Full-automatic material and bag arranging type packing machine

A fully automatic, bag-packing technology, which is applied in the field of cooking bag packaging machine and automatic cooking bag packaging machine, can solve the problems affecting the quality and output of edible fungi, the unevenness of the bag tie, and the weight deviation of the culture material, etc. , to achieve the effect of reducing the probability of insufficient bag supply, reducing manpower input, and improving the completion rate of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below with specific examples.

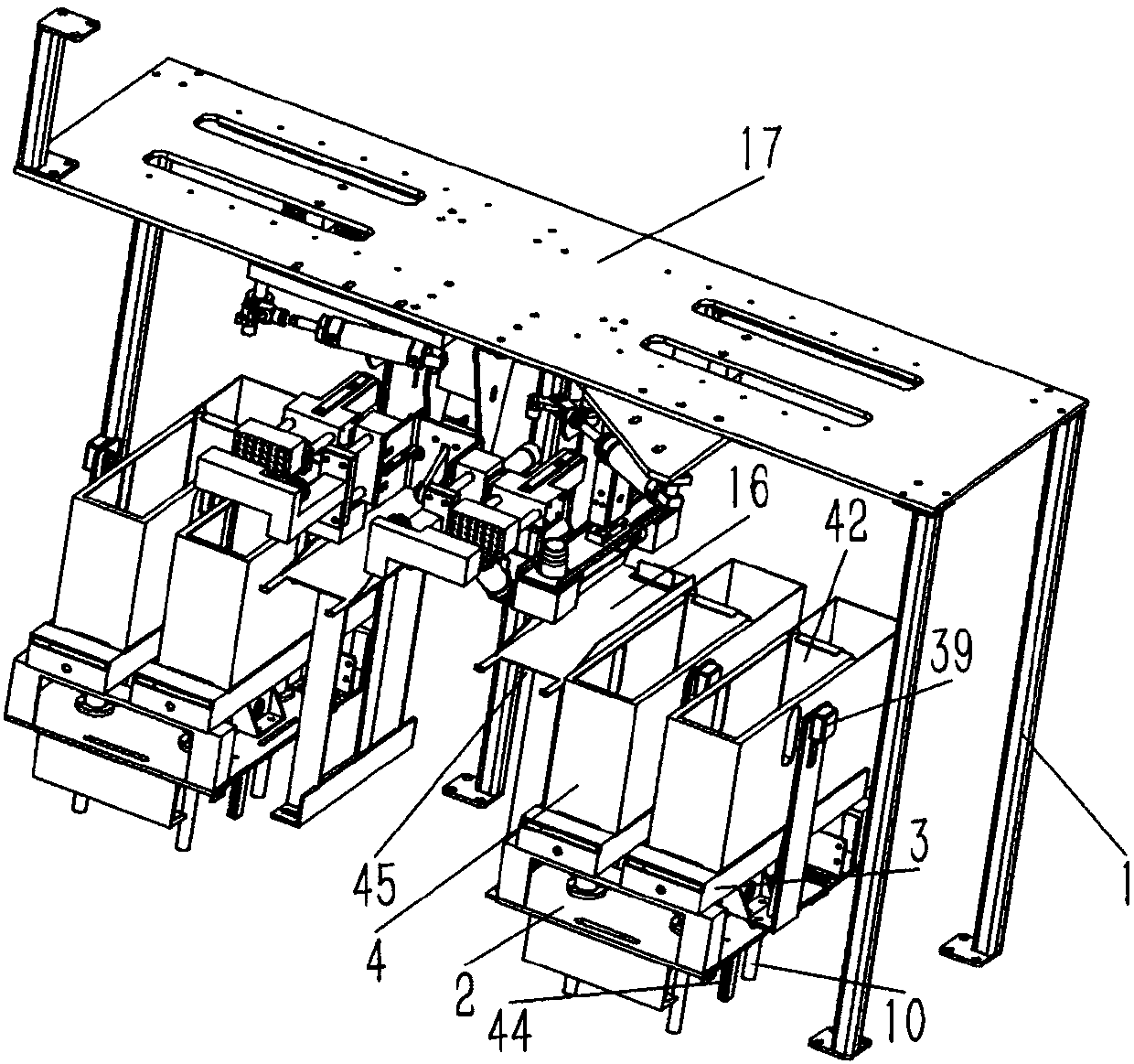

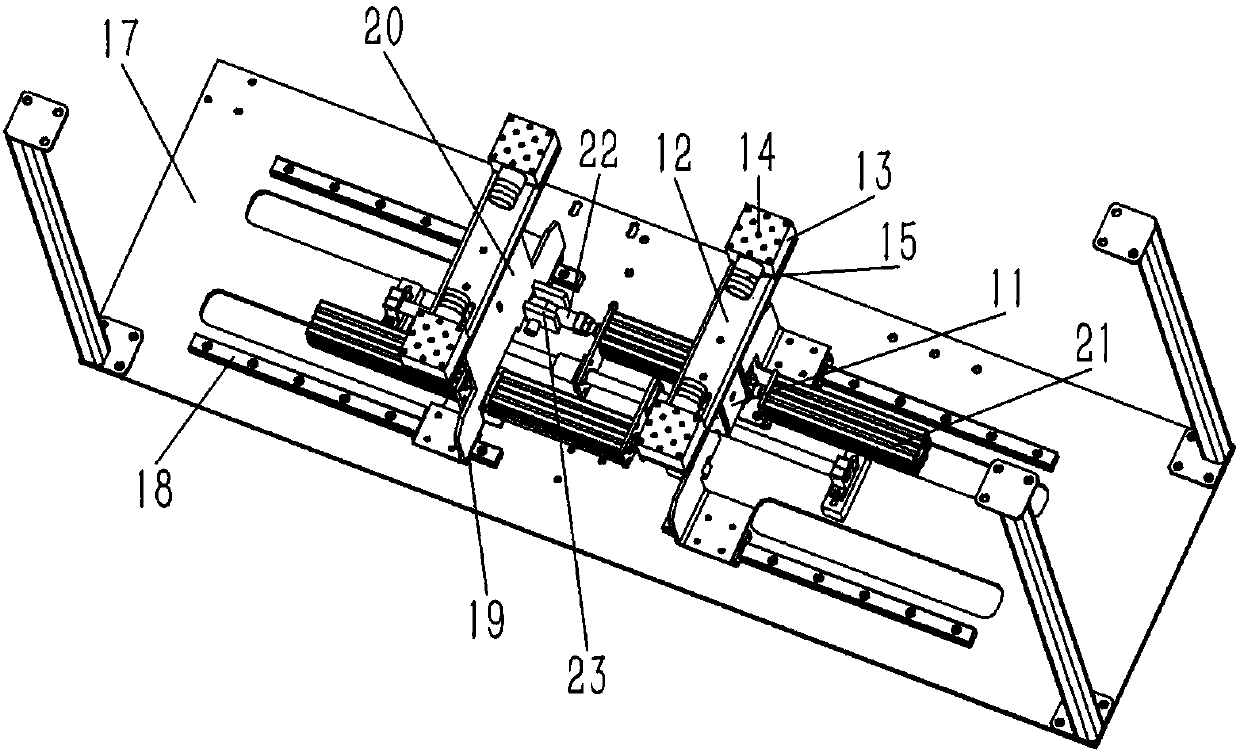

[0043] A fully automatic cooking bag packaging machine, comprising a packaging bag adsorption part arranged on a frame 1, a culture material bagging part arranged above the packaging bag adsorption part, and a packaging sealing part arranged on the side of the culture material bagging part And the outlet part of the finished product in the bag of culture material arranged at one end of the sealing part of the package;

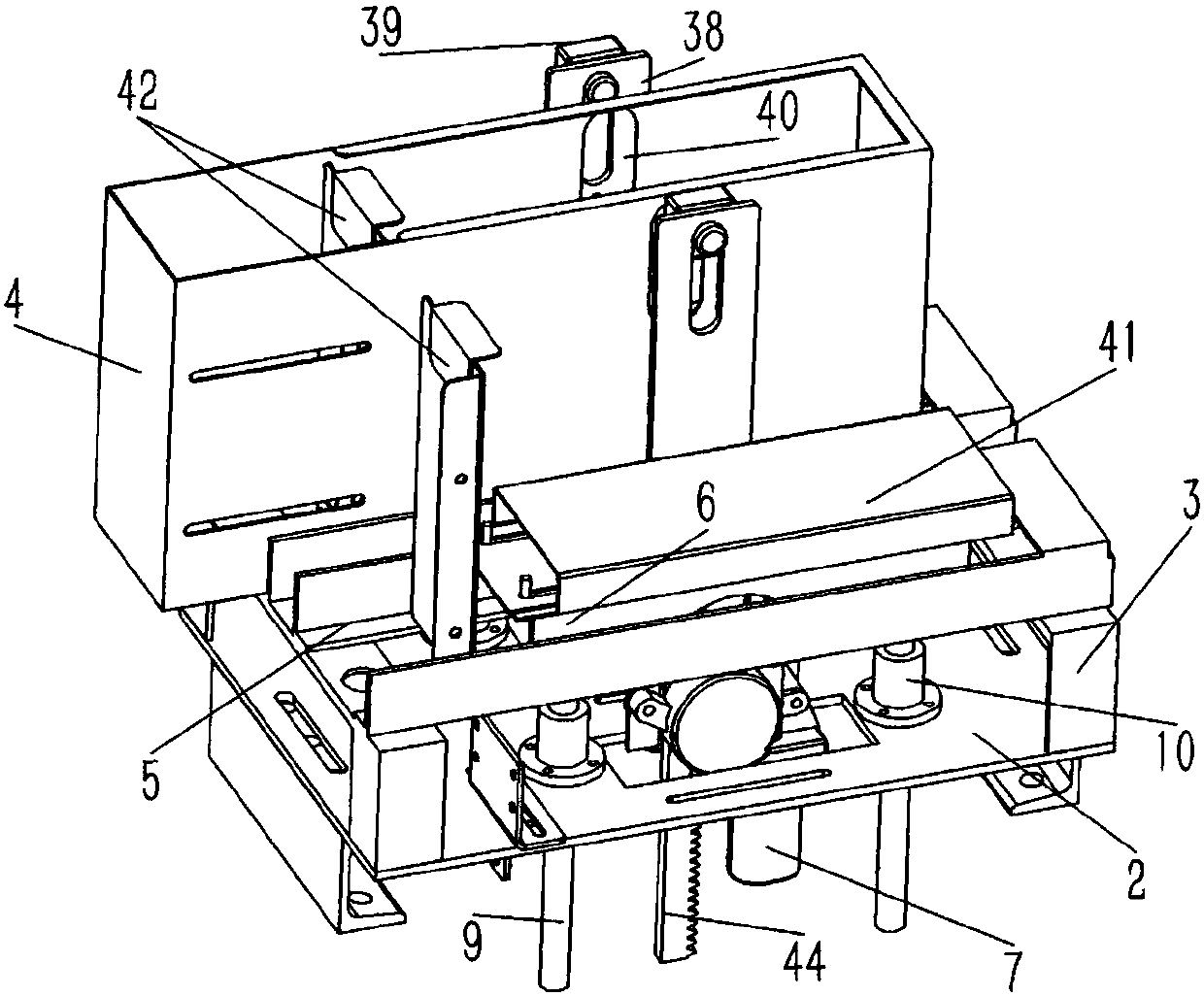

[0044] The suction part of the packaging bag mainly includes the bag box 4 containing the packaging bag, a lifting device for controlling the lifting of the bag box 4 is arranged below the bag box 4, and a suction device installed on the frame 1 is arranged above the bag box 4. Bag device, the suction bag device transports the packaging bag to the lower part of the bagging part of the culture material, and also includes a "U" shaped bag box base 3 arranged on the bag box bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com