Optical fiber annealing extending pipe

An extension tube and annealing technology, which is applied in manufacturing tools, glass manufacturing equipment, glass production, etc., can solve the problems of reducing the strength of optical fibers, affecting gas flow, and affecting the quality of optical fibers, so as to reduce fiber breakage rate, improve production efficiency, and improve The effect of brushed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

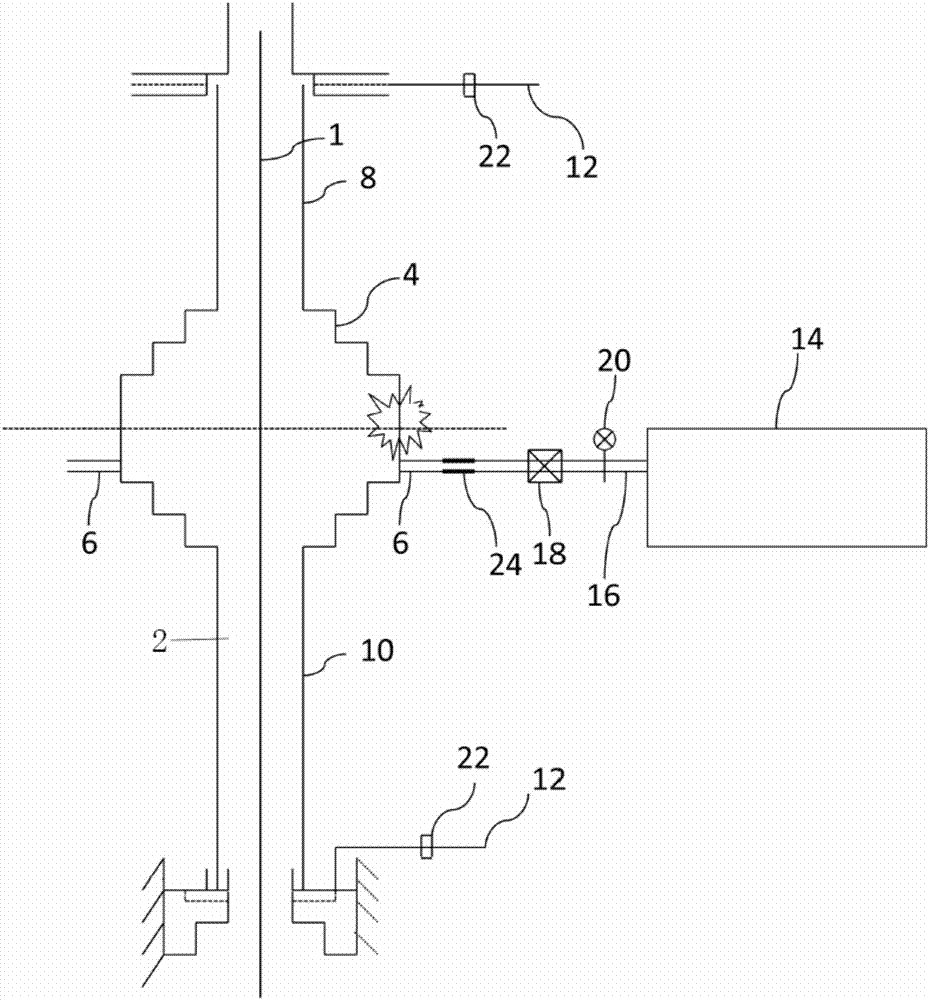

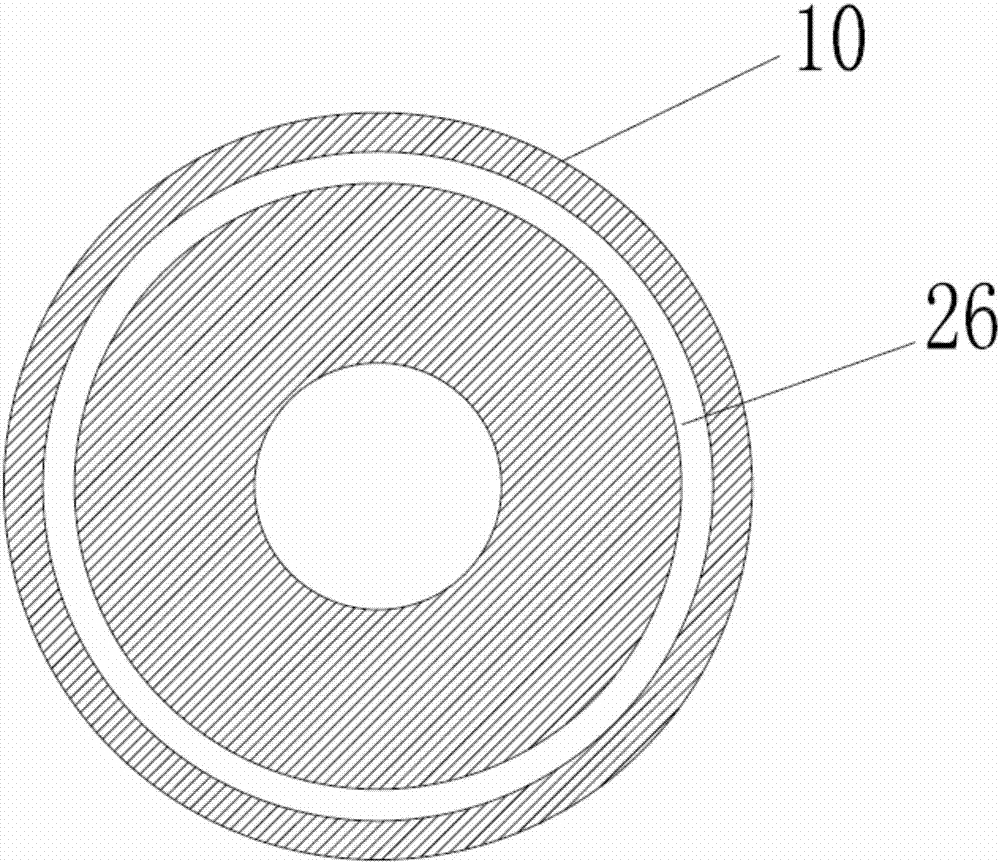

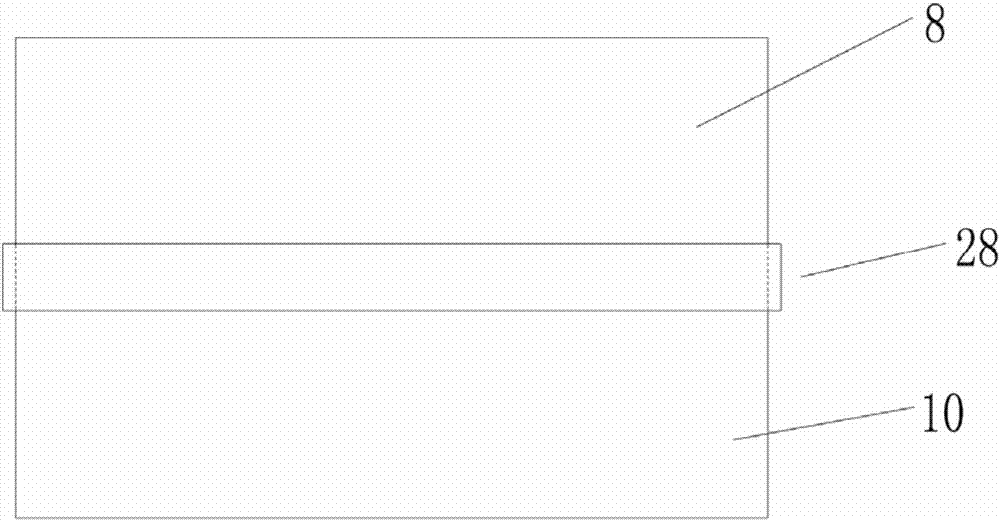

[0029] Such as figure 1 As shown, this embodiment discloses an optical fiber annealing extension tube, which includes a quartz main tube 2, which is connected to the drawing furnace. When in use, the optical fiber 1 passes through the central axis hole in the quartz main tube 2, and the above-mentioned reducing tube section 4 A quartz branch pipe 6 is connected to the top, and the above-mentioned quartz branch pipe 6 is connected to the maximum pipe diameter of the variable diameter pipe section 4. The above-mentioned quartz branch pipe 4 communicates with the quartz main pipe 2, and the other end of the above-mentioned quartz branch pipe 6 is connected with a negative pressure suction device; In the technical solution of the invention, the central part of the above-mentioned quartz main pipe 2 in the axial direction is a variable-diameter pipe section 4, and the pipe diameters of the above-mentioned quartz main pipe 2 located on both sides of the variable-diameter pipe section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com