Patents

Literature

76results about How to "Great exciting force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

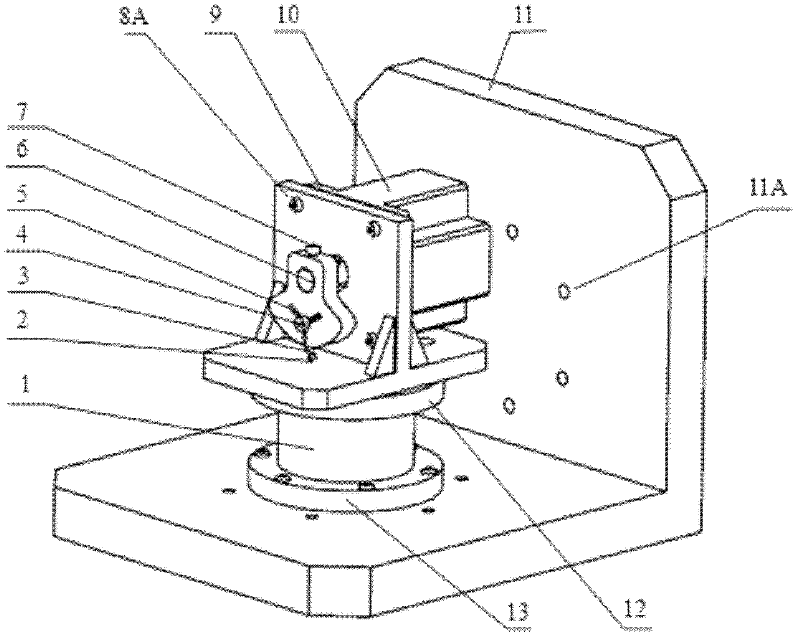

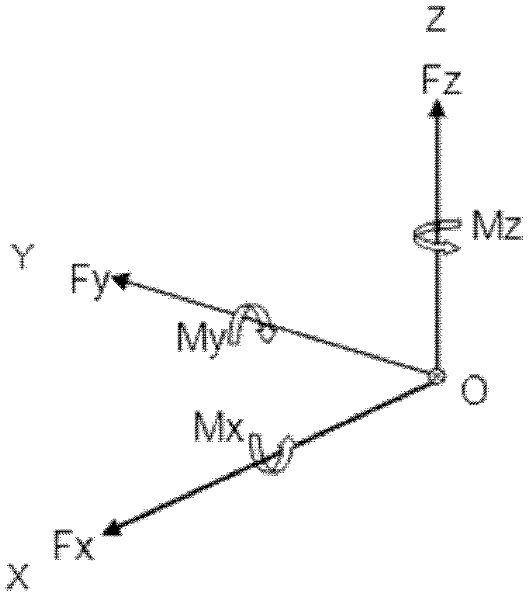

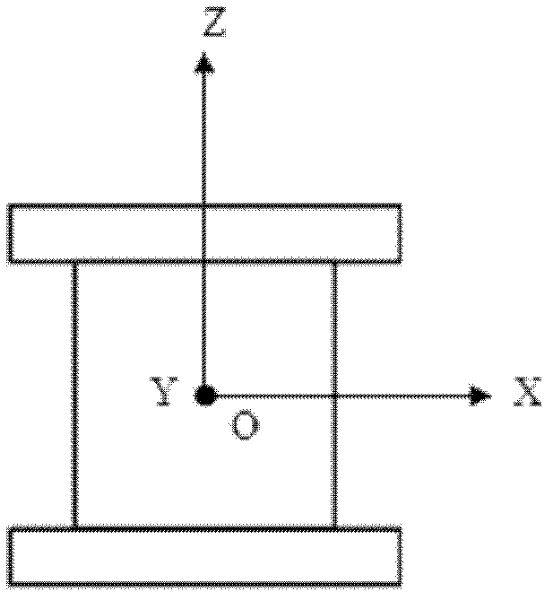

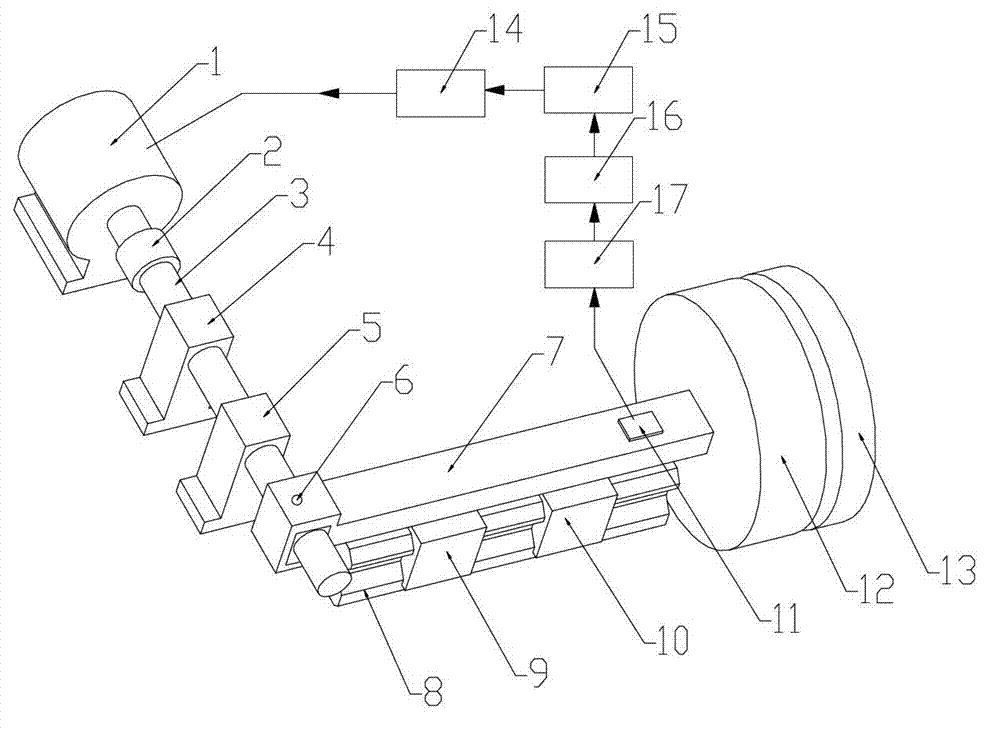

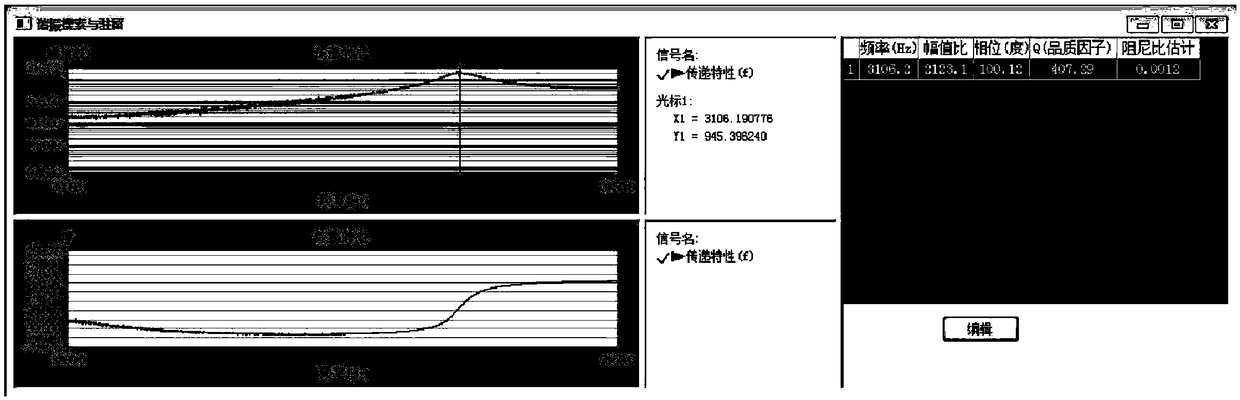

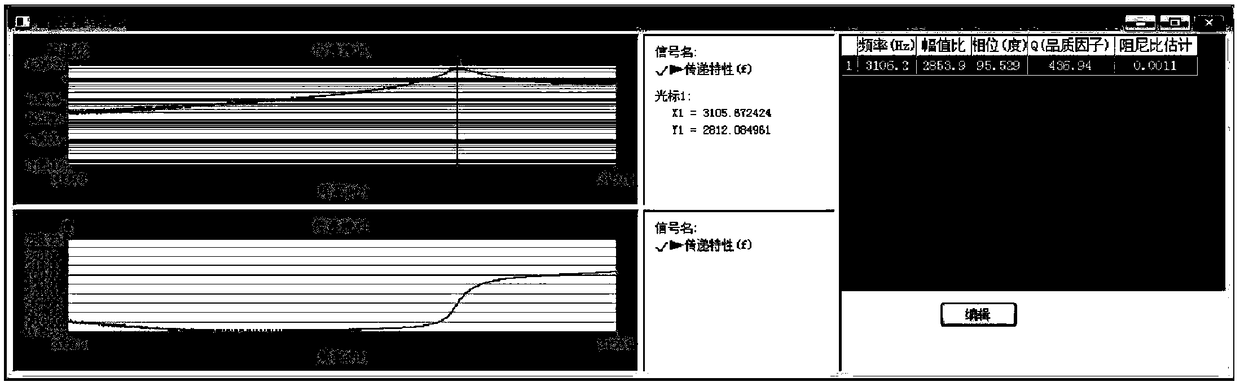

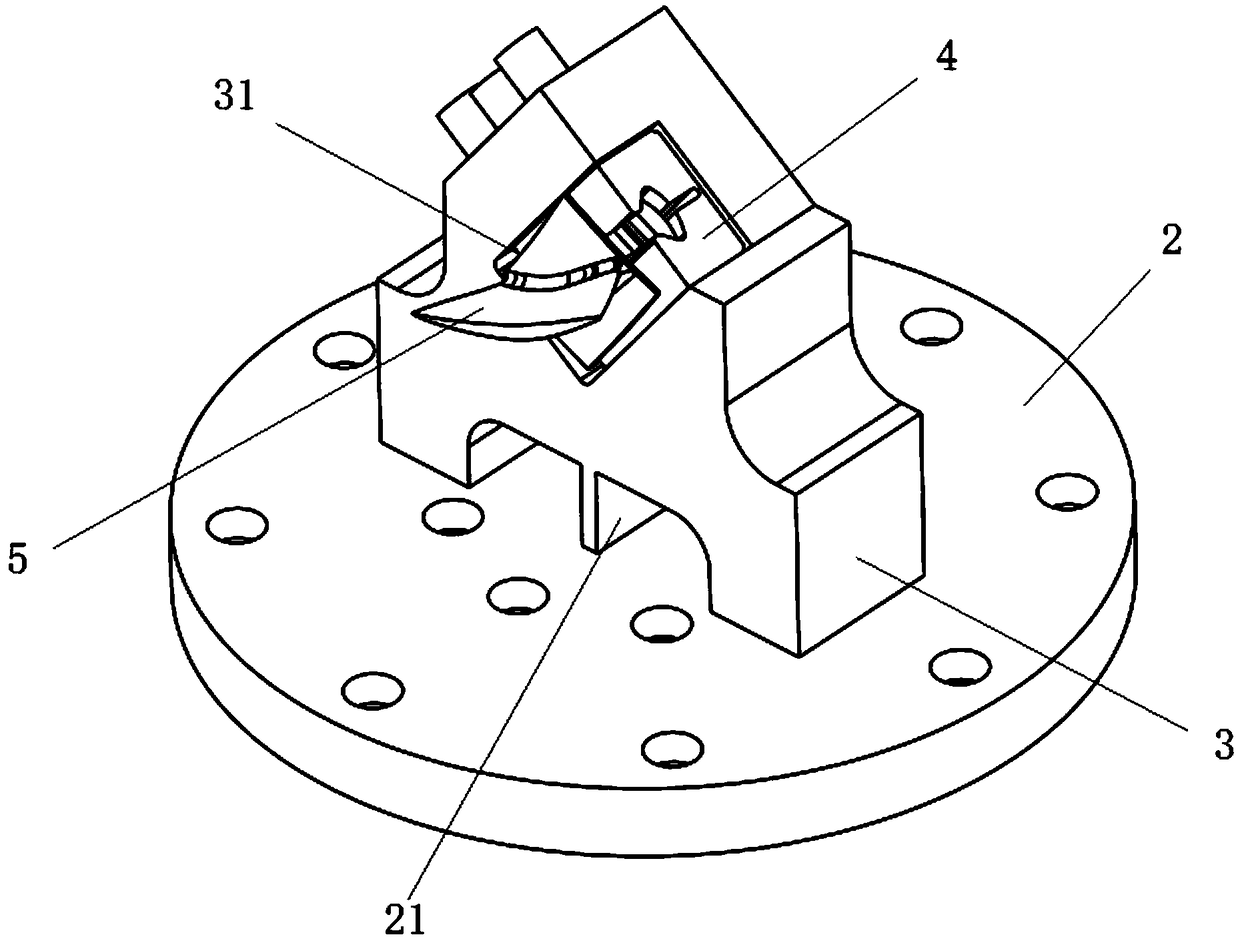

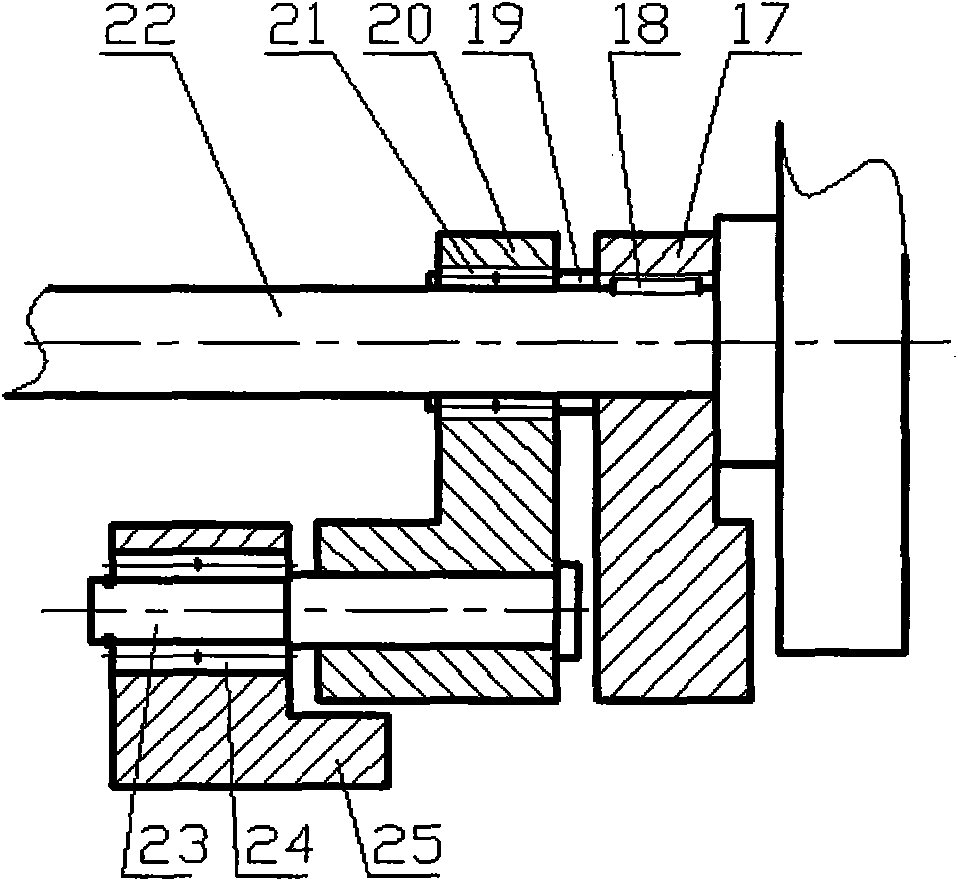

Multi-dimensional force sensor dynamic experiment device based on stable-state sine exciting force

ActiveCN102564685AReduce distanceGreat exciting forceForce/torque/work measurement apparatus calibration/testingPeriodic excitationStable state

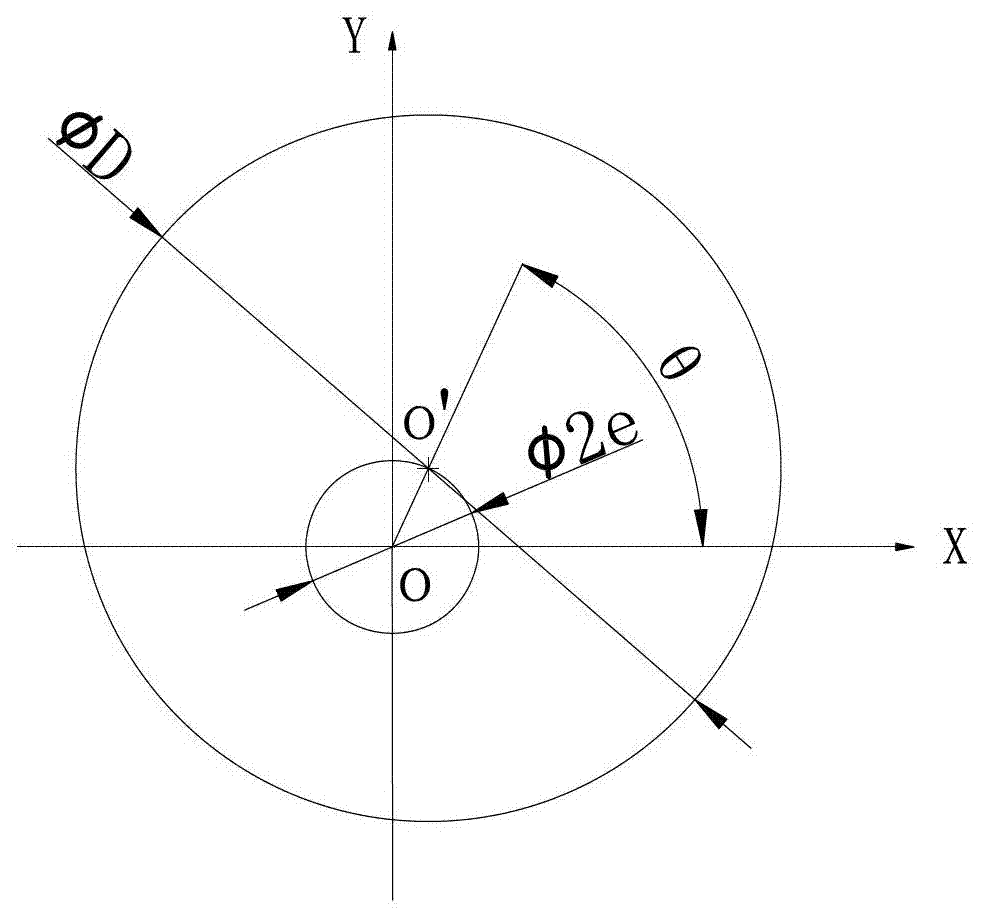

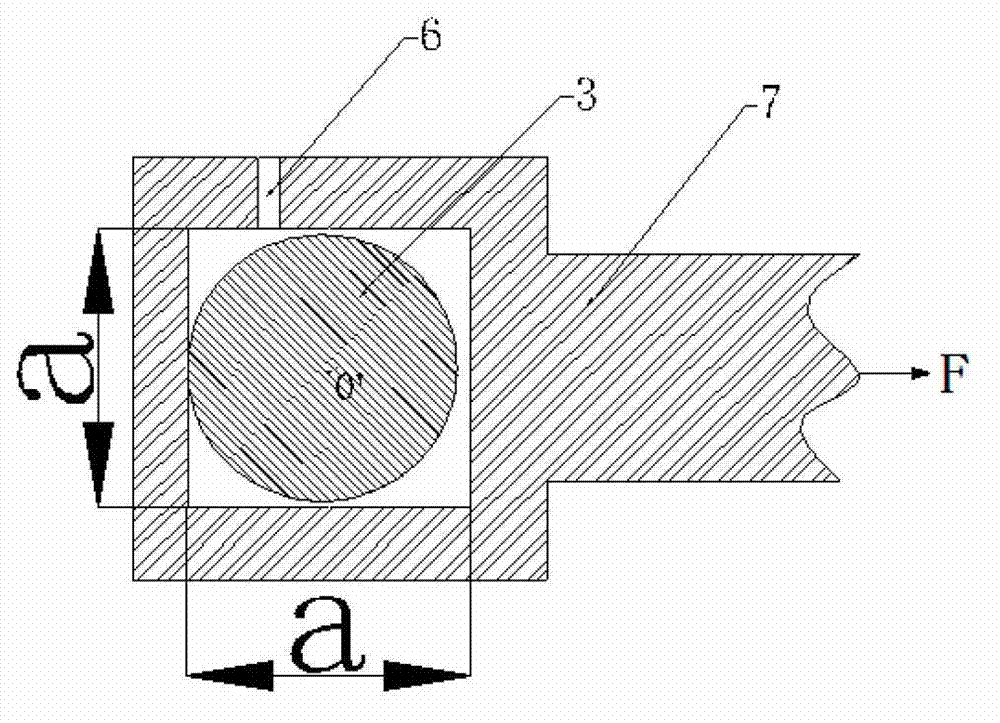

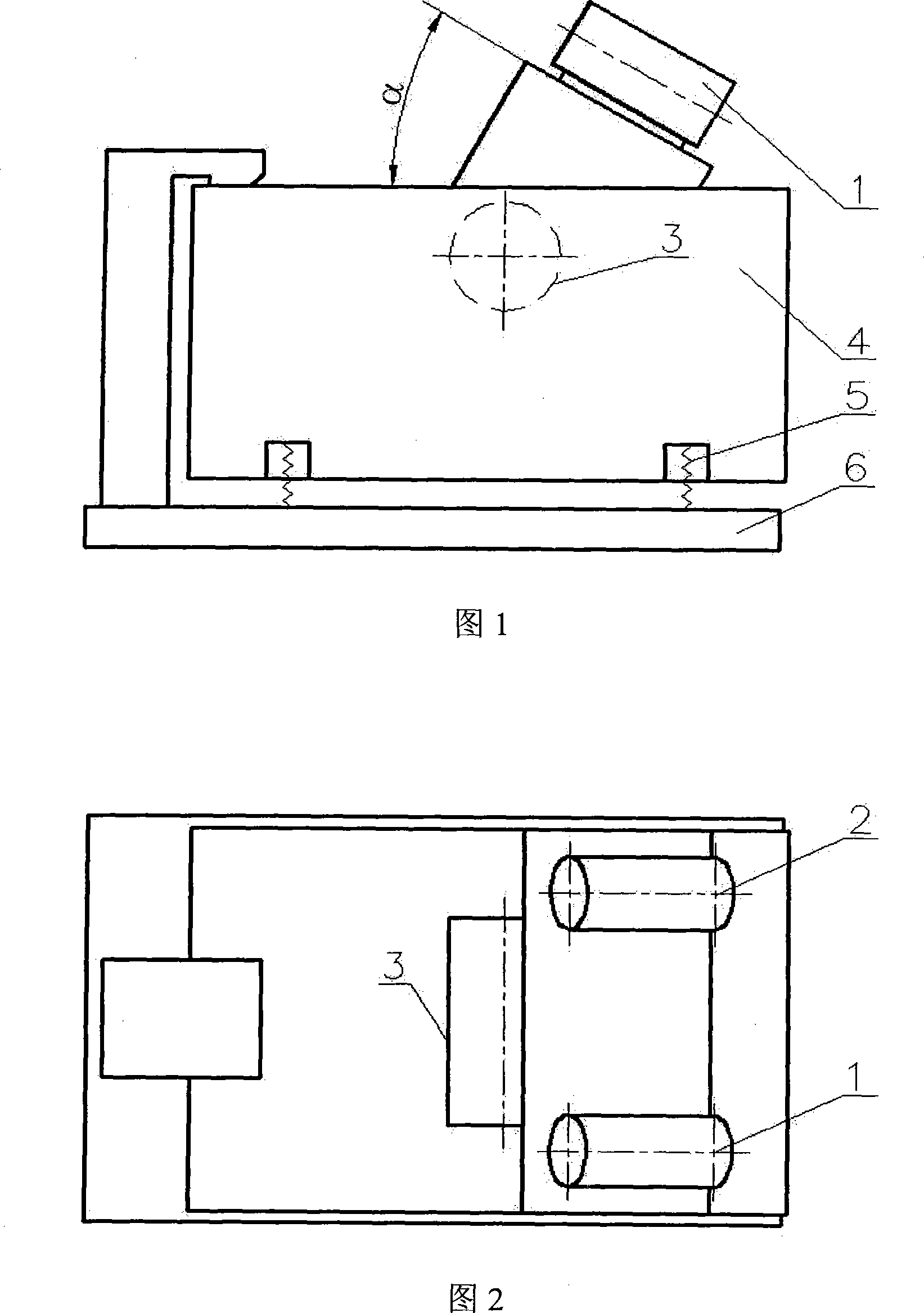

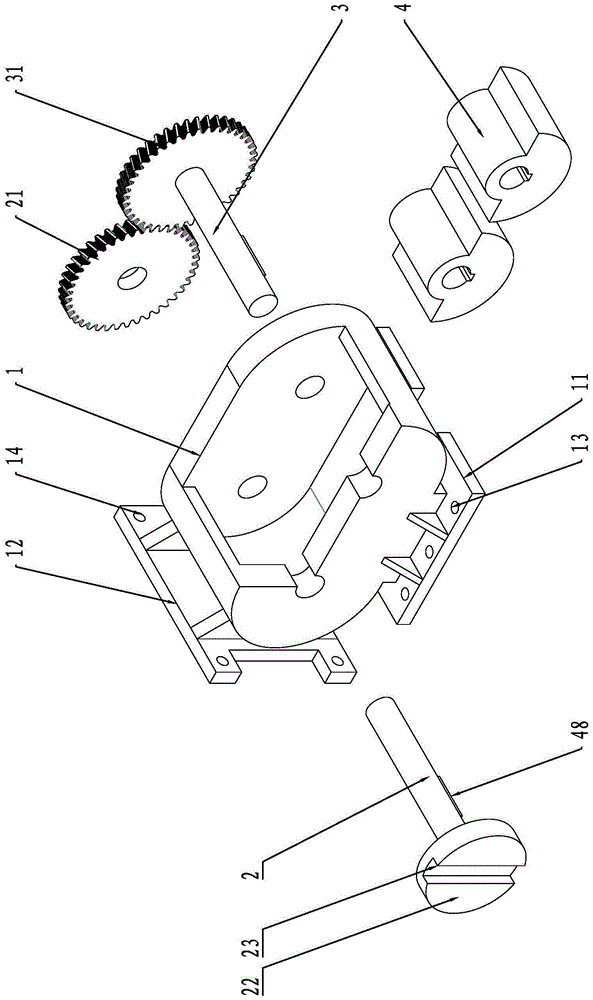

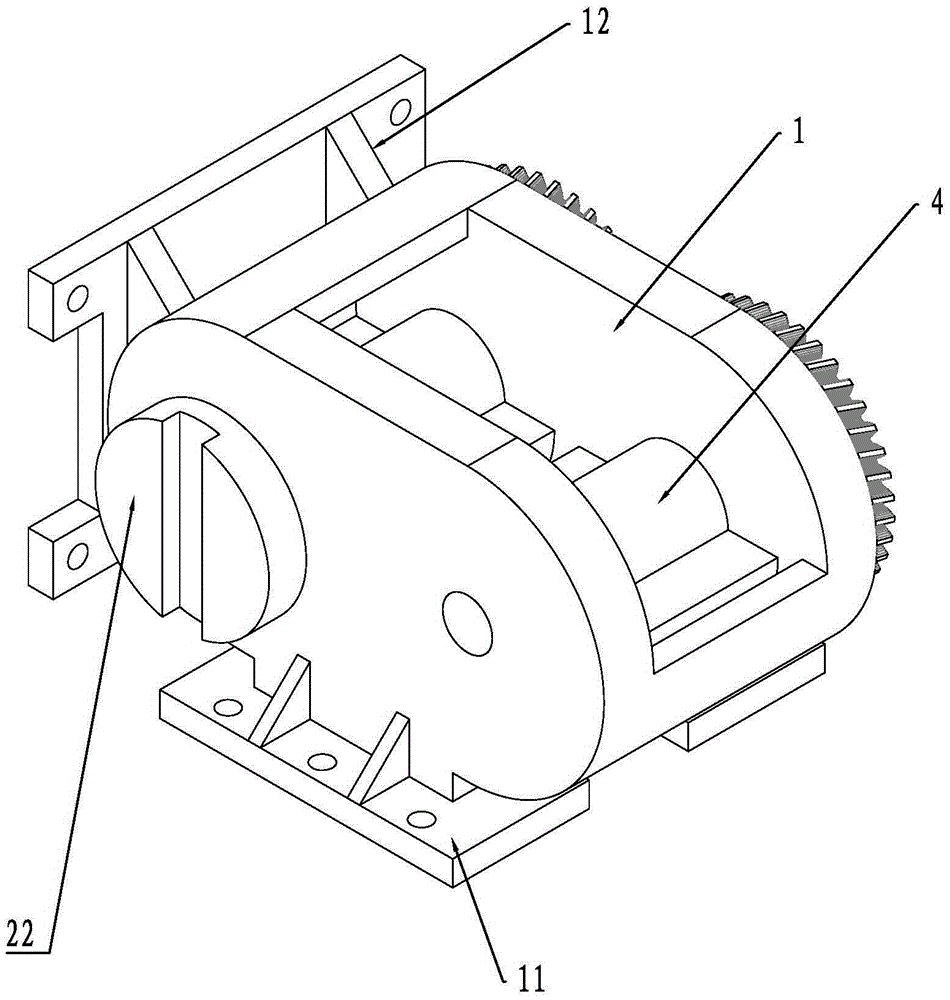

The invention provides a multi-dimensional force sensor dynamic experiment device based on a stable-state sine exciting force, comprising a T-shaped rack and an L-shaped rack, wherein when a force sensor to be detected is fixedly arranged on the an end face of a horizontal plate of a base and is loaded by the T-shaped rack, the loading of the exciting force or an exciting force moment is realized; when the force sensor to be detected is fixedly arranged on the end face of a vertical plate of a base and is loaded by the L-shaped rack, the L-shaped rack is used as a switchover piece of the force sensor to be detected and the T-shaped rack and is used for changing a stressing direction of the force sensor to be detected and realizing different combined types of loading. When a motor is rotated at a certain rotating speed, sine exciting forces with different amplitudes can be obtained through adjusting the position of an adjusting block in a diameter-changing slide groove in an eccentric exciting block, so as to realize an amplitude-frequency property test. In the rotation process of the eccentric exciting block, a permanent magnet steel block periodically stimulates a Hall sensor to output a pulse signal and utilizes a pulse signal triggering moment to determine the maximum value time slot of a component force amplitude of an eccentric force at a certain stressing direction, so as to recover the known sine exciting force signal and realize a phase-frequency property test.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

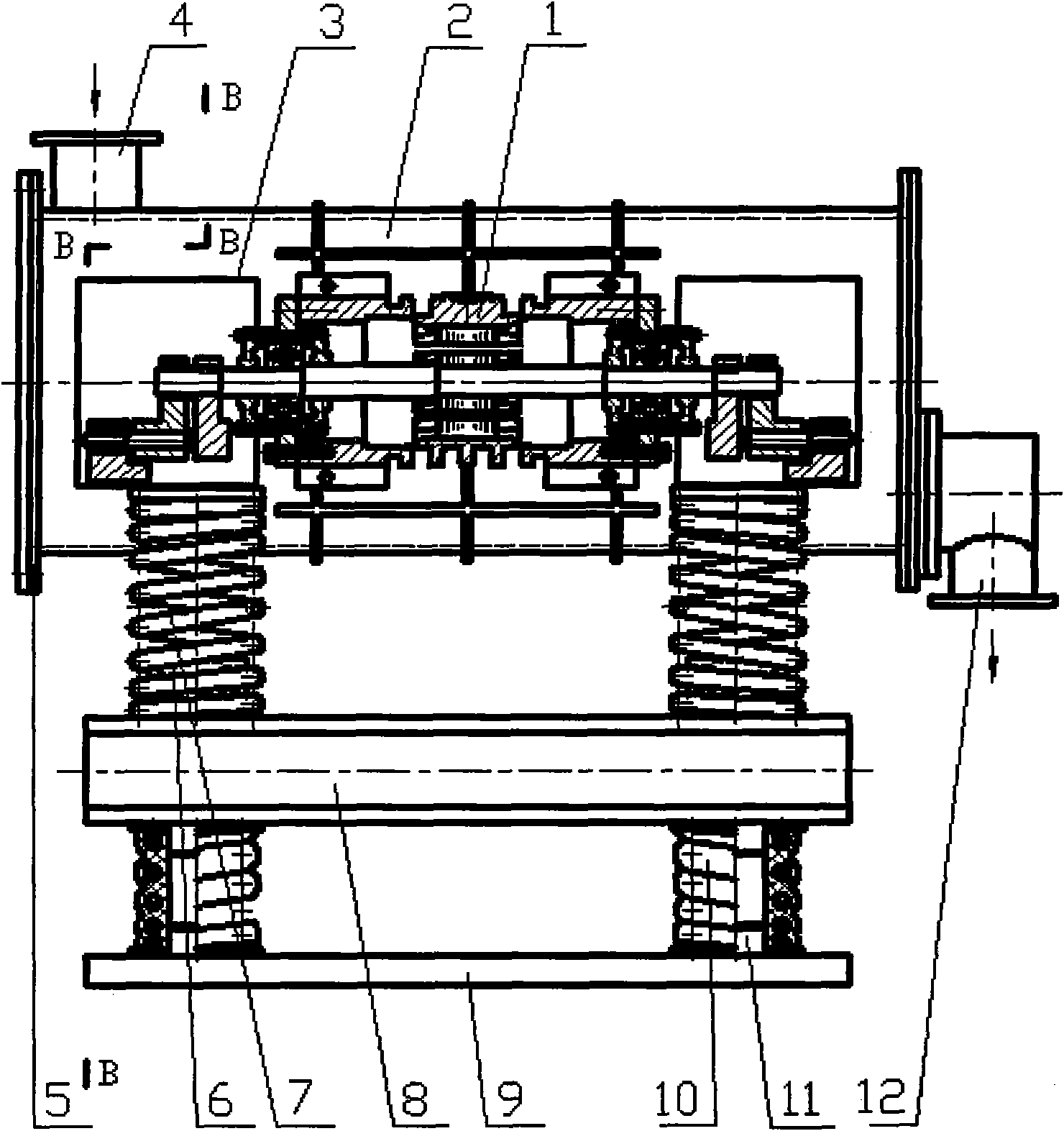

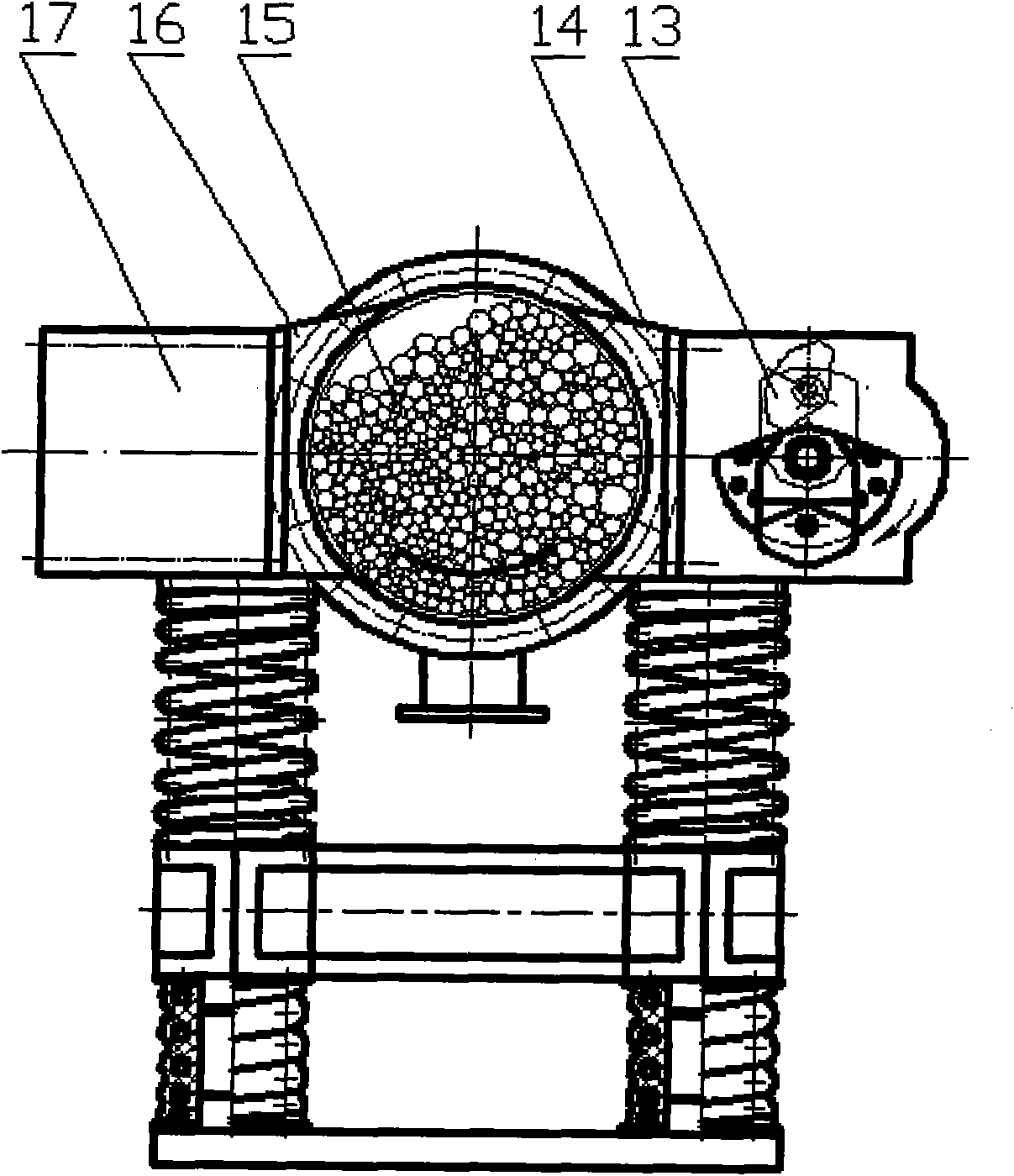

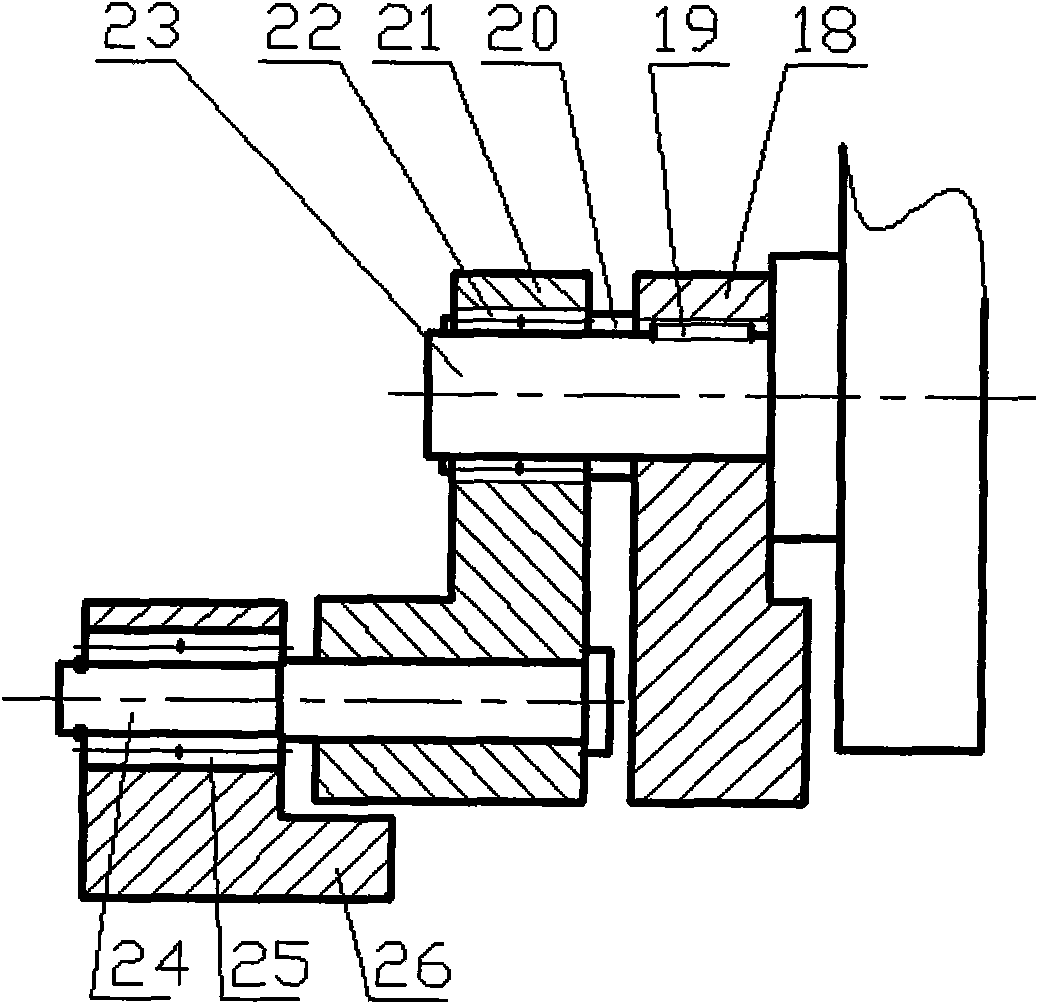

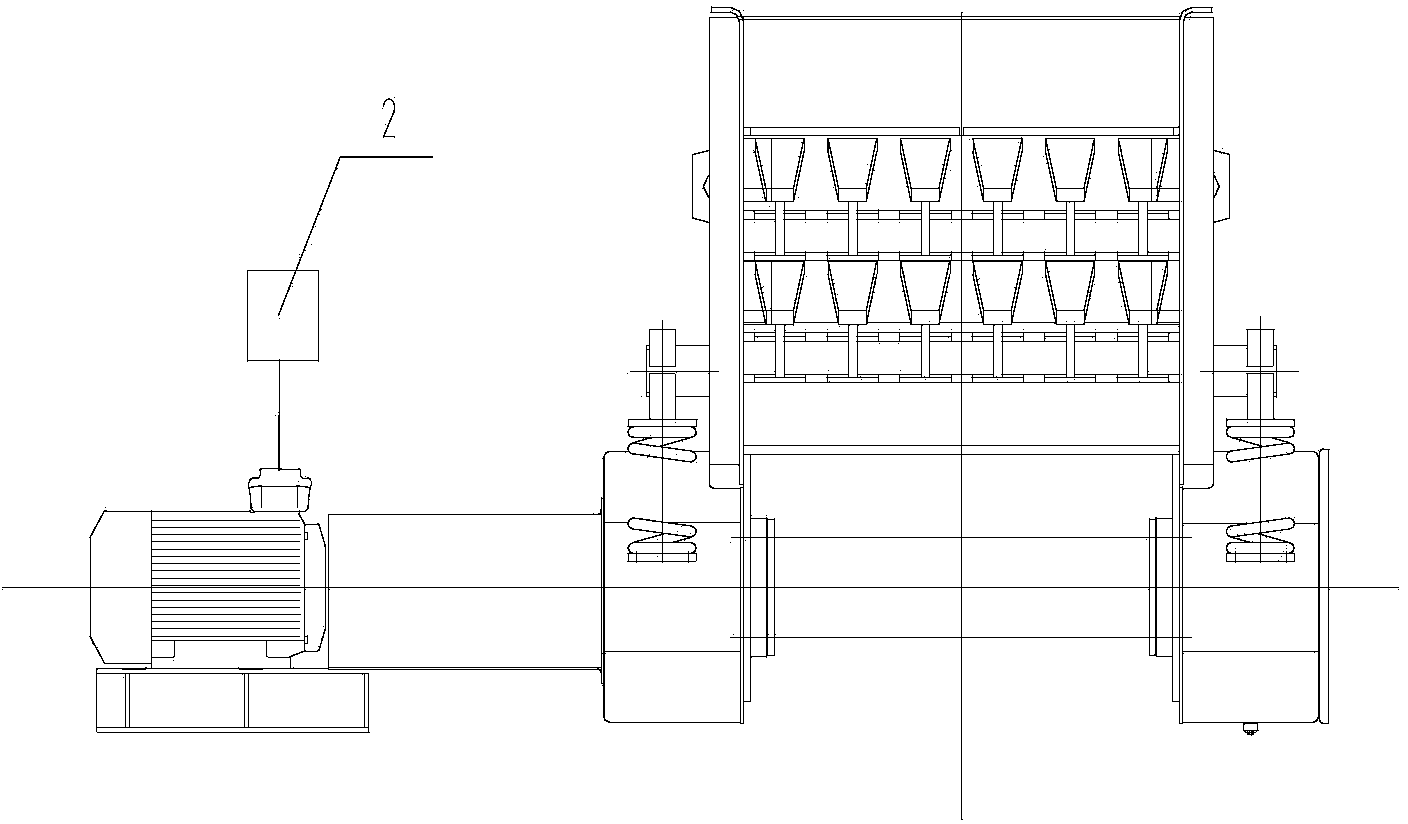

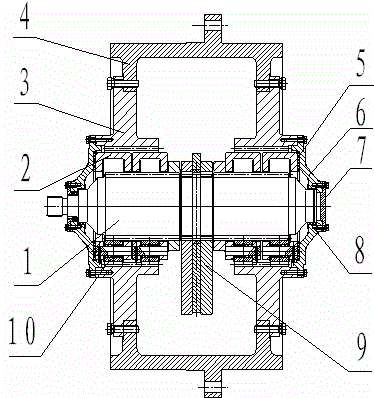

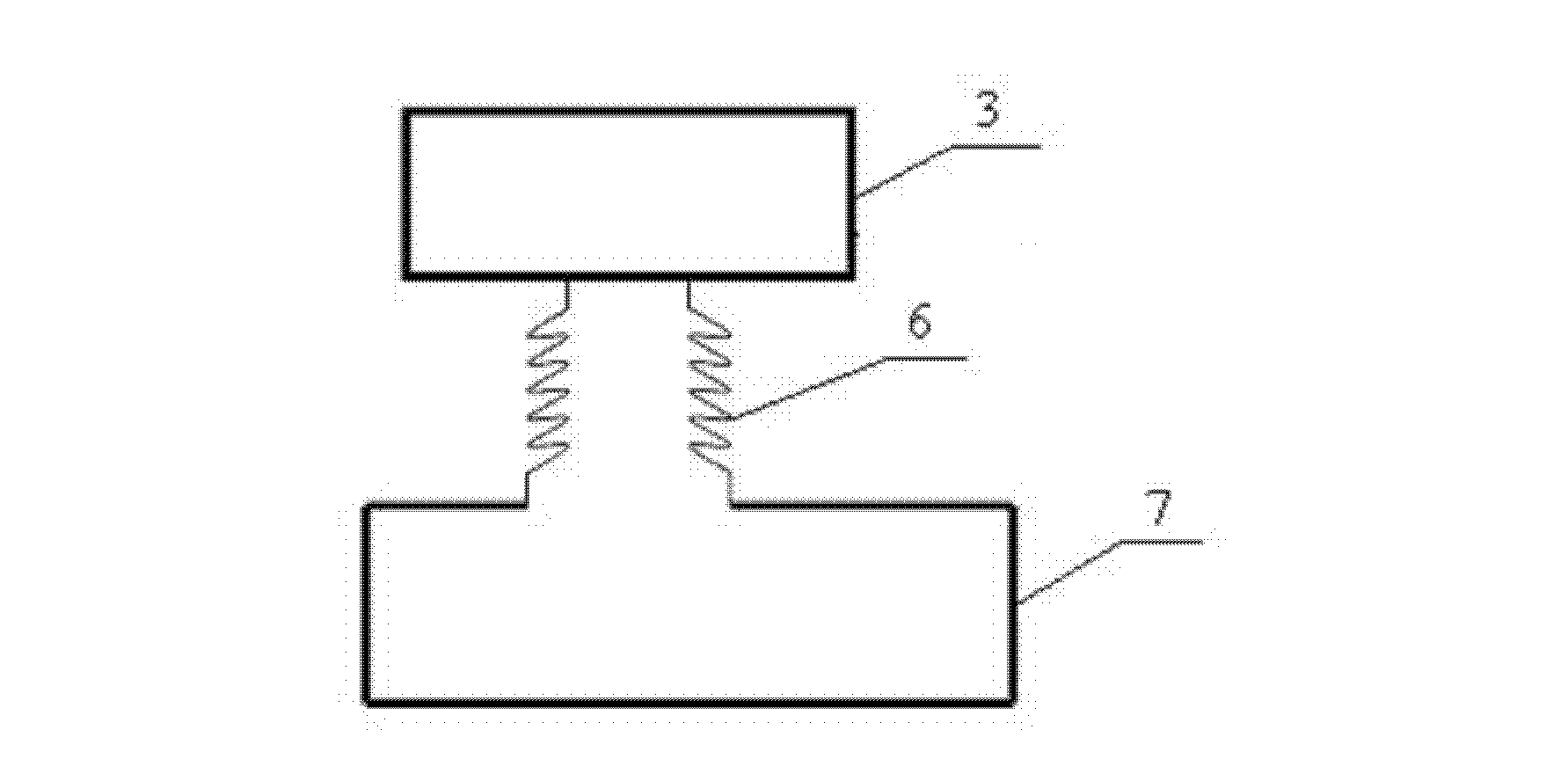

Variable stiffness double-mass two-stage pendulum chaotic vibromill

The invention discloses a variable stiffness double-mass secondary pendulum chaotic vibromill and relates to a vibromill, and in particular relates to a variable stiffness double-mass two-stage pendulum chaotic vibromill. The chaotic vibromill comprises an upper mass, a lower mass, a main vibration spring, a vibration isolation spring, a base, and the like, wherein the upper mass mainly comprises a vibration motor, a cylinder body, a right connecting frame, a left connecting frame and a counter weight; the cylinder body mainly comprises a feed inlet, an end cover, a discharge hole and a mill medium; the upper mass and the lower mass are connected through the main vibration spring, and the inner diameter of the main vibration spring is matched with the outer diameters of spring guide posts on the upper mass and the lower mass; the lower mass is supported on the base through the vibration isolation spring; the vibration motor comprises pendulum assemblies, and the pendulum assemblies are symmetrically distributed at the left end and the right end of a vibration motor shaft; and each pendulum assembly comprises a fixed pendulum, a flat key, a shaft sleeve, a primary movable pendulum, a bearing 1, a vibration motor shaft, a secondary movable pendulum shaft, a bearing 2 and a secondary movable pendulum.

Owner:江华瑶族自治县金牛开发建设有限公司

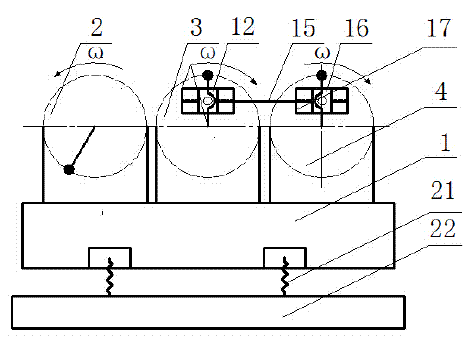

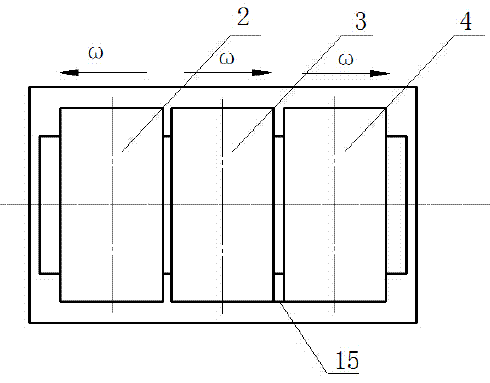

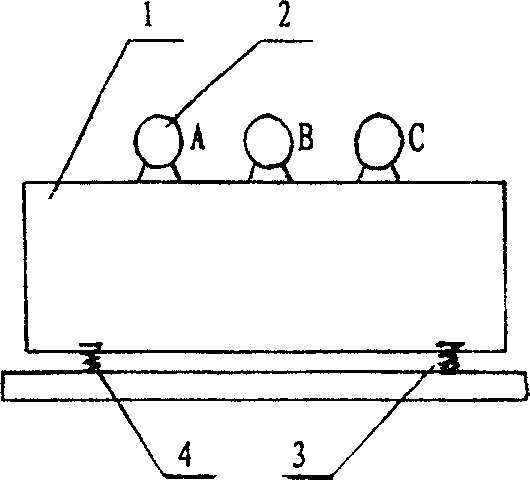

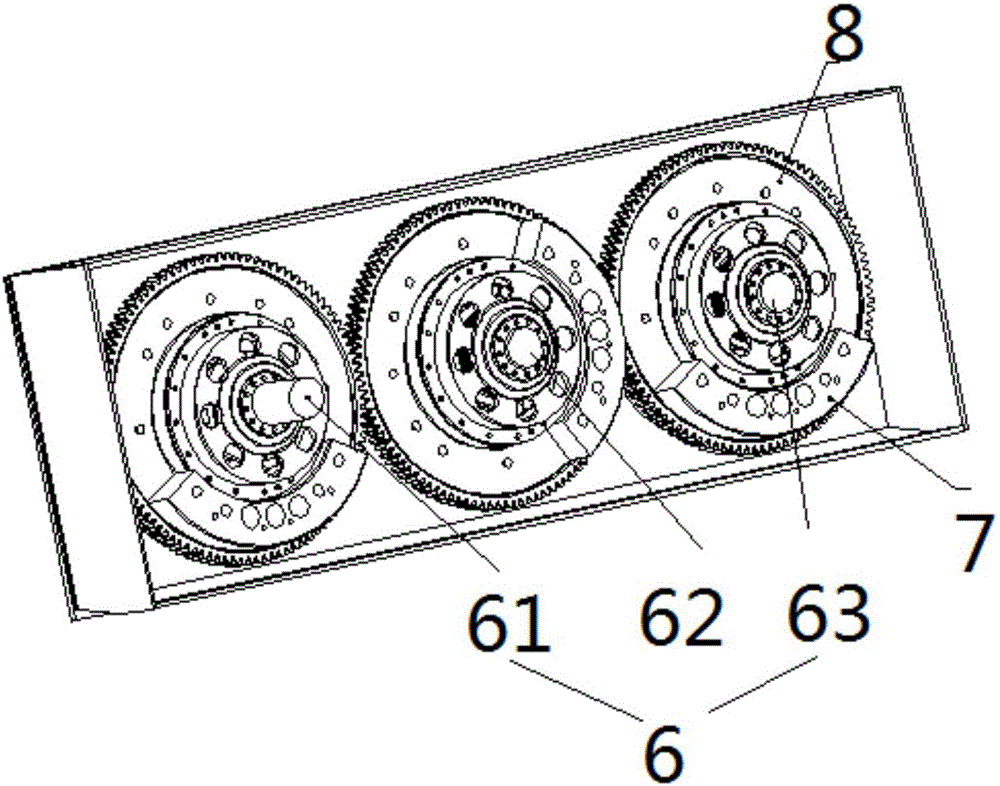

Three-shock-excitation-motor elliptical vibrating screen based on elastic coupling

ActiveCN104759409AMeet job needsOvercome the shortcomings such as slippingSievingScreeningCouplingPhysics

The invention relates to a three-shock-excitation-motor elliptical vibrating screen based on elastic coupling. The three-shock-excitation-motor elliptical vibrating screens based on the elastic coupling is mainly composed of a first shock excitation motor, a second shock excitation motor, a third shock excitation motor, a connecting rod, sliding grooves, a motor base, a screen box, sliding blocks, springs and the like. The motor base is fixed to a side plate of the screen box, and the three shock excitation motors are connected to the motor base through bolts. A sliding groove is welded to each of the two ends of the connecting rod, and the sliding grooves are parallel to each other. The second shock excitation motor and the third shock excitation motor are installed with axes parallel, the second shock excitation motor and the third shock excitation motor rotate in the same direction, and sliding blocks capable of rotating relative to eccentric blocks are installed at the positions with same radious vector on the same-side eccentric blocks of the second shock excitation motor and the third shock excitation motor. A shock excitation inertia force generated by the first shock excitation motor is also a circular exciting force, the circumferential changing direction of the shock excitation inertia force is opposite to that of a circular exciting force combined by the second shock excitation motor and the third shock excitation motor, and the shock excitation inertia force and the circular exciting force are combined to an elliptical exciting force with the center fixed. According to the three-shock-excitation-motor elliptical vibrating screen based on the elastic coupling, the exciting forces of the three shock excitation motors can be brought into play to achieve the maximization of a general exciting force, the structure is simple, the installation is easy, the noise is low, and the cost is low.

Owner:SOUTHWEST PETROLEUM UNIV

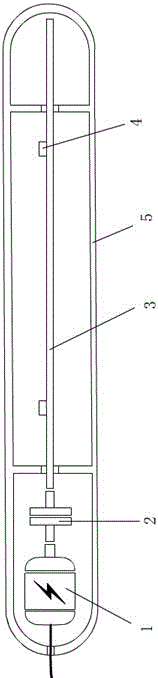

Series connection type high energy electromagnetic actuator

InactiveCN1431757AIncrease the number ofSmall magnetic resistanceDynamo-electric machinesConnection typeHigh energy

The vibrator of the actuator consists of the two or more blocks of high tensile magnet, the two outboard magnet plates are the one of more middle magnet plates assembled, according to the desired sequence in series. The thickness of the magnet plates in middle of the vibrator is thicker than the outboard magnet plates. Two magnets with their homopolars face to face clamp the magnet plates in middle. The coil holder, the magnet coil and the magnet outer tube are cemented as one body. The through bolt and the sheet spring connect the vibrator and the magnet outer tube. The shortened magnetic circuit, the reduced magnetic resistance and more magnet plates utilized make the effective turns of the magnet coil increase greatly so as to increase the exciting force of the actuator greatly.

Owner:郭晨海

Motor-driven non-contact shock excitation device and shock excitation method thereof

InactiveCN103091062AConvenient axial excitationGreat exciting forceVibration testingIndustrial PCMotor drive

The invention discloses a motor-driven non-contact shock excitation device and a shock excitation method of the motor-driven non-contact shock excitation device. The motor-driven non-contact shock excitation device comprises a stepping motor, a subdivision actuator, a coupler, two supporting bearings, an eccentric shaft, a linear guide rail and two sliding blocks, a connection rod, an electricity permanent magnet and an armature, a strain foil bridge, a strain signal conditioning circuit, an alternating current / direct current (A / D ) converter and an industrial computer. The shock excitation device is a slider-crank mechanism as a whole, the eccentric shaft is driven by the stepping motor to rotate, the stepping motor drives the electricity permanent magnet to move on the linear guide rail in a reciprocation mode, the thickness of the air gap between the electricity permanent magnet and the armature is changed, and the dynamic shock excitation electromagnetic force is generated. The motor-driven non-contact shock excitation device can impose the large margin period excitation force or the sine excitation force on a rotary shaft, and is suitable for testing the dynamic characteristic of a high-rigidity sliding thrust bearing.

Owner:XI AN JIAOTONG UNIV

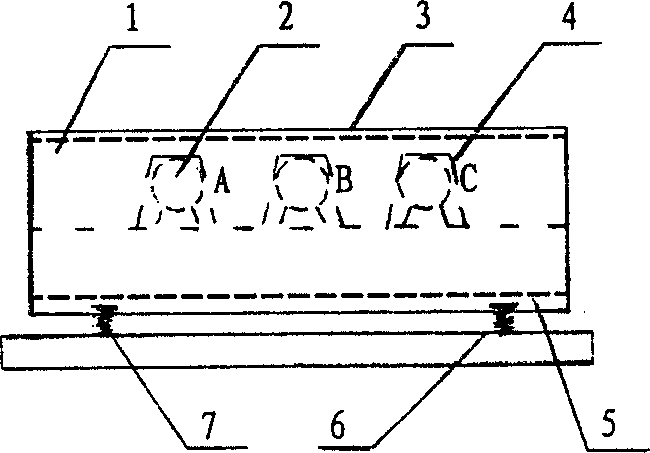

Three-electric motor self-synchronizing elliptical vibrating screen based on movement composition principle

InactiveCN101244420AEasy elliptical exerciseEasy to change elliptical motionSievingScreeningVibration controlElectric machinery

The invention relates to a tri-exciting-motor self synchronizing elliptical vibrating screen based on the principle of kinematic synthesis, belonging to the technical fields of petroleum drilling, chemical fertilizer, construction, food and pharmacy. The technical proposal adopted is that: the axes of a vibration motor (1) and a vibration motor (2) are parallel to each other, and the eccentric mass-radius products of the two motors are identical; while in operation, the two motors rotate at the same speed while in the reverse direction, the axis of a vibration motor (3) is perpendicular to those of the vibration motors (1) and (2), and the rotation speed of the vibration motor (3) is equal to those of the vibration motors (1) and (2); the rectilinear motions of the vibration motors (1) and (2) are synthesized with the circular motion produced by the vibration motor (3), so as to achieve the elliptical motion of a screen box. By adjusting the eccentric mass-radius product, the ellipticity and the amplitude of the elliptical vibration can be varied; by changing the relative position between the vibration motors and the overall center of mass of the screen box, the balance elliptical motion or variable elliptical motion of the screen box can be accomplished. By adopting the three exciting motors, the elliptical vibration screen has the advantages of generating larger vibrating force, being applicable to the vibration screens with large screening areas, and achieving elliptical, rectilinear and circular three vibration motions.

Owner:SOUTHWEST PETROLEUM UNIV

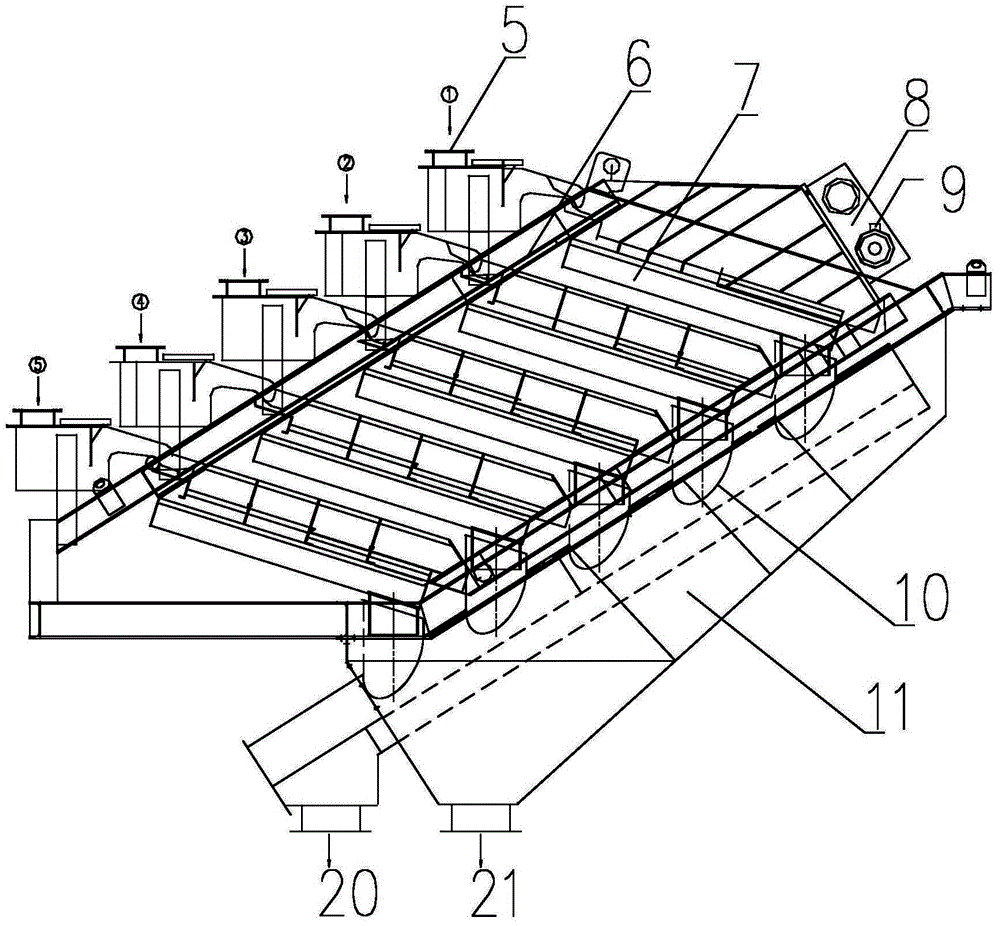

Layered high-frequency fine vibrating screen

InactiveCN104148278AIncrease the eccentric distanceEasy to handleSievingScreeningDistribution systemEngineering

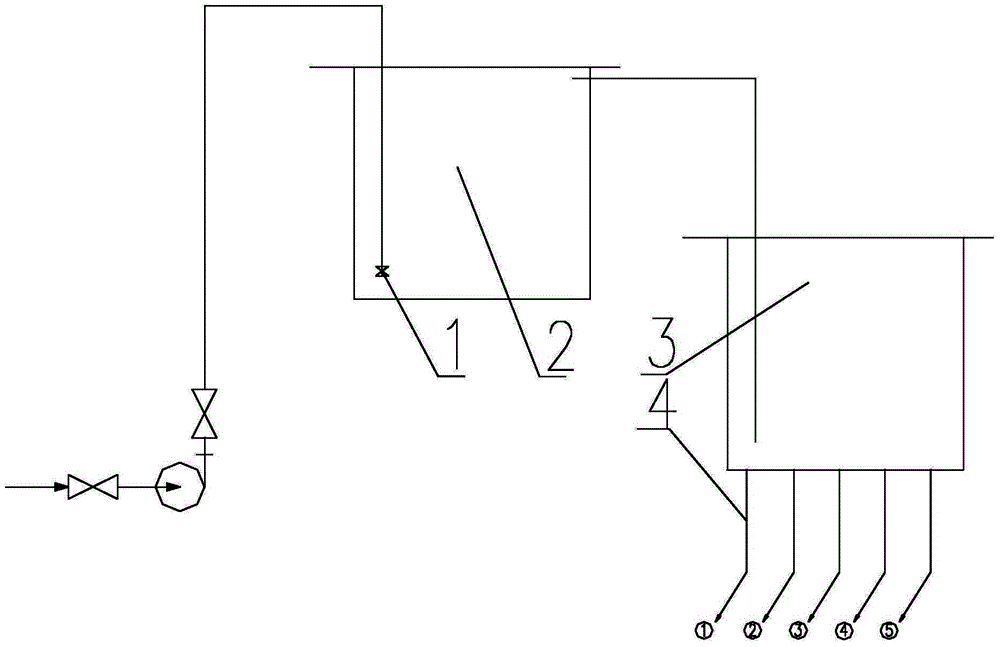

The invention discloses a layered high-frequency fine vibrating screen. The layered high-frequency fine vibrating screen is composed of an ore pulp distribution system, a screening system and a discharging system. The ore pulp distribution system structurally comprises a first-level ore pulp tank (2), a second-level ore pulp tank (3) and hoppers (5), wherein the feed end of the first-level ore pulp tank (2) is connected with a multihole energy dissipation valve (1); an overflow port of the first-level ore pulp tank (2) is connected with the second-level ore pulp tank (3); the hoppers (5) are connected to the lower portion of the second-level ore pulp tank (3). The screening system is composed of a vibration excitation unit, a classifying unit and a supporting unit. The discharging system has the functions of collection and discharge of materials below the screen and collection and discharge of materials on the screen, wherein the materials below all layers of high-frequency screen assemblies (7) are connected with upper chutes (10) through short pipes; the upper chutes (10) are connected with a material-below-screen main outlet (20); the materials on all the layers of high-frequency screen assemblies (7) are connected with lower chutes (11); a subsidiary discharge port (21) is connected to the lower chutes (11). The layered high-frequency fine vibrating screen has the advantages of being uniform in ore pulp feeding, high in screening efficiency and processing capacity and capable of adapting to different working conditions.

Owner:HUNAN ZHAOSHENG MINING MACHINERY

Stepless adjustable vibration generator of vibrating roller

The invention relates to a stepless adjustable vibration generator of a vibrating roller, which is used for a controller controlling a complete appliance. The controller is connected with a valve by a lead, and the valve is communicated with a hydraulic lock by a revolving joint arranged on a pipeline; the hydraulic lock is communicated with the stepless adjustable vibration generator by the pipeline, and the stepless adjustable vibration generator is connected with a transmission shaft. The invention utilizes the stepless adjustable vibration generator, and a fixed eccentric block and a movable eccentric block of the stepless adjustable vibration generator cause the center of gravity of the stepless adjustable vibration generator to deviate from a center line; the stepless adjustable vibration generator generates larger exciting force when a hydraulic motor drives the stepless adjustable vibration generator to rotate. The invention has the advantages of reasonable design, simple structure, high efficiency, large vibration force, and the like. The compaction effect is good and the roller compaction times are fewer when the invention is installed on a roller of a roll. The invention can be widely applied to rollers of rolls.

Owner:赵铁栓

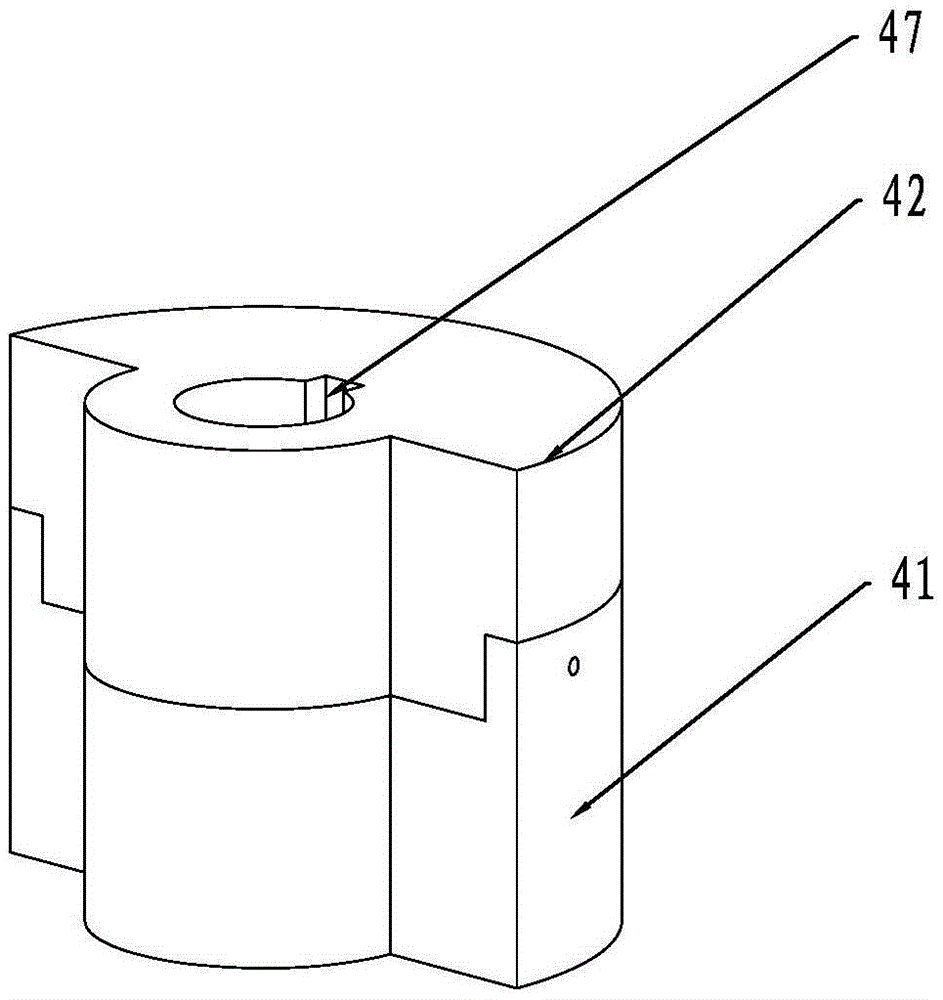

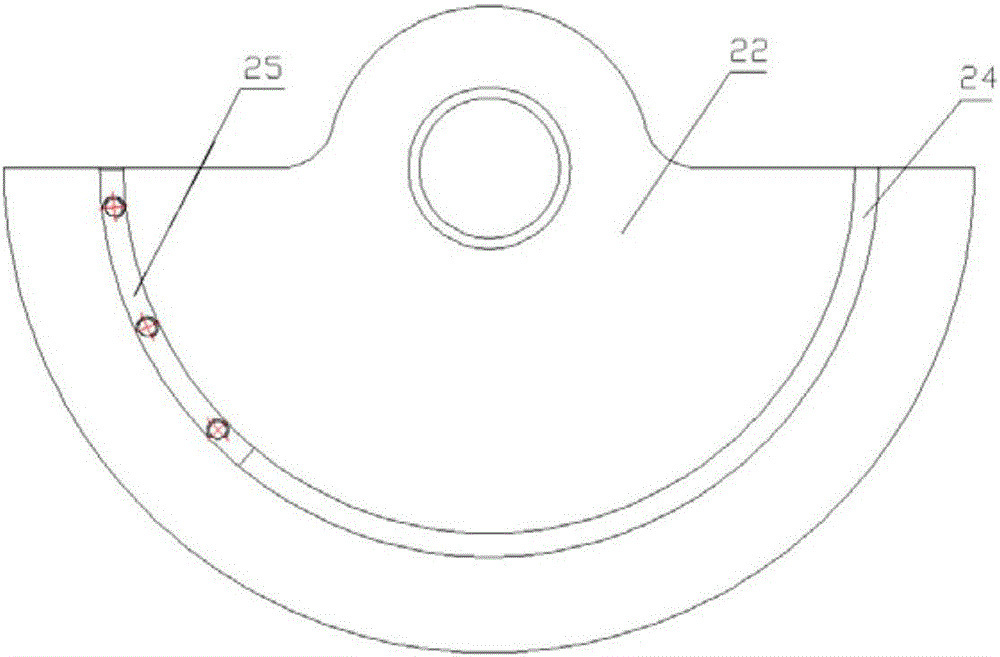

Eccentric vibration device of road roller and arranging structure thereof

PendingCN106638238AReduce manufacturing difficultyReduce installation difficultyRoads maintainenceEngineeringStructural engineering

The invention relates to an eccentric vibration device of a road roller and an arranging structure thereof. The device comprises a vibration shaft and a movable eccentric block group, wherein the movable eccentric block group is arranged on the vibration shaft; the movable eccentric block group comprises movable eccentric blocks, limiting rings and fixing keys; the limiting rings are fixed to the vibration shaft through the fixing keys, limiting grooves being matched with limiting convex blocks on the limiting rings are formed in the movable eccentric blocks, and the central angles of the limiting grooves are equal to or larger than those of the limiting convex blocks; and when the central angles of the limiting grooves are larger than those of the limiting convex blocks, the limiting grooves are matched with the limiting convex blocks, so that when the vibration shaft positively rotates or negatively rotates, the movable eccentric blocks provided with two vibration limitation positions correspondingly. According to the eccentric vibration device of the road roller and the arranging structure thereof, structures of the movable eccentric blocks are greatly simplified, and manufacturing and installing difficulties of the eccentric blocks are lowered; and meanwhile, the movable eccentric blocks are integrally formed, thus the movable eccentric blocks are not prone to being damaged during using, and during working, stability and reliability are highly maintained.

Owner:合肥永安绿地工程机械有限公司

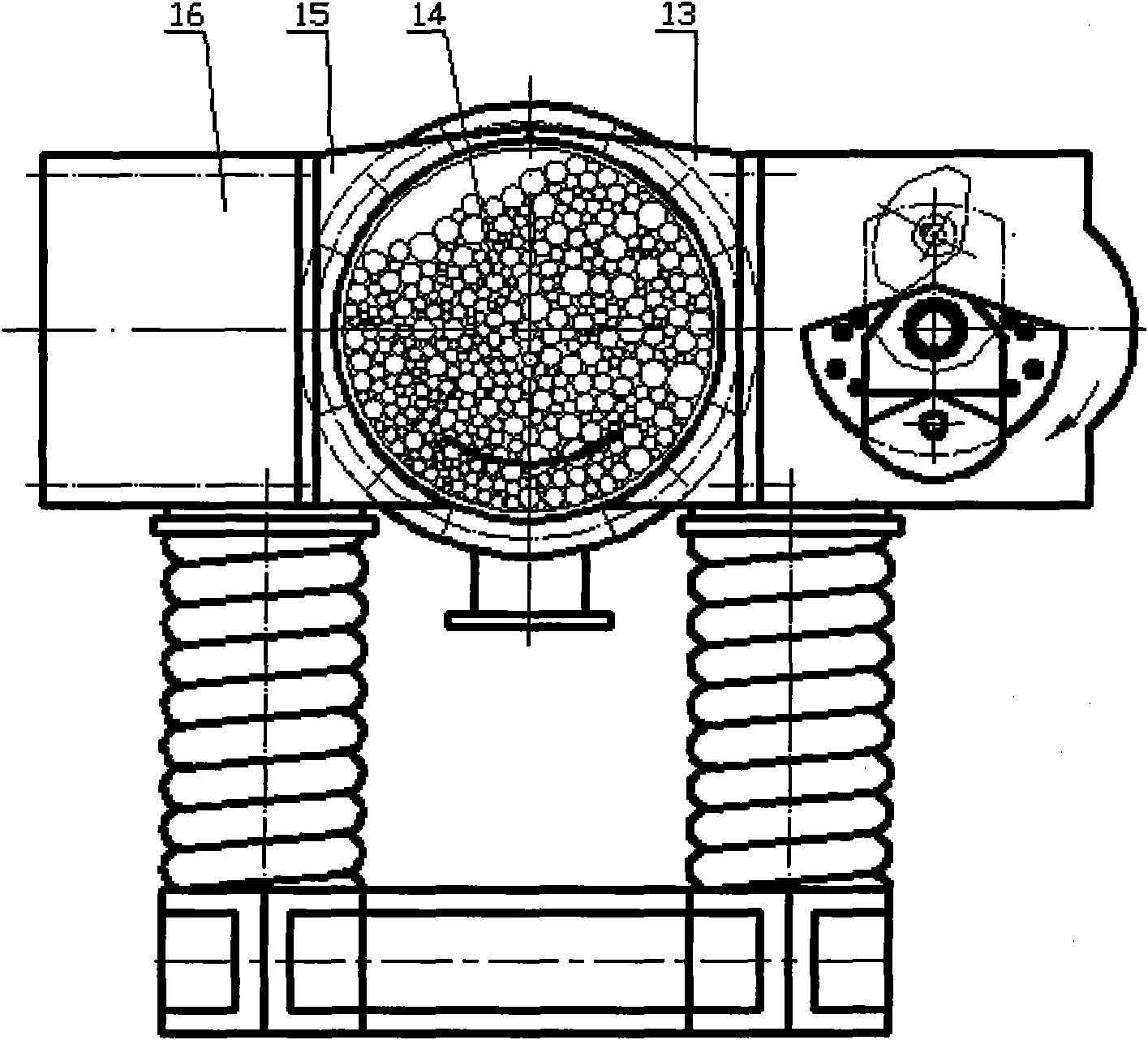

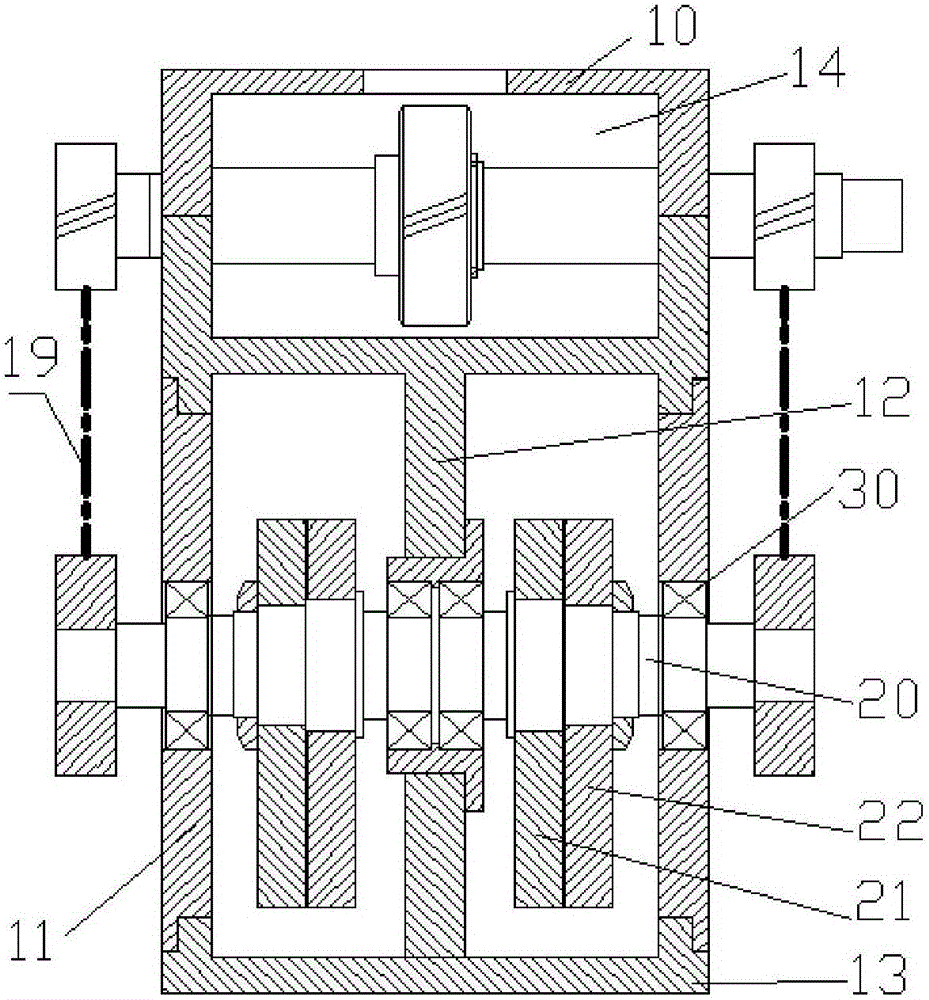

Three-joint three-phase asynchronous flame proof vibrating motor

ActiveCN101577458AExciting force action point span is largeReduce weightMechanical energy handlingSupports/enclosures/casingsThree-phaseMechanical engineering

The invention relates to a three-joint three-phase asynchronous flame proof vibrating motor that consists of two vibrators (2) and a three-phase asynchronous flame proof motor. The three-phase asynchronous flame proof motor consists of a base (4), and a rotor (19) and a stator (18) which are in the middle of the base. An inner seat cover (17) and a bearing which plays a role of supporting are arranged between the stator and a bearing support (13). Two ends of the base are respectively provided with a vibrator (2). Each vibrator is internally provided with two eccentric blocks (9) which are in key connection with a rotor spindle; the right side and left side of each eccentric block are respectively provided with a bearing for supporting the vibrator. Due to the adoption of the novel structure, the motor solves the technical difficulties of the prior art, can not only realize self synchronization shock excitation after being directly mounted on a vibrating machine, but also conveniently realize a plurality of purposes of light weight, long span, low power, large shock excitation force, flame proofing and the like, and can be widely applied to relevant self synchronization vibrating screens of a plurality of industries.

Owner:钟祥新宇机电制造股份有限公司

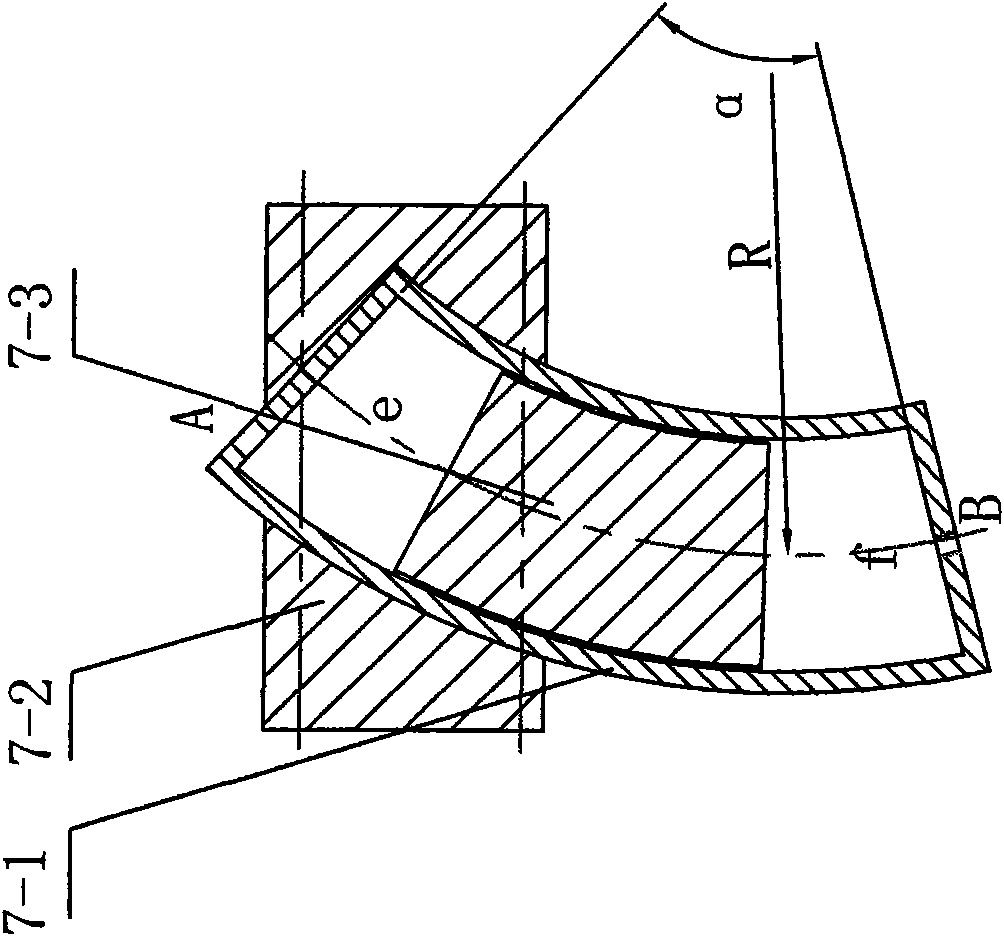

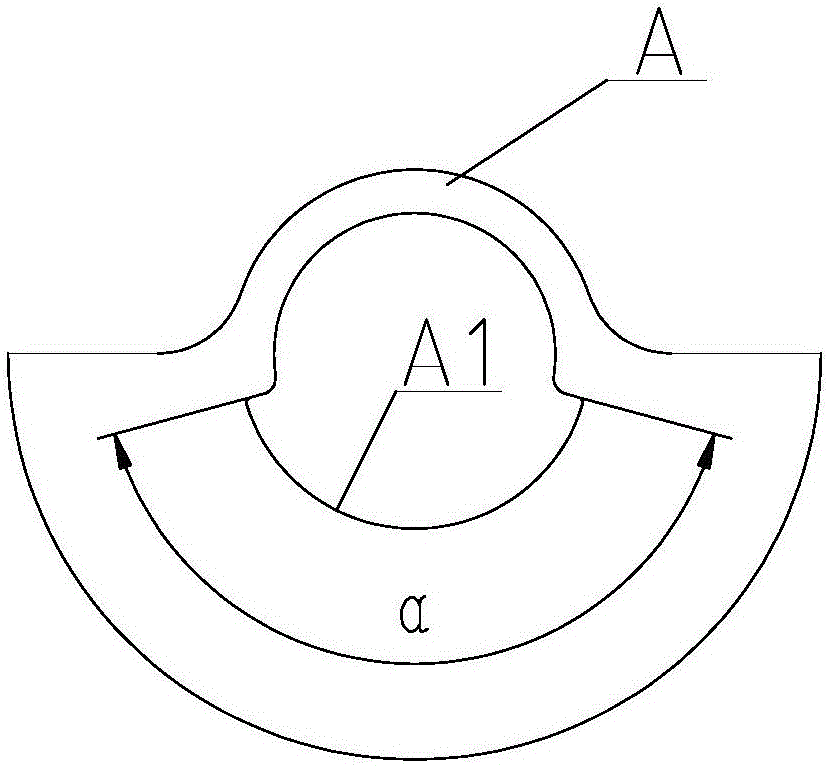

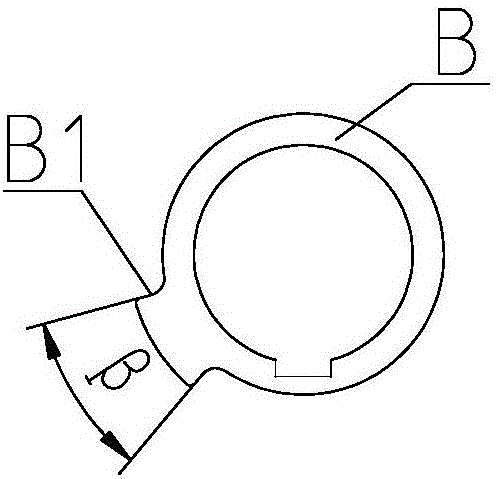

Method for amplifying beam structure and improving amplitude ratio in blade vibration fatigue test

PendingCN109163870AIncrease stiffnessRaise the first order resonance frequencyVibration testingEngineeringHigh frequency

The invention discloses a method for amplifying a beam structure and improving an amplitude ratio in a blade vibration fatigue test. The method is applied to the blade vibration fatigue test, and comprises a base, an amplifying body and a fixture body are arranged on the base, the fixture body is fixed above the magnifying body, and the fixture body and the magnifying body are integrally arranged;and a pressing block is arranged on the fixture body, the pressing block can be fixed with a blade through a connecting component, the connecting component comprises a tenon and a mortise, the mortise is formed in the pressing block, and the blade comprises the tenon that can be embedded in the mortise. The amplitude ratio in the vibration fatigue test can be improved, so that the blade vibrationfatigue test with relatively large exciting force and relatively high frequency can be implemented.

Owner:苏州长菱测试技术有限公司

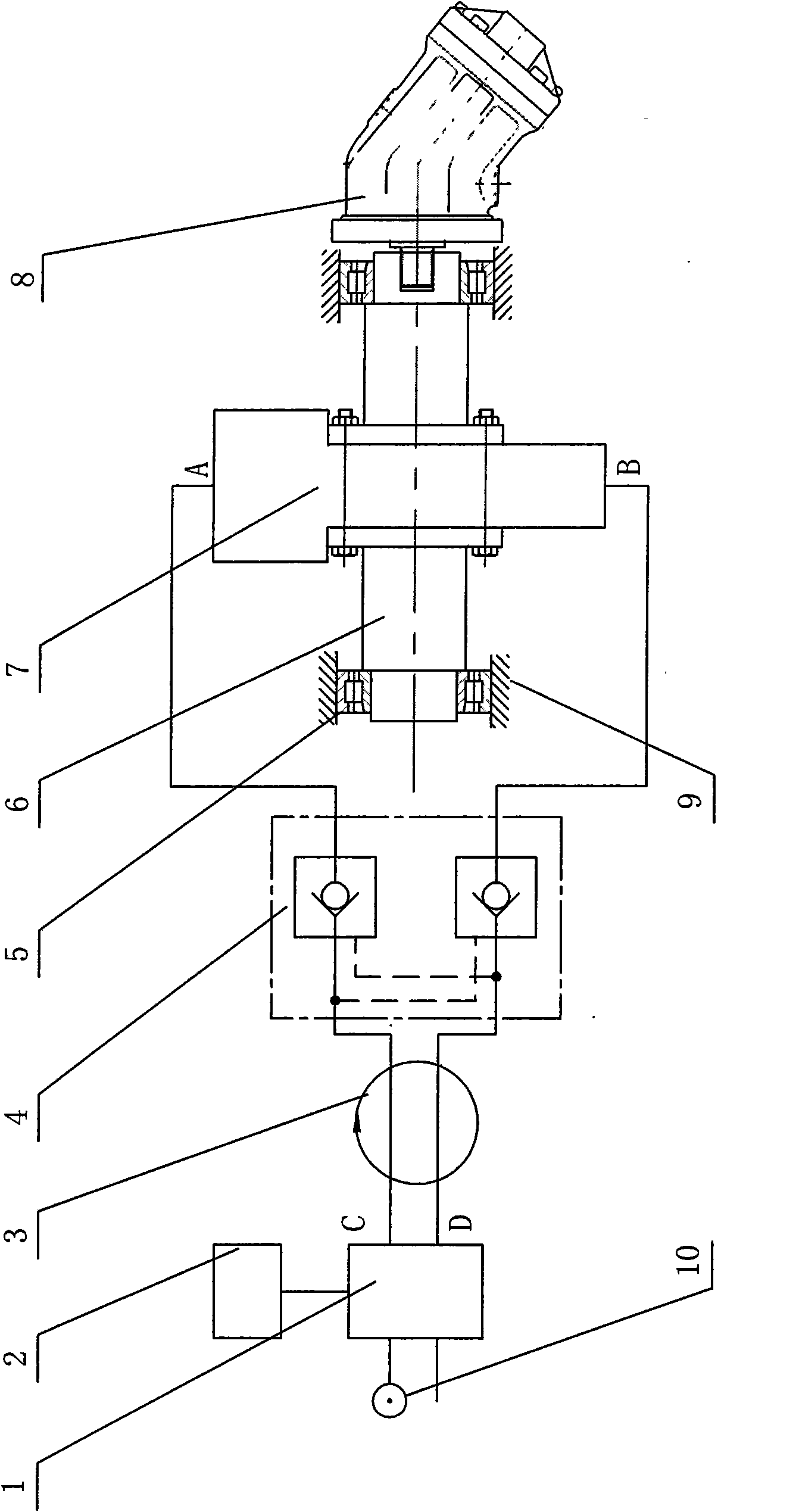

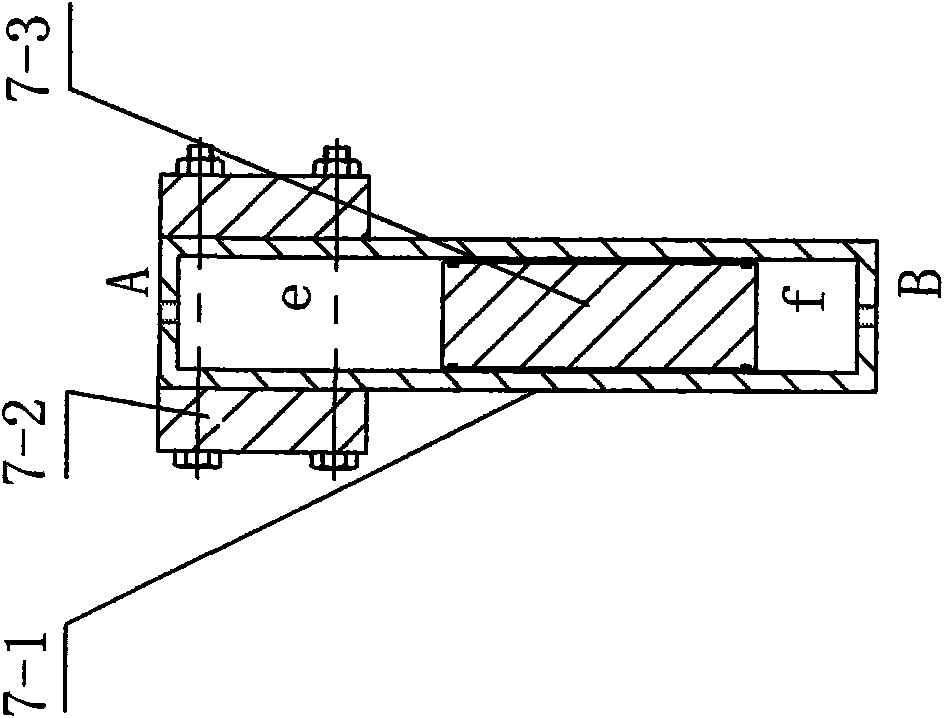

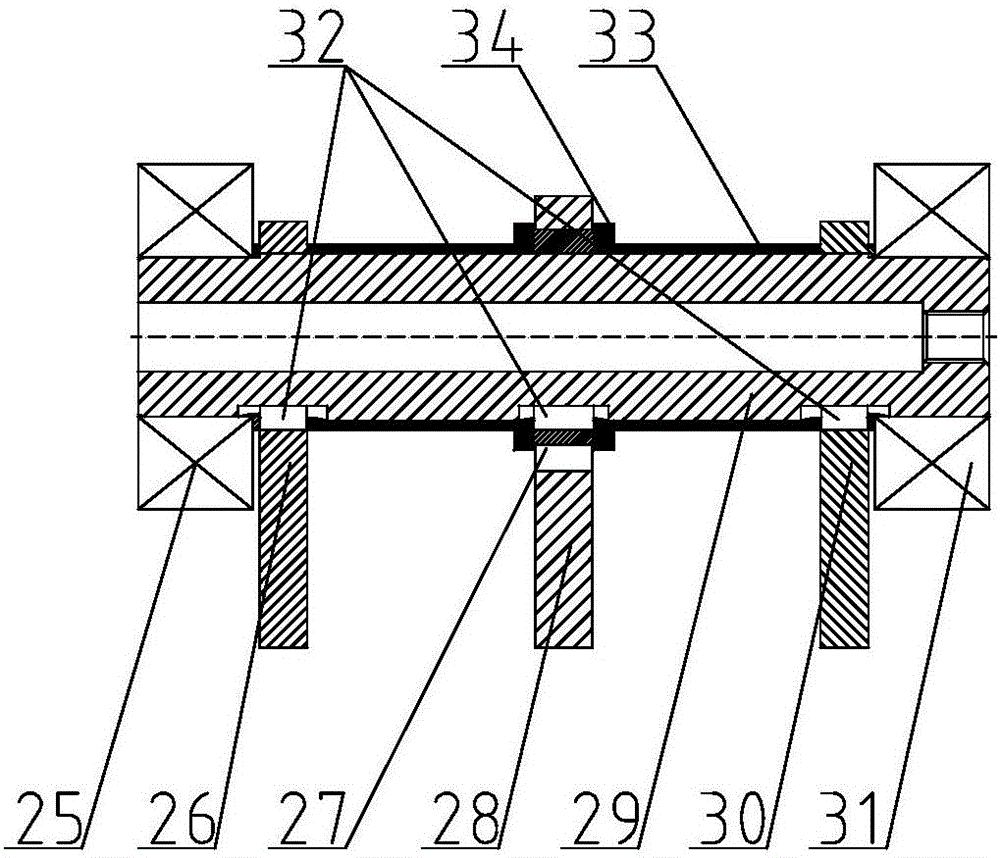

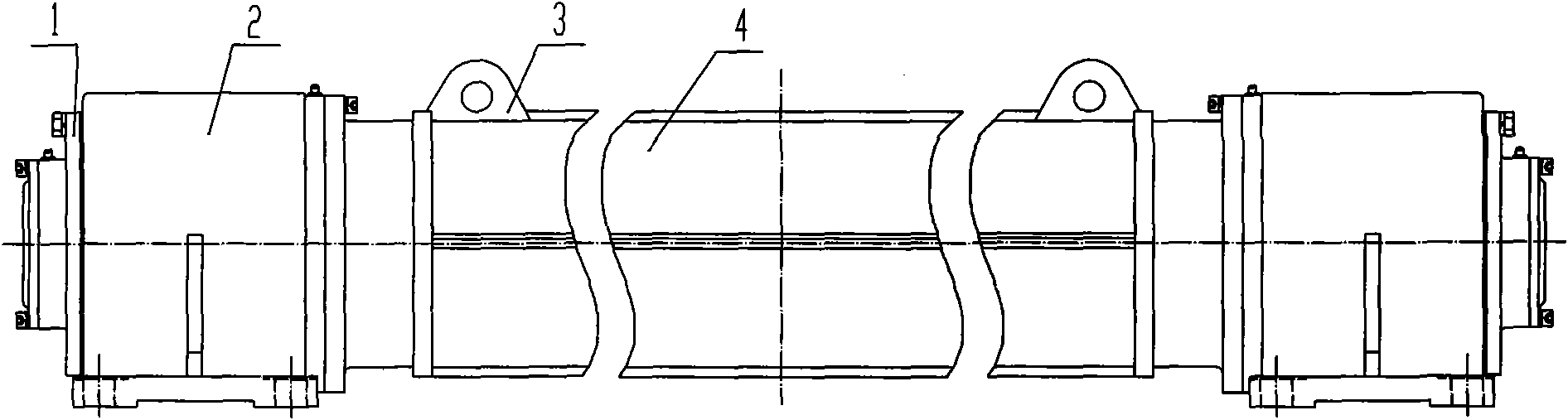

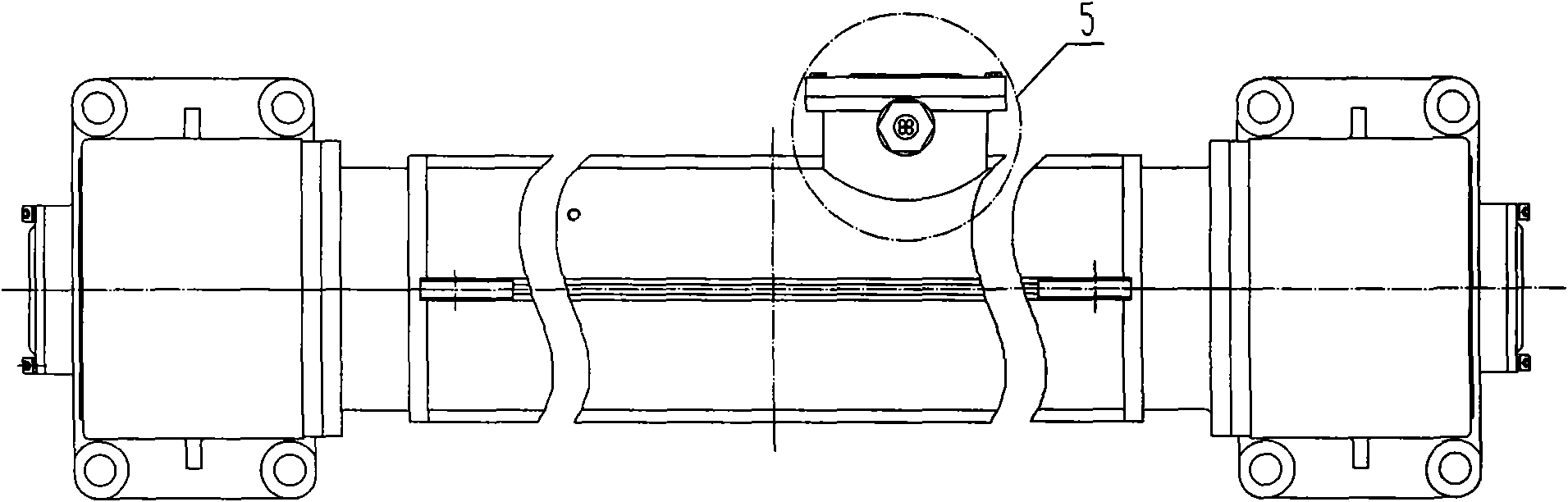

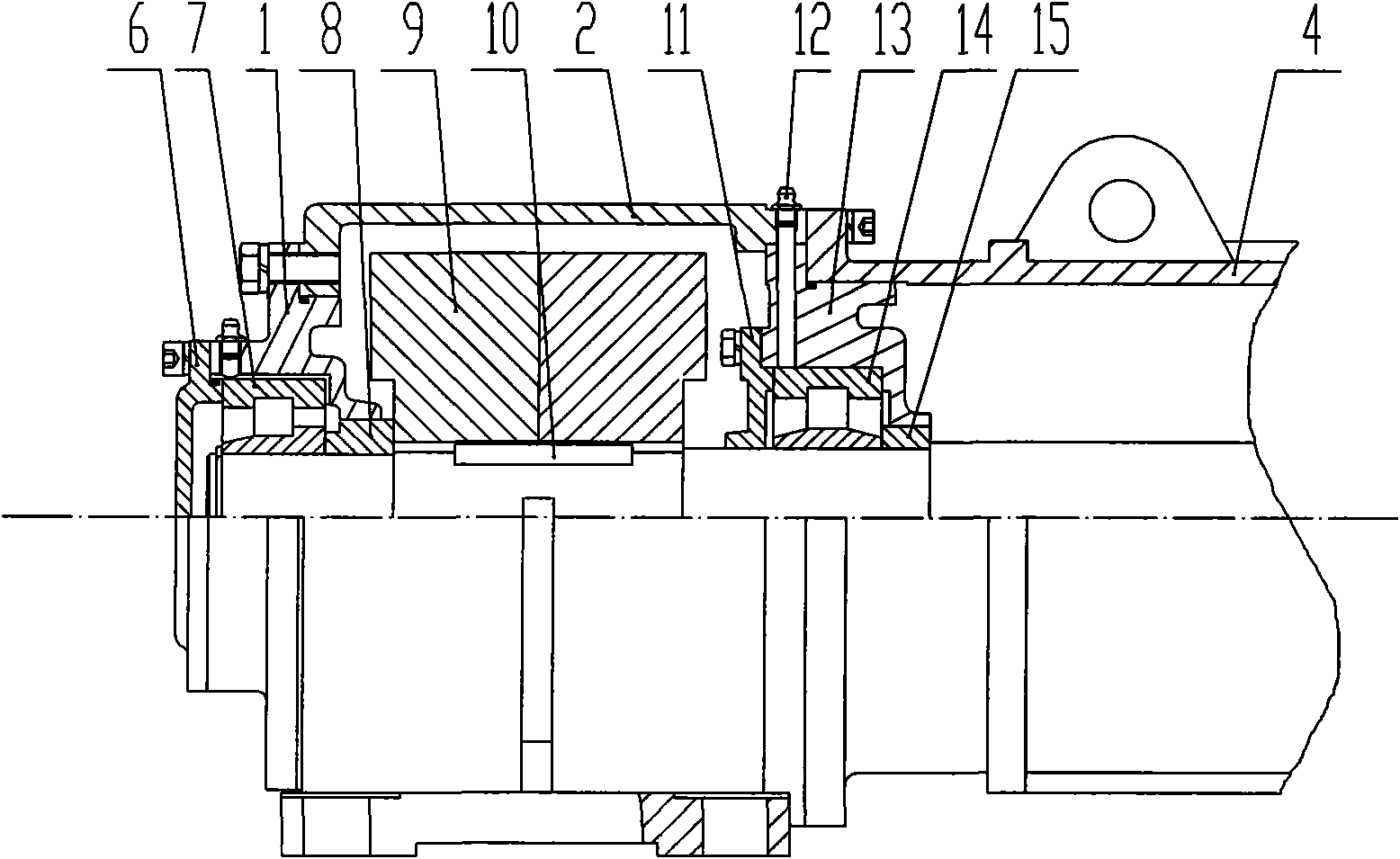

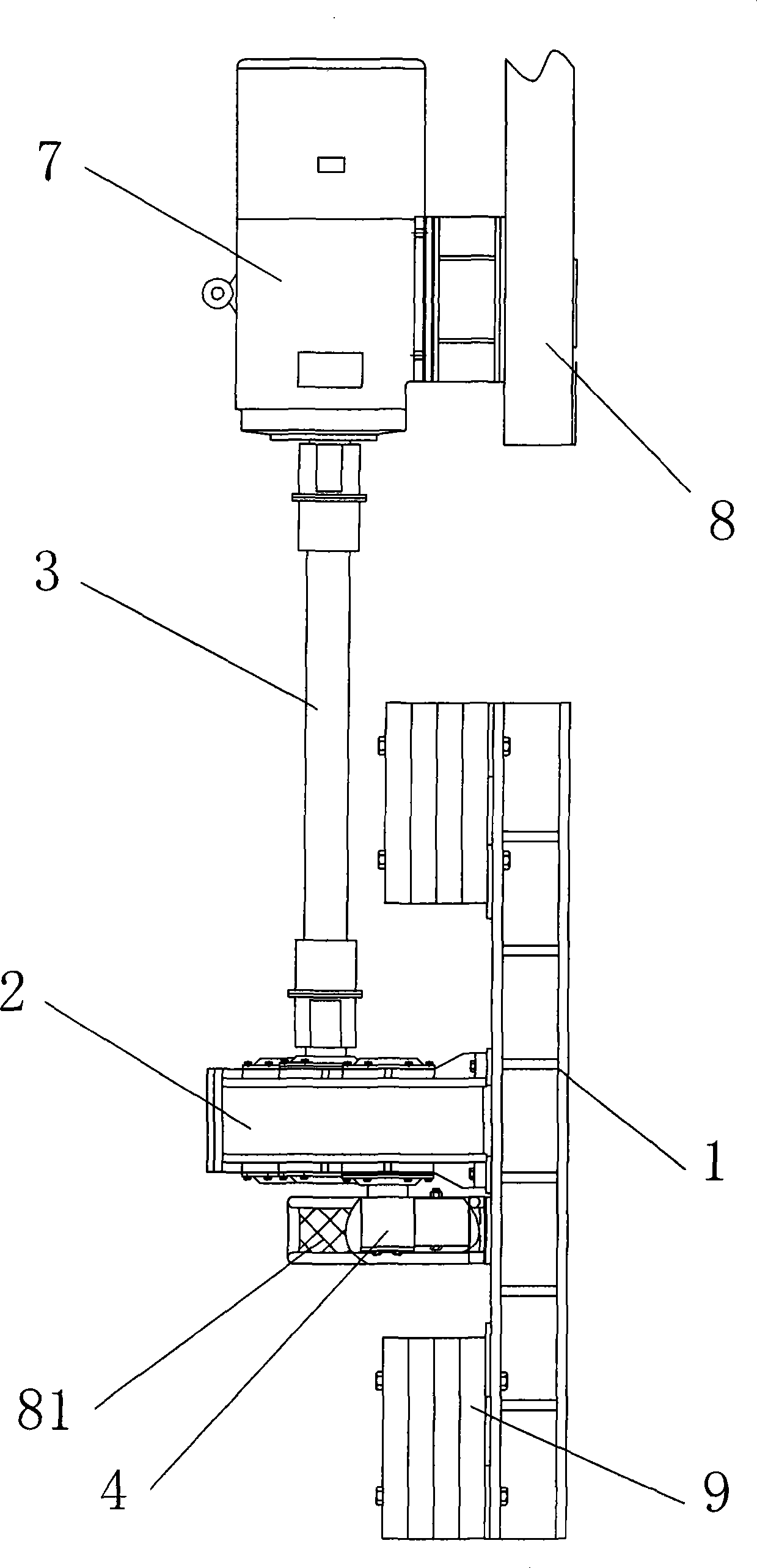

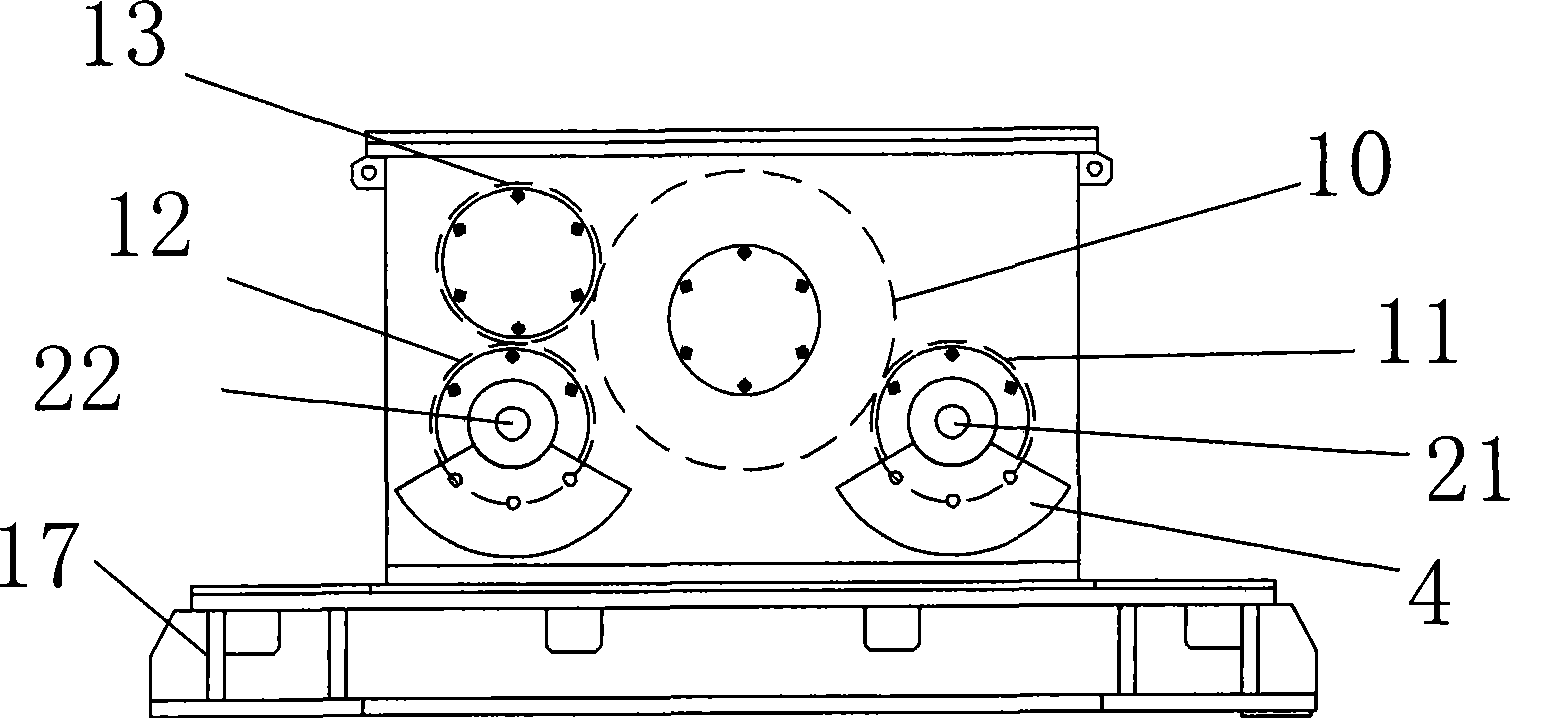

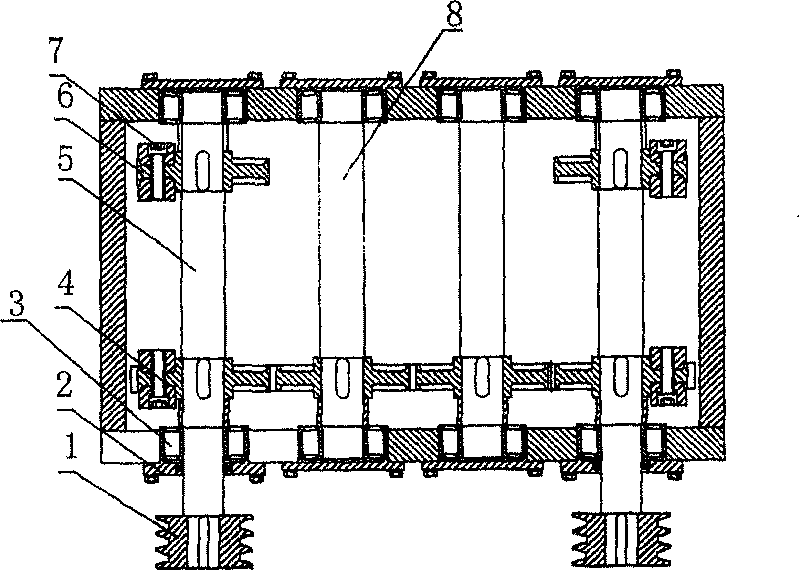

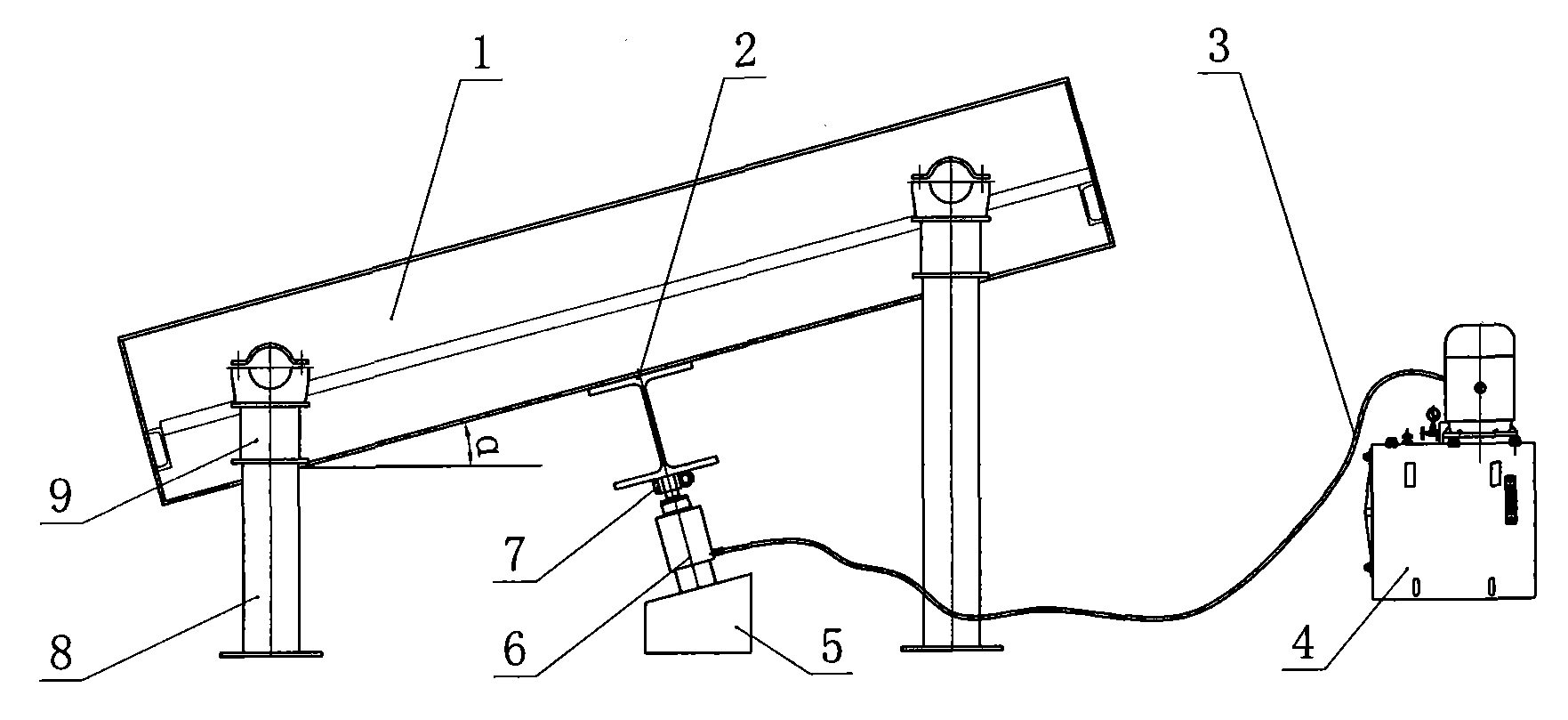

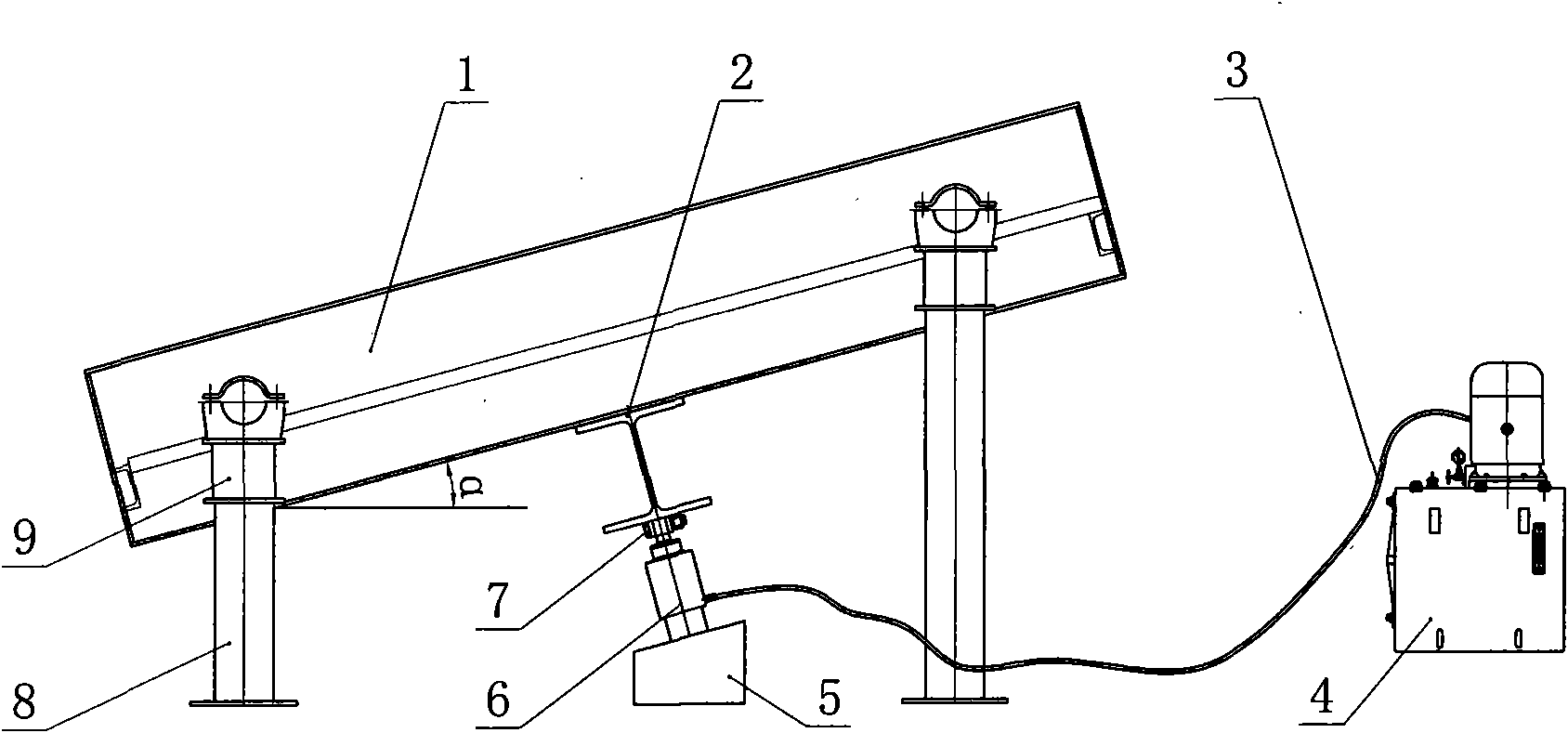

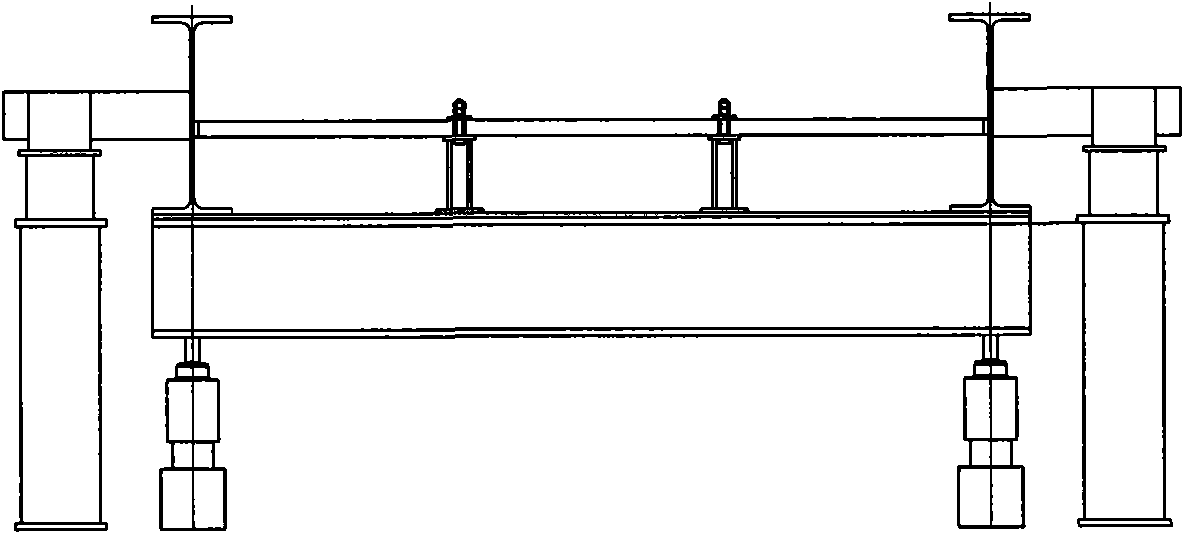

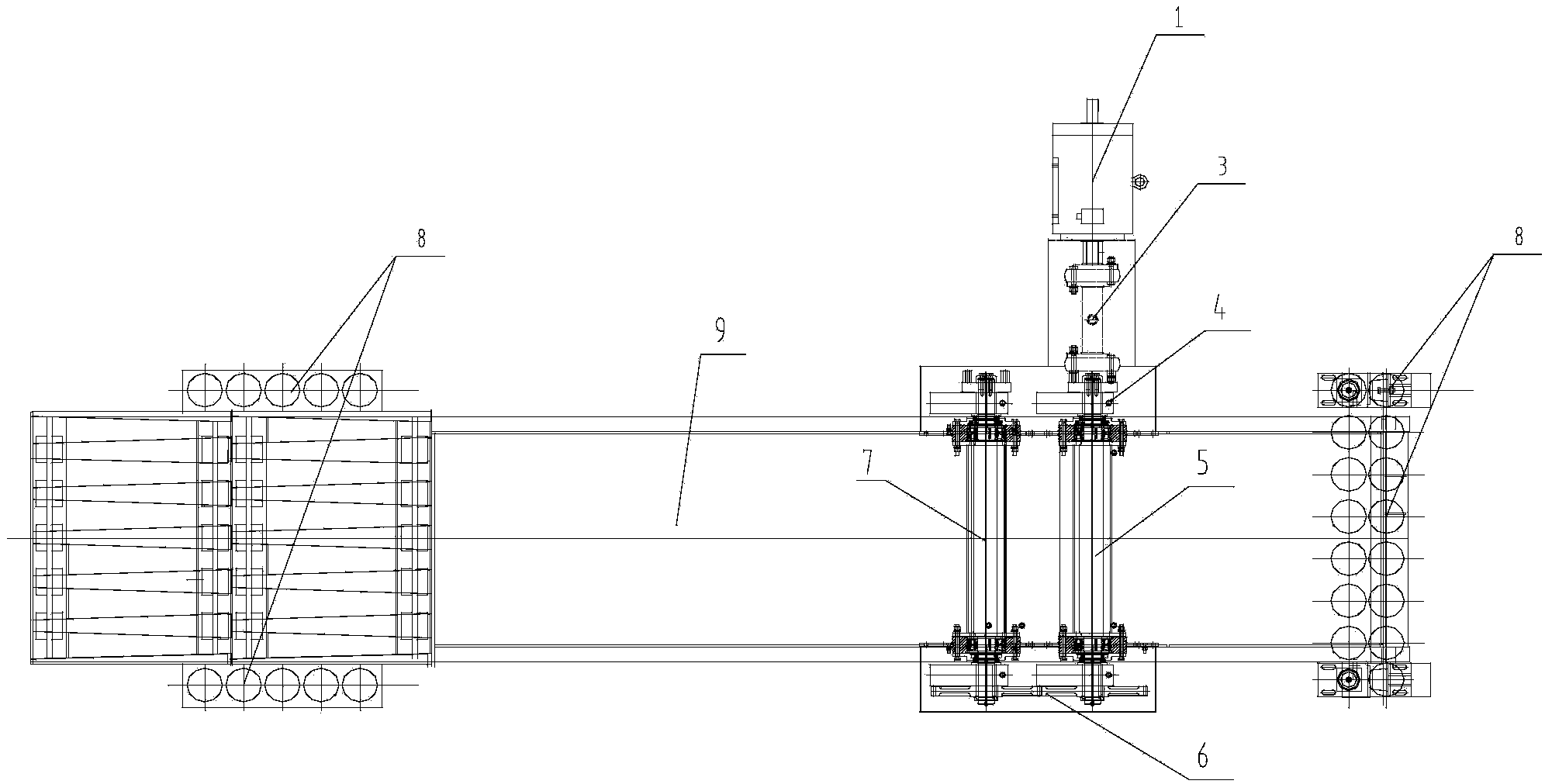

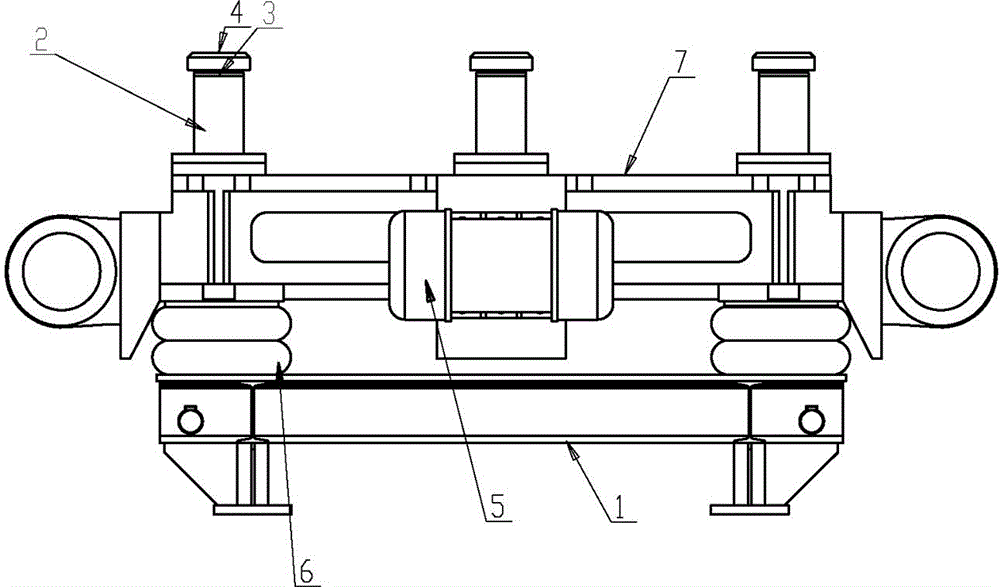

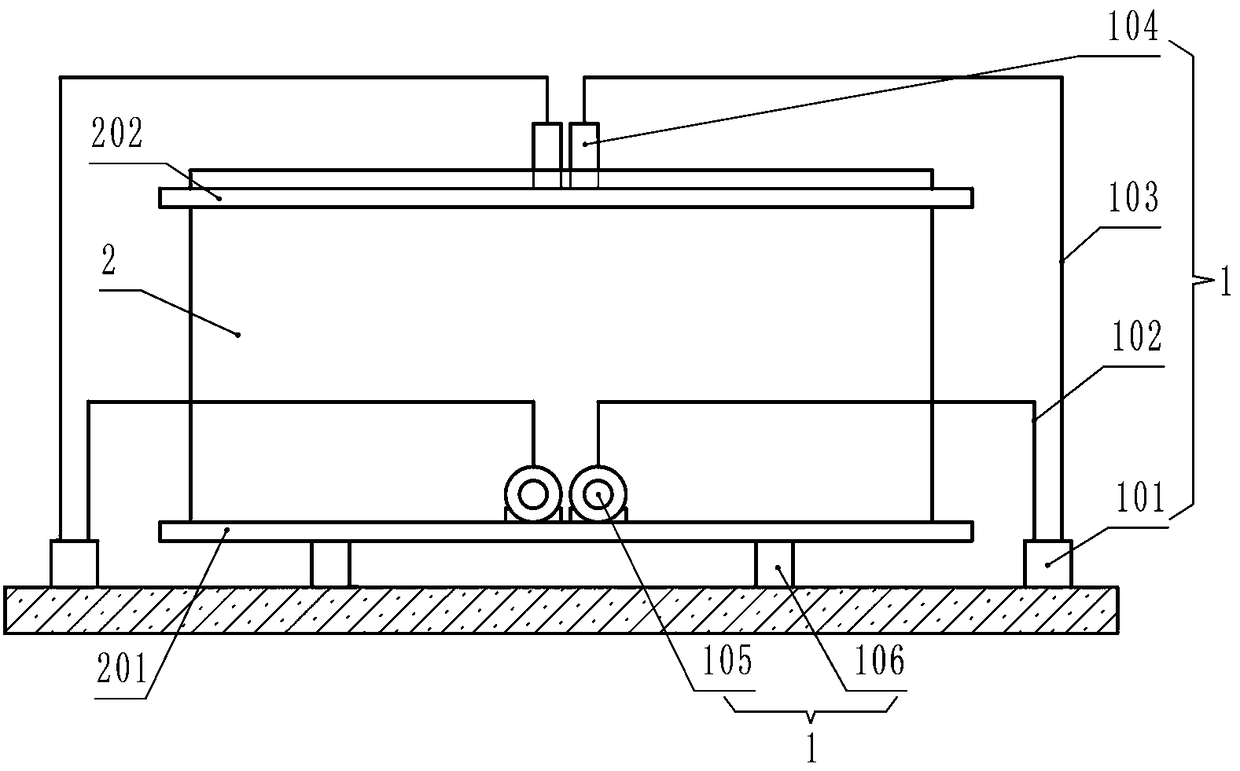

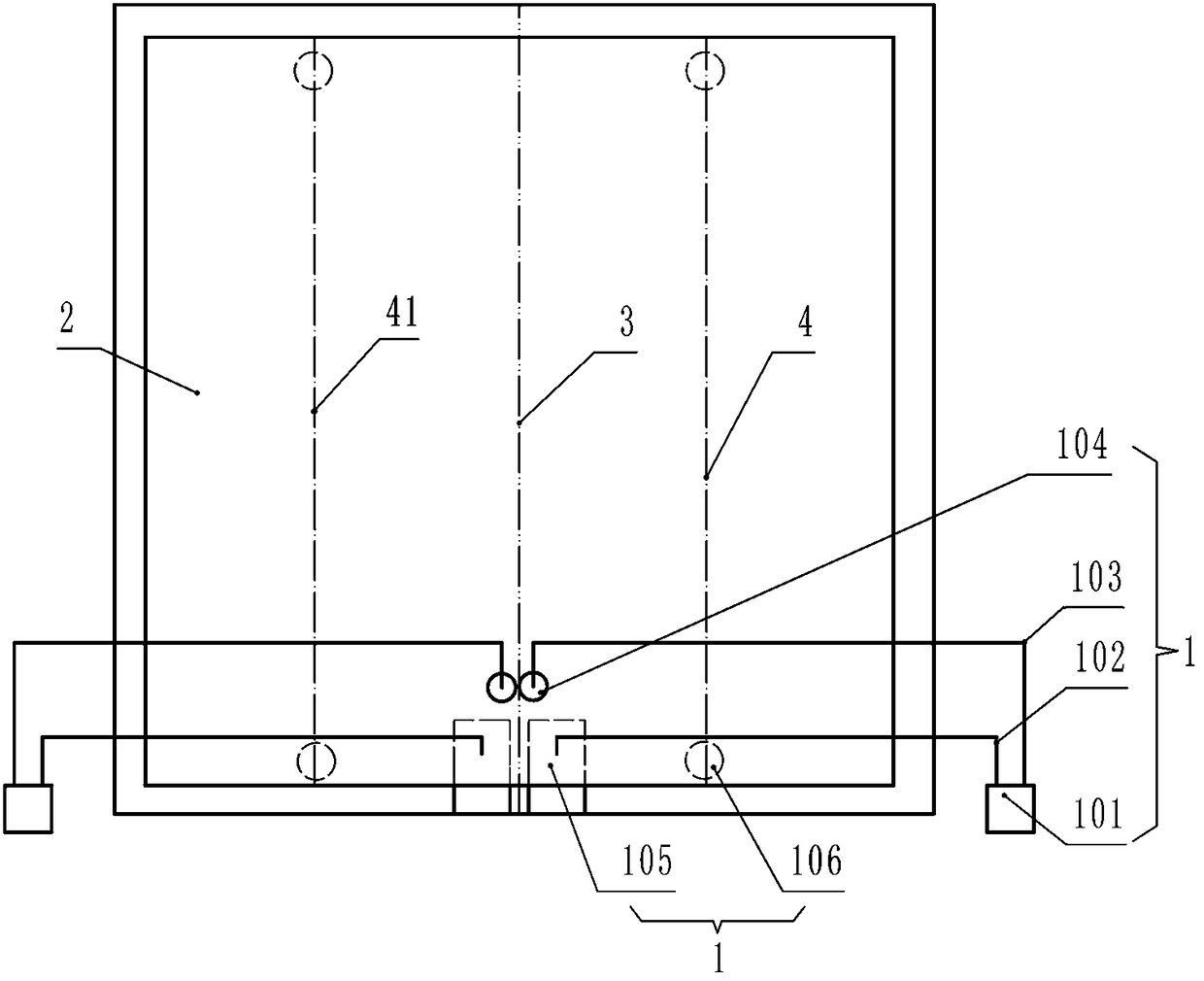

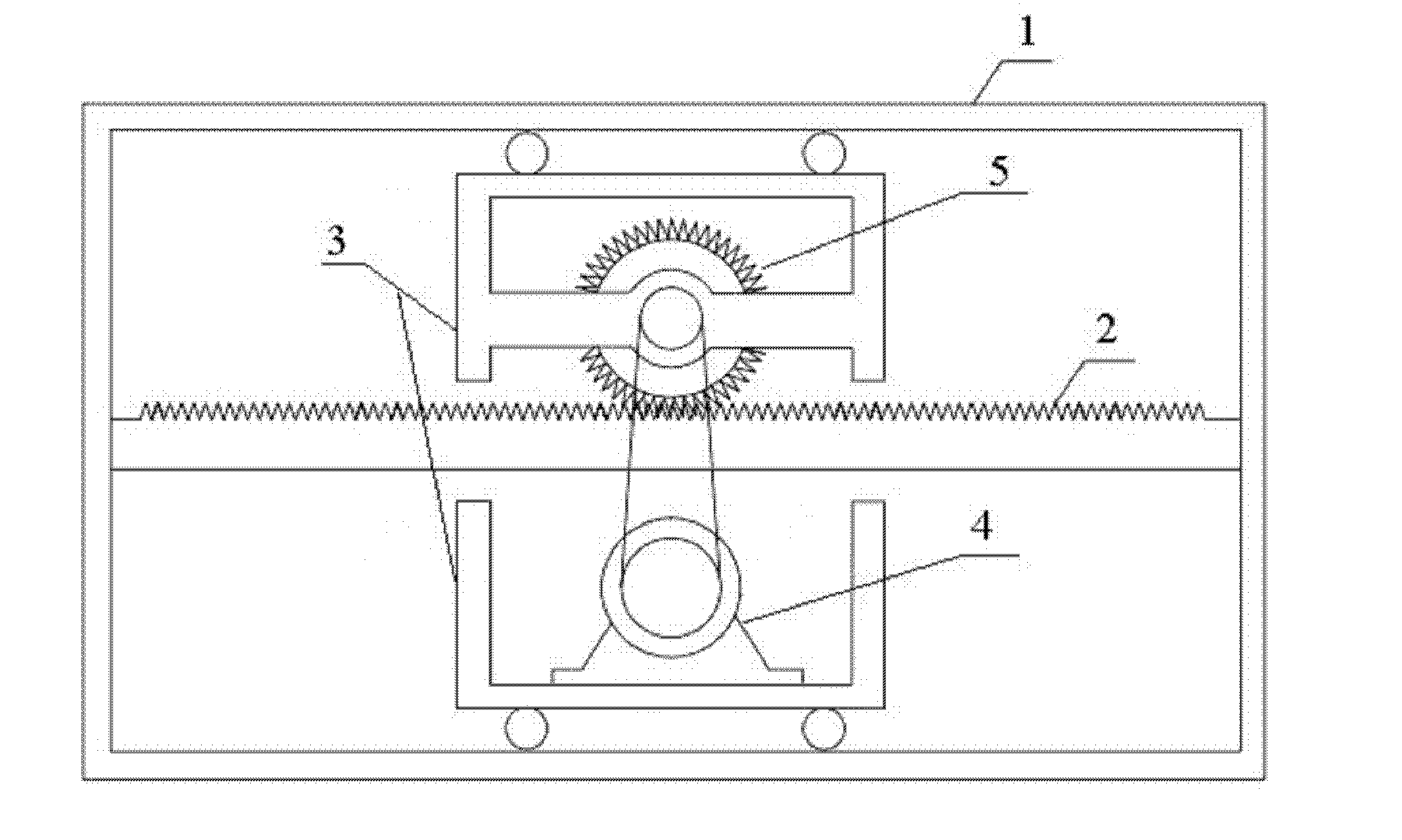

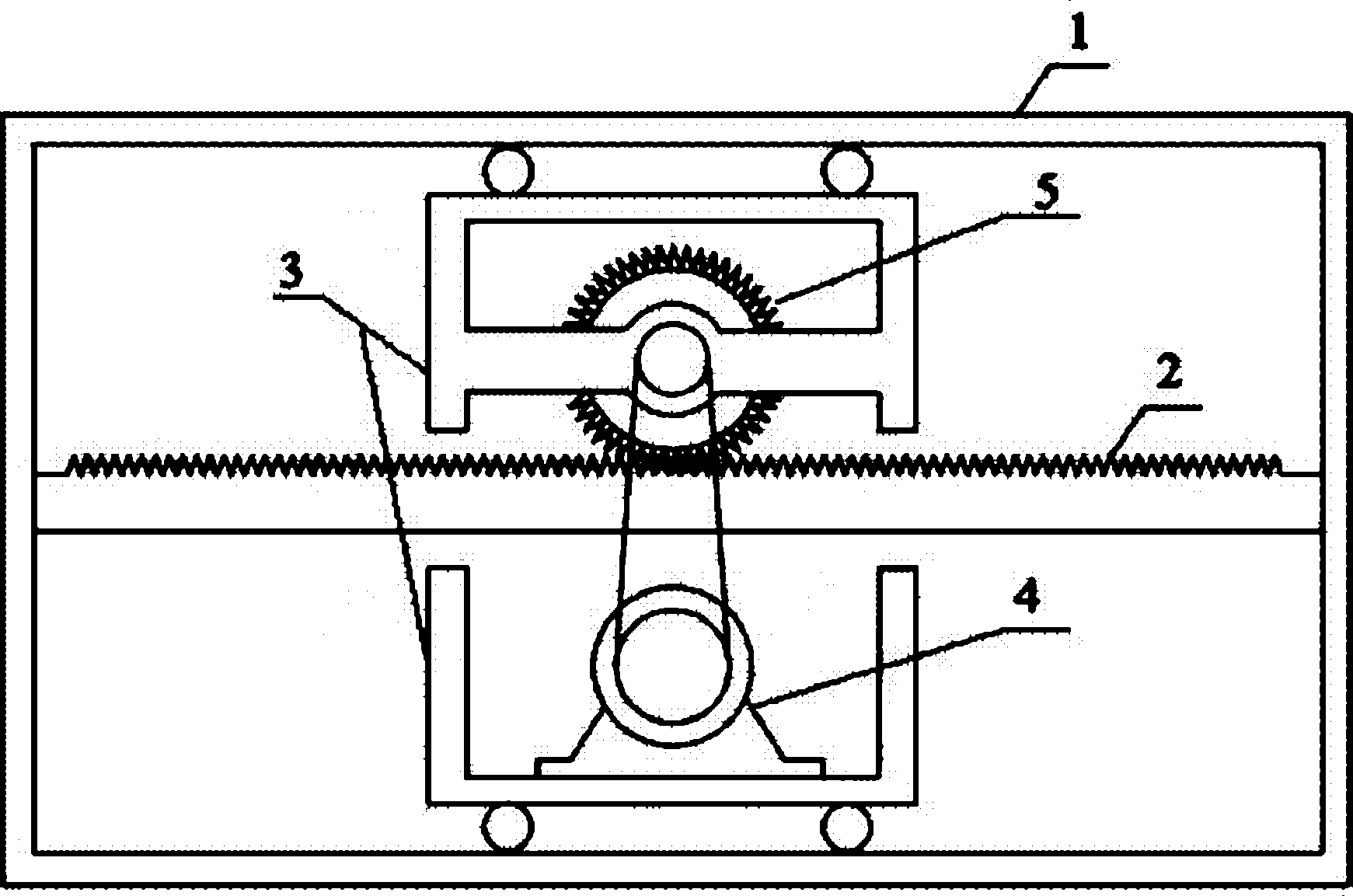

In-situ modeling test system for live loading of high-speed railway

InactiveCN101465575AExtended service lifeImprove reliabilityMechanical energy handlingModel testControl theory

The invention relates to a high-speed railway live-loading field analog experiment system, comprising: a frequency control motor (7) is fixedly arranged on a mounting trolley (8) of the motor, the shaft of the motor (7) is connected with the input shaft at one side of a speed increaser (2) by a universal coupler (3); the front and rear output shafts (21, 22) with the same height at the other side of the speed increaser (2) are connected with same eccentric blocks (4), and the rotating speed of the front and rear output shafts (21, 22) is same, the rotating direction thereof is reverse; the speed increaser (2) is fixed in the center of the upper surface of a vibrating grid (1). The exciting force of the system is strong, excited frequency thereof is high, the reliability is high, and installation and debugging are convenient; therefore, the system is particularly suitable for the high-speed railway live-loading field analog experiments.

Owner:SOUTHWEST JIAOTONG UNIV

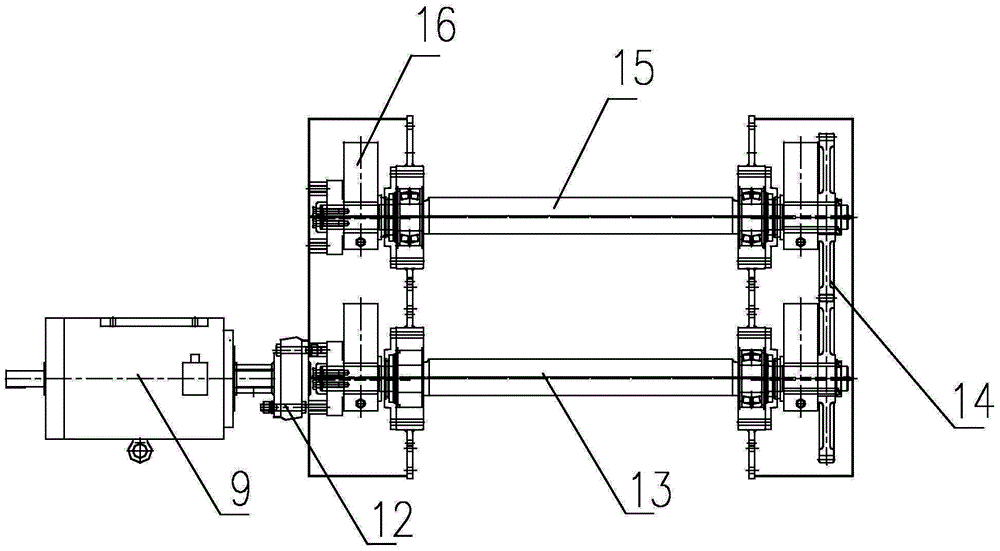

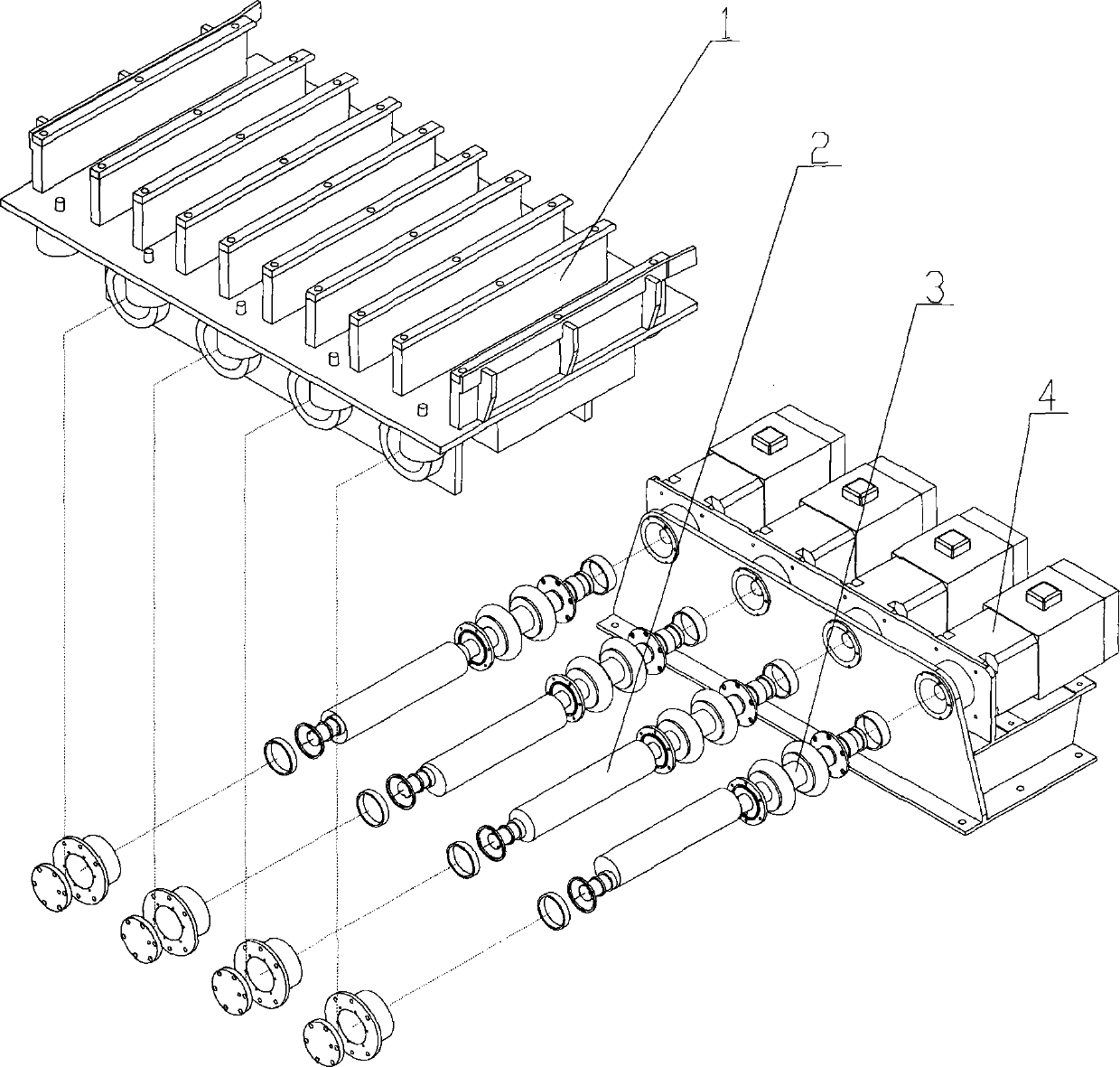

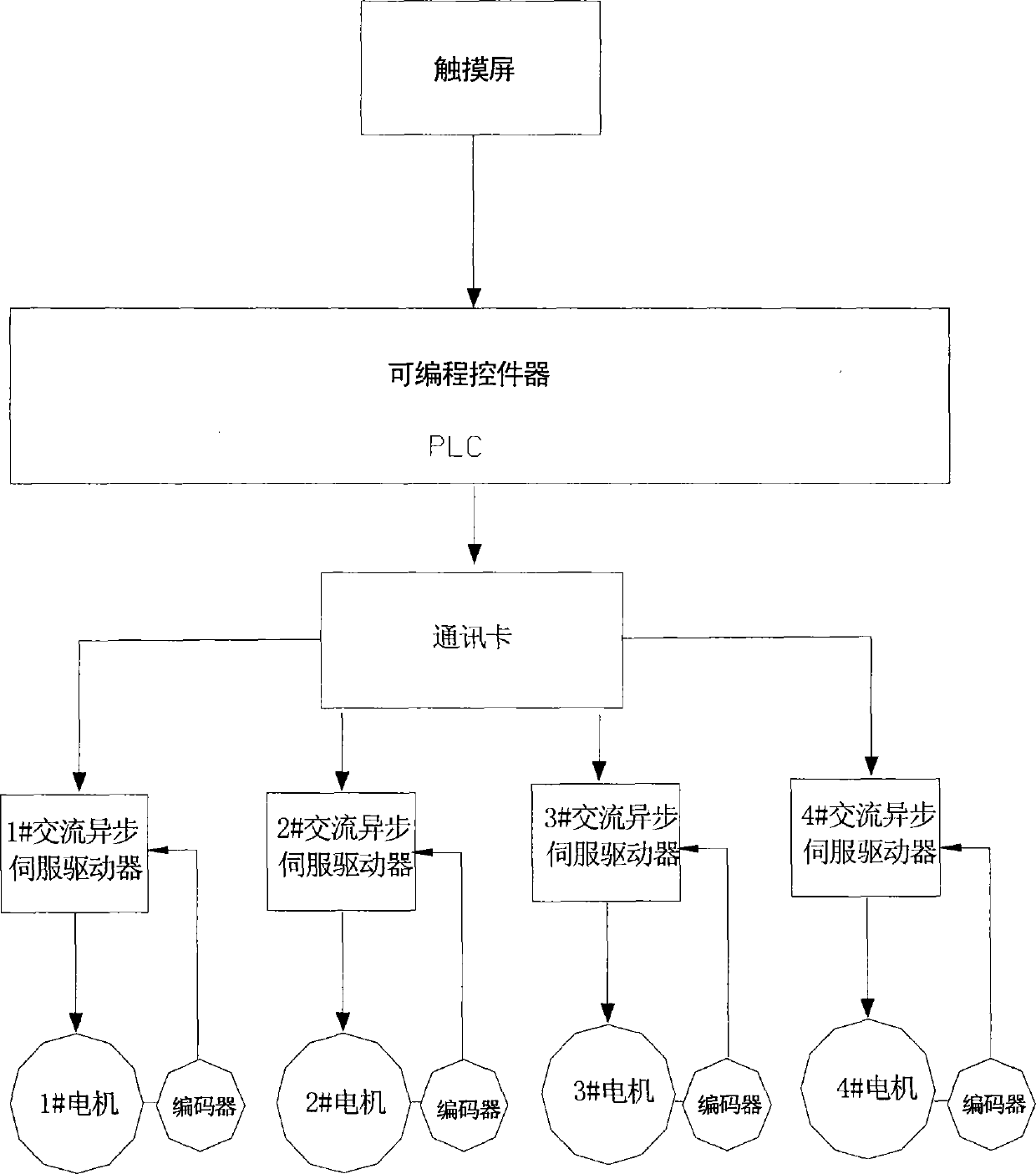

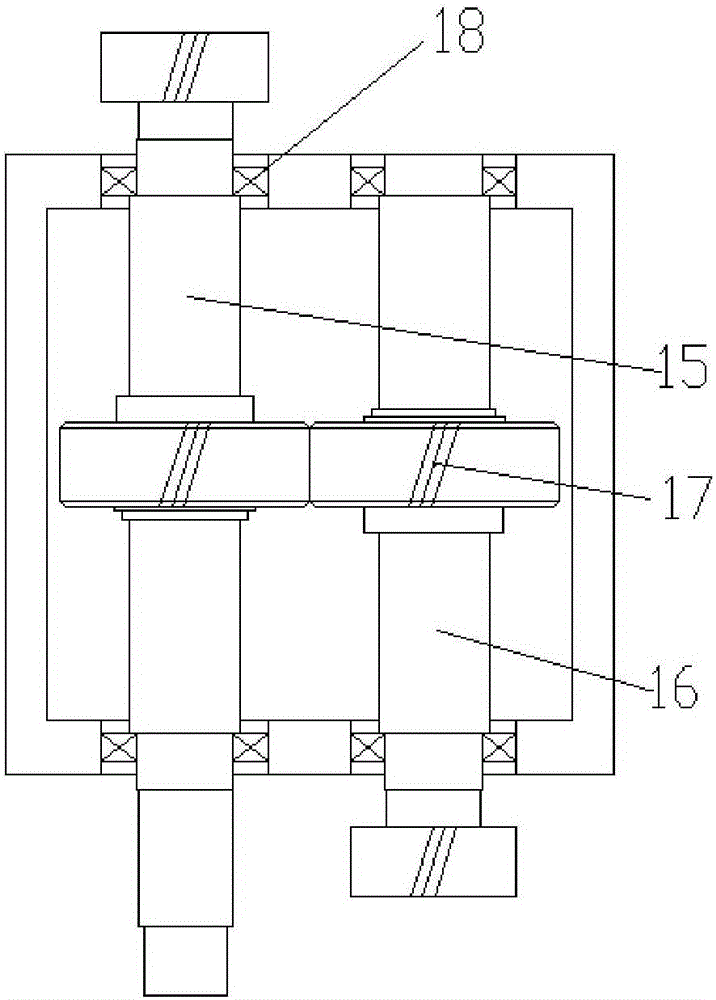

Variable-frequency and variable-amplitude vertical vibration device of block forming machine

InactiveCN103465340AQuality assuranceEliminate wear and tearCeramic shaping apparatusVertical vibrationVibration amplitude

The invention discloses a variable-frequency and variable-amplitude vertical vibration device of a block forming machine, and belongs to the technical field of design and manufacture for variable-frequency and variable-amplitude vertical vibration devices of block forming machines. The variable-frequency and variable-amplitude vertical vibration device comprises an electronic control portion and a mechanical portion. The electronic control portion comprises a touch screen, a programmable controller, a communication card and an alternating-current asynchronous servo driver. The mechanical portion comprises a vibration table and four vibration units. Each vibration unit comprises an eccentric shaft, a flexible coupling and a motor. Two rotation units of each group constantly keep oppositely and synchronously rotating under the control of the electronic control portion, and the vibration amplitude of the variable-frequency and variable-amplitude vertical vibration device can be changed by means of changing an included angle between two groups of rotation units during operation. The variable-frequency and variable-amplitude vertical vibration device has the advantages that the optimal vibration amplitude value and the optimal vibration frequency value can be selected according to forming requirements of concrete mixtures, so that the material application range can be expanded, and the quality of finished products can be guaranteed; the eccentric shafts are directly driven by the couplings to rotate, so that connecting assemblies such as eccentric shaft coupling gears of original equipment are omitted; problems of abrasion and damage of the assemblies such as the coupling gears due to frequent starting and stopping and high-speed violent vibration are solved.

Owner:营口惠邦科技发展有限公司

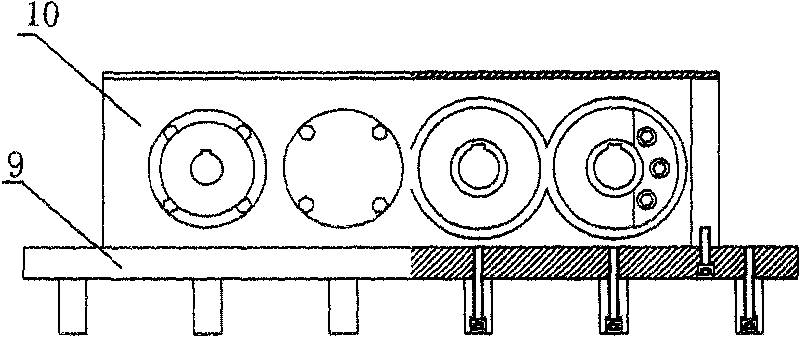

Vibration box of brick making machine

InactiveCN101708622AShorten molding cycleImprove eccentricityCeramic shaping apparatusHydraulic motorBrick

The invention discloses a vibration box of a brick making machine, which comprises a vibration box body fixed on a vibration platform, wherein two main shafts and two transmission shafts are arranged in the box body; one end of the two main shafts passes through the box body; belt pulleys are arranged at end parts of the main shafts; the main shafts and the transmission shafts are provided with a synchromesh gear respectively, and the synchromesh gears are meshed mutually; the rear ends of the two main shafts are provided with a flange plate respectively; and eccentric blocks are fixed on the synchromesh gears on the main shafts and end faces of both sides of the flange plates. When the vibration box operates, two main shafts of the vibration box are driven by a motor or a hydraulic motor through the belt pulleys to make synchronous reverse rotation, so that the vertical directional vibration of the vibration platform of the brick making machine and a casting box is realized. The vibration box has the advantages of large excentricity, small starting drag torque, quick vibration starting, short time of vibration starting and vibration stop and large exciting force.

Owner:高成法

Vibrating screen with hydraulic cylinder

InactiveCN101811117AGuaranteed uptimeMeet actual needsSievingScreeningExcitation beamHydraulic cylinder

The invention discloses a vibrating screen with a hydraulic cylinder, which belongs to screening equipment and can be widely used for screening and classifying ores, coals and other non-metal materials. The vibrating screen comprises a screen body, a screen body excitation beam, a pump station system, a base frame, the hydraulic cylinder, a fixed component, a bracket and a damping spring, wherein the screen body is supported on the bracket by the damping spring. The vibrating screen is characterized in that: one end of a hydraulic oil pipe is connected with the pump station system, while the other end is connected with the hydraulic cylinder; and the hydraulic cylinder is fixed on the base frame and is connected with the screen body excitation beam through the fixed component. The hydraulic cylinder can drive a plurality of types of vibration equipment through excitation and can realize stepless speed adjustment to the maximum of 1,000 times per minute, vibration parameters of the hydraulic cylinder are adjustable, are easy to control, and can ensure that a screening machine runs stably without resonances; besides, one pump station system can drive a plurality of hydraulic cylinders to perform excitation, and can increase the exciting force and meet the needs of a heavy-type efficient vibrating screen.

Owner:陆信

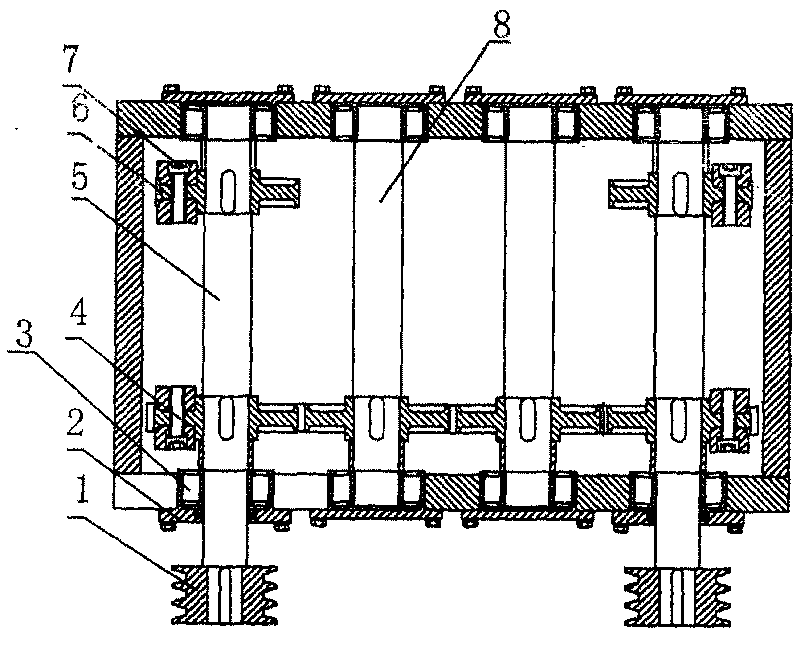

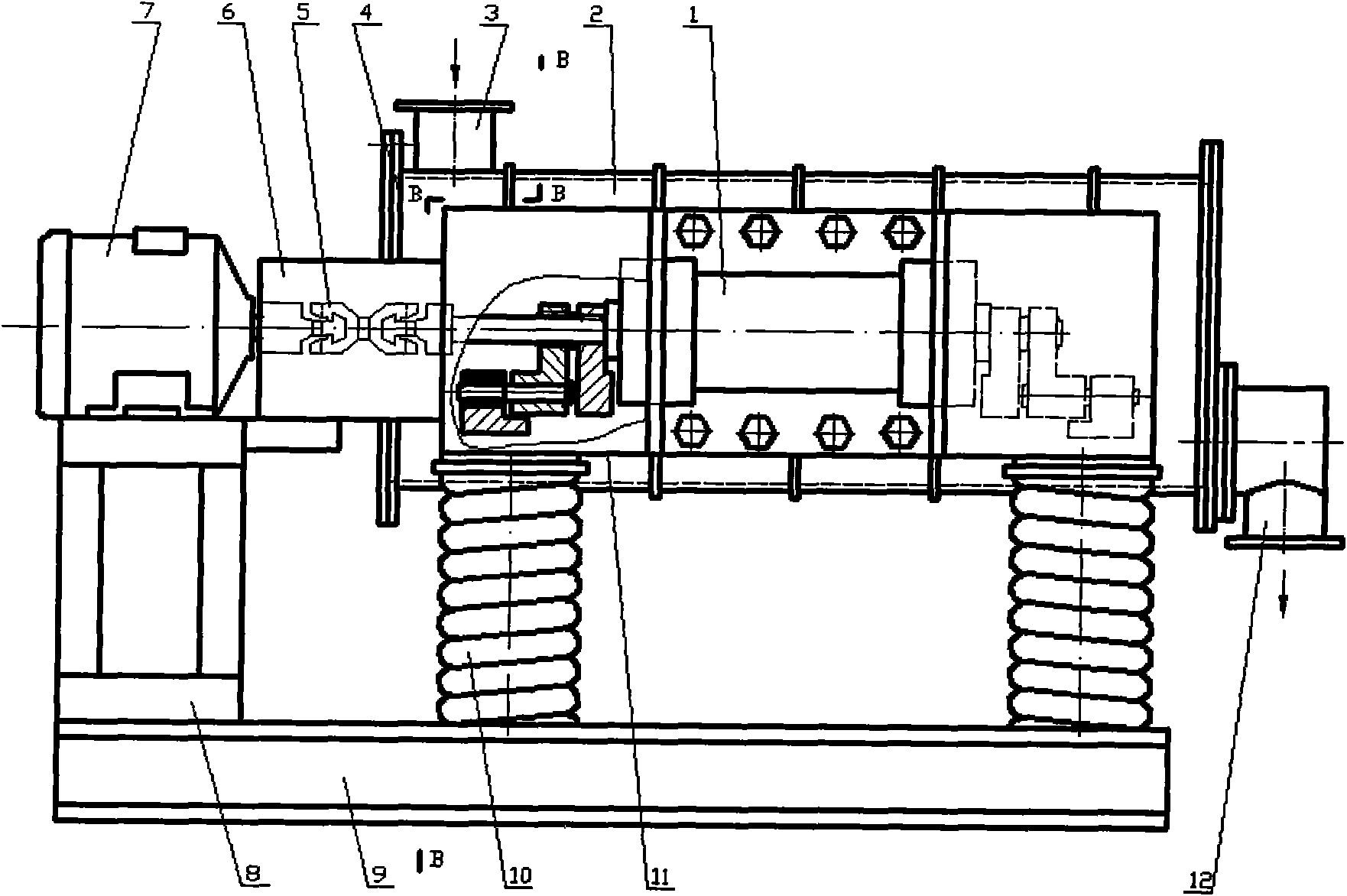

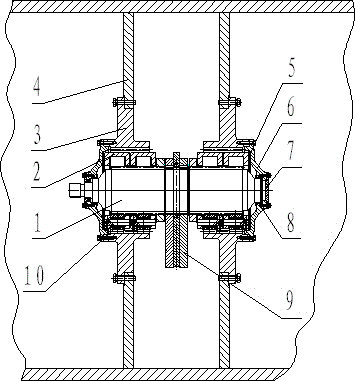

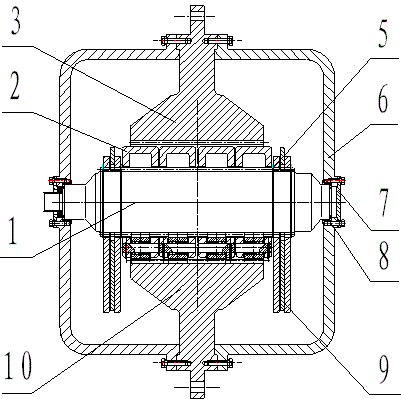

Secondary variable pendulum chaotic vibrating mill

InactiveCN101972689ASmall starting torqueIncrease speedMechanical vibrations separationGrain treatmentsCouplingCoil spring

The invention discloses a secondary variable pendulum chaotic vibrating mill, relating to a vibrating mill capable of generating special inertia excitation capacity, in particular to a vibrating mill with special vibrating effect, chaotic vibrating characteristics and a secondary variable pendulum structure. The vibrating mill comprises a vibration excitor, a cylinder body, a feed inlet, end covers, a coupling, a motor, a motor seat, a base, a helical spring, a discharge outlet, a right connecting bracket, a milling medium, a left connecting bracket and a balance weight body, wherein the vibration excitor is rigidly fixed at the right side of the cylinder body through the right connecting bracket; the balance weight body is rigidly fixed at the left side of the cylinder body through the left connecting bracket; the lower parts of the cylinder body and the vibration excitor are installed on the base through the helical spring; the vibration excitor comprises a bearing seat assembly, a vibration excitor shaft and a secondary variable pendulum assembly; the motor is connected with the vibration excitor shaft through the coupling; the secondary variable pendulum assembly comprises an invariable pendulum, a primary variable pendulum, a secondary variable pendulum, a secondary variable pendulum shaft, a bearing I and a bearing II; and the cylinder body is provided with the feed inlet and the discharge outlet, the end covers are installed at two sides of the cylinder body, and the milling medium is installed in the cylinder body.

Owner:江华瑶族自治县金牛开发建设有限公司

Novel vibrating screen based on multi-motor frequency conversion excitation

InactiveCN1669673AExtended service lifeIncrease delivery speedSievingScreeningFrequency conversionElectric machinery

The invention relates to a new jigging screen based on the multi-motor frequency-changing exciting, which primarily comprises screen box, exciting apparatus and chassis, wherein the screen box set on the chassis through the spacer spring, characterized in that the exciting apparatus uses three or more rectangle or short exciting motors setting on the upper, middle or lower of the screen box, each exciting motor has different eccentric center qualities according to the actual need, the exciting motors can synchronous operate stably. The invention uses the frequency-changing apparatus to adjust the exciting rotary speed, which can meet the requirements of different behaviors. When the exciting motors operating stably, it can keep only one motor working and shut the rest, and the jigging screen can also move in a needed track.

Owner:SOUTHWEST PETROLEUM UNIV

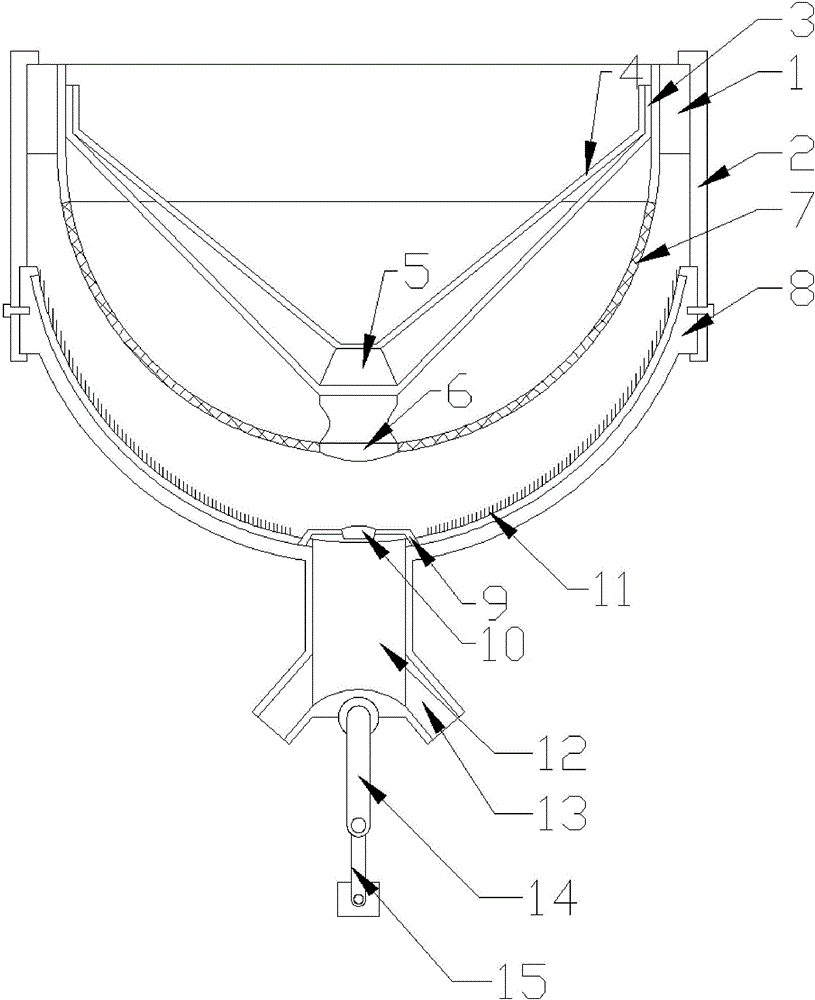

Stirring screen for powder metallurgy raw materials

The invention relates to a stirring screen for powder metallurgy raw materials. The stirring screen comprises a vibrating screen body fixed on a machine frame. The vibrating screen body comprises a supporting ring and a separating screen, wherein the supporting ring is fixedly connected with the machine frame; the edge of the separating screen is fixedly connected with the inner wall of the supporting ring; the separating screen is made of elastic metal wires; and a driving block is fixed to the middle of the separating screen. A driving plate is arranged at the lower end of the vibrating screen body; the driving plate is a hemispherical plate corresponding to the hemispherical outline of the separating screen; fibers are densely distributed in the hemispherical plate; a discharging pipe is connected with the middle of the driving plate; a hammering block corresponding to the driving block is further arranged in the position, corresponding to the middle portion of the driving plate, of the end of the discharging pipe; a crankshaft is connected with the bottom of the discharging pipe through a connecting rod; and the discharging pipe is driven by the driving plate to move vertically. A guiding sleeve is fixedly connected with the periphery of the driving plate coaxially; the inner wall of the guiding sleeve is slidably connected with the outer wall of the supporting ring; and an annular limiting ring is further arranged at the end of the guiding sleeve.

Owner:扬州派德粉末冶金有限公司

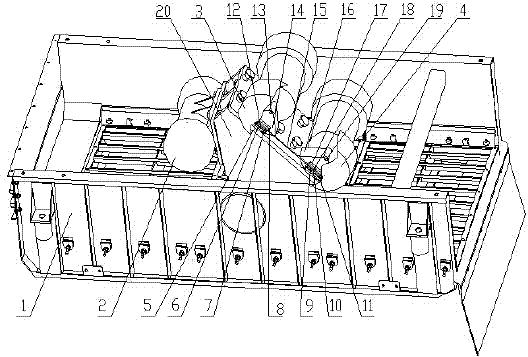

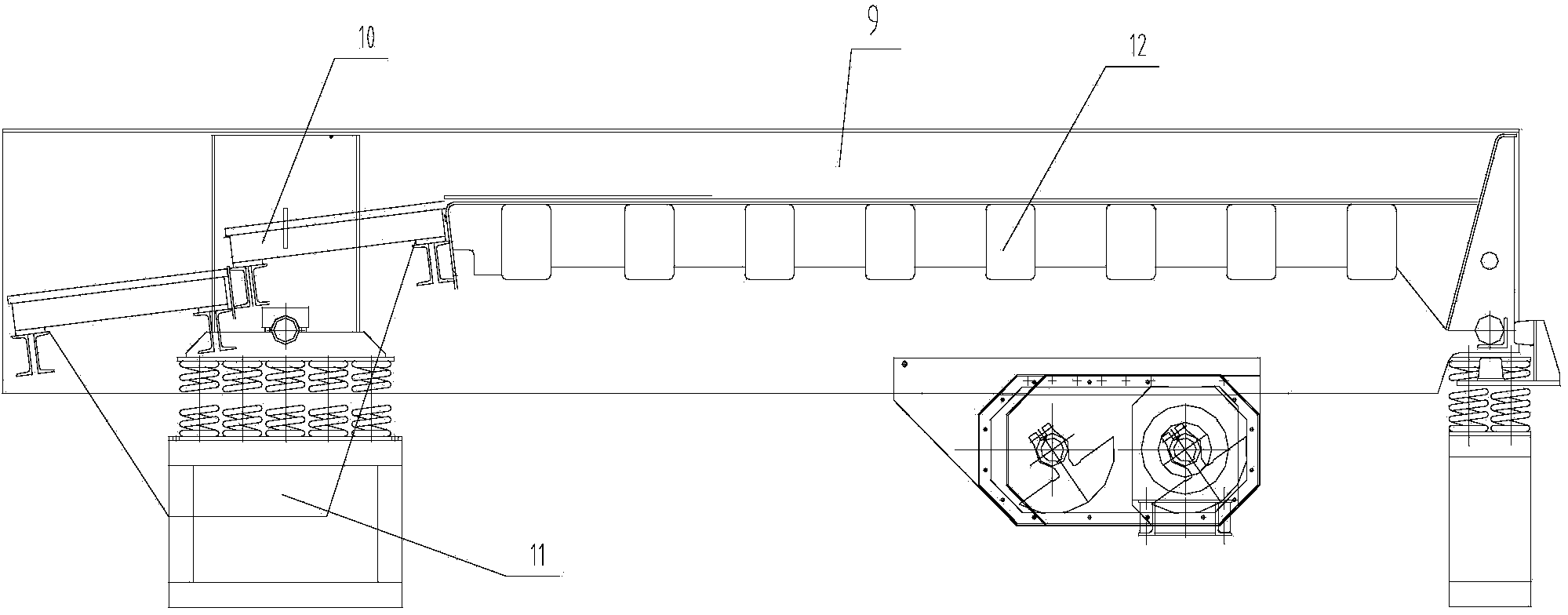

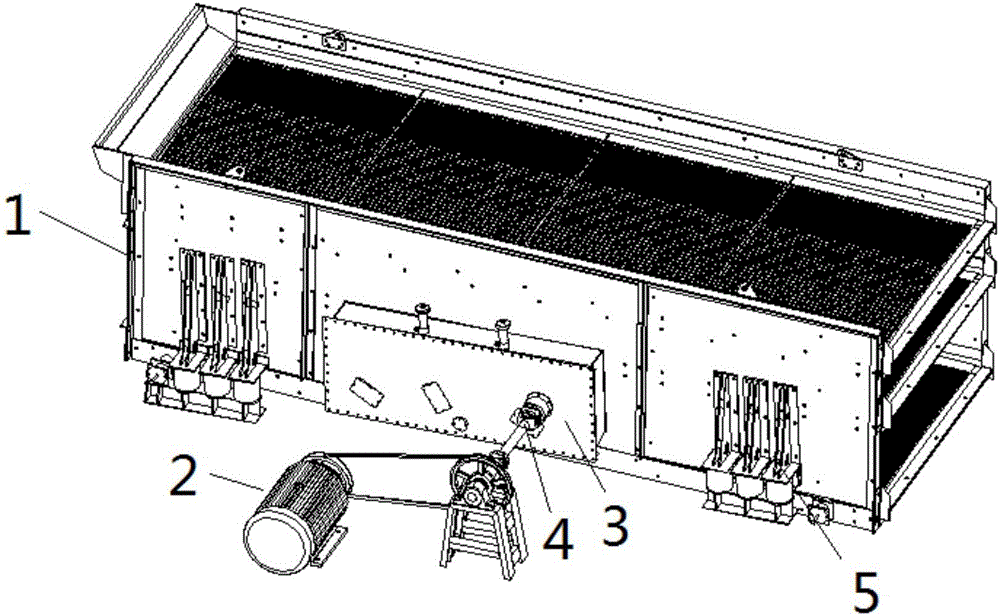

Rod screening and feeding machine

InactiveCN104070007AGreat exciting forceEasy to handleSievingScreeningElectric machineControl system

The invention discloses a rod screening and feeding machine which comprises a feeding machine tank composed of a feeding tank (9), a bar section (10) and a fine screen (11). The feeding machine tank is provided with an excitation system. The excitation system is a double-shaft excitation device. The excitation system is arranged on the lower portion of the feeding machine tank. According to the structure of the double-shaft excitation device, a control system of a motor (1) is connected with a frequency converter (2), a main shaft of the motor (1) is connected with a main eccentric shaft (5) through a flexible coupler (3), and the main eccentric shaft (5) is connected with an auxiliary eccentric shaft (7) through a gear (6) in a transmission mode. The rod screening and feeding machine is large in excitation force and high in processing ability, and the feeding quantity can be convenient to adjust.

Owner:HUNAN ZHAOSHENG MINING MACHINERY

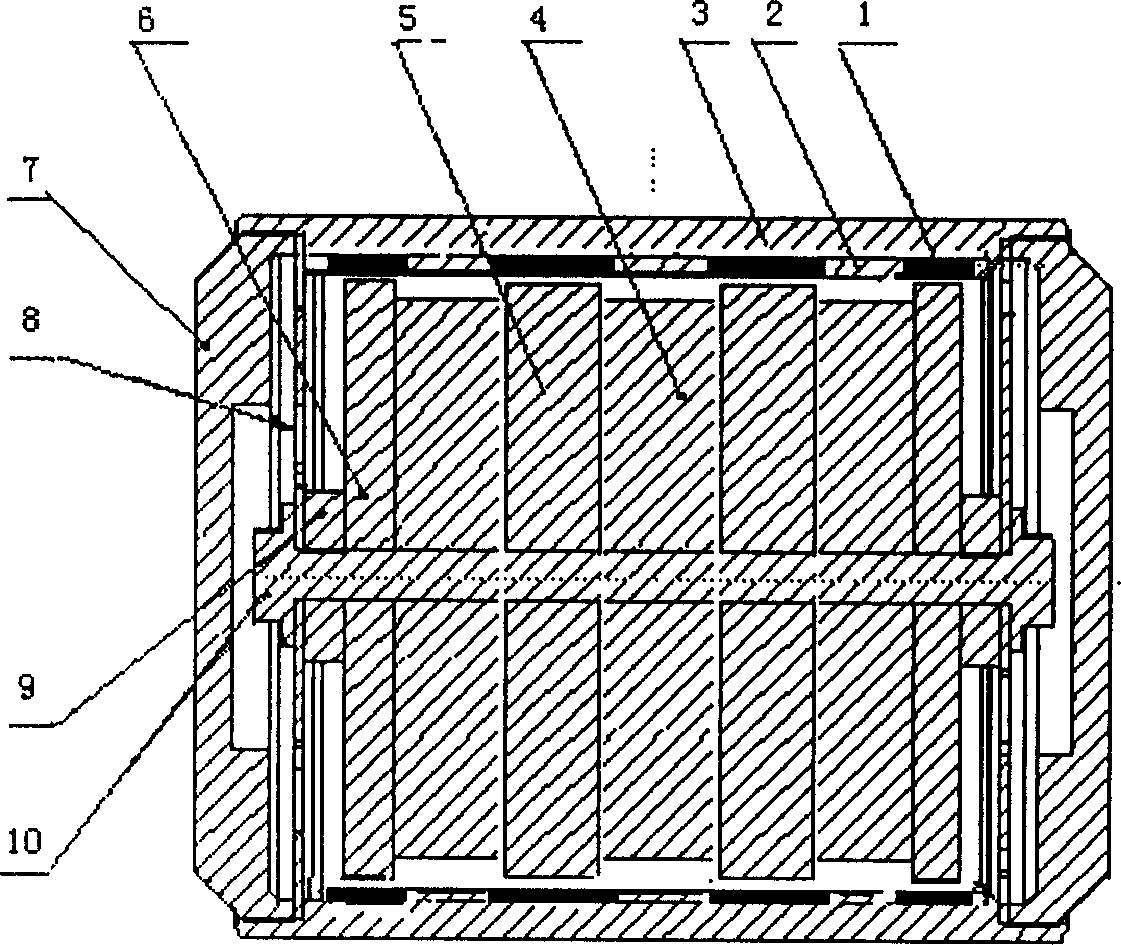

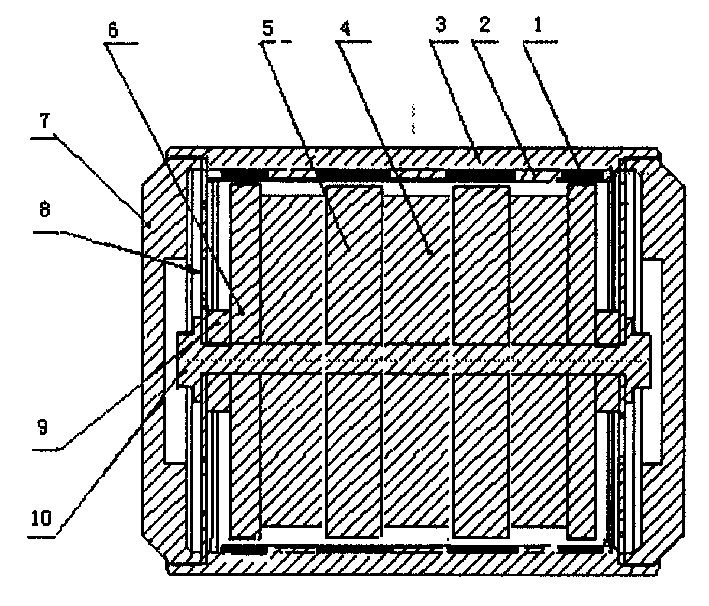

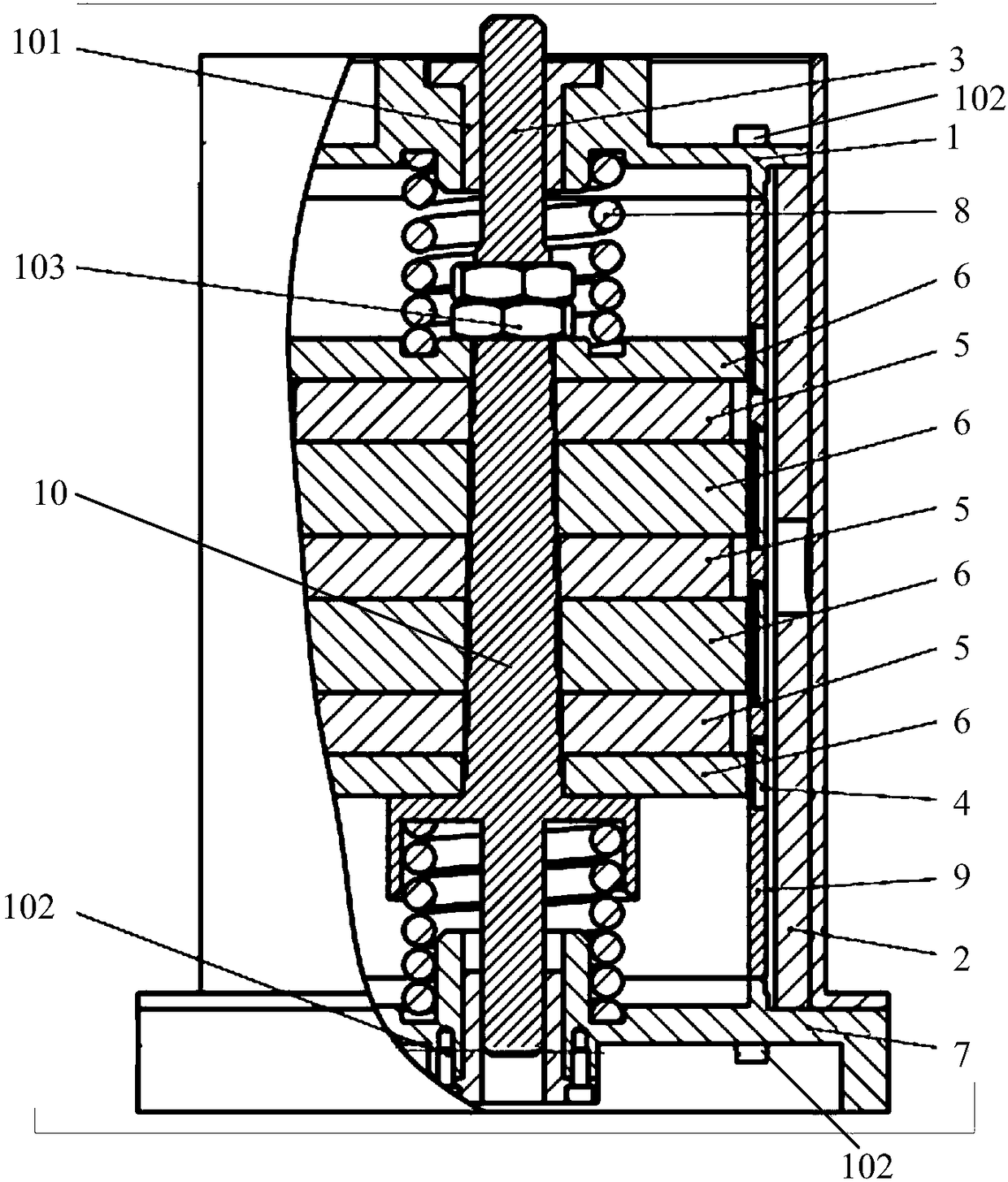

Vibration damping device

InactiveCN108361307AGreat exciting forceImprove load carrying capacity and fatigue strengthMagnetic springsShock absorbersWorking lifeCarrying capacity

The invention provides a vibration damping device which comprises an end cover, an outer shell, a main shaft, coils, permanent magnets, magnetic conductive plates, a base and cylindrical springs, wherein the main shaft is positioned in the outer shell; the permanent magnets and the magnetic conductive plates alternately sleeve the main shaft; the same poles of the adjacent permanent magnets are oppositely arranged; the magnetic conductive plates are arranged on both the upper and lower sides of the permanent magnets; the coils and the magnetic conductive plates are oppositely arranged; throughthe winding direction or the wiring design of the coils, the current flow directions of any two adjacent coils can be opposite; the coils are fixed in the outer shell; two ends of the main shaft arecorrespondingly fixed on the end cover and the base; one cylindrical spring is arranged between the end cover and the magnetic conductive plate which is close to the end cover; and the other cylindrical spring is arranged between the base and the magnetic conductive plate which is close to the base. The fatigue strength and the carrying capacity of the whole vibration damping device can be improved, and then the working life of the vibration damping device can be prolonged.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

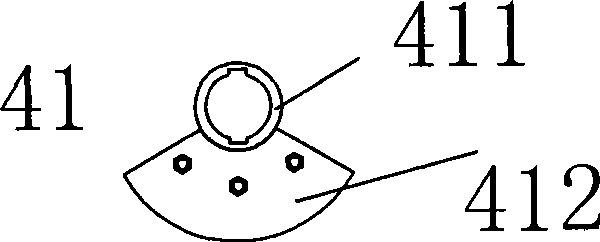

Mechanical vibration exciter and torsion test vibration excitation equipment adopting same

ActiveCN105537092AMeet the test requirementsSimple structureMechanical vibrations separationTorsion testDrive shaft

The invention belongs to the technical field of vibration excitation equipment and aims at providing a mechanical vibration exciter which is simple in structure, convenient to use, large in vibration excitation force and high in test result accuracy and torsion test vibration excitation equipment adopting the vibration exciter. A bottom plate is mounted at the bottom of a support, a side plate is mounted on one side wall of the support, a driving shaft and a driven shaft are mounted on the support, and the driving shaft is in transmission connection with the driven shaft. Vibration excitation blocks are respectively mounted on the driving shaft and the driven shaft, the structures of the two vibration excitation blocks are identical, and the projections of the vibration excitation blocks in the axial direction are fan-shaped. The mechanical vibration exciter is convenient to mount and use, can respectively provide vertical disturbing force and horizontal disturbing force through mounting the vibration exciters in different modes, is large in vibration excitation force, can meet the test requirements of large test foundations and is large in the range of applications. The vibration excitation force of the torsion vibration of the torsion test vibration excitation equipment can reach 6.66 tons and is much larger than the vibration excitation force of an electromagnetic vibration exciter. The two vibration exciters are driven by the same motor and synchronously vibrate, and the test result accuracy is high.

Owner:中航蓝天工程技术有限公司

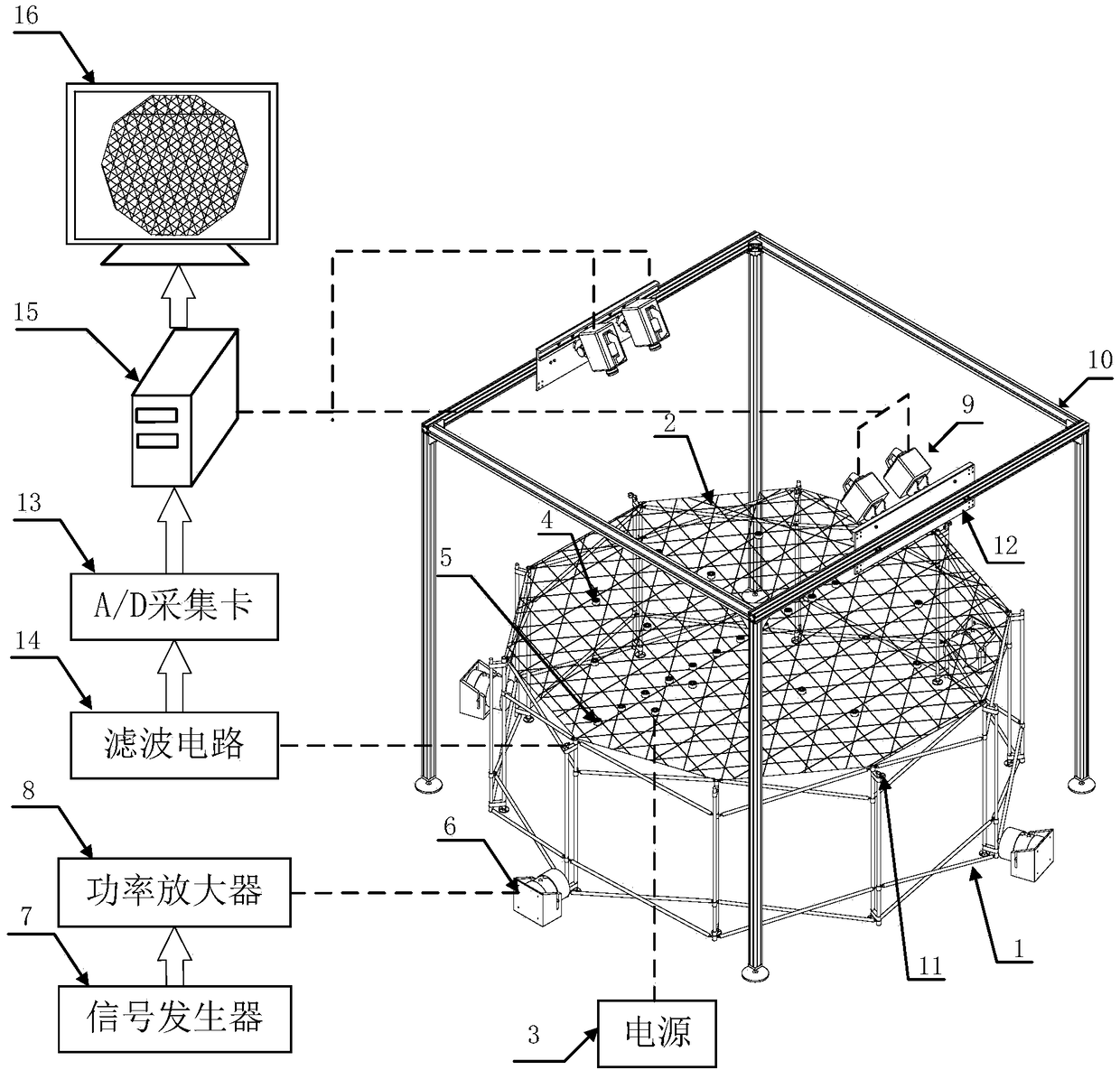

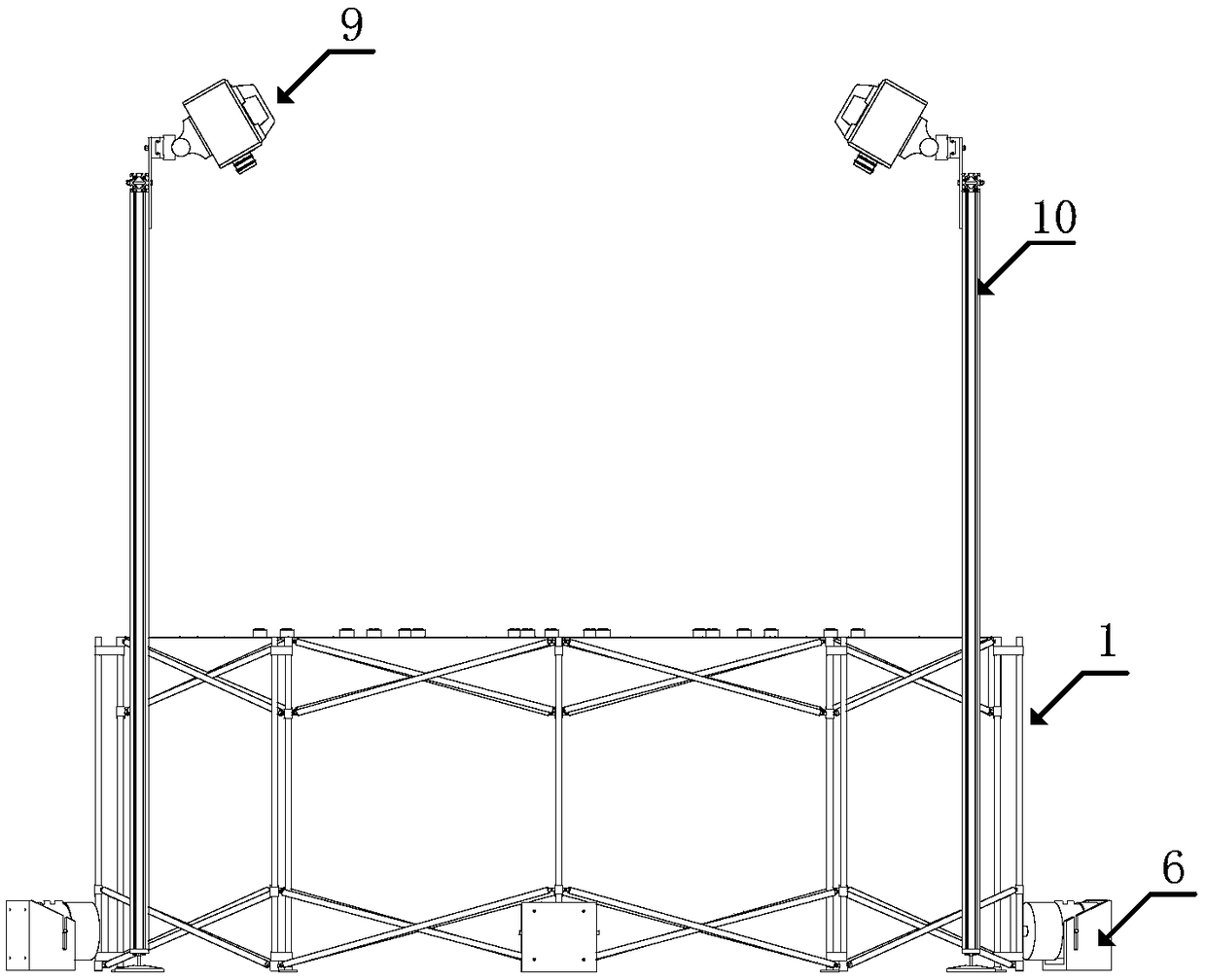

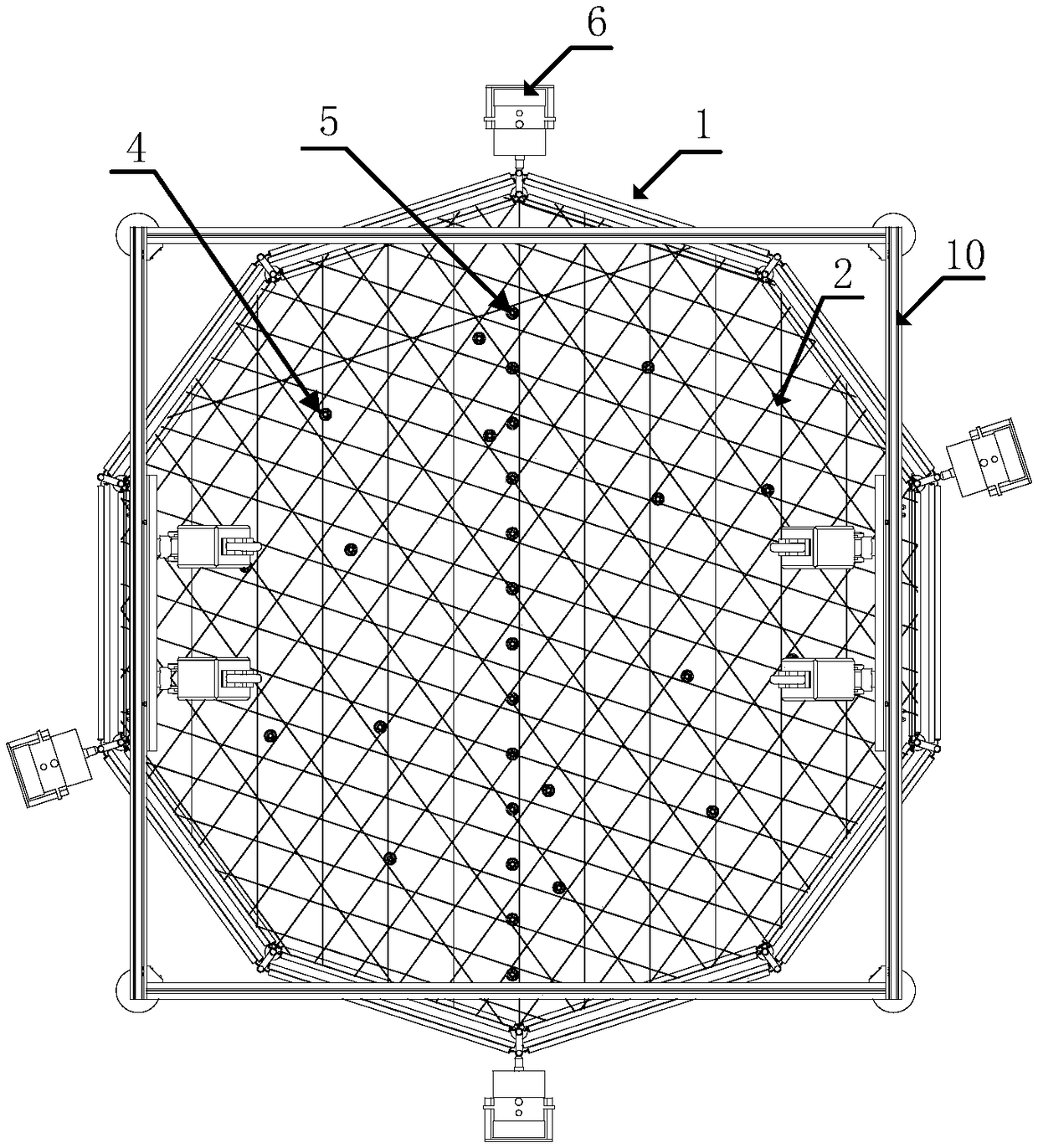

Astromesh deployable reflector vibration detection device and method

PendingCN108709630AGreat exciting forceIncrease flexibilitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansEngineeringVibration detection

The invention discloses an astromesh deployable reflector vibration detection device and method. The device comprises an astromesh deployable reflector, a vibration driving mechanism and a vibration detection mechanism. The vibration driving mechanism is connected with the astromesh deployable reflector and used for driving the astromesh deployable reflector to vibrate. The vibration detection mechanism comprises two groups of binocular vision systems, a cubic supporting frame, a plurality of acceleration sensors and processing equipment. The binocular vision systems are symmetrically arrangedon the cubic supporting frame and used for detecting mark point areas on the surface of the astromesh deployable reflector; the acceleration sensors are arranged on the astromesh deployable reflectorand uniformly distributed around the astromesh deployable reflector; the processing equipment is connected with the binocular vision systems and the acceleration sensors. The astromesh deployable reflector is detected by vision and the acceleration sensors, and accuracy of detection results is improved by combination of advantages of the two detection modes.

Owner:SOUTH CHINA UNIV OF TECH

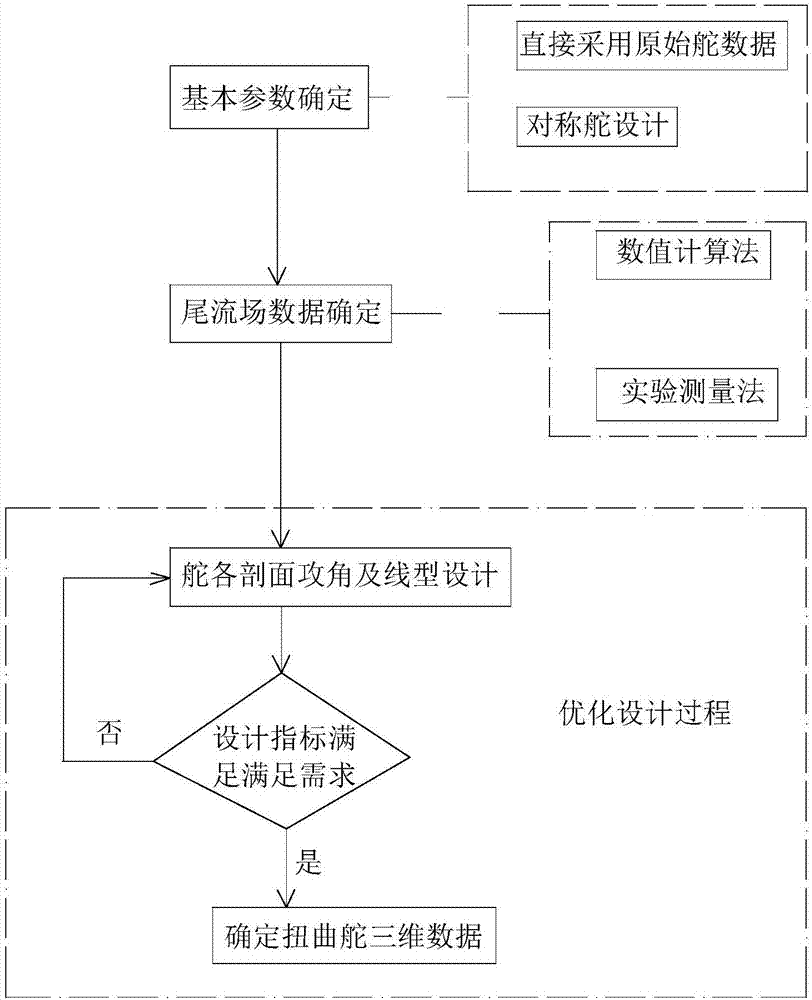

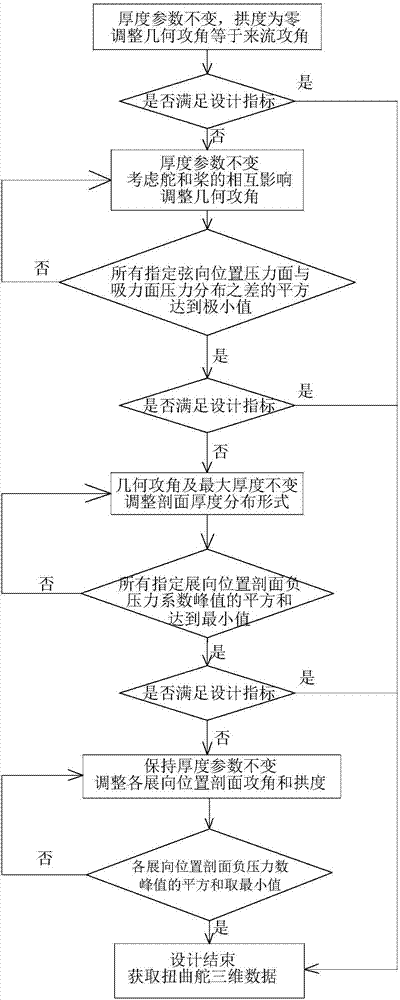

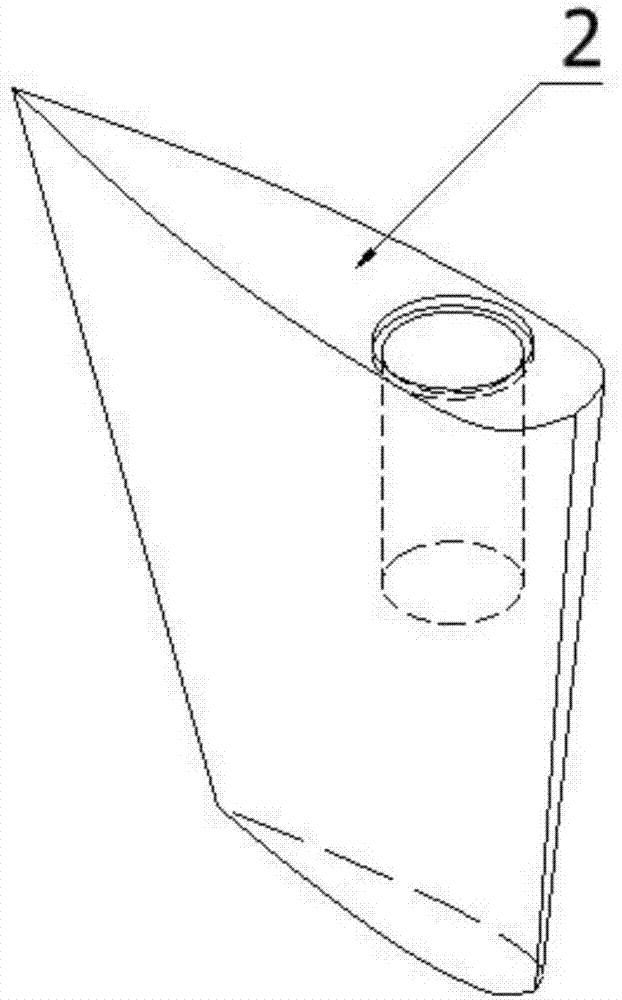

Anti-cavitation twisted rudder and design method thereof

ActiveCN107264763AImprove pressure distributionIncrease critical speedSteering ruddersVessel designingCavitationPropeller

The invention belongs to the field of ship or rudder design and particularly relates to an anti-cavitation twisted rudder and a design method thereof. On the basis that the influence of various factors such as the rotational speed in the ship propeller wake flow on the rudder is fully considered, the geometrical attack angles and line types of all the spanwise position sections are designed and determined through the distribution characteristic of a propeller rear wake flow field in direct sailing of a ship, so that the geometrical shape of the rudder is matched with that of the propeller wake flow field, and the purposes that the pressure distribution of the rudder surface is improved, the cavitation starting sailing speed of the rudder is increased, the time of rudder cavitation is shortened, the area of rudder cavitation is decreased, vibration and noise caused by the rudder are reduced, cavitation denudation of the rudder surface is restrained, the maintenance cost of the rudder is saved, the force state of rudder blades is improved, the rudder efficiency is improved, and the load of the rudder is reduced are achieved.

Owner:NAVAL UNIV OF ENG PLA

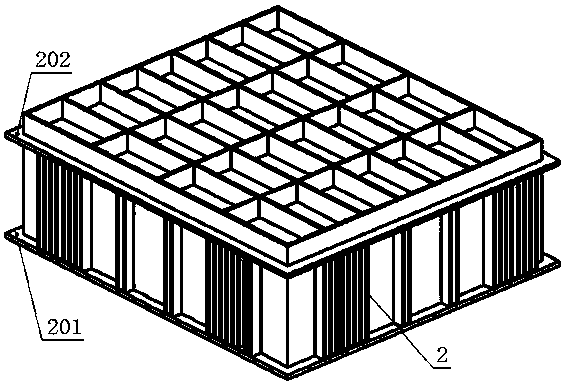

Table top of vibration platform

InactiveCN102744376AEfficient deliverySimple structureMoulding machinesLow noiseStructural engineering

The invention discloses a table top of a vibration platform, and a sand box can be mounted on the table top movably. The table top includes a bedplate (7) driven to vibrate by a vibration mechanism. The invention is characterized in that the bedplate (7) is provided with three supporting pillars (2). One ends of the supporting pillars (2) are positioned with the bedplate (7) through spigots, and are connected to the bedplate (7) by bolt pairs. The other ends of the supporting pillars (2) are equipped with connecting seats (3) for mounting the sand box. And the contact surfaces between the connecting seats (3) and the sand box are convex conical surfaces. With simple structure and low noise, the invention can realize automatic position of the sand box without clamping, and can effectively transmit a vibration source and has a great excitation force. Meanwhile, the use of only one pair of motors can generate three-dimensional vibration.

Owner:桃江新兴管件有限责任公司

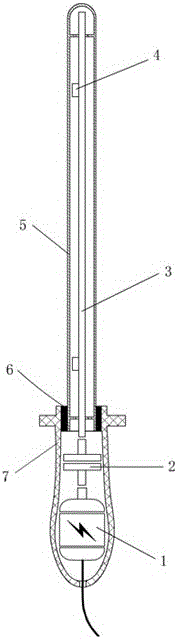

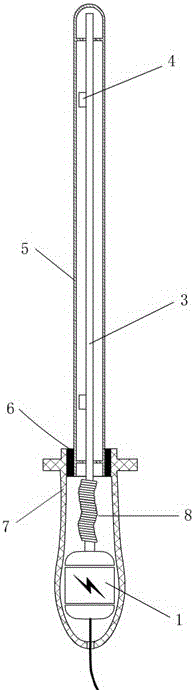

Vibration massage stick

PendingCN106691814ASimple structureReduce manufacturing costOperating tablesDevices for pressing relfex pointsMassageBody positions

The invention provides a vibration massage stick. A motor, a torsional part and a rotating shaft are installed in a handlebar and a stick body. The motor rotates fast through the rotating pipe possessing an eccentric mass in the torsional part drive sleeve pipe or a suspending rotating shaft with one conical end to make the stick body vibrate circumferentially. The massage stick presses the main collateral circulating lines, the high frequency, low amplitude massage vibration waves are used for stimulating the autonomic nerves, activating the cells, promoting the blood circulation of the capillary vessels. The stick can massage a certain length of body position for once. The vibration massage stick is simple in structure, immune to pressure, free of noise, low in production cost, easy to product, and strong in practicality.

Owner:韦志锋

Bridge pier VSR (vibration stress relief) method for steel structural bridge

ActiveCN108130414AVibration aging treatment time is smallNo damage to surface qualityStress reliefMultiple resonance

The invention discloses a bridge pier VSR (vibration stress relief) method for a steel structural bridge and relates to the technical field of stress relief treatment of steel structure parts. A bridge pier of the steel structural bridge is a high-rigidity and heavy large structural part, and stress relief treatment is difficult to perform with existing thermal stress relief, natural stress relief, ultrasonic impact stress relief and VSR methods. According to the method, the bridge pier is supported by a support pad, multiple sets of VSR equipment are used, multiple vibration exciters are adjacently fixed on a lower frame beam of the bridge pier, multiple vibration testers are adjacently fixed on an upper frame beam of the bridge pier, then, multiple vibration exciters are controlled by use of multiple controllers, co-frequency sub-resonance vibration is performed on multiple resonance peaks of the bridge pier for several hours, the purpose of effectively relieving the residual stressis achieved, the average relief rate of the residual stress reaches 43%, the problem of difficulty in relieving the residual stress of the bridge pier is solved, and the method can be applied to steelstructural bridges.

Owner:NANNING SHENHUA VSR TECH RES INST +1

Gear shock excitation mechanism

InactiveCN102107181BReduce stressAchieve vibrationToothed gearingsMechanical vibrations separationEngineeringMechanical engineering

The invention discloses a gear shock excitation mechanism which belongs to a shock excitation mechanism applied to the engineering machinery. The gear shock excitation mechanism is provided with a sun wheel shaft, wherein one end of the sun wheel shaft is connected with an external drive mechanism through a spline, and the other end of the sun wheel shaft is connected to an end cover through a slide bearing; the sun wheel shaft is provided with a gear; the sun wheel shaft, a planetary wheel and an inner gear are meshed with each other; the outer end of the inner gear is connected with a working device; the planetary wheel is mounted on a planetary wheel frame; a central hole of a fixed eccentric block is an inner gear which is arranged on the sun wheel shaft and integrally connected with the sun wheel shaft. The central hole of a slide sleeve is an inner gear, and a movable eccentric block is arranged on the outer circle of the slide sleeve. The gear shock excitation mechanism has thefollowing advantages: 1, the shock excitation force is transferred among gears, and the bearing with great shock excitation force is not used; 2, a vibration shaft is connected with an eccentric block mechanism through a gear pair so as to meet the need for large-tonnage shock excitation force; 3, the oil temperature is reduced, and the working conditions of the vibration mechanism are improved; and 4, the service life is long, and the shock excitation force is much larger than that of the existing vibration mechanism.

Owner:潘国梁

Three-shaft linkage block eccentric linear vibrating screen

Owner:SHANGHAI FENGLIN PRECISION IND MACHINERY MFG CO LTD

Exciter used for active vibration-reduction and vibration damper provided with same

ActiveCN105944948AGreat exciting forceLarge outputMechanical vibrations separationControl theoryActive vibration control

The invention discloses an exciter used for active vibration-reduction and a vibration damper provided with the same. The exciter used for active vibration-reduction comprises a shell, a motor and two connecting shafts which are supported by the shell. The motor serves as a power source and is in transmission connection with the two connecting shafts; an eccentric block assembly is arranged on each connecting shaft; and the two connecting shafts are coaxially arranged and operate reversely to drive the eccentric block assemblies on the two connecting shafts correspondingly to operate reversely. The vibration damper is provided with the exciter used for active vibration-reduction. The exciter used for active vibration-reduction and the vibration damper provided with the same have the characteristic of large output force, stepless regulation for the output force can be conducted conveniently, and directional output of the force can be achieved.

Owner:中国船舶集团有限公司第七一一研究所

Inertia force vibration exciter

ActiveCN102615038AImprove versatilityThe transmission is compactMechanical vibrations separationDrive motorUltra low frequency

The invention discloses an ultra-low frequency inertia force vibration exciter in a super-huge type structure. The exciter comprises a support and guide framework, a movement mass block and a driving system, wherein rails are arranged inside the support and guide framework, the movement mass block is arranged inside the support and guide framework, the driving system consists of a driving device and a transmission device connected with the driving device, and the driving device comprises a driving motor with a speed reducer. The ultra-low frequency inertia force vibration exciter is characterized in that the driving system is arranged inside the movement mass block and drives the movement mass lock to do reciprocating movement along the rails. The driving system consisting of the driving device and the transmission device is arranged inside the movement mass block to become one part of the effective movement mass, the exciting force is obtained through the reciprocating movement of the movement mass on the rails, and the total weight of the exciter is reduced; during the horizontal and vertical vibration excitation, the basic structure of the exciter is not changed, and the universality of the exciter is improved; and the transmission structure of the exciter is compact, so the stroke of the movement mass can be increased for enhancing the exciting force, and faults can be reduced.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com