Patents

Literature

420 results about "Bare fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structured fiber optic cassette with multi-furcated cable access

ActiveUS7747125B1Space minimizationCable retention force consistent and easy for fiber routing/reworkCoupling light guidesFiberAdhesive

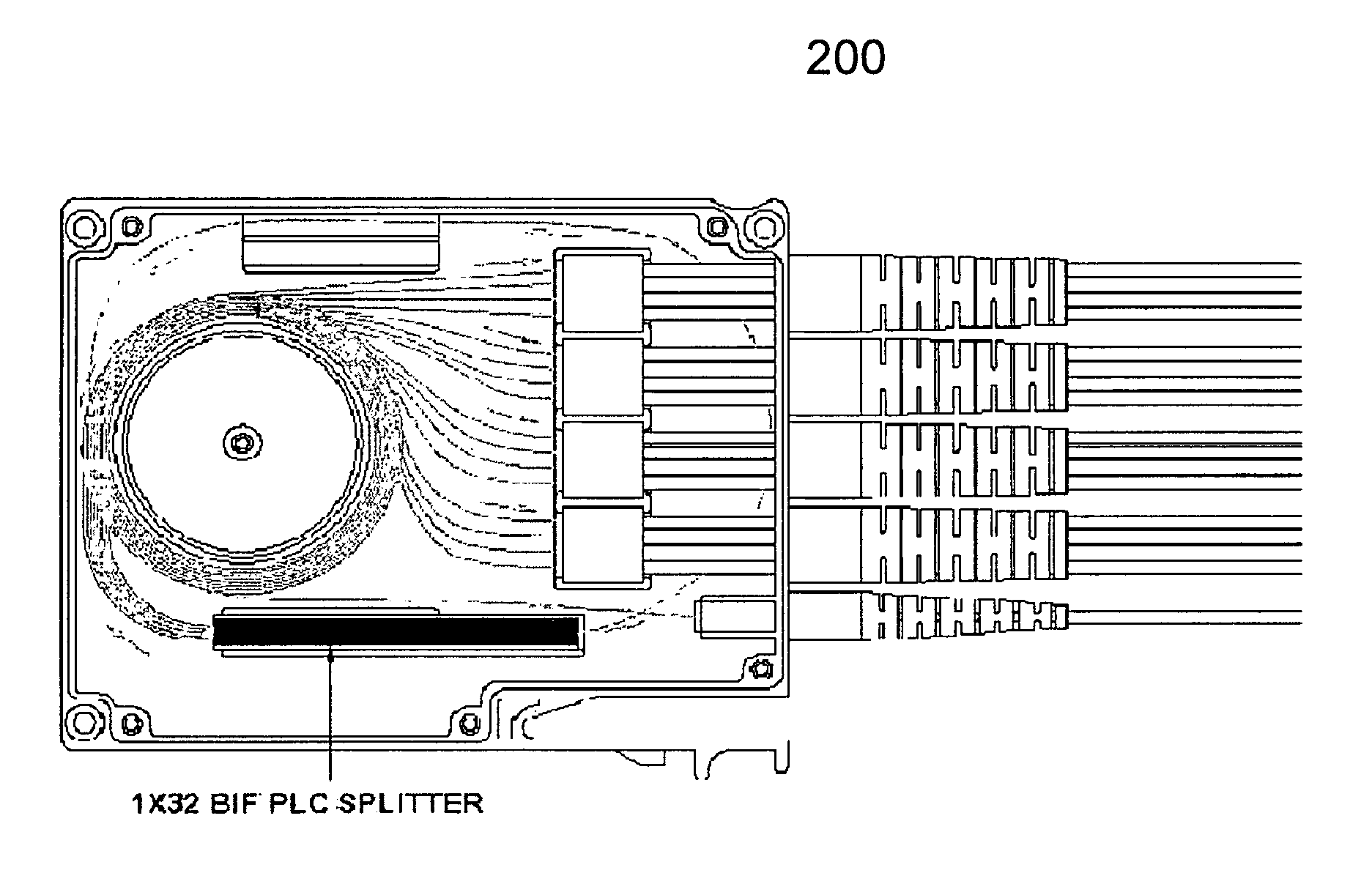

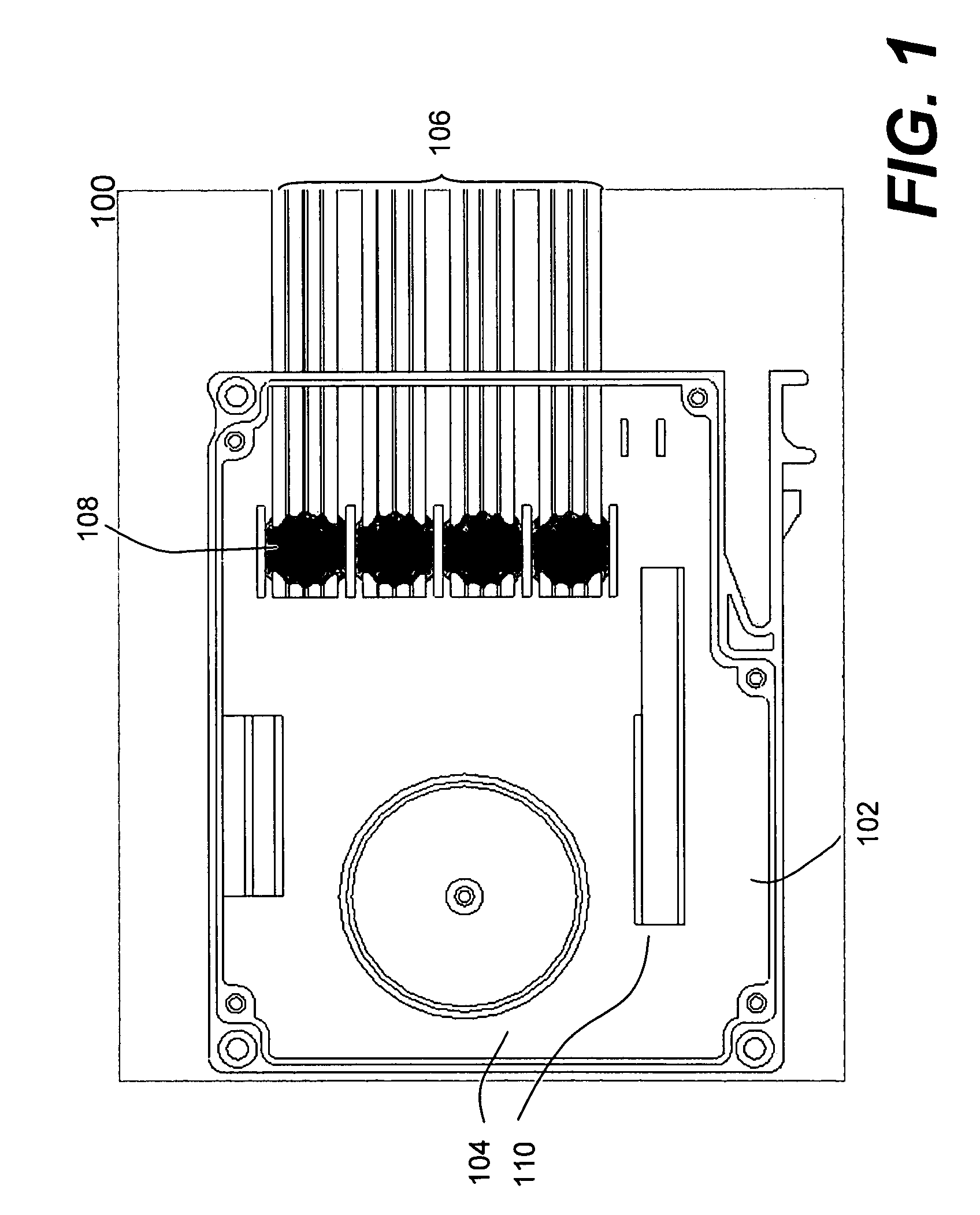

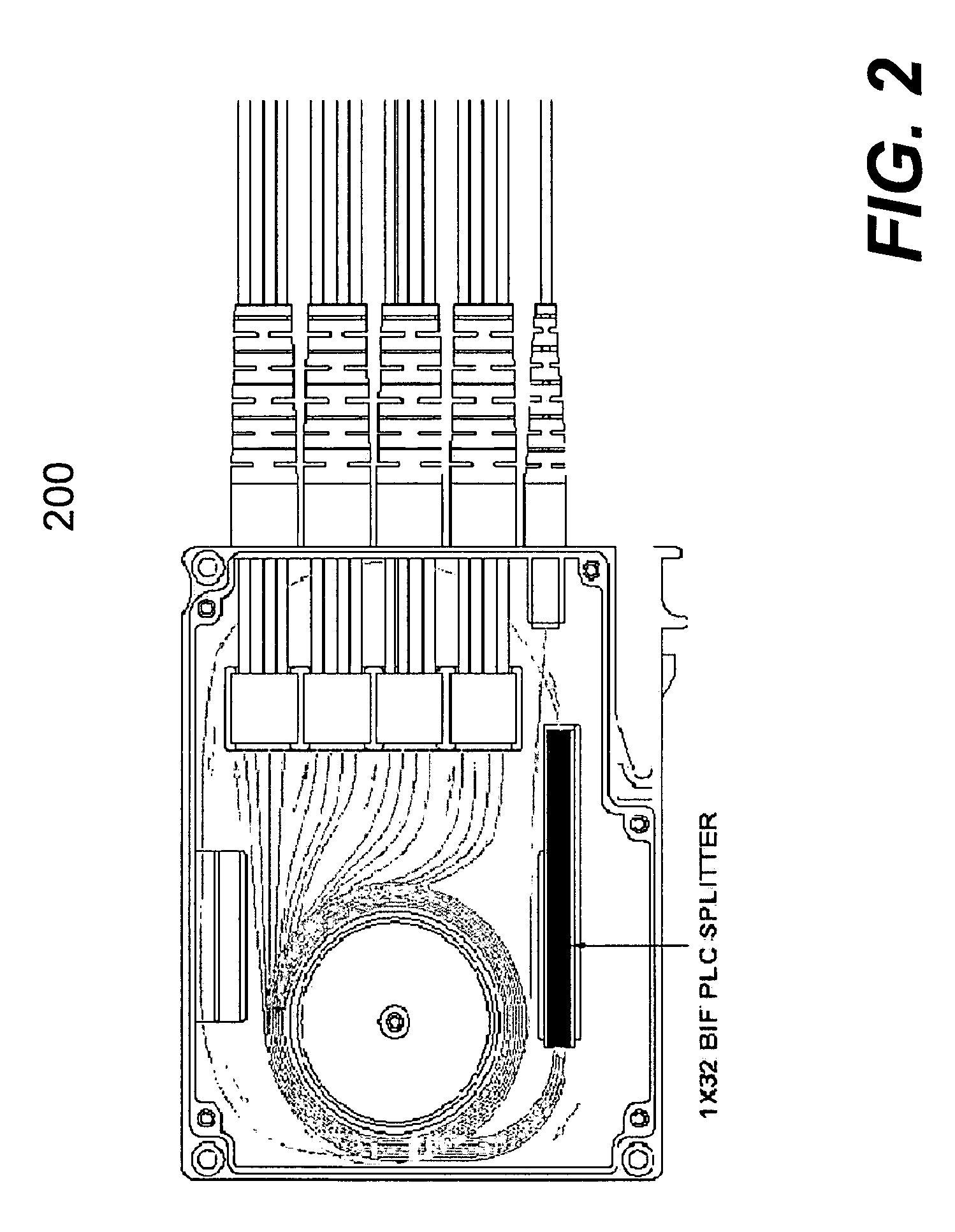

To minimize the space requirement inside a cassette and make cable retention force consistent and easy for fiber routing / rework, a cassette includes a cassette base molded to include a plurality of holders, a cassette cover to close the cassette base, and a plurality of blocks, respectively disposed into the holders, each of the blocks including one or more holes to accommodate one or more fiber cables. The fiber cables are fixed in the holes using a type of adhesive. In addition, bare fibers are placed inside the cassette to communicate respectively with the fiber cables.

Owner:CORNING OPTICAL COMM LLC

Fiber grating strain and temperature simultaneously measuring sensor

InactiveCN101539403AHighly integratedHigh precisionThermometers using physical/chemical changesUsing optical meansFiberGrating

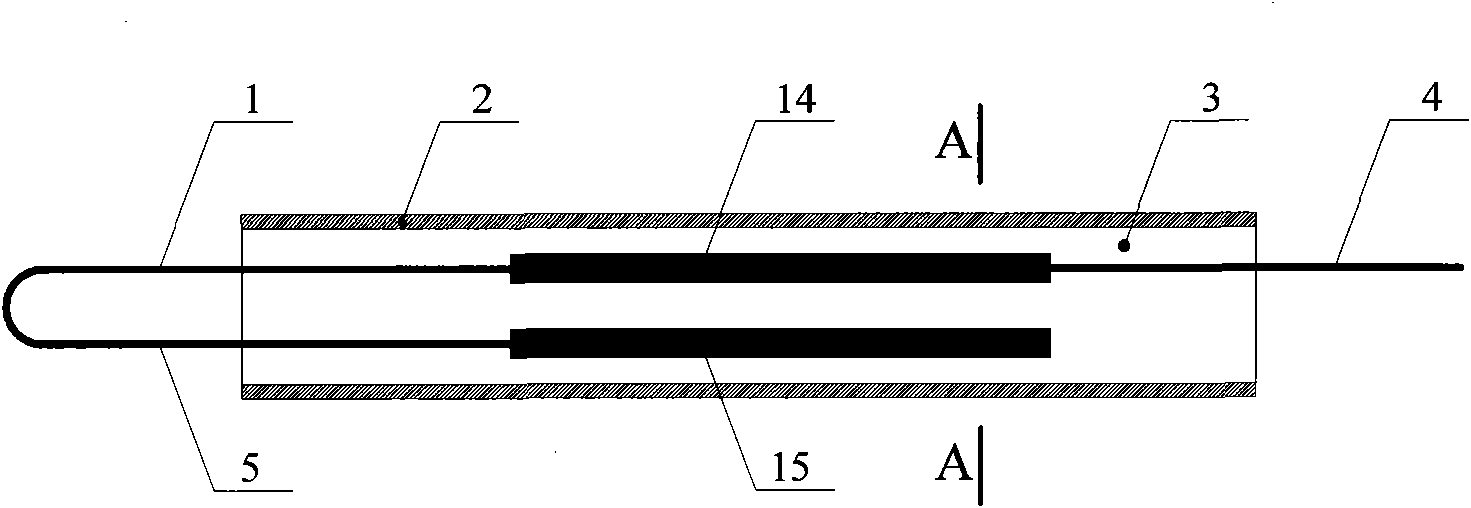

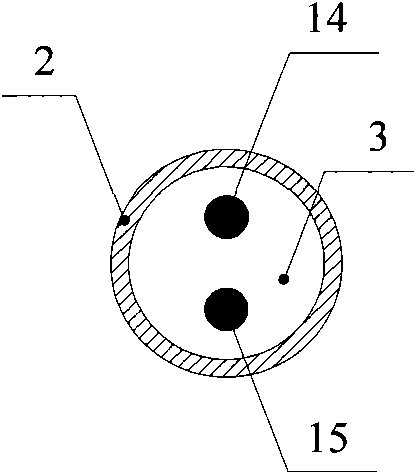

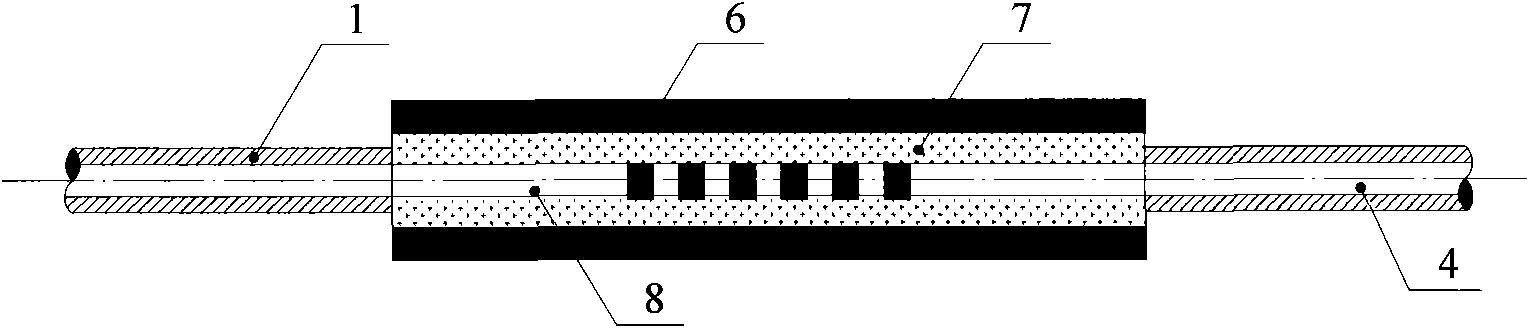

The invention relates to a fiber grating strain and temperature simultaneously measuring sensor. A fiber grating strain sensor is formed by utilizing a second stainless steel pipe to package bare fiber grating, a fiber grating temperature sensor is formed by utilizing a metal pipe to package bare fiber grating, and the fiber grating strain sensor and the fiber grating temperature sensor are packaged in parallel in a first stainless steel pipe by adopting epoxide resin. When the sensor is arranged on an engineering structure, the first stainless steel pipe produces the distortion and transmits the temperature and the strain of the structure to the fiber grating strain sensor at the inner part and the fiber grating temperature sensor without strain influence through the epoxide resin, the measuring value of the strain sensor is compensated by the temperature sensor so as to achieve the simultaneous measurement of the strain and the temperature of the structure.

Owner:SOUTHEAST UNIV

Methods for centering optical fibers inside a connector ferrule and optical fiber connector

Owner:CORNING OPTICAL COMM LLC

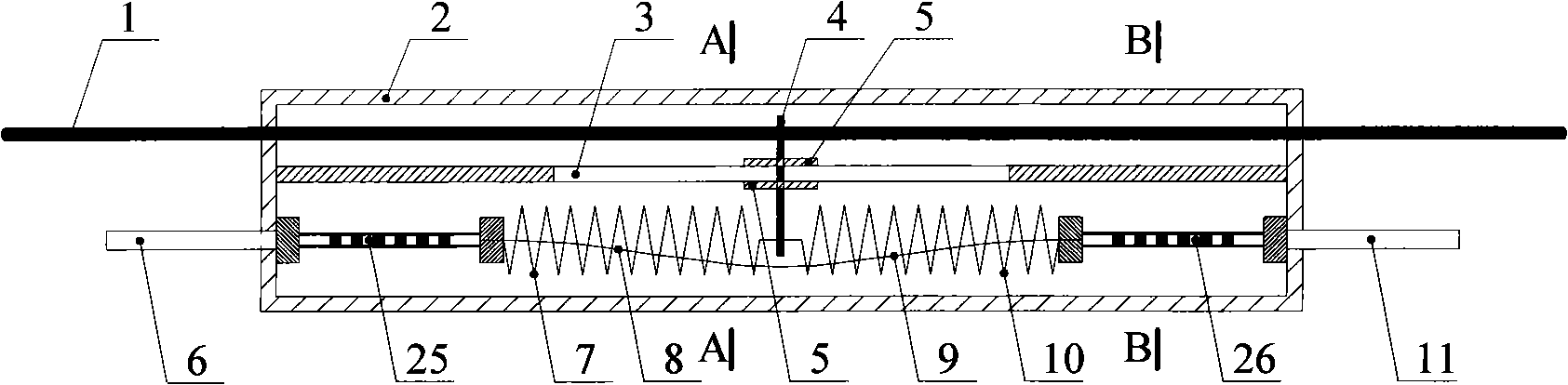

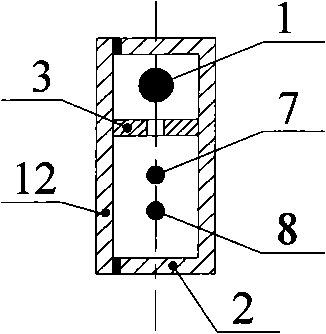

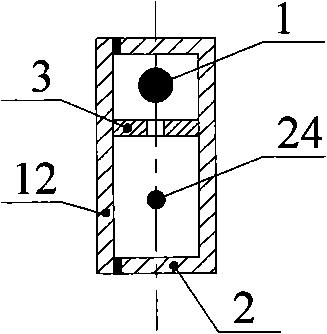

Temperature self-compensation fiber grating displacement sensor

InactiveCN101526339AWith temperature self-compensation functionImprove performanceThermometers using physical/chemical changesUsing optical meansFiberGrating

The invention provides a temperature self-compensation fiber grating displacement sensor which has a structure that two bare fiber gratings which are encapsulated by capillary metal tubes are connected with a probe through a metal connecting block, a spring and a centre rod to form a main body of the temperature self-compensation fiber grating displacement sensor to execute functions; then the main body is arranged in a metal box; finally, the end parts of the capillary metal tubes are fixed with the metal box through the metal connecting block, fibers penetrate out from small holes positioned on the metal connecting block and the lateral wall of the metal box, and the probe can freely stretch through a guide rod hole of the metal box. When a displacement sensor is arranged on the structure, the probe and the metal box relatively move to enable the bare fiber gratings to extend or shorten so as to generate the drift of the operating wavelength of the bare fiber gratings when the structure generates displacement, and the displacement and the temperature of the structure can be tested by utilizing a temperature compensation principle and a displacement computing formula of the displacement sensor.

Owner:SOUTHEAST UNIV

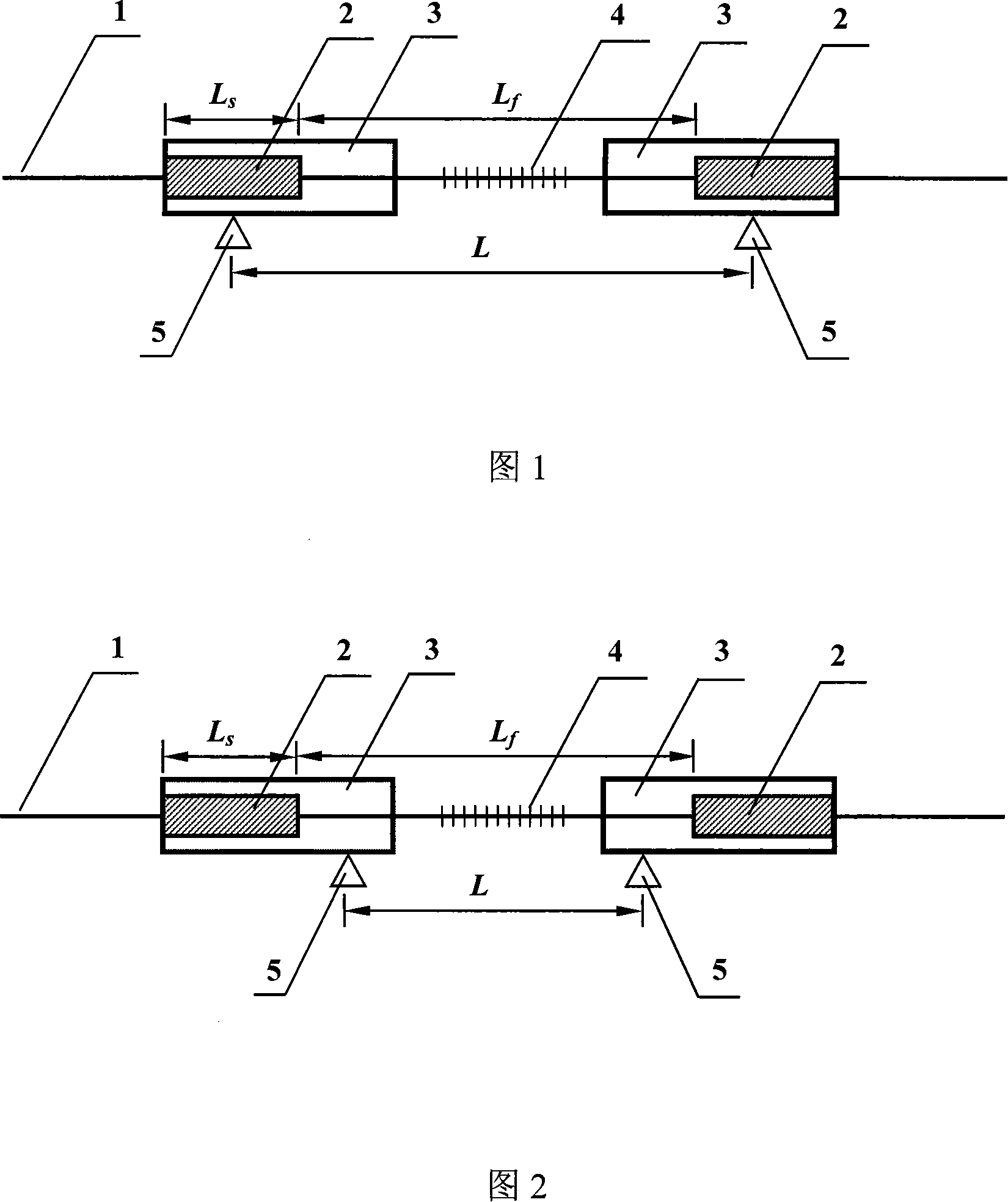

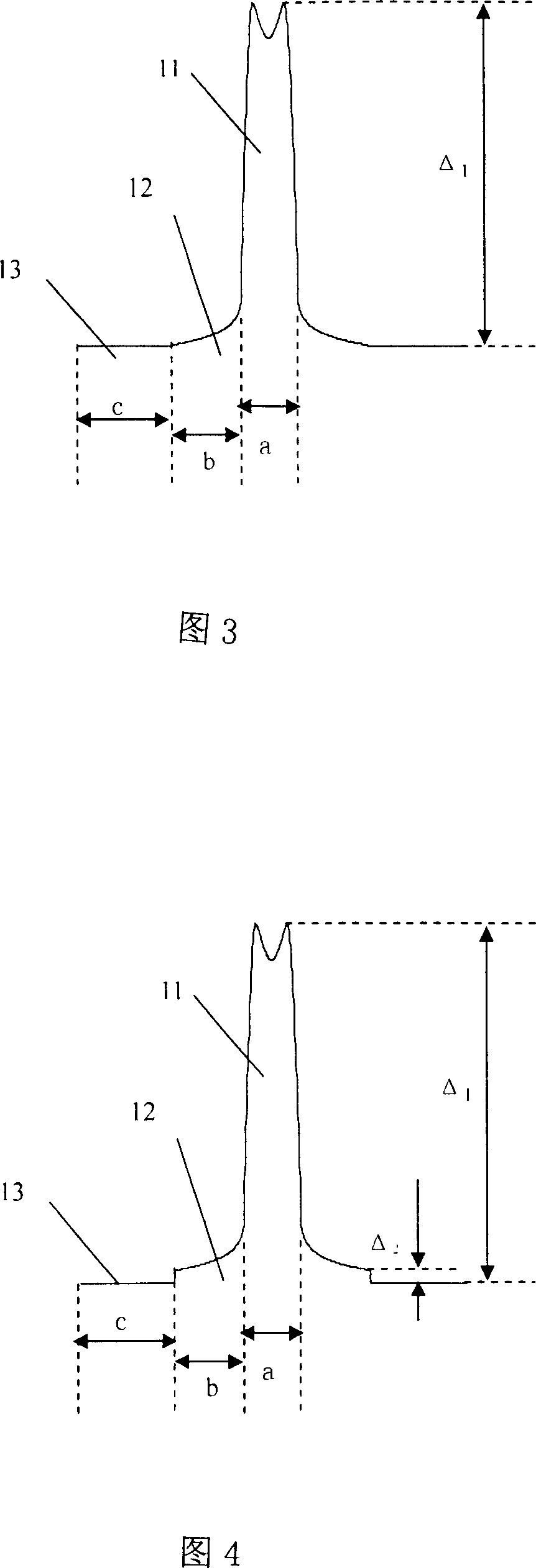

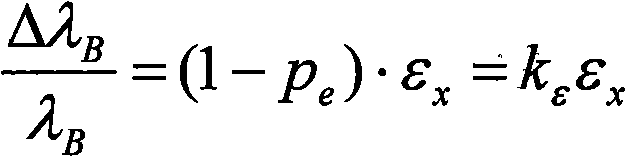

Encapsulation method for optical fibre grating add-and-subtract quick strain sensor

The invention provides a packaging method for a fiber grating sensitivity-increasing / decreasing strain sensor, belonging to the sensing technology field, which comprises a sensitivity-increasing / decreasing theory for the fiber grating strain sensor, a formula for sensitivity-increasing / decreasing coefficients, a sensor structure and a packaging method. The packaging method for a fiber grating strain sensor not only effectively protects the bare fiber grating, but also can change the strain sensitivity of the fiber grating; the sensitivity-increasing / decreasing coefficients can be customized according to the dimensions of the packaging materials in order to meet the requirements of different measurement. The invention has the advantages of that the fiber grating strain sensor based on the packaging method provides the monitoring means of large strain range and high measurement accuracy for the surface and internal strain measurement of large engineering structures.

Owner:DALIAN UNIV OF TECH

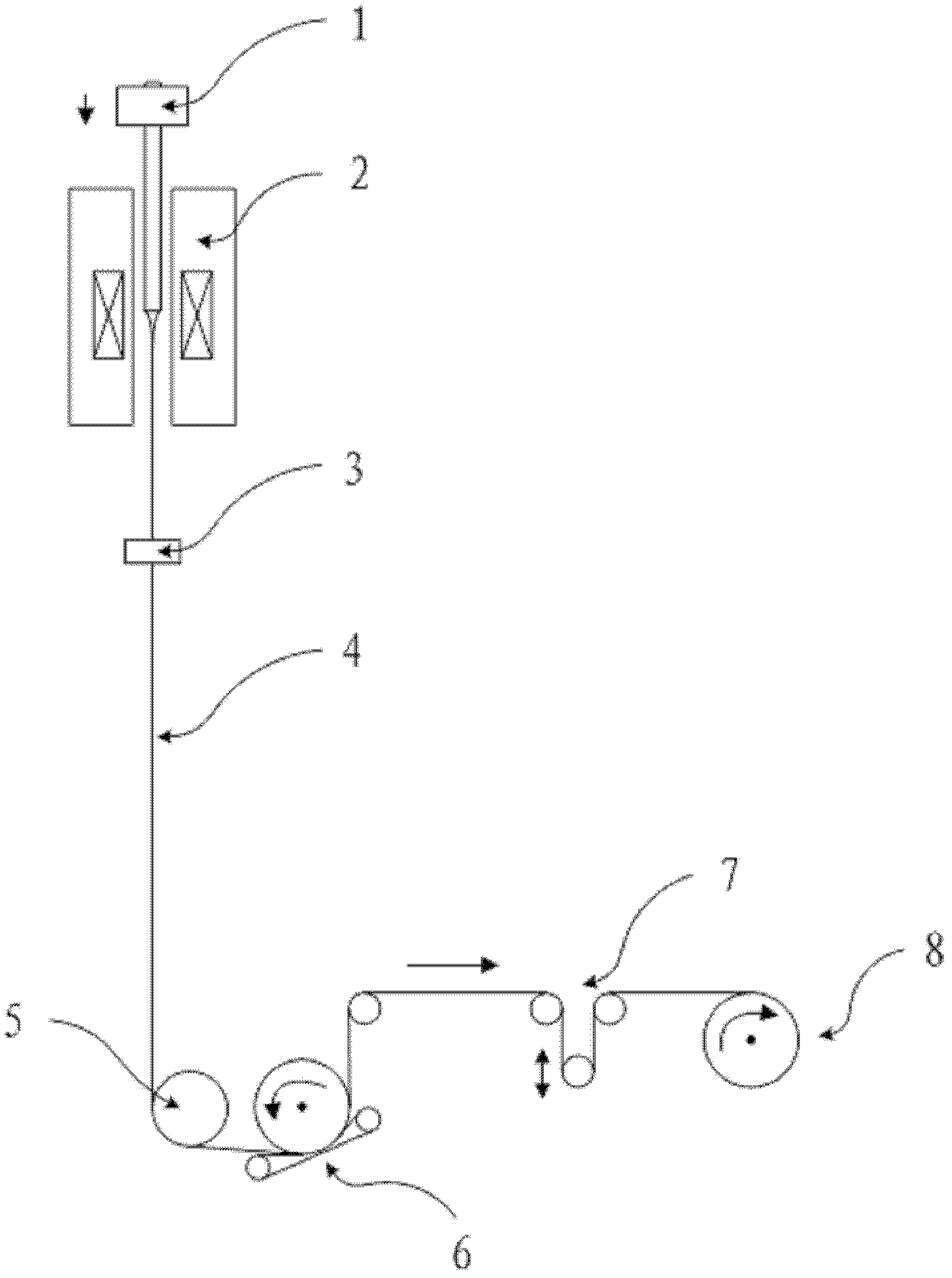

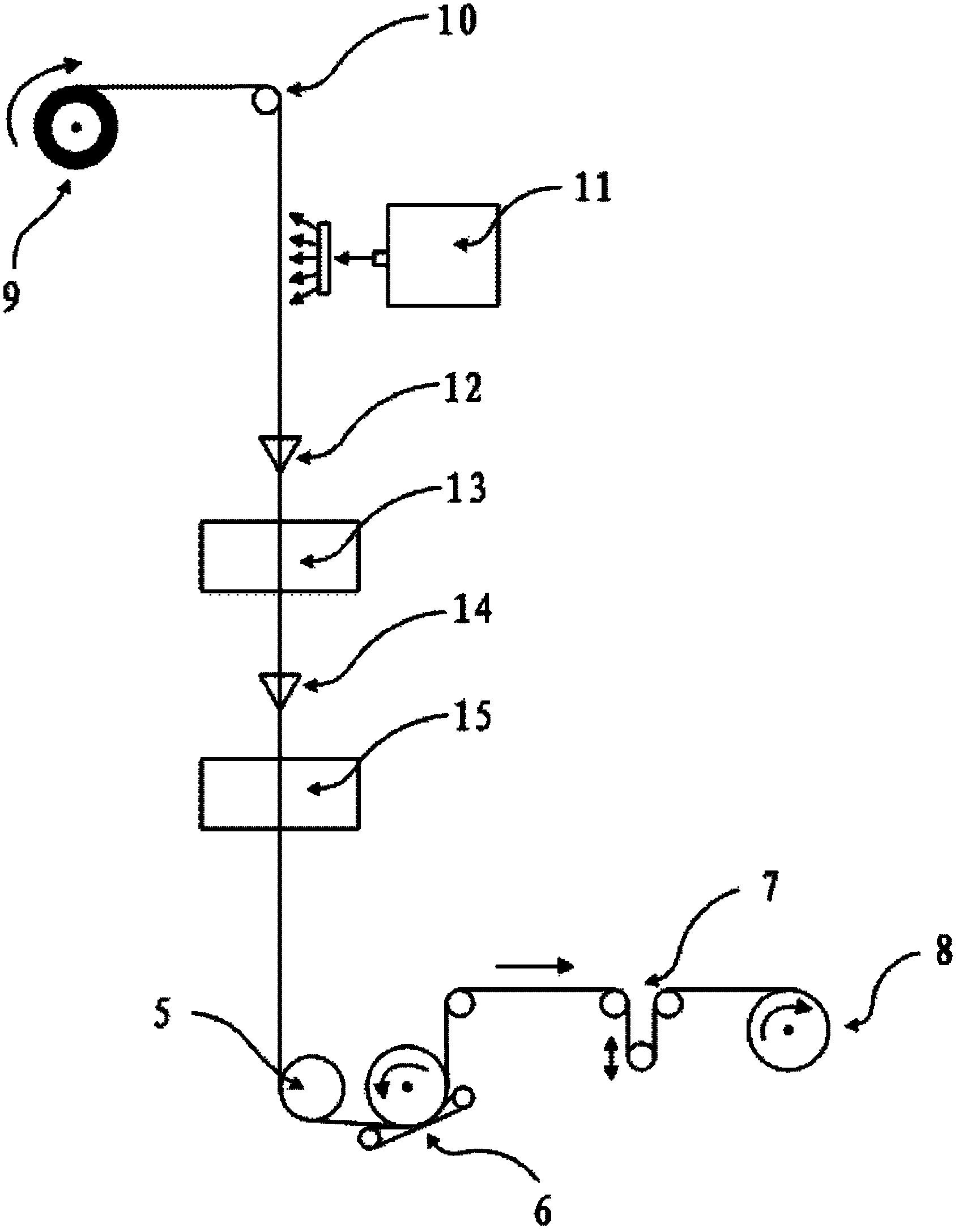

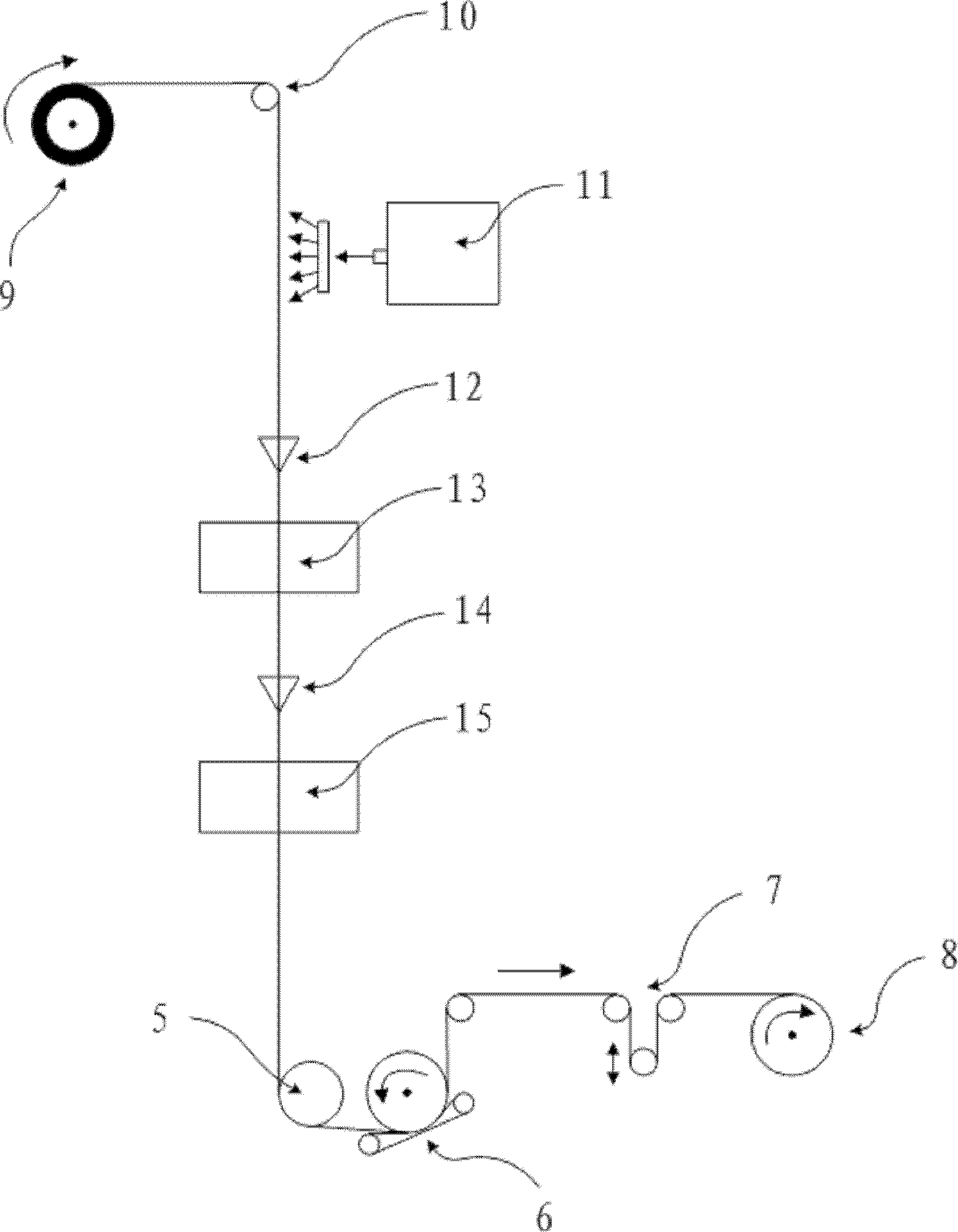

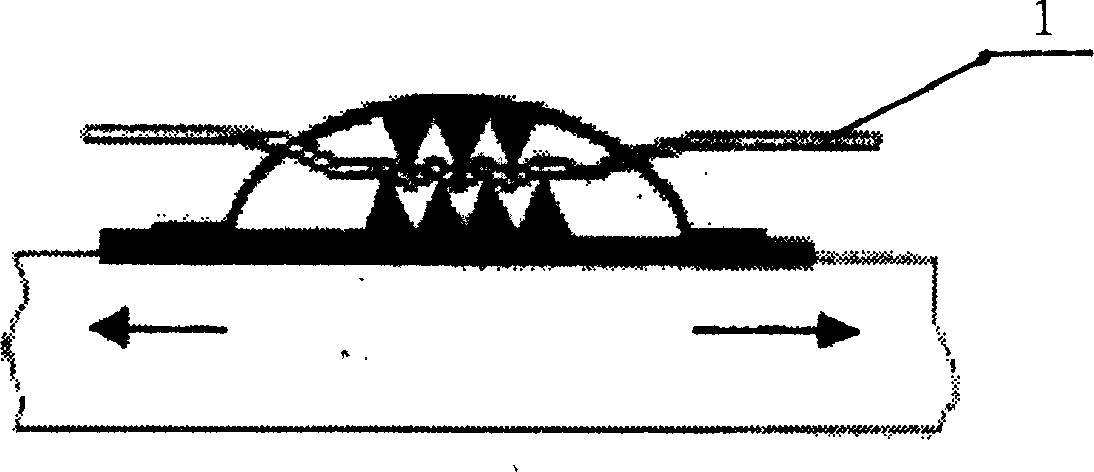

Preparation method of fiber grating

ActiveCN104678486AImprove consistencyThe process is reasonable and simpleCladded optical fibreOptical waveguide light guideGratingBare fiber

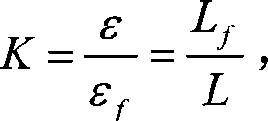

The invention relates to a preparation method of a fiber grating. The preparation method comprises the following steps: clamping a quartz glass matrix optical fiber performing bar on an optical fiber drawing tower to be molten and drawn, performing grating writing on the continuously descending bare fiber, coating the bare fiber with a coating, and performing ultraviolet curing, and at last reeling through a take-up reel, wherein the preparation method is characterized in that the grating writing adopts a phase-mask technique and uses a 193 nm excimer laser to perform monopulse exposure to write the bare fiber in the grating. The preparation method disclosed by the invention can be used for dynamically and continuously preparing the fiber grating array online, is simple, convenient and reasonable in process, and high in manufacturing efficiency; the grating written by the phase-mask technique and the 193 nm excimer laser is stable in central wavelength, good in spectral form, and high in consistency of grating reflectivity; the method can be used for preparing the high-quality grating array and solves the problems that the grating prepared by the fiber drawing tower online is poor in stability, low in reliability, poor in grating quality and low in efficiency; the prepared fiber grating array can be used for long-distance detection and signal transmission.

Owner:武汉烽理光电技术有限公司

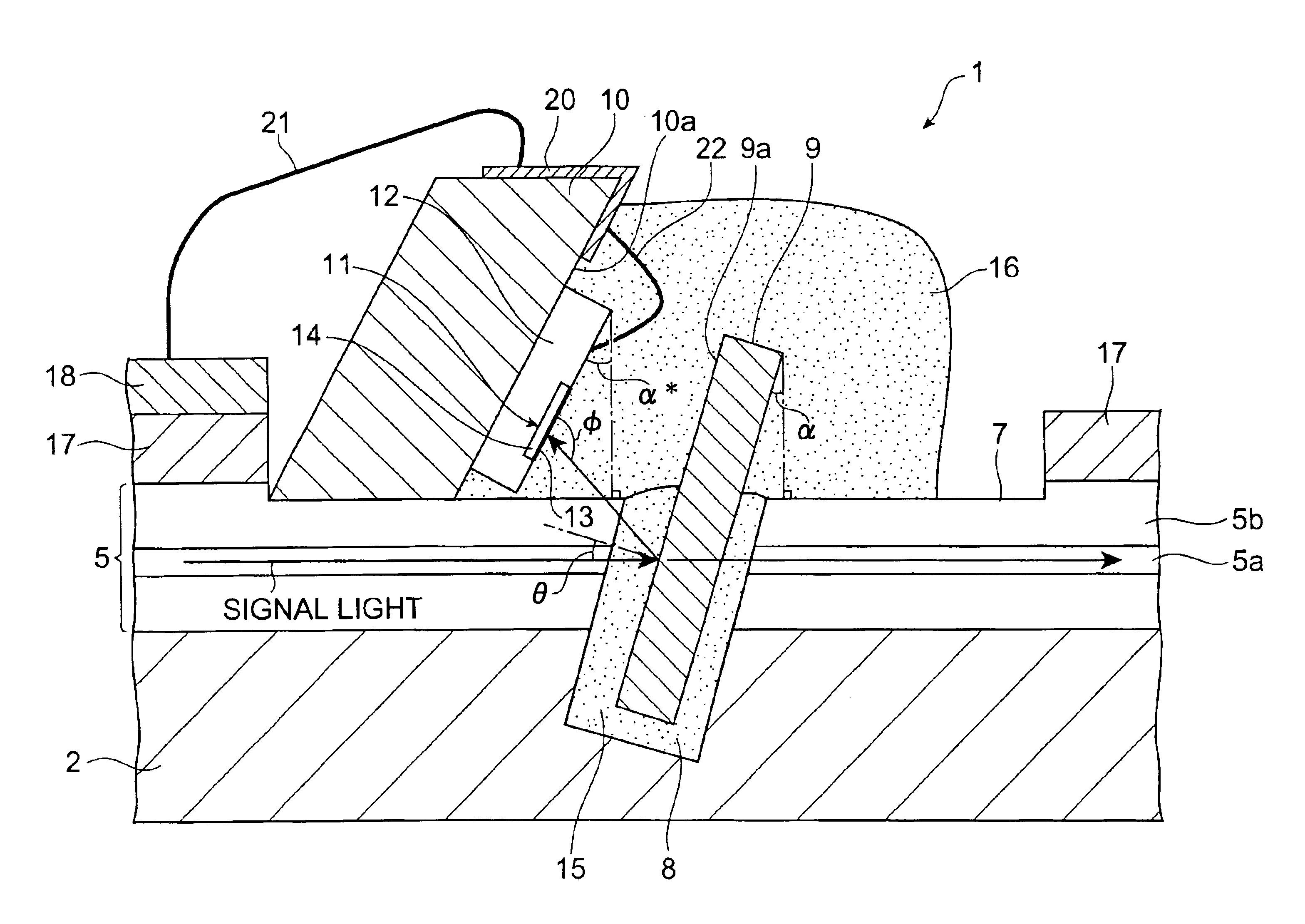

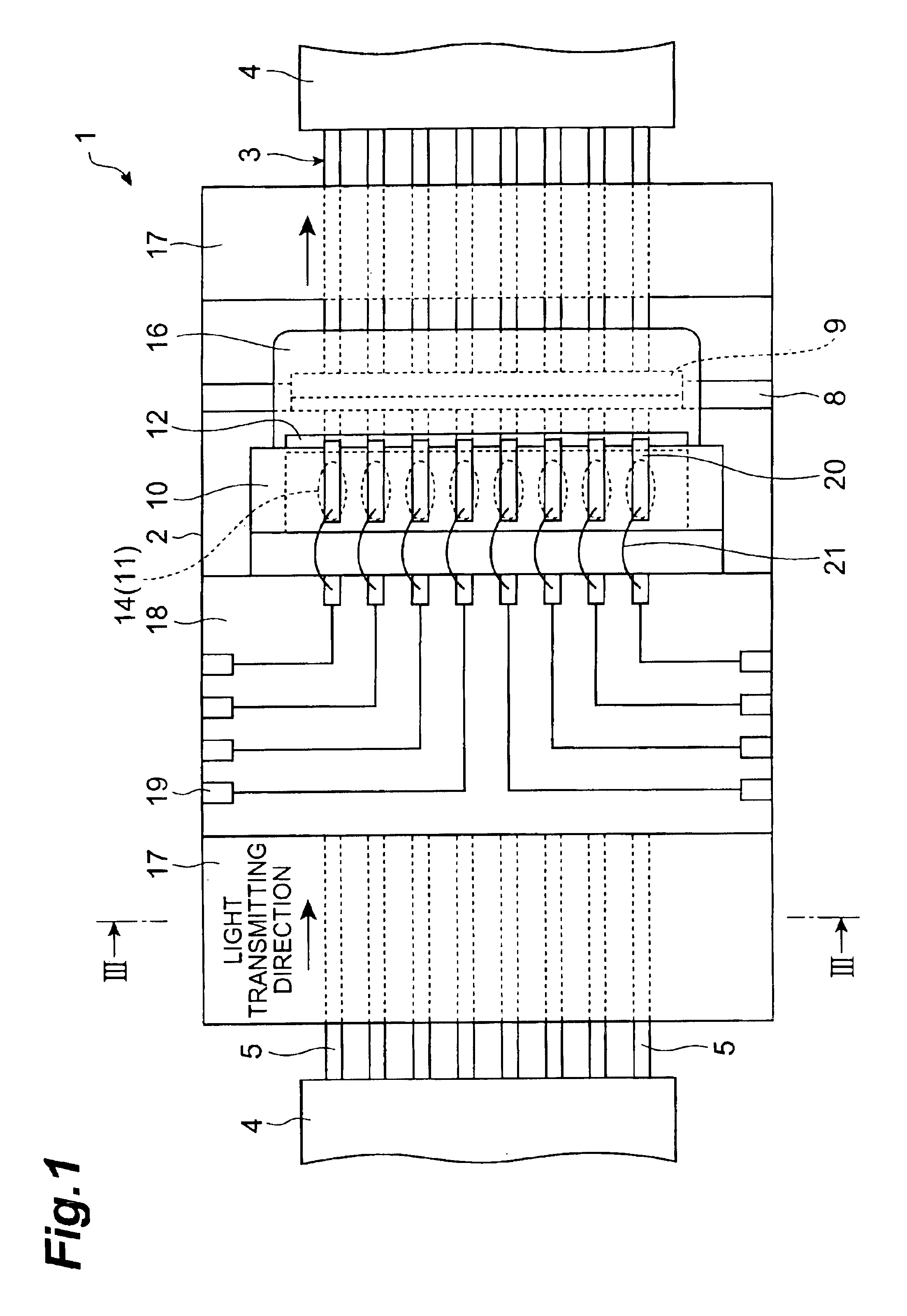

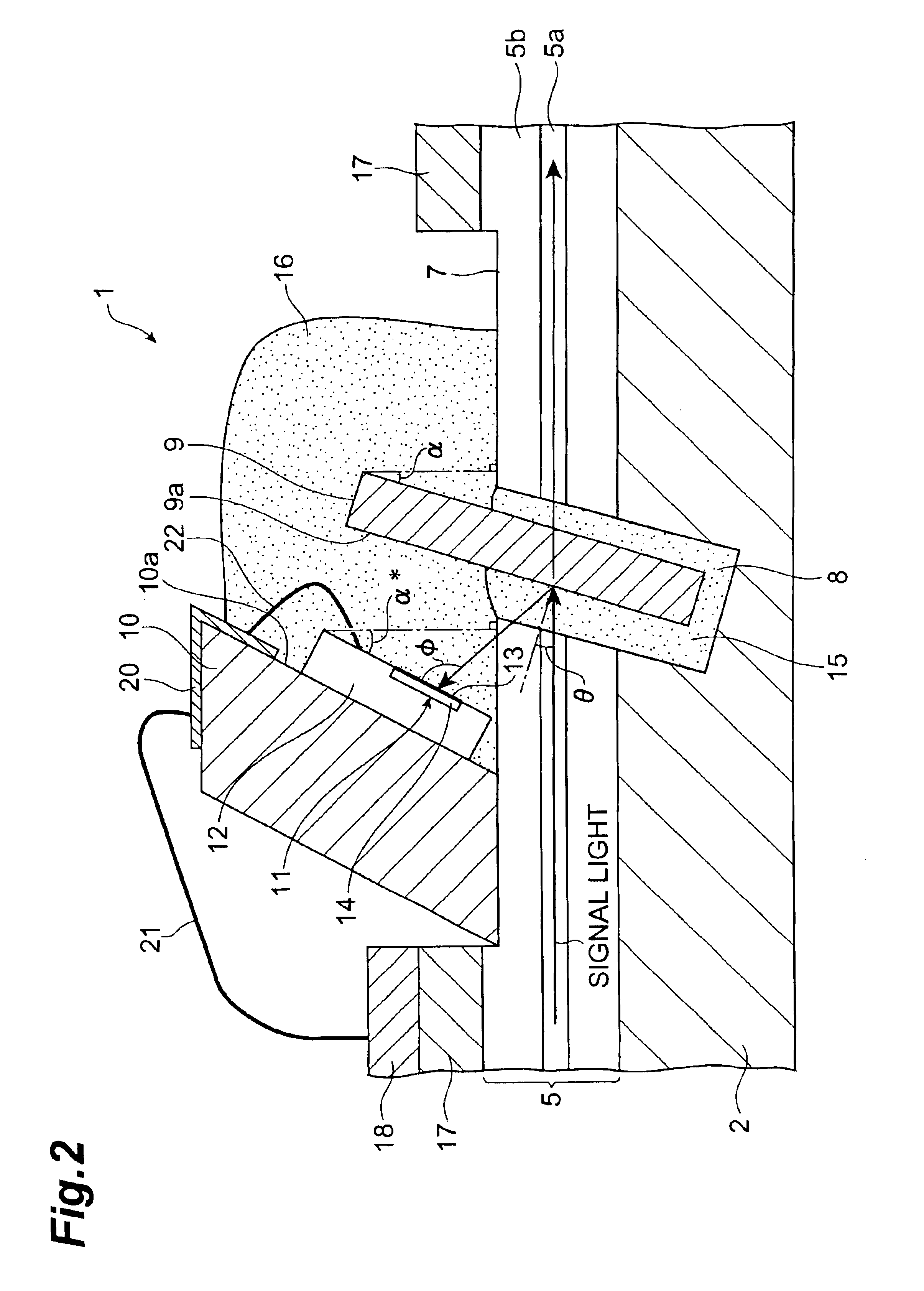

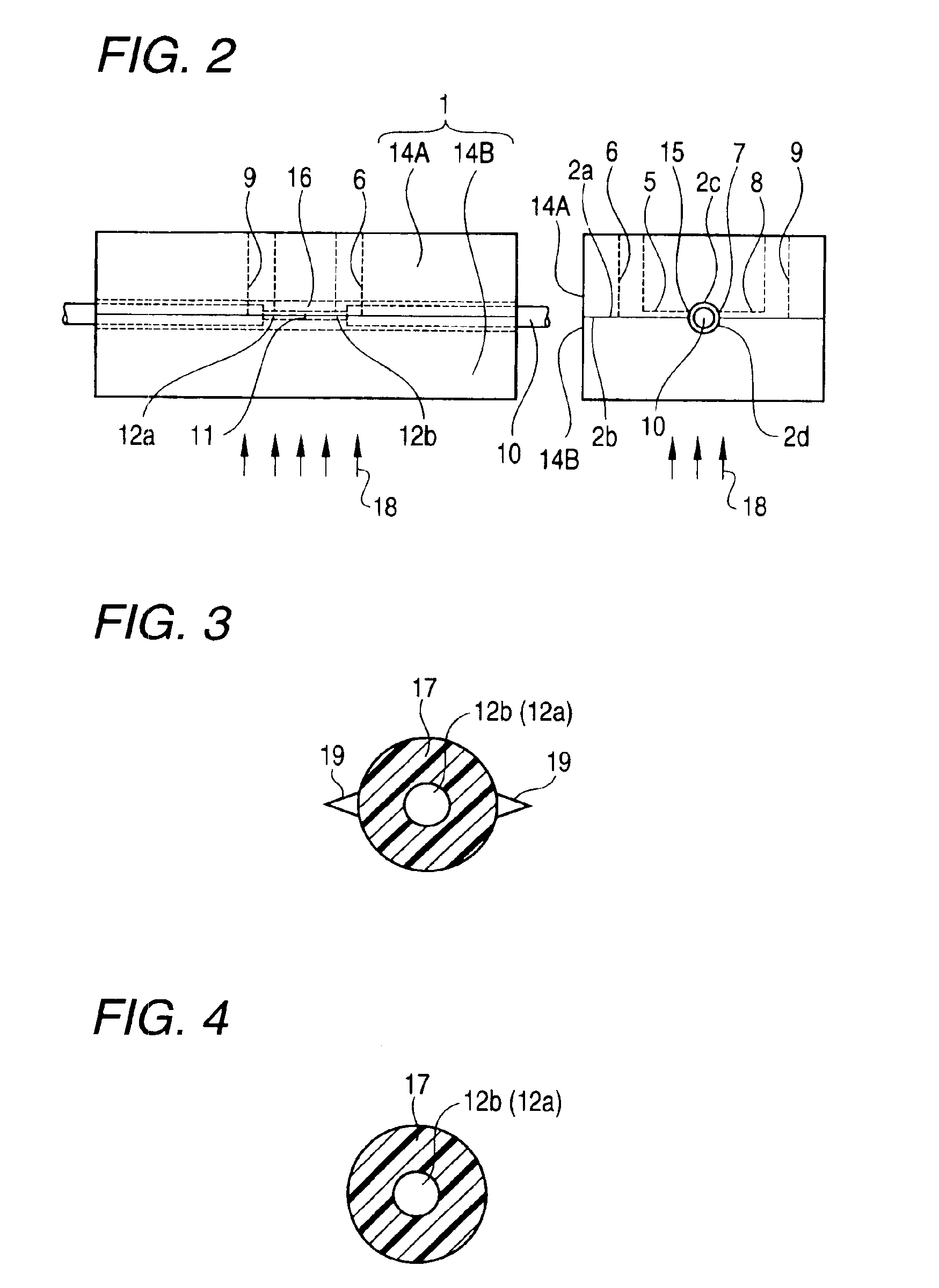

Optical device

InactiveUS6850674B2Deterioration of characteristicCheap to achieveLaser detailsCoupling light guidesPhotovoltaic detectorsPhotodetector

An optical device 1 has a substrate 2, whereas bare fibers 5 exposed from a coated optical fiber tape 3 by removing a coating 4 from its middle part are secured to the upper face part of the substrate 2. In the substrate 2, a transverse groove 8 is formed obliquely with respect to an axis of the bare fibers 5 so as to traverse core parts 5a of the bare fibers. An optical member 9 for reflecting a part of signal light transmitted through the bare fibers 5 is inserted in the transverse groove 8. A support member 10 is provided on the upper side of the bare fibers 5, whereas a support surface 10a of the support member 10 is provided with photodetectors 11 for detecting light reflected by the optical member 9. The support surface 10a of the support member 10 is inclined with respect to the upper face of the substrate 2, whereby the light entrance surface 13 of each photodetector 11 is inclined by a predetermined angle with respect to the upper face of the substrate 2. Such a configuration realizes an optical device which can lower the polarization dependence of received light in the photodetectors.

Owner:SUMITOMO ELECTRIC IND LTD

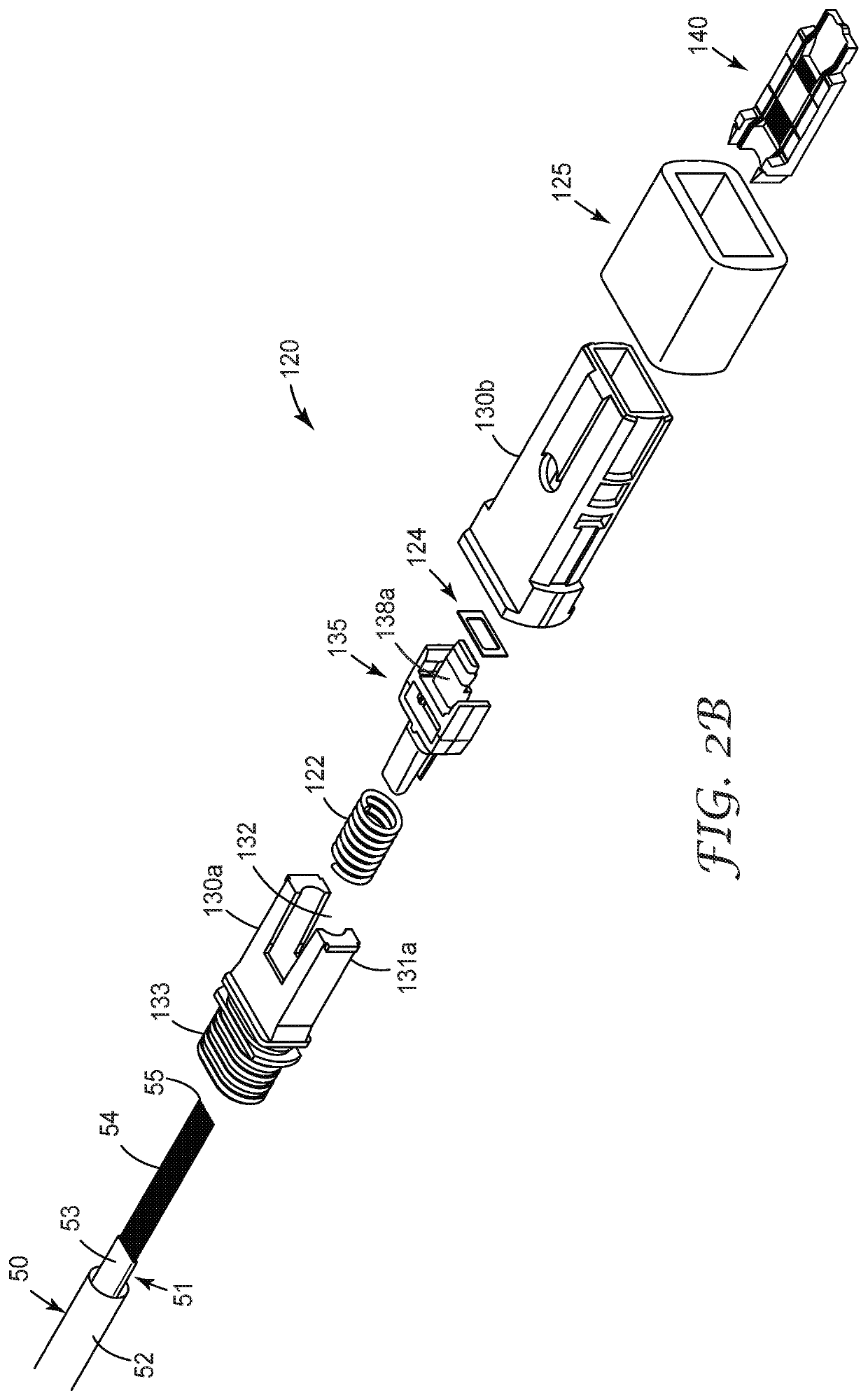

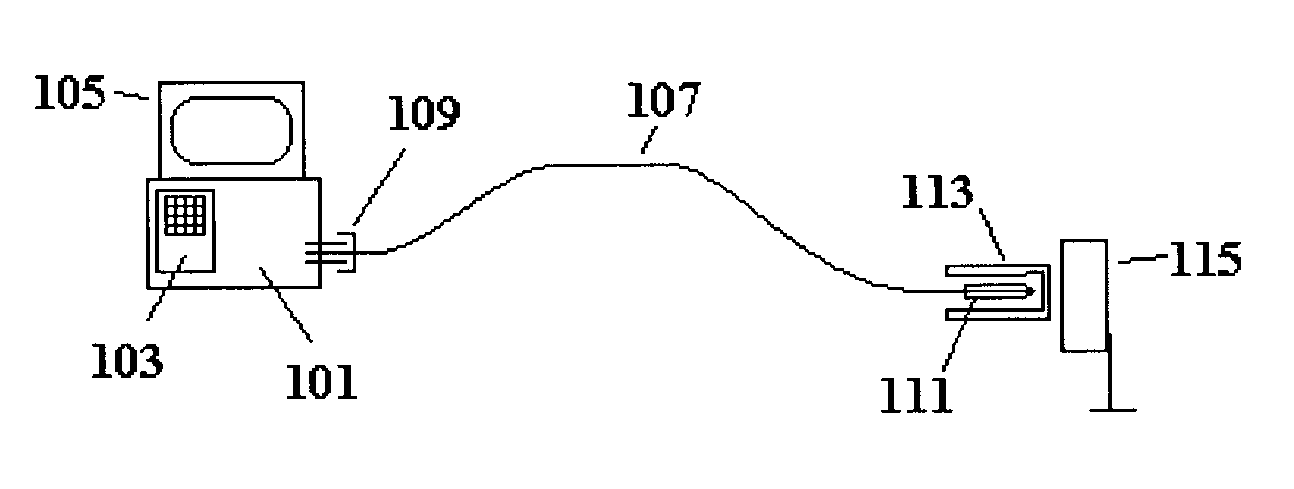

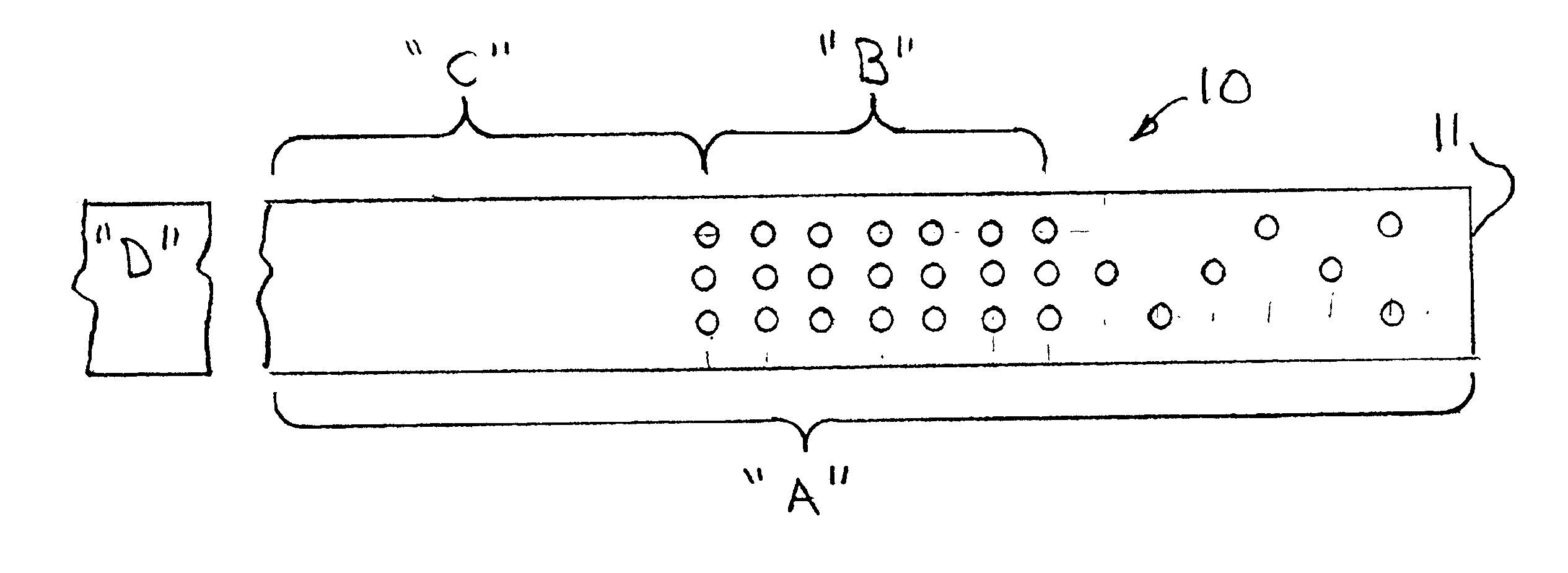

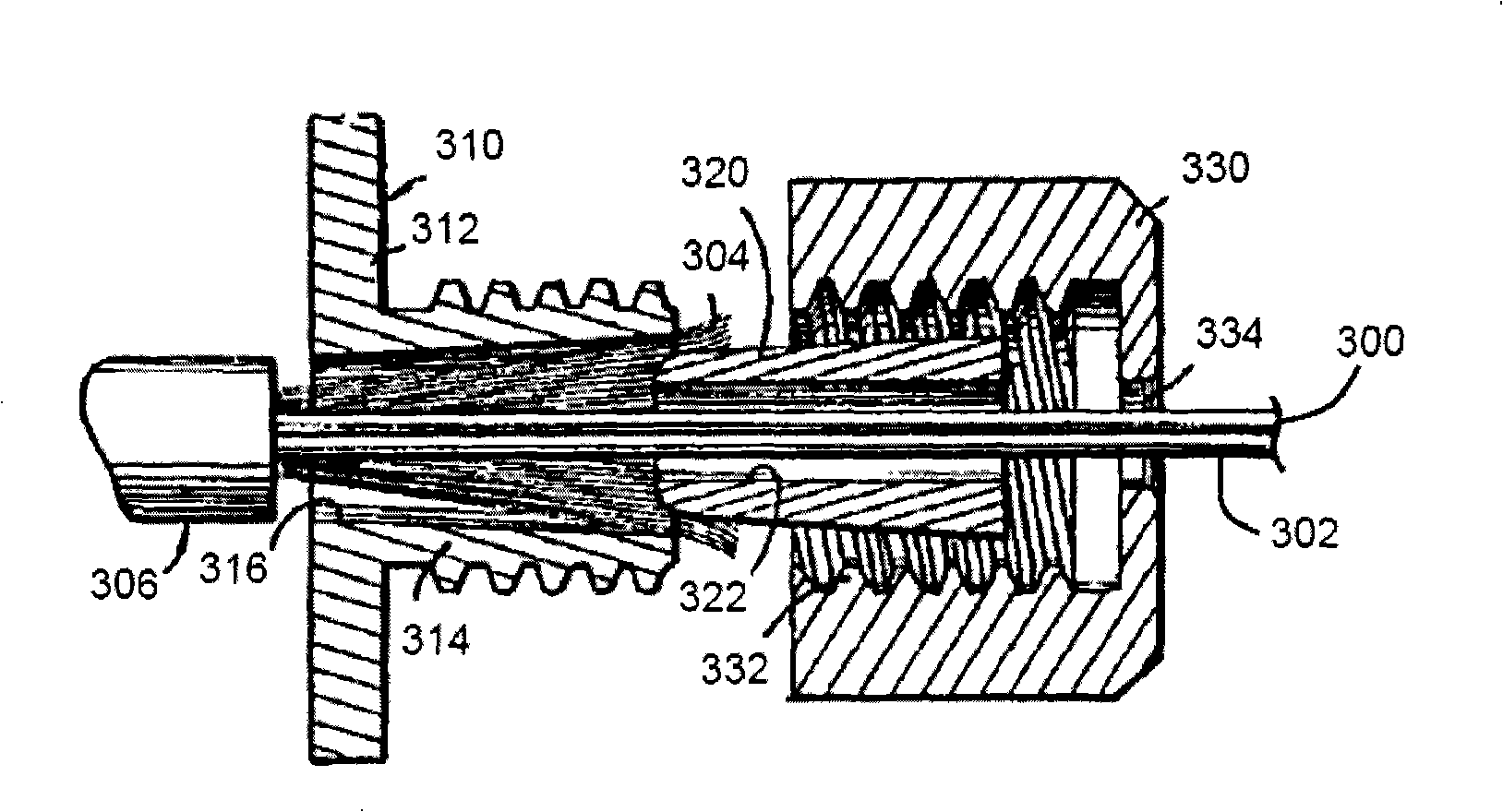

Optical fiber connection system

An optical fiber connection system (600) configured to interconnect a plurality of first and second optical fibers (54, 54′) is described. The connection system comprises a first bare fiber holder (620) that includes a clamping plate (540) having an interconnection portion (544) with a generally planar surface, wherein bare ends of the plurality of first optical fibers (54) are disposed adjacent to interconnection portion (544) and wherein the plurality of first optical fibers (54) are secured in the first bare fiber holder (620) at a first distance from the bare ends of the plurality of first optical fibers (54) and a second bare fiber holder (620′) that includes a splicing plate (580) having a plurality of alignment channels (585), wherein a bare end of each of the second optical fibers (54′) extend at least partially into one of the plurality of alignment channels (585) and wherein the plurality of second optical fibers (54′) are held at a second distance from the bare ends of the plurality of second optical fibers (54′).

Owner:3M INNOVATIVE PROPERTIES CO

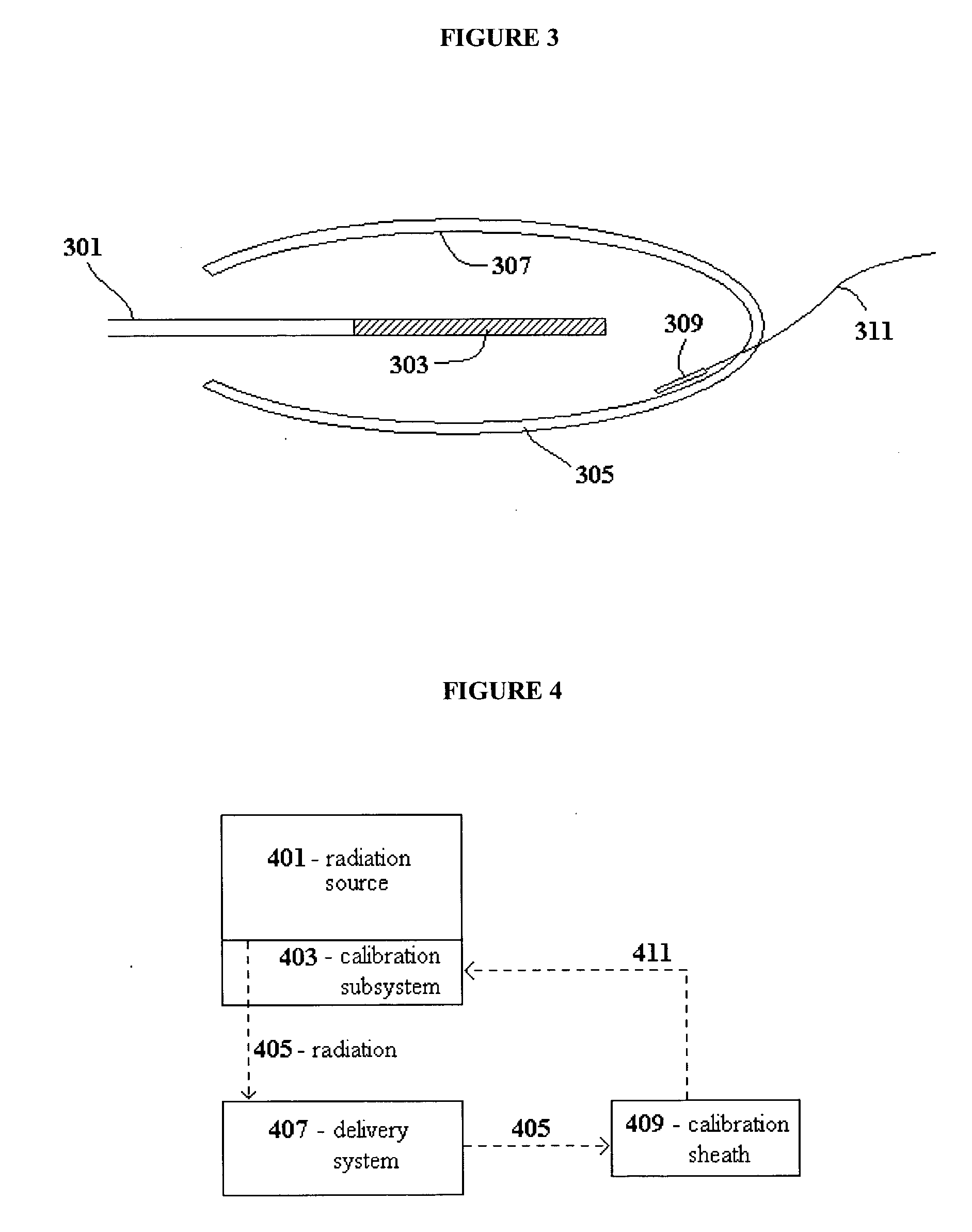

Autocalibrating medical diode laser system

InactiveUS20040227056A1Easy to useReduce energy lossPhotometry using reference valueInvestigating moving sheetsFiberBare fiber

Briefly stated, the present invention discloses a novel device that automatically calibrates and adjusts the intensity, dosage, and other parameters of a radiation delivery system and radiation source based on selected or detected radiation delivery systems. Such radiation delivery systems include optical fiber systems, and any type of diffuser, as well as bare fiber tips. The functions of a radiation source and a calibration device are combined by storing the characteristics of a wide variety of delivery system types and brands and calibrating the radiation based on those stored characteristics. In a preferred embodiment, a calibration sheath is provided that fits over a delivery system, such as a bare fiber tip or a diffuser at the distal end of a fiber, to both protect the system during calibration and direct output radiation to a detector. In another embodiment, one or more detectors are situated on the interior surface of the calibration sheath to directly measure at least a preselected portion of the emitted radiation. Power readings are directed to a calibration subsystem from the detector or detectors, which then adjusts the emitted power to conform to desired treatment parameters. The need for different calibration devices based on the characteristics of the delivery system is alleviated.

Owner:BIOLITEC UNTERNEHMENSBETEILLIGUNGS II AG

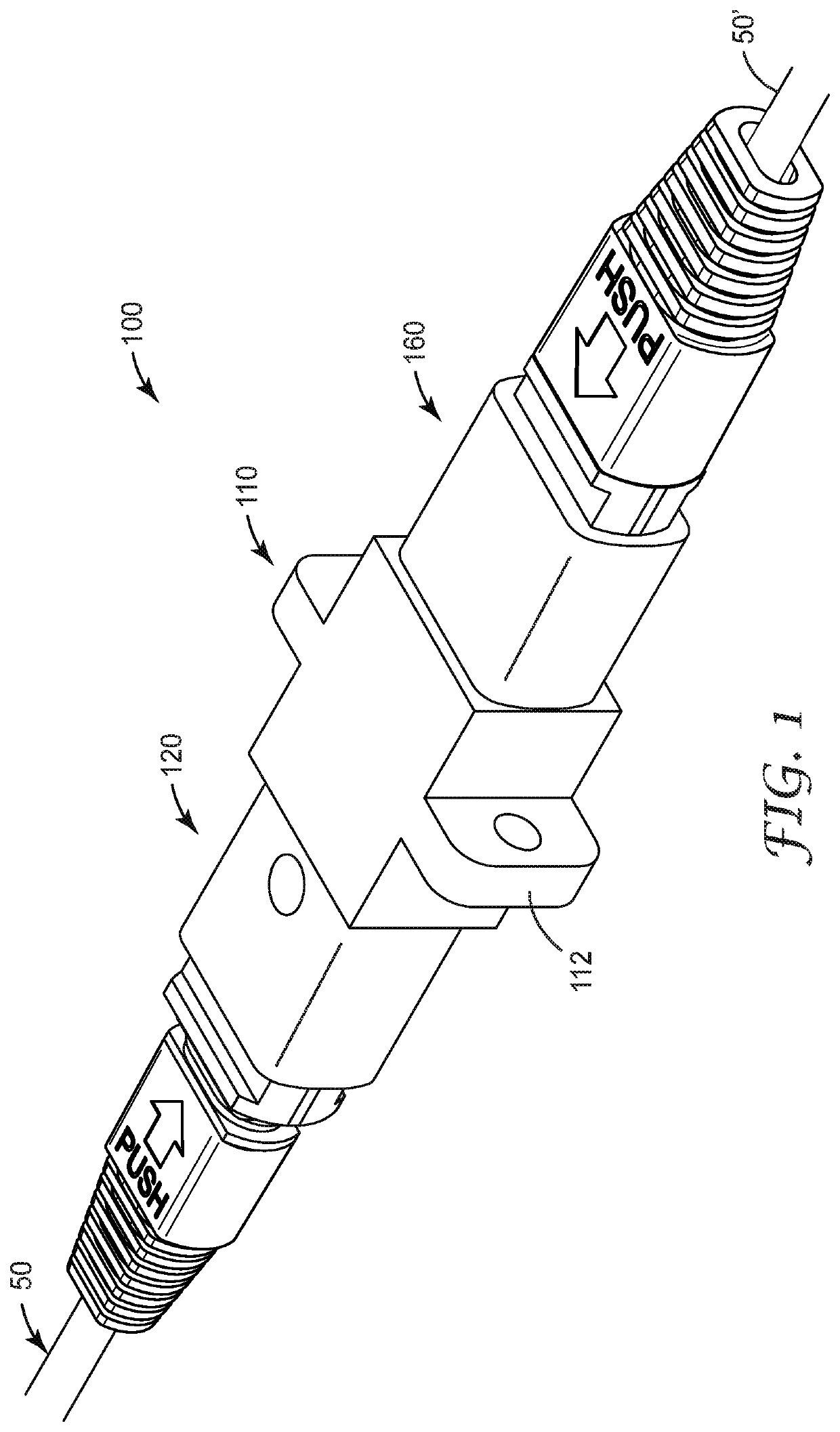

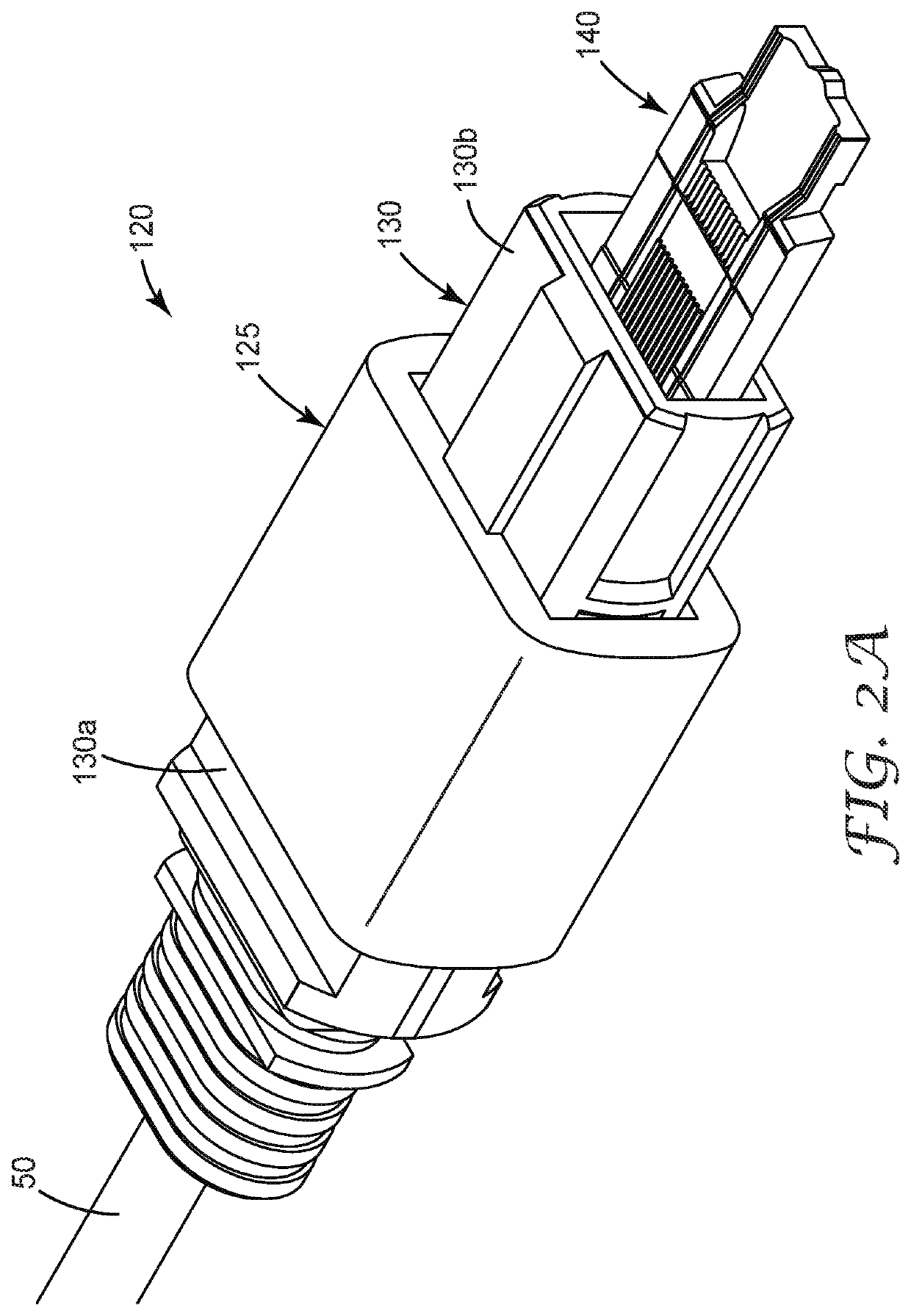

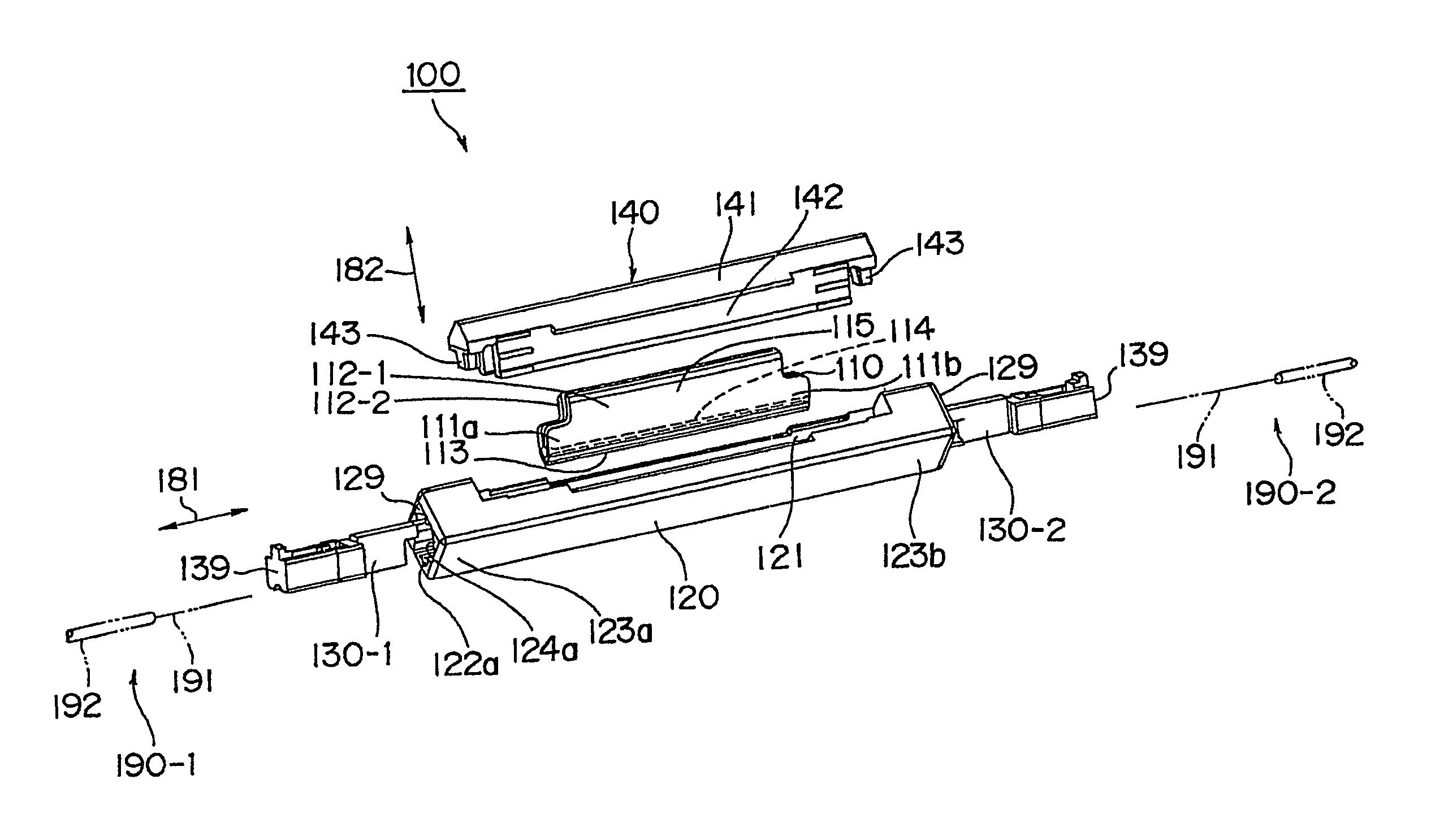

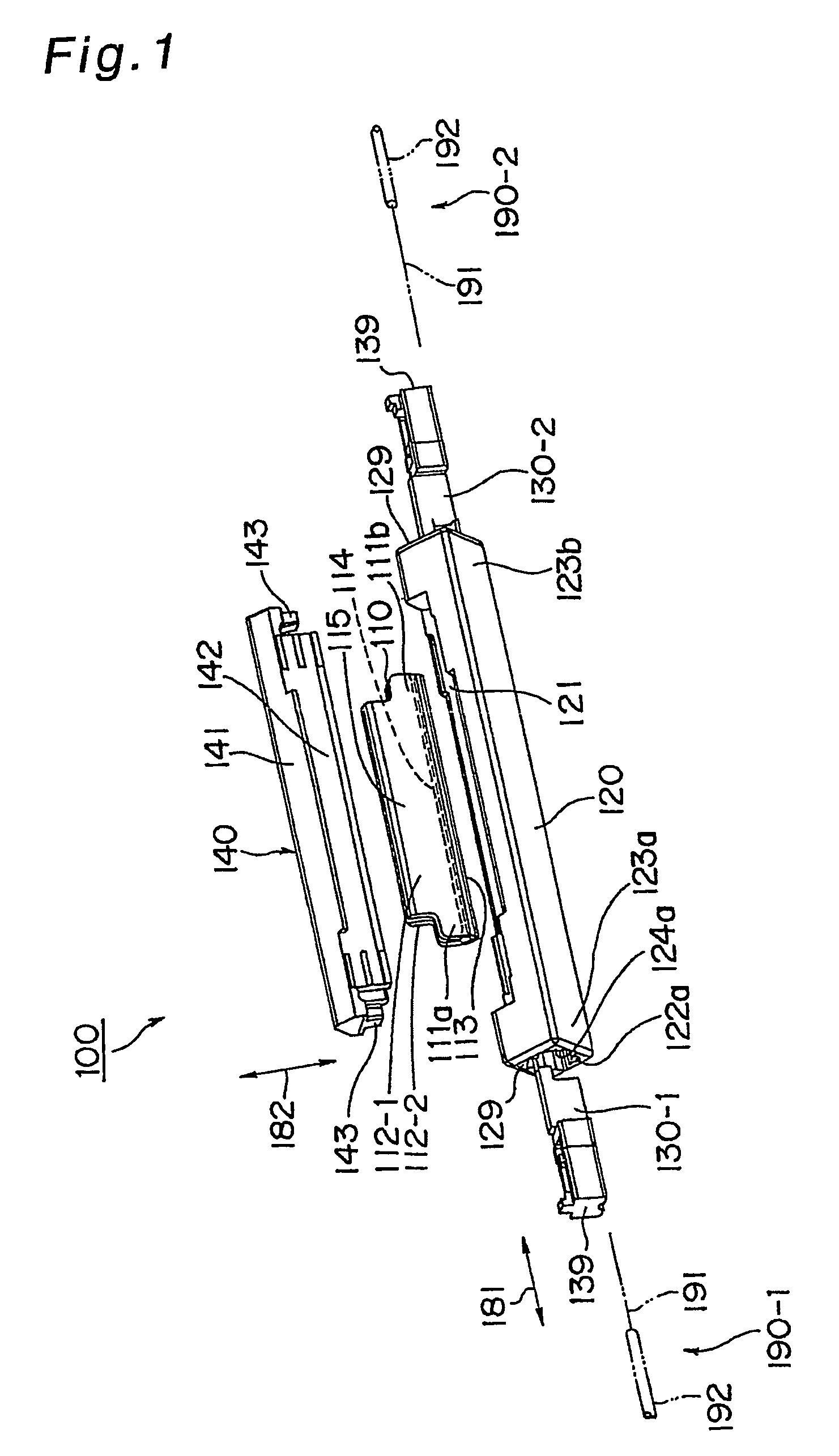

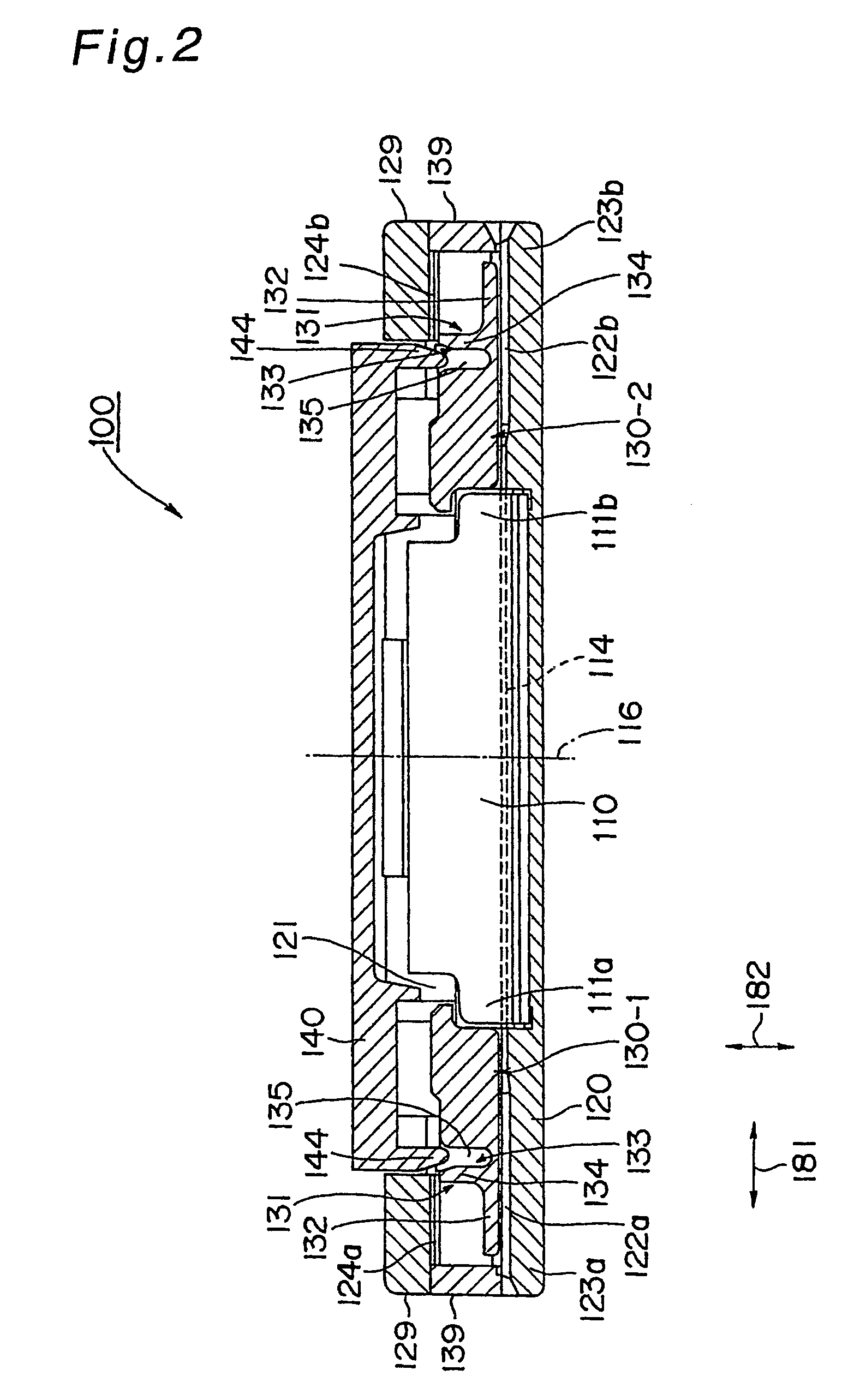

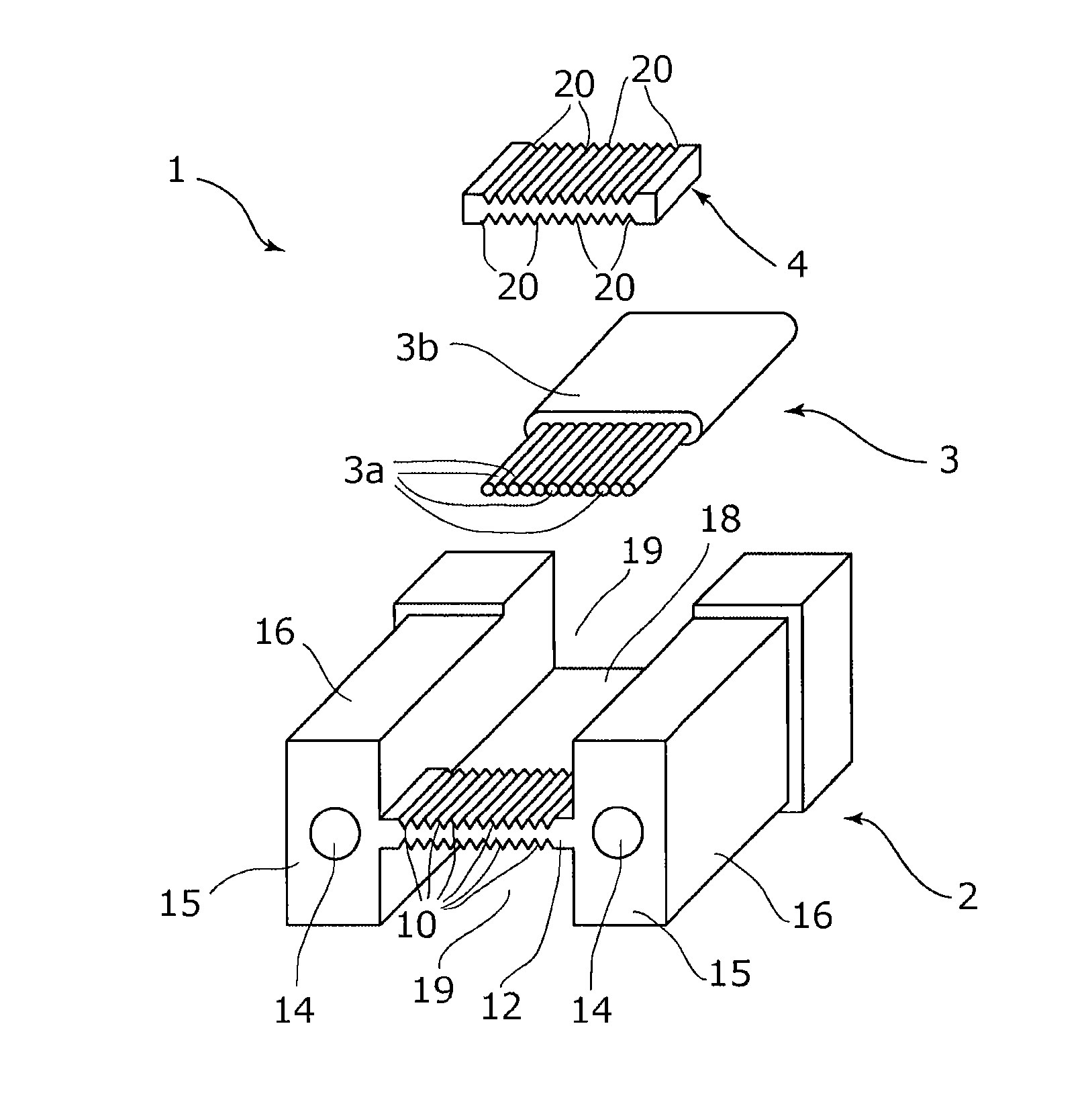

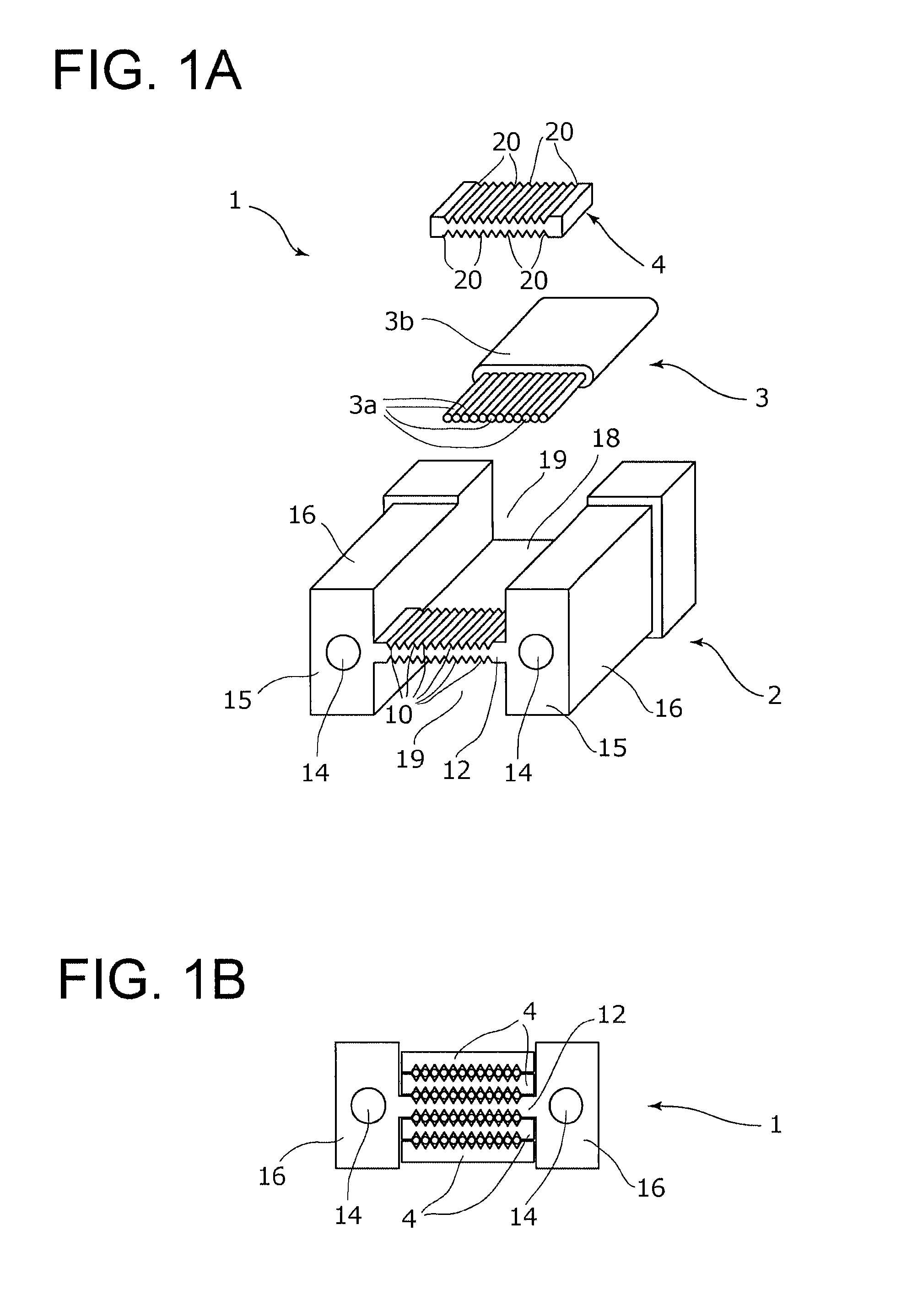

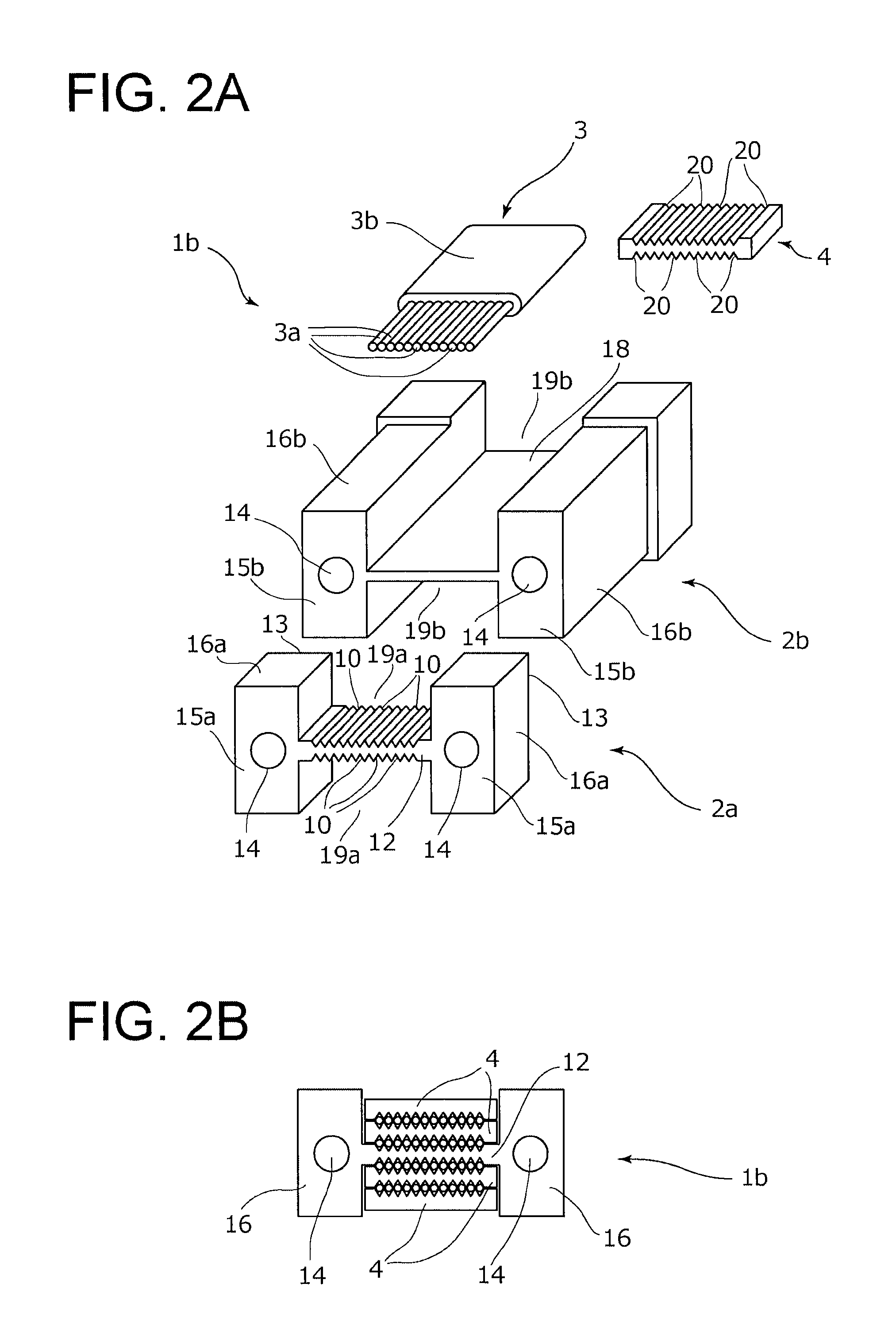

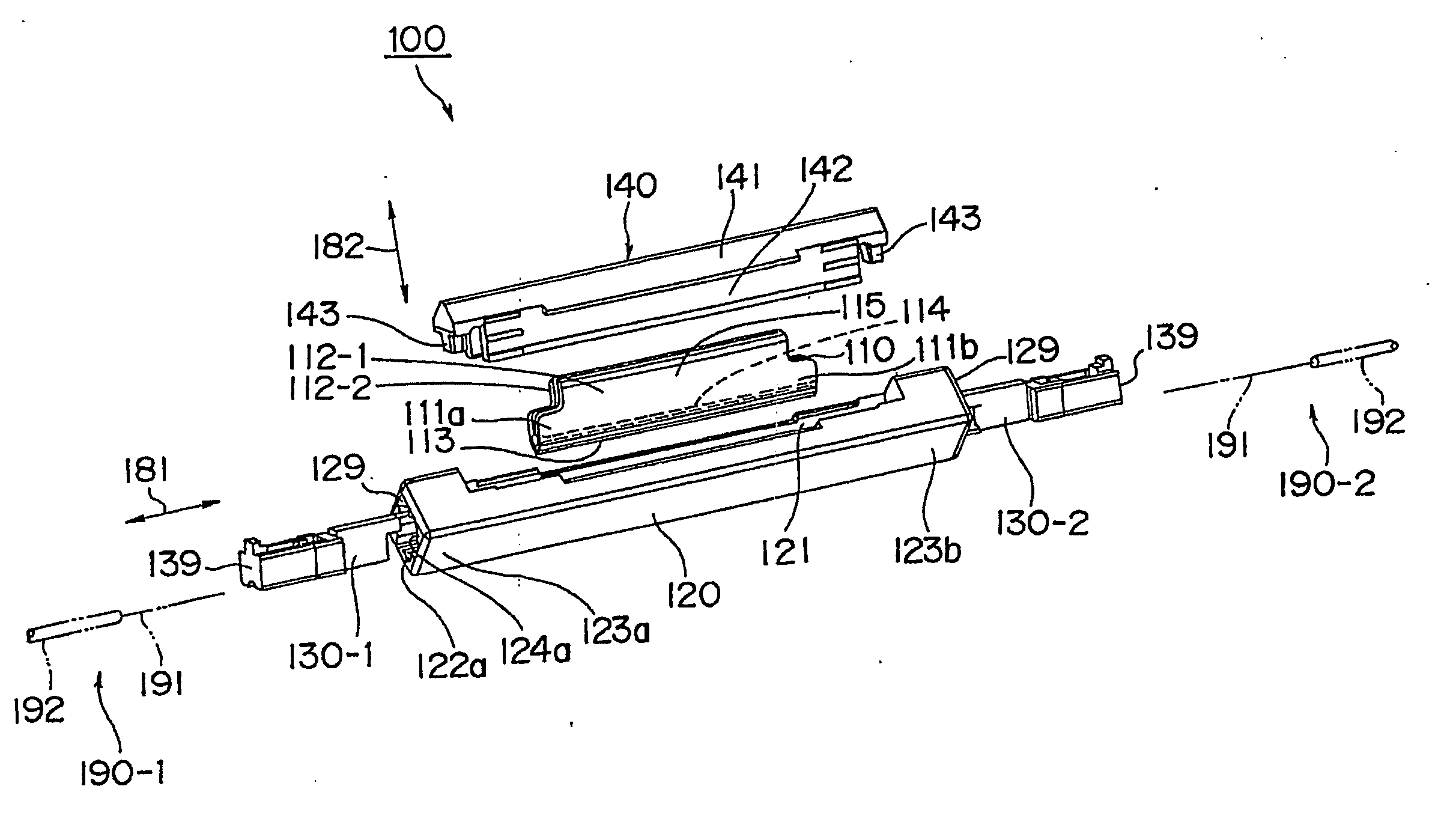

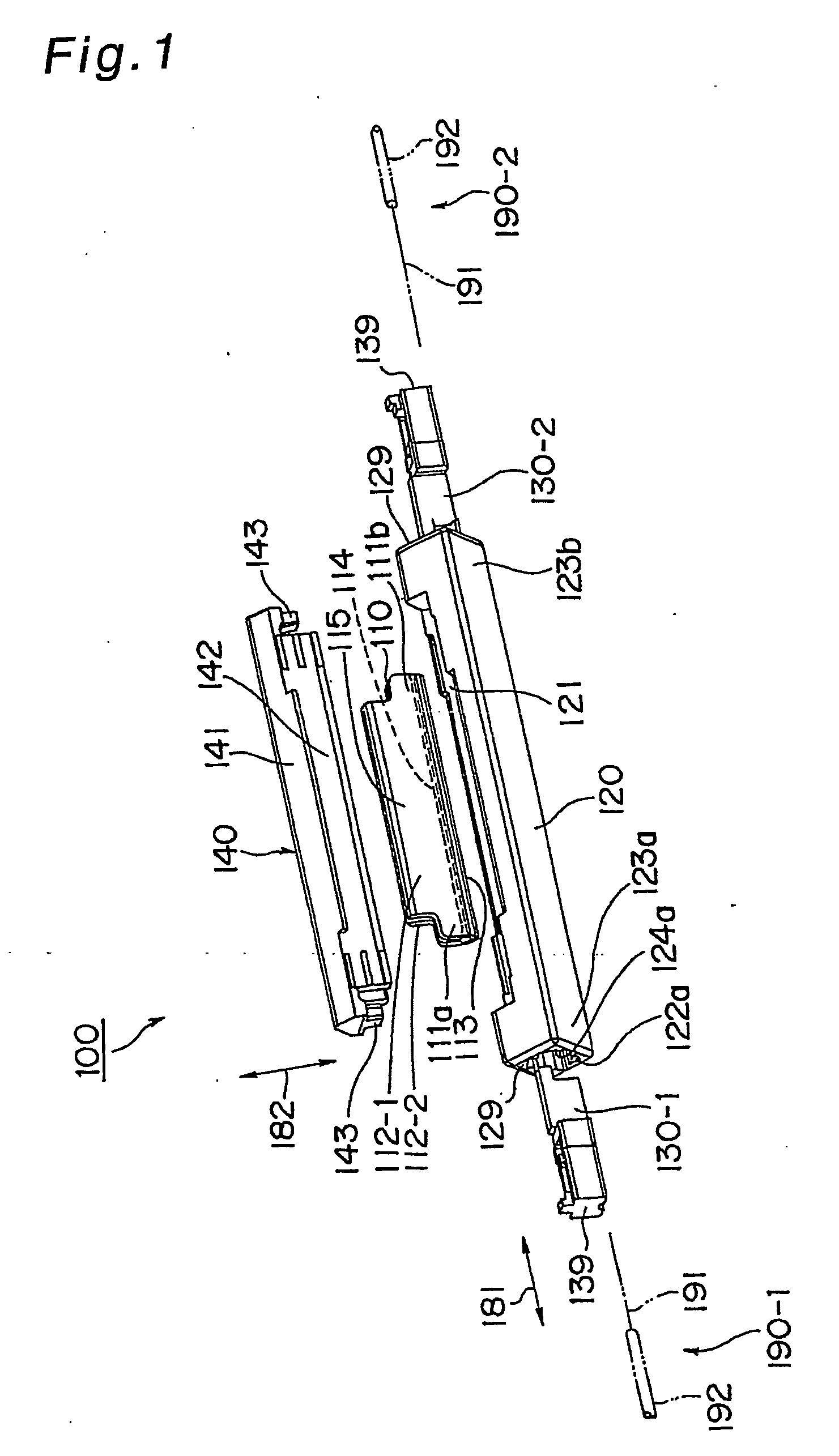

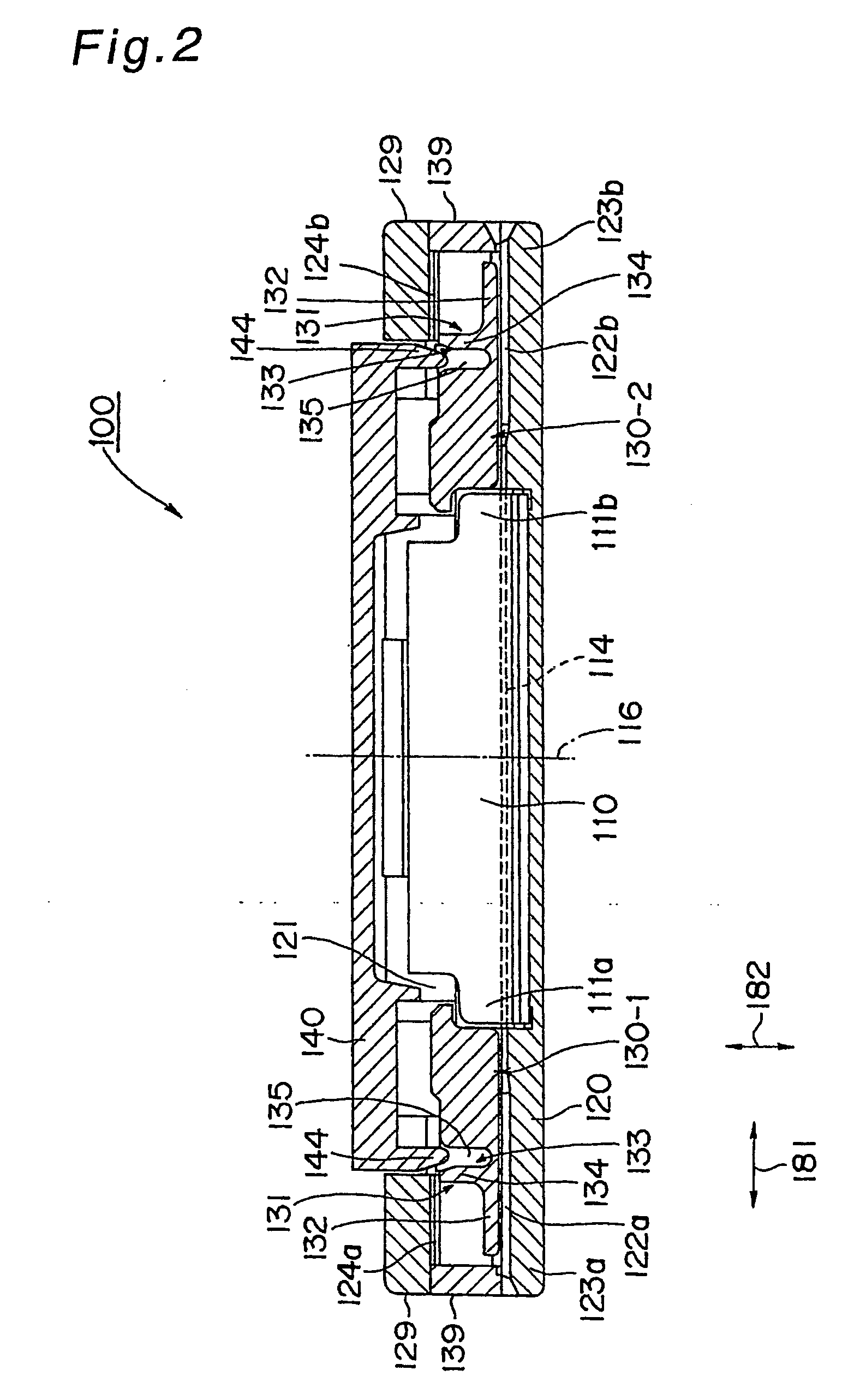

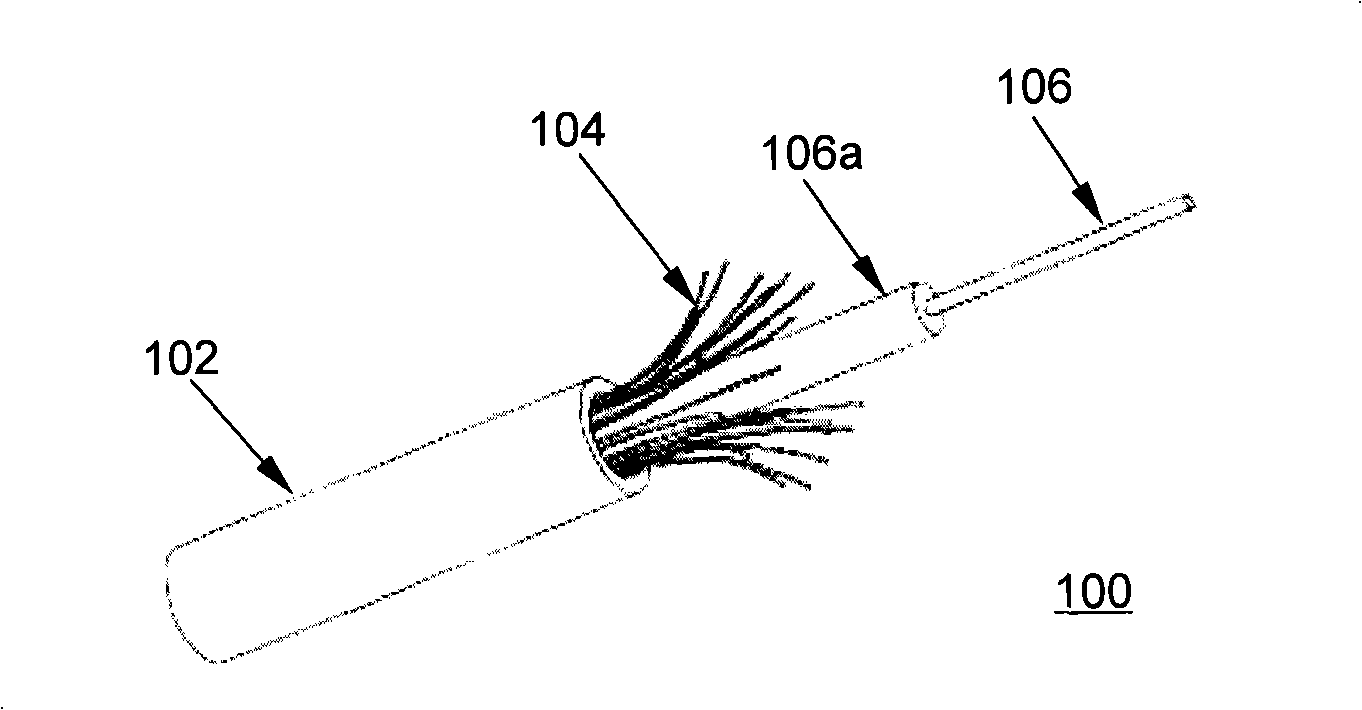

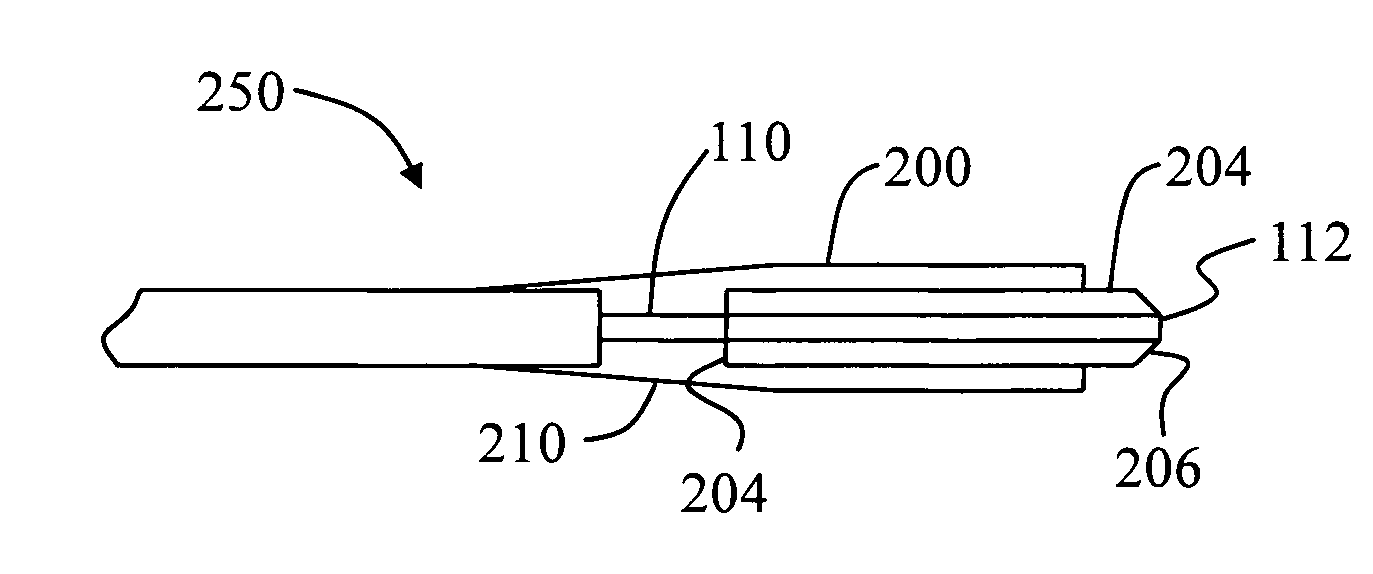

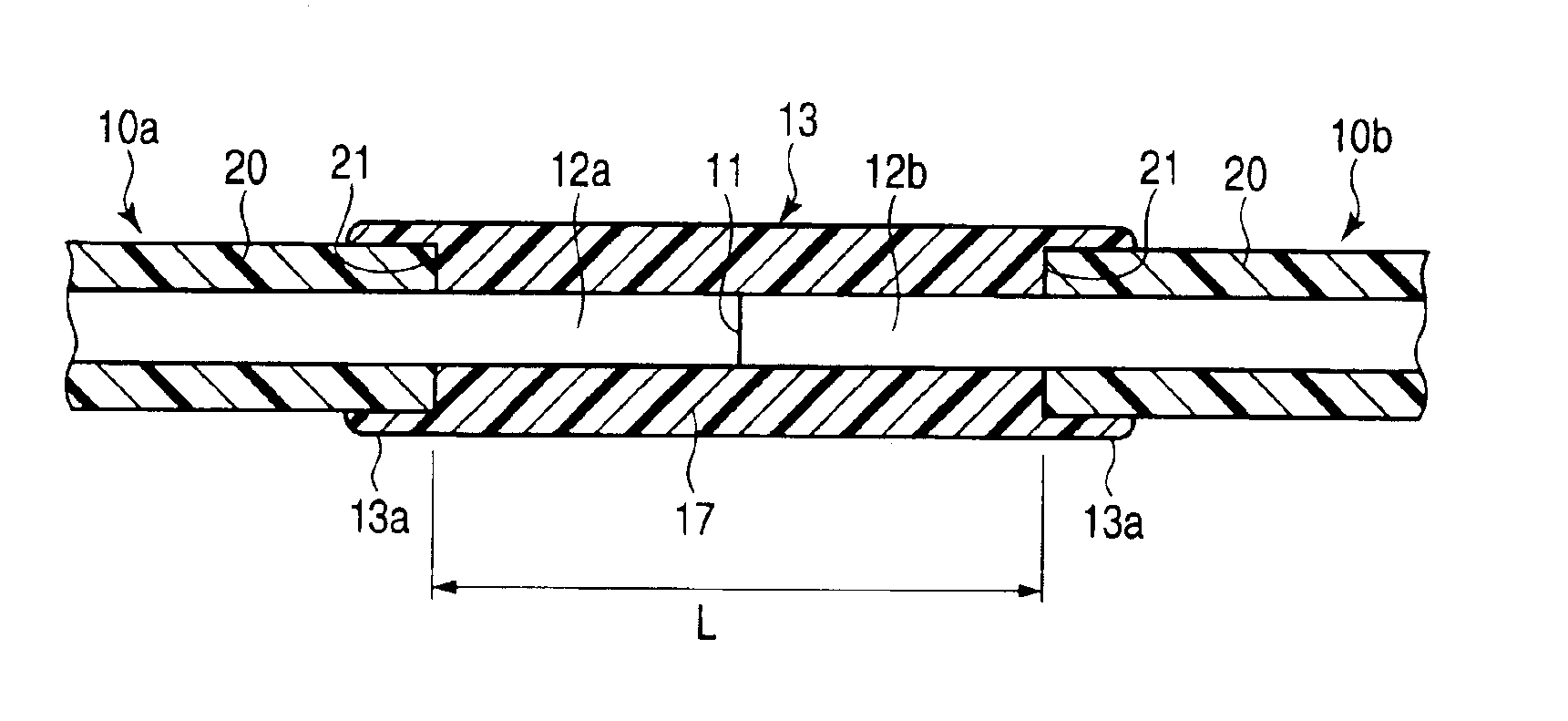

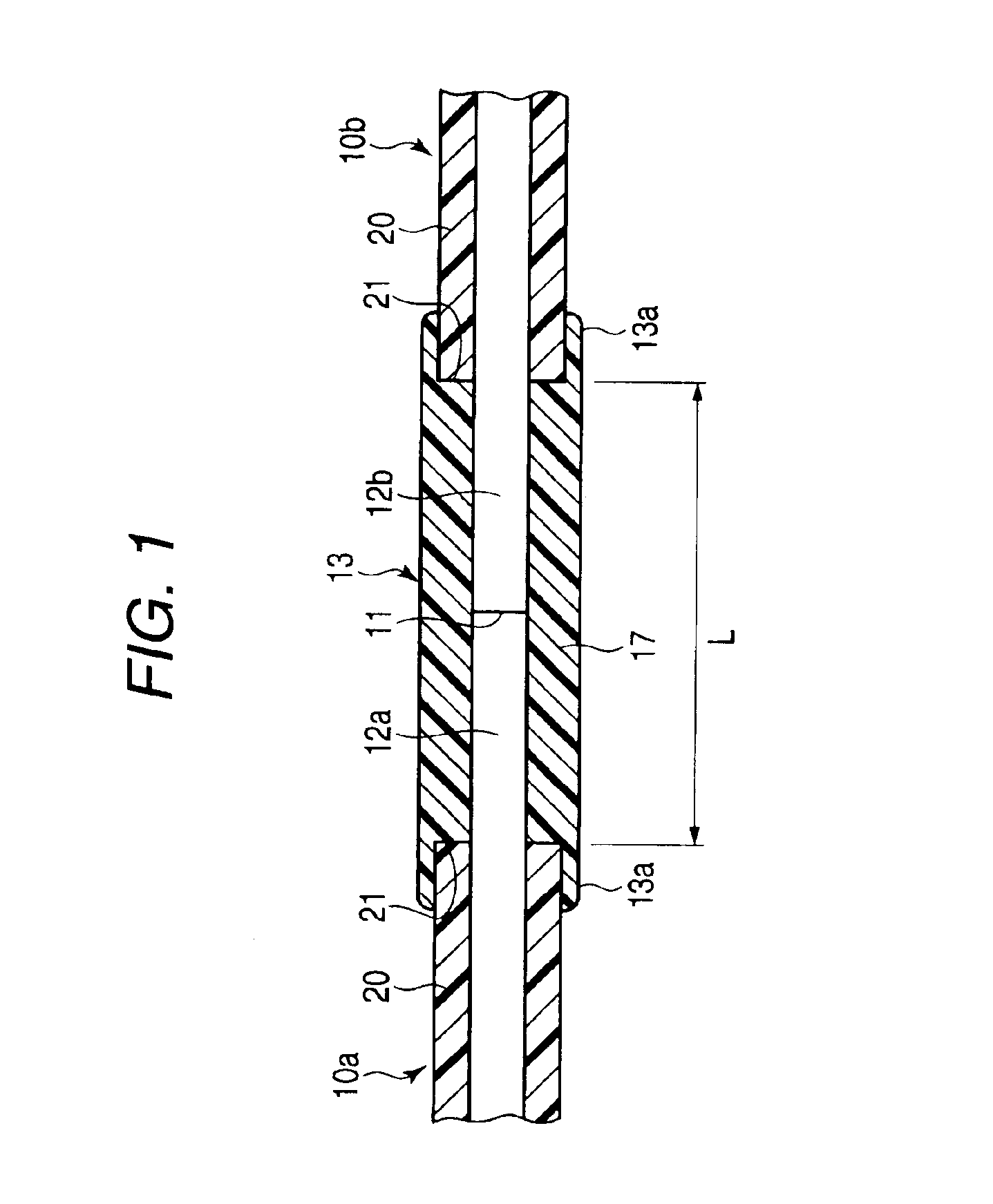

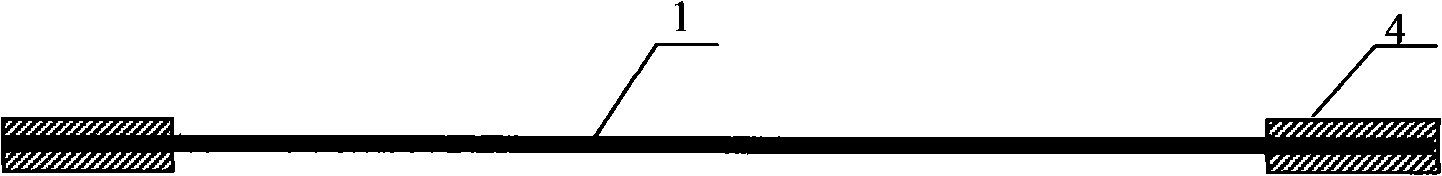

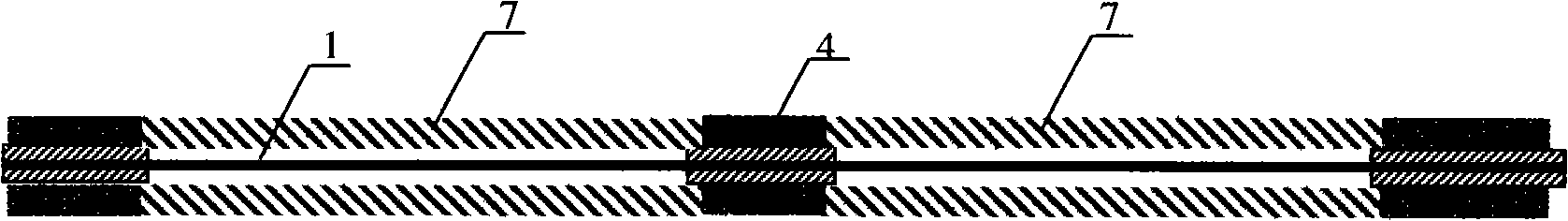

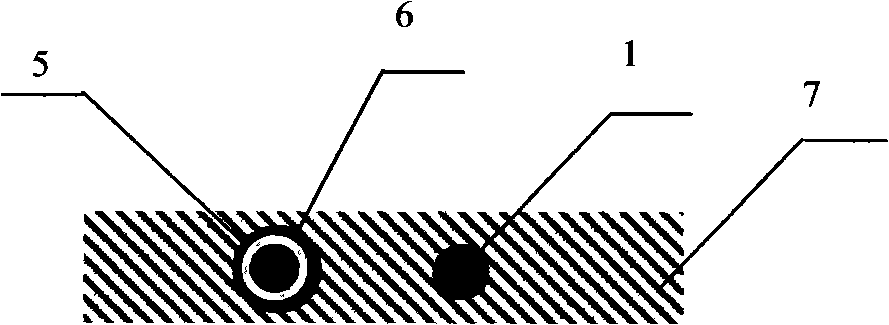

Optical fiber mechanical splice with strain relief mechanism

InactiveUS7140787B2Simple structureUsage existGlass making apparatusCoupling light guidesMechanical spliceBare fiber

An optical fiber splicing member can hold optical fiber buffer coatings stably in a simple structure as compared with conventional art and enables use of an existing splicing tool. There are provided a joint element 110, a jacket 120, buffer retainers 131 and a cap 140. By setting and pressing the cap to the jacket, it becomes possible to splice bare fibers of optical fibers 190 with each other by the joint element and to press the buffer coatings 192 by the buffer retainers. Assembling the splicing member is thus facilitated while the existing optical fiber splicing tool is utilizable as it is. The buffer coatings can be held stably because the holding is achieved through the pressing.

Owner:CORNING RES & DEV CORP

Optical connector ferrule

The optical connector ferrule has a second alignment board and a housing part having a first alignment board and a pair of side support parts. The first alignment board has a surface in which bare fiber parts of a optical fiber ribbon are positioned in a width direction and has holding grooves for arranging bare fiber parts. Side support parts support ends of the first alignment board and have an open part larger than a width of the ribbon in a upper and / or lower surface side of the first alignment board. The second alignment board has a positioning part for positioning in the width direction by engaging with a part of bare fiber parts on holding grooves and a fixing part for pressing and fixing bare fiber parts. The second alignment board is arranged to face the first alignment board and to sandwich bare fiber parts.

Owner:FURUKAWA ELECTRIC CO LTD

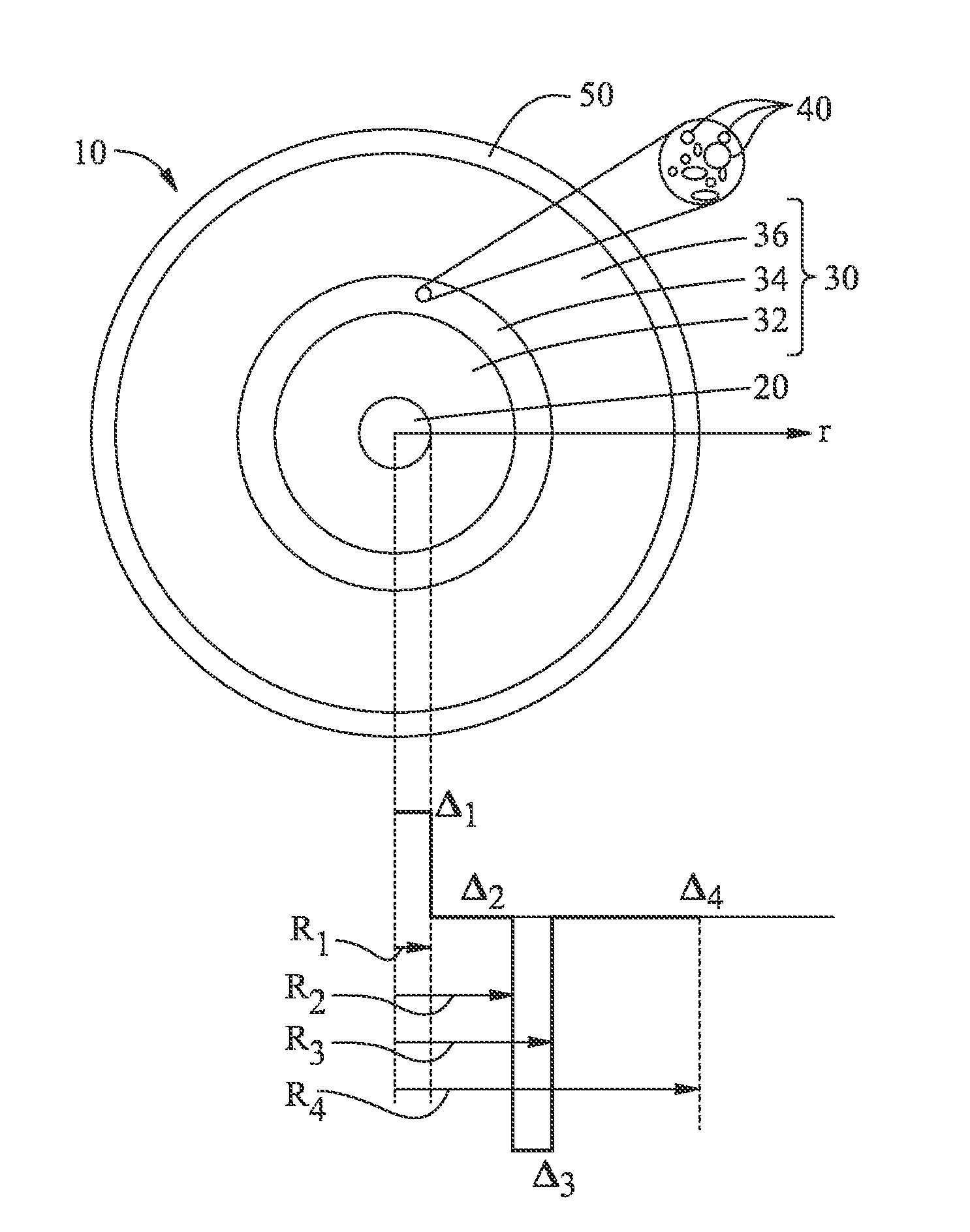

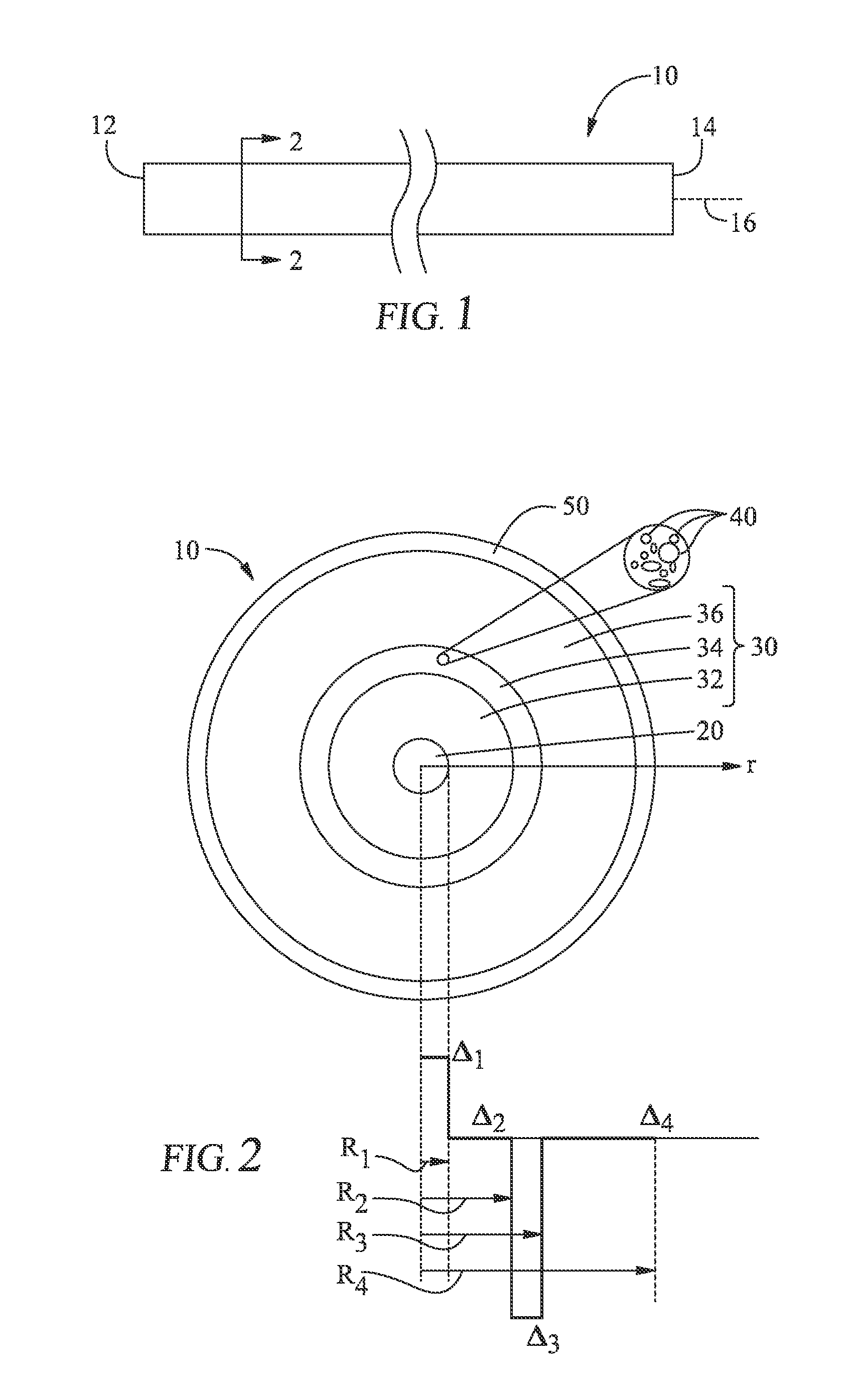

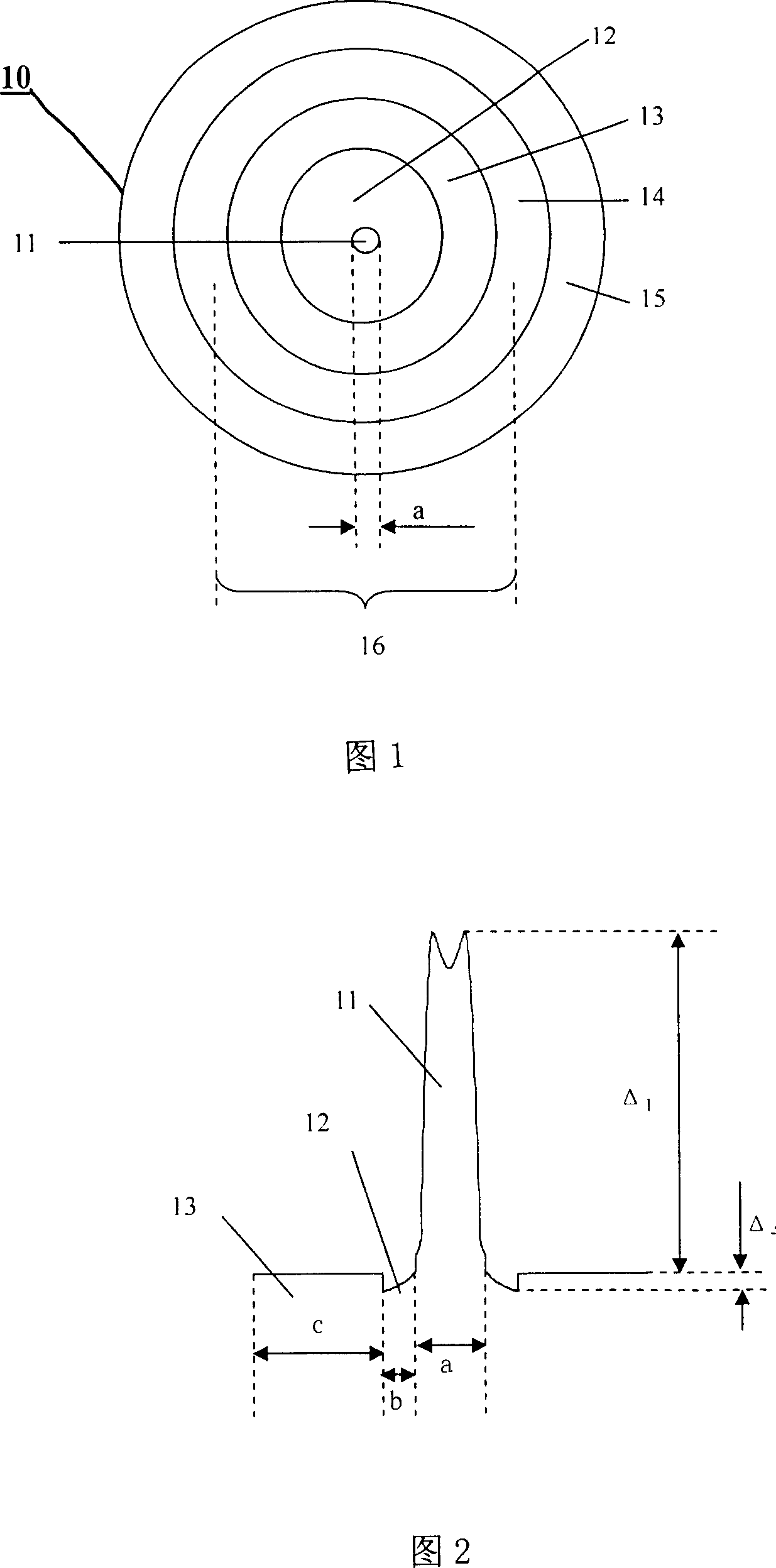

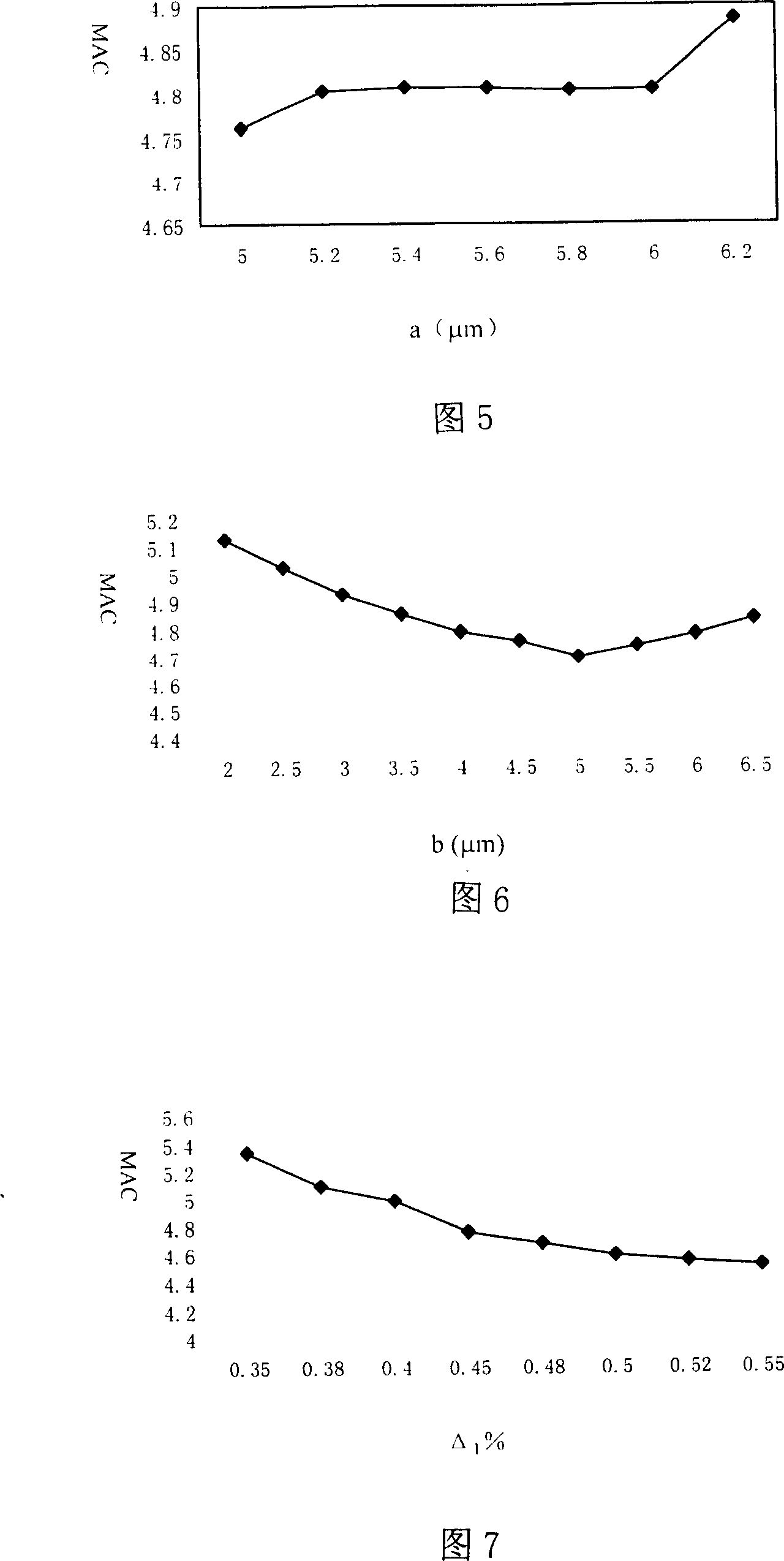

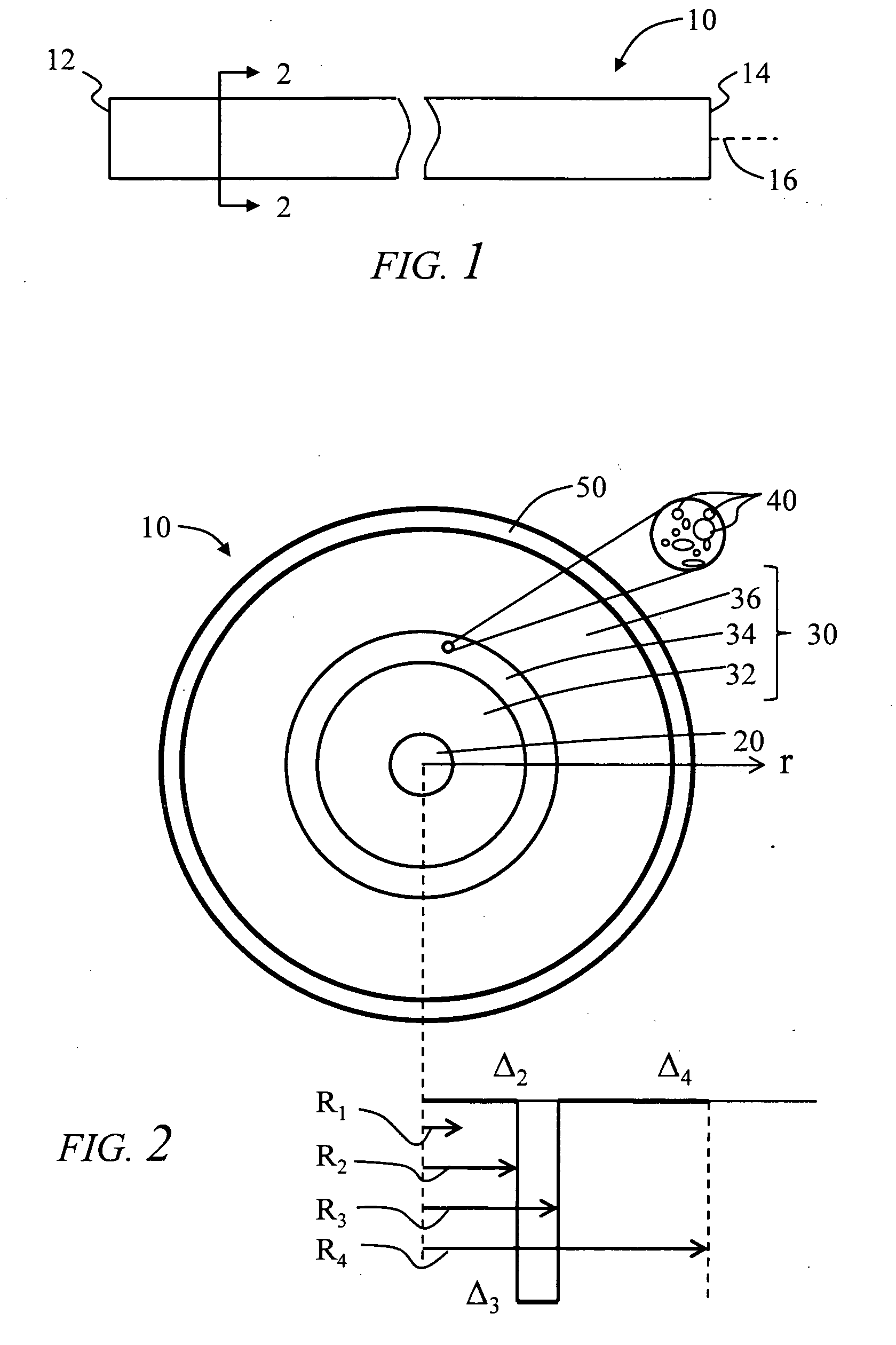

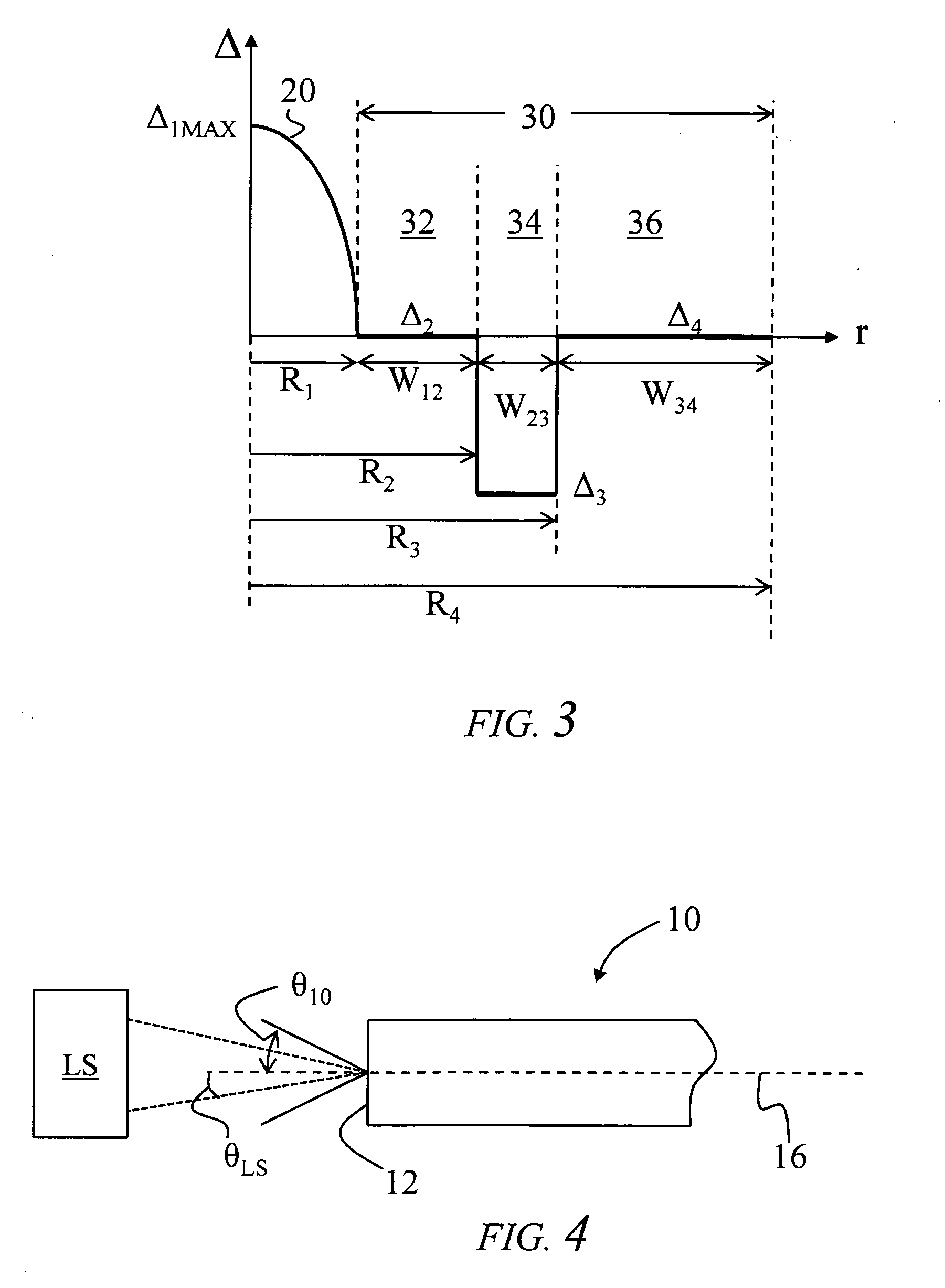

A low bending loss superfine low water peak fiber

ActiveCN1971321AUnique Refractive Index ProfileUnique DimensionsCladded optical fibreOptical waveguide light guideBare fiberUltra fine

An ultra-fine low-flow peak optical fibre with low bending loss relates to a optical fibre, specially the low bending-loss ultra-fine low-flow peak optical fibre which fits for the wavelength-division multiplex (WDM) transmission in band of 1285-1625nm. The utility model discloses a low bending-loss ultra-fine low-flow peak monomode optical fiber which comprises silica glass core, silica glass cladding and inner and outer resin layer, the refractive index of the core layer is 1.4629-1.4664, thickness of the core layer is 2.3-3.2 mum; The refractive index of the first cladding is 1.4562-1.4582, thickness is 2.5-6.5 mum; The second cladding is pure silica glass, its thickness is 8.5-12.3 mum. The utility model optical fibre possesses perfect bending resistance, but also the ultra-fine size, the diameter of bare fiber is about 80 mum, the diameter of fiber which is coated with resin is about 140 mum.

Owner:HANGZHOU FUTONG COMM TECH CO LTD

Method for manufacturing intelligent composite-material laminates used for monitoring structural longitudinal strain

The invention provides a method for manufacturing intelligent composite-material laminates used for monitoring structural longitudinal strain. In order to solve the technical problems that as fiber grating sensors are bonded to the surface of a structure through polyimide resin or epoxy resin commonly used in the prior engineering, optic fiber in service is easily destroyed; the optic fiber can get encapsulation protection but cause the concentration of surrounding stress / strain thereof if the optic fiber is directly embedded in a composite-material structure; and thermal residual stress produced in a material-curing process can cause chirp phenomena of fiber grating reflection spectrum to affect the measurement accuracy of grating strain, and the like, the invention provides the method for manufacturing intelligent composite-material laminates used for monitoring structural longitudinal strain. In the method, the fiber grating sensors are embedded in composite-material layers to replace resistance strain gauges commonly used in the field of monitoring structural health; by applying prestress to embedded fiber gratings, the influence of the curing residual stress of composite material on the fiber grating reflection spectrum is reduced so as to avoid the chirp phenomena; and the stability and repeatability of the sensors are improved. In addition, the composite material plays a good role in encapsulating and protecting bare fiber gratings, and meets engineering construction requirement on sensor sensitivity.

Owner:SHENYANG INST OF AERONAUTICAL ENG +1

Optical fiber mechanical splice with strain relief mechanism

InactiveUS20060072884A1Simple structureUsage existGlass making apparatusCoupling light guidesMechanical spliceBare fiber

To provide an optical fiber splicing member which can hold optical fiber buffer coatings stably in a simple structure as compared with conventional art, and which enables use of an existing splicing tool. There are provided a joint element (110), a jacket (120), buffer retainers (131) and a cap (140). By setting and pressing the cap to the jacket, it becomes possible to splice bare fibers of optical fibers (190) with each other by the joint element and to press the buffer coatings (192) by the buffer retainers. Assembling the splicing member is thus facilitated while the existing optical fiber splicing tool is utilizable as it is. The buffer coatings can be held stably because the holding is achieved through the pressing.

Owner:CORNING RES & DEV CORP

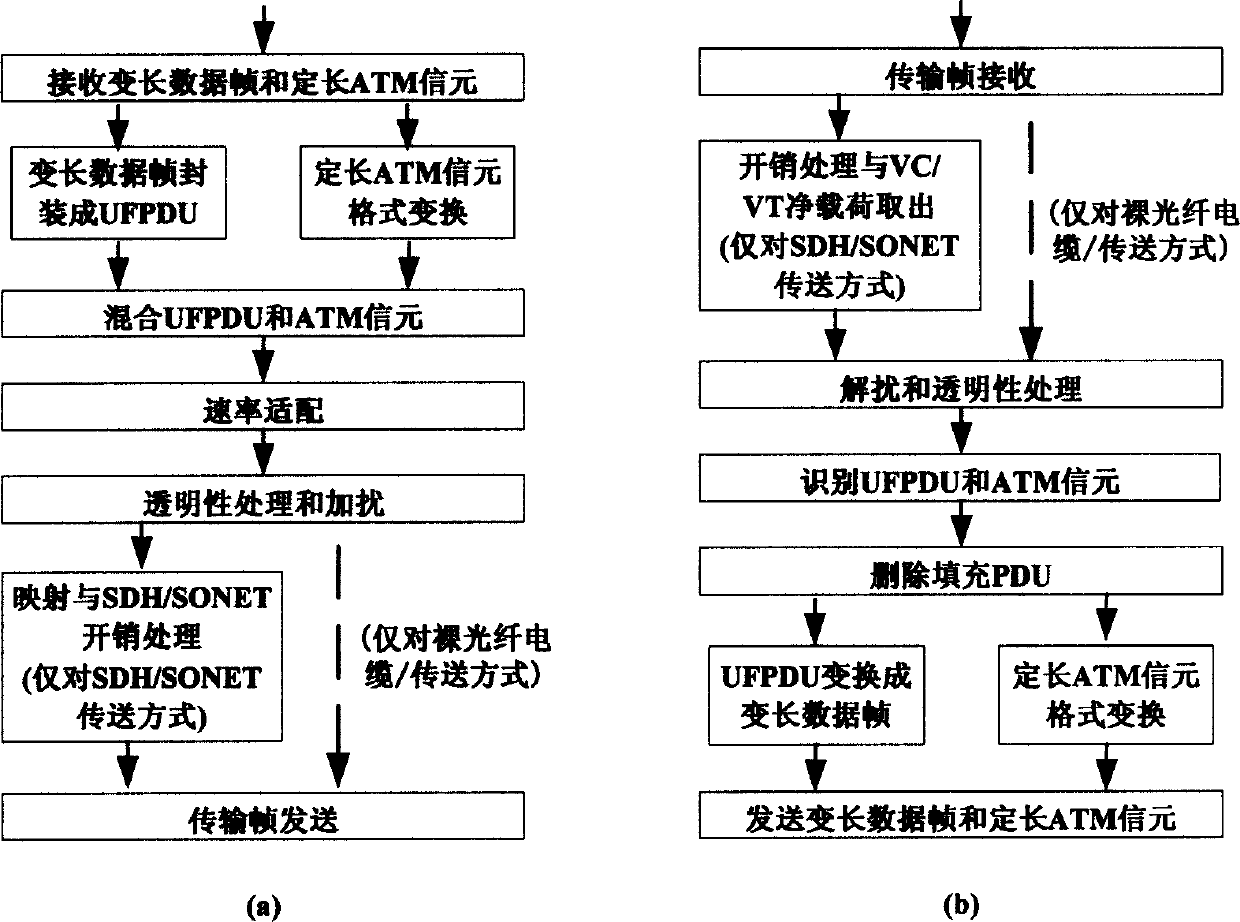

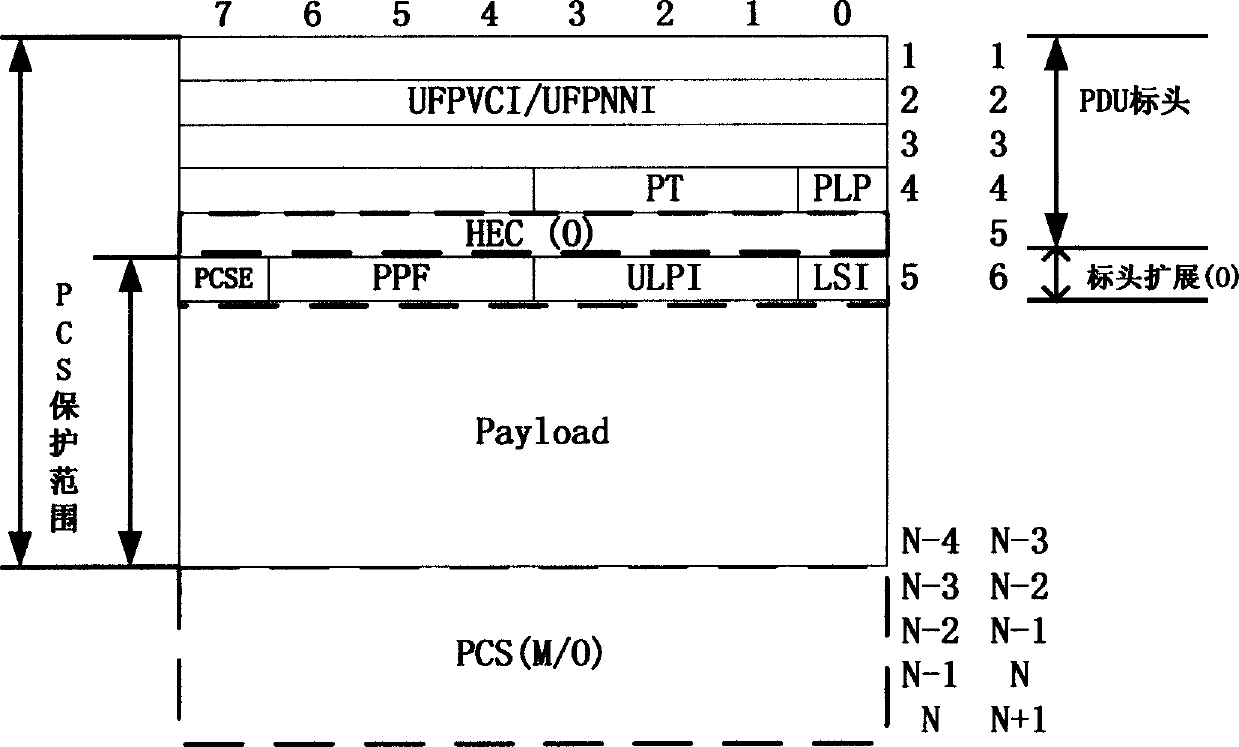

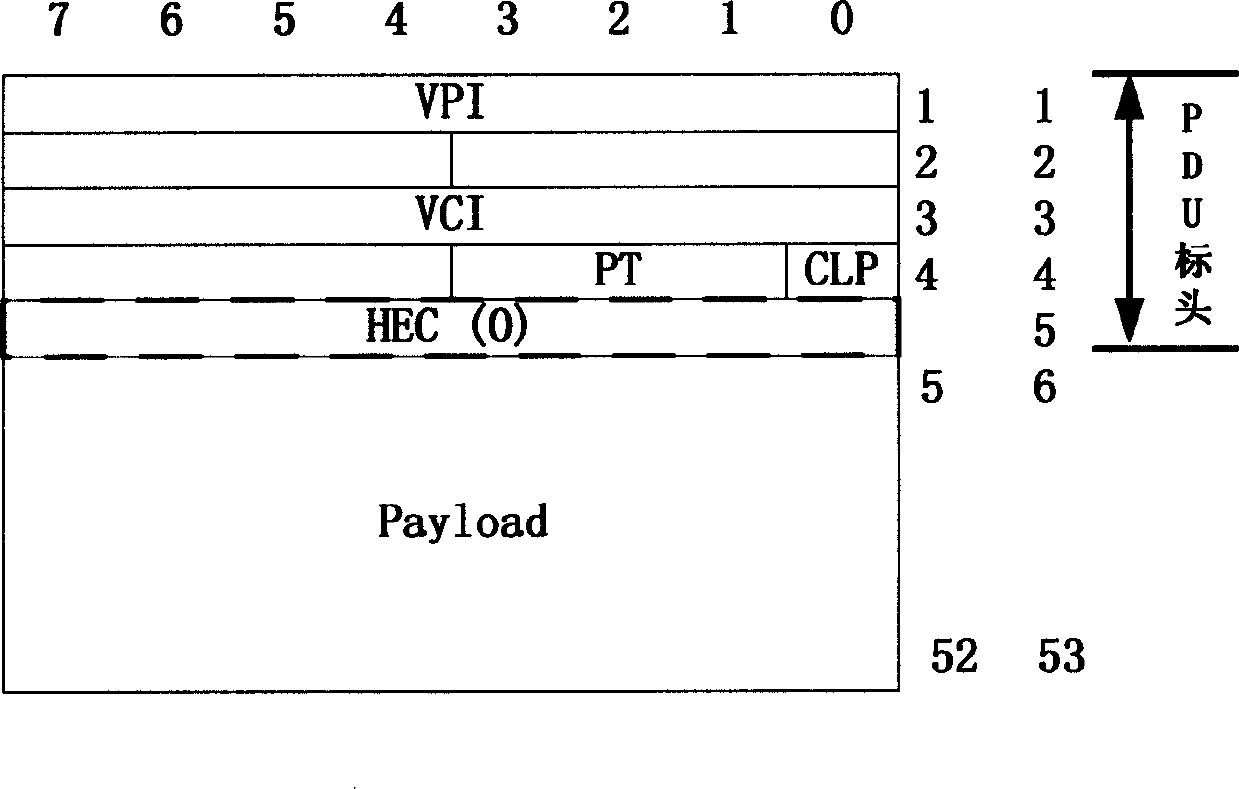

Method for hybrid transmission of variable-length data packet and fixed length cell, and adaptation device

InactiveCN1543162AImprove transmission efficiencyReduce processing complexityData switching networksRate adaptationBare fiber

This invention discloses a method and an adaptive device for hybrid- transferring variable-length data packets and fixed size cells. The method and the device finish the images between the packet and the UFPDU, the fixed size cell and the rectified asynchronous transition mode (ATM) cell. The UFPDU and rectified ATM cell are transferred on a same VC / VT or a bare fiber / cable of SDH / SONET after processed by mix or separation, rate adaptation, penetrability conversion, scrambling or de-scrambling, image or fetch. The mark of UFPDU is compatible with that of the ATM, connection or connectionless ways are applied for the variable length data packet transfer.

Owner:XIDIAN UNIV +1

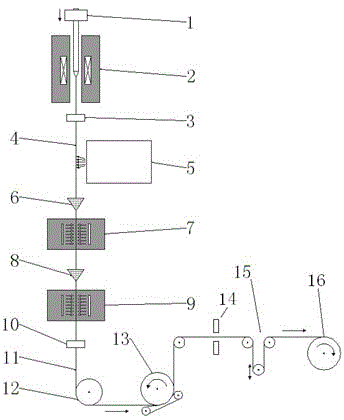

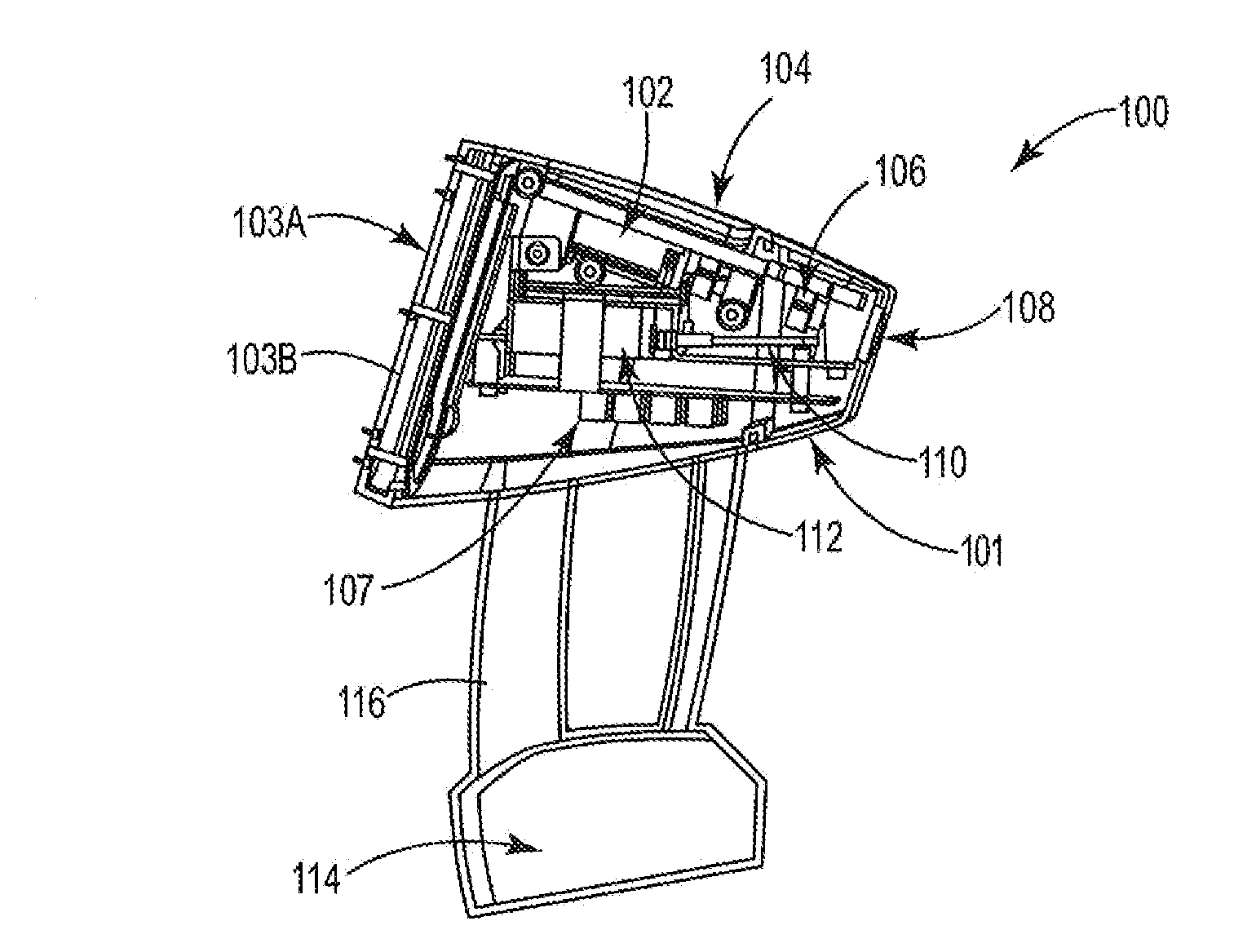

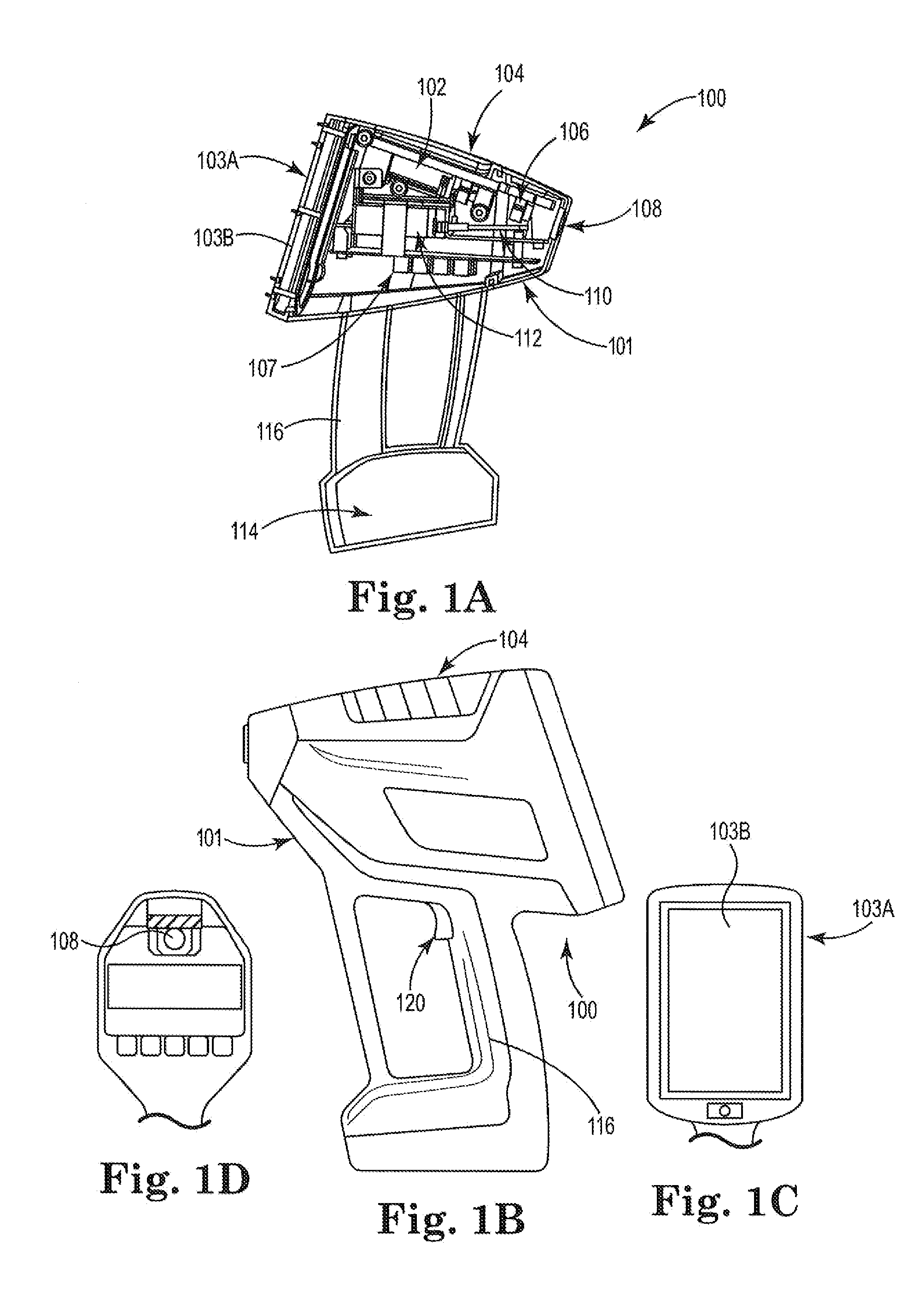

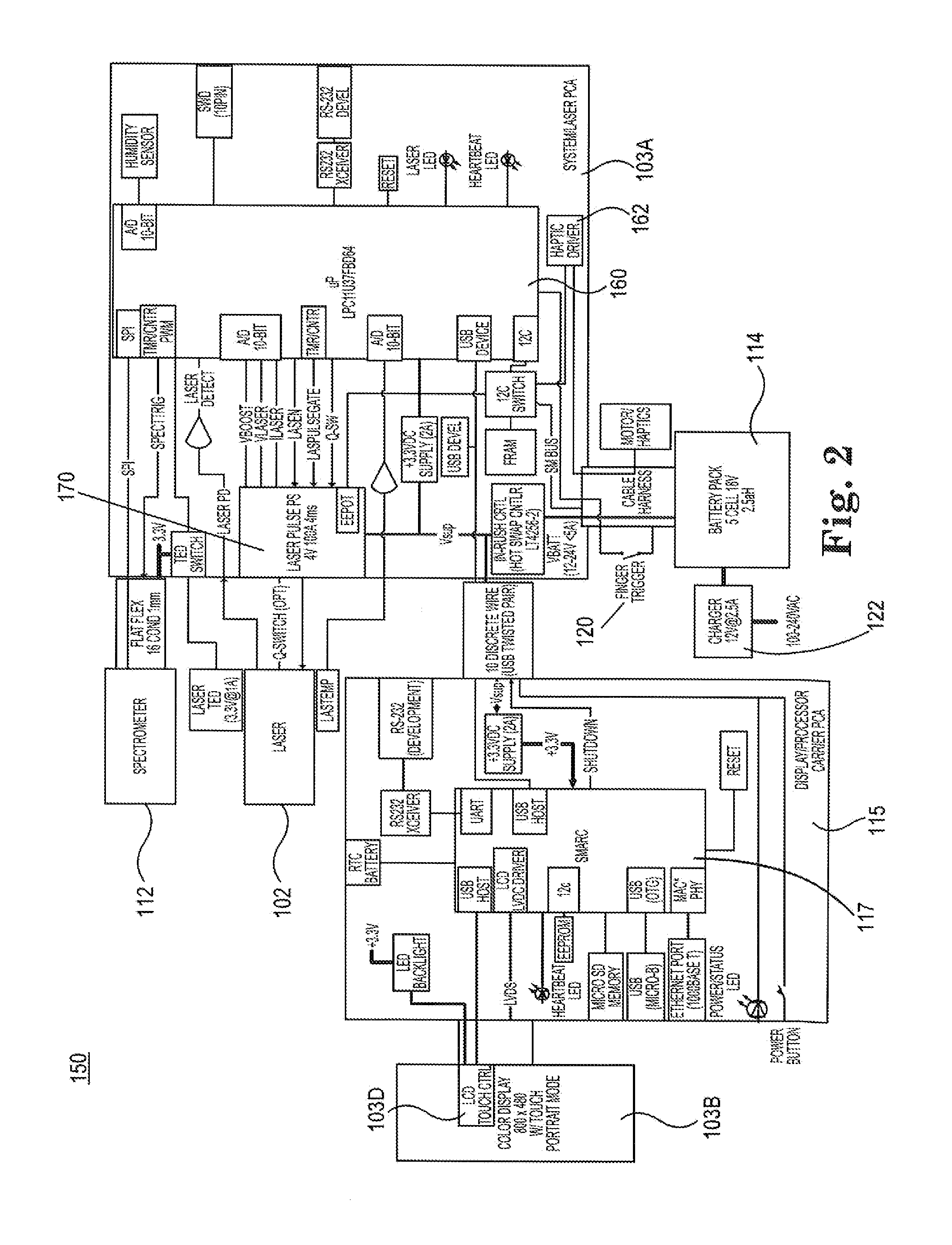

Handheld laser induced breakdown spectroscopy device

ActiveUS20150103334A1High precisionProlong lifeEmission spectroscopyRadiation pyrometryContact testGrating

A novel device, method and systems disclosed managing the thermal challenges of LIBS laser components and a spectrometer in a handheld structure as well the use of simplified light signal collection which includes a bare fiber optic to collect the emitted light in close proximity to (or in contact with) the test material. In one example embodiment of the handheld LIBS device, a burst pulse frequency is 4 kHz is used resulting in a time between pulses of about 250 μs which is a factor of 10 above that of other devices in the prior art. In a related embodiment, an active Q-switched laser module is used along with a compact spectrometer module using a transmission grating to improve LIBS measurement while substantially reducing the size of the handheld analyzer.

Owner:TSI INC

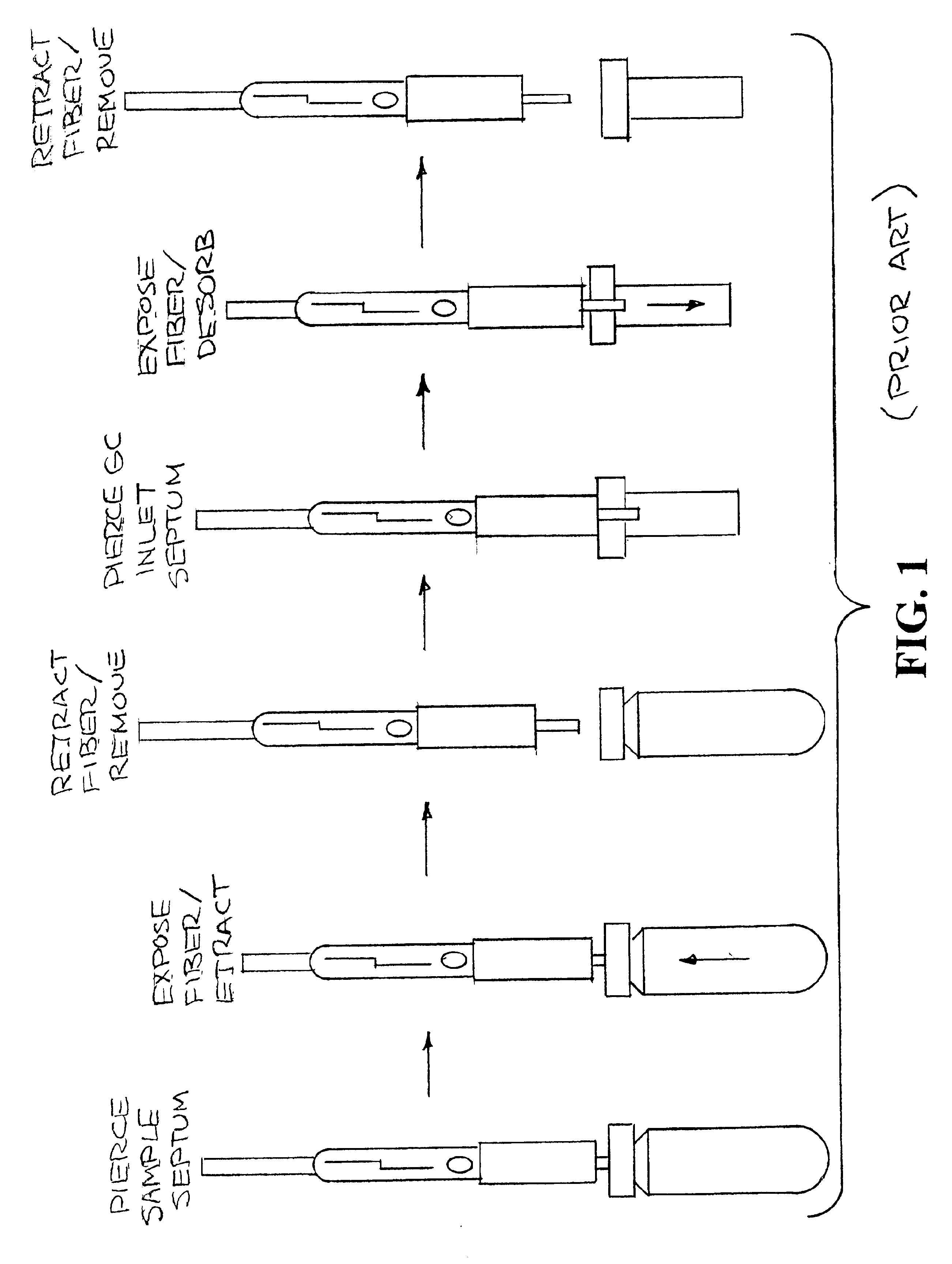

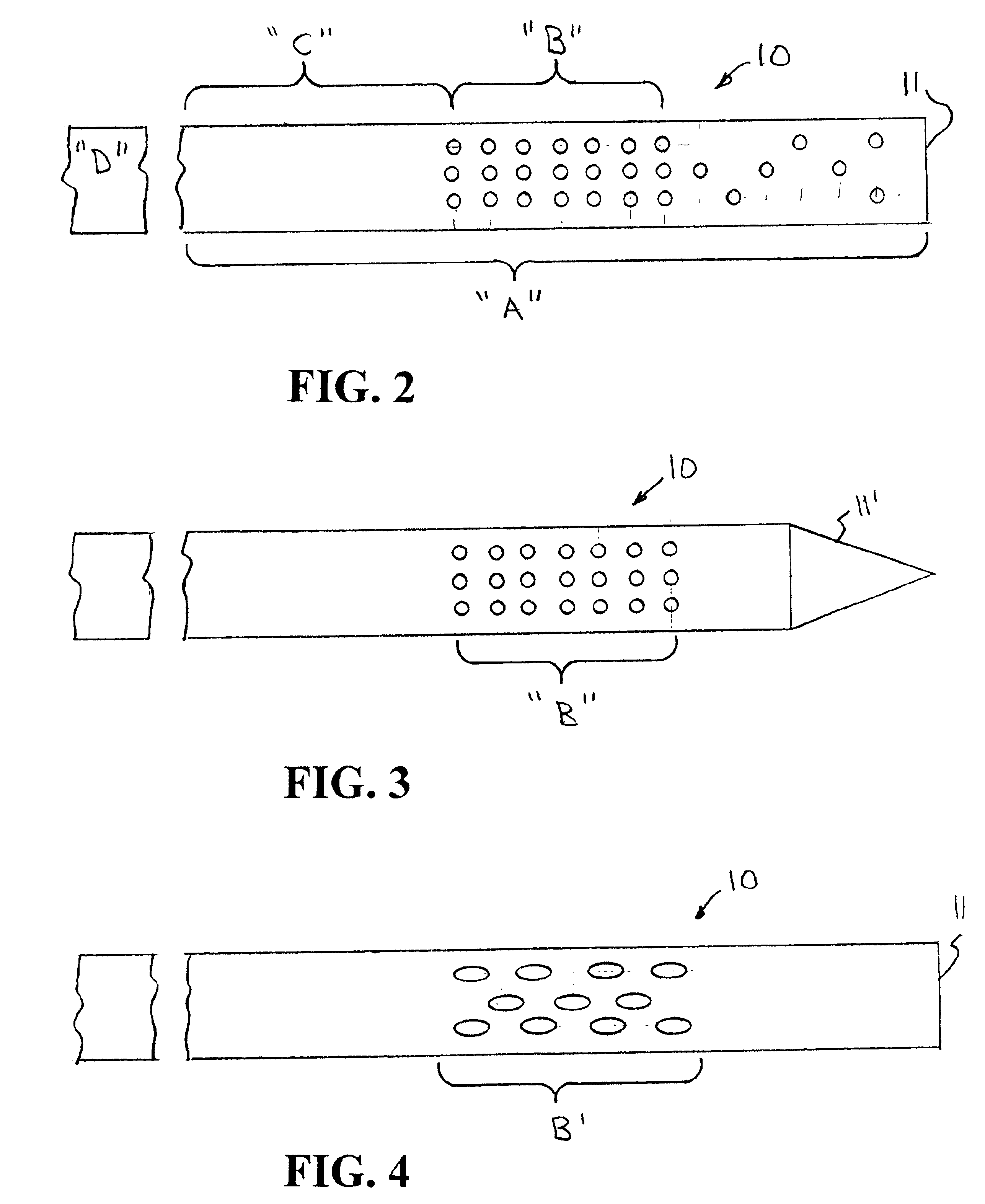

Porous protective solid phase micro-extractor sheath

InactiveUS6871556B2Analysis using chemical indicatorsComponent separationBare fiberSolid-phase microextraction

A porous protective sheath for active extraction media used in solid phase microextraction (SPME). The sheath permits exposure of the media to the environment without the necessity of extending a fragile coated fiber from a protective tube or needle. Subsequently, the sheath can pierce and seal with GC-MS septums, allowing direct injection of samples into inlet ports of analytical equipment. Use of the porous protective sheath, within which the active extraction media is contained, mitigates the problems of: 1) fiber breakage while the fiber is extended during sampling, 2) active media coating loss caused by physical contact of the bare fiber with the sampling environment; and 3) coating slough-off during fiber extension and retraction operations caused by rubbing action between the fiber and protective needle or tube.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Ferrule for optical connector

In an optical connector ferrule comprising an insertion opening through a bare fiber, from which the coating is removed, of one end of a coated optical fiber is inserted, a guide groove for guiding the bare fiber inserted through the insertion opening, a fiber hole into which the bare fibers guided by the guide groove is inserted, and an injection port through which adhesive for securing the coated optical fiber to the ferrule is injected, guide surfaces for guiding the bare fiber to the guide grooves are formed at sides of the guide groove. In the similar optical connector ferrule, there is provided an enlarged portion extending forwardly from a leading edge of the injection port in a fiber inserting direction and communicated with a filling space into which the adhesive is filled. Further, a ceiling surface of the enlarged portion is inclined downwardly forwardly from the injection port.

Owner:FURUKAWA ELECTRIC CO LTD +1

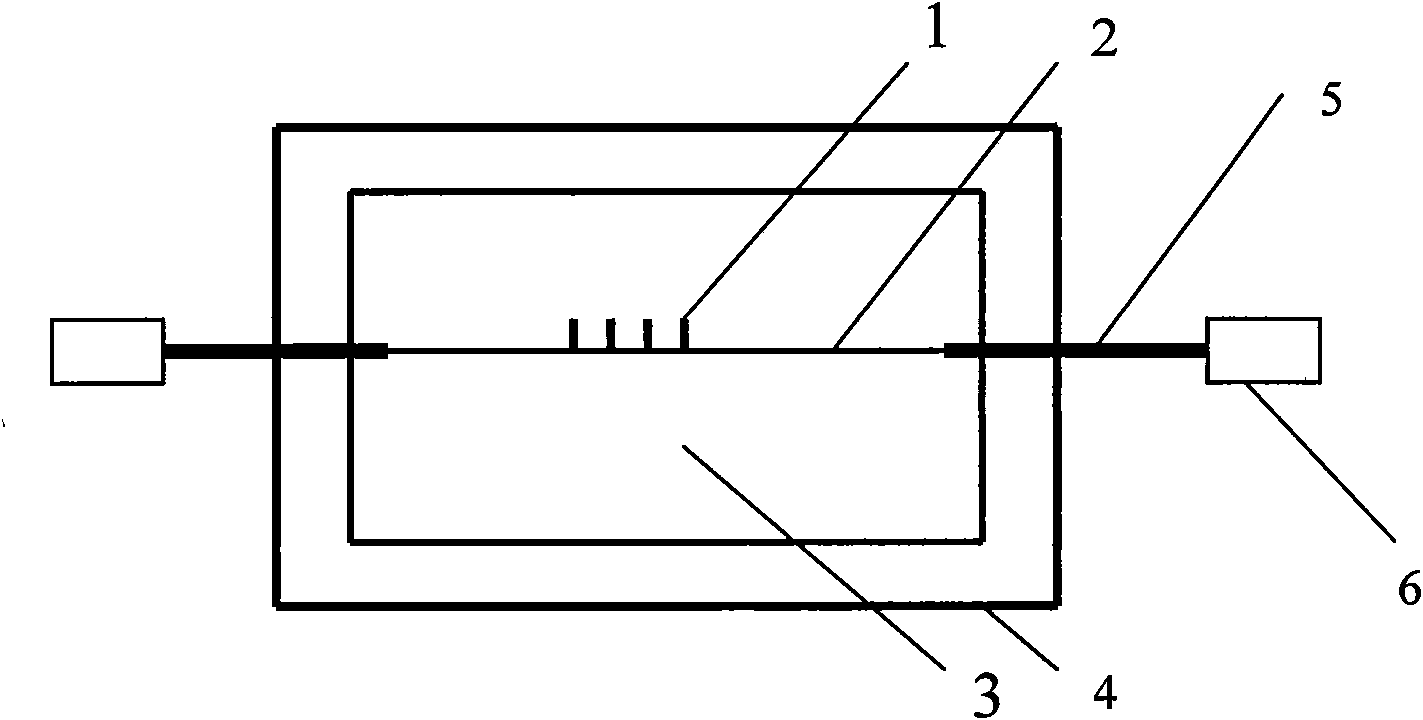

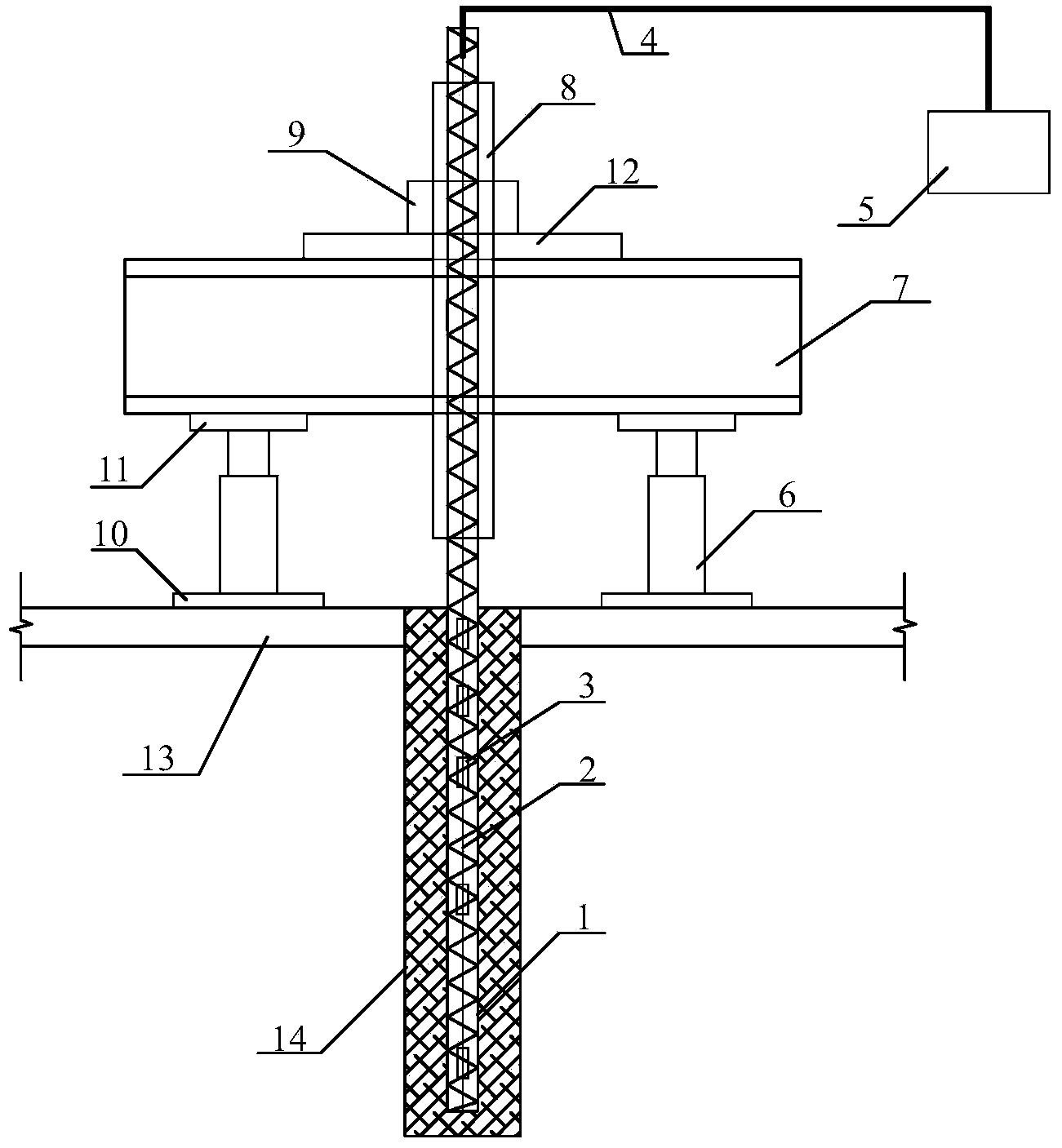

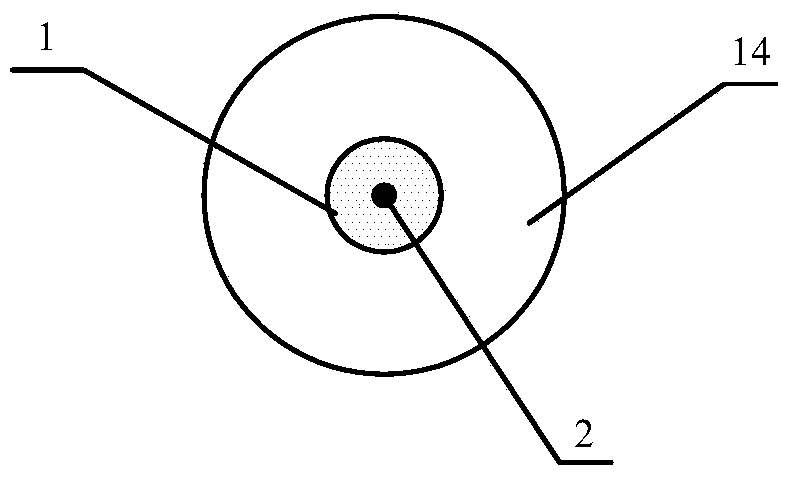

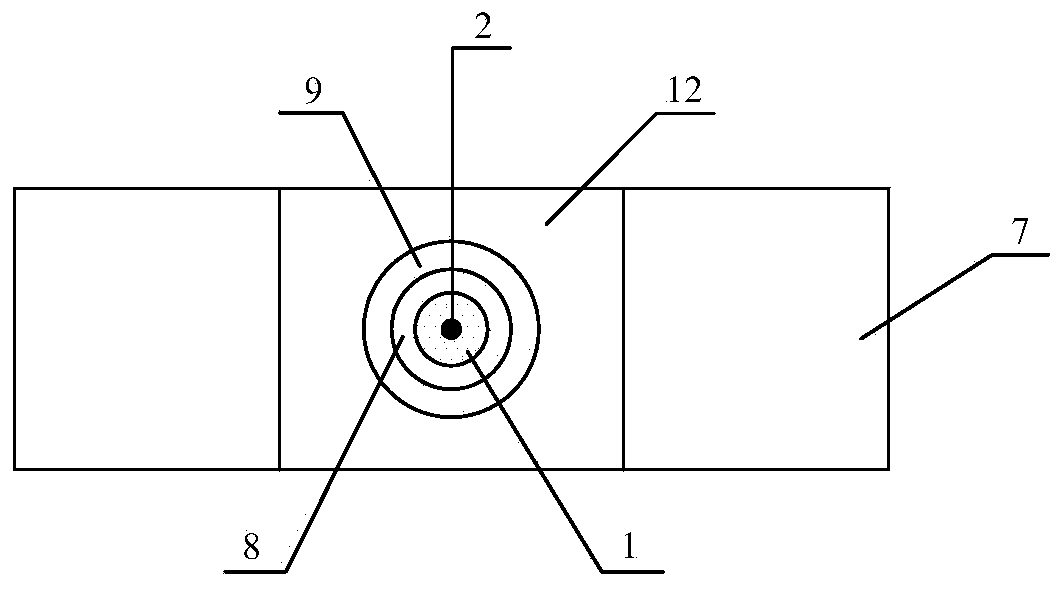

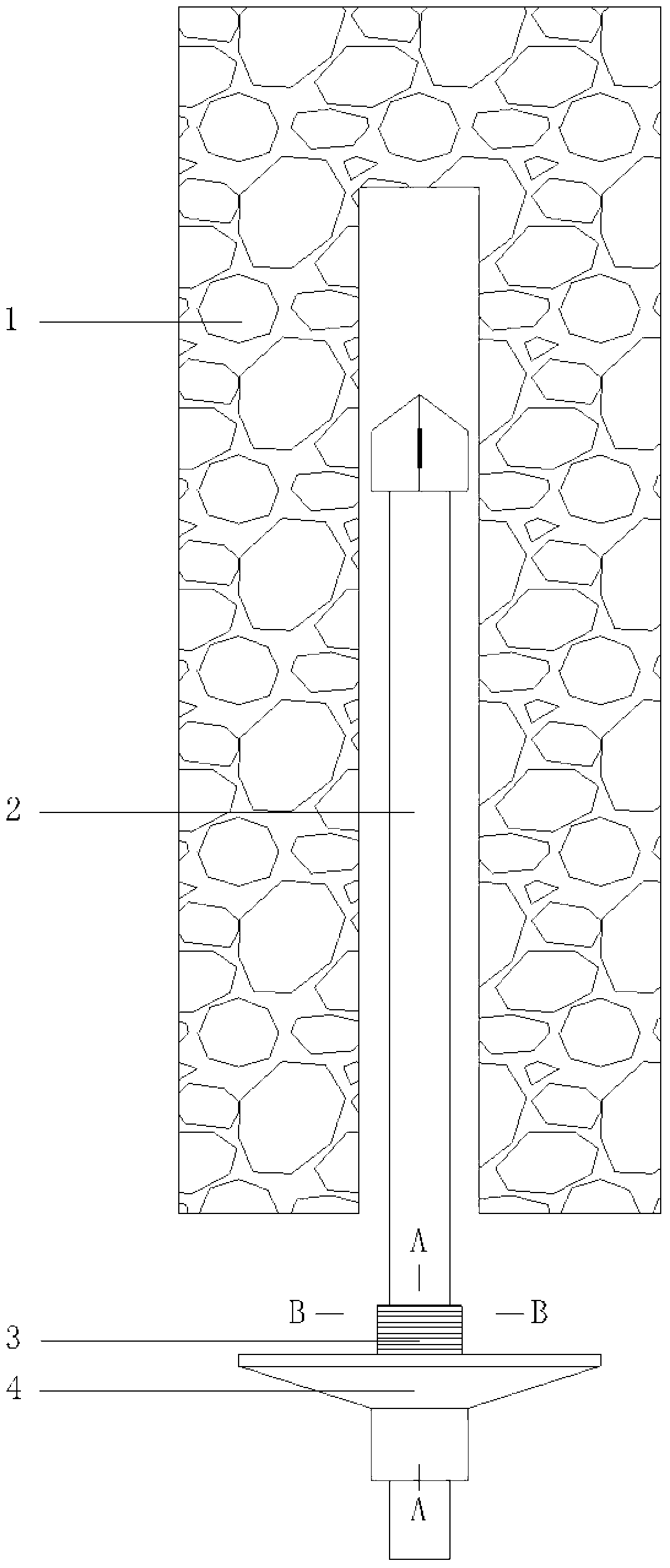

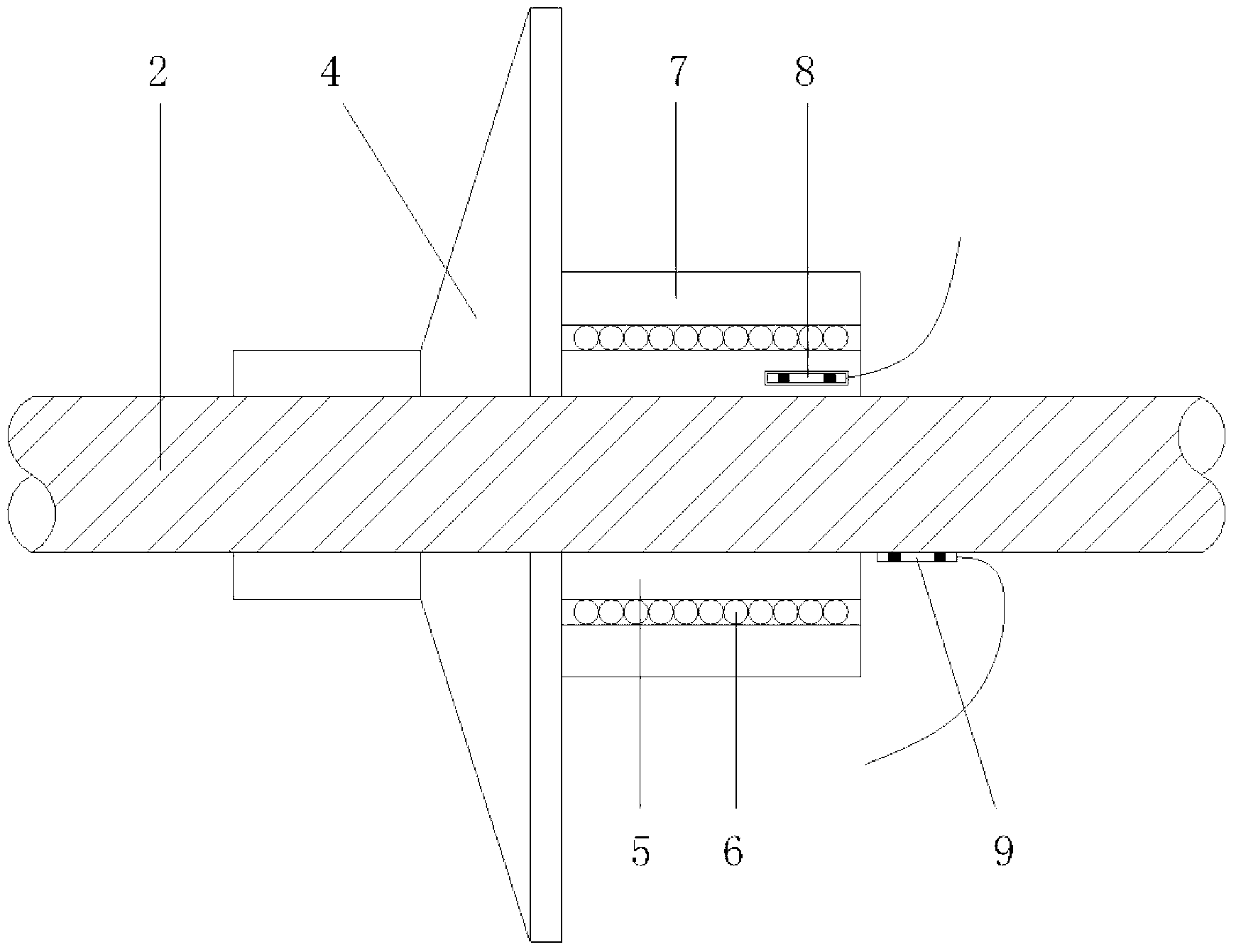

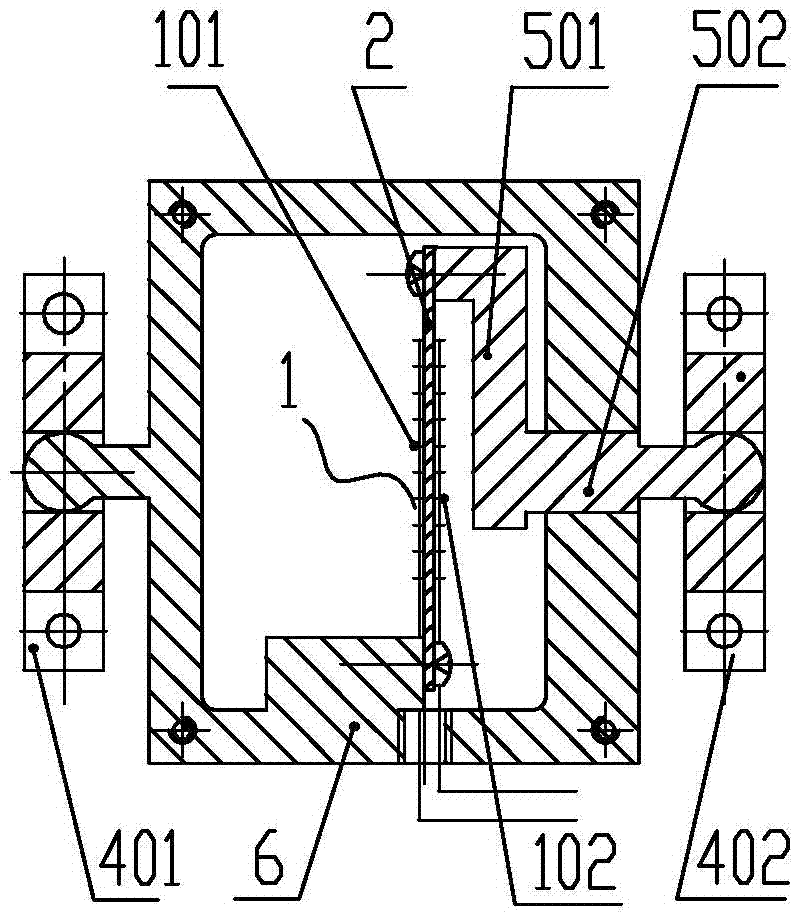

Stress testing device for non-metal anti-floating anchor rod body

InactiveCN103471747ASimple structureEasy to installForce measurement by measuring optical property variationGratingBare fiber

The invention belongs to the technical field of stress testing devices and relates to a stress testing device for a non-metal anti-floating anchor rod body. The stress testing device is characterized in that the lower end of an anchor rod body is inserted into an anchor rod hole; a grating sensor is etched into a bare fiber to form a fiber grating string, and the fiber grating string is buried and strung into the middle of an anchor rod; an armored cable for protecting the bare fiber at the tip of the anchor rod body is connected with a data collection system; two first steel plates are mounted on the upper surface of a cushion layer and are placed on two sides of the anchor rod body, and lifting jacks are placed at the middles of the first steel plates; counter-force beams in which holes are preformed in the middles are placed on the lifting jacks, and second steel plates are additionally arranged between the counter-force beams and the lifting jacks; a third steel plate is arranged on the tops of the counter-force beams, and an anchoring tool is fixedly arranged on the third steel plate; a steel sleeve is sleeved on the upper end of the anchor rod body, the inner side of the steel sleeve is connected with the anchor rod body, and the outer side of the steel sleeve is connected with the anchoring tool. The stress testing device is simple in structure, high in measurement accuracy, sensitivity and survival rate and strong in electromagnetic field interference resistance, is convenient to mount and is capable of realizing automatic monitoring.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

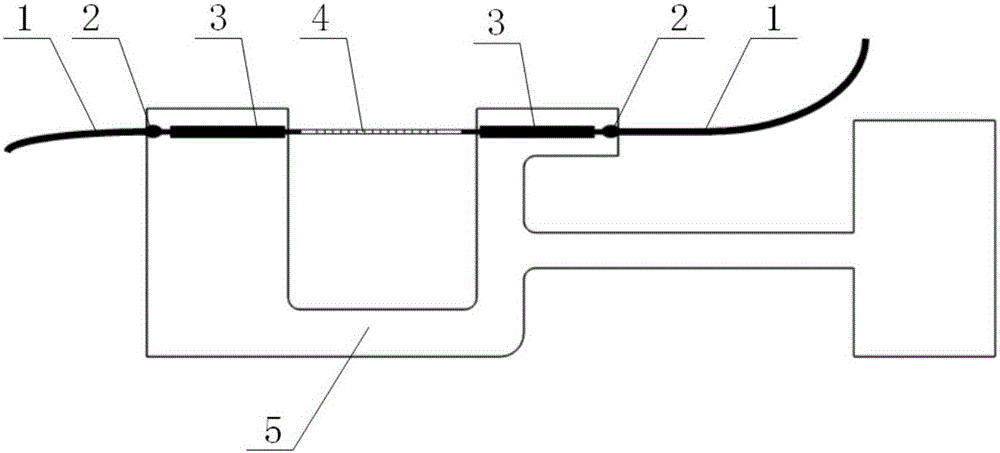

Optical fiber connection protecting box

The present invention discloses an optical fiber connection protecting box for connecting the tail fiber of the common indoor optical fiber and the leather-wire optical fiber. The optical fiber connection protecting box comprises the following components: a substrate which includes a locating part of the tail fiber fixing mechanism and a locating part of the leather-wire optical fiber fixing mechanism which are arranged spacing with each other for a certain distance; a bare fiber connection device which connects the common indoor optical fiber and the bare fiber in the leather-wire optical fiber; a tail wire fixing device which is fixed on the locating part of the tail fiber fixing mechanism of the substrate and connects the tail fiber in the common indoor optical fiber, wherein the bare fiber of the tail fiber traverses the tail fiber fixing device with a prearranged length and the bare fiber connecting device executes connection; and a leather-wire fixing mechanism which is fixed on the locating part of the skin-wire optical fiber fixing mechanism of the substrate and is connected with the leather-wire optical fiber, and the bare fiber of the leather-wire optical fiber traverses the leather-wire optical fiber fixing mechanism with a prearranged length and the bare fiber connecting mechanism executes the connection to the bare fiber of the tail fiber. The invention can effectively connect the leather-wire optical fiber with the tail fiber of the common indoor optical fiber and directly fixes the tail fiber through a reinforcing piece in the tail fiber. The leather-wire optical fiber and the tail fiber can be firmly and stably connected, and the fiber core wherein can be effectively protected.

Owner:CORNING RES & DEV CORP

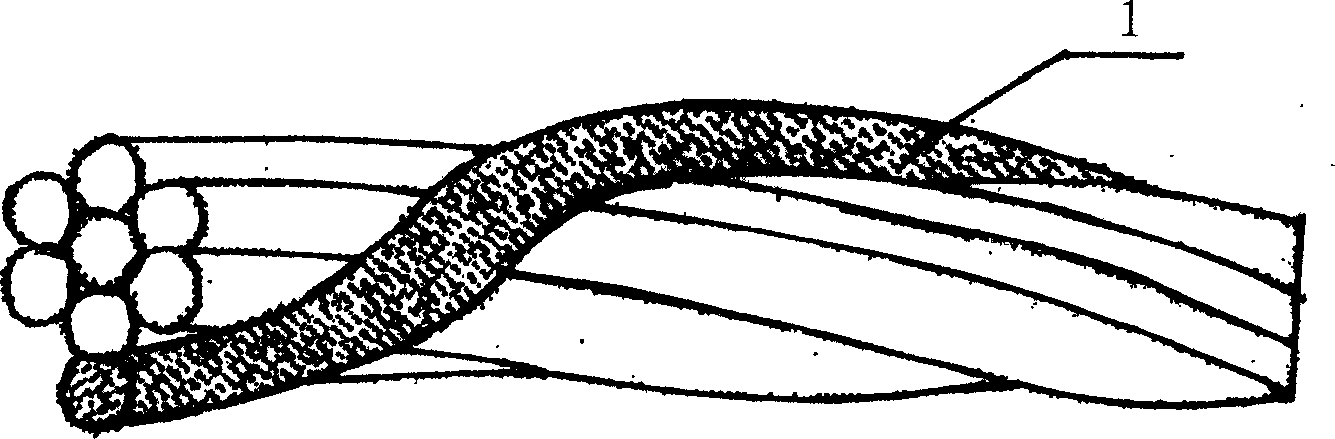

Method for continuously preparing fiber gratings on line

InactiveCN102590929AImprove consistencyElimination of mutual negative effectsCladded optical fibreOptical waveguide light guideGratingBare fiber

The invention discloses a method for continuously preparing fiber gratings on line. According to the method, coating and curing of a prefabricated bar high-temperature drawn bare fiber and a bare fiber protective layer are separated. By the method, adverse interaction between a wire drawing process and an on-line grating write-in and coating process is eliminated; the method is easy to control; and the operation of a system is stable. In addition, mutual constraint factors between the processes are eliminated, the two processes are respectively performed under optimal process conditions, and many technical problems of conventional dynamic on-line grating formation are well solved.

Owner:WUHAN UNIV OF TECH

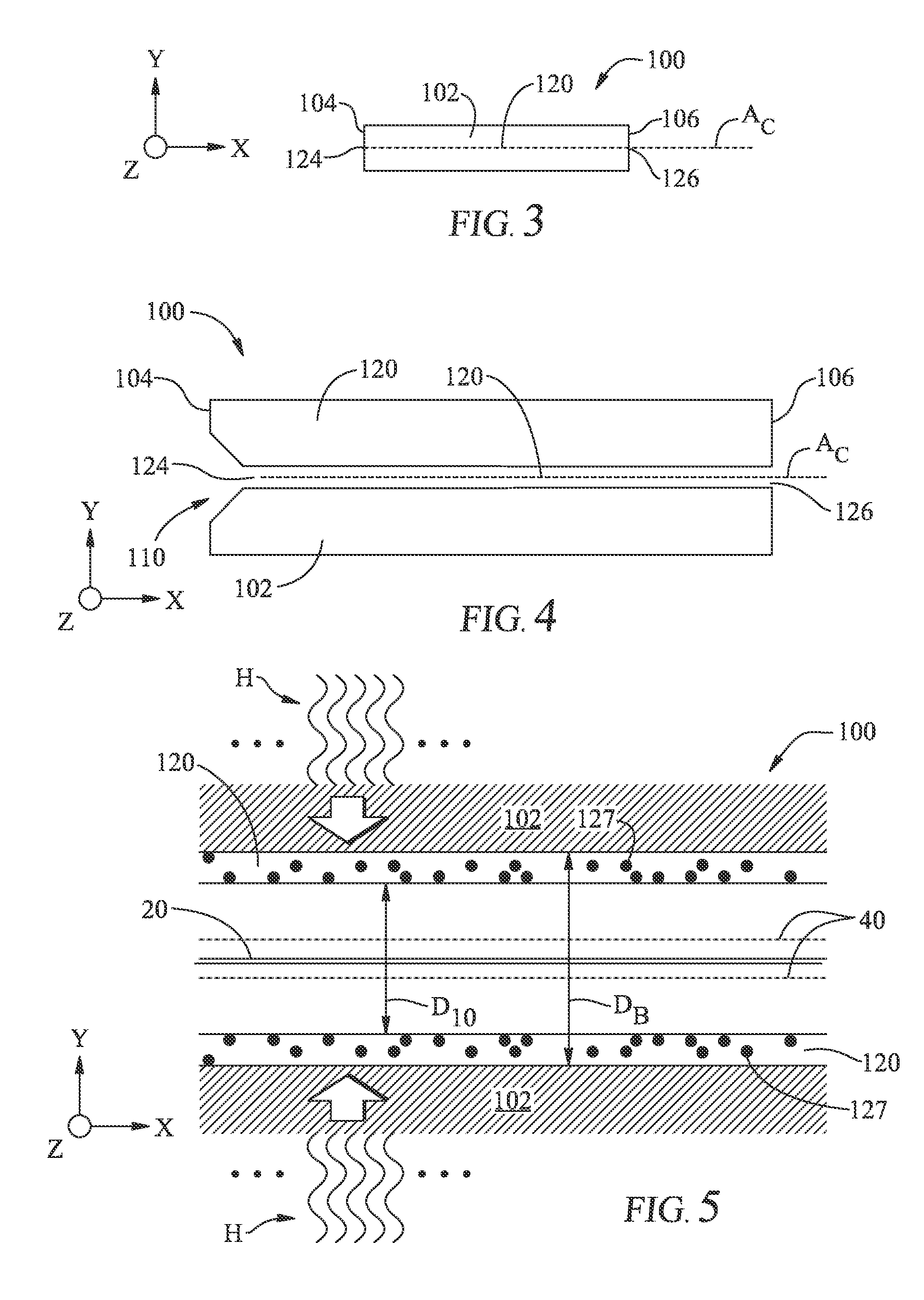

Connectorized nano-engineered optical fibers and methods of forming same

InactiveUS20080304796A1Eliminate pollutionAvoid pollutionGlass making apparatusNanotechFiberBare fiber

Connectorized nano-engineered optical fibers and method for forming them are disclosed. The methods include heating a mid-span bare fiber portion of the nano-engineered fiber to substantially collapse the airlines therein so as to form a substantially airline-free portion. The fiber is then inserted into a ferrule channel so that the fiber end protrudes beyond the ferrule end face, but with the substantially airline-free portion positioned at the ferrule end face. The fiber is then cleaved at or near the ferrule end face in the substantially airline-free portion, and the new fiber end face polished to create a solid fiber end face that coincides with the ferrule end face. The methods result in relatively small changes to the mode field diameter (MFD) and / or to the outer cladding diameter.

Owner:CORNING CABLE SYST LLC

Snake type fiber-optical sensor burying and detecting method and its snake type fibre-optical sensor

InactiveCN1588013ATest destructionHigh deformation testMaterial analysis by optical meansCoupling light guidesTerrainBare fiber

The invention relates to the imbedding and test method for a snake optical fiber sensor and the snake optical fiber sensor. The method involves making and imbedding the optical fiber sensor, connecting the optical fiber sensor to a transition optical fiber with a bonding machine to position the the optical fiber sensor, testing the loss initial value, after excavating, test system loss changing curve of the optical fiber test system and observing the deformation and damage condition of the terrain; processing the OTDR test data with program. The bare fiber is covered with a bushing on the outside diameter and equipped with a protecting device on both end. The fiber can form many minor bend point used to monitor the deformation of rock whose strength is lower than quartz glass and the generating, developing, microdeformation and macrodeformation of the cranny of large deformed rocks. The initial deformation of the terrain, even the damage of materials,can be detected with the accuracy within plus or minus 0.01mm. The marodeformation reaches 35-50 mm, far higher than the concrete deformation detection. It is a distributed optical fiber detecting instrument, the fiber is connected with the detecting device, convenient to operating, detection is stable, highly accurate.

Owner:CCCC TUNNEL ENG +1

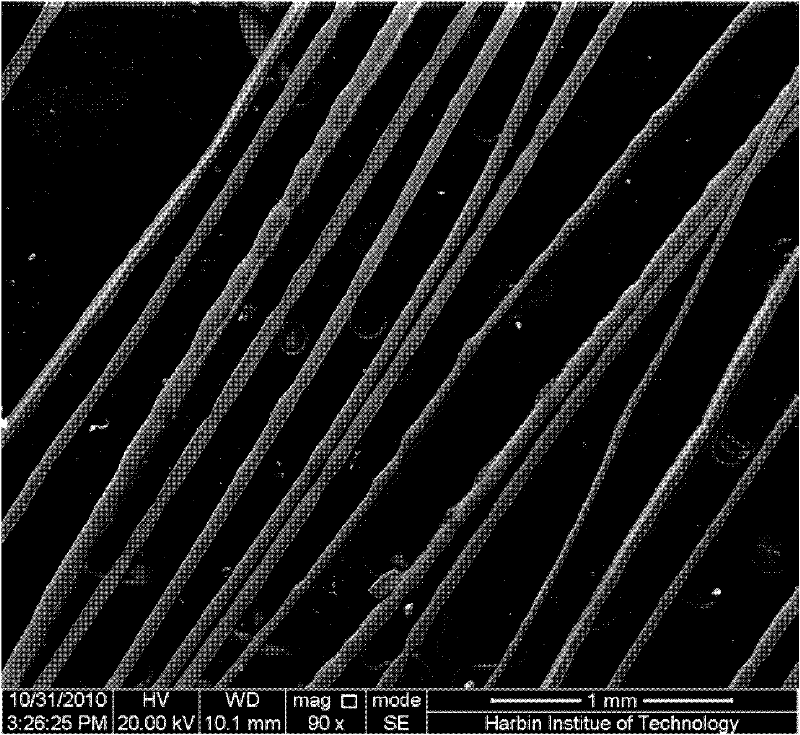

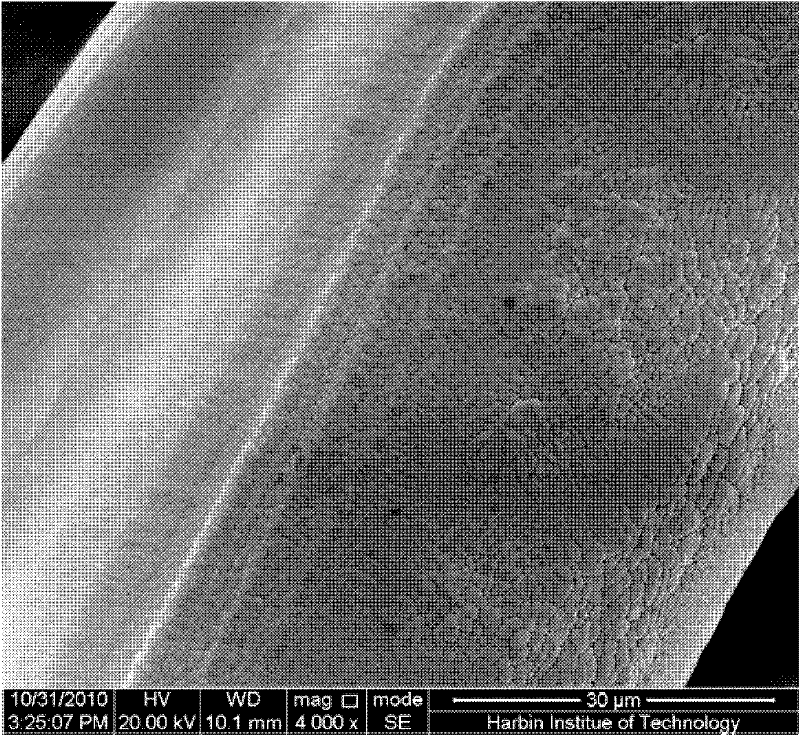

Method for preparing Ni-Mn-Ga ferromagnetic shape memory alloy continuous fibers by adopting spinning method

The invention discloses a method for preparing Ni-Mn-Ga ferromagnetic shape memory alloy continuous fibers by adopting a spinning method, and relates to a preparation method of Ni-Mn-Ga ferromagnetic shape memory alloy continuous fibers. The method solves the problems that the conventional glass coating method for preparing the Ni-Mn-Ga fibers has low production efficiency and poor process repeatability and bare fibers cannot be directly obtained. The method comprises the following steps of: putting Ni-Mn-Ga alloy ingots into a crucible of a device for preparing metallic amorphous wires, charging argon protection gas into a cavity, starting a metallic roller, heating the crucible, controlling the crucible to move to the metal roller after the alloy is smelted, and spinning the metal into the fibers when the high-speed rotating metal roller is in contact with the molten metal. The length of the prepared fibers reaches 1 to 10 centimeters, the diameter of the fibers is 30 to 80 microns, and the size of the fibers is uniform. The components of the fibers are uniform and consistent with the adopted alloy ingot components. The preparation method has high production efficiency and good process repeatability, the bare fibers can be directly obtained, and good surface state is kept.

Owner:HARBIN INST OF TECH

Fiber anchor pole corrosion sensor

InactiveCN103323385AIncreased durabilityInnovative designWeather/light/corrosion resistanceFiberGrating

A fiber anchor pole corrosion sensor, belongs to a geotechnical engineering technology field. The fiber anchor pole corrosion sensor is characterized in that: the sensor is composed of a fiber corrosion expansion monitoring unit, a fiber grating temperature compensating unit and a fiber grating stress correction unit in layers, wherein the fiber corrosion expansion monitoring unit, which is a key component, is composed of a porous medium cushion layer, a bare fiber winding layer, an externally-coated cement mortar protective layer and an armoured signal transmission optical cable. The optical fiber is wound on a steel bar anchor pole and a steel strand anchor pole, protective layers are internally and externally arranged, radial expansion strain of the anchor pole caused by corrosion is measured, and quantitative monitor of corrosion degree of an anchor pole steel bar or a steel strand is implemented. The invention provides an anchor pole corrosion monitoring sensor which has advantages of clear principle, high measurement precision, low cost and high endurance, and the anchor pole corrosion monitoring sensor can implement long-term and stable quantitative monitor on a corrosion state of the anchor pole, and makes sure structural safety of the anchor pole.

Owner:DALIAN UNIV OF TECH

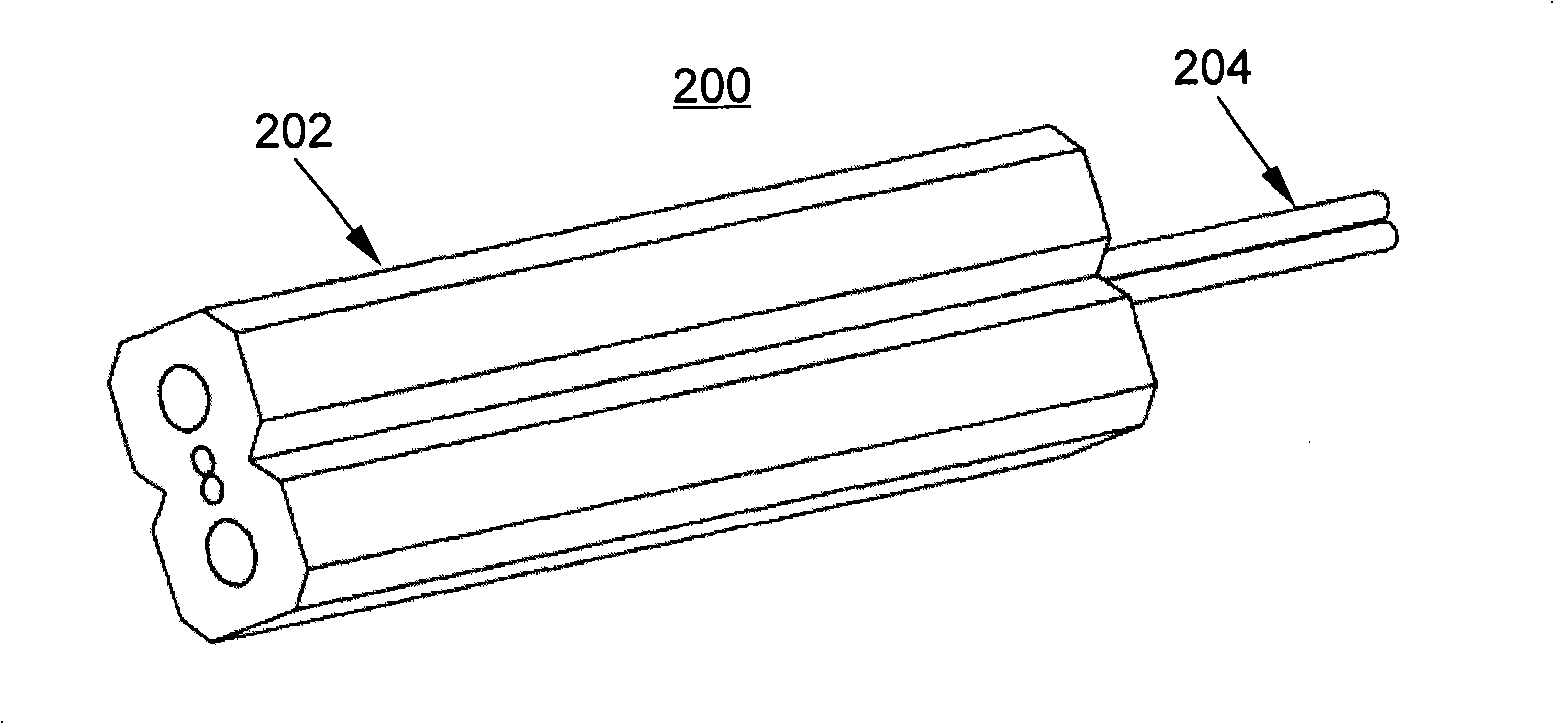

Method for molding optical fiber fusion spliced portion and optical fiber with molded fusion spliced portion

InactiveUS6908236B2Large elongationHigh tensile strengthCladded optical fibreOptical articlesBare fiberOptoelectronics

Owner:SUMITOMO ELECTRIC IND LTD

Distributed type non-slippage optical fiber strain sensor and manufacturing method thereof

ActiveCN101275916AImproved compression setGood for measuring compression setOptically investigating flaws/contaminationUsing optical meansEpoxyBare fiber

A distributed no-slippage optical fiber stain sensor and a manufacturing method thereof are a distributed no-slippage Brillouin scattering optical fiber which is used for the health detection and monitoring of the structural facility and the manufacturing method thereof. The invention is characterized in that the sensor uses an UV resin signle mode fiber as a substrate, and a single mode bare fiber part which is eliminated with an UV resin coating layer is provided thereon. The exterior part of the bare fiber is provided with a basalt fiber packaging layer to form an optical fiber strain sensor. To the total adhibition packaging mode, the exterior part is immersed with epoxy resin and is packaged. To the fixed-point adhibition packaging optical fiber, a sleeve pipe is provided outside the bare optical fiber. A certain space is preserved between the sleeve pipes. The bare fiber between the sleeve pipes and the sleeve pipes are fixed on the immersed basalt fiber through the epoxy resin. The distributed no-slippage optical fiber sensor of the invention has high precision and high sensitivity. The long-distance and large-area structural stain information can be accurately obtained, and the manufacturing method is simple and easy.

Owner:SOUTHEAST UNIV +1

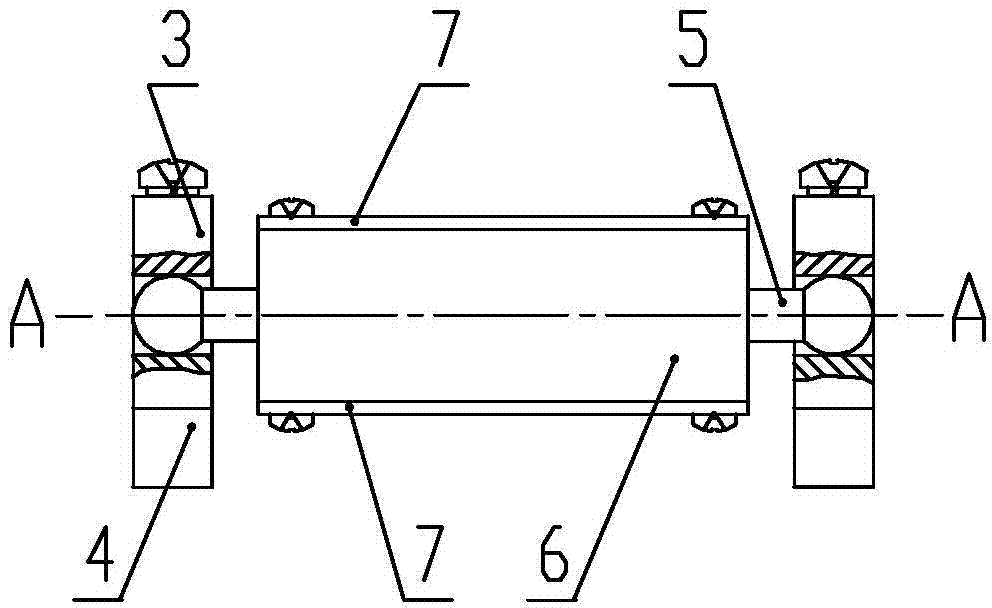

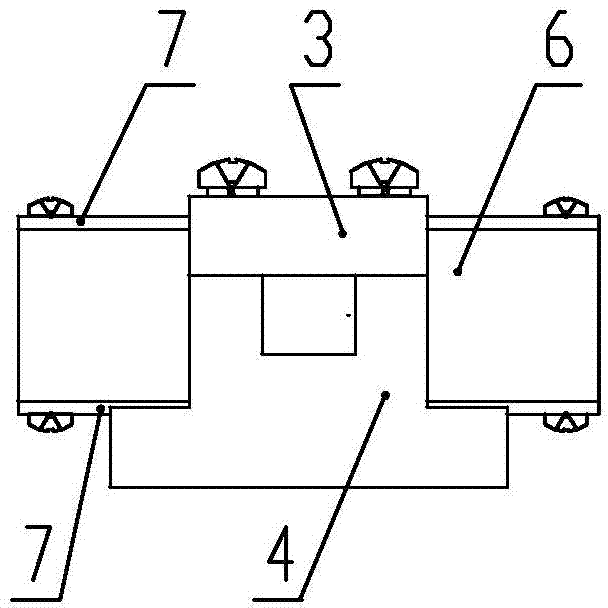

Fiber grating strain sensibilization sensor

InactiveCN106441140ASensitivity adjustableAdjust the sensitization factorUsing optical meansFiberGrating

The invention discloses a fiber grating strain sensibilization sensor, which comprises a fiber grating and an elastic sensitization substrate. The fiber grating is fixedly arranged on the elastic sensitization substrate; and the fiber tails at the two ends of the fiber grating are respectively sleeved by a fiber protection sleeve. The elastic sensitization substrate comprises a fiber grating fixation mechanism and a lever sensibilization mechanism, which are in an integrated structure. The fiber grating fixation mechanism is provided with two sections of semicircular fine grooves. The two sections of semicircular fine grooves are used for fixing the fiber grating and the fiber protection sleeves, and under the condition that the fiber grating is suspended between the two sections of semicircular fine grooves, fixation is realized by applying a pretightening force and through a fiber fixation coating layer; and by changing the structure size of the lever sensibilization mechanism, adjustment of the sensibilization effect is realized. The fiber grating strain sensibilization sensor has higher strain sensibilization coefficient, and the strain sensitivity thereof is 5-6 times higher than that of a bare fiber grating; and meanwhile, the fiber grating strain sensibilization sensor is simple in structure and convenient to install, has higher consistency and reliability and can be used repeatedly.

Owner:WUHAN UNIV OF TECH

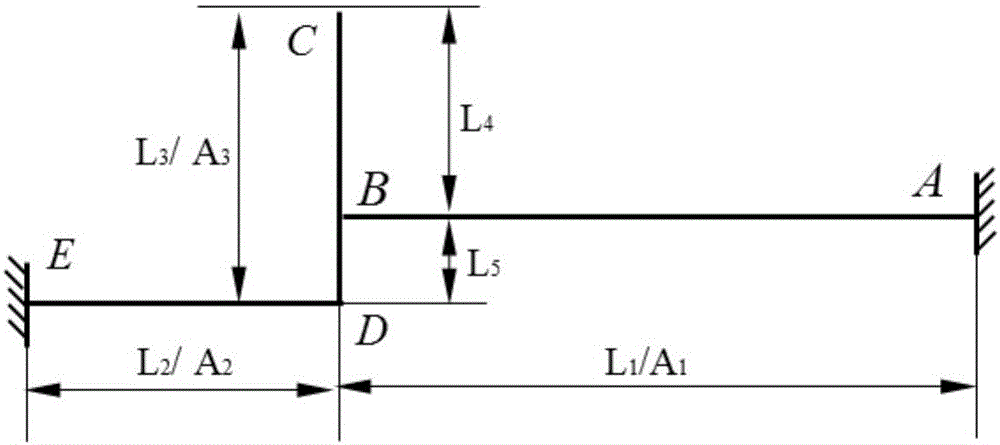

Temperature-self-compensating-integrated fiber bragg grating strain transducer and method for monitoring cable force of inhaul cable through integrated temperature self-compensating fiber bragg grating strain transducer

ActiveCN103791850AWith temperature self-compensation functionHigh sensitivityForce measurement by measuring optical property variationUsing optical meansFiberCantilevered beam

A temperature-self-compensating fiber-integrated bragg grating strain transducer comprises a fiber bragg grating transducer body composed of two bare fiber bragg gratings with the same model but different wave bands, an elastic sheet composed of high-elasticity metal thin sheets, clamping pieces, bases, a Z-shaped movable piece composed of L-shaped steel plates and a metal frame. The metal frame is provided with a frame shaft hole and a frame connecting shaft, and a connecting shaft of the Z-shaped movable piece penetrates through the frame shaft hole to be fixedly connected with the base II through the clamping piece II and can relatively move in the frame shaft hole. One end of the elastic sheet is fixedly connected with the L-shaped plates of the Z-shaped movable piece, and the other end of the elastic sheet is fixed on the metal frame. The frame connecting shaft is fixedly connected with the base I through the clamping piece I. A cantilever beam stress structure is formed by the frame, the Z-shaped movable piece, the elastic sheet, the bases and the clamping pieces. Under the working state, the two bases are fixed on the surface of a component to be tested in a bolting or welding mode, and when the component to be tested is strained, the bases and the Z-shaped movable piece are driven to drive the elastic sheet to deform, and then the fiber bragg gratings deform.

Owner:LIUZHOU OVM MASCH CO LTD

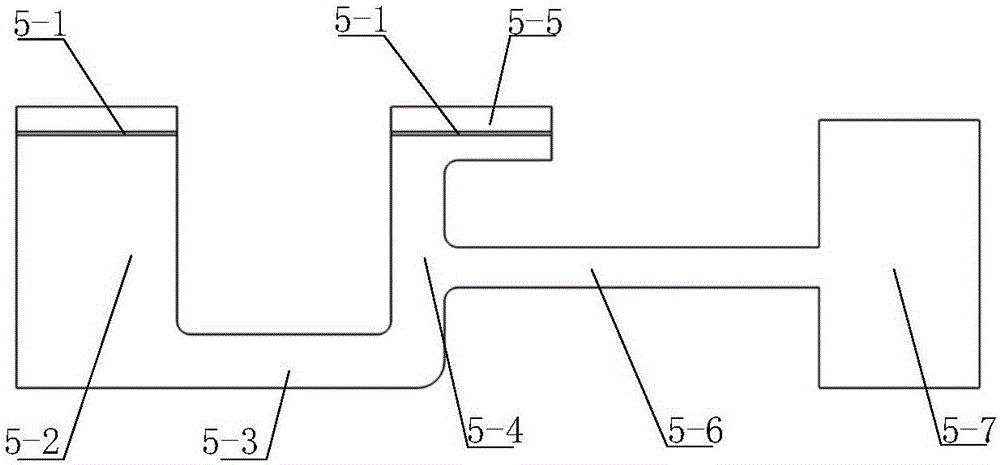

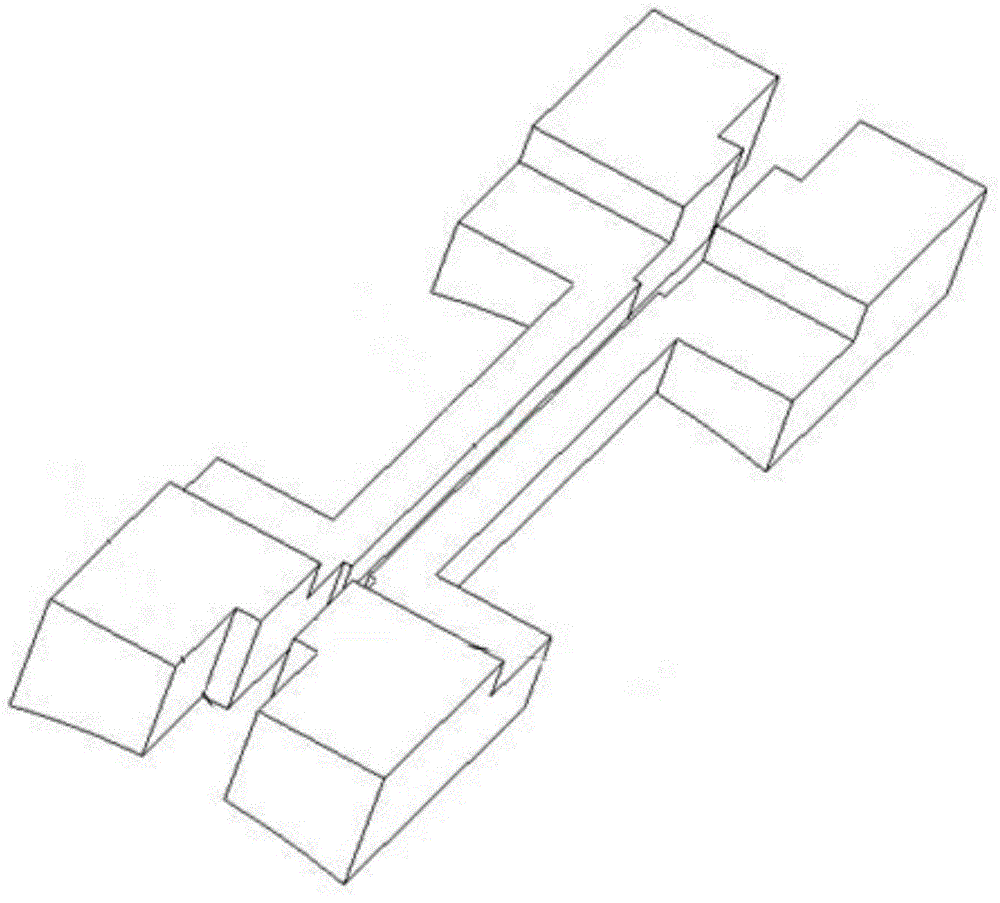

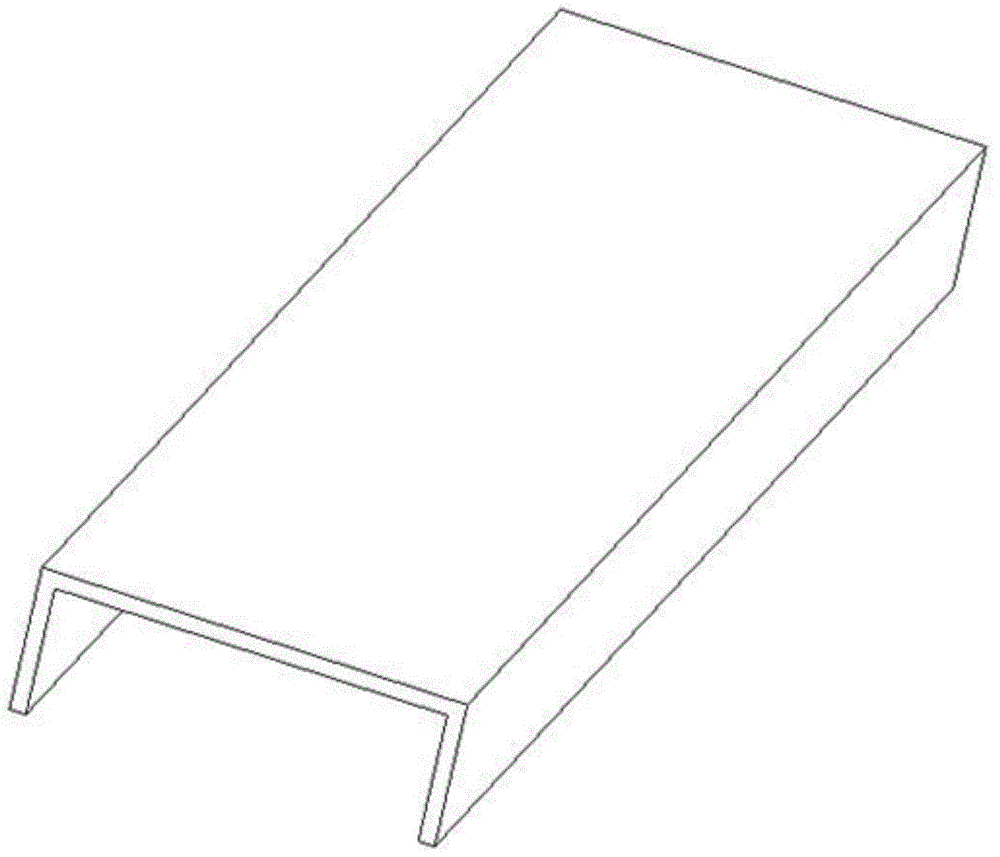

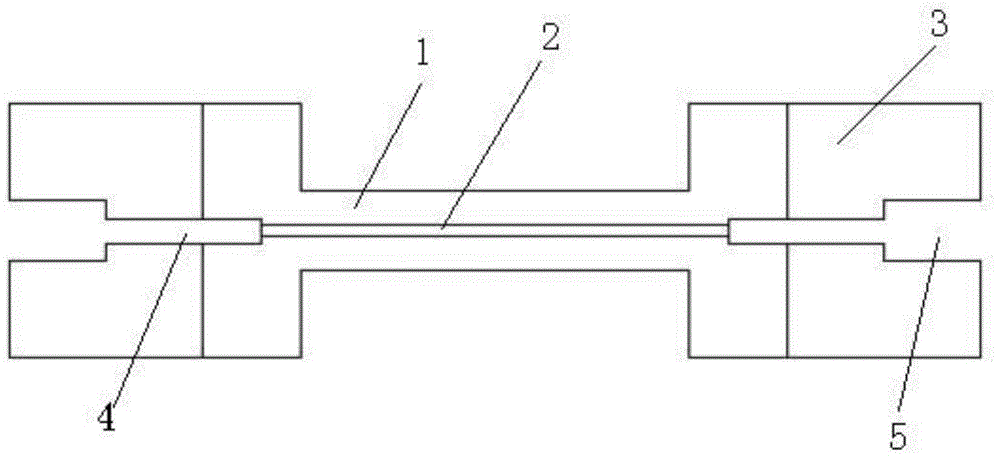

Fiber grating sensor packaging device for measuring support and hanger pull rod strain

The invention discloses a fiber grating sensor packaging device for measuring support and hanger pull rod strain. The device is formed by a base and a cover plate. The base is formed by two clamping components which are symmetrically arranged at left and right sides. The two clamping components are connected to be a whole body through an arc bottom face. Each of the clamping components is formed by end parts arranged at two ends and a center part arranged in the middle. A bare grating area is arranged between the two clamping components which are symmetrically arranged at left and right sides. Two ends of the bare grating area are provided with fiber areas. The other end of each of the fiber areas is provided with a fiber clamp area. According to the technical scheme of the invention, in order to raise the fitness of a fiber grating sensor pull rod, the base is designed to be a circular arc surface which is matched with the curve of a fixed position, in the process of packaging, the fiber grating is placed into the bare fiber area and the fiber areas and is clamped tightly through fiber clamps, an instantaneous drying adhesive is used to fix a fiber position to be tightly attached with a package base, an epoxy resin adhesive is used for permanent fixation, and finally a cover plate and the base are bonded to be a whole body.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com