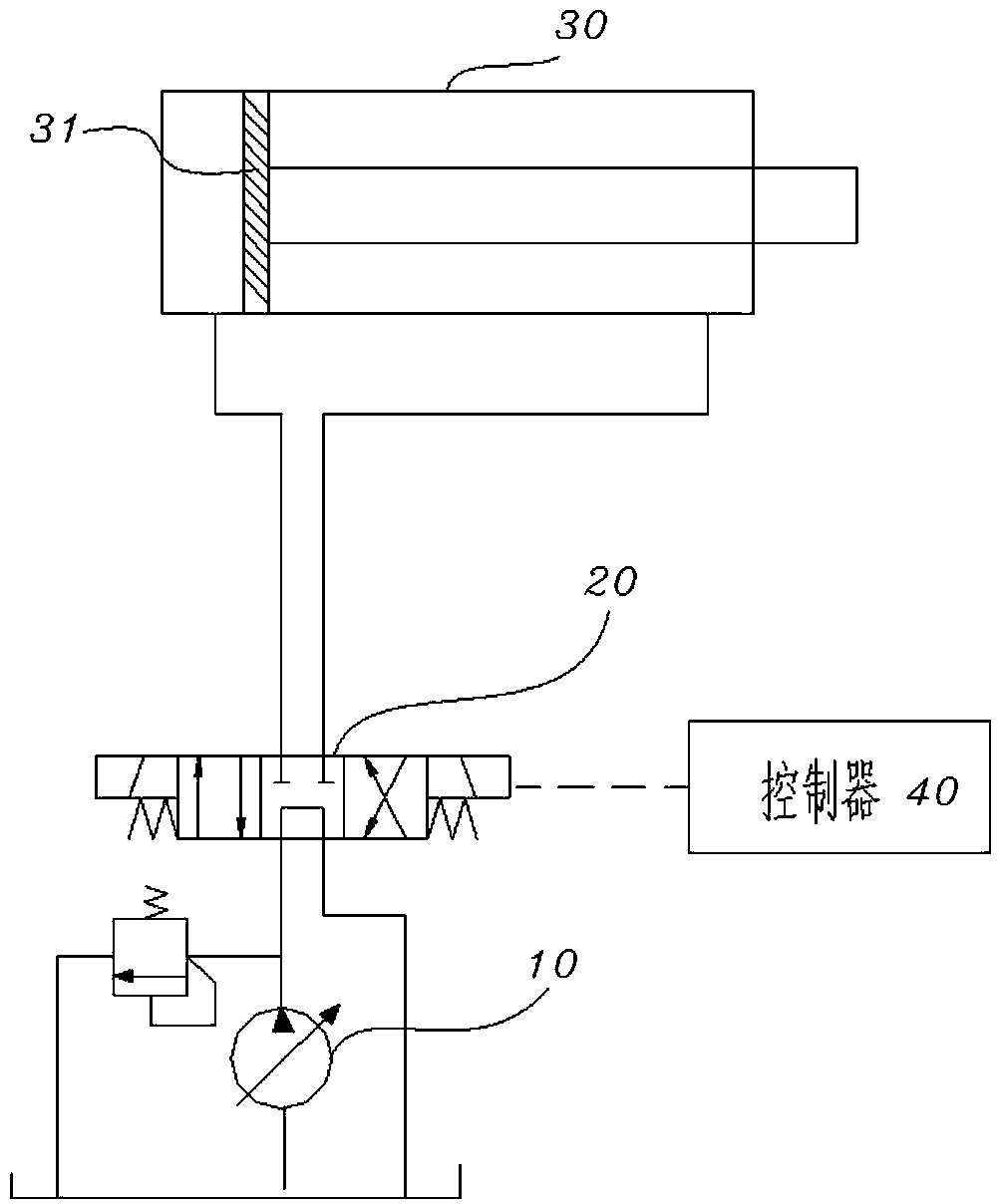

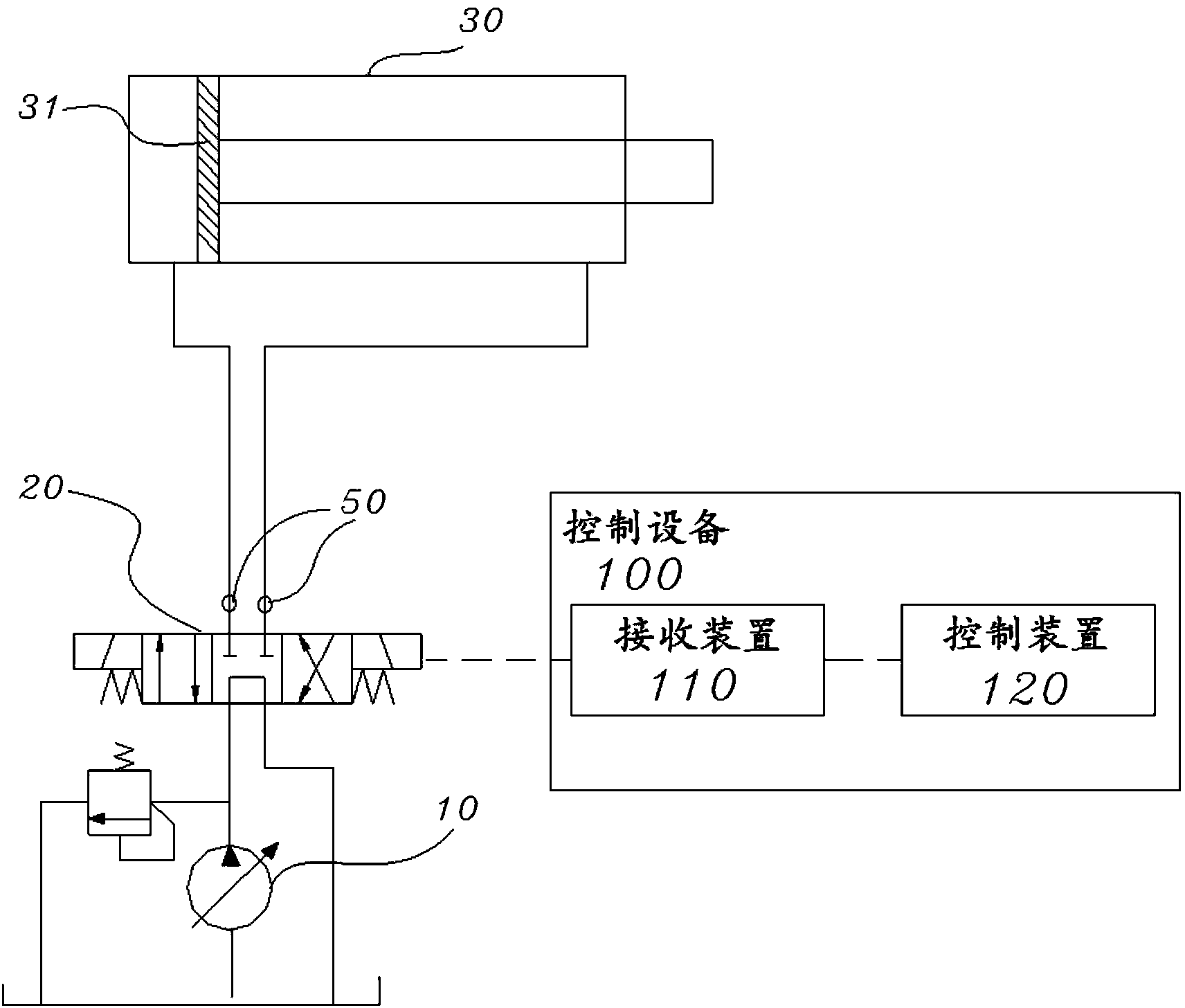

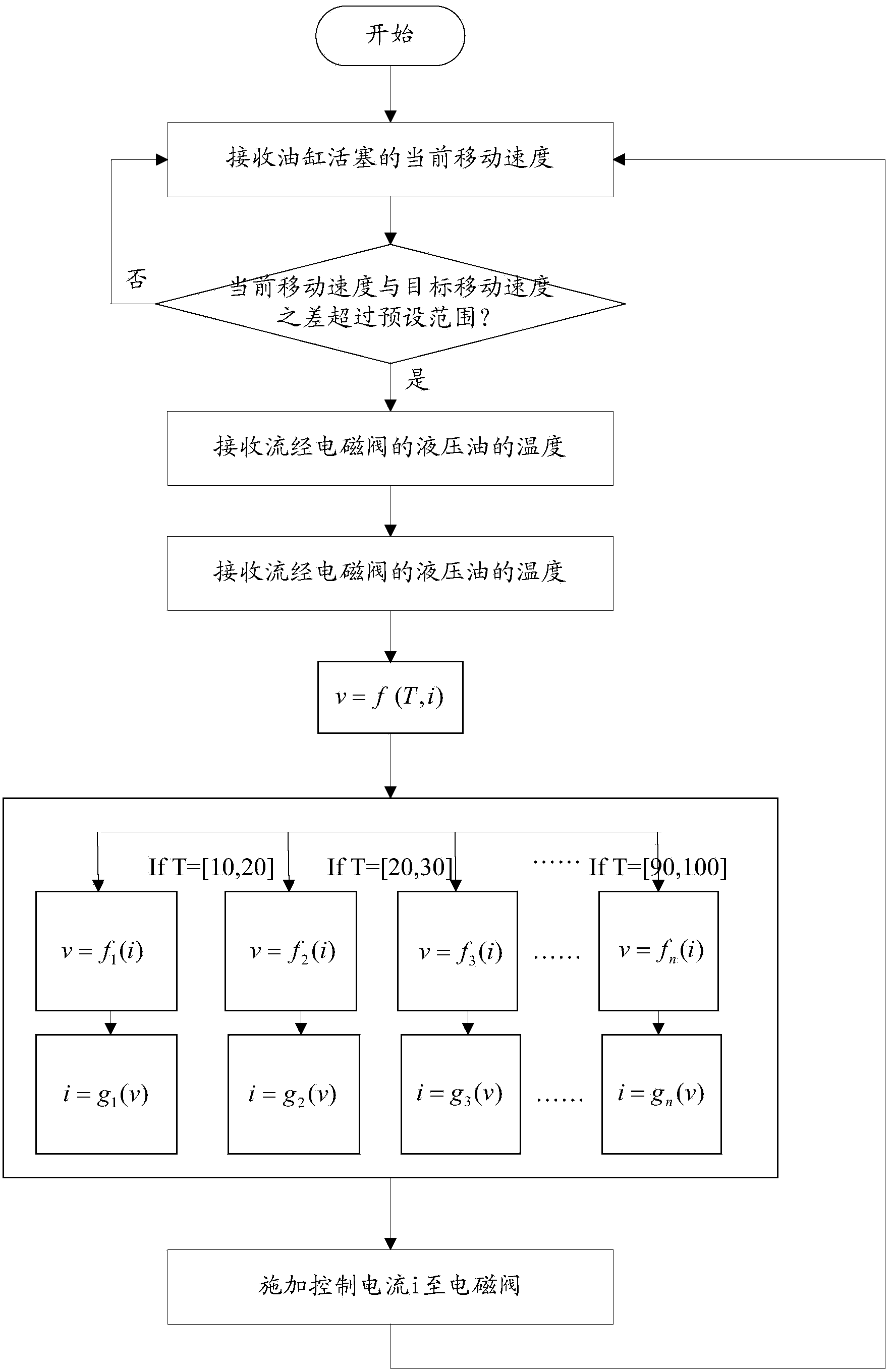

Hydraulic control device, method and system and engineering machine

The invention discloses a hydraulic control device, method and system and an engineering machine. Hydraulic oil driven by a hydraulic pump flows in an oil cylinder through an electromagnetic valve to drive a piston in the oil cylinder to move. The hydraulic control device comprises a receiving device and a control device, wherein the receiving device is used for receiving the temperature of the hydraulic oil flowing through the electromagnetic valve and the target moving speed of the piston, and the control device is used for controlling a control current exerted on the electromagnetic valve based on the temperature and the target moving speed to enable the moving speed of the piston to meet the target moving speed. By means of the technical scheme, accurate control over oil cylinder and piston based on temperature compensation can be achieved to address the influences of different oil temperatures on the circulating flow of a valve opening of the electromagnetic valve.

Owner:HUNAN ZOOMLION INTELLIGENT TECH +1

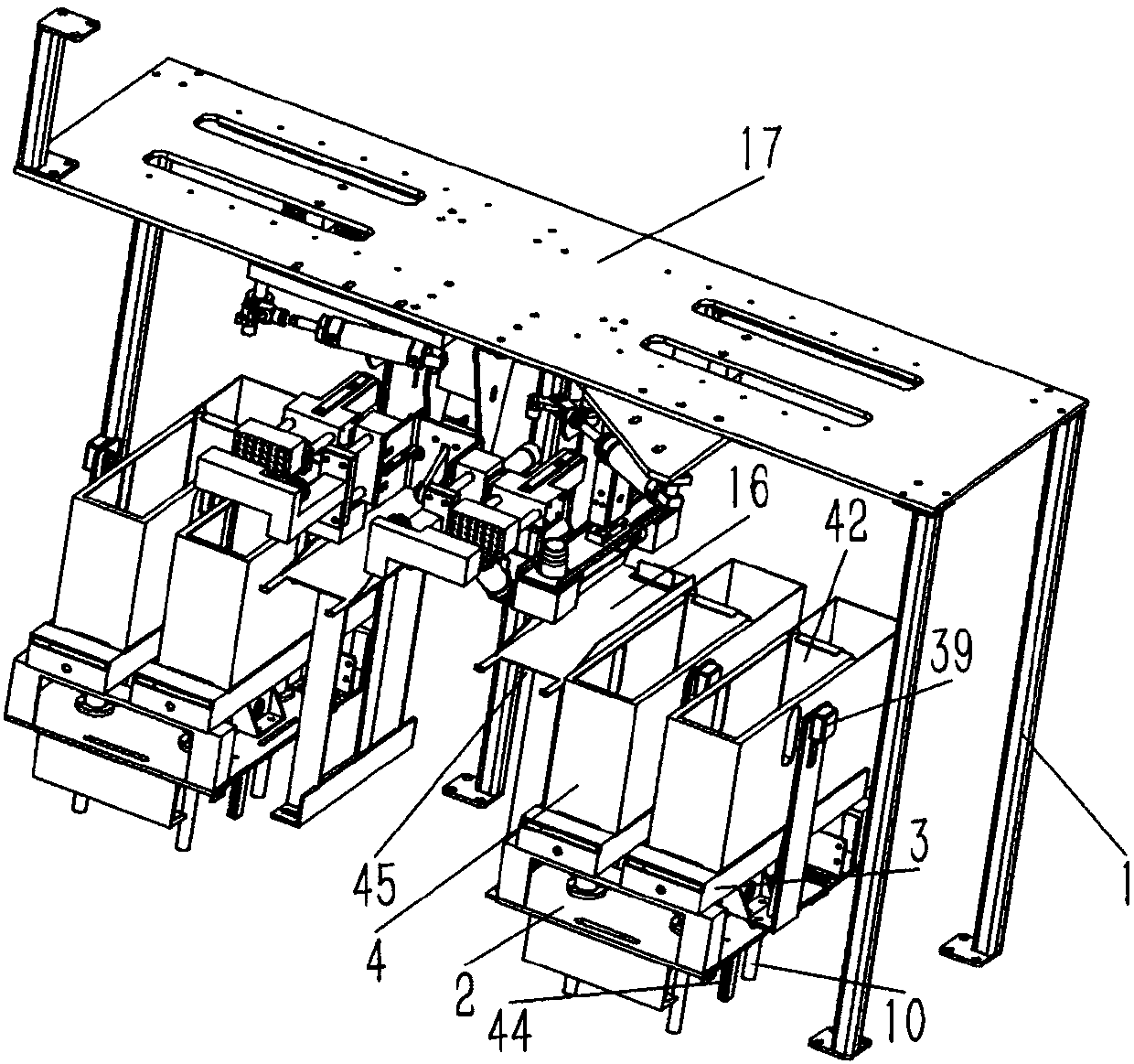

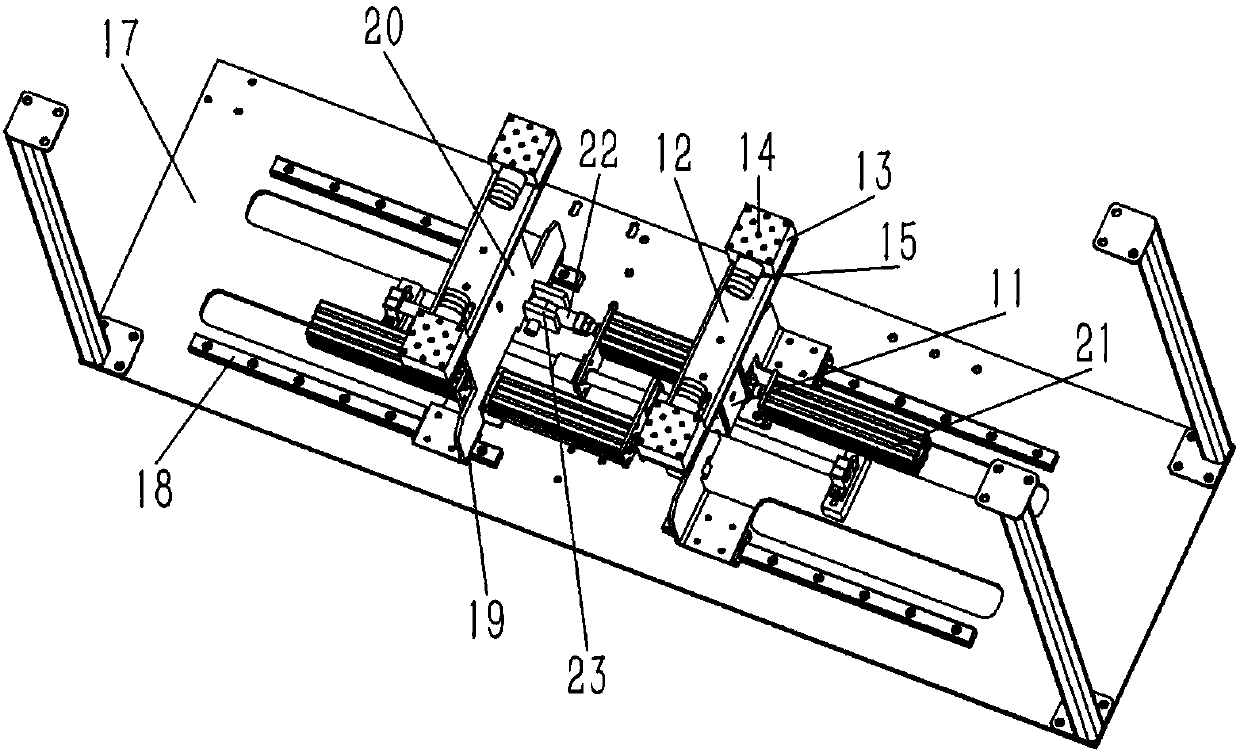

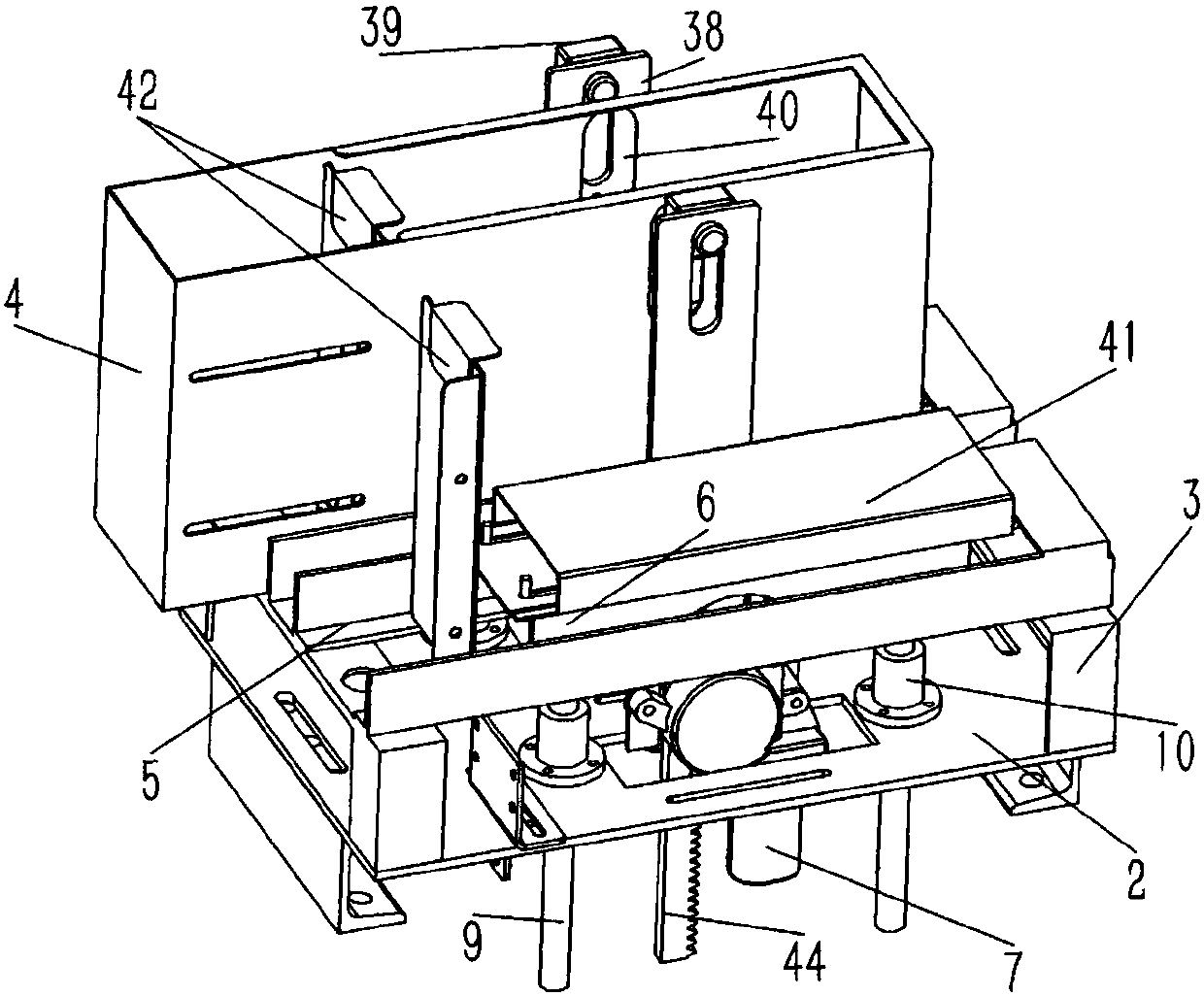

Full-automatic material and bag arranging type packing machine

ActiveCN107600473AOutstanding and Beneficial Technical EffectsPrevent Dry Run ConditionsWrapper twisting/gatheringPackaging automatic controlEdible mushroomEngineering

The invention provides a full-automatic material and bag arranging type packing machine, belongs to the technical field of packing machines, and aims at overcoming the shortages of low automation degree, low production efficiency and high labor input in the prior art. The machine comprises a packing bag absorbing part which is arranged on a rack, a culture material bagging part which is arranged above the packing bag absorbing part, a packing sealing part which is arranged at one side of the culture material bagging part, and a culture material bagged product outlet part which is formed in oneend of the packing sealing part, wherein a display screen for human-machine interaction and a PLC control box are arranged beside the culture material bagged product outlet part. Compared with the prior art, the machine has the advantages of being high in automation degree, high in production efficiency, and low in labor input cost; the machine is applicable to packing bag arranging, etc., and particularly applicable to the environment of massive bagging of edible mushroom culture materials.

Owner:ZHEJIANG HONGYE EQUIP TECH

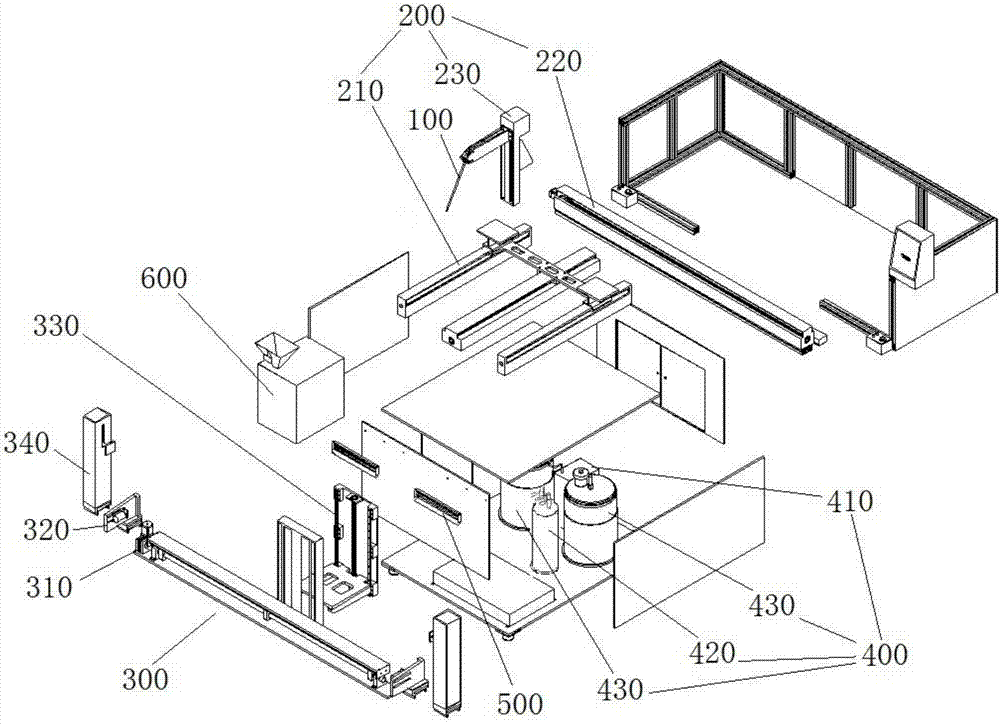

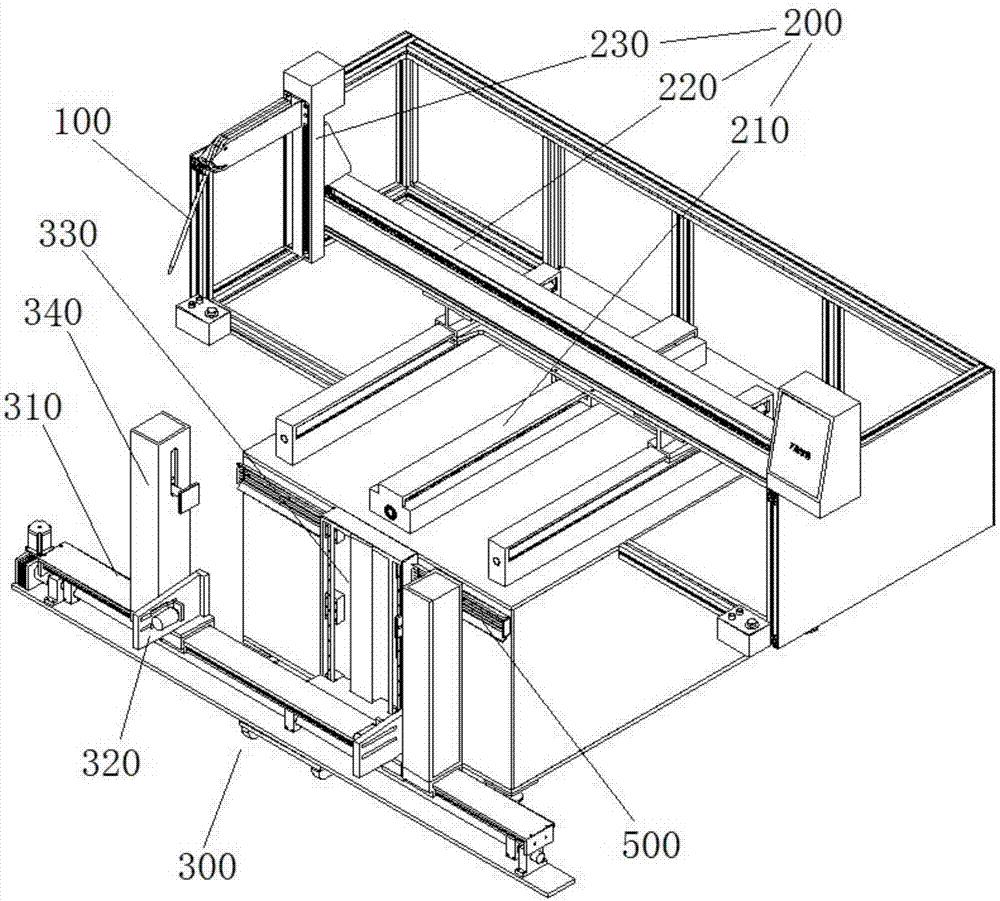

Glue coating equipment

ActiveCN107042188AControl the amount of glue injectedControl movement speedPretreated surfacesCoatingsEngineeringMaterial resources

The invention provides glue coating equipment. The glue coating equipment comprises a glue gun, a three-dimensional moving device, a frame adjusting device, a feeding device and a drying device. The glue gun is mounted on the three-dimensional moving device. The three-dimensional moving device can drive the glue gun to move front and back, left and right, and up and down. The frame adjusting device is mounted on the front side of the three-dimensional moving device and can fix a frame and adjust the relative angle of the frame and the glue gun. The feeding device is connected with the glue gun through a pipeline. The feeding device can convey glue to the glue gun to coat the frame with the glue. The drying device is mounted on one side of a frame glue coating position. The drying device can dry the glue on the frame. By adopting the glue coating equipment, glue coating can be completed rapidly and efficiently; mechanization is realized in the glue coating process of frame filters; manpower and material resources are greatly reduced; the product quality is guaranteed; and the glue coating efficiency of the frame filters is improved.

Owner:广州金田瑞麟环境科技有限公司

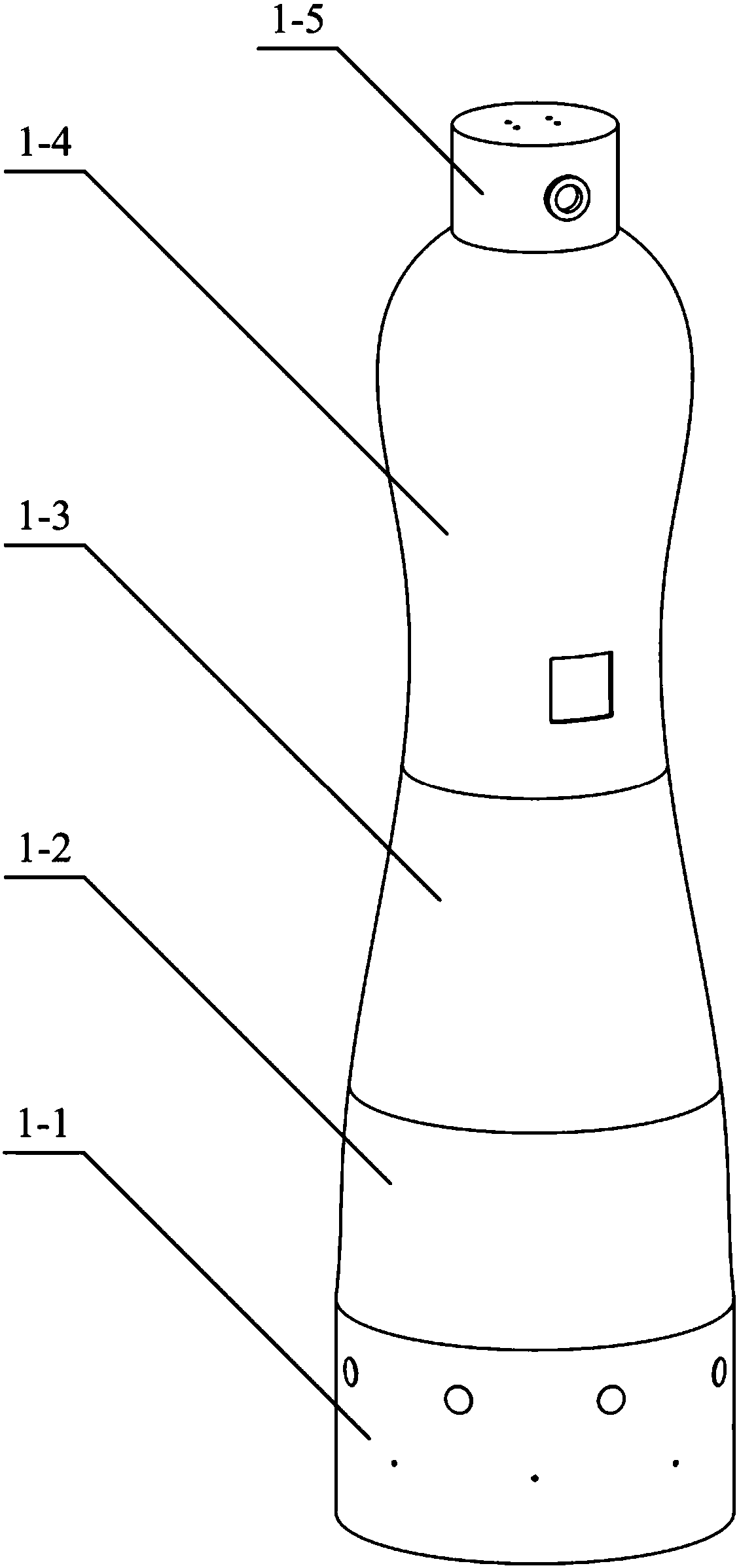

Split type intelligent plunger with pulley mechanism

InactiveCN109723408AReal-time control of motion speedAvoid damageFlexible member pumpsFluid removalDual mechanismButterfly valve

The invention relates to the field of gas well drainage and gas production, in particular to a split type intelligent plunger with a pulley mechanism. The split type intelligent plunger with pulley mechanism is characterized in that the intelligent plunger comprises a plunger body, a pulley mechanism at the lower end of the plunger body, a plunger sleeve, a spring slip arranged in the plunger sleeve, an open butterfly valve with a locking device, an upper buffer, a lower buffer, a self-adaptive valve mechanism arranged in the lower buffer and a pressure sensor, a temperature sensor, a speed sensor and a microprocessor control attached to the plunger body and the plunger sleeve; the speed of the plunger body and the plunger sleeve in the ascending or descending process is controlled by controlling the action of the pulley mechanism. Compared with the prior art, the split type intelligent plunger with pulley mechanism has the advantages that the defect that the speed of the plunger usedfor draining water in the prior continuous production operation without closing the well is not controllable is solved, and the problem that an underground or wellhead accident is caused due to serious collision between the plunger body and the plunger sleeve in the a ascending or descending process is effectively avoided.

Owner:SOUTHWEST PETROLEUM UNIV

Skiff retracting and releasing device

The invention discloses a skiff retracting and releasing device. According to the device, a cabin for placing skiffs is formed in a hull, a stern of the hull is provided with a channel inclining downwards, one end of the channel is connected with the cabin, and a stern door capable of rotating downwards is hinged to the other end of the channel; the stern door, the channel and the cabin are respectively provided with a plurality of idler roller set formed by idler rollers supporting the bottoms of the skiffs from the two sides, the two sides of each idler roller set of the cabin are respectively provided with a movable guide rail, and a trolley is arranged on the movable guide rail on each side and provided with a draft gear and a skiff pushing device. According to the skiff retracting and releasing device, the stern door can rotate downwards, so that the skiffs slide to the hull from the idler roller sets on the stern door through the channel conveniently and are pushed to the corresponding positions of the cabin through the trolleys to be fixed, the operation is convenient to carry out, the multiple skiffs can be retracted and released through the retracting and releasing device on a mother ship, and the skiff retracting and releasing device is convenient to operate and high in safety.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Directional silk distribution short carbon fiber thermoplastic resin based prepreg preparation device and method

The invention discloses a directional silk distribution short carbon fiber thermoplastic resin based prepreg preparation device and method and belongs to the field of composite material preparation. By utilizing the special structure of a vibration sieve, through the restriction effect of vibration sieve holes, carbon fiber silks which fall off through vibration from slender sieve holes to performvertical motion of a free falling body; when one ends of the fiber silks are adhered to a resin film in the falling process, the carbon fiber silks are reversely fixed by utilizing the viscosity of the resin film and one-way relative motion of the carbon fiber silks and a two-dimensional movement platform, directional arrangement and uniform distribution of carbon fibers in a movement direction are realized, and the problems of uneven distribution and difficulty in orientation of short carbon fibers in thermoplastic resin are well solved; and through control on a movement speed of the two-dimensional movement platform and control on number of times of laying, accurate control on the content of the carbon fibers in a prepreg is realized, orientation of the carbon fiber silks can be an arbitrary two-dimensional direction, crossing distribution of multiple layers of resin films and multiple layers of carbon fibers is realized, and the mechanical performance of a carbon fiber composite material is improved.

Owner:JIANGSU UNIV

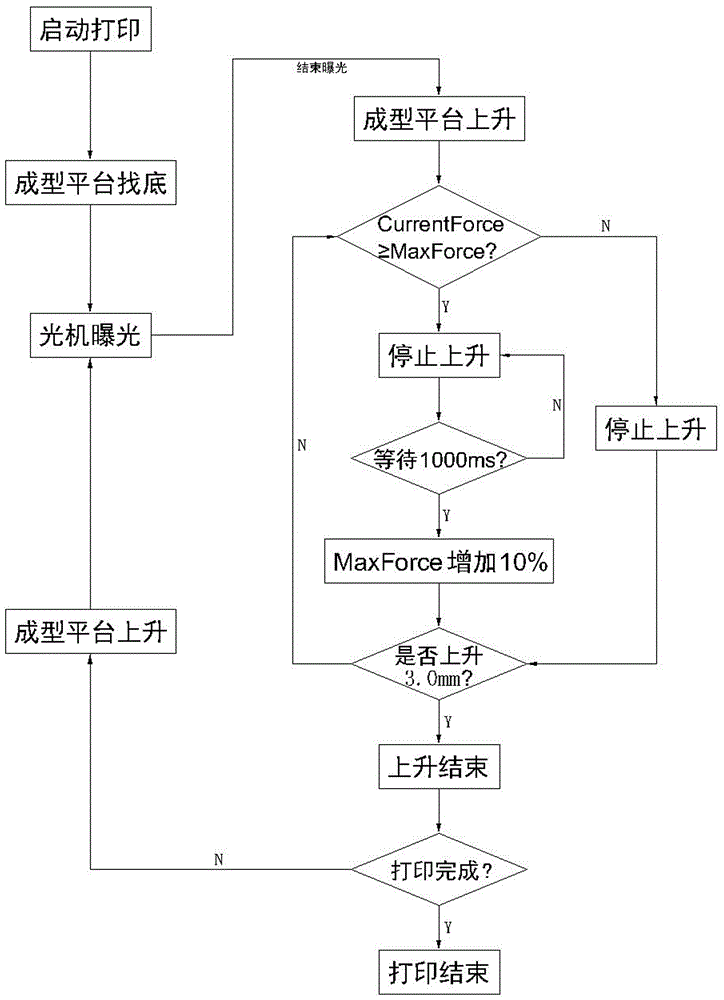

3D printing method based on force feedback system

ActiveCN106273513AGuaranteed print qualityIncrease success rateAdditive manufacturing apparatusEngineeringMotor drive

The invention discloses a 3D printing method based on a force feedback system. The method includes the following steps that firstly, when printing is started, a motor drives a forming platform to begin to move downwards, and the force feedback system controls the forming platform to successfully find the bottom; secondly, exposure printing of a first layer is carried out; thirdly, after exposure is finished, the forming platform moves upwards for stripping, and meanwhile the current stripping force CurrentForce is compared with a threshold value MaxForce set in the current state of the force feedback system; fourthly, if CurrentForce>=MaxForce, the forming platform stops moving upwards or moves upwards in a decelerating mode, and the fifth step is executed, and if CurrentForce<MaxForce, the forming platform continues moving upwards, and the sixth step is executed; fifthly, MaxForce is automatically increased by a scale value, and the fourth step is executed again; sixthly, the forming platform stops when moving upwards to a set height distance, and stripping is completed; seventhly, the motor drives the forming platform to move downwards again for exposure printing of a next layer; eighthly, the third step to the seventh step are repeated till printing of a printout is completed. By means of the force feedback system, the printing process is more intelligent, and the printing success rate and the printout quality are greatly improved.

Owner:GUANGZHOU HEYGEARS INTELLIGENT TECH CO LTD

Abdominal wall supporting device for gasless laparoscopic surgery

InactiveCN108670325AReduce surgical riskAvoid crushing internal organsDiagnosticsSurgeryLaparoscopic surgeryMoving speed

The invention relates to the field of medical devices, and in particular to an abdominal wall supporting device for a gasless laparoscopic surgery. The device comprises a rod-shaped body that cooperates with a cavity mirror puncture, wherein the rod-shaped body is provided with a through hole that cooperates with a laparoscope, the rod-shaped body is provided with at least one supporting mechanism, and the supporting mechanism comprises a telescopic tube and a slider which are detachably connected to each other, the slider is made of silicone material, and the telescopic tube is detachably connected with a gas supply device, the gas supply device controls the amount of gas in the telescopic tube, changes the distance between the slider and the rod-shaped body, and the telescopic tube is ina contracted state when the rod-shaped body is placed in the abdominal cavity in order to prevent the supporting mechanism from causing damage to the cavity mirror puncture, during the extension of the telescopic tube, the slider made of silicone material does not cause damage to the organ, at the same time, the gas supply device is used to control the moving speed of the slider, so as to avoid the crushing injury caused by the slider moving too fast, the abdominal wall and the internal organs can separate safely to form a surgical space for laparoscopic surgery in the abdominal cavity.

Owner:SICHUAN LIZHI JIUCHUANG INTPROP OPERATION CO LTD

Large-sized hydraulic speed change floating box flap valve

InactiveCN102095004AReduce noiseAvoid damageBarrages/weirsOperating means/releasing devices for valvesEngineeringFlap valve

The invention discloses a large-sized hydraulic speed change floating box flap valve. The flap valve comprises a hinged support (1), a valve seat (3), an upper valve leaf (5) and a lower valve leaf (8), wherein both the valve seat (3) and the hinged support (1) are fixed on a pump station base; the upper valve leaf (5) is hinged with the hinged support (1) through a pin shaft (2); the lower valveleaf (8) is hinged with the upper valve leaf (5); the upper valve leaf (5) and the lower valve leaf (8) are hermetically contacted and matched with the valve seat (3) through a sealing structure, andthe upper valve leaf (5) is connected with the lower valve leaf (8) through at least one hydraulic mechanism (7); and one end of the hydraulic mechanism (7) is hinged with the upper valve leaf (5), and the other end of the hydraulic mechanism (7) is hinged with the lower valve leaf (8). After the structure is adopted, since the upper valve leaf and the lower valve leaf are provided with the hydraulic mechanism, the collision force of the valve leaves and the valve seat can be buffered by the hydraulic mechanism; thus water sealing rubber for sealing the valve leaves and the valve seat is prevented from being damaged so as to reduce the cost; meanwhile, the noise produced during collision is also reduced.

Owner:NINGBO JUSHEN PUMPS IND

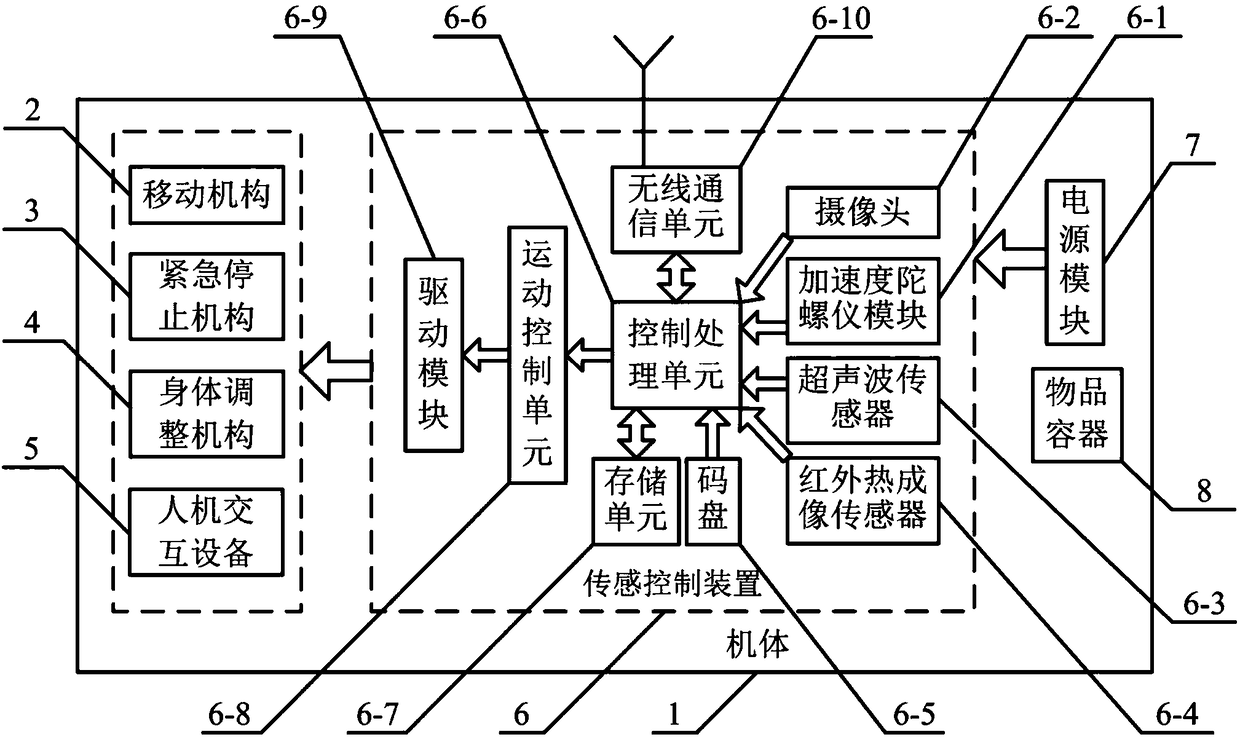

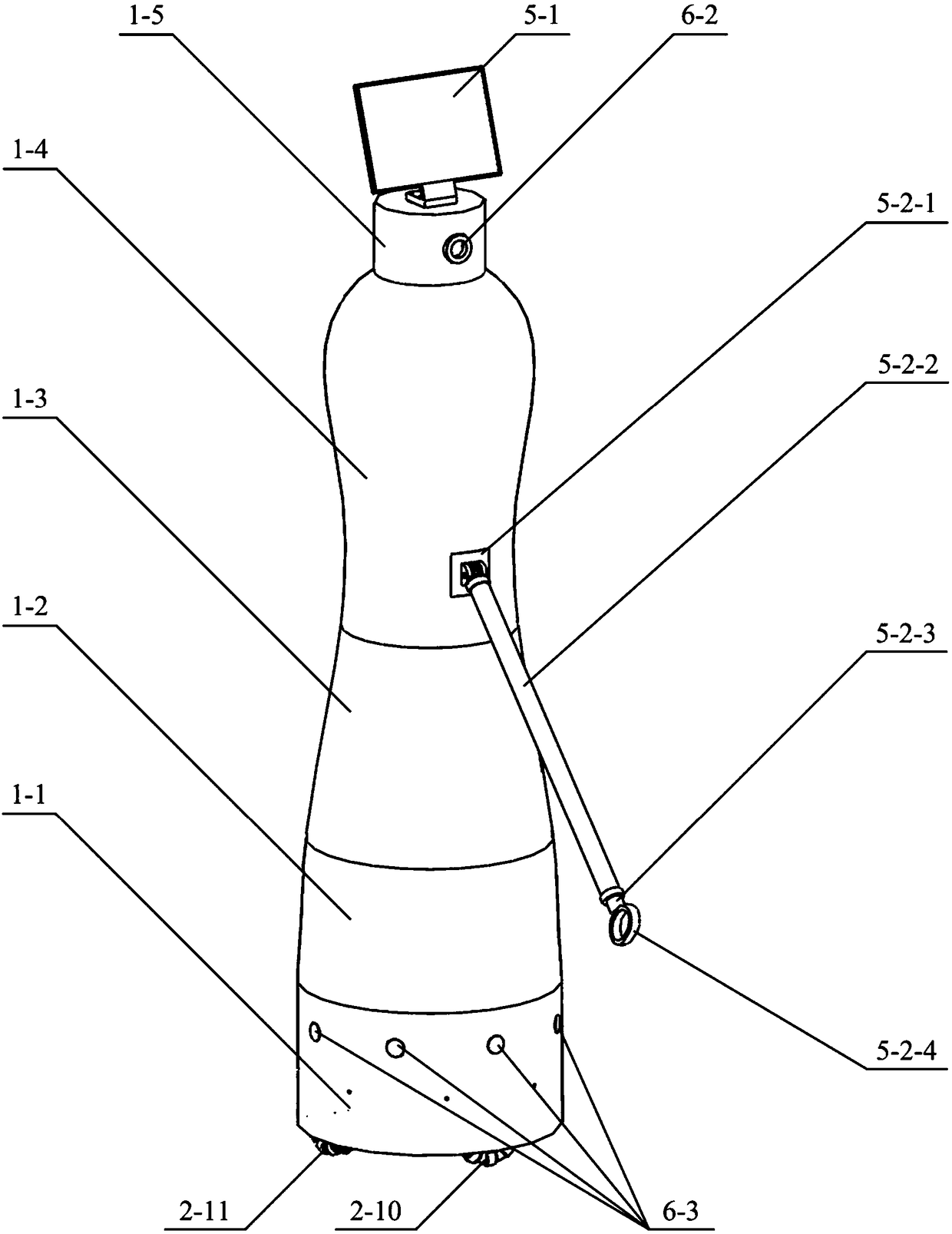

Robot and control method

PendingCN108555935AGuaranteed negative pressureCause an accidentProgramme-controlled manipulatorGear wheelSolenoid valve

The invention discloses a robot and a control method. The robot comprises a body, a moving mechanism, an emergency stop mechanism and a body adjusting mechanism, the moving mechanism drives the body to move, the emergency stop mechanism comprises a connecting frame, a sliding rod, a sucker seat, a compression spring, a sucker, a cylindrical cam, a pulley shaft, a pulley, a driven stop gear, a driving stop gear, a stop motor and a solenoid valve, and the body adjusting mechanism comprises a fixed frame, a fixed column, a pitching motor seat, a pitching motor, a primary framework, a secondary framework, a rack, a telescopic motor and a rack driving gear. The emergency stop mechanism can achieve the emergency stop function of the robot under emergency circumstances such as pedestrians, animals and carts in the rapid movement process of the robot, and safety accidents caused by knock into the pedestrians and the like are prevented. The emergency stop mechanism can further prevent the robotfrom turnover due to over-high gravity center and dynamic change in the cargo handling process.

Owner:SOUTHEAST UNIV

Automatic tin adding machine

InactiveCN102582230AControl flowControl movement speedScreen printersPrinting press partsEngineeringFlange

The invention discloses an automatic tin adding machine, which comprises a controller, a horizontal transmission mechanism and an automatic tin adding mechanism. The automatic tin adding mechanism is connected with the horizontal transmission mechanism via a connecting support and comprises a vertical transmission mechanism, a squeezing flange and a fixing flange, the vertical transmission mechanism is connected with the connecting support, the squeezing flange is connected with the vertical transmission mechanism and used for downwards squeezing a tin cream box, the fixing flange is connected with the connecting support and used for fixing the tin cream box, and the horizontal transmission mechanism and the vertical transmission mechanism are electrically connected with the controller. The automatic tin adding machine can achieve purposes of uniformly squeezing out tin cream, increasing the quality of products and saves resources.

Owner:SUZHOU HUILONG AUTOMATION EQUIP

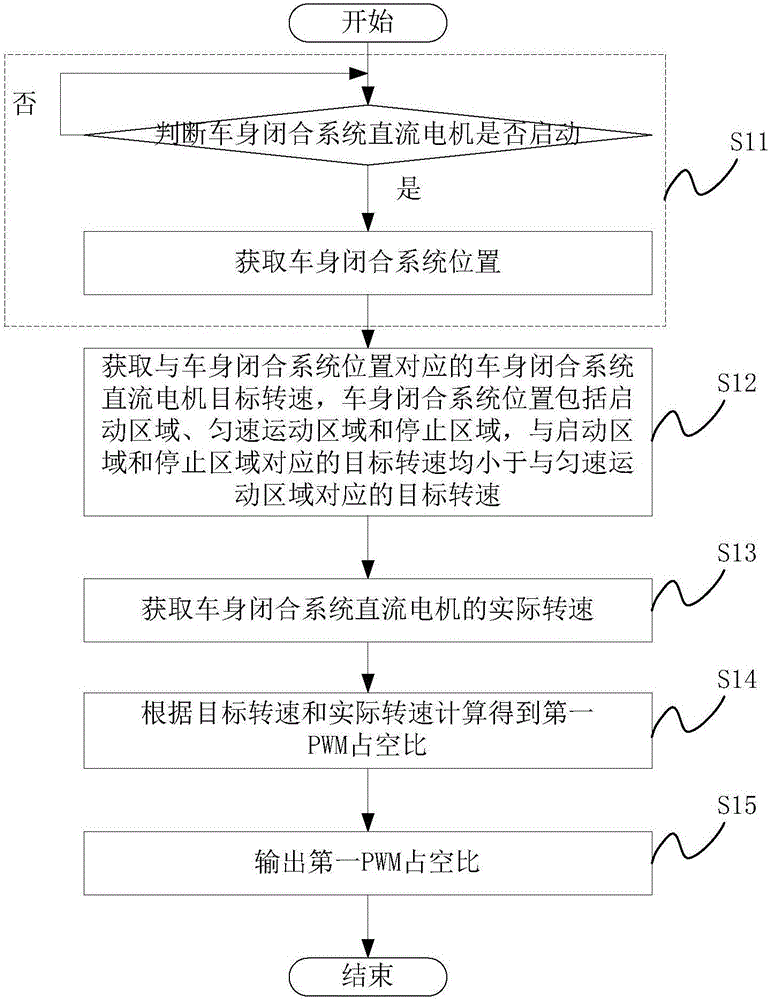

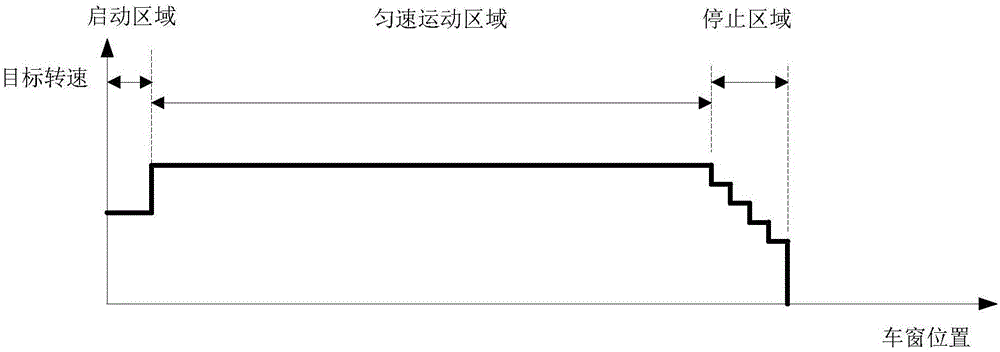

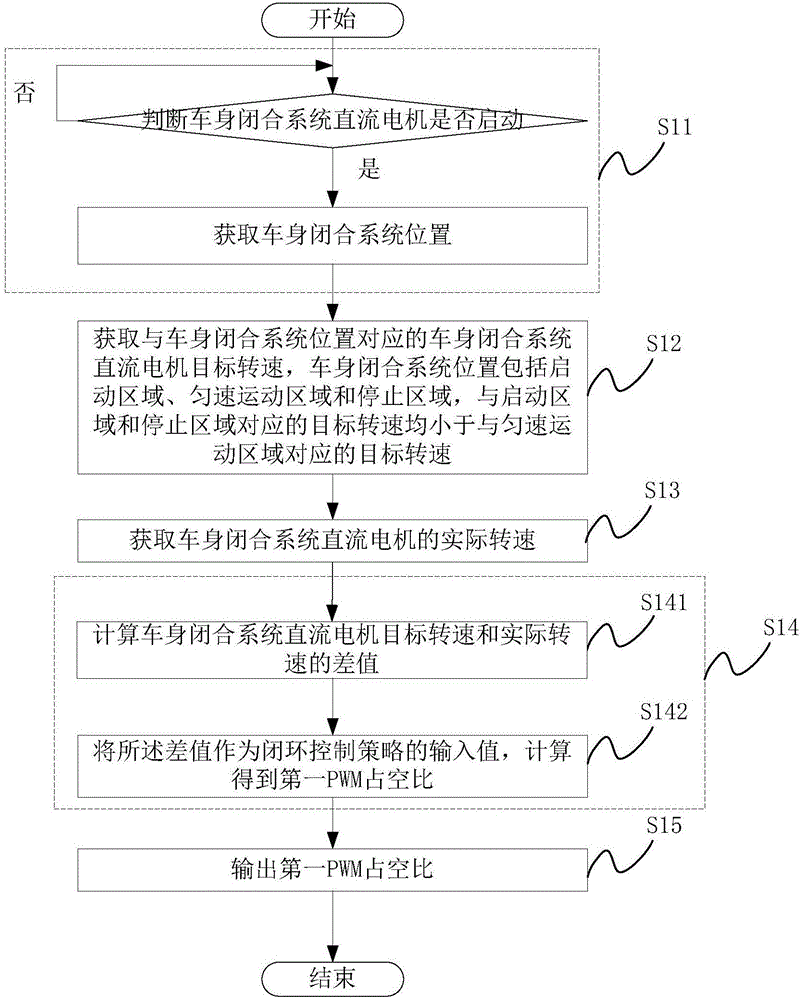

Control method and apparatus for direct current motor of car body closing system

ActiveCN106788008AReduce noiseControl movement speedField or armature current controlPower-operated mechanismLow noiseEngineering

The invention provides a control method and apparatus for a direct current motor of a car body closing system. The control method comprises the steps of obtaining positions of the car body closing system and target rotary speeds of the direct current motor corresponding to the positions; obtaining an actual rotary speed of the direct current motor; and calculating a first PWM duty ratio and outputting the duty ratio according to the target rotary speeds and the actual rotary speed. The positions of the car body closing system comprise a starting region, a uniform motion region and a stopping region; and the target rotary speeds of the direct current motor corresponding to the starting region and the stopping region are both less than the target rotary speed of the direct current motor corresponding to the uniform motion region, so that the actual rotary speed of the direct current motor is changed slowly and smoothly, and the noise generated by the movement of the car body closing system is relatively low. According to the control method and apparatus, by regulating the PWM duty ratio, a driving voltage supplied to the direct current motor of the car body closing system by a vehicle-mounted storage battery is adjusted, and the rotary speed of the direct current motor of the car body closing system is adjusted, and the movement speed of the car body closing system is controlled, so as to further lower noise in the movement of the car body closing system and improve use comfort degree of a user.

Owner:BEIJING JINGWEI HIRAIN TECH CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com