Patents

Literature

57results about How to "The docking position is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

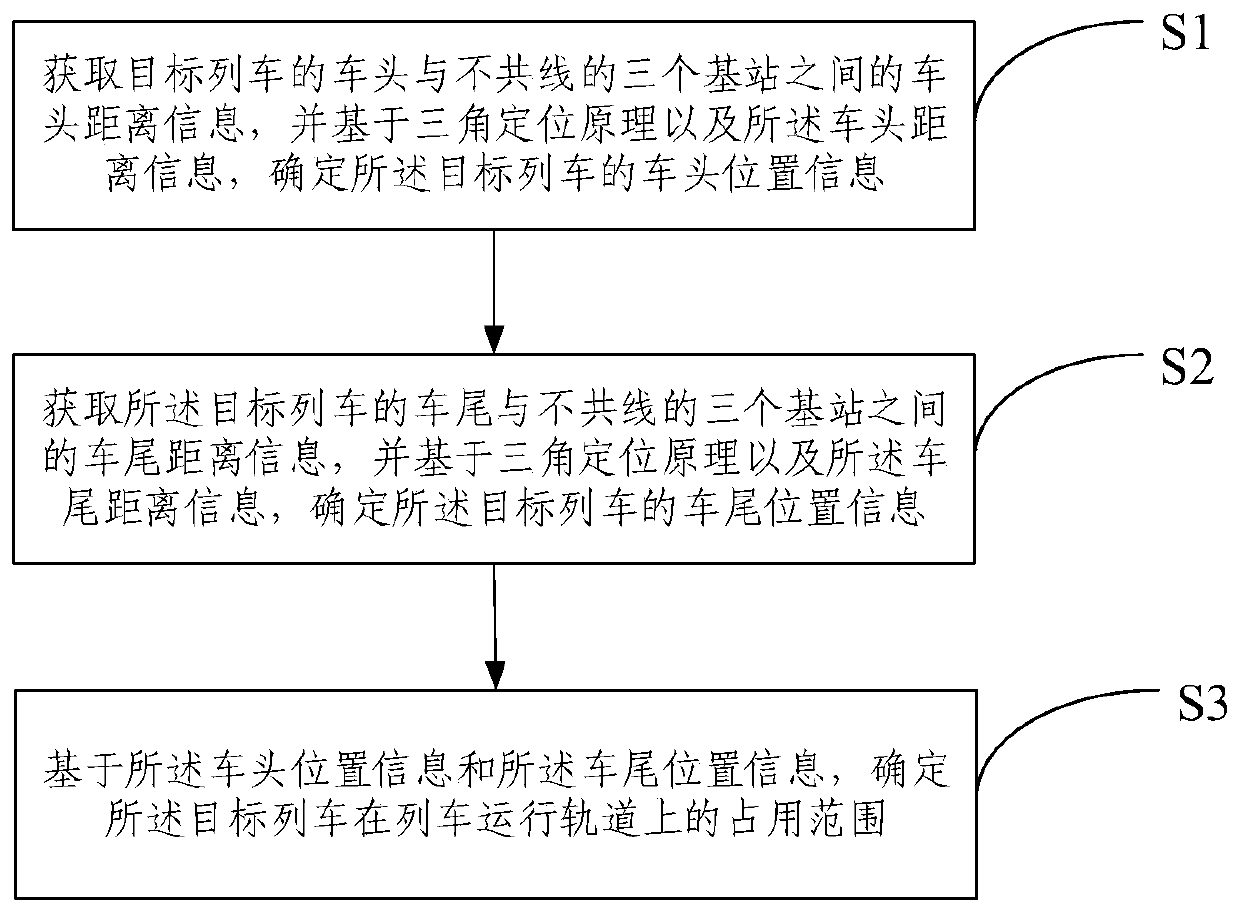

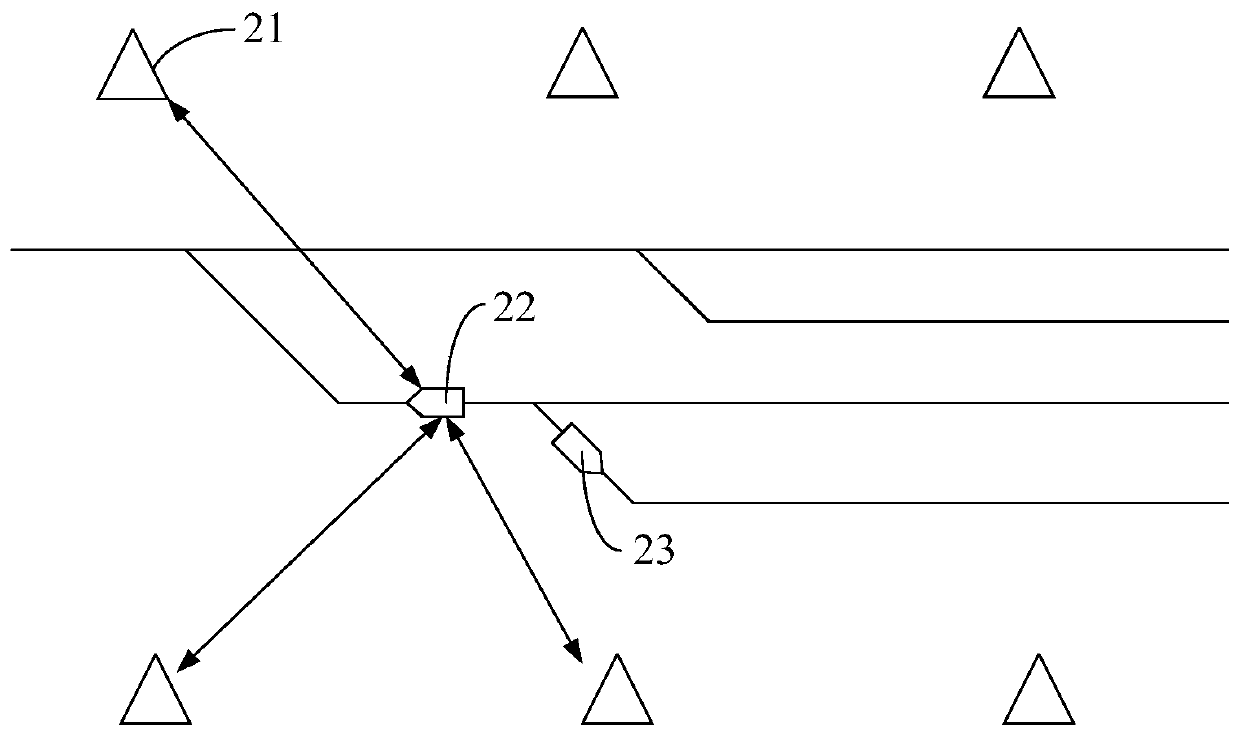

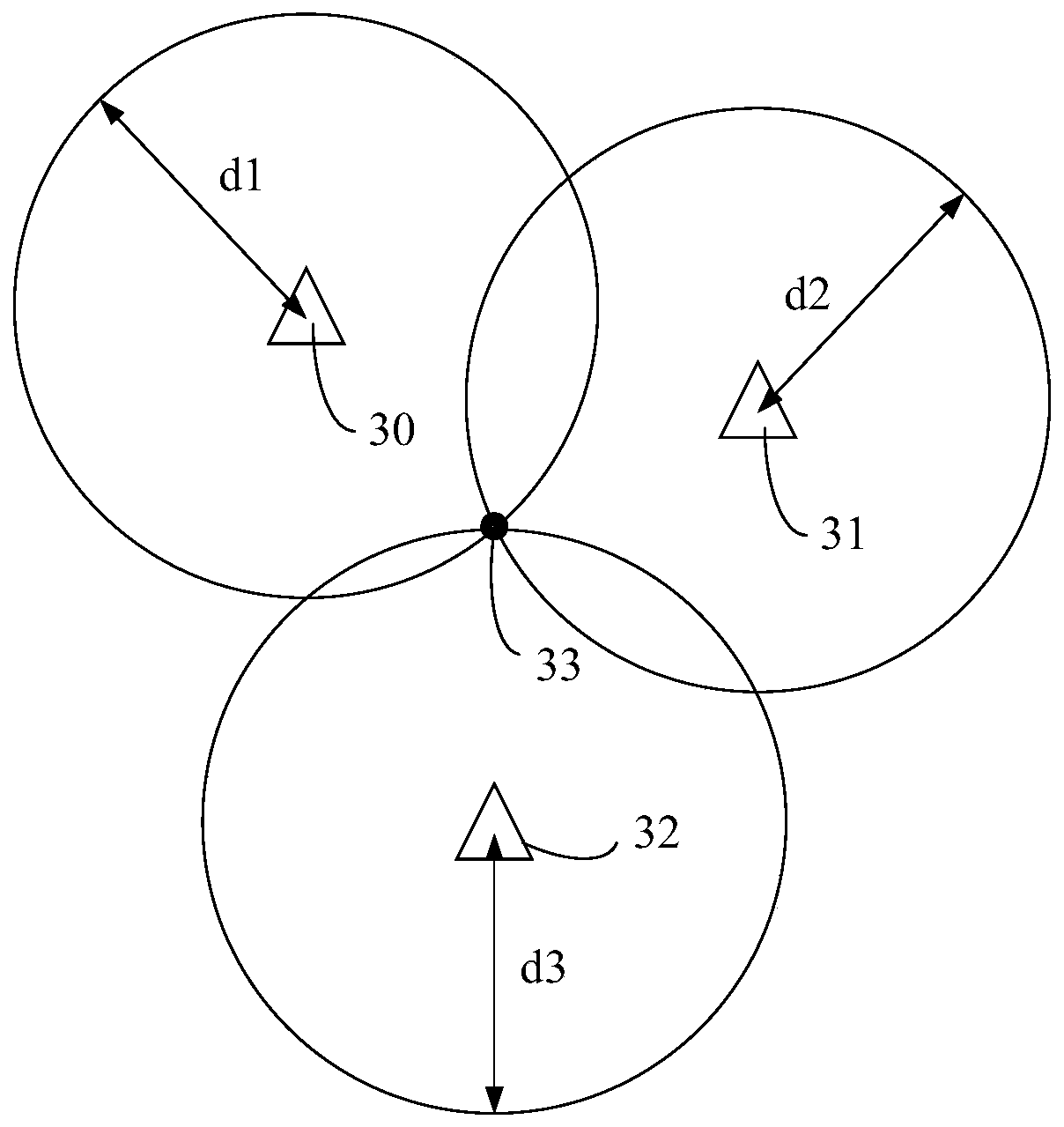

Method and system for monitoring trains in metro depot based on UWB

ActiveCN110775105AThe docking position is accurateComplete marshallingVehicle route interaction devicesThird partyTrain

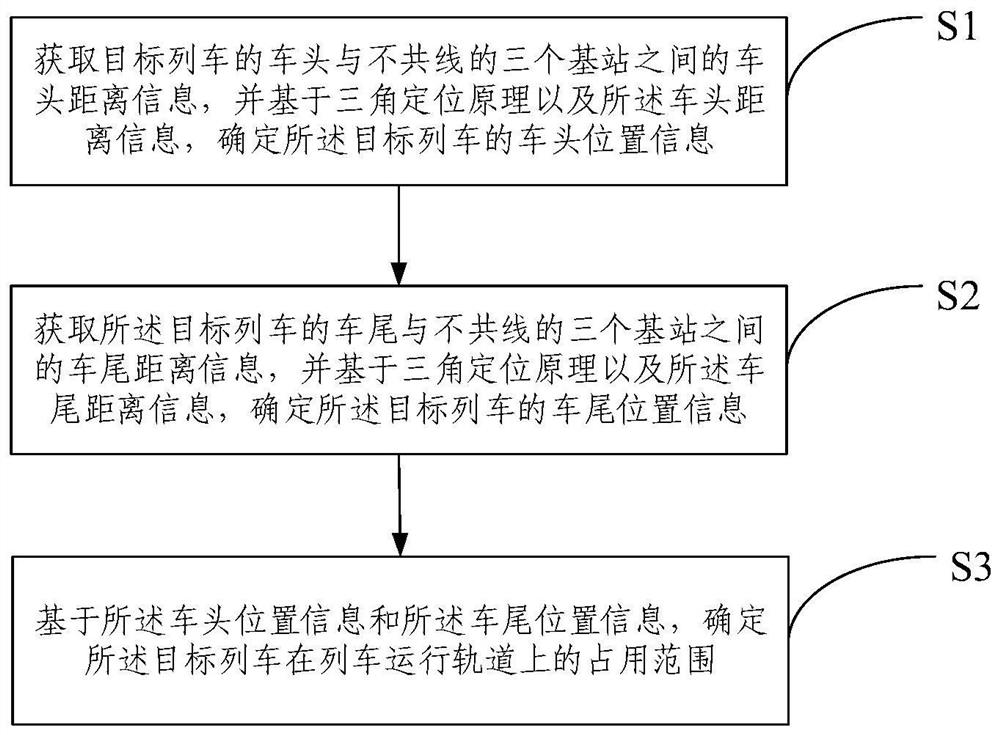

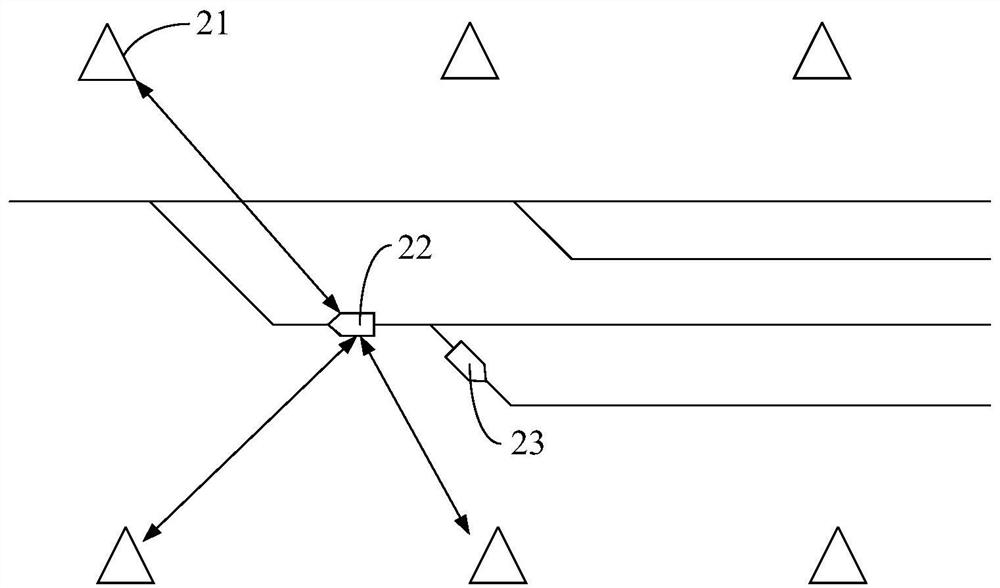

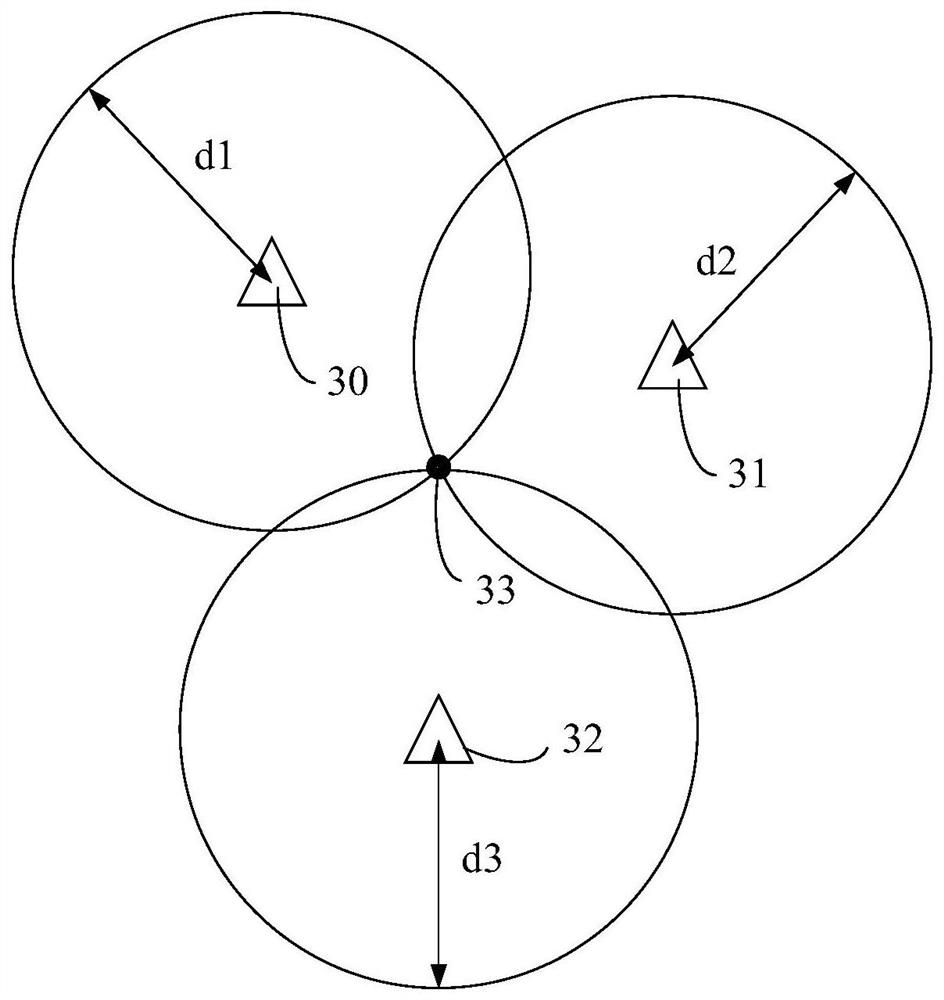

An embodiment of the invention provides a method and system for monitoring trains in metro depots based on UWB. By means of the method, train head distance information and train tail distance information which are determined based on a UWB technology are obtained; train head position information is determined based on the train head distance information; train tail position information is determined based on the train tail distance information; and finally, based on the train head position information and the train tail position information, the occupation range of a target train on a train running track is determined, and the target train is positioned. Third-party equipment data are introduced in the entire positioning process, a train head and a train tail of the target train are accurately positioned through the two-dimensional precise ranging capability of the UWB and the triangular positioning principle, the occupation scope of the target train on the train running track can be determined, the accurate train parking position can be ensured by the metro depots, whether the target train is complete or not can be further determined, and the complete marshalling of the target train is ensured.

Owner:TRAFFIC CONTROL TECH CO LTD

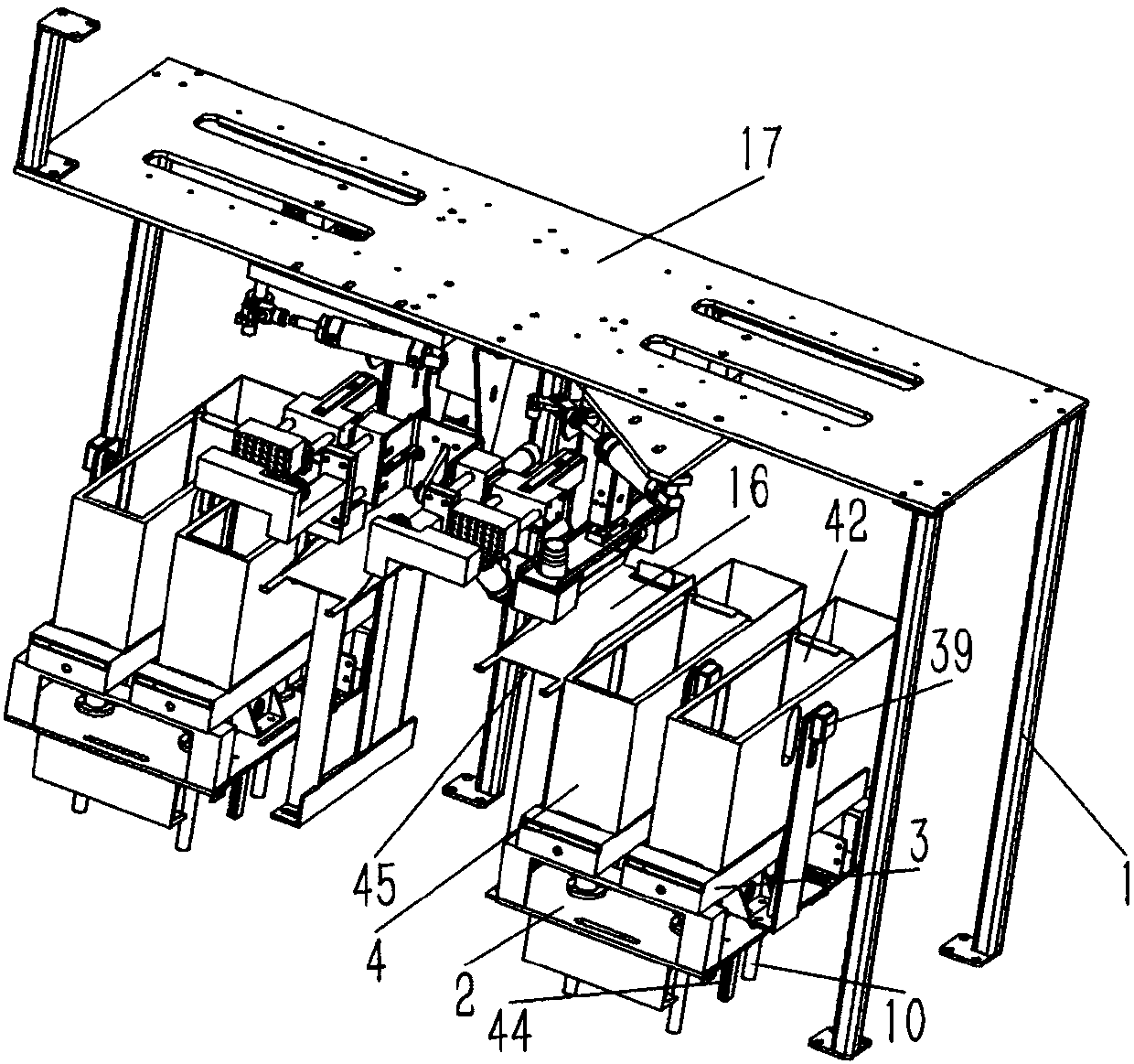

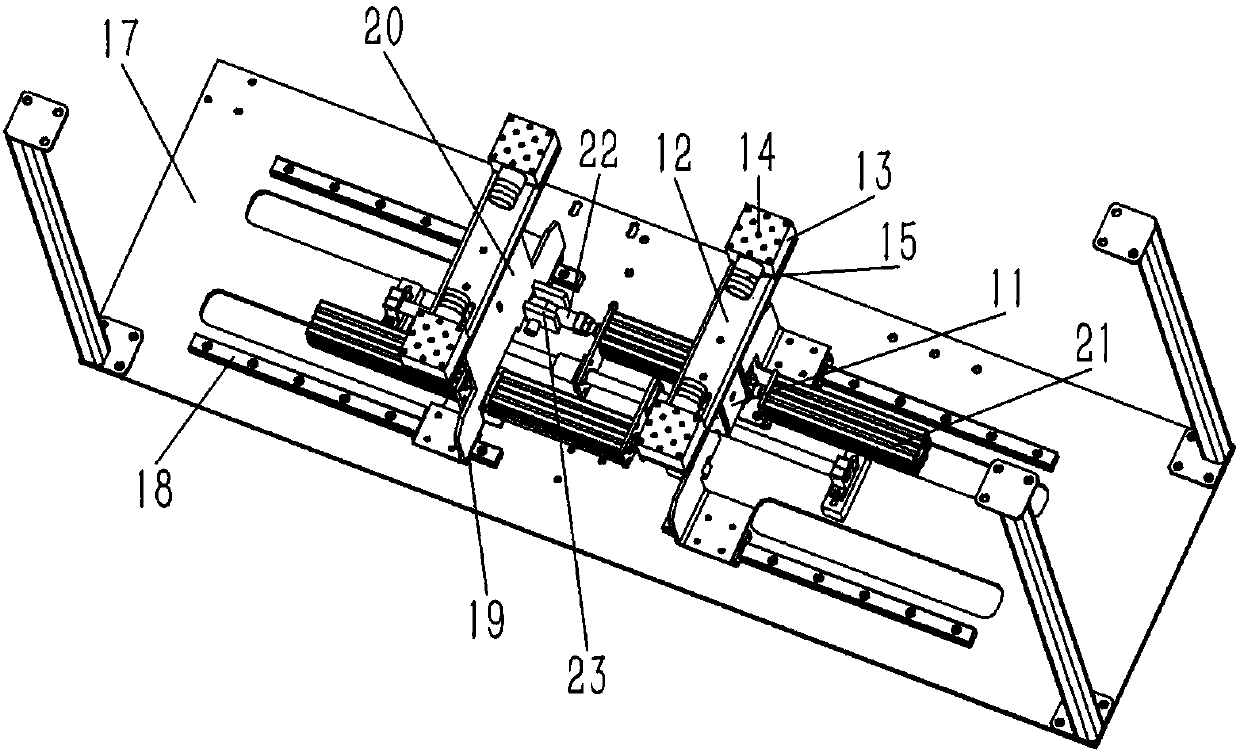

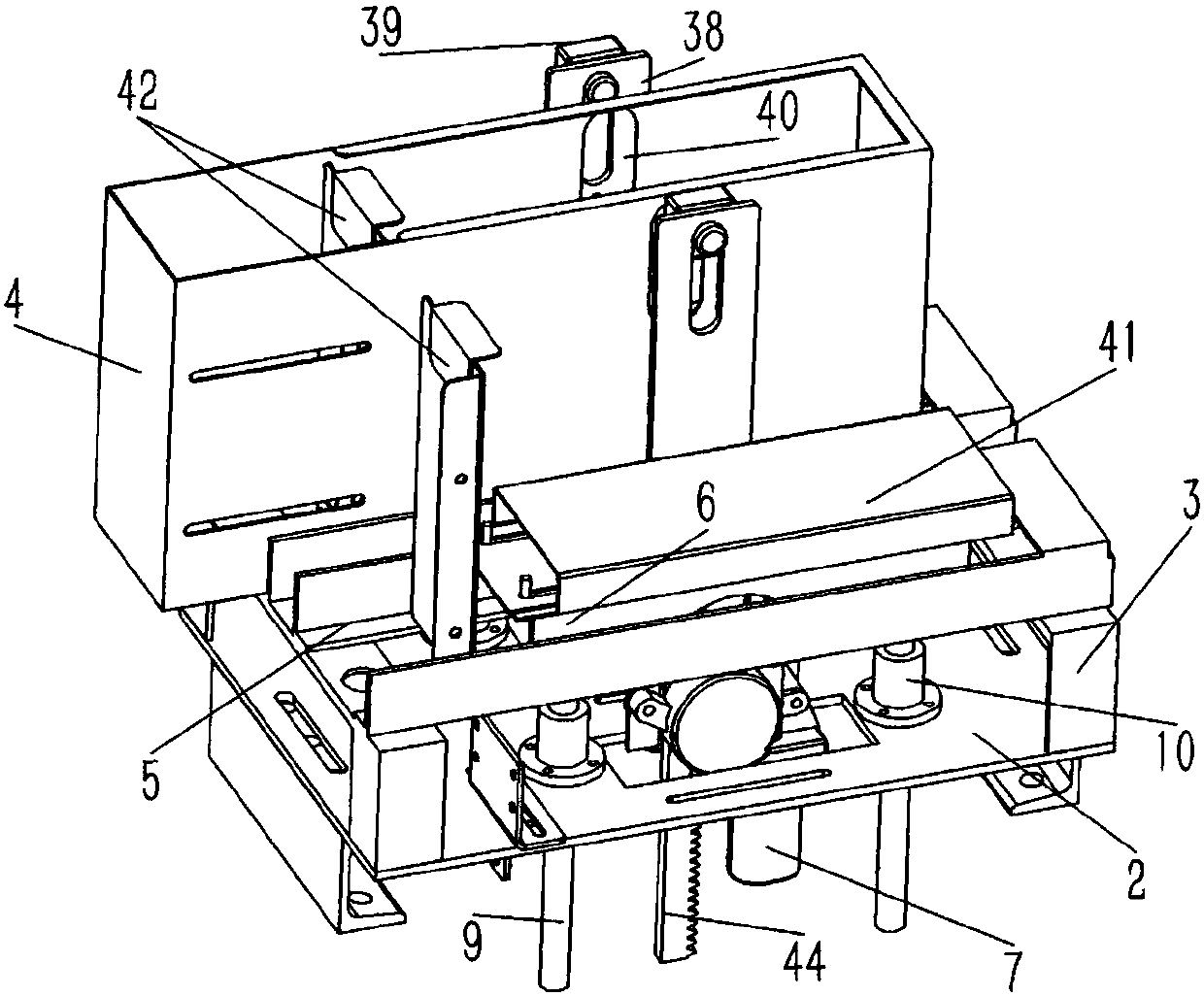

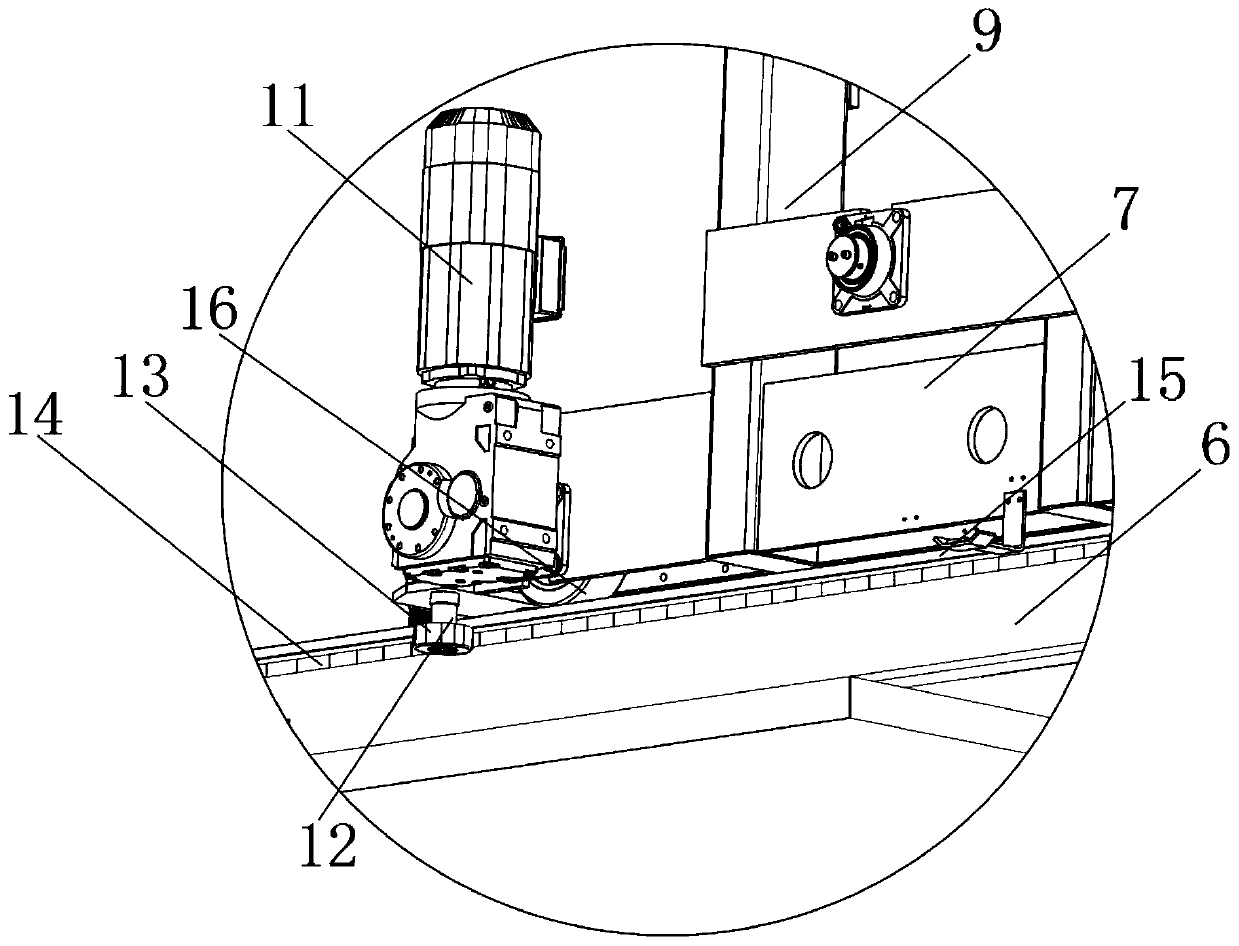

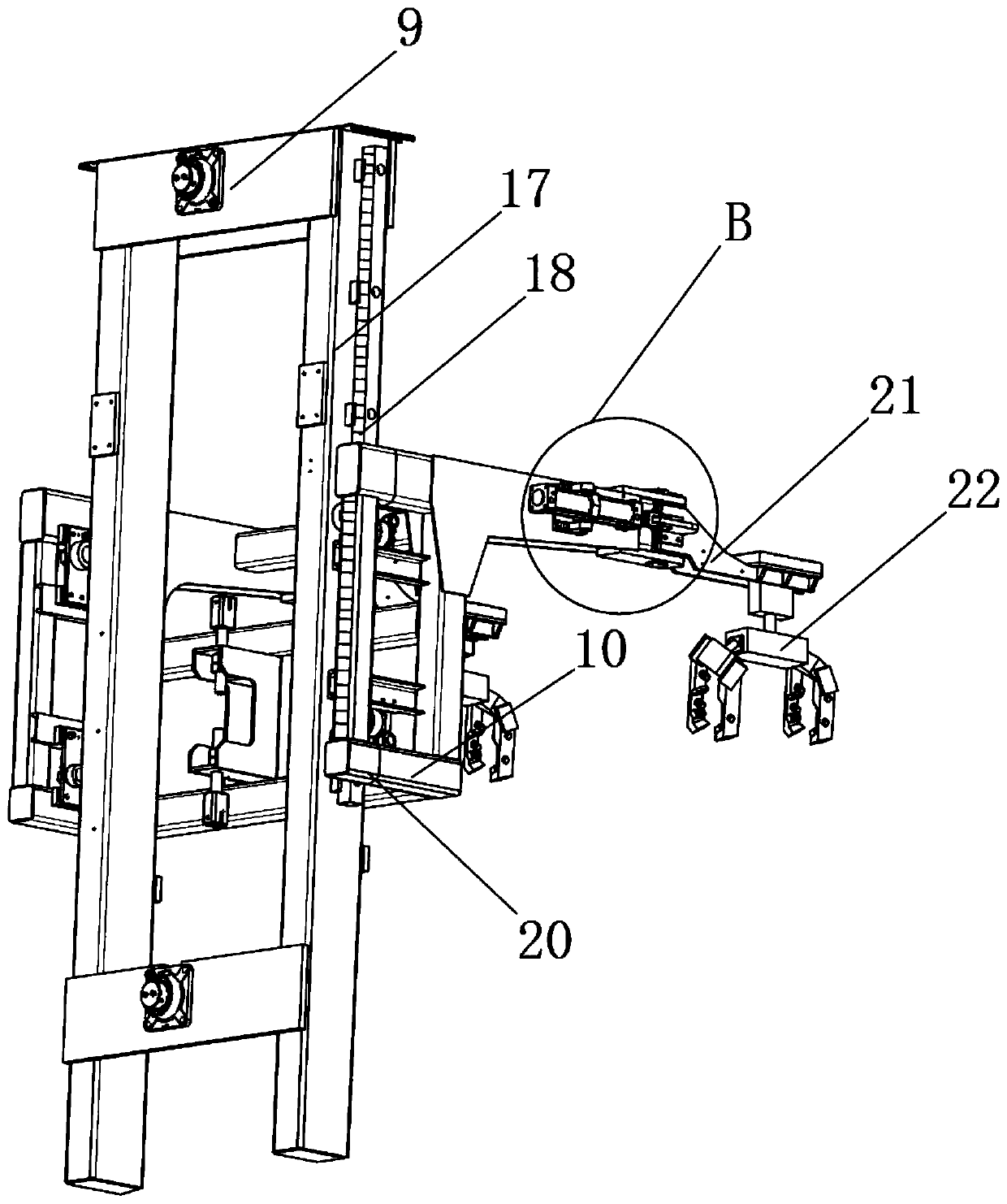

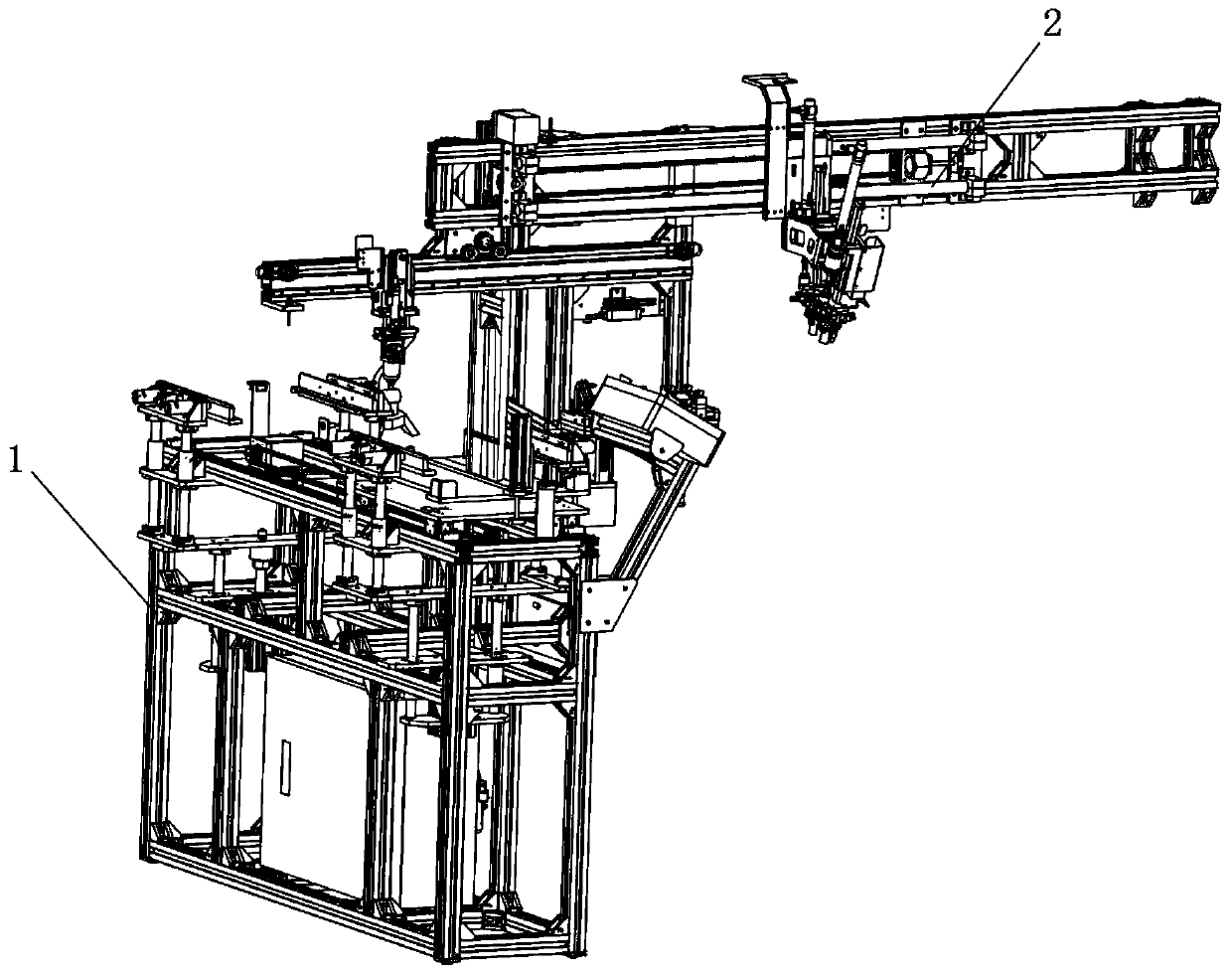

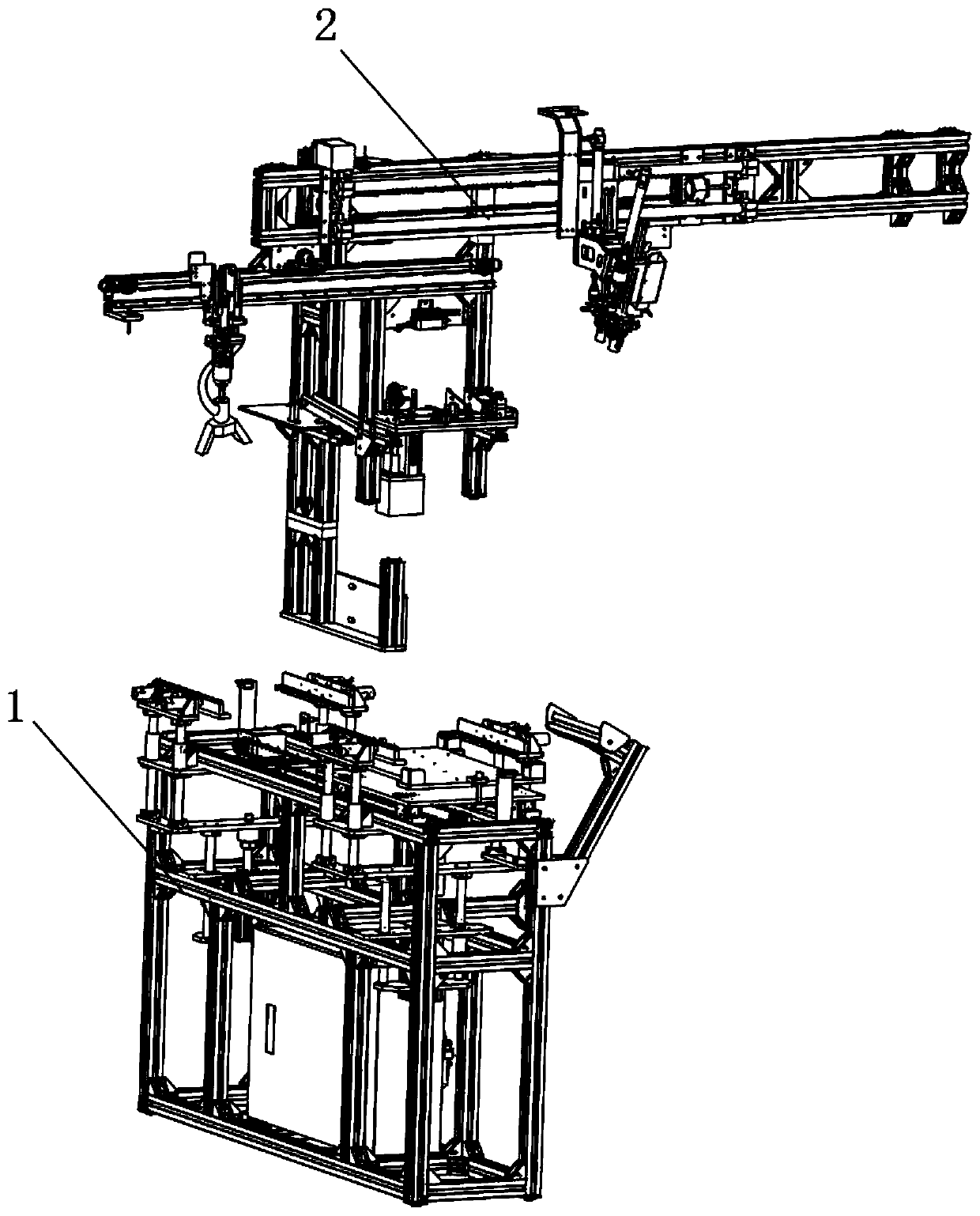

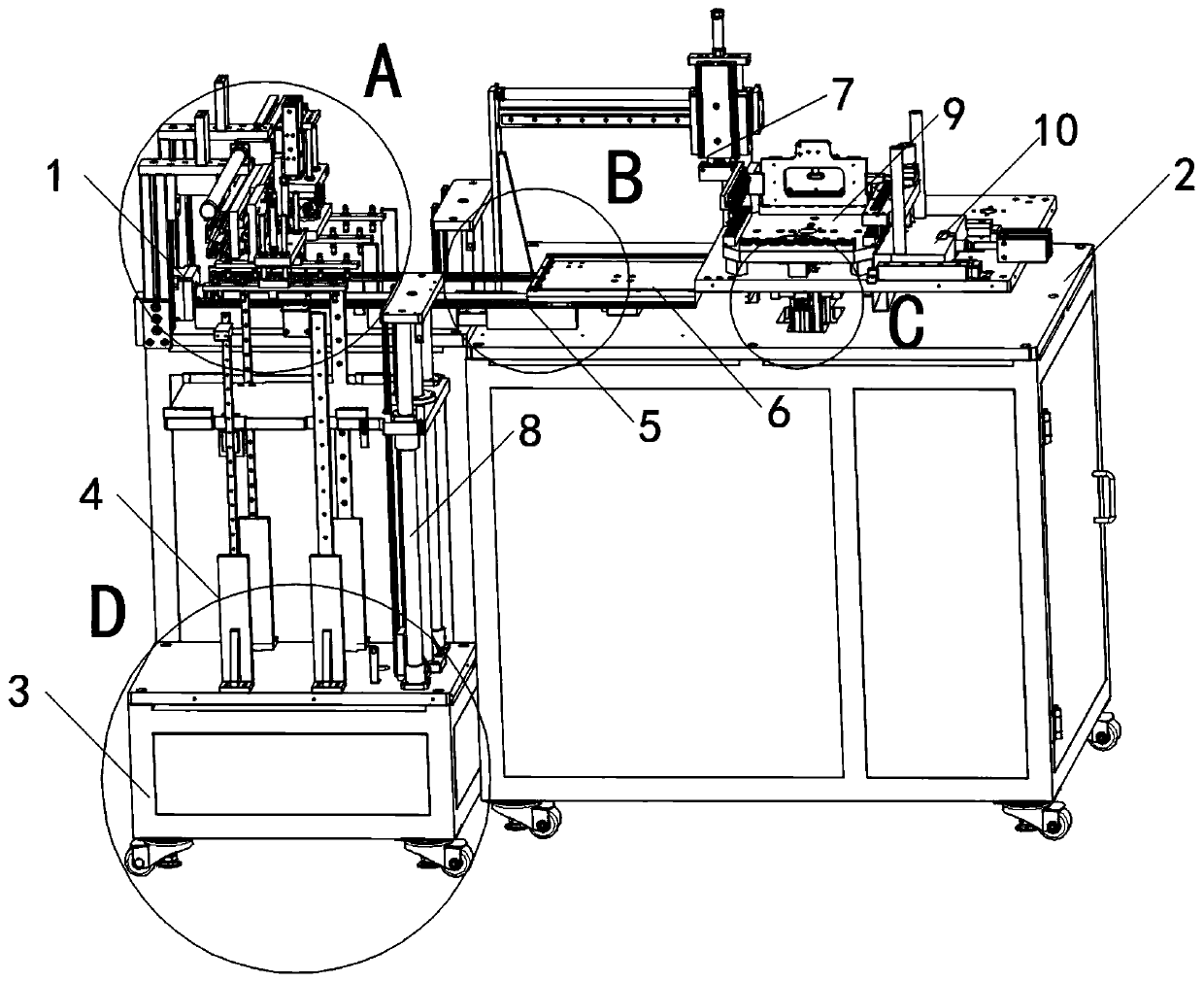

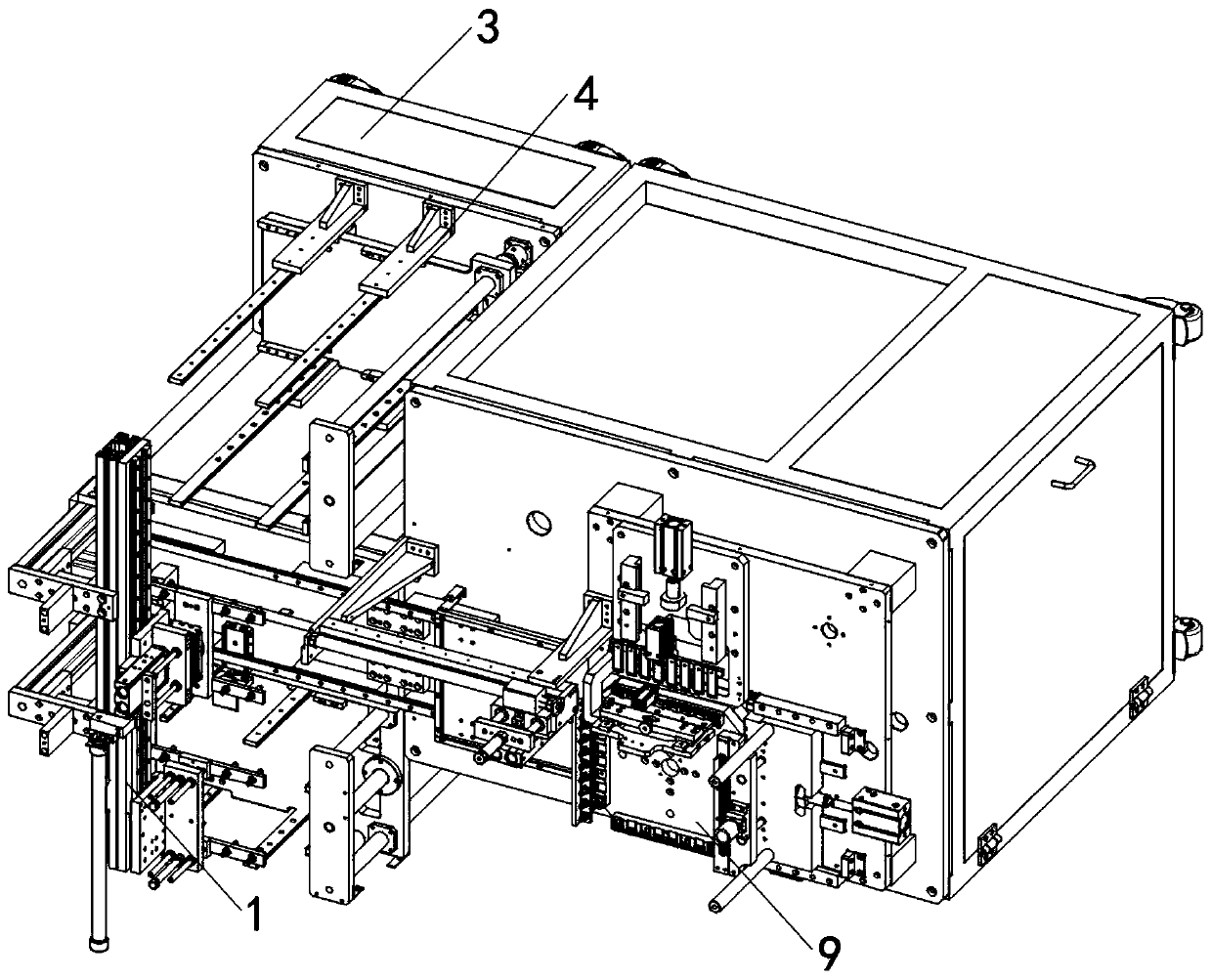

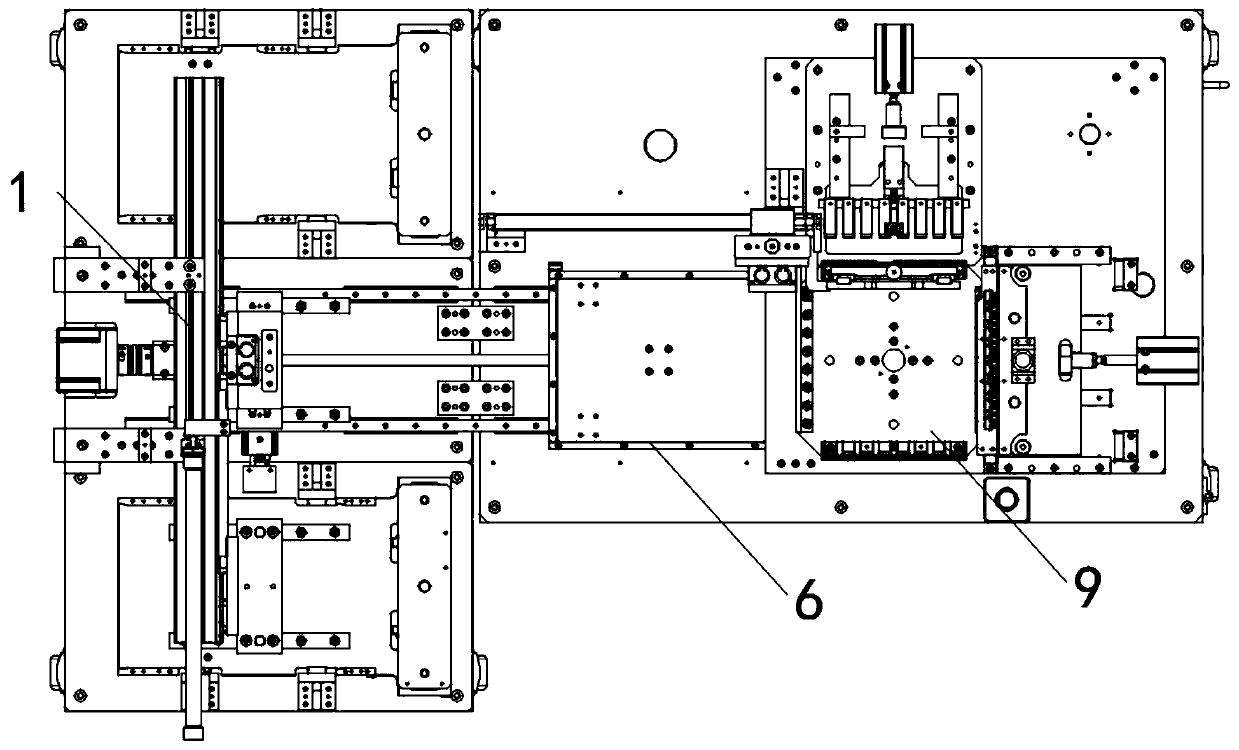

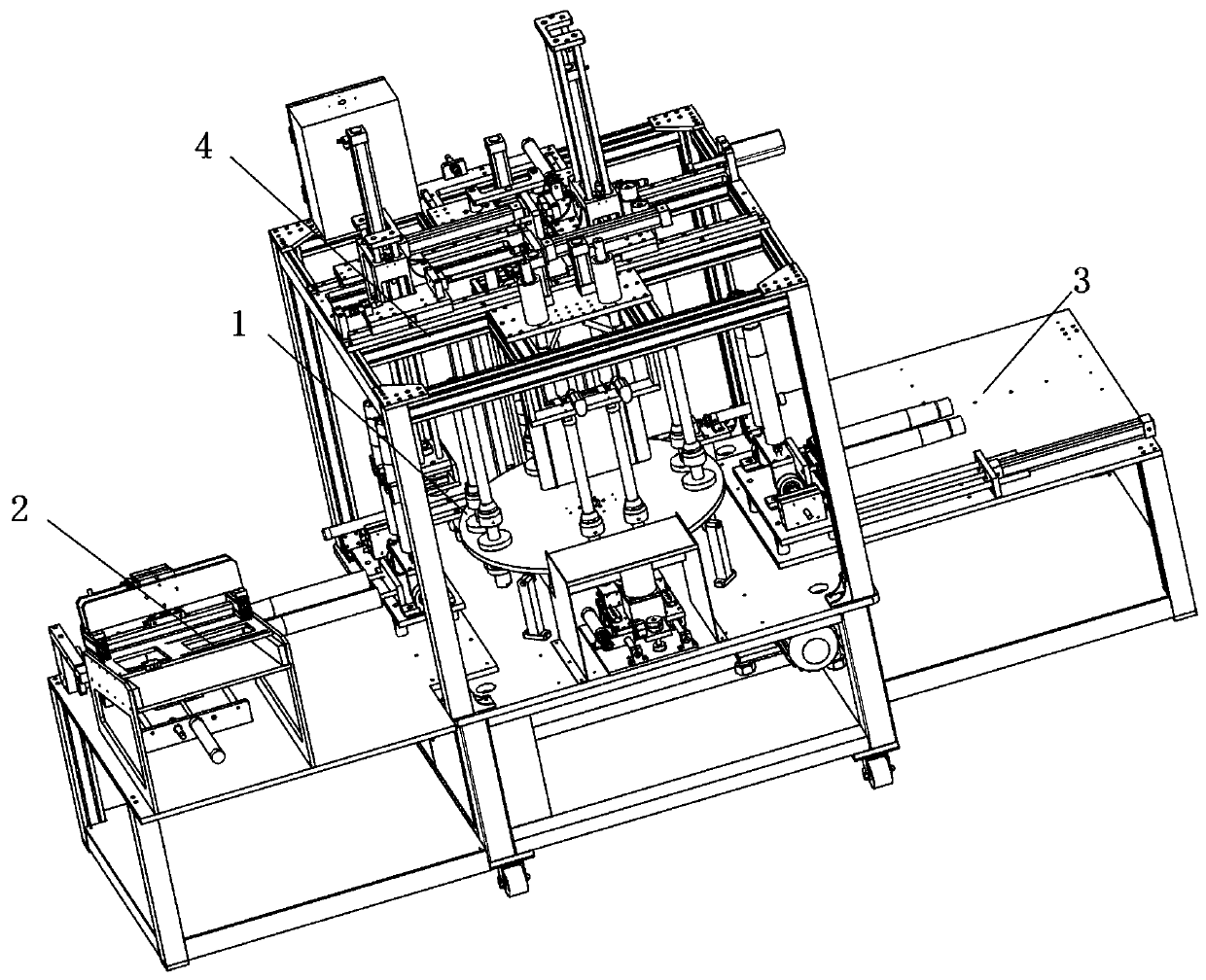

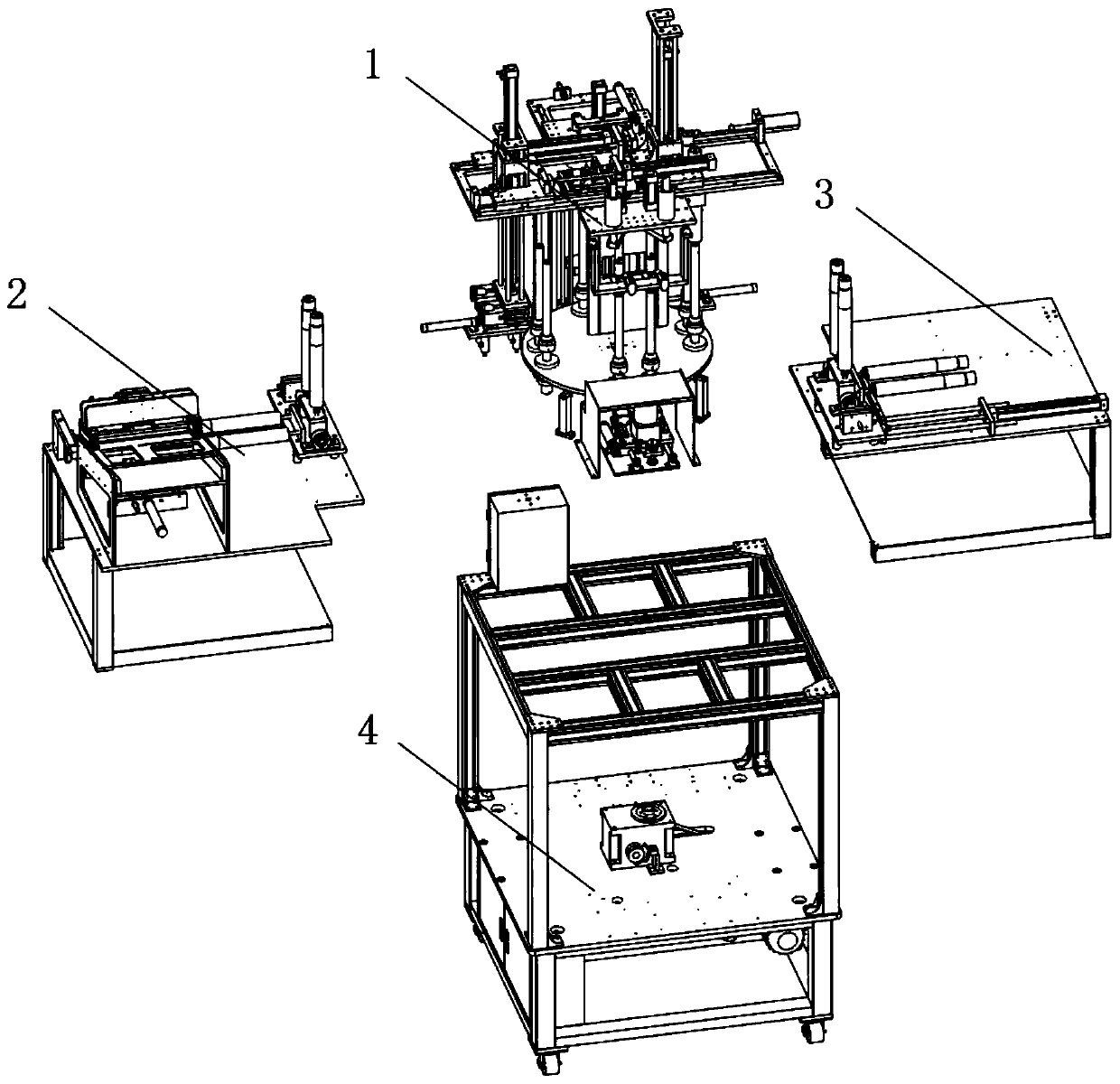

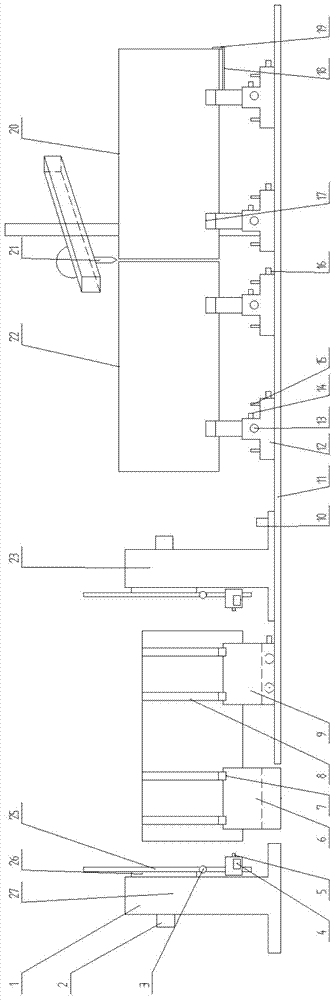

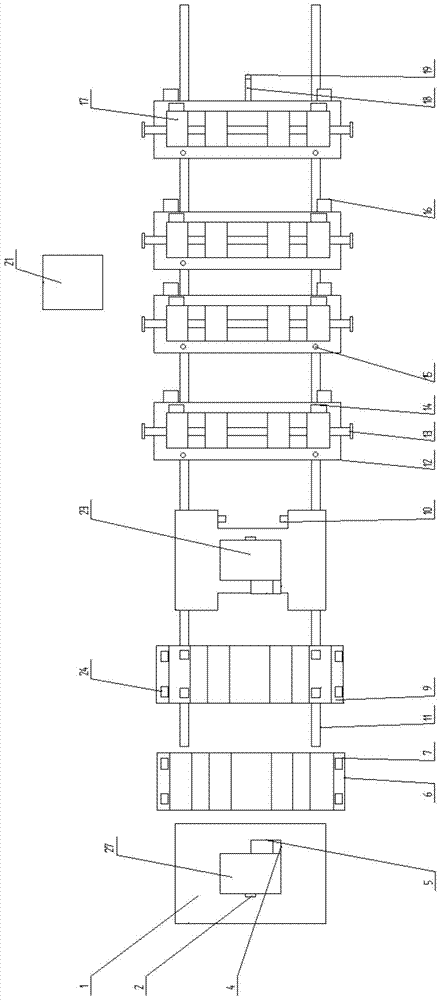

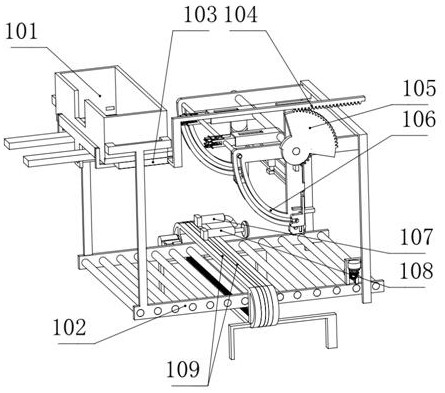

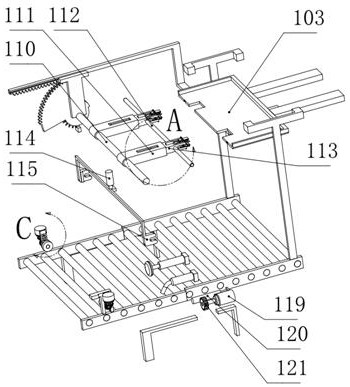

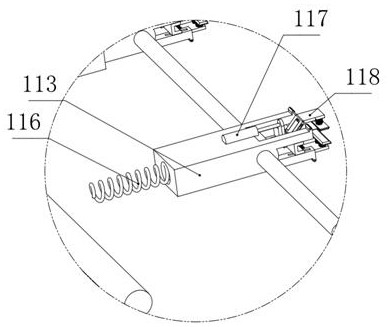

Full-automatic material and bag arranging type packing machine

ActiveCN107600473AOutstanding and Beneficial Technical EffectsPrevent Dry Run ConditionsWrapper twisting/gatheringPackaging automatic controlEdible mushroomEngineering

The invention provides a full-automatic material and bag arranging type packing machine, belongs to the technical field of packing machines, and aims at overcoming the shortages of low automation degree, low production efficiency and high labor input in the prior art. The machine comprises a packing bag absorbing part which is arranged on a rack, a culture material bagging part which is arranged above the packing bag absorbing part, a packing sealing part which is arranged at one side of the culture material bagging part, and a culture material bagged product outlet part which is formed in oneend of the packing sealing part, wherein a display screen for human-machine interaction and a PLC control box are arranged beside the culture material bagged product outlet part. Compared with the prior art, the machine has the advantages of being high in automation degree, high in production efficiency, and low in labor input cost; the machine is applicable to packing bag arranging, etc., and particularly applicable to the environment of massive bagging of edible mushroom culture materials.

Owner:ZHEJIANG HONGYE EQUIP TECH

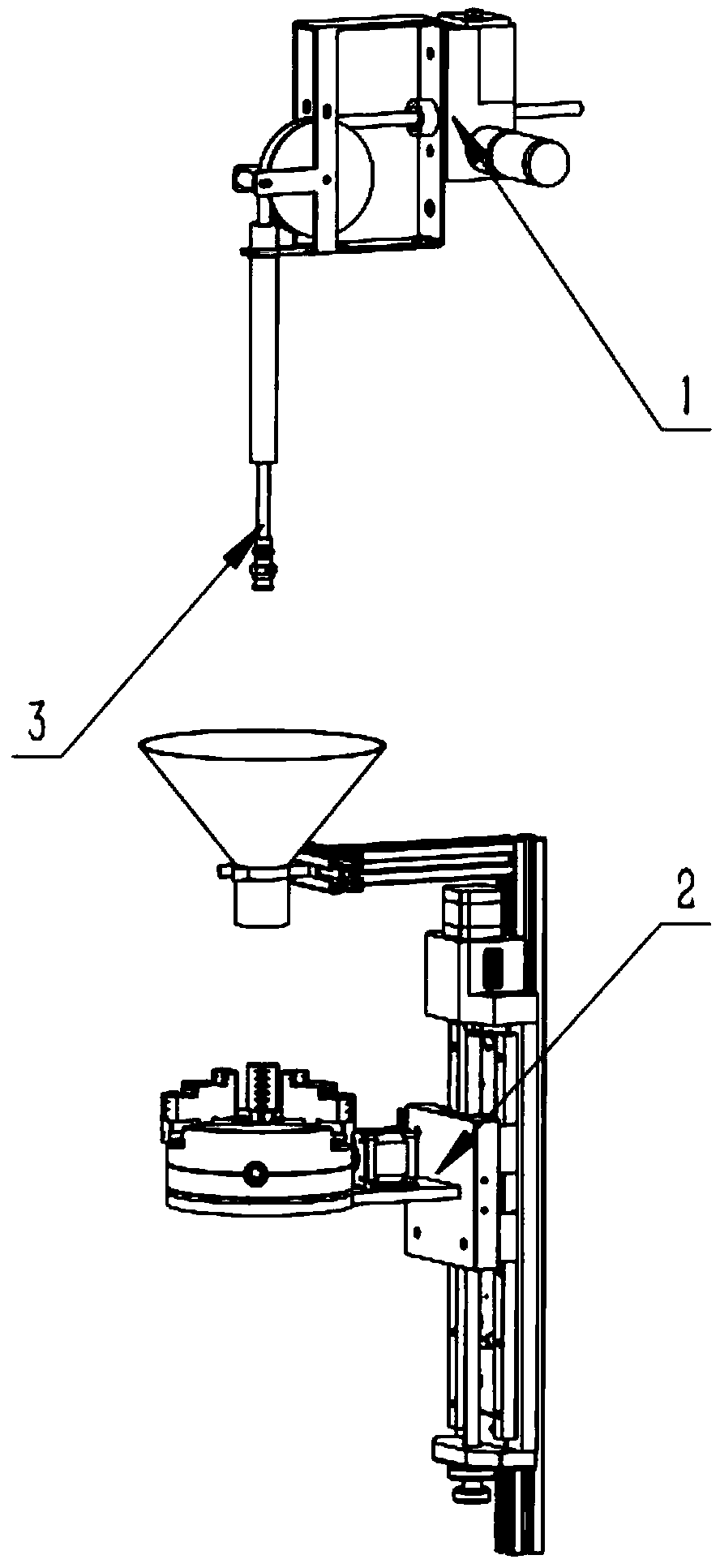

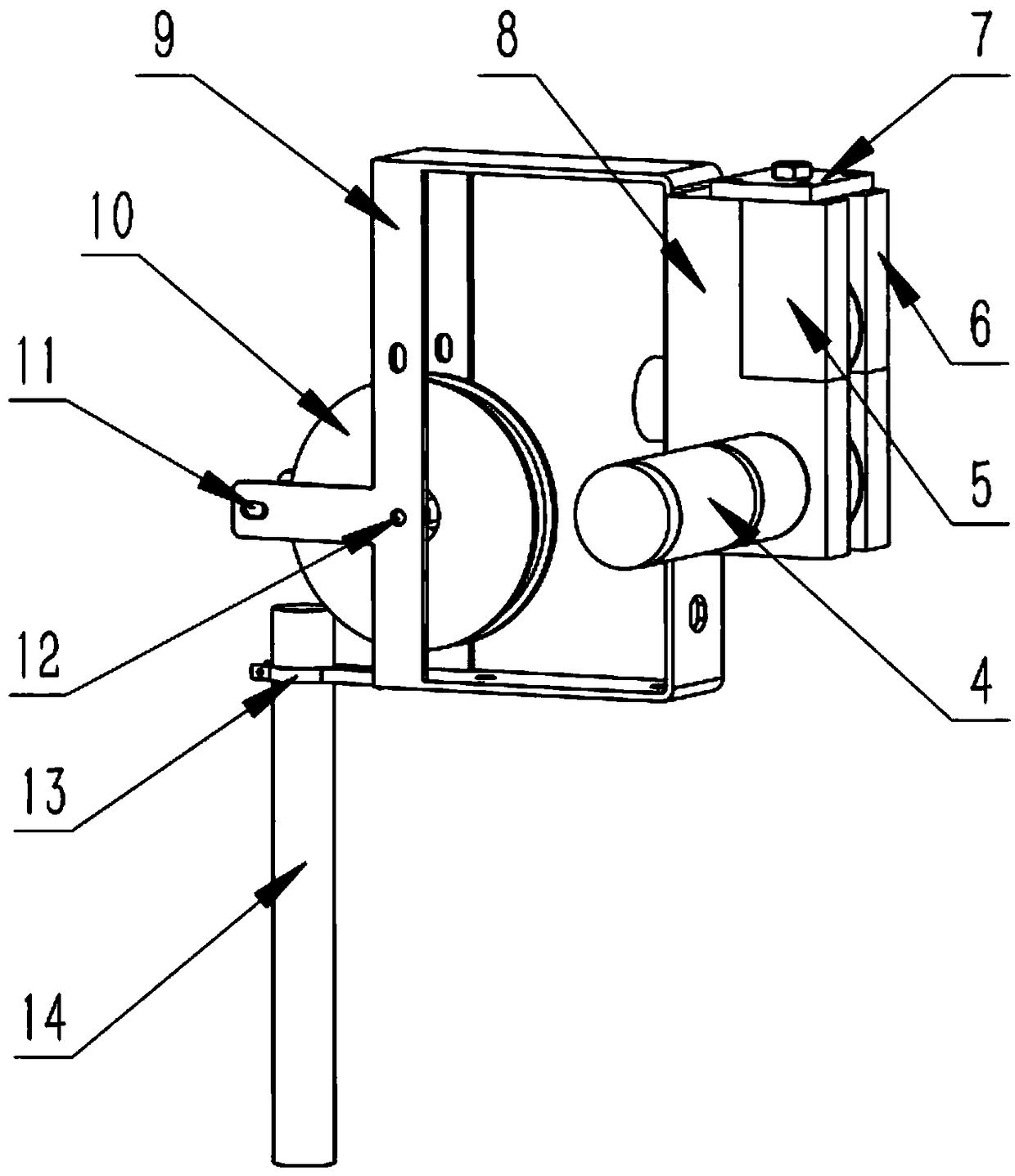

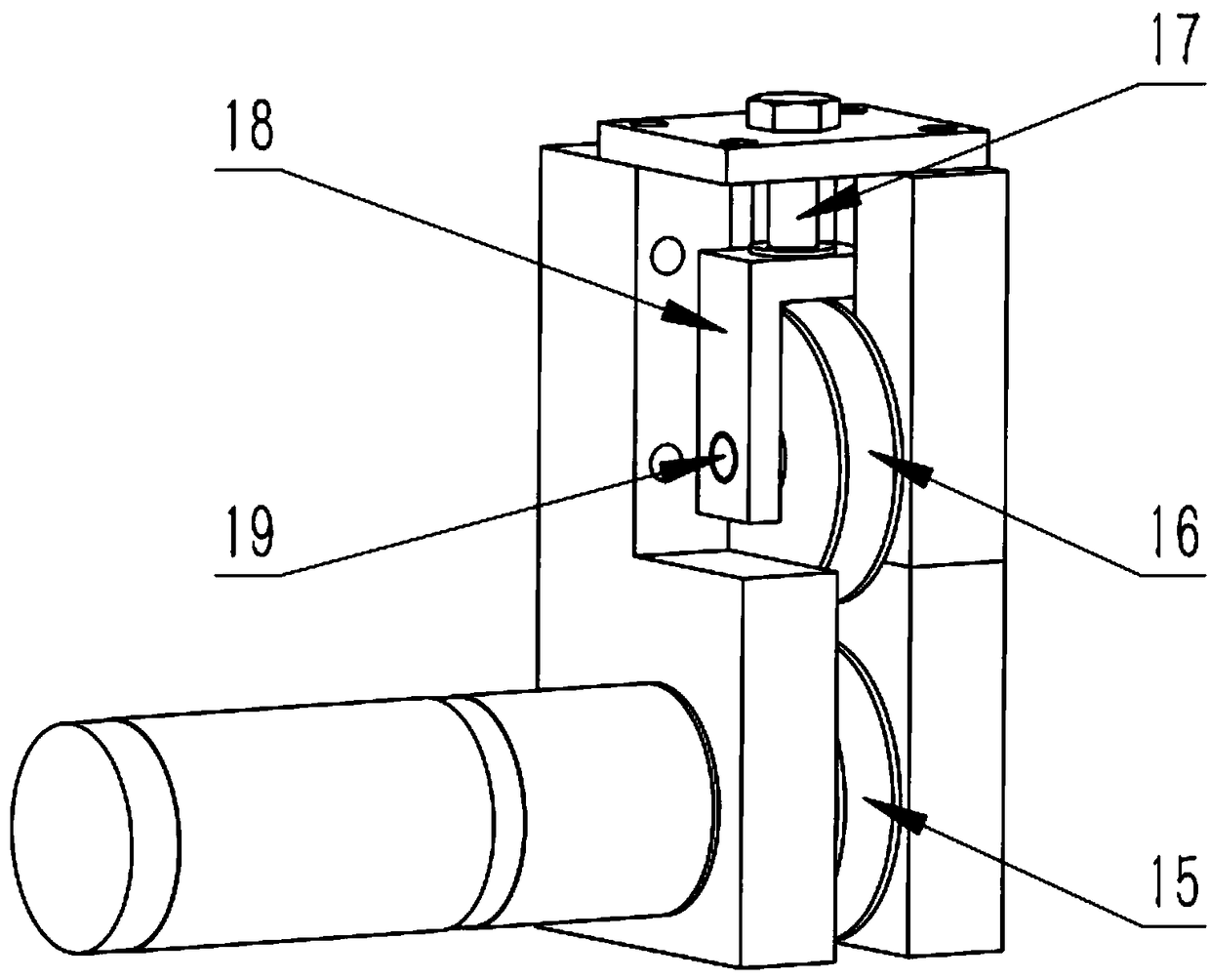

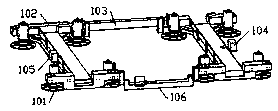

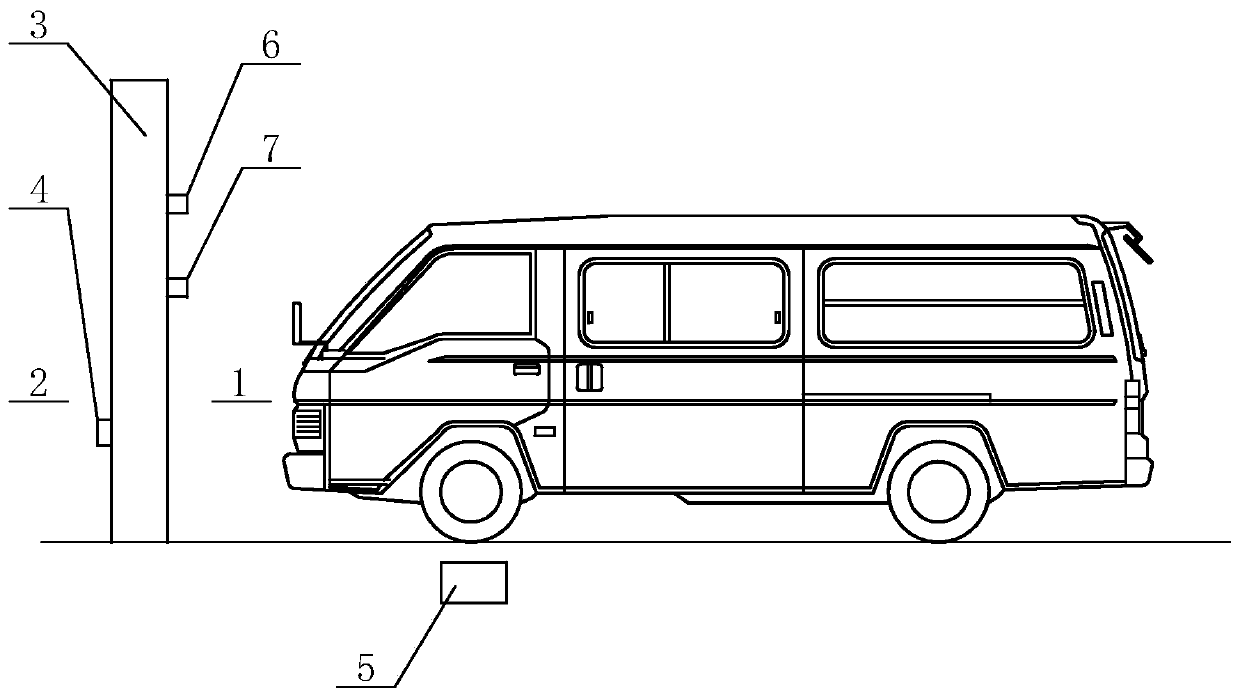

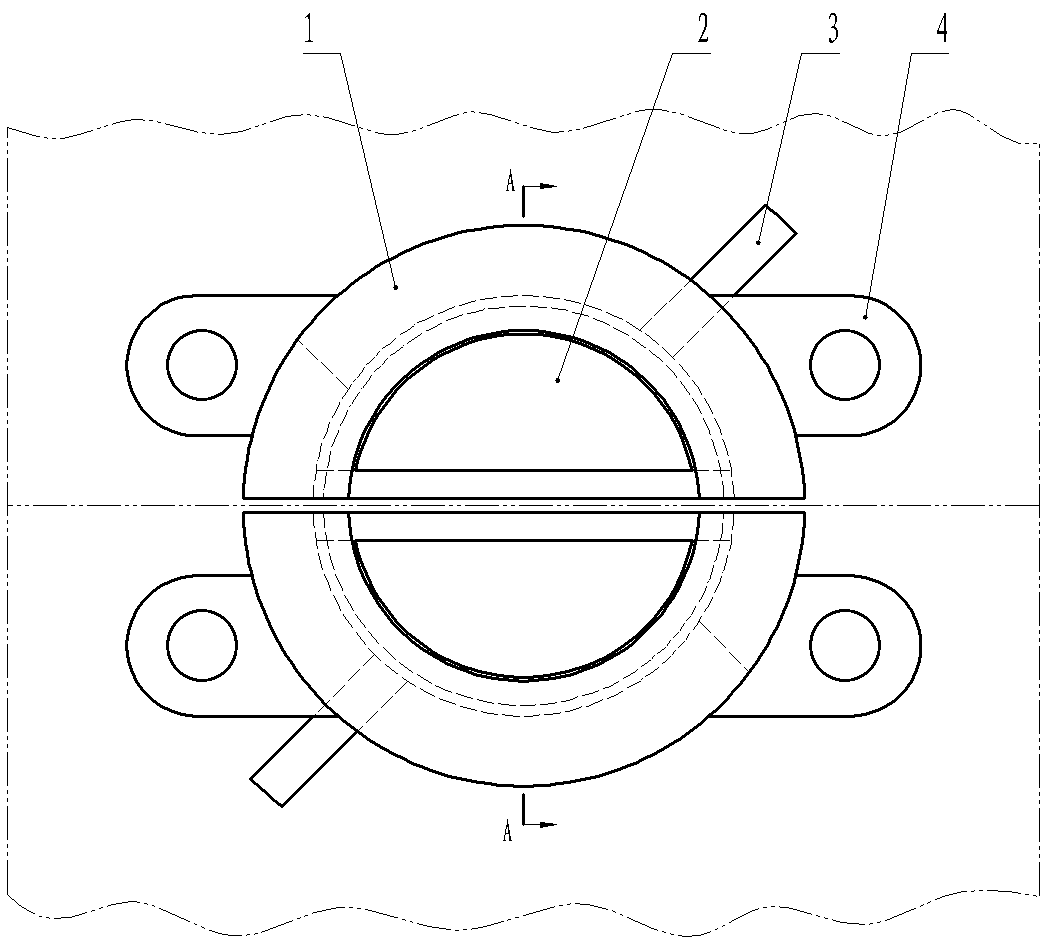

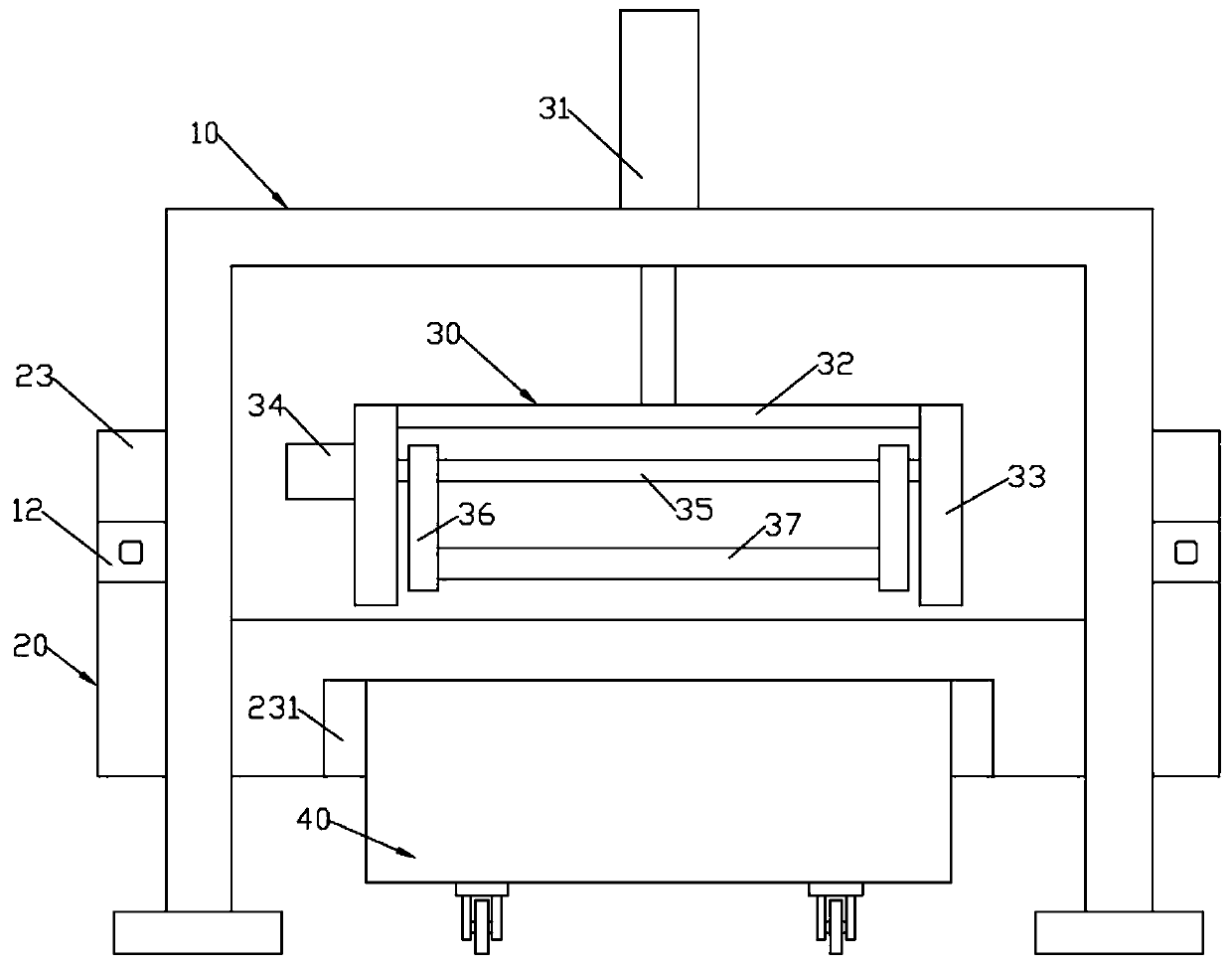

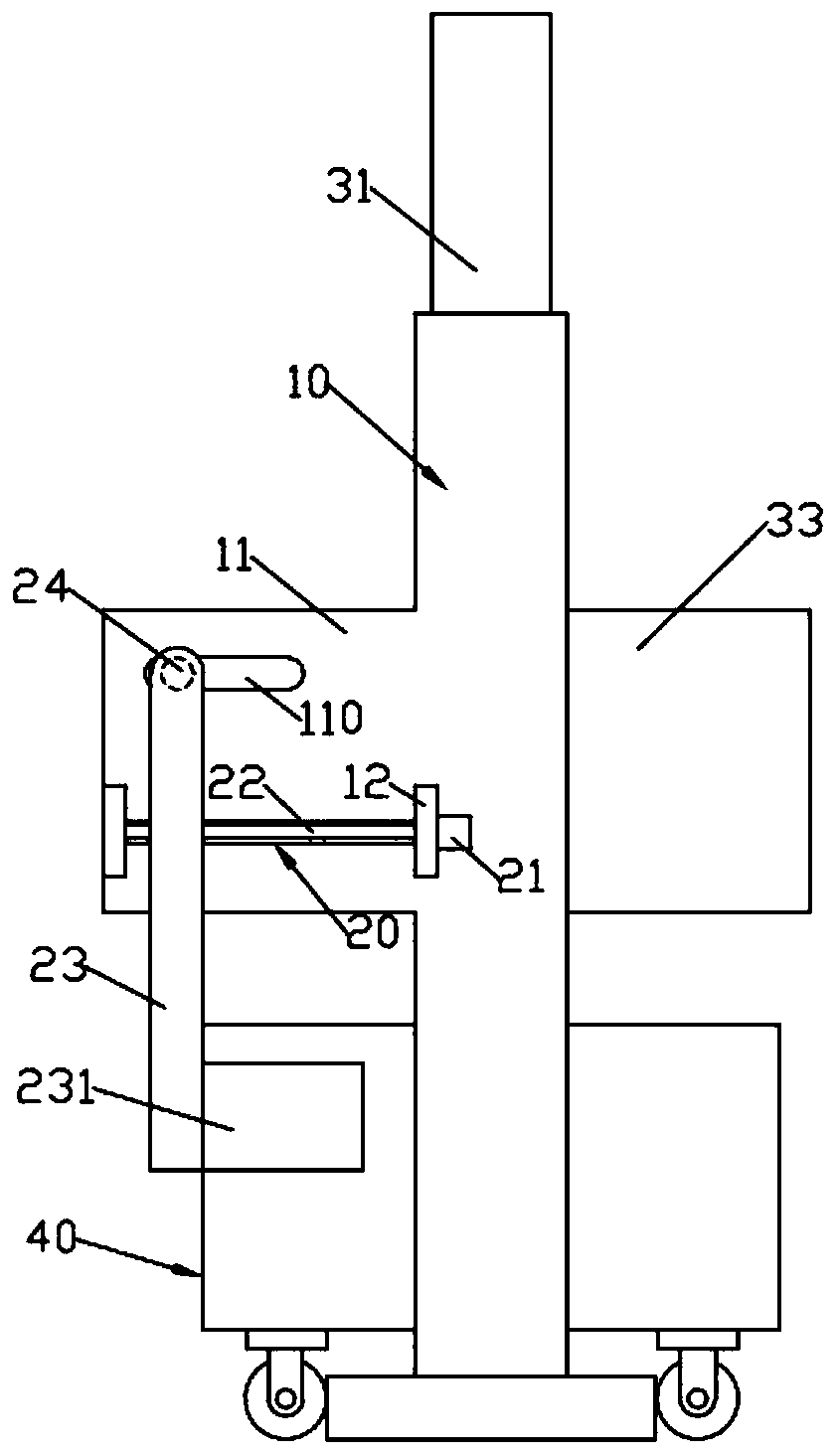

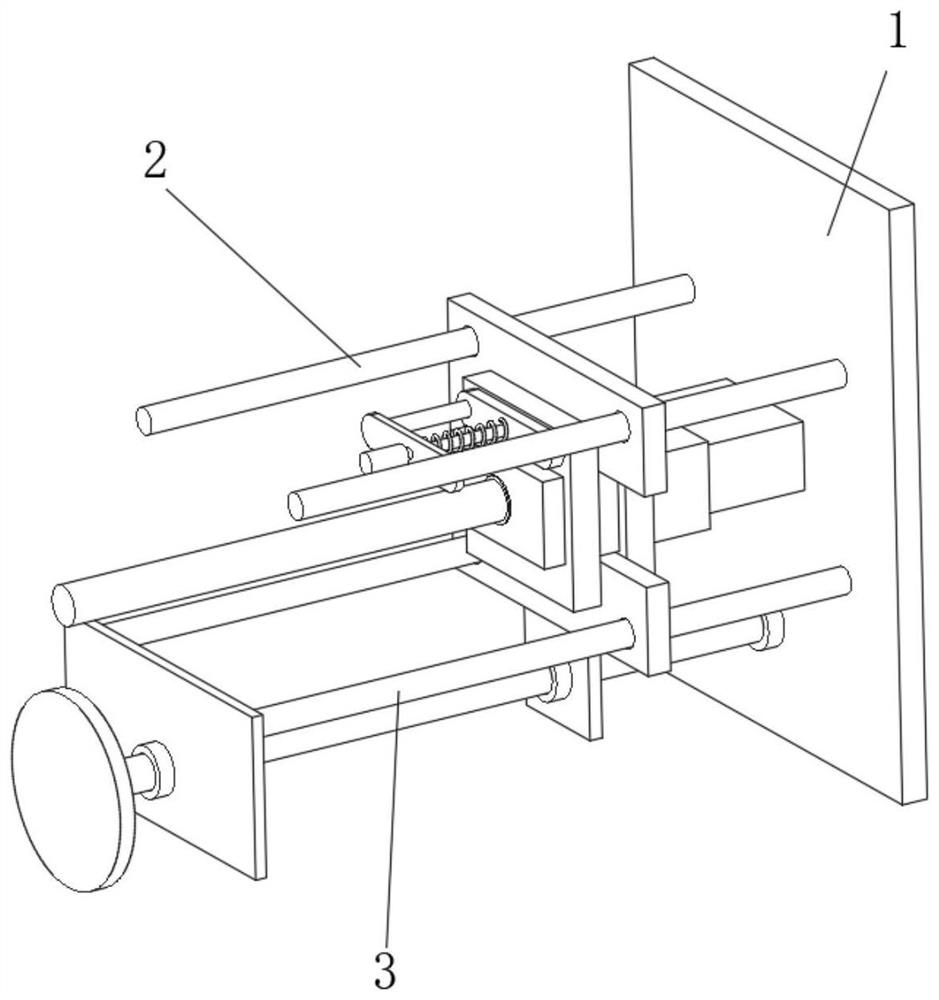

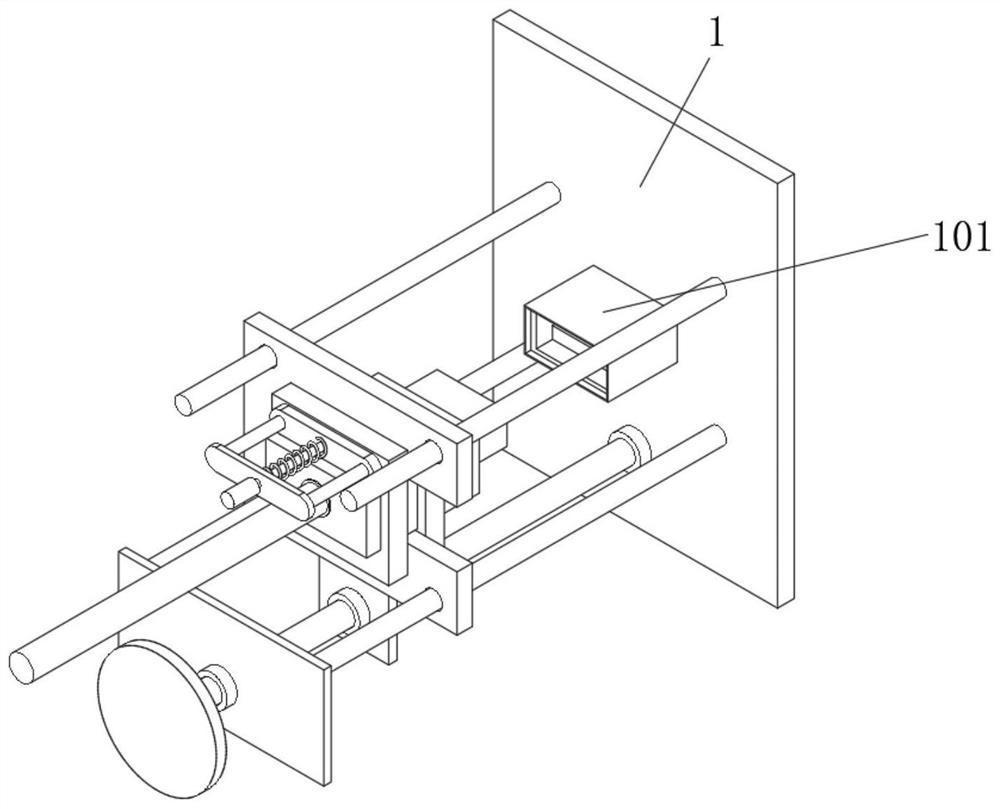

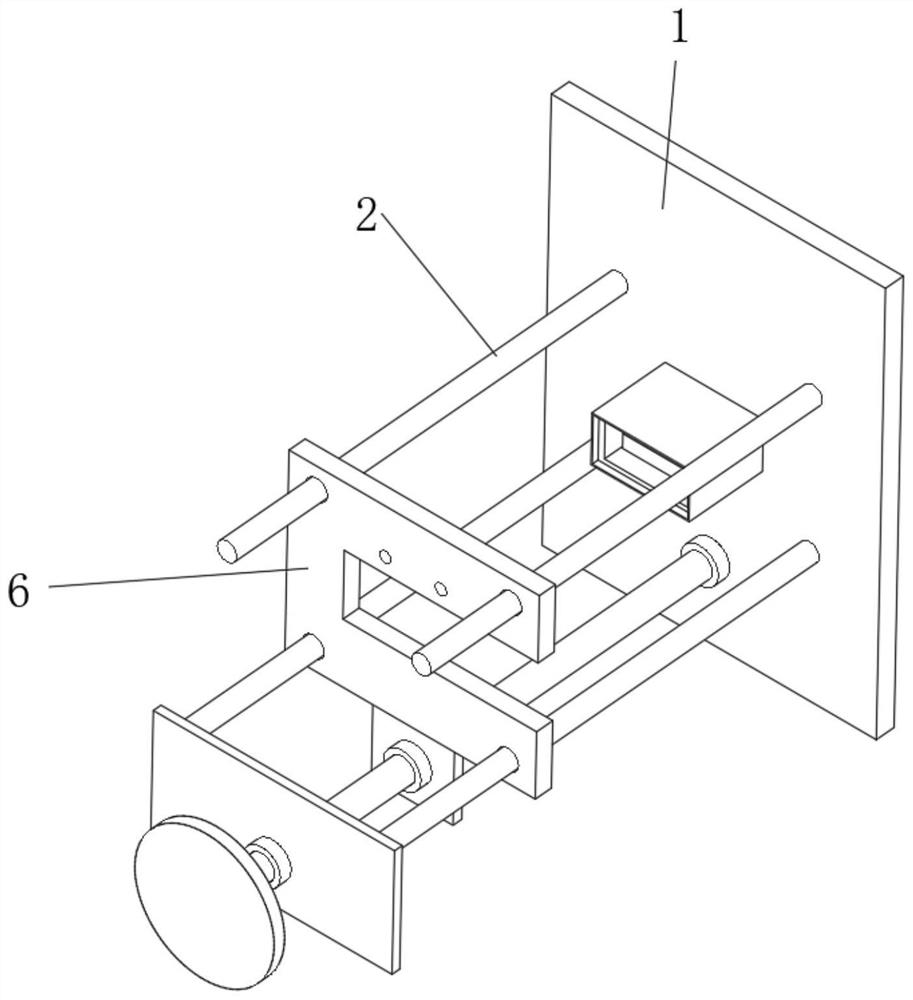

Marine self-refueling device for unmanned boat

ActiveCN109019499AGuaranteed freedomMeet fueling requirementsLiquid transferring devicesMarine engineeringElectric control

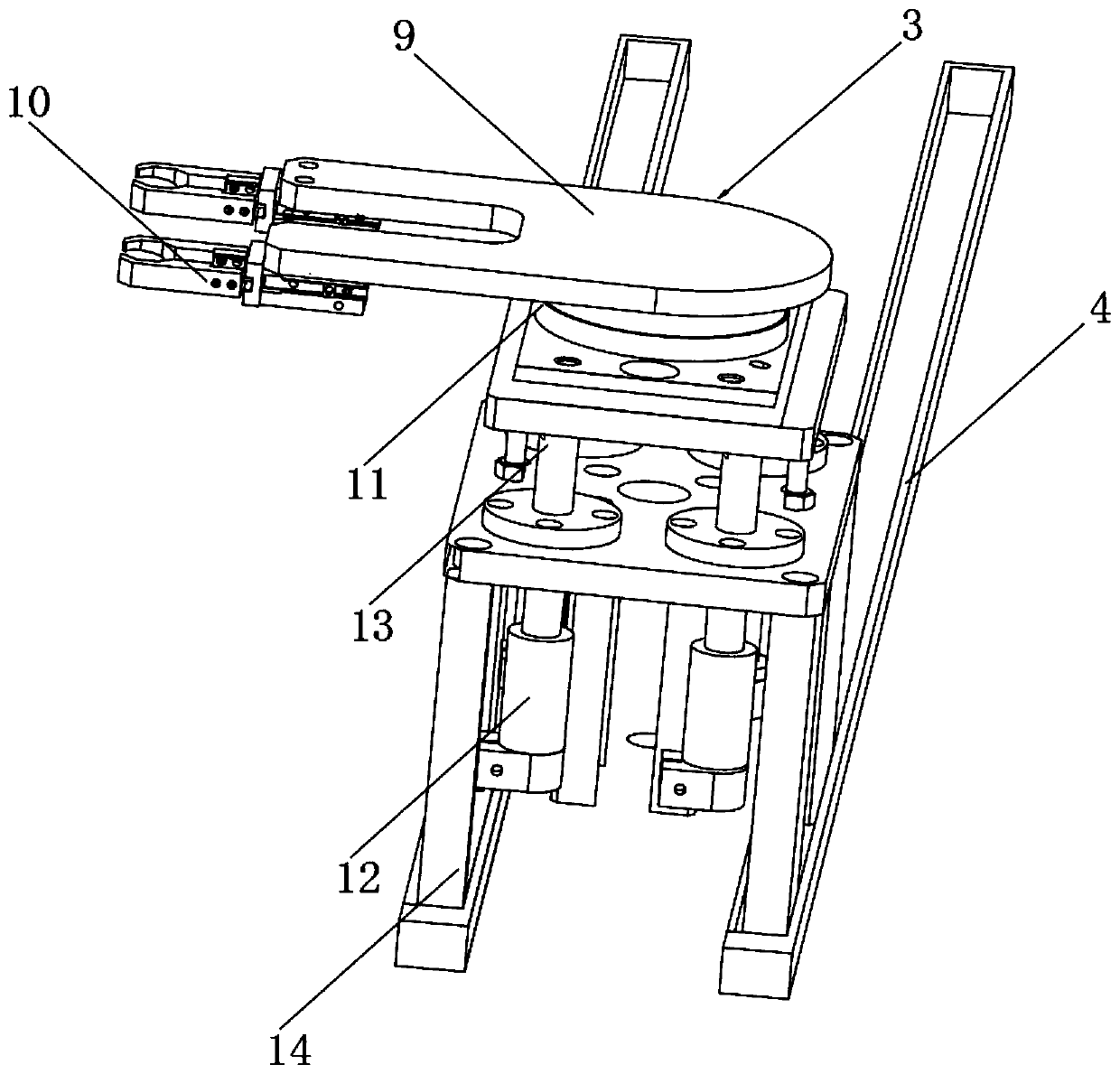

The invention discloses a marine self-refueling device for an unmanned boat, and relates to the technical field of unmanned boat application. The device includes a fuel pipe retracting and releasing mechanism, a fuel pipe alignment, clamping and docking mechanism and a controller. The fuel pipe retracting and releasing mechanism is arranged above the tubing alignment clamping and docking mechanism, the fuel pipe retracting and releasing mechanism is used for driving the fuel pipe, the fuel pipe alignment, clamping and docking mechanism includes a lower bracket, a guide mechanism, a self-centering mechanism and a Z-axis electric control translation table, the guide mechanism is fixed to the upper part of the lower bracket, the guide mechanism is arranged above the self-centering mechanism,the Z-axis electric control translation table is fixed on the side wall of the lower bracket, the self-centering mechanism is fixed on one side of the Z-axis electric control translation table, the self-centering mechanism is driven by the Z-axis electric control translation table and makes the fuel pipe connected with an oil receiving port of the unmanned boat, and the controller is connected with a friction wheel transmission mechanism, the self-centering mechanism and the Z-axis electric control translation table. The device can refuel the unmanned boat without lifting the unmanned boat toa mother ship, thus realizing self-refueling and improving the working efficiency.

Owner:SHANGHAI UNIV

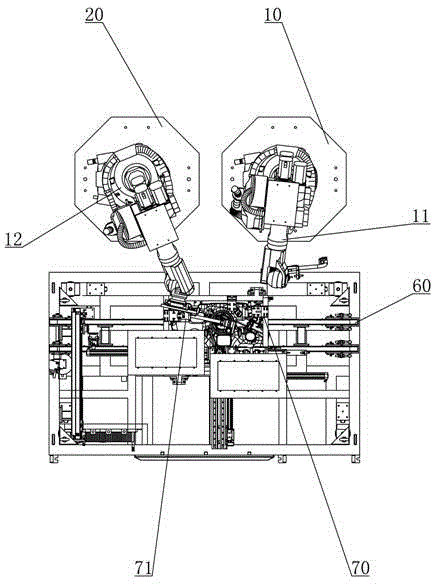

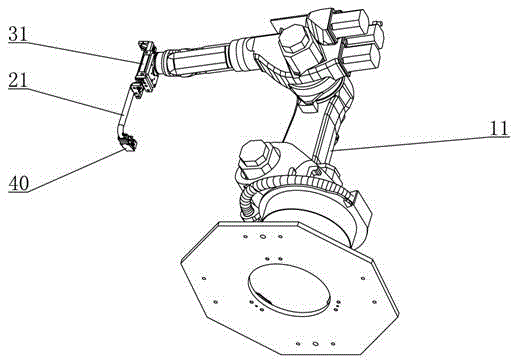

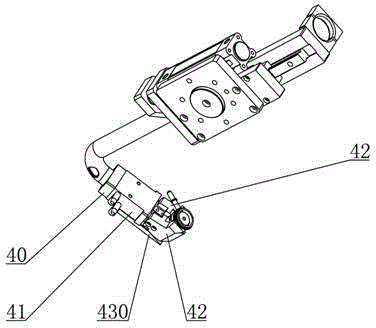

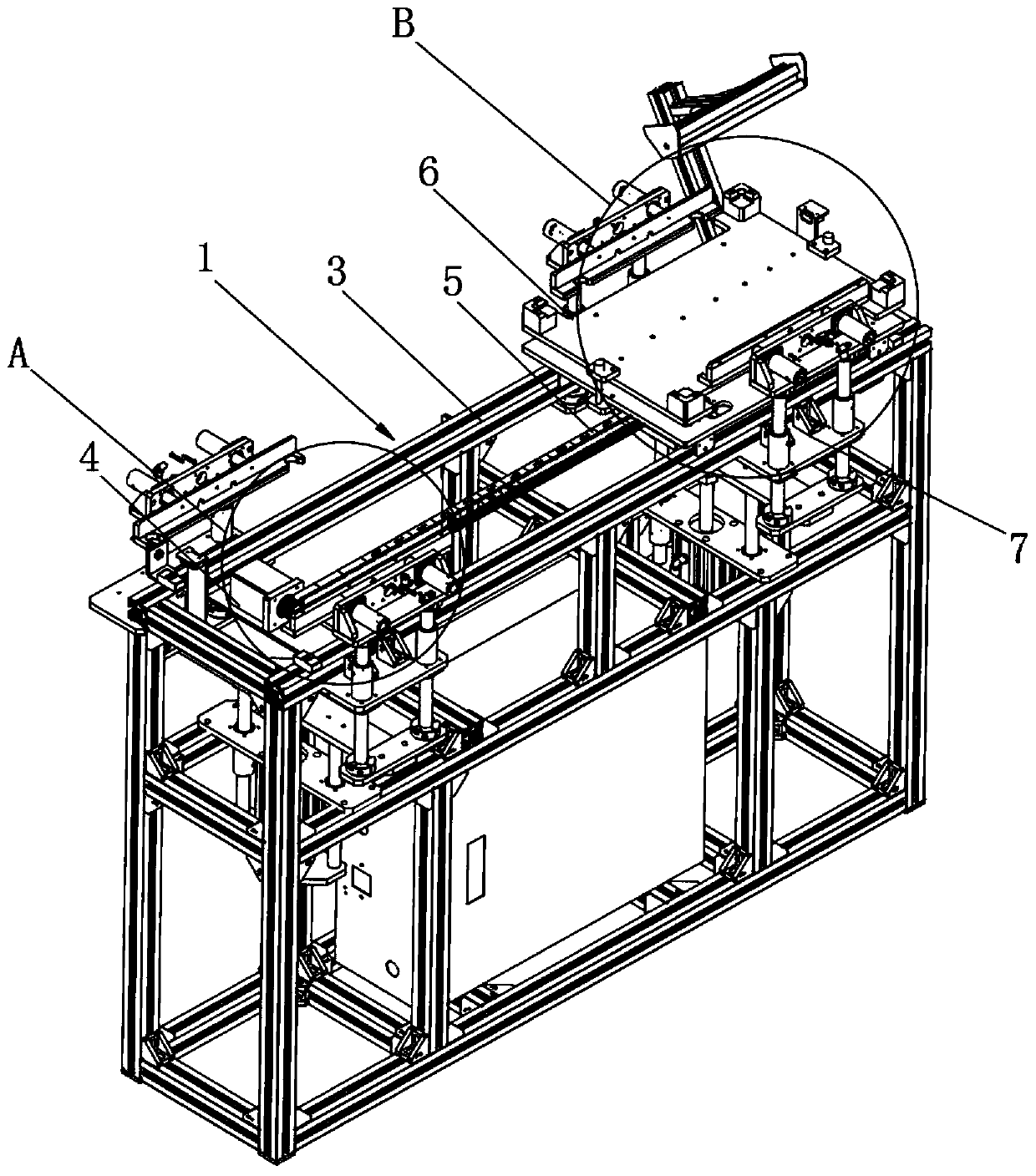

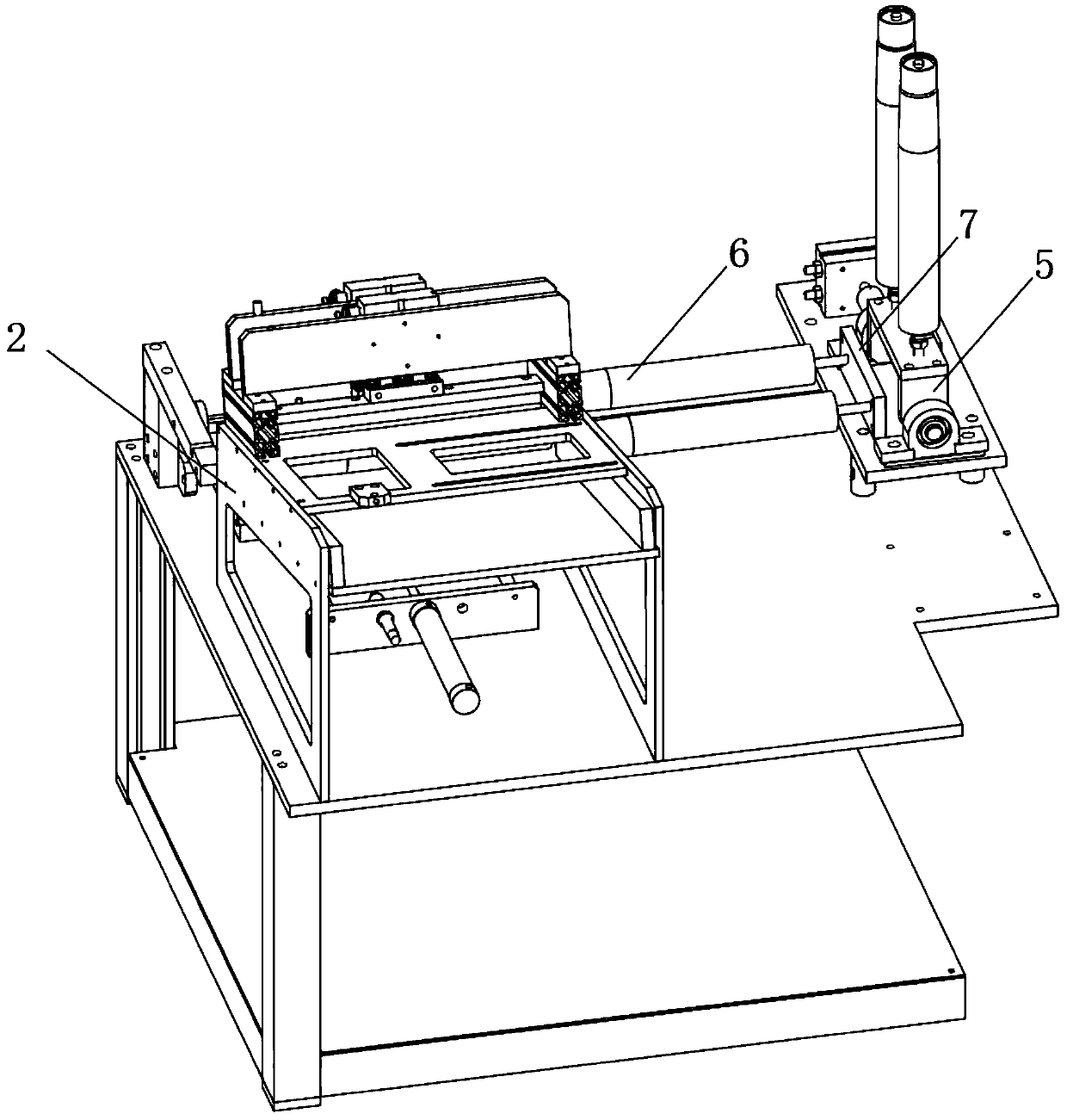

Automatic welding equipment of plastic case

The invention discloses automatic welding equipment of a plastic case. The automatic welding equipment comprises a control system, a welding device and a conveyer device and a fixation device which are arranged below the welding device. The welding device, the conveyer device and the fixation device are all electrically connected with the control system. The welding device comprises a weldment clamping mechanism and a hot mould mechanism. The weldment clamping mechanism contains a first six-axis manipulator and an L-shaped first linking arm connected with the first six-axis manipulator. The other end of the first linking arm is connected with a clamping jaw. The hot mould mechanism contains a second six-axis manipulator and an L-shaped second linking arm connected with the second six-axis manipulator. The other end of the second linking arm is connected with a heating module. By the welding equipment, weldments can efficiently be welded from an inner side of an enclosed case towards an inner wall of the enclosed case, and welding quality is raised greatly.

Owner:深圳市远望工业自动化设备有限公司

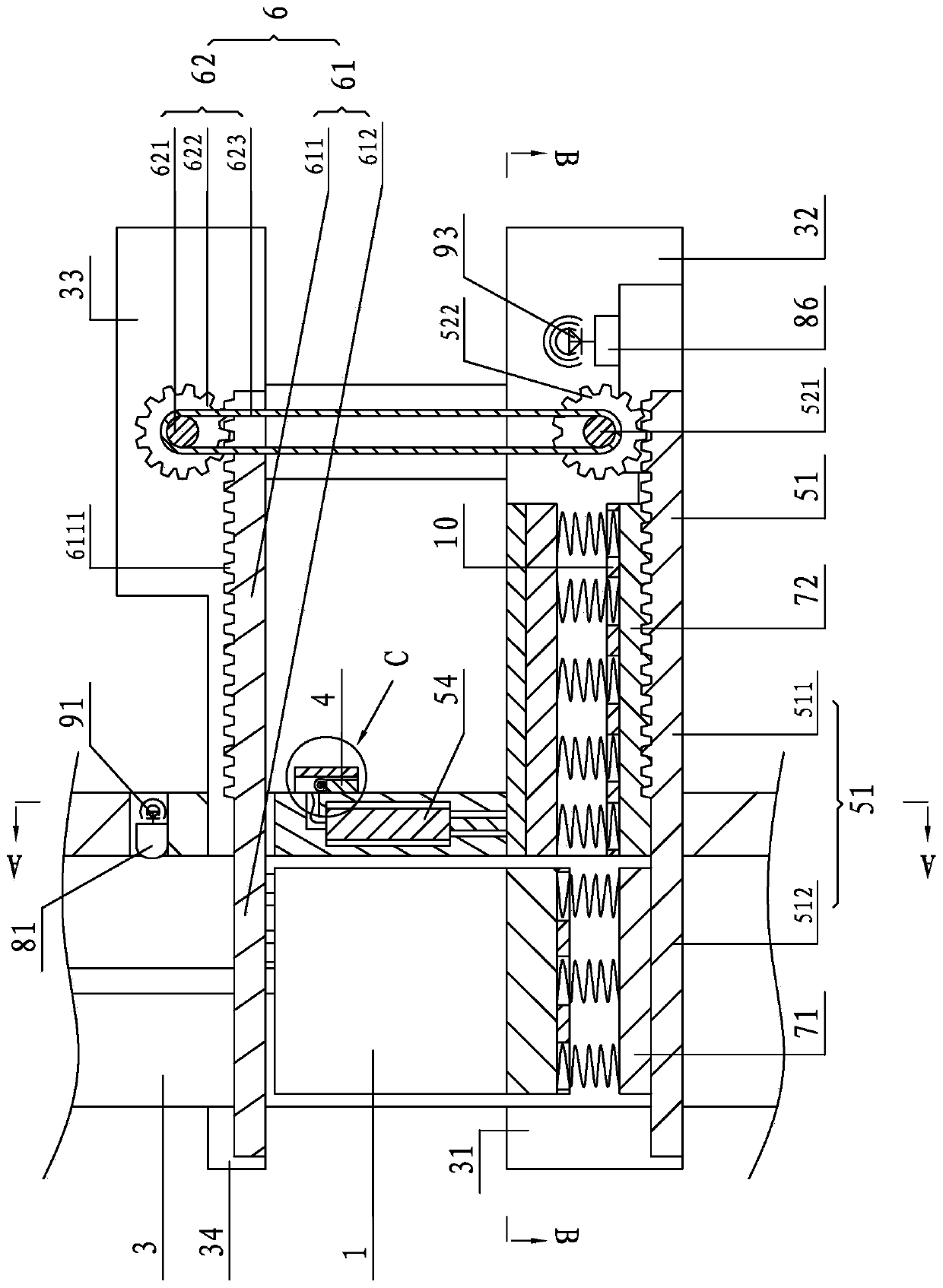

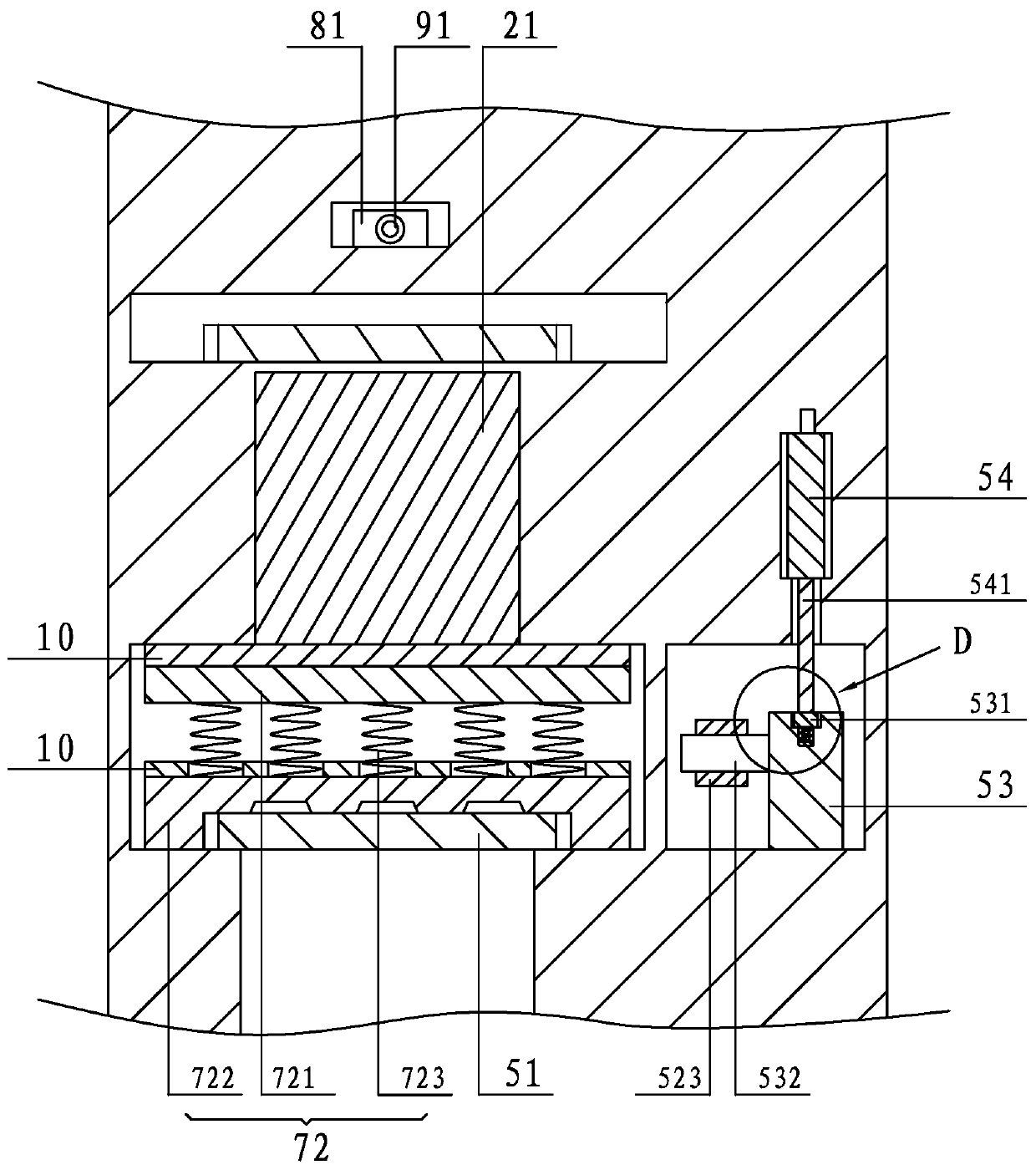

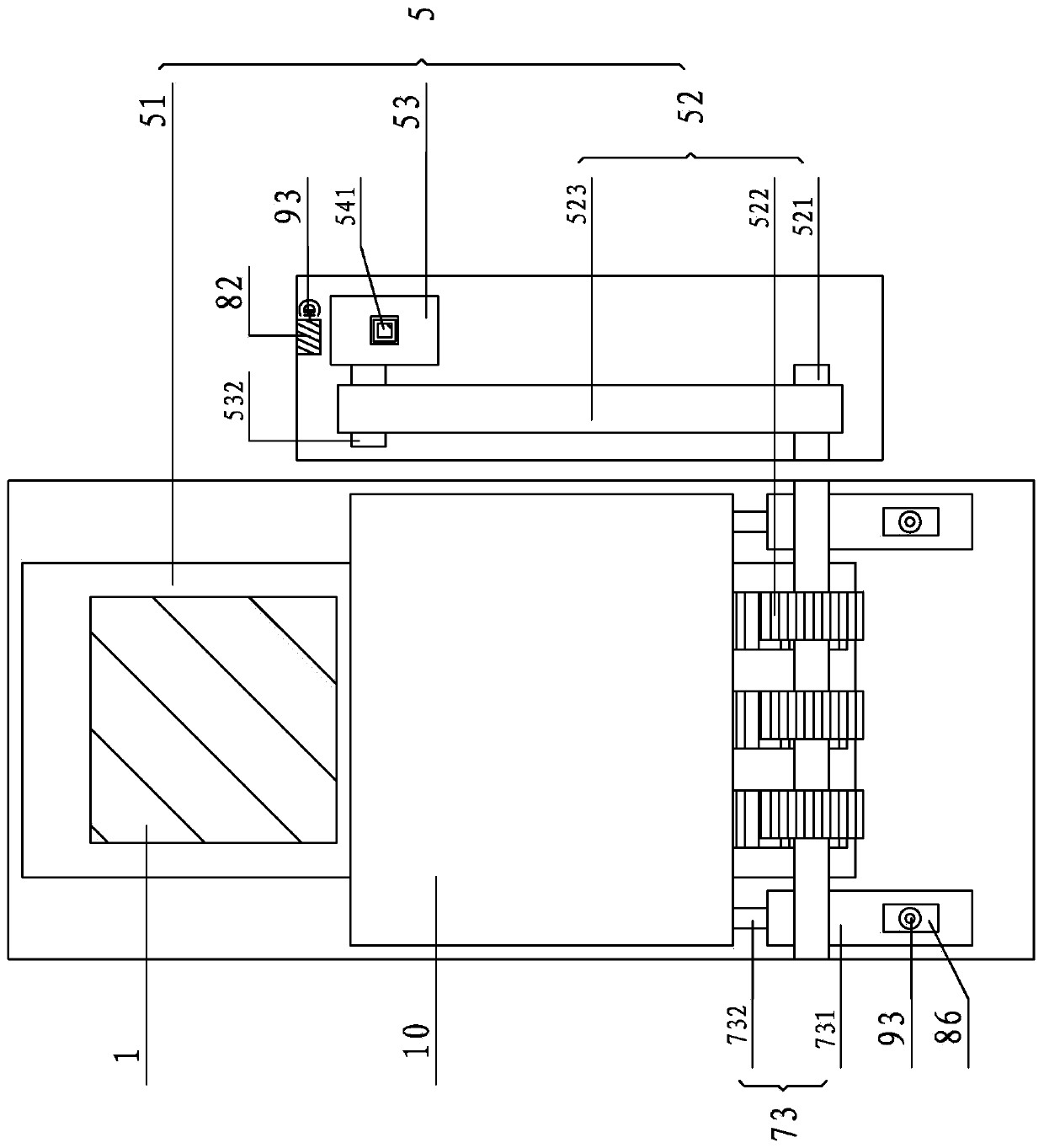

Falling-preventing and high-safety elevator

The invention relates to a falling-preventing and high-safety elevator. The falling-preventing and high-safety elevator comprises an elevator car, landing parts, a shaft part, a control panel, a support mechanism, a buffer mechanism, an intelligent sensing mechanism and a wireless device and is characterized in that the support mechanism comprises a support plate, a transmission mechanism, a motorand a first pneumatic cylinder; the motor is provided with a spring button, and the first pneumatic cylinder is provided with a first piston rod abutted against the spring button; the buffer mechanism comprises a first buffer device, a second buffer device and a second pneumatic cylinder; the first buffer device is connected with the lower surface of the elevator car; each of the first buffer device and the second buffer device comprises two parallel buffer plates and springs arranged between the two buffer plates; the second buffer device is connected with the second pneumatic cylinder; whenthe spring button is pressed, the support plate moves transversely to support the elevator car; when the elevator falls, the intelligent sensing mechanism controls the second pneumatic cylinder to telescope, the first buffer device contacts with the second buffer device, and pressure is buffered through the springs.

Owner:JIANGSU FOUNDER ELEVATOR

Power generation and energy storage equipment adjusting device and method

ActiveCN110729819AEasy to disassembleQuick and easy disassemblyElectrical storage systemSupports/enclosures/casingsMotor driveElectric machine

The invention discloses a power generation and energy storage equipment adjusting device, which comprises a first motor of a cylindrical structure, a supporting plate, side supporting frames, upper conveying tables and vertical installing tables. A rotary base is arranged above the first motor. A cuboid-shaped rotary adjusting base is horizontally arranged at the top of the rotary base, and the side supporting frames are arranged at the two ends of the rotary adjusting base. In the process of installing power generation and energy storage equipment on the device, fifth motors drive a clampingbase to rotate for adjustment through rotary columns to change the connection position and angle of buckling plates and the power generation and energy storage equipment, a sixth motor drives seventhmotors and the buckling plates to turn over up and down for adjustment through turning and swinging shafts, and the seventh motors drive the buckling plates to rotate for position adjustment through third transmission shafts. On one hand, it is guaranteed that the position of a component can be adjusted more flexibly and rapidly, the efficiency of installing the power generation and energy storageequipment on the device is greatly improved. On the other hand, the accuracy of the installing position of the device and the power generation and energy storage equipment is greatly improved.

Owner:HUAIYIN TEACHERS COLLEGE

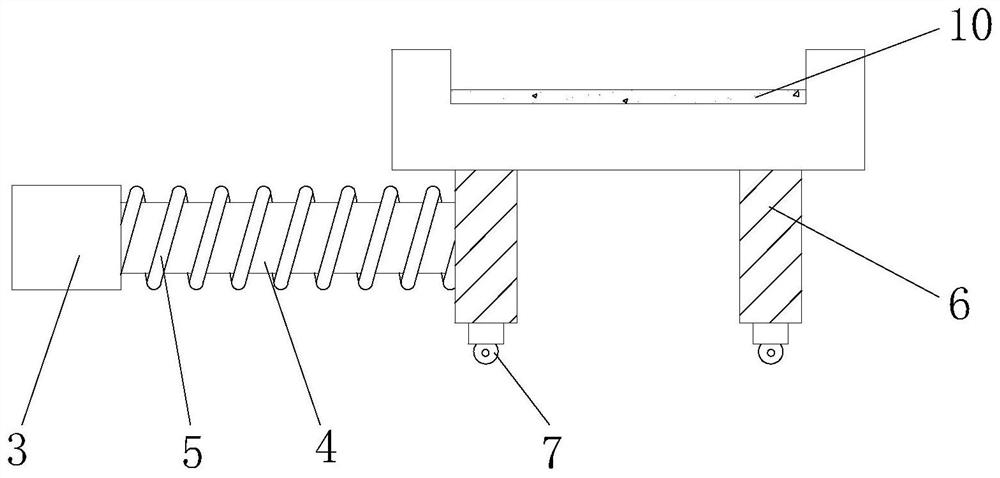

Automatic feeding device for permanent magnet slurry, and feeding method thereof

ActiveCN111013479AWell mixedAdd evenlyTransportation and packagingMixer accessoriesReciprocating motionElectric machine

The invention discloses an automatic feeding device for a permanent magnet slurry, and a feeding method thereof. The device comprises a placing seat and a working disc, wherein the working disc is fixedly installed at the upper end of the placing seat, a top clamping frame is horizontally arranged at the top of the placing seat, and first motors are embedded in the middles of the two ends of the top clamping frame. According to the invention, a third motor drives a first feeding disc to perform reciprocating motion on a top loading table, and a second motor is matched to drive the top loadingtable and the first feeding disc to rotate and swing through a rotating disc, so that a permanent magnet slurry is added into a mixing tank uniformly and comprehensively, and the permanent magnet slurry is added into the mixing tank through the device so as to be more fully and uniformly mixed with other raw materials of permanent magnet ferrite; and the first motor on the placing seat drives a loading table to reciprocate back and forth on the top clamping frame through a first steel belt, and the first feeding disc and a second feeding disc are matched to movably feed materials into the mixing tank, so that the working coverage area of the permanent magnet slurry placed in the mixing tank by the device is enlarged.

Owner:安徽中马磁能科技股份有限公司

Green and intelligent storage system

The invention discloses a green and intelligent storage system. The system includes a storage part, a fetching part and a transfer part, wherein the storage part is arranged between the indoor bottom layer of a building and the indoor surface pavement layer of the building, the fetching part is arranged above the indoor surface pavement layer of the building, and the transfer part is arranged below the fetching part and used for connecting the storage part with the fetching part; the fetching part includes a plurality of storage trolleys and a transportation mechanism which makes the storage trolleys move between a specific storage position and the transfer part; the fetching part includes a lifting part which is used for lifting the storage trolleys located above the transfer part onto the indoor surface pavement layer of the building. According to the system, a space between the indoor bottom layer of the building and the indoor surface pavement layer of the building serves as a storage space, the storage space is large and hidden, the activity space is increased largely, articles are stored in the storage trolleys in sequence according to the types, when the articles need to be fetched, the articles can be conveniently fetched through the action of the transportation mechanism and the fetching part, and the problems that the storage space is small and the articles are placed in a messy state and thus difficult to find are thoroughly solved.

Owner:HUZHOU VOCATIONAL TECH COLLEGE

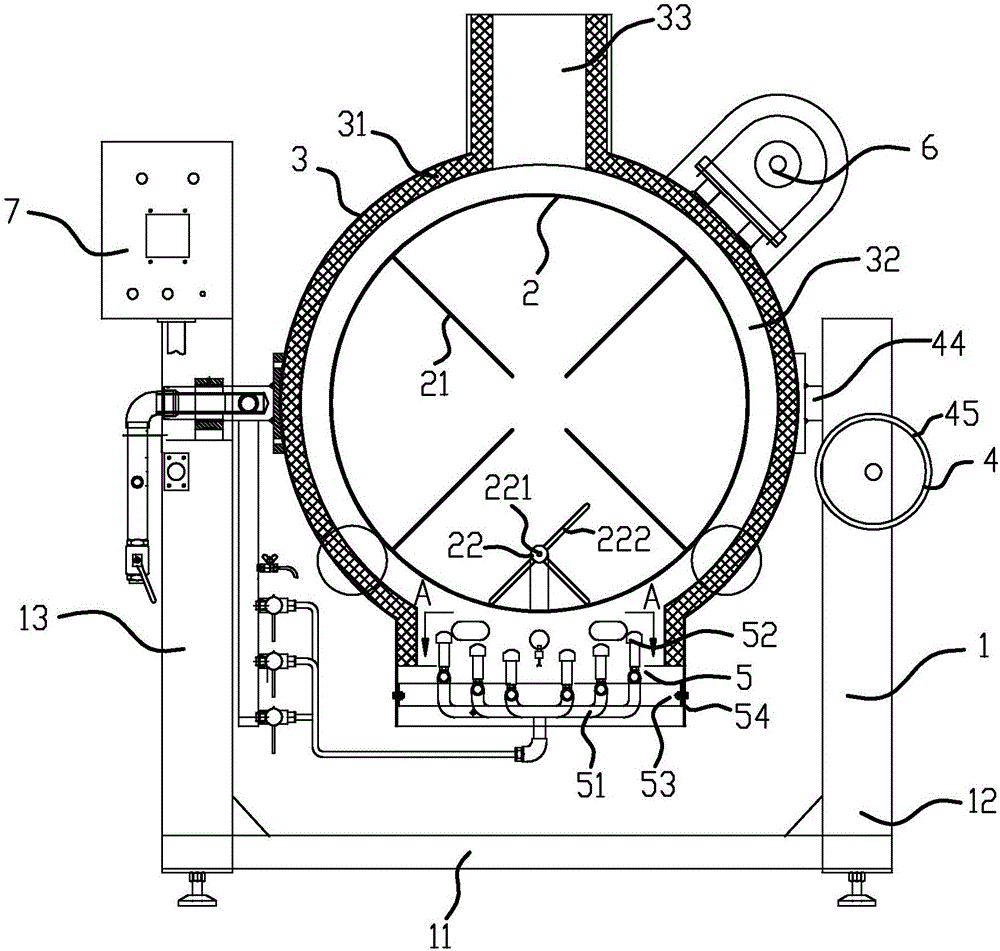

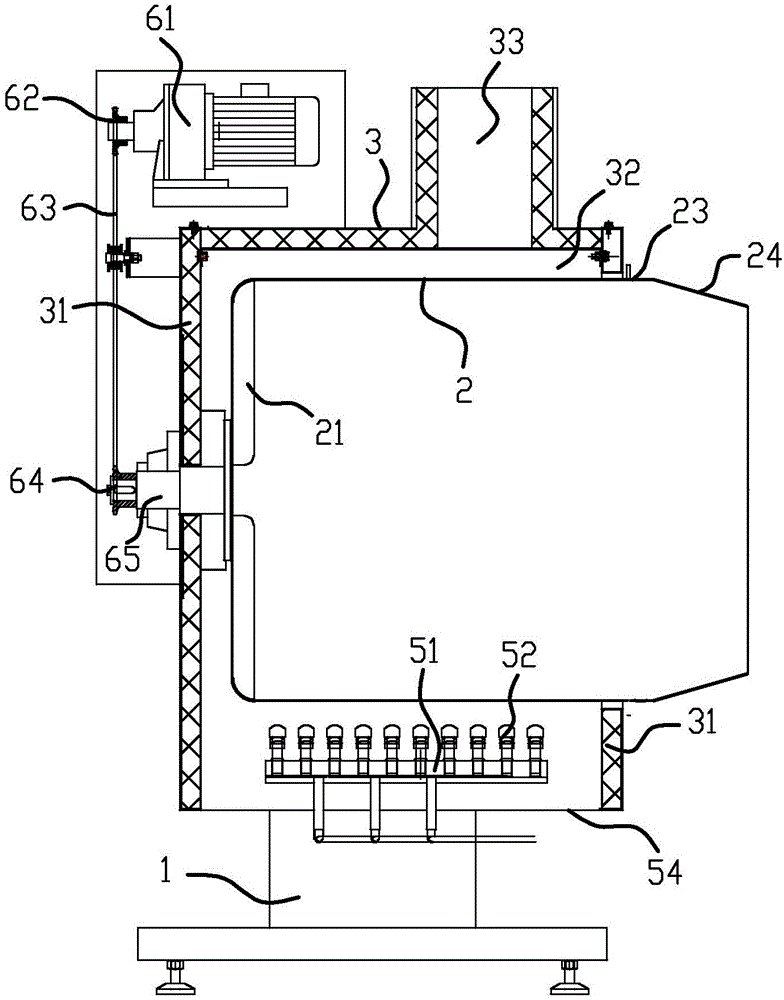

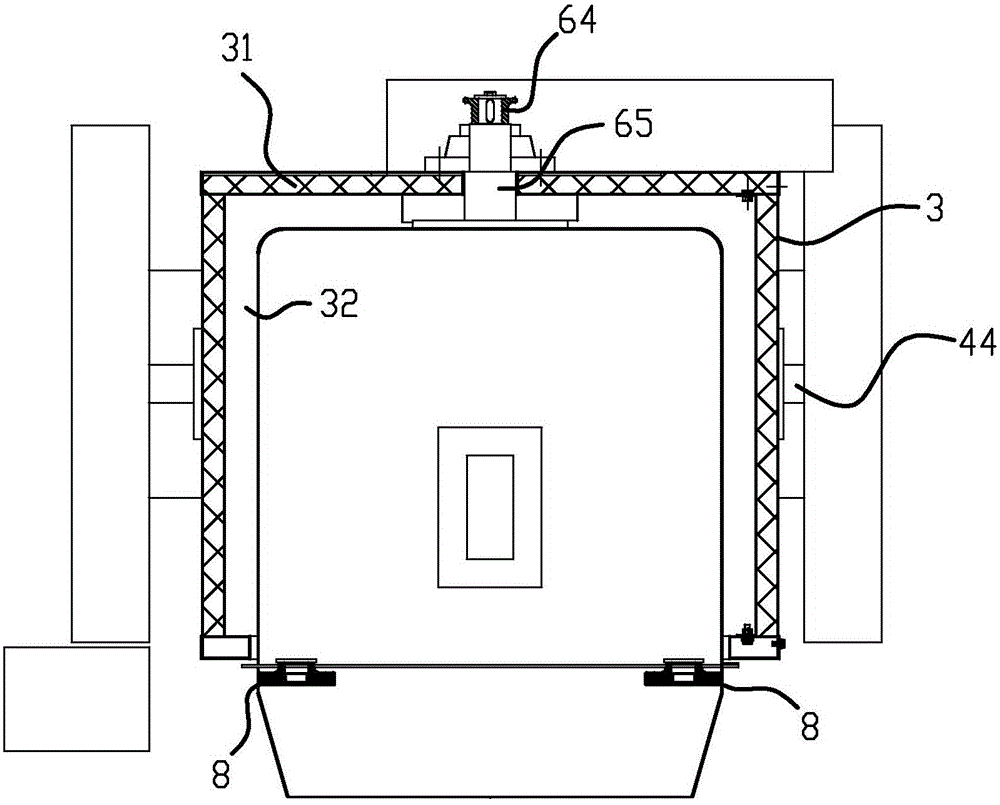

Horizontal-type automatic cooker

ActiveCN105030044ANot easy to run outImprove efficiencyWarming devicesCooking vessel supportBarrel ShapedEngineering

The invention provides a horizontal-type automatic cooker which belongs to the technical field of kitchen appliances and solves the problems that existing cooking devices have small adjustment scopes and a lot of use limitations. The horizontal-type automatic cooker comprises a rack, a pan body, a shell and a rotation device, wherein one side of the rack is equipped with a turnover device; the pan body is bucket-shaped, a stirring rod is firmly connected inside the pan body, and a plurality of turnover ribs are disposed on the inner wall of the pan body; the shell sleeves the outside of the pan body and is hinged and installed on the rack, the turnover device is connected to the shell and can drive the shell to rotate at an angle between 0 DEG and 90 DEG, a fuel gas device is installed on one side of the shell, and the pan body can be heated by the fuel gas device; and the rotation device is installed on the shell and can drive the pan body to rotate along the axis direction. The horizontal-type automatic cooker provided by the invention is advantageous in a large rotation scope and simple operations.

Owner:ZHEJIANG XIANGYING CENT KITCHEN EQUIP CO LTD

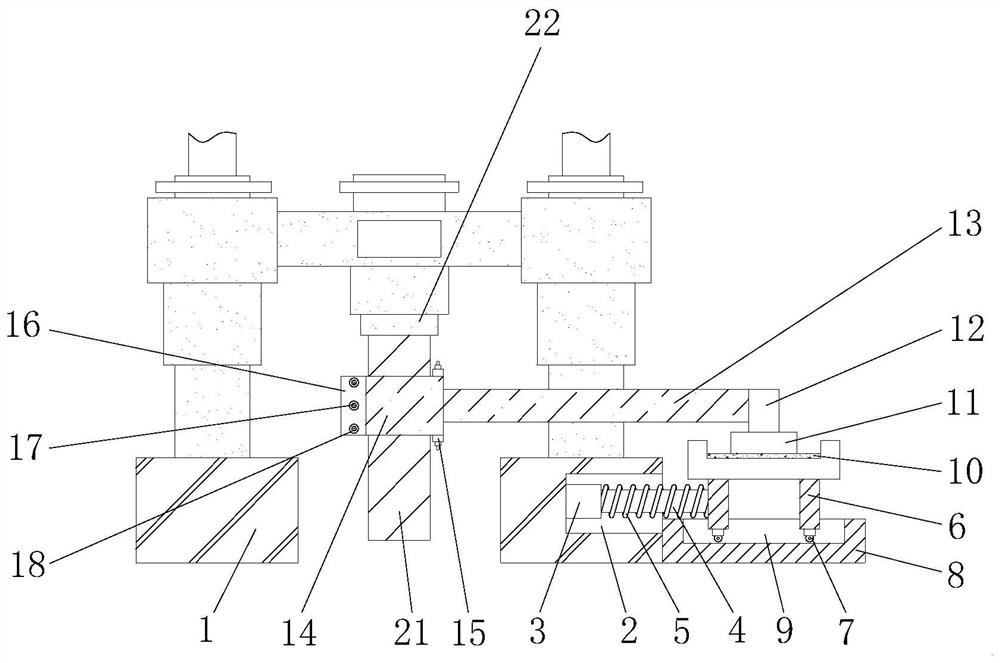

High-efficiency impact grinding and slotting device used for aviation equipment pipe bodies

ActiveCN109746811AImprove grindingImprove polishing efficiencyEdge grinding machinesGrinding carriagesAviationHydraulic pump

The invention discloses a high-efficiency impact grinding and slotting device used for aviation equipment pipe bodies. The high-efficiency impact grinding and slotting device comprises a front grinding table, a holding seat, a mounting box, first hydraulic pumps, first sliding rails, a transport tray, a rear grinding table and a slotting table; the bottom part of the front grinding table is provided with the mounting box, and one side of the front grinding table is provided with the holding seat in a cuboid shape; and the first hydraulic pumps are longitudinally arranged at the four corners ofthe mounting box correspondingly. The high-efficiency impact grinding and slotting device disclosed by the invention has the beneficial effects that a plurality of first motors arranged on each of mounting rods equidistantly are used for performing impact grinding on the pipe bodies synchronously at different positions through rotary grinding heads, so that the efficiency of performing impact grinding and polishing on the pipe bodies by the device is increased, and it is guaranteed that the working gap between every two supporting plate rods is more suitable; impact grinding components on thedevice cannot be scratched or damaged when the pipe bodies are processed by the impact grinding components; and the mounting rods are driven to vertically shifted synchronously through two second hydraulic columns by connection blocks, so that the mounting rods can be vertically adjusted and moved more steadily, the rotary grinding heads and the pipe bodies are prevented from being forcefully collided, and it is guaranteed that the surface of each pipe body is more smooth by impact grinding and has no dents.

Owner:灵璧县浩翔信息科技有限公司

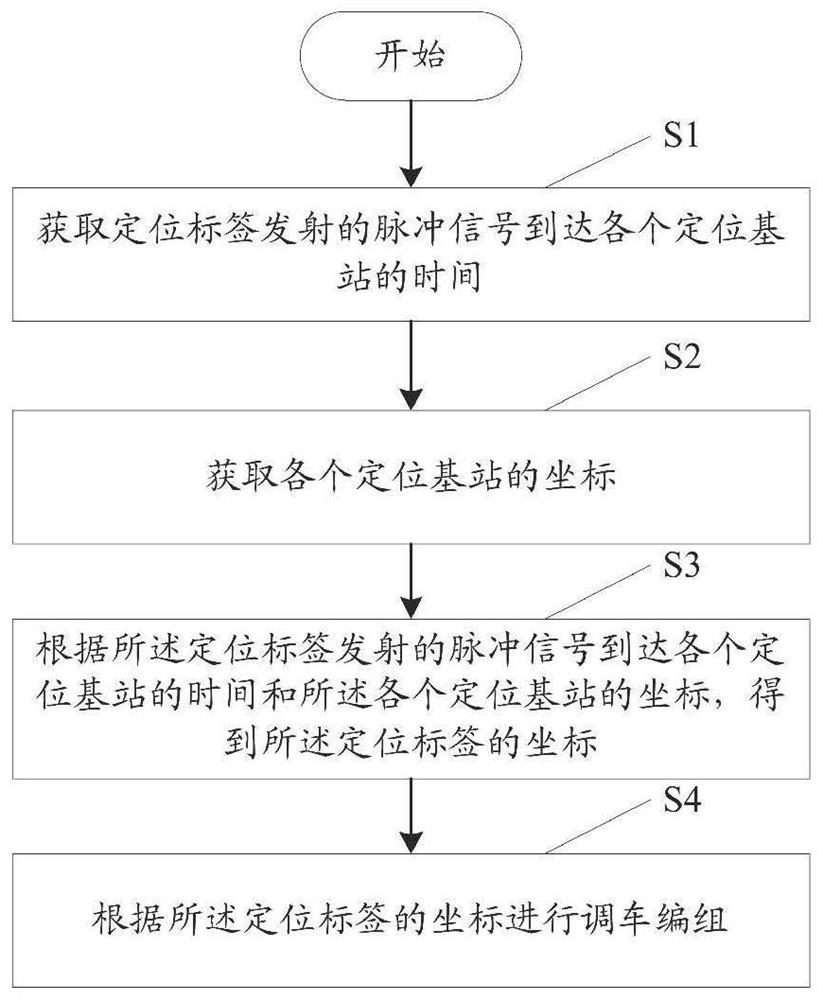

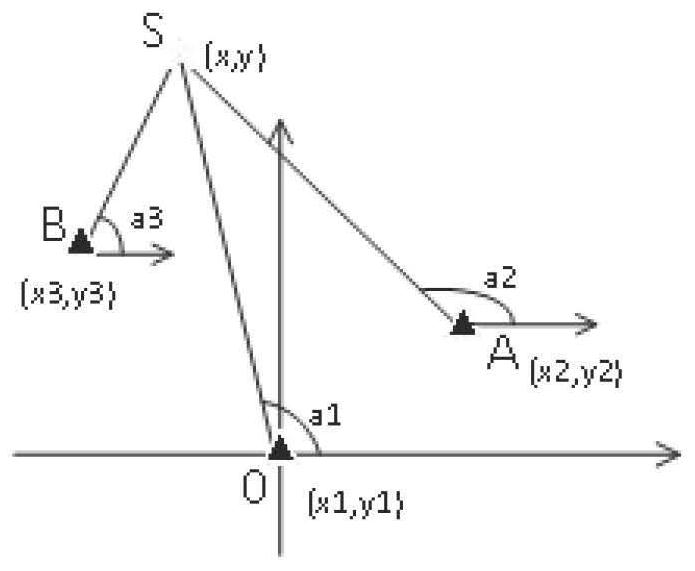

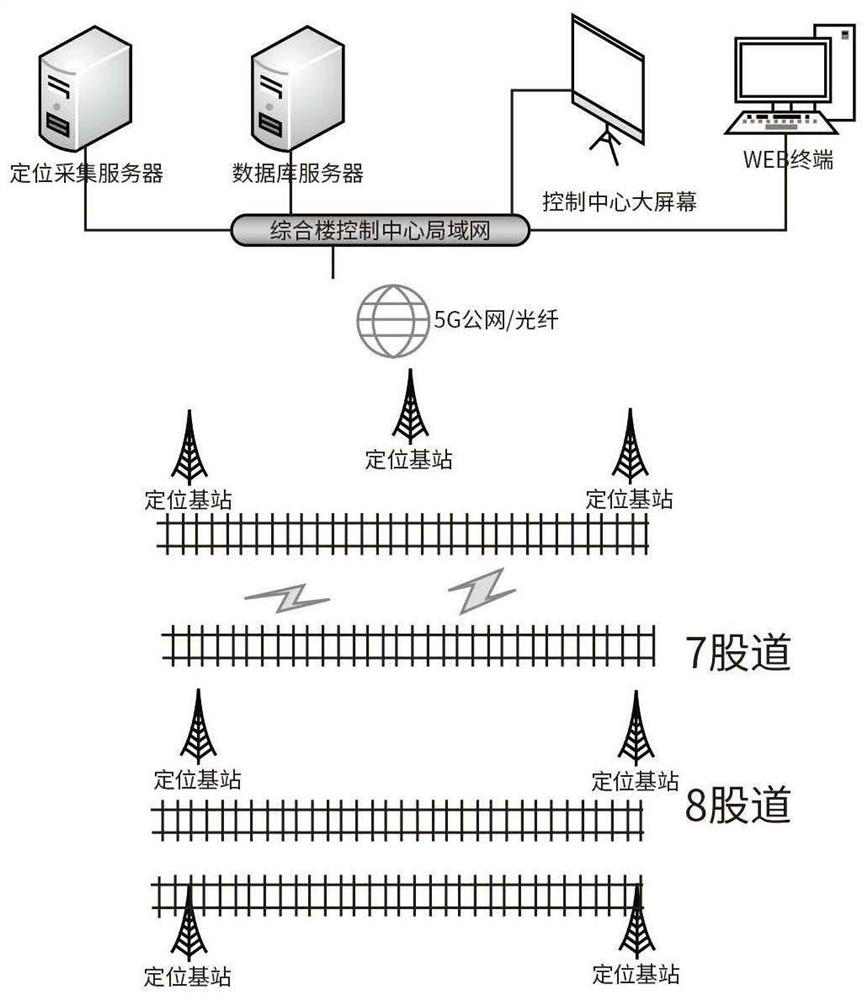

Railway freight vehicle shunting marshalling method and system based on UWB positioning technology

PendingCN114325572AImprove the operating environmentPrecise positioningParticular environment based servicesPosition fixationRail freight transportEngineering

The invention relates to a railway freight vehicle shunting marshalling method and system based on a UWB positioning technology, and the method comprises the following steps: obtaining the time when a pulse signal transmitted by a positioning tag arrives at each positioning base station; obtaining coordinates of each positioning base station; obtaining the coordinate of the positioning label according to the time when the pulse signal transmitted by the positioning label arrives at each positioning base station and the coordinate of each positioning base station; and shunting marshalling is carried out according to the coordinates of the positioning labels. The real-time positions of the locomotive and the vehicle can be obtained in real time, when the locomotive approaches to the to-be-grouped vehicle, the real-time position is fed back to the locomotive cab in real time, it is guaranteed that the vehicle hanging speed is lower than the set range, and shunting safety is guaranteed.

Owner:珠海新星心科技有限公司

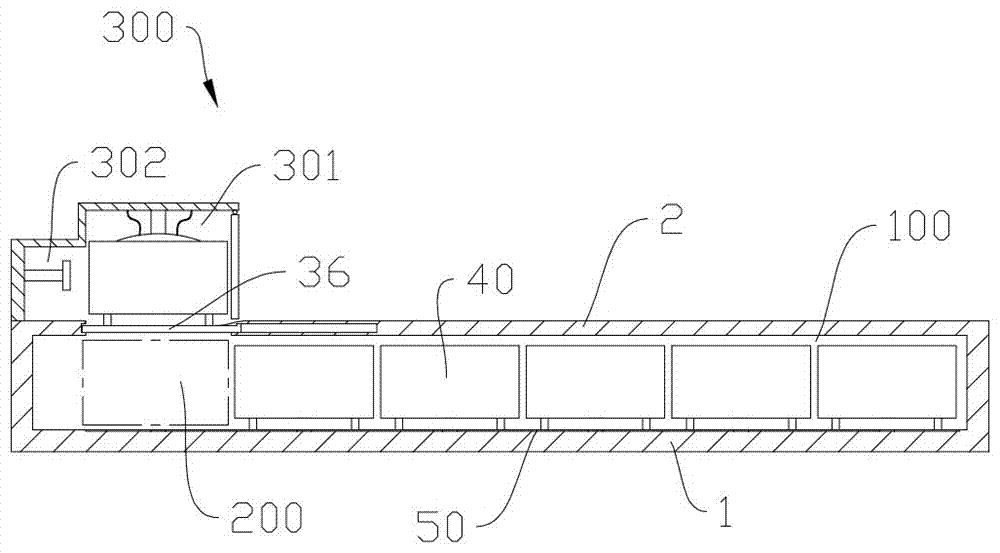

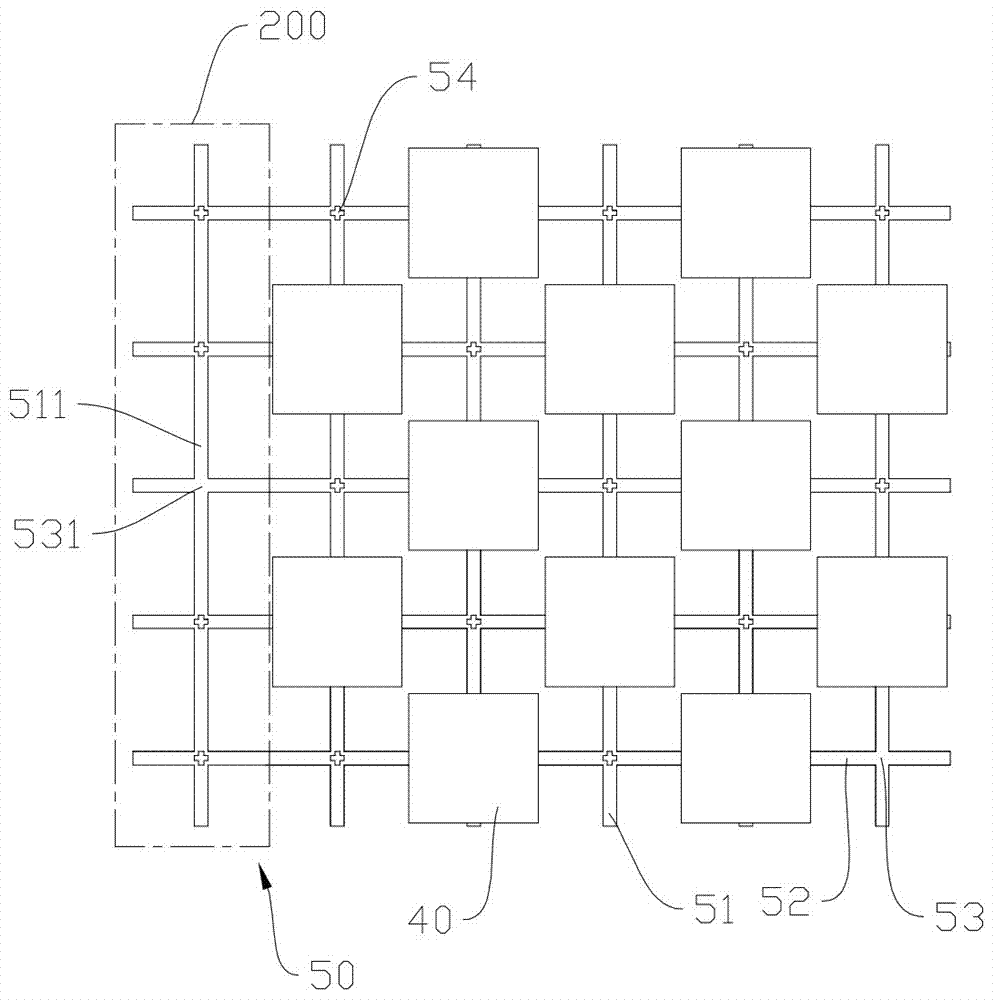

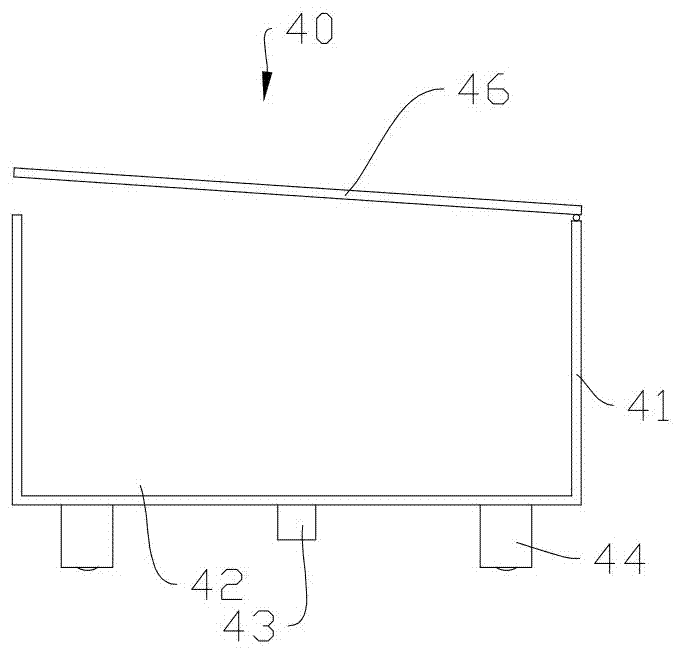

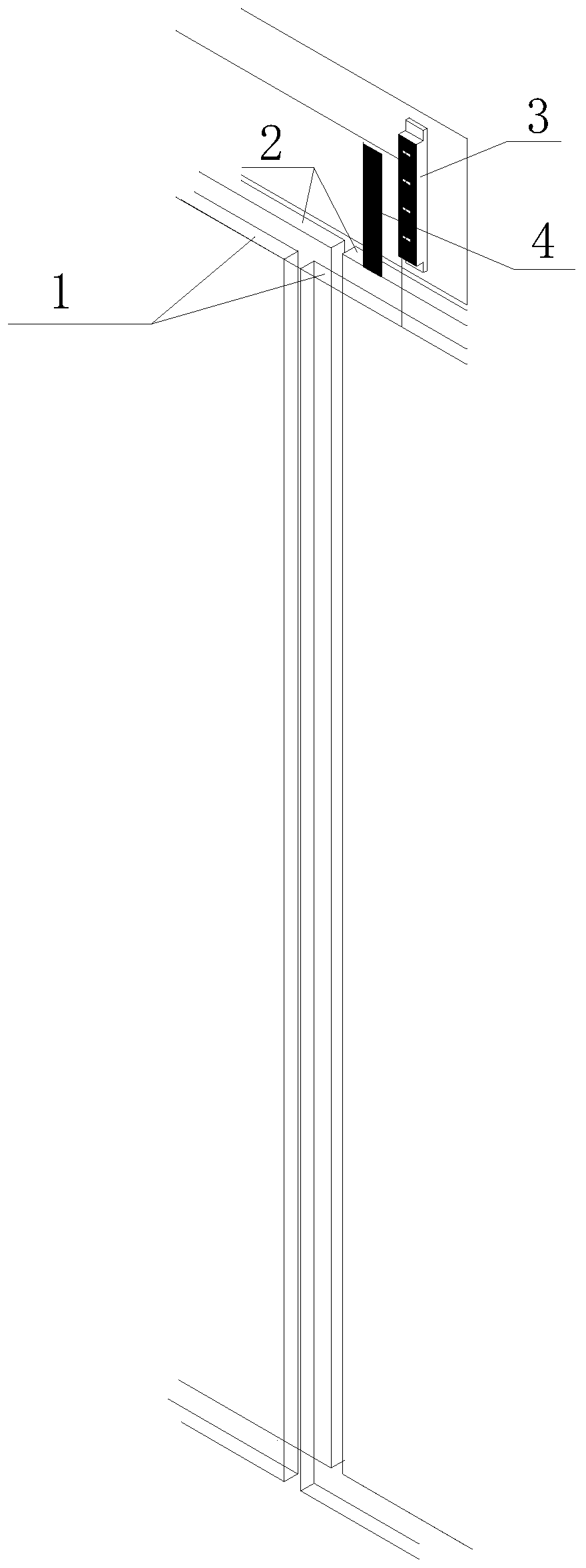

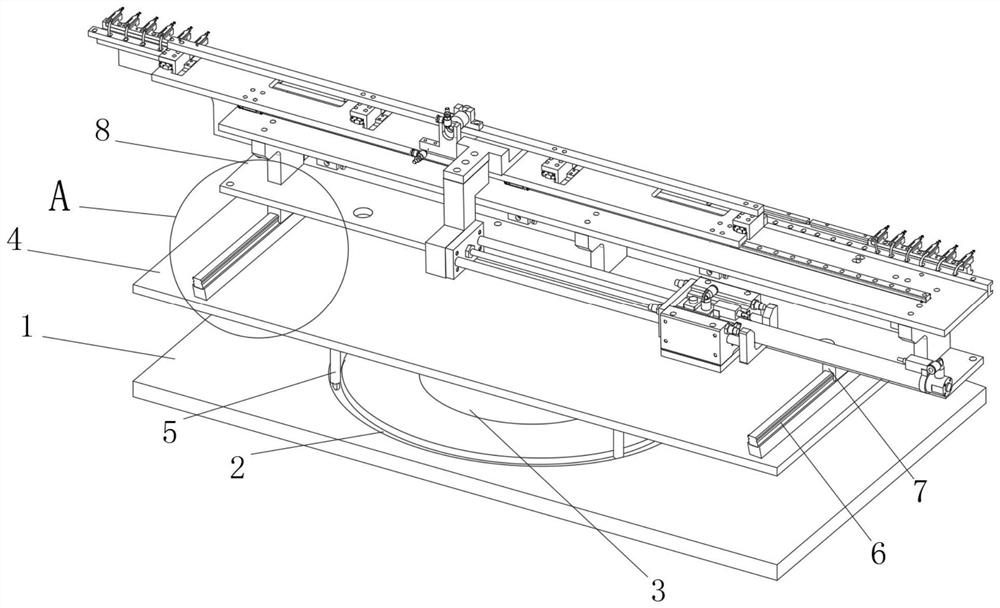

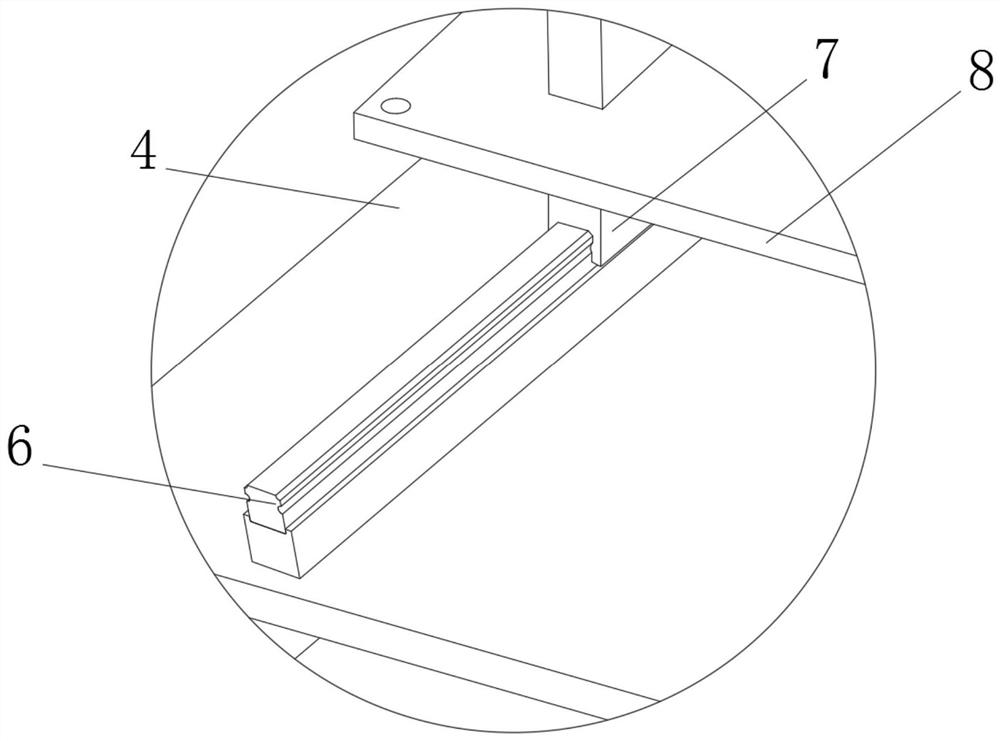

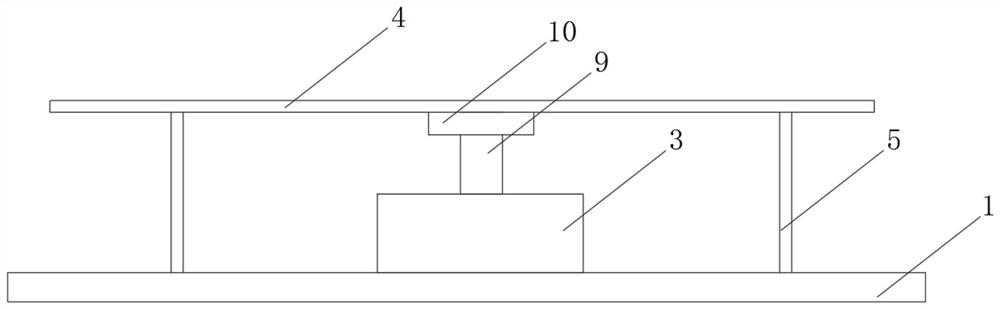

Movable storage trolley and track thereof

ActiveCN109484421ASpeed controlThe docking position is accurateCarriagesApplication siteMechanical engineering

The invention discloses a movable storage trolley and a track thereof. The storage trolley comprises a storage trolley body and the track; the storage trolley body includes a hollow trolley body witha storage space, an openable trolley roof, a sensor group and a wheel set, wherein the sensor group is arranged at the bottom of the hollow trolley body and matched with the track to guide the advancing route of the storage trolley, and the wheel set is used for achieving the movement function of the storage trolley. The track is flush with a ground surface, and the color of the track is obviouslydifferent from objects around the track; the track comprise a plurality of transverse track bodies and vertical track bodies, wherein the transverse track bodies and the vertical track bodies are perpendicular to each other and are sequentially connected with each other end to end, and adjacent corners of the transverse track bodies and vertical track bodies form parking points. According to thestorage trolley, the storage trolley can regularly run along the track between a storage position and an application site, manual operation is not needed, and the objects along a road cannot be damaged.

Owner:ZHEJIANG RADIO & TV UNIV

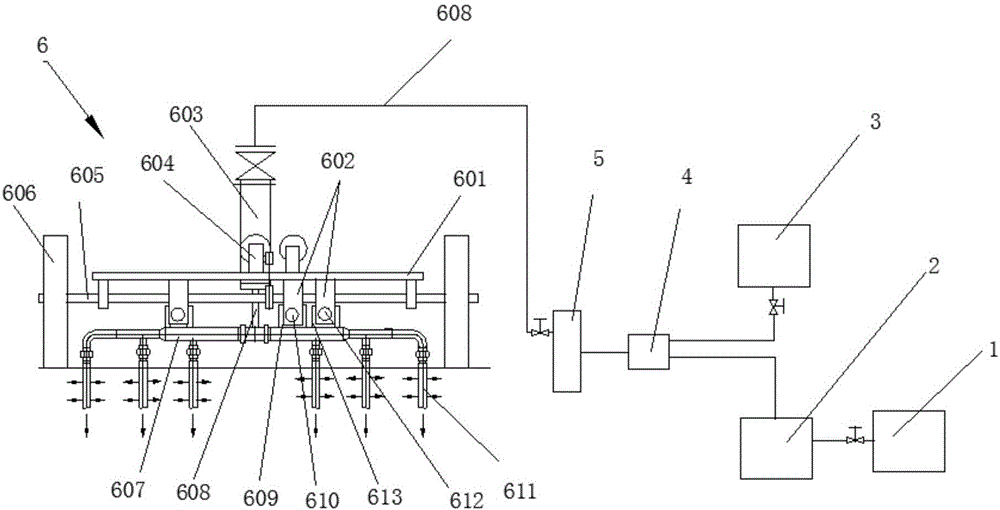

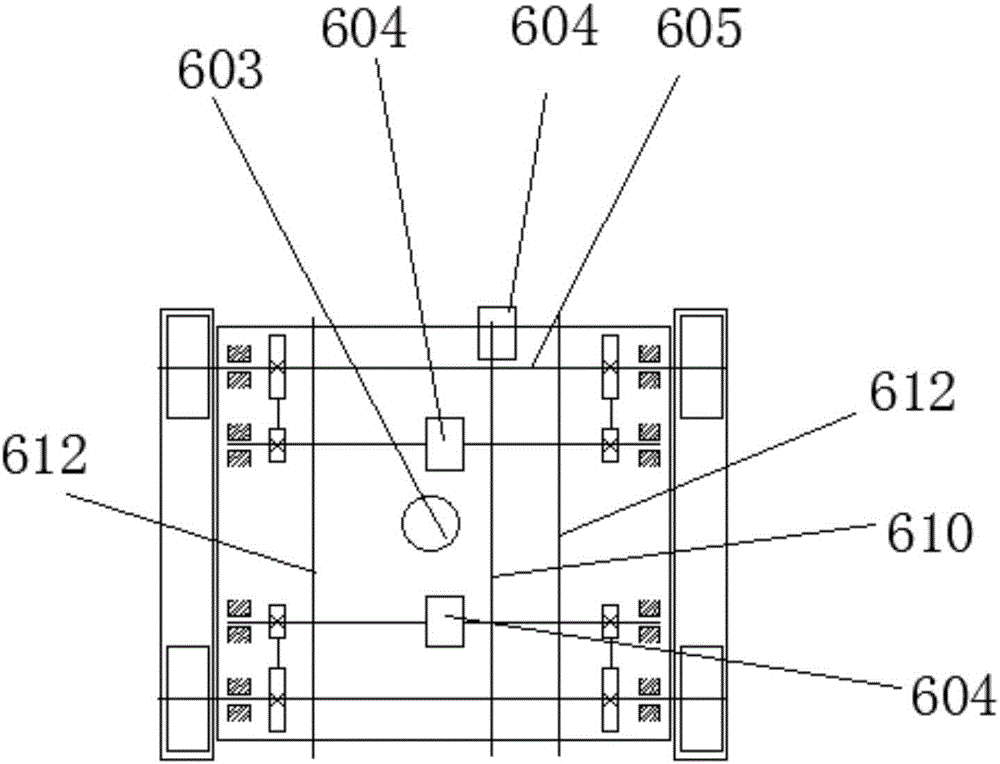

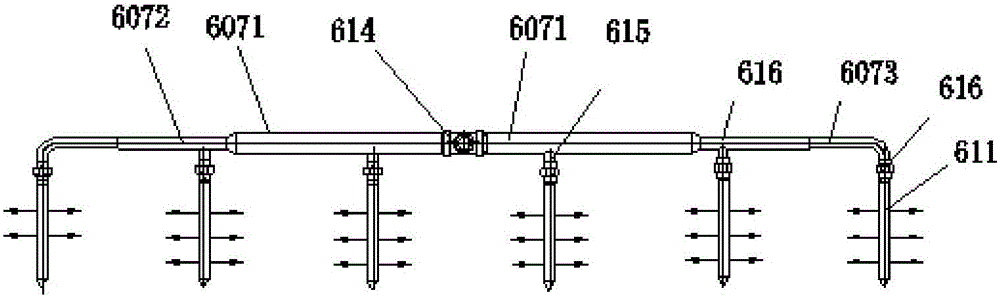

Medicine spraying device

The invention provides a medicine spraying device which comprises a medicine spray preparation system and an injection robot, wherein the medicine spray preparation system comprises a liquid medicine tank, an air compressor and an air injection pump; a liquid inlet of the air injection pump is communicated with the liquid medicine tank through a pipeline, and an air inlet of the air injection pump is communicated with the air compressor through a pipeline; the injection robot comprises a frame as well as a running device and an injection device which are arranged on the frame; and an air outlet of the air injection pump is communicated with an air inlet of a mixed gas main pipe through a hose, and an air outlet of the mixed gas main pipe is communicated with a liquid inlet of the injection device through a pipeline. In the medicine spraying device provided by the invention, the liquid medicine and air are mixed into a spray state through the air compressor and the air injection pump; the medicine spray preparation system and the robot are arranged separately, thereby relieving the robot load and facilitating technical operation; the medicine spraying operation can be automatically finished, and the medicine spray can be applied to grain in time; and the medicine spraying is uniform, and the medicine spraying effect is good.

Owner:TIANJIN MESSCCOER TECH CONSULTING +2

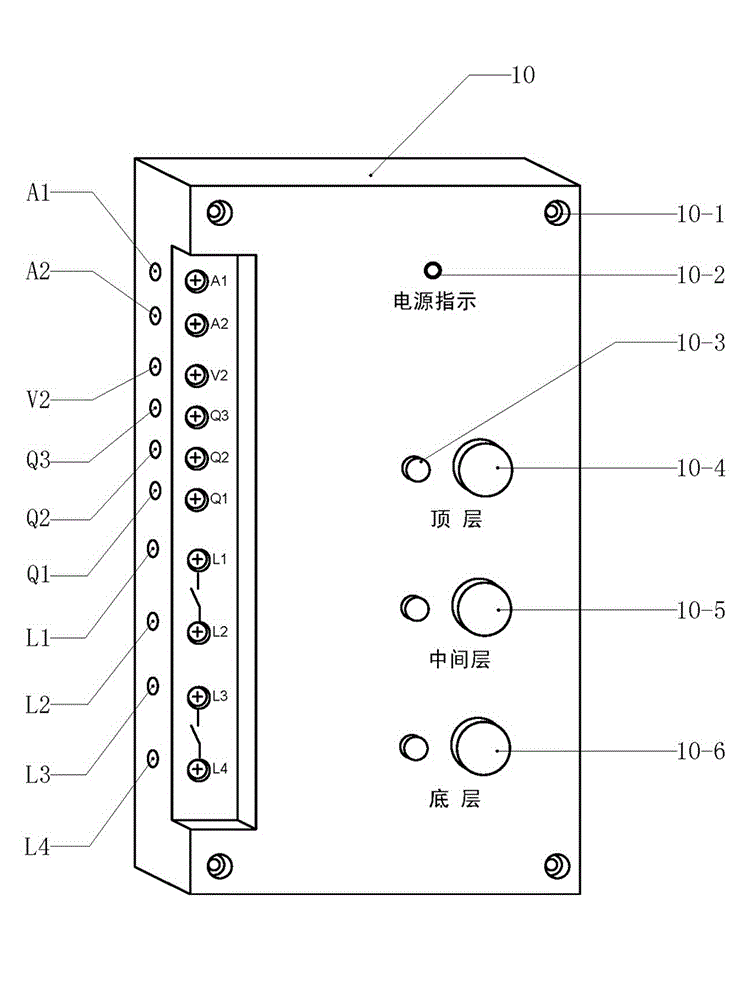

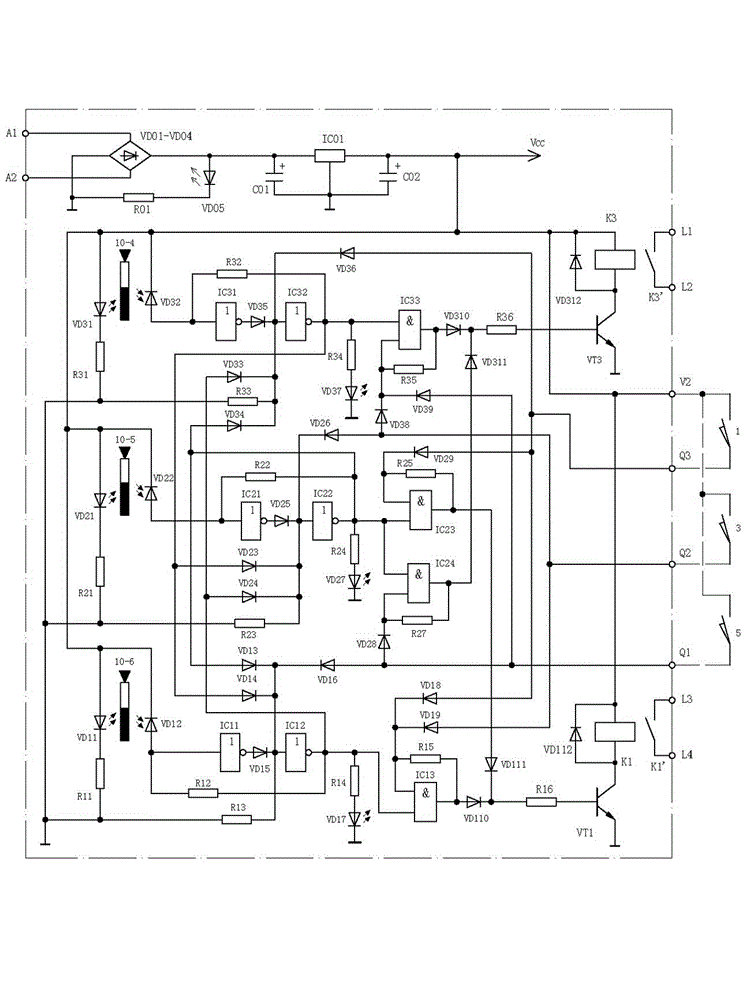

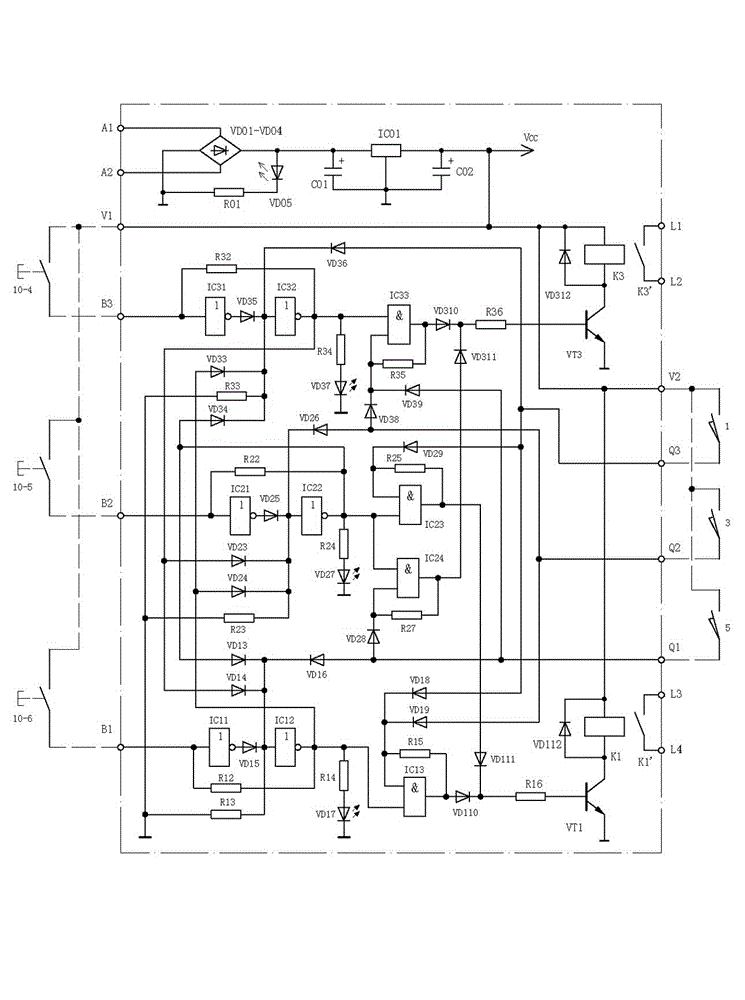

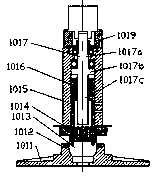

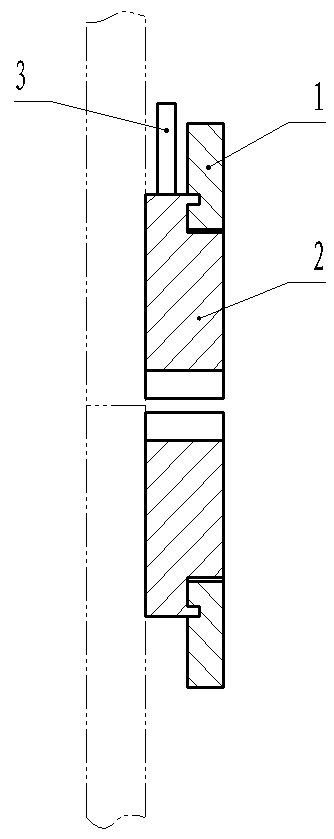

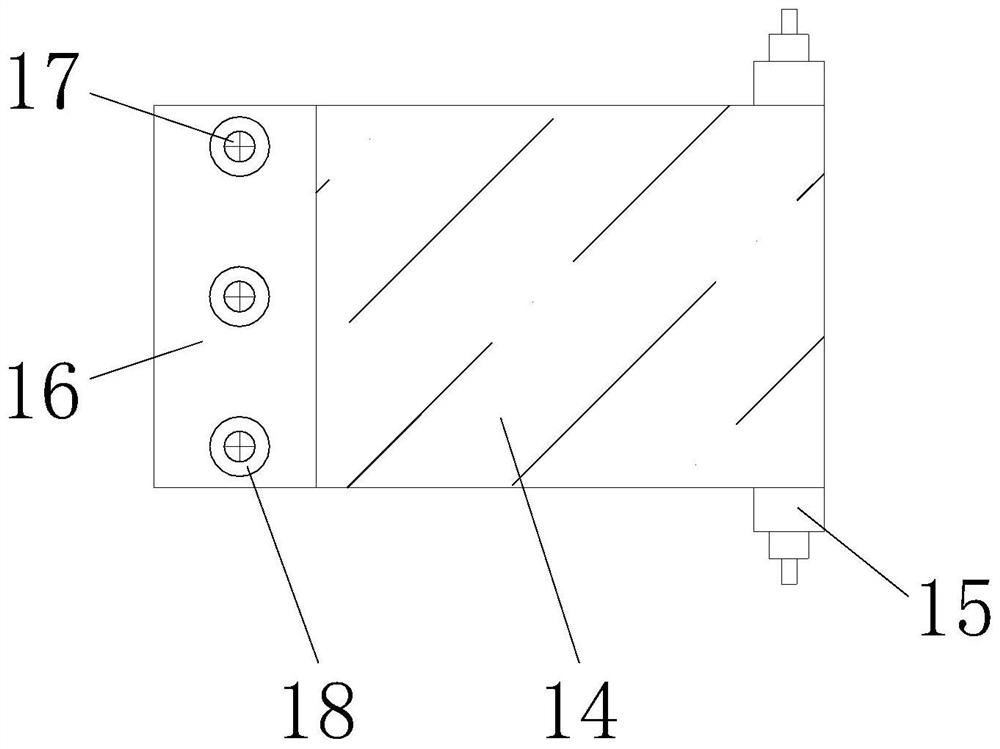

Material hoister control module

InactiveCN103332543ARealize automatic dockingThe docking position is accurateElevatorsPower circuitsControl circuit

The invention discloses a material hoister control module and relates to control devices of engineering construction hoisters. The material hoister control module is mainly composed of a circuit board, a shell body and encapsulating materials. A working power supply circuit, a bottom-layer stop control circuit, a middle-layer stop control circuit and a top-layer stop control circuit are installed on the circuit board. The circuit board is installed inside the shell body. The circuit board is encapsulated and fixed through the encapsulating materials. The bottom-layer stop control circuit is composed of a negation gate 1a, a negation gate 1b and a gate 1. The middle-layer stop control circuit is composed of a negation gate 2a, a negation gate 2b, a gate 2a and a gate 2b. The top-layer stop control circuit is composed of a negation gate 3a, a negation gate 3b and a gate 3. An uplink output circuit is composed of an isolated diode 3b, an isolated diode 3c, a triode b, a clamping diode 3 and a relay b. A downlink output circuit is composed of an isolated diode 1b, an isolated diode 1c, a triode a, a clamping diode 1 and a relay a. The material hoister control module is applied to construction of a construction site, and achieves the objective that a basket can automatically stop on a floor and the stopping position is accurate.

Owner:高妍

Automatic flour hammering and twisting device for flour food processing and working method thereof

InactiveCN109730104AUniform hammering areaFull hammer areaMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsHydraulic pumpEngineering

The invention discloses an automatic flour hammering and twisting device for flour food processing. The device comprises a work table, a first push table, a second push table and a mounting frame, themounting frame of a hollow rectangular cuboid structure sleeves above the work table, and the two sides of the work table are respectively provided with the first push table and the second push table. The device has the advantages that a plurality of hammering frames arranged in the same arc move up and down by movable pressure hammers to hammer flour, a plurality of the hammering frames of the same arc synchronously hammer the flour at the edge of a flour basin, the first push table and the second push table on the two sides of the basin respectively push the flour basin to move left and right through pushing plates, cooperating with a third push table on one end of the flour basin, a hydraulic rod is driven to stretch to drive the third push table to move through a hydraulic pump, the third push table pushes the flour basin to move front and back to make a hammering area of the hammering frames for the flour more uniform and comprehensive, it is ensured that the device is more time-saving and labor-saving during use, and the hammering and twisting of the flour are more efficient during use.

Owner:江川

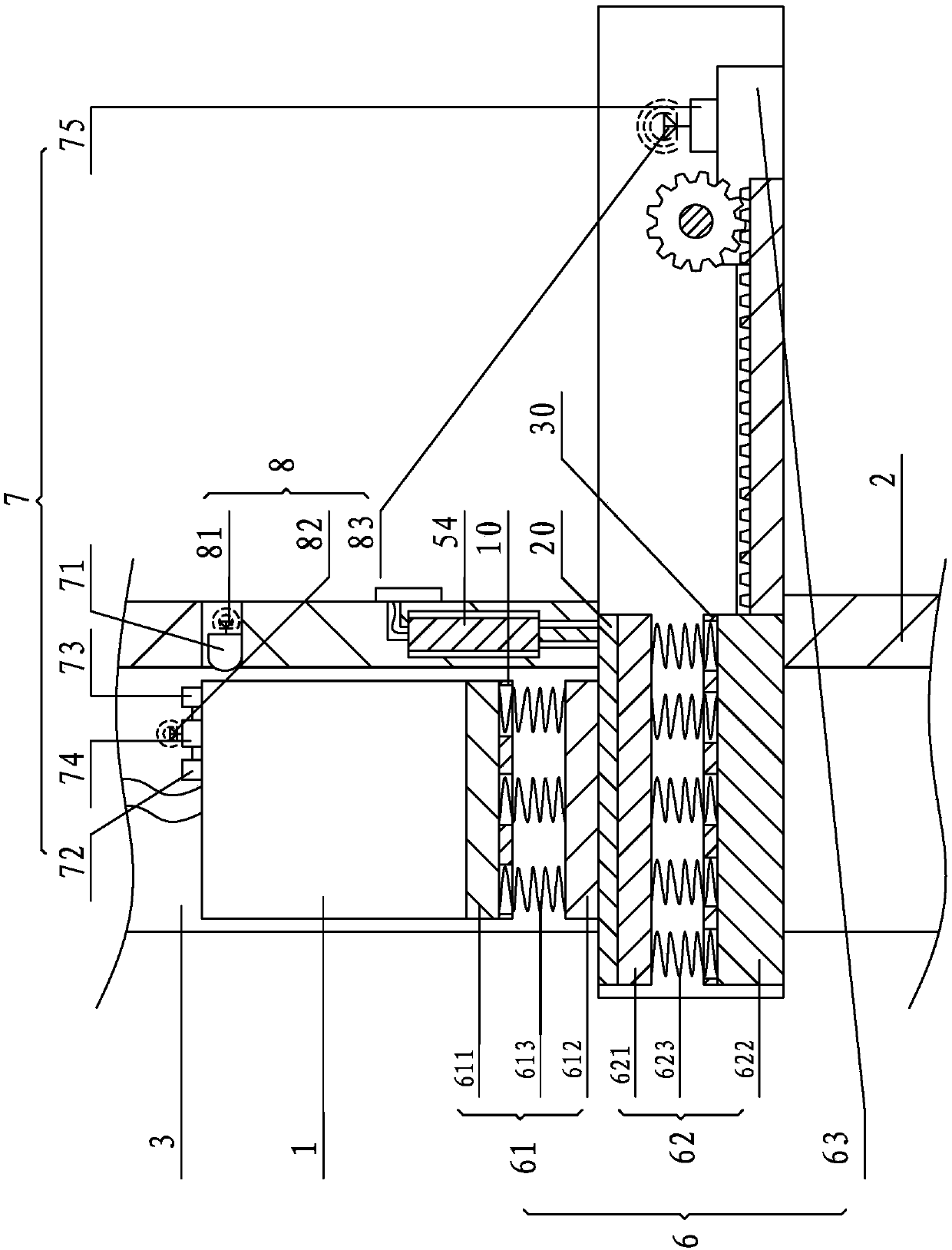

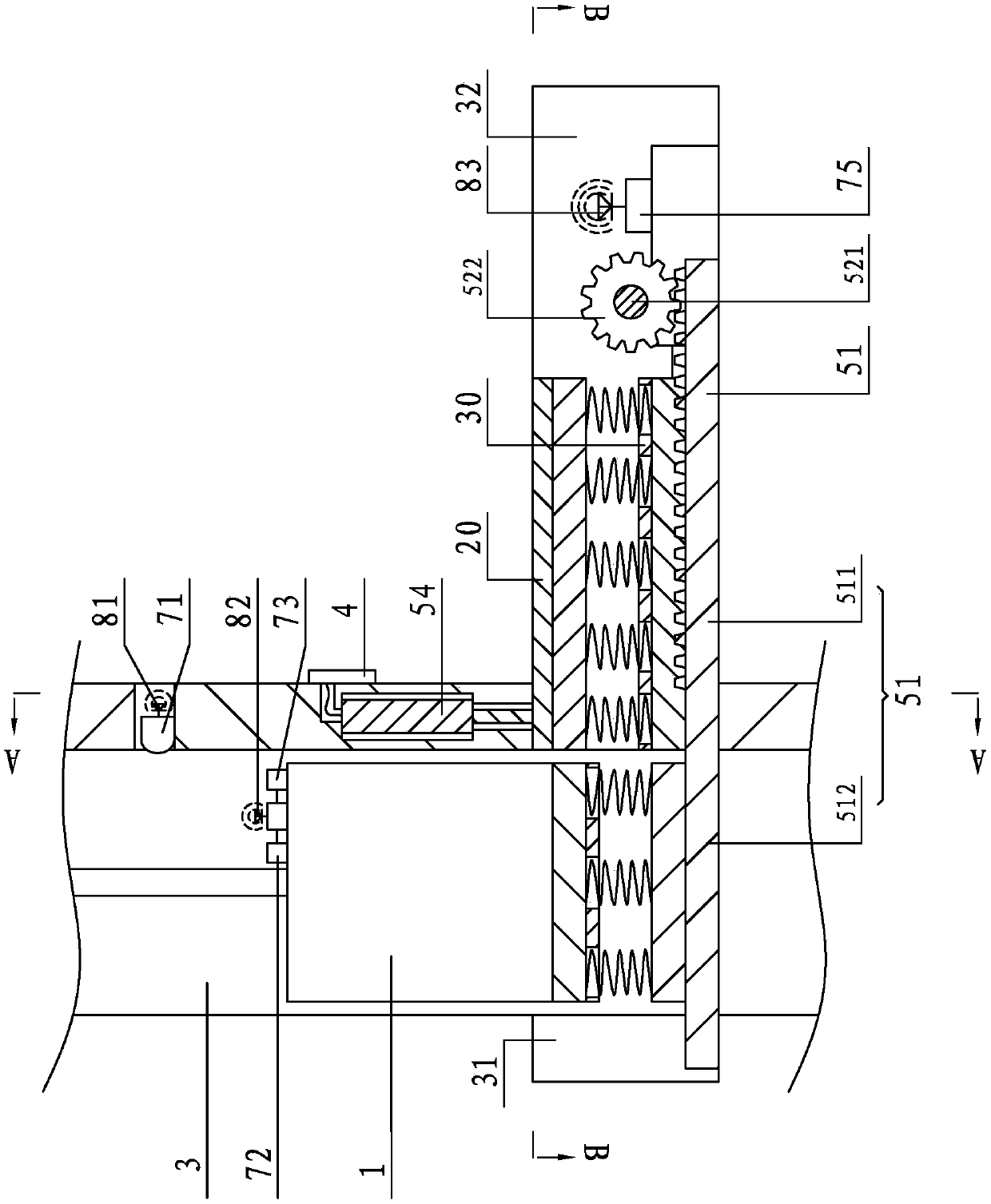

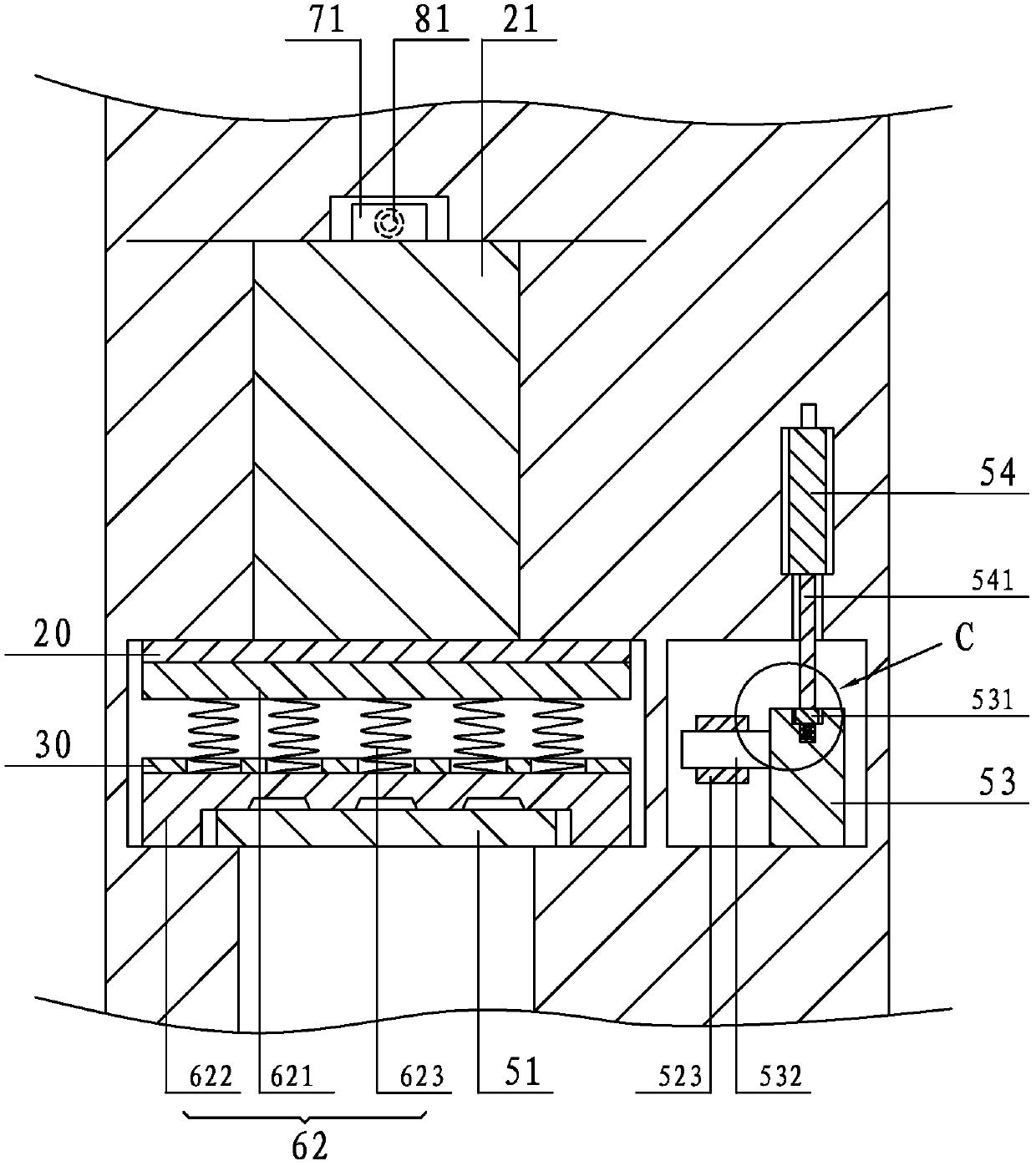

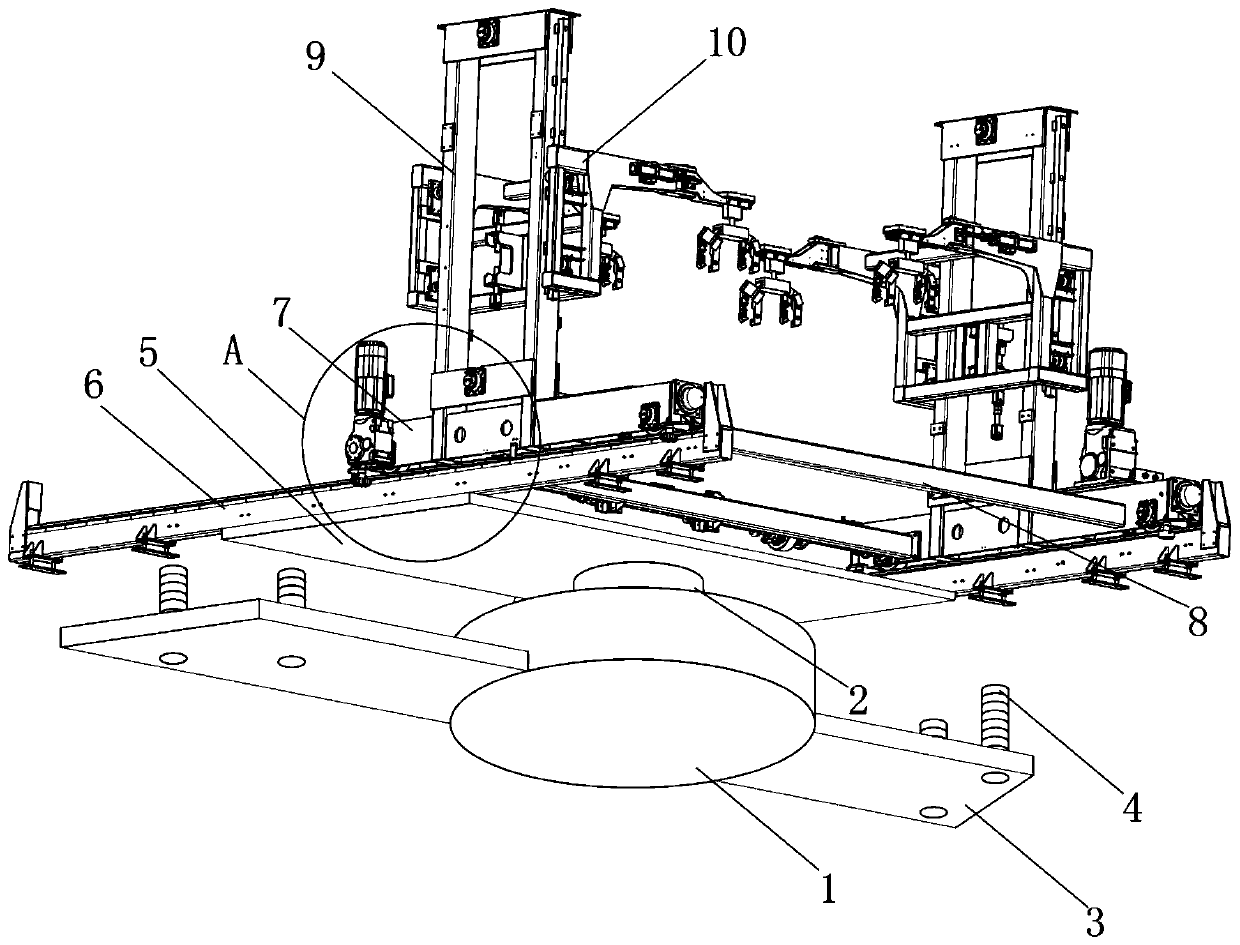

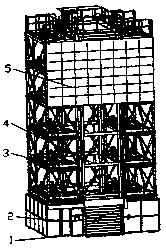

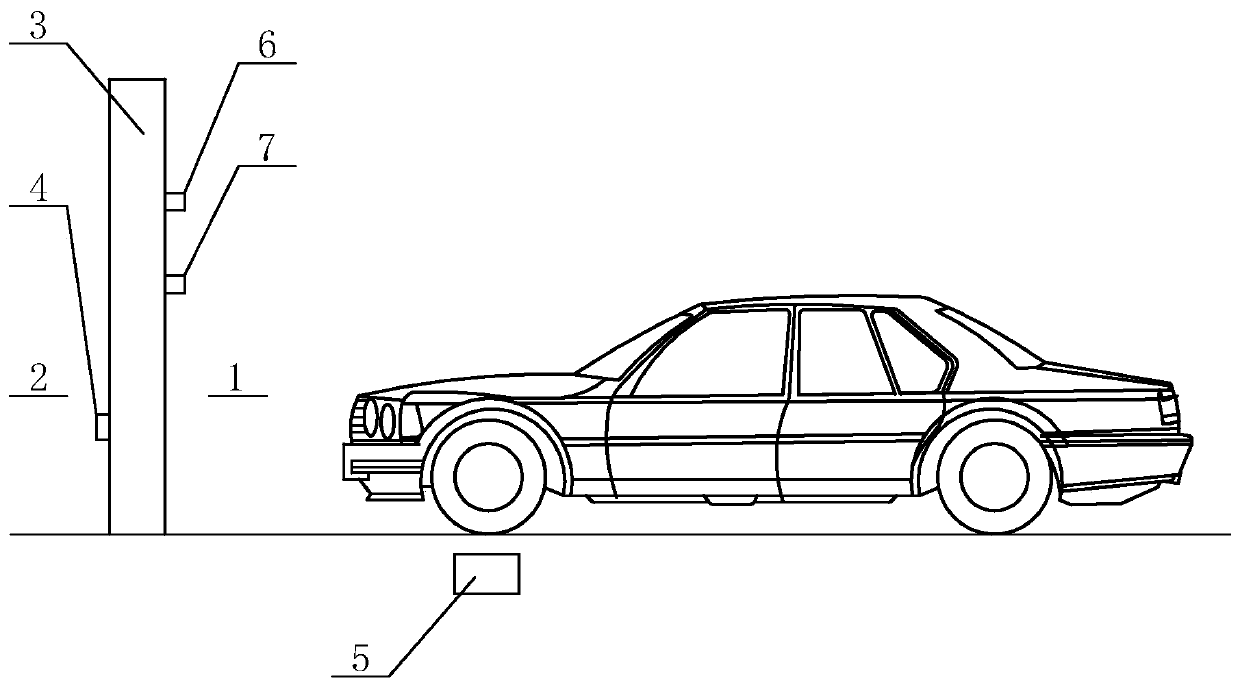

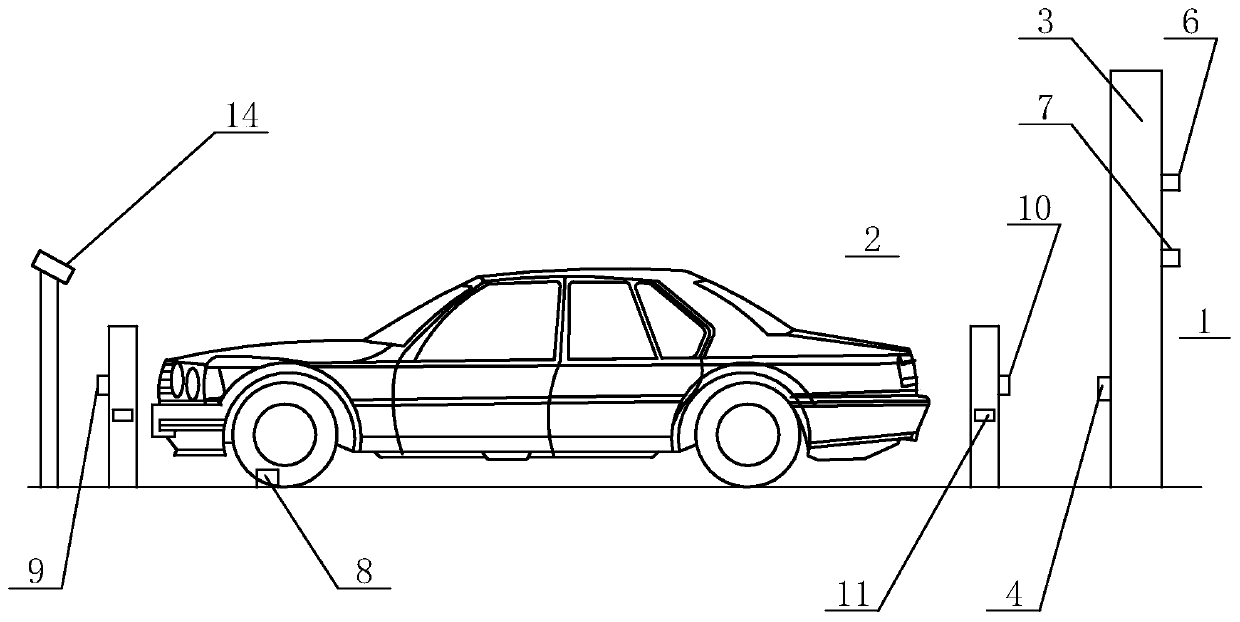

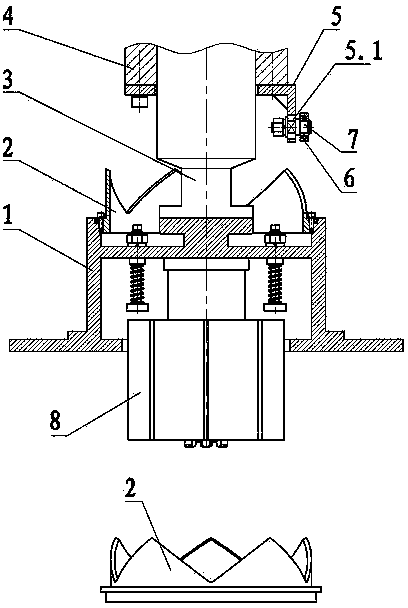

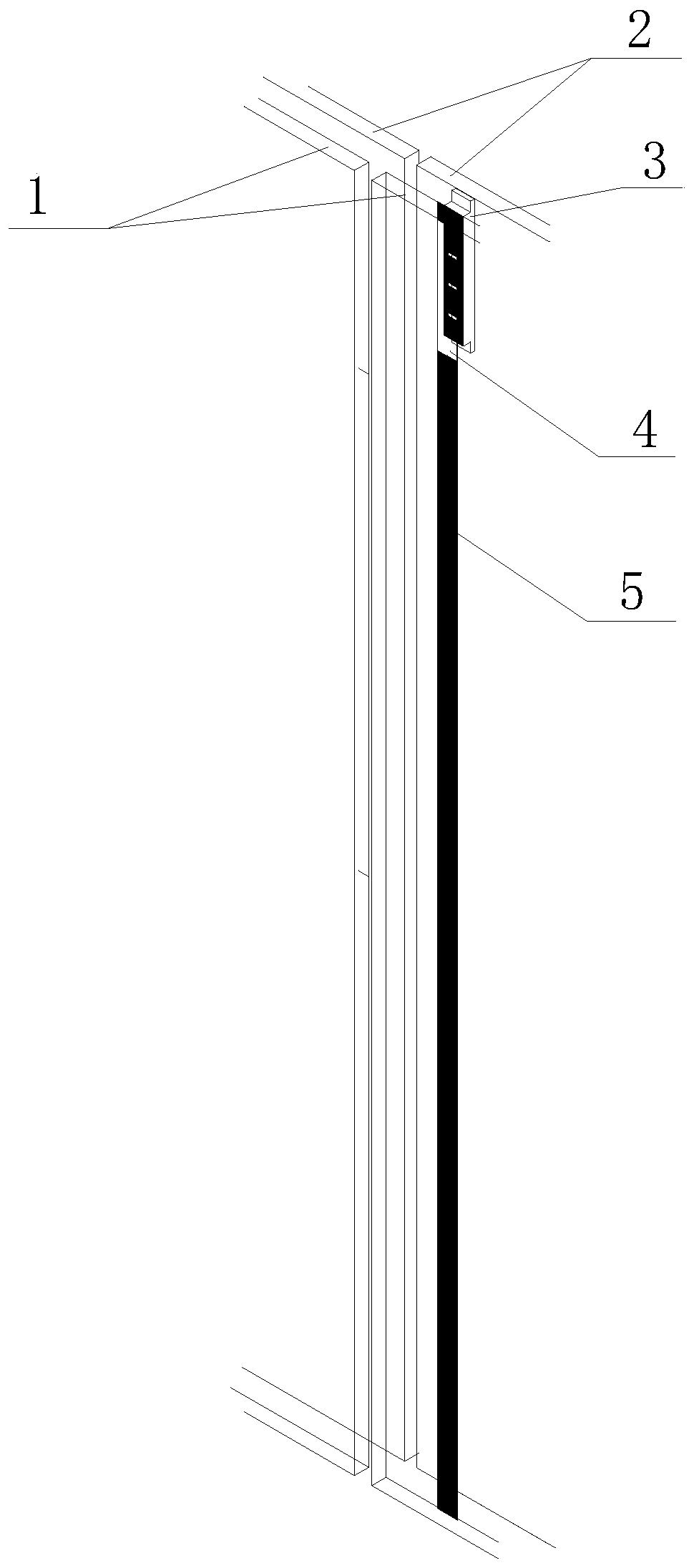

Three-dimensional parking robot

PendingCN109132928AWith self-adjusting heightGuaranteed levelVehicle manoeuvring devicesLifting framesSupporting systemSystems design

The invention discloses a three-dimensional parking robot. The three-dimensional parking robot comprises a multi-foot support system, a human-vehicle separating stack, a vertical conveying system anda berth unit module system. The three-dimensional parking robot has the beneficial effects that (1) a civil foundation is not needed, approval and construction troubles are reduced, the height of themulti-foot support system can be adjusted by self, so that a robot body is kept horizontal, and additionally, the stress condition of each foot can be monitored, so that the safety and the reliabilityof the robot are guaranteed; (2) the berth unit module system is designed, so that the whole robot product is like building blocks and can be quickly combined and disassembled, different scales of three-dimensional parking robot products can be realized according to the site change, additionally, the product consistency is guaranteed by modular units, batch production of a factory can be realized, and the quality is guaranteed; and (3) the vertical conveying system is adopted, so that the movement is stable, and the parking position is accurate.

Owner:沈阳清静科技有限公司

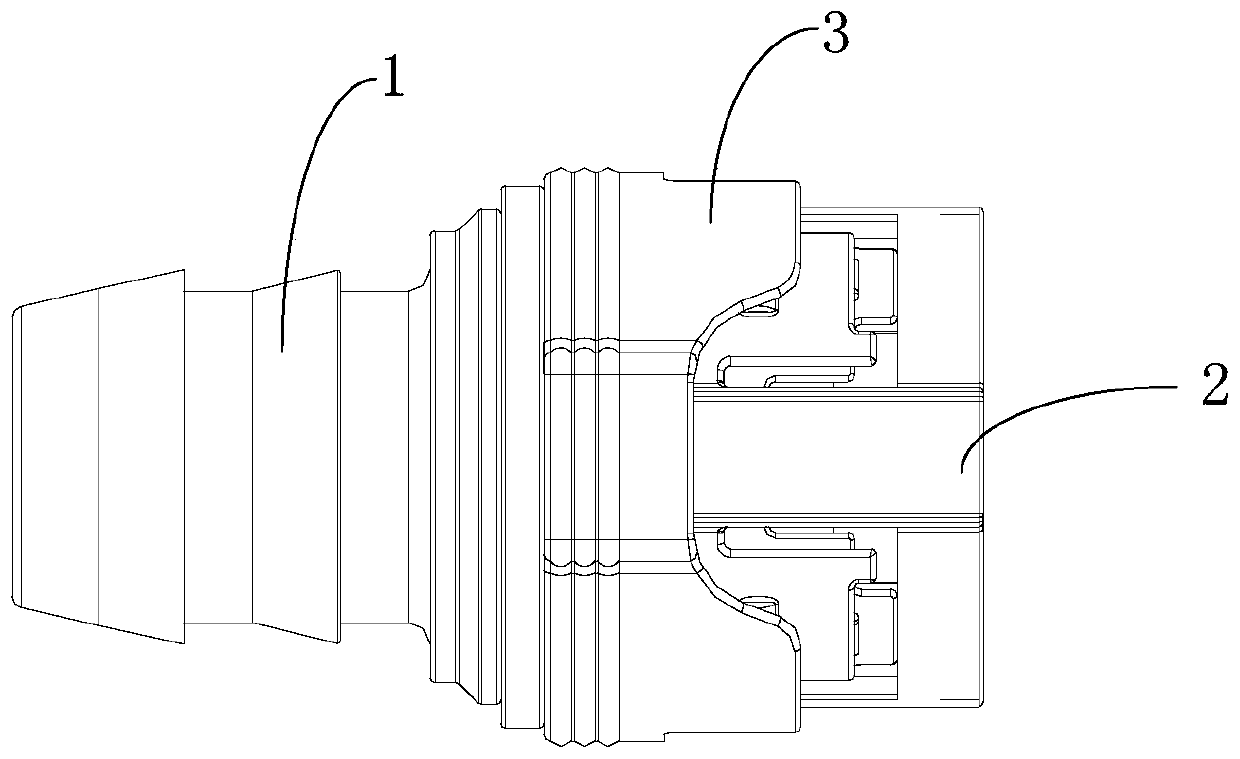

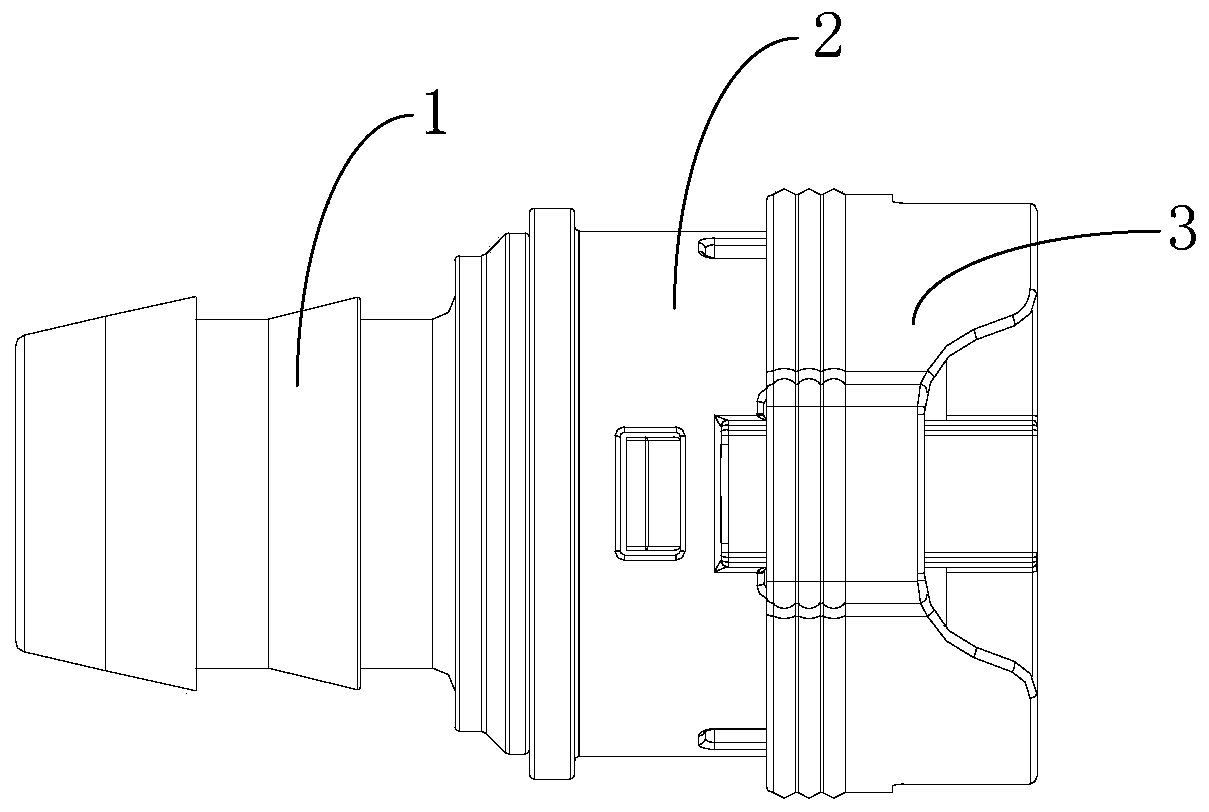

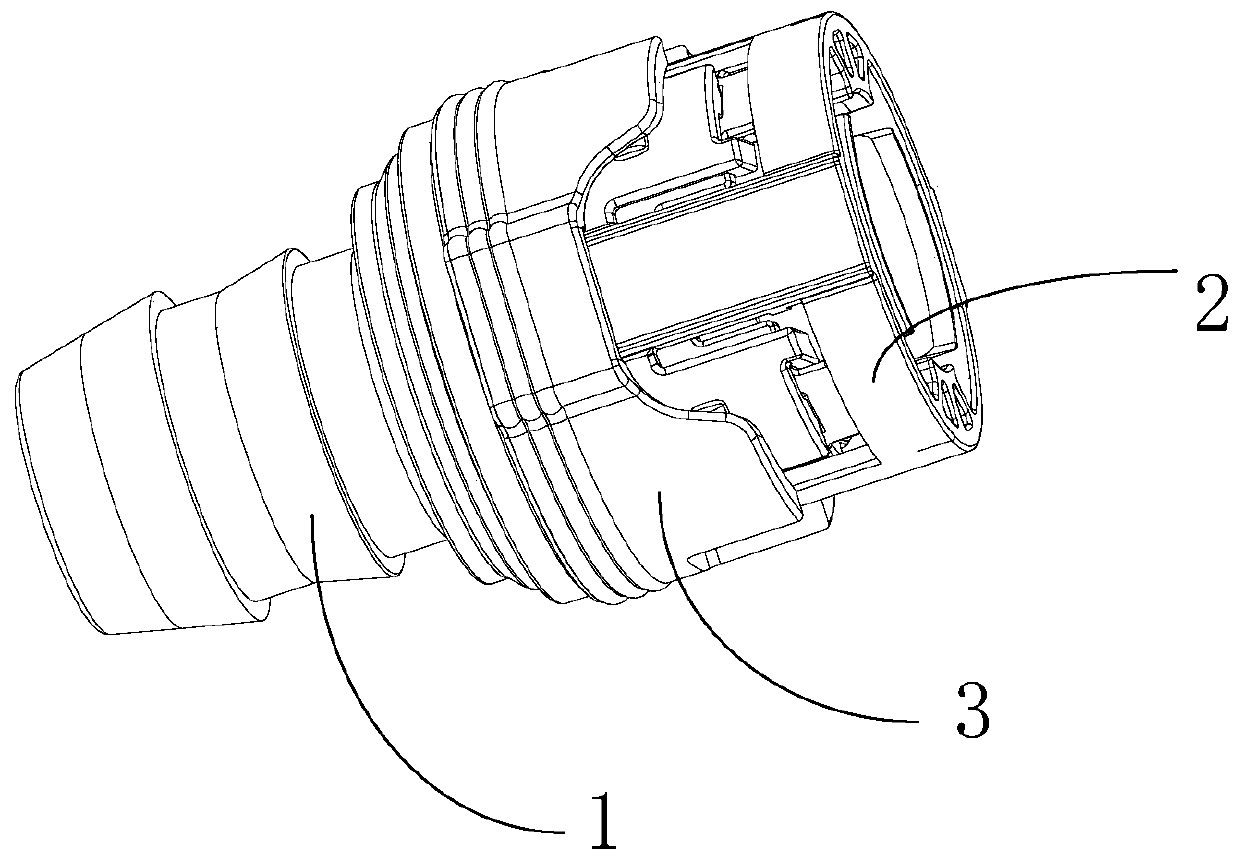

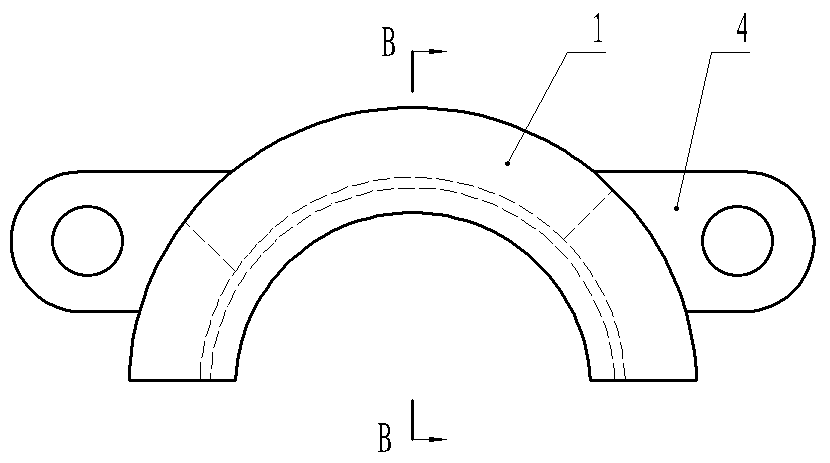

Quick pipe joint and joint assembly

The invention provides a quick pipe joint and a joint assembly, and relates to the technical field of pipeline connecting pieces. The quick pipe joint comprises a joint body and an integrated clampingsleeve, wherein the joint body is provided with a pipe cavity used for being connected with a opponent piece, and the integrated clamping sleeve comprises a buckle sleeve and a guide sleeve connectedto the interior of the buckle sleeve through a connecting rib; one end of the joint body is inserted between the buckle sleeve and the guide sleeve, so that the joint body is connected with the buckle sleeve and / or the guide sleeve; the inner wall face of the buckle sleeve is provided with a opponent piece clamping bulge used for being clamped with the opponent piece, and the buckle sleeve is made of elastic material; and the joint assembly comprises the opponent piece and the quick pipe joint, and a opponent piece clamping groove matched with the opponent piece clamping bulge is formed in the peripheral face of the opponent piece. According to the joint and the joint assembly, the technical problems that a traditional joint is difficult to assemble and disassemble and high in use cost inthe prior art can be solved.

Owner:弗兰科希管件系统(上海)有限公司

Stereo garage safety detection method

ActiveCN111576973AHidden dangers of effective operationAvoid operational hazardsRoad vehicles traffic controlGeological measurementsControl engineeringVehicle detector

The invention discloses a stereo garage safety detection method, and belongs to the technical field of stereo garages. When a vehicle runs to a cache region, a vehicle detector determines that the vehicle is a vehicle, a height detection module sends a height detection signal of the vehicle to a controller of a stereo garage, and the controller judges whether the vehicle is too high or not; if thevehicle is not too high, the controller provides a parking space for an entrance and exit of the stereo garage, and a garage door is opened; when the vehicle enters the garage, whether the vehicle isin place or not is detected; if the vehicle is in place, whether the vehicle is too long and too wide or not is detected; if the vehicle is not too long and too wide, the controller judges whether adriver leaves the garage or not; if the driver leaves the garage, the controller authorizes the operation right of a garage operator, and vehicle storage is allowed; and in the closing process of thegarage door, if a door anti-pinch detection module has no signal, the garage door is closed to be completely closed. According to the method, the vehicle is subjected to ultrahigh detection outside the stereo garage, whether the driver leaves the garage or not is determined, and the operation of the stereo garage and the safety of the driver are effectively guaranteed.

Owner:DAYANG PARKING CO LTD

Looping head automatic reset device

ActiveCN103434891ARealize fixed-point docking and automatic resetEnsure one-to-one correspondenceFilament handlingEngineeringAutomatic testing

Owner:JIANGSU SINGCHEER MACHINERY

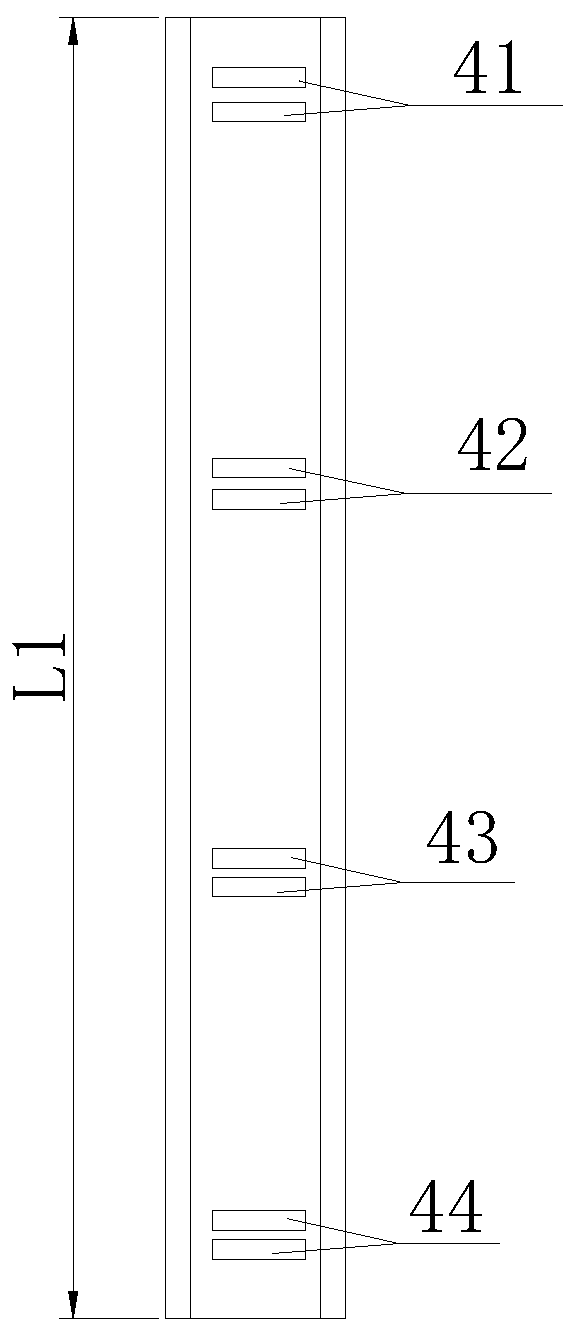

Door area detection device installed on elevator door and detection method thereof

PendingCN111137766AEasy wiringEasy to installElevatorsBuilding liftsElevator controlElectrical and Electronics engineering

The invention discloses a door area detection device installed on an elevator door. The door area detection device comprises a door area detection module installed on a car door and a flat layer magnet reflecting strip installed on a hall door, wherein the door area detection module comprises an upper door area sensor, a flat layer sensor I, a flat layer sensor II and a lower door area sensor; theupper door area sensor, the flat layer sensor I, the flat layer sensor II and the lower door area sensor have output signals when being aligned with the flat layer magnet reflecting strip, and the signal output of the above four sensors can enable an elevator controller to control an elevator to accurately stop at the door area flat layer and switch the door. The elevator door area detection device provided by the invention has the advantages of convenient installation, accurate parking, low cost and the like.

Owner:中山市通控电子有限公司

Template docking fixture

InactiveCN107119905BThe docking position is accurateThere will be no shifting phenomenonAuxillary members of forms/shuttering/falseworksEngineeringMechanical engineering

Owner:徐州致诚会计服务有限公司

Cloth accurate falling printing and dyeing cloth collection device

ActiveCN111285170AThe docking position is accurateExactly fall intoFolding thin materialsEngineeringElectrical and Electronics engineering

The invention discloses a cloth accurate falling printing and dyeing cloth collection device. The cloth accurate falling printing and dyeing cloth collection device comprises a support, trolley limiting devices, a cloth collection device body and a trolley. The support is in a U shape with a downward opening. A center supporting plate is arranged on the lower end face of a horizontal part in a lifting mode. Swing supporting plates are formed at the left and right ends of the center supporting plate correspondingly. The adjacent end faces of the two swing supporting plates are synchronously androtatably provided with swing plates. A pair of cloth driving rollers arranged in front-back symmetry are arranged at the lower ends of the adjacent end faces of the swing plates. Each trolley limiting device comprises a limiting supporting plate arranged on the front side of the support in a front-back moving mode, and a pair of left-right limiting plates arranged in bilateral symmetry are formed on the front end face of the limiting supporting plate. The left-right width of the trolley is equal to the left-right space between the pair of the left-right limiting plates. Through the cloth accurate falling printing and dyeing cloth collection device, the stop position of the trolley is accurate and can be slightly adjusted front and back; thus, the cloth accurate falling printing and dyeing cloth collection device ensures that cloth accurately falls into the trolley; the front-back width of the cloth during falling and folding is controllable, and the maximum cloth loading capacity ofthe trolley is ensured.

Owner:章华海

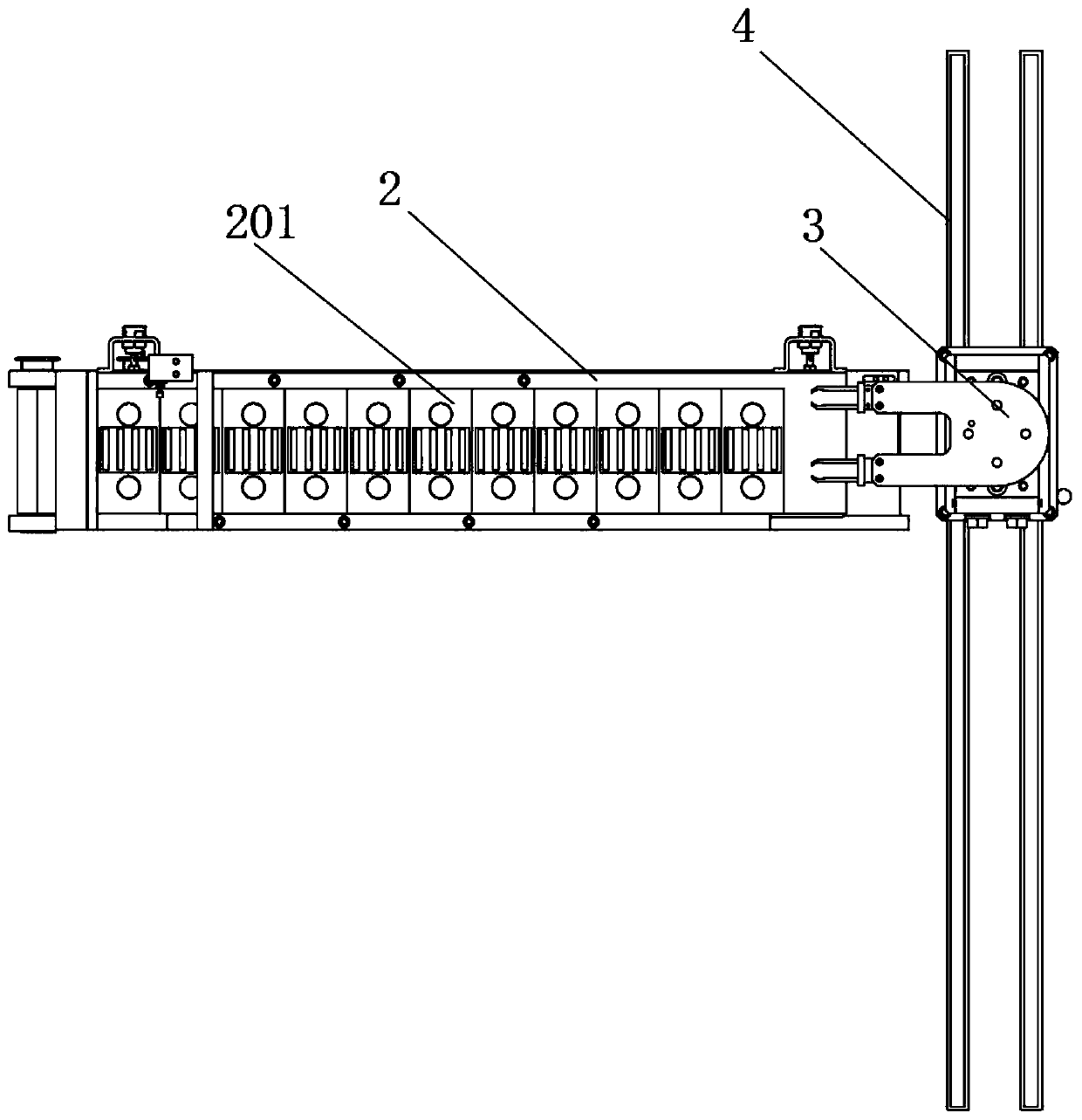

Drill rod conveying device and raise boring machine

ActiveCN112943123AImprove the delivery effectSolve the problem of poor delivery effectDrilling rodsDrilling casingsHydraulic cylinderButt joint

The invention relates to the technical field of raise boring machines, and discloses a drill rod conveying device and a raise boring machine. The drill rod conveying device comprises a base, one side of the base is provided with a placing groove, the inner wall of the placing groove is fixedly connected with a first hydraulic cylinder, the output end of the first hydraulic cylinder is movably connected with a first hydraulic rod, and one side of the first hydraulic cylinder is fixedly connected with a spring. According to the drill rod conveying device, the purpose that the conveying effect of the conveying device is good is achieved, so that the problem that a common drill rod conveying device is poor in conveying effect is solved, the conveying device can effectively convey a drill rod to a connector of the raise boring machine in the using process, the process is rapid and convenient, butt joint of the drill rod and the raise boring machine is more rapid and accurate, the butt joint time is reduced, so that the use cost of people is reduced, the working efficiency of people is also improved, people are more worry-saving in use, the use requirements of people are met, and convenience is brought to the work of people.

Owner:NINGXIA TIANDI BENNIU IND GRP +1

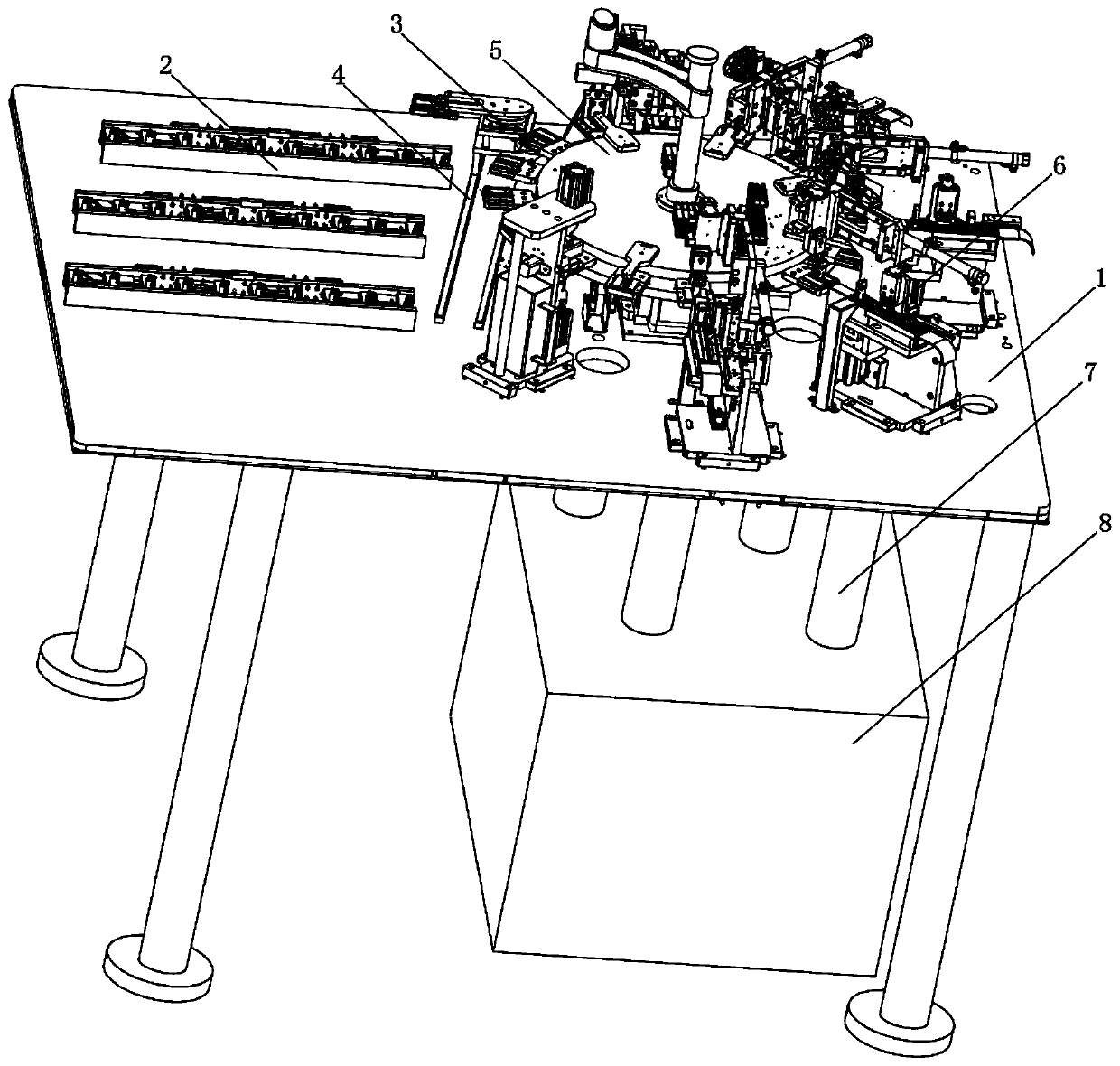

Full-automatic encapsulating device for inductor production and encapsulating method thereof

PendingCN110310819AHigh degree of automationSave time and effortEncapsulation/impregnationHydraulic cylinderInductor

The invention discloses a full-automatic encapsulating device for inductor production. The full-automatic encapsulating device comprises a worktable, conveyor tables, a shifter base, a rotary disk andan encapsulating frame. Three conveyor tables are arranged in parallel on one side of the upper end surface of the worktable in equal spacing. The full-automatic encapsulating device has the advantages that then the motor 4 drives the inductor to move directly below the encapsulating frame through the rotary disk, a hydraulic oil cylinder 2 drives an encapsulating separating cylinder to move downward through a hydraulic shaft 2, the encapsulating separating cylinder inserts the bottom of the adhesive tape into the groove at the connection between the inductor and the grip groove 2, then the motor 7 drive the rotating shaft and the inductor to rotate and wrap the adhesive tape, and the hydraulic oil cylinder 2 drives the encapsulating separating cylinder to move upwards at a uniform speedthrough the hydraulic shaft 2 so that the encapsulating work is performed on the inductor. The device has high automation degree of work and saves time and labor, the motor 3 drives the clamp 1 to swing to clamp the inductor, and the device can clamp and move the inductor of different width and sizes and thus the universality of the working adaptability of the device can be guaranteed.

Owner:ANHUI HEHAN OPTOELECTRONICS TECH

Method and system for train monitoring in subway depot based on uwb

ActiveCN110775105BThe docking position is accurateComplete marshallingVehicle route interaction devicesThird partyComputer science

The embodiment of the present invention provides a method and system for monitoring trains in subway depots based on UWB. The distance information of the head and the distance of the tail determined based on UWB technology are obtained respectively, and the position information of the head is determined according to the distance information of the head. The tail distance information determines the rear position information, and finally, based on the front position information and the rear position information, the occupied range of the target train on the train track is determined to realize the positioning of the target train. The entire positioning process does not introduce third-party equipment data. Through the two-dimensional precise ranging capability of UWB and the principle of triangulation positioning, the precise positioning of the front and rear of the target train is realized, and then the occupancy of the target train on the train track is determined. In the depot, it can ensure that the train stop position is accurate, and can further judge whether the target train is complete, so as to ensure the complete formation of the target train.

Owner:TRAFFIC CONTROL TECH CO LTD

Security protection interface device for cloud computing platform and usage method thereof

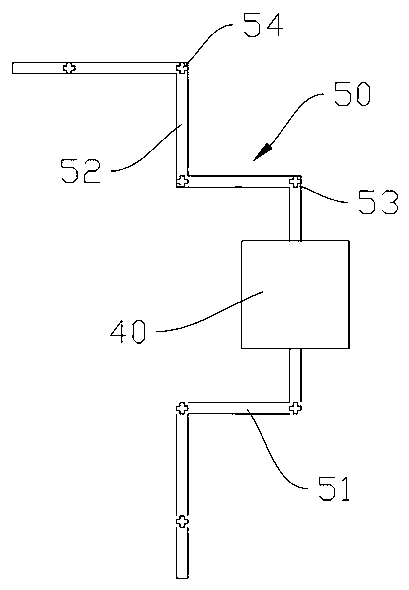

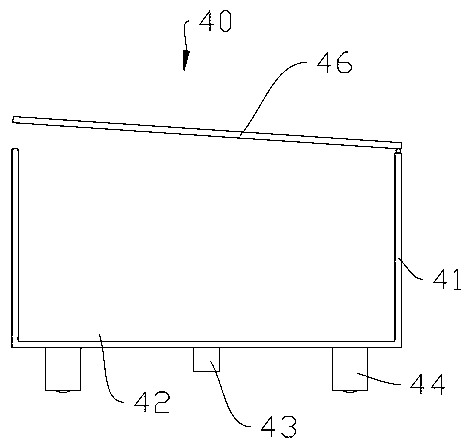

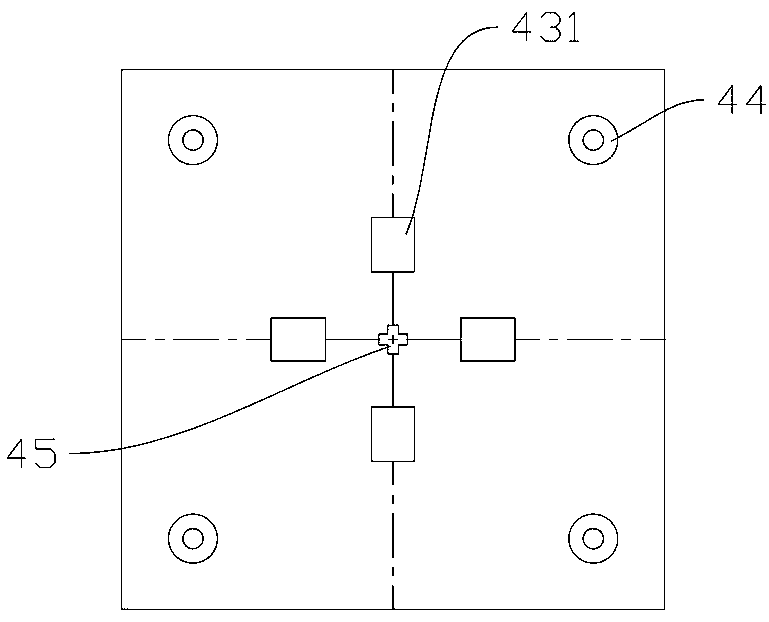

ActiveCN112072390BThe docking position is accurateExtend your lifeCoupling device detailsSoftware engineeringInterface (computing)

The invention discloses a safety protection interface device for a cloud computing platform and a use method thereof, comprising a computer body and a joint body, the front of the computer body is fixedly connected with a socket, and the front of the computer body is fixedly connected with two sets of first limit rods, The front of the computer main body is also fixed with two groups of second limit rods, the two groups of second limit rods are located directly below the first limit rods, and the end of the second limit rods away from the computer main body is fixedly connected with a fixed plate, and the fixed plate The side wall of the computer body is fixedly connected with a first bearing, the axis of the first bearing is rotatably connected with a screw rod, the side wall of the computer main body is fixedly connected with a second bearing, and the screw rod is rotatably connected in the second bearing. The beneficial effects of the present invention are: the docking position of the plug and the socket is accurate, the wear of the interface is reduced, and the service life of the interface is prolonged. Lost situation.

Owner:吕国群

Special equipment for large cylinder butt milling and welding

ActiveCN105537962BUniform docking positionThe docking position is accurateOther manufacturing equipments/toolsButt weldingEngineering

Owner:SHANDONG SHENGRUN AUTOMOBILE

An ink supply device for opera mural drawing box

InactiveCN110733244BImprove drawing qualityPrevent solidificationInking apparatusPrinting press partsMechanical engineeringHydraulic pressure

The invention discloses an ink supply device for an opera mural drawing box. The device comprises a cuboid bottom support table, a hydraulic pump I, a rotating support table and a work table, whereinthe hydraulic pump I is vertically arranged in the middle of the bottom support table, a hollow lower rolling groove of a ring-shaped structure is formed in the middle of the bottom support table, andthe hydraulic pump I is in extension connection with a motor II through a hydraulic column I. The device has the beneficial effects that a plurality of ink supply tables which are arranged on a transfer and supply mechanism at equal intervals supply ink of different colors to inside of different ink boxes in the drawing box, so that the ink supply device is more targeted and orderly during ink supply, mutual mixing of grinding liquid of different colors is avoided, and the device sends the ink into the ink boxes of the drawing box when the ink flows continuously, the ink supplied to the ink boxes is fresher, and sedimentation and layering caused by long-term storage of the ink in the ink boxes are prevented; besides, the ink is prevented from solidifying, so that when the drawing box is used for drawing, the ink is supplied in a timely and smooth manner, and drawing quality of the drawing box is improved.

Owner:CITY COLLEGE WENZHOU UNIV

A security type elevator that prevents the car from moving in advance

The invention discloses a security elevator capable of preventing a car from moving beforehand. The security elevator comprises a car body, a landing part, a hoistway, a control mechanism, a support mechanism, a butting mechanism, a buffer mechanism, an intelligent induction mechanism and a wireless device; the support mechanism comprises a support plate, a first transmission mechanism, a motor and a first air pressure cylinder; the motor is provided with a spring button; the first air pressure cylinder is provided with a first piston rod butting against the spring button; the butting mechanism comprises a butting plate arranged above the car body, and a second transmission mechanism for driving the butting plate; the buffer mechanism comprises a first buffer device arranged below the carbody, a second buffer device capable of extending, and a second air pressure cylinder; a second sensor senses the car body, and controls a third controller to work through wireless transmission; the first piston rod downwards pushes the spring button; the motor works; the support plate is shifted out to support the car body; and the butting plate is shifted out for shielding; and when the elevatorfalls, the pressure is buffered through the buffer mechanism.

Owner:枣庄市薛城区弘祥运输有限公司

Automatic welding device for transformer cooling fins

ActiveCN114101994AAccurate docking positionThe docking position is accurateWelding/cutting auxillary devicesAuxillary welding devicesPhysicsTransformer

The invention discloses an automatic welding device for transformer cooling fins, and relates to the technical field of welding, the automatic welding device comprises a conveying frame, a conveying part used for storing and conveying the cooling fins is arranged on the conveying frame, a welding part used for welding and detecting is arranged on the conveying frame, and the automatic welding device further comprises a reversing conveying part and a control part, the conveying frame is used for clamping the heat dissipation plate and conveying the heat dissipation plate to a preset position, so that the heat dissipation plate is converted into a vertical state from a horizontal state, and the heat dissipation plate is in T-shaped butt joint with the heat dissipation plate on the conveying frame; a meshing rack is arranged on the conveying component, a driving gear is arranged on the reversing conveying component, and when the conveying component moves and the meshing rack is meshed with the driving gear, the reversing conveying component is driven, the technical problem that at present, welding of transformer cooling fins is troublesome and laborious is solved, and manual work can be replaced for automatic welding.

Owner:南通睿达电力科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com