Patents

Literature

190results about How to "Improve drawing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

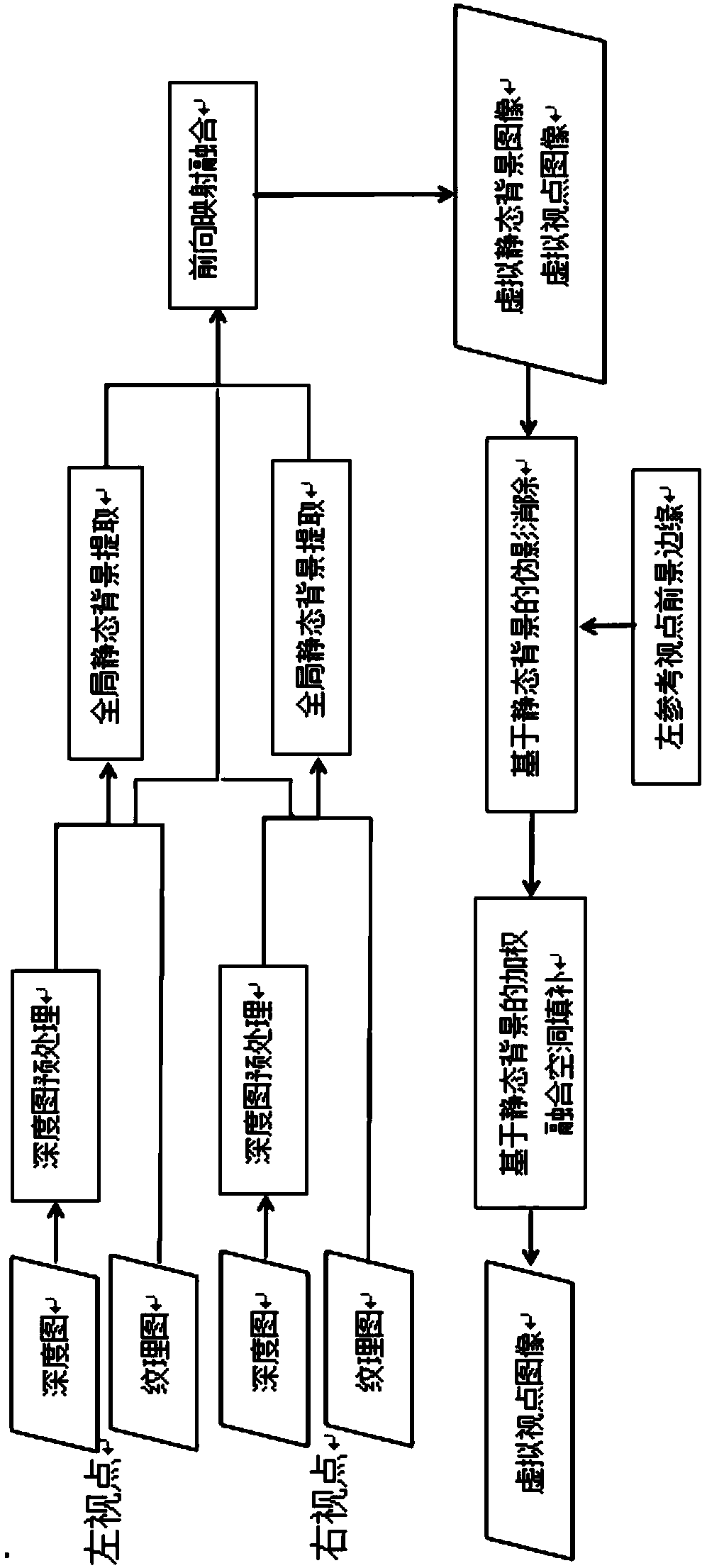

Method for processing multi-viewpoint depth video

InactiveCN102769746AImprove drawing qualityImprove coding efficiencyTelevision systemsDigital video signal modificationTime domainPretreatment method

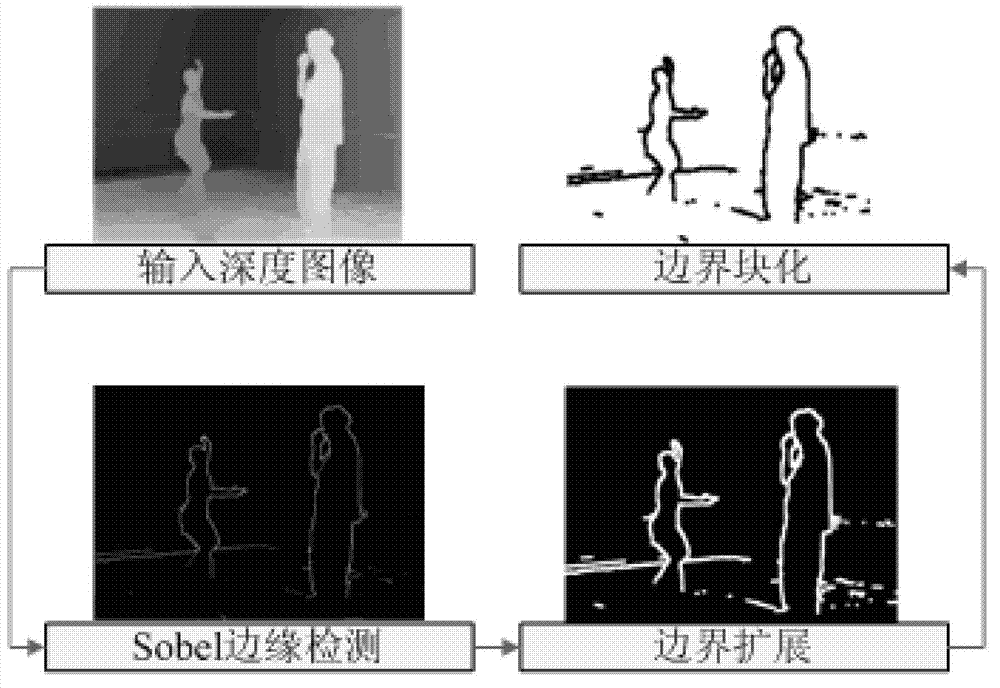

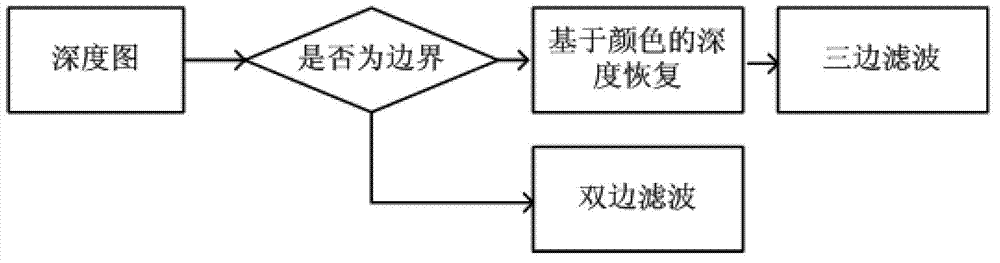

The invention discloses a method for processing a multi-viewpoint depth video. The method comprises the steps as follows: recombination conversion operation is executed aiming at the depth video; secondly, the converted depth video is smoothly processed in a time domain; thirdly, recombination conversion operation is executed aiming at the smoothly processed depth video to obtain a pretreated depth video; fourthly, coding compression, decoding recombination operation are executed aiming at the pretreated multi-viewpoint depth video; fifthly, depth recovery and null field smooth processing are executed aiming at decoded and recombined multi-viewpoint depth video; and lastly, a virtual viewpoint video image is mapped by the processed multi-viewpoint depth video. The method has the advantages that the pretreatment method can improve the time domain relativity of a depth video sequence, and further effectively improve the coding efficiency of the depth video; as for the situation of a code QP equal to 22, 27, 32 and 37, the coding efficiency can be saved by 17.07 percent to 38.29 percent, and the mapping quality of the obtained virtual viewpoint video image can be improved by about 0.05 dB.

Owner:NINGBO UNIV

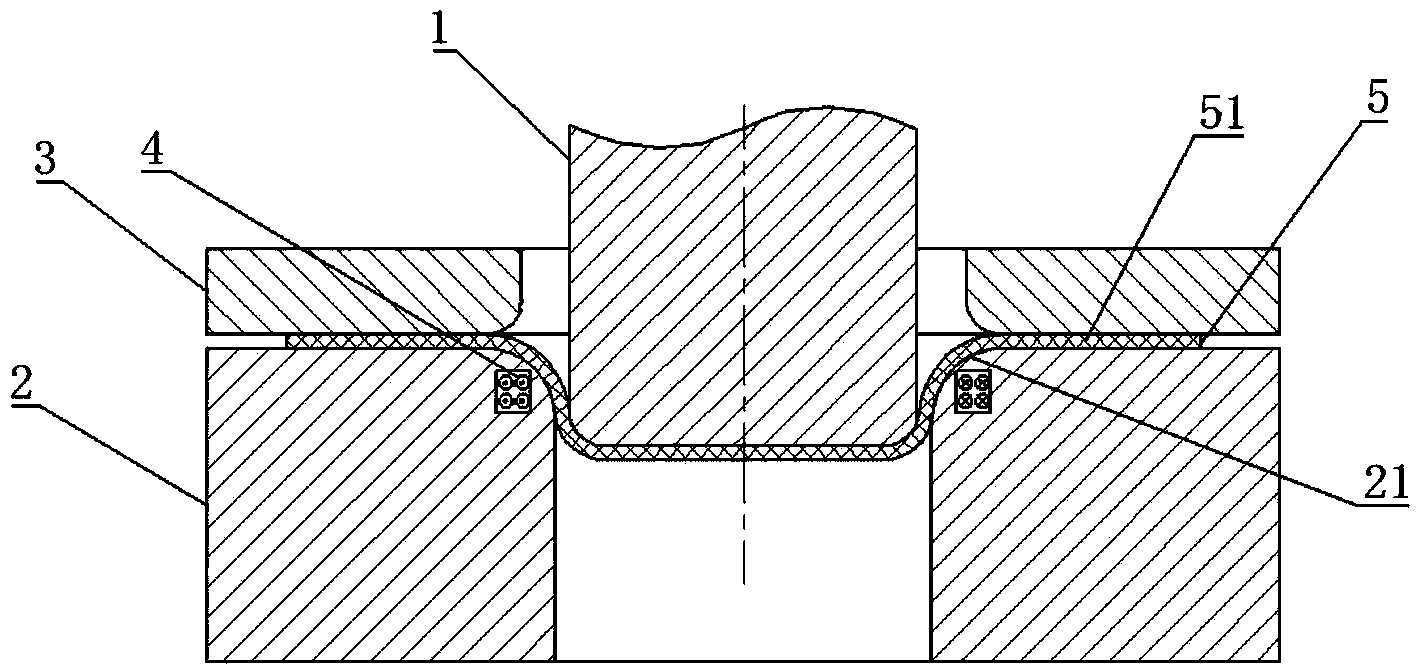

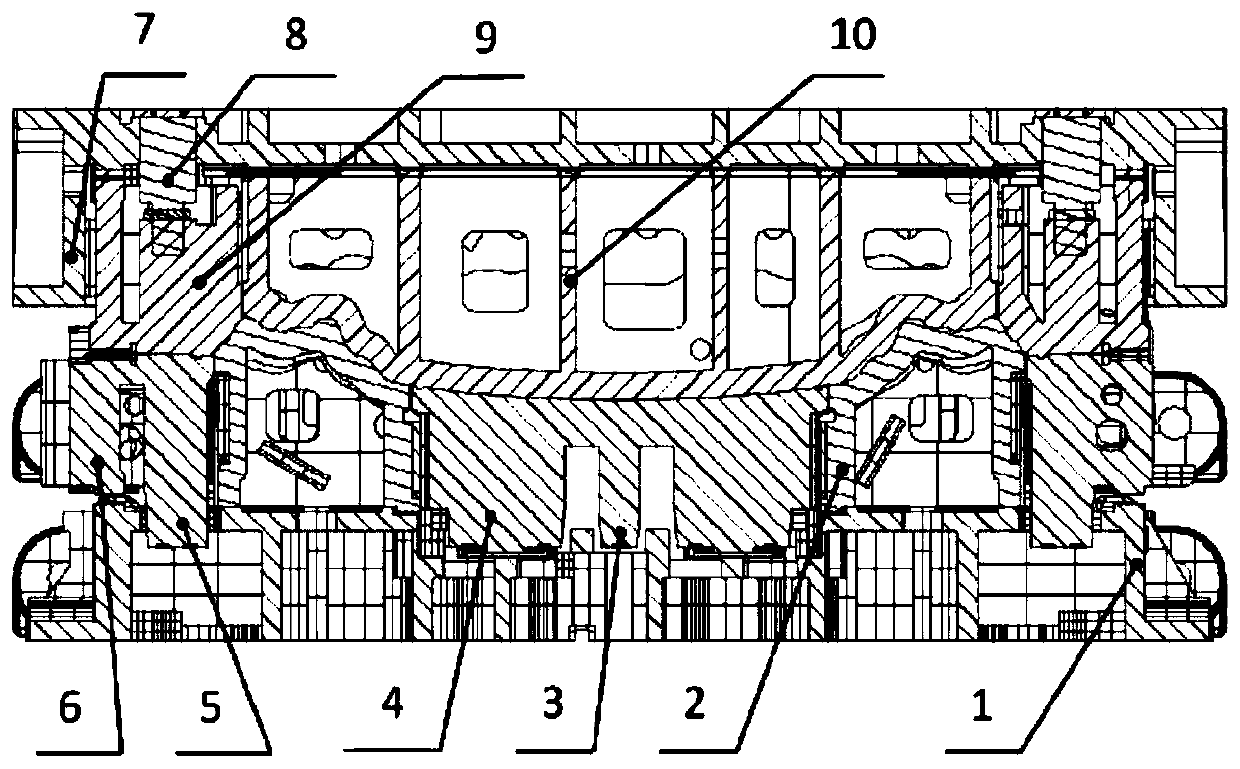

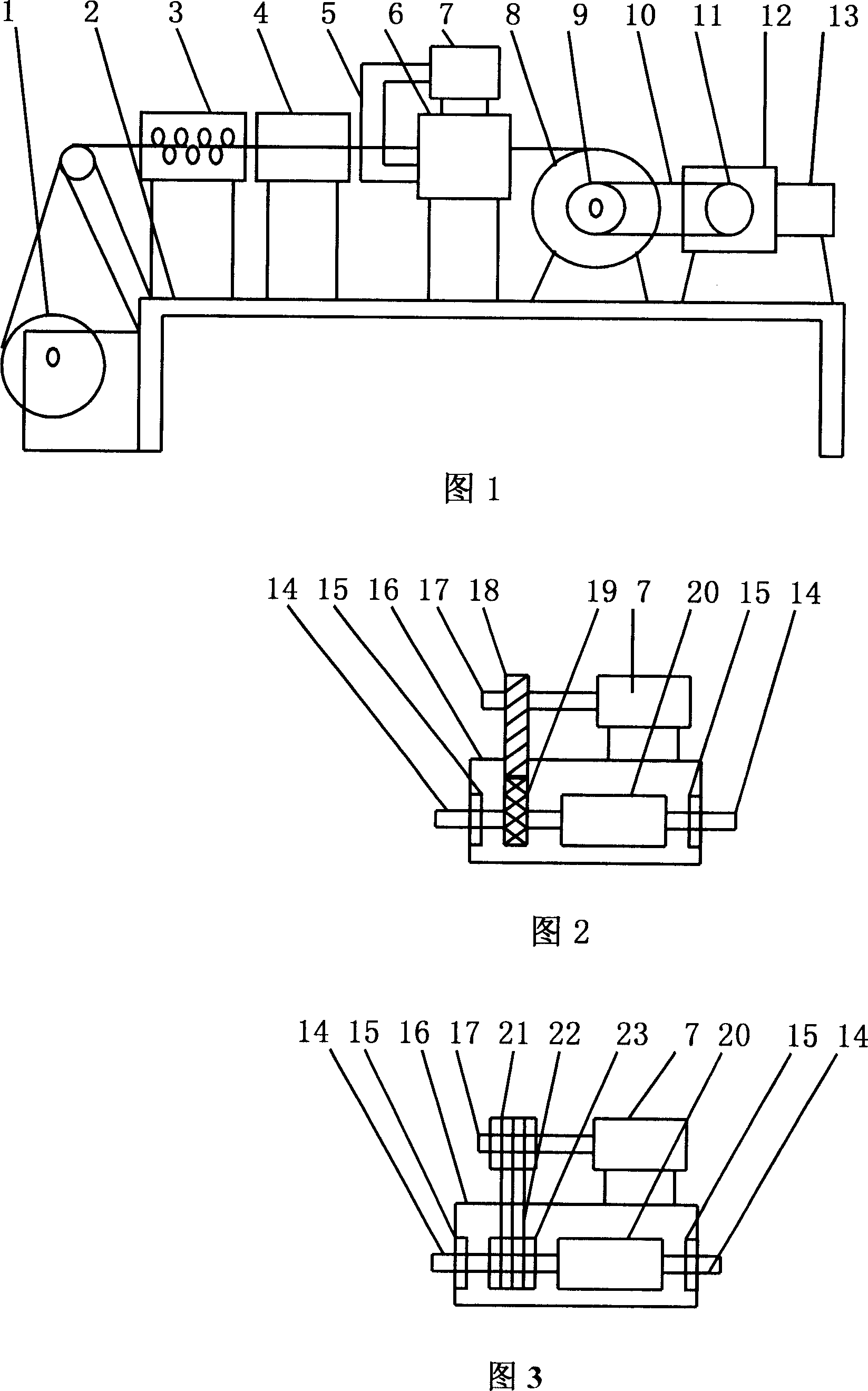

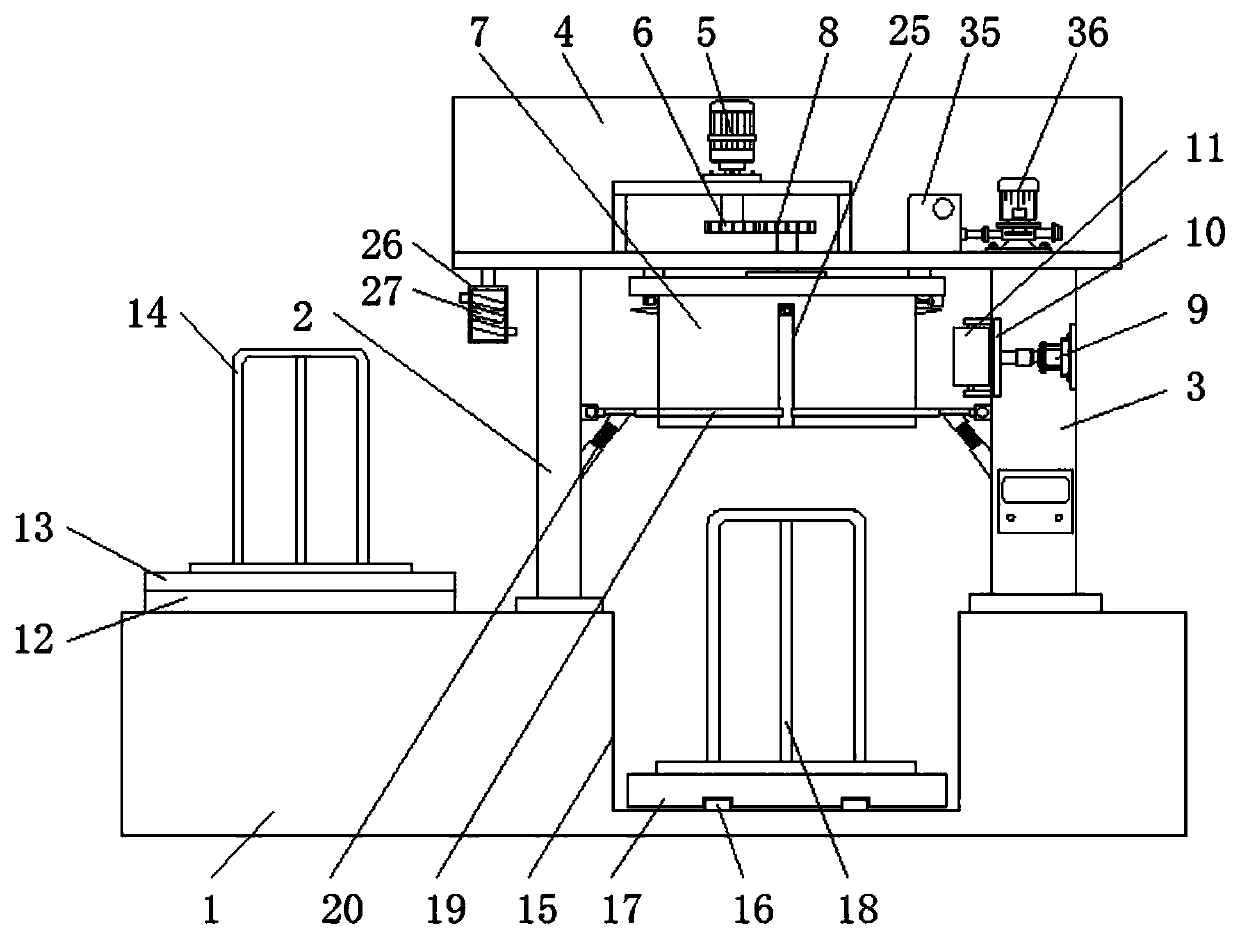

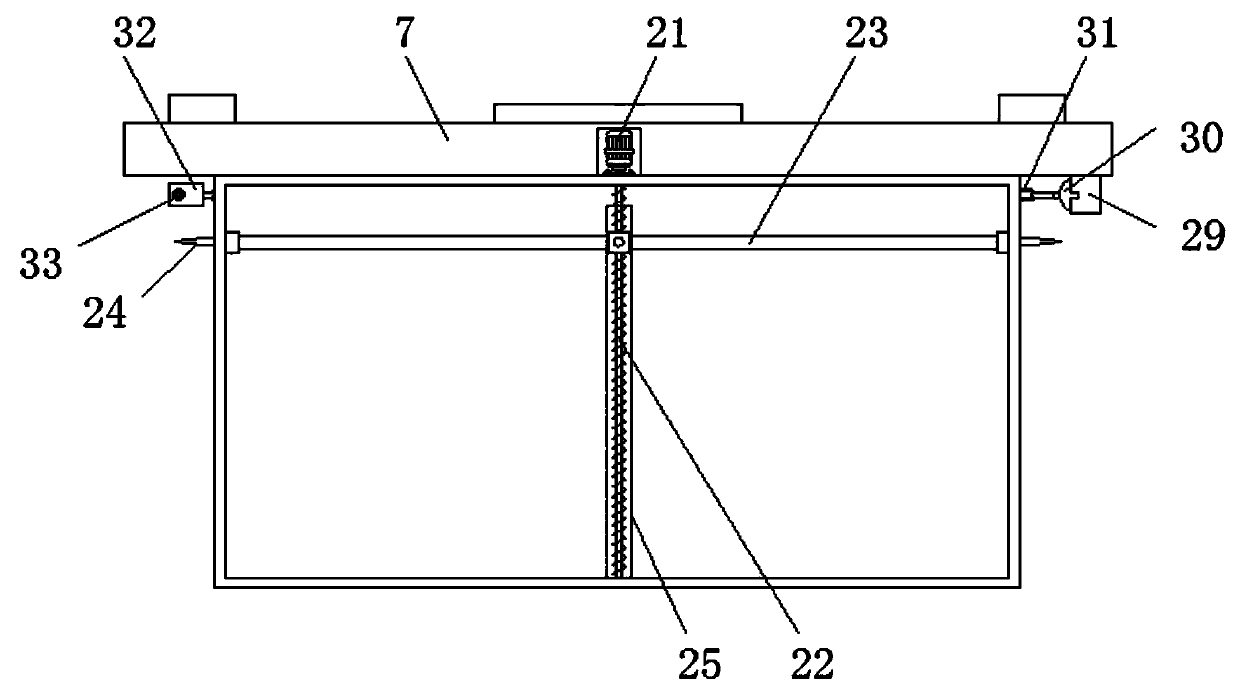

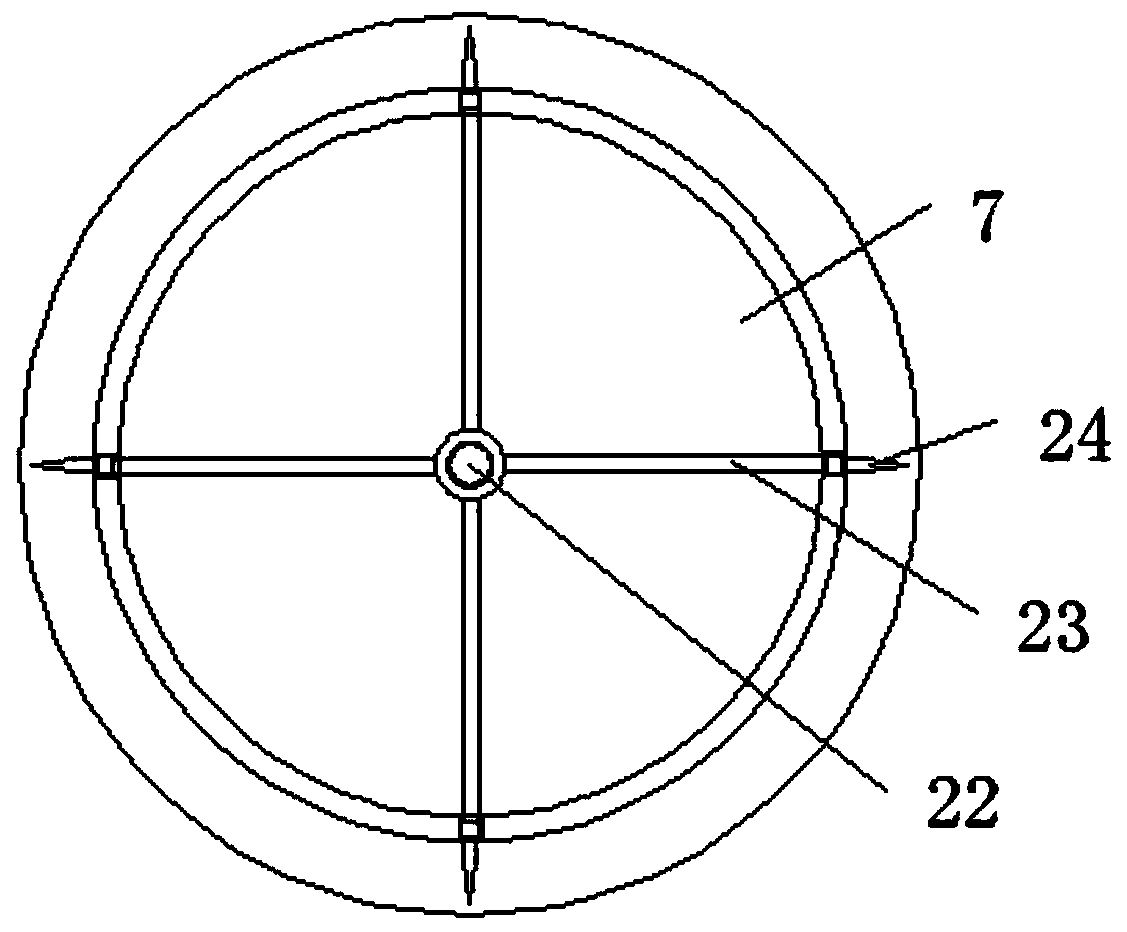

Plate packaging and drawing forming device and forming method

InactiveCN104353718AGive full play to the high speed of formingAchieve precise manufacturingShaping toolsEngineeringFlange

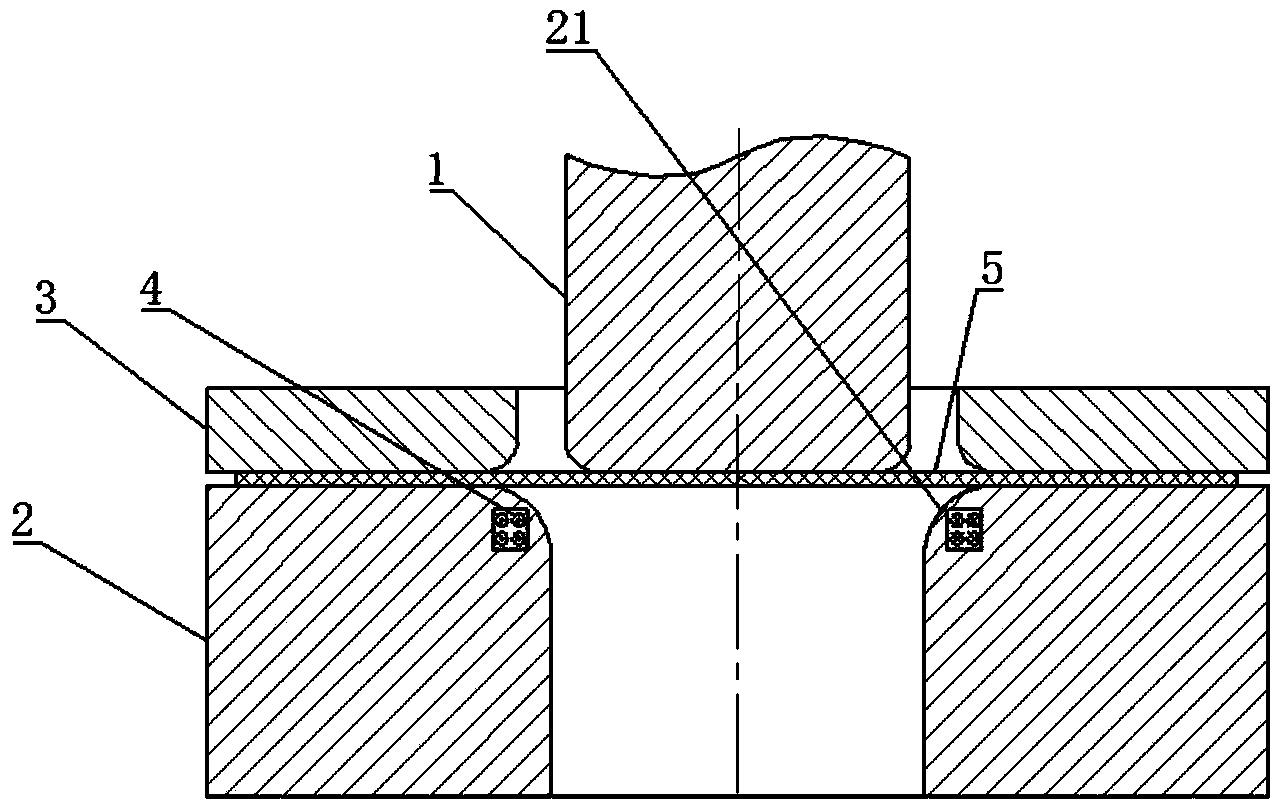

The invention discloses a plate packaging and drawing forming device which comprises a male die, a female die and an edge pressing ring which works together with the top end face of the female die to press a plate, wherein the edge pressing ring is positioned above the female die; a fillet convenient for drawing and forming of the plate is arranged on the female die; an anti-expansion coil is mounted on the female die and corresponds to the fillet; the anti-expansion coil is a concentric coil and is used for enabling the plate region sliding to the fillet of the female die to be bent and expanded in the direction far away from the fillet so as to form a bent and expanded part after the anti-expansion coil is powered on. An electromagnetic discharging coil is arranged at the fillet of the female die, so that the plate region opposite to the fillet of the female die can be bent and expanded; therefore, the flowability of a material of a flange part of the plate can be effectively improved, and the drawing and forming quality of a part is finally improved.

Owner:HUAZHONG UNIV OF SCI & TECH

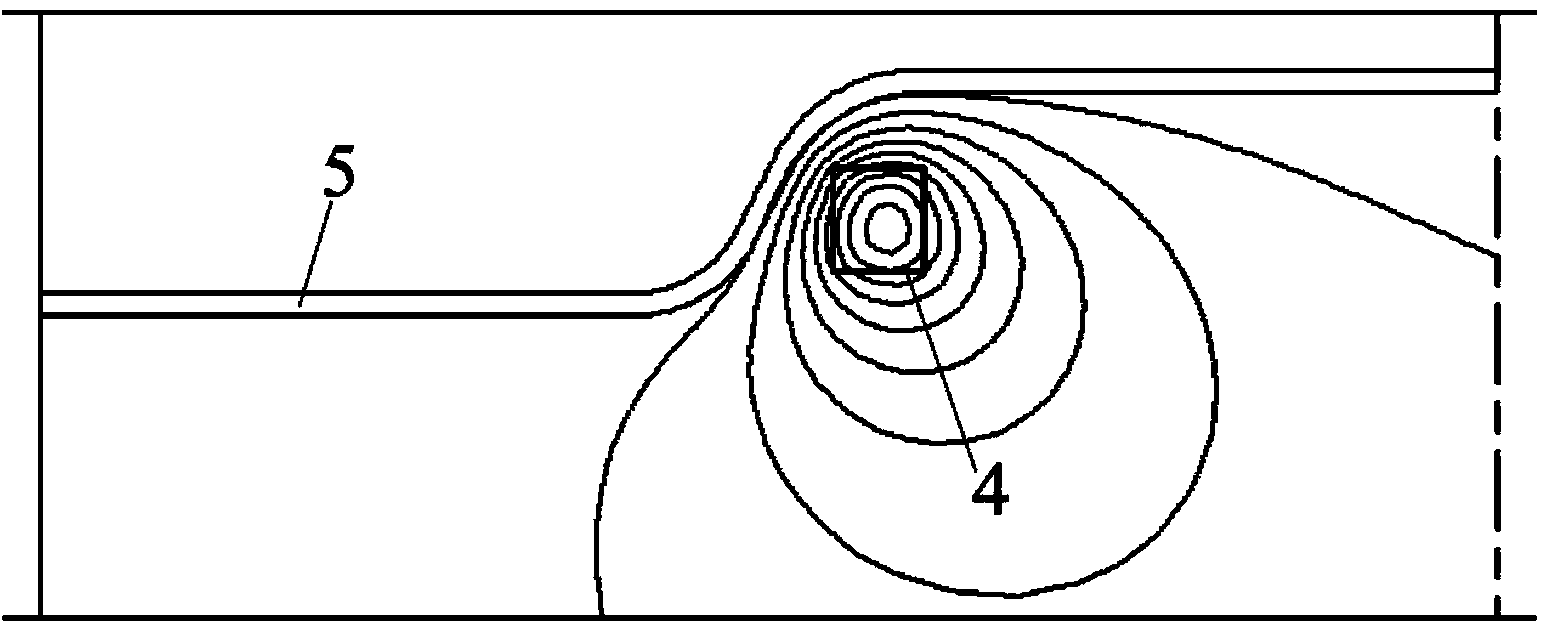

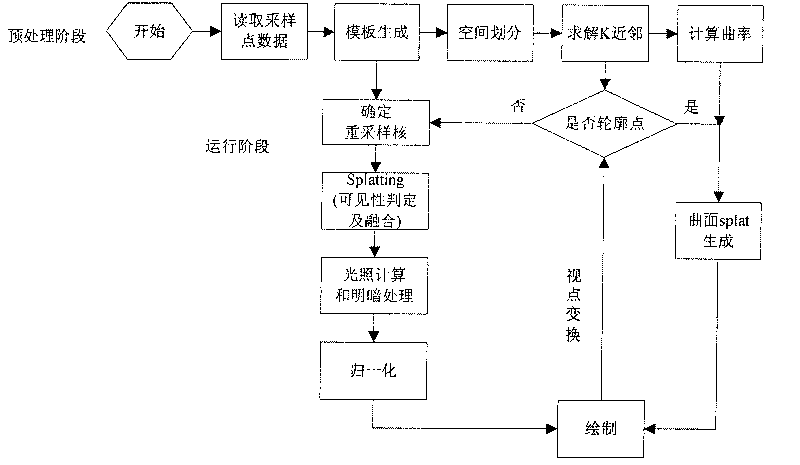

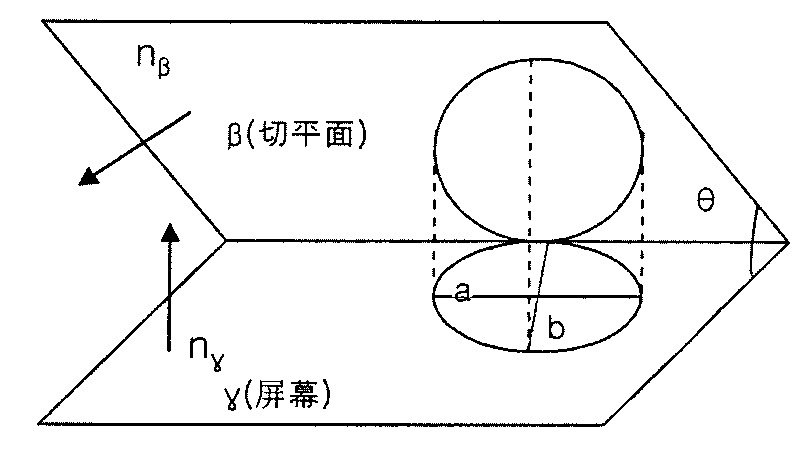

Method for drawing enhanced model contour surface point

InactiveCN101763649AQuality improvementPreserve high frequency signals2D-image generation3D modellingVisibilitySurface point

The invention relates to a method for drawing enhanced model contour surface point. At the stage of preprocessing, the spatial coordinates, normal vectors, radiuses and color information of sampled points are read and stored, a splat template is generated according to a given layer number, the sampled points are spatially divided according to a threshold specified by a user, k neighbors of each sampled point are solved, and finally, by utilizing the k neighbors, a coordinate transformation method is used to solve the curvature of each point. At the stage of operation, whether the sampled points are contour points or not is judged according to the normal vectors and visual angles of the sampled points, and if the sampled points are contour points, a series of vertex coordinates of curved surface splats with the sampled points as centers are calculated. If the sampled points are not contour points, a Surface Splatting algorithm is utilized to carry out drawing: a Jacobian matrix mapped by the 2D space of the sampled points is solved; the visibility of the splats projected on a screen is determined, and the splats are merged; the spatial light intensity of one pixel of the screen is calculated by utilizing an illumination model and shading; and finally, normalization is carried out. The drawing speed is high, the requirement on real time can be effectively met without hardware acceleration, and moreover, the drawing quality is high.

Owner:BEIHANG UNIV

Vehicle body side outer plate drawing mold and drawing method

ActiveCN105945150AImprove drawing qualityEliminate depth gapsShaping toolsVehicle componentsMechanical engineeringEngineering

Owner:CHERY AUTOMOBILE CO LTD

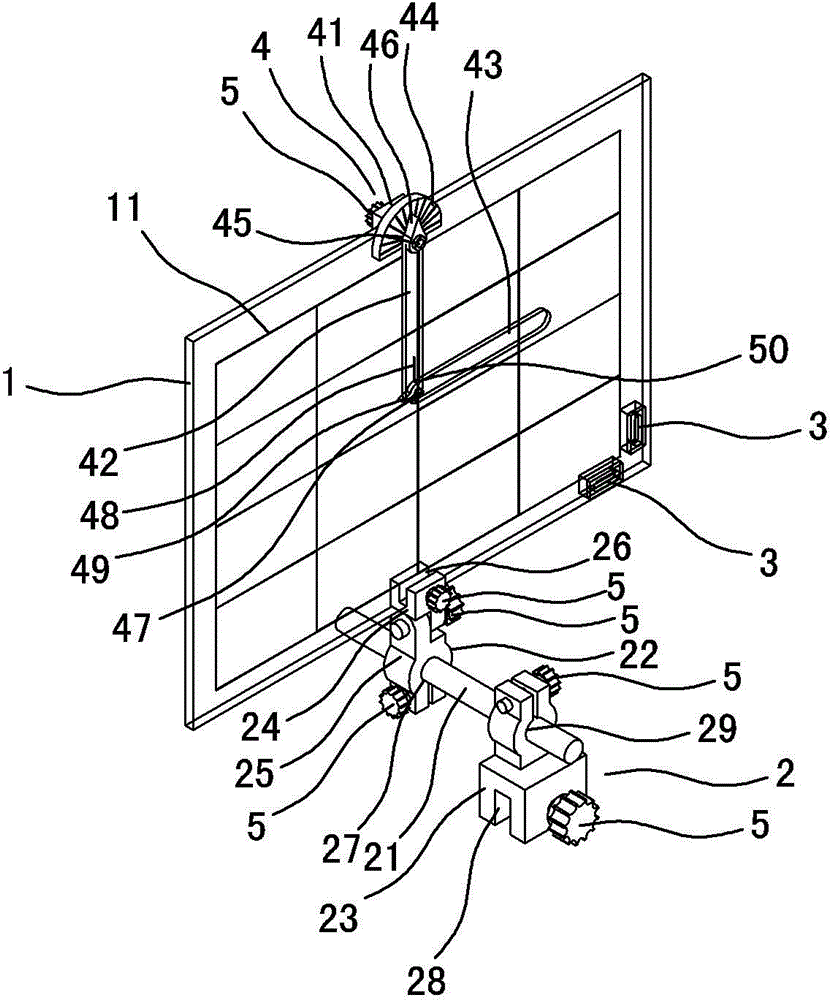

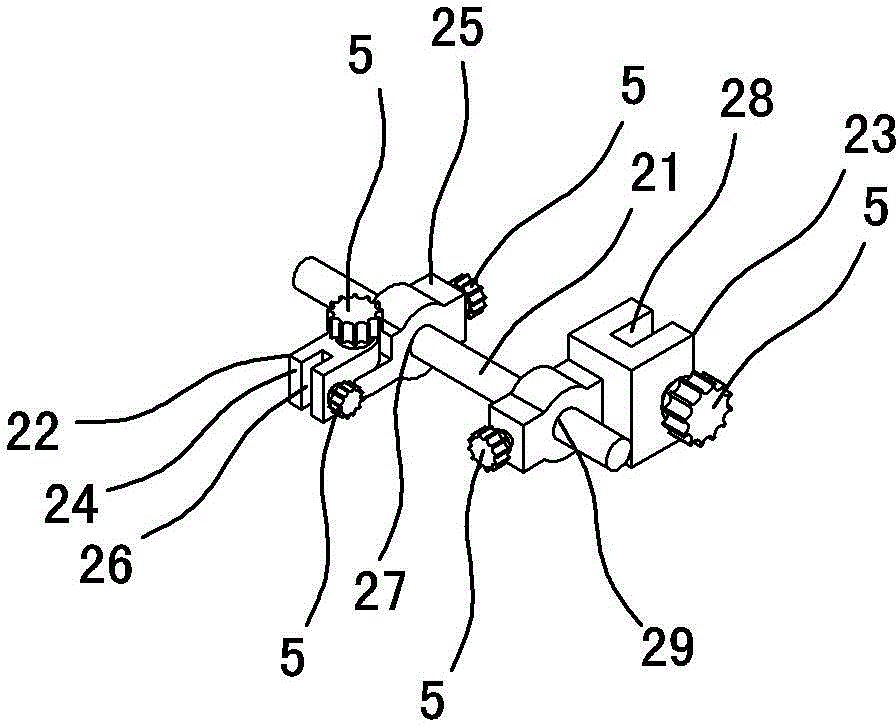

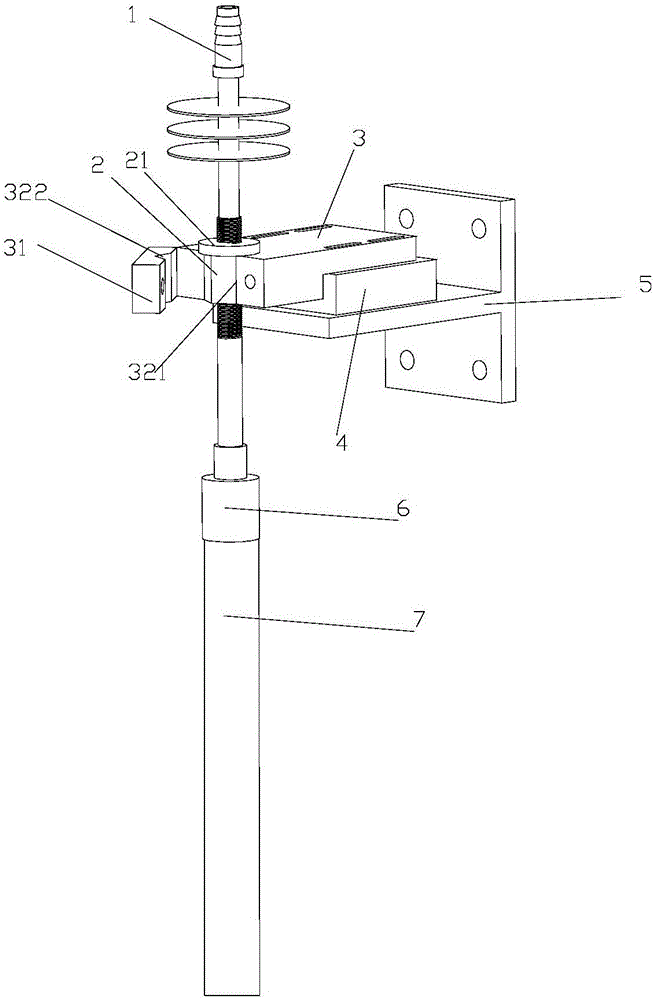

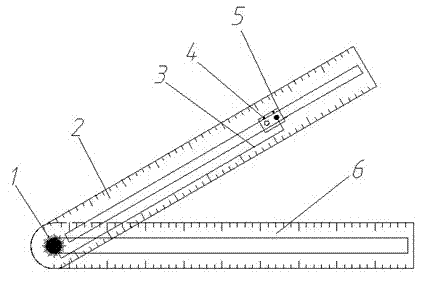

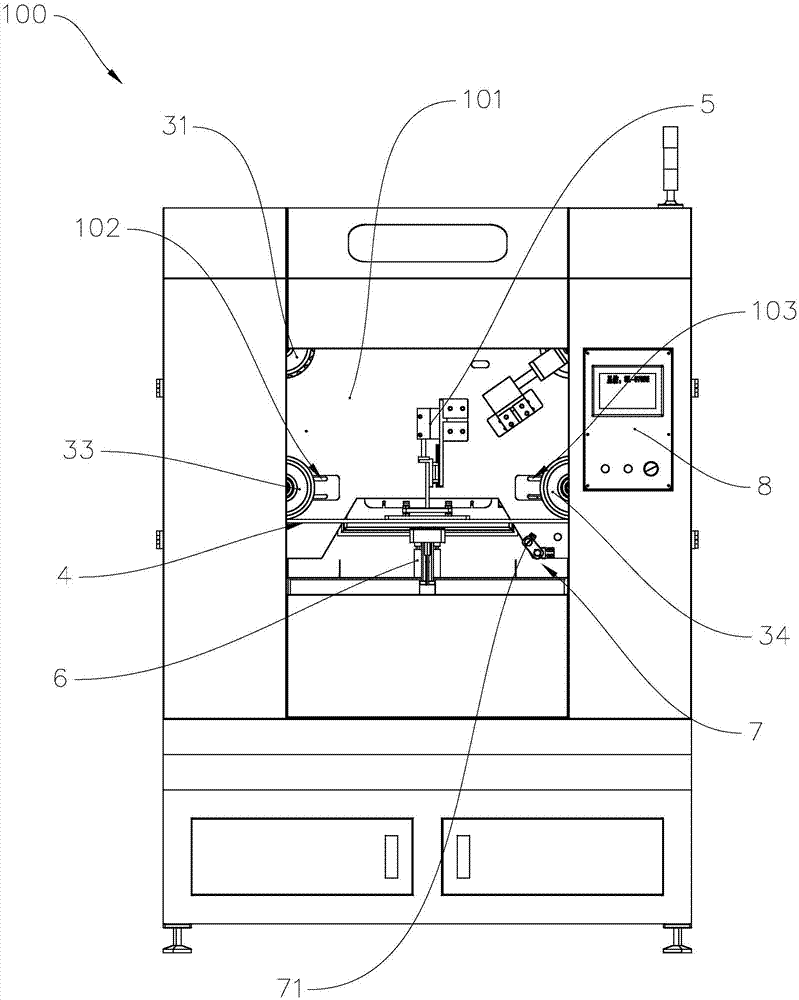

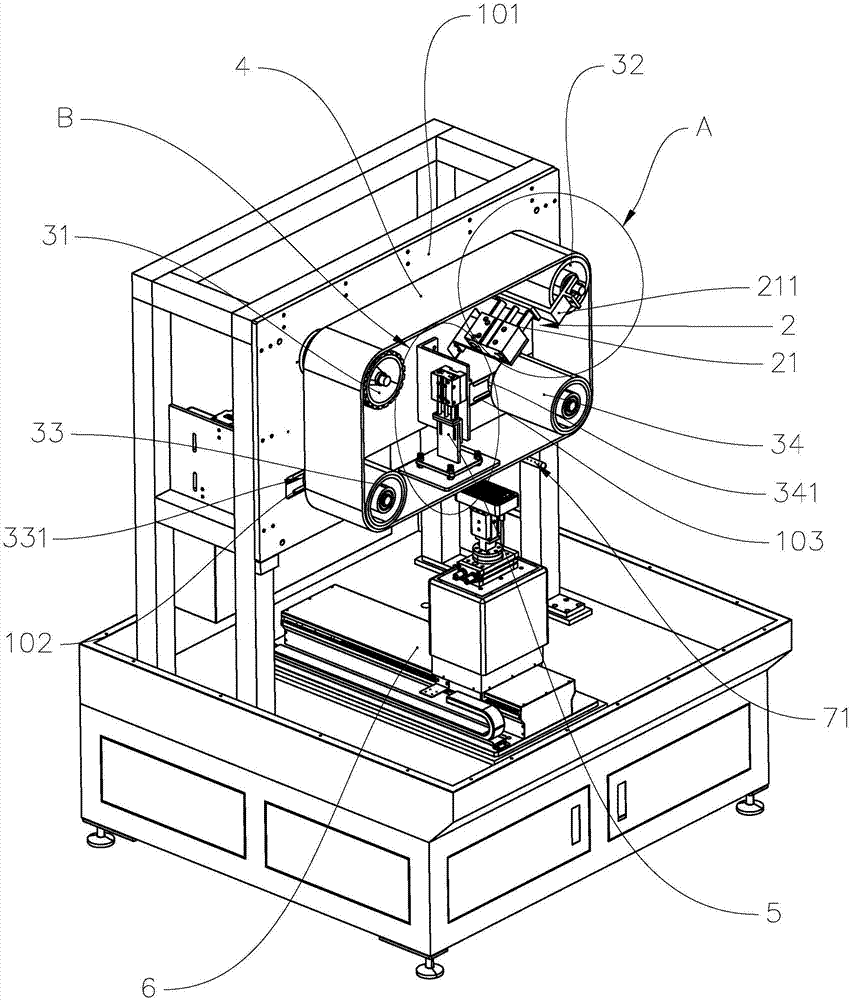

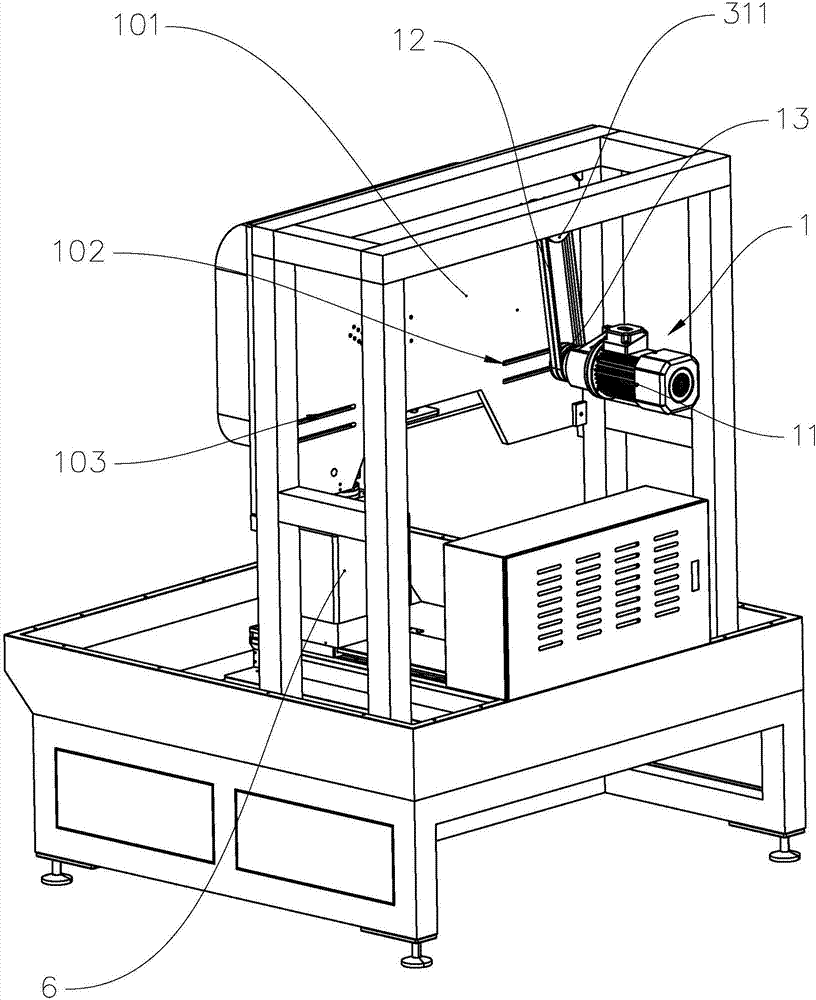

Art painting framing proportion perspective correcting machine

InactiveCN104875543AImprove drawing qualityAccurate proofreadingOther artistic work equipmentsFastenerProtractor

The invention relates to an art painting framing proportion perspective correcting machine which comprises a framing plate (1) and a mounting frame (2). Level bubble (3) is arranged at two perpendicular edges of the framing plate (1), a reference scale (4) is slidably mounted at the upper edge of the framing plate (1) and comprises a scale seat (41), a main scale (42) and an auxiliary scale (43), a protractor (44) is arranged on a clamp plate on the front side of a U-shaped slide groove in the scale seat (41), the upper end of the main scale (42) is rotationally mounted on the protractor (44), and an end of the auxiliary scale (43) is rotationally mounted on the main scale (42); the mounting frame (2) comprises a slide bar (21), a framing plate fastener (22) and a drawing board fastener (23). The art painting framing proportion perspective correcting machine has the advantages that real objects can be accurately observed by painters and painting beginners in particular during painting when the art painting framing proportion perspective correcting machine is used, framing composition can be properly carried out, correct perspective proportional relations of the objects can be clearly identified, outlines and shape structures of painting sketches can be quickly compared and corrected, and accordingly the painting quality, the efficiency and the professional quality of the painters can be effectively improved.

Owner:MUDANJIANG NORMAL UNIV

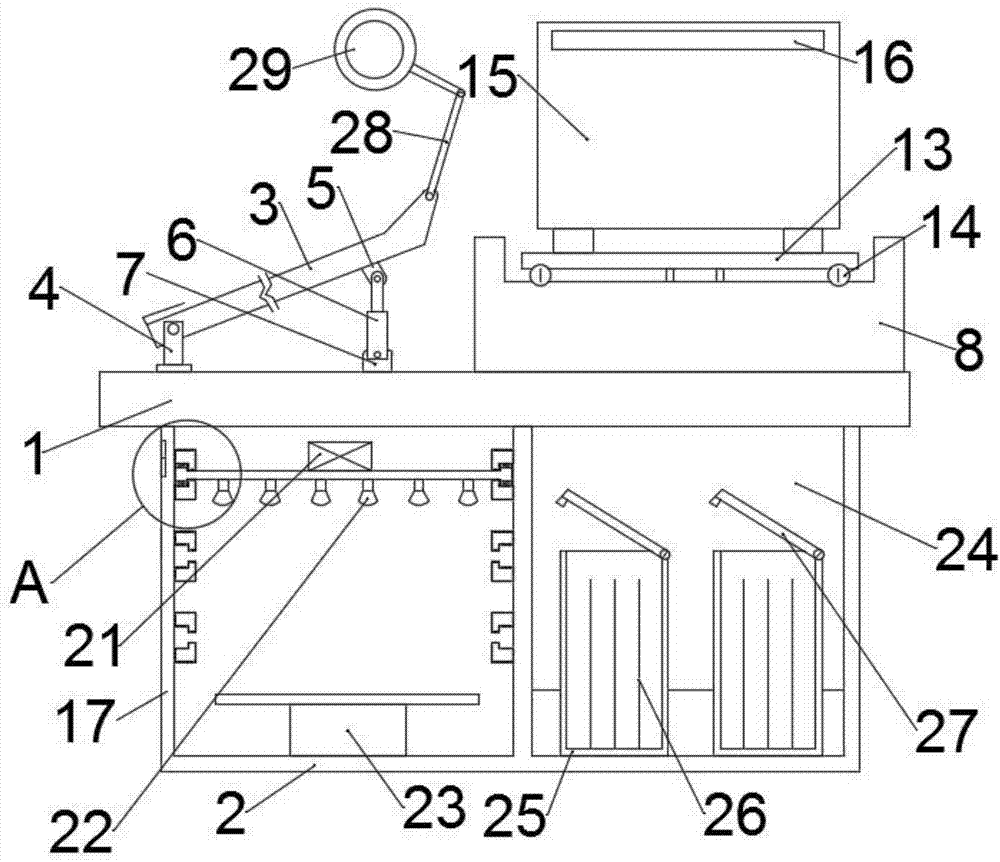

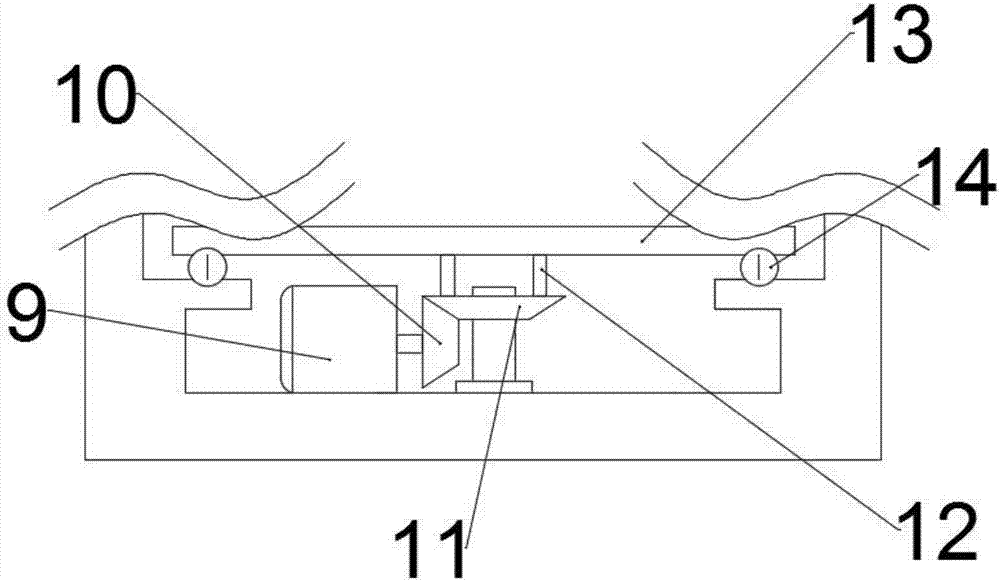

Drawing assistance desk special for self-shade art design

InactiveCN107280245AGuaranteed drynessRealize all-roundDrawing desksDrying machines with local agitationDeskSupport plane

The invention discloses a drawing assistance desk special for a self-shade art design. The desk comprises a desk top, a support box base is arranged below the desk top, and a first fixing support rack is arranged on the left side of the upper surface of the desk top; the first fixing support rack is hinged to the bottom side wall of a drawing board through a rotating shaft, a second fixing support rack is fixedly arranged on the back wall of the top side of the drawing board, and a hydraulic telescopic rod is hinged to the rack body of the second fixing support rack; the bottom end of the hydraulic telescopic rod is hinged to the rack body of a third fixing support rack, an adjustable installation support arm comprises a first rotating support arm and a second rotating support arm, and the first rotating support arm is hinged to the second rotating support arm. According to the drawing assistance desk, a desk top which is used for drawing art works is arranged on the left side of the desk top, so that students of the art major can draw patterns dependent on the drawing board, then the drawing quality of art students is improved, the drawing efficiency is improved, and the use requirements of multiple aspects are met.

Owner:湖北物连网智能用品有限公司

Metal spinning powder and preparation method thereof

ActiveCN104388155AEasy to cleanReduce friction damageLubricant compositionPotassium hydroxideHigh pressure

The invention discloses metal spinning powder and a preparation method thereof. The metal spinning powder is characterized by being prepared from the following raw materials in parts by weight: 100-300 parts of sodium carbonate or potassium carbonate, 1-5 parts of sodium benzoate, 300-600 parts of water, 10-60 parts of sulfonated castor oil, 5-30 parts of chlorcosane, 5-30 parts of tall oil, 2-15 parts of powdery sodium hydroxide or potassium hydroxide, and 5-30 parts of white carbon black. The invention also discloses the preparation method of the metal spinning powder. The metal spinning powder disclosed by the invention has the advantages of favourable lubricating property, corrosion resistance, high temperature resistance, high pressure resistance, lower cost and easy storage.

Owner:HENAN NORMAL UNIV

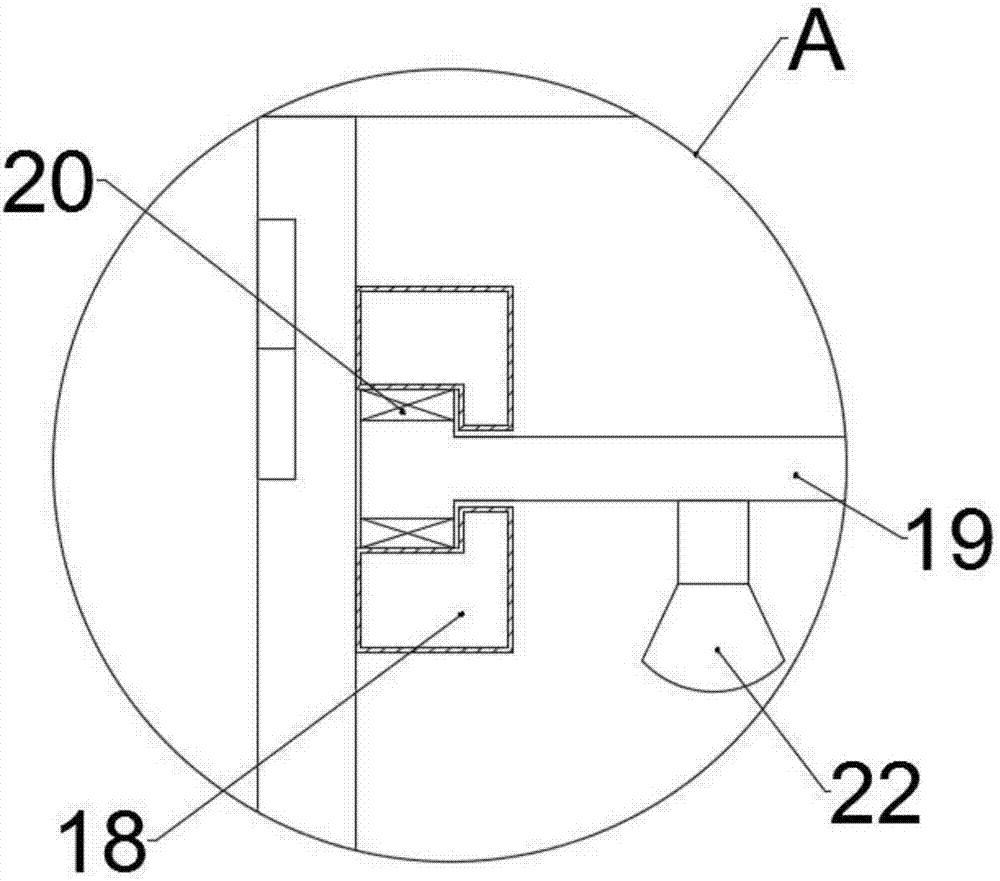

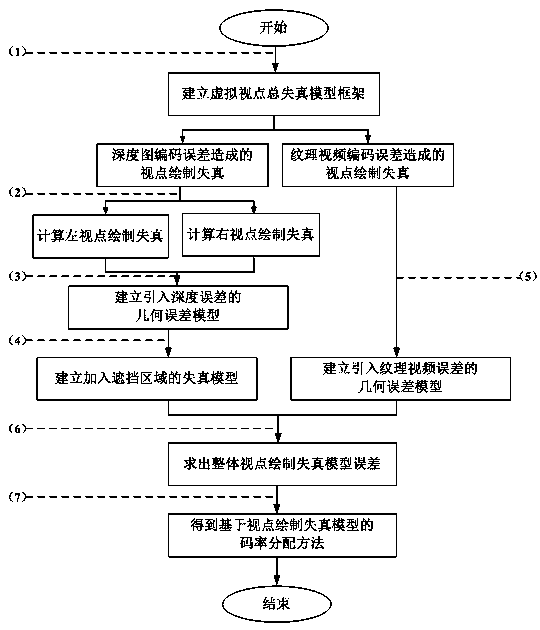

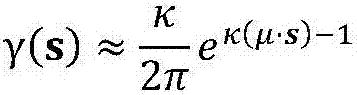

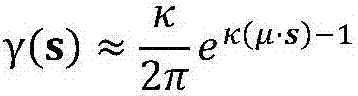

Rendering distortion model-based code rate allocation method of multi-viewpoint plus depth coding

ActiveCN105049866AImprove drawing qualityOptimize code rate allocationDigital video signal modificationSteroscopic systemsBase codeGeometric error

The invention relates to a rendering distortion model-based code rate allocation method of viewpoint plus depth coding. The objective of the invention is to optimize code rate allocation of texture video and depth map joint coding. The method includes the following steps that: a total distortion model frame of virtual viewpoints is built; rendering distortion of a left viewpoint and a right viewpoint is calculated; rendering distortion when a depth sensitive value is added is researched, and a geometric error model when a depth error is introduced is built; a distortion model when an occlusion region is added is built; a geometric error model when a texture video error is added is built; an overall viewpoint rendering distortion model error is obtained; and a viewpoint rendering distortion model-based code rate allocation method can be obtained. According to the rendering distortion model-based code rate allocation method of viewpoint plus depth coding, texture video difference and depth map difference are utilized to evaluate virtual viewpoint rendering distortion. The method can be used for optimizing the code rate allocation of texture videos and depth maps, and therefore, viewpoint rendering quality can be optimized. Reasonable bit allocation is performed between the viewpoints, and therefore, the quality balance of viewpoint coding images is high. The rendering distortion model-based code rate allocation method of viewpoint plus depth coding has the advantages of practical operability and convenience in application and realization.

Owner:郑州轻大产业技术研究院有限公司

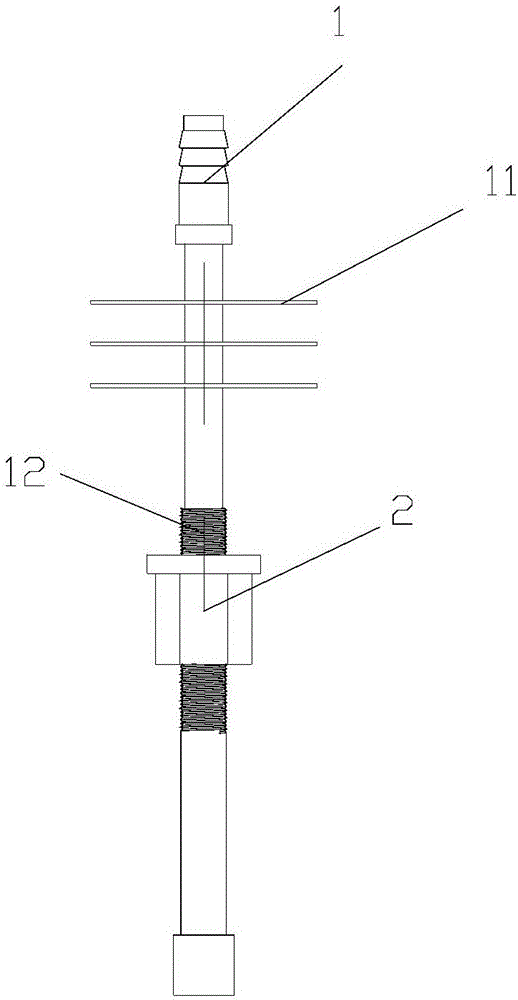

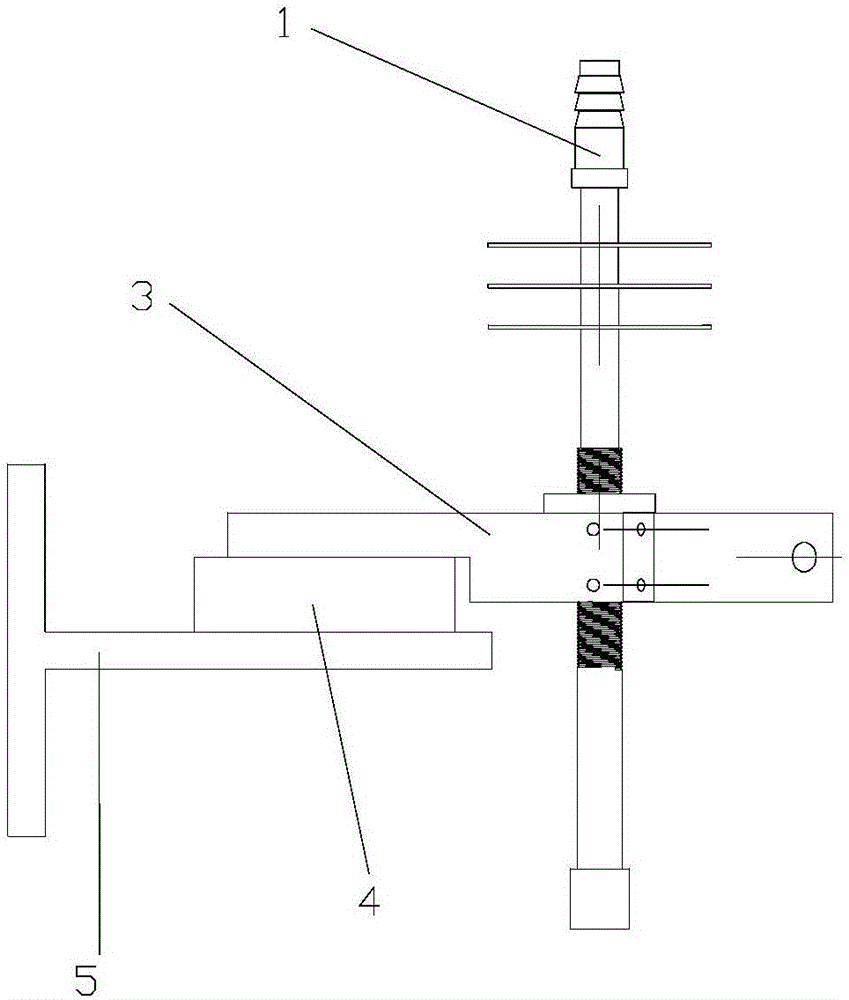

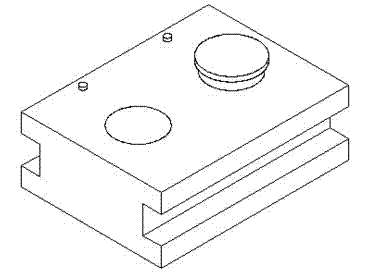

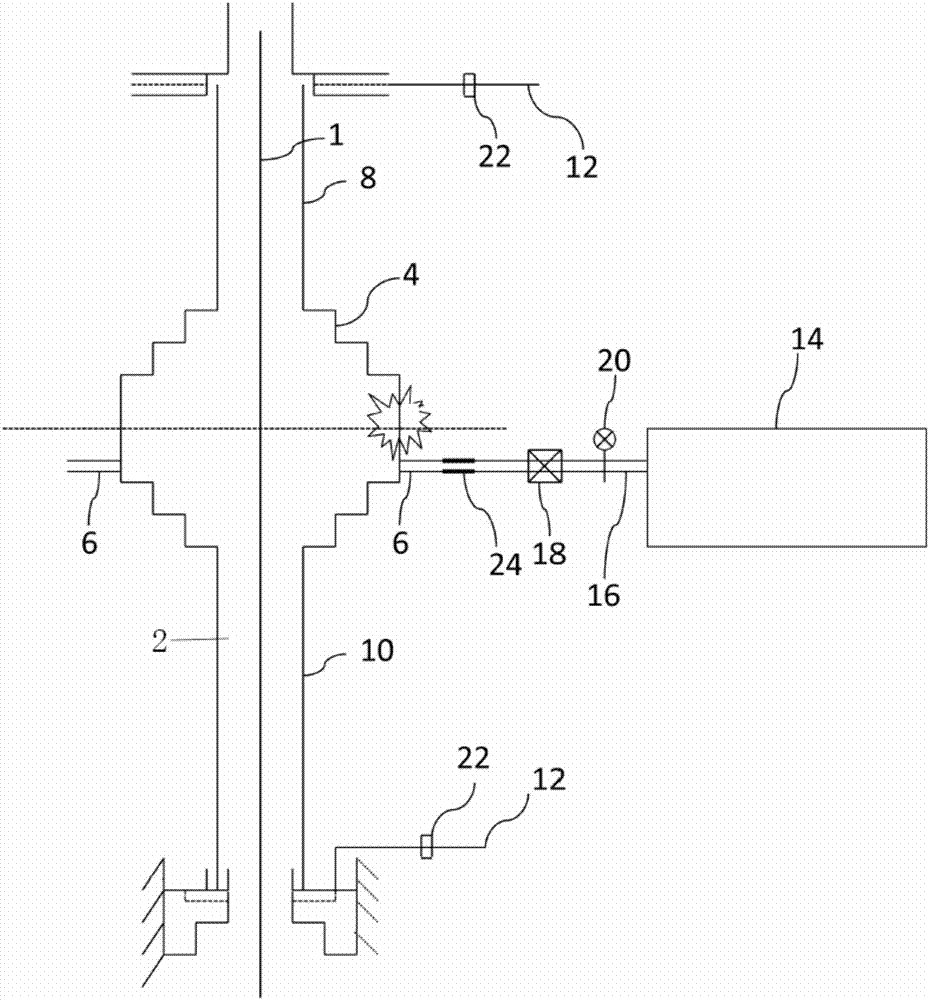

Optical fiber wiredrawing rod hanging mechanism

ActiveCN106477876AImprove quality controlGuaranteed verticalityGlass making apparatusBiochemical engineeringMachining

The invention discloses an optical fiber wiredrawing rod hanging mechanism which comprises a hanging rod. The hanging rod is arranged on a connecting block. A clamping piece is arranged on the hanging rod. An opening and closing piece is hinged to the connecting block. A first clamping groove is formed in the connecting block. A second clamping groove is formed in the opening and closing piece. The clamping piece is arranged between the first clamping groove and the second clamping groove. When the opening and closing piece is closed, the first clamping groove and the second clamping groove are matched with the outer surface of the clamping piece, and after the opening and closing piece is closed, the clamping piece is fixed to the connecting block through a fixing piece. According to the optical fiber wiredrawing rod hanging mechanism, the clamping piece is arranged on the hanging rod, the clamping piece is clamped when the connecting block is installed and the opening and closing piece is closed, the first clamping groove and the second clamping groove are matched with the outer surface of the clamping piece after the opening and closing piece is closed, close clamping of faces can be achieved, the perpendicularity of the hanging rod is effectively ensured, the optical fiber wiredrawing quality control is promoted, the wiredrawing quality is improved, and the optical fiber wiredrawing rod hanging mechanism is applicable to the field of optical fiber machining.

Owner:GUANGZHOU HONSUN OPTOELECTRONICS

Multifunctional drawing ruler

InactiveCN103496270AMany combinations without being bulkyVersatileNon-circular curve drawing instrumentsCircular curve drawing instrumentsGeometric figureEngineering management

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

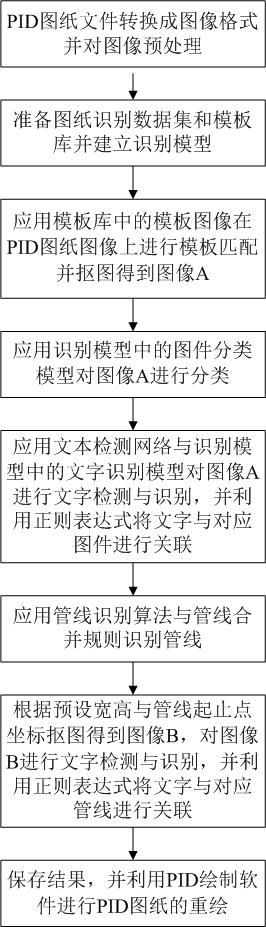

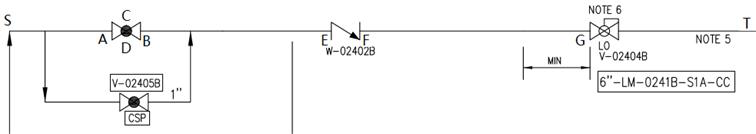

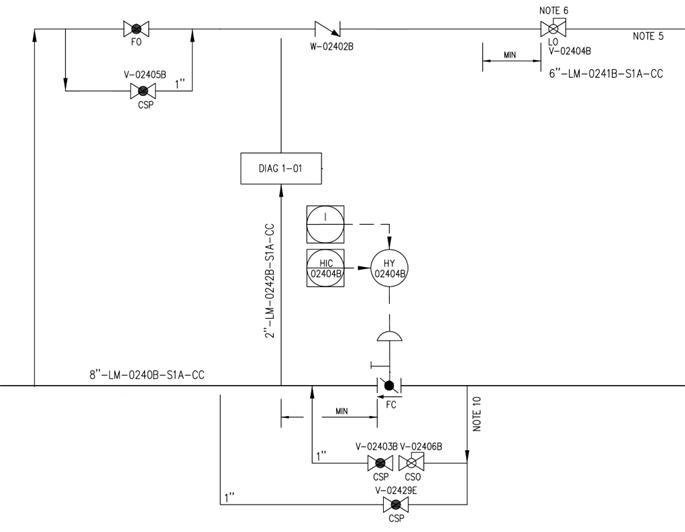

PID drawing intelligent identification and redrawing method

ActiveCN114694165AShorten the timeImprove drawing efficiencyGeometric CADDrawing from basic elementsComputer Aided DesignTemplate matching

The invention provides a PID drawing intelligent identification and redrawing method, and relates to the field of PID drawing identification, image processing and computer aided design. According to the method, template matching, deep learning, a pixel point-based pipeline identification algorithm and a merging rule method are adopted to realize positioning, classification and character detection and identification of drawings in a PID drawing image, the drawings and characters are associated by using a regular expression, and redrawing of the PID drawing is completed through PID drawing software. The time for professional engineers to manually draw the PID can be greatly shortened, and the drawing efficiency and quality are improved.

Owner:UNIV OF JINAN

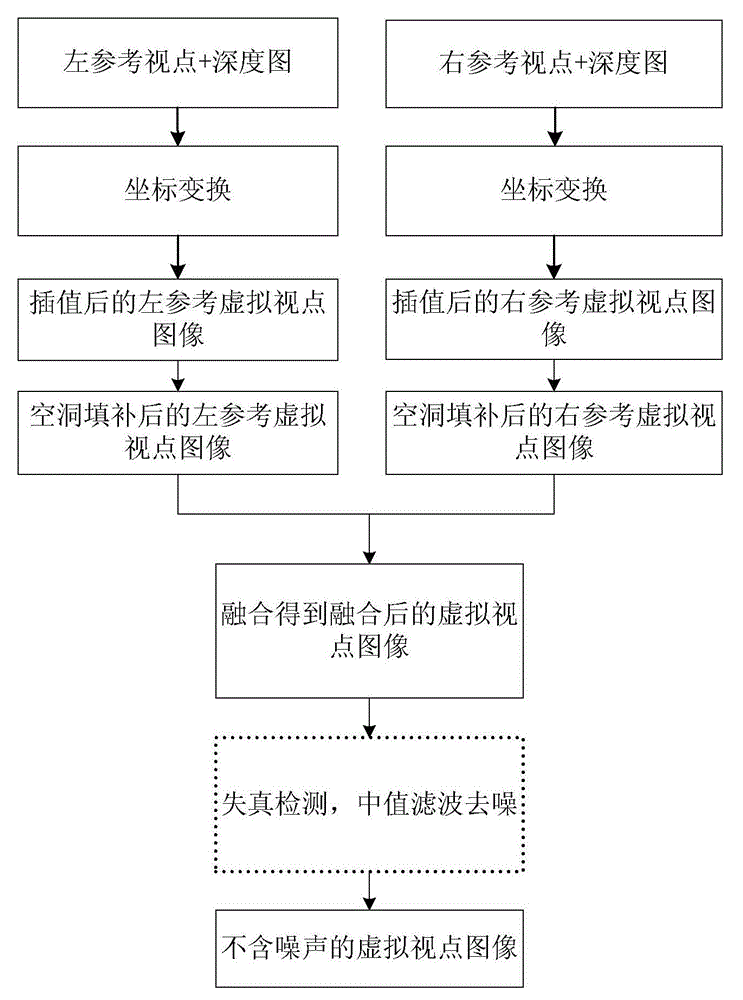

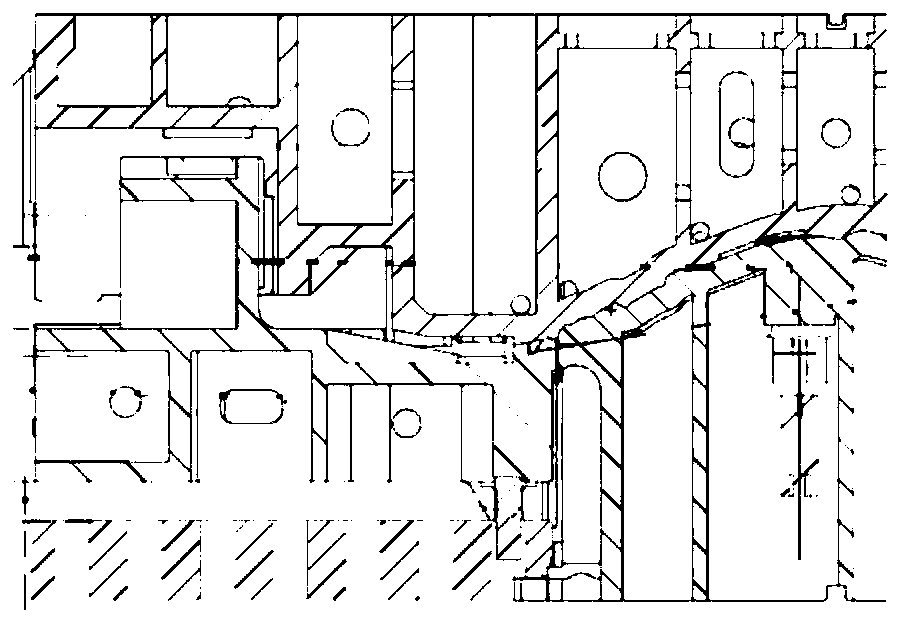

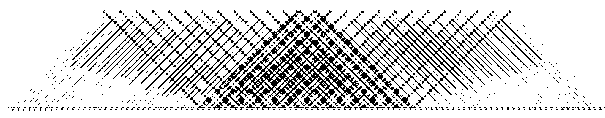

Virtual view point drawing method based on spatial weighting

ActiveCN104661013AReduce drawing timeReduce noiseDigital video signal modificationSteroscopic systemsObjective qualityComputer graphics (images)

The invention discloses a virtual view point drawing method based on a spatial weighting. According to the drawing method, the coordinate transformation of pixel points is performed by using rows as units so as to obtain actual projected pixel points, and then interpolation processing is performed by using the rows as the units, so that upper and lower sampling operations in the VSRS drawing method of virtual view points are omitted, and the drawing time is further shortened; the spatial positions of the projected pixel points, and the influences of a plurality of projected pixel points on the drawing quality are sufficiently considered, and a spatial weighting manner is adopted, so that noise caused by the inaccuracy of depth images is effectively decreased, the drawing precision is improved, and the subjective quality and the objective quality of virtual view-point images are further improved; the influences of different regions of reference view points on the drawing quality are sufficiently considered, the number of the projected pixel points near whole pixel points in the virtual view-point image broadwise reflects the regional distribution situation, and corresponding interpolation can be performed on different regions, so that the pixel points in the reference view points can be accurately inserted in the virtual view points, and the quality of the virtual view-point image is improved.

Owner:广西那还用问信息技术股份有限公司

Method for applying spherical harmonic lighting technology to surface rendering

ActiveCN103440684AAdd supportImprove drawing efficiencySpecial data processing applications3D modellingComputer graphics (images)Spherical harmonic lighting

Disclosed is a method for applying a spherical harmonic lighting technology to surface rendering. In the method, a texture backfill method is used so that the spherical harmonic lighting technology can be applied to the surface rendering. Therefore, carrying out discrete sampling on each surface patch in a surface model so that the surface model is converted into a point model; obtaining a spherical harmonic coefficient group of each point through a spherical harmonic lighting method; according to each discrete point and a corresponding spherical harmonic coefficient group of the point, generating a group of spherical harmonic coefficient textures for each face through the texture backfill method; finally, rendering the surface model through a surface rendering method and programming through GPU rendering pipelines so that spherical harmonic lighting simulation is completed. The method for applying the spherical harmonic lighting technology to the surface rendering improves a rendering quality obviously on the premise that a rendering efficiency is not sacrificed. At the same time, the method is capable of improving the rendering efficiency in a certain degree and overcoming different deformation problems generated by overlap of points or inadequacy of coverage ranges in rendering.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

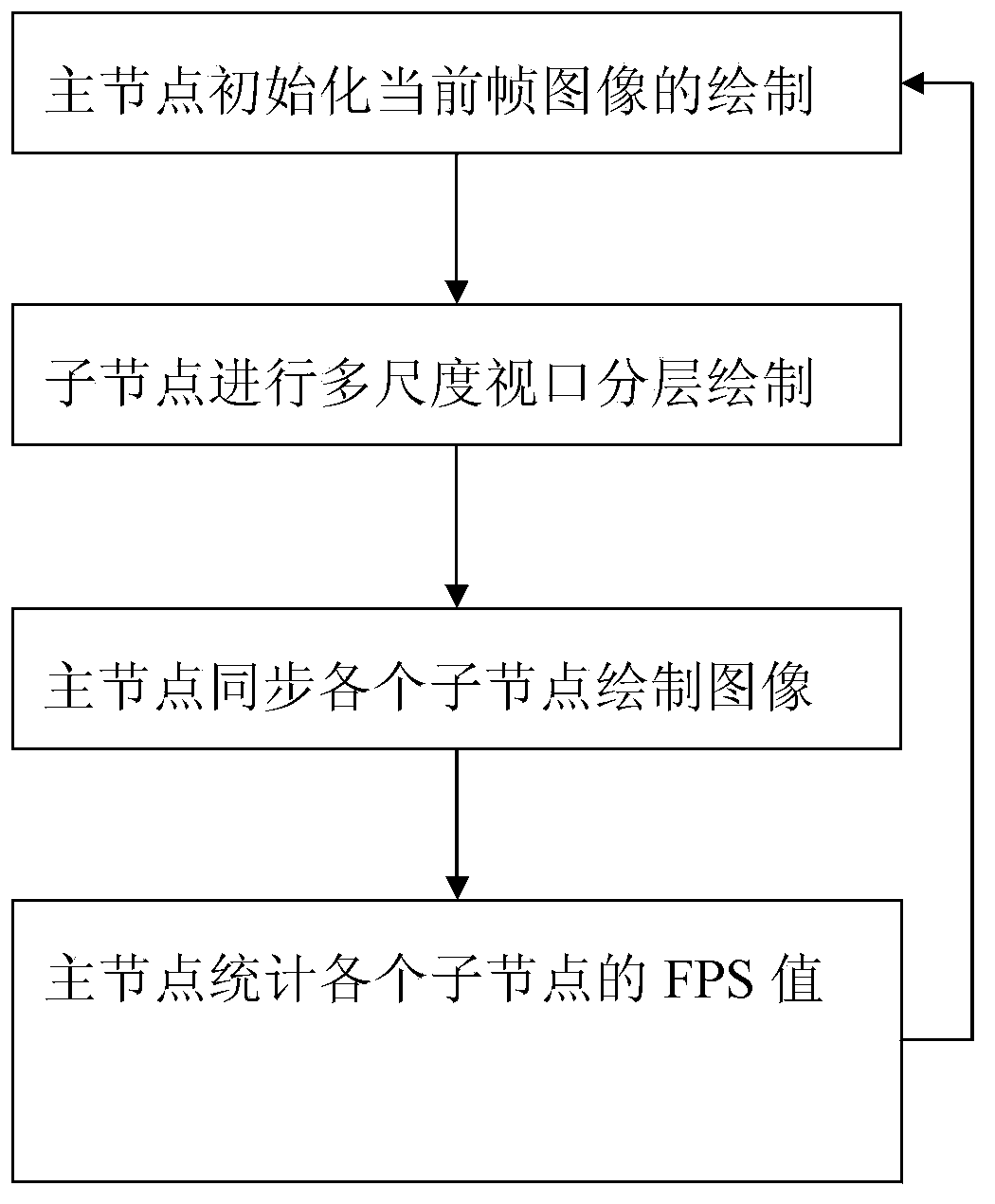

Low-noise real-time global illumination drawing method for three-dimensional geometric scene

ActiveCN103426199AQuick previewContinuous smooth transition3D-image renderingLow noiseComputer graphics (images)

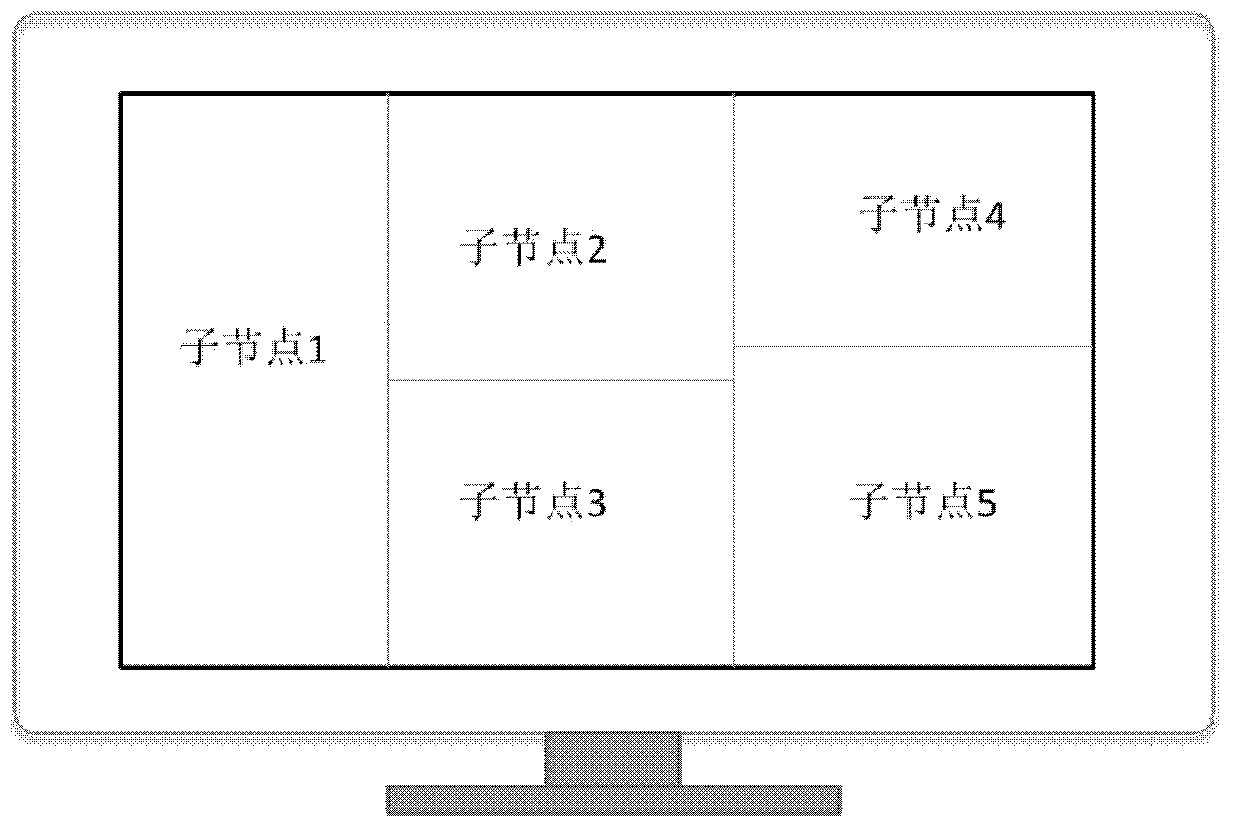

The invention discloses a low-noise real-time global illumination drawing method for a three-dimensional geometric scene. The low-noise real-time global illumination drawing method comprises the steps of: initializing drawing of a current frame image by a main node, including, drawing view-port segmentation, model differential transmission and drawing background chartlet, and distributing segmented view-port parameters, a three-dimensional model and a background chartlet to each sub-node; carrying out multi-scale view-port layered drawing for the received three-dimensional model and video-port parameters, and transmitting each layer of drawn images to the main node by the sub-node; synchronizing the image of the current frame drawn by each sub-node and displaying the images in the same layer in a splicing manner by the main node; counting the number of frames drawn by each sub-node every second and drawing the image of the next frame by the main node. As the global illumination way is adopted to draw a complex three-dimensional geometric scene, the low-noise real-time global illumination drawing method for the three-dimensional geometric scene can provide roaming and rapid browsing of fixed scenes and dynamic movable scenes for a user, and can reduce noise points in the drawing process, improve drawing quality and lower modeling cost of the three-dimensional scene.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Computer plotting system and computer plotting method for making signssigns

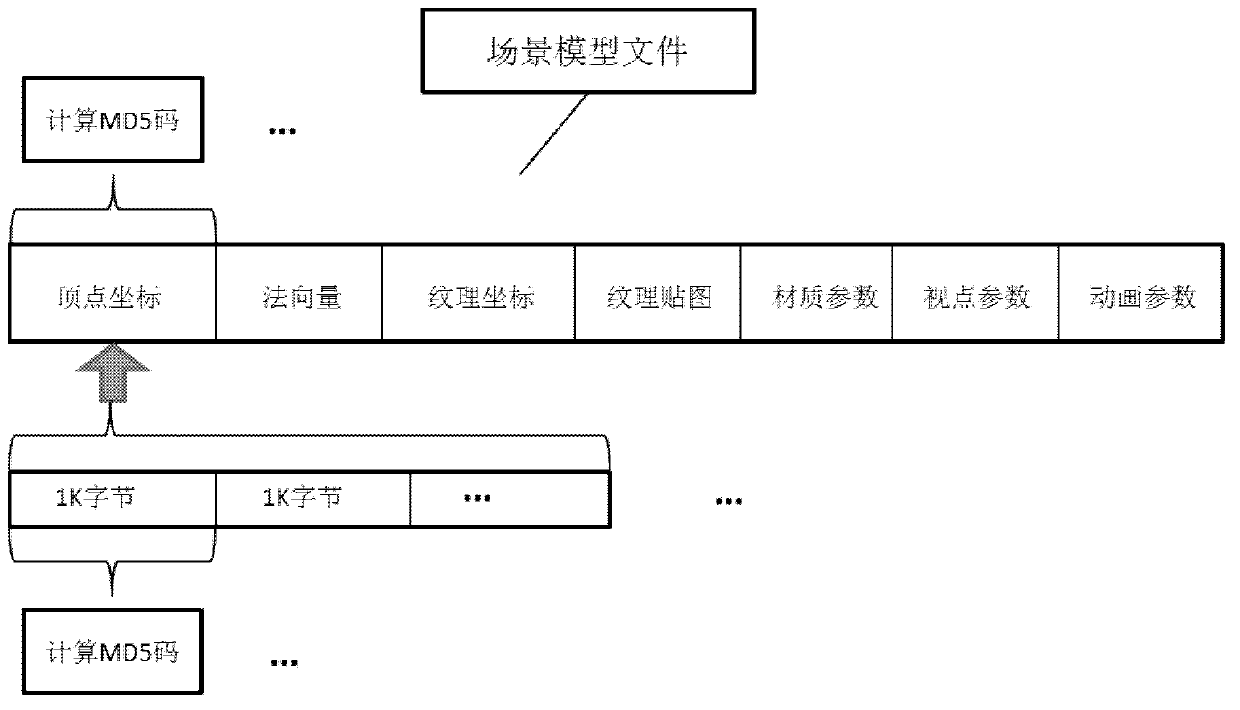

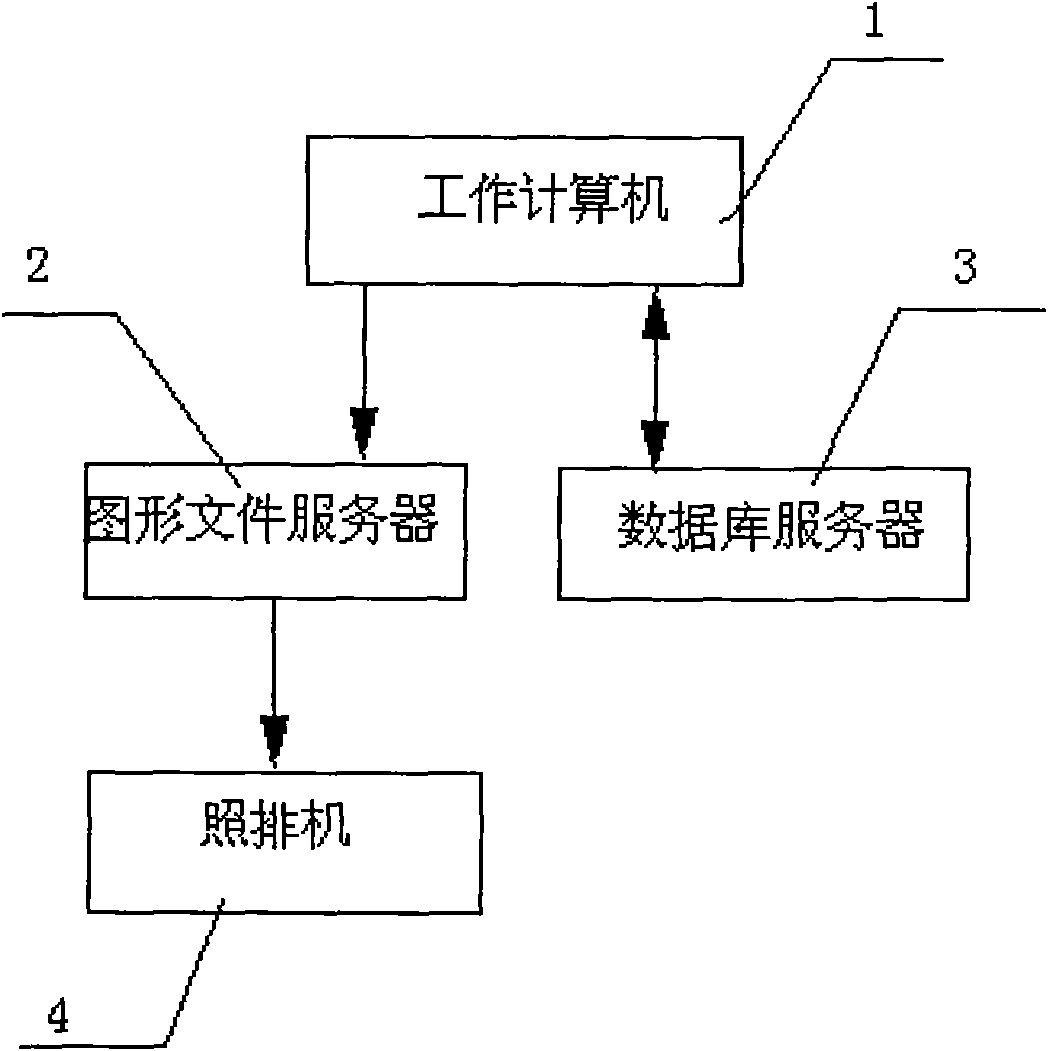

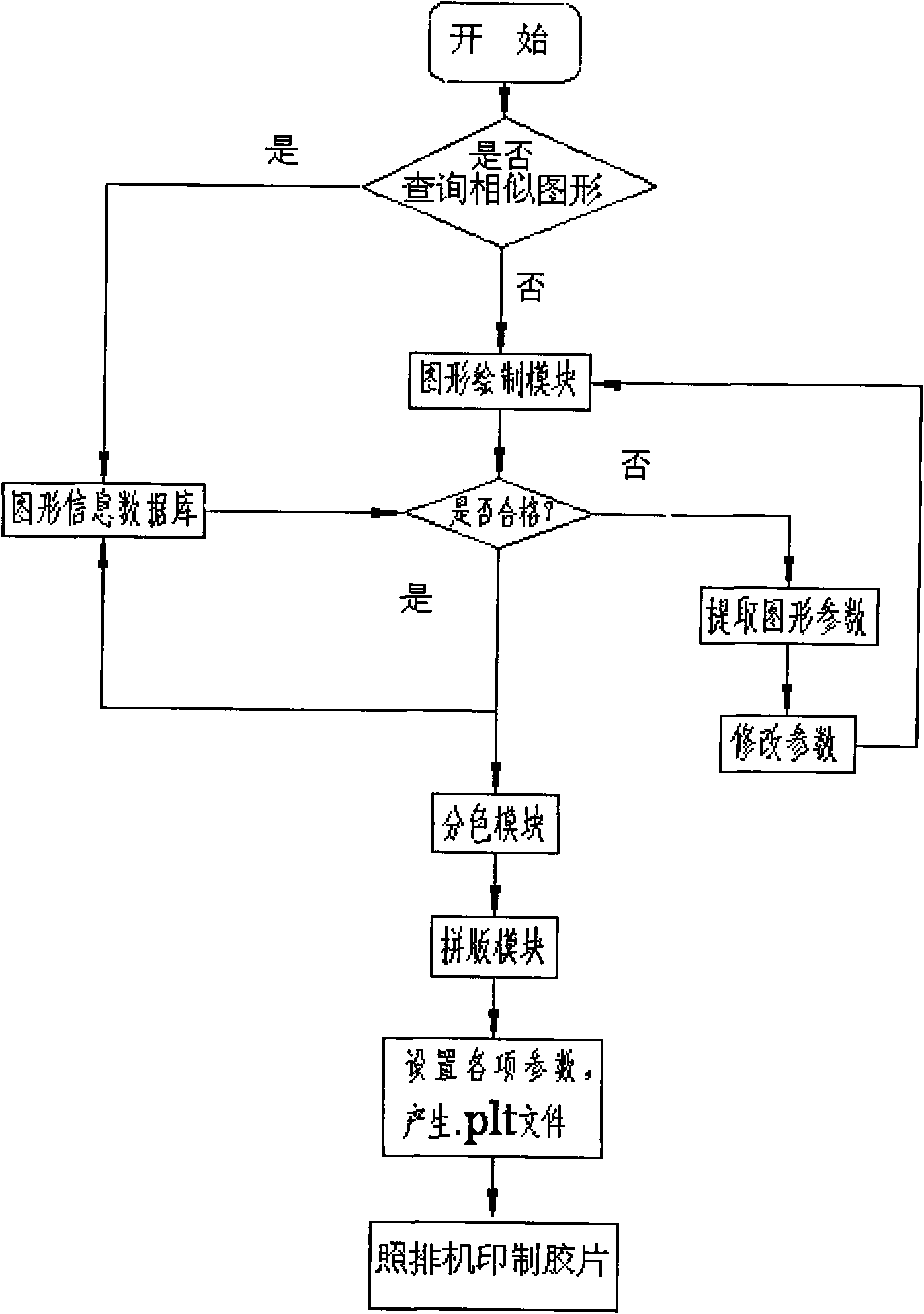

InactiveCN101625712AReduce capacityEasy to manageSpecial data processing applicationsGraphicsDatabase server

The invention discloses a computer plotting system and a computer plotting method for making signs. The computer plotting system comprises a working computer, a drawing file server, a database server and an imagesetter which are interconnected in the way of a local area network way. The computer plotting method for making the signs comprises the following steps: (1) judging if patterns similar to that of the signs which need to be plotted are searched or not; (2) if not, plotting the patterns of the signs according to needs; (3) judging if the patterns accord with requirements or not, if not, extracting parameters of the patterns; (4) after the patterns are modified, returning to a pattern plotting module to plot the patterns; (5) if a judging result of the step (3) is that the patterns accord with the requirements, transmitting a pattern file to a pattern information database for storage and also transmitting the pattern file to a color separation module to separate colors; (6) splicing a plurality of objects into a pattern integer; and (7) setting printing parameters of each item to generate a file in plt format for being distinguished by the imagesetter. The invention reduces the capacity of the pattern file from about 1G to dozens of k, thereby reducing the rigid disk resources occupying the computer.

Owner:JIANGSU KEDA HUIFENG SCI & TECH

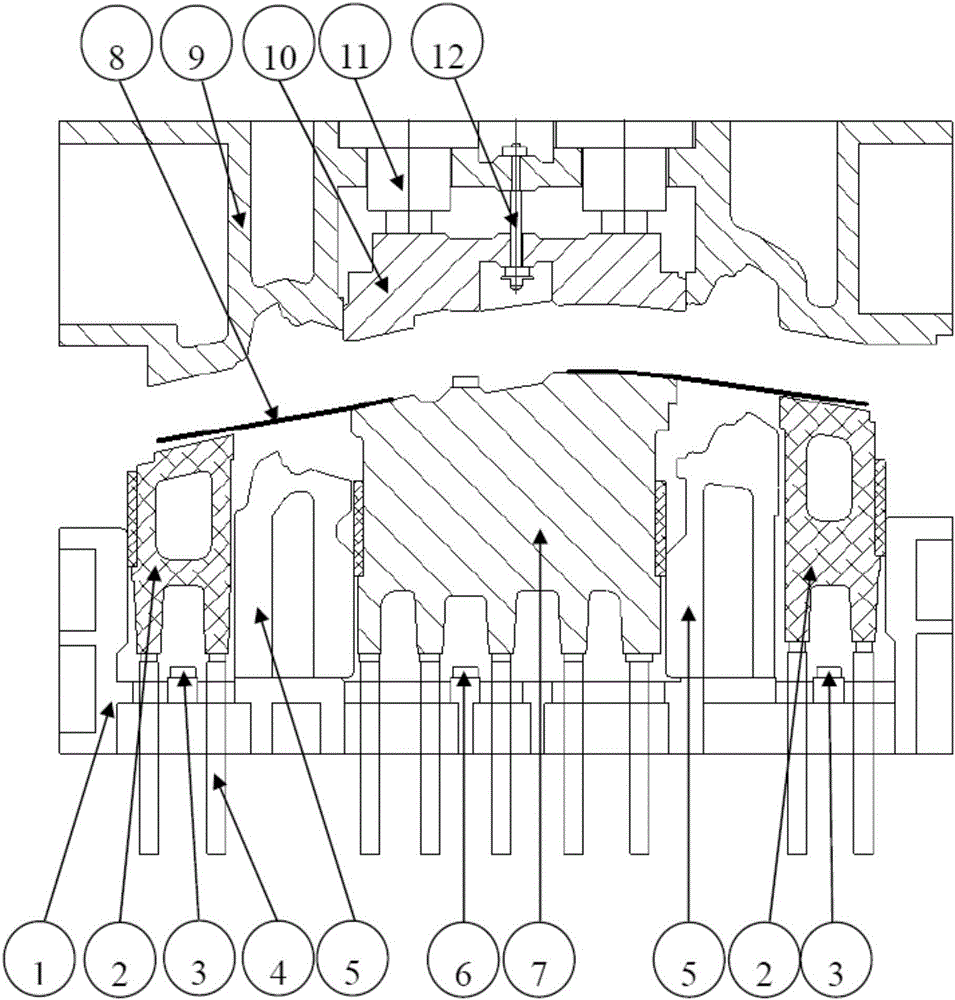

Out-sync swaging drawing forming mould and forming process thereof

PendingCN110064696ASolve the problem of insufficient wrinkling and crackingReasonable process designShaping toolsEngineeringBack door

The invention discloses an out-sync swaging drawing forming mould which comprises an upper die body, a lower die base, a male die and a female die. The female die is arranged on the lower part of theupper die body; the male die is arranged on the upper part of the lower die base and is fixedly arranged on the lower die base; a movable lower binder ring is arranged on the outer side of the male die; a movable support core is arranged in the center of the male die; the male die and the support core are in sliding fit; the female die is fixedly arranged on the upper die body so as to form a fixed male die; a movable upper binder ring is arranged on the outer wall of the female die and is arranged opposite to the lower binder ring up and down; and the lower surface of the female die and the upper surfaces of the male die and the support cores are arranged oppositely so as to be used for plate forming. A small-curvature back door inner plate out-sync binder ring drawing forming mould realizes multi-time drawing forming in one process, so that the problem that a small-curvature complex inner covering piece aluminum alloy workpiece is insufficient in drawing forming so as to be wrinkledand cracked is solved, the drawing quality is improved, and the cost is reduced since only one-step stamping forming is needed.

Owner:FUZHEN TECH RES ANHUI

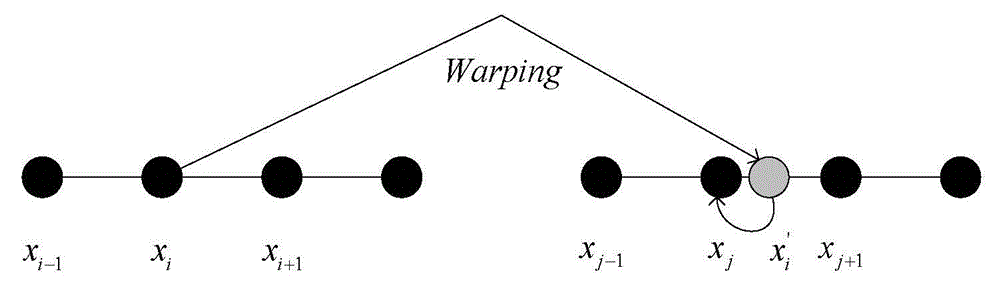

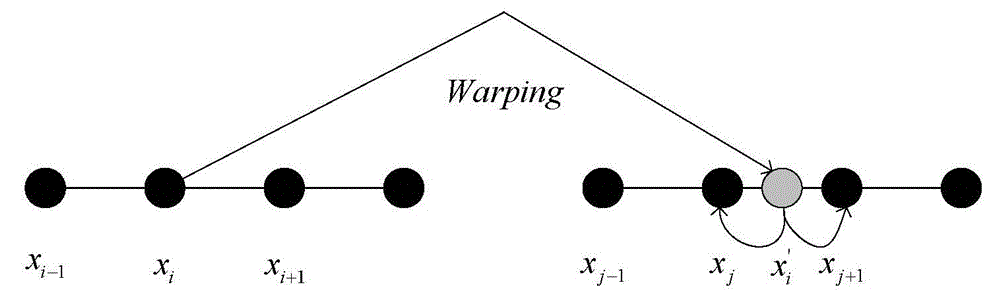

Virtual viewpoint synthesis method with spatiotemporal continuity

InactiveCN108833879AImprove drawing qualityMaintain time continuitySteroscopic systemsViewpointsSynthesis methods

The invention provides a virtual viewpoint synthesis method with spatiotemporal continuity. The method makes full use of correlation between adjacent frames in a reference viewpoint image sequence, aglobal static background map sequence of a scene is extracted from the reference viewpoint image sequence, and based on the global background map sequence, artifact elimination and hole filling are carried out on a virtual viewpoint image sequence synthesized by a left and a right reference viewpoint image sequence. Artifact and hole problems on a virtual viewpoint image can be well solved, the quality of a single frame of virtual viewpoint image is greatly improved, and the spatiotemporal continuity of the virtual viewpoint image is also well maintained.

Owner:SOUTHEAST UNIV

Image rendering method based on BRDF function linear filtering

ActiveCN107292946ABuild in real timeImprove drawing quality3D-image renderingGratingComputer graphics (images)

The invention discloses an image rendering method based on BRDF function linear filtering. The method comprises: creating a BRDF map; aimed at the BRDF map, creating texture cache, rasterizing geometrical triangles of each object to the texture cache; aimed at each texture pixel in the texture cache, calculating corresponding vMF distribution function parameters and ||r||; according to distribution of a normal in a scene, segmenting a region, the segmented texture pixel storing the vMF distribution function parameters corresponding to the region, splicing BRDF maps generated after segmentation to obtain BRDF maps which are performed by MIP-Map; aimed at each pixel in a to-be-rendered image, calculating the size of the region covered by the pixel, and thus obtaining a MIP-Map hierarchy corresponding to the pixel, then reading corresponding position information from the corresponding BRDF maps which are performed by MIP-Map, and rendering. Filtering is applied in real-time rendering, drawing quality is improved, and a calculation process is accelerated.

Owner:ZHEJIANG UNIV

Oil painting pigment

ActiveCN106554719ANo irritating smellGood water solubilityWax coatingsDrying oil coatingsSolubilityLinseed oil

The invention discloses an oil painting pigment, which comprises the following components, by weight percentage, 22.85-52.9% of linseed oil, 1-3% of cera alba, 1-3% of monostearin, 0.1-0.2% of a drying agent, 15-50% of barium sulfate, and 5-30% of pigment powder. The pigment is free of pungent smell, is safe and non-toxic, can directly contact the human body, and is excellent in water solubility. The pigment is easy to be washed off and is green and eco-friendly. The technical problems that an oil painting pigment in the prior art adheres to pencils and oil and power is prone to separate are solved, the painting quality can be improved, materials are saved, and environmental pollution is reduced.

Owner:SHUYANG PHOENIX ART PAINTS CO LTD

Mapping system for coal field seismic exploration

InactiveCN103310061AShorten the drawing periodImprove drawing qualitySpecial data processing applicationsDatabase serverData processing

The invention discloses a mapping system for coal field seismic exploration. The system comprises a data processing unit, a well log curve sampling module, a graphic preprocessing unit and a seismic report mapping unit which are sequentially connected, as well as a database server, a system interface module and a display output module which are connected with the four parts, wherein the data processing unit comprises a main processing module as well as a two-dimensional seismic observing system data processing module, a three-dimensional seismic observing system data processing module, a three-dimensional seismic design drawing preprocessing mapping module and a man-machine interaction module which are connected with the main processing module; the graphic preprocessing unit comprises a mapping preprocessing module as well as a two-dimensional traced drawing module and a three-dimensional traced drawing module which are connected with the mapping preprocessing module; and the seismic report mapping unit comprises a two-dimensional seismic report mapping module and a three-dimensional seismic report mapping module. The mapping system for the coal field seismic exploration achieves overall-process automated mapping work of the seismic exploration from designing to reporting, greatly shortens mapping period of the seismic report, and greatly reduces manual workload and the production cost.

Owner:GEOPHYSICAL SURVEY TEAM ANHUI PROVINCIAL BUREAU OF COAL GEOLOGY

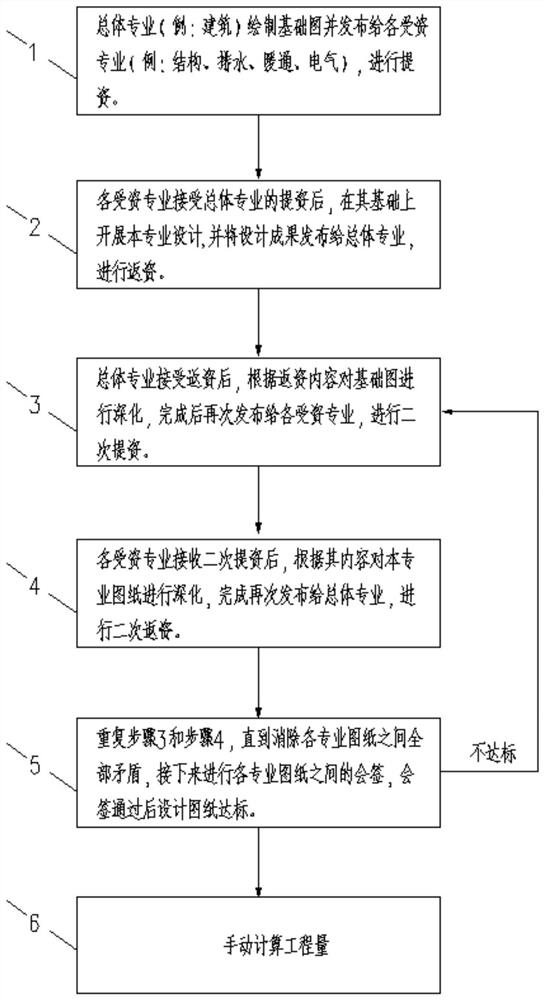

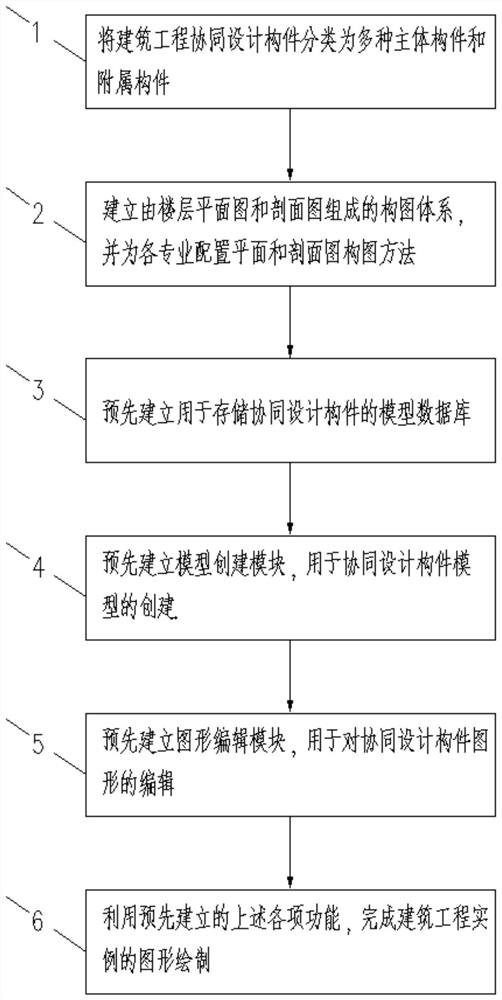

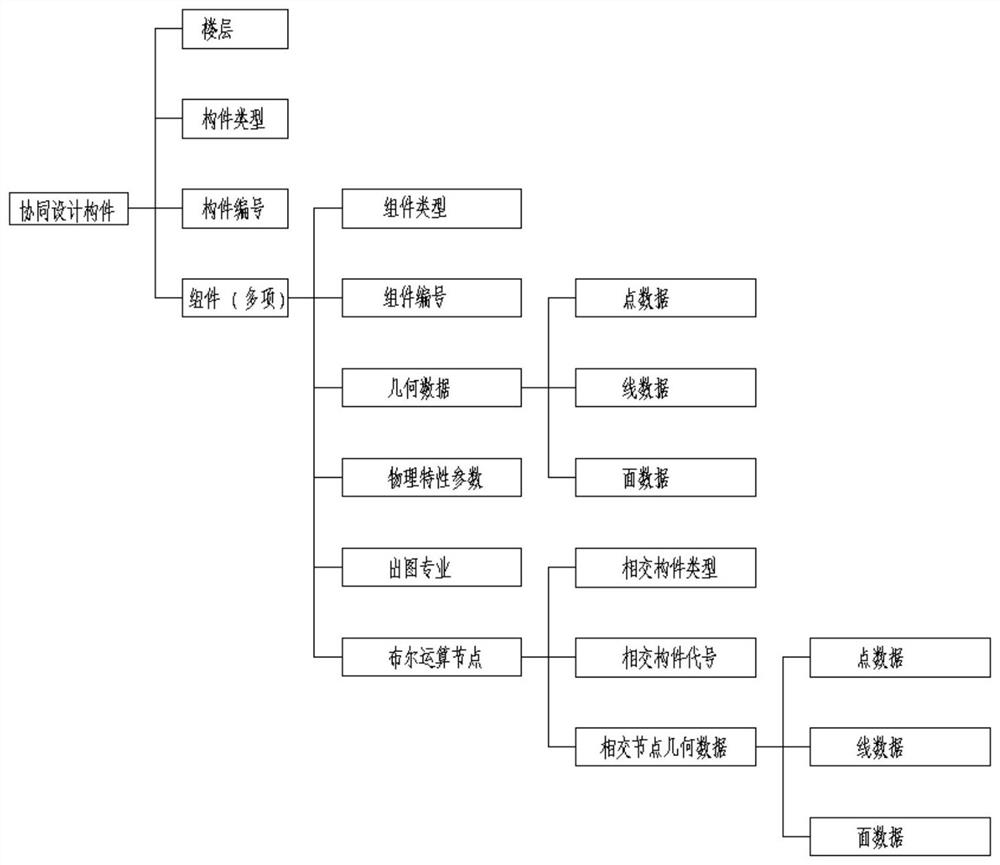

Constructional engineering collaborative design drawing method based on CAD platform

PendingCN112270033ARealize Graphical Collaborative DesignImprove drawing efficiencyGeometric CADConstraint-based CADGraphicsSoftware engineering

The invention discloses a constructional engineering collaborative design drawing method based on a CAD platform. The method comprises the following steps of 1, collaborative design components of constructional engineering being classified into multiple main body components and accessory components; 2, establishing a composition system composed of a planar graph and a profile graph, and configuring a mapping method of the planar graph and the profile graph for each specialty; 3, pre-establishing a model database for storing collaborative design components; 4, a model creation module being pre-established and used for creating a collaborative design component model; 5, a graph editing module being established in advance and used for editing the graph of the collaborative design component; and 6, drawing a constructional engineering instance graph by using the pre-established functional modules and adopting a collaborative design method. According to the method, graph collaborative design in and among constructional engineering majors is realized, and drawing efficiency and quality are remarkably improved.

Owner:卢娅

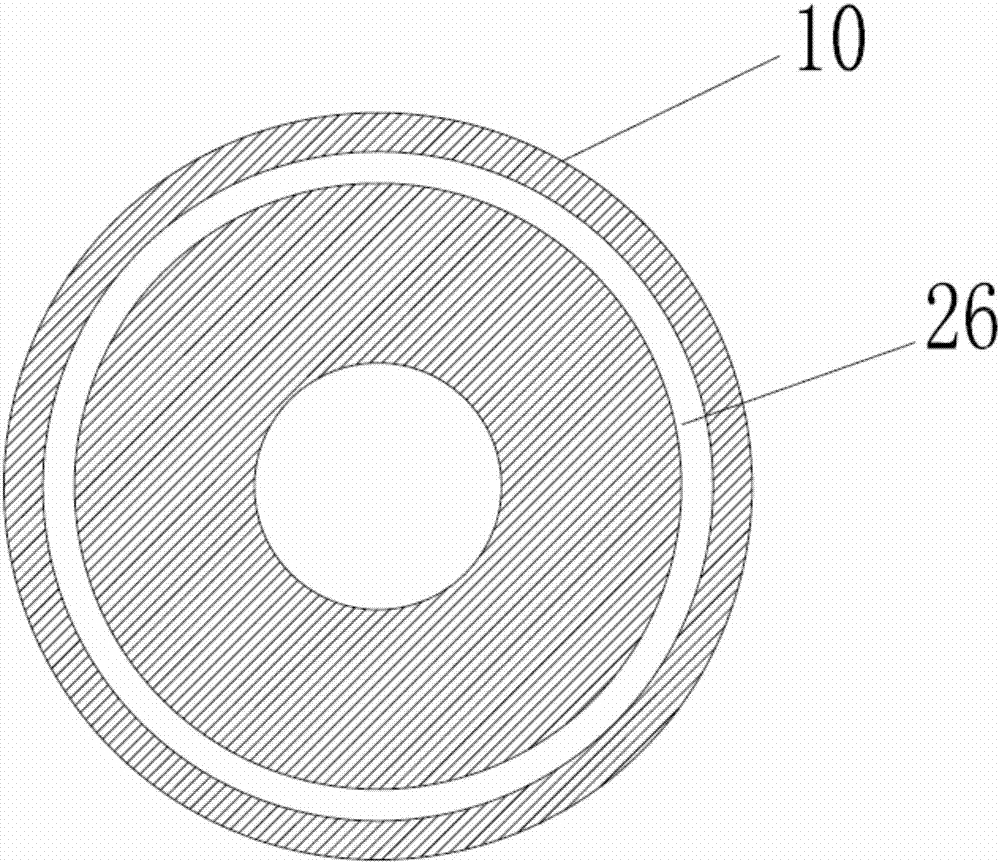

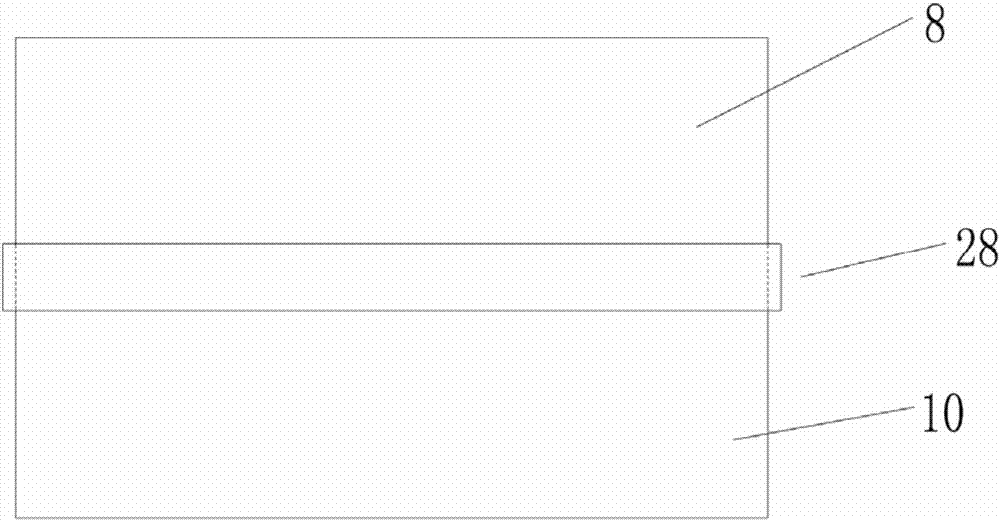

Optical fiber annealing extending pipe

ActiveCN107082560AQuality assuranceReduce fiber breakage rateGlass making apparatusGlass productionEngineeringOptical fiber cable

The invention provides an optical fiber annealing extending pipe, which comprises a quartz main pipe, wherein the middle position in the axial direction of the quartz main pipe is a variable-diameter pipe section; the pipe diameters of the pipe body, positioned at the two sides of the variable-diameter pipe section, of the quartz main pipe are smaller than the minimum pipe diameter in the variable-diameter pipe section; a quartz branch pipe is connected onto the variable-diameter pipe section; the quartz branch pipe is connected in the maximum pipe diameter position of the variable-diameter pipe section; the quartz branch pipe communicates with the inside of the quartz main pipe; the other end of the quartz branch pipe is connected with a negative pressure suction device; the pipe diameter of the upward middle pipe section of the variable-diameter pipe section is maximum; the pipe diameters of the pipe body, positioned at the two sides of the middle pipe section, of the variable-diameter pipe section are gradually reduced. The quartz main pipe using the optimized structure design is matched with the negative pressure suction device and can be used for performing online cleaning treatment on oxide, volatile substances and the like entering the annealing extending pipe; on the premise of ensuring the optical fiber quality, the optical fiber fracture rate is reduced; the production efficiency is improved.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH +1

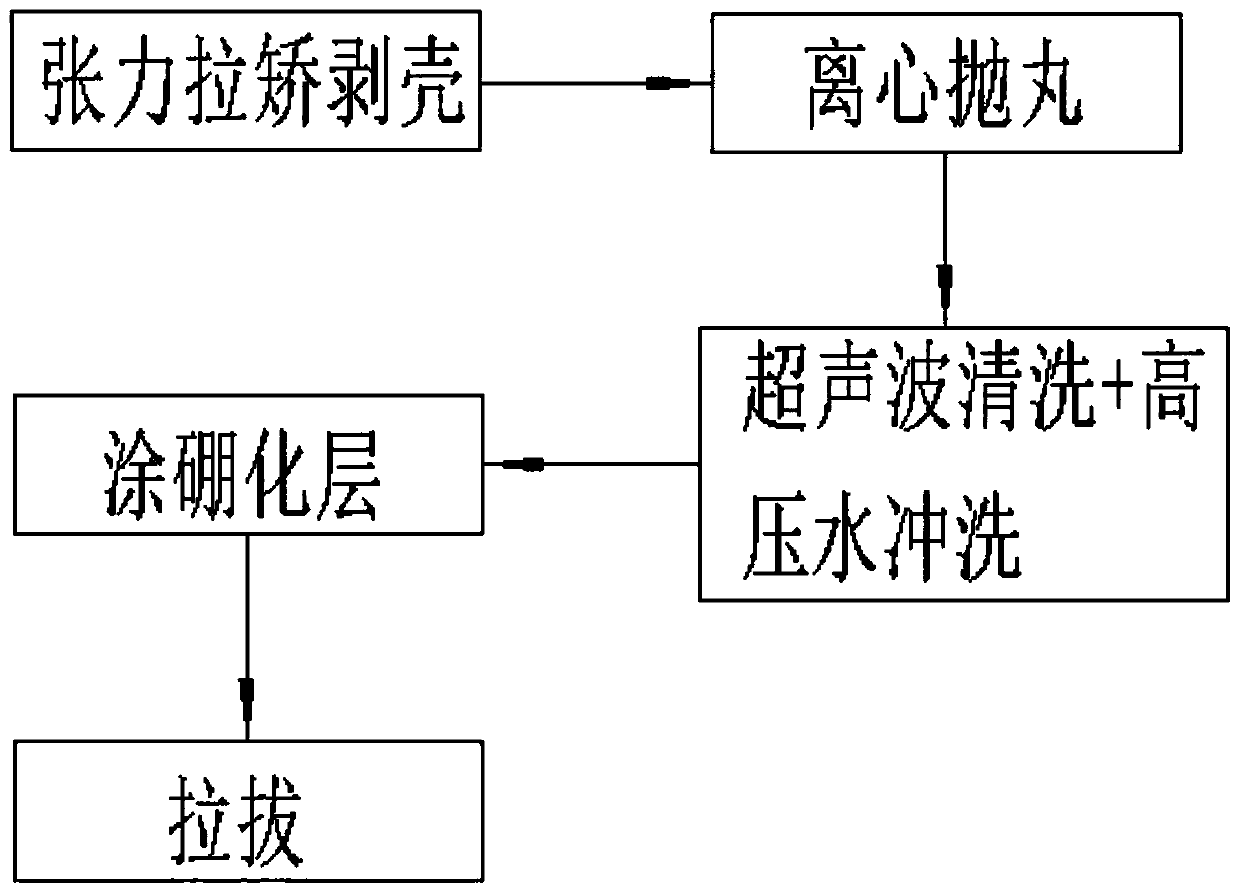

Wire rod pickling-free drawing production process

InactiveCN109940061AGuaranteed surface glossImprove drawing qualityExtrusion cleaning devicesReverse modeMegasonic cleaning

The invention discloses a wire rod steel wire rod pickling-free drawing production process, and belongs to the technical field of wire rod pickling-free drawing in steel strand production. According to the production process, an energy-saving and pollution-free production line is formed and a traditional pickling and phosphating production process is replaced by sequentially carrying out tension straightening and shelling, centrifugal shot blasting, ultrasonic cleaning, high-pressure water washing, boronizing layer coating and drawing, specifically, an oxide layer on the outer surface of the wire rod is effectively removed by using three five-roller centralized tension straightening machines simultaneously; in the process of centrifugal shot blasting, the surface of the wire rod achieves acorresponding glossiness level convenient for the boronizing layer coating by adopting a forward and reverse mode, a high speed mode and a high frequency mode; the wire rods preheated when the boronizing layer is coated, so that the production efficiency is greatly improved and the adsorption the surface of the wire rod to the boronizing liquid is enhanced; and the surface of the wire rod is quickly dried at high speed and high temperature in a direction perpendicular to the surface of the steel rod after coating, and the boronizing layer is prevented from absorbing water, so that the drawingquality is guaranteed.

Owner:安徽省力通稀土钢缆有限公司

Drawbench for carbon steel metal material

InactiveCN1994604ANot easy to wearImprove drawing qualityWire straightening devicesDrawing diesInduction heaterElectric machinery

The invention relates to a carbon steel wire drawer, wherein it comprises expand support, align machine, sensitive heater, drawer mould, collecting support, speed adjuster and large motor fixed from left to right on the frame; the large motor via speed adjuster, belt disc B, belt A, and belt disc A is connected to the collecting support; the mould box via roller, bearing is connected to the mould box; the small motor on the box via connector is connected to the mould box. The invention can make the force uniform on the mould hole and avoid groove on the mould hole, to improve product quality and reduce cost.

Owner:FUNDANT CHANGZHOU ADVANCED METAL TECH

Method for shortening natural aging of 82B wire rod

InactiveCN106011447AReduce occupancyShorten the aging period of wire rodFurnace typesMetallic material coating processesWire rodEngineering

The invention discloses a method for shortening the natural aging of a 82B wire rod. The method comprises the following steps: pickling a wire rod with gradient-concentration hydrochloric acid, wherein the pickling temperature reaches 30-50 DEG C, and the pickling time is 500-650 seconds; flushing with high-pressure water, and performing surface conditioning treatment; performing medium-temperature phosphorization in a phosphorization tank at 60-75 DEG C, wherein the phosphorization time is 200-260 seconds; putting the product in a high-temperature hot water tank at a temperature of over 85 DEG C, and staying for 70 seconds; and standing for 1-2 days for natural aging. The escape of hydrogen and the disappearance of residual stress can be accelerated, which is equivalent to artificial aging of the wire rod. In the invention, the aging period of the wire rod is greatly shortened, the mechanical properties of the wire rod are good, the problem in production turnover is solved, and the steel wire drawing quality is improved.

Owner:GUIZHOU WIRE ROPE

Body drawing visible method based on fractal

InactiveCN1932883AReduce computational complexityReduce time complexityImage codingComputer graphics (images)Large scale data

Owner:SHANGHAI JIAO TONG UNIV

Copper-clad aluminum conductor production process

The invention discloses a copper-clad aluminum conductor production process comprising the following processing steps of: 1, deoiling the aluminum conductor by soaking the aluminum conductor in a chemical solvent; 2, cleaning; 3, pickling the aluminum conductor in a pickling solution for activating; 4, pre-nickeling the aluminum conductor in a solution containing 5-30 g / L of nickel chlorite, 50-150 g / L of nickel aminosulfonate, 20-100 g / L of boric acid and additives; 5, cleaning; 6, coppering the pre-nickeled aluminum conductor in a solution containing 30-50 g / L of copper nitrate, hydroxy ethylidene diphosphate and additives at 25-40 DEG C and with current density of 2-5 A / dm<2>; 7, cleaning the aluminum conductor through clear water at 30-40 DEG C; and 8, winding and packaging the aluminum conductor. The copper-clad aluminum conductor production process disclosed by the invention is reasonable in process, the aluminum conductor is nickeled and coppered by the environmentally-friendly and non-pollution plating solutions, the plating combination strength of produced copper-clad aluminum conductors with various diameters is high, and the subsequent drawing quality of the conductors is good.

Owner:李振萍

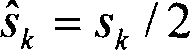

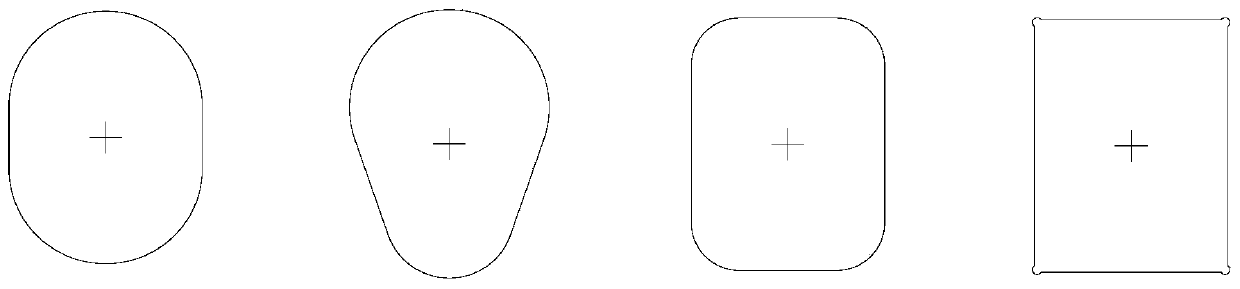

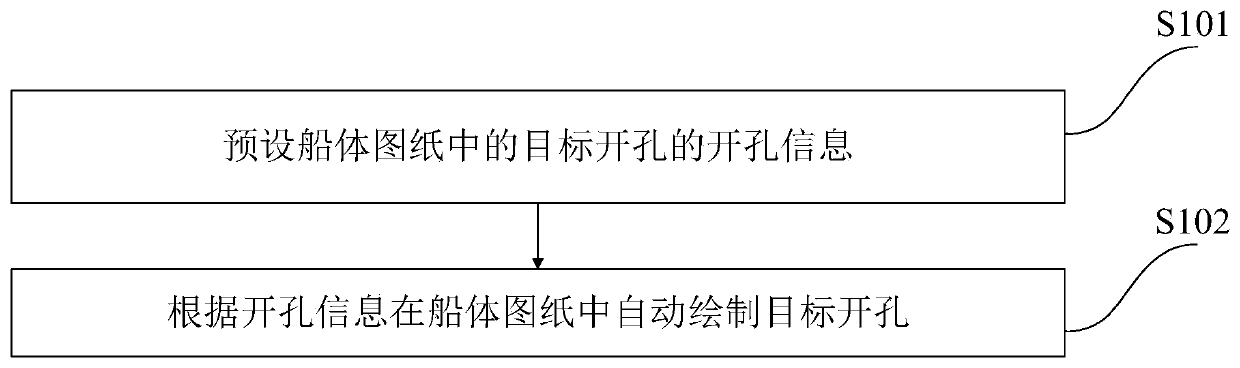

Automatic drawing method and system for open pores in hull drawing, equipment and storage medium

ActiveCN111523174AImprove drawing qualityReduce manual interventionGeometric CAD2D-image generationStructural engineeringMechanical engineering

The invention discloses an automatic drawing method and an automatic drawing system for open pores in a hull drawing, equipment and a storage medium. The automatic drawing method comprises the steps of: presetting open pore information of target open pores in the hull drawing; and automatically drawing the target open pores in the ship drawing according to the open pore information. According to the automatic drawing method, the open pore information of the target open pores in the hull drawing is preset, and the target open pores are automatically drawn in the hull drawing according to the open pore information; the target open pores are grouped and sequenced according to the open pore types and the open pore sizes, the open pores are numbered, and then open pore numbers are automaticallymarked at the centroid of the target open pores; meanwhile, an open pore detail table corresponding to the hull drawing is automatically generated according to the open pore types, the open pore sizes, the open pore codes and the open pore numbers, manual intervention in the existing open pore drawing process is reduced, the drawing efficiency is improved, the open pore drawing effect and numbermarking are more standardized, and the overall drawing quality of the hull drawing is improved.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Wire drawing machine for fastening part machining

The invention discloses a wire drawing machine for fastening part machining. The machine involves a ground, wherein the top of the ground is fixedly connected with a first supporting column and a second supporting seat through bolts, the first supporting column is located on one side of the second supporting seat, the top of the first supporting column and the top of the second supporting seat areprovided with a machine body, the interior of the machine body is fixedly connected with a driving motor through bolts, and one end of the driving motor is rotationally connected with a driving gearthrough a rotating shaft. According to the wire drawing machine for fastening part machining, a wire bunching barrel on one side of a bearing roller can be used for providing binding force for a wirebefore wire drawing, a spiral pipe is used for tensioning a cable, the cable is ensured to be in the tensioned state, the wire is ensured to be stably conveyed in the wire drawing process of a wire drawing machine, the problem that coiling of the wire is loose and not tight is avoided, the quality of wire drawing of the wire drawing machine is improved, the coiled wire can be scraped off from thebearing roller through a vertically-lifting inserting rod, automatic discharging is realized, and the trouble of manual discharging is reduced.

Owner:嘉兴金凌五金科技股份有限公司

Wire drawing machine and machining method thereof

PendingCN107414640AEnough tensionGuaranteed drawing effectGrinding drivesBelt grinding machinesEngineeringMachine

The invention provides a wire drawing machine and a machining method thereof. The wire drawing machine comprises a machine frame, a first driving mechanism, a second driving mechanism, a plurality of roll shafts, a wire drawing belt, a downward pressing device and a fixture device. The first driving mechanism and the second driving mechanism are fixedly connected with the machine frame. The first roll shaft is connected with the machine frame, and the first driving mechanism drives the first roll shaft to rotate. The second roll shaft is rotationally connected with the second driving mechanism, and the second driving mechanism drives the second roll shaft to move in the axial direction of the second driving mechanism. The third roll shaft is connected with the machine frame. The wire drawing belt is wound on the multiple roll shafts. The downward pressing device comprises a third driving mechanism and a downward pressing assembly. The fixture device comprises a tool fixture, the tool fixture and the downward pressing assembly are located on the two sides of the wire drawing belt correspondingly, the tool fixture is opposite to the downward pressing assembly, and the third driving mechanism drives the downward pressing assembly to push the wire drawing belt towards the tool fixture. The invention further provides the machining method of the wire drawing machine. The wire drawing machine and the machining method thereof have the advantages of being good in wire drawing effect and high in wire drawing quality and wire drawing efficiency.

Owner:珠海桑贝思精密科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com