Rod screening and feeding machine

A bar screen and feeder technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of unsupported material column pressure, poor pressure bearing capacity, inconvenient adjustment of feeding amount, etc., and achieve reduction The effect of crushing cost, large pressure bearing capacity and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

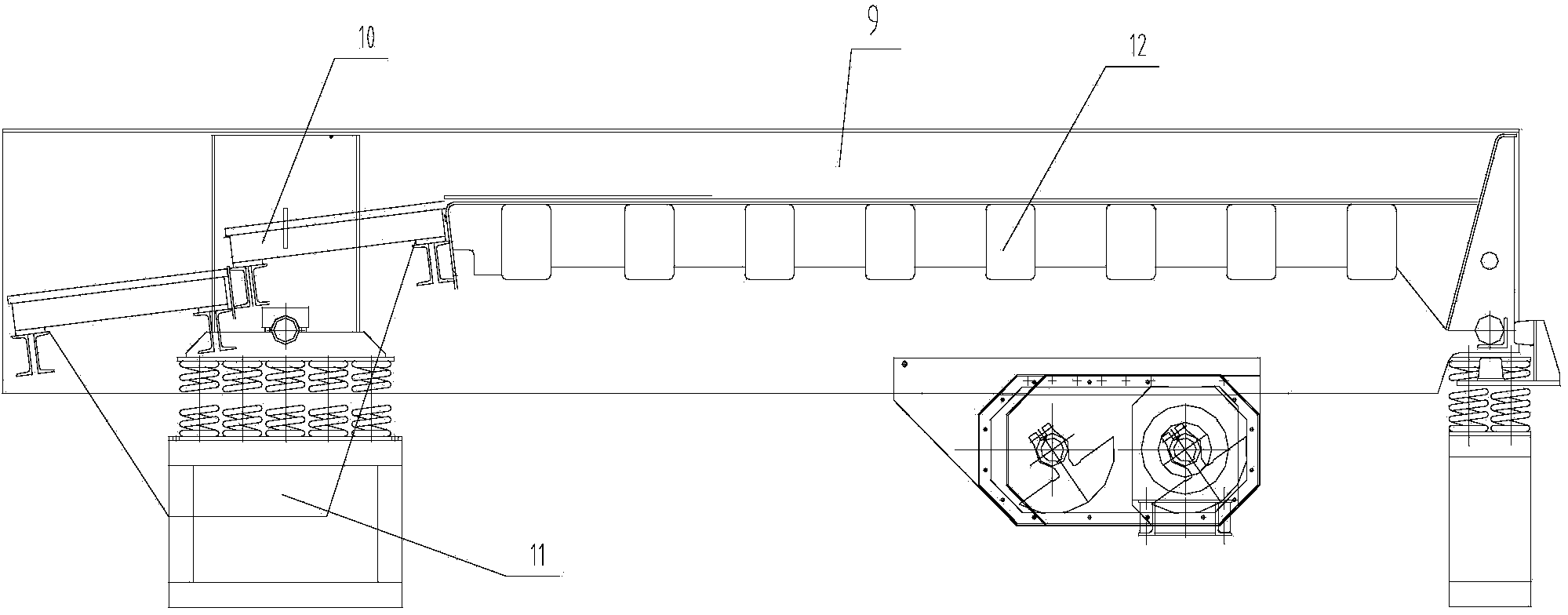

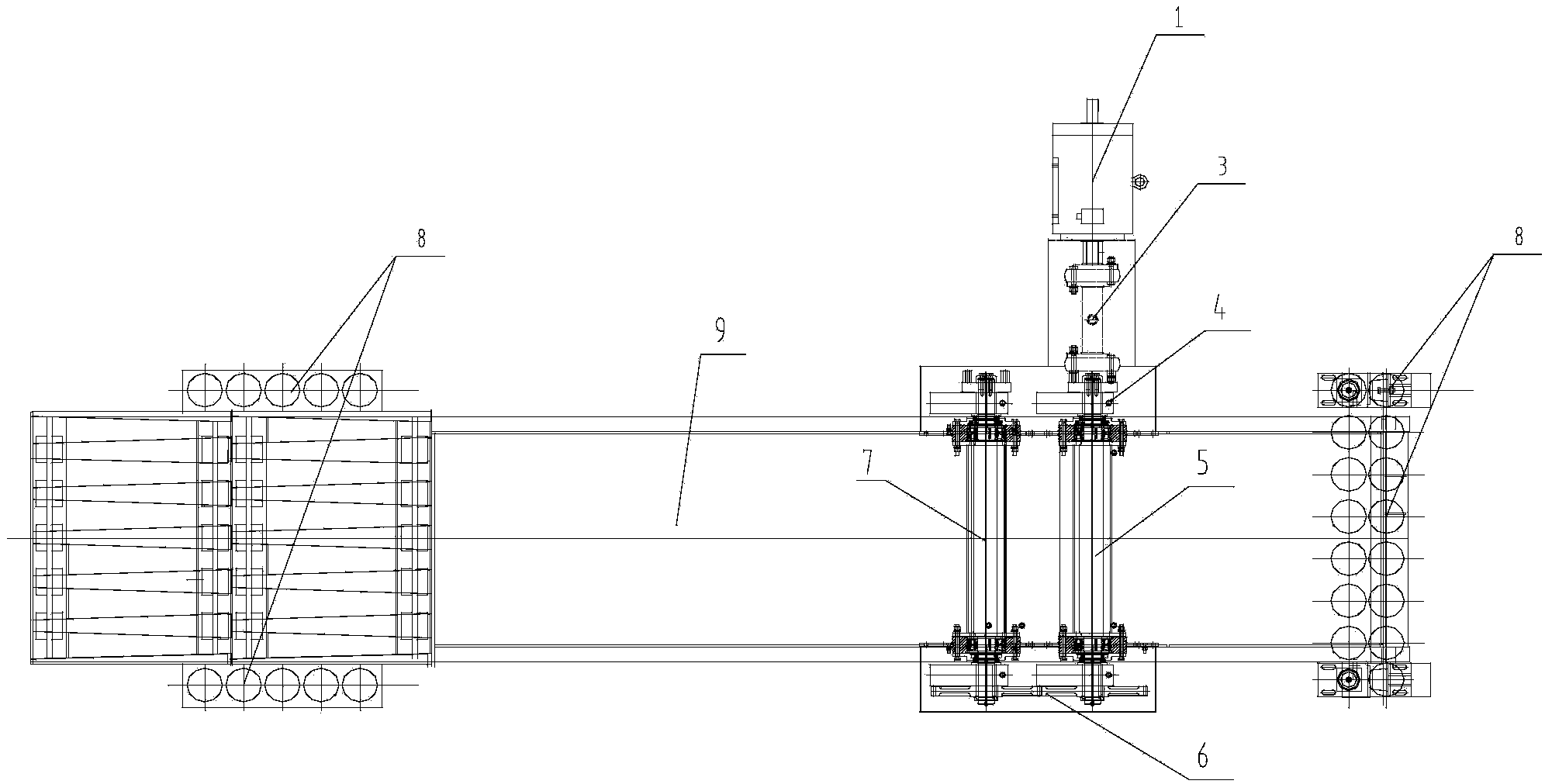

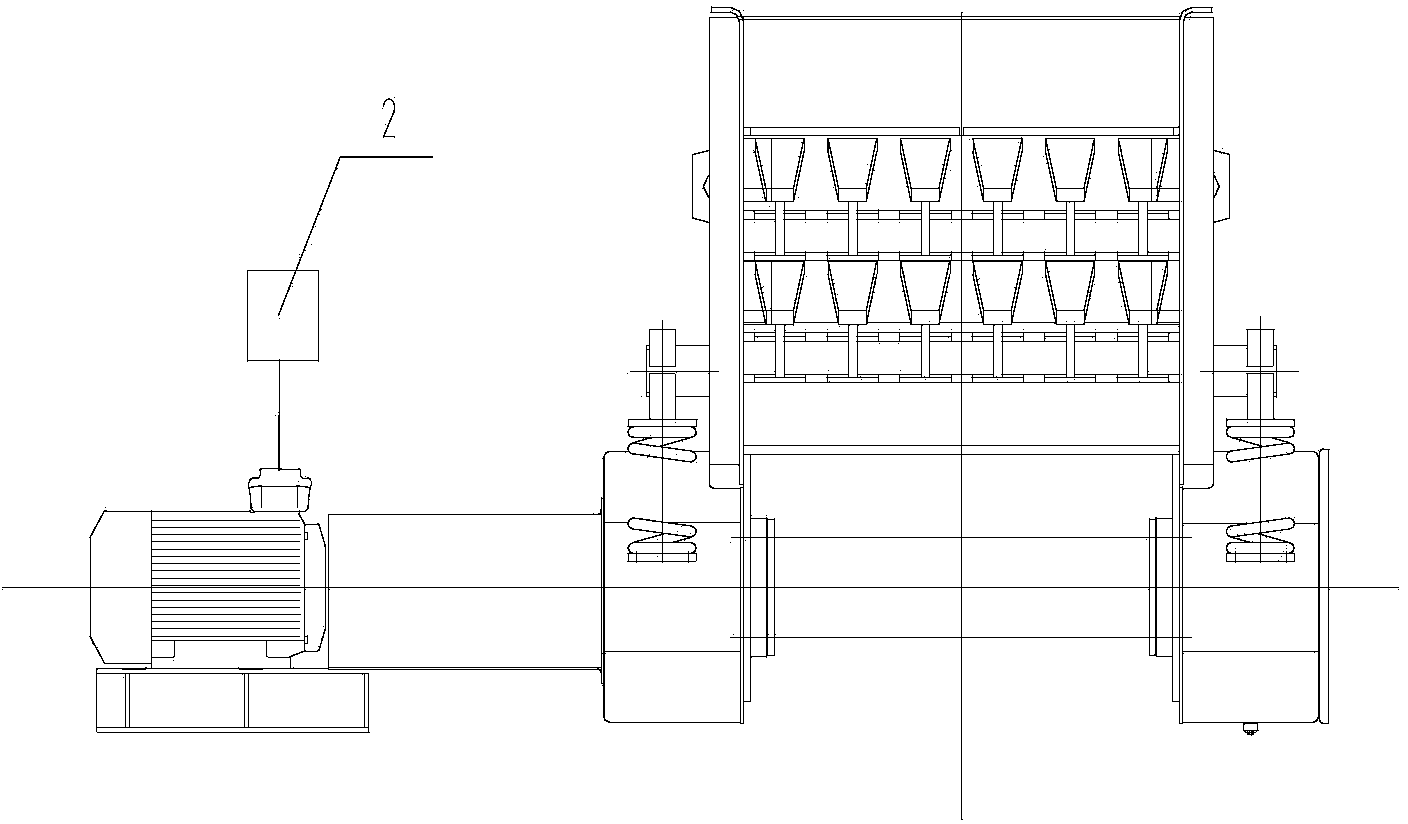

[0034] see figure 1 , figure 2 and image 3 , the feeder trough body that is made up of feeding chute 9, bar section 10 and fine screen 11, the front end of feeding chute 9 is connected with bar section 10, the lower end of bar section 10 is connected with fine sieve 11, bar section 10 Adopt the bar of changeable pitch, the bar of bar section 10 of the present invention is 2 sections, also can be designed as 1 section, mainly determines how much according to the specification of feeder and the content of fine-grained grade in the material. A vibration excitation system is installed on the feeder tank body, preferably, the vibration excitation system is a biaxial vibration excitation device. The structure of the double-axis excitation device is: the control system of the motor 1 is connected with the frequency converter 2, the main shaft of the motor 1 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com