Patents

Literature

343 results about "Contact test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

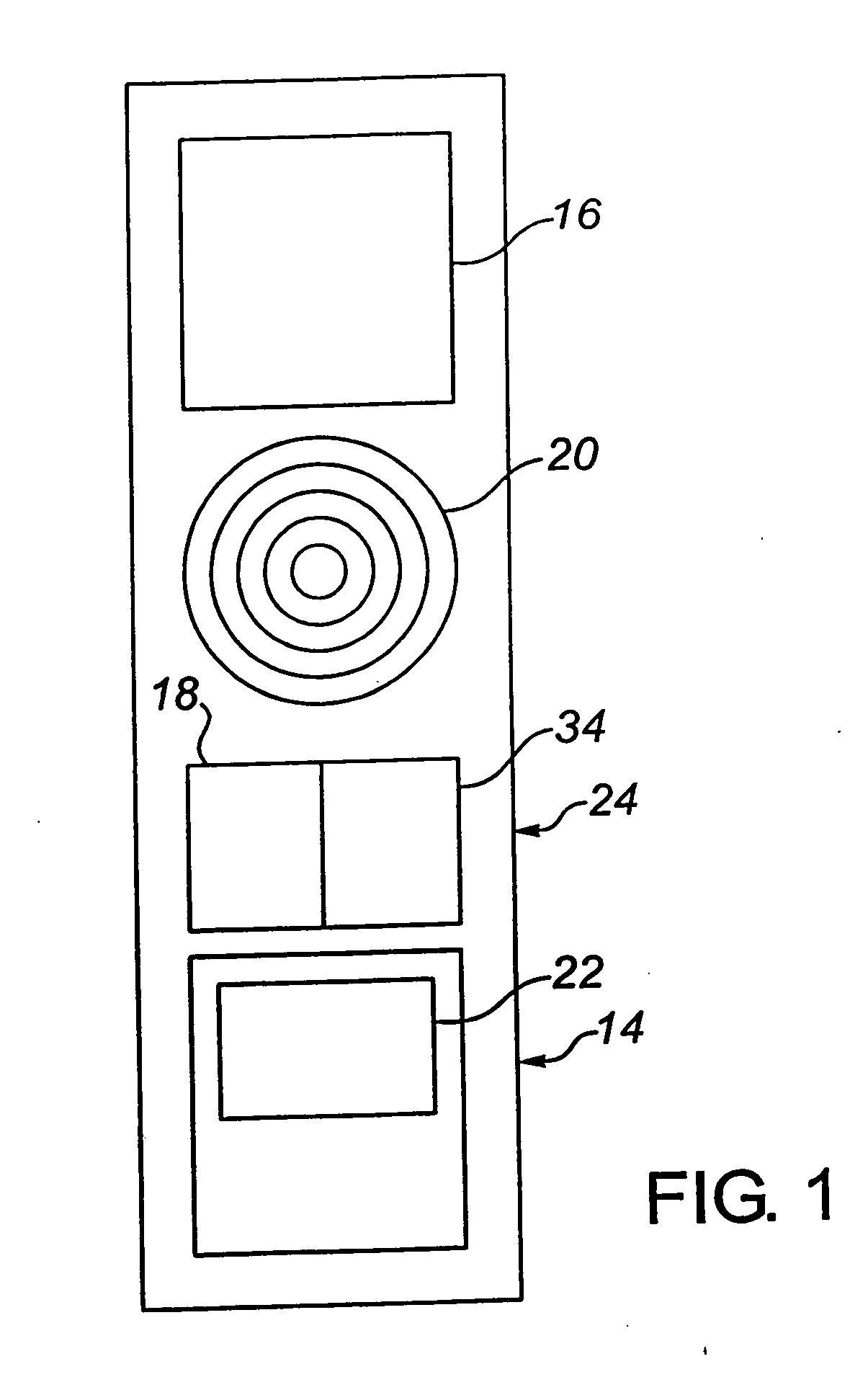

Device with proximity detection capability

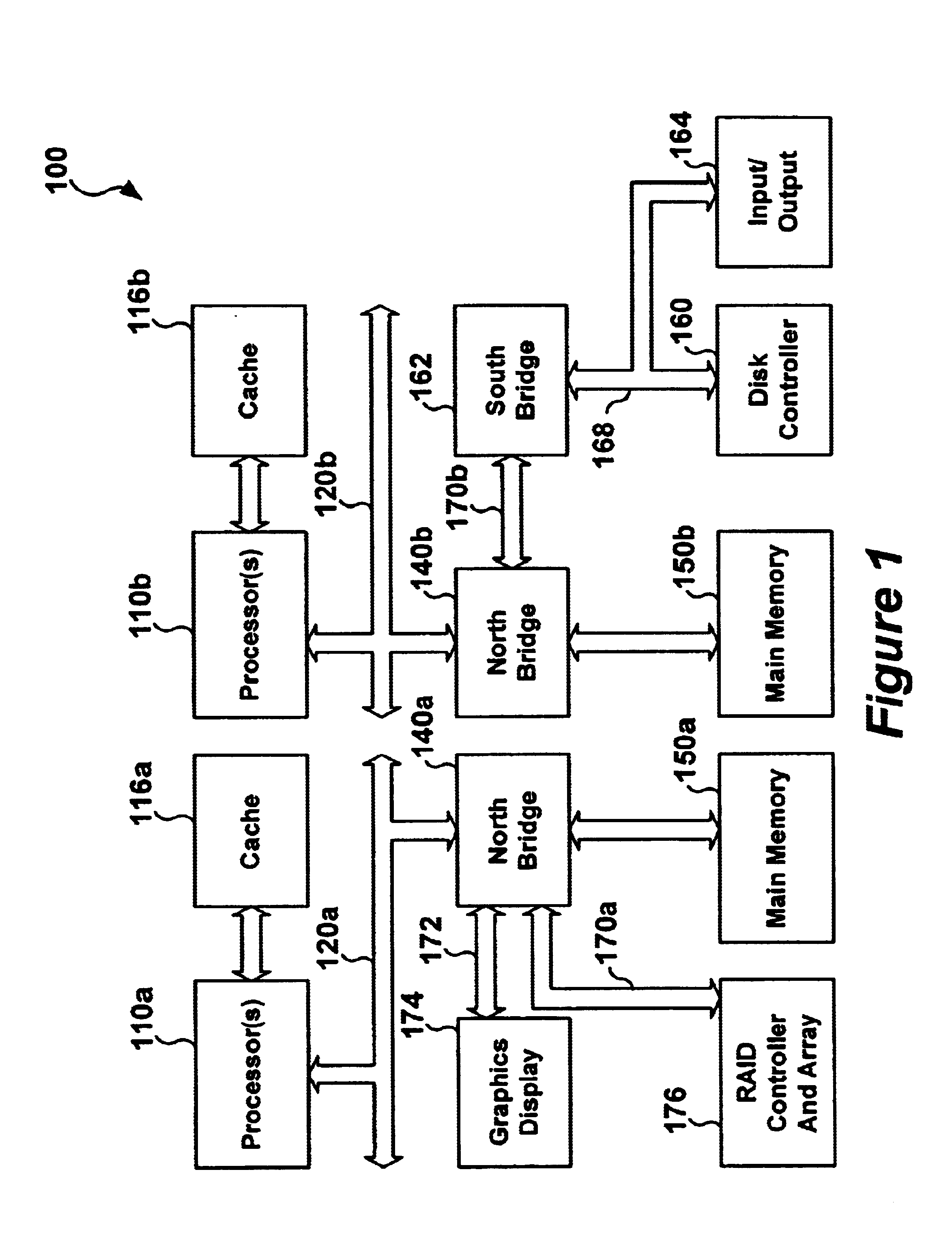

InactiveUS8115499B2Resistance/reactance/impedenceDigital data processing detailsContact testMultiplexer

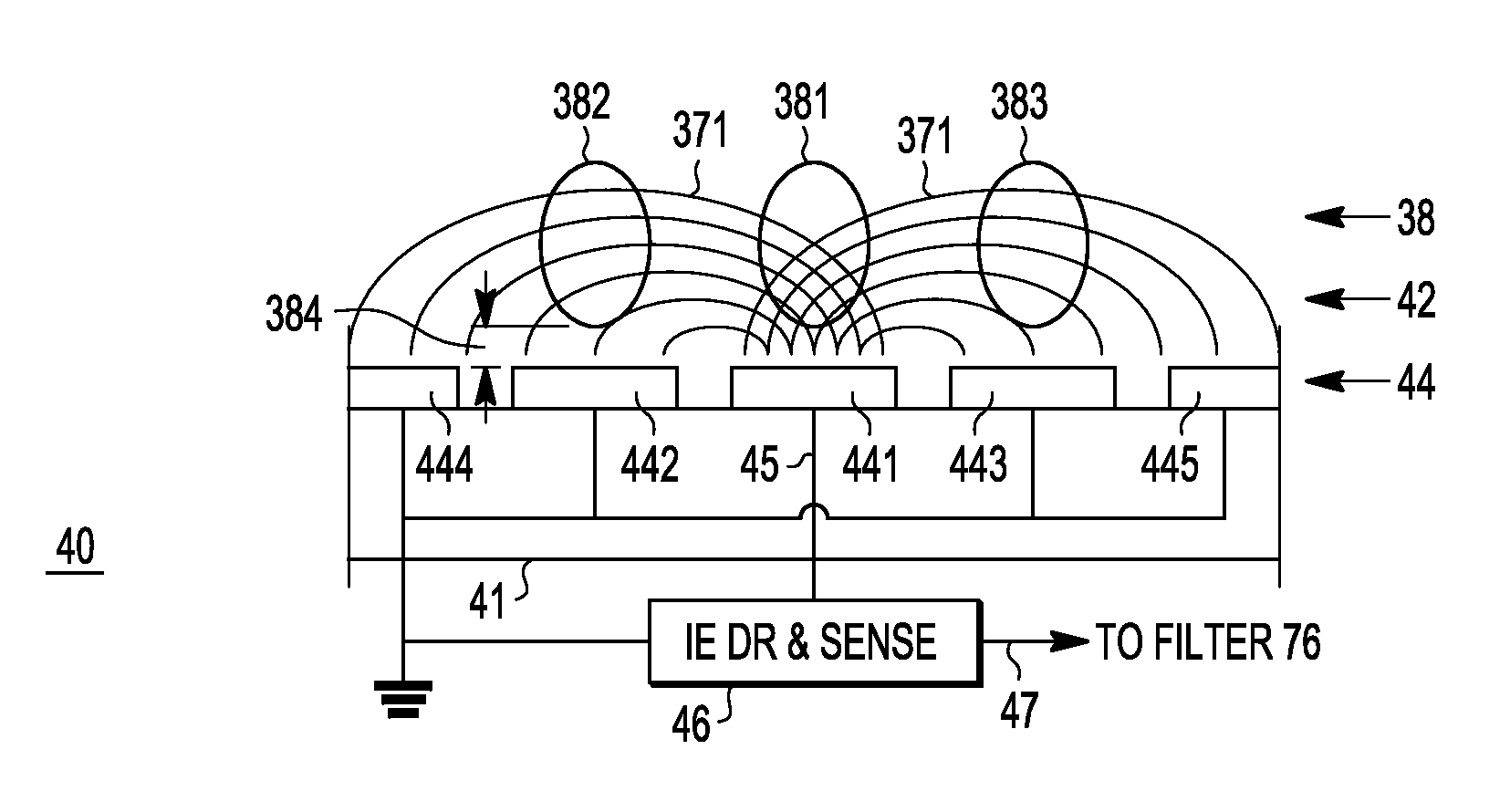

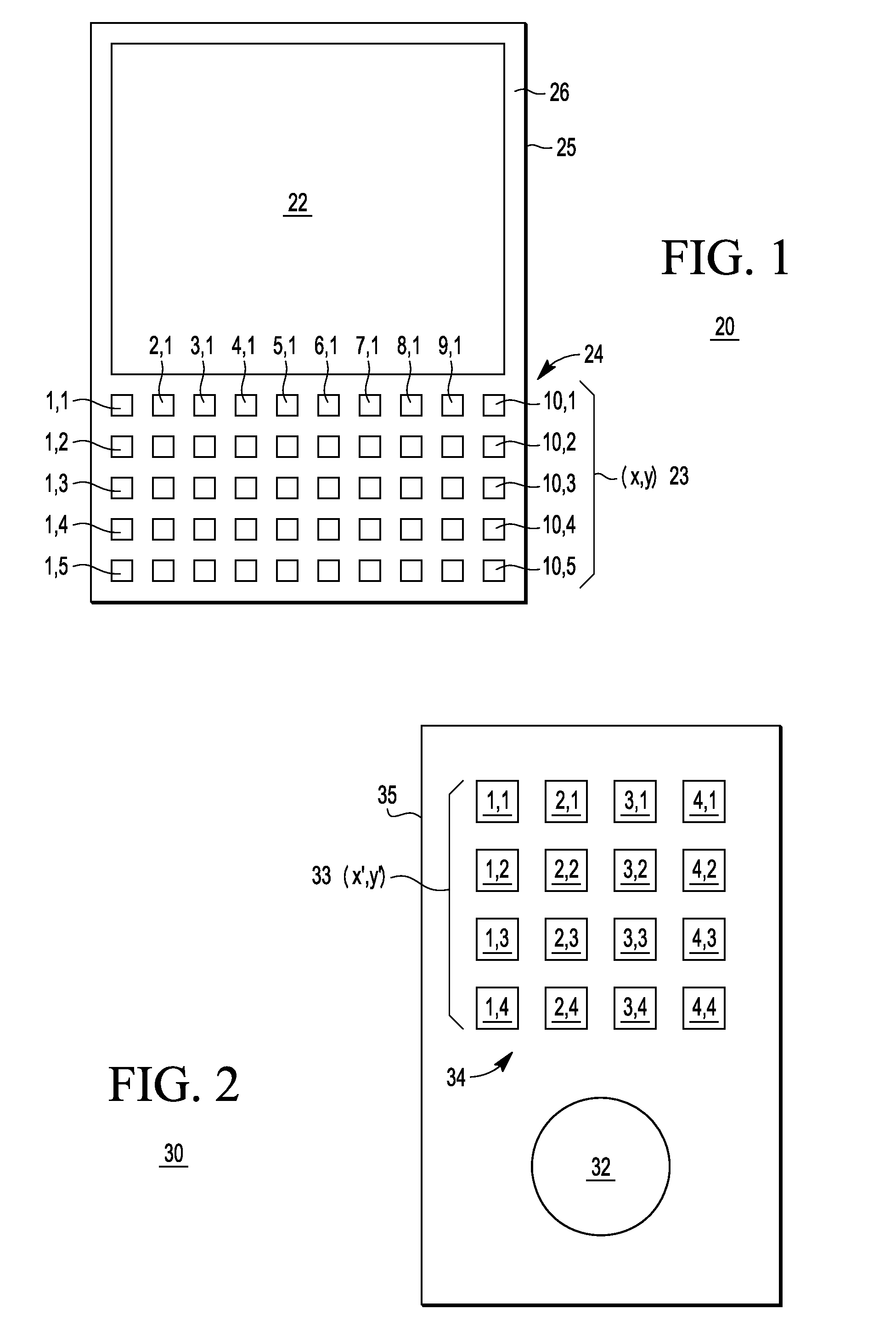

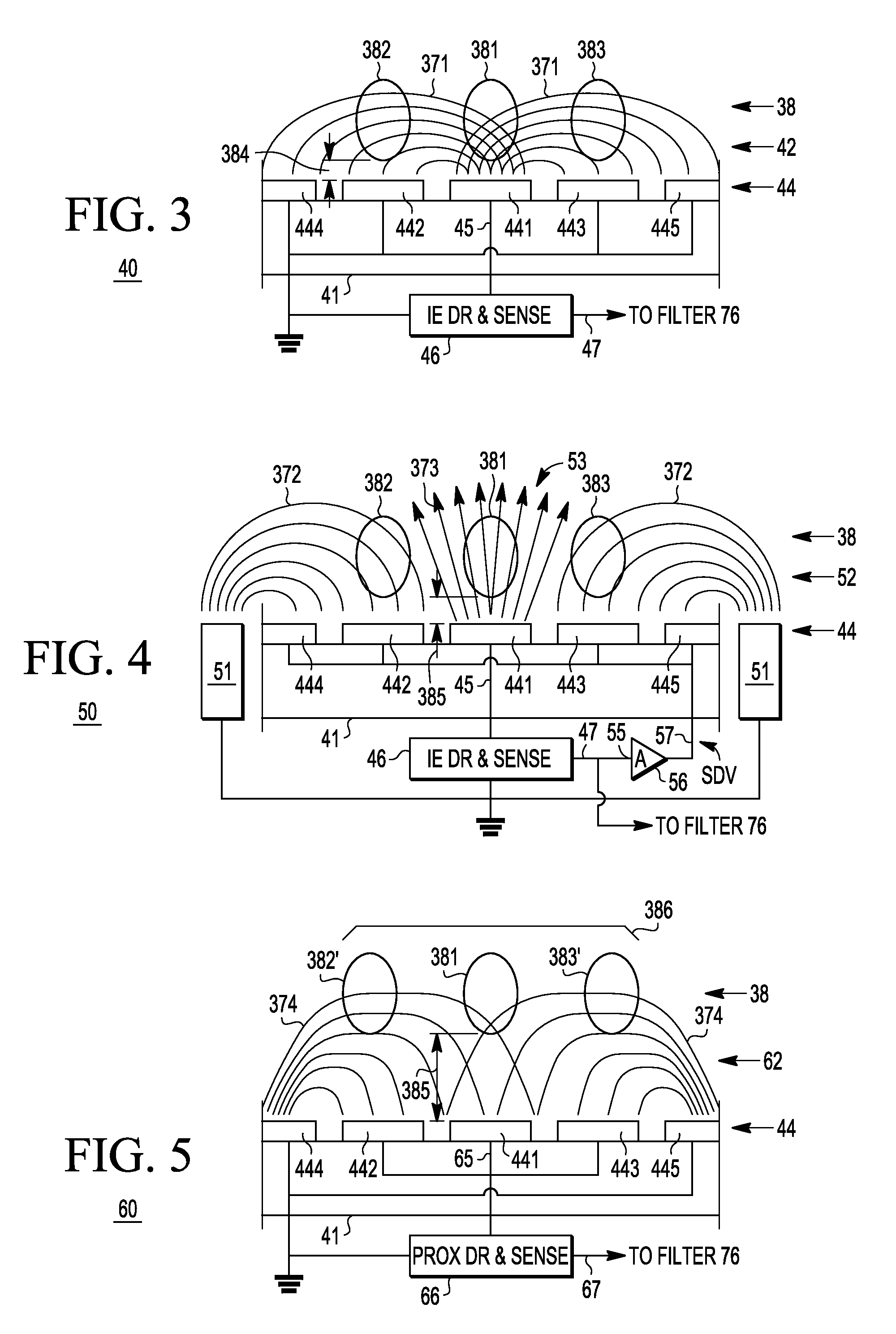

The electrical equivalent of a relatively large area proximity detection capability is provided in a space limited electronic device (20, 30) with many individual input electrodes (24, 34, 44) by dynamically coupling parallel groups of the individual electrodes (24, 34, 44) and applying a proximity and / or contact test thereto. The parallel grouped electrodes act like a single large electrode and permit proximity detection at greater distances and with greater sensitivity. A multiplexer (74) automatically couples individual input electrodes (23, 24, 44) and then parallel grouped electrodes to the proximity (or contact) sensor(s) (46, 66), so that they are scanned and sensed individually and collectively in a time less than human reaction time, whereby the proximity sense function appears as if provided by a separate large area electrode. Proximity spatial detection accuracy is increased by using some of the electrodes (24, 34, 44) as driven shields to remove positional ambiguity.

Owner:NORTH STAR INNOVATIONS

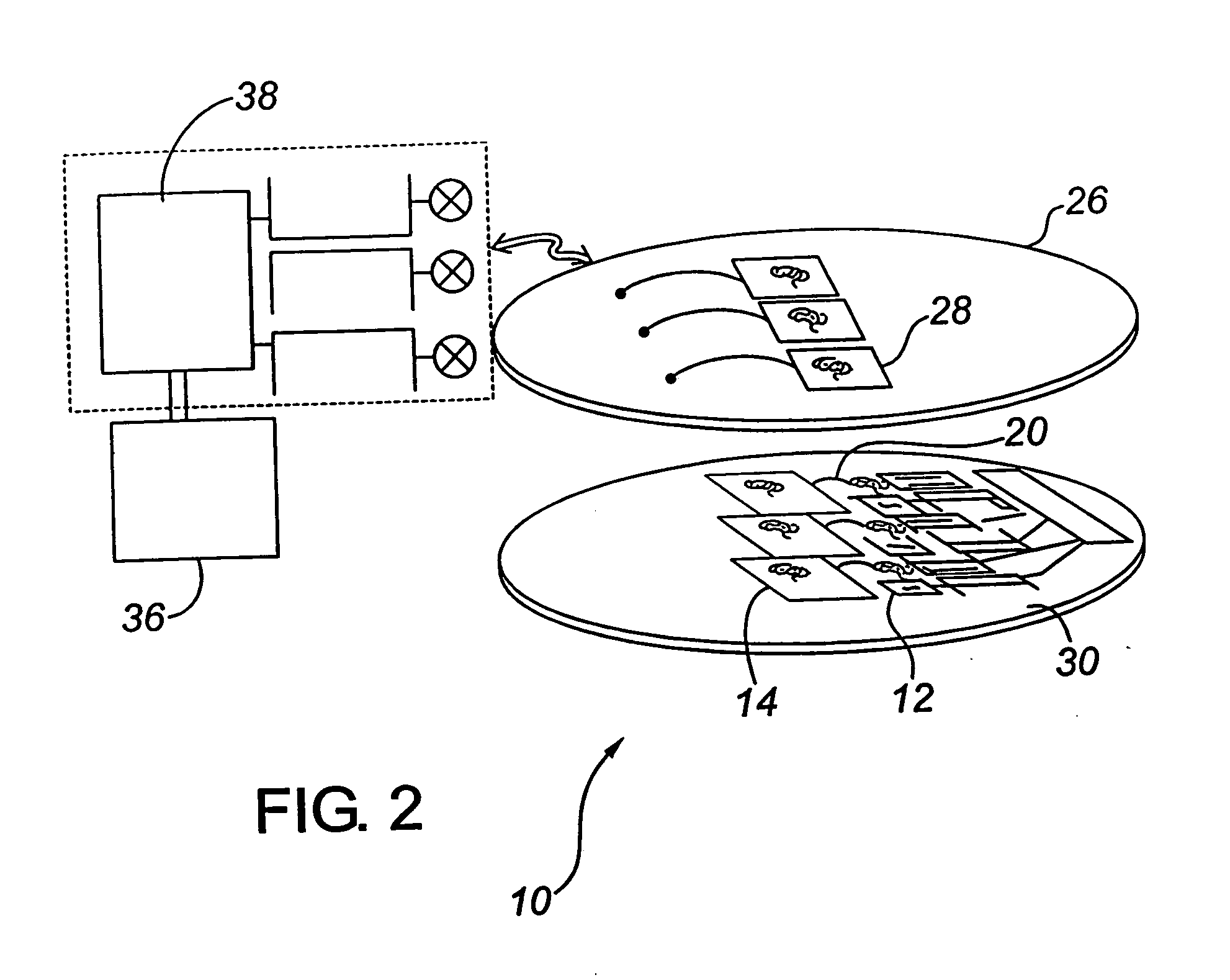

Non-contact tester for electronic circuits

InactiveUS20060066326A1Radiofrequency circuit testingContactless circuit testingContact testTester device

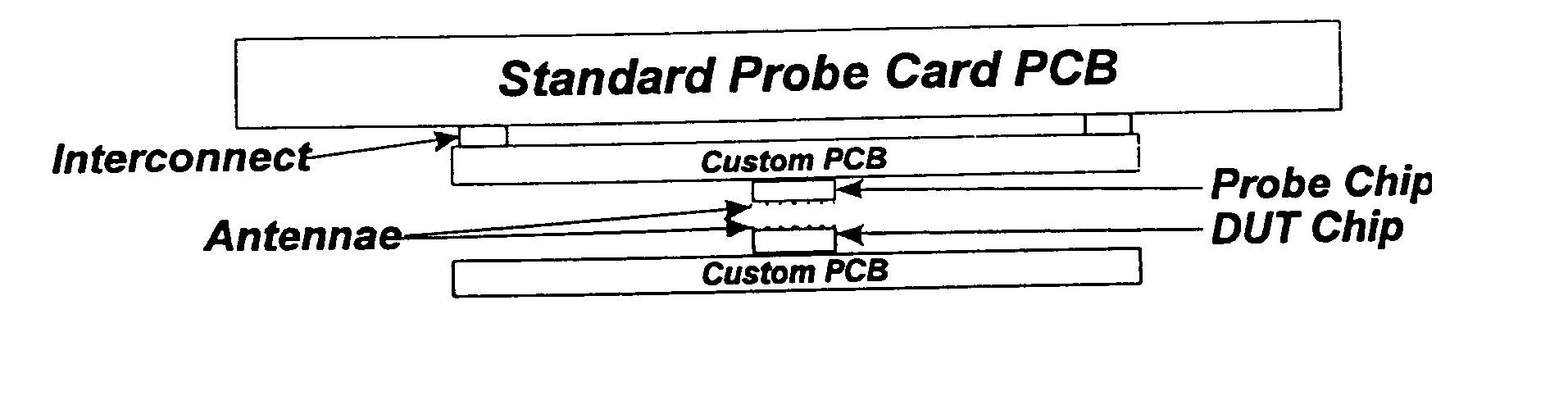

A non-contact tester for electronic circuits consists of an electronic circuit and independent scanning head, in combination. The electronic circuit includes a micro-fabricated wireless i / o cell and means for sending and receiving signals via the wireless i / o cell. The independent scanning head has a wireless i / o cell that is compatible with the wireless i / o cell on the electronic circuit. This enables data to be exchanged with the electronic circuit to confirm proper functioning of the electronic circuit.

Owner:SCANIMETRICS

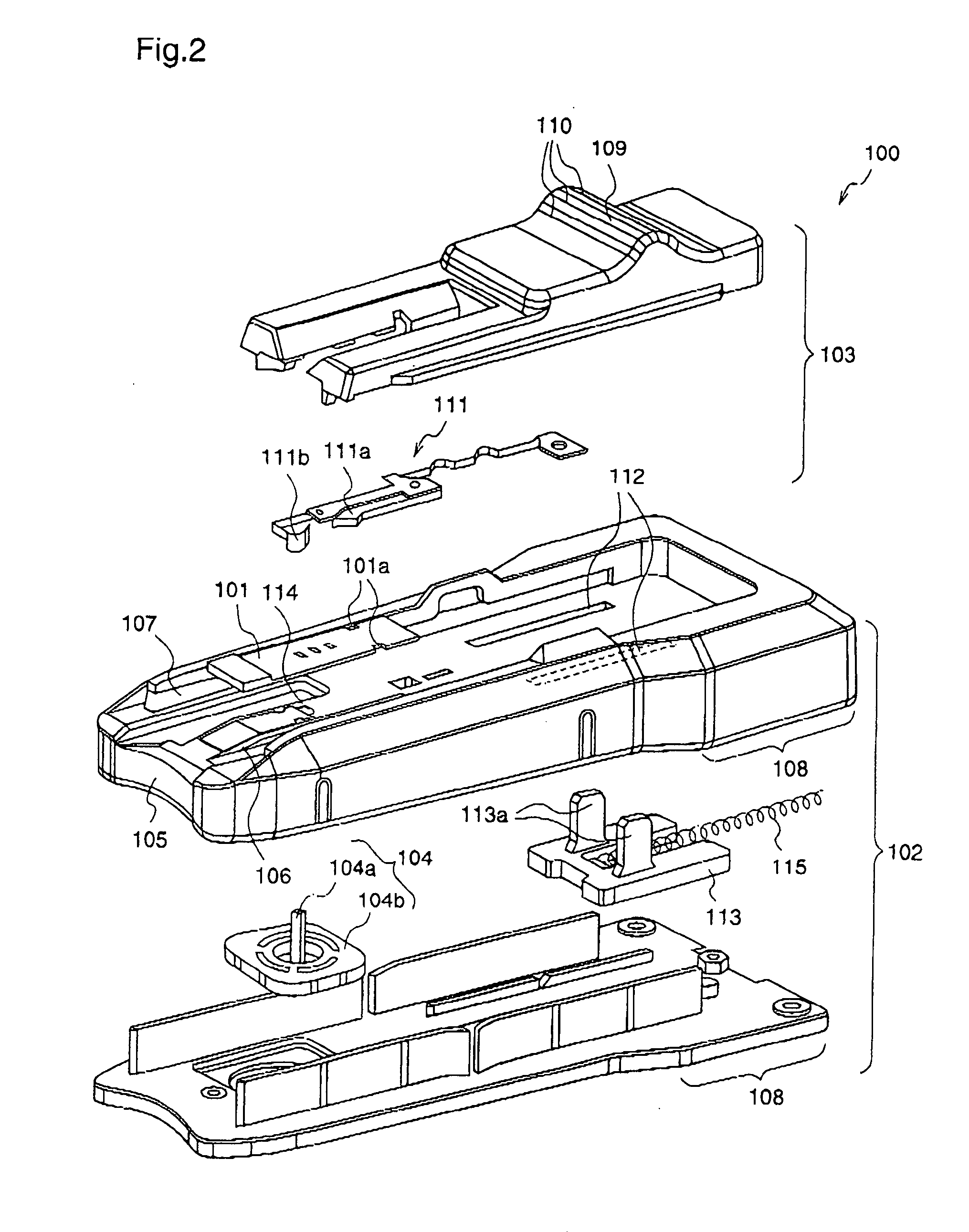

Test strip holder

InactiveUS20060133956A1Avoid contactEasy to testMaterial analysis by optical meansBiological testingContact testMeasurement test

A test strip holder comprises a rectangular base having a concave part on its upper surface, arid a slidable moving part that is slidably fitted to the concave part of the base. When measuring the test strip, the test strip is reliably held between the base and the slidable moving part. After measurement, the test strip is ejected semiautomatically from the test strip holder by sliding of the slidable moving part with respect to the base. Therefore, the test strip after measurement, which has health problem and risk of infection, can be semiautomatically discarded without touching the test strip.

Owner:PANASONIC CORP

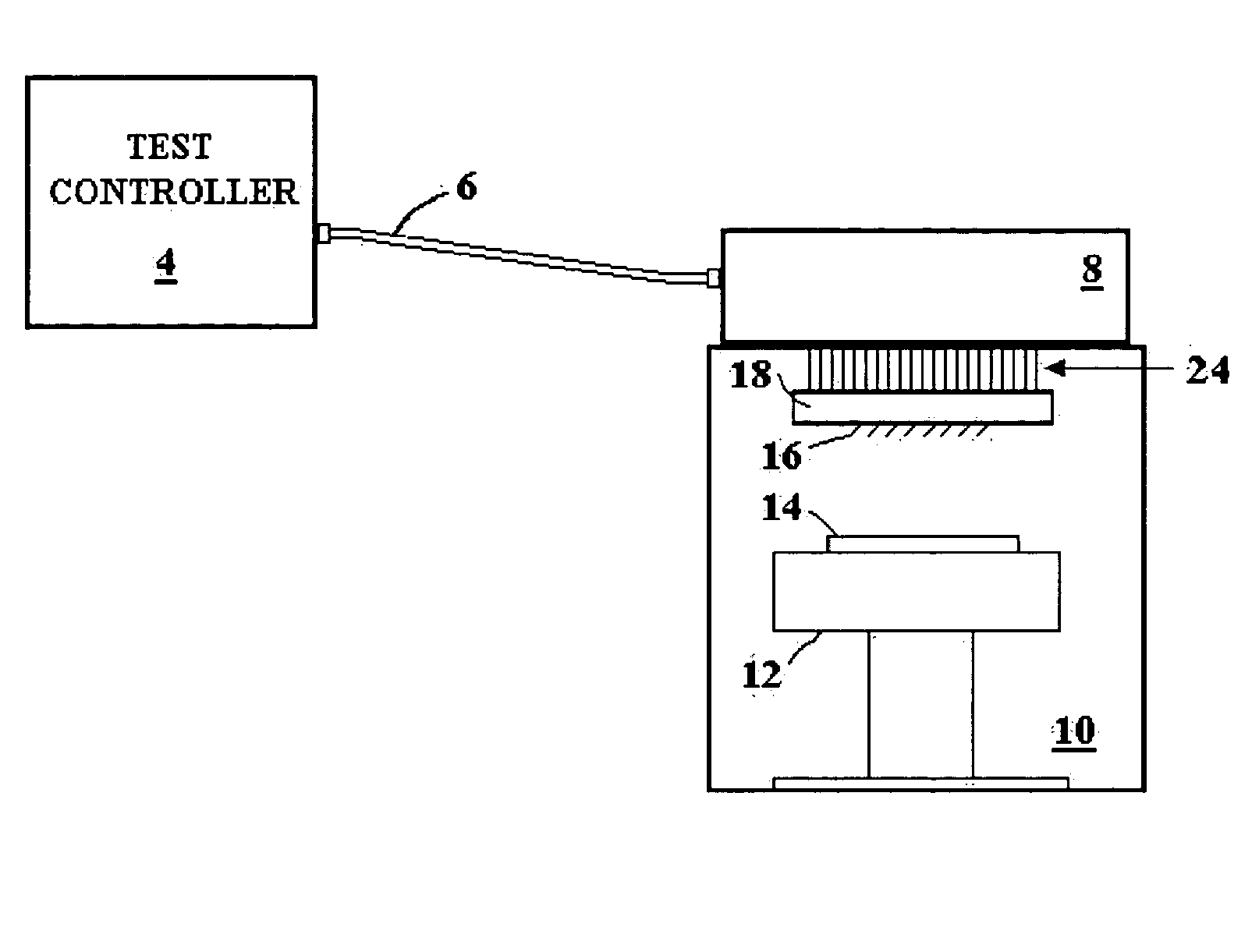

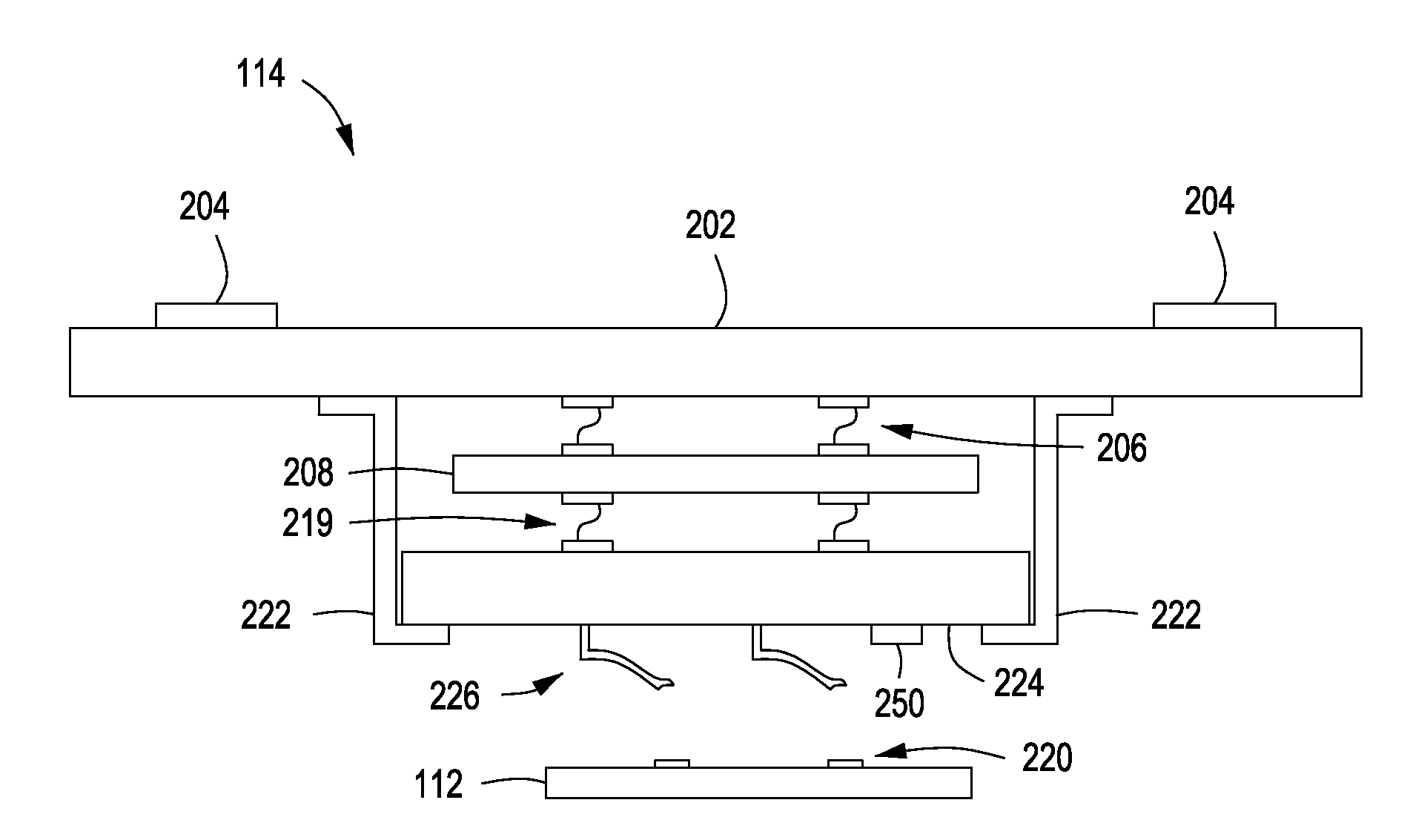

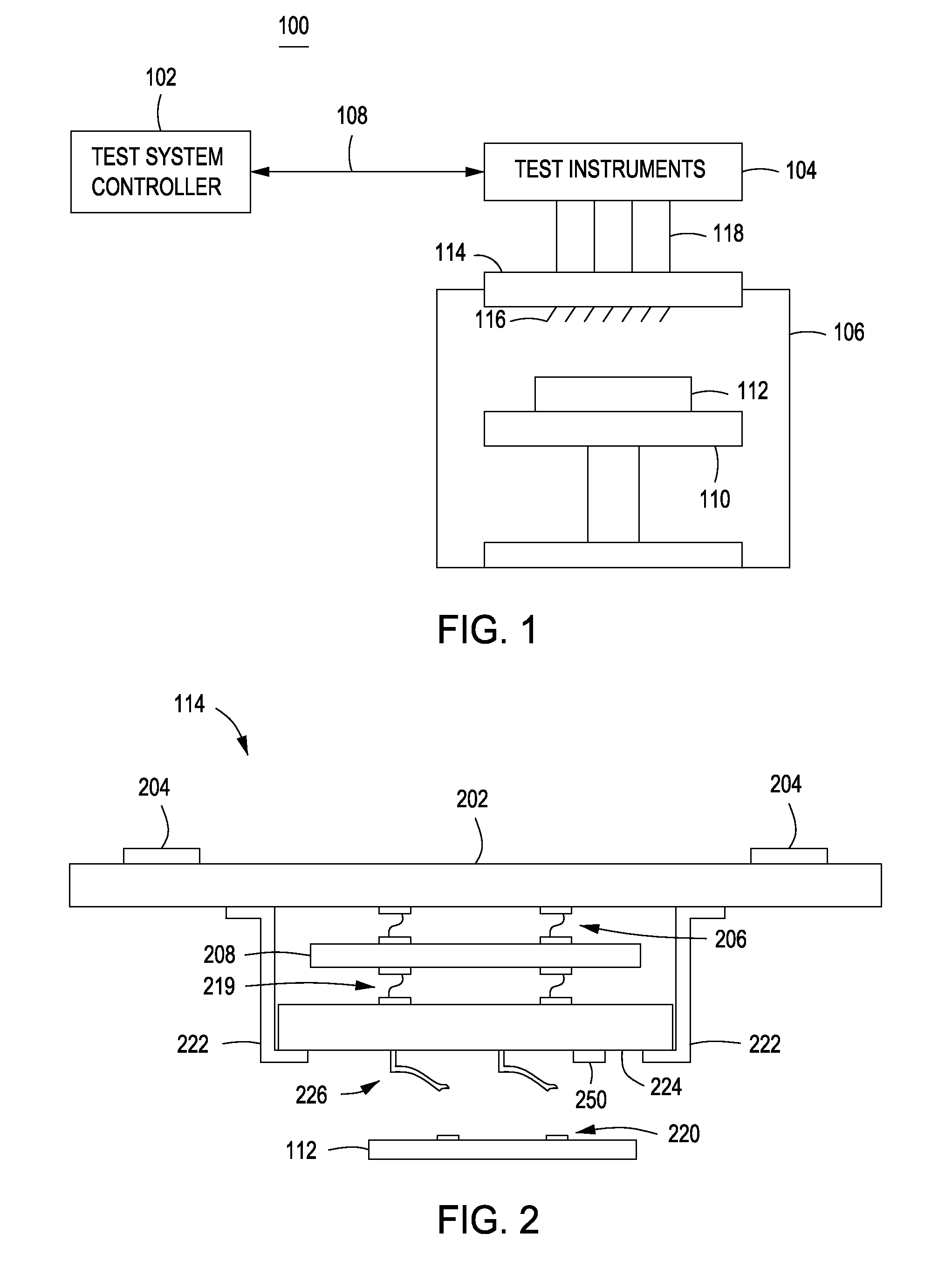

Mechanically reconfigurable vertical tester interface for IC probing

InactiveUS20050277323A1Minimize signal trace lengthEasy trace length matchingElectronic circuit testingCoupling device detailsContact testProbe card

A wafer test assembly includes multiple probe head substrates arranged like tiles with connectors attached to one side and probes supported on the opposing side. In one embodiment, flexible cable connectors directly connect the connectors on the probe head tile to a test head, while in another embodiment the flexible cables connect the probe head tile to a PCB providing horizontal routing to test head connectors. In one embodiment, leveling pins provide a simplified support structure connecting to a retaining element attached to the tiles to provide for applying a push-pull leveling force. A test head connector interface frame enables rearrangement of connectors between the test head and the probe card to provide for both full wafer contact or partial wafer contact. The test head connectors are rearranged by being slidable on rails, or pluggable and unpluggable enabling movement over a range of positions.

Owner:FORMFACTOR INC

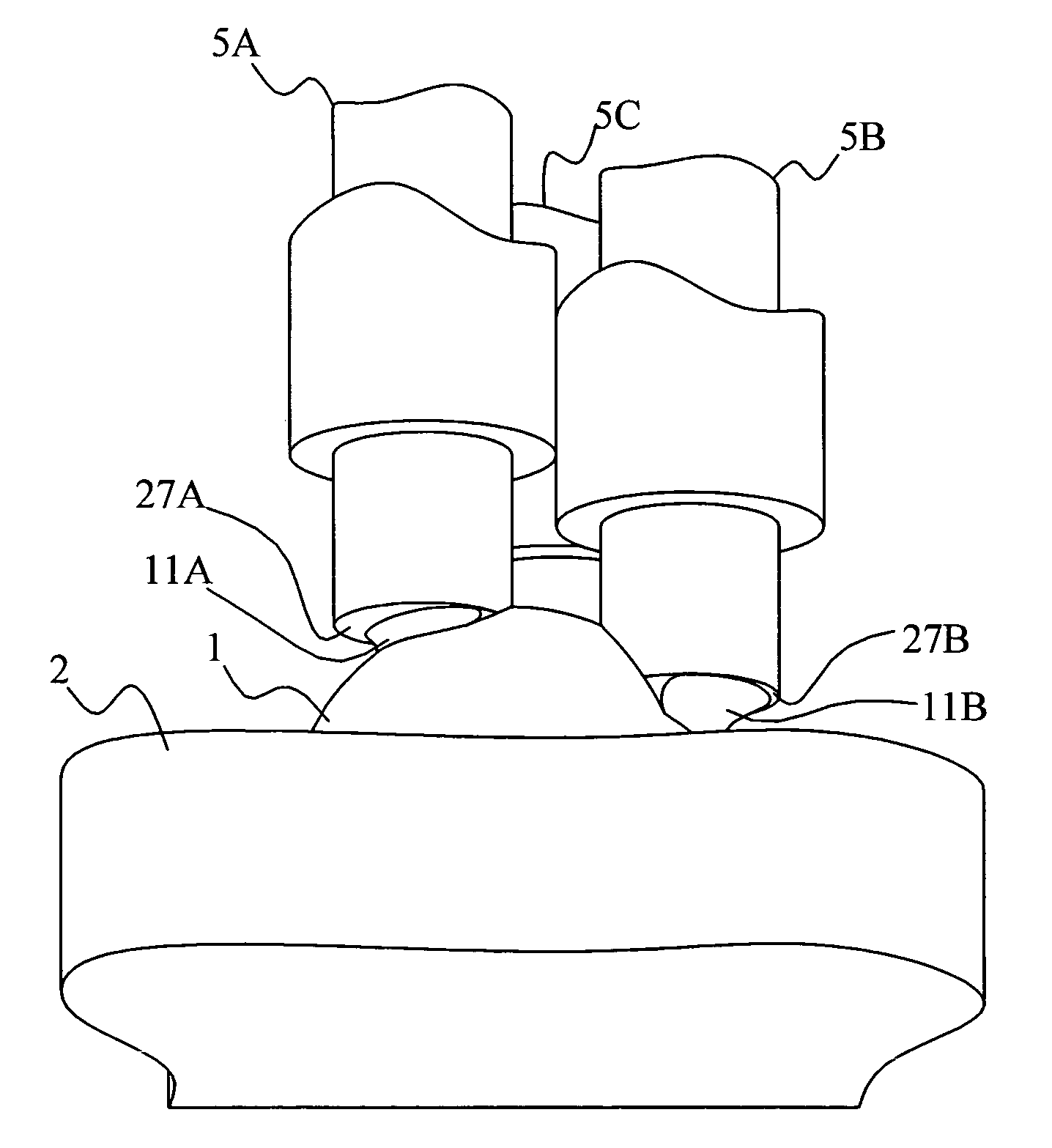

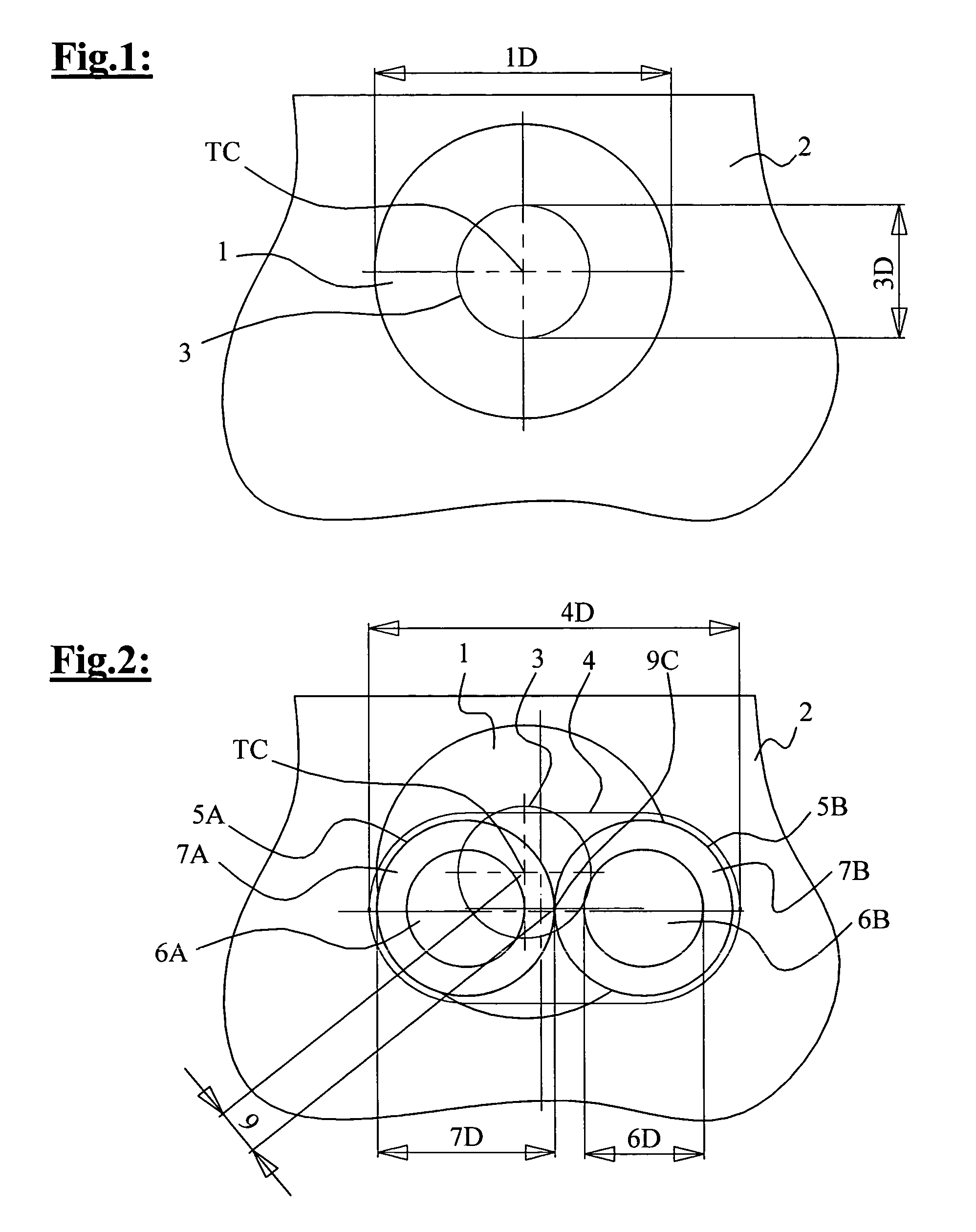

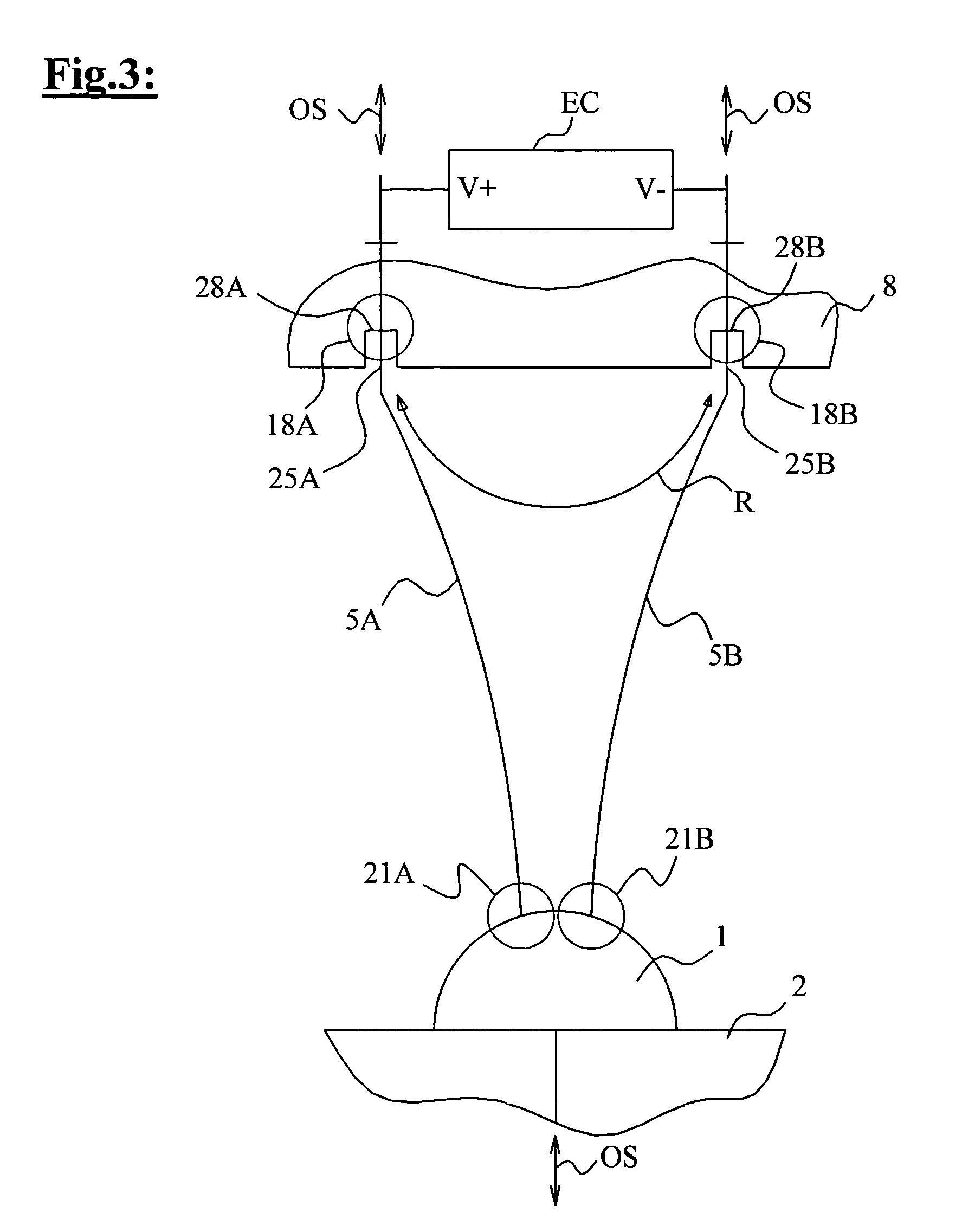

Bundled probe apparatus for multiple terminal contacting

InactiveUS7064564B2Resistance/reactance/impedenceElectronic circuit testingElectrical resistance and conductanceContact test

A probe apparatus having probe groups comprising two or three probes that independently contact single terminals of tested chips. As a result, the probe apparatus is capable of recognizing voltage drops of a test signal applied prior to the chip testing onto a test path along two or three probes contacting, the terminal and the interfaces between them. The test path does not pass through the chip. An electronic circuit measures the voltage drops and compensated accordingly operational signals passing through the terminals, the probes and the interfaces during the chip testing. A first embodiment comprises two probes per group. A second embodiment comprises three probes per group. In the second embodiment, the variable resistance component of three resistance measurements of first / second, first / third and second / third resistance paths are compared by the electronic circuit, in order to determine absolute resistance values for each of the three signal paths. Consequently, in the second embodiment, the voltage drops may be individually adjusted for each of the three operational signal paths.

Owner:INTERCONNECT DEVICES

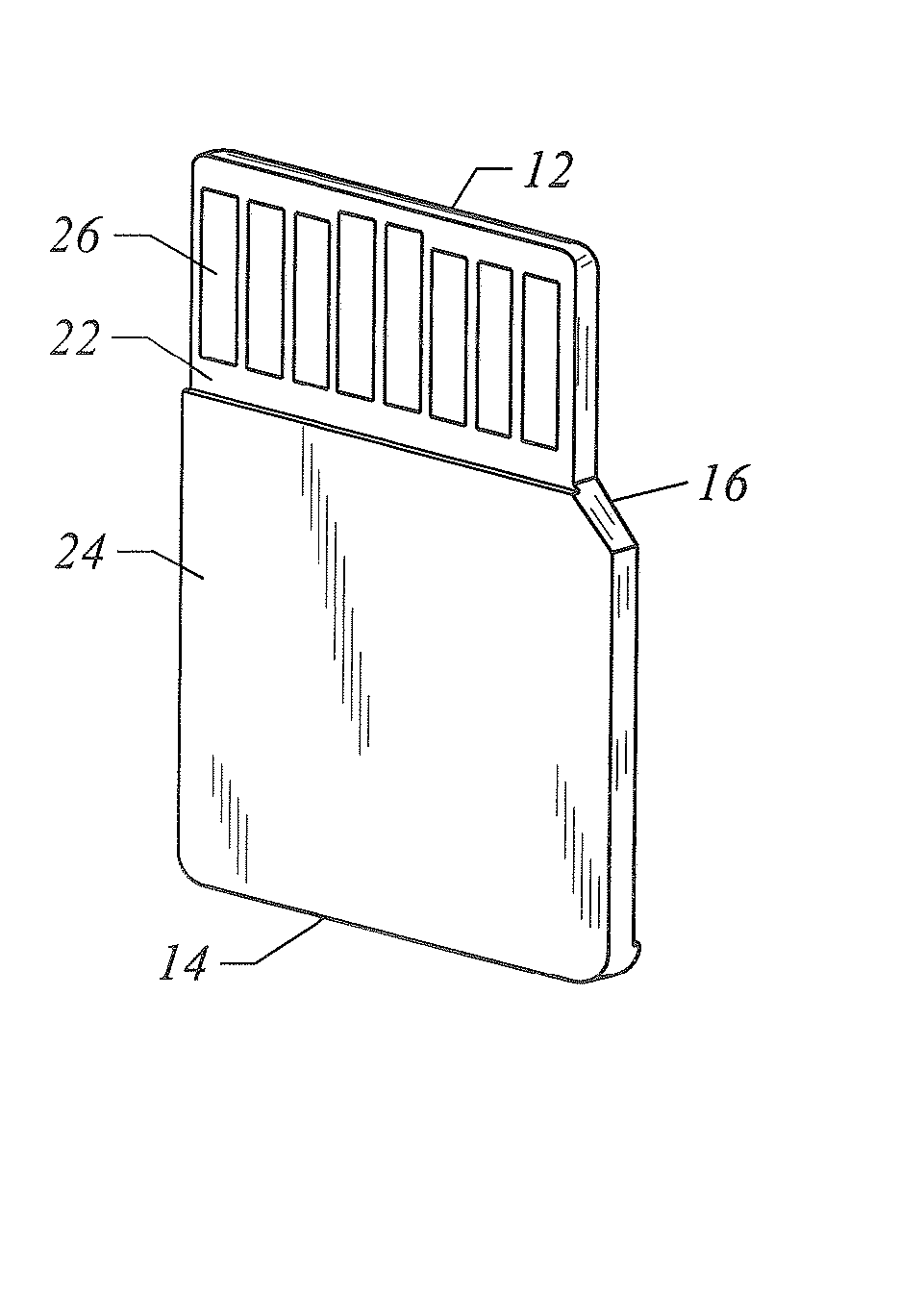

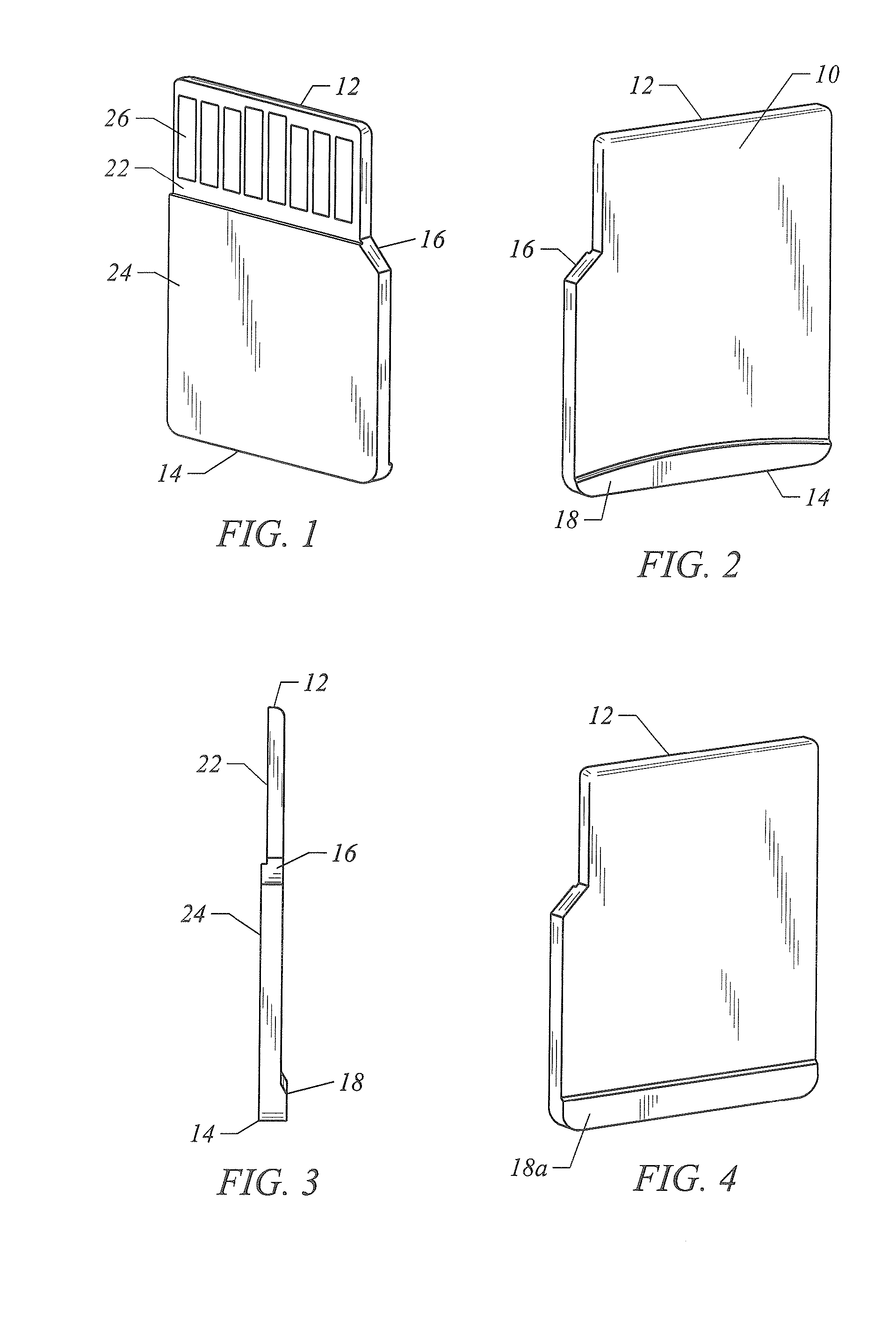

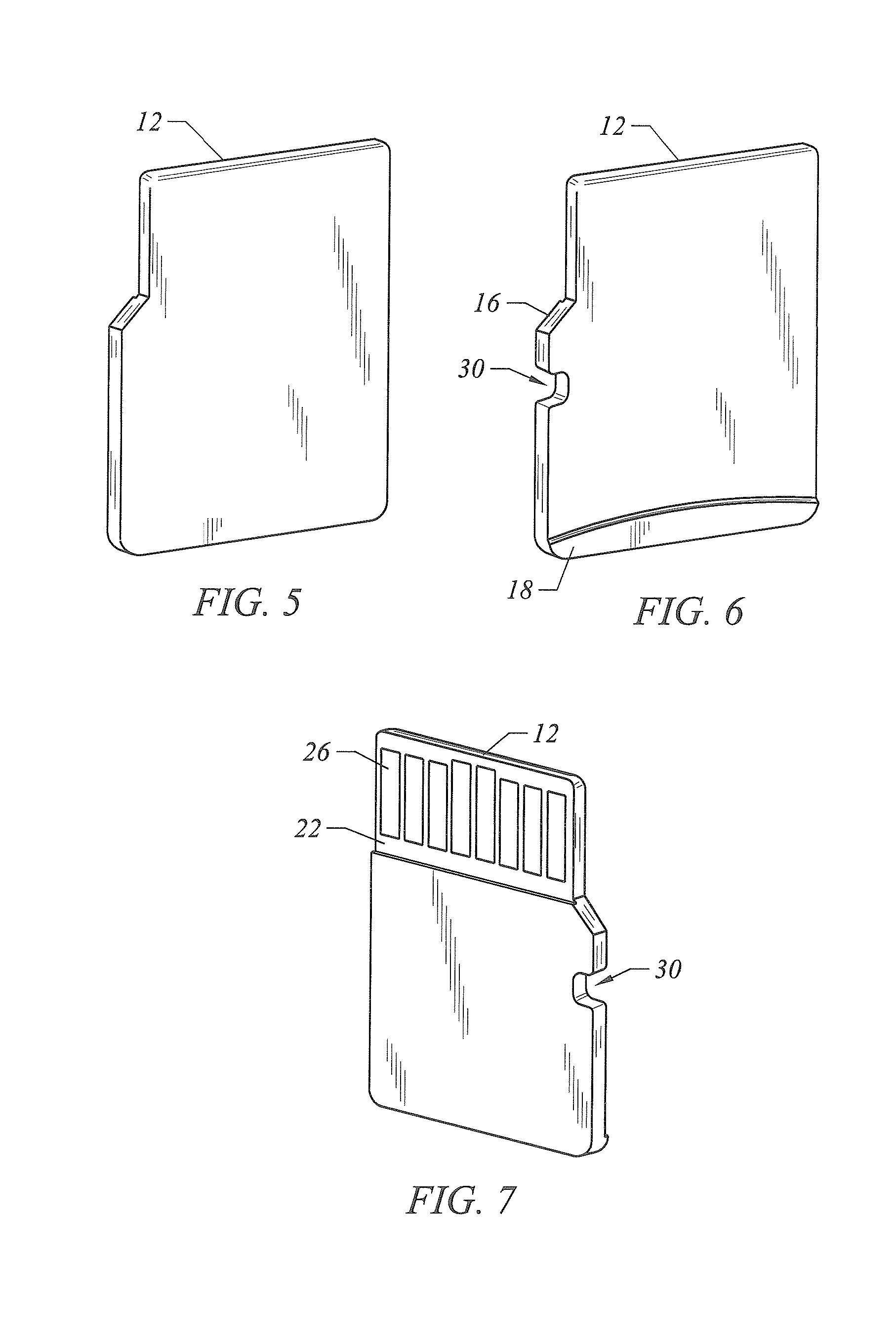

Peripheral card with hidden test pins

InactiveUS20080049392A1Avoid accessDigital data processing detailsCross-talk/noise/interference reductionContact testEngineering

A peripheral card includes a circuit board, various circuit elements on the circuit board, a set of user terminals, a set of test terminals, and an enclosure that covers a portion of the circuit board and the circuit elements. The enclosure does not cover the user terminals and test terminals. After the peripheral card is tested, the test terminals are covered with a conformal contact coating in order to prevent access to the test terminals.

Owner:SANDISK TECH LLC

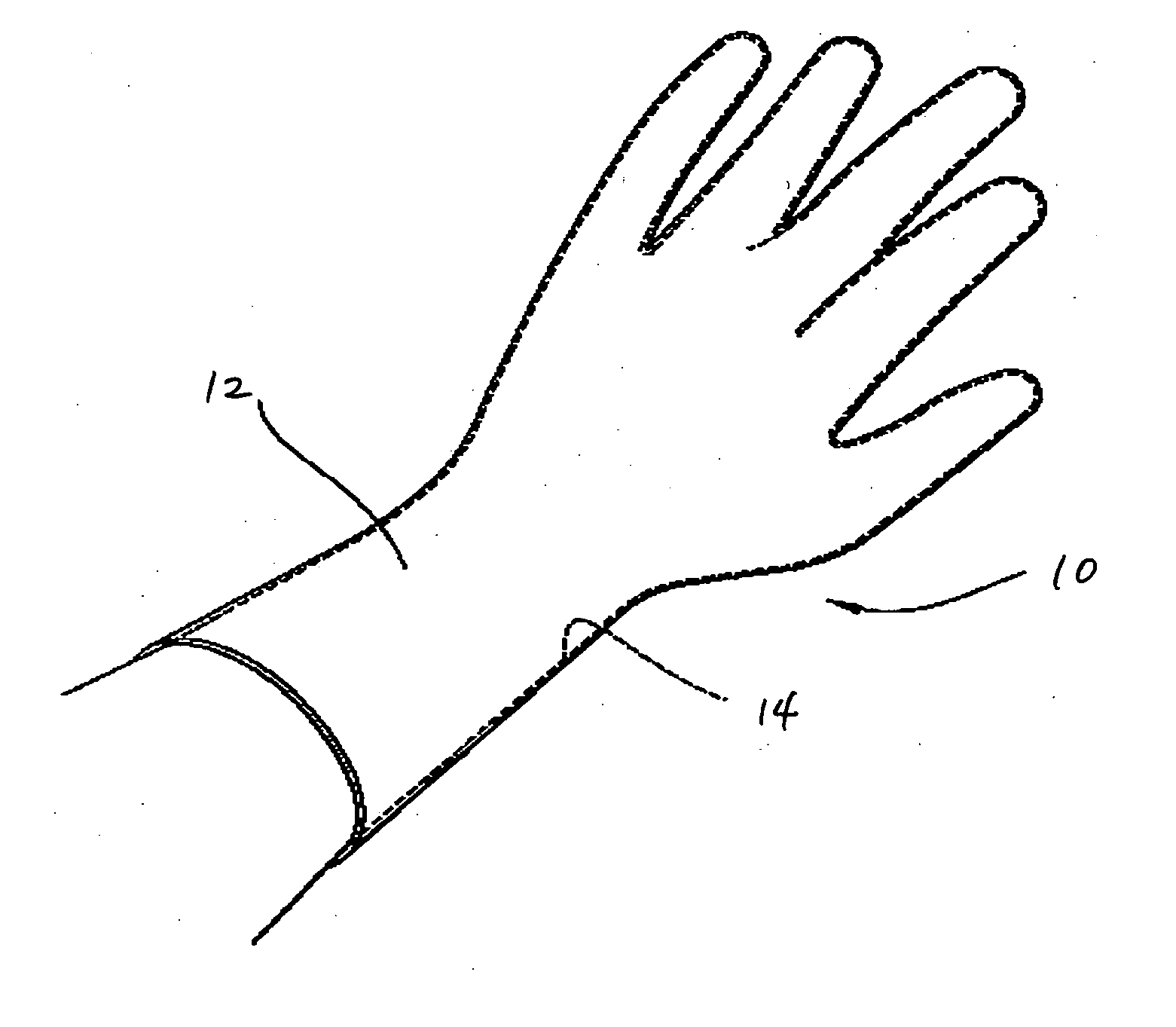

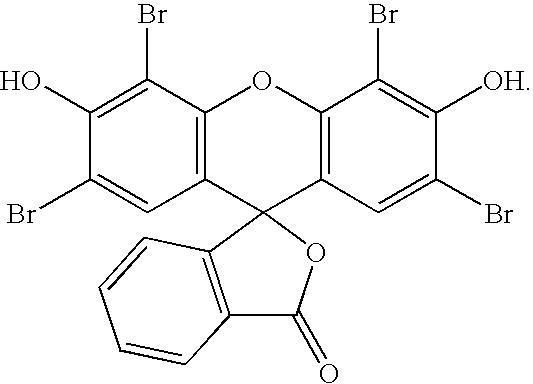

Application of an antimicrobial agent on an elastomeric article

An elastomeric article having reducing microbe affinity and transmission and methods for applying and immobilizing antimicrobial compounds to the elastomeric substrate surface are disclosed. The elastomeric article has a body formed of a natural or synthetic polymer latex having an outer surface and an inner surface. The body has a coating of an antimicrobial agent over at least a portion of said outer surface. The treatment involves applying according to either a spraying or dipping process an antimicrobial polymer or composition to a surface of the elastomeric substrate; binding the antimicrobial composition to the surface in a manner such that said treat antimicrobial coating passes either one or another or both versions of a zone of inhibition test, such test including: a) a dry-leaching or agar-plate-based contact test, according to AATCC 147 protocol, or b) a wet-leaching or dynamic shake flask test according to ASTM E-2149-01 protocol. The substrate is further subject to a rapid germicidal contact-transfer test of relatively short duration. The antimicrobial polymer can include an organosilane quaternary ammonium or a biguanide compound which can disrupt the ionic charges of microbial cellular membranes.

Owner:KIMBERLY-CLARK WORLDWIDE INC

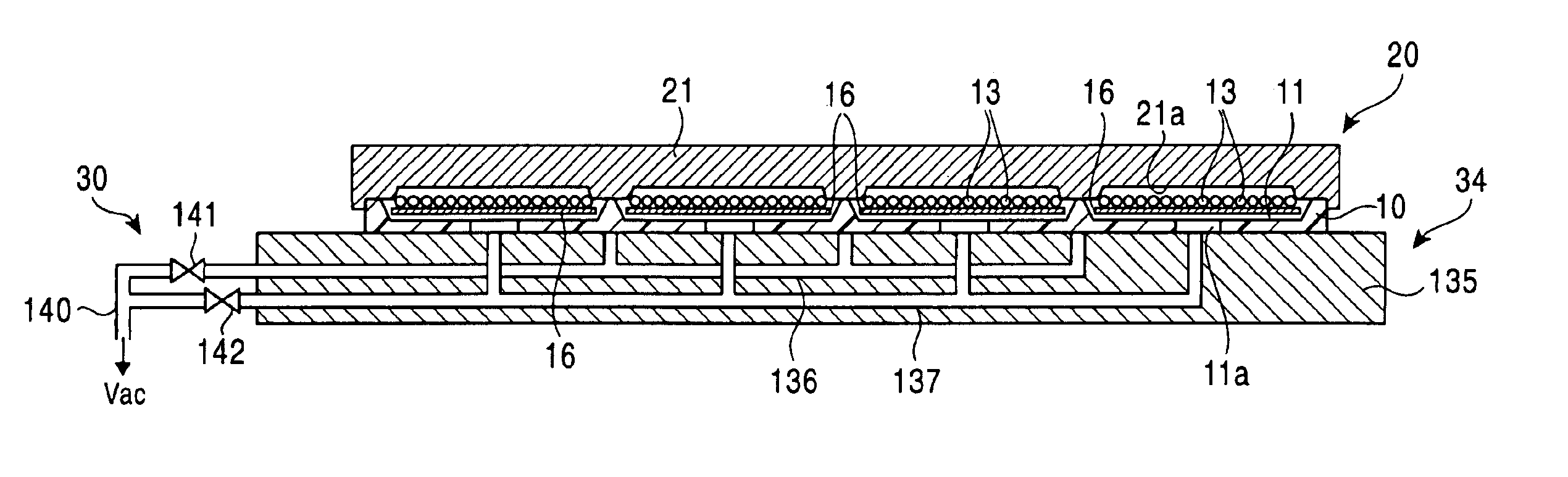

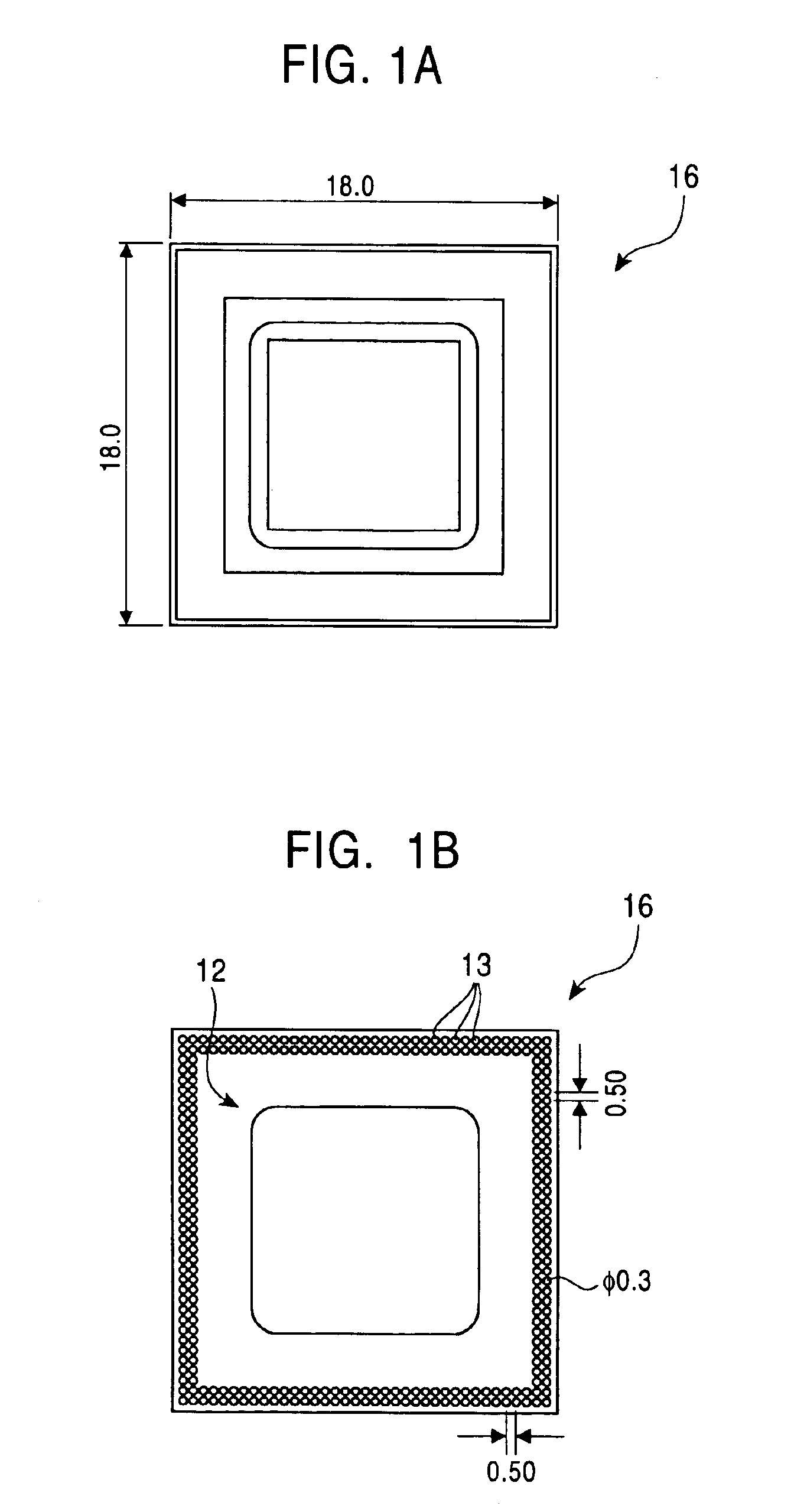

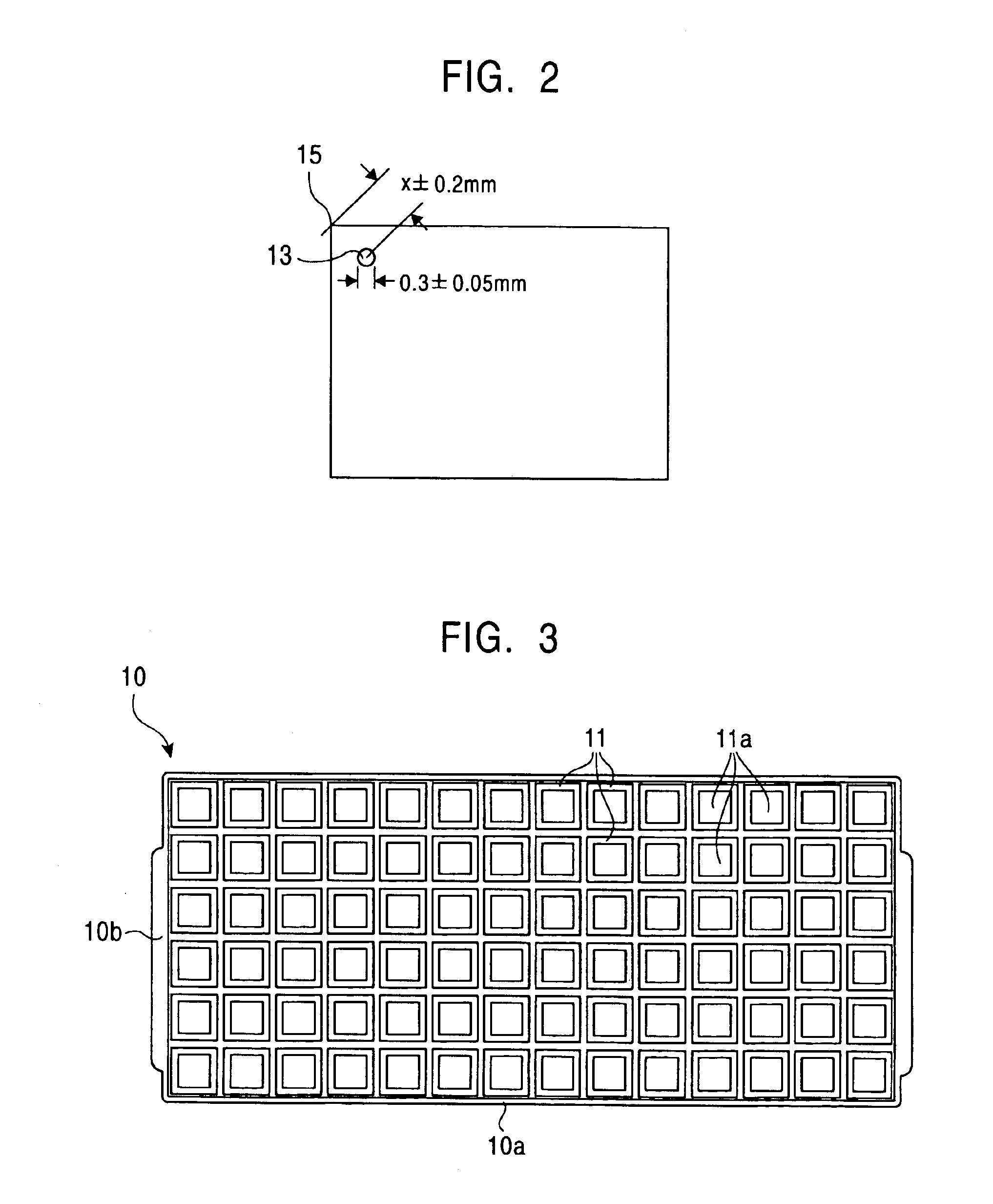

Method and apparatus for testing BGA-type semiconductor devices

InactiveUS6924656B2Avoid failureElectronic circuit testingMeasurement instrument housingContact testSemiconductor

A plurality of semiconductor devices is placed in pockets of a tray with terminal surfaces facing upward. Positions of bump terminals of the semiconductor devices are adjusted relative to the tray. The tray is successively moved such that the bump terminals of the semiconductor devices are successively placed at a testing position. The semiconductor devices are successively tested at the testing position by, for example, contacting test electrodes to the bump terminals.

Owner:KAWASAKI MICROELECTRONICS

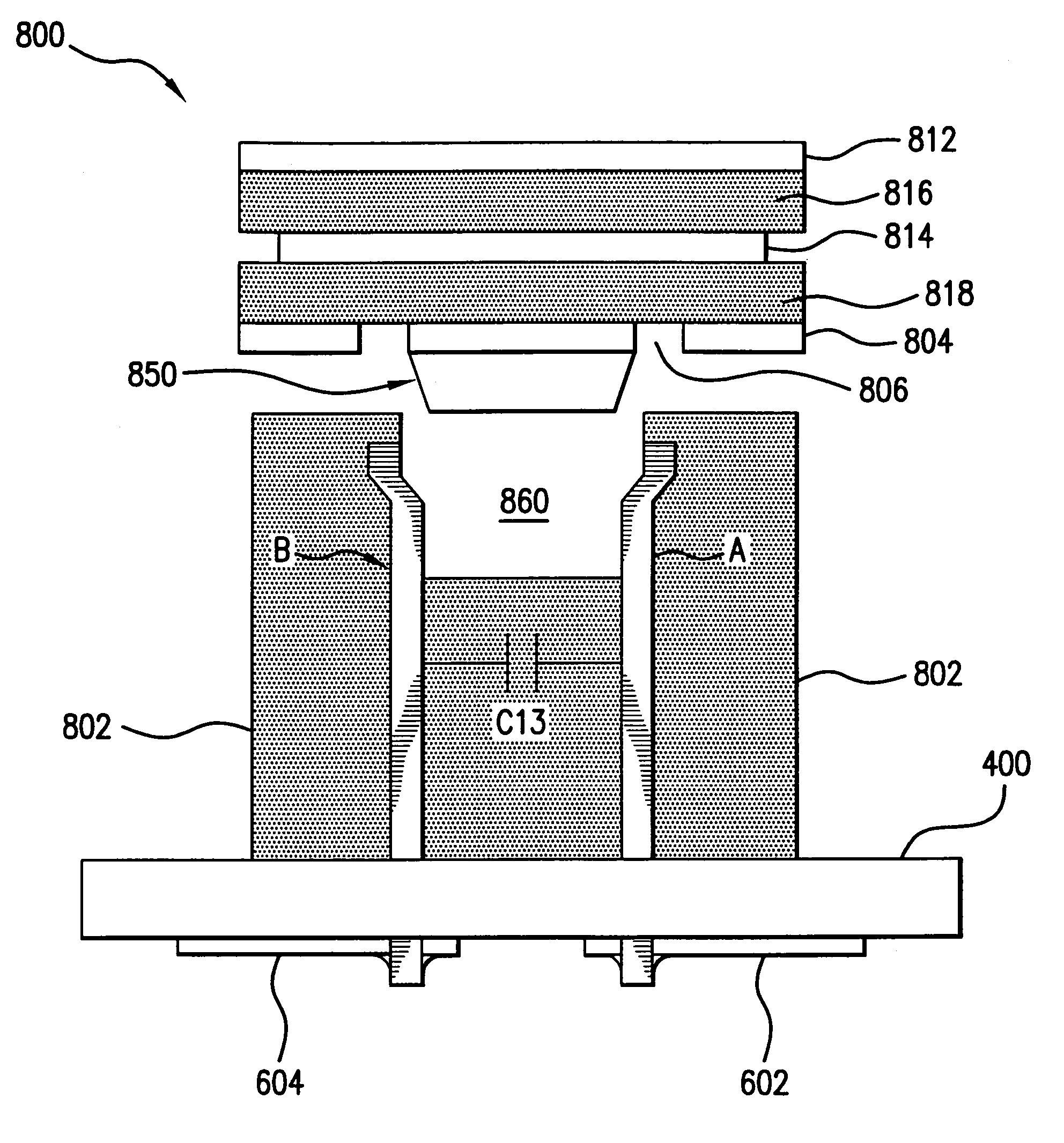

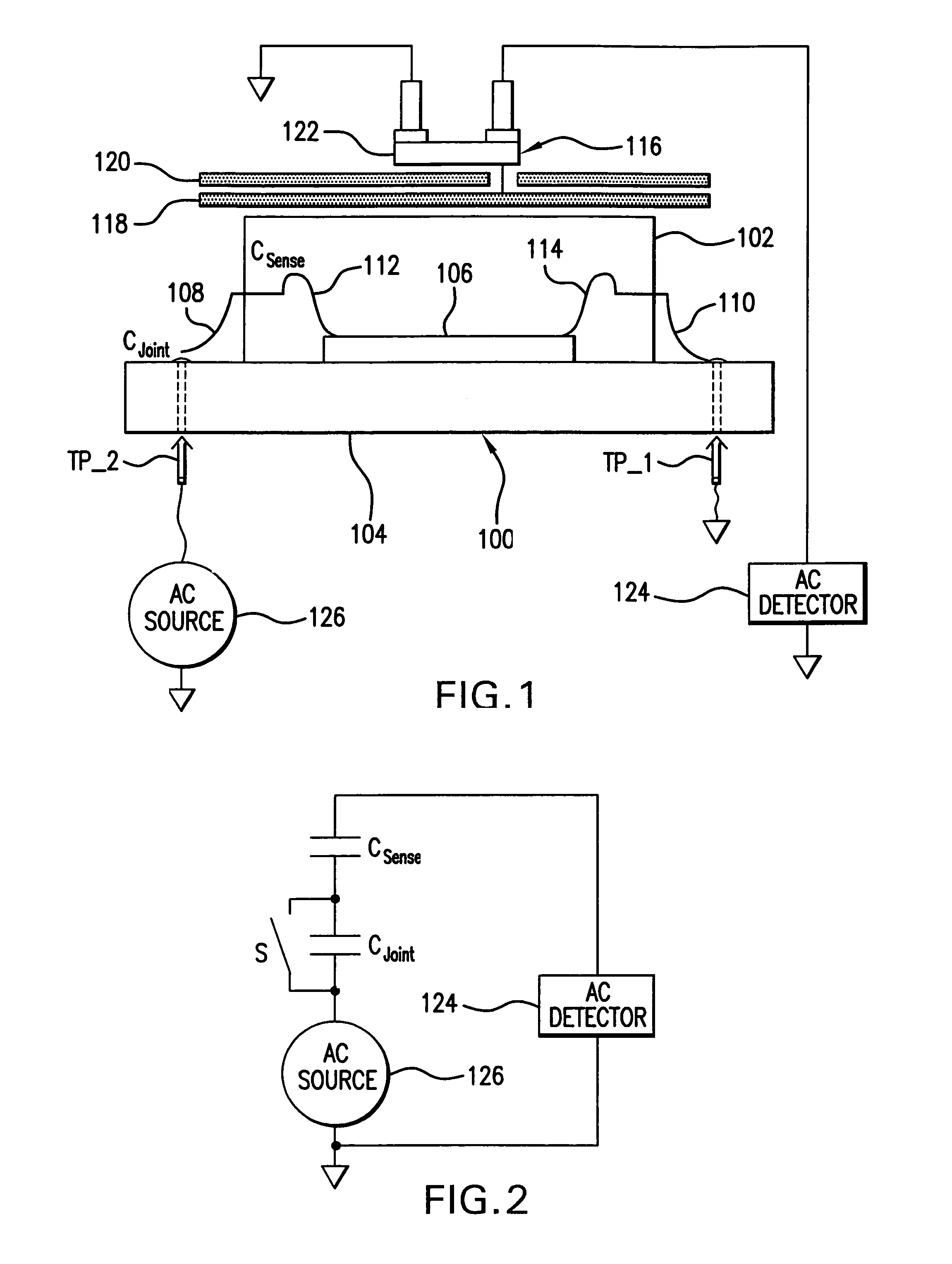

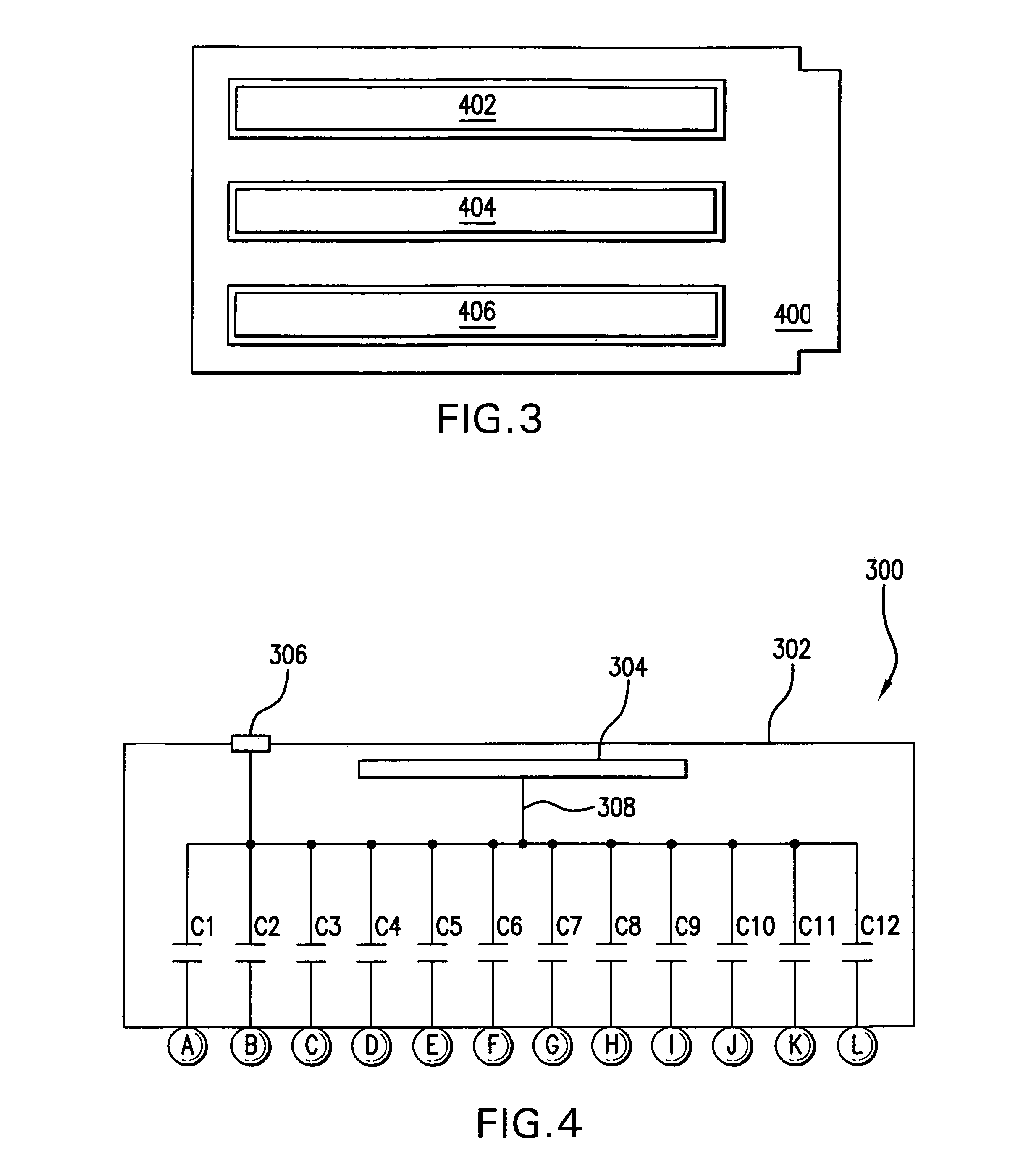

Method and apparatus for non-contact testing and diagnosing electrical paths through connectors on circuit assemblies

A device for enabling testing of electrical paths through a circuit assembly is presented. The device may include a non-contact connector test probe for a testing a connector of the circuit assembly. A method for testing continuity of electrical paths through a circuit assembly is presented. In the method, one or more nodes of the circuit assembly are stimulated, connector pins of a connector on the circuit assembly are capacitively coupled to a non-contact connector test probe, and an electrical characteristic is measured by a tester coupled to the non-contact connector test probe to determine continuity of electrical paths through the circuit assembly.

Owner:AGILENT TECH INC

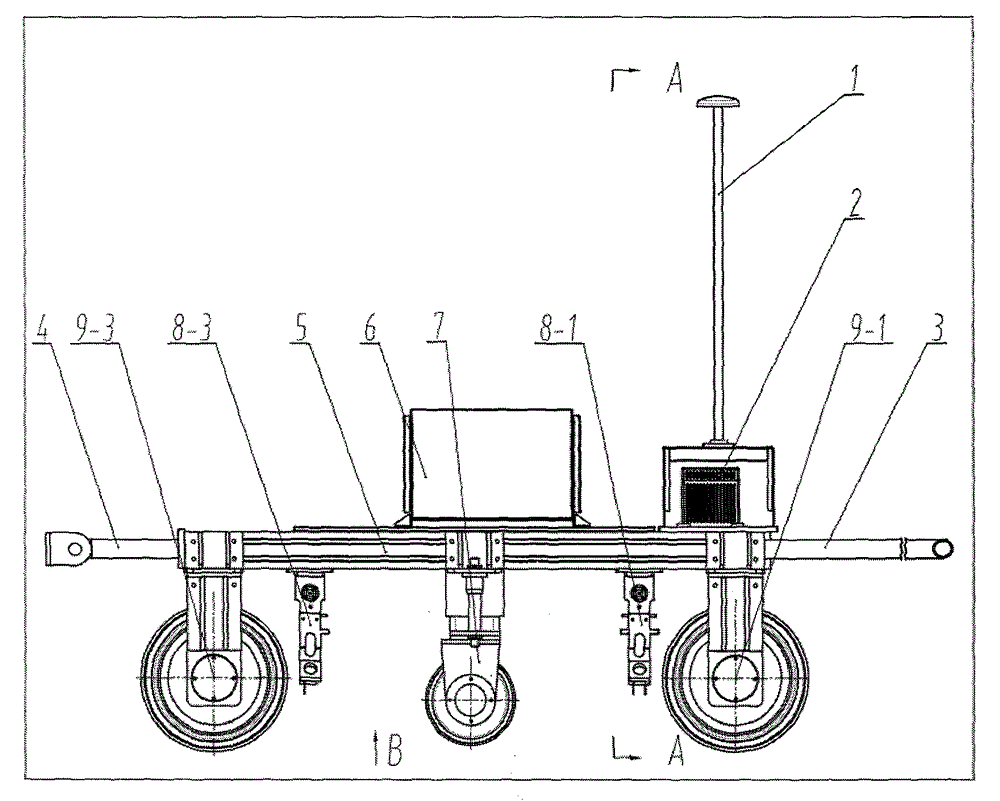

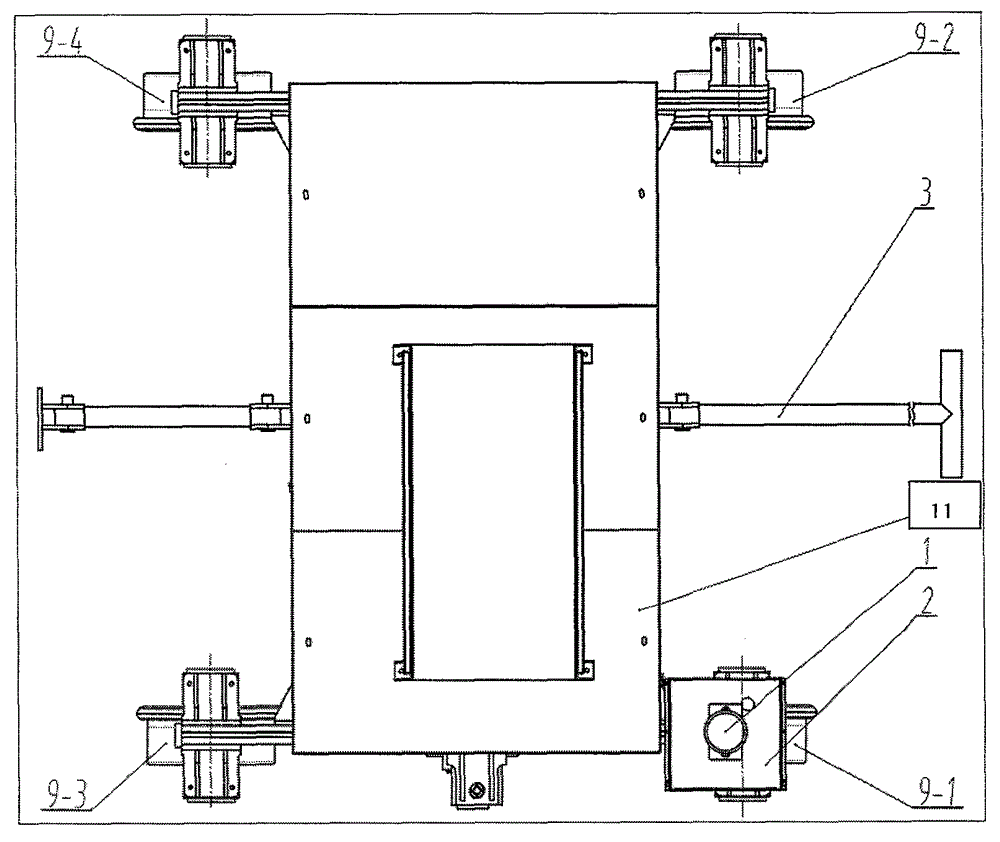

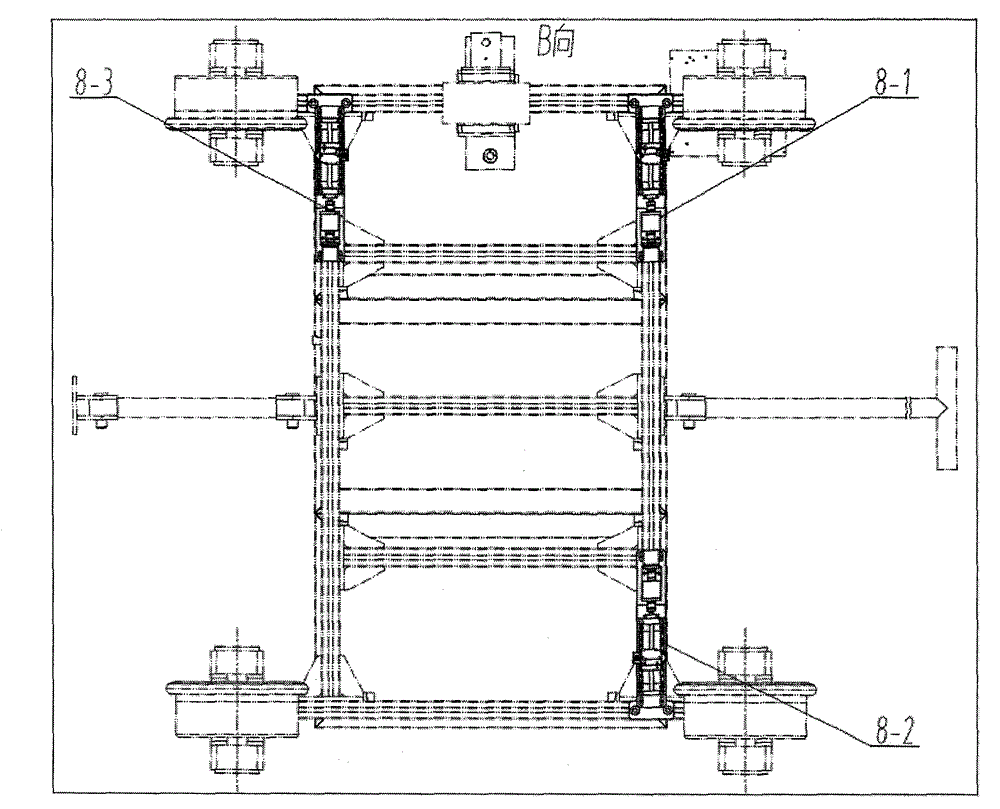

Track parameter dynamic test car based on combination of inertial sensor and navigational satellite

ActiveCN105316986AHigh measurement accuracyEasy to operateMeasuring apparatusContact testMobile station

The invention discloses a track parameter dynamic test car based on a combination of an inertial sensor and a navigational satellite. The track parameter dynamic test car based on the combination of the inertial sensor and the navigational satellite comprises a car body assembly, an inertial sensor assembly, a navigational satellite mobile station assembly, a navigational satellite base station assembly, a track distance measuring assembly, a speedometer assembly and a track test car control computer assembly. The track parameter dynamic test car based on the combination of the inertial sensor and the navigational satellite can automatically complete dynamic detection of nine track parameters such as height, track direction, distortion, level and superelevation, twist warps, plane degree, track distance, turn radius and mileage and the like after running on a track to be tested, achieves no-contact test, and achieves the highest test speed which is 60Kg / h. The track parameter dynamic test car based on the combination of the inertial sensor and the navigational satellite has the advantages of high and steady measurement accuracy, simple structure and easy operation, and is beneficial to generalize and use.

Owner:北京星网宇达科技股份有限公司

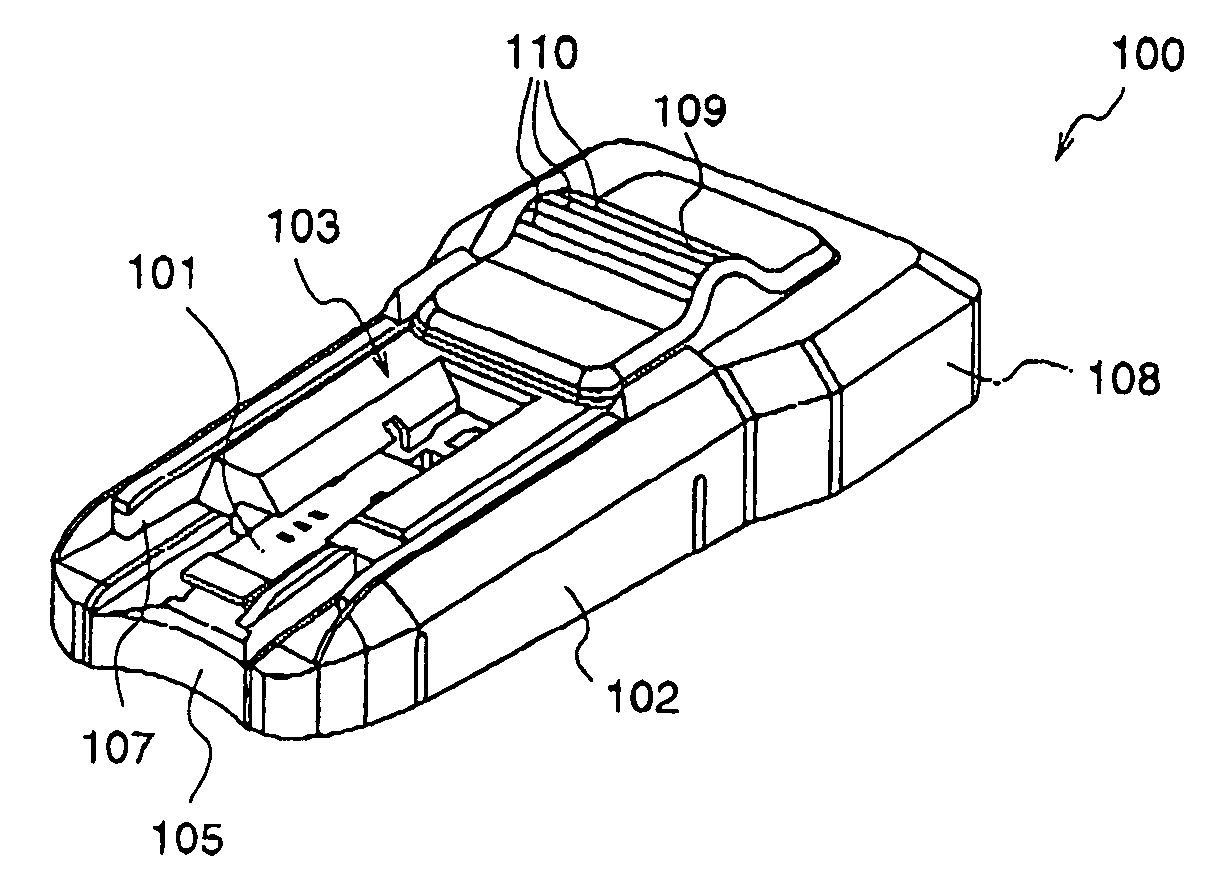

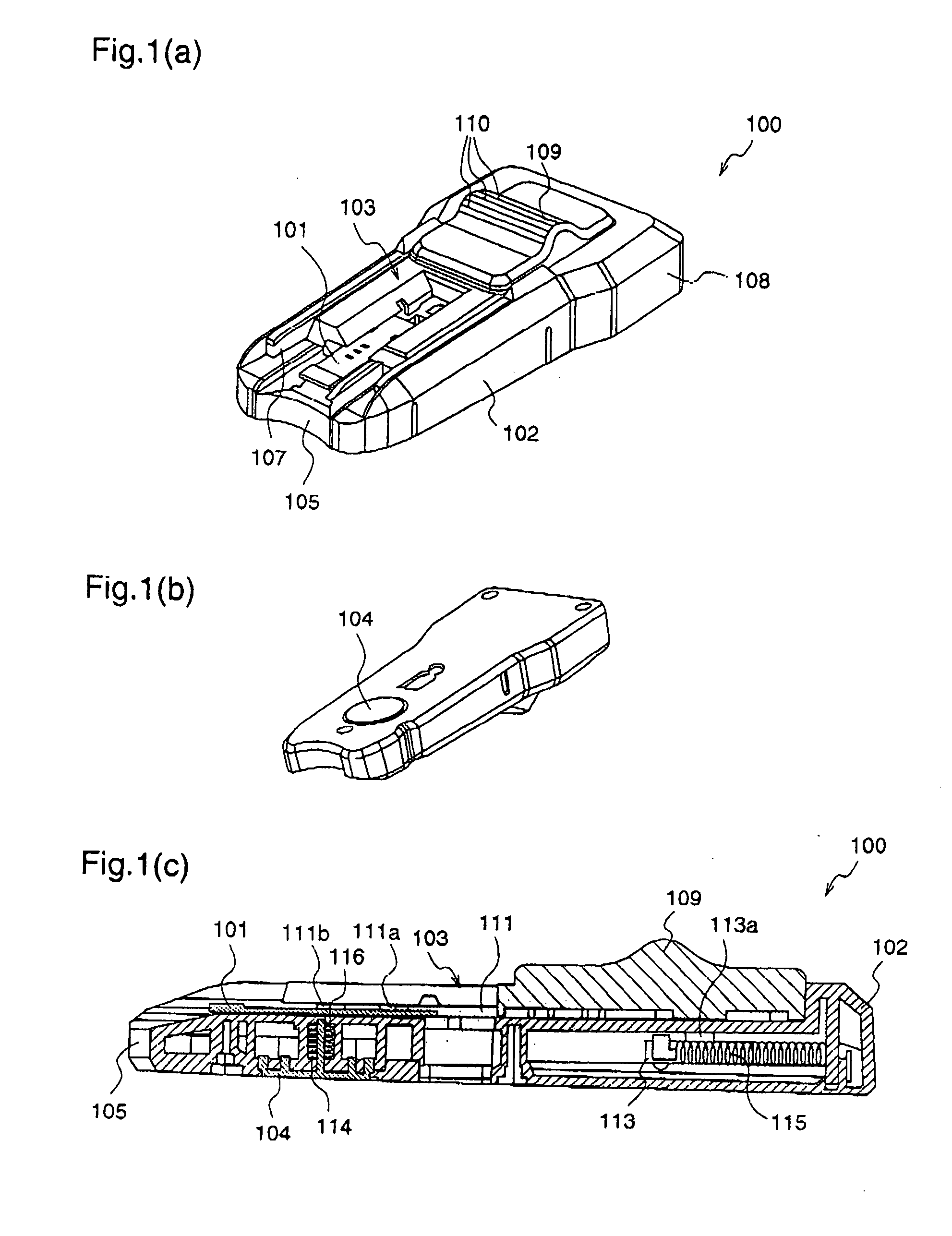

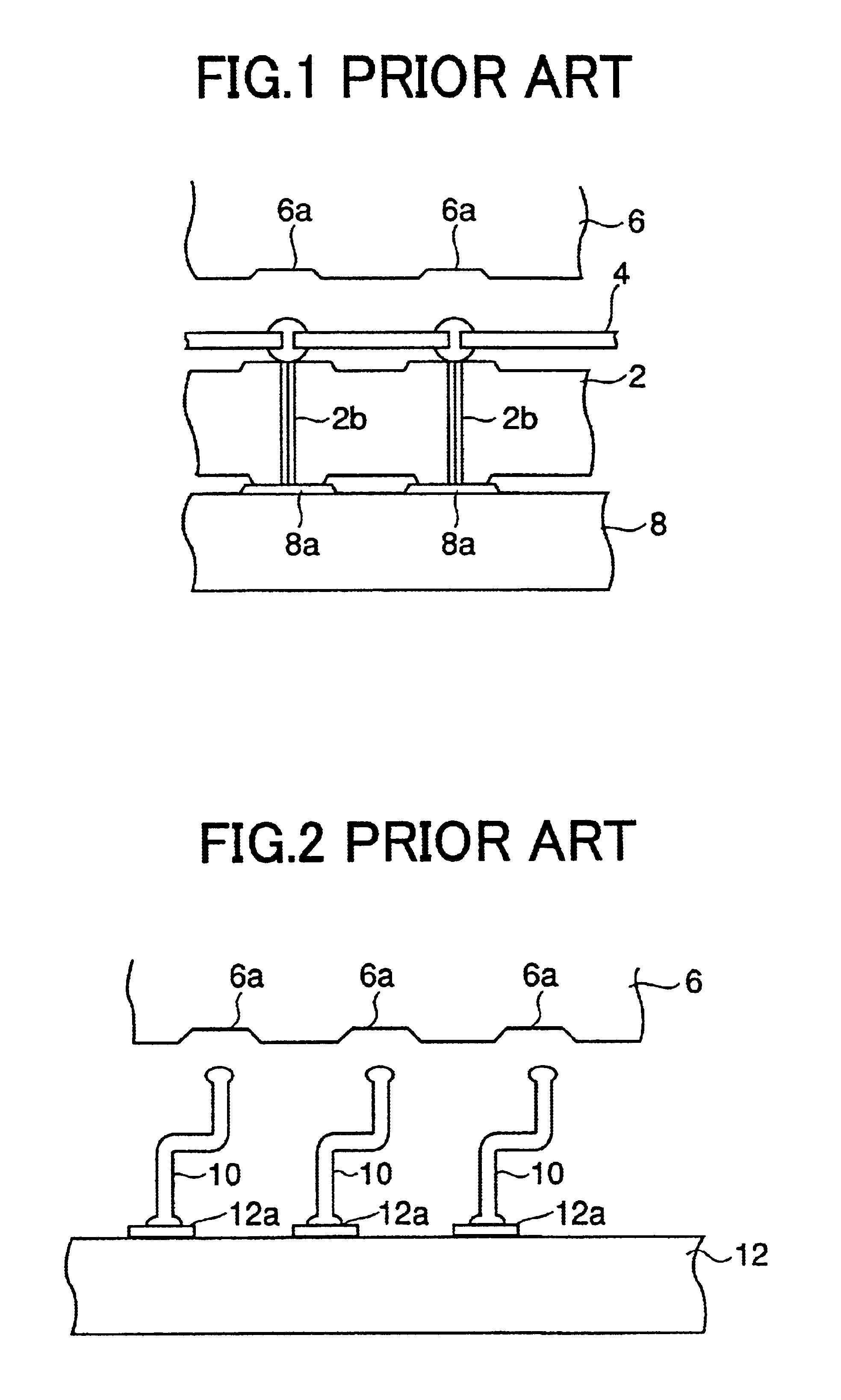

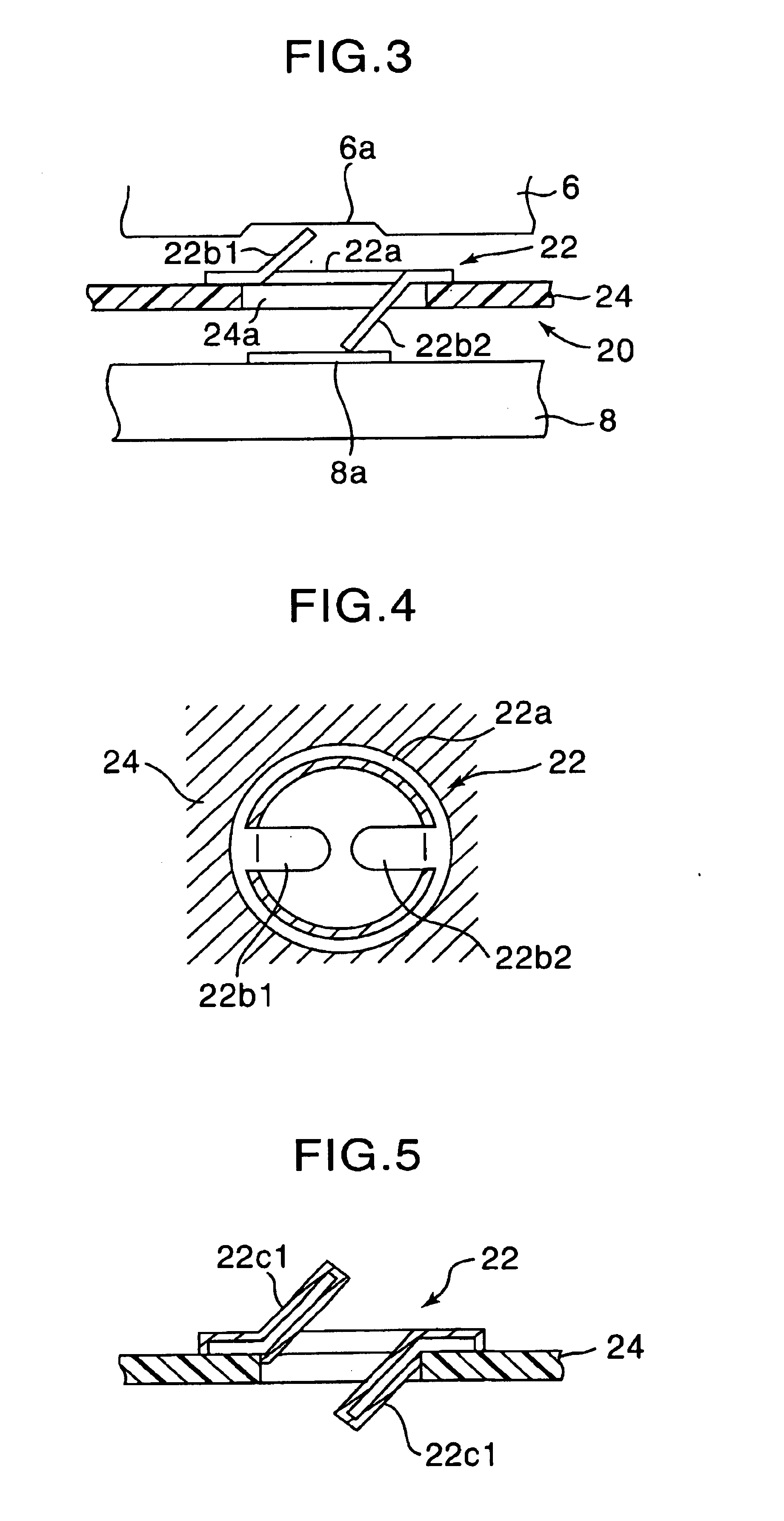

Semiconductor device testing contactor having a circuit-side contact piece and test-board-side contact piece

InactiveUS6939142B2Eliminate the problemImprove heat resistancePrinted circuit assemblingCoupling device connectionsContact testElectricity

A contactor is placed between a semiconductor device and a test board. A contact electrode of the contactor electrically connects the semiconductor device to the test board. The contact electrode is formed of a conductive layer provided on an insulating substrate. The contact electrode includes a first contact piece which contacts a terminal of the semiconductor device, a second contact piece which contacts an electrode of the test board, and a connecting portion which electrically connects the first contact piece and the second contact piece.

Owner:SOCIONEXT INC

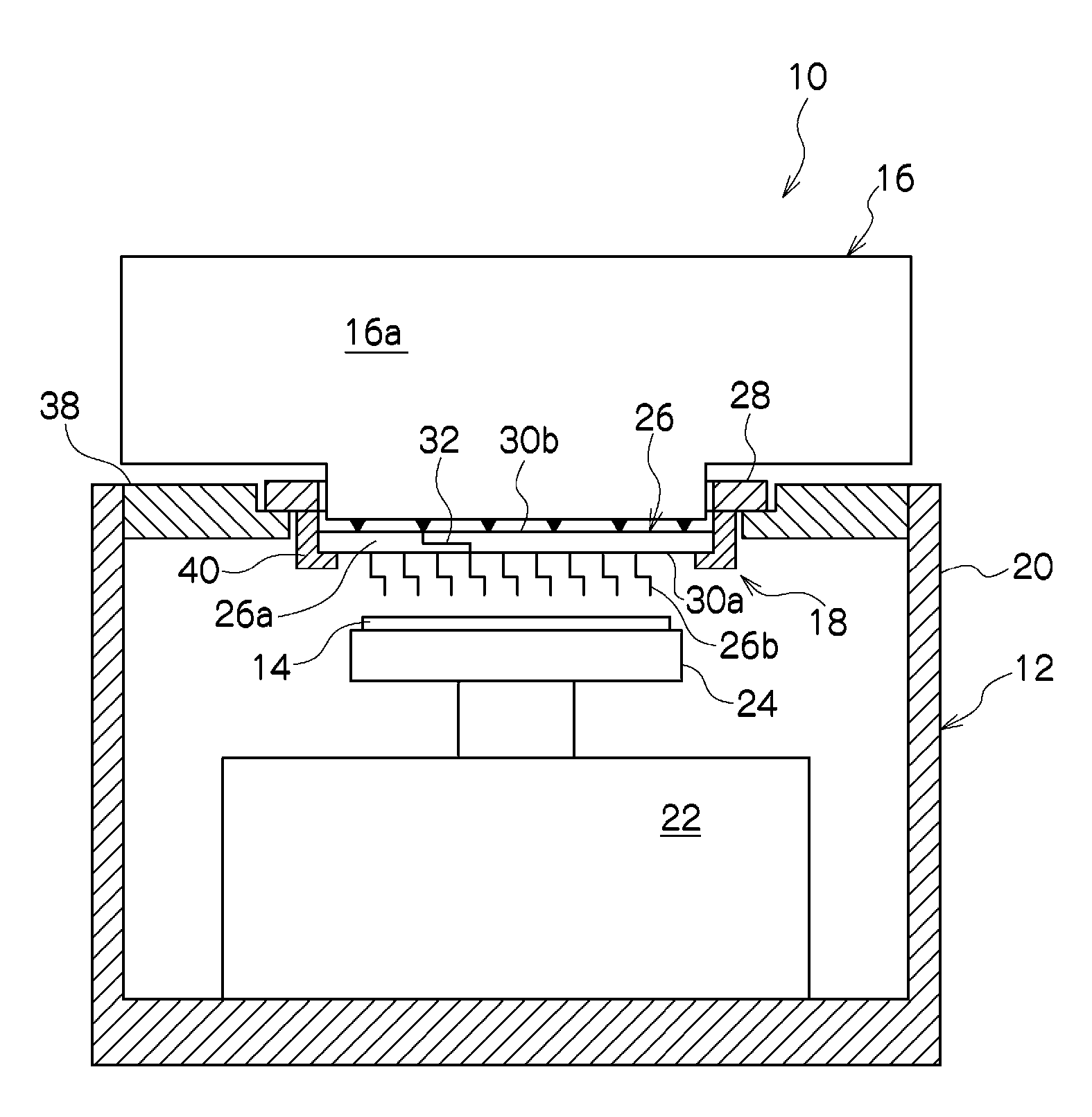

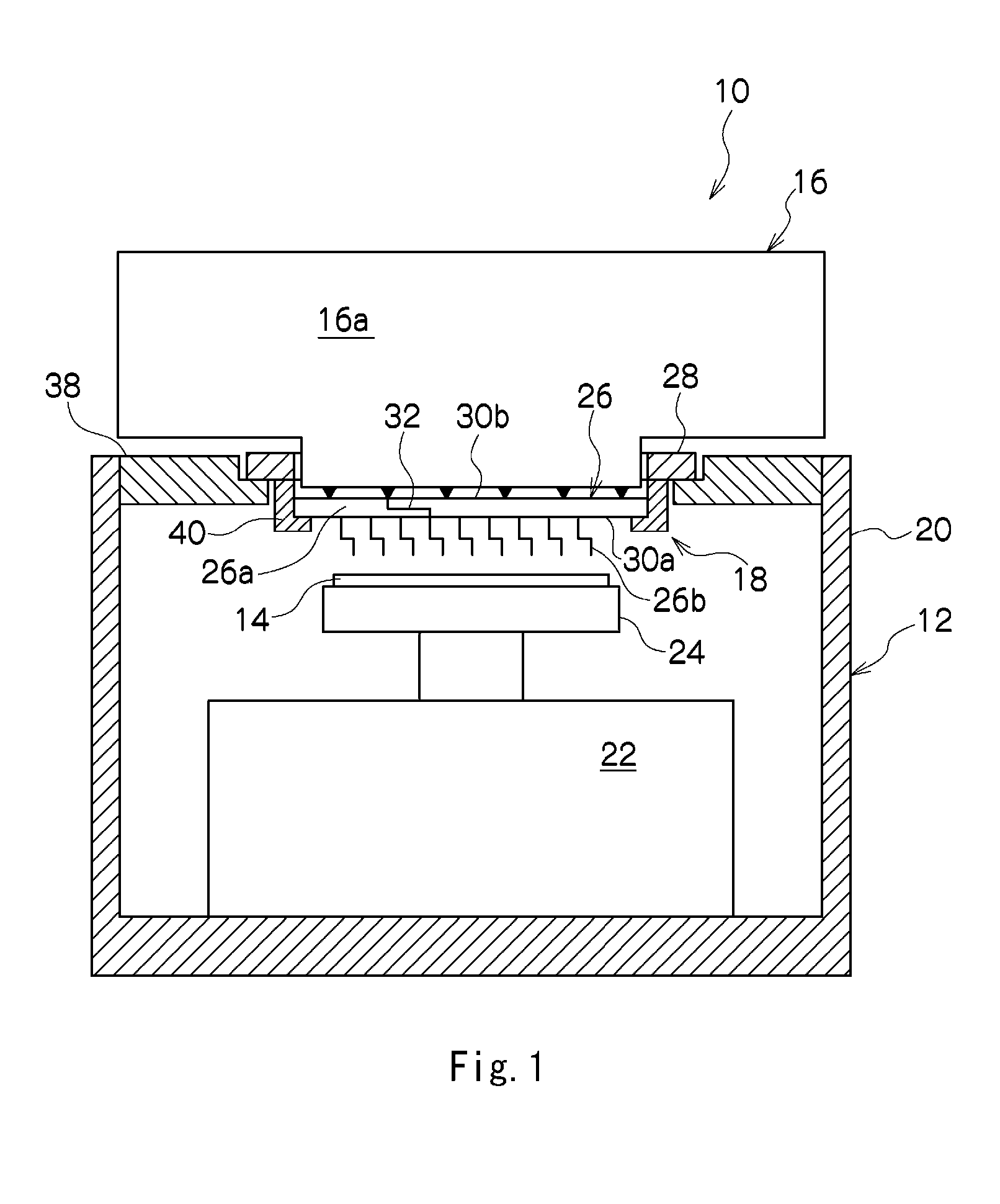

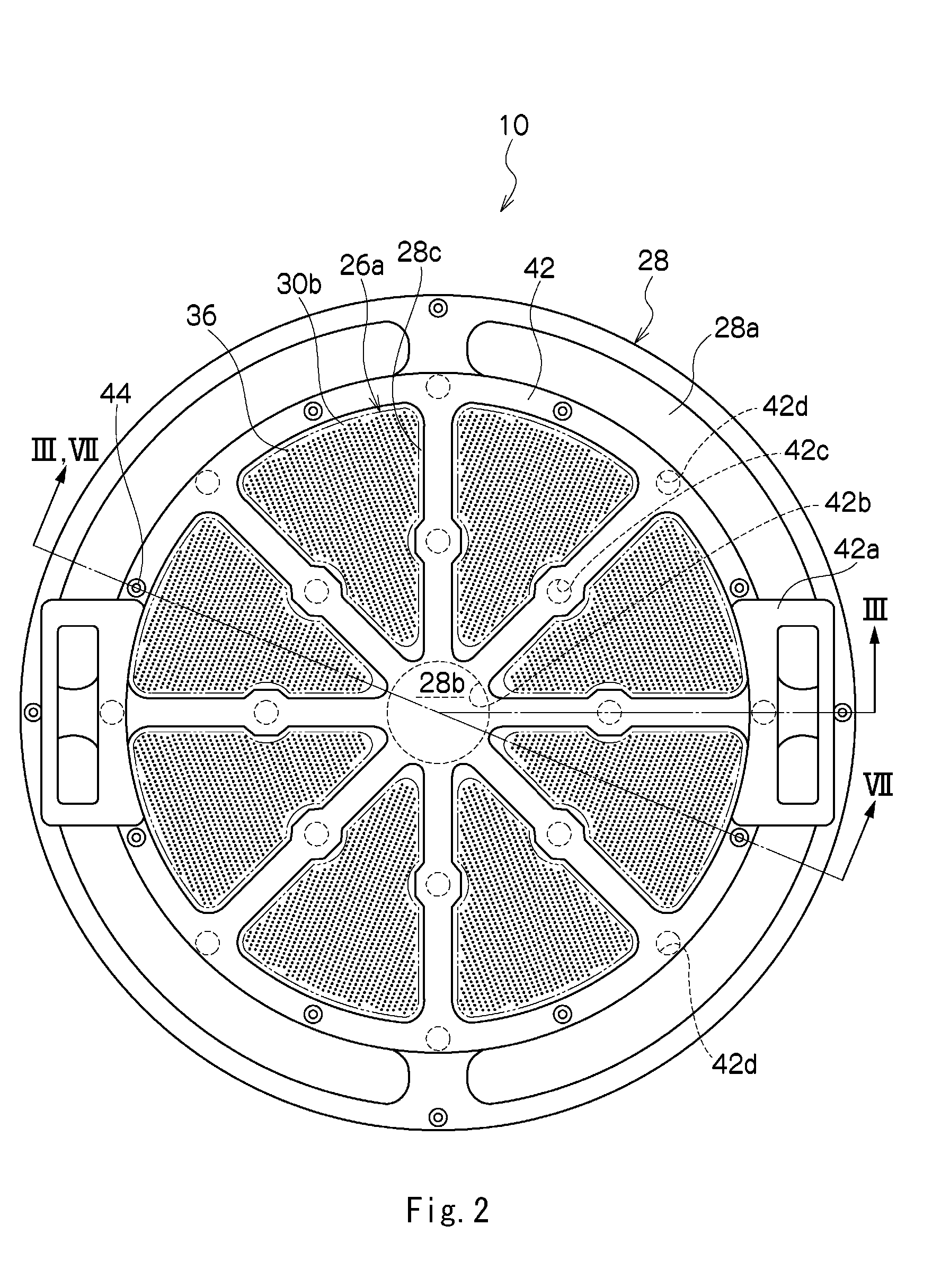

Semiconductor test apparatus

InactiveUS20080297184A1Low costThe testing process is simpleElectrical measurement instrument detailsIndividual semiconductor device testingElectricityContact test

The present invention provides a semiconductor test apparatus that can reduce influence of noise in high-frequency measurement and that can be manufactured inexpensively by simplification of the constitution. A semiconductor test apparatus according to the present invention is one for use in an electrical test of a semiconductor wafer in which numerous integrated circuits each having electrode pads are incorporated. It comprises a probe card and a tester having a connection portion to the probe card. The probe card has numerous probes that can be connected to the electrode pads of the semiconductor wafer and a probe board having on one surface probe lands to which the probes are attached, having on the other surface tester lands corresponding to the probes, and having wiring paths each connecting the probe land and the tester land corresponding to each other. The tester is directly connected to the probe card as the connection portion contacts the tester lands.

Owner:NIHON MICRONICS

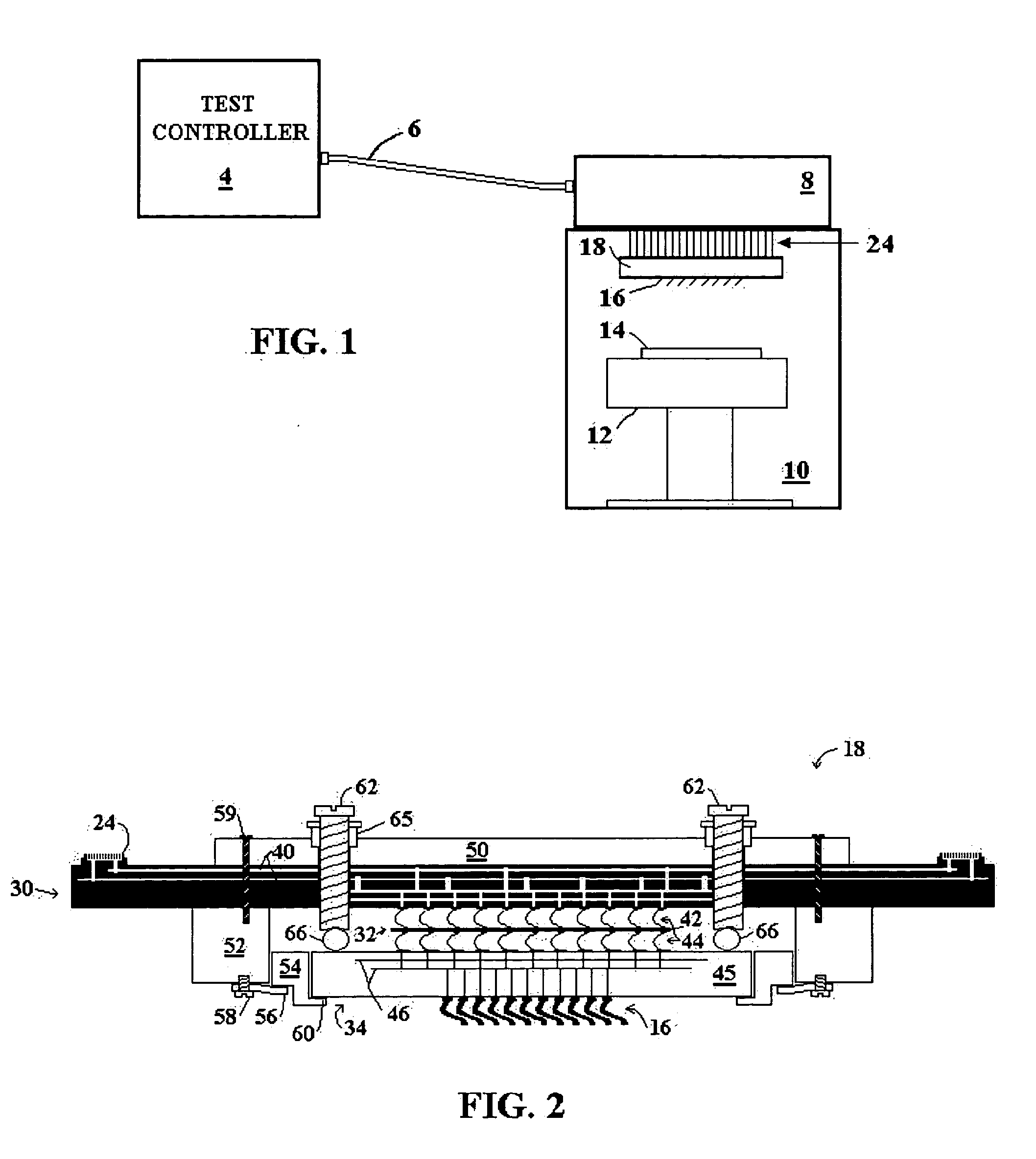

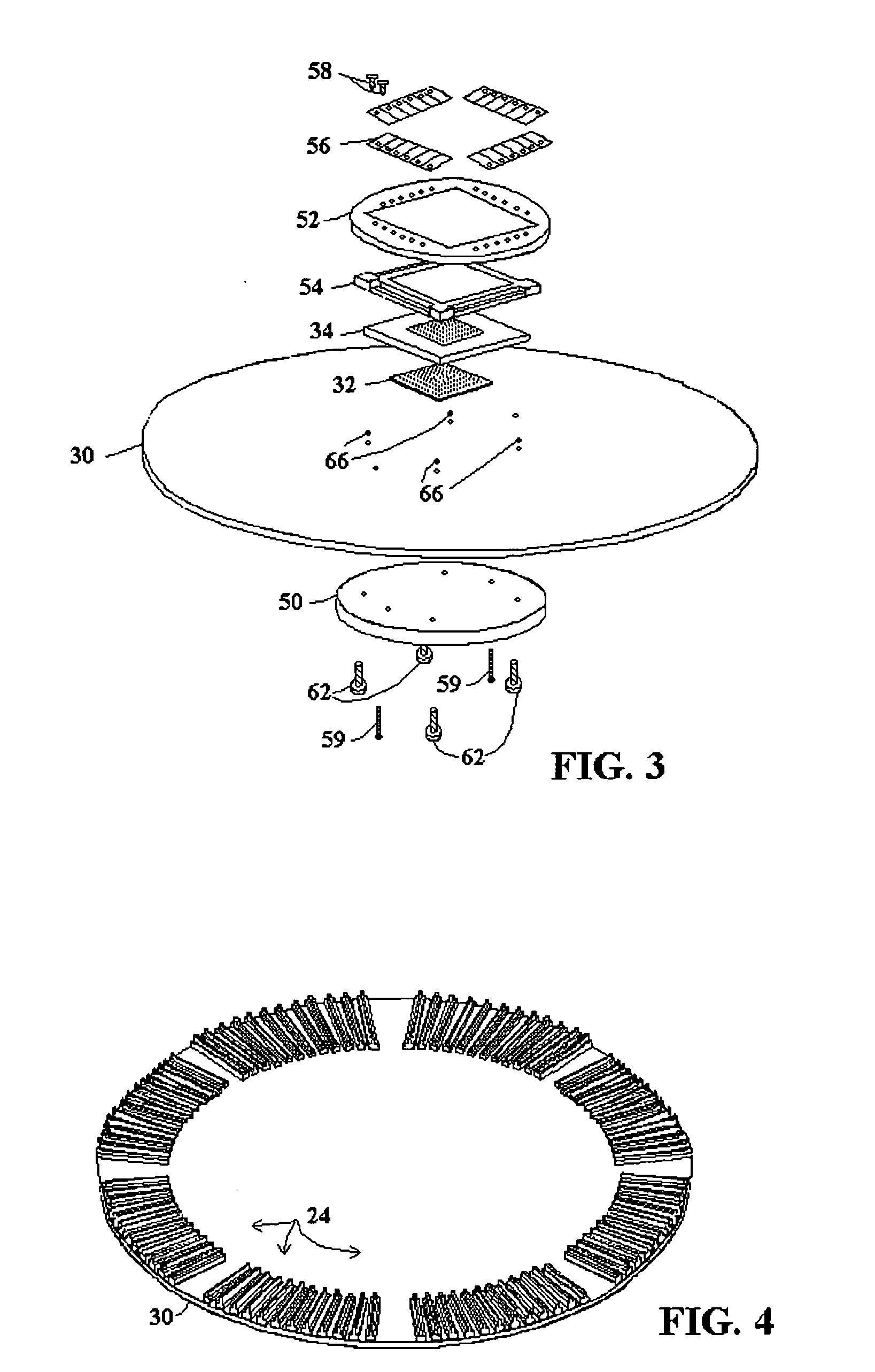

Mechanically reconfigurable vertical tester interface for IC probing

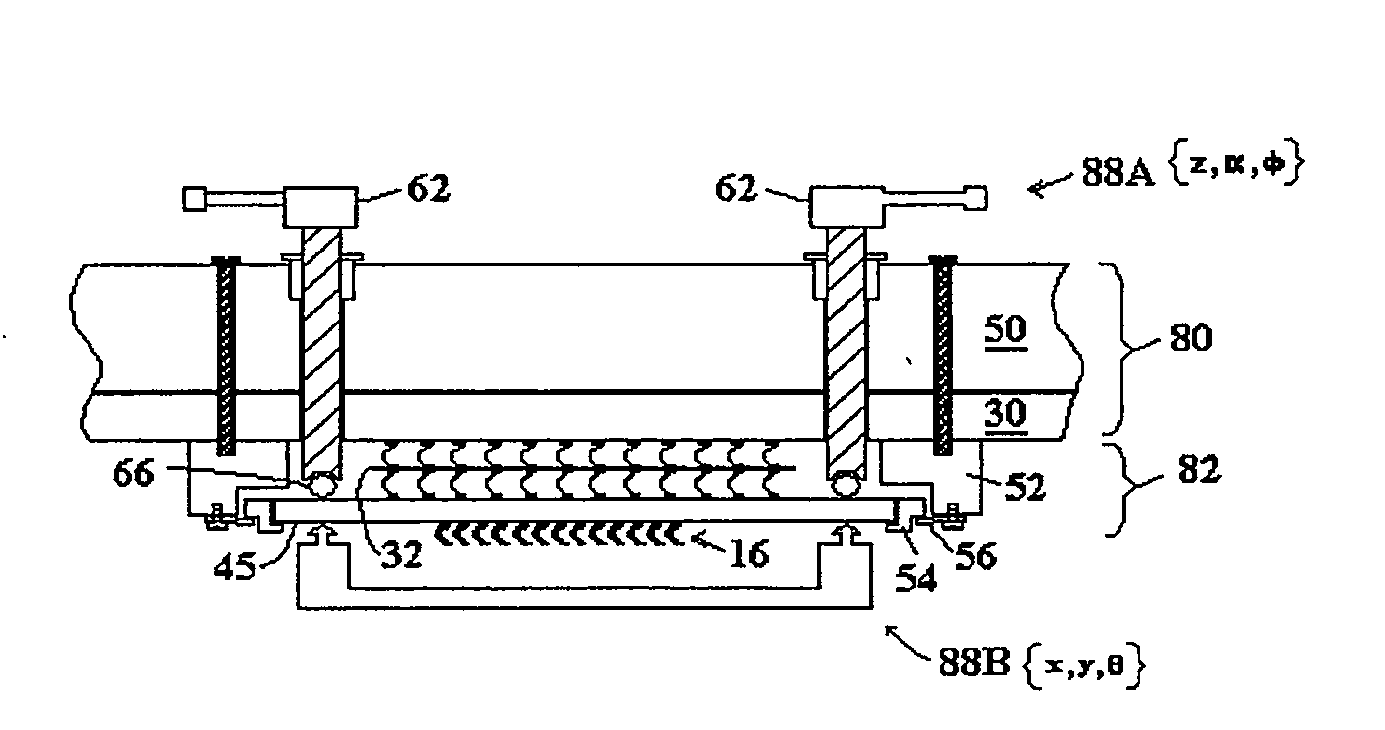

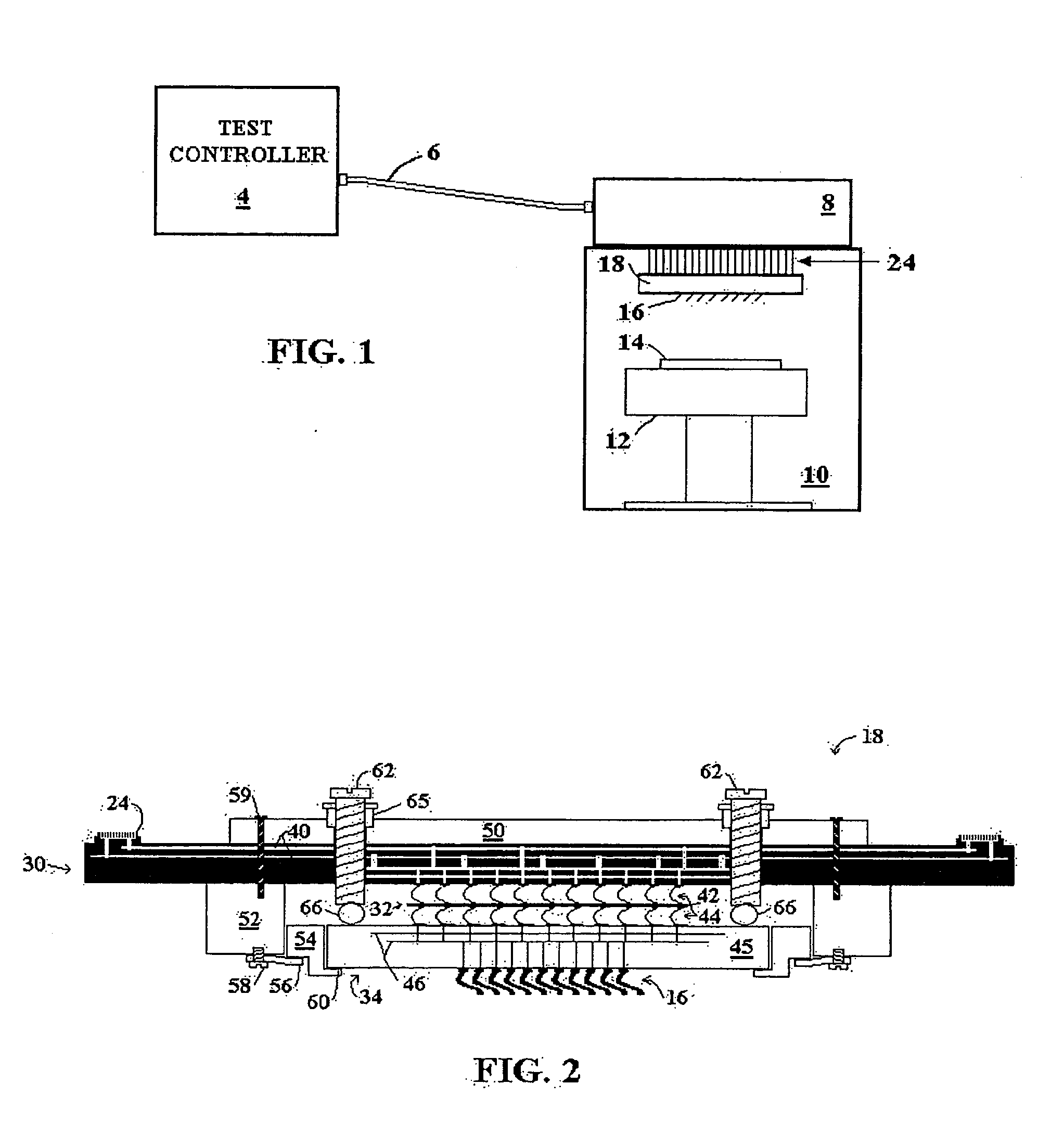

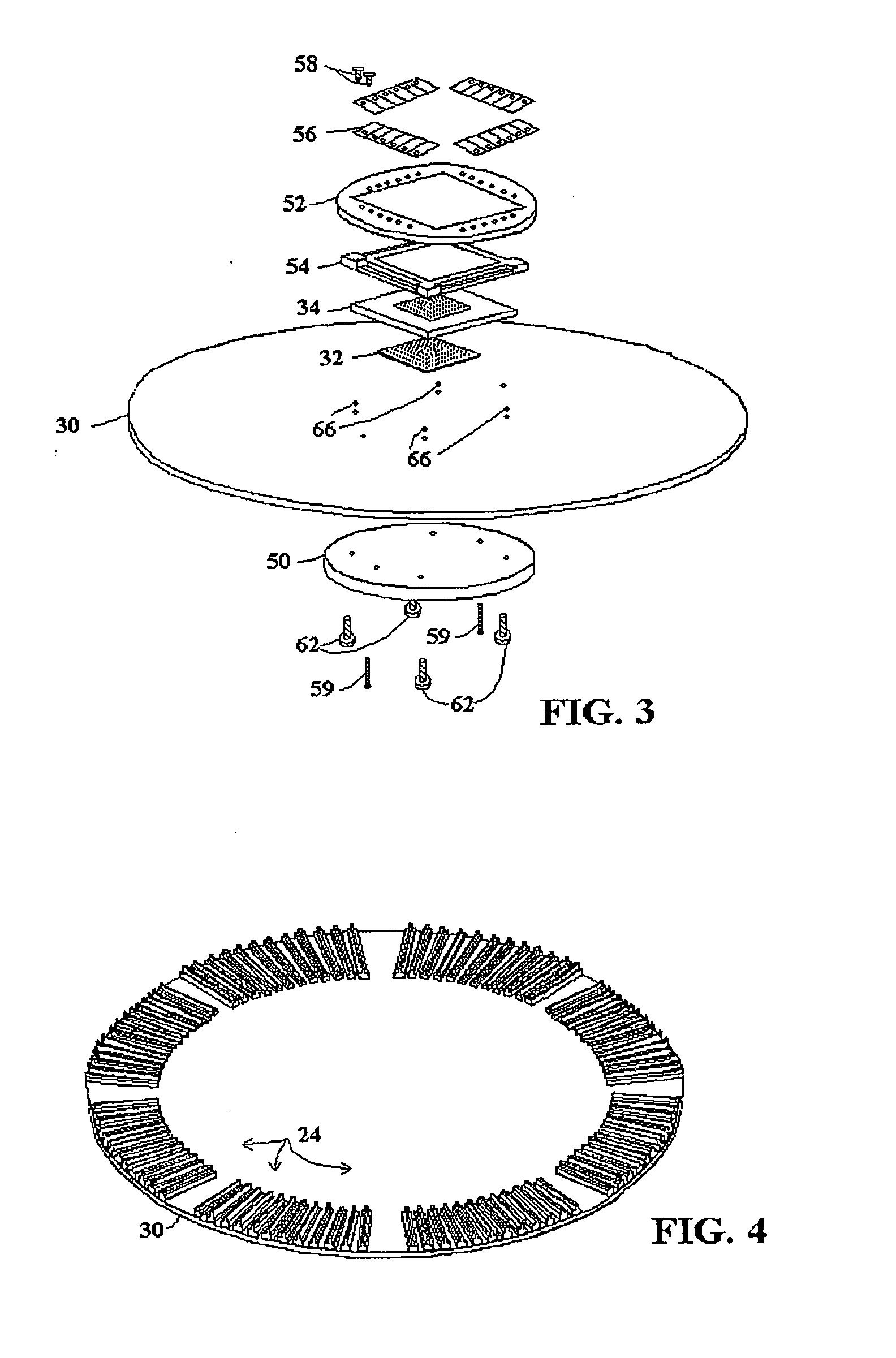

InactiveUS20070229102A1Better provide minimal trace lengthsLimit support structureElectronic circuit testingMeasurement instrument housingContact testProbe card

A wafer test assembly includes multiple probe head substrates arranged like tiles with connectors attached to one side and probes supported on the opposing side. In one embodiment, flexible cable connectors directly connect the connectors on the probe head tile to a test head, while in another embodiment the flexible cables connect the probe head tile to a PCB providing horizontal routing to test head connectors. In one embodiment, leveling pins provide a simplified support structure connecting to a retaining element attached to the tiles to provide for applying a push-pull leveling force. A test head connector interface frame enables rearrangement of connectors between the test head and the probe card to provide for both full wafer contact or partial wafer contact. The test head connectors are rearranged by being slidable on rails, or pluggable and unpluggable enabling movement over a range of positions.

Owner:FORMFACTOR INC

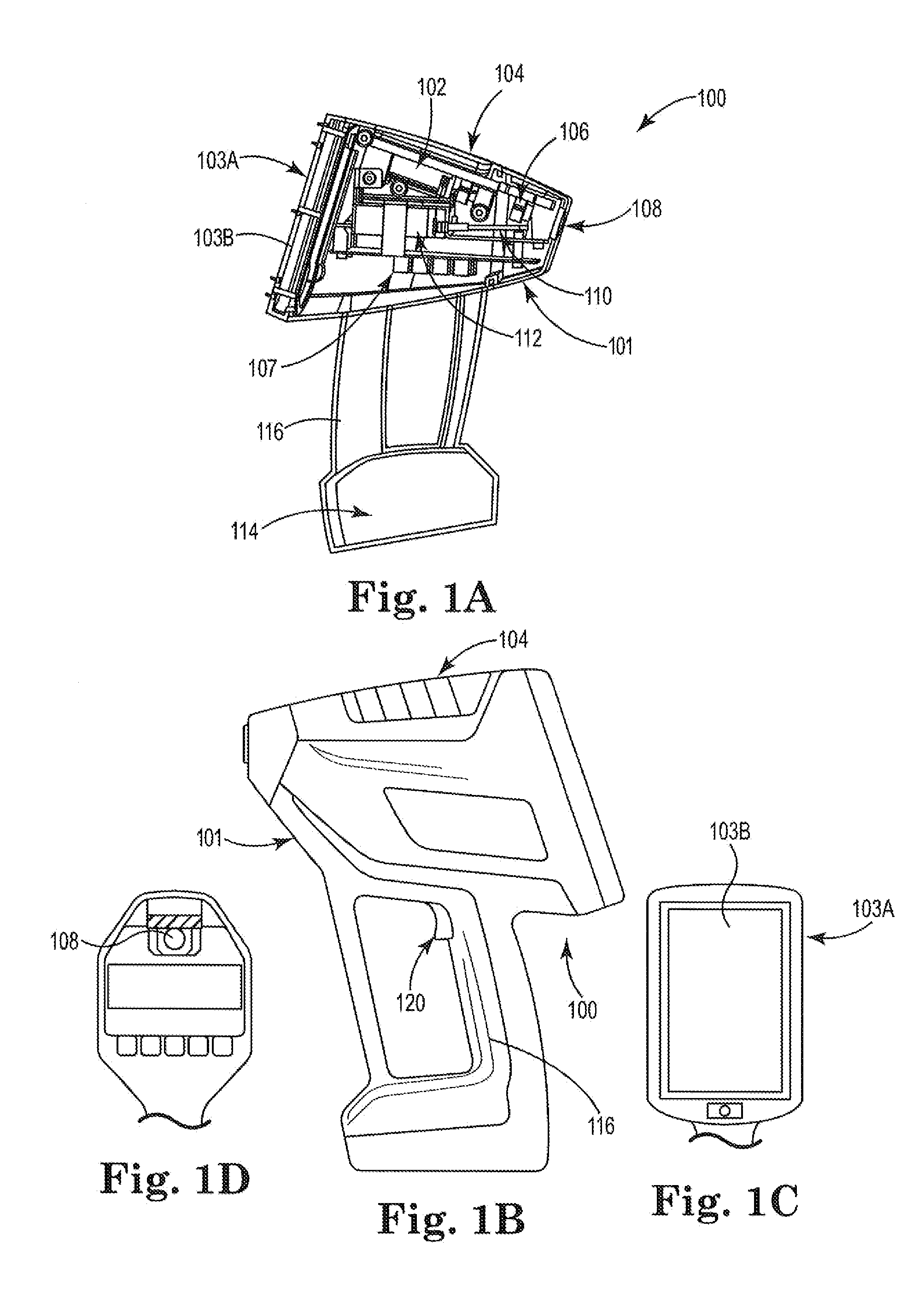

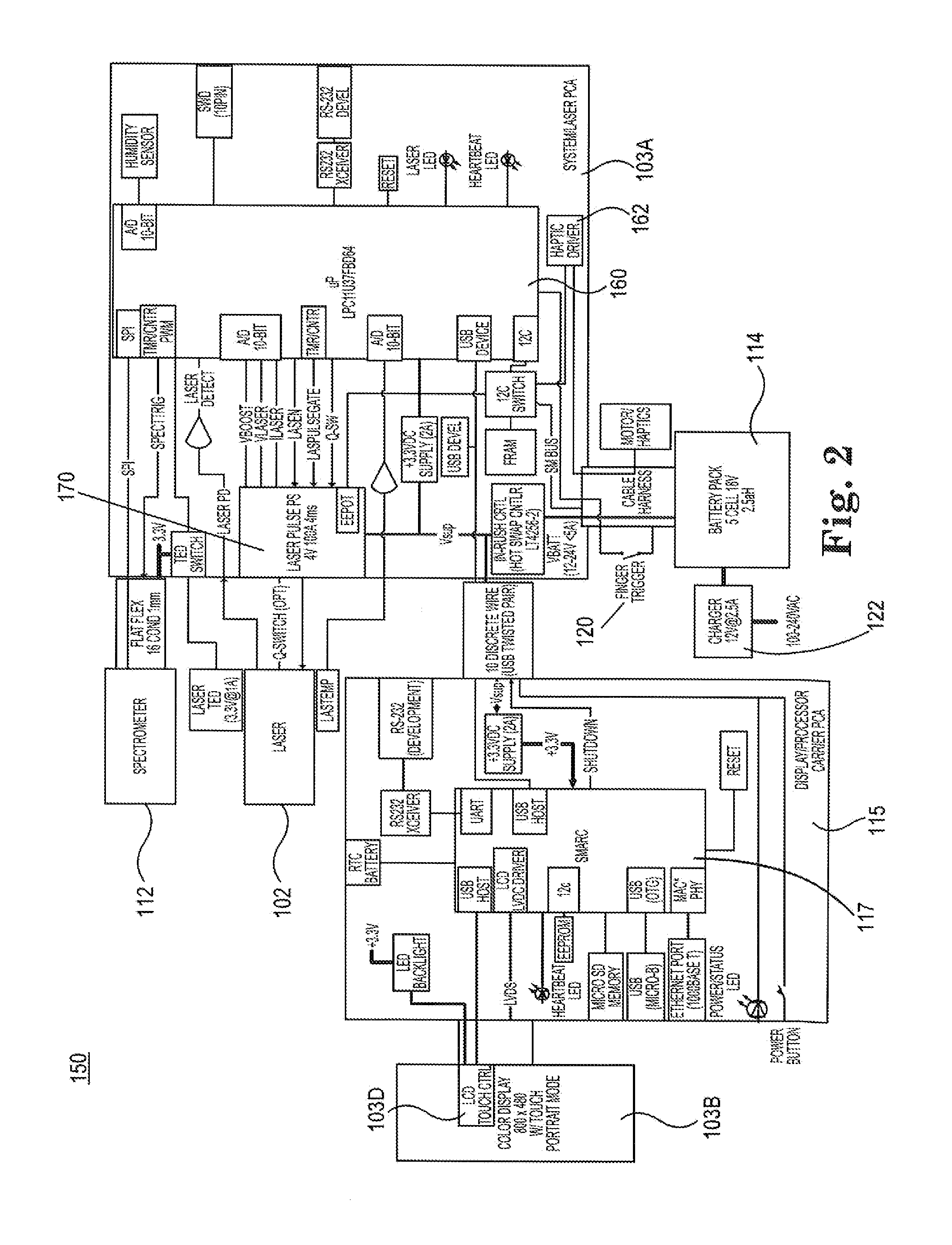

Handheld laser induced breakdown spectroscopy device

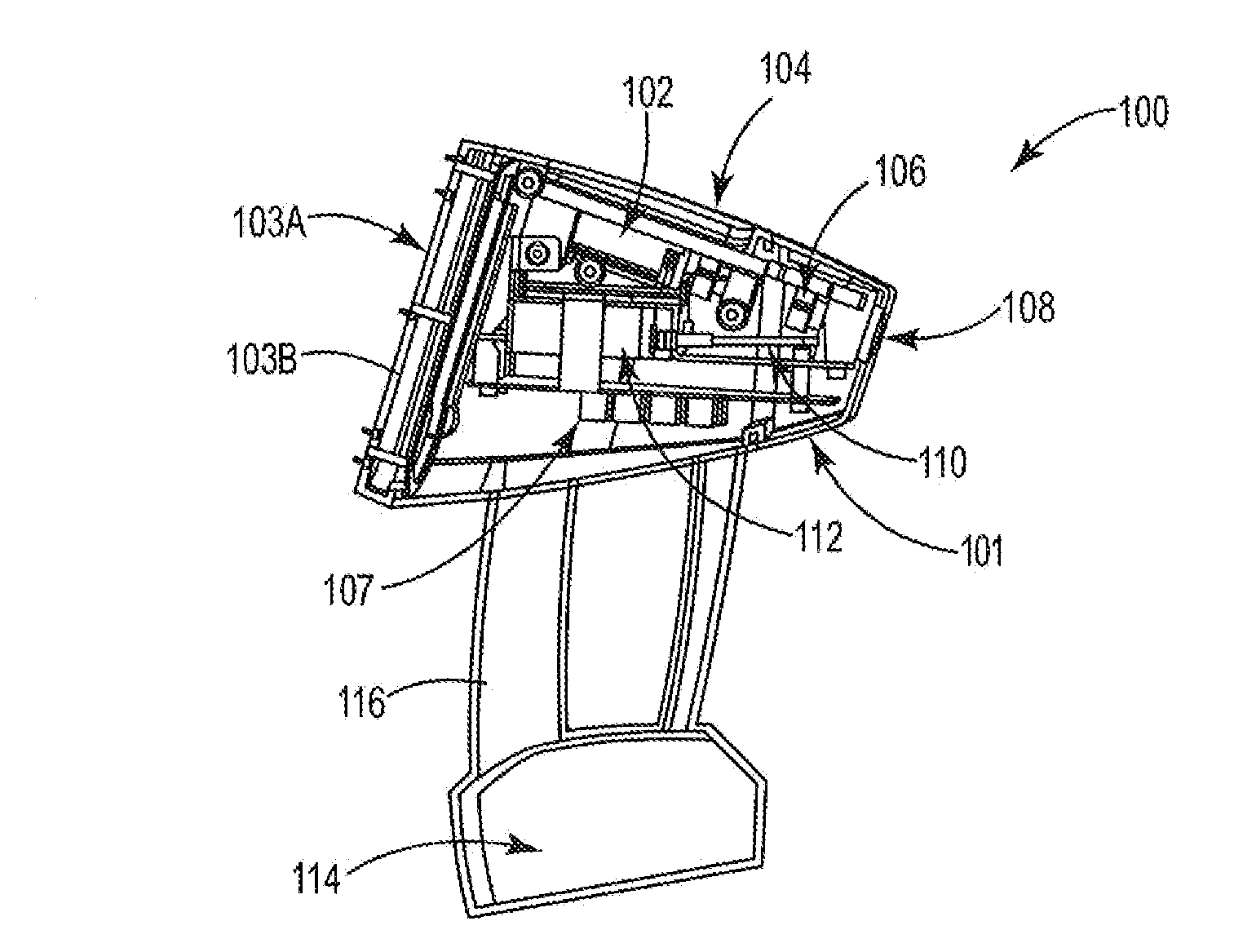

ActiveUS20150103334A1High precisionProlong lifeEmission spectroscopyRadiation pyrometryContact testGrating

A novel device, method and systems disclosed managing the thermal challenges of LIBS laser components and a spectrometer in a handheld structure as well the use of simplified light signal collection which includes a bare fiber optic to collect the emitted light in close proximity to (or in contact with) the test material. In one example embodiment of the handheld LIBS device, a burst pulse frequency is 4 kHz is used resulting in a time between pulses of about 250 μs which is a factor of 10 above that of other devices in the prior art. In a related embodiment, an active Q-switched laser module is used along with a compact spectrometer module using a transmission grating to improve LIBS measurement while substantially reducing the size of the handheld analyzer.

Owner:TSI INC

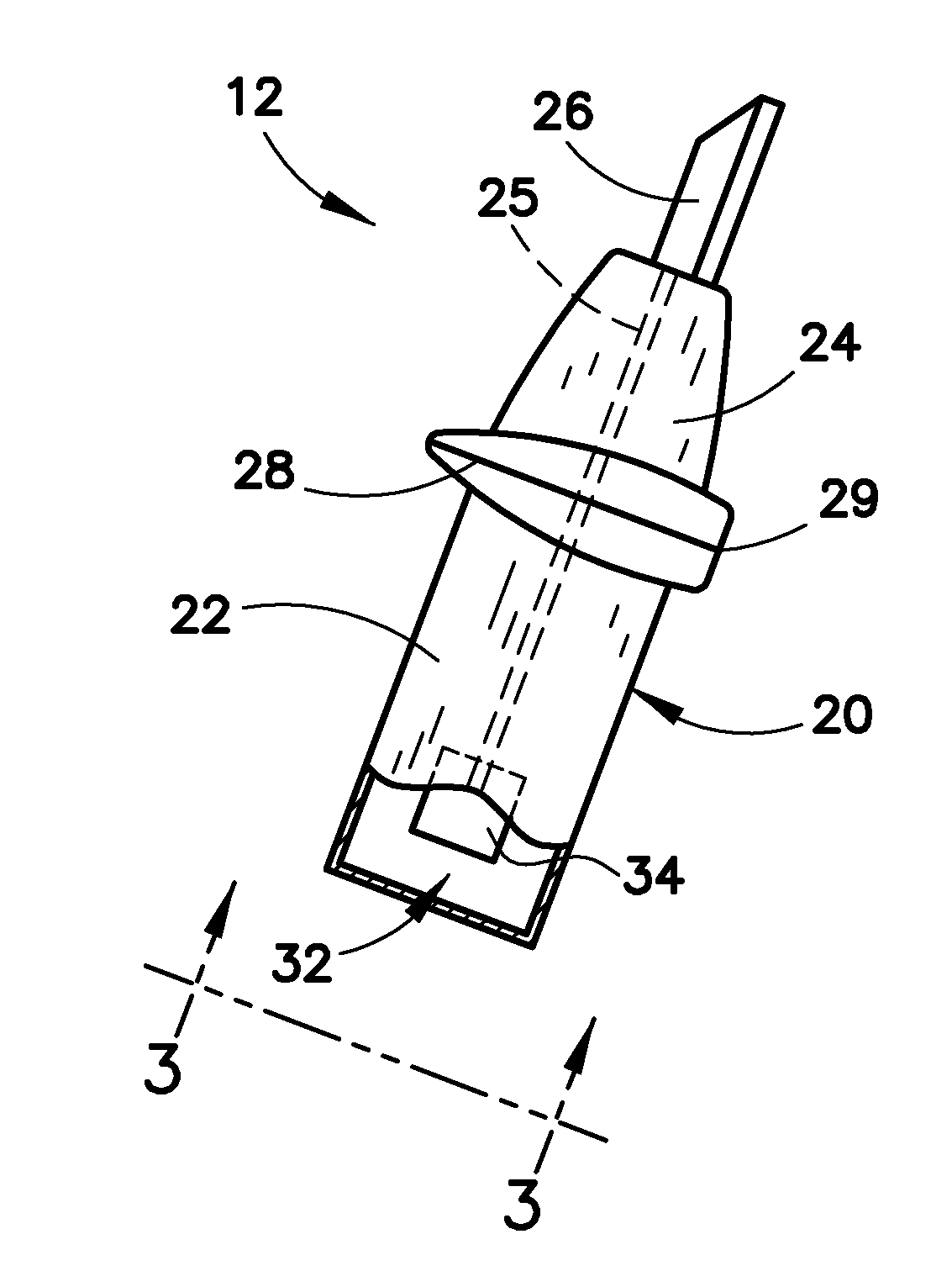

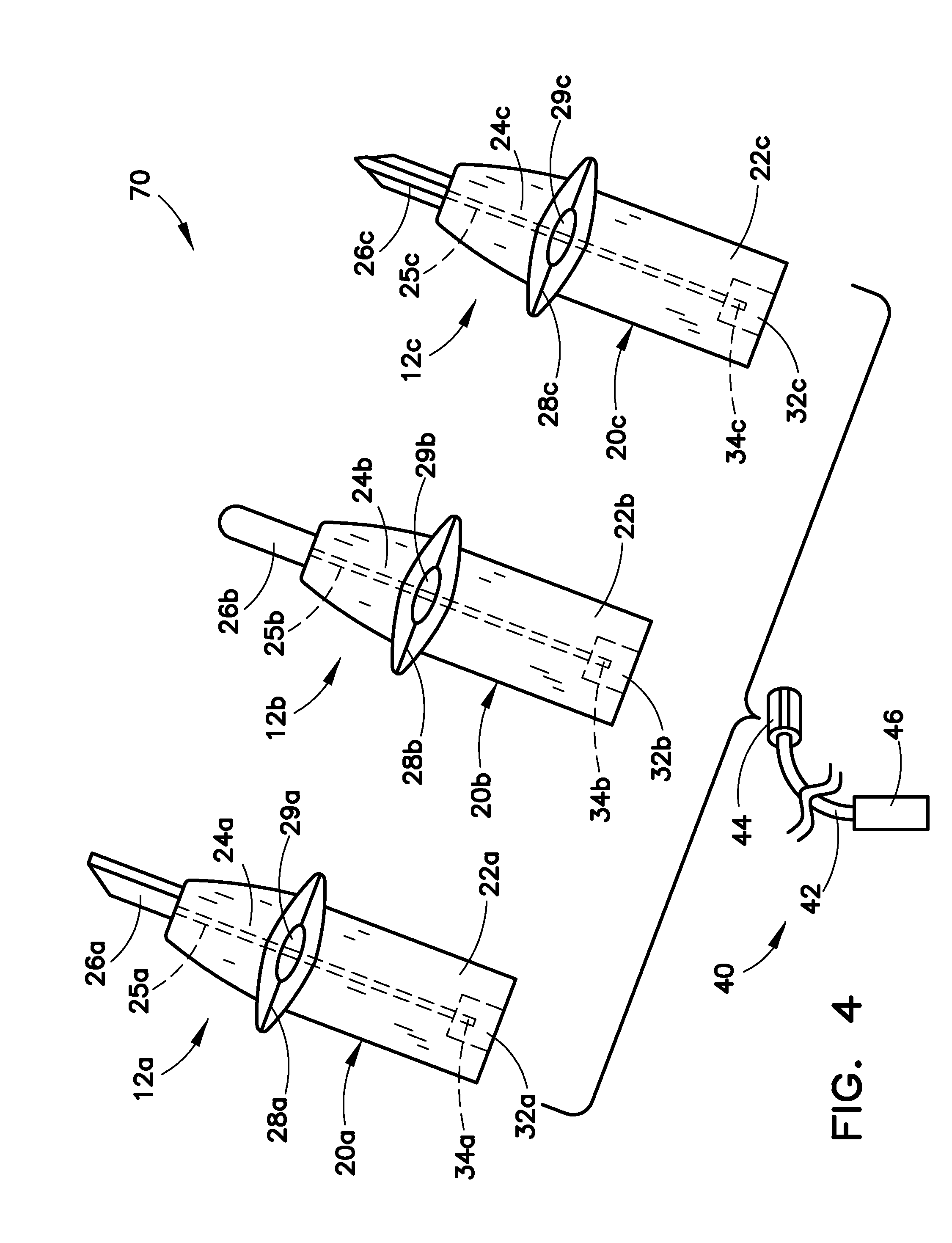

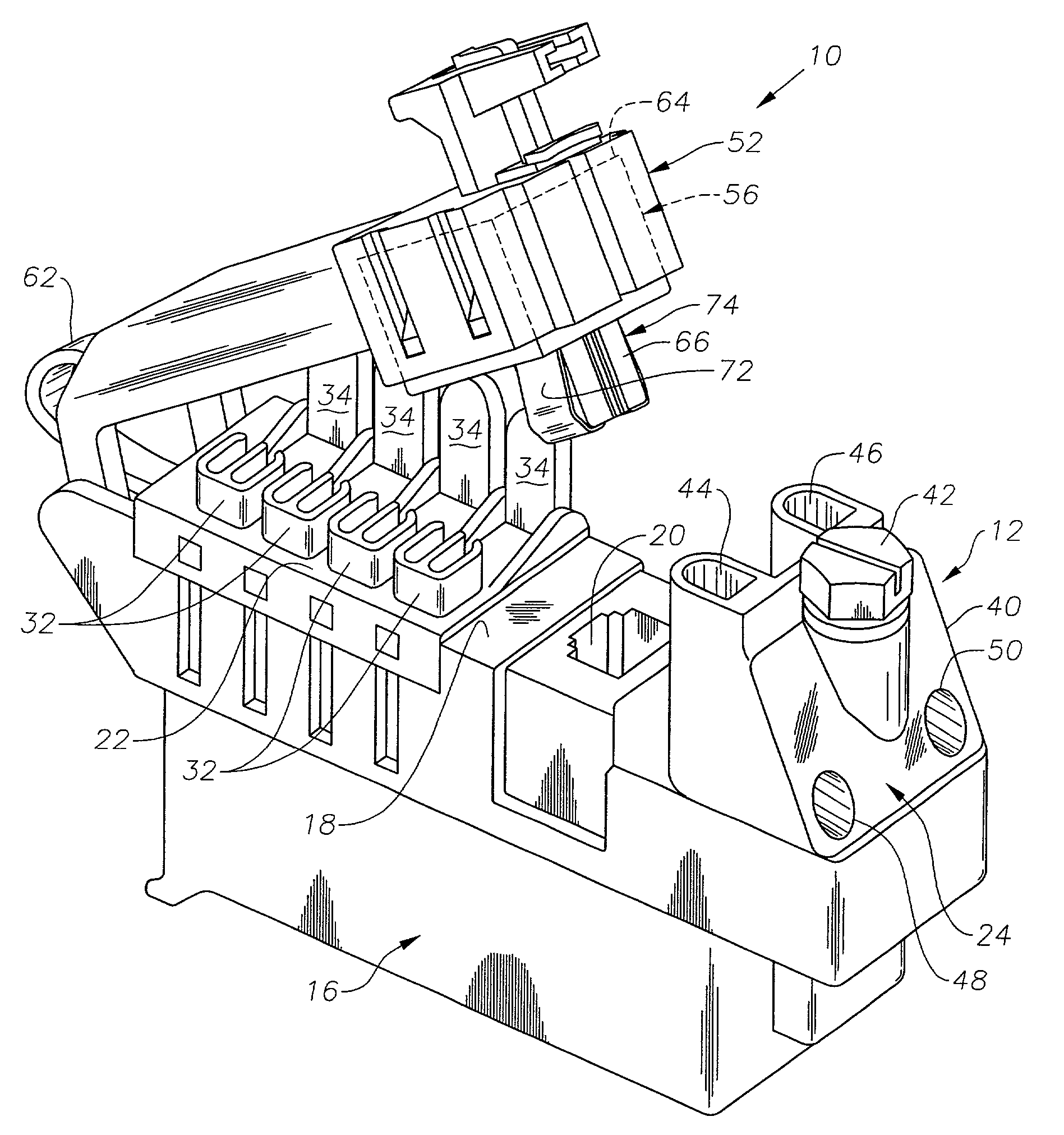

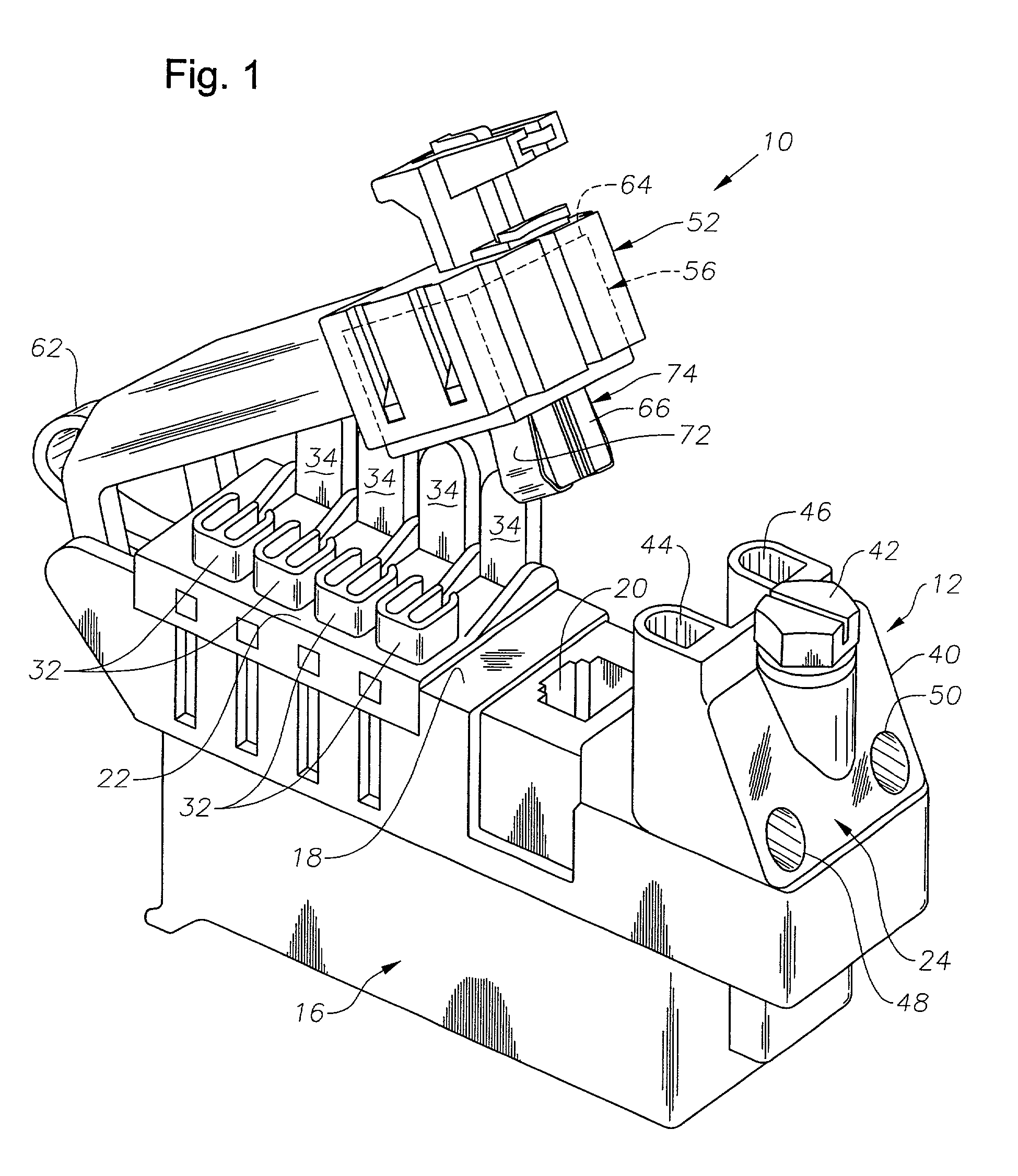

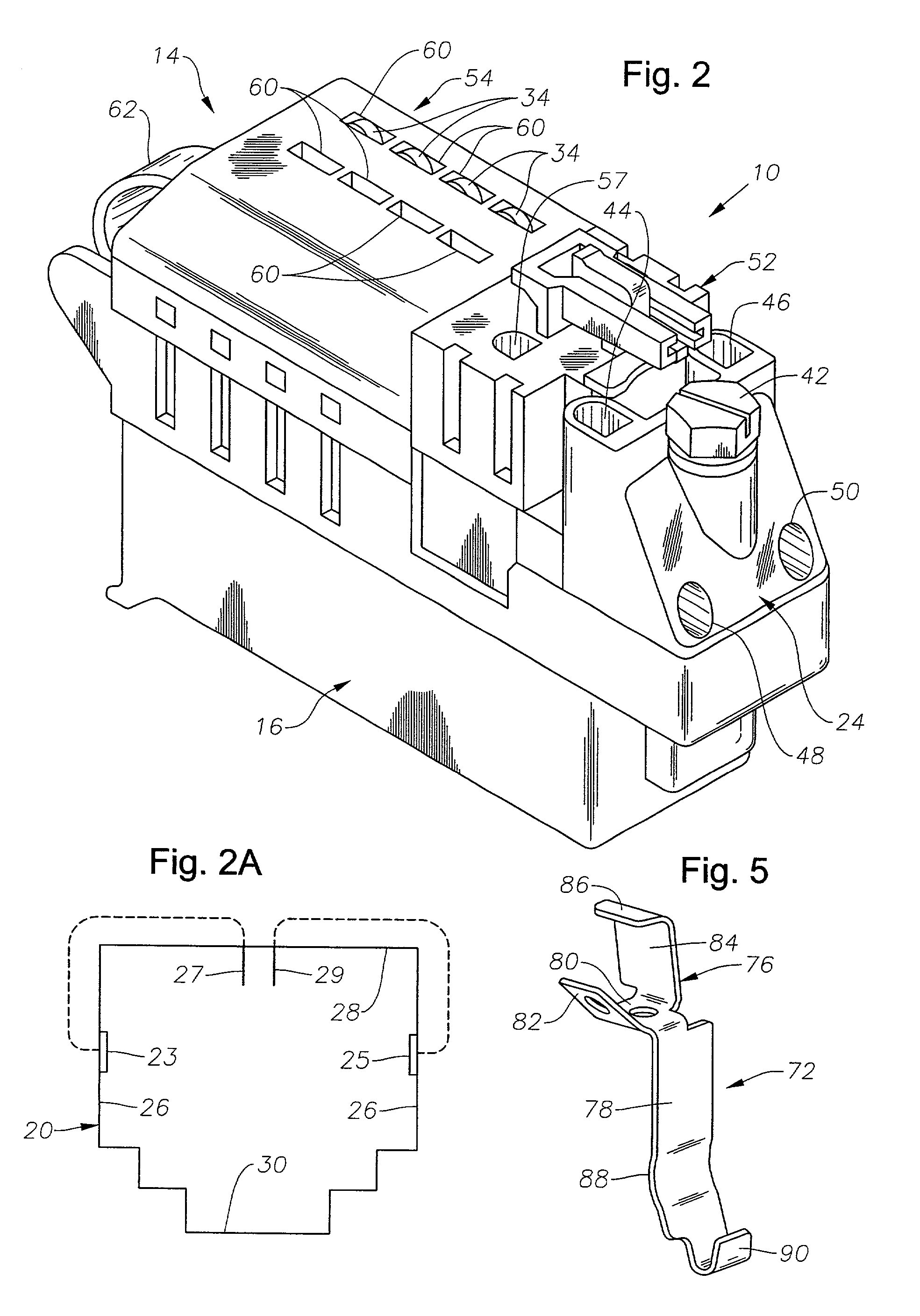

Multi-Meter Test Lead Probe For Hands-Free Electrical Measurement of Control Panel Industrial Terminal Blocks

InactiveUS20100090682A1Take electrical measurementLess strainElectrical testingMeasurement leads/probesElectricityComputer module

An electrical test lead probe for use with a multi-meter provides for releasable retention in and electrical contact with a terminal of an industrial terminal block. The test lead probe includes a self-adjoining electrically conducting tip that is configured for automatic releasable receipt into a terminal block socket of various styles of terminal blocks, the terminal block socket housing a terminal of the terminal block. The present terminal block probe, in one form, is permanently attached to a multi-meter test lead. In another form, the present terminal block probe is coupled to a modular multi-meter test lead. In yet another form, the present terminal block probe has a removable head incorporating an electrically conducting, self-adjoining tip wherein the body is permanently attached to a multi-meter test lead. In a modular form, a plurality of terminal block probes may be provided each one of which has an electrically conducting tip of a different configuration corresponding to different configurations and / or sizes of terminal block sockets.

Owner:ARMSTRONG ERIC A

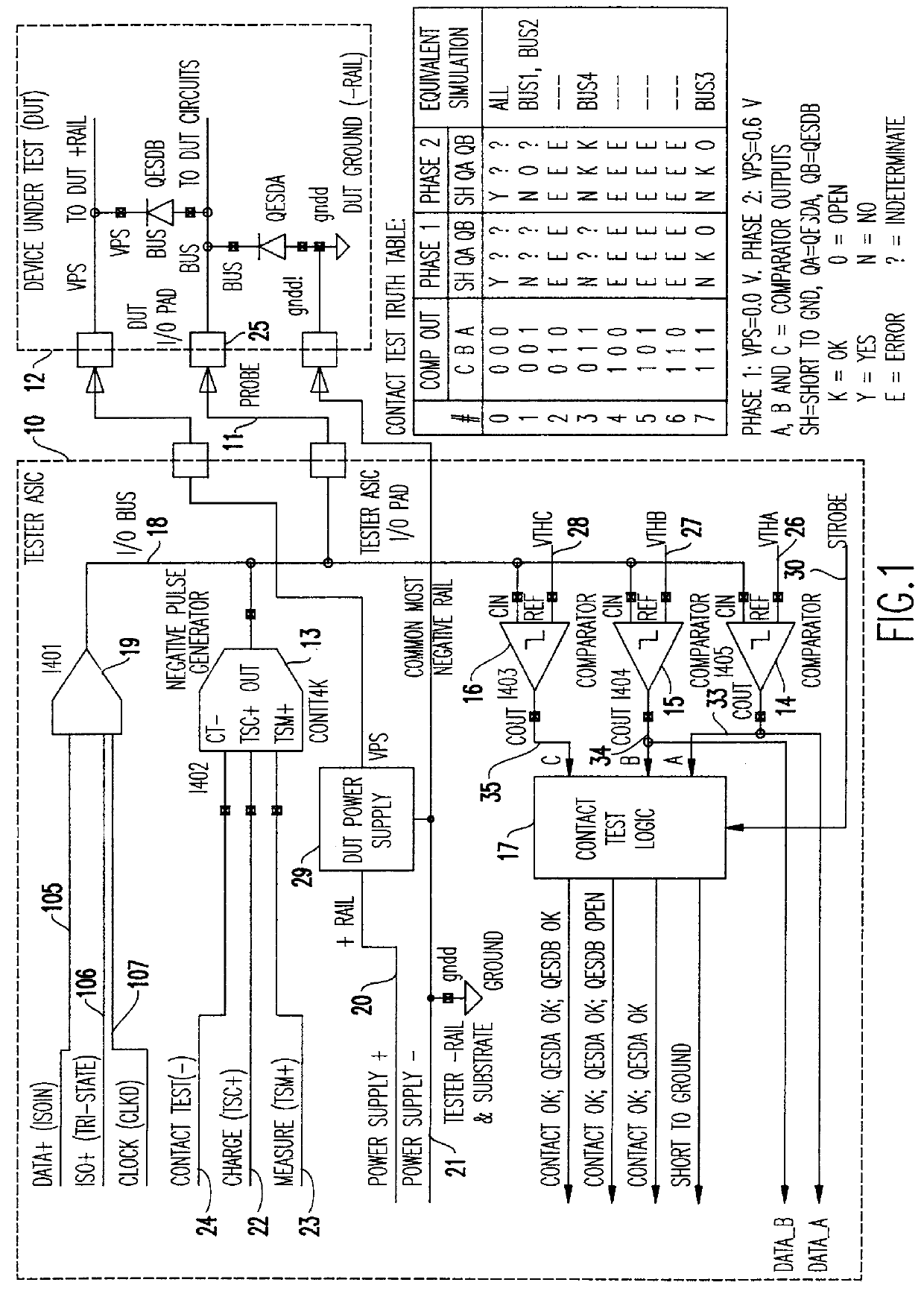

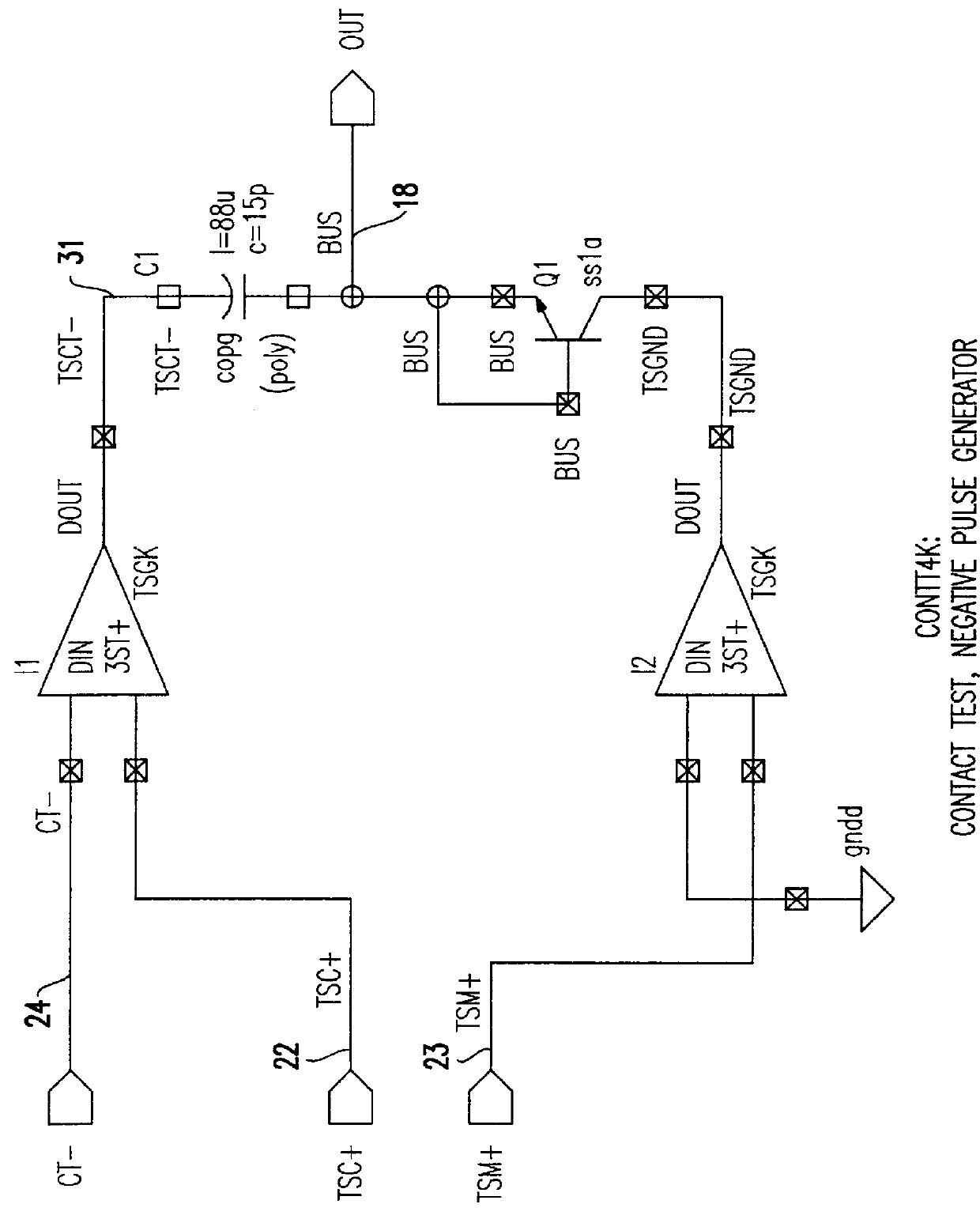

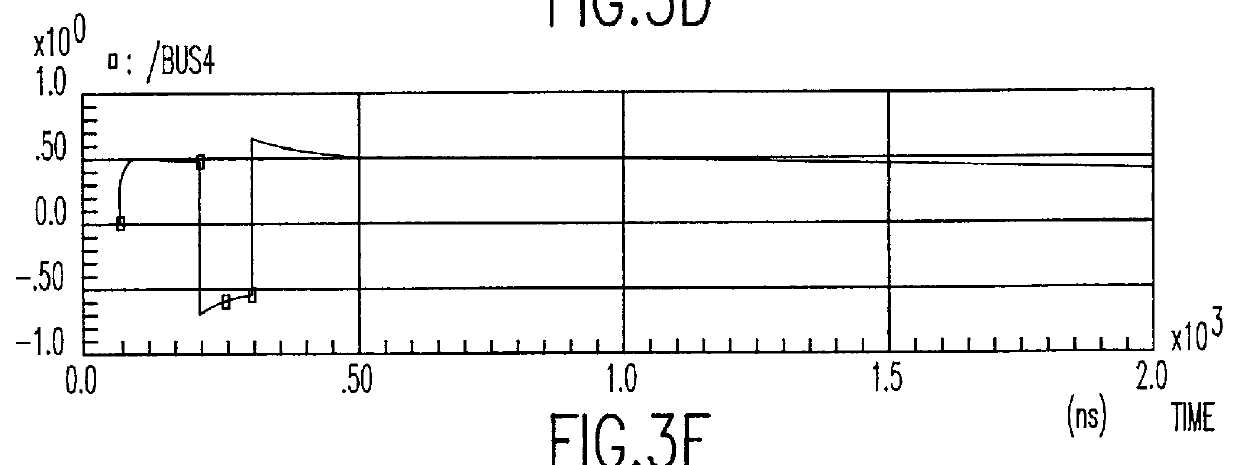

Contact test circuit

InactiveUS6087841AMore currentIncrease speedElectrical measurement instrument detailsElectric connection testingTest phaseInput device

A method and apparatus for contact testing a plurality of devices under test, either sequentially or simultaneously. In a first test phase it is determined whether the test probe to each contact is shorted to the most negative rail. In a second phase it is determined whether the test probe has made proper contact, and whether ESD diodes on the devices under test are functional. In both test phases a negative pulse is generated on a tester bus and applied to the contact by the test probe. In the first test phase the positive rail of the device under test is grounded; in the second test phase the positive rail of the device under test is made positive. The negative rail of the device under test is connected to the negative rail of the tester. In both test phases, upon termination of the negative pulse, the bus is restored to a positive voltage which is dependent upon the condition of the contact and the condition of expected input devices at the contact. The bus voltage is measured in accordance with a logic which determines the condition of the contact and the condition of expected input devices at the contact. Data signals for functional testing of the device under test are can be applied to the bus through an isolating driver which preserves the logic of the contact test.

Owner:IBM CORP

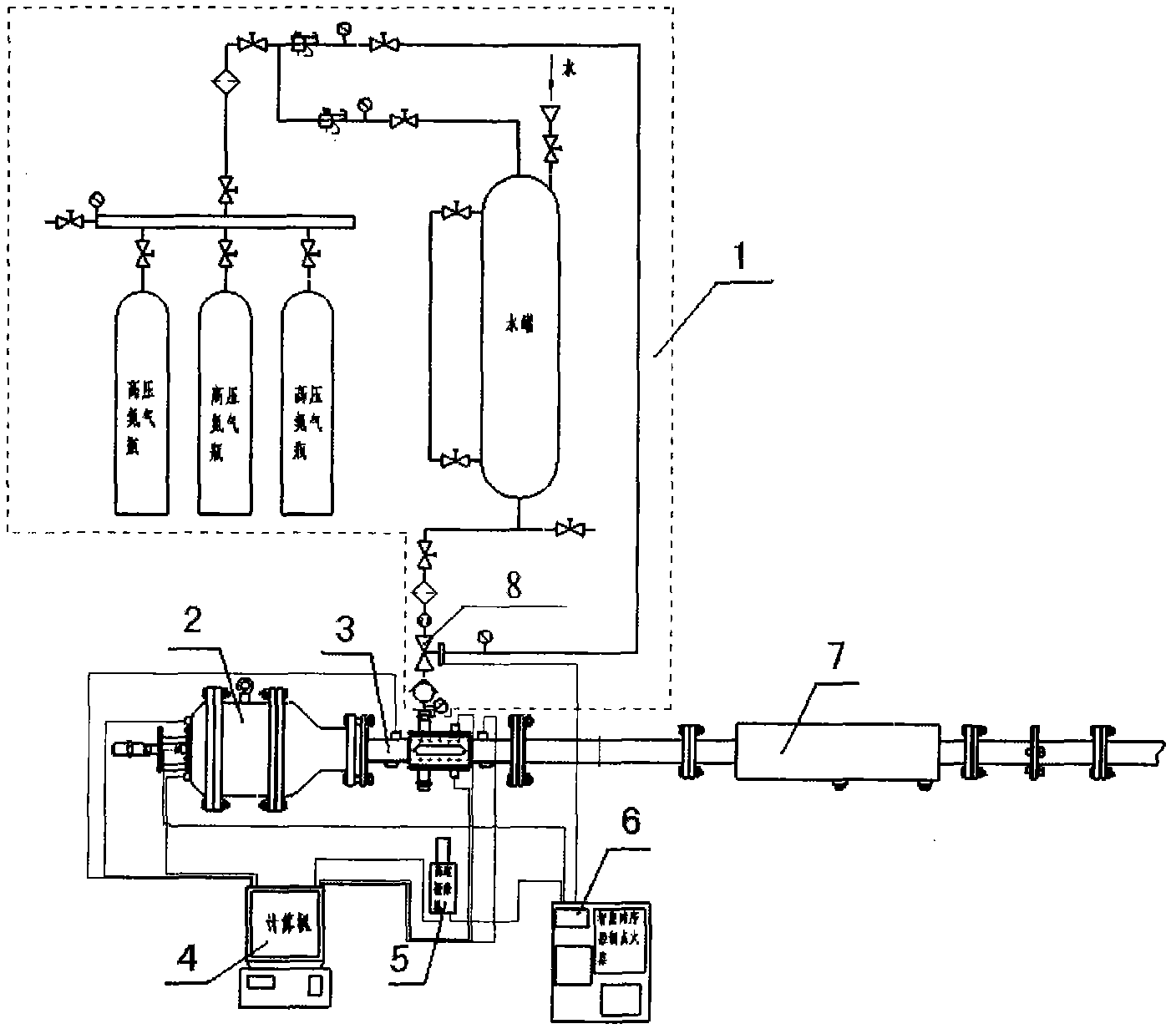

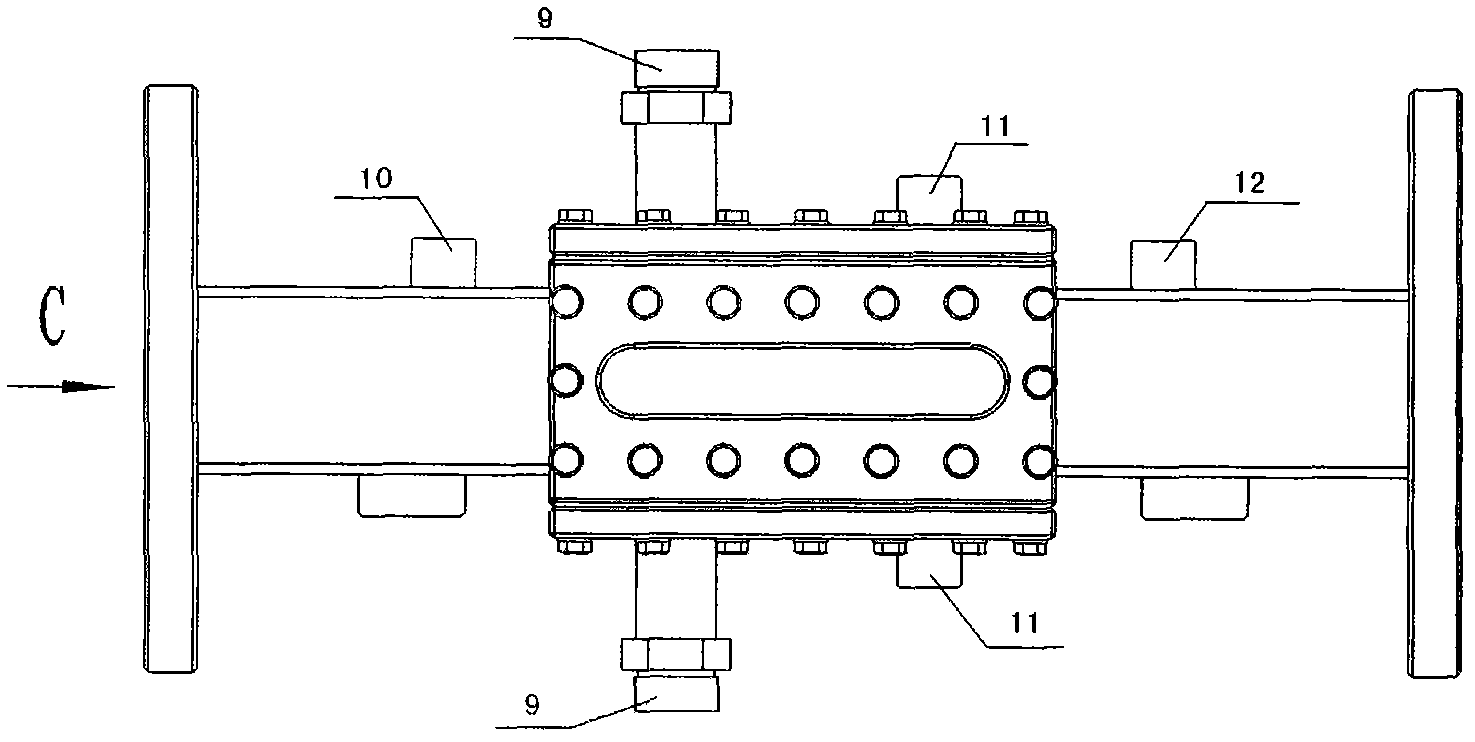

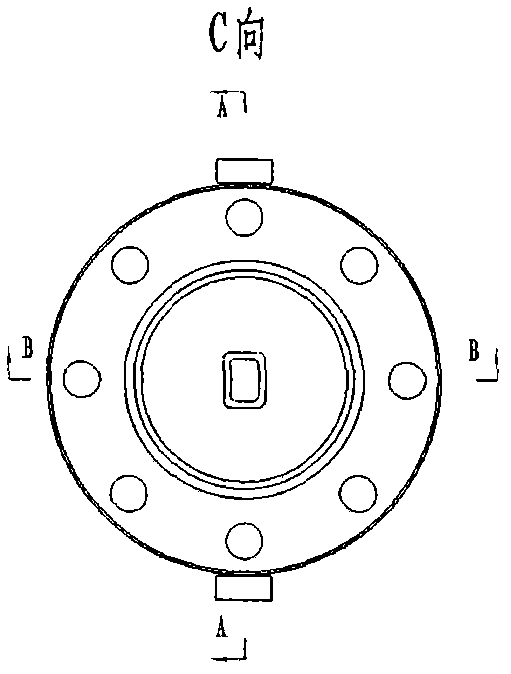

Experiment device for researching jet atomizing characteristic of jet nozzle

The invention provides an experiment device for researching the jet atomizing characteristic of a jet nozzle. The experiment device can provide a fuel gas environment similar to a fuel gas-vapor type launch power device, simulate the pressure intensity, the temperature, the speed and other parameters of airflow behind the jet nozzle, provide various test interfaces including a conventional test means and a non-contact test means; and in addition, the experiment device can obtain the jet atomizing characteristic of a jet nozzle for the researches on primary atomizing of cooling water at the outlet of the jet nozzle, secondary atomizing and vaporizing of the cooling water in lateral high-speed flue gas flow, water-vapor two phase flow with phase changes and other complicated flowing processes in the fuel gas-vapor type launch power device used for underwater launch, and provide a theoretical basis for the design of the fuel gas-vapor type launch power device.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

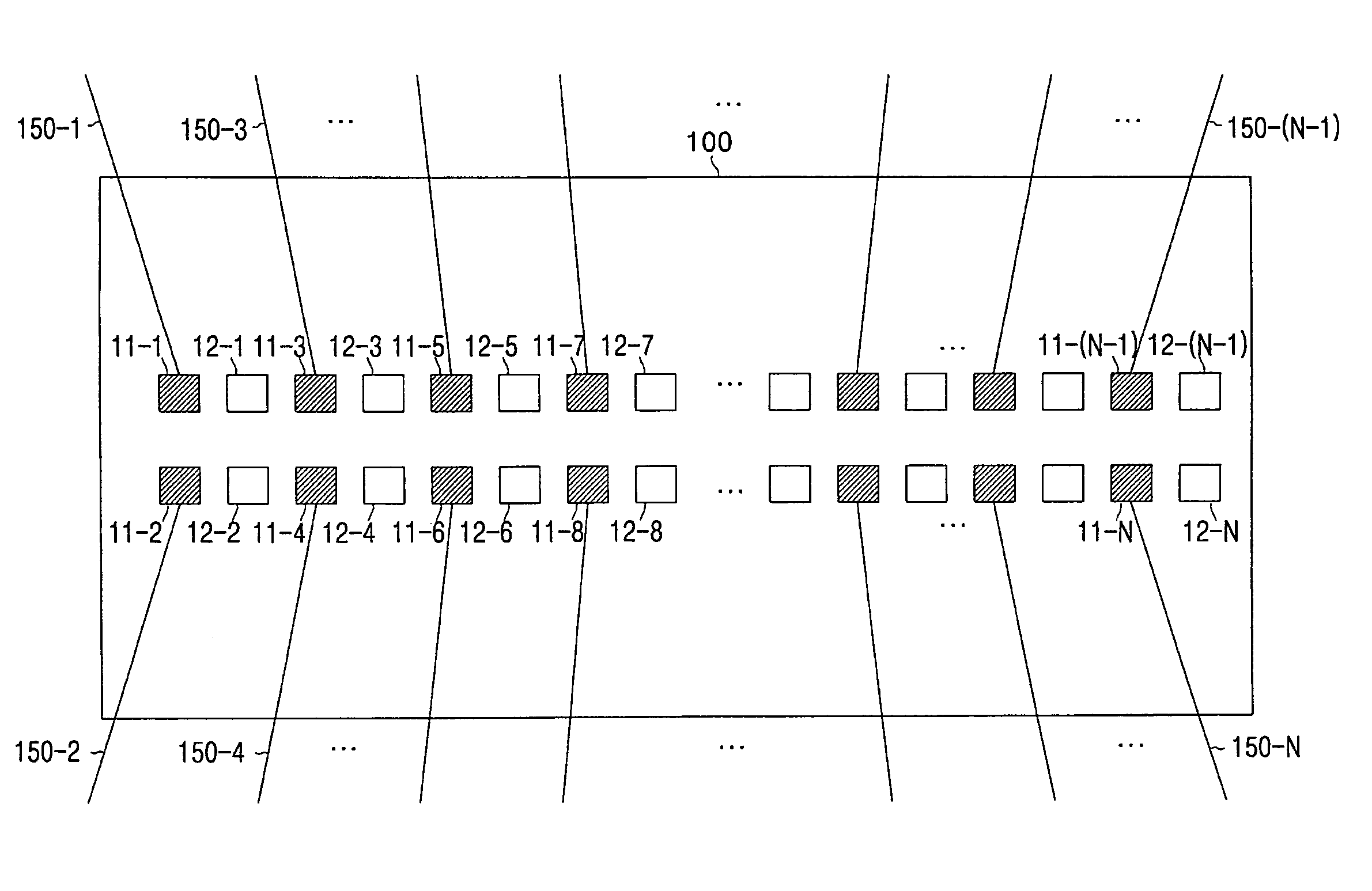

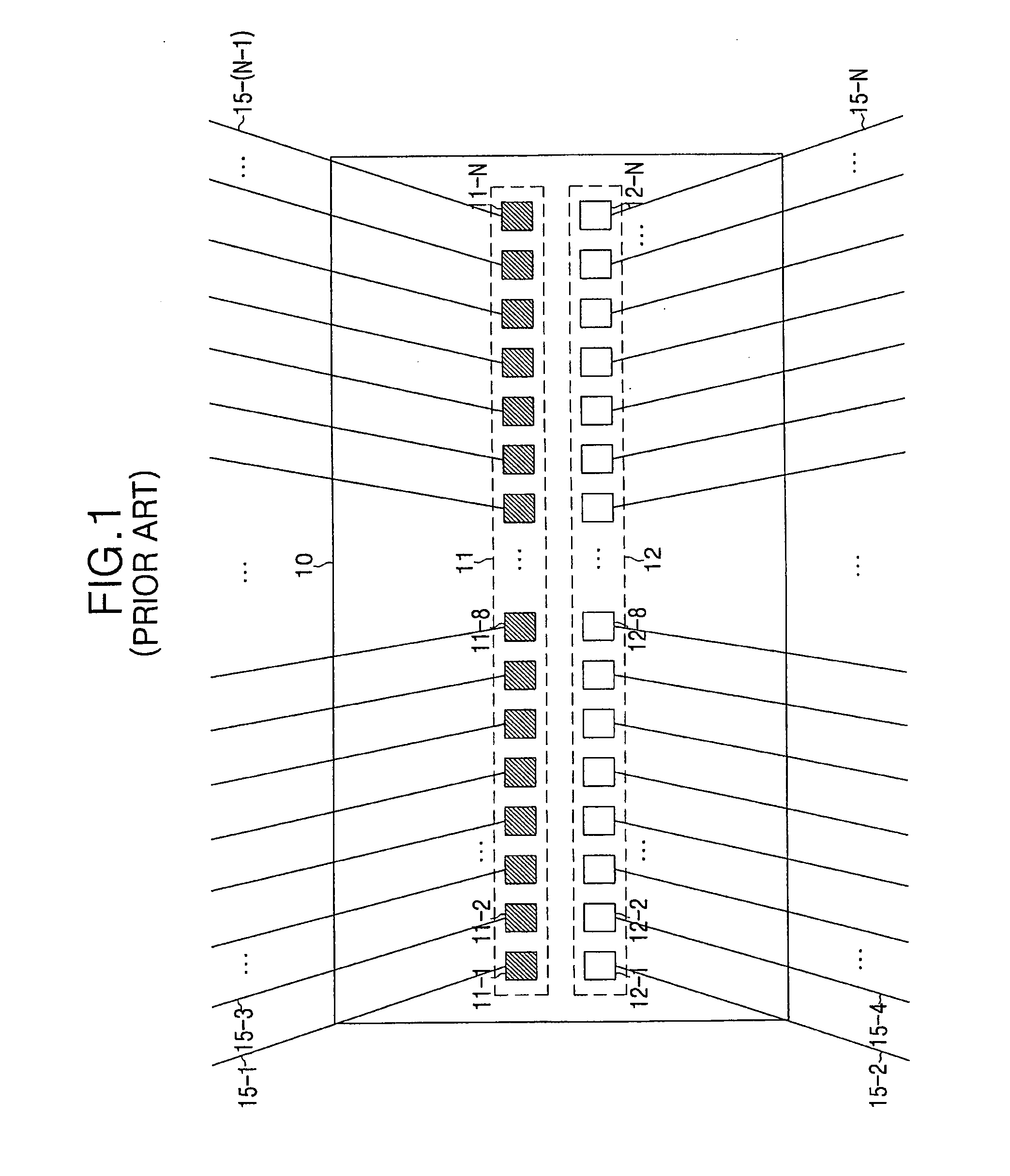

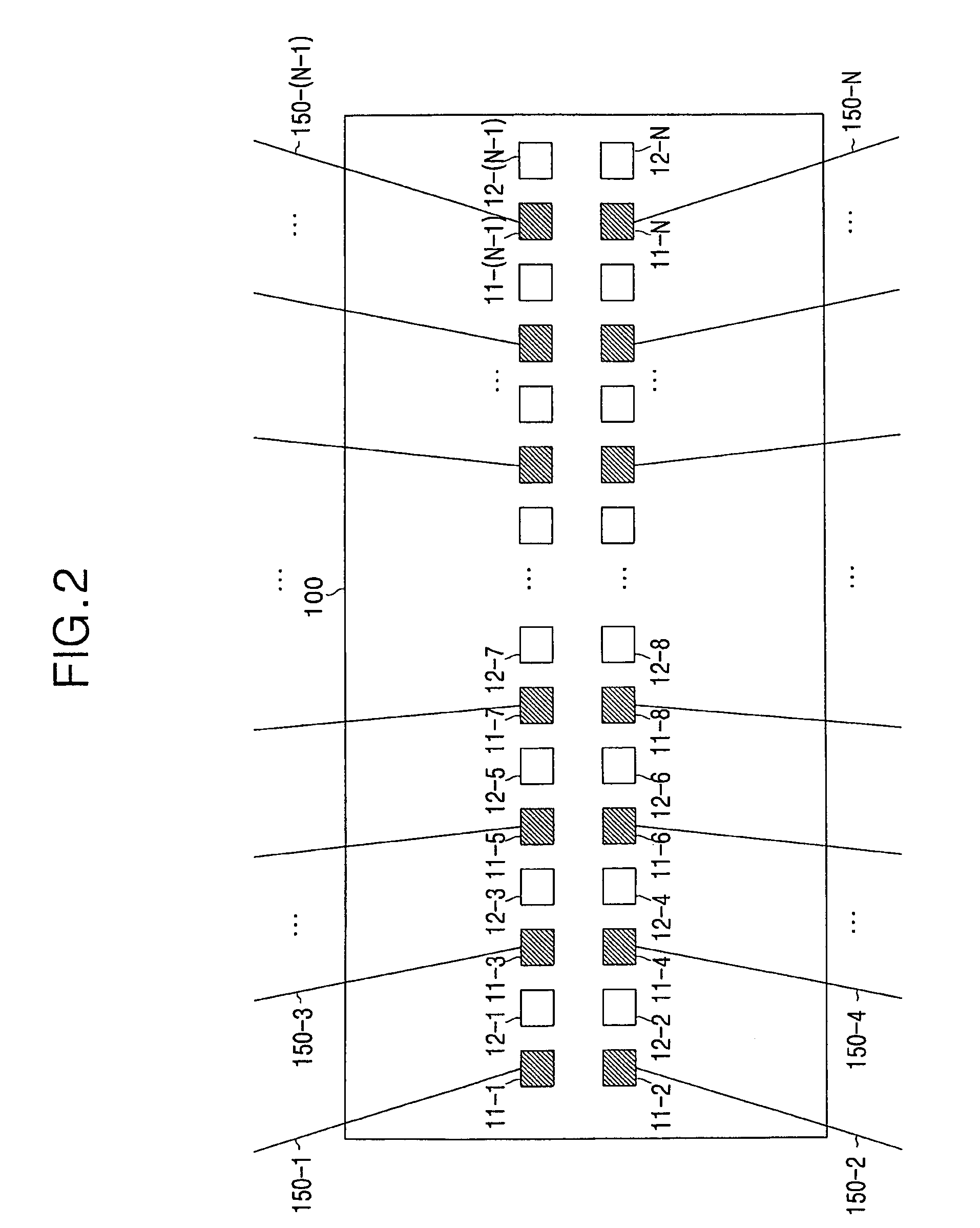

Semiconductor memory device and test method thereof

ActiveUS20080175080A1Minimize the numberSemiconductor/solid-state device testing/measurementSolid-state devicesContact testProbe card

Provided are a semiconductor memory device and a test method thereof. The semiconductor memory device includes: a die in which a plurality of internal circuits are integrated; a plurality of first and second channel pads having a first pad size and a first pad pitch, disposed in an alternating manner in a straight line at a center part of the die, and divided into a plurality of parallel rows, wherein the plurality of first and second channel pads are configured to selectively contact test probes in an alternating manner to receive an external wafer test signal and to output a signal generated by the plurality of internal circuits to the exterior. Therefore, it is possible to perform a test using plural channel pads during a wafer test of the semiconductor memory device using a plurality of probes of a probe card without incorrect contacts or non-contact with adjacent pads.

Owner:SAMSUNG ELECTRONICS CO LTD

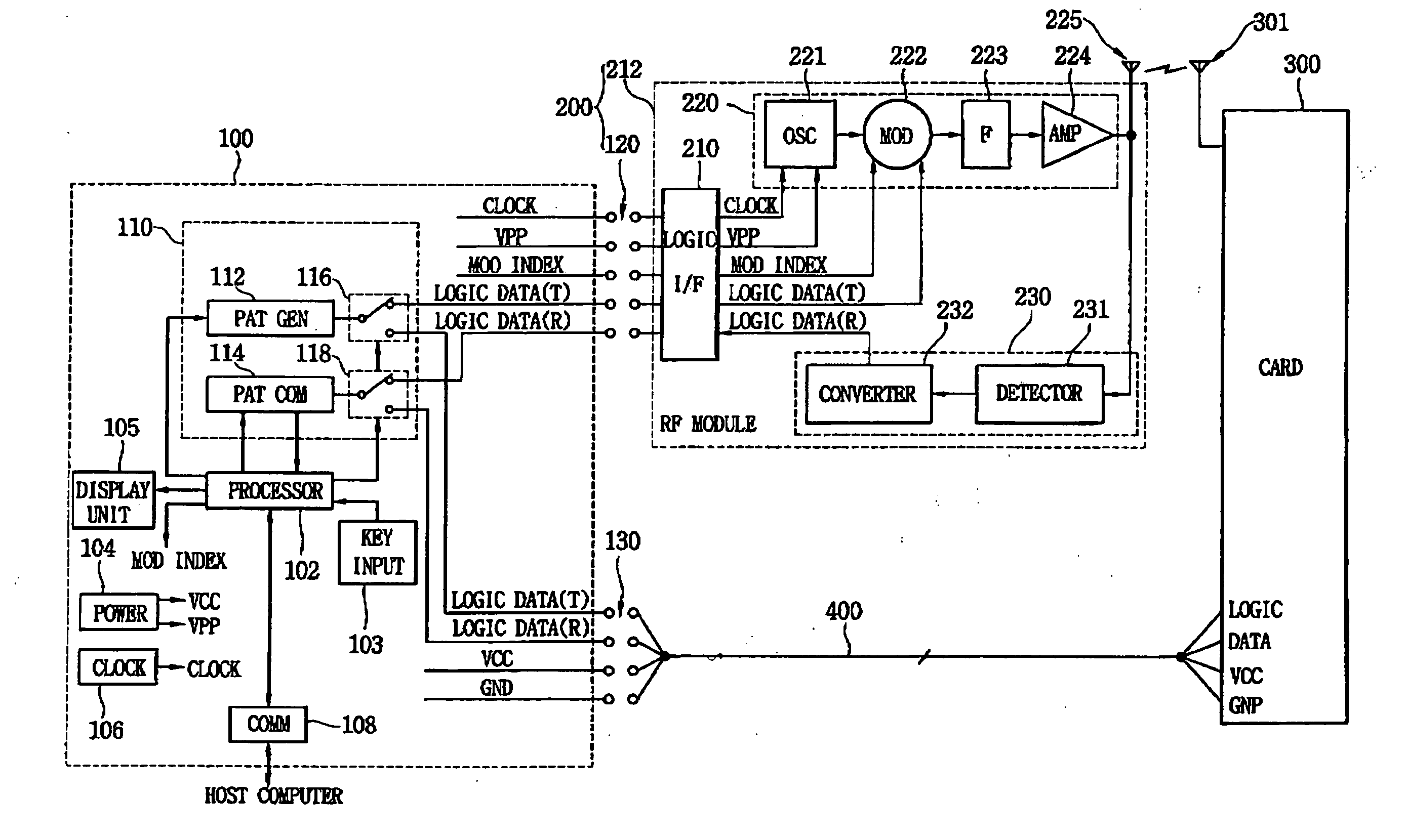

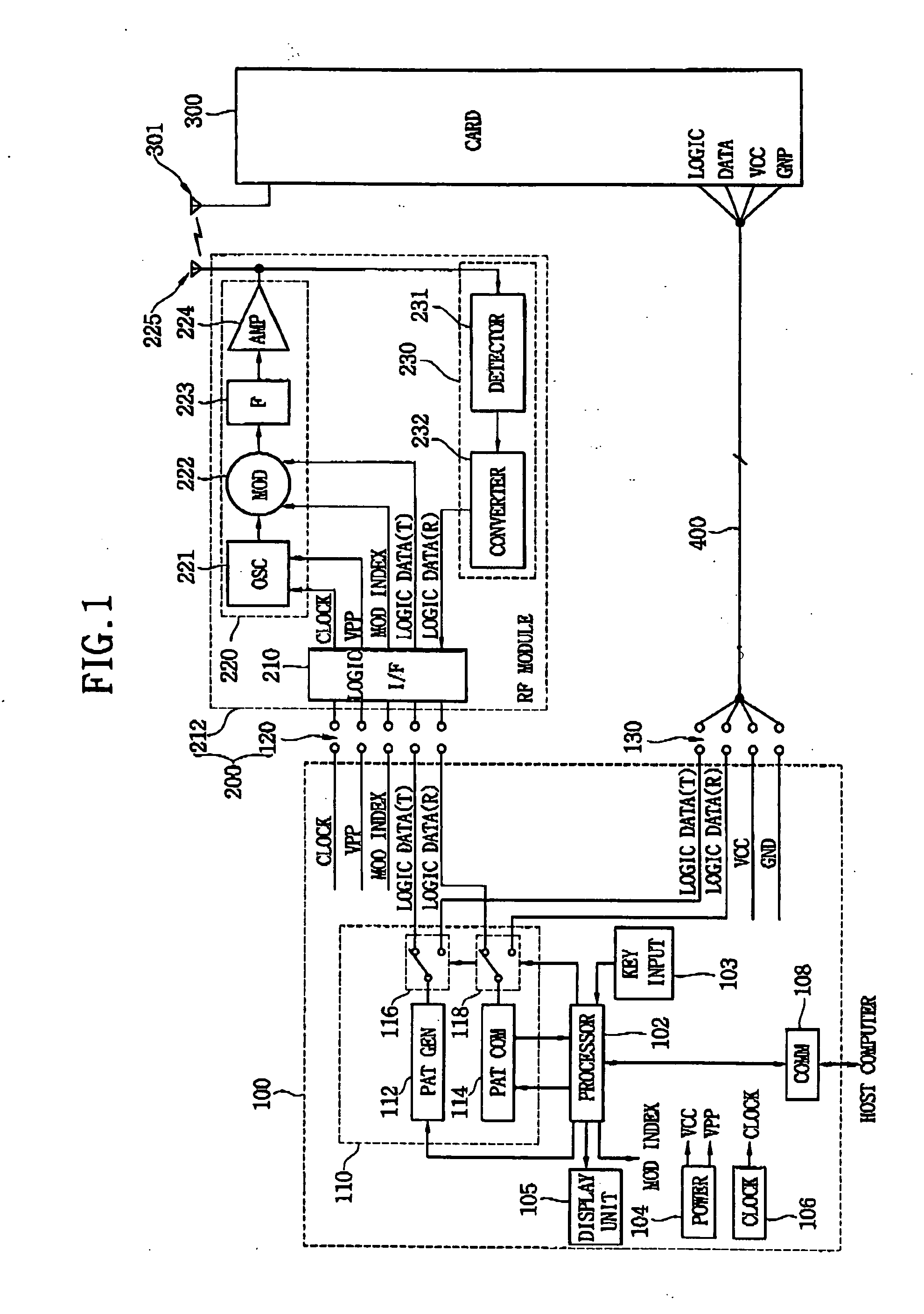

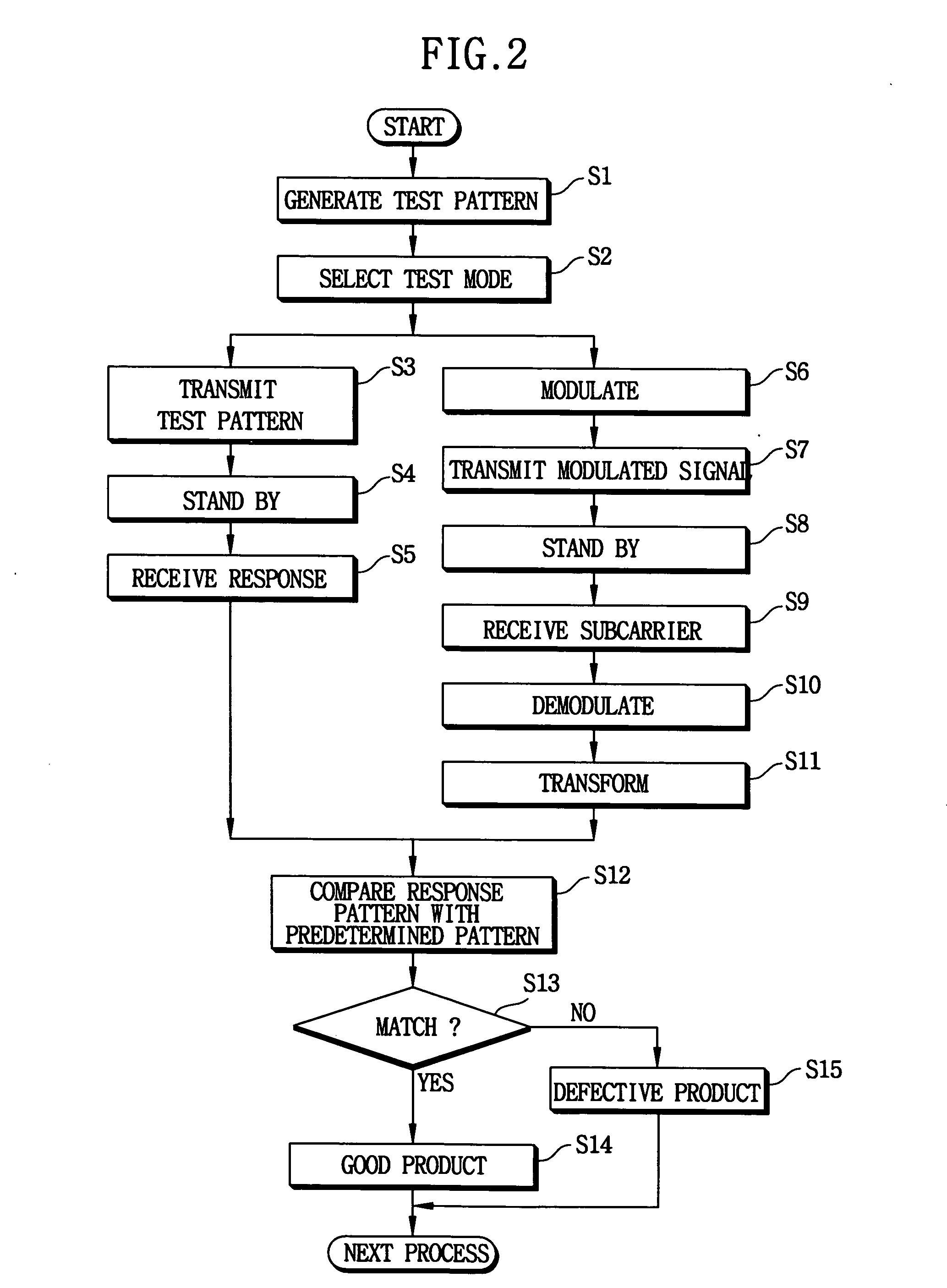

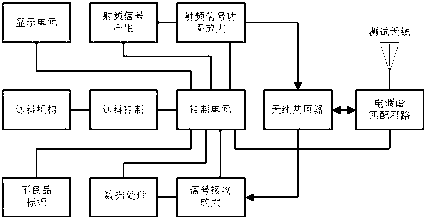

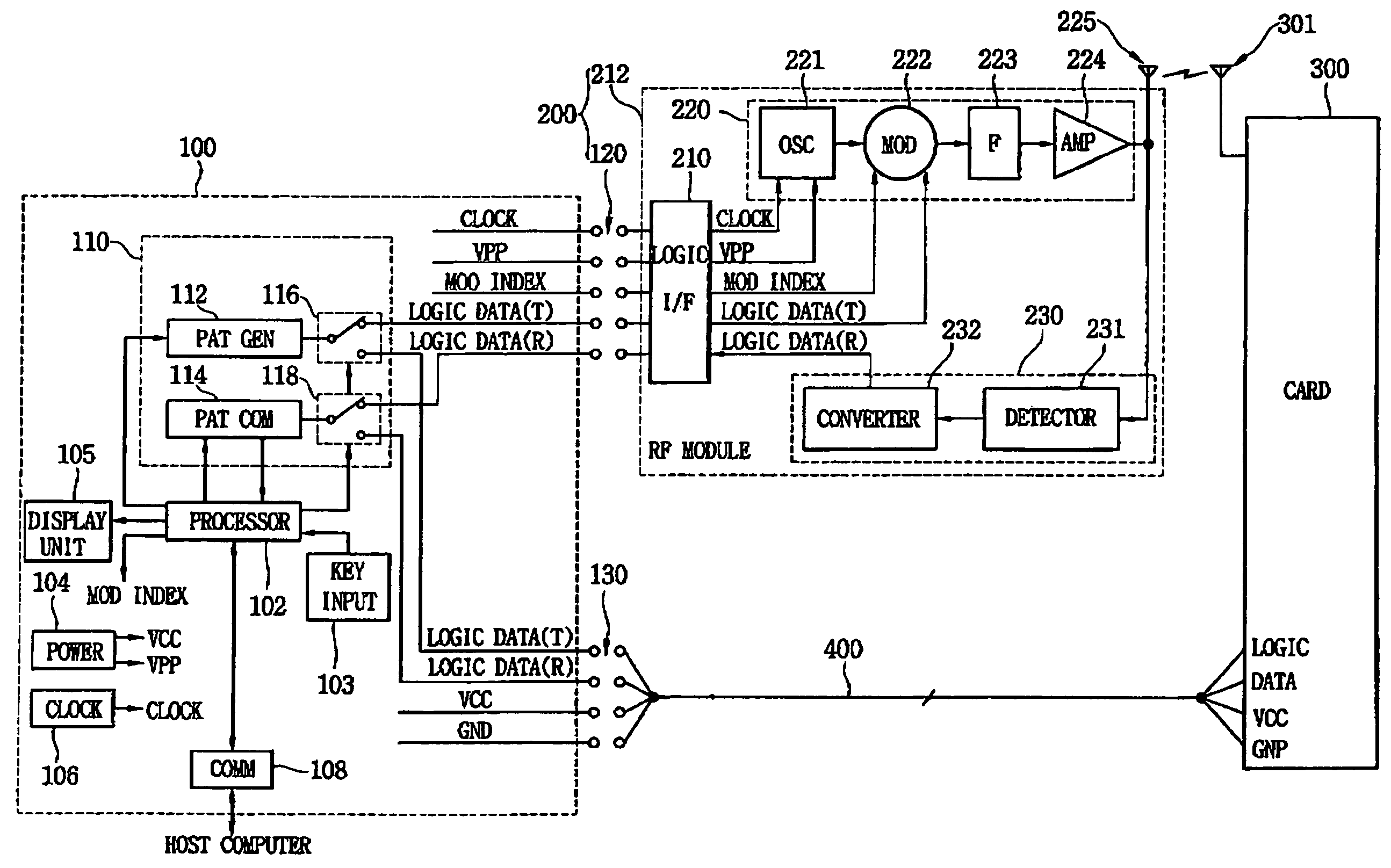

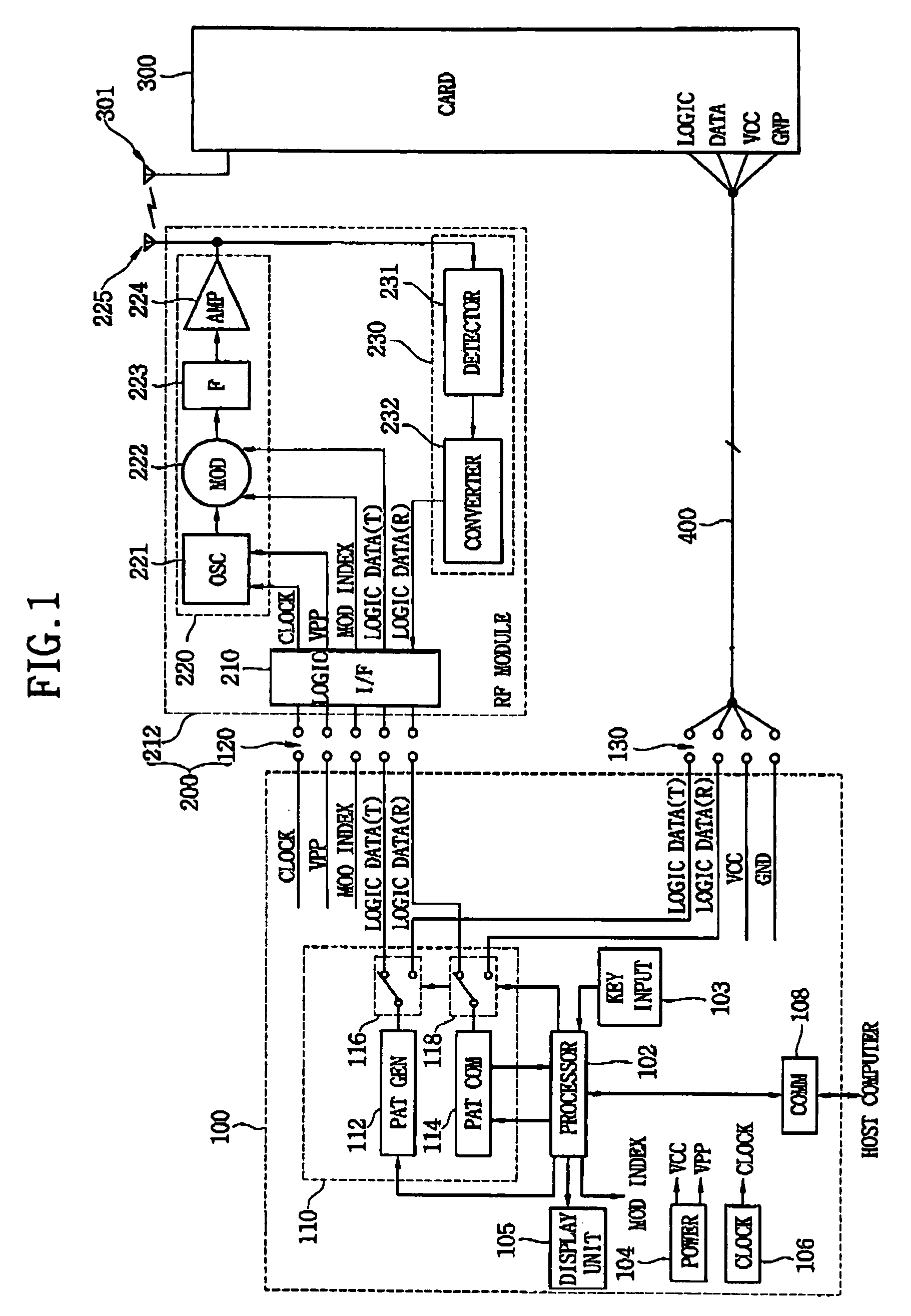

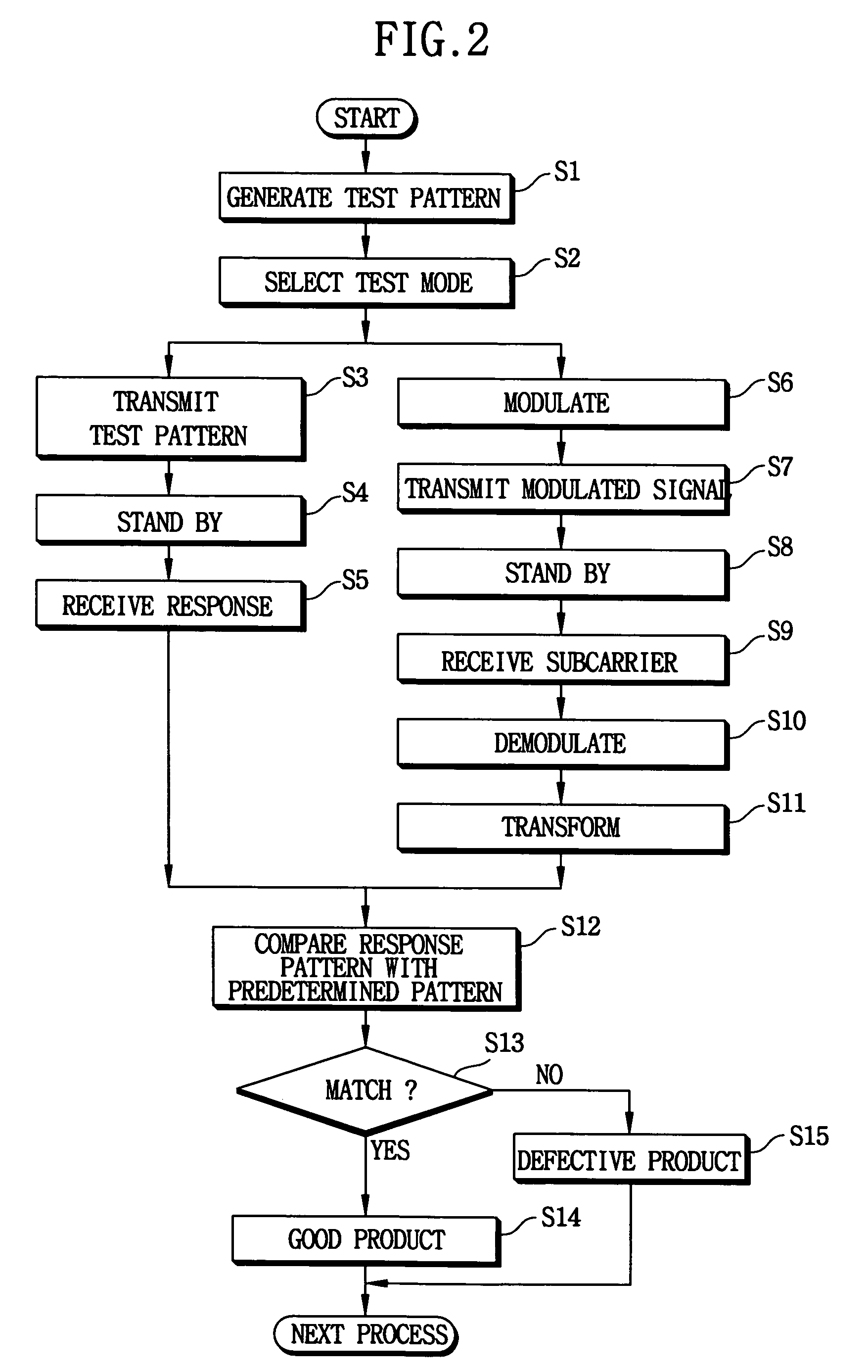

Device for testing smart card and method of testing the smart card

InactiveUS20050034028A1Testing sensing arrangementsElectronic circuit testingHybrid typeContact test

Devices and methods are provided for testing various types of smart cards including contact, contactless, and hybrid type (contact / contactless) smart cards. A test device includes a logic tester, a contactless interface unit, and a contact interface unit. The logic tester generates a test pattern that is transmitted to a smart card to test the smart card and compares a received response pattern with a response pattern to test a status of the smart card. The contactless interface unit enables a contactless test mode of operation and the contact interface unit enables a contact test mode of operation.

Owner:SAMSUNG ELECTRONICS CO LTD

Wire termination device having test contacts on cover

InactiveUS7168992B2Easy to useIncrease the areaInterconnection arrangementsElectrically conductive connectionsContact testTerminal equipment

A wire termination device, such as a protected termination device (“PTD”), is provided for establishing and testing telephone wiring connections. Conductive contacts provided on the cover of the PTD are incorporated into a plug assembly mounted on the cover. The plug assembly is then brought into engagement with the jack of the PTD when the cover is closed. A preferred embodiment of the plug assembly incorporates laterally disposed bypass contacts that are brought into engagement with conductive plates within the jack. An alternative embodiment of the plug assembly has conductive contacts that are brought into contact with the tip and ring contacts of the jack when the cover is closed. In either case, test contacts are accessible through the cover of the PTD so that the cover of the PTD can be opened and closed without having to disconnect and reconnect the test probes from the test contact points.

Owner:CORNING OPTICAL COMM LLC

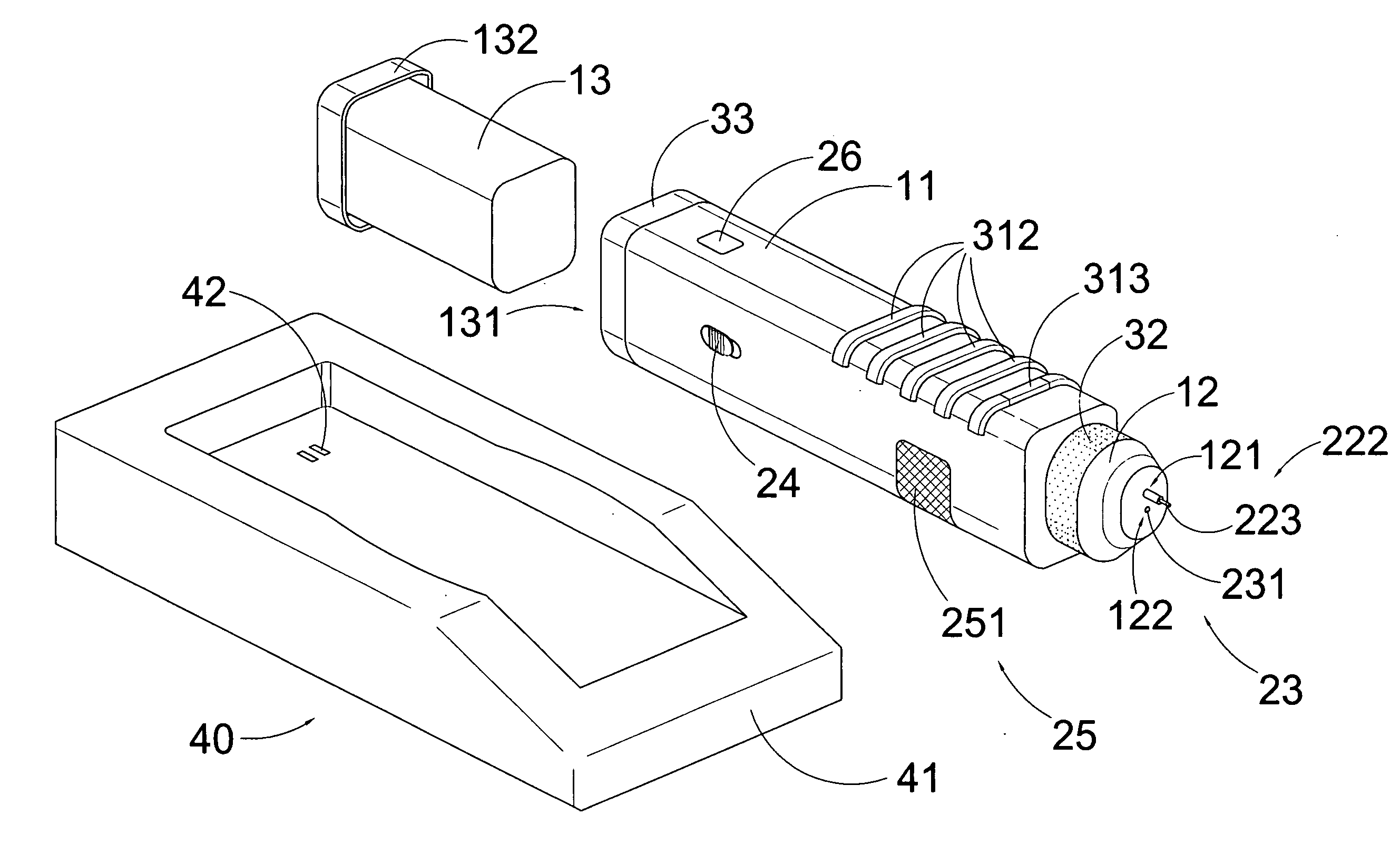

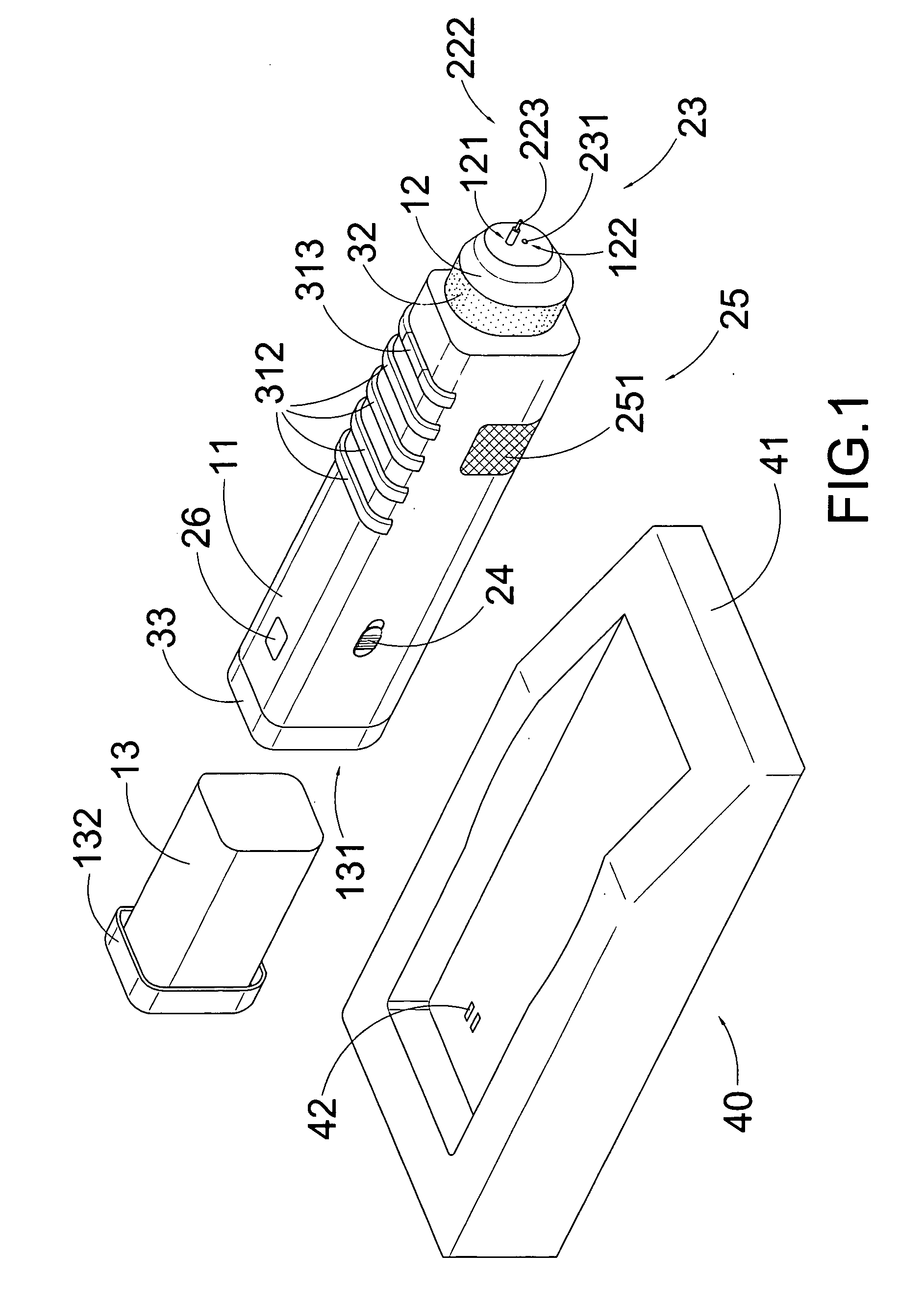

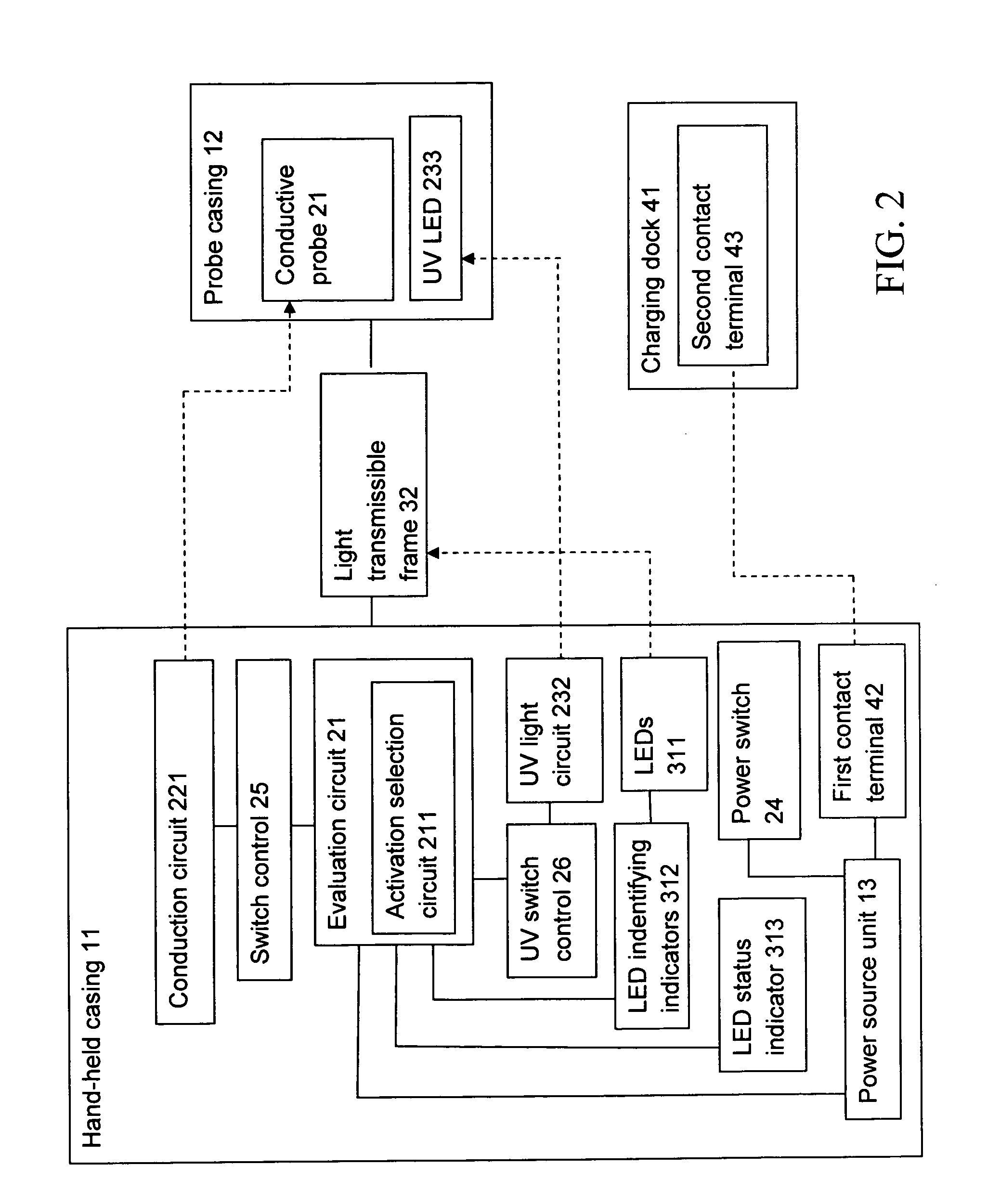

Multi-functional precious stone testing apparatus and method thereof

ActiveUS20120007619A1Accurate classificationInvention is simple and easyBatteries circuit arrangementsMaterial thermal conductivityContact testHand held

A multi-functional precious stone testing apparatus includes a portable housing, a testing unit, and an indication unit. The portable housing includes a hand-held casing and a probe casing extended from a front end of the hand-held casing. The testing unit includes a conductive probe having a testing end portion extended out of a tip end of the probe casing for contacting a testing object to determine a conductivity of the testing object. The indication unit includes a LED light unit received in the hand-held casing for illuminating the testing end portion of the conductive probe during testing, wherein the LED light unit is positioned away from the tip end of the probe casing for preventing heat generated from the LED light unit being transmitted toward the conductive probe to affect an accurate measurement for the conductivity of the testing object.

Owner:SHENZHEN DIKAI IND CO LTD

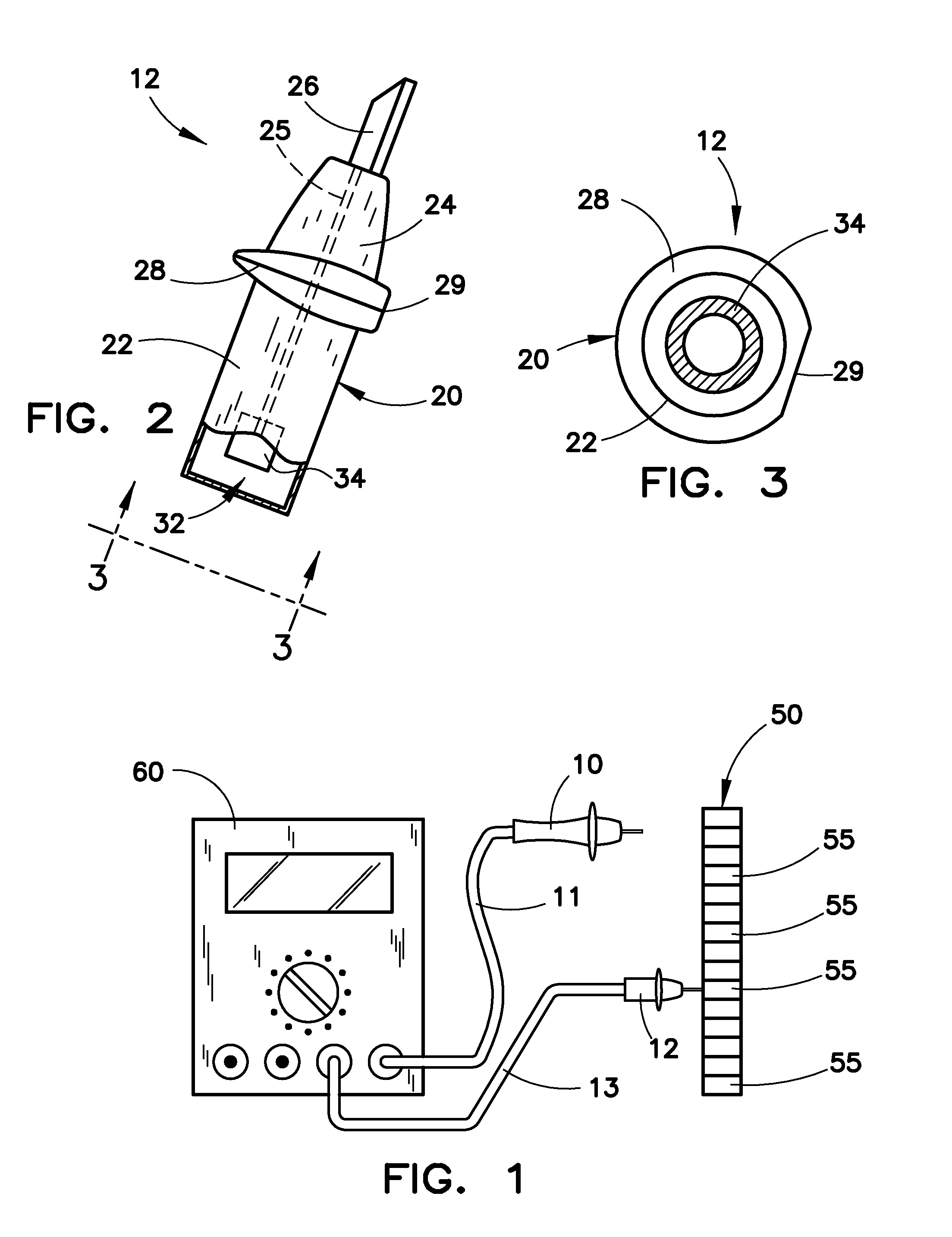

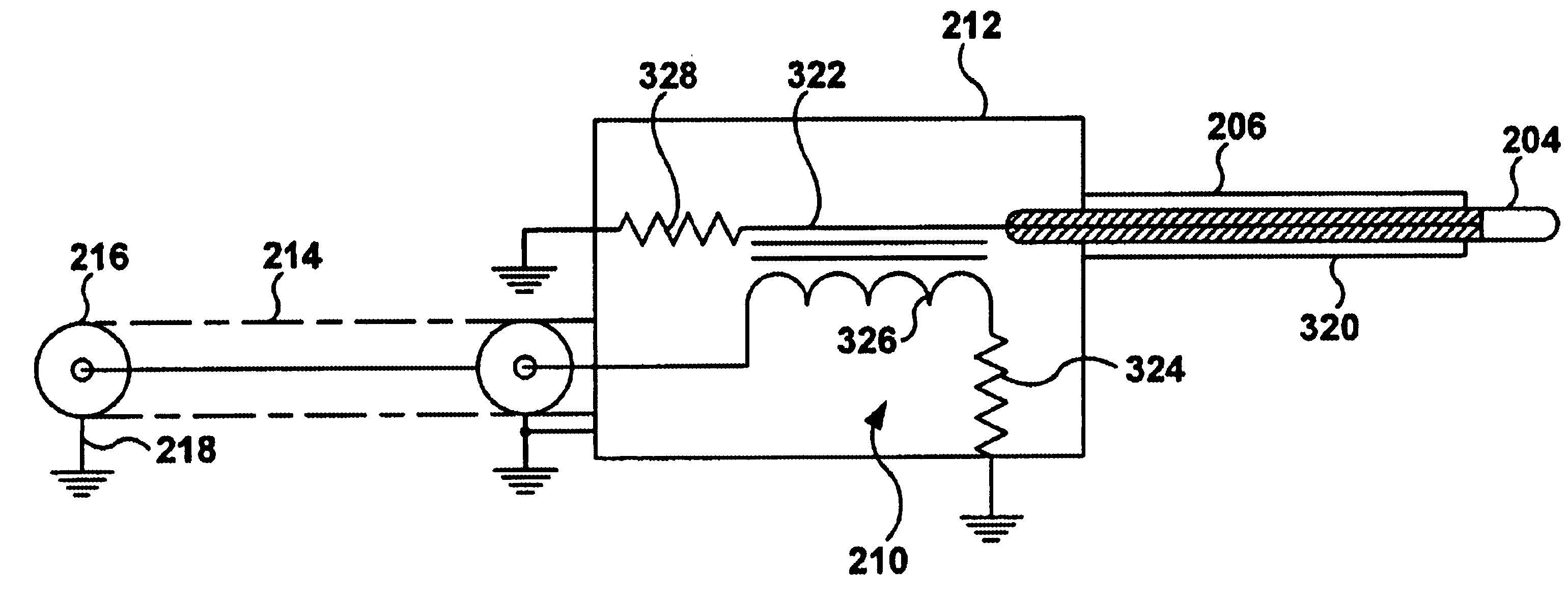

Inductively coupled direct contact test probe

ActiveUS6841986B1Minimize pickupWithout risk of damageResistance/reactance/impedenceElectrical measurement instrument detailsDielectricElectrical conductor

A probe for measuring radio frequency / electromagnetic interference (RF / EMI) is used in combination with a spectrum analyzer or oscilloscope (measuring equipment) to measure and / or test for EMI in electronic equipment. The RF / EMI probe has high dielectric transformer isolation between the input of the measuring equipment and the circuit under test so as to prevent damaging the measuring equipment if a high voltage or current is encountered in the circuit being tested. The RF / EMI probe comprises a measurement tip connected to a shielded sense line, the shielded sense line is electro-magnetically coupled to a toroid forming a RF transformer, a high impedance termination load is connected to the shielded sense line, a shielded coaxial cable having a center conductor connected to a secondary winding on the toroid transformer, the shielded coaxial cable being adapted for connection to an input of the measuring equipment. The shield of the coaxial cable is continuous between the input connector of the measuring equipment and a shielded enclosure surrounding the toroid transformer. The coaxial cable may terminate in a RF connector, e.g., BNC and the like, for quick connection to and disconnection from the measuring equipment.

Owner:DELL PROD LP

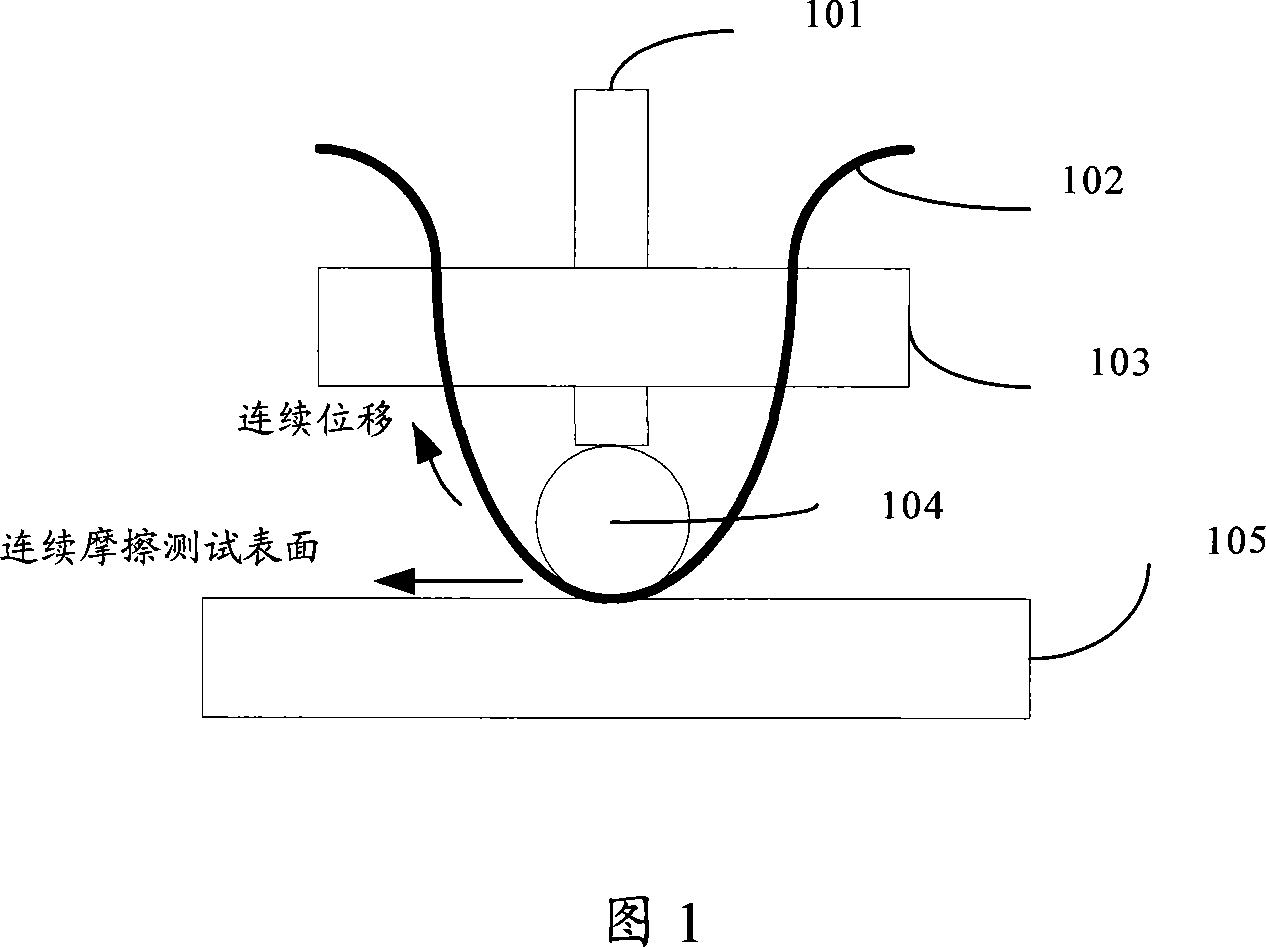

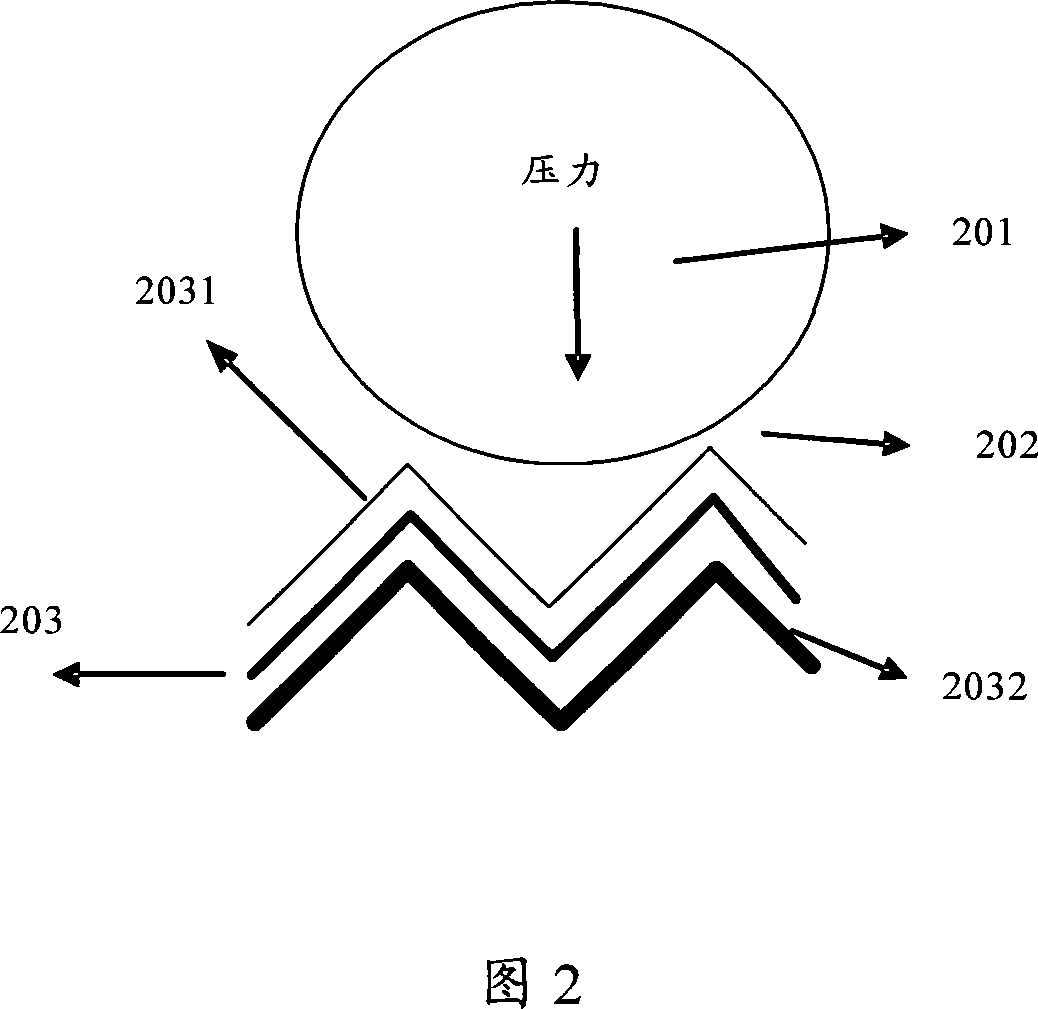

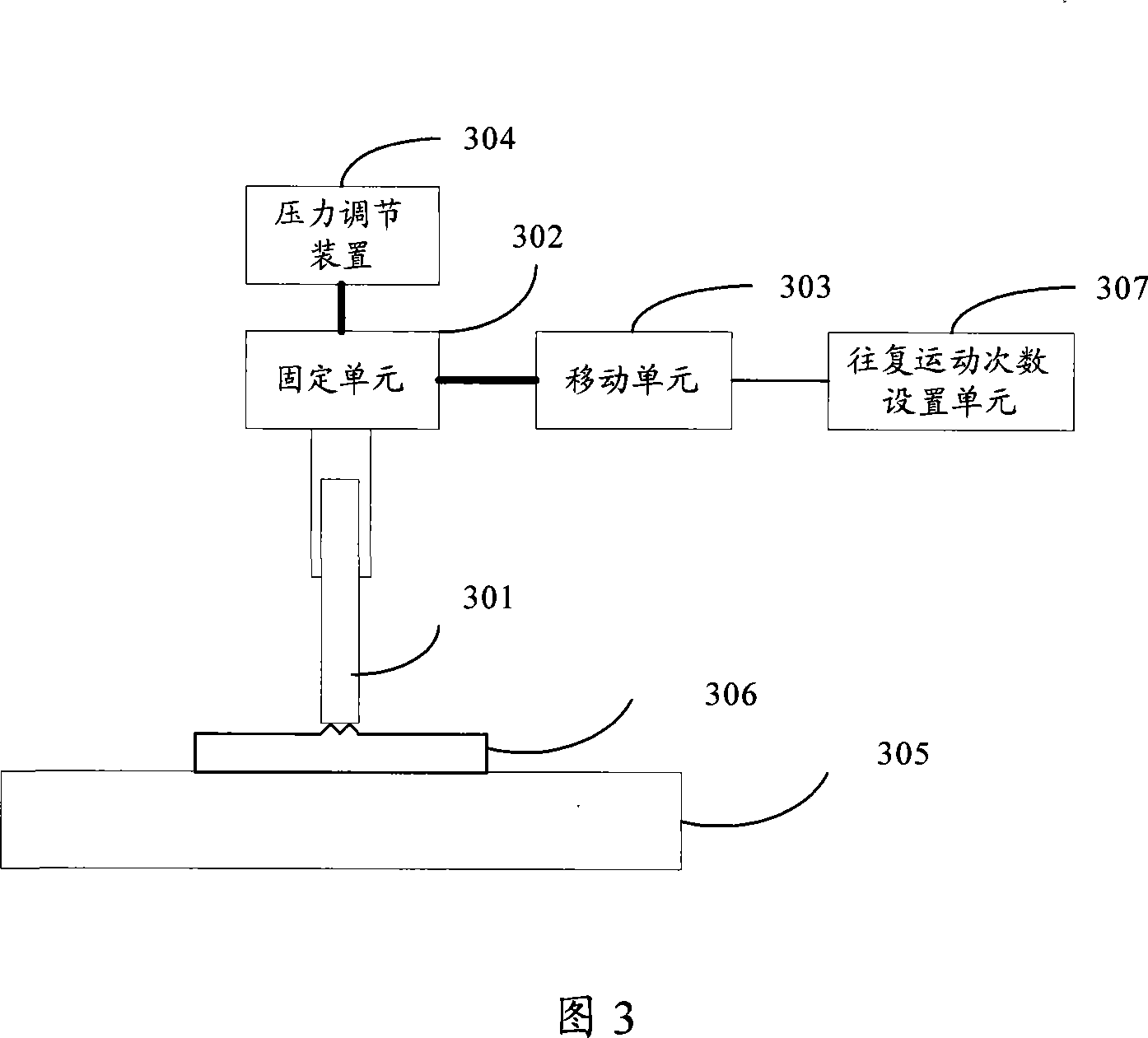

Wearability test method and implementation device

InactiveCN101059414ANot easy to slideStable and accurate test pressureUsing mechanical meansInvestigating abrasion/wear resistanceContact testReciprocating motion

The invention discloses a device for test abrasion resistance, used to test the object with irregular surface. The invention comprises a test head, a movable unit and a fixed platform, wherein an object is arranged on the fixed platform, the test head controlled by the movable unit reciprocally moves on the object, the test head is made from rigid and brittle material, the end of the test head is flat, test head has better contact with the surface of the object in the reciprocal movement. The invention also provides a relative abrasion-resistance test method. When in use and in friction, since the end of the pencil is flat and the pencil is rigid, the invention can accurately pickup test point, to contact the test point accurately, therefore, the test pressure is accurate, and the test result can represent whole effect, to accurately evaluate the plated structure art of lathe tool, and the abrasion resistance of structure of other lathe tool.

Owner:HUAWEI TECH CO LTD

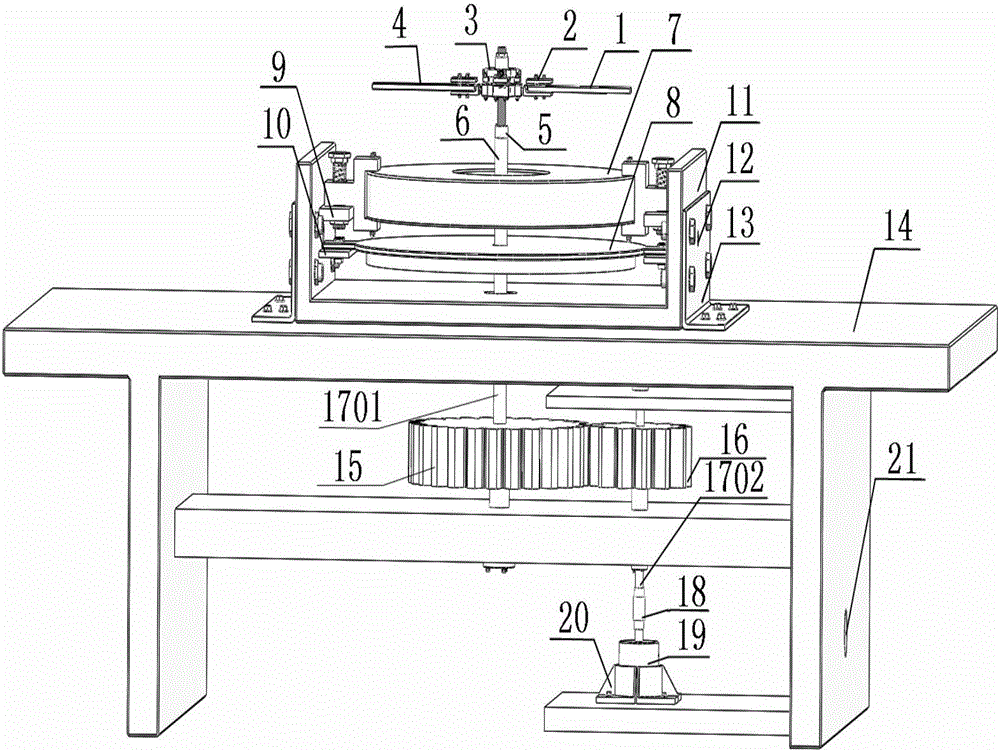

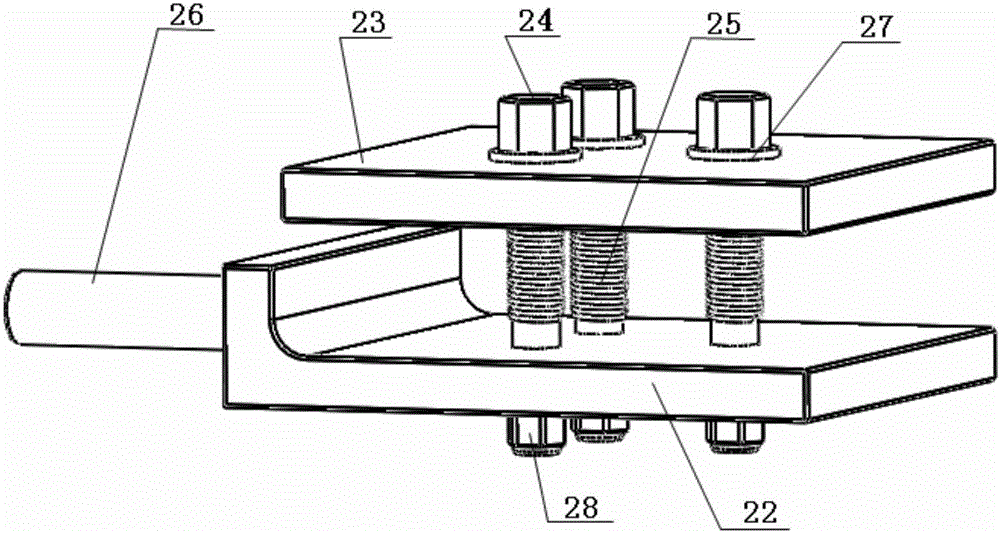

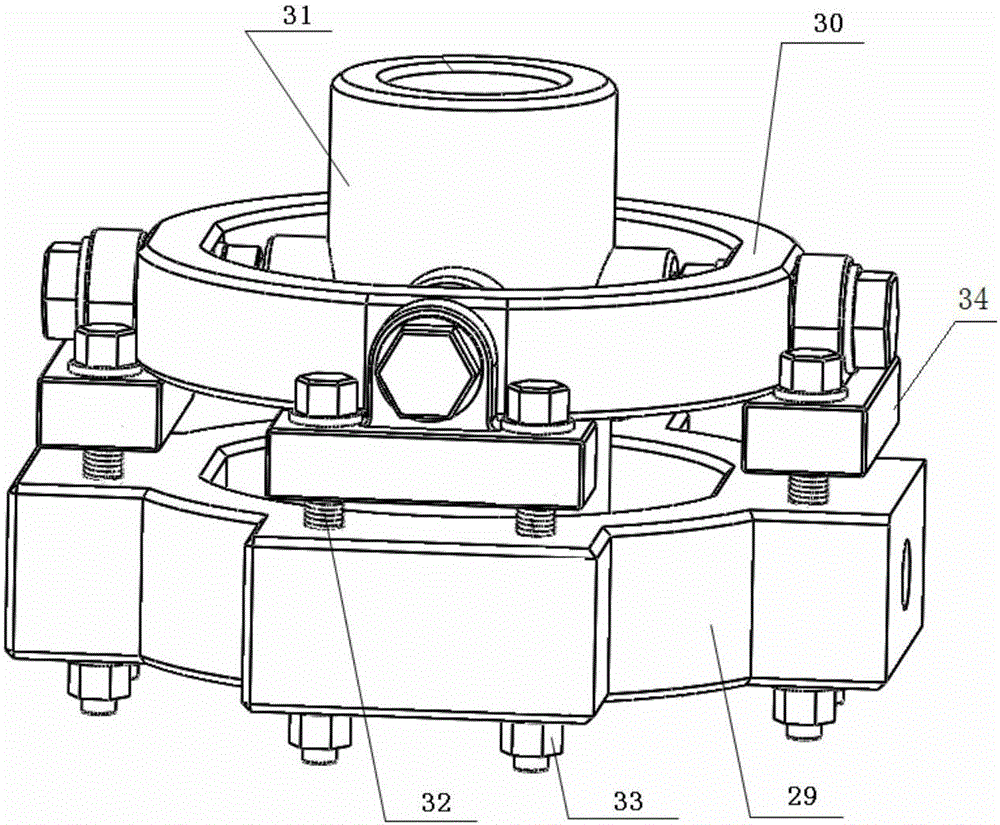

Accurate controllable non-contact test piece rotary magnetic field fatigue excitation and vibration test device

ActiveCN105910780AWide range of applicable objectsReduce the impactVibration testingVibration accelerationDynamic balance

The invention provides an accurate controllable non-contact test piece rotary magnetic field fatigue excitation and vibration test device. The device comprises a vibration damping insulation clamp, a vibration damper, a dynamic balance device, a vibration exciter, an electromagnetic piezoelectric coupling vibration sensor, a test station, a transmission device and an accurate control device. The excitation and vibration test device is suitable for rotary test pieces and especially suitable for vibration characteristic researches on a wind power blade, an engine, a turbine blade, a helicopter rotor and a tail rotor blade, the excitation and vibration test device can vividly simulate vibration fatigue states of rotary test pieces respectively under conditions of 360-DEG all directions, same rotating speed and different excitation forces, same excitation force and different rotating speeds, and different rotating speeds and different excitation forces, the excitation and vibration test device can monitor related vibration characteristic parameters such as the excitation force, the vibration displacement, the vibration speed and the vibration acceleration continuously, and the excitation and vibration test device is suitable for vibration fatigue characteristic analysis on stationary test pieces.

Owner:CHONGQING UNIV

Non-contact test system and method of RFID label antenna

ActiveCN103267911AReduce work intensityReduce false positivesElectrical testingContact testTag antenna

The invention discloses a non-contact test system and method of an RFID label antenna. The non-contact test system of the RFID label antenna comprises a display unit, a data processing and controlling unit, a radio-frequency signal transmit / receive unit, a feed mechanism unit and a test antenna unit. The data processing and controlling unit is connected with the display unit, the radio-frequency signal transmit / receive unit and the feed mechanism unit in sequence, and the test antenna unit is connected with the radio-frequency signal transmit / receive unit. Due to the fact that non-contact test is adopted, test can be carried out free of requirement of binding a chip, dissipation of the chip is reduced, and working strength of testing personnel is reduced; the fault testing rate and the leak testing rate are low; automatic testing can be achieved, and testing efficiency is high; indirect measurement to electrical property can be achieved. The non-contact test system and method of the RFID label antenna can achieve automatic test and greatly reduces demands for mechanical mechanisms, and are very suitable for large-batch production testing.

Owner:SUZHOU ZUENS IOT TECH CO LTD

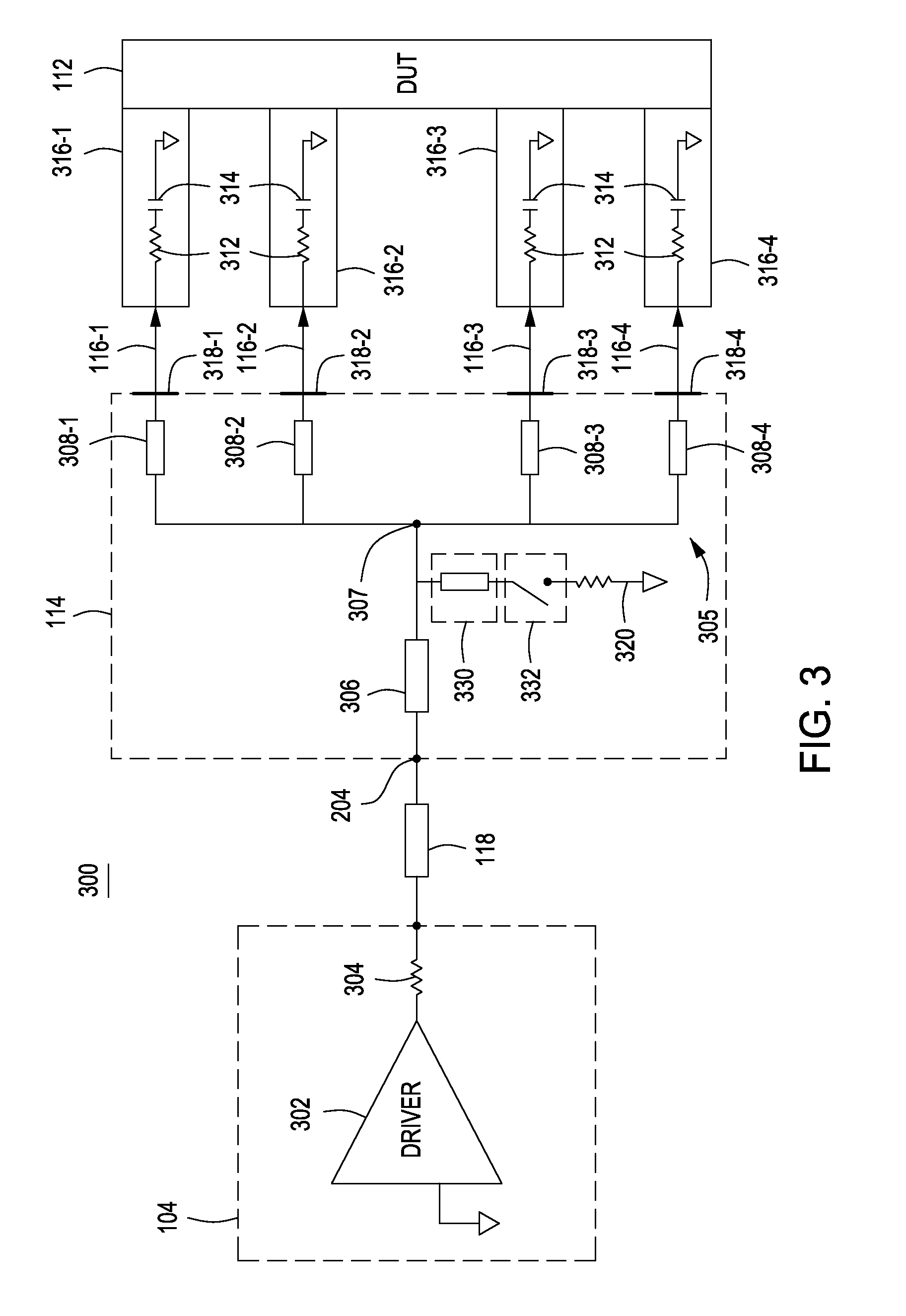

Method and apparatus for Terminating A Test Signal Applied To Multiple Semiconductor Loads Under Test

ActiveUS20100253374A1Shorten test timeElectrical measurement instrument detailsIndividual semiconductor device testingContact testElectrical resistance and conductance

Apparatus for terminating a test signal applied to multiple semiconductor loads under test is described—for example apparatus for interfacing a test signal between a tester and a semiconductor device under test (DUT). In some examples, a probe card assembly may include at least one probe substrate each having test probes configured to contact test features of a DUT; a wiring substrate, coupled to the at least one probe substrate, having a connector configured for coupling with a source termination of a tester; a signal path formed on and / or in the wiring substrate and the at least one probe substrate, the signal path having a trace and trace stubs fanning out from the trace, an input of the trace being coupled to the connector and outputs of the trace stubs being coupled to the test probes; and a resistive termination coupled between the trace and at least one potential.

Owner:FORMFACTOR INC

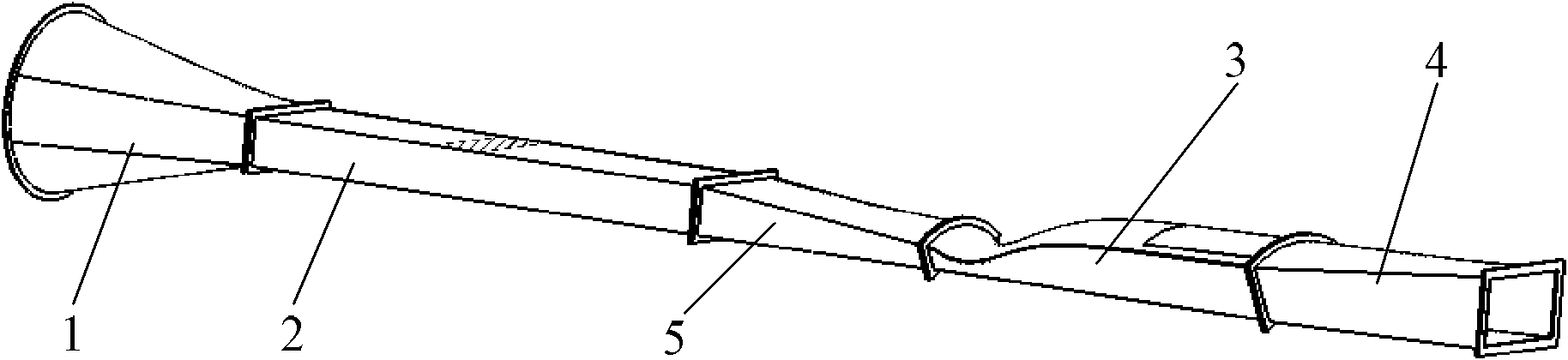

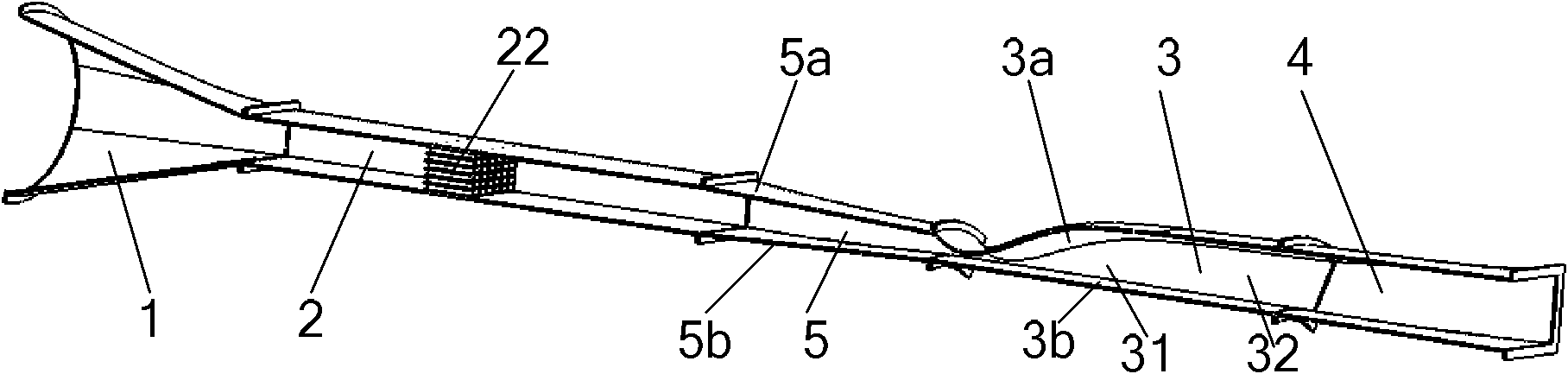

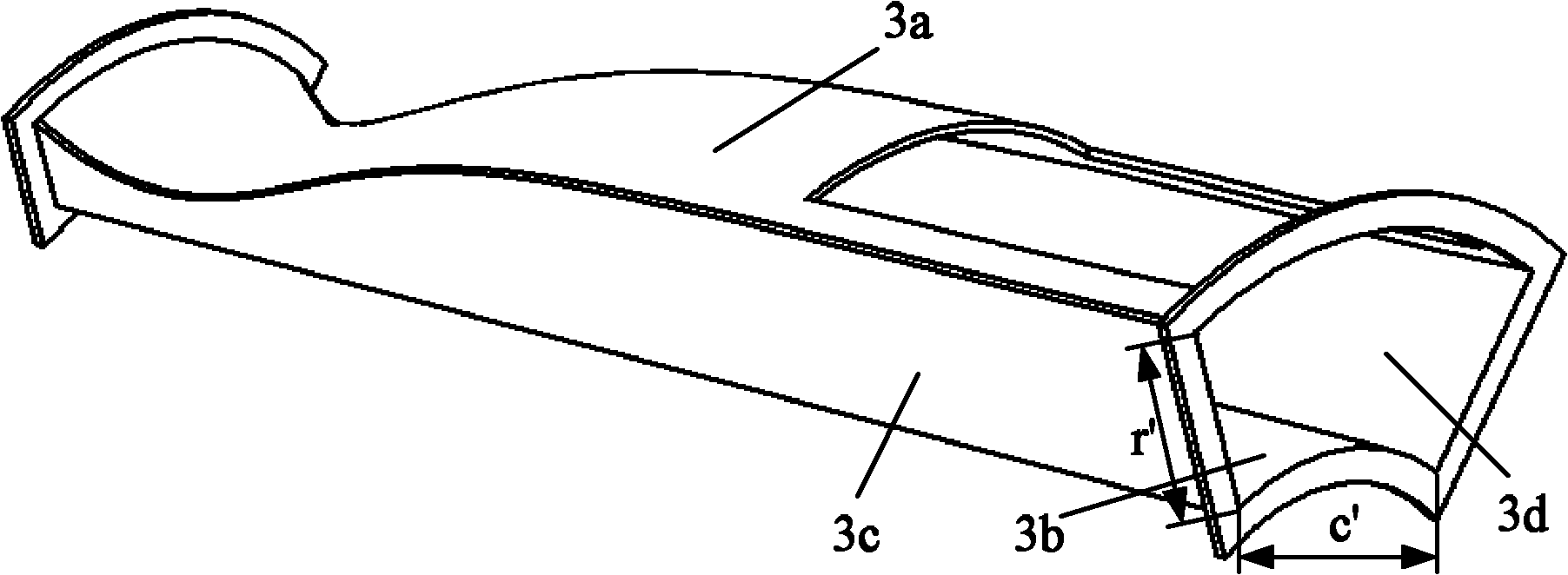

Supersonic velocity axisymmetrical boundary layer wind tunnel

ActiveCN102023077AFlow field characteristics researchInto a stableAerodynamic testingContact testEngineering

The invention provides a supersonic velocity axisymmetrical boundary layer wind tunnel which comprises a front transition section (1), a stabilizing section (2) and a spray pipe experiment section (3), wherein the front transition section (1) is used for introducing air flows and carrying out primary rectification on the air flows; the stabilizing section (2) is connected to the downstream of the transition section (1) and used for carrying out secondary rectification on the air flows; the spray pipe experiment section (3) is connected to the downstream of the stabilizing section (2) and is in a fan-shaped axisymmetrical structure relative to a rotation axis (O); the spray pipe experiment section (3) comprises an outer peripheral wall (3a), an inner peripheral wall (3b) and two side walls (3c and 3d) connected with the outer peripheral wall (3a) and the inner peripheral wall (3b); transparent windows are at least formed on the side walls; the spray pipe experiment section (3) also comprises a spray pipe part (31) which is in a single-side expansion spray pipe structure and an experiment part (32) which is positioned on the downstream of the spray pipe part and can be used for carrying out observation and an optical non-contact test on an axisymmetrical boundary layer flow field formed in a spray pipe experiment section so as to research the flow field characteristics of the supersonic velocity boundary layer.

Owner:NAT UNIV OF DEFENSE TECH

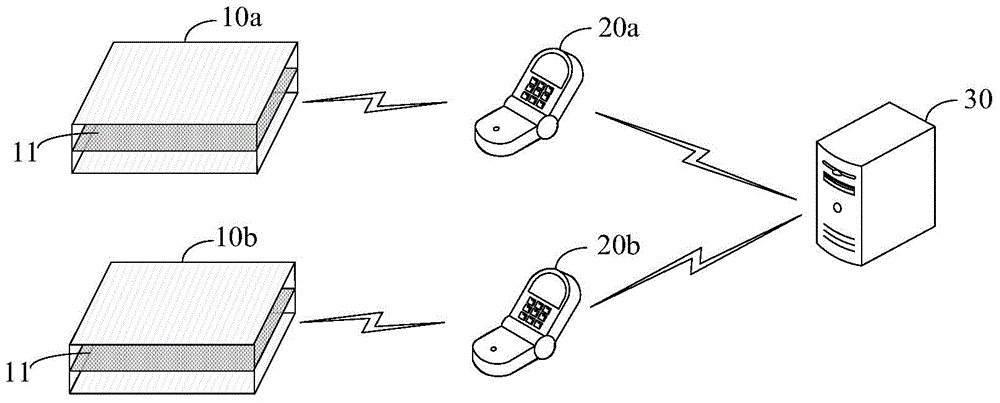

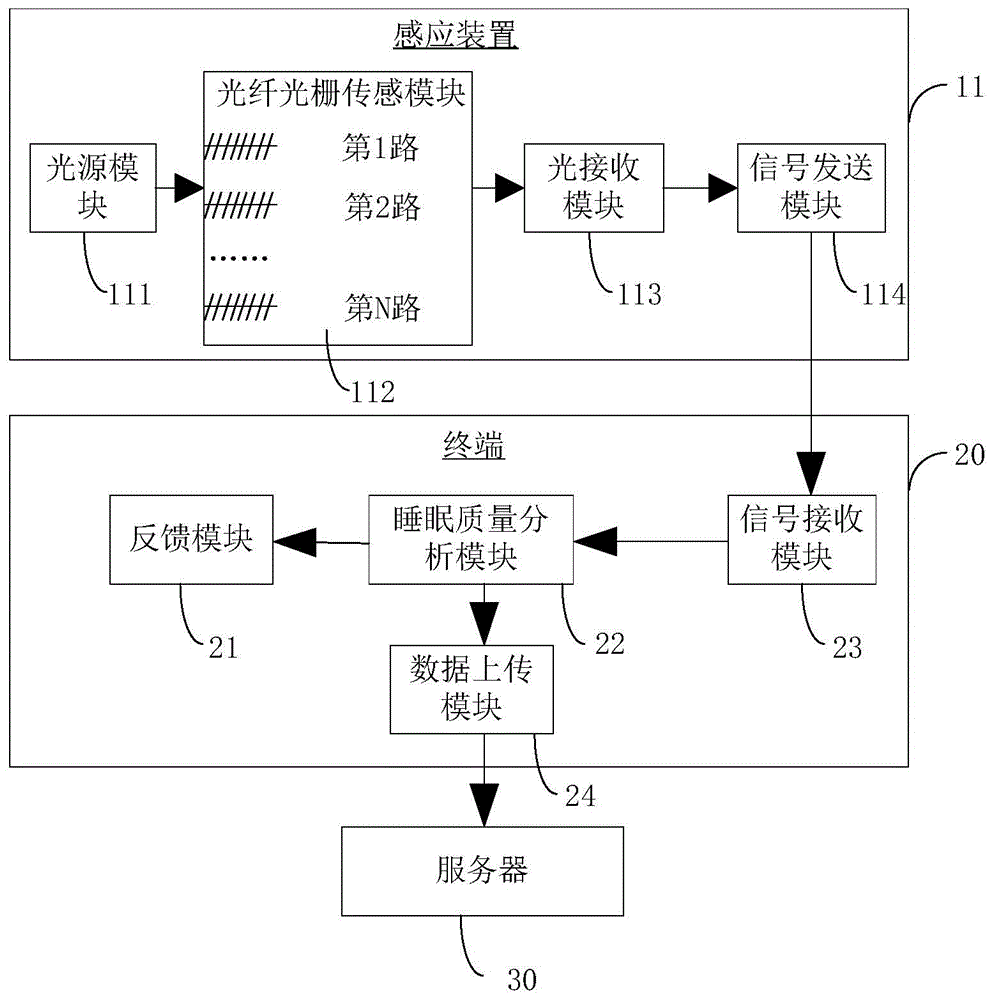

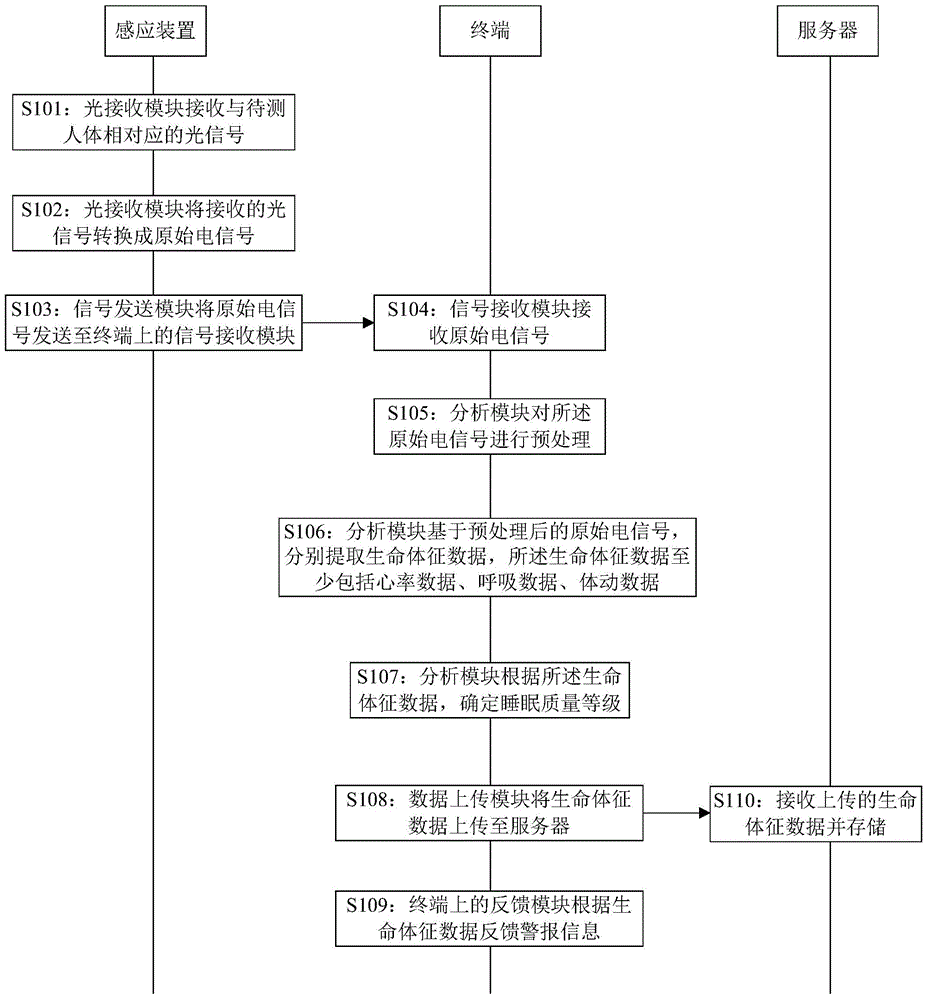

System and method for monitoring sleep quality and vital signs

InactiveCN105030198AAvoid discomfortImprove accuracySensorsMeasuring/recording heart/pulse rateHuman bodyContact test

The invention relates to a system and a method for monitoring sleep quality and vital signs. The system comprises an induction device and a terminal in communication with the induction device, wherein the induction device is arranged inside a part contacting a tested person. According to the device and the method provided by the invention, a fiber bragg grating sensing module of a sensing device is used for sensing an optical signal corresponding to the tested person, an optical receiving module is used for converting the optical signal into an original electric signal, then the original electric signal is sent to the terminal communicated with the sensing module, finally the terminal analyzes according to the received original electric signal, and thus the sleep quality data corresponding to the tested user are obtained. In the above process, the sensing device is arranged inside the part contacting the tested person, therefore, the sensing device is not in direct contact with the human body, and the discomfort caused to the user due to the adoption of the direct-contact test process is avoided.

Owner:ANLIGHT OPTOELECTRONICS TECH INC

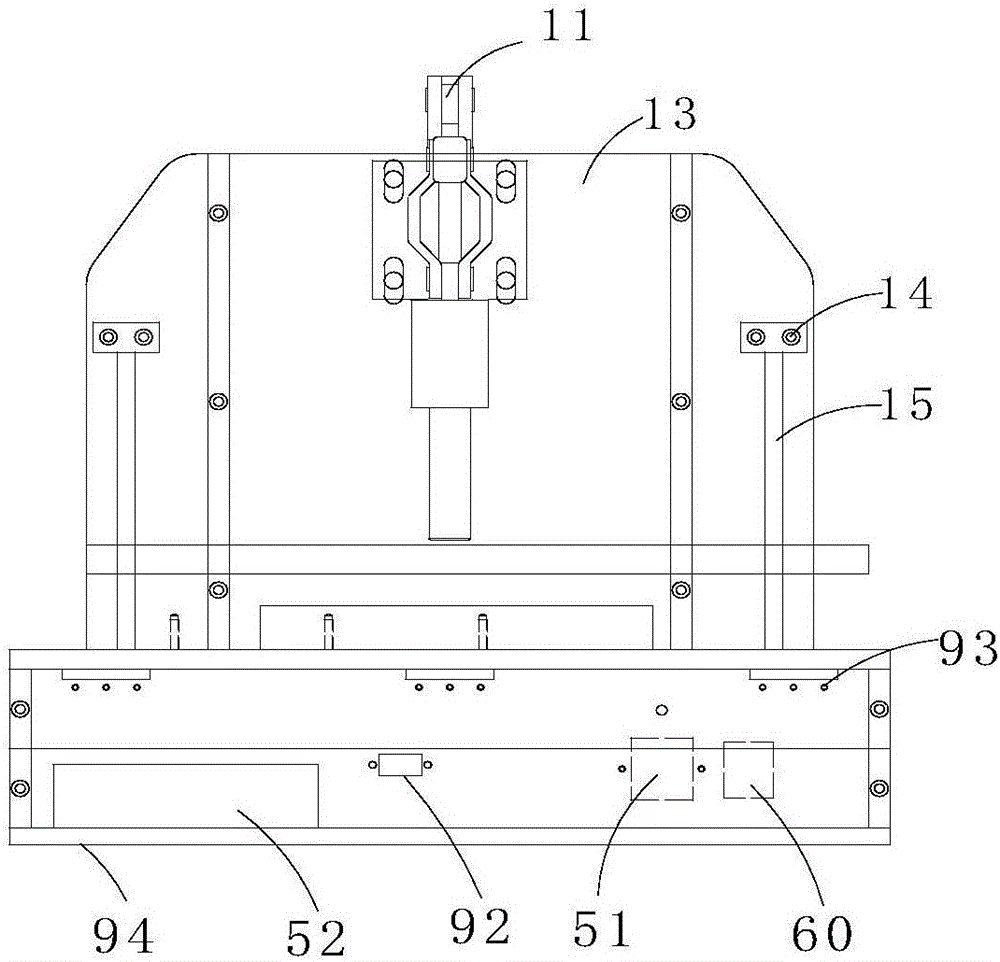

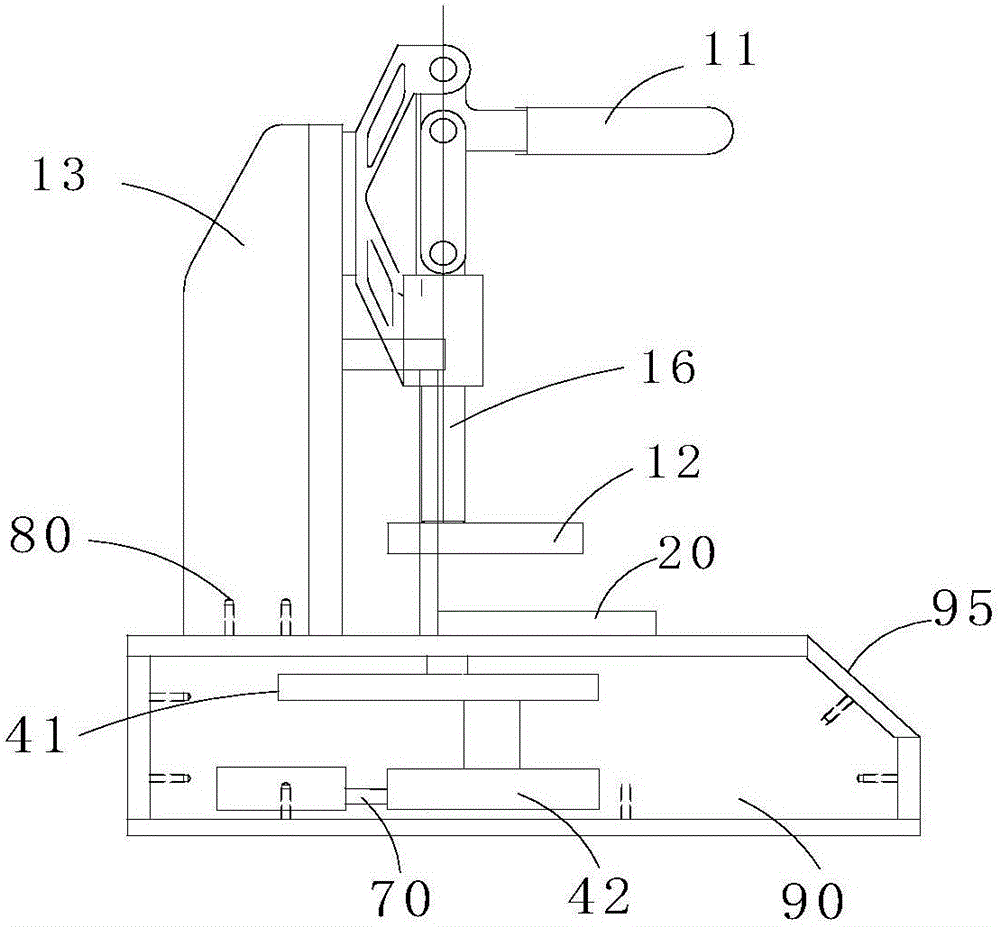

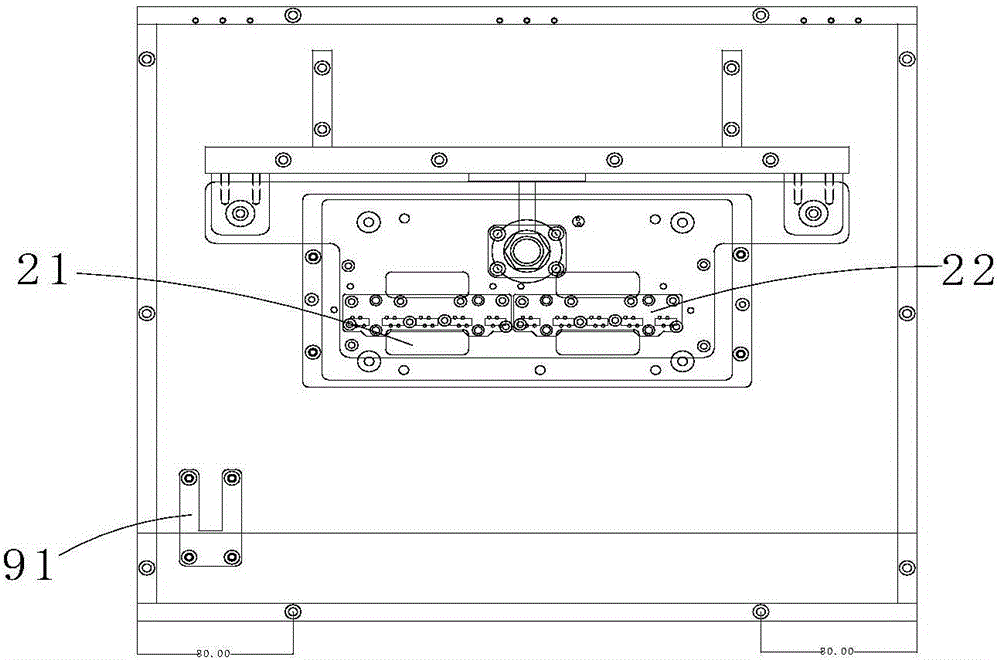

Circuit board testing jig and circuit board testing system

InactiveCN105842608AIncrease production capacityEasy to detectPrinted circuit testingMeasurement instrument housingElectricityContact test

The invention relates to a circuit board testing jig and a circuit board testing system. The circuit board testing jig comprises a jig bottom housing, an elevating assembly, a product supporting board, a probe assembly and a master control module. The elevating assembly is used for downwards pressing the product supporting board. The product supporting board is arranged above the probe assembly and is elastically connected with the probe assembly. Furthermore the product supporting board is used for placing a to-be-tested circuit board and is provided with a plurality of first probe holes which correspond with testing points in the to-be-tested circuit board. The probe assembly comprises probes. The first end of each probe is electrically connected with the master control module, and the second end is used for passing through the first probe hole and contacting with the testing point after the product supporting board is pressed. The master control module is used for receiving and processing the testing data of the to-be-tested circuit board through the probes. The circuit board testing jig and the circuit board testing system can realize mechanical testing on the quality of the circuit board and overcomes a problem in testing the quality of a nut coil circuit board by means of human eyes according to a traditional testing method.

Owner:SHENZHEN KEMI INTEGRATED CIRCUIT CO LTD

Device for testing smart card and method of testing the smart card

Devices and methods are provided for testing various types of smart cards including contact, contactless, and hybrid type (contact / contactless) smart cards. A test device includes a logic tester, a contactless interface unit, and a contact interface unit. The logic tester generates a test pattern that is transmitted to a smart card to test the smart card and compares a received response pattern with a response pattern to test a status of the smart card. The contactless interface unit enables a contactless test mode of operation and the contact interface unit enables a contact test mode of operation.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com