Patents

Literature

169 results about "Welding helmet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

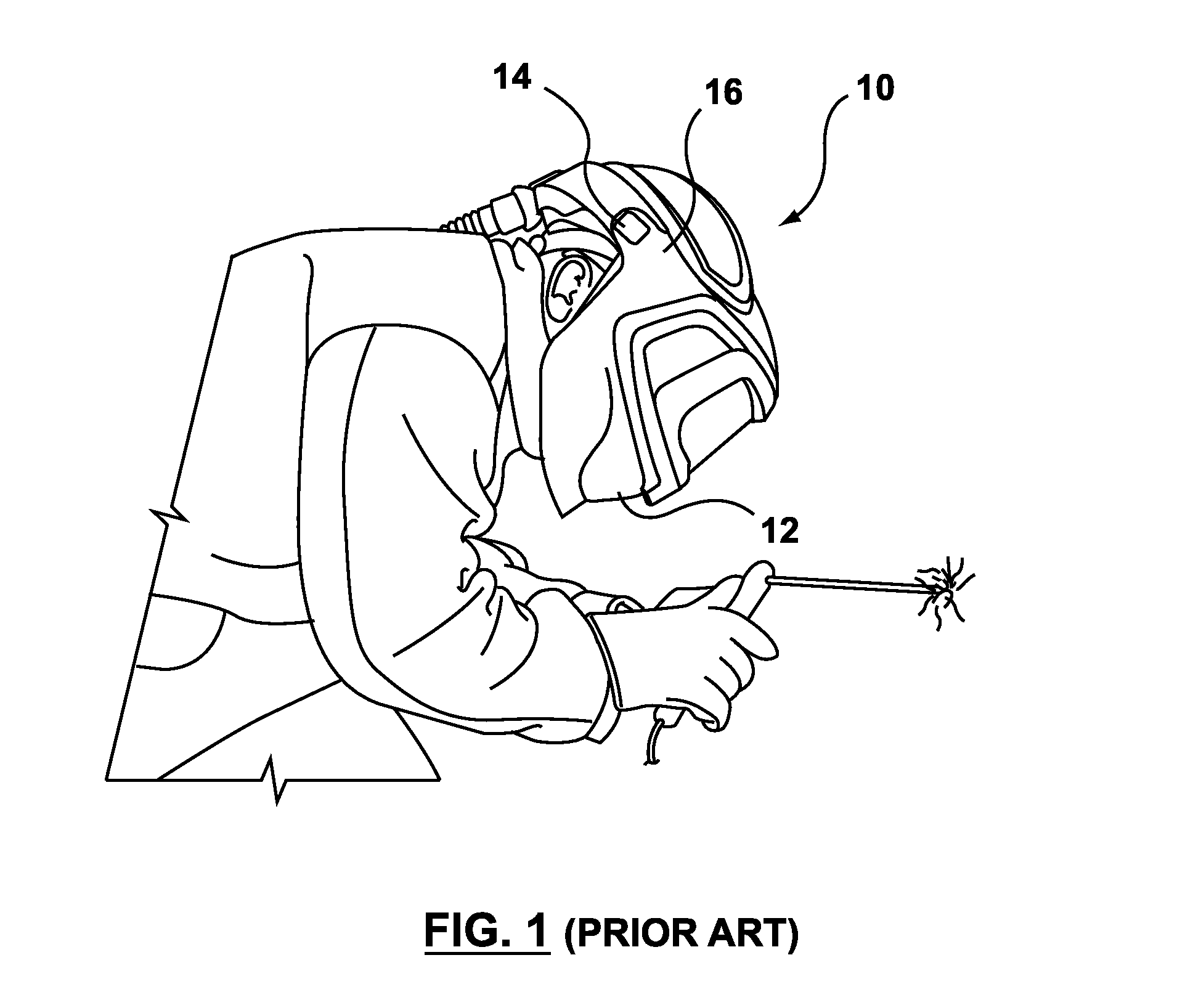

A welding helmet is a type of headgear used when performing certain types of welding to protect the eyes, face and neck from flash burn, ultraviolet light, sparks, infrared light, and heat. Welding helmets are most commonly used with arc welding processes such as shielded metal arc welding, gas tungsten arc welding, and gas metal arc welding. They are necessary to prevent arc eye, a painful condition where the cornea is inflamed. Welding helmets can also prevent retina burns, which can lead to a loss of vision. Both conditions are caused by unprotected exposure to the highly concentrated ultraviolet and infrared rays emitted by the welding arc. Ultraviolet emissions from the welding arc can also damage uncovered skin, causing a sunburn-like condition in a relatively short period of welding. In addition to the radiation, gasses or splashes can also be a hazard to the skin and the eyes.

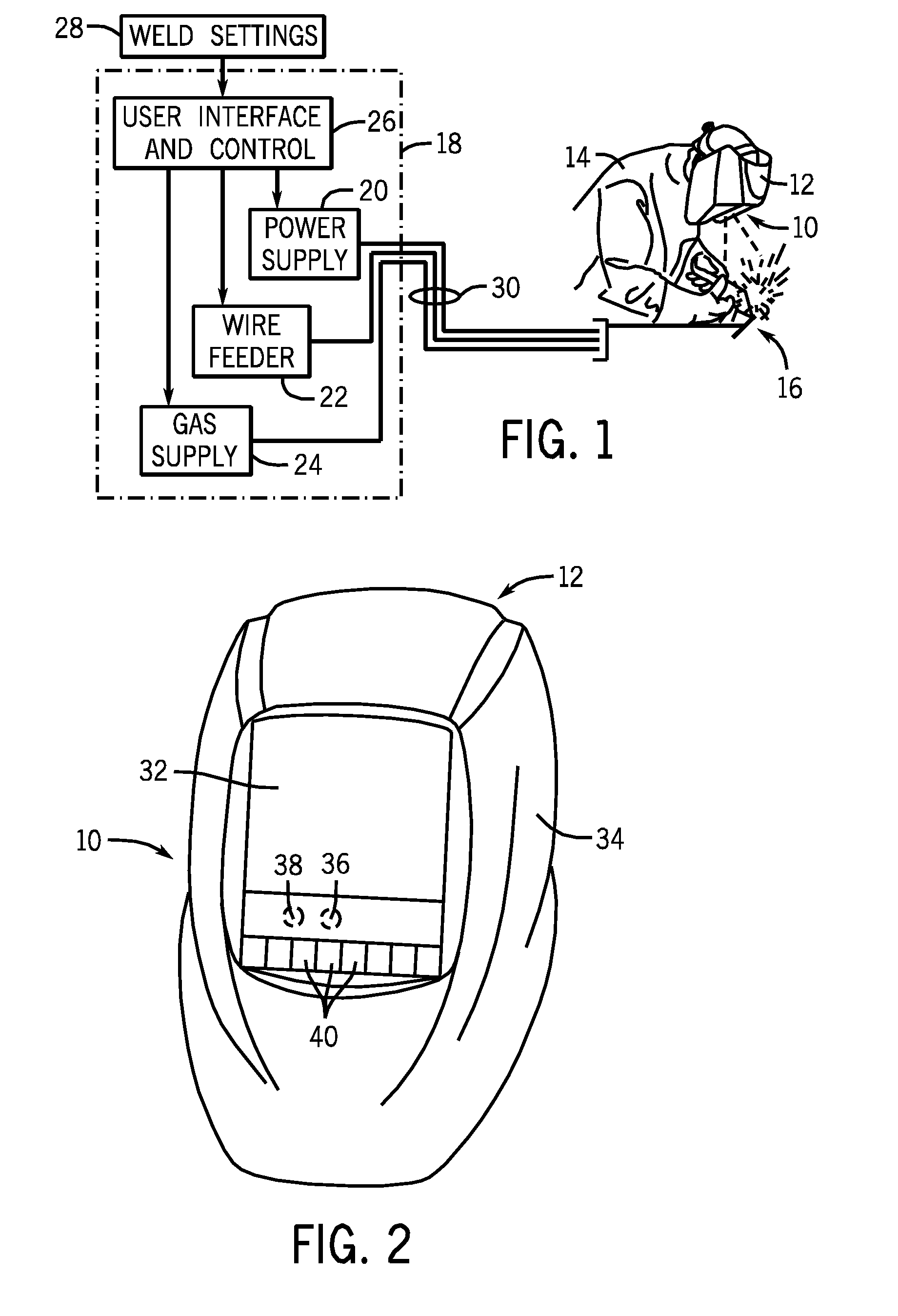

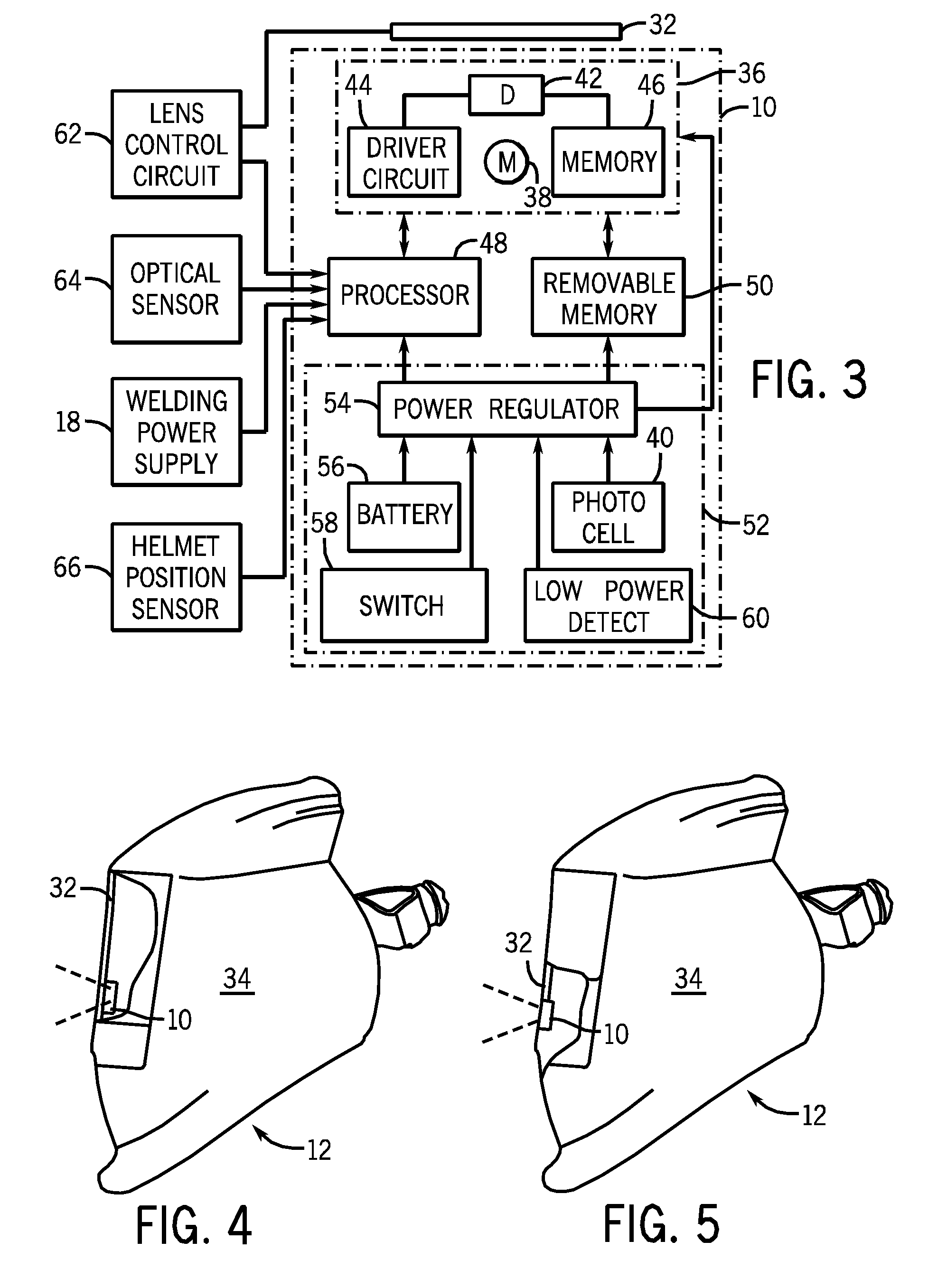

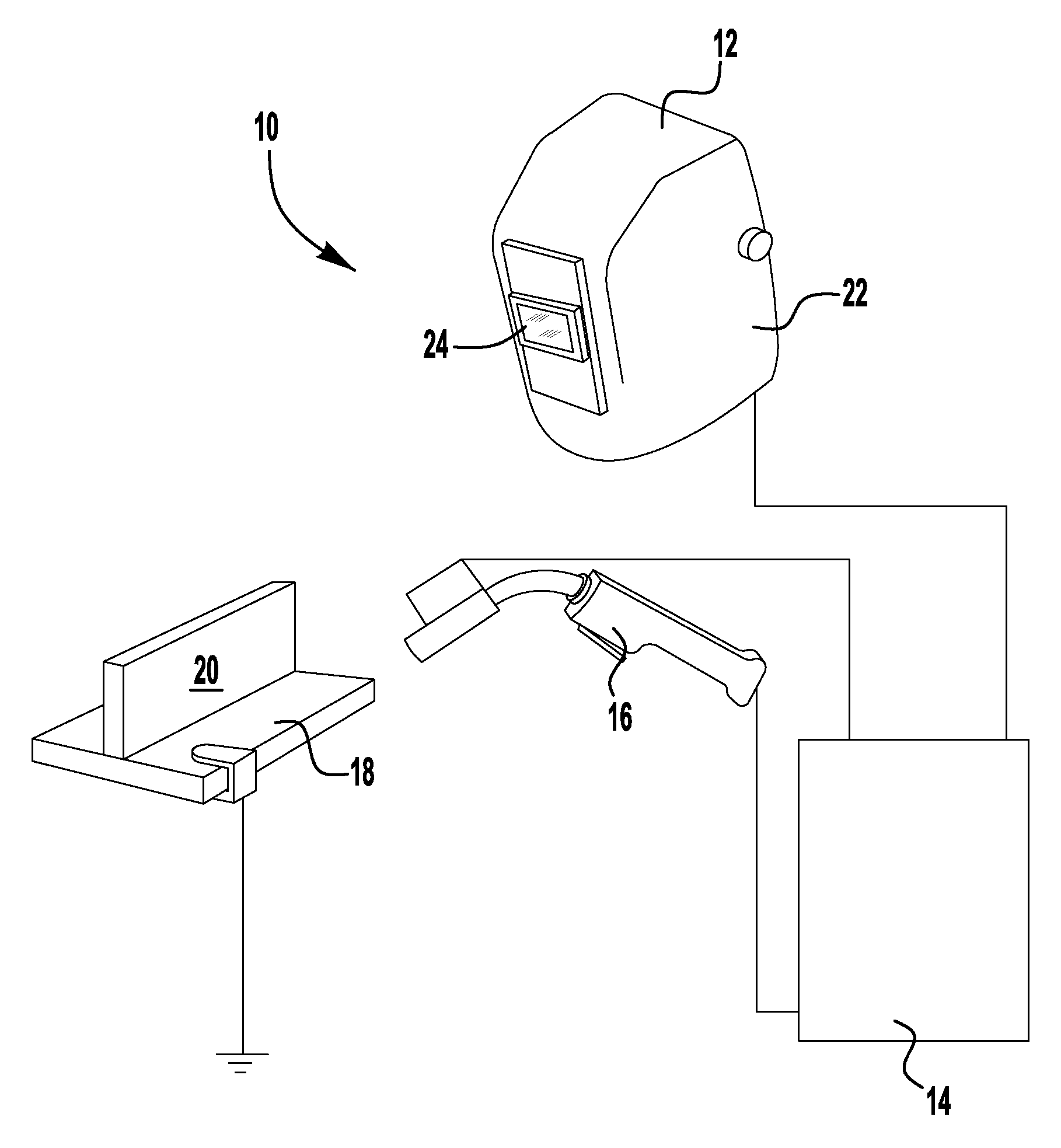

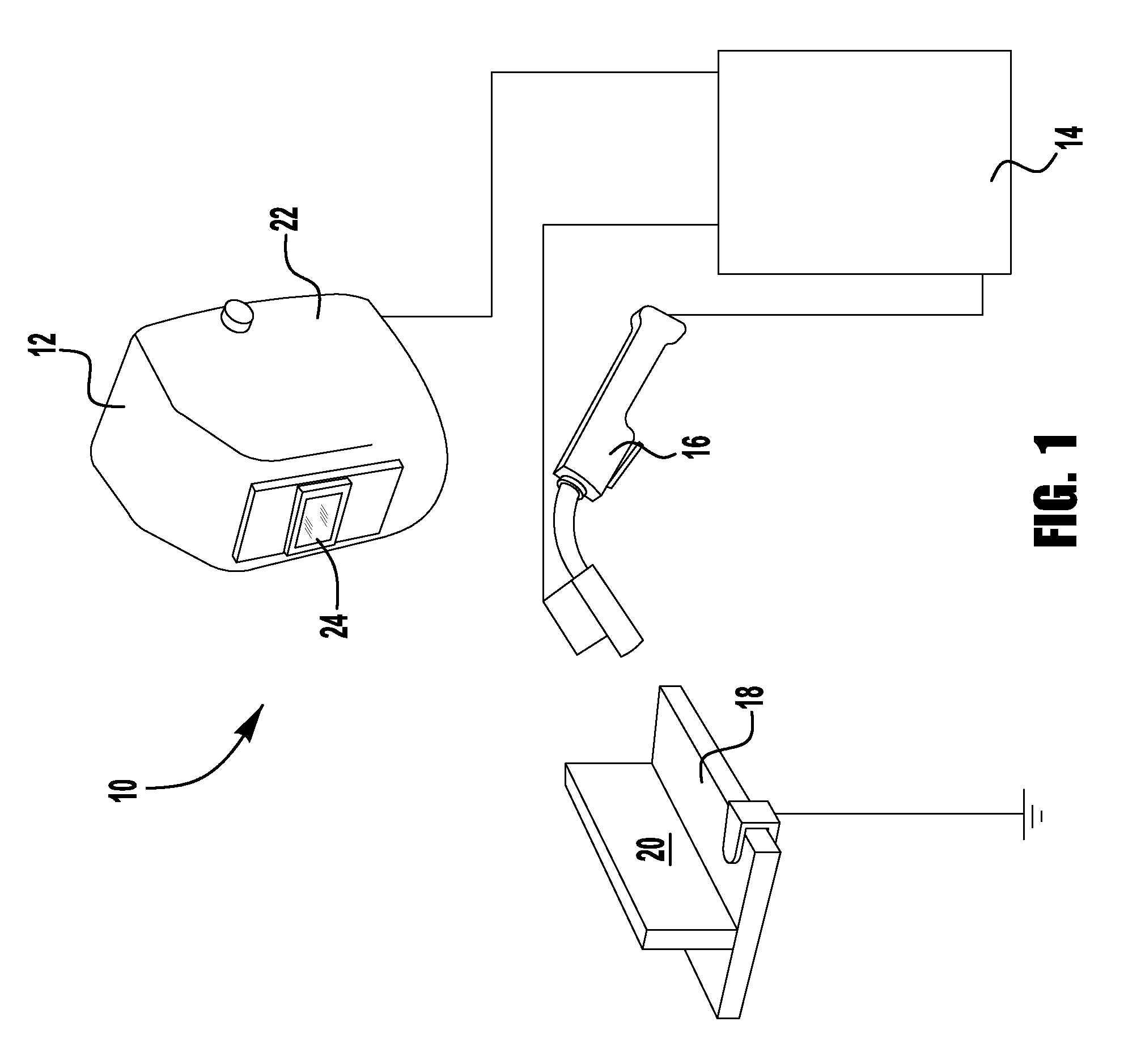

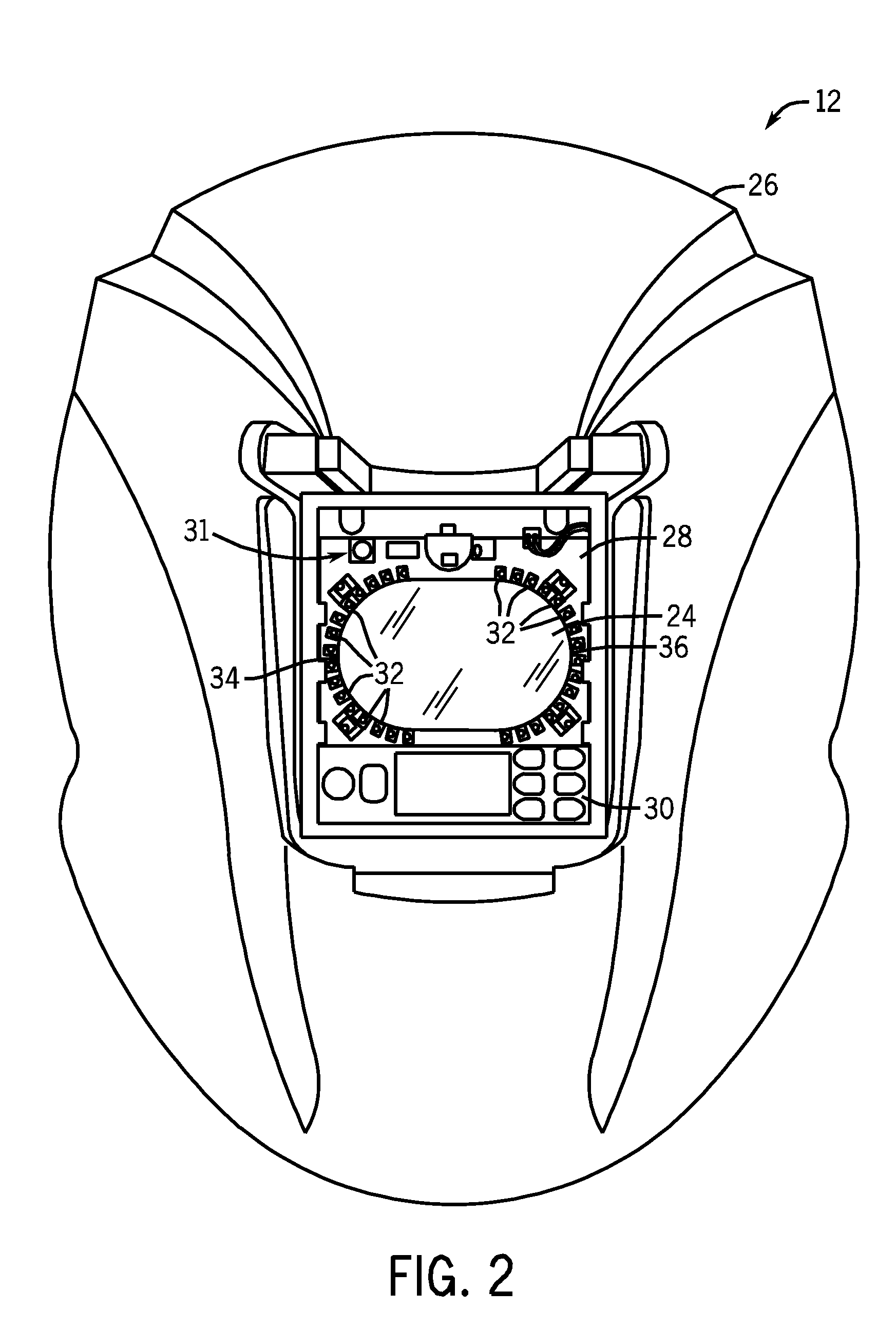

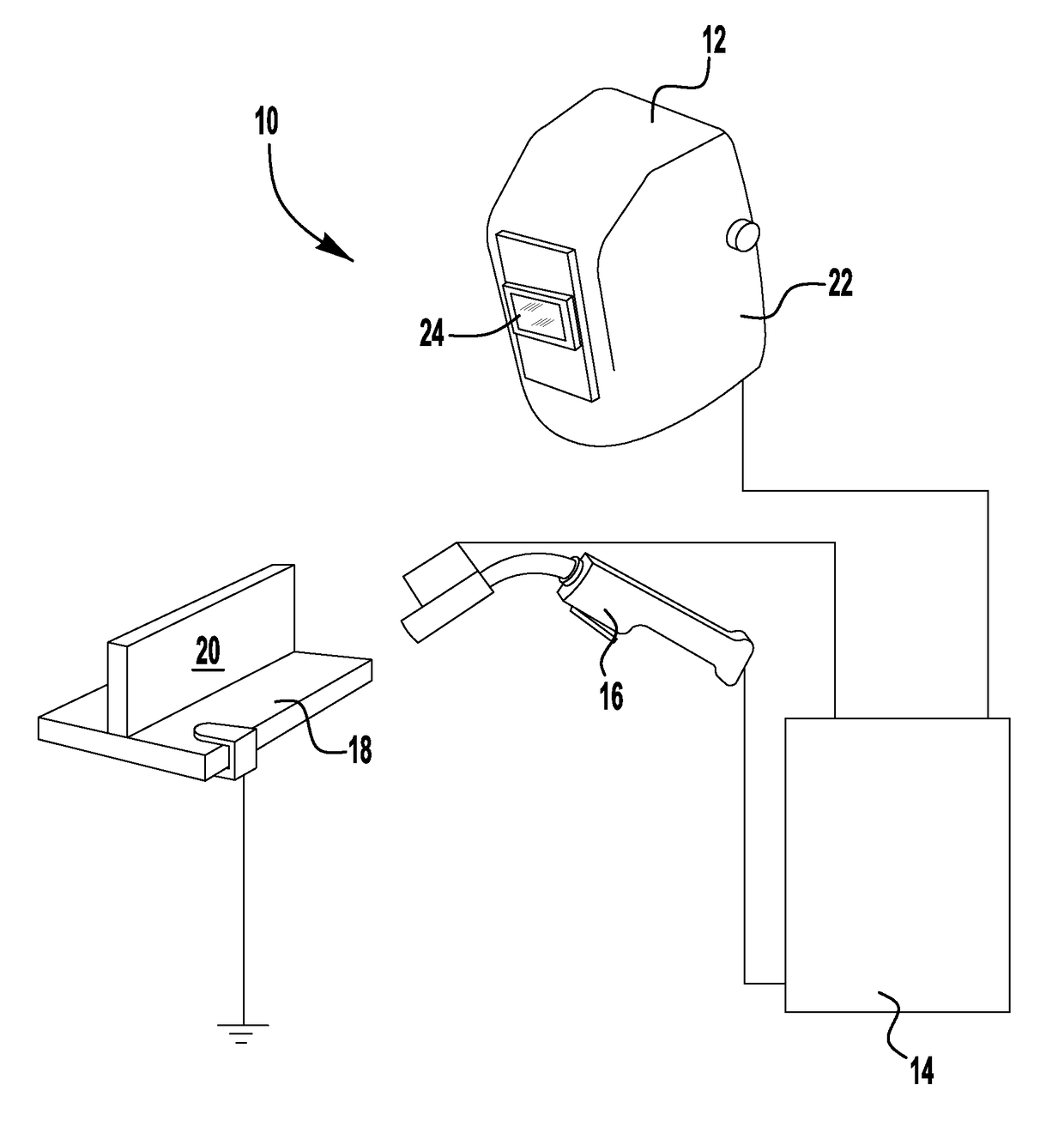

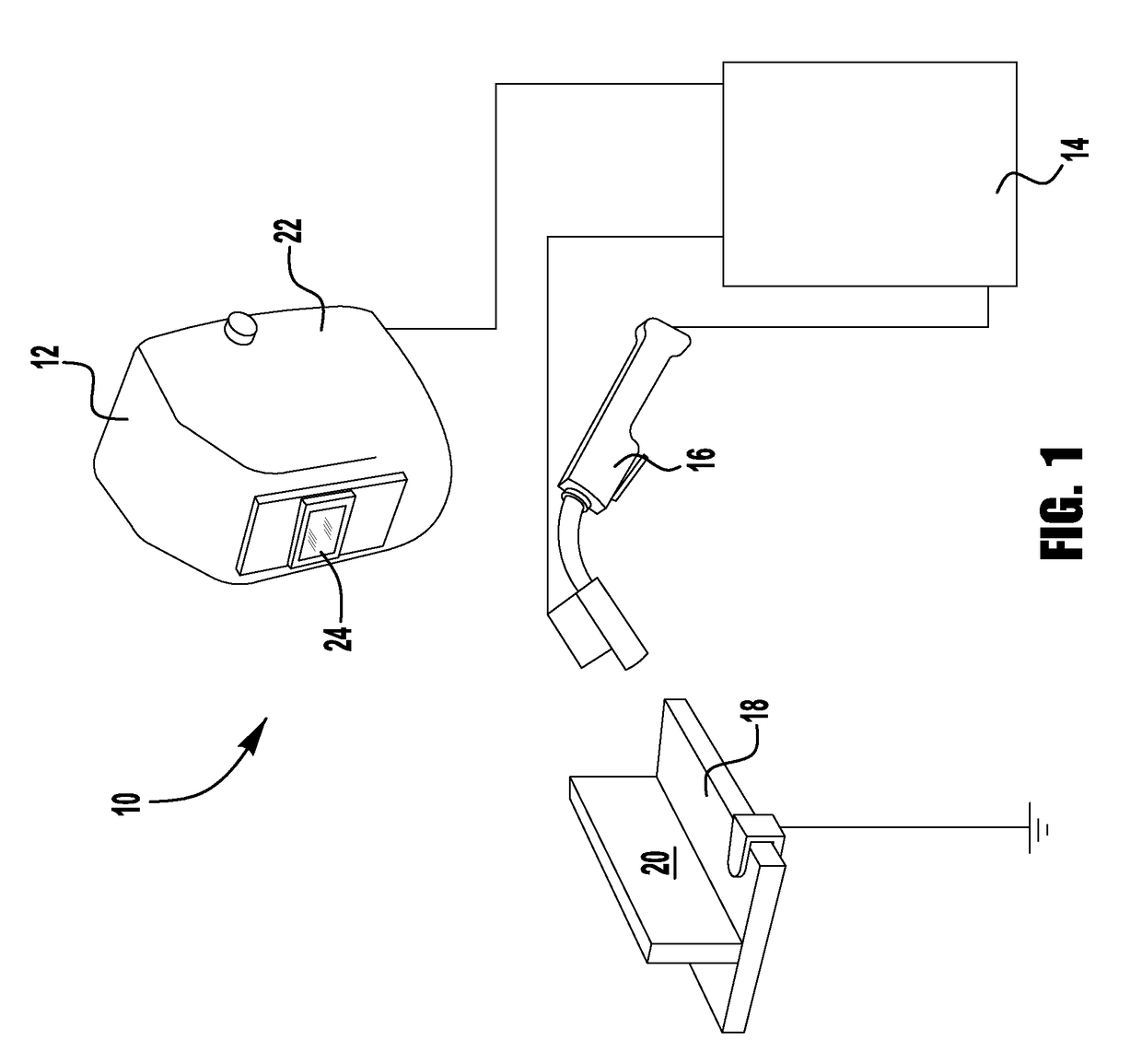

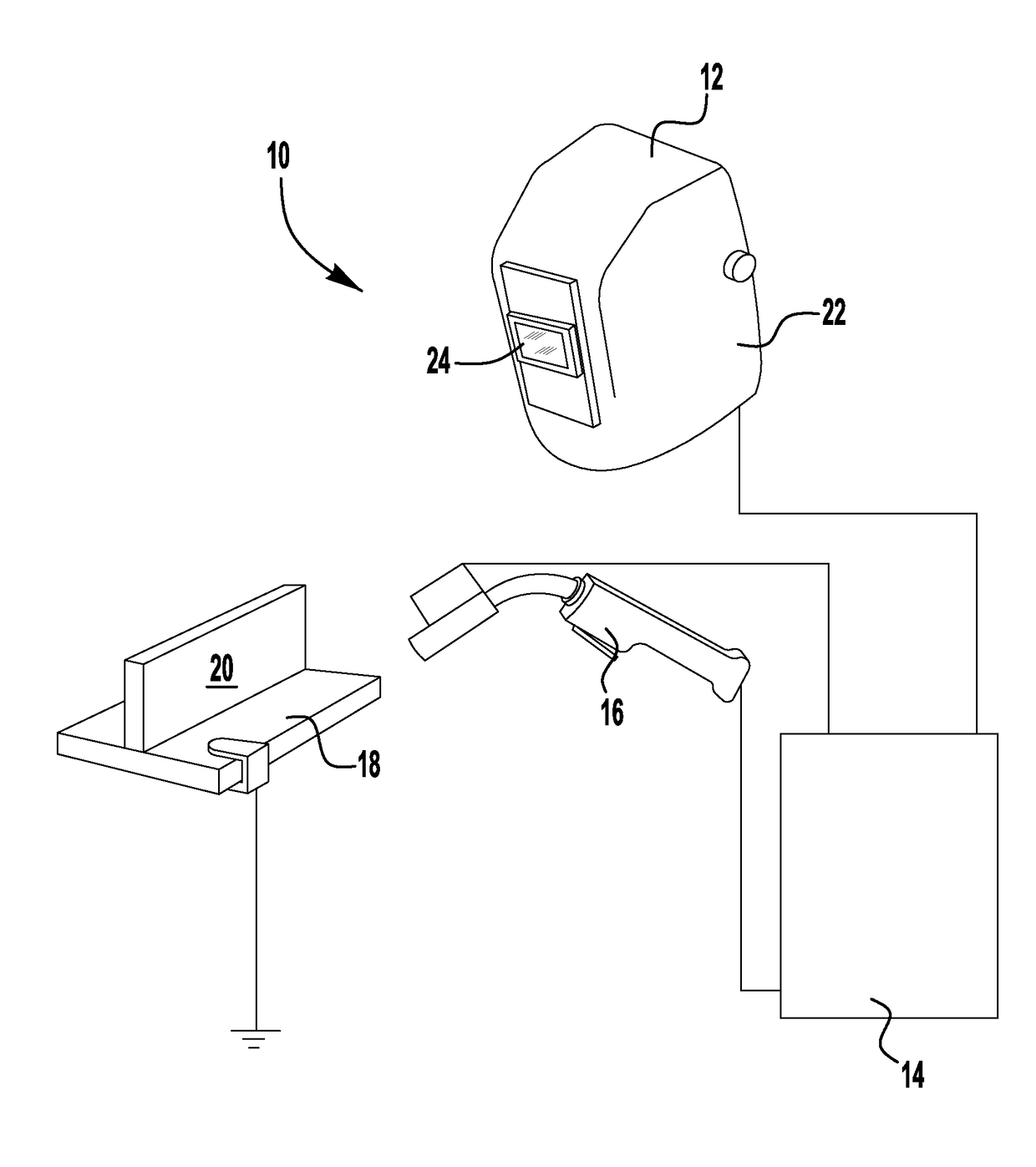

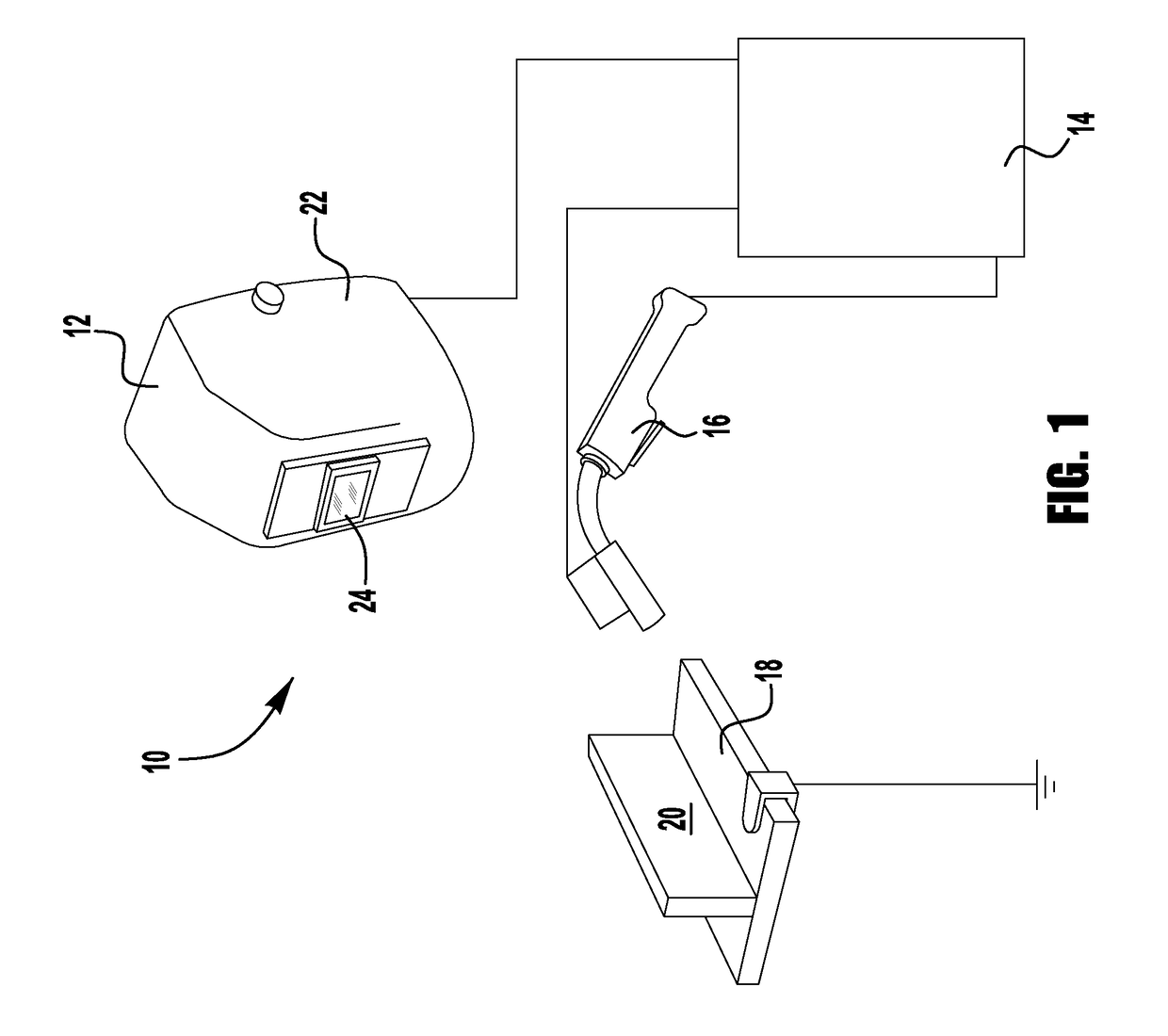

Video recording device for a welder's helmet

ActiveUS20090231423A1Television system detailsColor television signals processingComputer hardwareVideo record

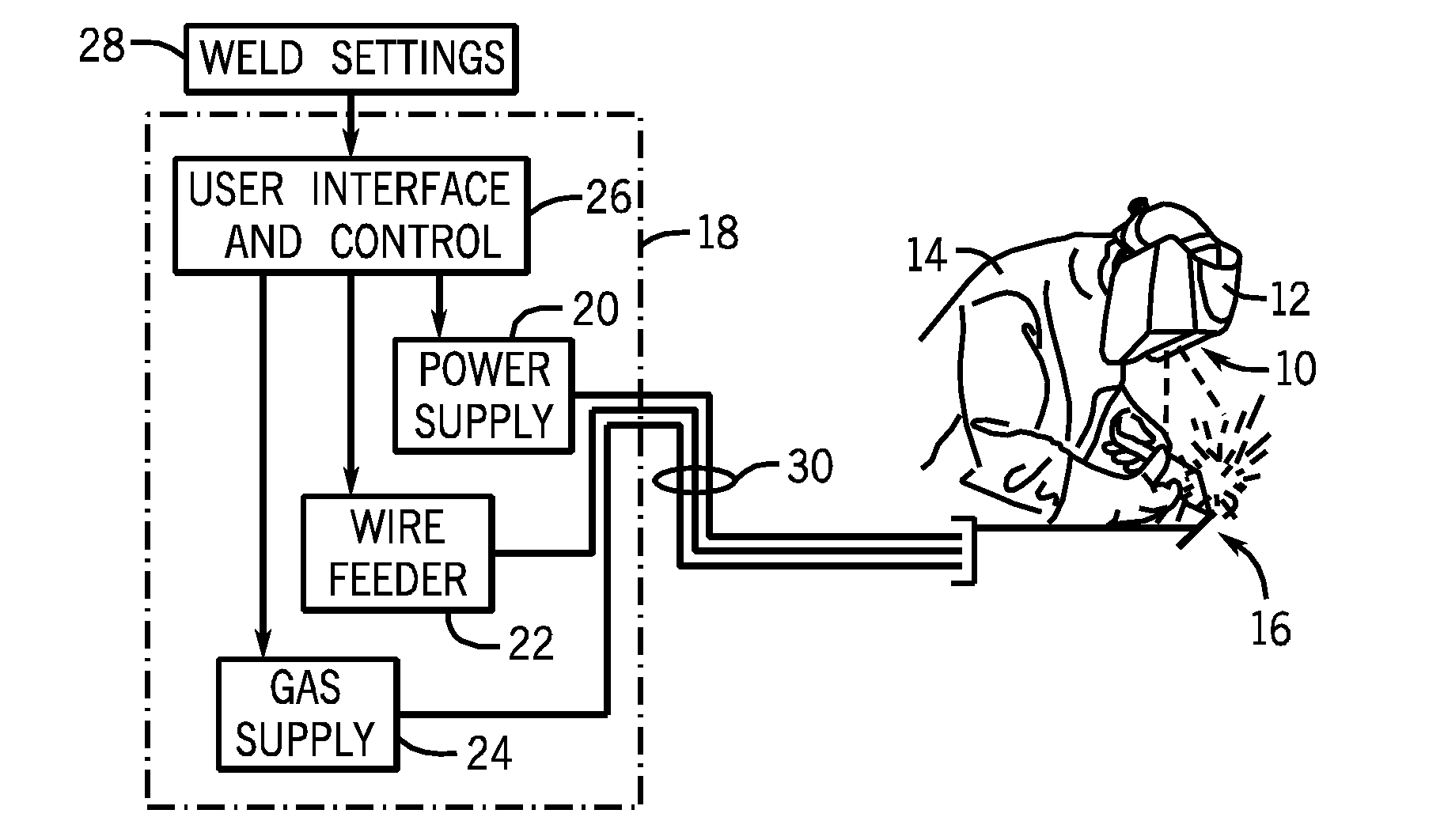

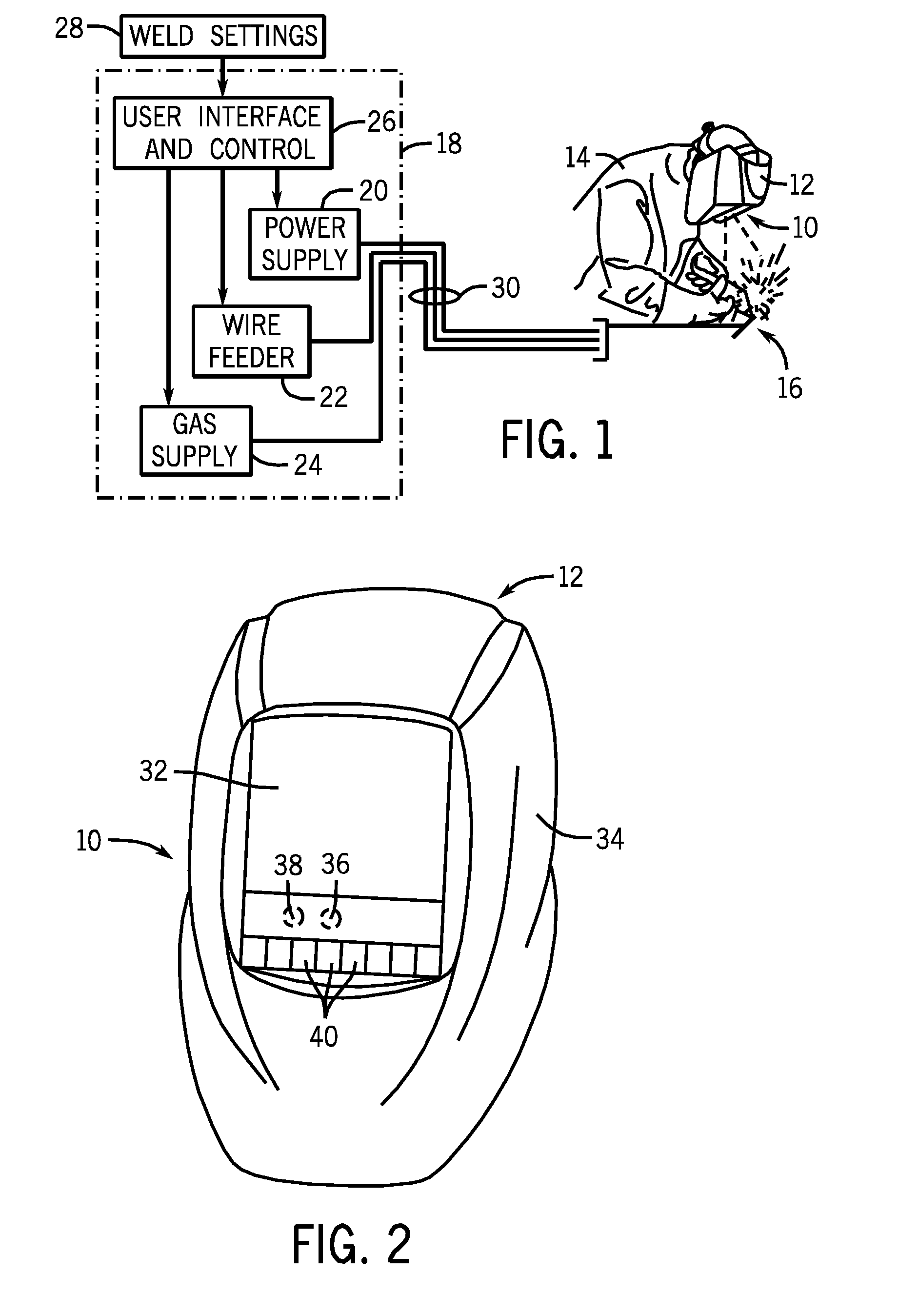

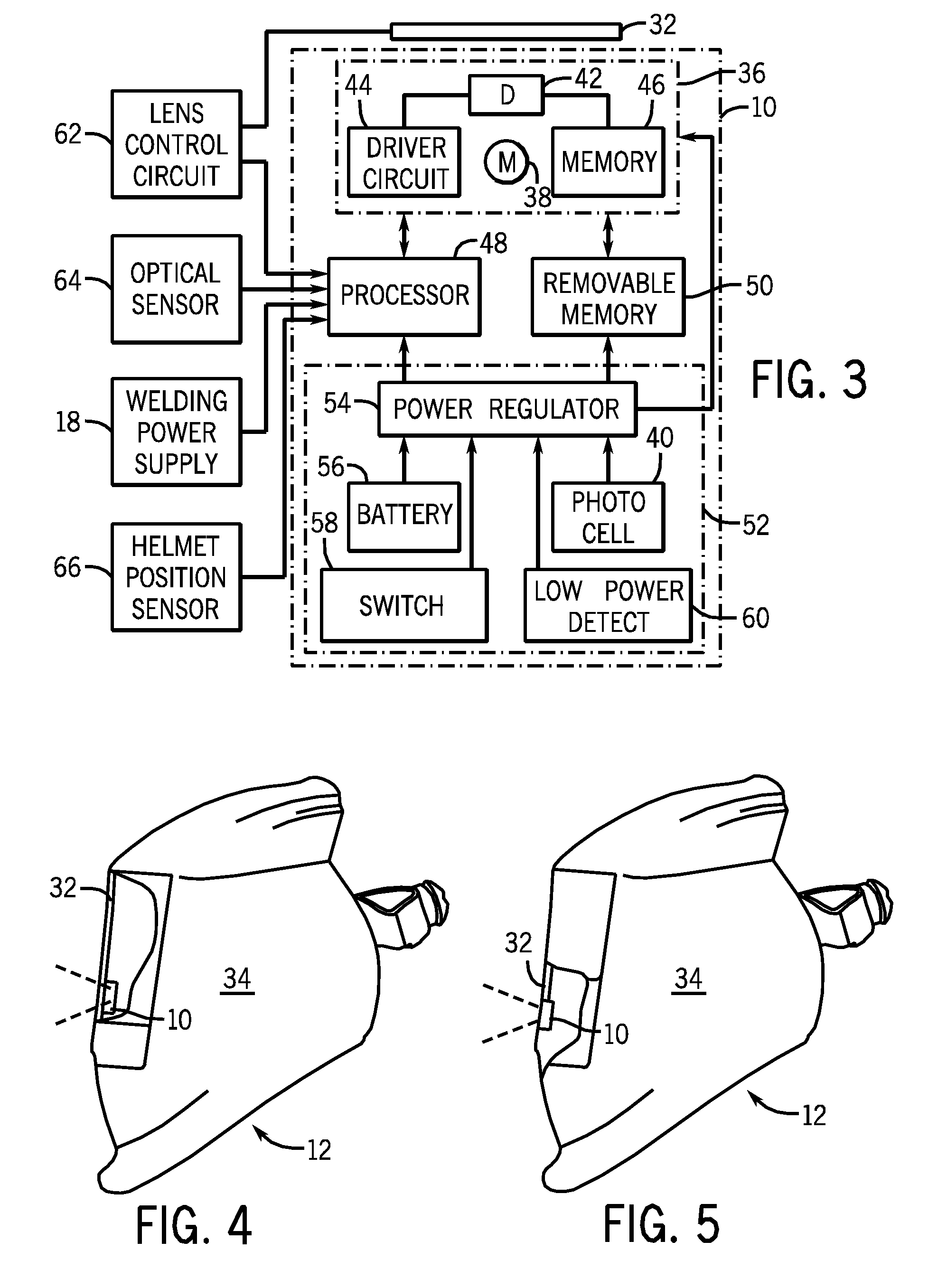

A weld recording system mounted in or on a welding helmet is provided. The weld recording system includes a camera assembly unit, a power supply unit, a processor, and removable memory. The weld recording system interfaces with lens control circuitry, an optical sensor, a welding power supply, and a helmet position sensor. Logic is provided for the triggering and recording of video and audio signals, which are eventually stored in a file for future reference. Transmission of signals from one or more welders to a monitoring station for eventual display is presented. An image processing algorithm is provided to combine multiple images with varied exposure times into a visual image of the weld and its surroundings.

Owner:ILLINOIS TOOL WORKS INC

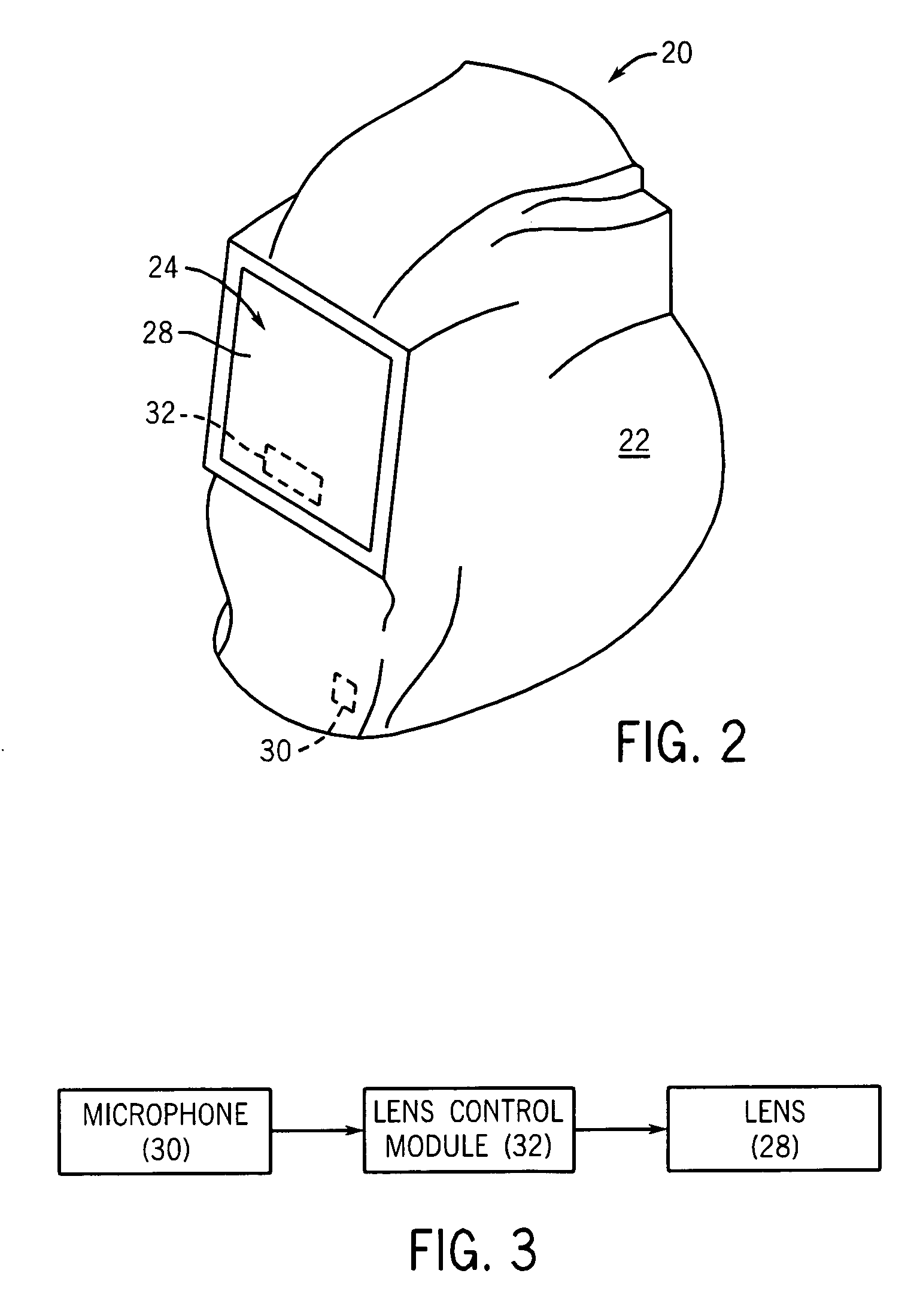

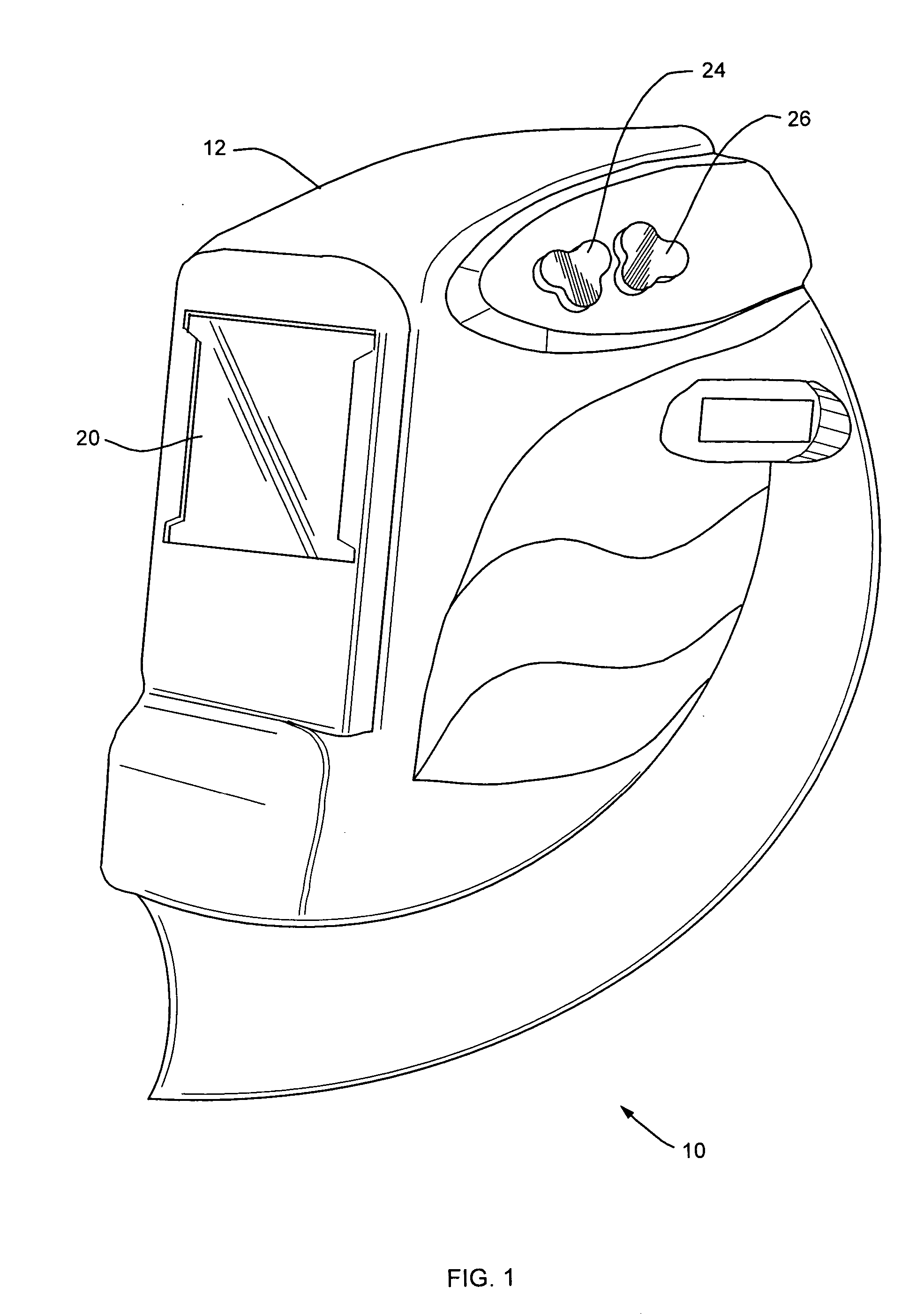

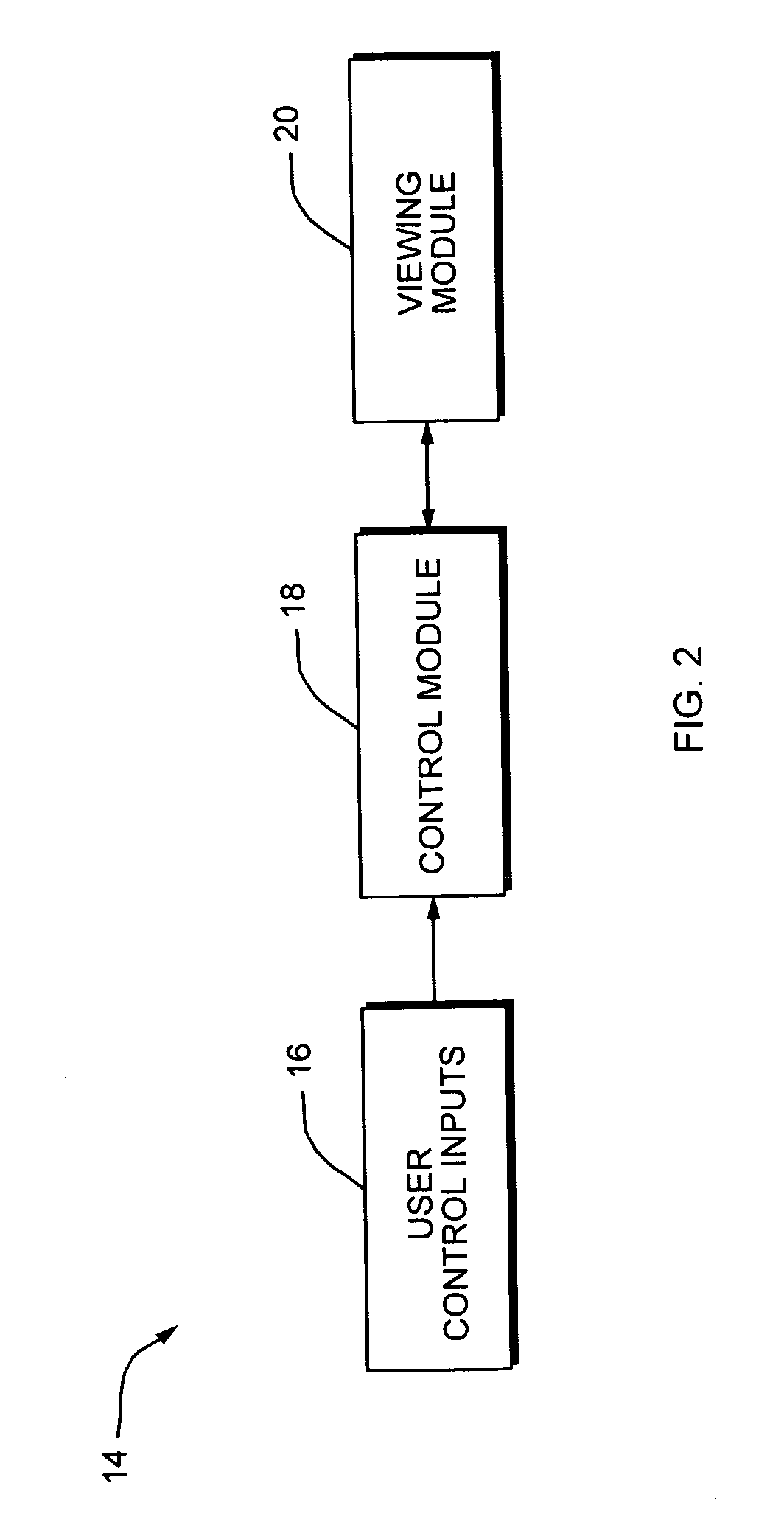

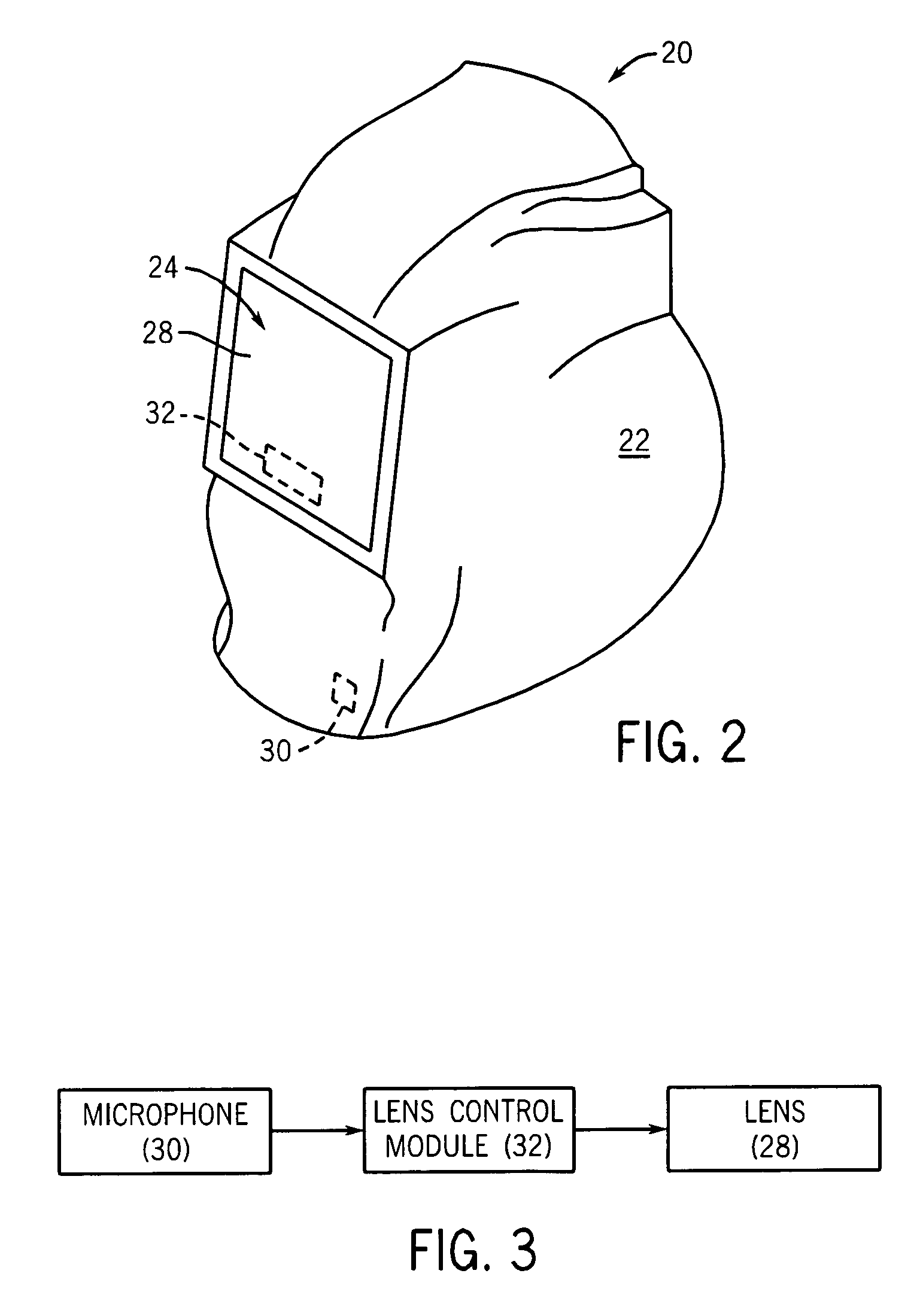

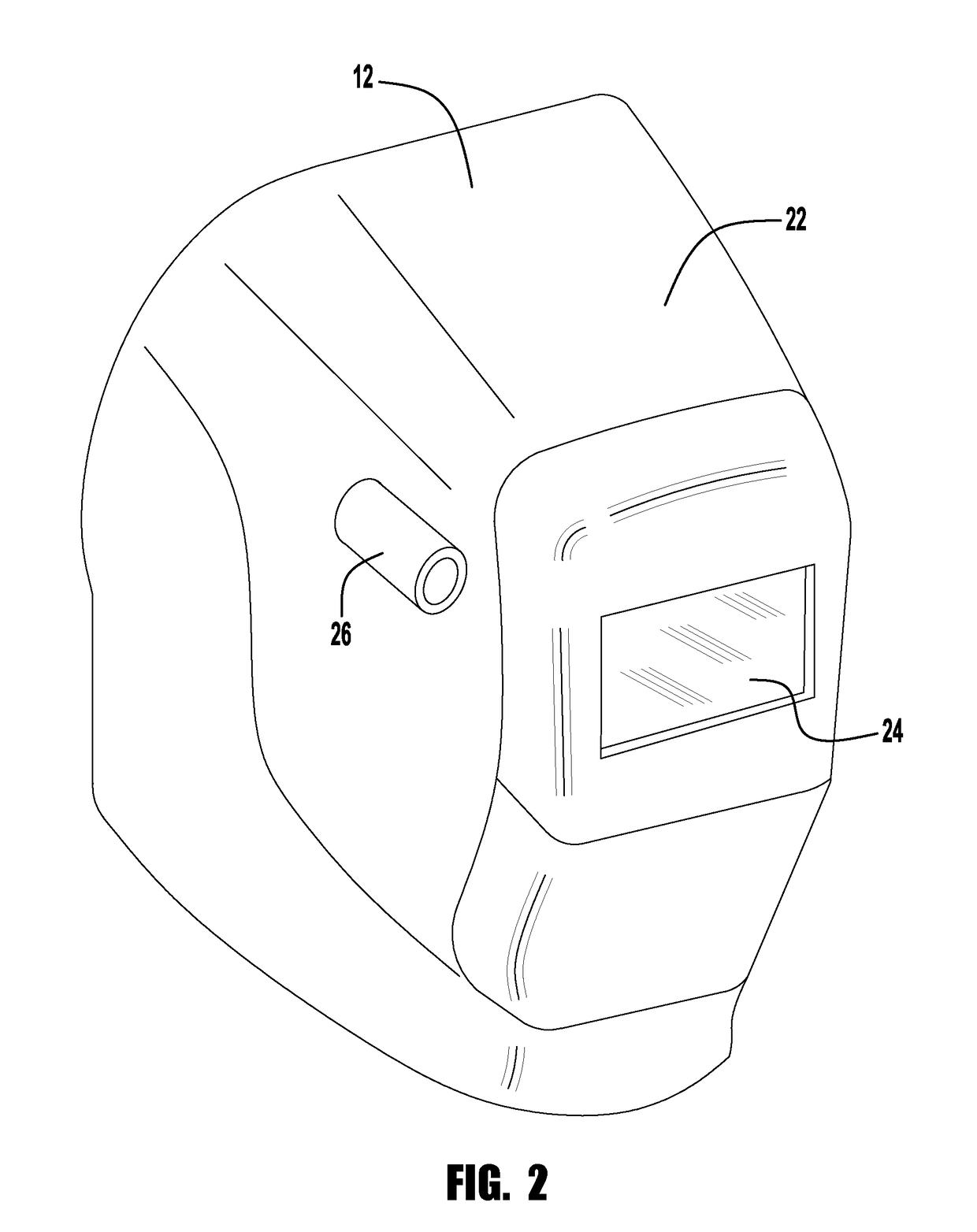

Voice control welding/cutting helmet functions and settings

Provided for is a control system for a welding helmet comprising: an electronically controllable lens configured to be mounted in a welding helmet shell, a microphone configured to receive an audible input and to generate a signal in response to the audible input received and an electronic control module coupled to the lens and to the microphone and configured to control the electronically controllable lens based upon the signal. Also provided for is a welding helmet implementing a control system and a method of manufacturing a welding helmet including a control system.

Owner:ILLINOIS TOOL WORKS INC

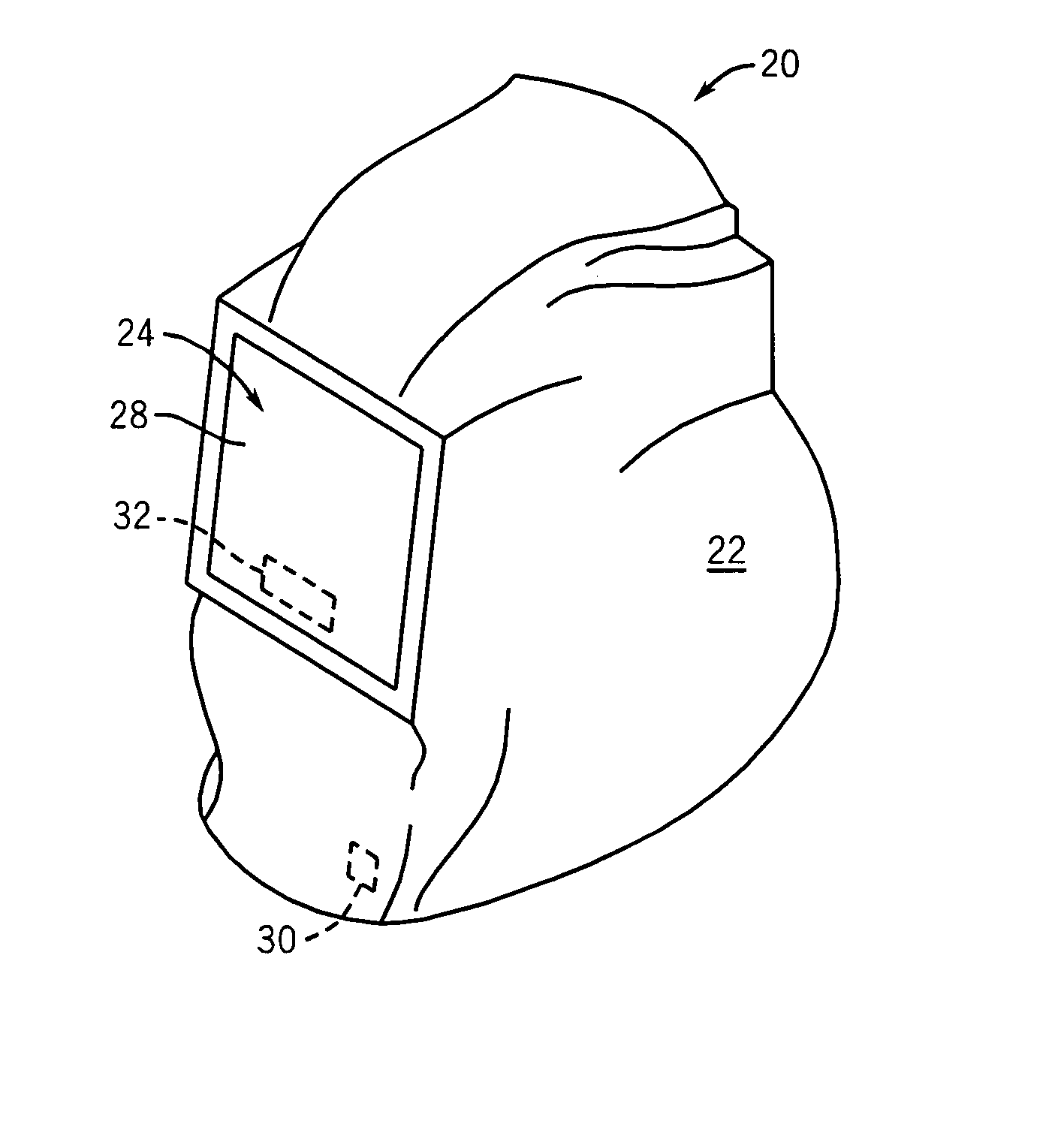

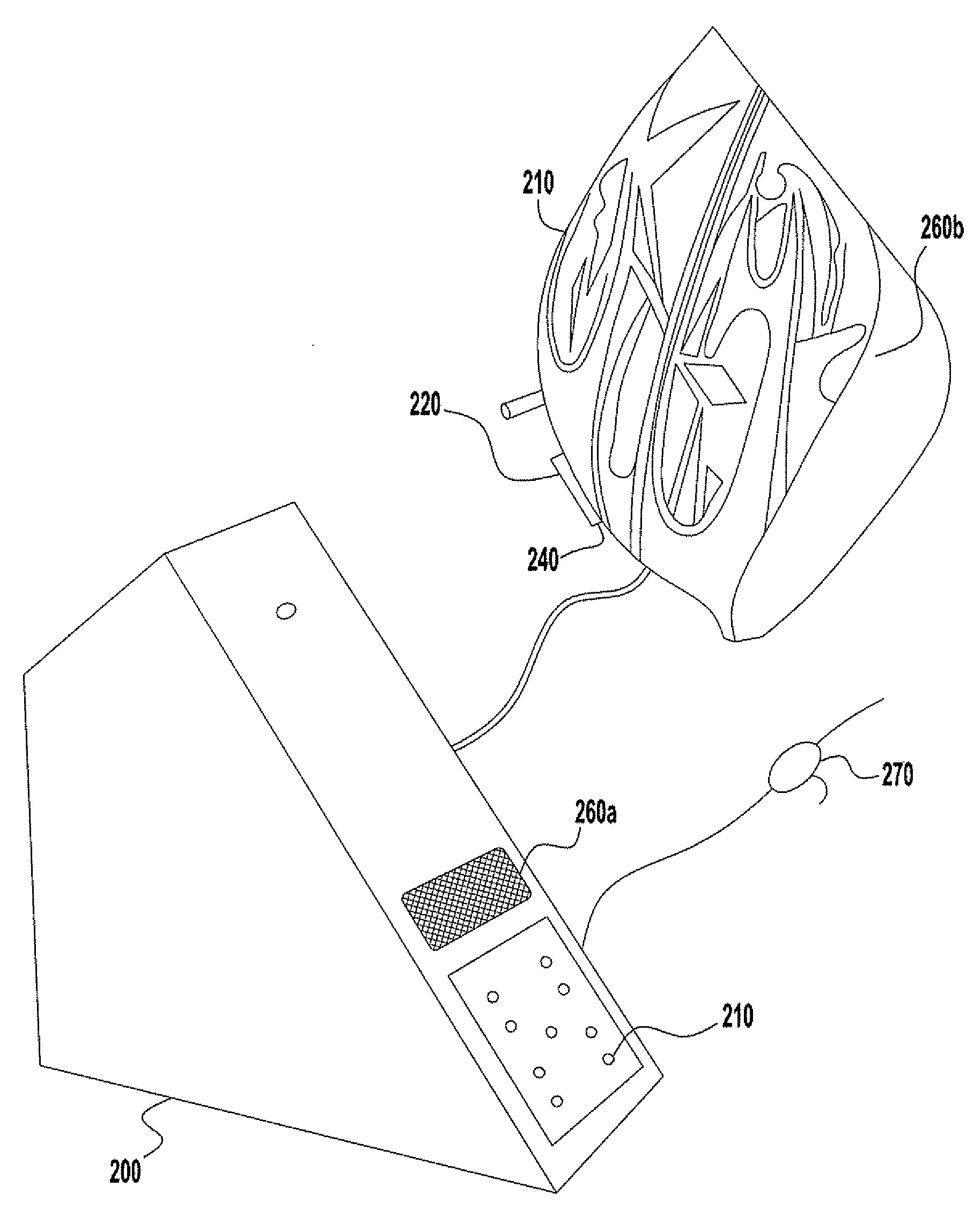

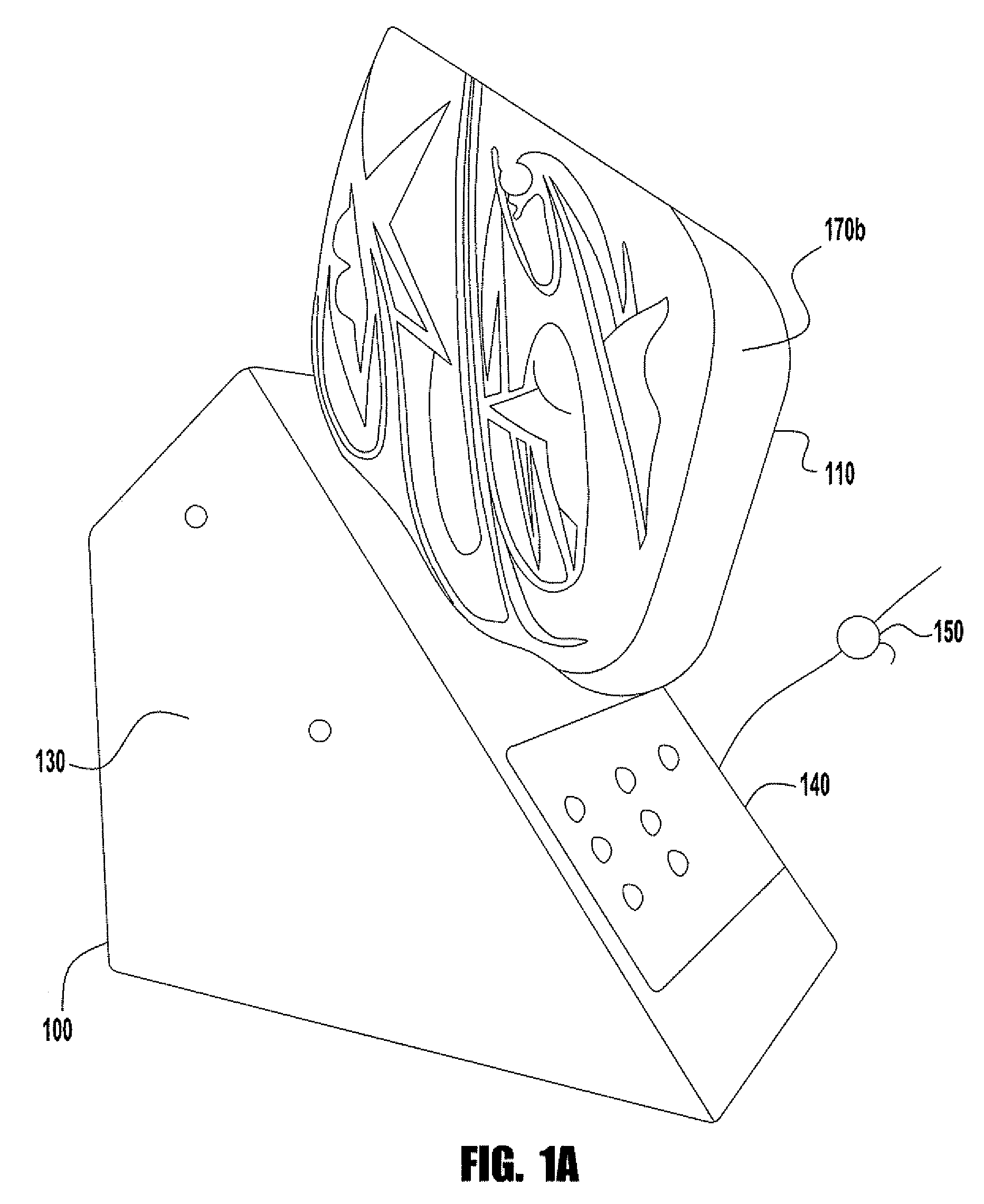

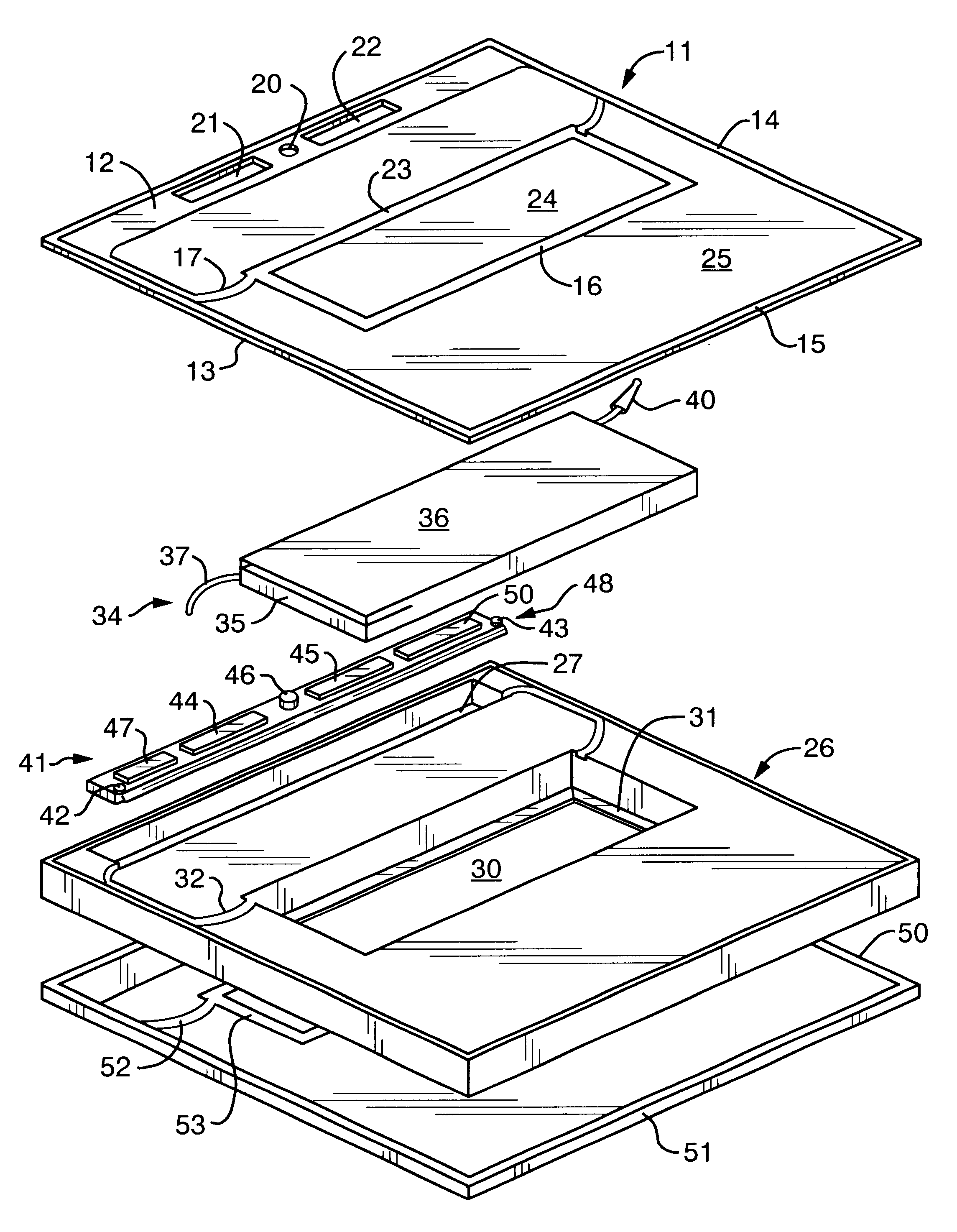

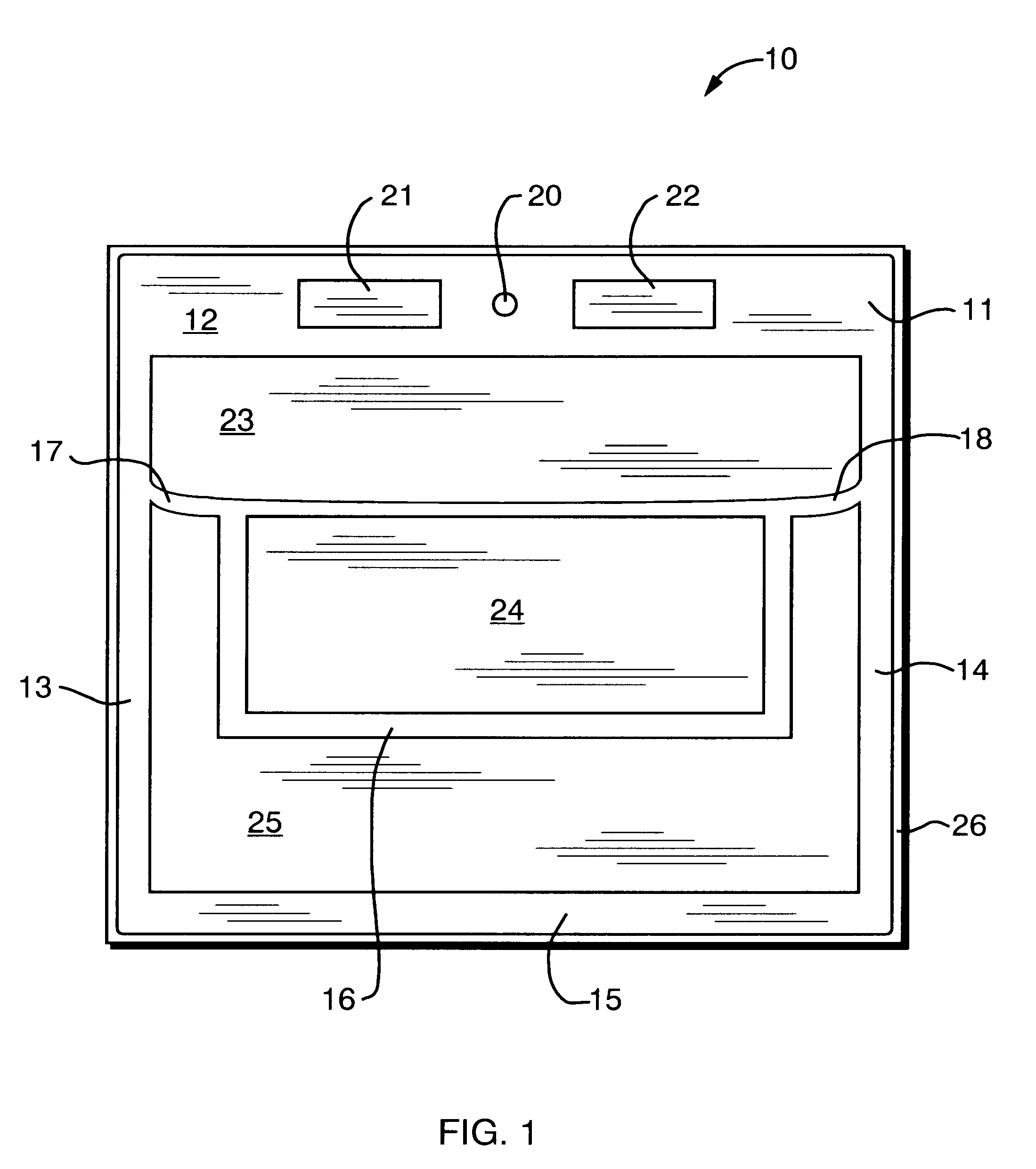

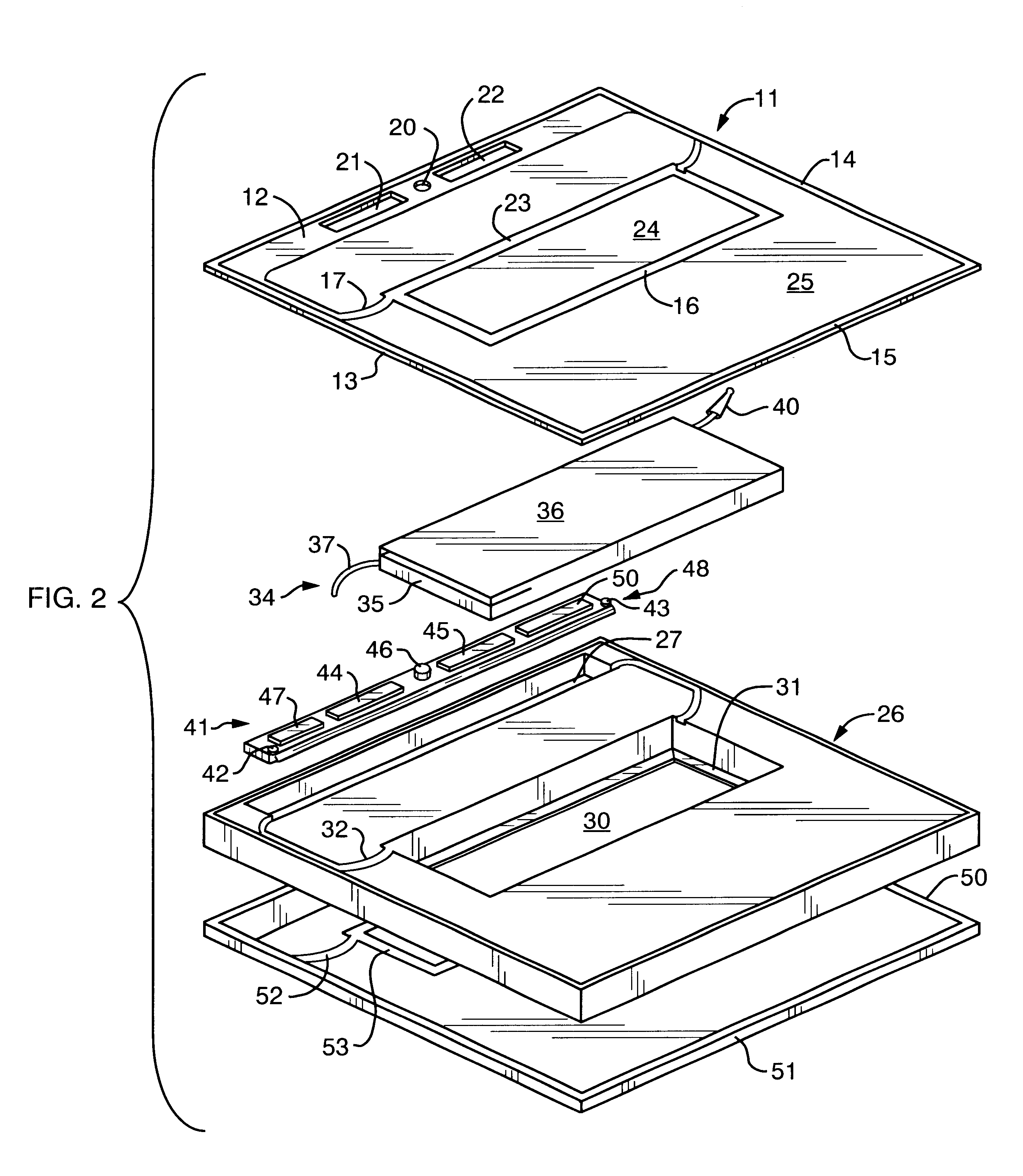

Display with replica welding helmet viewer

InactiveUS8248324B2Comprehensive informationEye-masksCathode-ray tube indicatorsDisplay deviceControl equipment

A display device that includes a housing that houses a display, and a control panel. Control panel and display are connected to a controller disposed inside of the housing. A control device can also be attached to display device. The control device is configured to resemble a welding gun. The control device is also connected to the controller. A viewer, such as welding mask viewer, is be mounted to the housing of display device.

Owner:LINCOLN GLOBAL INC

Welding helmet with heads up display

A welding system and welding helmet is provided, where the welding helmet is capable of providing an image representative of information from an associated welding operation where the image appears as a head-up display (HUD) in the welding helmet. The helmet displays the information at a focal point which coincides with a working distance of a welding operation so that a user need not change his / her focus during a welding operation.

Owner:LINCOLN GLOBAL INC

Video recording device for a welder's helmet

A weld recording system mounted in or on a welding helmet is provided. The weld recording system includes a camera assembly unit, a power supply unit, a processor, and removable memory. The weld recording system interfaces with lens control circuitry, an optical sensor, a welding power supply, and a helmet position sensor. Logic is provided for the triggering and recording of video and audio signals, which are eventually stored in a file for future reference. Transmission of signals from one or more welders to a monitoring station for eventual display is presented. An image processing algorithm is provided to combine multiple images with varied exposure times into a visual image of the weld and its surroundings.

Owner:ILLINOIS TOOL WORKS INC

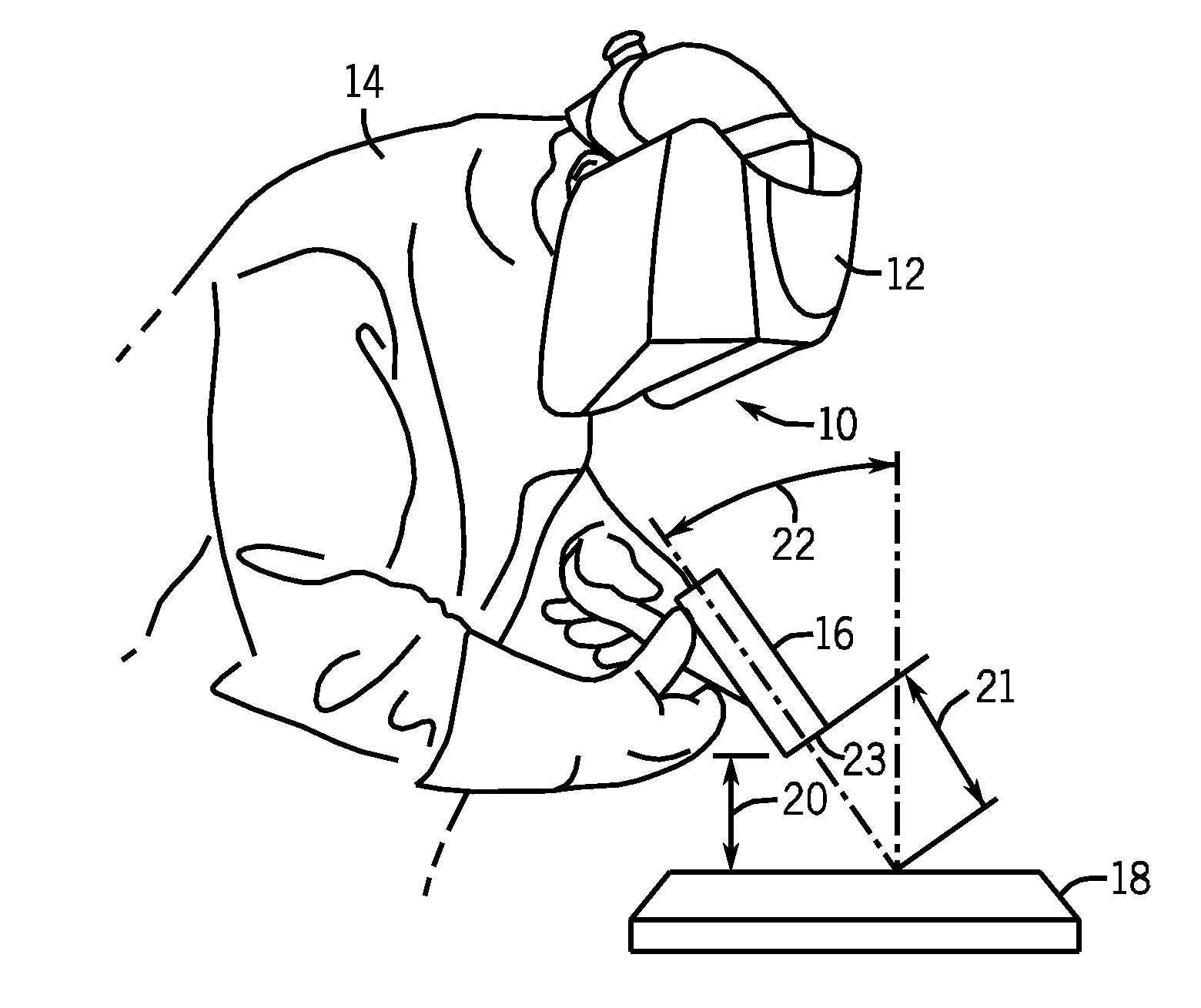

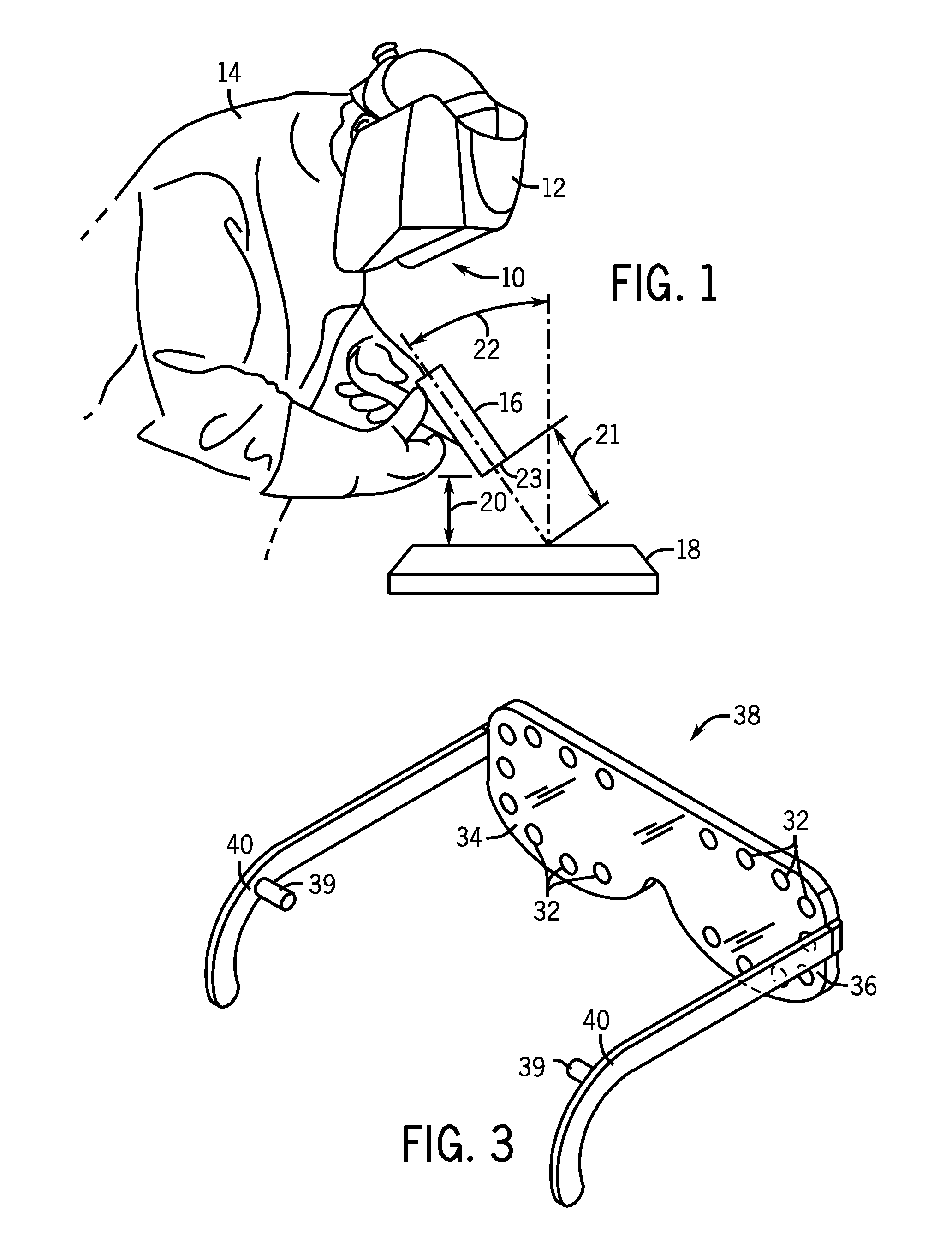

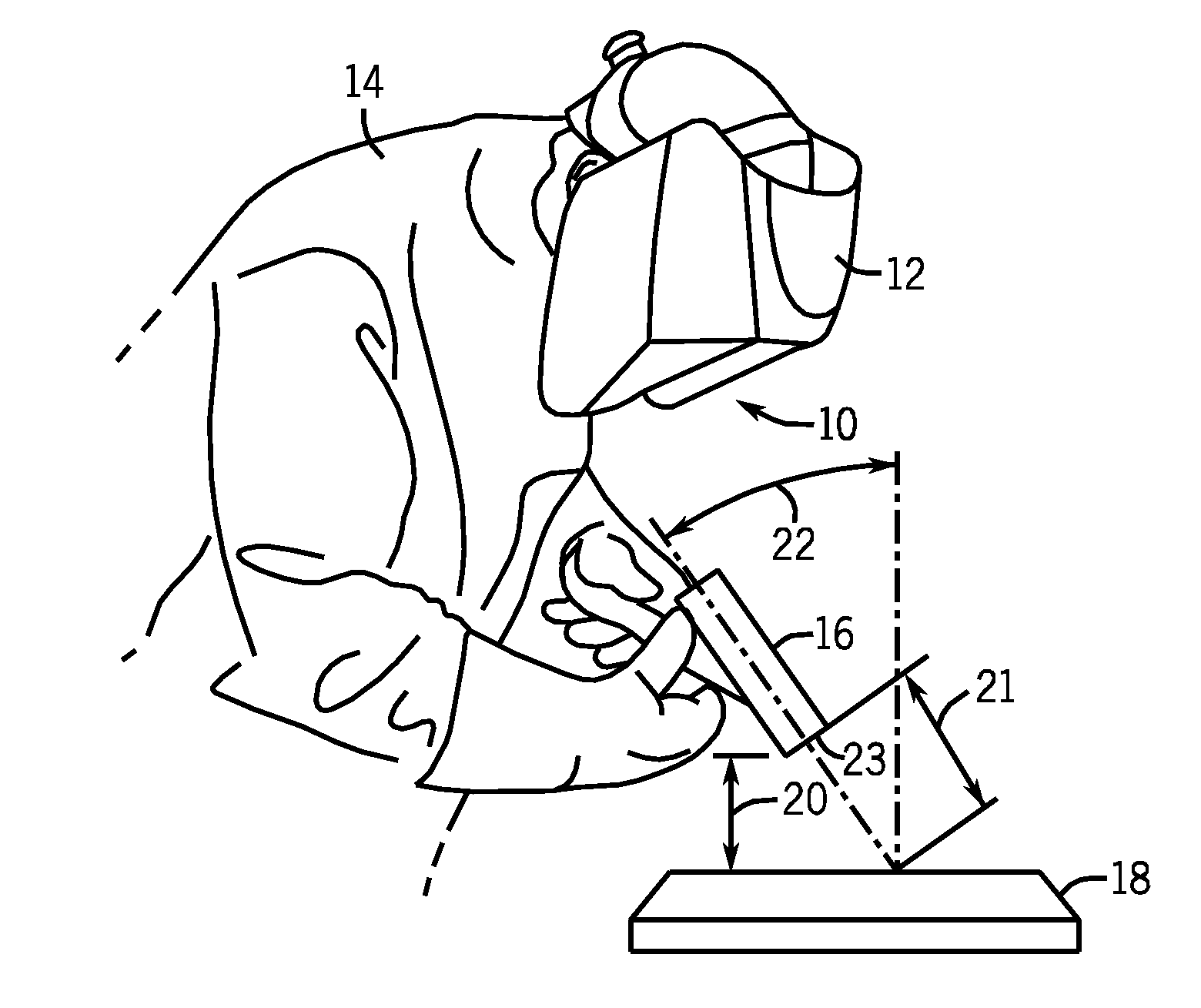

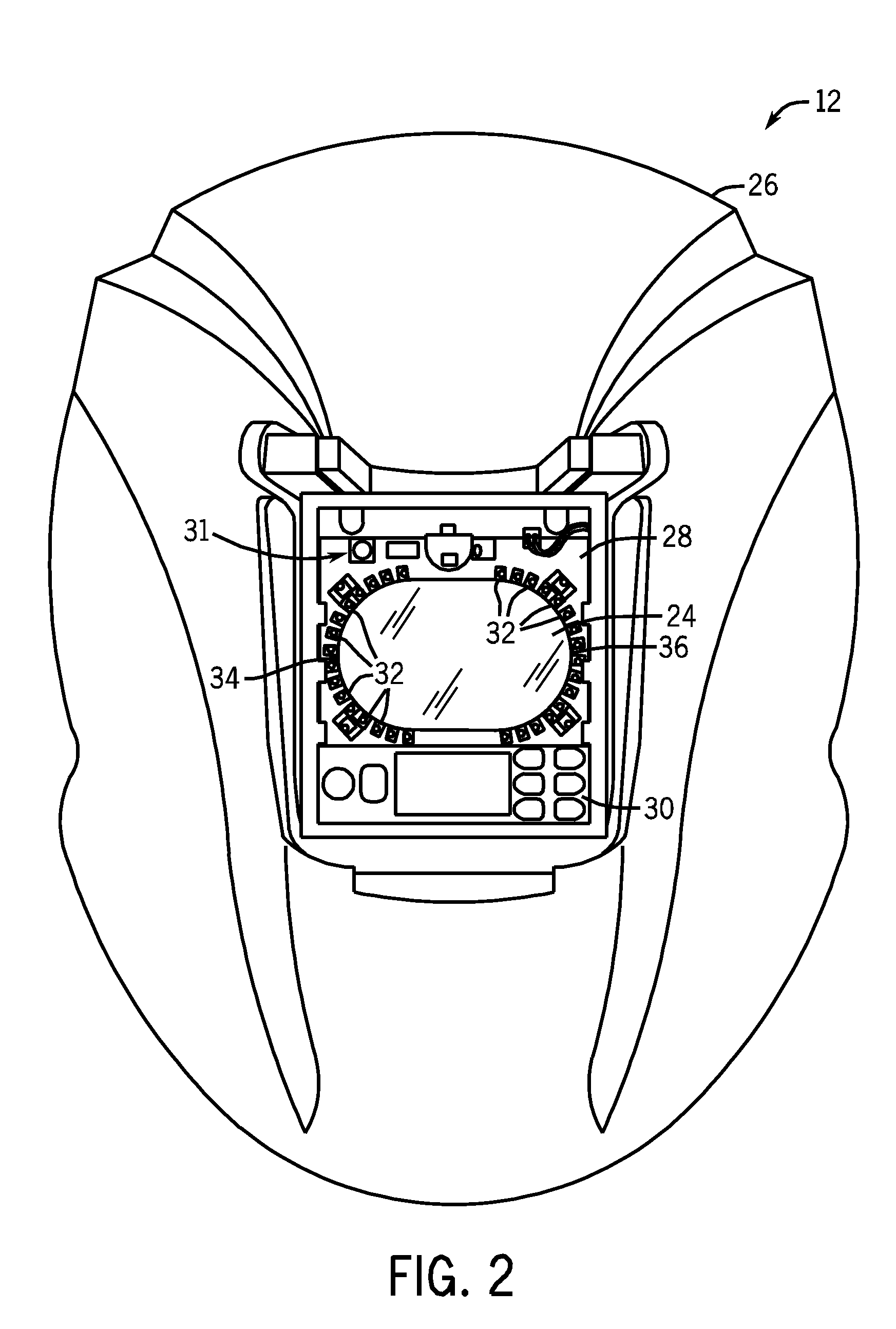

Weld characteristic communication system for a welding mask

Methods and systems for transmitting a torch angle and / or a torch-to-workpiece distance error to a welding operator when these parameters are outside of a preset optimal range via real time visual and / or audio cues are provided. One embodiment of the present disclosure relates to weld characteristic communication via intuitive arrays of visual indicators located on the periphery of a lens, which indicate to the welding operator the direction and severity of the torch angle error. In one embodiment, audio cues, such as pulsed or continuous tones may be used to communicate torch-to-workpiece distance to the welding operator. In certain embodiments, vertical visual indicator arrays may be used to indicate additional weld or auxiliary information, such as battery charge state, torch speed and so forth, to the welding operator. All the components of the communication system may be located in or on the welding helmet or the components may be split between the helmet and a belt pack.

Owner:ILLINOIS TOOL WORKS INC

Display with replica welding helmet viewer

InactiveUS20090109128A1Comprehensive informationEye-masksCathode-ray tube indicatorsDisplay deviceEngineering

A display device that includes a housing that houses a display, and a control panel. Control panel and display are connected to a controller disposed inside of the housing. A control device can also be attached to display device. The control device is configured to resemble a welding gun. The control device is also connected to the controller. A viewer, such as welding mask viewer, is be mounted to the housing of display device.

Owner:LINCOLN GLOBAL INC

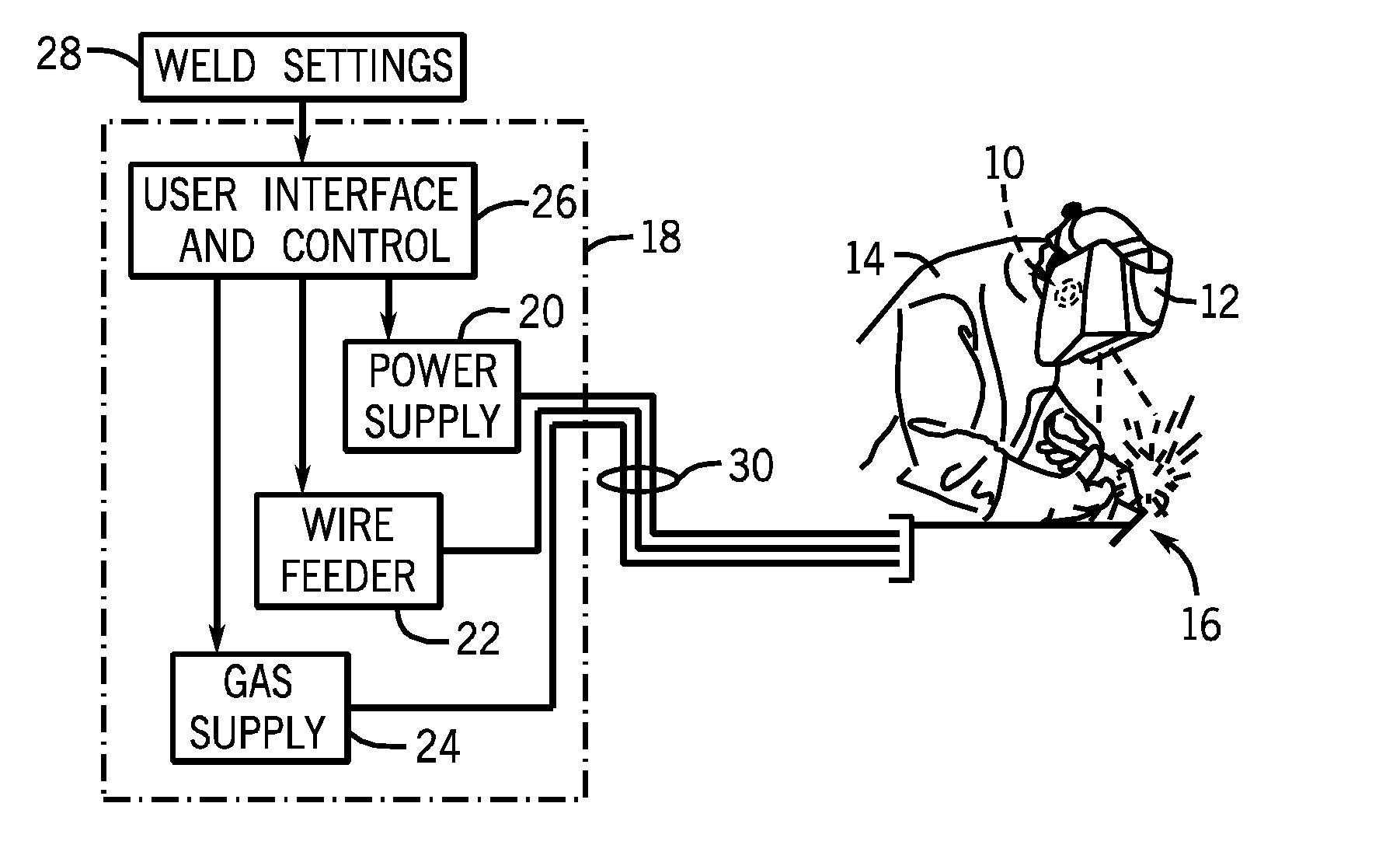

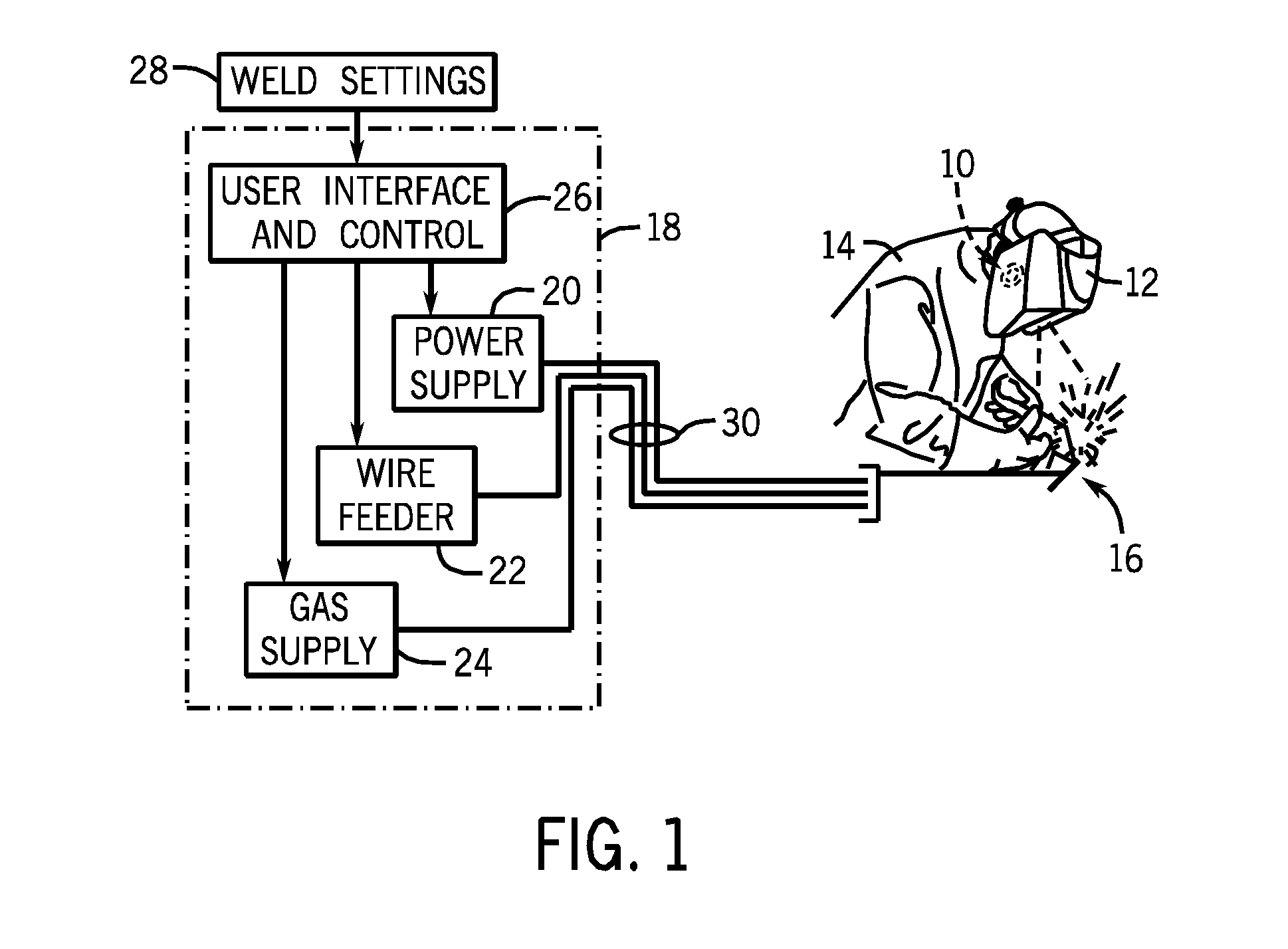

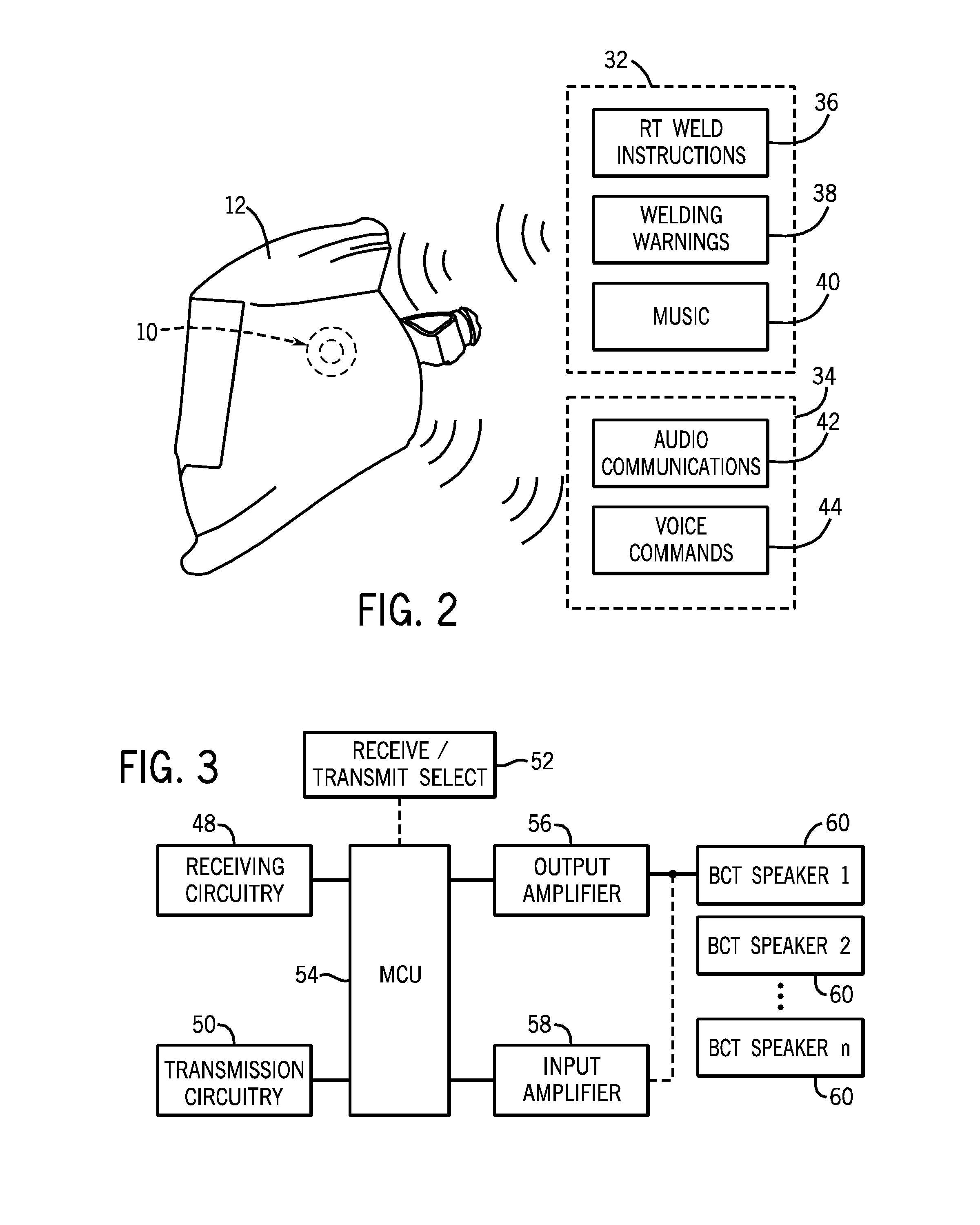

Welding helmet audio communication systems and methods with bone conduction transducers

InactiveUS20100223706A1Facilitate signaling communicationImprove sound transmissionBone conduction transducer hearing devicesEye-masksCommunications systemTransducer

A system for welding communication that includes a welding headgear and a bone conduction transducer (BCT) disposed in or on the welding headgear is provided. The BCT facilitates communication of signals to a welding operator via bone conduction. The bone conduction facilitates the transmission of sound directly to an inner ear of the welding operator.

Owner:ILLINOIS TOOL WORKS INC

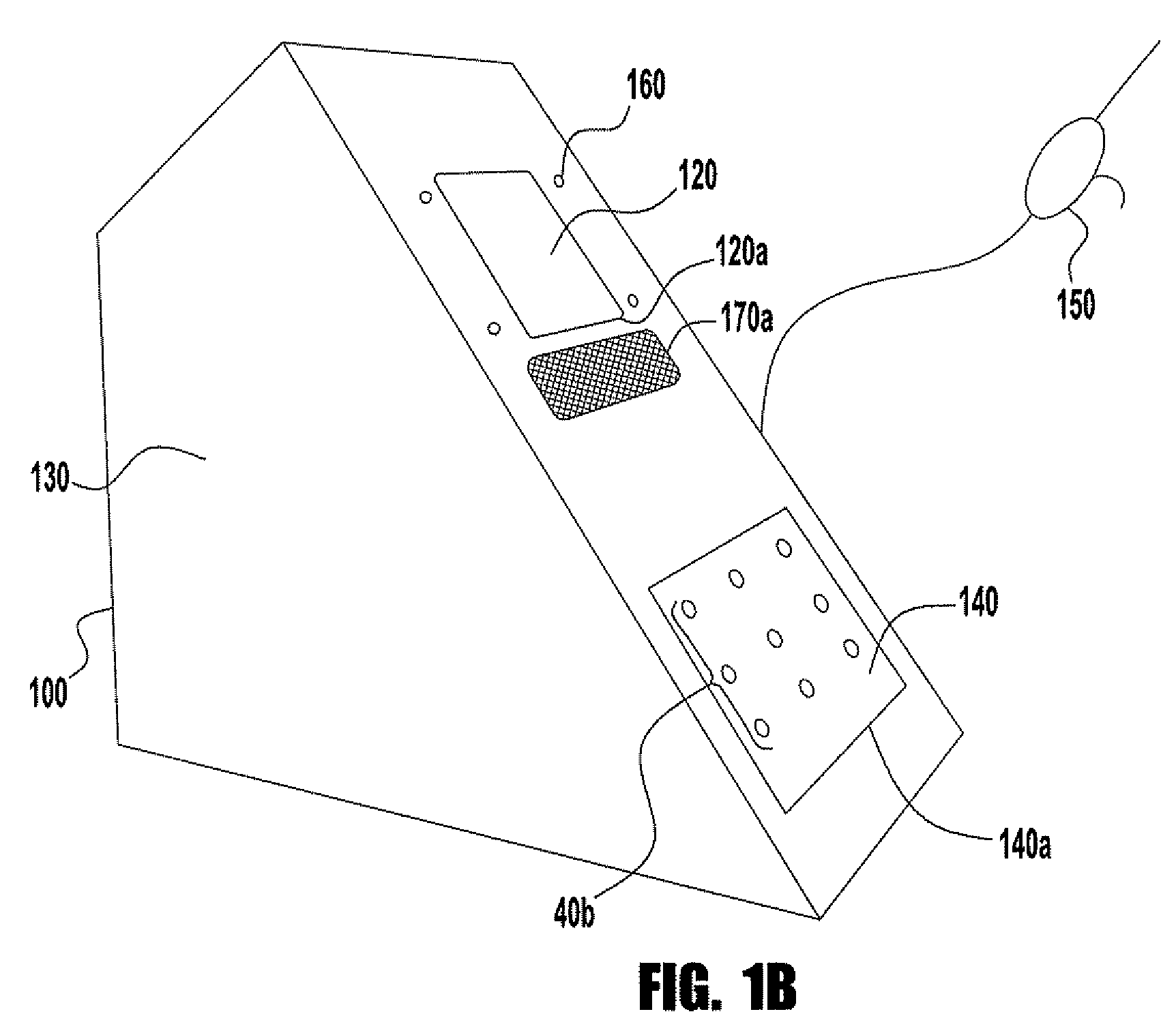

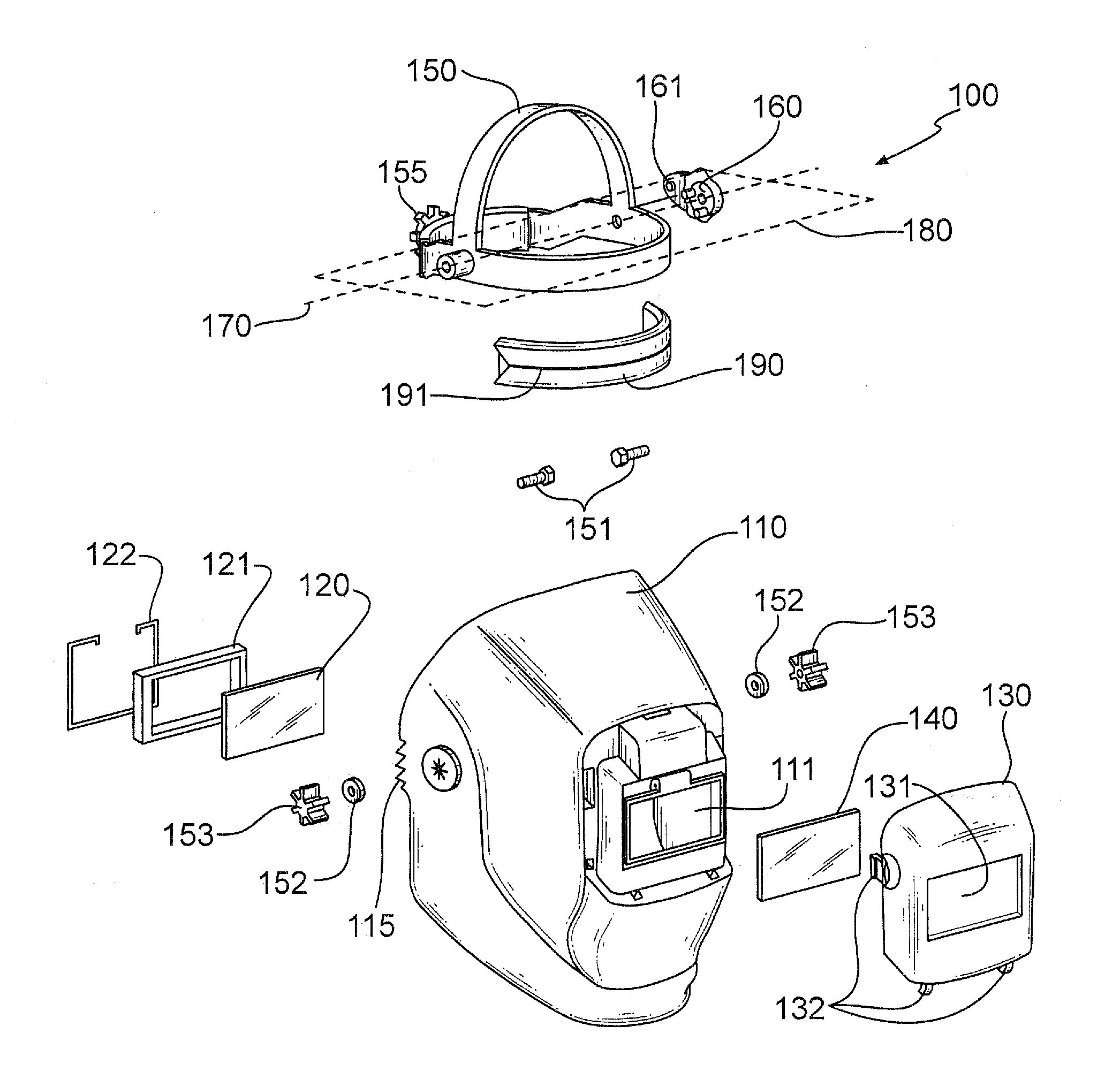

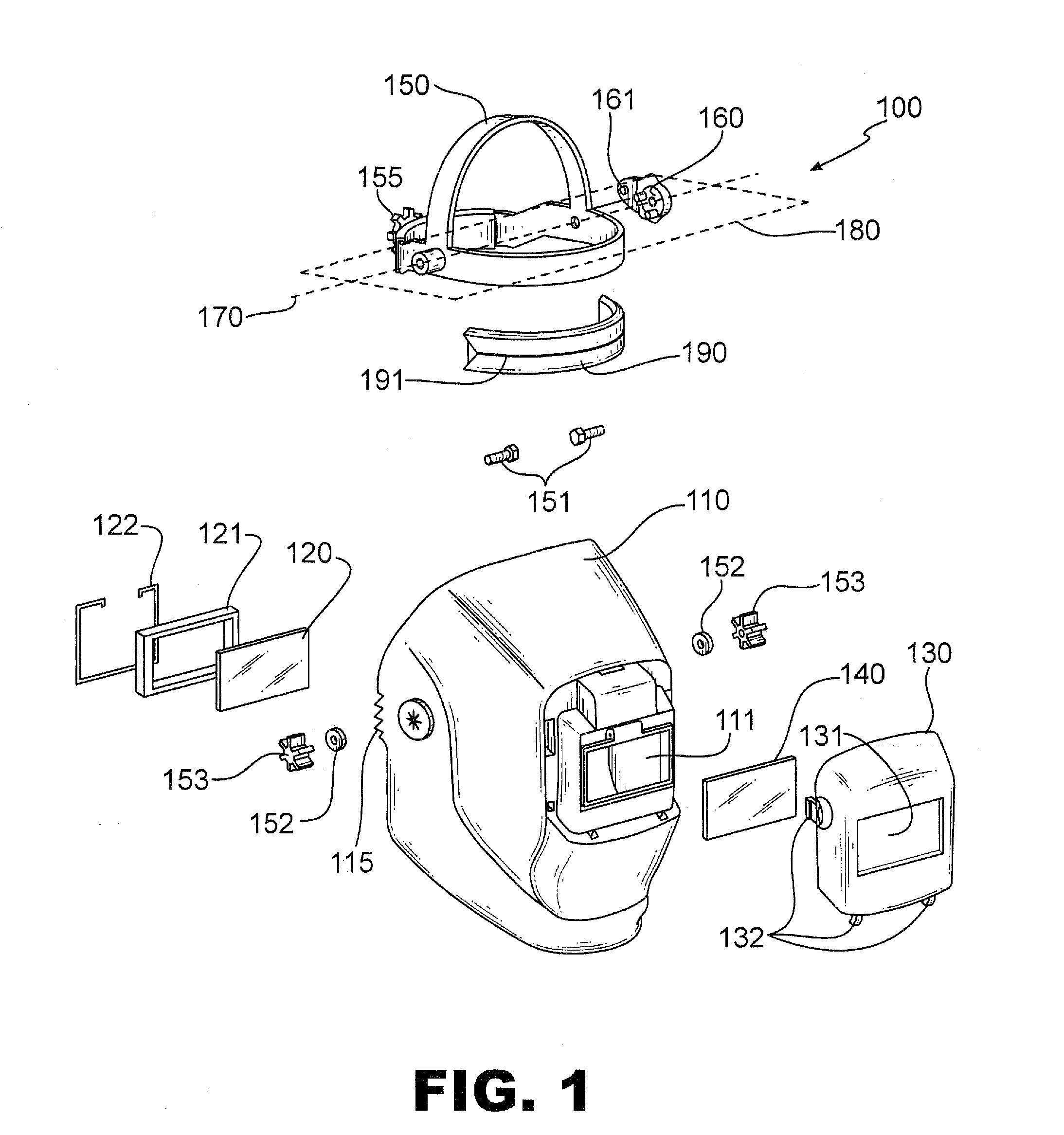

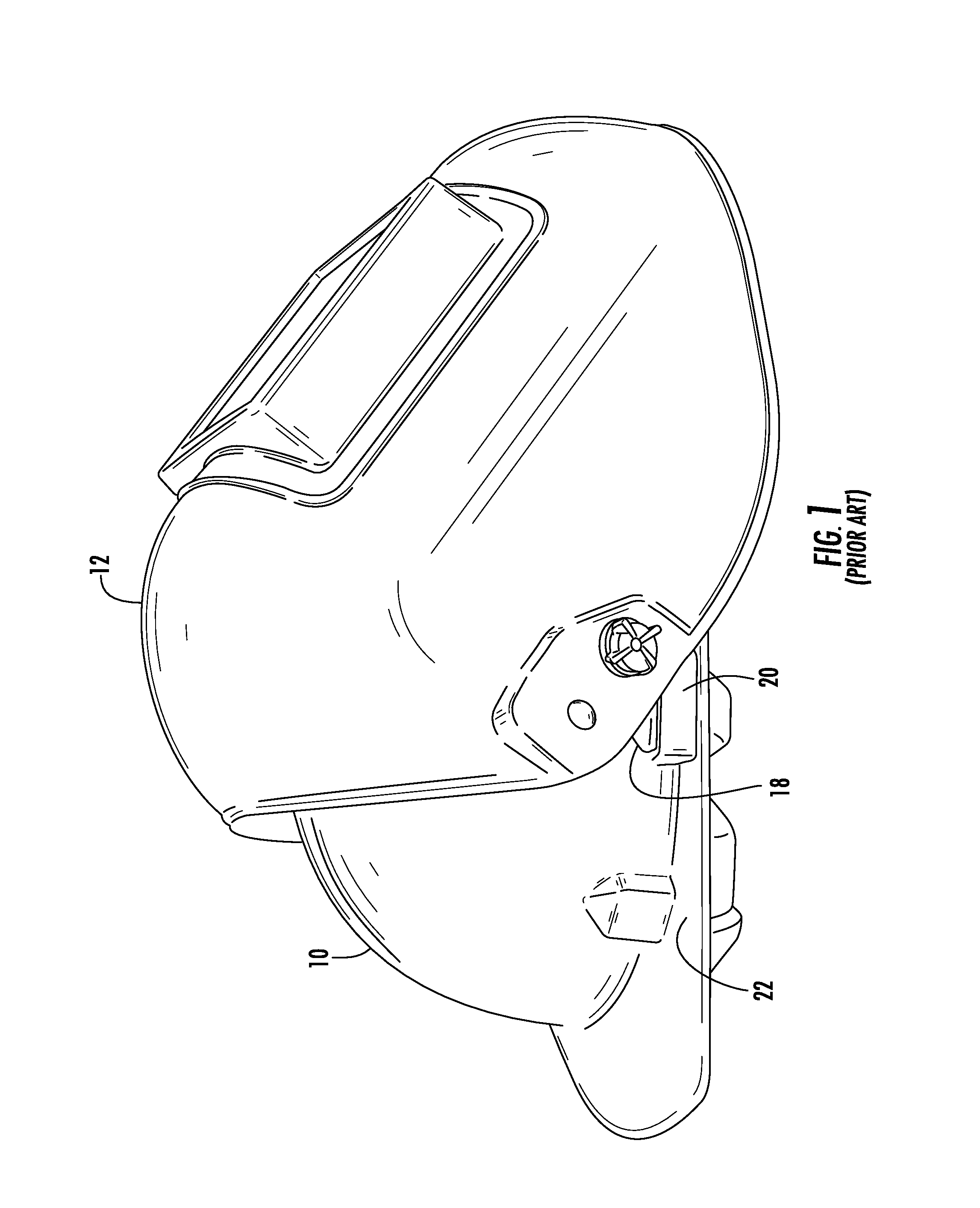

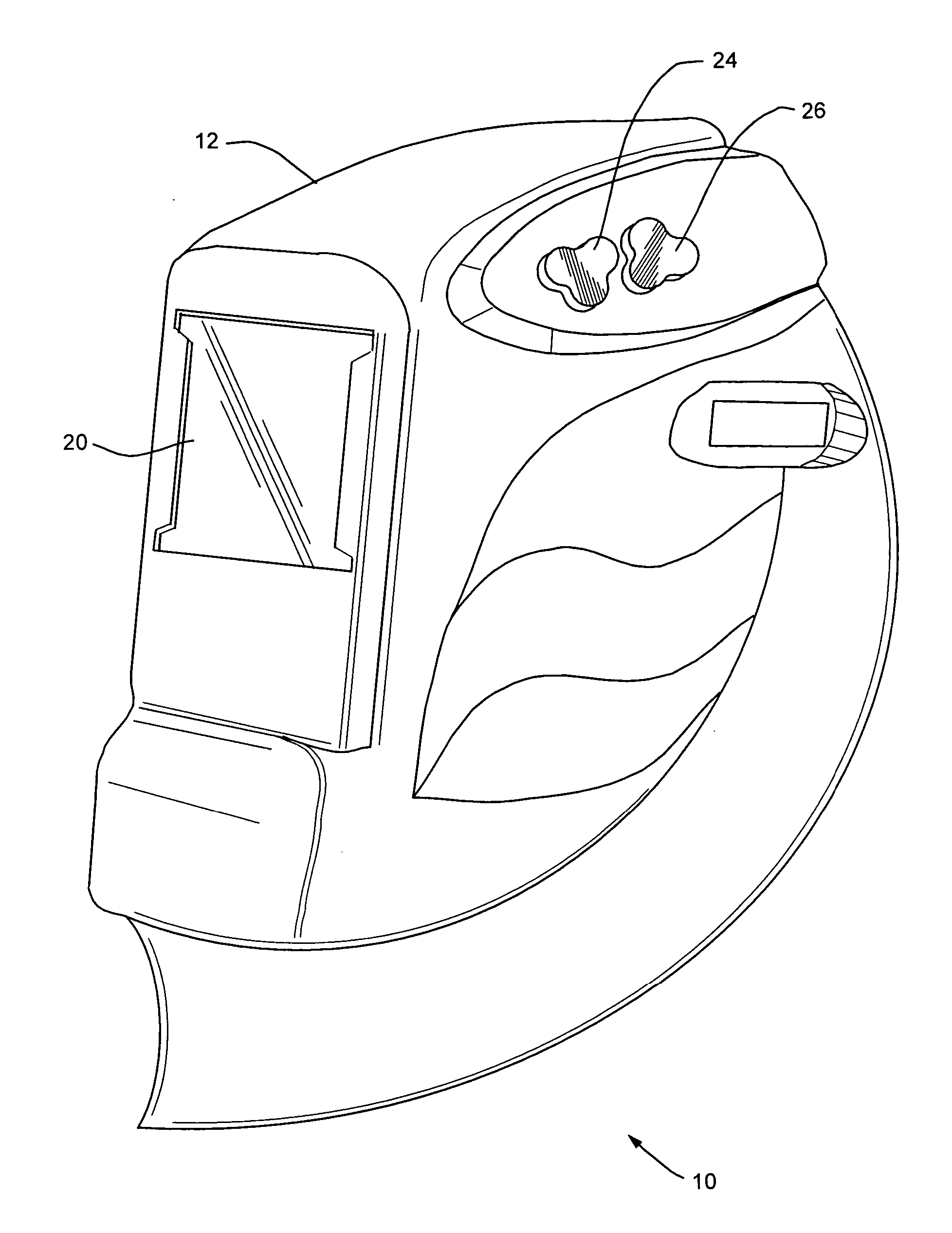

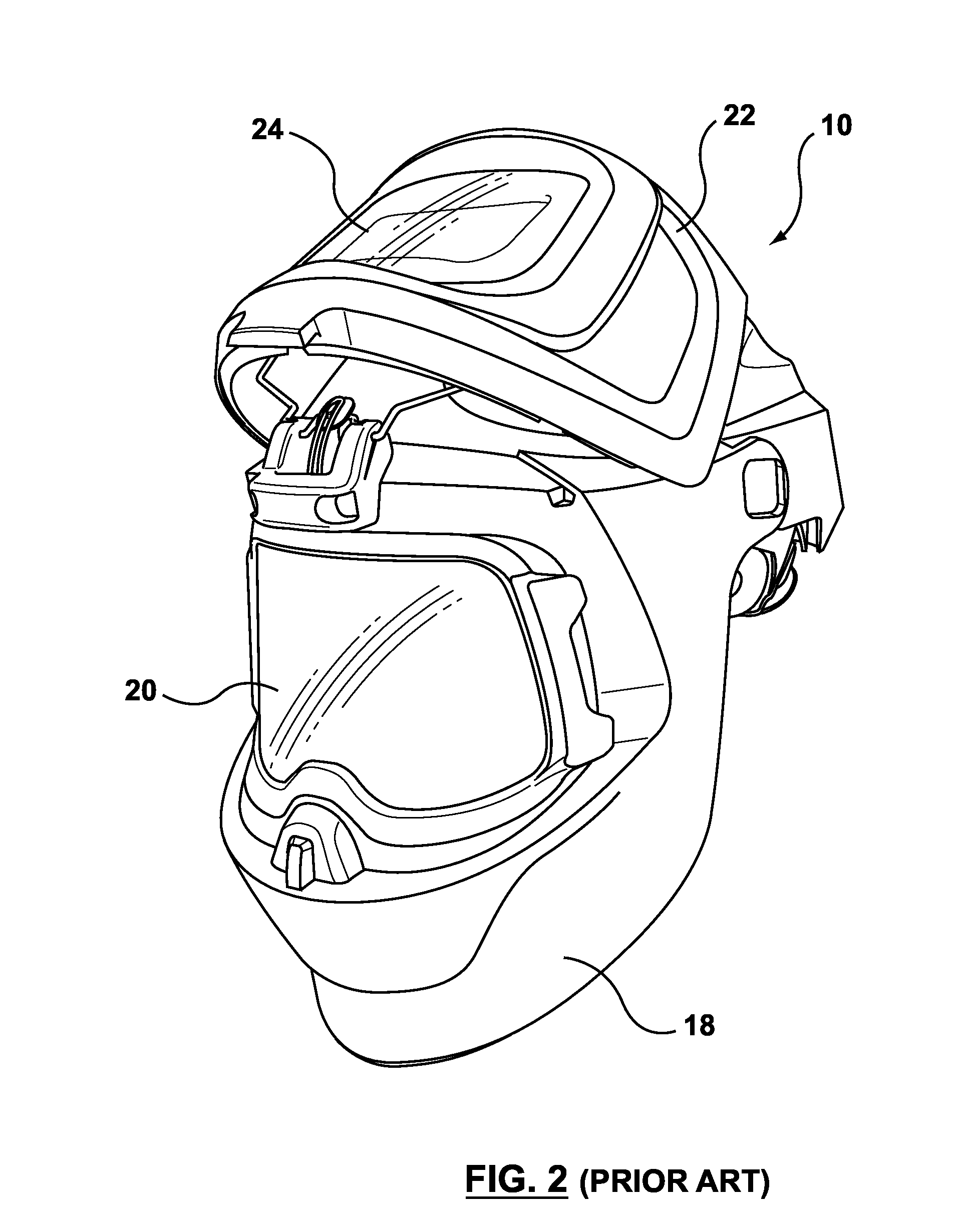

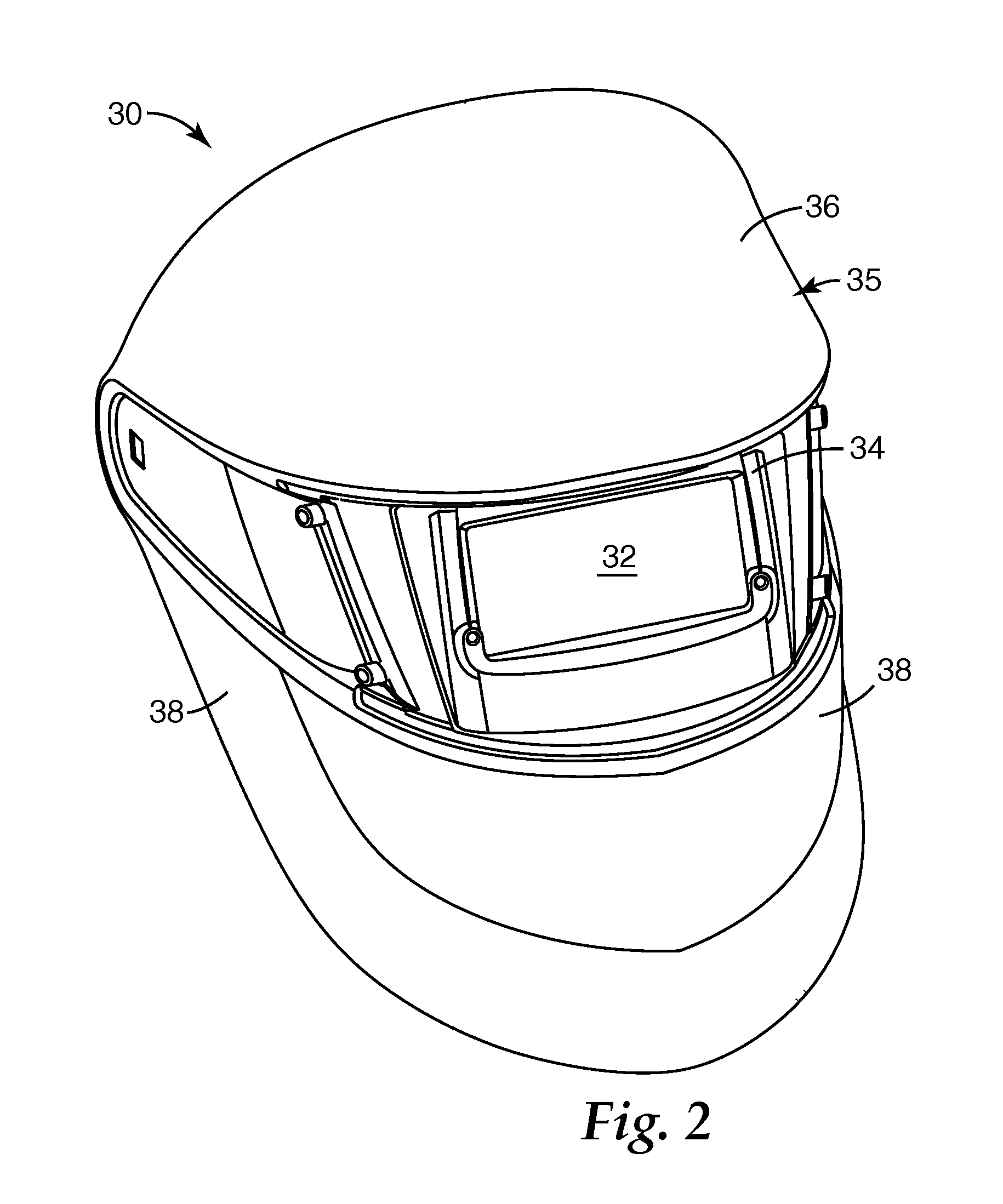

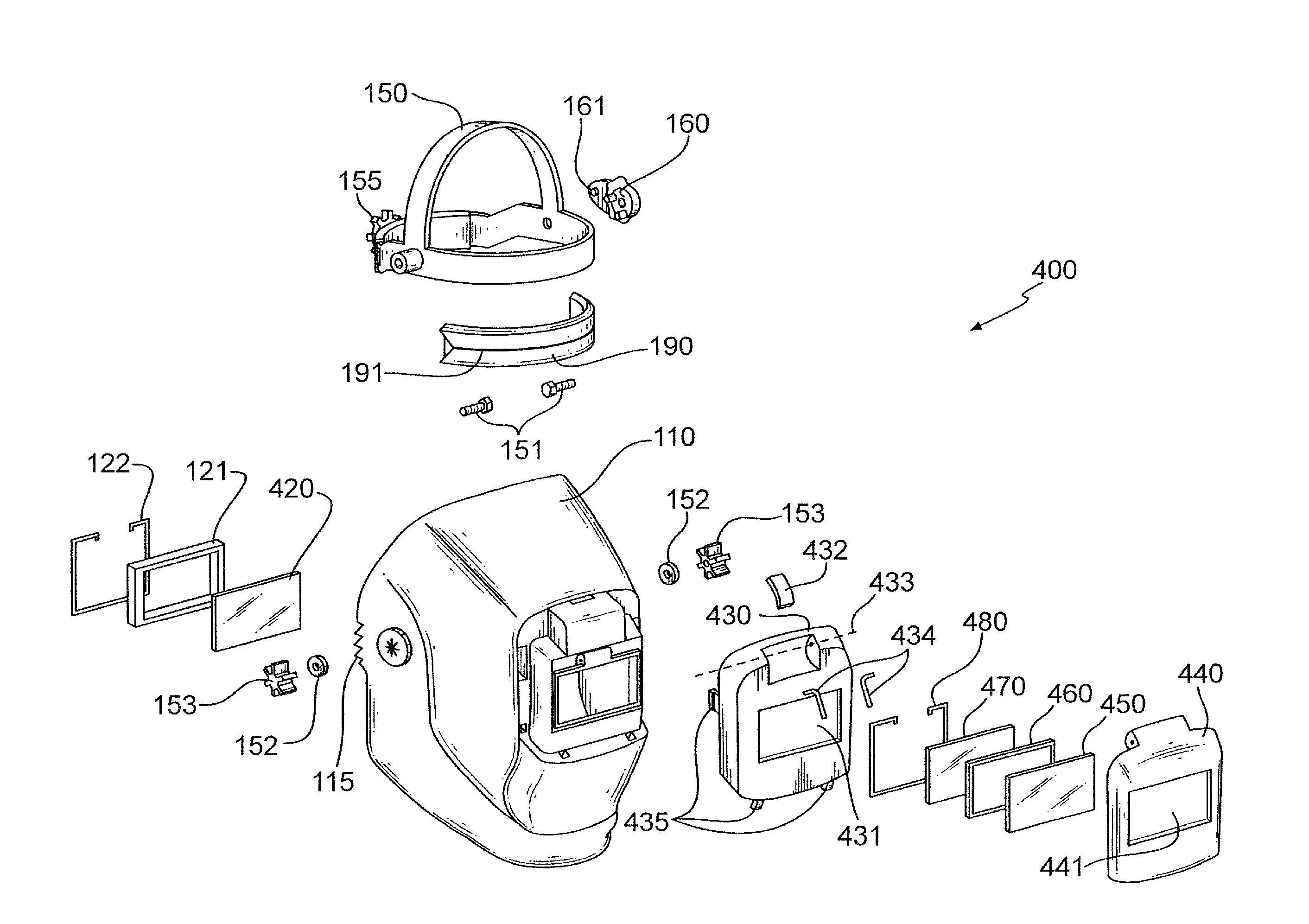

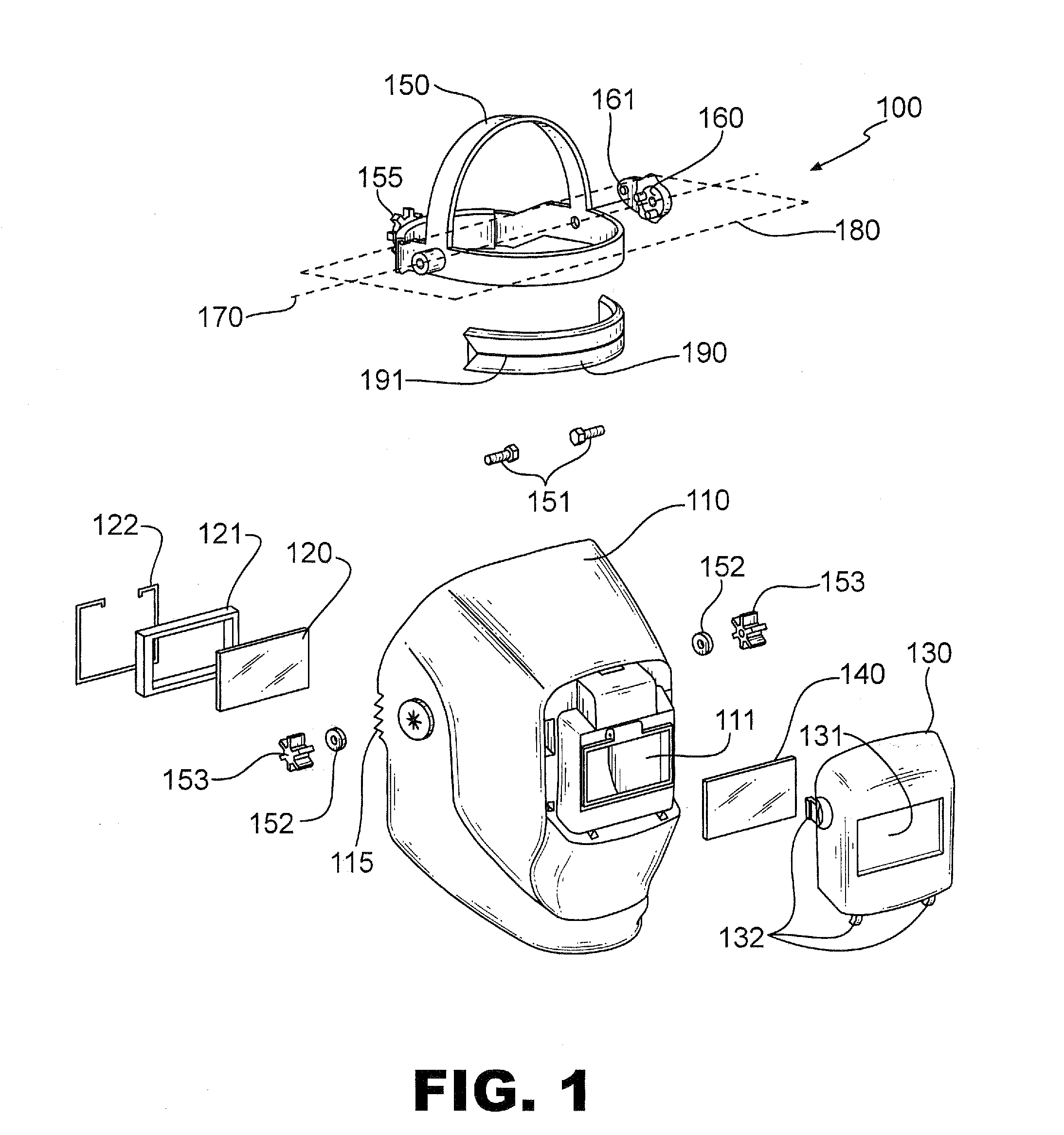

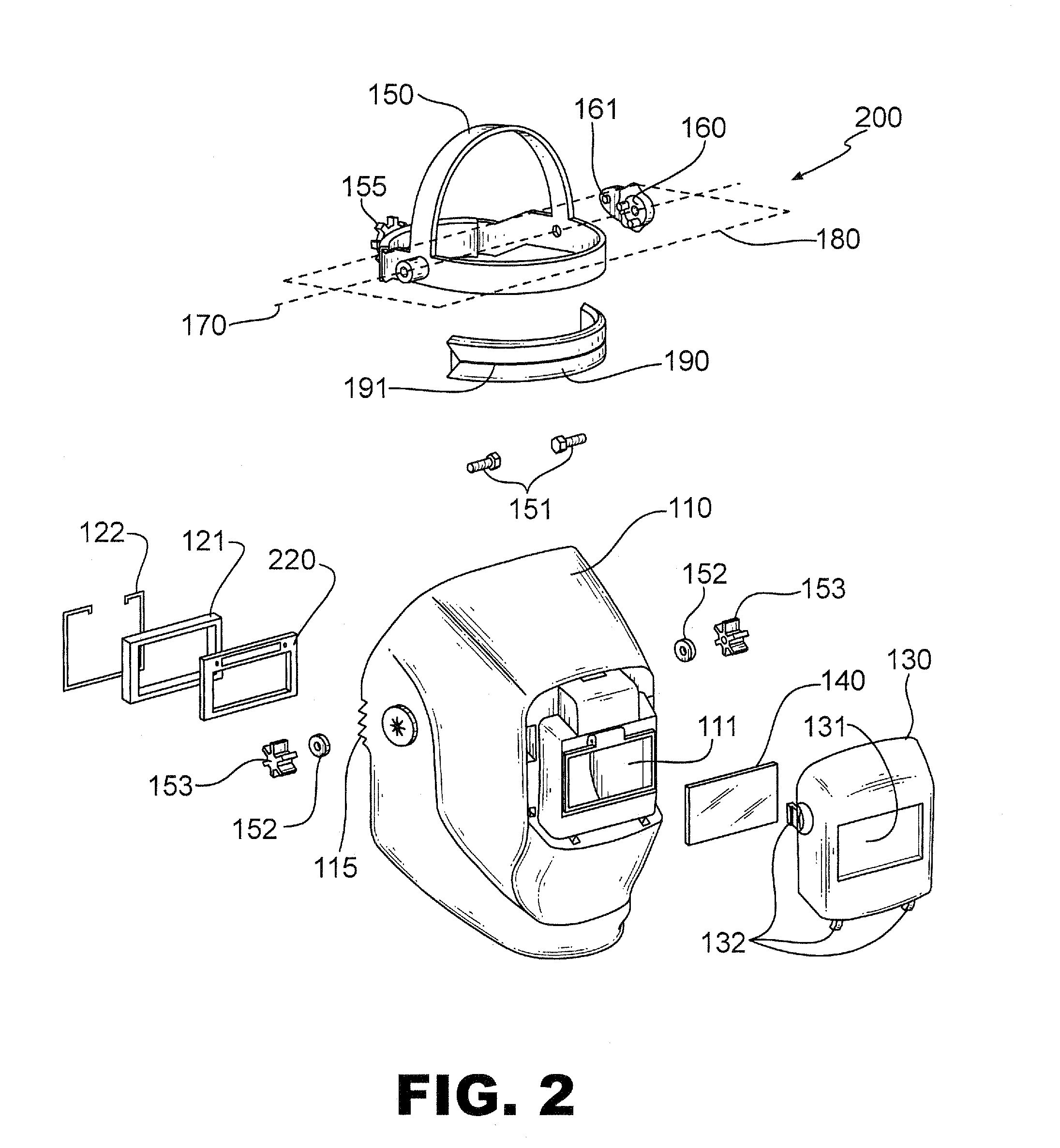

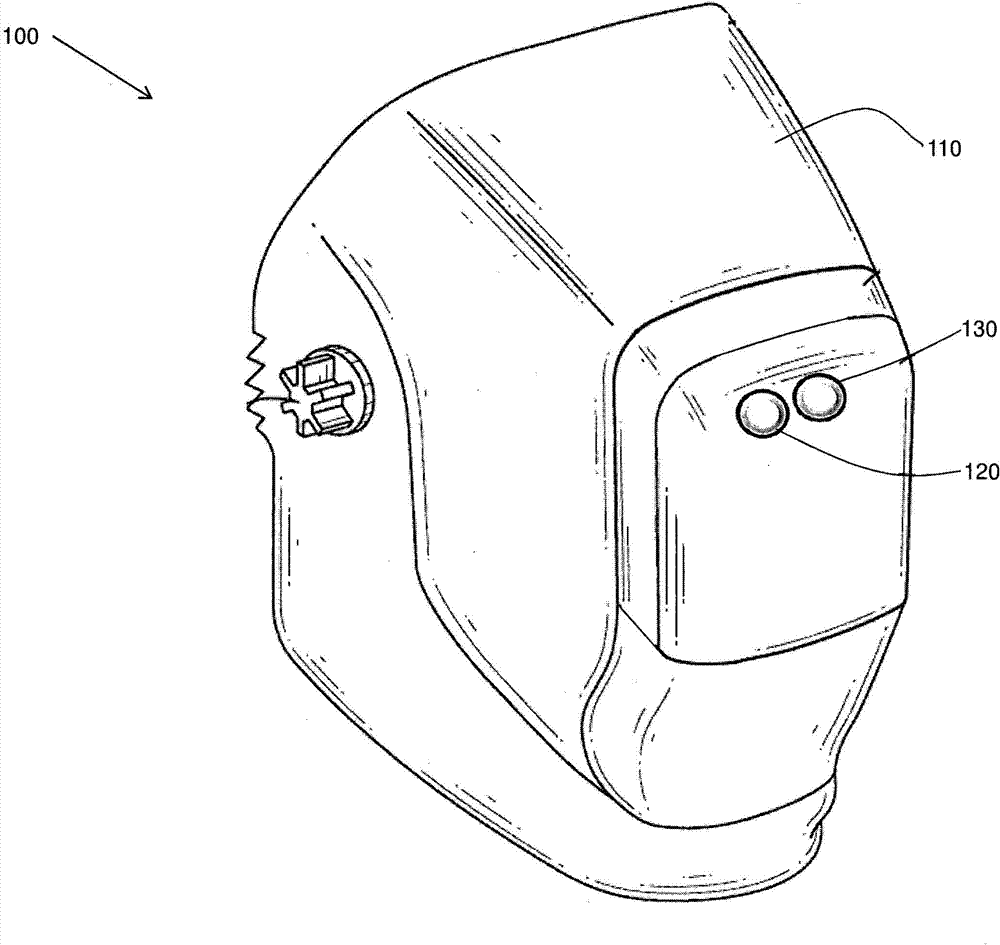

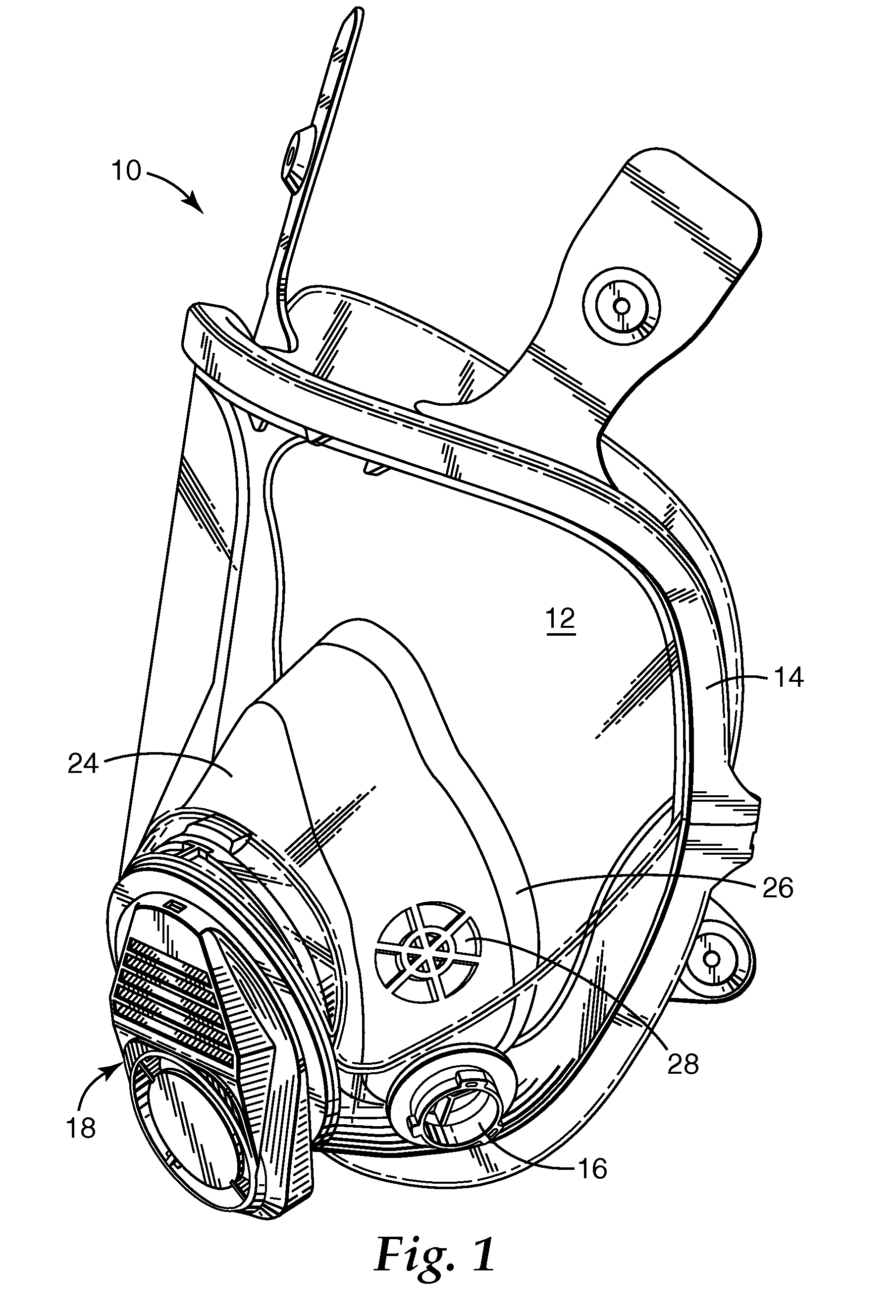

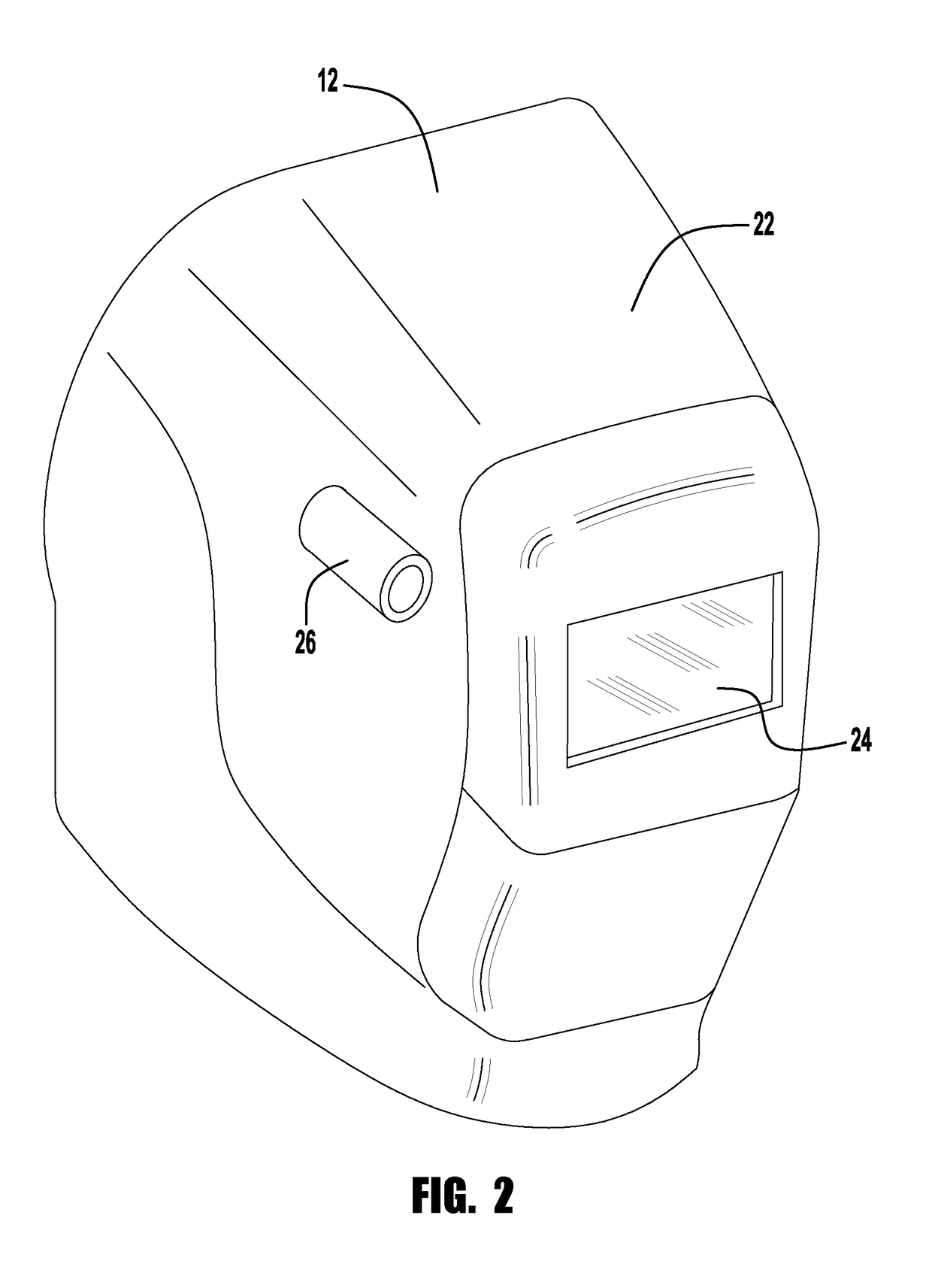

User-friendly welding helmet assembly

ActiveUS20080060102A1Good adhesionEasy detachmentGogglesEngineering safety devicesDetentWelding helmet

User-friendly welding helmet assembly configurations to be worn on the head of a weldor are disclosed. The welding helmet assembly configurations include various advanced features including a spatter shield that is easily replaceable from an external front portion of a shell of the helmet assembly configuration, and an adjustable ratchet headgear within the shell having a repositionable lever adapted to easily adjust a detent position of the ratchet headgear with respect to the shell. Other user-friendly features are also provided, in accordance with various embodiments of the present invention.

Owner:LINCOLN GLOBAL INC

Glare shielding device of welding helmet and method of controlling the same

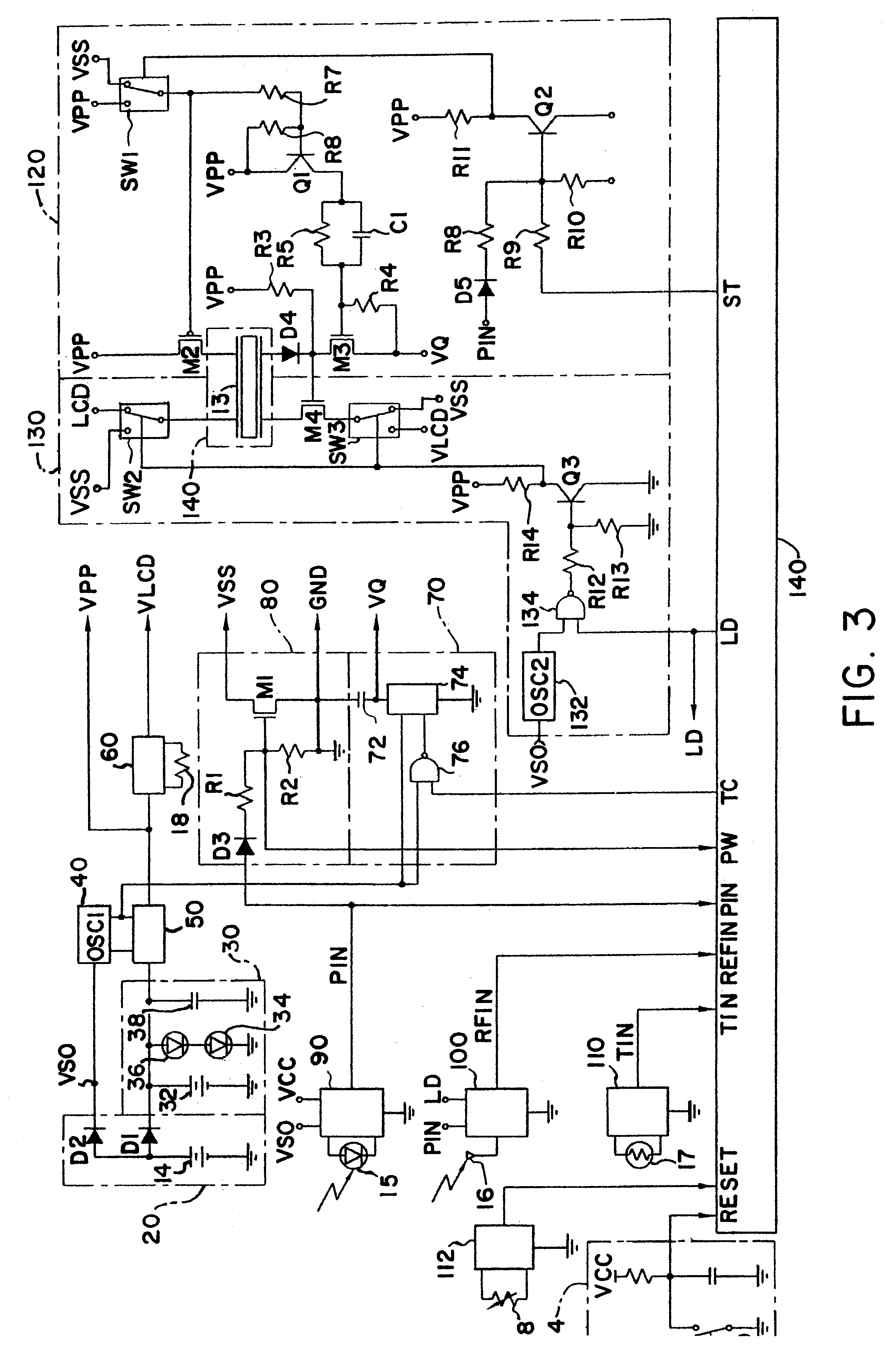

InactiveUS6614409B1Minimize power consumptionImprove shielding effectPhotometry using reference valueMaterial analysis by optical meansControl signalEngineering

The present invention discloses a glare shielding device. The glare shielding device includes a microprocessor for controlling an activation time and a driving time of a liquid crystal panel. The microprocessor generates an activation control signal of a liquid crystal activating portion, a driving control signal of a liquid crystal driving portion, and a power off control signal in response to a simultaneous detection of a welding light and a high frequency generated during a welding process. The liquid crystal activating portion becomes a floating state in a standby mode and activates the liquid crystal panel using a minus voltage between a high voltage and an activation voltage. The liquid crystal driving portion becomes a floating state in a standby mode and drives the liquid crystal panel in response to the driving control signal.

Owner:OTOS TECH

Weld characteristic communication system for a welding mask

Methods and systems for transmitting a torch angle and / or a torch-to-workpiece distance error to a welding operator when these parameters are outside of a preset optimal range via real time visual and / or audio cues are provided. One embodiment of the present disclosure relates to weld characteristic communication via intuitive arrays of visual indicators located on the periphery of a lens, which indicate to the welding operator the direction and severity of the torch angle error. In one embodiment, audio cues, such as pulsed or continuous tones may be used to communicate torch-to-workpiece distance to the welding operator. In certain embodiments, vertical visual indicator arrays may be used to indicate additional weld or auxiliary information, such as battery charge state, torch speed and so forth, to the welding operator. All the components of the communication system may be located in or on the welding helmet or the components may be split between the helmet and a belt pack.

Owner:ILLINOIS TOOL WORKS INC

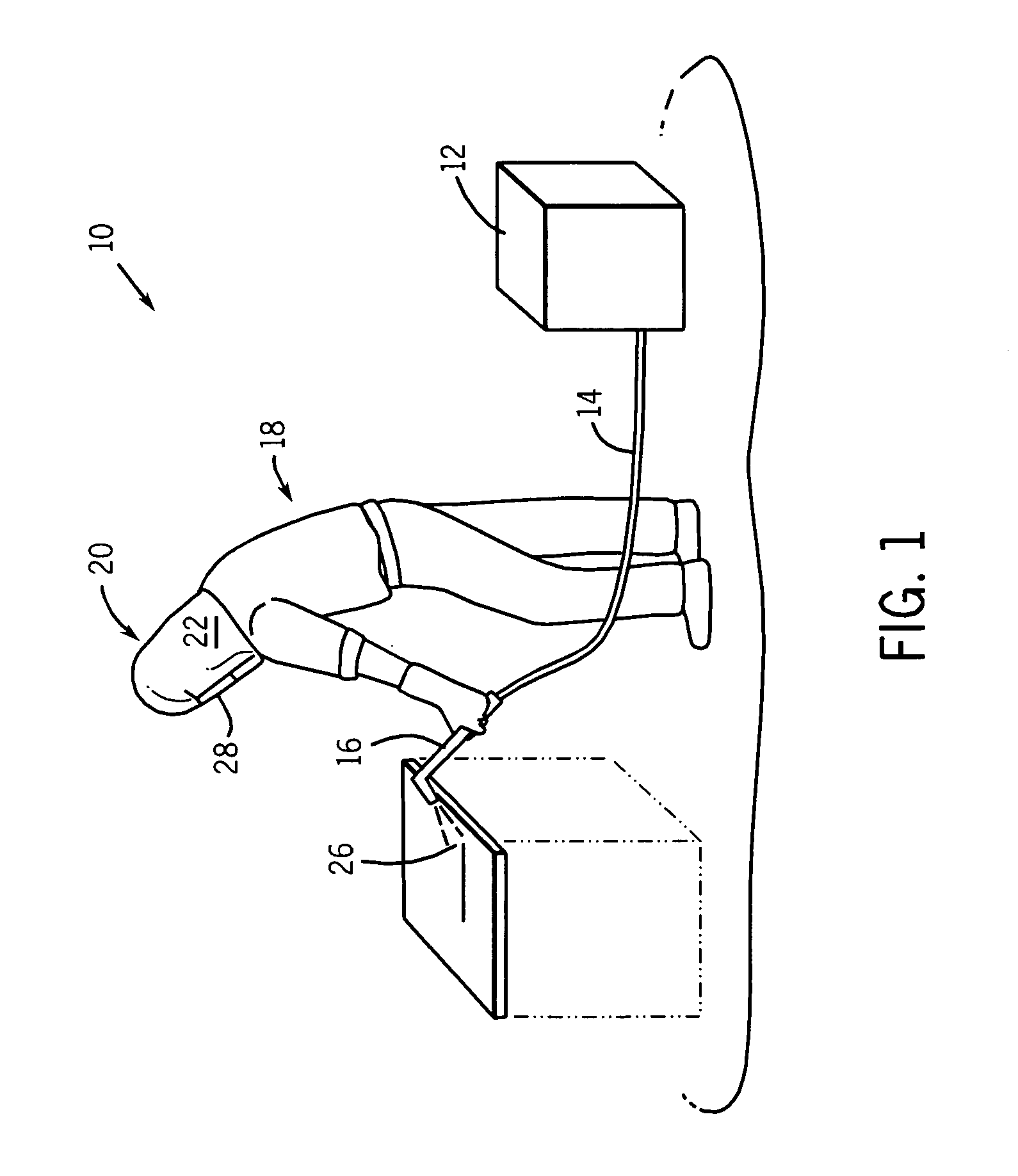

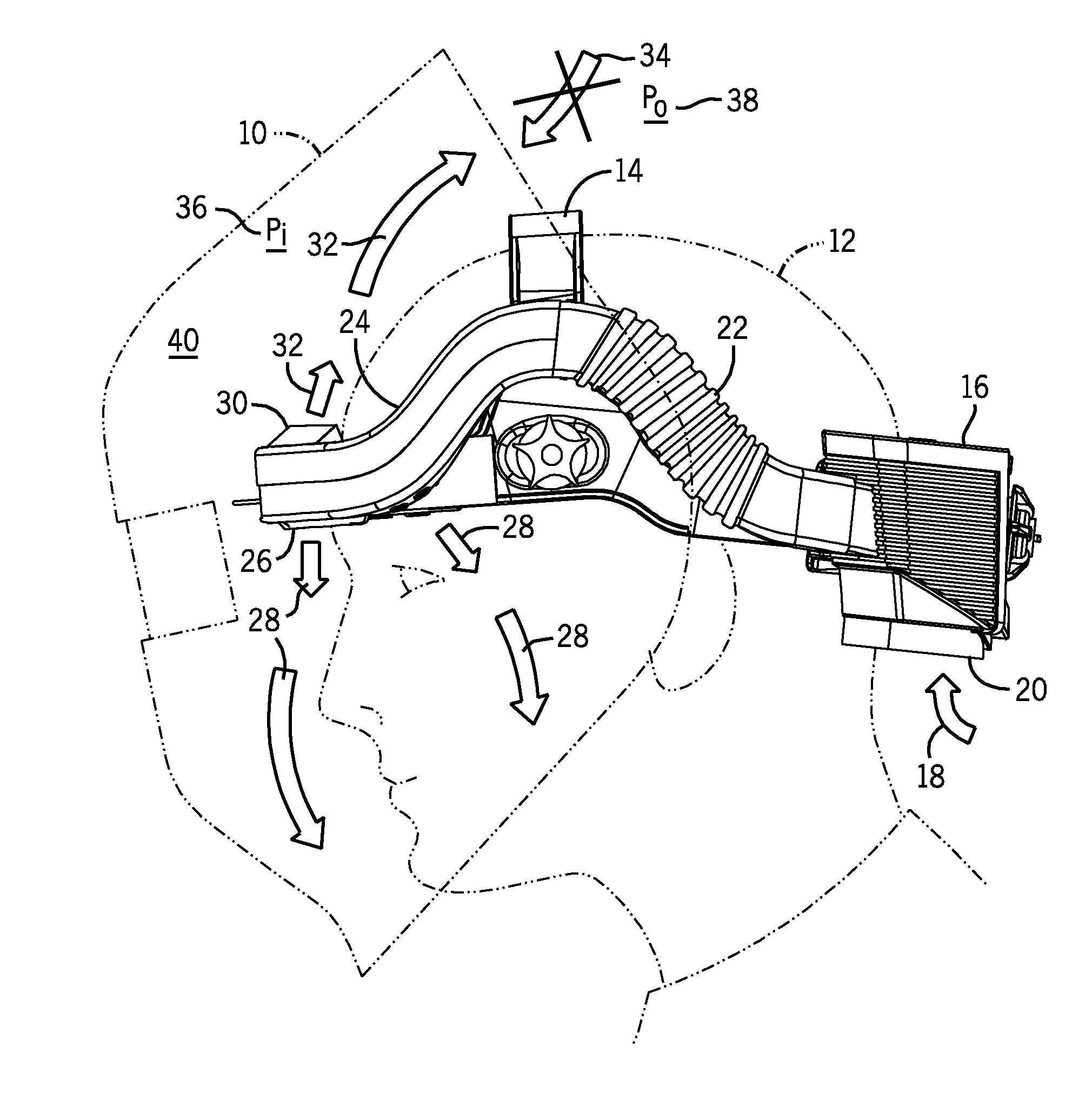

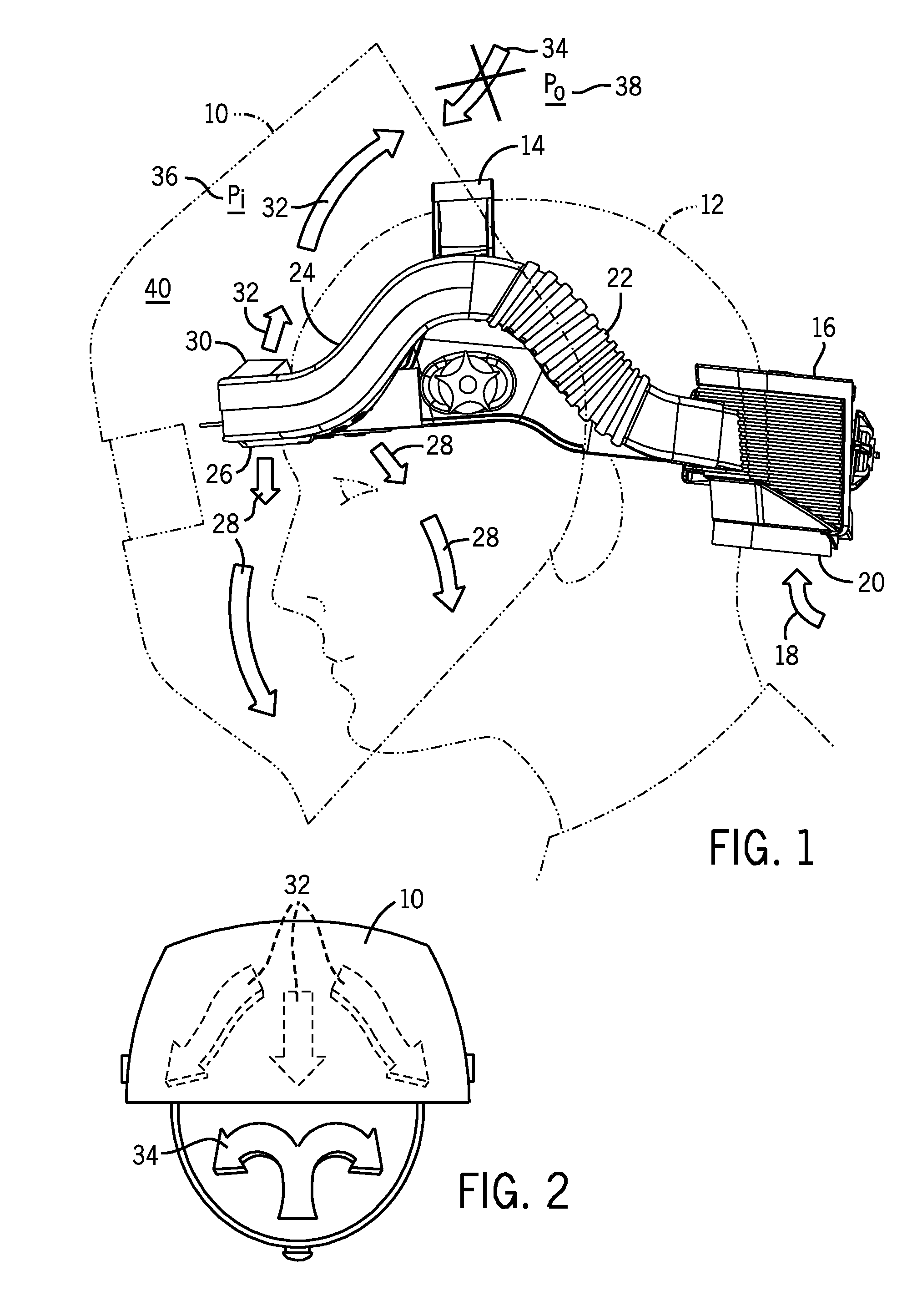

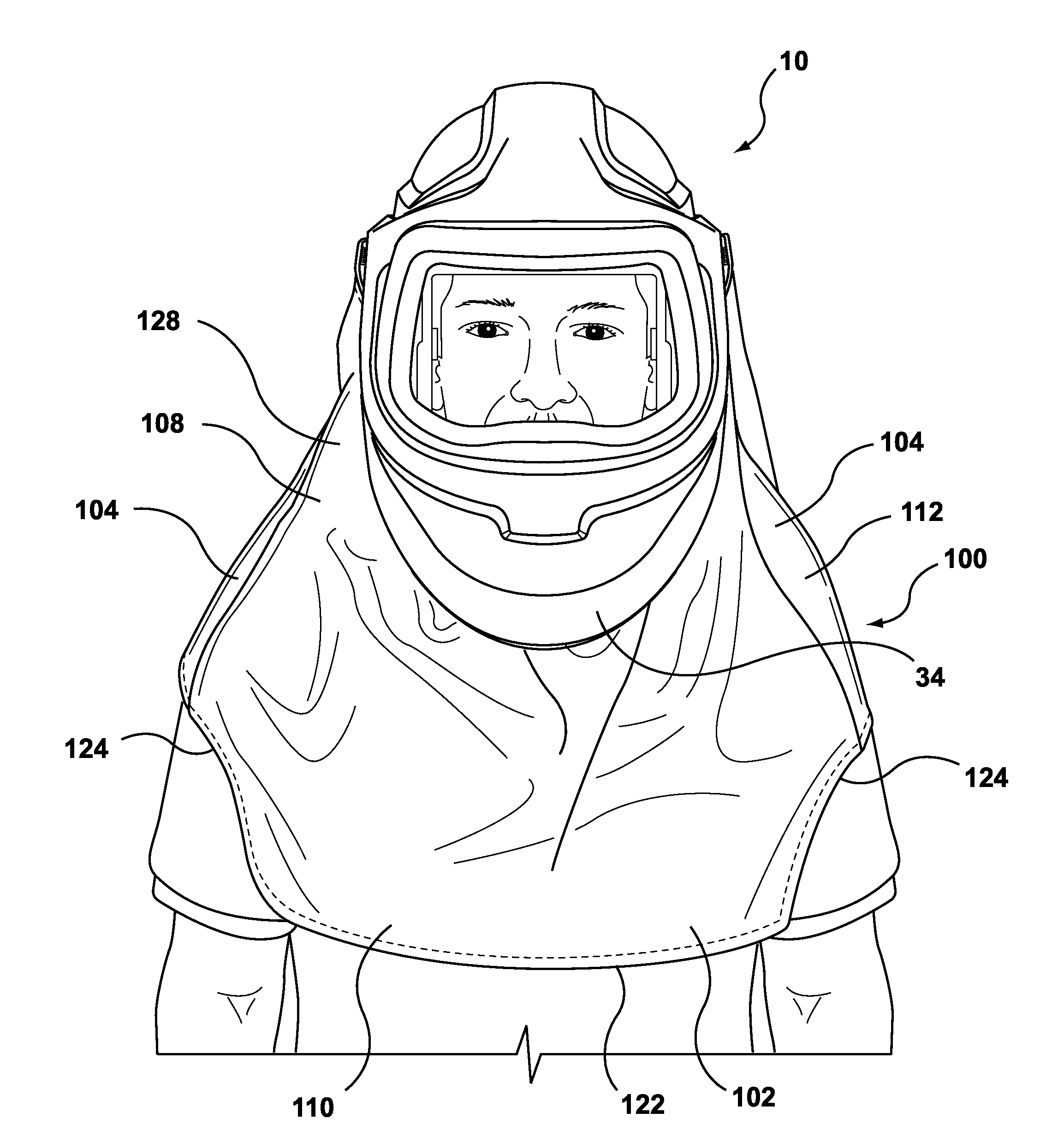

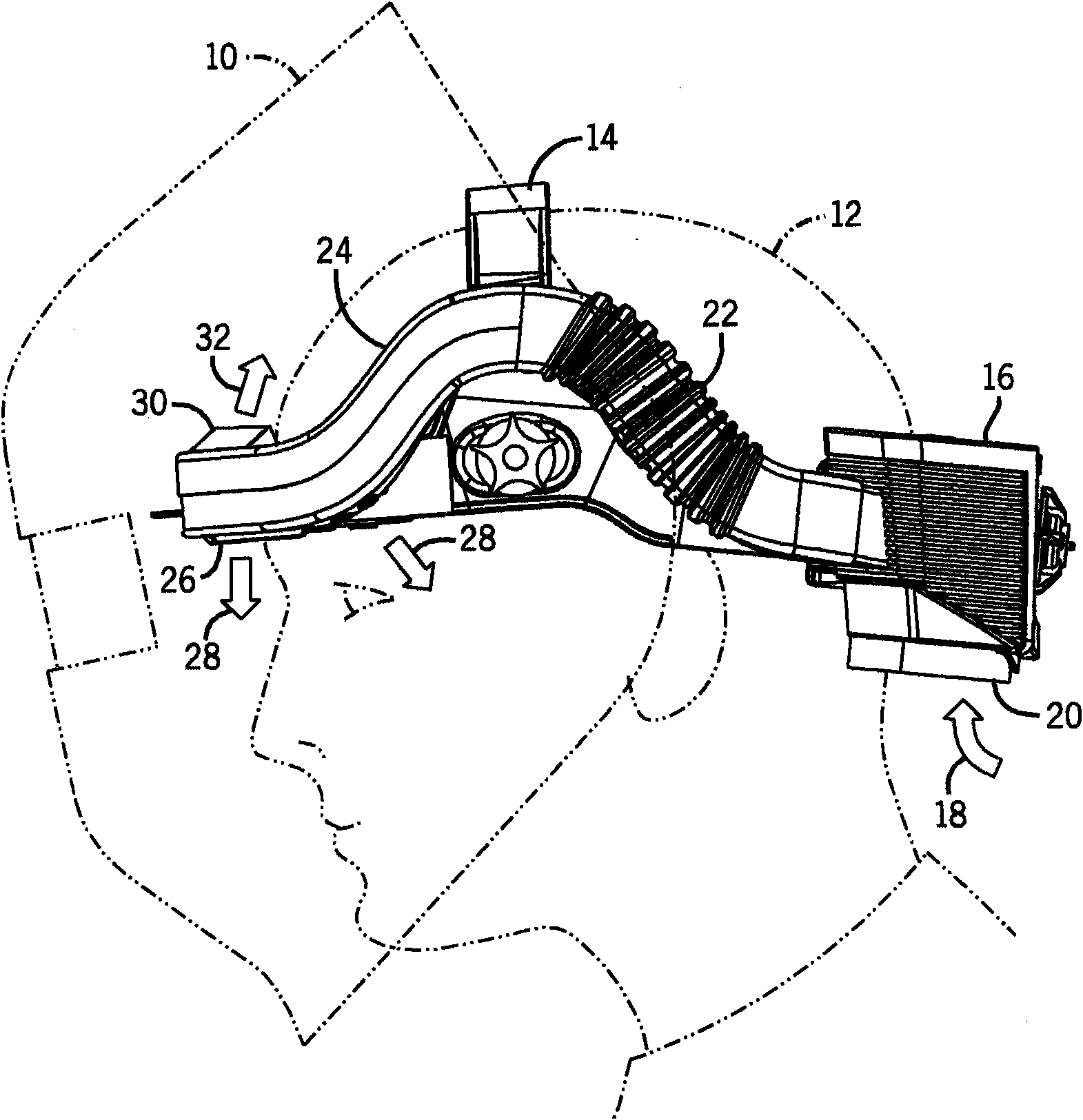

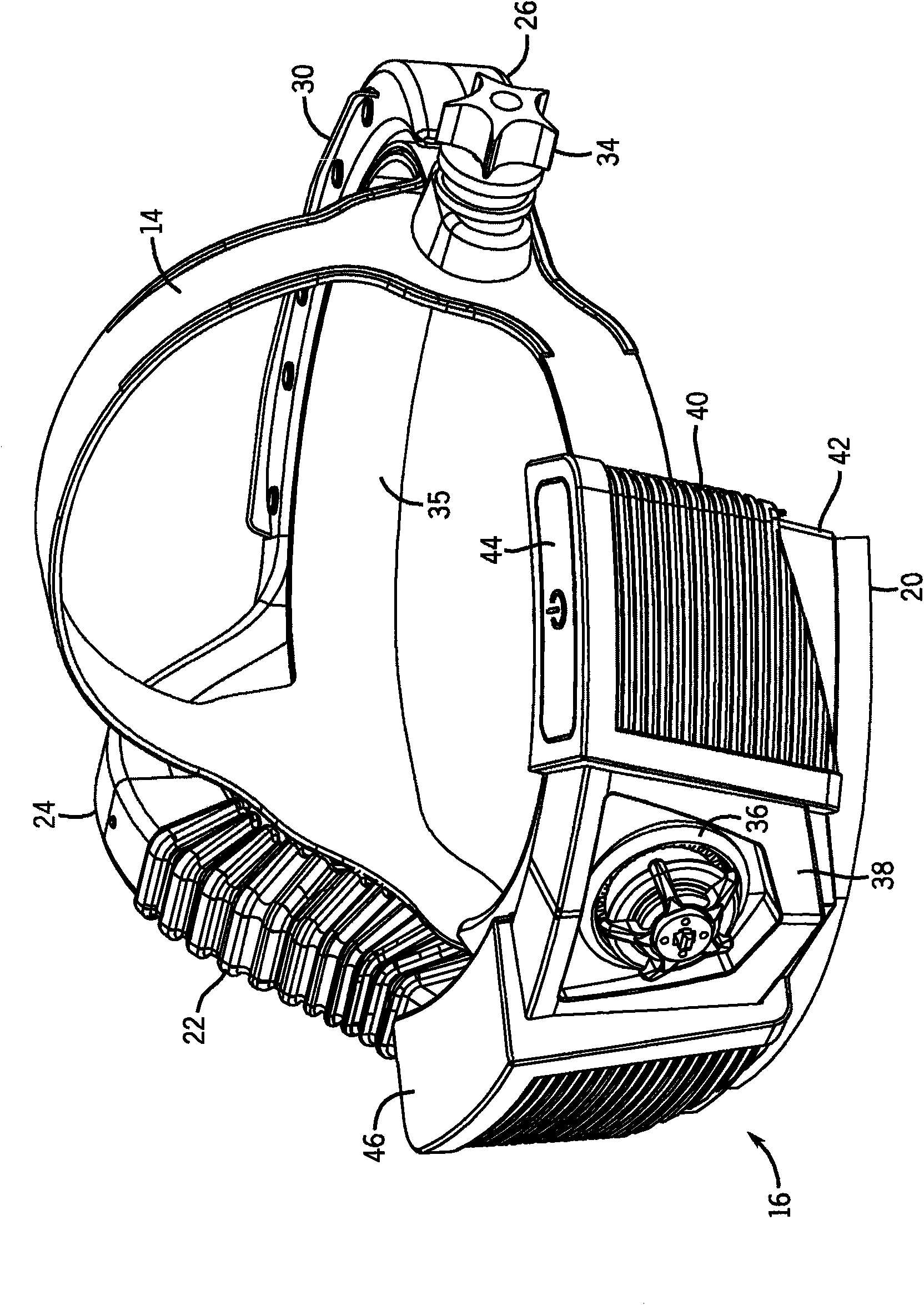

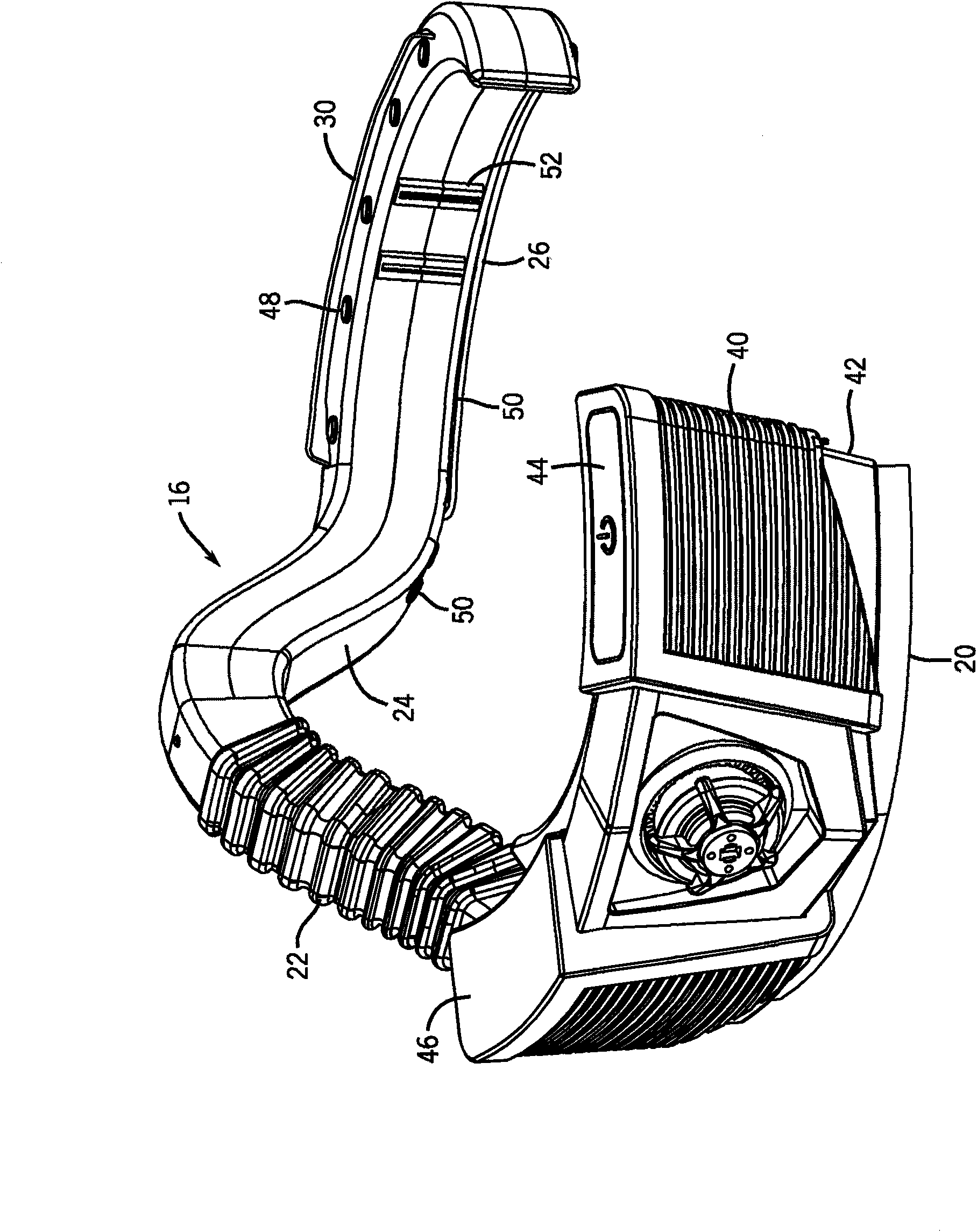

Welding helmet positive air pressuring system and method

A method and system for controlling ventilation in a welding helmet is provided. The invention may be adapted to a wide variety of system types, and may reduce or eliminate the need for a shroud or barrier around the head and neck of the welder, of the type used in PAPR systems. The airflow system includes forward and rearward air streams, directed onto the face of the welder, onto the top of the head of the welder, and toward the back of the head of the welder. The air streams help to cool the welder, provide a fresh source of air for breathing, and create a positive pressure system that reduces or excludes entrainment of contaminated external air into the forwardly directed air flow. Certain embodiments may include streams that are filtered, split or redirected via deflectors and conduits to achieve the aforementioned goals.

Owner:ILLINOIS TOOL WORKS INC

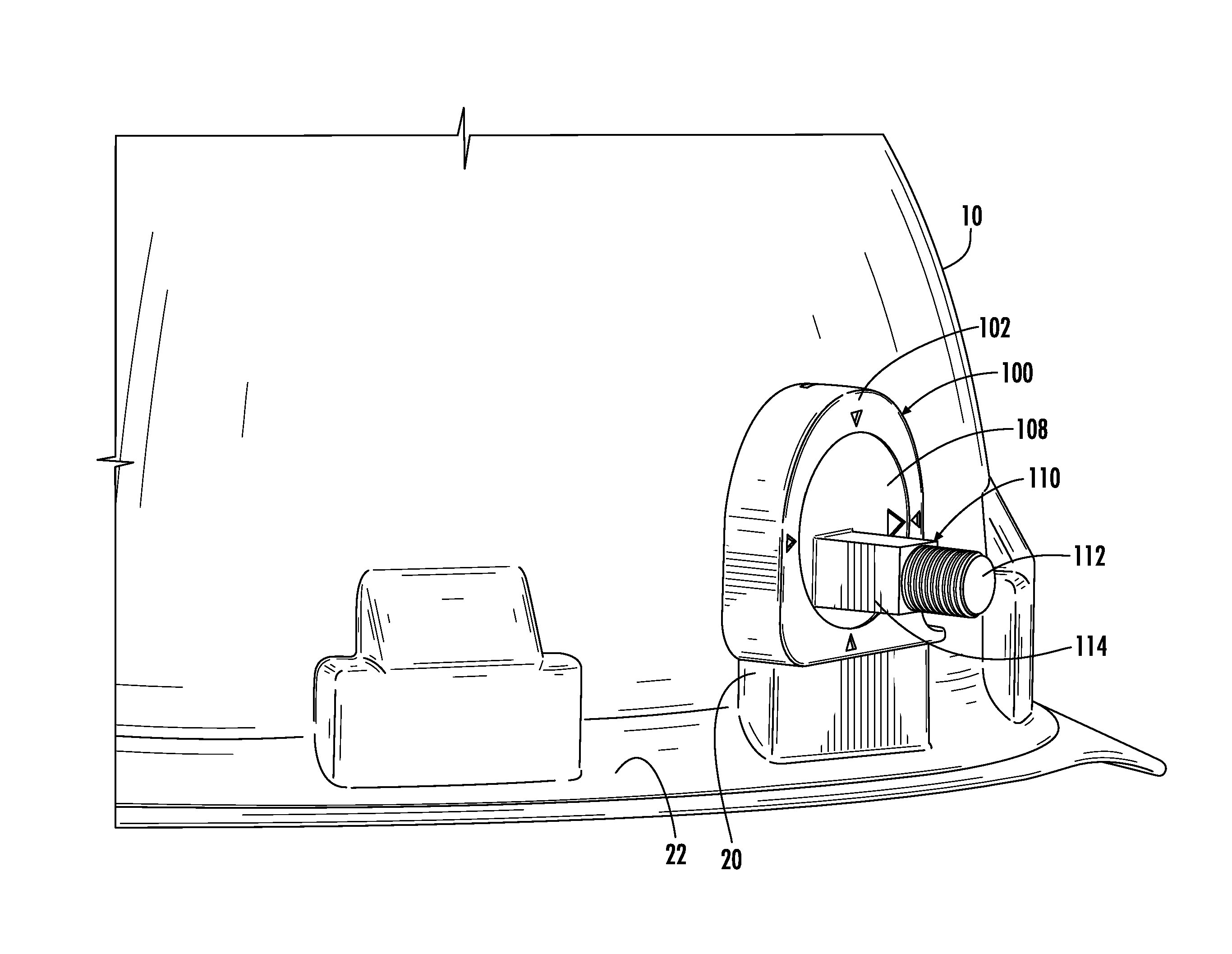

Hard hat adapter for a welding helmet

A hard hat adapter for a welding helmet is disclosed. The dapater includes a housing which has an outer wall, an interior surface and a bottom surface. The outer wall includes a surface defining a window therethrough. The interior surface includes a recessed surface circumscribing the window. The recessed surface includes at least one planar surface thereon. A rotatable boss is captured within the housing against the interior surface. The boss has an annular lip that includes at least one planar surface thereon configured to selectively engage the planar surface on the recessed surface of the housing and prevent the boss from rotating when engaged thereon and freely rotatable when disengaged therefrom. A mounting post extends from the boss and projects through the window on the housing. The mounting post is configured to selectively couple to a welding helmet. The welding helmet may include a rotatable cam configured to engage a lever arm on the hard hat adapter.

Owner:HONEYWELL SAFETY PROD USA INC

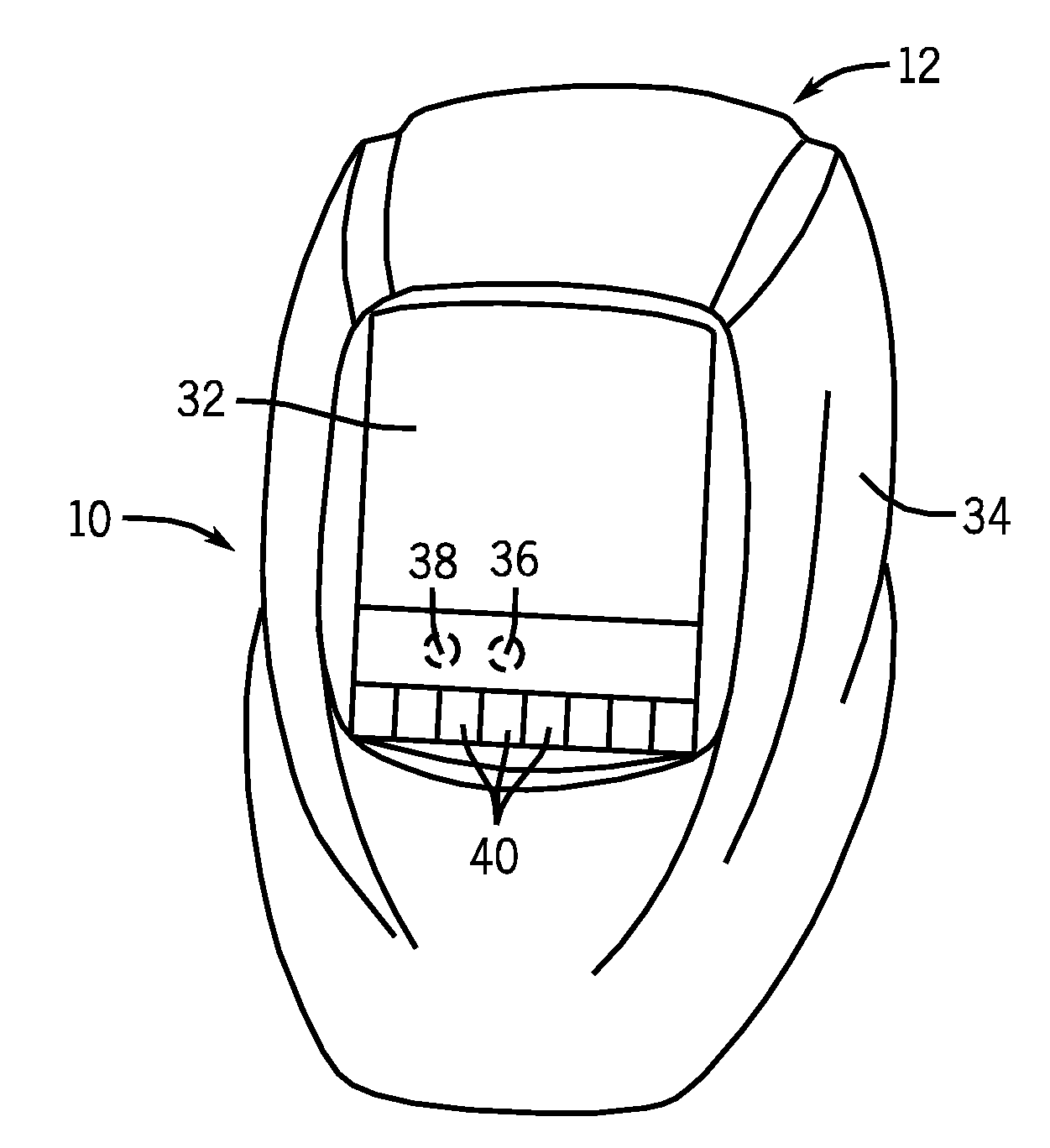

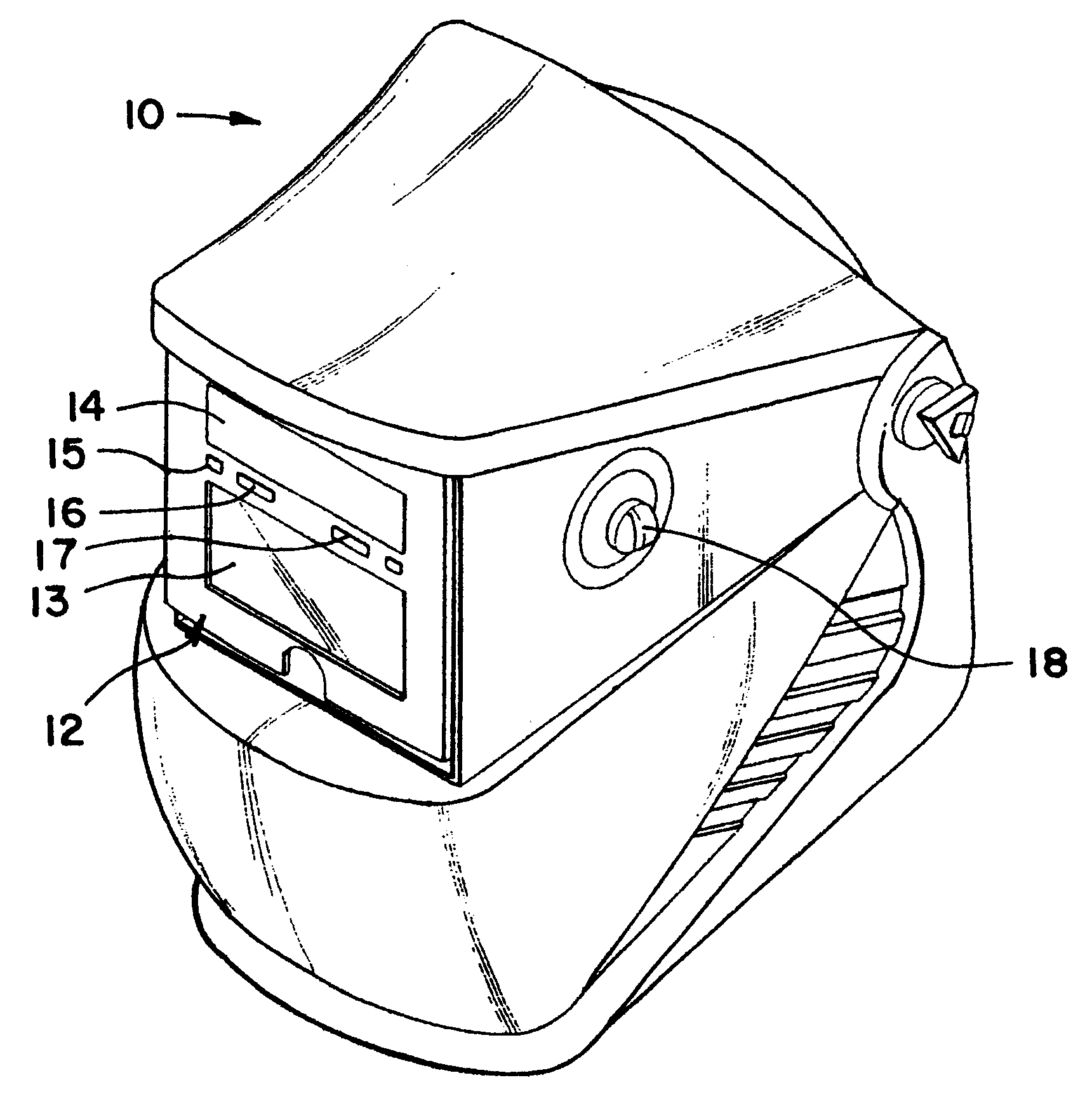

Modular auto-darkening welding filter

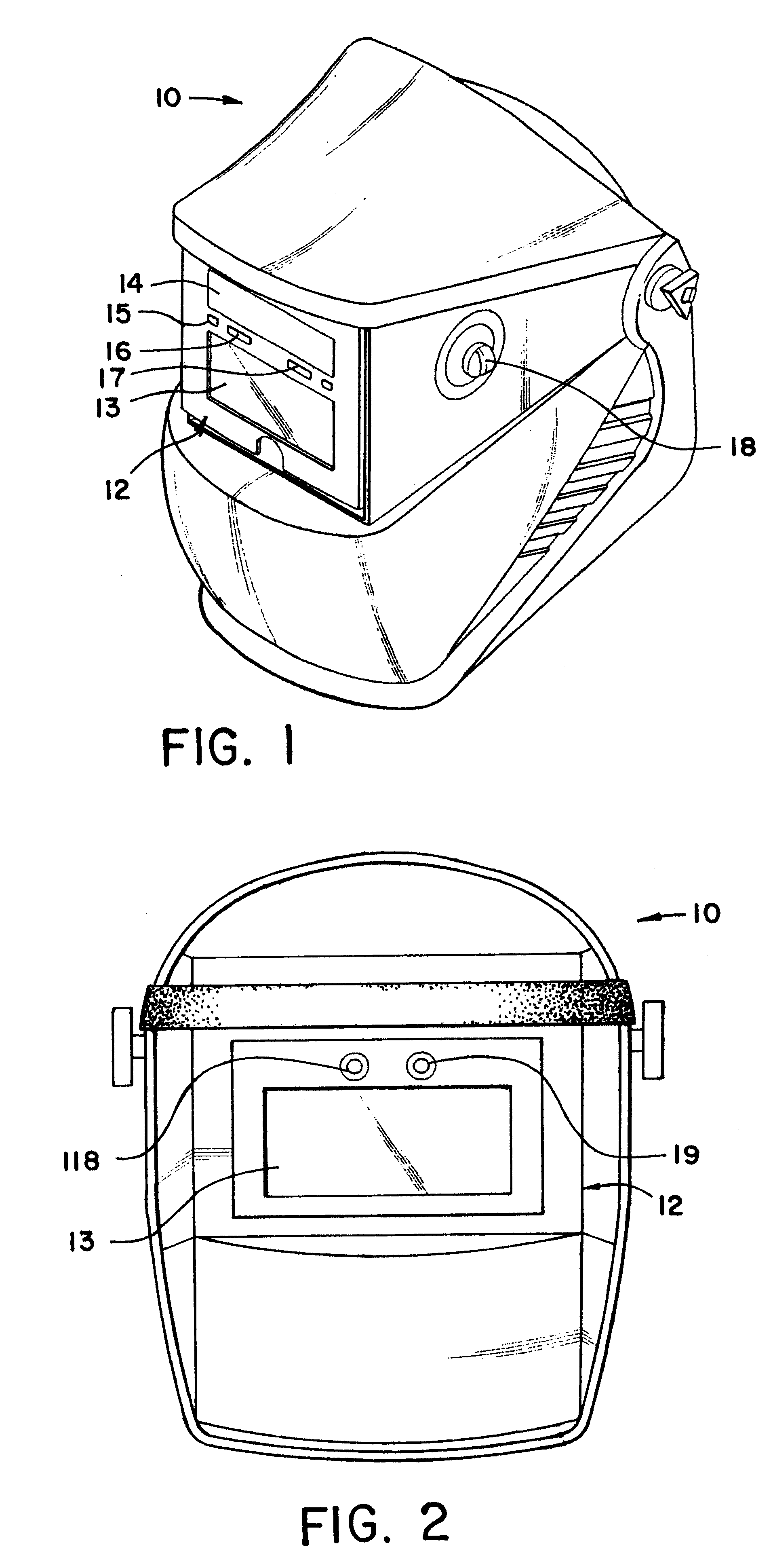

A welding helmet having an auto-darkening welding filter comprises a viewing module and a control module attached to the helmet separate from the viewing module. In a first embodiment a control module is attached to a side of the welding helmet having a pair of variable resistor shafts extending through the side housing of welding helmet for adjustment of the auto-darkening viewing module by a user without removing the welding helmet from in front of the user's eyes. In a second embodiment the control module is attached to the inside of the helmet below the auto-darkening viewing module, and the control module comprises switches integrated on a surface of the control module which are operated by the user.

Owner:A C E INT

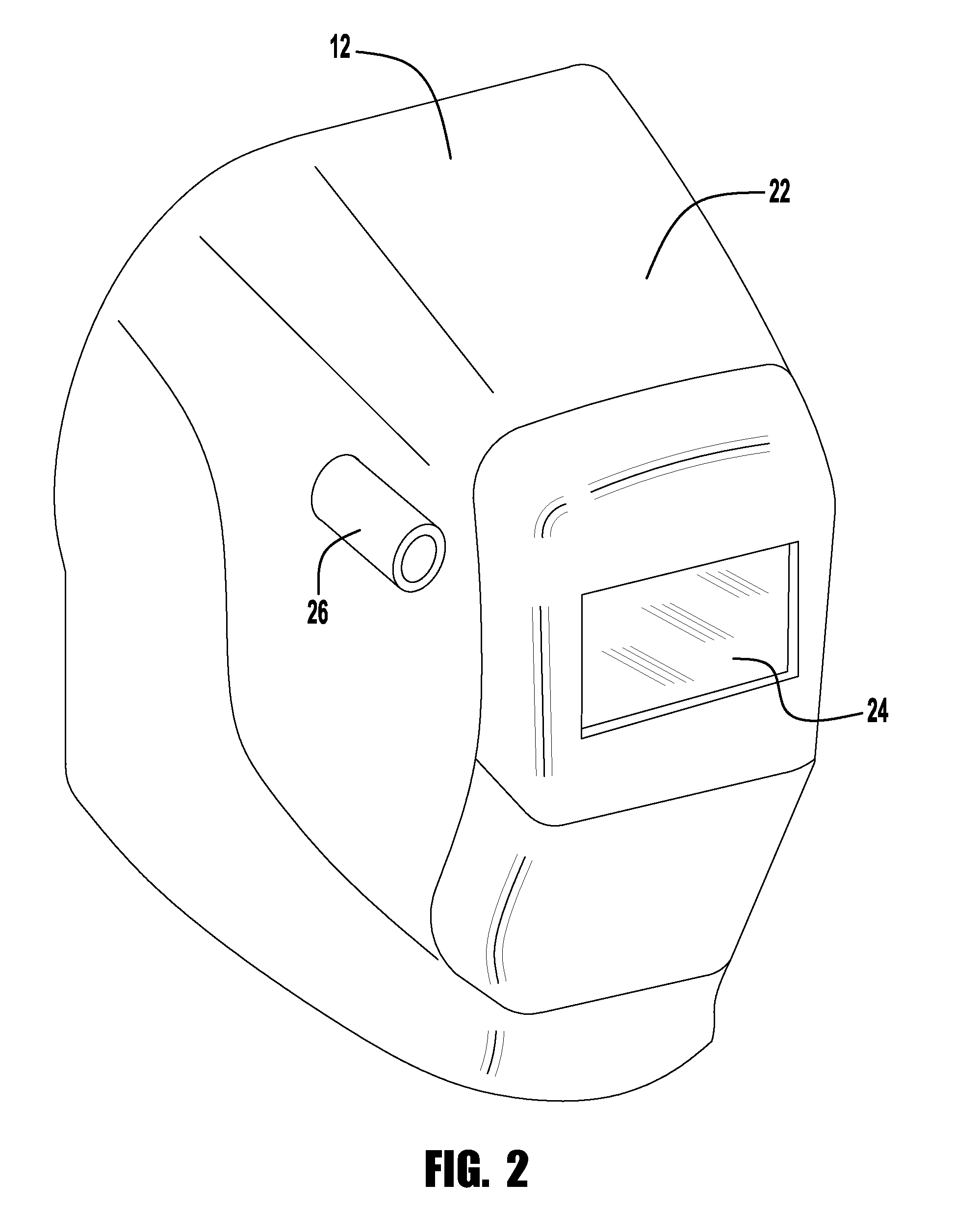

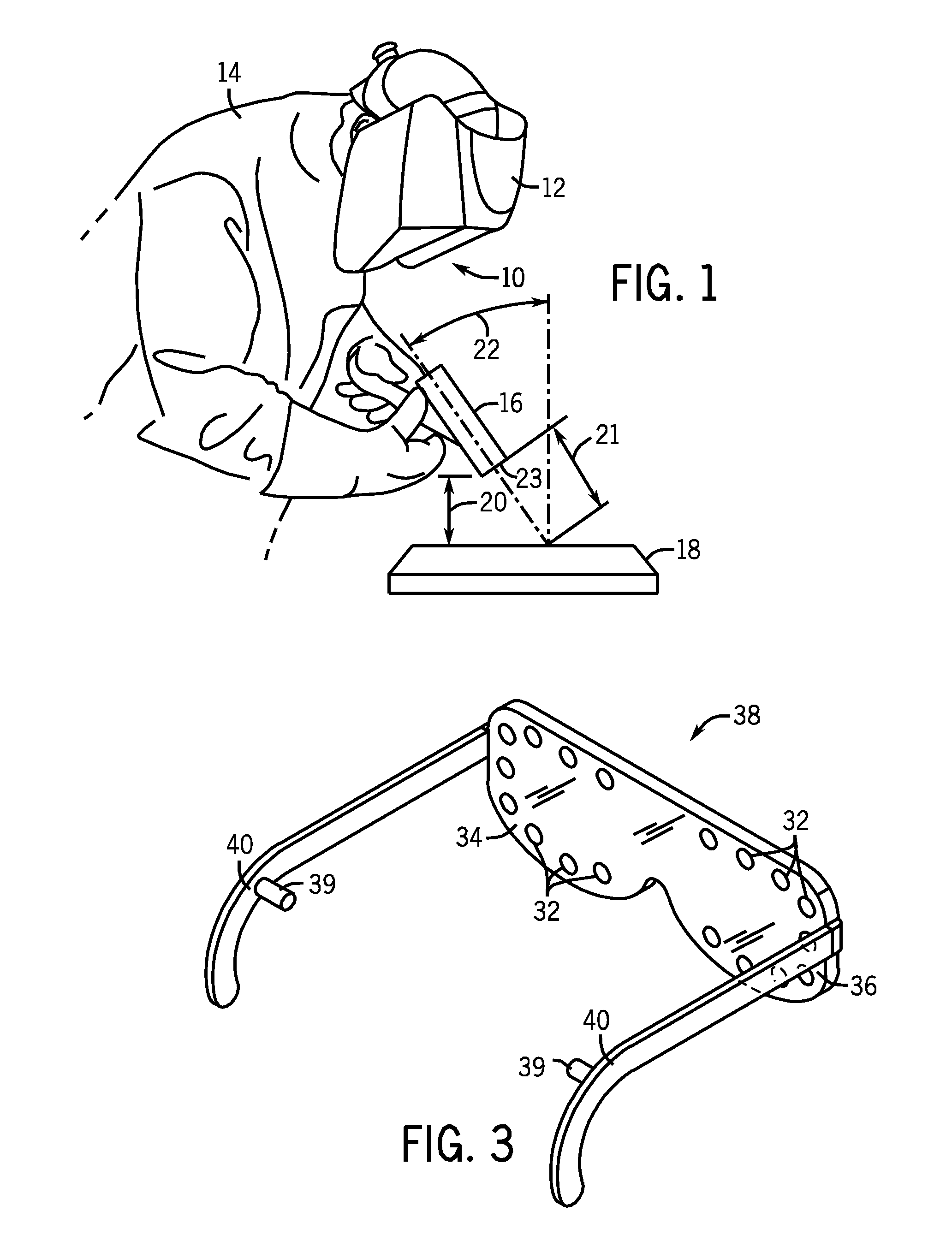

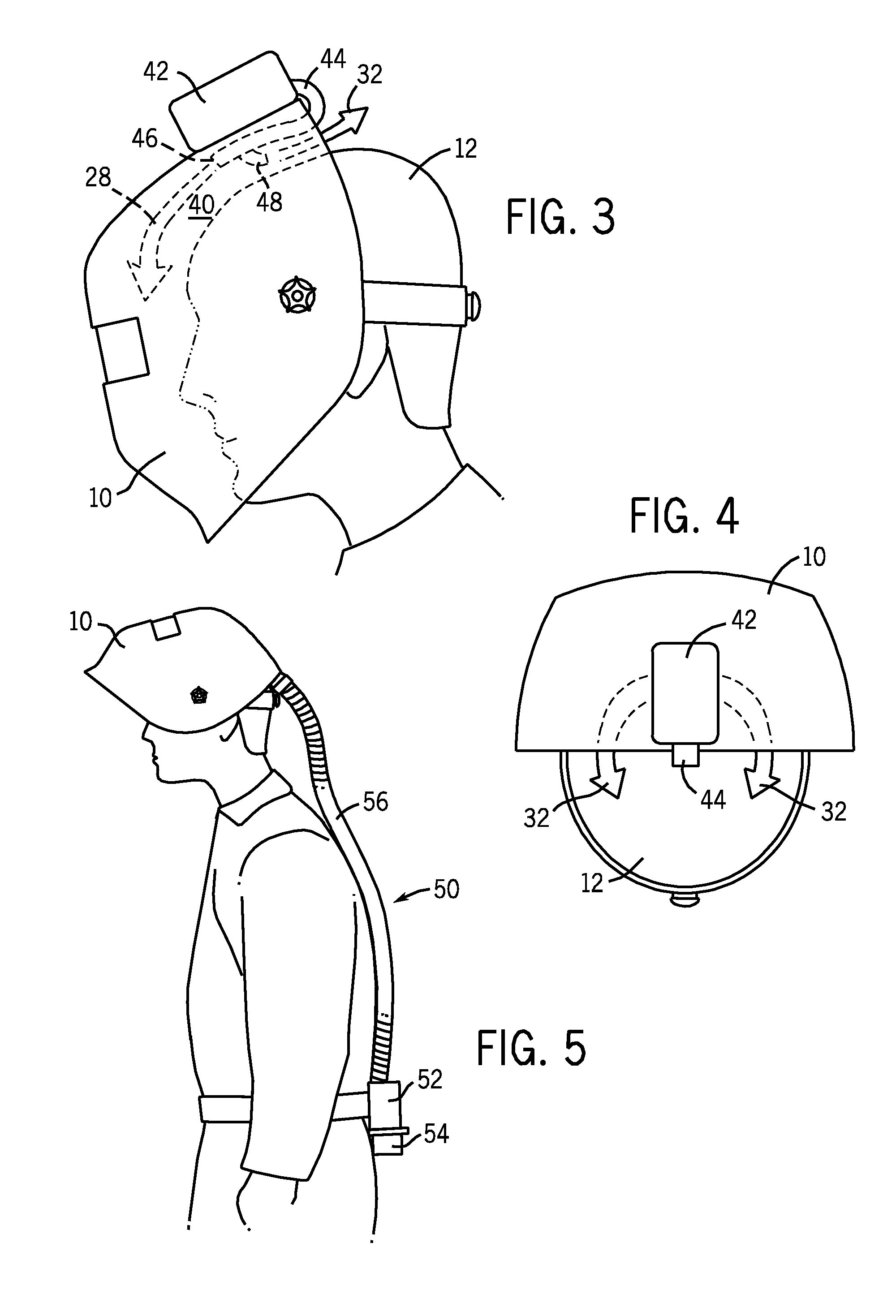

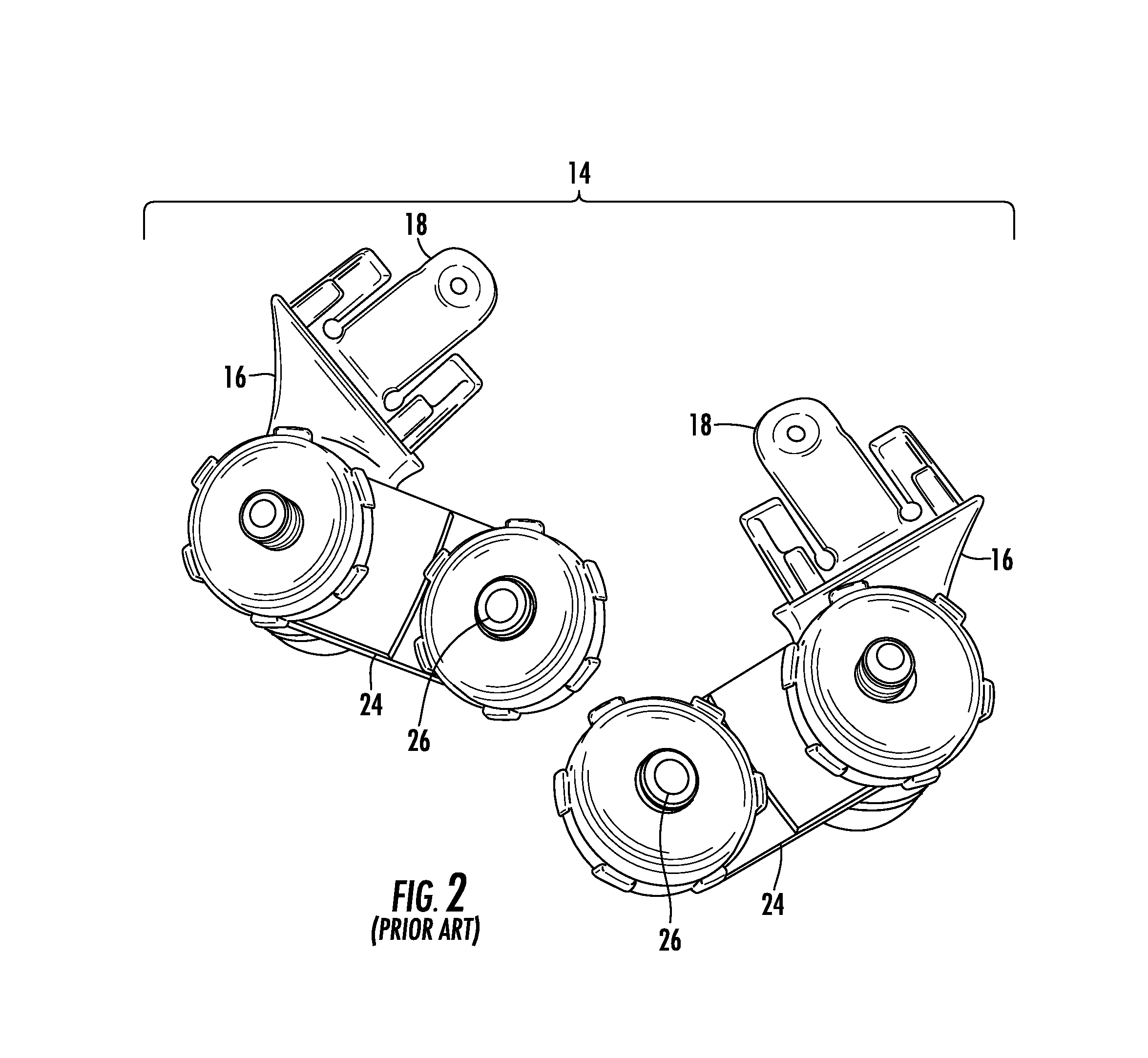

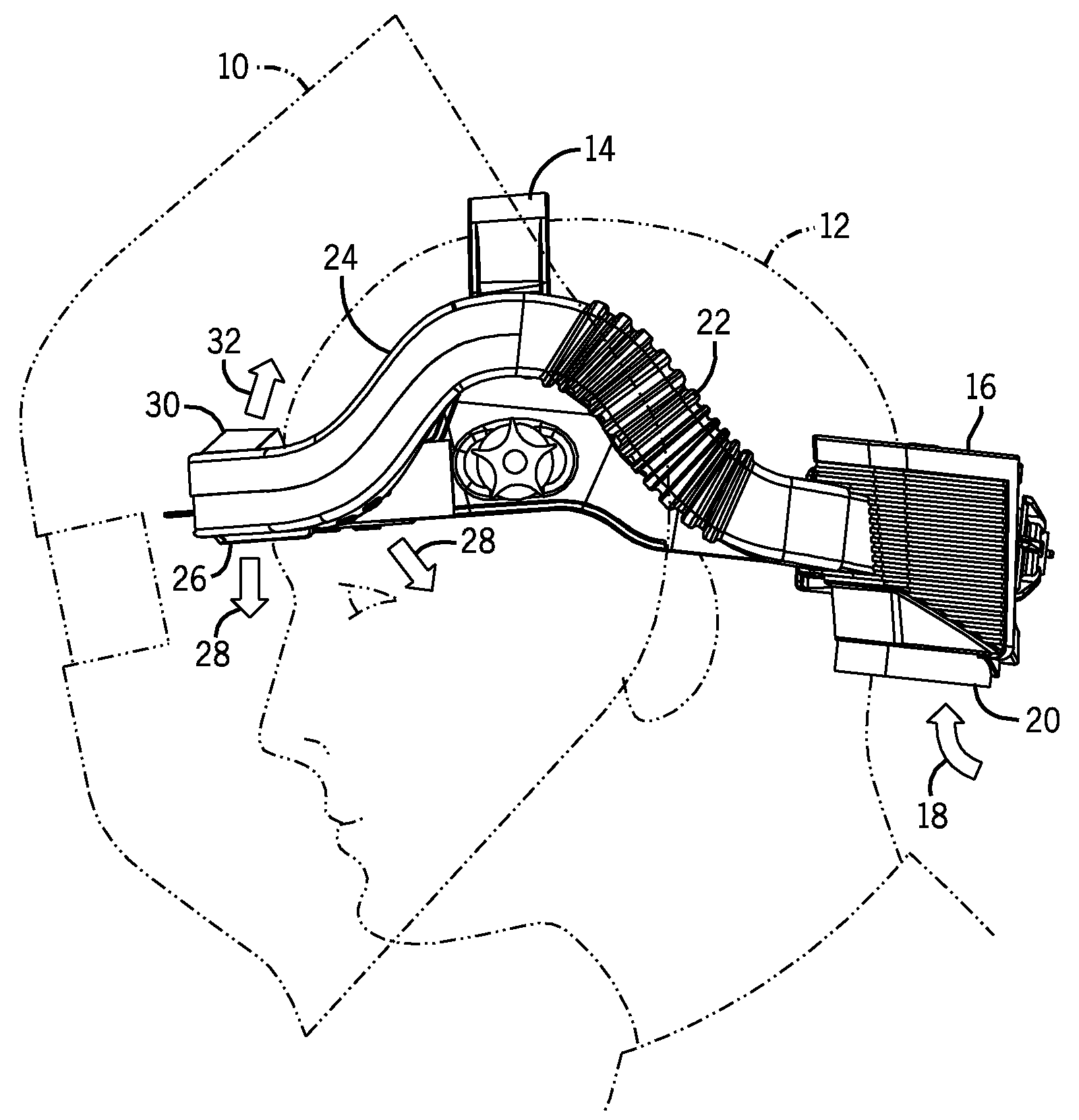

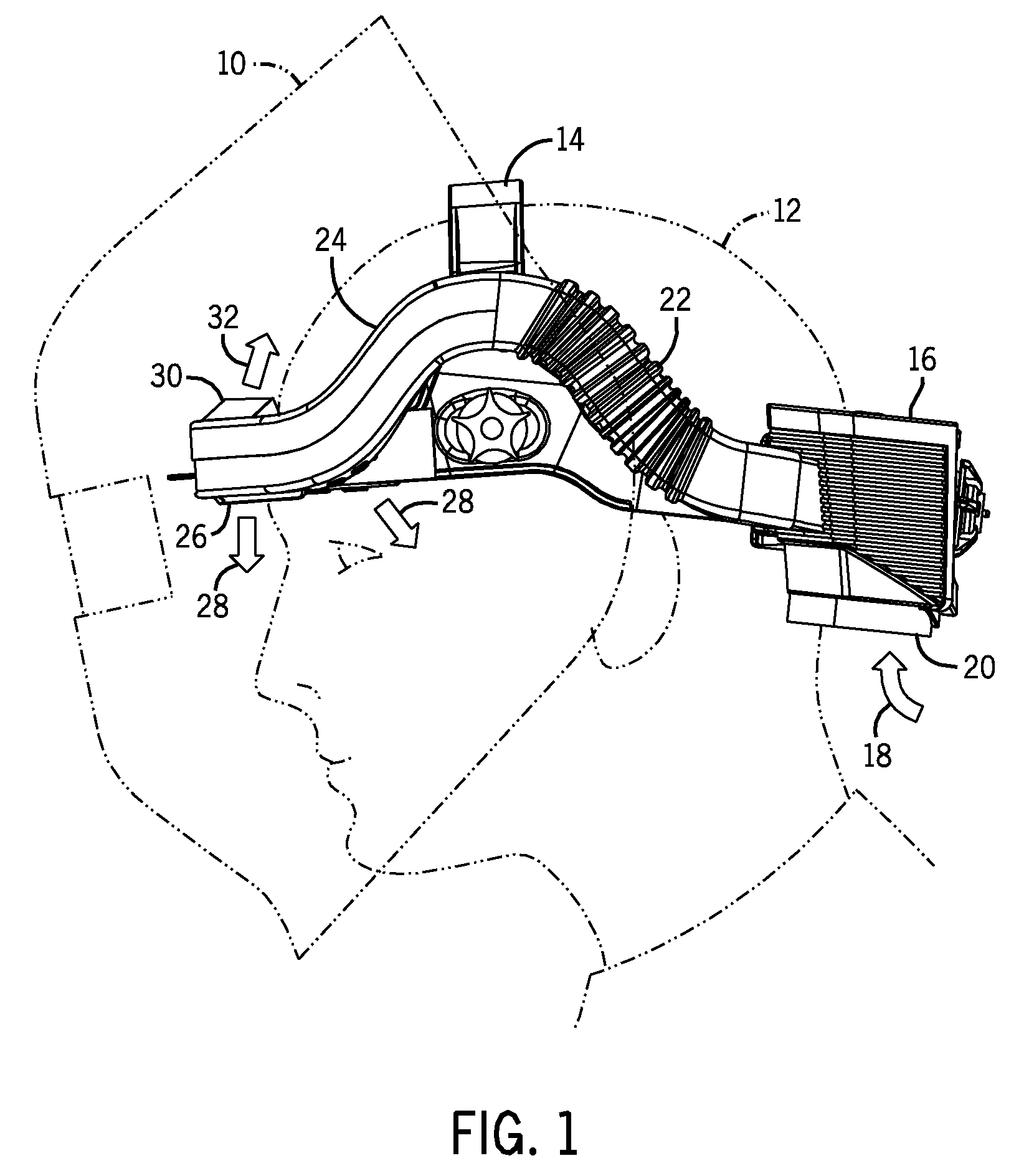

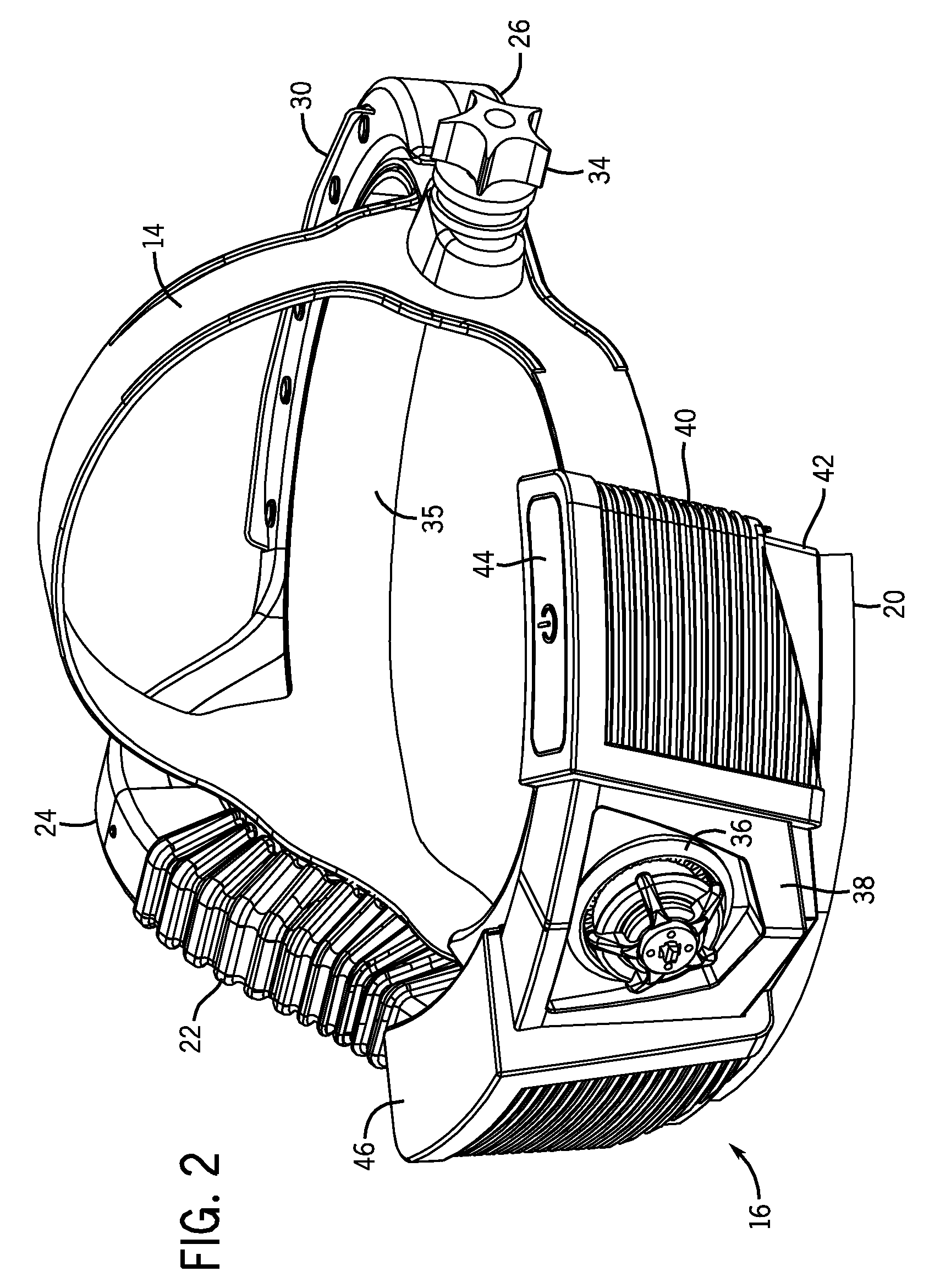

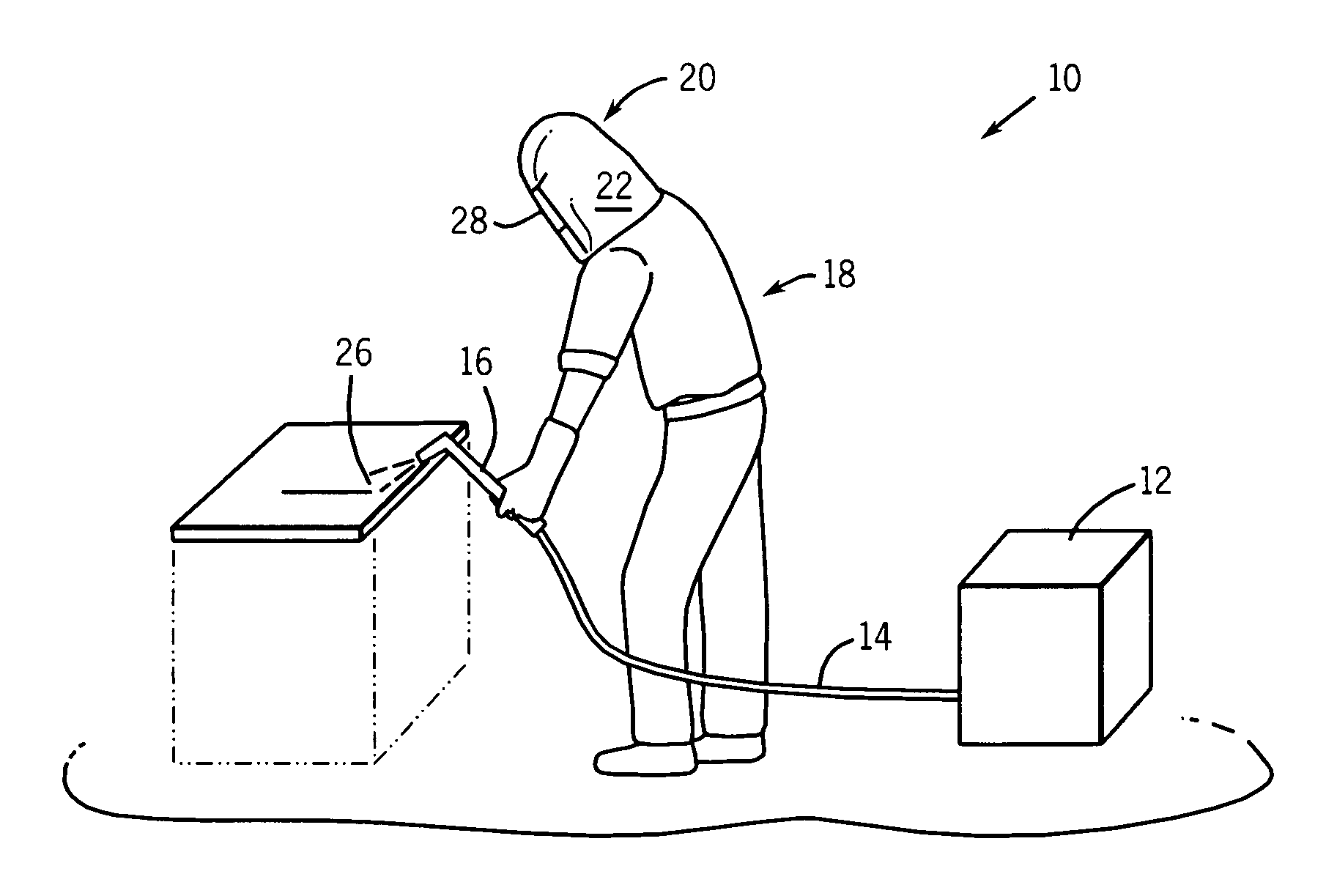

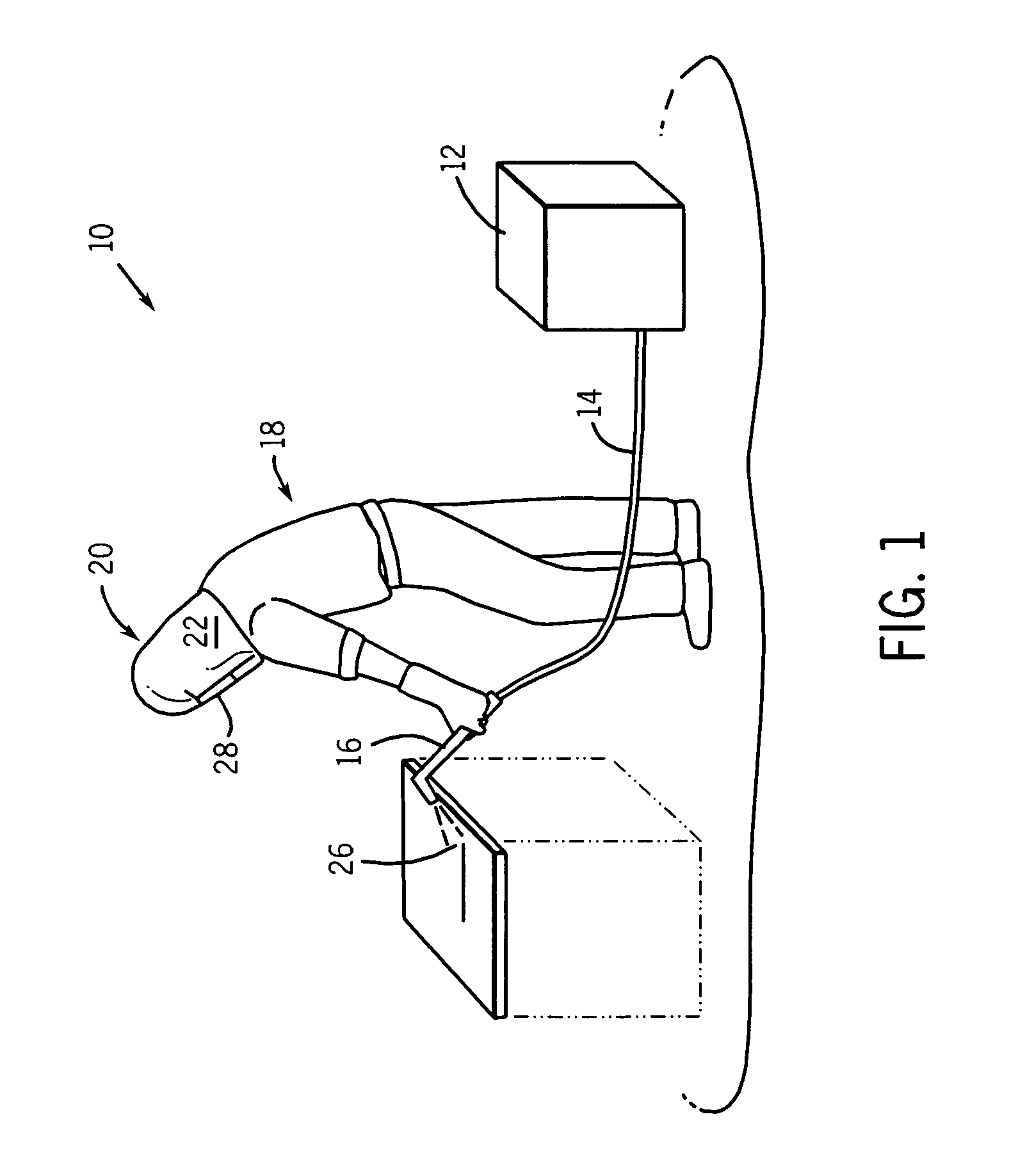

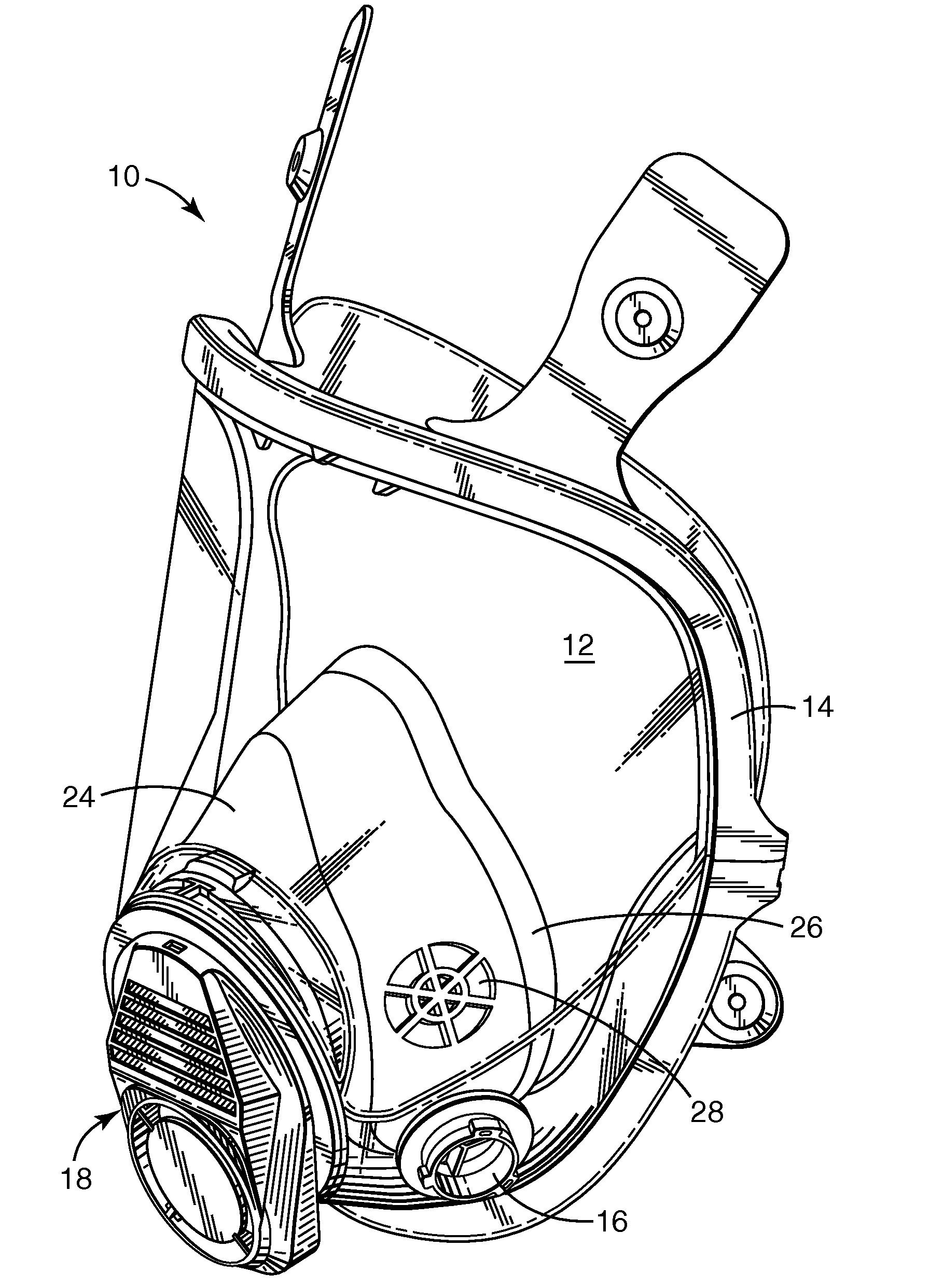

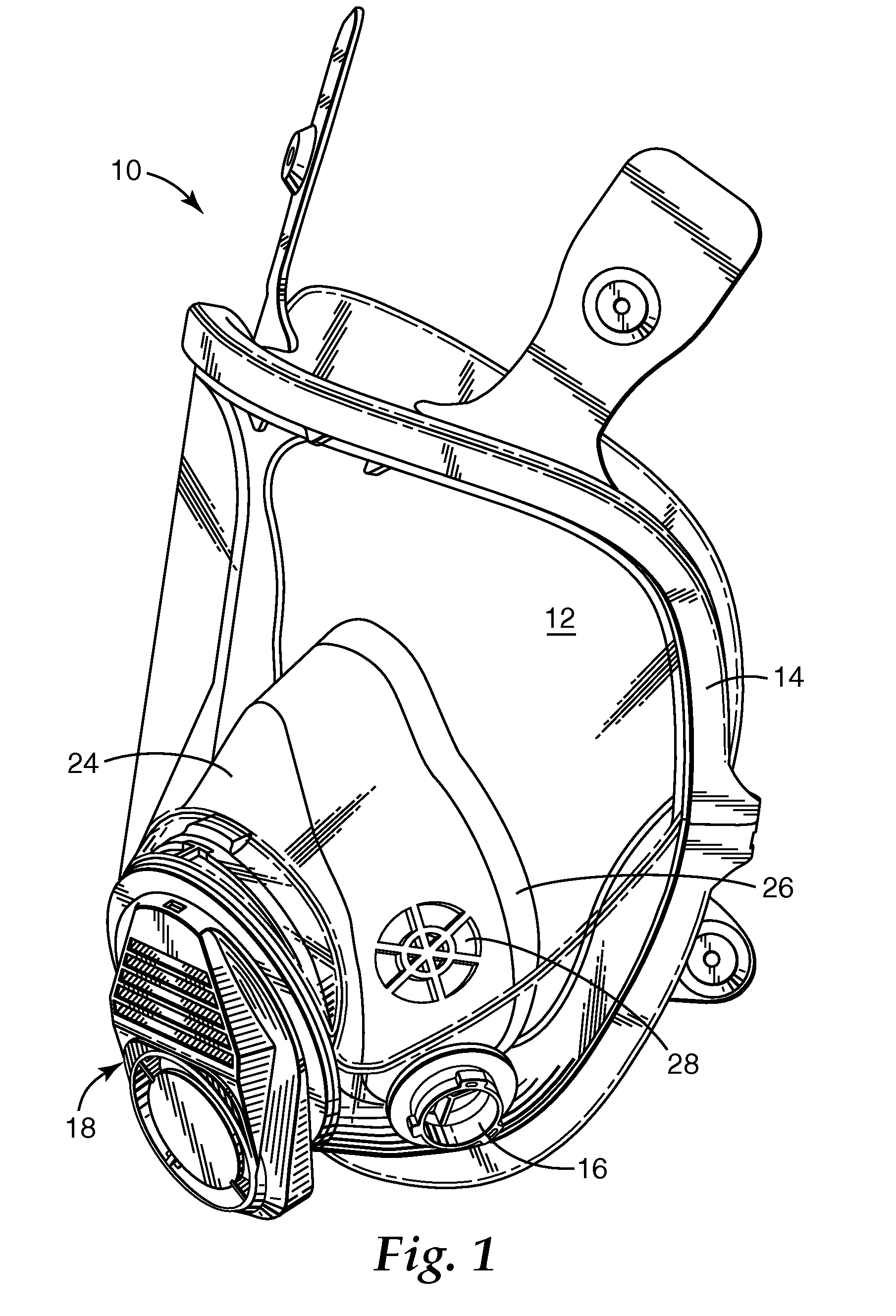

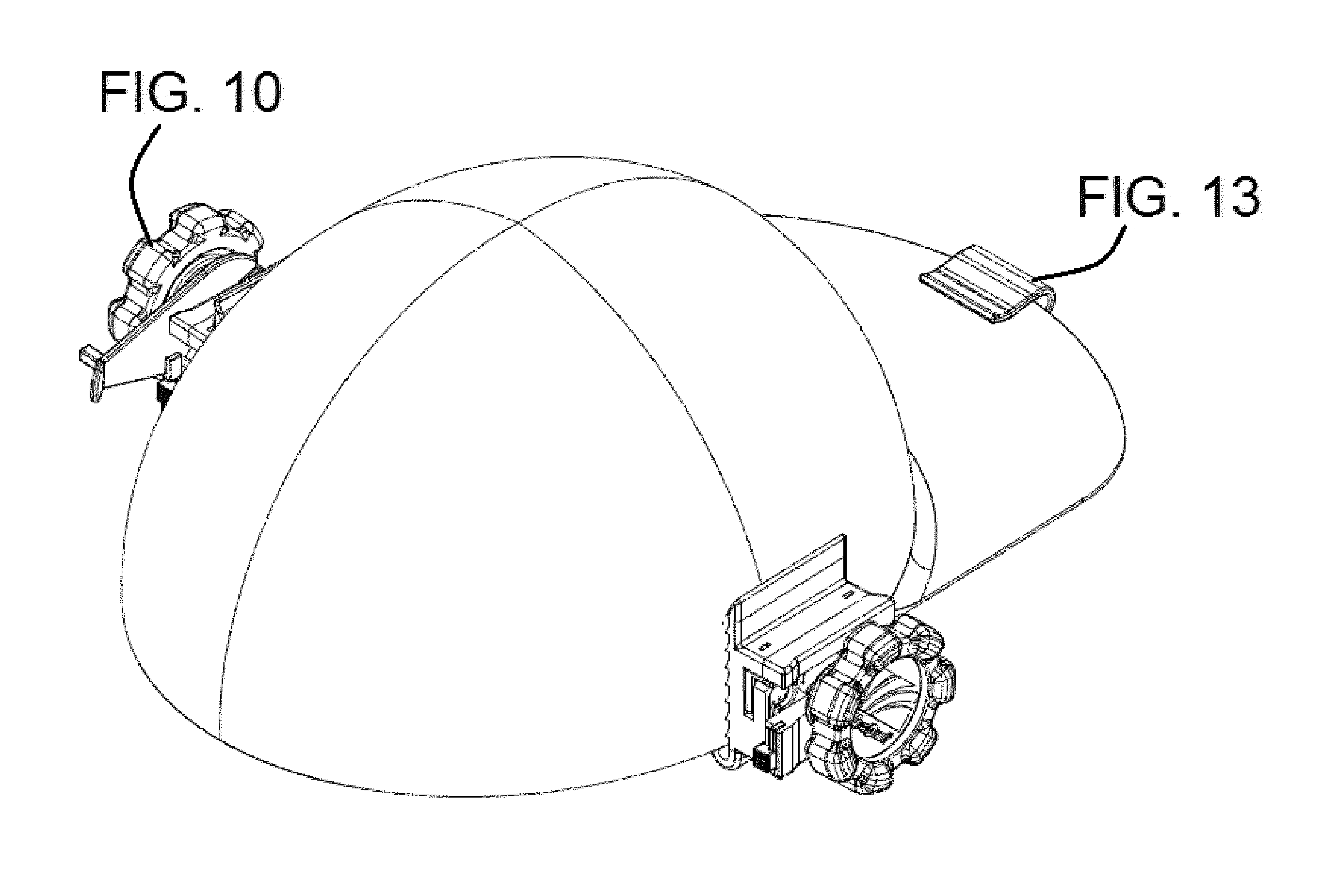

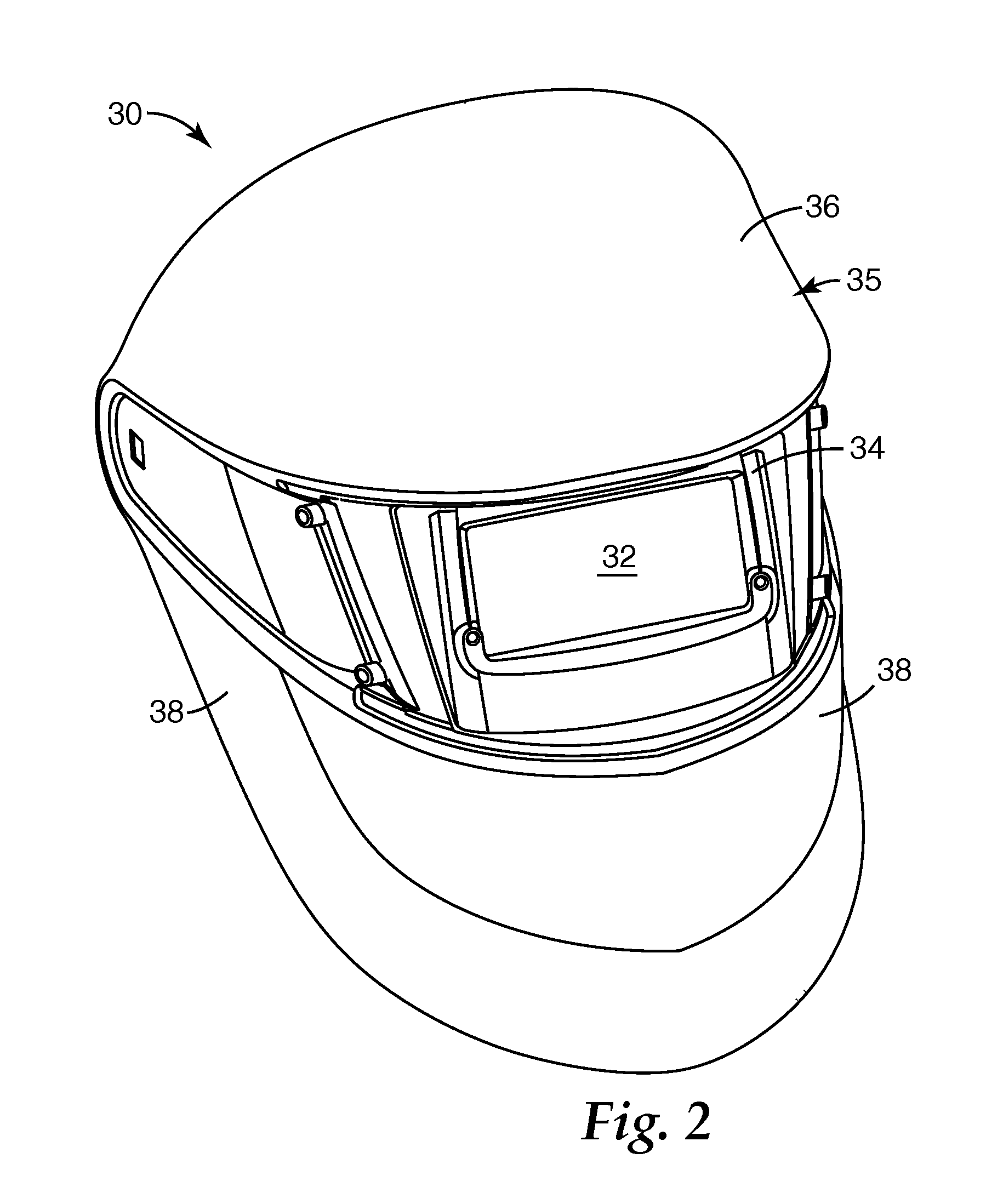

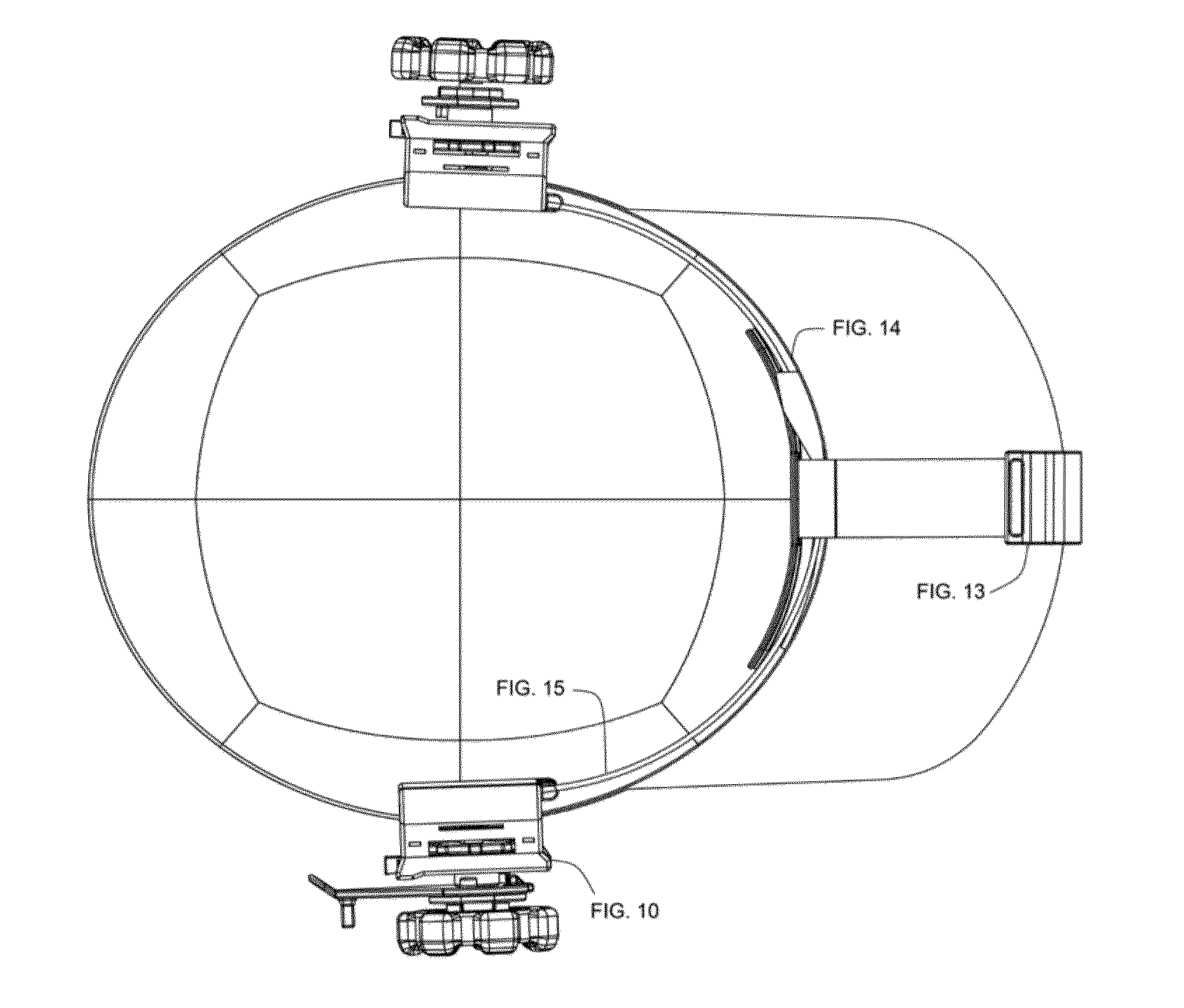

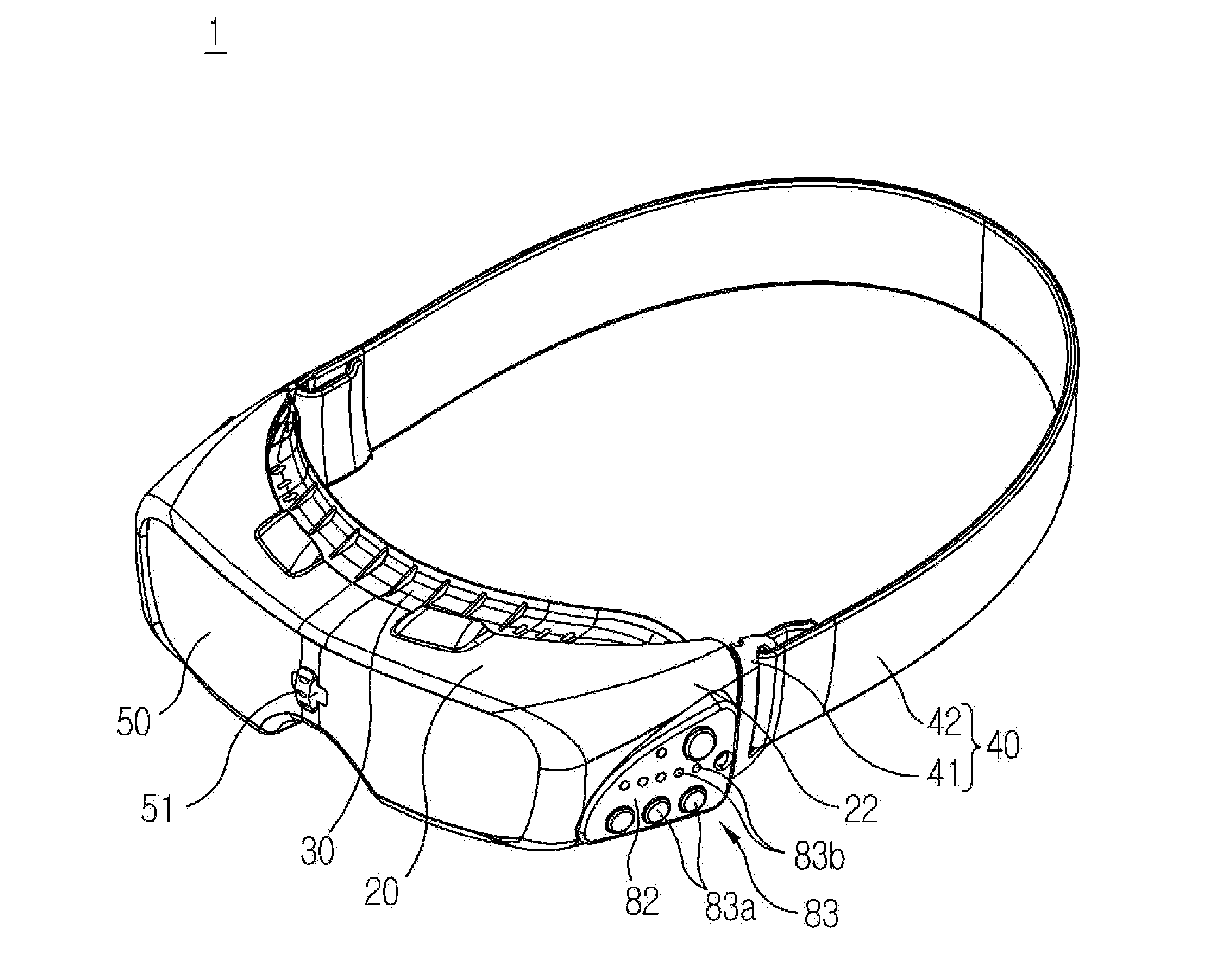

Airflow Headgear for a Welding Helmet

InactiveUS20090055987A1Improve balancePositive pressureBreathing masksEye-masksPositive pressureEngineering

An airflow system is provided for a welding helmet. The airflow system includes an air intake with a filter, a blower, and a battery mounted to the rear of headgear for a welding helmet. A manifold wraps around the side and front of the headgear and directs air from the blower to the front of the headgear. The manifold includes a lower vent for directing air onto a user's face and an upper vent for directing air over a user's head toward the rear of the headgear. The vents are intended to create positive pressure to impede the entry of unfiltered air into the user's breathing zone. The manifold further includes a portion of flexible tubing for adjusting the size of the airflow system in conjunction with adjustment of the headgear diameter. The airflow system generally conforms to the structure and shape of the headgear to maintain a location close to the user's head.

Owner:ILLINOIS TOOL WORKS INC

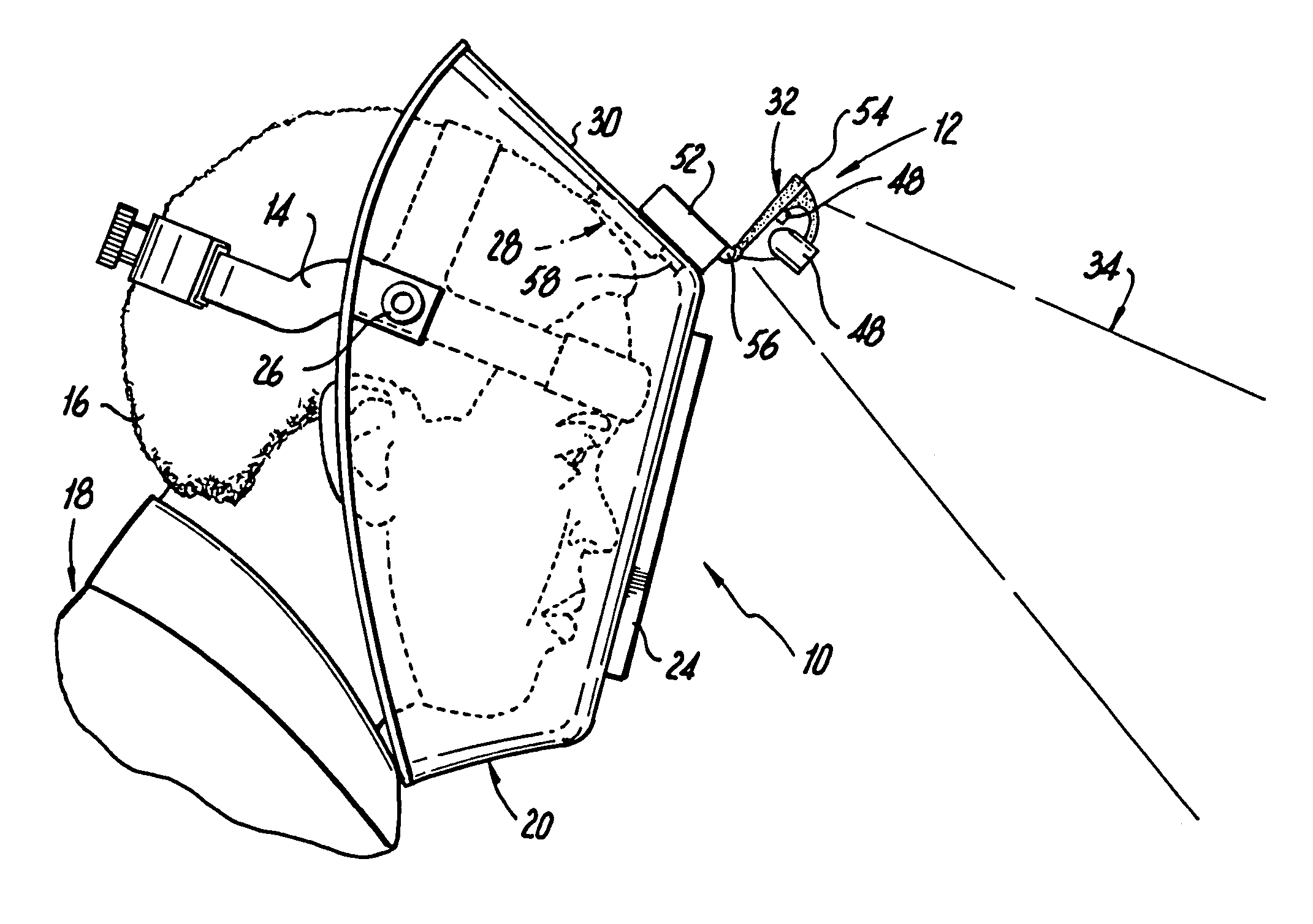

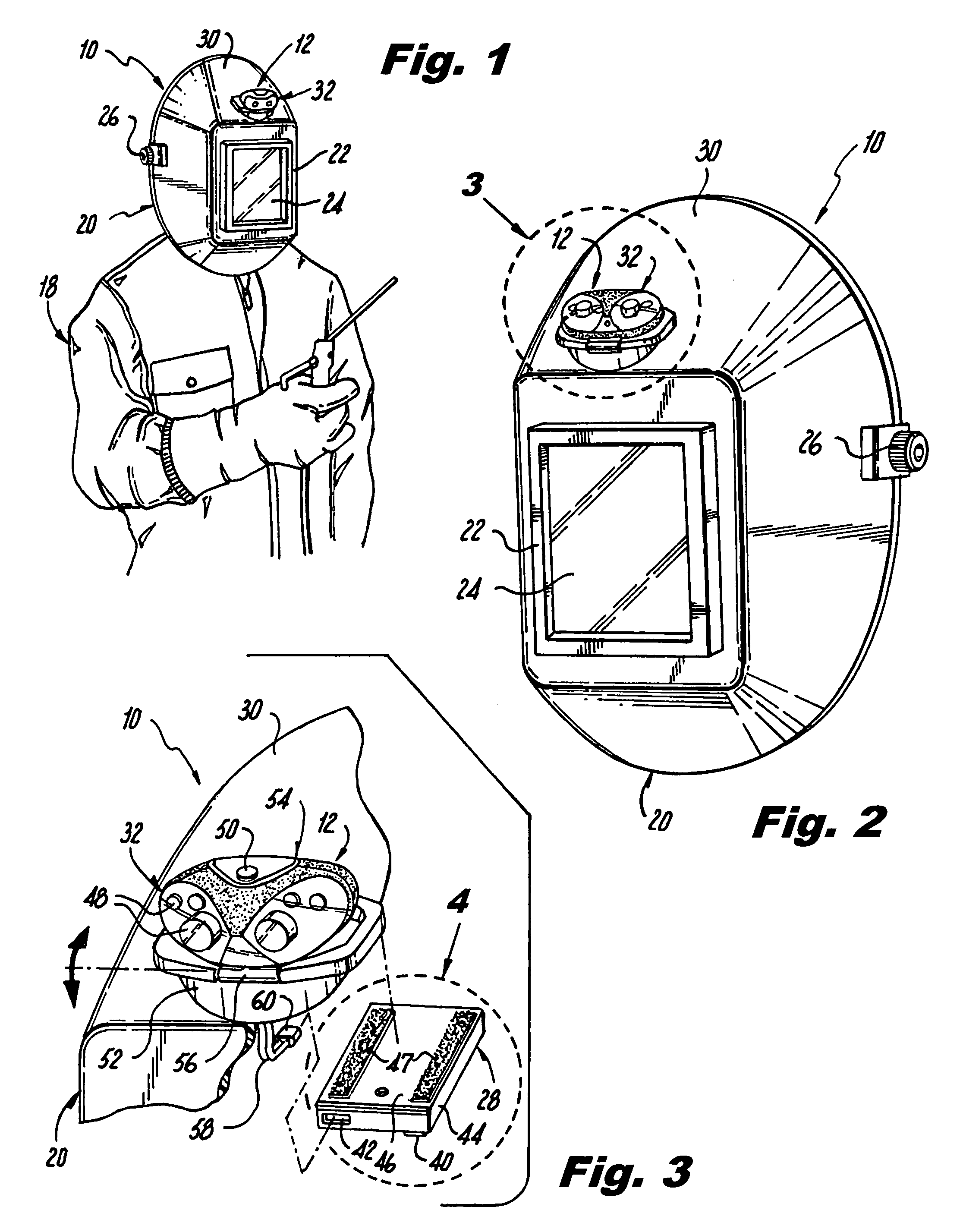

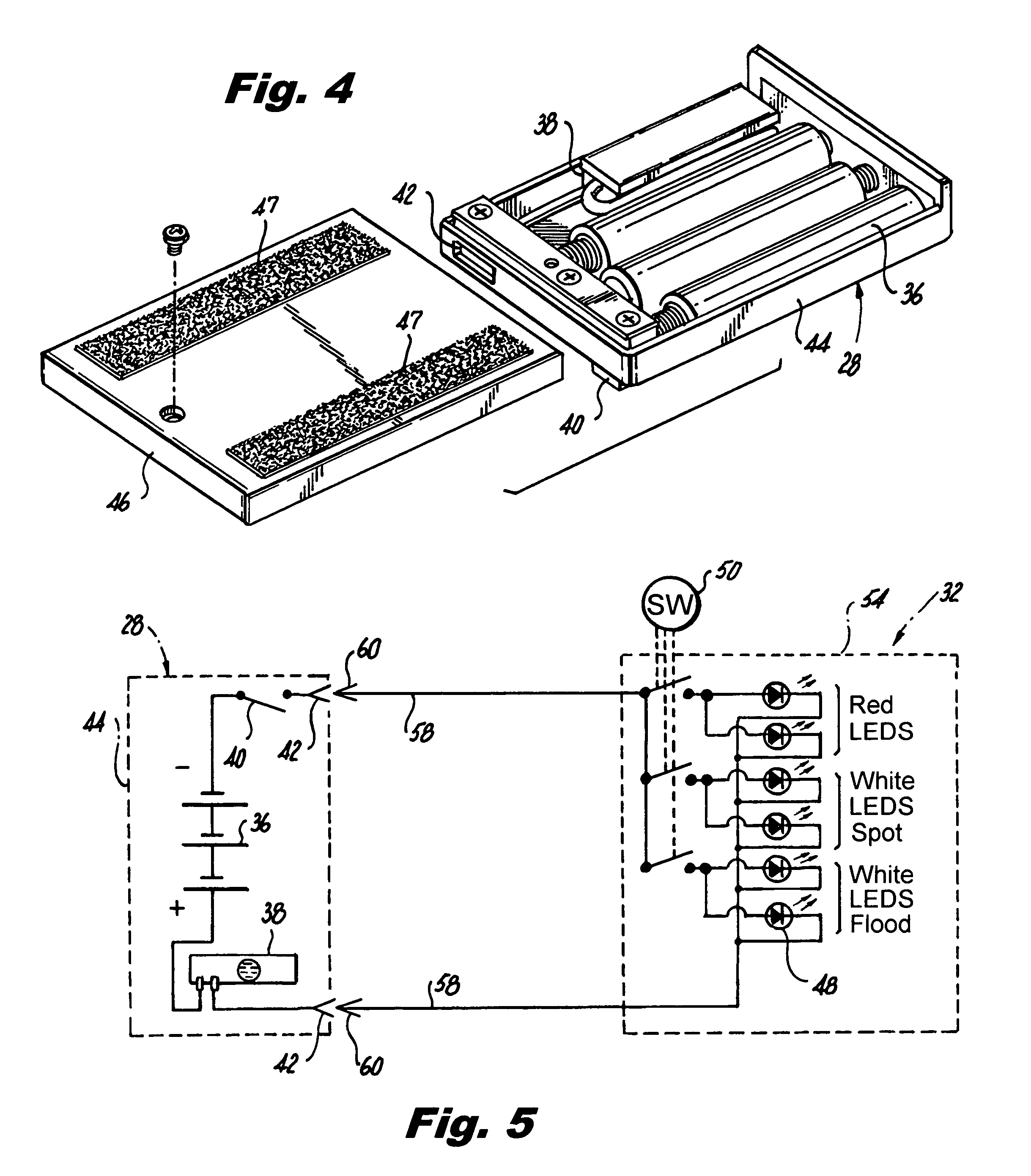

Welding helmet having an automatic lighting system

InactiveUS7934846B1Avoid disadvantagesSimple and inexpensive to manufactureLighting support devicesPoint-like light sourceEngineeringLighting system

A welding helmet having a headband that fits upon a head of a welder, and a face shield with a viewing port having a light filtering window that pivots on the headband between a raised up non-shielding position and a lower down shielding position has an automatic lighting system with a power source component secured to a interior bottom surface of a top portion of the face shield, and an illumination component secured to a top exterior surface of the top portion of the face shield for lighting a work area outside the helmet. The energizing of the lighting system is responsive to the position of the raising and lowering of the face shield of the helmet so as to permit the welder to better perceive his / her surroundings.

Owner:SCHWANZ KENNETH H

Voice control welding/cutting helmet functions and settings

Provided for is a control system for a welding helmet comprising: an electronically controllable lens configured to be mounted in a welding helmet shell, a microphone configured to receive an audible input and to generate a signal in response to the audible input received and an electronic control module coupled to the lens and to the microphone and configured to control the electronically controllable lens based upon the signal. Also provided for is a welding helmet implementing a control system and a method of manufacturing a welding helmet including a control system.

Owner:ILLINOIS TOOL WORKS INC

Protective shroud for a welding helmet, kits and helmets including the same

A protective shroud for a welding helmet. The shroud includes fabric that may be arranged to form an open-ended continuous loop. The loop may be sized to cover at least a portion of a user's neck. The shroud may also include one or more fasteners. Each fastener may be connected to the fabric and removably securable to the welding helmet. In other embodiments, a kit including a protective shroud, and a welding helmet including a protective shroud.

Owner:TOWNSEND JR RODMAN +7

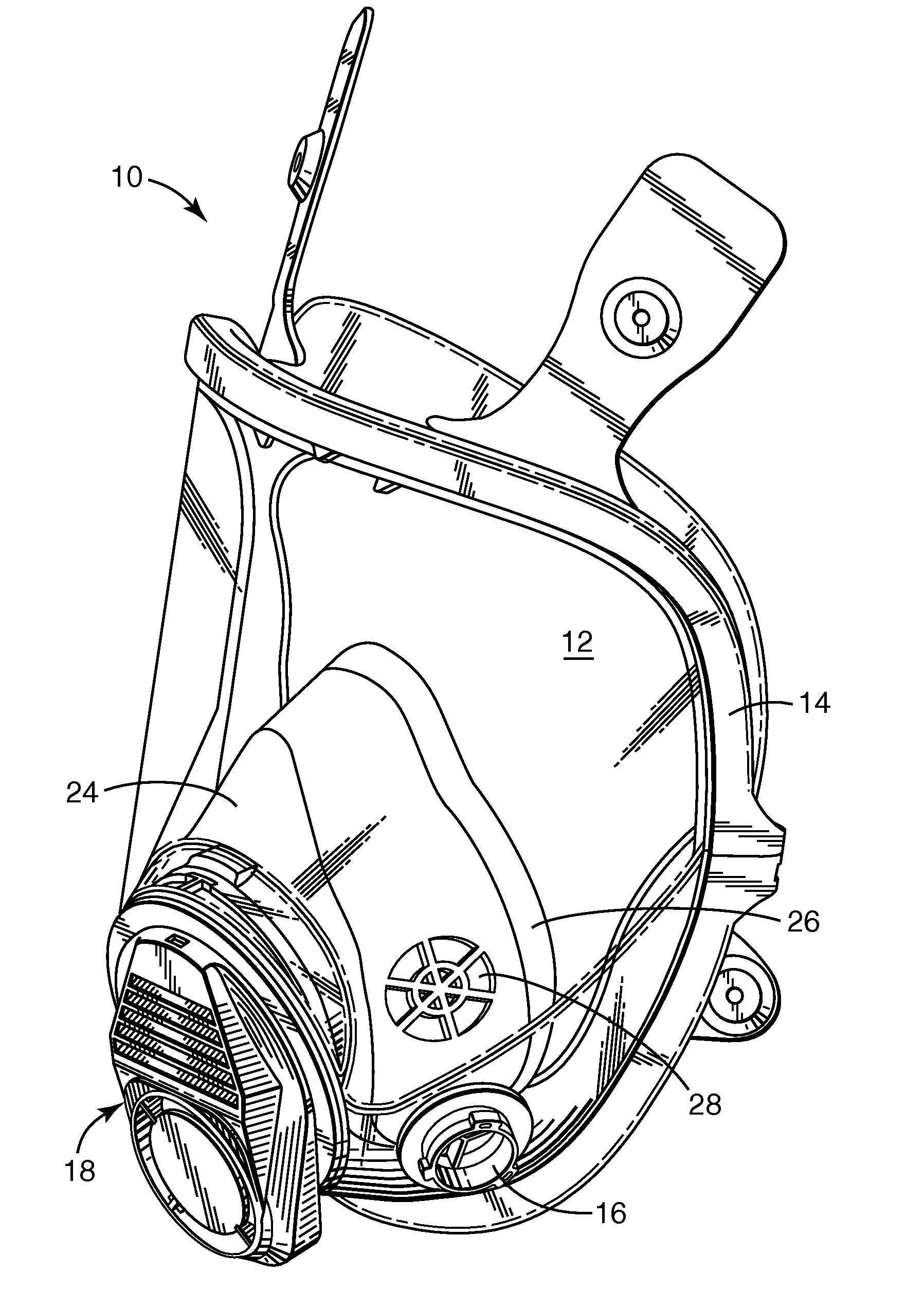

Respirator, welding helmet, or face shield that has low surface energy hard-coat lens

ActiveUS20090025727A1Good chemical-resistanceGood scratchChemical protectionHeat protectionPerfluoropolyetherRespirator

A personal safety protective device that includes a lens and a support structure onto which the lens is secured. The lens includes a substrate and a hard-coat layer located on the substrate of the lens. The hard-coat layer has a low surface energy outer surface that is derived from a) an additive that includes at least one of i) a perfluoropolyether urethane that includes hydrolysable silane groups, and ii) an acrylate polymer that includes at least one perfluoropolyether moiety and at least one hydrolysable silane group, and b) a silsesquioxane-based hard-coat composition. The provision of such a lens on a personal safety protective device enables the lens to be durable to abrasion and to be easily cleaned without use of solvents that could shorten the service life of the lens.

Owner:3M INNOVATIVE PROPERTIES CO

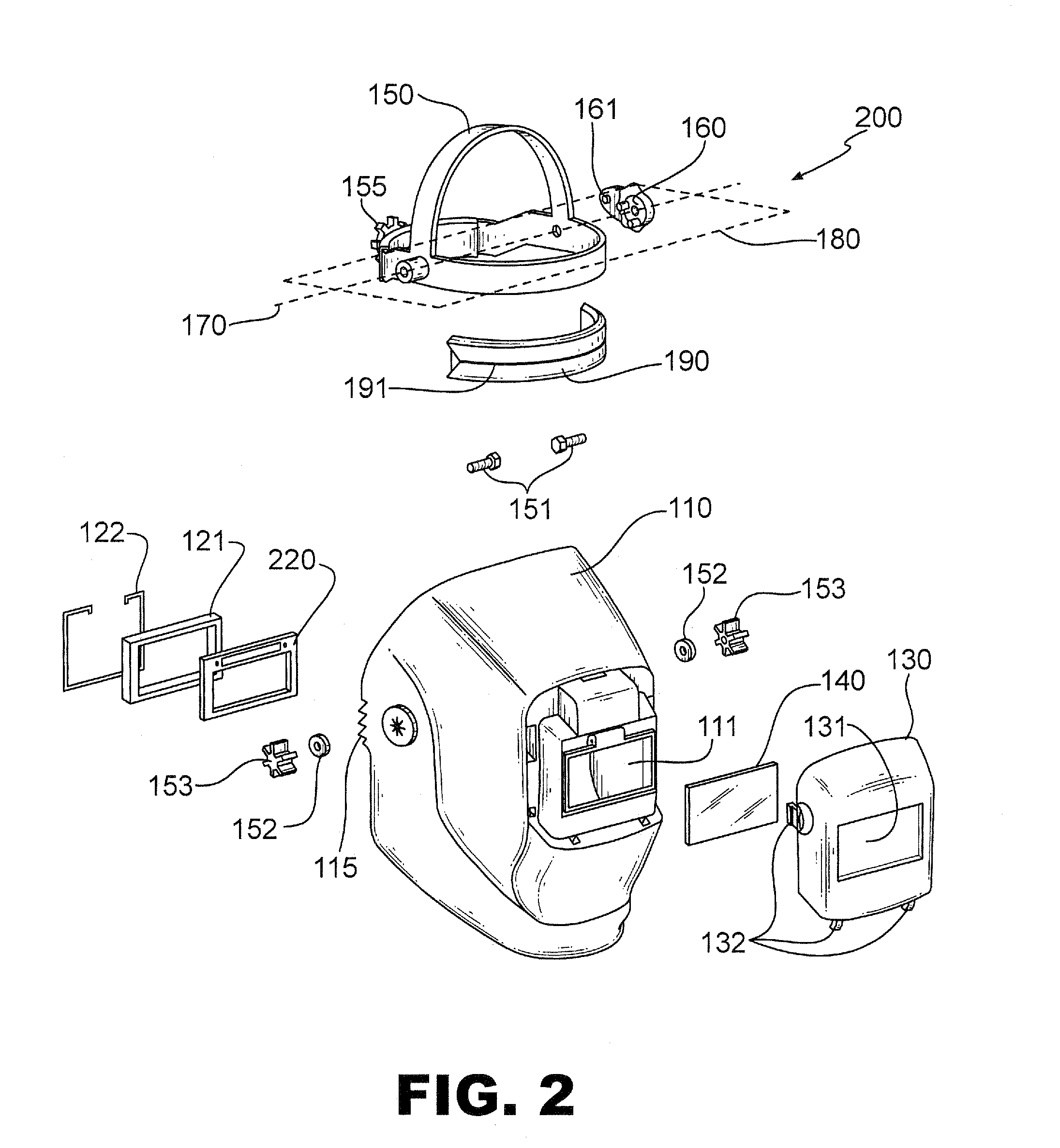

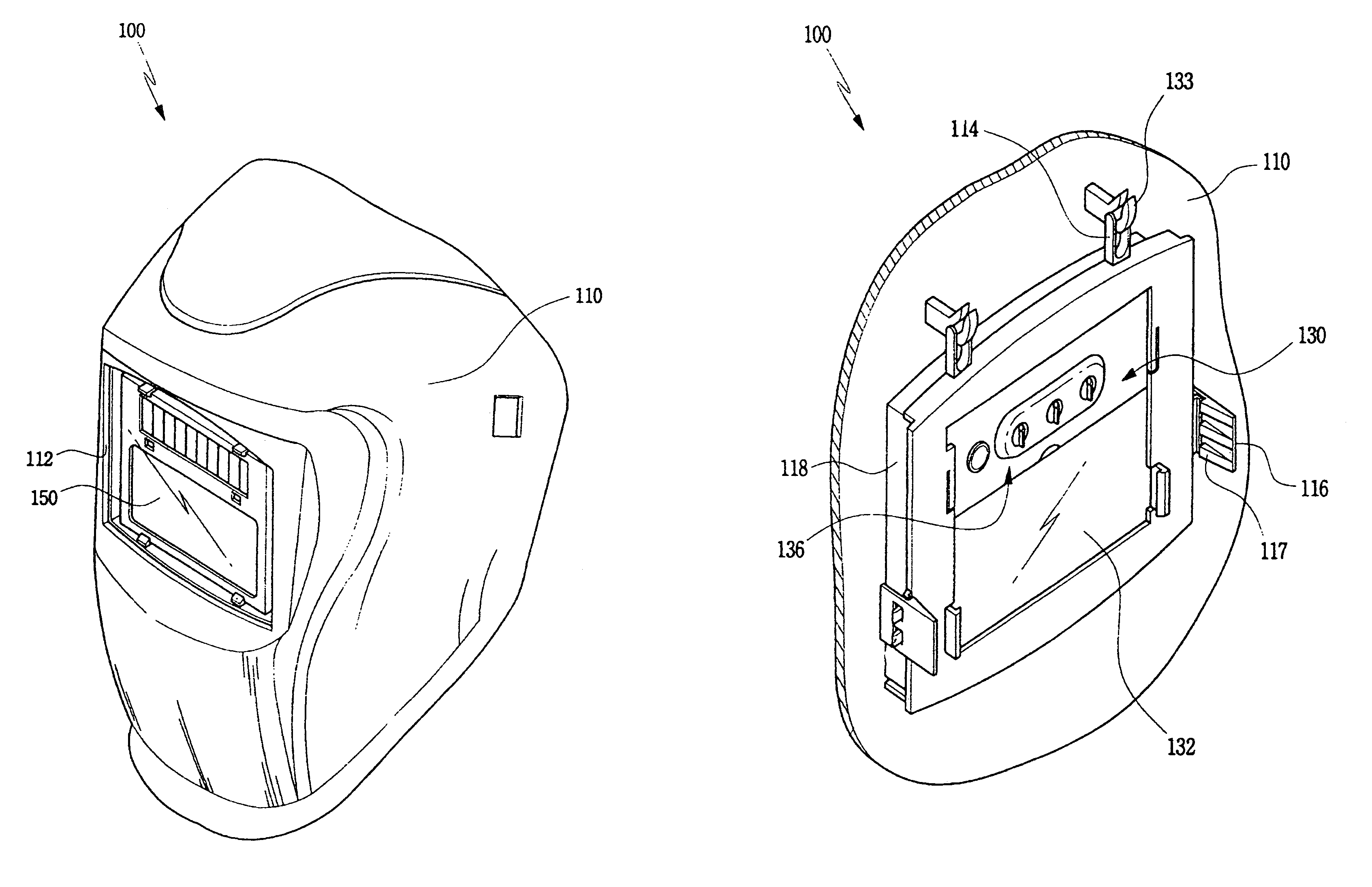

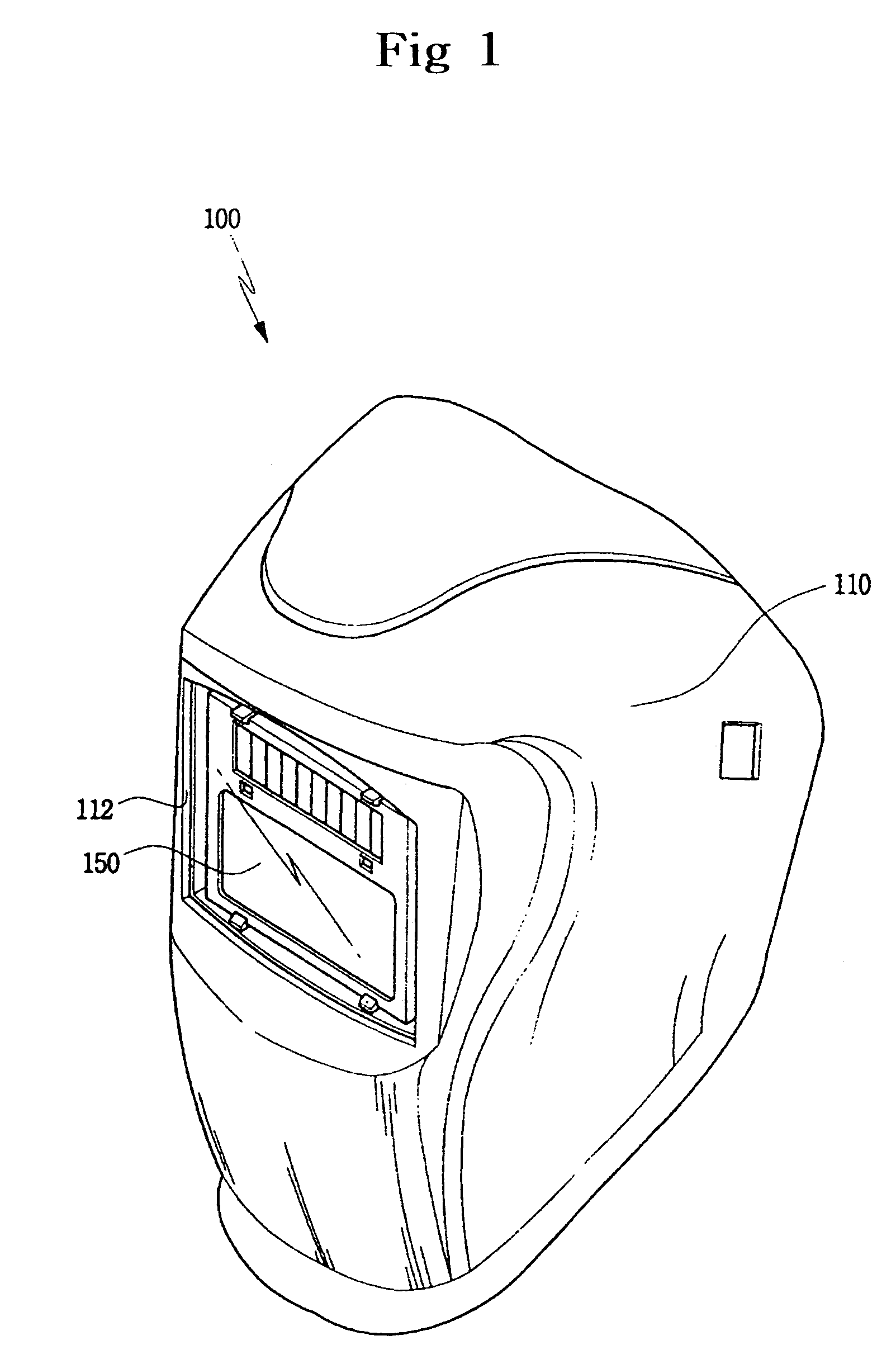

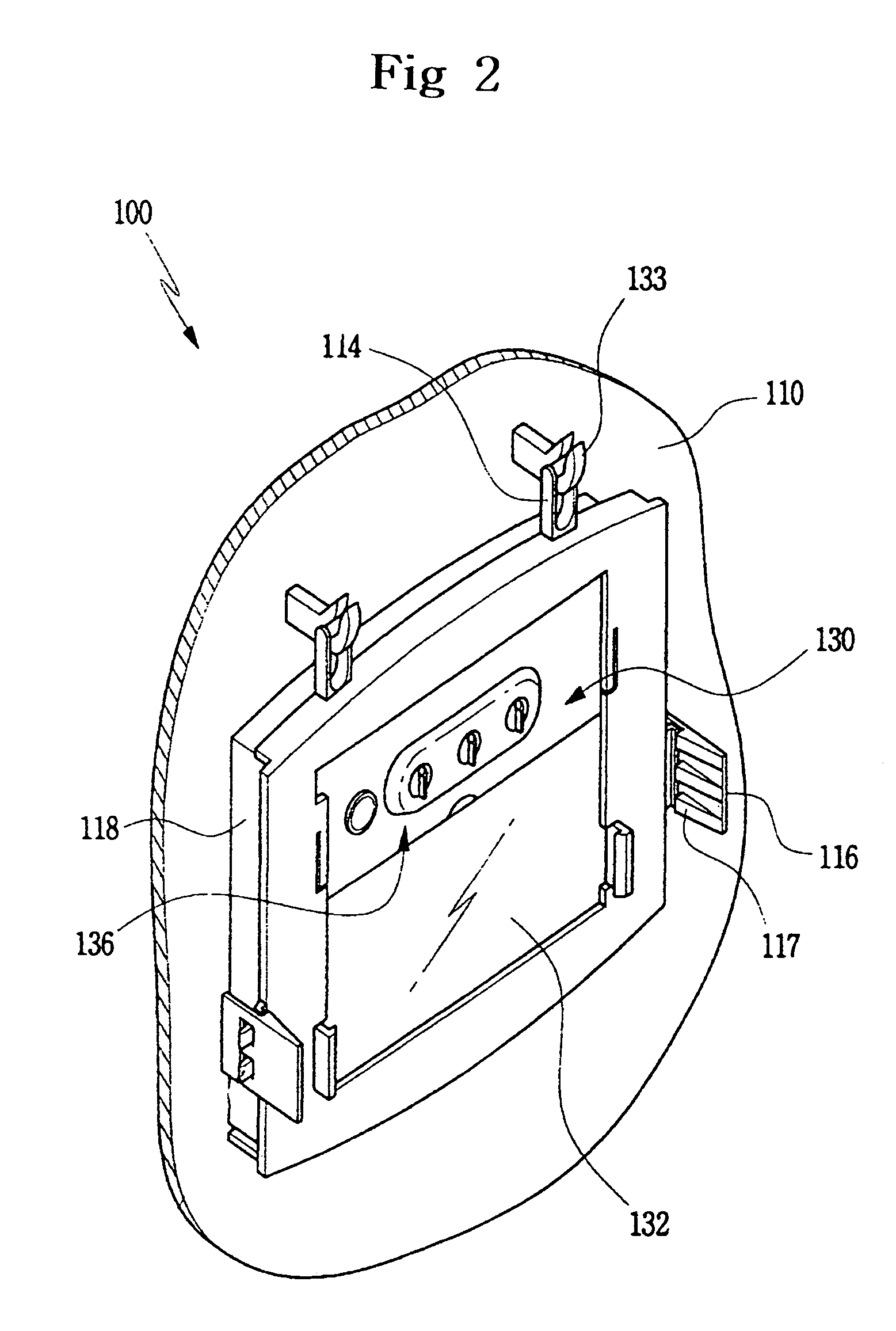

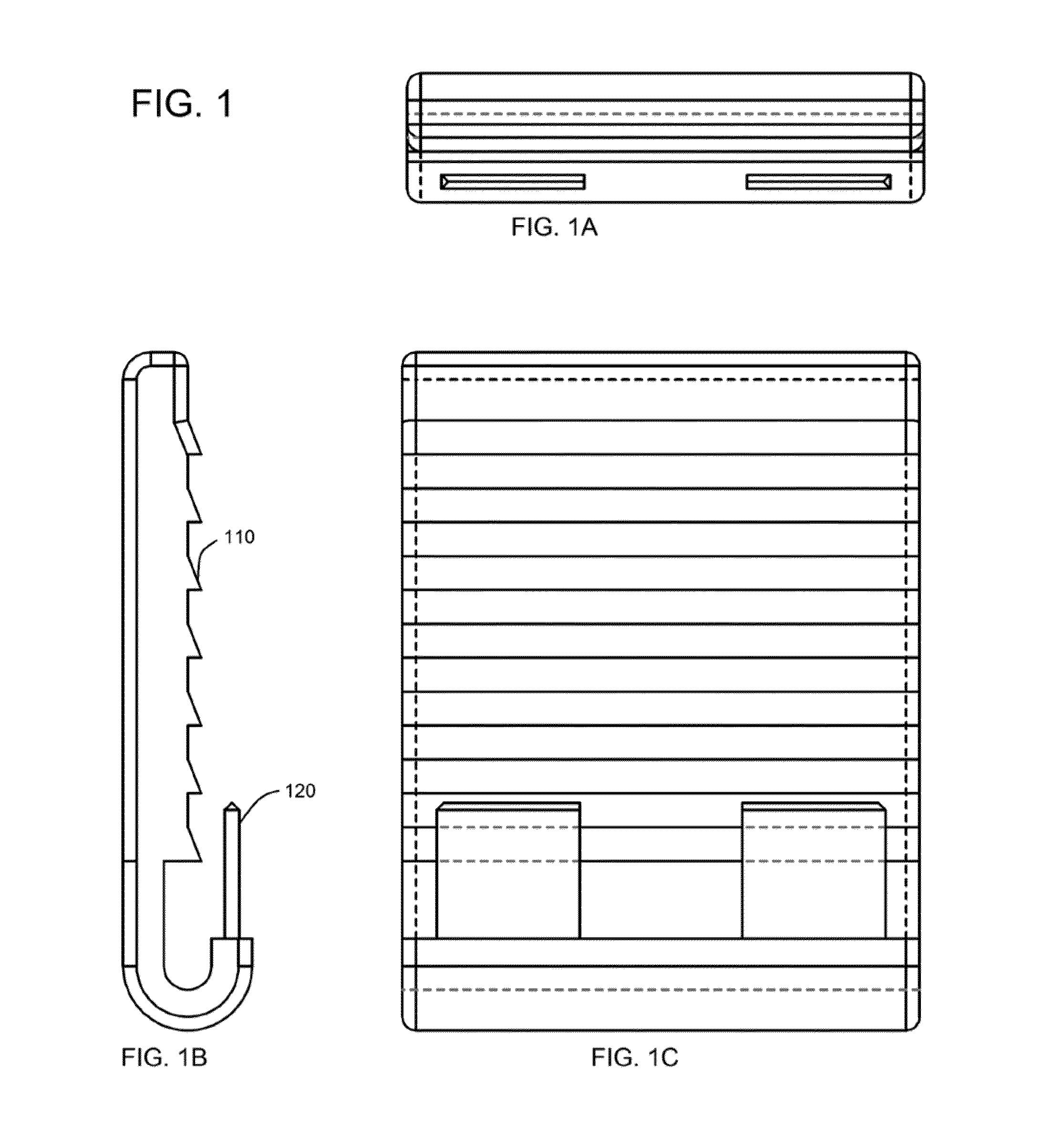

Welding helmet removable cartridge

InactiveUS6973672B2Reduce stepsPreventing fumes generatedEye-masksProtective garmentMechanical engineeringWelding helmet

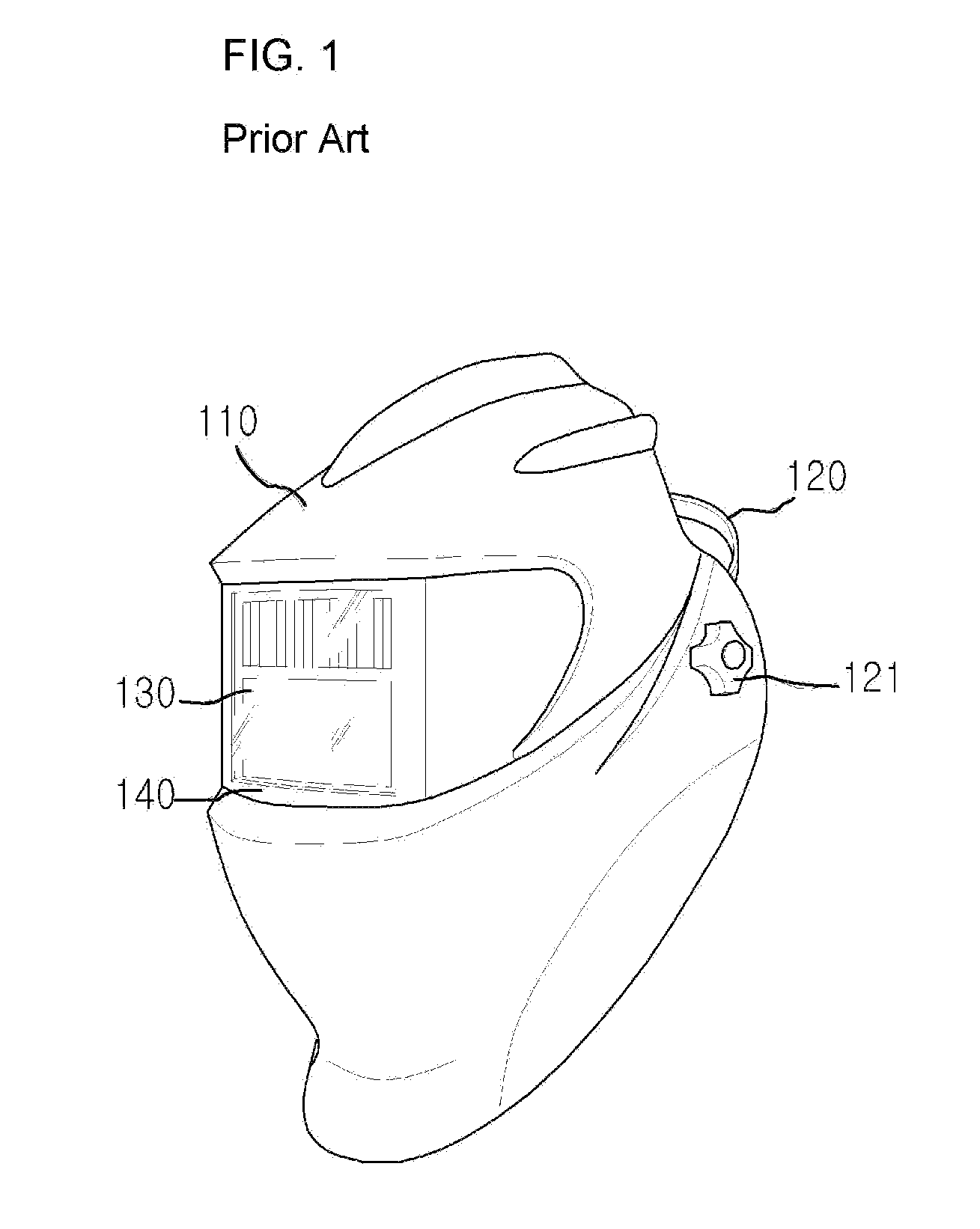

A welding helmet includes a helmet body for covering the face of an operator, an opening in a front surface of the helmet body, a cartridge for protecting the eyes of the operator from light generated during a welding operation, and structure including hooks projected from an upper side of the opening in the helmet body, pressing projections projected from both sides of the opening in the helmet body, hooking projections projected from an upper side of the cartridge to engage with the hooks, and fitting projections from both sides of the cartridge to fit to the pressing projections, the aforementioned structure removably engaging the cartridge to the helmet body. Fumes generated upon welding or cutting are prevented from directly flowing into the helmet body and injurious light generated upon welding is blocked. The cartridge can be readily removed for repair or replacement.

Owner:OTOS TECH

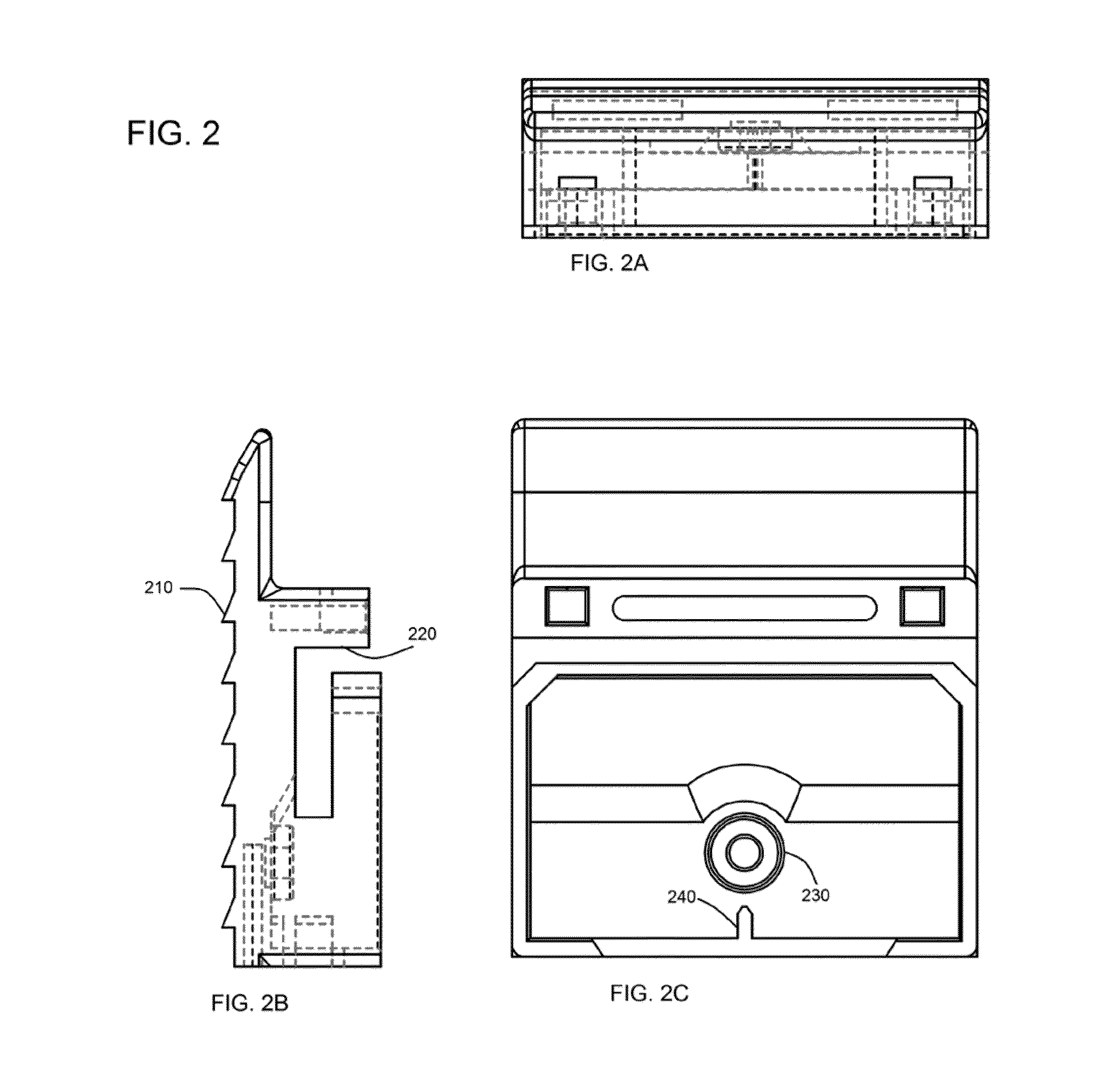

Replaceable, self-contained expanded viewing light shield cartridge for welding helmet

InactiveUS6557174B2Increase viewable areaReduce optical densityEye-masksNon-linear opticsProtecting eyeEngineering

An electronic quick change cartridge for a welding helmet. The cartridge base is formed of an optically dense polycarbonate or like material that acts as a passive filter to provide eye protection during the welding process. A port in the base receives a variable density LCD cell and a cavity formed in the base receives the electronics for driving the cell. Optical masks prevent light leakage through any interfaces of the structure. When low light levels are present, the welder views a work piece through an essentially transparent or slightly opaque LCD cell. When an arc is struck, the LCD cell darkens to a shade corresponding to the shade of the surrounding polycarbonate material. The welder then can view the work piece through the LCD cell and all the optically unobstructed portions of the polycarbonate base surrounding the LCD cell thereby to have an expanded viewing area during the actual welding operation.

Owner:WALTER SURFACE TECH

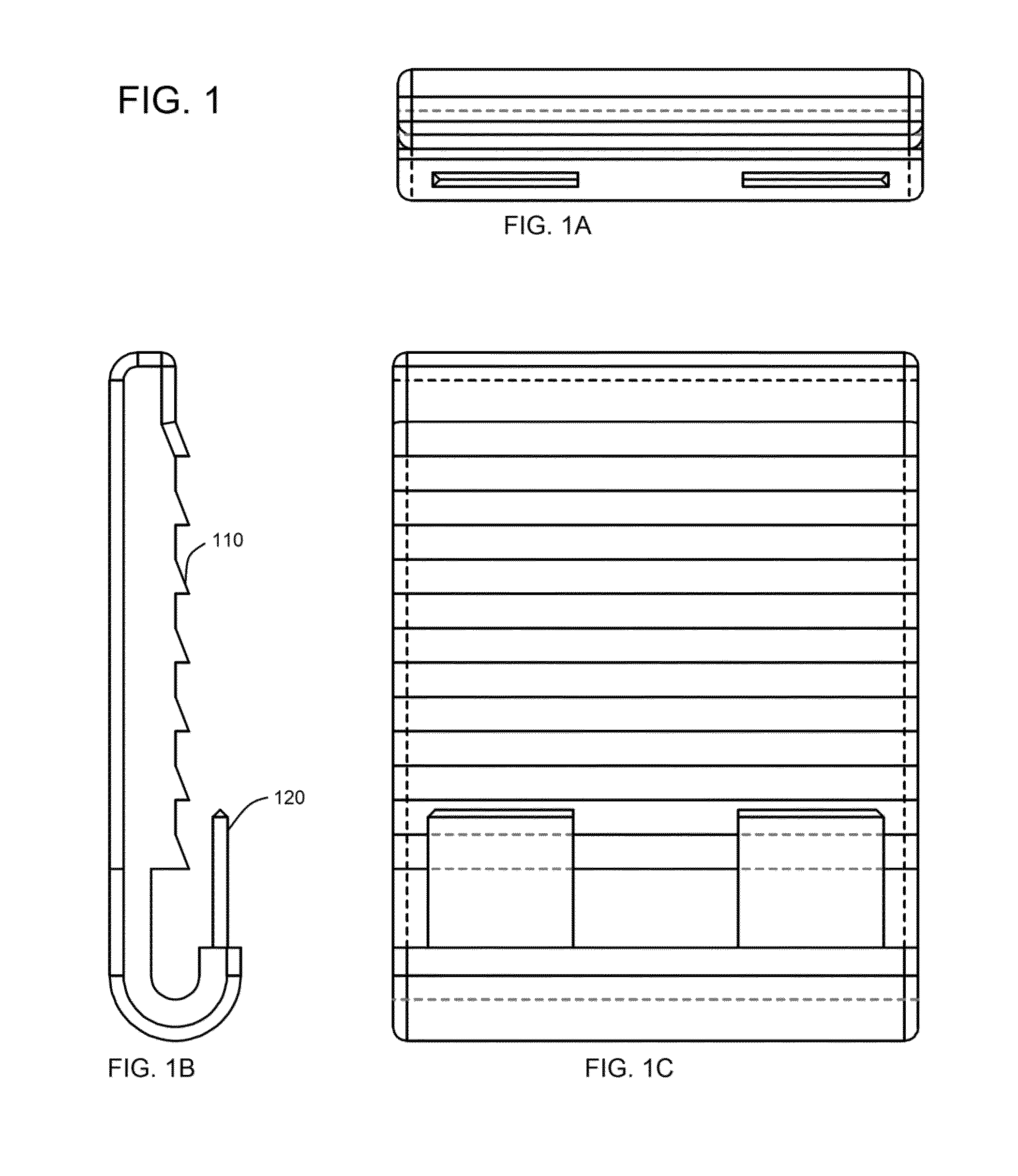

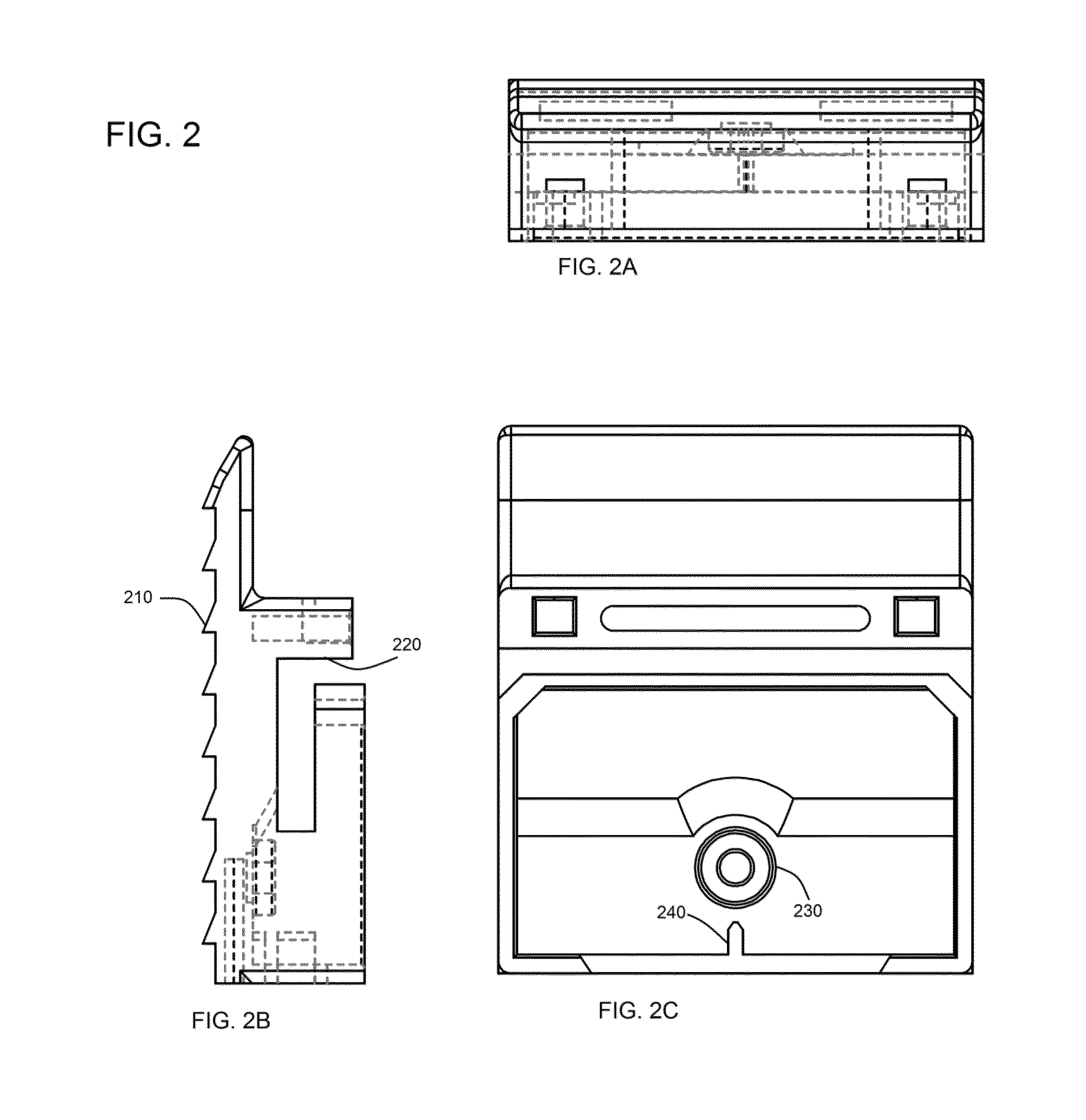

Adapter for protective head gear

The adapter comprises a clip with a groove, and a rack that engages with the groove. The clip attaches securely to an edge of a fabric, for example, a panel on a baseball cap. The rack includes an angle adjuster, on which a brow guard, welding helmet, or other protective gear can be mounted.

Owner:WALTER SURFACE TECH

User-friendly welding helmet assembly

User-friendly welding helmet assembly configurations to be worn on the head of a weldor are disclosed. The welding helmet assembly configurations include various advanced features including a spatter shield that is easily replaceable from an external front portion of a shell of the helmet assembly configuration, and an adjustable ratchet headgear within the shell having a repositionable lever adapted to easily adjust a detent position of the ratchet headgear with respect to the shell. Other user-friendly features are also provided, in accordance with various embodiments of the present invention.

Owner:LINCOLN GLOBAL INC

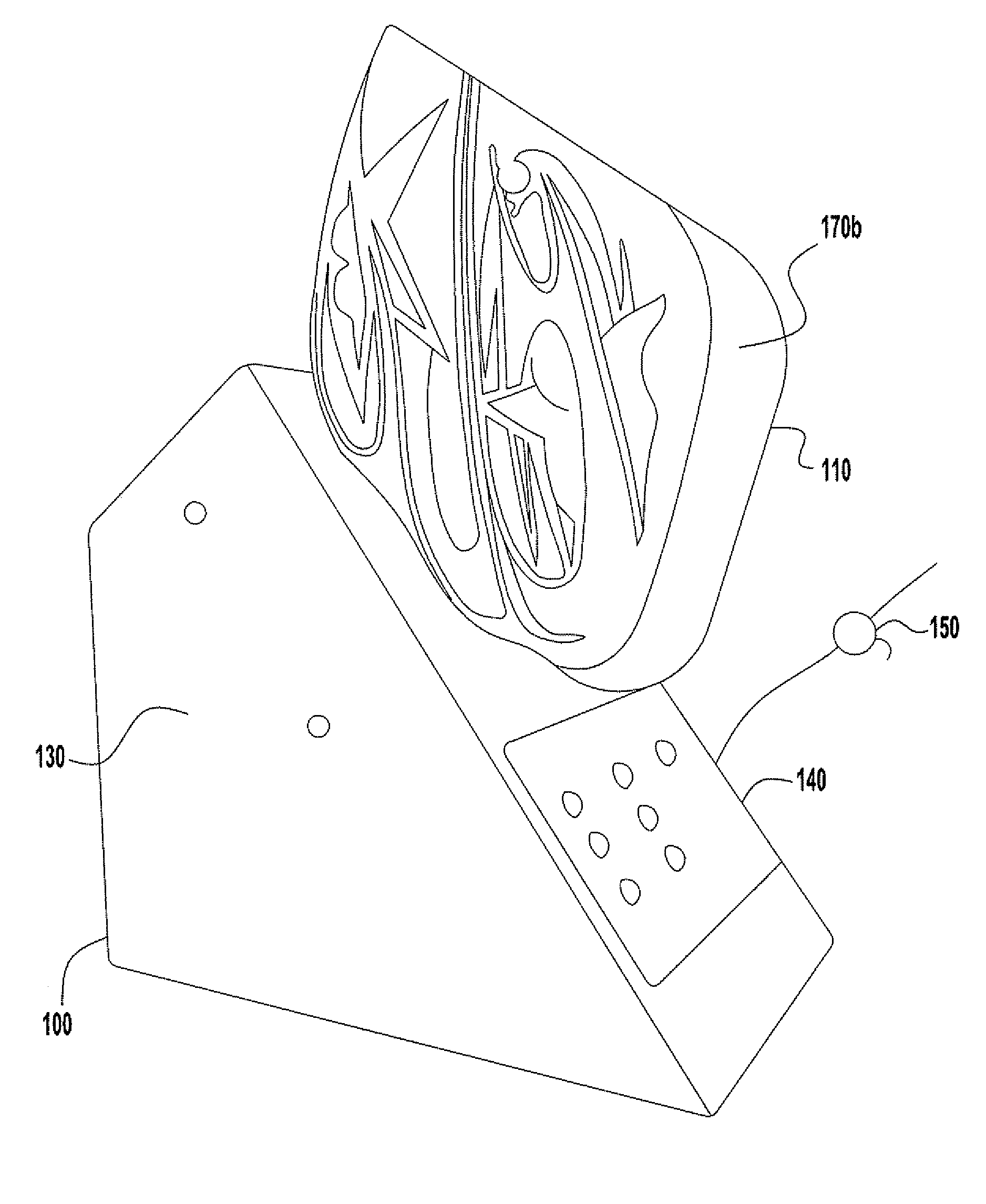

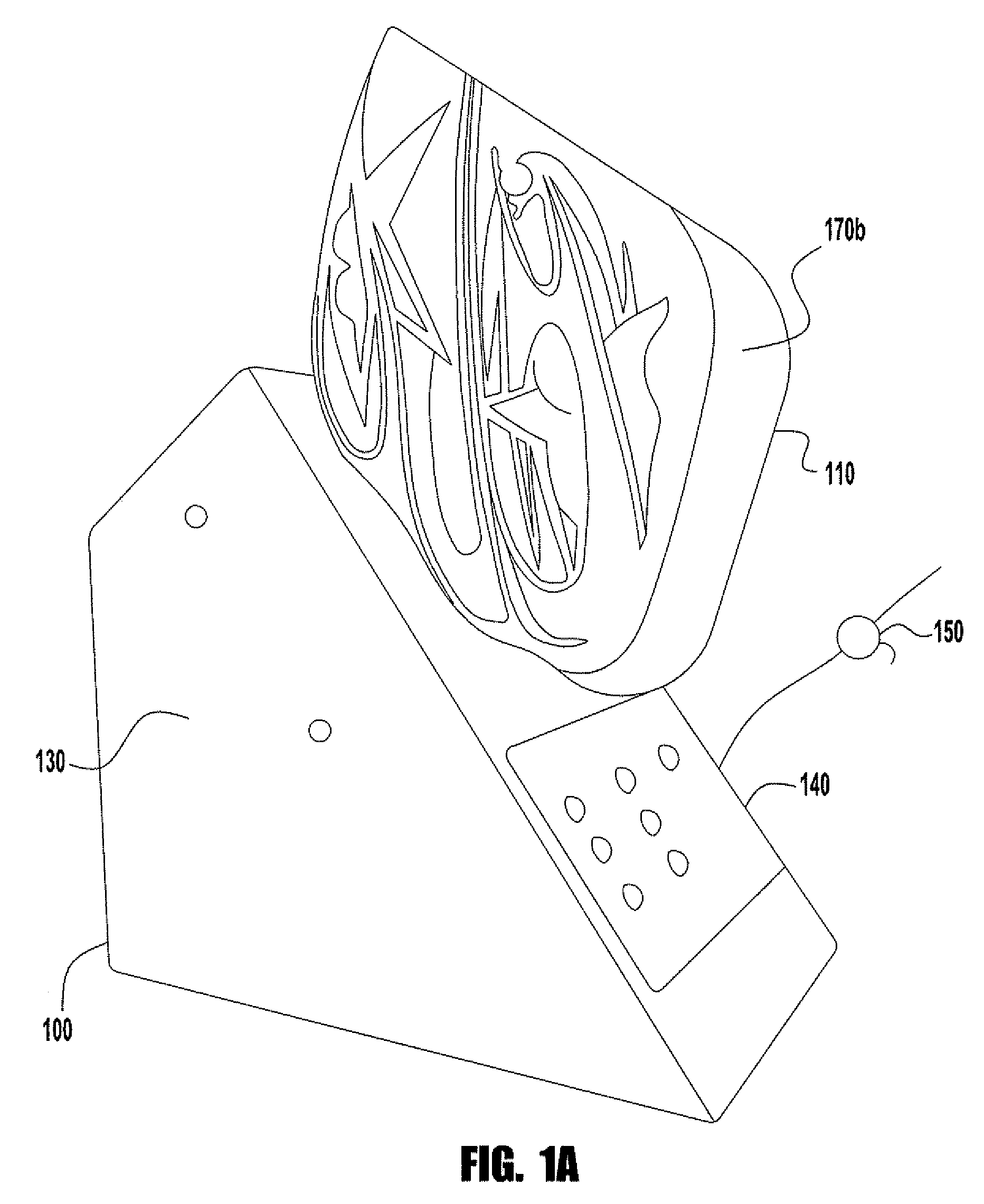

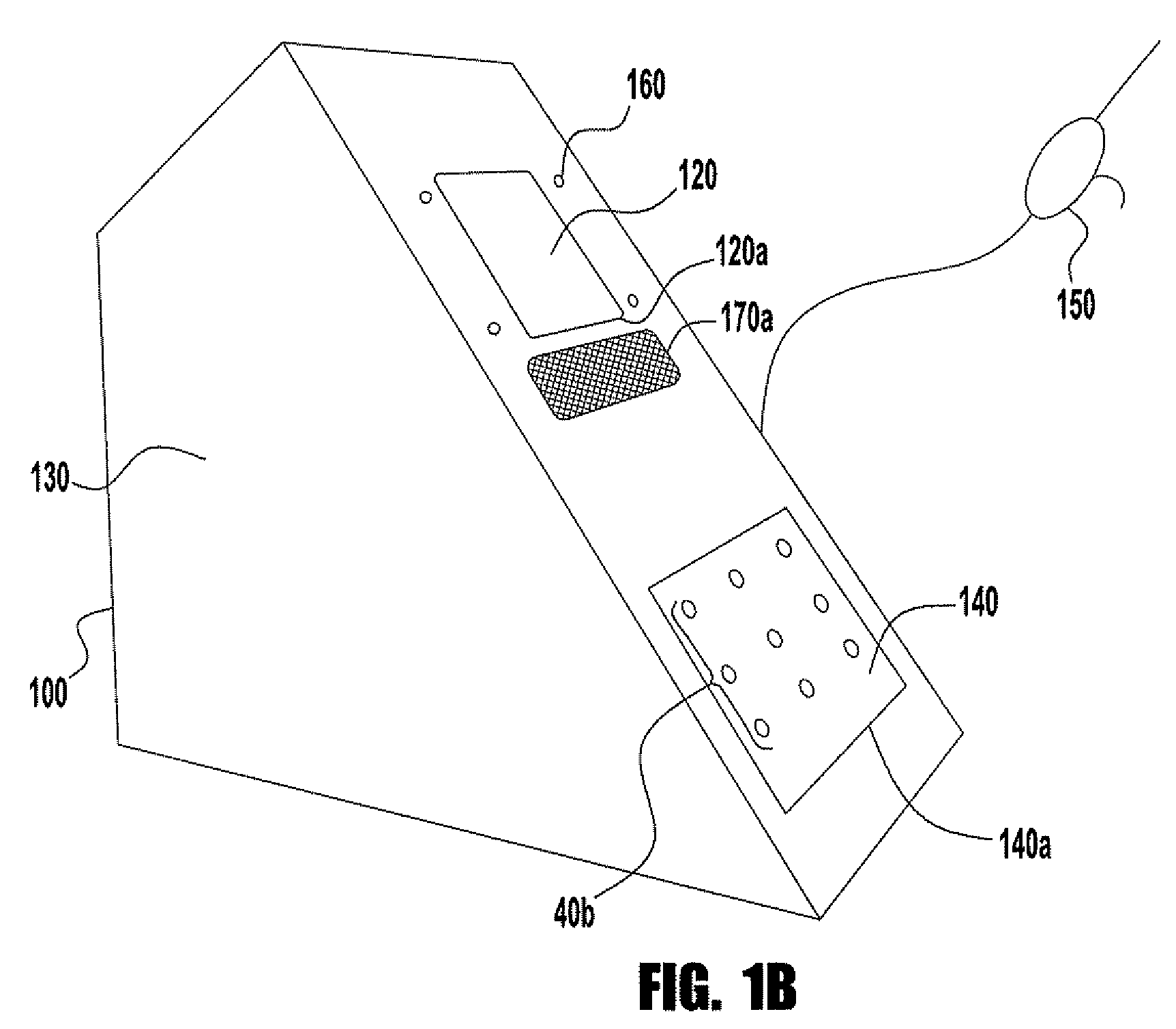

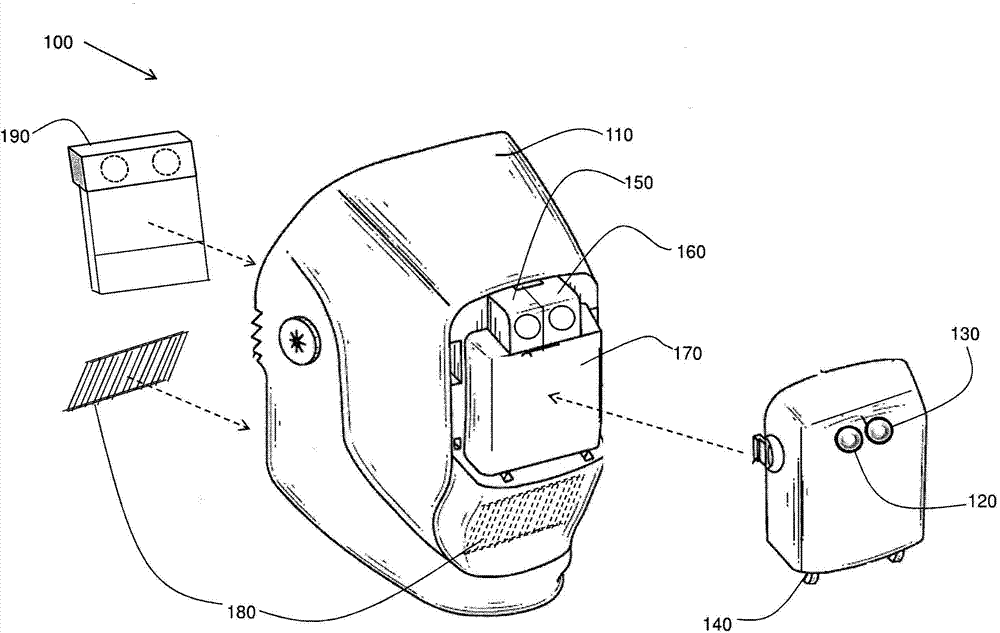

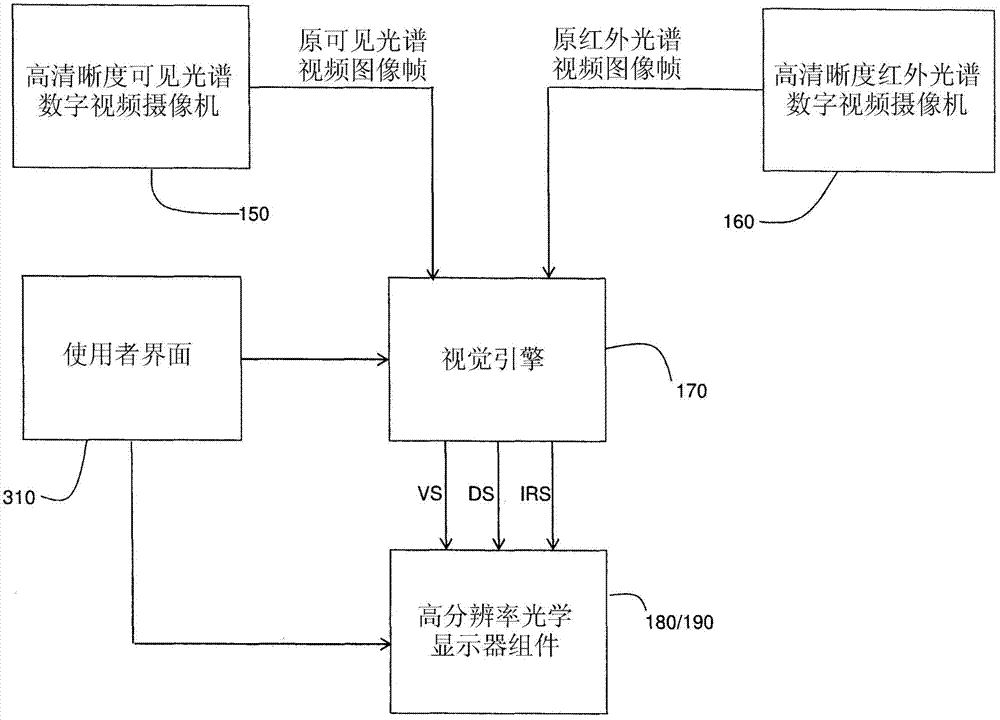

Dual-spectrum digital imaging welding helmet

Arc welding systems, methods, and apparatus that provide dual-spectrum, real-time viewable, enhanced user-discrimination between arc welding characteristics during an arc welding process. Welding headgear (110) is configured to shield a user from harmful radiation and to include a digital camera or cameras (150, 160) to provide dual-spectrum (i.e., both visible spectrum and infrared spectrum) real-time digital video image frames. The welding headgear (110) is also configured with an optical display assembly for displaying real-time digital video image frames to the user while wearing the headgear (110) during an arc welding process. Image processing is performed on the visible and infrared spectrum video image frames to generate dual-spectrum video image frames providing an integrated and optimized view of both the visible and thermal characteristics of the arc welding process which can be viewed by the user on the optical display assembly in real time.

Owner:LINCOLN GLOBAL INC

Respirator, welding helmet, or face shield that has low surface energy hard-coat lens

ActiveUS8015970B2Good chemical-resistanceGood scratchChemical protectionHeat protectionPerfluoropolyetherRespirator

Owner:3M INNOVATIVE PROPERTIES CO

Adapter for protective head gear

The adapter comprises a clip with a groove, and a rack that engages with the groove. The clip attaches securely to an edge of a fabric, for example, a panel on a baseball cap. The rack includes an angle adjuster, on which a brow guard, welding helmet, or other protective gear can be mounted.

Owner:WALTER SURFACE TECH

Welding trainer utilizing a head up display to display simulated and real-world objects

A system for aiding a user in at least one of welding, cutting, joining, and cladding operations is provided. The system includes a welding tool and a welding helmet with a face-mounted display. The system also includes a spatial tracker configured to track the welding helmet and the welding tool in 3-D space relative to an object to be worked on. A processor based subsystem is configured to generate virtual objects based on objects found in a welding environment and transmit the virtual objects to a predetermined location on the face-mounted display.

Owner:LINCOLN GLOBAL INC

Airflow headgear for a welding helmet

InactiveCN101795645AAvoid enteringImprove balanceBreathing masksEye-masksPositive pressureEngineering

An airflow system is provided for a welding helmet. The airflow system includes an air intake (16) with a filter, a blower, and a battery mounted to the rear of headgear for a welding helmet. A manifold wraps around the side and front of the headgear and directs air from the- blower to the front of the headgear. The manifold includes a lower vent (26) for directing air onto a user's face and an upper vent (30) for directing air over a user's head toward the rear of the headgear. The vents are intended to create positive pressure to impede the entry of unfiltered air into the user's breathing zone. The manifold further includes a portion of flexible tubing (22) for adjusting the size of the airflow system in conjunction with adjustment of the headgear diameter. The airflow system generally conforms to the structure and shape of the headgear to maintain a location close to the user's head.

Owner:ILLINOIS TOOL WORKS INC

Welding system providing visual and audio cues to a welding helmet with a display

A system for aiding a user in at least one of welding, cutting, joining, and cladding operations is provided. The system includes a welding tool and a welding helmet with a face-mounted display. The system also includes a spatial tracker configured to track the welding helmet and the welding tool in 3-D space relative to an object to be worked on. A processor based subsystem is configured to generate visual cues based on information from the spatial tracker and transmit the visual cues to a predetermined location on the face-mounted display.

Owner:LINCOLN GLOBAL INC

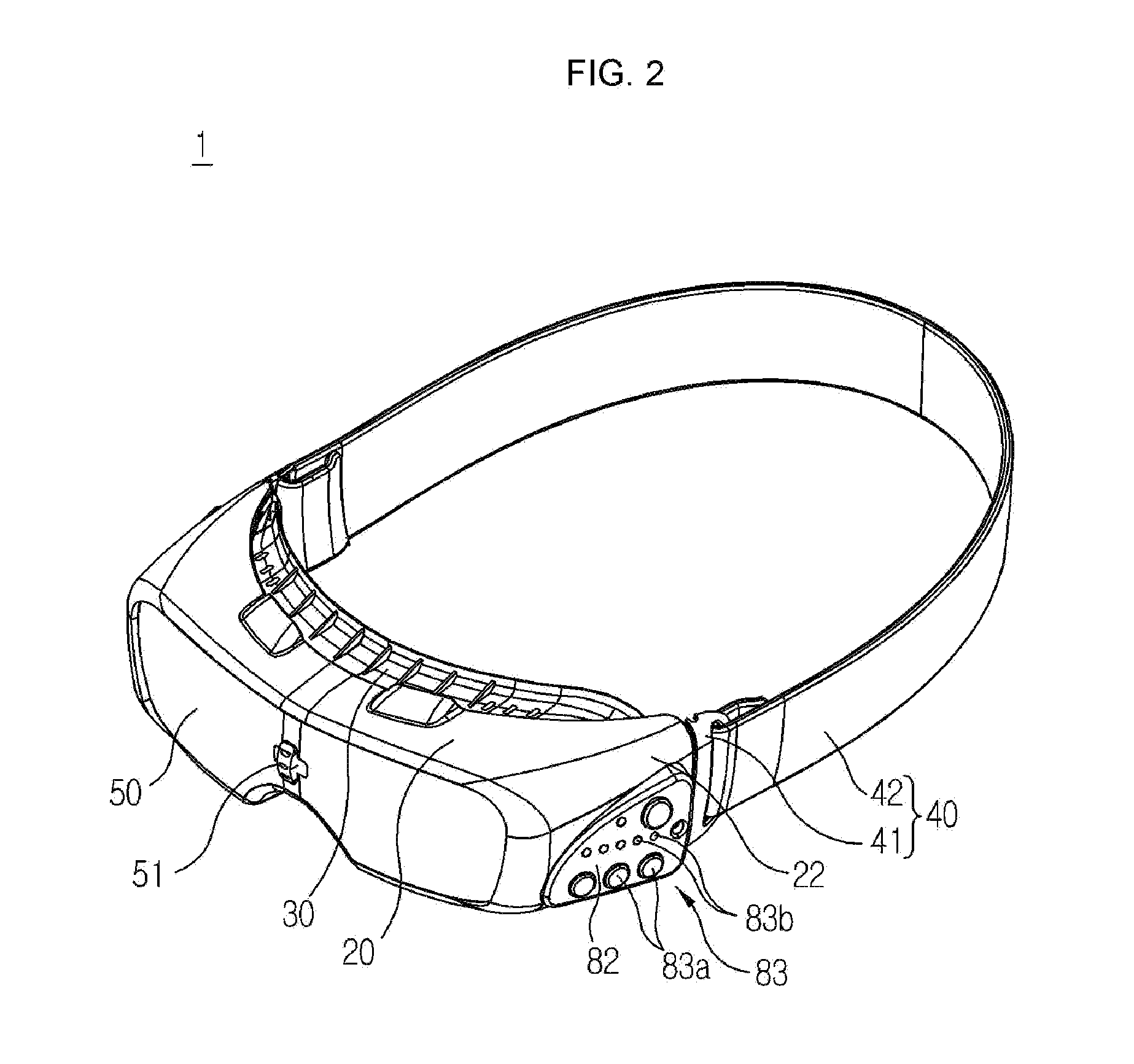

Automatic shading goggles

ActiveUS20120204303A1Reduce the burden onEasy to distinguishGogglesEngineering safety devicesEngineeringWelding helmet

Provided is automatic shading goggles in that a welding helmet is manufactured in a goggle shape, so that the size thereof is compact and the weight thereof is light and a shading degree of a LCD lens can be selectively adjusted in any one mode of a welding mode for shielding a harmful light generated during welding operation and a security mode for shielding a visible ray, so that it can reduce a burden of the weight applied to a worker, block a strong light during welding operation, and easily distinguish the surrounding objects, when the welding operation is not performed.

Owner:SERVORE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com