Method for dynamically and invertibly regulating solid material surface wettability

A solid material and wettability technology, which is applied in the field of dynamic reversible regulation of the surface wettability of solid materials, can solve the problems such as the range of surface wettability changes is not too large, the material surface properties have special requirements, and the operation is difficult. To achieve the effect of good surface wettability controllable performance, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

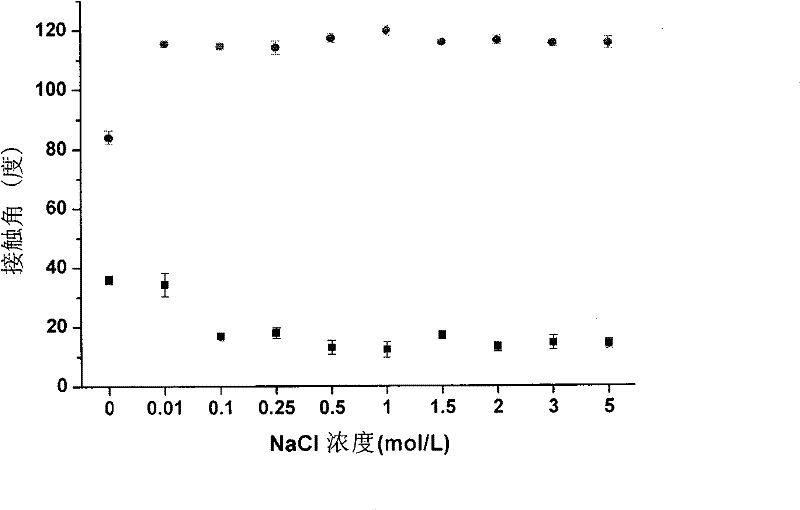

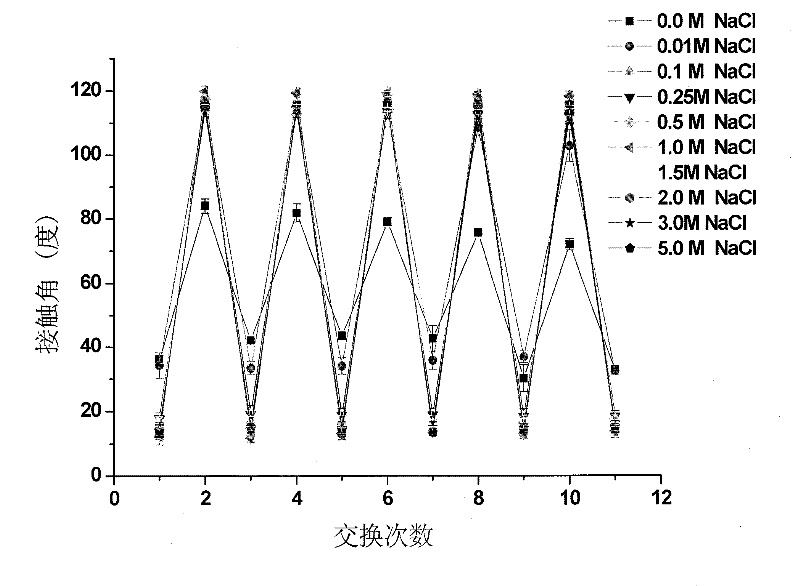

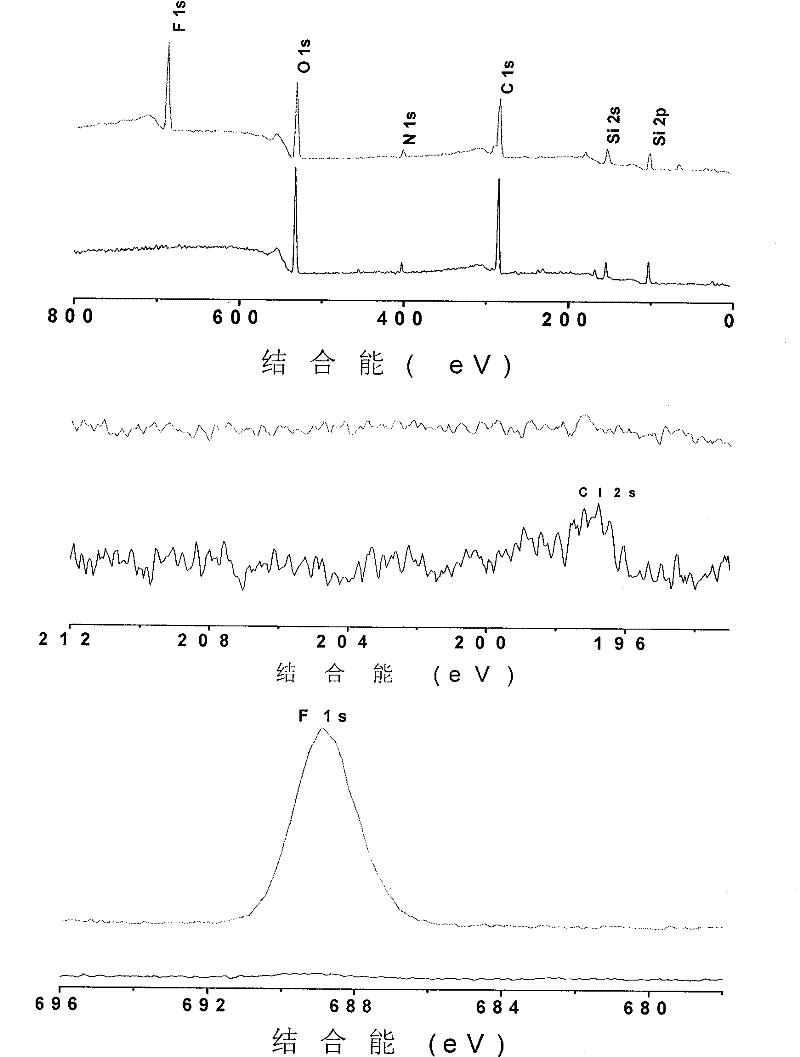

[0036] Example 1: The surface-charged Si sheet after treatment is assembled on the surface according to the method of literature (G.Decher, J.B.Schlenoff, Multilayer Thin Film--Sequential Assembly of NanocompositeMaterials, Weinheim: Wiley-VCH, 2003.) Membrane, the outermost layer of multilayer membrane is polycationic PDDA; put it in 0.00001mol / L C 7 f 15 After exchanging anions in the COONa aqueous solution for 60 hours, take it out, wash and dry it to obtain a surface with a contact angle of about 85°.

Embodiment 2

[0037] Example 2: The treated Si sheet with charged surface is assembled on the surface according to the method of literature (G.Decher, J.B.Schlenoff, Multilayer Thin Film--Sequential Assembly of NanocompositeMaterials, Weinheim: Wiley-VCH, 2003.) Membrane, the outermost layer of the multilayer membrane is polycationic PDDA, after taking it out, place it in 0.001mol / L C 7 f 15 After exchanging the anions in the COONa aqueous solution for 30 hours, take it out, wash and dry it to obtain a surface with a contact angle of about 85°.

Embodiment 3

[0038] Embodiment 3: The Si sheet with charged surface after treatment is assembled on the surface with polyelectrolyte multilayer according to the method of literature (G.Decher, J.B.Schlenoff, Multilayer Thin Film--Sequential Assembly of NanocompositeMaterials, Weinheim: Wiley-VCH, 2003.) Membrane, the outermost layer of the multilayer membrane is polycationic PDDA, after taking it out, place it in 0.01mol / L C 7 f 15 After exchanging the anions in the COONa aqueous solution for 20 hours, take it out, wash and dry it to obtain a surface with a contact angle of about 85°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com