Accurate controllable non-contact test piece rotary magnetic field fatigue excitation and vibration test device

A non-contact, rotary technology, applied in the direction of measuring devices, vibration testing, machine/structural components testing, etc., can solve the problems of less vibration characteristic devices and increase the complexity of test devices, etc., and achieve accurate and reliable speed adjustment Convenience and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment is aimed at rotating specimens.

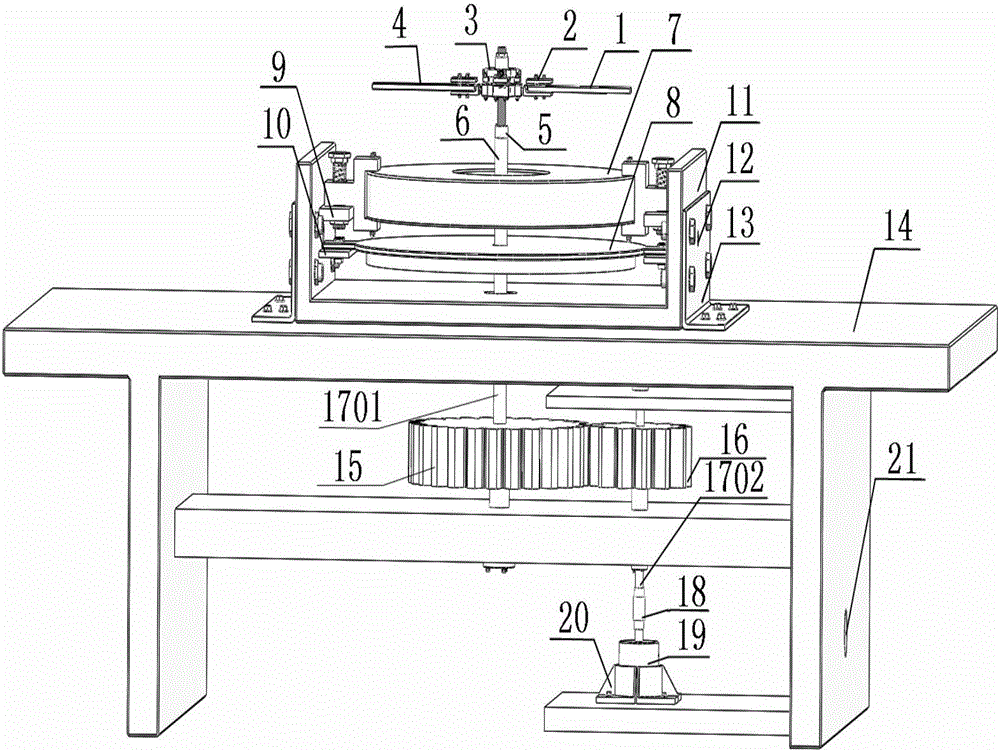

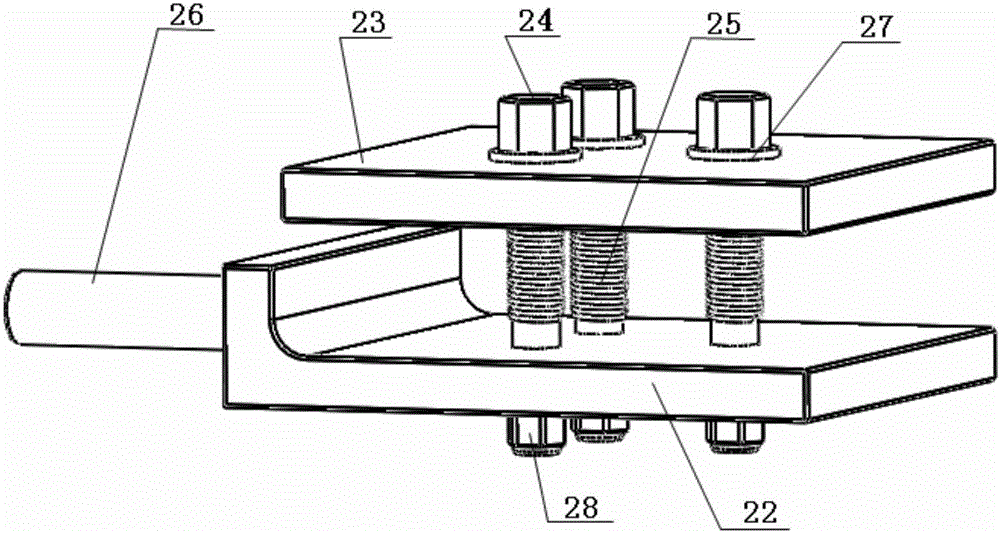

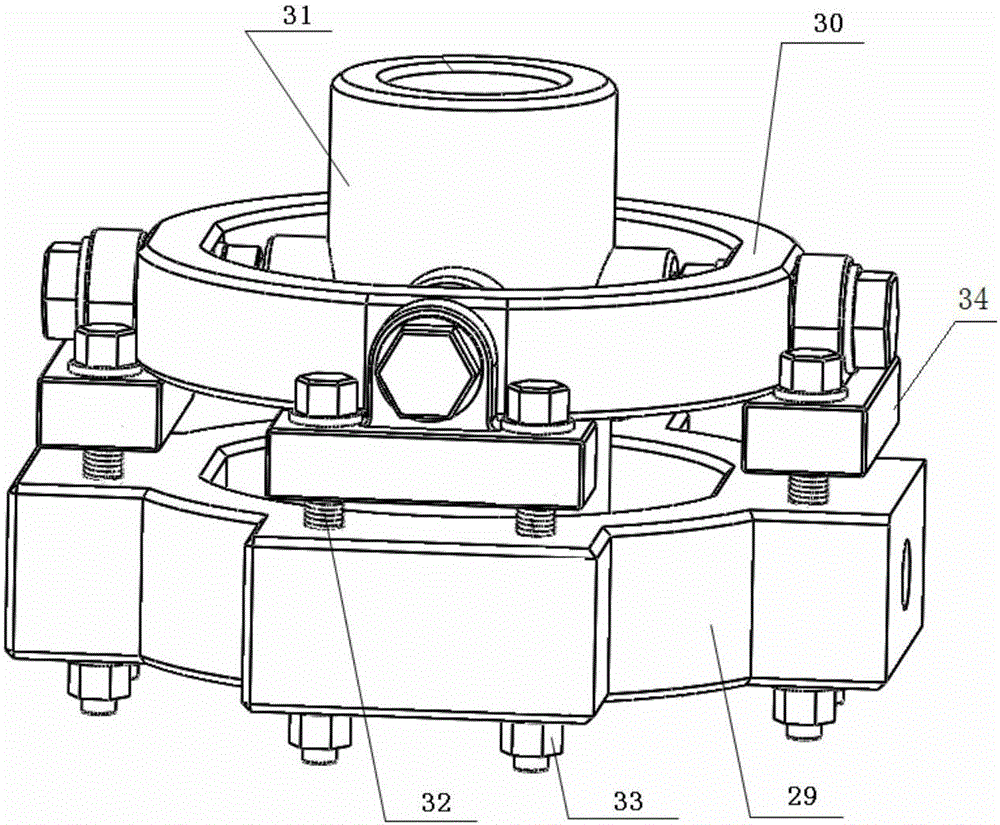

[0053] A precise and controllable non-contact test piece rotating magnetic field fatigue excitation and vibration measurement device, including vibration-reducing and insulating fixture 2, vibration absorber 3, dynamic balance device 4, vibration exciter 7, electromagnetic piezoelectric coupling vibration measurement sensor 8 , Test bench 14, transmission device and precise control device.

[0054] see figure 1 , the electromagnet support frame 11 is installed on the table of the test bench 14 . The electromagnet support frame 11 is U-shaped, and a through hole is provided in the center of its bottom plate, and a vibration exciter clamping platform 9 and an electromagnetic piezoelectric coupling vibration measuring sensor clamping platform 10 are provided on the inner walls of its two side plates.

[0055] see first Figure 6 to Figure 11 , the part of the electromagnetic piezoelectric coupling vibration measuring sen...

Embodiment 2

[0088] This embodiment is aimed at static test pieces.

[0089] The implementation mode and principle of static test pieces are similar to those of rotating test pieces. Specifically, when the test piece is in a static state, the structure and working principle of the clamp, shock absorber, self-locking screw adjustment device and vibration exciter of the present invention are the same as those in the rotating state, and the control device and principle of the vibration source are also the same ; The difference is: cut off the power supply of the stepless speed-adjustable AC motor, so that the test piece is tested in a static state; and the object of the test is wider than that in the rotating state; in addition, the vibration measuring device can be different. In addition to using electromagnetic piezoelectric coupling sensors, the device can also use wired sensors to measure vibration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com