Patents

Literature

56results about How to "Reduce optical density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

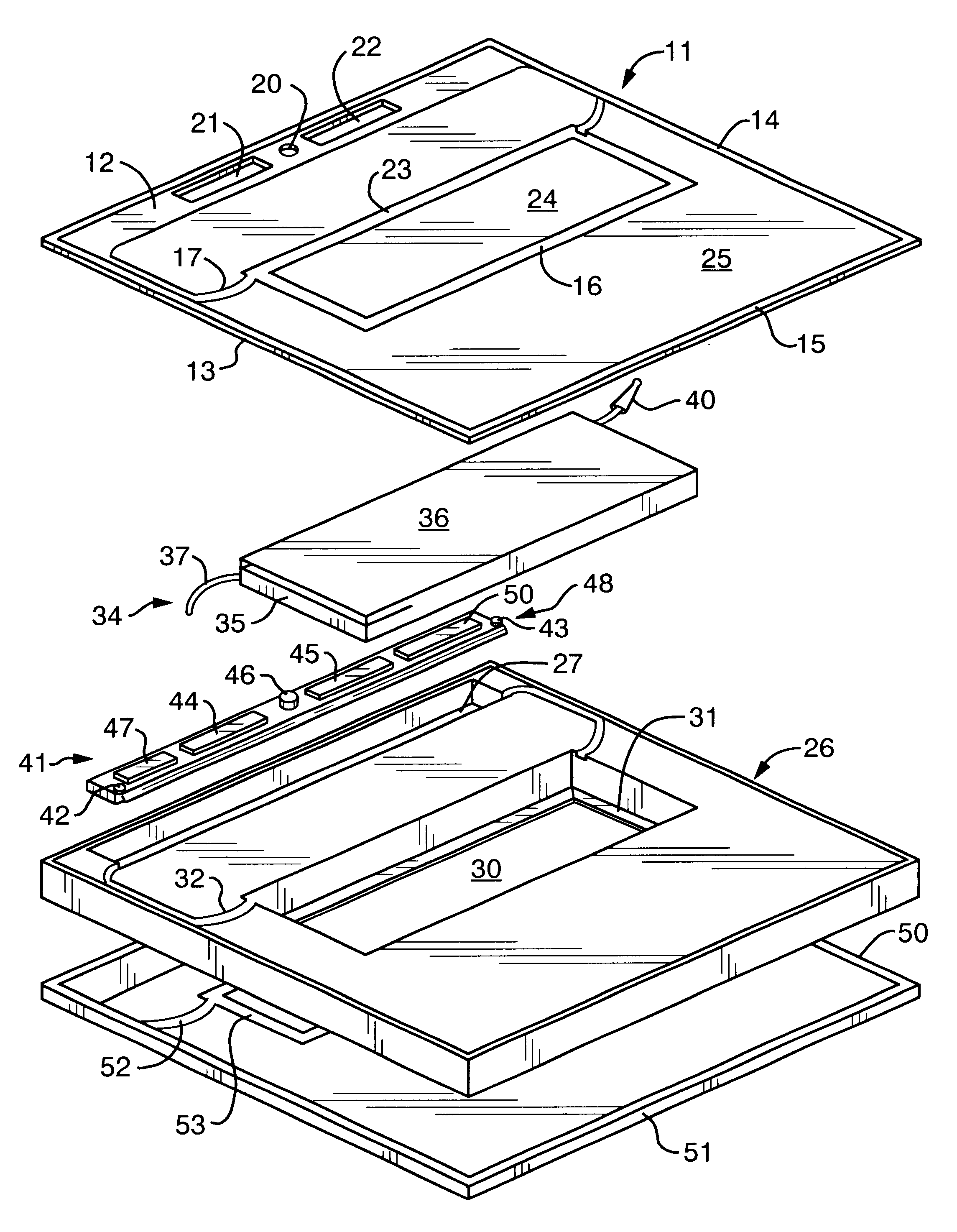

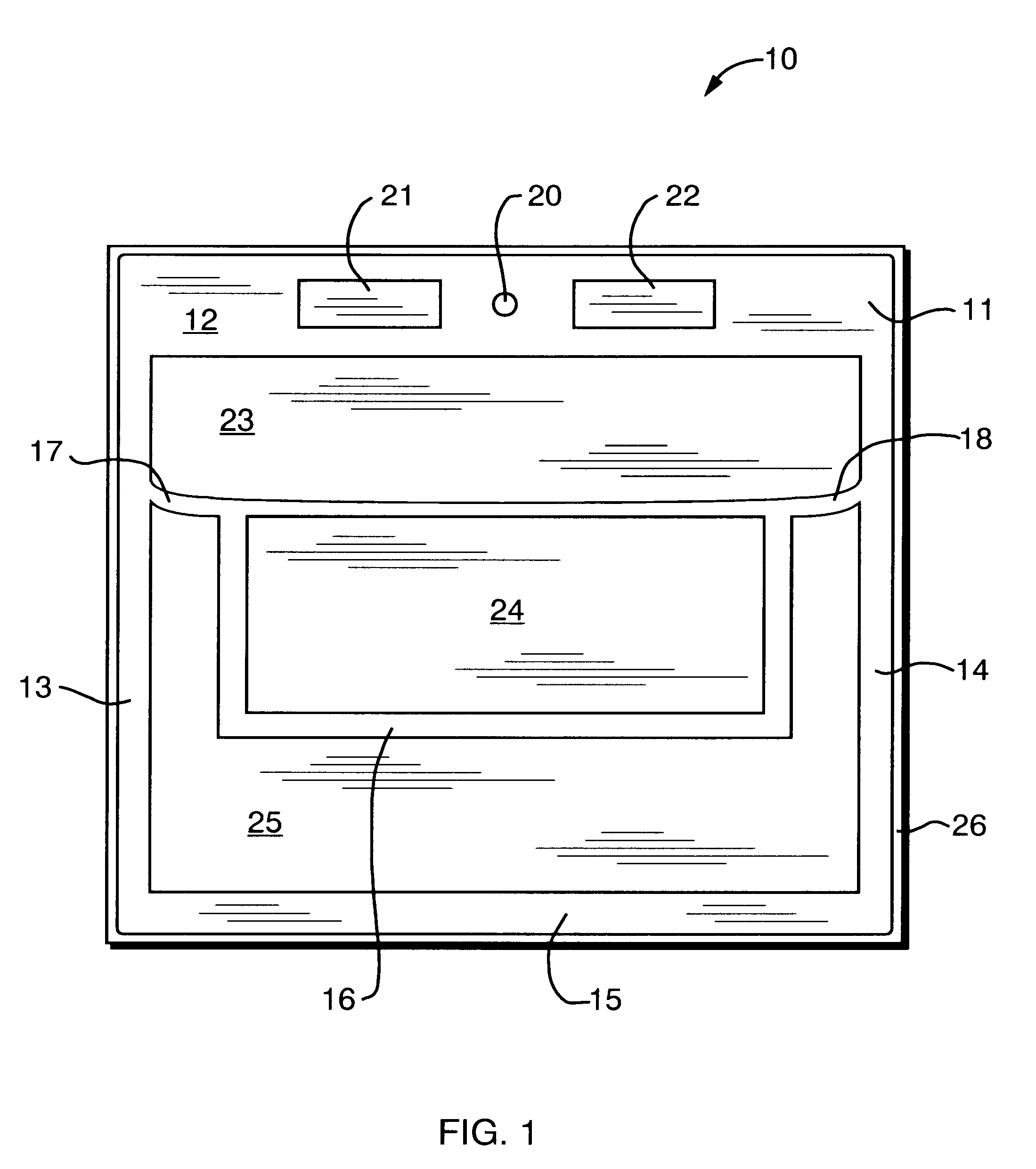

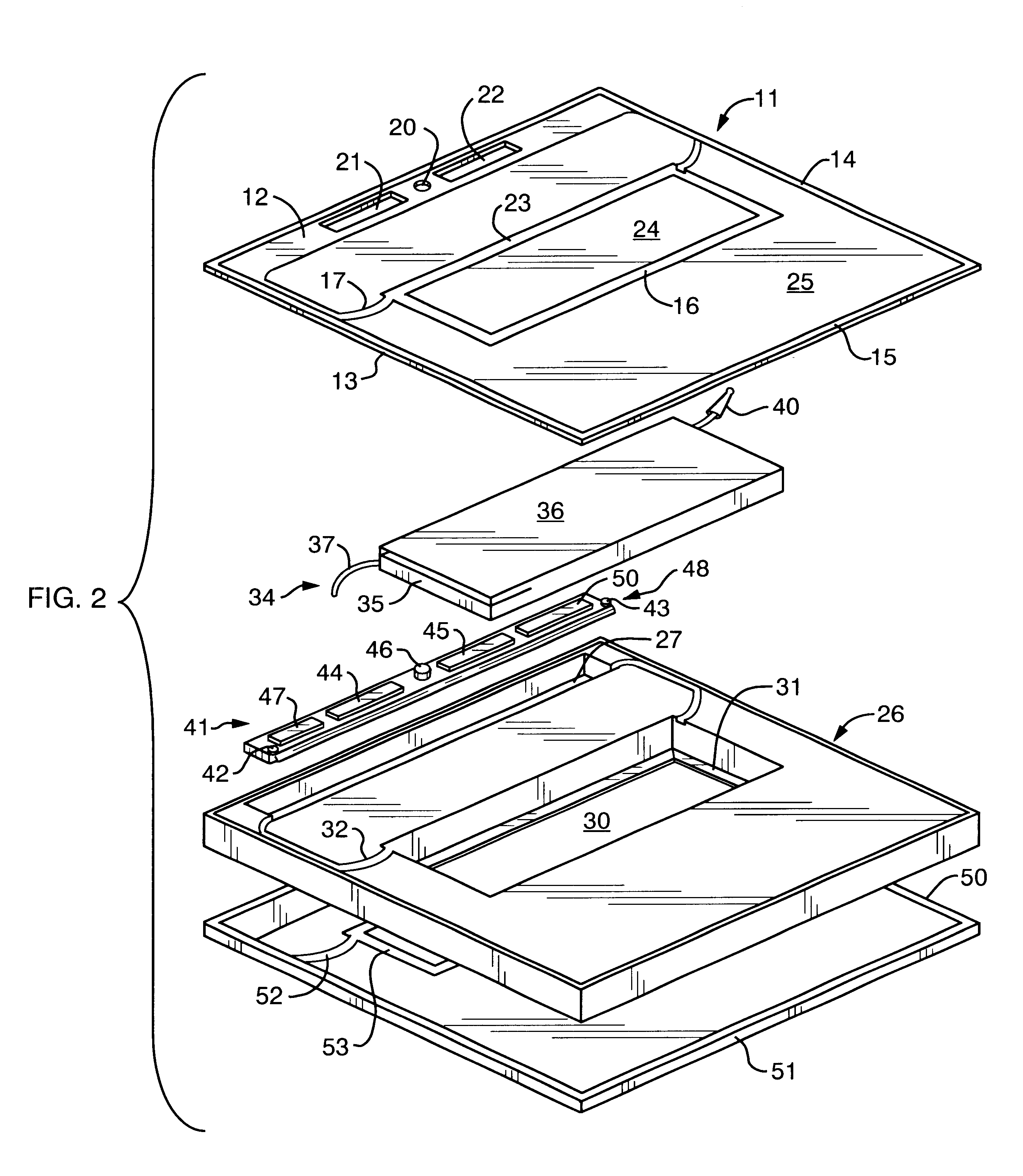

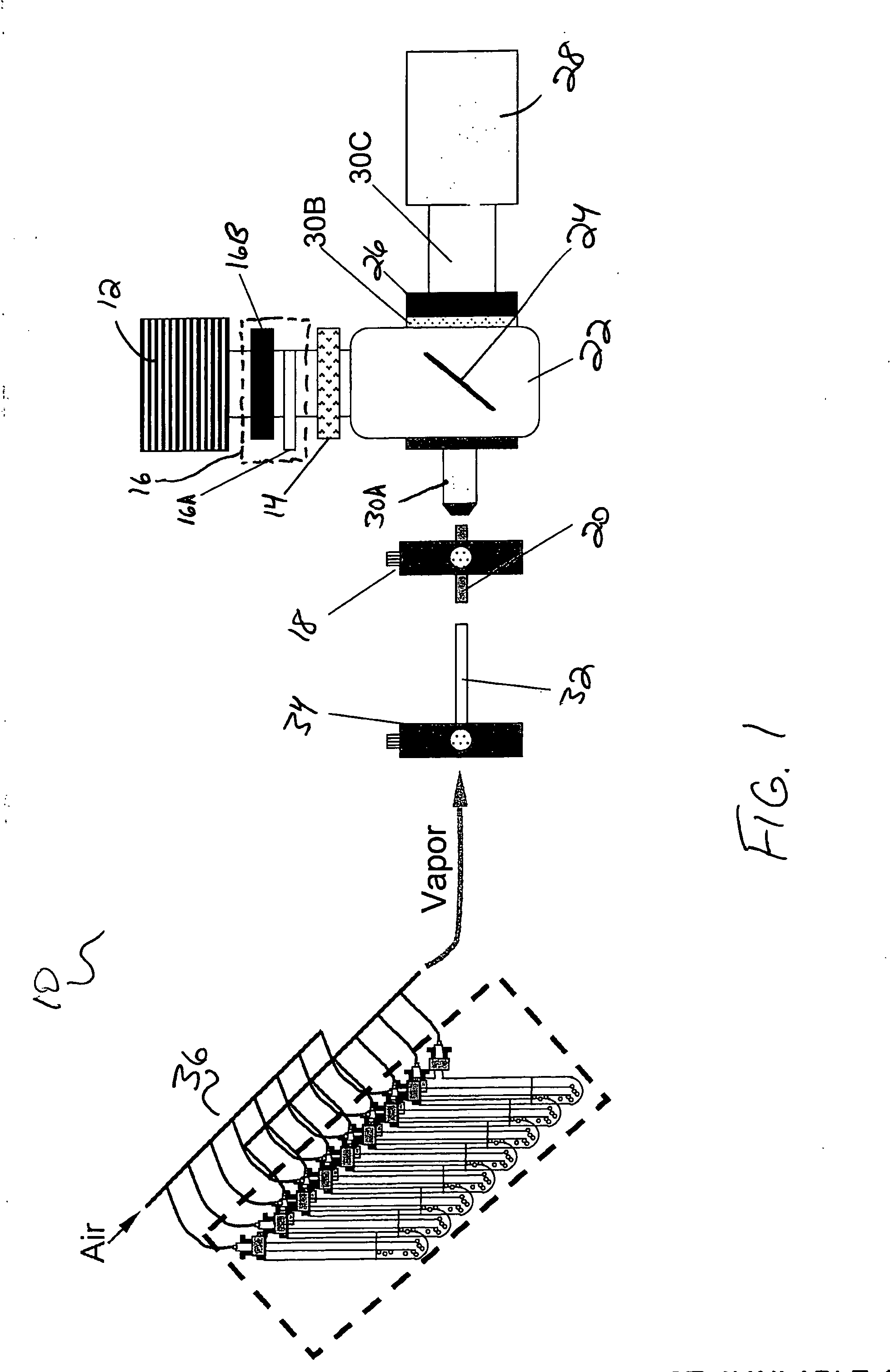

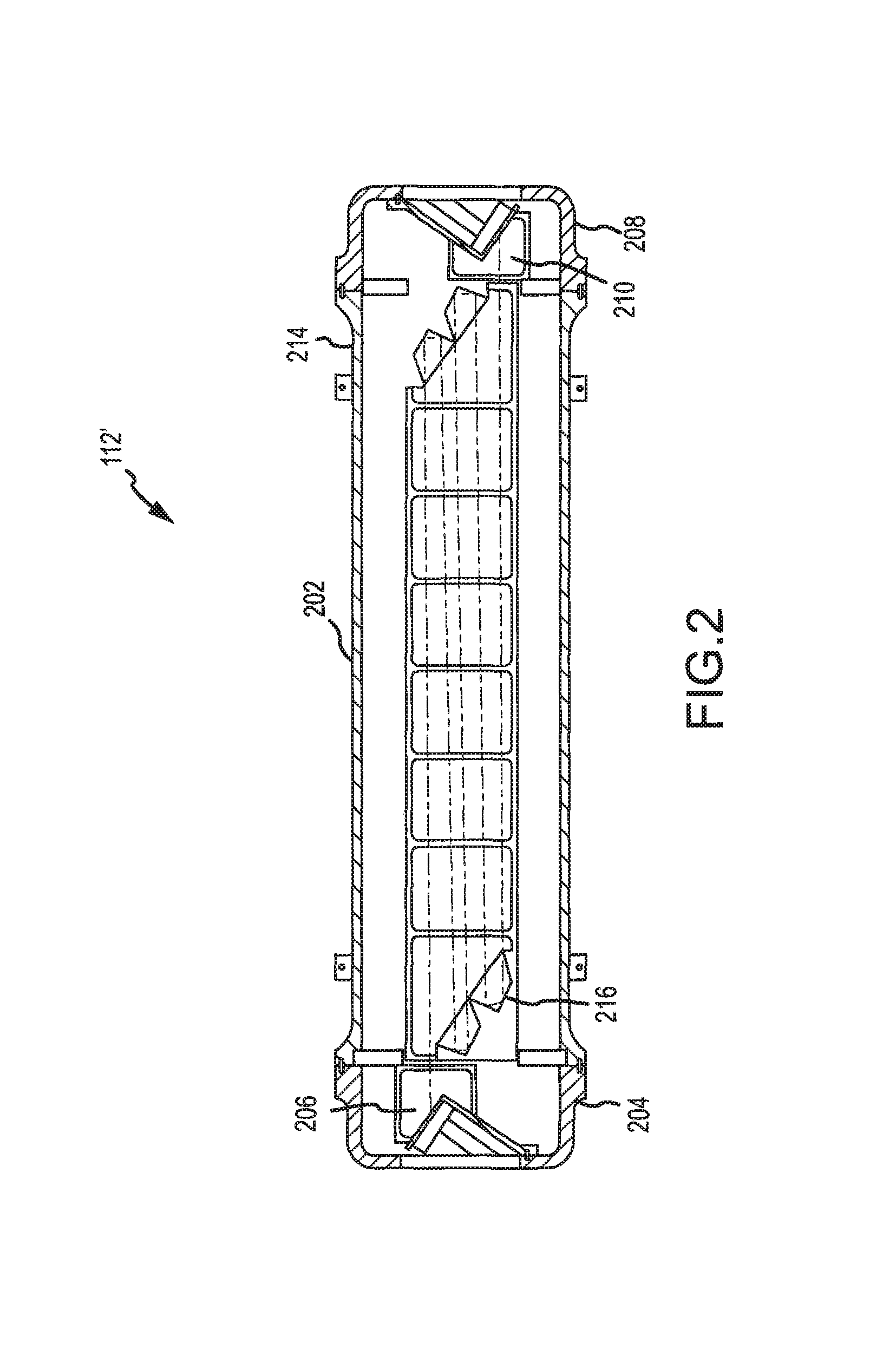

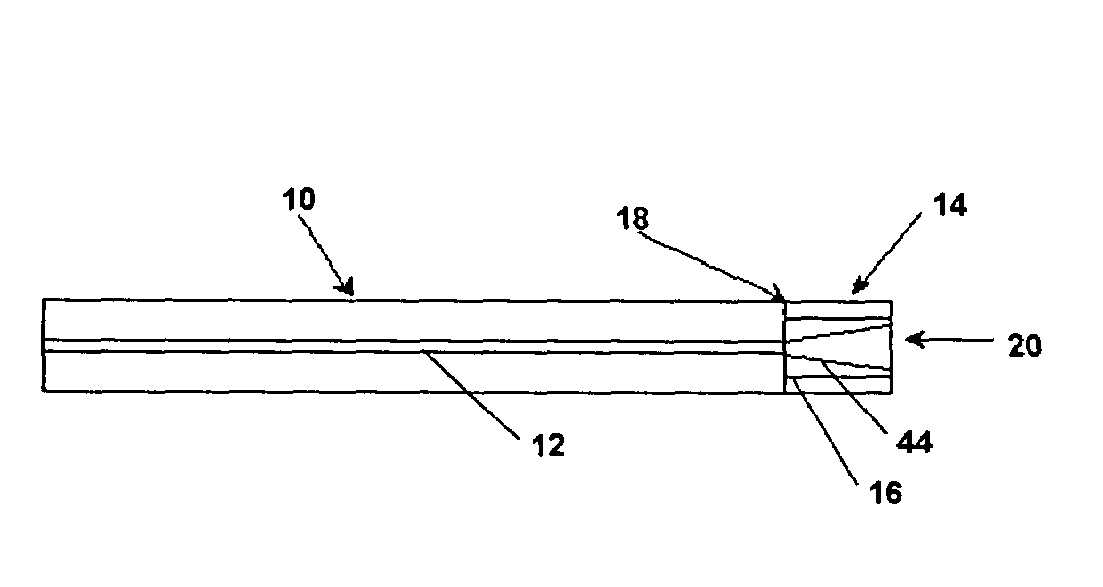

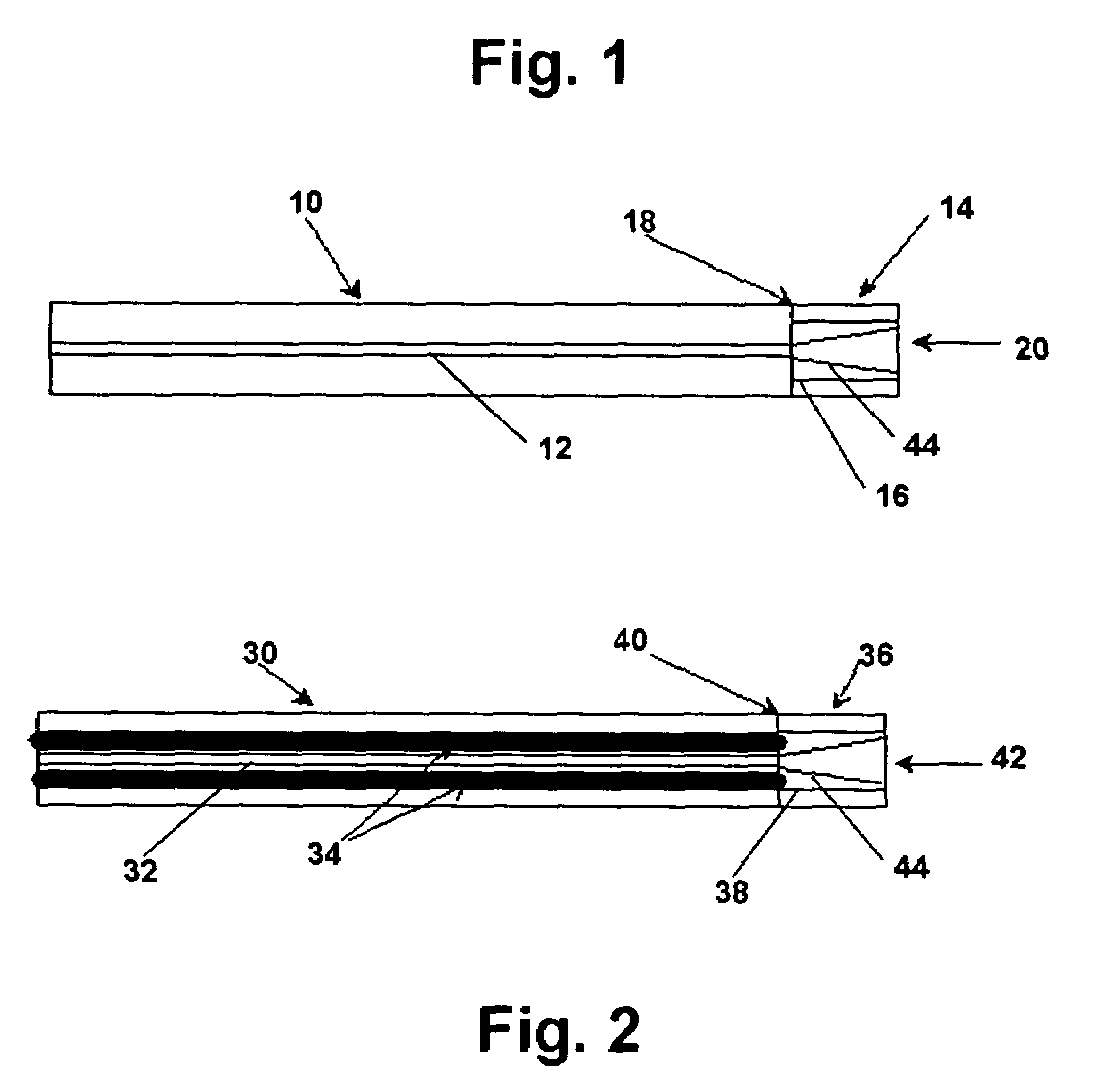

Replaceable, self-contained expanded viewing light shield cartridge for welding helmet

InactiveUS6557174B2Increase viewable areaReduce optical densityEye-masksNon-linear opticsProtecting eyeEngineering

An electronic quick change cartridge for a welding helmet. The cartridge base is formed of an optically dense polycarbonate or like material that acts as a passive filter to provide eye protection during the welding process. A port in the base receives a variable density LCD cell and a cavity formed in the base receives the electronics for driving the cell. Optical masks prevent light leakage through any interfaces of the structure. When low light levels are present, the welder views a work piece through an essentially transparent or slightly opaque LCD cell. When an arc is struck, the LCD cell darkens to a shade corresponding to the shade of the surrounding polycarbonate material. The welder then can view the work piece through the LCD cell and all the optically unobstructed portions of the polycarbonate base surrounding the LCD cell thereby to have an expanded viewing area during the actual welding operation.

Owner:WALTER SURFACE TECH

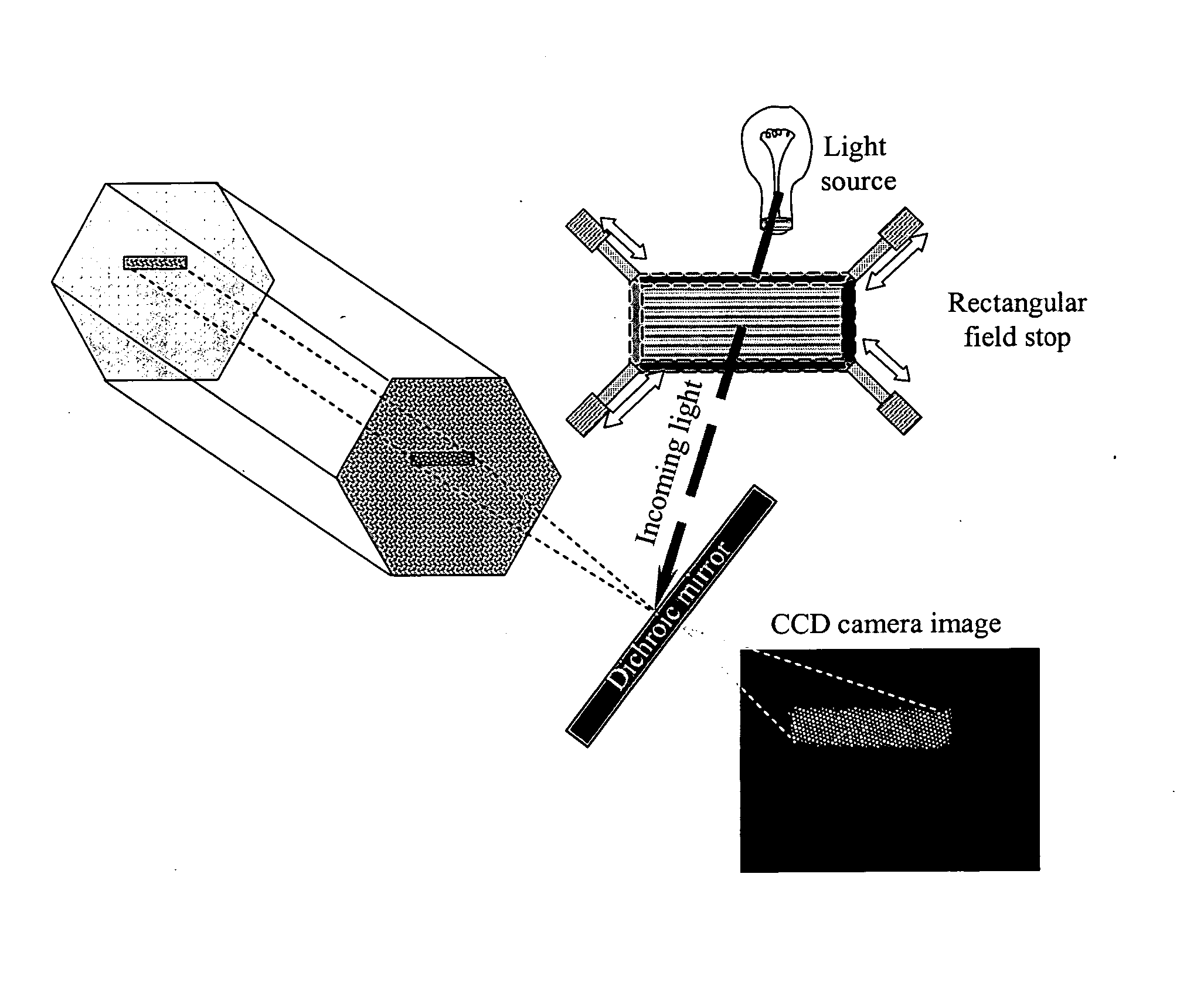

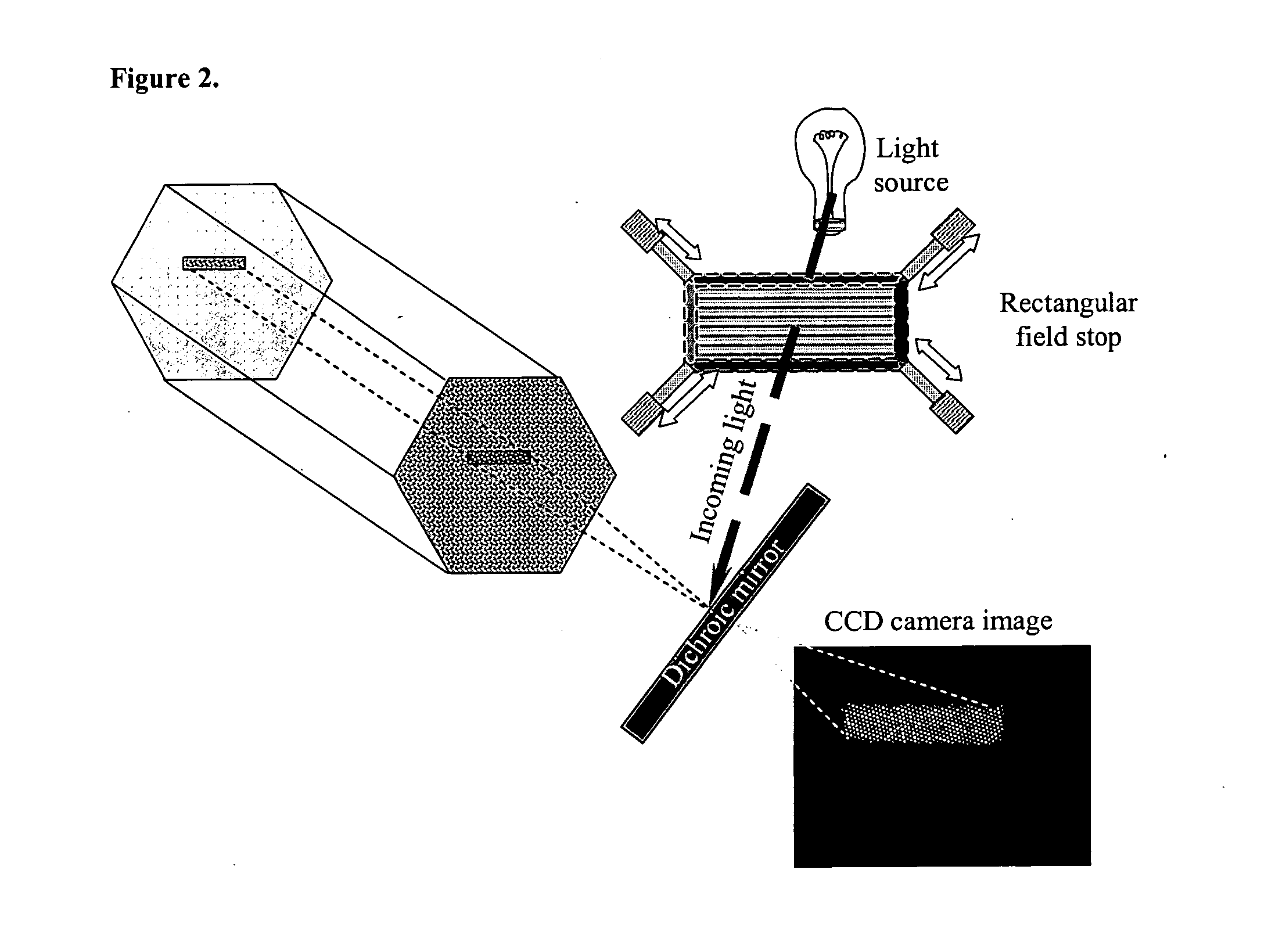

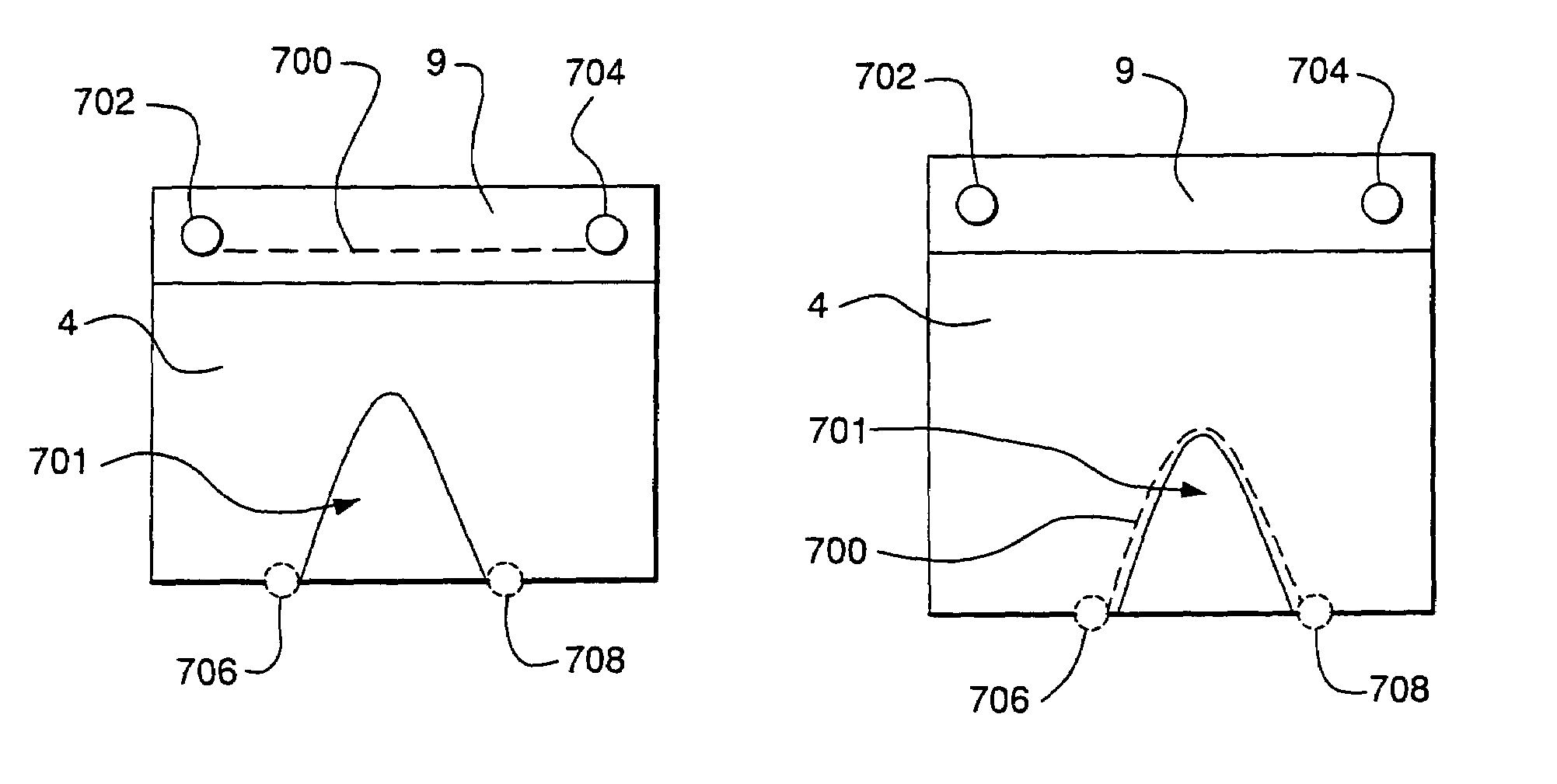

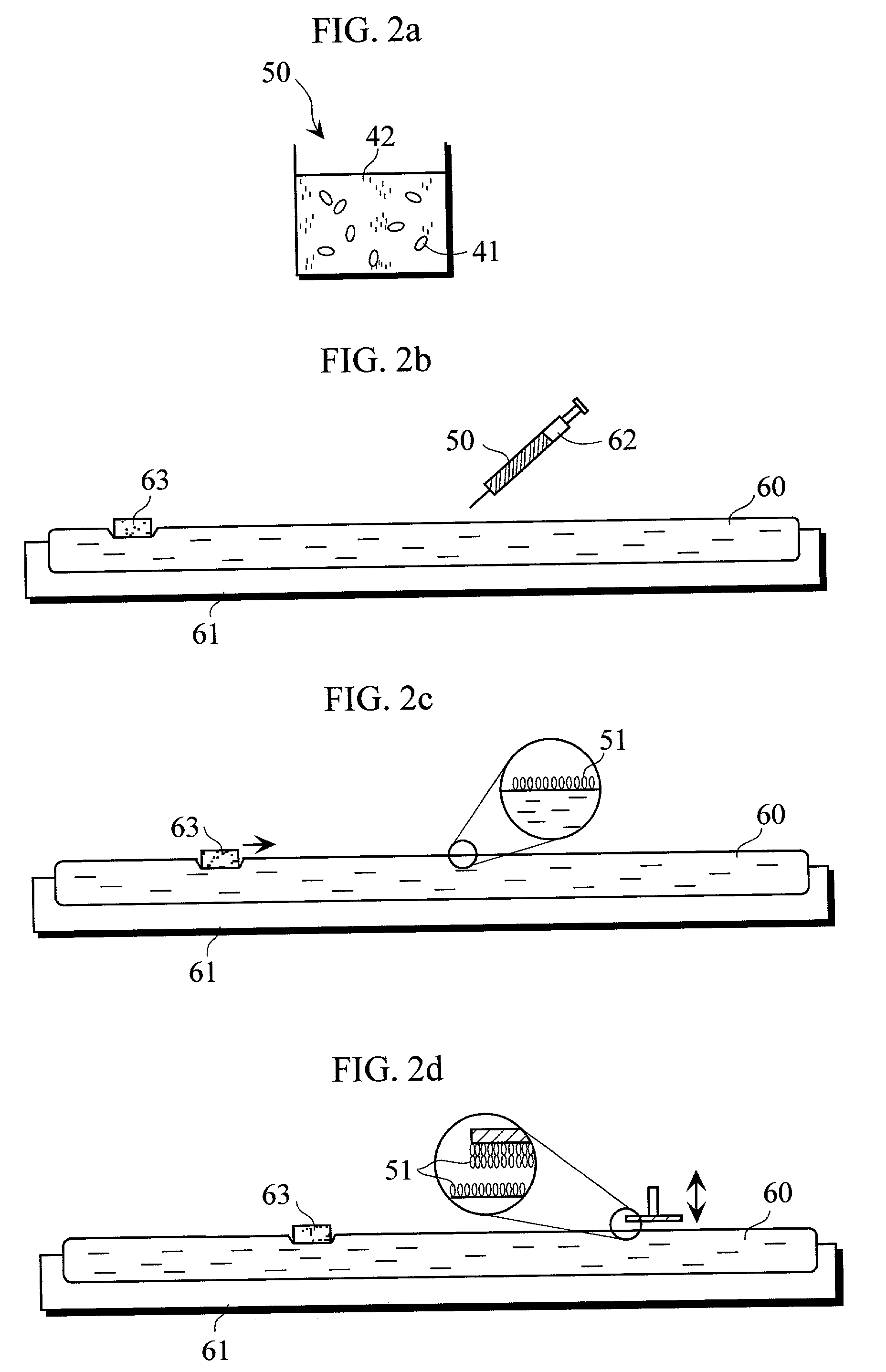

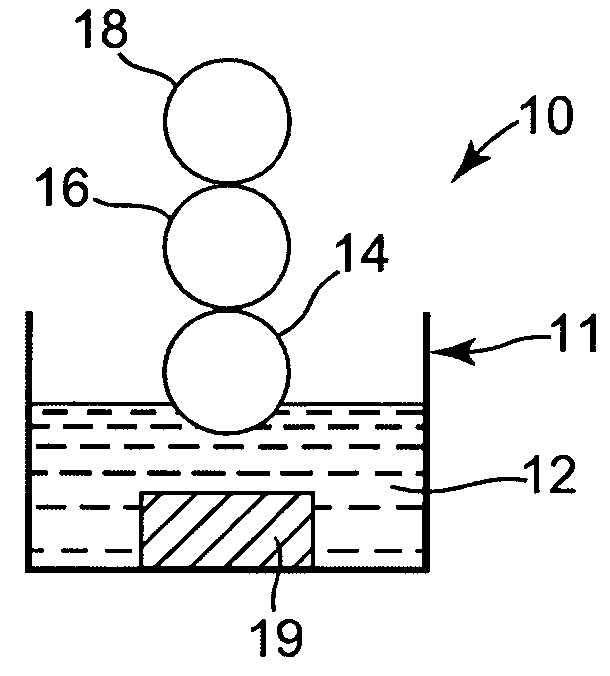

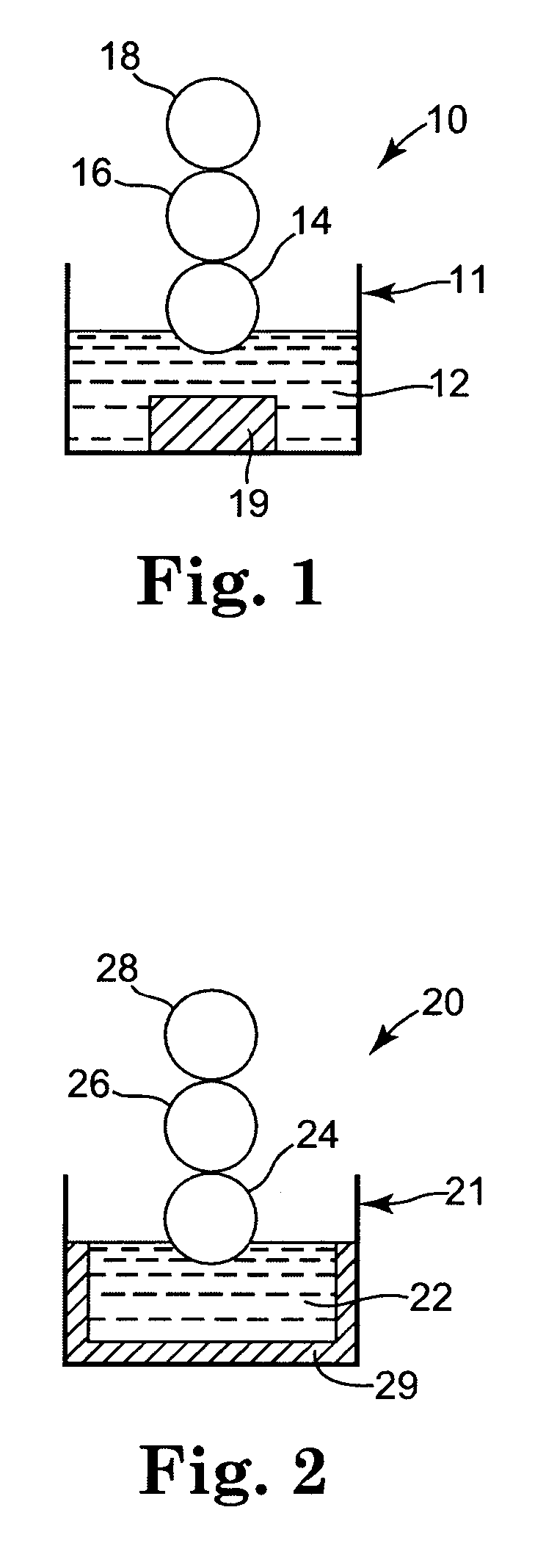

Method and system of array imaging

ActiveUS20070040095A1Reduce optical densityPhotometry using reference valueRaman/scattering spectroscopySensor arrayFilter system

The present invention relates to a method and system of array imaging that extends or maximizes the longevity of the sensor array by minimizing the effects of photobleaching. The imaging system has a light source, a variable exposure aperture, and a variable filter system. The system extends the longevity of sensors by (1) using the variable exposure aperture to selectively expose sections of the sensor array containing representative numbers of each type of sensor, and / or (2) using the variable filter system to control the intensity of the excitation light, providing only the intensity required to induce the appropriate excitation and increasing that intensity over time as necessary to counteract the effects of photobleaching.

Owner:TUFTS UNIV

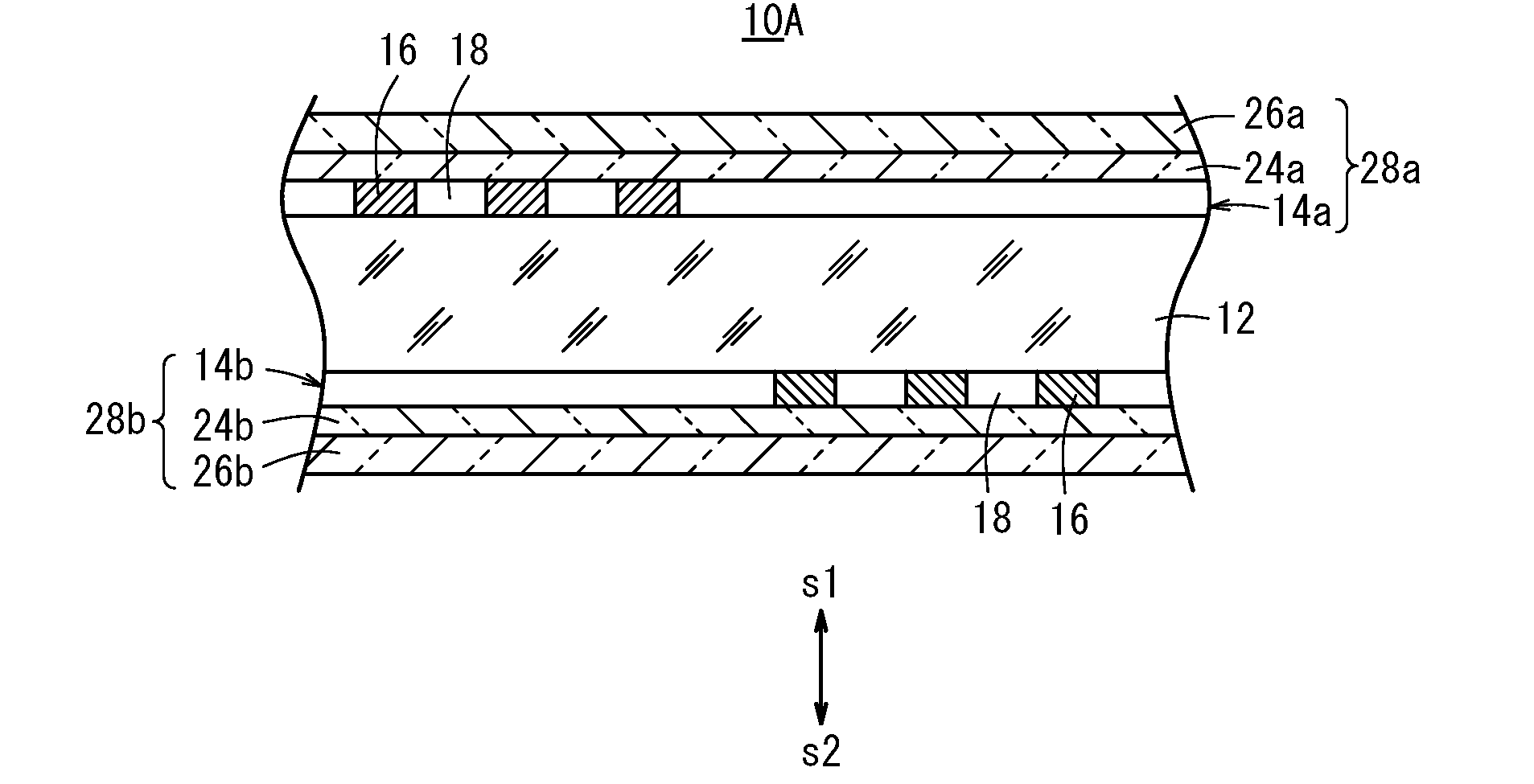

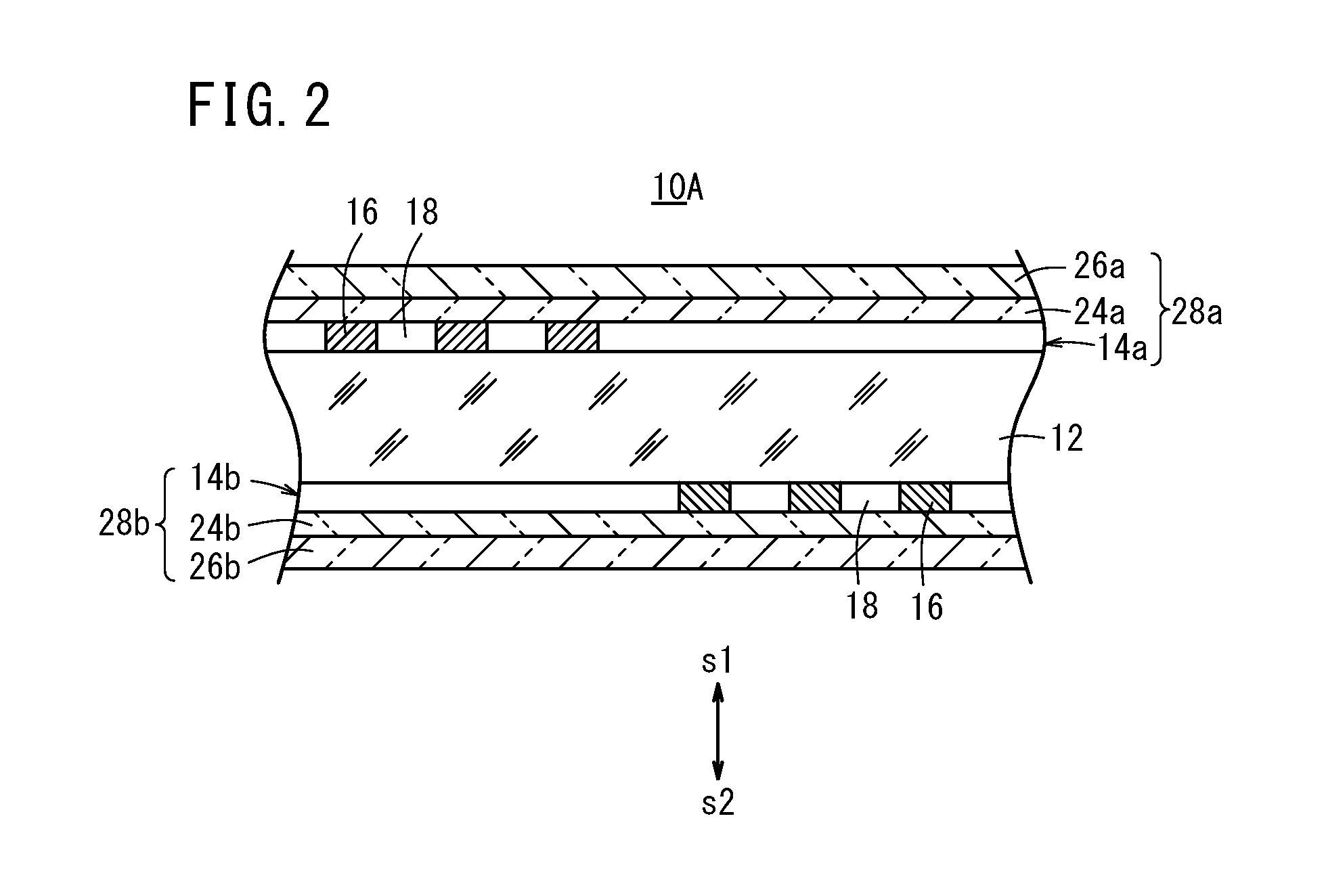

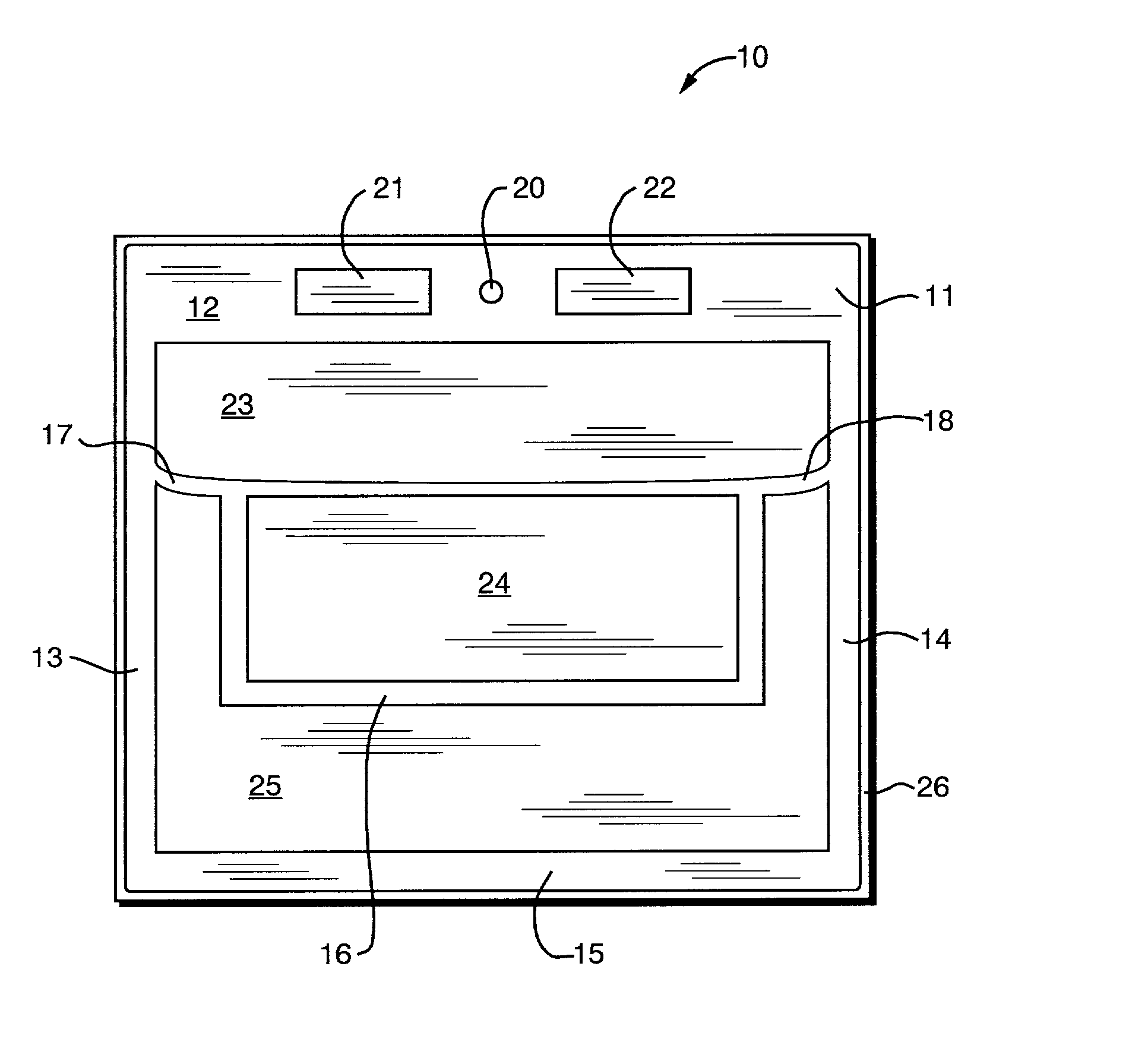

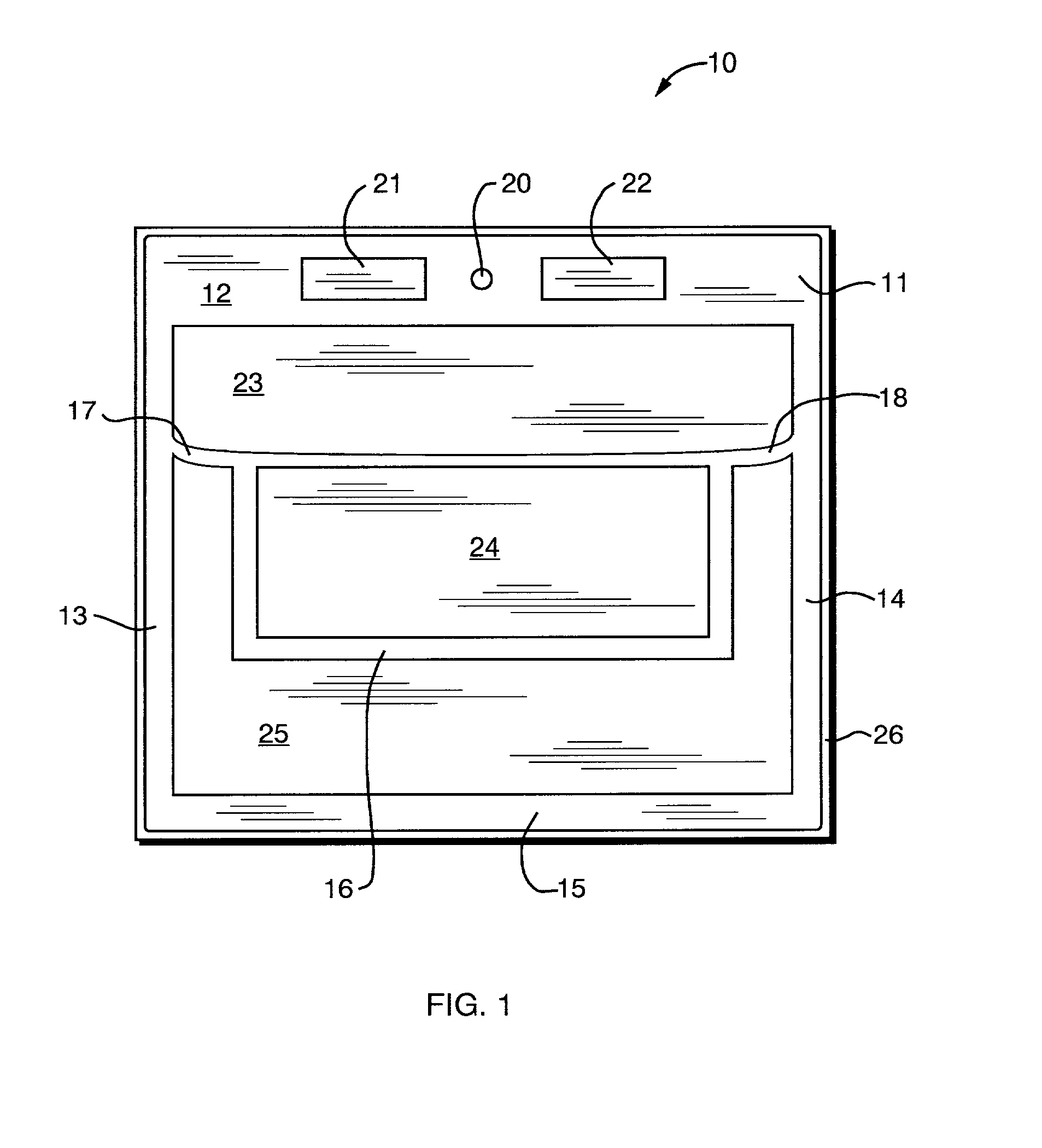

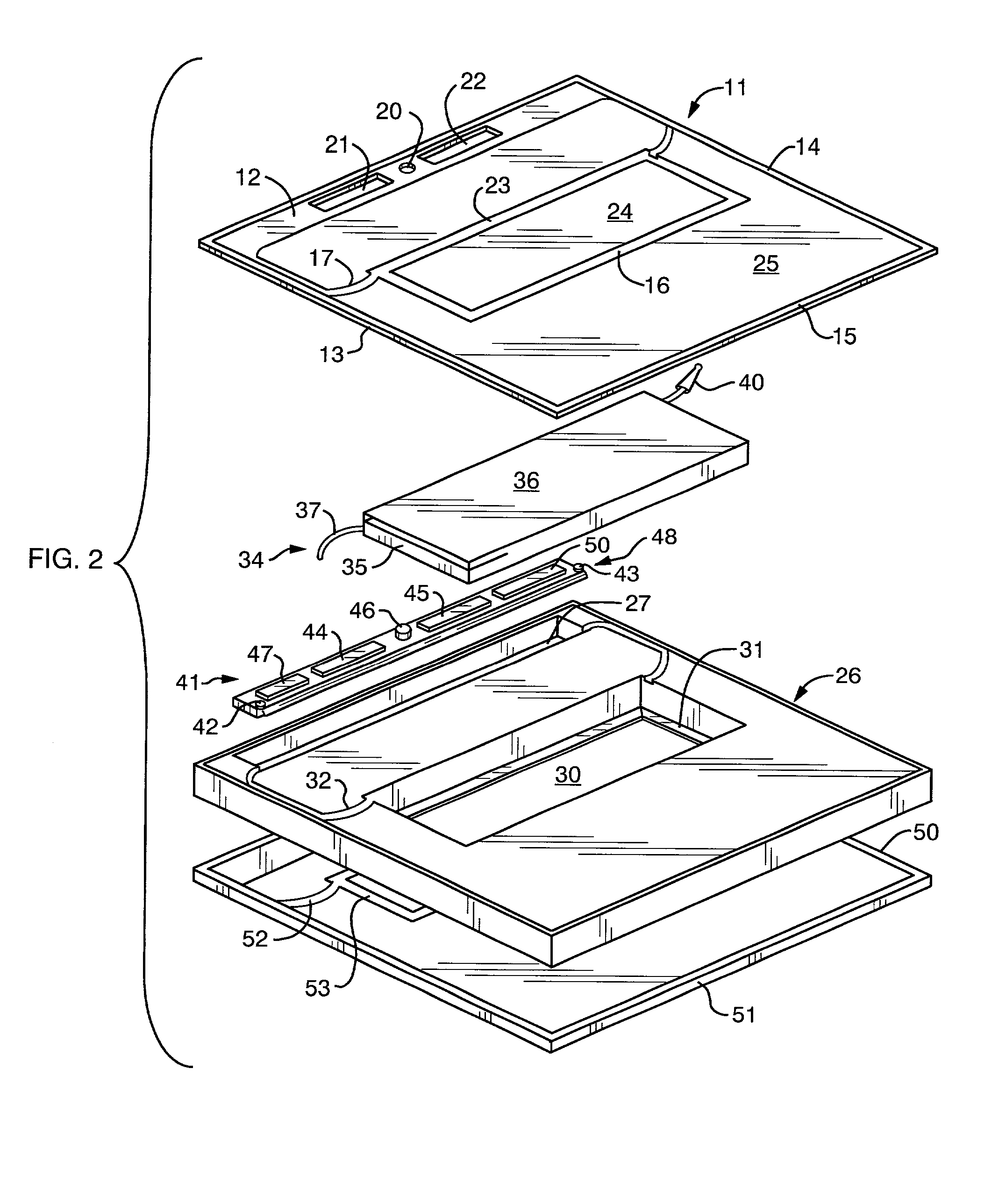

Conductive laminate body, touch panel, and display device

ActiveUS20140098307A1Easy to seeIncrease the differenceStatic indicating devicesSynthetic resin layered productsRelative refractive indexDisplay device

This present invention pertains to: a conductive laminate body, a touch panel, and a display device. In the present invention, the relative refractive index of a substrate with respect to a first protective sheet, and / or the relative refractive index of the substrate with respect to a second protective sheet is 0.86-1.15. The relative refractive index of a first substrate with respect to the first protective sheet, and / or the relative refractive index of a second substrate with respect to the second protective sheet is 0.86-1.15.

Owner:FUJIFILM CORP

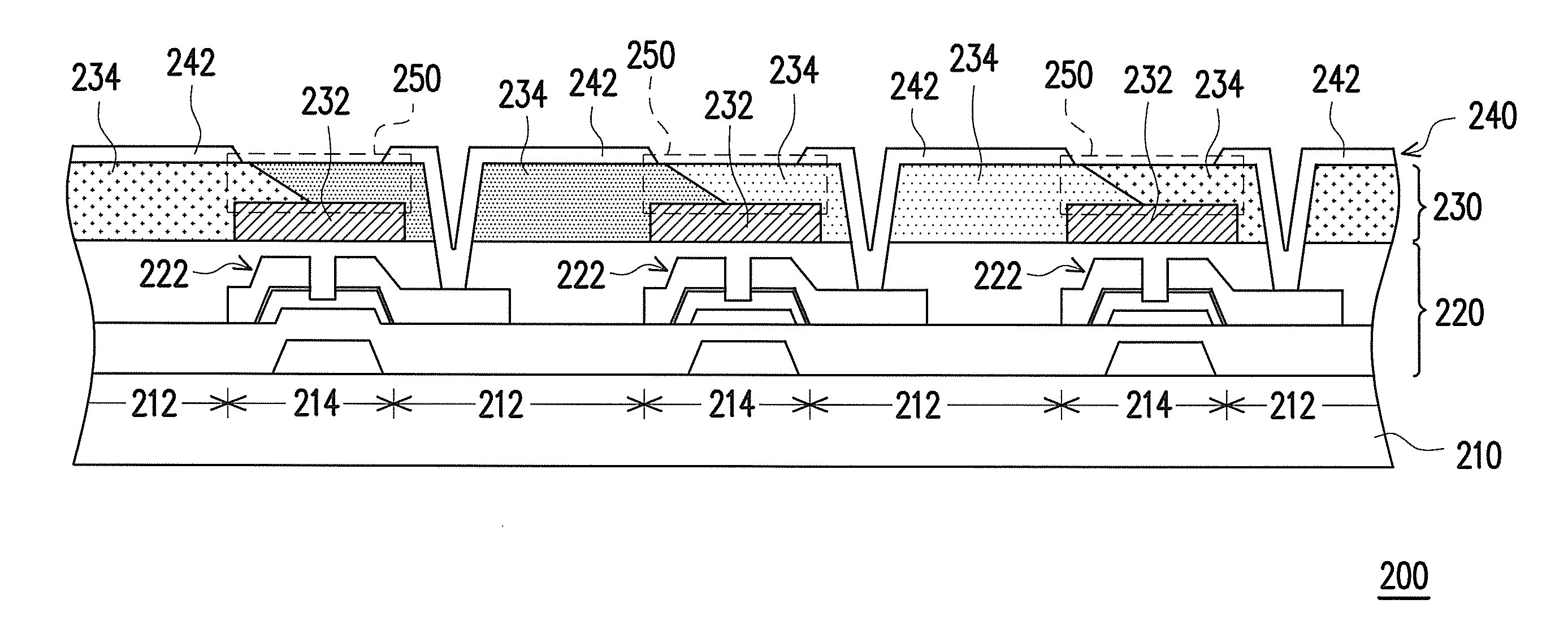

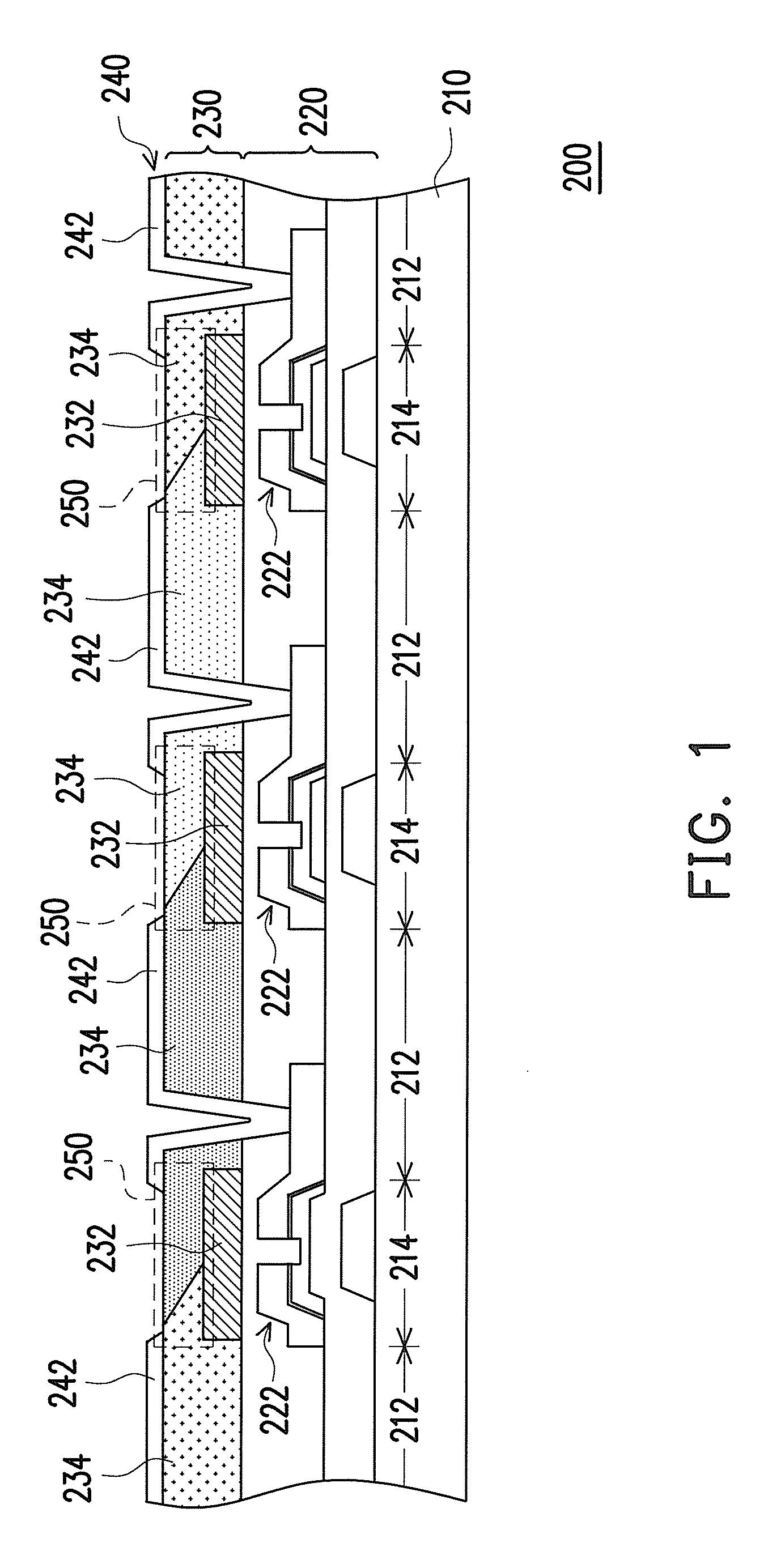

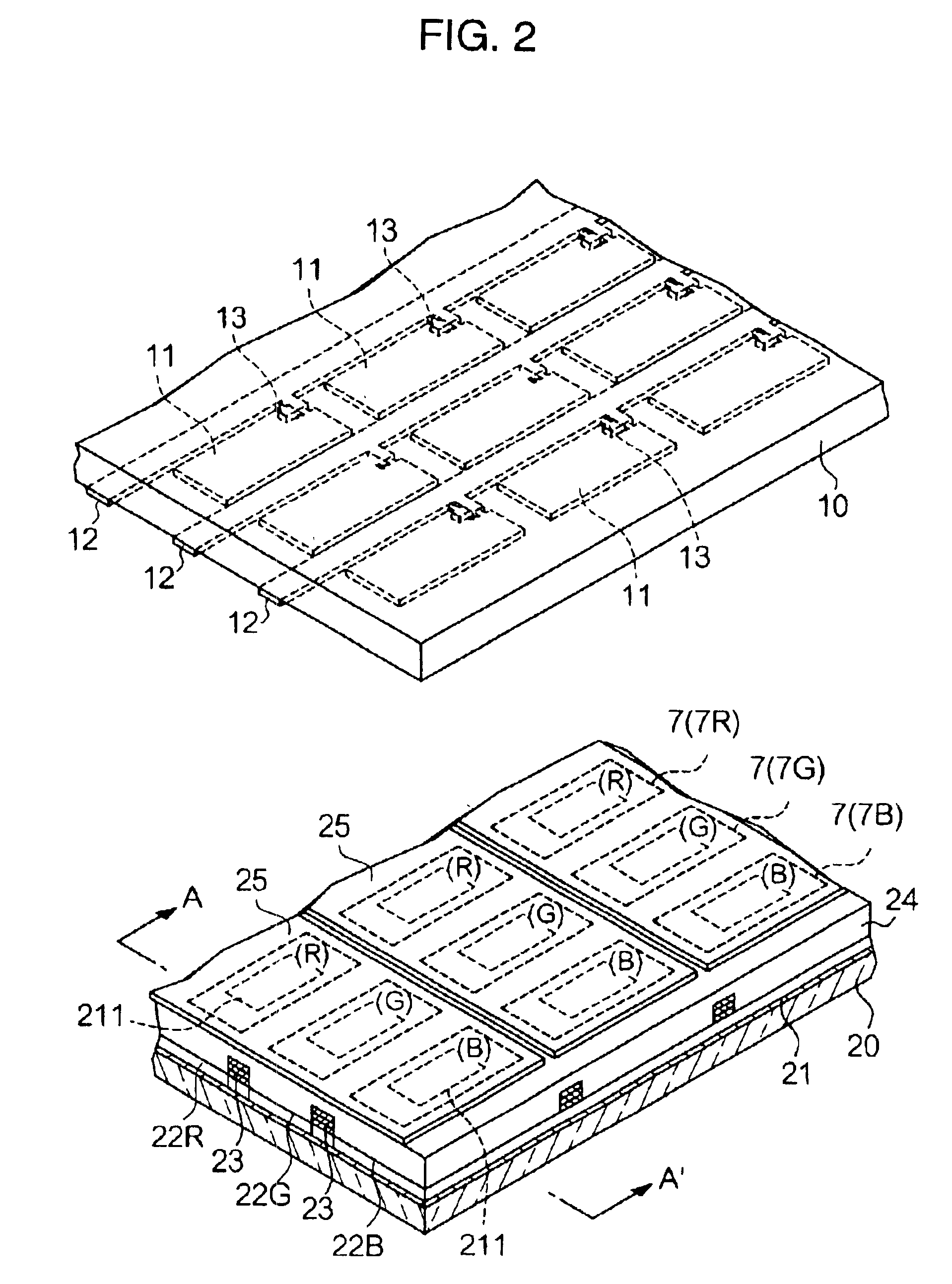

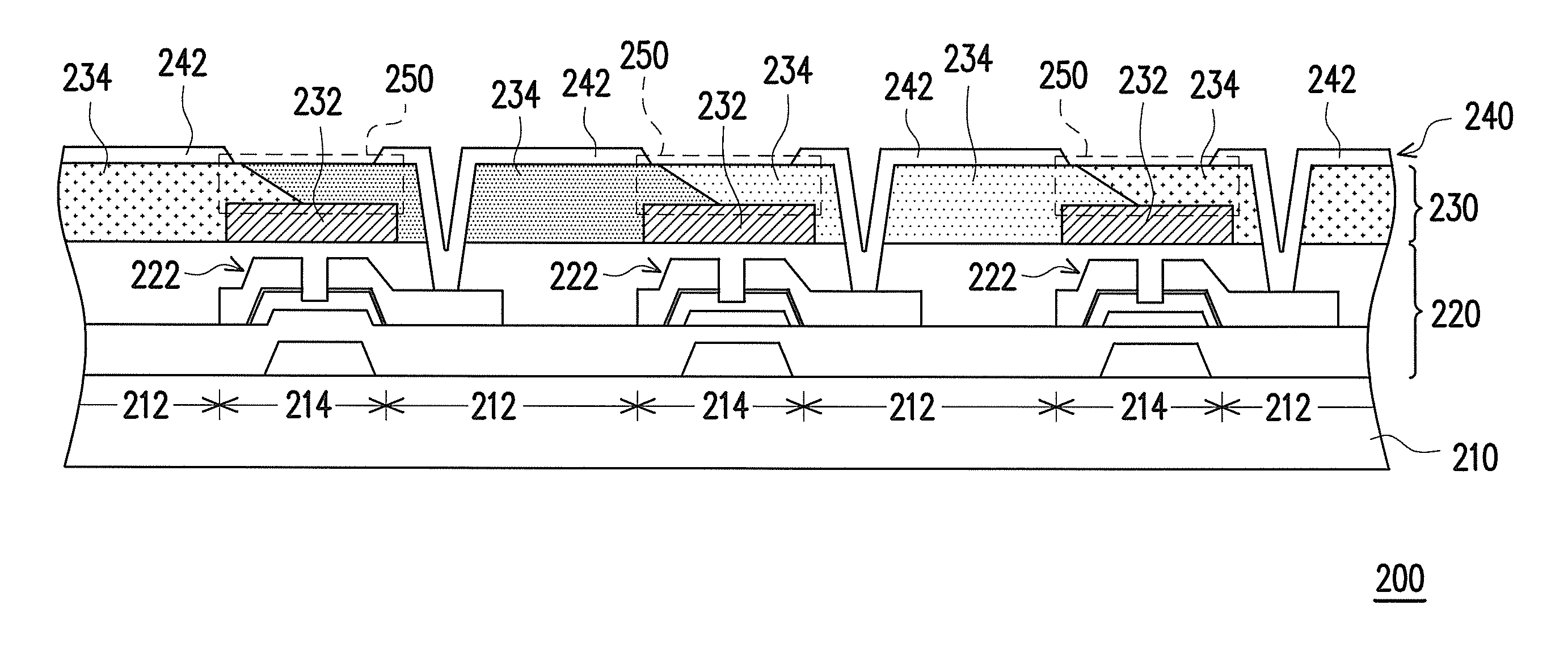

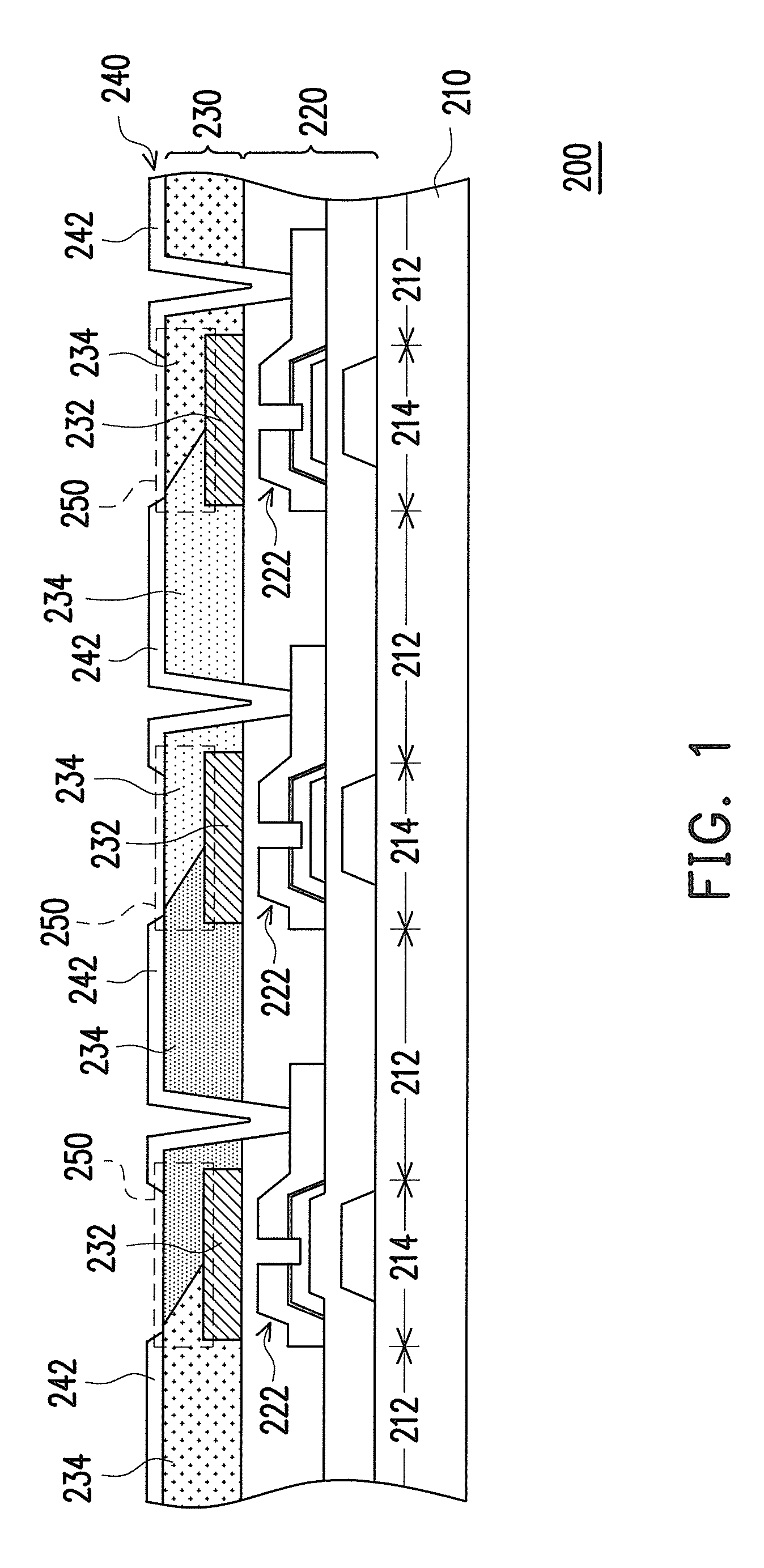

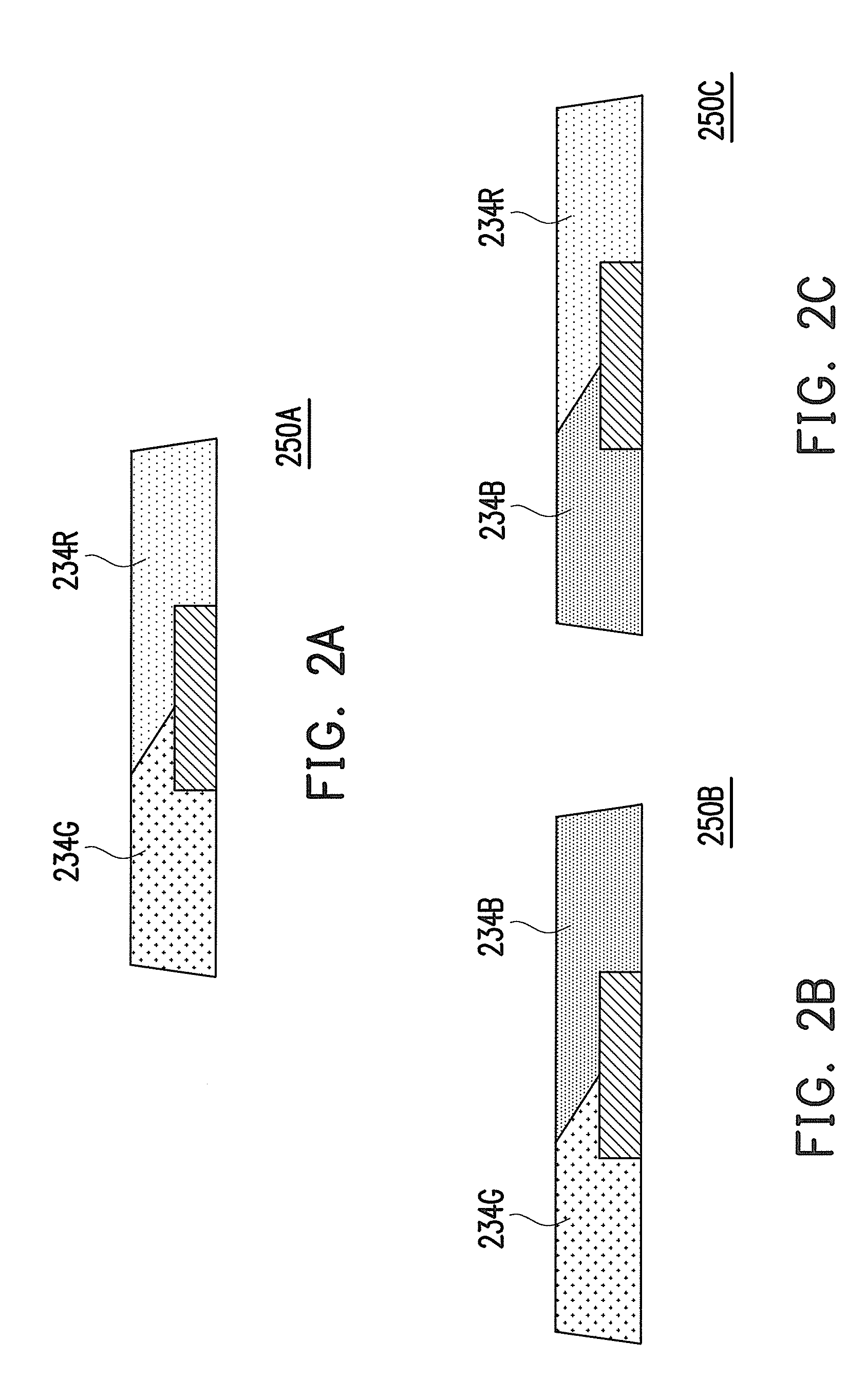

Color filter array on pixel array substrate and display panel

ActiveUS20110001909A1Improve production yieldReduce manufacturing costNon-linear opticsColor filter arrayPixel array

A color filter array on pixel array substrate including a substrate, an active device array, a color filter array and a pixel electrode layer is provided. The substrate has a plurality of pixel regions and a light-shielding region. The active device array is disposed on the substrate. The color filter array is disposed on the substrate, and includes a light shielding patterned layer and a plurality of color filter patterns, wherein the light-shielding patterned layer is disposed in the light-shielding region. The color filter patterns are respectively disposed in the pixel regions and extend from the pixel regions into the light shielding regions, wherein the color filter patterns extending from adjacent pixel regions constitute a stacked structure within the light shielding regions. The pixel electrode layer is electrically connected to the active device array.

Owner:AU OPTRONICS CORP

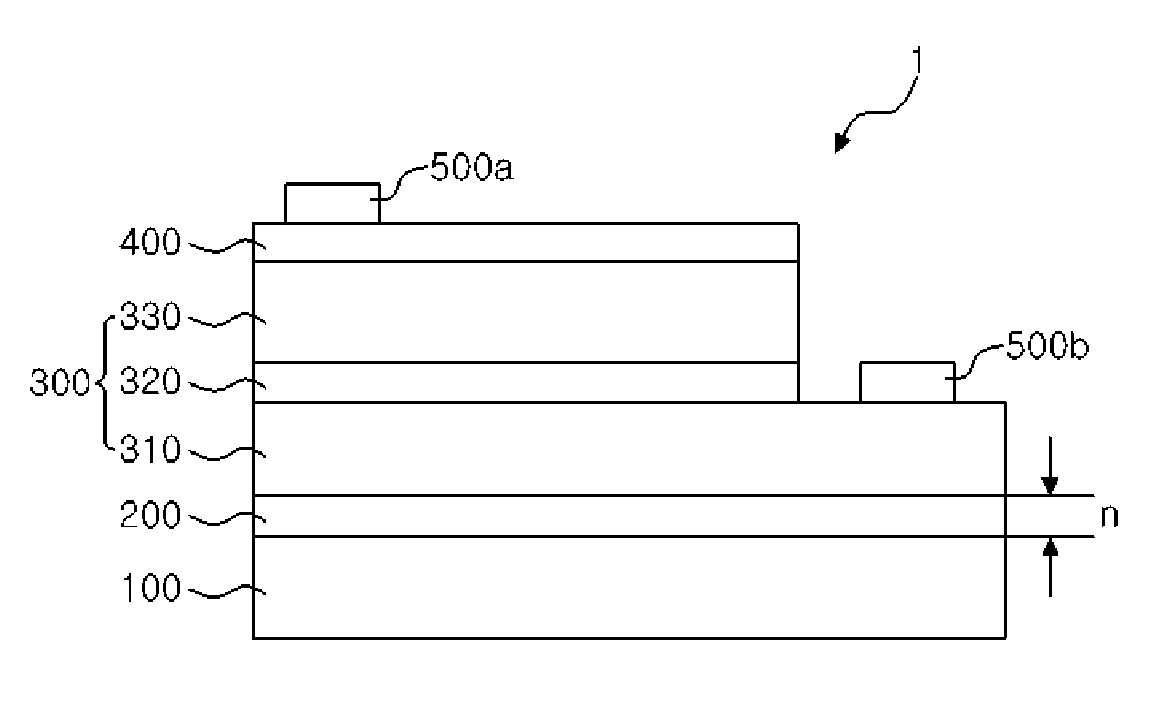

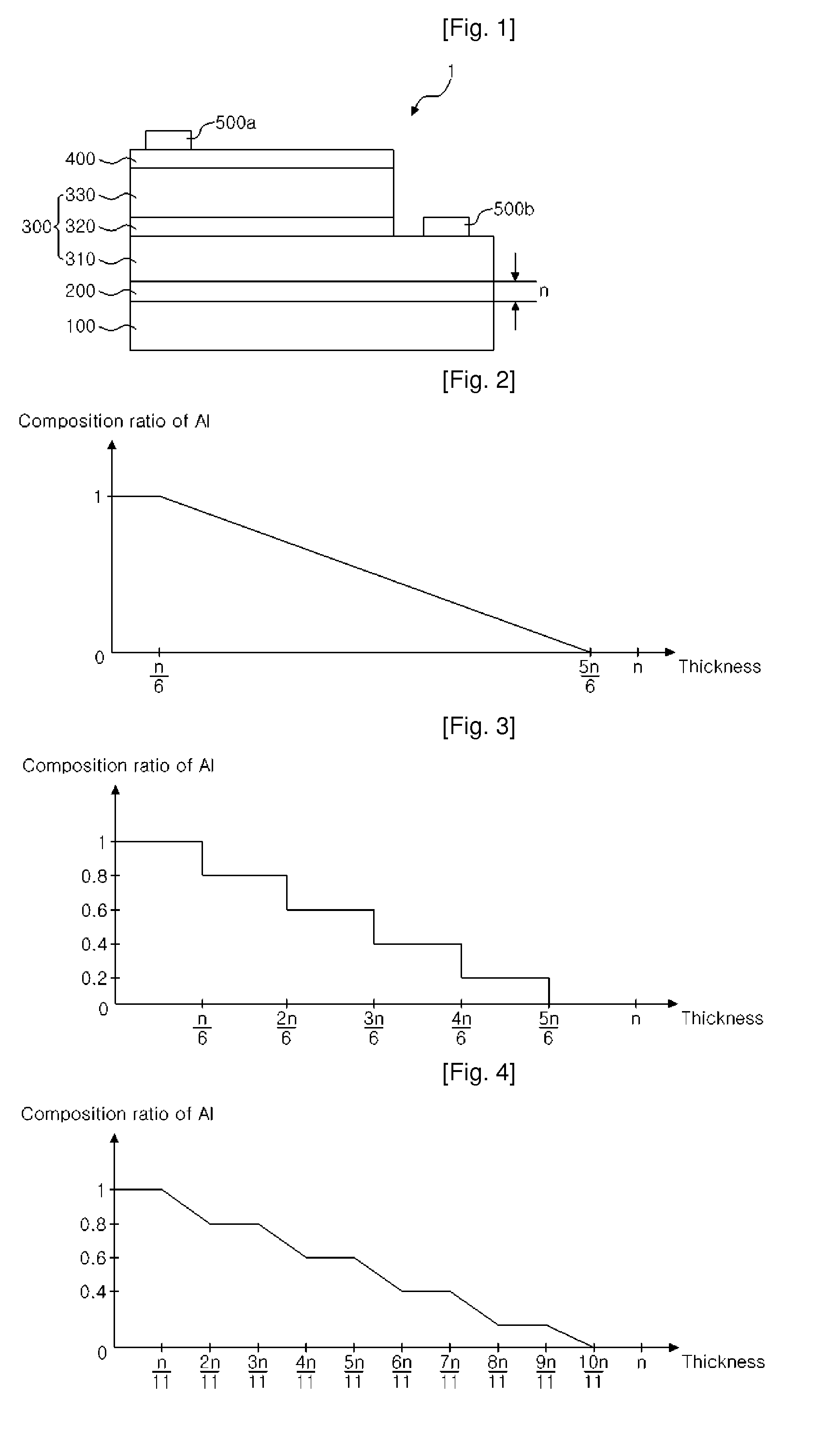

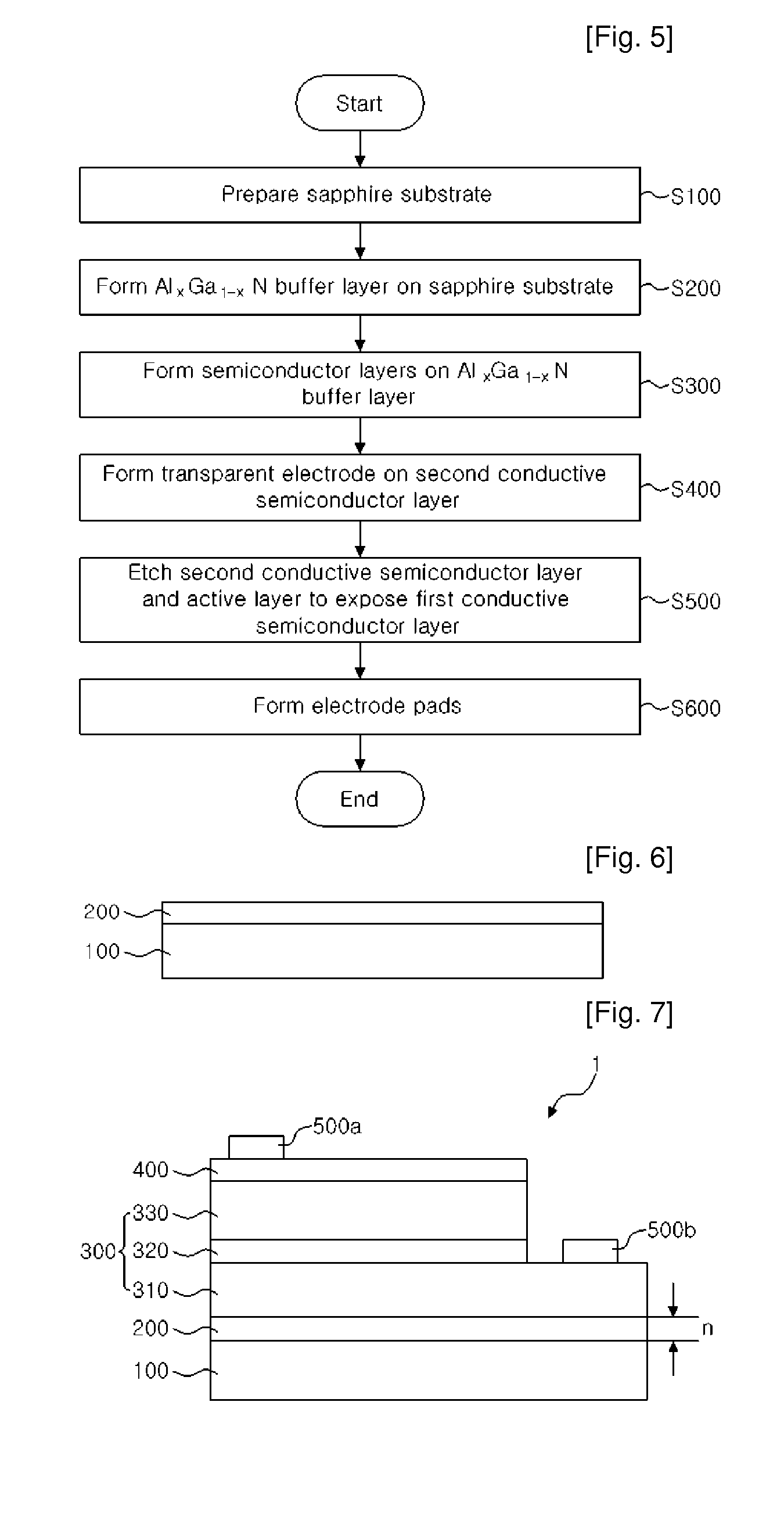

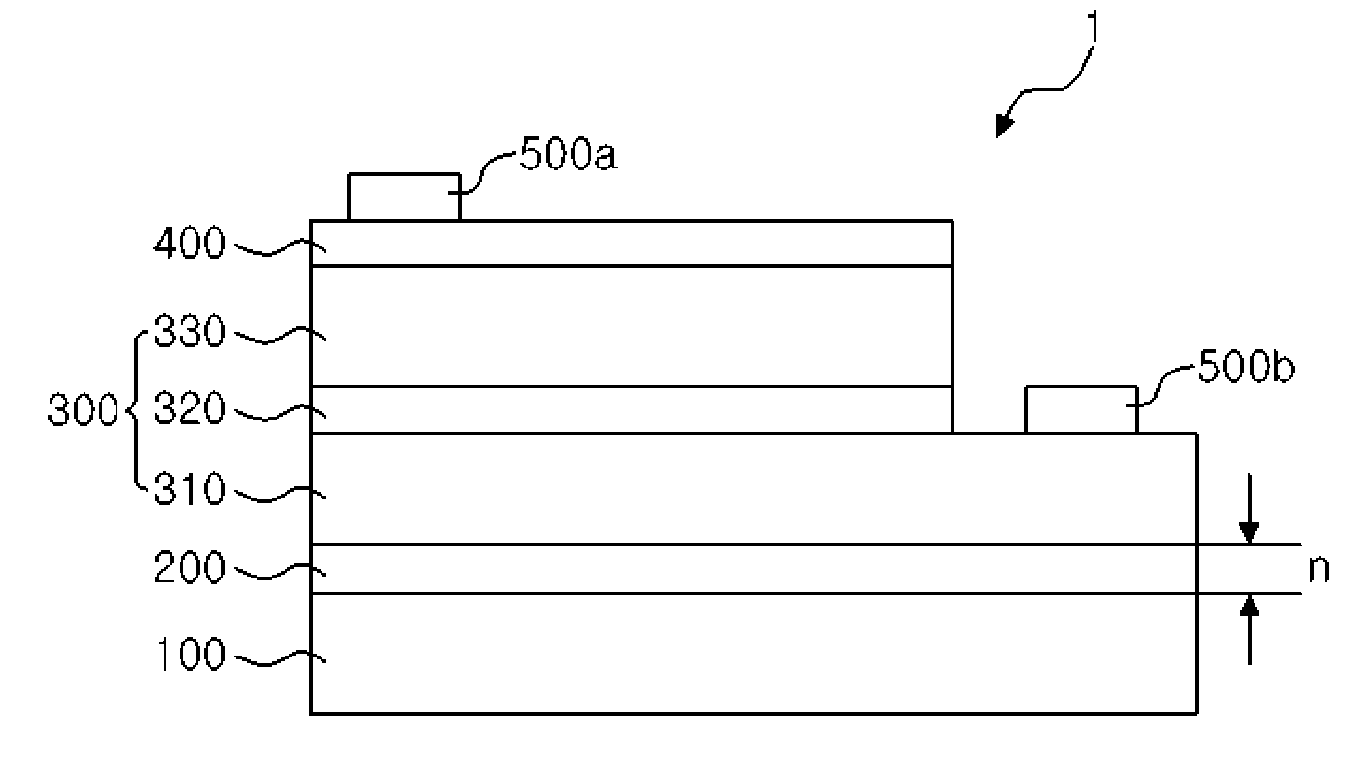

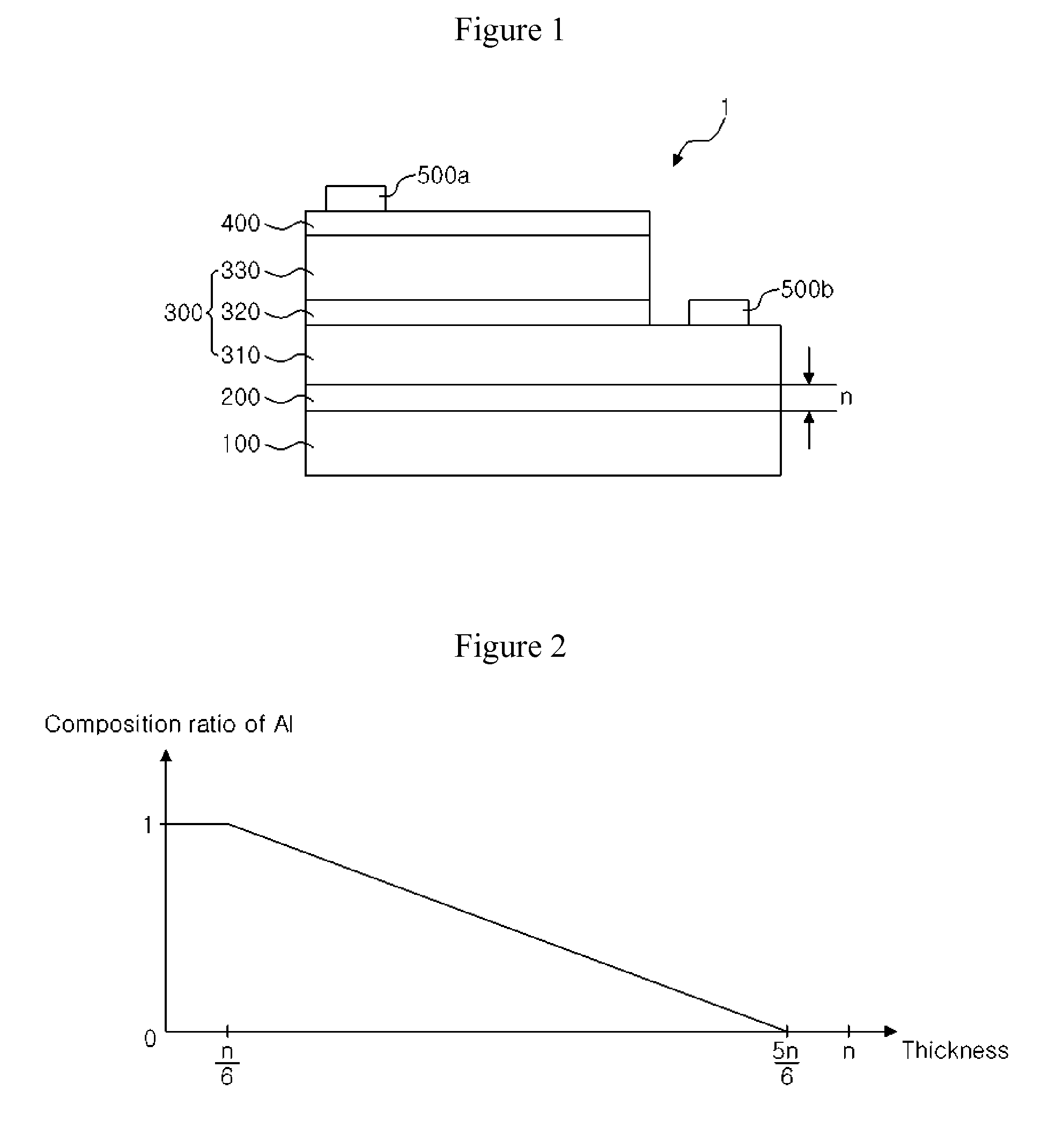

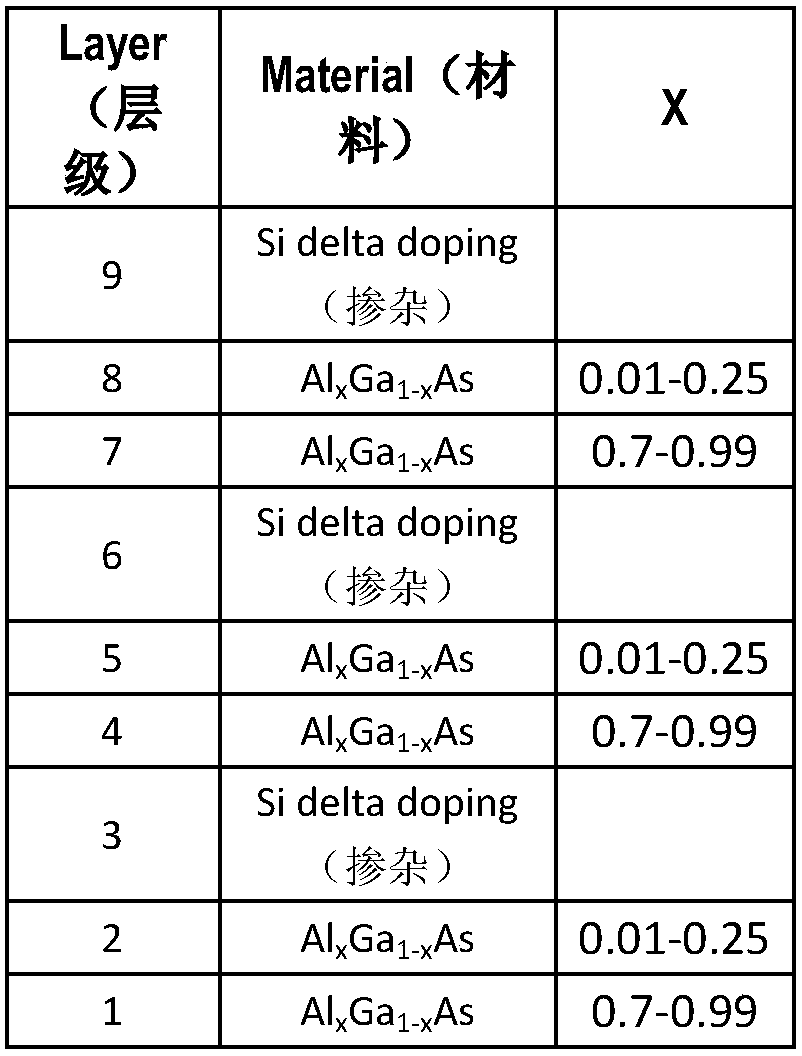

Light emitting diode having algan buffer layer and method of fabricating the same

ActiveUS20090032833A1Reduce optical densityReducing latticeAcoustic signal devicesSemiconductor/solid-state device manufacturingLattice mismatchLight-emitting diode

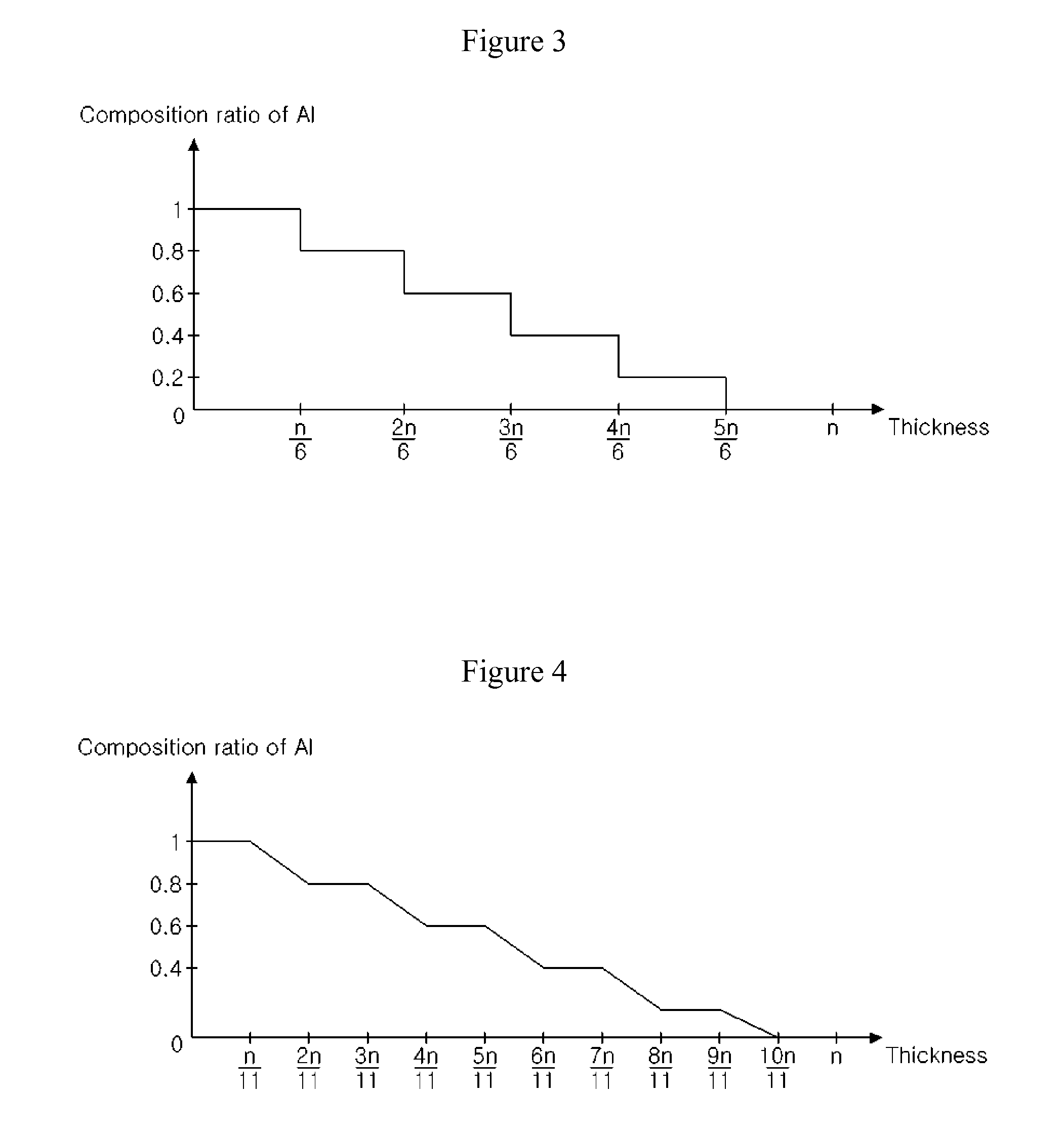

The present invention relates to a light emitting diode having an AlxGa1-xN buffer layer and a method of fabricating the same, and more particularly, to a light emitting diode having an AlxGa1-xN buffer layer, wherein between a substrate and a GaN-based semiconductor layer, the Al x Ga 1-x N (O≦x≦1) buffer layer having the composition ratio x of Al decreasing from the substrate to the GaN-based semiconductor layer is interposed to reduce lattice mismatch between the substrate and the GaN-based semiconductor layer, and a method of fabricating the same. To this end, the present invention provides a light emitting diode comprising a substrate; a first conductive semiconductor layer positioned on the substrate; and an AlxGa1-xN (O≦x≦1) buffer layer interposed between the substrate and the first conductive semiconductor layer and having a composition ratio x of Al decreasing from the substrate to the first conductive semiconductor layer.

Owner:SEOUL VIOSYS CO LTD

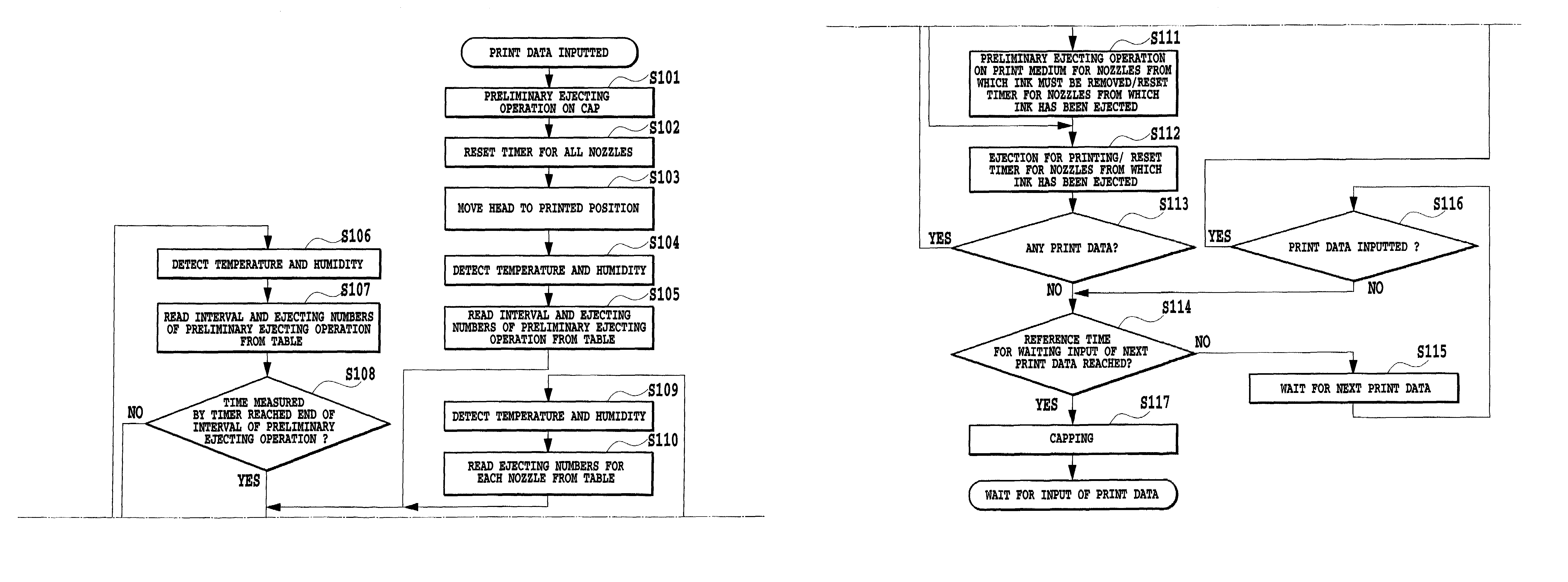

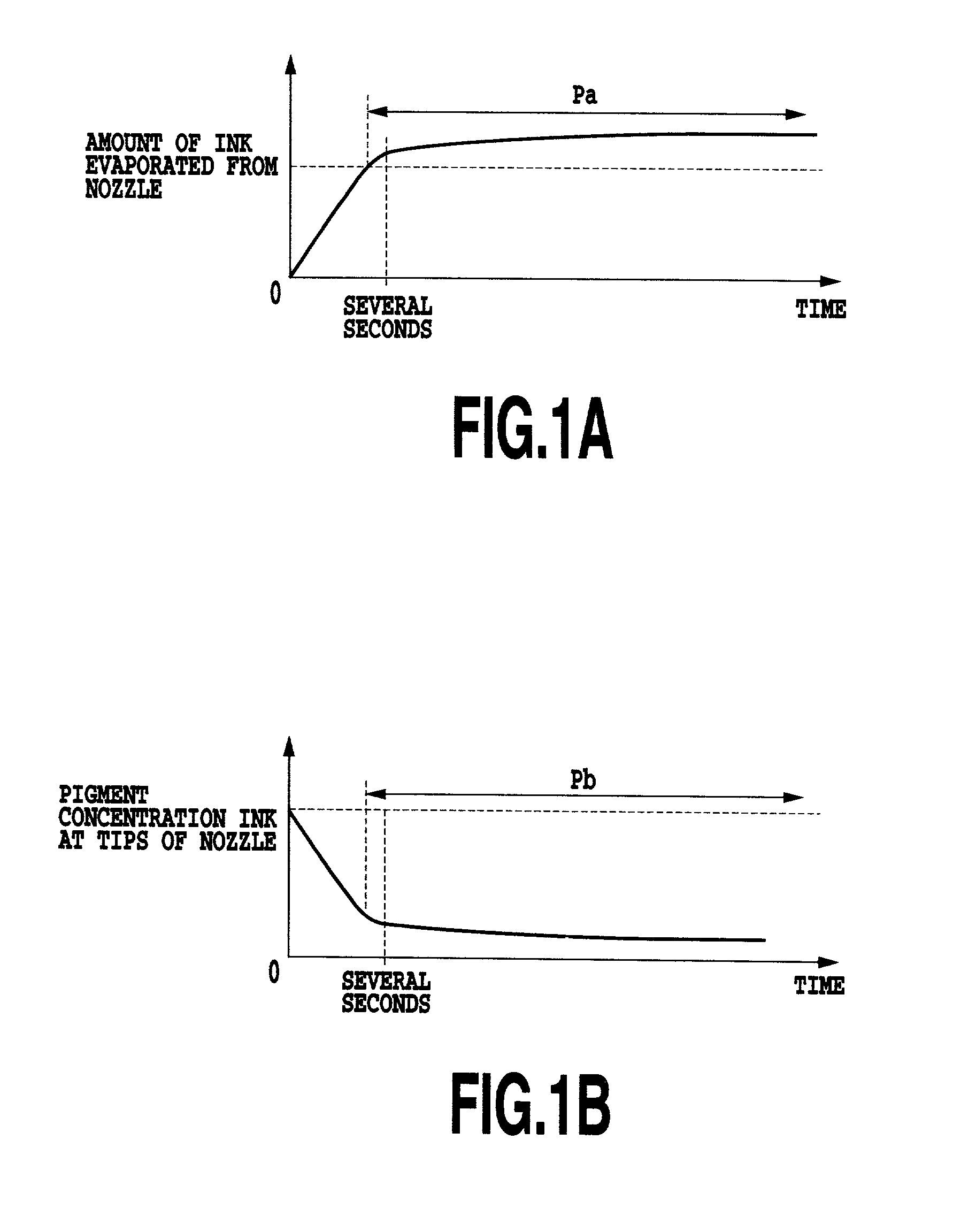

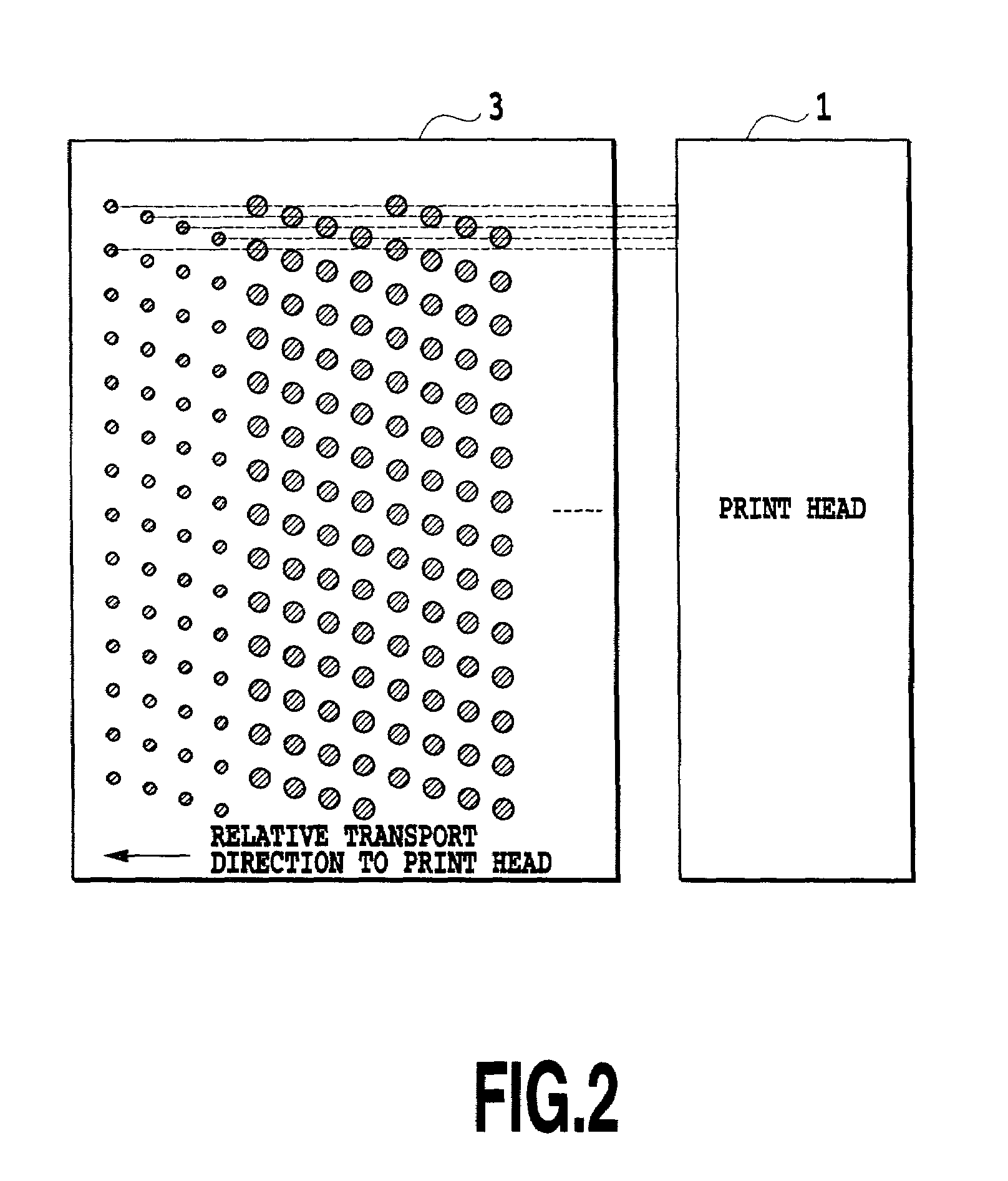

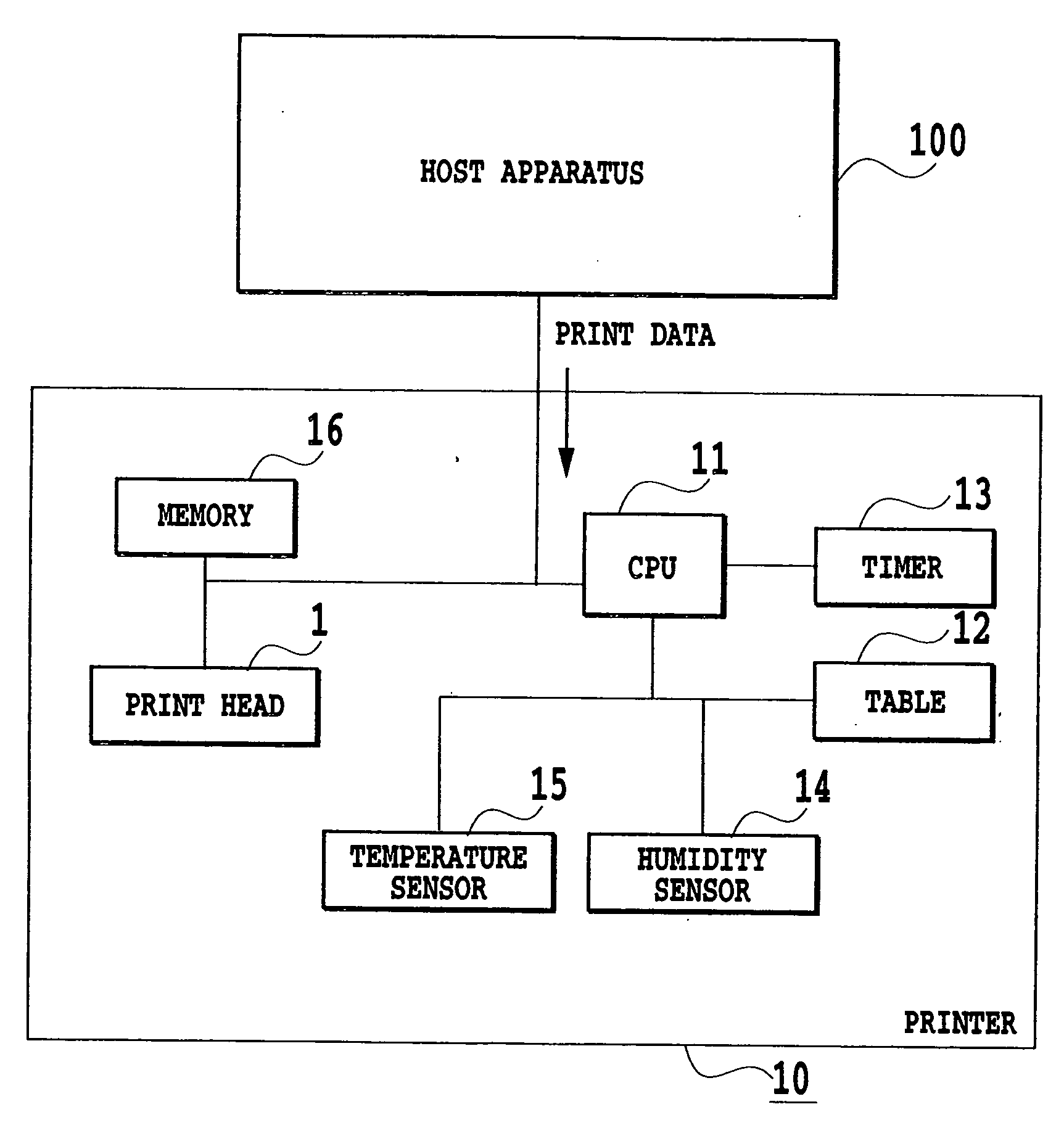

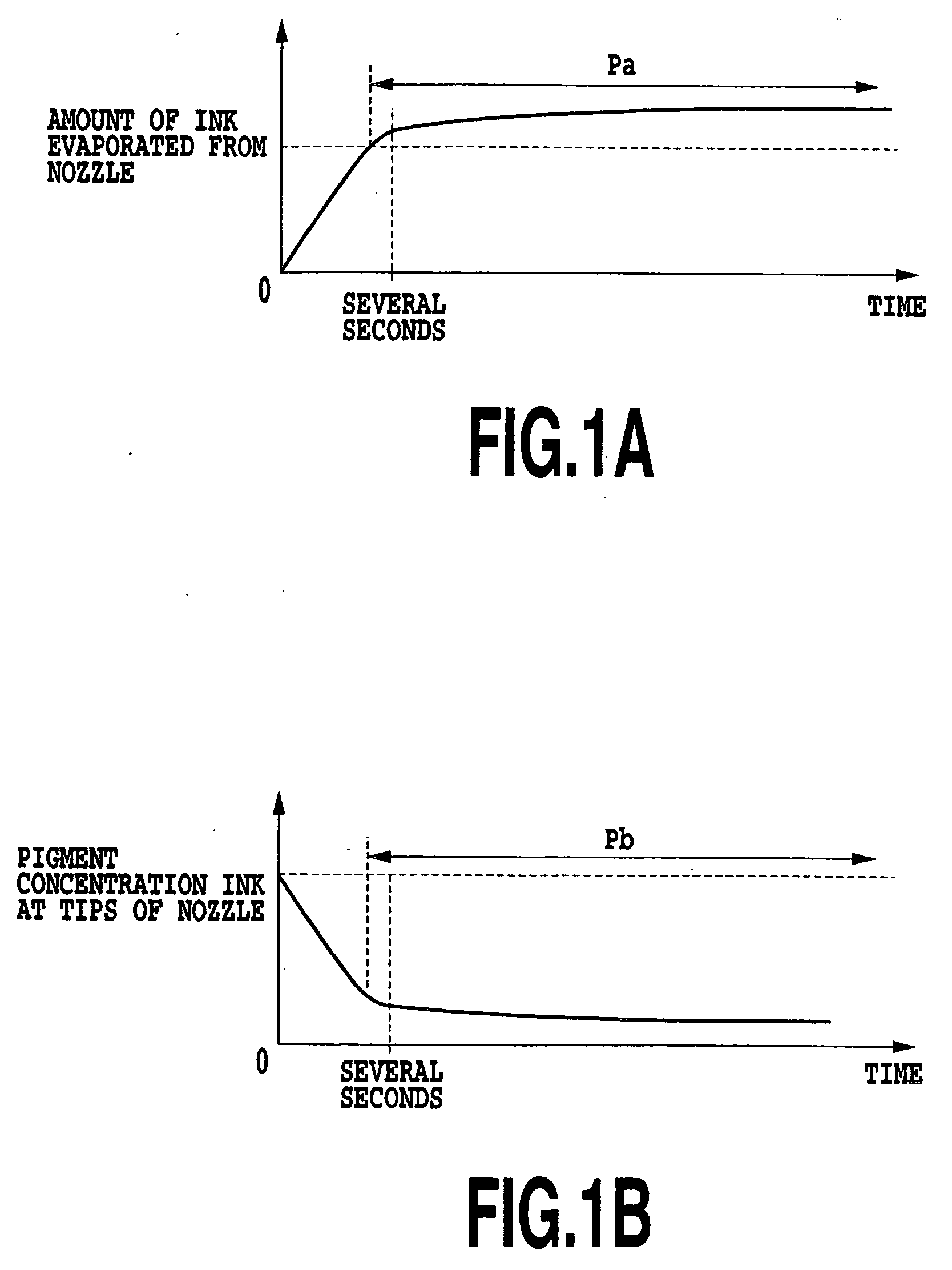

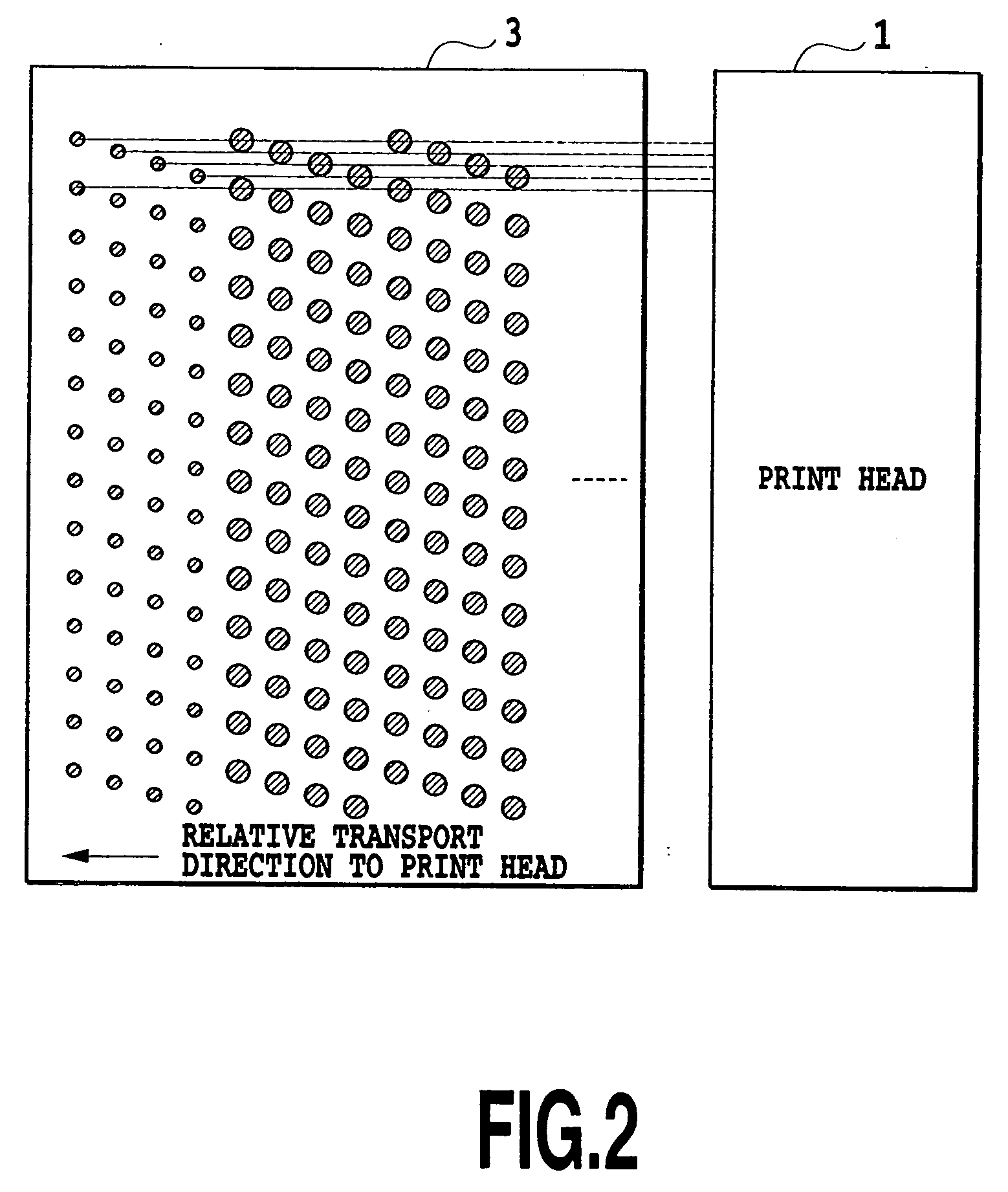

Ink jet printing apparatus and preliminary ejecting method

The present invention provides an ink jet printing apparatus and a preliminary ejecting method. In both a full-line and a serial printer, the amount of ink passing through nozzles of print heads is sometimes decreased below a normal value before and during actual printing, In the printer of present invention, a preliminary ejecting operation is performed taking the opportunity in which the amount of ink passing through nozzles is decreased below a normal value. Then, the amount of ink passing through nozzles recovers to the normal value at an ink ejection after the preliminary ejecting operation. Since only a small amount of ink is ejected through the nozzles during the preliminary ejection operation, dots formed on a print sheet are not noticeable. Further, it is unnecessary to move the print heads to a home position where an ejection recovering process is executed to remove ink having an increase viscosity.

Owner:CANON KK

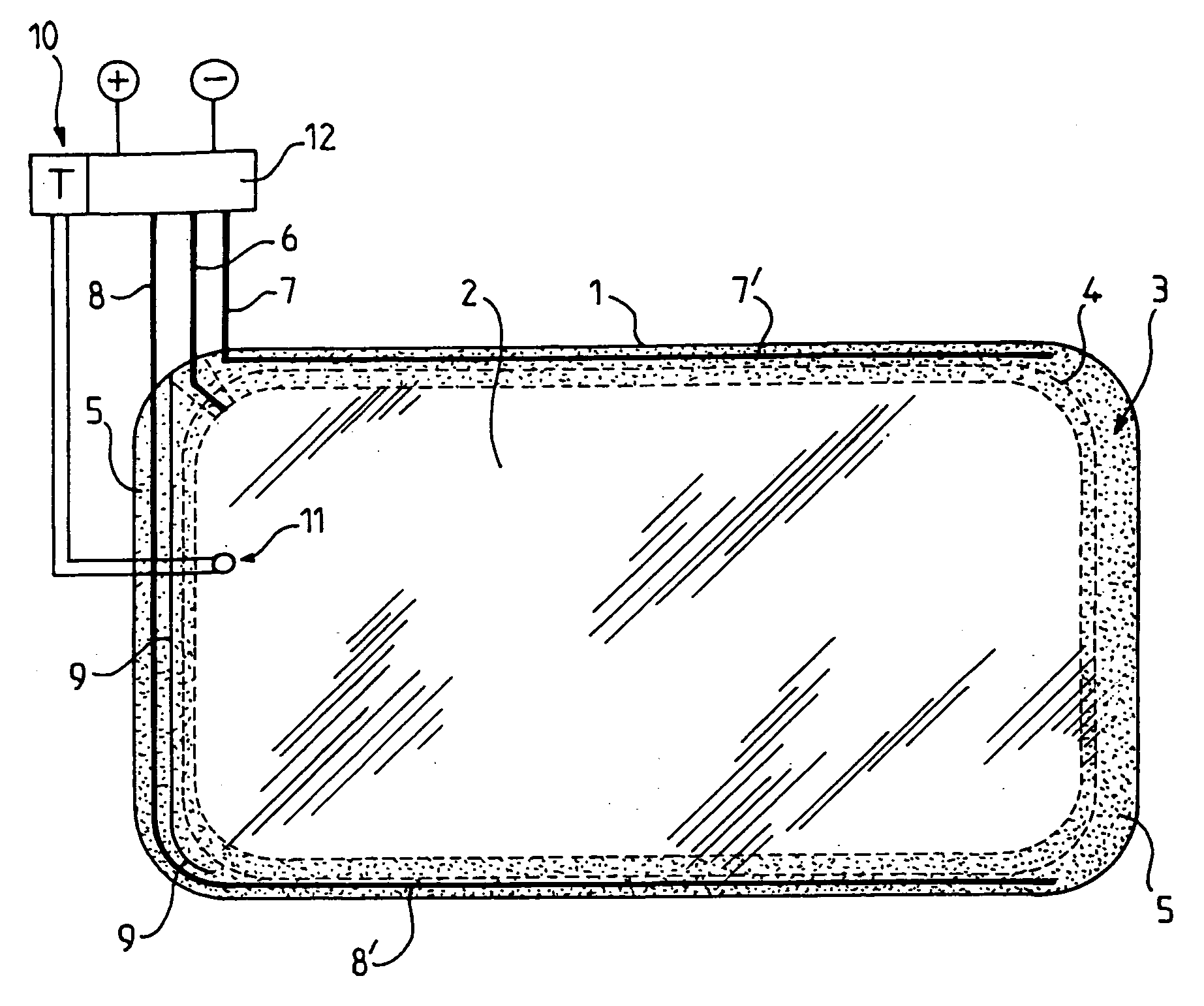

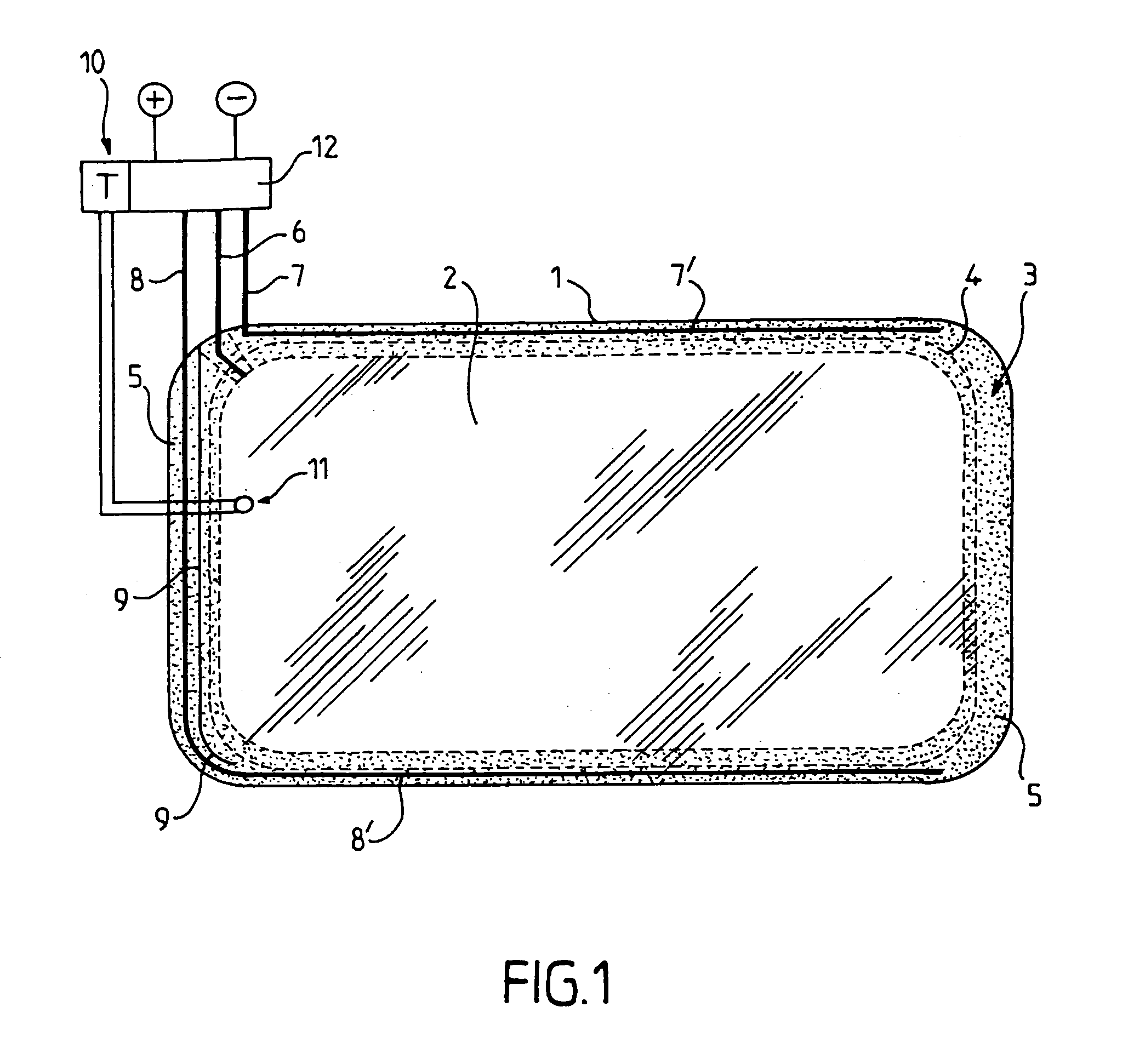

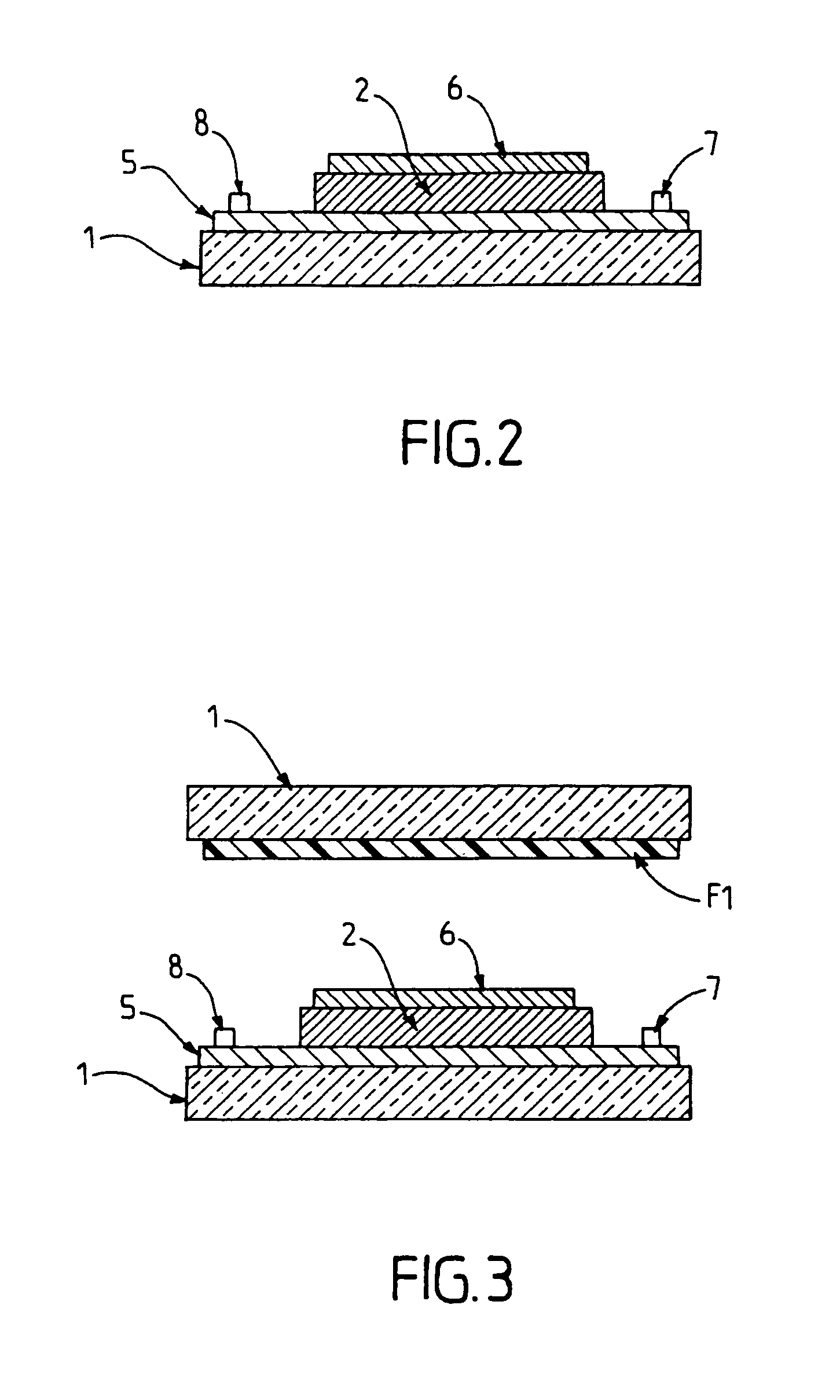

Laminated glass plane with electrically controlled functional element

InactiveUS7009156B2Significant positive effectGood colorVehicle interior lightingElectroluminescent light sourcesOptical propertyConductive coating

The invention concerns a laminated glass pane (1) with at least a rigid pane and a flat electrically controlled functional element (2) as well as at least a thin electrically conductive coat (5), wherein, in accordance with the invention, the coat (5) also constitutes a flat electrode of the functional element, the coat being capable of being heated by being powered with an electric voltage, independently of the power supply of the functional element (2). Thus, unwanted variations of the optical properties of the functional elements are reduced when such a laminated glass pane is used at highly fluctuating temperatures, in particular at low temperatures.

Owner:SAINT-GOBAIN GLASS FRANCE

Plasma treatment of porous inkjet receivers

InactiveUS20050123696A1Small spreadReduce optical densityCoatingsThermographyRecord elementMaterials science

An inkjet recording element comprising a porous ink-receiving layer having interconnecting voids is disclosed in which an upper surface of the ink-receiving layer has been subjected to plasma treatment, and wherein the upper surface of the ink-receiving layer, prior to the plasma treatment, has a measured carbon elemental content of at least 40 percent. The invention can provide increased dot spread.

Owner:EASTMAN KODAK CO

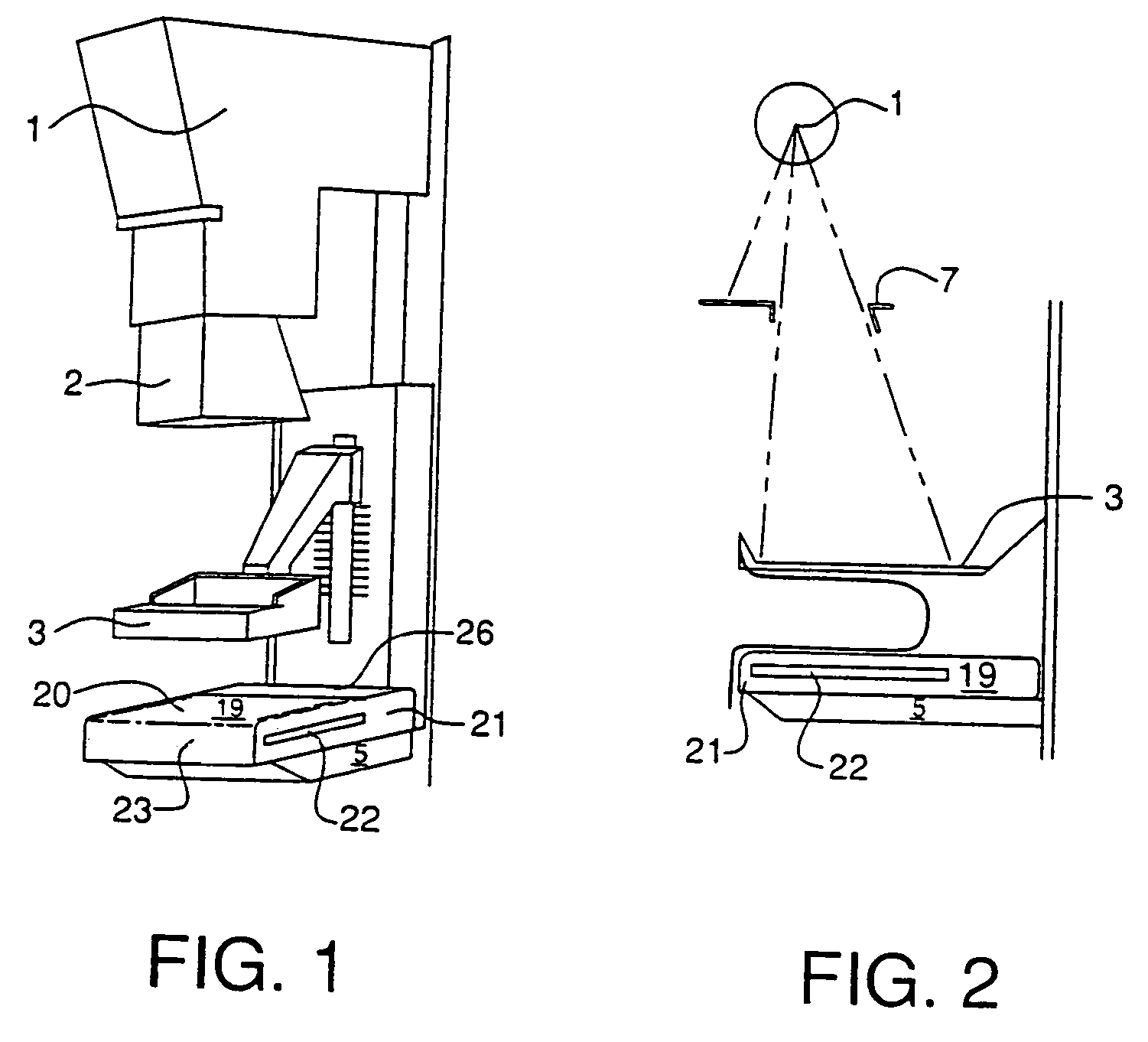

Mammography cushioning devices and methods

InactiveUS7142631B2Less discomfortReducing patient discomfortPatient positioning for diagnosticsMammographyPatient comfortBiomedical engineering

A mammography comfort device comprises a compressible bolster and a separate x-ray transparent compressible pad. The bolster, affixed to the sides of a bucky, retains the pad on the imaging surface. A radiopaque identifier permanently affixed to the pad imparts information about the pad onto a mammogram. The comfort device can be used with an x-ray transparent disposable cover. A kit comprising at least two disposable covers and a comfort device can be supplied. A separate stretchable retainer holds a breast on the bucky and serves as an exposure equalizer. A compression paddle adapted with a bolster and a light transparent panel facilitates proper placement of a breast for compression. When the bolster comprises sections having different identification force deflection values the panel angles to the approximate shape of a compressed breast to distribute compression force more evenly. A vented panel provides for passage of warm air for patient comfort.

Owner:GALKIN BENJAMIN M

Light emitting device

ActiveCN1789795APrevent deteriorationPrevent heat generation and deteriorationLaser detailsMechanical apparatusPhysicsLight source

The present invention provides a light emitting device comprising: an excitation light source which radiates excitation light; a wavelength converting member which absorbs and converts the wavelength of at least part of the excitation light radiated from the excitation light source, and releases light with a predetermined wavelength band; a light guide for guiding the excitation light radiated from the excitation light source to the wavelength converting member, with one end at the excitation light source and the other end at the wavelength converting member, wherein the refractive index of the cross-sectional center region (core) is higher than that of the circumferential region (clad); and a thermally conductive transparent film which contacts with the wavelength converting member.

Owner:NICHIA CORP

Light transmission type image recognition device and image recognition sensor

InactiveUS20020126877A1Accurate contourReduce optical densityCharacter and pattern recognitionLight transmissionImage identification

A light transmission type image recognition device comprises a first transparent substrate having a plurality of transparent pixel electrodes formed in a two-dimensional array on its surface, a second transparent substrate having a transparent faced electrode formed on its surface, and a visual pigment similar protein oriented film layer and a transparent insulating layer which are arranged between both the electrodes.

Owner:SANYO ELECTRIC CO LTD

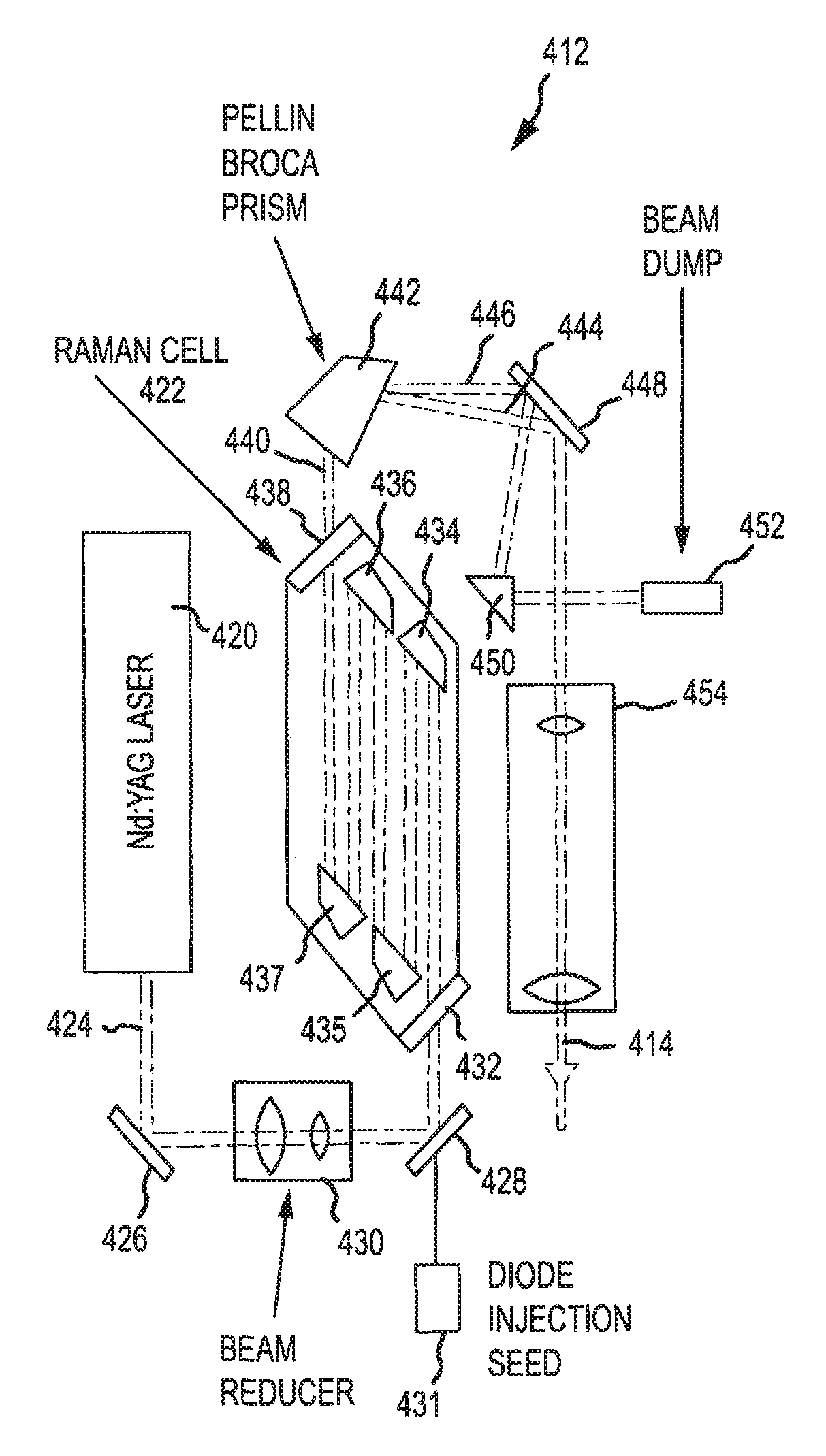

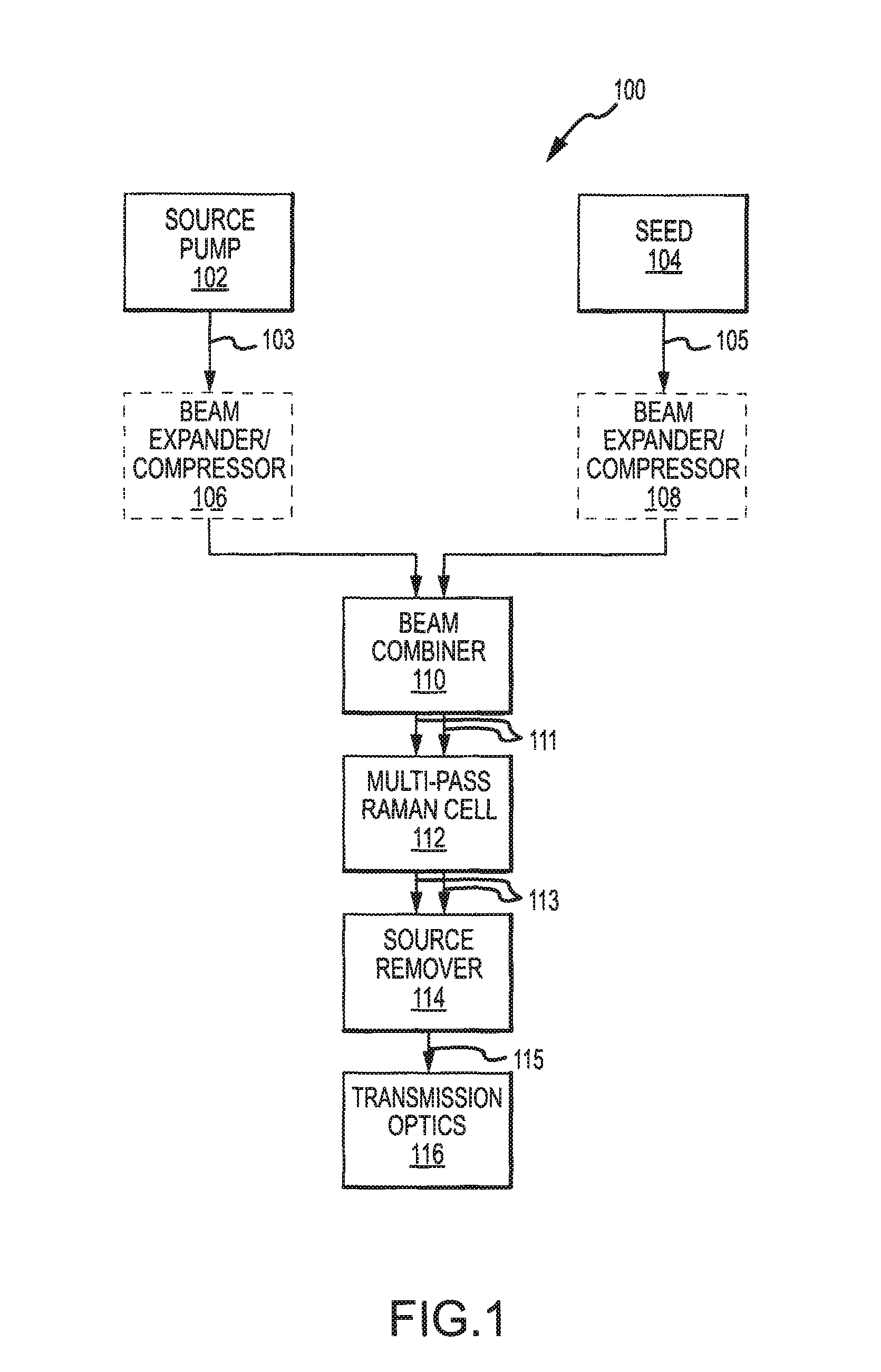

Raman cell for high power applications

ActiveUS7869469B1Improved medium circulationReduce and substantially avoid multiple illuminationLaser using scattering effectsLight demodulationCell culture mediaLight beam

A Raman shifter is provided with improved optical efficiency and robustness, particularly for high power applications. In one embodiment, a source system (100) includes a source pump laser (102) and a seed laser (104). Beams from the pump laser (102) and seed laser (104) combine for transmission into a Raman cell (112). Folding optics define a multi-pass pathway through the Raman cell (112). Such folding optics may include an internal reflectance element. An entry window into the Raman cell, an exit window from the Raman cell, and the internal reflectance elements include surfaces disposed at a Brewster angle relative to the incident beam. The Raman cell medium is circulated in a direction transverse to the beam pathways through the cell. In this manner, improved optical efficiency and robustness is achieved as well as improved performance over a significant wavelength band.

Owner:UNIV FOR ATMOSPHERIC RES

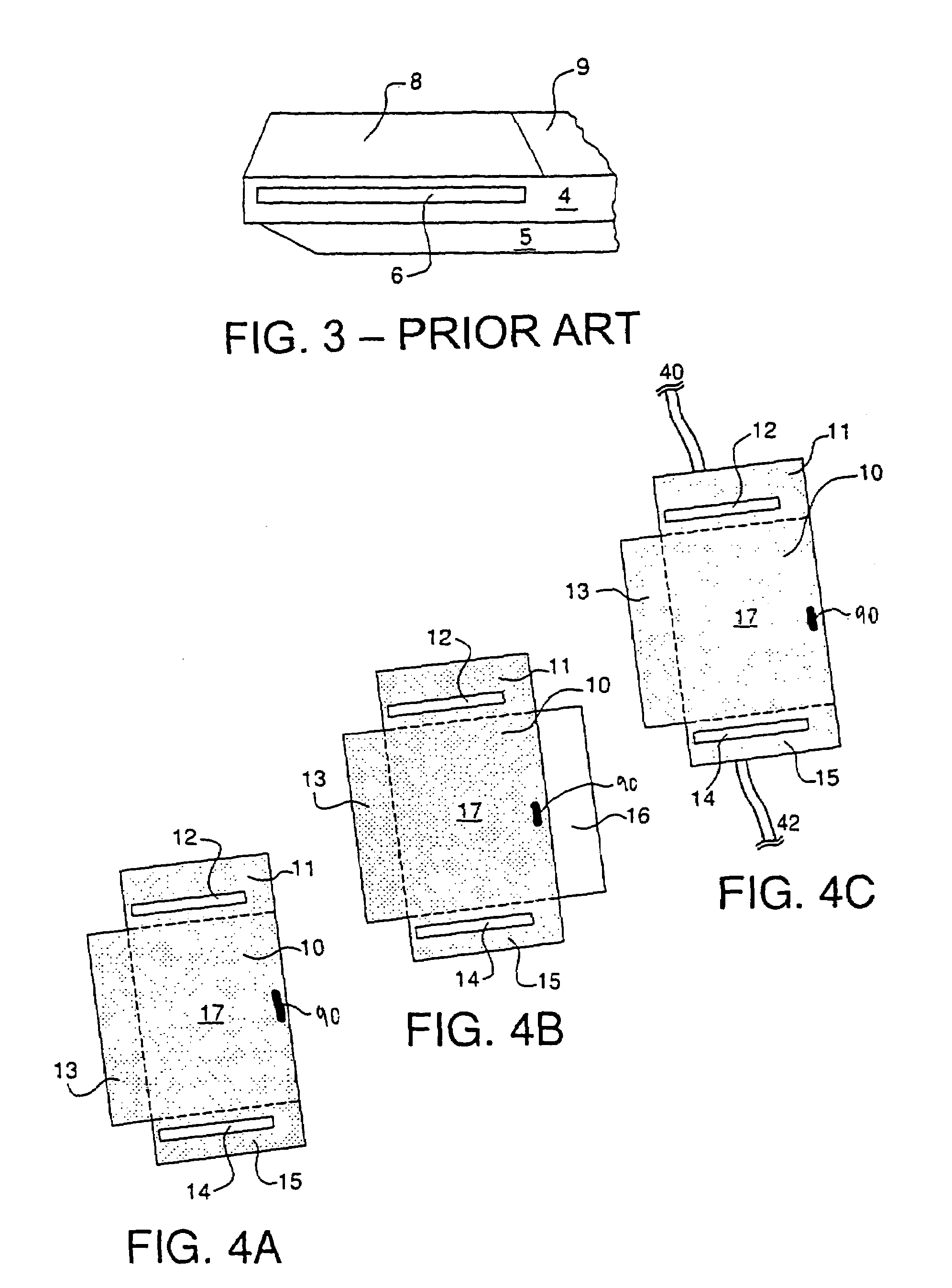

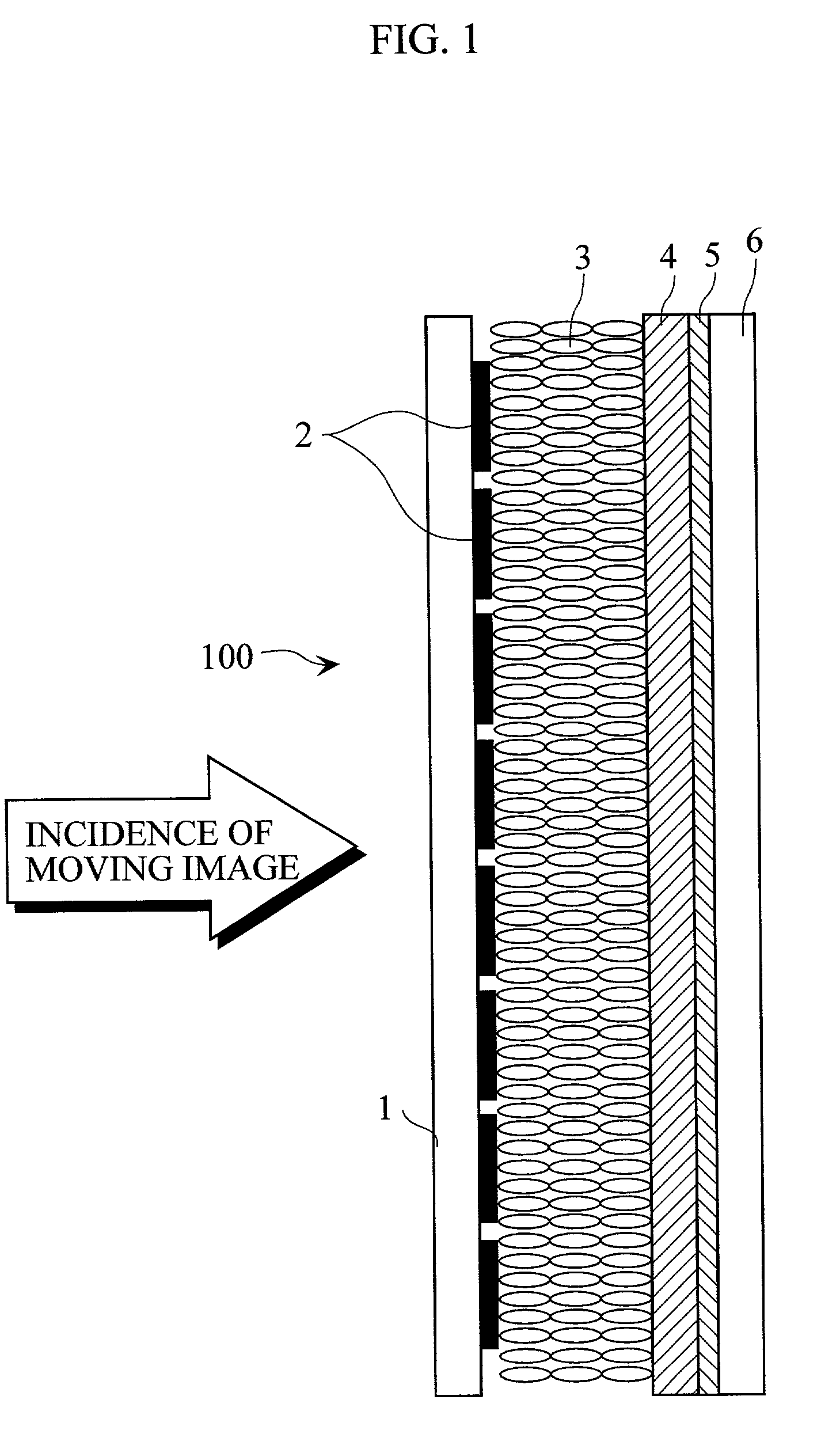

Replaceable, self-contained expanded viewing light shield cartridge for welding helmet

InactiveUS20020024739A1Increase viewable areaImprove viewing effectEye-masksNon-linear opticsProtecting eyeEngineering

An electronic quick change cartridge for a welding helmet. The cartridge base is formed of an optically dense polycarbonate or like material that acts as a passive filter to provide eye protection during the welding process. A port in the base receives a variable density LCD cell and a cavity formed in the base receives the electronics for driving the cell. Optical masks prevent light leakage through any interfaces of the structure. When low light levels are present, the welder views a work piece through an essentially transparent or slightly opaque LCD cell. When an arc is struck, the LCD cell darkens to a shade corresponding to the shade of the surrounding polycarbonate material. The welder then can view the work piece through the LCD cell and all the optically unobstructed portions of the polycarbonate base surrounding the LCD cell thereby to have an expanded viewing area during the actual welding operation.

Owner:WALTER SURFACE TECH

Ink jet printing apparatus and preliminary ejecting method

The present invention provides an ink jet printing apparatus and a preliminary ejecting method. In both a full-line and a serial printer, the amount of ink passing through nozzles of print heads is sometimes decreased below a normal value before and during actual printing. In the printer of present invention, a preliminary ejecting operation is performed taking the opportunity in which the amount of ink passing through nozzles is decreased below a normal value. Then, the amount of ink passing through nozzles recovers to the normal value at an ink ejection after the preliminary ejecting operation. Since only a small amount of ink is ejected through the nozzles during the preliminary ejection operation, dots formed on a print sheet are not noticeable. Further, it is unnecessary to move the print heads to a home position where an ejection recovering process is executed to remove ink having an increase viscosity.

Owner:CANON KK

Plasma treatment of porous inkjet receivers

InactiveUS7150901B2Little dot spreadReduce optical densityCoatingsThermographyRecord elementPlasma processing

An inkjet recording element comprising a porous ink-receiving layer having interconnecting voids is disclosed in which an upper surface of the ink-receiving layer has been subjected to plasma treatment, and wherein the upper surface of the ink-receiving layer, prior to the plasma treatment, has a measured carbon elemental content of at least 40 percent. The invention can provide increased dot spread.

Owner:EASTMAN KODAK CO

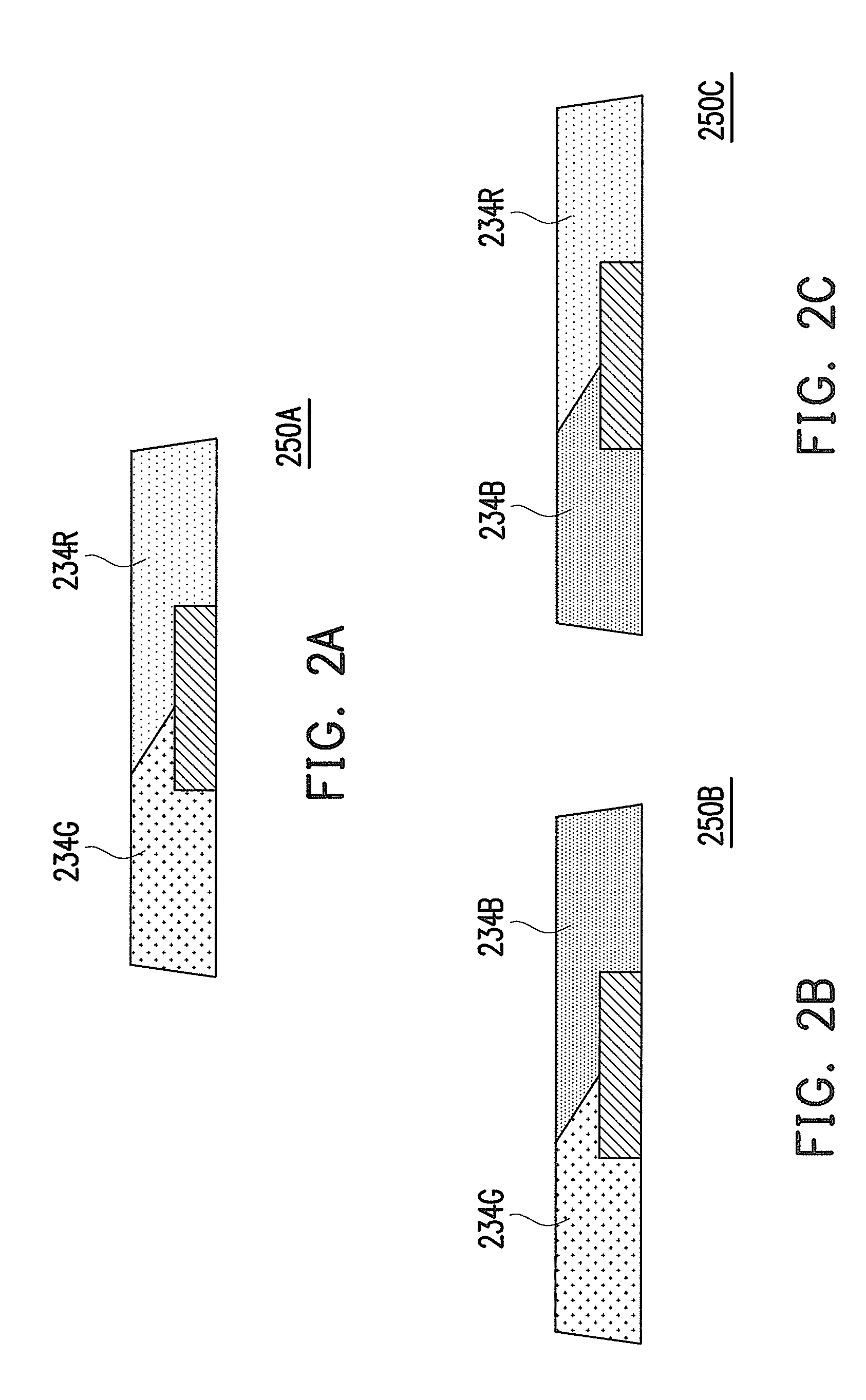

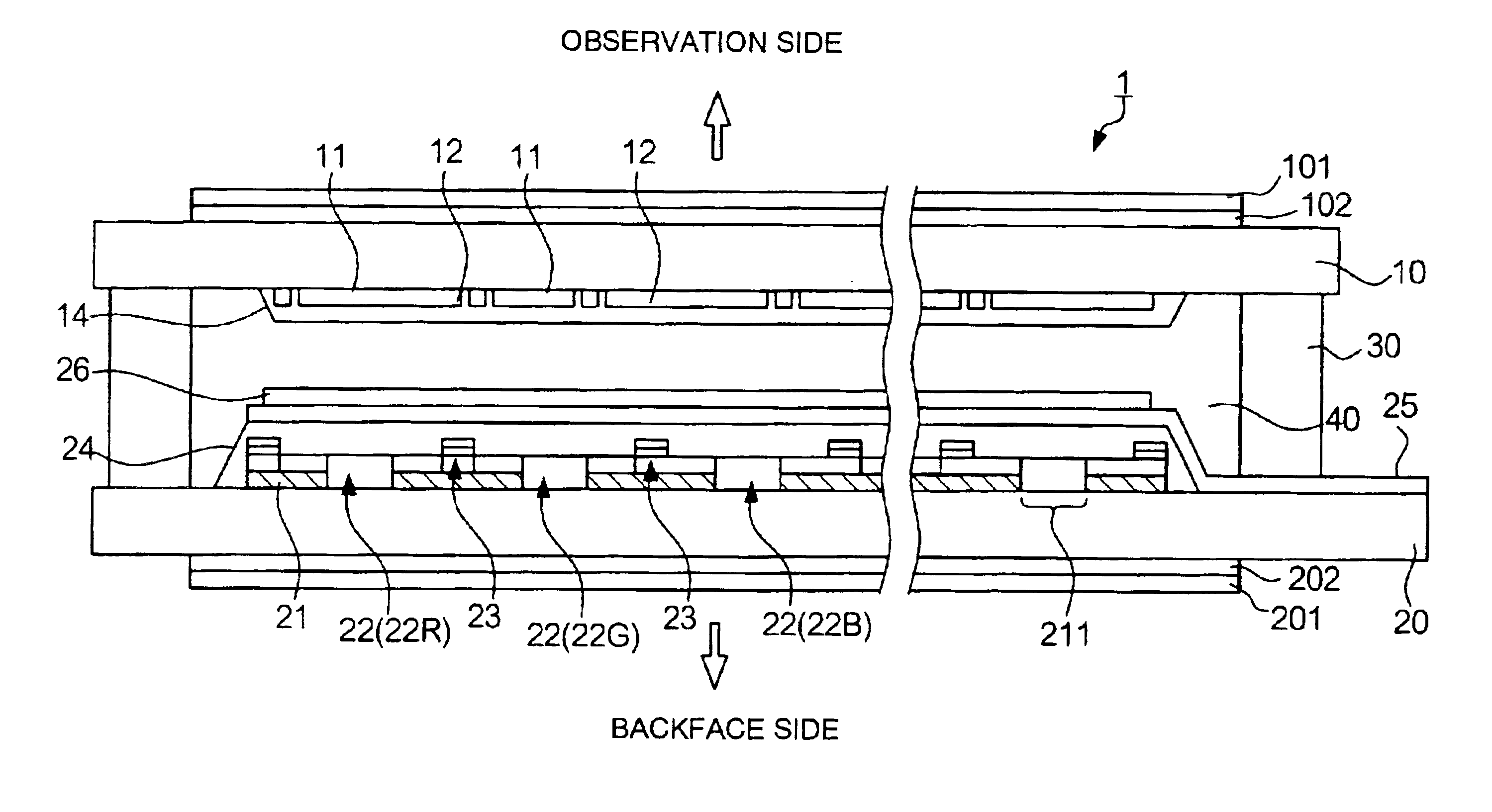

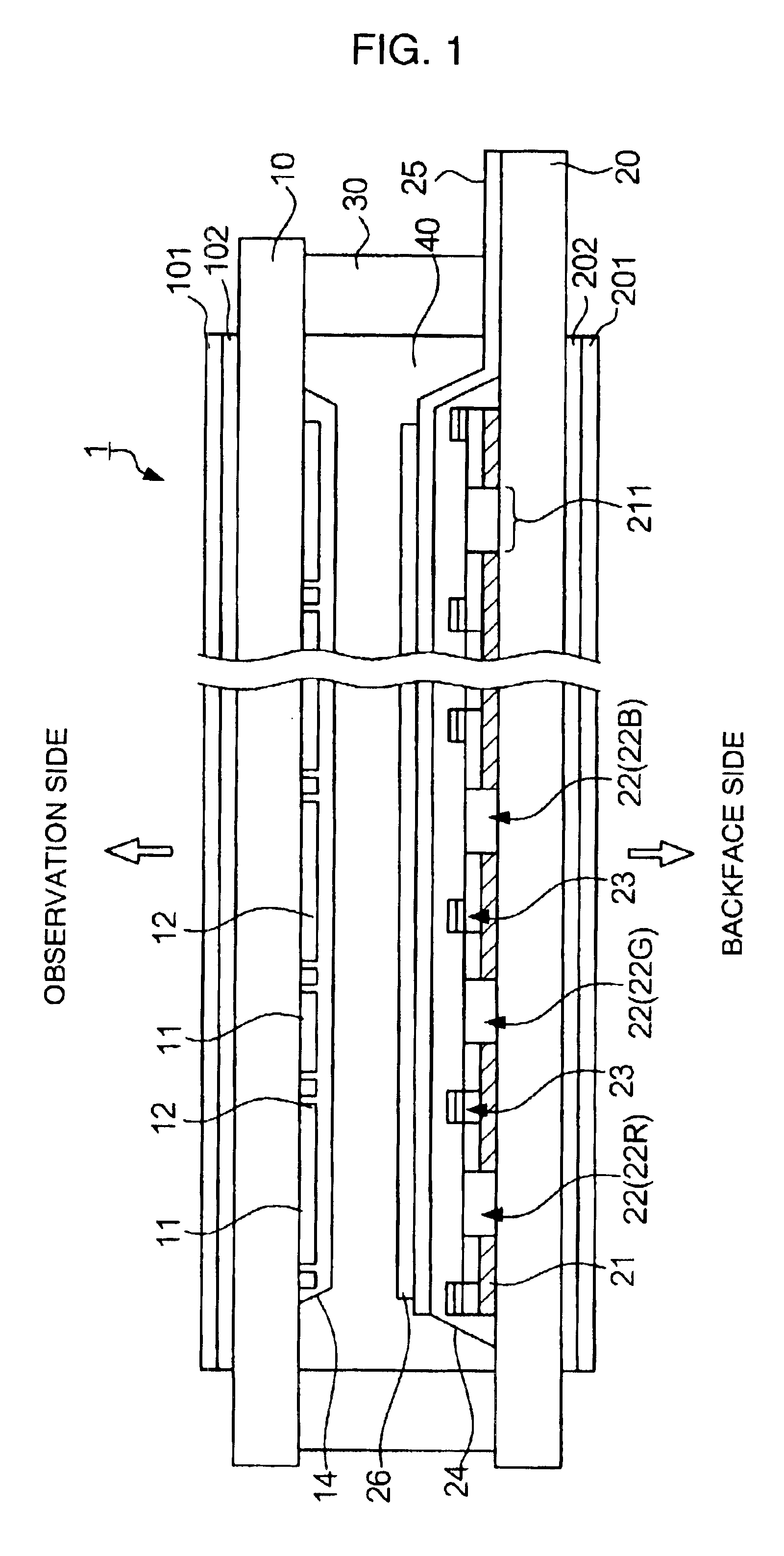

Color filter substrate, method for manufacturing the same, liquid crystal display panel, and electronic equipment

InactiveUS6954241B2Reduce optical densityHigh reflective brightnessMirrorsDiffusing elementsLiquid-crystal displayEngineering

Each color filter 22 includes a deep-color portion 221 being superimposed on a translucent portion 211 of a reflection layer 21 and a light-color portion 222 having an optical density lower than that of the deep-color portion 221. A light-shielding layer 23 for shielding the gaps between individual subpixels 7 from light is a laminate composed of at least a deep-color portion 221B of a blue color filter 22B, a deep-color portion 221R of a red color filter 22R, and a deep-color portion 221G of a green color filter 22G.

Owner:138 EAST LCD ADVANCEMENTS LTD

Recording fluid and recording method using the same

InactiveUS20070165086A1Excellent ejection stabilityHigh optical densityMeasurement apparatus componentsDuplicating/marking methodsPolymer scienceOrganic solvent

Disclosed is a recording liquid essentially composed of water, a coloring material, an organic solvent and a surfactant. The surfactant is composed of a specified ethylene oxide / propylene oxide / ethylene oxide block copolymer, a specified ethylene oxide / butylene oxide / ethylene oxide block copolymer or a specified propylene oxide / ethylene oxide / propylene oxide block copolymer. The recording liquid is superior in ejection stability and high in optical density even on multi-color recording letters / characters or images on an ordinary paper sheet so that it allows for high quality recording free of boundary bleeding or all-over color unevennesses otherwise caused by color mixing.

Owner:SONY CORP

Light emitting diode having algan buffer layer and method of fabricating the same

ActiveUS20100032650A1Reduce optical densityReducing latticeAcoustic signal devicesSemiconductor/solid-state device manufacturingLattice mismatchLight-emitting diode

The present invention relates to a light emitting diode having an AlxGa1-xN buffer layer and a method of fabricating the same, and more particularly, to a light emitting diode having an AlxGa1-xN buffer layer, wherein between a substrate and a GaN-based semiconductor layer, the AlxGa1-xN (0≦x≦1) buffer layer having the composition ratio x of Al decreasing from the substrate to the GaN-based semiconductor layer is interposed to reduce lattice mismatch between the substrate and the GaN-based semiconductor layer, and a method of fabricating the same. To this end, the present invention provides a light emitting diode comprising a substrate; a first conductive semiconductor layer positioned on the substrate; and an AlxGa1-xN (0≦x≦1) buffer layer interposed between the substrate and the first conductive semiconductor layer and having a composition ratio x of Al decreasing from the substrate to the first conductive semiconductor layer.

Owner:SEOUL VIOSYS CO LTD

Dot Gain And Color Linearization Dual Calibration

InactiveUS20070237534A1Improve stabilityIncrease sensitivityDevelopersElectrographic process apparatusLinearizationEngineering

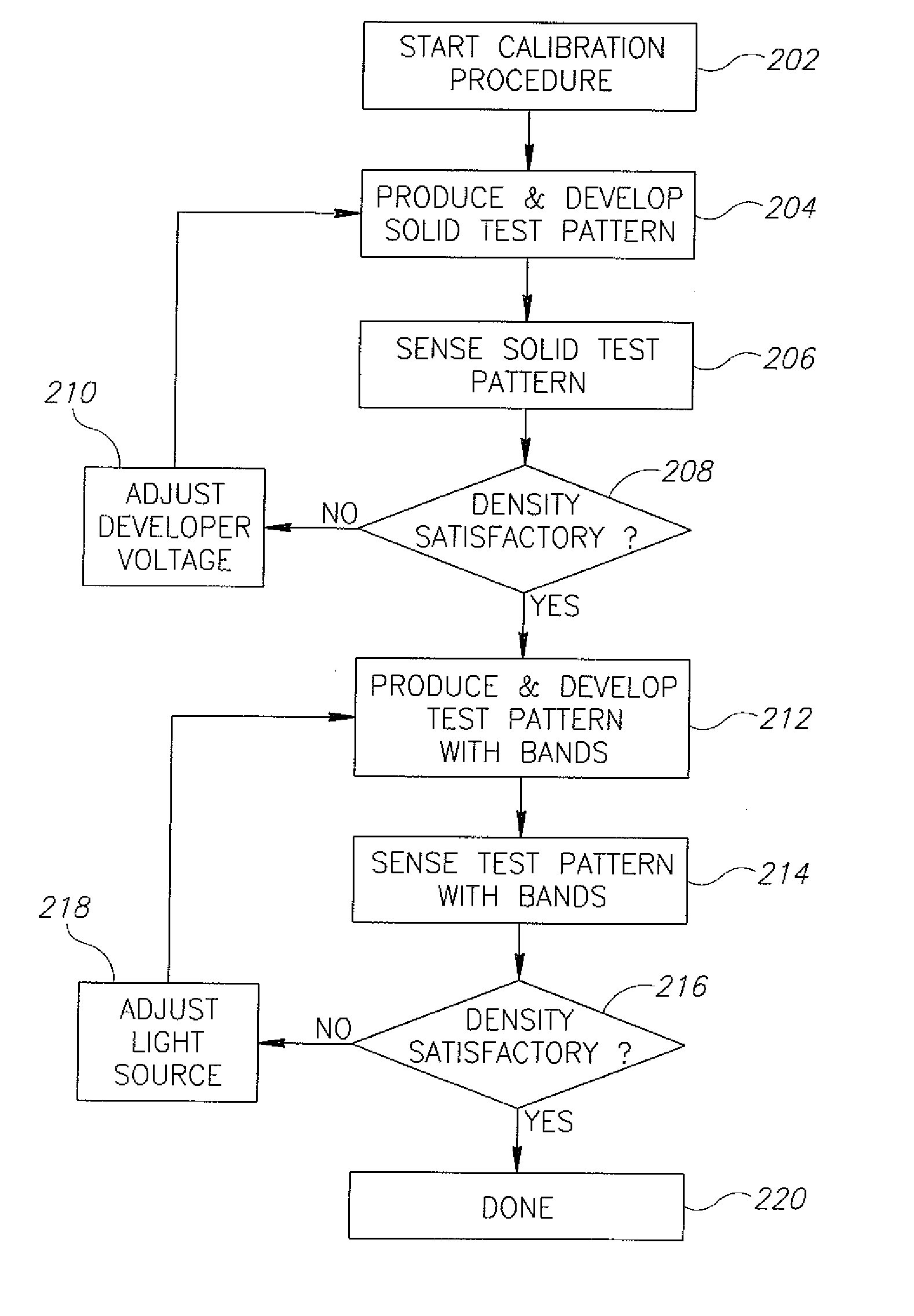

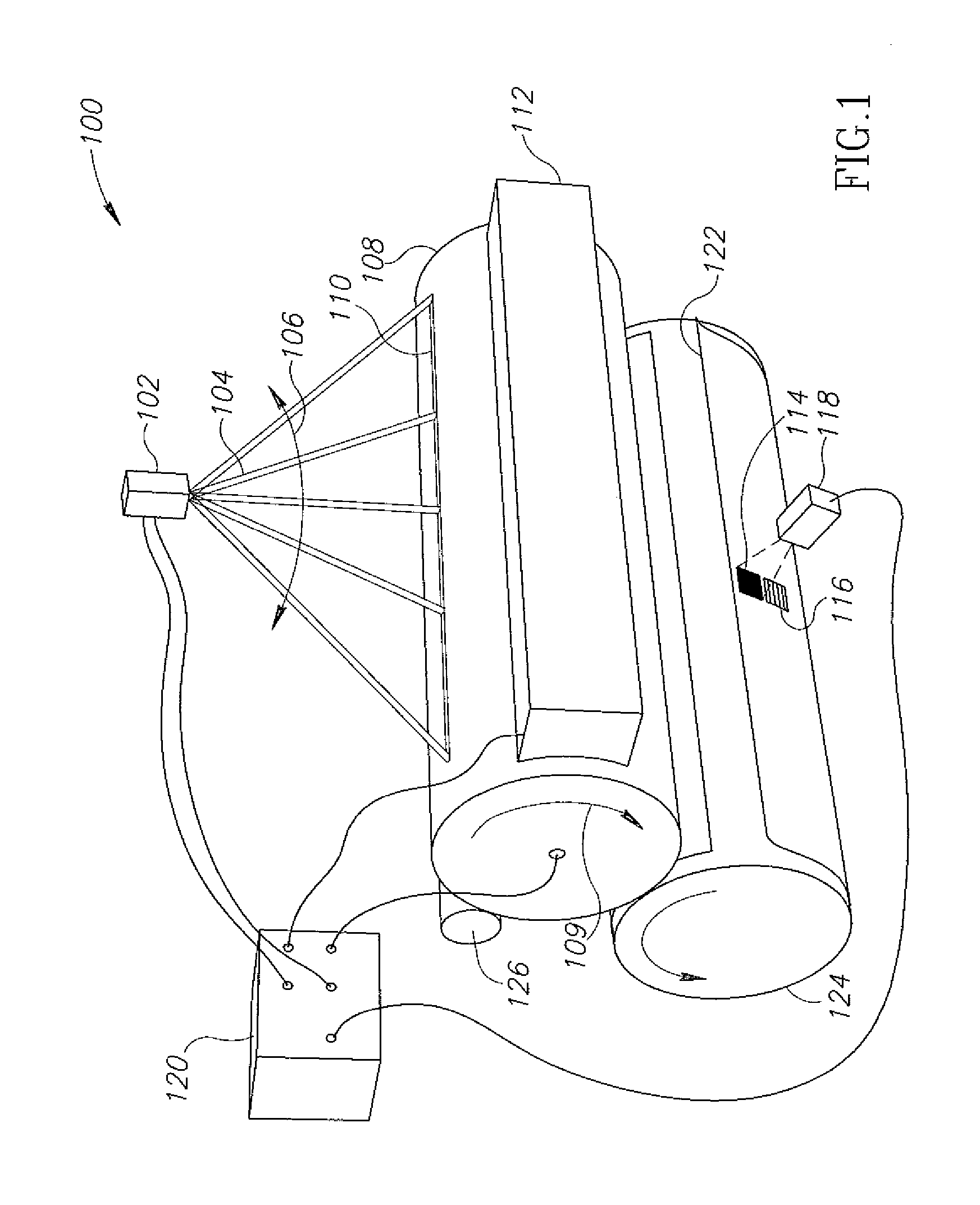

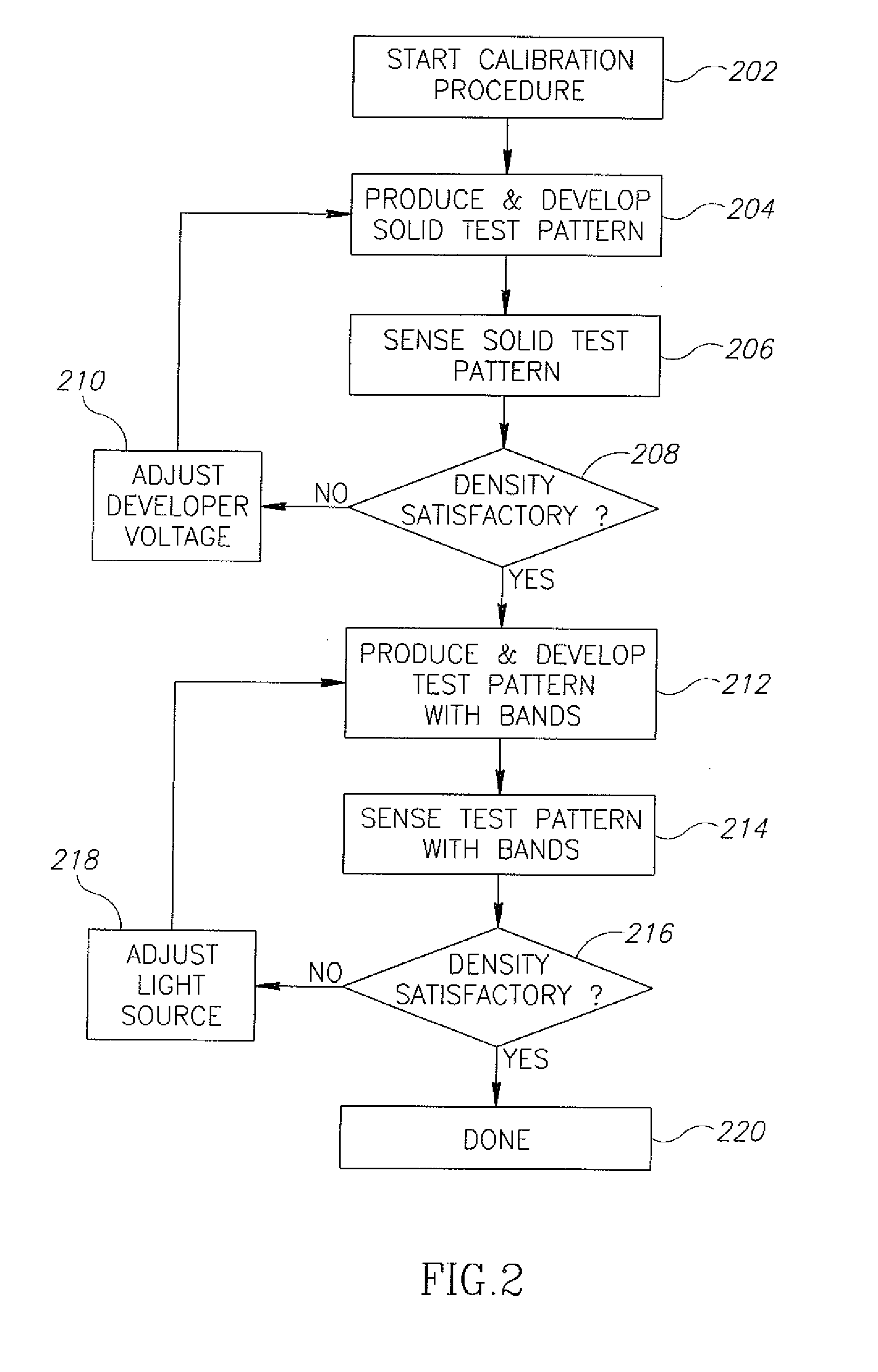

A method of calibrating an electrographic printer, comprising: a) producing a latent image of a banded test pattern and a solid test pattern, using a beam of a light source of controllable power; b) developing the banded test pattern and the solid test pattern with a toner, utilizing an electrode with a developing voltage; c) measuring an average toner optical density of the developed banded test pattern and an average optical toner density of the developed solid test pattern; and d) adjusting one or both of (i) the developing voltage and (ii) the power and / or the diameter of the beam such that the measured average toner optical density of the two patterns matches, within predetermined limits, desired optical densities.

Owner:HARUSH SHLOMO +2

Thermal transfer sheet and thermal transfer recording method

InactiveUS6849311B2Avoid decompositionReduce optical densityAblative recordingCoatingsImage formationHeat sensitive

A thermal sheet transfer having on a support, an image formation layer wherein the image formation layer includes as a colorant, an organic pigment having a melting point not less than 310° C.

Owner:FUJIFILM CORP +1

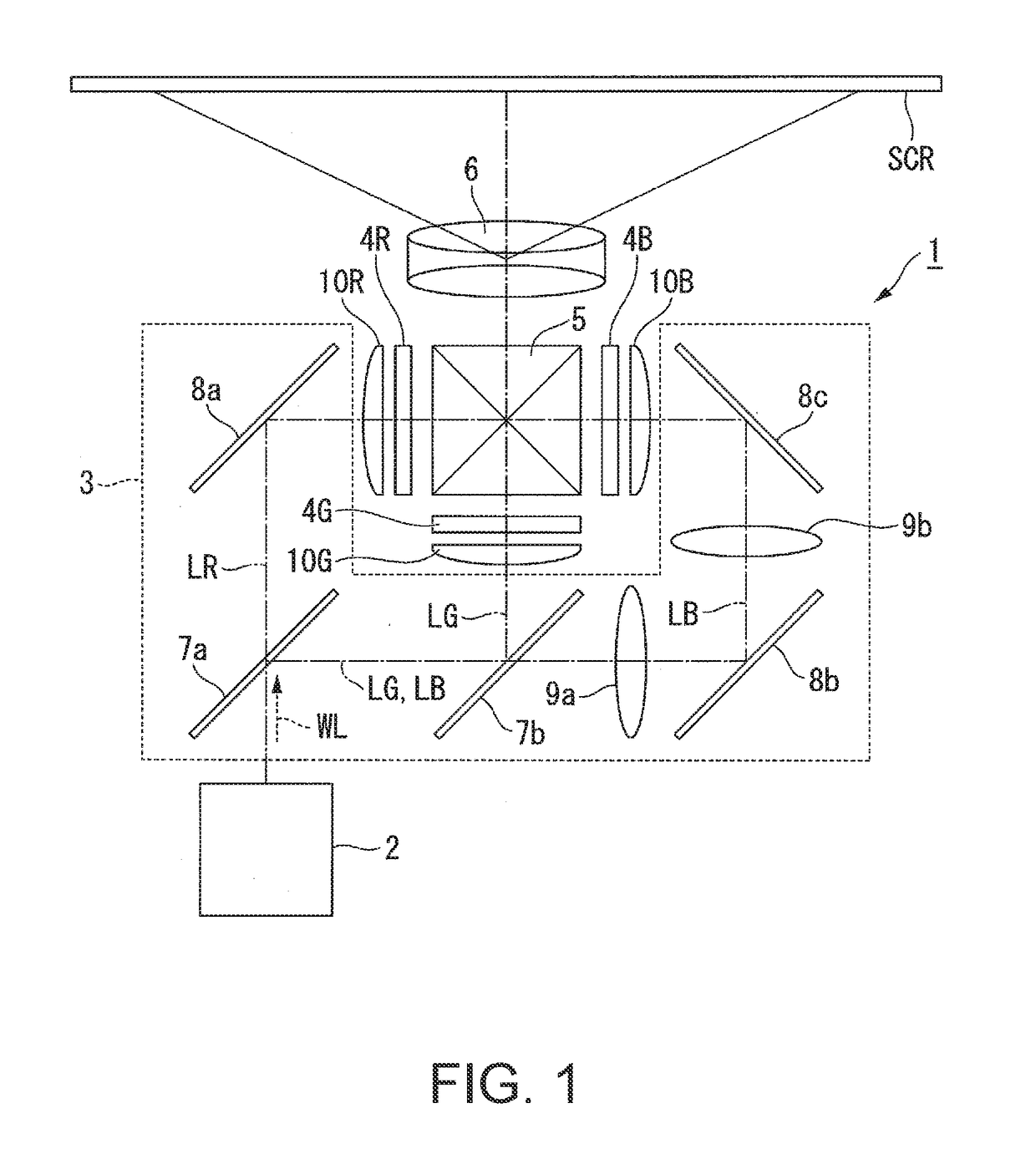

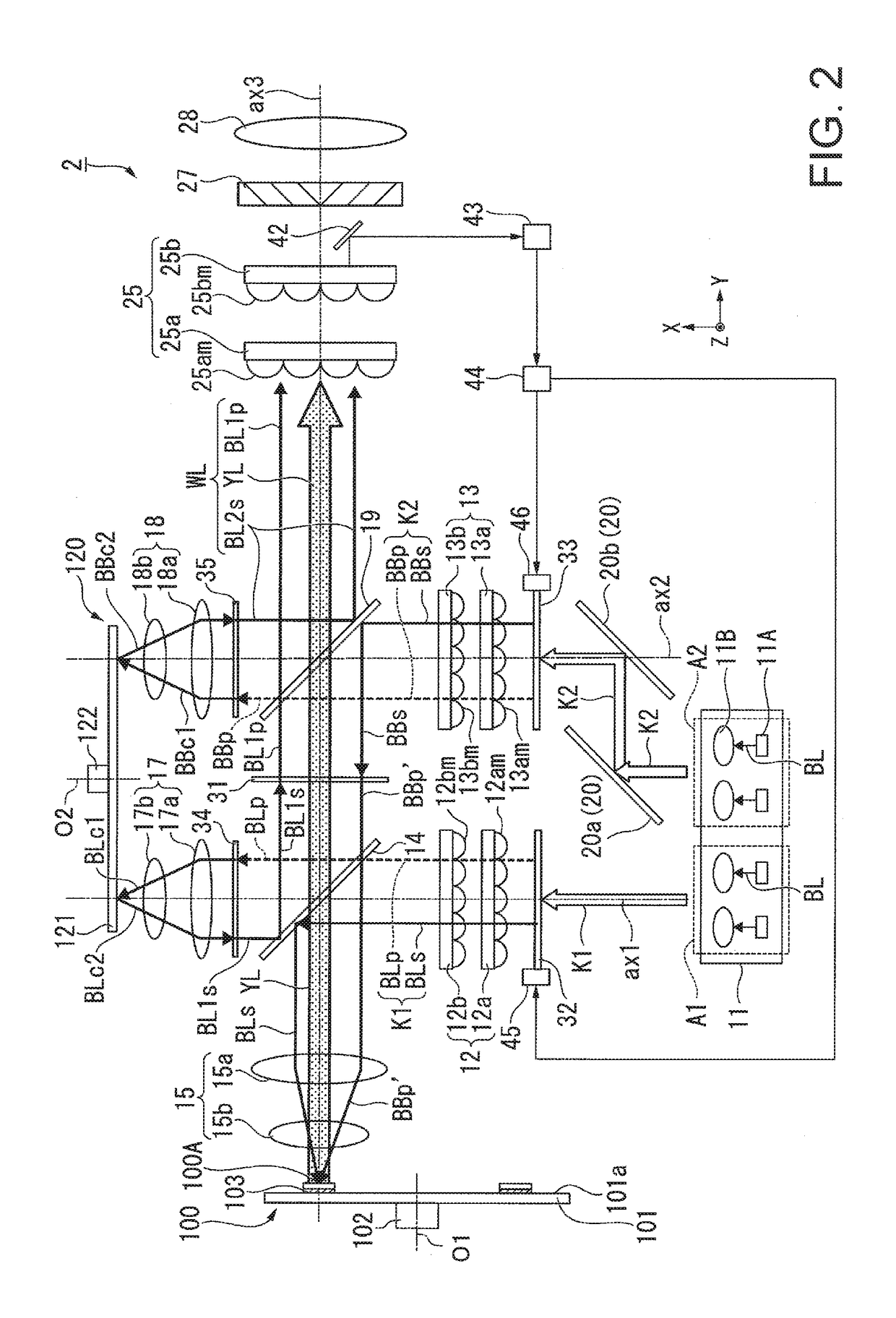

Light source apparatus and projector

ActiveUS20190064645A1Improve reliabilitySmall sizeDiffusing elementsProjectorsLight beamWavelength conversion

A light source apparatus includes a light source section that outputs first and second light beam fluxes, first and second polarization separation elements, a rotary diffuser plate that diffuses the first light beam flux and the second light beam flux, a first retardation film that converts the incident second light beam flux polarized in a first direction into the second light beam flux polarized in a second direction, and a wavelength conversion element on which the first light beam flux polarized in the first direction and the second light beam flux polarized in the second direction, are incident and which converts the first and second light beam fluxes into a third light beam flux that belongs to a wavelength band different from the wavelength band to which the first and second light beam fluxes belong. The third light beam flux passes through the first and second polarization separation elements.

Owner:SEIKO EPSON CORP

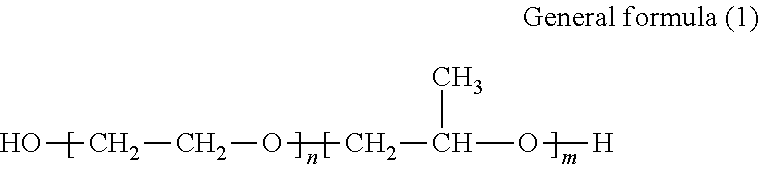

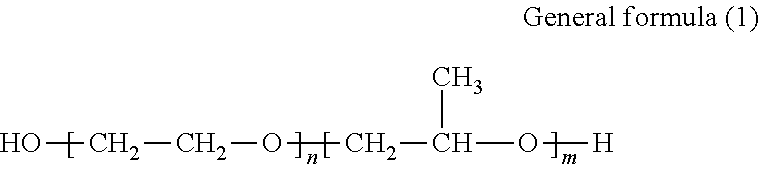

Ink, ink cartridge and ink jet recording process

The invention provides an ink for use in an ink jet recording process in which an ink is ejected from a recording head by the action of thermal energy, the ink comprising a pigment, a water-soluble polyurethane polymer, a compound represented by a general formula (1) having a weight-average molecular weight of 1,000 or more and 8,500 or less, and a polyethylene oxide alkyl ether, the alkyl group of which has 12 or more carbon atoms,wherein, based on the total mass of the ink, the content (mass %) of the compound represented by the general formula (1) is 0.4 times or more and 10.0 times or less in terms of mass ratio with respect to the content (mass %) of the polyethylene oxide alkyl ether.

Owner:CANON KK

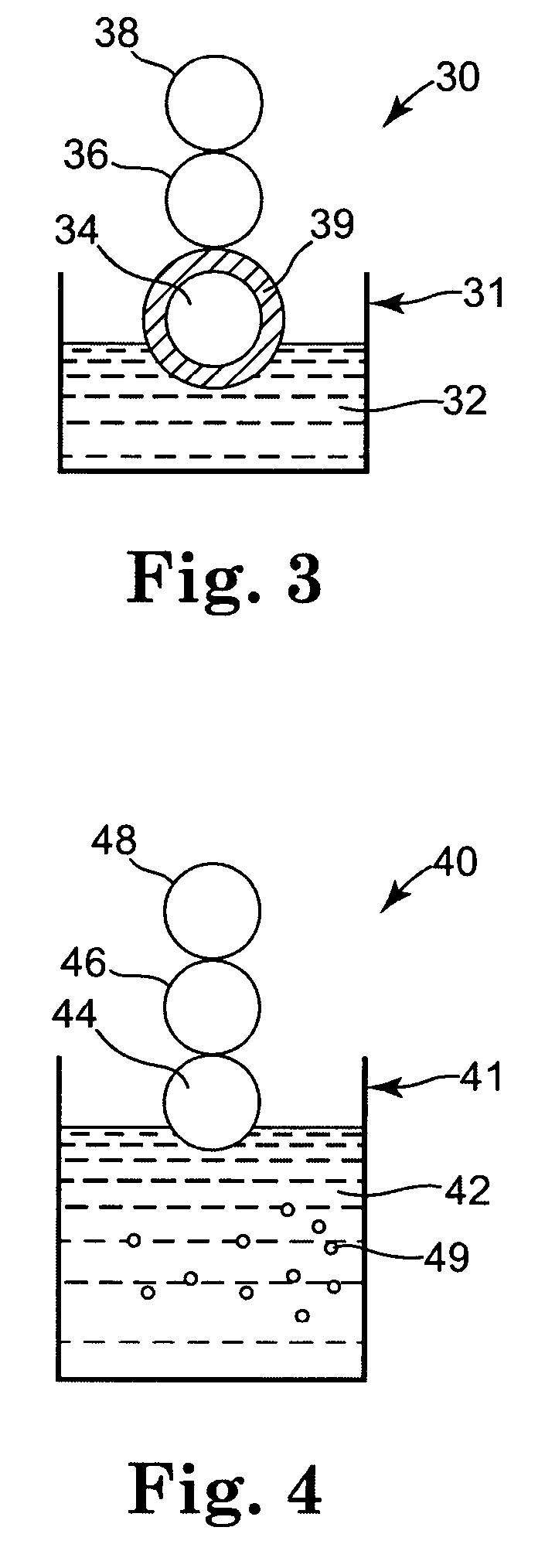

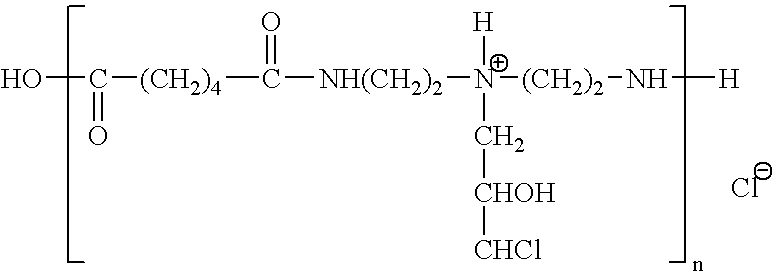

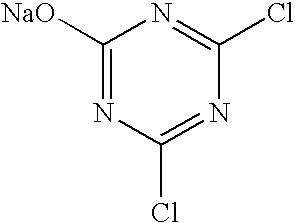

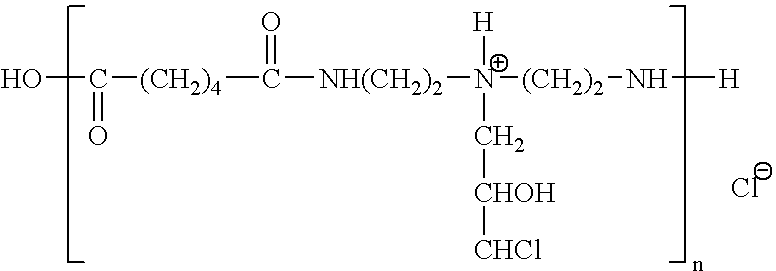

Charge adjuvant delivery system and methods

InactiveUS20050069806A1Reduce optical densityLimited solubilitySubstation equipmentElectrographic process apparatusSolubilityAdjuvant

A system for printing a liquid toner is provided comprising a liquid electrographic toner composition comprising a liquid carrier having a Kauri-Butanol number less than about 30 mL and a plurality of charged toner particles dispersed in the liquid carrier, wherein the toner particles comprise a polymeric binder. The system also comprises a charge control adjuvant having limited solubility in the liquid carrier. The charge control adjuvant preferably is present in the liquid carrier in an amount in excess of the solubility of the adjuvant in the liquid carrier. Alternatively, the charge control adjuvant may be dispersed in a matrix having limited solubility in the liquid carrier or encapsulated within a matrix to form microcapsules having limited solubility in the liquid carrier. The charge control adjuvant in any of the above forms may be provided in a number of formats for release into the toner composition as needed. The charge control adjuvant is released into the toner composition as needed to provide charge control relative to the bulk conductivity of the toner composition and / or the charge per unit mass of the toner particles.

Owner:S PRINTING SOLUTION CO LTD

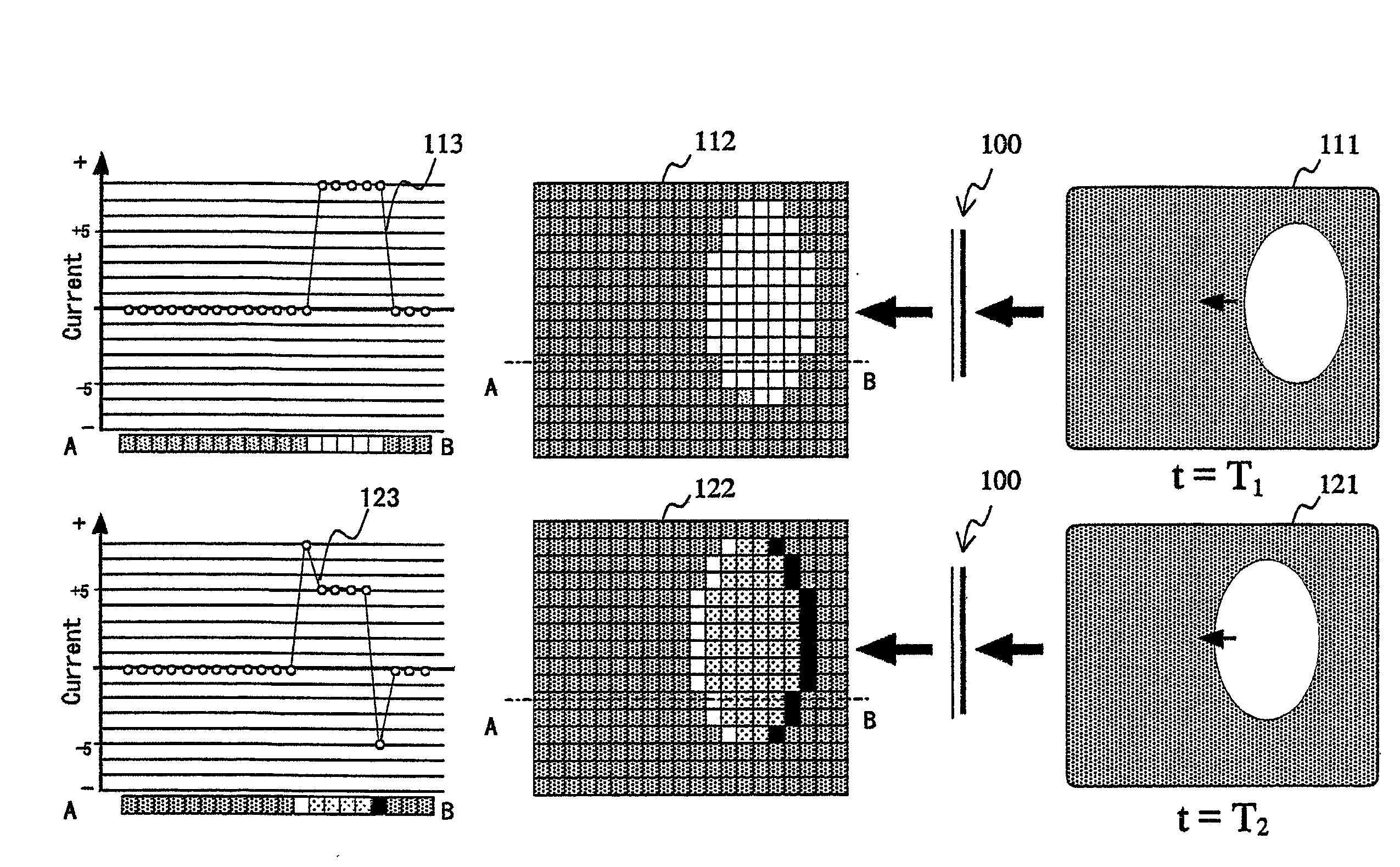

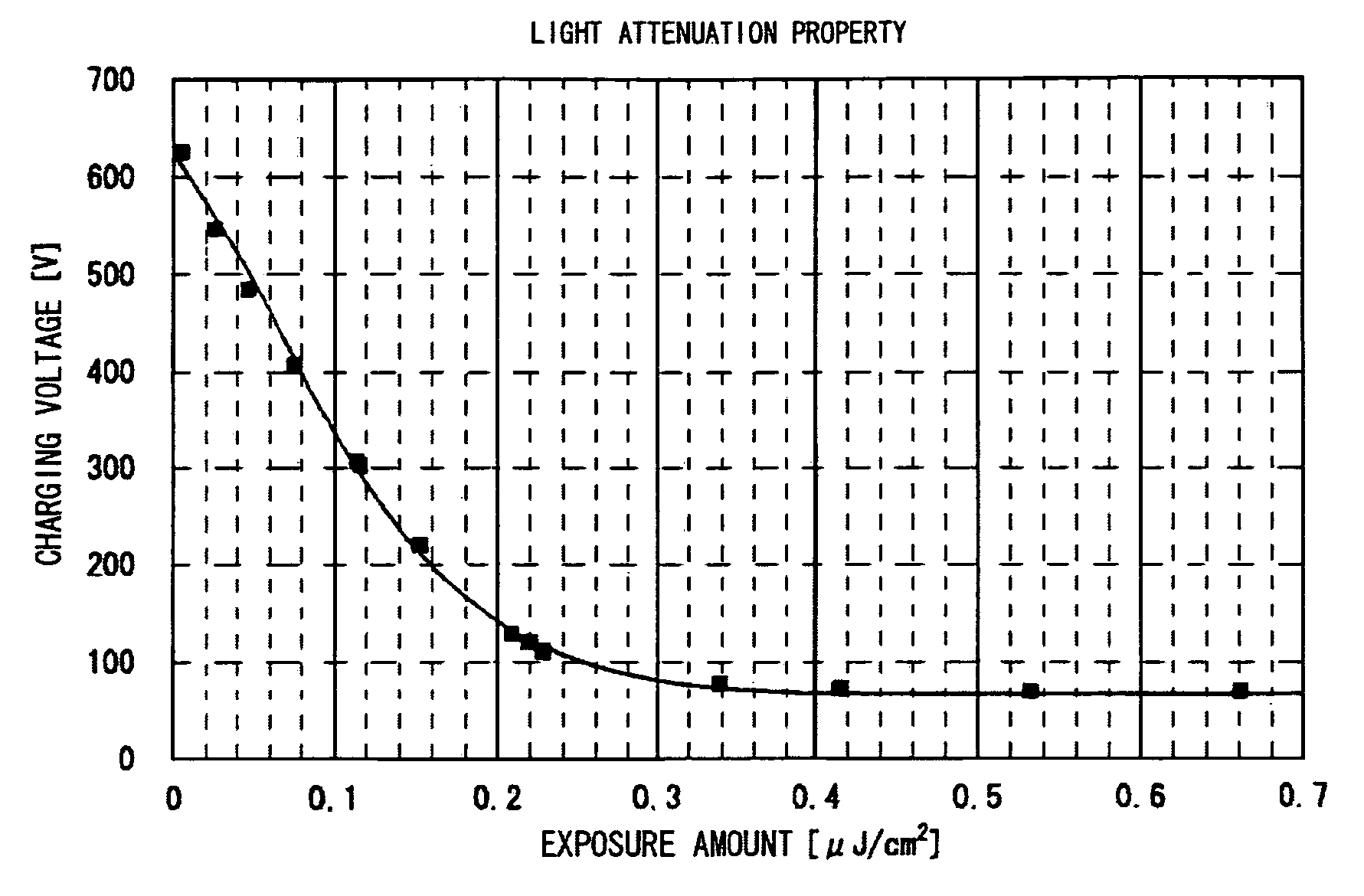

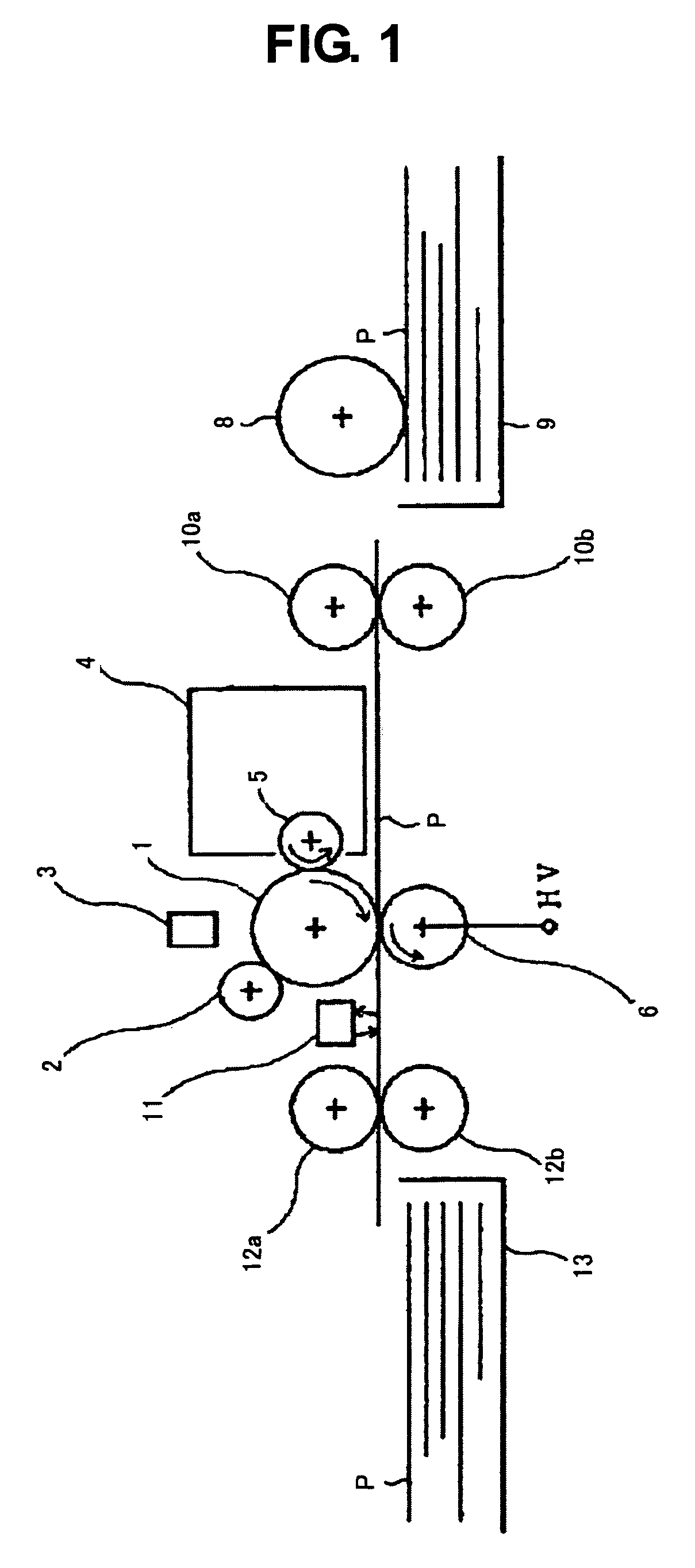

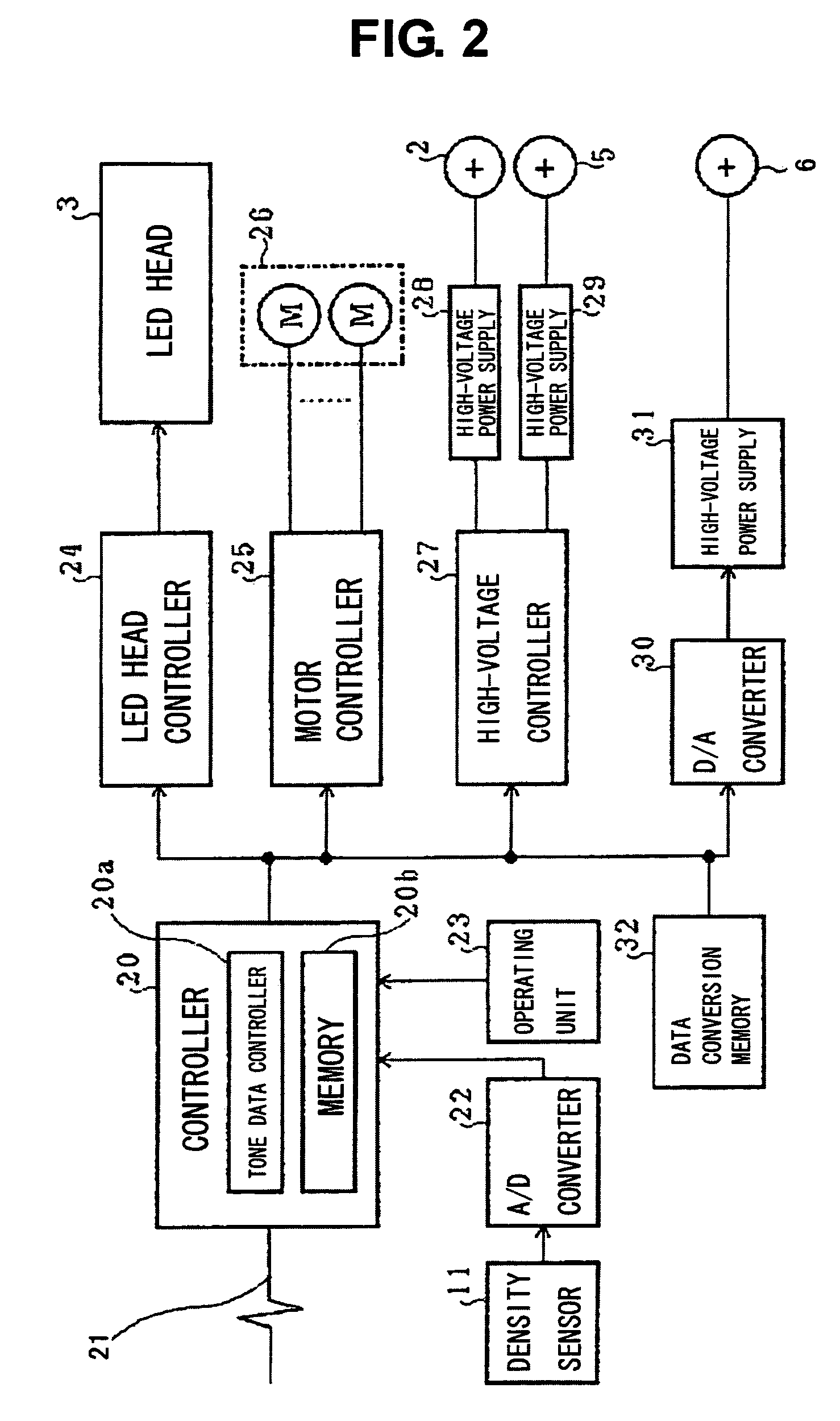

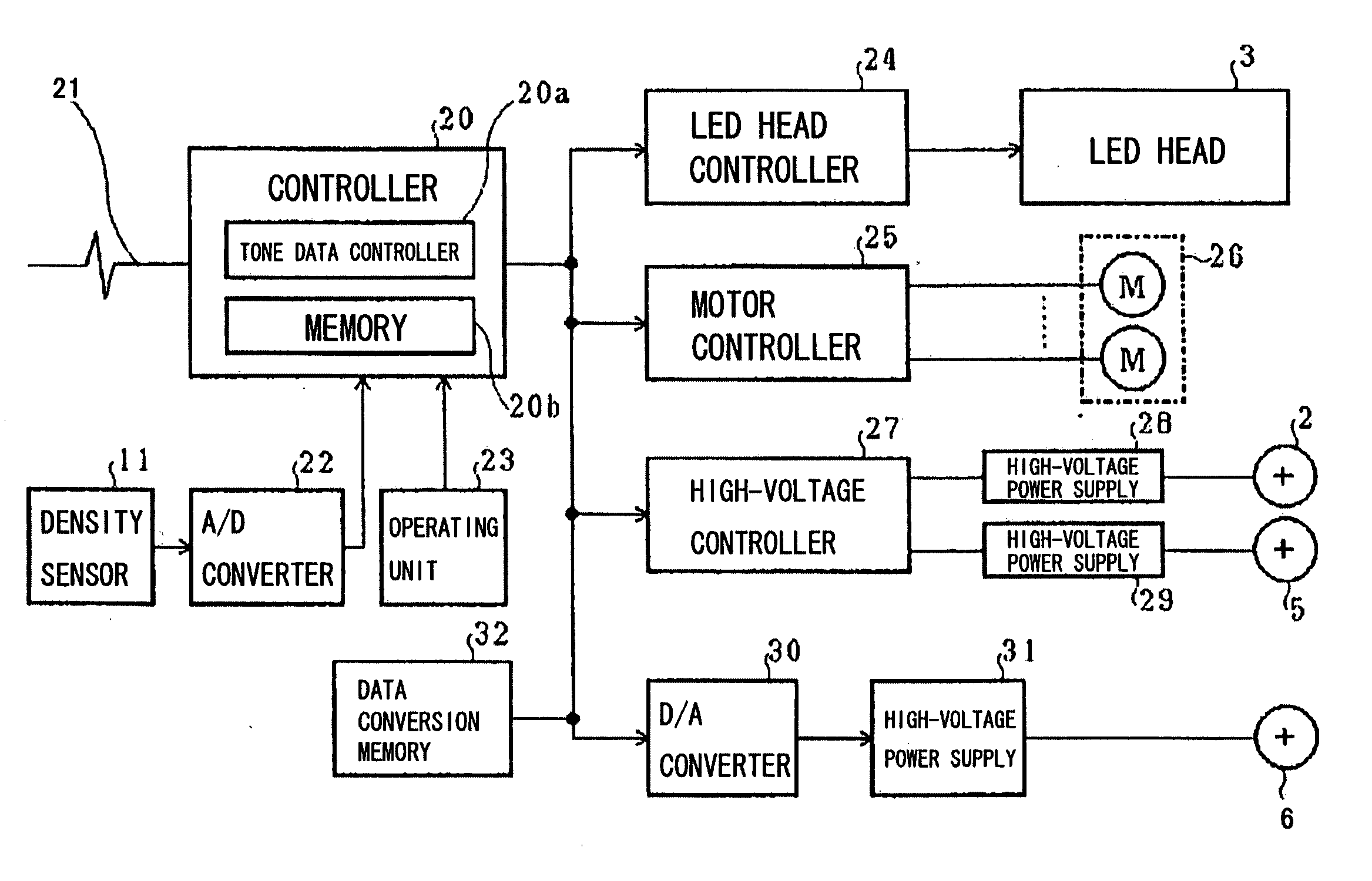

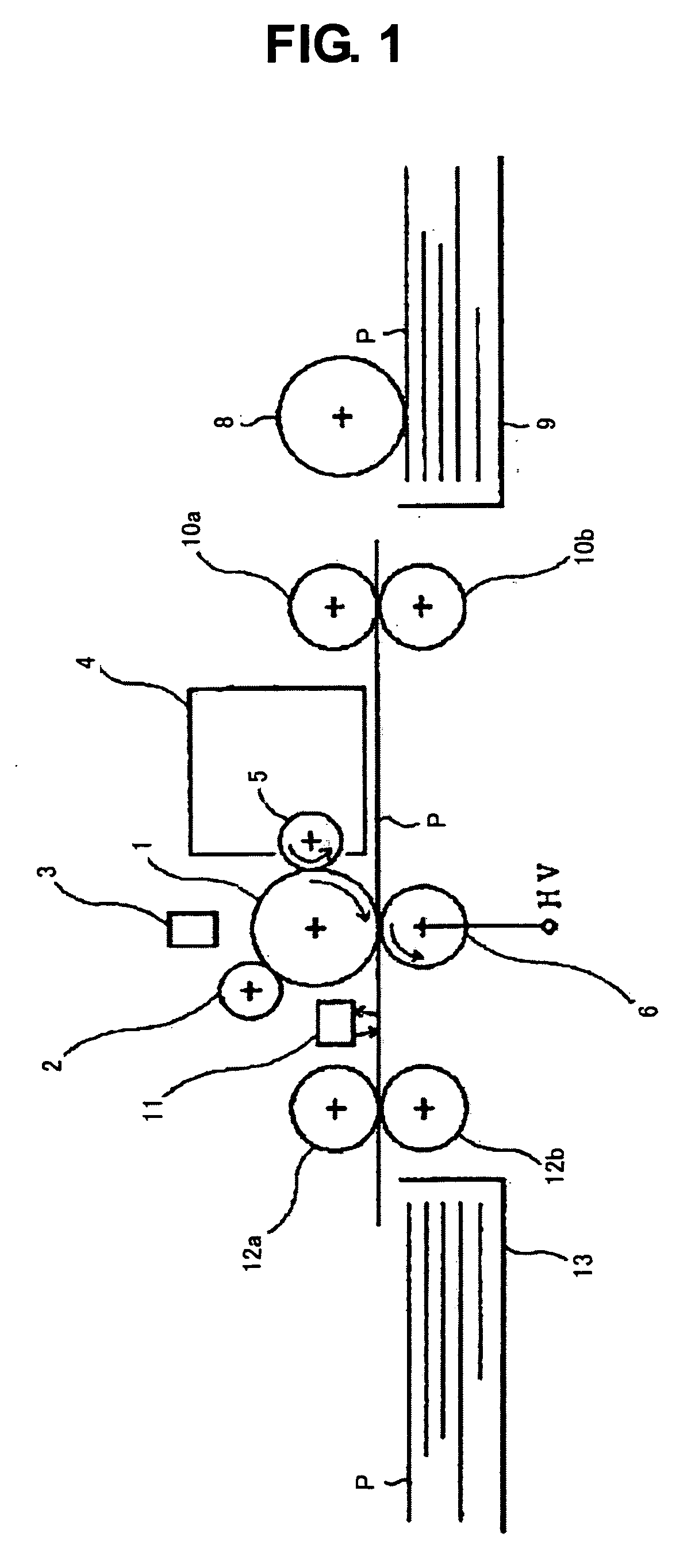

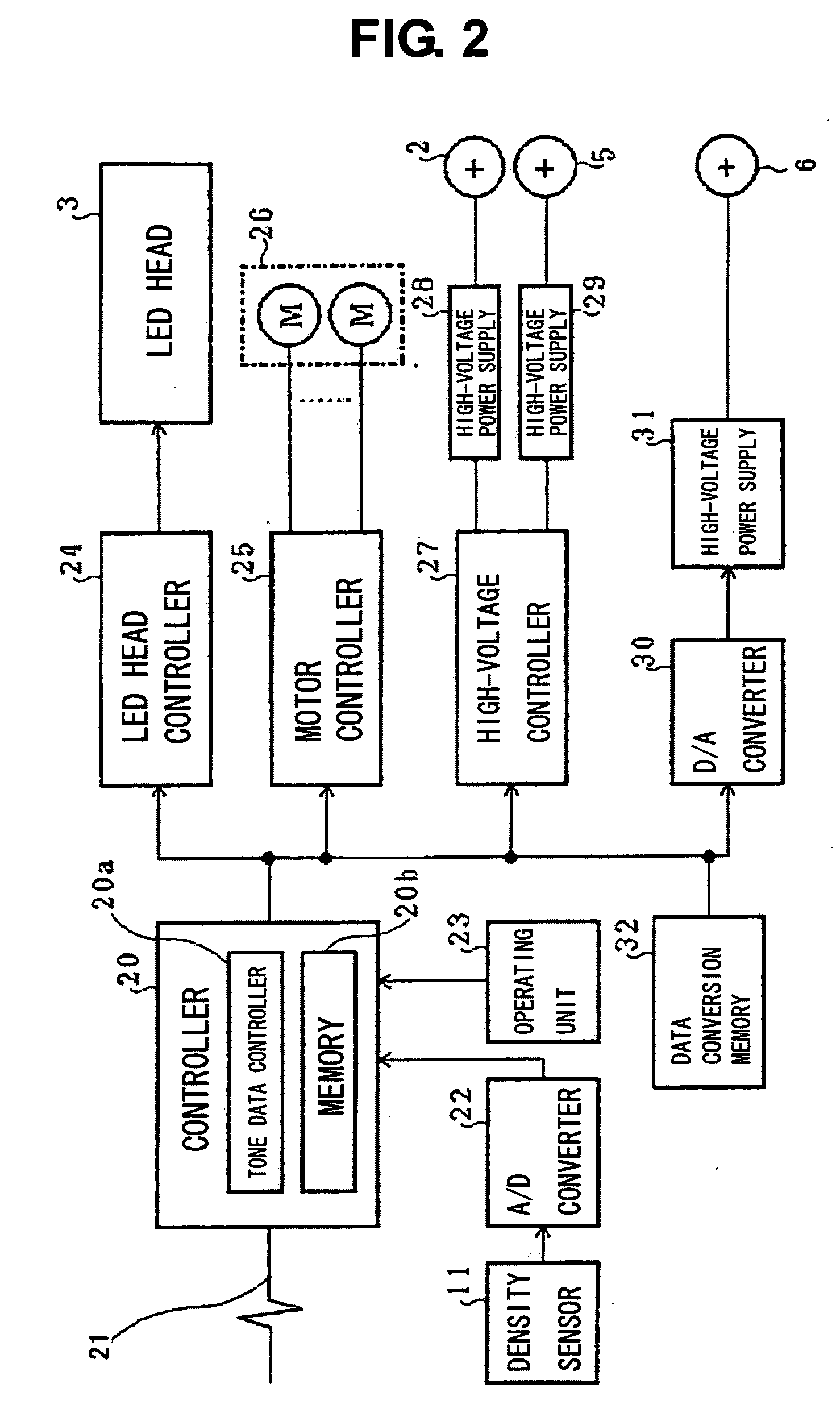

Printing apparatus

ActiveUS7358983B2Increase of recording energyKeep energy smallRecording apparatusElectrode and associated part arrangementsLatent imageEngineering

Owner:OKI ELECTRIC IND CO LTD

Color filter array on pixel array substrate and display panel

ActiveUS8724057B2Improve alignment accuracyImprove production yieldNon-linear opticsColor filter arrayPixel array

A color filter array on pixel array substrate including a substrate, an active device array, a color filter array and a pixel electrode layer is provided. The substrate has a plurality of pixel regions and a light-shielding region. The active device array is disposed on the substrate. The color filter array is disposed on the substrate, and includes a light shielding patterned layer and a plurality of color filter patterns, wherein the light-shielding patterned layer is disposed in the light-shielding region. The color filter patterns are respectively disposed in the pixel regions and extend from the pixel regions into the light shielding regions, wherein the color filter patterns extending from adjacent pixel regions constitute a stacked structure within the light shielding regions. The pixel electrode layer is electrically connected to the active device array.

Owner:AU OPTRONICS CORP

Film for assaying protease activity

InactiveUS20030148399A1Easy to detectReduce optical densityMicrobiological testing/measurementBiological material analysisProteinase activityThin membrane

A thin membrane for measuring protease activity, which is formed on a support and, which comprises one or more kinds of substances selected from the group consisting of a transferrin derivative and an albumin derivative and is crosslinked and / or substantially water-insoluble. The membrane enables selective measurement of protease activity of a particular class of protease such as matrix metalloproteinase 7.

Owner:FUJIFILM HLDG CORP +1

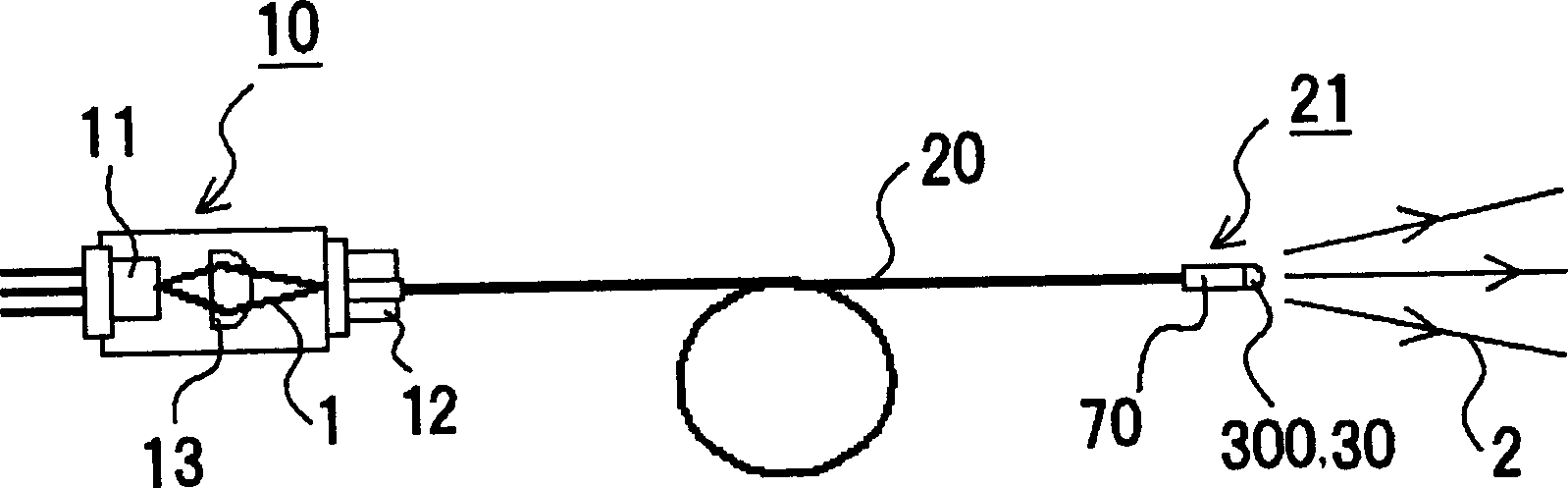

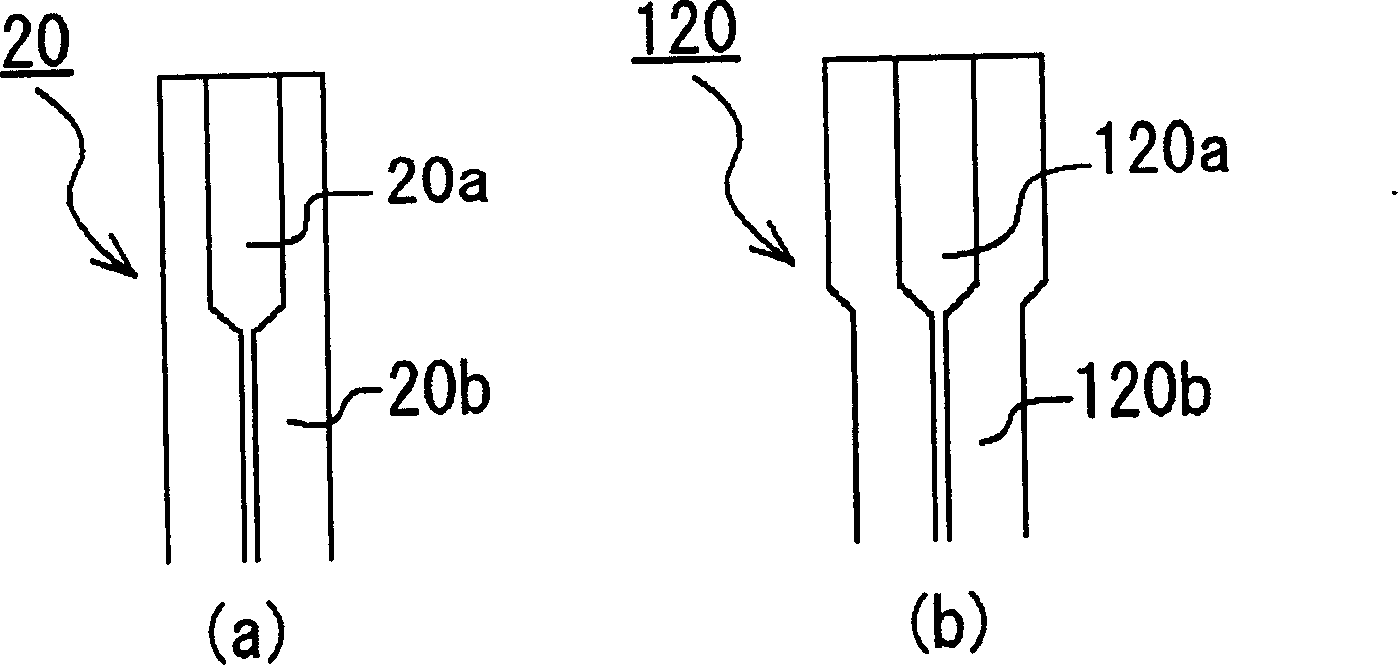

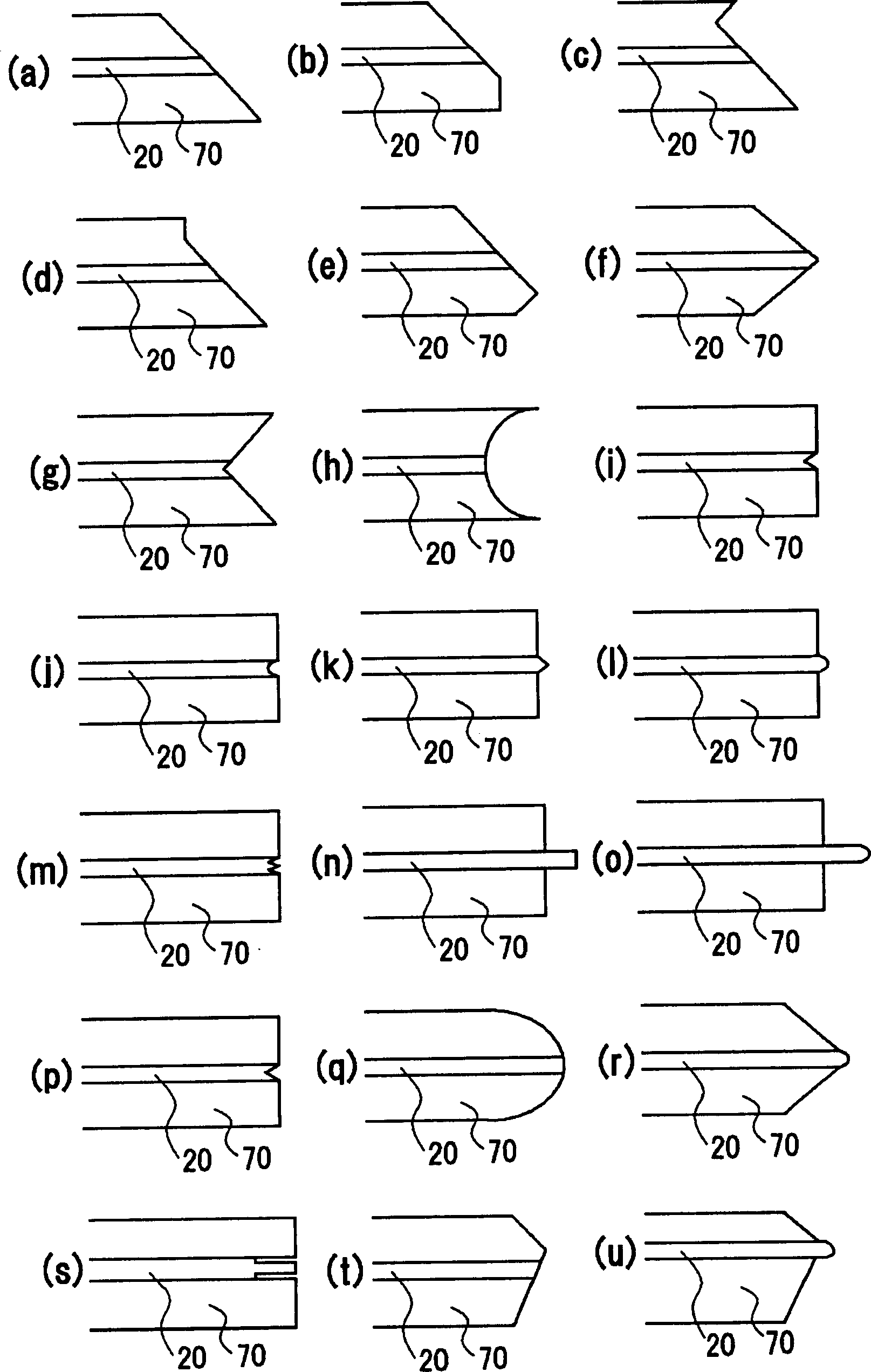

Expanding single mode fiber mode field for high power applications by fusion with multimode fiber

ActiveUS7280734B2Low loss couplingLow loss high power couplingGlass making apparatusOptical fibre with multilayer core/claddingCouplingPolarization-maintaining optical fiber

Apparatus and methodology for the low coupling of optical fibers in high power applications. An end of a single mode optical fiber, or a polarization maintaining fiber, is cut and spliced to a relatively short segment of an index matched multi-mode fiber or an optical fiber without cladding (air cladded) having approximately similar diameter as the single mode fiber which in turn is coupled to the external device. The free end of the multi-mode fiber may be cleaved, polished and have an anti-reflection applied to it. The beam emitted by the small core of the single mode optical fiber expands into the larger core of the multi-mode fiber providing low loss high power coupling of the optical fiber to the external device.

Owner:LOCKHEED MARTIN CORP

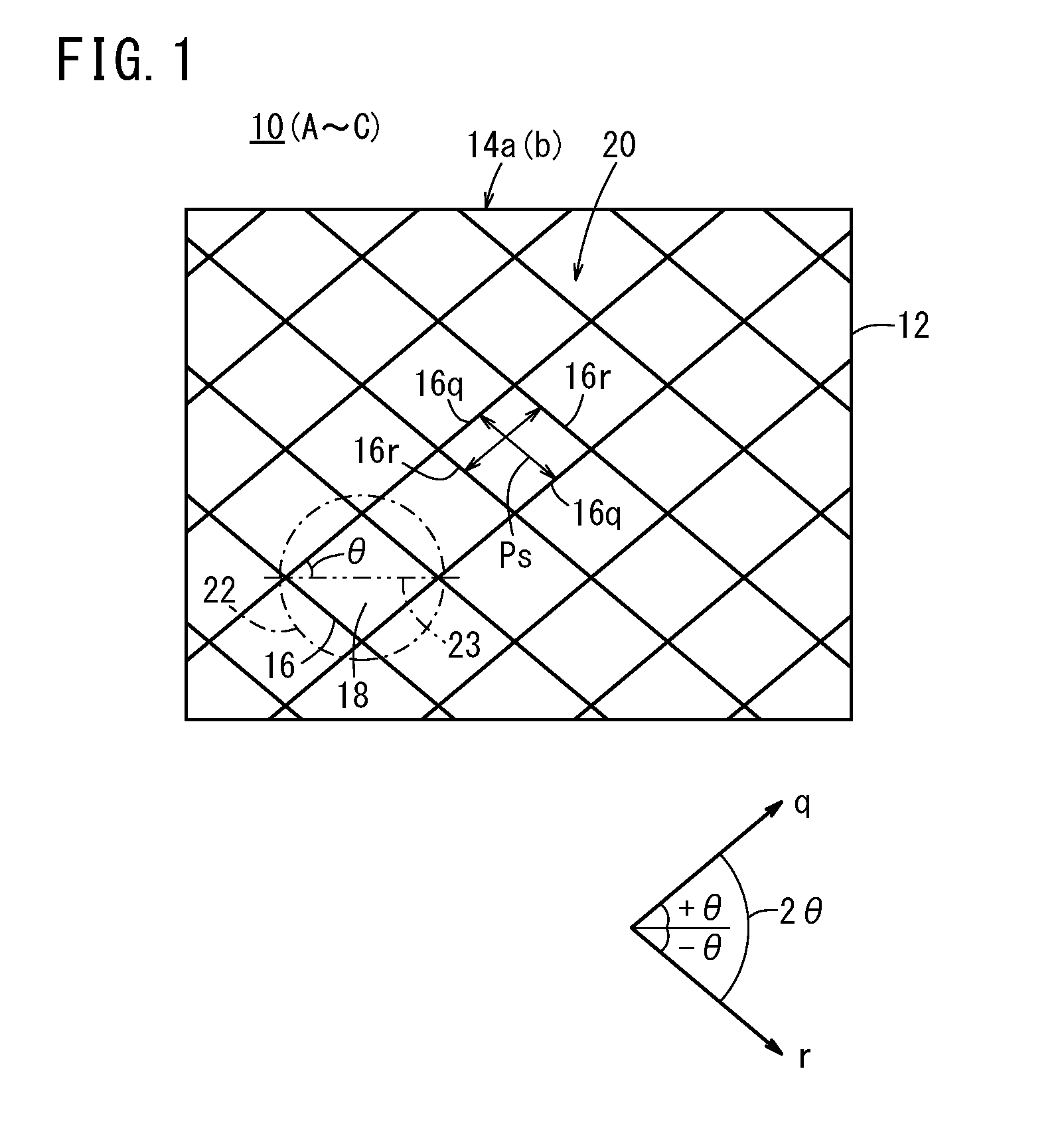

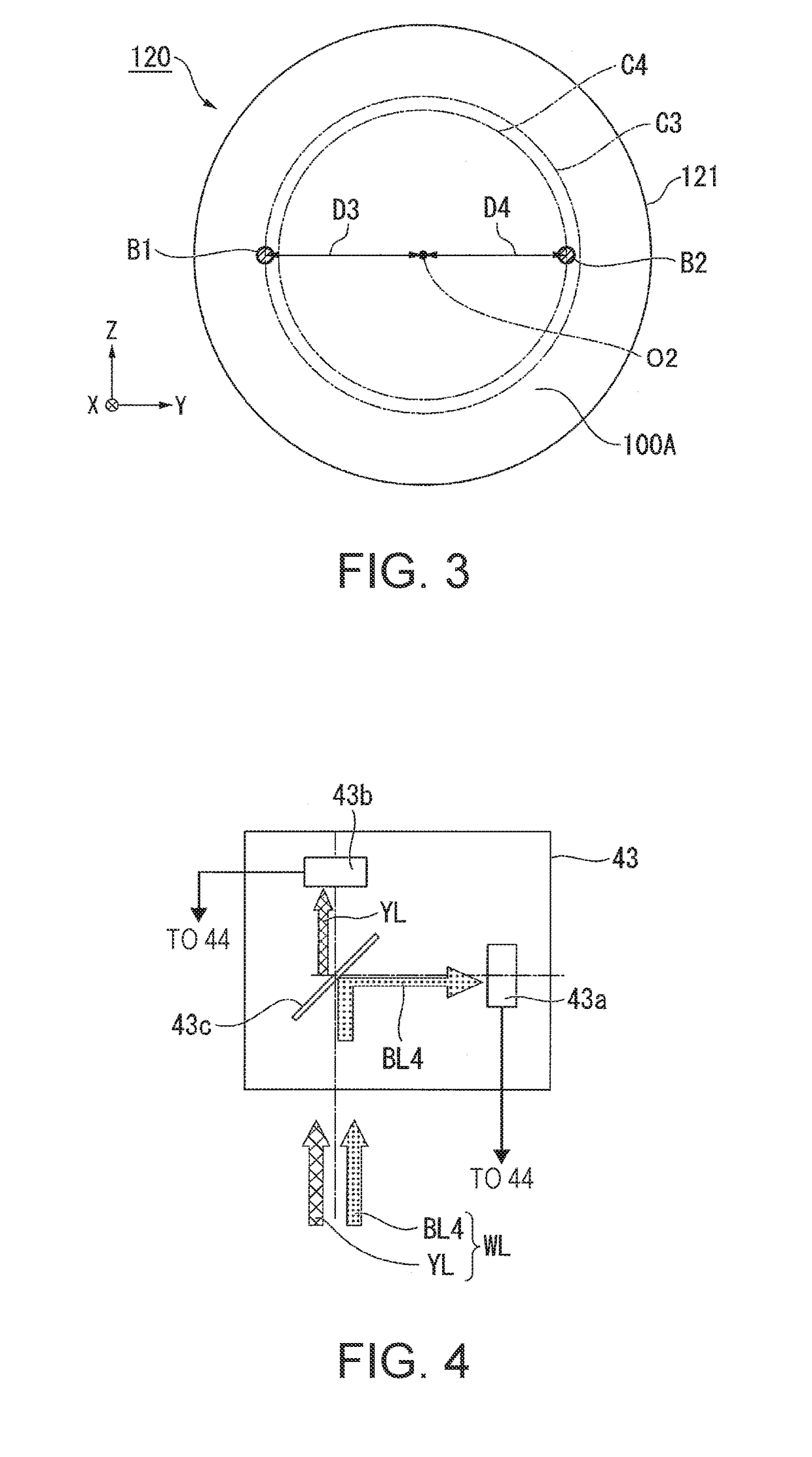

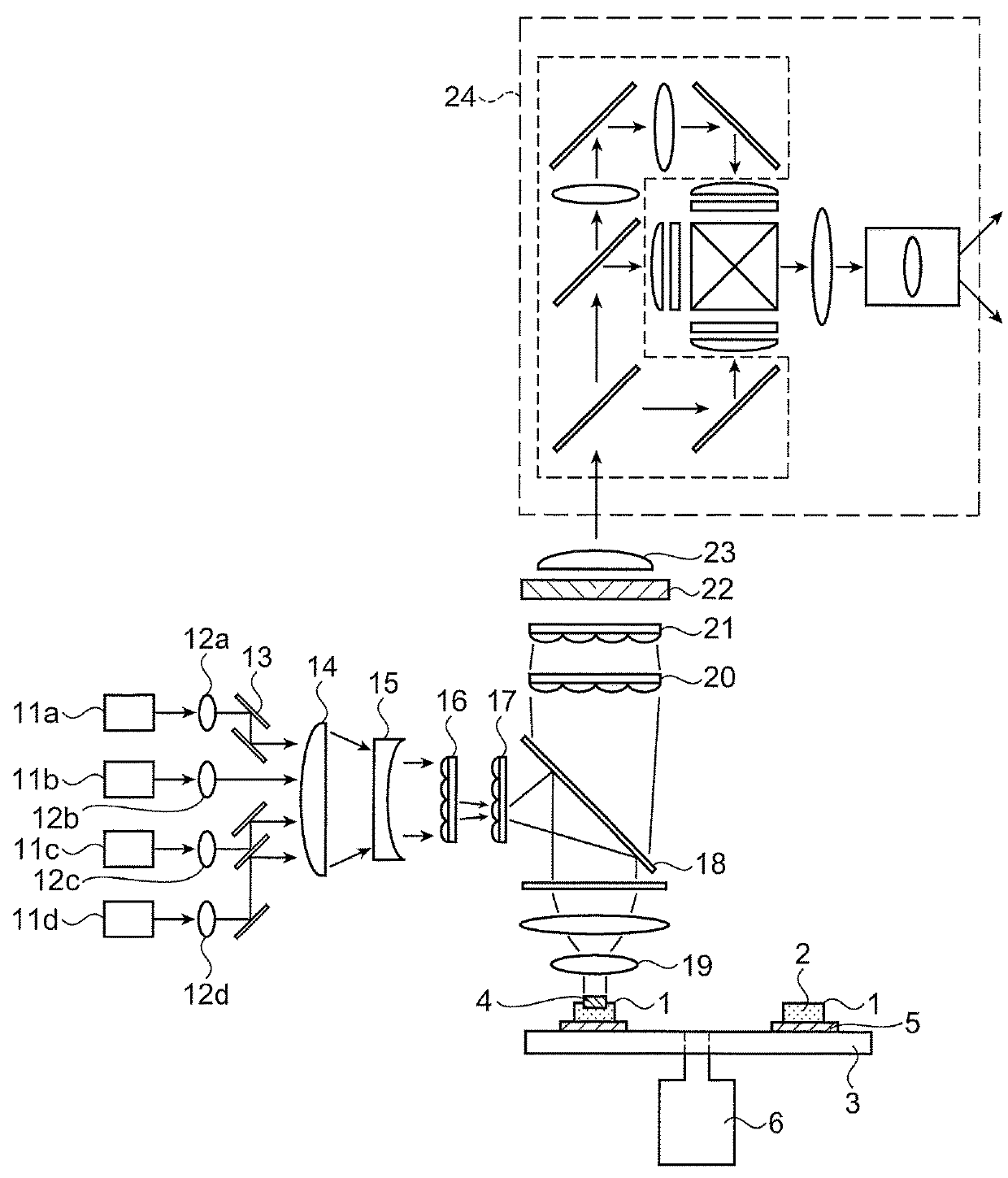

Light source apparatus and projector

ActiveUS9964842B2Increase temperatureReduce pointsProjectorsSpectral modifiersLight emitting deviceWavelength conversion

A light source apparatus includes a light source that outputs excitation light, and a rotating light emitting device in which a wavelength conversion element that emits light when irradiated with the excitation light is provided on a rotating disk. A spot of the excitation light on the wavelength conversion element has a shape that is long in a radial direction of the rotating disk and short in a circumferential direction of the rotating disk. Alternatively, an orthogonally projected length of the spot in the radial direction is greater than an orthogonally projected length of the spot in the circumferential direction.

Owner:SEIKO EPSON CORP

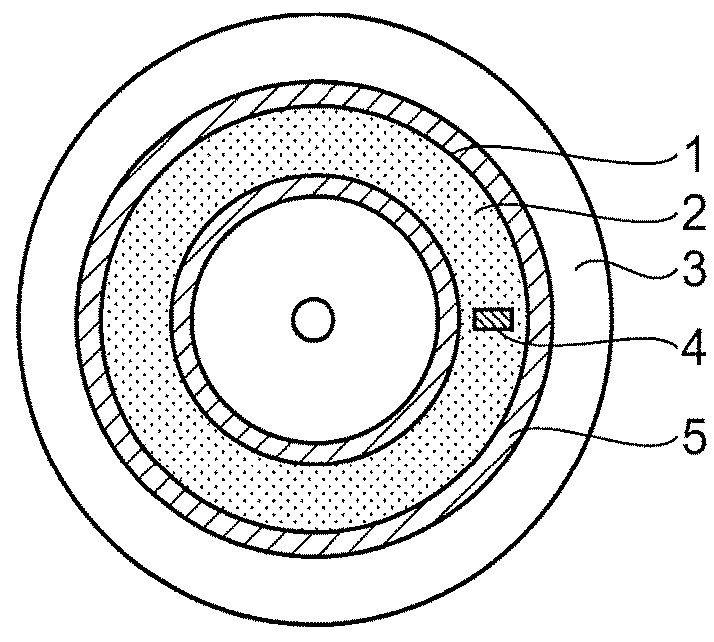

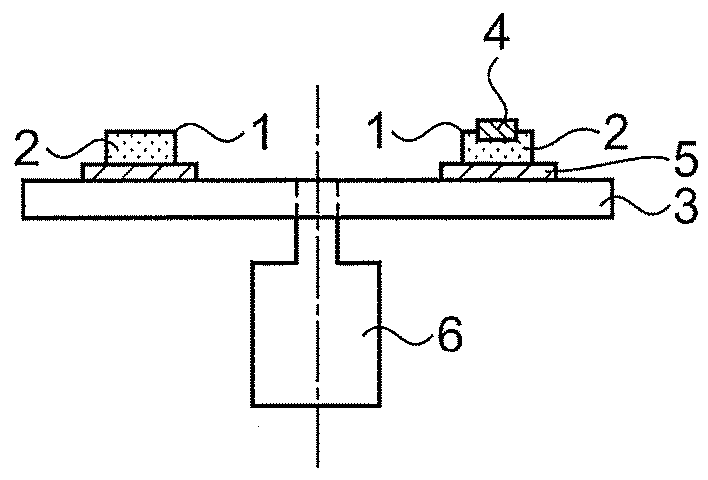

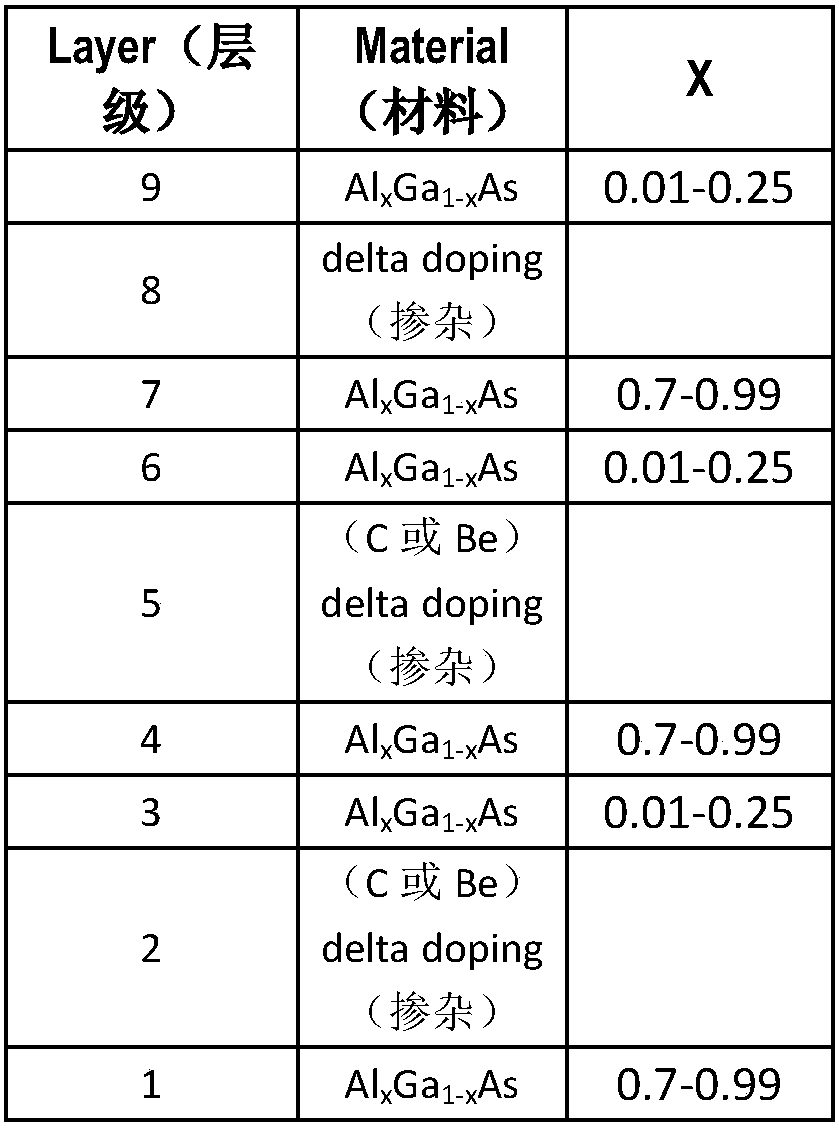

DBR growth method applied to VCSEL as well as DBR and VCSEL

InactiveCN109462143AReduced series resistanceReduce thicknessLaser detailsSemiconductor lasersStanding waveHigh reflectivity

The invention provides a DBR (distributed Bragg reflector) growth method applied to a VCSEL (vertical cavity surface emitting laser) as well as a DBR and a VCSEL. Doping concentration on a DBR reflector interface is periodically regulated, namely a tunnel current formed by tunnel effect is increased through delta heavy doping, and corresponding series resistance can be reduced. Along with increaseof the doping concentration, the total series resistance of a periodically doped reflector is obviously reduced, and thickness of surface depletion layers of homogenous type heterojunctions is reduced. The surfaces of the heterojunctions correspond to nodes of light standing waves in the DBR, and the heavily doped regions are low in optical density, so that free carrier absorption is low, and theperiodically doped reflector has low resistance and high reflectivity.

Owner:中科芯电半导体科技(北京)有限公司

Printing apparatus

ActiveUS20060164499A1Reduce optical densityIncrease valueRecording apparatusElectrode and associated part arrangementsLatent imageEngineering

A printing apparatus for printing an image onto a recording medium based on input image data, comprises an electrostatic latent image carrier for forming an electrostatic latent image, and an exposure controller for forming the electrostatic latent image corresponding to one pixel upon exposure of the electrostatic latent image carrier with a combination of a plurality of different exposure amounts, wherein the exposure controller performs the exposure with the combination of the plurality of exposure amounts in a manner to satisfy a condition for an index value LNR expressed by a following general equation (1) using an optical density od (n) standardized on the condition of the maximum optical density equal to 1.0, identification information comb assigned to identify each combination of the plurality of exposure amounts, and the number of varieties m of a cumulative exposure amount used for modulation of the image data. LNR≤2 / mLNR(comb)=∑n=0m-3[{(od(n+2)-od(n+1))-(od(n+1)-od(n))}2] / (m-2)(1)

Owner:OKI ELECTRIC IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com