Patents

Literature

44results about How to "Increase the exciting force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

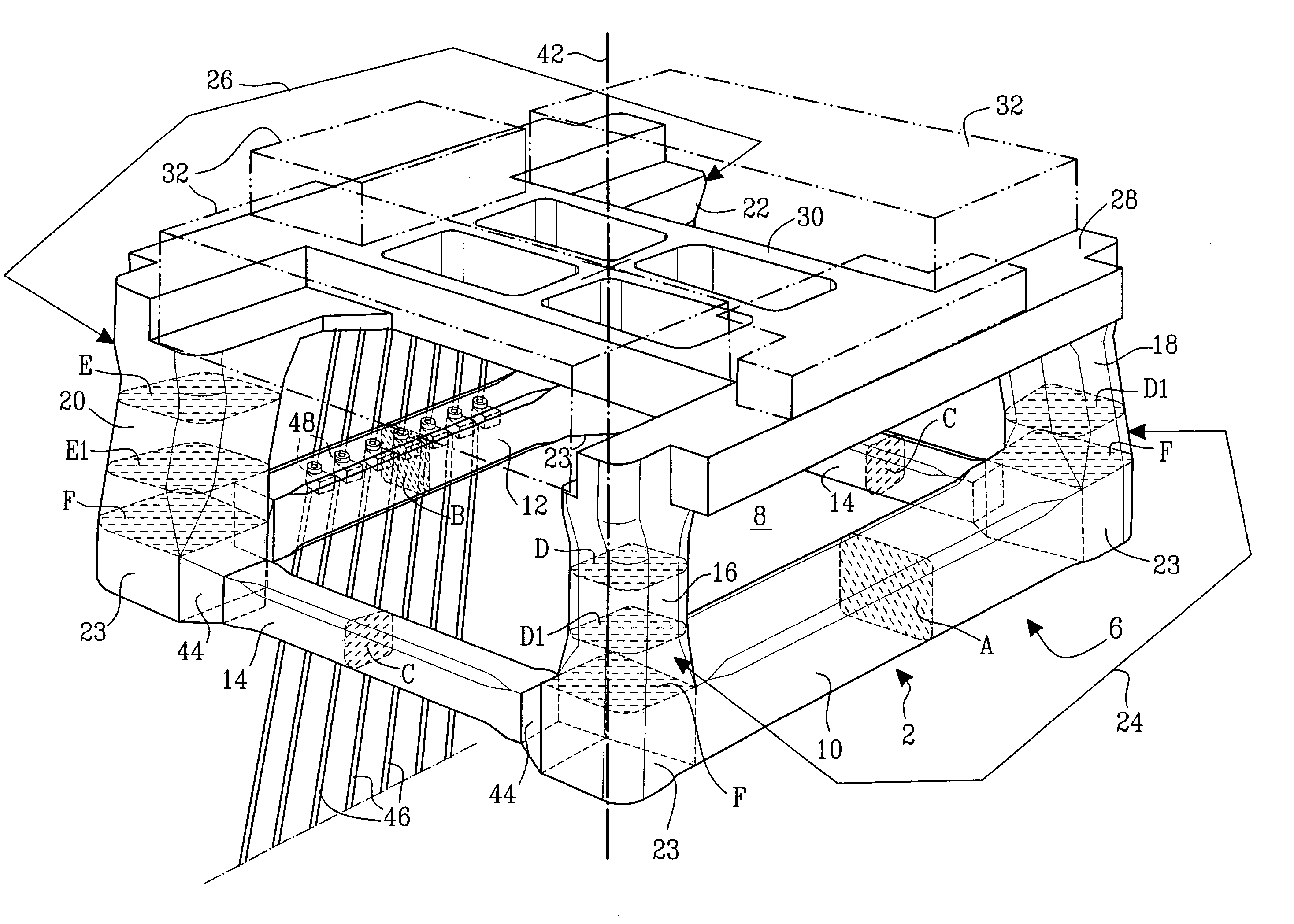

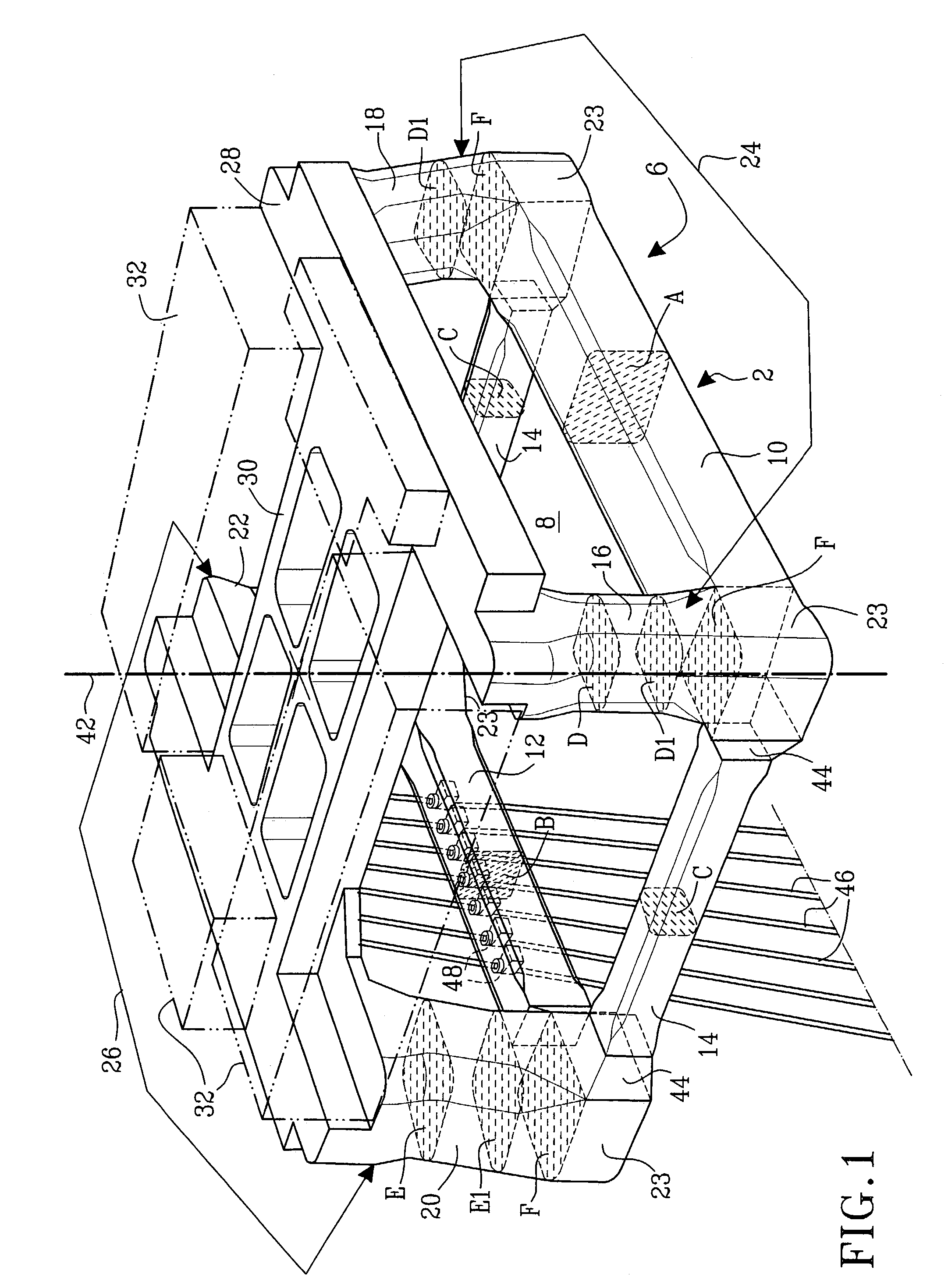

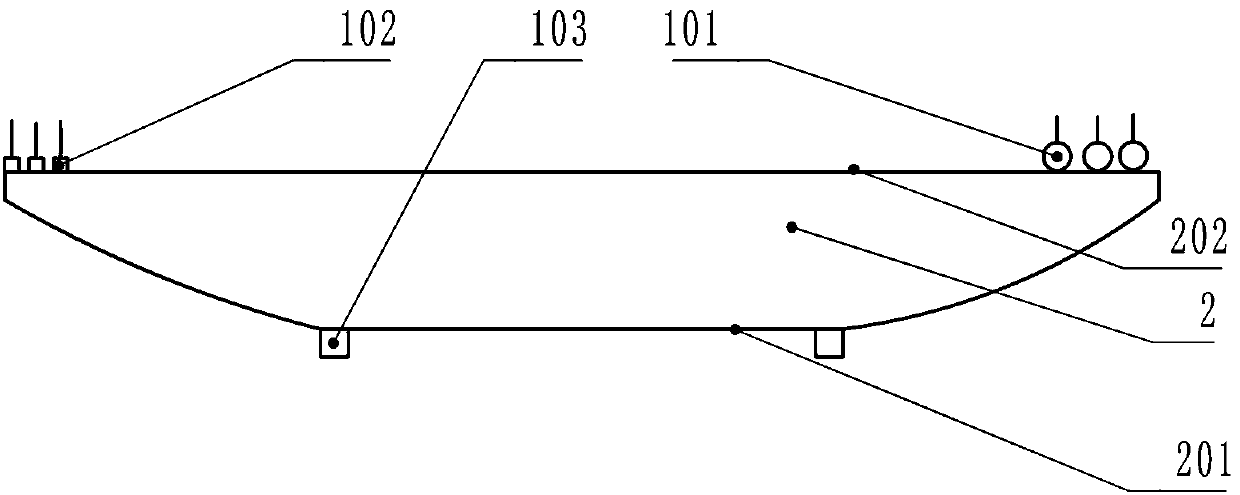

Semi-submersible offshore vessel

ActiveUS20050058513A1Reduce the excitation forceIncrease the exciting forceDrilling rodsHydraulic engineering apparatusPontoon bridgeBoard structure

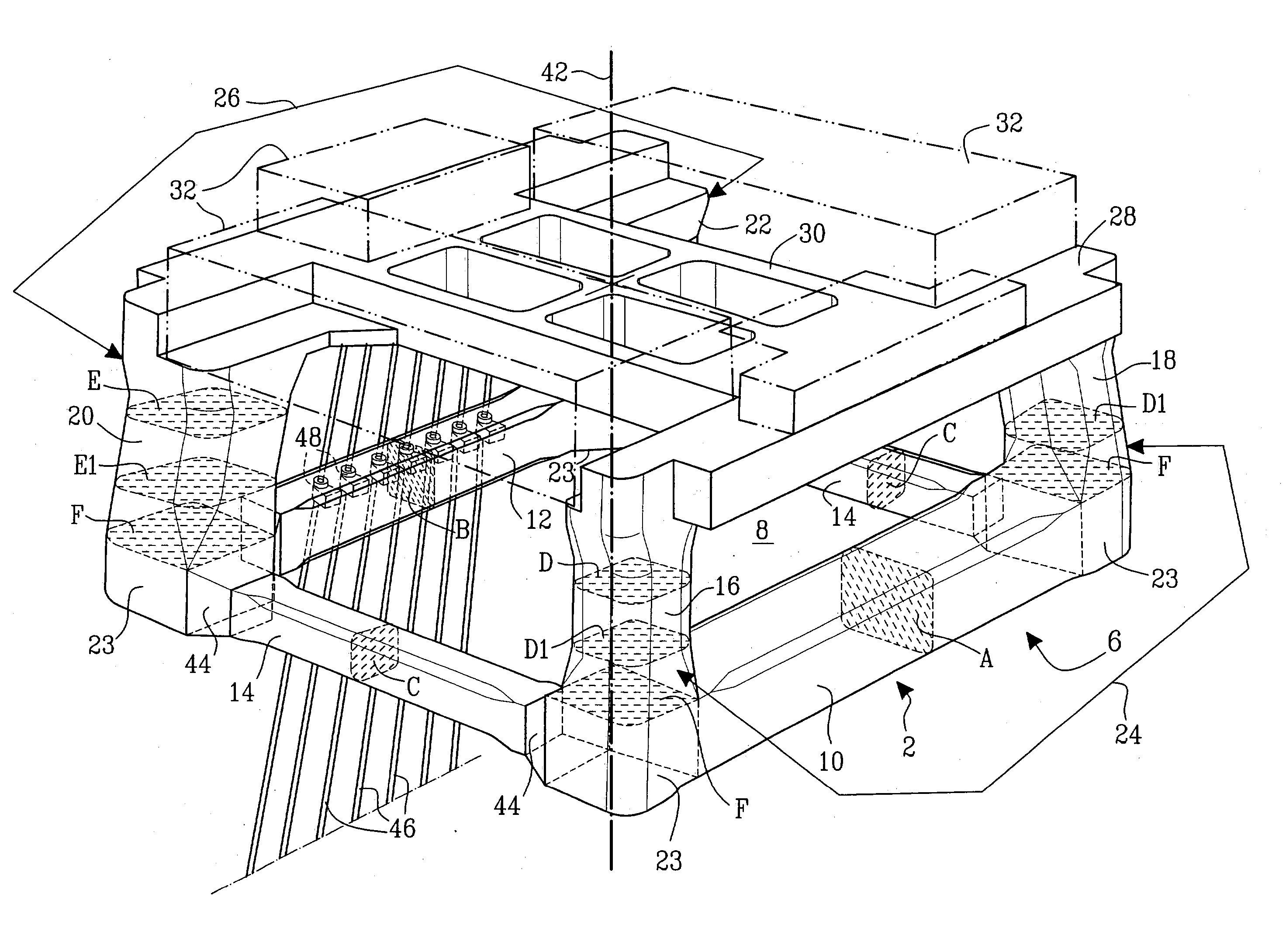

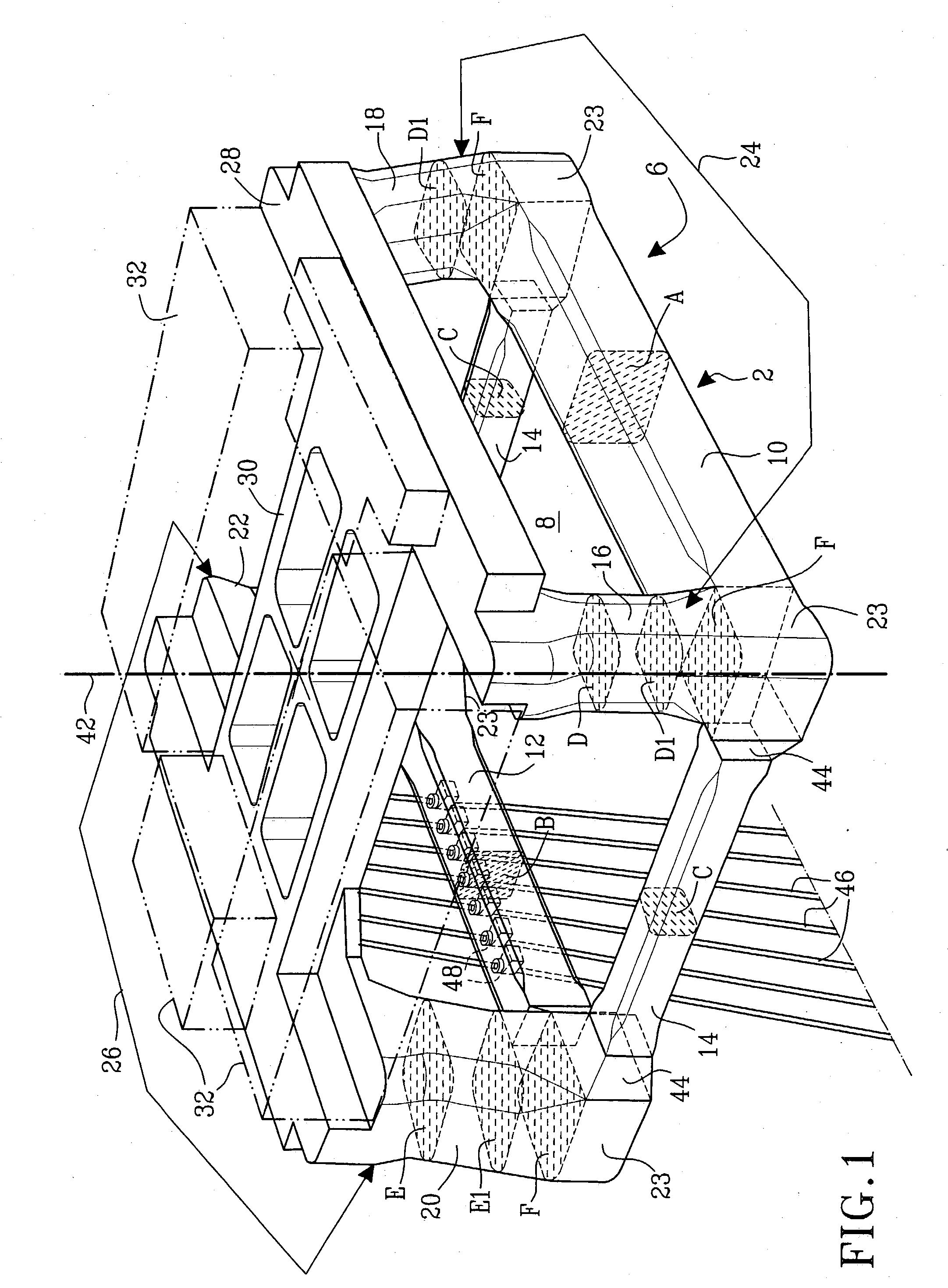

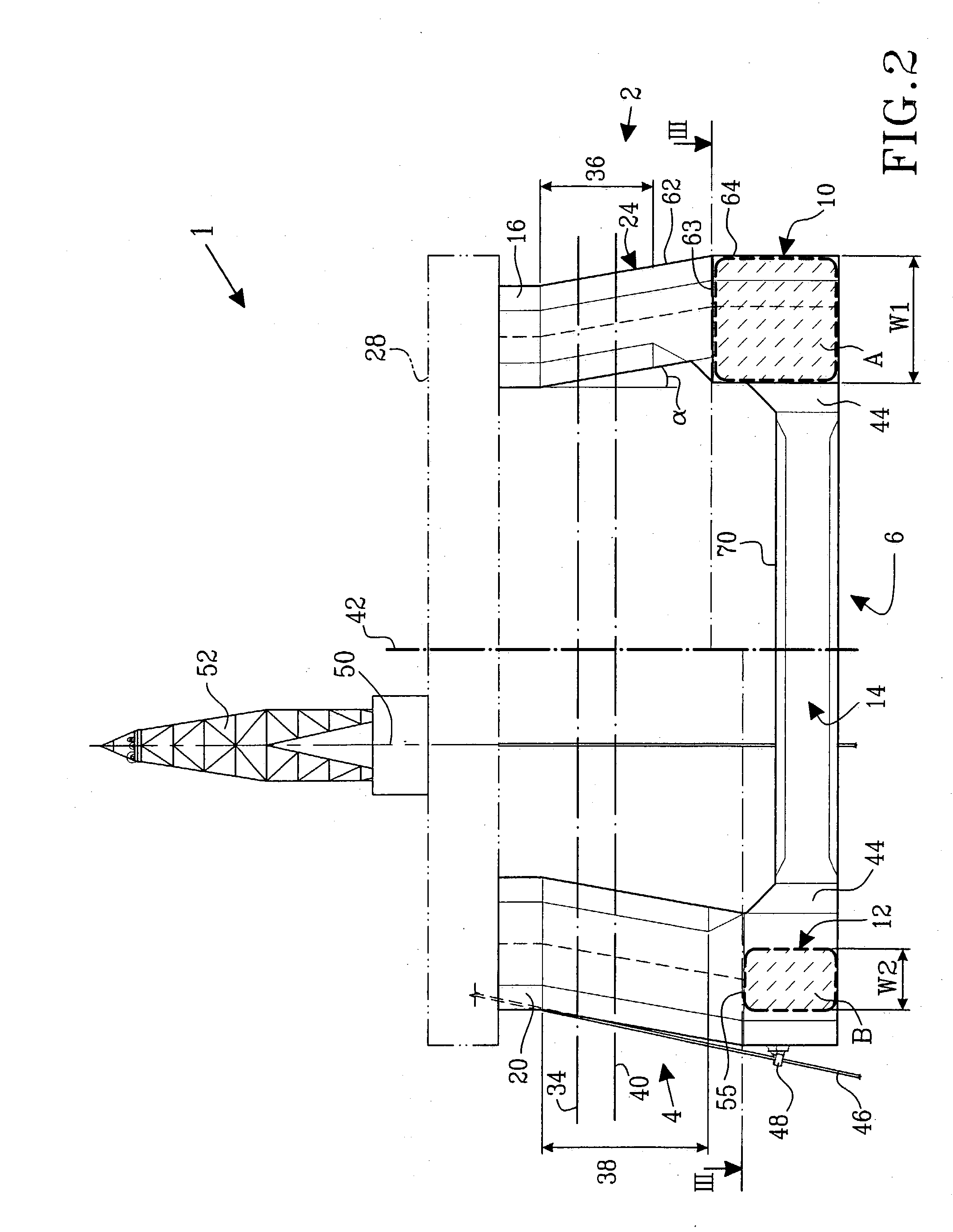

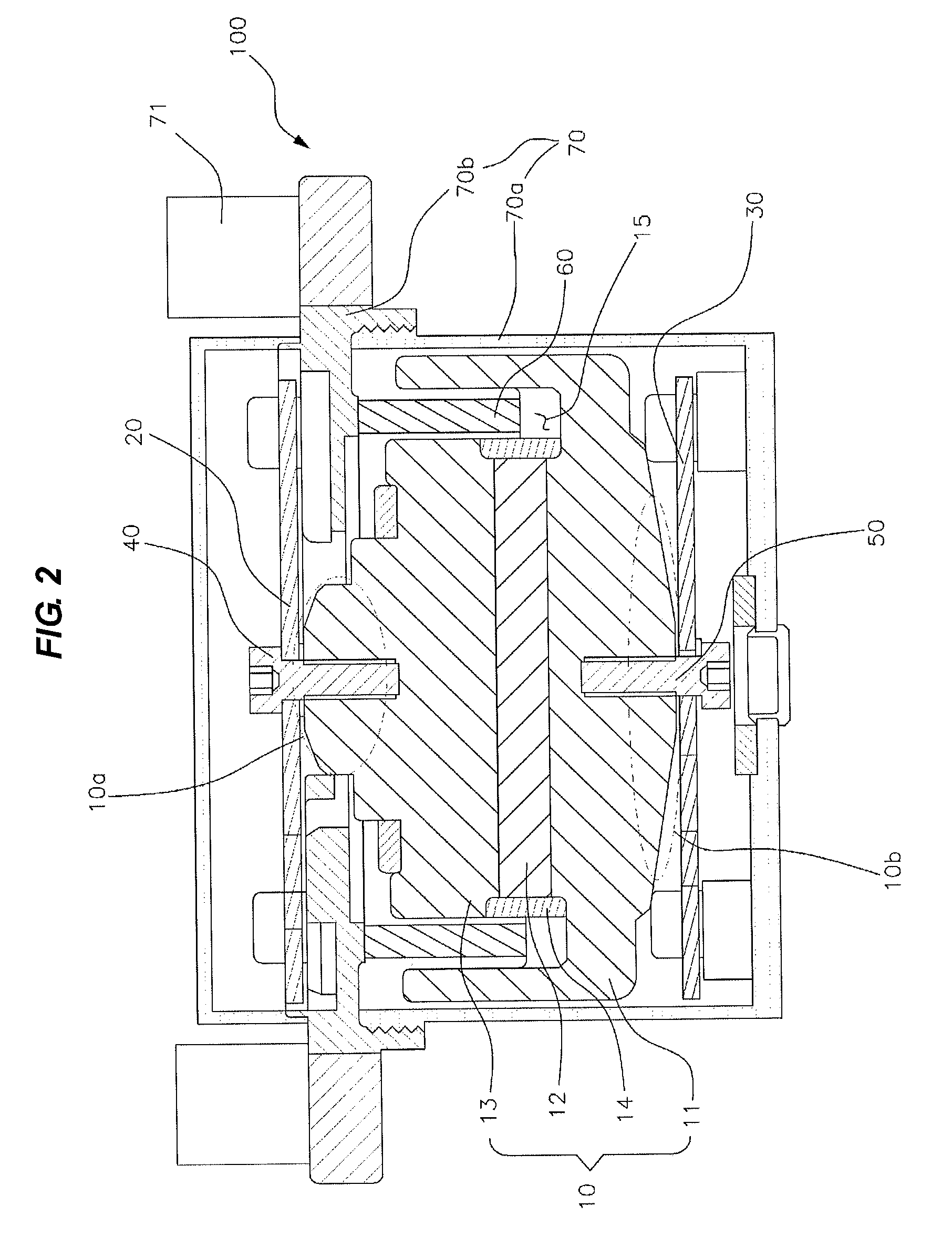

A semi-submersible offshore vessel (1) exhibiting a first end (2), for example constituting the forward end of the vessel, and a second end (4), for example constituting the aft end of the vessel (1), or vice versa, wherein the vessel (1) includes a substantially rectangular ring-pontoon (6) including a first transverse pontoon section (10) located at the first end (2) of the vessel (1); a second transverse pontoon section (12) located at the second end (4) of the vessel (1), the second transverse pontoon section (12) being parallel to the first transverse pontoon section (10), the ring-pontoon (6) further including two mutually parallel longitudinal pontoon sections (14) extending between the first (2) and the second end (4) of the vessel (1); at least four support columns (16, 18, 20, 22) extending upwardly from respective edge-portions (23) of said ring-pontoon (2), the support columns (16, 18, 20, 22) being arranged in a first column pair (24) located at the first end (2) of the vessel (1) and a second column pair (26) located at the second end (4) of the vessel (1); and an upper deck structure (28) positioned upon the support columns (16, 18, 20, 22). The first transverse pontoon section (10) may also include a vertical mean cross-section area (A) which exceeds the corresponding vertical mean cross-section area (B) of the second transverse pontoon section (12), and the support columns (20, 22) in the second column pair (26) each has a water-plane area (E) which exceeds the water-plane area (D) of each of the support columns (16, 18) in the first column pair (24).

Owner:GVA GONSULTANTS

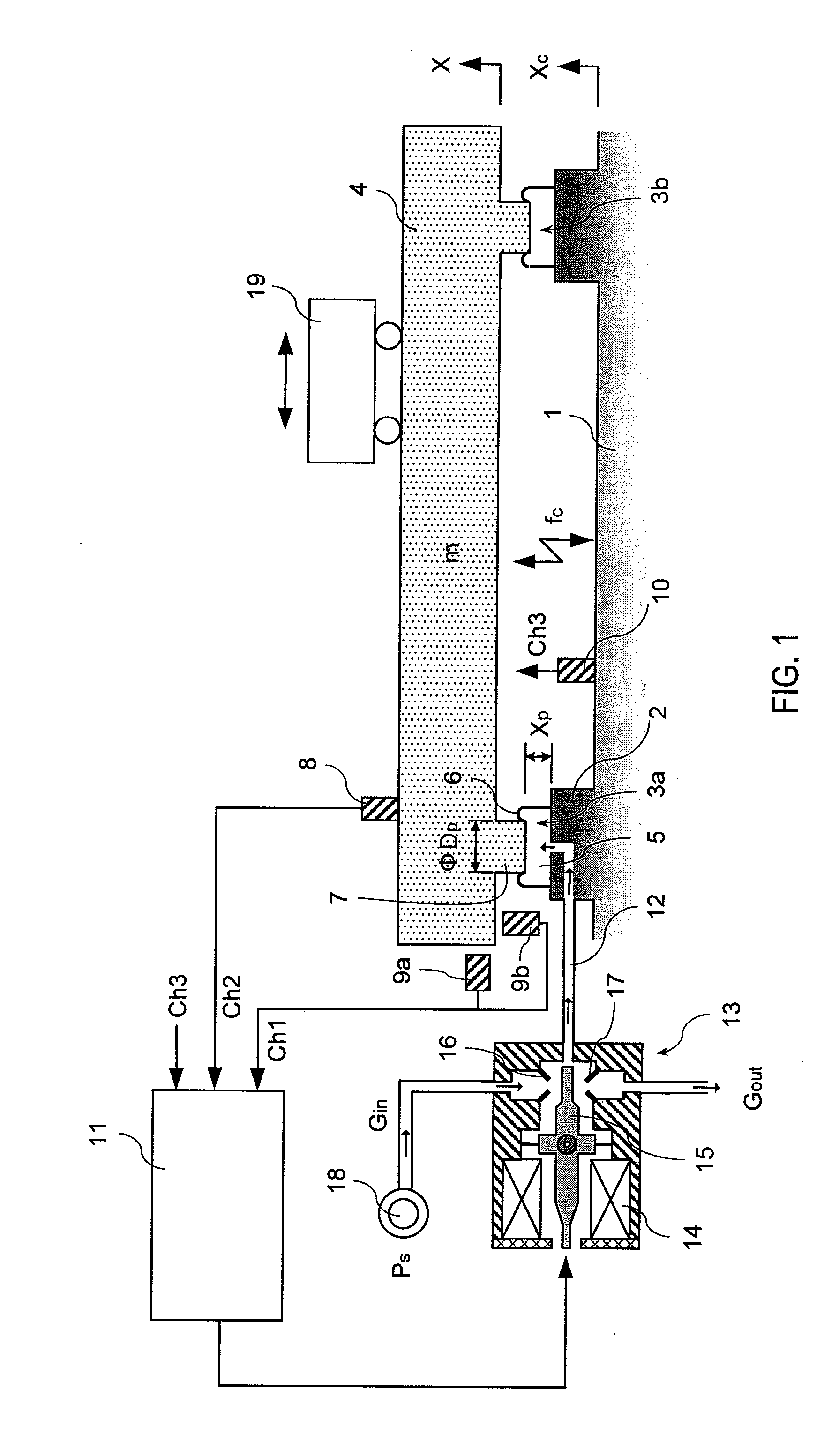

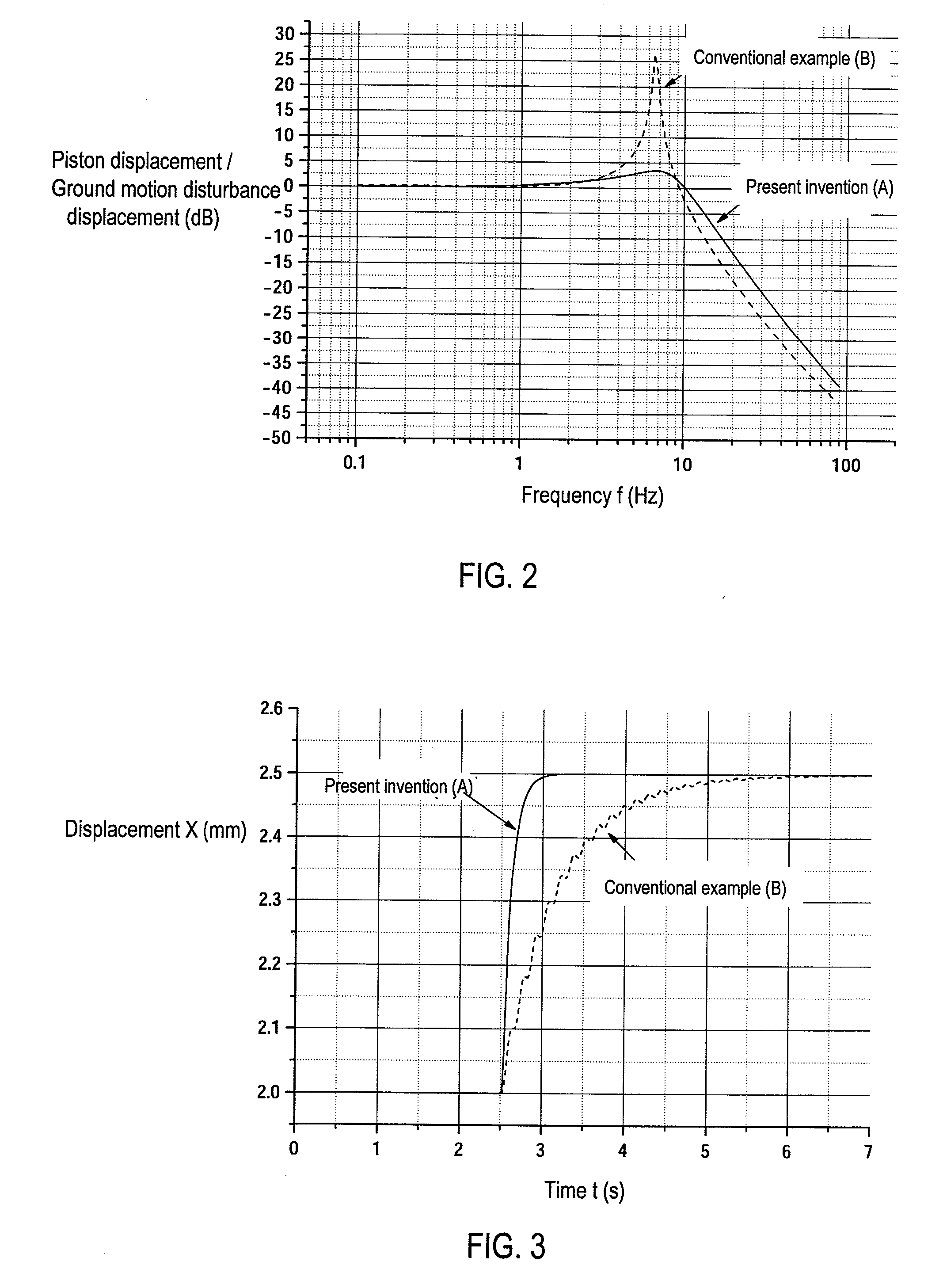

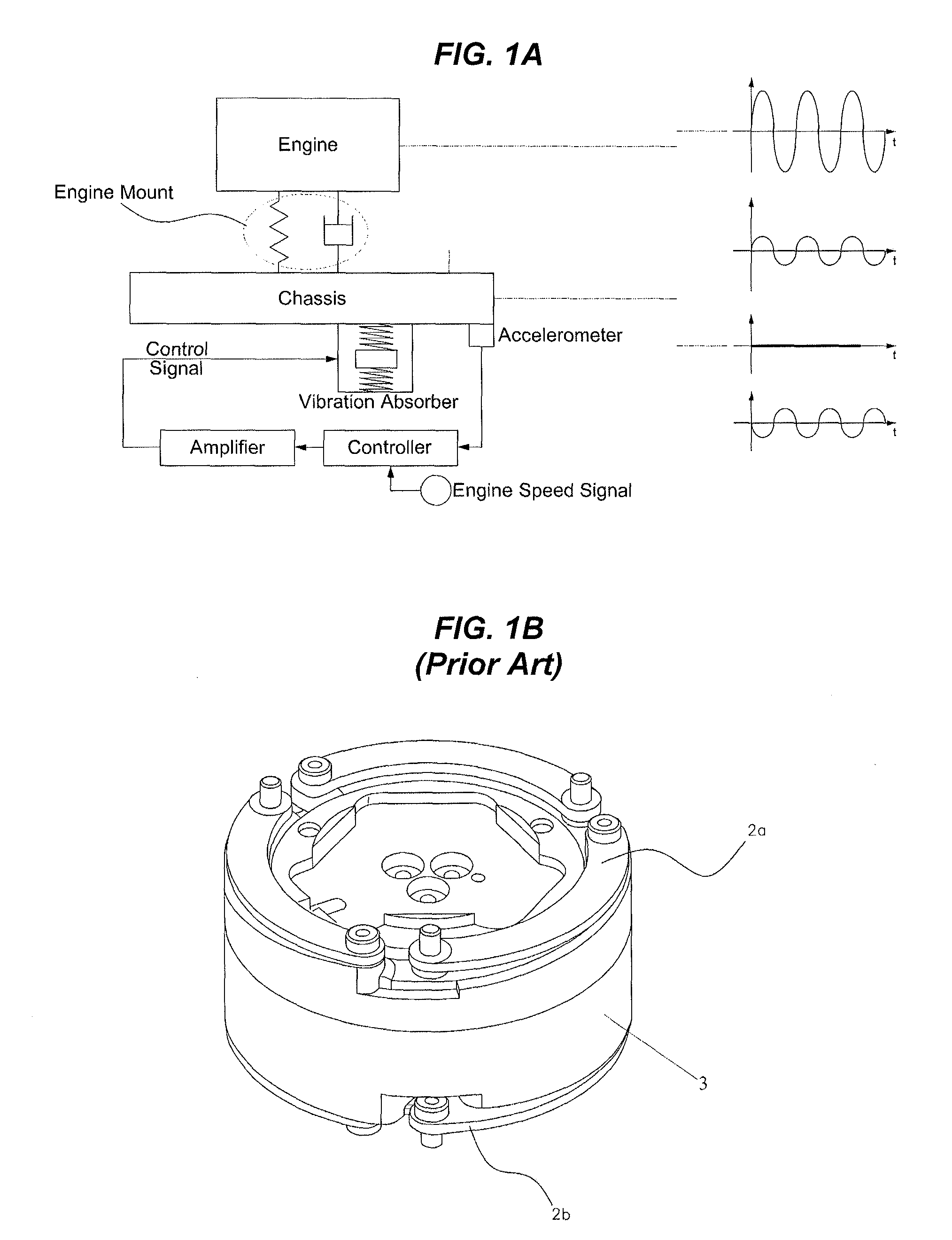

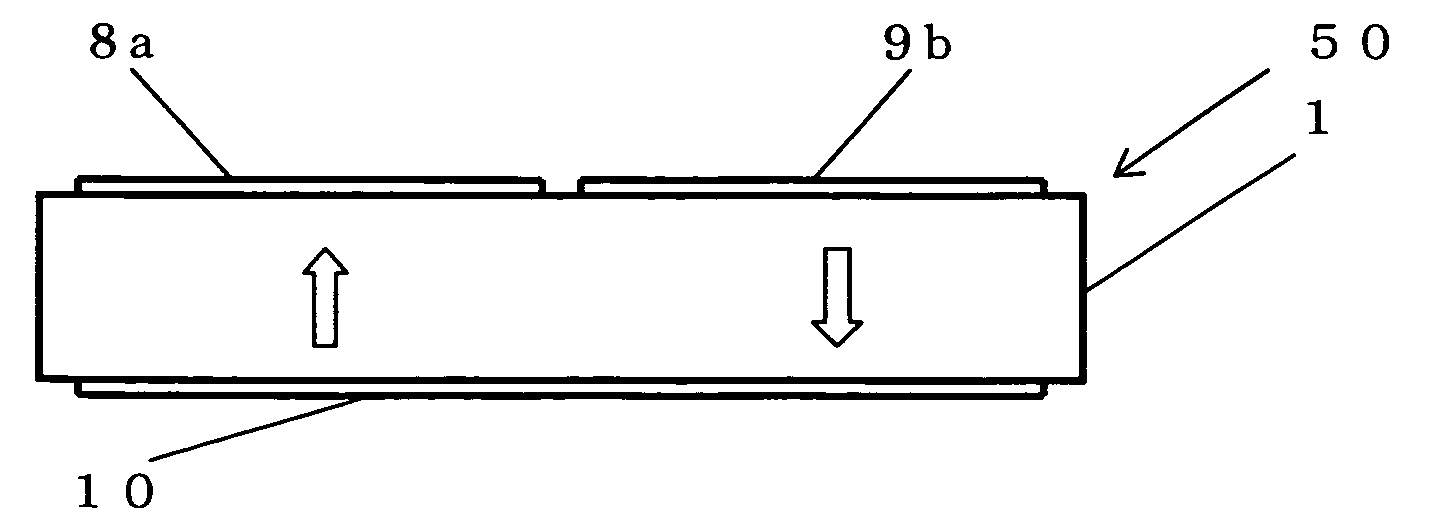

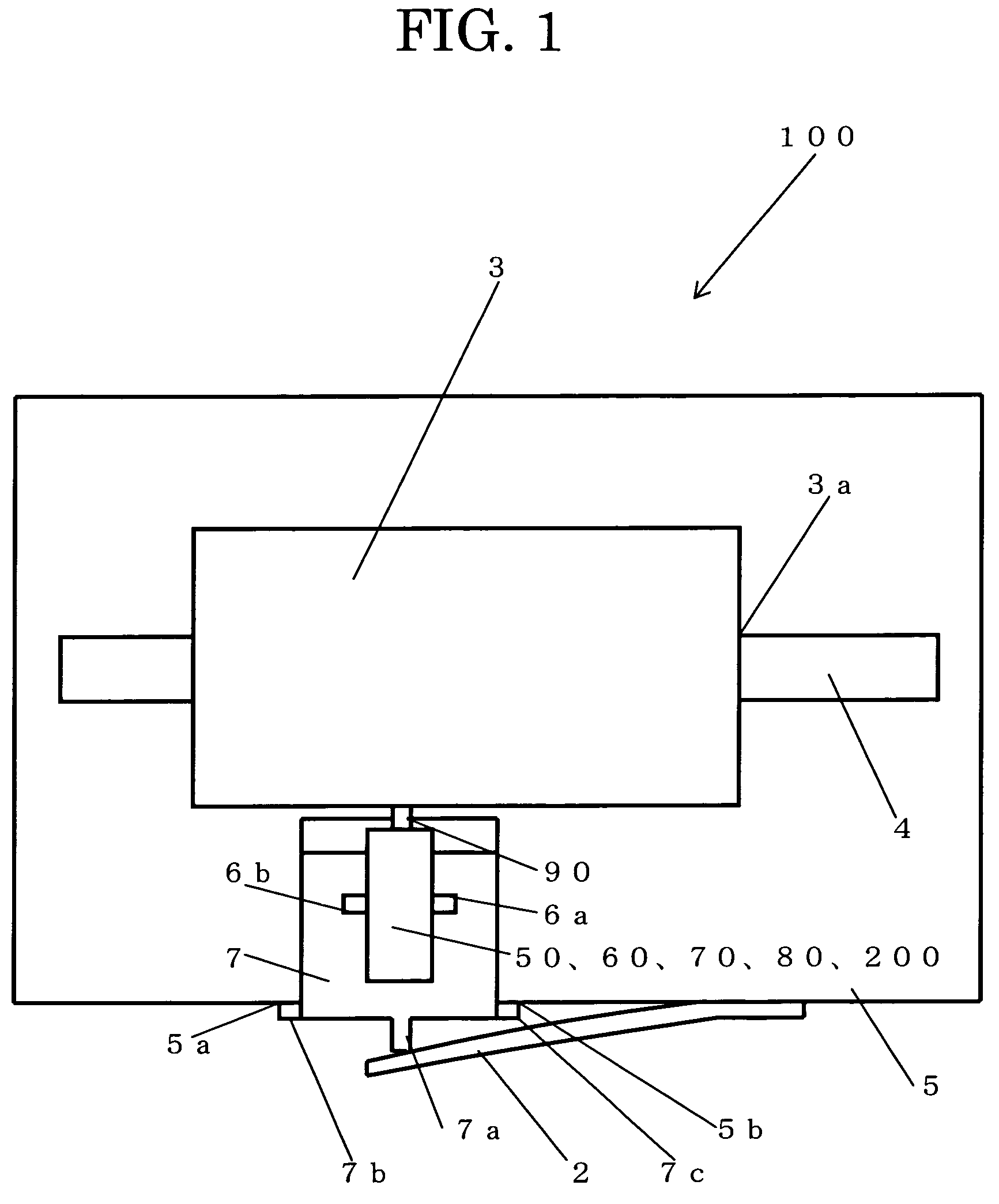

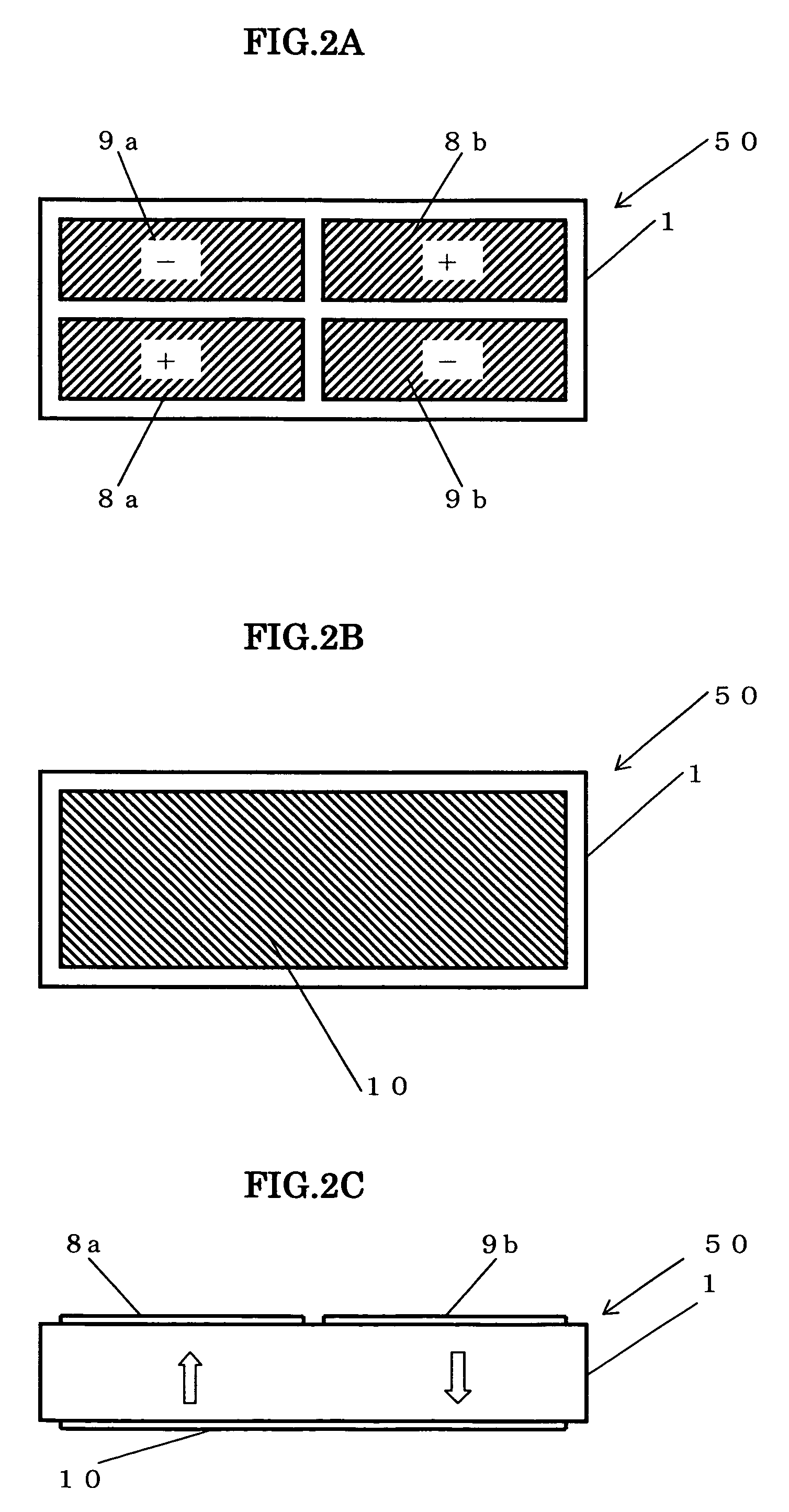

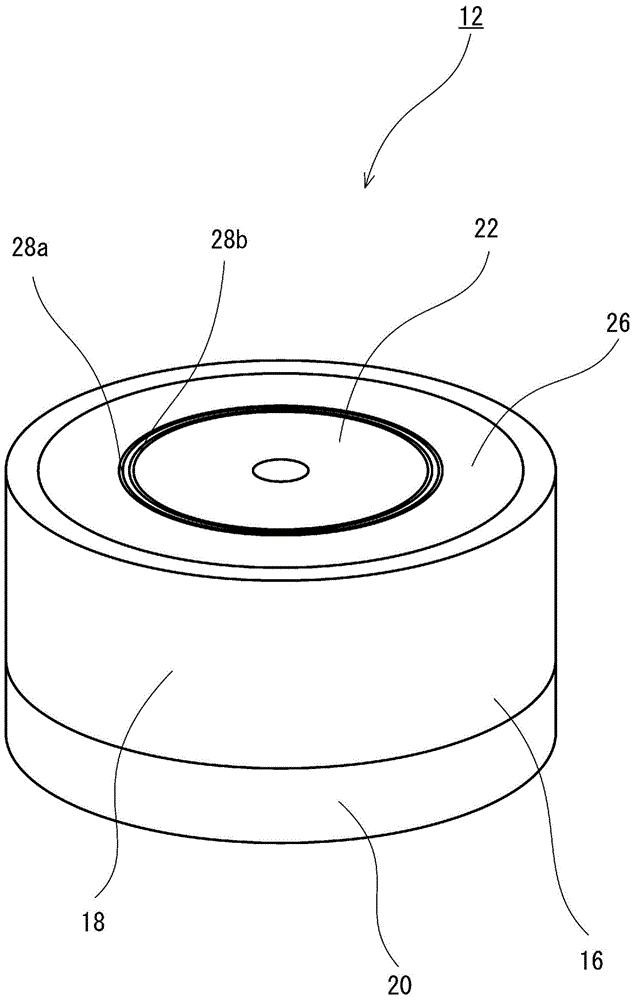

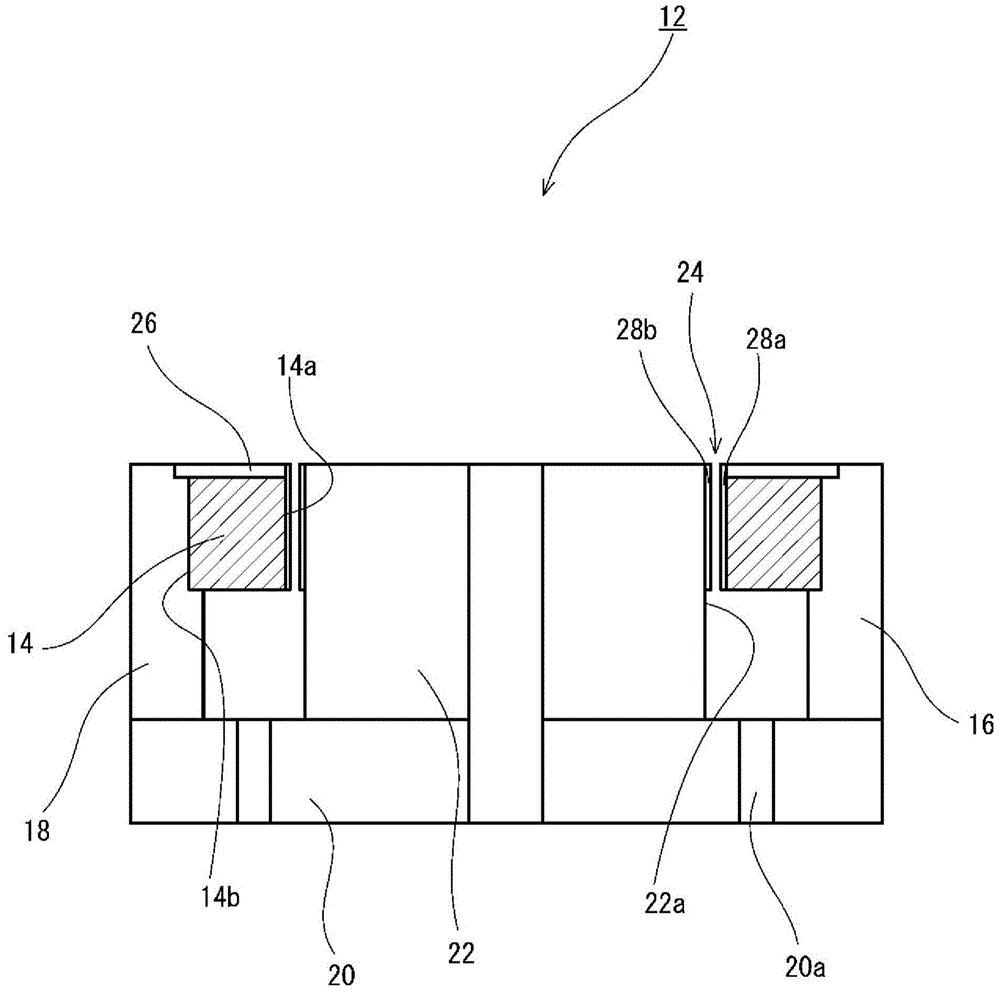

Vibration isolator

InactiveUS20100001445A1Improve loading qualityImprove the vibration isolation effectStuffed mattressesSpring mattressesVibration controlEngineering

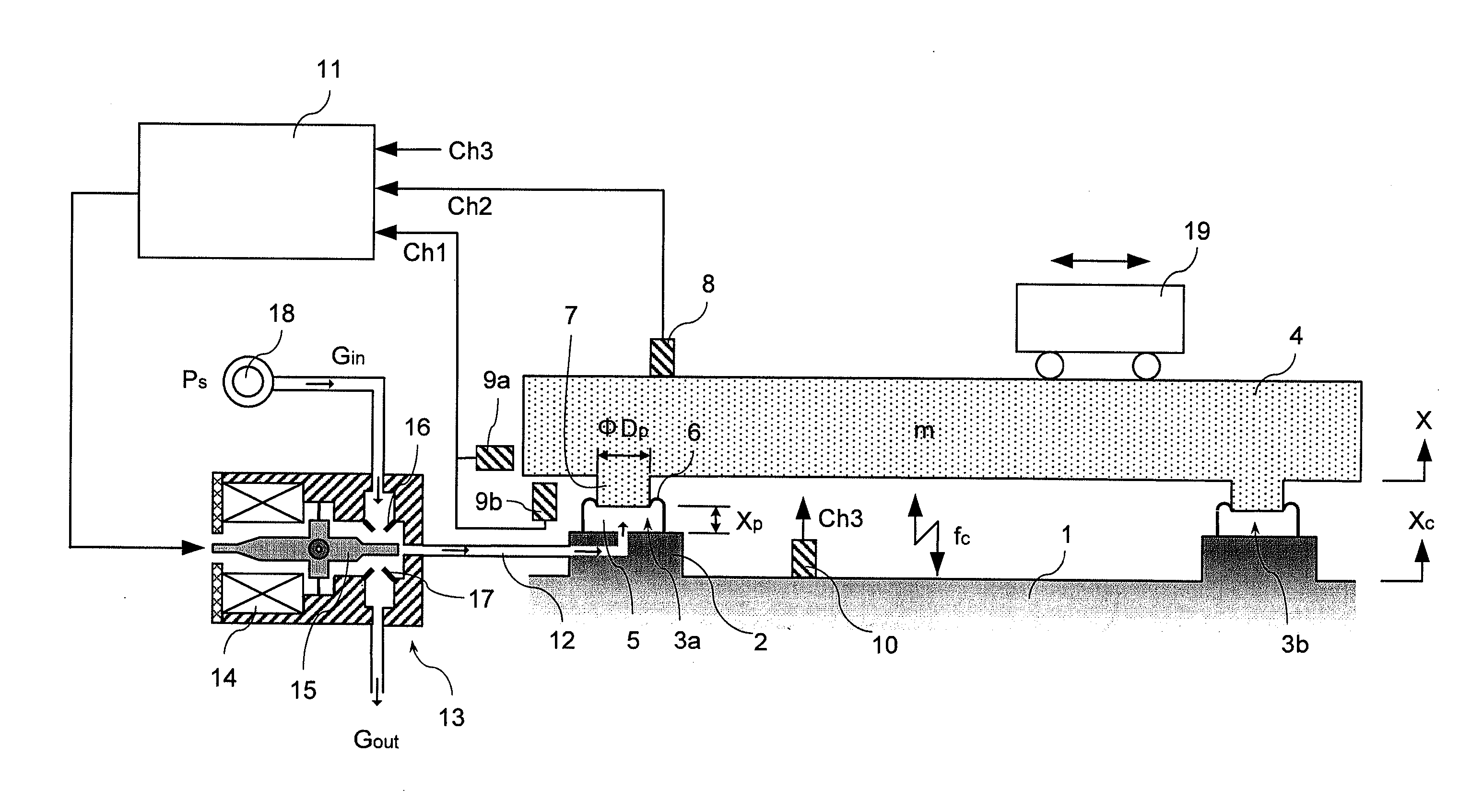

There is provided a vibration isolator capable of, (1) vibration isolation performance for ground motion disturbance: vibration isolation for floor vibration, and (2) vibration control performance for direct acting disturbance: suppression of swing due to driving reaction force caused by stage movement, significantly improving the above (2), i.e., the vibration control performance, with keeping the above (1), i.e., the vibration isolation performance, at a high level.

Owner:TOKKYOKIKI CORP

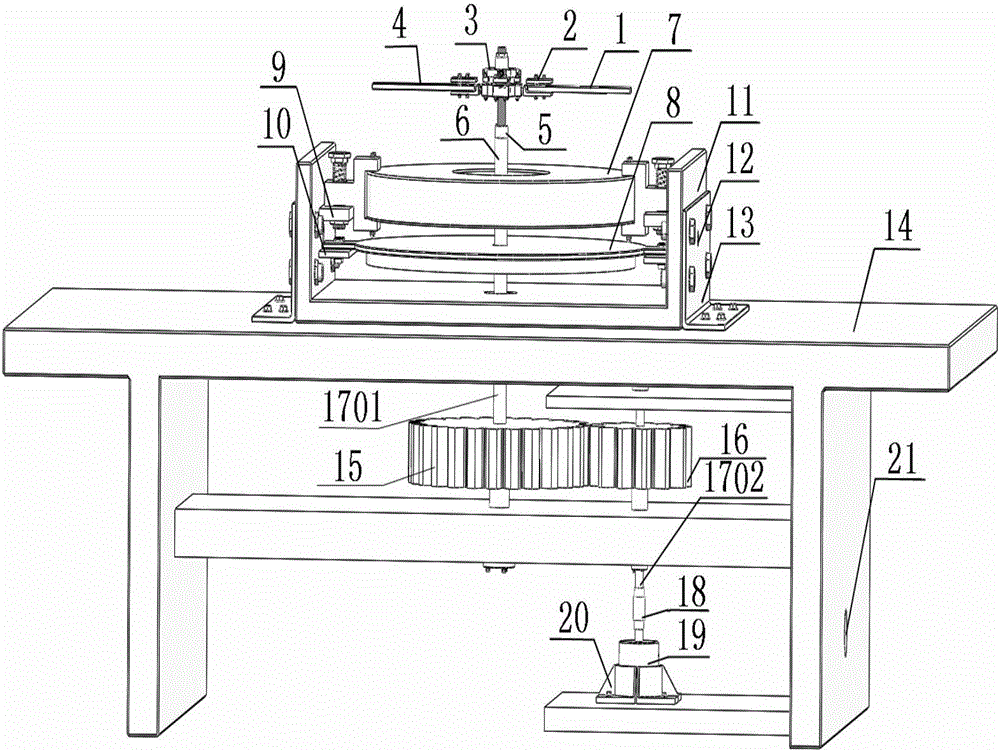

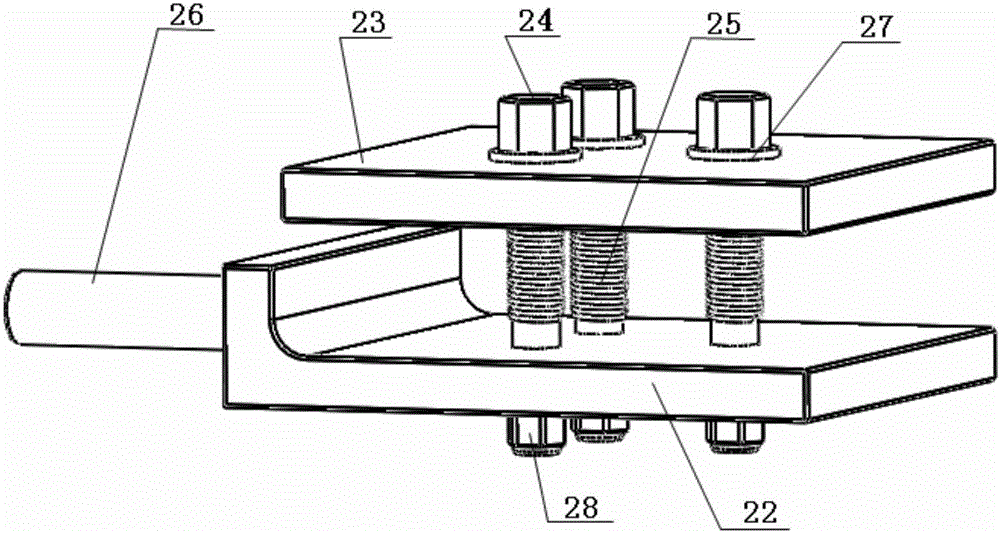

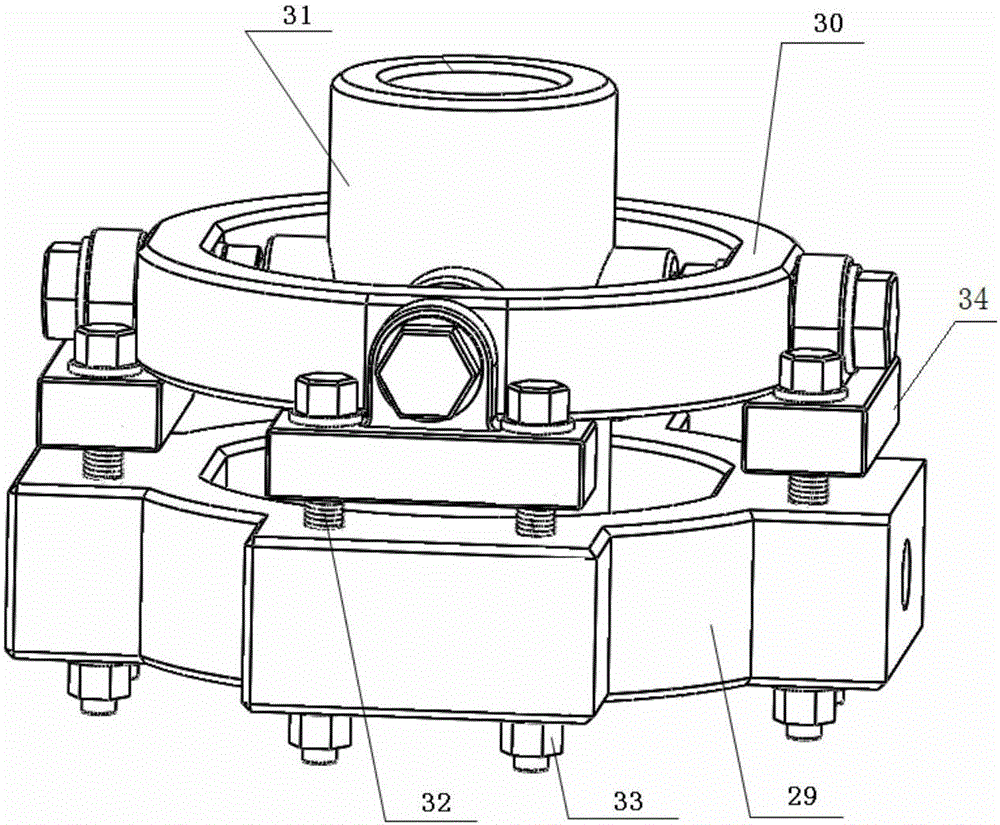

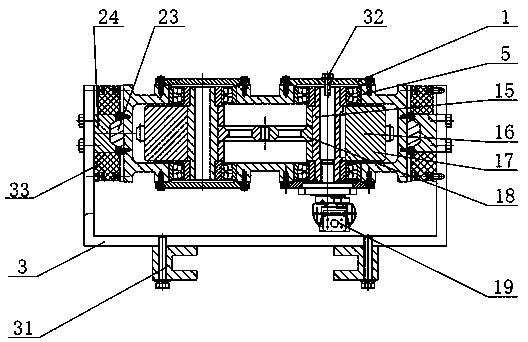

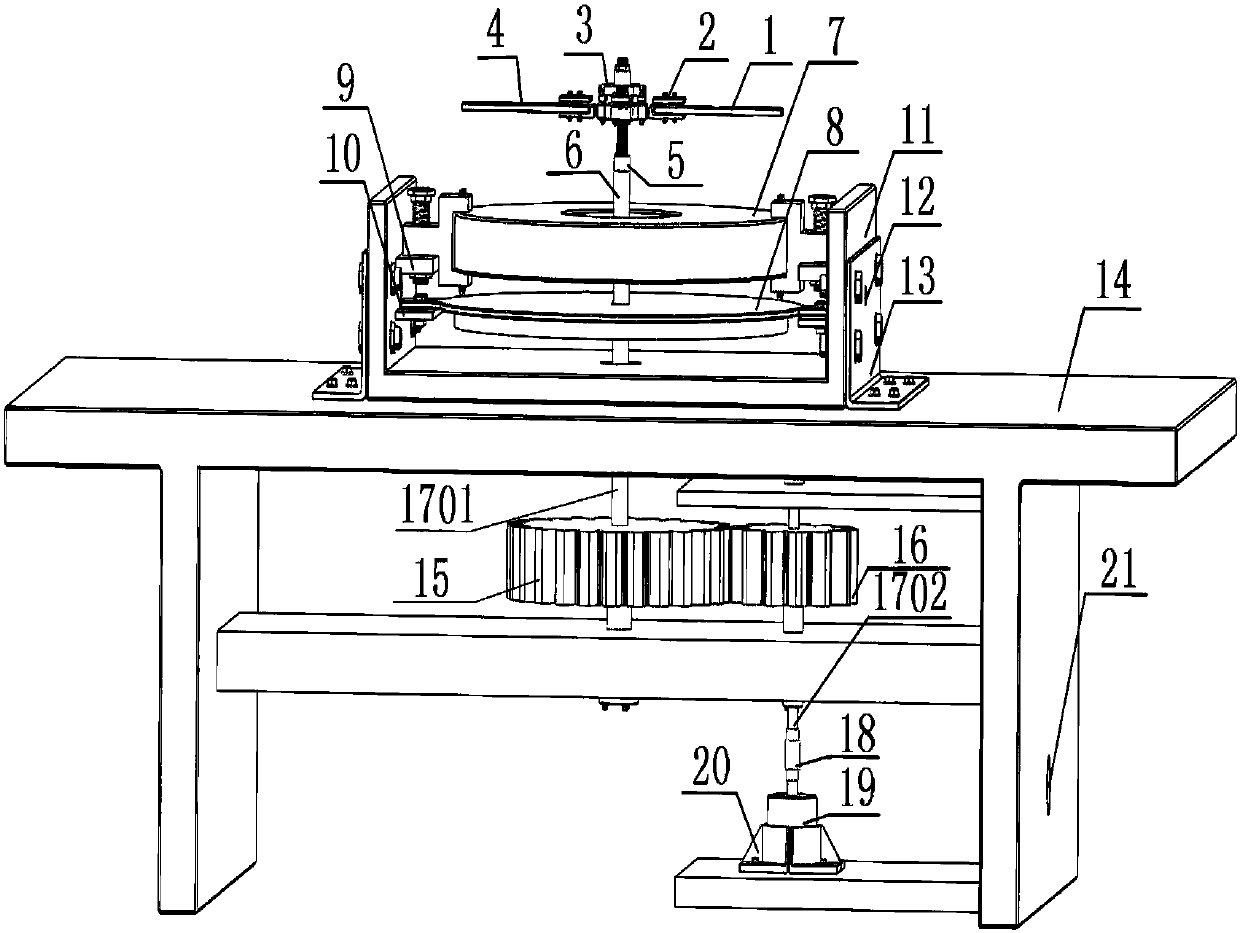

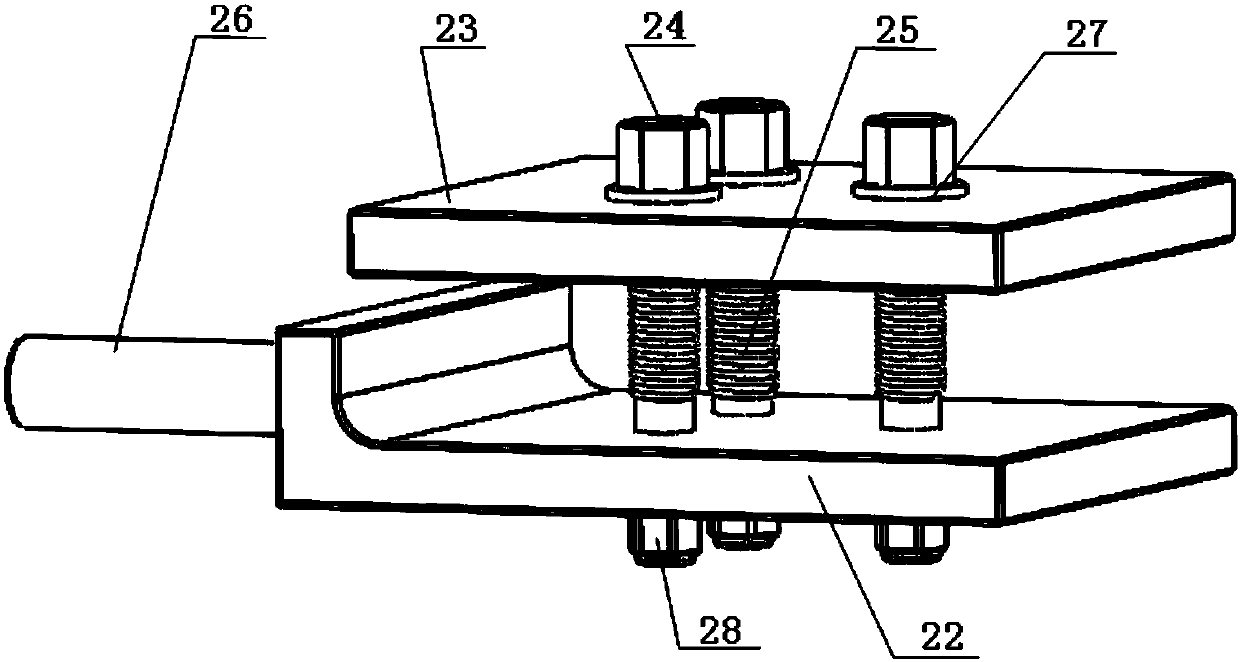

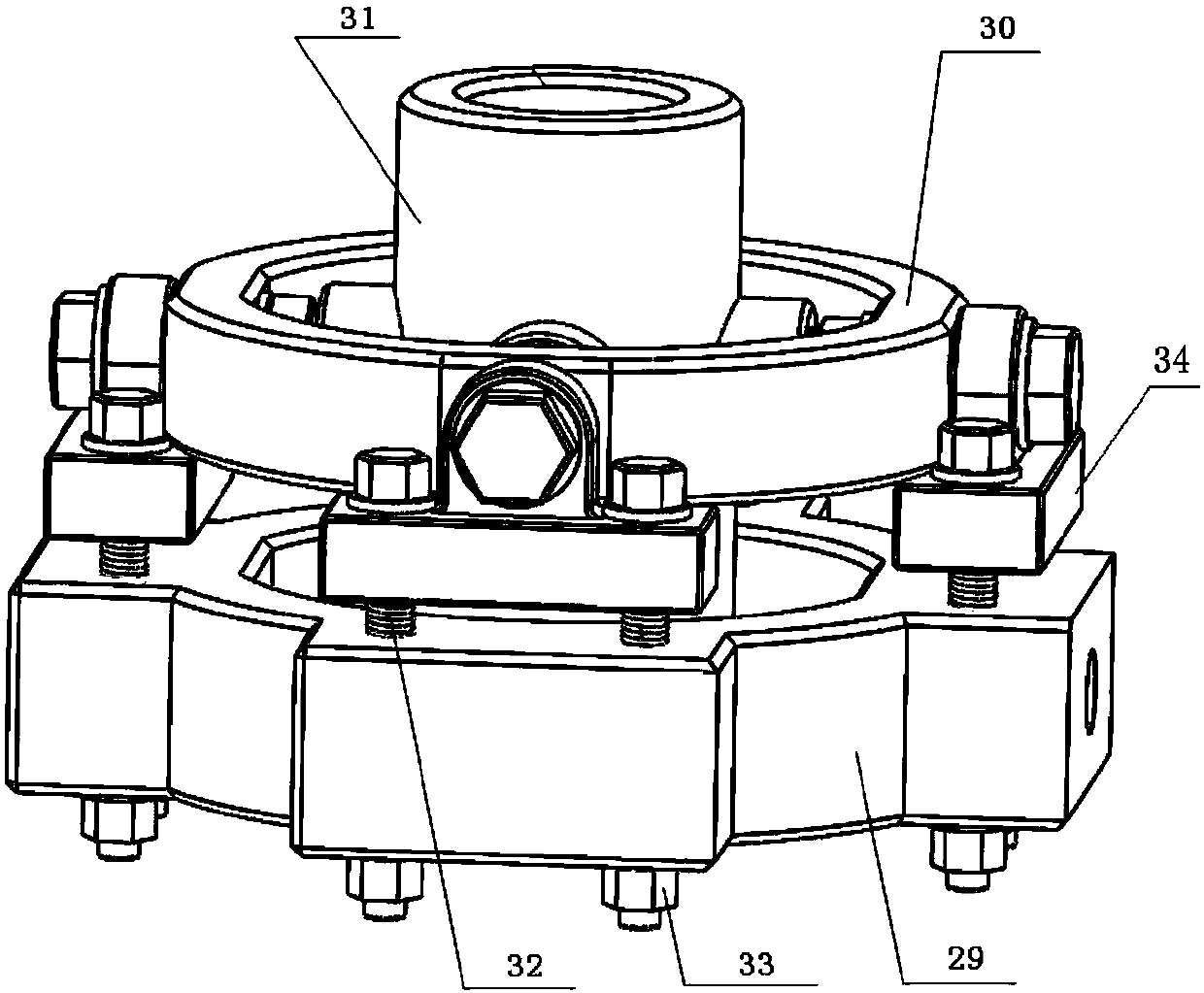

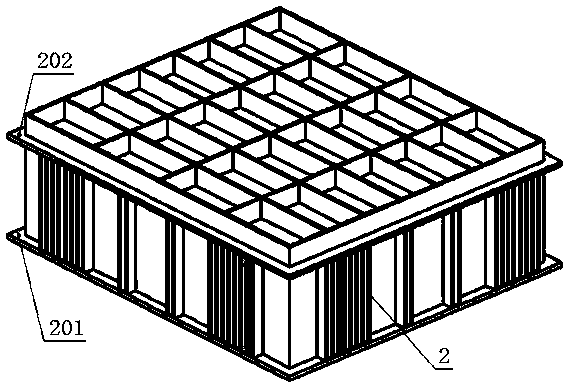

Accurate controllable non-contact test piece rotary magnetic field fatigue excitation and vibration test device

ActiveCN105910780AWide range of applicable objectsReduce the impactVibration testingVibration accelerationDynamic balance

The invention provides an accurate controllable non-contact test piece rotary magnetic field fatigue excitation and vibration test device. The device comprises a vibration damping insulation clamp, a vibration damper, a dynamic balance device, a vibration exciter, an electromagnetic piezoelectric coupling vibration sensor, a test station, a transmission device and an accurate control device. The excitation and vibration test device is suitable for rotary test pieces and especially suitable for vibration characteristic researches on a wind power blade, an engine, a turbine blade, a helicopter rotor and a tail rotor blade, the excitation and vibration test device can vividly simulate vibration fatigue states of rotary test pieces respectively under conditions of 360-DEG all directions, same rotating speed and different excitation forces, same excitation force and different rotating speeds, and different rotating speeds and different excitation forces, the excitation and vibration test device can monitor related vibration characteristic parameters such as the excitation force, the vibration displacement, the vibration speed and the vibration acceleration continuously, and the excitation and vibration test device is suitable for vibration fatigue characteristic analysis on stationary test pieces.

Owner:CHONGQING UNIV

Semi-submersible offshore vessel

InactiveUS7011472B2Reduce the excitation forceIncrease the exciting forceVessel safetyVessel movement reduction by mass displacementPontoon bridge

Owner:GVA GONSULTANTS

Bobbin, motor, and method of winding magnet wire

InactiveUS20050040725A1Increase the winding spaceIncrease the diameterSynchronous generatorsMagnetic circuit rotating partsBobbinMagnet wire

A bobbin comprises three hollow-cylindrical sections, specifically a middle body section, and two lateral body sections. The middle body section has its diameter diminished compared to the two lateral body sections thus forming an annular recess which allows a magnet wire to be wound with an additional number of turns around the bobbin without increasing a motor size. With this bobbin structure, when the number of turns of a magnet wire is set to remain unchanged, the diameter of flanges of the bobbin can be reduced resulting in a downsized motor.

Owner:MINEBEA CO LTD

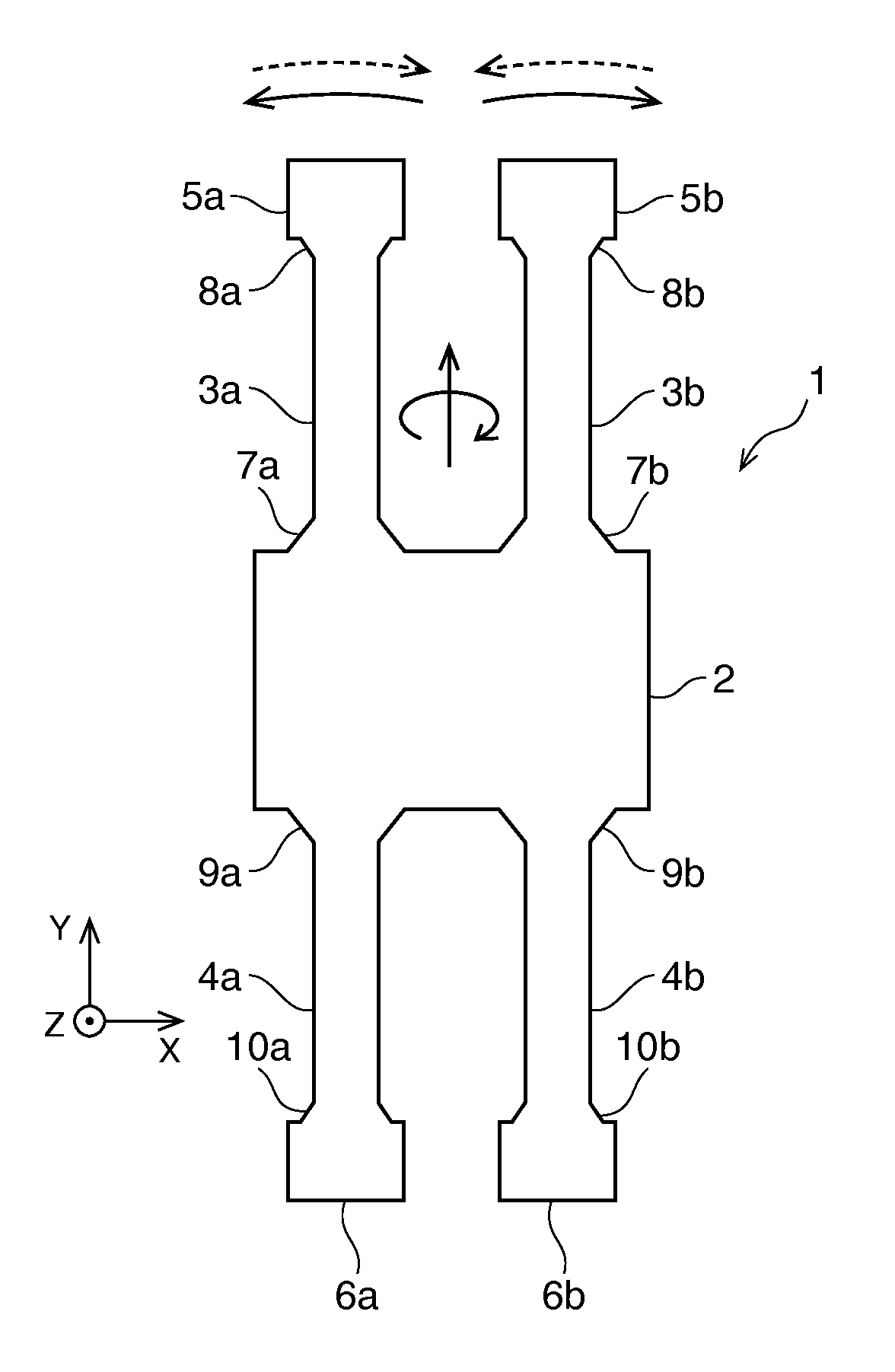

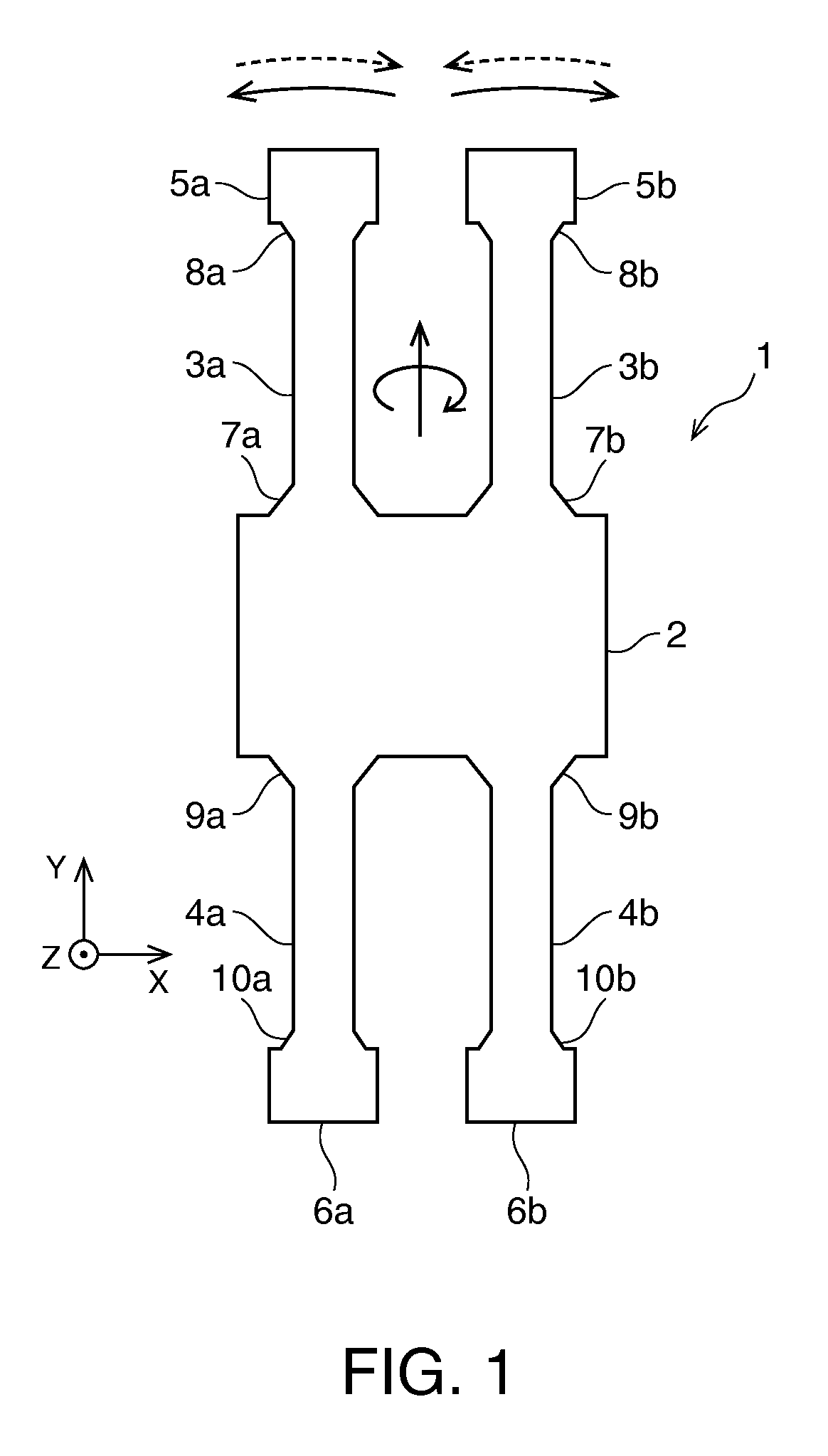

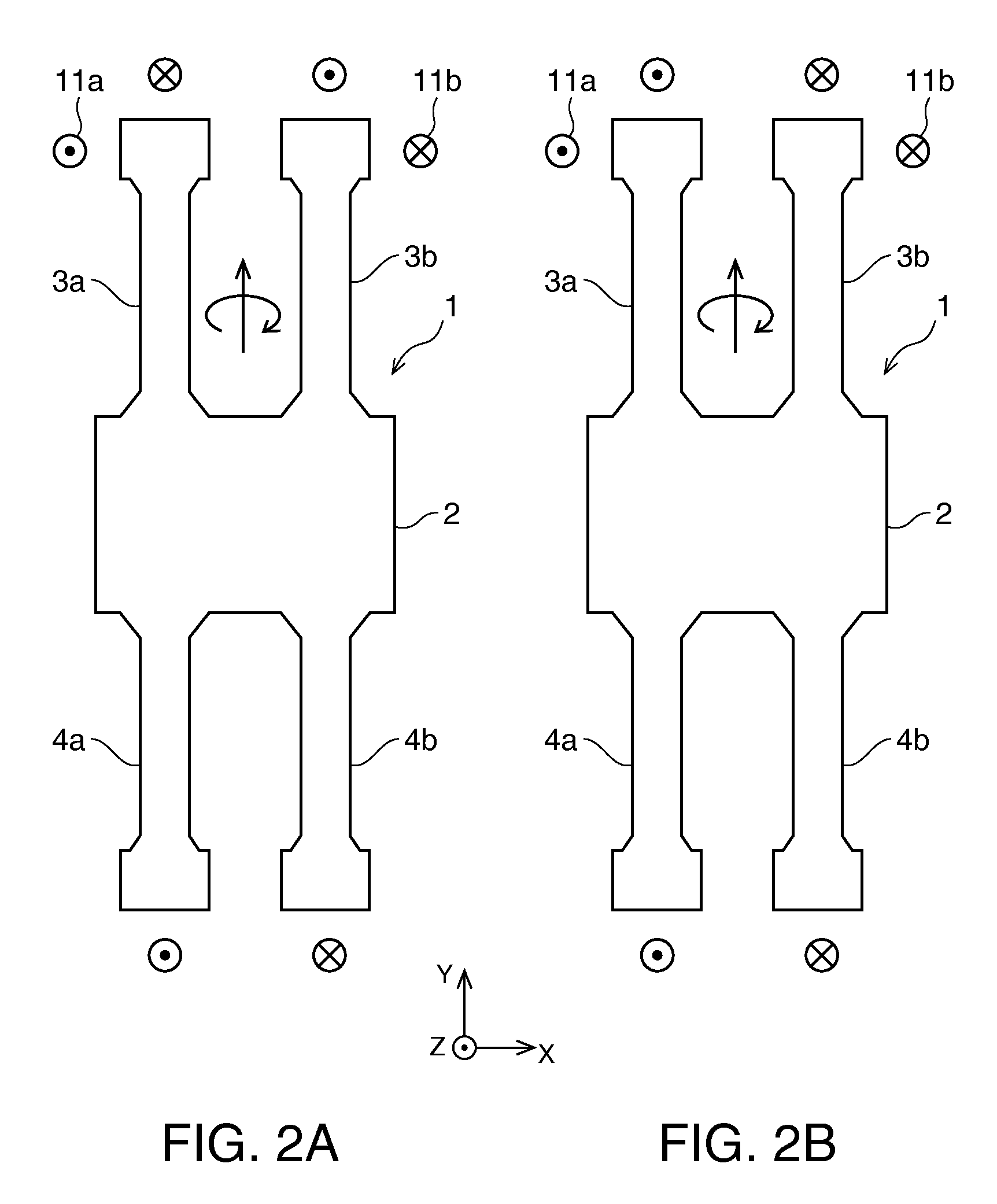

Vibration gyro element, gyro sensor, and electronic apparatus

ActiveUS20130019681A1Increase the exciting forceImprove vibrationAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsClassical mechanicsCoriolis force

A vibration gyro element includes drive vibrating arms and detection vibrating arms at the opposite side, and has a first detection mode in which the drive vibrating arms flexurally vibrate oppositely to each other in an out-of-plane direction in an opposite phase to an action direction of Coriolis force and the detection vibrating arms flexurally vibrate oppositely to each other in the out-of-plane direction in an opposite phase to that of the drive vibrating arms, and a second detection mode in which the drive vibrating arms flexurally vibrate oppositely to each other in the out-of-plane direction in the same phase as the action direction of the Coriolis force and the detection vibrating arms flexurally vibrate oppositely to each other in the out-of-plane direction in the same phase as that of the drive vibrating arms.

Owner:SEIKO EPSON CORP

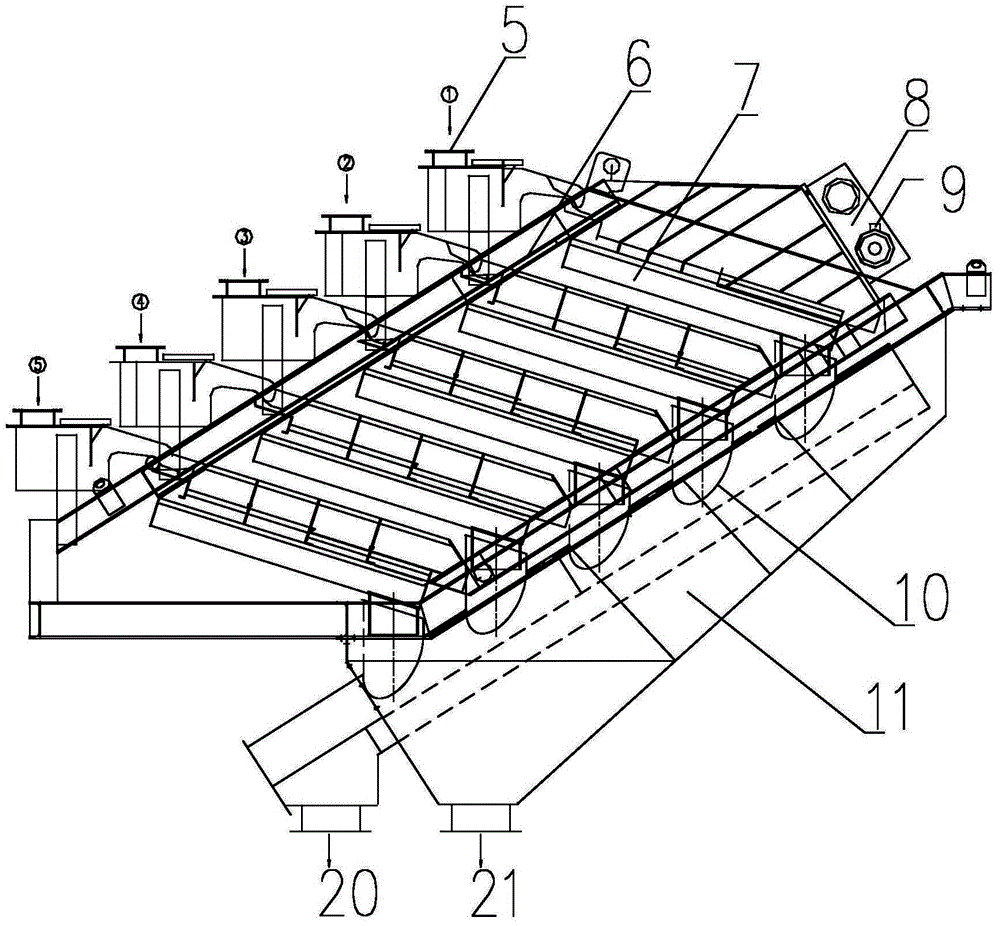

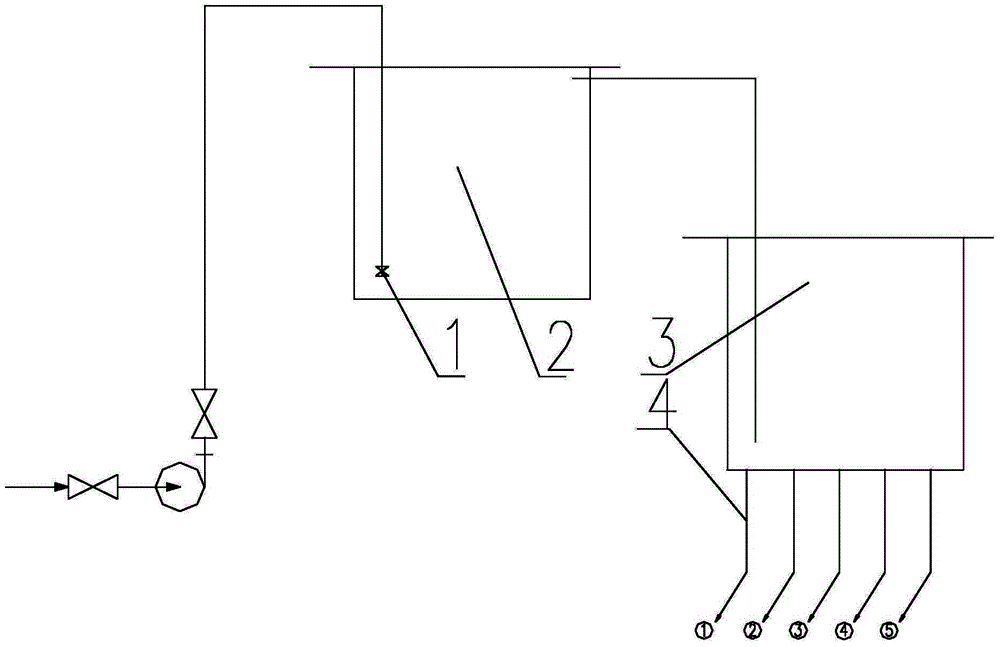

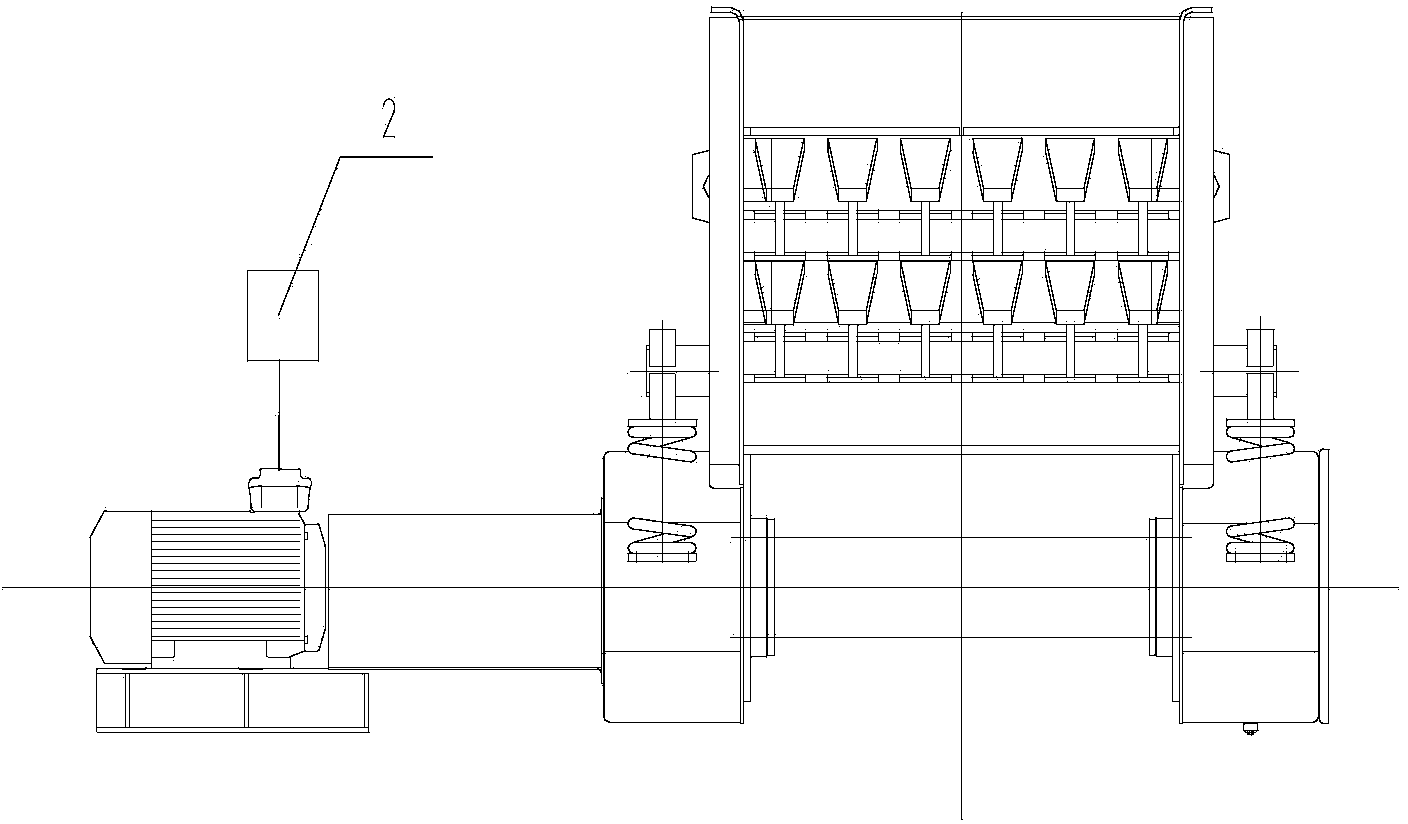

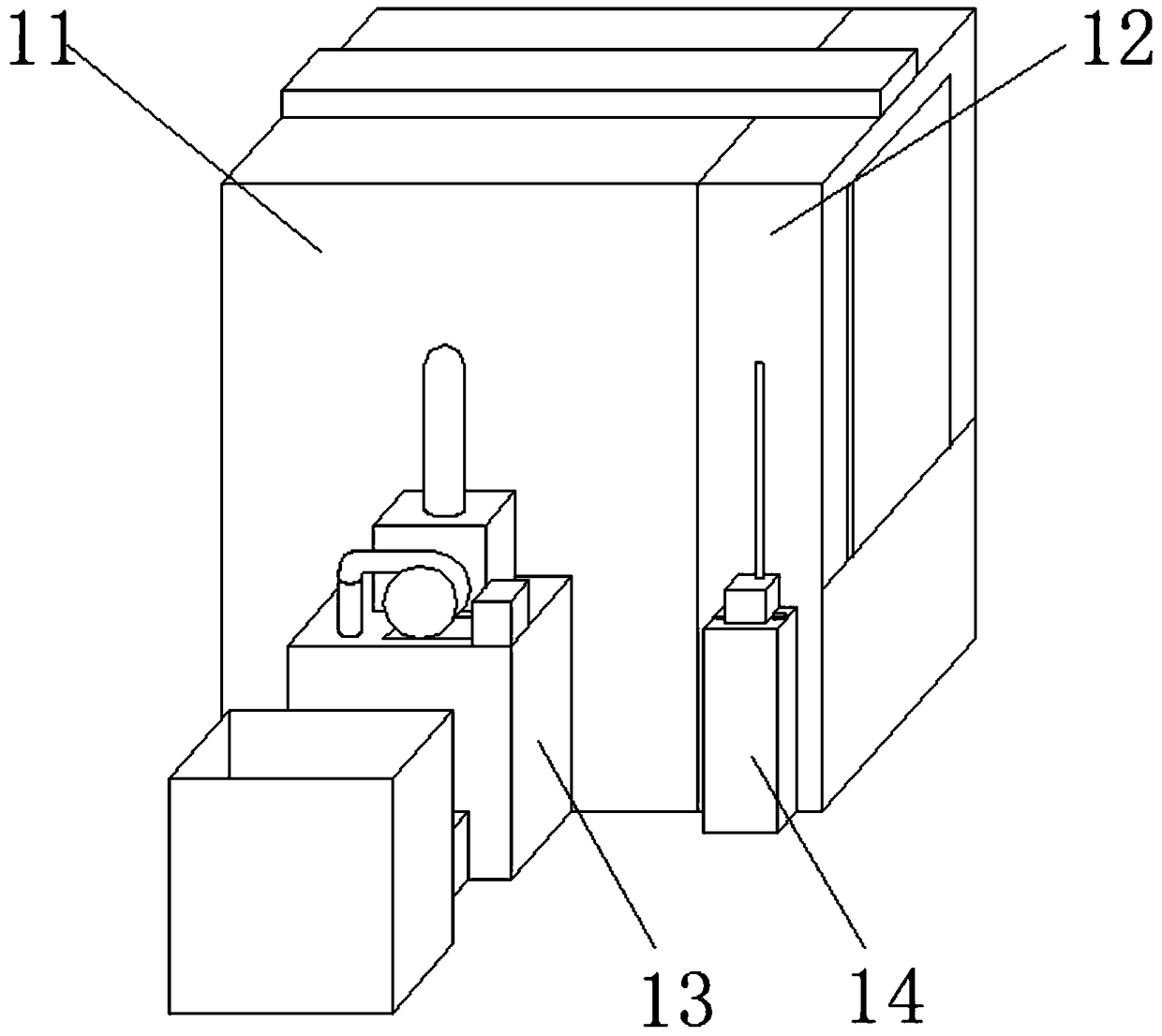

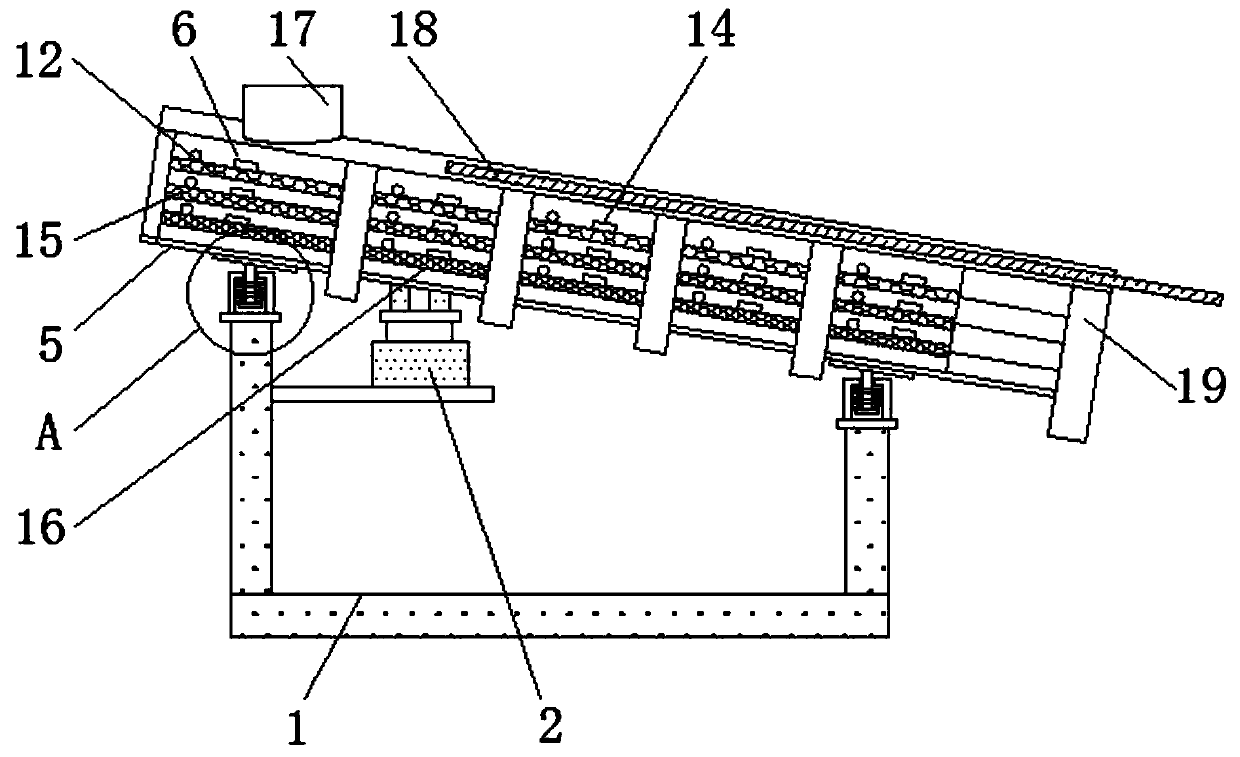

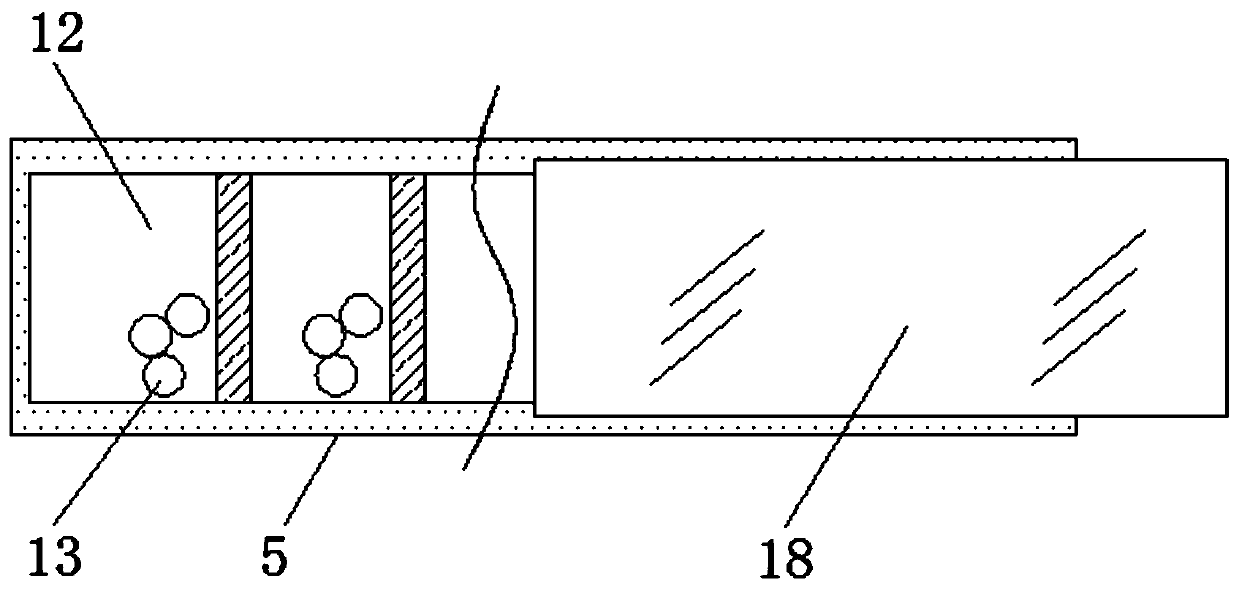

Layered high-frequency fine vibrating screen

InactiveCN104148278AIncrease the eccentric distanceEasy to handleSievingScreeningDistribution systemEngineering

The invention discloses a layered high-frequency fine vibrating screen. The layered high-frequency fine vibrating screen is composed of an ore pulp distribution system, a screening system and a discharging system. The ore pulp distribution system structurally comprises a first-level ore pulp tank (2), a second-level ore pulp tank (3) and hoppers (5), wherein the feed end of the first-level ore pulp tank (2) is connected with a multihole energy dissipation valve (1); an overflow port of the first-level ore pulp tank (2) is connected with the second-level ore pulp tank (3); the hoppers (5) are connected to the lower portion of the second-level ore pulp tank (3). The screening system is composed of a vibration excitation unit, a classifying unit and a supporting unit. The discharging system has the functions of collection and discharge of materials below the screen and collection and discharge of materials on the screen, wherein the materials below all layers of high-frequency screen assemblies (7) are connected with upper chutes (10) through short pipes; the upper chutes (10) are connected with a material-below-screen main outlet (20); the materials on all the layers of high-frequency screen assemblies (7) are connected with lower chutes (11); a subsidiary discharge port (21) is connected to the lower chutes (11). The layered high-frequency fine vibrating screen has the advantages of being uniform in ore pulp feeding, high in screening efficiency and processing capacity and capable of adapting to different working conditions.

Owner:HUNAN ZHAOSHENG MINING MACHINERY

Bidirectional discharge circular vibrating screen

InactiveCN101462110AMultiple screening specificationsQuick NestSievingScreeningChemical industryBuilding material

The invention discloses a bidirectional discharge circular vibrating screen, which consists of a screen body, a vibration generator, springs, a support and a transmission device, and is characterized in that the screen body consists of a screen frame, an upper screen mesh and a lower screen mesh; the upper screen mesh is provided with a discharge opening I, and the lower screen mesh is provided with a discharge opening II; the support is arranged on the lower part of the screen body which is fixedly connected with the support through four groups of springs; and the vibration generator is arranged on the upper part of the gravity center of the screen body. The bidirectional discharge circular vibrating screen has the advantages that the material circular vibrating screen adopts a simple eccentric shaft block to adjust the amplitude, has the characteristics of long slip screen line, multiple screening specifications, quick discharge and high classification efficiency, also has the characteristics of reliable structure, strong excitation force, high screening efficiency, small vibrating noise, firmness and durability, convenient maintenance, safe use and the like, and can be widely applied to classification and separation of materials in the industries such as mining, building material, traffic, energy and the chemical industry.

Owner:陆信

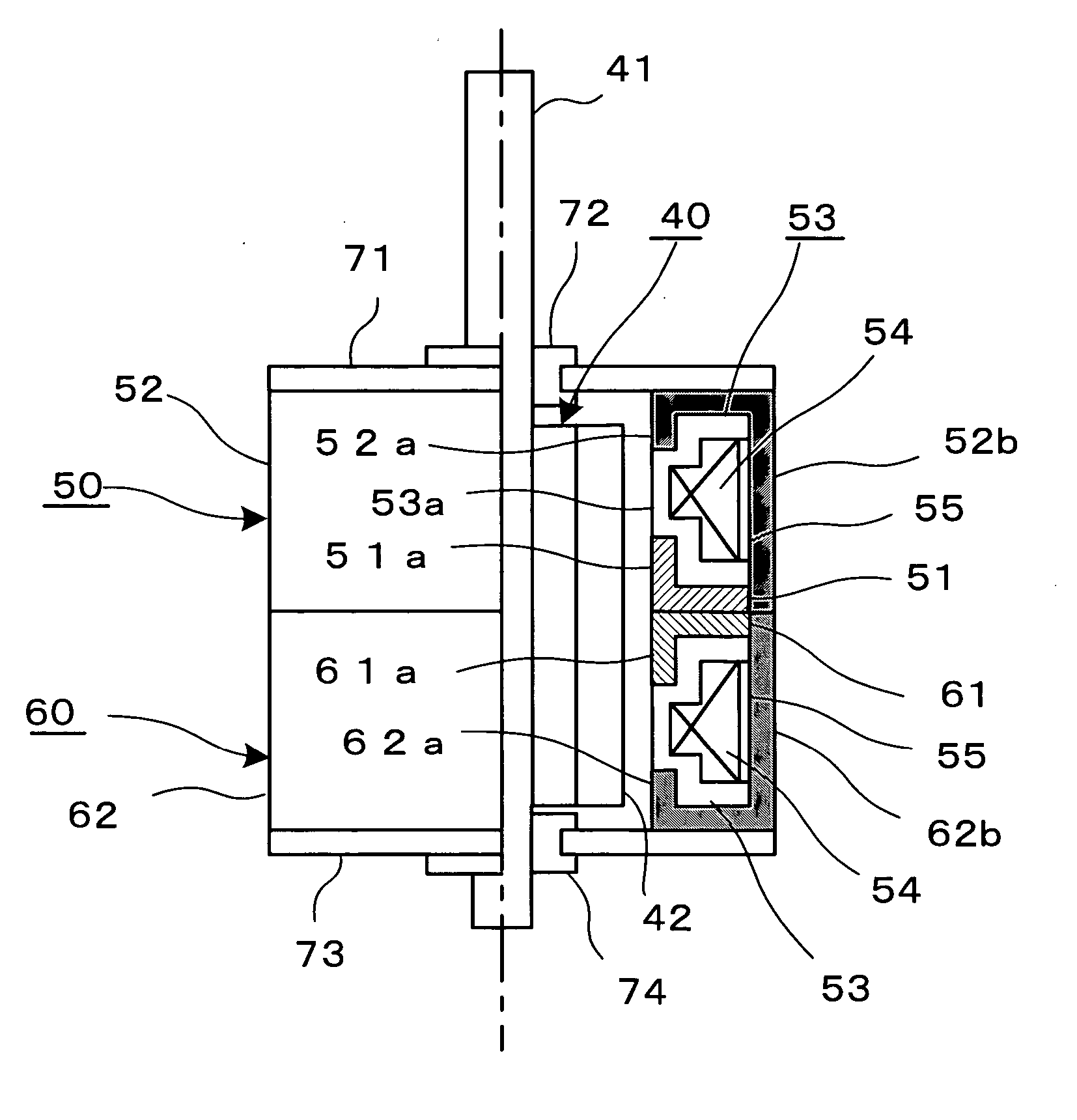

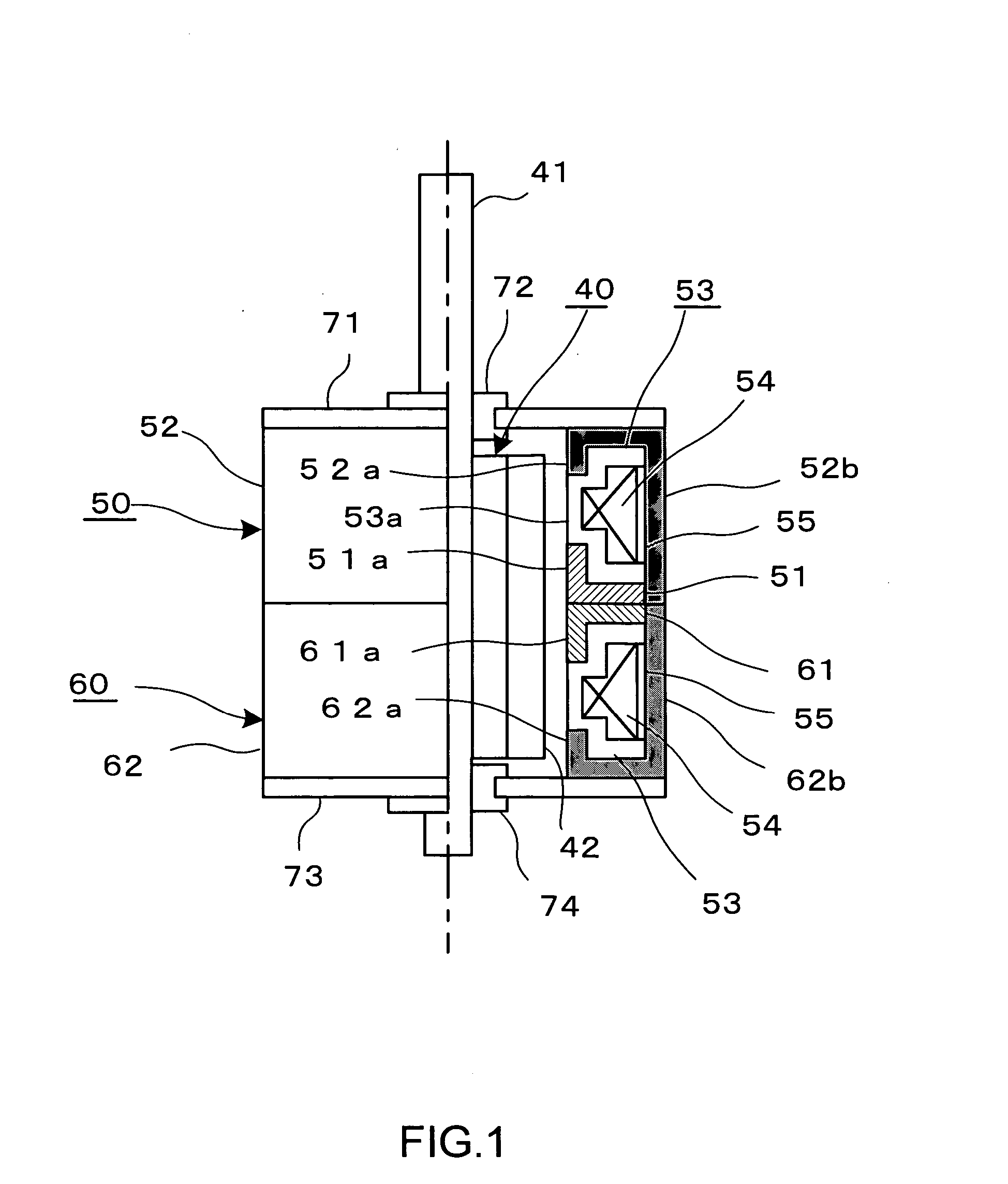

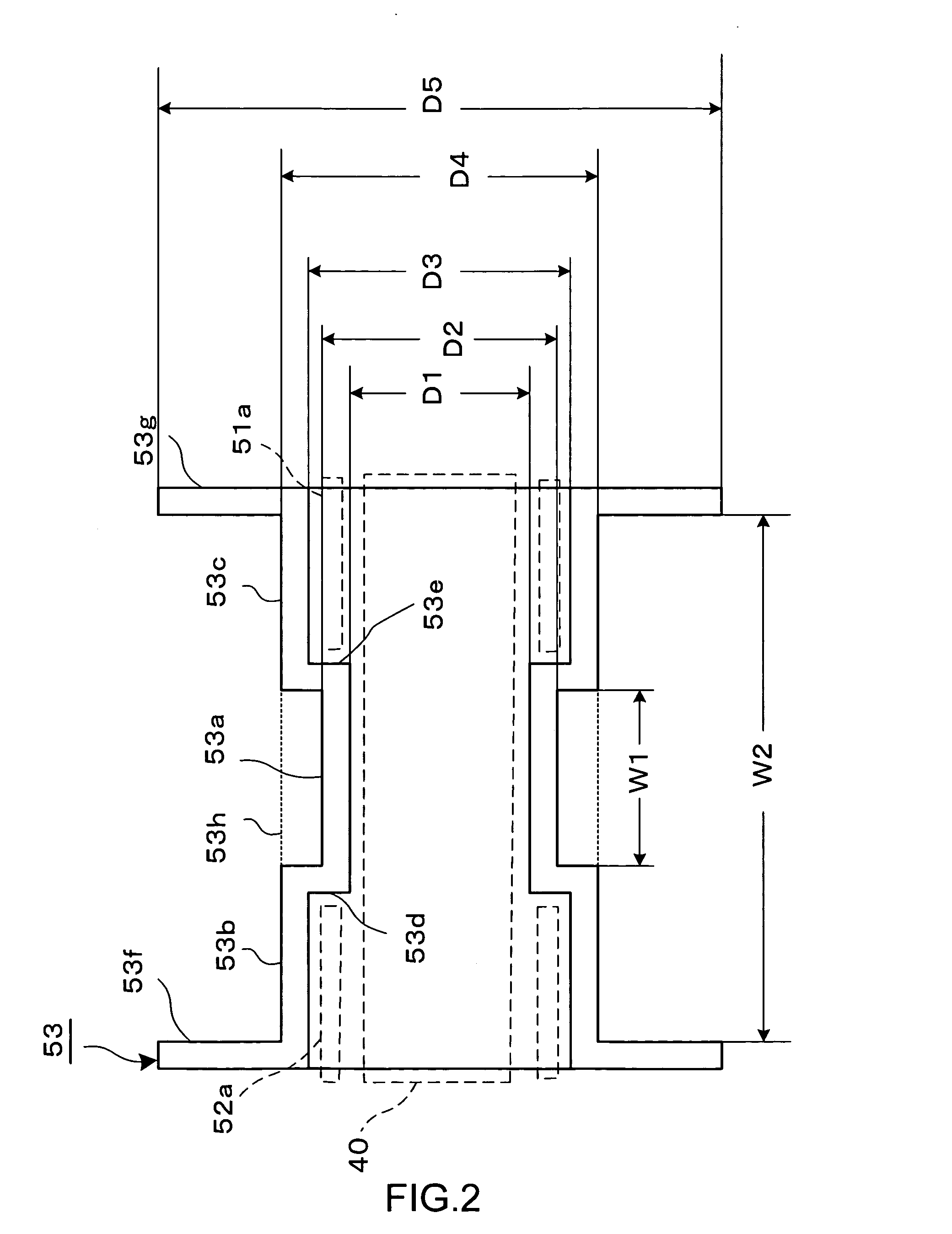

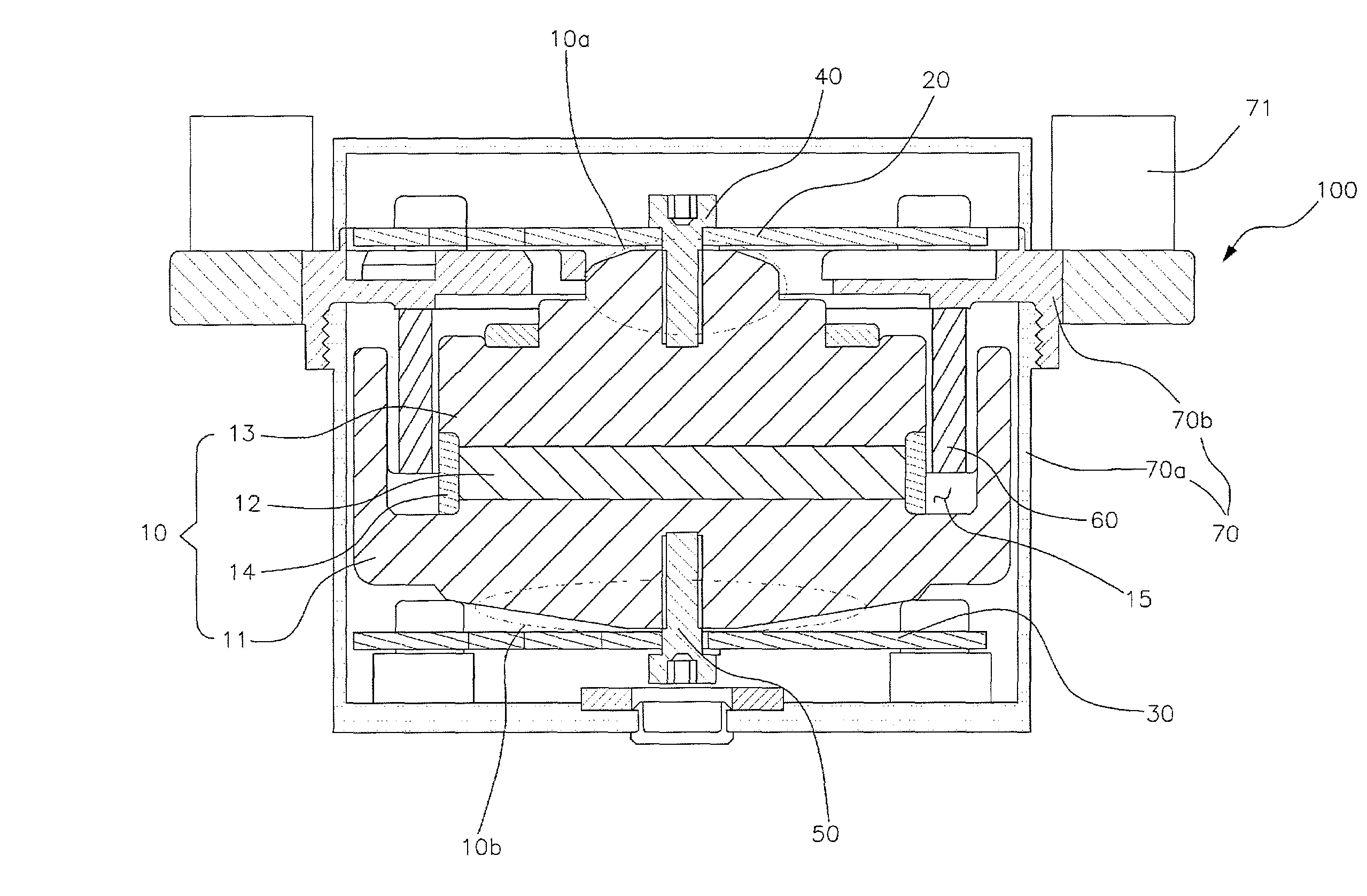

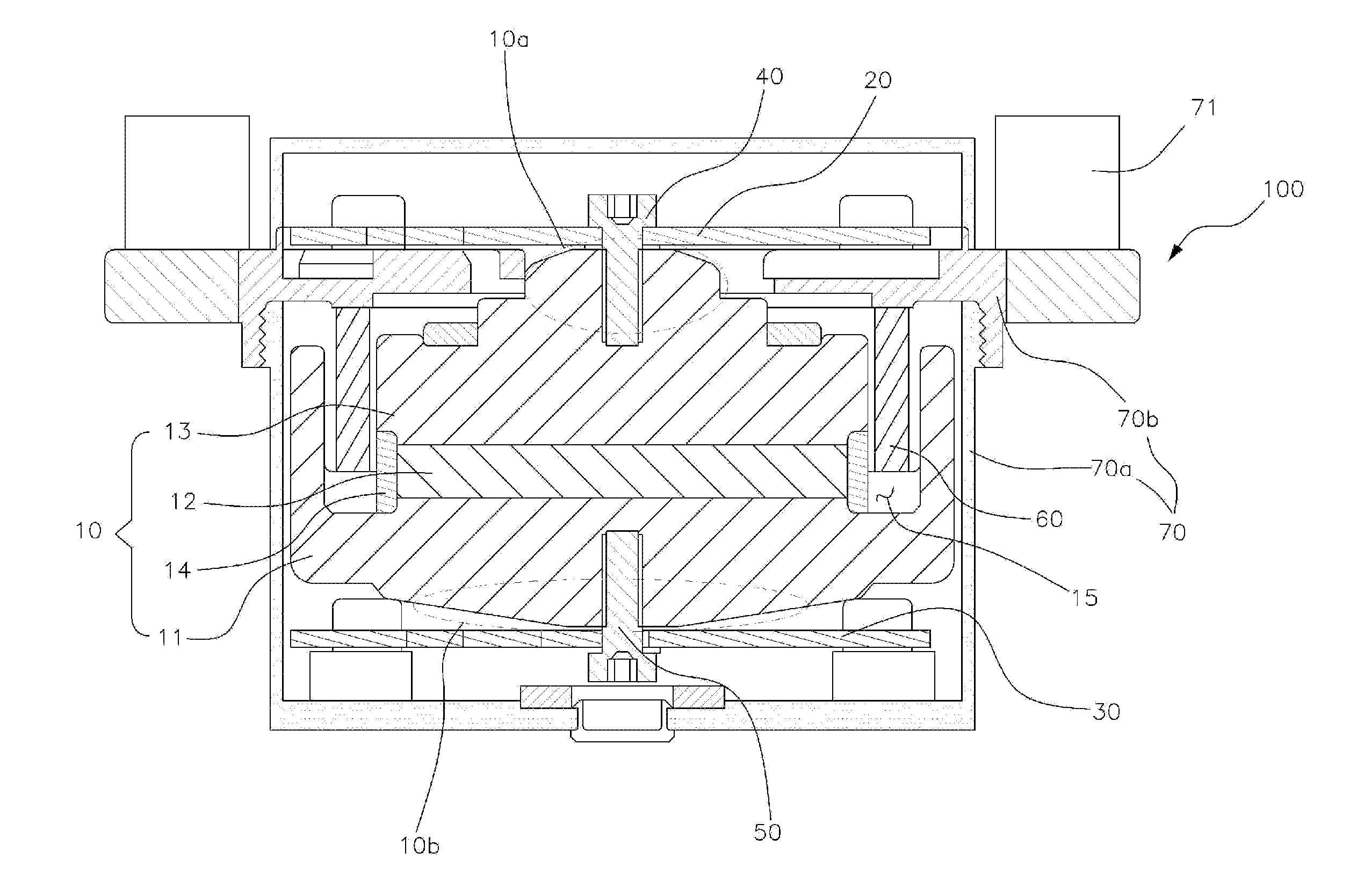

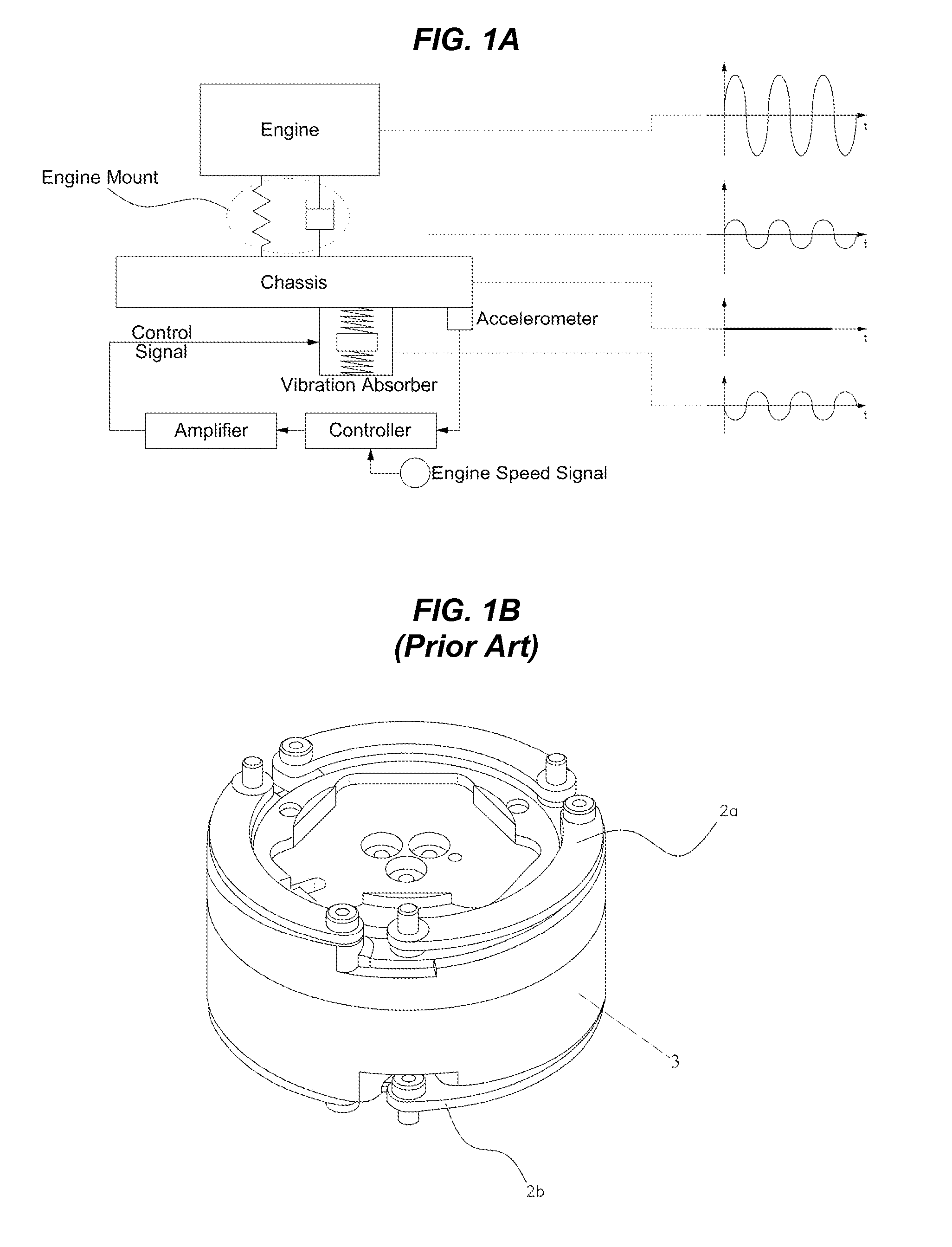

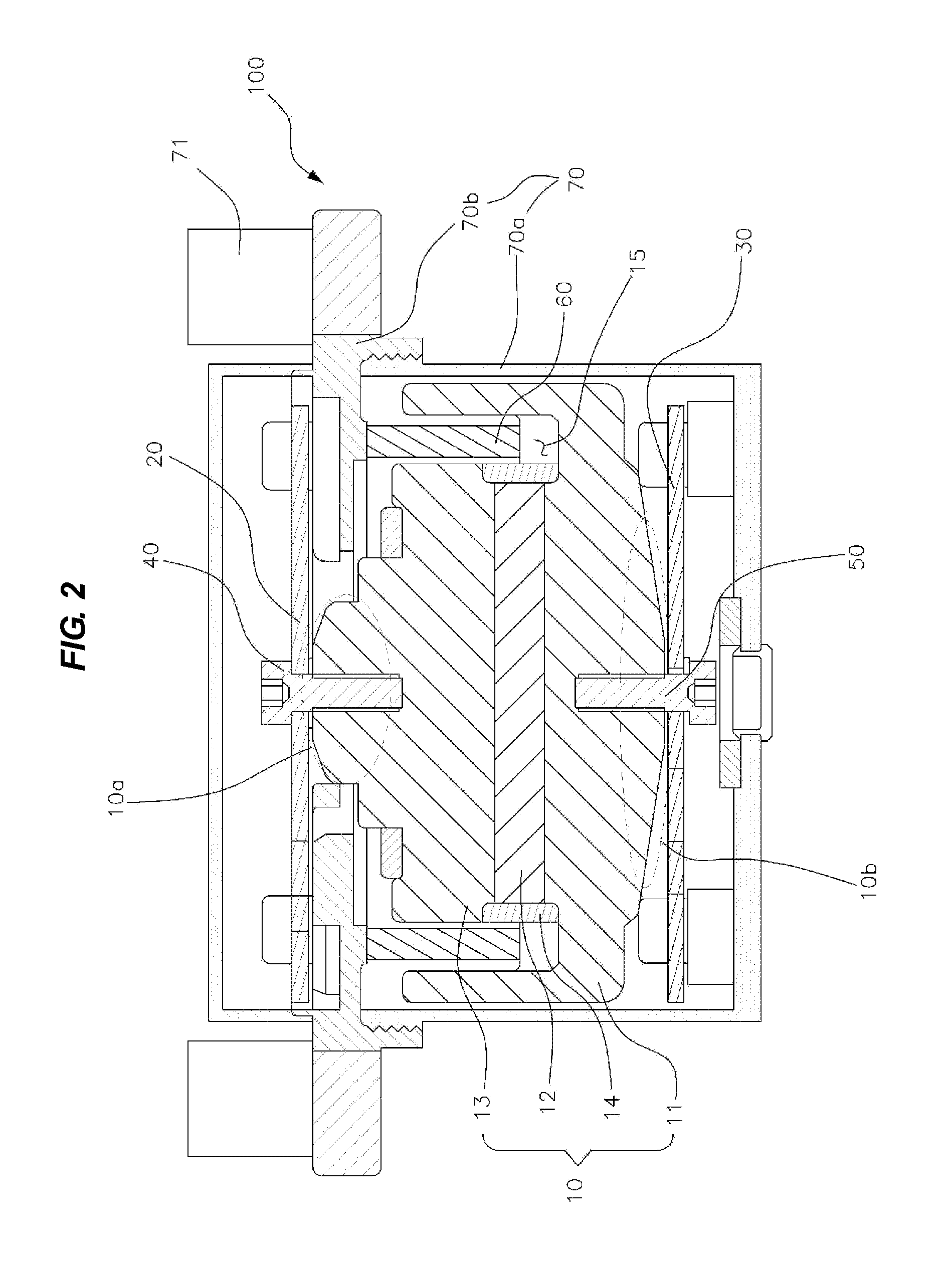

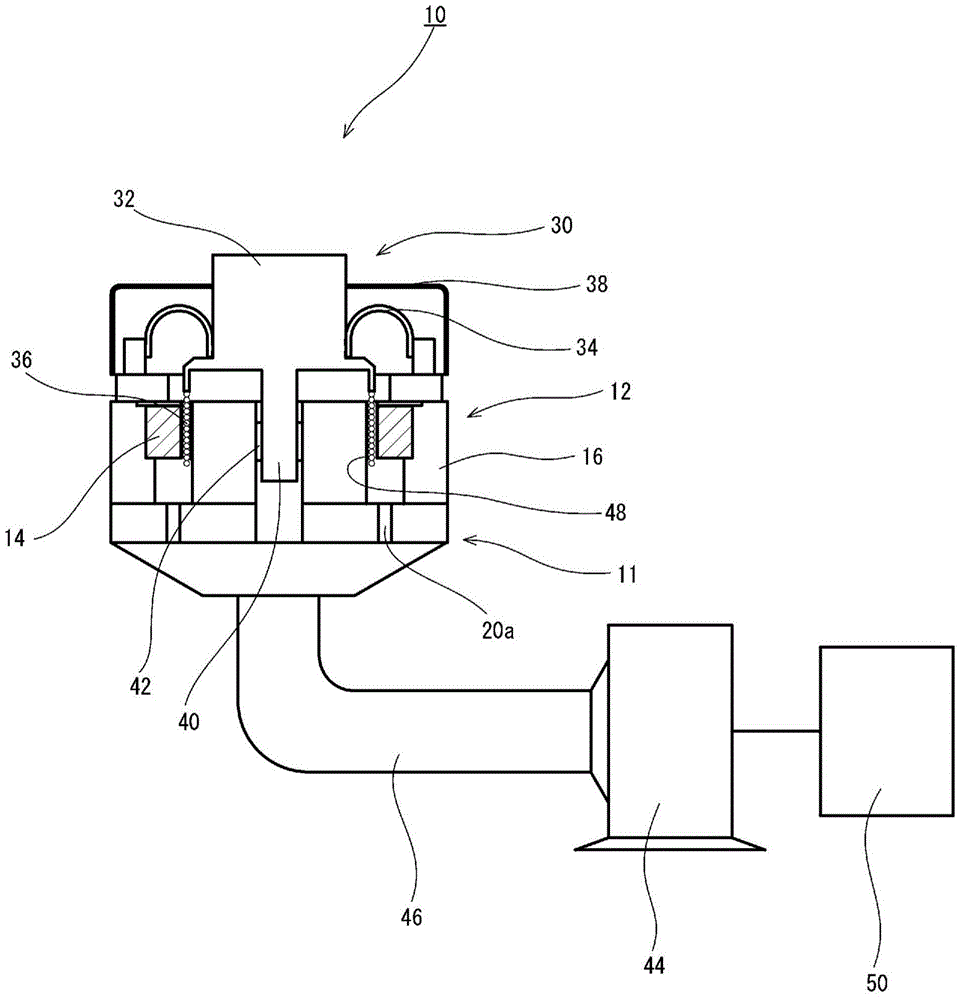

Active dynamic vibration absorber apparatus for vehicle

ActiveUS8616536B2Generate efficientlyEfficiently vibrate up/downPortable framesNon-rotating vibration suppressionEngineeringDynamic Vibration Absorber

An active dynamic vibration absorber apparatus for a vehicle that may be mounted to a frame of the vehicle and vibrates when power may be supplied to attenuate vibration of the vehicle, may include a housing, an upper spring and a lower spring, and a yoke assembly disposed between the upper spring and the lower spring which may be plates arranged in parallel, and selectively vibrates up / down in the housing, wherein the yoke assembly has an upper protrusion and a lower protrusion that protrude from the top and the bottom thereof, respectively, the upper protrusion being fastened to the center of the upper spring through the housing, and the lower protrusion being fastened to the center of the lower spring in the housing.

Owner:PYUNG HWA IND CO LTD +1

Bobbin, motor, and method of winding magnet wire

InactiveUS7132774B2Reduce the overall diameterIncrease the winding spaceSynchronous generatorsWindings insulation shape/form/constructionBobbinEngineering

A bobbin comprises three hollow-cylindrical sections, specifically a middle body section, and two lateral body sections. The middle body section has its diameter diminished compared to the two lateral body sections thus forming an annular recess which allows a magnet wire to be wound with an additional number of turns around the bobbin without increasing a motor size. With this bobbin structure, when the number of turns of a magnet wire is set to remain unchanged, the diameter of flanges of the bobbin can be reduced resulting in a downsized motor.

Owner:MINEBEA CO LTD

Ultrasonic motor and electronic device using the same

InactiveUS7642697B2Increase productionImprove vibrationPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesClassical mechanicsUltrasonic motor

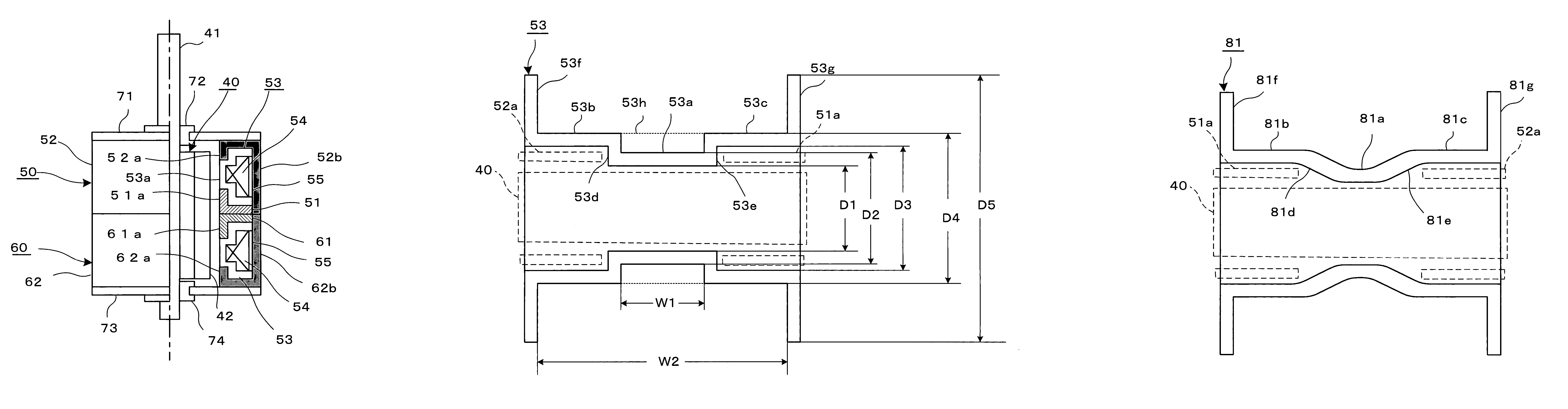

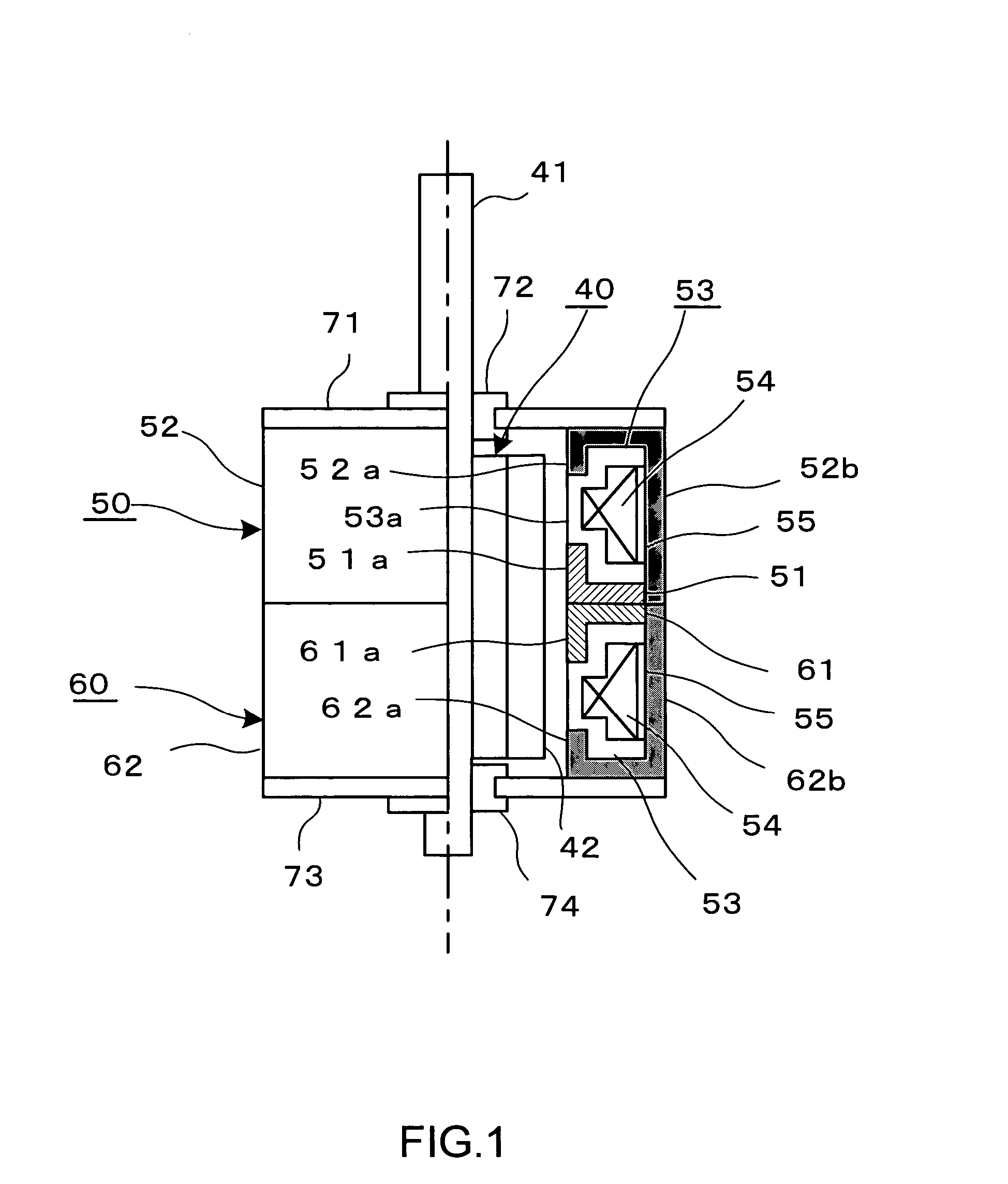

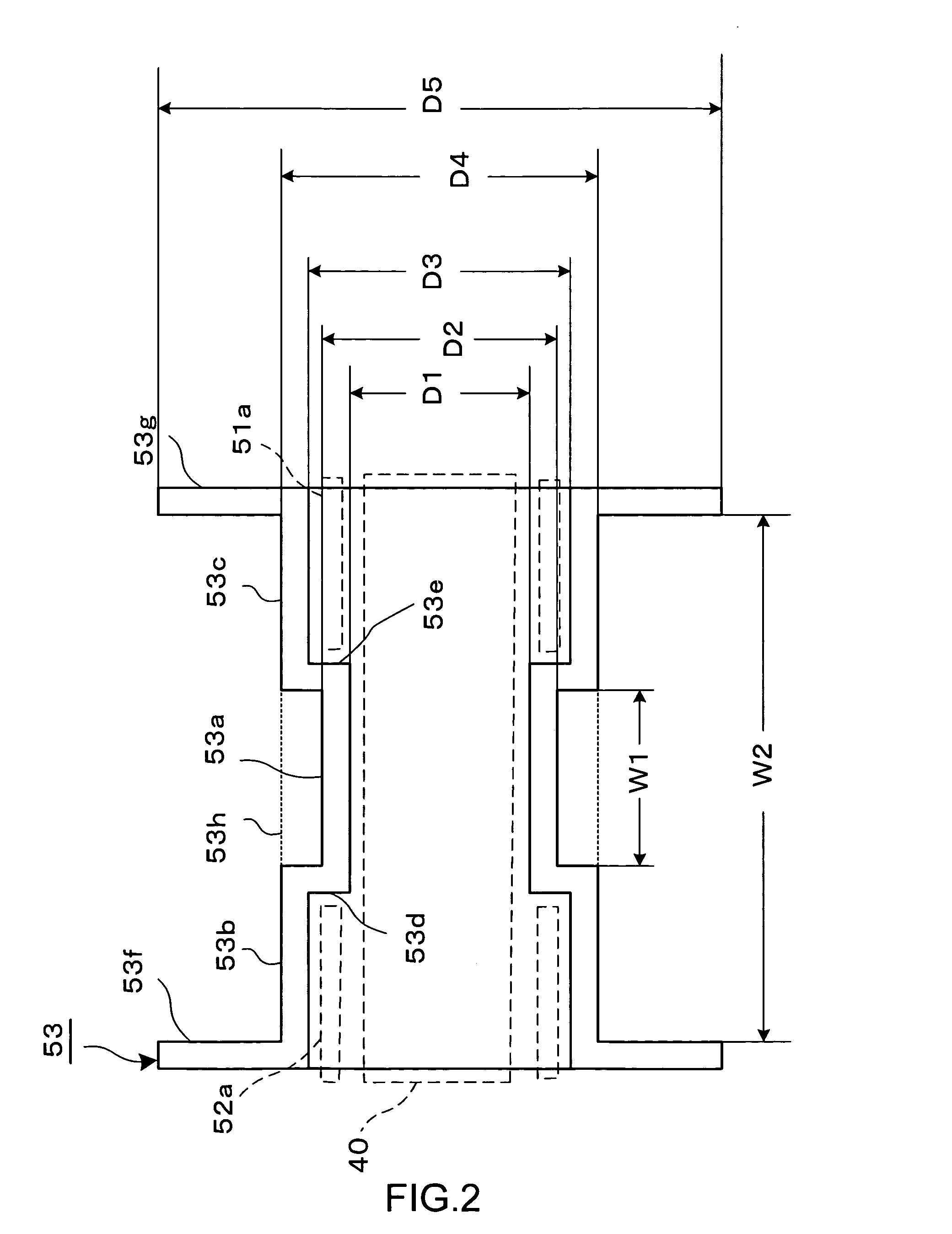

Disclosed is an ultrasonic motor whose output is improved by enhancing the exciting force of a vibration caused on a vibrating body having a rectangular portion. The ultrasonic motor includes the vibrating body having a piezoelectric element, and a moving body which contacts the vibrating body. The phases of two difference vibrations caused on the vibrating body are changed to make the moving direction of the moving body or the vibrating body itself variable by selecting whether to apply a drive signal to first electrodes provided at one side of the piezoelectric element or to apply a drive signal to second electrodes provided at a portion whose polarization direction differs from that of the first electrodes.

Owner:FUKOKU CO LTD

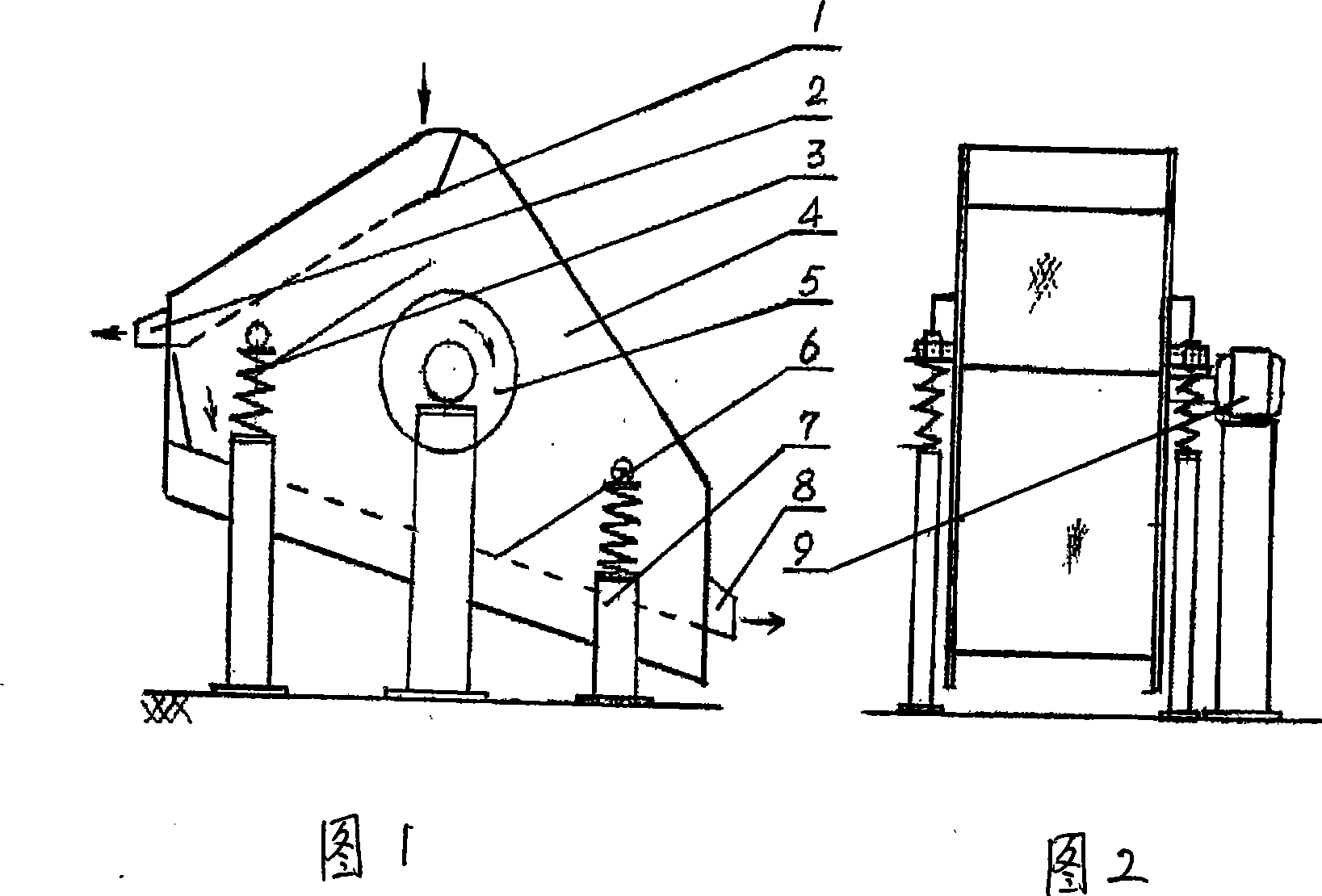

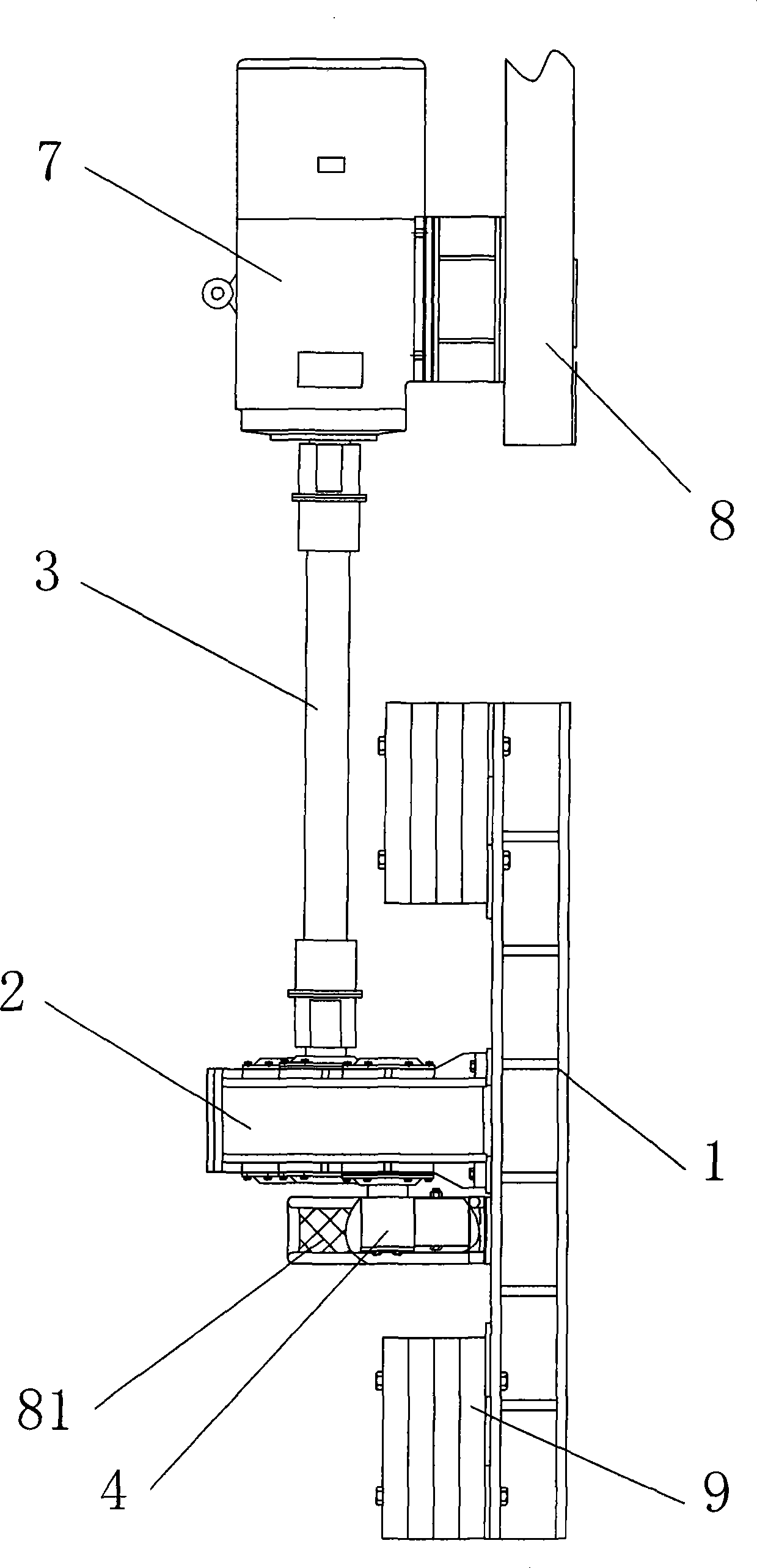

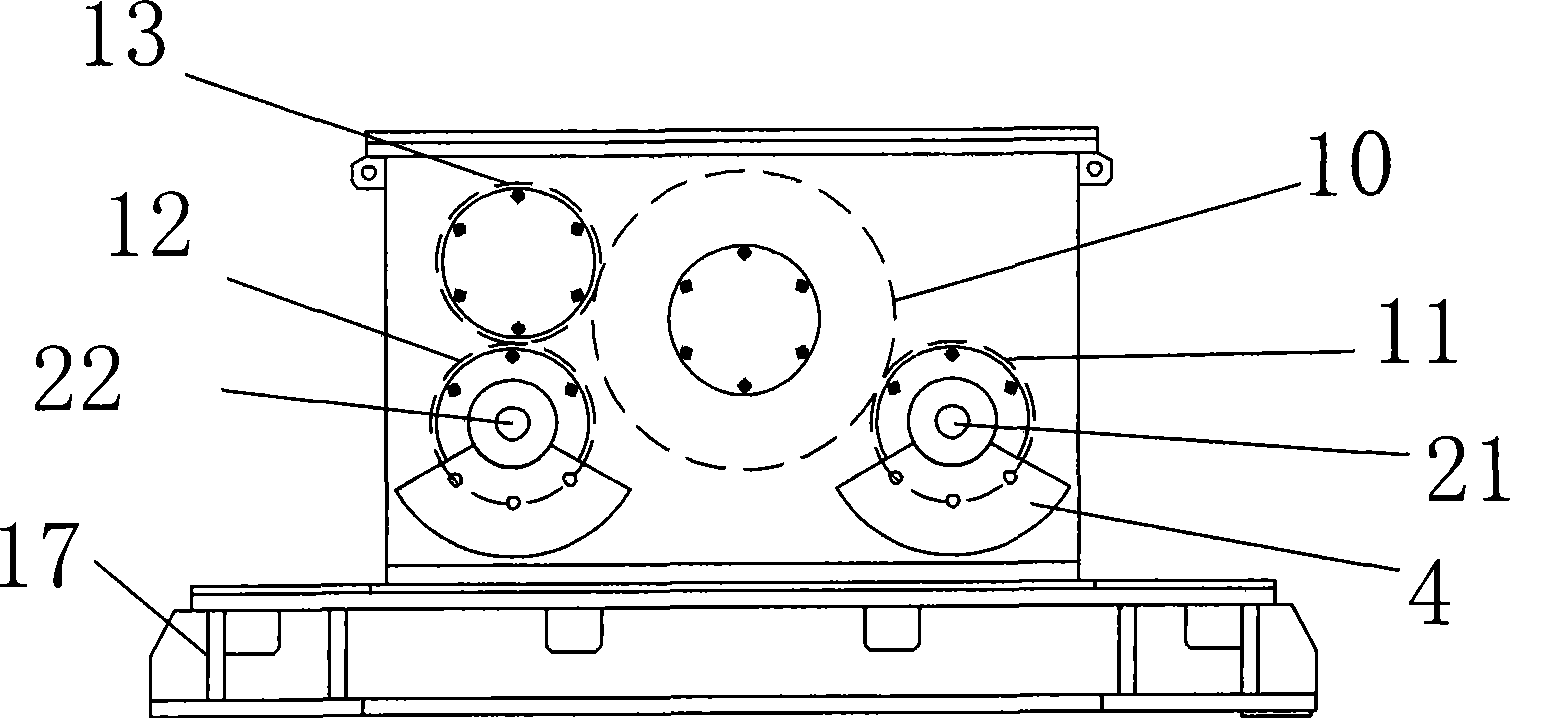

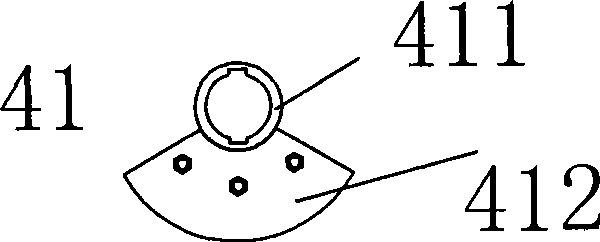

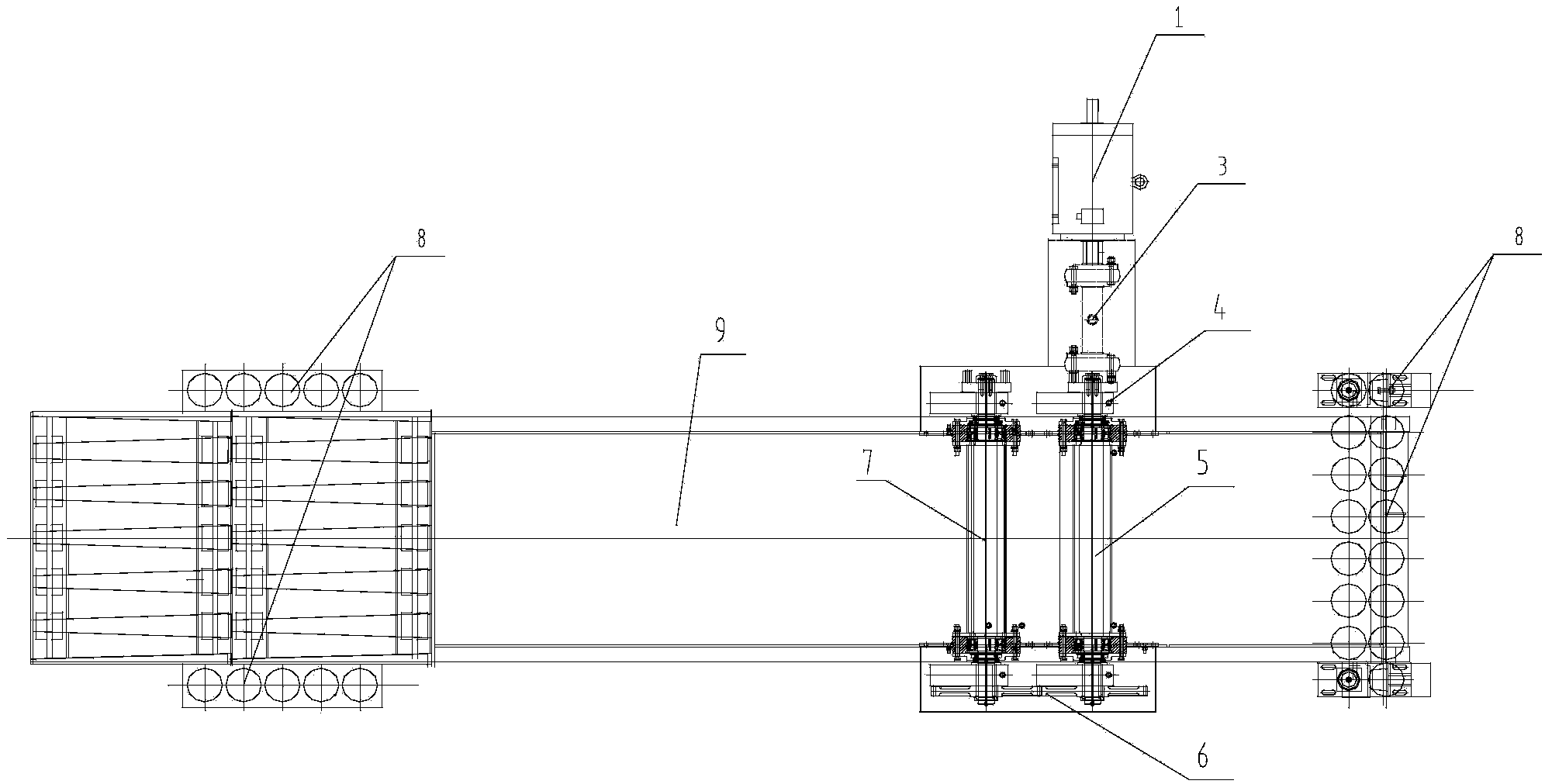

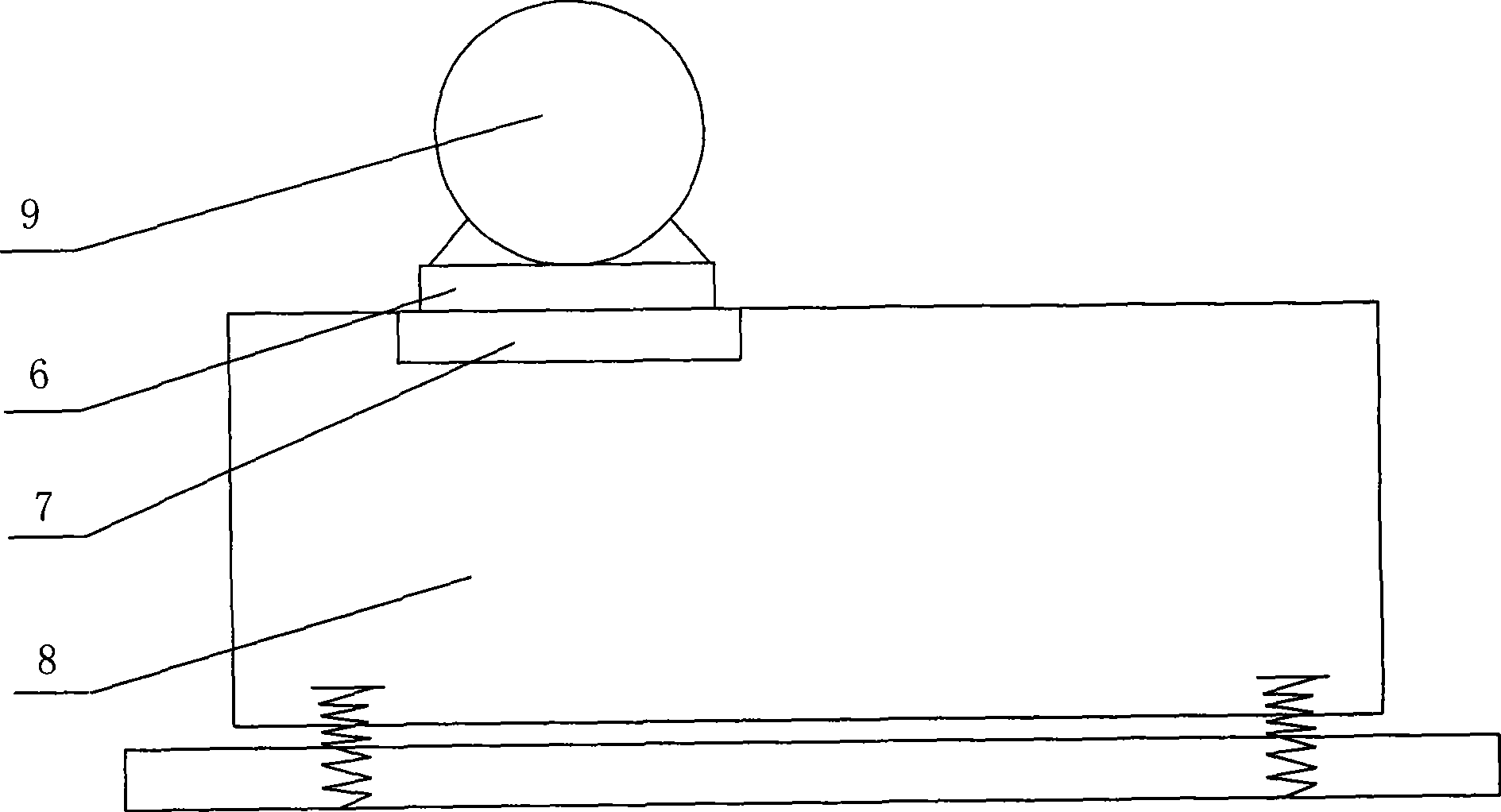

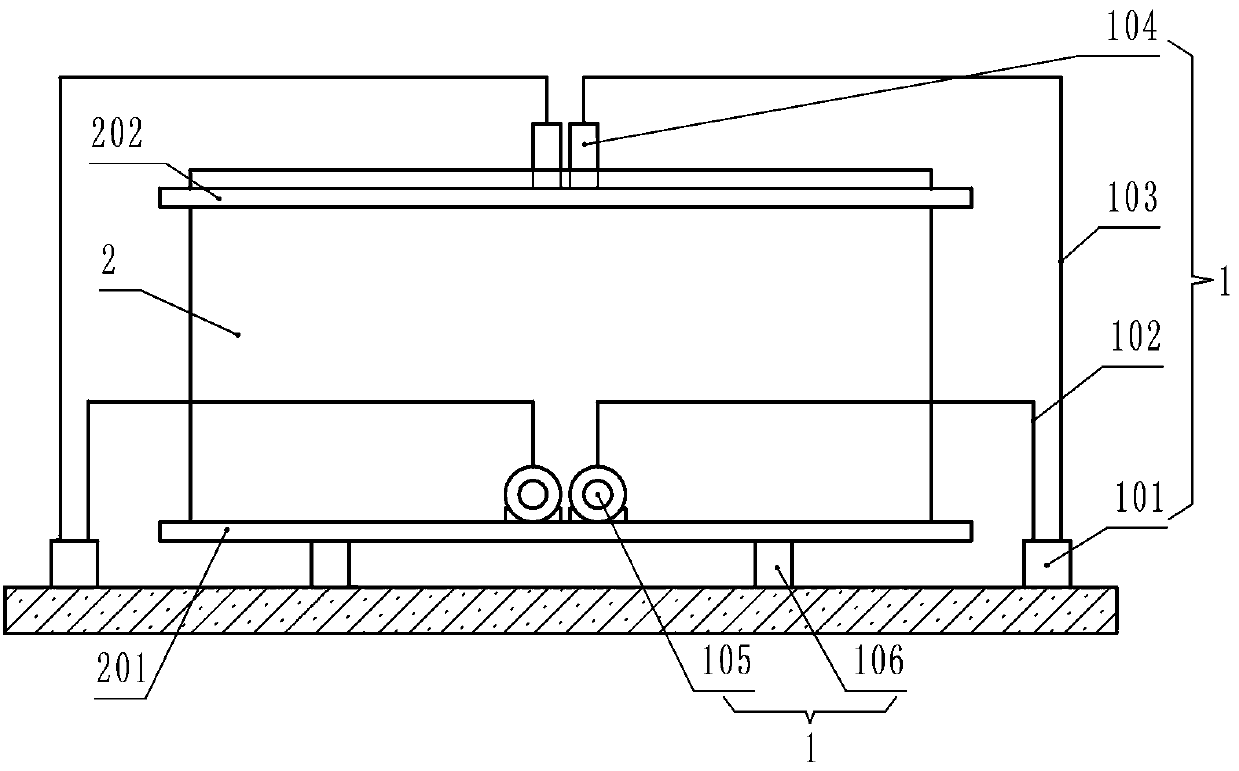

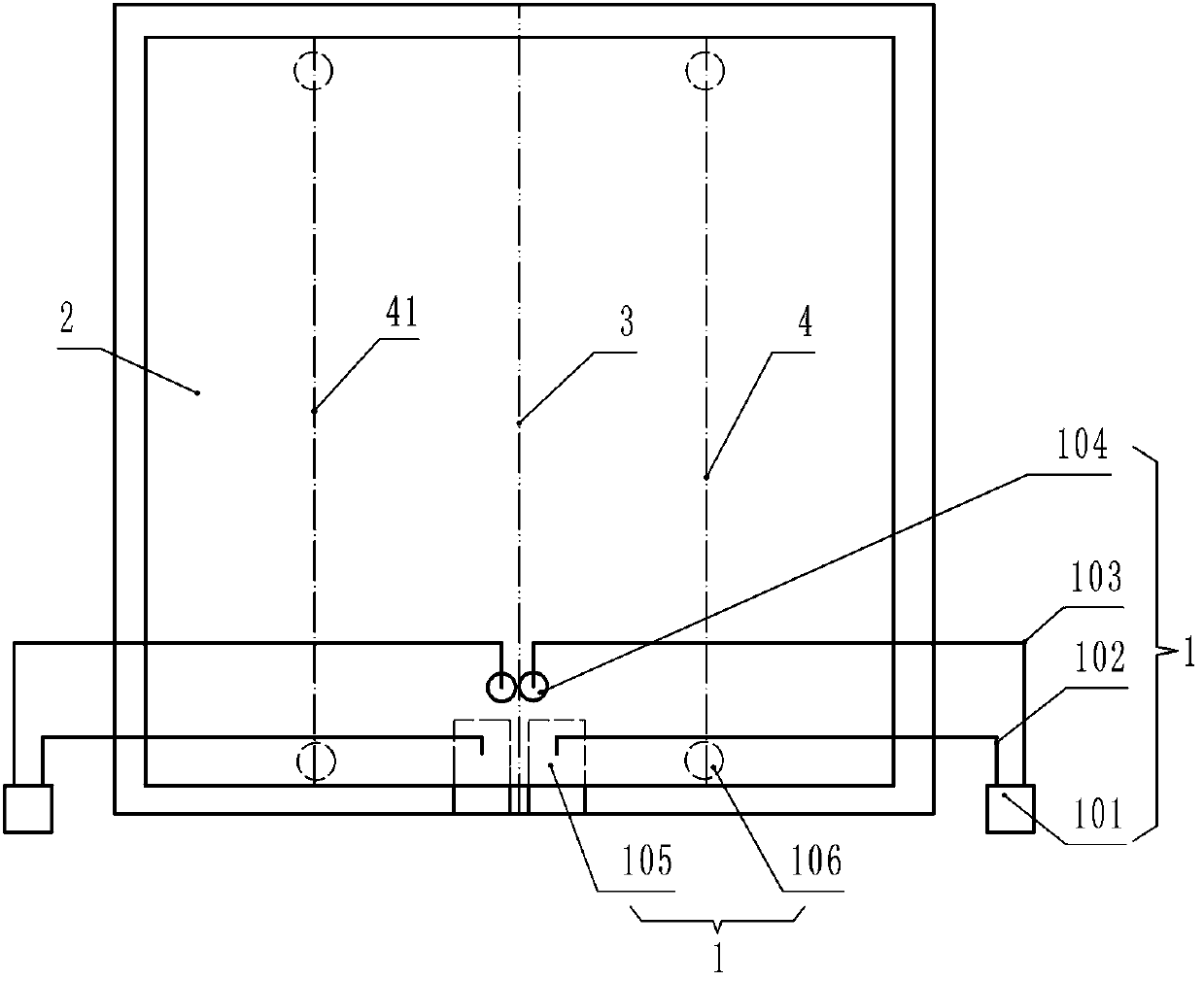

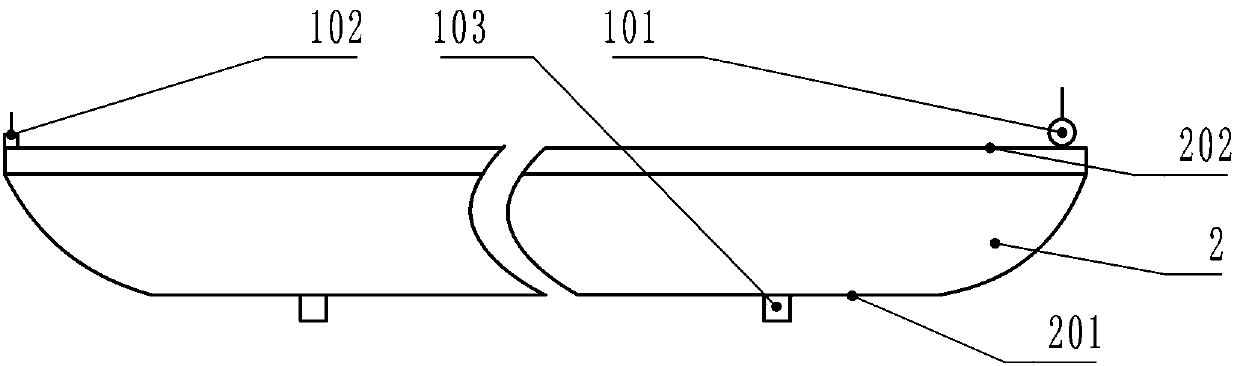

In-situ modeling test system for live loading of high-speed railway

InactiveCN101465575AExtended service lifeImprove reliabilityMechanical energy handlingModel testControl theory

The invention relates to a high-speed railway live-loading field analog experiment system, comprising: a frequency control motor (7) is fixedly arranged on a mounting trolley (8) of the motor, the shaft of the motor (7) is connected with the input shaft at one side of a speed increaser (2) by a universal coupler (3); the front and rear output shafts (21, 22) with the same height at the other side of the speed increaser (2) are connected with same eccentric blocks (4), and the rotating speed of the front and rear output shafts (21, 22) is same, the rotating direction thereof is reverse; the speed increaser (2) is fixed in the center of the upper surface of a vibrating grid (1). The exciting force of the system is strong, excited frequency thereof is high, the reliability is high, and installation and debugging are convenient; therefore, the system is particularly suitable for the high-speed railway live-loading field analog experiments.

Owner:SOUTHWEST JIAOTONG UNIV

Active dynamic vibration absorber apparatus for vehicle

ActiveUS20110316206A1Increase weightIncrease in excite forcePortable framesNon-rotating vibration suppressionEngineeringMechanical engineering

An active dynamic vibration absorber apparatus for a vehicle that may be mounted to a frame of the vehicle and vibrates when power may be supplied to attenuate vibration of the vehicle, may include a housing, an upper spring and a lower spring, and a yoke assembly disposed between the upper spring and the lower spring which may be plates arranged in parallel, and selectively vibrates up / down in the housing, wherein the yoke assembly has an upper protrusion and a lower protrusion that protrude from the top and the bottom thereof, respectively, the upper protrusion being fastened to the center of the upper spring through the housing, and the lower protrusion being fastened to the center of the lower spring in the housing.

Owner:PYUNG HWA IND CO LTD +1

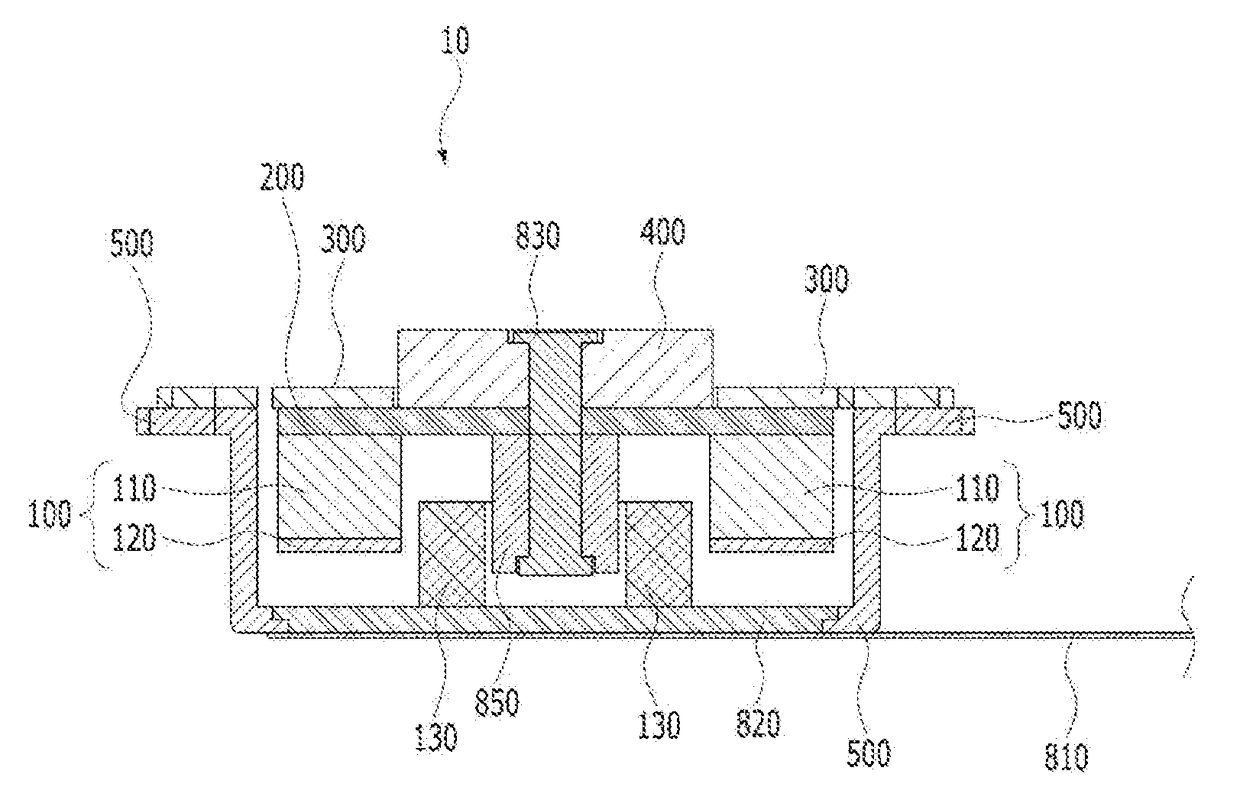

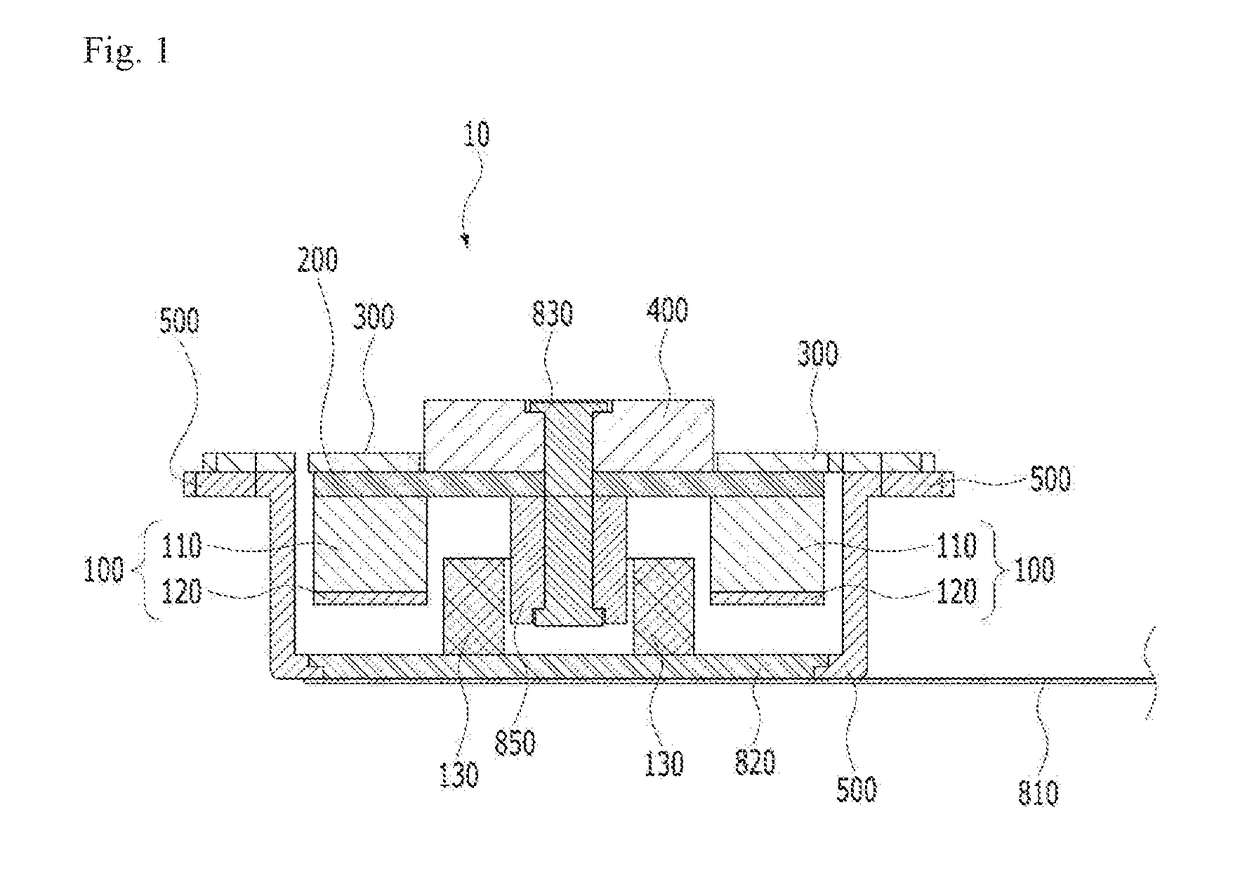

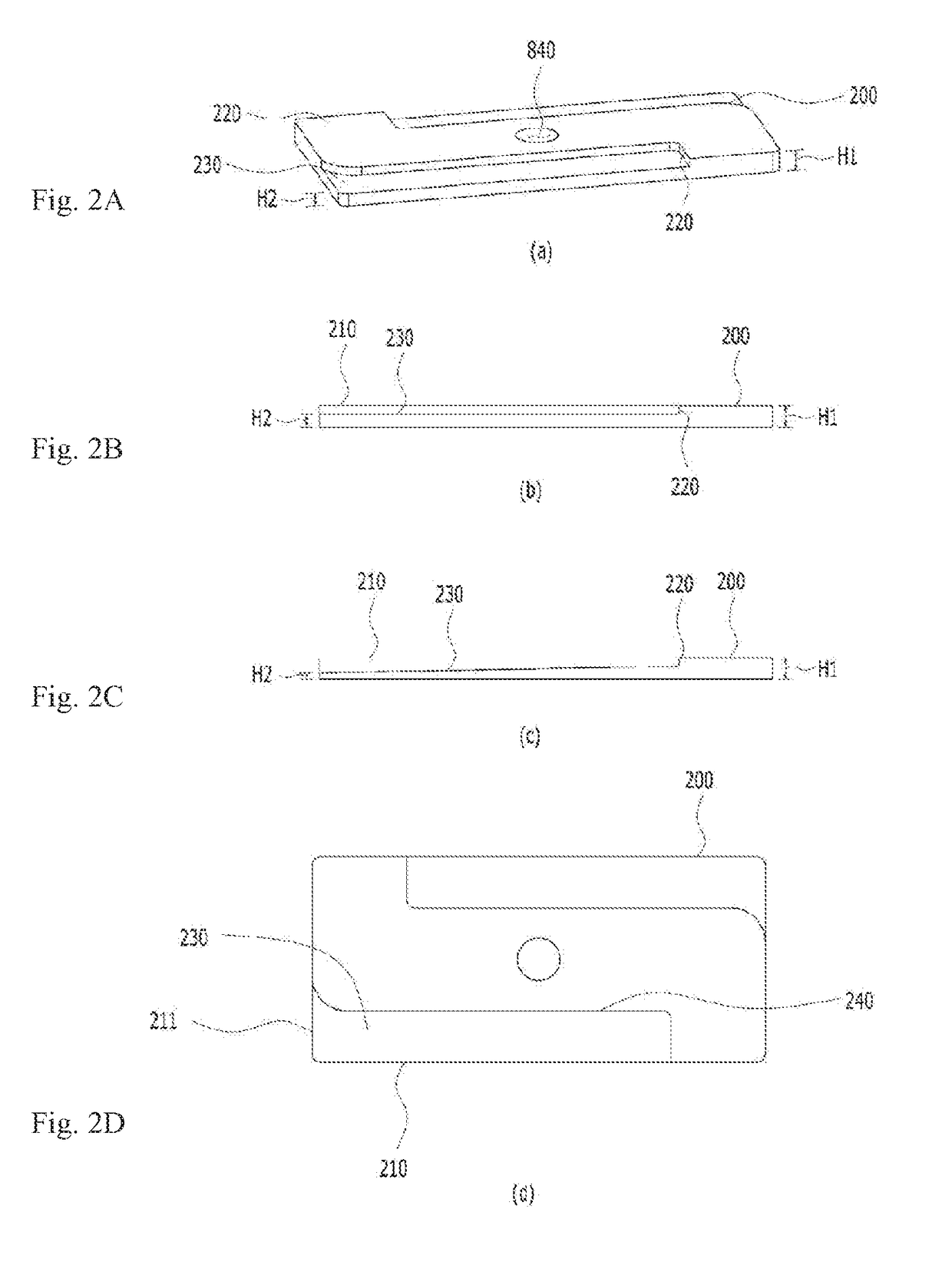

Vibration output apparatus and portable electronic device comprising vibration output apparatus

InactiveUS20180048962A1Increase the exciting forceTransmitted directlyMicrophonesLoudspeakersOutput deviceEngineering

The present invention relates to an apparatus for outputting vibration, and an exemplary embodiment of the present invention may provide an apparatus for outputting vibration, the apparatus including: a magnetic circuit which generates vibration; a yoke which is in contact with an upper surface of the magnetic circuit and has a raised spot with different heights in a height direction in at least one of lateral surfaces of the yoke such that one or more spaces are formed in an upper surface of the yoke; and an elastic body which is in contact with at least a part of the upper surface of the yoke, and vibratorily moves in the one or more spaces.

Owner:YEIL ELECTRONICS

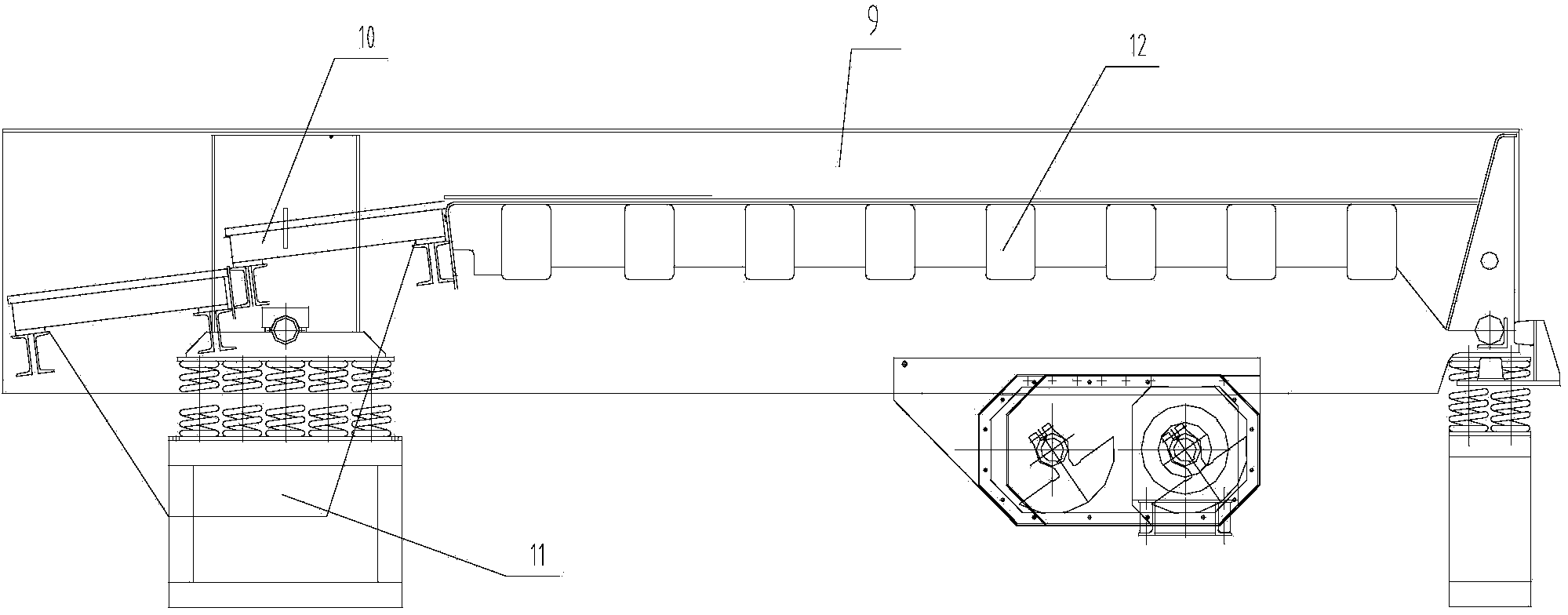

Rod screening and feeding machine

InactiveCN104070007AGreat exciting forceEasy to handleSievingScreeningElectric machineControl system

The invention discloses a rod screening and feeding machine which comprises a feeding machine tank composed of a feeding tank (9), a bar section (10) and a fine screen (11). The feeding machine tank is provided with an excitation system. The excitation system is a double-shaft excitation device. The excitation system is arranged on the lower portion of the feeding machine tank. According to the structure of the double-shaft excitation device, a control system of a motor (1) is connected with a frequency converter (2), a main shaft of the motor (1) is connected with a main eccentric shaft (5) through a flexible coupler (3), and the main eccentric shaft (5) is connected with an auxiliary eccentric shaft (7) through a gear (6) in a transmission mode. The rod screening and feeding machine is large in excitation force and high in processing ability, and the feeding quantity can be convenient to adjust.

Owner:HUNAN ZHAOSHENG MINING MACHINERY

Large-span vibrator

InactiveCN101428277ASimple structureEasy to manufacture and installSievingScreeningCouplingDrive shaft

The invention relates to a large-span vibrating screen exciter for sludge water treatment, slurry treatment and material screening and conveying. The large-span vibrating screen exciter comprises a motor and a vibrating screen, wherein the motor adopts a shock-proof motor, the two ends of the shock-proof motor are connected with a universal transmission shaft through a coupling, the universal transmission shaft is connected with at least two eccentric mass blocks through the coupling, and the eccentric mass blocks are supported on a motor base through a bearing and a bearing support; and the entire exciter is connected to be a whole through an extension cylinder component connected at the two ends of the casing of the shock proof motor. The shock-proof motor can be a flame-proof or non-flame-proof shock-proof motor. The invention effectively realizes the improvement on the force-mass ratio and the large span of the excitation system. The invention has the advantages of simple structure, convenient manufacturing and assembly, long service life and low cost. Compared with the prior special long-shaped large-span exciting motor, the cost performance of the invention is improved greatly, and the limitation that the prior long-shaped large-span exciting motor can not be enlarged further is broke through.

Owner:四川鑫源丰机电有限公司

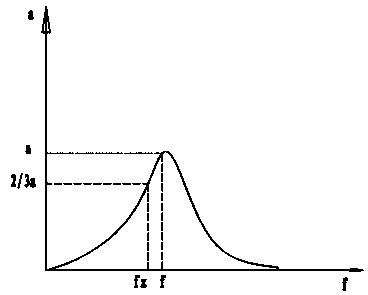

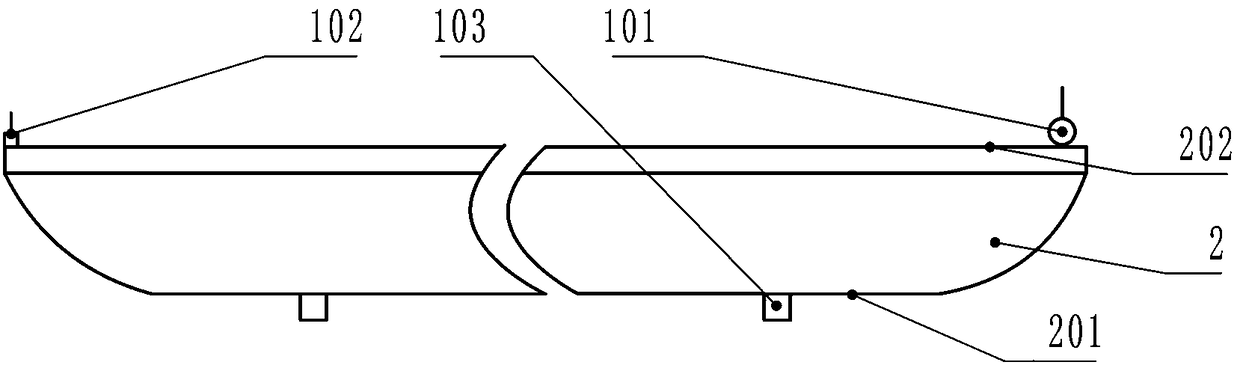

Bridge pier VSR (vibration stress relief) method for steel structural bridge

ActiveCN108130414AVibration aging treatment time is smallNo damage to surface qualityStress reliefMultiple resonance

The invention discloses a bridge pier VSR (vibration stress relief) method for a steel structural bridge and relates to the technical field of stress relief treatment of steel structure parts. A bridge pier of the steel structural bridge is a high-rigidity and heavy large structural part, and stress relief treatment is difficult to perform with existing thermal stress relief, natural stress relief, ultrasonic impact stress relief and VSR methods. According to the method, the bridge pier is supported by a support pad, multiple sets of VSR equipment are used, multiple vibration exciters are adjacently fixed on a lower frame beam of the bridge pier, multiple vibration testers are adjacently fixed on an upper frame beam of the bridge pier, then, multiple vibration exciters are controlled by use of multiple controllers, co-frequency sub-resonance vibration is performed on multiple resonance peaks of the bridge pier for several hours, the purpose of effectively relieving the residual stressis achieved, the average relief rate of the residual stress reaches 43%, the problem of difficulty in relieving the residual stress of the bridge pier is solved, and the method can be applied to steelstructural bridges.

Owner:NANNING SHENHUA VSR TECH RES INST +1

Shot blasting deruster

InactiveCN109500746AEasy to adjust the positionEasy to useLighting elementsAbrasive feedersEngineeringElectric control

The invention provides a shot blasting deruster, which comprises a deruster body. The deruster body comprises a derusting bin, a spraying bin, a shot blasting device, spraying equipment and an electric control box; the derusting bin comprises a workpiece fixing device and a screening device, and the screening device comprises a first filtering screen, a second filtering screen, a collecting bin, asecond motor and a second connecting rod; the spraying bin comprises a spraying bin body and a waste liquid recovering bin; the shot blasting device comprises a shot blasting equipment main body anda dedusting device, and the dedusting device comprises a dedusting pipe, an exhaust fan and a dedusting box; and the spraying equipment comprises a liquid storage box, a water pump, a liquid feeding box, a liquid discharging pipe and a spray head, and the liquid storage box comprises a box body, a liquid injecting hole, a second sensor and an LED lamp. The function of automatic shot conveying is achieved, shot is dedusted, the undamaged shot can be recycled, finally a workpiece is sprayed with an anti-rusting agent, and the shot blasting deruster is simple in structure, complete in function and high in automation degree.

Owner:王大旗

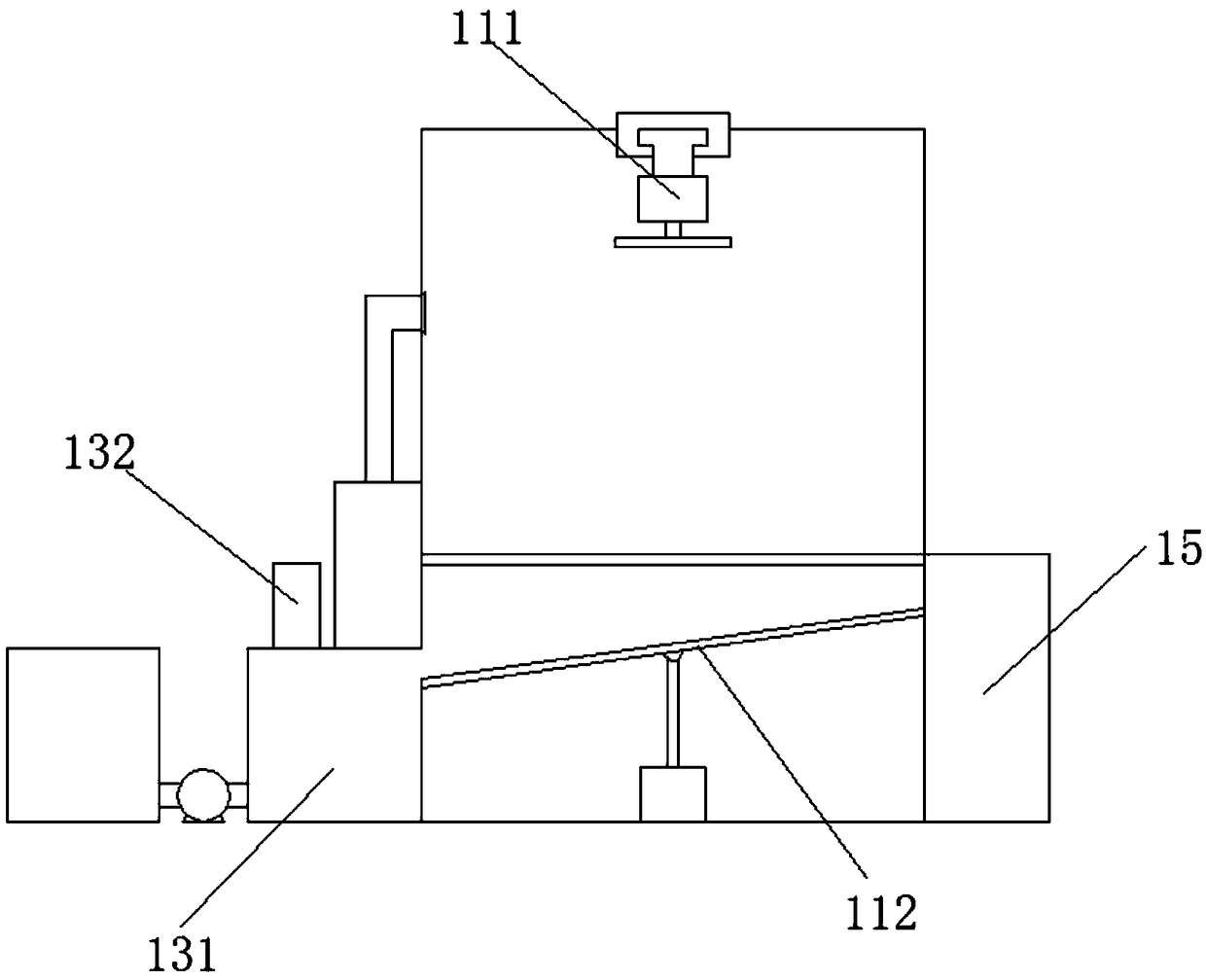

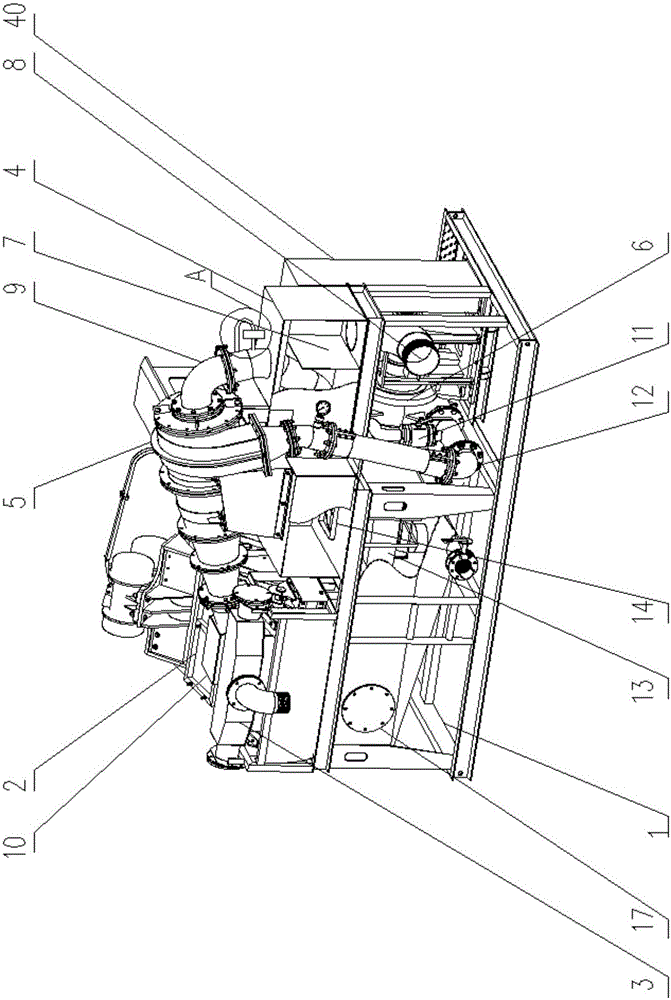

Automatic mud desanding and purification equipment

InactiveCN105920913AIncrease speedReduce speedWater treatment parameter controlSludge treatment by de-watering/drying/thickeningArchitectural engineeringSolid content

The invention provides automatic mud desanding and purification equipment. The automatic mud desanding and purification equipment comprises a rack (1). A feed port (3) is fixed to the rack (1). A vibrating coarse screen plate (22) is fixed to the lower end of the feed port (3). A mud storage tank (17) is fixed to the lower end of the coarse screen plate (22). The mud storage tank (17) is communicated with a suction opening of a mud residue pump (6). A discharge port of the mud residue pump (6) is communicated with a feed port of a swirler (5) fixed to the rack (1), a vibrating fine screen plate (23) is fixed to the lower end of a bottom flow opening (10) in one end of the lower portion of the swirler (5), the vibrating fine screen plate (23) is located at the upper end of the mud storage tank (17) and located above the vibrating coarse screen plate (22), and the equipment is provided with a mud concentration online detection and control device. The solid content of mud can be automatically controlled in real time, and the stability and quality of the mud are improved.

Owner:徐州汉晨机械制造有限公司

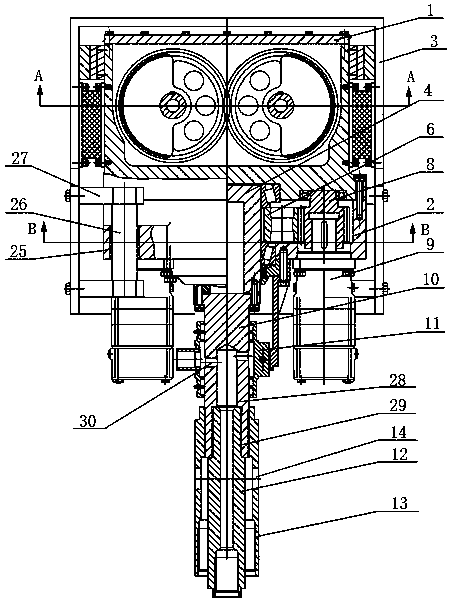

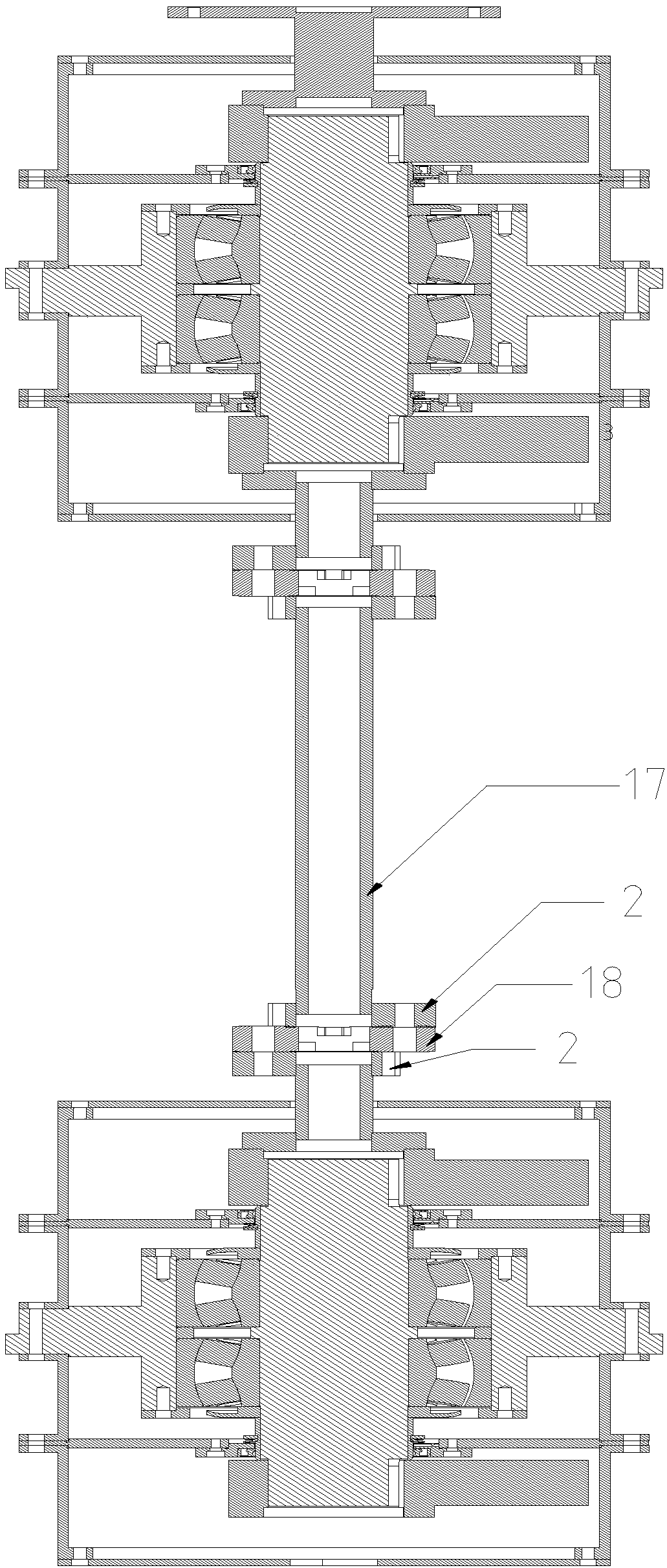

Vibrating type power head device

The invention discloses a vibrating type power head device which includes a vibration assembly and an external box which is arranged outside of the vibration assembly; a guiding mechanism is arrangedbetween the vibration assembly and the external box; the vibration assembly includes a vibration box and a gear box, the front end of the gear box is connected to a drill tool by the output joint, andthe rear end is detachably connected to the vibration box. The vibration box directly drives the gear box and the spindle to vibrate together; the vibration box and the gear box are fixedly connected, ; thus driving the drill tool to vibrate and rotary drilling simultaneously; the damage of the main axle can effectively reduced when the vibration is vibrated, so that the transmission line of thevibration is more reasonable. Moreover, the vibration box and the gear box can ensure that the vibration assembly only take the axial vibration displacement in the axial direction, but restrict the unreasonable vibration in other directions by the guiding mechanism, so that the generate and transmit of the excitation force is stable and reliable, the impact direction is consistent, and the workingefficiency of drilling is improved.

Owner:无锡市安曼工程机械有限公司

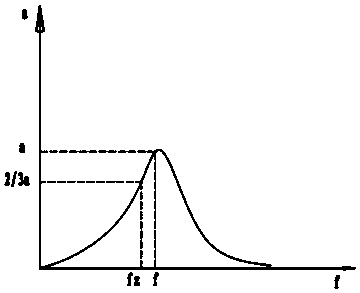

Vibration generator

InactiveCN104704338AReduce power consumptionInhibit speedMechanical vibrations separationCooling/ventillation arrangementDriving currentPower flow

[Problem] To provide a vibration generator that reduces power consumption for an entire vibration testing device and is not damaged even when intensifying the vibrating force or increasing the size of the vibration generator. [Solution] A vibration generator comprises a moving portion on which a test body is placed and a stationary portion having a magnetic circuit member, said magnetic circuit member having a magnet and a magnetic permeable yoke and being disposed so that a static magnetic field is formed in a cavity of the magnetic circuit member, and said moving portion having a driving coil and being disposed in a state where the driving coil is inserted in the cavity, and is configured so that a desired vibration is applied to the moving portion by applying a driving current to the driving coil. The vibration generator further comprises a cooling blower for cooling at least either of the magnet and the driving coil, a control device for controlling the rotational speed of the cooling blower, and a temperature measuring means for measuring the temperature of at least either of the magnet and the driving coil, and is configured so that the control device controls the rotational speed of the cooling blower on the basis of the temperature of at least either the magnet or the driving coil that was measured by the temperature measuring means.

Owner:EMIC LTDA

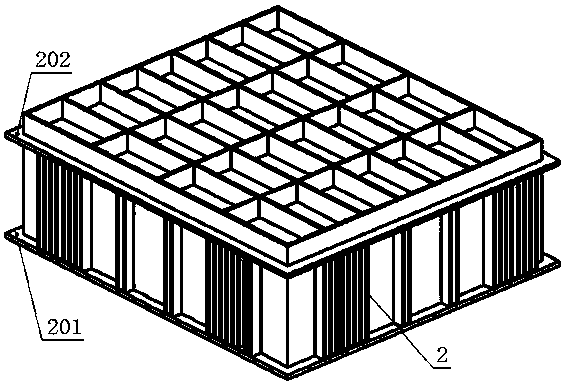

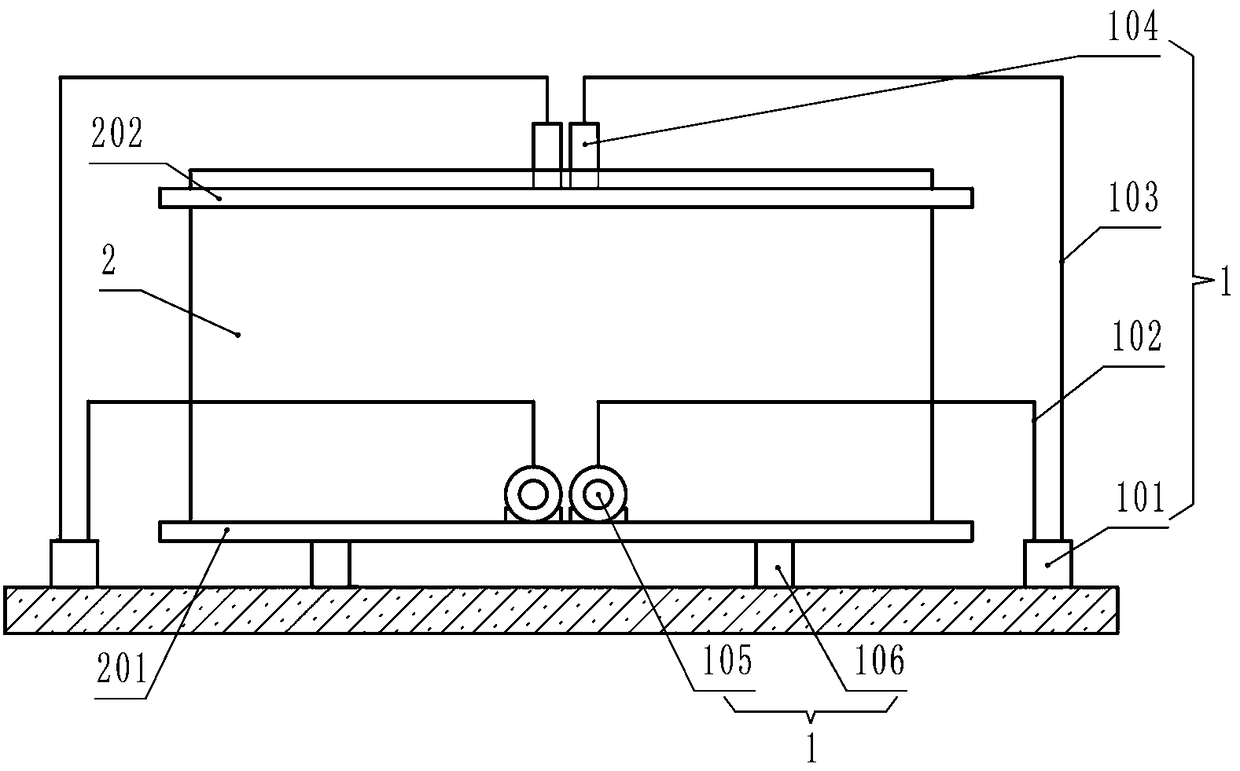

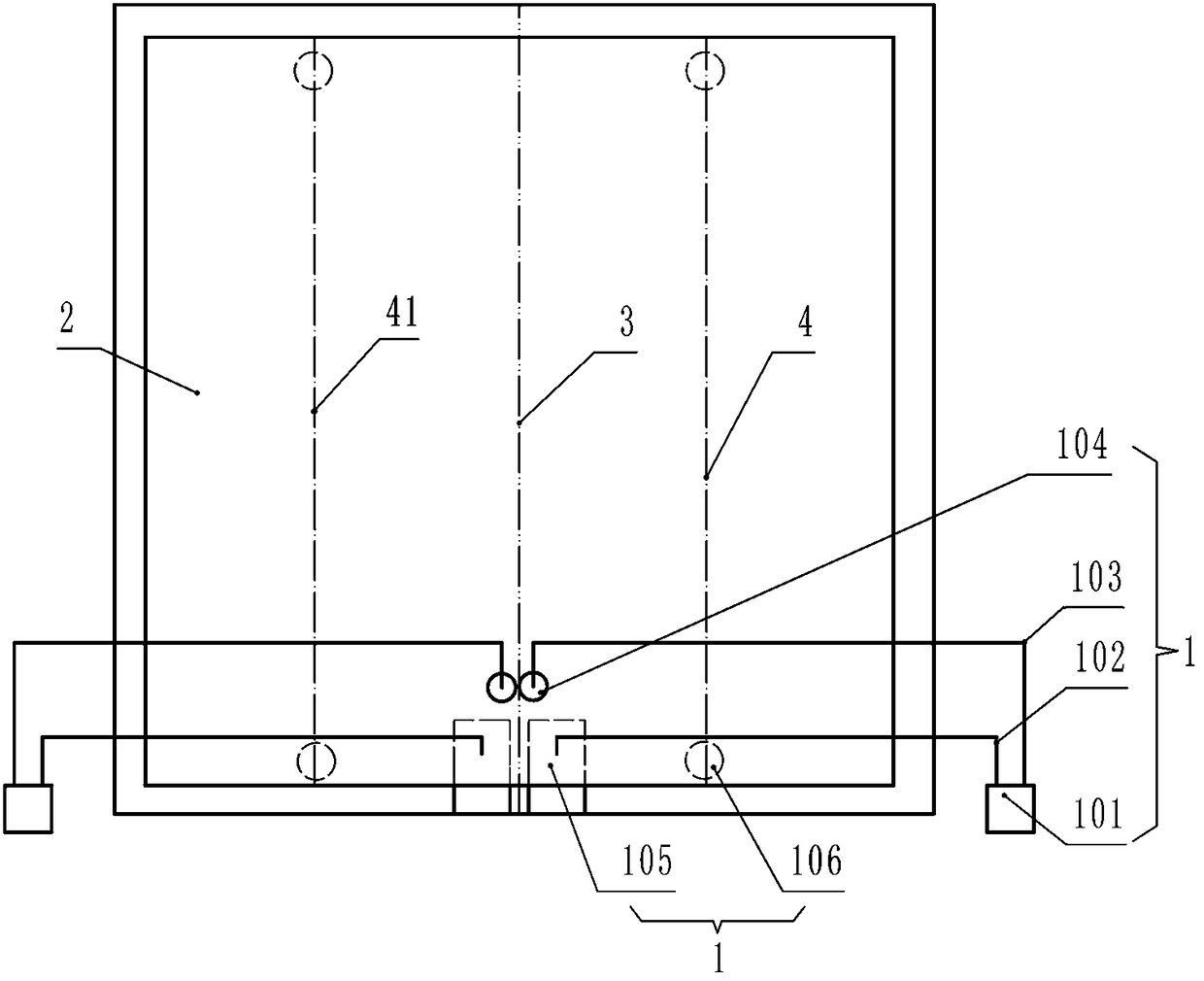

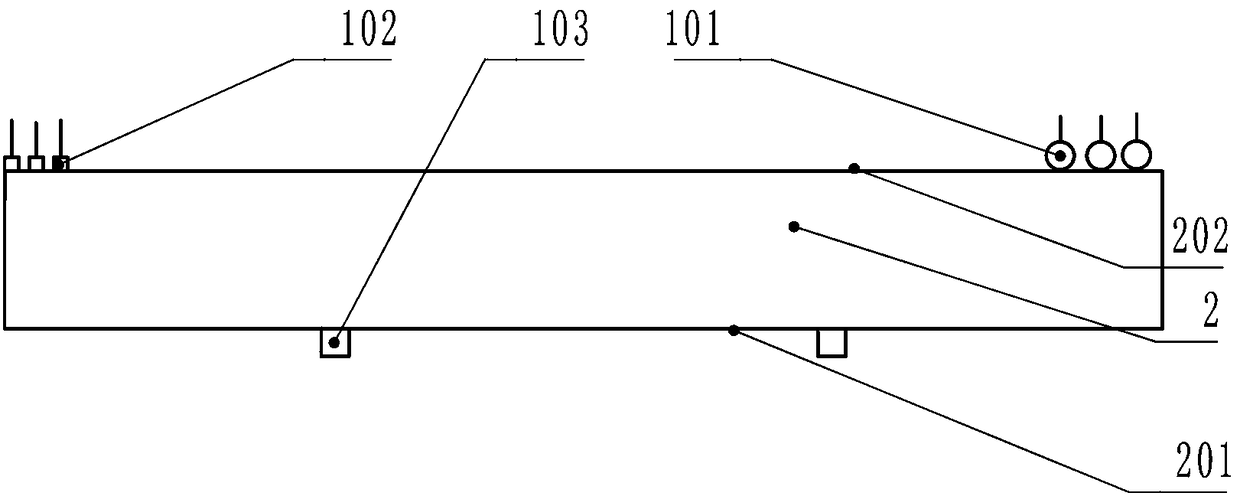

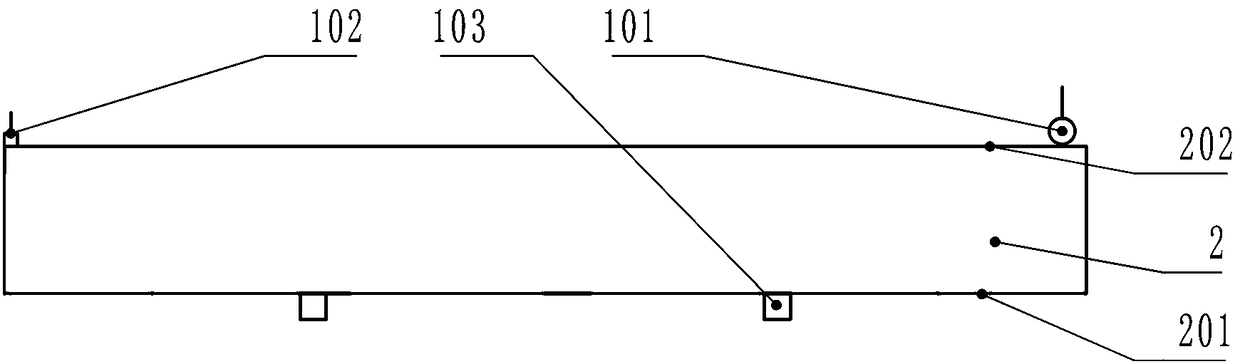

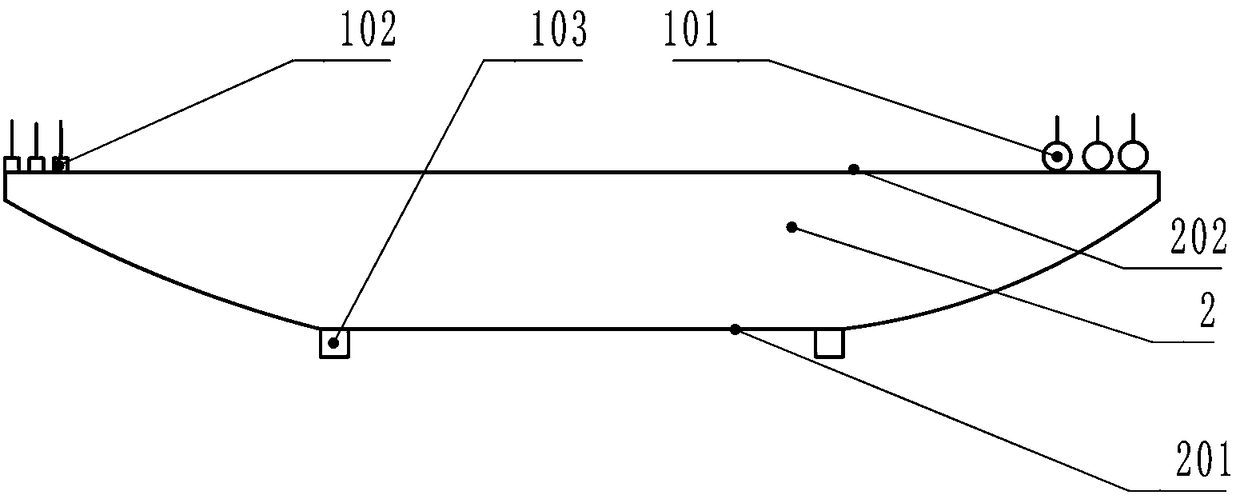

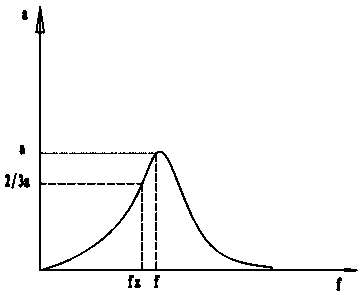

Vibration aging method for marine drilling platform

ActiveCN108285970AEfficient vibration aging treatmentVibration aging treatment energy saving and environmental protectionAge methodStress relief

The invention discloses a vibration aging method for a marine drilling platform, and relates to the technical field of stress relief treatment for steel structural parts. The marine drilling platformis a large welded structural part, and it is difficult for existing thermal aging and vibration aging methods to perform aging treatment on the marine drilling platform. According to the vibration aging method for the marine drilling platform, a plurality of vibration exciters are adjacently fixed to the marine drilling platform, then the vibration exciters are started and controlled and have thesame subresonant frequency in the marine drilling platform, at the same time, the same frequency subresonance vibration is carried out to effectively eliminate residual stress, and the average elimination ratio of the residual stress can reach 44.5%, so that the technical problem that the residual stress is difficult to eliminate by the marine drilling platform is solved; and the vibration agingmethod for the marine drilling platform can be used in marine drilling platform manufacturing industries.

Owner:NANNING SHENHUA VSR TECH RES INST +1

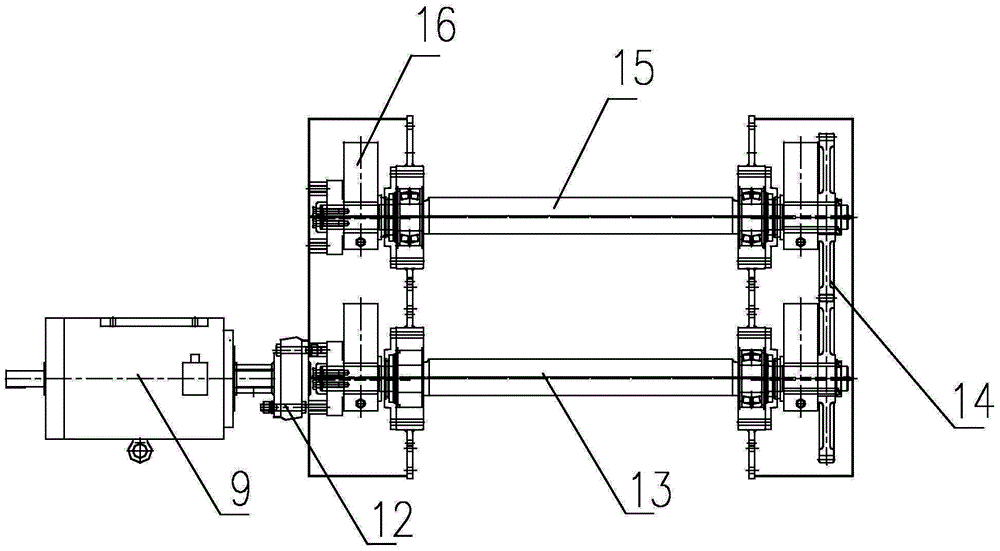

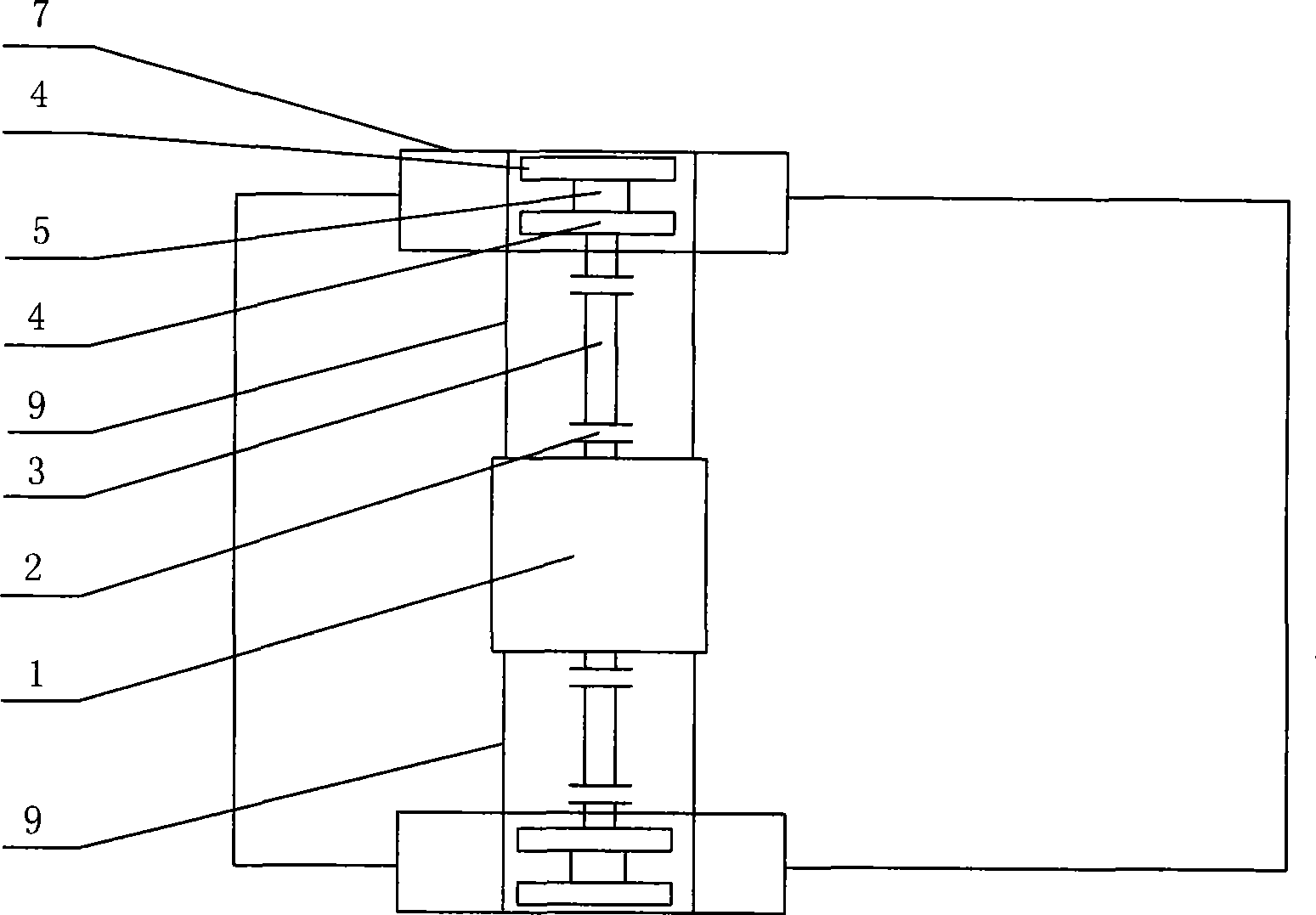

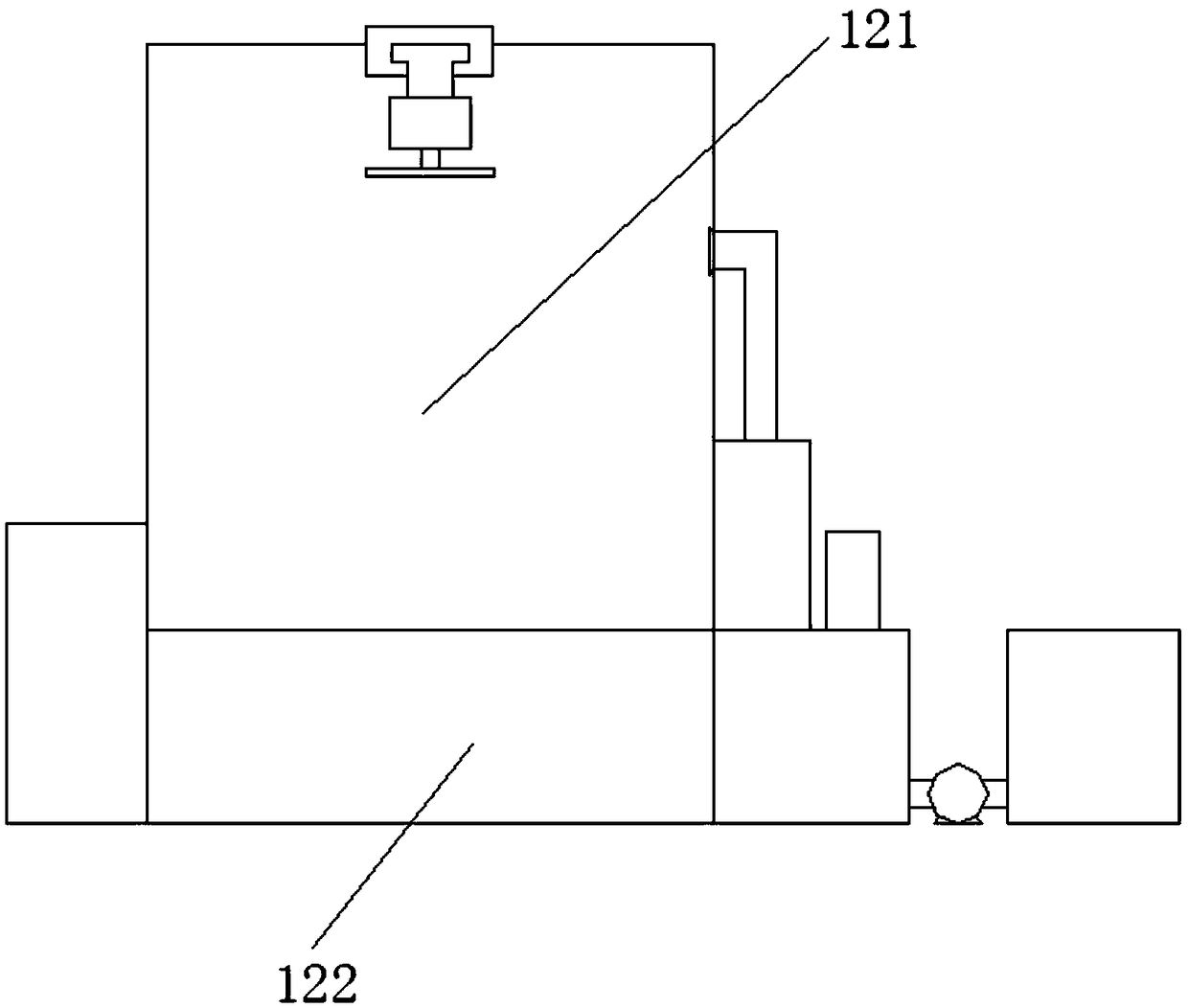

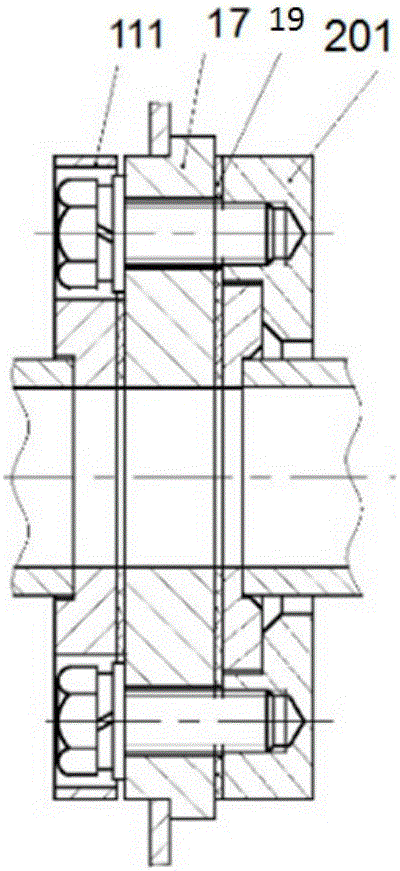

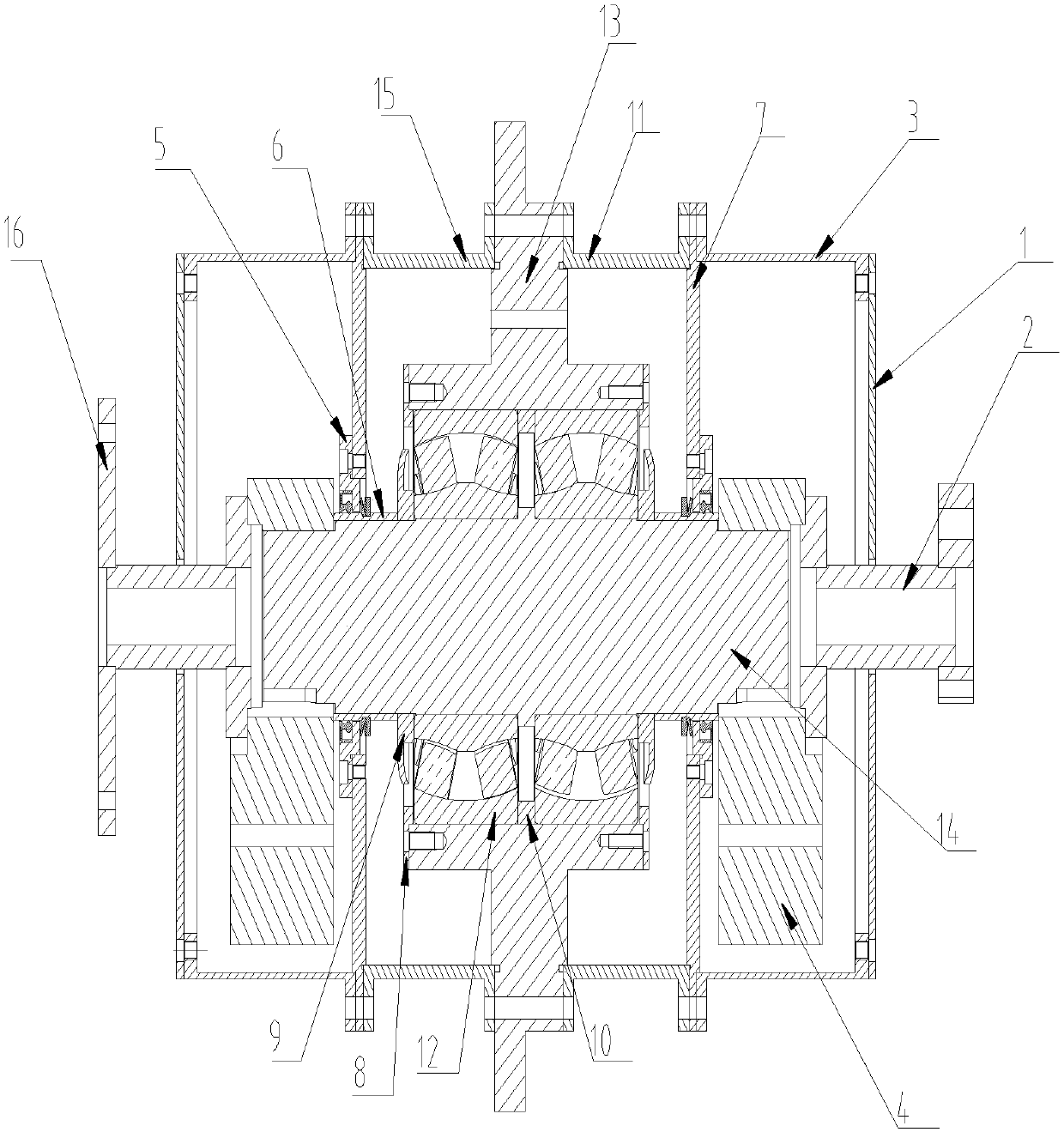

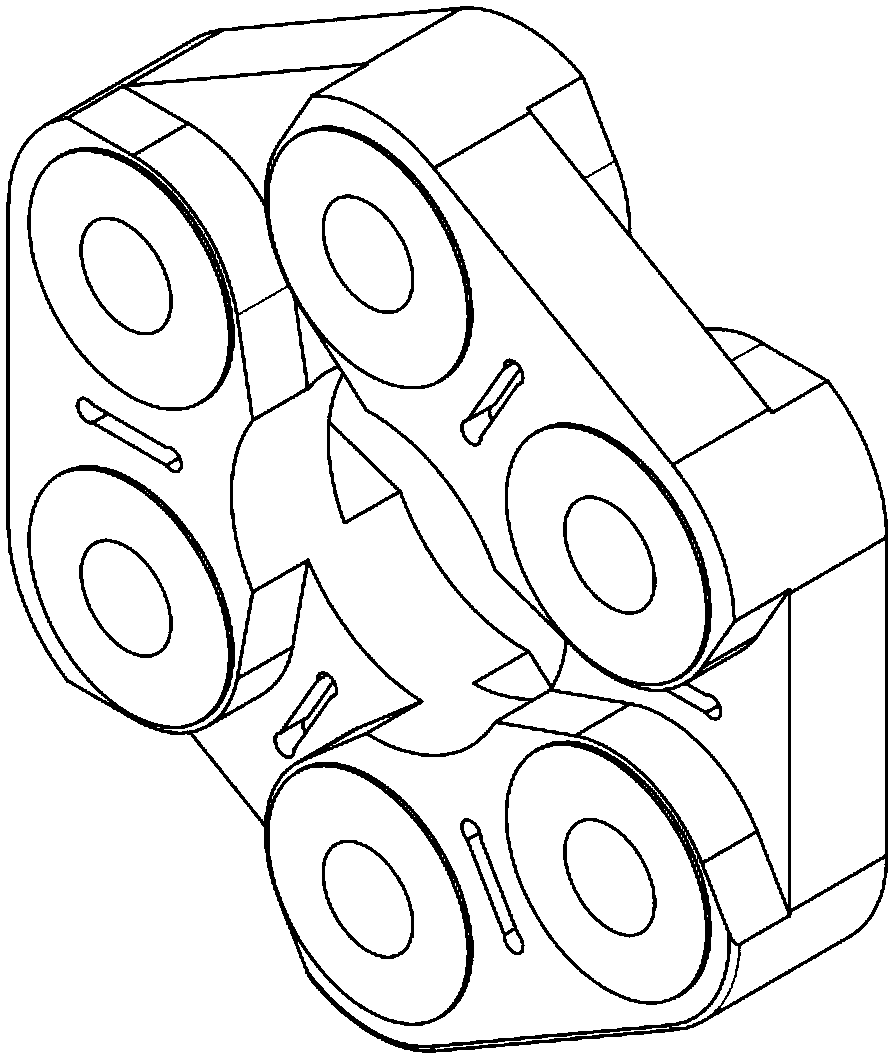

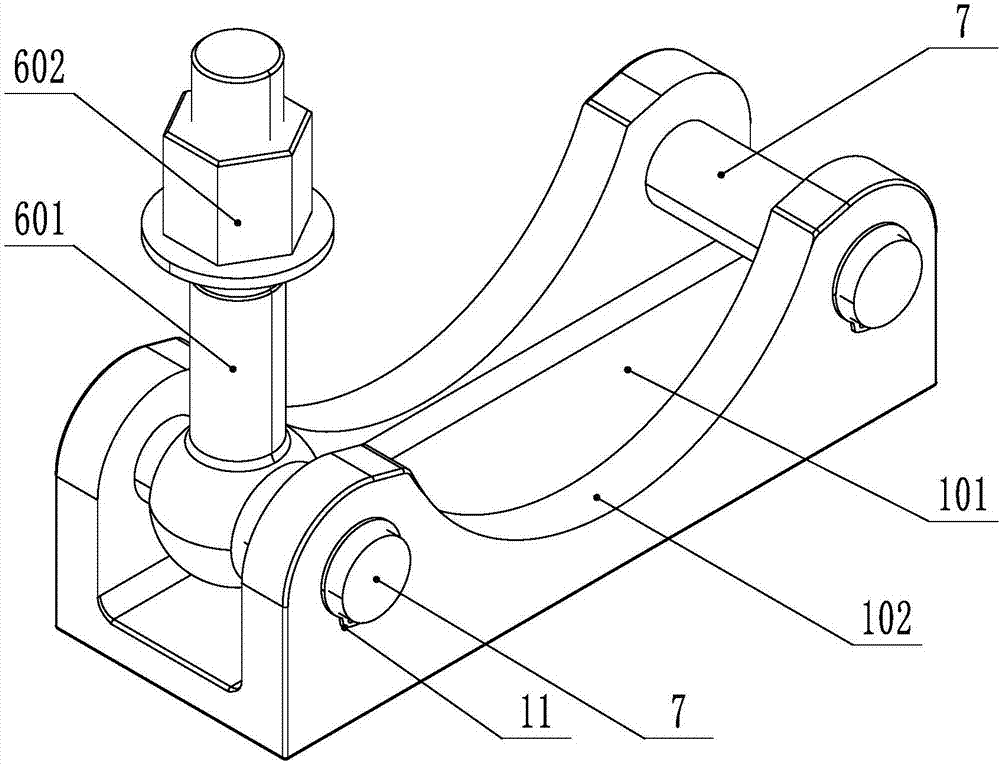

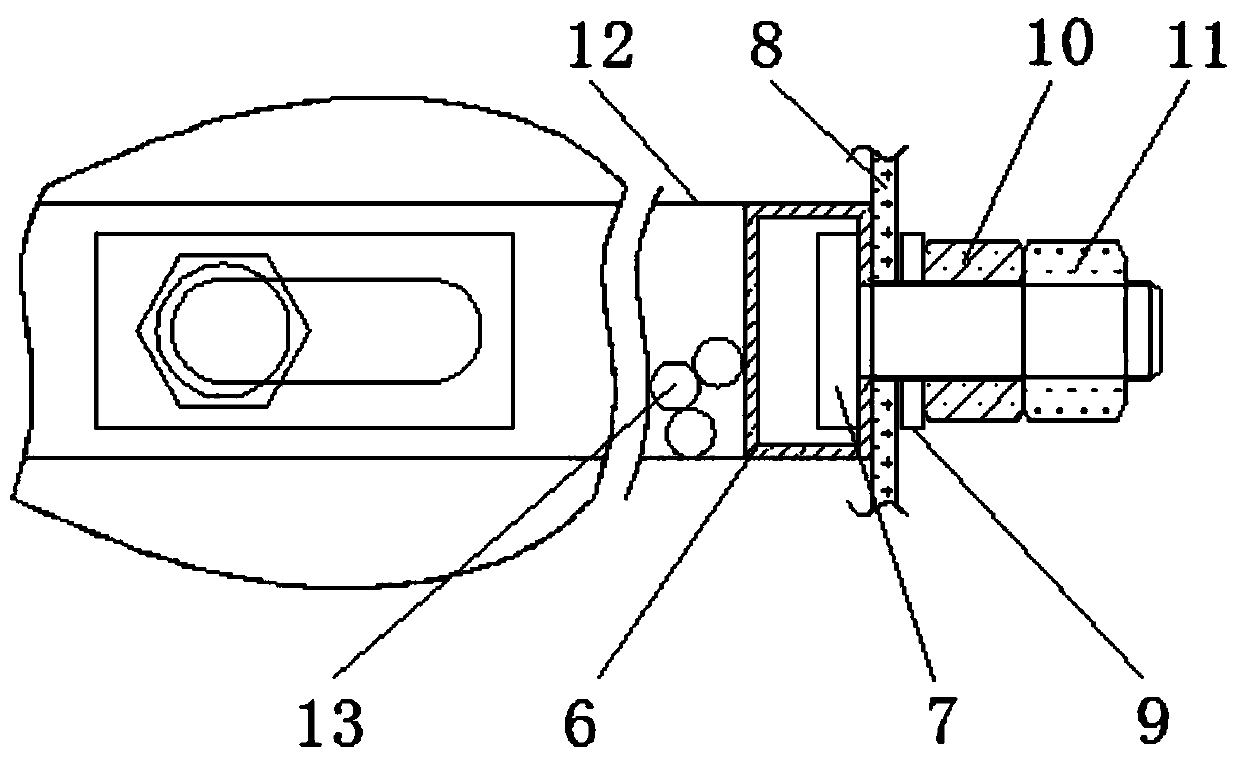

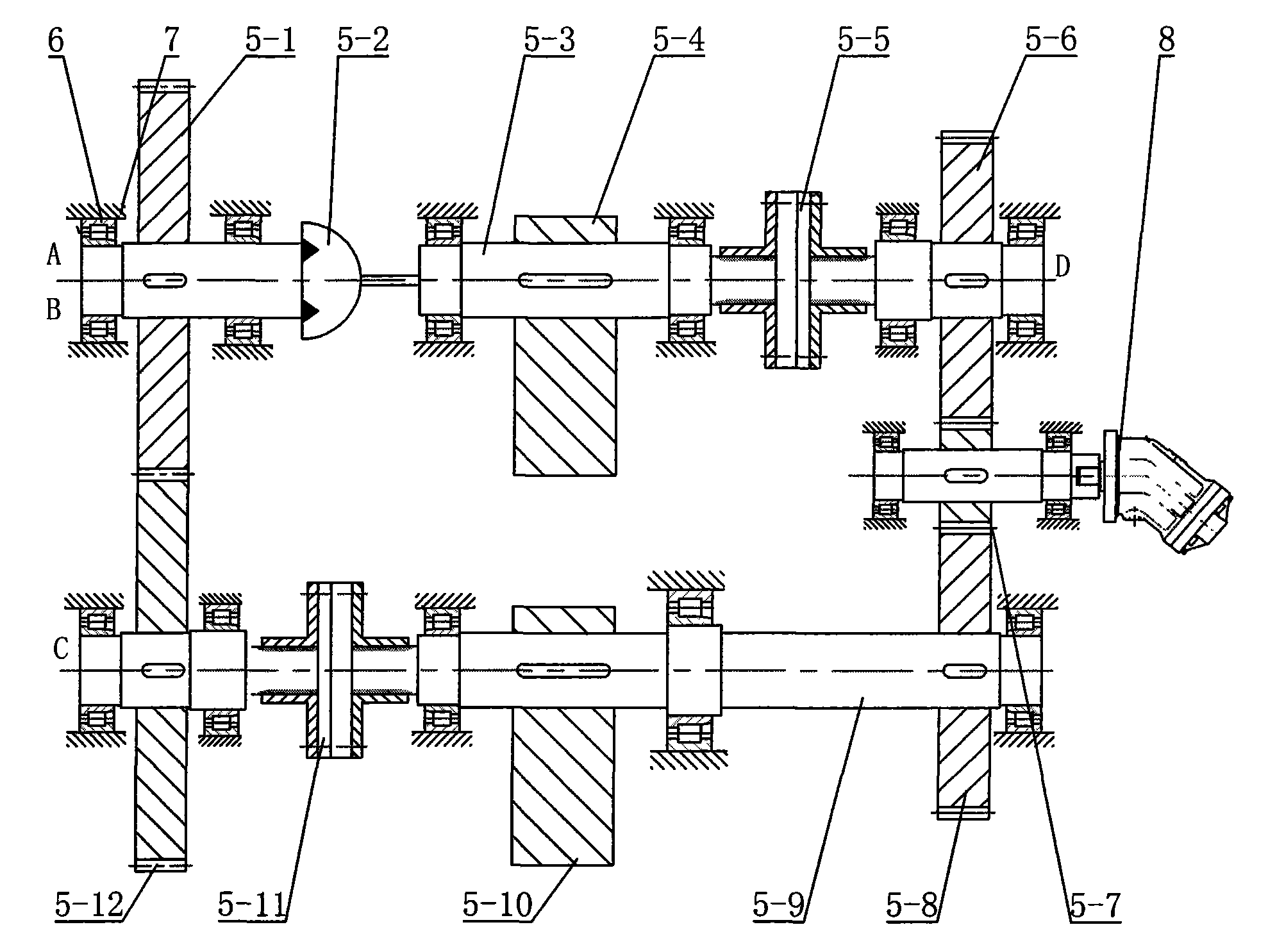

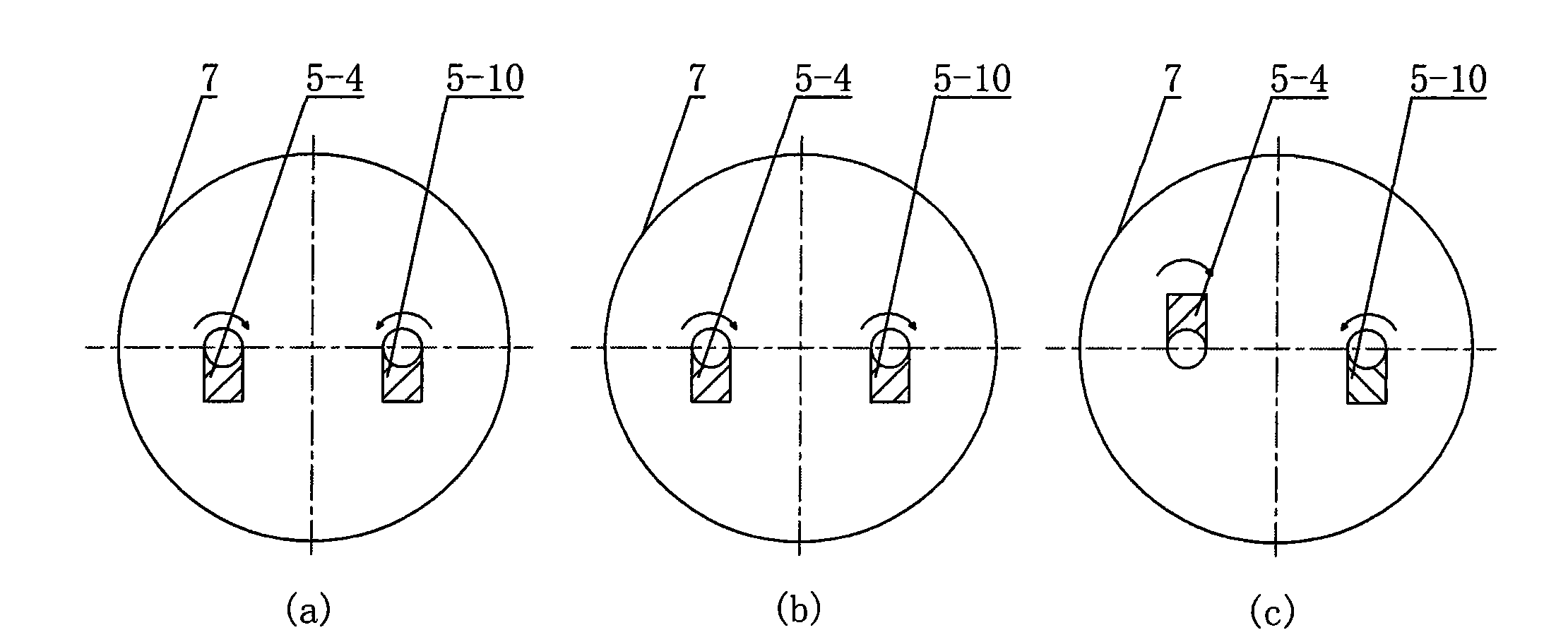

A vibration exciter assembly structure and vibrating screen

ActiveCN106166539BIncrease the exciting forceMeet actual production requirementsSievingScreeningVibration exciterAssembly structure

The invention provides a vibration exciter assembly structure and a vibration screen. The vibration exciter assembly structure comprises a power device and further comprises an external coupler, a spindle unit and a bearing structure. The external coupler is connected with the power device and the spindle unit. The bearing structure comprises two bearing sets which are symmetrically fixed to the two ends of the spindle unit respectively. Each bearing set comprises a bearing pedestal and two bearing pieces, wherein the two bearing pieces are installed in the bearing pedestal and connected to the spindle unit in a sleeving mode, and a balance weight is arranged on one side of each bearing piece and fixedly arranged on the spindle unit. The vibration screen comprises at least one vibration exciter assembly structure. The spindle unit can be provided with the two bearing sets. In each bearing set, the balance weights can be installed on one sides of the two bearing pieces, and the exciting force of the vibration exciter can be effectively improved. By means of the synchronizing wheel structure, the vibration screen can be provided with two or more vibration exciter assembly structures to further improve the exciting force, and the actual production requirement is met.

Owner:GUANGZHOU HUABAO MINING MACHINERY CO LTD +1

Novel rapid mounting pneumatic vibrator

PendingCN108000678AEasy to installEasy to operateCeramic shaping apparatusMechanical vibrations separationEngineeringSlide plate

The invention discloses a novel rapid mounting pneumatic vibrator, and relates to the field of pneumatic vibrators. At present, most pneumatic vibrators are trouble to mount, large in gas consumptionamount, small in exciting force, short in service life, easy to damage and the like. The pneumatic vibrator comprises a base, a machine base, a front end cover, a rear end cover, a middle shaft, an eccentric rotating inner casing pipe and an eccentric rotating outer casing pipe; an air chamber and a sliding groove are formed in the center and the outer side of the middle shaft, the side, located on the front end cover, of the middle shaft is provided with a connection port for connecting the air chamber and an air source, a side air outlet is formed in the air chamber and leads to the slidinggroove, a sliding plate capable of closing and opening the air outlet of the air chamber is arranged in the sliding groove, a rapid mounting structure is arranged between the machine base and the baseand can be detachably connected, the rapid mounting structure comprises a rapid positioning structure and a bolt type rapid fixing mechanism capable of turning over, and the bolt type rapid fixing mechanism can be rotatably connected to the base. According to the pneumatic vibrator, the gas consumption amount can be effectively reduced, the exciting force is improved, and starting and exhaust effect of the vibrator can be better ensured.

Owner:WOLONG ELECTRIC GRP CO LTD +1

Efficient carbon raw material screening linear sieve

The invention discloses an efficient carbon raw material screening linear sieve. A support is included. A vibration motor is fixed in the support. The output end of the vibration motor is connected with a sieve box. Fixing blocks are fixed to the top end of the support. A sieve frame is arranged in the sieve box. T-shaped bolts are fixed in the sieve frame. Side plates are connected to the right sides of the T-shaped bolts. The right sides of the side plates are provided with seal pads. Seal plates are connected to the right sides of the seal pads. A first screen is arranged below the sieve frame, and a second screen is arranged below the first screen. A feeding port is formed in the top end of the sieve box, and a sieve cover is arranged above the sieve frame. According to the efficient carbon raw material screening linear sieve, rapid screen replacement is convenient, various screens are allowed to be used, a screening machine is convenient to operate, the screening area is large, benefits are high, the service life of the screens is long, usage of fine net consumables is reduced, and cost is reduced.

Owner:DATONG YULINDE CARBON MATERIALS TECH

An Accurate and Controllable Non-contact Specimen Rotating Magnetic Field Fatigue Excitation and Vibration Measurement Device

ActiveCN105910780BWide range of applicable objectsImprove integrityVibration testingVibration accelerationDynamic balance

The invention provides an accurate controllable non-contact test piece rotary magnetic field fatigue excitation and vibration test device. The device comprises a vibration damping insulation clamp, a vibration damper, a dynamic balance device, a vibration exciter, an electromagnetic piezoelectric coupling vibration sensor, a test station, a transmission device and an accurate control device. The excitation and vibration test device is suitable for rotary test pieces and especially suitable for vibration characteristic researches on a wind power blade, an engine, a turbine blade, a helicopter rotor and a tail rotor blade, the excitation and vibration test device can vividly simulate vibration fatigue states of rotary test pieces respectively under conditions of 360-DEG all directions, same rotating speed and different excitation forces, same excitation force and different rotating speeds, and different rotating speeds and different excitation forces, the excitation and vibration test device can monitor related vibration characteristic parameters such as the excitation force, the vibration displacement, the vibration speed and the vibration acceleration continuously, and the excitation and vibration test device is suitable for vibration fatigue characteristic analysis on stationary test pieces.

Owner:CHONGQING UNIV

Aging Method of Pier Vibration for Steel Structure Bridges

ActiveCN108130414BVibration aging treatment time is smallNo damage to surface qualityAge methodStress relief

Owner:NANNING SHENHUA VSR TECH RES INST +1

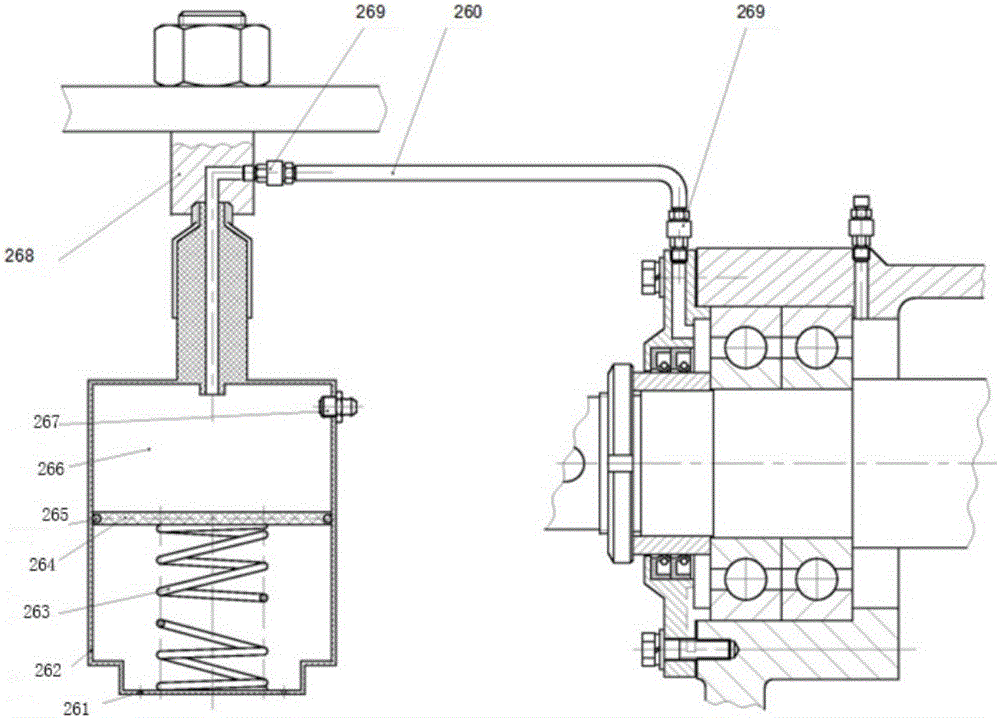

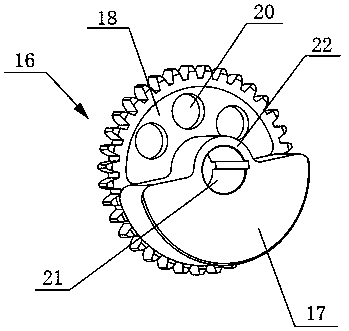

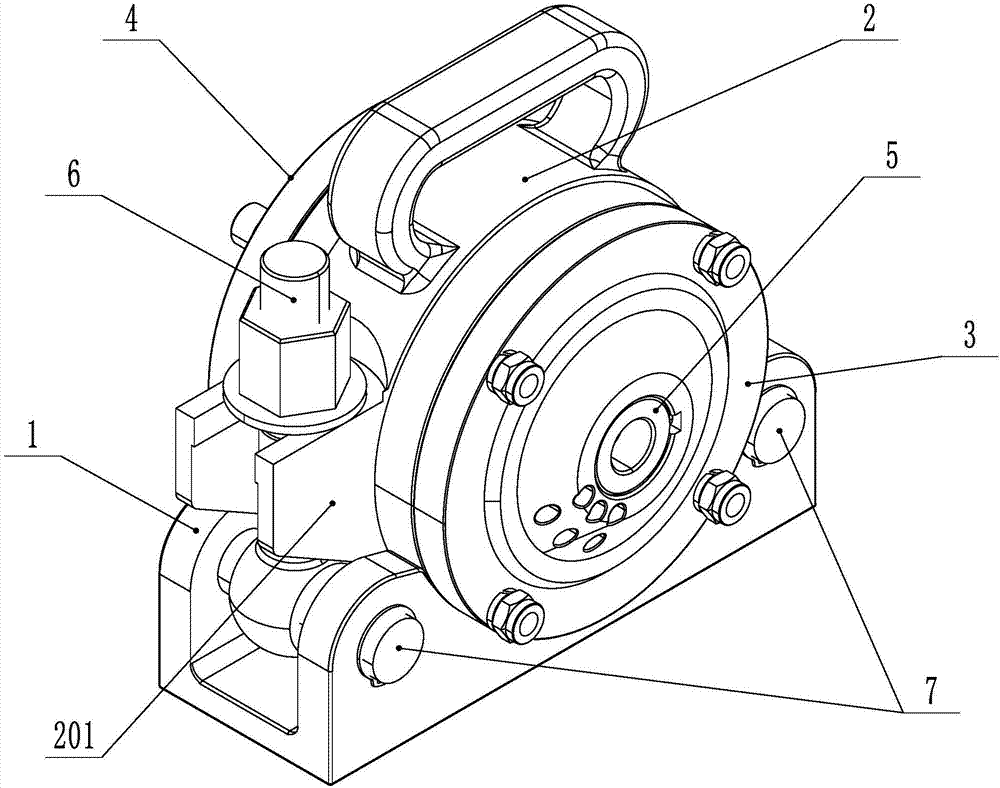

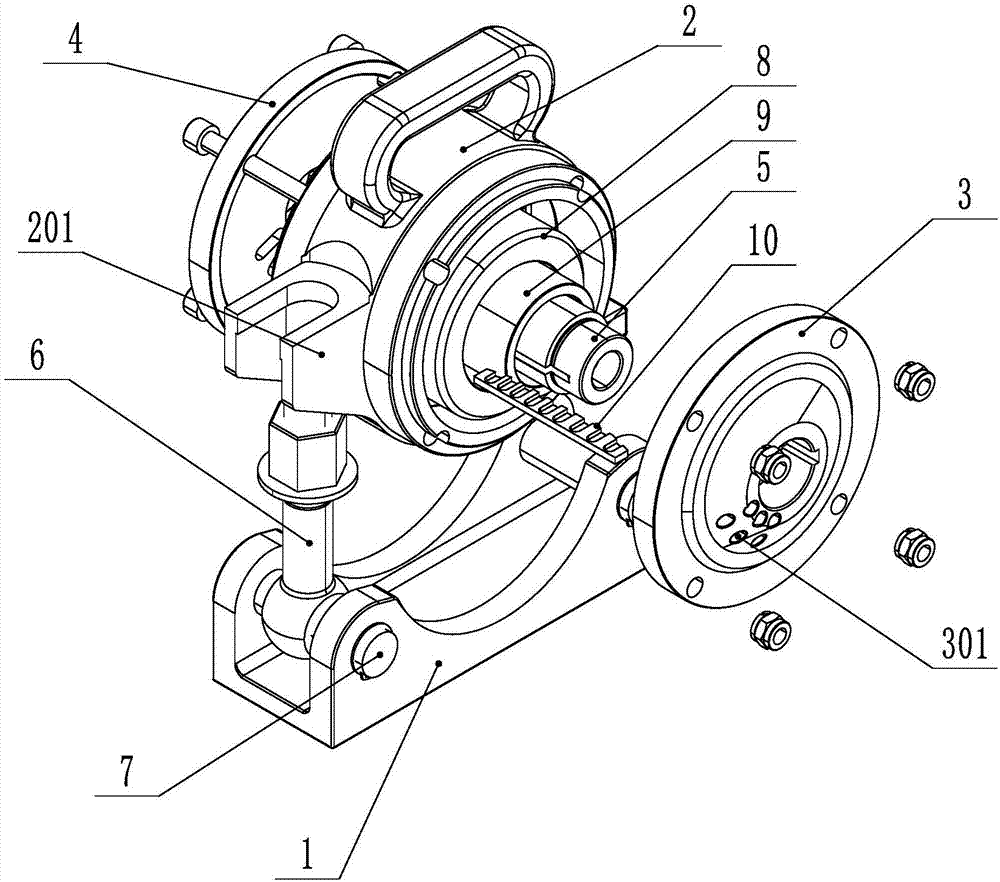

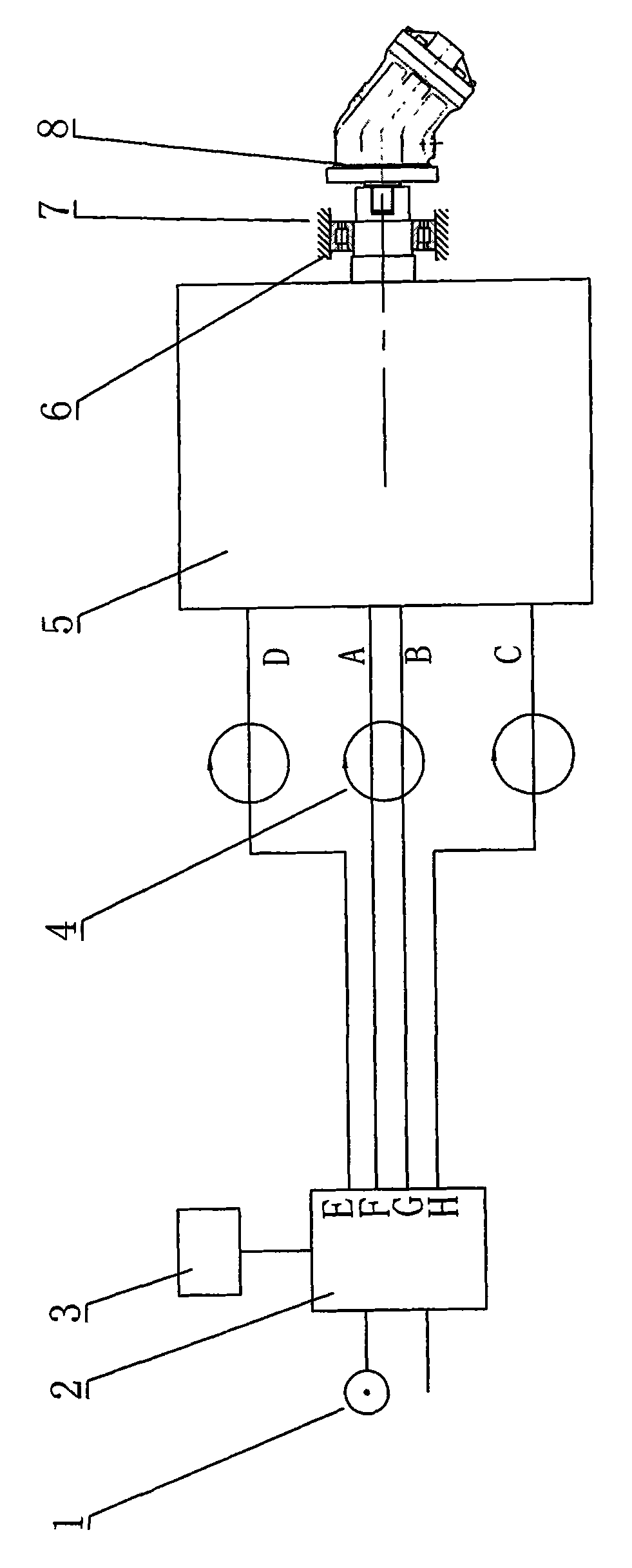

Adjustable multifunctional excitation device of vibratory roller

ActiveCN101634131BIncrease the exciting forceImprove efficiencyRoads maintainenceHydraulic motorGear wheel

The invention provides an adjustable multifunctional excitation device of a vibratory roller, which comprises a controller used for controlling the entire vibratory roller, wherein the controller is connected with a valve via conductors; the valve is communicated with a vibration exciter via a rotary connector and a hydraulic lock; the vibration exciter is characterized in that a main driving gear engaged with a primary forward gear and a secondary forward gear is arranged on the output shaft of a hydraulic motor; a primary driving shaft is arranged on the primary forward gear; a primary clutch and at least one primary eccentric block are arranged on the primary driving shaft; a gear shaft of a primary reverse gear is connected with a rotary oil cylinder; the oil port ends A and B of the rotary oil cylinder are communicated with the two corresponding oil port ends F and G of the valve via the rotary connector; the output shaft of the rotary oil cylinder is connected with the primary driving shaft; a secondary driving shaft is arranged on the secondary forward gear; a secondary clutch and at least one secondary eccentric block identical with the primary eccentric block are arrangedon the secondary driving shaft; and a secondary reverse gear engaged with the primary reverse gear is arranged at the other end of the secondary driving shaft.

Owner:CHANGAN UNIV

Hull Vibration Aging Method

ActiveCN108118140BEfficient vibration aging treatmentSolve quality problemsProcess efficiency improvementThermal ageingAge method

The invention discloses a vibration ageing method for a ship body, and relates to the technical field of stress-removal treatment of steel structural parts. The ship body is a large welding structuralpart, and an existing thermal-ageing and vibration-ageing method is difficult to perform ageing treatment on the ship body. The vibration ageing method is characterized in that a plurality of vibration exciters are fixedly arranged on the ship body in an adjacent mode, and then are started and controlled; and same-frequency sub-resonance vibration is performed while the ship body has same sub-resonance frequency, so that the purpose of effectively eliminating residual stress is achieved with an average residual stress eliminating rate of 47.5%, and therefore, the technical problem that residual stress of the ship body is difficult to eliminate is solved, and the vibration ageing method can be applied in the ship-making industry.

Owner:NANNING SHENHUA VSR TECH RES INST +1

Vibration ageing method for ship body

ActiveCN108118140AEfficient vibration aging treatmentSolve quality problemsProcess efficiency improvementThermal ageingAge method

The invention discloses a vibration ageing method for a ship body, and relates to the technical field of stress-removal treatment of steel structural parts. The ship body is a large welding structuralpart, and an existing thermal-ageing and vibration-ageing method is difficult to perform ageing treatment on the ship body. The vibration ageing method is characterized in that a plurality of vibration exciters are fixedly arranged on the ship body in an adjacent mode, and then are started and controlled; and same-frequency sub-resonance vibration is performed while the ship body has same sub-resonance frequency, so that the purpose of effectively eliminating residual stress is achieved with an average residual stress eliminating rate of 47.5%, and therefore, the technical problem that residual stress of the ship body is difficult to eliminate is solved, and the vibration ageing method can be applied in the ship-making industry.

Owner:NANNING SHENHUA VSR TECH RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com