Fiber grating sensor packaging device for measuring support and hanger pull rod strain

A fiber grating and packaging device technology, applied in the field of strain sensors, can solve the problems of being easily damaged by external forces and affected by the external environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

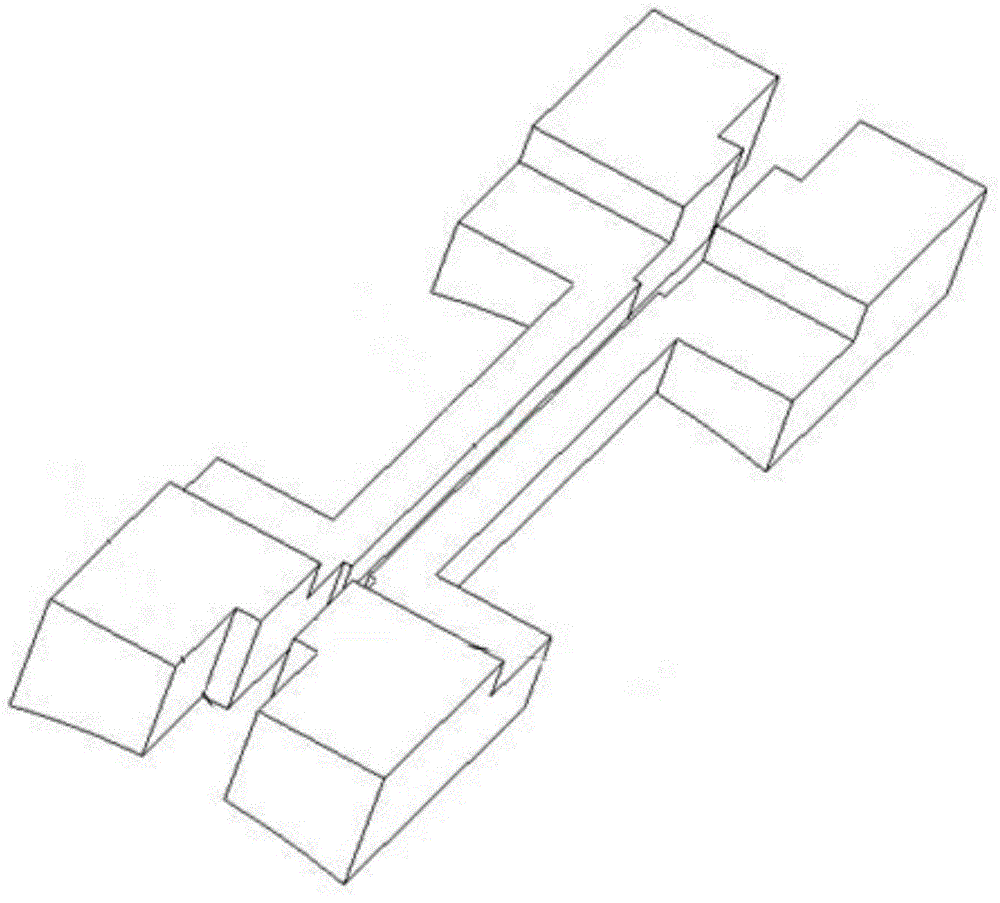

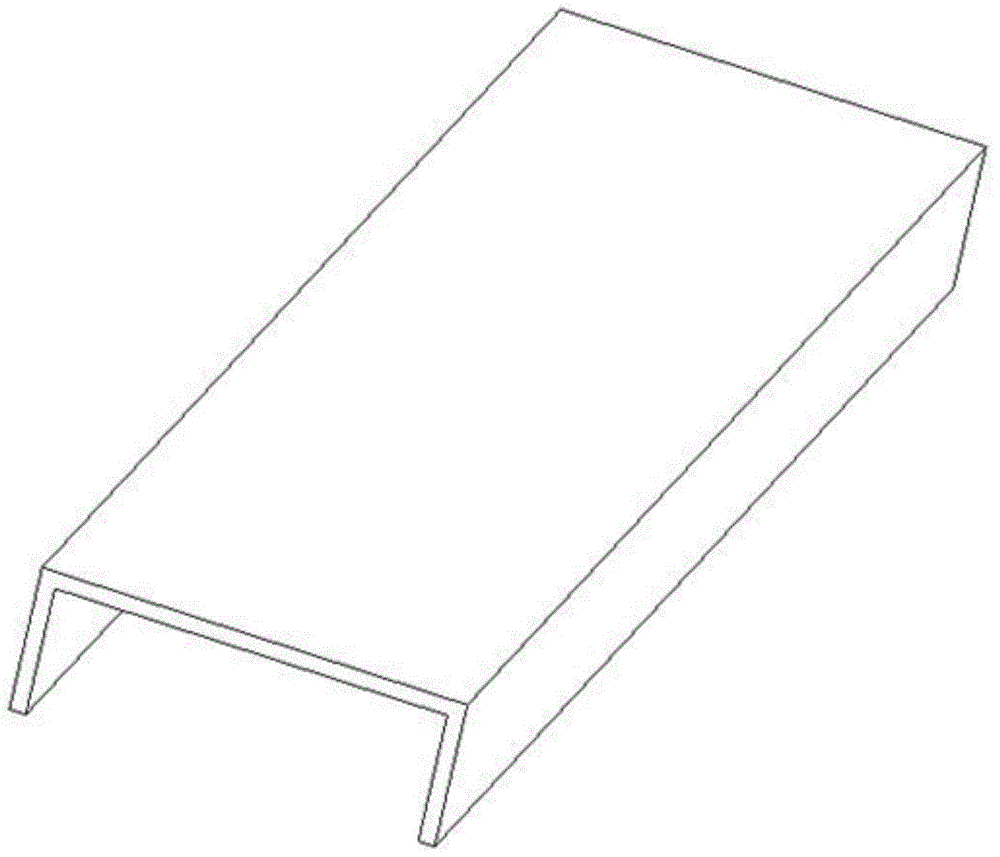

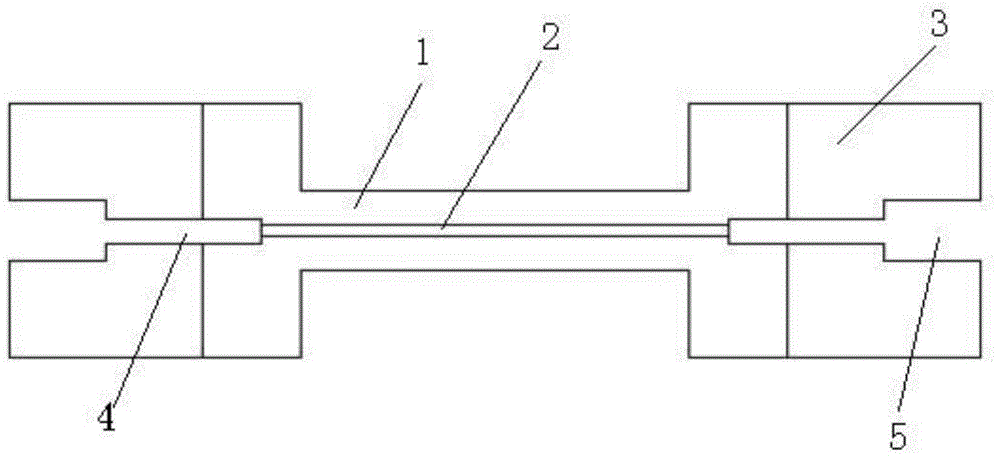

[0015] attached by figure 1 As shown in -4, 1 is an intermediate part, 2 is a bare grating area, 3 is an end part, 4 is an optical fiber area, and 5 is an optical fiber clamp area. The packaging device of the present invention is composed of a base and a cover. The cover is arranged above the base to protect and isolate the base. The base is composed of two clamping parts symmetrically arranged on the left and right. The two The clamping parts are connected as a whole through the arc bottom surface.

[0016] The clamping part is composed of end parts 3 arranged at both ends and an intermediate part 1 arranged in the center, and a bare grating area 2 is arranged between the two symmetrically arranged clamping parts. An optical fiber section 4 is provided at both ends of the optical fiber section, and an optical fiber clamp section 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com